Page 1

Instruction Sheet

Bulletin 1403 Powermonitor II

(Cat. No. 1403-MM, 1403-LM, 1403-DM)

Cat. No. 1403-DM

Cat. No. 1403-MM, 1403-LM

Publication 1403-IN001A-US-P

Page 2

Important User Information

Solid-state equipment has operational

characteristics differing from those of

electromechanical equipment. Safety Guidelines

for the Application, Installation, and

Maintenance of Solid-state Controllers

(Publication SGI-1.1) describes some important

differences between solid-state equipment and

hard-wired electromechanical devices. Because

of this difference, and also because of the wide

variety of uses for solid-state equipment, all

persons responsible for applying this equipment

must satisfy themselves that each intended

application of this equipment is acceptable.

In no event will Rockwell Automation be

responsible for indirect or consequential

damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are

included soely for illustrative purposes. Because

of the many variables and requirements

associated with any particular installation, the

Rockwell Automation cannot assume

responsibility or liability for actual use based on

the examples and diagrams.

No patent liability is assumed by the Rockwell

Automation with respect to use o f information,

circuits, equipment, or software descr ibe d i n t his

manual. Reproduction of the contants of this

manual, in whole or in part, without written

permission of Rockwell Automation, is

prohibited.

Throughout this manual we use notes to make

you aware of safety considerations:

ATTENTION: Identifies

information about practices or

!

Attention statements help you to:

• identify a hazard

• avoid the hazard

• recognize the consequences.

Important:Identifies information that is critical

circumstances that can lead ot

personal injury or death, prop er ty

damage or economic loss.

for successful application and

understanding of the product.

Publication 1403-IN001A-US-P

Page 3

Using This Instruction Sheet Preface

What This Instruction Sheet Contains. . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

For More Information on Additional Power Quality Products . . . . . . . . P-1

Terms and Conventions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Product Description Chapter 1

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

General Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Performance Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Device Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Quick Start - Minimum Device Configuration . . . . . . . . . . . . . . . . . . . . 1-2

Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Software and System Integration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

PLC Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Setup/Monitoring Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Control Relays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Status Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Data Logging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Min/Max Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Snapshot Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Oscillography (1403-MM only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Operational Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1403-MM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1403-LM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Table of Contents

Installation Chapter 2

Prevent Electrostatic Discharge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Mounting of Master Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Mounting of Display Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Wiring of Master Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Control Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Voltage and Current Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Status Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

LED Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Wiring of Display Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Communication Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

1403-IN001A-US-P

Page 4

ii

Maintenance Chapter 3

Battery Installation and Replacement Procedures . . . . . . . . . . . . . . . . . . 3-1

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Disposal of Discharged Lithium Batteries. . . . . . . . . . . . . . . . . . . . . 3-3

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Cleaning Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Field Service Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

General Operation Chapter 4

General Functionality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Key Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Editing a Digital Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Issuing a Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Configuration Items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Demand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Metering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Voltage/Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Cumulative Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

Harmonic Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Setpoints. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Theory of Setpoint Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Over Forward Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Over Reverse Setpoint. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Under Forward Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Under Reverse Setpoint. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Equal Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Not Equal Setpoint. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Examples of Setpoint Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Setpoint Example 1 - Over kW Forward (+). . . . . . . . . . . . . . . . . . 4-22

Setpoint Example 2 - Under kW Forward (+). . . . . . . . . . . . . . . . . 4-22

Setpoint Example 3 - Over kW Reverse (-). . . . . . . . . . . . . . . . . . . 4-22

Setpoint Example 4 - Under kW Reverse (-). . . . . . . . . . . . . . . . . . 4-22

Relay Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Data Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Event Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Snapshot Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Min/Max Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Oscillography (1403-MM only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Self-test/Diagnostic Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Bulletin Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Options Bit Field . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Overall Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Master Module ROM Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Master Module RAM Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Master Module NVRAM Status . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Master Module Power Supply Status . . . . . . . . . . . . . . . . . . . . . . . 4-29

1403-IN001A-US-P

Page 5

Master Module Data Acquisition Status. . . . . . . . . . . . . . . . . . . . . 4-29

Master Module Watchdog Timer Status. . . . . . . . . . . . . . . . . . . . . 4-29

Real Time Clock Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Battery Usage Timer Value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Smart Communication Card Status. . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Smart Communication Card Type . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Smart Communication Card Firmware Revision Number . . . . . . . 4-30

Number of Display Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Display Module Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Display Module Self-test Results Word 1. . . . . . . . . . . . . . . . . . . . 4-30

Display Module Self-test Results Word 2. . . . . . . . . . . . . . . . . . . . 4-30

Display Module # 1, #2, #3 Firmware Revision Number. . . . . . . . 4-31

Master Module EEPROM Status . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Master Module Device ID. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

General Purpose Status Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

BT Error Status Word 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

BT Error Status Word 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Catalog Number Explanation Appendix A

Master Module/Limited Metering Master Module . . . . . . . . . . . . . . . . . A-1

Display Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Communications Cards/Peripherals/Software. . . . . . . . . . . . . . . . . . . . . A-2

Fiber Optic Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

iii

Mechanical Dimensions Appendix B

Technical Specifications Appendix C

Product Approvals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

CE Certification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Low Voltage Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

International Standard IEC 529 / NEMA / UL 508 Degree of ProtectionC-1

ANSI/IEEE Tested (1403-MM only) . . . . . . . . . . . . . . . . . . . . . . . . C-1

Measurement Accuracy, Resolution, and Range. . . . . . . . . . . . . . . . . . . C-2

General Input, Output, and Environmental Ratings . . . . . . . . . . . . . . . . C-3

Glossary Appendix D

1403-IN001A-US-P

Page 6

iv

1403-IN001A-US-P

Page 7

Preface

Using This Instruction Sheet

What This Instruction Sheet Contains

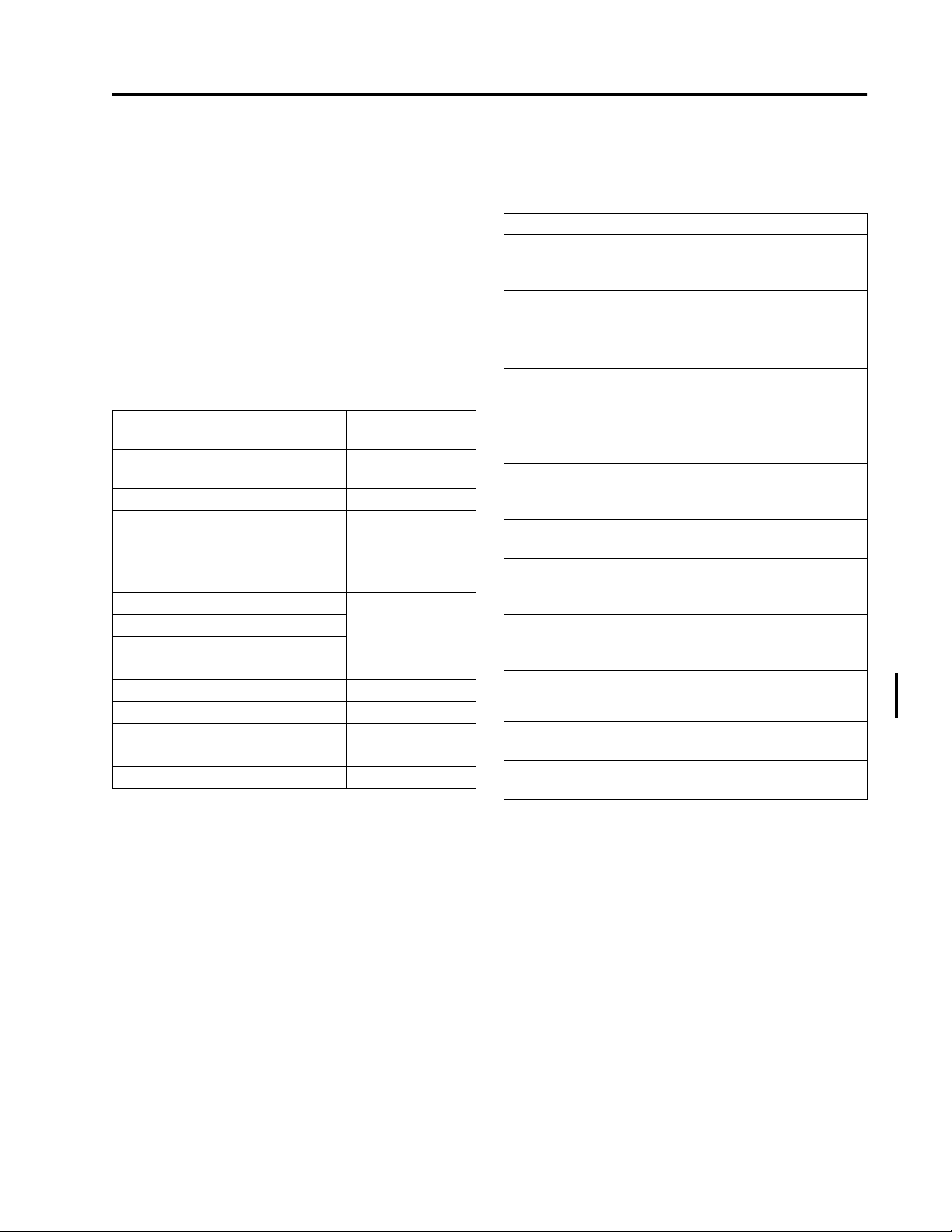

Review the table below to familiarize yourself with

the topics contained in this instruction sheet.

For information about: Refer to

chapter:

Product Features and System

Applications

Installing the Master Module

Installing the Display Module

Wiring and Transformer

Selection

Maintenance

Modes of Operation

Display Module

Configuration Information

Configuration Information

Catalog Number Explanation

Mechanical Dimensions

Technical Specifications

Glossary

Index

1

2

2

2

3

4

Appendix A

Appendix B

Appendix C

Appendix D

Index

For More Information on Additional Power Quality Products

For this information: Refer to:

Cat. No. 1403-NSC Smart

Communications Card

Instruction Sheet

Bulletin 1403 Powermonitor II

Tutorial

Cat. No. 1400-PD Installation

and Operation Manual

Cat. No. 1400-SP Installation

and Operation Manual

Cat. No. 1400-DCU Installing

the Communication Card

Instructions

Cat. No. 1400-CC RS-232C

and RS-485 Convertor

Instructions

Cat. No. 6190-PMO

ControlView Software

Cat. No. 1402-LS LSM

Installation and Operation

Manual

Cat. No. 1403-NENET Ethernet

Communications Card

Instruction Sheet

Cat. No. 1403-NDNET DeviceNet

Communications Card Instruction

Sheet

Cat. No. 9307RSE32E

RSEnergy Installation Guide

Cat. No. 9307RSPDEVD

Getting Results with RSPower

Publication

1403-5.1

Publication

1403-1.0.2

Publication

1400-5.2

Publication

1400-801

Publication

1400-5.0

Publication

1400-5.1

Publication

6190-6.5.29

Publication

1402-5.0

Publication

1403-5.3

Publication

1403-5.4

9399ENERGYIG

POWERBW-

07.24.97

If you would like a manual, you can:

• download a free electronic version from the

internet at www.theautomationbookstore.com

• purchase a printed manual by:

– contacting your local distributor or Rockwell

Automation representative

– visting www.theautomationbookstore.com

and placing your order

– calling 1.800.963.9548 (USA/Canada) or

001.330.725.1547 (Outside USA/Canada)

1403-IN001A-US-P

Page 8

P-2 Using This Instruction Sheet

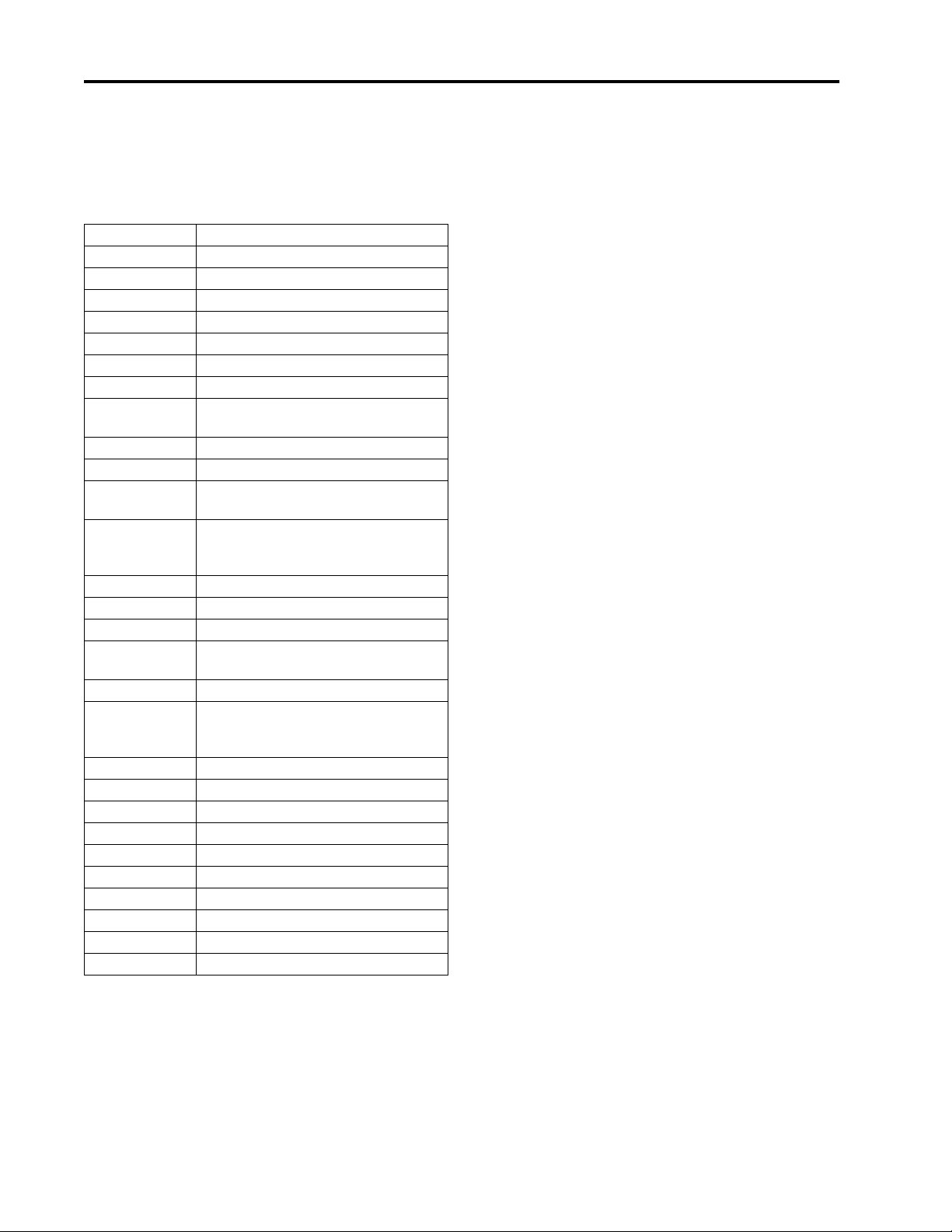

Terms and Conventions

In this manual, the following terms and conventions

are used:

Abbreviation Term

AWG Amer ican Wire Gage

BTR Block Transfer Read

BTW Block Transfer Write

CF Cable Fiber

CSA Canadian Standards Association

CT Current Transformer

DM Display Module

EEPROM Electrically Erasable

Programmable ROM

EMI Electromagnetic Interference

ID Identification

IEC International Electrotechnical

Commission

I/O Inputs and Outputs should be

considered with respect to the

PLC processor

LED Light Emitting Diode

LSM Line Synchronization Module

MM Master Module

NEMA National Electrical Manufacturers

Association

PLC Programmable Logic Controller

PT Potential Transformer

(Also known as VT in some

countries)

RAM Random Access Memory

RFI Radio Frequency Interference

R I/O Remote Input/Output

RMS Root-mean-square

ROM Read-onl y Mem ory

SLC Small Logic Controller

SPDT Single Pole Double Throw

UL Underwriters Laboratories

VA Volt-ampere

VAR Volt-ampere Reactive

Battery: In this manual, the term battery refers to the

lithium cell contained in the Master Module.

