Page 1

DT 4/366 AN

english edition

GUIDE FOR THE FITTING

OF BODYWORK FOR THE

RENAULT MIDLUM

Series

50 21 008 236 - 04/02

édition anglaise

RENAULT V.I.

S.A. au capital de 50 000 000 €.

Siège social : 99, route de Lyon - 69802 Saint-Priest

IMPORTANT

Reading the “Guide for the Fitting of Bodywork for the MIDLUM series”

The “Guide for the Fitting of Bodywork for the RENAULT MIDLUM series” ushers in a new type

of presentation for bodywork fitting guides.

This new presentation sets out in one single document all those details which are necessary

for the bodybuilder and equipment manufacturer to have available.

The present document consists of three sections:

A - “General features”: This describes the relevant general principles and basic rules applicable

for the conversion and fitting of equipment to vehicles in most cases for the majority of

applications.

B -“RENAULT MIDLUM special bodybuilding features”: This deals in greater detail with presen-

tation of the vehicle, attachment of the body, electrical pre-arrangements, trade vehicles

and trade packs.

C -“Supplementary information on the RENAULT MIDLUM Euro 3 vehicle”: This deals in

greater detail with power take-offs, air-operated and specific equipment, assembly of

equipment to chassis and cab.

If a topic is dealt with in the three sections, the relative information may be:

- complementary: in this case the “Special bodybuilding features” section provides details or

values relating to the topic dealt with in “General features”.

- partially or fully contradictory: when the RENAULT MIDLUM vehicle is endowed with a

special feature whose characteristics go against general principles. In such case, the elements regarding this specificity in the “Special bodybuilding features” section supersede

those dealing with the same topic in the “General features” section.

You may need, when looking for information on a specific point, to consult the three “General

features”, “Special bodybuilding features” and “Supplementary information on the RENAULT

MIDLUM vehicle” sections, so as to ensure that you have obtained all the relevant details.

The information given by the Manufacturer in this document is compiled in relation to

the technical specifications in force on the date of drafting of the document.

It is subject to modification in the event of changes made by the OEM during the manufacture of the different units and accessories for vehicles of its make.

