Page 1

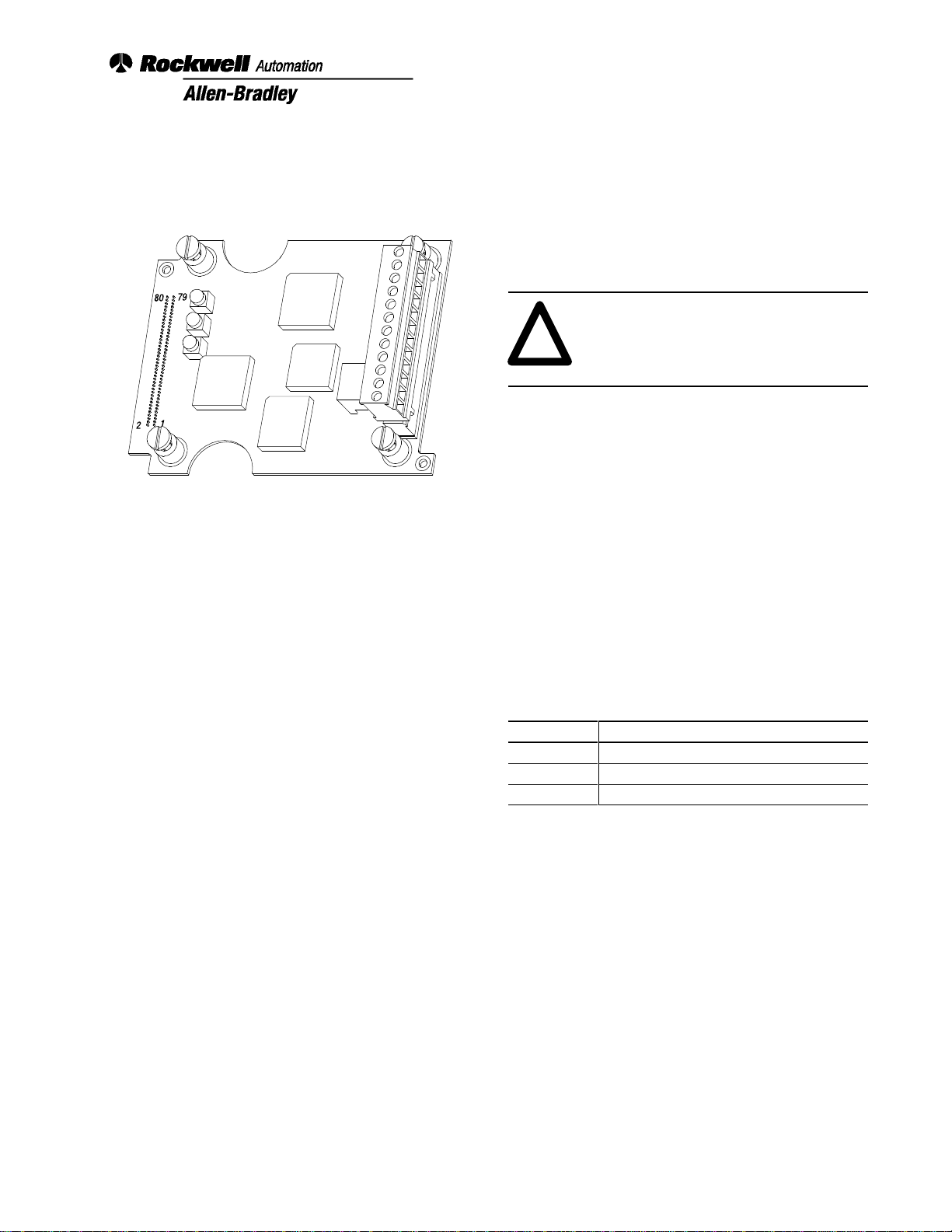

Smart Communications Card

(Cat. No. 1403-NSC)

Throughout this manual we use notes to make you aware

of safety considerations:

!

Attention statements help you to:

• identify a hazard

• avoid the hazard

•

recognize the consequences

Instruction Sheet

ATTENTION: Identifies information

about practices or circumstances that can

lead to personal injury or death, property

damage or economic loss.

Important User Information

Solid-state

differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation, and

Maintenance of Solid-state Controllers (Publication

SGI-1.1) describes some important dif

solid-state equipment and hard-wired electromechanical

devices. Because of this dif

the wide variety of uses for solid-state equipment, all

persons responsible for applying this equipment must

satisfy themselves that each intended application of this

equipment is acceptable.

In no event will the Allen-Bradley Company, Inc. be

responsible for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included

solely for illustrative purposes. Because of the many

variables and requirements associated with any particular

installation, the Allen-Bradley Company, Inc. cannot

assume responsibility or liability for actual use based on

the examples and diagrams.

No patent liability is assumed by the Allen-Bradley

Company, Inc. with respect to use of information,

circuits, equipment, or software described in this manual.

equipment has operational characteristics

ferences between

ference, and also because of

Important:

Identifies information that is critical for

successful application and understanding

of the product.

Terms and Conventions

In this instruction sheet, the following terms and

conventions are used:

Abbreviation Term

BTR Block Transfer Read

BTW Block Transfer Write

MSG Message

Table of Contents

Product

Description

Installation 3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation

General

Catalog

Number Explanation

Communication Card Data T

Smart

Communication Protocol T

Smart

Ladder Listing

Sample

Technical

Specifications

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

ables

. . . . . .

utorial

. . . . . . .

App. A

App. B

App. C

App. D

App. E

2. . . . . . . . . . . . . . . . . . . . .

8. . . . . . . . . . . . . . . . . . . . . .

Reproduction of the contents of this manual, in whole or

in part, without written permission of Allen-Bradley

Company, Inc., is prohibited.

PLC is a registered trademark of Allen-Bradley Company, Inc.

Data Highway Plus and SLC are trademarks of Allen-Bradley Company, Inc.

Publication 1403-5.1

Page 2

2

Smart Communications Card

Product Description

Chapter

After completing this chapter

identify the product features and system applications.

Objectives

, you should be able to

Introduction

The Cat. No. 1403-NSC Smart Communications Card is

a microprocessor-controlled dual-port communication

plug-in accessory to the Powermonitor II Master Module.

This accessory provides the Powermonitor II with two

active communication ports which can be used at the

same time. Required configuration parameters (R I/O

rack address, baud rates, etc.) are provided by

configuring the Master Module. One port is dedicated to

the Allen-Bradley PLC R I/O network and the other

port is software configurable for either EIA Standards

RS-232C or RS-485. (There are no hardware options to

configure when the card is installed.)

Figure 1. Cat. No 1403-NSC Communications Module

Serial Transmit (TXD) LED

Serial Receive (RXD) LED

Performance Features

The Smart Communication Card performance features

include:

• PLC via R I/O

• SLC 500 via R I/O with (1747-SN) Series B or later

scanner module

• SLC 500 via DF-1 master slave protocol

• R I/O Baud rates: 57.6K baud-230K baud

• Serial Baud rates: 1,200–19,200 baud

• Simultaneous R I/O and serial communication

• 124 units per subnet, 255 per network via RS-485

•

500 V isolation on communications ports

• Fully software configurable, no hardware jumpers

required

Finger hold

Publication

1403-5.1

Captive fastening screw

R I/O Active LED

Connector

Page 3

Installation

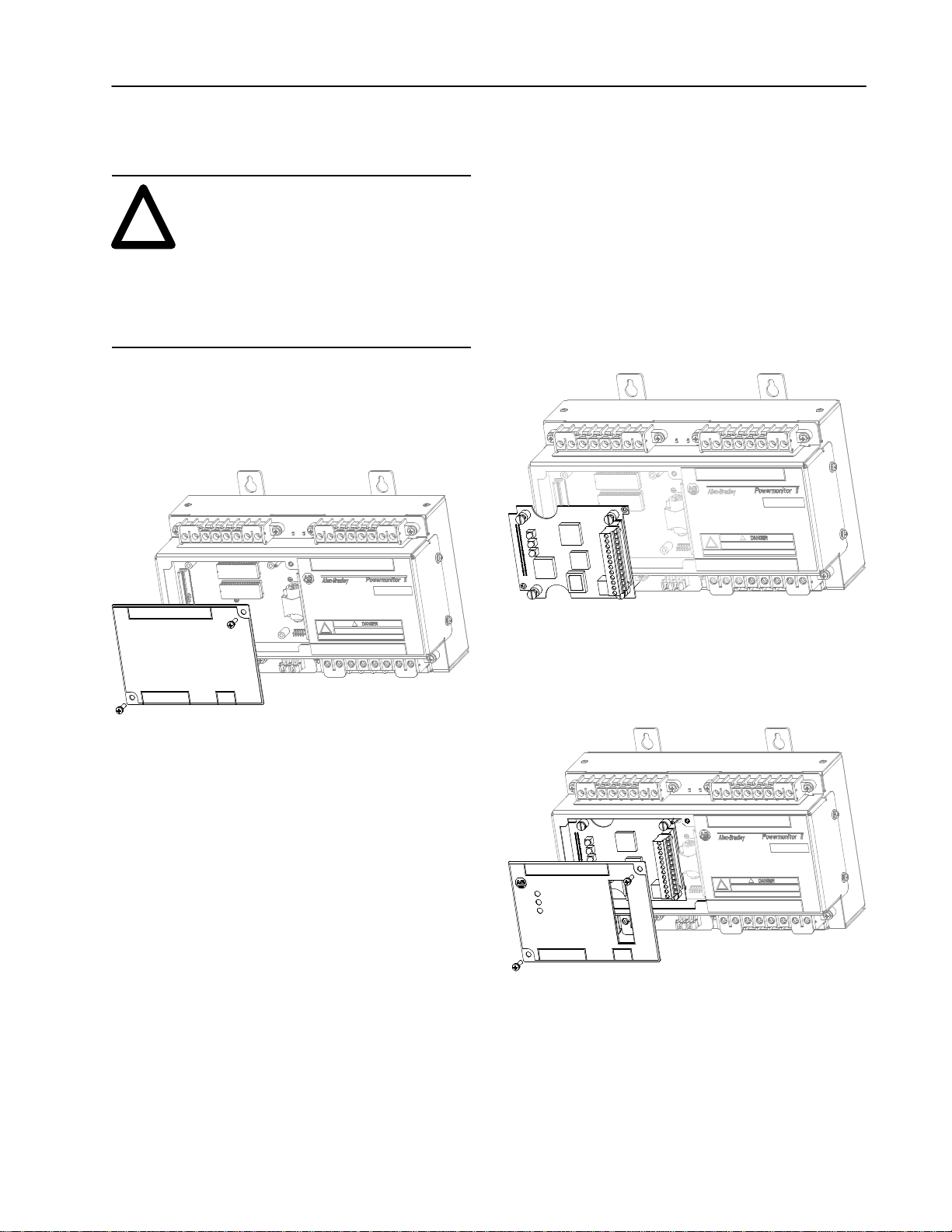

ATTENTION: Please follow

appropriate ESD procedures before

!

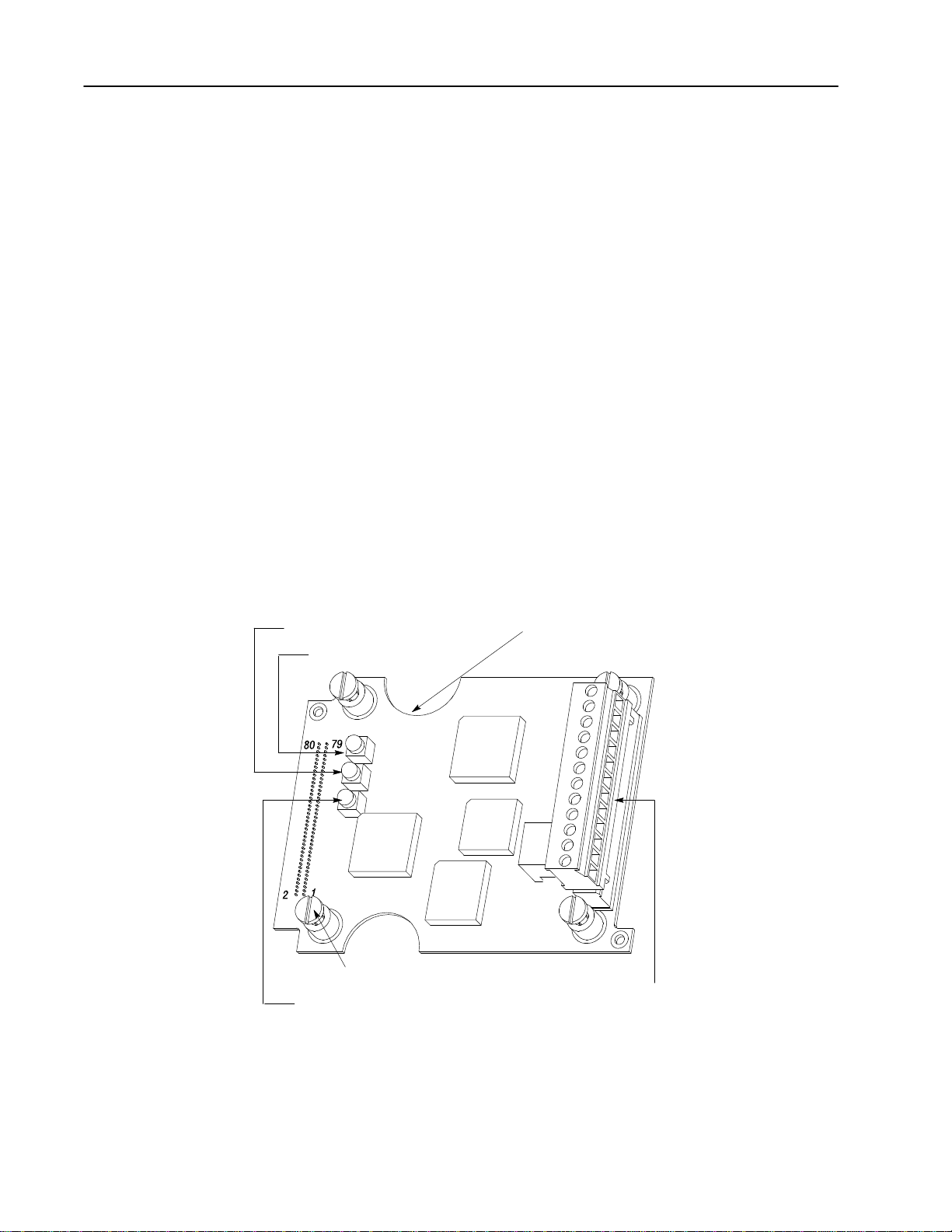

1. T

o remove the blank plate on the Master Module,

unscrew the two corner retaining screws as shown in

Figure 2. Save these two screws for reassembly

Figure 2.

removal and/or installation of the Smart

Communications Card. Failure to follow

these procedures can result in physical

damage to both the Smart

Communications Card and the Master

Module.

Smart Communications Card

ith the Master Module labels right side up, place

5. W

the card into opening on the left side. The card to

Master Module connector should align properly when

the top right and bottom left guide pins of the Master

Module mate with holes in the card. W

thumb, press just above the card to Master Module

connector to attach the connector. Tighten the four

corner screws.

Figure 3.

.

ith your left

3

2. If you plan to remove the communications card at a

later date, retain the blank plate. Otherwise, dispose

of properly.

3. Remove the communications card from the static

protection shipping bag.

4.

Grasp the card with the components side up and the

three LEDs on the left. Place the right index finger in

the top notch and the thumb in the bottom notch.

6. Place the closure plate over the opening and secure it

with the two screws from the original blank plate.

Figure 4.

Note: Refer to Appendix E, Specifications for screw

torque requirements and wire sizes.

Publication

1403-5.1

Page 4

4

RS 485

(

)

4000 ft/19.2kB

3-wire Shielded

1770 CD

10,000 ft /57.6kBaud

R I/O

(Bl

)

5,000 ft/115.2kBaud

Smart Communications Card

Wiring

ATTENTION: Special high level

isolation is required between units when

!