1403-IN001A-US-P

Page 9

Chapter

1

Product Description

Chapter Objectives

After completing this chapter, you should be able to

identify the prod uct features and system applications.

Introduction

The Bulletin 1403, Powermonitor II, is uniquely

designed and developed to meet the needs of

producers and consumers of electric power. The

Powermonitor II is a microprocessor based

monitoring and control device well suited for a

variety of applicat ions. Use of voltage, curr ent, status

inputs, and relay connections allows the

Powermonitor II to provide monitoring and control

information . This data is u seful in substation and

distribution centers, electrical control panels, and

many utility, commercial, and industrial applications

including mo tor control centers. The Powermonitor

II is a sophisticated modern alternative to traditional

electro-mechanical metering devices. One

Powermonitor II can replace many individual

transducers and meters within a single package. The

Powermonitor II is operato r friendly and provides the

user with easy to understand, accurate information in

a compact economical package.

A second op tional feature allows for remote

communications through the use of a Smart

Communications Card co-located with the Master

Module. Both the Display Module and the Smart

Communications Card are microprocessor based

providing better resolution, accuracy, and speed to

the Bulletin 1403 Master Module. The bulletin 1403

Powermonitor II and the Communication Cards are

Year 2000 compliant.

Performance Features

The Powermonitor II performance features include:

Vo ltage , cur rent, p ower me asure ments and dis pla y

•

28 ms to 90 ms selectable update rates for

•

metering results (1403-MM only)

90 ms fixed update rate (1403-LM only)

•

Communications

•

Software and system integration

•

PLC-5 compatibility

•

SLC-500 compatibility

•

Output control via control relays or PLC

•

Demo mode for training

•

Input monitoring via status inputs

•

Time stamped data logging of system

•

measurements and events

Harmonic Analysis (1403-MM only)

•

Simultaneou s multi-channel oscillogr aph

•

recordings (1403-MM only)

General Description

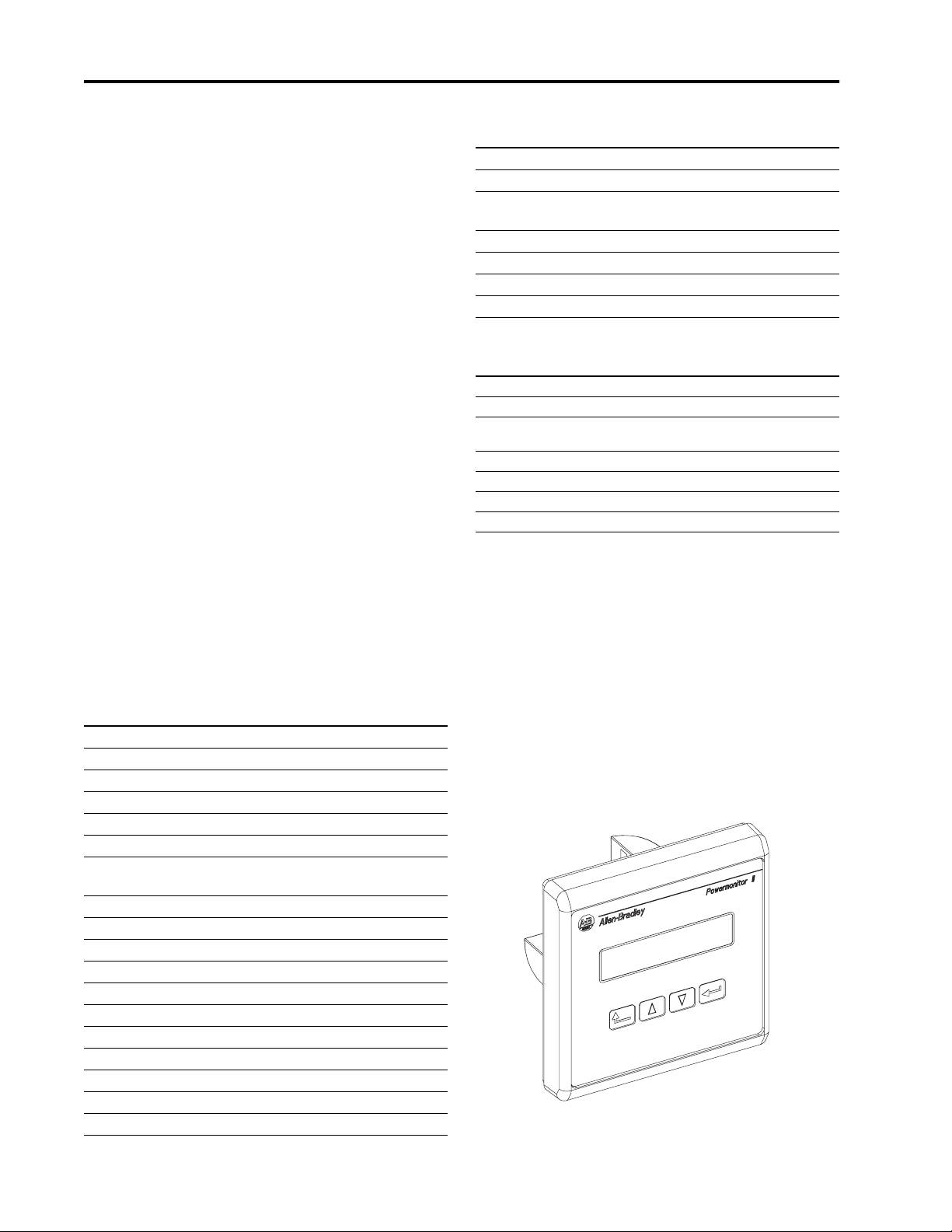

The Bulletin 1403 Display Module, an optional

input/ output device, can be used to set up and

configure the Bulletin 1403 Master Module for

operation. This is accomplished through the Display

Module’s front panel which includes four tactile

operator buttons and a liquid crystal display. All

communications between the Display Module and

Master Module are conducte d over a serial fiber optic

link. (The Display Module is easily mounted into a

typical instrument panel analog meter cutout.)

Device Configuration

The Powermonitor II comes from the factory with

default settings but can be configured for local sitespecific requirements. This is accomplished using the

Display Module or one of the Communications Cards

which allow operation and configuration parameters

to be sent to the Master Module.

In conjunction with the Communications Cards, a

personal computer running RSPower™ or

RSEnergy™ software can be sent to the Master

Module.

1403-IN001A-US-P

Page 10

1-2 Product Description

Quick Start - Minimum Device Configuration

At a minimum, the following steps MUST be

followed for proper operation of your Powermonitor

II. Any other device configuration options are only

required fo r operation of additional functions of the

Powermonitor II.

1. Configure the PT and CT ratios to match your

system. Remember, for systems with greater than

120 volts applied to the voltage inputs, the PT

secondary must be configured to greater than 137

volts to switch to high voltage mode. For

example: a 600 V

L-L

(347 V

) direct-connect

L-N

system is configured with a PT ratio of 347:347.

2. Configure the Voltage Mode to match your syste m

wiring. Use the wiring diagrams in Chapter 2,

Figure 2.2 through Figure 2.13 to select the

appropriate mode.

Measurements

Table 1.1 Real Time Metering Measurements

Distortion PF (total, and per phase on 4-wire systems)

Power Consumption in kW Hours (forward, reverse, and net)

Reactive Po wer Consumption in kVAR Hours (forward, rev erse ,

and net)

Demand (Amps, Watts, VAR, and VA)

Instantaneous Demand (Amps, Watts, VAR, and VA)

First Order Projected Demand (Amps, Watts, VAR, and VA)

Second Order Projected Demand (Amps, Watts, VAR, and VA)

Table 1.2 Real Time Harmonic Analysis (V1, V2, V3, I1, I2, I3,

and neutral)

Percent Distortion up to 41st Harmonic (1403-MM only)

IEEE Percent Total Harmonic Distortion

IEC Percent Total Harmonic Distortion (Distortion Index)

(DIN)

IEEE-519 Compliance (1403-MM only)

Telephone Interference Factor (1403-MM only)

Crest Factor (1403-MM only)

K-Factor (1403-MM only)

Note: Update rates and accuracy are listed in

Appendix C, Technical Specifications

The Powermonitor II provides numerous display

measurements and programming charact er is ti cs.

Table 1.1 Real Time Metering Measurements

Current in Amps (per phase and neutral)

Average Current in Amps

Positive Sequence Current in Amps

Negative Sequence Current in Amps

Percent Current Unbalance

Voltage in Volts (per phase L-L, and L-N on 4-wire systems)

Average Voltage in Volts (per phase L-L, and L-N on 4-wire

systems)

VAUX (auxiliary voltage input)

Positive Sequence Volts in Volts

Negative Sequence Volts in Volts

Percent Voltage Unbalance

Frequency in Hz

Phase Rotation (ABC, ACB)

Watts (total, and per phase on 4-wire systems)

VAR (total, and per phase on 4-wire systems)

VA (total, and per phase on 4-wire systems)

True PF (total, and per phase on 4-wire systems)

Displacement PF (total, and per phase on 4-wire systems)

Displays

The Powermonitor II Master Module communicates

to the Display Module over a fiber optic serial

communications link. Up to three Display Modules

can connect to one Master Module.

Figure 1.1 Display Module

1403-IN001A-US-P

Page 11

Product Description 1-3

Communications

Both versions of the Powermonitor II can use the

1403-NSC Smart Communications Card for

communications via Allen-Bradley Remote I/O, RS232 or RS-485, the 1403-NENET card for

communications via Ethernet, or the 1403-NDNET

card for communications via DeviceNet. Refer to

Publication 1403-5.1 Smart Communications Card

Instruction Sheet, Publication 1403-5.3 Ethernet

Communications Card Instruction Sheet, or

Publication 1403-5.4 DeviceNet Communication

Card Instruction Sheet for additional information.

Software and System Integration

An IBM PC, or compatible, host computer may

communicate with the Powermonit or II via RS-232C,

RS-485, R I/O, DeviceNet, or Ethernet using:

RSPower

•

RSView

•

RSEnergy

•

RSLinx

•

User generated software (using open protocol -

•

see Publication 1403-5.1, Smart Communications

Card Instruction Sheet)

User generated software (using open protocol -

•

see Publication 1403-5.3, Ethernet

Communications Card Instruction Sheet)

RS-232C/RS-485 may be used to support up to 124

Powermonitor IIs per sub net, 250 per network.

PLC Configuration

Setup/Monitoring Software

The Windows-based RSPower and RSEnergy

software packages are currently available from

Rockwell Software for configuring, monitoring, and

control of the Powermonitor II units. This software

package is designed t o b e i nte gr ate d wi th RSVi ew or

function as a stand alone package. It is capable of

graphically displaying a system and its components

and providing real time data and graphics on the

same screen. Real time data can be displayed in

digital or analog presentation using preconfigured

gauges. Spectral analysis, oscillograph recordings,

logging, and trending are also easily configured.

When either software is used in conjunction with

RSView, data can be ente red into the tag database

editor. Configuration and real time data can be

downloaded and retrieved from any Bulletin 1400/

1403 Powermonitor on the system.

Note: Spectral analysis and oscillog raph recordings

are only available through the 1403-MM

only.

Control Relays

The Powermonitor II provi de s t wo hi gh s peed SPDT

control relays which may function as:

Alarm relays

•

Setpoint relays

•

Remote control relays operated by command via

•

the communications port or Display Module.

Relays controlled by user-defined conditions

•

• kWH or kVARH pulse outputs

• Relay operations may be logged to a PC printer

output using a software package.

Certain circumstances may require a number of

Powermonitor IIs to provide feedback while

monitoring and control li ng a fa cility. To manage this

effectively, Allen-Bradley PLC processor

communication ports can be integrated to

communicate and respond to the gathered

information.

Status Inputs

The Powermonitor II has four self-powered status

inputs. These inputs c an b e used to sense and control

the state of an external contact. Each of the status

inputs has a counter associated with it. The status of

these inputs can be viewe d from the Powe rmonit or II

Display Module. They may also be viewed and

logged from RSPower or RSEnergy software or user

generated software.

1403-IN001A-US-P

Page 12

1-4 Product Description

Data Logging

The Powermonitor II provides three data logs: the

Event log, the Min/Max log, and the Snapshot log.

Each record of the three logs is date and time

stamped to the nearest hundredth of a second.

Event Log

The Event log consists of the 100 most recent events

that occurred in the Powermonitor II. Such events

consist of power up/ power d own, set point acti vation ,

new configuration data, etc.

Min/Max Log

The Min/Max log records the minimum and

maximum values for 84 parameters for the 1403-MM

and 63 parameters for the 1403-LM. These items

consist of voltage, current, power, total harmonic

distortion, etc. This log can be disabled to increase

real time metering update rate performance.

Both types of oscillography can be triggered

manually or as the result of a setpoint. All channels

are continuously sampled at a 10.8 kHz sample rate.

Operational Characteristics

1403-MM

The Powermonitor II MM module has selectable

accuracy (+/- 0.05% no minal) an d update r ates (28 to

90 ms) by changing various configuration

parameters. If update rates are critical, then a user

can select a modest filtering mode or disable

unnecessary features. However, if maximum

accuracy is a ne cessity fo r a specif ic applicat ion, then

the user can select an additional filtering mode. The

Powermonitor II allows a user to trade update speed

for accuracy.

