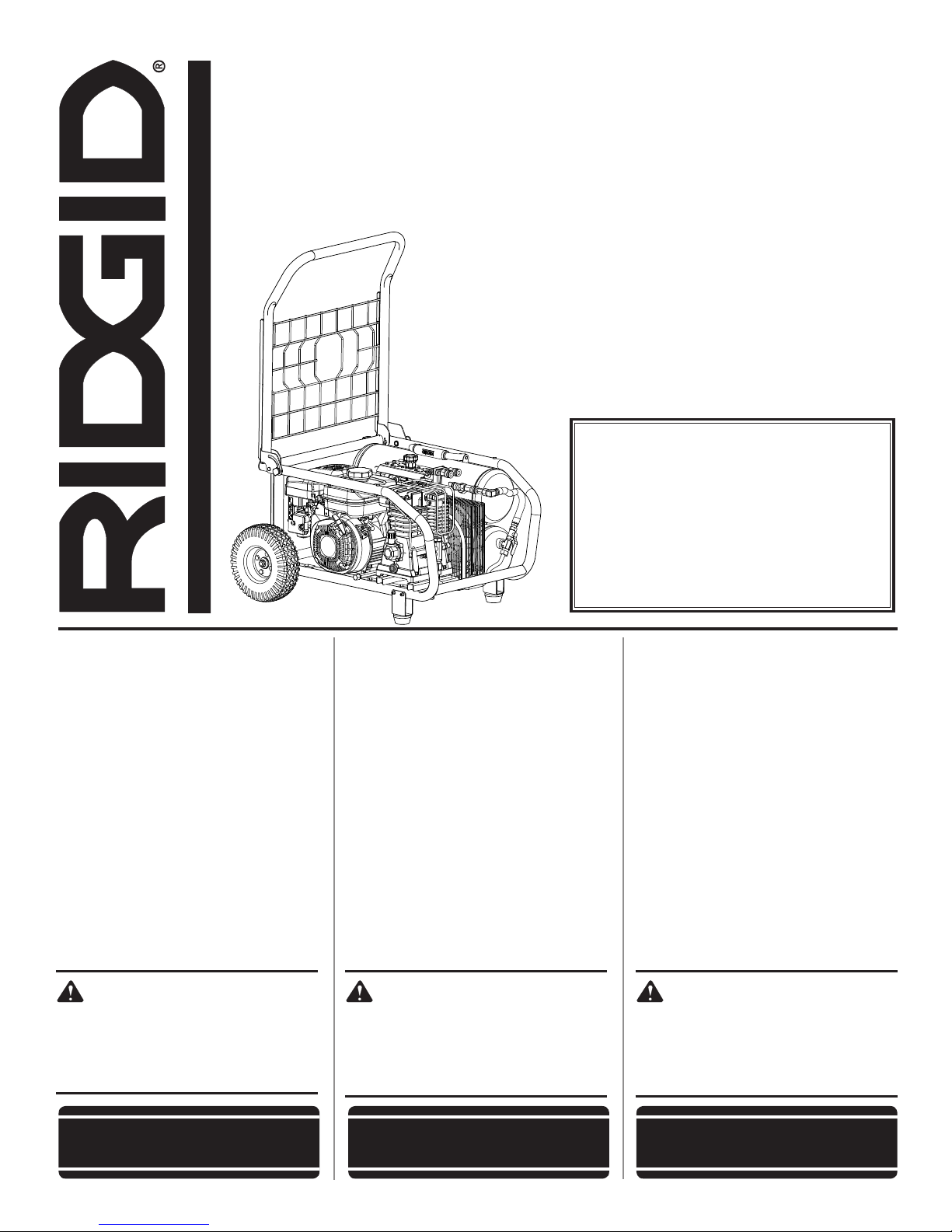

Page 1

OPERATOR’S MANUAL

MANUEL D’UTILISATION

MANUAL DEL OPERADOR

8 GALLON PORTABLE AIR COMPRESSOR

COMPRESSEUR D’AIR PORTABLE

DE 30,3 LITRES (8 GALLONS)

COMPRESOR DE AIRE PORTÁTIL

DE 30,3 LITROS (8 GALONES)

GP80150RT

To register your RIDGID product, please

visit: http://register.RIDGID.com

Pour enregistrer votre produit de

RIDGID, s’il vous plaît la visite :

http://register.RIDGID.com

INCLUDES: Air Compressor, Feet, Wheels,

Mounting Hardware, Engine Oil, Pump Oil,

Operator’s Manual

TABLE OF CONTENTS

****************

General Safety Rules .......................3-4

Specific Safety Rules .........................5

Symbols ..............................................6

Glossary of Terms ............................... 7

Special Terms ..................................... 7

Features .............................................. 8

Assembly .........................................8-9

Operation .....................................10-16

Maintenance ................................17-19

Troubleshooting ...........................20-21

Warranty ...........................................22

Illustrations ..................................23-29

Parts Ordering / Service ..... Back Page

WARNING:

To reduce the risk of injury, the

user must read and understand

the operator’s manual before

using this product.

INCLUT : Compresseur d’air, pieds,

roues, quincaillerie de montage, huile

moteur, huile pompe, manuel d’utilisation

TABLE DES MATIÈRES

****************

Règles de sécurité générales ............. 3-4

Règles de sécurité particulières ............. 5

Symboles ...............................................6

Glossaire ................................................7

Termes spécialisés .................................7

Caractéristiques .....................................8

Assemblage........................................ 8-9

Utilisation ......................................... 9-16

Entretien ......................................... 17-20

Dépannage ..................................... 20-21

Garantie ................................................22

Illustrations ..................................... 23-29

Commande de pièces /

réparation ............................. Page arrière

AVERTISSEMENT :

Pour réduire les risques de

blessures, l’utilisateur doit lire

et veiller à bien comprendre

le manuel d’utilisation avant

d’utiliser ce produit.

Para registrar su producto

de RIDGID, por favor visita:

http://register.RIDGID.com

INCLUYE: Compresor de aire, patas, ruedas,

piezas de montaje, aceite para motor, aceite

de bomba, manual del operador

ÍNDICE DE CONTENIDO

****************

Reglas de seguridad generales .......... 3-4

Reglas de seguridad específicas ........... 5

Símbolos ................................................ 6

Glosario de términos .............................. 7

Términos especiales ..............................7

Características ....................................... 8

Armado ............................................... 8-9

Funcionamiento................................ 9-16

Mantenimiento ............................... 17-20

Solución de problemas .................. 20-21

Garantía ................................................22

Ilustraciones ................................... 23-29

Pedidos de piezas /

servicio .............................. Pág. posterior

ADVERTENCIA:

Para reducir el riesgo de

lesiones, el usuario debe leer

y comprender el manual del

operador antes de usar este

producto.

SAVE THIS MANUAL FOR

FUTURE REFERENCE

CONSERVER CE MANUEL

POUR FUTURE RÉFÉRENCE

GUARDE ESTE MANUAL

PARA FUTURAS CONSULTAS

Page 2

DANGER:

This compressor/pump is not equipped and should not be used to supply breathing quality air. Additional equipment would be necessary to properly filter and purify the air to meet minimal specifications for Grade D breathing

as described in Compressed Gas Association Commodity Specification G 7.1 - 1966, OSHA 29 CFR 1910.134.

Compressed Gas Association, 4221 Walney Road, Fifth Floor, Chantilly, VA 20151-2923, (703) 788-2700,

www.cganet.com. Any such additional equipment has not been examined and no implication of proper use for

breathing air is intended or implied.

If this compressor is altered in any way, existing warranties shall be voided. RIDGID® and One World Technologies,

Inc., disclaim any liabilities whatsoever for any loss, personal injury, or damage.

DISCLAIMER OF WARRANTIES

In the event the compressor is used for the purpose of breathing air application and proper in-line safety and alarm

equipment is not simultaneously used, existing warranties shall be voided, and RIDGID® disclaims any liabilities

whatsoever for any loss, personal injury, or damage.

DANGER :

Ce compresseur / pompe n’est pas équipé et ne doit pas être utiliser pour fournir de l’air de qualité respirable. Un

équipement supplémentaire est nécessaire pour filtrer et purifier l’air conformément aux spécifications minimum

d’air respirable de qualité D G 7.1 - 1966, OSHA 29 CFR 1910. 134 de la Compressed Gas Association, 4221

Walney Road, Fifth Floor, Chantilly, VA 20151-2923, (703) 788-2700, www.cganet.com. Un tel équipement n’a pas

été examiné et nulle implacation d’utilisation propre pour l’air respirable n’est prévue ou implicite.

Si ce compresseur est modifier de quelle que manière que ce soit, les garanties en vigueur seront déclarées

nulles et non avenues. RIDGID®. et One World Technologies, Inc., déclineront toute responsabilité pour les pertes,

blessures et dommages résultant de son utilisation.

EXONÉRATION DE GARANTIES

Si ce compresseur est utilisé pour des applications d’air respirable sans un système de sécurité et d’alarme

approprié, les garanties en vigueur seront déclarées nulles et non avenues et RIDGID® déclinera toute responsabilité

pour les pertes, blessures et dommages résultant de son utilisation.

PELIGRO:

Este compresor (o bomba) no está equipado y debe evitarse utilizarlo para suministrar aire para respirar. Es necesario

equipo adicional para filtrar y purificar debidamente el aire a fin de que cumpla las especificaciones mínimas de

Grado D para respiración, según se explica en la Especificación de Productos G 7.1 - 1966 de la Asociación de

Proveedores de Equipo de Gas Comprimido (Compressed Gas Association), OSHA 29 CFR 1910.134. Compressed

Gas Association, 4221 Walney Road, Fifth Floor, Chantilly, VA 20151-2923, (703) 788-2700, www.cganet.com.

Tal equipo adicional no ha sido examinado y no debe suponerse o deducirse ninguna conclusión con respecto

al correcto uso del aire de respiración.

Si se altera de cualquier forma este compresor, quedan anuladas todas las garantías presentes. RIDGID®. y

One World Technologies, Inc., se eximen de toda responsabilidad de cualquier tipo por cualquier pérdida, lesión

corporal o daño material.

EXTENCIÓN DE RESPONSABILIDAD DE LAS GARANTÍAS

En caso de utilizarse los compresores para suministrar aire de respiración, y no utilizarse simultáneamente equipo

en línea de seguridad y alarma apropiado, se anulan todas las garantías presentes, y RIDGID® se exime de toda

responsabilidad de cualquier tipo por cualquier pérdida, lesión física o daño material que resulte.