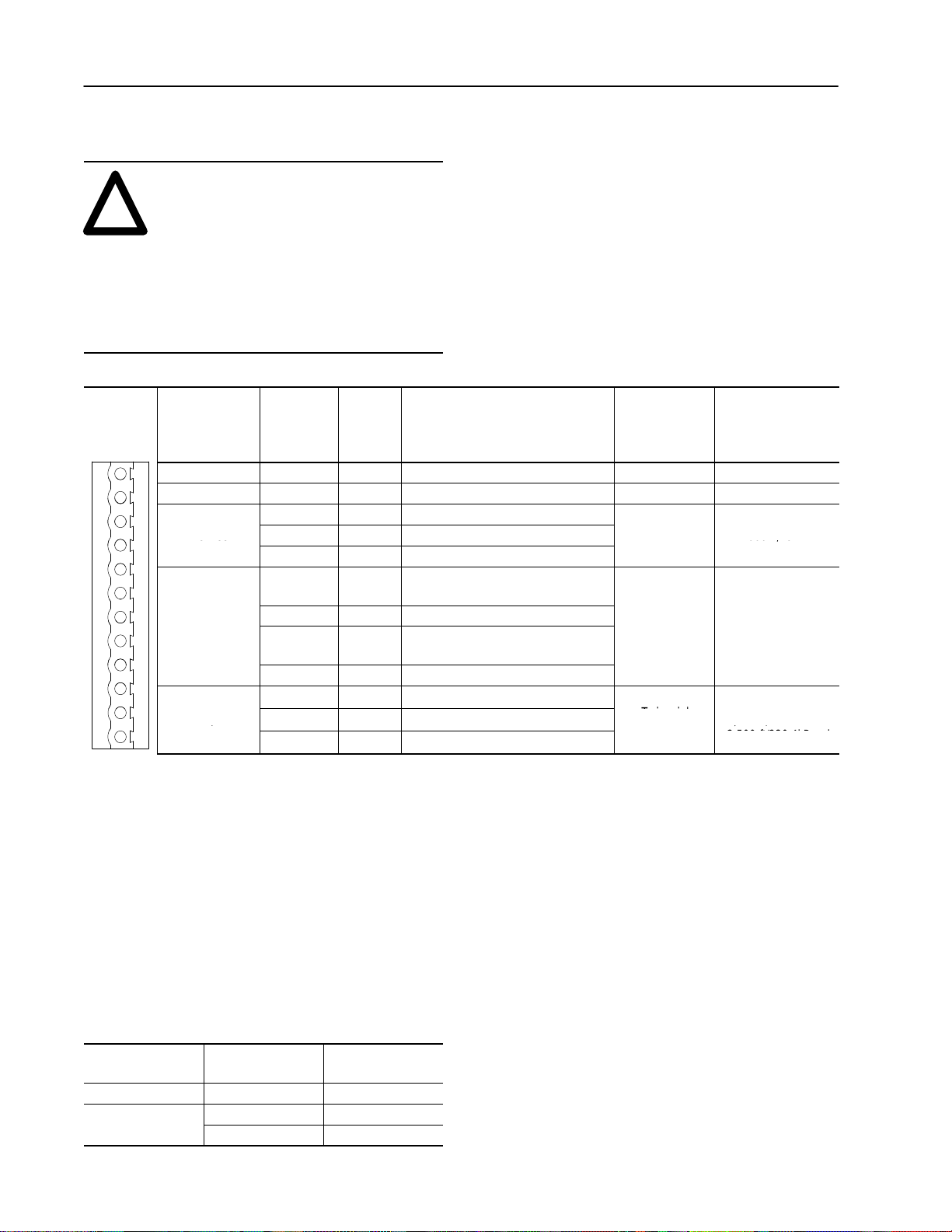

Table A. Wiring Connections

Connector

the possibility of high ground potential

dif

ferences exist. This may occur when

separate grounds are used or when

communicating to a unit connected to a

power ground mat. Failure to do so can

lead to personal injury or death, property

damage, or economic loss.

Communication

Format

RS-485

RS-232

R-I/O

Terminal #

(Counting

from the

bottom up)

12 Do not connect

11 Do not connect

10 SHLD Cable shield grounding point

9 – Minus signal data

8 + Plus signal data

7 RXD

6 TXD PC Receive, DB25, pin3 (DB9, pin 2)

5 SG

4 SHLD Cable Shield

3 1 Blue Wire insulation

2 SHLD Cable shield ground point

1 2 Clear wire insulation

Terminal

Label

Intended Use, Pin Connection,

or Wire Color

PC Transmit, DB25, pin 2,

(DB9, pin 3)

PC signal return, DB25, pin 7

(DB9, pin 5)

Recommended

Cable Type

2-wire shielded

Belden 9841

3-wire Shielded

(Belden 9608)

1770-CD

Twinaxial

ue Hose

(Belden 9463)

Maximum Cable

Length/Baud Rate

4000 ft/19.2kB

50 ft/19.2kB

1

ft 7.kB

5,000 ft/115.2kBaud

2,500 ft/230.4kBaud

Notes:

1. The communications topology for both R I/O and

RS-485 is designed to operate in a daisy-chain

topology. Use of the star or bridging method will

cause signal distortion unless impedances are

matched for each spur. Bridging is not recommended

without matching networks.

2. To prevent end reflections, each end of the daisy-

chain should be terminated in the characteristic

impedance for the cable, the baud rate, and frequency

used.

Communication

RS-485 1200–19.2k

R I/O

Publication

Format

1403-5.1

Baud Rate

57.6–115.2k

230.4k

Terminating

Resistor

150 Ω 1/4 W

150 Ω 1/4 W

84 Ω 1/4 W

3. Each

end section of cable should have the shield

connected to the terminal labeled SHLD. This SHLD

ground provides a high frequency ground, while

limiting DC or power line frequencies from flowing

down the cable shield.

4. The RS-485 receivers in the communications card

provide a 1/4 load impedance instead of the normal

full load impedance. This therefore allows the use of

four times the number of receivers (32 4 or 128

total) on one network.

Page 5

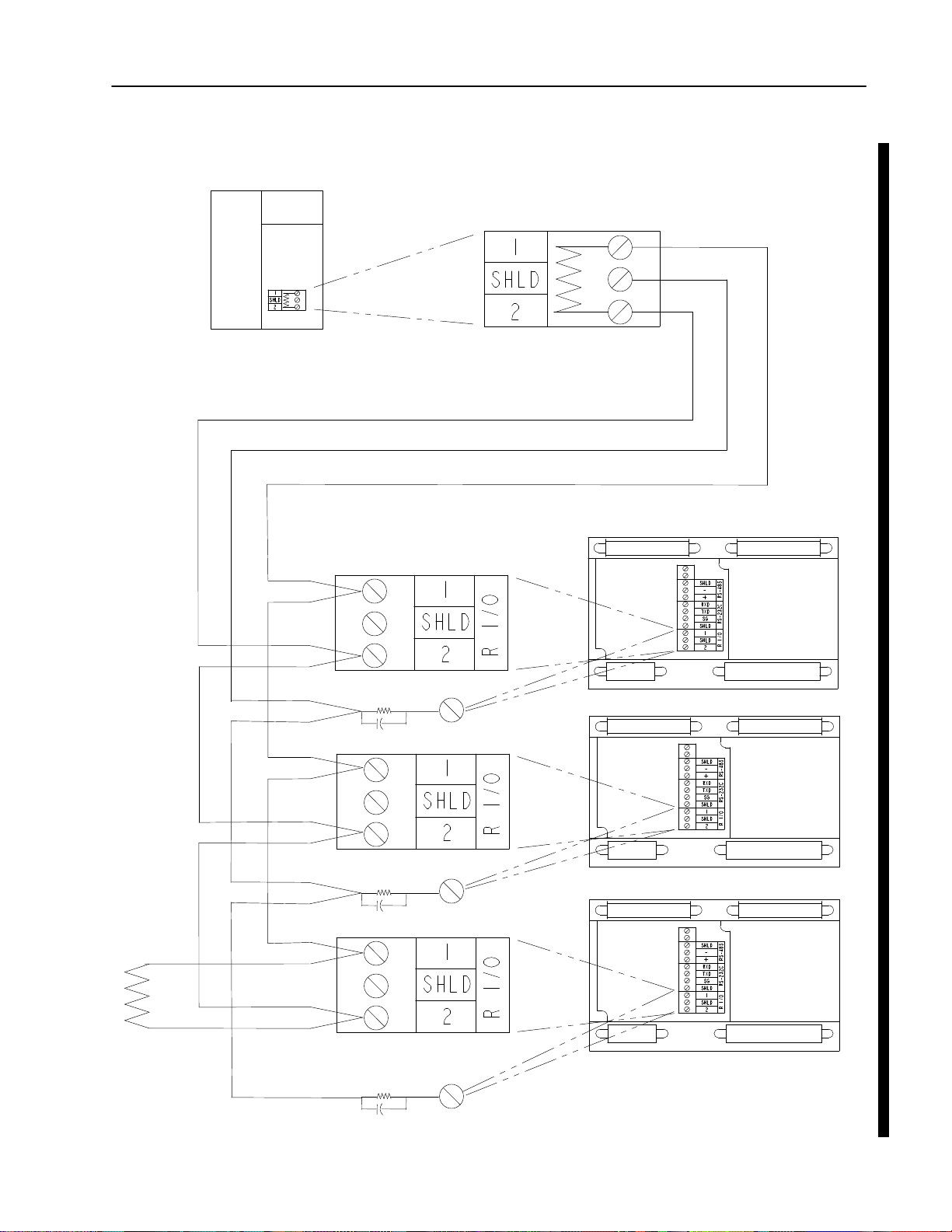

Figure 5. R I/O Wiring

PLC PROCESSOR

INTERNAL TERMINATING

150Ω

RESISTOR

Smart Communications Card

BLUE

SHIELD

CLEAR

5

150KΩ

0.047uF

150KΩ

0.047uF

Powermonitor

DEVICE #1

Powermonitor

DEVICE #2

Powermonitor

DEVICE #3

II

II

II

84Ω OR

150

Ω RESISTOR

150KΩ

0.047uF

Note: All

possible between the R/C and the cover plate.

ground wires should be kept as short as

Publication

1403-5.1

Page 6

6

Smart Communications Card

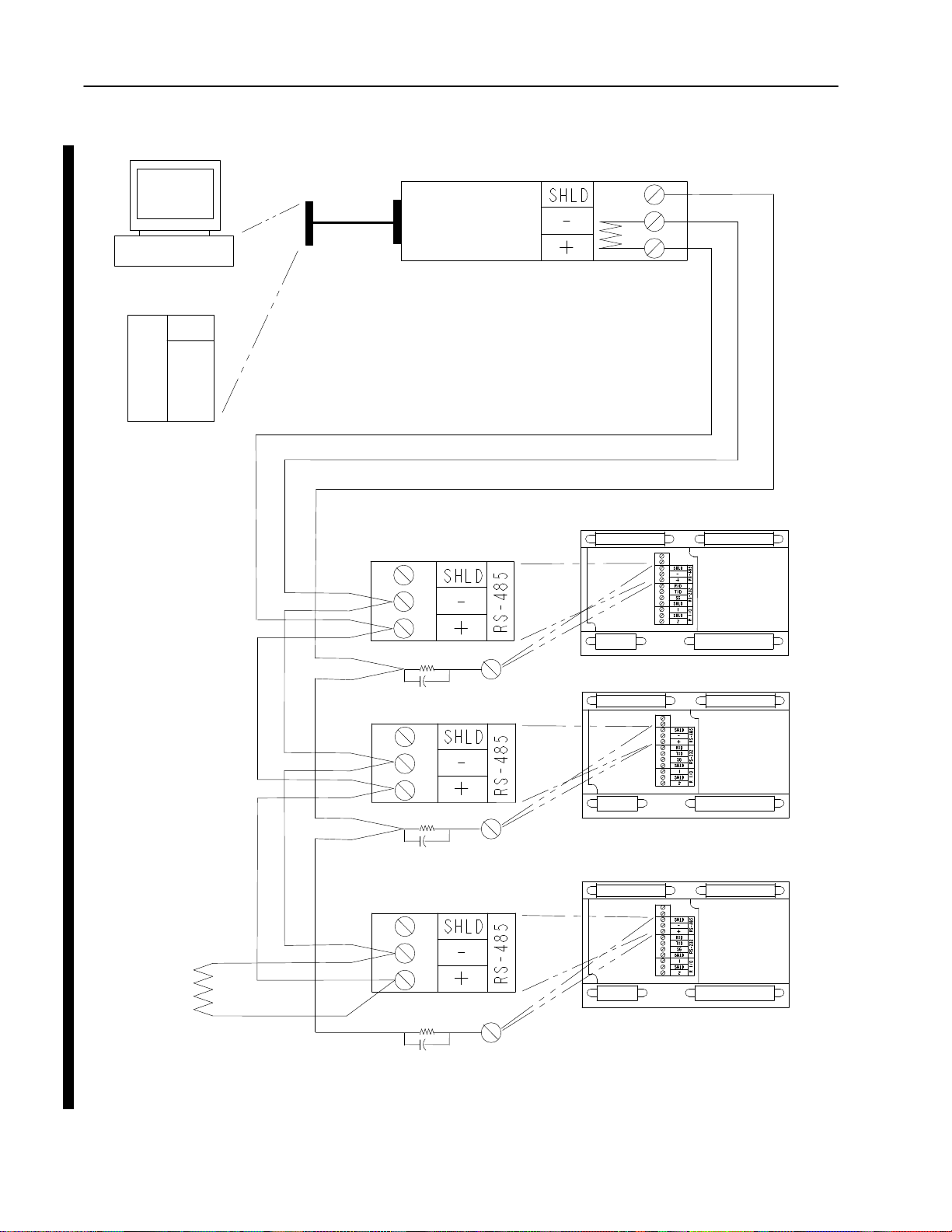

Figure 6. RS-485 Wiring

IBM PC

PLC PROCESSOR

RS–232C

EXTERNAL

RS–232C

TO RS–485

CONVERTER

150Ω

RESISTOR

150Ω RESISTOR

150KΩ

0.047uF

150KΩ

0.047uF

150KΩ

0.047uF

Note: All

possible between the R/C and the cover plate.

Powermonitor

DEVICE #1

Powermonitor II

DEVICE #2

Powermonitor II

DEVICE #3

II

ground wires should be kept as short as

Publication

1403-5.1

Page 7

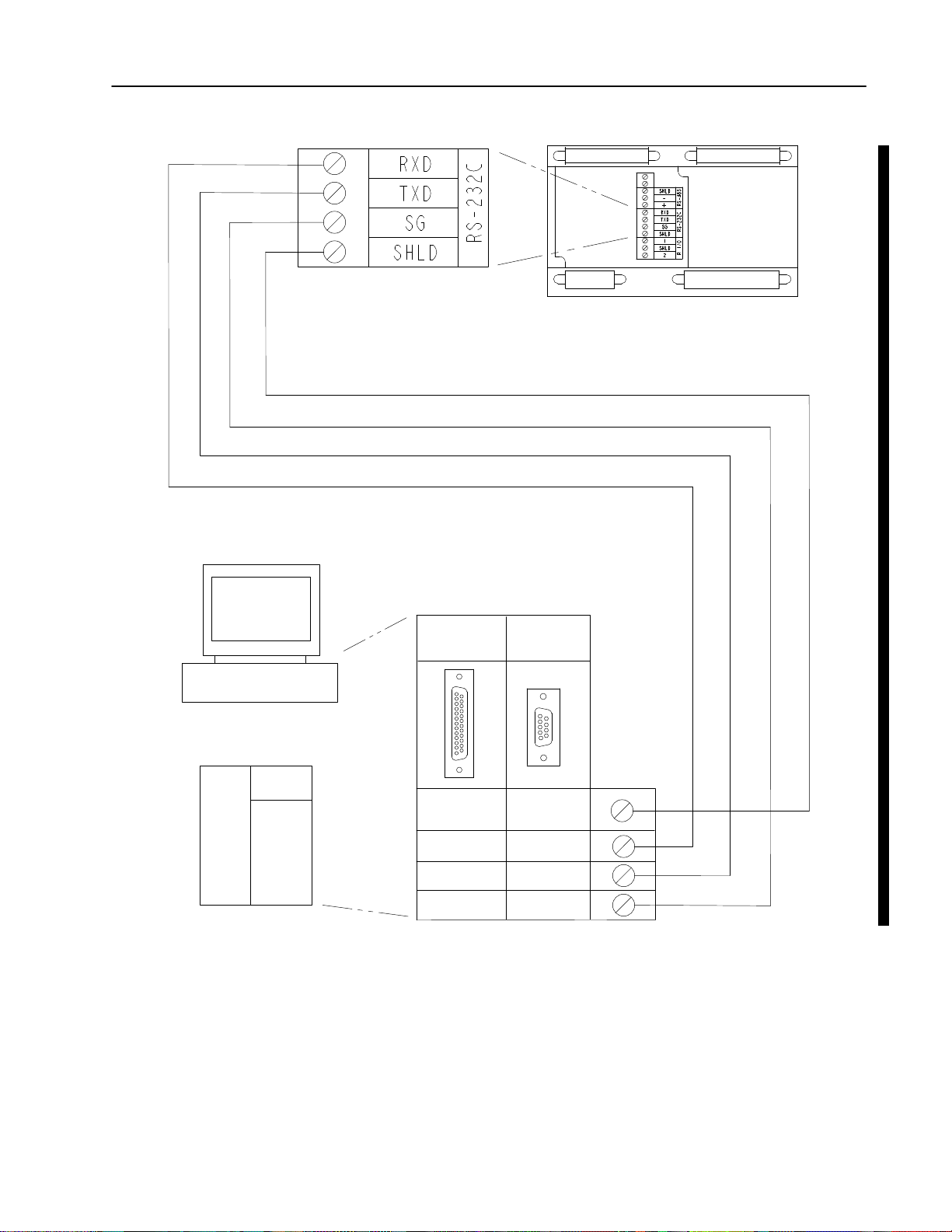

Figure 7. RS-232C Wiring

Smart Communications Card

Powermonitor II

7

IBM PC

PLC PROCESSOR

Note: For

be connected directly to the chassis ground terminal

located on the communication card cover plate. The

exposed shield wire should be as short as possible.

CE compliance, the communication cable shield must

25 PIN

D–SHELL

9 PIN

D–SHELL

Field Service Considerations

If the Smart Communications Card requires service,

please contact your nearest Allen-Bradley Sales Of

To minimize your inconvenience, the initial installation

should be performed in a manner which makes

removal easy

.

fice.

1

7

CASE

GROUND

2

3

3

2

5

Publication

1403-5.1

Page 8

8

Smart Communications Card

General Operation

Communications Card Set-Up

All

communications card options such as

communications format, baud rate, address, etc., are set

by configuring the Master Module. Refer to

Powermonitor II Instruction Sheet

Chapter 4.

Table B. LED Indicators

LED

Location

Top Red RS-232 or RS-485 Receive

Middle Red RS-232 or RS-485 Transmit

Bottom Green

Configuration

Items

Communication

, Publication 1403-5.0,

LED

Color

Port Assignment LED State and Communications Condition

R I/O

Indicators

Figure 1. on page 2 shows the location of the LED

Indicators on the communications card.

