Page 1

Installation Instructions

Bulletin 1403 Ethernet® Communications

Card

(Catalog Number 1403-NENET)

1 Publi cation 1403-IN005A-EN-P

Page 2

Bulletin 1403 Ethernet® Communications Card

Important User Information

Because of the variety of uses for the products described in this publication,

those responsible for the application and use of this control equipment must

satisfy themselves that all necessary steps have been taken to assure that each

application and use meets all performance and safety requirements, including

any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in this

guide are intended solely for purposes of example. Since there are many

variables and requirements associated with any particular installation,

Allen-Br adley d oes no t assum e resp onsibi lit y or lia bility (t o inc lude in tellec tual

property liability) for actual use based upon the examples shown in this

publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application,

Installation and Maintenance of Solid-State Control (available from your local

Allen-Bradley office), describes some importa n t differences between soli d-state

equipment and electromechanical devices that should be taken into

consideration when applying products such as those described in this

publication.

Reproduction of the contents of this copyrighted publication, in whole or part,

without written permission of Rockwell Automation, is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION

Identifies information about practices or circumstances

that can lead to personal injury or death, propertydamage

or economic loss

!

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

IMPORTANT

PLC and PLC-5 are registered trademarks of Rockwell Automation.

RSView32, RSLinx, and SLC 500 are trademarkes of Rockwell Automation.

Ethernet is a registered trademark of Digital Equipment corporation, Intel Corporation, and Xerox Corporation.

Identifies information that is critical for successful

application and understanding of the product.

Publication 1403-IN005A-EN-P

Page 3

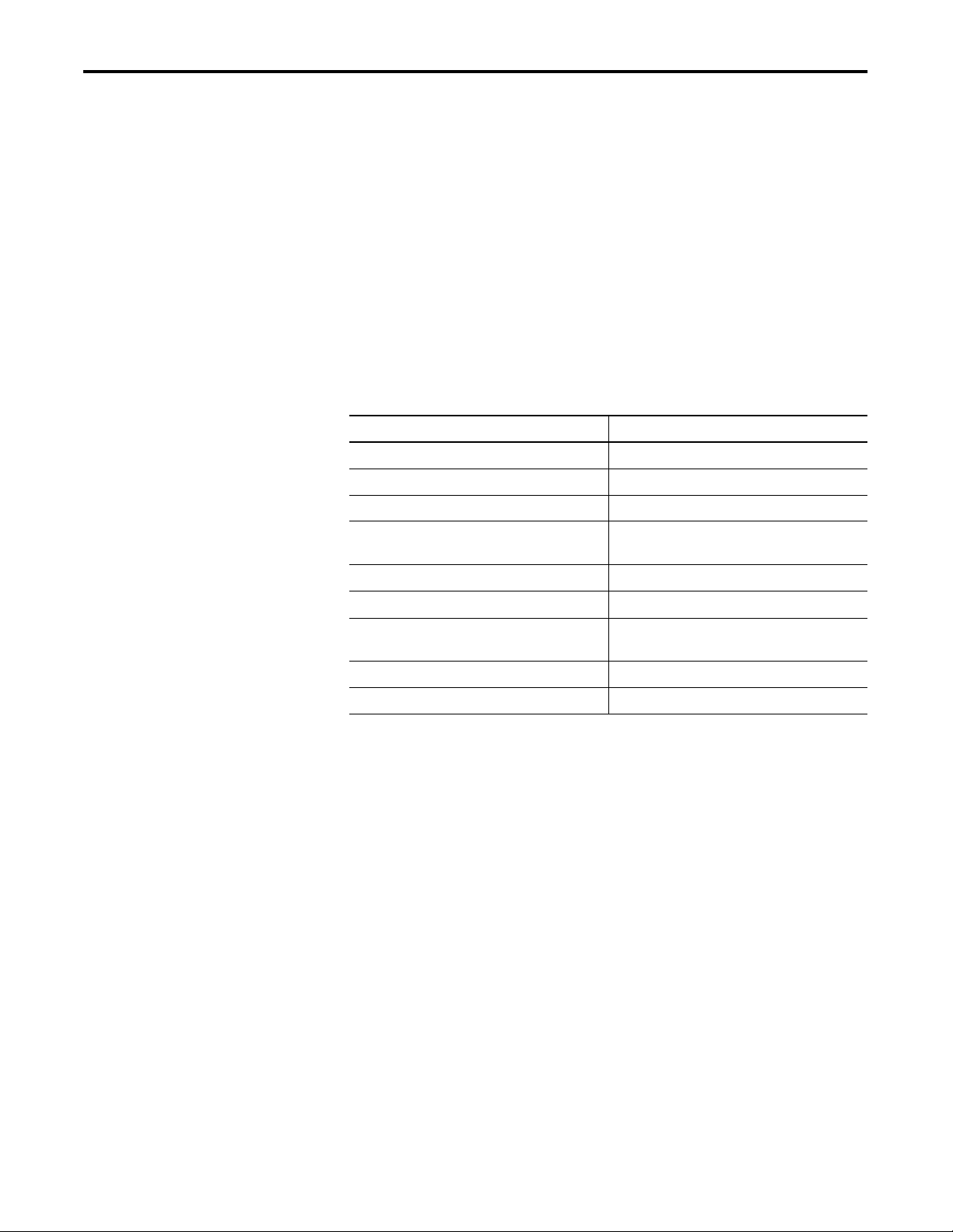

Table of Contents

Product Description

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Terms and Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Abbreviations and Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Field Service Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Communication Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Configuration Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Communication Configuration Items . . . . . . . . . . . . . . . . . . . . . . . . 6

1403-NENET Web Access Overview . . . . . . . . . . . . . . . . . . . . . . . . . 7

Catalog Number Explanation Appendix A

Communications Cards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Ethernet Communication Card

Data Tables

Appendix B

Data Table List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Device Configuration Data Tabl e - Write and Read (File N11) . . . B-2

Configurable Snapshot Parameter List (selection list for Table B.2,

parameters 1.19, 1.20 and 1.21) . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Communications Configur a tion Ta bl e -

Write and Read (File N12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-6

Command Data Table Write (File N13) . . . . . . . . . . . . . . . . . . . . B-7

Bit Fields for Command Data Table -(Command Word 1) . . . . . . B-8

Bit Fields for Command Data Table - (Command Word 2) . . . . . B-8

Voltage/Current Data - Read (File F14) . . . . . . . . . . . . . . . . . . . . . B-9

Real-Time Power Data - Read (File F15) . . . . . . . . . . . . . . . . . . . B-10

Cumulative Power Data - Read (File N16) . . . . . . . . . . . . . . . . . . B-11

Demand Data - Read (File F17) . . . . . . . . . . . . . . . . . . . . . . . . . . B-12

Event Log - Read (File N18) . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-13

Snapshot 46 Parameter Record Table Read (File F19) . . . . . . . . . B-14

Snapshot 16 Parameter Record Table Read (File F19) . . . . . . . . . B-15

Snapshot 8 Parameter Record Table Read (File F19) . . . . . . . . . . B-16

Snapshot 4 Parameter Record Table Read (File F19) . . . . . . . . . . B-17

Snapshot 3 and 7 Parameter Record Table Read (File F19) . . . . . B-18

Snapshot 1 Parameter Record Table Read (File F19) . . . . . . . . . . B-19

Power Snapshot Log Data Table (File F20) . . . . . . . . . . . . . . . . . B-20

Min_Max Log - Read (File N21) . . . . . . . . . . . . . . . . . . . . . . . . . B-22

Log Selection Command Table Write (File N22) . . . . . . . . . . . . . B-23

Available Min/Max Log Parameters

(Identifiers for parameter 12.4) . . . . . . . . . . . . . . . . . . . . . . . . . . B-24

Even Harmonic Distortion Table -

Channel 1 to 7 Read (File F23) . . . . . . . . . . . . . . . . . . . . . . . . . . B-25

i Publi cation 1403-IN005A-EN-P

Page 4

Table of Contents ii

Odd Harmonic Distortion Table -

Channels 1 to 7 Read (File F24) . . . . . . . . . . . . . . . . . . . . . . . . . . B-26

Even Harmonic Magnitude Data Table

Channel 1 to 7 Read (File F25) . . . . . . . . . . . . . . . . . . . . . . . . . . B-28

Odd Harmonic Magnitude Data Table (File F26) . . . . . . . . . . . . B-29

Even Harmonic Phase Angle Data Table

Channels 1 to 7 Read (File F27) . . . . . . . . . . . . . . . . . . . . . . . . . . B-31

Odd Harmonic Phase Angle Data Table (File F28) . . . . . . . . . . . B-32

Waveform Capture Data - Read (File N29) . . . . . . . . . . . . . . . . . B-34

Diagnostic Data Table (Self-test Results) Read (File N30) . . . . . . B-37

Setpoint Setup Data Table - Write/Read (File N31) . . . . . . . . . . B-39

Setpoint Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-40

Setpoint Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-41

Relay/Setpoint Status Table Read (File N32) . . . . . . . . . . . . . . . . B-41

Status Inputs Bitfield Definitions . . . . . . . . . . . . . . . . . . . . . . . . . B-43

Alarm Word Bitfield Definitions . . . . . . . . . . . . . . . . . . . . . . . . . B-43

Setpoint Status Bitfield Definitions . . . . . . . . . . . . . . . . . . . . . . . B-43

Combined Real-Time Data Table Read (File F40) . . . . . . . . . . . . B-44

Sample Ladder Listing Appendix C

Ladder Program Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

Data Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-2

MSG Read Data Table Locations . . . . . . . . . . . . . . . . . . . . . . . . . . C-3

MSG Write Table Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Sample Ladder Listing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6

Technical Specifications Appendix D

Product Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-1

Revenue Meter Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-1

Compliance to European Union Directives . . . . . . . . . . . . . . . . . .D-1

Publication 1403-IN005A-EN-P

Page 5

Product Description

Product Description

Chapter Objectives

Terms and Conventions

After completing this chapter, you should be able to identify the product

features and system applications.

In this instruction sheet, the following terms and conventions are used:

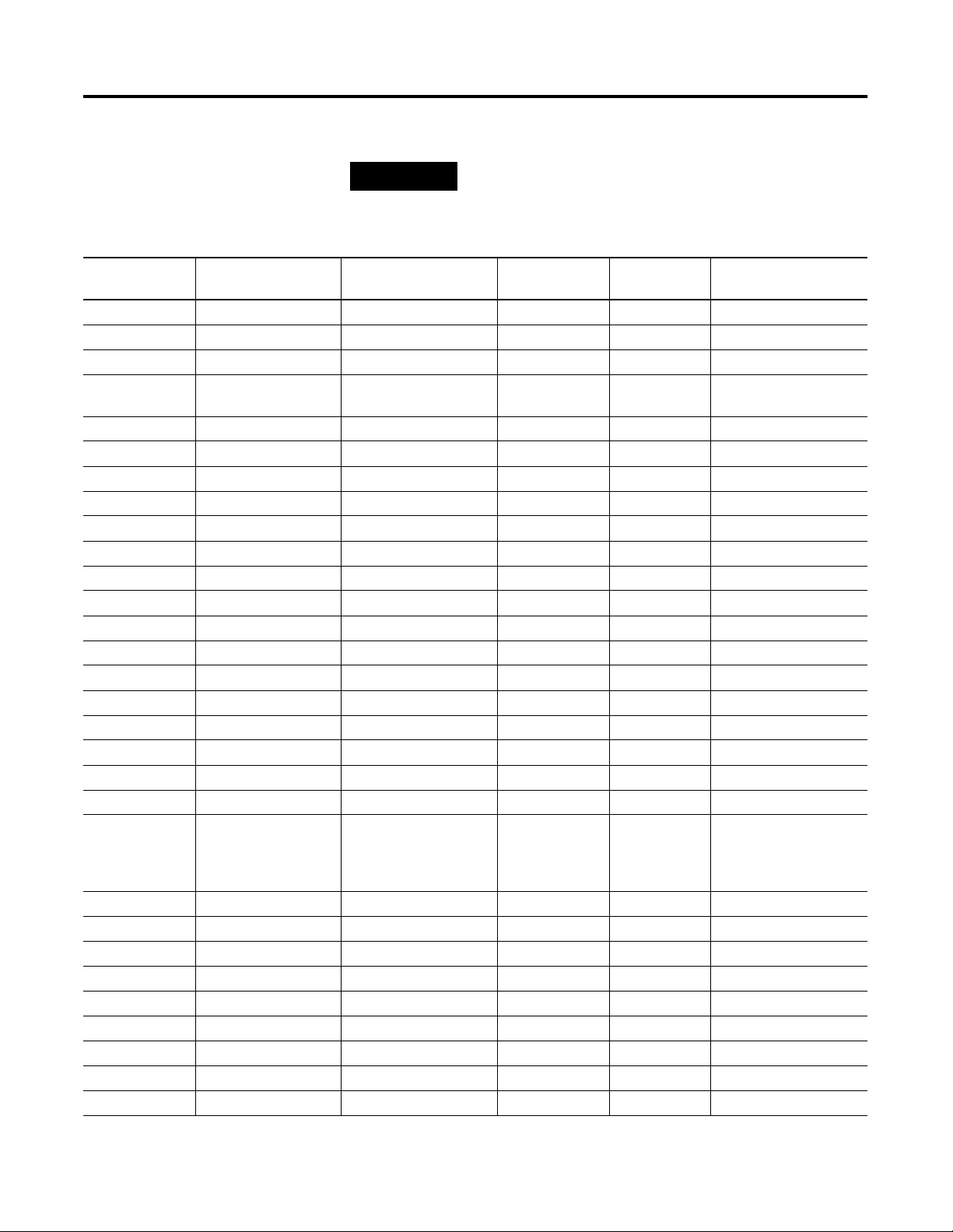

Table 1 Abbreviations and Terms

Abbreviation Term

MSG Message

IP Internet Protocol

Gateway An internet or intranet routing device

Subnet Mask Subdivides the host portion an IP address

into su bn et and host

UTP Unshie l ded Twist ed Pair

AUI Attachment Unit Interface

BOOTP Bootst ra p Protocol; prov ides dynami c

assign me nt o f I P ad dr es ses

Hub A central wiring termination device

ESD Electrostatic Discharge

Introduction

1 Publi cation 1403-IN005A-EN-P

The Catalog Number 1403-NENET Ethernet Card is a

microprocessor-controlled, dual-port communication plug-in accessory to the

Po w ermonito r II Ma ster M odu le. This ac cesso ry provid es the Po wermon itor II

with three communication ports. Two of these ports are the 10BaseT and

10Base5 Ethe rnet ports, while the third is an RS-232 local configuratio n p ort.

Required configuration parameters (IP Address, Gateway, Subnet Mask,

Physical Ethernet Port, etc.) are provided by configuring the Master Module.

(There are no hardware jumpers to configure when the card is installed.)

