Page 1

OPERATOR’S MANUAL

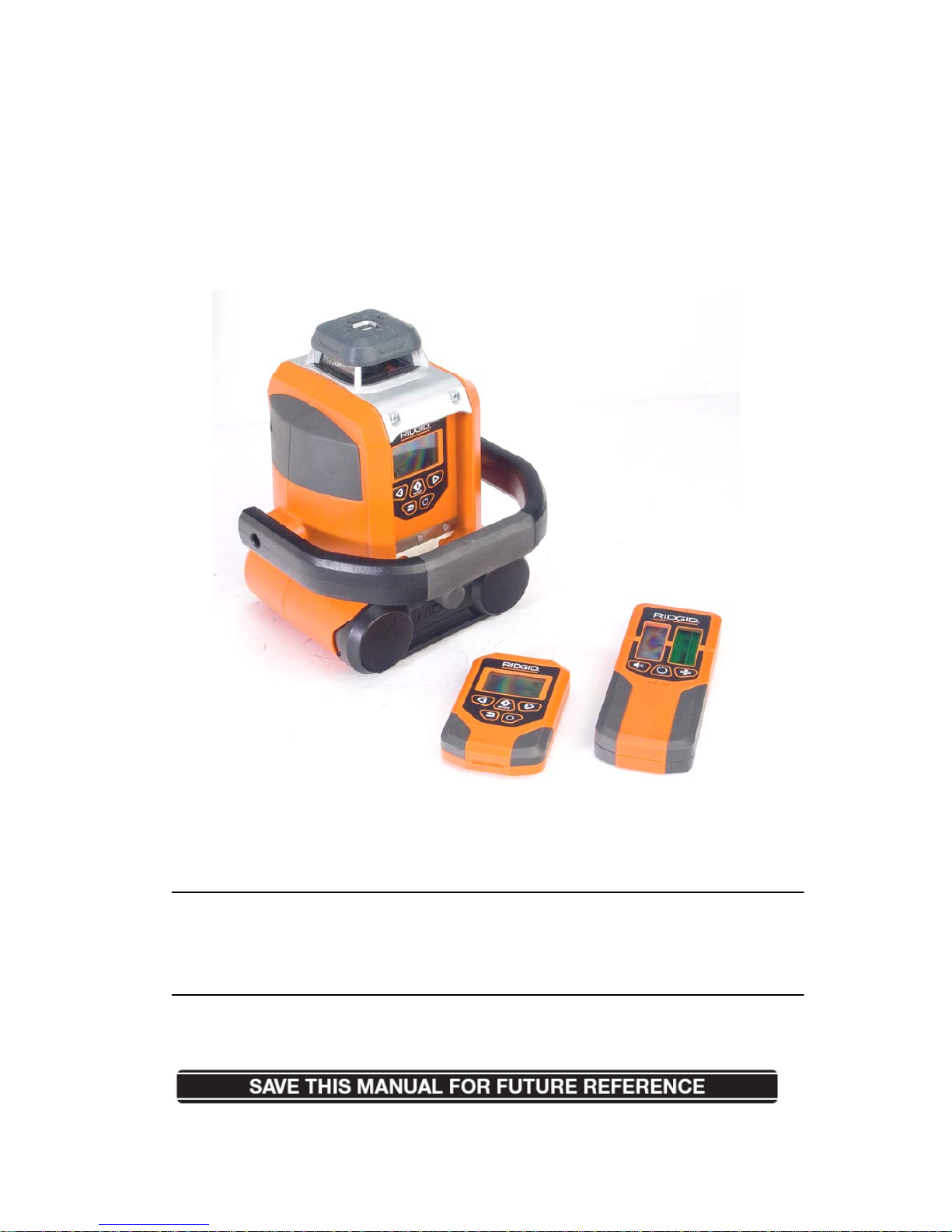

Green Auto Leveling Rotary Laser Level

GRL9202

WARNING:

To reduce the risk of injury, the user must read and understand the operator’s manual

before using this product.

Thank you for buying a RIDGID product.

Page 2

TABLE OF CONTENTS

General Safety Instruction

Safety Symbols

Damage Prevention and Information Messages

Safety Precautions for Lasers and Operations

Electricity Safety

Service Safety

FCC Statement

Unpacking and Checking Contents

Unpacking

List of Contents

Getting to Know Your Green Auto Leveling Rotary Laser Level

Main Parts

Keyboard Functions

Technical Specifications

Operation

To Install / Change Batteries

To Connect AC/DC Adapter to the Green Auto Leveling Rotary Laser Level

Turn ON/OFF the Green Auto Leveling Rotary Laser Level

Choose the Working Mode

Axis Drive Error

Remote Control

Green Laser Detector

Detector Mounting Base

Wall mounting Base

Surveyor’s tripod

Leveling rod

Application

Maintaining Your Green Auto Leveling Rotary Laser Level

Accuracy Checking and Calibration

Troubleshooting

Warranty

Page 3

GENERAL SAFETY INSTRUCTIONS

The purpose of safety symbols is to attract your attention to possible dangers. The

safety symbols and the explanations with them deserve your careful attention and

understanding. The symbol warnings DO NOT, by themselves, eliminate any danger.

The instructions and warnings they give are no substitutes for proper accident

prevention measures.

Safety Symbols

SAFETY ALERT SYMBOL: Indicates DANGER, WARNING, OR CAUTION;

may be used in conjunction with other symbols or pictographs.

DANGER: Failure to obey this safety warning WILL result in death or serious

injury to you or to others. Always follow the safety precautions to reduce the risk of fire,

electric shock, and personal injury.

WARNING: Failure to obey this safety warning CAN result in death or serious

injury to you or to others. Always follow the safety precautions to reduce the risk of fire,

electric shock, and personal injury.

CAUTION: Failure to obey this safety warning MAY result in personal injury to

you or to others or property damage. Always follow the safety precautions to reduce

the risk of fire, electric shock, and personal injury.