OFF = Idle

ON/OFF Pulsing = Receiving Data

OFF = Idle

ON/OFF Pulsing = Transmitting Data

ON = Communications Established

ON/OFF Blinking = Communications Established With Some Errors

OFF = Communications Not Established

Table C. Communication Configuration Items

Parameter

R I/O Rack Address

R I/O Group Number Determines the group number of the logical rack.

R I/O Last Rack

R I/O Baud Rate Specifies the baud rate of the RIO network.

Serial Delay

Serial Mode Specifies the serial communications mode.

RS-232/RS-485 Baud

Rate

Serial Device Identifier

Specifies the logical rack of the Smart Communication

Card.

Defines whether or not the configured rack is the last

rack.

Defines the delay in ms between the request and

response serial packets.

Determines the baud rate for the serial communications.

Defines the specific serial address. A value of 255 is

used as a broadcast address.

Description Range Default

0 to 63 1

0 = First Quarter

2 = Second Quarter

4 = Third Quarter

6 = Fourth Quarter

0 = No

1 = Yes

0 to 56K

1 to 115K

2 to 230K

0 to 15 0

0 = RS-485

1 = RS-232

0 to 1200

1 to 2400

2 to 4800

3 to 9600

4 to 19200

0 to 254 Device ID#

0 = First

Quarter

0 = No

0 to 56K

1 = RS-232

3 to 9600

User

Setting

Publication

1403-5.1

Page 9

Catalog Number Explanation

Communications Cards

Appendix A

1403

Bulletin Number Type of Device

Power Quality and

1403 = Plug-in Communications Card for Bulletin 1403-MM Devices

Automation Products

- NSC

NSC =

(RS-232C / RS-485 / Allen-Bradley R I/O Protocols)

Publication

1403-5.1

Page 10

A–2 Catalog Number Explanation

Publication

1403-5.1

Page 11

Appendix B

Block Transfer Read/

Smart Communication Card Data Tables

Table B.1 Data Table List

Table Name

Device Configuration Data Table 32 44

Smart Communication Card Data Table 21 30

Command Data Table 12 22 Block Transfer Write B–5

Bit Fields for Command Data Table

(Command Word 1)

Bit Fields for Command Data Table

(Command Word 2)

Voltage/Current Data 23 53 Block Transfer Read B–6

Real Time Power Data 25 62 Block Transfer Read B–7

Cumulative Power Data 7 45 Block Transfer Read B–9

Demand Data 18 42 Block Transfer Read B–10

Event Log 12 23 Block Transfer Read B–11

Voltage/Current/Miscellaneous Snapshot Log

Data Table

Power Snapshot Log Data Table 30 59 Block Transfer Read B–13

Min_Max Log 8 24 Block Transfer Read B–15

Log Selection Command Table 4 9 Block Transfer Write B–16

Available Min/Max Log Parameters 84 — — B–17

Even Harmonic Distortion Table 29 60 Block Transfer Read B–18

Odd Harmonic Distortion Table 29 61 Block Transfer Read B–19

Even Harmonic Magnitude Data Table 29 58 Block Transfer Read B–21

Odd Harmonic Magnitude Data Table 29 57 Block Transfer Read B–22

Even Harmonic Phase Angle Data Table 29 56 Block Transfer Read B–24

Odd Harmonic Phase Angle Data Table 29 55 Block Transfer Read B–25

Oscillogram Capture Data 54 63 Block Transfer Read B–27

Diagnostic Data Table (Self-test Results) 35 39 Block Transfer Read B–29

Setpoint Setup Data Table 9 20

Setpoint Type — — — B–31

Setpoint Action — — — B–31

Relay/Setpoint Status Table 29 38 Block Transfer Read B–32

Status Inputs Bitfield Definitions 16 bits — — B–33

Alarm Word Bitfield Definitions 16 bits — — B–33

Setpoint Status Bitfield Definitions 16 bits — — B–33

Number of

Parameters

— — — B–6

— — — B–6

28 54 Block Transfer Read B–12

ID/Number

of Words

Type of Table Page

Block Transfer Read/

Write

Block Transfer Read/

Write

Block Transfer Read/

Write

B–2

B–4

–

B–30

Publication

1403-5.1

Page 12

B–2 Smart Communication Card Data Tables

БББББББББ

БББББББББ

Á

Á

Á

БББББББББ

Á

Á

Á

БББББББББ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

БББББББББ

Á

Á

Á

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

БББББББББ

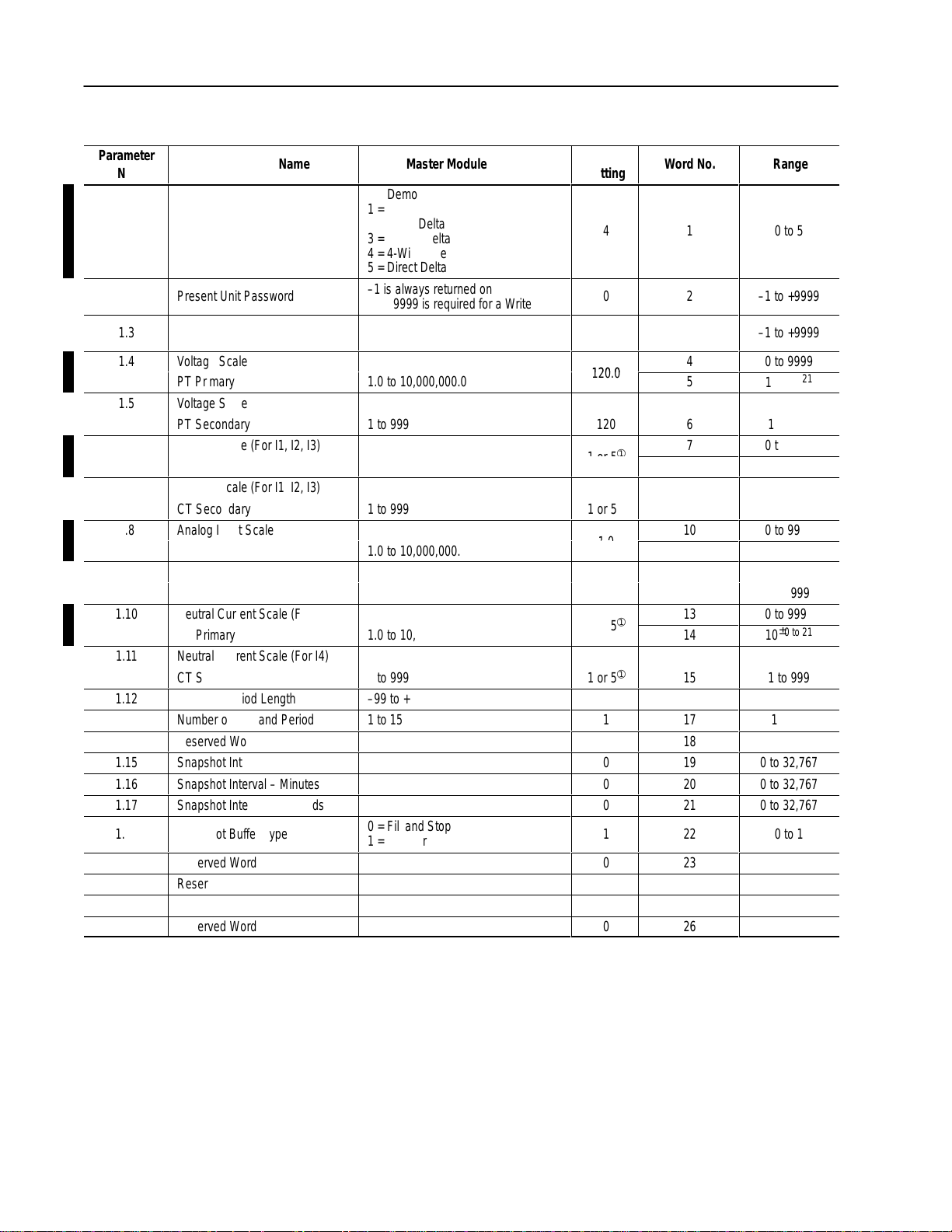

Table B.2 Device Configuration Data Table – Write and Read

Parameter

No.

ÁÁÁ

1.1

ÁÁÁ

ÁÁÁ

1.2

ÁÁÁ

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

1.11

1.12

1.13

1.14

1.15

1.16

1.17

1.18

Parameter Name

ББББББББ

Voltage Mode

ББББББББ

ББББББББ

Present Unit Password

ББББББББ

New Password

Voltage Scale

PT Primary

Voltage Scale

PT Secondary

Current Scale (For I1, I2, I3)

CT Primary

Current Scale (For I1, I2, I3)

CT Secondary

Analog Input Scale

PT Primary

Analog Input Scale

PT Secondary

Neutral Current Scale (For I4)

CT Primary

Neutral Current Scale (For I4)

CT Secondary

Demand Period Length

Number of Demand Periods

Reserved Word

Snapshot Interval – Hours

Snapshot Interval – Minutes

Snapshot Interval – Seconds

Snapshot Buffer Type

Reserved Word

Reserved Word

Reserved Word

Reserved Word

Master Module Range

0 = Demo

1 = Single

ББББББББ

2 = Open Delta

ББББББББ

3 = 3-Wire Delta

4 = 4-Wire Wye

ББББББББ

5 = Direct Delta

–1 is always returned on a Read

0 to 9999 is required for a Write

ББББББББ

–1 does not change the password

0 to 9999 is new password value

1.0 to 10,000,000.0

1 to 999

1.0 to 10,000,000.0

1 to 999

1.0 to 10,000,000.0

1 to 999

1.0 to 10,000,000.0

1 to 999

–99 to +99

1 to 15

0 = Fill and Stop

1 = Circular

Default

Setting

ÁÁ

4

ÁÁ

ÁÁ

0

ÁÁ

0

120.0

120

1 or 5

1 or 5

1.0

1

1 or 5

1 or 5

1

1

0

0

0

0

1

0

0

0

0

Word No.

ÁÁÁÁ

1

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ2ÁÁÁÁ

3

4

5

6

➀

➀

7

8

➀

9

10

11

12

➀

➀

13

14

➀

15

16

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

–1 to +9999

–1 to +9999

0 to 9999

10

1 to 999

0 to 9999

10

1 to 999

0 to 9999

10

1 to 999

0 to 9999

10

1 to 999

–99 to +99

17

18

19

20

21

0 to 32,767

0 to 32,767

0 to 32,767

22

23

24

25

26

Range

0 to 5

±

0 to 21

±

0 to 21

±

0 to 21

±

0 to 21

1 to 15

0 to 1

Publication

1403-5.1

Page 13

B–3Smart Communication Card Data Tables

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

0

Á

Á

Á

Á

Á

0

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

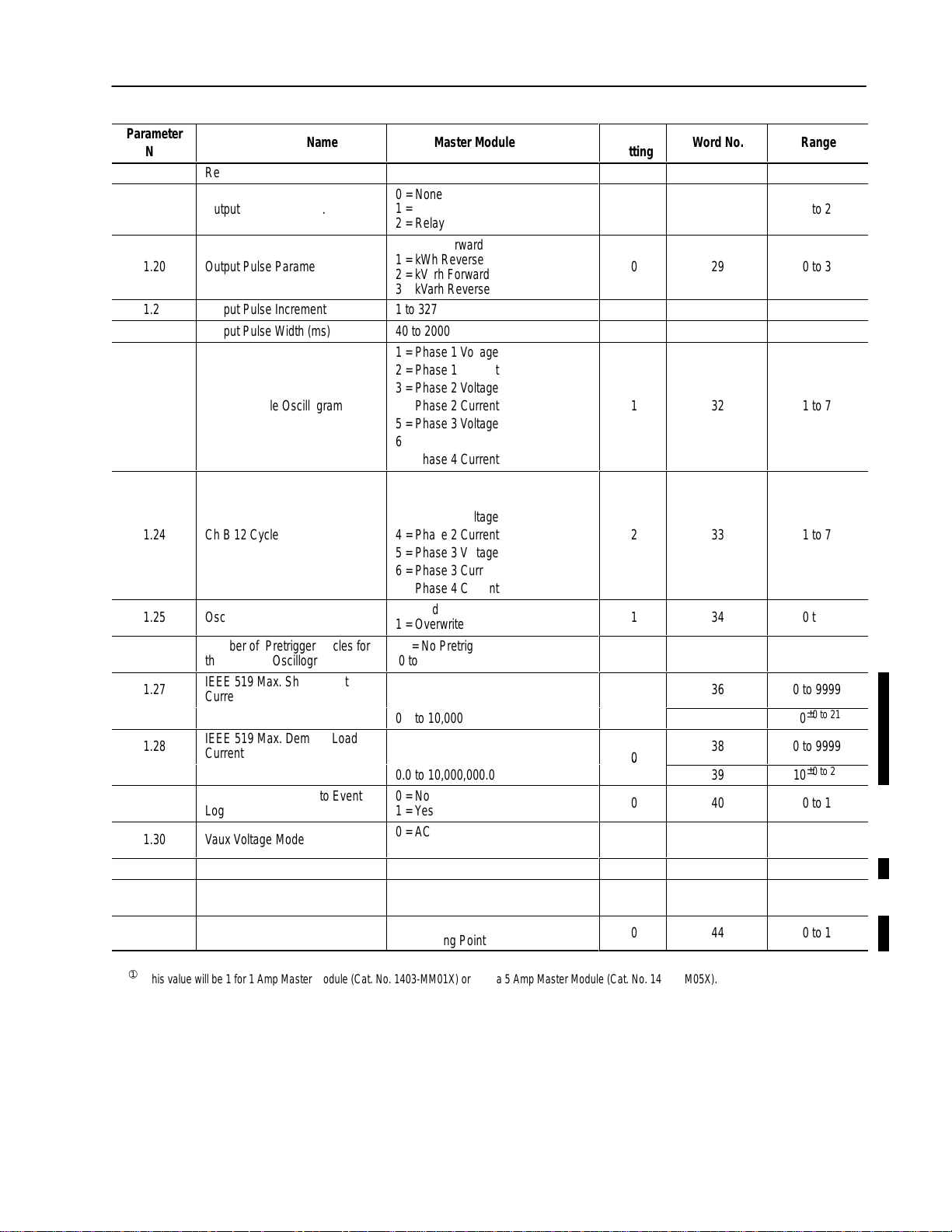

Parameter

No.

1.19

ÁÁÁ

ÁÁÁ

1.20

ÁÁÁ

1.21

1.22

ÁÁÁ

ÁÁÁ

1.23

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

1.24

ÁÁÁ

ÁÁÁ

ÁÁÁ

1.25

1.26

ÁÁÁ

1.27

1.28

ÁÁÁ

1.29

ÁÁÁ

1.30

1.31

1.32

ÁÁÁ

1.33

Parameter Name

Reserved Word

Output Pulse Relay No.

БББББББ

БББББББ

Output Pulse Parameter

БББББББ

Output Pulse Increment

Output Pulse Width (ms)

БББББББ

БББББББ

Ch A 12 Cycle Oscillogram

БББББББ

БББББББ

БББББББ

БББББББ

Ch B 12 Cycle Oscillogram

БББББББ

БББББББ

БББББББ

Oscillography Type

Number of Pretrigger Cycles for

the 12 Cycle Oscillogram

БББББББ

IEEE 519 Max. Short Circuit

Current

IEEE 519 Max. Demand/Load

Current

БББББББ

Save Status Changes to Event

БББББББ

Log

Vaux Voltage Mode

Enable THD

Enable Min_Max Log

БББББББ

Data Format

Master Module Range

0 = None

1 = Relay 1

ББББББББ

2 = Relay 2

0 = kWh Forward

ББББББББ

1 = kWh Reverse

2 = kVarh Forward

ББББББББ

3 = kVarh Reverse

1 to 32766

40 to 2000

1 = Phase 1 Voltage

2 = Phase 1 Current

ББББББББ

3 = Phase 2 Voltage

ББББББББ

4 = Phase 2 Current

5 = Phase 3 Voltage

ББББББББ

6 = Phase 3 Current

ББББББББ

7 = Phase 4 Current

1 = Phase 1 Voltage

ББББББББ

2 = Phase 1 Current

3 = Phase 2 Voltage

ББББББББ

4 = Phase 2 Current

ББББББББ

5 = Phase 3 Voltage

ББББББББ

6 = Phase 3 Current

7 = Phase 4 Current

ББББББББ

0 = Hold

1 = Overwrite

–1 = No Pretrig

0 to +8 = Cycles

ББББББББ

0.0 to 10,000,000.0

ББББББББÁÁ

0.0 to 10,000,000.0

0 = No

ББББББББ

1 = Yes

0 = AC

1 = DC

0 or 1

0 = No

ББББББББ

1 = Yes

0 = Integer/Exponent

1 = Floating Point

Default

Setting

0

0

Á

Á

0

Á

1

100

Á

Á

1

Á

Á

Á

Á

2

Á

Á

Á

1

0

Á

0

0

0

Á

0

1

1

Á

0

Word No.

27

28

ÁÁÁÁ

ÁÁÁÁ

29

ÁÁÁÁ

30

31

ÁÁÁÁ

ÁÁÁÁ

32

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

33

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

34

35

ÁÁÁÁ

36

37

38

ÁÁÁÁ

39

40

ÁÁÁÁ

41

42

43

ÁÁÁÁ

44

Range

0 to 2

ÁÁÁ

ÁÁÁ

0 to 3

ÁÁÁ

1 to 32766

40 to 2000

ÁÁÁ

ÁÁÁ

1 to 7

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

1 to 7

ÁÁÁ

ÁÁÁ

ÁÁÁ

0 to 1

–1 to +8

ÁÁÁ

0 to 9999

±

0 to 21

10

0 to 9999

ÁÁÁ

±

0 to 21

10

0 to 1

ÁÁÁ

0 to 1

0 to 1

0 to 1

ÁÁÁ

0 to 1

➀

This

value will be 1 for 1 Amp Master Module (Cat. No. 1403-MM01X) or 5 for a 5 Amp Master Module (Cat. No. 1403-MM05X).