Page 6

2 Product Description

Features

The Ethernet Communication Card features include:

• Connect to Allen-Bradley PLC-5

• Connect to Allen-Bradley SLC 5/05™ Ethernet processor

• Built-in in ternet web page support

• Compatible with RSEnergy™, RSView32™ and RSPower32™

®

Ethernet processors

software

• Ethernet communication rate: 10Mbps

• Comp atible w i th commercially available network bridges and routers

• Fully software configurable

• Sup ports RSLi nx™ and WINtelligent Linx™ (emulates SLC 500™)

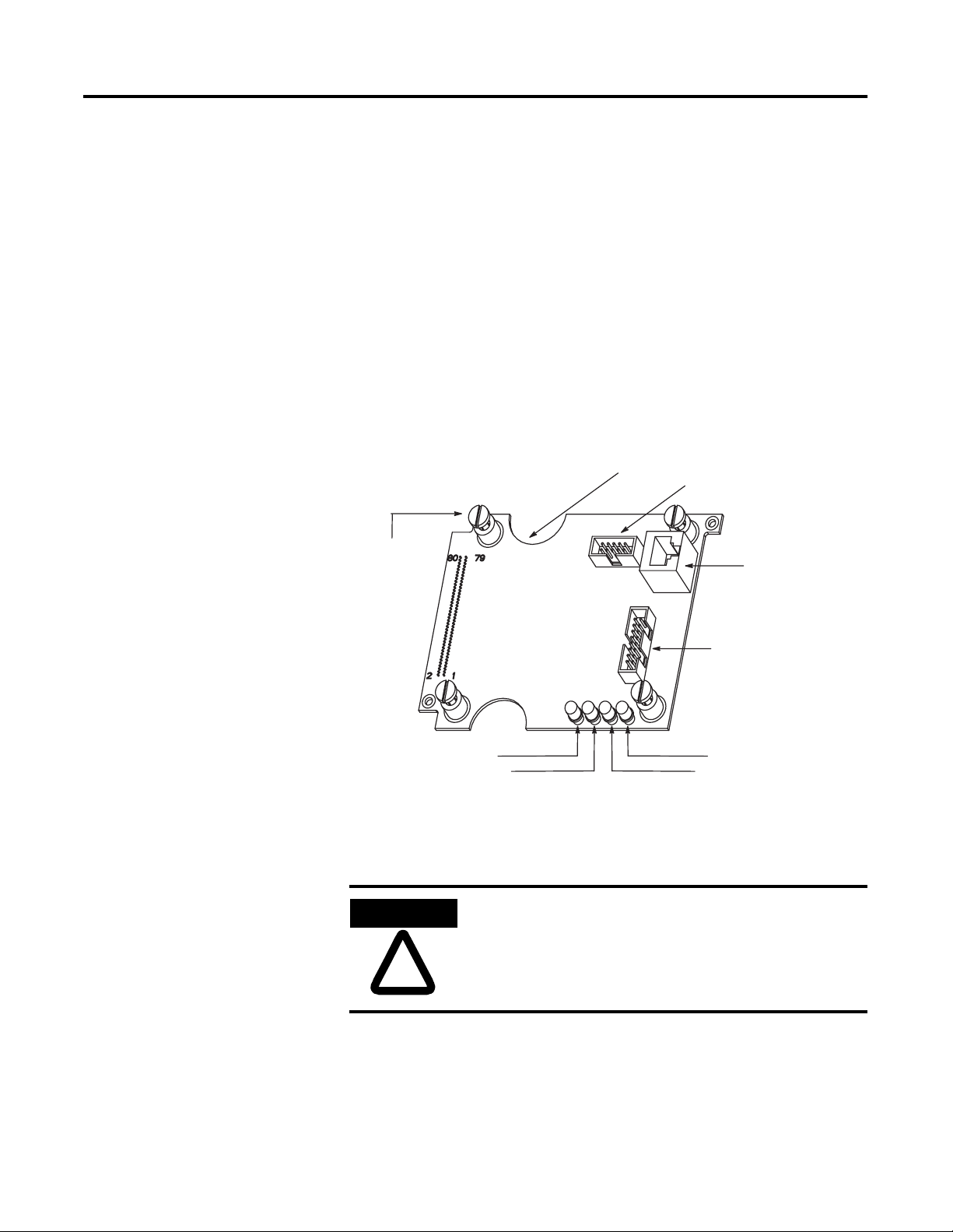

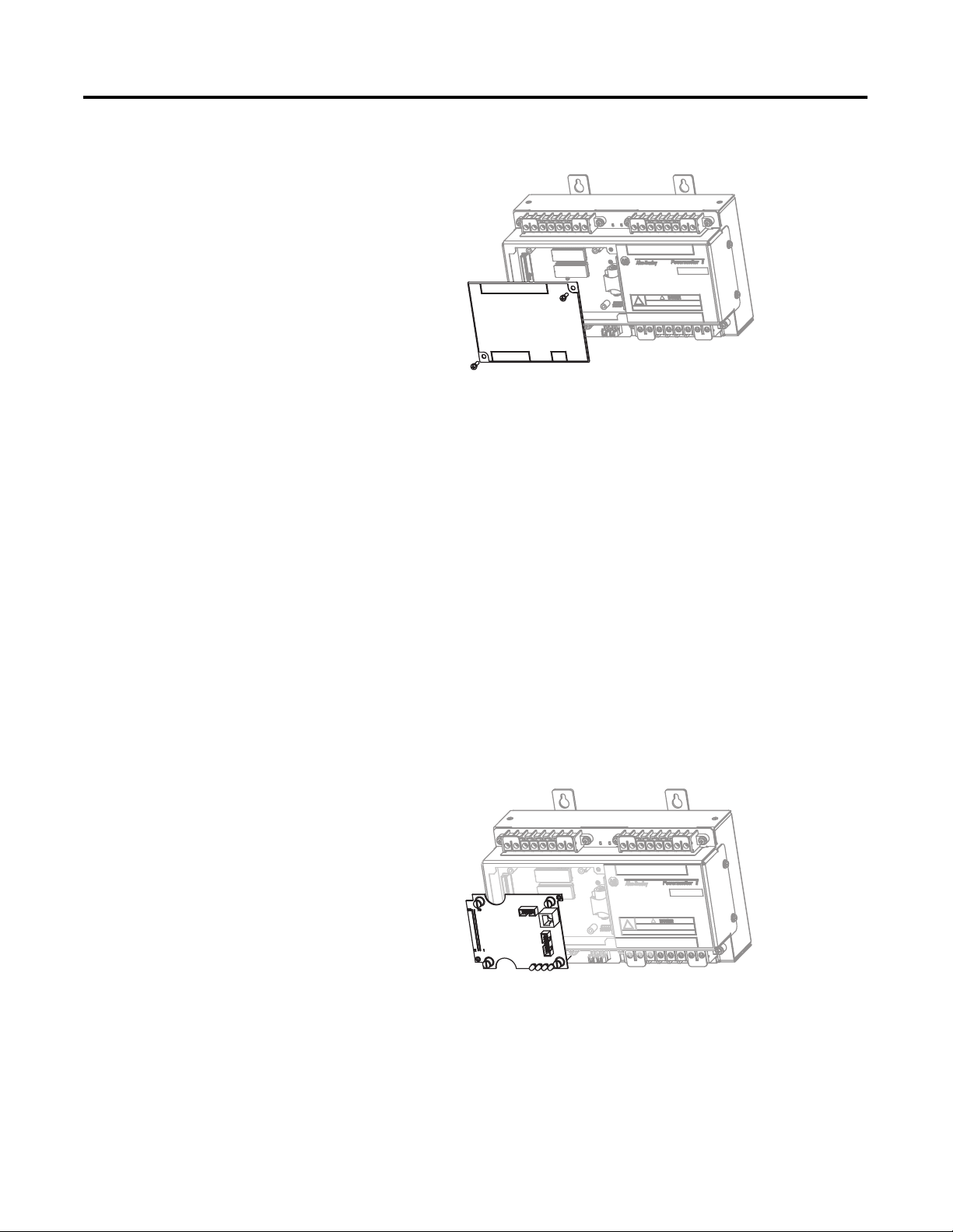

Figure 1 Catalog Number 1403-NENET Communications Module

Finger Hol d

Captive Fastening Screw

Internal RS-232 Connector

10BT Connector

Installation

Internal 10B5 Connector

Ready (RDY) L ED

Link (LK) LED

ATTENTION

Please follow appropriate ESD procedures before removal

and/or installation of the Ethernet Communications Card.

Receive (RX) L ED

Transmit (TX) LED

Failure to follow these procedures can result in physical

!

damage to both the Ethernet Communications Card and

the Master Module.

1. Remove Master Module control power .

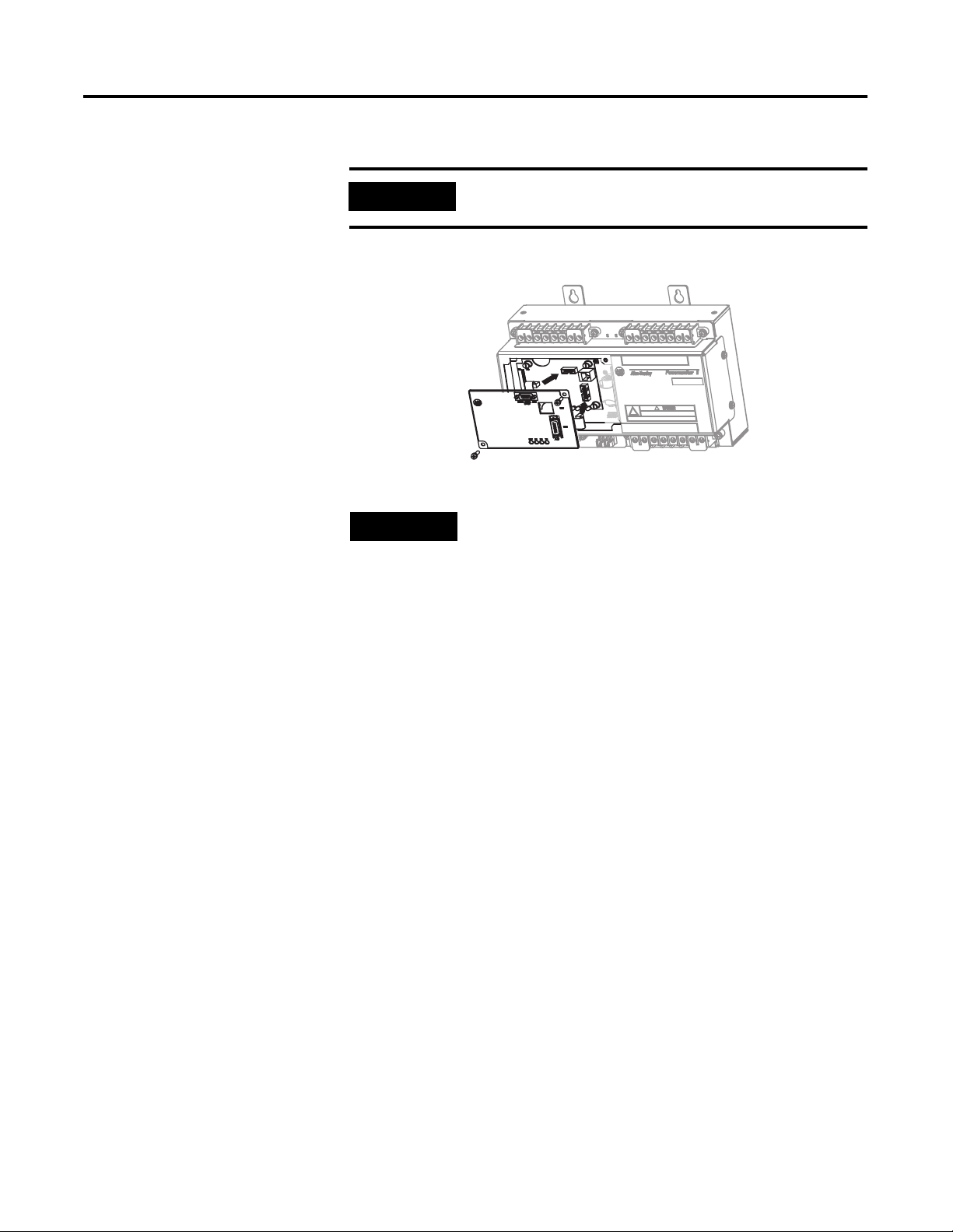

2. Remove the blank plate by unscrewing the two corner retaining screws

as shown i nFigure 2. Save these two screws for assembly.

Publication 1403-IN005A-EN-P

Page 7

Product Description 3

Figure 2 Blank Plate Removal

3. If you plan to remove the communications card at a later date, retain the

blank plate. Otherwise, dispose of properly.

4. Remove the communications card from the static protection shipping

bag.

5. Grasp the card with the components side up and the four LEDs on the

bottom. Place the right index finger in the top notch and the thumb in

the bottom notch.

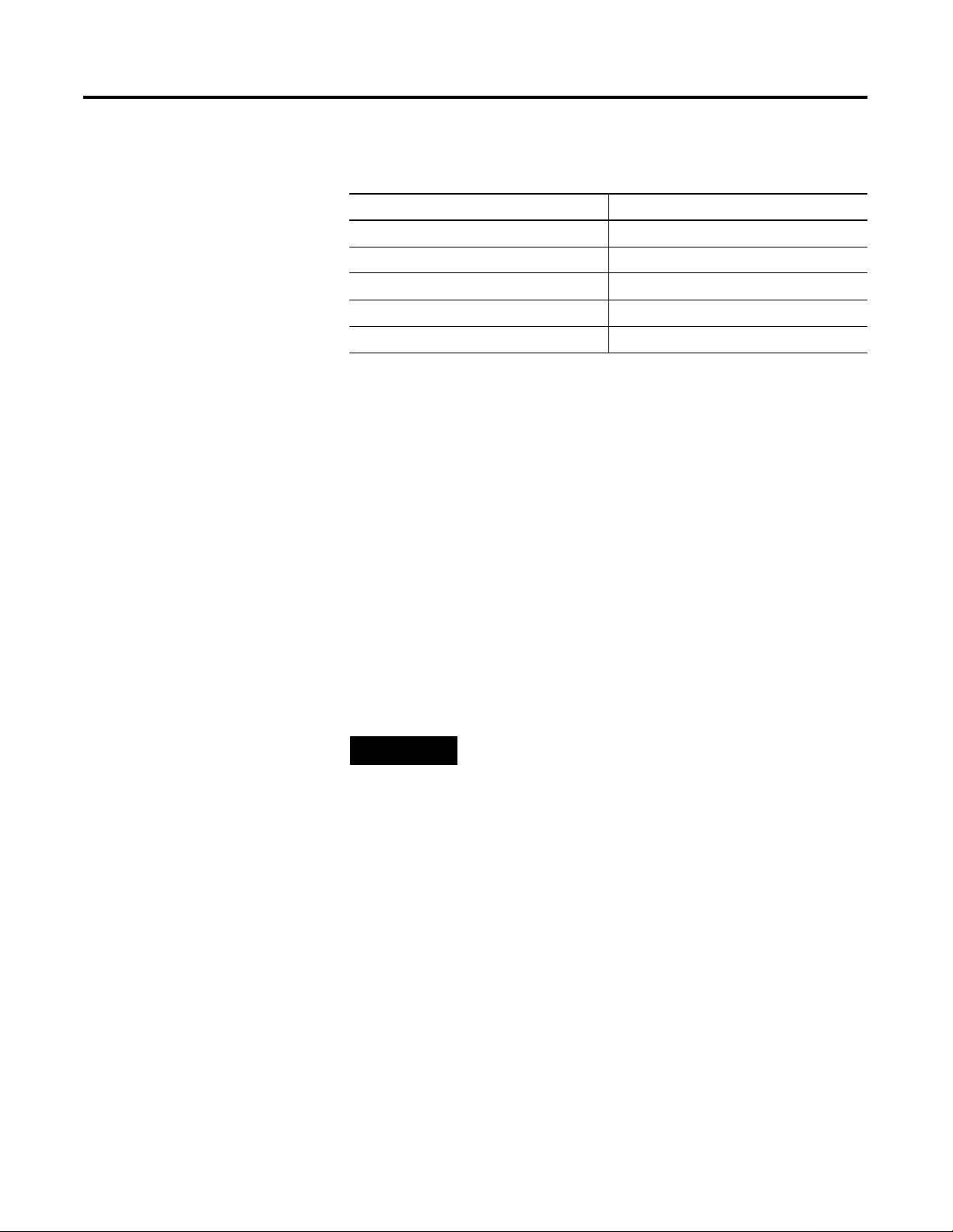

6. With the Master Module labels right side up, place the card into

opening on the left side, as shown in Figure 3. The card to Master

Module connector should align properly when the top right and bottom

left guide pins of the Master Module mate with holes in the card. With

your left thumb, press just above the card to Master Module connector

to attach the connector. Tighten the fo ur corner screws on the

communication card.

Figure 3 Installing Communication Card

7. Place the closure plate over the opening. Connect the closure plate

ribbon connectors to the communication card connectors. Secure it with

the t wo scre ws from the original blank plate as sh own inFig ure 4.

Publi cation 1403-IN005A-EN-P

Page 8

4 Product Description

Field Service Considerations

IMPORTANT

Figure 4 Installing Closure Plate

NOTE

8. Apply Master Module control power.

If the Ethernet Communications Card requires service, please contact your

nearest Rockwell Automation Sales Office. To minimize your inconvenience,

the initial installation shoul d be performed in a manner which makes removal

easy .

Make sure cables do not twist.

Refer to Appendix D on page D-1, for screw torque

requirements and wire sizes.

General Operation

Publication 1403-IN005A-EN-P

Communications Card Set-Up

All Ethernet card configuration items (Table 4 on page 6) can be changed via

the Display Module or via the RS-232 setup port on the Ethernet card . If using

a Display Module for Ethernet card configuration, all of the communication

configuration items can be found in the Display Module menu/parameter

structure unde r: Program

1403 Powermonitor II Instruction Sheet, Publication 1403-IN001A-US-P for

general information on Display M odule operation.)

The serial port on the 1403-NENET may be used to set communications

options as well. Follow these steps:

1. Connect to a PC using a standard RS-232 null modem cable.

2. Run a communication application (such as Hyper Terminal) on the PC.

3. Set the communications parameters. Se eTable 2 for communications

parameter settings.

