Page 1

Allen-Bradley

ALLEN-BRADLEY

Line

Synchronization

Module

(Bulletin 1402 LSM)

Installation

and Operation

Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. “Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls” (Publication SGI-1.1)

describes some important differences between solid state equipment and

hard–wired electromechanical devices. Because of this difference, and also

because of the wide variety of uses for solid state equipment, all persons

responsible for applying this equipment must satisfy themselves that each

intended application of this equipment is acceptable.

In no event will the Allen-Bradley Company be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, the Allen-Bradley Company cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Allen-Bradley Company with respect to use

of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of the Allen-Bradley Company is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

!

damage, or economic loss.

Attentions help you:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is especially important for successful

application and understanding of the product.

PLC and PLC–5 are registered trademarks of Allen-Bradley Company, Inc.

ControlView is a trademark of the Allen-Bradley Company, Inc.

Page 3

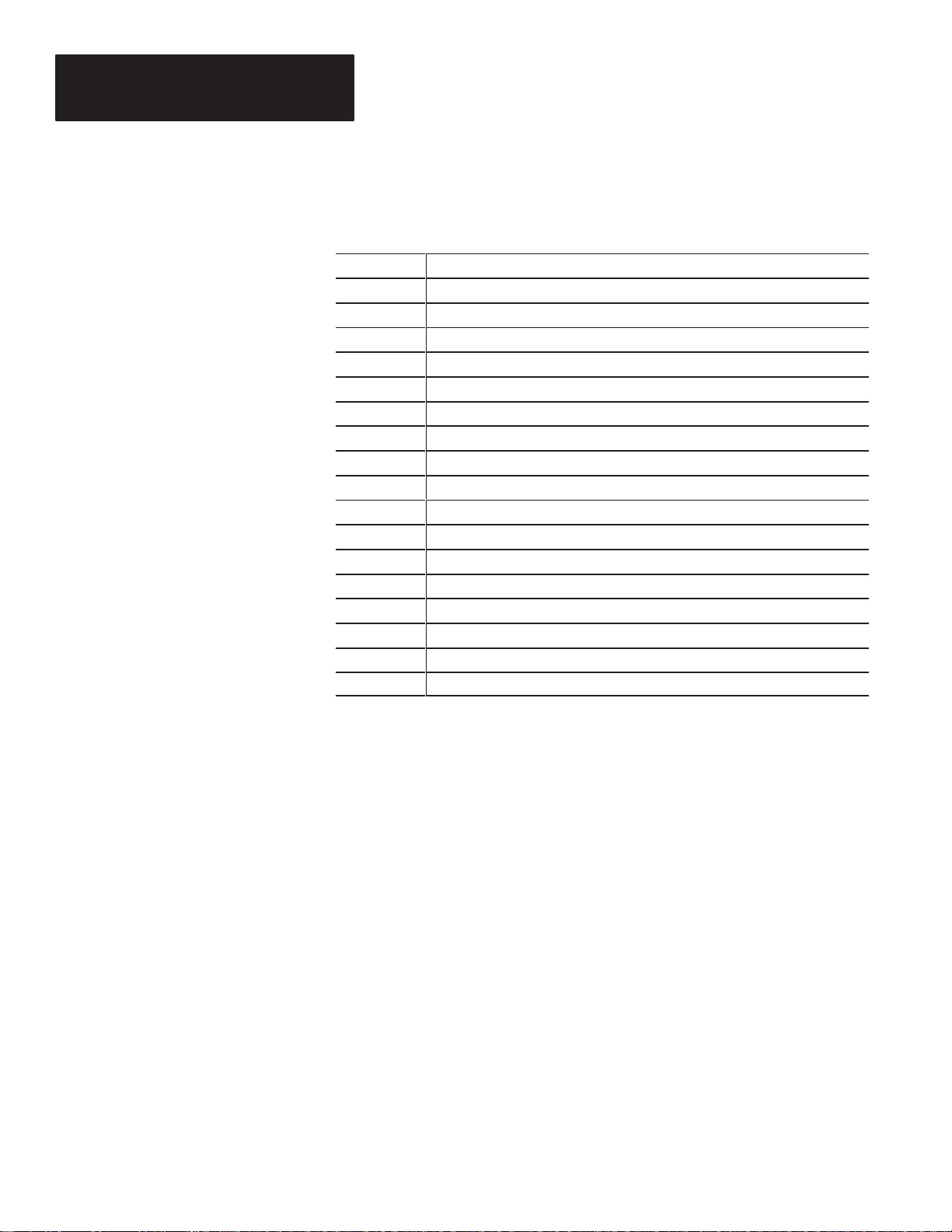

Table of Contents

Product Description 1–1.

. . . . . . . . . . . . . . . . . . . . . . . . .

Chapter Objectives 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Description 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Synchronization and Load Share Errors 1–2. . . . . . . . . . . . . .

Measurements 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Configuration 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 2–1.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Enclosure 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chassis Grounding 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Swing Arm 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prevent Electrostatic Discharge 2–2. . . . . . . . . . . . . . . . .

PT and CT Transformer Selection 2–3. . . . . . . . . . . . . . . . . .

PT Selection 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CT Selection 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PT and CT Wiring Connections 2–4. . . . . . . . . . . . . . . . . . . .

Connection for Three Phase WYE (Star),

4 Wire Systems 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection for Three Phase WYE (Star),

3 Wire Systems 2–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection for Three Phase Delta,

3 Wire Systems with 3 PT’s & 3 CT’S 2–5. . . . . . . . . . . .

Connection for Three Phase Open Delta,

3 Wire Systems with 2 PT’s & 3 CT’S 2–5. . . . . . . . . . . .

Connection for Three Phase Open Delta,

3 Wire Systems with 2 PT’s & 2 CT’S 2–5. . . . . . . . . . . .

Neutral Connection 2–5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Current Transformer Connections 2–6. . . . . . . . . . . . . . .

Maintenance 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration 2–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Field Service Considerations 2–6. . . . . . . . . . . . . . . . . . . . . .

General Operation 3–1.

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter Objectives 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operational Characteristics 3–1. . . . . . . . . . . . . . . . . . . . . . .

Functional 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Synchronization 3–4. . . . . . . . . . . . . . . . . . . . . . . . . .

Power Monitoring 3–6. . . . . . . . . . . . . . . . . . . . . . . . .

Load Sharing 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self–test 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Update Rate 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accuracy 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 4

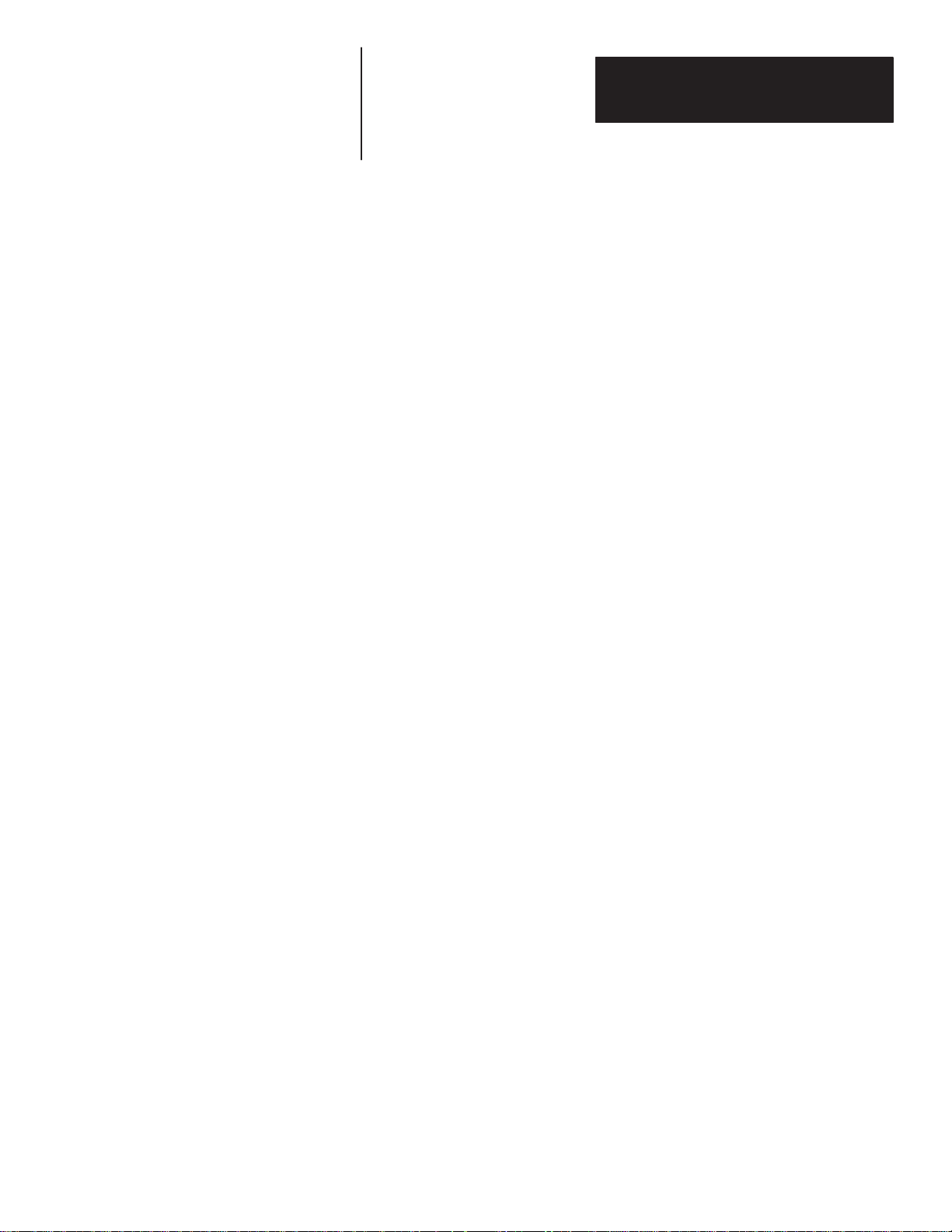

T

able of Contents

PLC Interface 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Discrete I/O Interface 3–9. . . . . . . . . . . . . . . . . . . . . . . . .

Discrete Outputs (From the PLC Processor) 3–10. . . .

Discrete Inputs (To the PLC Processor) 3–10. . . . . . . .

Block Transfer Data Interface 3–10. . . . . . . . . . . . . . . . . . .

Configuration Software Support 3–11. . . . . . . . . . . . . . . . .

6200 Software 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Application Information 4–1.

. . . . . . . . . . . . . . . . . . . . . .

Overview 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modes of Operation 4–1. . . . . . . . . . . . . . . . . . . . . . . . . .

Monitor Only 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Monitor with Load Share 4–1. . . . . . . . . . . . . . . . . . .

Synchronization and Monitor 4–1. . . . . . . . . . . . . . . .

Synchronization and Monitor with Load Share 4–2. .

Interfacing to the LSM 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Transfer Communications 4–2. . . . . . . . . . . . . . . .

Configuration 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acquiring Data From the LSM 4–4. . . . . . . . . . . . . . .

Discrete Input / Output Control of the LSM 4–4. . . . . . . .

Discrete Outputs From The PLC–5 4–4. . . . . . . . . . .

Discrete Inputs to the PLC–5 4–6. . . . . . . . . . . . . . . .

Ladder Program Description 4–8. . . . . . . . . . . . . . . . . . . . . .

Data Files Used 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessing BTR Data from PLC Ladder 4–11. . . . . . . . . . .

Catalog Number Explanation A–1.

. . . . . . . . . . . . . . . . . . .

Line Synchronization Module A–1.

Block Transfer and Discrete I/O Definition B–1.

Sample Ladder Listing C–1.

. . . . . . . . . . . . . . . . . . .

. . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

Line Synchronization Module

Mechanical Dimensions D–1.

Bulletin 1402 Technical Specifications E–1.

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

CSA Hazardouis Location Approval E–2. . . . . . . . . . . . . . . .

