Page 1

Drain Cleaning

Machines

OPERATOR’S

MANUAL

• Français – 15

• Castellano – pág. 31

K-75A/B

K-1500A/B

K-1500SP

W ARNING!

Read this Operator’s Manual

carefully before using this

tool. Failure to understand

and follow the contents of

this manual may result in

electrical shock, fire and/or

serious personal injury.

Page 2

Table of Contents

Recording Form for Machine Model and Serial Number............................................................................................1

General Safety

Work Area Safety........................................................................................................................................................2

Electrical Safety...........................................................................................................................................................2

Personal Safety...........................................................................................................................................................2

Tool Use and Care......................................................................................................................................................3

Service ........................................................................................................................................................................3

Specific Safety Information

Drain Cleaner Safety...................................................................................................................................................3

Description, Specifications and Standard Equipment

Description ..................................................................................................................................................................4

Specifications..............................................................................................................................................................4

Standard Equipment....................................................................................................................................................4

Machine Inspection .......................................................................................................................................................5

Machine Set-Up..............................................................................................................................................................6

Operating Instructions..................................................................................................................................................7

Special Procedures

Reverse Operation......................................................................................................................................................8

Cable Applications.......................................................................................................................................................8

Storing and Transporting Cable (“A” Frame Models)..................................................................................................9

Accessories

Cable Selection...........................................................................................................................................................9

Accessories and Tools Available For Cables............................................................................................................10

Maintenance Instructions

Lubrication.................................................................................................................................................................11

Cables.......................................................................................................................................................................11

Clutch Jaws Replacement.........................................................................................................................................11

Removing Clutch End Play........................................................................................................................................11

V-Belt Adjustment......................................................................................................................................................12

Machine Storage..........................................................................................................................................................12

Service and Repair ......................................................................................................................................................12

Wiring Diagram.......................................................................................................................................................13-14

Lifetime Warranty..........................................................................................................................................Back Cover

Ridge Tool Companyii

K-75A/B, K-1500A/B, & K-1500SP Drain Cleaning Machines

Page 3

Drain Cleaning Machines

Record Serial Number below and retain product serial number which is located on nameplate.

Serial

No.

K-75A/B, K-1500A/B &

K-1500SP

Drain Cleaning Machines

Page 4

K-75A/B, K-1500A/B, & K-1500SP Drain Cleaning Machines

Ridge Tool Company2

General Safety Information

WARNING! Read and understand all instructions. Failure

to follow all instructions listed below may

result in electric shock, fire, and/or serious

personal injury.

SAVE THESE INSTRUCTIONS!

Work Area Safety

• Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

• Do not operate tools in explosive atmospheres,

such as in the presence of flammable liquids,

gases, or dust. Tools create sparks which may ignite

the dust or fumes.

• Keep bystanders, children, and visitors away while

operating a tool. Distractions can cause you to lose

control.

Electrical Safety

• Grounded tools must be plugged into an outlet,

properly installed and grounded in accordance

with all codes and ordinances. Never remove the

grounding prong or modify the plug in any way.

Do not use any adapter plugs. Check with a qualified electrician if you are in doubt as to whether

the outlet is properly grounded. If the tools should

electrically malfunction or break down, grounding provides a low resistance path to carry electricity away

from the user.

• Avoid body contact with grounded surfaces such

as pipes, radiators, ranges and refrigerators. There

is an increased risk of electrical shock if your body is

grounded.

• Don’t expose electrical tools to rain or wet conditions. Water entering a power tool will increase the

risk of electrical shock.

• Do not abuse cord. Never use the cord to carry the

tools or pull the plug from an outlet. Keep cord

away from heat, oil, sharp edges or moving parts.

Replace damaged cords immediately. Damaged

cords increase the risk of electrical shock.

• When operating a power tool outside, use an outdoor extension cord marked “W-A” or “W”. These

cords are rated for outdoor use and reduce the risk of

electrical shock.

• Use only three-wire extension cords which have

three-prong grounding plugs and three-pole receptacles which accept the machine’s plug. Use of

other extension cords will not ground the tool and increase the risk of electrical shock.

• Use proper extension cords. (See chart.) Insufficient

conductor size will cause excessive voltage drop and

loss of power.

• Before using, test the Ground Fault Circuit Interrupter (GFCI) provided with the power cord to

insure it is operating correctly. GFCI reduces the risk

of electrical shock.

• Extension cords are not recommended unless

they are plugged into a Ground Fault Circuit Interrupter (GFCI) found in circuit boxes or receptacles.

The GFCI on the machine power cord will not prevent electrical shock from the extension cords.

• Keep all electrical connections dry and off the

ground. Do not touch plug with wet hands. Reduces

the risk of electrical shock.

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a power tool. Do not

use tool while tired or under the influence of drugs,

alcohol, or medications. A moment of inattention

while operating power tools may result in serious personal injury.

• Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair, clothing, and gloves away from moving parts. Loose

clothes, jewelry, or long hair can be caught in moving

parts.

• Avoid accidental starting. Be sure switch is OFF before plugging in. Carrying tools with your finger on the

switch or plugging tools in that have the switch ON in-

vites accidents.

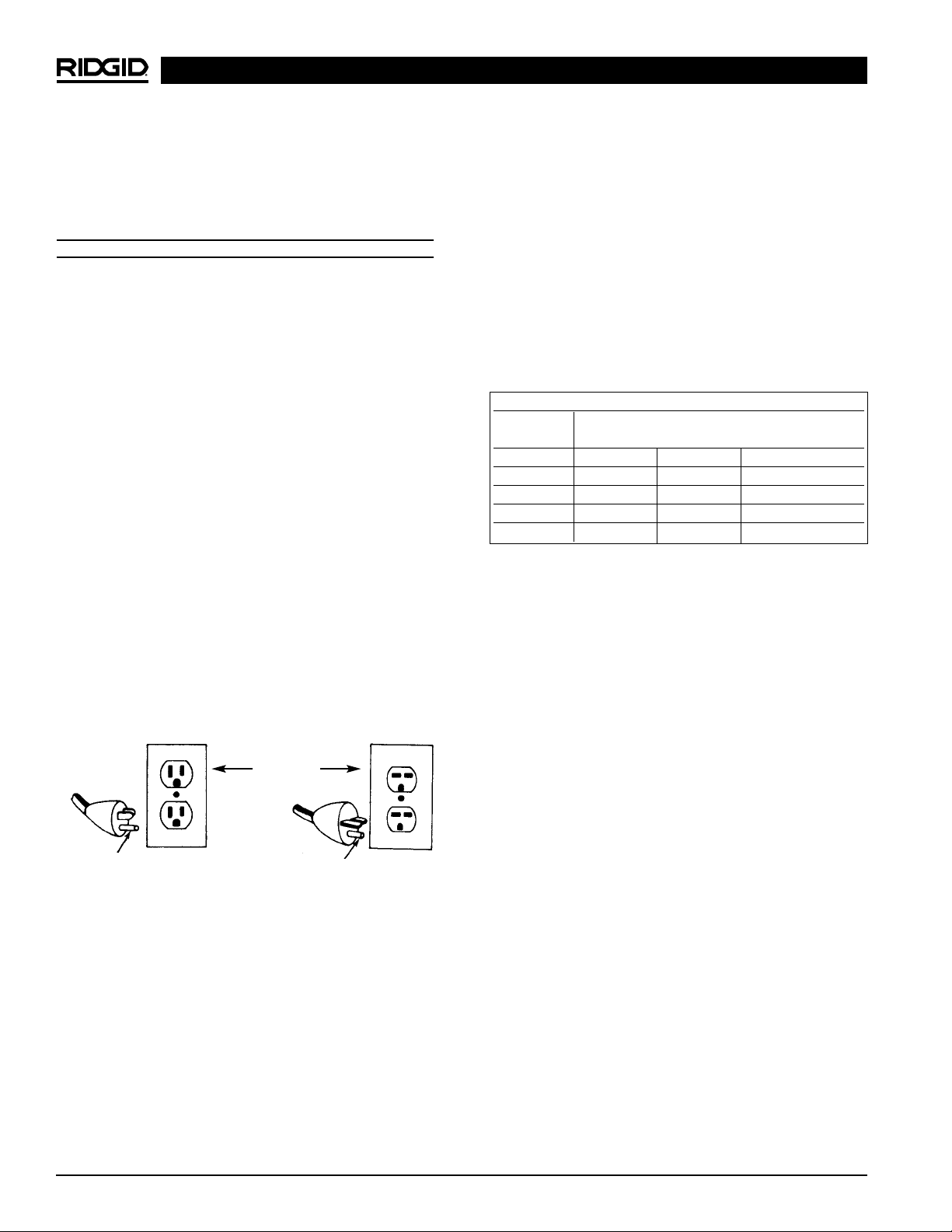

Grounding prong

Cover of

grounded

outlet box

Grounding prong

Minimum Wire Gauge for Extension Cord

Nameplate

Amps

Total Length (in feet)

0 – 25 26 – 50 51 – 100

0 – 6 18 AWG 16 AWG 16 AWG

6 – 10 18 AWG 16 AWG 14 AWG

10 – 12 16 AWG 16 AWG 14 AWG

12 – 16 14 AWG 12 AWG

NOT RECOMMENDED

Page 5

K-75A/B, K-1500A/B, & K-1500SP Drain Cleaning Machines

Ridge Tool Company 3

• Remove adjusting keys or wrenches before turning

the tool ON. A wrench or a key that is left attached to

a rotating part of the tool may result in personal injury.

• Do not over-reach. Keep proper footing and balance at all times. Proper footing and balance enables

better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes, hard hat,

or hearing protection must be used for appropriate

conditions.

Tool Use and Care

• Use clamp or other practical way to secure and

support the workpiece to a stable platform. Holding

the work by hand or against your body is unstable

and may lead to loss of control.

• Do not force tool. Use the correct tool for your

application. The correct tool will do the job better

and safer at the rate for which it is designed.

• Do not use tool if switch does not turn it ON or

OFF. Any tool that cannot be controlled with the switch

is dangerous and must be repaired.

• Disconnect the plug from the power source before

making any adjustments, changing accessories, or

storing the tool. Such preventive safety measures re-

duce the risk of starting the tool accidentally.

• Store idle tools out of the reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp

and clean. Properly maintained tools with sharp cutting

edges are less likely to bind and are easier to control.

• Check for misalignment or binding of moving

parts, breakage of parts, and any other condition

that may affect the tool's operation. If damaged,

have the tool serviced before using. Many acci-

dents are caused by poorly maintained tools.

• Use only accessories that are recommended by the

manufacturer for your model. Accessories that may

be suitable for one tool may become hazardous when

used on another tool.

• Keep handles dry and clean; free from oil and

grease. Allows for better control of the tool.

Service

• Tool service must be performed only by qualified

repair personnel. Service or maintenance performed

by unqualified repair personnel could result in injury.

• When servicing a tool, use only identical replace-

ment parts. Follow instructions in the Maintenance

Section of this manual. Use of unauthorized parts or

failure to follow maintenance instructions may create a

risk of electrical shock or injury.

Specific Safety Information

WARNING

Read this operator’s manual carefully before using

the K-75/K-1500 Drain Cleaners. Failure to understand and follow the contents of this manual may

result in electrical shock, fire and/or serious personal injury.

Call the Ridge Tool Company, Technical Service Department at (800) 519-3456 if you have any questions.

Drain Cleaner Safety

• Wear leather mitt provided with the machine. Never

grasp a rotating cable with a rag or loose fitting

cloth glove. It could get wrapped around the cable and

cause serious injury.

• Do not overstress cables. Keep one hand on the

cable for control when the machine is running.

Overstressing cables because of obstruction may

cause twisting or kinking or breaking of the cable and

result in serious injury.

• Position machine within two feet of inlet. Use Front

End Guide Hose when it is difficult to locate the

machine near the access or clean out. Greater dis-

tances can result in cable twisting or kinking.

• Do not operate machine in (REV) reverse. Operating

machine in reverse can result in cable damage and is

used only to back tool out of an obstruction.

• Operate machine from the side with the FOR/OFF/REV Switch. Allows for better control of the machine.

• Use Rear Guide Hose. Prevents cable from whip-

ping and picking up debris.

• Never operate machine with belt guard removed.

Fingers can be caught between the belt and pulley.

• Be careful when cleaning drains where cleaning

compounds have been used. Avoid direct contact

with skin and eyes. Serious burns can result from

some drain cleaning compounds.

• Do not operate machine if operator or machine is

standing in water. Will increase the risk of electrical

shock.

