Page 1

N.T. 3323A

JA0C

Features of the Scénic JA0C fitted

with F4R engine

For all parts not dealt with in this Technical Note, refer to Workshop Repair Manual MR 312

77 11 294 602

"The repair methods given by the manufacturer in this document are based on the

technical specifications current when it was prepared.

The methods may be modified as a result of changes introduced by the manufacturer

in the production of the various component units and accessories from which his

vehicles are constructed."

MARCH 2000

© RENAULT 2000

EDITION ANGLAISE

All copyrights reserved by Renault.

Copying or translating, in part or in full, of this document or use of the service part

reference numbering system is forbidden without the prior written authority of Renault.

Page 2

Contents

LIFTING

02

Underbody lifts 02-1

07

VALUES AND SETTINGS

Capacities - Grades 07-1

Accessories belt tension 07-3

Procedure for tensioning the timing belt 07-4

Tightening the cylinder head 07-26

Tyres and wheels 07-27

Brakes 07-28

Underbody height 07-29

Front axle angle checking values 07-30

Rear axle angle checking values 07-31

ENGINE AND PERIPHERALS

10

Identification 10-1

Oil pressure 10-2

Engine - gearbox assembly 10-3

Sump 10-10

TOP AND FRONT OF ENGINE

11

Timing belt 11-1

Cylinder head gasket 11-9

Page

ANTIPOLLUTION

14

Fuel vapour rebreathing 14-1

16

STARTING - CHARGING

Alternator 16-1

Starter motor 16-3

INJECTION

17

Technical specifications 17-1

Immobiliser function 17-2

Injection/Air conditioning diagram 17-3

Idle speed correction 17-4

Richness regulation 17-5

Adaptive richness correction 17-7

Camshaft dephaser 17-8

Central coolant management GCTE 17-9

Computer 17-10

Features of the "On Board Diagnostic"

system 17-11

Illumination conditions of the "On Board

Diagnostic" light 17-12

Fault finding conditions 17-13

Combustion misfire fault finding 17-14

Catalytic converter fault finding 17-15

Oxygen sensor fault finding 17-16

Page

FUEL MIXTURE

12

Technical specifications 12-1

Air filter unit 12-4

Inlet manifold 12-5

Injector holder shims 12-6

Exhaust manifold 12-8

COOLING SYSTEM

19

Filling - bleeding 19-1

Diagram 19-2

Radiator 19-3

Water pump 19-4

Suspended engine mounting 19-5

Fuel tank 19-6

Catalytic converter 19-9

Page 3

Contents

CLUTCH

20

Mechanism - Plate 20-1

21

MANUAL GEARBOX

Identification 21-1

Ratios 21-1

Capacity - Lubricants 21-2

Gearbox (Removal - Refitting) 21-3

Differential cover seal 21-10

th

5

gear housing seal 21-12

FINAL DRIVE

26

General - Identification 26-1

Final drive (Removal - Refitting) 26-2

Viscous coupling 26-5

Tapered torque seal 26-6

Input shaft seal 26-8

Transverse driveshaft seal 26-10

Final drive differential cover seal 26-13

TRANSMISSION

29

Page

FRONT AXLE

31

Sub-frame 31-1

33

REAR AXLE

Stabiliser bar 33-1

Shock absorber 33-2

Spring 33-3

Rear suspension arm 33-5

Wheel bearing 33-8

Sub-frame 33-10

STEERING

36

Power assisted steering rack 36-1

Retractable shaft 36-5

MECHANICAL ELEMENT CONTROLS

37

Exploded view 37-1

Clutch transmitter cylinder 37-2

Clutch receiver cylinder 37-4

Clutch control pipes 37-6

Page

Transverse driveshaft 29-1

Longitudinal driveshaft 29-4

ELECTRONICALLY CONTROLLED

38

HYDRAULIC SYSTEM

BOSCH ABS 38-1

Page 4

102

LIFTING

LIFTING

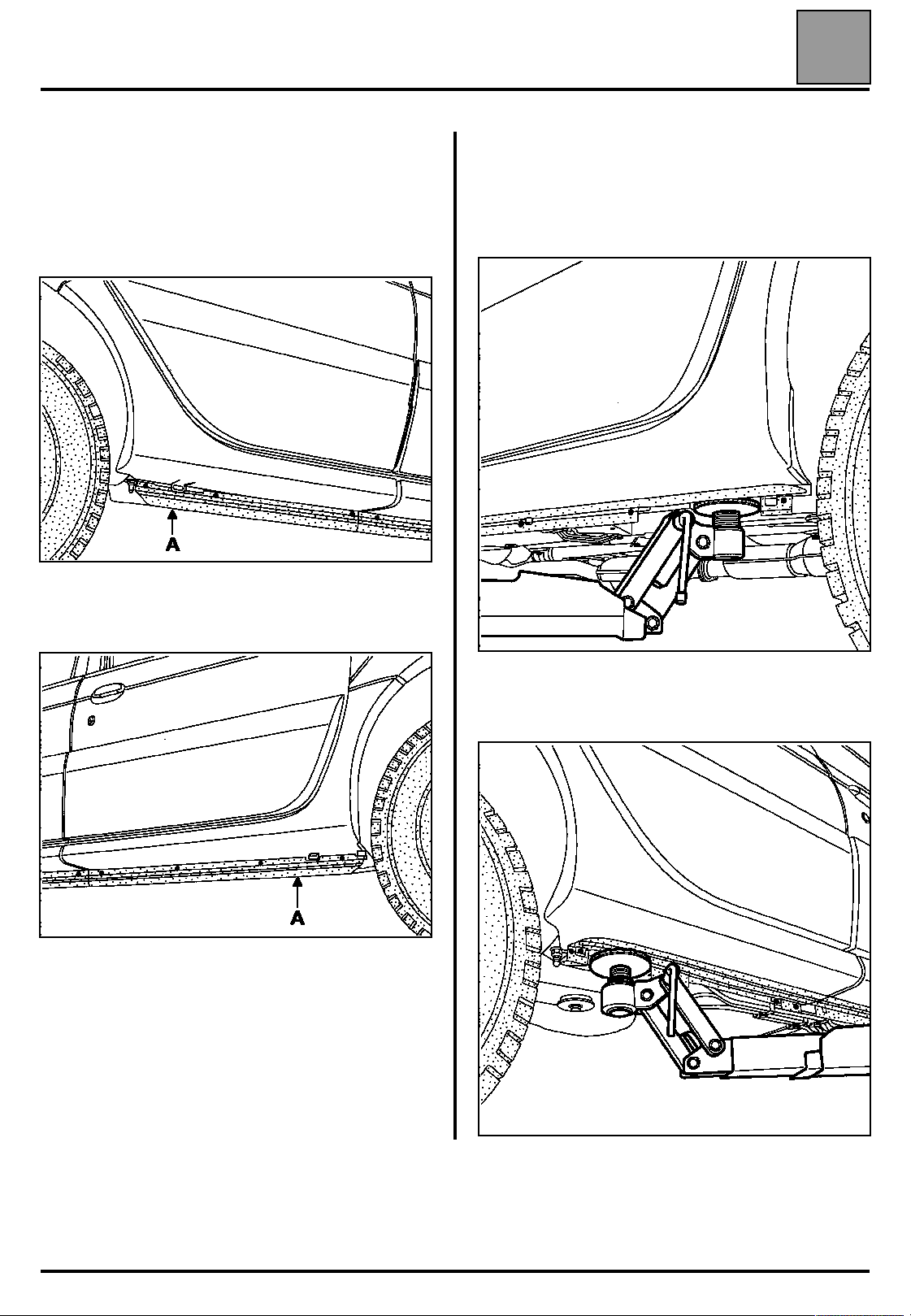

Underbody lifts

Underbody lifts

In order to position the lifting pads under the body

flange, the edges of the valance protector (A) have to

be removed by unclipping them.

Rear protector

02

POSITION OF THE LIFTING PADS

Front

Front protector

18111R

18109S

Rear

18112R

02-1

18110S

Page 5

VALUES AND SETTINGS

VALUES AND SETTINGS

107

Components

Petrol engine

(oil)

Capacity in

litres

(approx.)*

For oil

changes

Capacities - Grades

Capacities - Grades

Grade

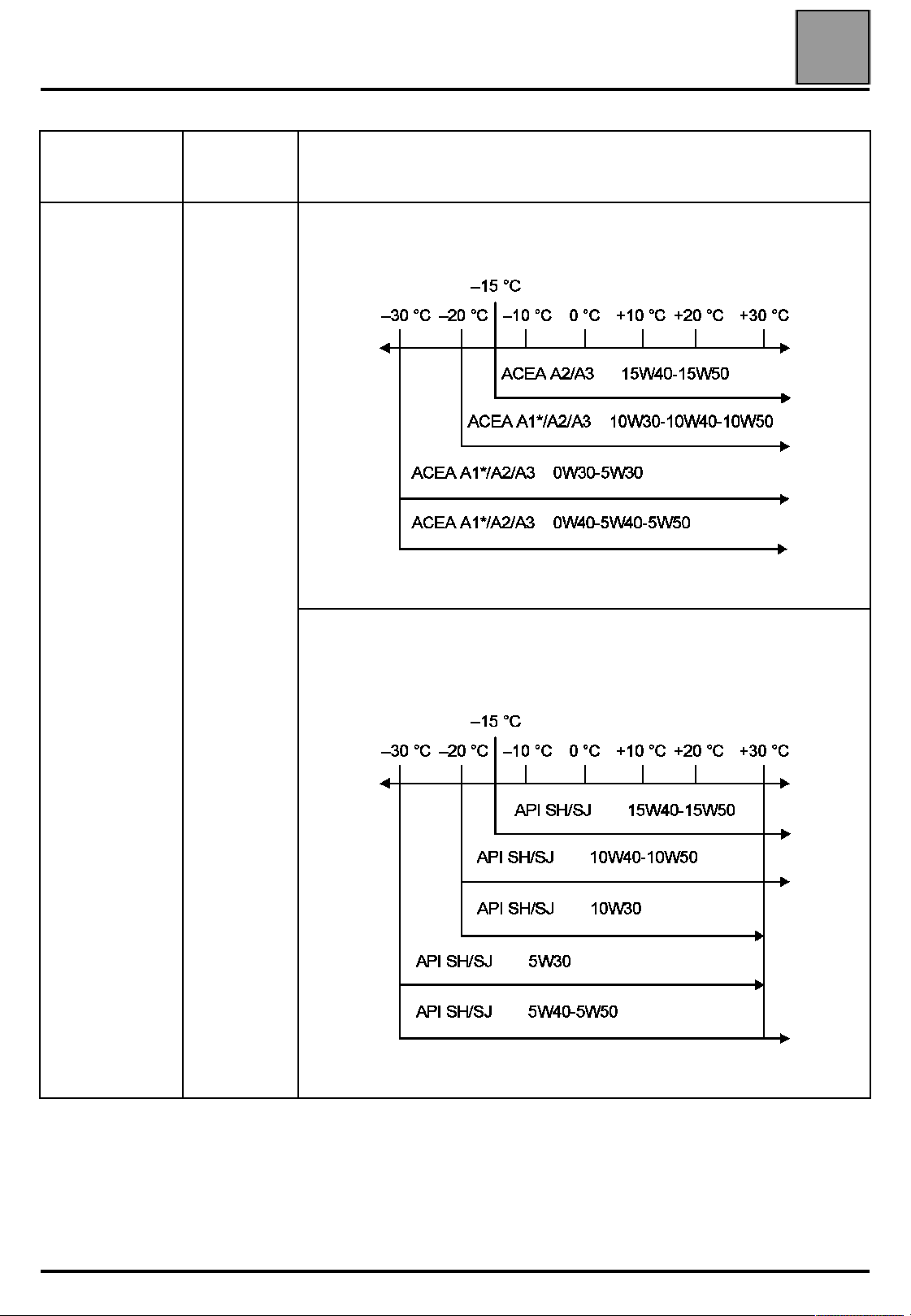

Countries in the European Union and Turkey

PETROL

07

F4R

4.4

4.55 (1)

Standard ACEA A1-98

* Oil for fuel economy

Other countries

When the lubricants specified for the countries of the European Union are not

available, the following specifications should be used:

PETROL

* Adjust using a dipstick

(1) After replacing the oil filter

Oil for fuel economy:

Standard API SJ-IL SAC GF2

07-1

Page 6

VALUES AND SETTINGS

Components

Gearbox JC7 3.3

Final drive SD1 0.8

Cooling circuit

F4R

Capacity in

litres

7.9

Capacities - Grades

Grade Special notes

All countries: TRANSELF TRX 75 W 80 W

(Standards API GL5 or MIL-L 2105 G or D)

TRANSELF 80 W 90

(to be ordered from ELF)

Glacéol RX

(type D)

Protection to - 20 ˚C ± 2 ˚C for warm, moderate

and cold climates.

Protection to - 37˚C ± 2˚C for very cold climates.

07

07-2

Page 7

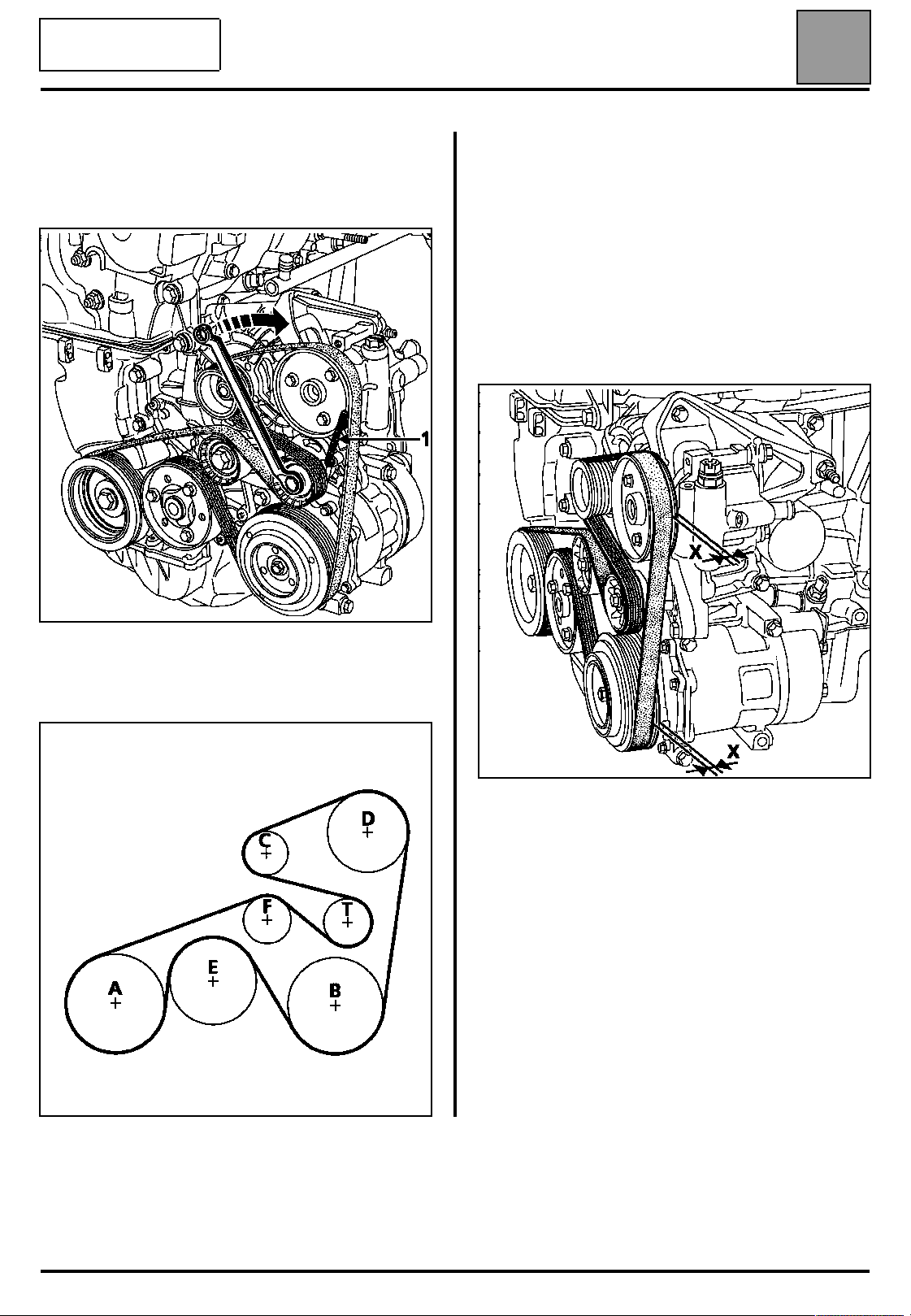

WITH

AIRCONDITIONING

VALUES AND SETTINGS

Accessories belt tension

Accessories belt tension

07

To remove the belt, pivot the automatic belt tensioner

in the direction shown below using a 13 mm angled

ring spanner. Tighten the tensioning roller using a

6 mm Allen key (1).