2 – English

Page 3

GENERAL SAFETY RULES

WARNING:

Read and understand all instructions. Failure

to follow all instructions listed below may result

in electric shock, fire and/or carbon monoxide

poisoning which will cause death or serious

personal injury.

SAVE THESE INSTRUCTIONS

Do not overreach. Keep proper footing and balance

at all times. Proper footing and balance enables better

control of the product in unexpected situations.

Use safety equipment. Always wear eye protection.

Dust mask, nonskid safety shoes, hard hat, or hearing

protection must be used for appropriate conditions.

Do not use on a ladder or unstable support. Stable

footing on a solid surface enables better control of the

air compressor in unexpected situations.

WORK AREA

Keep your work area clean and well lit. Cluttered

benches and dark areas invite accidents. Floor must not

be slippery from wax or dust.

Do not operate air compressors in explosive atmo-

spheres, such as in the presence of flammable liquids,

gases, or dust. Air compressors create sparks which may

ignite the dust or fumes.

Keep bystanders, children, and visitors away while

operating an air compressor. Distractions can cause you

to lose control.

Operate air compressor in an open area at least 18 in.

away from any wall or object that could restrict the

flow of fresh air to ventilation openings.

PERSONAL SAFETY

Always wear eye protection with side shields marked

to comply with ANSI Z87.1 as well as hearing protection when operating this equipment.

The employer and/or user must ensure that proper

eye protection is worn. We recommend a Wide Vision

Safety Mask for use over eyeglasses or standard safety

glasses that provide protection against flying particles

both from the front and side. Always use eye protection

which is marked to comply with ANSI Z87.1.

Additional safety protection will be required in some

environments. For example, the working area may

include exposure to a noise level which can lead to hearing damage. The employer and user must ensure that any

necessary hearing protection is provided and used by the

operator and others in the work area. Some environments

will require the use of head protection equipment. When

required, the employer and user must ensure that head

protection marked to comply with ANSI Z89.1 is used.

Stay alert, watch what you are doing, and use com-

mon sense when operating the air compressor. Do

not use product while tired or under the influence of

drugs, alcohol, or medication. A moment of inattention

while operating an air compressor may result in serious

personal injury.

Dress properly. Do not wear loose clothing or jewelry.

Contain long hair. Keep your hair, clothing, and gloves

away from moving parts. Loose clothes, jewelry, or long

hair can be caught in moving parts.

AIR COMPRESSOR USE AND CARE

For outdoor use only.

Do not exceed the pressure rating of any component

in the system.

Protect material lines and air lines from damage or

puncture. Keep hose away from sharp objects, chemical

spills, oil, solvents, and wet floors.

Check hoses for weak or worn condition before each

use, making certain all connections are secure. Do not

use if defect is found. Purchase a new hose or notify a

qualified service center for examination or repair.

Release all pressures within the system slowly. Dust

and debris may be harmful.

Store idle air compressors out of the reach of children

and other untrained persons. Air compressors are dan-

gerous in the hands of untrained users.

Maintain air compressors with care. Follow mainte-

nance instructions. Properly maintained products are

easier to control.

Check for misalignment or binding of moving parts,

breakage of parts, and any other condition that may

affect the product’s operation. If damaged, have the

air compressor serviced before using. Many accidents

are caused by poorly maintained products.

Keep the exterior of the air compressor dry, clean, and

free from oil and grease. Always use a clean cloth when

cleaning. Never use brake fluids, gasoline, petroleumbased products, or any strong solvents to clean the unit.

Following this rule will reduce the risk of deterioration of

the enclosure plastic.

Keep the engine free of grass, leaves, or grease to

reduce the chance of a fire hazard.

Keep guards in place and in working order. Never oper-

ate the tool with any guard or cover removed. Make sure

all guards are operating properly before each use.

Do not operate the engine in a confined space where

dangerous carbon monoxide fumes can collect. Carbon

monoxide, a colorless, odorless, and extremely dangerous gas, can cause unconsciousness or death.

Keep the exhaust pipe free of foreign objects.

Do not operate around dry brush, twigs, cloth rags, or

other flammable materials.

3 – English

Page 4

GENERAL SAFETY RULES

Never pick up or carry a machine while the engine is

running.

Never start the machine if ice has formed in any part

of the equipment.

Always operate the machine on a level surface. If the

engine is on an incline, it could seize due to improper

lubrication (even at the maximum oil level).

Never attempt to make any adjustments while the

engine (motor) is running (except where specifically

recommended by the manufacturer).

Protective covers must always cover rotating parts

when the engine is running.

Keep cooling air intake (recoil starter area) and muffler

side of the engine at least 3 feet away from buildings,

obstructions, and other combustible objects.

Keep the engine away from flammables and other

hazardous materials.

Keep away from hot parts. The muffler and other engine

parts become very hot; use caution.

Do not touch the spark plug and ignition cable when

starting and operating the engine.

Check fuel hoses and joints for looseness and fuel

leakage before each use.

Check bolts and nuts for looseness before each use.

A loose bolt or nut may cause serious engine problems.

Always refuel outdoors. Never refuel indoors or in a

poorly ventilated area.

Never store the machine with fuel in the fuel tank

inside a building where ignition sources are present,

such as hot water and space heaters, clothes dryers,

and the like.

If the fuel tank has to be drained, do this outdoors into

a container approved for gasoline and away from all

ignition sources.

To reduce the risk of fire and burn injury, handle fuel

with care. It is highly flammable.

Do not smoke while handling fuel.

Add fuel before starting the engine. Never remove the

cap of the fuel tank or add fuel while the engine is running

or when the engine is hot.

Loosen fuel cap slowly to release pressure and to keep

fuel from escaping around the cap.

Replace all fuel tank and container caps securely.

Wipe spilled fuel from the unit. Move 30 feet away from

refueling site before starting engine.

If fuel is spilled, do not attempt to start the engine but

move the machine away from the area of spillage and

avoid creating any source of ignition until fuel vapors

have dissipated.

Never attempt to burn off spilled fuel under any

circumstances.

Before storing, allow the engine to cool.

Store fuel in a cool, well-ventilated area, safely away

from spark and/or flame-producing equipment.

Store fuel in containers specifically designed for this

purpose.

Empty fuel tank and restrain the unit from moving

before transporting in a vehicle.

Make sure minimum clearance of 3 feet is maintained

from combustible materials.

SERVICE

When servicing a product, use only recommended

or equivalent replacement parts. Follow instructions

in the Maintenance section

unauthorized parts or failure to follow Maintenance

instructions may create a risk of injury.

Service must be performed only by qualified repair

personnel. Service or maintenance performed by

unqualified personnel may result in a risk of injury.

Disconnect the spark plug wire, open drain valve to

decompress tanks and allow water to drain, and allow

air compressor to become cool to the touch before

servicing. Turn pressure regulator knob fully counter-

clockwise after shutting off air compressor.

of this manual. Use of

4 – English

Page 5

SPECIFIC SAFETY RULES

Know your air compressor. Read operator’s manual

carefully. Learn its applications and limitations, as well

as the specific potential hazards related to this product.

Following this rule will reduce the risk of electric shock,

fire, or serious injury.

Drain tanks of moisture after each day’s use. If unit will

not be used for a while, it is best to leave drain valve open

until such time as it is to be used. This will allow moisture

to completely drain out and help prevent corrosion on the

inside of tanks.

Risk of Fire or Explosion. Do not spray flammable liquid

in a confined area. Spray area must be well ventilated. Do

not smoke while spraying or spray where spark or flame

is present. Keep compressors as far from the spraying

area as possible, at least 15 feet from the spraying area

and all explosive vapors.

Risk of Bursting. Do not adjust regulator to result in

output pressure greater than marked maximum pressure

of attachment. Do not use at pressure greater than 150 psi.

Inspect tanks yearly for rust, pin holes, or other

imperfections that could cause it to become unsafe.

Never weld or drill holes in the air tanks.

Make sure the hose is free of obstructions or snags.

Entangled or snarled hoses can cause loss of balance or

footing and may become damaged.

Use the air compressor only for its intended use. Do

not alter or modify the unit from the original design

or function.

Do not sit or stand on the air compressor frame or

attempt to use the frame as a work surface.

Always be aware that misuse and improper handling of

this product can cause injury to yourself and others.

Never leave a tool unattended with the air hose

attached.

Never point any air tool toward yourself or others.

Do not operate this air compressor if it does not

contain a legible warning label.

Do not continue to use a tool or hose that leaks air or

does not function properly.

Always disconnect the air supply and remove spark

plug wire before making adjustments, servicing a

product, or when a product is not in use.

Do not attempt to pull or carry the air compressor by

the hose.

Your tool may require more air consumption than this

air compressor is capable of providing.

Always follow all safety rules recommended by the

manufacturer of your air tool, in addition to all safety

rules for the air compressor. Following this rule will

reduce the risk of serious personal injury.

Never direct a jet of compressed air toward people or

animals. Take care not to blow dust and dirt towards

yourself or others. Following this rule will reduce the risk

of serious injury.

Do not use this air compressor to spray chemicals.

Your lungs can be damaged by inhaling toxic fumes. A

respirator may be necessary in dusty environments or

when spraying paint. Do not carry while painting.

Inspect hoses periodically and, if damaged, have

repaired at your nearest Qualified Service Center.

Check damaged parts. Before further use of the air

compressor or air tool, a guard or other part that is

damaged should be carefully checked to determine

that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding

of moving parts, breakage of parts, mounting, and

any other conditions that may affect its operation. A

guard or other part that is damaged should be properly

repaired or replaced by a qualified service center.

Following this rule will reduce the risk of shock, fire, or

serious injury.

Never store a tool with air connected. Storing the tool

with air connected can result in unexpected firing and

possible serious personal injury.

Protect your lungs. Wear a face or dust mask if the

operation is dusty. Following this rule will reduce the risk

of serious personal injury.

Save these instructions. Refer to them frequently and use

them to instruct others who may use this product. If you

loan someone this product, loan them these instructions

also.