1403-LM

Snapshot Log

The Snapshot log consis ts of 5 0 r ecords . Each re cord

consists of 46 parameters. These parameters include

voltage, current, power, power factor, etc. This log

can be updated on a periodic basis set by the

configuration data, and/or it can be updated

asynchronously as a result of a setpoint action.

Oscillography (1403-MM only)

The Powermonitor II provides two types of

oscillography:

(1)

• Simultaneous 7-channel 2-cycle

recording

• User configurable simultaneous 2-channel 12-

(2)

cycle

oscillograph rec ording wit h up to 8 cycles

of pretrigger data.

oscillograph

The Powermonitor II LM module has a fixed

accuracy (+/- 0.1 nominal) and a f ixe d upda te r at e of

90 ms.

(1) 2-cycle is specified at 50 Hz (2.4 cycles at 60 Hz). Therefore, more data will

be available at frequencies greater than 50 Hz, while less will be available at

frequencies less than 50 Hz.

1403-IN001A-US-P

(2) 12 cycles is specified at 50 Hz (14.4 cycles at 60 Hz). Therefore, more data

will be available at frequencies greater than 50 Hz, while less will be

available at frequencies less than 50 Hz.

Page 13

Chapter

2

Installation

Prevent Electrostatic D ischarge

A TTENTION: Electrostatic

discharge can damage integrated

!

Mounting of Master Module

circuits or semicondu ctors i f you touch

backplane connector pins . Follow these

guidelines when you handle the

module.

•

Touch a grounded object to discharge static

potential.

•

Wear an approved wrist-strap grounding

device.

•

Do not touch the backplane connector or

connector pins.

•

Do not touch circuit components inside the

module.

•

If available, use a static-safe work station.

•

When not in use, keep the module in its

static-shield box.

free convection cooling of the Master Module’s

internal electronic components.

Important:Do not block ventilation holes of the

Master Module. All wiring and other

obstructions

The mounting hole pattern for the Master Module is

defined by the dimensional drawing in Figure B.2,

Appendix B. The Master Module can be mounted

with either four No. 10 or M5 bolts or screws with

flat washe rs and an internal lock washer or

equivalent.

Mounting of Display Module

Protective Enclos ure A suitable enclosure should be

used to protect the rear surfaces of the Display

Module from atmospheric contaminants such as oil,

moisture, dust and corrosive vapors plus other

harmful airborne substances. The Display Module’s

gasketed front panel interface to the protective

enclosure is rated as an IP65 degree of protection

[National Electrical Manufacturer’s Association

(NEMA)/Underwriters Laboratories (UL) 508, Type

4X (Indoor)] per International Standard IEC 529.

Protective Enclosur e A suitable enclosure should be

used to protect the Master Module from atmospheric

contaminan ts such as oil, mo isture, dust, and

corrosive vapors or other harmful airborne

substance s; if not, a reduced servi ce life can be

expected.

The enclosure should be mounted in a position that

allows the access doors to open fully. This will

provide easy access to the wiring of the Master

Module and related components. A suggested

method for spacing and wiring layout for the Master

Module is shown in Appendix B. Also, see Appendix

B for drilling template.

Installation and Orientation Normal installation

and orientation of the Master Module within its

protective enclosure is defined in Figure B.1,

Appendix B. This orientation will ensure adequate

Installation and Orientation The Display Module

can be oriented in any position. The most typical

orientation is shown in Figure B.1, Appendix B. The

Display Module is designed to fit into the protective

enclosure cutout with a minimum installation depth

of 50.8 mm (2.0 in.) behind the mounting panel as

shown in Figure B.2, Appendi x B. The recommended

Display Module mounting hole pattern and

dimensions are defined in Figure B.3, Appendix B.

Ensure that the gasket provided is not contaminated

with foreign matter and is installed in the Display

Module correctly. Install the Display Module into the

protective enclosure’s front panel using four M4 nut/

lockwasher assemblies as shown in Figure B.4,

Appendix B. Tighten the M4 nut/lockwasher

assemblies to 0.9 to 1.1 Nm (8 to 10 lb-in.)

Note: Eight flat washers are provided for retrofit

applications with larger hole sizes.

1403-IN001A-US-P

Page 14

2-2 Installation

ATTENTION: Failure to comply

with these mounting requirements

!

may cause damage to the Display

Module or compromise the IP65

[NEMA/UL 508, Type 4X (Indoor)]

degree of protection per International

Standard IEC 529.

Wiring of Master Module

Terminal Blocks Wire Sizes and Screw Torques

Observe all wire lug sizes and screw torques. Refer to

Appendix C, Specifications.

Chassis Grounding

Module to the wiring installation via a bonding

terminal. R efer to Technical Specifications,

Appendix C. This protective earthing terminal shall

have no other function per local codes (ground bond

largest measured co nductor size) . All grou nd wires

≥

should be kept as short as possible; 30cm (12 in.) or

less is sugg ested.

Electrically bond the Master

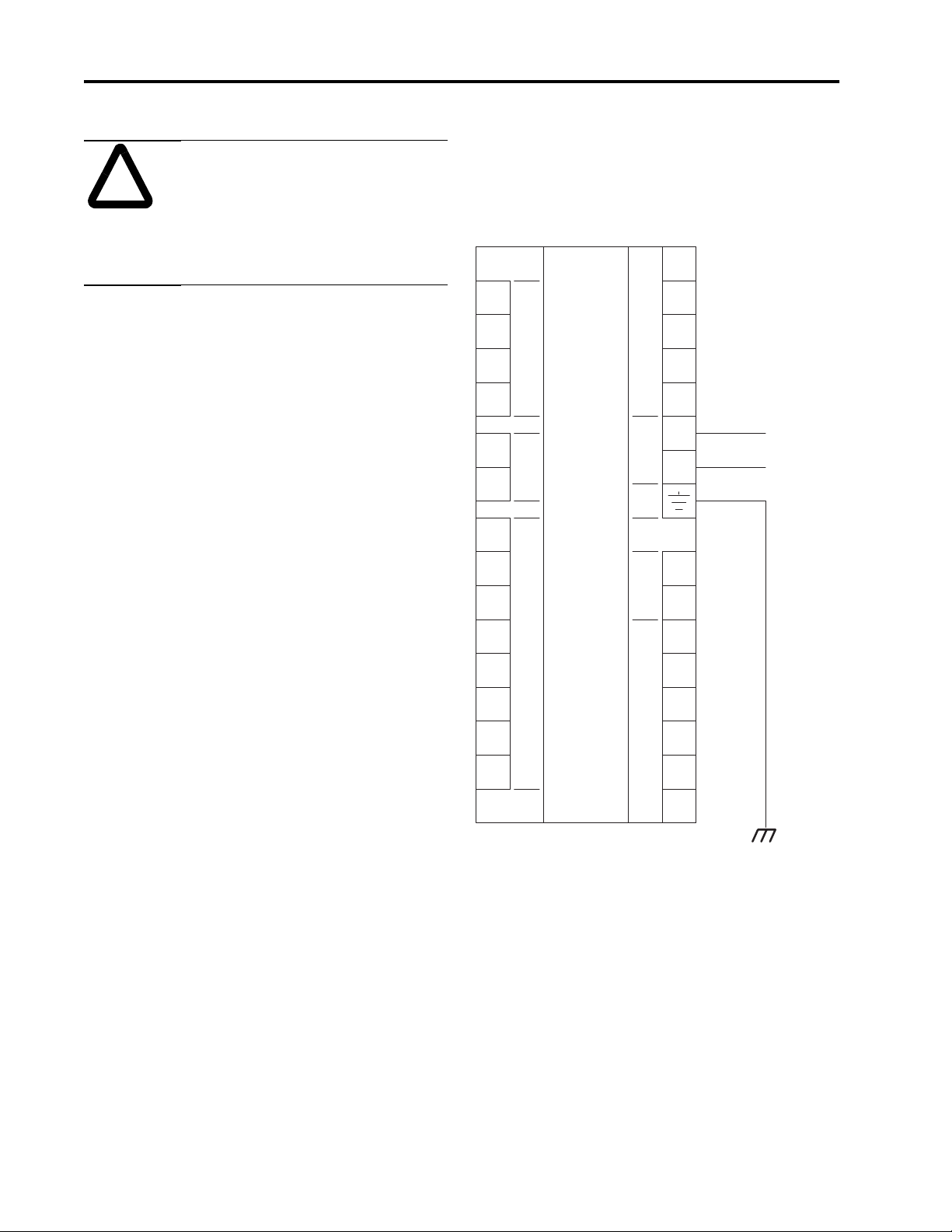

Figure 2.1 Bulletin 1403-XMXX

Cat. No. 1403-xMXXA

120/240 AC 50/60 HZ

125/250 DC

V1

V2

V3

N

Fiber

Rx

Fiber

Tx

I1+

I1-

I2+

Voltage

Inputs

Display

Module

Fiber

GRD

PM-II

Master

Module

Cat. No. 1403-xMXXB

24 AC 50/60 HZ

12/24 DC

S1

S2

Status

Inputs

S3

S4

Scom

L/+

Power

N/-

Ain

Analog

Input

Acom

L1

N/L2

Control Po we r

The power required by the Master Module is less

than 25VA to facilitate retrofit applications, but th e

terminal block connections accept up to #12 AWG

2

(4 mm

powered directly from a local branch circuit. It

should be fused per local code.

) wire with lugs. The Master Module can be

I2-

I3-

I3+

I4+

I4-

Current

Inputs

R14

R11

R12

R24

R21

R22

Relay

Outputs

Local Frame

Ground

Voltage and Current Inputs

Voltage Input and Potential Transformer (PT) Selection

All Bulletin 1403-xM Powermonitor II devices

handle direct connection for line to neutral voltages

of 120, 277, and 347 (line to line voltages of 208,

480, and 600V, respectively).

1403-IN001A-US-P

Page 15

Installation 2-3

Use instrument accura cy PTs when the vol tage level s

being measured exceed the vo ltage in put ratings . The

PT accuracy rating directly affects the system

accuracy. For maximum accuracy, the PT used must

provide linearity across the voltage range and must

introduce a minimal phase angle shift.

Note: Remember, for systes with greater than 120

volts applied to the voltage inputs, the PT

secondary must be confi gured to greate r than

137 volts to switch to high voltage mode.

Example: A 600 V

(347 V

L-L

) direct-

L-N

connect system would be configured with a

PT ratio of 347:347.

Current Inputs and Current Transformer (CT) Selection

The Powermonitor II is available in two models: a 5

Amp or 1 Amp model. Each current input to the

Powermonitor II is internally CT isolated to 5kV.

Each current input may b e connected di rectly into th e

power line as long as t he current s do not e xceed the 5

Amp or 1 Amp ratings.

Customer provided CTs are required where input is

higher than the device rating. The values for the

primary and secondary CT ratings must be

configured into the Powermonitor II in order to

properly scale the displayed readings.

The accuracy of the current input reading is

dependent on the CT class. An Instr ument Clas s 1 or

better is recommended. Ca re shou ld be take n that th e

combined load of wiring and the Powermonitor II

match closely to the VA rating of the CT for

maximum accuracy.

ATTENTION: A CT secondary

circuit must not be opened with

!

primary current applied. Wiring

between the CTs and the

Powermonitor II should include a

terminal block for shorting the CT

secondary circuit. Shorting the

secondary with primary current

present will allow other connections

to be removed if needed. An open CT

secondary with primary current

applied will produce a hazardous

voltage, which can lead to personal

injury, death, property damage or

economic loss.

1403-IN001A-US-P

Page 16

2-4 Installation

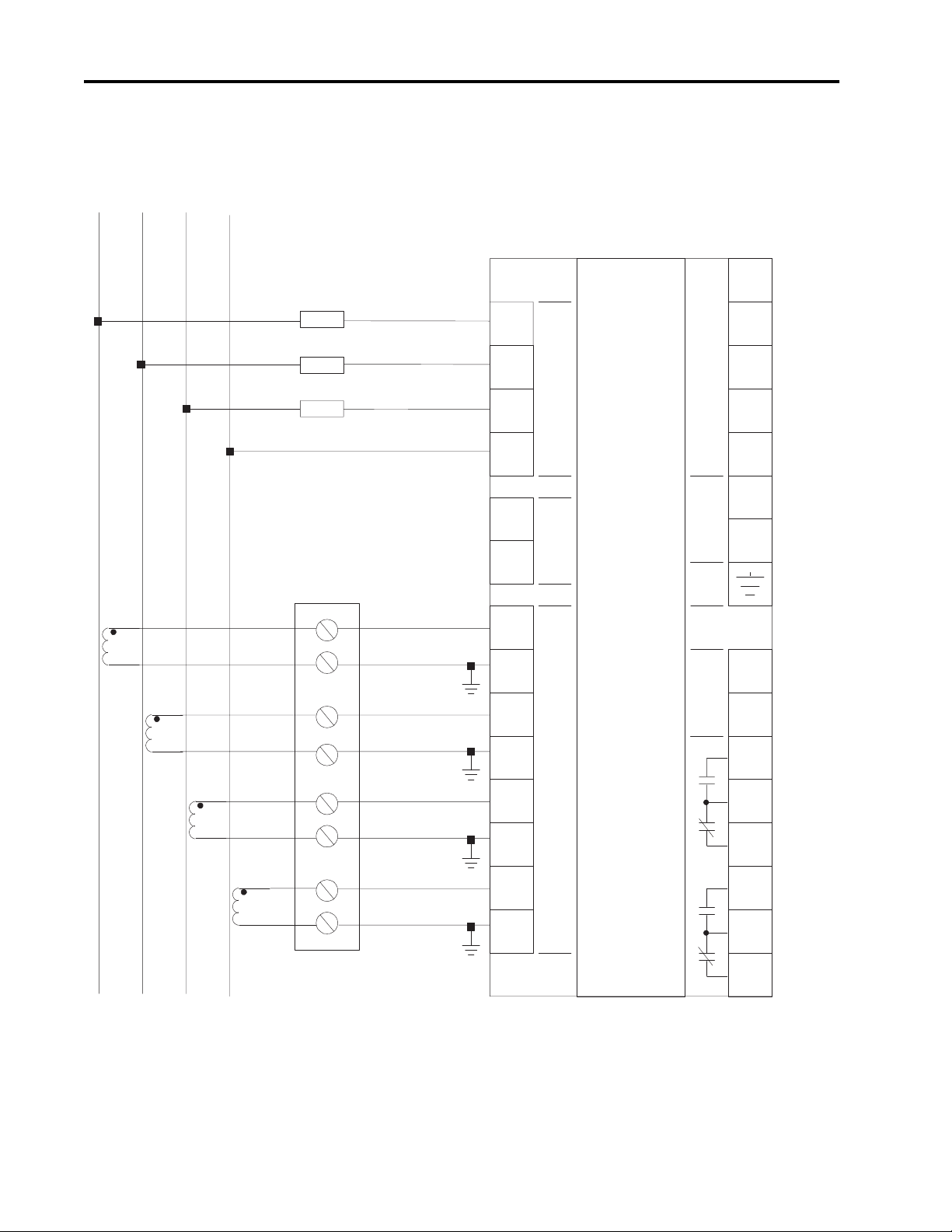

Figure 2.2 Single Phase Direct Connection Wiring Diagram

L1

L2 N

Voltage mode = Single Phase

Fuse

Fuse

Customer Supplied CT

Shorting Switch or Test

Block

V1

V2

V3

N

Fiber

Rx

Fiber

Tx

I1+

Voltage

Inputs

Display

Module

Fiber

Powermonitor II

Master Module

Status

Inputs

Power

GRD

S1

S2

S3

S4

Scom

L/+

N/-

Load

Customer

Chassis

Ground

Note:

I1-

Analog

I2+

Input

I2-

Current

Inputs

I3+

I3-

Relay

Outputs

I4+

I4-

• Careful attention must be paid to correct

phasing and polarity for proper

operation.

