Ricoh JP1030 Service Manual

®

®

RICOH GROUP COMPANIES

C231

SERVICE MANUAL

PN: RCSMC231

®

®

®

SERVICE MANUAL

C231

RICOH GROUP COMPANIES

C231

SERVICE MANUAL

PN:RCSMC231

n

t

s

r

h

g

o

l

y

WARNING

The Service Manual contains informatio

regarding service techniques, procedures,

processes and spare parts of office equipmen

distributed by Ricoh Corporation. Users of thi

manual should be either service trained o

certified by successfully completing a Rico

Technical Training Program.

Untrained and uncertified users utilizin

information contained in this service manual t

repair or modify Ricoh equipment risk persona

injury, damage to property. or loss of warrant

protection.

Ricoh Corporation

LEGEND

PRODUCT CODE COMPANY

RICOH SAVIN GESTETNER

C231 JP1030 3150DNP 5306L

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

* 7/98 Original Printing

C231

TABLE OF CONTENTS

OVERALL INFORMATION...............................................................1-1

1.1 SPECIFICATION...................................................................................... 1-1

1.2 GUIDE TO COMPONENTS AND THEIR FUNCTION.............................. 1-5

1.2.1 MACHINE EXTERIOR..................................................................... 1-5

1.2.2 MACHINE INTERIOR...................................................................... 1-6

1.2.3 OPERATION PANEL....................................................................... 1-7

Keys..................................................................................................... 1-7

Indicators ............................................................................................. 1-9

1.3 PRINTING PROCESS............................................................................ 1-10

1.4 MECHANICAL COMPONENT LAYOUT................................................. 1-11

1.5 ELECTRICAL COMPONENT LAYOUT.................................................. 1-12

1.5.1 ADF................................................................................................ 1-12

1.5.2 MAIN BODY................................................................................... 1-13

Boards................................................................................................ 1-14

Motors................................................................................................ 1-14

Solenoids........................................................................................... 1-15

Switches............................................................................................. 1-15

Sensors.............................................................................................. 1-15

Counters ............................................................................................ 1-16

Others................................................................................................ 1-16

1.6 DRIVE LAYOUT ..................................................................................... 1-17

DETAILED SECTION DESCRIPTIONS............................................2-1

2.1 SCANNER AND OPTICS ......................................................................... 2-1

2.1.1 BOOK SCANNER OVERVIEW........................................................ 2-1

2.1.2 ADF OVERVIEW ............................................................................. 2-2

2.1.3 CONTACT IMAGE SENSOR........................................................... 2-4

2.1.4 DRIVE MECHANISM....................................................................... 2-5

Book Scanner....................................................................................... 2-5

ADF...................................................................................................... 2-6

2.1.5 PICK-UP AND FEED (ADF)............................................................. 2-7

2.1.6 SEPARATION MECHANISM (ADF) ................................................ 2-8

2.1.7 ERROR CONDITIONS .................................................................... 2-9

Book Scanner....................................................................................... 2-9

ADF...................................................................................................... 2-9

2.2 IMAGE-PROCESSING........................................................................... 2-10

2.2.1 OVERVIEW ................................................................................... 2-10

2.2.2 A/D CONVERSION PROCESSING............................................... 2-11

Shading Distortion Correction............................................................ 2-11

Original Background Correction......................................................... 2-12

Peak Hold .......................................................................................... 2-12

SM C231

i

2.2.3 BINARY PROCESSING................................................................. 2-13

Data Compensation Processing......................................................... 2-13

MTF Correction.................................................................................. 2-14

Binary Processing in Letter/Photo Mode............................................ 2-14

Error Diffusion.................................................................................... 2-15

2.2.4 MAIN SCAN MAGNIFICATION...................................................... 2-16

2.2.5 IMAGE POSITION ADJUSTMENT IN THE MAIN

SCAN DIRECTION........................................................................ 2-17

2.2.6 PASTE SHADOW ERASE MODE................................................. 2-17

2.2.7 THERMAL HEAD........................................................................... 2-18

Specifications..................................................................................... 2-18

Thermal Head Control........................................................................ 2-18

Thermal Head Protection................................................................... 2-18

Remarks for Handling the Thermal Head........................................... 2-19

2.3 MASTER EJECT .................................................................................... 2-20

2.3.1 OVERALL...................................................................................... 2-20

2.3.2 MASTER CLAMPER OPEN MECHANISM.................................... 2-21

Drum Position Lock Mechanism......................................................... 2-21

2.3.3 MASTER EJECT ROLLER MECHANISM ..................................... 2-22

2.3.4 PRESSURE PLATE MECHANISM................................................ 2-23

2.4 MASTER FEED...................................................................................... 2-24

2.4.1 OVERALL...................................................................................... 2-24

2.4.2 MASTER FEED MECHANISM....................................................... 2-25

2.4.3 MASTER CLAMPER OPERATION AND TENSION ROLLER

RELEASE MECHANISM............................................................... 2-26

2.4.4 CUTTER MECHANISM ................................................................. 2-27

2.5 DRUM..................................................................................................... 2-28

2.5.1 OVERALL...................................................................................... 2-28

2.5.2 DRUM DRIVE MECHANISM ......................................................... 2-29

2.5.3 INK SUPPLY MECHANISM........................................................... 2-30

2.5.4 INK ROLLER MECHANISM........................................................... 2-31

2.5.5 INK SUPPLY CONTROL............................................................... 2-32

2.5.6 DETECTION OF MASTERS ON THE DRUM................................ 2-33

2.6 PAPER FEED......................................................................................... 2-34

2.6.1 OVERALL...................................................................................... 2-34

2.6.2 PAPER FEED MECHANISM......................................................... 2-35

2.6.3 PAPER FEED/SEPARATION PRESSURE ADJUSTMENT

MECHANISM................................................................................. 2-36

2.6.4 REGISTRATION ROLLER MECHANISM...................................... 2-37

Registration Roller Drive.................................................................... 2-37

