Page 1

Instruction Sheet

(Cat. No. 1403-DMA or 1403-DMB)

Figure 1. Display Module

Description

The microprocessor based Bulletin 1403 Display

Module, an optional input device, can be used to set up

and configure the Bulletin 1403 Master Module for

operation. This is accomplished through the Display

Module’s front panel which includes four tactile operator

buttons and a liquid crystal display. All communications

between the Display Module and Master Module is

conducted over a serial fiber optic link.

Installation and Orientation The Display Module can be

oriented in any position. The most typical orientation is

shown in Bulletin 1403 Powermonitor II Instruction

Sheet, Publication 1403–5.0, Figure B.1, Appendix B.

The Display Module is designed to fit into the protective

enclosure cutout with a minimum installation depth of

50.8 mm (2.0 in.) behind the mounting panel as shown in

Bulletin 1403 Powermonitor II Instruction Sheet,

Publication 1403–5.0, Figure B.2, Appendix B. The

recommended Display Module mounting hole pattern

and dimensions are defined in Bulletin 1403

Powermonitor II Instruction Sheet, Publication

1403–5.0, Figure B.3, Appendix B. Ensure that the

gasket provided is not contaminated with foreign matter

and is installed in the Display Module correctly. Install

the Display Module into the protective enclosure’s front

panel using the four M4 nut/lockwasher assemblies as

shown in Bulletin 1403 Powermonitor II Instruction

Sheet, Publication 1403–5.0, Figure B.4, in Appendix B.

Tighten the M4 nut/lockwasher assemblies to 0.9 to 1.1

Nm (8 to 10 lb-in.) Note: Eight flat washers are

provided for retrofit applications with larger hole sizes.

ATTENTION: Failure to comply with

these mounting requirements may cause

!

damage to the Display Module or

compromise the IP65 [NEMA/UL 508,

T ype 4X (Indoor)] degree of protection

per International Standard IEC 529.

Mounting of Display Module

Protective Enclosure A suitable enclosure should be

used to protect the Master Module from atmospheric

contaminants such as oil, moisture, dust, and corrosive

vapors or other harmful airborne substances. The

Display Module’ s gasketed front panel interface to the

protective enclosure is rated as an IP65 degree of

protection [National Electrical Manufacturer’s

Association (NEMA)/Underwriter’s Laboratories (UL)

508, T ype 4X (Indoor)] per International Standard IEC

529.

Wiring of Display Module

Power The Display Module can be operated on either

AC or DC power. Two models have been developed to

operate on various AC/DC voltage ranges as defined in

T able A. A single, three-position connector is provided

for all power connections to the Display Module.

Publication 1403-5.2 – September 1996

Page 2

Bulletin 1403 Powermonitor II Display Module2

Table A. Voltage Ratings

Cat. No./

Voltage Range

1403-DMA/High

Voltage

1403-DMB/Low

Voltage

AC Voltages/DC Voltages

(+10% to –20%)

120V/ 240V AC 50/60 Hz or 125V/250V DC

12V/24V AC or 12/24/48V DC

Terminal Block Wire Sizes and Screw T orque Values All

terminal block wire sizes and terminal block screw

torque values are shown in Bulletin 1403 Powermonitor

II Instruction Sheet, Publication 1403–5.0, Appendix C.

