Page 1

Bulletin 1400

Powermonitor Software

(Catalog Number 1400–SP)

Installation and Operation Manual

ALLEN-BRADLEY

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. “Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls” (Publication SGI-1.1)

describes some important differences between solid state equipment and

hard–wired electromechanical devices. Because of this difference, and also

because of the wide variety of uses for solid state equipment, all persons

responsible for applying this equipment must satisfy themselves that each

intended application of this equipment is acceptable.

This equipment generates, uses, and can radiate radio frequency energy and

if not installed and used in accordance with the instructions manual, may

cause interference to radio communications. It has been tested and found to

comply with the limits for a Class A computing device pursuant to Subpart J

of Part 15 of FCC Rules, which are designed to provide reasonable

protection against such interference when operated in a commercial

environment. Operation of this equipment in a residential area is likely to

cause interference in which case the user at his own expense will be required

to take whatever measures may be required to correct the interference.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

!

damage, or economic loss.

Attentions help you:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is especially important for successful

application and understanding of the product.

PLC are registered trademarks of the Allen–Bradley Company.

IBM PC, IBM AT, & IBM XT are registered trademarks of IBM Corporation.

Lotus 1–2–3 is a registered trademark of Lotus Development Corporation.

Page 3

Using This Manual

Preface

A–B

What This Manual Contains

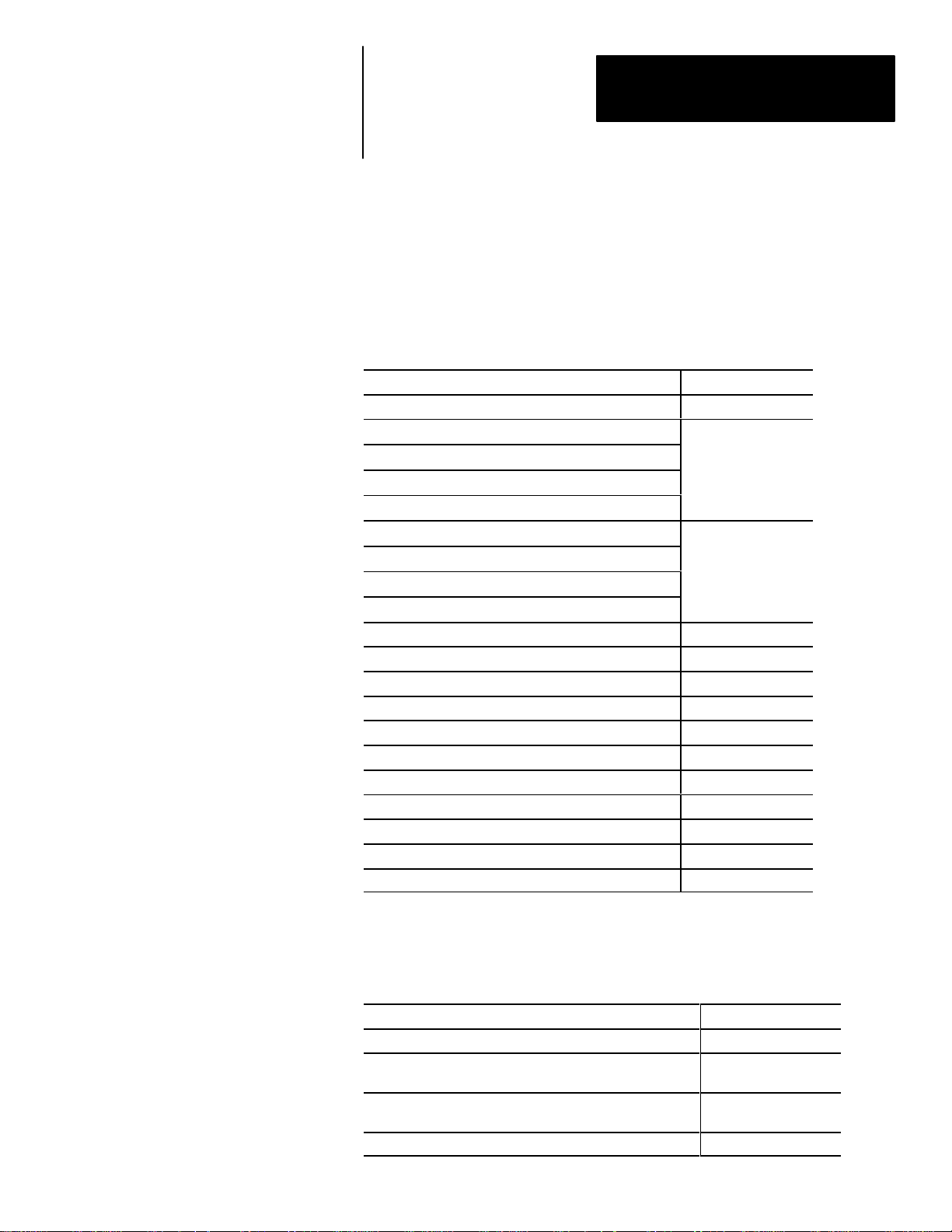

Review the table below to familiarize yourself with the topics contained in

this manual.

For information about: Refer to chapter:

System Components and features 1

System and Computer Requirements

Version of DOS Required

RS–232C vs RS–485 communications

Connection to Remote Sites Via Telephone Lines/Modems

Installation of the Communication Hardware

Connection To Single/Multiple Powermonitors

Modem Configuration Information

Installation of the System Software

Using the Software 4

Powermonitor Data Display and Configuration 5

Manual Control of Powermonitor Internal Relays 6

Printing Log Disk Files 7

Troubleshooting information 8

Warranty information 9

Catalog Number Explanation Appendix A

Communications Application Note Appendix B

Setpoint parameter form Appendix C

Keyboard Reference Appendix D

Loading Event, MIN/MAX, or Snapshot Log Files into Lotus Appendix E

2

3

For More Information

For this information: Refer to:

Catalog Number 1400–PD Installation and Operation Manual Publication 1400–800

Installing the Communications Card Instructions

Catalog Number 1400–DCU

RS–232C and RS–485 Convertor Instructions

Catalog Number 1400–CC

Catalog Number 6190–PMO ControlView Software A–B Highland Heights

Publication

1400–5.0

Publication

1400–5.1

i

Page 4

Preface

Using This Manual

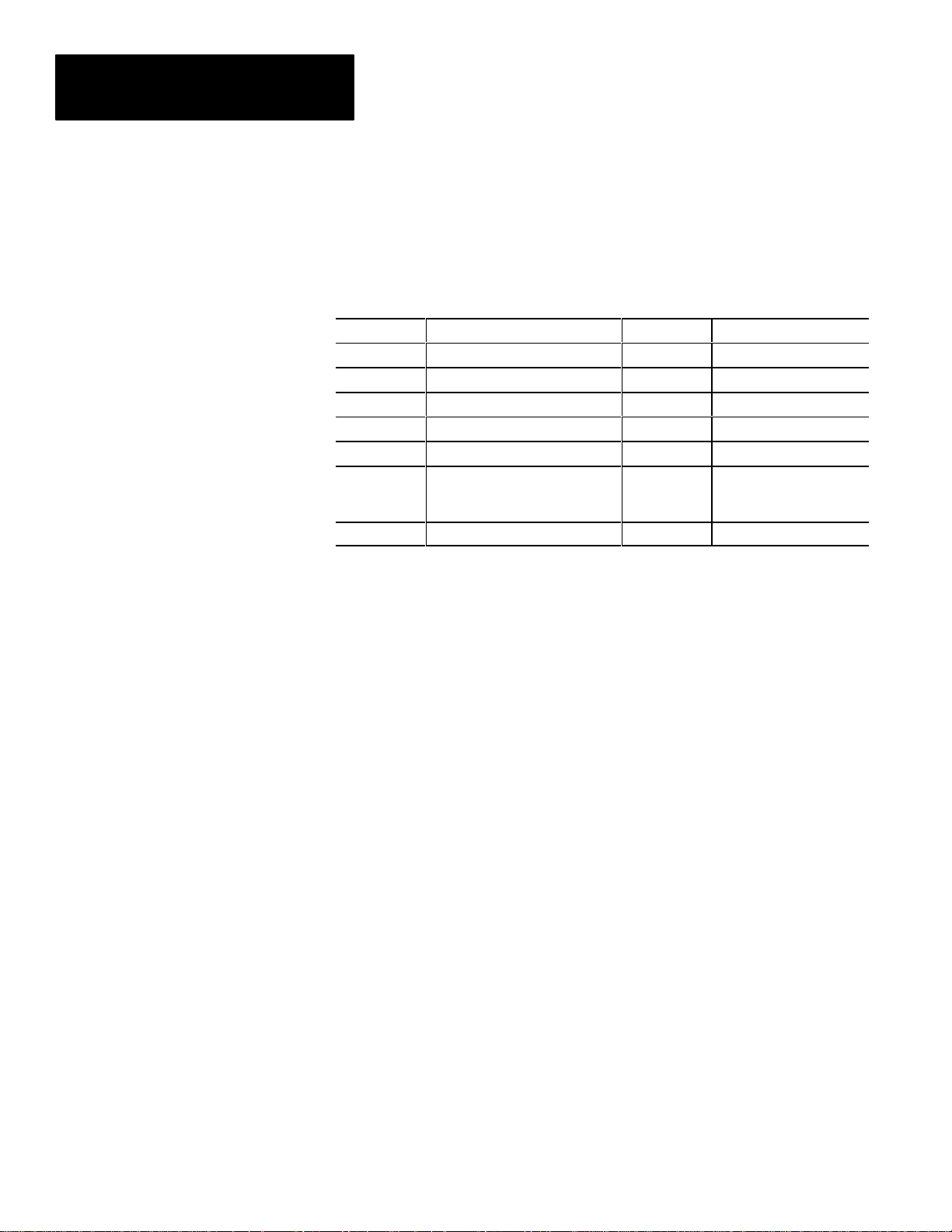

Terms and Conventions

In this manual, the following terms and conventions are used:

Abbreviation Term Abbreviation Term

CTS Clear To Send RTU Remote Terminal Unit

DCE Data Communications Equipment RXD RS–232C Receive Data

DTE Data Terminal Equipment SG RS–232C Signal Ground

GND Chassis Ground SHLD RS–485 Shield

LAN Local Area Network TXD RS–232C Signal Ground

RI/O Remote I/O 6190–PMO Bulletin 6190–Powermonitor

Option ControlView

Software

RTS Request to Send

ii

Page 5

Table of Contents

Bulletin 1400 Powermonitor Software

Installation and Operation Manual

Overview

System Requirements

Chapter 1

Chapter Objectives 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Components 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Computer Station 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Powermonitor Display Module 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communication Links 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Features 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Features 1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Acquisition Features 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Display Features 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operator Support 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2

Computer Requirements 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Version Of DOS Required 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communications System Hardware Requirements 2–1. . . . . . . . . . . . . . . .

Number Of Serial Ports Required 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS–232C vs RS–485 Communications 2–2. . . . . . . . . . . . . . . . . . . . . . . . .

Connection To Remote Sites Via Telephone Lines and Modems 2–2. . . . .

Installation

Chapter 3

Chapter Objectives 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Of The Communications Hardware 3–1. . . . . . . . . . . . . . . . . .

Connection To A Single Powermonitor Via RS–232C 3–2. . . . . . . . . . . . .