Damage Prevention and Information Messages

These inform user of important information and/or instructions that could lead to

equipment or other property damage if not followed. Each message is preceded by

the word “NOTE:” as in the example below:

NOTE: Equipment and/or property damage may result if these instructions are not

followed.

WARNING: Be sure to read and understand all safety instructions in this manual,

including all safety alert symbols such as “DANGER,” “WARNING,” and “CAUTION,”

before using this Green Auto Leveling Rotary Laser Level. Failure to follow all

Page 4

instructions listed below may result in electric shock, fire, and/or serious personal

injury.

Safety Precautions for Lasers and operations

DANGER: DO NOT OPERATE the leveling rod during storms or near high

voltage, if the leveling rod were to fall and contact high voltage it will result in serious

electric shock and/or bodily injury.

WARNING: Use of controls, adjustments, or performance of procedures other

than those specified in this manual may result in hazardous radiation exposure.

WARNING: The use of optical instruments such as, but not limited to,

telescopes or transits to view the laser beam will increase eye hazard.

CAUTION: Do not attempt to modify the performance of the level in any way.

This may result in a dangerous exposure to laser radiation.

WARNING:

Batteries can explode or leak, causing injury or fire. To reduce this

risk, always follow all instructions and warning on the battery label and package.

CAUTION: The following labels are on your level. They indicate the location

from which the green rotary laser level emits the laser light. Be aware of the laser light

location when using the level. Always make sure that any bystanders in the vicinity of

use are made aware of the dangers of looking directly into the laser.

YWKRC9202

YWKGRL9202

Page 5

WARNING: Laser radiation. AVOID DIRECT EYE EXPOSURE. Class a Ⅲ

Laser Product!

• Do not remove or deface any product labels.

• Avoid direct eye exposure. The laser beam can cause flash blindness.

• Never direct the laser light emitted from this level towards any person for any

reason.

• Do not place the level in a position that may cause anyone to stare at the laser

beam, whether intentionally or unintentionally.

• Do not use on surfaces that have shiny, reflective surfaces such as sheet steel.

The shiny surface could reflect the beam back at the operator.

• Always turn the green rotary laser level off when it is not in use. Leaving the level

on increases the risk of someone inadvertently staring into the laser beam.

• Do not operate the green rotary laser level around children or allow children to

operate the tool.

• Always keep this green rotary laser level, batteries and the accessories out of the

reach of children. They are not toys.

• Do not operate the green rotary laser level in combustible areas, such as in the

presence of flammable liquids, gases, or dust.

• Always use only accessories that are designed for use with this product. Use of

accessories that have been designed for use with other laser tools could result in

serious injury.

• Do not attempt to modify the performance of this laser level in any way. This may

result in a dangerous exposure to laser radiation.

• Always check to be sure that the green rotary laser level is securely mounted on

the base when using any of the base plates. Damage to the tool and/or serious

injury to the user could result if the level falls.

• Do not use the laser enhancing glasses as safety goggles. The laser enhancing

Page 6

glasses are intended to improve visibility of the laser beam, but they do not

protect against laser radiation or injuries to the eyes.

• Do not use the laser enhancing glasses as sun glasses or in traffic. The laser

enhancing glasses do not afford complete UV protection and can reduce color

perception.

• Do not use this green rotary laser level for any purpose other than those outlined

in this manual. This could result in serious injury.

• For further information regarding lasers, refer to ANSI-Z136.1, the Standard for

the Safe Use of Lasers, available from the Laser Institute of America (407)

380-1553.

• Do not short any battery terminals.

• Do not attempt to recharge alkaline batteries.

• Do not mix old and new batteries. Replace all of them at the same time with new

batteries of the same brand and type.

• Always dispose of the used batteries according to your local ordinance; do not

incinerate the batteries.

• Keep batteries out of reach of children.

• Remove batteries if the device will not be used for several months.

Electricity Safety

• Before using the power adapter, be sure that the outlet voltage supplied is same

as the voltage marked on the level’s power adapter.

• Do not expose the power adapter to rain or wet conditions. Water entering the

adapter will increase the risk of electric shock.

• Always use an outdoor extension cord marked “W-A” or “W” when operating the

power adapter outside. These cords are rated for outdoor use and reduce the risk

of electric shock.

CAUTION: To reduce the risk of electric shock, use the tool only in dry location.

Page 7

Service Safety

Do not attempt to repair or disassemble the Green Auto Leveling Rotary Laser Level.

If unqualified persons attempt to repair this product, serious injury may occur. Any

repair required on this laser tool should be performed only by authorized service

personnel.

FCC Statement

FCC STATEMENT

1. This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions:

(1) This device may not cause harmful interference.

(2) This device must accept any interference received, including interference that may

cause undesired operation.

2. Changes or modifications not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation.

This equipment generates uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following

measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

Page 8

Consult the dealer or an experienced radio/TV technician for help.

UNP ACKING AND CHECKING CONTENTS

The Green Auto Leveling Rotary Laser Level level kit comes in one box. Do not

discard any packing materials until all of the contents are accounted for.

Separate all the parts from the packing materials. Refer to the “List of Contents” and

Fig. 1a to Fig. 1c to make certain that all of the items are accounted for before

discarding any packing material. Call the RIDGID Service Center if any parts are

damaged or missing.