Registration Roller Up/Down Mechanism........................................... 2-38

2.6.5 PRINTING PRESSURE MECHANISM.......................................... 2-39

2.6.6 PAPER TABLE MECHANISM........................................................ 2-40

Table Up and Down Mechanism........................................................ 2-40

Paper End Detection Mechanism....................................................... 2-40

Paper Table Side Fence Mechanism................................................. 2-41

Paper Table Side-to-Side Shift Mechanism ....................................... 2-41

Side Fence Friction Pads................................................................... 2-42

C231 SM

ii

2.7 PAPER DELIVERY................................................................................. 2-43

2.7.1 OVERALL...................................................................................... 2-43

2.7.2 PAPER DELIVERY UNIT DRIVE MECHANISM............................ 2-44

2.7.3 PAPER SEPARATION FROM DRUM ........................................... 2-45

2.7.4 EXIT PAWL DRIVE MECHANISM................................................. 2-46

2.8 ERROR DETECTION............................................................................. 2-47

2.8.1 ORIGINAL JAM DETECTION........................................................ 2-47

2.8.2 MASTER EJECT JAM DETECTION.............................................. 2-47

2.8.3 MASTER FEED JAM DETECTION................................................ 2-48

2.8.4 PAPER FEED JAM DETECTION.................................................. 2-49

INSTALLATION................................................................................3-1

3.1 INSTALLATION REQUIREMENTS .......................................................... 3-1

3.1.1 OPTIMUM ENVIRONMENTAL CONDITION................................... 3-1

3.1.2 ENVIRONMENTS TO AVOID.......................................................... 3-1

3.1.3 POWER CONNECTION.................................................................. 3-1

3.1.4 ACCESS TO MACHINE................................................................... 3-2

3.2 INSTALLATION PROCEDURE ................................................................ 3-3

3.2.1 MAIN BODY..................................................................................... 3-3

Accessory Check ................................................................................. 3-3

Installation Procedure .......................................................................... 3-4

3.2.2 AUTO DOCUMENT FEEDER (OPTION)......................................... 3-9

Accessory Check ................................................................................. 3-9

Installation Procedure ........................................................................ 3-10

3.2.3 TAPE MARKER (OPTION)............................................................ 3-14

Accessory Check ............................................................................... 3-14

Installation Procedure - For C231 -.................................................... 3-15

3.2.4 COLOR DRUM (OPTION)............................................................. 3-17

3.2.5 INTERFACE BOARD (OPTION).................................................... 3-18

Accessory Check ............................................................................... 3-18

Installation Procedure ........................................................................ 3-18

SERVICE TABLES...........................................................................4-1

4.1 SERVICE REMARKS............................................................................... 4-1

4.1.1 MASTER FEED SECTION............................................................... 4-1

1. Thermal Head Installation................................................................ 4-1

2. Thermal Head Voltage Adjustment .................................................. 4-1

4.1.2 PAPER FEED SECTION................................................................. 4-1

1. Friction Pad...................................................................................... 4-1

2. Paper Feed Roller and Paper Separation Roller.............................. 4-1

3. Paper Guide Plate Position for Registration Roller........................... 4-1

4.1.3 DRUM AND DRUM DRIVE SECTION............................................. 4-2

1. Main Motor....................................................................................... 4-2

2. Doctor Roller.................................................................................... 4-2

3. Drum Master Clamper...................................................................... 4-2

SM C231

iii

4. Ink Roller Unit................................................................................... 4-2

5. Ink Pump.......................................................................................... 4-2

4.1.4 PAPER DELIVERY SECTION......................................................... 4-3

1. Exit Pawl.......................................................................................... 4-3

4.1.5 ELECTRICAL COMPONENTS........................................................ 4-3

1. Main Processing Unit (MPU) 1......................................................... 4-3

2. Main Processing Unit (MPU) 2......................................................... 4-3

3. Power Supply Unit............................................................................ 4-3

4. Sensor Adjustments......................................................................... 4-3

4.2 DIP SW, LED, VR, TP, AND FUSE TABLES............................................ 4-4

4.2.1 TEST POINTS................................................................................. 4-4

MPU..................................................................................................... 4-4

4.2.2 POTENTIOMETERS........................................................................ 4-4

MPU..................................................................................................... 4-4

Power Supply Unit................................................................................ 4-4

4.2.3 LED'S............................................................................................... 4-4

4.2.4 FUSES............................................................................................. 4-5

MPU..................................................................................................... 4-5

PSU...................................................................................................... 4-5

4.3 SERVICE CALL CODES.......................................................................... 4-6

4.4 SERVICE PROGRAM MODE................................................................... 4-8

4.4.1 ACCESS PROCEDURE.................................................................. 4-8

Service Program Mode Access Procedure (For Engineers)................. 4-8

Service Program Mode Access Procedure (For Users)....................... 4-9

Change Adjustment Values or Modes................................................ 4-10

4.4.2 SERVICE PROGRAM TABLE....................................................... 4-11

Remarks............................................................................................. 4-20

4.4.3 INPUT/OUTPUT CHECK MODE................................................... 4-23

Input/Output Check Mode Access Procedure.................................... 4-23

Input Check Table.............................................................................. 4-24

Output Check Table........................................................................... 4-26