• All ground wires should be taken

individually to Customer Chassis

Ground for a single point of grounding.

Ain

Acom

R14

R11

R12

R24

R21

R22

1403-IN001A-US-P

Page 17

Figure 2.3 Single Phase with PTs Wiring Diagram

Installation 2-5

L1

L2

N

Voltage Mode = Single Phase

Fuse

Fuse

Customer Supplied CT Shortin g

Switch or Test Block

V1

V2

V3

N

Fiber

Rx

Fiber

Tx

I1+

Voltage

Inputs

Display

Module

Powermonitor II

Master Module

Status

Inputs

Power

GRD

S1

S2

S3

S4

Scom

L/+

N/-

Load

Customer

Chassis

Ground

Note:

I1-

Ain

Analog

I2+

I2-

Current

Input

Acom

R14

Inputs

I3+

I3-

R11

R12

Relay

I4+

I4-

Output

R24

R21

R22

• Careful attention must be paid to correct

phasing and polarity for proper operation.

• All ground wires should be taken individually

to Customer Chanssis Ground for a single

point of grounding.

1403-IN001A-US-P

Page 18

2-6 Installation

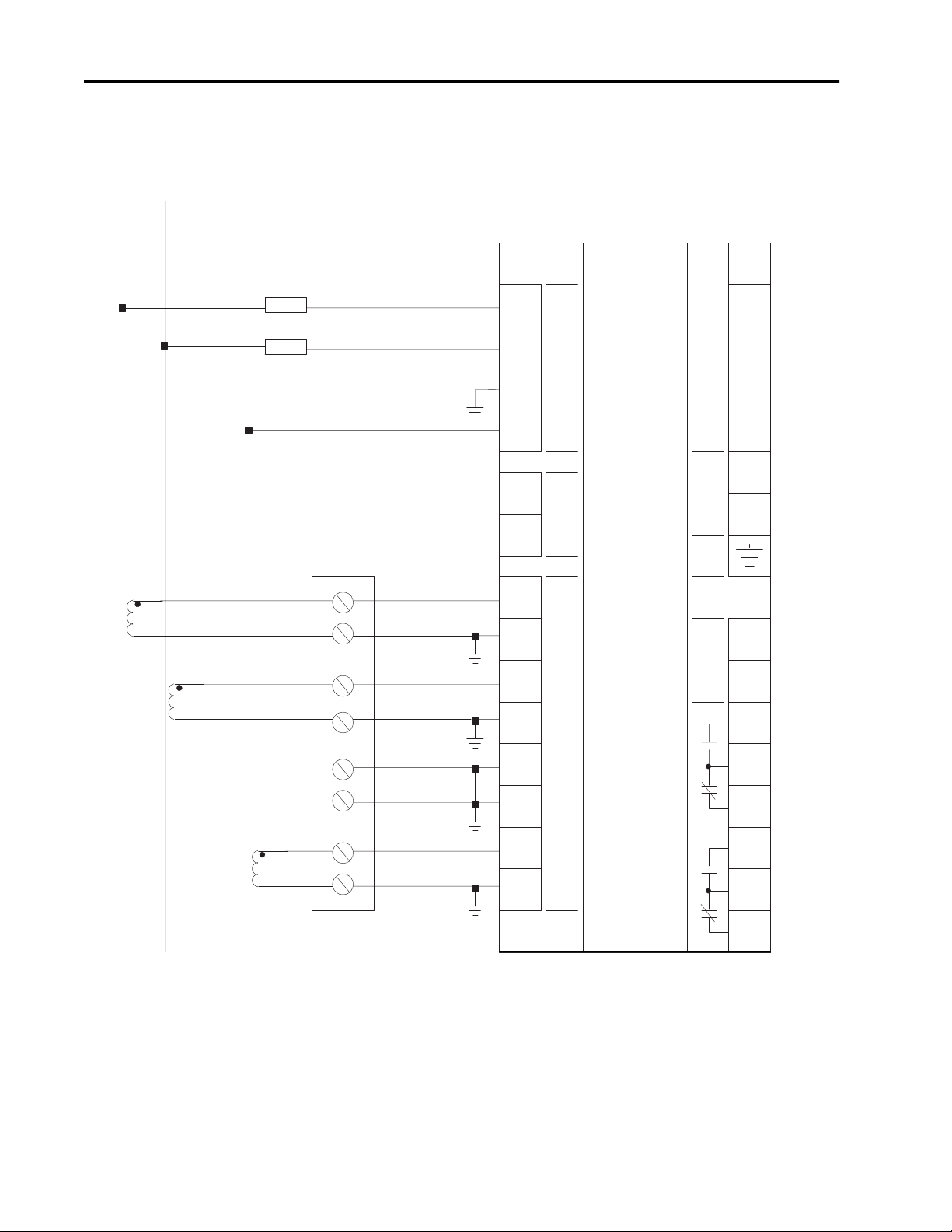

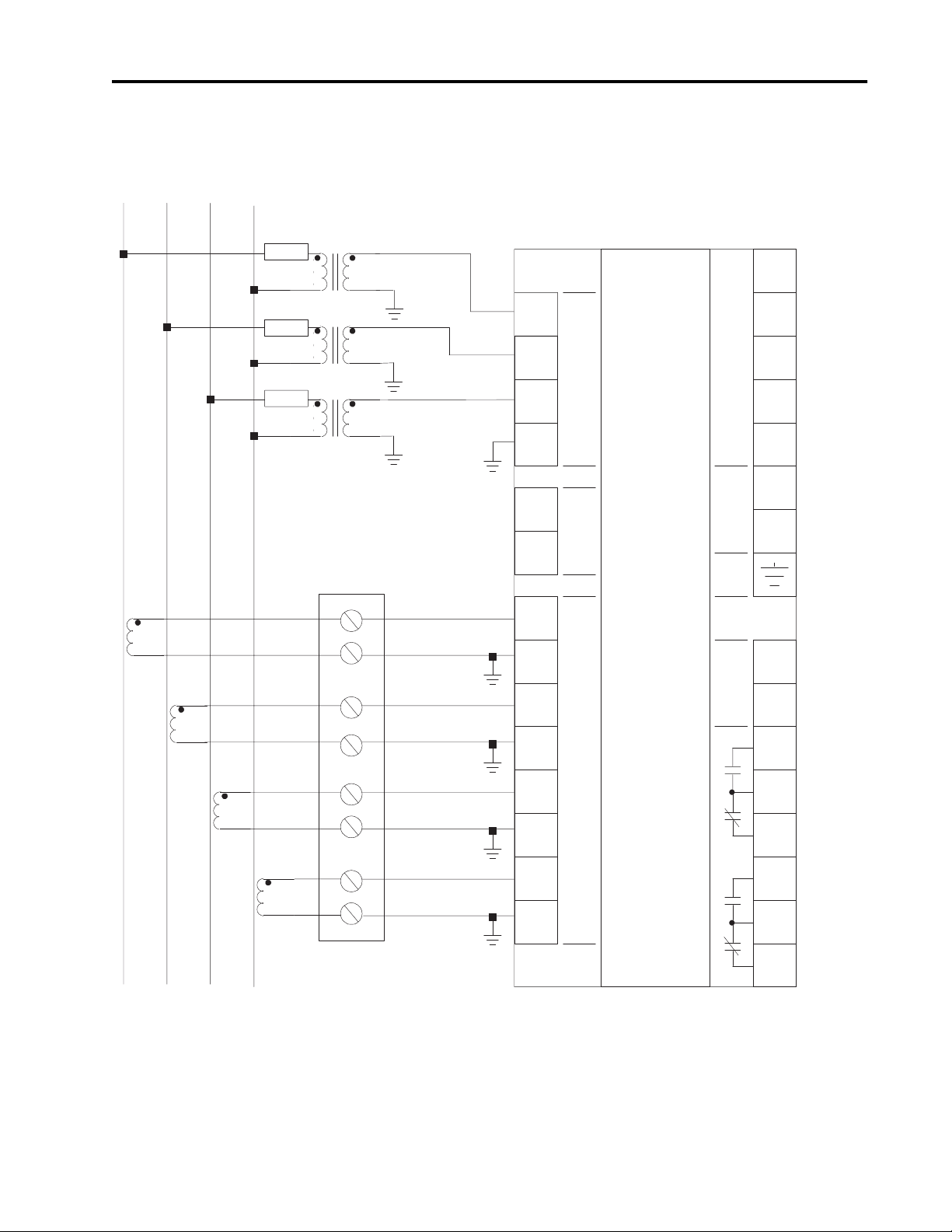

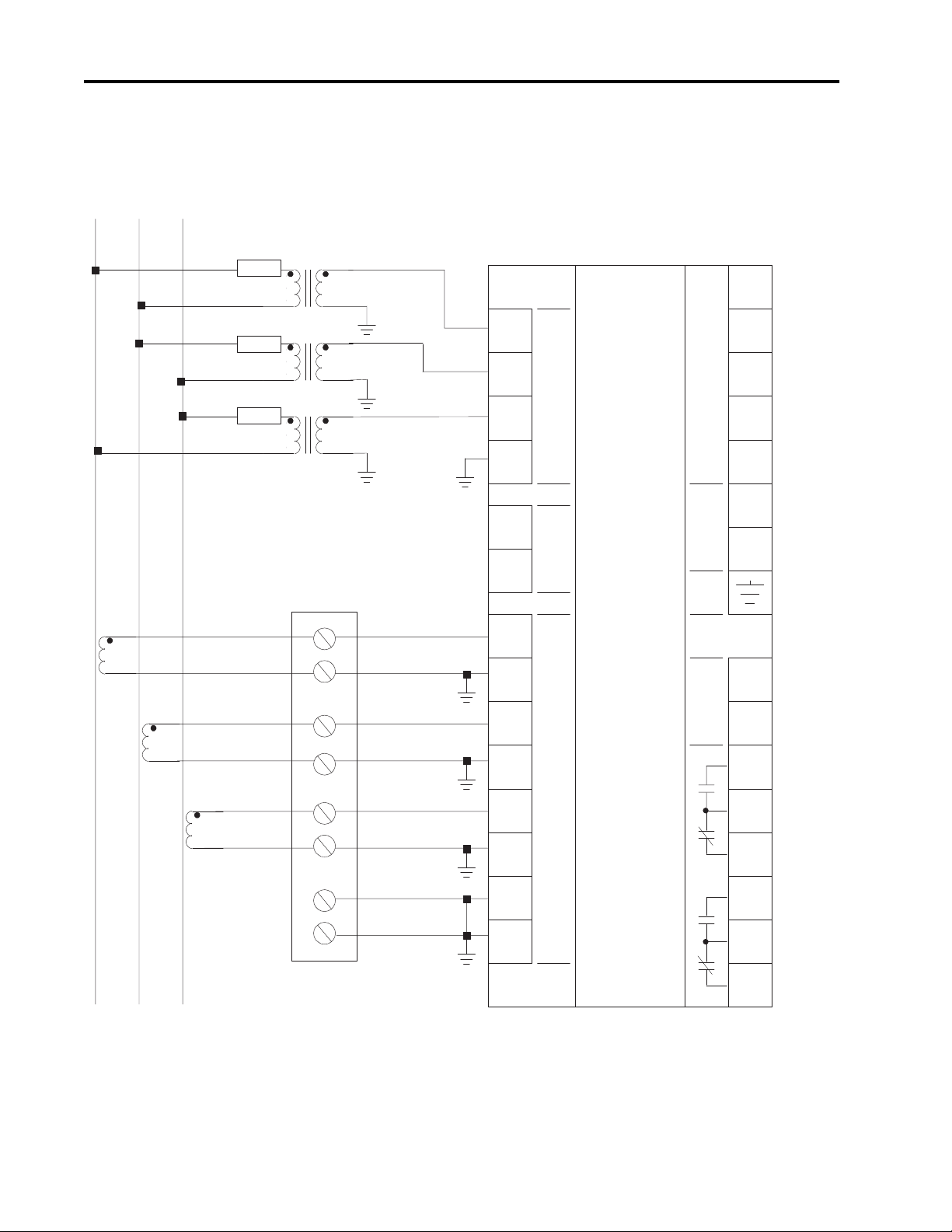

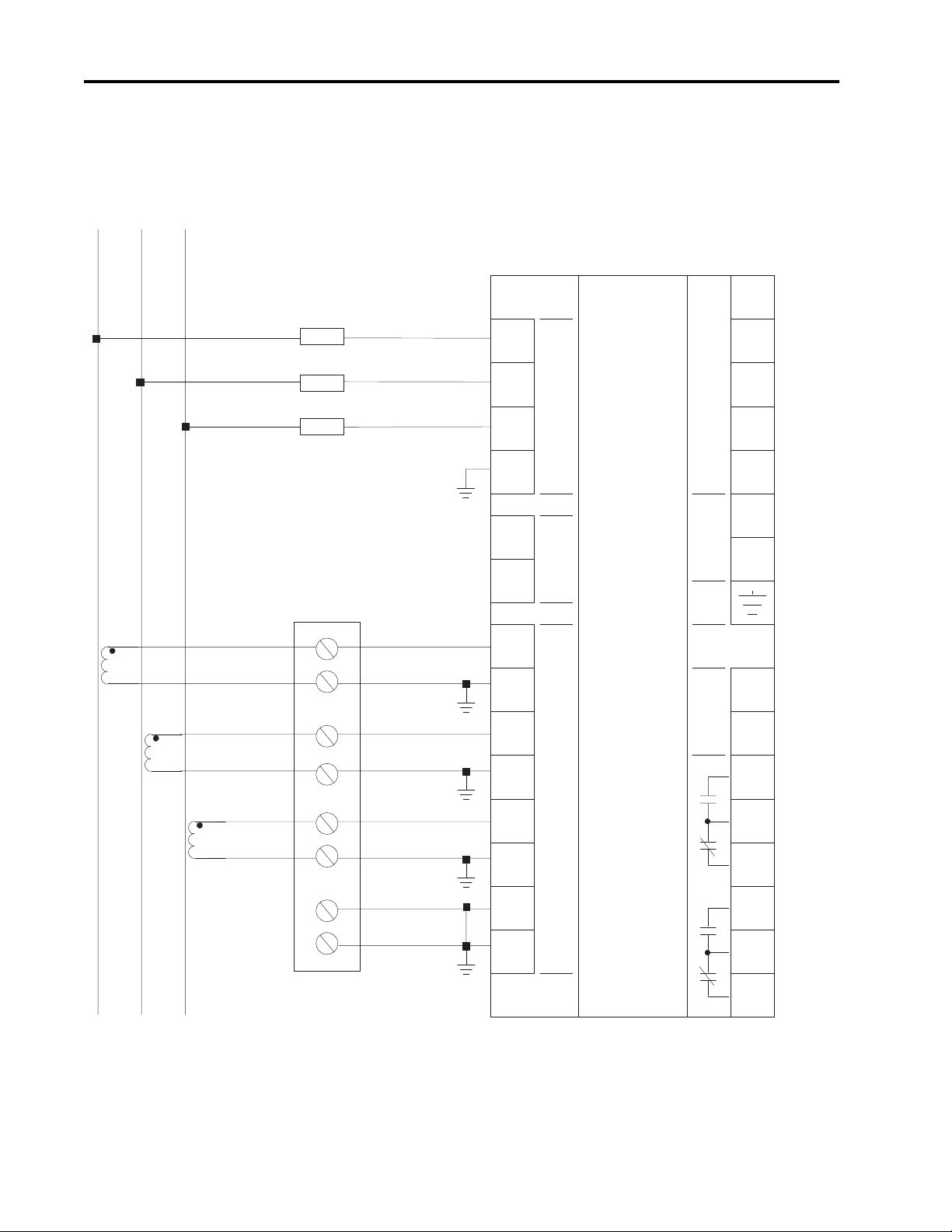

Figure 2.4 3-phase 4-wire Wye Direct Connect Wiring

Diagram

L1

L2

LINE

L3

N

Customer Supplied CT

Shorting Switch or Test

Block

Voltage Mode = Wye

Fuse

Fuse

Fuse