Page 6

K-75A/B, K-1500A/B, & K-1500SP Drain Cleaning Machines

Ridge Tool Company4

Specifications

Line Capacity...............Depends on choice of cable.

Refer to the chart for recommendations

Motor:

K-75A/B

Type.............................115V/60Hz, Reversible

Rating ..........................1/2HP

Amps............................7.2

K-1500A/B

Type...............................115V/60Hz, Reversible, 230V-

240V/50Hz Versions Available

Upon Request

Rating ..........................3/4HP

Amps............................10.4

K-1500A/B-SP

Type.............................115V/240V/50-60Hz, Rev-

ersible, Total Enclosed Fan

Cooled

Rating ..........................1 HP

Amps............................15

Frame:

A Style.........................2 Wheels In Rear w/Upright

Handle On Frame Assembly

and Cable Storage Capacity

B Style .........................2 Wheels In Front On Frame

Assembly.

See the RIDGID RT Catalog for machine model options

and accessories. Every machine model includes as standard equipment:

• A-1 Operator’s Mitt

• A-12 Pin Key

• A-34-12 Rear Guide Hose

• Wear safety glasses and rubber soled, non-slip

shoes. Use of this safety equipment may prevent serious injury.

• Only use the K-75 to clean drain lines up to 4″ in di-

ameter and the K-1500 machine up to 10″ in diameter. Follow instructions on the use of the machine. Other uses or modifying the drain cleaner for

other applications may increase the risk of injury.

Description, Specifications and

Standard Equipment

Description

The RIDGID K-75A/B, K-1500A/B & K-1500SP Drain

Cleaning Machines are for cleaning 11/4″ through 10″

lines. These machines are driven by induction motors

that have a grounded electrical system. An integral Ground

Fault Interrupter (GFCI) is built into the line cord. A toggle

or rotary switch provides FORWARD/OFF/REVERSE

control of the motor.

Machines are designed to use sectional-type cable that

has a quick coupling system for disconnecting tools.

The cable is manually fed in and out of the machine

and rotates at a cable speed of 600 to 700 RPM. The rotation of the cable is controlled by a clutch handle. The

cable stops instantly when the clutch handle is released.

K-75 machines come equipped to run 7/8″ cable to clean

2″ – 4″ lines through 175′. They can be adapted to use

5

/8″ cable to clean 11/4″ to 3″ lines.

K-1500 machines come equipped to run 11/4″ cable to

clean 3″ – 10″ lines through 200′ – the 1500SP through

300′. They can be easily adapted to use 7/8″ cable to

clean 2″ – 4″ lines.

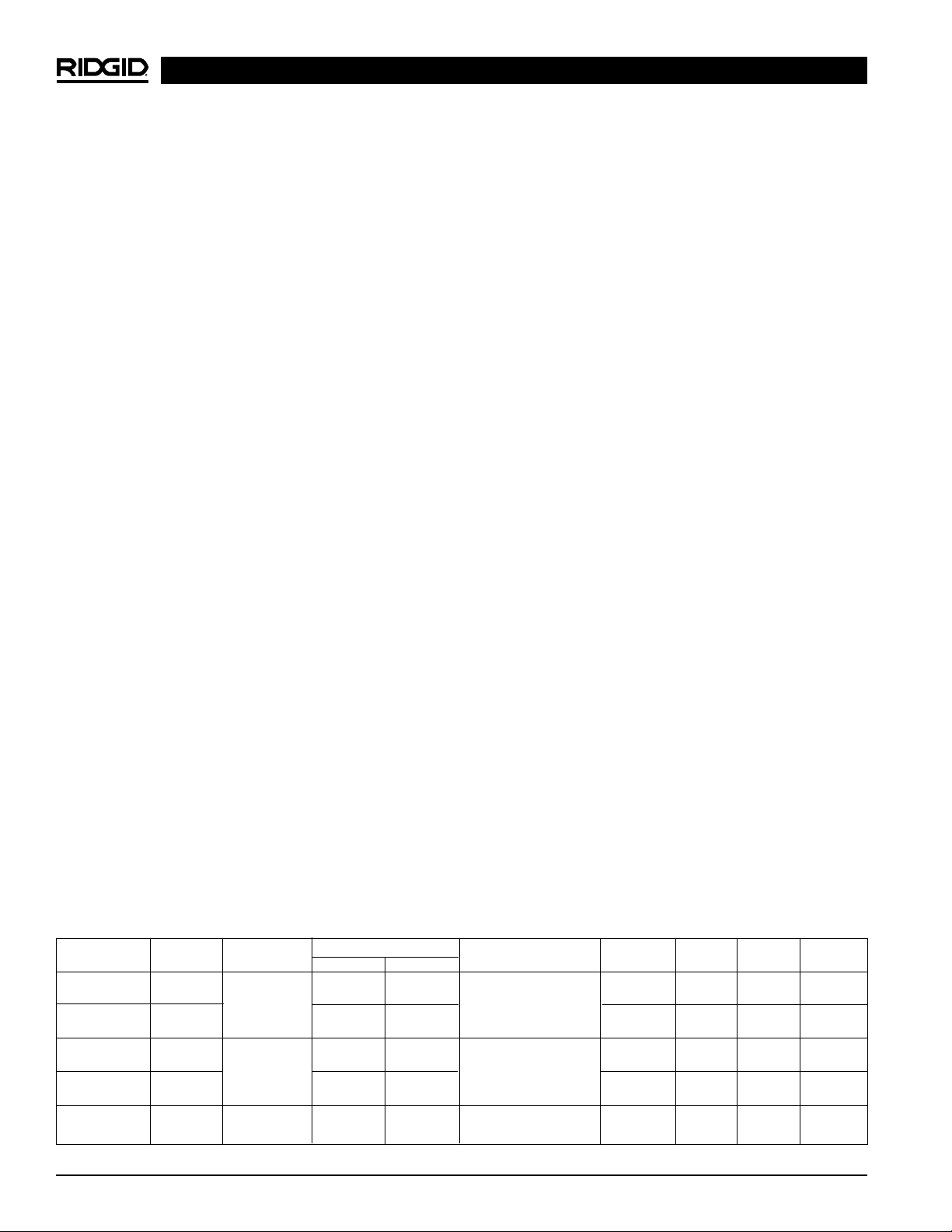

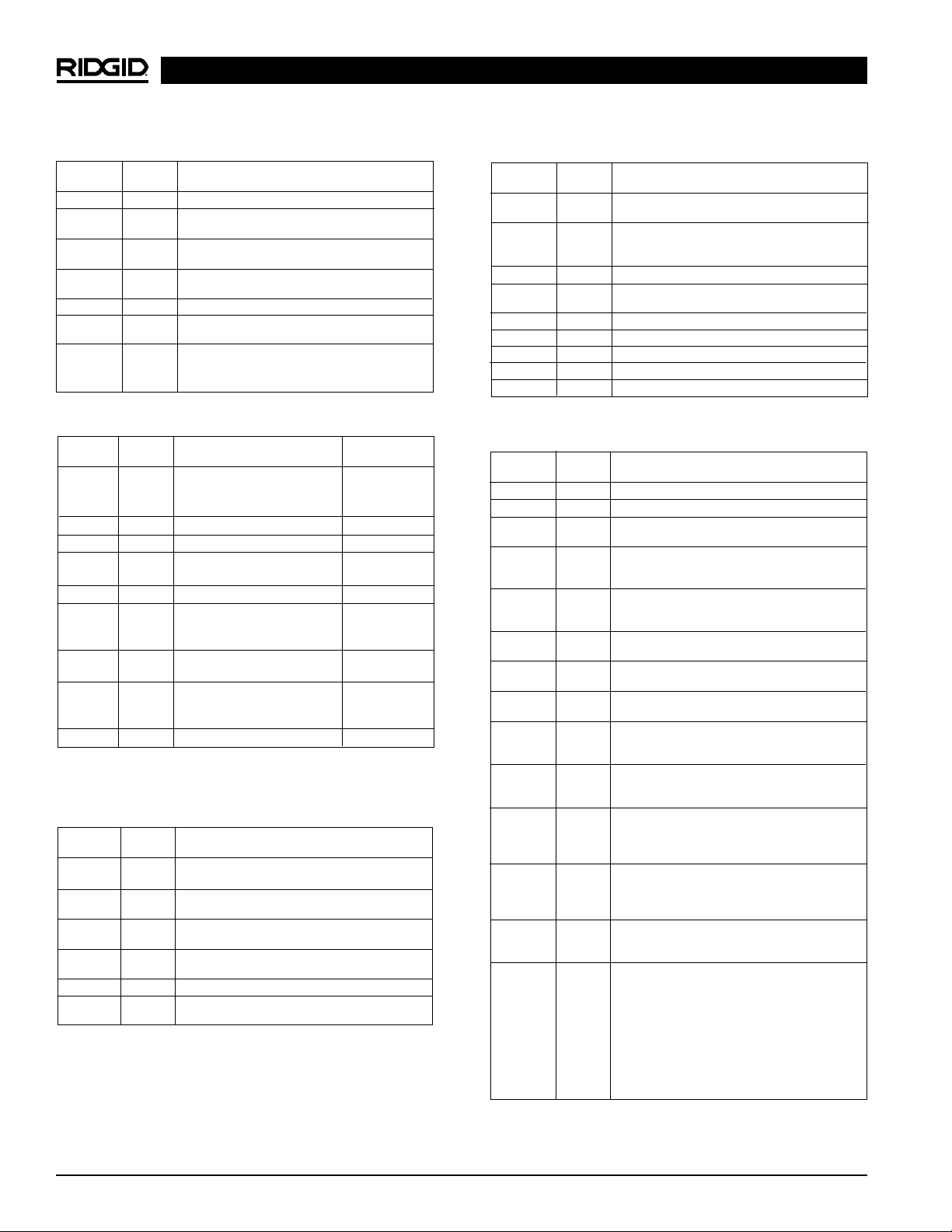

Model Frame Cable Capacity Overall Machine

No. Style Size Line Reach Horsepower Height Width Length Wt. Lbs.