4.5 TEST PATTERN IMAGE MODE............................................................. 4-28

4.6 USER CODE MODE............................................................................... 4-29

PREVENTIVE MAINTENANCE........................................................ 5-1

5.1 MAINTENANCE TABLE ........................................................................... 5-1

REPLACEMENT AND ADJUSTMENT............................................. 6-1

6.1 EXTERIOR COVER REMOVAL............................................................... 6-1

6.1.1 ADF.................................................................................................. 6-1

6.1.2 OPERATION PANEL....................................................................... 6-2

6.1.3 PLATEN COVER AND UPPER COVERS....................................... 6-3

6.1.4 TOP COVER AND EXPOSURE GLASS......................................... 6-3

6.1.5 OTHER COVERS............................................................................ 6-4

C231 SM

iv

6.2 COPY IMAGE ADJUSTMENT.................................................................. 6-6

6.2.1 LEADING EDGE REGISTRATION ADJUSTMENT......................... 6-6

6.2.2 SIDE-TO-SIDE REGISTRAION ADJUSTMENT.............................. 6-7

6.2.3 VERTICAL MAGNIFICATION ADJUSTMENT................................. 6-8

6.2.4 LEADING EDGE BLANK MARGIN ADJUSTMENT......................... 6-9

6.3 MPU REPLACEMENT............................................................................ 6-10

6.4 ORIGINAL FEED SECTION................................................................... 6-11

6.4.1 ADF ROLLER ASSSEMBLY.......................................................... 6-11

6.4.2 PICK-UP ROLLER......................................................................... 6-11

6.4.3 FEED ROLLER.............................................................................. 6-12

6.4.4 SEPARATION ROLLER ................................................................ 6-12

6.4.5 ADF MOTOR AND COVERS......................................................... 6-13

6.4.6 R0 AND R1 ROLLERS .................................................................. 6-13

6.4.7 R2 ROLLER................................................................................... 6-14

6.4.8 DOCUMENT SENSOR.................................................................. 6-15

6.4.9 SCAN LINE SENSOR.................................................................... 6-15

6.4.10 COVER SENSORS...................................................................... 6-16

6.5 MASTER FEED SECTION..................................................................... 6-17

6.5.1 MASTER MAKING UNIT REMOVAL............................................. 6-17

6.5.2 THERMAL HEAD REMOVAL........................................................ 6-19

Remarks for thermal head installation................................................ 6-20

6.5.3 THERMAL HEAD VOLTAGE ADJUSTMENT................................ 6-21

6.5.4 MASTER END SENSOR ADJUSTMENT...................................... 6-23

6.6 MASTER EJECT SECTION.................................................................... 6-24

6.6.1 MASTER EJECT UNIT REMOVAL................................................ 6-24

6.7 PAPER FEED SECTION........................................................................ 6-25

6.7.1 PAPER FEED ROLLER, PICK-UP ROLLER,

AND FRICTION PAD.................................................................... 6-25

6.7.2 PAPER SEPARATION PRESSURE ADJUSTMENT..................... 6-26

6.7.3 PAPER FEED PRESSURE ADJUSTMENT .................................. 6-27

6.7.4 REGISTRATION ROLLER CLEARANCE ADJUSTMENT............. 6-28

6.8 PRINTING SECTION.............................................................................. 6-29

6.8.1 PRESS ROLLER REMOVAL......................................................... 6-29

6.8.2 PRESS ROLLER LOCK LEVER ADJUSTMENT........................... 6-30

6.8.3 PRINTING PRESSURE ADJUSTMENT........................................ 6-32

6.9 DRUM AND DRIVE SECTION................................................................ 6-33

6.9.1 DRUM CLOTH SCREEN REMOVAL............................................. 6-33

Remarks for the cloth screen installation ........................................... 6-34

6.9.2 DRUM MASTER CLAMPER AND METAL SCREEN REMOVAL.. 6-36

Remarks for drum screen installation................................................. 6-38

6.9.3 INK ROLLER UNIT REMOVAL...................................................... 6-39

6.9.4 DOCTOR ROLLER GAP ADJUSTMENT ...................................... 6-41

6.9.5 INK DETECTION ADJUSTMENT.................................................. 6-43

6.9.6 INK PUMP REMOVAL AND PLUNGER

POSITION ADJUSTMENT............................................................. 6-44

6.9.7 MAIN DRIVE TIMING BELT TENSION ADJUSTMENT................. 6-46

6.9.8 MAIN MOTOR PULLEY POSITION ADJUSTMENT...................... 6-48

SM C231

v

6.10 PAPER DELIVERY SECTION.............................................................. 6-49

6.10.1 VACUUM UNIT REMOVAL.......................................................... 6-49

6.10.2 DELIVERY BELT/PAPER EXIT SENSOR REMOVAL................. 6-50

6.10.3 VACUUM MOTOR REMOVAL..................................................... 6-51

6.10.4 EXIT PAWL CLEARANCE ADJUSTMENT.................................. 6-52

6.10.5 EXIT PAWL DRIVE TIMING ADJUSTMENT ............................... 6-53

TAPE MARKER C532

SPECIFICATIONS............................................................................7-1

BASIC OPERATION ........................................................................ 7-2

2.1 OVERVIEW .............................................................................................. 7-2

2.2 DRIVE AND CUTTING MECHANISM....................................................... 7-3

2.3 MANUAL CUT .......................................................................................... 7-4

REPLACEMENT AND ADJUSTMENT............................................. 7-5

3.1 CUTTER REPLACEMENT ....................................................................... 7-5

3.2 CUTTER HOME POSITION SENSOR REPLACEMENT.......................... 7-6

3.3 TAPE CUT LENGTH ADJUSTMENT ....................................................... 7-7

PRIPORT CONTROLLER USER’S GUIDE......................................8-1

POINT TO POINT DIAGRAM

C231 SM

vi

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the printer and peripherals, make

sure that the power cord is unplugged.

2. The wall outlet should be near the printer and easily accessible.

3. If any adjustment or operation check has to be made with exterior covers off or

open while the main switch is turned on, keep hands away from electrified or

mechanically driven components.

HEALTH SAFETY CONDITIONS

1. If you get ink in your eyes by accident, try to remove it with eye drops or flush

with water as first aid. If unsuccessful, get medical attention.

2. If you ingest ink by accident, induce vomiting by sticking a finger down your

throat or by giving soapy or strong salty water to drink.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The printer and its peripherals must be installed and maintained by a customer

service representative who has completed the training course on those models.

CAUTION

The RAM has a lithium battery which can explode if handled incorrectly.

Replace only with the same type of RAM. Do not recharge or burn this

battery. Used RAM's must be handled in accordance with local regulations.

