Page 1

SC600Y&SC600T

Hardware Design

Smart Module Series

Rev: SC600Y&SC600T_Hardware_Design_V1.0

Date: 2019-09-02

Status: Released

www.quectel.com

Page 2

SC600Y&SC600T Hardware Design

Smart Module Series

Our aim is to provide customers with timely and comprehensive service. For any

assistance, please contact our company headquarters:

Quectel Wireless Solutions Co., L td.

Building 5, Shanghai Business Park Phase III (Area B), No.1016 Tianlin Road, Minhang District, Shanghai

200233, China

Tel: +86 21 5108 6236

Email: info@quectel.com

Or our local office. For more information, please visit:

http://www.quectel.com/support/sales.htm

For technical support, or to report documentation errors, please visit:

http://www.quectel.com/support/technical.htm

Or email to: support@quectel.com

GENERAL NOTES

QUECTEL OFFERS THE INFORMATION AS A SERVICE TO ITS CUSTOMERS. THE INFORMATION

PROVIDED IS BASED UPON CUSTOMERS’ REQUIREMENTS. QUECTEL MAKES EVERY EFFORT

TO ENSURE THE QUALITY OF THE INFORMATION IT MAKES AVAILABLE. QUECTEL DOES NOT

MAKE ANY WARRANTY AS TO THE INFORMATION CONTAINED HEREIN, AND DOES NOT ACCEPT

ANY LIABILITY FOR ANY INJURY, LOSS OR DAMAGE OF ANY KIND INCURRED BY USE OF OR

RELIANCE UPON THE INFORMATION. ALL INFORMATION SUPPLIED HEREIN IS SUBJECT TO

CHANGE WITHOUT PRIOR NOTICE.

COPYRIGHT

THE INFORMATION CONTAINED HERE IS PROPRIETARY TECHNICAL INFORMATION OF QUECTEL

WIRELESS SOLUTIONS CO., LTD. TRANSMITTING, REPRODUCTION, DISSEMINATION AND

EDITING OF THIS DOCUMENT AS WELL AS UTILIZATION OF THE CONTENT ARE FORBIDDEN

WITHOUT PERMISSION. OFFENDERS WILL BE HELD LIABLE FOR PAYMENT OF DAMAGES. ALL

RIGHTS ARE RESERVED IN THE EVENT OF A PATENT GRANT OR REGISTRATION OF A UTILITY

MODEL OR DESIGN.

Copyright © Quectel Wireless Solutions Co., Ltd. 2019. All rights reserved.

SC600Y&SC600T_Hardware_Design 1 / 134

Page 3

SC600Y&SC600T Hardware Design

Smart Module Series

About the Document

History

Revision Date Author Description

1.0 2019-09-02

Light WANG/

Rock CHEN

Initial

SC600Y&SC600T_Hardware_Design 2 / 134

Page 4

SC600Y&SC600T Hardware Design

Smart Module Series

Contents

About the Document ........................... ........ .... ..... .... ........ .... .... ..... .... ........ .... .... ..... ........ .... ......................... 2

Contents ................................................... ........................................................................... ......................... 3

Table Index ................................................................................................................................................... 6

Figure Index ................................................................................................................................ ................. 8

1 Introduction ........................................................... .................................................. ........................... 10

1.1. Safety Information ..................................................................................................................... 11

2 Product Concept ..................................................................................................... ........................... 12

2.1. General Description .................................................................................................................. 12

2.2. Key Features ............................................................................................................................. 14

2.3. Functional Diagram ................................................................................................................... 17

2.4. Evaluation Board ....................................................................................................................... 18

3 Application Interfaces ....................................................................................................................... 19

3.1. General Description .................................................................................................................. 19

3.2. Pin Assignment ......................................................................................................................... 20

3.3. Pin Description .......................................................................................................................... 21

3.4. Power Supply ............................................................................................................................ 37

3.4.1. Power Supply Pins ......................................................................................................... 37

3.4.2. Decrease Voltage Drop .................................................................................................. 37

3.4.3. Reference Design for Power Supply .............................................................................. 38

3.5. Turn on and off Timing .............................................................................................................. 39

3.5.1. Turn on Module Using the PWRKEY ............................................................................. 39

3.5.2. Turn off Module .............................................................................................................. 41

3.6. VRTC Interface ......................................................................................................................... 42

3.7. Power Output ............................................................................................................................ 43

3.8. Battery Charge and Management ............................................................................................. 44

3.9. USB Interface ............................................................................................................................ 46

3.10. UART Interfaces ........................................................................................................................ 49

3.11. (U)SIM Interfaces ...................................................................................................................... 51

3.12. SD Card Interface ..................................................................................................................... 54

3.13. GPIO Interfaces ........................................................................................................................ 56

3.14. I2C Interfaces ............................................................................................................................ 59

3.15. I2S Interface .............................................................................................................................. 60

3.16. SPI Interfaces ............................................................................................................................ 61

3.17. ADC Interfaces .......................................................................................................................... 62

3.18. Vibrator Drive Interface ............................................................................................................. 63

3.19. LCM Interfaces .......................................................................................................................... 64

3.20. Touch Panel Interfaces ............................................................................................................. 68

3.21. Camera Interfaces ..................................................................................................................... 70

SC600Y&SC600T_Hardware_Design 3 / 134

Page 5

SC600Y&SC600T Hardware Design

Smart Module Series

3.21.1. Design Considerations ................................................................................................... 75

3.21.2. Flashlight Interfaces ....................................................................................................... 77

3.22. Sensor Interfaces ...................................................................................................................... 78

3.23. Audio Interfaces ........................................................................................................................ 79

3.23.1. Reference Circuit Design for Microphone Interfaces ..................................................... 80

3.23.2. Reference Circuit Design for Earpiece Interface ........................................................... 81

3.23.3. Reference Circuit Design for Headphone Interface ....................................................... 81

3.23.4. Reference Circuit Design for Loudspeaker Interface..................................................... 82

3.23.5. Audio Interfaces Design Considerations ........................................................................ 82

3.24. Emergency Download Interface ................................................................................................ 83

4 Wi-Fi and BT ....................................................................................................................................... 84

4.1. Wi-Fi Overview .......................................................................................................................... 84

4.1.1. Wi-Fi Performance ......................................................................................................... 84

4.2. BT Overview .............................................................................................................................. 86

4.2.1. BT Performance ............................................................................................................. 96

5 GNSS ..................................................... ............................................................... ............................... 97

5.1. GNSS Performance .................................................................................................................. 97

5.2. GNSS RF Design Guidelines .................................................................................................... 97

6 Antenna Interfaces ............................................................ ..... .... ........ .... .... ..... .... ........ .... ................... 99