K-75A

A

5

/8″ 11/4″ - 3″ 125′

1

/2HP at 640 RPM

41

1

/2″ 203/4″ 16″ 88

K-75A-SE

K-75B

B

7

/8″ 2″ - 4″ 175′ 273/4″ 203/4″ 405/8″ 76

K-75B-SE

K-1500A

A

7

/8″ 2″ - 4″ 175′

3

/4HP at 710 RPM

41

1

/2″ 203/4″ 16″ 92

K-1500A-SE

K-1500B

B1

1

/4″ 3″ - 10″ 200′ 273/4″ 203/4″ 405/8″ 80

K-1500B-SE

K-1500SP B

7

/8″ 2″ - 4″ 175′ 1HP at 600 RPM 273/4″ 203/4″ 405/8″ 110

K-1500SPA A 1

1

/4″ 3″ - 10″ 300′ 411/2″ 203/4″ 16″ 138

Chart 1

or

or

Page 7

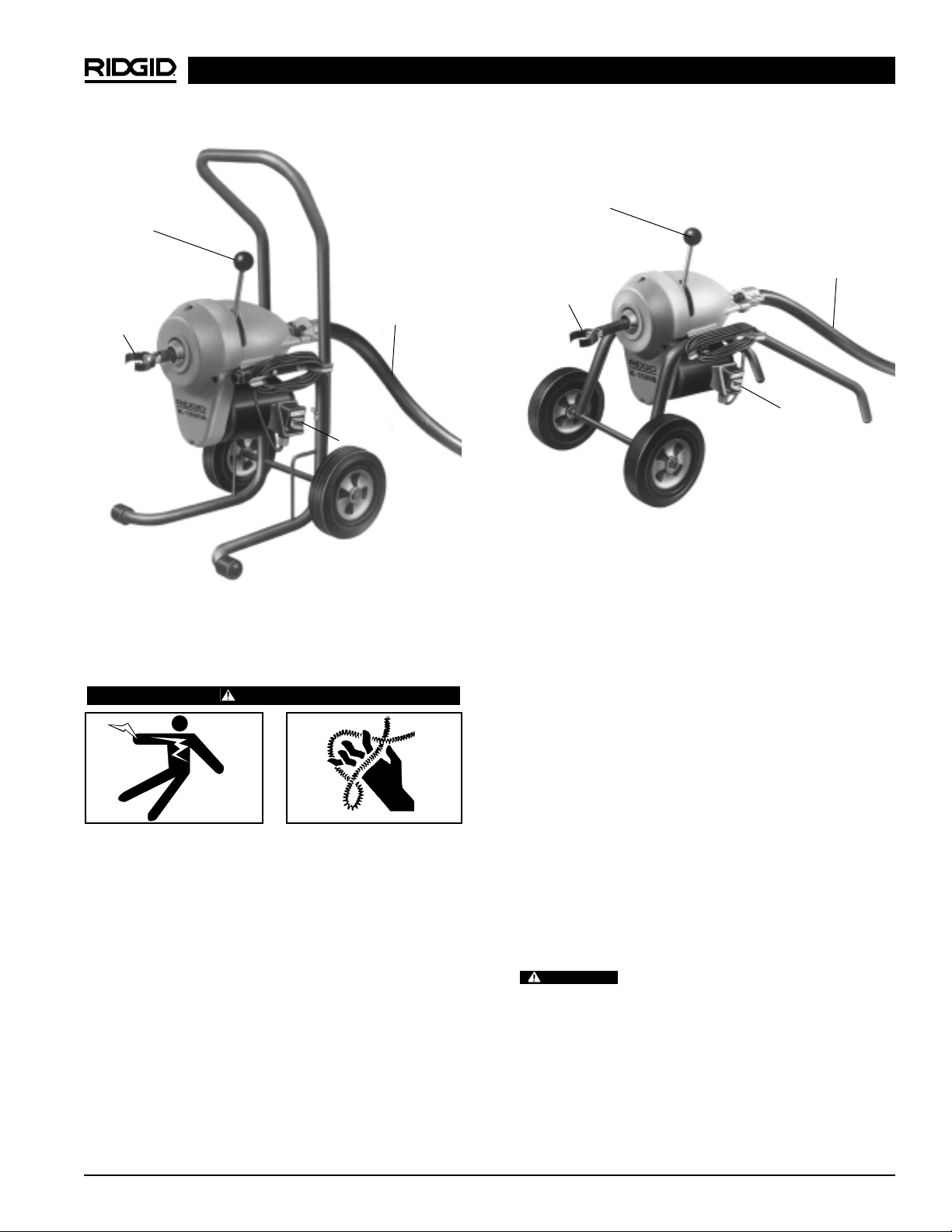

Figure 1 – K-75A, K-1500A and K-1500SPA Drain Cleaners

Machine Inspection

WARNING

To prevent serious injury, inspect your Drain

Cleaning Machine. The following inspection procedures should be performed before each use.

1. Make sure the Drain Cleaning Machine is unplugged

and the directional switch is set to the OFF position

(Figures 1 and 2).

2. Inspect the power cord, Ground Fault Circuit Interrupter (GFCI) and plug for damage. If the plug has

been modified, is missing the grounding prong or if the

cord is damaged, do not use the Drain Cleaning

Machine until the cord has been replaced.

3. Inspect the Drain Cleaning Machine for any broken,

missing, misaligned or binding parts as well as any

other conditions which may affect the safe and normal

operation of the machine. If any of these conditions

K-75A/B, K-1500A/B, & K-1500SP Drain Cleaning Machines

Ridge Tool Company 5

are present, do not use the Drain Cleaning Machine

until any problem has been repaired.

Figure 2 – K-75B, K-1500B and K-1500SP Drain

Cleaning Machines

4. Lubricate the Drain Cleaning Machine, if necessary,

according to the Maintenance Instructions.

5. Use tools and accessories that are designed for your

drain cleaner and meet the needs of your application.

The correct tools and accessories allow you to do the

job successfully and safely. Accessories suitable for

use with other equipment may be hazardous when

used with this drain cleaner.

6. Clean any oil, grease or dirt from all equipment handles and controls. This reduces the risk of injury due

to a tool or control slipping from your grip.

7. Inspect the cutting edges of your tools. If necessary,

have them sharpened or replaced prior to using the

Drain Cleaning Machine. Dull or damaged cutting

tools can lead to binding and cable breakage.

8. Inspect cables and couplings for wear and damage.

Cables should be replaced when they become severely worn or corroded. A worn cable can be identified when the outside coils become flat.

Worn or damaged cables can break caus-

ing serious injury.

Clutch

Handle

Tool

FOR/OFF/REV

Switch

Guide

Hose

Clutch

Handle

Guide

Hose

FOR/OFF/REV

Switch

Tool

WARNING

Page 8

K-75A/B, K-1500A/B, & K-1500SP Drain Cleaning Machines

Ridge Tool Company6

Machine Set-Up

WARNING

Do not place machine in water. Water entering

the motor can result in electrical shock.

To prevent serious injury, proper set-up of the machine and work area is required. The following

procedures should be followed to set-up the machine:

1. Check work area for:

• Adequate lighting

• Grounded electrical outlet

• Clear path to the electrical outlet that does not

contain any sources of heat or oil, sharp edges or

moving parts that may damage electrical cord.

• Dry place for machine and operator. Do not place

the machine in water.

• Flammable liquids, vapors or dust that may ignite.

2. Position the Drain Cleaning Machine within 2′ of

sewer inlet. Greater distance can result in cable twisting or kinking.

3. Make sure FOR/OFF/REV switch is in the OFF position.

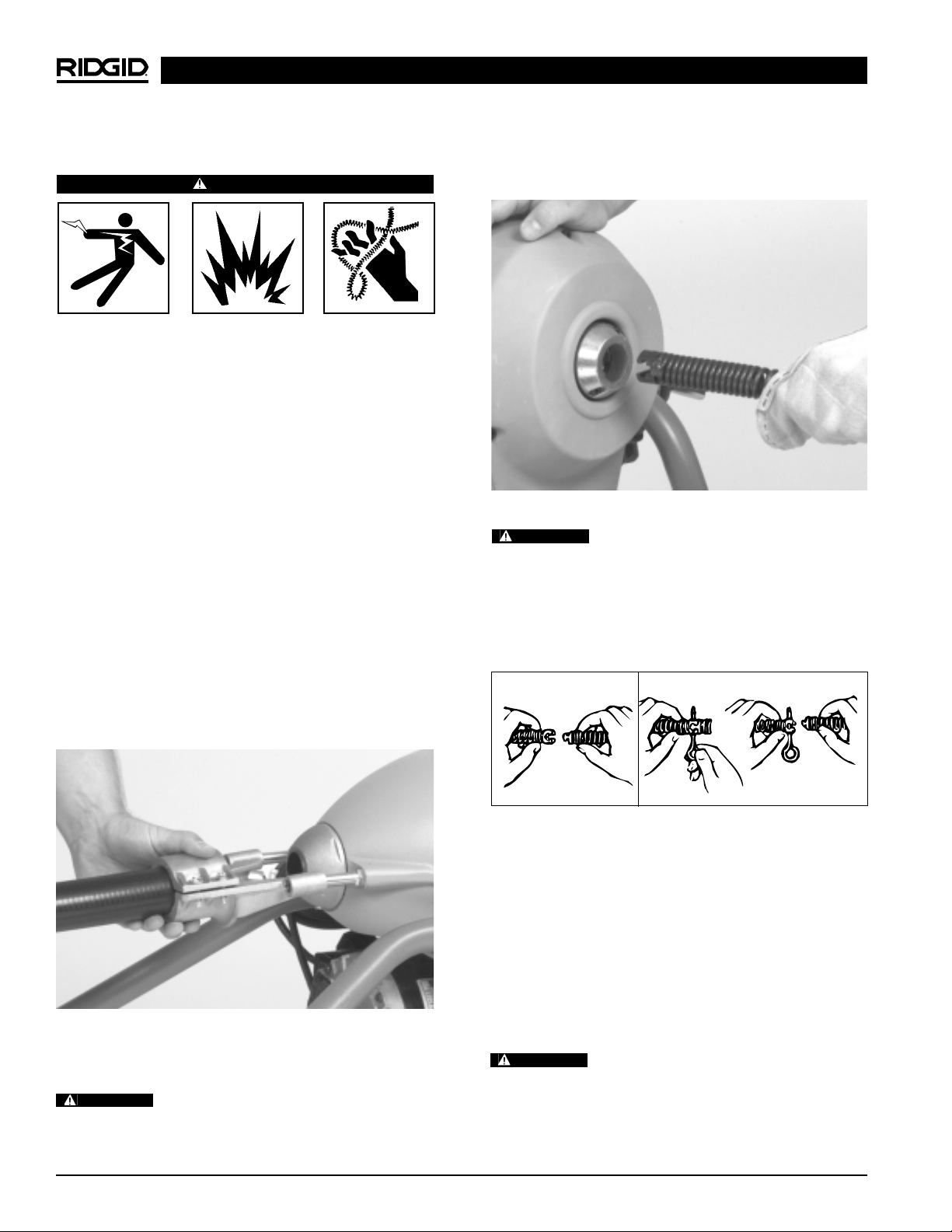

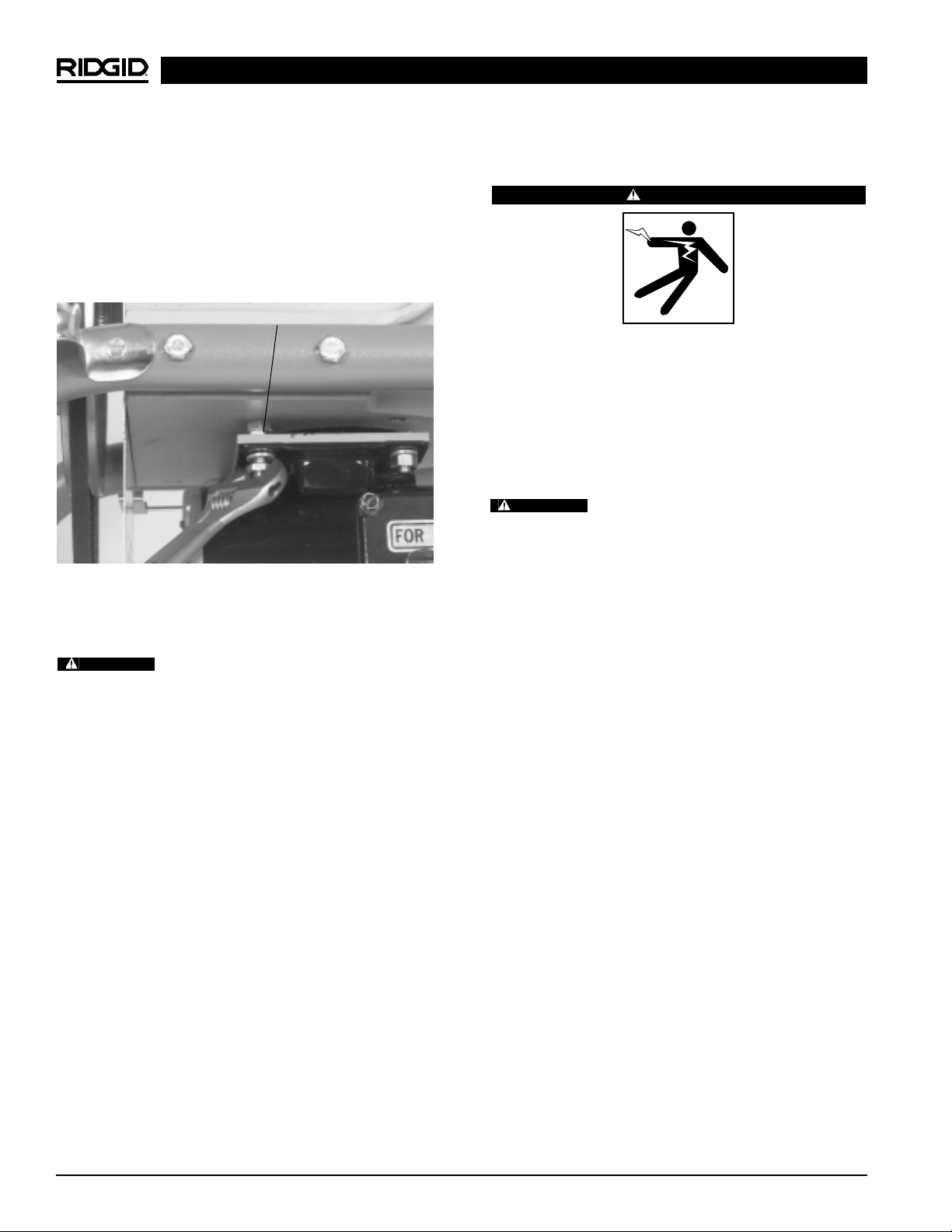

Figure 3 – Rear Guide Hose Attachment

4. Attach the rear guide hose by sliding guide hose

adapter onto the guide hose pins (Figure 3).