➞ Configuration ➞ Communication. (Refer to

Page 9

Product Description 5

Table 2 Communication Parameters

Parameter Value

Baud Rate 38,400

Parity None

Data Bits 8

Stop Bits 1

Flow Control None

4. Apply control power to the Master Module.

5. Press Enter (or Return) on the PC.

6. Follow the on-screen instructions to modify and save the options.

Connections

There are two communication connection types for the 1403-NENET.

• UTP (10BaseT) - use a standard straight through RJ45 cable to connect

to an Ethernet hub.

• AUI - attach an Ethernet transceiver to the DB15 connector.

NOTE

The final installation should contain wiring to one port

only .

Publi cation 1403-IN005A-EN-P

Page 10

6 Product Description

Indicators

Four LED indicators provide information about the operating status of the

card.

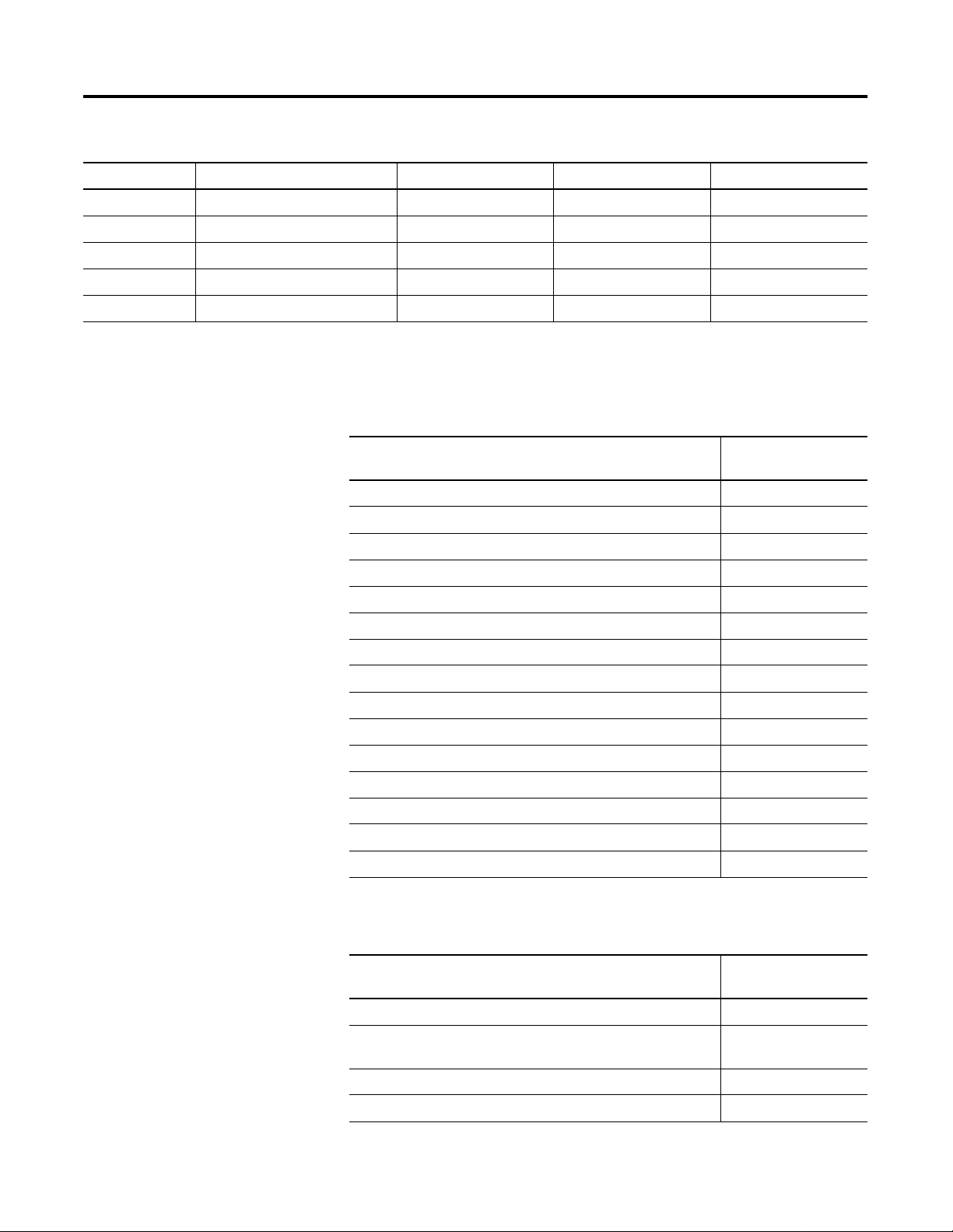

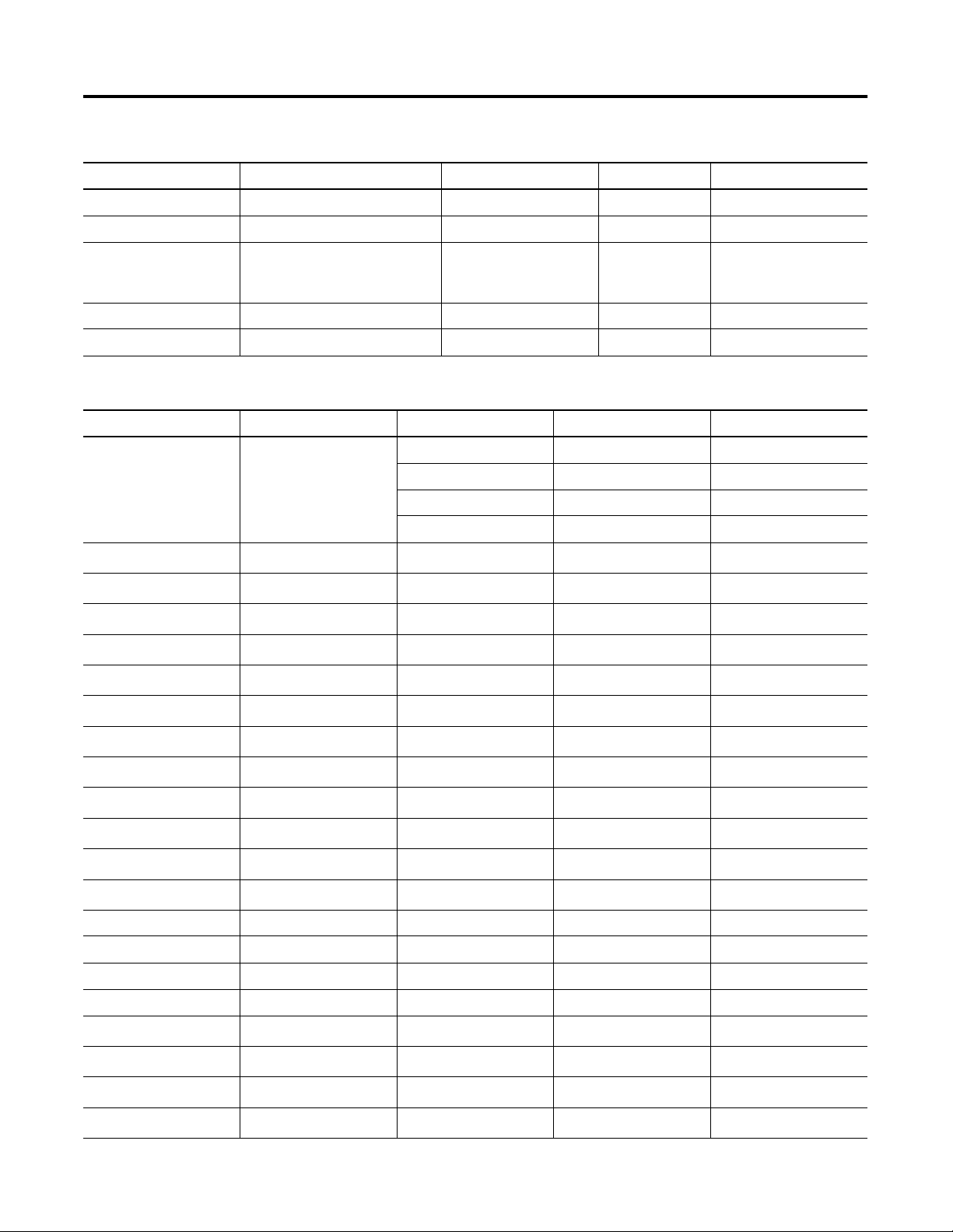

Table 3 LED Indicators

Label Name LED Color LED State and Communications Condition

RDY Ready Red ON = Control power applied

ON/OFF Flashing = Self-test initialization

LK Link Green ON = UTP (10BaseT) cable properly connected

RX Receive Green ON/OFF Fl a shi n g = R eceiving Data

TX Transmit Green ON/OF F Flas h i ng = Tr an smitting D ata

Configuration Items

Table 4 Communication Configuration Items

Communication Parameter Description Range Default

IP Address Byte a IP address of this Powermonitor. (Normally in the form

IP Address Byte b 1

IP Address Byte c 1

IP Address Byte d Devi ce ID#

Subnet Mask Byte a Specifies the subnet mask to apply to the IP address.

Subnet Mask Byte b 255

Subnet Mask Byte c 255

Subnet Mask Byte d 0

Physical Ethernet Por t Selects the Etherne t medi a (0=UTP/1 0B a s eT, 1=AUI/

Keep Alive Time The maximum allowable time any socket is dedicated to a

Inactivity Time The maximum allowable time the entire Ethernet

128.1.1.1)

Network ID and Host are specified by address class. Zero

bits in the mask indicate bit positions of the host number;

one bits are for subnet ID. (Normally in the form

255.255.255.0)

10Base 5)

connection that is not respo nding.

communi cation ca rd waits with no network activity

befor e re booting.

Set parameter to zero to disable inactivity time.

Communication

0 to 255 128

0 to 255 255

0 = UTP, 1 =AUI 0 = UTP

5 to 3600 seconds 30

0 to 1440 minutes

0 = Disabled

30

Publication 1403-IN005A-EN-P

NOTE

BOOT P, the dynamic acquisition of an IP address, is

enabled when all four address bytes of the programmed IP

address are set to zero. (0.0.0.0)

Page 11

Product Description 7

1403-NENET Web Access Overview

The HTTP (Web) interface is accessed from a web browser by entering the IP

address of the Powermonitor II in the address combo box

(example: http://128.1.1.151).

A menu of all the available tables is presented with each table name shown as a

hyperlink. Clicking on the link brings up a tabular display of the values in that

table and the value descriptions.

Publi cation 1403-IN005A-EN-P

Page 12

8 Product Description

Publication 1403-IN005A-EN-P

Page 13

Communications Cards

Bulletin Number Type of Device

Catalog Number Explanation

1403 - NENET

Appendix

A

1403 = Powermonitor II Family of products. NENET = Plug-in Communication Card for Bulletin 1403-MM and 1403-LM

Devices (TCP/IP Ethernet).