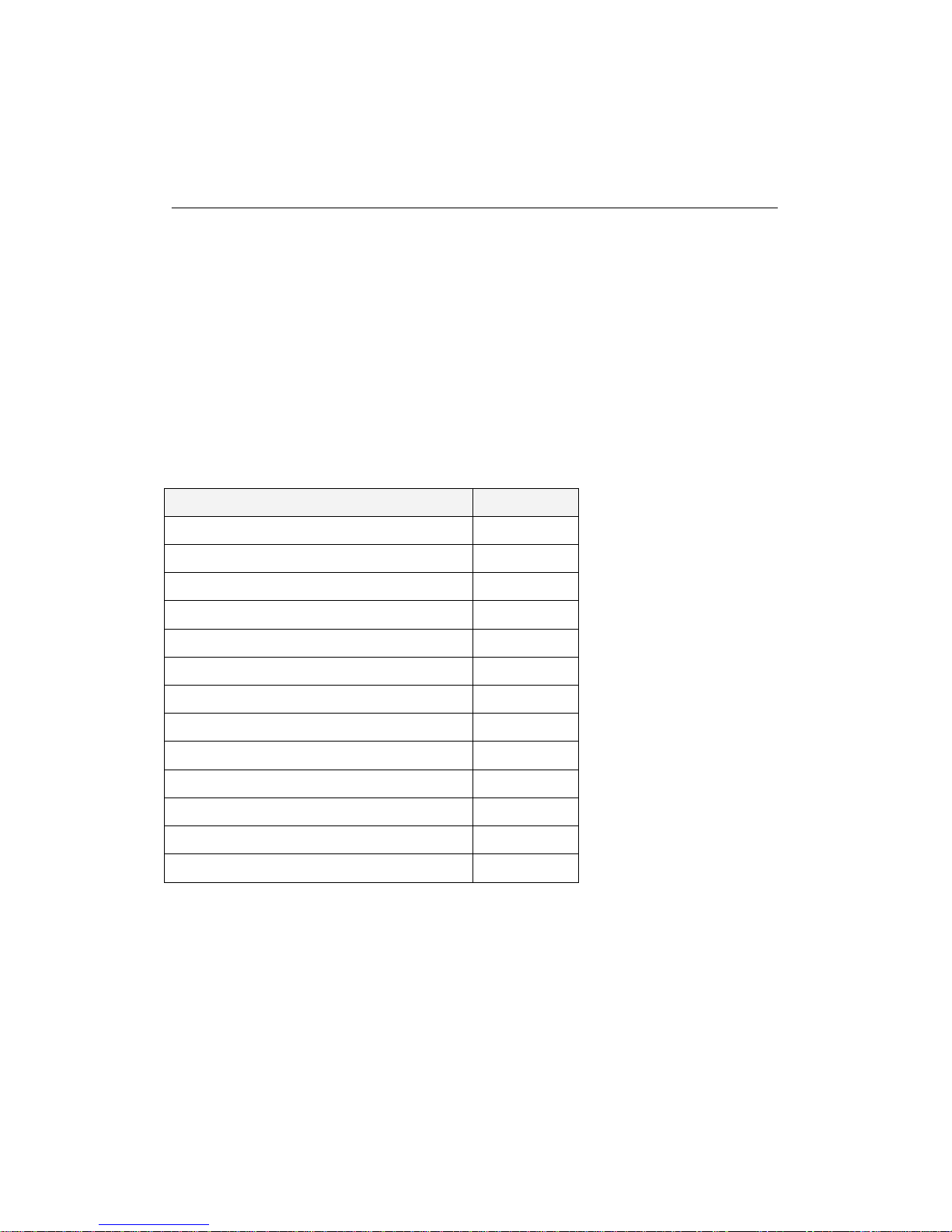

List of Contents

PART NAME QUANTITY

Green Auto Leveling Rotary Laser Level 1

Remote control 1

Green laser detector 1

AC/DC adapter 1

Wall mounting base 1

Detector mounting base 1

Green laser enhancing glasses 1

Magnetic laser target 1

Batteries for green rotary laser level 4

Batteries for remote control 2

Battery for green laser detector 1

Surveyor’s tripod 1

Leveling rod 1

Page 9

GETTING TO KNOW YOUR GREEN AUTO LEVELING ROTARY LASER LEVEL

Laser aperture

Protective cover

LCD panel

Keypad

Handle

Battery compartment

6V AC/DC Adapter

Battery cover knob

5/8” tripod screw (inside

the base

)

Fig. 1a

Top mounted sight

5/8” tripod screw

Rubber foot

Rubber foot

Rubber foot

Fig. 1b

Page 10

Batteries for

rotary laser

Batteries for

remote control

Batteries for

laser detector

Wall mounting base

Leveling rod

Surveyor’s

tripod

AC/DC adapter

Green laser

enhancing glasses

Magnetic laser

tar

g

et

Detector mounting base

Remote control

Green laser detector

Fig. 1c

Page 11

Protective cover

Protects the laser from dirt, water droplets and accidental damage.

Laser aperture

Laser is emitted from this aperture. AVOID direct eye exposure to the laser beam.

LCD panel

Large panel with blue backlight clearly displays the working mode and status.

Keypad (Fig. 2)

Keypad functions:

1. ON/OFF: press to turn on the level, press again to turn it off.

2. Return - return to the main menu from the submenu

3. Mode – choose among different working modes; enter the submenu

4. Left arrow – moves the cursor in the menu; moves the laser dot or chalk line

in the counter-clockwise direction.

5. Right arrow – moves the cursor in the menu; moves the laser dot or chalk line

in the clockwise direction.

Handle

Overmold handle for secure and comfortable transport.

6V AC/DC Adapter receptacle

For connection to the AC/DC adapter.

Battery cover knob

1

2

3 4 5

Fig. 2

Page 12

Turn to lock/unlock the battery cover.

Battery compartment

For 4 alkaline LR20 D batteries.

5/8” tripod screws

There are two 5/8” tripod screws: one is inside the bottom base, the other is inside the

side base. They are used to connect the level to the surveyor’s tripod or to the wall

mounting base.

Top mounted sight

To orient the level to your target, and to locate the high and low points within the arc.

Rubber feet

The rubber feet keep the level stable on the working base.

Remote control

For remote operation within a range of 133 feet.

Green laser detector

Asists the detection of the green laser line position within a maximum range of

330 feet.

AC/DC adapter

The level can be powered with the AC/DC adapter for prolonged operation.

Laser enhancing glasses

Made of laser light enhancing material, the glasses is improve the visibility of the

tool’s laser line.

