Red Lion CR1000 Instruction Manual

Bulletin No. CR1000-B

Drawing No. LP1019

Released 2018-01-12

Model CR1000 Industrial Operator Interface With TFT Display

•

•

CONFIGURED USING CRIMSON® 3.1 SOFTWARE

TWO SERIAL COMMUNICATION PORTS, (1 RS-232 and 1 RS-232/422/485)

•10 BASE T/100 BASE-TX ETHERNET PORT COMMUNICATES WITH UP TO FOUR PROTOCOLS SIMULTANEOUSLY

•UNIT’S CONFIGURATION IS STORED IN NON-VOLATILE FLASH

•

•

•

•

•

•

MEMORY

SD CARD SOCKET FOR LOADING DATABASE IN FIELD INDUSTRIAL TFT LCD COLOR DISPLAY

NEMA 4X/IP66 FRONT PANEL

THREE FRONT PANEL LED INDICATORS POWER UNIT FROM 24 ±20% VDC RESISTIVE ANALOG TOUCHSCREEN

C UR L US LISTED

IND. CONT. EQ.

E302106

GENERAL DESCRIPTION

The CR1000 is the perfect solution for applications that require the operator to monitor and control more than just a single device. With two serial ports and an Ethernet port, these HMI displays can connect to multiple serial and Ethernet devices simultaneously, including PLCs, motor drives, bar code scanners, etc.

The CR1000 performs the functions of a multiple protocol converter, using two high-speed serial communications ports and a 10/100 BaseTX Ethernet port. The Ethernet port supports up to four protocols simultaneously, allowing dissimilar Ethernet based products to communicate with one another. The SD card slot can be used to load the unit's configuration file, allowing configuration changes to be made and saved to the card for later transfer.

The CR1000 range of HMIs is programmed with Red Lion's free Crimson 3.1 software. Crimson offers easy to use drag and drop communications configuration, while the embedded image library allows the programmer to create intuitive screens and prompts for the operator.

CONTENTS OF PACKAGE

-CR1000 Operator Interface

-Hardware packet and plate for mounting unit into panel

-Terminal block for connecting power

-Panel gasket

SAFETY SUMMARY

All safety related regulations, local codes and instructions that appear in the manual or on equipment must be observed to ensure personal safety and to prevent damage to either the instrument or equipment connected to it. If equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired.

Do not use the unit to directly command motors, valves, or other actuators not equipped with safeguards. To do so can be potentially harmful to persons or equipment in the event of a fault to the unit.

