Page 1

Kollmann

5

/8″ Cage Machine

OPERATOR’S

MANUAL

• Pour français voire page 13

• Para el castellano vea la

paginá 27

K-750R

W ARNING!

Read this Operator’s Manual

carefully before using this

tool. Failure to understand

and follow the contents of

this manual may result in

electrical shock, fire and/or

serious personal injury.

Page 2

Table of Contents

Recording Form for Machine Model and Serial Number............................................................................................1

General Safety

Work Area Safety........................................................................................................................................................2

Electrical Safety...........................................................................................................................................................2

Personal Safety...........................................................................................................................................................2

Tool Use and Care......................................................................................................................................................3

Service ........................................................................................................................................................................3

Specific Safety Information

Drain Cleaner Safety...................................................................................................................................................3

Description, Specifications and Standard Equipment

Description ..................................................................................................................................................................4

Specifications..............................................................................................................................................................4

Standard Equipment....................................................................................................................................................4

Machine Assembly

Instructions for Mounting Handles and Belt Guard......................................................................................................5

Instructions for Installing Cable...................................................................................................................................5

Machine Inspection .......................................................................................................................................................5

Machine Set Up..............................................................................................................................................................6

Operating Instructions..................................................................................................................................................7

Special Applications Procedure

Main Sewer or Septic Tank Overrun...........................................................................................................................8

Reverse Operation......................................................................................................................................................8

Loading Machine On Vehicle ......................................................................................................................................8

Drum Assembly Removal and Installation...................................................................................................................9

Pigtail Removal and Installation................................................................................................................................10

Accessories..................................................................................................................................................................10

Maintenance Instructions

Lubrication.................................................................................................................................................................10

Cables.......................................................................................................................................................................10

Machine Storage..........................................................................................................................................................10

Service and Repair ......................................................................................................................................................10

Trouble Shooting.........................................................................................................................................................11

Wiring Diagram............................................................................................................................................................11

Lifetime Warranty..........................................................................................................................................Back Cover

Ridge Tool Companyii

K-750R 5/8″ Cage Machine

Kollmann

Page 3

K-750R 5/8″ Cage Machine

Record Serial Number below and retain product serial number which is located on nameplate.

Serial

No.

K-750R

5

/8″ Cage Machine

Kollmann

Page 4

K-750R 5/8″ Cage Machine

Kollmann

Ridge Tool Company2

General Safety Information

WARNING! Read and understand all instructions. Failure

to follow all instructions listed below may

result in electric shock, fire, and/or serious

personal injury.

SAVE THESE INSTRUCTIONS!

Work Area Safety

• Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents.

• Do not operate power tools in explosive atmo-

spheres, such as in the presence of flammable

liquids, gases, or dust. Tools create sparks which

may ignite the dust or fumes.

• Keep bystanders, children, and visitors away while

operating a power tool. Distractions can cause you to

lose control.

Electrical Safety

• Grounded tools must be plugged into an outlet,

properly installed and grounded in accordance

with all codes and ordinances. Never remove the

grounding prong or modify the plug in any way.

Do not use any adapter plugs. Check with a qualified electrician if you are in doubt as to whether

the outlet is properly grounded. If the tool should

electrically malfunction or break down, grounding provides a low resistance path to carry electricity away

from the user.

• Avoid body contact with grounded surfaces such

as pipes, radiators, ranges and refrigerators. There

is an increased risk of electrical shock if your body is

grounded.

• Do not expose electrical tools to rain or wet con-

ditions. Water entering a tool will increase the risk of

electrical shock.

• Do not abuse cord. Never use the cord to carry the

tools or pull the plug from an outlet. Keep cord

away from heat, oil, sharp edges or moving parts.

Replace damaged cords immediately. Damaged

cords increase the risk of electrical shock.

• When operating a tool outside, use an outdoor

extension cord marked “W-A” or “W”. These cords

are rated for outdoor use and reduce the risk of electrical shock.

• Use only three-wire extension cords which have

three-prong grounding plugs and three-pole receptacles which accept the tool’s plug. Use of other

extension cords will not ground the tool and increase

the risk of electrical shock.

• Use proper extension cords. (See chart.) Insufficient

conductor size will cause excessive voltage drop, loss

of power.

• Before using, test the Ground Fault Circuit

Interrupter (GFCI) provided with the power cord

to insure it is operating correctly. GFCI reduces

the risk of electrical shock.

• Extension cords are not recommended unless

they are plugged into a Ground Fault Circuit

Interrupter (GFCI) found in circuit boxes or receptacles. The GFCI on the machine power cord will not

prevent electrical shock from the extension cords.

• Keep all electrical connections dry and off the

ground. Do not touch plugs or tool with wet hands.

Reduces the risk of electrical shock.

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a power tool. Do not

use tool while tired or under the influence of drugs,

alcohol, or medications. A moment of inattention

while operating power tools may result in serious personal injury.

• Dress properly. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair, clothing, and gloves away from moving parts. Loose

clothes, jewelry, or long hair can be caught in moving

parts.

• Avoid accidental starting. Be sure switch is OFF

before plugging in. Carrying tools with your finger

on the switch or plugging tools in that have the switch

ON invites accidents.

• Remove adjusting keys or switches before turning

Minimum Wire Gauge for Cord Set

Nameplate

Amps

Total Length (in feet)

0 – 25 26 – 50 51 – 100

0 – 6 18 AWG 16 AWG 16 AWG

6 – 10 18 AWG 16 AWG 14 AWG

10 – 12 16 AWG 16 AWG 14 AWG

12 – 16 14 AWG 12 AWG

NOT RECOMMENDED

Grounding pin

Cover of

grounded

outlet box

Grounding pin

Page 5

K-750R 5/8″ Cage Machine

Kollmann

Ridge Tool Company 3

the tool ON. A wrench or a key that is left attached to

a rotating part of the tool may result in personal injury.

• Do not over-reach. Keep proper footing and bal-

ance at all times. Proper footing and balance enables

better control of the tool in unexpected situations.

• Use safety equipment. Always wear eye protec-

tion. Dust mask, non-skid safety shoes, hard hat,

or hearing protection must be used for appropriate

conditions.

Tool Use and Care

• Use clamp or other practical way to secure and

support the workpiece to a stable platform. Holding

the work by hand or against your body is unstable

and may lead to loss of control.

• Do not force tool. Use the correct tool for your

application. The correct tool will do the job better

and safer at the rate for which it is designed.

• Do not use tool if switch does not turn it ON or

OFF. Any tool that cannot be controlled with the switch

is dangerous and must be repaired.

• Disconnect the plug from the power source before

making any adjustments, changing accessories, or

storing the tool. Such preventive safety measures

reduce the risk of starting the tool accidentally.

• Store idle tools out of the reach of children and

other untrained persons. Tools are dangerous in

the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp

and clean. Properly maintained tools with sharp cutting edges are less likely to bind and are easier to

control.

• Check for misalignment or binding of moving

parts, breakage of parts, and any other condition that may affect the tool's operation. If damaged, have the tool serviced before using. Many

accidents are caused by poorly maintained tools.

• Use only accessories that are recommended by the

manufacturer for your model. Accessories that may

be suitable for one tool may become hazardous when

used on another tool.

• Keep handles dry and clean; free from oil and

grease. Allows for better control of the tool.

Service

• Tool service must be performed only by qualified

repair personnel. Service or maintenance performed

by unqualified repair personnel could result in injury.

• When servicing a tool, use only identical replace-

ment parts. Follow instructions in the Maintenance

Section of this manual. Use of unauthorized parts or

failure to follow maintenance instructions may create a

risk of electrical shock or injury.

Specific Safety Information

WARNING

Read this operator’s manual carefully before using

the RIDGID/Kollmann K-750R Drain Cleaner. Failure

to understand and follow the contents of this manual may result in electrical shock, fire, and/or

severe personal injury.

Call Ridge Tool Company, Technical Service at (800)

519-3456 if you have any questions.

Drain Cleaner Safety

• Wear gloves provided with the machine. Never

grasp a rotating cable with a rag or loose fitting

cloth glove. Could become wrapped around the cable

and cause serious injury.

• Never operate machine with belt guard removed.

Fingers can be caught between the belt and pulley.

• Do not overstress cables. Keep two hands on the

cable for control when machine is running.

Overstressing cables may cause twisting or kinking

and result in serious injury.

• Position machine within three feet of inlet. Greater

distances can result in cable twisting or kinking.

• Machine is designed for one person operation.

Operator must control foot switch and cable.

• Use foot switch to operate machine while main-

taining good footing and balance. Do not operate

machine in (REV) reverse. Operating machine in

reverse can result in cable damage and is used only to

back tool out of an obstruction.