Compliance to European Union Directives E–4. . . . . . . . . . .

ii

Page 5

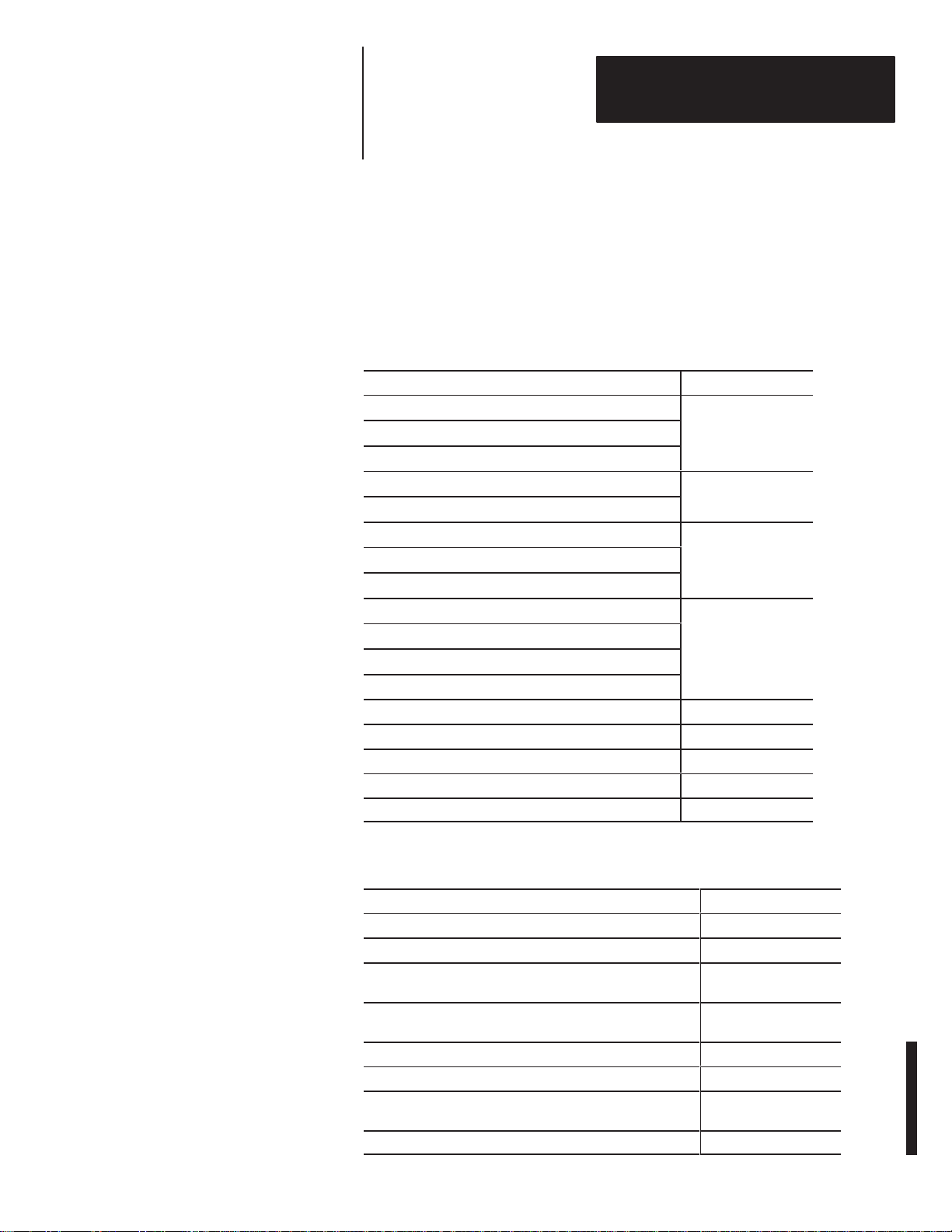

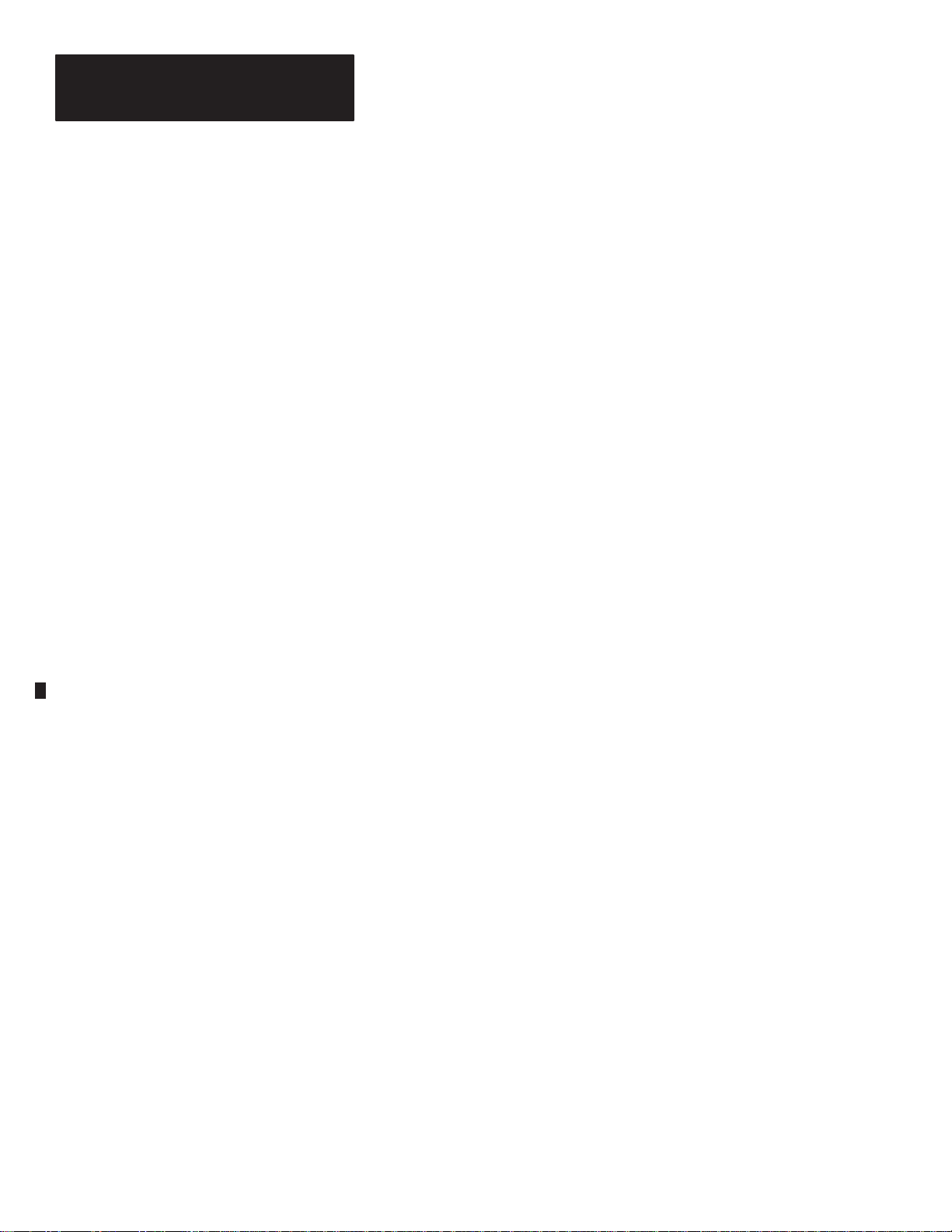

Using This Manual

Preface

A–B

What This Manual Contains

Review the table below to familiarize yourself with the topics contained in

this manual.

For information about: Refer to chapter:

Product features and System applications

Synchronization Functions

Extensive Array of Monitoring Information

Installing the Line Synchronization Module

Wiring and Transformer Selection

Operational Characteristics

PLC Interface

Configuration Software Support – 6200 Software

Modes of Operation

Block Transfer Communications

Configuration Information

Ladder Program Description

Catalog Number Explanation Appendix A

Block Transfer and Discrete I/O Definition Appendix B

Sample Ladder Listing Appendix C

Mechanical Dimensions Appendix D

Technical Specifications Appendix E

1

2

3

4

For More Information on Additional Power Quality Products

For this information: Refer to:

Catalog Number 1400–PD Installation and Operation Manual Publication 1400–5.2

Catalog Number 1400–SP Installation and Operation Manual Publication 1400–801

Installing the Communications Card Instructions

Catalog Number 1400–DCU

RS–232C and RS–485 Convertor Instructions

Catalog Number 1400–CC

LSM Application Notes Publication 1402Catalog Number 1403-MM Powermonitor II Instruction Sheet Publication 1403-5.0

Catalog Number 1003-NSC Smart Communications Card

Instruction Sheet

Powermonitor II Tutorial Publication 1403-1.0.2

Publication

1400–5.0

Publication

1400–5.1

Publication 1403-5.1

i

Page 6

Preface

Using This Manual

Terms and Conventions

In this manual, the following terms and conventions are used:

Abbreviation Term

AWG American Wire Gage

BTR Block Transfer Read

BTW Block Transfer Write

CT Current Transformer

EEPROM Electrically Erasable Programmable ROM

EMI Electromagnetic Interference

ID Identification

LED Light Emitting Diode

I/O Inputs and Outputs should be considered with respect to the PLC processor

LSM Line Synchronization Module

PT Potential Transformer

RAM Random Access Memory

RFI Radio Frequency Interference

RMS Root–mean–square

ROM Read Only Memory

VA Volt–ampere

VAR Volt–ampere Reactive

ii

Page 7

Chapter

Chapter

Objectives

Introduction

A–B

1

Product Description

After reading this chapter, you should be able to identify the product features

and system applications.

The Bulletin 1402, Line Synchronization Module (LSM), is designed to meet

the needs of manufacturers, system integrators, and users of 3 phase

alternators and cogeneration systems or for applications that require two

three–phase systems to be synchronized with each other. The module

provides means for automatic synchronization, load sharing, and high speed

power system monitoring.

General Description

The Line Synchronization Module (LSM) is a two slot 1771 form factor

module that fits into a standard Allen–Bradley 1771 I/O chassis. It performs

three functions:

1. Measures appropriate parameters from the two three–phase systems and

provides control and error signals to implement engine governor control

for synchronization.

2. Provides an analog output that is representative of the ratio of the power

being supplied by the alternator to the output rating of the alternator,

reads an analog input that represents the ratio of the total system load

being supplied to the total system capacity, and provides an error signal to

adjust the alternator for proper load sharing based on the instantaneous

load requirements.

3. Performs as a multi–function digital power monitor for the system.

These functions provide data and control signals which are communicated to

the PLC-5 via the 1771 backplane.

1–1

Page 8

Chapter 1

Product Description

Synchronization and Load Share Errors

In order to synchronize two three phase systems without high instantaneous

energy transfer, the voltage, frequency, and phase displacement of the two

systems must be matched. Kilowatt Load Sharing can be implemented by

matching the ratio of power system load to system capacity to the ratio of

actual alternator power to rated alternator power. The LSM provides the

following information to allow the user’s system to achieve the necessary

control actions.

• Voltage Match Error (in steps of 0.05 percent)

• Frequency Match Error, or slip (in steps of 0.01 Hz)

• Synchronizing Bus to Reference Bus Phase Match Error (in steps of 1

degree)

• Load Sharing Error (scalar quantity between 0.000 and 1.000)

• Synchronization Status

— Frequency Within Limits

— Voltage Within Limits

— Phase Within Limits

— Synchronization Mode Conflict Failure

— Phase Rotation Mismatch Failure (3 phase synchronization mode only)

— No Reference Bus Voltage Present Failure

— No Synchronizing Bus Voltage Present Failure

— Reference Bus Over Voltage Failure

— Synchronizing Bus Over Voltage Failure

1–2

Page 9

Chapter 1

Product Description

Measurements

Synchronizing Bus

Synchronizing Bus

Reference Bus

In addition to the synchronization function, the LSM provides an extensive

array of monitoring information for systems wired in Wye, Delta, or Open

Delta. The monitored data is shown below:

T

able 1.1

Current in Amps (per phase & neutral)

Average Current in Amps

Positive Sequence Current in Amps

Negative Sequence Current in Amps

Percent Current Unbalance

Voltage in Volts (per phase L–L, also L–N on 4–wire systems)

Average Voltage in Volts (L–L, also L–N on 4–wire systems)

Positive Sequence Voltage in Volts

Negative Sequence Voltage in Volts

Percent Voltage Unbalance

Frequency in Hz

Phase Rotation (ABC, ACB)

Power Factor in Percent (total, also per phase on 4–wire systems)

Watts (total & per phase on 4–wire systems)

VA (total & per phase on 4–wire systems)

VAR (total & per phase on 4–wire systems)

Power Consumption in kW Hours

Reactive Power Consumption in kVAR Hours

Demand (Amps, VA, & Watts)

Voltage per phase in Volts (per phase L–L, also L–N on 4–wire systems)

Average Voltage in Volts (L–L, also L–N on 4–wire systems)

Frequency in Hz

Phase Rotation (ABC, ACB)

Module Configuration

All voltage and current measurements are true RMS. The power

measurements are calculated from the instantaneous voltage and current

measurements. The remainder of the monitoring information is derived from

these values.