Publication

1403-5.1

Page 14

B–4 Smart Communication Card Data Tables

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

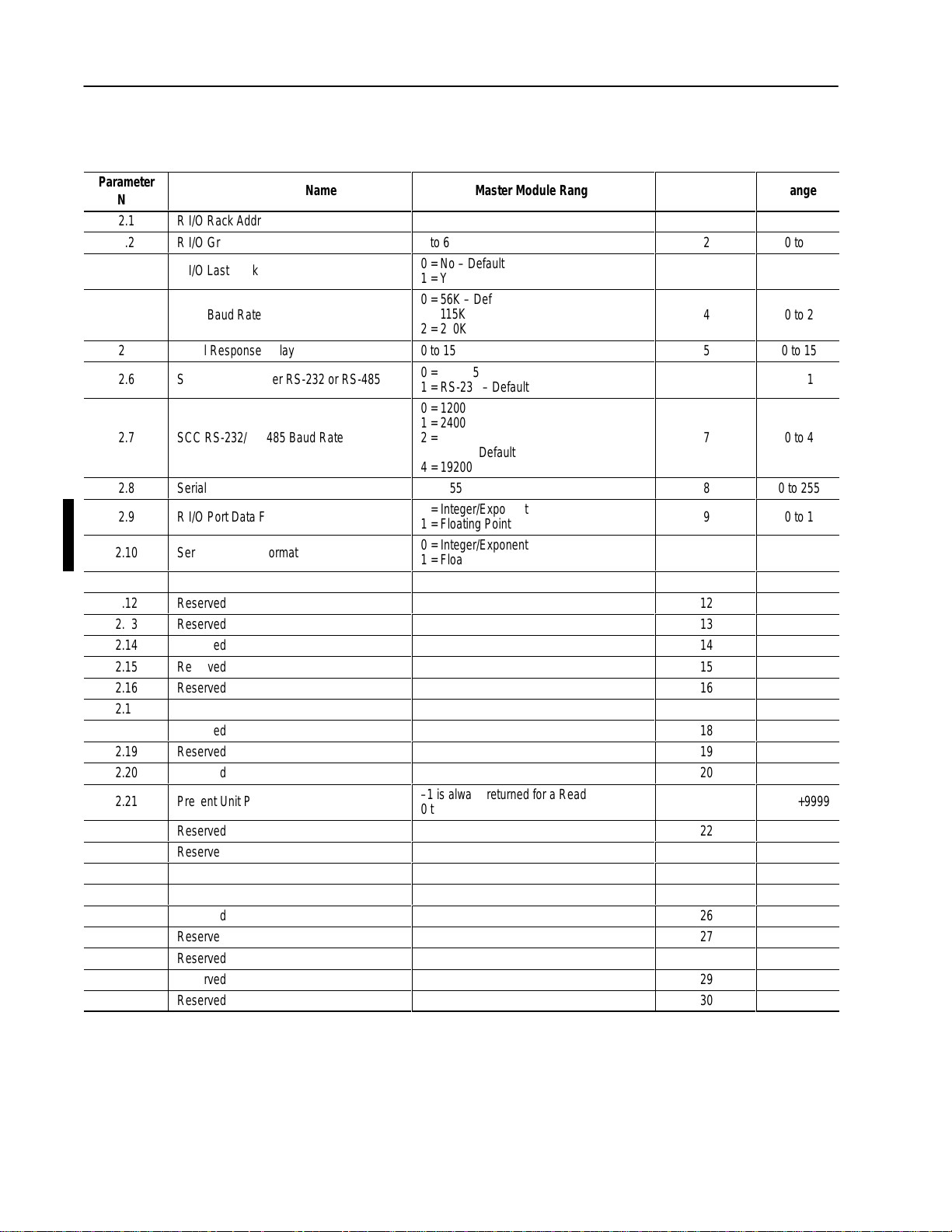

Á

Table B.3 Smart Communication Card Data Table – Write and Read

Note: The device will not respond to a broadcast of this table.

Parameter

No.

2.1

2.2

2.3

ÁÁÁ

2.4

ÁÁÁ

2.5

2.6

ÁÁÁ

2.7

ÁÁÁ

ÁÁÁ

2.8

2.9

ÁÁÁ

2.10

2.11

2.12

2.13

2.14

2.15

2.16

2.17

2.18

2.19

2.20

2.21

ÁÁÁ

Parameter Name

R I/O Rack Address

R I/O Group Number

R I/O Last Rack

ББББББББББ

R I/O Baud Rate

ББББББББББ

Serial Response Delay

Serial Type Specifier RS-232 or RS-485

ББББББББББ

SCC RS-232/RS-485 Baud Rate

ББББББББББ

ББББББББББ

Serial Device Identifier

R I/O Port Data Format

ББББББББББ

Serial Port Data Format

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Present Unit Password

ББББББББББ

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Reserved

Master Module Range

0 to 63

0 to 6

0 = No – Default

1 = Yes

БББББББББ

0 = 56K – Default

1 = 115K

2 = 230K

БББББББББ

0 to 15

0 = RS-485

1 = RS-232 – Default

0 = 1200

1 = 2400

БББББББББ

2 = 4800

БББББББББ

3 = 9600 – Default

4 = 19200

БББББББББ

0 to 255

0 = Integer/Exponent

БББББББББ

1 = Floating Point

0 = Integer/Exponent

1 = Floating Point

–1 is always returned for a Read

БББББББББ

0 to 9999 is required for a Write

PLC Word No.

1

2

3

ÁÁÁ

4

ÁÁÁ

5

6

ÁÁÁ

7

ÁÁÁ

ÁÁÁ

8

9

ÁÁÁ

10

11

12

13

14

15

16

17

18

19

20

21

ÁÁÁ

22

23

24

25

26

27

28

29

30

Range

0 to 63

0 to 6

0 to 1

ÁÁÁ

0 to 2

ÁÁÁ

0 to 15

0 to 1

ÁÁÁ

0 to 4

ÁÁÁ

ÁÁÁ

0 to 255

0 to 1

ÁÁÁ

0 to 1

–1 to +9999

ÁÁÁ

Publication

1403-5.1

Page 15

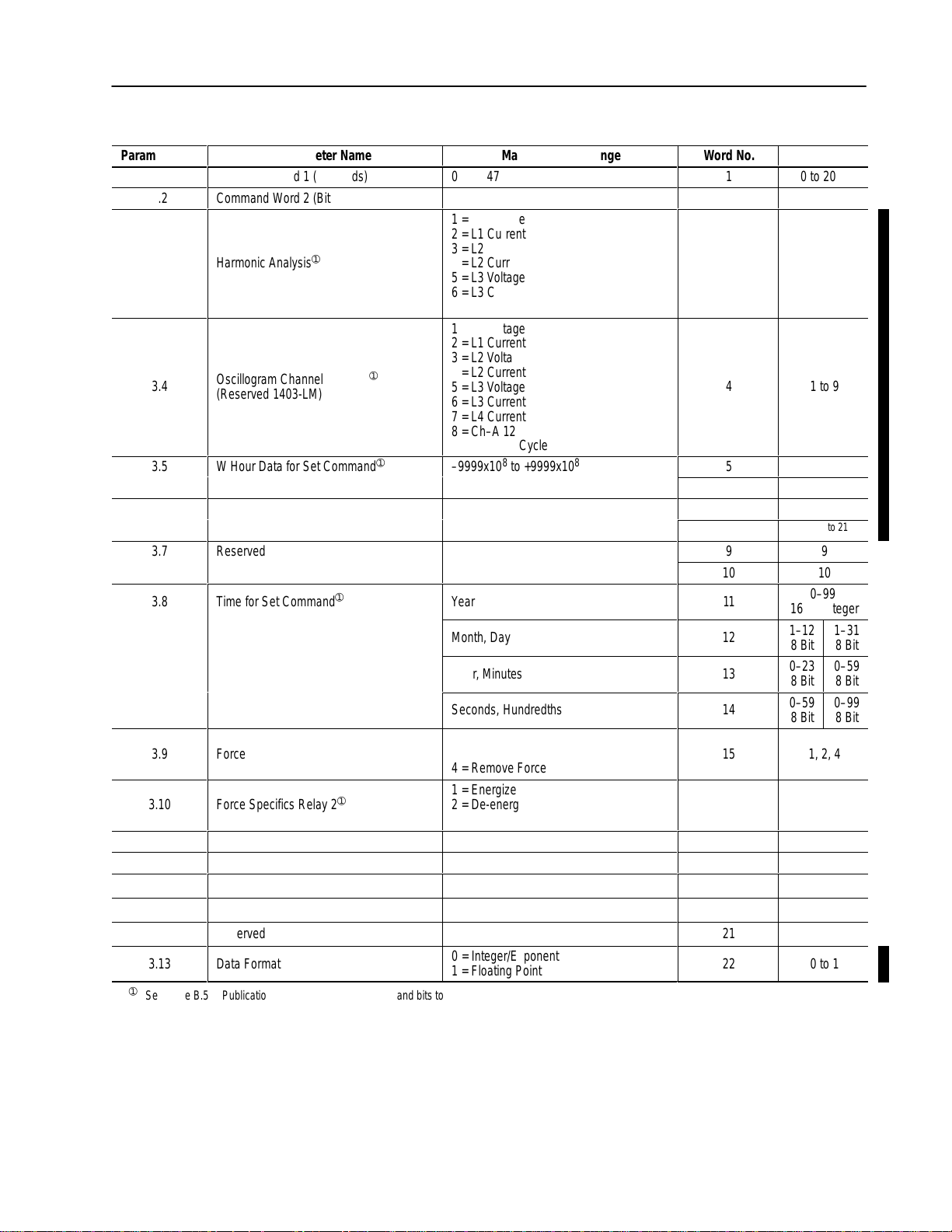

Table B.4 Command Data Table Write

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

B–5Smart Communication Card Data Tables

Parameter No.

3.1

3.2

Command Word 1 (Bit Fields)

Command Word 2 (Bit Fields)

Parameter Name

Master Module Range

0 to 2047

0 to 511

1 = L1 Voltage

ÁÁÁ

ÁÁÁ

3.3

ÁÁÁ

ÁÁÁ

БББББББББ

БББББББББ

Harmonic Analysis

БББББББББ

БББББББББ

➀

БББББББББ

2 = L1 Current

3 = L2 Voltage

БББББББББ

4 = L2 Current

5 = L3 Voltage

БББББББББ

6 = L3 Current

БББББББББ

7 = L4 Current

1 = L1 Voltage

ÁÁÁ

ÁÁÁ

3.4

ÁÁÁ

ÁÁÁ

ÁÁÁ

3.5

3.6

3.7

3.8

ÁÁÁ

ÁÁÁÁБББББББББÁБББББББББ

БББББББББ

БББББББББ

Oscillogram Channel Request

(Reserved 1403-LM)

БББББББББ

БББББББББ

БББББББББ

W Hour Data for Set Command

➀

➀

VAR Hour Data for Set Command➀–9999x108 to +9999x10

Reserved

Time for Set Command

БББББББББ

➀

2 = L1 Current

БББББББББ

3 = L2 Voltage

4 = L2 Current

БББББББББ

5 = L3 Voltage

БББББББББ

6 = L3 Current

7 = L4 Current

БББББББББ

8 = Ch–A 12 Cycle

9 = Ch–B 12 Cycle

БББББББББ

–9999x108 to +9999x10

8

8

Year

БББББББББ

Month, Day

Hour, Minutes

ÁÁÁ

ÁÁÁÁБББББББББÁБББББББББ

3.9

ÁÁÁ

3.10

ÁÁÁ

3.11

3.12

БББББББББ

Force Specifics Relay 1

БББББББББ

Force Specifics Relay 2

БББББББББ

Setpoint Number

➀

➀

➀

Present Unit Password

БББББББББ

Seconds, Hundredths

1 = Energize

2 = De-energize

БББББББББ

4 = Remove Force

1 = Energize

2 = De-energize

БББББББББ

4 = Remove Force

1 to 20

0 to 9999

Reserved

Reserved

Reserved

3.13

ÁÁÁ

➀

See T

able B.5 in Publication 1403-5.1 for specific command bits to

enable these features.

Data Format

БББББББББ

0 = Integer/Exponent

1 = Floating Point

БББББББББ

Word No.

1

2

ÁÁÁ

ÁÁÁ

3

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

4

ÁÁÁ

ÁÁÁ

ÁÁÁ

5

6

7

8

9

10

Range

0 to 2047

0 to 511

ÁÁÁ

ÁÁÁ

1 to 7

ÁÁÁ

ÁÁÁ

ÁÁÁ

ÁÁÁ

1 to 9

ÁÁÁ

ÁÁÁ

ÁÁÁ

–9999 to 9999

±

0 to 21

10

–9999 to 9999

±

0 to 21

10

9

10

0–99

ÁÁÁ11ÁÁÁ

12

ÁÁÁ

ÁÁÁ13Á

14

ÁÁÁ

15

ÁÁÁ

16

ÁÁÁ

17

18

16 Bit Integer

1–12

1–31

Á

Á

ÁÁÁ

ÁÁÁ

8 Bit

0–23

8 Bit

0–59

8 Bit

1, 2, 4

1, 2, 4

Á

8 Bit

0–59

8 Bit

Á

0–99

Á

8 Bit

1 to 20

0 to 9999

19

20

21

22

ÁÁÁ

0 to 1

ÁÁÁ

Publication

1403-5.1

Page 16

B–6 Smart Communication Card Data Tables

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

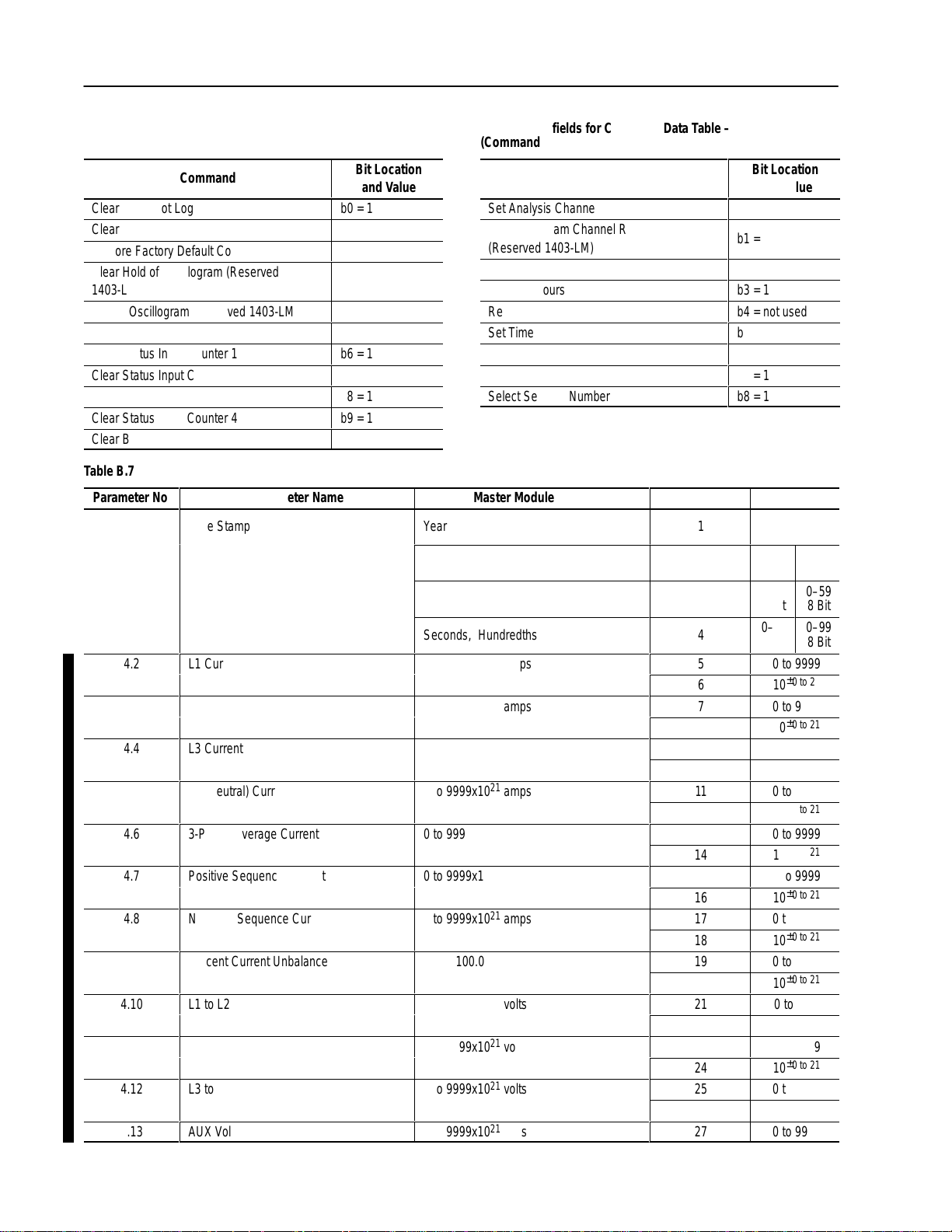

Table B.5 Bit Fields for Command Data Table –

(Command Word 1)

БББББББББ

Command

Clear Snapshot Log

Clear Min_Max Log

Restore Factory Default Configuration

Clear Hold of Oscillogram (Reserved

БББББББББ

1403-LM)

Initiate Oscillogram (Reserved 1403-LM)

Force Self Test

Clear Status Input Counter 1

Clear Status Input Counter 2

Clear Status Input Counter 3

Clear Status Input Counter 4

БББББББББ

Clear Battery Usage Timer

Bit Location

ÁÁÁÁ

and Value

b0 = 1

b1 = 1

b2 = 1

b3 = 1

ÁÁÁÁ

b4 = 1

b5 = 1

b6 = 1

b7 = 1

b8 = 1

b9 = 1

ÁÁÁÁ

b10 = 1

Table B.6 Bit fields for Command Data Table –

(Command Word 2)

БББББББББ

Command

Set Analysis Channel Request

Set Oscillogram Channel Request

(Reserved 1403-LM)

Set W Hours

Set VAR Hours

Reserved

Set Time

Relay 1

Relay 2

Select Setpoint Number

Table B.7 Voltage/Current Data – Read

Parameter No.