5 – English

Page 6

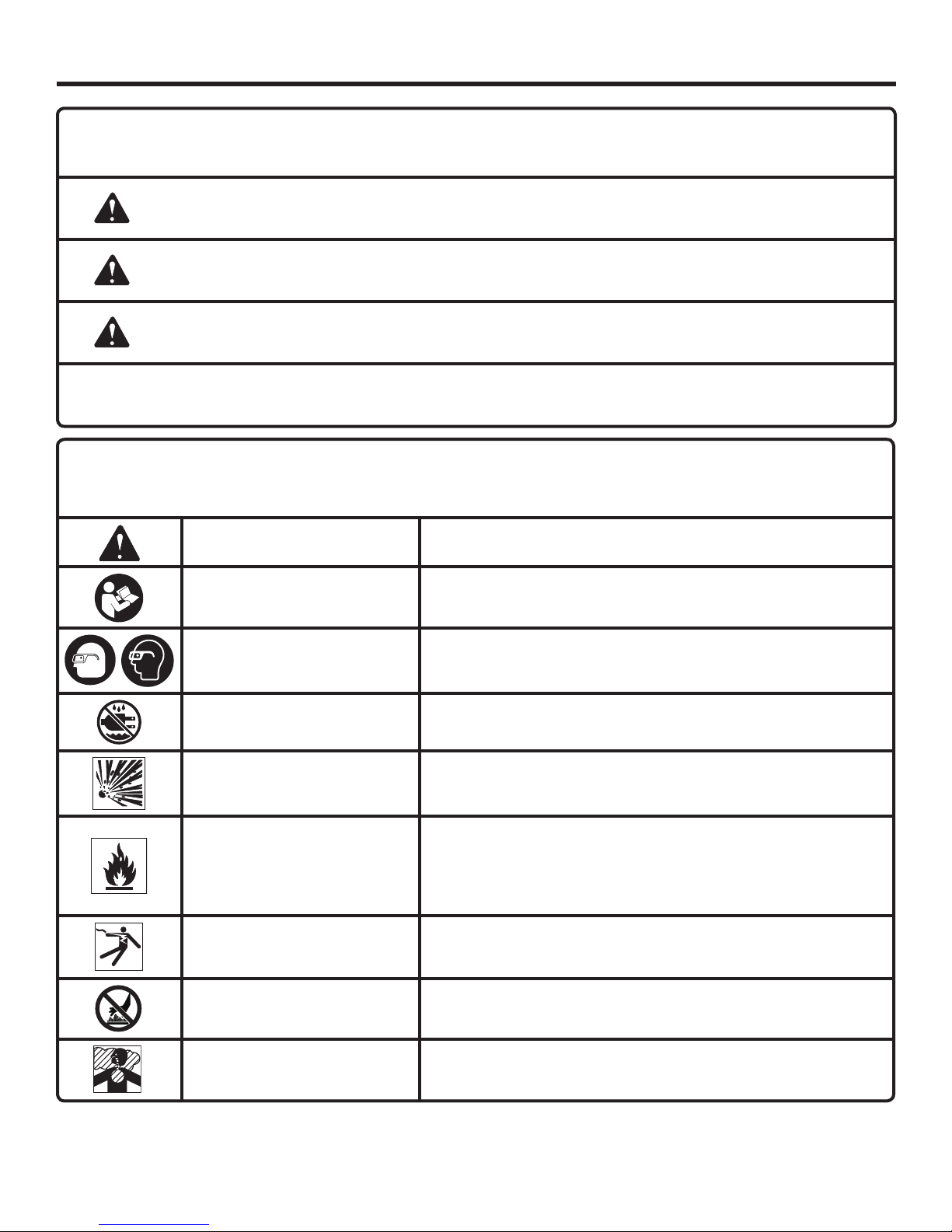

SYMBOLS

The following signal words and meanings are intended to explain the levels of risk associated with this product.

SYMBOL SIGNAL MEANING

DANGER:

WARNING:

CAUTION:

NOTICE:

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper

interpretation of these symbols will allow you to operate the product better and safer.

SYMBOL NAME

Safety Alert Indicates a potential personal injury hazard.

Read Operator’s Manual

Indicates an imminently hazardous situation, which, if not avoided, will result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, could result

in death or serious injury.

Indicates a potentially hazardous situation, which, if not avoided, may result in

minor or moderate injury.

(Without Safety Alert Symbol) Indicates important information not related to an

injury hazard, such as a situation that may result in property damage.

DESIGNATION/EXPLANATION

To reduce the risk of injury, user must read and understand

operator’s manual before using this product.

Eye Protection

Wet Conditions Alert Do not expose to rain or use in damp locations.

Risk of Bursting

Risk of Fire or Explosion

Risk of Electrical Shock

Hot Surface

Risk to Breathing

Always wear eye protection with side shields marked to comply

with ANSI Z87.1.

Do not adjust regulator to result in output pressure greater than

marked maximum pressure of attachment. Do not use at pressure

greater than 150 PSI.

Do not spray flammable liquid in a confined area. Spray area must

be well ventilated. Do not smoke while spraying or spray where

spark or flame is present. Keep compressors as far from the spraying area as possible, at least 15 feet from the spraying area and

all explosive vapors.

Failure to use in dry conditions and to observe safe practices can

result in electric shock.

To reduce the risk of injury or damage, avoid contact with any hot

surface.

Air obtained directly from the air compressor should never be used

to supply air for human consumption.

6 – English

Page 7

GLOSSARY OF TERMS

Air Filter

Porous element contained within a metal or plastic housing

attached to the compressor cylinder head which removes

impurities from the intake air of the compressor.

Air Tank

Cylindrical component which contains the compressed air.

Belt Guard

Protects the operator from coming in contact with the belt

and rotating pulleys.

Cut-In Pressure

The low pressure at which the engine speed will automatically

increase to full speed.

Cut-Off Pressure

The high pressure at which the engine speed will automatically

decrease to idle speed.

NPT (National Pipe Thread)

A seal thread tape must be used to provide a leak-free seal

on pipe threaded connections.

On/Off Switch

Control which turns the air compressor on or off. The

pressure switch will not automatically start and control the

compressor unless the manual on/off switch is in the ON

( l ) position.

Pressure Regulator Knob

Regulates the outgoing pressure from the air outlet to the

tool. It is possible to increase or decrease the pressure at

the outlet by adjusting this control knob.

Pressure Unloader

Controls the speed of the compressor’s engine. The engine

runs at idle speed when the cut-off pressure in the tank is

reached and switches the engine to full speed once the

pressure drops below the cut-in pressure.

PSI (Pounds Per Square Inch)

Measurement of the pressure exerted by the force of the

air. The actual psi is measured by a pressure gauge on the

compressor.

Pump

Produces the compressed air with a reciprocating piston

contained within the cylinder.

Quick Connect Couplers

The 1/4 in. quick connect couplers allow the operator to

easily attach air hoses to the compressor.

Outlet Pressure Gauge

Displays the current line pressure. Line pressure is adjusted

by rotating the pressure regulator knob.

Safety Valve

Prevents air pressure in the air tank from rising over a

predetermined limit.

SCFM (Standard Cubic Feet Per Minute) or CFM (Cubic

Feet Per Minute)

A unit of measure of air delivery.

Tank Pressure Gauge

Indicates the pressure in the air tank.

SPECIAL TERMS

Belt Tensioner Bolt

This bolt moves the engine toward or away from the pump

to allow you to reposition or replace the drive belt.

Compressor Tank

The air compressor and 4 gallon stationary tank.

Quarter Turn Drain Valves

Quarter turn drain valves are located on tanks for easy draining of condensate to help prevent tank corrosion.

Removable Tank

The 4 gallon tank that is removable.

Unregulated Air Hose

This hose transmits the compressed air from the compressor

tank to the removable tank.

Unregulated Air Quarter Turn Ball Valve Lever

This valve opens to allow compressed air to flow from the

compressor tank to the removable tank and closes to stop

air flow from the compressor tank to the removable tank.

Unregulated Air Intake Coupler

This coupler is an air inlet only for the unregulated air hose

and is located on the removable tank.

Unregulated Air Fitting

This 1/4 in. NPT quick-connect fitting connects the unregulated air hose and is located on the compressor tank.

7 – English

Page 8

FEATURES

PRODUCT SPECIFICATIONS

Air Tank Capacity ........................................................................................................................................................... 8 gal.

Air Pressure .........................................................................................................................................................150 psi max.

Air Delivery ............................................................................................................................................. 10.2 SCFM @ 90 psi

Engine.................................................................................................................................................................. 170 cc OHC

Gauges .............................................................................................................................................................. 2 in. diameter

CALIFORNIA PROPOSITION 65

WARNING:

This product, its exhaust, and other substances that may become airborne from its use may contain chemicals,

including lead, known to the State of California to cause cancer, birth defects, or other reproductive harm. Wash

hands after handling.

ASSEMBLY

UNPACKING

This product requires assembly.

Carefully remove the tool and any accessories from the

box. All items listed in the Includes section must be

included at the time of purchase.

WARNING:

Items in this Assembly section are not assembled

to the product by the manufacturer and require

customer installation. Use of a product that may

have been improperly assembled could result in

serious personal injury.

If any parts are damaged or missing, please call

1-866-539-1710 for assistance.

WARNING:

Do not attempt to modify this product or create

accessories or attachments not recommended

for use with this product. Any such alteration

or modification is misuse and could result in a

hazardous condition leading to possible serious

personal injury.

WARNING:

To prevent accidental starting that could cause

serious personal injury, always disconnect the

engine spark plug wire from the spark plug when

assembling parts.

WARNING:

If any parts are damaged or missing do not operate

this product until the parts are replaced. Use of

this product with damaged or missing parts could

result in serious personal injury.

8 – English

Page 9

ASSEMBLY

LOOSE PARTS LIST

See Figure 1, page 23.

The following items are included with the air compressor:

Key

No. Description Qty.

1 Axle Bolt ..............................................................2

2 Spacers ...............................................................2

3 Lock Washer (18 mm) ..........................................2

4 Flat Washer (18 mm) ............................................2

5 Wheel ...................................................................2

6 Legs with Rubber Feet ........................................2

7 Nut (5 mm) ...........................................................4

8 Flat Washer (5 mm) ..............................................4

9 Lock Washer (5 mm) ............................................4

10 Screw ...................................................................4

11 Spark Plug Wrench ..............................................1

Pump Lubricant (not shown) ...............................1

Engine Lubricant (not shown) ..............................1

Operator’s Manual (not shown) ...........................1

TOOLS NEEDED

The following tools (not included) are needed for assembling

or maintaining the air compressor.

Hex Keys

Adjustable Wrench

NOTE: Do not put fuel or oil in the air compressor before

installing the legs and wheels.

Raise the front end of the air compressor, where the pump

is located, high enough to gain access to the frame bottom; securely position props underneath to support.

Position a leg over the holes on each side of the frame.

Insert each screw through a lock washer and a flat washer,

then insert the screws through the two holes in the leg

and the frame.

Install a nut over each screw on the inside of the frame

and tighten securely.

Repeat with remaining leg.

INSTALLING THE WHEELS

See Figure 3, page 24.