Connection To Multiple Powermonitors Via RS–485 3–3. . . . . . . . . . . . . .

Connection To Single Powermonitor Sites Via The Telephone Network 3–5

Modem Configuration Information 3–7. . . . . . . . . . . . . . . . . . . . . . . . .

Modems should be configured as follows: 3–7. . . . . . . . . . . . . . . . . . .

Connection To Multiple Powermonitor Sites Via Telephone Network 3–8.

Connection To Remote Sites Using Other Methods of Communications 3–9

Installation Of The System Software 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents of the Powermonitor Software Package 3–10. . . . . . . . . . . . . .

Creating A Backup Copy of the Powermonitor Software 3–10. . . . . . . . . . .

Installing The Software Onto A Hard Drive 3–11. . . . . . . . . . . . . . . . . . . . .

I

Page 6

Table of Contents

Bulletin 1400 Powermonitor Software

Installation and Operation Manual

Using The Software

Chapter 4

Chapter Objectives 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Startup 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To Run The Software From The Hard Drive 4–1. . . . . . . . . . . . . . . . . .

To Run The Software From The Floppy Diskette 4–1. . . . . . . . . . . . . .

Possible Errors On Startup 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Establishing Connection With A Remote Device 4–2. . . . . . . . . . . . . . . . .

Connection Screen 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Establishing Communications 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting With The Remote Device 4–5. . . . . . . . . . . . . . . . . . . . . . .

The Menu System 4–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Help/Message Line 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Screens And Functions 4–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Screens And Functions Continued 4–9. . . . . . . . . . . . . . . . . . . . . . . . .

Shortcut Keys 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Screen Descriptions 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Password 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

On–Line Help 4–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Update Unit Time 4–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exit To DOS 4–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connection Configuration Save Feature 4–12. . . . . . . . . . . . . . . . . . . . .

Powermonitor Data Display

And Configuration

II

Chapter 5

Chapter Objectives 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displaying Single Device Data 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Display Formats 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displaying Device Data 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displaying Additional Data 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To Exit From Any Data Display Screen 5–3. . . . . . . . . . . . . . . . . . . . . .

Configuring Powermonitors 5–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displaying The Setup Or Setpoint Parameters Of Any Devices 5–3. . .

Modifying Parameter Values 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Re–configuring The Device With The New Parameter Values 5–4. . . .

Data Display and Configuration Screens 5–5. . . . . . . . . . . . . . . . . . . . . . . .

Main Menu 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Real Time Data 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Event Log 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Save Disk 5–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Snapshot Log 5–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Save 5–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Data 5–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Relay 5–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 7

Table of Contents

Bulletin 1400 Powermonitor Software

Installation and Operation Manual

Powermonitor Data Display

And Configuration Continued

Manual Control Of

Powermonitor Internal Relays

Chapter 5 Continued

Status Input 5–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Count 5–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Active Alarms 5–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Date and Time 5–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MIN/MAX Log 5–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Device Setup 5–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setup Parameter Descriptions 5–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Save & Exit 5–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setpoint/Relay Setup 5–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setpoint Parameter Descriptions 5–16. . . . . . . . . . . . . . . . . . . . . . . . . . .

Save And Exit 5–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clear Functions 5–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6

Chapter Objectives 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Effect Of Relay Mode On Manual Control 6–1. . . . . . . . . . . . . . . . . .

Logging Of Relay Control Commands 6–2. . . . . . . . . . . . . . . . . . . . . . . . .

Manual Relay Operations 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printing Log Disk Files

Troubleshooting

Warranty

Chapter 7

Chapter Objectives 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Description 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Saving A Log To Disk 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Location And Filenames Of Log Files 7–1. . . . . . . . . . . . . . . . . . . . . . . . .

Contents Of Log Files 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printing Log Disk Files 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer Considerations 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 8

Troubleshooting 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 9

Hardware 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software and Firmware 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

III

Page 8

Table of Contents

Bulletin 1400 Powermonitor Software

Installation and Operation Manual

Catalog Number Explanation

Communications Application

Note

Appendix A

Powermonitor Display Module A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Powermonitor Block Module A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communications Cards / Peripherals / Software A–2. . . . . . . . . . . . . . . . . .

Appendix B

Introduction B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What is RS–232C? B–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What is RS–485? B–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Summary Of Advantages And Disadvantages Of RS–232C Vs RS–485 B–2

Choosing Powermonitors With Communications Capability B–3. . . . . . . .

Common RS–485 Topologies B–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Straight–Line Topology B–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loop Topology B–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calculating Overall Cable Length B–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Modems B–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP Switch Configuration B–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Via Communications–Standard Modem Setup B–6. . . . . . .

Configuration Via Communications–Custom Modem Setup B–7. . . . . . . .

Setpoint Parameter Form

Keyboard Reference

Loading Event, MIN/MAX, or

Snapshot Log Files Into

Lotus

Appendix C

Setpoint Parameter Form C–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix D

Keyboard Reference D–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix E

Loading Event, MIN/MAX, or Snapshot Log Files Into Lotus E–1. . . . . .

IV

Page 9

Chapter

Chapter Objectives

Introduction

A–B

1

Overview

This chapter is an overview of Powermonitor Software system components

and capabilities. Detailed information regarding system requirements can be

found in Chapter 2.

Powermonitor Software is a software package designed to remotely display

the data measured by the Powermonitor. The Powermonitor Software is

capable of configuring and controlling all aspects of remote devices. In

addition, the Software can up load and store the Event and Snapshot Logs of

the devices onto disk files for database analysis or printout.

System Components

The Powermonitor Software system is comprised of a personal computer that

is connected via communication links to a Powermonitor through a Bulletin

1400–DCU communications card.

Computer Station

The Powermonitor Software requires an IBM Personal Computer AT, 286, or

386, or a true compatible with a monochrome or color monitor. The

computer must have a minimum 256K of RAM, an 80 column monochrome

or color monitor, and either a 5–1/4” (360KB or 1.2MB) or 3–1/2” (720KB

or 1.44MB) floppy disk drive. A hard disk drive is optional.

The computer set at a minimum should be equipped with one (RS–232C)

serial interface (port). With two serial (RS–232C) interface ports the

computer could be connected to a Powermonitor via one port and at the same

time be connected to another Powermonitor via the other port.

For remote connection, one port could have an internal modem or one of the

serial ports could be connected to an external modem. Modem connection

allows communication via the telephone network, radio links, fiber optic

links, and microwave data links.

The computer running the Powermonitor Software provides the system

operator interface to perform the following functions:

• Remote device programming.

• Data display from each device in the system.

• Communication of manual relay control commands to Powermonitors.

• Access to logs (Min./Max., etc.) setpoint control

1–1

Page 10

Chapter 1

Overview

The Powermonitor Software data files format allows the user to apply

TM

standard database application programs such as Lotus

or others to produce

system reports such as:

a. load trending

b. trouble analysis

c. cost analysis

d. cost allocation

e. demand scheduling

f. performance analysis and reporting

g. shadow billing

h. engine/generator efficiency studies

Powermonitor Display Module

The Powermonitor provides electrical monitoring and control functions in a

wide variety of applications. The Powermonitor can be operated

independently in stand–alone applications, or used with a computer running

Powermonitor Software for local or remote device programming, setpoint

control, viewing of data, and manual relay operation. All functions of each

Powermonitor may be accessed from the Powermonitor Software computer

station. The Powermonitor Software also provides access to features that are

not accessible when the Powermonitor is used in strictly stand–alone

applications.

1–2

The Powermonitor performs high accuracy measurement of Volts (L–L,

L–N), Amps, kW, kVA, kVAR, kW Demand, Amps Demand, Power Factor,

Frequency, kWH, kVARH, kVAH, and Neutral Current. Dependent on the

range, connections can be made directly to potential transformers and current

transformers without the need for intermediate transducers.

An auxiliary voltage input can be used to measure parameters, such as,

transformer temperature or battery voltage. Four status inputs can be used to

monitor circuit breaker status, ground fault relay status, or any other voltage

input within the status input range.

The Powermonitor has an extensive user–programmable setpoint system.

Three on–board relay outputs can be used for fully automated demand,

power factor, or load control, or to trip a critical breaker or activate an alarm

in the event of under/over voltage, voltage or current unbalance, phase

reversal, etc. The three relays can be programmed for multiple setpoints.

On–board data logging capabilities provide Event/Alarm, Min/Max, and

Snapshot data which can be accessed and displayed through Powermonitor

Software.

Page 11

Chapter 1

Overview

Communication Links

Many forms of communication can be used to transfer power data on a local

data bus to the computer running the Powermonitor Software. The local data

buses presently used by the Catalog Number 1400–DCU communications

card are either the electrical standards RS–232C or RS–485 and

Allen–Bradley Remote I/O link for PLCR (programmable logic controllers)

processors.

The RS–232C electrical standard is commonly used for point–to–point

communications and is excellent when only one

installed at a site.

For sites requiring more than one Powermonitor device, the RS–485

electrical standard is used. This standard utilizes a shielded two–wire twisted

pair cable as the communications media and can operate at distances up to

4000 feet.

Powermonitor is to be

System Features

ATTENTION: Special high level isolation is required between

units when the possibility of high ground potential differences

!

exist. This may occur when separate grounds are used, or when

communicating to a unit off of the power ground matt. Failure to

do so can lead to personal injury or death, property damage, or

economic loss.

The Powermonitor Software uses a non–proprietary packet protocol to

transfer information and data between the computer running the

Powermonitor Software and remote devices connected on the RS–485 bus.

The packet protocol features unit addressing and error checking capability.

Generally, a Catalog Number 1400–CC communications converter will be

needed to convert the computer RS–232C to RS–485 communications.

The Powermonitor Software does not support Allen–Bradley’s Remote I/O

network.

Control Features

The Powermonitor is equipped with on–board control relays. The relays may

be manually controlled by the system operator, or placed under automatic

control of the device itself in accordance with user defined parameters.

Only computer system operators with the appropriate password have access

to the relay control functions. The Powermonitor Software forced relay

requests require confirmation. This minimizes unintentional relay activity.

All forced relays return to normal operation if power to the unit is lost.

1–3

Page 12

Chapter 1

Overview

Data Acquisition Features

A Powermonitor has on–board Snapshot logging capability which allows

each device to store instantaneous measured values (ex. Volts, Amps, kW,

kVAR, etc.) at user–defined intervals ranging from 1 second to 400 days.

A computer running the Powermonitor Software can up load and display

Snapshot Logs, and save an entire log to a disk file for analysis at a later

date. The Powermonitor Software disk files are stored in format that is easily

converted to a LOTUS 1–2–3

TM

compatible format allowing users to apply

their own database application programs to generate any desired type of

report or graph. The use of this standard database file format also allows the

user to apply presently existing database application macros that have

already been developed.

Data Display Features

All real–time measured data, relay and status input conditions, and on–board

data logs can be accessed from a Powermonitor.

Operator Support

The Powermonitor Software provides an on–screen HELP utility which

provides information regarding communications, modem usage, and how to

obtain technical assistance should a user experience difficulties.

1–4

Page 13

Chapter

Computer Requirements

A–B

2

System Requirements

The Powermonitor Software software package is designed to run on a

Personal Computer AT, 286, 386, or a true IBM compatible. The computer

must have a minimum 256K of RAM, an 80 column monochrome or color

monitor, and either a 5–1/4” (360KB or 1.2MB) or 3–1/2” (720KB or

1.44MB) floppy disk drive. A hard disk drive is optional. The computer

must also have a communications interface capable of supporting the

required number of sites. See the paragraph on communications system

hardware requirements.