A Crankshaft

B Air conditioning compressor

C Alternator

D Assisted steering pump

E Water pump

F Fixed roller

T Automatic tensioning roller

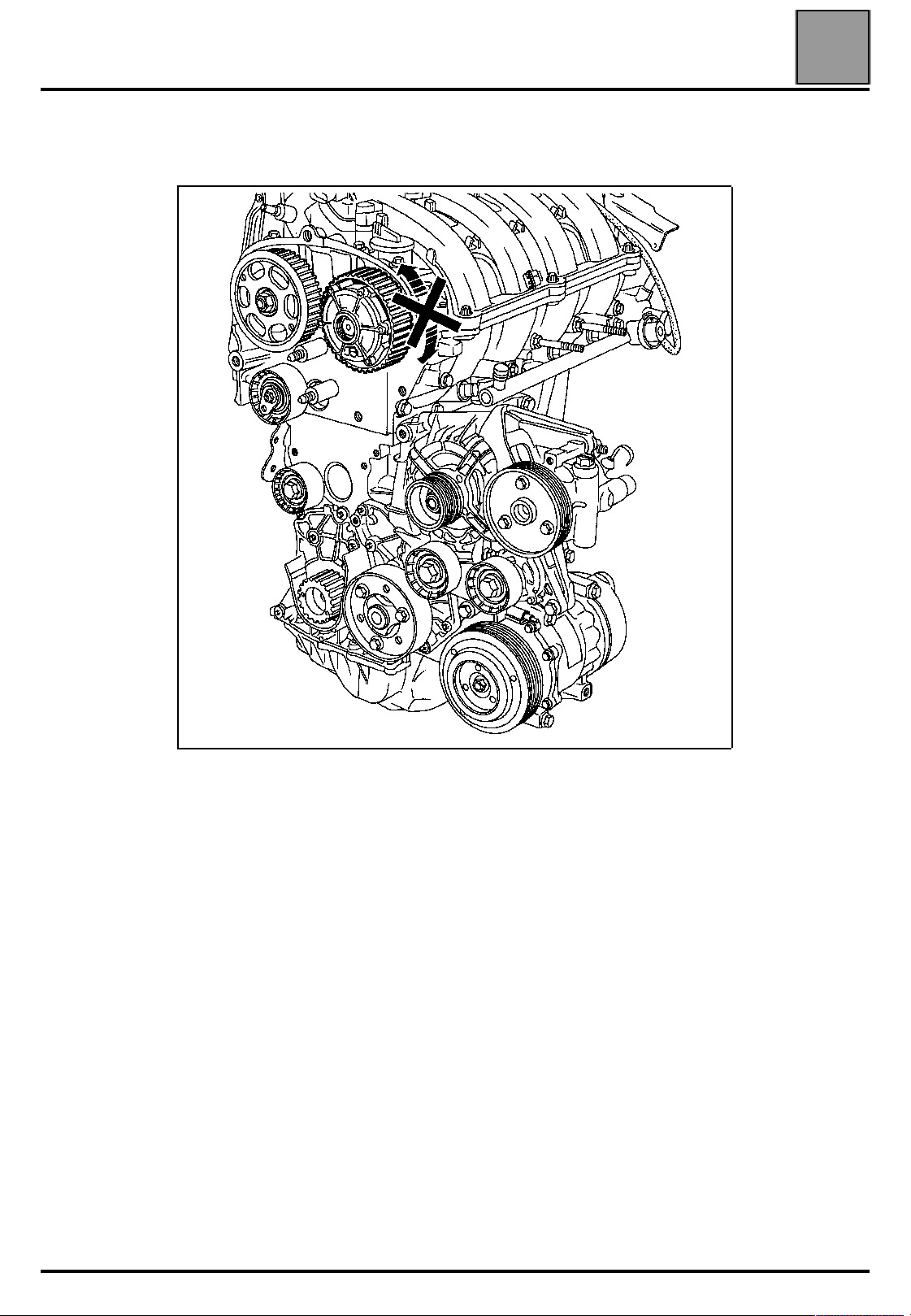

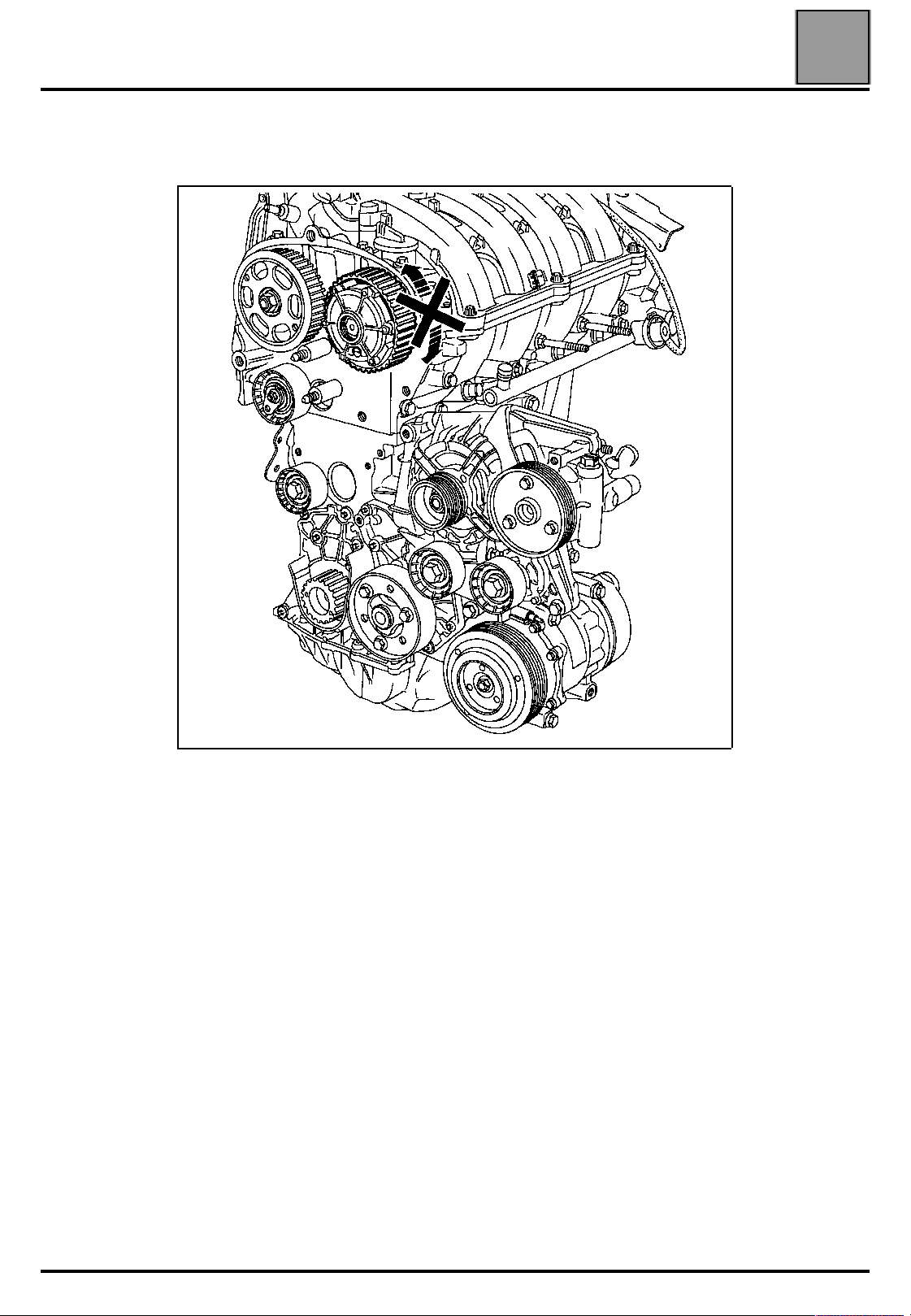

When refitting the belt, it is essential to ensure that

the tooth (X) inside the pulleys (timing side)

remains "free".

ALTERNATOR, POWER STEERING AND AIR

CONDITIONING

15111R

15110R

The engine must be turned through two

revolutions in order to position the belt correctly.

15304R

07-3

Page 8

VALUES AND SETTINGS

Timing belt tensioning procedure

Timing belt tensioning procedure

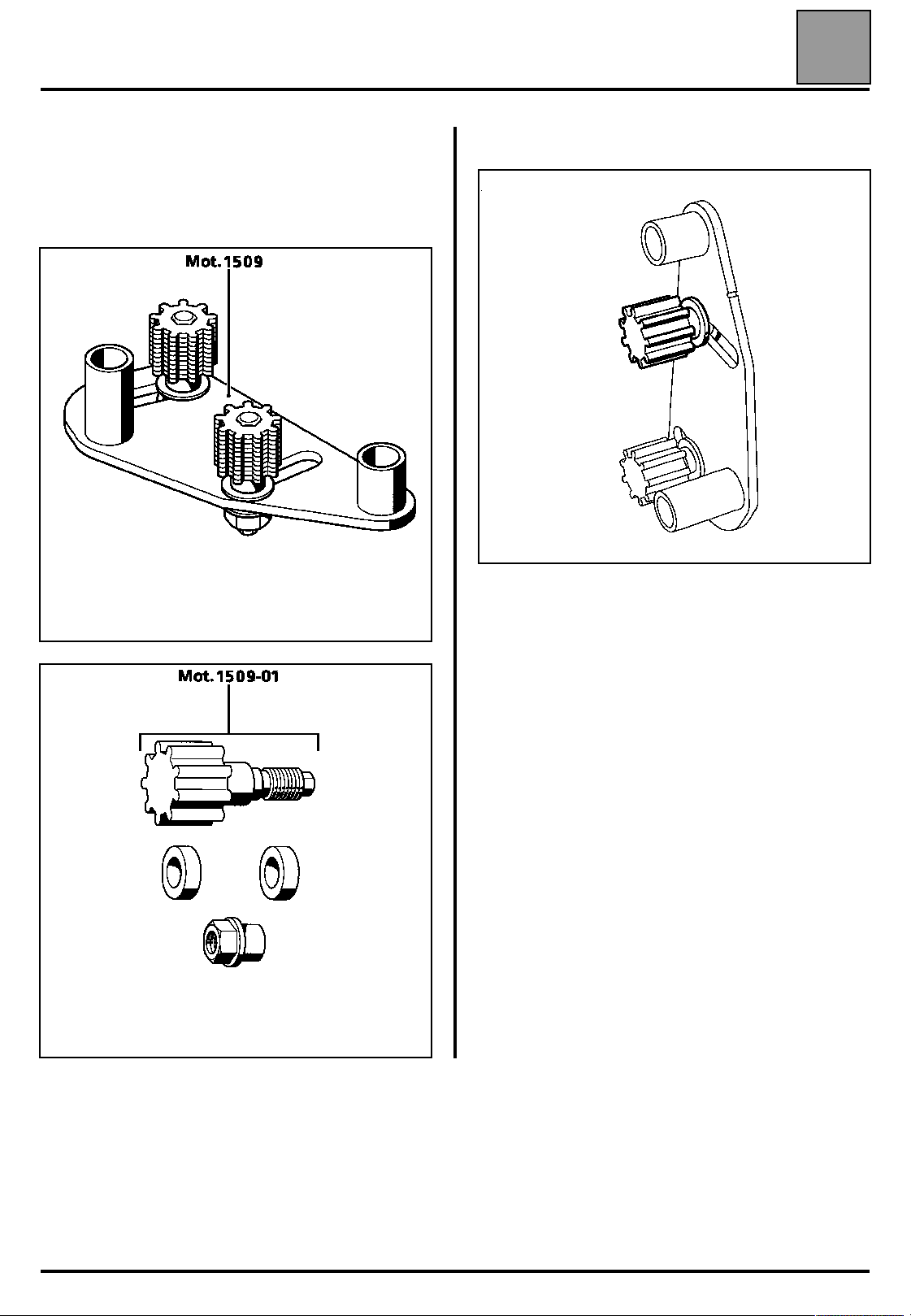

SPECIAL TOOLING REQUIRED

Mot. 799-01 Tool for immobilising pinions on

the toothed timing belt

Mot. 1054 Top Dead Centre pin

Mot. 1453 Engine support

Mot. 1496 Tool for setting the camshaft

Mot. 1509 Tool for locking the camshaft

pulleys

Mot. 1509-01 Addition to Mot. 1509

Mot. 1517 Tool for fitting inlet camshaft seals

EQUIPMENT REQUIRED

Angular tightening spanner

07

There are two distinct procedures for setting the

timing.

WARNING: the lower timing cover must be fitted

before the crankshaft accessories pulley.

st

1

PROCEDURE

The first procedure is used for replacing all

components which require the exhaust camshaft

pulley and the inlet camshaft dephaser to be

slackened.

During this operation, the following must be

replaced:

– the nut of the exhaust camshaft pulley,

– the bolt of the inlet camshaft dephaser,

– the seal of the camshaft dephaser,

– the seal of the dephaser blanking plate.

07-4

Page 9

VALUES AND SETTINGS

Timing belt tensioning procedure

Method for slackening the exhaust camshaft

pulley and the inlet camshaft dephaser.

The operation is performed using tools Mot. 1509

and Mot. 1509-01.

07

Remove the upper toothed pinion from the bracket.

15865R

16017S

16014R

07-5

Page 10

VALUES AND SETTINGS

Timing belt tensioning procedure

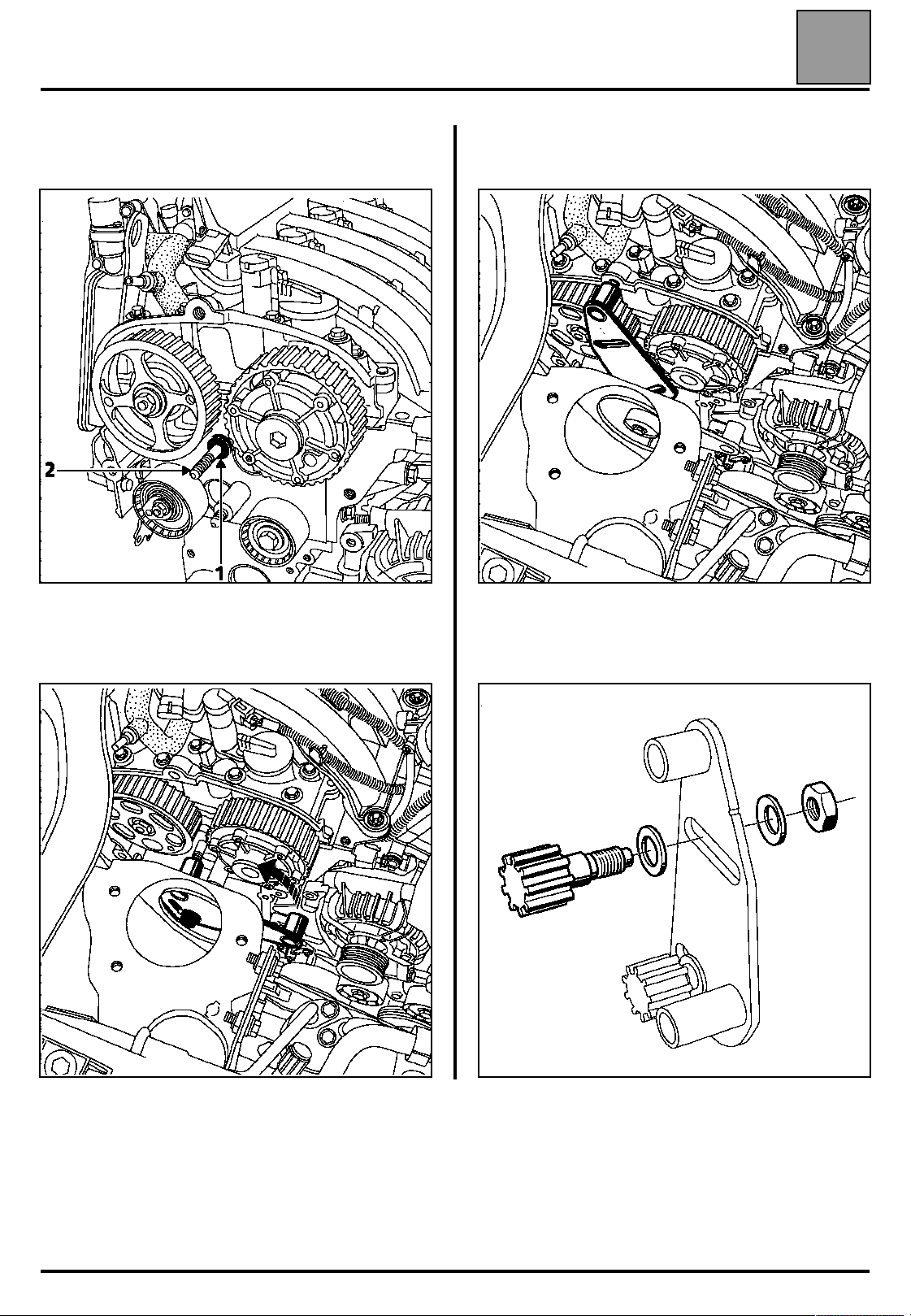

Fit:

– the spacer (1) of tool Mot. 1509-01 on the stud (2),

07

Pivot tool Mot. 1509 until the position shown on the

diagram below is reached.

16019R

– tool Mot. 1509 as shown on the diagram below, by

adjusting the position of the engine using engine

support Mot. 1453.

17719-1S

Fit:

– the pinion of tool Mot. 1509-01 (using the two

washers and the nut of tool Mot. 1509),

17719-2S

16018S

07-6

Page 11

VALUES AND SETTINGS

Timing belt tensioning procedure

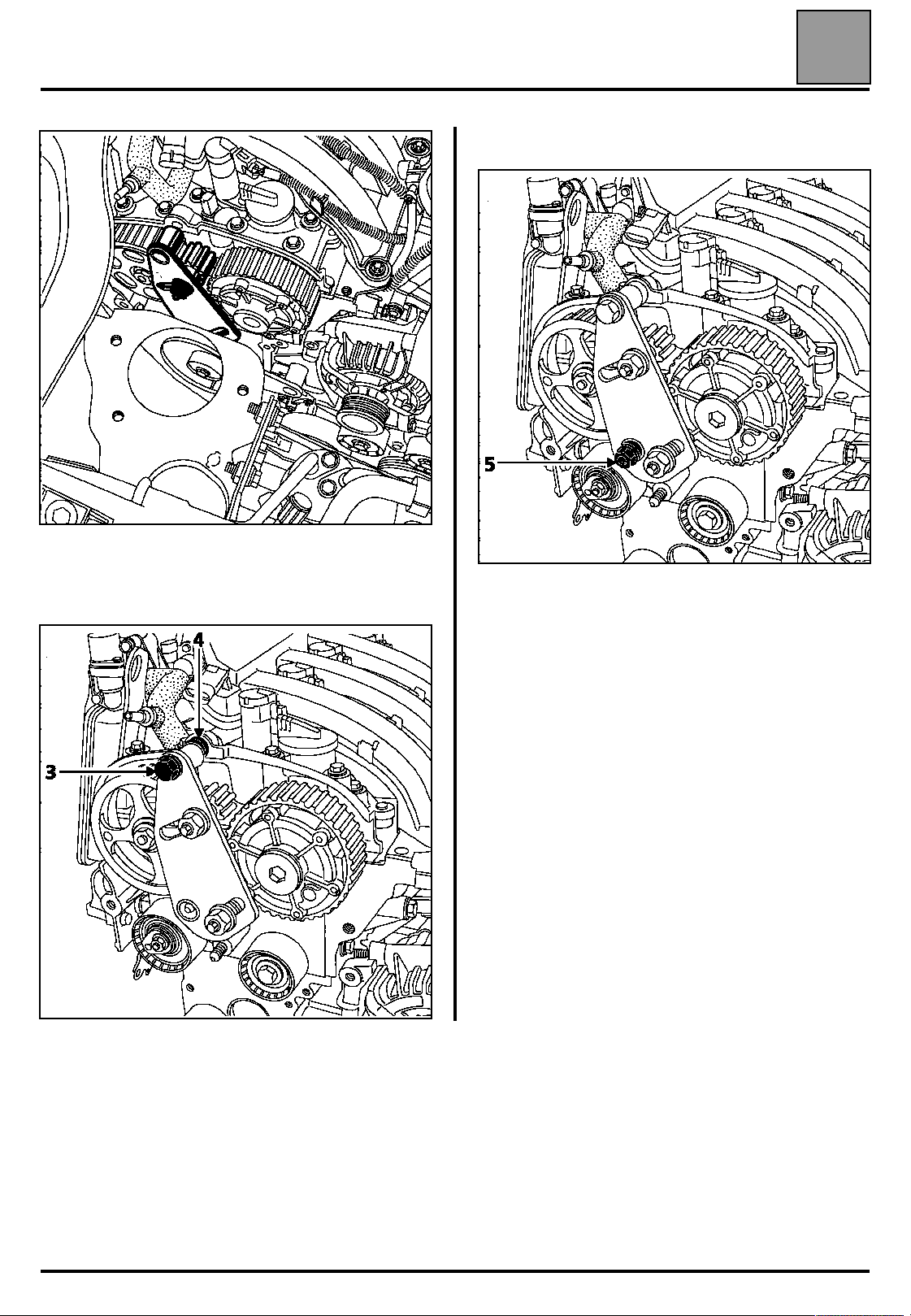

– the shouldered nut (5) of tool Mot. 1509-01.

17719S

07

– the upper bolt (3) whilst positioning the spacer (4) of

tool Mot. 1509-01 between the tool and the camshaft

bearing cap housing (do not lock the bolt).