6.1. Main/Rx-diversity Antenna Interfaces ....................................................................................... 99

6.2. Wi-Fi/BT/FM Antenna Interface ................................................................................................ 99

6.3. GNSS Antenna Interface ......................................................................................................... 100

6.3.1. Recommended Circuit for Passive Antenna ................................................................ 101

6.3.2. Recommended Circuit for Active Antenna ................................................................... 101

6.4. Antenna Installation ................................................................................................................. 102

6.4.1. Antenna Requirements ................................................................................................ 102

6.4.2. Recommended RF Connector for Antenna Installation ............................................... 102

Reference Design of RF Layout .......................................................................................... 104

7 Electrical, Reliability and Radio Characteristics ......................................................... ................. 107

7.1. Absolute Maximum Ratings .................................................................................................... 107

7.2. Power Supply Ratings ............................................................................................................. 107

7.3. Operation and Storage Temperatures ..................................................................................... 108

7.4. Electrostatic Discharge ........................................................................................................... 109

8 Mechanical Dimensions .............................................................................................................. .... 110

8.1. Mechanical Dimensions of the Module ................................................................................... 110

8.2. Recommended Footprint ........................................................................................................ 112

8.3. Top and Bottom View of the Module ....................................................................................... 113

9 Storage, Manufacturing and Packaging ................................................................... ..................... 114

9.1. Storage .................................................................................................................................... 114

9.2. Manufacturing and Soldering .................................................................................................. 115

9.3. Packaging................................................................................................................................ 116

SC600Y&SC600T_Hardware_Design 4 / 134

Page 6

SC600Y&SC600T Hardware Design

Smart Module Series

10 Appendix A References ......................................................................... .......................................... 118

删除的内容: About the

Document 2

Contents 3

Table Index 6

Figure Index 8

1 Introduction 10

1.1. Safety Information 11

2 Product Concept 12

2.1. General Description 12

2.2. Key Features 15

2.3. Functional Diagram 19

2.4. Evaluation Board 20

3 Application

Interfaces 21

3.1. General Description 21

3.2. Pin Assignment 22

3.3. Pin Description 23

3.4. Power Supply 39

3.4.1. Power Supply Pins 39

Decrease Voltage

3.4.2.

Drop 39

3.4.3. Reference Design for

Power Supply 40

3.5. Turn on and off

Timing 41

3.5.1. Turn on Module Using

the PWRKEY 41

3.5.2. Turn off Module 43

3.6. VRTC Interface 44

3.7. Power Output 45

3.8. Battery Charge and

Management 46

3.9. USB Interface 48

3.10. UART Interfaces 51

3.11. (U)SIM Interfaces 53

3.12. SD Card Interface 56

3.13. GPIO Interfaces 58

3.14. I2C Interfaces 61

3.15. I2S Interface 62

3.16. SPI Interfaces 63

3.17. ADC Interfaces 64

3.18. Vibrator Drive

Interface 65

3.19. LCM Interfaces 66

... [1]

SC600Y&SC600T_Hardware_Design 5 / 134

Page 7

SC600Y&SC600T Hardware Design

Smart Module Series

Table Index

TABLE 1: SC600Y-EM/SC600T-EM FREQUENCY BANDS ........................................................................... 12

TABLE 2: SC600Y-NA/SC600T-NA FREQUENCY BANDS ............................................................................ 12

TABLE 3: SC600Y-JP/SC600T-JP FREQUENCY BANDS .............................................................................. 13

TABLE 4: SC600Y-WF/SC600T-WF FREQUENCY BANDS ........................................................................... 13

TABLE 5: SC600Y/SC600T KEY FEATURES ................................................................................................. 14

TABLE 6: I/O PARAMETERS DEFINITION..................................................................................................... 21

TABLE 7: PIN DESCRIPTION ........................................................................................................................ 21

TABLE 8: POWER DESCRIPTION ................................................................................................................. 43

TABLE 9: PIN DEFINITION OF CHARGING INTERFACE .............................................................................. 44

TABLE 10: PIN DEFINITION OF USB INTERFACE ....................................................................................... 46

TABLE 11: USB TRACE LENGTH INSIDE THE MODULE ............................................................................. 48

TABLE 12: PIN DEFINITION OF UART INTERFACES ................................................................................... 49

TABLE 13: PIN DEFINITION OF (U)SIM INTERFACES ................................................................................. 51

TABLE 14: PIN DEFINITION OF SD CARD INTERFACE ............................................................................... 54

TABLE 15: SD CARD SIGNAL TRACE LENGTH INSIDE THE MODULE ...................................................... 55

TABLE 16: PIN DEFINITION OF GPIO INTERFACES ................................................................................... 56

TABLE 17: PIN DEFINITION OF I2C INTERFACES ....................................................................................... 59

TABLE 18: PIN DEFINITION OF I2S INTERFACE ......................................................................................... 60

TABLE 19: PIN DEFINITION OF SPI INTERFACES ....................................................................................... 61

TABLE 20: PIN DEFINITION OF ADC INTERFACES ..................................................................................... 62

TABLE 21: PIN DEFINITION OF VIBRATOR DRIVE INTERFACE ................................................................. 63

TABLE 22: PIN DEFINITION OF LCM INTERFACES ..................................................................................... 64

TABLE 23: PIN DEFINITION OF TOUCH PANEL INTERFACES .................................................................... 68

TABLE 24: PIN DEFINITION OF CAMERA INTERFACES ............................................................................. 70

TABLE 25: MIPI TRACE LENGTH INSIDE THE MODULE ............................................................................. 75

TABLE 26: PIN DEFINITION OF FLASHLIGHT INTERFACES ....................................................................... 77

TABLE 27: PIN DEFINITION OF SENSOR INTERFACES ............................................................................. 78

TABLE 28: PIN DEFINITION OF AUDIO INTERFACES ................................................................................. 79

TABLE 29: WI-FI TRANSMITTING PERFORMANCE ..................................................................................... 84

TABLE 30: WI-FI RECEIVING PERFORMANCE ............................................................................................ 85

TABLE 31: BT DATA RATE AND VERSIONS .................................................................................................. 96

TABLE 32: BT TRANSMITTING AND RECEIVING PERFORMANCE ............................................................ 96

TABLE 33: GNSS PERFORMANCE ............................................................................................................... 97

TABLE 34: PIN DEFINITION OF MAIN/RX-DIVERSITY ANTENNA INTERFACES ........................................ 99

TABLE 36: WI-FI/BT/FM FREQUENCY ........................................................................................................ 100

TABLE 37: PIN DEFINITION OF GNSS ANTENNA ...................................................................................... 100