V1

V2

V3

N

Fiber

Rx

Fiber

Tx

I1+

Voltage

Inputs

Display

Module

Fiber

Powermonitor II

Master Module

Status

Inputs

Power

GRD

S1

S2

S3

S4

Scom

L/+

Load

Customer

Chassis

Ground

Note:

I1-

Ain

Analog

I2+

I2-

Current

Input

Acom

R14

Inputs

I3+

I3-

R11

R12

Relay

I4+

I4-

Outputs

R24

R21

R22

• Careful att ention must be paid to correct phasing

and polarity for proper operation.

• All ground wires should be taken individually to

Customer Chassis Ground for a single point of

grounding.

1403-IN001A-US-P

Page 19

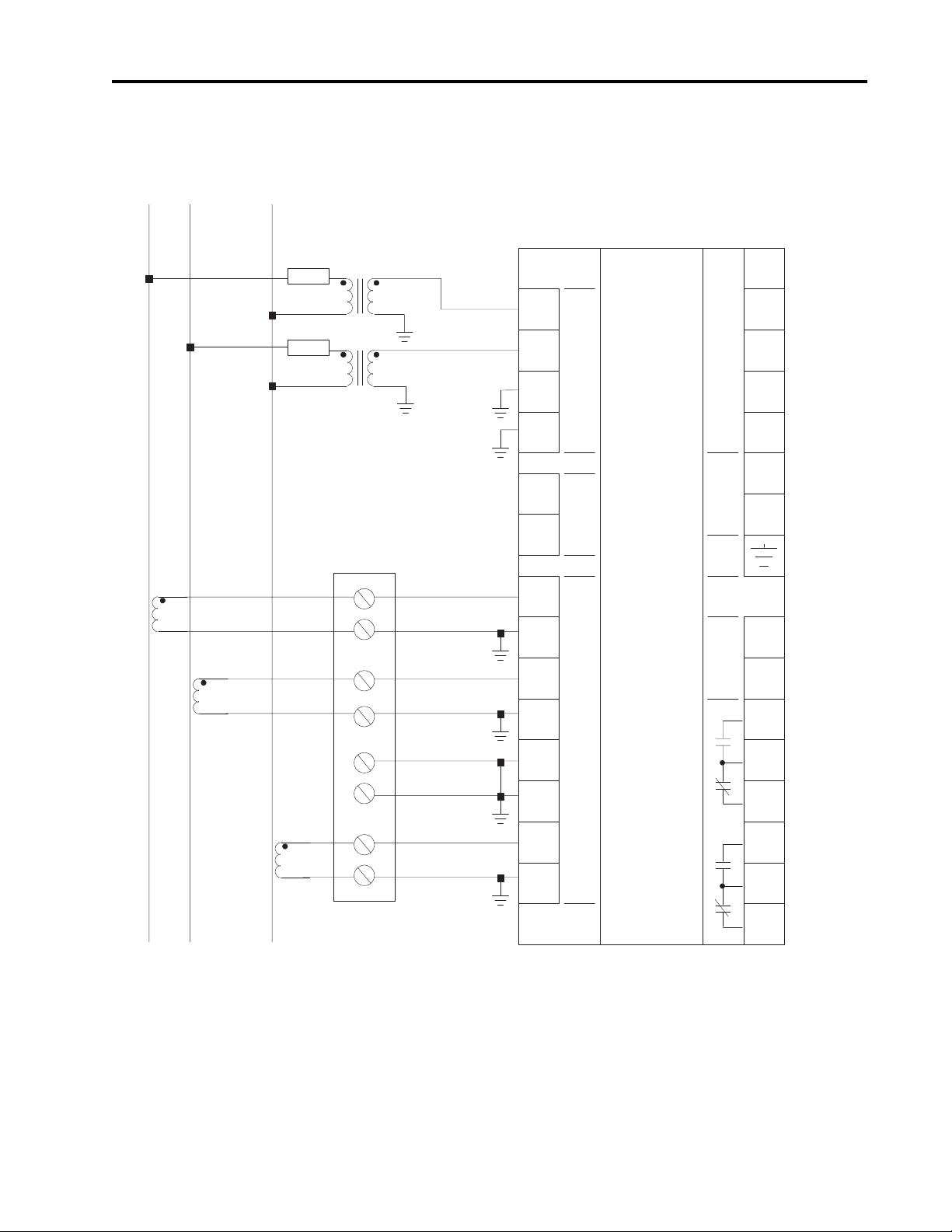

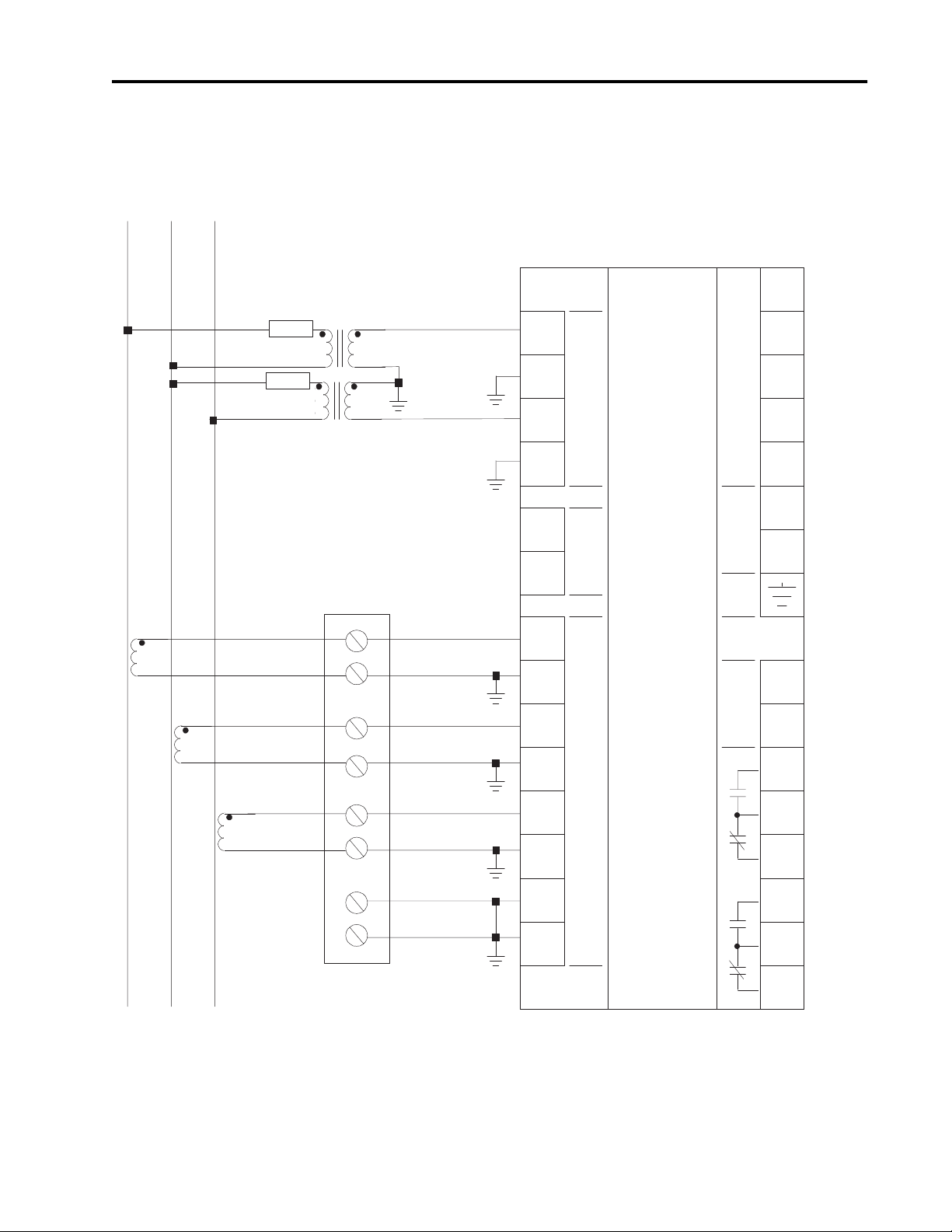

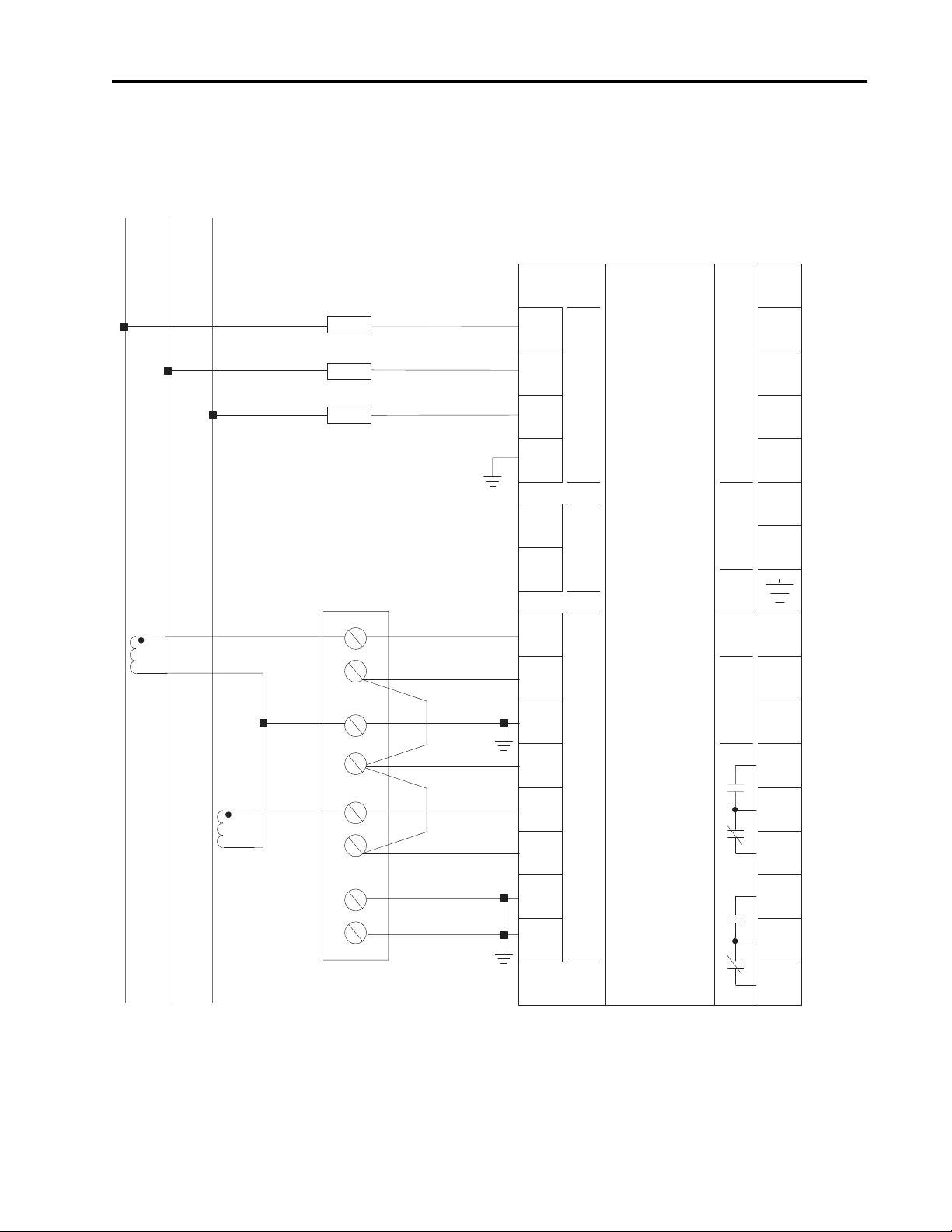

Figure 2.5 3-phase 4-wire with PTs Wiring Diagram

Installation 2-7

L1

L2

LINE

L3

Voltage Mode = Wye

N

Fuse

Fuse

Fuse

Customer Supplied CT

Shorting Switch or Tes t

V1

V2

V3

N

Fiber

Rx

Fiber

Tx

I1+

Voltage

Inputs

Display

Module

Powermonitor II

Master Module

Status

Inputs

GRD

S1

S2

S3

S4

Scom

L/+

N/-

Load

Customer

Chassis

Ground

Note:

I1-

Analog

I2+

I2-

Input

Acom

R14

Current

Inputs

I3+

I3-

R11

R12

Relay

I4+

I4-

Output

R24

R21

R22

• Careful attention must be paid to correct phasing

and polarity for prope r operation.