• Keep hands away from rotating drum and guide

tube. Do not reach into drum unless machine is

unplugged. Hand may be caught in the moving parts

resulting in serious injury.

• Use kickstand during operation. The kickstand sta-

bilizes machine to prevent tipping.

• Do not use this machine in drains where cleaning

compounds have been used. Serious burns can

result from some drain cleaning compounds.

Page 6

K-750R 5/8″ Cage Machine

Kollmann

Ridge Tool Company4

Standard Features

K-750R

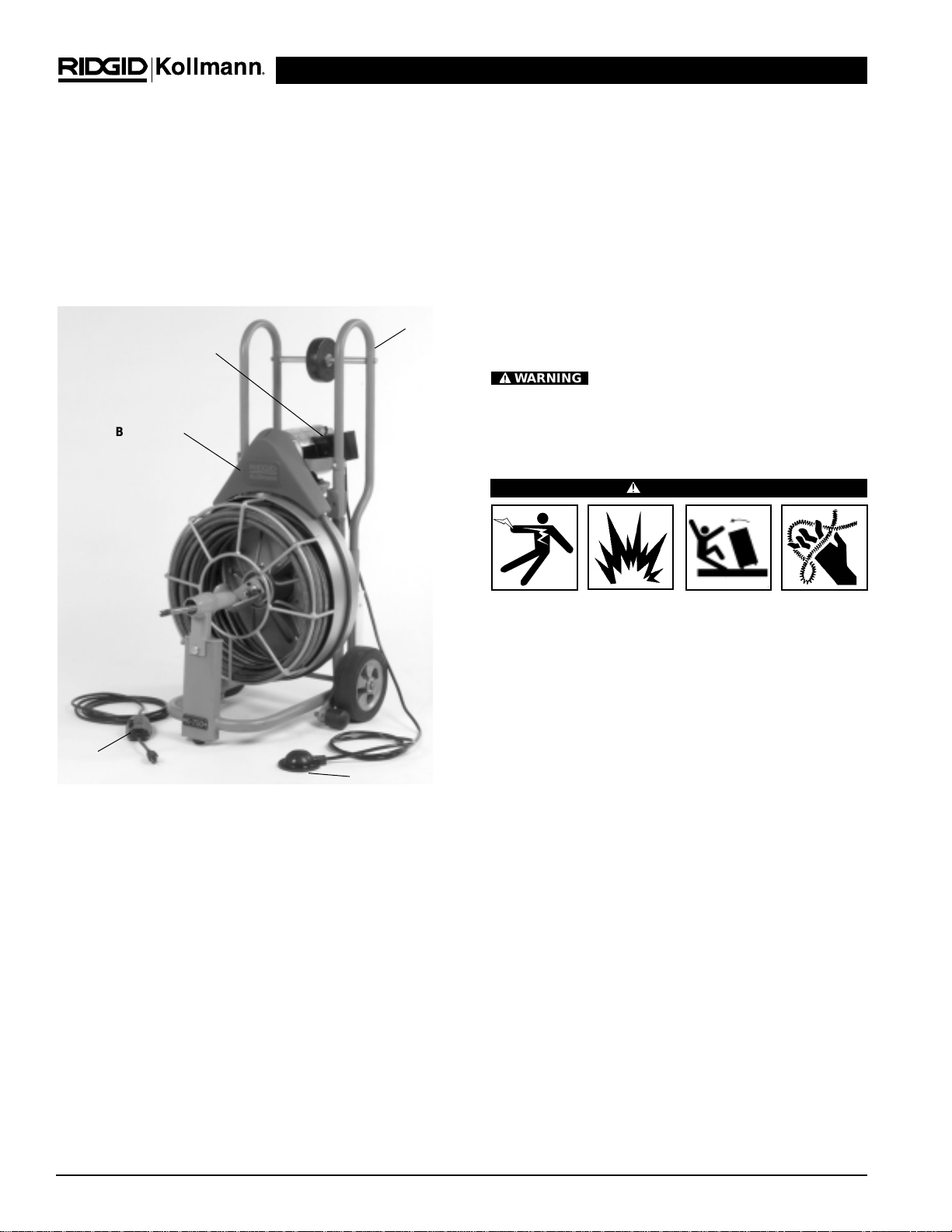

• K-750R Cage Machine (Figure 1)

• C-24 IW Solid Core Cable (Integral Wound)

(5/8″ x 100′)

• 1 Pair Gloves

• T-403 P-Trap Cutter (Figure 2)

• T-406 Spade Cutter (Figure 3)

• T-411 2″ Cutter (Figure 4)

• T-413 3″ Cutter (Figure 4)

• T-414 4″ Cutter (Figure 4)

• Safety & Instruction Card

• Rental Checklist Card

• Instruction Video

• Toolbox

Figure 1 – Machine With Gloves

Figure 2 – T-403 3″ P-Trap Cutter: Used for exploring

and breaking up stoppages.

• Do not operate machine if operator or machine is

standing in water. Will increase the risk of electrical

shock.

• Wear safety glasses and rubber soled, non-slip

shoes. Use of this safety equipment may prevent serious injury.

• Only use the K-750R to clean drain lines 3″ to 6″ in

diameter. Follow instructions on the use of the

machine. Other uses or modifying the drain cleaner for

other applications may increase the risk of injury.

Description, Specifications and

Standard Equipment

Description

The RIDGID/Kollmann K-750R Drain Cleaning Machine

will clean drain lines 3″ to 6″ in diameter and 100 feet in

length. It is specifically designed with a steel wire drum to

allow for inspection and cleaning of the cable.

The steel wire drum is belt-driven by a 1/2HP electric

motor that has a grounded electrical system. An integral

Ground Fault Interrupter (GFCI) is built into the line cord

and a “kickstand” base is provided for machine stability

during operation. A pneumatic foot actuator provides

ON/OFF control of the motor.

The drum powers a 5/8″ inner core cable that has a quick

change coupling system for connecting or disconnecting

tools. The cable is manually fed in and out of the drain. An

integral torque limiter will cause the drum to stop rotating

whenever excessive torque is created when the cutting tool

attached to the cable hits a snag and stops rotating.

Specifications

Line Capacity...............3″ – 6″ Lines, Up To 100 feet

Drum Capacity.............100′ of 5/8″ Cable

Motor Type...................115V, Reversible, Single

Phase, AC (60Hz)

Rating............................1/2HP @ 1725 RPM

Amps............................6.5

Weight

(Machine & Cable) ........194 lbs.

Length..........................26″

Width............................21″

Height ..........................43″

Page 7

K-750R 5/8″ Cage Machine

Kollmann

Ridge Tool Company 5

Figure 3 – T-406 Spade Cutter: Used to get soft grease

or debris moving in the drain.

Figure 4 – T-411 2″, T-413 3″ & T-414 4″ Cutter: Used for

general cleaning to remove tree roots and

materials clinging to pipe walls.

Machine Assembly

WARNING

To prevent serious injury, proper assembly of the

Drain Cleaner is required. The following procedures should be followed:

Instructions For Mounting Handles and

Belt Guard

Handles – Assemble handles to machine frame and

secure with two (2) belt guard screws.

Belt Guard – Check the belt guard to ensure that it is

approximately 1/4″ from the drum. Reposition guard if

necessary and tighten bolts (Figure 5).

Gap between belt guard and drum

should not exceed

1

/2″ to prevent fingers being caught

between belt and pulley. Do not operate machine without belt guard.

Instructions For Installing Cable

Do not remove bands or staples from

cable shipping carton. Cable is under tension and will

whip causing injury.

Retrieve end of cable through the center hole of carton and

remove enough cable to connect with drum pigtail. Connect

to pigtail by sliding cable couplings together and turning

screwdriver slot in coupler 180°. Couplings are in locked

position when hash mark is on opposite side of screwdriver

slot as shown in Figure 5. Manually feed cable into drum.

Machine Inspection

WARNING

To prevent serious injury, inspect your Drain

Cleaning Machine. The following inspection procedures should be performed before each use.

1. Make sure the Drain Cleaning Machine is unplugged

and the directional switch is set to the OFF position

(Figure 6).

Figure 5 – Disconnecting/Connecting Cable or Tool

QUICK-CONNECT CABLE & TOOLS

Rotate pin one-half turn in either direction to

quickly add cable or tools.

Hash Mark

(Locked position)

Screwdriver Slot

Hash Mark

(Un-locked position)

Screwdriver Slot

LOCKED

Hash mark CLOSED aligned with L stamped on coupling.

UNLOCKED

Hash mark OPEN aligned opposite L stamped on coupling.