Locate the following items:

2 axle bolts

2 spacers

2 lock washers (18 mm)

2 flat washers (18 mm)

2 wheels

Raise the back end of the air compressor, where the

engine is located, high enough to gain access to the frame

bottom; securely position props underneath to support.

Insert a wheel spacer into the center of the wheel.

Insert axle bolt through lock washer and flat washer,

through the spacer and wheel, and then into threaded

opening on air compressor frame. Tighten axle bolt

securely.

Repeat the process on the other side to install second

wheel.

INSTALLING LEGS

See Figure 2, page 24.

Locate the following items:

2 legs with rubber feet

4 lock washers (5 mm)

4 flat washers (5 mm)

4 nuts (5 mm)

4 screws

REMOVING THE PUMP OIL LABEL

See Figure 4, page 24.

The air compressor has a label installed between the pump

oil cap and the oil fill hole. Before using the unit the first time,

remove the pump oil cap and label, then reinstall the cap.

Make sure to add oil before first use. See Adding/Checking

Pump Oil before first time operation.

9 – English

Page 10

OPERATION

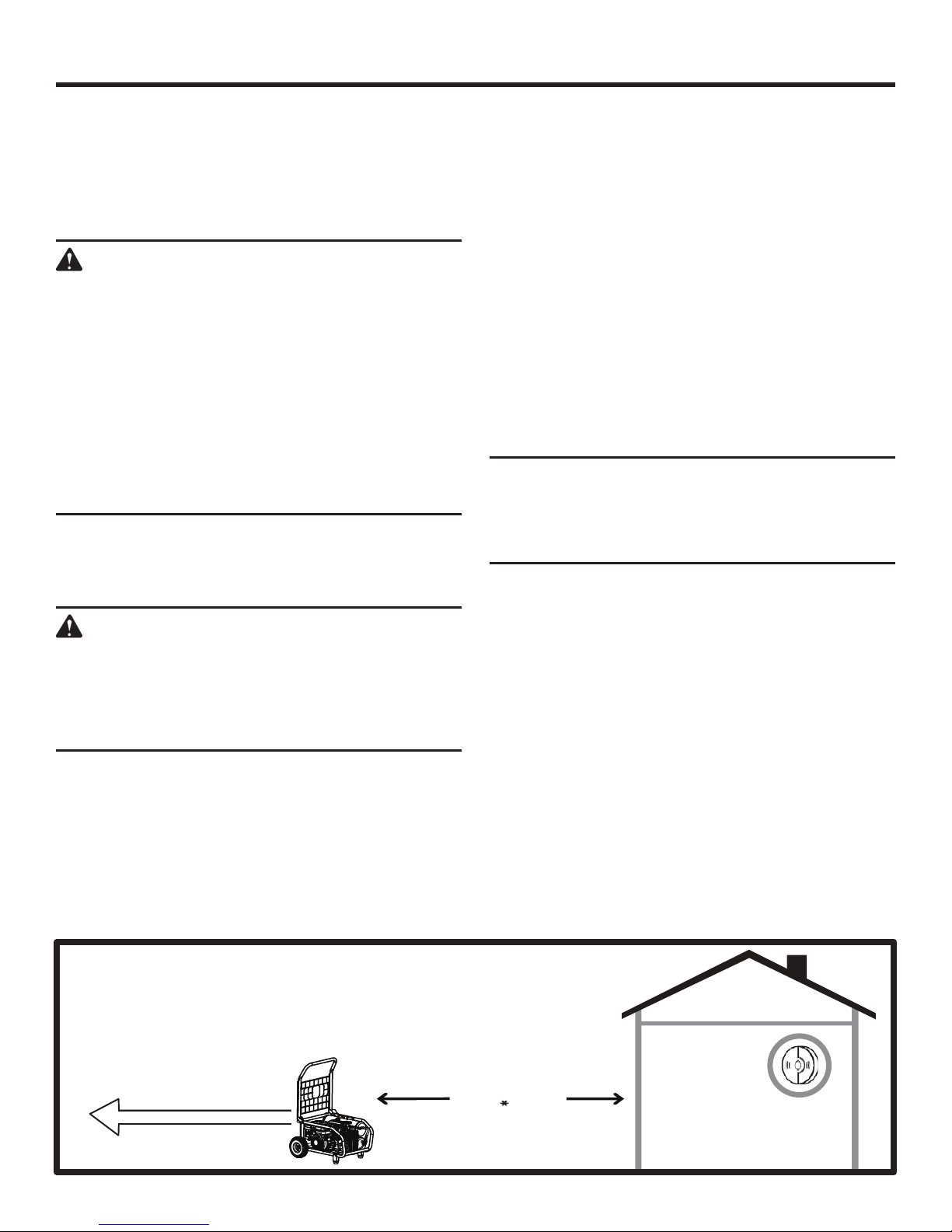

DANGER:

Carbon Monoxide. Using a gas-powered air

compressor indoors CAN KILL YOU IN MINUTES.

Engine exhaust contains high levels of carbon

monoxide (CO), a poisonous gas you cannot see

or smell. If you can smell the engine exhaust, you

are breathing CO. But even if you cannot smell the

exhaust, you could be breathing CO.

Never use a gas-powered air compressor

inside homes, garages, crawlspaces, or other

partly enclosed areas. Deadly levels of carbon

monoxide can build up in these areas. Using a

fan or opening windows and doors does NOT

supply enough fresh air.

ONLY use gas-powered air compressors

outdoors and far away from open windows,

doors, and vents. These openings can pull in

engine exhaust.

Even when you use a gas-powered air compressor

correctly, CO may leak into the home. ALWAYS use

a battery-powered or battery-backup CO alarm in

the home.

If you start to feel sick, dizzy, or weak after the air

compressor has been running, move to fresh air

RIGHT AWAY. See a doctor. You could have carbon

monoxide poisoning.

WARNING:

Never direct a jet of compressed air toward people

or animals. Take care not to blow dust and dirt

towards yourself or others. Following this rule will

reduce the risk of serious injury.

WARNING:

Do not attach any tools to the open end of the hose

until start-up has been completed.

NOTICE:

Do not use in an environment that is dusty or

otherwise contaminated. Using the air compressor

in this type of environment may cause damage to

the unit.

NOTICE:

This product is not equipped with a spark arrestor

and cannot be used on U.S. forest lands; in

addition, product users must comply with Federal,

State, and local fire prevention regulations.

Check with appropriate authorities. Refer to

accompanying engine manual for maintenance

and replacement parts.

DANGER:

Do not disassemble pressure unloader, tank drain

valves or safety relief valve with air in tank — bleed

tanks.

WARNING:

Do not allow familiarity with products to make you

careless. Remember that a careless fraction of a

second is sufficient to inflict severe injury.

WARNING:

Always wear eye protection with side shields

marked to comply with ANSI Z87.1. Failure to do

so could result in objects being thrown into your

eyes resulting in possible serious injury.

WARNING:

This equipment incorporates parts, such as snap

switches, receptacles, and the like that tend to

produce arcs or sparks and, therefore, when

located in a garage, it should be in a room or

enclosure provided for the purpose, or should be

18 in. or more above the floor.

NOTICE:

Before each use, inspect the entire product for

damaged, missing, or loose parts such as screws,

nuts, bolts, caps, etc. Tighten securely all fasteners

and caps and do not operate this product until all

missing or damaged parts are replaced. Please

contact customer service or a qualified service

center for assistance.

APPLICATIONS

Air compressors are utilized in a variety of air system

applications. Match hoses, connectors, air tools, and

accessories to the capabilities of the air compressor.

You may use this product for the purposes listed below:

Operating some air-powered tools

Operating air accessories such as air nozzles and tire

inflators

Operating some air-powered paint spraying products

RAISING AND LOWERING THE HANDLE

See Figure 5, page 24.

To raise the handle (for moving the air compressor): pull

the handle release knob until the handle is up and release

to lock in place. Insert the handle lock pin to secure the

handle in place.

10 – English

Page 11

OPERATION

To lower the handle (for storing or transporting the air

compressor): remove the handle lock pin, then pull the

handle release knob out and lower the handle to the down

position.

Never use the handle to lift the air compressor. The handle

should only be used for moving the unit by rolling it on its

wheels.

ADDING/CHECKING ENGINE OIL

See Figures 6 - 7, page 24.

NOTE: This machine has been shipped with approximately

2 oz. of oil in the engine from testing. You must add oil to

the engine before starting it the first time.

NOTICE:

Any attempt to start the engine without adding oil

will result in engine failure.

To add engine oil:

Place air compressor on a flat, level surface. Do not tilt.

Unscrew the engine oil cap/dipstick by turning counter-

clockwise.

Add 4-stroke engine oil (SAE 30 or SAE 10W30) until the

fluid level rises between the hatched area on the dipstick.

Do not overfill.

NOTE: Avoid using too much oil. Ensure that the level of

oil does not rise above the upper hatched area. For easier

access when adding engine oil, use a long-neck funnel.

Replace the engine oil cap/dipstick and securely tighten.

NOTE: This engine has a total oil capacity of 20 oz. (0.6 liters).

To check engine oil level:

Place air compressor on a flat, level surface. Do not tilt.

Remove engine oil cap/dipstick.

Wipe engine oil cap/dipstick clean and re-seat in hole.

Do not rethread.

Remove engine oil cap/dipstick again and check oil level. Oil

level should be between the hatched area on the dipstick.

If level is low, add engine oil until the fluid level rises to

the upper portion of the hatched area on the dipstick.

Replace and secure the engine oil cap/dipstick.

NOTICE:

Do not overfill. Overfilling the crankcase may cause

excessive smoke and engine damage.

Add SAE 5W40 synthetic pump oil into the oil reservoir

until the fluid level rises to the top of the red dot in the

center of the sight glass. Do not overfill.

NOTE: Avoid using too much oil. Ensure that the level

of the oil does not exceed the top of the red dot in the

center of the sight glass. For easier access when adding

pump oil, use a long-neck funnel.

NOTICE:

Pump oil drains very slowly from the fill area into

the pump. Pause often while filling to allow the oil

to drain completely into the pump before checking

the level in the sight glass.

Replace the pump oil cap and securely tighten.

NOTE: This pump has a total oil capacity of 27 oz.

OXYGENATED FUELS

NOTICE:

Do not use E15 or E85 fuel in this product. It is

a violation of federal law and will damage the

unit and void your warranty. Only use unleaded

gasoline containing up to 10% ethanol.

Fuel system damage or performance problems resulting

from the use of an oxygenated fuel containing more than

the percentages of oxygenates previously stated are not

covered under warranty.