• All ground wires should be taken individually to

Customer Chassis Ground for a single point of

grounding.

Ain

1403-IN001A-US-P

Page 20

2-8 Installation

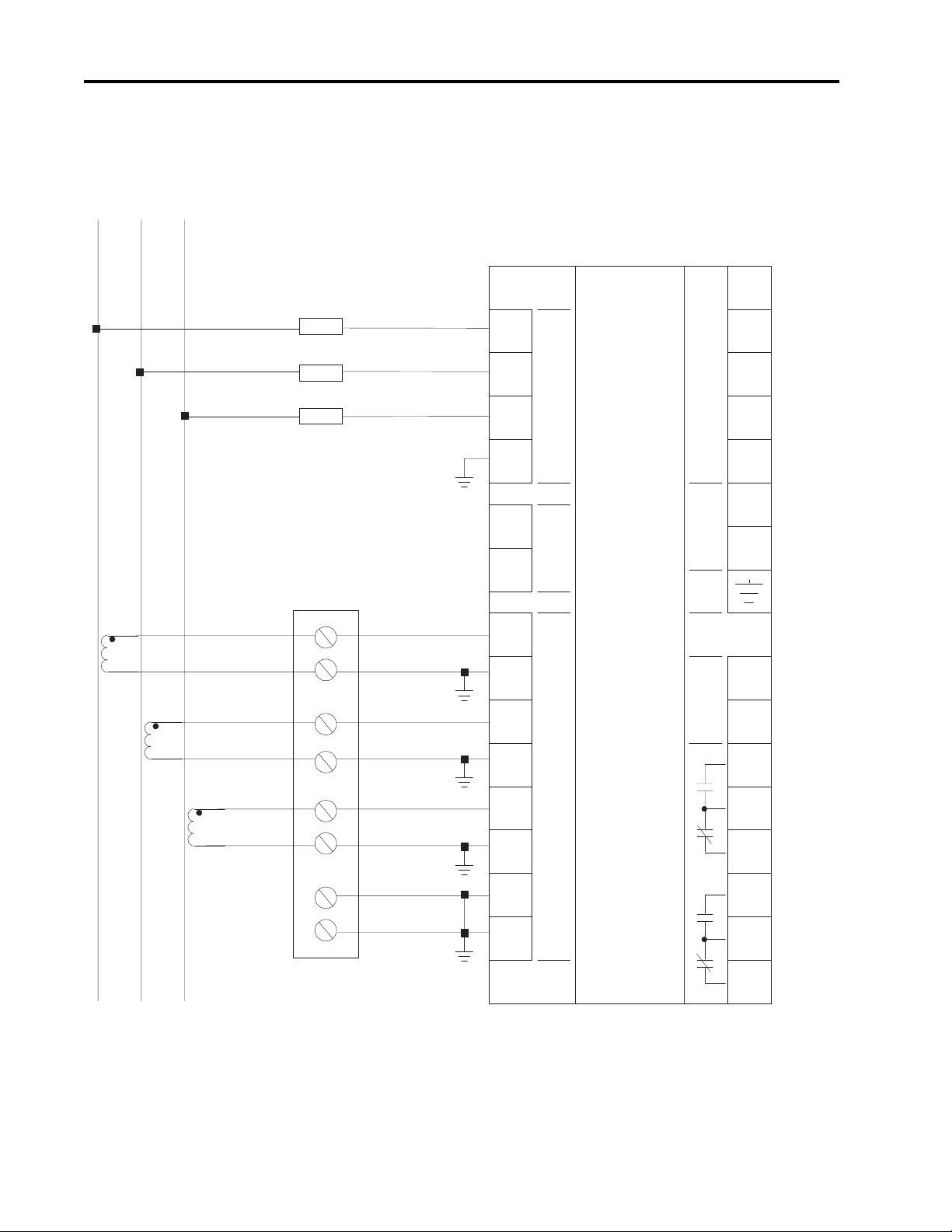

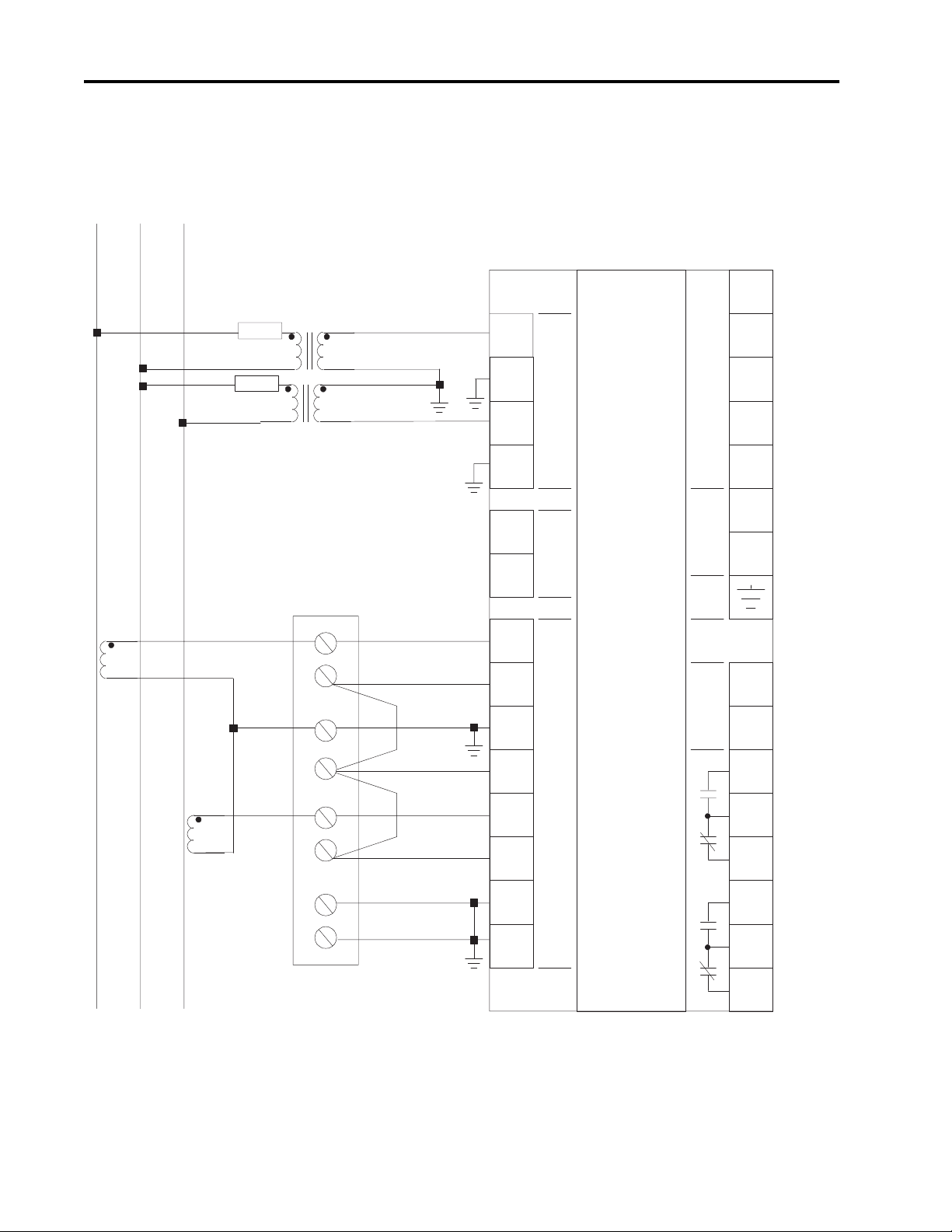

Figure 2.6 3-phase 3-wire Grounded Wye Direct Connection

Wiring Diagram

Voltage Mode = WyeLINE

L1

L2

L3

S1

Fuse

Fuse

Fuse

Customer Supplied CT Shorting Switch or Test

Block

V1

V2

V3

N

Fiber

Rx

Fiber

Tx

I1+

I1-

I2+

I2-

I3+

Voltage

Inputs

Display

Module

Fiber

Current

Inputs

Powermonitor II

Master Module

Status

Inputs

Power

GRD

Analog

Input

S2

S3

S4

Scom

L/+

N/-

Ain

Acom

R14

R11

Load

1403-IN001A-US-P

Customer

Chassis

Ground

Note:

I3-

Relay

R12

Output

I4+

I4-

R24

R21

R22

• Careful attention must be paid to correct phasing and

polarity for proper operation.

• All ground wires should be taken individually to

Customer Chassis Ground for a single point of

grounding.

Page 21

Figure 2.7 3-phase 3-wire Grounded Wye with PTs Wiring

Diagram

Voltage Mode = Wye

LINE

L3

L2

L1

Fuse

Installation 2-9

S1

Fuse

Fuse

Customer Supplied CT Shorting

Switch or Test Block

V1

V2

V3

N

Fiber

Rx

Fiber

Tx

I1+

I1±

I2+

I2±

I3+

Voltage

Inputs

Display

Module

Fiber

Current

Inputs

Powe rmonitor II

Master Module

Status

Inputs

Power

GRD

Analog

Input

S2

S3

S4

Scom

L/+

N/±

Ain

Acom

R14

R11

Load

Customer

Chassis

Ground

Note:

I3±

R12

Relay

I4+

I4±

Output

R24

R21

R22

• Careful attention must be paid to correct phasing and

polarity for proper operation.

• All ground wires should be taken individually to

Customer Chassis Ground for a single point of

grounding.

1403-IN001A-US-P

Page 22

2-10 Installation

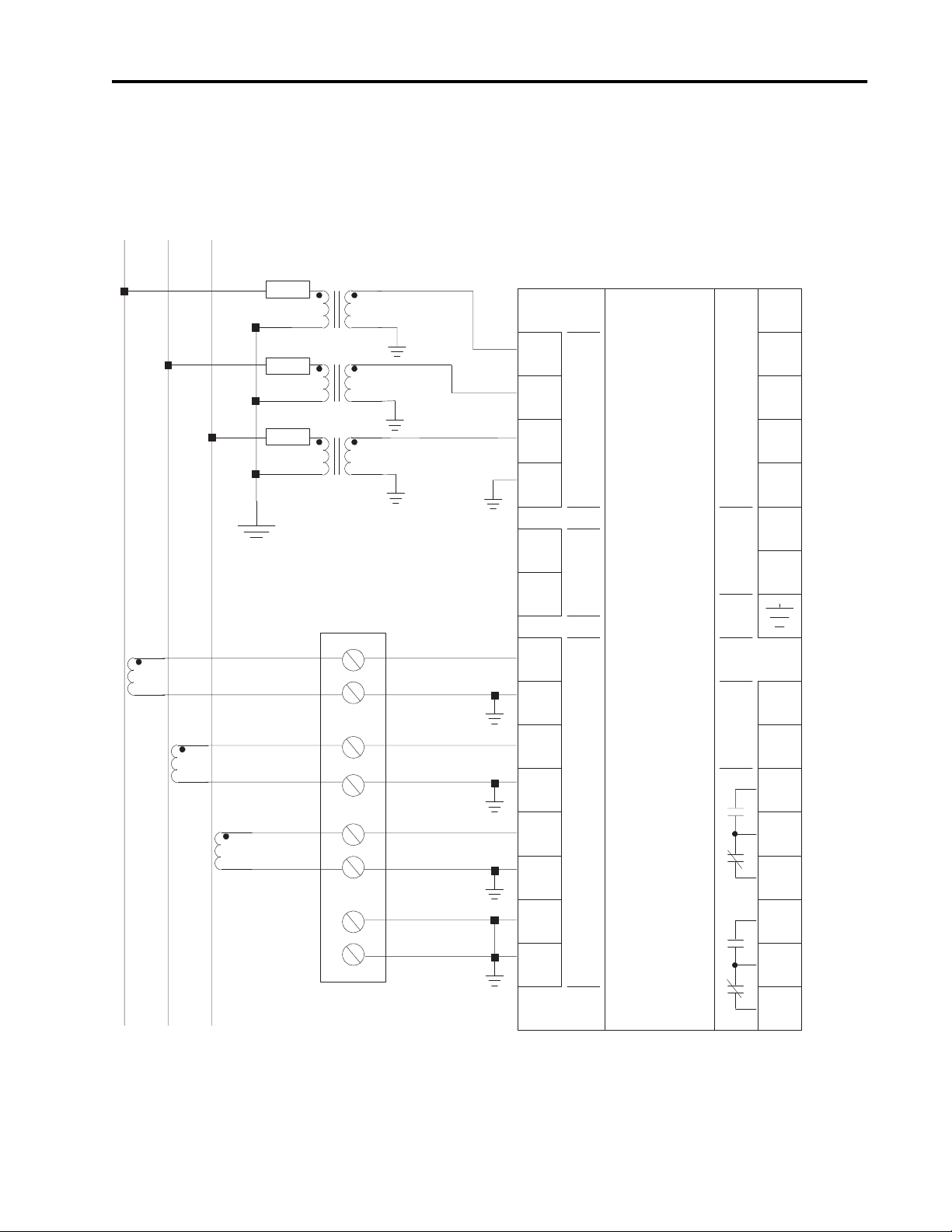

Figure 2.8 3-phase 3-wire Delta with Three PTs and Three

CTs Wiring Diagram

L1

L2

LINE

L3

Fuse

Fuse

Fuse

Customer Supplied CT Shorting Switch or

Test Block

Voltage Mode = Delta

V1

V2

V3

N

Fiber

Rx

Fiber

Tx

I1+

Voltage

Inputs

Display

Module

Fiber

Powermonitor II

Master Module

Status

Inputs

Power

GRD

S1

S2

S3

S4

Scom

L/+

N/-

Load

Note:

I1-

Ain

Analog

I2+

I2-

Input

Acom

R14

Current

Inputs

I3+

I3-

R11

R12

Relay

I4+

I4-

Output

R24

R21

Customer

Chassis

R22

Ground

• Careful attention must be paid to correct phasing and polarity for

proper operation.