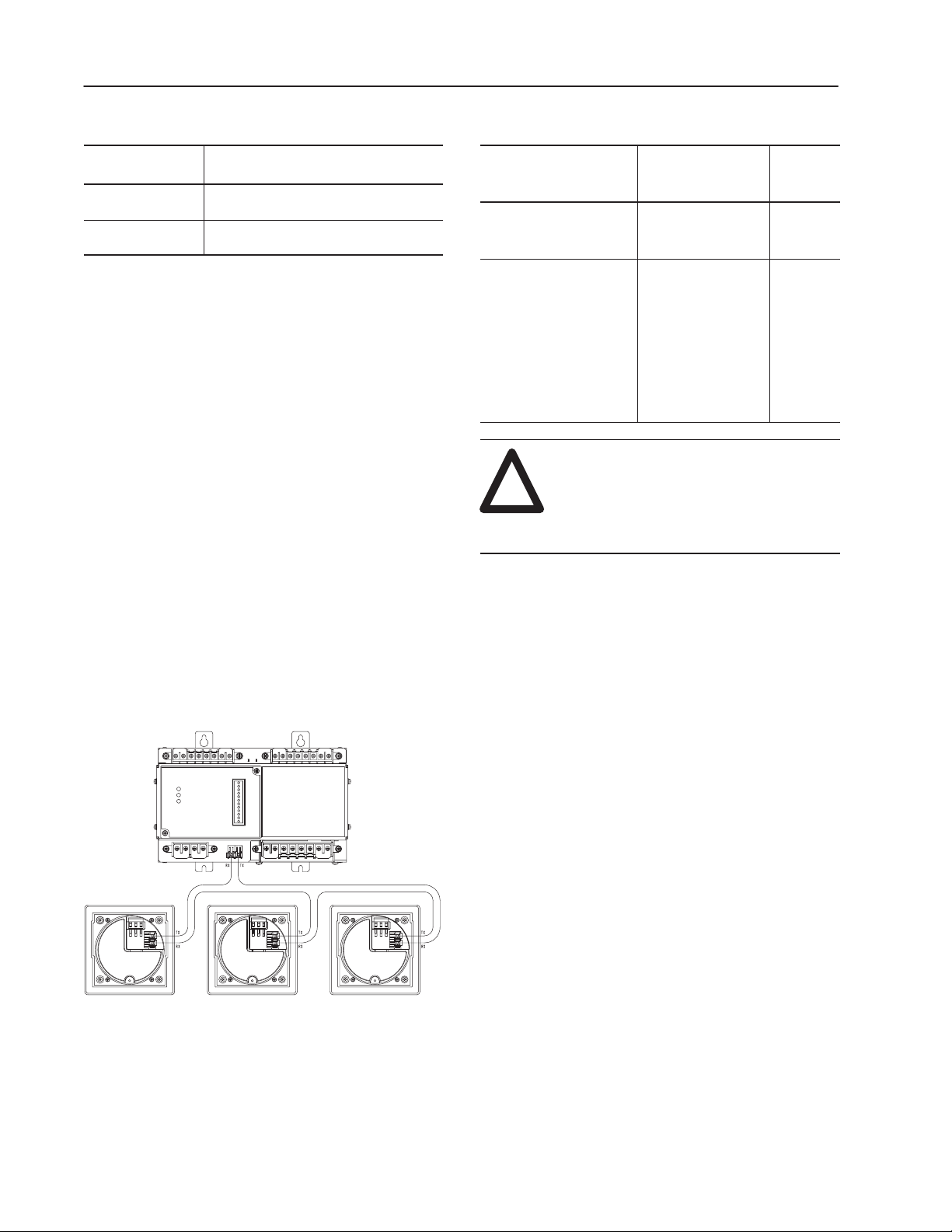

Fiber Optics The Powermonitor II communications

architecture consists of a fiber optic ring between the

Bulletin 1403 Master Module and up to three Display

Modules. The black transmitter component (TX) of a

unit must be connected to the blue receiver (RX)

component of the next unit and repeated for each

additional module until the ring is completed. Figure 2

shows a typical layout of the fiber optic cabling between

one Master Module and three Display Modules. Fiber

optic cable assembly specifications are given in T able B.

Table B. Fiber Optic Cable Assembly Specifications

Parameter

Cable Length:

Distance between two

adjacent devices

Minimum inside bend

radius

Minimum Cable

Length

25 cm (approx. 10 in.)

shortest Allen-Bradley

standard

25.4 mm (1 in.) Any

bends with a shorter

inside radius can

permanently damage

the fiber optic cable.