Before the LSM can perform its intended functions, it must be configured by

the user. The module is configured by providing the required data via a block

transfer to the module. The block transfer data can be entered into the PLC-5

manually or with the 6200 Version 4.4 I/O Configuration Software. The 6200

Software can also be used to monitor the operation of the module.

1–3

Page 10

Chapter 1

Product Description

1–4

Page 11

Chapter

Location

Enclosure

A–B

2

Installation

The Bulletin 1402 Line Synchronization Module (LSM) should be installed

in a Bulletin 1771 I/O chassis that is located in a dry, dirt free environment

away from heat sources and very high electric or magnetic fields. The

module is designed to operate in an ambient temperature between 0 and 60°

Celsius. The LSM is typically installed in a local rack in order to maximize

data transfer rates.

This equipment is classified as open equipment and must be installed

(mounted in an enclosure during operation as a means of providing safety

protection. The enclosure chosen should protect the LSM from atmospheric

contaminants such as oil, moisture, dust, corrosive vapors, or other harmful

airborne substances. A steel enclosure is recommended to guard against EMI

(Electromagnetic Interference) & RFI (Radio Frequency Interference).

Mounting

Power Supply

Chassis Grounding

The enclosure should be mounted in a position that allows the doors to open

fully. This will allow easy access to the wiring of the LSM and related

components so that servicing is convenient.

When choosing the enclosure size, extra space should be allowed for

associated application equipment such as, transformers, fusing, disconnect

switch, master control relay, and terminal strips.

The LSM mounts in two slots of a Bulletin 1771 Series B, I/O chassis.

Mounting dimensions will vary with the size of the chassis selected. Refer to

the appropriate 1771 literature for specific dimensions.

The LSM backplane power requirement is 1.1A at 5V DC. Refer to the

appropriate 1771 literature for additional information on available power

supply current.

For correct and reliable performance, the grounding recommendations

specified for Allen–Bradley PLC systems must be followed.

2–1

Page 12

Chapter 2

Installation

Swing Arm

Wiring

The LSM requires the use of a Cat. No. 1771-WC (10 position, gold

contacts) Swing Arm.

There are two sets of terminals associated with the LSM; a 10 position

swingarm and an 8 position fixed terminal block. All customer wiring to the

LSM is accomplished via these terminals on the front of the module. The

10–position swingarm is used to make all of the voltage (PT) connections to

the module as well as the Load Share connections. These connections are

designed to accommodate wire size 0.5 mm

2

mm

(14 AWG). The 8–position fixed terminal block is used to make all of

the current (CT) connections. These connections are designed to

accommodate gauge wire size 0.5 mm

3.25 mm

Phasing and polarity of the AC current and voltage inputs and their

relationship are critical for the correct operation of the unit. Figure 2.1

through Figure 2.5 shown on Pages 2–7 through 2–11 provide wiring

diagrams to help ensure correct installation.

Two (2) conductor shielded wire (22 gauge or greater) should be used for

Load Share wiring. The shield shall be grounded at the PLC Chassis ground

point only.

2

(12 AWG).

2

(22 AWG) through size 2.0

2

(22 AWG) through ring lugs size

Prevent Electrostatic Discharge

ATTENTION: Electrostatic discharge can damage integrated

circuits or semiconductors if you touch backplane connector pins.

!

Follow these guidelines when you handle the module:

• Touch a grounded object to discharge static potential.

• Wear an approved wrist-strap grounding device.

• Do not touch the backplane connector or connector pins.

• Do not touch circuit components inside the module.

• If available, use a static-safe work station.

• When not in use, keep the module in its static-shield box.

2–2

Page 13

Chapter 2

Installation

PT and CT Transformer Selection

For proper monitoring and synchronization, correct selection of current

transformers (CT’s) and potential transformers (PT’s) is critical. The

following paragraphs provide the information required to choose these

transformers. Also refer to transformer operational characteristics Pages 3–2

and “Factory Configuration Parameters” listed on Page B–2.

PT Selection

The LSM is designed for a nominal full scale input voltage of 120V AC. The

user must supply transformers to scale down the system L–N (Wye) or L–L

(Delta) voltage to the full scale input rating of the module. The PT’s should

be selected as follows:

• Wye (Star) Configuration – PT primary rating = L–N voltage or nearest

higher standard size. PT secondary rating = 120 Volts.

• Delta or Open–Delta Configuration – PT primary rating = system L–L

voltage. PT secondary rating = 120 Volts.

PT quality directly affects system accuracy. The PT’s must provide accurate

linearity and maintain the proper phase relationship between voltage and

current in order for the Phase Error, Volts, kW, and Power Factor readings to

be valid. Instrument accuracy Class 1 or better is recommended. The LSM

PT inputs represent a O.O2 VA burden.

CT Selection

The LSM uses current transformers (CT’s) to sense the current in each phase

of the power feed from the synchronizing voltage source, and may optionally

be included in the ground or neutral conductor. The precision of the selected

CT’s will directly affect the device accuracy.

The CT secondary should have a rating of 5A full scale and a burden

capacity greater than 3VA. The LSM Module CT Inputs represent a burden

of 0.0025VA.

ATTENTION: The CT primary rating is normally selected to be

equal to the current rating of the power feed protection device.

However, if the peak anticipated load is much less than the rated

!

system capacity, then improved accuracy and resolution can be

obtained by selecting a lower rated CT. Generally, the CT size

should be the maximum expected peak current +25%, rounded

up to the nearest standard CT size.

2–3

Page 14

Chapter 2

PT an

ing Connections

Installation

Other factors may affect CT accuracy. The length of the CT cabling should

be minimized because long cabling could contribute to excessive power load

on the CT and inaccuracy. The CT burden rating must exceed the combined

burden of the LSM plus cabling plus any other devices connected in the

measuring circuit (burden is the amount of load being fed by the CT,

measured in Volt–Amps calculated at 5A full scale.).

Overall accuracy is dependent on the combined accuracy of the Bulletin

1402, the CT’s, and the PT’s. Instrument accuracy Class 1 or better is

recommended.

ATTENTION: A CT circuit must not be opened under power.

Wiring between the CT’s and the LSM should include a terminal

!

block for shorting the CT’s. Open CT’s secondaries can produce

hazardous voltages, which can lead to personal injury or death,

property damage or economic loss.

d CT Wir

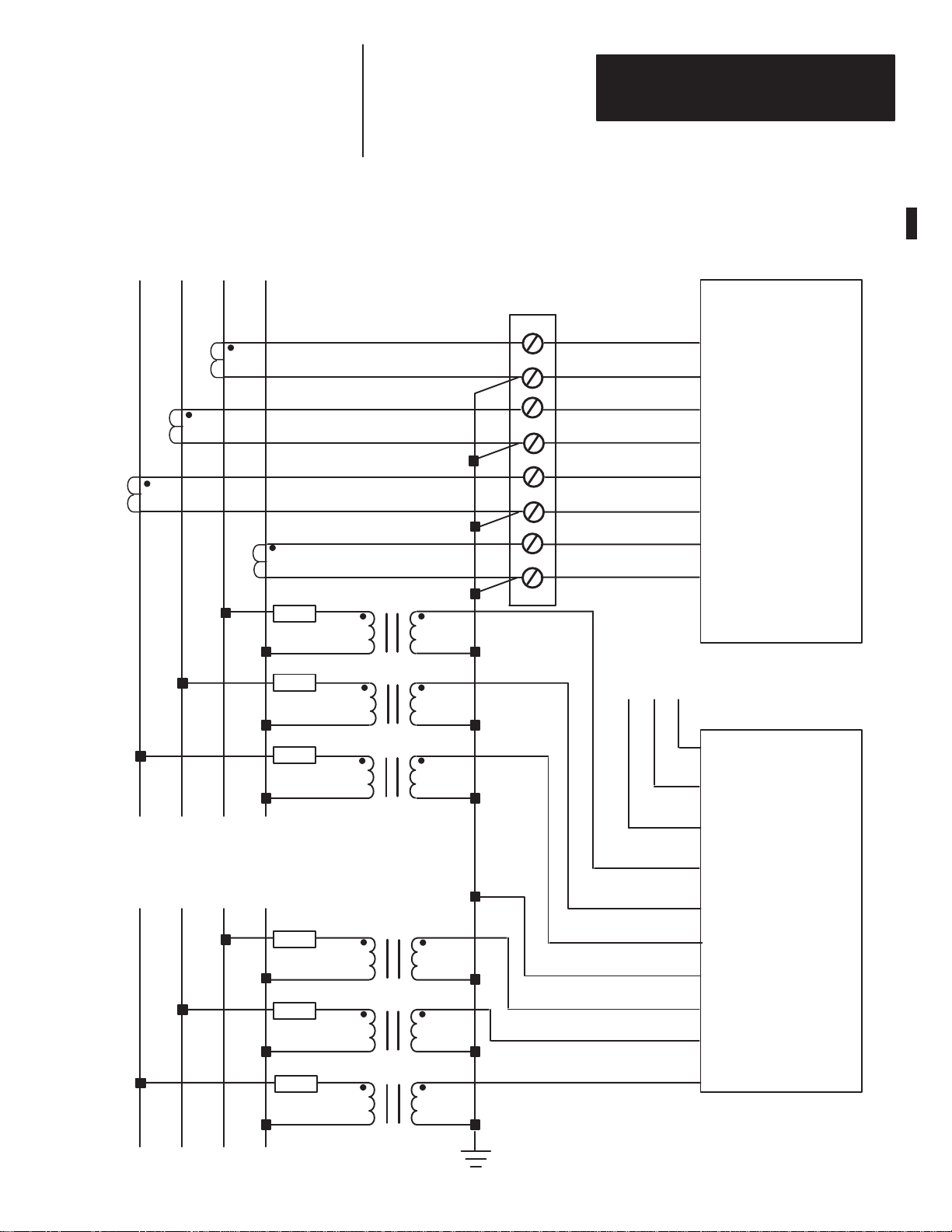

Connection for Three Phase WYE (Star), 4 Wire Systems

Figure 2.1 shown on Page 2–7 provides a wiring diagram for 4–wire WYE

(Star) systems. The “Voltage Mode” of the LSM should be set to “1” (as

described in Chapter 3, “General Operation”) for 4–wire WYE systems.

The LSM senses the line to neutral (or ground) voltage of each phase. The

PT primaries and secondaries must be wired in a WYE (Star) configuration

as shown in the figure. Voltage input leads should be protected by circuit

breakers or fuses at their source. If the power rating of the PT’s is over 25

Watts, secondary fuses should be used. Wiring and polarity marks must be

exactly as shown for correct operation.