4.1

ÁÁÁÁБББББББББÁБББББББББ

Time Stamp

Parameter Name

Master Module Range

Year

Month, Date

Hour, Minute

ÁÁÁÁБББББББББÁБББББББББ

4.2

4.3

L1 Current

L2 Current

Seconds, Hundredths

0 to 9999x1021 amps

0 to 9999x1021 amps

4.4

4.5

4.6

4.7

4.8

ÁÁÁ

L3 Current

L4 (Neutral) Current

3-Phase Average Current

Positive Sequence Current

Negative Sequence Current

БББББББББ

0 to 9999x1021 amps

0 to 9999x1021 amps

0 to 9999x1021 amps

0 to 9999x1021 amps

0 to 9999x1021 amps

БББББББББ

4.9

4.10

4.11

4.12

ÁÁÁ

4.13

Percent Current Unbalance

L1 to L2 Voltage

L2 to L3 Voltage

L3 to L1 Voltage

БББББББББ

AUX Voltage

0.0 to 100.0

0 to 9999x1021 volts

0 to 9999x1021 volts

0 to 9999x1021 volts

БББББББББ

0 to 9999x1021 volts

Bit Location

ÁÁÁÁ

and Value

b0 = 1

b1 = 1

b2 = 1

b3 = 1

b4 = not used

b5 = 1

b6 = 1

b7 = 1

b8 = 1

Word No.

1

2

ÁÁÁ

3

4

ÁÁÁ

5

6

7

8

9

10

11

12

13

14

15

16

ÁÁÁ17ÁÁÁ

18

19

20

21

22

23

24

25

ÁÁÁ26ÁÁÁ

27

Range

0–99

16 Bit Integer

1–12

1–31

Á

8 Bit

0–23

8 Bit

0–59

Á

8 Bit

Á

8 Bit

0–59

8 Bit

0–99

Á

8 Bit

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

Publication

1403-5.1

Page 17

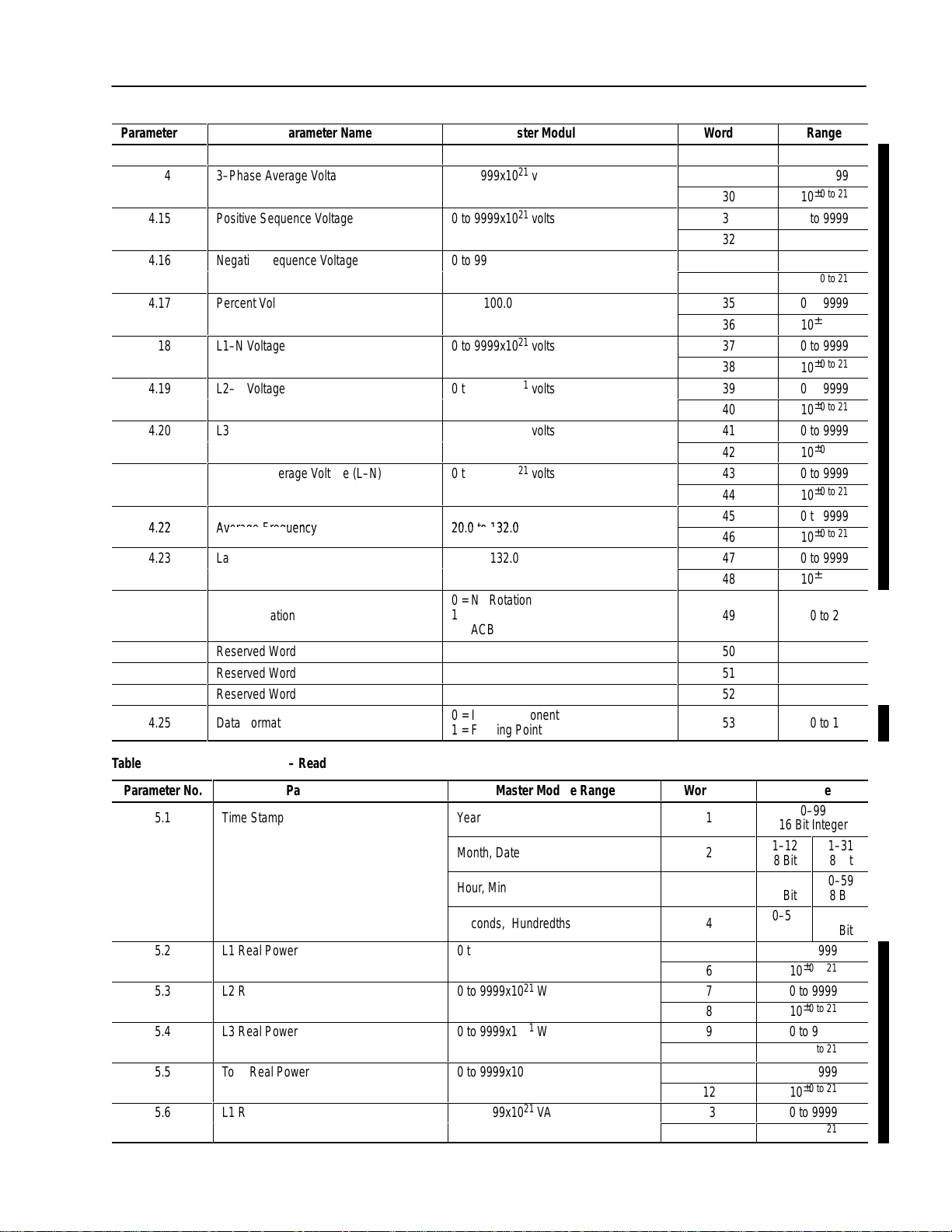

B–7Smart Communication Card Data Tables

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Parameter No.

4.14

4.15

4.16

4.17

4.18

ÁÁÁ

4.19

4.20

4.21

4.22

4.23

4.24

ÁÁÁ

4.25

ÁÁÁ

Parameter Name

3–Phase Average Voltage (L–L)

Positive Sequence Voltage

Negative Sequence Voltage

Percent Voltage Unbalance

L1–N Voltage

БББББББББ

L2–N Voltage

L3–N Voltage

3–Phase Average Voltage (L–N)

Average Frequency

Last Cycle Frequency

Phase Rotation

БББББББББ

Reserved Word

Reserved Word

Reserved Word

Data Format

БББББББББ

Master Module Range

0 to 9999x1021 volts

0 to 9999x1021 volts

0 to 9999x1021 volts

0.0 to 100.0

0 to 9999x1021 volts

БББББББББ

0 to 9999x1021 volts

0 to 9999x1021 volts

0 to 9999x1021 volts

20.0 to 132.0

20.0 to 132.0

0 = No Rotation

1 = ABC

БББББББББ

2 = ACB

0 = Integer/Exponent

1 = Floating Point

БББББББББ

Word No.

28

29

30

31

32

33

34

35

36

ÁÁÁ37ÁÁÁ

38

39

40

41

42

43

44

45

46

47

48

49

ÁÁÁ

Range

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 2

ÁÁÁ

50

51

52

53

ÁÁÁ

0 to 1

ÁÁÁ

Table B.8 Real Time Power Data – Read

Parameter No.

5.1

ÁÁÁ

ÁÁÁÁБББББББББÁББББББББ

Time Stamp

БББББББББ

Parameter Name

Master Module Range

Year

ББББББББ

Month, Date

Hour, Minute

ÁÁÁ

ÁÁÁÁБББББББББÁББББББББ

5.2

БББББББББ

L1 Real Power

ББББББББ

Seconds, Hundredths

0 to 9999x1021 W

5.3

5.4

5.5

5.6

L2 Real Power

L3 Real Power

Total Real Power

L1 Reactive Power

0 to 9999x1021 W

0 to 9999x1021 W

0 to 9999x1021 W

0 to 9999x1021 VAR

Word No.

1

ÁÁÁ

2

ÁÁÁ

Range

16 Bit Integer

ÁÁÁÁ

1–12

ÁÁ

8 Bit

0–23

ÁÁÁ3ÁÁ

4

ÁÁÁ

5

6

7

8

9

10

11

12

13

14

8 Bit

0–59

ÁÁ

8 Bit

0 to 9999

10

0 to 9999

10

0 to 9999

10

0 to 9999

10

0 to 9999

10

Publication

0–99

1–31

ÁÁ

8 Bit

0–59

8 Bit

ÁÁ

0–99

ÁÁ

8 Bit

±

0 to 21

±

0 to 21

±

0 to 21

±

0 to 21

±

0 to 21

1403-5.1

Page 18

B–8 Smart Communication Card Data Tables

Á

Á

Á

Á

Á

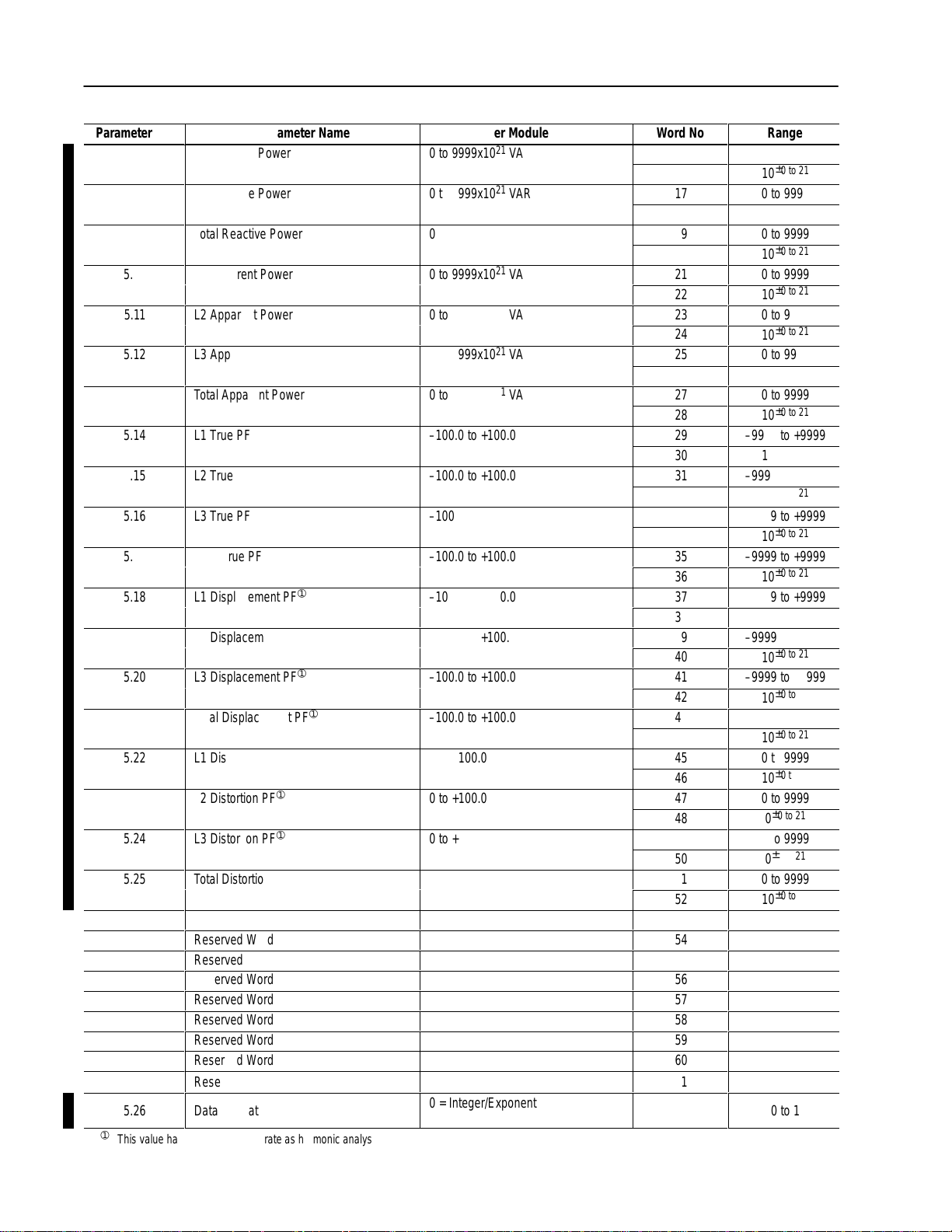

Parameter No.

5.7

5.8

5.9

5.10

5.11

5.12

5.13

5.14

5.15

5.16

5.17

5.18

5.19

5.20

5.21

5.22

5.23

5.24

5.25

L2 Reactive Power

L3 Reactive Power

Total Reactive Power

L1 Apparent Power

L2 Apparent Power

L3 Apparent Power

Total Apparent Power

L1 True PF

L2 True PF

L3 True PF

Total True PF

L1 Displacement PF

L2 Displacement PF

L3 Displacement PF

Total Displacement PF

L1 Distortion PF

L2 Distortion PF

L3 Distortion PF

Total Distortion PF

Parameter Name

➀

➀

➀

➀

➀

➀

➀

➀

Reserved Word

Reserved Word

Reserved Word

Reserved Word

Reserved Word

Reserved Word

Reserved Word

Reserved Word

Reserved Word

5.26

ÁÁÁ

➀

This

value has the same update rate as harmonic analysis.

Data Format

БББББББББ

Master Module Range

0 to 9999x1021 VAR

0 to 9999x1021 VAR

0 to 9999x1021 VAR

0 to 9999x1021 VA

0 to 9999x1021 VA

0 to 9999x1021 VA

0 to 9999x1021 VA

–100.0 to +100.0

–100.0 to +100.0

–100.0 to +100.0

–100.0 to +100.0

–100.0 to +100.0

–100.0 to +100.0

–100.0 to +100.0

–100.0 to +100.0

0 to +100.0

0 to +100.0

0 to +100.0

0 to +100.0

0 = Integer/Exponent

ББББББББ

1 = Floating Point

Word No.

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

ÁÁÁ

Range

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

–9999 to +9999

±

0 to 21

10

–9999 to +9999

±

0 to 21

10

–9999 to +9999

±

0 to 21

10

–9999 to +9999

±

0 to 21

10

–9999 to +9999

±

0 to 21

10

–9999 to +9999

±

0 to 21

10

–9999 to +9999

±

0 to 21

10

–9999 to +9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

0

0 to 9999

±

0 to 21

0

0 to 9999

±

0 to 21

10

0 to 1

ÁÁÁÁ

Publication

1403-5.1

Page 19

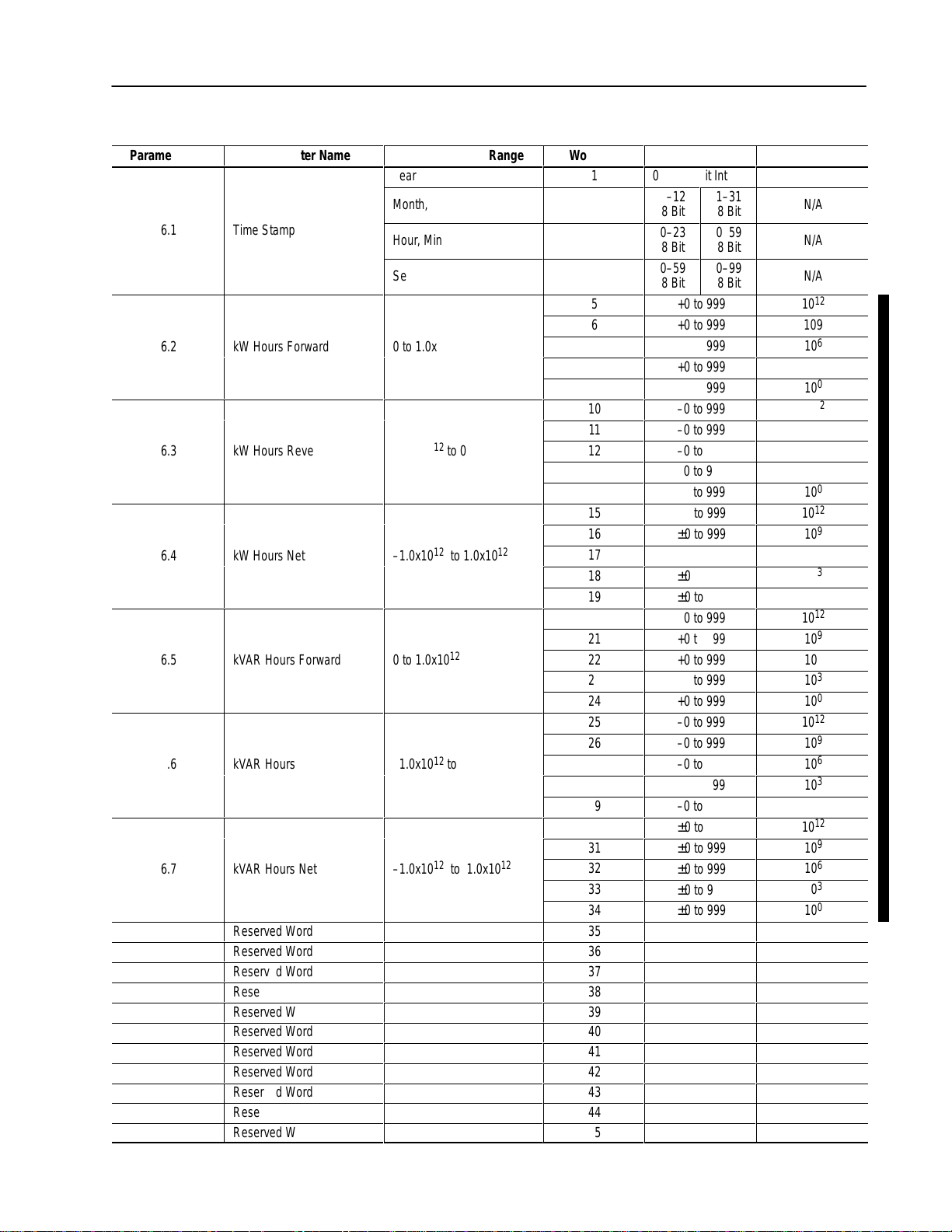

Table B.9 Cumulative Power Data – Read

Á

Á

Á

Á

Á

Á

Á

Á

6.2

kW Hours Forward

0 to 1.0x10

6.3

kW Hours Reverse

1.0x10 to 0

6.4

kW Hours Net

1.0x10 to 1.0x10

6.5

kVAR Hours Forward

0 to 1.0x10

6.6

kVAR Hours Reverse

1.0x10 to 0

6.7

kVAR Hours Net

1.0x10 to 1.0x10

B–9Smart Communication Card Data Tables

Parameter No.