TABLE 38: GNSS FREQUENCY .................................................................................................................. 100

TABLE 39: ANTENNA REQUIREMENTS ..................................................................................................... 102

TABLE 40: ABSOLUTE MAXIMUM RATINGS .............................................................................................. 107

TABLE 41: SC600Y/SC600T POWER SUPPLY RATINGS ........................................................................... 107

TABLE 42: OPERATION AND STORAGE TEMPERATURES ...................................................................... 108

SC600Y&SC600T_Hardware_Design 6 / 134

Page 8

SC600Y&SC600T Hardware Design

Smart Module Series

TABLE 50: RECOMMENDED THERMAL PROFILE PARAMETERS ............................................................. 115

TABLE 51: REEL PACKAGING ...................................................................................................................... 117

TABLE 52: RELATED DOCUMENTS ............................................................................................................. 118

TABLE 53: TERMS AND ABBREVIATIONS ................................................................................................... 118

删除的内容: TAB LE 1:

SC600Y-EM/SC600T-EM

FREQUENCY BANDS 12

TABLE 2:

SC600Y-NA/SC600T-NA

FREQUENCY BANDS 13

TABLE 3:

SC600Y-JP/SC600T-JP

FREQUENCY BANDS 13

TABLE 4:

SC600Y-WF/SC600T-WF

FREQUENCY BANDS 14

TABLE 5: SC600Y/SC600T

KEY FEATURES 15

TABLE 6: I/O PARAMETERS

DEFINITION 23

TABLE 7: PIN

DESCRIPTION 23

TABLE 8: POWER

DESCRIPTION 45

TABLE 9: PIN DEFINITION

OF CHARGING

INTERFACE 46

TABLE 10: PIN DEFINITION

OF USB INTERFACE 48

TABLE 11: USB TRACE

LENGTH INSIDE THE

MODULE 50

TABLE 12: PIN DEFINITION

OF UART INTERFACES 51

TABLE 13: PIN DEFINITION

OF (U)SIM INTERFACES 53

TABLE 14: PIN DEFINITION

OF SD CARD

INTERFACE 56

TABLE 15: SD CARD SIGNAL

TRACE LENGTH INSIDE

THE MODULE 57

TABLE 16: PIN DEFINITION

OF GPIO INTERFACES 58

TABLE 17: PIN DEFINITION

OF I2C INTERFACES 61

TABLE 18: PIN DEFINITION

OF I2S INTERFACE 62

... [2]

SC600Y&SC600T_Hardware_Design 7 / 134

Page 9

SC600Y&SC600T Hardware Design

Smart Module Series

Figure Index

FIGURE 1: FUNCTIONAL DIAGRAM ............................................................................................................. 18

FIGURE 2: PIN ASSIGNMENT (TOP VIEW) .................................................................................................. 20

FIGURE 3: VOLTAGE DROP SAMPLE .......................................................................................................... 37

FIGURE 4: STAR STRUCTURE OF POWER SUPPLY .................................................................................. 38

FIGURE 5: REFERENCE CIRCUIT OF POWER SUPPLY ............................................................................. 38

FIGURE 6: TURN ON THE MODULE USING DRIVING CIRCUIT ................................................................. 39

FIGURE 7: TURN ON THE MODULE USING KEYSTROKE .......................................................................... 40

FIGURE 8: TIMING OF TURNING ON MODULE ........................................................................................... 40

FIGURE 9: TIMING OF TURNING OFF MODULE ......................................................................................... 41

FIGURE 10: RTC POWERED BY COIN CELL ............................................................................................... 42

FIGURE 11: REFERENCE DESIGN FOR BATTERY CHARGING CIRCUIT .................................................. 45

FIGURE 12: MICRO USB INTERFACE REFERENCE DESIGN ..................................................................... 47

FIGURE 13: USB TYPE-C INTERFACE REFERENCE DESIGN .................................................................... 48

FIGURE 14: REFERENCE CIRCUIT WITH LEVEL TRANSLATOR CHIP (FOR UART5) ............................... 50

FIGURE 15: RS232 LEVEL MATCH CIRCUIT (FOR UART5) ........................................................................ 51

FIGURE 16: REFERENCE CIRCUIT FOR (U)SIM INTERFACE WITH AN 8-PIN (U)SIM CARD CONNECTOR

....................................................................................................................................................................... 52

FIGURE 17: REFERENCE CIRCUIT FOR (U)SIM INTERFACE WITH A 6-PIN (U)SIM CARD CONNECTOR

....................................................................................................................................................................... 53

FIGURE 18: REFERENCE CIRCUIT FOR SD CARD INTERFACE ................................................................ 54

FIGURE 19: REFERENCE CIRCUIT FOR VIBRATOR CONNECTION .......................................................... 63

FIGURE 20: REFERENCE CIRCUIT DESIGN FOR LCM0 INTERFACE........................................................ 66

FIGURE 21: REFERENCE CIRCUIT DESIGN FOR LCM1 INTERFACE........................................................ 67

FIGURE 22: REFERENCE DESIGN OF LCM1 EXTERNAL BACKLIGHT DRIVING CIRCUIT ....................... 68

FIGURE 23: REFERENCE CIRCUIT DESIGN FOR TOUCH PANEL INTERFACES ...................................... 69

FIGURE 24: REFERENCE CIRCUIT DESIGN FOR TWO-CAMERA APPLICATIONS ................................... 73

FIGURE 25: REFERENCE CIRCUIT DESIGN FOR THREE-CAMERA APPLICATIONS ............................... 74

FIGURE 26: REFERENCE CIRCUIT DESIGN FOR FLASHLIGHT INTERFACES ......................................... 78

FIGURE 27: REFERENCE CIRCUIT DESIGN FOR ANALOG ECM-TYPE MICROPHONE ........................... 80

FIGURE 28: REFERENCE CIRCUIT DESIGN FOR MEMS-TYPE MICROPHONE ....................................... 80

FIGURE 29: REFERENCE CIRCUIT DESIGN FOR EARPIECE INTERFACE ............................................... 81

FIGURE 30: REFERENCE CIRCUIT DESIGN FOR HEADPHONE INTERFACE .......................................... 81

FIGURE 31: REFERENCE CIRCUIT DESIGN FOR LOUDSPEAKER INTERFACE ...................................... 82

FIGURE 32: REFERENCE CIRCUIT DESIGN FOR EMERGENCY DOWNLOAD INTERFACE .................... 83

FIGURE 33: REFERENCE CIRCUIT DESIGN FOR MAIN AND RX-DIVERSITY ANTENNA INTERFACES .. 99

FIGURE 34: MICROSTRIP DESIGN ON A 2-LAYER PCB ............................................................................. 99