16019-2R

16019-3R

07-7

Page 12

VALUES AND SETTINGS

Timing belt tensioning procedure

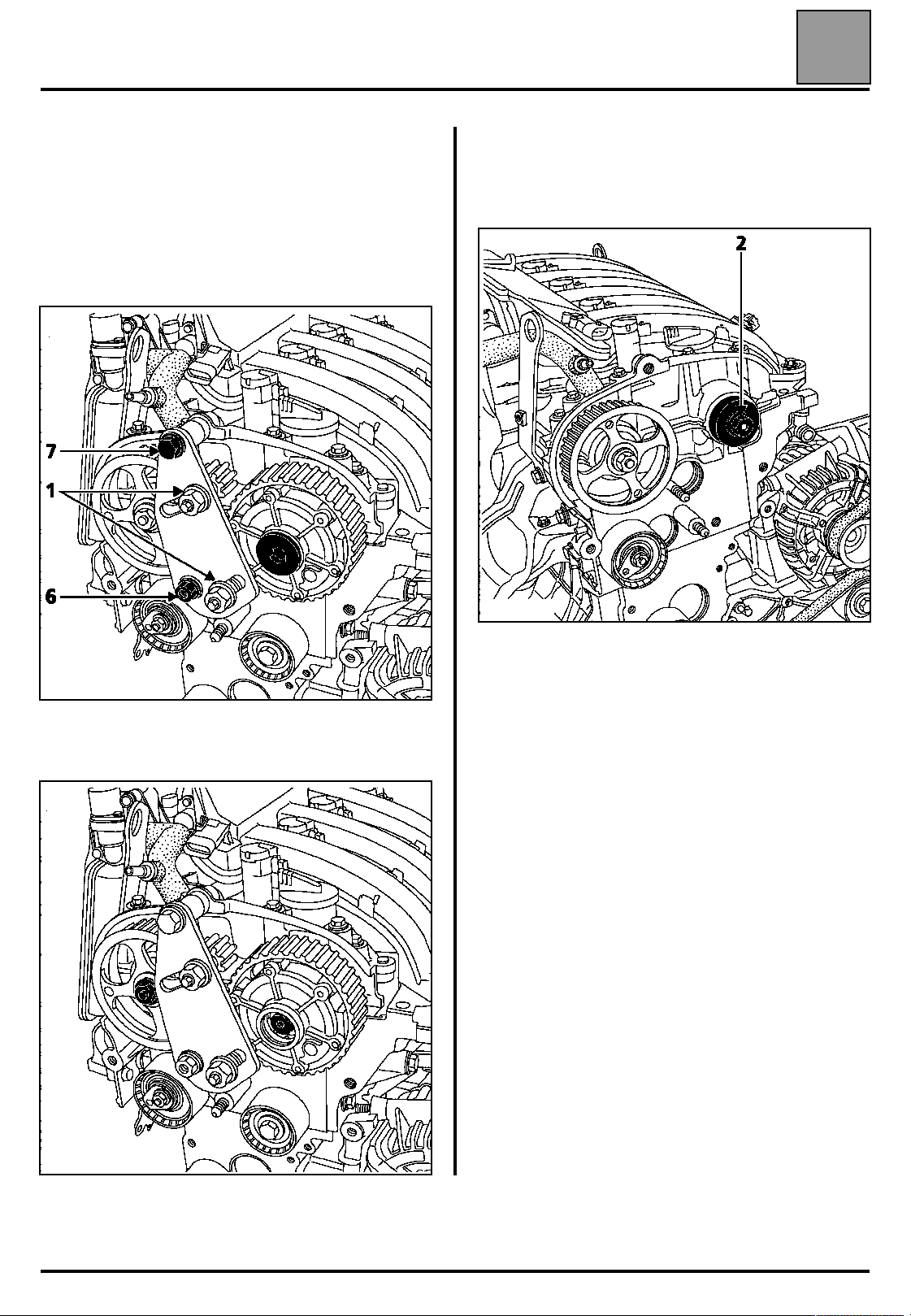

Tighten the shouldered nut (6) and the bolt (7), then

bring the pinions of tool Mot. 1509 into contact with the

camshaft pulleys by tightening the nuts (1) to a torque

of 8 daN.m.

Remove:

– the blanking plate of the inlet camshaft dephaser

using a 14 mm Allen key,

07

Replacing the inlet camshaft dephaser seal

Fit the seal of the inlet camshaft dephaser using tool

Mot. 1517 and the old bolt (2).

– the nut of the exhaust camshaft pulley,

– the bolt of the inlet camshaft dephaser.

16015-1R

NOTE: to use tool Mot. 1517, the hole must be

modified to a diameter of 13 mm.

16019-4R2

16019-5S

07-8

Page 13

VALUES AND SETTINGS

Timing belt tensioning procedure

Adjusting the timing

WARNING:

it is essential to degrease the end of the crankshaft (timing side), the

bore and the bearing faces of the timing pinion, the bearing faces of the

accessories pulley and the ends of the camshafts (timing side), the

bores and the bearing faces of the exhaust camshaft pulley and the inlet

camshaft dephaser; to prevent there being any slip between the timing,

the crankshaft, the exhaust camshaft pulleys and the inlet dephaser,

which may damage the engine.

NOTE:

to make it easier to position the grooves horizontally, position the pulley and

dephaser, then tighten the old nut of the pulley and the old bolt of the

dephaser to a torque of 1.5 daN.m MAXIMUM.

Check that the pistons are positioned at mid-stroke (to prevent any

contact between the valves and the pistons).

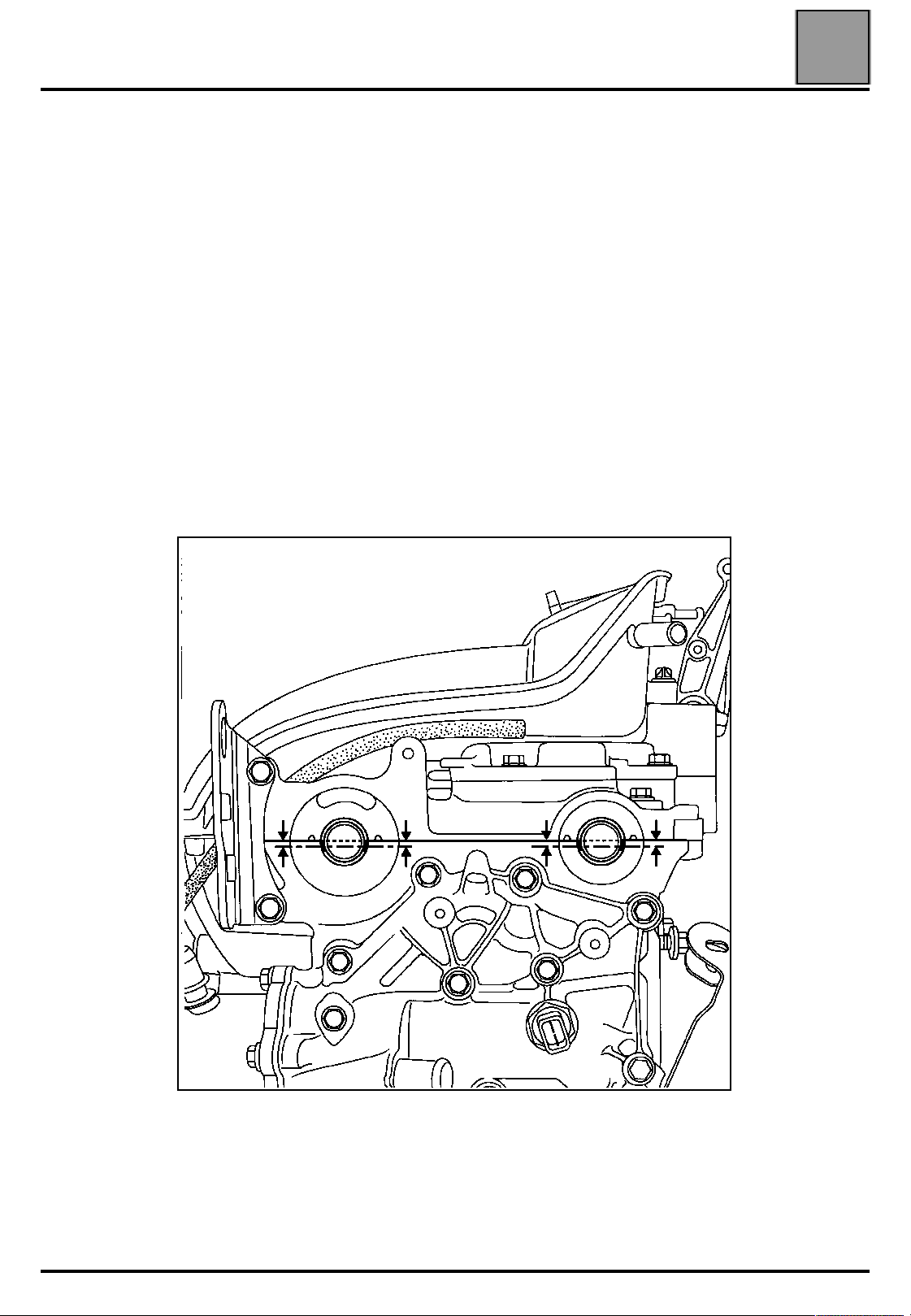

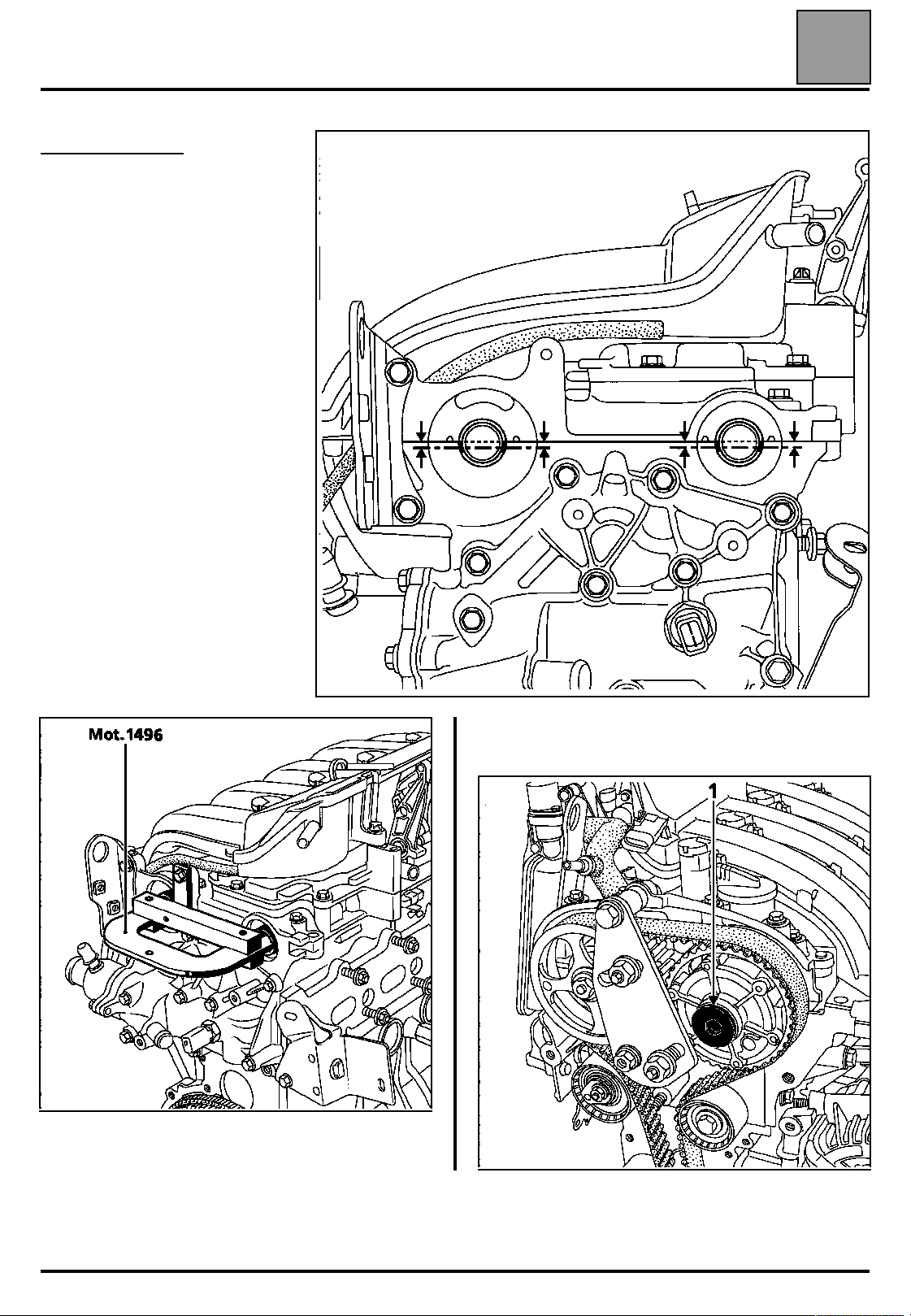

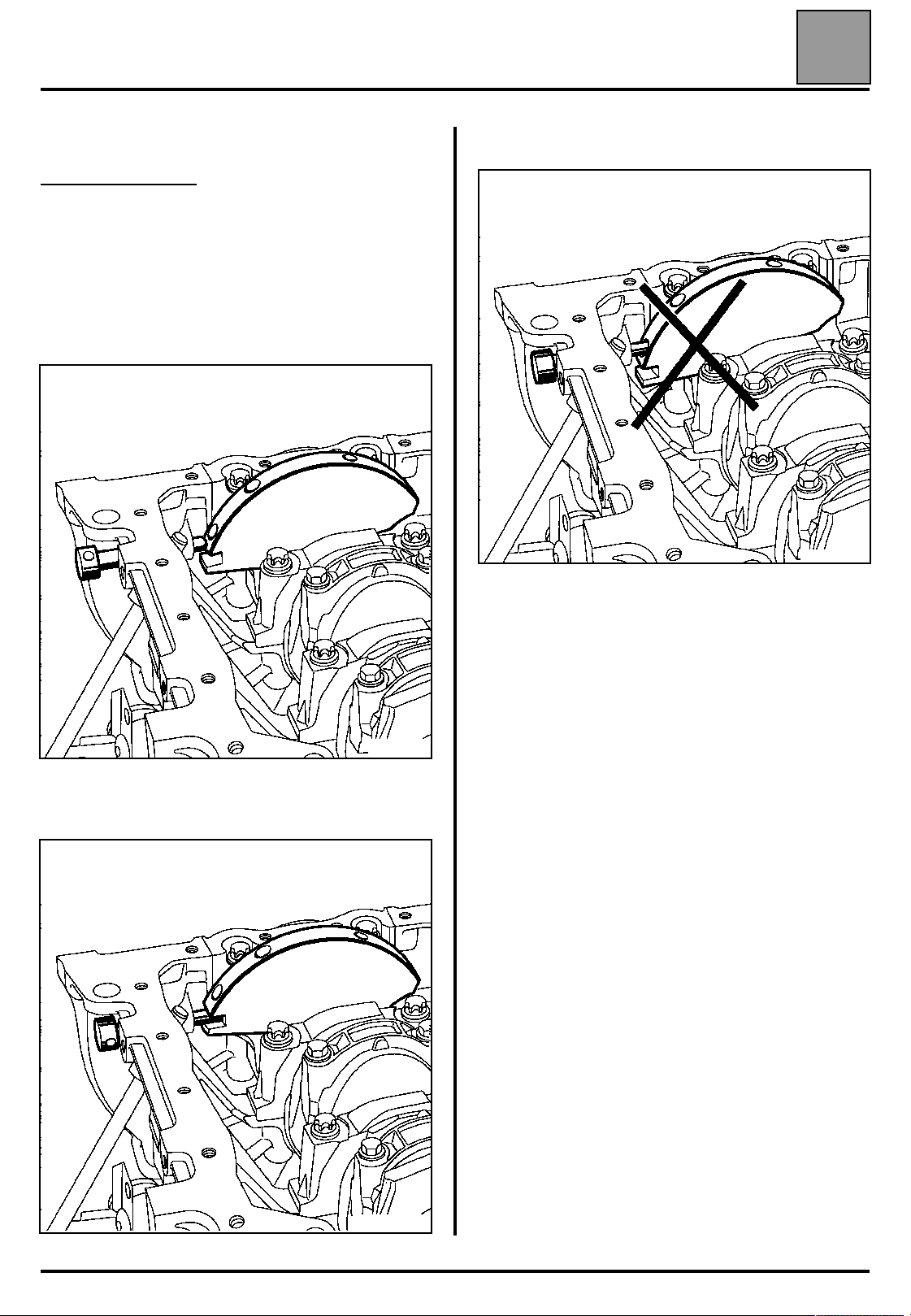

Position the grooves of the camshafts horizontally as shown in the diagram

below (rotating the camshafts using tool Mot. 799-01 if necessary).

07

07-9

15106-1S

Page 14

VALUES AND SETTINGS

Timing belt tensioning procedure

Check that the ring of the camshaft dephaser is correctly locked (no rotation

of the ring to the left or to the right).