ATTENTION

La carte RAM comporte une pile au lithium qui présente un risque

d'explosion en cas de mauvaise manipulation. Remplacer la pile

uniquement par une carte RAM identique. Ne pas recharger ni brûler cette

pile. Les cartes RAM usagées doivent être éliminées conformément aux

réglementations locales.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Dispose of replaced parts in accordance with local regulations.

2. Used ink and masters should be disposed of in an environmentally safe

manner and in accordance with local regulations.

3. When keeping used lithium batteries (from the main processing units) in ord er

to dispose of them later, do not store more than 100 batteries (from the main

processing units) per sealed box. Storing larger numbers or not sealing them

apart may lead to chemical reactions and heat build-up.

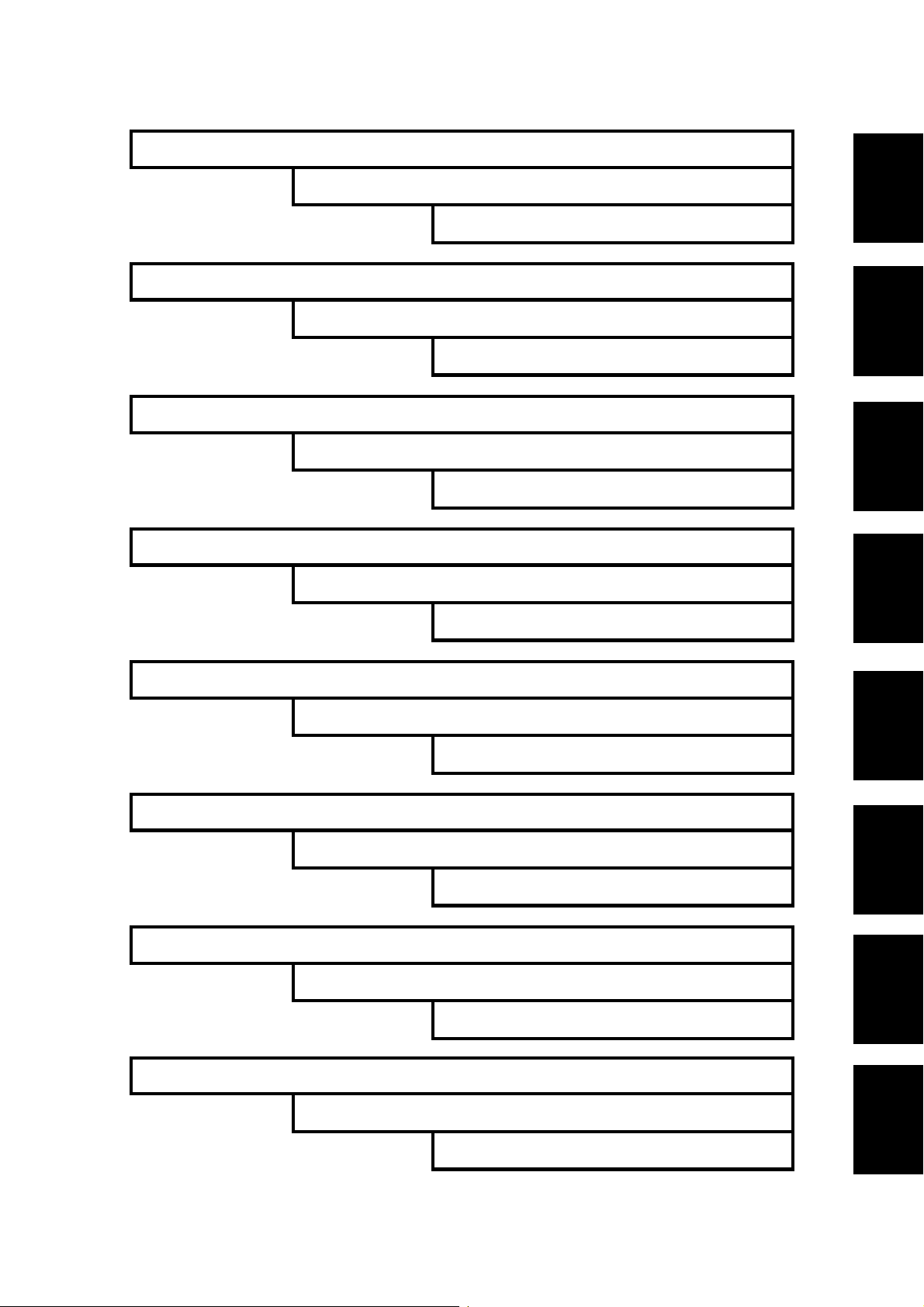

OVERALL INFORMATION

DETAILED SECTION DESCRIPTIONS

INSTALLATION

SERVICE TABLES

TAB

POSITION 1

TAB

POSITION 2

TAB

POSITION 3

PREVENTIVE MAINTENANCE

REPLACEMENT AND ADJUSTMENT

TAPE MARKER C532

TAB

POSITION 4

TAB

POSITION 5

TAB

POSITION 6

TAB

POSITION 7

PRIPORT CONTROLLER USER’S GUIDE

TAB

POSITION 8

OVERALL

INFORMATION

1. OVERALL INFORMATION

SPECIFICATION

1.1 SPECIFICATION

Configuration: Desktop

Master Processing: Digital with 300 dpi thermal head

Scanning (Pixel Density): Contact image sensor (300 dpi), with xenon lamp

* In Fine mode, 400 dpi in the sub-scanning

resolution

Printing Process: Fully automatic one-drum stencil system

Original Type: Sheet/Book

In Platen Mode: Document size:

Maximum 257 x 364 mm [10.2" x 14.4"]

Thickness: Less than 30 mm

Weight: Less than 5 kg

In ADF Mode: Document size:

Maximum 257 x 364 mm [10.2" x 14.4"]

Minimum 148 x 105 mm [5.8" x 4.1"]

Overall

Information

Document weight:

50 - 90 g/m2 [13.3 - 23.9 lb]