The specific computer hardware required depends upon the size of the

system, the number of substation sites, and the number of Powermonitors.

For large systems, an IBM–PC/AT or PC/286 class computer or better is

recommended.

Printer

Version Of DOS Required

Communications System Hardware Requirements

A dot matrix printer is optional. A wide carriage model dot matrix printer

capable of compressed mode is recommended to retain the proper page

formatting of the Powermonitor Software output. A standard width dot

matrix printer may be used; however, proper page formatting will not be

retained in some cases.

DOS versions 2.0 or greater can be used with the Powermonitor Software.

The computer running the Powermonitor Software utilizes one serial port to

communicate with the Powermonitors at each site in the system. Each

computer serial port can be connected to one or more Powermonitors via a

wide array of communications interface hardware options. Examples of

communications options supported by Powermonitor Software include direct

connection to single Powermonitors or telephone modem links via RS–232C,

and direct connection to multiple device sites via RS–485 local area

networks.

Number Of Serial Ports Required

The Powermonitor Software supports dual RS–232C or RS–485 serial ports

(COM1 and COM2). COM1 must be set to IRQ4 and COM2 to IRQ3.

The number of serial ports required by the computer varies from system to

system and will depend on the size of the system to be monitored.

2–1

Page 14

Chapter 2

System Requirements

RS–232C vs RS–485 Communications

The Powermonitor Software can communicate to all Powermonitors in the

system either via the RS–232C electrical standard or via the RS–485

standard. The type of communication hardware required at each site is

dependant on which of these electrical standards is used by the

Powermonitors located at that site.

If there is only one Powermonitor installed at a site, then the optional port

can be set for either the RS–232C standard or the RS–485 standard. If more

than one Powermonitor is installed at a site, then the RS–485 electrical

standard must be used and all Powermonitors located at that site must have

their optional RS–232C/RS–485 port set for RS–485 communications.

ATTENTION: Special high level isolation is required between

units when the possibility of high ground potential differences

!

exist. This may occur when separate grounds are used, or when

communicating to a unit off of the power ground matt. Failure to

do so can lead to personal injury or death, property damage, or

economic loss.

To determine the setting of optional RS–232C/RS–485 port refer to

Publication 1400–5.0, ‘‘Catalog Number 1400–DCU Communications Card

Instructions Sheet.”

Connection To Remote Sites Via Telephone Lines and Modems

2–2

The Powermonitor Software supports Hayes compatible internal and external

modems at 300, 1200, 2400, 4800, 9600 and 19.2K baud. Before selecting a

particular baud rate, verify that all equipment used supports that particular

baud rate.

Installations using modems require individual RS–232C and telephone cables

at each modem location.

Configuration of external modems is described in Chapter 3, ‘‘Installation.”

Internal modems should be useable with their factory–configured settings. If

necessary, please contact Allen–Bradley.

Chapter 3, ‘‘Installation” contains detailed instructions regarding the

installation of telephone modem data links.

Page 15

Chapter

Chapter Objectives

Installation Of The Communications Hardware

A–B

3

Installation

This chapter discusses the installation of the Powermonitor Software.

The installation procedure is divided into two phases. The first phase covers

installation of the hardware used to implement the Powermonitor Software

communications system between the computer running the Powermonitor

Software and the Powermonitors. The second phase covers installation of

the Powermonitor Software software on the computer.

Prior to reading the information given below, it is recommended that the

reader become familiar with the information contained in Appendix B.

Appendix B contains an Engineering Application Note that gives an

overview of the RS–232C and RS–485 electrical standards and their bearing

on the communication links between the computer running Powermonitor

Software and each Powermonitor site. In addition, this note explains the

benefits and limitations of the RS–232C and RS–485 standards.

The following sections cover the most common methods of connection

between the Powermonitor Software computer and the devices at each site.

These methods are:

1. Connection to a single Powermonitor via RS–232C.

2. Connection to multiple Powermonitors via RS–485.

3. Connection to single Powermonitor sites via MODEMs.

4. Connection to multiple Powermonitor sites via MODEMs.

5. Connection to remote sites using other methods (fiber optic, radio,

microwave, etc.)

3–1

Page 16

Chapter 3

Installation

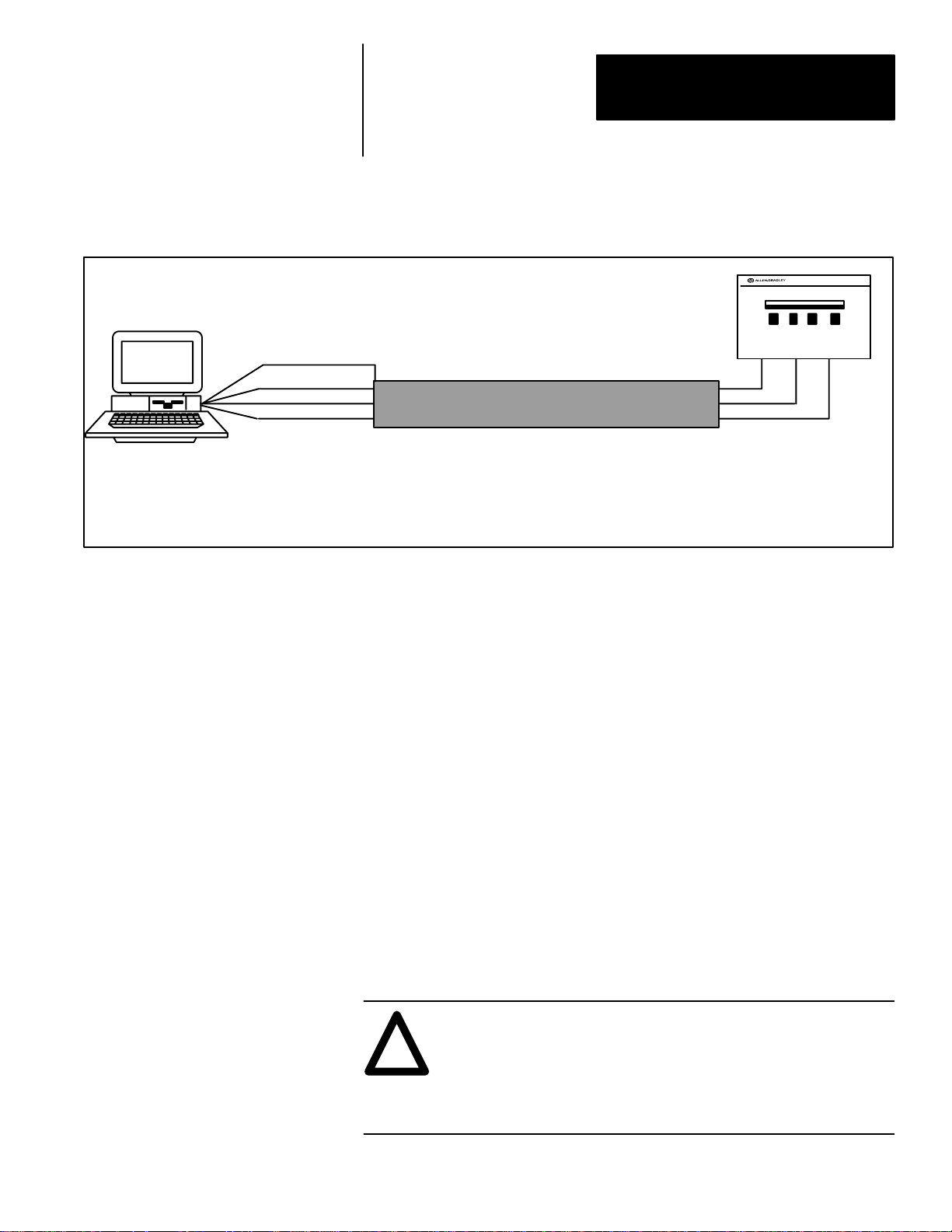

Connection To A Single

Powermonitor Via RS–232C

This section provides the information necessary to connect the computer to a

single Powermonitor via an RS–232C communications link.

To install an RS–232C communications link, both the computer running the

Powermonitor Software and the Powermonitor must be configured for

RS–232C communications.

ATTENTION: Before attempting to connect any

communications cables, confirm that each device is equipped

!

with a Catalog Number 1400 – DCU communication card, and

the port has been configured for RS–232C operation. For

jumper configuration, refer to Publication 1400–5.0

Instruction Sheet.

To implement an RS–232C communications link, a three conductor

RS–232C cable is required between the RS–232C serial port of the computer

and the serial port of the Powermonitor. If you wish to assemble the

RS–232C cable yourself, the cable pin assignments are given below.

Alternatively, pre–assembled RS–232C cables can be ordered from

Allen–Bradley.

To install the RS–232C cable, connect one end of the RS–232C cable to the

desired serial port at the back of the computer running Powermonitor

Software. The three conductors at the other end of the cable are then inserted

into the appropriate communications connection points located on the

Powermonitor. The three connection lines are as follows (refer to Figure 3.1

on Page 3–3.):

3–2

1. Computer DB–25P pin 2 (computer Tx ) connect to the RXD of the

communications card.

2. Computer DB–25P pin 3 (computer Rx ) connect to the TXD of the

communications card.

3. Computer DB–25P pin 7 (computer signal GND) connect to the SG of the

communications card.

Important: The RS–232C communications link described above allows

only one device to be connected to each computer serial port.

Page 17

Chapter 3

Installation

Figure 3.1

Connection to a Single Powermonitor via RS–232C

Important: Note cable

RS–232C

Port

25 Pin (9 Pin)

IBM PC (DTE)

NOTES:

1. RS–232C Cables: 25 pin DB25 or 9 pin DB9, plug (male) or socket (female) depending on mating connector at computer serial port,

50 feet maximum length.

2. If connected directly to data communications equipment (DCE), the Tx and Rx leads need to be reversed at the RS–232C port .

3. A Request To Send signal is required when a modem or a Catalog Number 1400–CC Converter is being used. Connect to T erminal 4 of

the Powermonitor for the RTS signal.