FIGURE 35: COPLANAR WAVEGUIDE DESIGN ON A 2-LAYER PCB .......................................................... 99

FIGURE 36: COPLANAR WAVEGUIDE DESIGN ON A 4-LAYER PCB (LAYER 3 AS REFERENCE GROUND)

....................................................................................................................................................................... 99

FIGURE 37: COPLANAR WAVEGUIDE DESIGN ON A 4-LAYER PCB (LAYER 4 AS REFERENCE GROUND)

....................................................................................................................................................................... 99

删除的内容: 20

删除的内容: 22

删除的内容: 39

删除的内容: 40

删除的内容: 40

删除的内容: 41

删除的内容: 42

删除的内容: 42

删除的内容: 43

删除的内容: 44

删除的内容: 47

删除的内容: 49

删除的内容: 50

删除的内容: 52

删除的内容: 53

删除的内容: 54

删除的内容: 55

删除的内容: 56

删除的内容: 65

删除的内容: 68

删除的内容: 69

删除的内容: 70

删除的内容: 71

删除的内容: 75

删除的内容: 76

删除的内容: 80

删除的内容: 82

删除的内容: 82

删除的内容: 83

删除的内容: 83

删除的内容: 84

删除的内容: 85

删除的内容: 95

删除的内容: 96

删除的内容: 96

删除的内容: 97

删除的内容: 97

SC600Y&SC600T_Hardware_Design 8 / 134

Page 10

SC600Y&SC600T Hardware Design

Smart Module Series

FIGURE 38: REFERENCE CIRCUIT DESIGN FOR WI-FI/BT ANTENNA INTERFACE ............................... 100

FIGURE 39: REFERENCE CIRCUIT DESIGN FOR FM ANTENNA INTERFACE ........................................ 100

FIGURE 40: REFERENCE CIRCUIT DESIGN FOR GNSS PASSIVE ANTENNA ........................................ 101

FIGURE 41: REFERENCE CIRCUIT DESIGN FOR GNSS ACTIVE ANTENNA .......................................... 102

FIGURE 42: DIMENSIONS OF THE U.FL-R-SMT CONNECTOR (UNIT: MM) ............................................. 102

FIGURE 43: MECHANICALS OF U.FL-LP CONNECTORS ......................................................................... 103

FIGURE 44: SPACE FACTOR OF MATED CONNECTOR (UNIT: MM) ........................................................ 103

FIGURE 45: MODULE TOP AND SIDE DIMENSIONS .................................................................................. 110

FIGURE 46: MODULE BOTTOM DIMENSIONS (TOP VIEW) ....................................................................... 111

FIGURE 47: RECOMMENDED FOOTPRINT (TOP VIEW) ............................................................................ 11 2

FIGURE 48: TOP VIEW OF SC600Y/SC600T MODULE ............................................................................... 11 3

FIGURE 49: BOTTOM VIEW OF SC600Y/SC600T MODULE ....................................................................... 113

FIGURE 50: RECOMMENDED REFLOW SOLDERING THERMAL PROFILE .............................................. 11 5

FIGURE 51: TAPE DIMENSIONS .................................................................................................................. 116

FIGURE 52: REEL DIMENSIONS ................................................................................................................. 117

删除的内容: 98

删除的内容: 99

删除的内容: 100

删除的内容: 100

删除的内容: 102

删除的内容: 102

删除的内容: 103

删除的内容: 119

删除的内容: 120

删除的内容: 121

删除的内容: 122

删除的内容: 122

删除的内容: 124

删除的内容: 125

删除的内容: 126

SC600Y&SC600T_Hardware_Design 9 / 134

Page 11

SC600Y&SC600T Hardware Design

Smart Module Series

1 Introduction

This document defines the SC600Y/SC600T module and describes its air interfaces and hardware

interfaces which are connected with customers’ applications.

This document helps customers quickly understand module interface specifications, electrical and

mechanical details as well as other related information of SC600Y/SC600T module. Associated with

application note and user guide, customers can use SC600Y/SC600T module to design and set up

mobile applications easily.

SC600Y&SC600T_Hardware_Design 10 / 134

Page 12

Smart Module Series

SC600Y&SC600T Hardware Design

1.1. Safety Information

The following safety precautions must be observed during all phases of operation, such as usage, service

or repair of any cellular terminal or mobile incorporating SC600Y/SC600T module. Manufacturers of the

cellular terminal should send the following safety information to users and operating personnel, and

incorporate these guidelines into all manuals supplied with the product. If not so, Quectel assumes no

liability for customers’ failure to comply with these precautions.

Full attention must be given to driving at all times in order to reduce the risk of an

accident. Using a mobile while driving (even with a handsfree kit) causes

distraction and can lead to an accident. Please comply with laws and regulations

restricting the use of wireless devices while driving.

Switch off the cellular terminal or mobile before boarding an aircraft. The operation

of wireless appliances in an aircraft is forbidden to prevent interference with

communication systems. If the device offers an Airplane Mode, then it should be

enabled prior to boarding an aircraft. Please consult the airline staff for more

restrictions on the use of wireless devices on boarding the aircraft.

Wireless devices may cause interference on sensitive medical equipment, so

please be aware of the restrictions on the use of wireless devices when in

hospitals, clinics or other healthcare facilities.

Cellular terminals or mobiles operating over radio signals and cellular network

cannot be guaranteed to connect in all possible conditions (for example, with

unpaid bills or with an invalid (U)SIM card). When emergent help is needed in such

conditions, please remember using emergency call. In order to make or receive a

call, the cellular terminal or mobile must be switched on in a service area with

adequate cellular signal strength.

The cellular terminal or mobile contains a transmitter and receiver. When it is ON, it

receives and transmits radio frequency signals. RF interference can occur if it is

used close to TV set, radio, computer or other electric equipment.

In locations with potentially explosive atmospheres, obey all posted signs to turn

off wireless devices such as your phone or other cellular terminals. Areas with

potentially explosive atmospheres include fuelling areas, below decks on boats,

fuel or chemical transfer or storage facilities, areas where the air contains

chemicals or particles such as grain, dust or metal powders, etc.

SC600Y&SC600T_Hardware_Design 11 / 134

Page 13

SC600Y&SC600T Hardware Design

Smart Module Series

2 Product Concept

2.1. General Description

SC600Y/SC600T is a series of Smart module based on Qualcomm platform and Android operating

system, and provides industrial grade performance. Their general features are listed below:

Support short-range wireless communication via Wi-Fi 802.11a/b/g/n/ac and BT4.2 LE standards

Integrate GPS/GLONASS/BeiDou satellite positioning systems

Support multiple audio and video codecs

Built-in high performance Adreno

Provide multiple audio and video input/output interfaces as well as abundant GPIO interfaces

SC600Y (standard version) and SC600T (high-performance version) are available in SC600Y-EM/

SC600T-EM, SC600Y-NA/SC600T-NA, SC600Y-JP/SC600T-JP and SC600Y-WF/SC600T-WF.