Do not use machine without rear guide

hose attached. Prevents cable whipping, possible entanglement and a cleaner jobsite.

5. Insert first cable into front of machine (female end first)

and push through guide hose until approximately one

foot remains out the front of the machine (Figure 4).

Figure 4 – Inserting Cable Into Front Of Machine

Never couple more than one cable at a

time. Cable will extend behind rear guide tube.

6. Select and install the proper tool to the end of the

cable. The T-Slot Coupler allows the tool to be snapped into the cable coupler (Figure 5). To remove tool,

use the pin key to depress the plunger and slide the

coupling apart.

Figure 5 – Coupling and Uncoupling Tools

NOTE! Proper Tool Selection

A good rule of thumb is to use a tool at least 1″

smaller than the line to be cleaned. The style of the

tool is determined by the nature of the job and is left

up to the operator.

7. Plug the Drain Cleaning Machine into the electrical

outlet, making sure to position the power cord along

the clear path selected earlier. If the power cord does

not reach the outlet, use an extension cord in good

condition.

To avoid electric shock and electrical fires,

never use an extension cord that is damaged or does not

meet the following requirements:

• The cord has a three-prong plug similar to shown in

Electrical Safety section.

WARNING

To Couple Cable

and Tools

Snap Together Insert Pin Slide Apart

To Uncouple Cable and Tools

WARNING

WARNING

Page 9

K-75A/B, K-1500A/B, & K-1500SP Drain Cleaning Machines

Ridge Tool Company 7

• The cord is rated as “W” or “W-A” if being used outdoors.

• The cord has sufficient wire thickness (14 AWG - 50′). If

the wire thickness is too small, the cord may overheat,

melting the cord’s insulation or causing nearby objects

to ignite.

To reduce risk of electrical shock, keep all

electrical connections dry and off the ground. Do not

touch plug with wet hands. Test the Ground Fault Circuit

Interrupter (GFCI) provided with the electric cord to insure

it is operating correctly. When test button is pushed in,

the indicator light should go off. Reactivate by pushing

the reset button in. If indicator light goes on, the machine

is ready to use. If the GFCI does not function correctly,

do not use the machine.

Operating Instructions

WARNING

Wear mitts with rivets provided with machine.

Never grasp a rotating cable with a rag, loose fitting cloth or leather glove that may become

wrapped around the cable causing serious injury.

Always wear eye protection to protect your eyes

against dirt and other foreign objects. Wear rubber

soled, non-slip shoes.

Be very careful when cleaning drains where cleaning compounds have been used. Wear gloves when

handling cable and avoid direct contact to the

skin and especially the eyes and facial area as serious burns can result.

Do not operate if clutch handle is damaged or

does not function properly. Clutch is a safety feature designed to stop rotation of cable when

released.

It is important to know approximate distance

from inlet to main sewer or septic tank. Over-running

cable too far into main sewer or septic tank can cause cables to knot up and prevent their return through small

lines. If main is 12 inches or larger and standard 11/

4

″

cable is being used, do not allow more than 10 to 15

feet of overrun. When working into a septic tank do not

allow more than 3 to 5 feet overrun.

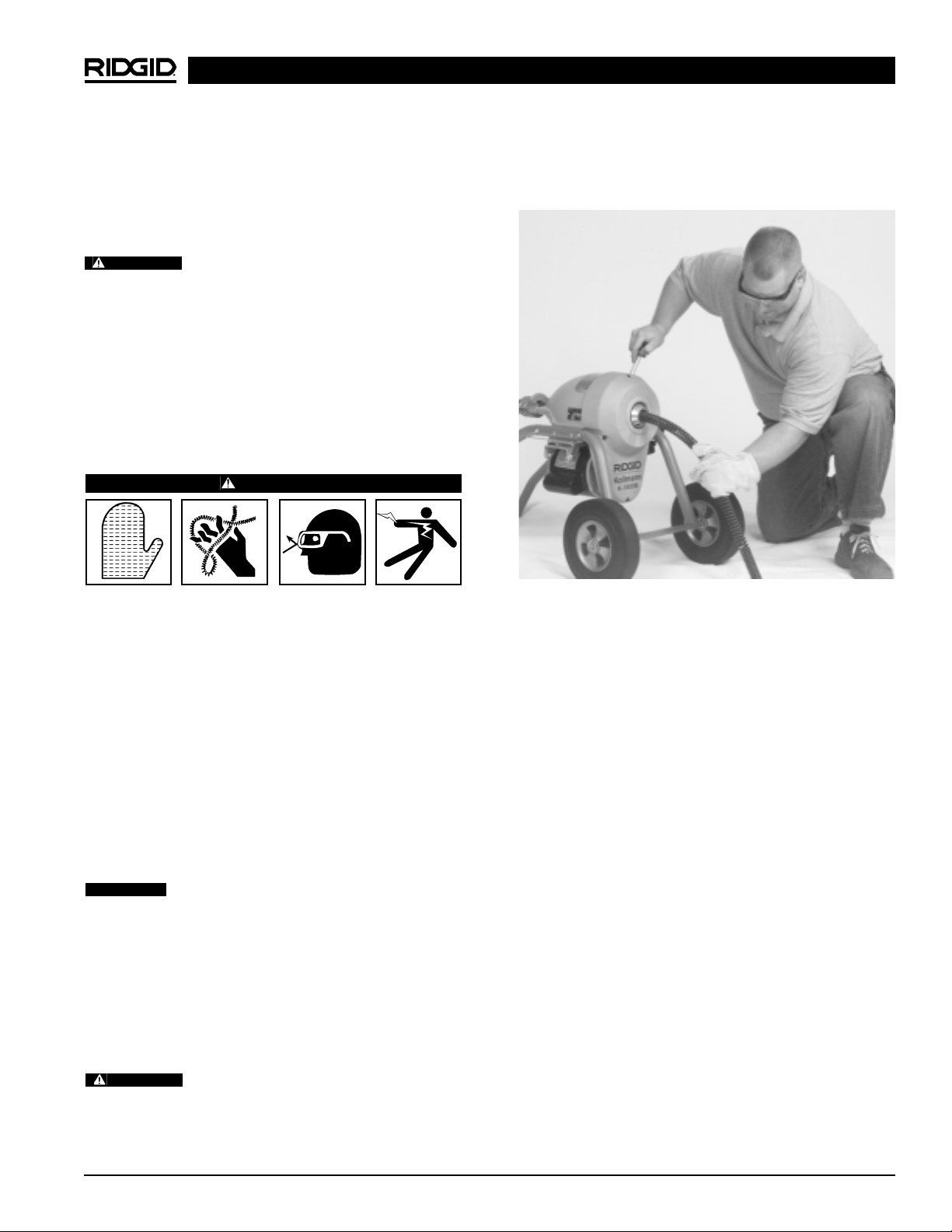

1. Assume the correct operating posture in order to

maintain proper balance (Figure 6).

Should an unexpected situation arise,

this posture provides you with the opportunity to safely

keep control of the machine and cable.

• Be sure you can quickly release the clutch handle.

• Hand must be on the cable to control its twisting

action when it hits an obstruction.

• Must have access to FOR/OFF/REVERSE switch.

Figure 6 – Proper Operating Position

2. Pull sufficient cable out of the machine to start tool and

cable into the sewer inlet. Push cable into inlet as far

as it will go.

3. Pull enough extra cable through machine to form almost a half circle between machine and line opening.

4. Hold cable loosely in mitted hand. Put FOR/OFF/REVERSE/ switch in FOR (forward) position.

NOTE! The motor will start but cable will not rotate.

5. With mitted hand on cable, push down on clutch handle with opposite hand to engage cable. Push down

on top of the cable loop with a definite snap to advance the cable.

NOTE! A slow or gradual engaging of the clutch handle

causes excessive wear of the jaw set. The clutch

is instant-acting and returning clutch handle to its

original position frees cable instantly.

6. As soon as excess cable has gone into line, release

clutch handle and pull six to ten inches of cable out of

machine with mitted hand.

7. Continue to feed the cable into the line until resistance

or obstruction is encountered. This will become apparent to operator as it will be difficult to feed additional

cable into line and/or the cable will have a tendency to

twist sideways in operator’s hands.

WARNING

WARNING

CAUTION

Page 10

K-75A/B, K-1500A/B, & K-1500SP Drain Cleaning Machines

Ridge Tool Company8

8. If cable loads down in the obstruction, relieve load by

pulling back on cable with short, quick jerks to free

cutter. Slowly advance cable back into the obstruction.

Repeat this process until the obstruction is clear.

Remember, make sure the cutter is rotating at all

times and never force the cable. At this point, progress depends upon the sharpness of the tool and

nature of the obstruction.

WARNING

Do not allow tension to build up in the cable. This

will happen if the cutting tool hits a snag and stops

turning, but the motor and cable continue to rotate. Torque builds until the cable suddenly twists,

potentially wrapping around your hand or arm. This

can happen quickly and without warning, so proceed

slowly and carefully as you feed the cable into the

drain. Releasing clutch handle will stop the cable rotating and releases the torque. If tool gets hung up

in an obstruction, refer to Reverse Operating

Instructions in the “Special Procedures” section.

9. Once obstruction is cleared, it is recommended that

operator flush debris from line with running water.

Repeat Step 8 several times if necessary for thorough

cleaning job and then work cable through additional

stoppages as required.

10. To add cable, the following procedure should be followed:

• After reaching the end of each cable section, turn

the machine OFF.

• Secure the cable by looping it in the line (Figure 7).

This procedure is especially useful when cleaning

a line with a steep grade.

Figure 7 – Looping Cable In Line

• With line secured, insert another section of cable

in through the front of the machine (female end

first) until approximately one foot remains out the

front of the machine.

• Attach cable to cable in line and resume operation.

11. To retrieve cable from drain line, the following procedure should be followed:

• Leave FOR/OFF/REV switch in FOR (forward) po-

sition.

• Push down on clutch handle to engage cable.

With mitted hand pull cable out of line (if possible)

or hold cable against edge of inlet to thread the

cable out until loop forms in front of the machine.

NOTE! By holding the cable against the edge of the inlet,

the rotation will rapidly “thread” the cable out of the

line.

• When loop forms, release clutch handle and push

excess cable back through machine. Disconnect

one section at a time.

When disconnecting sections, remem-

ber to turn unit off and secure cable in line.

• Once section of cable is removed, insert the secured cable in through the front of the machine and

continue removing sections until tool on last section

of cable is just inside sewer inlet.

HINT! When placing removed cables back into cable

carrier, reconnect all cables. This assures easy

removal at next job.

Never retract tool from sewer inlet while

cable is rotating. Tool can whip causing serious injury.

12. Turn FOR/OFF/REV Switch to OFF position.

13. Pull remaining cable and tool from sewer.

14. Unplug power cord and remove guide hose.

After using, thoroughly flush and drain ca-

bles, couplings and tools with water due to damaging

effects of some drain cleaning compounds.

Special Procedures

Reverse Operation

Running machine in reverse will cause premature failure of cable. Use reverse only to free a tool or cable

caught in an obstruction. If this should occur, immediately release clutch handle and place FOR/OFF/REV

switch to OFF position. After motor comes to a complete

stop, place FOR/OFF/REV switch in the REV (reverse) direction. Engage clutch handle only until cable or tool is free

of obstruction. Once it is free, release clutch handle immediately. Turn unit OFF. Run unit in FOR (forward)

direction and follow normal operating procedure.

Never operate this machine in REV (reverse) for any other purpose. Operating in reverse can

damage a cable and cause serious injury.