Connection To Multiple

Powermonitors Via RS–485

pin–out numbers

1 (Case Ground)

(2)

3

(3)

2

(5)

7

Bulletin 1400

Powermonitor

TXD RXD SG

SHIELD

RS232C Cable

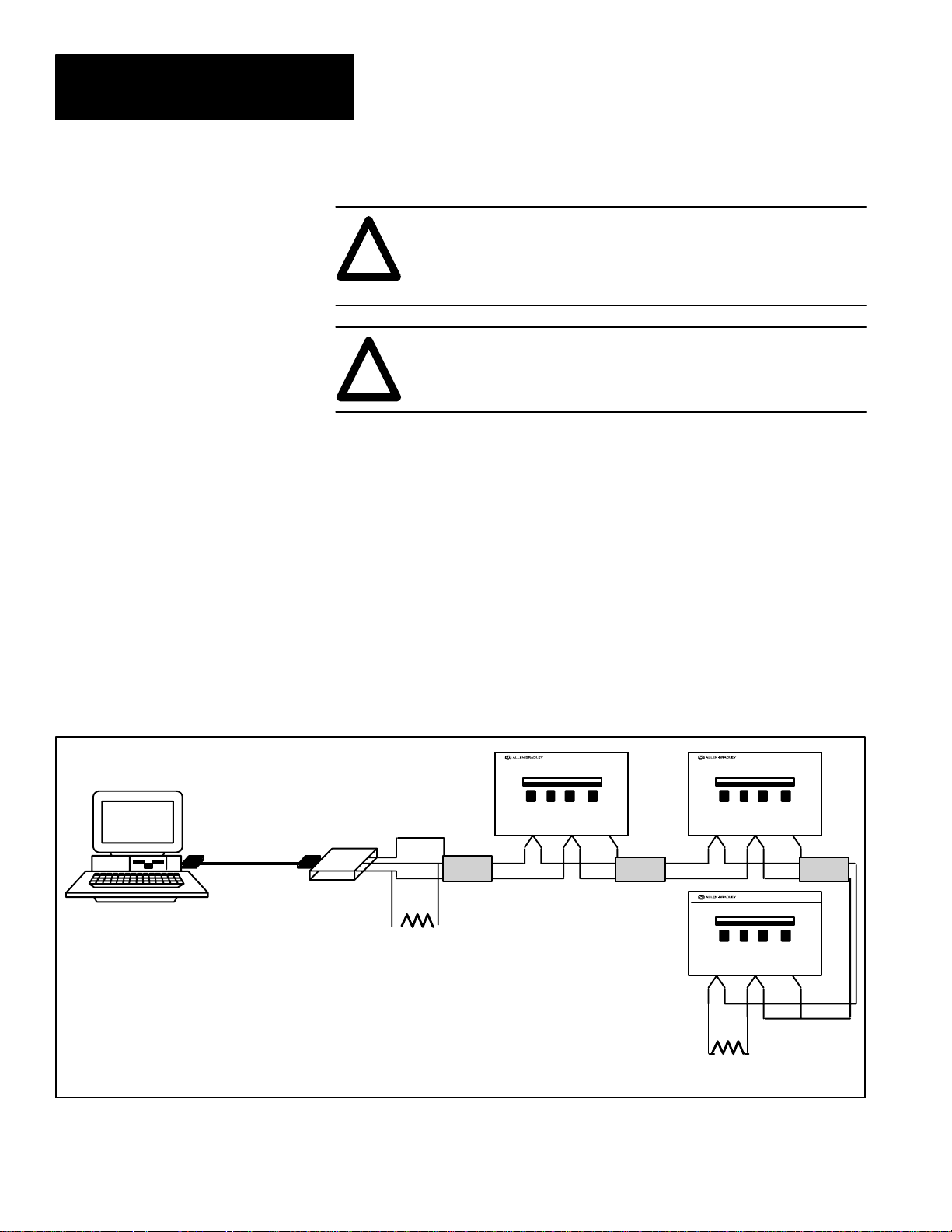

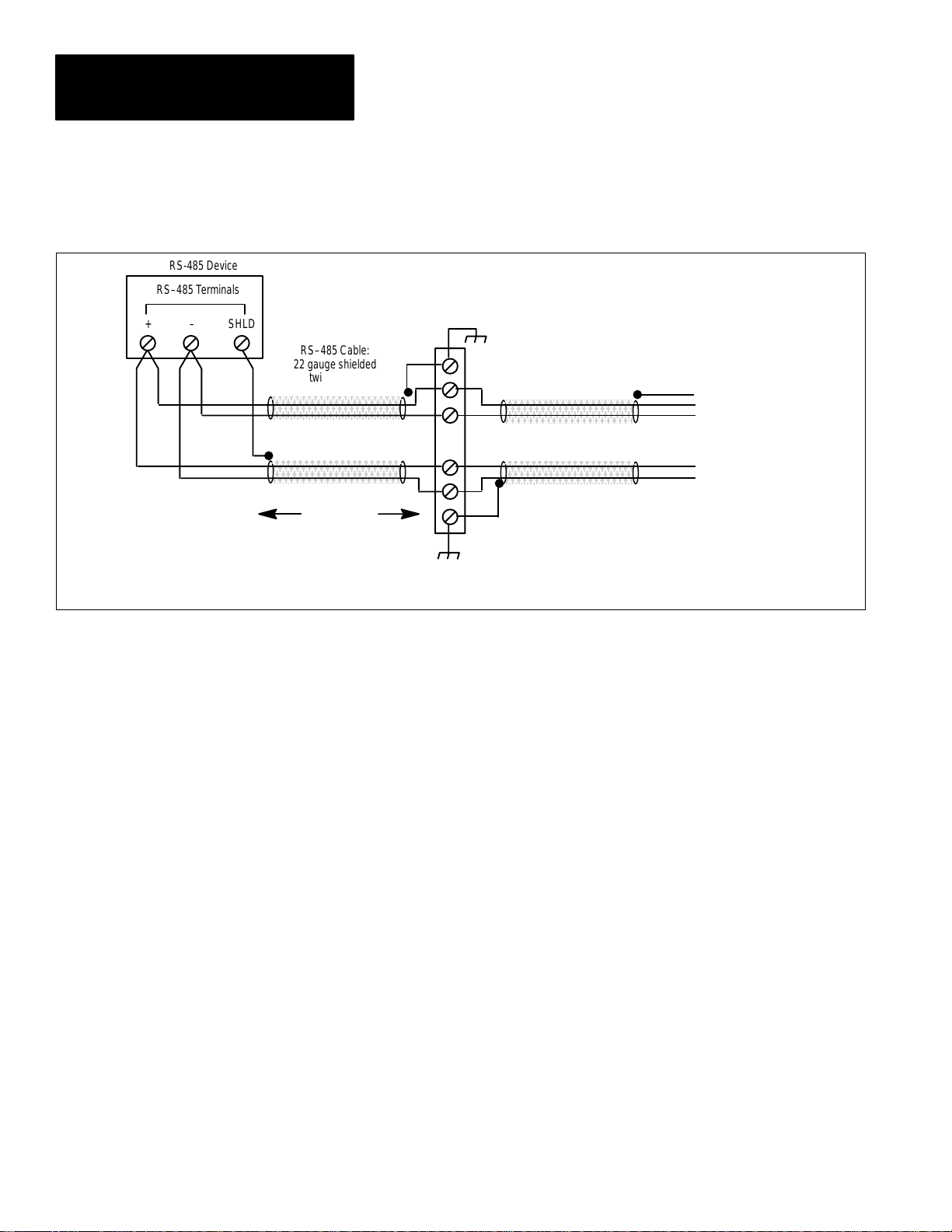

This section provides the information necessary to connect the computer

running Powermonitor Software to multiple Powermonitors via an RS–485

communications link.

An RS–485 communications link permits many Powermonitors to be

networked together on a two–wire twisted–pair local area network or LAN.

The computer can access information from any one of and up to 32 devices

connected to the RS–485 LAN.

To implement an RS–485 communications link, the computer running the

Powermonitor Software must be equipped with either an internal RS–485

communications card or an RS–232C serial port and an external RS–232C to

RS–485 converter. The Catalog Number 1400–CC converter can be used for

this purpose. Each Powermonitor to be connected to the RS–485 LAN must

be equipped with a Catalog Number 1400–DCU communications card

configured for RS–485. The communications cable required to connect the

computer to each of the Powermonitors consists of a shielded two conductor

twisted pair cable.

ATTENTION: Before connecting any communications cables,

confirm that every Powermonitor is equipped with a RS–485

!

communications port, and the port has been configured for

RS–485 operation. Refer to Publication 1400–800, ‘‘Bulletin

1400 Powermonitor Installation and Operation Manual,” for the

device to determine correct configuration of the port.

3–3

Page 18

Chapter 3

Installation

ATTENTION: Never connect an RS–232C equipped

device to the DATA+ or DATA– lines of an RS–485

!

equipped communication system. Doing so will damage

the RS–485 driver circuits of every device within the site.

ATTENTION: Converters such as the Catalog Number

1400–CC converter must always be used between devices

!

that use RS232C/RS–485 communications standards.

If the computer running the Powermonitor Software uses an RS–232C serial

port in conjunction with an external Catalog Number 1400–CC RS–232C to

RS–485 converter, then install a straight 25–conductor RS–232C cable or a

cable configured with (3) wires to pins 2, 3, and 7 from the desired serial port

at the back of the computer to the RS–232C input on a Catalog Number

1400–CC converter. The DATA+ and DATA– lines on the RS–485 side of

the converter are then connected to the DATA+ and DATA– on each

Powermonitor via a shielded two–wire twisted pair cable as shown in

Figure 3.2.

IBM PC (DTE)

25 Pin

Female

Connector

(DB 25)

RS–232C

Port

RS–232C

Important: Be sure to connect both ends of the shield between devices.

Figure 3.2

RS–485 Communications Connections – External Converter

25 Pin

Male

Connector

(DB 25)