Parameter Name

Master Module Range

Year

ÁÁÁÁÁББББББÁББББББ

6.1

ÁÁÁÁÁББББББÁББББББ

6.2

6.3

6.4

6.5

6.6

6.7

Time Stamp

kW Hours Forward

kW Hours Reverse

kW Hours Net

kVAR Hours Forward

kVAR Hours Reverse

kVAR Hours Net

Month, Date

Hour, Minute

Seconds, Hundredths

0 to 1.0x10

12

–1.0x1012 to 0

–1.0x1012 to 1.0x10

0 to 1.0x10

12

12

–1.0x1012 to 0

–1.0x1012 to 1.0x10

12

Reserved Word

Reserved Word

Reserved Word

Reserved Word

Reserved Word

Reserved Word

Reserved Word

Reserved Word

Reserved Word

Reserved Word

Reserved Word

Word No.

1

0–99 16 Bit Integer

1–12

ÁÁÁÁ2ÁÁ

3

8 Bit

0–23

8 Bit

0–59

ÁÁÁÁ4ÁÁ

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

8 Bit

+0 to 999

+0 to 999

+0 to 999

+0 to 999

+0 to 999

–0 to 999

–0 to 999

–0 to 999

–0 to 999

–0 to 999

±

±

±

±

±

+0 to 999

+0 to 999

+0 to 999

+0 to 999

+0 to 999

–0 to 999

–0 to 999

–0 to 999

–0 to 999

–0 to 999

±

±

±

±

±

35

36

37

38

39

40

41

42

43

44

45

Range

1–31

Á

8 Bit

0–59

8 Bit

0–99

Á

8 Bit

0 to 999

0 to 999

0 to 999

0 to 999

0 to 999

0 to 999

0 to 999

0 to 999

0 to 999

0 to 999

Modulus

N/A

ÁÁÁÁ

N/A

N/A

ÁÁÁÁ

12

10

109

6

10

3

10

0

10

12

10

9

10

6

10

3

10

0

10

12

10

9

10

6

10

3

10

0

10

12

10

9

10

6

10

3

10

0

10

12

10

9

10

6

10

3

10

0

10

12

10

9

10

6

10

3

10

0

10

Publication

1403-5.1

Page 20

B–10 Smart Communication Card Data Tables

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

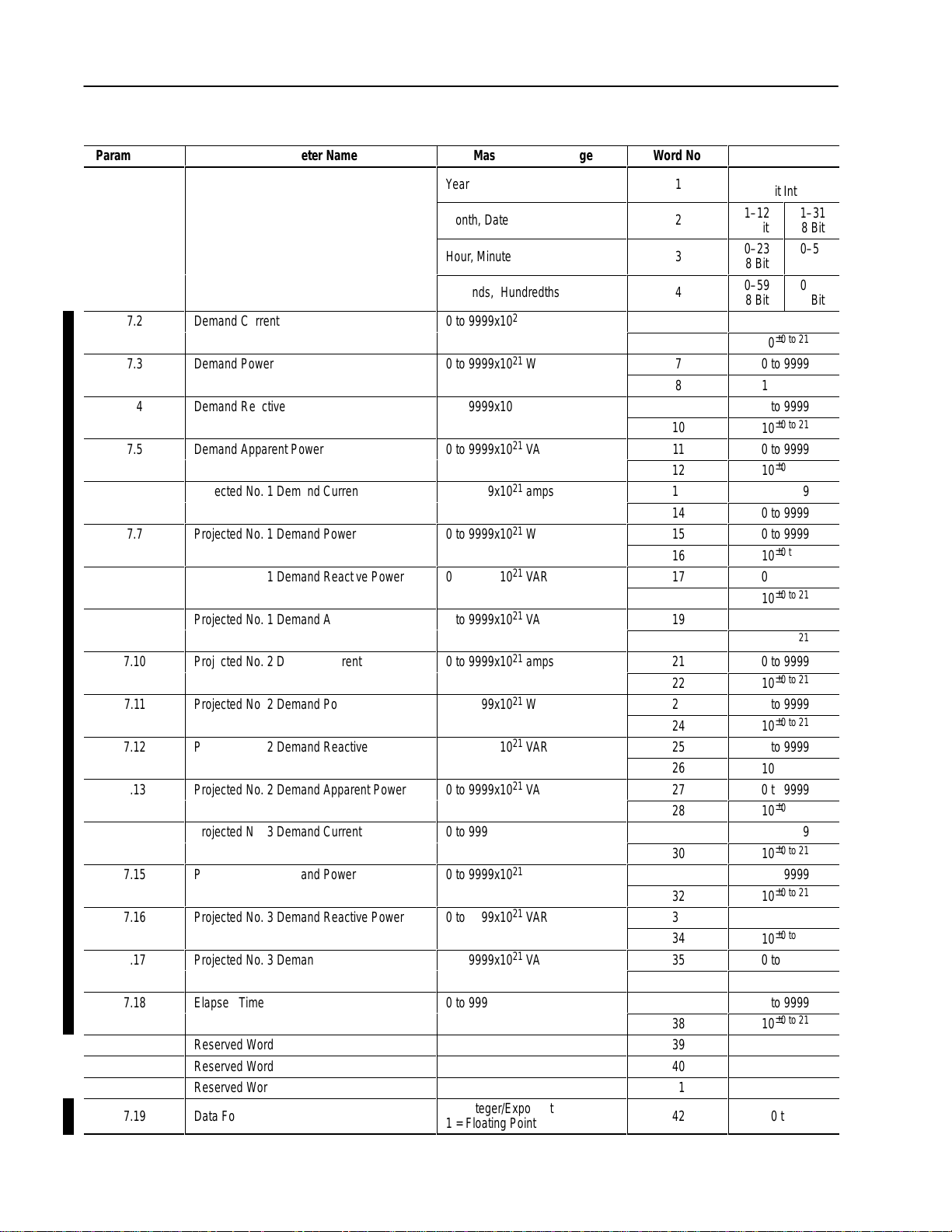

Table B.10 Demand Data – Read

Parameter No.

7.1

ÁÁÁ

Time Stamp

ББББББББББ

Parameter Name

Master Module Range

Year

БББББББ

Month, Date

ÁÁÁ

ÁÁÁÁББББББББББÁБББББББ

ББББББББББ

БББББББ

Hour, Minute

Seconds, Hundredths

ÁÁÁÁББББББББББÁБББББББ

7.2

7.3

7.4

7.5

7.6

7.7

7.8

7.9

7.10

7.11

ÁÁÁ

7.12

7.13

7.14

7.15

7.16

7.17

7.18

Demand Current

Demand Power

Demand Reactive Power

Demand Apparent Power

Projected No. 1 Demand Current

Projected No. 1 Demand Power

Projected No. 1 Demand Reactive Power

Projected No. 1 Demand Apparent Power

Projected No. 2 Demand Current

Projected No. 2 Demand Power

ББББББББББ

Projected No. 2 Demand Reactive Power

Projected No. 2 Demand Apparent Power

Projected No. 3 Demand Current

Projected No. 3 Demand Power

Projected No. 3 Demand Reactive Power

Projected No. 3 Demand Apparent Power

Elapsed Time

0 to 9999x1021 amps

0 to 9999x1021 W

0 to 9999x1021 VAR

0 to 9999x1021 VA

0 to 9999x1021 amps

0 to 9999x1021 W

0 to 9999x1021 VAR

0 to 9999x1021 VA

0 to 9999x1021 amps

0 to 9999x1021 W

БББББББ

0 to 9999x1021 VAR

0 to 9999x1021 VA

0 to 9999x1021 amps

0 to 9999x1021 W

0 to 9999x1021 VAR

0 to 9999x1021 VA

0 to 9999x10

21

Reserved Word

Reserved Word

Reserved Word

7.19

ÁÁÁ

Data Format

ББББББББББ

0 = Integer/Exponent

БББББББ

1 = Floating Point

Word No.

1

ÁÁÁ

ÁÁÁ2Á

3

ÁÁÁ

4

ÁÁÁ

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

ÁÁÁ23ÁÁÁÁ

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

Range

0–99

ÁÁÁÁ

16 Bit Integer

1–12

8 Bit

0–23

Á

8 Bit

0–59

8 Bit

Á

1–31

8 Bit

ÁÁ

0–59

ÁÁ

8 Bit

0–99

8 Bit

ÁÁ

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

0 to 9999

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

39

40

41

42

ÁÁÁ

0 to 1

ÁÁÁÁ

Publication

1403-5.1

Page 21

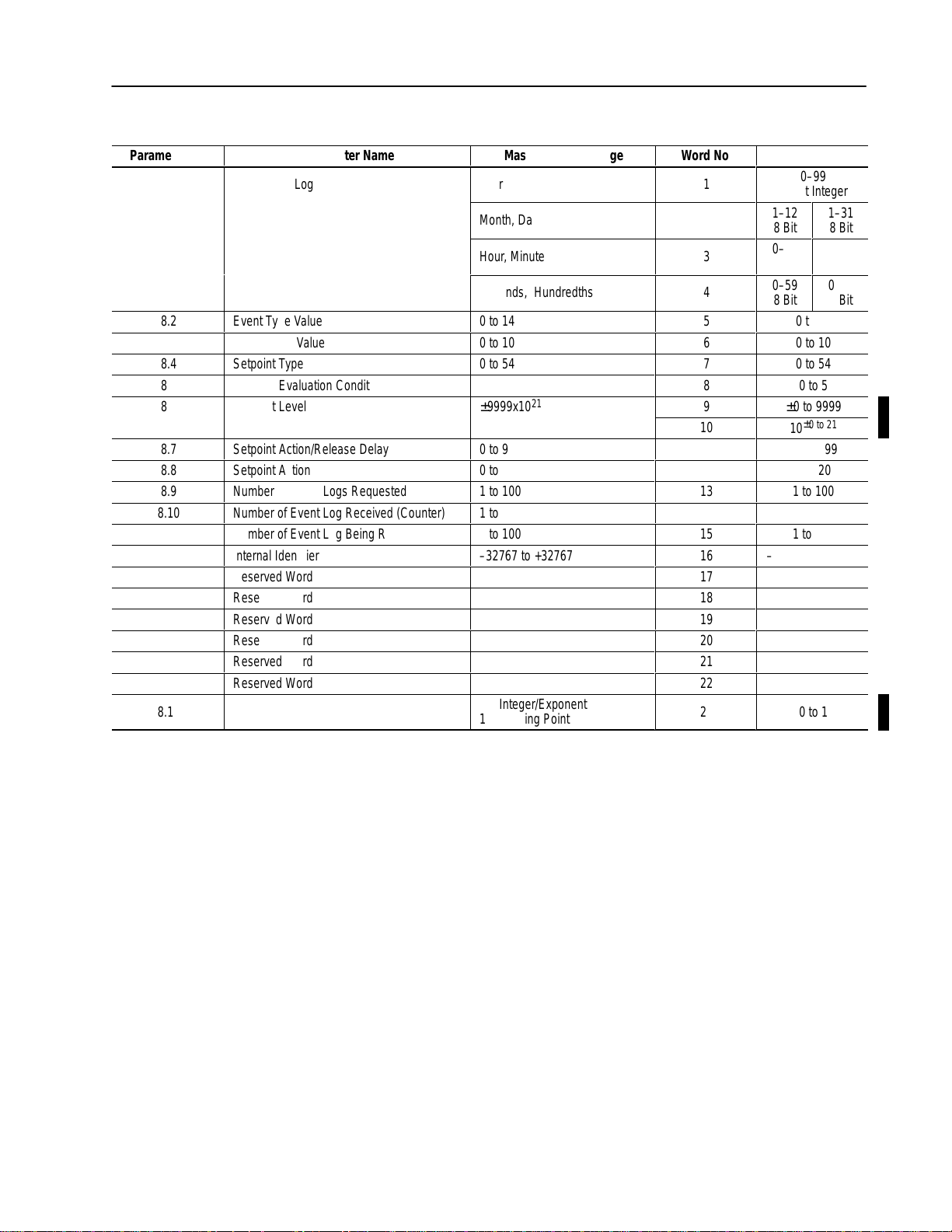

Table B.11 Event Log – Read

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

B–11Smart Communication Card Data Tables

Parameter No.

8.1

ÁÁÁÁ

Event Time Log Stamp

БББББББББ

Parameter Name

Master Module Range

Year

БББББББ

Month, Date

ÁÁÁÁ

ÁÁÁÁÁБББББББББÁБББББББ

БББББББББ

БББББББ

Hour, Minute

Seconds, Hundredths

ÁÁÁÁÁБББББББББÁБББББББ

8.2

8.3

8.4

8.5

8.6

8.7

8.8

8.9

8.10

8.11

8.12

Event Type Value

Event Code Value

Setpoint Type

Setpoint Evaluation Condition

Setpoint Level

Setpoint Action/Release Delay

Setpoint Action

Number of Event Logs Requested

Number of Event Log Received (Counter)

Number of Event Log Being Returned

Internal Identifier

0 to 14

0 to 10

0 to 54

0 to 5

9999x10

21

±

0 to 9999

0 to 20

1 to 100

1 to 100

1 to 100

–32767 to +32767

Reserved Word

Reserved Word

Reserved Word

Reserved Word

Reserved Word

Reserved Word

ÁÁÁÁ

8.13

БББББББББ

Data Format

0 = Integer/Exponent

БББББББ

1 = Floating Point

Word No.

1

ÁÁÁ

Range

ÁÁÁÁ

16 Bit Integer

1–12

ÁÁÁ2ÁÁ

3

ÁÁÁ

4

ÁÁÁ

5

6

7

8

9

10

11

12

13

14

15

16

8 Bit

0–23

ÁÁ

8 Bit

0–59

8 Bit

ÁÁ

0 to 14

0 to 10

0 to 54

0 to 5

±

0 to 9999

10

0 to 9999

0 to 20

1 to 100

1 to 100

1 to 100

–32767 to +32767

17

18

19

20

21

22

ÁÁÁ

23

ÁÁÁÁ

0 to 1

0–99

ÁÁ

ÁÁ

ÁÁ

±

0 to 21

1–31

8 Bit

0–59

8 Bit

0–99

8 Bit

Publication

1403-5.1

Page 22

B–12 Smart Communication Card Data Tables

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

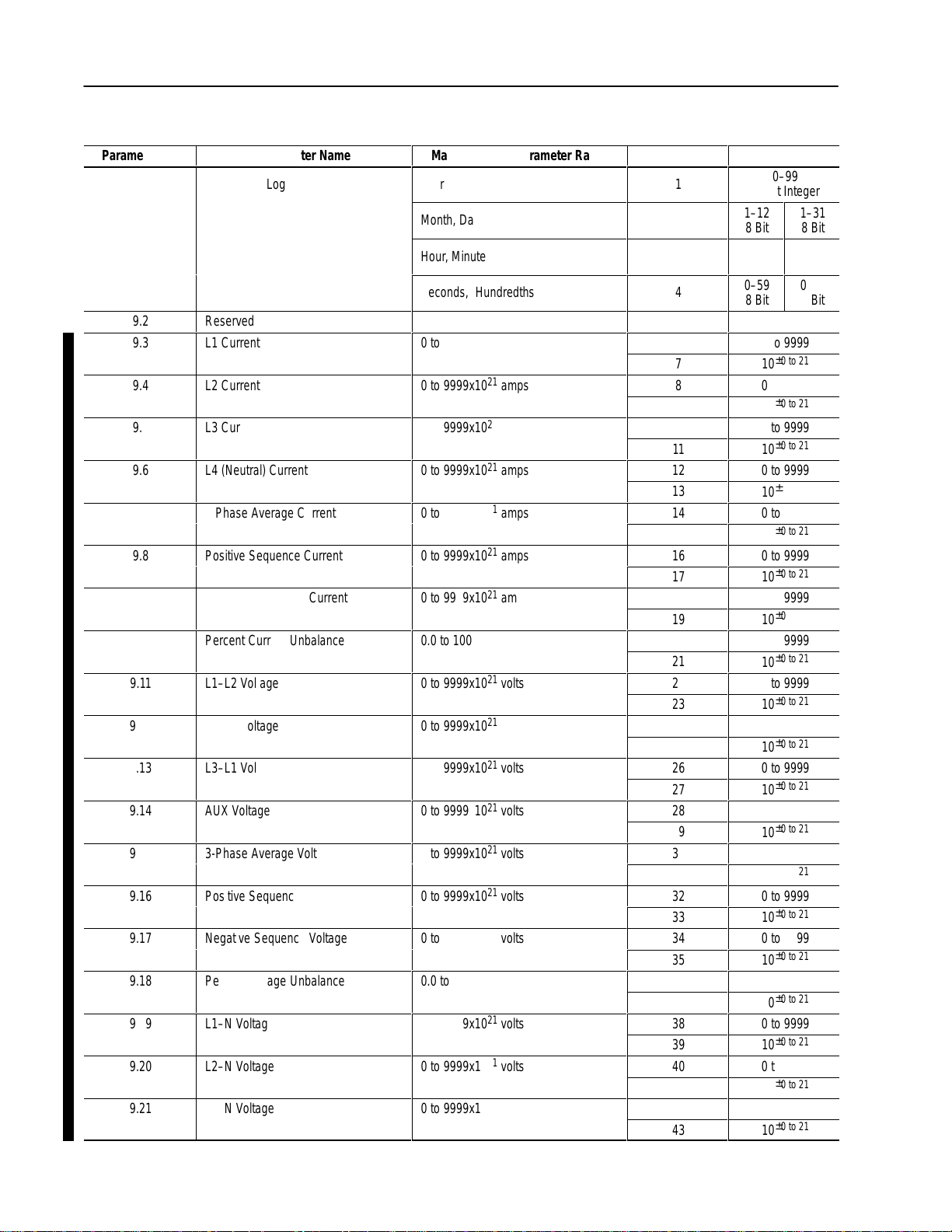

Table B.12 Voltage/Current/Miscellaneous Snapshot Log Data Table Read

Parameter No.