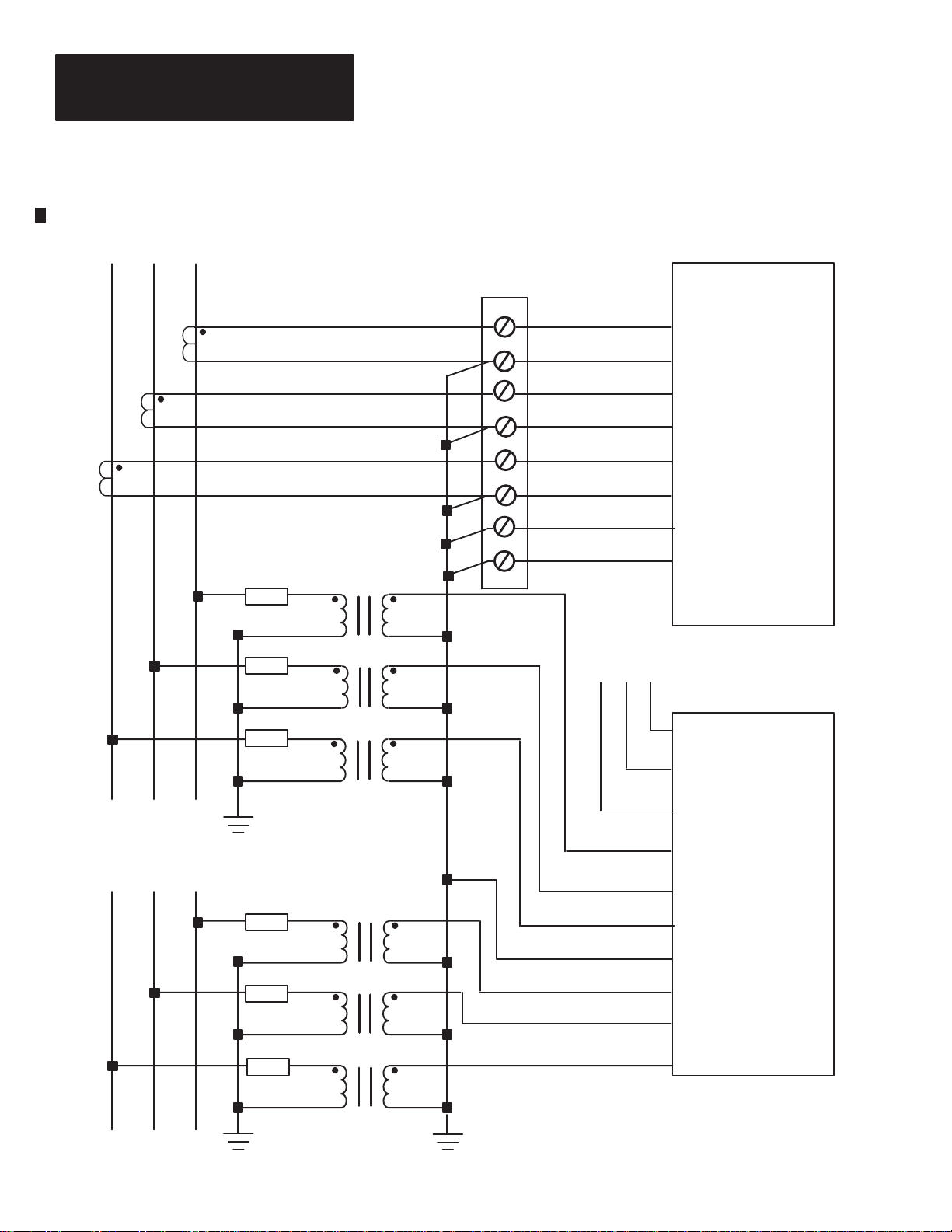

Connection for Three Phase WYE (Star), 3 Wire Systems

Figure 2.2 shown on Page 2–8 provides a wiring diagram for 3–wire WYE

(Star) systems. The “Voltage Mode” of the LSM should be set to “1” (as

described in Chapter 3, “General Operation”) for 3–wire WYE systems.

The LSM senses the line to neutral voltage of each phase. The PT primaries

and secondaries must be wired in a WYE (Star) configuration as shown in

the figure. Voltage input leads should be protected by circuit breakers or

fuses at their source. If the power rating of the PT’s is over 25 Watts,

secondary fuses should be used. Wiring and polarity marks must be exactly

as shown for correct operation.

2–4

Page 15

Chapter 2

PT an

ing Connections

Installation

d CT Wir

Continued

Connection for Three Phase Delta, 3 Wire Systems with 3 PT’s & 3 CT’S

When configured for ungrounded (floating) Delta operation, the LSM senses

the L–L voltages between each of the phases. The “Voltage Mode” of the

LSM should be set to “2” (as described in Chapter 3, “General Operation”).

Figure 2.3 shown on Page 2–9 provides the wiring diagram for this

configuration. Wiring and polarity marks must be exactly as shown for

correct operation.

Connection for Three Phase Open Delta, 3 Wire Systems with

2 PT’s & 3 CT’S

When configured for ungrounded or Open Delta operation, the LSM senses

the L–L voltages between each of the phases. The “Voltage Mode” of the

LSM should be set to “4” (as described in Chapter 3, “General Operation”).

Figure 2.4 shown on Page 2–10 provides the wiring diagram for this

configuration. Wiring and polarity marks must be exactly as shown for

correct operation.

Connection for Three Phase Open Delta, 3 Wire Systems with

2 PT’s & 2 CT’S

When configured for ungrounded (floating) Open Delta operation, the LSM

senses the L–L voltages between each of the phases. The “Voltage Mode” of

the LSM should be set to “4” (as described in Chapter 3, “General

Operation”). Figure 2.5 shown on Page 2–11 provides the wiring diagram for

this configuration. Wiring and polarity marks must be exactly as shown for

correct operation.

Neutral Connection

The voltage reference terminal, “Neutral”, of the LSM serves as the zero

voltage reference for voltage readings. A low impedance Neutral connection

is essential for accurate measurement. The length of the wire should be as

short as possible. It should be made using a dedicated size 2.0 mm

AWG) wire, or larger, to a point in close proximity to the LSM. This will

provide minimal voltage error due to other distribution voltage drops.

The connection point for “Neutral” is the point where the PT secondary leads

are common.

2

(14

2–5

Page 16

Chapter 2

Installation

Current Transformer Connections

The LSM is equipped with four CT inputs, designated I1 – I4. Inputs I1 – I3

are used to measure the current in the synchronizing circuit. These inputs are

wired as shown on Pages 2–7 through 2–11 in Figure 2.1 through Figure 2.5.

Input I4 is optional and is typically used to measure current in the neutral or

ground conductor. The primary rating for I4 can be different than the primary

rating for transformers I1 – I3. However, the secondary rating for all of the

CT’s must be 5 Amps.

Current connections may remain unused for a system that only performs

synchronization. Unused terminals should be wired to chassis ground for

noise immunity.

Maintenance

Calibration

Field

Service Considerations

The LSM does not require any special maintenance.

The calibration interval for the LSM depends on the user’s accuracy

requirements. To meet general operating requirements, regular calibration is

not necessary.

Contact your nearest Allen–Bradley Sales Office for calibration or service

information.

If the LSM requires servicing, please contact your nearest Allen-Bradley

Sales Office. To minimize your inconvenience, the initial installation should

be performed in a manner which makes removal easy.

1. A CT shorting block should be provided to allow the LSM current inputs

to be disconnected without open circuiting the user supplied CTs. The

shorting block should be wired to prevent any effect on the external

protective relays.

2. All wiring should be routed to allow easy maintenance at connections to

the LSM terminal strips, the swing-arm, and the LSM itself.

2–6

ATTENTION: A CT circuit must not be opened with primary

current present.. Wiring between the CT’s should include a

!

terminal block for shorting the CT’s. Open CT secondaries will

produce hazardous voltages, which can lead to personal injury or

death, property damage, economic loss or CT failure.

Page 17

Chapter 2

Installation

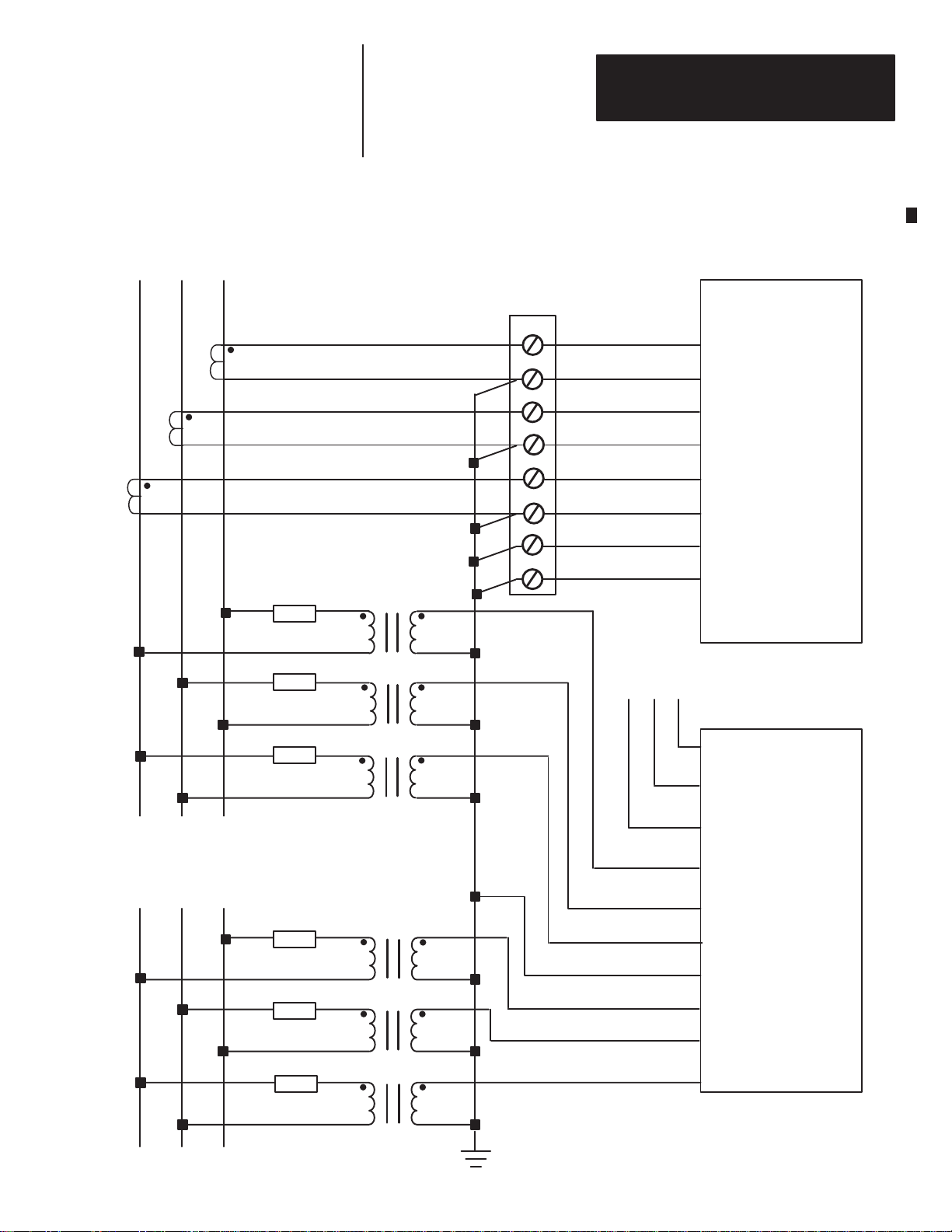

Synchronizing

L1 L2 L3 N

CT

CT

Bus V

oltage

CT

Fuse

Fuse

Fuse

Figure 2.1

PT

PT

PT

– Wiring Diagram for 4–Wire Wye Connection

Customer Supplied

CT Shorting Switch

or T

est Block

Load Share Circuit

1

L3+

2

L3–

3

L2+

4

L2–

5

L1+

6

L1–

7

Neutral +

Neutral –

8

A

Load Share +

0

Load Share –

LSM

CT Terminal Block

LSM

Swingarm

Reference Bus V

L1 L2 L3 N

oltage

Fuse

Fuse

Fuse

PT

PT

PT

NOTE: See Appendix E for CE compliant wiring requirements.