07

07-10

Page 15

VALUES AND SETTINGS

Timing belt tensioning procedure

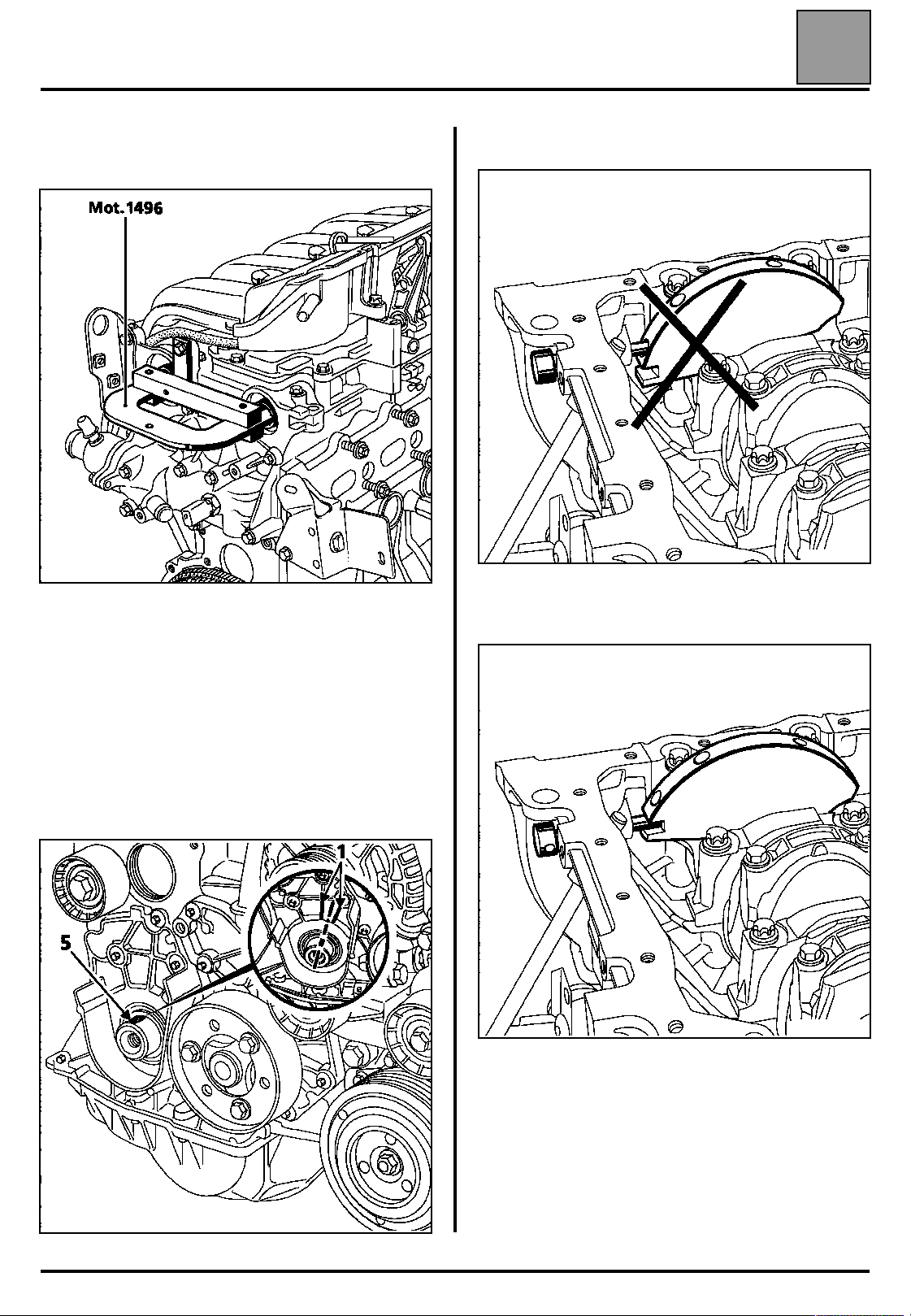

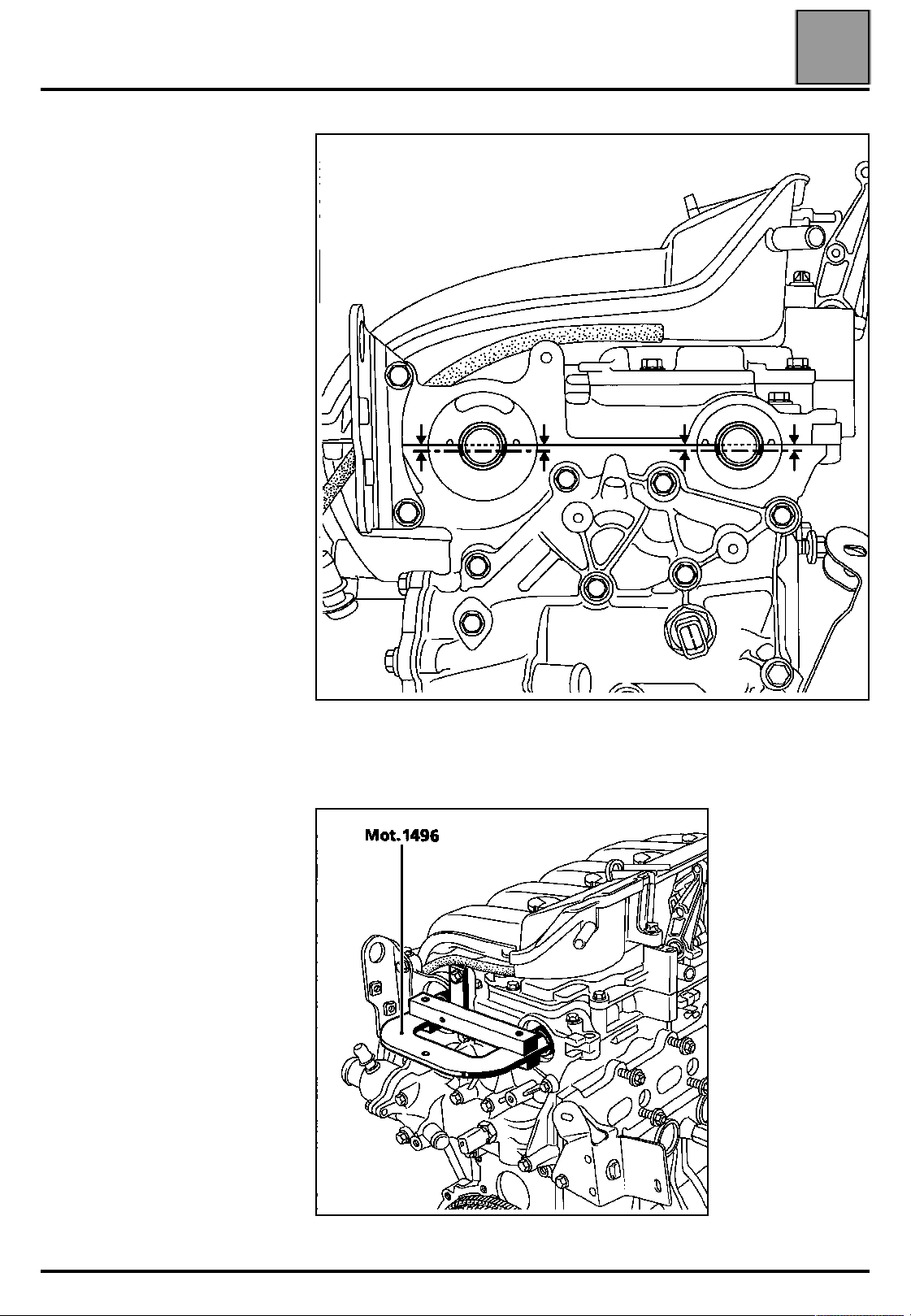

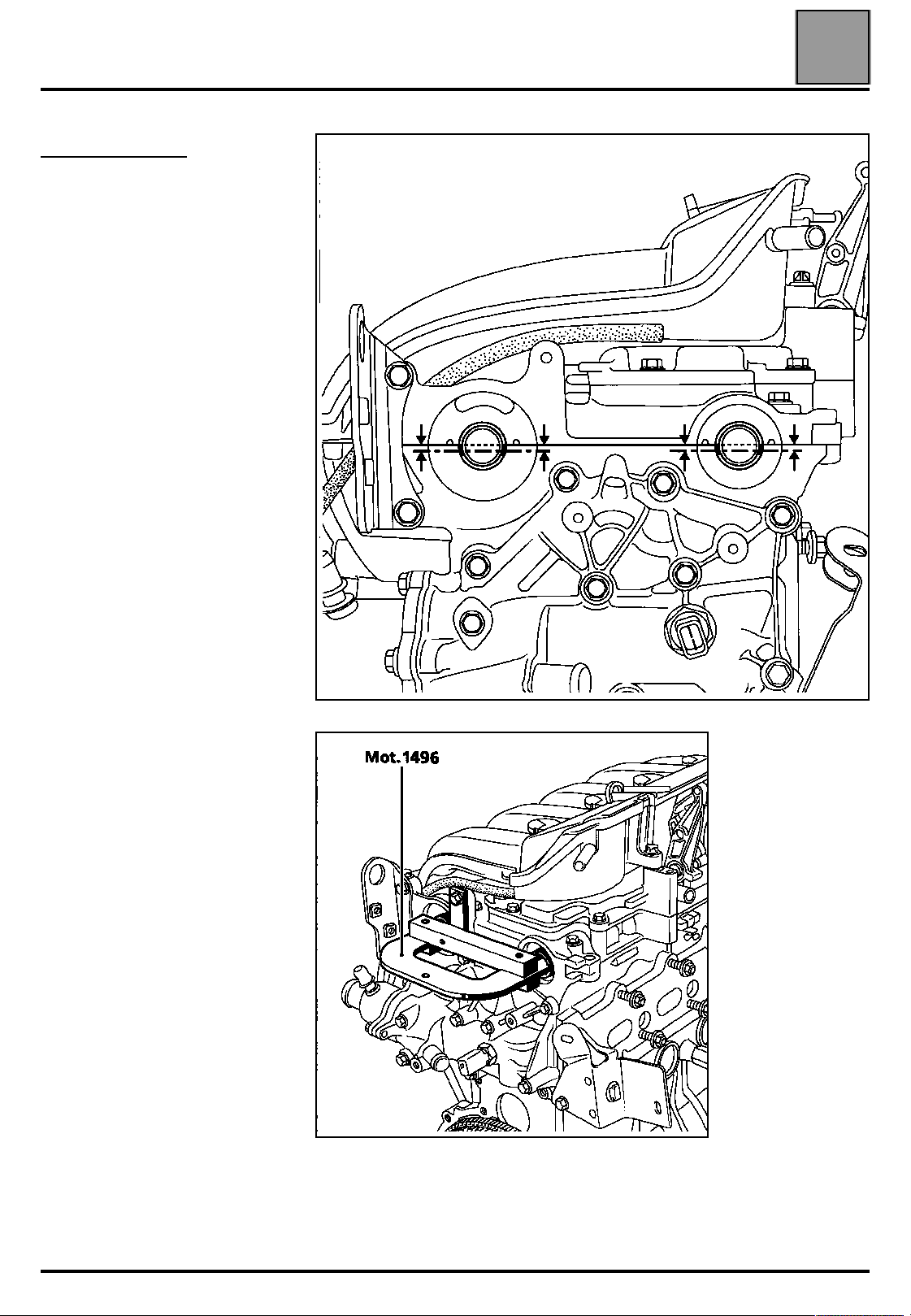

Position tool Mot. 1496, onto the ends of the

camshafts.

07

Incorrect position

15104R

Remove the old nut from the pulley, the old bolt

from the dephaser and replace them with a new

nut and bolt (leave a clearance of 0.5 - 1 mm

between the nut or the bolt and the camshaft

pulleys).

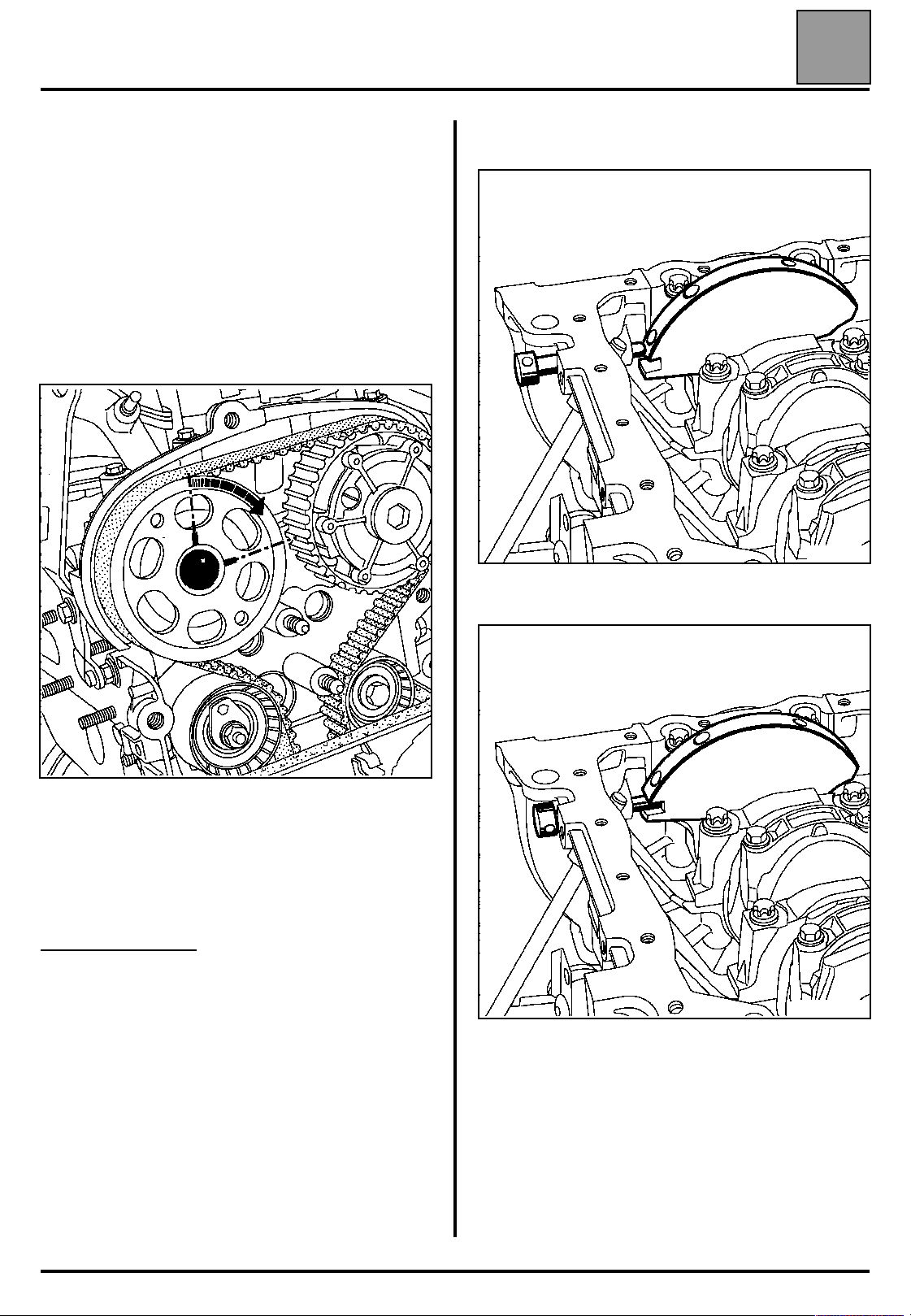

Ensure that the crankshaft is correctly pinned at

Top Dead Centre and not in the balancing hole

(groove (5) of the crankshaft must be positioned in

the middle of the two webs (1) of the crankshaft

closure panel).

15163S

Pinned crankshaft

15114-1R

15163-1S

07-11

Page 16

VALUES AND SETTINGS

Timing belt tensioning procedure

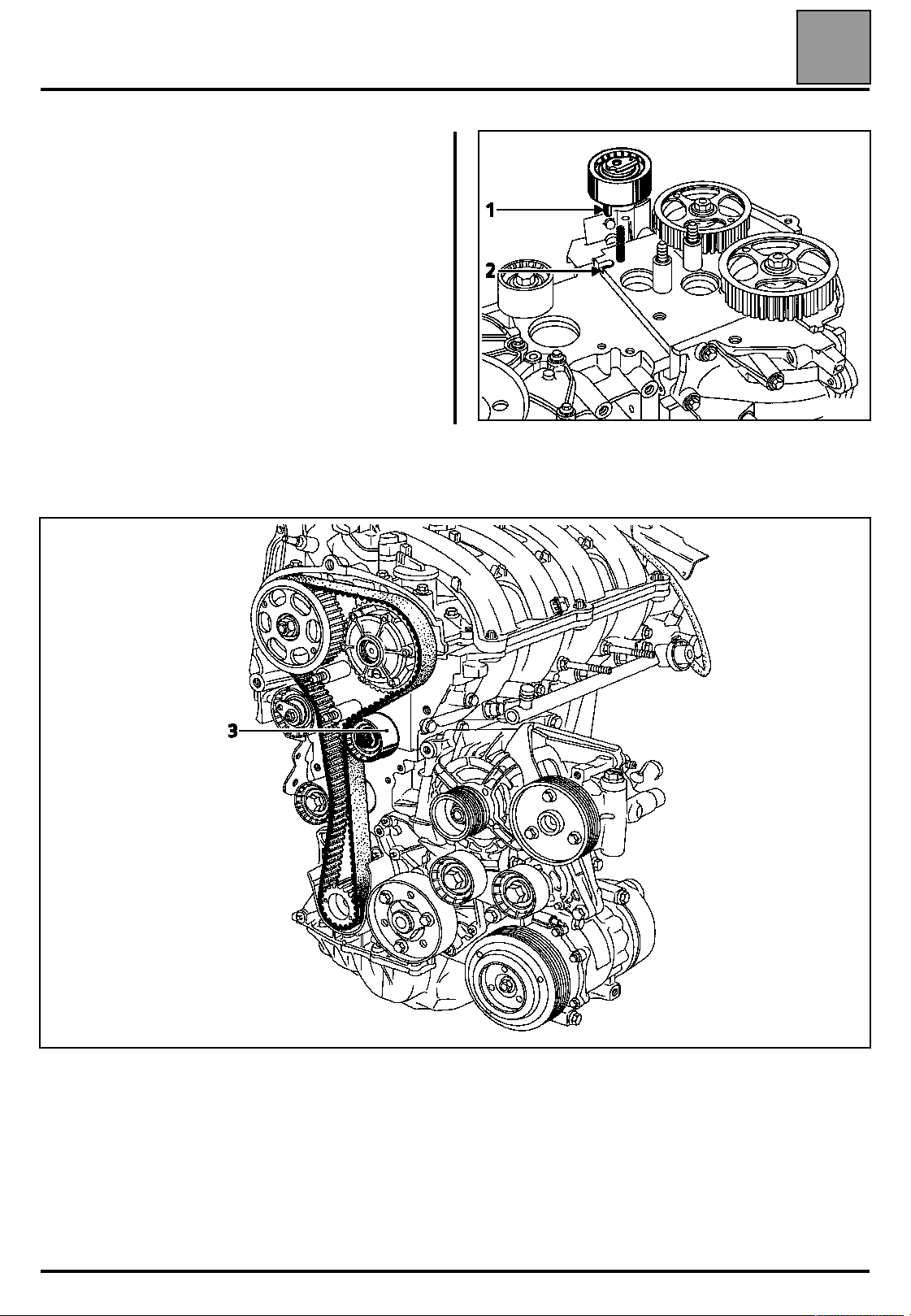

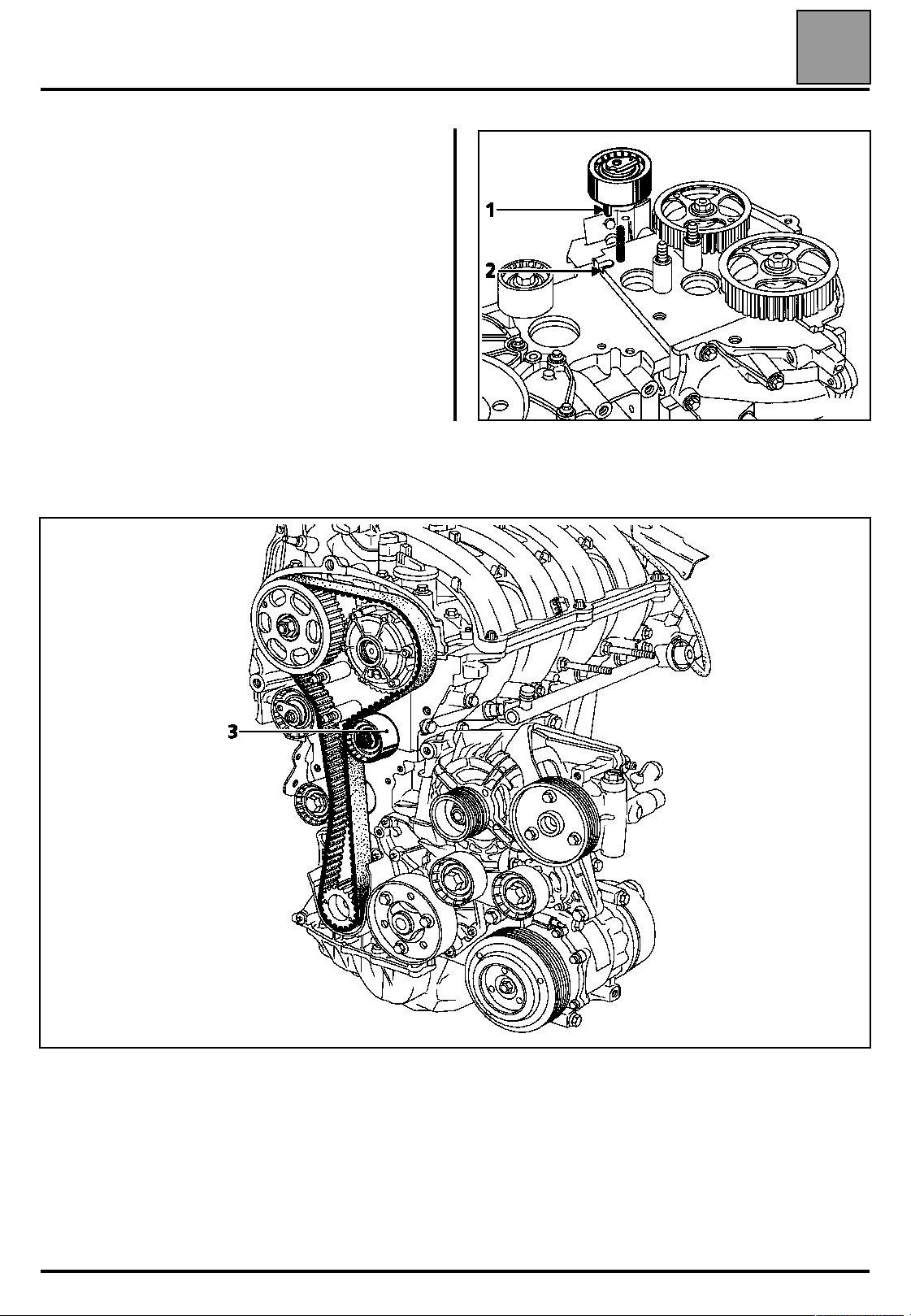

When replacing the timing belt, the tensioning and

fixed rollers must be replaced.

Ensure that the lug (1) of the tensioning roller is

correctly positioned in the groove (2).

Refit:

– the timing belt,

– the fixed roller (3) tightening the mounting bolt to a torque of 4.5 daN.m,

07

15201R

– the lower timing cover without tightening the bolts,

– the crankshaft accessories pulley, pre-tightening the bolt (without locking the bolt, clearance of 2 - 3 mm

between the bolt and the pulley).

NOTE:

– the crankshaft accessories pulley bolt can be reused if the length under its head does not exceed 49.1 mm

(otherwise replace it),

– do not oil the new bolt. However, when reusing the bolt, it must be oiled on the threads and under the head.