Coupling features stainless steel pin and spring: eliminates need for

punches, stands, or expansion pins.

WARNING

CAUTION

Page 8

Ridge Tool Company6

2. Make sure the foot switch is present and attached to

the Drain Cleaning Machine (Figure 6). Do not operate the machine without a foot switch.

3. Inspect the power cord, Ground Fault Circuit

Interrupter (GFCI) and plug for damage. If the plug has

been modified, is missing the grounding prong or if the

cord is damaged, do not use the Drain Cleaning

Machine until the cord has been replaced.

Figure 6 – K-750R Drain Cleaner

4. Inspect the Drain Cleaning Machine for any broken,

missing, misaligned or binding parts as well as any

other conditions which may affect the safe and normal

operation of the machine. If any of these conditions are

present, do not use the Drain Cleaning Machine until

any problem has been repaired.

5. Lubricate the Drain Cleaning Machine, if necessary,

according to the Maintenance Instructions.

6. Use tools and accessories that are designed for your

drain cleaner and meet the needs of your application.

The correct tools and accessories allow you to do the

job successfully and safely. Accessories suitable for

use with other equipment may be hazardous when

used with this drain cleaner.

7. Clean any oil, grease or dirt from all equipment handles and controls. This reduces the risk of injury due

to a tool or control slipping from your grip.

8. Inspect the cutting edges of your tools. If necessary,

have them sharpened or replaced prior to using the

Drain Cleaning Machine. Dull or damaged cutting

tools can lead to binding and cable breakage.

9. Inspect cables and couplings for wear and damage.

Cables should be replaced when they become severely worn or corroded. A worn cable can be identified

when the outside coils become flat.

Worn or damaged cables can break

causing serious injury.

Machine Set-Up

WARNING

To prevent serious injury, proper set-up of the machine

and work area is required. The following procedures

should be followed to set-up the machine:

1. Check work area for:

• Adequate lighting

• Grounded electrical outlet

• Clear path to the electrical outlet that does not

contain any sources of heat or oil, sharp edges or

moving parts that may damage electrical cord.

• Dry place for machine and operator. Do not use

the machine while standing in water.

• Flammable liquids, vapors or dust that may ignite.

2. Position the Drain Cleaning Machine within 3′ of

sewer inlet. Greater distances can result in cable

kinking or twisting.

3. Tilt machine forward and use foot to extend “kickstands” so that machine rests firmly on them. For

best results, extend one kickstand and rest machine

on it before extending second kickstand. (Figure 7)

K-750R 5/8″ Cage Machine

Kollmann

WARNING

Belt Guard

Foot Switch

GFCI and Plug

Handle

Electrical Switch

Page 9

Ridge Tool Company 7

Figure 7 – Extending Kickstand

To prevent tipping during use, machine

should rest firmly on the kickstand.

4. Position the air foot switch pedal for easy operator

accessibility. Machine is designed for one person

operation.

5. Make sure FOR/OFF/REV switch is in the OFF position.

6. Select and install the proper tool to the end of the

cable Put screwdriver in slot, turn 180 degrees and

slide apart. To connect, slide tool or cable together

and turn screwdriver slot in coupler 180 degrees.

Coupling is in locked position when hash mark is on

opposite side of screwdriver slot as shown (Figure 5).

NOTE! Proper Tool Selection

The tools provided with this drain cleaner along with a

description of their intended use is shown in Figures 2, 3

and 4. A good rule of thumb is to use a tool at least 1″

smaller than the line to be cleaned. The style of the

tool is determined by the nature of the job and is left up

to the operator. A good starting tool is the T-403 Cutter

(Figure 2).

7. Plug the Drain Cleaning Machine into the electrical

outlet, making sure to position the power cord along

the clear path selected earlier. If the power cord does

not reach the outlet, use an extension cord in good

condition.

To avoid electric shock and electrical

fires, never use an extension cord that is damaged or

does not meet the following requirements:

• The cord has a three-prong plug similar to shown in

Electrical Safety Section.

• The cord is rated as “W” or “W-A” if being used out-

doors.

• The cord has sufficient wire thickness (16 AWG

below 50′/14 AWG 50′-100′). If the wire thickness is

too small, the cord may overheat, melting the cord’s

insulation or causing nearby objects to ignite.

To reduce risk of electrical shock, keep

all electrical connections dry and off the ground. Do not

touch plug with wet hands. Test the Ground Fault Circuit

Interrupter (GFCI) provided with the electric cord to

insure it is operating correctly. When test button is

pushed in, the indicator light should go off. Reactivate by

pushing the reset button in. If indicator light goes on, the

machine is ready to use. If the GFCI does not function

correctly, do not use the machine.

Operating Instructions

WARNING

Wear gloves provided with machine. Never grasp a

rotating cable with a rag or loose fitting cloth

glove that may become wrapped around the cable

causing serious injury.

Always wear eye protection to protect your eyes

against dirt and other foreign objects. Wear rubber

soled, non-slip shoes.

Do not use this machine in drains containing drain

cleaning compounds. Recommend calling a drain

cleaning professional.

Always assume the correct operating

posture in order to maintain proper balance (Figure 8).

Should an unexpected situation arise, this posture provides you with the opportunity to safely keep control of

the machine and cable.

• Be sure you can quickly remove your foot from the foot

switch.

• Hand must be on the cable to control its twisting

action when it hits an obstruction.

• Keep hands away from rotating drum and guide tube.

Do not reach into drum unless machine is unplugged.

K-750R 5/8″ Cage Machine

Kollmann

WARNING

WARNING

WARNING

WARNING

Page 10

Ridge Tool Company8

Figure 8 – Proper Operating Position

1. Manually pull a sufficient length of cable out of the

drum to start the tool and cable into the sewer inlet.

2. Move FOR/OFF/REV switch into FOR (forward) position. Do not step on the air foot switch pedal at this

time.

3. Pull 18″ – 24″ cable from the machine – enough to

form a slight loop – and apply slightly downward

pressure with both hands on the cable. Do not force

the cable. Allow it to feed itself into the drain.

WARNING

Before starting machine, both operator’s gloved

hands must be on the cable.

4. Exert sufficient downward pressure on cable to keep

it in sewer line while depressing air foot switch pedal

to start cable rotating.

5. Pull cable out of drum and allow cable to feed itself

into the line. Always keep hand on the cable to feel the

tension.

6. Continue to feed the cable into the line until resistance

or obstruction is encountered. The condition will generally become apparent to the operator as the cable

will have a tendency to twist sideways in the operator’s hands.

7. Pull back sharply on the cable to free the cutter and

relieve the load on the cable. Slowly advance cable

back into the obstruction. Repeat this process until the

obstruction is clear. Remember, make sure the cutter

is rotating at all times and never force the cable. If

motor turns but the drum stops, the torque limiter is

slipping because of excessive force. Pull back on

cable to relieve torque and drum will begin to spin.

WARNING

Do not allow tension to build up in the cable. This

will happen if the cutting tool hits a snag and

stops turning, but the motor and its drum continue

to rotate. Torque builds until the cable suddenly

twists, potentially wrapping around your hand or

arm. This can happen quickly and without warning,

so proceed slowly and carefully as you feed the

cable into the drain. If tool gets hung up in an

obstruction, refer to Reverse Operating Instructions

in the “Special Procedures” section.

8. Several passes through thoroughly blocked drain

lines are recommended. After establishing drain flow,

increase cutter size to thoroughly clean the lines.

9. Push cable into the drum with machine in FOR (forward). The machine should be kept running during the

process for thorough cleaning and uniform re-setting

of cable in the drum.

NOTE! A continuous flush of water should be used to

clean the cable and tool as they are retrieved.

10. When the tool is just inside the sewer inlet, release the

air foot switch pedal and allow the machine to come to

a complete stop.

Never retract tool from sewer inlet while

cable is rotating. Tool can whip causing serious injury.

11. Turn FOR/OFF/REV switch to OFF position and

remove cord from power source.

12. Pull the remaining cable and tool from the sewer.

Hand feed the cable into the machine.

13. Disengage the kickstands by tilting the machine forward.

Special Procedures

Main Sewer Or Septic Tank Overrun

It is very important to know the approximate distance

from inlet to main sewer or septic tank. Over-running

cable too far into main sewer or septic tank can allow

cables to knot-up and prevent their return.