Bulletin 1400–CC

External RS–232C to

RS–485 Converter

SHLD

+

–

150Ω

Resistor

Power–

monitor

#1

SHIELD

Power–

monitor

SHLD SHLD

–

+

To other

devices

#2

SHIELD

Power–

monitor

#3

+

+

150Ω

Resistor

–

SHIELD

SHLD

–

3–4

Page 19

Chapter 3

Installation

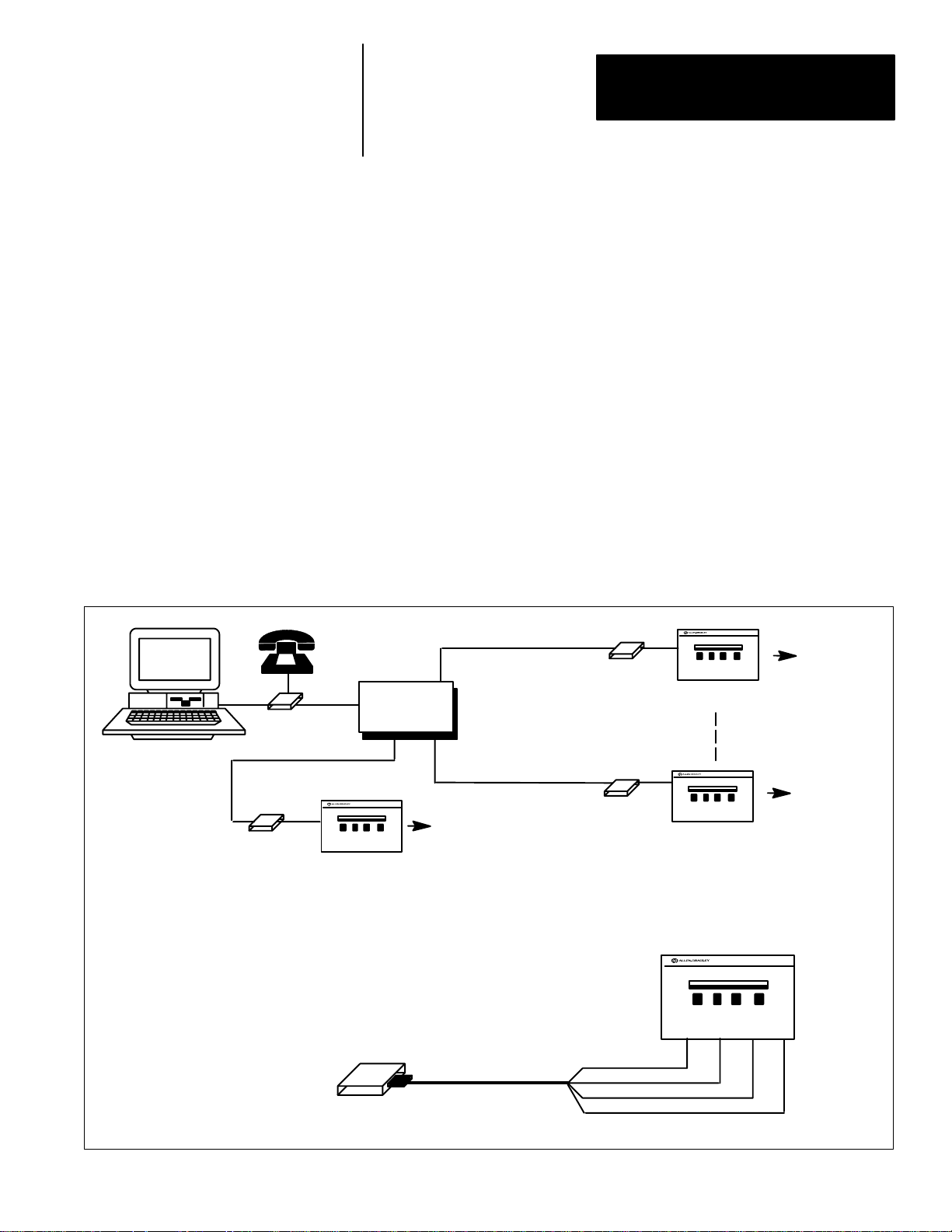

Connection To Single Powermonitor Sites Via The T elephone Network

Telephone

Modem

Site 1

Modem

Line

Telephone

Line

RS–232C

This section provides the information necessary to implement a telephone

modem link between the computer and sites with only single remote

Powermonitors.

Important: The multi–device remote site configuration outlined on page 3–8

should be used if more than one Powermonitor is to be installed at the remote

site in the future, or if a single device at a remote site is located more than 50

feet from the telephone modem.

To implement a telephone modem link, two telephone modems are required.

One modem must be located at the computer and one located at each remote

site requiring a Powermonitor. The single device port at the remote site must

be configured for an RS–232C communications port. The connection

diagram for the modem at the remote site is shown in Figure 3.3. Note that

this configuration (RS–232C) permits only one Powermonitor to be

connected to each modem.

Figure 3.3

Modem Connection to Sites with One Powermonitor

RS–232C

Telephone

Powermonitor

Line

Telephone

Network

Telephone

Line

T o Feeders,

Transducers, or

Pulse Initiations

Requiring

Monitoring

Modem

Site 32

RS–232C

Modem

Site 2

Powermonitor

Transducers, or

Pulse Initiations

Powermonitor

T o Feeders,

Transducers, or

Pulse Initiations

Requiring

Monitoring

T o Feeders,

Requiring

Monitors

Modem

(DCE)

Important: Note cable pin–out numbers

RS232C Cable

Powermonitor

TXD RXD

2

3

7

5

SG

RTS

3–5

Page 20

Chapter 3

Installation

ATTENTION: Before connecting any communications cables,

confirm that the Powermonitor is configured for RS–232C

!

communications and the computer port has been configured for

RS–232C operation. Refer to Publication 1400–800, ‘‘Bulletin

1400 Powermonitor Installation and Operation Manual,” to

determine correct configuration of the port.

The remote site requires a RS–232C cable between the modem and the serial

port of the Powermonitor. If you wish to assemble the RS–232C cable

yourself, the cable pin assignments are given below. Alternatively,

pre–assembled RS–232C cables can be ordered from Allen–Bradley.

Modem Connector DB–25, pin DCU Card Labeled

2 (Rx)

3 (Tx) wire to RXD

7 (signal ground) wire to SG

5 (RTS)

wire to TXD

wire to RTS

1. Modem DB–25S pin 3 (modem Tx ) goes to device RXD.

2. Modem DB–25S pin 7 (modem GND) goes to device GND.

3. Modem DB–25S pin 4 is jumpered to modem DB–25S pin 5.

4. Modem DB–25S pin 6 is jumpered to modem DB–25S pin 20.

To install the RS–232C cable, connect the DB25 connector end of the

RS–232C cable to the serial port at the back of the modem. The four

conductors at the other end of the cable are then connected to the appropriate

communications points located on the Catalog Number 1400–DCU

communications card. The connections are shown in Figure 3.3 on page 3–5.

3–6

Page 21

Chapter 3

Installation

Modem Configuration Information

Modems used with computers running the Powermonitor Software must be

fully Hayes compatible.

If the modems are configured via their communications ports, the

Powermonitor Software will configure them automatically using a set of

default commands. These commands assume that a standard Hayes modem

is being used. If you are using a modem which requires a unique command

set to configure it, refer to Appendix B for instructions on creating a special

MODEM.CFG file for Powermonitor Software to use.

If the modems are configured via hardware DIP switches or a similar

method, configure them to the specifications on next page.

Modems should be configured as follows:

The modem located at the destination site must be configured for

“auto–answer” mode. The modem connected to the computer running the

Powermonitor Software must be configured for “originate” mode.

Both modems must also be configured as follows:

1. Force the RS–232C Data Terminal Ready lead true.

2. Result codes must be sent as numbers.

3. Result codes must be sent by the modem.

4. Echo characters while in command state.

5. Do not force Carrier Detect lead true.

6. Single line connection.

7. Enable modem command recognition.

8. 8 data bits per byte.

9. No parity.

10. 1 stop bit.

The modem must be Hayes compatible. If you are using a sophisticated or

high speed modem, some of the advanced features need to be disabled.

To use a Telebit 3000 modem, disable flow control, disable data compression

and specify CTS operation and delay. Re–configure modem command

register as shown below: (This is an example only.)

AT Z Reset Modem

AT &RO CTS follows RTS

AT S26=1 RTS to CTS Delay Interval

AT S50=6 9600 Baud per second (V.32)

AT S58=O Disable Flow Control

AT S190=O Disable Data Compression

3–7

Page 22

Chapter 3

Installation

Modem Configuration Information Continued

You will need to check the modem’s user’s guide for the codes applicable to,

and appropriate for your modem.

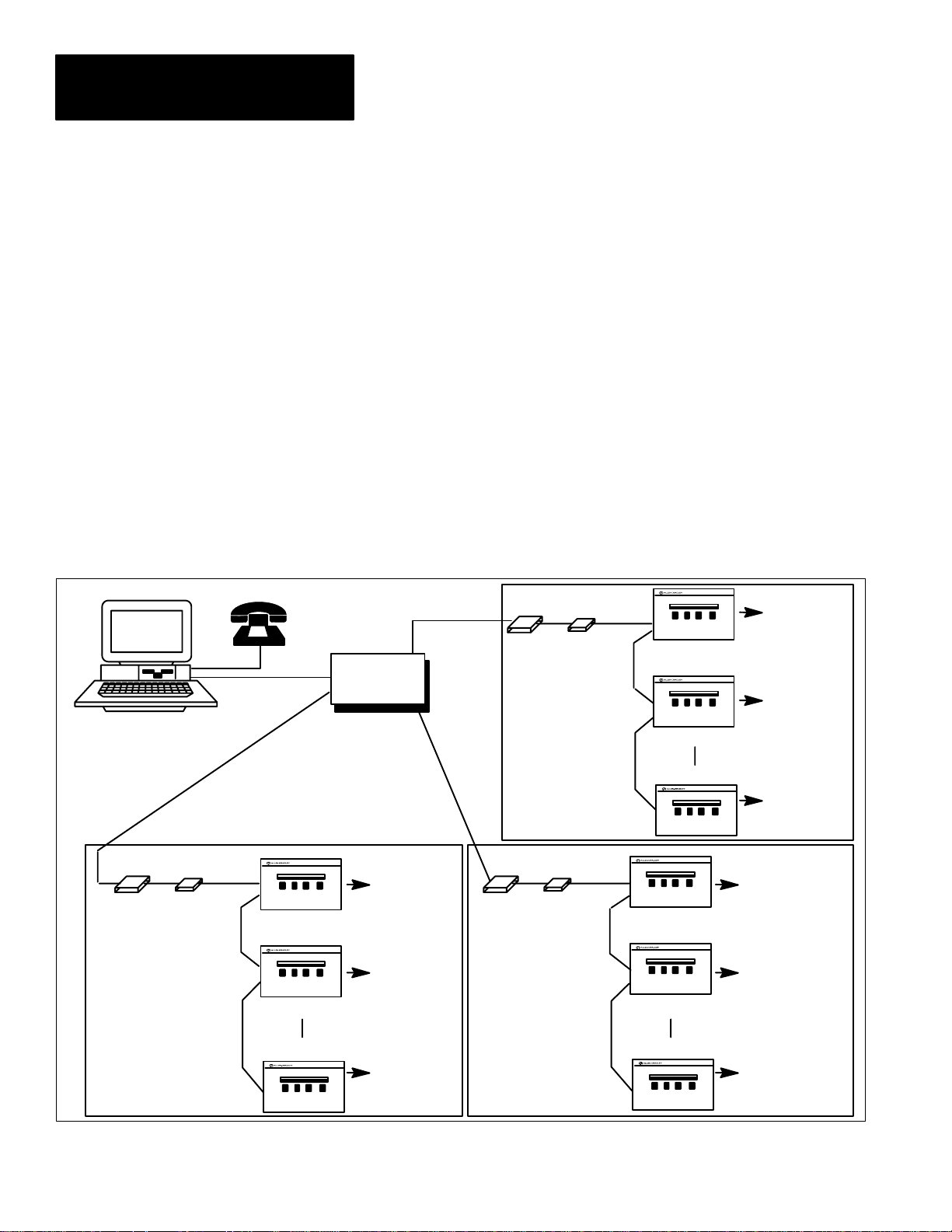

Connection To Multiple Powermonitor Sites Via The T elephone Network

Telephone

Line

IBM PC with Hayes Modem

Telephone

Line

Modem sites having more than one device are similar to sites with one

device except that a Catalog Number 1400–CC RS–232C to RS–485

converter must be used and the Powermonitor communications card must be

configured for RS–485 communications.

The connection diagram for this configuration is shown in Figure 3.4.

Telephone modems must be configured in the manner described on Page 3–7.

Figure 3.4

Modem Connection to Sites with One or More Powermonitors

Telephone

Network

Telephone

Line

Telephone

Line

RS–232C

Modem

Site 3

Catalog

Number

1400-CC

RS–485

RS–485

Powermonitor #1

T o Feeders,

Transducers, or

Pulse Initiations

Powermonitor #2

Powermonitor #32

3–8

Modem

Site 1

RS–232C

Catalog

Number

1400-CC

Modem

RS–232C

Catalog

Number

1400-CC

RS–485

RS–485

Powermonitor #1

T o Feeders,

RS–485 RS–485

Powermonitor #2

Powermonitor #32

Transducers, or

Pulse Initiations

Site 2

Powermonitor #1

T o Feeders,

Transducers, or

Pulse Initiations

Powermonitor #2

Powermonitor #32

Page 23

Chapter 3

Installation

ATTENTION: Special high level isolation is required between

units when the possibility of high ground potential differences

!

exist. This may occur when separate grounds are used, or when

communicating to a unit off of the power ground matt. Failure to

do so can lead to personal injury or death, property damage, or

economic loss.