WARNING: These glasses will not protect your eyes from damage that could result

from looking directly at the laser projection.

Magnetic laser target

The laser target helps to improve the visibility of the green laser lines.

When the surrounding light is too bright, the laser line may be difficult to observe.

Surveyor’s tripod

Support the laser level and permits height adjustment

Leveling rod

Supports the detector mounting base and green laser detector for detailed surveys.

Page 13

Detector mounting base

Permits the laser detector to be mounted on the leveling rod or a vertical pillar.

Wall mounting base

Hang the mounted laser level can be hung from nails or screws on a wall or clamp it to

a beam.

Technical Specifications

Power supply

4 pcs 1.5V “D” batteries for green rotary-laser level

2 pcs 1.5V “AAA” battery for remote control

1 pc 9V “6LR61” battery for green laser detector

AC/DC adapter Output: 6V dc/Input: 100-240V, 50/60Hz

Laser Diode Type Green Laser Diode 522-542nm

Laser Class Class IIIa, output <5mW

Working range

Maximum 100 ft. (30m) without detector, depending

upon light conditions

Maximum 330 ft. (100m) with detector

Working range of remote

control

133 feet (40m)

Accuracy of the rotary laser ±0.1mm/m

Accuracy of the detector Fine, ±3mm; Medium, ±5mm; Coarse, ±8mm

Auto leveling range ±5°

Leveling time About 45s

Operating time Approx. 40 hours with alkaline batteries.

Optimum operating

temperature range

0-40°C

Storage temperature range -20-60°C

Protection against water IP54

Page 14

OPERATION

To Install /Change Batteries for the Green Auto Leveling Rotary Laser Level

This green rotary laser level uses four “D” 1.5V batteries, included.

1. Turn the battery cover knob counterclockwise to open the battery compartment

(Fig. 3).

2. Install four, new, “D” size, alkaline batteries according to the polarity indicators (+

and -) inside the battery compartment (Fig. 4).

3. Replace the battery compartment in the tool and tighten the battery cover knob

clockwise to lock it.

To Connect AC/DC Adapter to the Green Auto Leveling Rotary Laser Level

The green rotary laser level can also be powered with the AC/DC adapter.

1. Insert the connecting plug into the adapter receptacle, located in the right top of

the battery compartment (Fig. 5).

2. Plug the AC/DC adapter into the correct power outlet.

Fig. 3 Fig. 4

Page 15

Turn ON/OFF the Green Auto Leveling Rotary Laser Level

Press the power button to turn on the Green Auto Leveling Rotary Laser Level:

• The display backlight will illuminate for increased visibility.

• The backlight will turn off automatically after one minute has elapsed without

keypad operation.

• The Green Auto Leveling Rotary Laser Level will automatically self-adjust to

level in approximately 45 seconds.

• After self-leveling, the level will start operating in Rotation mode. (The default

mode is Rotation.)

Either H or V will display in the upper line, next to the battery level indicator on the

LCD when the level is turned on (Fig. 6).

H indicates that the level is positioned horizontally and will perform a leveling

measurement;

V Indicates that the level is positioned vertically and will perform a plumb

measurement.

The battery level indicator in the upper right of the display communicates the

remaining charge in the batteries in the Green Auto Leveling Rotary Laser Level (Fig.

6). Press the

button again to turn off power to the Green Auto Leveling Rotary

Laser Level.

Page 16

WARNING: When turning ON the Green Auto Leveling Rotary Laser Level, ALWAYS

be aware of protecting your eyes and the eyes of those around you from the laser.

NEVER point the laser at anyone’s face, including your own.

WORKING MODES

Press the Mode button

to enter the main menu (Fig. 7a); there are four options

on the screen: ROTATE, SWEEP, AUTO LEVEL and GRADE. Press the

or

button to move the cursor among these options. Press the button to

enter the submenu or confirm the chosen option; press the back button

to

return to the main menu.

1. ROTATEMODE (Fig. 7a)

The default ROTATE mode generates a 360º horizontal (level) or vertical (plumb)

reference, depending on the orientation of the Green Auto Leveling Rotary Laser

Level. The 360º reference laser appears on all walls of a room (horizontal) or

ceiling, floor, and opposite walls (vertical).

The ROTATE mode is automatically selected (light letters on a dark rectangle;

see Fig.7a), after the Green Auto Leveling Rotary Laser Level is turned on or use

the

button to select the ROTATE mode after another mode has been

highlighted.

With ROTATE selected (highlighted) press the

button again to enter the

sub menu to select among rotation speeds.

Fig. 7b

Fig. 7a

Page 17

− Fast (Fig.7b):, the green laser line pulses very quickly; this is useful in darker or

low light situations.

− Medium (Fig.7c): the green laser line appears to flash intermittently; this is

useful in normal indoor light condition..

− Slow (Fig.7d): low speed, the laser flashes more slowly; this is useful in bright

conditions out doors.

2. SWEEP MODE (Fig. 8a)

Instead of creating a 360º line, the Sweep (Scanning) Mode creates a shorter,

brighter laser “chalk line” that can be used for leveling or plumbing doors,

windows, fixtures, and more. You may also use this feature to keep the level from

interfering with other lasers and detectors on site.

In the main menu, press the arrow buttons

or to move the cursor

to “SWEEP” (Fig. 8a). Press the

button to enter the submenu to select the

desired configuration

Fig. 8b

Fig. 7d Fig. 7c

Fig. 8a

Page 18

− Spot mode (Fig. 8b): creates a motionless laser dot for reference, allowing the

level to be used as a straight-line laser.

− Medium (Fig. 8c): the tool produces a green laser line medium length

− Short (Fig. 8d): produces a short green laser line.

− Long (Fig. 8e): the tool sweeps a long green laser line.

Press the

button again to enter an additional submenu to change the dot

or sweep direction. The laser dot or chalk line can be moved left or right by

pressing the

or button (Fig. 8f).