Reverse Operation

Running machine in reverse will cause premature failure

of cable. Use reverse only to free a tool caught in an

obstruction. If this should occur, immediately remove

foot from air foot switch pedal and allow machine to

come to a full and complete stop. Place FOR/OFF/REV

switch to REV (reverse) position. If machine has automatic feed, loosen feed knob. Grasp cable with gloved

hands and pull while jogging air foot switch pedal. When

tool is dislodged and drum has stopped rotating, place

K-750R 5/8″ Cage Machine

Kollmann

WARNING

Page 11

Ridge Tool Company 9

FOR/OFF/REV switch in FOR (forward) position and

follow normal operating procedure.

Never operate this machine in REV

(reverse) for any other purpose. Operating in reverse can

damage a cable and cause serious injury.

Loading The Machine On Vehicle

Tip machine backwards and rest handles on truck bed.

Lift up on front of machine and slide onto truck.

Use proper lifting technique – lift with

your legs, not your back!!

NOTE! Take care not to damage electrical cord or air

foot switch hose.

Drum Removal & Installation Procedure

WARNING

Make sure FOR/OFF/REV switch is in OFF position

and machine is unplugged from power source.

1. Push down on motor table handle to release belt

tension and slip belt off drum. (Figure 9)

2. Use 3/4″ wrench to remove bolt that fastens drum

assembly to machine frame. (Figure 10)

Figure 9 – Release Belt Tension

Figure 10 – Remove Bolt Which Fastens Drum Assembly

to Machine Frame

Figure 11 – Lift Drum From Mounting Position

3. Lay machine back so that it rests on handles. Grasp

drum with both hands and lift it out of its mounting

position on machine (Figure 11).

To avoid back injury, be sure to bend

your knees and lift with your legs.

4. To install drum assembly, place it in its mount on

machine frame. Drum assembly should slide onto

shaft mounted on frame.

5. Carefully return machine to its upright position and

reverse Steps 1 through 5 to prepare machine for

operation.

K-750R 5/8″ Cage Machine

Kollmann

WARNING

WARNING

CAUTION

Page 12

Pigtail Removal and Installation

WARNING

FOR/OFF/REV switch should be OFF and machine is

unplugged before removing or installing pigtail.

1. Remove all cable from the drum except the pigtail.

2. Remove the bolt anchoring the pigtail. It is located on

the back of the drum (Figure 12).

Figure 12 – Removing Pigtail Anchoring Bolt

3. Remove the pigtail from drum by pulling it through the

guide tube.

4. Insert new pigtail by pushing it through the guide

tube into the drum.

5. Align hole in pigtail fastener with the hole in the back

of the drum. Insert bolt, washers and nut and tighten

securely. Push the remainder of the pigtail into drum.

Accessories

Only the following RIDGID/Kollmann

products have been designed to function with the K750R Drain Cleaning Machine. Other accessories suitable for use with other tools may become hazardous

when used on the K-750R. To prevent serious injury, use

only the accessories listed below.

K-750R 5/8″ Cage Machine

Kollmann

Maintenance Instructions

WARNING

Make sure machine is unplugged from power

source before performing maintenance or making

any adjustments.

Lubrication

Grease all exposed, moving and rotating parts as required.

Grease drum assembly fitting periodically.

Cables

Drain drum after every use. Flush drum periodically,

remove sediment that can corrode cable.

Cables should be thoroughly flushed with water to prevent damaging effects of drain cleaning compounds.

Periodically lubricate cables and couplings with

RIDGID/Kollmann Cable Rust Inhibitor. See accessories

regarding catalog numbers.

When not in use, store cables indoors to prevent deterioration by the elements.

Cables should be replaced when they become severely

corroded or worn. A worn cable can be identified when

outside coils of cable become flat.

Machine Storage

Motor-driven equipment must be kept

indoors or well covered in rainy weather. Store the

machine in a locked area that is out of reach of children

and people unfamiliar with drain cleaners. This machine

can cause serious injury in the hands of untrained users.

Service and Repair

Service and repair work on this Drain Cleaner must be

performed by qualified repair personnel. Machine should

be taken to a RIDGID Independent Authorized Service

Center or returned to the factory. All repairs made by

Ridge service facilities are warranted against defects

in material and workmanship.

When servicing this machine, only identical replacement parts should be used. Failure to follow

these instructions may create a risk of electrical shock or

other serious injury.

If you have any questions regarding the service or repair

of this machine, call or write to:

Ridge Tool Company

Technical Service Department

400 Clark Street

Elyria, Ohio 44036-2023

Tel: (800) 519-3456

E-mail: TechServices@ridgid.com

Ridge Tool Company10

WARNING

WARNING

Catalog Model

No. No. Description

87602 C-24 IW

5

/8″ x 100′ Solid Core Cable

92485 T-403 P-Trap Cutter

92495 T-406 Spade Cutter

92510 T-411 2″ Cutter

92520 T-413 3″ Cutter

92525 T-414 4″ Cutter

41937 — Gloves

59360 — Toolbox

43642 A-75 Autofeed Assembly

59982 — Cable Rust Inhibitor, 1 Quart

59987 — Cable Rust Inhibitor, 1 Gallon

WARNING

Page 13

K-750R 5/8″ Cage Machine

Kollmann

Ridge Tool Company 11

Wiring Diagram

PROBLEM POSSIBLE REASONS SOLUTION

Cable kinking or breaking.

Drum stops while pedal is

depressed. Restarts when

pedal is re-depressed.

Drum turns in one direction but not the other.

Ground Fault Circuit Interrupter Trips when machine

is plugged in or when foot

pedal is depressed.

Motor turning but cage is

not.

Chart 1 Trouble Shooting

Cable is being forced.

Cable used in incorrect pipe diameter.

Motor switched to reverse.

Cable exposed to acid.

Cable worn out.

Hole in pedal or hose.

Hole in diaphragm switch.

Faulty reverse switch.

Damaged power cord.

Short circuit in motor

Faulty Ground Fault Circuit Interrupter.

Torque limiter slipping because cable is being forced.

Do Not Force Cable! Let the cutter do the work.

Use 5/8″ cables in 3″ to 6″ lines.

Use reverse only if cable gets caught in pipe.

Clean and oil cables routinely.

If cable is worn, replace it.

Replace damaged component.

If no problem found with pedal or hose, replace

diaphragm switch.

Replace switch.

Replace cord set.

Take motor to authorized service center.

Replace cord set that includes a Ground Fault

Circuit Interrupter.

Do not force cable.

For name and address of your nearest Independent

Authorized Service Center, contact the Ridge Tool

Company at (800) 519-3456 or http://www.ridgid.com

Page 14

Ridge Tool Company12

K-750R 5/8″ Cage Machine

Kollmann

Page 15

Dégorgeoir à cage de

5

/

8

″

K-750R

Kollmann

Dégorgeoir à cage de 5/8″ K-750R

Inscrivez ci-dessous le numéro de série de la plaque signalétique l’appareil pour future référence.

N° de

série :

Page 16

Table des matières

Fiche d’enregistrement du numéro de série de la machine....................................................................................13

Consignes générales de sécurité

Sécurité du chantier ..................................................................................................................................................15

Sécurité électrique.....................................................................................................................................................15

Sécurité personnelle..................................................................................................................................................15

Utilisation et entretien de l’appareil ...........................................................................................................................16

Réparations...............................................................................................................................................................16

Consignes de sécurité particulières

Sécurité du dégorgeoir..............................................................................................................................................17

Description, spécifications et équipements de base

Description ................................................................................................................................................................17

Spécifications............................................................................................................................................................17

Equipements de base................................................................................................................................................18

Préparation de l’appareil

Installation des poignées et du carter de courroie.....................................................................................................18

Installation du câble...................................................................................................................................................19

Inspection de l’appareil...............................................................................................................................................19

Installation de l’appareil..............................................................................................................................................20

Mode d’emploi .............................................................................................................................................................21

Procédés spéciaux

Débordement dans l’égout ou dans la fosse septique ..............................................................................................22

Utilisation de la marche arrière..................................................................................................................................22

Chargement de l’appareil sur véhicule......................................................................................................................22

Dépose et installation du tambour.............................................................................................................................22

Dépose et installation du raccord en tire-bouchon....................................................................................................23

Accessoires .................................................................................................................................................................24

Entretien

Lubrification...............................................................................................................................................................24

Câbles.......................................................................................................................................................................24

Stockage de l’appareil.................................................................................................................................................24

Entretien et réparations ..............................................................................................................................................24

Dépannage ...................................................................................................................................................................25

Schéma électrique.......................................................................................................................................................26

Garantie à vie ...........................................................................................................................................Page de garde

Ridge Tool Company14

Dégorgeoir à cage de 5/8″ K-750R

Kollmann

Page 17

Ridge Tool Company 15

Dégorgeoir à cage de 5/8″ K-750R

Kollmann

Consignes de Sécurité Générales

MISE EN GARDE ! Familiarisez-vous avec l’ensemble des

instructions. Le respect des consignes

suivantes vous permettra d’éviter les

risques de choc électrique, d’incendie

et de blessure corporelle grave.