Page 2

RENAULT V.I. - 04/02 - Imprimé en France

Page 3

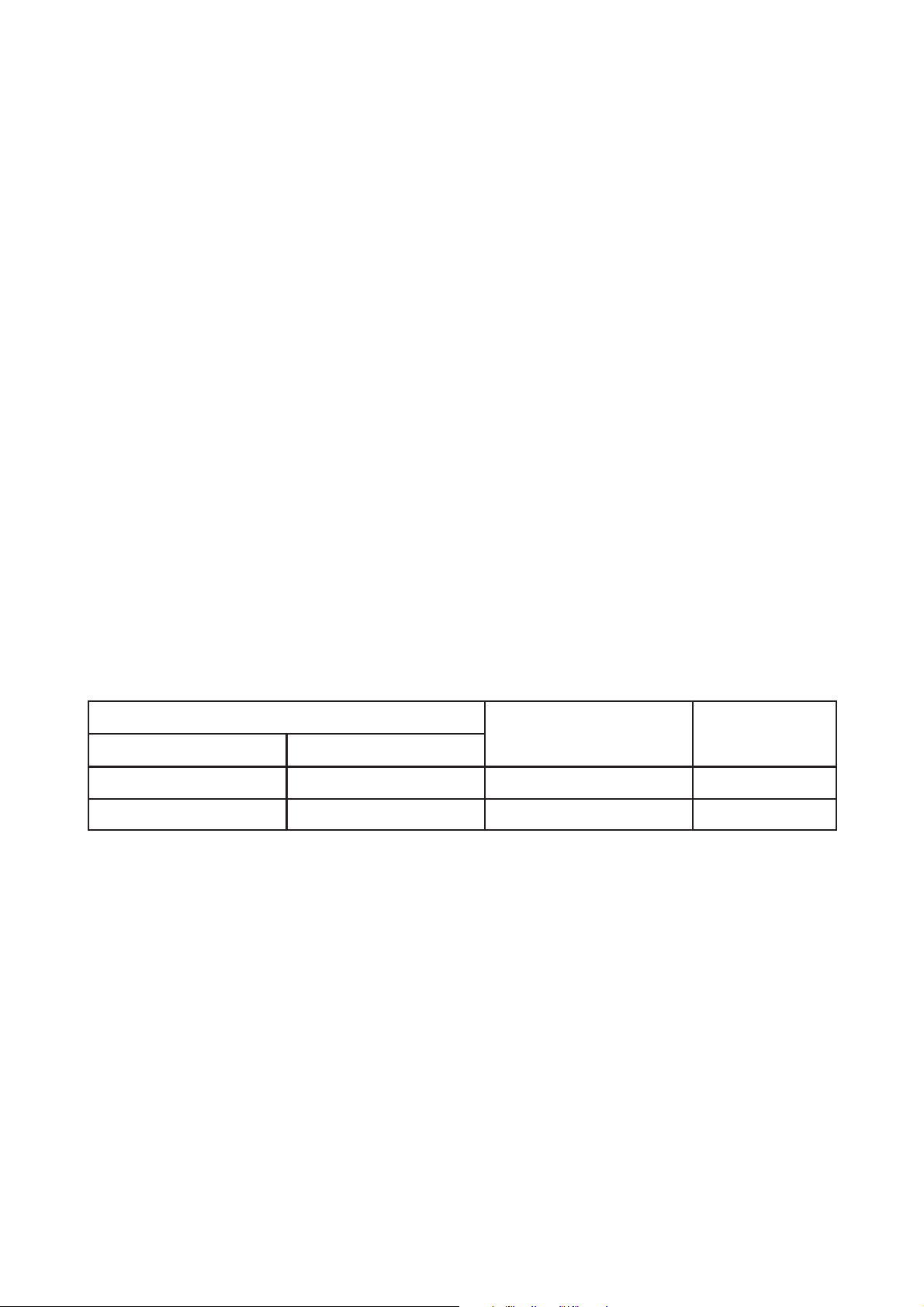

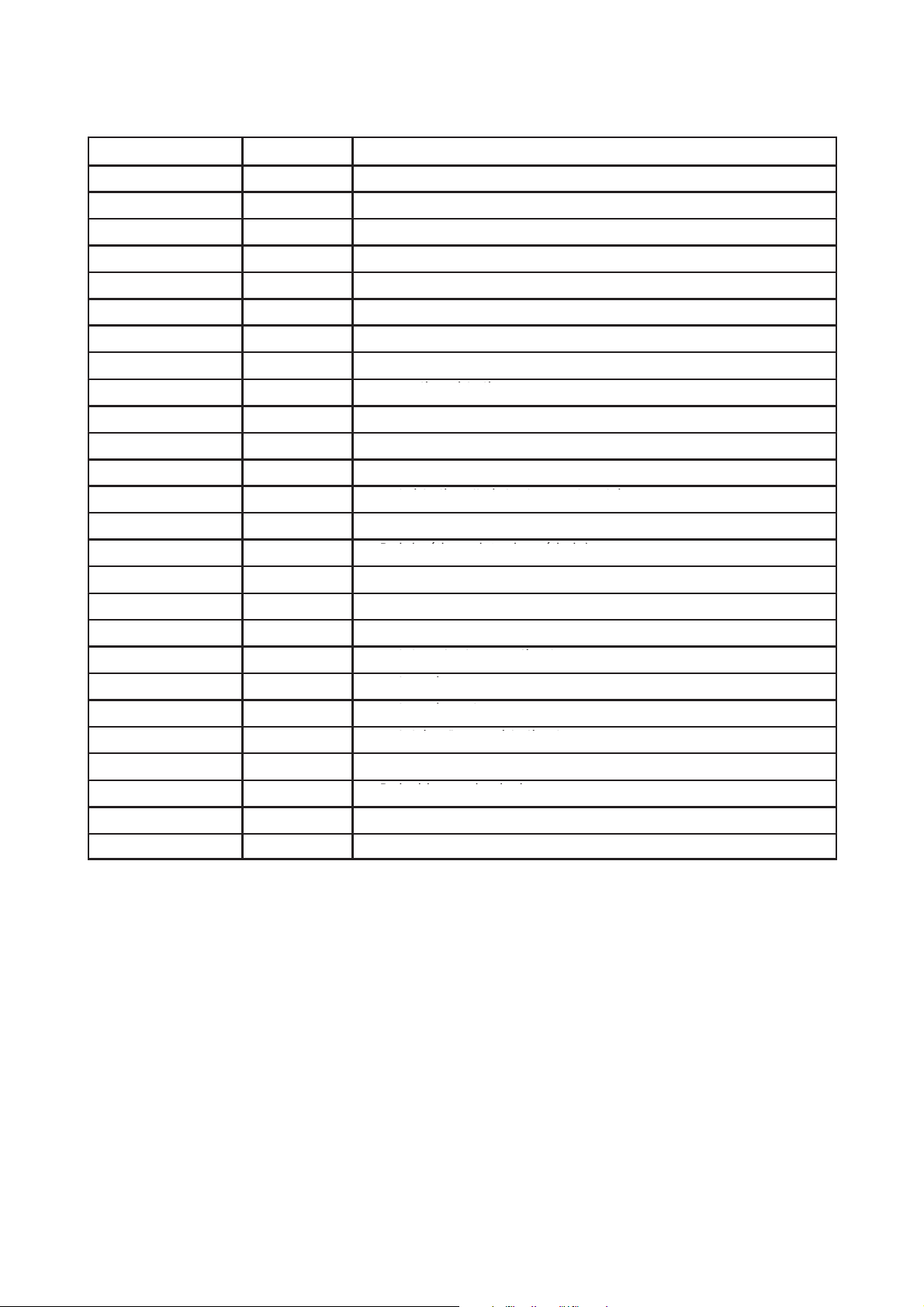

CONTACTS

Belgique België

RENAULT TRUCKS Belgique SA

Avenue du port 138,

1000 Bruxelles

Télèphone fax

Correspondant carrossier

00.32/02.421.76.31 00.32./02.425.56.06

Ceská Republika

RENAULT TRUCKS CR s.r.o.

Saldova 425/12,

18621 Praha 8,

Ceská Republika

Télèphone fax

Technicky inspektor

00.42/24.23.20.80 00.42/24.23.20. 84

Deutschland

RENAULT LKW Deutschland Gmbh

Renault StraBe 12,

50321 Brühl

Télèphone fax

Verkaufstechn. und Aufbauberatung

00.49/0.222.32.7077.142 00.49/0.222.32.7077.181

España

RENAULT TRUCKS España, s.a.

C/Eduardo Barreiros, 104

28080 Madrid

Teléfono fax

Tecnico comercial

00.34/91.3.47.13.84 00.34/91.3.47.13.53

France

RENAULT TRUCKS

99, route de lyon,

69800 Saint–Priest

Télèphone fax

Technico comercial

04.72.96.96. 70 04.72.96.81.93

DT 4/366 RENAULT V.I. 04/02

Page 4

RENAULT V.I. 04/02 DT 4/366

Great–Britain

RENAULT TRUCKS UK Ltd,

Boscombe Road,

Dunstable,

Bedfordshire LU5 4LX

Télèphone fax

Applications Engineering Manager

00.44/1582.479150 00.44/1582.479328

Italia

RENAULT TRUCKS Italia S.P.A.

Via Castiglioni 20,

20010 Arluno (MI)

Telefonico fax

Marketing

00.39/02.902.52.267 00.39/290.376.800

Magyarország

RENAULT TRUCKS Hungária Kft.

2046 Törökbálint, Tó Park

Magyarország

Telefon fax

Müszaki–kereskedelmi munkatárs

00 .36/23.51.35.13 00 .36/23.51.35.14

Nederland

RENAULT TRUCKS Nederland B.V.

Edisonweg 8

4132 PC Vianen

Télèphone fax

Begeleiding carrosseriebow

00.31/31.347.323624 00.31/31.347.323650

Österreich

RENAULT LKW Österreich

Industriestrasse 5

A–2353 Guntramsdorf

Télèphone fax

Dispo

00.43/22.36.41.171.48 02236/860166

Page 5

Polska

RENAULT TRUCKS Polska Sp.Z.o.o.

ul. Polczynska 10

01–378 Warszawa

Telefon fax

Dyrektor Techniczny

00.48/22.66.45.199 00.48/22.66.45.040

Portugal

RENAULT TRUCKS Polska Sp.Z.o.o.

ul. Polczynska 10

01–378 Warszawa

Teléfono fax

Técnico–comercial

00.351/263.28.0864 00.351/263.28.0850

Schweiz Suisse Svizzera

RENAULT NUTZFAHRZEUGE (Schweiz) AG

Rütiweg 5

4133 Pratteln

Télèphone fax

Responsabile tecnico

00.41/61.82.10.811 00.41/61.82.10.817

Slovenská Republika

RENAULT TRUCKS CR s.r.o.

organizacná zlozka RENAULT TRUCKS SR

Teslova 30, P.O. BOX 168, 820 05

Bratislava 25,

Slovenská Republika

Télèphone fax

Obchodno–Technicky inspektor

421/2/43 41 27 96–7 421/2/43 63 36 01

Türkiye

RENAULT TRUCK Ticaret A.