Important: For each site, total RS–485 cable length (Maximum 4,000–ft.)

between all devices in the RS–485 network when using 22 gauge shielded

twisted pair.

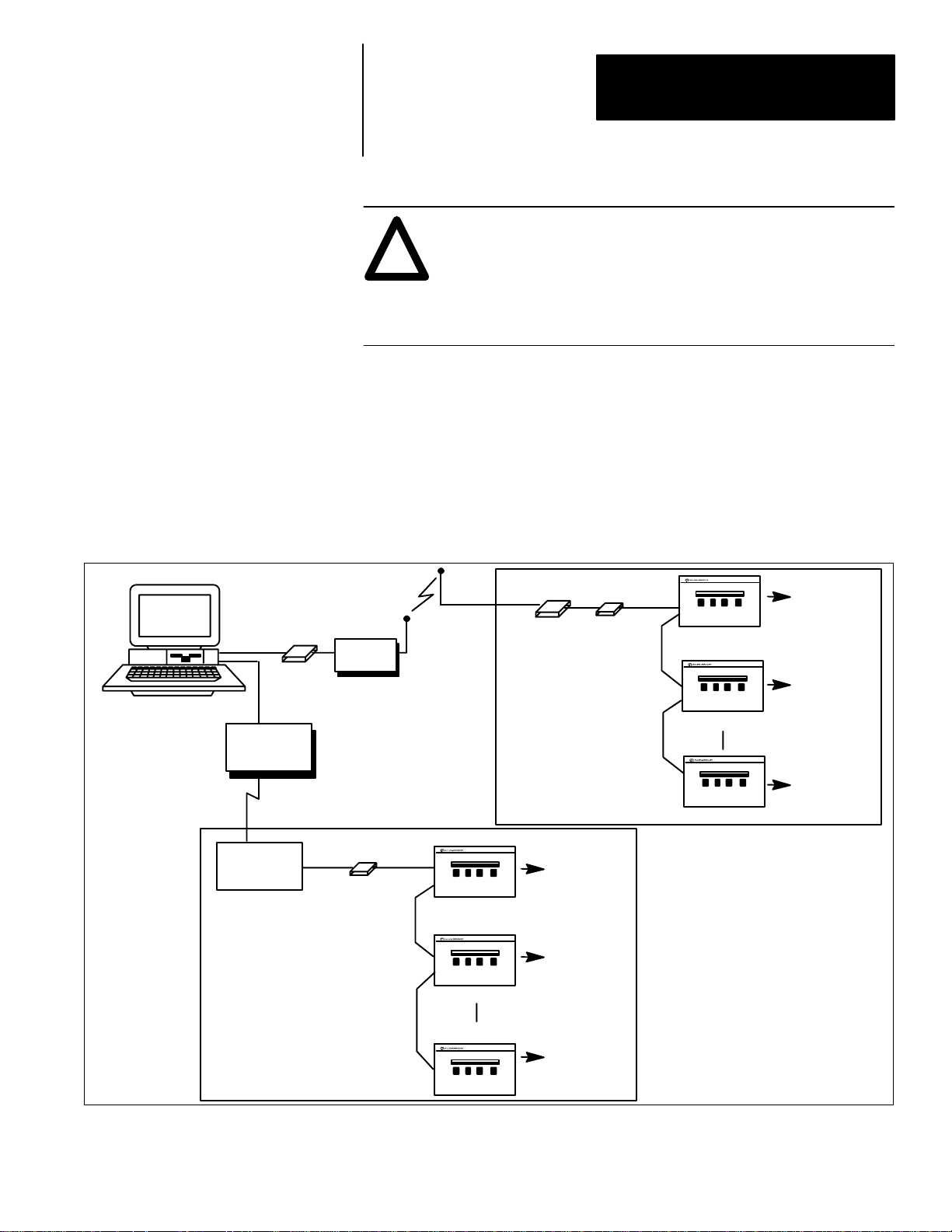

Connection To Remote Sites Using Other Methods of Communications

IBM PC with Hayes Modem

Fiber Optic

Converter to

RS–232C Output

Fiber Optic

Link

Fiber Optic

Converter to

RS–232C Output

Additional methods of connecting the computer running Powermonitor

Software to Powermonitor sites include fiber optic, radio, and microwave

links. See Figure 3.5.

Figure 3.5

Connection to Remote Sites using Other Methods of Communications

Radio

TX/RX

RS–232C

Catalog

Number

1400-CC

RS–232C

Modem

Site 2

RS–485

Powermonitor #1

Catalog

Number

1400-CC

RS–485

Powermonitor #1

Powermonitor #2

Powermonitor #32

T o Feeders,

Transducers, or

Pulse Initiations

Site 1

T o Feeders,

Transducers, or

Pulse Initiations

Powermonitor #2

Powermonitor #32

Contact the Allen–Bradley Support Division for information regarding

remote links using any of the above methods or any methods not shown.

3–9

Page 24

Chapter 3

Installation

Installation Of The System Software

Creating A Backup Copy of the Powermonitor Software

Contents of the Powermonitor Software Package

Upon receipt of the Powermonitor Software software package, it is important

to check its contents to ensure that you have received the necessary items.

Your package should contain:

1. Publication 1400–801 ‘‘Powermonitor Software Installation and

Operation Manual.”

2. The Powermonitor Software diskettes(Double Sided, Double Density in

sizes 3–1/2 and 5–1/4 inches)

Should any of the above items be missing, contact Allen–Bradley

immediately and report the missing items.

Before using the Powermonitor Software, create a backup of the software by

copying the entire contents of the Powermonitor Software diskette onto

backup diskette. Store the original diskette in a safe place and use only the

backup copy to run the Powermonitor Software.

3–10

Page 25

Chapter 3

Installation

Installing The Software Onto A Hard Drive

The Powermonitor Software is designed to run either from the floppy disk it

comes on, or from a hard disk drive, onto which it can be copied.

If you wish to run the Powermonitor Software from the floppy disk, proceed

to Chapter 4 for instructions on starting and running the Powermonitor

Software.

If you wish to run the Powermonitor Software from the hard drive of your

computer, first perform the following steps to install the Powermonitor

Software onto the hard drive:

1. Create a directory called SP on your hard disk. You may select any drive

to create the directory on (C:, D:, etc.). The following instruction set

creates the directory on the C: drive:

C: <Enter>

MD SP <Enter>

2. Insert the Powermonitor Software program diskette into the A: drive of

your computer and copy the entire contents of the disk into the SP

directory on your hard disk. The following instruction assumes that the

SP directory was created on your C: drive. If this is not the case, replace

C: with the appropriate drive designation.

COPY A:*.* C:\SP <Enter>

3. Check that the SP directory on your hard disk contains the following files:

SP.EXE

SP.EXE is the Powermonitor Software program.

PASSWORD.CFG

Password.CFG is the Powermonitor Software password and setup file.

This file must be present to allow any protected functions to be performed

such as: changes to Powermonitor parameters, or relay control

commands. This file also allows communications setups to be saved.

Chapter 4 describes this in more detail.

The Powermonitor Software has now been installed on your hard disk. Refer

to Chapter 4 for instructions on starting up and using the Powermonitor

Software program.

3–11

Page 26

Chapter 3

Installation

3–12

Page 27

Chapter

Chapter Objectives

Startup

A–B

4

Using The Software

This chapter provides general instructions on starting the Powermonitor

Software, establishing communications with a remote device, using the

Powermonitor Software menu system, and using the on–screen help feature.

To Run The Software From The Hard Drive

If the user has performed the hard drive installation procedure given in

Chapter 3, the Powermonitor Software may be run from the hard drive by

entering the following commands:

CD \SP <Enter>

SP <Enter>

After a moment, the Powermonitor Software TITLE screen will appear on

the monitor (see Figure 4.1 on Page 4–2), followed by the Powermonitor

Software CONNECTION SCREEN.

To Run The Software From The Floppy Diskette

ATTENTION: The floppy diskette used to run the Powermonitor

Software must not be write protected, since the Powermonitor

!

Software saves the last CONNECTION screen data entered by

the user, and the Powermonitor Software PASSWORD to the

currently selected drive when the user exits to DOS.

If the user wishes to run the Powermonitor Software from the floppy

diskette, enter the following commands:

A: <Enter>

SP <Enter>

After a moment, the TITLE screen will appear on the computer monitor

(see Figure 4.1 on Page 4–2), followed by the CONNECTION SCREEN.

4–1

Page 28

Chapter 4

Using The Software

Figure 4.1

Powermonitor Software Title Screen

VERSION: 1.0

COPYRIGHT 1993

Possible Errors On Startup

Establishing Connection With A Remote Device

If difficulty is experienced when starting the Powermonitor Software

program, re–check each of the steps on Page 3–8 through 3–10 and Page 4–1

to ensure they have been performed correctly. Check the help screen for

other suggestions. If difficulties persist, contact Allen–Bradley for assistance.

Connection Screen

The CONNECTION SCREEN (See Figure 4.2 on Page 4–3), which appears

following the TITLE screen on power–up, is used to establish

communications between the computer and a Powermonitor.

4–2

Page 29

Figure 4.2

Connection Screen

Chapter 4

Using The Software

At any time the CONNECT STATUS may be verified by pressing F6, which

presents the CONNECTION SCREEN. This CONNECTION SCREEN may

be displayed at any time by returning to the MAIN MENU (by pressing the

Esc key), positioning the cursor onto the CONNECT option and pressing the

<Enter> key. The user may, alternately, press F6 to directly display this

screen.

Establishing Communications

The user is required to enter information into six data fields prior to

establishing communications (ie. connecting) to a Powermonitor.

The flashing data field indicates the present cursor position. The arrow keys

are used to move the cursor to the data entry fields on the CONNECTION

screen. A help line at the bottom of the screen indicates the options available

for each field.

The following fields on the CONNECTION screen require information to be

entered by the operator prior to connecting with the device.

a. SITE ID. This field is used to assign a name to the location of the

Powermonitor which is to be accessed. The name used here will

appear on each data screen accessed.

To change the SITE ID field, position the cursor onto the field, type

any alphanumeric site name (up to 10 characters) and press the

<Enter> key. This field now becomes a label used on other

screens.

b. UNIT ID. This field specifies which Powermonitor to address and

establish communications with.

4–3

Page 30

Chapter 4

Using The Software

Each Powermonitor has its own unique 4 digit UNIT ID (Address)

that can be viewed or changed from the device’s front panel. Each

Powermonitor should initially have an address. Enter the number

into the UNIT ID field of the device whose data you wish to

display. The UNIT ID must be set before communications can be

established with that device.

To change the UNIT ID field, position the cursor, enter a four digit

number and press the <ENTER> key. The devices’ default number

is assigned at the factory and inked on the back of the device.

c. COMM PORT. This field identifies which of the computer’s

serial ports is connected to the remote device. Position the cursor

onto the PORT field and press the plus or minus (“+” or “–”) keys

to select the serial port which will be used for communication to

that site (COM1 or COM2).

d. BAUD RATE. Position the cursor onto the BAUD field and press

the plus or minus keys to select the baud rate of the serial port. The

Powermonitor Software supports 300, 1200, 2400, 4800, 9600, and

19.2K baud rates.

Important: When setting the BAUD RATE parameter, the system operator

must ensure that all modems and devices connected to the assigned serial

port have also been configured to operate at the same baud rate.

e. DIAL (PHONE #). This field is used only when the

Powermonitor Software is communicating with a remote device via

telephone modems. To change this parameter field, type the

telephone number of the destination site and press <Enter>.