CONSERVEZ CES INSTRUCTIONS !

Sécurité du chantier

• Gardez le chantier propre et bien éclairé. Les étab-

lis encombrés et les locaux mal éclairés sont une invitation aux accidents.

• N’utilisez pas d’appareils électriques dans un

milieu explosif tel qu’en présence de liquides de

gaz ou de poussière inflammable. L’appareil produit

des étincelles qui pourraient causer la poussière ou les

vapeurs de s’enflammer.

• Gardez les tiers, les enfants et les visiteurs à l’écart

lorsque vous utilisez un appareil électrique. Les distractions peuvent vous faire perdre le contrôle de

l’appareil.

Sécurité électrique

• Les appareils électriques avec terre doivent être

branchés sur une prise avec terre appropriée et

conforme aux normes en vigueur. Ne jamais

enlever la barrette de terre ou tenter de modifier la

fiche d’aucune manière. Ne jamais utiliser d’adaptateurs de prise. Consultez un électricien qualifié

en cas de doute sur la bonne mise à la terre de la

prise. Dans le cas d’une panne ou d’une défaillance

électrique de l’appareil, la terre assure un passage de

faible résistance qui éloigne le courant électrique de

l’opérateur.

• Evitez de venir en contact avec des masses telles

que les tuyaux, les radiateurs, les cuisinières et les

réfrigérateurs. Les risques de choc électrique aug-

mentent lorsque votre corps est à la masse.

• N’exposez pas les appareils électriques à la pluie

ou aux intempéries. Toute pénétration d’eau à

l’intérieur d’un appareil électrique augmente les risques

de choc électrique.

• Ne maltraitez pas le cordon électrique de l’appareil.

Ne jamais porter l’appareil par son cordon électrique, ni tirer sur celui-ci pour débrancher

l’appareil. Gardez le cordon à l’abri des sources de

chaleur, de l’huile, des angles tranchants et des

pièces mobiles. Remplacez immédiatement tout

cordon endommagé. Les cordons endommagés aug-

mentent les risques de choc électrique.

• A l’extérieur, utilisez exclusivement des rallonges

électriques portant la mention “W-A” ou “W”. Ce

type de cordon est prévu pour être utilisé à l’extérieur

et réduit les risques de choc électrique.

• Utilisez uniquement des rallonges électriques à

trois fils équipées d’une fiche bipolaire plus terre à

trois barrettes et d’une prise bipolaire plus terre qui

correspond à la fiche de l’appareil. L’utilisation

d’autres types de rallonge électrique n’assurera pas la

mise à la terre de l’appareil et augmentera les risques

de choc électrique.

• Utilisez la section de rallonge électrique appro-

priée (voir le tableau). Une section de conducteurs

insuffisante entraînera des pertes de charge excessive

et un manque de puissance.

• Avant d’utiliser l’appareil, testez le disjoncteur dif-

férentiel du cordon d’alimentation afin de vous

assurer de son bon fonctionnement. La présence

d’un disjoncteur différentiel réduit les risques de choc

électrique.

• Il est déconseillé d’utiliser des rallonges élec-

triques sans disjoncteur différentiel à la source

d’alimentation. Le disjoncteur différentiel de l’appareil

ne protège pas contre les risques de chocs électriques

au niveau des rallonges.

• Gardez les connexions des rallonges électriques

au sec et surélevées. Ne pas manipuler les connexions avec les mains mouillées. Cela réduit les

risques de choc électrique.

Sécurité personnelle

• Restez attentif, faites attention à ce que vous faites

et faites preuve de bon sens lorsque vous utilisez

un appareil électrique. N’utilisez pas ce type

d’appareil lorsque vous êtes fatigués ou lorsque

Barrette de terre

Prise

avec

terre

Barrette de terre

Section minimale des fils conducteurs des rallonges

Ampères indiqués

sur la plaque Longueur totale (en pieds)

signalétique

0 à 25 26 à 50 51 à 100

0 à 6 18 AWG 16 AWG 16 AWG

6 à 10 18 AWG 16 AWG 14 AWG

10 à 12 16 AWG 16 AWG 14 AWG

12 à 16 14 AWG 12 AWG

Déconseillé

Page 18

Ridge Tool Company16

Dégorgeoir à cage de 5/8″ K-750R

Kollmann

vous prenez des médicaments, de l’alcool ou des

produits pharmaceutiques. Un instant d’inattention

peut entraîner de graves blessures lorsque l’on utilise

un appareil électrique.

• Habillez-vous de manière appropriée. Ne portez

pas de vêtements amples ni de bijoux. Attachez les

cheveux longs. Gardez vos cheveux, vos vêtements et vos gants à l’écart des pièces mobiles.

Les vêtements amples, les bijoux et les cheveux longs

peuvent s’entraver dans les pièces mobiles.

• Evitez les risques de démarrage accidentel. Vérifier

que l’interrupteur marche/arrêt est en position

OFF avant de brancher l’appareil. Porter l’appareil

avec un doigt sur la gâchette ou le brancher lorsque

son interrupteur est en position ON sont des invitations

aux accidents.

• Enlevez les clés de réglage et autres outils avant de

mettre l’appareil en marche. Une clé laissée sur

une partie rotative de l’appareil peut entraîner des

blessures corporelles.

• Ne vous mettez pas en porte-à-faux. Gardez une

bonne assise et un bon équilibre à tous moments.

Une bonne assise et un bon équilibre vous assurent de

mieux contrôler l’appareil en cas d’imprévu.

• Utilisez les équipements de sécurité appropriés.

Portez une protection oculaire systématiquement.

Un masque à poussière, des chaussures de sécurité,

le casque et/ou une protection auditive doivent être

portés selon les conditions d’utilisation.

Utilisation et entretien de l’appareil

• Utilisez un serre-joint ou autre moyen approprié

pour arrimer l’ouvrage sur une plate-forme stable. Tenir l’ouvrage à la main ou contre le corps peut

vous mettre en position d’instabilité et vous faire perdre

le contrôle de l’appareil.

• Ne forcez pas l’appareil. Utilisez l’appareil adapté

au travail prévu. L’outil approprié assurera un meilleur

travail et une meilleure sécurité s’il est utilisé au régime

prévu.

• N’utilisez pas un appareil si son interrupteur ne

permet pas de le mettre en marche ou de l’arrêter.

Tout appareil qui ne peut pas être contrôlé par son

interrupteur est dangereux et doit être réparé.

• Débranchez le cordon électrique de l’appareil avant

le réglage, le changement d’accessoires ou le

rangement de celui-ci. De telles mesures préven-

tives réduisent le risque de démarrage accidentel de

l’appareil.

• Rangez les appareils non utilisés hors de la portée

des enfants et des amateurs. Ces appareils sont

dangereux entre les mains de personnes non initiées.

• Entretenez les appareils consciencieusement.

Maintenez les outils de coupe bien affûtés et en bon

état de propreté. Les outils bien entretenus et affûtés

réduisent les risques de grippage et sont plus faciles à

contrôler.

• Vérifier qu’il n’y a pas de mauvais alignement ou de

grippage des pièces rotatives ou d’autres conditions qui pourraient entraver le bon fonctionnement

de l’appareil. Le cas échéant, faire réparer l’appareil

avant de vous en servir. De nombreux accidents

sont le résultat d’un appareil mal entretenu.

• Utilisez exclusivement les accessoires recom-

mandés par le fabricant pour votre appareil particulier. Des accessoires prévus pour un certain type

d’appareil peuvent être dangereux lorsqu’ils sont montés sur un autre.

• Gardez les poignées de la machine propres, sèch-

es et dépourvues d’huile ou de graisse. Cela vous

permettra de mieux contrôler l’appareil.

Réparations

• Toutes réparations de l’appareil doivent être confiées à un réparateur qualifié. La réparation ou

l’entretien de l’appareil par du personnel non qualifié

peut entraîner des blessures.

• Lors de la réparation de l’appareil, utilisez exclu-

sivement des pièces de rechange identiques à

celles d’origine. Suivez les instructions de la section “Entretien” du mode d’emploi. L’utilisation de

pièces de rechange non homologuées et le non respect

des consignes d’entretien peut créer un risque de

choc électrique ou de blessure corporelle.

Consignes de sécurité

particulières

MISE EN GARDE !

Lisez ce mode d’emploi soigneusement avant

d’utiliser le dégorgeoir K-750R. Tout manque de

compréhension et de respect des consignes du

mode d’emploi vous met à risque de choc électrique, d’incendie et/ou de graves blessures corporelles.