ADDING GASOLINE TO THE FUEL TANK

See Figure 9, page 24.

DANGER:

Risk of fire and serious burns: Never remove

fuel cap when unit is running. Shut off engine and

allow the unit to cool at least five minutes. Remove

cap slowly.

WARNING:

Gasoline and its vapors are highly flammable and

explosive. To prevent serious personal injury and

property damage, handle gasoline with care. Keep

away from ignition sources, handle outdoors only,

do not smoke while adding fuel, and wipe up spills

immediately.

ADDING/CHECKING PUMP OIL

See Figure 8, page 24.

NOTE: There is no pump oil in the unit when shipped from

the factory. You must add oil to the pump before using

the air compressor.

Unscrew the pump oil cap by turning counterclockwise.

When adding gas to the air compressor, make sure the unit

is sitting on a flat, level surface. If the engine is hot, let the

air compressor cool before adding gas. ALWAYS fill the fuel

tank outdoors with the machine turned off.

NOTE: Use unleaded gas only. DO NOT mix oil with gas.

Before removing the fuel cap, clean the area around it.

Remove the fuel cap.

11 – English

Page 12

OPERATION

Insert a clean funnel into the fuel tank then slowly

pour gasoline into the tank. Fill tank to approximately

1-1/2 in. below the top of the tank neck (this allows for

fuel expansion).

Replace fuel cap and tighten securely.

Clean up any spills before starting the engine.

WARNING:

Always shut off engine before fueling. Never

remove fuel cap or add fuel to a machine with

a running or hot engine. Make sure the unit is

sitting on a flat, level surface and only add fuel

outdoors. If the engine is hot, let the unit cool

for at least five minutes before adding fuel. After

fueling, immediately replace fuel cap and tighten

securely. Move at least 30 ft. from refueling site

before starting engine. Do not smoke and stay

away from open flames and sparks! Failure to

follow these instructions could result in a fire and

cause serious personal injury.

CONNECTING/DISCONNECTING AIR HOSE

(NOT PROVIDED)

See Figure 10, page 24.

WARNING:

Never exceed the air tool’s pressure rating as

recommended by the manufacturer. When using

this air compressor as an inflation device, always

follow the maximum inflation guidelines stated by

the manufacturer of the item being inflated.

Make sure the air compressor is off.

Rotate pressure regulator knob fully in the counter-

clockwise direction so that the outlet pressure is at zero

(0) psi.

Attach an air hose with 1/4 in. NPT quick-connect air fitting

to a quick connect coupler (1/4 in.) on air compressor.

Make sure to push the air fitting fully into the coupler until

the sleeve springs forward to lock in place.

To disconnect an air hose or an air tool:

Make sure the air compressor is off.

Confirm that the outlet pressure is at zero (0) psi.

When disconnecting a hose from quick connect coupler

(1/4 in.), always firmly hold fitting end of hose.

Pull back on the release sleeve on the 1/4 in. quick-

connect coupler.

With a firm grip, pull out the quick-connect air fitting that

is attached to the quick connect coupler.

BREAK-IN PERIOD

Before first use, run the air compressor at zero tank pressure

with the drain valves fully open for 30 minutes.

STARTING AND STOPPING THE AIR

COMPRESSOR

See Figures 11 - 15, page 25.

NOTICE:

On a level surface with the engine off, check the

pump and engine oil levels before each use of the

compressor.

Before starting the engine:

Connect all hoses.

Check all fluids (oil and gas).

To start the engine:

Turn the fuel valve to the OPEN position.

Move the choke lever to the START position.

NOTE: If the engine is warm, leave the choke lever in the

RUN position.

Place the pressure unloader in the vertical position.

Put the on/off switch in the ON position.

Grasp the recoil starter and pull slowly until resistance is

felt. Give the recoil starter a short, brisk pull to start the

engine (no more than 4 pulls).

NOTE: Do not allow the recoil starter to snap back after

starting; return it gently to its original place.

NOTE: If the engine fails to start, wait several minutes

then repeat the above steps as needed.

LOCATE AIR COMPRESSOR AT LEAST 20 FT.* AWAY TO REDUCE

THE RISK OF CARBON MONOXIDE GETTING INSIDE THE HOME

* Minimum distance as recommended by U.S. Department of Health and Human

Services Centers for Disease Control and Prevention (www.cdc.gov/co). Your specific

home and/or wind conditions may require additional distance.

Exhaust (CO)

Direct exhaust AWAY

from all windows, doors,

and vents.

KEEP AT LEAST

20 FT. AWAY

Only use OUTSIDE and

FAR AWAY from windows,

doors, and vents.

12 – English

CO Detector

in Living Areas

Page 13

OPERATION

Allow the engine to run for 30 seconds, then move the

choke lever to the RUN position and place the pressure

unloader in the horizontal position.

NOTE: Once the air compressor is started, pressure

inside the air tank will build until the compressor reaches

150 psi. After reaching maximum tank pressure the

engine will idle allowing the pressure inside the air tank to

decrease until it reaches a preset level. When the pressure

falls below the preset level, the engine will accelerate and

provide additional air pressure.

WARNING:

Never exceed the air tool’s pressure rating as

recommended by the manufacturer. When using

this air compressor as an inflation device, always

follow the maximum inflation guidelines stated by

the manufacturer of the item being inflated.

To stop the engine:

Put the on/off switch in the OFF position.

WARNING:

The pump exhaust tube will become hot during

use. Avoid contact with the pump exhaust tube

when stopping the engine.

WARNING:

Always ensure the on/off switch is in the OFF (O)

position and the outlet pressure gauge reads zero

before changing air tools or disconnecting the hose

from the air outlet. Failure to do so could result in

possible serious personal injury.

Turn the fuel valve to the CLOSED position.

NOTICE:

Keep the air compressor on a flat, level surface

during operation. Operation of the unit at an angle

may result in damage to the air compressor and

could void your warranty.

COMPRESSOR TANK AND REMOVABLE TANK

TOGETHER — FOR MAXIMUM TANK CAPACITY

See Figures 16 - 18, pages 25 - 26.

Keep compressor tank and removable tank together for

maximum tank capacity.

Make sure the air compressor is off.

Attach hose(s) to one of the quick-connect couplers

(1/4 in.) on removable tank.

NOTE: If two tools are installed on the removable tank,

they must use the same psi.

Attach a 1/4 in. NPT quick-connect air fitting to accessory

or tool(s) you intend to use.

Insert the other end of the quick-connect air fitting to the

quick coupler on the open end of hose.

Start the air compressor as described in Starting and

Stopping the Air Compressor.

Check that ball valve lever on unregulated air hose is in

the ON position, allowing air flow from compressor tank

to removable tank.

Pull out and rotate pressure regulator knob to desired

line pressure. Turning the knob clockwise increases air

pressure at the outlets; turning counterclockwise reduces

air pressure at the outlets.

Following all safety precautions in this manual and the

manufacturer’s instructions in the air tool manual, you

may now proceed to use your air-powered tool.

USING THE AIR COMPRESSOR

This air compressor can be operated in 3 arrangements for

easy carry and ease of use.

NOTE: Before using the air compressor, always check the

safety valves for proper function as described in Checking

the Safety Valves later in this manual.

CAUTION:

Only use removable tank with air compressor Model

No. GP80150RT to avoid damage to the tool or

risk of personal injury.

WARNING:

The compressor tank will become hot during use.

Failure to avoid contact with the hot surface may

result in serious personal injury.

CAUTION:

Air powered tools may require more air consumption

than this air compressor is capable of providing.

Check the tool manual to avoid damage to the tool

or risk of personal injury.

Control the amount of air flow with the pressure regulator

knob. Turning the knob fully counterclockwise will

completely stop the flow of air.

NOTE: Always use the minimum amount of pressure

necessary for your application. Using a higher pressure

than needed will drain air from the tank more rapidly and

cause the unit to cycle on more frequently.

When finished, always stop the engine and drain the

tanks. Never leave the unit running unattended.

13 – English

Page 14

OPERATION

REMOVABLE TANK ALONE — REGULATED

CARRY TANK FOR SMALL JOBS

See Figures 16 - 17 and 19, pages 25- 26.

The removable tank can be separated from compressor

tank to be carried to remote location for small jobs. One tool

should be used in this instance.

Make sure the air compressor is off.

Rotate pressure regulator knob fully in the counterclock-

wise direction so that the outlet pressure is at zero (0) psi.

Turn ball valve lever on unregulated air hose to OFF posi-

tion.

NOTE: Be sure unregulated air hose is turned off before

connecting or disconnecting from unregulated air intake

coupler.

Disconnect unregulated air hose.

Carefully lift and remove removable tank from compressor

tank and move removable tank to job site.

WARNING:

The compressor tank will become hot during use.

Failure to avoid contact with the hot surface may

result in serious personal injury.

Attach hose to one of the two quick-connect couplers

located on front gauge panel of the removable tank as

previously instructed.

Attach 1/4 in. NPT quick-connect air fitting to accessory

or tool you intend to use.

Insert the other end of the quick-connect air fitting to the

quick-connect coupler on the open end of hose.

Pull out and rotate pressure regulator knob to desired

line pressure. Turning the knob clockwise increases air

pressure at the outlet; turning counterclockwise reduces

air pressure at the outlet.

Following all safety precautions in this manual and the

manufacturer’s instructions in the air tool manual, you

may now proceed to use your air-powered tool.

CAUTION:

Air powered tools may require more air consumption

than this air compressor is capable of providing.

Check the tool manual to avoid damage to the tool

or risk of personal injury.

Control the amount of air flow with the pressure regulator

knob. Turning the knob fully counterclockwise will

completely stop the flow of air.

NOTE: Always use the minimum amount of pressure

necessary for your application. Using a higher pressure

than needed will drain air from the tank more rapidly and

cause the unit to cycle on more frequently.

When finished, always stop the engine and drain the tank.

Never leave the unit running unattended.

COMPRESSOR TANK AND REMOVABLE TANK

SEPARATED AND CONNECTED WITH A HOSE

See Figures 16 - 17 and 20, pages 25 - 26.

The compressor tank and removable tank can be separated

and connected with a hose (up to 50 ft.) for maximum flexibility at job site, remote regulation, to prevent pressure drop

and to keep noise outside.

Make sure the air compressor is off.

Rotate pressure regulator knob fully in the counterclock-

wise direction so that the outlet pressure is at zero (0) psi.

Turn ball valve lever on unregulated air hose to OFF posi-

tion.

NOTE: Be sure unregulated air hose is turned off before

connecting or disconnecting from unregulated air intake

coupler.

