RIDGID jobmax R8223407 Operator Maintenance

OPERATOR’S MANUAL

MANUAL DEL OPERADOR

JobMax™ JIG SAW HEAD

TÊTE À SCIE SAUTEUSE JobMax

Use only with base model Series A, B, D, E

• Series A includes models R8223400, R8223500

• Series B includes model R2850, R2851

• Series D includes model P246

• Series E includes model R8620

Compatible uniquement avec le base modèle de série

A, B, D, E

• Série A inclut modèle R8223400, R8223500

• Série B inclut modèle R2850, R2851

• Série D inclut modèle P246

• Série E inclut modèle R8620

Utilizar sólo con el Modelo base número serie A, B, D, E

• Serie A incluye modelos R8223400, R8223500

• Serie B incluye modelos R2850, R2851

• Serie D incluye modelos P246

• Serie E incluye modelos R8620

MANUEL D’UTILISATION

™

CABEZAL DE SIERRA

DE VAIVÉN JobMax™

R8223407

To register your RIDGID

product, please visit:

http://register.RIDGID.com

Pour enregistrer votre

produit de RIDGID,

s’il vous plaît la visite:

http://register.RIDGID.com

Para registrar su producto

de RIDGID, por favor visita:

http://register.RIDGID.com

Your JobMax™ accessory has been engineered and manufactured to our high standards for dependability, ease of operation,

and operator safety. When properly cared for, it will give you years of rugged, trouble-free performance.

WARNING:

To reduce the risk of injury, the user must read and understand the operator’s manual before using this product.

Thank you for your purchase.

SAVE THIS MANUAL FOR FUTURE REFERENCE

Cette JobMax™ accessoire a été conçue et fabriquée conformément

à nos strictes normes de fiabilité, de simplicité d’emploi et de

sécurité d’utilisation. Correctement entretenue, elle vous donnera

des années de fonctionnement robuste et sans problème.

AVERTISSEMENT :

Pour réduire les risques de blessures, l’utilisateur doit

lire et veiller à bien comprendre le manuel d’utilisation

avant d’employer ce produit.

Merci de votre achat.

CONSERVER CE MANUEL POUR

FUTURE RÉFÉRENCE

Su JobMax™ accesorio para la obra ha sido diseñado y fabricado

de conformidad con nuestras estrictas normas para brindar

fiabilidad, facilidad de uso y seguridad para el operador. Con el

debido cuidado, le brindará muchos años de sólido y eficiente

funcionamiento.

ADVERTENCIA:

Para reducir el riesgo de lesiones, el usuario debe leer

y comprender el manual del operador antes de usar

este producto.

Le agradecemos su compra.

GUARDE ESTE MANUAL PARA

FUTURAS CONSULTAS

TABLE OF CONTENTS

TABLE DES MATIÈRES / ÍNDICE DE CONTENIDO

Introduction ......................................................................................................................................................................2

Introduction / Introducción

Specific Safety Rules ........................................................................................................................................................ 3

Règles de sécurité particulières / Reglas de seguridad específicas

Symbols ............................................................................................................................................................................ 4

Symboles / Símbolos

Features ............................................................................................................................................................................5

Caractéristiques / Características

Assembly .......................................................................................................................................................................... 6

Assemblage / Armado

Operation .......................................................................................................................................................................6-8

Utilisation / Funcionamiento

Maintenance ..................................................................................................................................................................... 8

Entretien / Mantenimiento

Warranty ...........................................................................................................................................................................9

Garantie / Garantía

Figure numbers (illustrations) ....................................................................................................................................10-11

Figure numéros (illustrations) / Figura numeras (ilustraciones)

Parts Ordering and Service ...............................................................................................................................Back Page

Commande de pièces et réparation / Pedidos de piezas y servicio ......................................................... Page arrière / Pág. posterior

INTRODUCTION

INTRODUCTION / INTRODUCCIÓN

This product has many features for making its use more pleasant and enjoyable. Safety, performance, and dependability

have been given top priority in the design of this product making it easy to maintain and operate.