Cable Applications

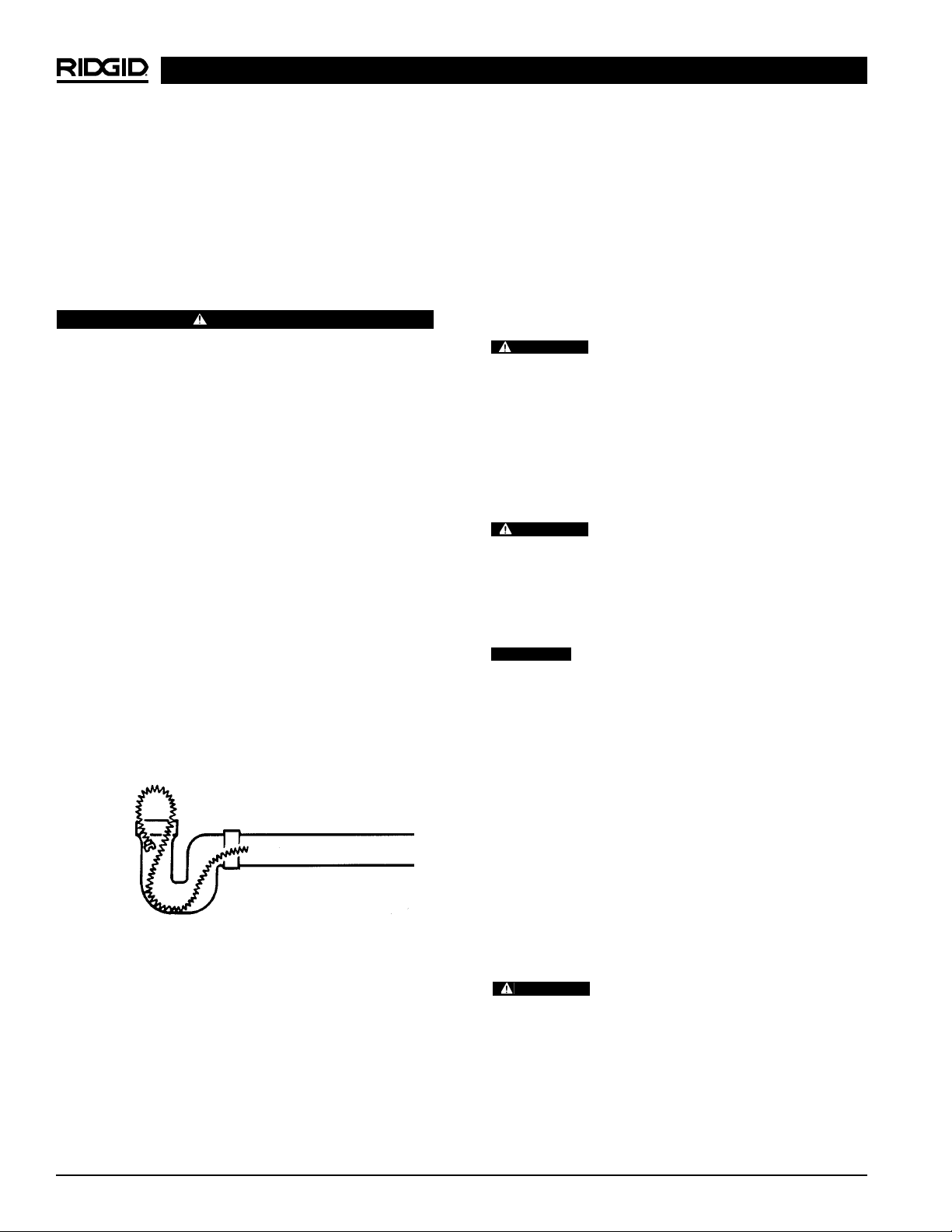

Standard Cable Standard 7/8″ or 11/4″ cable can be

used in straight lines from 3″ through 6″ and through fittings. (Figure 8)

WARNING

WARNING

WARNING

CAUTION

Page 11

Figure 11 – Storing Cables On “A” Frame Models

Accessories

Only the following RIDGID products have

been designed to function with the Sectional Drain Cleaning Machines. Other accessories suitable for use with

other tools may become hazardous when used on the machines. To prevent serious injury, use only the recommended accessories.

K-75A/B Machines

K-75A/B, K-1500A/B, & K-1500SP Drain Cleaning Machines

Ridge Tool Company 9

Figure 8 – Standard Cable Application

Heavy-Duty Cable Where conditions allow, heavy-

duty 11/4inch cable, such as C-14, should be used for

faster results and longer cable life. The heavy-duty cables

work effectively in 4″ through 8″ straight lines. (Figure 9)

NOTE! This type cable should not be used in areas

where 4″ “P” traps or 4″ running traps are currently in use.

Figure 9 – Heavy Duty Cable Application

Faster Cleaning Obstructions of grease or fats can

be cleaned faster and more effectively by bending the

cable some 6″ or 8″ behind the cutter. (Figure 10)

Figure 10 – Bending Cable for Faster Cleaning

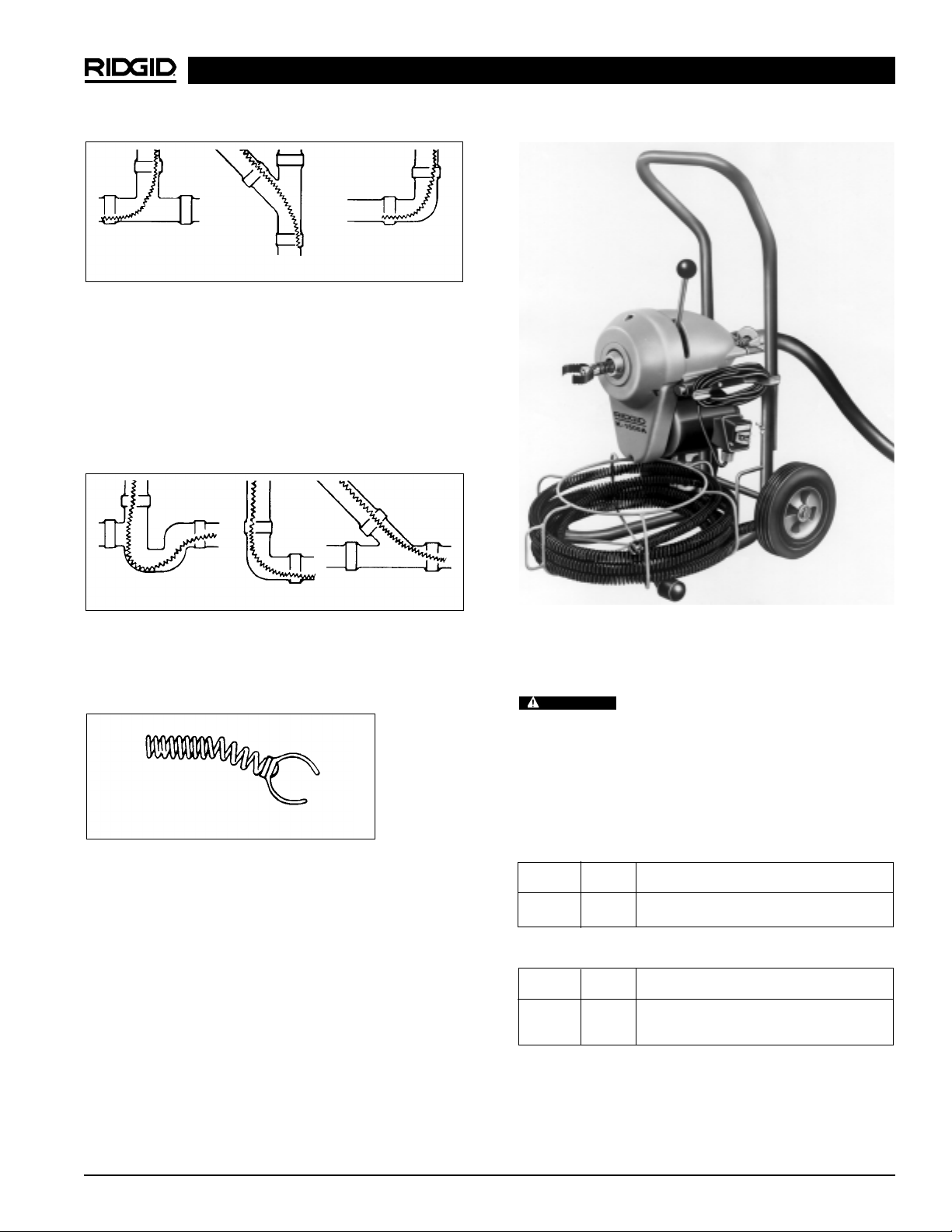

Storing And Transporting Cable

(“A” Frame Models Only)

Cables can be stored and transported on “A” frame

models as shown in Figure 11.

4″ and 6″ Tees

3″, 4″ and 6″ Y’s

3″, 4″ and 6″ Ells

6″ to 8″

Running Traps

4″ to 8″ Ells

4″ to 8″

Cleanouts

Bent Cable

WARNING

Catalog Model

No. No. Description

62275 C-10 15′ All-Purpose Wind (4.6m)

30007 T-1277/8″ Trap Leader

Catalog Model

No. No. Description

51317 C-9 10′ Heavy-Duty (3m)

62270 C-8 71/2′ All-Purpose Wind (2.3m)

62265 C-7 71/2′ Tight-Wind (2.3m)

Cables and Leaders

5

/8″ Cables

Page 12

K-75A/B, K-1500A/B, & K-1500SP Drain Cleaning Machines

Ridge Tool Company10

K-1500A/B Machines

Catalog Model

No. No. Description

62840 T-1 Straight Auger

61800 T-2 Heavy-Duty Straight Auger

63105 T-3 Funnel Auger

61790 T-4 Heavy-Duty Funnel Auger

63190 T-5 Straight Retrieving Auger

63195 T-6 Funnel Retrieving Auger

63200 T-7 Hook Auger

63205 T-8 Grease Cutter, 21/

2

″

63210 T-9 Grease Cutter, 31/

2

″

62845 T-10 Grease Cutter, 41/

2

″

59480 T-11 “H” Cutter, 2

1

/

2

″

59485 T-12 “H” Cutter, 31/

2

″

61970 T-13 Sawtooth Cutter, 21/

2

″

61975 T-14 Sawtooth Cutter, 31/

2

″

61770 T-15A Expanding Cutter, 4″ - 6″

61825 T-15B Expanding Cutter, 6″ - 8″

61960 T-16 Spiral Bar Cutter, 4″

61850 T-17 Spiral Bar Cutter, 6″

61855 T-18 Spiral Bar Cutter, 8″

59625 T-21 Spiral Sawtooth Cutter, 31/

2

″

63075 T-22 Spiral Sawtooth Cutter, 3″

63085 T-23 Spiral Sawtooth Cutter, 4″

59765 T-24 4-Blade Cutter, 21/

2

″

59770 T-25 4-Blade Cutter, 31/

2

″

59775 T-26 4-Blade Cutter, 41/

2

″

59780 T-26A 4-Blade Cutter, 51/

2

″

98030 T-50 Three Blade, 3″ − 4″− 5″

98035 T-50-1 Sharktooth Cutter, 3″

98040 T-50-2 Sharktooth Cutter, 4″

98045 T-50-3 Sharktooth Cutter, 6″

63110 T-31 Chain Knocker, 3″ − 4″ Pipe

63115 T-32 Chain Knocker, 6″ Pipe

63120 T-33 Chain Knocker, 8″ Pipe

63145 T-38 Flue Brush, 1

1

/

2

″

63150 T-39 Flue Brush, 2″

63155 T-40 Flue Brush, 2

1

/

2

″

63160 T-41 Flue Brush, 3″

63165 T-42 Flue Brush, 31/

2

″

63170 T-43 Flue Brush, 4″

63175 T-44 Flue Brush, 4

1

/

2

″

63240 T-45 Flue Brush, 5″

63180 T-46 Flue Brush, 51/

2

″

63185 T-47 Flue Brush, 6

Catalog Model

No. No. Description

59360 A-3 Tool Box

59205 A-1 Left-Hand Mitt

59295 A-2 Right-Hand Mitt

59225 A-12 Pin Key, 7/8″ Cable

59230 A-13 Pin Key, 5/8″ Cable

59470 A-8 Cable Carrier (Five Sections/C-10)

59210 A-10 Cable Carrier (Three Sections/C-10)

59425 A-36 Cable Caddy

59330 A-376X Jawset Adapts K-75 to 5/8″ Cable

59325 A-368X7/8″ Replacement Jawset

84315 A-34-8 8′ Rear Guide Hose

59415 A-34-10 10′ Rear Guide Hose

59395 A-34-12 12′ Rear Guide Hose

Accessories

Tools for C-11, C-12, C-14 and C-15 Cables 11/

4

″

Catalog Model Replacement

No. No. Description Blade(s)

62850 T-101 Straight Auger —

62855 T-102 Funnel Auger —

27642 T-125 Retrieving Auger —

62860 T-103 Sawtooth Cutter, 21/2″ 98070

62865 T-104 “H” Cutter, 21/2″ 97800

62870 T-105 Grease Cutter, 21/2″ 97920

62875 T-106 Grease Cutter, 31/2″ 97925

62880 T-107 Spade Cutter, 13/4″ 92850

62915 T-109 Spiral Sawtooth Cutter, 13/4″ 97930

62920 T-110 Spiral Sawtooth Cutter, 21/4″ 97935

62925 T-111 Spiral Sawtooth Cutter, 3″ 92890

62930 T-112 4-Blade Cutter, 13/4″ 97915

62935 T-113 4-Blade Cutter, 3″ 97940

98050 T-150 Sharktooth Cutter, 3″ and 4″ See Below

98055 T-150-1 Sharktooth Cutter, 3″ Blade 98005

98060 T-150-2 Sharktooth Cutter, 4″ Blade 98010

62940 T-114 Chain Knocker 97985

Tools for C-10 Cable - 7/

8

″

Catalog Model

No. No. Description

92280 C-11 15′ Standard All-Purpose Wind, 3/8″ Pitch.

Good for 4″ Traps, 3″ - 8″ Lines.