The following table shows the supported frequency bands of SC600Y/SC600T.

TM

506 graphics processing unit

删除的内容: <#>Support

worldwide LTE-FDD,

LTE-TDD, DC-HSDPA,

DC-HSUPA, HSPA+, HSDPA,

HSUPA, WCDMA, EDGE,

GPRS and GSM coverage

Table 1: SC600Y-EM/SC600T-EM Frequency Bands

Type Frequency Bands

Wi-Fi 802.11a/b/g/n/ac 2402MHz~2482MHz; 5180MHz~5825MHz*

BT4.2 LE 2402MHz~2480MHz

GPS: 1575.42MHz±1.023MHz

GNSS

Table 2: SC600Y-NA/SC600T-NA Frequency Bands

Type Frequency Bands

Wi-Fi 802.11a/b/g/n/ac 2402MHz~2482MHz; 5180MHz~5825MHz*

BT4.2 LE 2402MHz~2480MHz

SC600Y&SC600T_Hardware_Design 12 / 134

GLONASS: 1597.5MHz~1605.8MHz

BeiDou: 1561.098MHz±2.046MHz

删除的内容: LTE-FDD

删除的内容: LTE-FDD

... [3]

... [4]

Page 14

SC600Y&SC600T Hardware Design

Smart Module Series

GPS: 1575.42MHz±1.023MHz

GNSS

GLONASS: 1597.5MHz~1605.8MHz

BeiDou: 1561.098MHz±2.046MHz

Table 3: SC600Y-JP/SC600T-JP Frequency Bands

Type Frequency Bands

Wi-Fi 802.11a/b/g/n/ac 2402MHz~2482MHz; 5180MHz~5825MHz*

BT4.2 LE 2402MHz~2480MHz

GPS: 1575.42MHz±1.023MHz

GNSS

GLONASS: 1597.5MHz~1605.8MHz

BeiDou: 1561.098MHz±2.046MHz

Table 4: SC600Y-WF/SC600T-WF Frequency Bands

Type Frequency Bands

Wi-Fi 802.11a/b/g/n/ac 2402MHz~2482MHz; 5180MHz~5825MHz *

BT4.2 LE 2402MHz~2480MHz

GNSS /

SC600Y/SC600T is an SMD-type module, which can be embedded into applications through its 323 pins

(including 152 LCC pins and 171 LGA pins). With a compact profile of 43.0mm × 44.0mm × 2.85mm,

SC600Y/SC600T can meet almost all requirements for M2M applications such as smart metering, smart

home, security, routers, wireless POS, mobile computing devices, PDA phone, tablet PC, etc. Additionally,

SC600Y/SC600T supports AI applications such as face and vehicle recognition.

* The device is restricted to indoor use only when operation in the 5150 to 5350 MHz frequency range.

删除的内容: LTE-FDD

删除的内容: LTE-FDD

... [5]

... [6]

SC600Y&SC600T_Hardware_Design 13 / 134

Page 15

SC600Y&SC600T Hardware Design

Smart Module Series

2.2. Key Features

The following table describes the detailed features of SC600Y/SC600T module.

Table 5: SC600Y/SC600T Key Features

Features Details

SC600Y

Octa-core ARM Cortex-A53 64-bit CPU @1.8GHz (standard)

Two quad-core processors with 512KB L2 cache

Application Processor

Modem system

GPU

Operating System Android OS 9.0

Power Supply

WLAN Features

Bluetooth Features BT4.2 LE

SC600T

Octa-core ARM Cortex-A53 64-bit CPU @2.0GHz (high performance)

One quad-core with 1MB L2 cache

One quad-core with 512KB L2 cache

Hexagon DSP v56 core up to 850MHz

768KB L2 caches

SC600Y

TM

Adreno

506 with 64-bit addressing, designed for 600MHz

SC600T

TM

Adreno

506 with 64-bit addressing, designed for 650MHz

VBAT Supply Voltage: 3.55V~4.4V

Typical: 3.8V

2.4GHz/5GHz, 802.11a/b/g/n/ac, maximally up to 433Mbps

Support AP and STA modes

删除的内容: Memory

删除的内容: Transmitting

Power

... [7]

... [8]

GNSS Features GPS/GLONASS/BeiDou

Text and PDU mode

SMS

Point-to-point MO and MT

SMS cell broadcast

Support two groups of 4-lane MIPI_DSI

Support dual LCDs

LCM Interfaces

Support WUXGA up to (1920×1200) at 60fps

Provide one high voltage output for powering a string of WLEDs

Provide four drivers for sinking the current from WLED strings, and each sink

current can reach up to 25mA

Camera Interfaces

Support three groups of 4-lane MIPI_CSI, up to 2.1Gbps per lane

Support 3 cameras (4-lane + 4-lane + 4-lane) or 4 cameras (4-lane + 4-lane +

SC600Y&SC600T_Hardware_Design 14 / 134

Page 16

SC600Y&SC600T Hardware Design

Smart Module Series

2-lane + 1-lane)

SC600Y

Up to 21MP with dual ISP

SC600T

Up to 24MP with dual ISP

SC600Y

Video encoding and decoding: up to 1080P @60fps

Video Codec

Wi-Fi Video: encoding up to 1080P @30fps; decoding up to 1080P @60fps

SC600T

Video encoding and decoding: up to 4K @30fps, up to 1080P @60fps

Wi-Fi Video: encoding up to 1080P @30fps; decoding up to 1080P @60fps

Audio Input

Three analog microphone inputs, integrating internal bias voltage

Audio Interfaces

Audio Output

Class AB stereo headphone output

Class AB earpiece differential output

Class D speaker differential amplifier output

Audio Codec

G711, QCELP, EVRC, EVRC-B, EVRC-WB, AMR-NB, AMR-WB, GSM-EFR,

GSM-FR, GSM-HR

Support with USB 3.0 or 2.0 specifications, with transmission rates up to

5Gbps on USB 3.0 and 480Mbps on USB 2.0

USB Interface

Support USB OTG

Used for AT command communication, data transmission, software debugging

and firmware upgrade

4 UART Interfaces: UART5, UART6, UART4 and UART2

UART5 & UART6: 4-wire UART interface with RTS/CTS hardware flow

UART Interfaces

control, baud rate up to 4Mbps

UART4: 2-wire UART interface

UART2: 2-wire UART interface used for debugging

Vibrator drive interface Drive ERM vibrator

SD Card Interface

Support SD 3.0

Support SD card hot-plug

2 (U)SIM interfaces

(U)SIM Interfaces

Support USIM/SIM card: 1.8V/2.95V

Support Dual SIM Dual Standby (supported by default)

I2C Interfaces 5 I2C interfaces, used for peripherals such as TP, camera, sensor, etc.