Disconnect unregulated air hose.

Carefully lift and remove removable tank from compressor

tank.

Attach unregulated air hose on compressor tank to air

hose (up to 50 ft.).

Attach a 1/4 in. NPT quick-connect air fitting to air hose

and connect to 1/4 in. quick-connect intake coupler on

removable tank.

WARNING:

Only connect unregulated air hose between

compressor tank and unregulated air intake

coupler.

Move removable tank to job area.

Attach hose to one of the two quick-connect couplers

located on front gauge panel of the removable tank as

previously instructed.

NOTE: If two tools are installed on the removable tank,

they must use the same psi.

Attach 1/4 in. NPT quick-connect air fitting to accessory

or tool you intend to use.

Insert the other end of the quick-connect air fitting to the

quick-connect coupler on the open end of hose.

Start the air compressor as described in Starting and

Stopping the Air Compressor.

Turn ball valve lever on unregulated air hose to ON

position, allowing air flow from compressor tank to

removable tank.

Pull out and rotate pressure regulator knob to desired

line pressure. Turning the knob clockwise increases air

pressure at the outlet; turning counterclockwise reduces

air pressure at the outlet.

Following all safety precautions in this manual and the

manufacturer’s instructions in the air tool manual, you

may now proceed to use your air-powered tool.

14 – English

Page 15

OPERATION

CAUTION:

Air powered tools may require more air consumption

than this air compressor is capable of providing.

Check the tool manual to avoid damage to the tool

or risk of personal injury.

Control the amount of air flow with the pressure regula-

tor knob. Turning the knob fully counterclockwise will

completely stop the flow of air.

NOTE: Always use the minimum amount of pressure

necessary for your application. Using a higher pressure

than needed will drain air from the tank more rapidly and

cause the unit to cycle on more frequently.

When finished, always stop the engine and drain the

tanks. Never leave the unit running unattended.

DRAINING THE TANKS

See Figure 21, page 27.

To help prevent tank corrosion and keep moisture out of the

air used, the air tanks of the compressor should be drained

daily.

NOTE: The air compressor has two tanks and two drain

valves. Be sure to perform this operation for each tank.

To drain:

Make sure the air compressor is off.

Pull the ring on the safety valve to release air until tank

pressure gauge reads less than 20 psi.

Release the ring.

Rotate drain valve counterclockwise (ON) to open.

Tilt tank to drain moisture from tank into a suitable

container.

NOTE: Condensate is a polluting material and should be

disposed of in compliance with local regulations.

If drain valve is clogged, release all air pressure, remove

and clean valve, then reinstall.

WARNING:

Stop the air compressor, disconnect the spark

plug wire, and release all air from the tanks before

servicing. Failure to depressurize tanks before

attempting to remove valve can cause serious

personal injury.

Rotate drain valve clockwise (OFF) until tightly closed.

Repeat above procedure for second tank.

WARNING:

RISK OF BURSTING. All compressed air

tanks have a limited lifespan. The lifespan can

be affected by a number of factors, including

operating conditions of the air compressor, proper

maintenance of the tank, and unauthorized repairs

and modifications. Since deterioration of the tank

can occur internally with no outward signs, the

air tank(s) on this compressor MUST be removed

from service by the end of the year shown on the

data label.

Tank life may be extended beyond this date by

having a certified tank inspection performed

before this date, and every 5 years following this

date, for as long as the tank is in use. Use of the

air compressor after this date without passing the

certified inspection increases the risk of an air tank

rupture, which could result in serious personal

injury.

CHECKING THE SAFETY VALVES

See Figure 21, page 27.

DANGER:

Do not attempt to tamper with the safety valves.

Anything loosened from this device could fly up

and hit you. Failure to heed this warning could

result in death or serious personal injury.

Safety valves will automatically release air if the air tank

pressure exceeds the preset maximum. The valves should be

checked before each day of use by pulling the ring by hand.

NOTE: The air compressor has two safety valves. Be sure

to check both.

Start the air compressor and allow the tanks to fill. The

compressor will shut off when the pressure reaches the

preset maximum.

Turn the air compressor off.

Pull the rings on both safety valves to release air for three

to five seconds.

WARNING:

If air leaks after the ring has been released, or if

the valve is stuck and cannot be actuated by the

ring, do not use the air compressor until the safety

valve has been replaced. Use of the air compressor

in this condition could result in serious personal

injury.

15 – English

Page 16

OPERATION

MOVING THE AIR COMPRESSOR

See Figure 22, page 27.

Raise the handle to the up position.

Make sure the air compressor is off.

Close the fuel valve.

With your foot on the rear of the frame, tilt the machine

toward you until it balances on the wheels, then roll the

machine to the desired location.

Allow 30 minutes of “cool down” time before storing the

machine.

CHANGING COUPLERS AND FITTINGS

FROM 1/4 IN. SIZE TO 3/8 IN. SIZE

See Figures 23 - 24, page 27.

This air compressor is equipped with high flow 3/8-in. air line

construction, but features couplings and fittings with 1/4-in.

internal diameter on all the air outlets since this is the most

common fitting size in use.

For optimal performance, you can replace these 1/4-in. couplings with 3/8-in. internal diameter couplings and fittings

(not provided). This will allow you to achieve higher volume

air flow with lower pressure drop.

To replace the fittings:

Turn off the air compressor and release all pressure from

both air tanks.

Using an adjustable wrench, remove the 1/4-in. quick

connect couplers and air reducers.

Apply pipe sealant to new 3/8-in. couplers and then install.

Tighten securely.

Disconnect the unregulated air fitting from the unregulated

air intake coupler.

Remove the 1/4-in. unregulated air intake coupler and air

reducer.

Apply pipe sealant to new 3/8-in. coupler and then install.

Tighten securely.

Remove the 1/4-in. unregulated air fitting and air reducer.

Apply pipe sealant to new 3/8-in. air fitting and then install.

Tighten securely.

Connect the new unregulated air fitting into the new

unregulated air intake coupler.

16 – English

Page 17

MAINTENANCE

Normal maintenance, replacement or repair of emission control devices and systems may be performed by any qualified

repair establishment or individual with original or equivalent

parts. Warranty and recall repairs must be performed by an

authorized service center; please contact customer service

for assistance.

WARNING:

When servicing use only recommended or

equivalent replacement parts. Use of any other

parts may create a hazard or cause product

damage.

WARNING:

Always wear eye protection with side shields

marked to comply with ANSI Z87.1. Failure to do

so could result in objects being thrown into your

eyes resulting in possible serious injury.

WARNING:

Before inspecting, cleaning or servicing the

machine, shut off engine, wait for all moving parts

to stop, and disconnect spark plug wire and move

it away from spark plug. Failure to follow these

instructions can result in serious personal injury

or property damage.

NOTICE:

Before each use, inspect the entire product for

damaged, missing, or loose parts such as screws,

nuts, bolts, caps, etc. Tighten securely all fasteners

and caps and do not operate this product until all

missing or damaged parts are replaced. Please

contact customer service or a qualified service

center for assistance.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use. Use

clean cloths to remove dirt, dust, oil, grease, etc.

As a routine part of air compressor maintenance, it is also

advised that the oil is routinely checked for proper levels.

WARNING:

Do not at any time let brake fluids, gasoline,

petroleum-based products, penetrating oils, etc.,

come in contact with plastic parts. Chemicals can

damage, weaken or destroy plastIc which may

result in serious personal injury.

CLEANING EXHAUST PORT AND MUFFLER

NOTICE:

This product is not equipped with a spark arrestor

and cannot be used on U.S. forest lands; in

addition, product users must comply with Federal,

State, and local fire prevention regulations.

Check with appropriate authorities. Refer to

accompanying engine manual for maintenance

and replacement parts.

Depending on the type of fuel used, the type and amount of

oil used, and/or your operating conditions, the exhaust port

and/or muffler may become blocked with carbon deposits.

If you notice a power loss with your gas powered tool, you

may need to remove these deposits to restore performance.

We highly recommend that only qualified service technicians

perform this service.

CLEANING THE AIR FILTERS

See Figure 25 - 26, page 27.

The air compressor has air filters to protect both its engine

and pump. Dirty air filters will cause starting difficulty, loss

of performance, and shorten the life span of the compressor.

Check the air filters monthly. For best performance, replace

both air filters at least once a year.

Cleaning the engine air filter:

Turn off the air compressor.

Lift the latch on the air filter cover to open, then remove

the air filter cover.

Lift the edge of the air filter carefully and pull it out.

Wash the air filter with warm, soapy water.

Rinse and squeeze to dry.

Put small amount of motor oil (SAE 30, or SAE 10W30) on

the filter sponge. Squeeze out the excess oil then reinstall

the air filter.

NOTE: Make sure the filter is seated properly inside the

housing. Installing the filter incorrectly will allow dirt to

enter the engine, causing rapid engine wear.

Reinstall the air filter cover.

Cleaning the pump air filter:

Turn off the air compressor.

With one hand, secure the pump air filter cover. With the

other hand, remove the 6 mm soc. hex hd. bolts securing

the cover.

Remove the cover.

Remove the air filter from the housing.

Wash the air filter with warm, soapy water.

Rinse and squeeze to dry.

Reinstall the air filter.

Place the air filter cover back on the unit. Reinstall hex

bolts and tighten to secure.

17 – English

Page 18

MAINTENANCE

CHANGING THE ENGINE OIL

See Figure 27, page 27.

Replace the engine oil after the first 100 hours of operation

and every 100 hours following the first oil change.

Turn off the air compressor.

Place a suitable container underneath the drain hole to

collect used oil.

Remove the drain line cap with an adjustable wrench.

Allow lubricant to drain completely.

NOTE: Drain the lubricant while the engine is still warm

but not hot. Warm lubricant will drain quickly and more

completely.

WARNING:

Do not change engine lubricant while it is hot.

Accidental contact with hot engine lubricant could

result in serious burns.

Reinstall the cap and tighten with the wrench.

Remove the engine oil cap/dipstick.

Refill with lubricant following the instructions in the

Adding/Checking Engine Oil section. For amount of oil

needed to refill, see Product Specifications earlier in this

manual or the accompanying engine manual, if applicable.

Reinsert the oil cap/dipstick securely into the oil fill hole.

NOTE: Consult hazardous waste management guidelines in

your area for the proper way to dispose of used oil.

CHANGING THE PUMP OIL

See Figure 28, page 28.

Turn off the air compressor.

Place a suitable container underneath the drain plug to

collect used pump oil.

Loosen the pump oil cap/dipstick. Remove the drain plug

and washer and drain the old pump oil.