Hülagûl Cad. Tepeüstü Sok. No: 30

81610 / Kavac k / Beykoz / Stanbul

Télèphone fax

Bayi Geli im Planlama Müdürü

00.90/216.413.69.16 00.90/216.331.21.98

DT 4/366 RENAULT V.I. 04/02

Page 6

RENAULT V.I. 04/02 DT 4/366

Page 7

DT 4/366 1 RENAULT V.I. 04/02

Page

1. GENERAL FEATURES

1.1 Scope of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A2

- Guarantee and responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A2

1.2 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A2

1.3 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A3

1.4 Quality assurance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A4

1.5 Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A4

1.6 General instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A5

1.7 Safety on tilt cabs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A6

1.8 Chassis markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A6

1.9 Adjustments to the vehicle settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A7

1.10 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A7

1.10.1 Bodywork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A7

1.10.2 Chassis/Underbodies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A7

1.10.3 Cleaning of the cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A7

1.10.4 Cleaning of the instrument panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A7

1.11 Safety and protection of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A7

1.12 Summary of definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A8

1.13 Certificate of approval of the conversion of a vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A9

1.13.1 Application for approval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A9

1.13.2 Body fitting certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A9

1.13.3 Responsibility for installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A9

1.14 Painting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A10

1.14.1 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A10

1.14.2 Major units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A10

- Retouch method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A10

1.14.3 Chassis frame and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A11

- Retouch method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A11

1.14.4 Recommended products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A12

- Manual cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A12

- High pressure cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A12

- Filling and sealing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A12

1.14.5 Marking of polymer components (recycling of plastics) . . . . . . . . . . . . . . . . . . . . . . . . .A13

- Table of the principal polymers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A14

1.15 Electrical equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A15

1.15.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A15

1.15.2 Wiring Harnesses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A15

1.15.3 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A16

1.15.4 Available power supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A16

1.15.5 Flasher units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A16

1.15.6 List of standard power sockets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A17

1.15.7 Additional direction indicator lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A19

CONTENTS

GENERAL RULES FOR CONVERSIONS

CHAPTER -A-

GENERAL FEATURES

Page 8

RENAULT V.I. 04/02 2 DT 4/366

1.16 Air-operated equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A20

1.16.1 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A20

1.16.2 Polyamide pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A20

- Identification marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A20

- Coding (RENAULT TRUCKS Standard) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A20

- Brakes code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A20

- Coding used on pneumatic appliances (DIN Standard) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A21

- Replacement of a brake line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A21

- Modification to the length of the chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A21

- Connections for firtree type pneumatic brake pipes type “RILAX 2000” . . . . . . . . . . . . . . . . .A21

2. GENERAL RULES TO BE OBSERVED WHEN FITTING BODYWORK

2.1 General principles of welding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A22

2.1.1 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A22

- Protection of the batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A22

- Soundproofing screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A22

- Protection of electrical and mechanical components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A22

2.1.2 Preparation of parts for welding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A22

- Preparation of specific edges on chassis frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A23

- Method of welding to be specifically used on chassis frames . . . . . . . . . . . . . . . . . . . . . . . . .A23

- Slave butts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A23

2.1.3 Welding process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A24

- Static or rotary arc welding set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A24

- Relevant standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A24

- MIG or MAG semi-automatic welding set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A24

2.1.4 Equivalent steel grades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A25

2.2 Reinforcement, extension, reduction of sidemembers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A26

2.2.1 Bans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A26

2.2.2 Reinforcement of sidemembers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A26

- Examples of reinforcements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A26

- Method of joining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A27

- Extension, shortening of sidemembers in the wheelbase . . . . . . . . . . . . . . . . . . . . . . . . . . . .A28

2.2.3 Modification of the rear overhang . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A29

- Attachment of cross-members . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A29

- Towing cross-members . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A29

- Intermediate cross-members . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A29

2.3 Attachment of bodywork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A30

2.3.1 Bans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A30

2.3.2 Protection against exhaust heat radiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A30

2.4 Sub-frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A31

2.4.1 Finishing of sub-frames behind the cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A31

2.5 Nuts and bolts, tightening torque for parts in steel and cast iron . . . . . . . . . . . . . . . . . . . . . .A31

2.6 Addition of equipment to the bodywork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A34

2.7 Rear run-under guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A35

3. SPECIFIC EQUIPMENT FEATURES

3.1 Running the engine when vehicle stationary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A35

3.2 Mounting of power take-offs and flanged pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A35

3.3 Front power take-offs (crankshaft nose) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A36

3.4 Front and rear power take-offs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A36

3.4.1 Propeller shaft alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A36

- Angularity criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A36

- Angular acceleration criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A37

- Transversal stress criteria for prop shaft tubes and bearings . . . . . . . . . . . . . . . . . . . . . . . . .A37

Page 9

DT 4/366 3 RENAULT V.I. 04/02

3.4.2 Propeller shaft balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A38

3.4.3 Maximum permissible length of a prop shaft as a function of the rotating speed . . . . . .A38

3.5 Vehicle driveline (powertrain) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A38

3.6 Mounting of handling cranes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A39

3.6.1 Mounting on the sub-frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A39

3.6.2 Graph of the moment of inertia of the sub-frame as a function of the lifting torque . . . .A40

3.6.3 Crane in the rear overhang . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A41

3.7 Tail lifts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A42

3.7.1 Sub-frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A42

3.7.2 Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A42

3.7.3 Electrical connections for a tail lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A42

3.7.4 Special recommendations for tail lifts from 1500 to 2000 kg without landing legs . . . . .A42

3.7.5 Graph of the moment of inertia of the sub-frame as a function of the lifting torque . . . .A43

3.8 Sub-frame box sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A44

3.9 Fitting of specific equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A44

3.9.1 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A44

3.9.2 Installation of receivers or generators with a voltage of more than 24 V . . . . . . . . . . . . .A44

3.10 Tapping on the diesel fuel tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A44

3.11 Fifth wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A45

3.11.1 Mounting standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A45

- Kingpin 50 mm (2”) dia. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A45

- Kingpin 90 mm (3.5”) dia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A45

CHAPTER -B-

RENAULT MIDLUM SPECIAL BODYBUILDING FEATURES

1. PRESENTING THE “RENAULT MIDLUM” SERIES

1.1 Make-up of the range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B3

1.2 Changes to “RENAULT MIDLUM” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B4

1.3 Electronic management of “RENAULT MIDLUM” vehicles . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B5

1.3.1 Operating principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B5

1.3.2 Bodybuilders’ electrical pre-arrangements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B6

1.4 Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B6

1.5 Trade vehicle models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B7

- “Normal use” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B7

- “Tanker vehicle” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B7

- “Refuse collector vehicle” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B8

- “Road sweeper vehicle” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B8

- “Light fire tender vehicle” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B8

- “Buildings and public works vehicle” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B9

1.6 Make-up of “Trade packs” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B9

- “Crane” installation pre-arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B9

- “Tail lift” installation pre-arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B9