1 Publi cation 1403-IN005A-EN-P

Page 14

A-2 Catalog Number Explanation

Publication 1403-IN005A-EN-P

Page 15

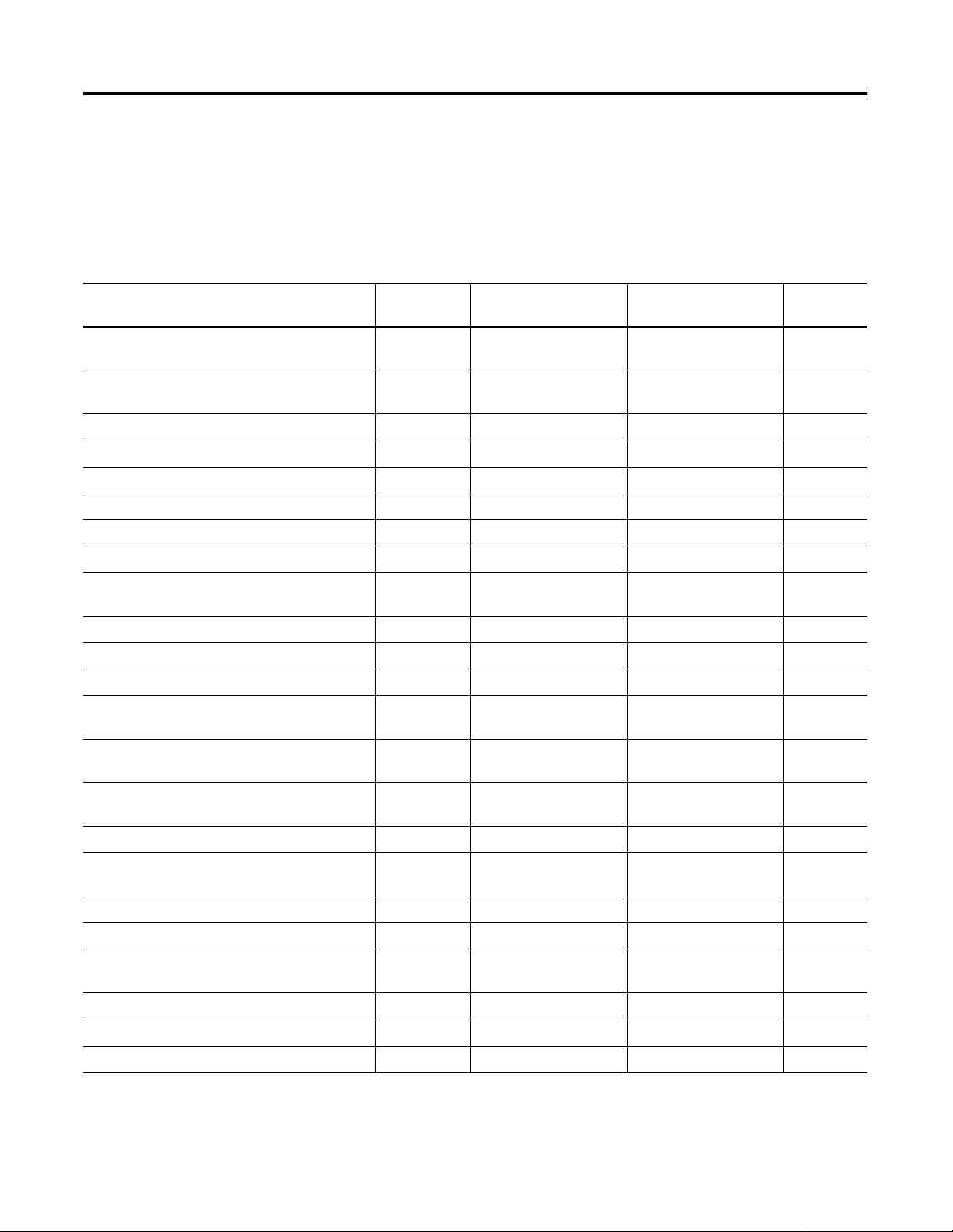

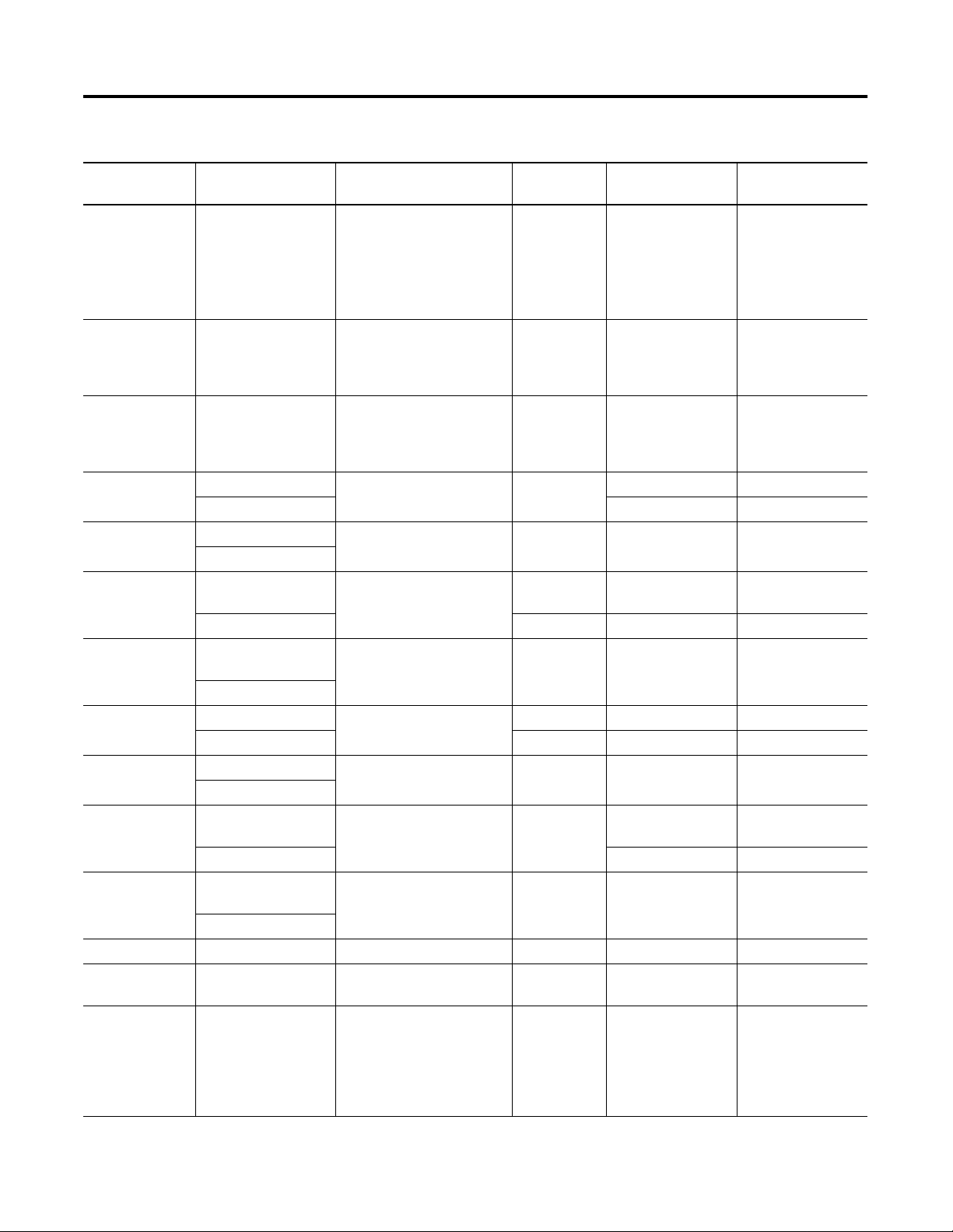

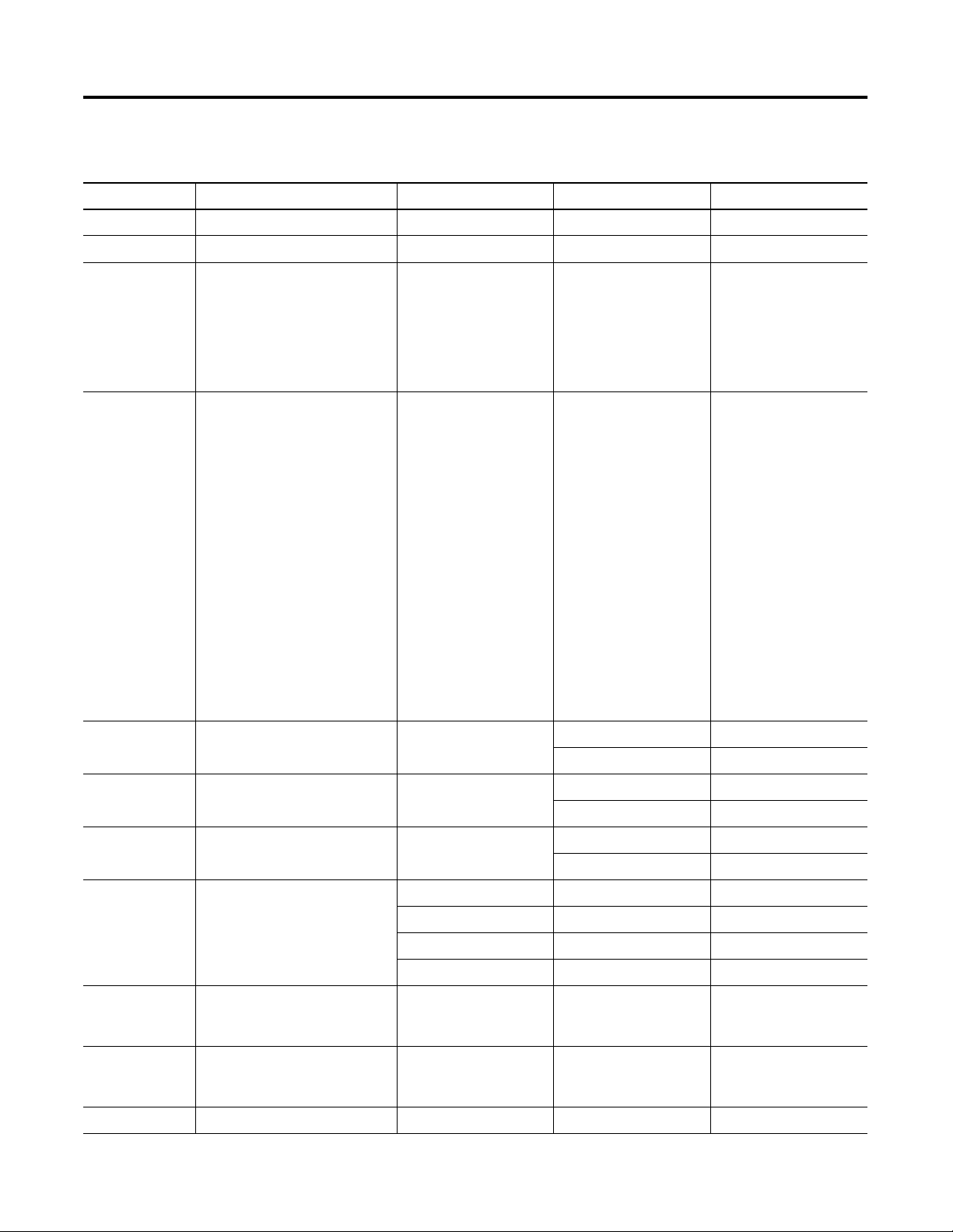

Table B.1 Data Table List

Appendix

Ethernet Communication Card Data Tables

B

Table Name Number of

Parameters

Device Configuration Data T able - Write and Read

(File N11)

Communications Configuration Table - Write and

Read (File N12)

Command Data Table Write (File N13) 12 N13/22 Write B-7

Voltage/Current Data - Read (File F14) 24 F14/29 Read B-9

Real- Time Power Data - Read (File F15) 25 F15/33 Read B-10

Cumulative Power Data - Read (File N16) 7 N16/45 Read B-11

Demand Data - Read (File F17) 18 F17/23 Read B-12

Event Log - Read (File N18) 12 N18/23 Read B-13

Snapshot 46 Parameter Record Table Read (File

F19)

Power Snapshot Log Data Table (File F20) 30 F20/34 Read B-20

Min_Max Log - Read (File N21) 8 N21/24 Read B-22

Log Selection Command Table Write (File N22) 4 N22/9 Write B-23

Even Harmonic Distortion Table - Channel 1 to 7

Read (File F23)

37 N11/44 Read/Write B-2

21 N12/30 Read/Write B-6

29 F19/32 Read B-14

29 F23/32 Read ( Channels 1 to 7) B-25

File/

Number of Elements

Type of Table Page

Odd Harm onic Distortion Table - Channels 1 to 7

Read (File F24)

Even Harmonic Magnitude Data Table Channel 1

to 7 Read (File F25)

Odd Harmonic Magnitude Data Table (File F26) 29 F26/30 Read (Channel 1 to 7) B-29

Even Harmonic Phase Angle Data Table Channels

1 to 7 Read (File F27)

Odd Harmonic Phase Angle Data Table (File F28) 29 F28/29 Read (Channel 1 to 7) B-32

Waveform Capture Data - Read (File N29) 54 N29/63 Read B-34

Diagnostic Data Table (Self-test Results) Read

(File N30)

Setpoint Setup Data Table - Write/Read (File N31) 9 N31/20 Read/Write B-39

Relay/Setpoint Statu s Table Read (File N32) 29 N3 2/38 Read B-41

Combined Real-Time Data T able Read (File F40) 81 F40/94 Read B-44

1 Publi cation 1403-IN005A-EN-P

29 F24/32 Read ( Channels 1 to 7) B-26

29 F25/31 Read (Channel 1 to 7) B-28

29 F27/30 Read (Channel 1 to 7) B-31

33 N30/39 Read B-37

Page 16

B-2 Ethernet Communication Card Data Tables

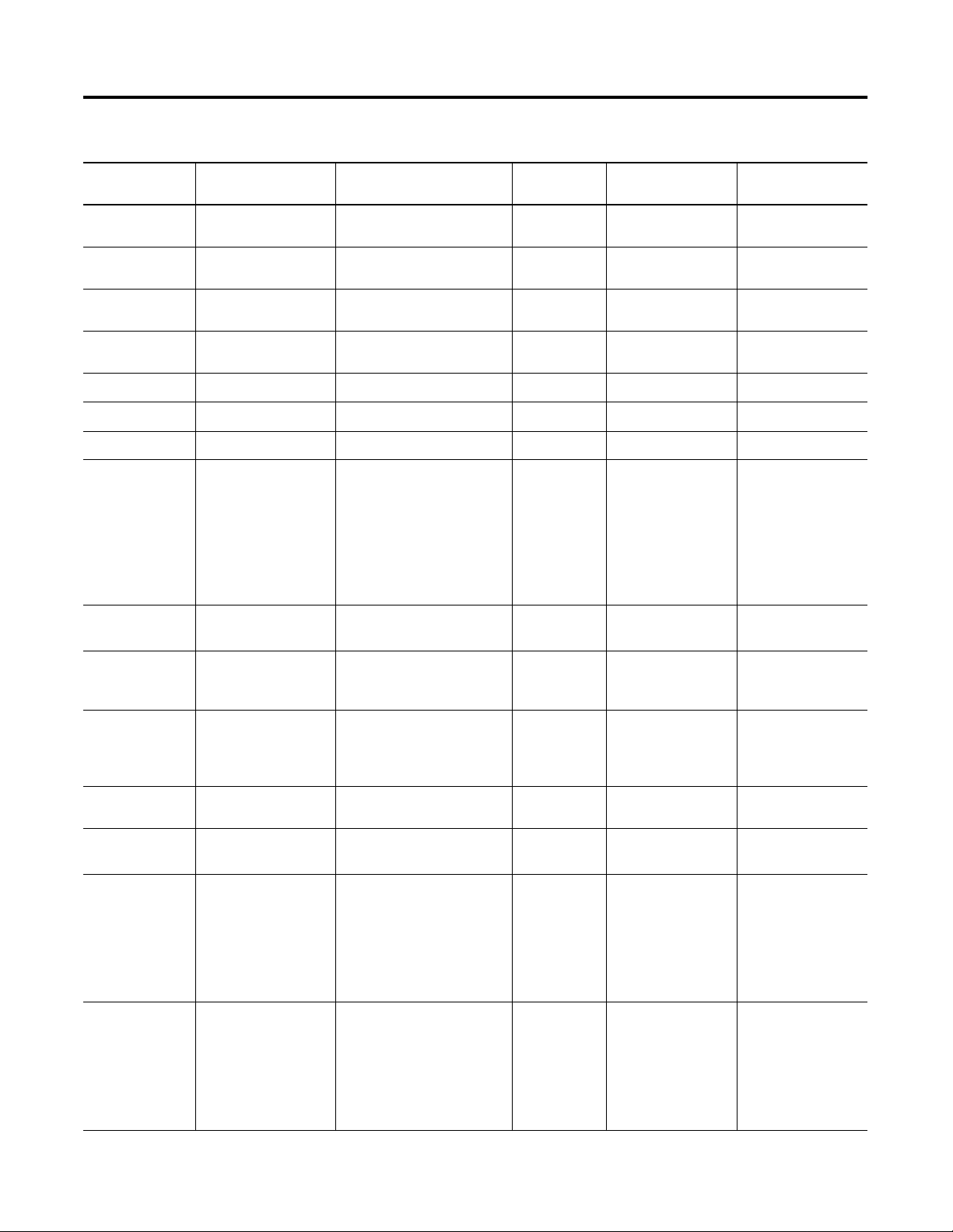

Table B.2 Device Configuration Data Table - Write and Read (File N11)

Parameter No. Parameter Name Master Module Range Default

Element Range

Setting

1.1 Voltage Mode 0 = Demo

41 0 to 5

1 = Single

2 = Open Delta

3 = 3-Wire Delta

4 = 4-Wire Wye

5 = Direct Delta

1.2 Present Unit Password -1 is always returned on a

(1)

0 2 -1 to +999 9

Read

0 to 9999 is required for a

Write

1.3 New Passwor d -1 does not chan ge the

0 3 -1 to +999 9

password

0 to 9999 is new password

value

1.4 Voltage Scale 1.0 to 10,000,000.0 120.0 4 0 to 9999

PT Primary 5 0 to 4

1.5 Voltage Scale 1 to 999 120 6 1 to 999

PT Seco nd ary

1.6 Current Scale (For I1,

1.0 to 10,000,000.0

1 or 5

(2)

7 0 to 9999

I2, I3)

CT Primary 8 0 to 4

1.7 Current Scale (For I1,

1 to 999

1 or 5

(2)

9 1 to 999

I2, I3)

CT Secondary

1.8 Analog Input Scale 1.0 to 10,000,000.0 1.0 10 0 to 9999

PT Primary 11 0 to 4

1.9 Analog Input Scale 1 to 999 1 12 1 to 999

PT Seco nd ary

1.10 Neutral Current Scale

1.0 to 10,000,000.0

1 or 5

(2)

13 0 to 9999

(For I4)

CT Primary 14 0 to 4

1.11 Neutral Current Scale

1 to 999

1 or 5

(2)

15 1 to 999

(For I4)

CT Secondary

1.12 Demand Period Length -99 to +99 1 16 -99 to +99

1.13 Number of Demand

1 to 15 1 17 1 to 15

Periods

1.14

Snapshot Log Type

(3)

0 = 46 param record

018 0 to 5

1 = 16 param record

2 = 8 param record

3 = 4 param record

4 = 3 and 7 param record

5 = 1 param record

Publication 1403-IN005A-EN-P

Page 17

Table B.2 Device Configuration Data Table - Write and Read (File N11)

Ethernet Communication Card Data Tables B-3

Parameter No. Parameter Name Master Module Range Default

Setting

1.15 Snapshot Interval -

0 19 0 to 32,767

Hours

1.16 Snapshot Interval -

0 20 0 to 32,767

Minutes

1.17 Snapshot Interval -

0 21 0 to 32,767

Seconds

1.18 Snapshot Buffer Type 0 = Fill and Stop

122 0 to 1

1 = Circular

(3)

1.19

1.20

1.21

1.22

Snaps ho t Param #1

Snaps ho t Param #2

Snaps ho t Param #3

Oscillograph Type

SeeTable B.3 62 23 0 to 64

(3)

SeeTable B.3 63 24 0 to 64

(3)

SeeTable B.3 47 25 0 to 64

(3)

0 = V2.10 or earlier

026 0 to 6

compatible mode

1 = 1 0 .8 kHz, 1 capture

2 = 1 0 .8 kHz, 2 captures

3 = 5.4 kH z, 1 capture

4 = 5.4 kH z, 2 captures

5 = 2.7 kH z, 1 capture

6 = 2.7 kH z, 2 captures

1.23 Oscillograph

Overwr i t e Timeou t

1.24 Output Pulse Relay

No.

1 to 4320 minutes 1 27 1 to 4320

(3)

0 = None

028 0 to 2

1 = Relay 1

2 = Relay 2

1.25 O utput Pulse

Parameter

0 = kWh Forward

1 = kWh Reverse

029 0 to 3

2 = kVarh Forward

3 = kVarh Reverse

1.26 O utput Pulse

1 to 32766 1 30 1 to 32766

Increment

1.27 Outp u t Puls e Width

(4)

(ms)

1.28 Ch A 12 Cycle

Oscillogram

(5)

0, 40 to 2000 100 31 40 to 2000

1 = Phase 1 Voltage

132 1 to 7

2 = Phase 1 Current

3 = Phase 2 Voltage

4 = Phase 2 Current

5 = Phase 3 Voltage

6 = Phase 3 Current

7 = Phase 4 Current

1.29 Ch B 12 Cycle

Oscillogram

(5)

1 = Phase 1 Voltage

2 = Phase 1 Current

233 1 to 7

3 = Phase 2 Voltage

4 = Phase 2 Current

5 = Phase 3 Voltage

6 = Phase 3 Current

7 = Phase 4 Current

Element Range

Publi cation 1403-IN005A-EN-P

Page 18

B-4 Ethernet Communication Card Data Tables

Table B.2 Device Configuration Data Table - Write and Read (File N11)

Parameter No. Parameter Name Master Module Range Default

Setting

1.30 Oscillograph Buffer

(5)

Type

1.31 Number of Pretrigger

Cycles for the 12 Cycle

Oscillogram

(5)

1.32 IEEE 519 Max. Short

Circuit Current

(5)

1.33 IEEE 519 Max.

0 = Hold

134 0 to 1

1 = Overwrite

-1 = No Pret rig

0 35 -1 to +8

0 to +8 = Cycles

0.0 to 10,000,000.0 0 36 0 to 9999

0.0 to 10,000,000.0 0 38 0 to 9999

Demand/Load

(5)

Current

1.34 Save Status Changes

to Event Log

1.35 Vaux Voltage Mode 0 = AC

0 = No

1 = Yes

040 0 to 1

041 0 to 1

1 = DC

1.36 Filter Mo de (14 03 -MM)

Enable THD (1403- LM)

1.37 Enable Min_Max Log 0 = No

1 to 3 (1403-MM)

0 to 1 (1403-LM)

2 (1403-MM)

0 (1403-LM)

143 0 to 1

1 = Yes

Reserved 44

Element Range

37 0 to 4

39 0 to 4

42 1 to 3 (1403-MM)

0 to 1 (1403-LM)

(1) Available on 1403-MM firmware V2.0 o r later and 1403-LM firmware V1.01 or later.