• All ground wires should be taken individually to Customer

Chassis Ground for a single point of grounding.

• The Two CT wiring diagrams in Figure 2.10 may be used for any

of the delta or open delta wiring or voltage modes shown.

Whether there are two or three CTs in a circuit does NOT affect

the voltage wiring or mode selection.

1403-IN001A-US-P

Page 23

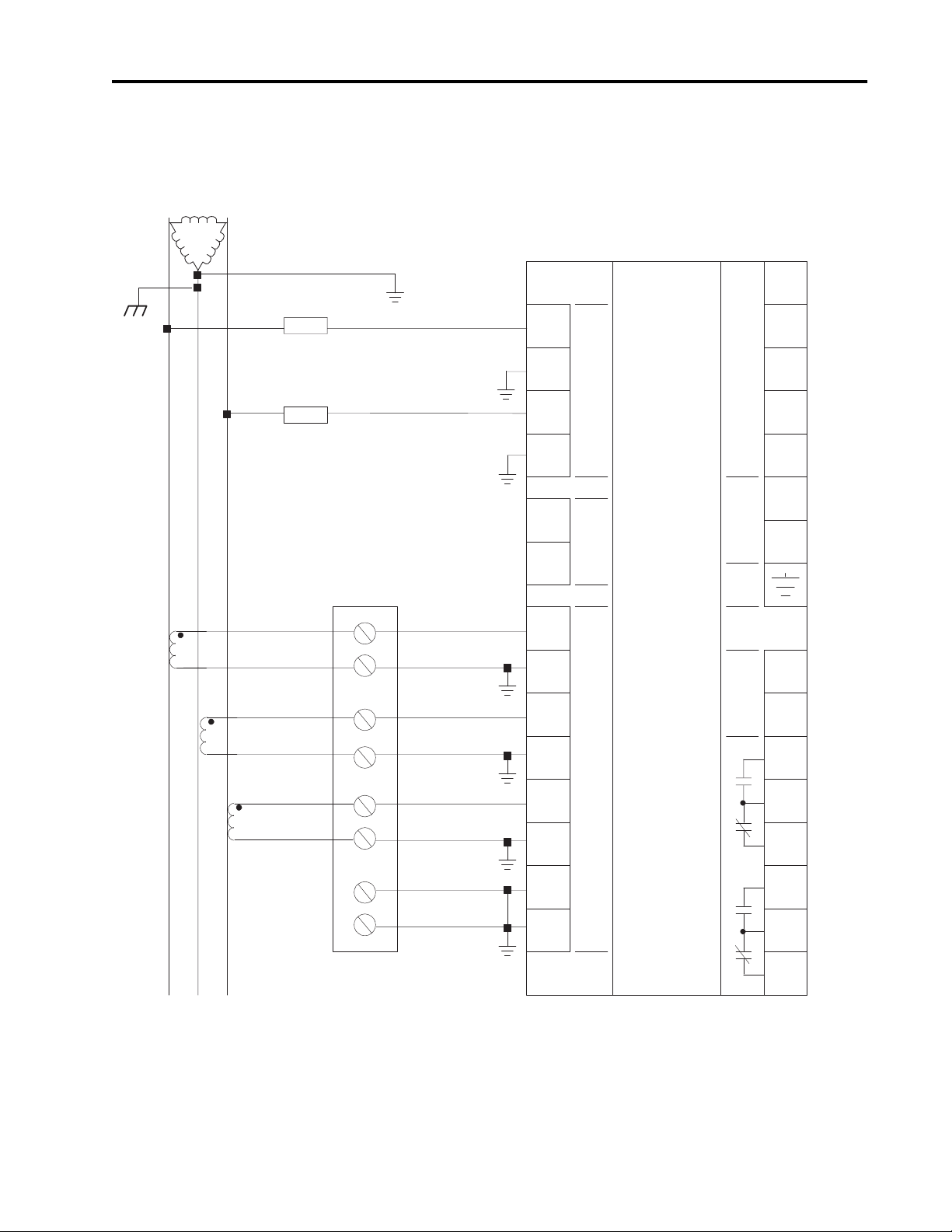

Figure 2.9 3-phase 3-wire Open Delta with Two PTs and

Three CTs Wiring Diagram

Installation 2-11

L1

LINE

L2

L3

Fuse

Fuse

Customer Supplied CT Shorting

Switch or Test Block

Voltage Mode = Open Delta

V1

V2

V3

N

Fiber

Rx

Fiber

Tx

I1+

Voltage

Inputs

Display

Module

Fiber

Powermonitor II

Master Module

Status

Inputs

Power

GRD

S1

S2

S3

S4

Scom

L/+

N/-

Load

I1-

I2+

I2-

Current

Inputs

I3+

I3-

I4+

I4-

Customer

Chassis

Ground

• Careful attention must be paid to correct phasing and polarity for

Note:

proper opera t i o n .

• All ground wires shoul d be taken individually to Customer

Chassis Ground for a single point of grounding.

• The Two CT wiring diagrams in Figure 2.10 may be used for any

of the delta or open d elta wir ing or volta ge mode s shown . Whethe r

there are two or three CTs in a circuit does NOT affect the voltage

wiring or mode selection.

Analog

Input

Relay

Output

Ain

Acom

R14

R11

R12

R24

R21

R22

1403-IN001A-US-P

Page 24

2-12 Installation

Figure 2.10 3-phase 3-wire Open Delta with Two PTs and

Two CTs Wiring Diagram

LINE

L1

L2

L3

Voltage Mode = Open Delta

S1

Fuse

Fuse

Customer Supplied CT Shorting

Switch or Test Block

V1

V2

V3

N

Fiber

Rx

Fiber

Tx

I1+

I1-

I2+

I2-

Voltage

Inputs

Display

Module

Fiber

Current

Inputs

Powe rmonitor II

Master Module

Status

Inputs

Power

GRD

Analog

Input

S2

S3

S4

Scom

L/+

N/-

Ain

Acom

R14

Load

1403-IN001A-US-P

Note:

I3+

I3-

R11

R12

Relay

Output

R24

R21

Customer

I4+

I4-

Chassis

Ground

R22

• Careful attention must be paid to correct phasing and polarity for

proper operation.

• All ground wires should be taken individually to Customer

Chassis Ground for a single point of grounding.

• The Two CT wiring diagrams in Figure 2.10 may be used for any

of the delta or open delta wiring or voltage modes shown.

Whether there are two or three CTs in a circuit does NOT affect

the voltage wiring or mode selection.

Page 25

Figure 2.11 3-phase 3-wire Grounded L2(B) Phase Open

Delta Direct Connect with Three CTs Wiring Diagram

Installation 2-13

L1

Distribution

Ground

LINE

L3

Voltage Mode = Open Delta

Fuse

Fuse

Line-to-Line Voltage must not exceed 347V

(otherwise, step down transformers are

required).

Customer Supplied CT Shorting

Switch or Test Block

V1

V2

V3

N

Fiber

Rx

Fiber

Tx

I1+

Voltage

Inputs

Display

Module

Fiber

Powermonitor II

Master Module

Status

Inputs

Power

GRD

S1

S2

S3

S4

Scom

L/+

N/-

L1

L2

Load

L3

I1-

I2+

I2-

Current

Inputs

I3+

I3-

I4+

Customer

I4-

Chassis

Ground

• Careful attention must be paid to correct phasing and polarity for

Note:

proper operation.

• All ground wires should be taken individually to Customer

Chassis Ground for a single point of grounding.

• The Two CT wiring diagrams in Figure 2.10 may be used for any

of the delta or open delta wiring or voltage modes shown.

Whether there are two or three CTs in a circuit does NOT affect

the voltage wiring or mode selection.

Analog

Input

Relay

Output

Ain

Acom

R14

R11

R12

R24

R21

R22

1403-IN001A-US-P

Page 26

2-14 Installation

Figure 2.12 3-phase 3-wire Delta Direct Connect with Three

CTs Wiring Diagram

L1

LINE

L2

L3

600 V

Voltage Mode = Direct Connect Delta

Fuse

Fuse

Fuse

L-L

Customer Supplied CT Shorting

Switch or Test Block

V1

V2

V3

N

Fiber

Rx

Fiber

Tx

I1+

Voltage

Inputs

Display

Module

Fiber

Powermonitor II

Master Module

Status

Inputs

Power

GRD

S1

S2

S3

S4

Scom

L/+

N/-

Load

Customer

Chassis

Ground

Note:

I1-

Ain

Analog

I2+

I2-

Input

Acom

R14

Current

Inputs

I3+

I3-

R11

R12

Relay

I4+

I4-

Output

R24

R21

R22

• Careful attention must be paid to correct phasing and

polarity for proper operation.

• All ground wires should be taken individually to

Customer Chassis Ground for a single point of

grounding.

1403-IN001A-US-P

Page 27

Figure 2.13 3-phase 3-wire Delta Direct Connect with Three

CTs Wiring Diagram

Installation 2-15

L1

LINE

L2

L3

600 V

Voltage Mode = Direct Connect Delta

Fuse

Fuse

Fuse

L-L

Customer Supplied CT Shorting

Switch or Test Block

V1

V2

V3

N

Fiber

Rx

Fiber

Tx

I1+

Voltage

Inputs

Display

Module

Fiber

Powermonitor II

Master Module

Status

Inputs

Power

GRD

S1

S2

S3

S4

Scom

L/+

N/-

Load

Customer

Chassis

Ground

Note:

I1-

Ain

Analog

I2+

I2-

Input

Current

Acom

R14

Inputs

I3+

I3-

R11

R12

Relay

I4+

I4-

Output

R24

R21

R22

• Careful attention must b e paid to correct phasing and

polarity for proper operation.

• All ground wires shoul d be taken individually to

Customer Chassis Ground for a single point of

grounding.

1403-IN001A-US-P

Page 28

2-16 Installation

Analog Input

This input is intended to accept input signals of zero

to one volt AC, 50/60 Hz, rms or plus/minus (±) 1.4

VDC.

Use twisted pair or shielded pair cable to reduce the

level of noise that may be induced on this low level

signal.

Do not use ground as a return path. A Ground

Potential Rise will add to or subtract from the input

signal level and affect the reading.

Relay Outputs

(Isolation Ratings = 2500V)

Table 2.1 Contact Ratings

Rating 50/60 Hz AC rms DC

Maximum Resistive

Load Switching

Minimum Load

Switching

UL 508, CSA 22.2,

IEC Rating Class

Maximum Make

Values Inductive Load

Maximum Break

Values Inductive Load

Maximum Motor Load

Switching

Table 2.2 Relay Life

10A at 250V

(2500VA)

10A at 30V and

0.25A at 250V

10mA at 24V 10mA at 24V

B300 Q300

30A at 120V

15A at 240V

(3600VA)

3A at 120V

1.5A at 240V

(360VA)

0.55A at 125V

0.27A at 250V

(69VA)

0.55A at 125V

0.27A at 250V

(69VA)

1/3 HP at 125V

1/2 HP at 250V

Figure 2.14 Control Relay Connections

S1

V1

V2

Voltage

Inputs

V3

N

Fiber

Rx

Display

Fiber

Module Fiber

Tx

I1+

I1-

I2+

I2-

Current

I3+

Inputs

I3-

I4+

I4-

PM-II

Master

Module

Relay

Outputs

Status

Inputs

GRD

Analog

Input

S2

S3

S4

Scom

L/+

N/-

Ain

Acom

R14

R11

R12

R24

R21

R22

L1

Power

Status Inputs

ATTENTION: Do not apply an

external voltage to a Status Input.

!

These inputs have an internal source

and are intended for dry contact input

only . Applyi ng a voltag e may damage

the associated input or internal power

supply.

10A Fuse

Load

Load

L2

N

Parameter Number of Operations

Mechanical

Electrical

5 X 10

1 X 10

6

5

Figure 2.14 shows one of the internal Form C Relay

contacts along with an exampl e of customer wiring to

a supply voltage and two loads.

1403-IN001A-US-P

All Status Inputs are common to an internal 24VDC

source on the SCOM te rminal. Sta tus in put termin al s

1-4 are positive polarity and SCOM is negative

polarity.

To prevent ground loops, each wire run to a Status

Input should have an accompanying return wire

connected to the SCOM (the common point for all

Status Inputs). (If more than two Status Inputs are

used, an external terminal block is recommended.)

Page 29

Installation 2-17

Table 2.3 Status Input

Parameter Condition 1 Condition 2

Applied resistance

verses status state

3.5K Ohms or less

= ON

5.5K Ohms or

greater = Off

Isolation Voltage 2500V status input to case 2500V

status input to internal digital circuitry

Figure 2.15 Status Inputs

N.O Contact

V1

V2

V3

Fiber

Rx

Fiber

Tx

I1+

I1±

I2+

I2±

I3+

I3±

I4+

I4±

S1

S2

Status

Inputs

Analog

Input

Relay

Outputs

Power

GRD

S3

S4

Scom

L/+

N/±

Ain

Acom

R14

R11

R12

R24

R21

R22

Voltage

Inputs

N

Display

Module

Fiber

PM-II

Master

Module

Current

Inputs

LED Indicators

The Powermonitor II is equipped with two light

emitting diodes (LED) labeled “Power” and “OK.”

The Power LED illuminates when suf ficient power is

applied to the device. The OK LED flashes when the

device is initially powere d; this indicates that the

device is running internal self tests. After the OK

LED flashes and the internal self tests pass, the OK

LED remains illuminated indicating that the device is

in good operating conditi on. If the OK LED does not

remain illuminated, this ind icates that an internal

self-test did not pass and service is needed (refer to

Chapter 3, Field Service Considerations ).

Figure 2.16 LED Indicators

Note: Status Input #4 can be configured for

external demand pulse input. See Table 4.2

on page 4-9, for informtion.

1403-IN001A-US-P

Page 30

2-18 Installation

L1/+

L1/-

Local Frame Ground

Wiring of Display Module

Note: All ground wires should be kept as short as

possible; 30cm (12 in.) or less is suggested.

Power

The Display Module can be operated on eithe r AC or

DC power. Two models have been developed to

operate on various AC/DC voltage ranges as defined

in Table 2.4. A single, three-position connector is

provided for all power connections to the Display

Module.

component of the next unit and repeated for each

additional module until th e ri ng is completed. Figure

2.17 shows a typical layout of the fiber optic cabling

between one Master Module and three Display

Modules. Fiber optic cable assembly specifications

are given in Table 2.5 on page 2-18.

Important:Always maintain furnished rubber plugs

in the transm itter and receiver when

cable end connectors are not in place.

This helps prevent dirt from

contaminating the transm itter or

receiver.