3. AUTO LEVEL MODE

In the main menu, press the arrow buttons

or to move the cursor

to AUTO LEVEL (Fig. 9a). Press the

button to enter the submenu to select

the desired action. (Figs 9b, 9c, 9d).

The Auto Level Mode determines how the level responds when it is moved out of

level. The Auto level Mode can be set to ON, OFF, or Anti-Drift System (ADS).

Fig. 8e

Fig. 8d Fig. 8c

Fig. 8f

Page 19

− ON: The level will automatically re-level when it is bumped or moved.

− OFF: The level will NOT re-level if it is moved out of level, and will continue to

operate on the non-level plane. Select this option when using an adapter or

mount that allows you to tilt the level to create a diagonal laser line.

− ADS (Anti-Drift System): The level will signal to the operator that it has been

moved out of level. The laser head will stop rotating and the laser beam will

blink.

NOTE:

OFF and ADS modes are not available when the level is working in the GRADE

mode.

When setting to OFF or ADS mode, allow the level to self-level, wait until the word

“Lock” or “ADS” shows on the LCD before the mode takes effect.

4. GRADE MODE- Dual or single axis grade

The dual grade function allows more specialized site preparations, such as

road grading and paving), irrigation, trenching, landfills, slopes and

embankments, and laying pipe.

Fig. 9c

Fig. 9b

Fig. 9d

Fig. 9a

Page 20

Use the top mounted sight to orient the level to your target and to locate the

high and low points within the arc (Fig. 10).

In the main menu, press the arrow buttons

or to move the cursor

to GRADE (Fig. 11a). Press the

button to enter the submenu to select the

desired x and y axis. (Figs 11b, 11c, 11d, 11e).

In the Grade submenu, use the

or button to choose the X axis

or Y axis (Fig. 11a & Fig. 11b). Press the

button again enter the

selected axis, press the

or button to reduce or increase the

percentage of the grade (Fig. 11c to Fig. 11e). The maximum grade range for

both X axis and Y axis is 8%.

The Grade Percentage can be adjusted at any time while in this mode. The

level will not move the desired grade until after it has self-leveled; allow

ample timefor the level to react to the input provided. Refer to examples in

the illustration below to predict your results (Fig. 12a to Fig. 12d).

To exit Grade Mode, press the

button, the level will re-level.

Fig. 11c

Fig. 11a

Fig. 10

Fig. 11b

Page 21

Axis Drive Error

If the level is set up beyond its self-leveling range of ±5°, the laser head will

initially attempt to level; however, when the self-leveling limit is reached, “Over”

will appear on the LCD to communicate the axis error (Fig. 13). The laser head

will stop running or chalking, and the laser blinks.

Move the level to a more level position and allow it to re-level.

Fig. 11e

Fig. 12d

Fig. 12a

Fig. 12b

Fig. 11d

Fig. 12c

Page 22

Remote Control

Description

The remote control can operate your Green Auto Leveling Rotary Laser Level

within a maximum distance of 133 feet. Except for the power button

” , the

functions of other buttons on the remote control are the same as the buttons on

the operation panel of the level.

POWER button the remote control

Turn on/off the remote control;

Put the Green Auto Leveling Rotary Laser Level in sleep mode when the

level is turned on; it cannot turn on the rotary laser level directly if the level is

powered off.

Wake up the Green Auto Leveling Rotary Laser Level if the level is in sleep

mode.

To Install/Change Batteries for the Remote

Control

The remote control uses two “AAA” batteries.

1) Open the battery cover.

2) Insert two, new “AAA “alkaline batteries

according to the polarity indicators (+ and -)

in the battery compartment (Fig. 14). Be

sure that the polarity is correct!

Fig. 13

Fig. 14

Page 23

3) Close the cover and lock it securely in place.

Turn On the Remote Control

The remote control and the Green Auto Leveling Rotary Laser Level have a

duplex communication. To operate the remote control, press the

button to

turn it on; the display on the remote control will synchronize the display on the

Green Auto Leveling Rotary Laser Level

NOTE: If the control distance exceeds the maximum range, or if the Green Auto

Leveling Rotary Laser Level is powered off when the remote control is turned on,

“Link Lost” will appear in remote control display.

Put the Green Auto Leveling Rotary Laser Level in Sleep Mode

Press the

button on the remote control again to turn off the remote control;

it will place the level in sleep mode. The “Sleep” will display on the Rotary Laser

Level and the display backlights will flash once every two seconds to remind you

that you can “wake” the level with the remote control within two hours. After two

hours in “sleep” mode, the level will automatically shut off completely, and the

remote control cannot operate the level. If the remote control is not operated in 5

minutes, the remote control will turn off automatically.

Wake Up the Green Auto Leveling Rotary Laser Level

To wake up the Green Auto Leveling Rotary Laser Level, press the

button

on the remote control; it will activate the level and turn on the remote control.

Green Laser Detector

Description (Fig. 15 & Fig. 16)

Perfect for use in outdoor conditions, where sunlight and distance may make

locating the beam more difficult, the green laser detector aids in locating and

targeting a visible or invisible beam emitted by the Green Auto Leveling Rotary

Laser Level within a maximum range of 330 feet, It cannot detect a red-laser line.

Page 24

1. Beam receiver window: receives the green laser signals.

2. LCD: indicates the detection result and the position of the laser line.

3. Power ON/OFF button: turns the detector on/off.

Page 25

4. Buzzer ON/OFF button: turns the buzzer on/off.

5. Coarse/Fine detection button: coarsely detects the laser position or accurately

detects the laser position.

6. Lineation arrow: helps in marking a target line.

7. Lineation slot: helps in marking a target line

8. Distance indicator: shows that the lineation slot is 2 inches (50mm) to the top of

the detector.

9. 1/4’ Mounting hole: for installation on the mounting base.