Customer Chassis

Ground

1

Load Share Shield

No Internal Connection

2

Synchronizing Bus V3

3

Synchronizing Bus V2

4

Synchronizing Bus V1

5

Neutral

6

Reference Bus V3

7

Reference Bus V2

B

Reference Bus V1

2–7

Page 18

Chapter 2

Installation

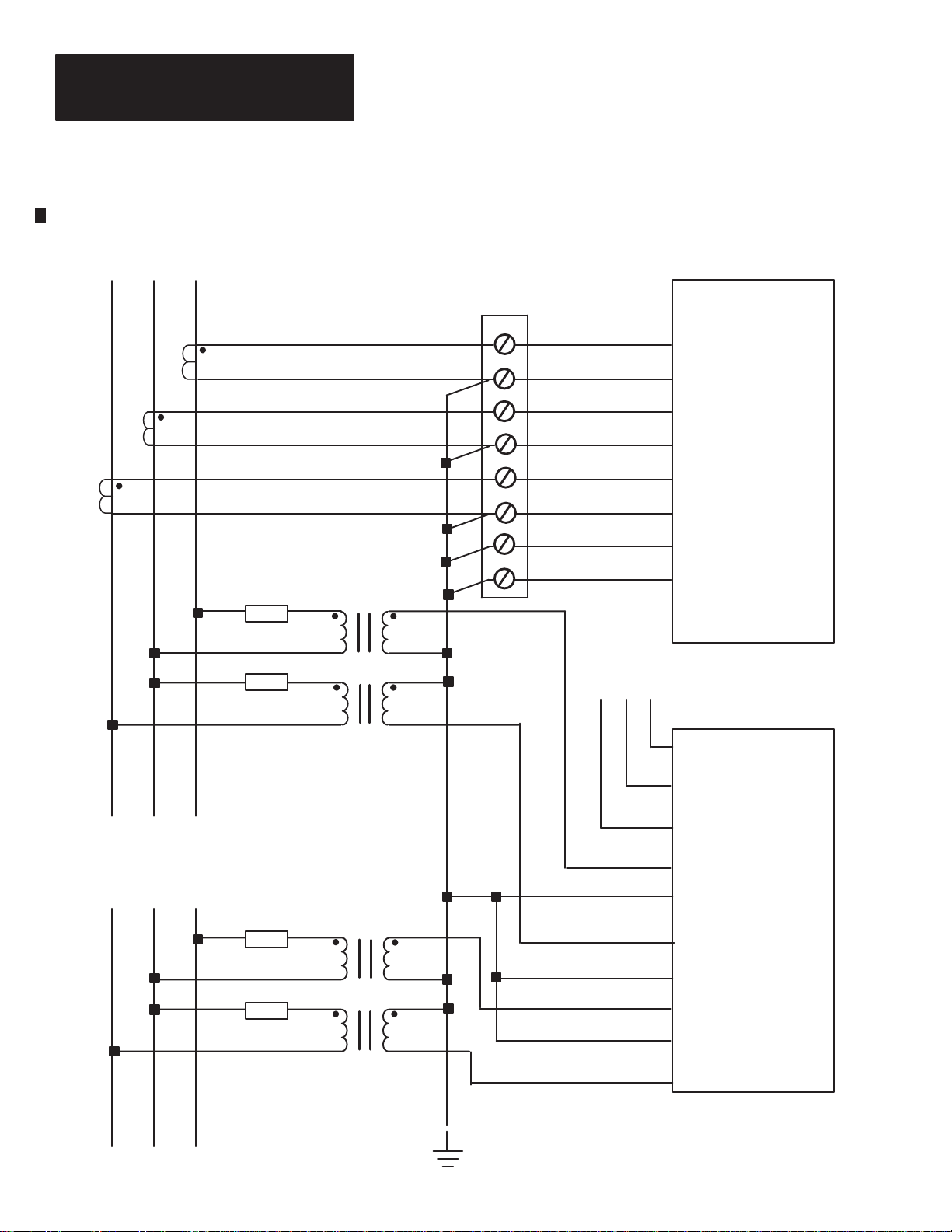

Synchronizing

L1 L2 L3

CT

Bus V

CT

oltage

CT

Fuse

Fuse

Fuse

Figure 2.2

PT

PT

PT

– Wiring Diagram for 3–Wire Wye Connection

Customer Supplied

CT Shorting Switch

est Block

or T

1

4

5

6

7

Load Share Circuit

A

L3+

2

L3–

3

L2+

L2–

L1+

L1–

Neutral +

Neutral –

8

Load Share +

0

Load Share –

LSM

CT Terminal Block

LSM

Swingarm

2–8

Reference Bus V

L1 L2 L3

oltage

Fuse

Fuse

Fuse

PT

PT

PT

NOTE: See Appendix E for CE compliant wiring requirements.

Customer Chassis

Ground

1

Load Share Shield

No Internal Connection

2

Synchronizing Bus V3

3

Synchronizing Bus V2

4

Synchronizing Bus V1

5

Neutral

6

Reference Bus V3

7

Reference Bus V2

B

Reference Bus V1

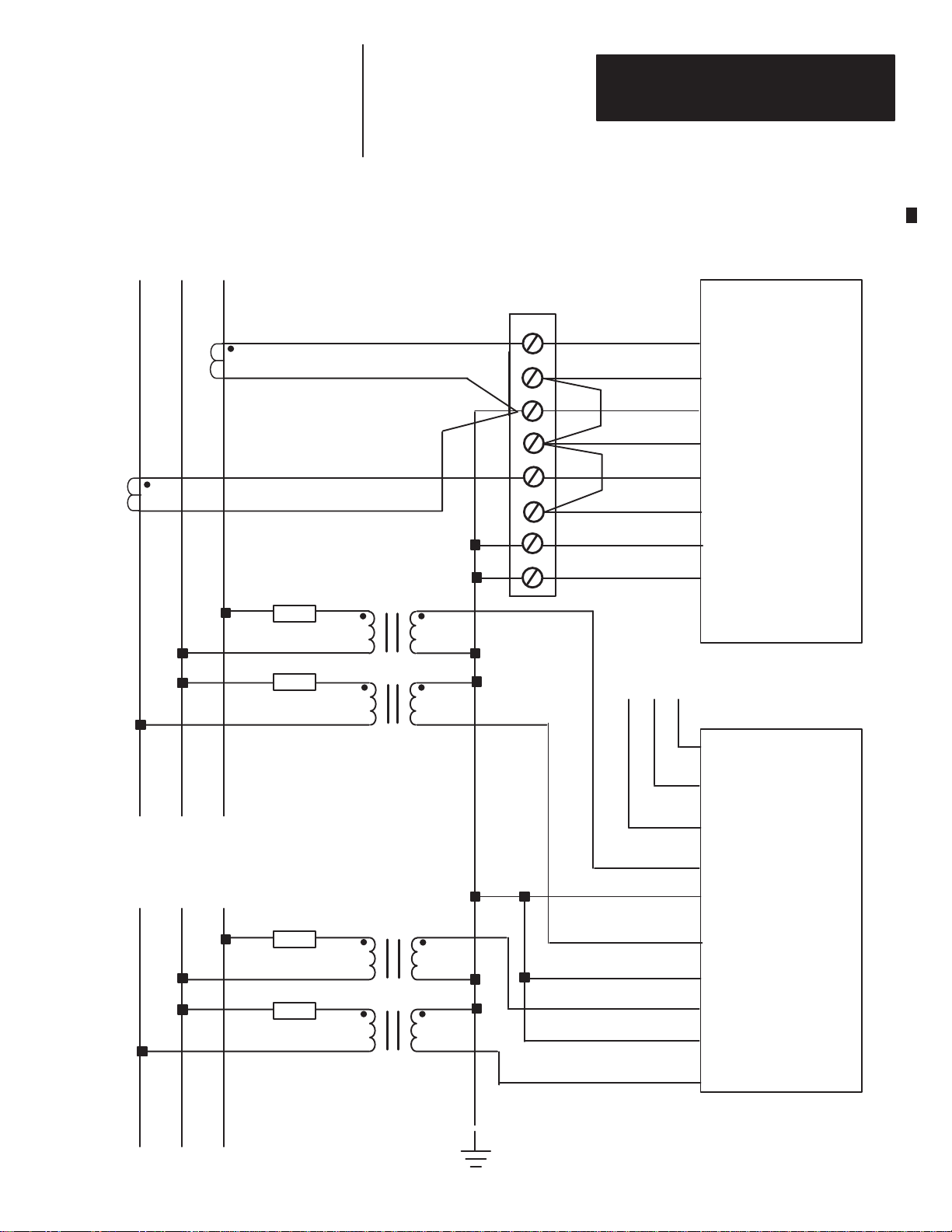

Page 19

Chapter 2

Installation

Synchronizing

L1 L2 L3

CT

Bus V

CT

oltage

CT

Fuse

Figure 2.3

PT

– Wiring Diagram for 3 Transformer Delta Connection

Customer Supplied

CT Shorting Switch

or T

est Block

1

2

3

4

5

6

7

8

L3+

L3–

L2+

L2–

L1+

L1–

Neutral +

Neutral –

CT Terminal Block

LSM

Reference Bus V

L1 L2 L3

oltage

Fuse

Fuse

Fuse

Fuse

Fuse

PT

PT

PT

PT

PT

NOTE: See Appendix E for CE compliant wiring requirements.

Customer Chassis

Ground

Load Share Circuit

A

0

1

2

3

4

5

6

7

B

LSM

Swingarm

Load Share +

Load Share –

Load Share Shield

No Internal Connection

Synchronizing Bus V3

Synchronizing Bus V2

Synchronizing Bus V1

Neutral

Reference Bus V3

Reference Bus V2

Reference Bus V1

2–9

Page 20

Chapter 2

Installation

Synchronizing

L1 L2 L3

CT

Bus V

CT

oltage

CT

Fuse

Figure 2.4

PT

– Wiring Diagram for 2 Transformer Open–Delta Connection

Customer Supplied

CT Shorting Switch

or T

est Block

1

2

3

4

5

6

7

8

L3+

L3–

L2+

L2–

L1+

L1–

Neutral +

Neutral –

LSM

CT Terminal Block

Reference Bus V

L1 L2 L3

oltage

Fuse

Fuse

Fuse

PT

PT

PT

NOTE: See Appendix E for CE compliant wiring requirements.

Customer Chassis

Ground

Load Share Circuit

A

0

1

2

3

4

5

6

7

B

LSM

Swingarm

Load Share +

Load Share –

Load Share Shield

No Internal Connection

Synchronizing Bus V3

Synchronizing Bus V2

Synchronizing Bus V1

Neutral

Reference Bus V3

Reference Bus V2

Reference Bus V1

2–10

Page 21

Chapter 2

Installation

Synchronizing

L1 L2 L3

CT

Bus V

oltage

CT

Fuse

Figure 2.5

PT

– Wiring Diagram for 2 Transformer Open–Delta Connection With 2 CT’

Customer Supplied

CT Shorting Switch

est Block

or T

1

2

3

4

5

6

7

8

L3+

L3–

L2+

L2–

L1+

L1–

Neutral +

Neutral –

LSM

CT Terminal Block

s

Reference Bus V

L1 L2 L3

oltage

Fuse

Fuse

Fuse

PT

PT

PT

NOTE: See Appendix E for CE compliant wiring requirements.

Customer Chassis

Ground

Load Share Circuit

A

0

1

2

3

4

5

6

7

B

LSM

Swingarm

Load Share +

Load Share –

Load Share Shield

No Internal Connection

Synchronizing Bus V3

Synchronizing Bus V2

Synchronizing Bus V1

Neutral

Reference Bus V3

Reference Bus V2

Reference Bus V1

2–11

Page 22

Chapter 2

Installation

2–12

Page 23

Chapter

ational

acteristics

Chapter

Oper

Objectives

Char

A–B

3

General Operation

This chapter:

• introduces the user to the controls and operation

• describes each function

• defines operating parameters

Functional

The LSM has six different modes of operation. These modes are described

below.

Configuration

Before the LSM can perform its intended functions, it must be configured by

the integrator/OEM or user. Configuration is accomplished by sending the

appropriate information to the module via the “Block Transfer Write”

mechanism. Configuration data is compared with acceptable values. The user

can obtain acknowledgment of the configuration data by using the “Block

Transfer Read” mechanism for access to the module’s response. If

out–of–range or illegal values were entered, an error indication that identifies

the illegal or out–of–range entries is returned. If the data is acceptable, an

acknowledgment indication is returned. The new configuration data is then

used to scale the monitoring data and to set up the synchronization and load

sharing functions.

Whenever new configuration data is sent to the LSM, all module functions

(synchronization, load–sharing, and monitoring) are terminated, and the

values for “Amps Demand”, “kVA Demand”, and “kW Demand” are cleared.

The values for “kW Hours” and “kVAR Hours” are maintained at the values

present before the new configuration data was sent. The new configuration

data is then evaluated. Upon acceptance of the new configuration data, the

module resumes normal operation.

A detailed description of the required configuration data follows. See “Block

Transfer Communications”, on Page 4–2 in the Application Information

chapter of this manual and Appendix B, “Block Transfer Tables and Discrete

I/O Definition”, for a detailed description of how the module performs block

transfers and how the associated data is organized.