NOTE: Drain the oil while the pump is still warm but not

hot. Warm oil will drain quickly and more completely.

Replace the drain plug and washer. Tighten securely.

Refill with pump oil following the instructions in the

Adding/Checking Pump Oil section.

Replace pump oil cap/dipstick and tighten securely.

NOTE: Consult hazardous waste management guidelines in

your area for the proper way to dispose of used oil.

SPARK PLUG MAINTENANCE

See Figures 29 - 30, page 28.

The spark plug must be properly gapped and free of deposits

to ensure proper engine operation. To check:

Turn off the air compressor.

Remove the spark plug cap.

Clean any dirt from around base of spark plug.

Remove spark plug using the spark plug wrench provided.

Inspect spark plug for damage, and clean with a wire

brush before reinstalling. If insulator is cracked or chipped,

spark plug should be replaced. For replacement spark

plug, see Product Specifications earlier in this manual

or the accompanying engine manual, if applicable.

Measure plug gap. The correct gap is 0.023−0.027 in.

(0.6 mm - 0.7 mm). To widen gap, if necessary, carefully

bend the ground (top) electrode. To lessen gap, gently

tap ground electrode on a hard surface.

Seat spark plug in position; thread in by hand to prevent

cross-threading.

Tighten with an adjustable wrench to compress washer.

If spark plug is new, use 1/2 turn to compress washer

appropriate amount. If reusing old spark plug, use 1/8 to

1/4 turn for proper washer compression.

NOTE: An improperly tightened spark plug will become

very hot and could damage the engine.

BELT REPLACEMENT

See Figures 31 - 35, pages 28 - 29.

The air compressor is powered by a belt-driven motor.

Periodically check the belt for wear and replace it when

necessary. Proceed as follows when replacement is required:

Turn off the air compressor and disconnect the spark plug

wire. Allow the engine to cool.

Remove the removable tank following instructions in

Removable Tank Alone — Regulated Carry Tank For

Small Jobs and set aside.

Using an adjustable wrench, remove the following bolts,

washers, nuts, and spacer securing the belt guard:

• one M10 flange hex hd. bolt, lock washer, flat washer,

and spacer from the top of pump

• two M6 soc. hex hd. bolts, lock washers, and square

washers from the ends of the belt guard

• four M6 flange hex hd. bolts, lock washers, flat

washers, and nuts on the sides of the belt guard

Carefully lift the belt guard off the air compressor and set

aside.

Loosen the four engine bolts and nuts securing the engine

in place.

Turn the belt tensioner bolt counterclockwise to move

the engine toward the pump until there is enough slack

in the belt for it to be removed from around the pulleys.

Place the new belt around the small pulley (narrow side

down), then install the belt over the large pulley.

Turn the belt by hand until you are certain it is properly

aligned on the grooves of the pulleys.

Turn the belt tensioner bolt clockwise to move the engine

away from the pump until there is tension in the belt.

18 – English

Page 19

MAINTENANCE

Check belt alignment by placing a straight edge across

the front of the large and small pulley as shown in figures

32 and 33. The straight edge should touch the rim of the

large pulley at two places. When viewed from above, the

belt should be parallel with the straight edge.

NOTE: If the belt is misaligned, move the engine toward

or away from the air tanks.

Check belt tension by squeezing the belt. Using light

pressure, the belt should deflect approximately 1/2 in.

NOTE: If belt tension is not correct, move the engine

toward or away from the pump.

Once belt tension and belt alignment are correct, retighten

engine bolts and nuts.

Reinstall the belt guard and secure with nuts, washers

and bolts.

Replace the removable tank.

STORING THE AIR COMPRESSOR

Store the air compressor with the gas tank empty by running

the air compressor until the gas runs out. Allow 30 minutes

of “cool down” time before storing the machine. Store in a

dry, covered area where the weather can’t damage it.

Air Compressor Tanks:

Release all air from the air tanks.

Drain all moisture from the air tanks, then close drain

valves.

Discharge Fuel:

Drain the fuel tank completely by running the air compressor

until the gas runs out. Stored gas can go stale in 30 days.

Engine Oil:

Drain the oil and replace with fresh, clean oil.

Spark Plug:

Disconnect spark plug wire and remove the spark plug.

Pour about a teaspoon of clean, air-cooled, four-cycle oil

through the spark plug hole into the combustion chamber.

Leaving the spark plug out, pull the starter cord two or

three times to coat the inside of the cylinder wall.

Inspect the spark plug and clean or replace, as necessary.

Reinstall the spark plug, but leave the spark plug wire

disconnected.

Air Filter:

Clean the air filter.

PREPARING FOR USE AFTER STORAGE

Pull the recoil starter three or four times to clean oil from

the combustion chamber.

Remove spark plug from the cylinder. Wipe oil from the

spark plug and return it to the cylinder.

Reconnect the spark plug wire.

Refuel the machine as described earlier in the operator’s

manual.

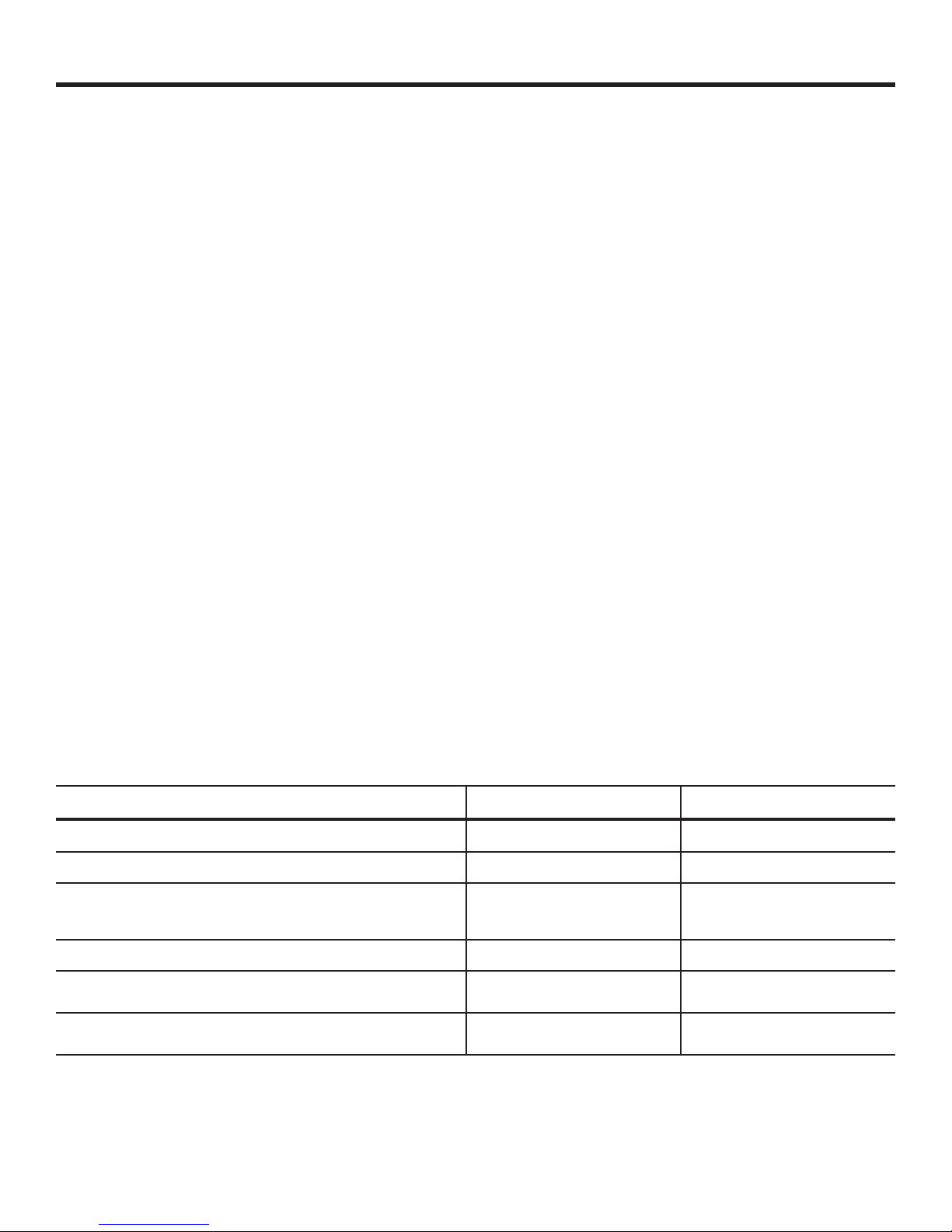

PERIODIC MAINTENANCE SCHEDULE TABLE

NOTE: If a separate engine manual is provided for this air compressor, please follow the maintenance schedule provided

in the engine manual instead of the maintenance information listed below.