Signal attenuation

increases with

decreased inside

bend radii.

ATTENTION: Any bend in a fiber optic

cable assembly with an inside radius of

!

less than 25.4 mm (1 in.) may

permanently damage the fiber optic cable

assembly.

Maximum

Cable

Length

500 m

(1650 ft.)

N/A

Important: Always maintain furnished rubber plugs in

the transmitter and receiver when cable

end connectors are not in place. This will

help prevent dirt from contaminating the

transmitter or receiver.

Figure 2. Fiber Optic Communications between a Bulletin 1403

Master Module and Three Display Modules

Publication 1403-5.2 – September 1996

Page 3

Bulletin 1403 Powermonitor II Display Module 3

Fiber Optic Cable Assembly Strain Relief A strain relief

feature at the rear of the Display Module and a wire tie

are provided for securing the fiber optic transmit and

receive cable assemblies. Use the strain relief feature to

protect the fiber optic connections at the rear of the

Display Module. Coil each fiber optic cable into an

approximately one inch diameter loop and secure each

loop to the rear of the Display Module with the wire tie

provided per Figures 3, 4, and 5.

Figure 3. Fiber Optics Strain Relief

Figure 5. Fiber Optics Strain Relief

3. Install and secure both fiber optic cables. The cables

should be coiled into one inch minimum diameter

loops and secured with the wire tie.

Cat. No. Explanation and Accessories See Bulletin 1403

Powermonitor II Instruction Sheet, Publication

1403–5.0, Appendix B for the Display Module Cat. No.

explanation and a listing of all fiber optic accessories.

1. Insert the wire tie into the slot on the Display

Module’s rear cover.

Figure 4. Fiber Optics Strain Relief

2. Push the wire tie into the slot and force it out of the

second, adjacent slot.

Additional Information

Refer to these sections of Bulletin 1403 Powermonitor II

Instruction Sheet, Publication 1403–5.0, for additional

information:

• Chapter 4, General Operation – for configuring the

Master Module using the Display Module

• Appendix B, Mechanical Dimensions

• Appendix C, T echnical Specifications

Publication 1403-5.2 – September 1996

Page 4

Bulletin 1403 Powermonitor II Display Module4

Allen-Bradley, a Rockwell Automation Business, has been helping its customers improve

productivity and quality for more than 90 years. We design, manufacture and support a broad

range of automation products worldwide. They include logic processors, power and motion

control devices, operator interfaces, sensors and a variety of software. Rockwell is one of the

world’s leading technology companies.

Worldwide representation.

Argentina • Australia • Austria • Bahrain • Belgium • Brazil • Bulgaria • Canada • Chile • China, PRC • Colombia • Costa Rica • Croatia • Cyprus • Czech Republic •

Denmark • Ecuador • Egypt • El Salvador • Finland • France • Germany • Greece • Guatemala • Honduras • Hong Kong • Hungary • Iceland • India • Indonesia •

Ireland • Israel • Italy • Jamaica • Japan • Jordan • Korea • Kuwait • Lebanon • Malaysia • Mexico • Netherlands • New Zealand • Norway • Pakistan • Peru •

Philippines • Poland • Portugal • Puerto Rico • Qatar • Romania • Russia–CIS • Saudi Arabia • Singapore • Slovakia • Slovenia • South Africa, Republic • Spain •

Sweden • Switzerland • Taiwan • Thailand • Turkey • United Arab Emirates • United Kingdom • United States • Uruguay • Venezuela • Yugoslavia

Allen-Bradley Headquarters, 1201 South Second Street, Milwaukee, WI 53204 USA, Tel: (1) 414 382-2000 Fax: (1) 414 382-4444

Publication 1403-5.2 – September 1996 40055-163-01 (A)

Publication 1403-5.2 – September 1996

Copyright 1996 Allen-Bradley Company, Inc. Printed in USA

Loading...

Loading...