Examples of valid formats for telephone number are:

123–4567 Regular seven digit number.

1–414–382–2000 Number with long distance prefix and area

code.

14143822000 Numbers can be entered without dashes

(using no spaces).

9,382–2000 Commas can be used to insert a time delay

(approx. 3 sec.) between the dialing of digits.

f. LINE TYPE. This field determines the type of connection to be

established between the Powermonitor Software and the remote

device. Pressing the plus (+) or minus (–) keys will select the

LINE TYPE. There are three valid line types:

• DIRECT CONNECT. If the site is connected to the computer

via a dedicated RS–232C or RS–485 communication link, then

choose the DIRECT CONNECT option.

4–4

Page 31

Chapter 4

Using The Software

If the site is only accessible via the telephone network using a

modem, then choose either the TOUCH (touch–tone) or PULSE

line type option, depending on the type of phone line dialing

system being used.

• MODEM (TOUCH TONE). Used when the computer is

connected to a remote device via a TOUCH TONE telephone

modem.

• MODEM (PULSE). Used when the computer is connected to a

remote device via a PULSE telephone modem.

Important: If either MODEM option is selected, the Powermonitor Software

will configure the connected modem using a set of default commands.

These commands assume that a standard Hayes modem is being used.

If you are using a modem which requires a different command set to

configure it, refer to Appendix B for instructions on creating a special

MODEM.CFG file for the Powermonitor Software to use.

Connecting With The Remote Device

Once the six data fields described above have been configured, the

CONNECT OPTION field is used to invoke the connection procedure. When

invoked, the Powermonitor Software will attempt to establish

communications with the remote device specified in the UNIT ID field.

To initiate the connection procedure, position the cursor over the CONNECT

OPTION field and press the <Enter> key.

The present CONNECT STATUS field will indicate if a connection to the

device was successful. The following status messages will be indicated in

the present CONNECT STATUS field, depending on the present status of

communications:

1. Connecting Directly. When using the DIRECT CONNECT line type,

the Powermonitor Software will display the message:

ATTEMPTING CONNECTION ...

When the Powermonitor Software establishes communication with the

specified unit, the CONNECT STATUS field will display:

DIRECT CONNECTION ESTABLISHED

and the entry in the CONNECT OPTION field will change to:

DISCONNECT

to allow disconnection, if desired.

4–5

Page 32

Chapter 4

Using The Software

When connection cannot be made, the Powermonitor Software will

display:

UNIT NOT RESPONDING

If this occurs, there is a problem that is preventing communications from

being established. Determine and correct the problem and retry

connection by pressing the <Enter> key again while on the flashing

CONNECT OPTION field. Chapter 8 provides troubleshooting

information in case of difficulty.

2. Connecting via Telephone Modem. When using either of the two

modem line types, the Powermonitor Software will display the message:

DIALING

while dialing the telephone number entered in the DIAL (PHONE #)

field.

When the Powermonitor Software establishes communication with the

destination site, the Powermonitor Software will display:

MODEM CONNECTED ... Unit responding.

and the CONNECT OPTION will change to:

DISCONNECT

to allow disconnection, if desired.

If a connection cannot be made, then one of the following messages will

be displayed:

MODEM CONNECTED ... Unit not

responding.

MODEM NOT RESPONDING

NO CARRIER PRESENT

LINE BUSY

COMMAND ABORTED

MODEM ERROR

Pressing the ESC key will abort the dialing process and the following

message will be displayed:

4–6

CONNECTION ABORTED

Chapter 8 lists possible causes for the above difficulties.

Page 33

Chapter 4

Using The Software

The Menu System

The Powermonitor Software is an easy–to–learn and simple–to–use software

package incorporating a very powerful menu–driven operator interface. The

MAIN MENU is illustrated in Figure 4.3. This menu can be displayed at any

time by pressing the <Esc> key.

Figure 4.3

Main Menu Screen

Important: The Powermonitor Software MAIN MENU will not be made

available to the operator if the PASSWORD.CFG file is missing from the SP

directory on disk. Instead, the operator may only use the function keys F1 to

F6 to connect with Powermonitors and view device data. The <Esc> key, in

this case, is used to escape to DOS.

Any screen or function option can be accessed by using the arrow (cursor)

keys. To select the option, position the highlighted cursor over the desired

name, then press the <Enter> key. Each time a menu item is selected, the

information requested will be displayed or the selected function will be

performed.

After selecting a menu option, the system operator can always return to the

MAIN MENU by pressing the <Esc> key.

ATTENTION: Device time and date must be set when

communication is first established and whenever the device

!

loses power.

4–7

Page 34

Chapter 4

Using The Software

Help/Message Line

The Powermonitor Software system provides a HELP/MESSAGE line at the

bottom of every screen, which serves two important purposes:

a. While any menu or screen is being displayed, a HELP line is

shown at the bottom indicating which keyboard keys are active on

the present screen. (Note: A quick keyboard reference for the

Powermonitor Software system is also given in Appendix D).

b. A MESSAGE line is used to display system status messages to the

operator. Examples of system status messages include password

prompts, modem connection status messages and system error

messages.

Screens And Functions

The Powermonitor Software automatically determines which type of remote

device it is communicating with, and configures the MAIN MENU

accordingly to provide the options specific to that device.

The MAIN MENU screen provides access to all of the Powermonitor

Software’s remote device data display and configuration screens and

functions, as well as the on–line HELP and the Powermonitor Software

PASSWORD screens.

Remote device data screens include:

a. REAL–TIME. Displays the real–time data being measured or

monitored by the remote device.

b. EVENT LOG. Up load and display the remote device’s Event Log.

c. SNAPSHOT LOG. Up load and display the remote device’s

on–board Snapshot Log.

d. STATUS LOG. Displays the present condition of the remote

device’s three on–board control relays and four status inputs.

e. MIN/MAX LOG. Up load and display the remote device’s

on–board Min/Max Log.

Remote device configuration screens include:

a. DEVICE SETUP. Allows the operator to remotely configure the

operating parameters of the device.

b. SETPOINT/RELAY SETUP. Allows the operator to configure the

setpoint parameters of the remote device.

c. CLEAR FUNCTIONS. A number of different functions are

provided for the purpose of clearing or resetting Min/Max Log

values, kWH, kVARH and kVAH totals, status input counters, etc.

4–8

Page 35

Chapter 4

Using The Software

Screens And Functions Continued

Other device functions include:

a. OPERATE RELAY. Allows the operate to manually control the

on–board relays of the remote device.

b. CONNECT. Selects the CONNECTION screen to enable the

operator to select another Powermonitor to communicate with.

c. MAIN MENU, CLEAR HOURS: After entering this menu

selection and successfully entering the SP software password, the

prompt“CLEAR ALL HRS,kWH,kVARH, OR kVAH–(0/1/2/3)?”

will be displayed. By entering the value of 0, this will clear the

kWH, kVARH and kVAH counters simultaneously. NOTE: The

kVAH option is displayed and cleared for those powermonitor units

with firmware version 0.7. or later.

Shortcut Keys

The Powermonitor Software provides a shortcut method for directly selecting

any of the five frequently used primary data screens, and the CONNECTION

screen. The following function keys can be used to quickly select screens:

Password

F1 REAL–TIME screen

F2 EVENT screen

F3 SNAPSHOT LOG screen

F4 STATUS screen

F5 MIN/MAX LOG screen

F6 CONNECTION screen

Screen Descriptions

Detailed descriptions of each remote device data and configuration screen

can be found in Chapter 5, ‘‘Powermonitor Data Display and Configuration.”

The Powermonitor Software provides a security system to protect

Powermonitors from inadvertently:

a. having their relays manually operated/released.

b. having their kWH, kVARH or kVAH totals cleared, or Min/Max

Logs reset.

c. having any of their user–programmable operating parameters reset

from the computer.

The Powermonitor Software password is used for this purpose. Prior to any

of the above listed operations, the Powermonitor Software will prompt the

user for the required password. If the password entered by the operator is

incorrect, the Powermonitor Software will abort the operation.

When the Powermonitor Software is run for the first time, the Powermonitor

Software password is set to the single digit zero (“0”). It is recommended

that the user change this default password as soon as possible, using the

Powermonitor Software PASSWORD screen (see Figure 4.4 on Page 4–10).

4–9

Page 36

Chapter 4

Using The Software

Important: The Powermonitor Software password is not the unit password.

Figure 4.4

Powermonitor Software Software Password Screen

To change the Powermonitor Software password, return to the MAIN MENU

by pressing the <Esc> key, position the cursor onto the CHANGE

PASSWORD option and press the <Enter> key.

The Powermonitor Software prompts the user to enter the present password.

When this password has been correctly entered, the user is asked to enter the

new password and then asked to re–enter the new password again for

confirmation. The password can be any alphanumeric string up to 20

characters in length. Blanks are not permitted.

If the attempt to change the Powermonitor Software password is successful,

the following message will be displayed:

PASSWORD

HAS BEEN UPDATED

If the attempt to change the Powermonitor Software password is not

successful, the following message will be displayed:

PASSWORD

HAS NOT CHANGED

On completion of the CHANGE PASSWORD function, the MAIN MENU

will be displayed.

4–10

Page 37

Chapter 4

Using The Software

On–Line Help

Update Unit Time

The Powermonitor Software provides an on–screen HELP feature which can

provide the operator with information about communication, modem usage,

and technical support, without having to refer back to Publication 1400–800,

‘‘Bulletin 1400 Powermonitor Installation and Operation.”Help is also

available from the connection screen, when not connected by pressing H.

To access the HELP INFORMATION SCREEN, select the HELP option

from the MAIN MENU.

The MAIN MENU provides a utility to update the time of a Powermonitor.

This function sets the on–board clock of the remote device to the value of the

computer’s internal clock. A remote device’s present time setting can be

viewed by simply displaying the REAL–TIME or STATUS screen for that

device. Time is displayed in the bottom right–hand corner for each of these

screens. While the Main Menu is displayed, press the F8 key to change the

unit time to the computers present system time. F8 – Update Unit Time. This

function is now password protected and displays the current PC Time to

allow the user to see what would be sent to each unit prior to sending the

time.

4–11

Page 38

Chapter 4

Using The Software

Exit To DOS

To exit from the Powermonitor Software program and return to DOS, the

operator must use the EXIT TO DOS option on the MAIN MENU screen:

1. Return to the MAIN MENU from any other screen by pressing the <Esc>

key.

2. Position the cursor over the EXIT TO DOS option using the arrow keys,

or by pressing the <Esc> key again.

3. Press the <Enter> key.

The operator will be immediately returned to DOS.

Connection Configuration Save Feature

Immediately prior to the operator being returned to DOS, the Powermonitor

Software will save the last information entered in the CONNECTION screen

(SITE ID, UNIT ID, COMM PORT, etc.) to a disk file.

When the Powermonitor Software is started again later, the previous

connection configuration will be loaded into the CONNECTION screen

automatically. This means the operator will not be required to re–enter data

in the CONNECTION screen fields, if connection to the same remote device

is desired. The operator need only position the cursor on the CONNECT

OPTION field and press <Enter> to reconnect to that device.