WCAUTION:RNING -RiskEXPLOSIONof DangerHAZARD. - DO NOT

EQUIPMENTReadcompleteUNLESSinstructionsPOWERprior HAStoinstallationBEEN SW

ORandAREAoperationIS KNOWNof the unitTO. BE NON-HAZARDO

ORDERING INFORMATION

MODEL NO. |

DESCRIPTION |

PART NUMBER |

|

|

4.3" HMI with 2 Serial Ports, 1 Ethernet Port, and USB Device Port |

CR1000 04000 00210 |

|

|

|

|

|

CR1000 |

7.0" HMI with 2 Serial Ports, 1 Ethernet Port, and USB Device Port |

CR1000 07000 00210 |

|

|

|

|

|

|

10.4" HMI with 2 Serial Ports, 1 Ethernet Port, and USB Device Port |

CR1000 10000 00210 |

|

|

|

|

|

SD |

SD Card 1 |

SDxxxxxx |

|

CBL |

Communications Cables and Adapter 1 |

CBLxxxxx |

|

|

Protective Film for CR1000 04xxx xxxxx |

G3FILM4K |

|

|

|

|

|

FILM |

Protective Film for CR1000 07xxx xxxxx |

G3FILM07 |

|

|

|

|

|

|

Protective Film for CR1000 10xxx xxxxx |

G3FILM10 |

|

|

|

|

|

CRA000 |

Adapter Plate from Kadet 7 to CRX000 07 |

CRA000 AD070 70000 |

|

|

|

||

Replacement Battery |

CRA000 BT3V0 00000 |

||

|

|||

|

|

|

1 Contact your Red Lion distributor or visit our website for selection of SD cards, adapters and cables.

-1-

Bulletin No. CR1000-B

Drawing No. LP1019

SPECIFICATIONS

1. POWER REQUIREMENTS:

Must use a Class 2 circuit according to National Electrical Code (NEC), NFPA-70 or Canadian Electrical Code (CEC), Part I, C22.1 or a Limited Power Supply (LPS) according to IEC 60950-1 or Limitedenergy circuit according to IEC 61010-1.

Power connection via removable three position terminal block. Supply Voltage: 24 VDC ±20%, Class 2

@ 24 VDC |

4-INCH |

7-INCH |

10-INCH |

Typical Power: |

3.9 W |

5.3 W |

8.3 W |

|

|

|

|

Max Power: |

5.0 W |

6.2 W |

9.0 W |

|

|

|

|

2. BATTERY: Lithium coin cell. Typical lifetime of 5 years, nominal.

To maintain UL rating, replacement battery must be: Red Lion CRA000 BT3V0 00000, Rayovac BR1225X-BA or Panasonic BR1225A/BN.

3. LCD DISPLAY:

|

4-INCH |

7-INCH |

10-INCH |

TYPE |

TFT |

TFT |

TFT |

|

|

|

|

COLORS |

16M |

16M |

16M |

|

|

|

|

PIXELS |

480 x 272 |

800 X 480 |

800 X 600 |

BRIGHTNESS |

500 cd/m2 |

430 cd/m2 |

400 cd/m2 |

BACKLIGHT TYPE |

LED |

LED |

LED |

|

|

|

|

BACKLIGHT LIFE |

30K HR TYP. |

50K HR TYP. |

50K HR TYP. |

|

|

|

|

4.TOUCHSCREEN: Four-wire resistive analog

5.MEMORY:

On Board User Memory: 512 Mbyte of non-volatile Flash memory. Memory Card: SD slot accepts standard capacity cards up to 16 GB.

6.COMMUNICATION CAPABILITIES:

USB Device Port: Isolated and adheres to USB specification 2.0 full

speed only using Type B connection. USB DEVICE PORT IS FOR

SYSTEM SET-UP AND DIAGNOSTICS AND IS NOT INTENDED FOR PERMANENT CONNECTION.

Serial Ports (2): Ports are individually isolated. Format and Baud Rates for each port are individually software programmable up to 115,200 baud.

Port to Port Isolation: 3000 Vrms for 1 minute. Signal Isolation: 500 V.

Released 2018-01-12

Ethernet Port: 10 BASE-T / 100 BASE-TX

RJ45 jack is wired as a NIC (Network Interface Card).

Isolation from Ethernet network to operator interface: 1500 Vrms

7.ENVIRONMENTAL CONDITIONS: Operating Temperature Range: -10 to 50 °C Storage Temperature Range: -20 to 70 °C

Vibration to IEC 68-2-6: Operational 5-500 Hz, 2 g Shock to IEC 68-2-27: Operational 30 g

Operating and Storage Humidity: 0 to 85% max. RH non-condensing Altitude: Up to 2000 meters

Installation Category II, Pollution Degree 2 as defined in IEC/EN 60664-1.

8.CERTIFICATIONS AND COMPLIANCES:

CE Approved

Immunity: IEC/EN 61000-6-2 for Industrial Locations

Emissions: IEC/EN 61000-6-4 for Industrial Locations; CISPR 11 Class A IEC/EN 61010-1

RoHS Compliant

UL Listed: File #E302106

Type 4X Indoor / IP66 Enclosure rating (Face only)

9.CONNECTIONS: High compression cage-clamp terminal block Wire Strip Length: 0.3" (7.5 mm)

Wire Gage Capacity: 12 to 24 AWG (3.31 to 0.20 mm2) copper wire Torque: 4.4-5.3 inch-lbs (0.5-0.6 N-m)

10.CONSTRUCTION: Polycarbonate enclosure with Type 4X/IP66 rating when correctly fitted per the mounting instructions provided.