(2) This va l ue is 1 for 1-Amp Ma ster Module (Cat. No. 1403-MM01X) or 5 for a 5-Amp Master Module (Cat. No. 1403-MM05X).

(3) Available on firmware V 3 .00 or later (reserved in previous versions).

(4) For transitional KYZ pulse enter 0.

(5) 1403-MM only , not available on 1403-LM version.

Publication 1403-IN005A-EN-P

Page 19

Ethernet Communication Card Data Tables B-5

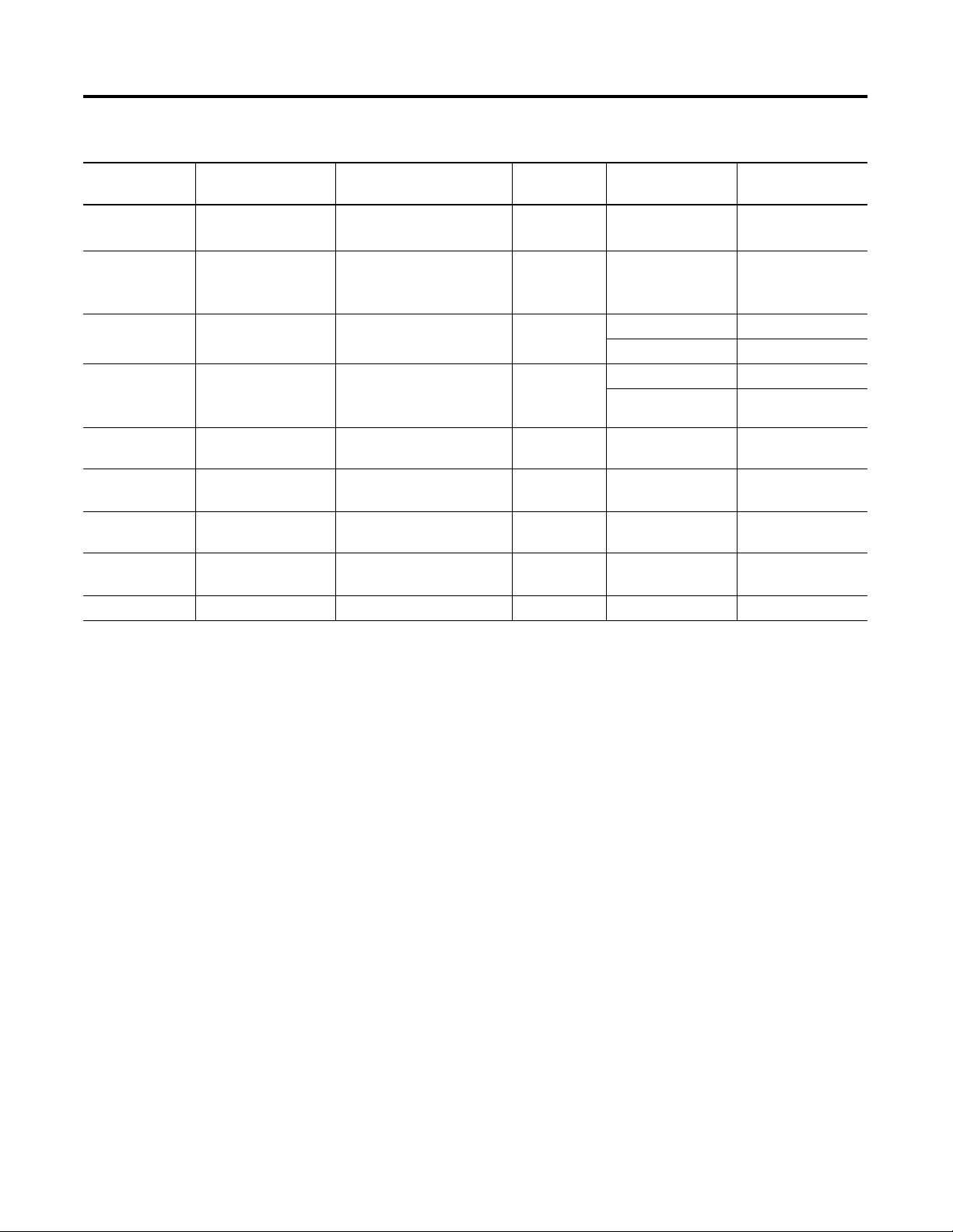

Table B.3 Configurable Snapshot Parameter List (selection list for Table B.2, parameters 1.19, 1.20 and 1.21)

Parameter Number Parameter Name Parameter Number Parameter Name

0 L1 Cu rrent 33 Total A pparent Power

1 L2 Current 34 L 1 True PF

2 L3 Current 35 L 2 True PF

3 Avg Current 36 L3 T rue PF

4 L4 Cu rrent 37 Total True PF

5 L1-N Voltage 38 L1 Displacement PF

6 L2-N Voltage 39 L2 Displacement PF

7 L3-N Voltage 40 L3 Displacement PF

8 Avg L-N Voltage 41 Total D is p l a c em e nt PF

9 L1-L2 Voltag e 42 L1 Distort ion PF

10 L2-L3 Voltage 43 L2 Dis t ortion PF

11 L3-L1 Voltage 44 L3 Dis t ortion PF

12 Avg L-L Voltage 45 Total Distortion PF

13 Frequency 46 Demand I

14 Pos Seq Current 47 Demand W

15 Neg Seq Current 48 Demand VAR

16 Current Unbalance 49 Demand VA

17 Pos Seq Voltage 50 Proj #1 Demand I

18 Neg Seq Voltage 51 Proj #1 Demand W

19 Voltage Unbalance 52 Proj #1 Demand VAR

20 Aux Voltage 53 Proj #1 Demand VA

21 Aux Frequency 54 Proj #2 De m and I

22 L1 Real Power 55 Proj #2 Demand W

23 L2 Real Power 56 Proj #2 Demand VAR

24 L3 Real Power 57 Proj #2 Demand VA

25 Total R eal Powe r 58 Proj #3 Demand I

26 L1 Reactive Power 59 Pro j # 3 D emand W

27 L2 Reactive Power 60 Pro j # 3 D emand VAR

28 L3 Reactive Power 61 Pro j # 3 D emand VA

29 Total R eactive Power 62 KWh net

30 L1 Apparent Power 63 KVARh net

31 L2 Apparent Power 64 KVAh net

32 L3 Apparent Power

Publi cation 1403-IN005A-EN-P

Page 20

B-6 Ethernet Communication Card Data Tables

NOTE

Table B.4 Communications Configuration Table - Write and Read (File N12)

Parameter

No.

2.1 IP Address Byte a 0 to 255 128 1 0 to 255

2.2 IP Address Byte b 0 to 255 1 2 0 to 255

2.3 IP Address Byte c 0 to 255 1 3 0 to 255

2.4 IP Address By te d 0 to 255 Unit ID 4 0 to 255

2.5 Reserved 0 0 5 0

2.6 Reserved 0 0 6 0

2.7 Reserved 0 0 7 0

2.8 Reserved 0 0 8 0

2.9 Subnet Mask Byte a 0 to 255 255 9 0 to 255

2.10 Subnet Mask Byte b 0 to 255 255 10 0 to 255

2.11 Subnet Mask Byte c 0 to 255 255 11 0 to 255

2.12 Subnet Mask Byte d 0 to 255 0 12 0 to 255

2.13 Physical Ethernet Port 0 = UTP, 1 = AUI 0 13 0 to 1

2.14 Keep Alive Time 5 to 3600 Seconds 30 14 5 to 3600

2.15 Inactivity Time 0 to 1440 Minutes 30 15 0 to 1440

2.16 Reserved 0 0 16 0

2.17 Reserved 0 0 17 0

2.18 Reserved 0 0 18 0

2.19 Reserved 0 0 19 0

2.20 Reserved 0 0 20 0

2.21 Present Unit Password -1 is always returned for

Parameter Name Master Module Range Default Element Range

a Read

0 to 9999 is re qu i red for a

Write

Reserved 0 0 22 0

Reserved 0 0 23 0

Reserved 0 0 24 0

Reserved 0 0 25 0

Reserved 0 0 26 0

Reserved 0 0 27 0

Reserved 0 0 28 0

Reserved 0 0 29 0

Reserved 0 0 30 0

The device does not respond to a broadcast of this table. IP

addresses are stored as a.b.c.d (e.g. 128.1.1.1; a=128).

-1 (Rea d) 21 -1 to +9999

Publication 1403-IN005A-EN-P

Page 21

Ethernet Communication Card Data Tables B-7

Table B.5 Command Data Table Write (File N13)

Parameter No. Parameter Name Master Module Range Element Range

3.1 Command Word 1 (Bit Fields) SeeTable B.6 1 0 to 32,767

3.2 Command Word 2 (Bit Fields) SeeTable B.7 2 0 to 511

3.3

Harmonic Analysis

(1)

1 = L1 Voltage

31 to 7

2 = L1 Current

3 = L2 Voltage

4 = L2 Current

5 = L3 Voltage

6 = L3 Current

7 = L4 Current

3.4 Oscill ograph Channel Request

(Not Av ailable on 1403-LM)

1 = Capture #1 V1

2 = Capture #1 I1

4 1 to 17

3 = Capture #1 V2

4 = Capture #1 I2

5 = Capture #1 V3

6 = Capture #1 I3

7 = Capture #1 I4

8 = Ch-A 12 Cycle

9 = Ch-B 12 Cycle

10 = Reser v ed

(2)

(2)

(2)

(2)

(2)

(2)

(2)

5 - 9999 to 999 9

6

8

7 - 9999 to 999 9

8

±0 to 8

±0 to 8

3.5 W Hour Data for Set Command

3.6 VAR Hour Data for Set Command

11 = Capture #2 V1

12 = Capture #2 I1

13 = Capture #2 V2

14 = Capture #2 I2

15 = Capture #2 V3

16 = Capture #2 I3

17 = Capture #2 I4

-9999x10

-9999x10

8

to +9999x108

8

to +9999x10

3.7 Reserved 9

10

3.8 Time for Set Command Year 11 1998 to 2097

Month, Day 12 8-bit, 8-bi t

Hour, Minutes 13 8-bit, 8-bit

Seconds, Hundredths 14 8-bit, 8-bit

3.9 Force Specifics Relay 1 1 = Energize

15 1, 2, 4

2 = De-energ ize

4 = Remove Fo r ce

3.10 Force Specifics Relay 2 1 = Energize

16 1, 2, 4

2 = De-energ ize

4 = Remove Fo r ce

3.11 Setpoint Number 1 to 20 17 1 to 20

Publi cation 1403-IN005A-EN-P

Page 22

B-8 Ethernet Communication Card Data Tables

Table B.5 Command Data Table Write (File N13)

Parameter No. Parameter Name Master Module Range Element Range

3.12 Present Unit Password 0 to 9999 18 0 to 9999

Reserved 19

Reserved 20

Reserved 21

Reserved 22

(1) S ee Tabl e B.6 o n pageB-8 for specific command bi ts to enable these features.

(2) Available on firmware V3.00 or later.

Table B.6 Bit Fields for Command Data Table -(Command Word 1)

Command Bit Location and

Value

Clear Snapshot Log b0 = 1

Clear Min_Max Log b1 = 1

Restore Factory Default Configuration b2 = 1

Clear Hold of Oscillog raph Capt ure #1 (Reserv ed on 1403 - LM) b3 = 1

Initiate Oscillograph Capture #1 (Reserved on 1403-LM) b4 = 1

Force Self Test b5 = 1

Clear Status Input Counter 1 b6 = 1

Clear Status Input Counter 2 b7 = 1

Clear Status Input Counter 3 b8 = 1

Clear Status Input Counter 4 b9 = 1

Clear Battery Usage Timer b10 = 1

Reserved b11 = 1

Synchronize Demand Interval b12 = 1

Clear Hold of Oscil l ograph Capture #2 (R es erved on 1403-LM) b13 = 1

Initiate Oscillograph Capture #2 (Reserved on 1403-LM) b14 = 1

Table B.7 Bit Fields for Command Data Table - (Command Word 2)

Command Bit Location and

Value

Publication 1403-IN005A-EN-P

Set Analysis Channel Request (DV1) b0 = 1

Set Oscillogram Channel Request (DV2)

b1 = 1

(Not Available on 1403-LM)

Set W Hours (DV3) b2 = 1

Set VAR Hours (DV4) b3 = 1

Page 23

Ethernet Communication Card Data Tables B-9

Table B.7 Bit Fields for Command Data Table - (Command Word 2)

Command Bit Location and

Value

Reserved b4 = not used

Set Time (DV6) b5 = 1

Relay 1 (DV7) b6 = 1

Relay 2 (DV8) b7 = 1

Select Setpoint Number ( D V9) b8 = 1

Table B.8 Voltage/Current Data - Read (File F14)

Parameter No. Parameter Name Master Module Range Element Range

4.1 Time Stamp Year 1 32-bit Float

Month, Date 2 32-bit Float

Hour, Minute 3 32-bit Float

Seconds, Hundredths 4 32-bit Float

4.2 L1 Current

4.3 L2 Current

4.4 L3 Current

4.5 L4 (Neutral) Current

4.6 3-Phase Average Current

4.7 Positive Sequence Current

4.8 Negative Sequence Current

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

21

21

21

21

21

21

21

amps

amps

amps

amps

amps

amps

amps

5

6

7

8

9

10

11

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

21

21

21

21

21

21

21

4.9 Percent Current Unbalance 0.0 to 100.0 12 0.0 to 100.0

4.10 L1 to L2 Voltage

4.11 L2 to L3 Voltage

4.12 L3 to L1 Voltage

4.13 AUX Voltage

4.14 3-Phase Average Voltage (L-L)

4.15 Positive Sequence Voltage

4.16 Negative Sequence Voltage

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

21

21

21

21

21

21

21

amps

volts

amps

volts

amps

volts

volts

13

14

15

16

17

18

19

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

4.17 Percent Voltage Unbalance 0.0 to 100.0 20 0.0 to 100.0

4.18 L1-N Voltage

4.19 L2-N Voltage

4.20 L3-N Voltage

4.21 3-Phase Average Voltage (L-N)

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

21

21

21

21

volts

volts

volts

volts

21

22

23

24

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

Publi cation 1403-IN005A-EN-P

21

21

21

21

21

21

21

21

21

21

21

Page 24

B-10 Ethernet Communication Card Data Tables

Table B.8 Voltage/Current Data - Read (File F14)

Parameter No. Parameter Name Master Module Range Element Range

4.22 Reserv ed Word 25

4.23 Last Cycle Frequency 20.0 to 132.0 26 0 to 9999

4.24 Phase Rotation 0 = No Rotation

27 0 to 2

1 = ABC

2 = ACB

Reserved Word 28

Reserved Word 29

Table B.9 Real-Time Power Data - Read (File F15)

Parameter No. Parameter Name Master Module Range Element Range

5.1 Time Stamp Year 1 32-bit Float

Month, Date 2 32-bit Float

Hour, Minute 3 32-bit Float

Seconds, Hundredths 4 32-bit Float

5.2 L1 Real Power

5.3 L2 Real Power

5.4 L3 Real Power

5.5 Total Real Power

5.6 L1 Reactive Power

5.7 L2 Reactive Power

5.8 L3 Reactive Power

5.9 Total Rea ctive Power

5.10 L1 App ar ent Power

5.11 L2 App ar ent Power

5.12 L3 App ar ent Power

5.13 Total Apparent Power

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

21

21

21

21

21

21

21

21

21

21

21

21

W

W

W

W

VAR

VAR

VAR

VAR

VA

VA

VA

VA

5

6

7

8

9

10

11

12

13

14

15

16

0 to 9999x1021

0 to 9999x1021

0 to 9999x1021

0 to 9999x1021

0 to 9999x1021

0 to 9999x1021

0 to 9999x1021

0 to 9999x1021

0 to 9999x1021

0 to 9999x1021

0 to 9999x1021

0 to 9999x1021

5.14 L1 True PF -100.0 to +100.0 17 -100.0 to +10 0. 0

5.15 L2 True PF -100.0 to +100.0 18 -100.0 to +10 0. 0

5.16 L3 True PF -100.0 to +100.0 19 -100.0 to +10 0. 0

5.17 Total True PF -100.0 to +100.0 20 -100.0 to +100.0

5.18

5.19

5.20

5.21

Publication 1403-IN005A-EN-P

L1 Displa cement PF

L2 Displa cement PF

L3 Displa cement PF

(1)

(1)

(1)

Total Displ acement PF

-100.0 to +100.0 21 -100.0 to +100.0

-100.0 to +100.0 22 -100.0 to +100.0

-100.0 to +100.0 23 -100.0 to +100.0

(1)

-100.0 to +100.0 24 -100.0 to +100.0

Page 25

Ethernet Communication Card Data Tables B-11

Table B.9 Real-Time Power Data - Read (File F15)

Parameter No. Parameter Name Master Module Range Element Range

5.22

5.23

5.24

5.25

L1 Distortion PF

L2 Distortion PF

L3 Distortion PF

T otal Di stortion PF

(1)

(1)

(1)

(1)

-100.0 to +100.0 25 -100.0 to +100.0

-100.0 to +100.0 26 -100.0 to +100.0

-100.0 to +100.0 27 -100.0 to +100.0

-100.0 to +100.0 28 -100.0 to +100.0

Reserved Word 29

(1) This value has the same update rate as harmonic analysis.