I2S Interface Support for I2S peripherals

2 high current Flash and torch LED driver

Flashlight Interfaces

Up to 0.75A each for two LEDs and 1.5A for one LED in Flash mode

Up to 300mA each for two LEDs and 300mA for one LED in torch mode

SC600Y&SC600T_Hardware_Design 15 / 134

Page 17

SC600Y&SC600T Hardware Design

Smart Module Series

ADC Interfaces

2 general purpose ADC interfaces

Support up to 15-bit sampling accuracy

2 SPI interfaces, only support master mode

SPI Interfaces

One SPI interface used for peripheral device

One SPI interface used for sensor application, such as fingerprint sensor

Charging Interface Used for battery voltage detection, fuel gauge, battery temperature detection

Real Time Clock Supported

Antenna Interfaces

Main antenna, Rx-diversity antenna, GNSS antenna, Wi-Fi/BT antenna and

FM antenna

Size: (43.0±0.15)mm × (44.0±0.15)mm × (2.85±0.2)mm

Physical Characteristics

Package: LCC + LGA

Weight: approx. 13.0g

1)

2)

Temperature Range

Operating temperature range: -35°C ~ +65°C

Extended temperature range: -40°C ~ +75°C

Storage temperature range: -40°C ~ +90°C

Firmware Upgrade Over USB interface

RoHS All hardware components are fully compliant with EU RoHS directive

NOTES

1. 1) Within operating temperature range, the module is 3GPP compliant.

2. 2) Within extended temperature range, the module remains the ability to establish and maintain a

voice, SMS, data transmission, emergency call, etc. There is no unrecoverable malfunction. There

are also no effects on radio spectrum and no harm to radio network. Only one or more parameters like

P

might reduce in their value and exceed the specified tolerances. When the temperature returns to

out

the normal operating temperature levels, the module will meet 3GPP specifications again.

SC600Y&SC600T_Hardware_Design 16 / 134

删除的内容:

Page 18

SC600Y&SC600T Hardware Design

Smart Module Series

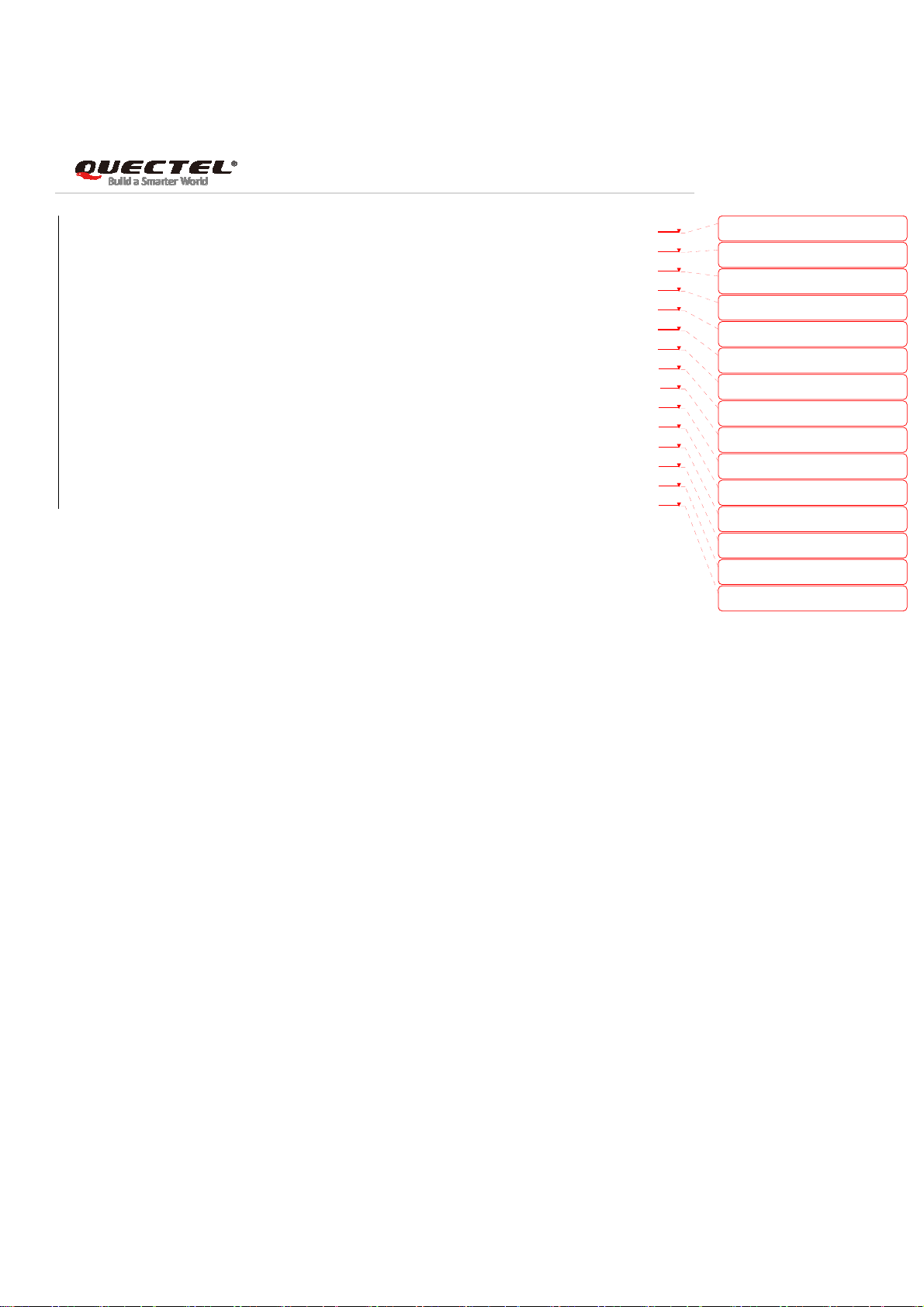

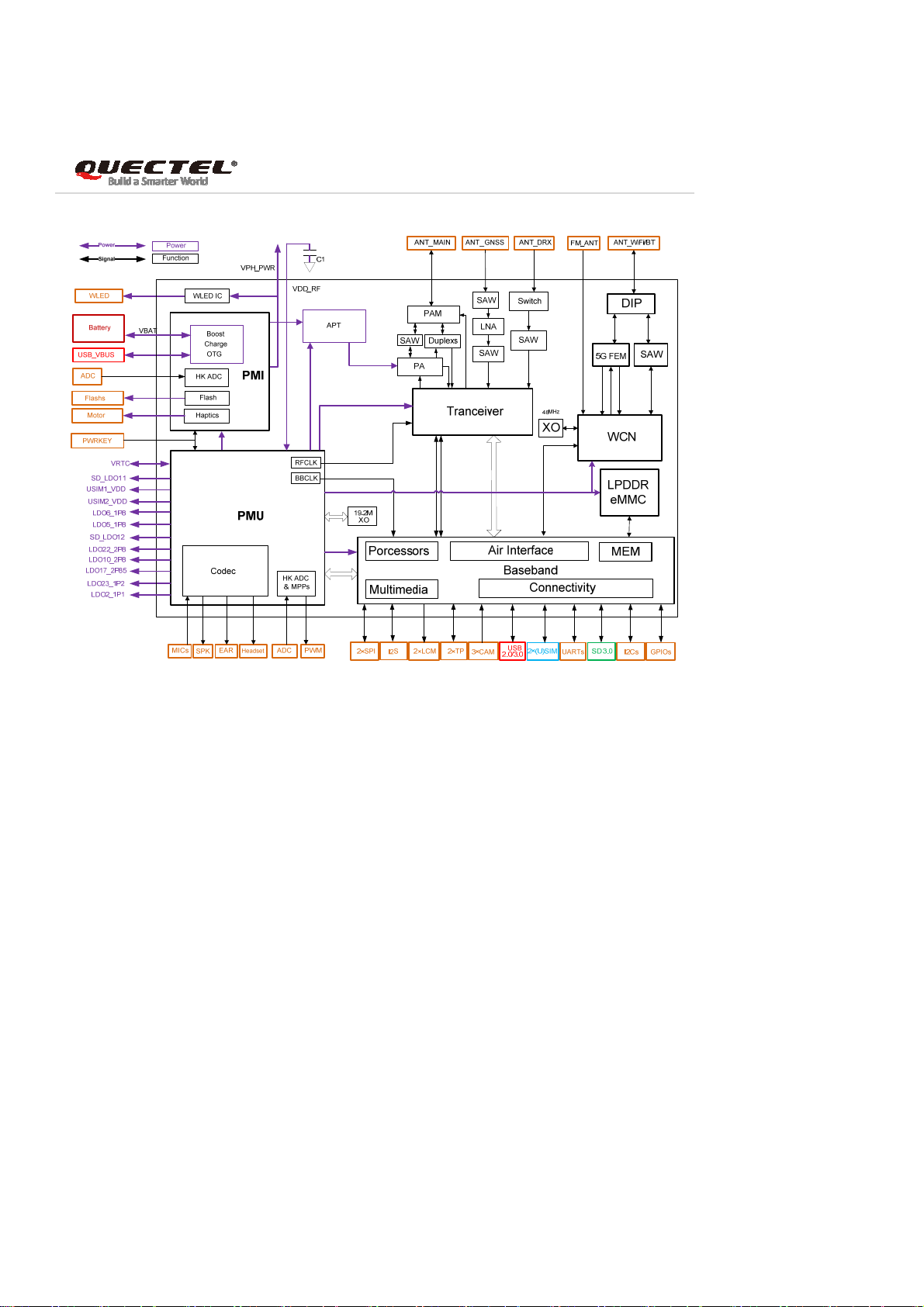

2.3. Functional Diagram

The following figure shows a block diagram of SC600Y/SC600T and illustrates the major functional parts.

Power management

Radio frequency

Baseband

LPDDR3+eMMC flash

Peripheral interfaces

-- USB interface

-- UART interfaces

-- (U)SIM interfaces

-- SD card interface

-- GPIO interfaces

-- I2C interfaces

-- I2S interface

-- SPI interfaces

-- ADC interfaces

-- Vibrator Drive interface

-- LCM (MIPI) interfaces

-- TP (touch panel) interfaces

-- Camera (MIPI) interfaces

-- Flashlight interfaces

-- Sensor interfaces

-- Audio interfaces

-- Emergency Download interface

SC600Y&SC600T_Hardware_Design 17 / 134

Page 19

SC600Y&SC600T Hardware Design

Smart Module Series

Figure 1: Functional Diagram

2.4. Evaluation Board

In order to help customers develop applications with SC600Y/SC600T conveniently, Quectel supplies the

evaluation board, USB to RS232 converter cable, USB Type-C data cable, power adapter, earphone,

antenna and other peripherals to control or test the module. For more details, please refer to document

[1].

SC600Y&SC600T_Hardware_Design 18 / 134

Page 20

SC600Y&SC600T Hardware Design

Smart Module Series

3 Application Interfaces

3.1. General Description

SC600Y/SC600T is equipped with 323 pins that can be embedded into cellular application platform. The

following chapters provide the detailed description of pins/interfaces listed below.