Figure 2.17 Fiber Optic Communications between a Bulletin

1403 Master Module and Three Display Modules

Table 2.4 Display Module Voltage Ratings

Cat. No./

Voltage Range

1403-DMA/High

Voltage

1403-DMB/Low

Voltage

Terminal Block Wire Sizes and Screw Torque

Values

All terminal block wire sizes and terminal block

screw torque values are shown in Appendix C,

Technical Specifications .

Fiber Optics

The Powermonitor II communications architecture

consists of a fiber optic ring between the Bulletin

1403 Master Module and up to three Display

Modules. The black transmitt er component ( TX) of a

unit must be connected to the blue receiver (RX)

AC Voltages/DC Voltages

(+10% to -20%)

120 VAC, 240 VAC / 125 VDC, 250 VDC

12 V A C , 24 VAC / 12 VDC, 24 VDC, 48 VDC

Table 2.5 Fiber Optic Cable Assembly Specifications

Parameter Minimum Maximum

Cable Length:

Distance between

two adjacent devices

Minimum inside bend

radius

25 cm (approx. 10 in.)

shortest Allen-Bradley

standard

25.4mm (1 in.) Any bends

with a shorter inside radius

can permanently damage

the fiber optic cable. Signal

attentuation increases with

decreased inside bend

radii.

500 m

(1650 ft.)

N/A

ATTENTION: Any bend in a fiber

optic cable assembly with an inside

!

radius of less than 25.4 mm (1 in.)

may permanently damage the fiber

optic cable assembly.

1403-IN001A-US-P

Page 31

Installation 2-19

Fiber Optic Cable Assembly Strain Relief

A strain relief feature at the rear of the Display

Module and a wire tie are provided for securing the

fiber optic transmit and receive cable assemblies. Use

the strain relief feature to protect the fiber optic

connections at the rear of the Display Module. Coil

each fiber optic cable into an approximat ely one inc h

diameter loop and secure each loop to the rear of the

Display Module with the wi re tie provi ded per Figur e

2.18, Figure 2.19, and Figure 2.20.

Figure 2.18 Fiber Optics Strain Relief

2. Push the wire tie into the slot and force it out of

the second, adjacent slot.

Figure 2.20 Fiber Optics Strain Relief

3. Install and secure both fiber optic cables. The

cables should be coiled into one inch minimum

diameter loops and secured with the wire tie.

1. Insert the wire tie into the slot on the Display

Module’s rear cover.

Figure 2.19 Fiber Optics Strain Relief

Cat. No. Explanation and Accessories

for the Display Module Cat. No. explanation and a

listing of all fiber optic accessories.

Additional Information

For addition al information regarding the use of the

Display Module to configure the Master Module,

refer to Chap ter 4, General Operation.

1403-IN001A-US-P

Page 32

2-20 Installation

Communication Connections

The Powermonitor II Master Module uses a

communications connector for all Communications

Cards. This Communications Card connector allows

different communication card types to be used to

provide the appropriate protocol for a specific

system. For example, Cat. No. 1403-NSC is used f or

Allen-Bradley DF-1 serial and R I/O

communications. (Refer to Publication 1403-5.1,

Smart Communications Card Instruction Sheet for

specific communicat ion info rmat ion.) Cat. No. 1403NENET is used for Ethernet communica tions. (Refer

to publication 1403-5.3, Ethernet Communications

Card Instruction Sheet for specific communication

information.) Cat. No. 1403-NDNET is used for

DeviceNet communications. (Refer to publication

1403-5.4, DeviceNet Communications Card

Instruction Sheet for specific communic ation

information .)

Figure 2.21 Smart Communications Card

Figure 2.22 Ethernet Communication Card

Figure 2.23 DeviceNet Communication Card

1403-IN001A-US-P

Page 33

Chapter

3

Maintenance

Battery Instal lation and Replacement Procedures

Installation

A TTENTION: This procedure may

be conducted with fu ll elect rical power

!

Note: For proper operation, the device should not

1. Remove the closure plate on the top face of the

Master Module per Figure 3.1. Electric al power is

normally connected to the Master Module.

applied to the Master Module. Use

extreme caution when installing the

lithium battery into your Bul letin 1403

Master Module. Fai lure t o use ex treme

caution can lead to personal injury or

death, property damage, or economic

loss.

be powered for an extended period of time

without a battery installed.

Figure 3.1 Battery Extractor Extended for Battery

Installation

Master Module shown with

closure plate removed.

Lithium battery is ready for

installation and the battery

extractor is extended.

2. Gently pull the retaining tab from its slot, then

unfold the battery extractor to completely expose

the battery holder.

3. Install the lithium battery noting the correct

polarity within the battery holder. Note that the

battery must be installed over top of the battery

extractor flap. Ensure th at the lithium battery is

securely held in place within the battery holder.

Refold the battery ext ractor over top of t he lithium

battery and insert the retaining tab back into the

slot per Figure 3.2.

1403-IN001A-US-P

Page 34

3-2 Maintenance

Figure 3.2 Master Module with Battery Installed

Removal

ATTENTION: When installing or

removing the battery within the

!

1. Remove the closure plate on the top face of the

Master Module with extreme caution per Figure

3.1. Electrical power i s normally connected to the

Master Module.

2. Gently pull the retaining tab of the battery

extractor from its slot, then unfol d and extend the

battery extractor upward or a way fr om the Maste r

Module as shown in Figure 3.3 to completely

expose the battery in its holder.

3. Gently pull upwards on th e battery ex tractor ta b to

remove the battery from its holder per Figure 3.3.

Bulletin 1403 Master Module, take

care not to come into contact with

metallic surfaces if power is applied.

4. Reinstall the access cover plate on the top face of

the Master Module.

5. A command should be issued to reset the real time

clock and clear the battery usage counter via the

Display Module or the Communications Card.

ATTENTION: Risk of fire or bur ns.

Do not recharge, disassemble, heat

!

!

above 212× F, or incinerate. Keep

battery out of reach of chil dren and in

original package until ready to use.

Dispose of used batteries promptly.

Never put batteries in mouth. If

swallowed, contact your physician or

local poison control center.

ATTENTION: Replace battery with

Allen-Bradley Cat. No. 1403-BA

only. Use of another battery may

present risk of fire or explosion.

Figure 3.3 Battery Extractor Extended for Battery Removal

1403-IN001A-US-P

Page 35

ATTENTION: The battery is held

under pressure within its holder and

!

4. Refer to Battery Installation and Replacement

Procedures on page 3-1 for installation of a new

battery.

5. Reinstall the access cover plate on the top face of

the Master Module.

may be forcefully ejected upon

extraction.

Disposal of Discharged Lithium Batteries

In the United States, transportation of depleted

lithium batteries for disposal is controlled by the

Code of Federal Regulations, Title 49. Depleted

lithium batteries are defined by the extent that the

open circuit voltage is less than the lower of:

2.0 volts or

•

Two-thirds of the voltage of a fully charged

•

battery

Maintenance 3-3

1. Turn off all electric al power supp lied to the

Master Module and Display Module.

2. Clean the Master Module with a dry, anti-static,

lint-free cloth. Remove all dust and any

obstructions from the cooling air vents on the

upper, lower, and ends of the module. Ensure that

the nameplate is clean and in good condition.

3. Clean the Display Module with a dry, anti-static,

lint-free cloth. Remove all dust and any foreign

material(s) from the exterior of the module.

Ensure that the graphic front panel overlay and

back nameplate are clean and in good condition.

Field Service Considerations

If the Powermonitor II requires servicing, please

contact your nearest Allen-Bradley Sales Office. To

minimize your inconvenience, the initial installation

should be performed in a manner which makes

removal easy.

Check the Code of Federal Regulations, Title 49 or

local regulations regarding the current methods and

procedures for the disposal of lithium batteries.

Calibration

The calibr ation interval for the Powermonitor II

depends on the user’s accuracy requirements. To

meet general operating requirements, regular

recalibration is not necessary.

Contact your nearest Allen-Bradley Sales Office for

calibration or servi ce inf orma ti on.

Cleaning Instructions

A TTENTION:

•

Disconnect and lock out all power sources

!

and short all current transformer secondaries

before servicing. Failure to comply with these

precautions can lead to personal injury or

death, property damage or economic loss.

•

Please follow appropriate Electrostatic

Sensitive Discharge (ESD) procedures during

cleaning.

1. A CT shorting block should be provided to allow

the Powermonitor II Master Module current

inputs to be disconnected without open circuiting

the user supplied CTs. The shorting block should

be wired to prevent any effect on the external

protective relays.

2. All wiring should be routed to allow easy

maintenance at connections to the Powermonitor

II terminal strips, the Powermonitor II rear cover,

and the Powermonitor II itself.

ATTENTION: A CT circuit must not

be opened with primary curre nt present.

!

Wiring bet ween t he CTs should include

a terminal b lock for shorting the CTs.

Open CT secondaries will produce

hazardous voltages, which can lead to

personal injury or death, property

damage, economic loss, or CT failure.

1403-IN001A-US-P

Page 36

3-4 Maintenance

1403-IN001A-US-P

Page 37

Chapter

4

General Operation

General Functionality

The Display Module acts as a simple terminal that

allows a user to easily view metering parameters or

change configuration items. This is accomplished by

using three modes of operation: Display mode,

Program mode, and Edit mode.

Display mode allows any user to view any of the

measured parameters that the Powermonitor II

provides including metering information, harmonic

analysis (1403-MM only), and logging information.

The user also has the option of selecting default

screens which are displayed at power-up or after 30

minutes of non-activity.

Program mode allows a privileged user to issue

commands or select a parameter to modify. Program

mode provides a basic security system where each

Powermonitor II is pass word pro tecte d, and onl y one

entity can m odify a Powermonitor II; an entity

includes one of the three possible Display Modules

or the Smart Communicatio n Card. When a u ser is i n

Program Mode, a flashing “P” is displayed at the

bottom right-hand corner of the Display Module.

Edit mode allows the privileged user to mo dify the

selected parameters. When a user is in Edit mode, the

parameter being modified flashes, and the flashing

“P” remains solid.

Key Functions

The Display Module has four keys located on its

front bezel: an Escape key, Up Arrow key, Down

Arrow key, and Enter key. These keys maintain their

same functionality for all of the Display M odule’s

modes making the Display Module easy to use. The

functionality of the four keys is shown in Figure 4.1.

Figure 4.1 Display Module Key Functionality

Escape Key Up Arrow Key Down Arrow Key Enter Key

Display Mode Returns to parent menu. Steps back to the previous

parameter/menu in the list.

Program Mode Returns to parent menu. Steps back to the previous

parameter/menu in the list.

Edit Mode Cancels changes to the

parameter, restores the

existing value, and returns

to Program mode.

Increments the parameter/

menu value.

Steps forward to the next

parameter/menu in the list.

Steps forward to the next

parameter/menu in the list.

Decrements the parameter

value.

Steps into a sub-menu or

sets as default screen.

Steps into a sub-menu or

selects the parameter to be

modified and changes to

Edit mode.

Saves the parameter

change to the Master

Module and returns to

Program mode.

1403-IN001A-US-P

Page 38

4-2 General Operation

New Password?

0000 P

New Password?

0000 P

Note: For additional information on measured

parameters listed in Chapter 4, refer to

Publication 1403-1.0.2, Bulleting 1403

Powermonitor II Tutorial.

Editing a Digital Parameter

1. Using the Display Module keys, move into

Program mode and display the parameter to be

modified. Notice the flashing “P” in the lower

right-hand corner.

New Password?

1234 P

4. After the desired parameter value is displayed,

press the Enter key to write the new value to the

Master Module and set the Display Module back

to Program mo de. Notice the “P” in the lowe r

right-hand corner is flashing, and the parameter

being modified is solid.

2. Set the Display Module into Edit mode by

pressing the Enter key. The “P” in the lower righthand corner remains solid, and the parameter

being modified is flashing.

3. Change the value of t he pa rameter by p ressi ng the

Up Arrow and Down Arrow keys until t he desir ed

parameter value is displayed. Notice the “P” in the

lower right-hand corner remains solid, and the

parameter being modified is still flashing.

New Password?

1234 P

5. In the event that an incorrect parameter is being

modified, pressing the Escape key returns the

original parameter value, do es not modify the

Master Module, and returns the Display Module

to Program mo de. Notice the “P” in the lowe r

right-hand corner is flashing, and the parameter

being modified is solid.

New Password?

0000 P

1403-IN001A-US-P

Page 39

Issuing a Command

Force Relay 1

{ or } P

Force Relay 1

{ or } P

1. Using the four Display Module keys, move into

Program mode and display the command to be

issued. Notice the flashing “P” in the lower righthand corner.

2. Set the Display Module into Edit mode by

pressing the Enter key. The “P” in the lower righthand corner remains solid, an d the command

option prompt is flashing.

General Operation 4-3

Force Relay 1

Energize P

4. After the desired parameter value is displayed,

press the Enter key to execute the command. The

selection prompt will reappear and the Display

Module is set back to Program mode. Notice the

“P” in the lower right-hand corner is flashing, and

the option prompt is solid.

3. Choose the option of the command by pressing

the Up Arrow and Down Arrow keys until the

desired option is displayed. Notice the “P” in the

lower right hand corner remains solid, and the

command option being selected is still flashing.

Force Relay 1

{ or } P

5. In the event that a command is to be aborted,

pressing the Escape key returns the Display

Module to Program mode, and the option prompt

is displayed. Notice the “P” in the lower righthand corner is flashing, and the option prompt is

solid.

Force Relay 1

{ or } P

1403-IN001A-US-P

Page 40

4-4 General Operation

Figure 4.2 Menu/Parameter Structure

Chart Key

Default

Screen

Level 1

Level 2

Level 3

Level 4

Select

Level 3

Metering

V / I

Level 4

3-phase L-N V / I

Phase 1 L-N V / I

Phase 2 L-N V / I

Phase 3 L-N V / I

Average L-N V / I

3-phase L-L Voltage

Phase 1-2 L-L V / I

Phase 2-3 L-L V / I

Phase 3-1 L-L V / I

Average L-L V / I

Aux/L4 V /

Freq/Phase Rotation

Pos/Neg Seq L-L Volt

Pos/Neg Seq Current

V / I % Phase Unbal.

Level 2

Metering

Power

3-phase Power W

T otal Power W

3-phase Rea. Pwr VAR

T otal Rea. Pwr VAR

3-phase APP. Pwr VA

T otal App. Pwr VA

3-phase PF

T otal/Dist/Disp PF

Default

Screen

Display

Meter

Metering

Σ

Power

kW Hours Forward

kW Hours Reverse

kW Hours Net