Important: The Powermonitor Software saves the connection setup to the

file in the SP disk directory named PASSWORD.CFG, which is the same file

containing the Powermonitor Software password. If this file is missing from

the SP directory, the Powermonitor Software will always display the default

communications options in the CONNECTION screen when the program is

first started.

4–12

Page 39

Chapter

Chapter Objectives

Displaying Single Device Data

A–B

5

Powermonitor Data Display And Configuration

This chapter describes the steps necessary to display real–time and logged

data from a Powermonitor, and how to configure the operating parameters of

the device.

Data Display Formats

Following connection to a Powermonitor (as described in Chapter 4) the

system operator can display data from that device by selecting the desired

data screen from the MAIN MENU. These include:

a. REAL–TIME

b. EVENT LOG

c. SNAPSHOT

d. STATUS (incl. Relay Status, Status Inputs, and Setpoint Status)

e. MIN/MAX

Displaying Device Data

To display data from a particular device:

1. Connect with the Powermonitor as described in Chapter 4 (if not

previously performed).

2. Return to the MAIN MENU by pressing <Esc>, select the desired data

screen using the cursor keys, and press <Enter>.

Alternately, the operator can use the shortcut keys to view data screens

directly, rather than using the MAIN MENU. Shortcut key functions are

listed in the HELP line at the bottom of the screen.

The most recent data for the selected device screen should appear almost

immediately.

Important: If the site is accessed via a modem that is not presently

connected, a series of messages will appear at the bottom of the screen

indicating modem connection status. It may take 30 seconds to establish

connection with the site before updated data will appear on the

Powermonitor.

5–1

Page 40

Chapter 5

Powermonitor Data Display and Configuration

Important: An audible alarm (beep) will be encountered if a

communications failure occurs when attempting to display any device screen.

In this case, the operator should verify communication with the device by

entering the CONNECTION screen and checking that the CONNECT

STATUS field is reading CONNECTED. If this is not the case, attempt to

reconnect with the device as described in Chapter 4, ‘‘Using The Software.”

If connection cannot be accomplished, refer to Chapter 8,‘‘Troubleshooting.”

An example of a typical device data screen is provided in Figure 5.1.

Figure 5.1

Example of Powermonitor Data Screen

5–2

At the bottom of each data screen the UNIT ID indicates from which unit

data is presently being monitored. The DATE and TIME shown at the

bottom of some screens (ex. REAL–TIME and STATUS screens) indicates

the time at which the data was last updated.

The data shown on each screen will be continually updated as long as the

device is connected. The rate at which data is refreshed will depend upon the

baud rate of the communications link.

Displaying Additional Data

In the case of screens which contain too much information to be shown at

once, such as the SNAPSHOT LOG, the up/down arrow or PgUp/PgDn keys

can be used to scroll or page up/down through the data, respectively. The

left/right arrow keys can also be used to select any available adjacent screens

(ex. SNAPSHOT Left, Center, Right).

Page 41

Chapter 5

Powermonitor Data Display and Configuration

If additional data is available, a message line at the bottom of the data screen

will tell the operator which key functions to use to view the data.

To Exit From Any Data Display Screen

To exit from any screen, the operator can either press the <Esc> key to return

to the MAIN MENU, or press one of the shortcut keys to display another

data screen directly.

Configuring Powermonitors

The Powermonitor Software gives the system operator the ability to remotely

view or reconfigure the DEVICE SETUP and SETPOINT/RELAY SETUP

parameters of a Powermonitor from the Master Display Station.

Displaying The Setup Or Setpoint Parameters Of Any Devices

All device configuration functions are accessed from the MAIN MENU. To

display data from a particular device:

1. Connect with the desired Powermonitor as described in Chapter 4.

2. Return to the MAIN MENU.

3. Place the cursor onto the DEVICE SETUP or SETPOINT/RELAY

SETUP field for the desired device (depending on which set of

parameters you wish to view and/or configure) and press the <Enter> key.

An example of a Powermonitor configuration screen is provided in

Figure 5.2.

Figure 5.2

Example of Powermonitor Configuration Screen

5–3

Page 42

Chapter 5

Powermonitor Data Display and Configuration

Important: Communication alarm conditions that were described for

displaying device data screens also apply to displaying configuration screens.

Important: Device configuration screens are not available to the operator if

the PASSWORD.CFG file is missing from the SP directory on disk.

Modifying Parameter Values

In the device configuration screens, the Powermonitor Software will prompt

the operator to enter the Powermonitor Software password. This is necessary

before any device parameters may be modified.

When working in the device configuration screens, the arrow keys are used

to position the cursor onto the desired parameter field. The cursor position is

indicated by a flashing parameter value.

Some parameter fields are changed by entering a numerical value. If an

attempt is made to set a parameter to a value outside its allowable limits, the

value is rejected. Should a value be rejected, the user must re–enter with a

proper value. The operator may also cancel the entry of any value by

pressing the <Esc> key.

Some parameter fields are changed by pressing the plus or minus keys which

cause the field to increment/decrement through a pre–defined range of

values, or number of parameter selections. This is indicated by +/– toggle

UP/DN appearing in the lower right hand portion of the screen.

Reconfiguring The Device With The New Parameter Values

The Powermonitor will be reconfigured using the new values entered into the

screen when the operator presses the <Esc> key to return to the MAIN

MENU. The <Esc> key, in this case, is used as a SAVE & EXIT command.

After transmitting the changes and returning to the MAIN MENU, it is

recommended that the operator redisplays the setup screen for that device to

verify that the new parameter values have, in fact, been implemented.

5–4

Page 43

Chapter 5

Powermonitor Data Display and Configuration

Data Display and Configuration Screens

Data display screens for the Powermonitor include:

REAL–TIME

EVENT LOG

SNAPSHOT

STATUS

MIN/MAX

Configuration screens for the Powermonitor Software include:

DEVICE SETUP

SETPOINT/RELAY SETUP

Additional device functions include:

CLEAR kWH

CLEAR kVAH

CLEAR kVARH

CLEAR S1 COUNTER

CLEAR MIN/MAX

CHANGE PASSWORD

All device data display screens, configuration screens and functions can be

accessed via the MAIN MENU.

Main Menu

For the Powermonitor, the operator must first select the CLEAR HOURS

option to access the CLEAR kWH, CLEAR kVARH, or kVAH functions for

the Powermonitor (Refer to Figure 5.3 on Page 5–5). The Powermonitor

Software will then prompt the operator for the password and then to specify

which total is to be cleared. After entering this menu selection and

successfully entering the SP software password, the prompt “ CLEAR ALL

HRS, kWH, kVARH, OR kVAH– (0/1/2/3) ?” will be displayed. By entering

the value of 0, this will clear the kWH, kVARH, and kVAH counters

simultaneously. NOTE: The kVAH option is displayed and cleared for only

those powermonitor units with firmware version 0.7 or later. The Main Menu

screen also provides an additional CLEAR S1 COUNTER function.

The RELAY CONTROL option of the MAIN MENU is described in

Chapter 6, ‘‘Manual Control of Powermonitor Internal Relays.”

5–5

Page 44

Chapter 5

Powermonitor Data Display and Configuration

Figure 5.3

Main Menu Screen

Real Time Data

The REAL–TIME screen for the Powermonitor displays the present

real–time readings of all values monitored by the device (see Figure 5.4). A

complete description of the parameters shown on the REAL–TIME screen is

given in Publication 1400–800, ‘‘Bulletin 1400 Powermonitor Installation

and Operation Manual.”

Figure 5.4

Real–Time Data Screen

5–6

The DATE and TIME at the bottom of the screen indicate the time at which

the displayed data was last updated.

Page 45

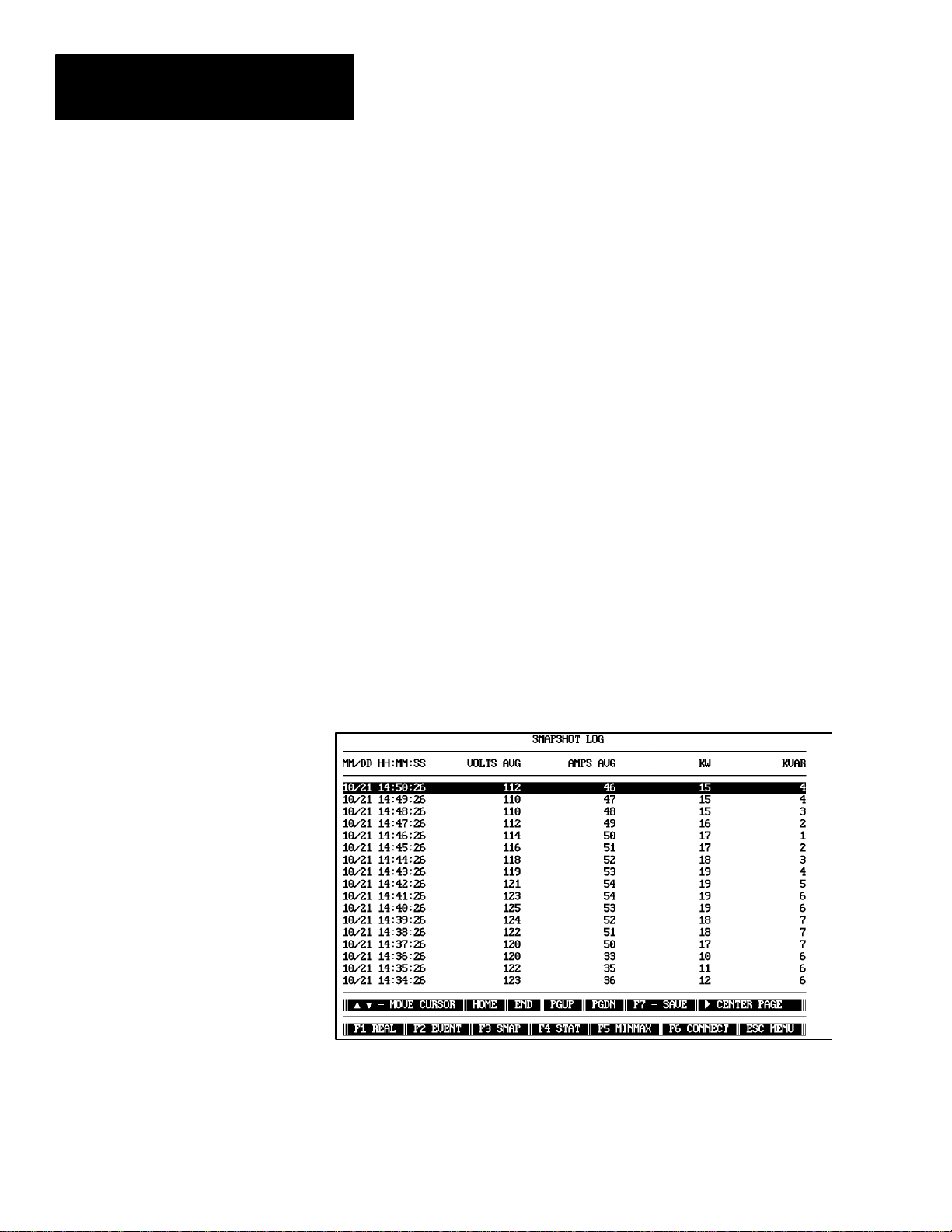

Chapter 5

Powermonitor Data Display and Configuration

Event Log

The Powermonitor contains a record of events that is stored within its

internal nonvolatile memory. An event is defined as any alarm condition,