3–1

Page 24

Chapter 3

ational

acteristics

General Operation

Oper

Continued

Char

Voltage Mode

This entry is used to indicate if the system being monitored is wired in a

WYE, a Delta, or an open Delta. A value of “1” will indicate a WYE

system, a value of “2” will indicate a three transformer Delta system, and

a value of “4” will indicate a two transformer Open Delta system.

Line–to–Neutral values will be provided only when a WYE is configured.

PT Primary Rating

This entry is used to indicate the primary voltage rating of the user

supplied potential transformers. This information is used for scaling

purposes. The value of this parameter must be between 120 and 115,000.

Line and Neutral CT Primary Ratings

These entries are used to indicate the primary ampere rating of the user

supplied line and neutral current transformers. This information is used

for scaling purposes. The value of this parameter must be between 5 and

10,000.

Synchronization Method

This configuration entry is used to indicate which method of

synchronization is to be implemented. A value of “0” indicates the

delayed acceptance window method.

3–2

ATTENTION: The following acceptance limit values must be

set to fit the customer applications.

!

Voltage Match Error Upper and Lower Acceptance Limits

These entries are used to specify the upper and lower acceptance limits

for matching Synchronizing Bus voltage to the Reference Bus voltage.

The value is specified in steps of 0.05% and must be between 0.00 and

25.00 percent.

Frequency Match Error Upper and Lower Acceptance Limits

These entries are used to specify the upper and lower acceptance limits

for matching Synchronizing Bus frequency to the Reference Bus

frequency. The value is specified in steps of 0.01 Hz and must be between

0.00 and 1.00.

Page 25

Chapter 3

ational

acteristics

General Operation

Oper

Continued

Char

Phase Match Error Upper and Lower Acceptance Limits

These entries are used to specify the upper and lower acceptance limits

for matching Synchronizing Bus phasing to the Reference Bus phasing.

The value is specified in degrees and must be between 0 and 45.

Acceptance Window Delay

This entry is used for the delayed acceptance window method of

synchronization. The value is specified in steps of 0.05 seconds and must

be between 0.00 and 10.00.

Maximum Synchronizing Bus Output Power

This entry is used to specify the power level at which the load sharing

output voltage will be at its maximum value. The ratio of the actual power

output to the value of this parameter is used to adjust the load sharing

output voltage. This value will be specified in kW and must be between 0

and 999,999.

Load Share Full–scale Voltage

This entry is used to specify the load share circuit’s full scale output

voltage. The value is specified in steps of 0.01 volts and must be between

2.00 and 4.00.

Load Share Excess

This entry is used to specify the threshold for initiating action to decrease

the Synchronizing Bus output power to the appropriate portion of the total

system load. The value is a scalar quantity between 0.000 and –0.500.

Load Share Deficit

This entry is used to specify the threshold for initiating action to increase

the Synchronizing Bus output power to the appropriate percentage of the

total system load. The value is a scalar quantity between 0.000 and

+0.500.

3–3

Page 26

Chapter 3

ational

acteristics

General Operation

Oper

Continued

Char

Demand Period

This entry is used to specify the desired period for demand measurement.

The value is specified in minutes and must be between 1 and 99.

Number Of Demand Periods

This entry specifies the number of demand periods that should be

averaged to determine the actual demand. The value must be between 1

and 15.

Synchronization

functionality of the synchronization process is based on the

The

synchronization discrete outputs from the PLC–5 received via the PLC

backplane. The “Initiate Synchronization” output from the PLC–5 begins the

synchronization process when it is asserted. It must remain asserted during the

entire process. If the initiate signal is removed, the synchronization process is

terminated. In addition to the initiate signal, one of the

“Auto–Synchronization”, “Check Synchronization”, or the “Permissive

Synchronization” discrete outputs from the PLC–5 must be asserted. If more

than one of those signals is present, the synchronization fails and the

“Synchronization Failure” discrete input to the PLC–5 will be asserted.

Additional information pertaining to the cause of the failure may be obtained

by reading the appropriate block transfer data from the “Synchronizing Bus

Error Parameters” table. (See Appendix B, “Block T

Definition”, for additional information.) If new setup information is received

via block transfer while the LSM is in the Synchronization mode,

synchronization is terminated. The new configuration data is evaluated and

normal operation is resumed upon acceptance of the data.

ransfer and Discrete I/O

3–4

The “Auto–Synchronization” discrete output from the PLC–5 causes the

LSM to issue the appropriate error signals, both continuous discrete inputs

and via block transfer, to cause, via the PLC–5, the synchronizing bus

voltage, frequency, and phase to align with the reference bus. Once these

conditions are satisfied, the “Close Breaker” discrete input to the PLC–5 is

asserted based on the synchronization configuration. In the event a “dead

reference bus” condition exists, the “Synchronization Failure” discrete input

to the PLC–5 is asserted. Additional information pertaining to the cause of

the failure may be obtained by reading the appropriate block transfer data

from the “Synchronizing Bus Error Parameters” table. (See Appendix B,

“Block Transfer and Discrete I/O Definition”, for additional information.)

The “Check Synchronization” discrete output from the PLC–5 causes the

LSM to function in the same manner as the “Auto–Synchronization” discrete

output from the PLC–5 except it will not assert the “Close Breaker” discrete

input to the PLC–5. This mode is useful for testing the system.

Page 27

Chapter 3

ational

acteristics

General Operation

Oper

Continued

Char

Synchronization Continued

The “Permissive Synchronization” discrete output from the PLC–5 prevents

the LSM from issuing any error signals, but it asserts the “Close Breaker”

discrete input to the PLC–5 if the synchronization criteria are satisfied. This

mode also recognizes a “dead reference bus” condition and asserts the “Close

Breaker” discrete input to the PLC–5 to allow an operator to bring the

synchronizing bus on line when the reference bus has failed.

The “Enable Single Phase Synchronization” discrete output from the PLC-5

allows for single phase synchronization. In this mode, only the voltages

applied to the V3 inputs of the synchronization bus and reference bus are

used for synchronization. Any voltages applied to the V1 and/or V2 inputs

are not used for synchronization purposes (i.e. phase rotation, dead-bus

conditions and over-voltage conditions). Other than not using the V1 and V2

inputs, single phase synchronization does not change the operation of Auto,

Check or Permissive synchronization functions.

• Voltage Match Error = 100 (Reference Bus Voltage – Synchronizing

Bus Voltage) /(Reference Bus Voltage)

• Frequency Match Error = (Reference Bus Frequency) – ( Synchronizing

Bus Frequency)

• Phase Match Error = (Reference Bus Voltage Zero–cross Degrees) –

(Synchronizing Bus Voltage Zero–cross Degrees) [This calculation is

performed on either both rising zero–crosses or both falling zero–crosses

and the result is adjusted to provide a value between –180 degrees and

+180 degrees.]

In the “Delayed Acceptance Window” method of synchronization, the “Close

Breaker” discrete input to the PLC–5 is asserted after the “Voltage Match

Error”, the “Frequency Match Error”, and the “Phase Match Error” have all

remained continuously within their respective acceptance windows for the

configured delay time, called: “Acceptance Window Delay”.

In the event the reference bus and synchronizing bus systems are opposite in

phase rotation, the synchronization fails. This is indicated by the

“Synchronization Failure” discrete input to the PLC–5. Additional

information pertaining to the cause of the failure may be obtained by reading

the appropriate block transfer data from the “Synchronizing Bus Error

Parameters” table. (See Appendix B, “Block Transfer and Discrete I/O

Definition”, for additional information.)

Important: While still indicated in single phase synchronization mode,

phase rotation mismatch will not set the “synchronization failure”

discrete input to the PLC-5.

3–5

Page 28

Chapter 3

+kVAR (Import

ational

acteristics

General Operation

Oper

Continued

Char

(Power Factor Leading)

(+)

Power Monitoring

In addition to the synchronization function, the LSM provides an extensive

array of monitoring information. This data is accessible through one of

several different block transfers. (See Appendix B, “Block Transfer Tables

and Discrete I/O Definition”, for additional information.) All voltage and

current measurements presented by the LSM are true RMS. The power

measurements are calculated from the instantaneous voltage and current

measurements. The remainder of the monitoring information is calculated

from these values.

The LSM will clip the input voltages at approximately 1.25 times the

maximum voltage input level. If this clipping takes place, the value 999 will

be returned in every data field affected by the clipped channel.

The monitored values are scaled and reported based on the configuration

entries that were provided by the user. This function is terminated if new

configuration data is received. The new configuration data is evaluated and

normal operation is resumed upon acceptance of the data. During

synchronization those parameters not required for synchronization are

monitored at a reduced priority. This allows critical synchronization data to

be updated at a faster rate.

)

kVARH–F (Forward)

90°

(Power Factor Lagging)

(–)

Pf = 0

–kW (Export)

kWH (Reverse)

(Power Factor Lagging)

NOTE: Lagging Factor indicated by a minus sign.

3–6

Pf = 100%

180° 0°

III

Pf = 100%

III IV

Pf = 0

(–)

270°

–kV

AR (Export)

kV

ARH–R (Reverse)

(Power Factor Leading)

+kW (Import)

kWH–F (Forward)

(+)

Page 29

Chapter 3

ational

acteristics

General Operation

Oper

Continued

Char

Load Sharing

The load sharing function allows multiple synchronizing buses to split the

load requirements on a power system based on the relative capacity of each

of the alternators. To use this function, the LSM must be configured with a

“Maximum Alternator Output Power” entry, a “Load Share Full–Scale

Voltage” entry, a “Load Share Deficit” entry, and a “Load Share Excess”

entry. The first entry specifies the maximum desired power output for the

alternator. The second entry specifies the load share output voltage that will

be created when the alternator is operating at maximum power. The third and

fourth entries define the regions where load sharing activity will take place.

The region between these two entries is the dead–band where no corrective

action takes place if the discrete inputs are being utilized for control. The

full–scale voltage is configurable to be between 2 and 4 volts.

The load sharing function is enabled when the “Load Share Disable” discrete

output from the PLC–5 is not asserted and the “Isochronous/Droop” discrete

output from the PLC–5 indicates isochronous mode. If new setup

information is received via block transfer while this function is enabled, load

sharing is terminated. The new configuration data is evaluated and normal

operation is resumed upon acceptance of the data.

The LSM provides a “Load Sharing Output” voltage that is resistively

coupled to the dual function input/output terminals. The magnitude of the

output voltage is calculated from the following formula:

(“Load Share Full–Scale Voltage”) (Actual Power) / (“Maximum

Alternator Output Power”)

The “Load Sharing Input” voltage is measured from the dual function

input/output terminals. The load sharing input is calculated by:

(“Load Sharing Input Voltage”) / (“Load Share Full–Scale Voltage”)

The “Load Share Error” is a fraction and is expressed as:

(Load Sharing Input Voltage) / (Load Share Full–Scale Voltage) – (Actual

Power) / (Maximum Alternator Output Power)

If the error is negative, the alternator is supplying too much of the load

requirements and the “Reduce Power – load share adjust” discrete input to

the PLC–5 is asserted when the error exceeds the “Load Share Excess” entry.

If the error is equal to zero, the load is being properly shared. If the error is

positive, the alternator is not supplying enough of the load requirements and

the “Raise Power – load share adjust” discrete input to the PLC–5 is asserted

when the error exceeds the “Load Share Deficit” entry.

The LSM load sharing circuit is isolated from the external circuitry whenever

load sharing is disabled, droop mode is indicated, or if power is removed

from the module.

3–7

Page 30

Chapter 3

ational

acteristics

General Operation

Oper

Continued

Char

Control

The user can direct the LSM to perform several different functions by

sending the appropriate block transfer data to the “Control Parameters

Table”. (See Appendix B, “Block Transfer Tables and Discrete I/O

Definition”, for additional information.) The functions that can be initiated

are as follows:

• Execute Self–Test (If the Execute Self–Test option is selected, no other

control options will be executed.)

• Clear kW–HR Counter

• Clear kVAR–HR Counter

Self–test

The LSM automatically performs a complete self–test every time the module

is powered up or when commanded by an instruction embedded in the data

sent via the control parameters block transfer write. The content of the data

memory before the test is executed will be destroyed. However, the

configuration parameters are maintained. If the self–test request is sent via

the block transfer, it is performed once. The request must be repeated for

additional tests. The self–test verifies the contents of the program memory,

verifies performance of data memory, verifies the stored configuration data,

checks the watchdog circuitry, and checks the performance of the analog

input and analog output circuits to the extent possible.