* * *

Ce produit offre de nombreuses fonctions destinées à rendre son utilisation plus plaisante et satisfaisante. Lors de la

conception de ce produit, l’accent a été mis sur la sécurité, les performances et la fiabilité, afin d’en faire un outil facile à

utiliser et à entretenir.

* * *

Este producto ofrece numerosas características para hacer más agradable y placentero su uso. En el diseño de este producto

se ha conferido prioridad a la seguridad, el desempeño y la fiabilidad, por lo cual se facilita su manejo y mantenimiento.

2

SPECIFIC SAFETY RULES

WARNING – To reduce the risk of injury, user

must read and understand this operator’s manual

as well as the operator’s manual for the battery

pack, charger, and power base before use. Ensure

compatibility and proper fit of head and power base

before using.

Hold power tool by insulated gripping surfaces, when

performing an operation where the cutting accessory

may contact hidden wiring or its own cord. Cutting

accessory contacting a “live” wire may make exposed

metal parts of the power tool “live” and could give the

operator an electric shock.

Use clamps or another practical way to secure and

support the workpiece to a stable platform. Holding

the work by hand or against your body leaves it unstable

and may lead to loss of control.

Know your power tool. Read operator’s manual

carefully. Learn its applications and limitations, as well

as the specific potential hazards related to this tool.

Following this rule will reduce the risk of electric shock,

fire, or serious injury.

Always wear eye protection with side shields marked

to comply with ANSI Z87.1. Failure to do so could

result in objects being thrown into your eyes, resulting in

possible serious injury.

Protect your lungs. Wear a face or dust mask if the

operation is dusty. Following this rule will reduce the risk

of serious personal injury.

Protect your hearing. Wear hearing protection during

extended periods of operation. Following this rule will

reduce the risk of serious personal injury.

Do not attempt to modify this product or create

accessories not recommended for use with this

product. Any such alteration or modification is misuse

and could result in a hazardous condition leading to

possible serious personal injury.

Do not attempt to use the handle without an accessory

head installed. Doing so could result in serious personal

injury.

Save these instructions. Refer to them frequently and

use them to instruct others who may use this tool. If you

loan someone this tool, loan them these instructions also

to prevent misuse of the product and possible injury.

NOTE: SEE YOUR POWER BASE OPERATOR’S MANUAL

FOR ADDITIONAL SAFETY RULES.