2. GENERAL REMARKS ON “RENAULT MIDLUM Euro 3” SERIES

2.1 Identification of the vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B10

2.2 General drilling principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B11

2.2.1 Drilling cab panels for fitting accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B11

2.2.2 Drilling in sidemembers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B12

- Anti-corrosion protection and paint retouches to the chassis . . . . . . . . . . . . . . . . . . . . . . . . .B12

2.3 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B13

Page 10

RENAULT V.I. 04/02 4 DT 4/366

2.3.1 Protection of wiring harnesses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B13

2.3.2 Protection of electrical installation prior to welding . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B13

2.4 Minimum load on front axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B15

2.5 Soundproofing screens and heat shields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B15

2.5.1 Instructions for soundproofing screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B15

2.5.2 Instructions for heat shields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B15

2.6 Side impact beams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B15

3. INSTALLATION OF BODYWORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B16

3.1 Use of 1/20th scale drawings and calculation sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B16

3.2 Example of a search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B16

3.3 Body start dimension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B19

3.3.1 Day cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B19

3.3.2 Behind-cab surrounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B20

3.3.3 Sleeper cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B21

3.3.4 4-door cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B21

3.3.5 Presentation of the different air intakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B22

3.4 Sub-frame sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B23

3.4.1 Minimum height according to range of suspension movement . . . . . . . . . . . . . . . . . . . .B23

3.4.2 Sub-frame minimum inertia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B24

3.5 Finishing of sub-frame entrance dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B24

- RENAULT MIDLUM B/C’/C/HD/Construction/D/4x4 day cab and under-floor air intake . . . . . .B25

- RENAULT MIDLUM B/C’/C/HD/Construction/D/4x4 sleeper cab whatever the air intake . . . . .B25

- RENAULT MIDLUM B/C’/C/HD/Construction/D/4x4 day cab and roof level air intake . . . . . . .B26

3.6 Lateral guiding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B27

- Inertia stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B27

3.7 Attachment of bodywork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B28

3.8 Attachment of sub-frames to brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B29

3.8.1 Fastening types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B29

- Guiding and fastening zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B29

3.8.2 Vertical positioning of brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B30

3.8.3 Types of bodywork attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B31

- Flexible attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B31

- Semi-flexible attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B33

- Rigid attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B34

3.8.4 Special features of vehicles with 4-door cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B35

3.8.5 Special features of vehicles with sleeper cab and vertical exhaust . . . . . . . . . . . . . . . . .B36

3.9 Longitudinal positioning of brackets on chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B37

3.9.1 RENAULT MIDLUM B 2-door day & sleeper cabs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B37

3.9.2 RENAULT MIDLUM B 4-door cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B37

3.9.3 RENAULT MIDLUM C’/C 2-door day & sleeper cabs . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B38

3.9.4 RENAULT MIDLUM C’/C 4-door cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B39

3.9.5 RENAULT MIDLUM HD / Construction 2-door day & sleeper cabs . . . . . . . . . . . . . . . . . .B40

3.9.6 RENAULT MIDLUM HD / Construction 4-door cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B40

3.9.7 RENAULT MIDLUM D 2-door day & sleeper cabs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B41

3.9.8 RENAULT MIDLUM 4x4 2-door cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B42

3.9.9 RENAULT MIDLUM 4x4 4-door cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B42

3.10 Changing the position of lateral flashing direction indicators . . . . . . . . . . . . . . . . . . . . . . . .B43

- Assembly on body front end . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B43

- Assembly on body side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B44

Page 11

DT 4/366 5 RENAULT V.I. 04/02

4. LEVEL 1 ELECTRICAL PRE-ARRANGEMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B46

4.1 Available power supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B46

4.2 Level 1 electrical pre-arrangements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B46

- In the cab on the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B46

- Available power supplies in the cab under the connection unit . . . . . . . . . . . . . . . . . . . . . . . .B48

- In the battery compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B49

4.3 Assembly of lateral signalling installation kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B50

4.4 Electrical diagram for level 1 available power supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B51

- Assignment of fuses concerning electrical pre-arrangements . . . . . . . . . . . . . . . . . . . . . . . . .B52

4.5 Bodywork attachment kit (located in cab and supplied with this pre-arrangement) . . . . . . . .B52

5. LEVEL 2 ELECTRICAL PRE-ARRANGEMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B54

5.1 Available power supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B54

5.2 Level 2 electrical pre-arrangements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B54

- In the cab on the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B54

- Available power supplies in the cab under the connection unit . . . . . . . . . . . . . . . . . . . . . . . .B56

- In the battery compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B57

- In the RH sidemember . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B57

5.3 Management of engine speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B56

5.4Power take-off wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B58

5.4.1 Vehicle fitted with one PTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B58

- A) Determining the rotating speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B58

- B) Using the chassis-mounted fast idling variable speed control . . . . . . . . . . . . . . . . . . . . . .B58

- C) Controlling speed regulation without cruise control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B59

5.4.2 Vehicle fitted with two PTOs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B59

- A) Determining the rotating speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B59

- B) Using the chassis-mounted fast idling variable speed control . . . . . . . . . . . . . . . . . . . . . .B59

- C) Controlling speed regulation without cruise control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B59

5.4.3 Vehicle fitted with three PTOs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B60

- A) Determining the rotating speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B60

- B) Using the chassis-mounted fast idling variable speed control . . . . . . . . . . . . . . . . . . . . . .B60

- C) Controlling speed regulation without cruise control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B60

5.4.4 Vehicle fitted with one engine rear PTO or no PTO at all . . . . . . . . . . . . . . . . . . . . . . . . . .B60

- A) Determining the rotating speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B60

5.5 Use of the steering wheel fast idling fingertip control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B61

5.5.1 Vehicle fitted with one power take-off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B61

5.6Engine speed information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B62

5.7Chassis-mounted starting and stop controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B63

Chassis-mounted stop control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B64

5.8Parking brake information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B64

5.9Vehicle speed limitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B64

5.10 Assembly of lateral signalling installation kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B64

5.11 Electrical diagram for level 2 available power supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B65

- Assignment of fuses concerning electrical pre-arrangements . . . . . . . . . . . . . . . . . . . . . . . . .B67

5.12 Bodywork attachment kit (located in cab and supplied with this pre-arrangement) . . . . . . .B67

5.13 Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B68

6. VEHICLE EQUIPPED WITH A TAIL LIFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B70

- “Tail lift” installation pre-arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B70

6.1 Fuse-holder 200 A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B70

6.2 Tail lift earth in rear overhang . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B70

Page 12

RENAULT V.I. 04/02 6 DT 4/366

7. TANKER VEHICLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B72

- Tanker special features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B72

- ADR equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B72

- Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B72

7.1 ADR plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B73

7.2 Remote controlled clutch release operating ram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B73

7.3 Assembly of chassis accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B73

7.4 Longitudinal positioning of brackets on chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B75

7.4.1 RENAULT MIDLUM C tanker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B75

7.4.2 RENAULT MIDLUM D 18 tonnes tanker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B75

7.5 Passage of wiring harnesses and compressed air pipes through cab . . . . . . . . . . . . . . . . . . .B76

8. “REFUSE COLLECTOR” VEHICLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B80