07-12

Page 17

VALUES AND SETTINGS

Timing belt tensioning procedure

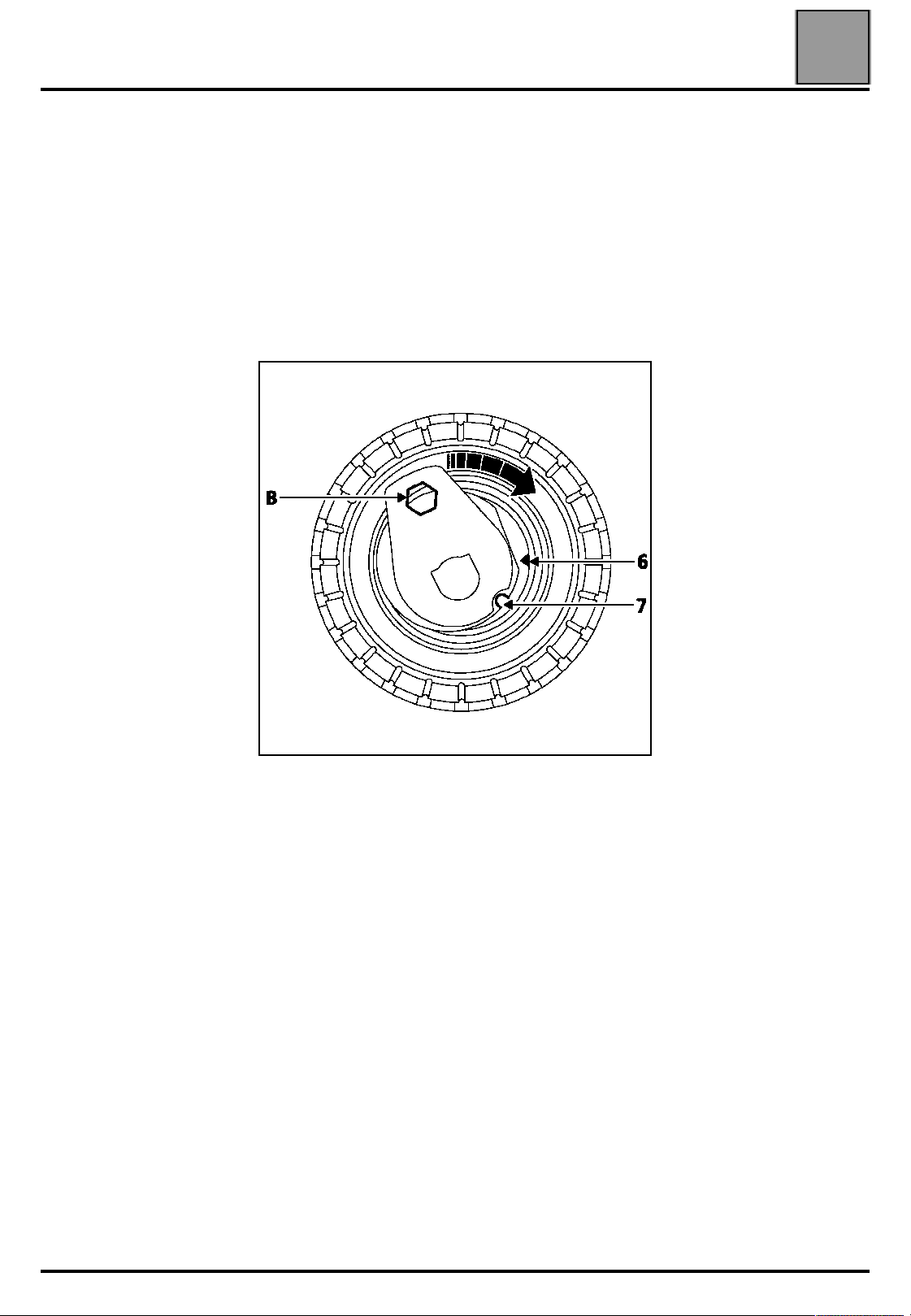

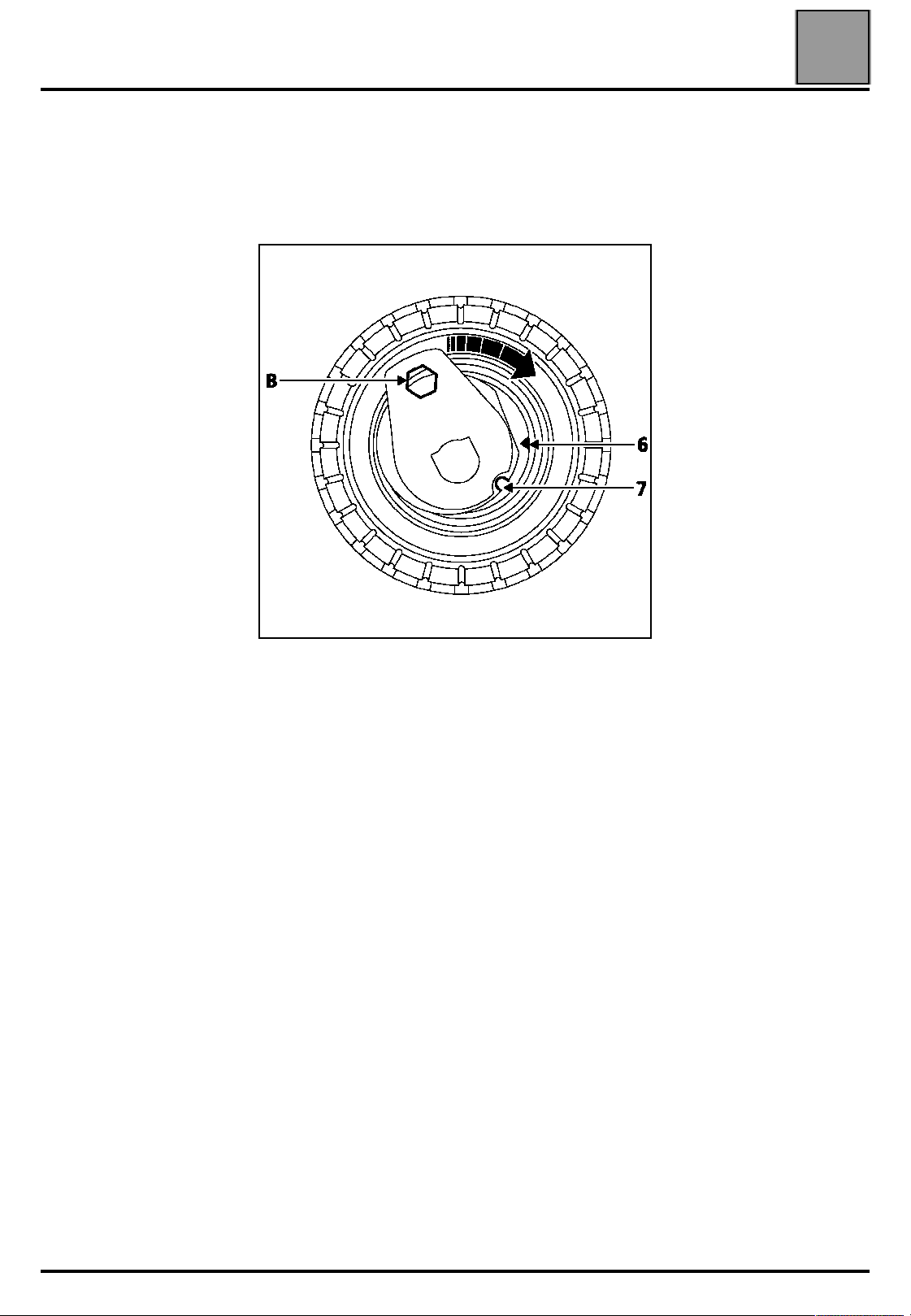

Belt tension

Check that there is always a clearance

of 0.5 - 1 mm between the nut, the bolt and the

camshaft pulleys.

NOTE: do not rotate the tensioning roller in an

anti-clockwise direction.

Align the references (6) and (7) of the tensioning roller

using a 6 mm Allen key at (B).

07

15256R

Pre-tighten the nut of the tensioning roller to a torque

of 0.7 daN.m.

Rotate the timing through six revolutions in a

clockwise direction (timing side) using the exhaust

pulley using tool du Mot. 799-01.

NOTE: check that the nut and the bolt of the camshaft

pulleys do not touch their respective pulleys. To do

this, from time to time, push the camshaft pulleys

against the camshafts.

Alight the references (6) and (7) if necessary,

slackening the nut of the tensioning roller by a

maximum of one turn whilst holding it with a 6 mm

Allen key. Then tighten the nut finally to a torque of

2.8 daN.m.

Tighten the bolt of the accessories crankshaft pulley to

a torque of 2 daN.m (Top Dead Centre pin still

positioned in the crankshaft).

07-13

Page 18

VALUES AND SETTINGS

Timing belt tensioning procedure

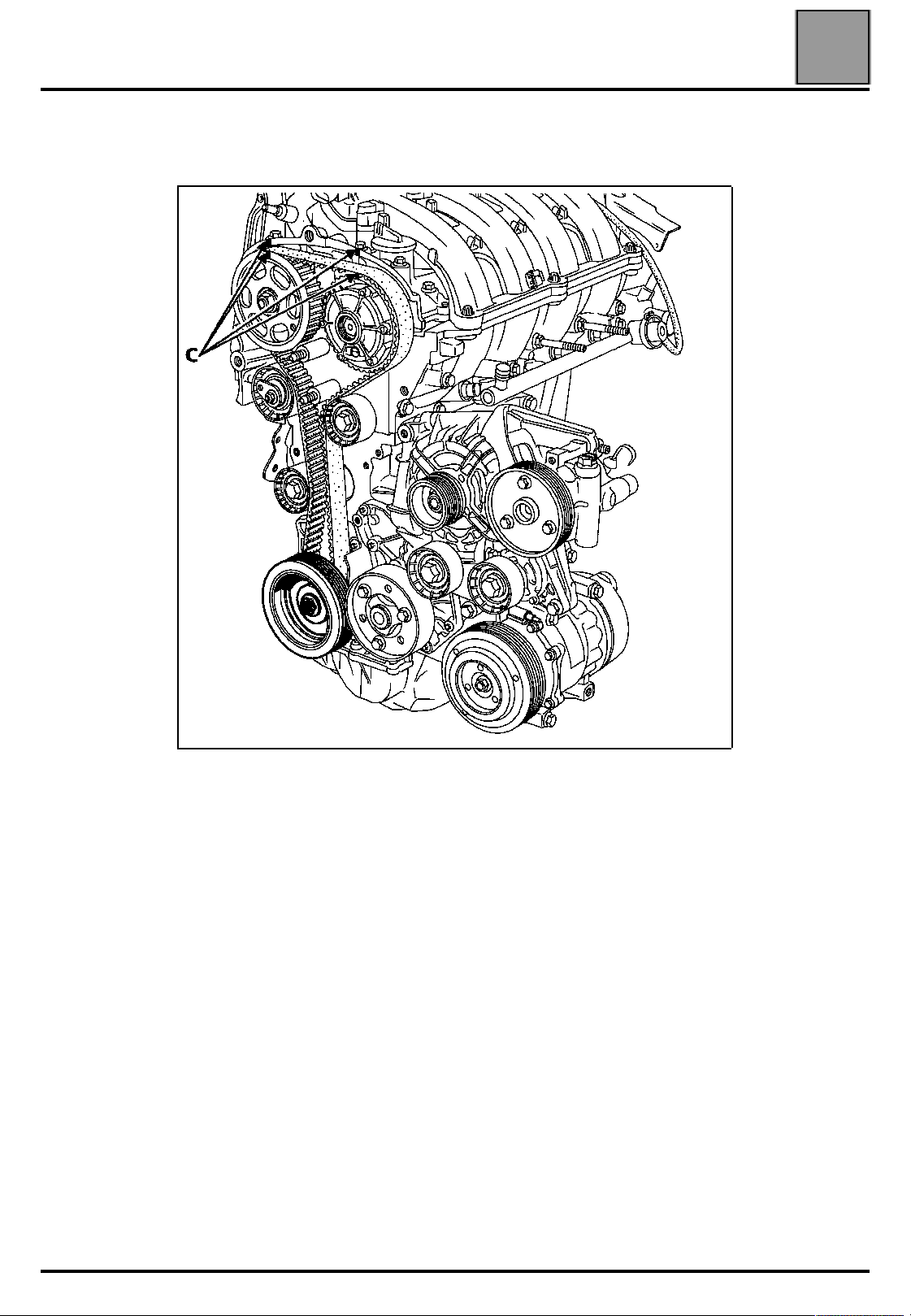

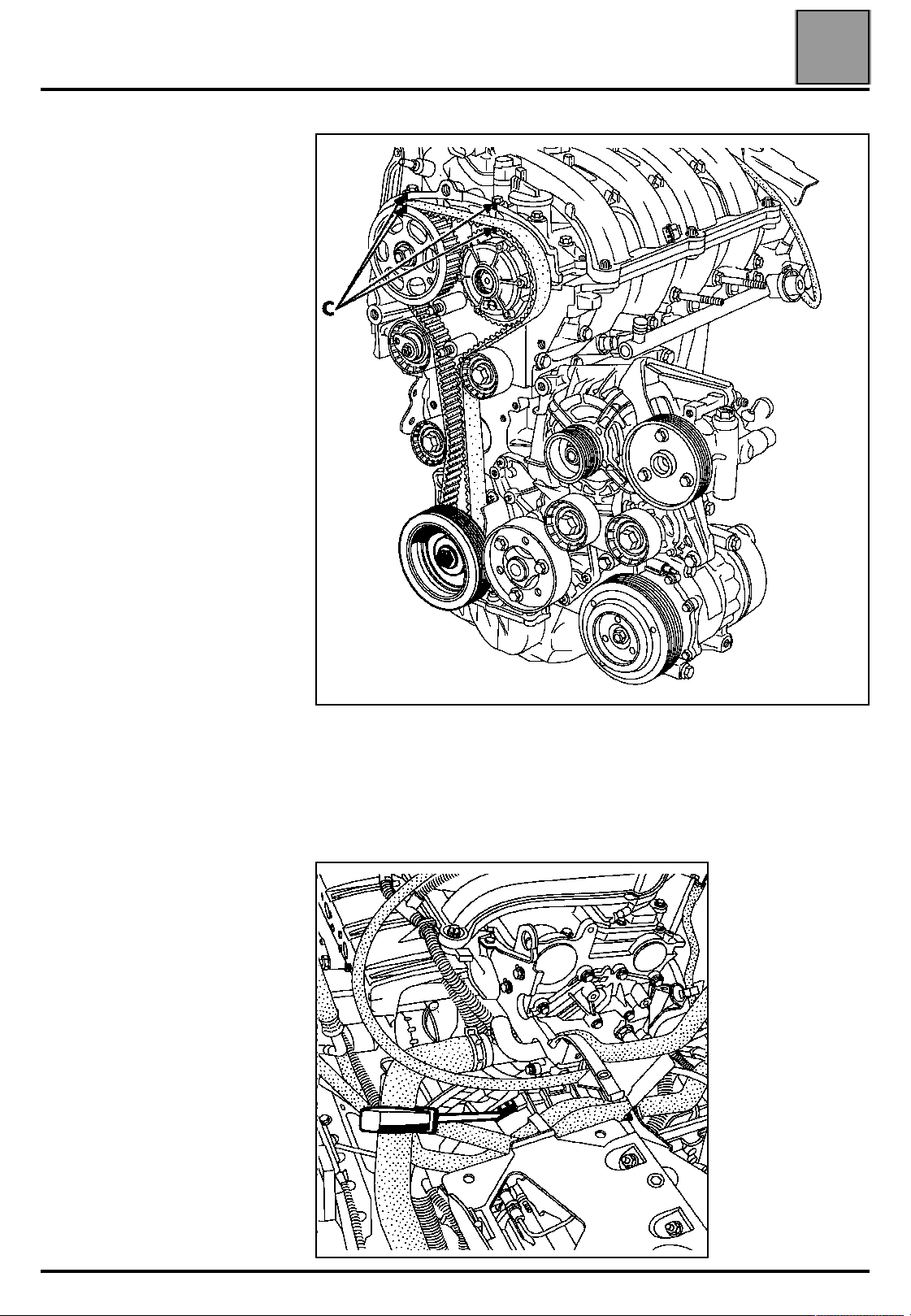

Mark a reference (C) using a pencil between the camshaft pulleys and the

camshaft bearing cap housing.

07

REMOVE THE TOP DEAD CENTRE PIN.

15815-8R

07-14

Page 19

VALUES AND SETTINGS

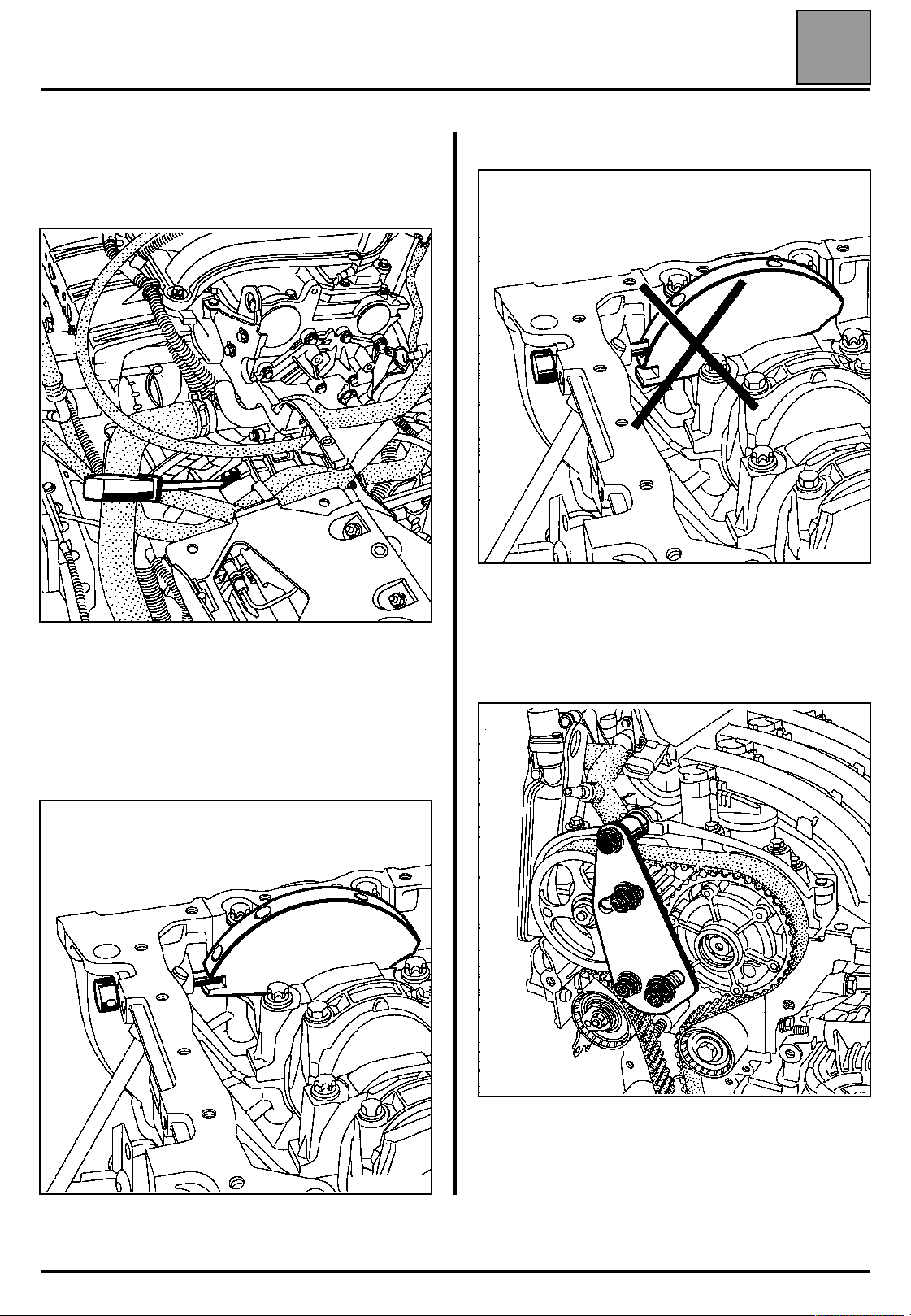

Timing belt tensioning procedure

Lock the flywheel using a large screwdriver, then turn

the bolt of the accessories crankshaft pulley though an

angle of 115˚ ± 15˚.