Table B.10 Cumulative Power Data - Read (File N16)

Parameter No. Parameter Name Master Module

Element Range Modulus

Range

6.1 Time Stamp Year 1 N/A

Month, D a te 2 N/A

Hour, Minute 3 N/A

Seconds,

4N/A

Hundredths

6.2 kW Hours Forward

6.3 kW Hours Reverse

6.4 kW Hours Net

0 to 1.0x10

-1.0x10

-1.0x10

1.0x10

12

12

to 0

12

to

12

5 +0 to 999

6 +0 to 999

7 +0 to 999

8 +0 to 999

9 +0 to 999

10 -0 to 999

11 -0 to 999

12 -0 to 999

13 -0 to 999

14 -0 to 999

15 ±0 to 999

16 ±0 to 999

17 ±0 to 999

18 ±0 to 999

19 ±0 to 999

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

0

3

6

9

12

0

3

6

9

12

0

3

6

9

12

Publi cation 1403-IN005A-EN-P

Page 26

B-12 Ethernet Communication Card Data Tables

Table B.10 Cumulative Power Data - Read (File N16)

Parameter No. Parameter Name Master Module

Range

6.5 kVAR Hours Forward

6.6 kVAR Hours Reverse

6.7 kVAR Hours Net

0 to 1.0x10

-1.0x10

-1.0x10

1.0x10

12

12

to 0

12

to

12

Reser v ed Word 35

Reser v ed Word 36

Reser v ed Word 37

Reser v ed Word 38

Reser v ed Word 39

Reser v ed Word 40

Reser v ed Word 41

Reser v ed Word 42

Reser v ed Word 43

Reser v ed Word 44

Reser v ed Word 45

Element Range Modulus

20 +0 to 999

21 +0 to 999

22 +0 to 999

23 +0 to 999

24 +0 to 999

25 -0 to 999

26 -0 to 999

27 -0 to 999

28 -0 to 999

29 -0 to 999

30 ±0 to 999

31 ±0 to 999

32 ±0 to 999

33 ±0 to 999

34 ±0 to 999

10

10

10

10

10

10

10

10

10

10

10

10

10

10

10

0

3

6

9

12

0

3

6

9

12

0

3

6

9

12

Table B.11 Demand Data - Read (File F17)

Parameter No. Parameter Name Master Module Range Element Range

7.1 Time Stamp Year 1 32-bit Float

Month, Date 2 32-bit Float

Hour, Minute 3 32-bit Float

Seconds, Hundredths 4 32-bit Float

7.2 Demand Current

Publication 1403-IN005A-EN-P

0 to 9999x10

21

amps

5

0 to 9999x10

21

Page 27

Ethernet Communication Card Data Tables B-13

Table B.11 Demand Data - Read (File F17)

Parameter No. Parameter Name Master Module Range Element Range

7.3 Demand Power

7.4 Demand Reactive Power

7.5 Demand Ap pa rent Power

7.6 Projected No. 1 Demand Current

7.7 Projected No. 1 Dema nd Power

7.8 Projected No. 1 Demand Reactive Power

7.9 Projected No. 1 Demand Apparent Power

7.10 Projected No. 2 Demand Current

7.11 Projected No. 2 Dema nd Power

7.12 Projected No. 2 Demand Reactive Power

7.13 Projected No. 2 Dema nd Apparent Power

7.14 Projected No. 3 Demand Current

7.15 Projected No. 3 Dema nd Power

7.16 Projected No. 3 Demand Reactive Power

7.17 Projected No. 3 Dema nd Apparent Power

7.18 Elap s ed Time

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

21

21

21

21

21

21

21

21

21

21

21

21

21

21

21

21

W

VAR

VA

amps

W

VAR

VA

amps

W

VAR

VA

amps

W

VAR

VA

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

Reserved Word 22

Reserved Word 23

21

21

21

21

21

21

21

21

21

21

21

21

21

21

21

21

Table B.12 Event Log - Read (File N18)

(1)

Parameter No. Parameter Name Master Module Range Element Range

8.1 Event Time Log Stamp Year 1 16 Bit Integer

Month, Date 2 8-bit, 8-bit

Hour, Minute 3 8-bit, 8-bit

Seconds, Hundredths 4 8-bit, 8-bit

8.2 Event Type Value 0 to 14 5 0 to 14

8.3 Event Code Value 0 to 10 6 0 to 10

8.4 Setpoint Type 0 to 54 7 0 to 54

8.5 Setpoint Evaluation Condition 0 to 5 8 0 to 5

8.6 Setpoint Level

±9999x10

21

9 ±0 to 9999

10

±0 to 21

8.7 Setpoint Action/Release Delay 0 to 9999 11 0 to 9999

8.8 Setpoint Action 0 to 20 12 0 to 20

8.9 Number of Event Logs Requested 1 to 100 13 1 to 100

8.10 Number of Event Log Received (Counter) 1 to 100 14 1 to 100

Publi cation 1403-IN005A-EN-P

Page 28

B-14 Ethernet Communication Card Data Tables

Table B.12 Event Log - Read (File N18)

(1)

Parameter No. Parameter Name Master Module Range Element Range

8.11 Number of Event Log Being Returned 1 to 100 15 1 to 100

8.12 Internal Identifier -32767 to +32767 16 -32767 to +32767

Reserved Word 17

Reserved Word 18

Reserved Word 19

Reserved Word 20

Reserved Word 21

Reserved Word 22

Reserved Word 23

(1) ID=23 for log selection command.

Table B.13 Snapshot 46 Parameter Record Table Read (File F19)

Parameter No. Parameter Name Master Module

(1)

Element Range

Parameter Range

9.1 Timestamp of Snapshot Record Year 1 32-bit Float

Month, Date 2 32-bit Float

Hour, Minute 3 32-bit Float

Seconds, Hundredths 4 32-bit Float

9.2 Reserved 5

9.3 L1 Current

9.4 L2 Current

9.5 L3 Current

9.6 L4 (Neutral) Current

9.7 3-Phase Average Current

9.8 Positive Sequence Current

9.9 Negative Sequence Current

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

21

21

21

21

21

21

21

amps

amps

amps

amps

amps

amps

amps

6

7

8

9

10

11

12

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

21

21

21

21

21

21

21

9.10 Percent Current Unbalance 0.0 to 100.0 13 0.0 to 100.0

9.11 L1-L2 Voltage

9.12 L2-L3 Voltage

9.13 L3-L1 Voltage

9.14 AUX Voltage

9.15 3-Phase Average Voltage (L-L)

9.16 Positiv e S equence Voltage

9.17 Negative Sequence Voltage

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

21

21

21

21

21

21

21

volts

volts

volts

volts

volts

volts

volts

14

15

16

17

18

19

20

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

21

21

21

21

21

21

21

9.18 Percent Voltage Unbalance 0.0 to 100.0 21 0.0 to 100.0

9.19 L1-N Voltage

9.20 L2-N Voltage

0 to 9999x10

0 to 9999x10

21

21

volts

volts

22

23

0 to 9999x10

0 to 9999x10

21

21

Publication 1403-IN005A-EN-P

Page 29

Ethernet Communication Card Data Tables B-15

Table B.13 Snapshot 46 Parameter Record Table Read (File F19)

Parameter No. Parameter Name Master Module

(1)

Element Range

Parameter Range

9.21 L3-N Voltage

9.22 3-Phase Average Voltage (L-N)

0 to 9999x10

0 to 9999x10

21

21

volts

volts

24

25

0 to 9999x10

0 to 9999x10

21

21

9.23 Reserved 26

9.24 Last Cycle Frequency 20.0 to 132.0 27 20.0 to 132.0

9.25 Phase Rotation 0 = No Rotation

28 0 to 2

1 = ABC

2 = ACB

9.26 Number of Snapshot Logs Requested 1 to 50 29 1 to 50

9.27 No. of Snapshot Log Received (Counter) 1 to 50 30 1 to 50

9.28 Number of Snapshot Log Being Returned 1 to 50 31 1 to 50

9.29 Internal Identifier -32767 to +32767 32 -32767 to +32767

(1) ID=54 for log selection command.

Table B.14 Snapshot 16 Parameter Record Table Read (File F19)

Parameter No. Parameter Name Master Module Parameter Range Element

9a.1 Timestamp; Year 1998 to 2097 1

Timestamp; Month, Date 257 to 3103

Month = Value/256

Date = Remainder of Value/256

Timestamp; Hour, Minute 0 to 5947

Hour = Value/256

Minute = Remainder of Value/256

Timestamp; Seconds, Hundreths 0 to 15203

Seconds = Value/256

hSeconds = Remainder of Value/256

9a.2 Reserved 0 5

9a.3 L1-L2 Voltage (in Delta modes) or

0 to 9999x10

21

Volts

L1-N Voltage (in non-Delta modes)

9a.4 L2-L3 Voltage (in Delta modes) or

0 to 9999x10

21

Volts

L2-N Voltage (in non-Delta modes)

9a.5 L3-L1 Voltage (in Delta modes) or

0 to 9999x10

21

Volts

L3-N Voltage (in non-Delta modes)

9a.6 L1 Current

9a.7 L2 Current

9a.8 L3 Current

9a.9 L4 Current

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

21

Amps

21

Amps

21

Amps

21

Amps

9a.10 Voltage Unbalance 0 to 100% 13

9a.11 Current Unbalance 0 to 100% 14

9a.12 Tota l Real Pow er

9a.13 Total Reactive Power

9a.14 Demand kW

0 to 9999x10

0 to 9999x10

0 to 9999x10

21

21

21

kW

kVAR

kW

2

3

4

6

7

8

9

10

11

12

15

16

17

Publi cation 1403-IN005A-EN-P

Page 30

B-16 Ethernet Communication Card Data Tables

Table B.14 Snapshot 16 Parameter Record Table Read (File F19)

Parameter No. Parameter Name Master Module Parameter Range Element

9a.15 Demand kV A R

0 to 9999x10

21

kVAR

9a.16 Total True PF -100 to +100 19

9a.17 kWh net

9a.18 kVARh net

-9999x10

-9999x10

21

to +9999x1021 kWh

21

to +9999x1021 kVARh

9a.19 Number of Records Requested 1 to 265 22

9a.20 Number of Records Read so far 1 to 265 23

9a.21 Record Number Returned 1 to 265 24

9a.22 Internal Identifier 0 to 255 25

9a.23 Reserved 0 26

9a.24 Reserved 0 27

9a.25 Reserved 0 28

9a.26 Reserved 0 29

9a.27 Reserved 0 30

9a.28 Reserved 0 31

9a.29 Reserved 0 32

18

20

21

Table B.15 Snapshot 8 Parameter Record Table Read (File F19)

Parameter No. Parameter Name Master Module Parameter Range Element

9b.1 Timestamp; Year 1998 to 2097 1

Timestamp; Month, Date 257 to 3103

Month = Value/256

Date = Remainder of Value/256

Timestamp; Hour, Minute 0 to 5947

Hour = Value/256

Minute = Remainder of Value/256

Timestamp; Seconds, Hundreths 0 to 15203

Seconds = Value/256

hSeconds = Remainder of Value/256

9b.2 Reserved 0 5

9b.3 Avg L-L Voltage (in Delta modes) or Avg L-N

0 to 9999x10

21

Volts

Voltage (i n non-De l ta modes)

9b.4 Averag e C ur rent

0 to 9999x10

21

Amps

9b.5 Total True PF -100 to +100 8

9b.6 Total Real Power

0 to 9999x10

21

kW

9b.7 Frequency 0 to 75 Hz 10

9b.8 Voltage Unbalance 0 to 100% 11

9b.9 Current Unbalance 0 to 100% 12

9b.10 Total Reacti v e Po we r

0 to 9999x10

21

kVAR

9b.11 Number of Records Requested 1 to 489 14

9b.12 Number of Records Read so far 1 to 489 15

9b.13 Record Number Returned 1 to 489 16

9b.14 Internal Identifier 0 to 255 17

2

3

4

6

7

9

13

Publication 1403-IN005A-EN-P

Page 31

Ethernet Communication Card Data Tables B-17

Table B.15 Snapshot 8 Parameter Record Table Read (File F19)

Parameter No. Parameter Name Master Module Parameter Range Element

9b.15 Reserved 0 18

9b.16 Reserved 0 19

9b.17 Reserved 0 20

9b.18 Reserved 0 21

9b.19 Reserved 0 22

9b.20 Reserved 0 23

9b.21 Reserved 0 24

9b.22 Reserved 0 25

9b.23 Reserved 0 26

9b.24 Reserved 0 27

9b.25 Reserved 0 28

9b.26 Reserved 0 29

9b.27 Reserved 0 30

9b.28 Reserved 0 31

9b.29 Reserved 0 32

Table B.16 Snapshot 4 Parameter Record Table Read (File F19)

Parameter No. Parameter Name Master Module Parameter Range Element

9c.1 Timestamp; Year 1998 to 2097 1

Timestamp; Month, Date 257 to 3103

Month = Value/256

Date = Remainder of Value/256

Timestamp; Hour, Minute 0 to 5947

Hour = Value/256

Minute = Remainder of Value/256

Timestamp; Seconds, Hundreths 0 to 15203

Seconds = Value/256

hSeconds = Remainder of Value/256

9c.2 Reserved 0 5

9c.3 Avg L-L Voltage (in Dealt modes) or Avg L-N

0 to 9999x10

21

Volts

Voltage (i n non-De l ta modes)

9c.4 Aver age Current

0 to 9999x10

21

Amps

9c.5 Total True PF -100 to +100 8

9c.6 To tal Real Power

0 to 9999x10

21

kW

9c.7 Number of Records Re quested 1 to 846 10

9c.8 Number of Records Read so far 1 to 846 11

9c.9 Record Number Returned 1 to 846 12

9c.10 Internal Identifier 0 to 255 13

9c.11 Reserved 0 14

9c.12 Reserved 0 15

9c.13 Reserved 0 16

9c.14 Reserved 0 17

9c.15 Reserved 0 18

2

3

4

6

7

9

Publi cation 1403-IN005A-EN-P

Page 32

B-18 Ethernet Communication Card Data Tables

Table B.16 Snapshot 4 Parameter Record Table Read (File F19)

Parameter No. Parameter Name Master Module Parameter Range Element

9c.16 Reserved 0 19

9c.17 Reserved 0 20

9c.18 Reserved 0 21

9c.19 Reserved 0 22

9c.20 Reserved 0 23

9c.21 Reserved 0 24

9c.22 Reserved 0 25

9c.23 Reserved 0 26

9c.24 Reserved 0 27

9c.25 Reserved 0 28

9c.26 Reserved 0 29

9c.27 Reserved 0 30

9c.28 Reserved 0 31

9c.29 Reserved 0 32

Table B.17 Snapshot 3 and 7 Parameter Record Table Read (File F19)