3 - English

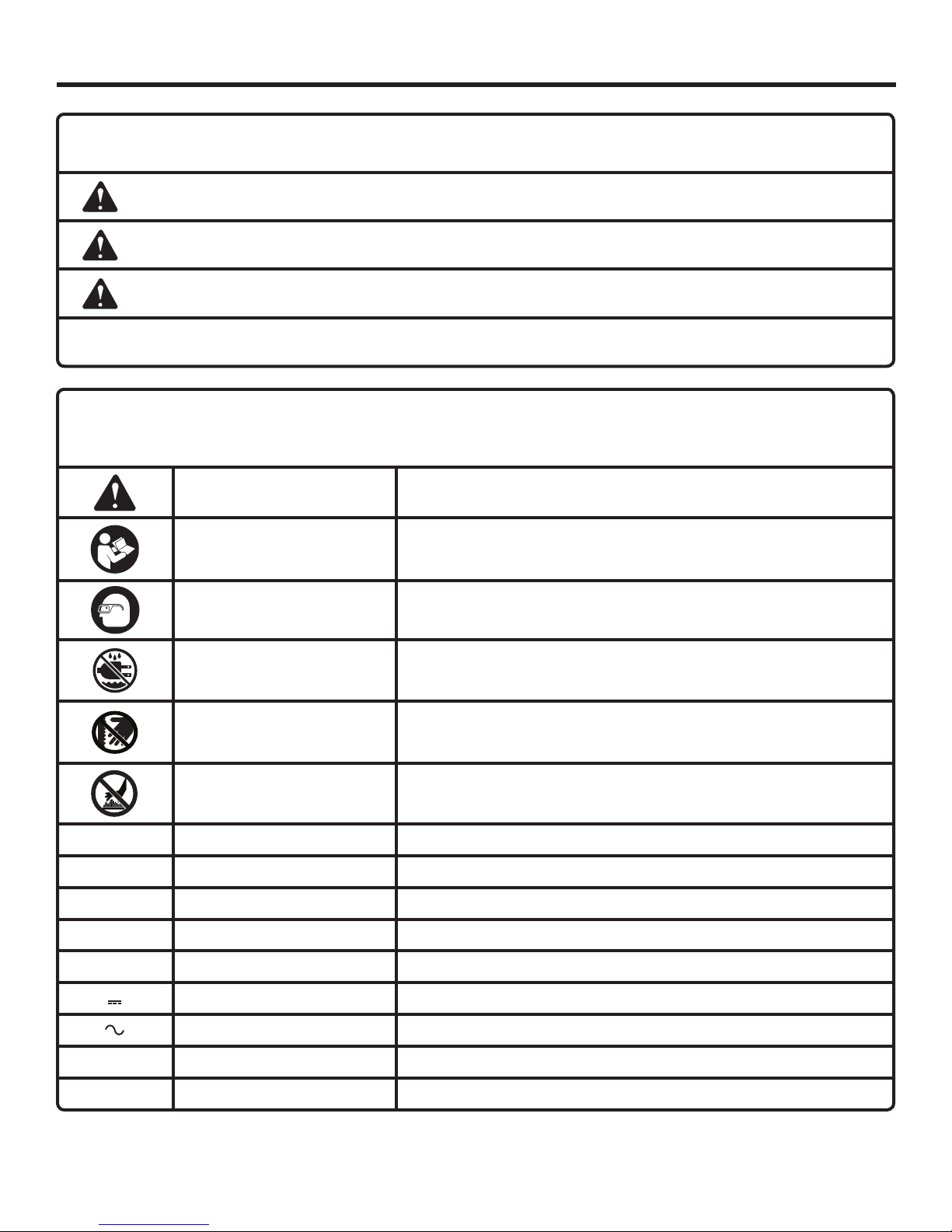

SYMBOLS

The following signal words and meanings are intended to explain the levels of risk associated with this product.

SYMBOL SIGNAL MEANING

DANGER:

WARNING:

CAUTION:

NOTICE:

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper interpretation of these symbols will allow you to operate the product better and safer.

Indicates an imminently hazardous situation, which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation, which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation, which, if not avoided, may result in minor or

moderate injury.

(Without Safety Alert Symbol) Indicates important information not related to an injury hazard,

such as a situation that may result in property damage.

SYMBOL NAME DESIGNATION/EXPLANATION

Safety Alert Precautions that involve your safety.

Read Operator’s Manual

Eye Protection

To reduce the risk of injury, user must read and understand operator’s

manual before using this product.

Always wear eye protection with side shields marked to comply with

ANSI Z87.1.

Wet Conditions Alert Do not expose to rain or use in damp locations.

No Hands Symbol

Hot Surface

V Volts Voltage

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

min Minutes Time

Direct Current Type or a characteristic of current

Alternating Current Type of current

n

o

.../min Per Minute Revolutions, strokes, surface speed, orbits etc., per minute

No Load Speed Rotational speed, at no load

Failure to keep your hands away from the blade will result in serious

personal injury.

To reduce the risk of injury or damage, avoid contact with any hot

surface.

4 - English

FEATURES

PRODUCT SPECIFICATIONS

No Load Speed .............................................................................................................................0-3000 strokes per minute

Stroke Length .................................................................................................................................................. 1/2 in. (13 mm)

KNOW YOUR JOBMAX™ JIG SAW HEAD

See Figure 1, page 10.

The safe use of this product requires an understanding of

the information on the product and in this operator’s manual

as well as a knowledge of the project you are attempting.

Before use of this product, familiarize yourself with all operating features and safety rules.

BI-DIRECTIONAL LOCK-OFF LEVER

The bi-directional lock-off lever reduces the possibility of

accidental starting.

NO-MAR PLATE

The no-mar plate has a smooth finish and can be snapped

on over the metal shoe of the jig saw. This makes it easier to

glide the tool along a delicate work surface without marring it.

BLADE GUARD

The blade guard helps protect the operator from accidental

contact with the saw blade.