3–8

A limited self–test that checks the validity of the stored configuration data

and a limited test of the performance of the analog inputs is automatically

performed at periodic intervals during normal operation.

Results of the self–test, either the full version or the limited version, are

indicated in the module diagnostics available from the block transfer read

data. (See Appendix B, “Block Transfer Tables and Discrete I/O Definition”,

for additional information.) The diagnostic information that is available from

the module is as follows:

• Bulletin Number

• Options

• Firmware Version

• ROM Status

• RAM Status

• EEPROM Status

• Analog Power Supply Status

• Data Acquisition Status

• Load Share D/A and A/D Converter Status

• Watchdog Timer Status

• Module Date / Time

Page 31

Chapter 3

ational

acteristics

General Operation

Oper

Continued

Char

Self–test Continued

The red Fault LED flashes while the complete self–test is being performed.

The Fault LED will remain on continuously if the self–test fails. The Fault

LED will turn off if the self–test is successfully completed.

The green Run LED is illuminated during the self–test and then turned off

after the test is completed. The Run LED also flashes each time a block

transfer is executed.

Update Rate

• Synchronizing Bus Error Parameters: 100 milliseconds

• Monitoring Parameters: 200 milliseconds (Synchronization Inactive) 1

second (Synchronization Active)

• Diagnostic Parameters: 1 second

Accuracy

The accuracy of the measurements and calculations made by the LSM are

directly affected by the quality of the user supplied current and voltage

transformers. Accuracy is affected by both the amplitude and phase errors

introduced by the user supplied transformers. It is recommended that these

transformers be Instrument Accuracy, Class 1 or better. The following

accuracy values are relative to the signals that are present at the input

terminals of the LSM.

PLC Interface

• Current Measurement = + /– 0.2 % of Full Scale

(Full Scale = 1.4 CT Primary)

• Voltage Measurement = + /– 0.2 % of Full Scale

(Full Scale = 1.25 PT Primary)

• Frequency Measurement = + /– 0.05 Hz

(within the 47 to 63 Hz range)

• Slip Frequency = + /– 0.05 Hz

(within the 47 to 63 Hz range)

• Power, Power Factor, VA + /– 0.4 % of Full Scale Power Consumption

(Full Scale = 1.75 CT Primary PT Primary)

The LSM exchanges data with the PLC backplane via both discrete I/O and

block transfers. Due to the physical size of the module’s internal

components, the LSM requires two slots in the I/O chassis. However,

addressing assignments are made to the lower numbered slot of the two slots

used.

Discrete I/O Interface

The LSM accepts six discrete outputs from the PLC–5, and provides twelve

discrete inputs to the PLC–5. See Appendix B, “Block Transfer Tables and

Discrete I/O Definition”, for additional information.

3–9

Page 32

Chapter 3

General Operation

PLC Interface Continued

Discrete Outputs (From the PLC Processor)

The following discrete output control signals will be provided from the

PLC–5 processor via the back plane:

• Initiate Synchronization

• Auto–Synchronization Mode

• Check Synchronization Mode

• Permissive Synchronization Mode

• Load Share Disable

• Isochronous/Droop Mode

• Enable Single Phase Synchronization

Discrete Inputs (To the PLC Processor)

The following discrete input control signals will be provided to the PLC–5

processor via the back plane:

• Module Status

• Raise Voltage

• Lower Voltage

• Raise Speed –– frequency adjust

• Lower Speed –– frequency adjust

• Raise Speed –– phase adjust

• Lower Speed –– phase adjust

• Raise Power –– load share adjust

• Reduce Power –– load share adjust

• Close Breaker

• Synchronization Failure

• Power–up Bit

3–10

Block Transfer Data Interface

The LSM is capable of exchanging large amounts of data with the PLC

processor via the Block Transfer mechanism. The amount of data greatly

exceeds that which could be accommodated by a single block transfer. As a

result, the data is divided into several different “files” and can be obtained

through the use of multiple Block Transfers. The sizes, structure, and

contents of the block transfer reads and writes supported by the LSM are

provided in Appendix B. See “Block Transfer Communications”, listed on

Page 4–2 in the Application Information chapter of this manual for further

details on using Block Transfers.

Page 33

Chapter 3

General Operation

PLC Interface Continued

Configuration Software Support

6200 Software

Setup assistance for the LSM module is provided through the 6200 version

4.4 or later I/O Configuration Software. This configuration software contains

the functionality to configure the module and to monitor the data produced

by an operating module.

To make use of the configuration software, the ladder must exist with block

transfer instructions programmed as shown in Appendix C. (See Sample

Ladder listings in Appendix C) The BTR instructions must occur through the

ladder to read data from the module. These are done through the use of the

sequencer and the data table values to insure that only one block transfer is

active at a given time.

This software also supports the setup of the Bulletin 1400 family of power

monitoring equipment. More 6200 I/O Configuration Software information

on the actual use of this tool is available in the 6200 Series software user’s

manual.

3–11

Page 34

Chapter 3

General Operation

3–12

Page 35

Chapter

LSM Modes o

Overview

A–B

4

Application Information

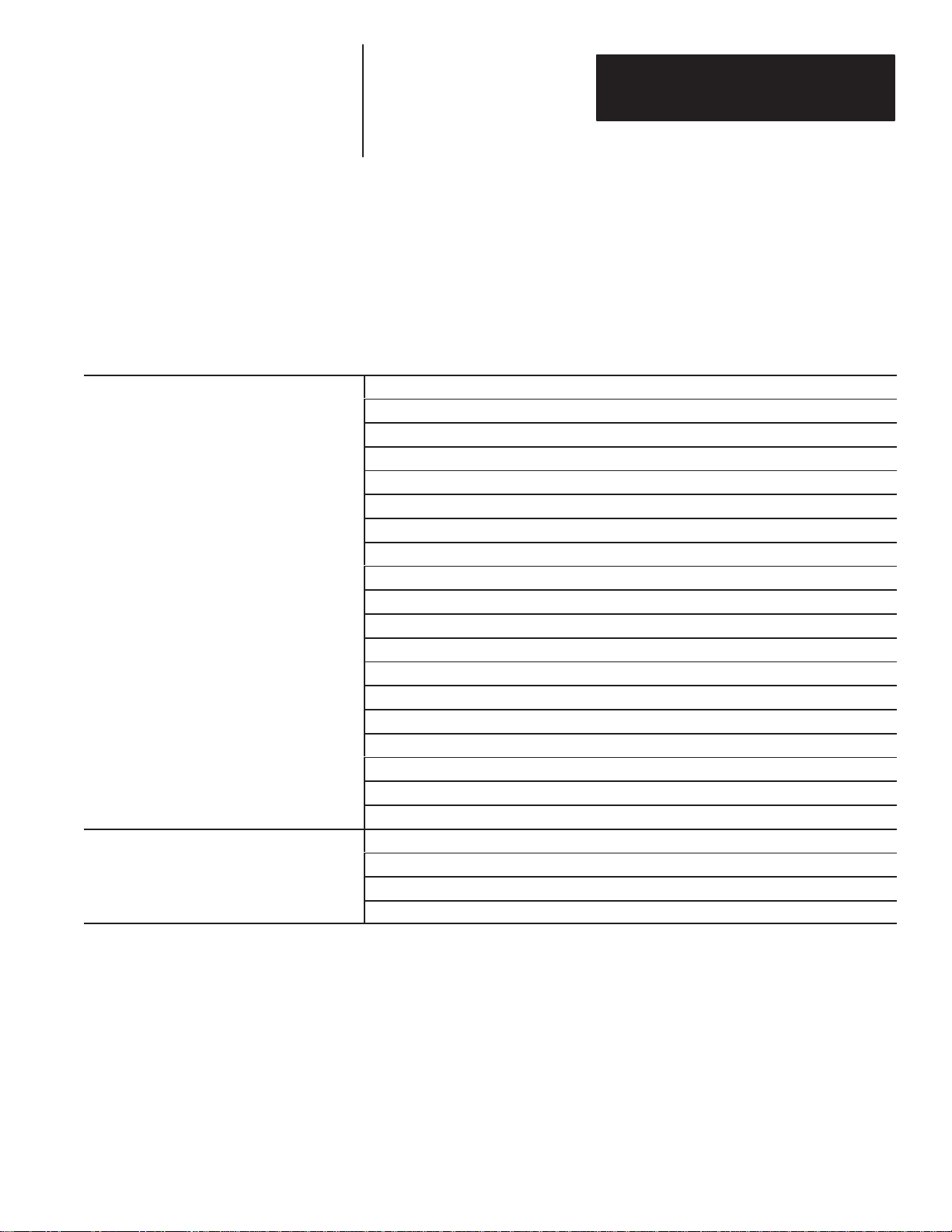

Modes of Operation

The Line Synchronization Module (LSM) has several modes of operation.

Upon successful configuration, or on power up with a previously configured

module, the LSM will be in one of the following modes:

• Monitor Only

• Monitor with Load Share

• Synchronization and Monitor

• Synchronization and Monitor with Load Share

The state of the discrete outputs from the PLC–5 to the LSM controls the

mode of operation of the LSM. This relationship is shown in Table 4.1.

T

able 4.1

f

Operation

Monitor Only

Monitor with Load Share 0 0 1

Synchronization and

Synchronization and

Monitor

Synchronization and

Monitor with Load Share

Monitor Only

In this mode of operation, data is returned for Synchronizing Bus voltage,

current, and power values, and Reference Bus voltage values. All error

values and discrete inputs to the PLC–5 will be set to zero.

Monitor with Load Share

this mode of operation, data is returned for Synchronizing Bus voltage,

In

current, and power values, and Reference Bus voltage values. The error

values and discrete inputs to the PLC–5 for load share are modified, while all

synchronization errors and discrete inputs to the PLC–5 remain set to zero.

Discrete Outputs From The PLC–5 to LSM

Initiate

Synchronization

0 1 0 or 1

0

1 1 0 or 1

1

1 0 1

Load Share

Disable

0 0

0 0

Isochronous/Droop

Mode

Synchronization and Monitor

In this mode of operation, data is returned for Synchronizing Bus voltage,

current, and power values, and Reference Bus voltage values. The error

values and discrete inputs to the PLC–5 for synchronization are modified

while the load share errors and discrete inputs to the PLC–5 remain set to

zero.

4–1

Page 36

Chapter 4

ontinu

Int

acing to t

LSM

Application Information

Overview C

erf

he

ed

Synchronization and Monitor with Load Share

In this mode of operation, data is returned for Synchronizing Bus voltage,

current, and power values, and reference bus voltage values. The error values

and discrete inputs to the PLC–5 for synchronization and load share are

modified.

Block Transfer Communications

The LSM is capable of exchanging large amounts of data with the PLC

processor via the Block Transfer mechanism. The amount of data greatly

exceeds that which could be accommodated by a single block transfer. As a

result, the data is divided into many different “files” and can be obtained

through the use of multiple Block Transfers.

The LSM uses a unique scheme for differentiating between sets of

parameters, or “files”, being written to or read from the module. The size of

the block transfer operation is used to define the size of the transaction and is

also used as a block type ID. Each of the “files” that the LSM recognizes has

a unique size and can therefore be identified by the module. This is a very

important aspect of understanding how the LSM communicates with the

PLC–5. The size, structure, and content of the block transfer reads and writes

supported by the LSM are provided in Appendix B.

ATTENTION: Only one block transfer at a time may be issued

to the LSM. This means that until a BTR or BTW to the LSM has

completed, another block transfer to the LSM must not be

!

initiated. Failure to observe this requirement will result in

improper operation of the data exchange with the module.

Only one block transfer at a time may be issued to the LSM. This means that

until a BTR or BTW to the LSM has completed, another block transfer to the

LSM must not be initiated. Failure to observe this requirement will result in

improper operation of the data exchange with the module.

The LSM uses a modulus method of accepting and returning numbers greater

than 1000 or between 0 and 1. The modulus method splits these types of

numbers into two or more words with the range 0– 999. The modulus is

given in the form 10

For example, the number 10,000 would be represented by a 10 in the

modulus 10

be represented by a 10 in the modulus 10

–3

10

word.

To process numbers received from the LSM in this format, the number in the

modulus 10

the modulus 10

3

word and a 0 in the modulus 100 word. The number 10.5 would

3

word must be multiplied by 1000 and added to the number in

6

, 103, 100, or 10–3.