Parameter No. Parameter Name Master Module Parameter Range Element

9d.1 Timestamp; Year 1998 to 2097 1

Timestamp; Month, Date 257 to 3103

Month = Value/256

Date = Remainder of Value/256

Timestamp; Hour, Minute 0 to 5947

Hour = Value/256

Minute = Remainder of Value/256

Timestamp; Seconds, Hundreths 0 to 15203

Seconds = Value/256

hSeconds = Remainder of Value/256

9d.2 Reserved 0 5

9d.3 The value of user selected parameter #1

0 to 9999x10

21

(SeeTable B.2, parameter 1.19)

9d.4 The value of user selected parameter #2

0 to 9999x10

21

(SeeTable B.2, parameter 1.20)

9d.5 The value of user selected parameter #3

0 to 9999x10

21

(SeeTable B.2, parameter 1.21)

9d.6 Avg L-L Voltage (in Dealt modes) or Avg L-N

0 to 9999x10

21

Volts

Voltage (i n non-De l ta modes)

9d.7 Averag e C ur rent

0 to 9999x10

21

Amps

9d.8 Voltage Unbalance 0 to 100% 11

9d.9 Current Unbalance 0 to 100% 12

9d.10 Total Real Power

9d.11 Demand VA R

0 to 9999x10

0 to 9999x10

21

21

kW

kVAR

9d.12 Total True PF -100 to +100 15

9d.13 Number of Records Requested 1 to 845 16

2

3

4

6

7

8

9

10

13

14

Publication 1403-IN005A-EN-P

Page 33

Ethernet Communication Card Data Tables B-19

Table B.17 Snapshot 3 and 7 Parameter Record Table Read (File F19)

Parameter No. Parameter Name Master Module Parameter Range Element

9d.14 Number of Records Read so far 1 to 845 17

9d.15 Record Number Returned 1 to 845 18

9d.16 Internal Identifier 0 to 255 19

9d.17 Reserved 0 20

9d.18 Reserved 0 21

9d.19 Reserved 0 22

9d.20 Reserved 0 23

9d.21 Reserved 0 24

9d.22 Reserved 0 25

9d.23 Reserved 0 26

9d.24 Reserved 0 27

9d.25 Reserved 0 28

9d.26 Reserved 0 29

9d.27 Reserved 0 30

9d.28 Reserved 0 31

9d.29 Reserved 0 32

Table B.18 Snapshot 1 Parameter Record Table Read (File F19)

Parameter No. Parameter Name Master Module Parameter Range Element

9e.1 Timestamp; Year 1998 to 2097 1

Timestamp; Month, Date 257 to 3103

Month = Value/256

Date = Remainder of Value/256

Timestamp; Hour, Minute 0 to 5947

Hour = Value/256

Minute = Remainder of Value/256

Timestamp; Seconds, Hundreths 0 to 15203

Seconds = Value/256

hSeconds = Remainder of Value/256

9e.2 Reserved 0 5

9e.3 The value of user selected parameter #1

0 to 9999x10

21

(SeeTable B.2, parameter 1.19)

9e.4 Number of Records Requested 1 to 1861 7

9e.5 Number of Records Read so far 1 to 1861 8

9e.6 Record Number Returned 1 to 1861 9

9e.7 Internal Identifier 0 to 255 10

9e.8 Reserved 0 11

9e.9 Reserved 0 12

9e.10 Reserved 0 13

9e.11 Reserved 0 14

9e.12 Reserved 0 15

9e.13 Reserved 0 16

9e.14 Reserved 0 17

2

3

4

6

Publi cation 1403-IN005A-EN-P

Page 34

B-20 Ethernet Communication Card Data Tables

Table B.18 Snapshot 1 Parameter Record Table Read (File F19)

Parameter No. Parameter Name Master Module Parameter Range Element

9e.15 Reserved 0 18

9e.16 Reserved 0 19

9e.17 Reserved 0 20

9e.18 Reserved 0 21

9e.19 Reserved 0 22

9e.20 Reserved 0 23

9e.21 Reserved 0 24

9e.22 Reserved 0 25

9e.23 Reserved 0 26

9e.24 Reserved 0 27

9e.25 Reserved 0 28

9e.26 Reserved 0 29

9e.27 Reserved 0 30

9e.28 Reserved 0 31

9e.29 Reserved 0 32

Table B.19 Power Snapshot Log Data Table (File F20)

Parameter No. Parameter Name Master Module

(1)

Element Range

Parameter Range

10.1 Snapshot Log Time Stamp Year 1 32-bit Float

Month, Date 2 16-bit, 16-bit

Hour, Minute 3 16-bit, 16-bit

Seconds, Hundredths 4 16-bit, 16-bit

10.2 Reserv ed Word 5

10.3 L1 Real Power

10.4 L2 Real Power

10.5 L3 Real Power

10.6 Total Real Power

10.7 L1 Reactive Power

10.8 L2 Reactive Power

10.9 L3 Reactive Power

10.10 Total Reacti v e Po we r

10.11 L1 Apparent Power

10.12 L2 Apparent Power

10.13 L3 Apparent Power

10.14 Total Apparent Power

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

21

21

21

21

21

21

21

21

21

21

21

21

W

W

W

W

VAR

VAR

VAR

VAR

VA

VA

VA

VA

6

7

8

9

10

11

12

13

14

15

16

17

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

10.15 L1 True PF -100.0 to +100.0 18 -100.0 to +100.0

10.16 L2 True PF -100.0 to +100.0 19 -100.0 to +100.0

21

21

21

21

21

21

21

21

21

21

21

21

Publication 1403-IN005A-EN-P

Page 35

Ethernet Communication Card Data Tables B-21

Table B.19 Power Snapshot Log Data Table (File F20)

Parameter No. Parameter Name Master Module

(1)

Element Range

Parameter Range

10.17 L3 True PF -100.0 to +100.0 20 -100.0 to +100.0

10.18 Total True PF -100.0 to +100.0 21 -100.0 to +100.0

10.19 L1 Displacement PF -100.0 to +100.0 22 -100.0 to +100.0

10.20 L2 Displacement PF -100.0 to +100.0 23 -100.0 to +100.0

10.21 L3 Displacement PF -100.0 to +100.0 24 -100.0 to +100.0

10.22 Total Displacement PF -100.0 to +100.0 25 -100.0 to +100.0

10.23 L1 Distortion PF -100.0 to +100.0 26 -100.0 to +100.0

10.24 L2 Distortion PF -100.0 to +100.0 27 -100.0 to +100.0

10.25 L3 Distortion PF -100.0 to +100.0 28 -100.0 to +100.0

10.26 Total Distortion PF -100.0 to +100.0 29 -100.0 to +100.0

10.27 Number of Snapshot Logs Requested 1 to 50 30 1 to 50

10.28 Number of s napshot Log Recei ved

1 to 50 31 1 to 50

(Counter)

10.29 Number of Snapshot Log Being Returned 1 to 50 32 1 to 50

10.30 Interna l Id entifier -32767 to +32767 33 -32767 to +32767

Reserved Word 34

(1) ID = 59 for log selection command.

Publi cation 1403-IN005A-EN-P

Page 36

B-22 Ethernet Communication Card Data Tables

Table B.20 Min_Max Log - Read (File N21)

Parameter No. Parameter Name Master Module

(1)

Element Range

Parameter Range

11.1 Time Stamp of last Min/Max Log Reset Year 1 16-bit Integer

Month, Date 2 8-bit, 8-bit

Hour, Minute 3 8-bit, 8-bit

Seconds, Hundredths 4 8-bit, 8-bit

11.2 Ti me Stamp of MIN for Parameter Year 5 16-bit Integer

Month, Date 6 8-bit, 8-bit

Hour, Minute 7 8-bit, 8-bit

Seconds, Hundredths 8 8-bit, 8-bit

11.3 MIN Value for Parameter

0 to 9999x10

21

9 0 to 9999

10 ±0 to 21

11.4 Ti me Stamp of MAX for Parameter Year 11 16-bit Inte ger

Month, Date 12 8-bit, 8-bit

Hour, Minute 13 8-bit, 8-bit

Second s, Hundred ths 14 8-bit, 8-bit

11.5 MAX Value for Parameter

0 to 9999x10

21

15 0 to 9999

16 ±0 to 21

11.6 Number of Min_Max Logs Requested 1 to 84 17 1 to 84

11.7 Number of Min_Max Log Received

1 to 84 18 1 to 84

(Counter)

11.8 Number of Min_Max Log Being Returned 1 to 84 19 1 to 84

Reserved Word 20

Reserved Word 21

Reserved Word 22

Reserved Word 23

Reserved Word 24

(1) ID=24 for log selection command

Publication 1403-IN005A-EN-P

Page 37

Ethernet Communication Card Data Tables B-23

Table B.21 Log Selection Command Table Write (File N22)

Param. No. Parameter Name Master Module Range Element Range

12.1 Selected Log 23 = Event Log

24 = Min/Max Log

54 = Snapshot V/I Log, or

16, 8, 3 and 7, 1

parameter recor ds

59 = Snapshot Power Log

12.2 Maximum Number of Data Sets 1 to 100 for Event Log

1 to 84 for Min/Max Log

1 to 50 for Snapshot V/I

Log

1 to 50 for Snapshot

Power Lo g

1 to 265 for snapshot 16

parameter log

(1)

1 to 489 for snapshot 8

parameter log

(1)

1 to 846 for snapshot 4

parameter log

(1)

1 to 100 for snapshot 7

parameter log

(1)

1 to 845 for snapshot 3

parameter log

(1)

1 to 1861 for snapshot 1

parameter log

(1)

1 23, 24 , 54, 59

2 1 to 100 for Event Log

1 to 84 for Min/Max Log

1 to 50 for Snapshot V/I

Log

1 to 50 for Snapshot

Power Lo g

1 to 265 for snapshot 16

parameter log

(1)

1 to 489 for snapshot 8

parameter log

(1)

1 to 846 for snapshot 4

parameter log

(1)

1 to 100 for snapshot 7

parameter log

(1)

1 to 845 for snapshot 3

parameter log

(1)

1 to 1861 for snapshot 1

parameter log

(1)

12.3 Chronology of Returned Data 0 = Reverse

30 to 1

1 = Forward

Note: Not used for Min/

Max Log

12.4 First Min/Max Parameter to be Returned 1 to 84 4 1 to 84

12.5

Snapshot Starting Record Offset

(1)

0 to

(parameter 12.2 max - 1)

50 to

(parameter 12.2 max - 1)

Reserved Word 6

Reserved Word 7

Reserved Word 8

Reserved Word 9

(1) Available on firmware V3.00 or later.

Publi cation 1403-IN005A-EN-P

Page 38

B-24 Ethernet Communication Card Data Tables

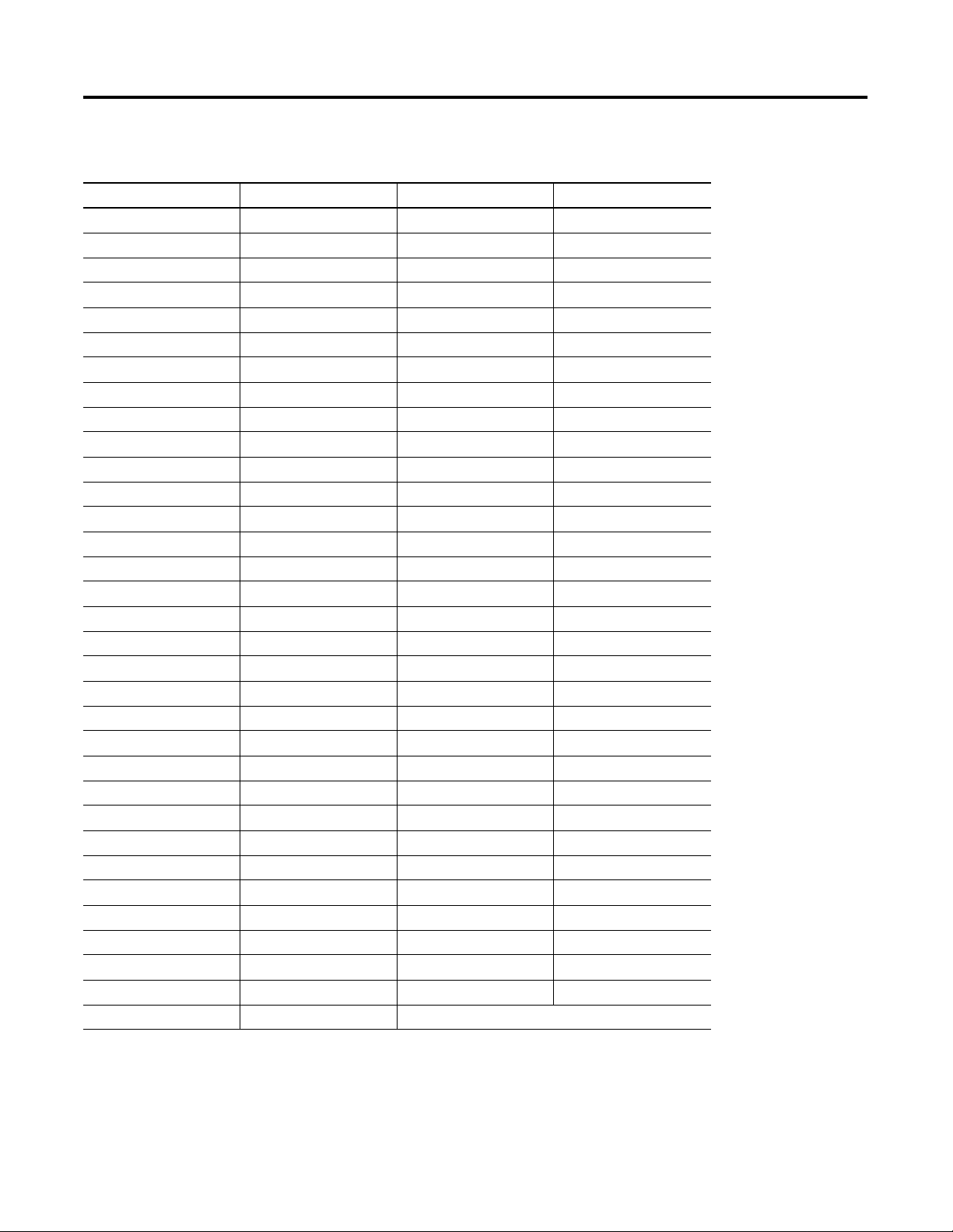

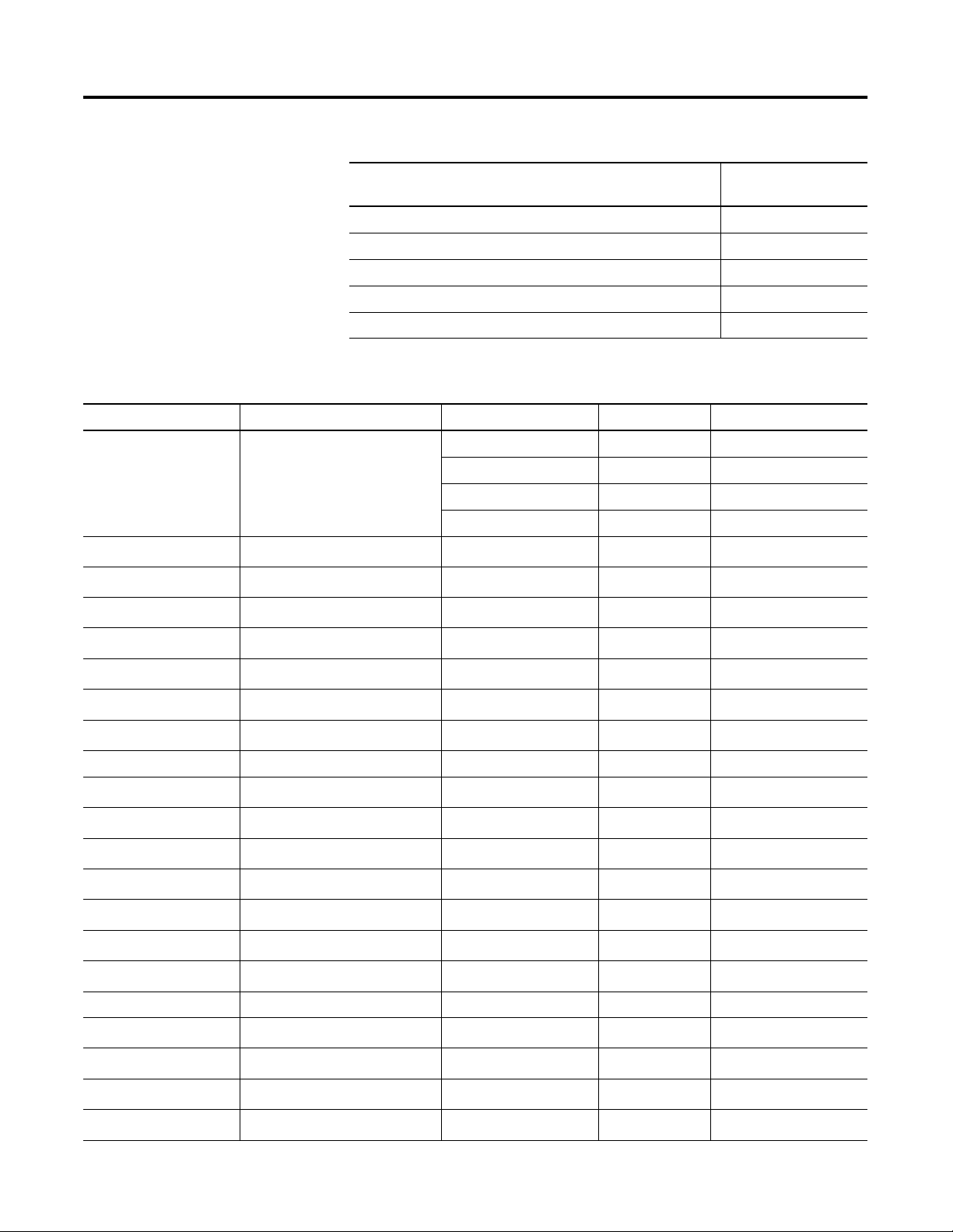

Table B.22 Available Min/Max Log Parameters (Identifiers for parameter 12.4)