- Refuse collector vehicle special features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B80

- Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B80

8.1 Longitudinal positioning of brackets on chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B81

8.1.1 RENAULT MIDLUM C refuse collector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B81

8.2 Passage of wiring harnesses and compressed air pipes through cab . . . . . . . . . . . . . . . . . . .B81

8.3 Electrical pre-arrangements for refuse collectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B83

- Available power supplies in cab under the connection unit . . . . . . . . . . . . . . . . . . . . . . . . . . .B83

- In the battery compartment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B84

8.4 Reversing safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B85

8.5 Assembly of lateral signalling installation kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B86

8.6 Electrical diagram for “refuse collectors” optional available power supplies . . . . . . . . . . . . .B87

- Assignment of fuses concerning electrical pre-arrangements . . . . . . . . . . . . . . . . . . . . . . . . .B89

8.7 Bodywork attachment kit (located in cab and supplied with this pre-arrangement) . . . . . . . .B89

9. ROAD SWEEPER VEHICLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B92

- Road sweeper special features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B92

9.1 Longitudinal positioning of brackets on chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B93

9.1.1 RENAULT MIDLUM C’/C road sweeper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B93

9.2 Passage of wiring harnesses and compressed air pipes through cab . . . . . . . . . . . . . . . . . . .B93

10. LIGHT FIRE TENDER VEHICLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B96

- Light fire tender special features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B96

- Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B96

10.1 Longitudinal positioning of brackets on chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B97

10.1.1 RENAULT RENAULT MIDLUM B 10 tonnes 4-door light fire tender . . . . . . . . . . . . . . . . .B97

10.2 Light fire tender electrical pre-arrangements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B98

- Available power supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B98

- Electrical diagrams for available power supplies on light fire tender . . . . . . . . . . . . . . . . . . .B102

11.BUILDINGS & PUBLIC WORKS VEHICLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B108

- Buildings and public works vehicle special features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B108

- Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B108

11.1 Fastening of tipper control in cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B109

11.1.1 Location on engine tunnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B109

11.1.2 Location on cab rear end . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B109

11.1.3 Location on side pillar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B110

11.2 Passage of wiring harnesses and compressed air pipes through cab . . . . . . . . . . . . . . . . .B111

Page 13

DT 4/366 7 RENAULT V.I. 04/02

11.3 Assembly of rear lamps to lighting bar - tractor version

(on RENAULT MIDLUM C/C’/D/HD/Construction only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B112

11.4 Fitting a tool-holder to the front of a vehicle with sheet metal bumper . . . . . . . . . . . . . . . .B113

12.BEHIND-CAB HANDLING CRANES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B116

12.1 Maximum lifting moment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B116

12.2 Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B116

12.2.1 Attachment of crane brackets to the sub-frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B117

12.2.2 Attachment of crane brackets to the chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B117

- Crane support plates assignment table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B117

- RENAULT MIDLUM C’/C/D/HD Construction day cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B118

- RENAULT MIDLUM C’/C/D/HD Construction sleeper cab . . . . . . . . . . . . . . . . . . . . . . . . . .B118

- RENAULT MIDLUM B day cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B119

- RENAULT MIDLUM B sleeper cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B119

12.3 Position of vertical centre-line of crane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B120

12.3.1 Day cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B120

12.3.2 Sleeper cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B121

13.INDEPENDENT REFRIGERATOR UNIT LOCATED ABOVE THE CAB . . . . . . . . . . . . . . . . . . . .B124

- Maximum permissible load on front axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B124

13.1 Mechanical receiver on crankshaft pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B125

- Position of receiver on the engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B125

13.2 Additional fuel tapping on fuel tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B126

14.SNOW CLEARING VEHICLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B128

14.1 Sheet metal bumper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B128

14.2 Signalling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B128

14.3 Hydraulic pump drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B128

CHAPTER -C-

SUPPLEMENTARY INFORMATION

ON THE “RENAULT MIDLUM” VEHICLE

1. MOUNTING OF POWER TAKE-OFFS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C3

1.1 Mechanical receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C3

1.1.1 Gearbox-mounted PTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C3

- Table of possible gearbox-mounted PTO assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C3

- HYDROCAR 2903 & 2904 PTOs with two independent outputs . . . . . . . . . . . . . . . . . . . . . . .C3

- PTO characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C4

- Flywheel-mounted PTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C5

- Maximum torque transmissible by the PTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C5

- Frequency of use of PTOs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C5

1.2 Instructions for the assembly of auxiliary hydraulic pumps to type “C” PTOs

(ZF or Hydrocar) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C6

1.2.1 Supplementary instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C6

- Fluidtight seal between pump and PTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C6

- Calculation of the weight torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C6

- Calculation method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C6

Page 14

RENAULT V.I. 04/02 8 DT 4/366

2. AIR-OPERATED EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C7

2.1 Connection of extra auxiliary equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C7

2.1.1 Coupling for extra auxiliary equipment to chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C7

- Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C8

2.1.2 Coupling for extra auxiliary equipment in cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C8

- Cab not equipped with air-operated appliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C8

- Cab equipped with air-operated appliances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C9

2.2 Table of compressors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C9

3. ELECTRICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C10

3.1 Earths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C10

3.1.1 Cab earths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C10

- Door earths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C10

- Front end earths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C10

- Cab floor earths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C10

- Fastening of earth lug or braid to cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C10

3.1.2 Chassis earths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C11

- Assembly to electrical earth points diameter 11 mm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C11

3.2 Hook-up of lateral lamps to the rear lamp

(vehicle with rear lighting bar, without variant 155 02 & 155 03) . . . . . . . . . . . . . . . . . . . . . . . .C12

3.3 Hook-up in front end connection zone

(vehicles without “bodybuilder pack” and refuse collectors) . . . . . . . . . . . . . . . . . . . . . . . . . .C12

3.4 Changing the position of vehicle rear lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C12

3.5 Doubling up the rear lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C13

- Assignment of connector terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C13

3.6 Extension of the wiring harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C15

3.7 Assembly of the immersion heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C15

4. CHASSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C16

4.1 Steel classes for sidemembers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C16

4.2 Sections of sidemembers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C16

- RENAULT MIDLUM B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C16

- RENAULTMIDLUM C’ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C16

- RENAULTMIDLUM C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C17

- RENAULTMIDLUM D & D Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C17

- RENAULTMIDLUM HD/Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C18

- RENAULTMIDLUM 4x4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C18

- Trade vehicles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C18

4.3 Reinforcement, extension, shortening of sidemembers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C19

4.3.1 Modification to the rear overhang . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C19

4.3.2 Modification to the wheelbase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C19

- RENAULTMIDLUM B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C19

- RENAULTMIDLUM C’ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C20

- RENAULTMIDLUM C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C20

- RENAULTMIDLUM D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C21

- RENAULTMIDLUM D Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C21

- RENAULTMIDLUM HD/Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C21

- Trade vehicles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C22

4.4 Intermediate cross-member . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C22

Page 15

DT 4/366 9 RENAULT V.I. 04/02

5. CHANGING THE POSITION OF EQUIPMENT ON CHASSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . .C23

5.1 Rear run-under guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C23

5.2 Changing the position of the rear run-under guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C24

- Table of possible vertical positionings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C24