10. Battery compartment: for holding a “6LR61” 9V battery

To Change/Install Battery for the Detector

1. Open the battery compartment cover.

2. Install one “6LR61” 9V battery (Fig. 17). Make sure the polarity (+/-) is

correct!

3. Close the battery compartment cover.

Locating the Green Laser Line with the Detector

NOTE: Always keep the instrument stable and level when detecting.

1. Press the

button to turn the detector on. The LCD symbols will

Fig. 17

Page 26

momentarily flash and the “coarse” indicator symbol will remain lit and the

audio signal will be on (Fig. 18a).

2. Expose the beam receive window of the laser detector towards the direction

of the rotating laser.

3. Slowly move the laser detector in an upward and downward direction until the

LCD beam indicator arrows appear and/or a pulsing audio signal is heard.

Use the coarse/fine detection button

to choose the beam resolution.

Coarse setting: used for approximating level or for initial location of the

center level point (Fig. 18a)

Medium setting: used for greater accuracy (Fig. 18b)

Fine setting: used for the most accurate pinpointing of level (Fig. 18c).

4. Move the detector upward when the low beam indicator arrow is lit (Fig. 19a).

Move the detector downward when the high beam indicator arrow is lit (Fig.

19b). When the beam is level, the level beam indicator line will be lit and a

solid audio tone will be heard (Fig. 19c).

5. Mark this position with a pencil through either side of the lineation slot.

If the detector is not struck by a laser beam after 3-4 minutes, the detector will

automatically shut itself off to preserve battery life. Turn it back on using the

power ON/OFF button.

Fig. 18a Fig. 18b Fig. 18c

Page 27

Detector Mounting Base

Description

1. Tightening knob: to securely attach the detector to a vertical pillar.

2. Release button: located on the both sides of the quick clamp. Push the buttons to

slide the quick clamp.

3. Quick clamp: slide to quickly clamp or unclamp.

Fig. 19a Fig. 19b Fig. 19c

Fig. 20

Tightening

knob

Quick

clamp

Release

button

1/4” mounting

thread screw

Round vial

Page 28

4. 1/4” mounting thread screw: Used to mount the detector.

5. Round vial: indicates whether the base is vertical and level.

Using the Detector Mounting Base

With the detector mounting base, the detector can be secured to a vertical pillar with

flat sides at 90° angles.. The maximum width the base can accommodate is 3.7”.

1. Inert the 1/4” mounting thread screw into the 1/4” mounting hole at the back of the

detector; tighten the screw to securely attach the detector (Fig. 21).

2. Press the two release buttons at the same time to slide the quick clamp and fit it

onto the vertical pillar (Fig. 22)

Fig. 21

Page 29

Wall mounting base

Description (Fig. 23)

1. Trough with 1/2” width and 1-1/8” depth - Attaches the wall-mounting base to

horizontal studs in a wall.

2. Lock screw - Secures the wall-mounting base to the stud.

3. Mounting hole - Used for hanging the wall-mounting base from a nail or screw on

a wall.

4. Pole with Inch scale: Refer to The scales when adjusting the platform up and

down.

5. Securing screw- Secures the platform to the pole.

6. Platform pivots – For easy storage of the wall mounting-base assembly.

7. Platform – Supports the Green Auto Leveling Rotary Laser Level.

Trough

Mounting hole

Fig. 23

Lock screw

Pole with Inch scale

Securing screw

Platform pivots

Platform

5/8’’ mounting

thread screw

Balance screw

Page 30

8. 5/8’’ mounting thread screw – Attaches the Green Auto Leveling Rotary Laser

Level to the base.

9. Balance screw – Adjusts the balance of the base.

Using the Wall Mounting Base

The wall mounting base can be hung from nails or screws on a wall or clamped onto a

beam. By using the wall mounting base, you can easily adjust the height and direction

of the laser to your reference object.

Hang from Nails or Screws:

The base has three mounting holes for secure attachment. Always use three screws

or nails, and make sure that these screws or nails are securely in place in the wall.

Clamp onto a Horizontal Stud

The base can only be attached to a level, horizontal stud; do not try to attach to a

vertical stud.

1. Turn the two lock screws counterclockwise (Fig. 24). Attach the wall mounting

base to a level stud, making sure that the stud is fully inserted into the trough.

2. Turn the two lock screws clockwise to secure the clamp.

3. Adjust the balance screw until the rubber support touches the wall. Ensure that the

platform is approximately level (Fig. 25).

Fig. 24

Page 31

Mount the Green Auto Leveling Rotary Laser Level on the Wall Mounting Base

1. Align the 5/8” screw on the platform with the screw hole in the bottom base or side

base of the tool.

2. Adjust the direction of the tool to your reference object.

3. Turn the screw clockwise to secure the tool on the base.

CAUTION! Whenever using the wall mounting base to secure the Green Auto

Leveling Rotary Laser Level on a stud, be sure to place the tool on the base

carefully, securing it with your hands at all times. Once you are certain that the

tool is attached firmly on the base with the screw, and the base is fastened on the

stud, you can safely remove your hands.

Adjust the Height of the Green Auto Leveling Rotary Laser Level

1. Support the base of the platform with one hand to hold the tool.

2. Turn the securing screw counterclockwise to loosen it.

3. Adjust the height of the platform to the desired position.

The platform height is

adjustable up to 11 inches.

4. Tighten the secure screw clockwise to fix the platform firmly.

Fig. 25

Page 32

Surveyor’s tripod

Description (Fig. 26)

1. 5/8’’ mounting screw – attaches the Green Auto Leveling Rotary Laser Level to

the tripod

2. Platform- supports the Green Auto Leveling Rotary Laser Level.

3. Lock lever- locks/unlocks the extension of the leg.

4. Belt- for convenient carrying or securing when not in use.

5. Leg- provides firm support.

6. Sharp foot- for stably stand in the working field

7. Pedal- step in the pedals to push the sharp feet into the ground.

5/8’’ mounting screw

Belt

Leg

Sharp foot

Mounting screw knob

Platform

Lock lever

Sharp foot

Pedal

Pedal

Fig. 26

Page 33

Using the Surveyor’s tripod

1. Expand the three legs of the tripod to a stable position; make sure the platform is

close to horizontal.