(40 - 120 g/m2 [10.6 - 31.9 lb]

in single sheet feed)

ADF capacity:

30 sheets (using 20 lb or 80 g/m2 paper)

Reproduction Ratios: Inch version Others

Full Size: 100% 100%

Reduction: 65% 71%

74% 82%

77% 87%

93% 93%

Enlargement: 121% 115%

129% 122%

155% 141%

Image Modes: Letter, Photo, Letter/Photo, Fine, Tint

SM C231

1-1

SPECIFICATION

M

Printing Area:

(At 20 °C/ 65 % RH)

B4 size drum models:

250 mm x 355 mm

Legal size drum models:

210 mm x 355 mm [8.2" x 13.9"]

A4 size drum models:

210 mm x 288 mm [8.2" x 11.3"]

Edge Margins: Leading edge:

5 ± 3 mm (At the "0" position of Image Shift mode)

Trailing edge:

2 mm

Print Paper Size: Minimum: 90 mm x 148 mm [3.6" x 5.9"]

Maximum: 267 mm x 390 mm [10.5" x 15.3"]

Print Paper Weight: 47.1 g/m2 to 157.0 g/m2 [12.5 lb to 41.7 lb]

Printing Speed: 80, 100, 120 sheets/minute (3 steps)

Master Process Time: Platen mode:

Less than 28 seconds (A4 paper)

ADF mode:

Less than 30 seconds (A4 paper)

Master Eject Box Capacity: 40 masters (Normal conditions)

(30 masters at low temperatures)

Side Registration Adjustable

±

10 mm

Range:

Vertical Registration Adjustable

±

10 mm

Range:

Paper Feed Table Capacity: 1000 sheets (80 g/m2 / 20 lb)

Paper Delivery Table Capacity: 1000 sheets (80 g/m2/ 20 lb)

Power Source: 110/120 V, 50/60 Hz: 2.5 A

220 - 240 V, 50/60 Hz: 1.5 A

Maximum Power Consumption: 250 W

Noise Emission:

(At operation position)

At 80 rpm printing speed: 71 dB

At 100 rpm printing speed:72 dB

At 120 rpm printing speed:72 dB

C231 S

1-2

Weight: 65 kg [143.3 lb]

68 kg [149.9 lb] with ADF

Dimensions:

(Width x Depth x Height)

Trays closed: 594 mm x 601 mm x 567 mm

With ADF:

594 mm x 601 mm x 617 mm

Trays open: 1187 mm x 601 mm x 567 mm

With ADF:

1187 mm x 601 mm x 617 mm

Master Type: Master for B4 drum

Thermal master roll type:

280 mm width, 125 m/roll

Yield:

260 masters/roll

Max run length per master:

2,000 prints

SPECIFICATION

Overall

Information

Master for A4/Legal drum

Thermal master roll type:

240 mm width, 125 m/roll

Yield:

300 masters/roll (A4 drum)

260 masters/roll (Legal drum)

Max run length per master:

2,000 prints

Master Storage Conditions: Temperature:

0 °C to 40 °C

Humidity:

10% to 95% RH

Recommended maximum storage period:

One year after production date

* Avoid locations exposed to direct sunlight.

SM C231

1-3

SPECIFICATION

M

Ink Type 600 ml cartridge type

Available colors:

Black, Red, Blue, Green, Brown

Ink Storage Conditions: Temperature:

-5 °C to 40 °C

(Optimum conditions: 15 °C to 25 °C)

Humidity:

10% to 95% RH

(Optimum conditions: 20% to 70% RH)

Recommended maximum storage period:

One year after production date

* Avoid locations exposed to direct sunlight.