TOOL-FREE BLADE CLAMP

There is a convenient lever on the blade clamp for changing

saw blades without the need for separate tools.

BLOWER PORT

The blower port directs debris away from the cut line to

improve line of sight.

CALIFORNIA PROPOSITION 65

WARNING:

This product and some dust created by power sanding, sawing, grinding, drilling, and other construction activities

may contain chemicals, including lead, known by the State of California to cause cancer, birth defects or other

reproductive harm. Wash hands after handling.

Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber.

Your risk from exposure to these chemicals varies, depending on how often you do this type of work. To reduce

your exposure, work in a well ventilated area and with approved safety equipment, such as dust masks that are

specially designed to filter out microscopic particles.

5 - English

ASSEMBLY

UNPACKING

This product has been shipped completely assembled.

Carefully remove the product and any accessories from

the box. Make sure that all items listed in the packing list

are included.

WARNING:

Do not use this product if it is not completely

assembled or if any parts appear to be missing

or damaged. Use of a product that is not properly

and completely assembled could result in serious

personal injury.

Inspect the product carefully to make sure no breakage

or damage occurred during shipping.

Do not discard the packing material until you have care-

fully inspected and satisfactorily operated the product.

If any parts are damaged or missing, please call

1-866-539-1710 for assistance.

PACKING LIST

Anti-splintering insert

JobMax™ Jig Saw Head

T-Shank Blade (wood)

Operator’s Manual

WARNING:

If any parts are damaged or missing do not operate

this product until the parts are replaced. Use of

this product with damaged or missing parts could

result in serious personal injury.

WARNING:

Do not attempt to modify this product or create

accessories not recommended for use with this

product. Any such alteration or modification is

misuse and could result in a hazardous condition

leading to possible serious personal injury.

WARNING:

To prevent accidental starting that could cause

serious personal injury, always remove the battery

pack from the product or disconnect it from the

power supply when assembling parts.

OPERATION

WARNING:

Do not allow familiarity with products to make you

careless. Remember that a careless fraction of a

second is sufficient to inflict severe injury.

WARNING:

Always wear eye protection with side shields

marked to comply with ANSI Z87.1. Failure to do

so could result in objects being thrown into your

eyes, resulting in possible serious injury.

WARNING:

Do not use any attachments or accessories not

recommended by the manufacturer of this product.

The use of attachments or accessories not

recommended can result in serious personal injury.

WARNING:

The product can be used with one or two hands

as shown in figures 7 and 8. Plan your hand

placement so your fingers will not be anywhere a

sudden slip could cause them to slide or fall into

the cutting path.

APPLICATIONS

You may use this product for the purposes listed below:

Cutting all types of wood products (lumber, plywood,

paneling, composition board, and hard board)

Cutting thin sheet metal (metal cutting blade sold separately)

Cutting plastics and laminates

INSTALLING AND REMOVING THE JIG SAW HEAD

See Figure 2, page 10.

To install the jig saw head:

Remove the battery pack from the power base or

disconnect the power base from the power supply.

6 - English

OPERATION

Place the head on the power base and push until the

latches click into position. Pull on the head to make sure

it is securely installed before proceeding.

Reinstall the battery pack or connect the power base to

the power supply.

To remove the jig saw head:

Remove the battery pack from the power base or

disconnect the power base from the power supply.

Depress the latches on the power base and pull the jig

saw head away from the power base.

TURNING THE JIG SAW ON AND OFF

See Figure 3, page 10.

To turn the jig saw on: Slide bi-directional lock-off lever

to the right or to the left, and press the switch trigger on

the power base.

To turn the jig saw off: Release the switch trigger on

the power base.

NOTICE:

Bi-directional lock-off lever should be in the LOCK

(center) position when saw is not in use or is being

transported.

ANTI-SPLINTERING INSERT

See Figures 4 - 5, page 10.

The anti-splintering insert is especially useful when cutting

plywood to reduce splintering. It should only be used when

making straight cuts or circle cuts. It is not for plunge

cutting.

To attach or remove the anti-splintering insert:

Remove the battery pack from the power base or

disconnect the power base from the power supply.

Remove the jig saw head from the power base.

Depress the tab on the no-mar plate and remove it from

the base.