Protection against mechanical impact up to 5 Joule, IK08 per IEC 62262.

11.MOUNTING REQUIREMENTS: Maximum panel thickness is 0.25" (6.35 mm) with included stiffener plate, or 0.375" (9.53 mm) without plate. For NEMA 4X / IP66 sealing, a panel with a minimum thickness of 0.06" (1.52 mm) is recommended.

Mounting screw torque: 4.0 lbf-in (0.45 Nm). CAUTION: DO NOT

OVERTIGHTEN THE CLAMPS

12.WEIGHT: Unit weight with stiffener plate and clips

CR1000 04: 15 oz (425 g)

CR1000 07: 1.91 lb (868 g)

CR1000 10: 3.08 lb (1.395 Kg)

DIMENSIONS IN inches (mm)

CR1000 04

5.14 (130.65)

5.14 (130.65)

|

|

|

|

|

|

|

4.62 |

|

|

|

|

|

|

|

|

4.12 |

|

|

4 inch |

|

|||

(104.69) |

|

|

|

|

(117.48) |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5.65 (143.51) |

1.50 |

(38.1) |

3.62 |

(92.08) |

|

|

THIS VIEW SHOWN WITH MOUNTING PLATE AND BRACKETS |

||

CR1000 07 |

|

|

|

2.00 |

|

7.63 (193.98) |

|

8.00 (203.2) |

|

|

|

(50.8) |

||

|

|

|

|

|

5.43 |

7 inch |

5.80 |

|

4.80 |

(138.02) |

|

(147.32) |

|

(121.92) |

|

|

THIS VIEW SHOWN WITH MOUNTING PLATE AND BRACKETS |

||

-2-

Released 2018-01-12 |

Bulletin No. CR1000-B |

|

Drawing No. LP1019 |

|

|

CR1000 10

10.78 (273.73) |

|

|

|

|

|

|

|

|

|

|

|

|

11.14 (282.96) |

|

|

|

|

2.00 |

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(50.8) |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8.50 |