•

Available Options

Color Drum

•

Document Feeder

•

Key Counter

•

Tape Marker

•

PC Controller

C231 S

1-4

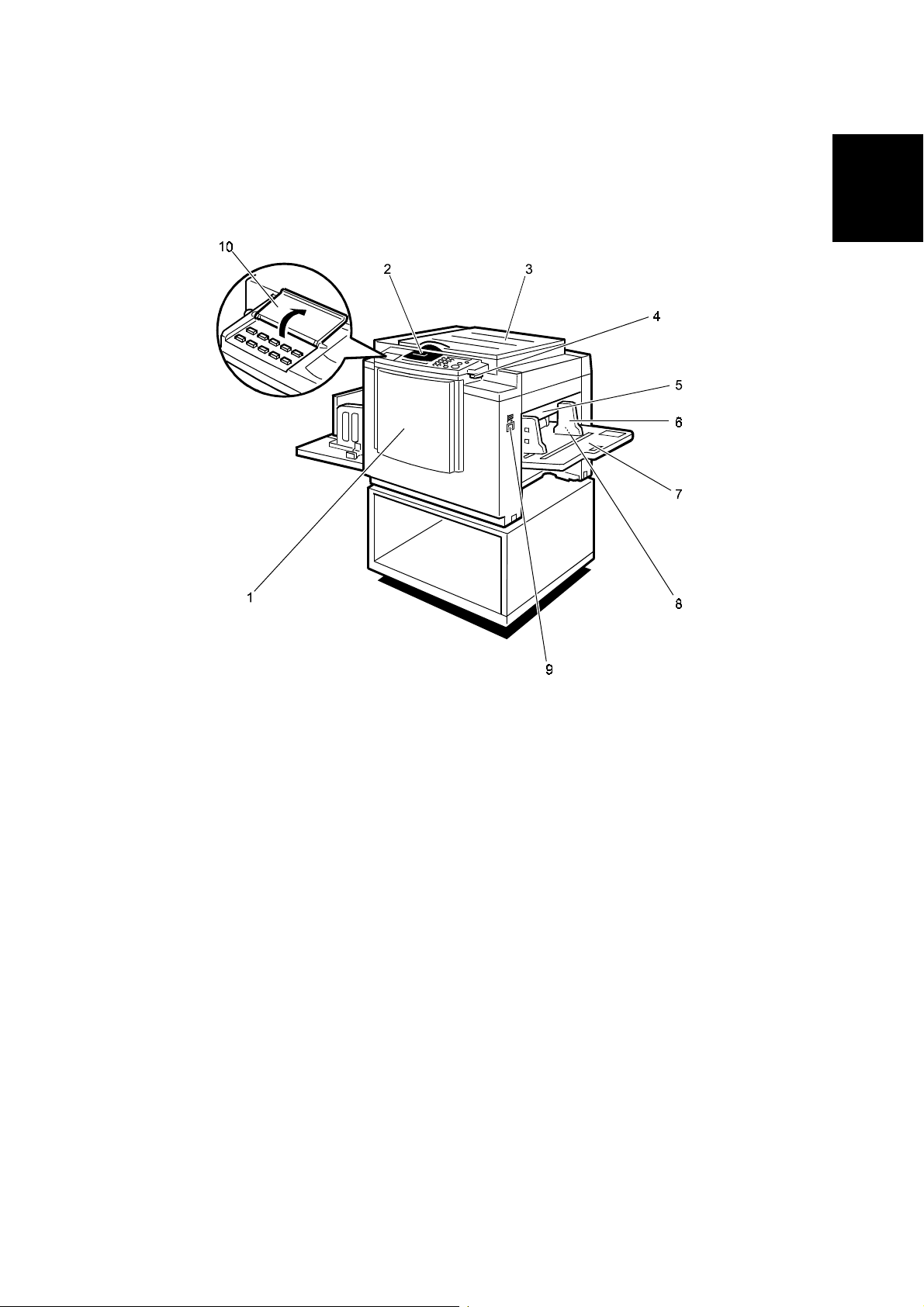

GUIDE TO COMPONENTS AND THEIR FUNCTION

1.2 GUIDE TO COMPONENTS AND THEIR FUNCTION

1.2.1 MACHINE EXTERIOR

Overall

Information

1. Front Door

2. Operation Panel

3. Platen Cover

4. Original Table Release

Lever

5. Feed Roller Pressure

Lever

6. Paper Feed Side Plates

7. Paper Feed Table

8. Side Table Fine Adjusting

Dial

9. Paper Feed Table Down

key

10. Behind Cover

C231V504.WMF

Open for access to the inside of t he machine.

Operator controls and indicators are locat ed her e.

Lower this cover over an original before printing.

Use to open the original table unit when installing the

master.

Use to adjust the contact pressure of the paper feed

roller according to paper thickness.

Use to prevent paper skew.

Set paper on this table for print ing.

Use to shift the paper feed table sideways.

Press to lower the paper feed table.

Flip up when you wish to use the keys underneath.