To attach: Slide the anti-splintering insert onto the base

with the notch facing the blade. The grooves on the antisplintering insert should engage the tabs on the base.

Replace the no-mar plate.

To remove: Grab the anti-splintering insert and slide it

away from the jig saw base. Replace the no-mar plate.

INSTALLING AND REMOVING BLADES

See Figure 6, page 10.

NOTE: The jig saw is designed to use T-shank and U-shank

blades only.

To install blades:

Remove the battery pack from the power base or

disconnect the power base from the power supply.

If attached, remove the anti-splintering insert.

Lift the tool-free blade clamp until it stops.

Holding the tool-free blade clamp up, insert the saw

blade as far as possible into the slot in the blade clamp

body and roller guide.

Check to make sure the back of the saw blade is

centered in the groove of the roller guide and blade

clamp body.

Release the tool-free blade clamp lever. Make sure the

blade is securely in place.

NOTE: Do not use the tool if the blade is not installed

correctly.

Reinstall the battery pack or connect the power base to

the power supply.

To remove blades:

Remove the battery pack from the power base or

disconnect the power base from the power supply.

If attached, remove the anti-splintering insert.

Lift the tool-free blade clamp until it stops.

Holding the tool-free blade clamp up, remove the saw

blade.

GENERAL CUTTING

See Figure 7, page 11.

Rest the front of the jig saw base on the workpiece and align

cutting edge of the blade with the line on your workpiece.

Start the power base and move it forward on the work

surface. Apply downward pressure to keep the jig saw

steady and only enough forward pressure to keep the blade

cutting. Do not force the tool. Forcing the tool may overheat

the motor and break saw blades. Broken and dull (or worn)

saw blades must be replaced with new saw blades.

STRAIGHT CUTTING

See Figure 8, page 11.

A straight cut can be made by clamping a piece of wood or

straightedge to the workpiece and guiding the edge of the

jig saw against it. Make the cut from one direction only; don’t

cut halfway and complete the cut from the opposite end.

SCROLL CUTTING

See Figure 9, page 11.

NOTE: Do not use the anti-splintering insert when making

scroll cuts, plunge cuts, and when cutting metal.

Scroll cuts can be made with the jig saw by guiding the direction

of the cut with applied pressure on the handle as shown.

WARNING:

To prevent accidental starting that could cause

serious personal injury, always remove the battery

pack from the product or disconnect it from the

power supply when assembling parts.

7 - English

OPERATION

PLUNGE CUTTING

See Figure 10 - 12, page 11.

Depending on the thickness of the material being cut, you

may need to drill a pilot hole before making plunge cuts.

WARNING:

To avoid loss of control, broken blades, or damage

to the material being cut, always use extreme

caution when making plunge cuts. We do not

recommend plunge cutting on materials other

than wood.

To make plunge cuts using pilot holes:

Mark the line of cut clearly on the workpiece.

Drill a pilot hole inside the area marked by the line of

cut. The pilot hole should be large enough to slide the

blade through the material.

Slowly lower the blade through the pilot hole in the

workpiece until the base contacts the work piece. Fully

squeeze the switch trigger to start the saw.

MAINTENANCE

Do not move the base forward until the blade is entirely

through the workpiece and the base is in complete

contact with the workpiece.

Move the saw forward to complete the opening.

To make plunge cuts without using pilot holes:

Mark the line of cut clearly on the workpiece.

Tilt the jig saw forward so that it rests on the front edge

of the base and blade will not come in contact with the

workpiece when the tool is turned on.

Make sure the blade is aligned with the area to be cut.

Fully squeeze the switch trigger and slowly lower the

blade into the workpiece until the blade cuts through

the workpiece.

Continue lowering the blade into the workpiece until the

base rests flat on the work surface, then move the jig

saw forward to complete the opening.

Use only the 7 teeth per inch blade for this type of cut.

WARNING:

When servicing use only identical RIDGID®

replacement parts. Use of any other parts may

create a hazard or cause product damage.

WARNING:

Always wear eye protection with side shields

marked to comply with ANSI Z87.1. Failure to do

so could result in objects being thrown into your

eyes, resulting in possible serious injury.