10.4 inch |

8.87 |

7.87 |

|

(215.99) |

(225.29) |

(199.9) |

||

|

THIS VIEW SHOWN

WITH MOUNTING PLATE

AND BRACKETS

INSTALLING AND POWERING THE CR1000

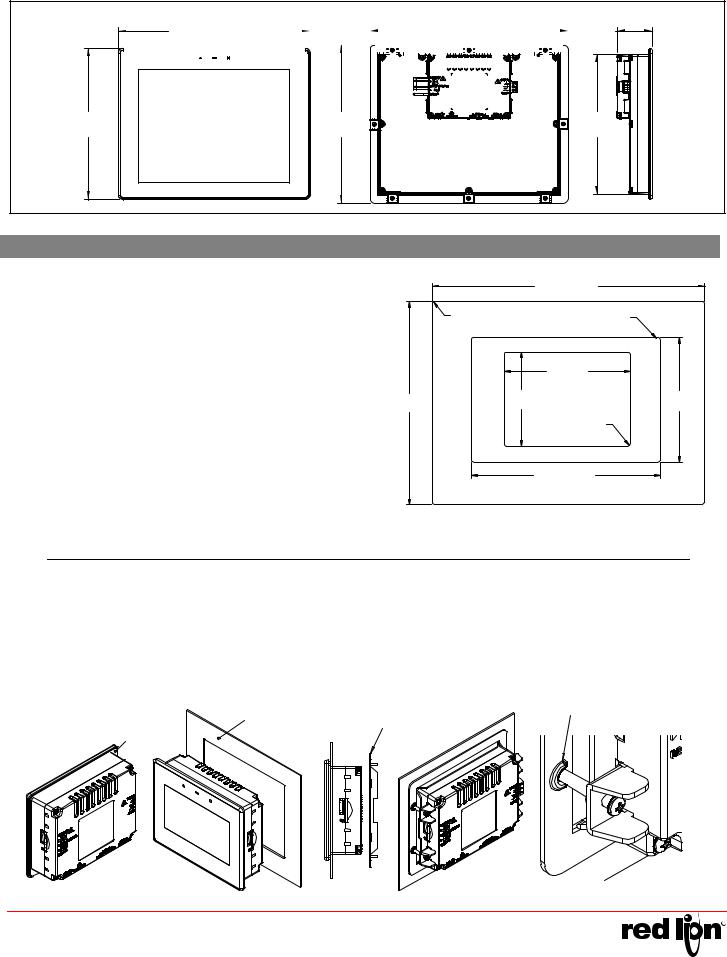

MOUNTINGINSTRUCTIONS

This operator interface is designed for through-panel mounting. The mounting surface should have a minimum thickness of 0.06" (1.53 mm) and maximum thickness of 0.375" (9.53 mm). There should be a minimum of 4" clearance behind the panel for unit installation. Allow a minimum of 2.5" below the bottom connectors for communication cables. Cut the mounting hole per the dimensions shown in the diagram. Care should be taken to remove any loose material from the mounting cut-out to prevent that material from falling into the operator interface during installation.

If installing the unit in an enclosure, follow the table below for minimum enclosure size to allow for proper ventilation and cabling to meet UL requirements. Consider heat produced by other devices in the enclosure.

PART NUMBER |

WIDTH |

HEIGHT |

DEPTH |

CR1000 04000 00210 |

10.5 inch |

12.5 inch |

6.25 inch |

|

|

|

|

CR1000 07000 00210 |

10.5 inch |

12.5 inch |

6.25 inch |

|

|

|

|

CR1000 10000 00210 |

12.55 inch |

14.55 inch |

8.31 inch |

|

|

|

|

7.93

(201.42)

|

|

10.20 (259.08) |

|

R |

0.10 |

R |

0.10 |

(2.54) |

(2.54) |

||

|

|

4.69 |

|

|

|

(119.13) |

|

|

3.66 |

|

4.87 |

|

(92.96) |

|

(123.7) |

R (2.03)0.08

4 INCH PANEL CUT-OUT

7 INCH PANEL CUT-OUT

7.06 (179.32)

10.4 INCH PANEL CUT-OUT

ALL TOLERANCES +/-0.03" (+/-0.762 mm)

Must meet hole tolerance specification for full NEMA4X and IP66 ingress protection.

Follow these steps to install the unit.

1.Make sure the bezel gasket is properly in place.

2.Place the unit into the front of the panel cutout.

3.Install stiffener plate over unit on the inside of the panel. This ensures the mounting surface is stiff enough for a proper seal. The plate is required to meet NEMA 4X and IP66.

4.Insert clamps into the slots provided on the sides (CR100004) or top and bottom (CR100007 and CR100010) of the unit.

5.Make sure the clamp’s screw sits in the “U” shaped feature located on the stiffener plate. This will prevent the screw from “walking”. Tighten

|

|

MOUNTING |

|

GASKET |

SURFACE |

|

|

|

1 |

2 |

3 |

the clamping screws in an even pattern until the unit is secured in the panel. To seal to Type 4X/IP66 specifications, all supplied mounting clamps must be used and be torqued to 4.0 lbf-in (0.45 Nm). CAUTION: DO NOT OVERTIGHTEN THE CLAMPS. The panel must not flex more than 0.010" for proper sealing. The safety of any system incorporating the equipment is the responsibility of the assembler of the system.

|

SCREW ANTI-WALK |

STIFFENER |

FEATURE |

PLATE |

|

4 |

5 |

-3-

Loading...

Loading...