SM C231

1-5

GUIDE TO COMPONENTS AND THEIR FUNCTION

M

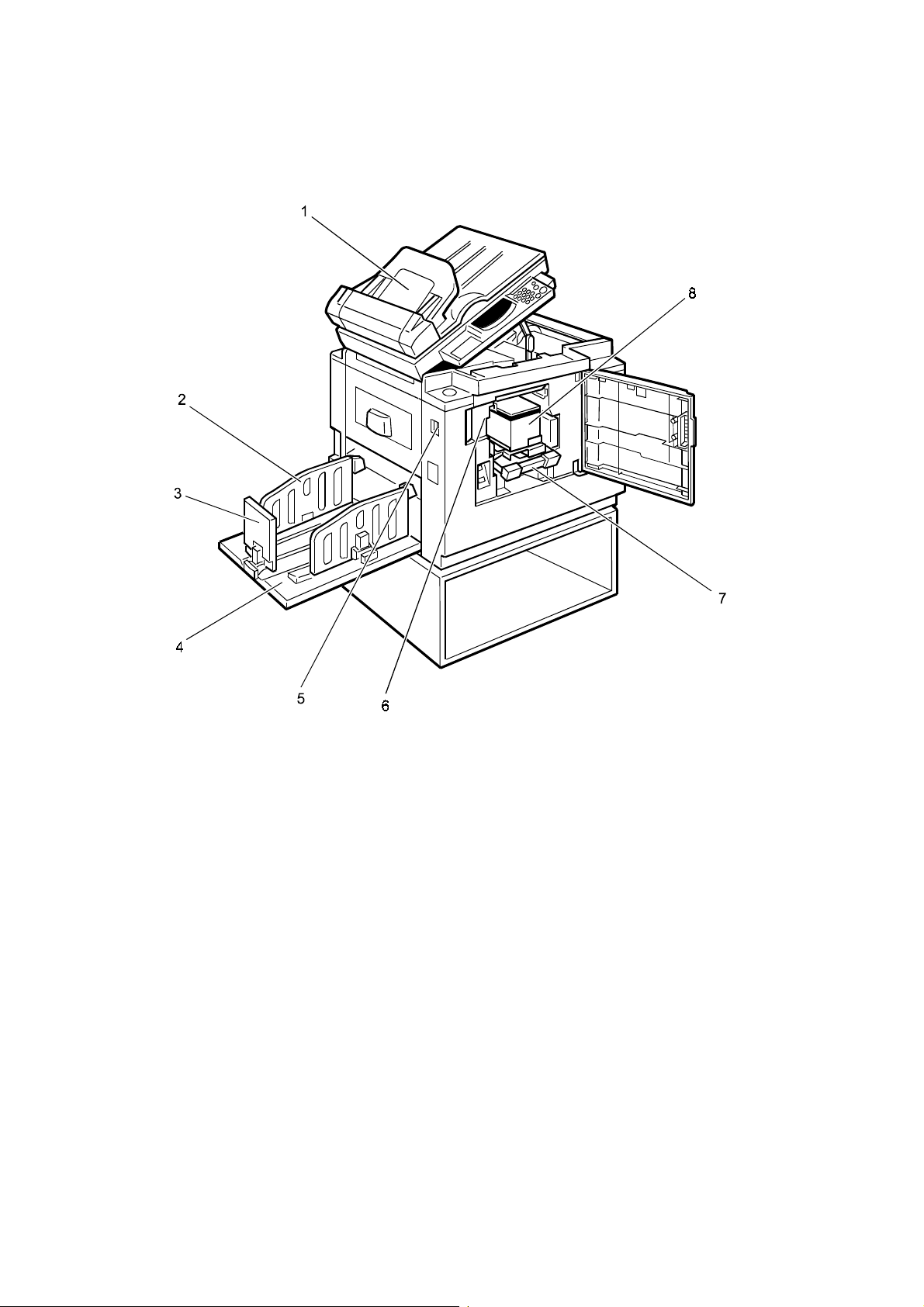

1.2.2 MACHINE INTERIOR

1. Document Feeder (Option)

2. Paper Delivery Side Plates

3. Paper Delivery End Plate

4. Paper Delivery Table

5. Main Switch

6. Drum Unit

7. Drum Unit Lock Lever

8. Ink Holder

C231V505.WMF

Originals inserted into the document feeder are

individually and automatically fed onto and

removed from the exposure glass.

Use to align the prints on the paper delivery table.

Use to align the leading edge of prints.

Completed prints are delivered here.

Use to turn the power on or off.

The master is wrapped around this unit.

Lift to unlock and pull out the dr um unit.

Set the ink cartridge in t his holder .