5.3 Changing the position of rear lighting bar lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C24

5.4 Changing the position of the towing cross-member . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C24

- Table of possible horizontal positionings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C24

- RENAULT MIDLUM B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C25

- Table of possible horizontal positionings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C26

- RENAULT MIDLUM C’/C/HD/Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C27

5.5 Assembly of rear lamps to lighting bar - tractor version

(on RENAULT MIDLUM C/C’/HD/Construction only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C28

5.6 Changing the position of the cab tilting manual pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C29

- RENAULT MIDLUM C/C’/HD/Construction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C29

- RENAULT MIDLUM B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C29

5.7 Trailer hitch coupling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C30

5.7.1 Maximum permissible range of movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C30

5.7.2 Towing cross-member . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C30

5.7.3 Hitch coupling for drawbar rigid trailers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C32

- Installation of an extra cross-member . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C32

- Minimum thickness (E) of stiffener plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C32

6. CAB FOOTPRINT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C33

6.1 Day cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C33

6.2 Sleeper cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C35

6.3 6/7 place cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C37

7. ASSEMBLY OF EQUIPMENT TO CAB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C39

7.1 Roof catwalk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C39

7.1.1 Attachment of catwalk to day cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C39

7.1.2 Attachment of catwalk to sleeper cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C40

7.2 Ladder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C41

7.2.1 Attachment of ladder to day cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C41

7.2.2 Attachment of ladder to sleeper cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C42

7.3 Assembly of accessories on roof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C43

- Table of roof assembly possibilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C43

7.3.1 Installation of antennae . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C44

7.3.2 Installation of revolving beacons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C45

7.3.3 Installation of air horns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C45

7.3.4 Installation of roof deflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C46

7.3.5 Installation of frontview mirror . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C47

7.3.6 Installation of sunshade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C48

7.3.7 Installation of gantry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C49

- Assembly of a gantry equipped with a frontview mirror . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C49

7.4 Assembly of accessories in cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C50

7.4.1 Location in dashboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C50

7.4.2 Location on engine tunnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C50

8. AIRBAG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C51

8.1 Identification of a vehicle equipped with an airbag system . . . . . . . . . . . . . . . . . . . . . . . . . . .C51

8.2 Work on the vehicle (excluding the airbag) requiring precautions

to be taken to avoid inadvertent deployment of the airbag . . . . . . . . . . . . . . . . . . . . . . . . . . . .C51

Page 16

RENAULT V.I. 04/02 10 DT 4/366

Page 17

DT 4/366 A1 RENAULT V.I. 04/02

CHAPTER -A-

GENERAL FEA TURES

IMPORTANT

General principles and basic rules applicable for the conversion and fitting of equipment to vehicles

in most cases for the majority of applications are detailed in this “General features” chapter.

Page 18

RENAULT V.I. 04/02 A2 DT 4/366

1. GENERAL FEATURES

1.1 Scope of liability

RENAULT TRUCKS vehicles are merchandized at the end of corroborated technical designwork and endurance testing, taking the various laws, regulations, standards... involved into consideration.

Modifications to a RENAULT TRUCKS vehicle for the fitting of bodywork and equipment should be carried out

in accordance with the rules and recommendations set out in this bodywork fitting guide and require an

“Agreement in Principle”, issued by the Product Applications Department.

Guarantee and responsibility

Any intervening party is responsible for his services in terms of guarantee and responsibility, including any damage caused by his work and/or the equipment installed on-vehicle or the basic product.

In the event of RENAULT TRUCKS (or its network) being prime contractor for its own equipment (in relation to

the end customer), the guarantee is considered as being at least that of the warranty offered by RENAULT

TRUCKS to its customer.

Unless clearly specified otherwise in the order, the equipment warranty shall be negotiated directly between the

end customer and the equipment manufacturer.

The meeting of recommendations contained in the present document can in no way be considered as relieving

the equipment manufacturer’s responsibility, but simply as complying with the basic rules for professional trade

practice.

Any breach of these recommendations must be considered as shortcoming in respect of the rules and shall relieve

RENAUL TTRUCKS of its liability in the event of damage connected directly or indirectly to such non-compliance.

All the equipment is considered to comply with these recommendations and shall not require any acceptance testing upon delivery to check the conformity.

RENAULT TRUCKS guarantees non-modified original parts and components.

Interventions, conversions, adaptations of fittings carried out by the intervening party involves his responsibility,

even if they are authorized administratively (Conversion appendix II).

Such conversions must not under any circumstance lead to any impairment of the quality or of the primary func-

tions of the component elements of the vehicle (whether these elements are affected directly or not by the intervention).

Any modification, changing of position of constituent vehicle parts or elements must be covered by an “Agreement

in Principle”, issued by the RENAULT TRUCKS Product Applications Department.

For further information or assembly agreement, contact:

TO OBTAIN ANY INFORMATION OR APPROVAL OF MOUNTING, PLEASE CONTACT:

For France:

SERVICE TECHNICO-COMMERCIAL

RENAUL TTRUCKS

API. COM 00A 238

69806 ST PRIEST CEDEX

Tel.: 04 72 96 68 14

Telex: 300 265 UDCF +

Fax: 04 72 96 81 93

1.2 Regulations

The bodybuilder must meet:

- the different European and/or destination country laws, regulations and standards governing driving and

vehicle building,

- the stipulations of the Highway Code and its various amendments and appendices,

- the different laws, regulations and standards governing road traffic in force in the country of destination.

For the United Kingdom:

Product Applications Department

RENAULT TRUCKS UNITED KINGDOM

Boscombe Road,

Dunstable

Bedfordshire LU5 4LX

Tel. (Switchboard): (+44) (0)1582 471 122

Fax (Marketing) (+44) (0)1582 479 146

Page 19

DT 4/366 A3 RENAULT V.I. 04/02

The scope of this compliance must cover:

- Lighting and signalling,

- Weight and dimensions,

- The field of vision and rear view,

- The regulation protection devices (e.g. side guards, anti-spray, run-under guard),

- The hitch coupling and towing systems, (compliance with standards and regulations),

- Specific clauses concerning the transport of dangerous goods (ADR, COSHH etc.),

- Sun-roofs,

- Pollution control standards,

- Electromagnetic compatibility standards for electronic equipment.