62285 C-12 15′ Extra-Heavy-Duty Wind, 3/8″ Pitch.

4″ - 10″ Long Runs, No 4″ Traps.

62295 C-14 15′ Heavy-Duty Wind,

1

/2″ Pitch. 3″ - 10″ Lines

Through Cleanout, No 4″ Traps.

62300 C-15 15′ Extra-Flexible Wind,

1

/2″ Pitch. 3″ - 6″ Lines

Good for Traps.

63090 T-27 1

1

/4″ x 25′ Leader

62275 C-10 15′ Standard All-Purpose Wind,

Requires A-368X Jawset

7

/8″ Tools

Cables and Leaders

Catalog Model

No. No. Description

59470 A-8 Cable Carrier, 60′ Capacity (11/4″)

59210 A-10 Cable Carrier, 150′ Capacity (11/4″)

59415 A-34-10 10′ Rear Guide Hose

59395 A-34-12 12′ Rear Guide Hose

59400 A-34-16 16′ Rear Guide Hose

59300 A-20 8′ Front Guide Hose Assembly

59205 A-1 Left-Hand Mitt

59295 A-2 Right-Hand Mitt

59360 A-3 Tool Box

59225 A-12 Coupling Pin Key

59440 A-4 Trap Spoon (30″)

59240 A-17 Manhole Guide Pipe

59320 A-369X 1

1

/4″ Replacement Jawset

Accessories

NOTE! See Ridge Tool Catalog for complete list of

tools and accessories.

Page 13

3. Slide out clutch driver jaws and replace with desired

size jaws.

Figure 13 – Replacing Clutch Jaws

4. Replace nose piece assembly, screws and guard.

Never operate machine with belt guard

removed. Fingers can be caught between the belt and

pulley.

Removing Clutch End Play

1. To remove end play from clutch, loosen screw in

Adjusting Nut. (Figure 14).

2. Turn lock and adjusting nut clockwise until snug

against housing, then back off one half turn.

3. Tighten screw in lock and adjusting nut.

Figure 14 – Removing Clutch End Play

K-75A/B, K-1500A/B, & K-1500SP Drain Cleaning Machines

Ridge Tool Company 11

Maintenance Instructions

WARNING

Make sure machine is unplugged from power

source before performing maintenance or making

any adjustment.

Moving Parts Lubrication

Grease all exposed moving parts such as rocker arms

and main bearing approximately every three months.

Make sure to grease main bearing thru grease fitting inside clutch handle slot.

Clutch Jaws Lubrication

Clean and lubricate clutch driver jaws with oil after each

use.

Cables

Cables should be thoroughly flushed with water to prevent damaging effects of sediment and drain cleaning

compounds. Periodically lubricate cables and couplings

with RIDGID Cable Rust Inhibitor.

When not in use, store cables indoors to prevent deterioration by the elements.

Cables should be replaced when they become severely

corroded or worn. A worn cable can be identified when

outside coils of cable become flat.

Clutch Jaws Replacement

1. Remove four screws holding the front guard to the

housing.

2. Remove screws from the nose piece assembly

(Figure 12).

Figure 12 – Replacing Clutch Jaws

WARNING

Page 14

Service and Repair

WARNING

The “Maintenance Instructions” will take care of most of

the service needs of this machine. Any problems not addressed by this section should only be handled by an

authorized RIDGID service technician.

Tool should be taken to a RIDGID Independent Authorized Service Center or returned to the factory. All repairs

made by Ridge service facilities are warranted against defects in material and workmanship.

When servicing this machine, only identical replacement parts should be used. Failure to follow

these instructions may create a risk of electrical shock or

other serious injury.

If you have any questions regarding the service or repair

of this machine, call or write to:

Ridge Tool Company

Technical Service Department

400 Clark Street

Elyria, Ohio 44035-6001

Tel: (800) 519-3456

E-mail: TechServices@ridgid.com

For name and address of your nearest Independent

Authorized Service Center, contact the Ridge Tool Company at (800) 519-3456 or http://www.ridgid.com

K-75A/B, K-1500A/B, & K-1500SP Drain Cleaning Machines

Ridge Tool Company12

V-Belt Adjustment

Check V-Belt periodically for loosening. V-Belt should be

kept tight at all times.

1. To tighten V-Belt remove Guard.

2. Loosen locknut, turn adjusting bolt slowly until VBelt stiffens, tighten locknut. (Figure 15).

Figure 15 – Adjusting V-Belt Tension

Machine Storage

Motor-driven equipment must be kept

indoors or well covered in rainy weather. Store the machine in a locked area that is out of reach of children and

people unfamiliar with drain cleaners. This machine

can cause serious injury in the hands of untrained users.

If machine has been exposed to freezing weather, unit

must be run for ten (10) to twenty (20) minutes without

load to warm up. Failing to do this will result in frozen

bearings. If machine is exposed to weather for a period

of time, moisture will form across motor windings causing motor to burn out.

WARNING

WARNING

Adjusting Nut

Page 15

K-75A/B, K-1500A/B, & K-1500SP Drain Cleaning Machines

Ridge Tool Company 13

K-75A/B & K-1500A/B Wiring Diagram

115V

Green

Blue

Red

Black

Yellow

Motor

Switch

Service Cord

Green

White

Black

Page 16

K-75A/B, K-1500A/B, & K-1500SP Drain Cleaning Machines

Ridge Tool Company14

K-1500SP Wiring Diagram

120V/60 Hz

K-1500SP Wiring Diagram

220-240V/50 Hz

Switch

Bk

Switch

Service Cord

W

O

Y

R

Y

W

W

Bl

Ground

Screw in

Switchbox

For Rev

L2

L1

Bk

U1

U2

Bl

Green

L2 White

L1 Black

RevBkFor

Z1

1

R

Green

Black

White

Line cord Modification:

Cut off existing terminals

Strip Wire Ends .25 in.

Y

L2 L1

Bl

Green-Yellow

L2 Brown

L1 Blue

RevBkFor

Green-Yellow

Brown

Line cord Modification:

Strip Wire Ends .25 in.

Blue

For Rev

Bl

Br

Ground

Screw in

Switchbox

Bk

W

O

Y

R

Bl

NOTE: Switch modified using

provided jumper terminals.

Page 17

Dégorgeoirs électriques

K-75A/B, K-1500A/B

et K-1500SP

Dégorgeoir électriques

Inscrivez ci-dessous le numéro de série de la plaque signalétique l’appareil pour future référence.

N° de

série :

Page 18

Table des matières

Fiche d’enregistrement du numéro de série de la machine....................................................................................15

Consignes générales de sécurité

Sécurité du chantier ..................................................................................................................................................17

Sécurité électrique.....................................................................................................................................................17

Sécurité individuelle ..................................................................................................................................................17

Utilisation et entretien de l’appareil ...........................................................................................................................18

Service après-vente ..................................................................................................................................................18

Consignes de sécurité particulières

Sécurité du dégorgeoir..............................................................................................................................................19

Description, spécifications et équipements de base

Description ................................................................................................................................................................19

Spécifications............................................................................................................................................................19

Equipements de base................................................................................................................................................20

Inspection de la machine............................................................................................................................................20

Préparation de la machine..........................................................................................................................................21

Utilisation de la machine ............................................................................................................................................23

Procédés spéciaux

Utilisation de la marche arrière..................................................................................................................................24

Câbles – types d’application......................................................................................................................................25

Stockage et transport des câbles (modèles à cadre type ‘A’)...................................................................................25

Accessoires

Sélection des câbles .................................................................................................................................................26

Accessoires et outils disponibles par type de câble..................................................................................................27

Entretien

Lubrification...............................................................................................................................................................27

Câbles.......................................................................................................................................................................27

Remplacement des mâchoires d’embrayage............................................................................................................27

Elimination du jeu de l’embrayage ............................................................................................................................28

Réglage de la courroie d’entraînement.....................................................................................................................28

Stockage de la machine..............................................................................................................................................28

Service après-vente et réparations............................................................................................................................29

Schéma électrique..................................................................................................................................................29-30

Garantie à Vie ...........................................................................................................................................Page de garde

Ridge Tool Company16

Dégorgeoirs électriques K-75A/B, K-1500A/B et K-1500SP

Page 19

Dégorgeoirs électriques K-75A/B, K-1500A/B et K-1500SP

Ridge Tool Company 17

Consignes générales de sécurité

MISE EN GARDE ! Familiarisez-vous complètement avec

l’ensemble des instructions. Le non-respect de ces consignes augmenterait

les risques de choc électrique, d’incendie et/ou de graves blessures corporelles.

CONSERVEZ CES INSTRUCTIONS !

Sécurité du chantier

• Maintenez le chantier propre et bien éclairé. Les

établis encombrés et le manque d’éclairage sont à

l’origine de nombreux accidents.

• N’utilisez pas d’appareils électriques en présence

de combustibles tels que les liquides, gaz ou poussières inflammables. Les appareils électriques

produisent des étincelles capables d’enflammer les

poussières et les émanations combustibles.

• Ecartez les curieux, les enfants et les visiteurs

lorsque vous utilisez un appareil électrique. Les dis-

tractions éventuelles peuvent vous faire perdre le

contrôle de l’appareil.

Sécurité électrique

• Les appareils électriques avec terre doivent être

branchés sur une prise avec terre appropriée et

conforme aux normes en vigueur. Ne jamais enlever

la barrette de terre ou tenter de modifier la fiche

d’aucune manière. Ne jamais utiliser d’adaptateurs

de prise. Consultez un électricien qualifié en cas de

doute sur la bonne mise à la terre de la prise. En cas de

panne ou de défaillance électrique de l’appareil, la

mise à la terre assure un passage de faible résistance

qui éloigne le courant électrique de l’opérateur.

• Evitez tout contact avec les masses telles que

tuyaux, radiateurs, cuisinières ou réfrigérateurs.

Les risques de choc électrique augmentent lorsque

votre corps est en contact avec une masse.

• N’exposez pas les appareils électriques à la pluie

ou aux intempéries. Toute pénétration d’eau à l’in-

térieur d’un appareil électrique augmente les risques de

choc électrique.

• Ne maltraitez pas le cordon électrique de l’ap-

pareil. Ne jamais porter l’appareil par son cordon

électrique, ni tirer sur celui-ci pour débrancher

l’appareil. Gardez le cordon à l’abri des sources de

chaleur, de l’huile, des angles tranchants et des

pièces mobiles. Remplacez immédiatement tout

cordon endommagé. Les cordons endommagés aug-

mentent les risques de choc électrique.

• Lorsque vous utilisez l’appareil à l’extérieur, utilisez

une rallonge électrique portant la désignation “WA” ou “W”. Ce type de rallonge est prévu pour être

utilisé à l’extérieur et réduit les risques de choc élec-

trique.

• Utilisez uniquement des rallonges à trois fils

équipées d’une fiche bipolaire plus terre à trois

barrettes et d’une prise bipolaire plus terre qui

correspond à la fiche de l’appareil. L’utilisation

d’autres types de rallonge électrique n’assurera pas la

mise à la terre de l’appareil et augmentera les risques

de choc électrique.

• Utilisez la section de rallonge appropriée (voir le

tableau). Une section de conducteurs insuffisante

provoquerait une perte de tension excessive, d’où un

manque de puissance.

• Vérifiez le bon fonctionnement du disjoncteur différentiel du cordon d’alimentation avant d’utiliser

l’appareil. Le disjoncteur différentiel réduit les risques

de choc électrique.

• L’utilisation de rallonges électriques est décon-

seillée sauf si celles-ci sont branchées sur une

boite de dérivation ou une prise équipée d’un disjoncteur différentiel. Le disjoncteur différentiel du

cordon d’alimentation de la machine n’assure aucune

protection contre les décharges électriques venant

des rallonges.