Appelez les services techniques de Ridge Tool Company

au (800) 519-3456 en cas de questions.

Page 19

Ridge Tool Company 17

Dégorgeoir à cage de 5/8″ K-750R

Kollmann

• N’utilisez le K-750R que pour le curage des canal-

isations d’évacuation de 3″ à 6″ de diamètre.

Respectez les instructions du mode d’emploi.

Toute autre utilisation ou modification du dégorgeoir

pour d’autres applications peut augmenter les risques

de blessure.

Description, spécifications et

équipements de base

Description

Le dégorgeoir RIDGID/Kollmann type K-750R est prévu

pour le curage des canalisations d’évacuation de 3″ à 6″

de diamètre et d’une longueur maximale de 100 pieds.

L’appareil est équipé d’un tambour grillagé en acier afin

de permettre l’inspection et le nettoyage du câble.

Le tambour grillagé en acier est entraîné par courroie et

utilise un moteur électrique de 1/2CV équipé d’un système

électrique avec prise de terre. Un disjoncteur différentiel

intégré fait partie du cordon d’alimentation et une béquille

est prévue pour assurer la stabilité de l’appareil. Une

pédale de commande pneumatique sert à la mise en

marche et l’arrêt du moteur.

Le tambour entraîne un câble à noyau central de 5/8″ de

diamètre équipé d’un système d’accouplement rapide

pour le montage ou le démontage des outils de curage. Ce

câble s’introduit et se retire de la canalisation manuellement. Un limiteur de couple incorporé arrête la rotation du

tambour lorsque l’outil de curage en bout du câble

s’accroche sur un obstacle et s’arrête de tourner.

Spécifications

Capacité de curage .....Canalisations de 3″ à 6″ de

diamètre et d’une longueur

maximale de 100 pieds

Capacité du tambour ...100′ de câble de 5/

8

″

Type de moteur............115V/60Hz, inversible, à

phase auxiliaire

Puissance.....................

1

/2CV à 1725 t/m

Ampères ......................6,5

Poids

(Appareil + câble) ........194 lbs.

Longueur......................26″

Largeur ........................21″

Hauteur........................43″

Sécurité du dégorgeoir

• Portez les gants livrés avec l’appareil. Ne jamais

tenter d’attraper un câble en rotation avec un chiffon ou des gants en toile trop grands. Ceux-ci

risquent de s’embobiner autour du câble et de provoquer de graves blessures.

• Ne jamais utiliser l’appareil sans son carter de

courroie. Vos doigts risquent d’être pris entre la courroie et sa poulie.

• Ne pas forcer les câbles. Contrôlez le câble à l’aide

de vos deux mains durant sa rotation. Toute sollicitation excessive des câbles face aux obstructions

peut entraîner leur bouclage et de graves blessures

corporelles.

• Positionnez l’appareil à moins de trois pieds de

l’entrée de la canalisation. Une distance plus importante risque de permettre le bouclage ou le pincement du câble.

• Cet appareil est prévu pour un opérateur seul.

L’opérateur doit simultanément assurer le contrôle de

la pédale de commande et du câble.

• Utilisez la pédale de commande pour faire fonc-

tionner l’appareil, tout en maintenant une bonne

assise et un bon équilibre. Ne pas utiliser l’appareil

en marche arrière (REV). L’utilisation de la marche

arrière risque d’endommager le câble et doit être

réservée au seul retrait du câble en cas d’obstruction.

• Ecartez vos mains du tambour et du tuyau du

guide-câble lorsqu’ils sont en rotation. Ne pas

introduire vos mains dans le tambour sans lavoir

débranché l’appareil. Vos mains risquent d’être pris-

es dans le mécanisme, d’où le risque de graves

blessures corporelles.

• Engagez la béquille durant l’utilisation de l’appareil.

La béquille sert à stabiliser l’appareil et à empêcher son

renversement.

• Ne pas utiliser cet appareil dans des canalisations

où ont été employées des solutions de nettoyage.

Certains produits de nettoyage peuvent provoquer de

graves brûlures. Le cas échéant, confiez le curage

de la canalisation à un professionnel.

• Ne pas utiliser cet appareil lorsque l’opérateur ou

l’appareil a les pieds dans l’eau. Cela augmente

les risques de choc électrique.

• Portez des lunettes de sécurité et des chaussures

antidérapantes à semelle en caoutchouc. Ces dispositifs de sécurité peuvent vous protéger contre de

graves blessures.

Page 20

Ridge Tool Company18

Dégorgeoir à cage de 5/8″ K-750R

Kollmann

Equipements de base

K-750R

• Appareil â cage type K-750R (Figure 1)

• Câble à âme pleine C-24 IW (bobinage monobloc) de

5

/8po x 100 pieds

• Une paire de gants

• Mèche à siphons en P T-403 (Figure 2)

• Mèche aspic T-406 (Figure 3)

• Mèche de curage de 2″ T-411 (Figure 4)

• Mèche de curage de 3″ T-413 (Figure 4)

• Mèche de curage de 4″ T-414 (Figure 4)

• Carte d’instructions et de sécurité

• Carte de contrôle de location

• Vidéo d’instructions

• Caisse à outils

Figure 1 – Appareil avec gants

Figure 2 – Mèche à siphons T-403 pour l’exploration et

le dégagement des bouchons.

Figure 3 – Mèche aspic T-406 pour le curage des

matières grasses et des débris

Figure 4 – Mèches de curage T-411 (2″), T-413 (3″) et

T-414 (4″) pour curage général et élimination

des racines d’arbre et autres matériaux

accrochés aux parois des canalisations

Préparation de l’appareil

MISE EN GARDE !

Le dégorgeoir doit être assemblé de manière

appropriée afin d’éviter de graves blessures corporelles. Respectez les instructions suivantes :

Installation de la poignée et du carter

de courroie

Poignées – Installez les poignées sur le cadre de

l’appareil et fixez-les à l’aide des deux (2) vis du carter

de courroie.

Carter de courroie – Vérifiez qu’il existe un écartement d’environ 1/4″ entre le carter de courroie et le tambour. Si nécessaire, réglez l’écart et serrez les boulons

(Figure 5).

Le jeu entre le carter de courroie et

le moteur ne doit pas être supérieur à

1

/2″ afin d’empêcher vos doigts d’être pris entre la courroie et la poulie. Ne

pas utiliser cet appareil sans carter de courroie.

MISE EN GARDE

Page 21

Ridge Tool Company 19

Dégorgeoir à cage de 5/8″ K-750R

Kollmann

Installation du câble

Ne pas enlever les cerceaux ou les

agrafes du carton d’emballage. Le câble est sous tension

et risque de se débander violemment.

Retirez l’embout du câble via l’orifice prévu dans le carton et tirez-en une longueur suffisante pour pouvoir le

raccorder à la queue de cochon du tambour. Raccordezle à la queue de cochon en emboîtant les deux

extrémités ensemble et en tournant la fente à tournevis

du raccord d’accouplement d’un demi-tour. Les raccords d’accouplement sont en position verrouillée lorsque

la striure se trouve du côté opposé à la fente de tournevis

comme indiqué à la Figure 5. Introduisez le câble dans

le tambour à la main.

Inspection de l’appareil

MISE EN GARDE !

Il est nécessaire d’inspecter le dégorgeoir afin d’éviter

les risques de blessure grave. L’inspection suivante

devrait être effectuée avant chaque utilisation.

1. Vérifier que le dégorgeoir est débranché et que l’interrupteur directionnel se trouve en position neutre (OFF)

(Figure 6).

2. Vérifiez le raccordement de la pédale de commande

(Figure 6). Ne pas utiliser l’appareil sans pédale de

commande.

3. Examinez le cordon d’alimentation, le disjoncteur différentiel et la fiche du cordon pour signes de détérioration. Si la fiche a été modifiée, qu’elle n’a pas de barrette de terre ou que le cordon est endommagé, ne

pas utiliser le dégorgeoir avant d’avoir remplacé le cordon d’alimentation.

Figure 6 – Dégorgeoir K-750R

4. Inspectez le dégorgeoir pour signes de pièces

endommagées, absentes ou grippées, ainsi que

pour signes d’autres anomalies qui risquent de nuire

au fonctionnement normal et à la sécurité de

l’appareil. Le cas échéant, ne pas utiliser le dégorgeoir avant de l’avoir réparé.

5. Lorsque nécessaire, lubrifiez le dégorgeoir selon les

instructions de la section Entretien.