1.3 Safety

All components having an influence on:

- The control of the driver of the trajectory and the ability to stop the vehicle and its trailer,

- The load distribution on the front or the rear, the left or the right,

- The risk of fire,

- and any other risk for the vehicle and its surrounding environment.

Among the components, we would mention, among others:

- The cab tilt mechanism,

- The wheels (tightening of the nuts),

- Seats and seat belts (anchorage points),

- The attachment of bodywork or equipment to be in conformity with the technical instruction document in force,

(i.e. the Guide for the Fitting of Bodywork),

- The hitch coupling and towing systems, (i.e. anchorages),

- Electrical systems (protection of circuitry, the electrical rating, attachment, conformity of the connections with

the technical instruction document, (i.e. the Guide for the Fitting of Bodywork),

- Warning systems and driver information systems, (i.e. no interference with the information given by the instru-

ment panel on the dashboard),

- Information for use affixed by the manufacturer to the vehicle (i.e. decals for tilting of the cab, drilling points,

welding points, batteries, etc.)

- Extension and reduction of the length of the wheelbase and the rear overhang.

- Re-location or replacement of the cross-members.

- Circuits for ancillary equipment.

In order to guarantee the safety and the satisfactory operation of the vehicle, modification of the following components is strictly forbidden:

- Brakes: circuits, controls and anchorages,

- Steering: circuits, controls, anchorages and geometry,

- Axle and axle housing assemblies,

- The air-bag system and pretensioning systems on the seat belts,

- The electronics.

Page 20

RENAULT V.I. 04/02 A4 DT 4/366

1.4 Quality assurance

Our permanent objective is to give satisfaction to our customers and we must achieve this in full on the final

product consisting of a chassis, bodywork and/or an item of equipment.

In order to achieve this objective, RENAULT TRUCKS expects from all those co-operating with it in the field

of mounting bodywork and equipment supply to implement a Quality Assurance System.

RENAULT TRUCKS can demand proof for the execution of all bodywork, the fitting of equipment or modification of a basic truck, in accordance with Standard ISO 9000, of:

- The conformity with all legislation, EC Directives and national regulations,

- The compliance with the manufacturers’ directions,

- The control of quality of the execution of the work.

This is done with the knowledge that, on the face of it, the vehicle is considered as complying with the

whole of the regulations.

1.5 Documentation

In all cases involving equipment, the installer is obliged to supply a manual covering the use, service, maintenance and safety of his installation.

Page 21

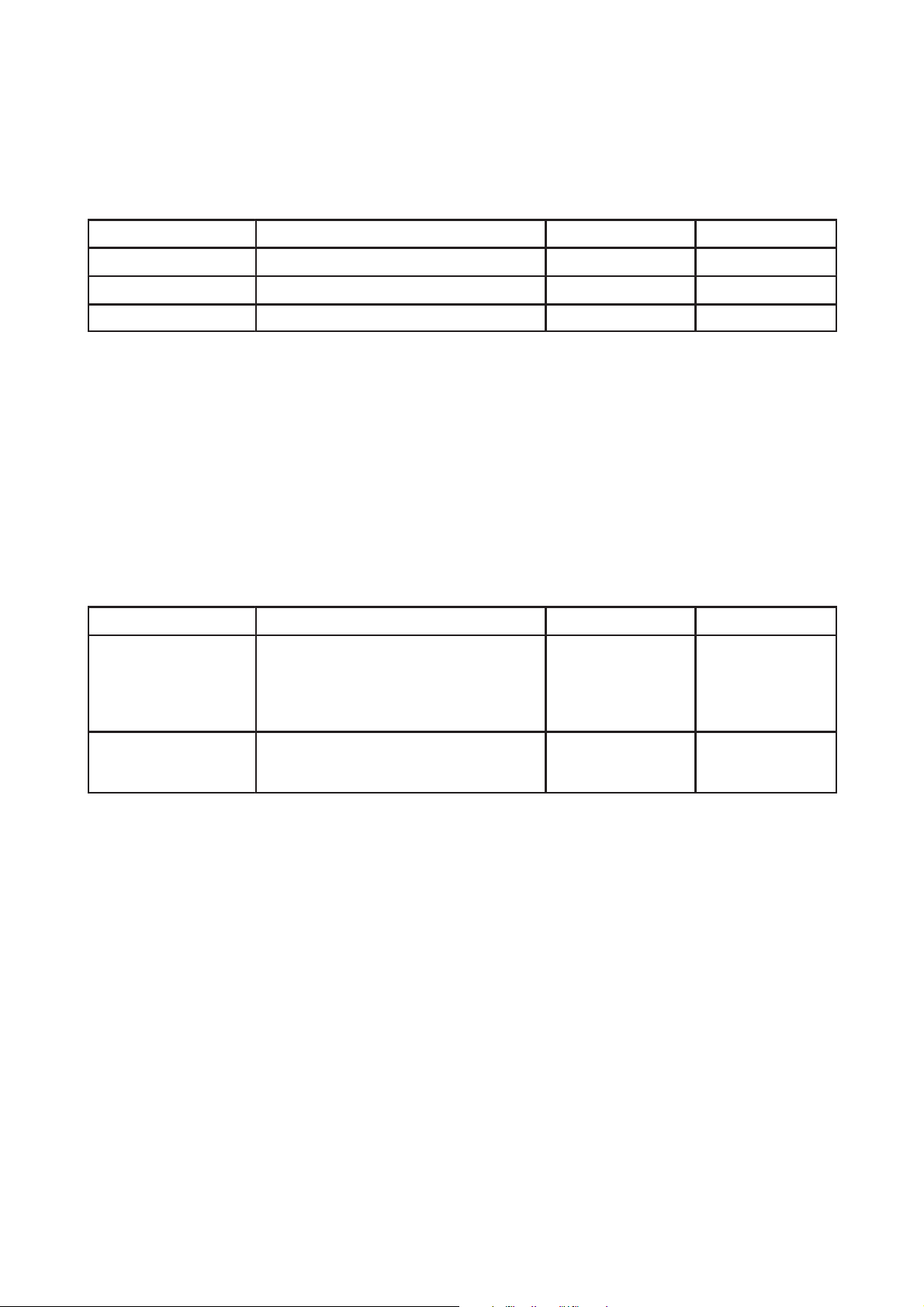

Tension aux bornes de l’accumulateur

’

batterie 6 Volts batterie 12 Volts

ens

e

e charge

6,3 Volts 12,7 Volts 1,27 100 %

6,2 Volts 12,5 Volts 1,24 80 %

DT 4/366 A5 RENAULT V.I. 04/02

1.6 General instructions

When building and fitting a body (including such equipment as rear run-under guards), a certain number of

requirements and a certain number of vital requirements specific to each type of vehicle must be taken into

consideration. These various points relate to maintenance, accessibility and the circulation of fluids.