Maintenance Items Each use 100 hours

Check pump oil level X

Check engine oil level X

Check for oil leaks - inspect oil seals, drain plug, oil plug,

sight glass

Change pump oil X

Change engine oil X

Check/clean engine and pump air filters X

X

19 – English

Page 20

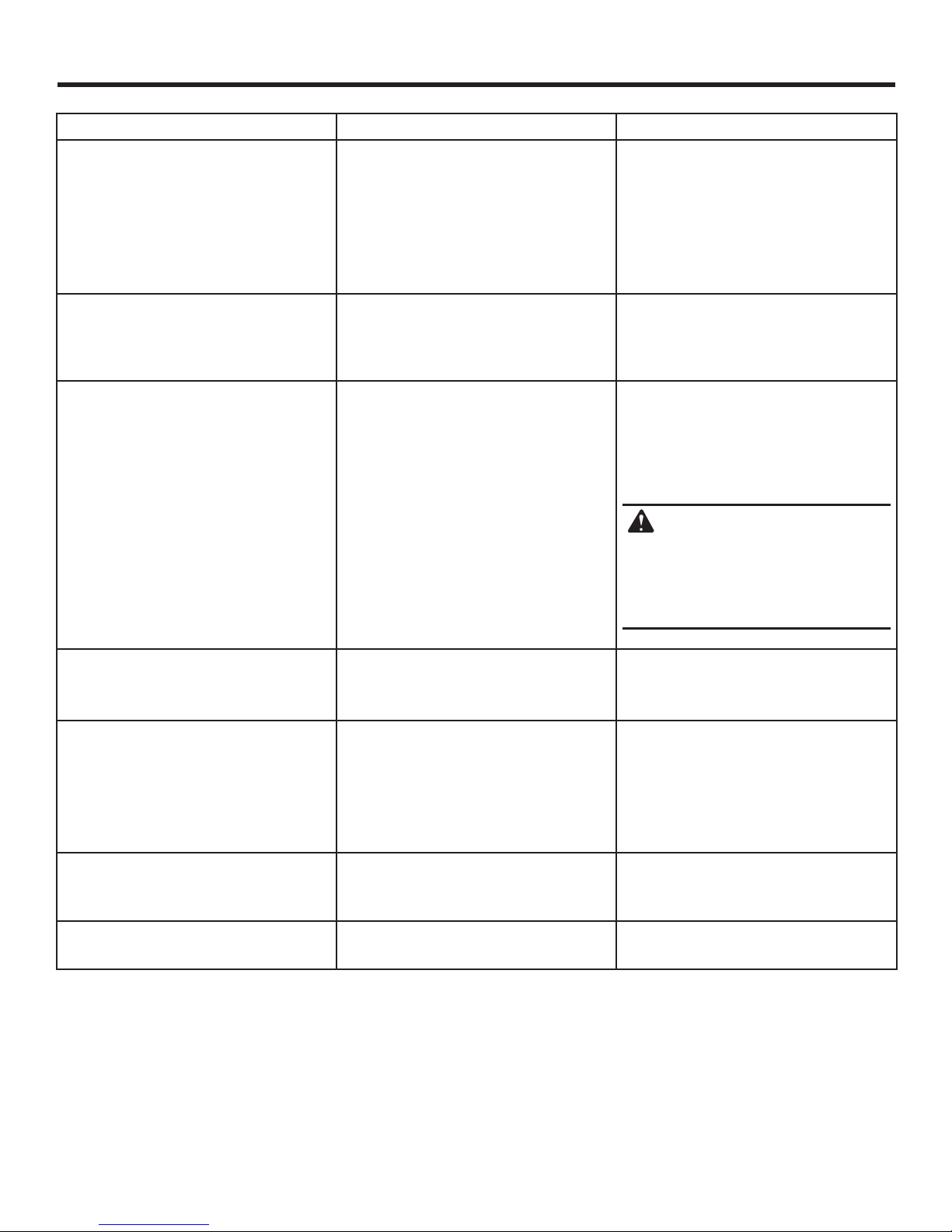

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

Engine will not start. On/stop switch is in off position.

No fuel.

Fuel valve is closed.

Spark plug faulty, fouled, or

improperly gapped.

Choke lever is in RUN position.

Turn the on/stop switch to ON.

Fill fuel tank.

Open fuel valve.

Replace spark plug.

Move choke lever to START position.

Engine lacks power. Fuel element clogged.

Defective pressure unloader.

Air tank pressure drops when compressor shuts off.

Excessive moisture in discharge air. Excessive water in air tanks.

Compressor runs continuously. Defective pressure unloader.

Air output lower than normal. Broken inlet valves.

Compressor cycles on and off

continuously.

Loose connections (fittings, tubing, etc.).

Loose drain valve.

Pressure unloader leaking.

High humidity.

Excessive air usage.

Piston rings are worn.

Connections leaking.

Pressure unloader clogged. Take compressor to a qualified service

Check air filter element. Clean or replace

as needed.

Take compressor to a qualified service

center.

Check all connections with soap and

water solution and tighten.

Tighten drain valve.

Take compressor to a qualified service

center.

DANGER:

Do not disassemble pressure

unloader, tank drain valves or safety

relief valve with air in tank — bleed

tanks.

Drain tanks.

Move to area of less humidity; use air

line filter.

Take compressor to a qualified service

center.

Decrease air usage; compressor not

large enough for tool’s requirement.

Replace piston rings; Call customer

service for assistance.

Take compressor to a qualified service

center.

Tighten connections.

center.

20 – English

Page 21

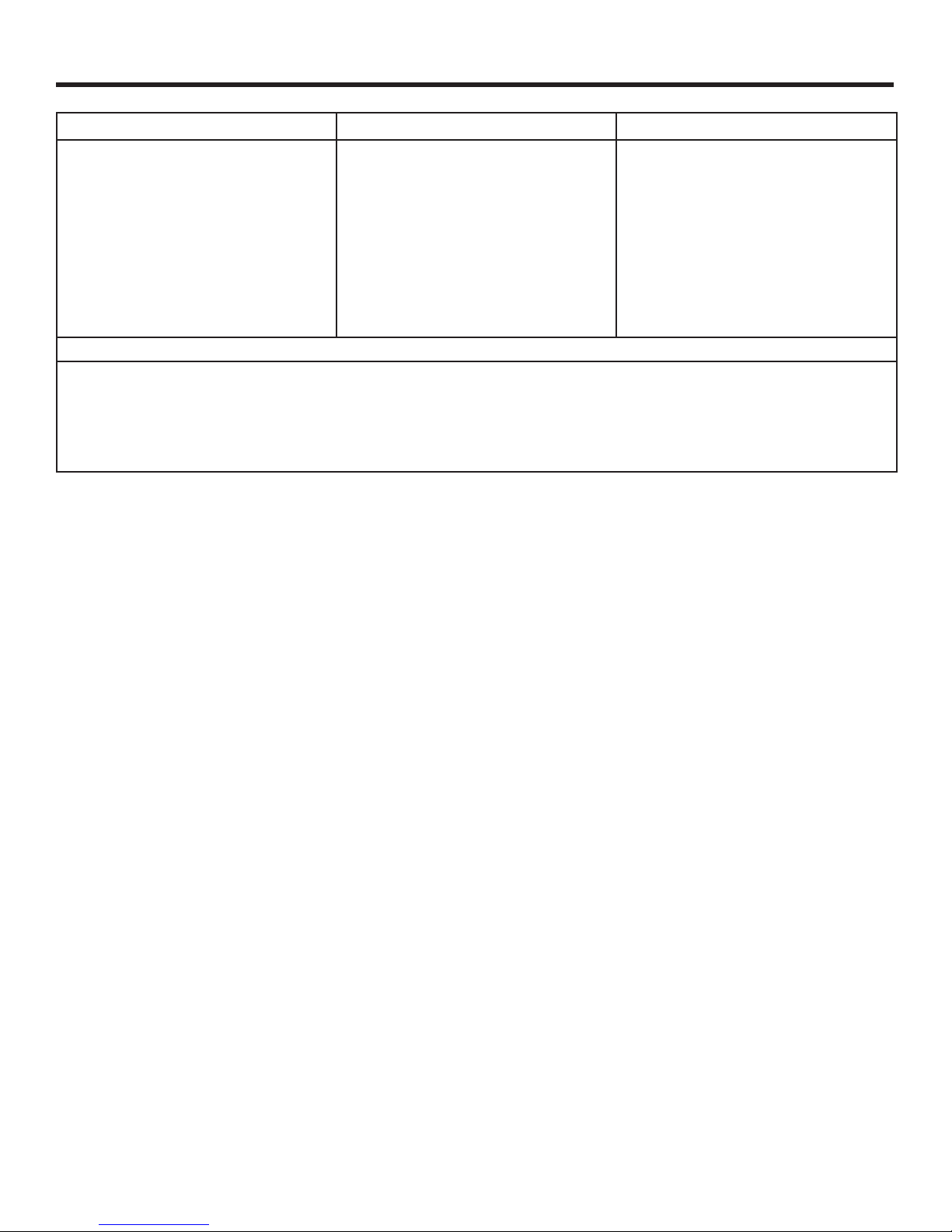

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE SOLUTION

Excessive pump oil use. Pump oil cap vent clogged.

Incorrect pump oil.

Pump air filter clogged/dirty.

Too much pump oil in crankcase.

Piston rings worn.

Cylinder scored.

If problem persists after trying the above solutions, contact customer service or a qualified service center for assistance.

NOTICE:

As the equipment owner, you are responsible for the performance of the required maintenance listed in the Maintenance

section. It is recommended that you retain all receipts covering maintenance on your equipment. Neglecting or failing

to perform the required maintenance may increase emissions, decrease fuel efficiency, degrade performance, cause

irreversible engine damage, and/or void your warranty.

NOTE: ILLUSTRATIONS START ON PAGE 23 AFTER

Remove clog from pump oil cap or

replace cap, if necessary.

Use only SAE 5W40 synthetic pump oil.

Clean/replace pump air filter.

Drain pump oil to the proper level.

Take compressor to a qualified service

center.

Take compressor to a qualified service

center.

FRENCH AND SPANISH LANGUAGE SECTIONS.

This product has a 90-Day Satisfaction Guarantee Policy, as well

as a Three-year Limited Warranty. For Warranty and Policy details,

please go to www.RIDGID.com or call (toll free) 1-866-539-1710.

21 – English

Page 22

WARRANTY

LIMITED 3 YEAR ENGINE WARRANTY

Limited Manufacturer’s Warranty from Subaru Robin

(Effective with engines purchased from Robin America, Wood Dale, IL, after April 1, 2008)

Robin America, Inc., a division of Fuji Heavy Industries, Ltd. (herein “Subaru Robin”), warrants that each new engine sold by it

will be free, under normal use and service, from defects in material and workmanship for a period listed below from the date

of sale to the original retail purchaser. Subaru Robin’s obligation under this Limited Warranty shall be limited to the repair and

replacement, at Subaru Robin’s option, of any part or parts which upon examination is/are found, in Subaru Robin’s judgment,

to have been defective in material or workmanship. It shall be a condition of Subaru Robin’s obligation under this Limited

Warranty that Subaru Robin, directly or through one of its Distributors or Service Centers authorized to service the particular

engine involved, receive prompt notice of any warranty claim and that the engine or the part or parts claimed to be defective

be promptly delivered, transportation prepaid, to such Distributor or Service Center for inspection and repair. All repairs qualifying under this Limited Warranty must be performed by Subaru Robin or one of its authorized Distributors or Service Centers.

WARRANTY PERIODS:

Subaru Robin Four-Cycle, Air-cooled, Gasoline Engines - Limited 3 YEAR Warranty (EX / EH and SP Series 4.3hp or

greater)

The repair or replacement of any part or parts under this Limited Warranty shall not extend the term of the engine warranty

beyond the original term as set forth above.

LIMITATIONS AND EXCLUSIONS: This Limited Warranty shall not apply to:

Bent or broken crankshaft or resultant damage caused by vibration related to a bent or broken crankshaft. Also, damage

caused by loose engine mounting bolts or improper or imbalanced accessories or blades mounted to the crankshaft.

Repairs required because of prolonged storage including damage caused by old or contaminated fuel in the fuel tank, fuel

lines or carburetor, sticky valves or corrosion and rust of engine parts.