• Gardez les connexions électriques au sec et

surélevées. Ne touchez pas la fiche avec les mains

mouillées. Cela réduit les risques de choc électrique.

Sécurité individuelle

1. Soyez attentif, concentrez-vous sur ce que vous

faites et faites preuve de bon sens lorsque vous

Barrette de terre

Prise

avec

terre

Barrette de terre

Section minimale des fils conducteurs des rallonges

Ampères indiqués

sur la plaque Longueur totale (en pieds)

signalétique

0 à 25 26 à 50 51 à 100

0 à 6 18 AWG 16 AWG 16 AWG

6 à 10 18 AWG 16 AWG 14 AWG

10 à 12 16 AWG 16 AWG 14 AWG

12 à 16 14 AWG 12 AWG

Déconseillé

Page 20

Dégorgeoirs électriques K-75A/B, K-1500A/B et K-1500SP

Ridge Tool Company18

utilisez un appareil électrique. N’utilisez pas ce

type d’appareil lorsque vous êtes fatigués ou

lorsque vous prenez des médicaments, de l’alcool

ou des produits pharmaceutiques. Un instant d’inat-

tention peut entraîner de graves blessures lorsque l’on

utilise un appareil électrique.

• Habillez-vous de manière appropriée. Ne portez

pas de vêtements amples ou de bijoux. Attachez

les cheveux longs. Gardez vos cheveux, vos vêtements et vos gants à l’écart du mécanisme. Les

vêtements amples, les bijoux et les cheveux longs

peuvent s’entraver dans le mécanisme.

• Evitez les risques de démarrage accidentel. As-

surez-vous que l’interrupteur marche/arrêt est en

position OFF avant de brancher l’appareil. Le fait de

porter l’appareil avec un doigt sur la gâchette ou le

brancher lorsque son interrupteur est en position de

marche (ON) est une invitation aux accidents.

• Enlevez les clés de réglage et autres outils avant de

mettre l’appareil en marche. Une clé laissée sur

une partie rotative de l’appareil peut entraîner des

blessures corporelles.

• Ne vous mettez pas en porte-à-faux. Gardez une

bonne assise et un bon équilibre à tous moments.

Une bonne assise et un bon équilibre vous permettent

de mieux contrôler l’appareil en cas d’imprévu.

• Utilisez les équipements de sécurité appropriés.

Portez systématiquement des lunettes de sécurité. Un masque à poussière, des chaussures de

sécurité, le casque et/ou une protection auditive doivent

être portés selon les conditions d’utilisation.

Utilisation et entretien de l’appareil

• Utilisez un serre-joint ou autre moyen approprié

pour arrimer l’ouvrage sur une plate-forme stable. Tenir l’ouvrage à la main ou contre le corps peut

vous mettre en position d’instabilité et vous faire perdre

le contrôle de l’appareil.

• Ne forcez pas l’appareil. Utilisez un appareil qui soit

adapté au travail prévu. L’outil approprié assurera un

meilleur travail et une meilleure sécurité s’il est utilisé au

régime prévu.

• N’utilisez pas un appareil si son interrupteur ne

permet pas de le mettre en marche ou de l’arrêter.

Tout appareil qui ne peut pas être contrôlé par son in-

terrupteur est dangereux et doit être réparé.

• Débranchez l’appareil avant tout réglage ou

changement d’accessoires, et avant de le ranger.

De telles mesures préventives réduisent le risque de

démarrage accidentel de l’appareil.

• Rangez les appareils non utilisés hors de la portée

des enfants et des personnes non initiées. Ces

appareils sont dangereux entre les mains de personnes

non initiées.

• Entretenez les appareils consciencieusement.

Maintenez les outils de coupe bien affûtés et en

bon état de propreté. Les outils bien entretenus et af-

fûtés réduisent les risques de grippage et sont plus

faciles à contrôler.

• Assurez-vous qu’il n’y a pas de mauvais alignement ou de grippage au niveau du mécanisme ou

d’autres conditions qui pourraient entraver le bon

fonctionnement de l’appareil. Le cas échéant, faire

réparer l’appareil avant de vous en servir. De nom-

breux accidents sont le résultat d’un appareil mal

entretenu.

• Utilisez exclusivement les accessoires recommandés par le fabricant pour votre appareil particulier. Des accessoires prévus pour un certain type

d’appareil peuvent être dangereux lorsqu’ils sont mon-

tés sur un autre.

• Gardez les poignées de la machine propres, sèches

et dépourvues d’huile ou de graisse. Cela vous

permettra de mieux contrôler l’appareil.

Service après-vente

• Toutes réparations de l’appareil doivent être confiées à un réparateur qualifié. La réparation ou

l’entretien de l’appareil par du personnel non qualifié

peut entraîner des blessures.

• Lors de la réparation de l’appareil, utilisez exclusivement des pièces de rechange identiques à

celles d’origine. Suivez les instructions de la section “Entretien” du mode d’emploi. L’utilisation de

pièces de rechange non homologuées et le non-respect

des consignes d’entretien peut créer un risque de

choc électrique ou de blessure corporelle.

Consignes de sécurité

particulières

MISE EN GARDE

Lisez soigneusement ce manuel avant d’utiliser les

dégorgeoirs RIDGID K-75 ou K-1500. Le non-respect

des consignes ci-devant augmenterait les risques de

choc électrique, d’incendie et/ou de graves blessures

corporelles.

Veuillez adresser toutes questions éventuelles aux services techniques de la Ridge Tool Company en composant

le (800) 519-3456.

Page 21

Dégorgeoirs électriques K-75A/B, K-1500A/B et K-1500SP

Ridge Tool Company 19

que la modification du dégorgeoir pour d’autres applications augmente les risques d’accident.

Description, spécifications et

équipements de base

Description

Les dégorgeoirs RIDGID K-75A/B, K-1500A/B et K-1500SP

sont prévus pour le curage des canalisations allant de 11/

4

à 10 po de diamètre. Ces machines sont entraînées par un

moteur à induction équipé d’un système électrique avec

terre. Un disjoncteur différentiel est incorporé au cordon

d’alimentation de l’appareil. Un interrupteur à bascule

(ou bouton rotatif) contrôle les fonctions ‘marche avant’,

‘arrêt’ et ‘marche arrière’ du moteur.

Ces machines utilisent des câbles et outils à raccord

rapide. Le câble est introduit et retiré manuellement de la

machine et tourne à un régime de 600 à 700 t/min. La ro-

tation du câble est contrôlée par un levier d’embrayage.

Le câble s’arrête instantanément dès que l’on lâche le

levier d’embrayage.

Les machines du type K-75 sont livrées équipées pour

câble de 7/8po, ce qui permet de curer les canalisations de 2 à 4 po sur une distance maximale de 175

pieds. Un câble de 5/8po peut y être adapté pour permettre le curage des canalisations de 11/4à 3 po de

diamètre.

Les machines du type K-1500 sont livrées équipées

pour câble de 11/4po, ce qui permet de curer les canalisations de 3 à 10 po sur une distance maximale de 200

pieds. Un câble de 7/8po peut y être facilement adapté

pour permettre le curage des canalisations de 2 à 4 po

de diamètre.

Spécifications

Capacité de curage......Selon l e choix de câble. Se re-

porter au tableau pour les

sections recommandées

Moteur :

K-75A/B

Type.............................Réversible, 115V/60Hz

Puissance....................1/2CV

Intensité.......................7,2 A

K-1500A/B

Type...........................Réversible, 115V/60Hz, ver-

sion 230V-240V/50Hz dispon-

ible sur demande

Puissance....................3/4CV

Intensité.......................10,4 A

Sécurité du dégorgeoir

• Portez les mitaines en cuir fournies avec la ma-

chine. Ne jamais tenter d’attraper un câble tournant

avec un chiffon ou un gant en tissu mal ajusté.

Ceux-ci pourraient s’entortiller autour du câble et

provoquer de graves blessures.

• Ne forcez pas les câbles. Gardez votre main sur le

câble afin de le contrôler durant sa rotation. Forcer

les câbles à la rencontre d’un obstacle risque de

provoquer leur bouclage ou leur pincement et entraîner de graves blessures.

• Positionnez la machine à moins de deux pieds

(50cm) de l’entrée de la canalisation. Utilisez le

guide-câble avant lorsqu’il est nécessaire de

l’éloigner du point d’accès. Un écartement supérieur

risque de provoquer le bouclage ou le plissage du

câble.

• Ne faites pas tourner la machine en marche arrière

(REV). L’utilisation de la marche arrière risque d’en-

dommager le câble et ne doit servir qu’à retirer l’outil

d’un obstacle.

• Ne faites pas tourner la machine en marche arrière

(REV).

• Tenez-vous du côté interrupteur FOR/OFF/REV

lorsque vous utilisez la machine. Cela permet de

mieux la contrôler.

• Utilisez le guide-câble arrière. Celui-ci empêche le

câble de fouetter et de s’encrasser.

• Ne jamais utiliser ce type de machine sans son

carter de courroie. Vos doigts risqueraient d’être pris

entre la courroie et sa poulie.

• Faites attention lors du curage des canalisations

qui ont été préalablement traitées avec des produits chimiques. Evitez tout contact direct avec la

peau et les yeux. Certains produits de nettoyage

peuvent provoquer de graves brûlures.

• N’utilisez pas cette machine lorsque l’opérateur

et/ou la machine ont les pieds dans l’eau. Cela

augmenterait les risques de choc électrique.

• Portez des lunettes de sécurité et des chaussures

antidérapantes à semelle en caoutchouc. Ces

équipements de sécurité peuvent éviter de graves

blessures corporelles.

• Utilisez le K-75 exclusivement pour le curage des

canalisations d’évacuation d’un diamètre maximal de 4 po, et le K-1500 pour ceux allant jusqu’à

10 po de diamètre. Respectez les consignes d’utilisation de l’appareil. Toute autre utilisation, ainsi

Page 22

Style de Section Capacités Hauteur Poids

Modèle cadre de câble Ø Distance Puissance hors tout Largeur Longueur machine (lb.)

K-75A

A

5

/8″ 11/4″ - 3″ 125′

1

/2CV à 640 t/min.

41

1

/2″ 203/4″ 16″ 88

K-75A-SE

K-75B

B

7

/8″ 2″ - 4″ 175′ 273/4″ 203/4″ 405/8″ 76

K-75B-SE

K-1500A

A

7

/8″ 2″ - 4″ 175′

3

/4CV à 710 t/min.

411/2″ 203/4″ 16″ 92

K-1500A-SE

K-1500B

B1

1

/4″ 3″ - 10″ 200′ 273/4″ 203/4″ 405/8″ 80

K-1500B-SE

K-1500SP B

7

/8″ 2″ - 4″ 175′ 1CV à 600 t/min. 273/4″ 203/4″ 405/8″ 110

K-1500SPA A 1

1

/4″ 3″ - 10″ 300′ 411/2″ 203/4″ 16″ 138

Tableau 1

ou

ou

Dégorgeoirs électriques K-75A/B, K-1500A/B et K-1500SP

Ridge Tool Company20

K-1500A/B-SP

Type.............................Réversible, 115V/60Hz, sys-

tème de ventilation électrique

caréné

Puissance....................1 CV

Intensité.......................15 A

Cadre :

Style A............................2 roues à l ’arrière avec poignée

verticale sur cadre et logement

pour câble

Style B .........................2 roues à l’avant du cadre

Se reporter au Catalogue RIDGID RT pour les options et

accessoires disponibles par type de machine. Chaque

modèle de machine comprend les équipements standards suivants :

• Mitaine d’utilisateur A-1

• Clé à broche A-12

• Guide-câble arrière A-34-12

Figure 1 – Dégorgeoirs K-75A, K-1500A et K-1500SP

Inspection de la machine

MISE EN GARDE

L’inspection du dégorgeoir vous permettra de limiter

les risques d’accident. Le processus d’inspection

suivant devrait précéder chaque utilisation de la machine.

Levier

d’embrayage

Outil

Commutateur

FOR/OFF/REV

Guide-câble

Page 23

Dégorgeoirs électriques K-75A/B, K-1500A/B et K-1500SP

Ridge Tool Company 21

1. Assurez-vous que le dégorgeoir est débranché et

que son commutateur directionnel se trouve en position OFF (arrêt) (Figures 1 and 2).

2. Examinez le cordon d’alimentation, le disjoncteur différentiel et la fiche du cordon pour signes de détérioration. Si la fiche a été modifiée, qui lui manque sa

barrette de terre ou que le cordon d’alimentation est

endommagé, n’utilisez pas le dégorgeoir avant que le

cordon ait été remplacé.