Param #Parameter

Description

Param #Parameter

Description

Param #Parameter

Description

1 L1 Current 22 L1 Watts 43 L2 Distortion Power

Factor

2 L2 Current 23 L2 Watts 44 L3 Distortion Power

Factor

3 L3 Current 24 L3 Watts 45 Total Distortion Power

Factor

4 L4 (Neutral) Current 25 Total Watts 46 Demand Current 67

5 3-Phase Average

26 L1 VAR 47 Demand Watts 68 L2 Current Crest

Current

6 Positive Sequence

27 L2 VAR 48 Demand VAR 69

Current

7 Negative Sequence

28 L3 VAR 49 Demand VA 70 L3 Voltage IEEE THD

Current

8 Percent Current

29 Total VAR 50 L1 Voltage IEEE THD 71 L3 Voltage IEC THD

Unbalance

9 L1-L2 Voltage 30 L1 VA 51 L1 Vol ta ge IEC THD 72

10 L2-L3 Voltage 31 L2 VA 52

L1 Voltage TIF

(1)

11 L3-L1 Voltage 32 L3 VA 53 L1 Voltage Crest

(1)

Factor

12 Auxiliary Voltage 33 Total VA 54

13 3-Phase Average L-L

34 L1 T r ue Power Fa c tor 55 L1 Curre nt IE EE THD 76 L3 Current IE C THD

L1 Voltage K-factor

(1)

Voltage

14 Positive Sequence

35 L2 T r ue Power Fa c tor 56 L1 Curre nt IE C THD 77

Voltage

15 Negative Sequence

36 L3 T r ue Power Fa c tor 57

L1 Current TIF

(1)

Voltage

16 Percent Voltage

Unbalance

17 L1-N Voltage 38 L1 Displacement

37 Total True Power

Factor

58 L1 Current Crest

(1)

Factor

59

L1 Current K-factor

(1)

Power Fa c to r

18 L2-N Voltage 39 L2 Displacement

60 L2 Voltage IEEE THD 81 L4 (Neutral) Current

Power Fa c to r

19 L3-N Voltage 40 L3 Displacement

61 L2 Voltage IEC THD 82 L4 (Neutral) Current

Power Fa c to r

20 3-Phase Average L-N

Voltage

41 Total Displaceme nt

Power Fa c to r

21 Freque nc y 42 L1 Dis tortion Power

Factor

62

L2 Voltage TIF

63 L2 Voltage Crest

Factor

(1)

(1)

Param #Parameter

Description

64

L2 Voltage K-factor

65 L2 Current IEEE THD

66 L2 Current IEC THD

L2 Current TIF

(1)

Factor

L2 Current K-factor

L3 Voltage TIF

73 L3 Voltage Crest

(1)

Factor

74

L3 Voltage K-factor

75 L3 Current IEEE THD

L3 Current TIF

78 L3 Current Crest

(1)

Factor

79

L3 Current K-factor

80 L4 (Neutral) Current

IEEE THD

IEC THD

(1)

TIF

83 L4 (Neutral) Current

Crest Factor

(1)

84 L4 (Neutral) Current

(1)

K-factor

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1) Not a vailable on 1403-LM.

Publication 1403-IN005A-EN-P

Page 39

Ethernet Communication Card Data Tables B-25

Harmonic Distortion T ables - Read

Harmonic Distortion Data Tables for Channel 1 through Channel 7 are

identical. There are a total of 14 tables for this information. (V1, V2, V3, I1,

I2, I3, I4) The table sizes indicate this is Harmonic Distortion Data. The

Channel Number designates which one.

Table B.23 Even Harmonic Distortion Table - Channel 1 to 7 Read (File F23)

Parameter No. Parameter Name Master Module Range Element Range

13.1 IEEE Total Harmonic Distortion 0 to 1000% 1 0 to 1000

13.2 IEC Total Harmonic Distortion 0 to 1000% 2 0 to 1000

13.3 Meets IEEE 519

(Not Av ailable on 1403-LM)

-1 = Unkn ow n

0 = Fail

1 = Pass

13.4 TIF (Not Available on 1403-LM)

13.5 Crest Factor (Not Available on 1403-LM)

13.6 K-Factor (Not Available on 1403-LM)

0 to 9999x10

0 to 9999x10

0 to 9999x10

13.7 Channel Numb er 1 = L1 Voltage

2 = L1 Current

3 = L2 Voltage

4 = L2 Current

5 = L3 Voltage

6 = L3 Current

7 = L4 Current

13.8 Harmonic Distortion - Fundamental (Not

0 to 1000% 8 0 to 1000

Available on 1403- LM)

13.9 Harmonic Distortion - Second (Not

0 to 1000% 9 0 to 1000

Available on 1403- LM)

13.10 Harmonic Distortion - Fourth (Not

0 to 1000% 10 0 to 1000

Available on 1403- LM)

13.11 Harmonic Distortion - Sixth (Not

0 to 1000% 11 0 to 1000

Available on 1403- LM)

13.12 Harmonic Distortion - Eighth (Not

0 to 1000% 12 0 to 1000

Available on 1403- LM)

13.13 Harmonic Distortion - Tenth (Not

0 to 1000% 13 0 to 1000

Available on 1403- LM)

13.14 Harmonic Distortion - Twelfth (Not

0 to 1000% 14 0 to 1000

Available on 1403- LM)

13.15 Harmonic Distortion - Fourteenth (Not

0 to 1000% 15 0 to 1000

Available on 1403- LM)

13.16 Harmonic Distortion - Sixteenth (Not

0 to 1000% 16 0 to 1000

Available on 1403- LM)

13.17 Harmonic Distortion - Eighteenth (Not

0 to 1000% 17 0 to 1000

Available on 1403- LM)

13.18 Harmonic Distortion - Twentieth (Not

0 to 1000% 18 0 to 1000

Available on 1403- LM)

21

21

21

3 -1 to +1

4

5

6

0 to 9999x10

0 to 9999x10

0 to 9999x10

71 to 7

21

21

21

Publi cation 1403-IN005A-EN-P

Page 40

B-26 Ethernet Communication Card Data Tables

Table B.23 Even Harmonic Distortion Table - Channel 1 to 7 Read (File F23)

Parameter No. Parameter Name Master Module Range Element Range

13.19 Harmonic Distortion - Twenty-second

0 to 1000% 19 0 to 1000

(Not Available on 1403-LM)

13.20 Harmonic Distortion - Twenty-fourth (Not

0 to 1000% 20 0 to 1000

Available on 1403- LM)

13.21 Harmonic Distortion - Twenty-sixth (Not

0 to 1000% 21 0 to 1000

Available on 1403- LM)

13.22 Harmonic Distortion - Twenty-eighth (Not

0 to 1000% 22 0 to 1000

Available on 1403- LM)

13.23 Harmonic Distortion - Thirtieth

0 to 1000% 23 0 to 1000

(Not Available on 1403-LM)

13.24 Harmonic Distortion - Thirty-second (Not

0 to 1000% 24 0 to 1000

Available on 1403- LM)

13.25 Harmonic Distortion - Thirty-fourth (Not

0 to 1000% 25 0 to 1000

Available on 1403- LM)

13.26 Harmonic Distortion - Thirty-sixth (Not

0 to 1000% 26 0 to 1000

Available on 1403- LM)

13.27 Harmonic Distortion - Thirty-eighth (Not

0 to 1000% 27 0 to 1000

Available on 1403- LM)

13.28 Harmonic Distortion - Fortieth

0 to 1000% 28 0 to 1000

(Not Available on 1403-LM)

13.29 FFT Chronological Reference Number 0 to 32767 29 0 to 32767

Reserved Word 30

Reserved Word 31

Reserved Word 32

Table B.24 Odd Harmonic Distortion Table - Channels 1 to 7 Read (File F24)

Parameter No. Parameter Name Master Module Range Element Range

14.1 IEEE Total Harmonic Distortion 0 to 1000% 1 0 to 1000

14.2 IEC Total Harmonic Distortion 0 to 1000% 2 0 t o 1000

14.3 Meets IEEE 519

(Not Available on 1403-LM)

-1 = Unkn ow n

0 = Fail

3 -1 to +1

1 = Pass

14.4 TIF Value (Not Available on 1403-LM)

14.5 Crest Factor (Not Available on 1403-L M)

14.6 K-Factor (Not Available on 1403-LM)

0 to 9999x10

0 to 9999x10

0 to 9999x10

14.7 Channel Number 1 = L1 Voltage

21

21

21

4

5

6

0 to 9999x10

0 to 9999x10

0 to 9999x10

71 to 7

2 = L1 Current

3 = L2 Voltage

4 = L2 Current

5 = L3 Voltage

6 = L3 Current

7 = L4 Current

14.8 Harmonic Distortion - Fundamental (Not

0 to 1000% 8 0 to 1000

Available on 1403- LM)

21

21

21

Publication 1403-IN005A-EN-P

Page 41

Ethernet Communication Card Data Tables B-27

Table B.24 Odd Harmonic Distortion Table - Channels 1 to 7 Read (File F24)

Parameter No. Parameter Name Master Module Range Element Range

14.9 Harmonic Distortion - Third

0 to 1000% 9 0 to 1000

(Not Av ailable on 1403-LM)

14.10 Harmonic Distortion - Fifth

0 to 1000% 10 0 to 1000

(Not Available on 1403-LM)

14.11 Harmonic Distortion - Seventh

0 to 1000% 11 0 to 1000

(Not Av ailable on 1403-LM)

14.12 Harmonic Distortion - Ninth

0 to 1000% 12 0 to 1000

(Not Av ailable on 1403-LM)

14.13 Harmonic Distortion - Eleventh

0 to 1000% 13 0 to 1000

(Not Av ailable on 1403-LM)

14.14 Harmonic Distortion - Thirteenth (Not

0 to 1000% 14 0 to 1000

Available on 1403- LM)

14.15 Harmonic Distortion - Fifteenth

0 to 1000% 15 0 to 1000

(Not Av ailable on 1403-LM)

14.16 Harmonic Distortion - Seventeenth (Not

0 to 1000% 16 0 to 1000

Available on 1403- LM)

14.17 Harmonic Distortion - Nineteenth (Not

0 to 1000% 17 0 to 1000

Available on 1403- LM)

14.18 Harmonic Distortion - Twenty-first (Not

0 to 1000% 18 0 to 1000

Available on 1403- LM)

14.19 Harmonic Distortion - T wenty-third (Not

0 to 1000% 19 0 to 1000

Available on 1403- LM)

14.20 Harmonic Distortion - Twenty-fifth (Not

0 to 1000% 20 0 to 1000

Available on 1403- LM)

14.21 Harmonic Distortion - Twenty-seventh 0 to 1000% 21 0 to 1000

14.22 Harmonic Distortion - Twenty-ninth (Not

0 to 1000% 22 0 to 1000

Available on 1403- LM)

14.23 Harmonic Distortion - Thirty-first (Not

0 to 1000% 23 0 to 1000

Available on 1403- LM)

14.24 Harmonic Distortion - Thirty-third (Not

0 to 1000% 24 0 to 1000

Available on 1403- LM)

14.25 Harmonic Distortion - Thirty-fifth (Not

0 to 1000% 25 0 to 1000

Available on 1403- LM)

14.26 Harmonic Distortion - Thirty-seventh (Not

0 to 1000% 26 0 to 1000

Available on 1403- LM)

14.27 Harmonic Distortion - Thirty-ninth (Not

0 to 1000% 27 0 to 1000

Available on 1403- LM)

14.28 Harmonic Distortion - Forty-first (Not

0 to 1000% 28 0 to 1000

Available on 1403- LM)

14.29 FFT Update Reference Number 0 to +32767 29 0 to +32767

Reserved Word 30

Reserved Word 31

Reserved Word 32

Publi cation 1403-IN005A-EN-P

Page 42

B-28 Ethernet Communication Card Data Tables

Harmonic Magnitude Data Tables for Channel 1 through Channel 7 are

identical. There are a total of 14 tables for this information. (V1, V2, V3, I1,

I2, I3, I4).

Table B.25 Even Harmonic Magnitude Data Table Channel 1 to 7 Read (File F25)

Parameter No. Parameter Name Master Module Range Element Range

15.1 IEEE Total Harmonic Distortion 0 to 1000% 1 0 to 1000

15.2 IEC Total Harmonic Distortion 0 to 1000% 2 0 t o 1000

15.3 Meets IEEE 519

(Not Available on 1403-LM)

-1 = Unkn ow n

0 = Fail

1 = Pass

15.4 TIF Value (Not Available on 1403-LM)

15.5 Crest Factor (Not Available on 1403-L M)

15.6 K-Factor (Not Available on 1403-LM)

0 to 9999x10

0 to 9999x10

0 to 9999x10

15.7 Channel Number 1 = L1 Voltage

2 = L1 Current

3 = L2 Voltage

4 = L2 Current

5 = L3 Voltage

6 = L3 Current

7 = L4 Current

15.8 Harmonic Magnitude - Fundamental (Not

0 to 9999x10

Available on 1403- LM)

15.9 Harmon ic M ag nitude - Seco nd ( Not

0 to 9999x10

Available on 1403- LM)

15.10 Harmonic Magnitude - Fourth (Not

0 to 9999x10

Available on 1403- LM)

15.11 Harmonic Magnitude - Sixth (Not

0 to 9999x10

Available on 1403- LM)

15.12 Harmonic Magnitude - Eighth (Not

0 to 9999x10

Available on 1403- LM)

15.13 Harmonic Magnitude - Tenth (Not

0 to 9999x10

Available on 1403- LM)

15.14 Harmonic Magnitude - Tw elfth (Not

0 to 9999x10

Available on 1403- LM)

15.15 Harmonic Magnitude - Fourteenth (Not

0 to 9999x10

Available on 1403- LM)

15.16 Harmonic Mag ni tude - Sixteenth (Not

0 to 9999x10

Available on 1403- LM)

15.17 Harmonic Magnitude - Eighteenth (Not

0 to 9999x10

Available on 1403- LM)

15.18 Harmonic Mag ni tude - Twentiet h (Not

0 to 9999x10

Available on 1403- LM)

15.19 Harmonic Magnitude - Tw enty-second

0 to 9999x10

(Not Available on 1403-LM)

15.20 Harmonic Mag ni tu de - Tw enty-fourth

0 to 9999x10

(Not Available on 1403-LM)

21

21

21

21

21

21

21

21

21

21

21

21

21

21

21

21

3 -1 to +1

4

5

6

0 to 9999x10

0 to 9999x10

0 to 9999x10

71 to 7

8

9

10

11

12

13

14

15

16

17

18

19

20

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

0 to 9999x10

21

21

21

21

21

21

21

21

21

21

21

21

21

21

21

21

Publication 1403-IN005A-EN-P

Page 43

Ethernet Communication Card Data Tables B-29

Table B.25 Even Harmonic Magnitude Data Table Channel 1 to 7 Read (File F25)

Parameter No. Parameter Name Master Module Range Element Range

15.21 Harmonic Magnitude - Twenty-sixth (Not

0 to 9999x10

21

21

0 to 9999x10

Available on 1403- LM)

15.22 Harmonic Magnitude - Twenty-eighth

0 to 9999x10

21

22

0 to 9999x10

(Not Av ailable on 1403-LM)

15.23 Harmonic Magnitude - Thirtieth (Not

0 to 9999x10

21

23