WARNING:

To avoid serious personal injury, always remove the

battery pack from the power base or disconnect

the power base from the power supply when

cleaning or performing any maintenance.

FIGURES (ILLUSTRATIONS) START ON PAGE 10

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use. Use

clean cloths to remove dirt, dust, oil, grease, etc.

WARNING:

Do not at any time let brake fluids, gasoline,

petroleum-based products, penetrating oils, etc.,

come in contact with plastic parts. Chemicals can

damage, weaken or destroy plastic which may

result in serious personal injury.

AFTER FRENCH AND SPANISH LANGUAGE SECTIONS.

8 - English

WARRANTY

RIDGID® HAND HELD AND STATIONARY POWER TOOL 3 YEAR LIMITED SERVICE

WARRANTY

Proof of purchase must be presented when requesting warranty service.

Limited to RIDGID® hand held and stationary power tools

purchased 2/1/04 and after. This product is manufactured

by One World Technologies, Inc. The trademark is licensed

from RIDGID®, Inc. All warranty communications should be

directed to One World Technologies, Inc., attn: RIDGID®

Hand Held and Stationary Power Tool Technical Service at

(toll free) 1-866-539-1710.

90-DAY SATISFACTION GUARANTEE POLICY

During the first 90 days after the date of purchase, if you are

dissatisfied with the performance of this RIDGID® Hand Held

and Stationary Power Tool for any reason you may return

the tool to the dealer from which it was purchased for a full

refund or exchange. To receive a replacement tool you must

present proof of purchase and return all original equipment

packaged with the original product. The replacement tool

will be covered by the limited warranty for the balance of

the 3 YEAR service warranty period.

WHAT IS COVERED UNDER THE 3 YEAR

LIMITED SERVICE WARRANTY

This warranty on RIDGID® Hand Held and Stationary Power

Tools covers all defects in workmanship or materials and normal wear items such as brushes, chucks, motors, switches,

cords, gears and even cordless batteries in this RIDGID®

tool for three years following the purchase date of the tool.

Warranties for other RIDGID® products may vary.

HOW TO OBTAIN SERVICE

To obtain service for this RIDGID® tool you must return it;

freight prepaid, or take it in to an authorized service center

for RIDGID® branded hand held and stationary power tools.

You may obtain the location of the authorized service center nearest you by calling (toll free) 1-866-539-1710 or by

logging on to the RIDGID® website at www.RIDGID.com.

When requesting warranty service, you must present the

original dated sales receipt. The authorized service center

will repair any faulty workmanship, and either repair or replace any part covered under the warranty, at our option, at

no charge to you.

WHAT IS NOT COVERED

This warranty applies only to the original purchaser at retail

and may not be transferred. This warranty only covers defects arising under normal usage and does not cover any

malfunction, failure or defect resulting from misuse, abuse,

neglect, alteration, modification or repair by other than an

authorized service center for RIDGID® branded hand held

and stationary power tools. Consumable accessories provided with the tool such as, but not limited to, blades, bits

and sand paper are not covered.

RIDGID, INC. AND ONE WORLD TECHNOLOGIES, INC.

MAKE NO WARRANTIES, REPRESENTATIONS OR

PROMISES AS TO THE QUALITY OR PERFORMANCE

OF ITS POWER TOOLS OTHER THAN THOSE SPECIFICALLY STATED IN THIS WARRANTY.

ADDITIONAL LIMITATIONS

To the extent permitted by applicable law, all implied warranties, including warranties of MERCHANTABILITY or FITNESS

FOR A PARTICULAR PURPOSE, are disclaimed. Any implied

warranties, including warranties of merchantability or fitness

for a particular purpose, that cannot be disclaimed under

state law are limited to three years from the date of purchase.

One World Technologies, Inc. and RIDGID®, Inc. are not

responsible for direct, indirect, incidental or consequential

damages. Some states do not allow limitations on how long

an implied warranty lasts and/or do not allow the exclusion

or limitation of incidental or consequential damages, so the

above limitations may not apply to you. This warranty gives

you specific legal rights, and you may also have other rights

which vary from state to state.

9 - English

Loading...

Loading...