3. Examinez le dégorgeoir pour signes de pièces endommagées, manquantes, désalignées ou grippées,

ainsi que pour toute autre anomalie qui pourrait nuire

au bon fonctionnement et à la sécurité de la machine. Le cas échéant, n’utilisez pas le dégorgeoir

avant que toute anomalie ait été réparée.

Figure 2 – Dégorgeoirs K-75B, K-1500B et K-1500SP

4. Si nécessaire, lubrifiez la machine selon les consignes de la section Entretien.

5. Utilisez les outils et accessoires prévus pour cet appareil et adaptés au chantier en question. Les outils et

accessoires appropriés vous permettront de faire le

travail correctement et en toute sécurité. Les accessoires prévus pour d’autres types d’appareil peuvent

être dangereux lorsqu’ils sont utilisés avec ce type de

dégorgeoir.

6. Eliminez toutes traces d’huile de graisse ou de crasse

des commandes et poignées du matériel. Cela réduira

les risques de blessure lorsqu’un outil ou une commande s’échappe de votre main.

7. Examinez le tranchant des outils utilisés. Si nécessaire, faites-les affûter ou remplacer avant d’utiliser le

dégorgeoir. Des outils émoussés ou endommagés

peuvent éventuellement provoquer le grippage et le

bris des câbles.

8. Examinez les câbles et les raccords pour signes

d’usure et de détérioration. Les câbles doivent être

remplacés dès qu’ils deviennent excessivement usés

ou corrodés. Un câble est considéré usé lorsque les

brins extérieurs s’aplatissent.

Les câbles usés ou endommagés

risquent de rompre et de provoquer de graves blessures

corporelles.

Préparation de la machine

MISE EN GARDE

N’installez pas la machine dans l’eau. Toute péné-

tration d’eau à l’intérieur du moteur risque de

provoquer des chocs électriques.

Une bonne préparation de la machine et du

chantier permettra de limiter les risques d’accident. Le processus de préparation suivant doit

être respecté lors de l’installation de la machine :

1. Examinez le chantier pour :

• Un éclairage suffisant.

• Une prise de courant avec terre.

• Un passage dégagé jusqu’à la prise de courant,

dépourvu de sources de chaleur, d’huile, d’arêtes

vives et de mécanismes qui risquent d’endommager le cordon électrique.

• Un endroit sec pour la machine et son utilisateur.

N’utilisez pas la machine lorsque vous avez les

pieds dans l’eau.

• La présence de liquides, de gaz ou de poussières

inflammables qui risquent de s’enflammer.

2. Positionnez le dégorgeoir à moins de 2 pieds du

point d’entrée. Une distance supérieure risque de

provoquer le bouclage ou le pincement du câble.

3. Assurez-vous que l’interrupteur/commutateur directionnel se trouve en position OFF (arrêt).

Levier

d’embrayage

Guide-câble

Commutateur

directionnel

FOR/OFF/REV

Outil

MISE EN GARDE

Page 24

Dégorgeoirs électriques K-75A/B, K-1500A/B et K-1500SP

Ridge Tool Company22

Figure 3 – Montage du guide-câble arrière

4. Attachez le guide-câble arrière en enfilant l’adaptateur

du guide-câble sur les broches prévues (Figure 3).

N’utilisez pas la machine sans guide-

câble arrière. Celui-ci empêche le câble de fouetter, éven-

tuellement s’emmêler, et salir les lieux.

5. Introduisez la première longueur de câble par l’avant

de la machine (raccord femelle en premier) et à travers

le guide-câble jusqu’à ce qu’il ne reste qu’environ 1

pied de câble à l’avant de la machine(Figure 4).

Figure 4 – Introduction du câble via l’avant de la machine

Ne jamais raccorder plus d’un câble

à la fois. Le câble s’étendrait au-delà du guide-câble ar-

rière.

6. Sélectionnez et montez l’outil approprié en bout du

câble. Son raccord rapide s’emboîte directement sur

celui du câble (Figure 5). Pour démonter l’outil du

bout du câble, enfoncez le piston de verrouillage du

raccord à l’aide de la broche fournie, puis séparez les

raccords.

Figure 5 – Montage et démontage des outils

NOTA ! Sélection de l’outil approprié

De manière générale, il est préférable d’utiliser un outil

dont le diamètre est d’au moins 1 pouce inférieur à

celui de la canalisation à curer. Dans la mesure où le

type d’outil utilisé dépend de la nature du curage,

son choix est laissé à la discrétion de l’utilisateur.

7. Après vous être assuré qu’il suit le passage dégagé

prévu, branchez le cordon d’alimentation du dégorgeoir. Si le cordon d’alimentation n’arrive pas jusqu’à

la prise de courant, utilisez une rallonge électrique en

bon état.

Afin d’éviter les risques de choc et

d’incendie électrique, ne jamais utiliser une rallonge élec-

trique endommagée ou qui ne répond pas aux critères

suivants :

• Toute rallonge électrique doit être équipée d’une fiche

à trois barrettes, semblable à celle indiquée à la sec-

tion Sécurité électrique.

• Toute rallonge électrique utilisée à l’extérieur doit être

du type “W” ou “W-A”.

• La rallonge électrique utilisée doit avoir des conduc-

teurs de section suffisante (14 AWG jusqu’à 50 pieds

de longueur). Une section de conducteurs insuffisante

risque de provoquer la surchauffe de la rallonge au

point de fondre son isolation et enflammer les objets à

proximité.

Afin de limiter les risques de choc

électrique, gardez toutes connexions électriques au sec et

surélevées. Ne touchez pas les fiches avec les mains

mouillées. Testez le disjoncteur différentiel fourni avec

le cordon d’alimentation afin de vous assurer de son bon

fonctionnement. Lorsque la touche d’essai est enfoncée,

le témoin lumineux doit s’éteindre. Réactivez-le en appuyant sur la touche de réarmement. Si le témoin lumineux

s’allume, c’est que la machine est prête à fonctionner. Si

le disjoncteur différentiel ne fonctionne pas correctement,

n’utilisez pas la machine.

Montage des outils

en bout de câble

Emboîter

Introduire la broche

Séparer

Démontage des outils en bout de câble

MISE EN GARDE

MISE EN GARDE

MISE EN GARDE

MISE EN GARDE

Page 25

Dégorgeoirs électriques K-75A/B, K-1500A/B et K-1500SP

Ridge Tool Company 23

Utilisation de la machine

MISE EN GARDE

Portez les mitaines à rivets fournies avec la machine. Ne jamais tenter d’attraper un câble en

rotation avec un chiffon ou des gants en tissu mal

ajustés qui risqueraient de s’entortiller autour du

câble et provoquer de graves blessures.

Portez systématiquement des lunettes de sécurité

afin de protéger vos yeux contre la projection de

débris ou autres objets divers. Portez des chaussures antidérapantes avec semelles en caoutchouc.

Faites particulièrement attention lors du curage

de canalisations qui ont été préalablement traités

aux produits chimiques. Portez des gants lors de la

manipulation des câbles, et évitez tout contact direct avec la peau et surtout avec les yeux et le

visage, car de graves brûlures pourraient en résulter.

Ne pas utiliser l’appareil si le levier d’embrayage est

endommagé ou ne fonctionne pas correctement.

Le levier d’embrayage est un dispositif de sécurité

qui arrête la rotation du câble dès qu’il est lâché.

Il est important de connaître la distance approximative entre le point d’entrée et l’égout ou la

fosse septique à l’autre bout. Un débordement excessif du

câble dans l’égout ou la fosse en question risque de le

laisser s’entortiller au point d’empêcher son retrait via

une canalisation de diamètre inférieur. Lors de l’utilisation

d’un câble de 11/4po en présence d’un égout de 12 po ou

plus, ne laissez pas le câble déborder de plus de 10 ou 15

pieds. Lorsqu’il s’agit d’une fosse septique, limitez ce

débordement à 3 ou 5 pieds au maximum.

1. Mettez-vous en position appropriée afin de maintenir

votre équilibre (Figure 6).

En cas d’imprévu, cette position vous

permettra de garder le contrôle de la machine et du câble

en toute sécurité.

• Assurez-vous de pouvoir lâcher le levier d’embrayage instantanément.

• Vous devez garder une main sur le câble pour

l’empêcher de fouetter lorsqu’il rencontre un obstacle.

• Vous devez pouvoir accéder au commutateur

FOR/OFF/REV.

Figure 6 – Position de travail appropriée

2. Tirez une longueur suffisante de câble de la machine

pour introduire l’outil et le câble dans la canalisation.

Enfoncez le câble dans la canalisation aussi loin que

possible.

3. Retirez une longueur supplémentaire de câble suffisante pour pouvoir presque former un demi-cercle

entre la machine et le point d’entrée.

4. Tenez le câble librement dans votre main gantée.

Mettez le commutateur FOR/OFF/REV en position

FOR (marche avant).

NOTA ! Le moteur se mettra alors en marche, mais sans

entraîner le câble.

5. Avec votre main gantée sur le câble, ramenez le

levier d’embrayage avec l’autre main afin d’engager le

câble. Appuyez sèchement sur le sommet de la

boucle du câble pour le faire avancer.

NOTA ! L’engagement trop lent ou progressif du levier

d’embrayage provoquera l’usure prématurée

des mâchoires du système d’engagement. Il

s’agit d’un système d’engagement direct, et le re-

tour du levier d’embrayage à sa position d’origine

assure la libération instantanée du câble.

6. Dès que le câble supplémentaire s’est engagé dans la

canalisation, lâchez le levier d’embrayage et retirez

une longueur de six à dix pouces de câble de la machine avec votre main gantée.

7. Continuez à faire avancer le câble dans la canalisation

jusqu’à ce que vous rencontrez une résistance ou un

obstacle. Une telle rencontre se traduira par la résis-

tance à l’avancement du câble et/ou sa tendance à se

tortiller latéralement dans la main de l’utilisateur.

AVERTISSEMENT

MISE EN GARDE

Page 26

Dégorgeoirs électriques K-75A/B, K-1500A/B et K-1500SP

Ridge Tool Company24

8. Si le câble se met en charge à la rencontre d’un obstacle, soulagez-le en y tirant dessus sèchement à

plusieurs reprises afin de dégager le couteau. Faites

à nouveau avancer le câble lentement vers l’obstacle.

Répétez ce processus jusqu’à l’élimination de l’ob-

stacle. N’oubliez pas qu’il faut que le couteau tourne

sans interruption et qu’il ne faut jamais forcer le câble.

A ce point, le progrès effectué dépendra de l’affûtage

de l’outil et la nature de l’obstacle.

MISE EN GARDE

Ne jamais permettre au câble de se mettre en

charge. Cela arrivera lorsque l’outil de coupe s’accroche et s’immobilise, tandis que le moteur et le

câble continuent à tourner. La torsion du câble

augmente jusqu’à ce que le câble se boucle,

éventuellement autours de votre bras ou de votre

main. Cela peut arriver soudainement et sans

préavis, d’où l’importance de procéder lentement et

précautionneusement lorsque vous faites avancer le

câble dans la canalisation. Le fait de lâcher le

levier d’embrayage arrêtera la rotation du câble et

le soulagera. Lorsqu’un outil s’entrave dans un obstacle, reportez-vous au chapitre ‘Utilisation de la

marche arrière’ de la section ‘Procédés spéciaux’.

9. Une fois l’obstacle dégagé, il est conseillé de rincer la

canalisation à grande eau pou en dégager les débris.

Si nécessaire, répétez l’étape n°8 à plusieurs reprises

afin d’assurer le nettoyage complet de cette section de

la canalisation avant de procéder au dégagement

des obstacles suivants.

10. Procédez comme suit pour ajouter des sections de

câble supplémentaires :

• Arrêtez la machine (position OFF) dès que vous

arrivez à la fin de la section de câble en cours.

• Arrimez le câble en le bouclant dans le point d’entrée (Figure 7). Cela peut s’avérer particulièrement

utile lorsqu’il s’agit d’une canalisation à forte pente.

Figure 7 – Bouclage du câble au point d’entrée

• Une fois le câble arrimé, introduisez une nouvelle

section de câble (raccord femelle en premier) via

l’avant de la machine jusqu’à ce qu’il n’en dépasse qu’environ 1 pied à l’avant de la machine.

• Raccordez ce câble à celui resté en attente dans

la canalisation, puis reprenez l’opération.

11. Utilisez la méthode suivante pour retirer le câble de la