2. Step on the pedals to push the sharp feet into the ground.

3. Place the Green Auto Leveling Rotary Laser Level on the tripod; holding it in place

with your hand, adjust the direction of the tool to your reference object.

4. While holding the Green Auto Leveling Rotary Laser Level in place with your hand,

align the 5/8” mounting screw in the platform with the screw hole in the bottom

base or side base of the tool.

5. Continuing to hold the Green Auto Leveling Rotary Laser Level in place with your

hand, turn the knob of the mounting screw clockwise to secure the Green Auto

Leveling Rotary Laser Level the tripod platform.

6. Open the three lock levers to unlock the leg extension, adjust the height of the

tripod to your reference.

7. Close the lock levers to lock the leg extension securely. Now you are ready to start

the work.

Leveling rod

This leveling rod can be extended to a maximum of 8 feet. When not in use, it can be

retracted to a length of 3 feet and 2 3/8 inches for storage.

Scales are printed on both surfaces: on one surface, the scales are in increments of

0.25-inch; on the reverse surface, the scales are in increments of 0.24 inch.

To extend the leveling rod, pull the components up.; to retract the, locate and press

each release button (Fig. 27) to unlock the extension and permit the rod to be

retracted.

Page 34

DANGER: DO NOT OPERATE the leveling rod during storms or near high voltage,

leveling rod falling or touching to the high voltage will result in serious electric shock

and/or bodily injury.

APPLICATION

Your Green Auto Leveling Rotary Laser Level is a highly versatile tool. Use it for the

following applications, among others:

Outdoor Site Preparation, Grading & Excavating, Batter boards and Foundations,

Masonry Work, Setting Concrete Forms, Marking elevation, Paving Roads, Checking

Depth of Trenches, Landscaping, Fencing.

Indoor Drop Ceiling Installation, Floors, cabinets & Shelves, Carpentry, Decks &

Patios, Tile Work, Partitions, Remodeling, Doors & Windows.

Mark the Height for Foundation Pit

1. Attach the Green Auto Leveling Rotary Laser Level to the surveyor’s tripod, allow

the level to self-level.

2. Use the Detector and Leveling Rod to read the height of the level based on the

height datum.

3. Calculate the height difference of the level to the specified position. Set the leveling

rod and mark it according to the calculation (Fig. 28).

Release knob

Fig. 27

Page 35

Drop Ceiling Applications

1. Attach the wall mounting base to the wall with screws or nails or clamp onto a

horizontal stud. make sure the hanging trough of the base approximate to the level

of ceiling grid.

2. Secure the Green Auto Leveling Rotary Laser Level on the wall mounting base;

adjust the balance screw to ensure that the platform is approximately level.

3. Turn on the level; allow the laser to self-level.

4. Raise or lower the laser on the Wall Mounting Base until the rotating beam is at

the same level as the perimeter ceiling grid. Use the line created by the laser as a

reference to attach the perimeter grid to the wall.

5. Attach the magnetic laser target to the ceiling trim being installed. Adjust the

height of the trim until the laser beam strikes the target, as Fig. 29 shown.

Page 36

MAINTENANCE

This Green Auto Leveling Rotary Laser Level has been designed to be a

low-maintenance tool.

However, in order to maintain its performance, you must always follow these simple

directions.

Always handle the level with care. Treat it as the fine optical device it is and as

you would treat a camera or binoculars.

Avoid exposing the level to shock, continuous vibration, or extreme hot or cold

temperatures.

Always store the level indoors. When not in use, always store the tool in its

protective case.

After you have finished using the level, always make sure that the level has been

turned off.

Always keep the level free of dust and liquids. If needed, only use a soft cloth or

cotton swab and glass cleaner to clean the laser emitting window.

Always wipe clean and thoroughly dry the level after each use.

Check the batteries regularly to avoid deterioration.

Always remove the batteries from the level, remote control and detector if they

are not going to be used for an extended period of time.

Always replace the batteries when the battery icon shows empty.

Page 37

Do not disassemble this green rotary laser level. This will not only void the

warranty, but could expose the user to hazardous radiation exposure.

Do not attempt to change any part of the laser lens.

Tool service must be performed only by an authorized service center. Service or

maintenance performed by unqualified personnel could result in risk of injury.

CHECKING ACCURACY AND CALIBRATION

This Green Auto Leveling Rotary Laser Level is a sealed level and is calibrated to

precise accuracies at the factory. However, a calibration check is recommended

before the initial use of your laser, and then periodically from that point forward.

Be sure to allow enough time (up to 60 seconds) for the level to completely

self-level before each check.

CAUTION: When performing a calibration, always use the remote control to

adjust the level, pressing buttons on the level will bring small movements to the

accurate electronic vials inside and result in incorrect calibration.

Checking Accuracy -X Axis

1. Mount the Green Auto Leveling Rotary Laser Level on a tripod or to a level,

sturdy surface and place it approximately 100 feet (30m) away from a wall.

Face the display toward you and “X+” to the target wall (Fig. 30 and Fig. 31).

Page 38

2. Press the

”button to turn on the Green Auto Leveling Rotary Laser Level

and allow the tool to self-level. Draw a plumb line on the wall; mark the

intersection of the plumb line and the laser beam as “A”.

3. Loosen the Green Auto Leveling Rotary Laser Level from the tripod and

rotate the Green Auto Leveling Rotary Laser Level 180°. Ensure that the

height of the tripod does not change, as this will affect the results. Secure the

Green Auto Leveling Rotary Laser (Fig. 32).

Fig. 31

Fig. 30

Page 39

4. Allow the tool to self-level. Mark the intersection of the plumb line and the

laser beam as “B”. No adjustment is necessary if the vertical difference

between A and B is less than 1/4” (6.5mm)

Repeat the above steps to ensure a correct reading. If the distance is greater

than 1/4”, you will need to calibrate the X axis.