0

word.

0

word and a 500 in the modulus

4–2

Page 37

Chapter 4

Int

acing to t

LSM Continu

Application Information

erf

he

ed

Block Transfer Communications Continued

For example, the words 10 modulus 103 and 0 modulus 100 would be

processed in this manner: (10 * 1000) + 0. The words 10 modulus 10

500 modulus 10

To process numbers to be sent to the LSM in this format, a number greater

than 1,000 needs to be divided by 1,000 to obtain the modulus 10

This word must then be re–multiplied by 1,000 and subtracted from the

original number to obtain the modulus 10

For example, the number 12,345 would be processed as follows:

• modulus 10

• modulus 10

Numbers such as 12.345 need to be processed as follows:

• modulus 10

• modulus 10

Configuration

The only method of configuring the LSM module is via the block transfer

operation of the PLC–5. The data to be sent to the LSM must be stored in a

data file of the PLC. There are two separate block transfer writes necessary

to completely configure the LSM. The address of these data files must be

used as the data file parameter of the BTW instruction with sizes of 35 and

12. Again, the correct sizes are necessary to identify to the LSM what type of

data is being sent. The size, configuration, and contents of the block transfer

tables accepted by the LSM are discussed in Appendix B.

–3

would be processed in this manner: 10 + (500 /1000).

0

word.

3

word = (12,345 /1,000) truncated to 12

0

word = 12,345 – (modulus 103 word 1000) = 345

0

word = 12.345 truncated to 12

–3

word = (12.345 – modulus 100 word) 1000 = 345

0

3

word.

and

The parameters sent to the LSM must be valid before the LSM will respond

and begin normal operation. The validity of data sent to the LSM may be

checked by requesting the Acknowledge Factory (or User) Configuration

Parameters tables from the LSM. This is accomplished by initiating BTRs of

size 25 or 15 from the LSM. The final non–reserved word of these tables is

the overall configuration status of the previous configuration BTR. If this

word is 0, the configuration succeeded and the LSM is running in one of the

modes previously described. If this word is 4, one or more of the

configuration parameters was out of range or illegal and all set up data is not

accepted. Each word of the Acknowledge Configuration Parameters table

should then be examined to determine which parameter was invalid.

4–3

Page 38

Chapter 4

Int

acing to t

LSM Continu

Application Information

erf

he

Acquiring Data From the LSM

ed

The data from the LSM is returned in four tables. These tables are again

differentiated by the size/ID of the BTR instruction. These tables are

Synchronizing Bus Error Parameters, Synchronizing Bus Voltage/Current

Parameters, Synchronizing Bus Power Parameters, and Reference Bus

Voltage Parameters. The sizes and contents of these tables are provided in

Appendix B of this document.

To acquire the table Synchronizing Bus Error Parameters from the LSM, the

PLC–5 must issue a BTR instruction with the size of this table. The data file

entry of the BTR is where the table from the LSM will be placed. Any

operations using this data must then be directed to this file within the PLC–5.

Discrete Input / Output Control of the LSM

The LSM uses both discrete outputs from the PLC–5 and inputs to the

PLC–5 in addition to its block transfer capabilities.

Discrete Outputs From The PLC–5

The discrete outputs from the PLC–5 to the LSM are as follows:

T

able 4.2

Octal

Bit

Number

17 15 Initiate Synchronization 1 = Initiate

16 14 Auto–Synchronization Mode 1 = Assert this mode

15 13 Check Synchronization Mode 1 = Assert this mode

14 12 Permissive Synchronization

13 11 Load Share Disable 1 = Disable Load Share

12 10 Isochronous/Droop Mode 1 = Isochronous Mode

11 9 Unused N/A

10 8 Enable Single Phase Syn-

Decimal Bit

Number

Output Description State Values

1 = Assert this mode

Mode

1 = Single Phase

chronization

0 = 3-Phase

The Initiate Synchronization output from the PLC–5 controls the operation

mode of the LSM. This output from the PLC–5 operates as shown in

Table 4.1 on Page 4–1.

The Auto Synchronization Mode output from the PLC–5, Check

Synchronization Mode output from the PLC–5, and the Permissive

Synchronization Mode output from the PLC–5 are only used when the

module is in a Synchronization mode (i.e. the Initiate Synchronization output

from the PLC–5 is set). Only one of these Synchronization Mode outputs

from the PLC–5 may be set at one time. If more than one of those signals is

4–4

Page 39

Chapter 4

Int

acing to t

LSM Continu

Application Information

erf

he

ed

Discrete Outputs From The PLC–5 Continued

present, the synchronization fails and the “Synchronization Failure” discrete

input to the PLC–5 will be asserted. Additional information pertaining to the

cause of the failure may be obtained by reading the appropriate block transfer

data from the “Synchronizing Bus Error Parameters” table. (See Appendix B,

“Block Transfer and Discrete I/O Definition”, for additional information.)

The Auto Synchronization Mode discrete output from the PLC–5 causes the

LSM to issue the appropriate error signals, both continuous discrete inputs to

the PLC–5 and via block–transfer, to cause via the PLC–5 the alternator

voltage, frequency, and phase to align with the Reference Bus. Once these

conditions are satisfied, the Close Breaker discrete input to the PLC–5 will

be asserted based on the synchronization configuration.

The Check Synchronization Mode discrete output from the PLC–5 causes the

LSM to function in the same manner as the Auto Synchronization Mode

output from the PLC–5, except it will not assert the Close Breaker discrete

input to the PLC–5. This mode is useful for testing the system.

The Permissive Synchronization discrete output from the PLC–5 will not

cause the LSM to issue any error signals, but it will assert the Close Breaker

discrete input to the PLC–5 if the synchronization criteria are satisfied.

The Load Share Disable discrete output from the PLC–5 when set to 1 will

cause the load share function of the LSM to be disabled.

The Isochronous/Droop Mode discrete output from the PLC–5 when set to 1

indicates Isochronous mode of load share operation. If this output from the

PLC–5 is cleared to 0 the LSM will operate in the droop mode of load share.

While the LSM is in Droop mode, all load share errors and discrete inputs to

the PLC–5 will be set to 0. The load share terminals on the front of the

module will be disconnected from internal circuitry, therefore, the load share

function is effectively disabled.

The Enable Single Phase Synchronization discrete output from the PLC-5,

when set to 1, allows the synchronization function to ignore the V1 and V2

inputs. In this mode, phase rotation mismatch does not cause a

synchronization failure, and the V1 and V2 inputs are not used for features

such as dead-bus detect or over-voltage detection. This mode allows

connection of the V3 inputs to single phase systems, or those systems with a

single transformer per 3-phase system.

4–5

Page 40

Chapter 4

Int

acing to t

LSM Continu

Application Information

erf

he

Discrete Inputs to the PLC–5

ed

The discrete inputs to the PLC–5 are as follows:

T

able 4.3

Octal

Bit

Number

17 15 Module Status 1 = Module Failed

16 14 Raise Voltage 1 = Raise

15 13 Lower Voltage 1 = Lower

14 12 Raise Speed – Frequency Adjust 1 = Raise

13 11 Lower Speed – Frequency Adjust 1 = Lower

12 10 Raise Speed – Phase Adjust 1 = Raise

11 9 Lower Speed – Phase Adjust 1 = Lower

10 8 Raise Power – Load Share Adjust 1 = Raise

7 7 Reserved N/A

6 6 Reserved N/A

5 5 Reserved N/A

4 4 Reduce Power – Load Share Adjust 1 = Lower

3 3 Close Breaker 1 = Close Breaker

2 2 Synchronization Failure 1 = Failure

1 1 Powered Up Bit 1 = Module Ready

0 0 Reserved N/A

Decimal Bit

Number

Input Description State Values

4–6

The Module Status discrete input to the PLC–5 when set to 1 indicates that

the LSM has identified a potential problem. A value of 0 indicates normal

operation of the LSM. Additional information pertaining to the cause of the

problem may be obtained by reading the appropriate block transfer data from

the “Diagnostic Parameters” Table B.11. (See Appendix B, “Block Transfer

Tables and Discrete I/O Definition”, for additional information.)

If the Module Status discrete input to the PLC–5 is set to 1, all block transfer

writes will be ignored and only the Diagnostic Parameters block transfer read

will return valid data. Any other block transfers should not be executed at

this time.

The Raise Voltage synchronization error discrete input to the PLC–5

indicates that the Synchronizing Bus has a lower voltage level than that of

the Reference Bus.

The Lower Voltage synchronization error discrete input to the PLC–5

indicates that the Synchronizing Bus has a higher voltage level than that of

the Reference Bus.

The Raise Speed – Frequency Adjust synchronization error discrete input to

the PLC–5 indicates that the Synchronizing Bus is producing voltage at a

frequency lower than that of the Reference Bus.

Page 41

Chapter 4

Int

acing to t

LSM Continu

Application Information

erf

he

ed

Discrete Inputs to the PLC–5 Continued

The Lower Speed – Frequency Adjust synchronization error discrete input to

the PLC–5 indicates that the Synchronizing Bus is producing voltage at a

frequency higher than that of the Reference Bus.

The Raise Speed – Phase Adjust synchronization error discrete input to the

PLC–5 indicates that the Synchronizing Bus is producing a voltage which is

between 0 and 180 degrees behind the Reference Bus.

Reference Bus V

Synchronizing Bus Voltage

Figure

oltage

4.1

The Lower Speed – Phase Adjust synchronization error discrete input to the

PLC–5 indicates that the Synchronizing Bus is producing a voltage which is

between 0 and 180 degrees ahead of the Reference Bus .

Reference Bus V

Synchronizing Bus Voltage

Figure

oltage

4.2

ATTENTION: If the Synchronization Bus and the Reference

Bus are moving towards synchronization, the discrete inputs to

!

the PLC–5 for Phase Adjust will not be asserted.

The Raise Power– Load Share Adjust discrete input to the PLC–5 indicates

the prime mover is not producing enough power. The RPM must be

increased.

The Reduce Power–Load Share Adjust discrete input to the PLC–5 indicates

the prime mover is producing an excess of power. The RPM must be

decreased.

4–7

Page 42

Chapter 4

Int

acing to t

LSM Continu

Application Information

erf

he

Ladder Program Description

Discrete Inputs to the PLC–5 Continued

ed

The Close Breaker discrete input to the PLC–5 indicates that all

synchronization criteria have been met and it is acceptable to close the

breaker between the Synchronizing Bus and the Reference Bus.

The Synchronization Failure discrete input to the PLC–5 indicates a

synchronization error. When this bit is set, the LSM cannot perform

Synchronizing Bus / Reference Bus synchronization.

When the Synchronization Failure discrete input to the PLC–5 is set, the

Synchronization Status word in the Synchronizing Bus Error Parameters

indicates the reason for synchronization failure.(See Appendix B Table B.6)

The Powered–up Bit discrete input to the PLC–5 indicates that the LSM has

completed internal self– tests and is ready to perform block transfers with the

PLC–5.

Included in Appendix B is a sample PLC–5 ladder program that interfaces

with the LSM. The data files used are described in Tables 4.4 and 4.5.

ATTENTION: Executing the Control Request BTW from the

sequencer file, or at a similar rate of speed could cause improper

!

operation of the LSM.

4–8

Page 43

Chapter 4

B

Application Information

Ladder Program Description

Continued

Data Files Used

T

able 4.4

Data File Data Description

b3/0 Internal Trigger

b3/1 Config Mode Enable

b3/2 Data Reset

b3/3 Run mode Sequence Complete

B3

N10 n10:0 Sequencer output (BT select word)

N21 Config mode sequencer input file.

N21:0 59

N21:1 59

N21:2 52

N21:3 60

N21:4 53

N22 Run mode sequencer input file

N22:0 54

N22:1 54

N22:2 50

N22:3 51

N22:4 55

N22:5 54

N22:6 56

N22:7 57

N22:8 58

b3/4 Valid Config Data

b3/5 Config Sequence Complete/Data Valid

b3/6 Module Config Complete

b3/9 One–shot bit

b3/10 One–shot bit

For proper configuration with the sequencer at rung 2:7 set to a

length of 4 words, the following data MUST be in file N21.

D Factory Configuration Parameters

D Factory Configuration Parameters

D Factory Acknowledge Configuration

D User Configuration Parameters

D User Acknowledge Configuration Parameters