07

Incorrect position

17786S

Pin the crankshaft using the references made

previously between the camshaft pulleys and the

camshaft bearing cap housing. These references must

be aligned, which will ensure that the pin is in the

pinning hole and not in the crankshaft balancing hole.

Correct position

15163S

Fit the tool for locking the camshaft pulleys Mot. 1509

fitted with the additional tool Mot. 1509-01.

Follow the same procedure as when removing.

15163-1S

16019-6S

07-15

Page 20

VALUES AND SETTINGS

Timing belt tensioning procedure

Tighten the new bolt of the inlet camshaft dephaser to

a torque of 10 daN.m.

Tighten the new nut of the exhaust camshaft pulley to

a torque of 3 daN.m, then turn through an angle of

90˚ (representing 1/4 of a turn of the nut).

NOTE: as it is not possible to tighten this nut

angularly using the angular tightening spanner,

this operation will be made easier by making

reference points on the pulley and on the nut.

07

Before pinning

17715S

Remove tool Mot. 1496 for setting the camshaft, tool

Mot. 1509 for locking the camshaft pulleys and tool

Mot. 1054, the Top Dead Centre pin.

Checking the timing and the tension

Checking the tension:

Rotate the crankshaft through two revolutions in a

clockwise direction (timing side), and before the end of

the two revolutions (in other words, before the

previously made references are aligned), insert the

Top Dead Centre pin (so as to be between the

balancing hole and the pinning hole) then put the

timing in its setting point.

15163-2S

Pinned crankshaft

15163-1S

Remove the Top Dead Centre pin.

Check that the references of the tensioning roller are

correctly aligned, otherwise repeat the tensioning

procedure. To do this, slacken the nut of the tensioning

roller by a maximum of one turn whilst holding it with a

6 mm Allen key.

07-16

Align the references of the tensioning roller and tighten

the nut finally to a torque of 2.8 daN.m.

Page 21

VALUES AND SETTINGS

Timing belt tensioning procedure

Checking the timing

Ensure that the references of the

tensioning roller are in the correct

position before checking the setting

of the timing.

Fit the Top Dead Centre pin (check

that the references made previously

on the camshaft pulleys are aligned).

Fit (without forcing) tool Mot. 1496 for

setting the camshaft (the camshaft

grooves must be horizontal and offset

towards the bottom). If the tool cannot

be inserted, the timing setting and

tensioning procedure must be

repeated.

07

15104R

15106-1S

Refit the blanking plate (1) (fitted with a new seal) of

the dephaser tightening it to a torque of 2.5 daN.m

07-17

16019-7R

Page 22

VALUES AND SETTINGS

Timing belt tensioning procedure

2nd PROCEDURE

The second procedure is used for

replacing all components located

on the front of the timing which do

not require the exhaust camshaft

pulley and the inlet camshaft

dephaser to be slackened.

Adjusting the timing

WARNING: it is essential to

degrease the end of the

crankshaft, the bore of the

crankshaft pinion and the bearing

faces of the crankshaft pulley to

prevent any slip between the

timing and the crankshaft which

may damage the engine.

Position the grooves of the camshafts

using tool Mot. 799-01 as shown in

the diagram opposite.

07

Position tool Mot. 1496, onto the ends of the

camshafts.

15106-1S

07-18

15104R

Page 23

VALUES AND SETTINGS

Timing belt tensioning procedure

Ensure that the crankshaft is correctly pinned at

Top Dead Centre and not in the balancing hole

(groove (5) of the crankshaft must be positioned in

the middle of the two webs (1) of the crankshaft

closure panel).

07

Pinned crankshaft

15114-1R

15163-1S

Incorrect position

07-19

15163S

Page 24

VALUES AND SETTINGS

Timing belt tensioning procedure

Check that the ring of the camshaft dephaser is correctly locked (no

rotation of the ring to the left or to the right).

07

15815-6S

07-20

Page 25

VALUES AND SETTINGS

Timing belt tensioning procedure

When replacing the timing belt, the timing

tensioning and fixed rollers must be replaced.

Ensure that the lug (1) of the tensioning roller is

correctly positioned in the groove (2).

Refit:

– the timing belt,

– the fixed roller (3) tightening the mounting bolt to a torque of 4.5 daN.m,

07

15201R

– the lower timing cover without tightening the bolts,

– the crankshaft accessories pulley, pre-tightening the bolt (without locking the bolt, clearance of 2 - 3 mm

between the bolt and the pulley).

NOTE:

– the crankshaft accessories pulley bolt can be reused if the length under its head does not exceed 49.1 mm

(otherwise replace it),

– do not oil the new bolt. However, when reusing the bolt, it must be oiled on the threads and under the head.

07-21

Page 26

VALUES AND SETTINGS

Timing belt tensioning procedure

NOTE: do not rotate the tensioning roller in an

anti-clockwise direction.

Align the references (6) and (7) of the tensioning roller

using a 6 mm Allen key at (B).

07

15256R

Pre-tighten the nut of the tensioning roller to a torque

of 0.7 daN.m.

Tighten the bolt of the accessories crankshaft pulley to

a torque of 2 daN.m (Top Dead Centre pin Mot. 1054

still positioned in the crankshaft).

07-22

Page 27

VALUES AND SETTINGS

Timing belt tensioning procedure

Mark a reference (C) on the ring of

the inlet camshaft dephaser and the

exhaust pulley in relation to the

camshaft bearing cap housing.

07

Remove tool Mot. 1496 for setting the camshaft as

well as the Top Dead Centre pin, tool Mot. 1054.

Tighten the crankshaft pulley bolt to an angle of

115˚± 15˚, locking the flywheel using a large

screwdriver.

15815-8R

07-23

17786S

Page 28

VALUES AND SETTINGS

Timing belt tensioning procedure

Checking the timing and the tension

Checking the tension:

Rotate the crankshaft through two revolutions in a

clockwise direction (timing side). Before the end of the

two revolution (in other words, half a tooth before

the previously made references are aligned), insert

the crankshaft Top Dead Centre pin (so as to be

between the balancing hole and the pinning hole) then

put the timing in its setting point.

07

Incorrect position

Correct position

15163S

Remove the Top Dead Centre pin, tool Mot. 1054.

Check that the references of the tensioning roller are

correctly aligned, otherwise repeat the tensioning

procedure. To do this, slacken the nut of the tensioning

roller by a maximum of one turn whilst holding it with a

6 mm Allen key.

15163-2S

Align the references of the tensioning roller and tighten

the nut finally to a torque of 2.8 daN.m.

15163-1S

07-24

Page 29

VALUES AND SETTINGS

Timing belt tensioning procedure

Checking the timing:

Ensure that the references of the

tensioning roller are in the correct

position before checking the setting

of the timing.

Fit the Top Dead Centre pin (check

that the references made previously

on the camshaft pulleys are aligned).

Fit (without forcing) tool Mot. 1496 for

setting the camshaft (the camshaft

grooves must be horizontal and offset

towards the bottom). If the tool cannot

be inserted, the timing setting and

tensioning procedure must be

repeated.

07

15104R

15106-1S

07-25

Page 30

VALUES AND SETTINGS

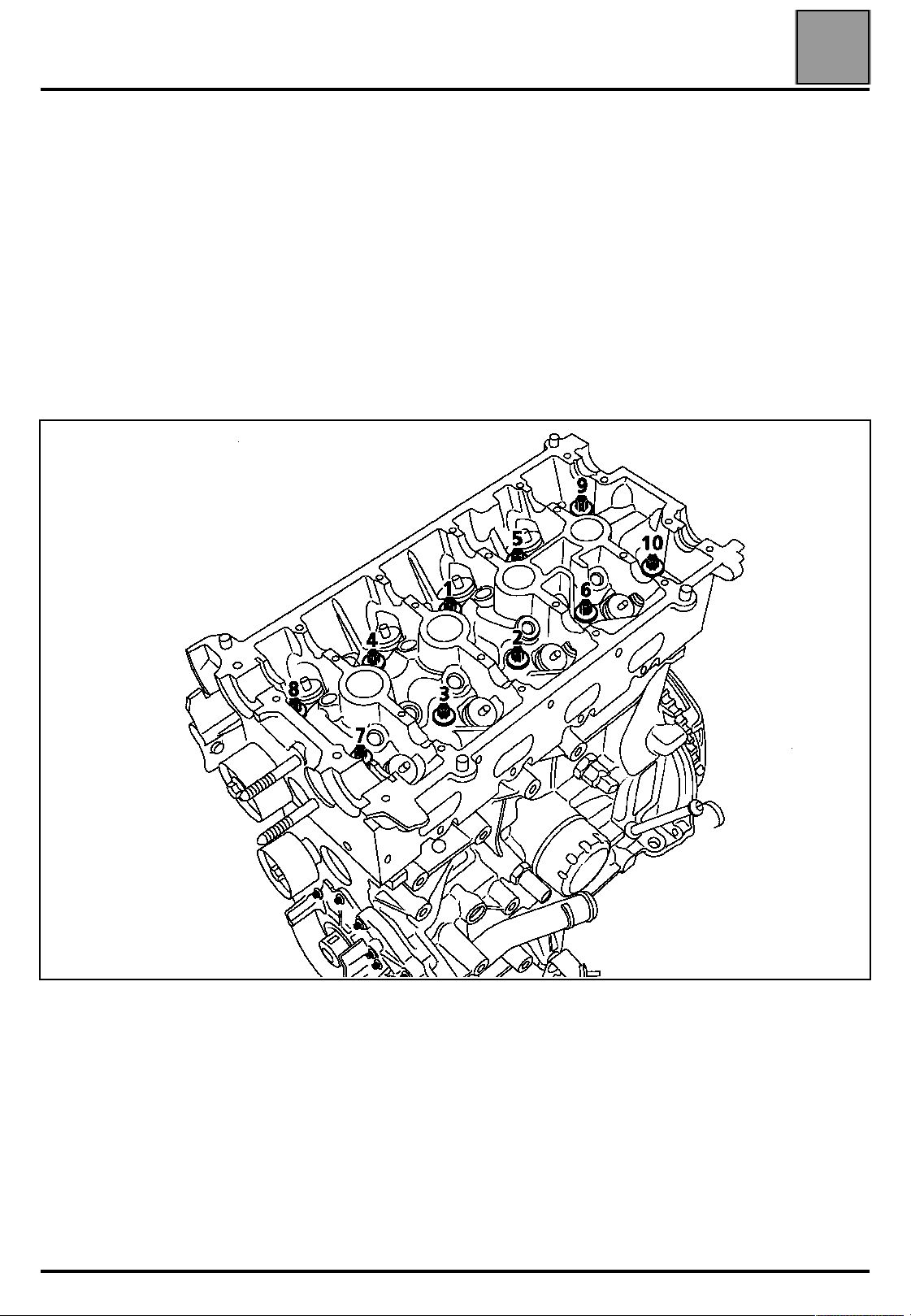

Tightening the cylinder head

Tightening the cylinder head

METHOD FOR TIGHTENING THE CYLINDER HEAD

The bolts can be reused if the length under the head does not exceed 118.5 mm (otherwise, replace all the

bolts).

Method for tightening the cylinder head

REMINDER: in order to tighten the bolts correctly, use a syringe to remove any oil which may have entered the

cylinder head mounting bolt holes.

Do not oil the new bolts. However, when reusing the bolts, they must be oiled.

Tighten all the bolts to 2 daN.m in the order recommended below.

07

Check that all the bolts are correctly tightened to 2 daN.m then, bolt by bolt, tighten to an angle of 165˚ ± 6˚.

Do not tighten the cylinder head bolts after applying this procedure.

07-26

15153-1R

Page 31

VALUES AND SETTINGS

Tyres and wheels

Tyres and wheels

Type Rim Tyres

JA0C 6.5 J 16 215/65 R 16 T 2 2

(1) During motorway use with full load.

Tightening torque of the wheel nuts: 10.5 daN.m

Rim run-out: 1.2 mm

07

Cold inflation pressure

(in bars) (1)

Front Rear

07-27

Page 32

VALUES AND SETTINGS

Type

JA0C 24 21.8 11 9.5

Maximum disc warp: 0.07 mm

Brakes

Brakes

Disc thickness

(in mm)

Front Rear

Front Front Normal Max.

Drum diameters or disc thicknesses (in mm)

07

Lining thicknesses (in mm) (including backing)

Type

New Min. New Min.

JA0C 18 6 15 5

Brake fluidFront Rear

SAE J1703

DOT 4

07-28

Page 33

VALUES AND SETTINGS

MEASUREMENT POINTS

Underbody height

Underbody height

07

Dimension H5 is measured from the axis of the

suspension arm.

16368R

07-29

17764R

Page 34

VALUES AND SETTINGS

CASTOR

CAMBER

Front axle angle checking values

Front axle angle checking values

ANGLES VALUES

5˚30′

4˚20′ ±30′

3˚50′

Max. right/left

difference = 1˚

- 0˚00′

- 0˚15′ ±30′

- 0˚30′

POSITION OF

FRONT AXLE

H5-H2 = 60 mm

H5-H2 = 80 mm

H5-H2 = 100 mm

H1-H2 = 100 mm

H1-H2 = 105 mm

H1-H2 = 110 mm

07

ADJUSTMENT

NOT

ADJUSTABLE

NOT

ADJUSTABLE

PIVOT

PARALLELISM

Max. right/left

difference = 1˚

13˚15′

13˚40′ ±30′

14˚00′

Max. right/left

difference = 1˚

(for 2 wheels)

toe-out

+ 0˚8′ ± 3′

+ 0.8 mm ± 0.3 mm

H1-H2 = 100 mm

H1-H2 = 105 mm

H1-H2 = 110 mm

UNLADEN

NOT

ADJUSTABLE

Adjusted by

rotating track

rod sleeves

1 turn= 30′

(3 mm)

POSITION FOR TIGHTENING RUBBER BUSHES

- UNLADEN -

07-30

Page 35

VALUES AND SETTINGS

Rear axle angles checking values

Rear axle angles checking values

ANGLES VALUES

CAMBER

- 0˚55′ ± 15′ UNLADEN

PARALLELISM

(for 2 wheels)

- 25′ ± 25′

Clamp

POSITION OF

REAR AXLE

UNLADEN

07

ADJUSTMENT

NOT

ADJUSTABLE

Adjustable by

eccentric

POSITION FOR TIGHTENING

RUBBER BUSHES

- 2.5 mm ± 2.5 mm

-

UNLADEN

Vehicle with

wheels on the

ground

-

07-31

Page 36

ENGINE AND PERIPHERALS

ENGINE AND PERIPHERALS

110

Identification

Identification

Vehicle type Engine Gearbox

JA0C F4R 744 JC7 1998 82.7 93 9.8/1

Section to be consulted: Mot. F4 and N.T. 3200A.

Capacity

3

)

(cm

Bore

(mm)

Stroke

(mm)

10

Compression

ratio

10-1

Page 37

ENGINE AND PERIPHERALS

Oil pressure

Oil pressure

SPECIAL TOOLING REQUIRED

Mot. 836-05 Kit for checking oil pressure

ESSENTIAL SPECIAL TOOLING

22 mm long socket or pipe spanner

CHECKING

The oil pressure should be checked when the engine

is warm (approximately 80° C).

Contents of kit Mot. 836-05.

10

USE

B + F

Connect the pressure gauge in place of the oil

pressure switch.

Oil pressure

Idling 1 bar

3 000 rpm 3 bar

10-2

87363R1

Page 38

ENGINE AND PERIPHERALS

Engine and gearbox assembly

Engine and gearbox assembly

SPECIAL TOOLING REQUIRED

Mot. 1294-01 Tool for removing windscreen

wiper arms

Mot. 1040-01 Dummy sub-frame for removing

and refitting engine and gearbox

assembly

Mot. 1159 Tool for maintaining engine on

subframe

Mot. 1202 -01

Mot. 1202 -02

Mot. 1233-01 Threaded rods for lowering the

Mot. 1448 Long nose pliers for hose clips

Mot. 1453 Engine support tool

Pliers for hose clips

sub-frame

10

TIGHTENING TORQUES (in daN.m)

Sub-frame front mounting bolts 6.2

Sub-frame rear mounting bolts 10.5

Mounting bolt for front right suspended

mounting cover to engine

Movement limiter mounting bolt 6.2

Mounting nut for rubber engine mounting

pad on front left-hand side member support 6.2

Shock absorber base bolts 18

Brake caliper mounting bolt 4

Steering shaft yoke bolt 3

Sub-frame - side member tie-rod bolts 3

Clutch bleed screw 1

Track rod end nut 3.5

Wheel bolts 9

REMOVAL

Put the vehicle on a two post lift. Refer to Section 02

"Underbody lift" for positioning the lifting pads.

6.2

Remove:

– the battery,

– the engine undertray.

Drain:

– the cooling circuit through the bottom hose of the

radiator,

– the gearbox and the engine (if necessary),

– the coolant circuit (if fitted) using filling equipment.

During this operation, the vehicle must be secured

to the lift with a strap to prevent it from becoming

unbalanced.

Refer to Technical Note 2988A for the strap

positioning procedure.

14893S

10-3

Page 39

ENGINE AND PERIPHERALS

Engine and gearbox assembly

Remove:

– the front wheels along with the mudguard,

– the sub-frame and body tie-rods,

– the mountings (A), as well as the rivets (B) and

remove the lower part of the bumper.

10

– the heat shield (C) as well as the mountings of the

precatalytic converter on the catalytic converter

(secure the exhaust pipe to the body),

17703R

– the mountings (2) of the longitudinal driveshaft and

secure it to the body,

– the gear control (3),

17595R

– the track rod ends,

– the brake calipers (as well as the ABS sensors, if

fitted) and secure them to the suspension springs,

– the shock absorber base bolts,

– the upper mountings of the stabiliser bar tie-rods and

slacken the lower mountings,

– the mountings (1) of the tie-rods,

17537R1

17704R1

– the horns,

– the two mountings of the power assisted steering

hoses on the right hand side of the sub-frame,

– the nut and the eccentric bolt of the steering shaft

yoke, after pushing back the guard.

10-4

Page 40

ENGINE AND PERIPHERALS

Engine and gearbox assembly

SPECIAL NOTES FOR VEHICLES FITTED WITH A

DRIVER'S AIRBAG

WARNING

In order to eliminate any risk of damaging the

rotary switch under the steering wheel, observe

the recommendations below:

Before the steering column and the steering

●

rack are uncoupled, the steering wheel MUST

be immobilised for the duration of the

operation with the wheels straight using a

"steering wheel locking tool".

If there is any doubt regarding the correct

●

alignment of the rotary switch the steering

wheel must be removed so that the alignment

procedure described in the "AIRBAG" section

can be applied.

REMINDER: in this case, only qualified

personnel who have received training may carry

out the operation.

10

– the closure panel of the plenum chamber,

11036R2

– the shock absorber cap protectors,

– the accelerator cable,

– the clutch receiver by removing the clip (C),

Disconnect:

– the oxygen sensor from the catalytic converter

(under the body),

– the connector of the pressure switch.

Unclip the power steering reservoir and release it.

Remove:

– the air resonator,

– the windscreen wiper arms using tool Elé. 1294-01,

– the front grilles,

17707R

– the brake servo vacuum pipe,

– the pipe as well as the connector on the canister,

11020R

10-5

Page 41

ENGINE AND PERIPHERALS

Engine and gearbox assembly

– the hoses on the heater radiator,

– the upper hose of the cooling radiator,

– the battery mounting,

– the mountings of the expansion bottle and release it,

– the relay plate at (5) and disconnect the

connectors (6), (7), (8) and (9) as well as the fuse

holder,

10

Fit the engine retaining tool Mot. 1453 ensuring that

the strap is correctly positioned.

13932R

Remove the suspended engine mounting cover.

16668R1

– the connectors of the fan unit,

– the earth strap on the bulkhead,

– the fuel pipe on the injection rail and unclip it from the

lower valve timing cover,

– the mountings of the air conditioning hoses (if

fitted) on the compressor and the dehydration

canister.

NOTE: plugs must be fitted onto the hoses and

pressure relief valve to prevent moisture from entering

the circuit.