Examples:

- Ease of access to the various maintenance and lubrication points, to the fuel tank and fuel gauge, to the

batteries and the various electrical terminal boxes.

- The ability to easily dismantle the various component parts of the transmission and the suspension.

- Access to the circuits for air-intake, exhaust, and fuel supply.

- Taking into account the wheel movement detailed on the bodywork drawing (i.e. take care to allow for snow

chains; extra clearance must be provided).

- Ventilation of the brake drums and discs and the battery compartment.

- The radiator inlet and outlet areas, which must not be modified.

- Full compliance with the dimensions and weights specified in our technical documents. Under all circumstances, the bodybuilder must ensure free movement and safe operation of all the moving component parts

of the chassis (i.e. springs, prop shaft, etc.)

- The addition of a body must not affect the vehicle running and driving safety. Take care to ensure that a

balanced distribution of the loads on the right and the left hand sides of the vehicle is obtained.

- For any bodywork installation, a calculation of load distribution must be made for each axle, in order to check

that the weight imbalance between the right and the left hand side is below 4%.

- The flow of the coolant must be maintained at all times. It is, therefore, not allowed to blank off, even partially, the air intakes provided (on the radiator grille or the front end). Orange ADR or similar “Hazardous

Substances” plates should be affixed to solid surfaces (i.e. without vent holes).

On the arrival of a vehicle in your workshop for body fitting, we recommend that you should check one hour

after the arrival of the vehicle, the state of charge of the batteries.

During the period for the fitting of the bodywork, you should particularly check that:

- The vehicle is not run without a battery.

- Do not move the vehicle on the starter motor.

- Do not use a booster starter.

- Ensure that the tyre pressure is checked and tyres inflated to the correct value where necessary.

- Protect body components or items of trim against all damage.

- Refit the original batteries, where these have been taken off.

IMPORTANT

- Whatever work you are doing on the vehicle, you must switch off the electrical circuit at the master switch or

by disconnecting the batteries in order to avoid any risk of electric shock during work.

- When a vehicle is laid up (i.e. at a standstill for longer than 10 days), disconnect the electrical circuit by removing the fuse or by the circuit-breaker so as to avoid discharge of the batteries through the tachograph.

Voltage at the battery terminals

Specific gravity

of the electrolyte

State of charge

6 Volt battery 12 Volt battery

6.3

6.2

12.5

12.7

1.24

1.27

D

ité de l’électrolyt

Etat d

Page 22

RENAULT V.I. 04/02 A6 DT 4/366

The information contained in this manual is only applicable to bodywork in steel. For aluminium bodies, refer

to the Product Applications Department of RENAULT TRUCKS.

It is forbidden to weld, grind, cut up, drill or heat the sidemembers or cross-members unless the contrary is

clearly stated. These operations may only be carried out in conformity with the recommendations laid down

in the present document.

Any special case, any bodywork fasteners and fittings not described in this manual must be submitted for our

approval prior to use.

Before commencing the fitting of any bodywork, you must consult:

- The Vehicle Technical Data Sheet,

- The bodybuilders drawing and the relevant calculation sheets which relate to the body to be fitted,

- The vehicle driving and maintenance handbook.

If you do not have these items available, you should obtain them from RENAULT TRUCKS Dealers or the

Product Applications Department.

In the technical manual and on the bodywork drawing is stated the permitted maximum and minimum length

of body; we would strongly advise you to stay within these limits.

Furthermore, it should be noted that the changing of position of a component such as spare wheel, tank, etc.,

the modification of a chassis without uniform weight distribution or the fitting of an over-cab extension, causes

a modification of the load distribution of a fully equipped chassis in every single case.

Modification to load distribution must be compensated for by an alteration in the permitted length for bodywork. It then becomes necessary to calculate the new position of the centre of gravity of the bodywork.

The weights specified in our technical data sheets refer to standard vehicles, ready for the road, without optional extras.

Furthermore, the weight of chassis cab is given with a tolerance of plus or minus 4%.

Optional equipment such as reinforced springs, power take-offs, different tyre fitments, will cause an increase in weight for the basic chassis.

For these reasons, when weighing the chassis cab, bodybuilders should weigh:

- The front axle(s),

- The rear axle(s),

- The complete vehicle,

without driver, without passenger, but with full fuel tanks and with vehicle on-board tool kit.

For the preparation and attachment of the various types of bodywork, it is preferable not to take off the wheels,

unless absolutely necessary.

Nevertheless, you must take the precautions set out below:

- It is forbidden to paint the bearing surfaces of the wheel rim hubs and the seating for wheel nuts.

- During fitting, make certain that the parts are perfectly clean prior to fitting.

- Tighten the wheel nuts to the torque recommended (cf. vehicle driving and maintenance handbook)

Installation fitted with key-operated locks: the section of such keys must be very different to that used for the

vehicle keys. Indeed, these keys should not be able to be put into the vehicle locks by mistake, thus avoiding

any risk of damage to the barrels of the locks.

1.7 Safety on tilt cabs

After the conversion of standard cabs by the bodybuilders, (i.e. extension, bunk adaptation, over-cab extension, etc.) because the weight distribution has changed, the tilt system may no longer meet the requirements

of the safety standards.

Under these circumstances, and without prior agreement from the manufacturer, the full and entire responsibility rests with the bodybuilder.

1.8 Chassis markings

The identification number of the vehicle is on the sidemember (refer to the vehicle driving handbook).

The identity markings of the vehicle must remain visible and accessible without having to remove any part of

the body.

Page 23

DT 4/366 A7 RENAULT V.I. 04/02

1.9 Adjustments to the vehicle settings

Under no circumstance may bodybuilder or converters make any alteration to the original settings of

RENAULT TRUCKS vehicles.

1.10 Cleaning

1.10.1 Bodywork

So as not to cause any damage to the condition of the paintwork and the seals:

- Avoid using a high temperature jet of steam.

- Restrict the use of brushes. They must be in good condition and well maintained.

- We advise against the use of brushes, during the first month of vehicle use.

- If you are using a high pressure jet wash unit, limit the pressure to 80 bars maximum.

- Keep the lance well away from the bodywork; do not spray fluidtight joints.

- Use neutral soap based products.

- In order to remove grease spots, use cleaning fluid (not petrol).

- Parts in aluminium must be cleaned with water to which a non-alkaline washing product has been added,

and rinsed with clean water.

- Spread a coat of Vaseline or talcum powder over the seals.

1.10.2 Chassis/Underbodies

Use a high pressure unit. Limit the pressure of the jet to 80 bars maximum and the time of use to the strict

minimum necessary.

In order to prevent any risk of a problem, do not spray:

- electronic or electrical boxes,

- the seals of link rods,

- hinge pins,

- air inlets for the heater, the engine air intake and air filter,

- pneumatic and electrical apparatus,

- absorbent materials and soundproofing screens,

- the fuel gauge.

1.10.3 Cleaning of the cab