C231 S

1-6

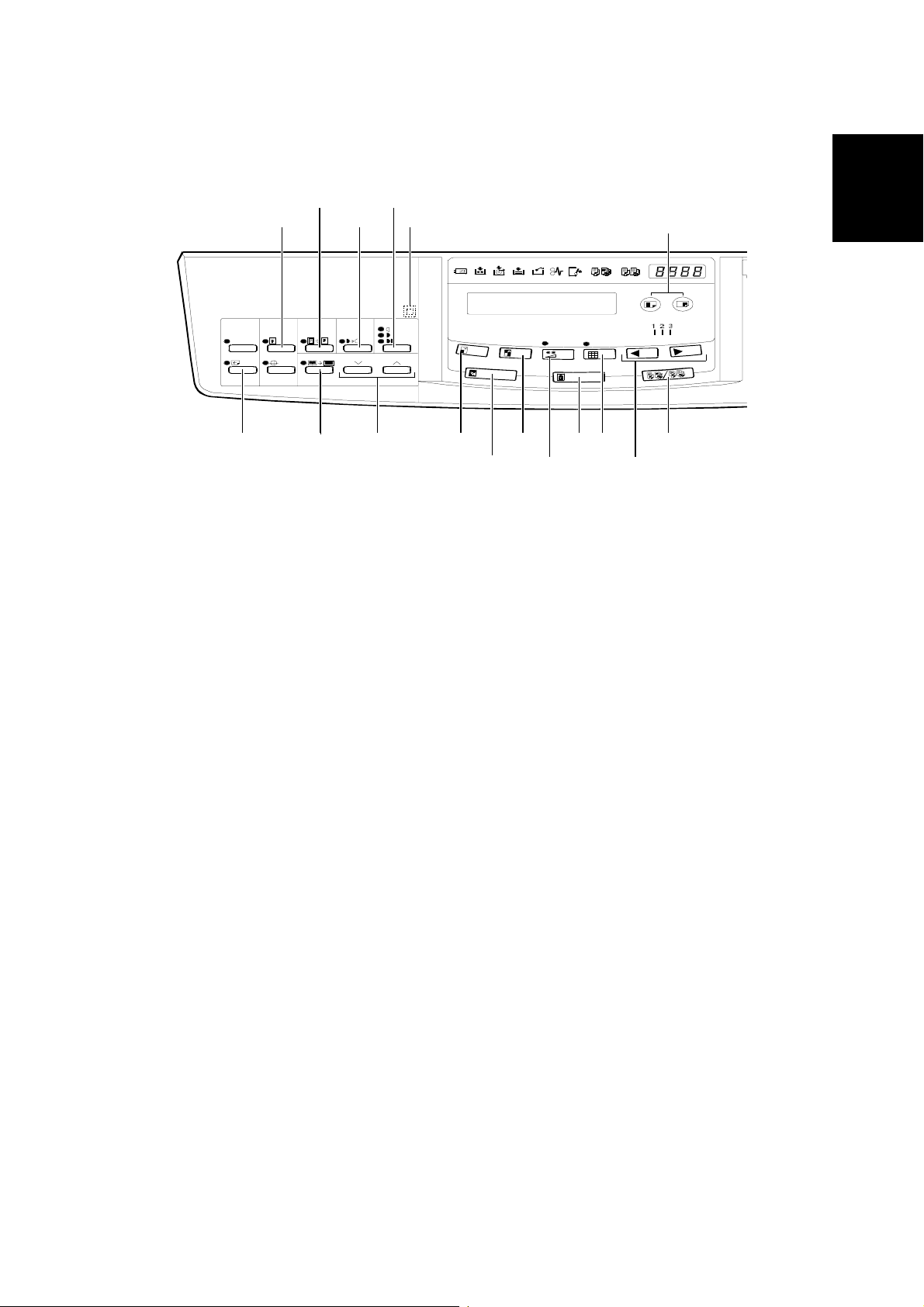

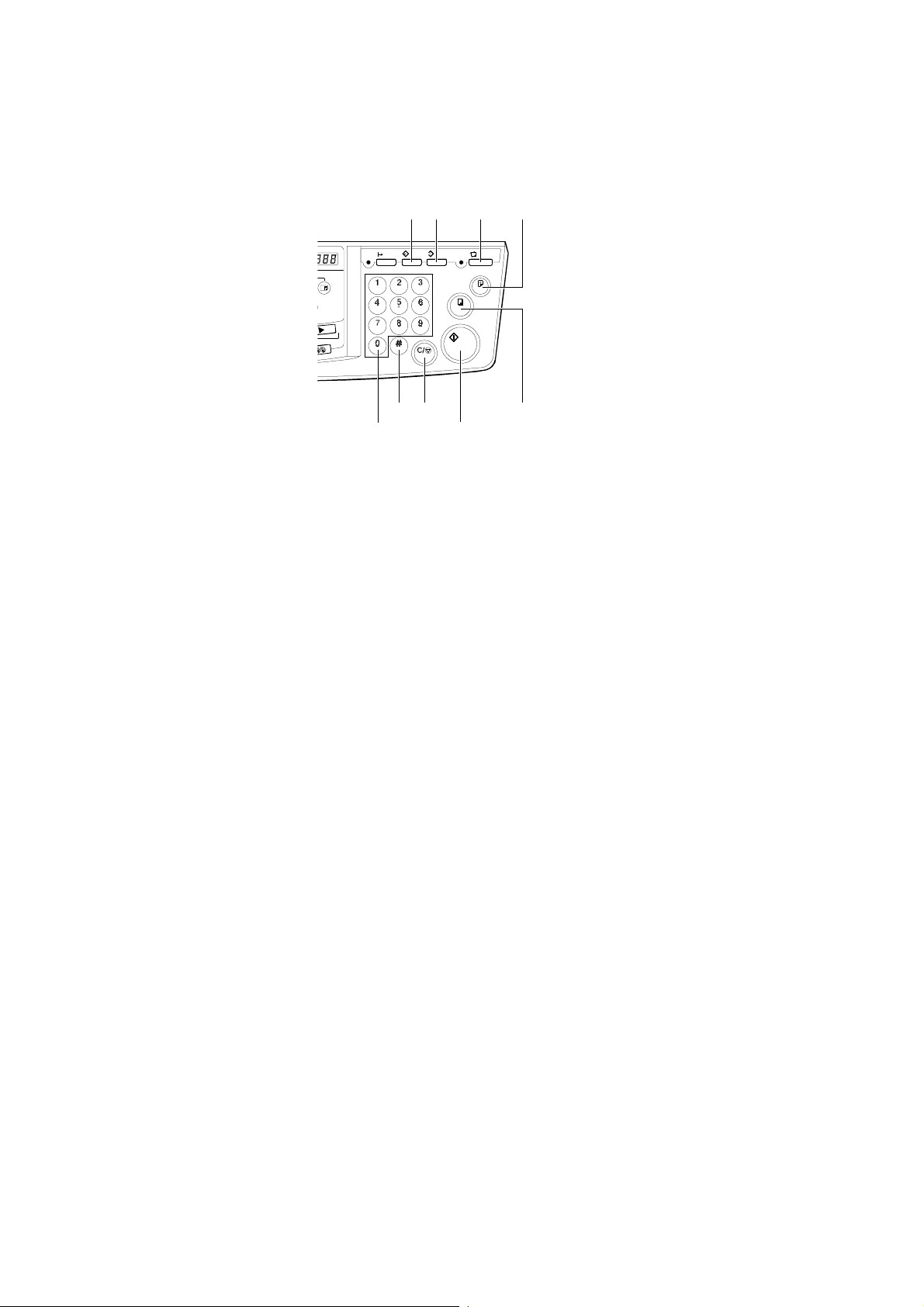

1.2.3 OPERATION PANEL

GUIDE TO COMPONENTS AND THEIR FUNCTION

Keys

6

C231V511.WMF

2

1

7

1. Security key

Press to make prints of

confidential documents.

2. Paste Shadow Erase key

Press to erase the shadows on

images of pasted originals.

3. Tint key

Press to make prints in grey.

(This is the Tint/Economy key for

the China version.)

4

3

5

8

9

10

11

12

13

14

15

21

20

Overall

Information

7. Center/Edge Erase key

Press to print book originals that

have a solid image on the center

or edges.

8. Scroll keys

Press to select size and direction

of paper or original for

Center/Edge Erase.

9. Reduce key

Press to reduce the image.

4. Image Density key

Press to make prints darker or

lighter.

5. Check Indicator

This indicator lights when you

have selected one or more of the

functions accessed by lifting the

behind cover and pressing the

keys underneath (e. g. Security

key, Paste Shadow Erase key

etc.). This lets you know whether

one or more of these functions is

selected, even if the cover is

lowered.

6. Skip Feed key

Press to select skip feed printing.

10. Full Size key

Press to make full size prints.

11. Enlarge key

Press to enlarge the image.

12. Economy key

Press to save ink. (This is the

Combine 2 Originals key for the

China version.)

13. Type of Original key

Press to select Letter, Photo, or

Letter/Photo mode.

14. Fine key

Press to select fine image mode.

15. Image Position key

Press to shift the image forwards

or backwards.

SM C231

1-7

GUIDE TO COMPONENTS AND THEIR FUNCTION

M

16

17

18

19

16. Program key

Press to input or recall user

programs.

17. Clear Modes key

Press to clear the previously

entered job settings.

18. Auto Cycle key

Use to process the master and

make prints automatically.

19. Proof key

Press to make proof prints.

20. Speed keys

Press to adjust the printing

speed.

21. Memory/Class key

Press to select Memory or Class

mode.

21

23

24

26

25

C231V511.WMF

22. Number keys

Press to enter the desired

number of prints and data for

selected modes.

23. # key

Use to enter data in selected

modes.

24. Clear/Stop key

While entering numbers, press to

cancel a number you have

entered. While copying, press to

stop copying.

25. Start key

Press to make a master.

26. Print key

Press to start printing.

C231 S

1-8

Indicators

GUIDE TO COMPONENTS AND THEIR FUNCTION

1. Error indicators

These indicators are lit when a

non-standard condition occurs

within the machine.

2. Memory/Class Indicator

Shows the number entered in

Memory or Class mode.

1

5

2

3

4

C231V512.WMF

Overall

Information

4. Counter

Displays the number of prints

entered. While printing, it shows

the number of prints remaining.

5. Guidance Display

Display the machine's condition.

3. Speed indicator

These indicators show the

printing speed that is selected.

SM C231

1-9

Loading...

Loading...