10-6

Page 42

ENGINE AND PERIPHERALS

Engine and gearbox assembly

Insert a wooden block between the gearbox and the

sub-frame.

Remove the nut (1), then tap it with a copper hammer

to release the suspended engine mounting stud.

10

15960R

Fit tool Mot. 1040-01 under the engine sub-frame.

Fit the two tools Mot. 1159 as shown below.

17720R

98755R1

Lower the lift until the tool touches the ground.

Remove the sub-frame mounting bolts and take out

the engine and gearbox assembly by lifting the body.

NOTE: for any operation requiring the engine, gearbox

and sub-frame assembly to be separated, take care to

mark the position of tool Mot. 1159 on the sub-frame.

10-7

Page 43

ENGINE AND PERIPHERALS

Engine and gearbox assembly

REFITTING

Features of the clutch receiver when separating

the engine and gearbox

NB: to avoid damaging the receiver, do not coat

the gearbox output shaft with grease.

NB: to avoid leaks, replace the receiver after

replacing the clutch mechanism.

Add brake fluid to the reservoir.

Bleed the circuit using the bleed screw (D) located on

the link on the receiver.

10

The alignment of the sub-frame with the body will be

made easier by positioning two threaded rods

Mot. 1233-01 in the two front mountings of the subframe on the body.

When lowering the body onto the engine - gearbox

assembly, ensure that the catalytic converter is

refitted.

Tighten the sub-frame mounting bolts to a torque of:

– 6.2 daN.m at the front,

– 10.5 daN.m at the rear.

17707R2

Refill the brake fluid.

IMPORTANT: tighten the bleed to the correct torque

(1 daN.m).

10-8

Page 44

ENGINE AND PERIPHERALS

Engine and gearbox assembly

NOTE:

– bolt (A) is longer than (B) and has a washer,

– follow the tightening order as shown below, ensuring that the reinforcement

mountings (C) are tightened at the same time.

10

Refer to section 19 "Suspended engine mounting" for the tightening

torques of the engine - gearbox supports.

Refitting is the reverse of removal.

Refit the heat shields correctly.

Apply Loctite FRENBLOC to the brake calliper mounting bolts before fitting

and tighten them to the correct torque.

Press the brake pedal several times to bring the pistons into contact with the

brake pads.

Fill:

– the engine and gearbox with oil (if necessary),

– the cooling circuit and bleed it (see section 19 "Filling - bleeding").

Fill the coolant circuit using the filling equipment (if fitted).

10-9

Page 45

ENGINE AND PERIPHERALS

SPECIAL TOOLING REQUIRED

Mot. 1233-01 Threaded rods for lowering the

sub-frame

TIGHTENING TORQUES (in daN.m)

Sub-frame front mounting bolts 6.2

Sub-frame rear mounting bolts 10.5

Sump bolts 1.4

Steering shaft yoke bolt 3

Lower ball joint mounting bolt 6

Engine tie bar bolt 6.2

Sub-frame - side member tie-rod bolts 3

Wheel bolts 9

Sump

Sump

10

Remove:

– the lower ball joint mountings as well as the track rod

ends,

– the sub-frame and body tie-rods,

– the lower mountings of the bumper as well as those

of the left hand mudguard,

– the gear control on the gearbox side,

– the horns,

– the bolt (3), and slacken the engine tie-bar bolt (2),

without removing it,

– the mountings (1) of the tie-rods,

REMOVAL

Put the vehicle on a two post lift. Refer to Section 02

"Underbody lift" for positioning the lifting pads.

Disconnect the battery.

Remove the engine undertray.

Drain the engine.

Remove:

– the front wheels along with the right hand mudguard,

– the nut and the eccentric bolt of the steering shaft

yoke, after pushing back the guard.

WARNING

In order to eliminate any risk of damaging the

rotary switch under the steering wheel, observe

the recommendations below:

Before the steering column and the steering

●

rack are uncoupled, the steering wheel MUST

be immobilised for the duration of the

operation with the wheels straight using a

"steering wheel locking tool".

If there is any doubt regarding the correct

●

alignment of the rotary switch the steering

wheel must be removed so that the alignment

procedure described in the "AIRBAG" section

can be applied.

17537R1

– the upper mountings of the stabiliser bar tie-rod and

slacken the lower mountings,

REMINDER: in this case, only qualified

personnel who have received training may carry

out the operation.

10-10

Page 46

ENGINE AND PERIPHERALS

Sump

– the sub-frame mounting bolts, inserting the threaded rods Mot. 1233-01 as you go.

Release the electrical harness from the sub-frame (left hand side).

Progressively lower the sub-frame using the threaded rods Mot. 1233-01 until the

dimension X

= 7 cm is reached.

1

10

Remove the sump.

10-11

Page 47

ENGINE AND PERIPHERALS

Sump

REFITTING

Put a drop of RHODORSEAL 5661 at (A) (on either

side of bearing N˚ 1), and at (B) (at the intersection of

the crankshaft closure panel and the cylinder block).

10

15159-2R

Refit the sump with a new seal, pre-tightening it to a

torque of 0.8 daN.m, then tighten it finally to a torque

of 1.4 daN.m in the order recommended below.

10-12

15195R

Page 48

TOP AND FRONT OF ENGINE

TOP AND FRONT OF ENGINE

111

Timing belt

Timing belt

SPECIAL TOOLING REQUIRED

Mot. 799 -01 Tool for immobilising pinions on the

toothed timing belt

Mot. 1054 TDC setting pin

Mot. 1453 Engine support tool

Mot. 1487 Tool for fitting inlet camshaft

sealing plug

Mot. 1488 Tool for fitting exhaust camshaft

sealing plug

Mot. 1496 Tool for setting the camshaft

Elé. 1294-01 Tool for removing windscreen wiper

arms

ESSENTIAL SPECIAL TOOLING

Angular tightening spanner

11

TIGHTENING TORQUES (In daN.m and/or °)

Fixed roller bolt 4.5

Crankshaft pulley bolt 2 + 135˚ ± 15˚

Tensioning roller nut 2.8

Mounting bolt for front right hand

suspended engine mounting cover on

engine 6.2

Mounting bolt for the movement limiter of

the front right hand suspended engine

mounting 6.2

Wheel bolts 9

REMOVAL

Put the vehicle on a 2 post lift. Refer to Section 02

"Underbody lift" for positioning the lifting pads.

Remove:

– the front right wheel as well as the mudguard,

– the windscreen wiper arms using tool Elé. 1294-01,

– the front grilles,

11020R

– the closure panel of the plenum chamber,

11 - 1

Page 49

TOP AND FRONT OF ENGINE

Timing belt

– the protector of the right hand shock absorber cap,

11036R2

Position the engine support, tool Mot. 1453 with the

retaining straps.

11

– the accessories belt (see Section 07 "Accessories

belt tension"),

– the plate (3) on the side member,

Remove:

– the suspended engine mounting cover and the

movement limiter,

15837R

– the upper radiator mountings.

Disconnect the connectors (4)

Unclip:

– the electrical harness on the upper timing cover and

separate the assembly,

– the petrol pipe on the intermediate timing housing.

13932R

11 - 2

16669R1

Page 50

TOP AND FRONT OF ENGINE

Timing belt

Remove:

– the camshaft sealing plugs,

11

– the Top Dead Centre pin plug.

15105S

11 - 3

15102-1S

Page 51

TOP AND FRONT OF ENGINE

Timing belt

Adjusting the timing

Rotate the engine in a clockwise direction (timing side) so as to position the

camshaft grooves towards the bottom in an almost horizontal position as

shown on the diagram below. Then insert the Top Dead Centre pin Mot. 1054

so as to be between the balancing hole and the crankshaft setting groove.

11

15163-2S

15106S

11 - 4

Page 52

TOP AND FRONT OF ENGINE

Timing belt

Rotate the engine slightly in the same direction, inserting the pin Mot. 1054

to the setting point.

The grooves of the camshafts must, at the setting point, be horizontal and

offset towards the bottom as shown on the diagram below.

11

15106-1S

Correct position Incorrect position (the pin is in the balancing hole).

15163-1S

15163S

11 - 5

Page 53

TOP AND FRONT OF ENGINE

Timing belt

Remove:

– the crankshaft pulley, locking the flywheel using a

screwdriver,

11

– the intermediate timing housing (1),

– the upper housing (2).

17786S

11 - 6

15815-1R

Page 54

TOP AND FRONT OF ENGINE

Timing belt

Slacken the timing belt by undoing the nut (1) of the tensioning roller.

To remove the timing belt, remove the fixed roller (2) and take care not to

drop the crankshaft pinion (as this does not have a key).

Remove the crankshaft timing pinion.

11

11 - 7

Page 55

TOP AND FRONT OF ENGINE

Timing belt

WARNING: it is essential to degrease the end of

the crankshaft, the bore of the crankshaft pinion

and the bearing faces of the crankshaft pulley to

prevent the timing slipping which may damage the

engine.

REFITTING

When replacing the timing belt, the timing

tensioning and fixed rollers must be replaced.

Refit:

– the timing belt (it is essential to follow the method

described in Section 07 "Tensioning the timing

belt"),

– the accessories belt (see Section 07 "Procedure for

tensioning the accessories belt"),

– the plug of the Top Dead Centre pin, applying a drop

of RHODORSEAL 5661 onto the thread,

– the new sealing plugs:

of the inlet camshaft (Mot. 1487),

●

of the exhaust camshaft (Mot. 1488).

●

11

14890R

– the right hand suspended engine mounting by

tightening it to the correct torque (see Section 19

"Suspended engine mounting").

11 - 8

Page 56

TOP AND FRONT OF ENGINE

Cylinder head gasket

Cylinder head gasket

SPECIAL TOOLING REQUIRED

Mot. 799-01 Tool for locking pinions for

toothed timing belt

Mot. 1054 TDC setting pin

Mot. 1159 Tool for securing engine

Mot. 1202-01

Mot. 1202-02

Mot. 1448 Long nose pliers for hose clips

Mot. 1453 Engine support

Mot. 1487 Tool for fitting inlet camshaft

Mot. 1488 Tool for fitting exhaust camshaft

Mot. 1496 Tool for setting the camshaft

Hose clip pliers

sealing plug

sealing plug

11

Mot. 1509

Mot. 1509-01

Mot. 1512 Tool for fitting exhaust camshaft

Mot. 1513 Tool for fitting the camshaft

Mot. 1517 Tool for fitting inlet camshaft

ESSENTIAL SPECIAL TOOLING

Tool for testing cylinder head

Cylinder head testing equipment

Tool for locking the camshaft

pulleys

seal

dephaser solenoid valve seal

seals

Angular tightening spanner

11 - 9

Page 57

TOP AND FRONT OF ENGINE

Cylinder head gasket

TIGHTENING TORQUES (In daN.m and/or°)

Fixed roller bolt 4.5

Crankshaft pulley bolt 2 + 135˚ ± 15˚

Tensioning roller nut 2.8

Exhaust camshaft pulley nuts 3 + 90˚

Camshaft dephaser bolts 10

Cylinder head bolts 1.2

Oil decanter bolts 1.3

Mounting bolt for front right hand

suspended engine mounting cover on

engine 6.2

Mounting bolt for the movement limiter of

the front right hand suspended engine

mounting 6.2

11

99024R2

Lower inlet manifold bolts 2.1

Coil bolts 1.3

Inlet manifold bolts 0.9

Throttle body bolts 1.5

Air filter unit bolt 0.9

Wheel bolts 9

REMOVAL

Put the vehicle on a 2 post lift. Refer to Section 02

"Underbody lift" for positioning the lifting pads.

Remove:

– the timing belt (see method described in section 11,

"Timing belt").

– the engine undertray.

Drain the cooling circuit (through the lower radiator

hose).

15960R

Remove the two power assisted steering hoses on the

right hand side of the sub-frame,

Position the tools Mot. 1159 as shown below:

11-10

Page 58

TOP AND FRONT OF ENGINE

Cylinder head gasket

Insert a wooden block between the gearbox and the

sub-frame.

Remove the engine support tool Mot. 1453.

Method for slackening the exhaust camshaft

pulley and the inlet camshaft dephaser.

The operation is performed using tools Mot. 1509

and Mot. 1509-01.

11

Preparation of tool Mot. 1509

Remove the upper toothed pinion from the bracket.

15865R

16017S

Fit:

– the spacer (1) of tool Mot. 1509-01 on the stud (2),

16014R

16019R

11-11

Page 59

TOP AND FRONT OF ENGINE

Cylinder head gasket

– tool Mot. 1509 as shown on the diagram below, by

adjusting the position of the engine using engine

support Mot. 1453.

11

Fit:

– the pinion of tool Mot. 1509-01 (reusing the two

washers and the nut of tool Mot. 1509),

17719-2S

Pivot tool Mot. 1509 until the position shown on the

diagram below is reached.

16018S

17719S

17719-1S

11-12

Page 60

TOP AND FRONT OF ENGINE

Cylinder head gasket

– the upper bolt (3) whilst positioning the spacer (4) of

tool Mot. 1509-01 between the tool and the camshaft

bearing cap housing (do not lock the bolt).

11

Tighten the shouldered nut (6) and the bolt (7), then

bring the pinions of tool Mot. 1509 into contact with the

camshaft pulleys by tightening the nuts (1) to a torque

of 8 daN.m.

Remove:

– the blanking plate of the inlet camshaft dephaser

using a 14 mm Allen key,

– the shouldered nut (5) of tool Mot. 1509-01.

16019-2R

16019-4R2

– the nut of the exhaust camshaft pulley,

– the bolt of the inlet camshaft dephaser.

16019-3R

16019-5S

11-13

Page 61

TOP AND FRONT OF ENGINE

Cylinder head gasket

Remove:

– the accelerator cable,

– the power steering reservoir from its support and

release it,

– the injection rail protector,

– the fuel supply pipe on the injection rail and release it.

Disconnect:

– the connector (3) as well as those of the coils,

– the vacuum pipe from the brake servo on the inlet

manifold,

– the air housing at (4).

11

15212S

14843R

NOTE: be careful of the vacuum outlet going from the

inlet manifold to the brake servo. The manifold has to

be replaced if this outlet is broken.

Move the air filter unit to the right in order to remove it.

The air filter unit can pass between the windscreen

aperture, the engine and the brake servo.

11-14

Page 62

TOP AND FRONT OF ENGINE

Cylinder head gasket

Remove:

– the stays (A),

11

17706R2

11-15

Page 63

TOP AND FRONT OF ENGINE

Cylinder head gasket

– the mountings of the catalytic converter, release it from the exhaust manifold and secure it to the exhaust pipe,

– the throttle body at (5),

– the oxygen sensor connector of the catalytic converter,

– the lifting bracket (6),

– the air distributor,

11

15149R

11-16

Page 64

TOP AND FRONT OF ENGINE

– the coils,

– the oil decanter,

Cylinder head gasket

11

15150-1S

11-17

Page 65

TOP AND FRONT OF ENGINE

Cylinder head gasket

– the lifting bracket on the flywheel side,

– the bolts of the cylinder head cover then release it vertically by tapping on

the "lugs" at (1) using a copper hammer and lever it using a screwdriver at

(2) (protect the screwdriver to avoid damaging the aluminium surfaces).

11

11-18

Page 66

TOP AND FRONT OF ENGINE

Cylinder head gasket

– the camshafts as well as the valve rockers,

– the hoses on the cylinder head water outlet housing

as well as the coolant temperature sensor connector,

– the mountings of the electrical harness bracket at

(10),

11

14889R1

11-19

Page 67

TOP AND FRONT OF ENGINE

– the cylinder head.

Cylinder head gasket

11

CLEANING

It is very important not to scratch the gasket faces

of all aluminium components.

Use the Décapjoint product to dissolve any part of the

gasket which remains attached.

It is recommended that gloves are worn during the

following operation:

apply the product to the part to be cleaned; wait for

about ten minutes, then remove it using a wooden

spatula.

We must draw your attention to the care which

must be taken during this operation, to prevent

any foreign bodies from being introduced into the

oil channels (channels located in the cylinder

block and in the cylinder head).

15153-1S

CHECKING THE GASKET FACE

Check that there is no gasket face bow.

Maximum deformation: 0.05 mm.

No regrinding of the cylinder head is permitted.

Check the cylinder head for cracks.

11-20

Page 68

TOP AND FRONT OF ENGINE

Cylinder head gasket

REFITTING

When dismantling and refitting the cylinder head,

please comply with the following points:

– It is important to re-prime the hydraulic tappets

as these may become drained after a long time.

To check whether they need repriming, press the

top of the tappet at (A) with your thumb and if the

tappet piston can be pressed down, submerge

the tappet in a container filled with diesel then

refit them.

11

14499R2

11-21

Page 69

TOP AND FRONT OF ENGINE

Cylinder head gasket

– Check:

that the exhaust heat shield is correctly positioned between the oxygen sensor and the manifold (so as

●

to prevent a chimney effect which might destroy the wiring of the upstream sensor),

the alignment (A) between the lower inlet manifold and the cylinder head (timing side), ensuring that the

●

tabs (B) are correctly touching those of the cylinder head cover.

11

The lower inlet manifold must be tightened to a torque

of 2.1 daN.m.

Position the pistons at mid-stroke to prevent any

contact with the valves when refitting the camshafts.

Position the cylinder head gasket then the cylinder

head.

Check the bolts then tighten the cylinder head (see

Section 07 "Tightening the cylinder head").

15148R

15154S

11-22

Page 70

TOP AND FRONT OF ENGINE

Cylinder head gasket

Refit:

– the valve rockers,

– the camshafts by oiling the bearings.

WARNING: do not put oil on the gasket face of the

cylinder head cover.

The camshafts can be identified by the pulley

mountings.

Detail of the pulley mountings:

F exhaust camshaft,

G inlet camshaft.

11

15152R

11-23

Page 71

TOP AND FRONT OF ENGINE

Cylinder head gasket

Position the grooves of the camshafts as shown in the diagram below.

11

NOTE: the gasket faces must be clean, dry and

free from grease (avoid finger marks).

Apply Loctite 518 using a stipple roller to the gasket

face of the cylinder head cover until it turns reddish in

colour.

15106-1S

14517S

11-24

Page 72

TOP AND FRONT OF ENGINE

Cylinder head gasket

Fit the cylinder head cover tightening it to the correct torque.

Tightening procedure

Assembly

Operation n˚ 1 22-23-20-13 - 0.8

Operation n˚ 2

Operation n˚ 3 - 22-23-20-13 -

Operation n˚ 4 22-23-20-13 - 1.2

Bolt tightening

order

1 to 12

14 to 19

21 and 24

Bolt slackening

order

- 1.2

Tightening torques

11

(in daN.m)

11-25

14497-4R1

Page 73

TOP AND FRONT OF ENGINE

Cylinder head gasket

NOTE: the gasket faces must be clean, dry and free from grease (avoid

finger marks).

Apply Loctite 518 using a stipple roller to the gasket face of the oil decanter

until it turns reddish in colour.

14516S

11

Fit the oil decanter and tighten it to a torque of 1.3 daN.m in the recommended order.

11-26

15150-1R

Page 74

TOP AND FRONT OF ENGINE

Cylinder head gasket

The seal of the control solenoid valve is replaced using

tool Mot. 1513.

11

16016R

11-27

Page 75

TOP AND FRONT OF ENGINE

Cylinder head gasket

Refit:

– the coils, tightening them to a torque of 1.3 daN.m,

– the inlet manifold (fitted with new seals), tightening it to a torque of 0.9 daN.m in the recommended order,

11

– the throttle body, tightening the bolts (A) to a torque of 1.5 daN.m,

– the air filter unit, tightening the bolts to a torque of 0.9 daN.m,

15149R1

11-28

Page 76

TOP AND FRONT OF ENGINE

Cylinder head gasket

Replacing the camshaft seals

Fit the seal of the exhaust camshaft dephaser using

tool Mot. 1512, using the old nut (1).

11

Adjusting the timing

WARNING: it is essential to degrease the tip of the

crankshaft, the bore of the timing pinion, the

bearing faces of the pulley as well as the ends of

the camshafts (timing side) and the bores of the

camshaft pinions to prevent the timing from

slipping which may damage the engine.