9.1

ÁÁÁÁ

Event Time Log Stamp

Parameter Name

ББББББББ

Master Module Parameter Range

Year

ББББББББ

Month, Date

ÁÁÁÁ

ÁÁÁÁÁББББББББÁББББББББ

ББББББББ

ББББББББ

Hour, Minute

Seconds, Hundredths

ÁÁÁÁÁББББББББÁББББББББ

9.2

9.3

9.4

Reserved

L1 Current

L2 Current

0 to 9999x1021 amps

0 to 9999x1021 amps

9.5

9.6

9.7

9.8

9.9

L3 Current

L4 (Neutral) Current

3-Phase Average Current

Positive Sequence Current

Negative Sequence Current

0 to 9999x1021 amps

0 to 9999x1021 amps

0 to 9999x1021 amps

0 to 9999x1021 amps

0 to 9999x1021 amps

9.10

9.11

ÁÁÁÁ

9.12

9.13

9.14

9.15

9.16

9.17

9.18

9.19

9.20

9.21

Percent Current Unbalance

L1–L2 Voltage

ББББББББ

L2–L3 Voltage

L3–L1 Voltage

AUX Voltage

3-Phase Average Voltage (L–L)

Positive Sequence Voltage

Negative Sequence Voltage

Percent Voltage Unbalance

L1–N Voltage

L2–N Voltage

L3–N Voltage

0.0 to 100.0

0 to 9999x1021 volts

ББББББББ

0 to 9999x1021 volts

0 to 9999x1021 volts

0 to 9999x1021 volts

0 to 9999x1021 volts

0 to 9999x1021 volts

0 to 9999x1021 volts

0.0 to 100.0

0 to 9999x1021 volts

0 to 9999x1021 volts

0 to 9999x1021 volts

Word No.

1

ÁÁÁ

ÁÁÁ2Á

3

ÁÁÁ

4

ÁÁÁ

Range

0–99

ÁÁÁÁ

16 Bit Integer

1–12

8 Bit

0–23

Á

8 Bit

0–59

8 Bit

Á

1–31

8 Bit

ÁÁ

0–59

ÁÁ

8 Bit

0–99

8 Bit

ÁÁ

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

ÁÁÁ23ÁÁÁÁ

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

Publication

1403-5.1

Page 23

B–13Smart Communication Card Data Tables

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

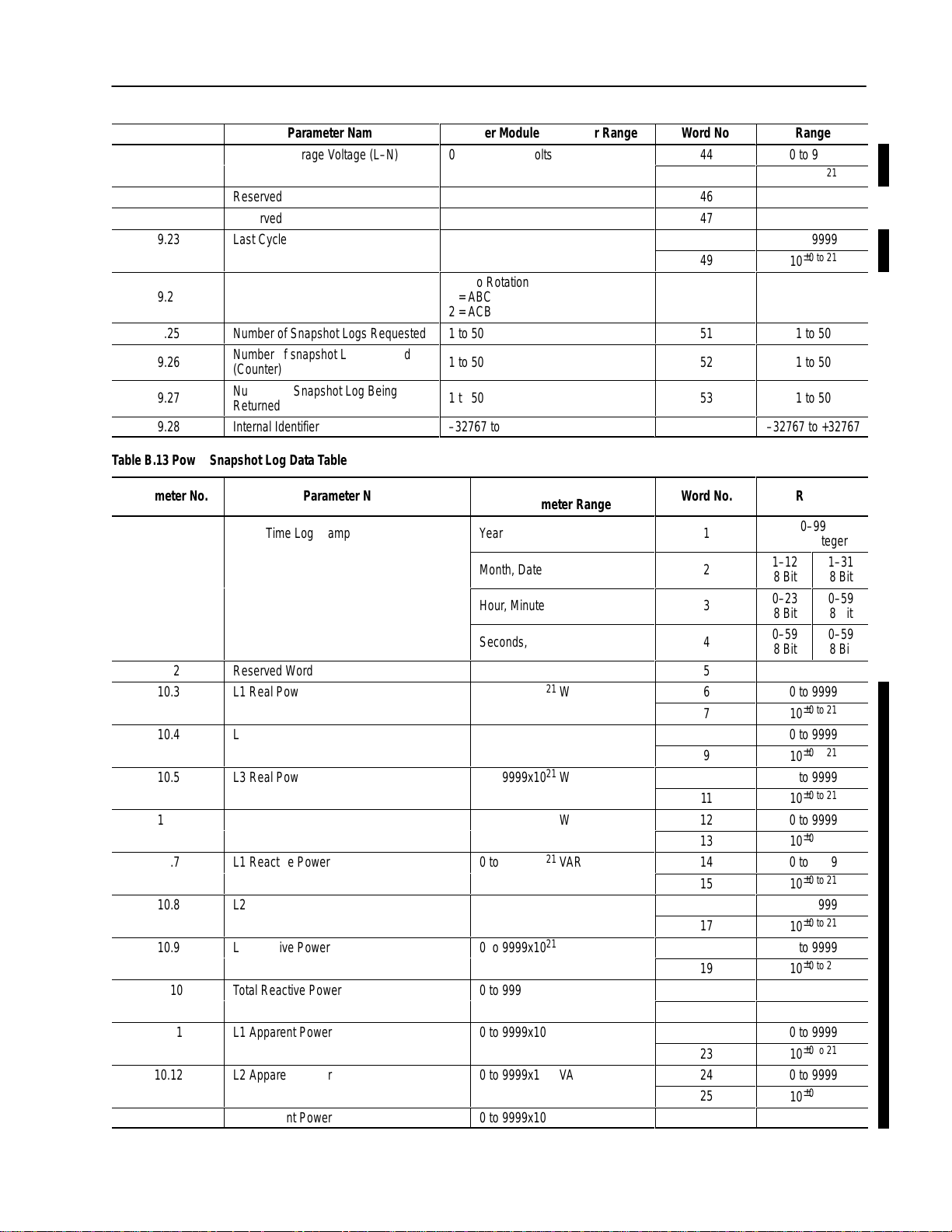

Parameter No.

9.22

Parameter Name

3–Phase Average Voltage (L–N)

Master Module Parameter Range

0 to 9999x1021 volts

Reserved

Reserved

9.23

Last Cycle Frequency

20.0 to 132.0

0 = No Rotation

9.24

ÁÁÁÁ

9.25

9.26

9.27

ÁÁÁÁ

9.28

Phase Rotation

ББББББББ

Number of Snapshot Logs Requested

Number of snapshot Log Received

(Counter)

Number of Snapshot Log Being

ББББББББ

Returned

Internal Identifier

1 = ABC

ББББББББ

2 = ACB

1 to 50

1 to 50

1 to 50

ББББББББ

–32767 to +32767

Table B.13 Power Snapshot Log Data Table

Parameter No.

ÁÁÁÁ

10.1

ÁÁÁÁ

БББББББББ

Event Time Log Stamp

БББББББББ

Parameter Name

Master Module

БББББББ

Parameter Range

Year

БББББББ

Month, Date

ÁÁÁÁÁБББББББББÁБББББББ

Hour, Minute

Seconds, Hundredths

10.2

10.3

10.4

10.5

10.6

10.7

10.8

10.9

10.10

10.11

10.12

10.13

Reserved Word

L1 Real Power

L2 Real Power

L3 Real Power

Total Real Power

L1 Reactive Power

L2 Reactive Power

L3 Reactive Power

Total Reactive Power

L1 Apparent Power

L2 Apparent Power

L3 Apparent Power

0 to 9999x1021 W

0 to 9999x10

21

W

0 to 9999x1021 W

0 to 9999x1021 W

0 to 9999x1021 VAR

0 to 9999x1021 VAR

0 to 9999x1021 VAR

0 to 9999x1021 VAR

0 to 9999x1021 VA

0 to 9999x1021 VA

0 to 9999x1021 VA

Word No.

44

45

46

47

48

49

50

ÁÁÁ

51

52

53

ÁÁÁ

54

Word No.

ÁÁÁ

1

ÁÁÁ

2

3

ÁÁÁ

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

Range

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 2

ÁÁÁÁ

1 to 50

1 to 50

1 to 50

ÁÁÁÁ

–32767 to +32767

Range

ÁÁÁÁ

0–99

16 Bit Integer

ÁÁÁÁ

1–12

8 Bit

0–23

8 Bit

ÁÁ

0–59

8 Bit

1–31

8 Bit

0–59

8 Bit

ÁÁ

0–59

8 Bit

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

Publication

1403-5.1

Page 24

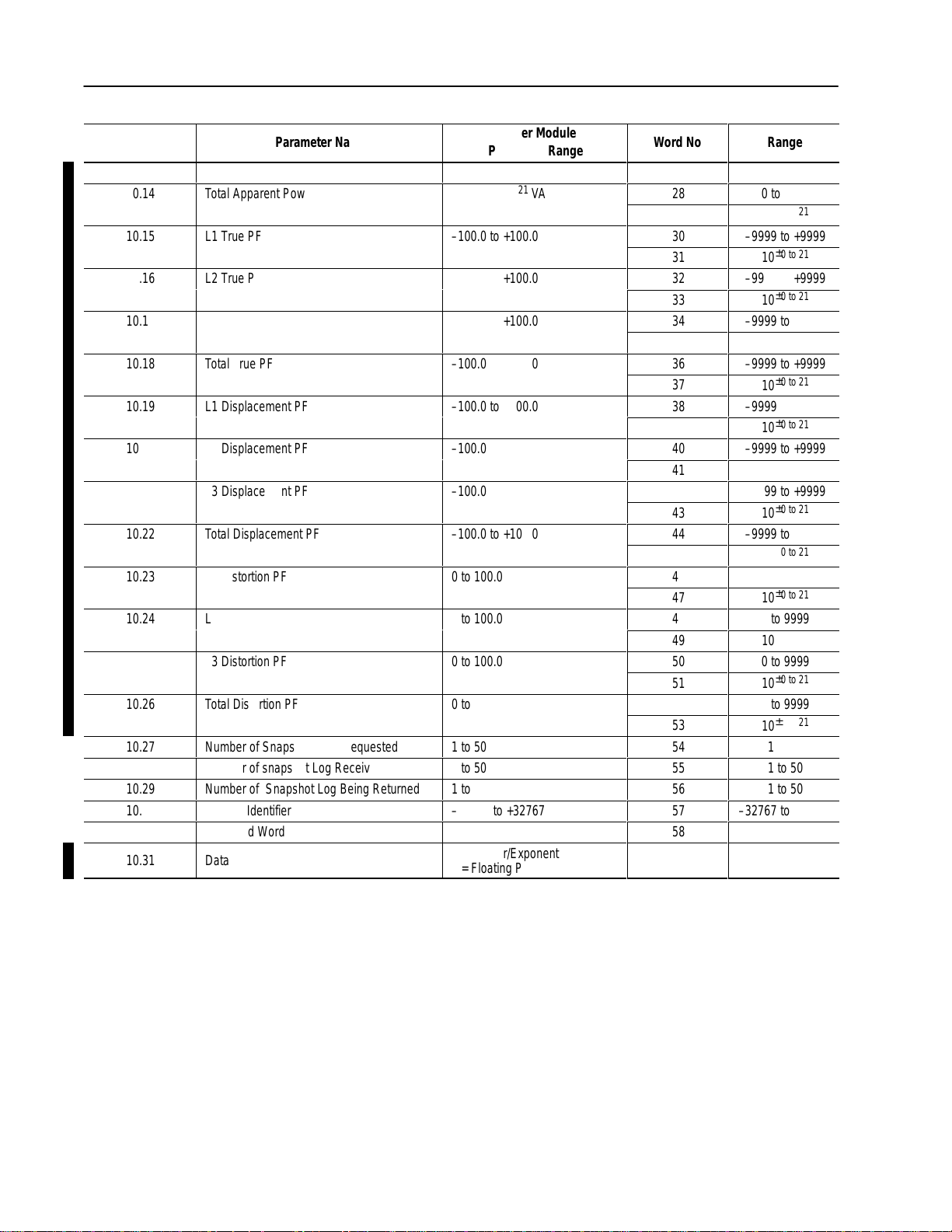

B–14 Smart Communication Card Data Tables

Parameter No.

10.14

10.15

10.16

10.17

10.18

10.19

10.20

10.21

10.22

10.23

10.24

10.25

10.26

ÁÁÁÁ

10.27

10.28

10.29

10.30

10.31

Parameter Name

Total Apparent Power

L1 True PF

L2 True PF

L3 True PF

Total True PF

L1 Displacement PF

L2 Displacement PF

L3 Displacement PF

Total Displacement PF

L1 Distortion PF

L2 Distortion PF

L3 Distortion PF

Total Distortion PF

БББББББББ

Number of Snapshot Logs Requested

Number of snapshot Log Received (Counter)

Number of Snapshot Log Being Returned

Internal Identifier

0 to 9999x1021 VA

–100.0 to +100.0

–100.0 to +100.0

–100.0 to +100.0

–100.0 to +100.0

–100.0 to +100.0

–100.0 to +100.0

–100.0 to +100.0

–100.0 to +100.0

0 to 100.0

0 to 100.0

0 to 100.0

0 to 100.0

БББББББ

1 to 50

1 to 50

1 to 50

–32767 to +32767

Reserved Word

Data Format

0 = Integer/Exponent

1 = Floating Point

Master Module

Parameter Range

Word No.

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

ÁÁÁ52ÁÁÁÁ

53

54

55

56

57

Range

±

0 to 21

10

0 to 9999

±

0 to 21

10

–9999 to +9999

±

0 to 21

10

–9999 to +9999

±

0 to 21

10

–9999 to +9999

±

0 to 21

10

–9999 to +9999

±

0 to 21

10

–9999 to +9999

±

0 to 21

10

–9999 to +9999

±

0 to 21

10

–9999 to +9999

±

0 to 21

10

–9999 to +9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

1 to 50

1 to 50

1 to 50

–32767 to +32767

58

59

0 to 1

Publication

1403-5.1

Page 25

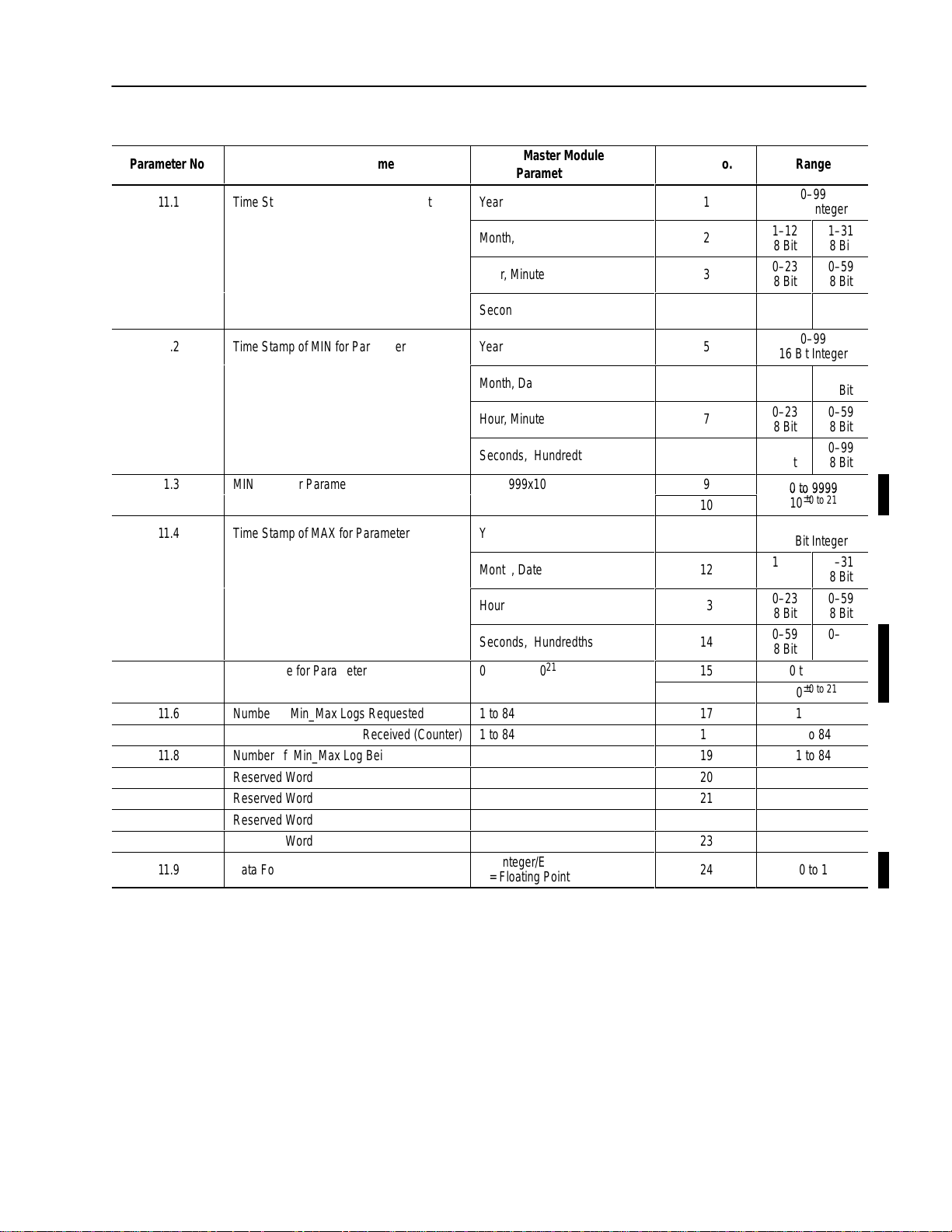

Table B.14 Min_Max Log – Read

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

0 to 9999

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

B–15Smart Communication Card Data Tables

Parameter No.