6. Utilisez les accessoires prévus pour votre type de

dégorgeoir et pour votre application particulière. Les

accessoires appropriés vous permettent d’effectuer le

Carter de courroie

Pédale de commande

Disjoncteur

différentiel et fiche

Poignée

Interrupteur électrique

Figure 5 – Déboîtement et raccordement des câbles et

mèches

CABLE & MECHES A RACCORDS RAPIDES

Tournez la broche d’un demi-tour dans un sens ou dans

l’autre pour rapidement ajouter un câble ou une mèche.

Striure

(position verrouillée)

Fente à tournevis

Striure

(position déverrouillée)

Fente à tournevis

VERROUILLE

Striure FERMEE alignée avec lettre “L” estampée sur raccord

DEVERROUILLE

Striure OUVERTE alignée à l’opposé de la lettre “L” estampée

sur le raccord.

Les raccords sont équipés de broches et de ressorts en acier inoxydable qui

éliminent le besoin de chasse-goupilles, de supports et de broches expansibles.

AVERTISSEMENT

Page 22

Ridge Tool Company20

Dégorgeoir à cage de 5/8″ K-750R

Kollmann

travail complètement et en toute sécurité. Les accessoires prévus pour d’autres types de matériel peuvent

être dangereux lorsqu’ils sont utilisés sur ce type de

dégorgeoir.

7. Eliminez toutes traces d’huile, de graisse ou de saleté

des poignées et commandes de l’appareil. Cela réduit

les risques de blessures provoquées par la perte de

contrôle de l’appareil.

8. Examinez le tranchant des mèches. Si nécessaire, les

affûter ou remplacer avant d’utiliser le dégorgeoir.

Les tranchants émoussés ou endommagés peuvent

provoquer le grippage ou la rupture du câble.

9. Examinez les câbles et les raccords pour signes

d’usure et de détérioration. Les câbles doivent être

remplacés lorsqu’ils deviennent excessivement usés

ou corrodés. Un câble est considéré usé lorsque ses

torons externes s’aplatissent ou lorsque le câble est

plissé à plusieurs endroits.

Les câbles usés ou endommagés

peuvent se rompre et causer de graves blessures corporelles.

Préparation de l’appareil

MISE EN GARDE !

L’appareil et le lieu de travail doivent être préparés de manière appropriée afin d’éviter les accidents graves. Les consignes suivantes doivent

être respectées lors de l’installation de l’appareil.

1. Vérifier que le lieu de travail :

• Est suffisamment bien éclairé.

• Est équipé d’une prise électrique avec terre.

• Offre un passage direct jusqu’à la prise électrique

qui ne contient pas de sources de chaleur, d’huile,

d’angles vifs ou de mécanismes qui risqueraient

d’endommager le cordon électrique.

• Est sec au niveau de l’appareil et de son opérateur. Ne jamais poser l’appareil dans l’eau.

• Est libre de liquides, de vapeurs ou de poussières

inflammables qui risquerait de s’enflammer.

2. Positionnez le dégorgeoir à moins de 3′ de l’entrée de

la canalisation. Un écartement supérieur risque de permettre au câble de se boucler ou de se pincer.

3. Basculez l’appareil vers l’avant et déployez les

béquilles avec votre pied en vous assurant que

l’appareil repose fermement sur elles. Pour de

meilleurs résultats, déployez une béquille et reposez

l’appareil sur elle avant de déployer la seconde

béquille (Figure 7).

Figure 7 – Déploiement des béquilles

L’appareil doit reposer sur ses

béquilles afin d’éviter les risques de renversement.

4. Positionnez la pédale de commande de manière à

pouvoir y accéder facilement. L’appareil peut être

manipulé par une seule personne.

5. Vérifier que l’interrupteur FOR/OFF/REV se trouve en

position OFF.

6. Sélectionnez et installez en bout du câble l’outil approprié. Introduisez le tournevis dans la fente du raccord, puis tournez-le sur 180° avant de déboîter.

Pour raccorder deux câbles ou une mèche et un

câble, emboîtez-les et servez-vous du tournevis pour

tourner la fente du raccord sur 180°. Le raccord

d’accouplement sera verrouillé lorsque la striure se

trouve du côté opposé de la fente à tournevis comme

indiqué à la Figure 5.

NOTA ! Sélection de la mèche de curage appropriée.

Les mèches de curage livrées avec le dégorgeoir, ainsi

que leurs applications particulières, sont indiquées aux

Figures 2, 3 et 4. Il est généralement conseillé d’utiliser

une mèche dont le diamètre est d’au moins 1″ inférieur à

celui de la canalisation à curer. Le type de mèche

dépend de la nature du curage et son choix est laissé à

la discrétion de l’utilisateur. Entamez le curage de

préférence avec la mèche de curage T-403 (Figure 2).

7. Branchez le cordon d’alimentation du dégorgeoir en

faisant attention de faire courir le cordon le long du

passage dégagé précédemment délimité. Si le cordon

d’alimentation n’arrive pas jusqu’à la prise, utilisez

une rallonge électrique en bon état.

MISE EN GARDE

MISE EN GARDE

Page 23

Ridge Tool Company 21

Dégorgeoir à cage de 5/8″ K-750R

Kollmann

Afin d’éviter les risques de choc

électrique et d’incendie, ne jamais utiliser de rallonge

électrique endommagée ou qui ne répondent pas aux

spécifications suivantes :

• Toute rallonge électrique doit être équipée d’une

prise de terre semblable à celle indiquée à la section

Sécurité électrique.

•

Toute rallonge électrique utilisée à l’extérieur doit

porter la mention “W” ou “W-A”.

• Toute rallonge électrique doit avoir des conducteurs

(fils) de section suffisante (16 AWG pour moins de 50′

/ 14 AWG de 50′ à 100′ de longueur). Une section de

conducteurs insuffisante risque de faire surchauffer la

rallonge, faire fondre son isolation, ou enflammer

des objets à proximité.

Afin de limiter les risques de choc

électrique, gardez toutes connexions électriques au sec

et surélevées. Ne pas toucher les fiches avec les mains

mouillées. Vérifiez le bon fonctionnement du disjoncteur différentiel du cordon d’alimentation. Le témoin

devrait s’éteindre lorsque vous appuyez sur la touche

d’essai. Réactivez le disjoncteur en appuyant sur la

touche de réarment. Si le témoin s’allume, c’est signe

que l’appareil est en état de marche. Si le disjoncteur ne

fonctionne pas correctement, ne pas utiliser l’appareil.

Mode d’emploi

MISE EN GARDE !

Portez les gants livrés avec l’appareil. Ne jamais

tenter d’attraper un câble en rotation avec un

chiffon ou des gants en toile trop grands qui

risquent de s’embobiner autour du câble et causer

de graves blessures.

Portez systématiquement des lunettes de sécurité

afin de protéger vos yeux contre la projection

éventuelle de saleté et autres débris. Portez des

chaussures antidérapantes avec semelles en

caoutchouc.

Ne pas utiliser cet appareil pour le curage de canalisations d’évacuation contenant des produits chimiques. Le cas échéant, consultez un professionnel.

Assumez systématiquement la position opérationnelle appropriée afin de maintenir votre

équilibre (Figure 8). En cas d’imprévu, cette position vous

permettra de mieux contrôler l’appareil et son câble.

• S’assurer de pouvoir rapidement retirer votre pied

de la pédale de commande.

• Vous devez garder une main sur le câble à tout

moment afin d’empêcher son bouclage lorsqu’il rencontre un obstacle.

• Ecartez vos mains du tambour lorsqu’il tourne. Ne pas

introduire vos mains dans le tambour avant d’avoir

débranché l’appareil.

Figure 8 – Position opérationnelle appropriée

1. Retirez manuellement une longueur de câble suffisante du tambour pour pouvoir introduire la mèche et

le câble dans la canalisation d’évacuation. Enfoncez

le câble dans la canalisation aussi loi que possible.

2. Mettez l’interrupteur FOR/OFF/REV à la position

FOR (marche avant). Ne pas appuyer sur la pédale

de commande à ce moment.

3. Retirez entre 18″ et 24″ de câble de l’appareil (juste

assez pour former une petite boucle), puis appuyez

légèrement sur la boucle avec vos deux mains. Ne

forcez pas le câble. Laissez-le avancer tout seul dans

la canalisation.

MISE EN GARDE !

Avant de démarrer l’appareil, les deux mains gantées de l’opérateur doivent se trouver sur le câble.

4. Appuyez sur le câble avec suffisamment de forcer

pour qu’il reste dans la canalisation tandis que vous

appuyez sur la pédale de commande pour entamer sa

rotation.