Calibration- X Axis

1. Keeping the Green Auto Leveling Rotary Laser Level in its current position,

turn the power off; turn the display toward you, and make X+ facing the target

(i.e. wall, detector), as shown in Fig. 30 and Fig. 31..

2. Turn on the level and remote control, press the “

” and “ ” button at

the same time to activate calibration mode.(Fig. 33a)

Fig. 32

Page 40

3. Use the

button to select “Xad” (Fig. 33b); press the ”button to

access the X axis for calibration (Fig. 33c).

WARNING: A wrong choice of other options may result in error. Press the back

button

to exit and re-choose the correct option.

4. You must raise or lower the beam to center it between points A and B on the

target. The level will react to “+” and “-“ input within the X+ quadrant.

If A is above B, press the

button on the remote control to move the

laser beam downward.

If A is below B, press the

button on the remote control to move the

laser beam upward.

NOTE: The parameters displayed on the display on the Green Auto Leveling

Rotary Laser Level can be ignored when performing the adjustment.

6. Press

button to save the calibration; press the button

repeatedly to exit from calibration mode.

7. Now repeat the X axis check to insure that you have made the correct

Fig. 33c

Fig. 33a

Fig. 33b

Page 41

calibration.

Checking Accuracy and Calibration- Y Axis

To check the Y axis, mount the Green Auto Leveling Rotary Laser Level l on a

tripod and place it approximately 100 feet (30m) away from the wall, with the Y+

quadrant facing the wall (Fig. 31); follow steps 2 through 4 of “Checking

Accuracy -X Axis”. Calibration as in “Calibration- X Axis”, choosing the “Yad” to

calibrate and adjusting “+” and “-“input as necessary within the Y+ quadrant (Fig.

34a and Fig. 34b).

Checking Accuracy - Z Axis

1. To check the Z axis, place the Green Auto Leveling Rotary Laser Level on its

back (display facing up), 100 feet (30m) from a wall on a flat, level surface

(Fig. 35).

2. Hang a plumb line down the wall at least 8 feet long.

3. Press the

button to turn on the level, allow the Green Auto Leveling

Rotary Laser Level l to self-level. If necessary, adjust the rotation speed to

easily view the laser beam on the wall.

4. Orient the Green Auto Leveling Rotary Laser Level parallel to the wall and

attempt to align the laser with your plumb line. If the laser line does not align

with the plumb line, then calibration is necessary.

Fig. 34b

Fig. 34a

Page 42

Calibration-Z Axis

Keep the Green Auto Leveling Rotary Laser Level in the current position, power

off the level.

1. Turn on the level and the remote control;. Press the

and

button on the remote control at the same time to enter calibration mode (Fig.

33a).

2. Use

button to select “Zad” (Fig. 36a); press the button to access

the Z axis for calibration (Fig. 36b).

3. Press the

button on the remote control to rotate the laser beam

counterclockwise, or press the

button on the remote control to rotate

the laser beam clockwise into alignment with your plumb line. For example,

Fig. 36b

Fig. 35

Fig. 36a

Page 43

the laser beam must rotate counterclockwise to align with the plumb line, so

you need to press the

button.

4. Press the

button to save the calibration, press button repeatedly

to exit from calibration mode.

5. Now repeat the Z axis checking to insure you have made the correct

calibration.

TROUBLESHOOTING

PROBLEM POSSIBLE CAUTION SOLUTION

Laser dot/line

projected is

weak, hard to

see

1. Battery is depleted.

2. The tool is out of the

operating temperature

range.

3. The tool is too far from

the target.

4. Working condition is too

bright.

1. Replace with new batteries or

run it with AC/DC adapter.

2. Make sure that the tool

operating temperature is

within 32°F to 104°F.

3. Move the tool closer to the

target.

4. Use green laser-enhancing

glasses and green-laser

detector to locate the laser

position.

Laser dot/line is

not projected

1. The tool is put in sleep

mode.

2. The tool is performing

leveling adjustment

automatically.

3. The tool suffers a sudden

shock

4. The tool is out of the

operating temperature

range.

1. Wake up the tool with the

remote control or turn off and

on again.

2. Wait until the Auto leveling

adjustment is finished.

3. Wait until the tool re-levels

automatically.

4. Make sure the tool operating

temperature is within 32°F to

104°F.

Page 44

The rotary laser

stops spinning

and the laser dot

winks

1. The tool is out of leveling

range.

2. The slope setting in slope

mode is out of the

adjustable range of the

tool.

3. The tool is set ADS in

Auto Level mode and

suffers a sudden shock in

working.

1. Adjust to make sure the

support for the tool is close to

horizontal.

2. Adjust to make sure the

support for the tool is close to

horizontal or reduce the slope

setting.

3. Change the Auto Level mode

to OFF first, recheck the

reference and set to ADS

again.

Laser dot/line

projected is not

level

1. The tool is in slope mode.

2. The tool is set to OFF in

Auto Level mode; it will

NOT re-level if the tool

was moved.

1. Press the Return button to go

back to the rotation mode; the

tool will re-level.

2. Set the tool to ON in Auto

Level Mode, it will re-level.

Detector cannot

find the laser

1. It detects a red laser line.

2. the detector is out of its

working range

3. Battery is depleted.

1. This detector can only detect

green pulse laser.

2. Make sure the distance

between tool and detector

does not exceed 330 feet.

3. Replace with a new battery.

The remote

control cannot

operate the tool,

and LCD shows

“LINK LOST”

1. The tool is shut off

2. The remote control is out

of its working range

1. Press the ON/OFF button to

turn on the tool first, then turn

on the remote control to

operate it.

2. Make sure the distance

between tool and remote

control does not exceed 133

feet.

The tool emits

continuous

sound inside.

The adjusting mechanical

inside is working

automatically.

This is normal.

Loading...

Loading...