11.1

ÁÁÁÁ

Parameter Name

Time Stamp of last Min/Max Log Reset

БББББББББ

Master Module

Parameter Range

Year

БББББББ

Month, Date

ÁÁÁÁÁБББББББББÁБББББББ

Hour, Minute

Seconds, Hundredths

11.2

ÁÁÁÁ

Time Stamp of MIN for Parameter

БББББББББ

Year

БББББББ

Month, Date

ÁÁÁÁÁБББББББББÁБББББББ

Hour, Minute

Seconds, Hundredths

11.3

11.4

ÁÁÁÁ

MIN Value for Parameter

Time Stamp of MAX for Parameter

БББББББББ

0 to 9999x10

Year

БББББББ

Month, Date

ÁÁÁÁÁБББББББББÁБББББББ

Hour, Minute

Seconds, Hundredths

11.5

11.6

11.7

11.8

MAX Value for Parameter

Number of Min_Max Logs Requested

Number of Min_Max Log Received (Counter)

Number of Min_Max Log Being Returned

0 to 9999x10

1 to 84

1 to 84

1 to 84

21

Reserved Word

Reserved Word

Reserved Word

Reserved Word

11.9

ÁÁÁÁ

Data Format

БББББББББ

0 = Integer/Exponent

1 = Floating Point

БББББББ

Word No.

1

ÁÁÁ

2

3

ÁÁÁ

4

5

ÁÁÁ

6

7

ÁÁÁ

8

9

10

11

ÁÁÁ

12

13

ÁÁÁ

14

15

16

17

18

19

20

21

22

23

24

ÁÁÁ

Range

0–99

16 Bit Integer

ÁÁÁÁ

1–12

8 Bit

0–23

ÁÁ

8 Bit

0–59

8 Bit

1–31

8 Bit

0–59

ÁÁ

8 Bit

0–99

8 Bit

0–99

ÁÁÁÁ

16 Bit Integer

1–12

8 Bit

0–23

ÁÁ

8 Bit

0–59

8 Bit

1–31

8 Bit

0–59

ÁÁ

8 Bit

0–99

8 Bit

0 to 9999

±

0 to 21

10

0–99

16 Bit Integer

ÁÁÁÁ

1–12

8 Bit

0–23

8 Bit

ÁÁ

0–59

8 Bit

1–31

8 Bit

0–59

8 Bit

ÁÁ

0–99

8 Bit

0 to 9999

±

0 to 21

10

1 to 84

1 to 84

1 to 84

0 to 1

ÁÁÁÁ

Publication

1403-5.1

Page 26

B–16 Smart Communication Card Data Tables

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Table B.15 Log Selection Command Table Write

Param. No.

ÁÁÁÁ

12.1

ÁÁÁÁ

ÁÁÁÁ

12.2

ÁÁÁÁ

12.3

ÁÁÁÁ

12.4

ÁÁÁÁ

Parameter Name

ББББББББ

Selected Log

ББББББББ

ББББББББ

Requested Number of Data Sets

ББББББББ

Chronology of Returned Data

ББББББББ

First Min/Max Parameter to be

Returned

ББББББББ

Reserved Word

Reserved Word

Reserved Word

Reserved Word

Reserved Word

Master Module Range

23 = Event Log

ББББББББ

24 = Min/Max Log

54 = Snapshot V/I Log

ББББББББ

59 = Snapshot Power Log

1 to 100 for Event Log

1 to 84 for Min/Max Log

ББББББББ

1 to 50 for Snapshot V/I Log

ББББББББ

1 to 50 for Snapshot Power Log

0 = Reverse

1 = Forward

ББББББББ

Note: Not used for Min/Max Log

1 to 84

ББББББББ

Word No.

ÁÁÁ

1

ÁÁÁ

ÁÁÁ

2

ÁÁÁ

3

ÁÁÁ

4

ÁÁÁ

5

6

7

8

9

Range

ÁÁÁÁ

23, 24, 54, 59

ÁÁÁÁ

1 to 100

1 to 84

ÁÁÁÁ

1 to 50

ÁÁÁÁ

1 to 50

0 to 1

ÁÁÁÁ

1 to 84

ÁÁÁÁ

Publication

1403-5.1

Page 27

Table B.16 Available Min/Max Log Parameters (Identifiers for parameter 12.4)

Parameter Number

Parameter Description

1 Phase 1 Current

2 Phase 2 Current

3 Phase 3 Current

4 Phase 4 Current

5 Average Current

6 Positive Sequence Current

7 Negative Sequence Current

8 Current Unbalance

9 Phase 1 L–L Voltage

10 Phase 2 L–L Voltage

11 Phase 3 L–L Voltage

12 Auxiliary Voltage

13 Average L–L Voltage

14 Positive Sequence Voltage

15 Negative Sequence Voltage

16 Voltage Unbalance

17 Phase 1 L–N Voltage

18 Phase 2 L–N Voltage

19 Phase 3 L–N Voltage

20 Average L–N Voltage

21 Frequency

22 Phase 1 Real Power

23 Phase 2 Real Power

24 Phase 3 Real Power

25 Total Real Power

26 Phase 1 Reactive Power

27 Phase 2 Reactive Power

28 Phase 3 Reactive Power

29 Total Reactive Power

30 Phase 1 Apparent Power

31 Phase 2 Apparent Power

32 Phase 3 Apparent Power

33 Total Apparent Power

34 Phase 1 True Power Factor

35 Phase 2 True Power Factor

36 Phase 3 True Power Factor

37 Total True Power Factor

38 Phase 1 Displacement Power Factor

39 Phase 2 Displacement Power Factor

40 Phase 3 Displacement Power Factor

41 Total Displacement Power Factor

42 Phase 1 Distortion Power Factor

Parameter Number Parameter Description

43 Phase 2 Distortion Power Factor

44 Phase 3 Distortion Power Factor

45 Total Distortion Power Factor

46 Current Demand

47 Real Power Demand

48 Reactive Power Demand

49 Apparent Power Demand

50 Phase 1 Voltage IEEE THD

51 Phase 1 Voltage IEC THD

52

53

54

55 Phase 1 Current IEEE THD

56 Phase 1 Current IEC THD

57

58

59

60 Phase 2 Voltage IEEE THD

61 Phase 2 Voltage IEC THD

62

63

64

65 Phase 2 Current IEEE THD

66 Phase 2 Current IEC THD

67

68

69

70 Phase 3 Voltage IEEE THD

71 Phase 3 Voltage IEC THD

72

73

74

75 Phase 3 Current IEEE THD

76 Phase 3 Current IEC THD

77

78

79

80 Phase 4 Current IEEE THD

81 Phase 4 Current IEC THD

82

83

84

B–17Smart Communication Card Data Tables

Phase 1 Voltage TIF

Phase 1 Voltage Crest Factor

Phase 1 Voltage K-factor

Phase 1 Current TIF

Phase 1 Current Crest Factor

Phase 1 Current K-factor

Phase 2 Voltage TIF

Phase 2 Voltage Crest Factor

Phase 2 Voltage K-factor

Phase 2 Current TIF

Phase 2 Current Crest Factor

Phase 2 Current K-factor

Phase 3 Voltage TIF

Phase 3 Voltage Crest Factor

Phase 3 Voltage K-factor

Phase 3 Current TIF

Phase 3 Current Crest Factor

Phase 3 Current K-factor

Phase 4 Current TIF

Phase 4 Current Crest Factor

Phase 4 Current K-factor

①

①

①

①

①

①

①

①

①

①

①

①

①

①

①

①

①

①

①

①

①

➀

Not

available on 1403-LM.

Publication

1403-5.1

Page 28

B–18 Smart Communication Card Data Tables

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Harmonic

Distortion T

ables – Read

Harmonic Distortion Data Tables for Channel 2 through Channel 7 are identical to the Even and Odd Harmonic

Distortion Tables for Channel 1. There are a total of 14 tables for this information.

(V1, V2, V3, I1, I2, I3, I4) The table sizes indicate this is Harmonic Distortion Data. The Channel Number designates

which one.

Table B.17 Even Harmonic Distortion Table – Channel 1

Parameter No.

13.1

13.2

13.3

ÁÁÁÁ

13.4

13.5

13.6

ÁÁÁÁ

13.7

ÁÁÁÁ

ÁÁÁÁ

13.8

13.9

13.10

13.11

13.12

13.13

13.14

13.15

13.16

13.17

13.18

IEEE Total Harmonic Distortion

IEC Total Harmonic Distortion

Meets IEEE 519

(Reserved 1403-LM)

TIF

(Reserved 1403-LM)

Crest Factor

(Reserved 1403-LM)

K-Factor

(Reserved 1403-LM)

Channel Number

Harmonic Distortion – Fundamental

(Reserved 1403-LM)

Harmonic Distortion – Second

(Reserved 1403-LM)

Harmonic Distortion – Fourth

(Reserved 1403-LM)

Harmonic Distortion – Sixth

(Reserved 1403-LM)

Harmonic Distortion – Eighth

(Reserved 1403-LM)

Harmonic Distortion – Tenth

(Reserved 1403-LM)

Harmonic Distortion – Twelfth

(Reserved 1403-LM)

Harmonic Distortion – Fourteenth

(Reserved 1403-LM)

Harmonic Distortion – Sixteenth

(Reserved 1403-LM)

Harmonic Distortion – Eighteenth

(Reserved 1403-LM)

Harmonic Distortion – Twentieth

(Reserved 1403-LM)

Parameter Name

ББББББББ

ББББББББ

ББББББББ

ББББББББ

Master Module Range

0 to 1000%

0 to 1000%

–1 = Unknown

0 = Fail

ББББББББ

1 = Pass

0 to 9999x10

0 to 9999x10

0 to 9999x10

21

21

21

1 = L1 Voltage

2 = L1 Current

ББББББББ

3 = L2 Voltage

4 = L2 Current

ББББББББ

5 = L3 Voltage

6 = L3 Current

ББББББББ

7 = L4 Current

0 to 1000%

0 to 1000%

0 to 1000%

0 to 1000%

0 to 1000 %

0 to 1000%

0 to 1000%

0 to 1000%

0 to 1000%

0 to 1000%

0 to 1000%

Word No.

1

2

3

4

5

ÁÁÁ

6

7

8

9

10

11

ÁÁÁ

12

ÁÁÁ

ÁÁÁ

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

Range

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

–1 to +1

ÁÁÁÁ

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

ÁÁÁÁ

1 to 7

ÁÁÁÁ

ÁÁÁÁ

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

Publication

1403-5.1

Page 29

B–19Smart Communication Card Data Tables

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Parameter No.

13.19

Harmonic Distortion – Twenty-second

Parameter Name

(Reserved 1403-LM)

13.20

Harmonic Distortion – Twenty-fourth

(Reserved 1403-LM)

13.21

Harmonic Distortion – Twenty-sixth

(Reserved 1403-LM)

13.22

Harmonic Distortion – Twenty-eighth

(Reserved 1403-LM)

13.23

ÁÁÁÁ

13.24

Harmonic Distortion – Thirtieth

(Reserved 1403-LM)

ББББББББ

Harmonic Distortion – Thirty-second

(Reserved 1403-LM)

13.25

Harmonic Distortion – Thirty-fourth

(Reserved 1403-LM)

13.26

Harmonic Distortion – Thirty-sixth

(Reserved 1403-LM)

13.27

Harmonic Distortion – Thirty-eighth

(Reserved 1403-LM)

13.28

Harmonic Distortion – Fortieth

(Reserved 1403-LM)

13.29

FFT Chronological Reference Number

Reserved Word

Reserved Word

Reserved Word

Reserved Word

13.30

Data Format

Table B.18 Odd Harmonic Distortion Table – Channel 1

Parameter No.

14.1

14.2

14.3

ÁÁÁÁ

14.4

IEEE Total Harmonic Distortion

IEC Total Harmonic Distortion

Meets IEEE 519

(Reserved 1403-LM)

ББББББББ

TIF Value

Parameter Name

(Reserved 1403-LM)

14.5

Crest Factor

(Reserved 1403-LM)

14.6

K-Factor

(Reserved 1403-LM)

ÁÁÁÁ

14.7

ÁÁÁÁ

ÁÁÁÁ

14.8

ББББББББ

Channel Number

ББББББББ

ББББББББ

Harmonic Distortion – Fundamental

Master Module Range

0 to 1000%

0 to 1000%

0 to 1000%

0 to 1000%

0 to 1000%

ББББББББ

0 to 1000%

0 to 1000%

0 to 1000%

0 to 1000%

0 to 1000%

0 to 32767

0 = Integer/Exponent

1 = Floating Point

Master Module Range

0 to 1000%

0 to 1000%

–1 = Unknown

0 = Fail

1 = Pass

ББББББББ

0 to 9999x10

0 to 9999x10

0 to 9999x10

21

21

21

1 = L1 Voltage

2 = L1 Current

ББББББББ

3 = L2 Voltage

4 = L2 Current

ББББББББ

5 = L3 Voltage

6 = L3 Current

ББББББББ

7 = L4 Current

0 to 1000%

Word No.

35

36

37

38

39

40

41

42

43

ÁÁÁ44ÁÁÁÁ

45

46

47

48

49

50

51

52

53

54

55

Range

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 32767

56

57

58

59

60

Word No.

1

2

3

4

5

ÁÁÁ

6

7

8

9

10

11

ÁÁÁ

12

ÁÁÁ

ÁÁÁ

13

0 to 1

Range

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

–1 to +1

ÁÁÁÁ

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

0 to 9999

±

0 to 21

10

ÁÁÁÁ

1 to 7

ÁÁÁÁ

ÁÁÁÁ

0 to 9999

Publication

1403-5.1

Page 30

B–20 Smart Communication Card Data Tables

Á

Á

Á

Á

Á

Parameter No.

14.9

14.10

14.11

14.12

14.13

14.14

14.15

14.16

14.17

14.18

14.19

14.20

14.21

14.22

14.23

14.24

14.25

14.26

14.27

14.28

14.29

14.30

ÁÁÁÁ

Parameter Name

(Reserved 1403-LM)

Harmonic Distortion – Third

0 to 1000%

(Reserved 1403-LM)

Harmonic Distortion – Fifth

0 to 1000%

(Reserved 1403-LM)

Harmonic Distortion – Seventh

0 to 1000%

(Reserved 1403-LM)

Harmonic Distortion – Ninth

0 to 1000%

(Reserved 1403-LM)

Harmonic Distortion – Eleventh

0 to 1000%

(Reserved 1403-LM)

Harmonic Distortion – Thirteenth

0 to 1000%

(Reserved 1403-LM)

Harmonic Distortion – Fifteenth

0 to 1000%

(Reserved 1403-LM)

Harmonic Distortion – Seventeenth

0 to 1000%

(Reserved 1403-LM)

Harmonic Distortion – Nineteenth

0 to 1000%

(Reserved 1403-LM)

Harmonic Distortion – Twenty-first

0 to 1000%

(Reserved 1403-LM)

Harmonic Distortion – Twenty-third

0 to 1000%

(Reserved 1403-LM)

Harmonic Distortion – Twenty-fifth

0 to 1000%

(Reserved 1403-LM)

Harmonic Distortion – Twenty-seventh

0 to 1000%

(Reserved 1403-LM)

Harmonic Distortion – Twenty-ninth

0 to 1000%

(Reserved 1403-LM)

Harmonic Distortion – Thirty-first

0 to 1000%

(Reserved 1403-LM)

Harmonic Distortion – Thirty-third

0 to 1000%

(Reserved 1403-LM)

Harmonic Distortion – Thirty-fifth

0 to 1000%

(Reserved 1403-LM)

Harmonic Distortion – Thirty-seventh

0 to 1000%

(Reserved 1403-LM)

Harmonic Distortion – Thirty-ninth

0 to 1000%

(Reserved 1403-LM)

Harmonic Distortion – Forty-first

0 to 1000%

(Reserved 1403-LM)

FFT Chronological Reference Number

0 to 32767

Reserved Word

Reserved Word

Reserved Word

Reserved Word

Reserved Word

Data Format

ББББББББ