5. Retirez le câble du tambour et laissez-le avancer

tout seul dans la canalisation. Gardez toujours une

main sur le câble pour pouvoir détecter une résistance

éventuelle.

6. Continuez à faire avancer le câble dans la canalisation

jusqu’à ce qu’il rencontre une résistance ou un obsta-

MISE EN GARDE

MISE EN GARDE

MISE EN GARDE

Page 24

Ridge Tool Company22

Dégorgeoir à cage de 5/8″ K-750R

Kollmann

cle. Cela se traduira par une résistance à l’avancement du câble, ou bien par sa tendance à se vriller

latéralement entre les mains de l’opérateur.

7. Si le câble s’embourbe, soulagez-le en tirant sèchement sur le câble à plusieurs coups secs afin de

libérer la mèche, puis faites délicatement avancer le

câble à nouveau vers l’obstacle. Répétez ce processus jusqu’à ce que l’obstacle soit éliminé. N’oubliez

pas que la mèche doit tourner constamment afin de ne

pas stresser le câble. Si le moteur continue à tourner

une fois le tambour arrêté, c’est signe que le limiteur

de couple dérape en raison d’une résistance excessive. Tirez sur le câble pour le soulager et le tambour

se mettra à tourner à nouveau.

MISE EN GARDE !

Ne pas solliciter le câble de manière excessive.

Cela arrive lorsque la mèche rencontre un obstacle

qui la bloque, tandis que le moteur et le tambour continuent à tourner. Le couple ainsi développé augmente jusqu’à ce que le câble se vrille subitement,

entourant parfois la main ou du bras qui le tient. Cela

peut arriver subitement et sans préavis. Il convient

donc de procéder lentement et soigneusement avec

l’avancement du câble dans la canalisation. Si la

mèche de curage s’entrave dans un obstacle,

reportez-vous au chapitre ‘Utilisation de la marche

arrière’ de la section “Procédés spéciaux”.

8. Dans le cas de canalisations sérieusement obstruées,

il est conseillé de faire plusieurs passes. Une fois

l’écoulement rétabli, passez à une mèche plus grande

pour parfaire le curage de la canalisation.

9. Gardez l’appareil en marche avant (FOR) lorsque

vous repoussez le câble dans le tambour en fin de

passe. L’appareil doit continuer à tourner lors du rembobinage du câble afin de nettoyer le câble et assurer

qu’il s’enroule de manière uniforme autour du tambour.

NOTA ! Il est conseillé de prévoir un filet d’eau constant afin

de rincer le câble et la mèche lors de leur retrait.

10. Juste avant que la mèche sorte de la canalisation,

lâchez la pédale de commande pneumatique et attendez que l’appareil s’arrête de tourner.

Ne jamais retirer la mèche de la

canalisation tandis que le câble tourne. La mèche risque

de fouetter et provoquer de graves blessures corporelles.

11. Mettez l’interrupteur FOR/OFF/REV en position OFF

et débranchez l’appareil.

12. Retirez le restant de câble et la mèche de la canalisation.

Réintroduisez le câble dans le tambour manuellement.

13. Faites basculer l’appareil vers l’avant et repliez les

béquilles.

Procédés spéciaux

Débordement dans l’égout ou dans la

fosse septique

Il est très important de connaître la distance aproximative

entre l’entrée de l’évacuation et l’égout ou la fosse septique. Tout débordement du câble dans un égout ou dans

une fosse septique risque de d’entraîner le bouclage du

câble et empêcher son retrait.

Utilisation de la marche arrière

Faire tourner l’appareil en marche arrière entraînera la

défaillance prématurée du câble Utilisez la marche

arrière exclusivement pour dégager une mèche embourbée dans un obstacle. Le cas échéant, lâchez immédiatement la pédale de commande et attendez que

l’appareil s’arrête complètement. Mettez l’interrupteur

FOR/OFF/REV en position REV (marche arrière). Si

l’appareil est équipé d’un système d’avancement automatique du câble, desserrez la molette d’avancement.

Prenez le câble entre vos deux mains gantées et tirez-le,

tout en tapotant sur la pédale de commande. Une fois la

mèche dégagée et le tambour arrêté, mettez l’interrupteur

FOR/OFF/REV en position FOR (marche avant), puis

reprenez le mode opératoire normal.

Ne jamais utiliser la marche arrière

pour d’autres raisons quelconques. L’utilisation de la

marche arrière risque d’endommager le câble et provoquer de graves blessures corporelles.

Chargement de l’appareil sur véhicule

Basculez l’appareil en arrière jusqu’à ce que ses manches reposent sur la ridelle du véhicule. Soulevez l’appareil

par l’avant et glissez-le dans le véhicule.

Respectez la technique de manutention appropriée – utilisez vos jambes et non votre dos ! !

NOTA ! Faites attention de ne pas endommager le cor-

don électrique ou le flexible de la pédale de

commande.

Dépose et installation du tambour

MISE EN GARDE !

S’assurer que l’interrupteur FOR/OFF/REV se trouve en position OFF et que l’appareil est débranché.

1. Appuyez sur la poignée de la table du moteur afin de

soulager la tension de la courroie, puis retirez la courroie du tambour (Figure 9).

2. Utilisez une clé de 3/4″ pour enlever le boulon de

montage du tambour (Figure 10).

MISE EN GARDE

MISE EN GARDE

MISE EN GARDE

Page 25

Ridge Tool Company 23

Dégorgeoir à cage de 5/8″ K-750R

Kollmann

Figure 9 – Soulager la tension de la courroie

Figure 10 – Enlever le boulon de montage du tambour

Figure 11 – Retirer le tambour

3. Couchez l’appareil sur ses poignées. Prenez le tambour

des deux mains et retirez-le de l’appareil (Figure 11).

N’oubliez pas de plier les genoux

afin d’éviter de vous faire mal au dos.

4. Pour installer le tambour, positionnez-le face à son

emplacement sur le cadre de l’appareil. Le tambour

devrait s’enfiler facilement sur l’arbre du cadre.

5. Remettez l’appareil d’aplomb et inversez les étapes 1

à 5 pour remettre l’appareil en état de marche

Dépose et installation de la queue de

cochon

MISE EN GARDE !

L’interrupteur FOR/OFF/REV doit se trouver en

position OFF et l’appareil doit être débranché

avant de déposer ou d’installer la queue de cochon.

1. Déroulez tout le câble du tambour jusqu’à ce que

vous arriviez à la queue de cochon.

2. Enlevez le boulon de retenue de la queue de cochon.

Celui-ci se trouve au dos du tambour (Figure 12).

Figure 12 – Dépose du boulon de retenue de la queue de

cochon

3. Retirez la queue de cochon du tambour en la faisant

passer par le guide-câble.

4. Introduisez une nouvelle queue de cochon en la

faisant passer à travers le guide-câble jusqu’au tambour.

5. Alignez le trou du support de la queue de cochon sur

celui qui se trouve sur la paroi arrière du tambour.

Installez le boulon, les rondelles et l’écrou, puis serrez

à fond. Enfilez le restant de la queue de cochon dans

le tambour.

AVERTISSEMENT

Page 26

Ridge Tool Company24

Stockage de l’appareil

Tout matériel électrique doit être

rangé à l’intérieur ou protégé par temps de pluie. Rangez

le dégorgeoir dans un endroit sous clé, hors de la portée

des enfants et des personnes qui ne connaissent pas les

dégorgeoirs. Cet appareil peut provoquer de graves

blessures corporelles lorsqu’il tombe entre les mains

de personnes non initiées.

Entretien et réparations

L’entretien et la réparation de ce dégorgeoir doivent

être effectués par un réparateur qualifié. L’appareil doit

être confié à un réparateur agréé par RIDGID ou renvoyé

à l’usine. Toutes réparations effectuées par les services

d’entretien Ridge sont garanties contre les vis de matériel

et de main d’oeuvre.

Utilisez exclusivement des pièces

de rechange identiques à celles d’origine lors de la réparation de l’appareil. Le non respect de ces consignes

augmente les risques de choc électrique ou autre grave

blessure corporelle.

Veuillez adresser toutes questions éventuelles concernant l’entretien ou la réparation de cet appareil aux

coordonnées suivantes :

Ridge Tool Company

Technical Service Department

400 Clark Street

Elyria, Ohio 44036-2023

Téléphone : (800) 519-3456

E-mail: TechServices@ridgid.com

Pour obtenir les coordonnées du réparateur agréé le

plus proche, veuillez consulter la Ridge Tool Company au

(800) 519-3456 ou http://www.ridgid.com

Dégorgeoir à cage de 5/8″ K-750R

Kollmann

Accessoires

Seuls les produits RIDGID/Kollmann