Refit:

– the timing belt (the method described in Section 07

"Timing belt tensioning procedure" must be

complied with),

– the accessories belt (see Section 07 "Accessories

belt"),

– the new sealing plugs:

of the inlet camshaft (Mot. 1487),

●

of the exhaust camshaft (Mot. 1488).

●

16015R

Fit the seal of the inlet camshaft dephaser using tool

Mot. 1517 and the old bolt (2).

16015-1R

NOTE: to use tool Mot. 1517, the hole must be

modified to a diameter of 13 mm.

14890R

– the right hand suspended engine mounting by

tightening it to the correct torque (see Section 19

"Suspended engine mounting").

Refitting is the reverse of removal.

Fill and bleed the cooling circuit, (see section 19

"Filling and Bleeding").

11-29

Page 77

FUEL MIXTURE

FUEL MIXTURE

112

Specifications

Specifications

Engine

Vehicle Gearbox

Type Suffix

JA0C JC7 F4R 744 82.7 93 1998 9.8/1

Engine

Engine

speed

Type Index CO (%) (1)

(rpm)

Bore

(mm)

Stroke

(mm)

Tests at idle speed*

Pollutant emission **

CO

(%)

2

Cubic

capacity

3

(cm

)

HC (ppm) Lambda (λ)

Ratio

Catalytic

converter

◊ C79

◊ C134

(minimum octane

Euro 2000

Fuel***

rating)

12

Depollution

standard

F4R 744 750 0.5 max 14.5 min 100 max 0.97<λ<1.03 Unleaded (OR 95)

(1) at 2500 rpm, CO must be a maximum of 0.3

At a coolant temperature greater than 80 ˚C and after a coolant engine speed of 2 500 rpm, for about

*

30 seconds. Test to be carried out after return to idle speed.

For legal values refer to your country specification.

**

***

OR 91 unleaded compatible.

Temperature in °C (± 1°)- 10 25 50 80 110

Air Temperature Sensor

Type "Negative Temperature

Coefficient" Resistance in Ohms

Air Temperature Sensor

Type "Negative Temperature

Coefficient" Resistance in Ohms

10 450 to 8 525 2 120 to 1 880 860 to 760 - -

- 2 360 to 2 140 770 to 850 275 to 290 112 to 117

12-1

Page 78

FUEL MIXTURE

Specifications

DESCRIPTION BRAND/TYPE SPECIAL NOTES

Computer

Injection - Sequential multipoint

Stepper motor PHILIPS Resistance: 53 ± 5 Ω at ambient temperature

Throttle potentiometer CTS

Magnetic sensor

(TDC and engine speed)

SIEMENS

"SIRIUS"

ELECTRIFIL

or

SIEMENS

90 tracks

Incorporate in throttle housing

Track resistance: 1 200 ± 240 Ω

Cursor resistance < 1 050 Ω

Track PL PF

A - B

A - C

B - C

Incorporated connector

Resistance = 200 to 270 Ω

1, 250 Ω

1, 245 Ω

2, 230 Ω

1, 250 Ω

2, 230 Ω

1, 245 Ω

12

Canister solenoid valve SAGEM

Injector

Air sensor JAEGER

Coolant sensor JAEGER

Pressure sensor

Pinking sensor SAGEM

Oxygen sensors

(Upstream and Downstream)

MAGNETI-

MARELLI PICO

DELCO

ELECTRONICS

BOSCH

Integrated into the canister

Resistance: 26 ± 4 Ω at 23 ˚C

Resistance: 14.5 Ω

Start of leak: 0.7 cm

CTN (see table)

Resistance: 2 500 Ω at 20 ˚C

CTN (see table)

Resistance: 3 500 Ω at 20 ˚C

Piezoelectric type

Replace the seal each time it is removed

Piezoelectric type

Tightening torque: 2 daN.m

Heater resistance

R ≈ 9 Ω at ambient temperature

Rich mixture = 840 mV ± 70

Lean mixture = 20 mV ± 50

3

/min maxi

12-2

Page 79

FUEL MIXTURE

Specifications

DESCRIPTION BRAND/TYPE SPECIAL NOTES

NIPPONDENSO

Ignition coil'

SAGEM

Spark plugs

Inlet manifold pressure - At idling speed: 300 ± 40 mb

Exhaust counter-pressure -

RC 82 YCL

(Champion)

Primary resistance: 0.48 - 0.52 Ω

Secondary resistance: 5.8 - 8.5 KΩ

Primary resistance: 0.52 - 0.56 Ω

Secondary resistance: 9 - 12.5 KΩ

Tightening torque: 2.5 to 3 daN.m

1 500 rpm.

3 000 rpm

4 500 rpm.

5 500 rpm.

upstream of the

pre-catalytic

converter

30

108

211

321

12

downstream of

the pre-catalytic

converter

23

84

153

266

Submerged feed pump

Pressure regulator -

Camshaft dephaser solenoid

valve

Coolant pressure sensor. -

BOSCH

or WALBRO

AISIN

Flow read: 80 - 100 litres/hour min.

Regulated pressure

Circuit without return: 3.5 ± 0.2 bars

"All or nothing" solenoid valve

Resistance: 7.1 ± 0.5 Ω

For air conditioning computer incorporated into injection

computer operation

12-3

Page 80

FUEL MIXTURE

Air filter unit.

Air filter unit.

SPECIAL TOOLING REQUIRED

Elé. 1294-01 Tool for removing windscreen

wiper arms

TIGHTENING TORQUES (in daN.m)

Air filter unit bolt 0.9

REMOVAL

Disconnect the battery.

Remove:

– the windscreen wiper arms using tool Elé. 1294-01,

– the plenum chamber panel,

12

– the air resonator,

– the brake servo vacuum pipe (manifold side),

– the mounting bolts of the air filter unit (3).

– the bulkhead plate,

11020R

11036R2

14843R1

Disconnect:

– the actuator (1),

– the fuel vapour rebreathing pipe (2).

Move the air filter unit to the right in order to remove it.

The air filter unit can pass between the windscreen

aperture, the engine and the brake servo.

REFITTING

Refitting is the reverse of removal.

NOTE: be careful of the vacuum outlet going from the

exhaust manifold to the brake servo. The inlet manifold

has to be replaced if this outlet is broken.

12-4

Page 81

FUEL MIXTURE

Inlet manifold

Inlet manifold

TIGHTENING TORQUES (in daN.m)

Manifold bolts 1

Air filter unit bolt 0.9

Throttle body bolts 1.5

REMOVAL

Disconnect the battery.

Remove the air filter unit (see Section 12 Fuel mixture

"Air filter unit").

Disconnect:

– the throttle potentiometer,

– the pressure sensor,

– the pencil coils,

– the air temperature sensor,

– the accelerator cable,

– the dephaser solenoid valve.

12

REFITTING

Refitting is the reverse of removal.

NOTE: use the recommended tightening order and the

tightening torque of the inlet manifold and throttle body

bolts.

If necessary, replace the seals of the manifold and the

throttle body.

Remove:

– the two mounting bolts of the throttle body (A),

– the bolts of the inlet manifold.

12-5

15149R1

Page 82

FUEL MIXTURE

Injector holder shim

Injector holder shim

TIGHTENING TORQUES (in daN.m)

Injector holder shim 2.1

Rail bolts 0.9

Inlet manifold bolts 1

REMOVAL

Disconnect the battery.

Remove:

– the inlet manifold (see Section 12 Fuel mixture "Inlet

manifold"),

– the injection rail protection,

– the flange of the injection harness.

Disconnect:

– the fuel inlet and return pipes (1) and (2) or the fuel

inlet pipe (depending on version),

– the regulator vacuum pipe (depending on version),

– the injectors.

12

Remove the front right hand mudguard.

Secure the automatic tensioner of the accessories

belt.

Remove the belt.

WARNING: all removed belts must be replaced. To do

this, refer to the method in Section 07 "Accessories

belt tension".

Remove:

– the assisted steering pump pulley,

– the three mounting bolts of the assisted steering

pump.

14844R5

Move aside the assisted steering pump, without

removing the pipes.

Remove the mounting bolts and the injector holder

shim.

14503R1

12-6

Page 83

FUEL MIXTURE

Injector holder shim

REFITTING

Replace the seal.

Check the alignment (at A) between the lower inlet manifold and the cylinder head, ensuring that the

distributor is touching (at B) the cylinder head cover.

12

Refitting is the reverse of removal.

Use the correct tightening torque for the mountings nuts and bolts of the shim.

Replace the accessories belt, see section 07 "Accessories belt tension".

15148R

12-7

Page 84

FUEL MIXTURE

Exhaust manifold

Exhaust manifold

SPECIAL TOOLING REQUIRED

Mot. 1495 Tool for removing and refitting

TIGHTENING TORQUES (in daN.m))

Upstream oxygen sensor 4.5

Manifold bolts 1.8

Three point flange nut 2

Heat shield bolts, 1

REMOVAL

Put the vehicle on a 2 post lift. Refer to Section 02

"Underbody lift" for positioning the lifting pads.

12

the upstream oxygen sensor.

Disconnect the battery.

Remove the air filter unit (see Section 12 Fuel mixture

"Air filter unit").

Disconnect and remove the oxygen sensor (1) using

tool Mot. 1495.

Remove the upper heat shield of the exhaust manifold.

Disconnect the exhaust downpipe.

15099R

Move the exhaust pipe backwards without removing it.

Position a block on the sub-frame to support the exhaust downpipe and

avoid damaging the hose which would require the catalytic converter to be

replaced.

12-8

Page 85

FUEL MIXTURE

Exhaust manifold

Remove the flange (A) between the exhaust manifold

and the cylinder block.

12

17706R

Release the manifold by pivoting it through 45˚, then

remove it from the side.

12-9

Page 86

FUEL MIXTURE

Exhaust manifold

REFITTING

Refitting is the reverse of removal.

NOTE: check that the heat shield is correctly positioned between the oxygen

sensor and the manifold (so as to prevent a chimney effect which might

destroy the wiring of the oxygen sensor).

Replace the gaskets of the manifold and of the three point mounting.

Use the correct order and tightening torque for the mountings nuts of the

manifold.'

WARNING: all damaged heat shields must be replaced to prevent the risk of

fire.

12

12-10

15101R1

Page 87

ANTIPOLLUTION

ANTIPOLLUTION

114

Fuel vapour rebreathing

Fuel vapour rebreathing

BASIC DIAGRAM OF THE CIRCUIT

14

97393-1R1

Inlet manifold

1

Recycling solenoid valve

2

Fuel vapour absorber with solenoid valve

3

Fuel tank

4

Breather

M

CANISTER PURGE CONDITIONS

The canister bleed solenoid valve is controlled by

track 4 of the computer when:

– the coolant temperature is greater than 55 ˚C,

– the air temperature is greater than 10 ˚C,

– the engine is not idling,

– a given load threshold is reached,

– the throttle potentiometer position is not at No Load,

The opening cyclic ratio of the canister bleed solenoid

valve can be viewed using the diagnostic tool, by

consulting the "Canister bleed solenoid valve OCR"

parameter.

The solenoid valve is closed for a value less than

1.5 %.

14-1

Page 88

STARTING - CHARGING

STARTING - CHARGING

116

Alternator

Alternator

IDENTIFICATION

Type Engine Alternator Current

JA0C F4R 744 BOSCH 0124 415 007 (AC) 98 A

CHECKING

After 15 minutes warming up with a voltage of 13.5 volts.

Rpm. 98 Amps

16

2 000 63

3 000 86

4 000 95

16-1

Page 89

STARTING - CHARGING

Alternator

REMOVAL

Put the vehicle on a 2 post lift. Refer to Section 02

"Underbody lift" for positioning the lifting pads.

Disconnect the battery.

Remove:

– the front right wheel as well as the mudguard,

– the accessories belt (see Section 07 "Accessories

belt tension"),

– the power steering reservoir on the fan unit and

release it,

– the mounting of the power assisted steering pipe

on the multifunction support,

– the assisted steering pump pulley,

– the power steering pump from its support and

release it,

– the power steering pump mounting,

16

– the alternator by disconnecting the electrical

connections.

REFITTING

Refit in reverse order to removal.

Refer to Section 07 "Accessories belt tension" for

the tensioning process.

16-2

Page 90

STARTING - CHARGING

IDENTIFICATION

Starter

Starter

Type Engine Starter motor

JA0C F4R 744 BOSCH 0001 106 012

16

16-3

Page 91

STARTING - CHARGING

SPECIAL TOOLING REQUIRED

T. Av. 476 Ball joint extractor

TIGHTENING TORQUES (in daN.m)

Shock absorber base bolt 18

Brake caliper mounting bolt 4

Lower ball joint mounting bolt 6

Track rod end nut 3.5

Wheel bolts 9

REMOVAL

Starter

– the heat shield of the precatalytic converter as well

– the starter motor feed and disconnect the winding,

– the air resonator,

– the starter motor mounting bolts.

To remove the starter motor, move it towards the

rear (1) and rotate (2).

16

as that of the exhaust manifold,

Put the vehicle on a 2 post lift. Refer to Section 02

"Underbody lift" for positioning the lifting pads.

Disconnect the battery.

Remove:

– the front right wheel as well as the engine undertray,

– the hub assembly fitted with the right hand driveshaft

from the vehicle,

– the stay (A),

17705R

Then pivot the starter motor until the position shown

below is reached and remove it.

17706R

16-4

Page 92

STARTING - CHARGING

Starter

16

REFITTING

Proceed in the reverse order from removal.

Check for the presence of the centring dowel (B).

Refit the heat shields correctly.

16-5

Page 93

INJECTION

INJECTION

117

Specifications

Specifications

SPECIAL FEATURES OF THE MULTIPOINT DIRECT INJECTION FITTED IN THE F4R 744 ENGINE

SIEMENS "SIRIUS 32" 90-way computer controlling the injection and the ignition.

●

Multipoint injection operating in sequential mode without cylinder reference and camshaft position sensor. This

●

means the phasing is carried out by a software program from the TDC sensor.

Injection warning light on instrument panel not operational.

●

Installation of a specific injection warning light (OBD light "On Board Diagnostic") which is illuminated for three

●

seconds when the ignition is switched on. Its presence is due to the fact that the OBD "On Board Diagnostic" fault

finding system is fitted.

Special precautions relating to the engine immobiliser:

●

Adoption of a 2

Fuel circuit without return to the tank (the regulator is located on the pump and sender unit).

●

Idle speed:

●

– nominal idle speed 750 rpm.

nd

generation type engine immobiliser requiring a specific computer replacement method.

17

Idle speed corrected in line with:

●

– air conditioning,

– the information from the power assisted steering pressure switch,

– electric balance,

– the headed windscreen.

Maximum engine speeds:

●

– when the coolant temperature is less than 75 ˚C or depending on a timer.

– when the temperature is greater than 75˚ C,

– in reverse gear

Canister bleed solenoid valve controlled by Opening Cyclic Ratio (OCR) depending on engine operation.

●

Control of the fan assemblies and of the coolant temperature warning light on the instrument panel by the injection

●

computer.

Automatic configuration when the air conditioning is operating by exchanging signals between the computers.

●

Inlet camshaft dephaser controlled by a solenoid valve operated by the computer depending on engine operation

●

(engine speed / load).

Use of two oxygen sensors located upstream and downstream of the catalytic converter.

●

Injection computer controlling the air conditioning (the air conditioning computer is no longer fitted).

●

5900 rpm.

6000 rpm.

4300 rpm.

17-1

Page 94

INJECTION

Immobiliser function

Immobiliser function

This vehicle is fitted with an engine immobiliser controlled by a random rolling code key recognition system.

REPLACING AN INJECTION COMPUTER

The injection computers are supplied without a code but they can all be programmed with one.

When replacing the computer, the vehicle code must be programmed in and then a check must be made to ensure

that the immobiliser system is operational.

To do this, simply switch on the ignition for a few seconds without starting the engine then switch it off. With the

ignition off, the engine immobiliser function comes into operation after approximately 10 seconds (the red engine

immobiliser warning light flashes).

IMPORTANT:

With this engine immobiliser, the computer keeps its immobiliser code for life.

In addition, this system does not have a security code.

17

Consequently, it is forbidden to perform tests with computers borrowed from the stores or from another

vehicle which must then be returned.

It will no longer be possible to decode them.

17-2

Page 95

INJECTION

Injection/air conditioning management

Injection/air conditioning management

THE COMPRESSOR IS OF VARIABLE DISPLACEMENT TYPE

There is no air conditioning computer on this type of engine. The injection computer directly controls the clutch

compressor, taking into account the power absorbed by the compressor and the pressure of the coolant fluid in the

circuit.

The tracks used for the air conditioning function are:

– one wire from the injection computer to track 10. This wire conveys information authorising or forbidding operation

of the compressor,

– one wire from track 46 which conveys information on the Power Absorbed,

– one wire from tracks 82 and 83 to supply the coolant pressure sensor,

– one wire from track 18 of the pressure sensor for information sent to the injection computer.

When the air conditioning switch is activated, the injection computer authorises the clutch compressor according to

the parameters and adopts a fast idling speed. This speed may reach 900 rpm. according to the power absorbed by

the compressor and the coolant pressure.

WARNING: the value in the: "PR power absorbed" parameter is never equal to 0, regardless of the state of the

compressor. The minimum value read is 250 watts.

17

COMPRESSOR OPERATION PROGRAMMING

During certain operating phases, the diesel injection computer stops the compressor from functioning.

Engine start programming

After the engine is started, the compressor is prevented from functioning for 10 seconds.

Thermal protection programming

The compressor does not engage in cases where the coolant temperature is greater than + 115 °C.

17-3

Page 96

INJECTION

Idle speed correction

Idle speed correction

POWER STEERING PRESSURE SWITCH - INJECTION COMPUTER CONNECTION

The injection computer receives information from the power assisted steering pressostat and modifies the engine's

idling speed to 780 rpm.

ELECTRICAL CORRECTION DEPENDING ON BATTERY VOLTAGE AND ELECTRICAL BALANCE

The lower the battery voltage, the greater the correction. Correction of the engine speed is therefore variable. It

begins when the voltage drops to below 12.7 Volts. The idling speed may reach 900 rpm maximum.

CORRECTION OF THE IDLING SPEED DEPENDING ON HEATED WINDSCREEN OPERATION

If the coolant temperature is less than 60˚ C, the idling speed is set to 990 rpm.

NOTE: after starting from cold and operating for a long time at idling speed, there may be a sudden fall in engine

speed by around 80 rpm. This fall in engine speed is due to the presence of an automatic starting device.

17

ADAPTIVE IDLE SPEED CORRECTION

This correction is only effective if the coolant temperature is greater than 80 ˚C, 20 seconds after the engine is

started and if an idle regulation phase is in progress.

VALUES OF THE IDLING OPENING CYCLIC RATIO (OCR) AND ITS ADAPTIVE CORRECTION

PARAMETERS F4R 744 engines

Nominal idle speed Χ = 750 rpm.

Idling Opening Cyclic Ratio 5 % ≤ Χ ≤ 26 %

Adaptive idling opening cyclic ratio Limit:

– min: - 8 %

– max: + 8 %

Every time the engine is switched off the computer resets the stepper motor to its lower limit.

IMPORTANT: after erasing the computer memory, it is essential to start the engine then stop it to allow the stepper

motor to be reset. Start it again and let it run at idle speed so that the adaptive correction can take place.

17-4

Page 97

INJECTION

Richness regulation

Richness regulation

The F4P 744 (EURO 2000) engine with the "SIRIUS 32" computer is fitted with two oxygen sensors called the

upstream sensor and the downstream sensor.

HEATING OF THE SENSORS

The sensors are heated by the computer:

– when the engine is started for the upstream sensor.

– after a certain cartographic operation time which depends on the top dead centres and the coolant temperature at

no load for the downstream sensor.

Heating the oxygen sensors is stopped:

– when the vehicle speed is greater than 140 km/h, (value given for information),

– depending on the load or the engine speed (for the upstream sensor only).

UPSTREAM SENSOR VOLTAGE