Power supply

VRTC interface

Charging interface

USB interface

UART interfaces

(U)SIM interfaces

SD card interface

GPIO interfaces

I2C interfaces

I2S interface

SPI interfaces

ADC interfaces

Vibrator drive interface

LCM interfaces

TP (touch panel) interfaces

Camera interfaces

Flashlight interfaces

Sensor interfaces

Audio interfaces

Emergency download interface

SC600Y&SC600T_Hardware_Design 19 / 134

Page 21

SC600Y&SC600T Hardware Design

Smart Module Series

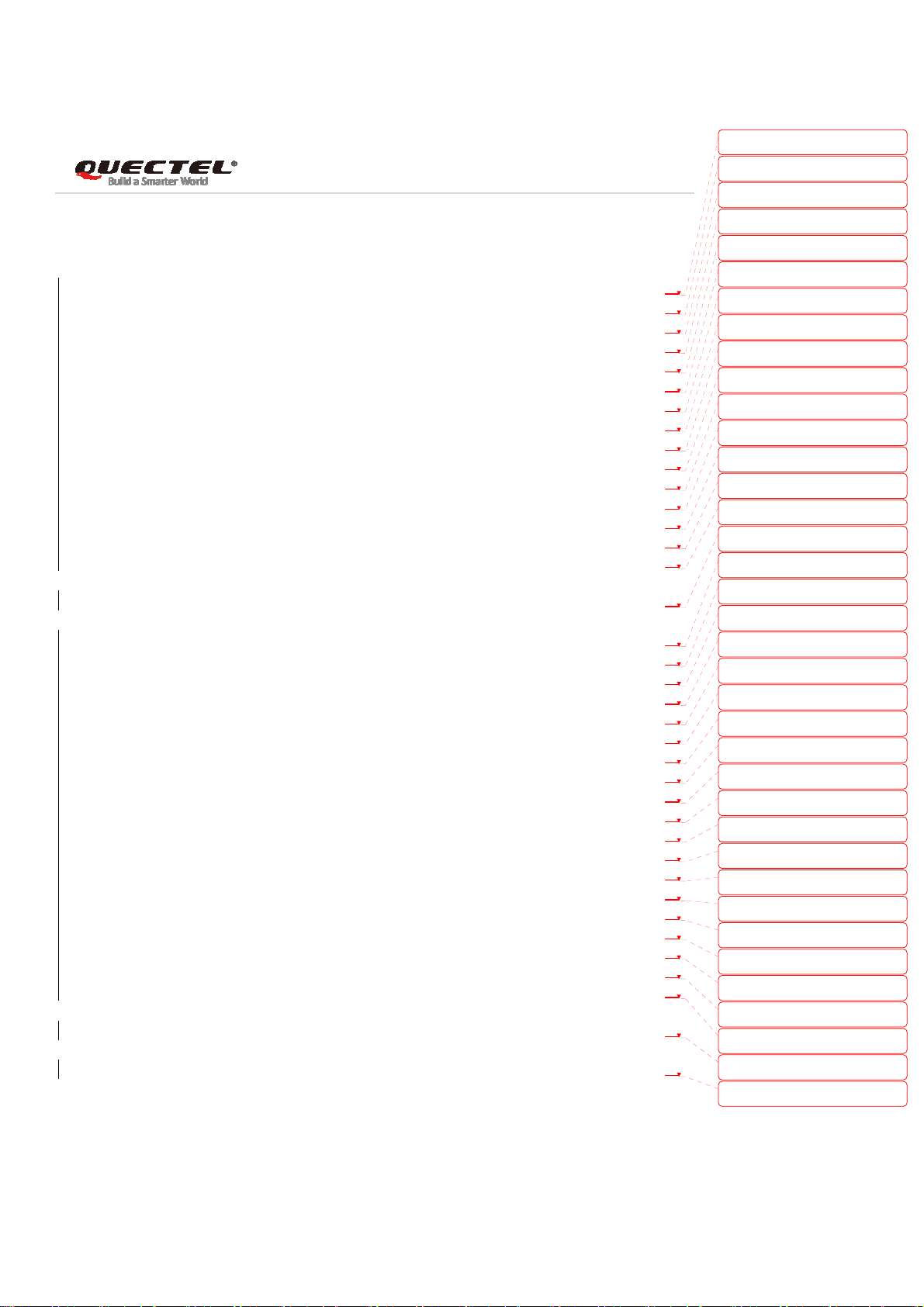

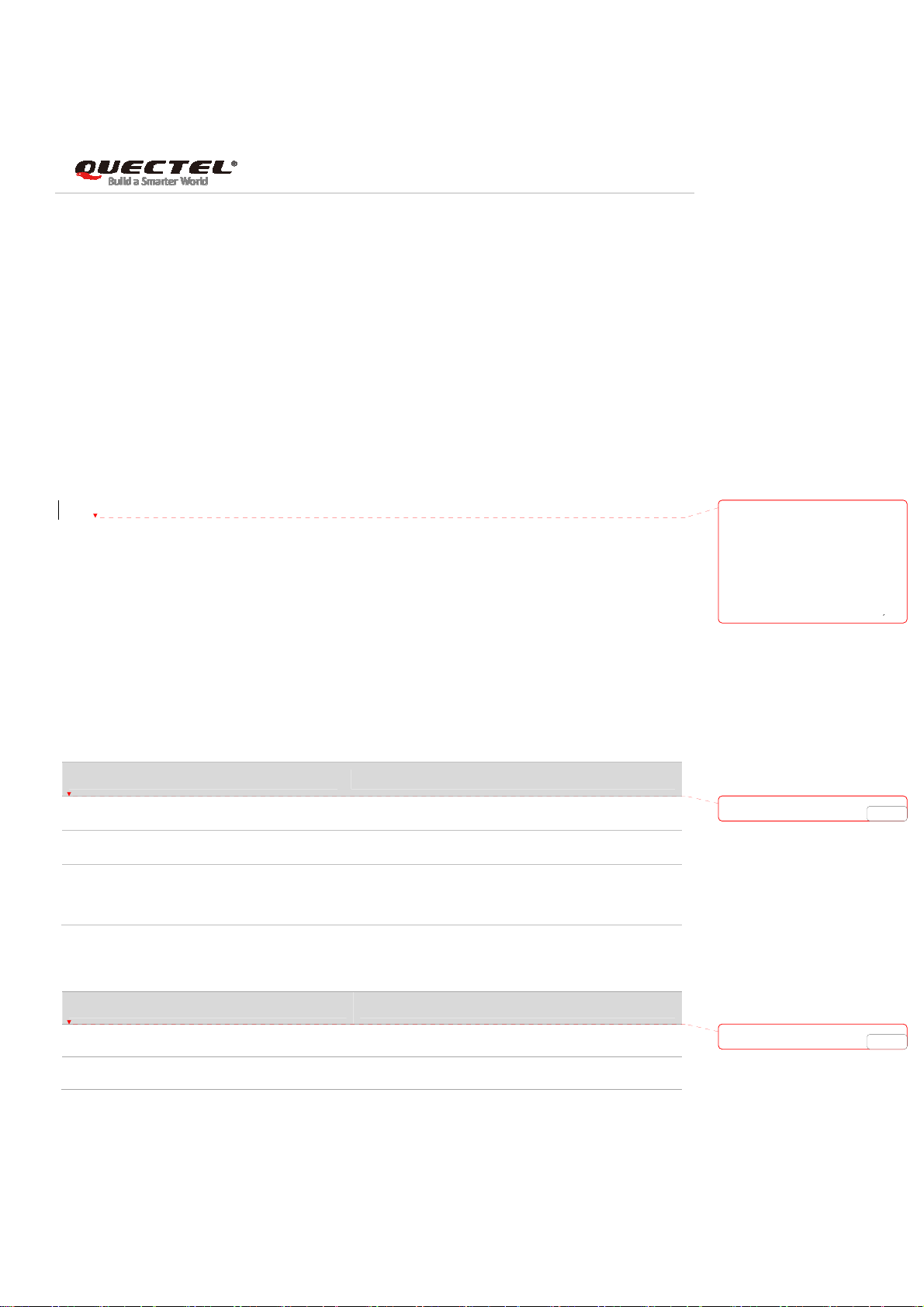

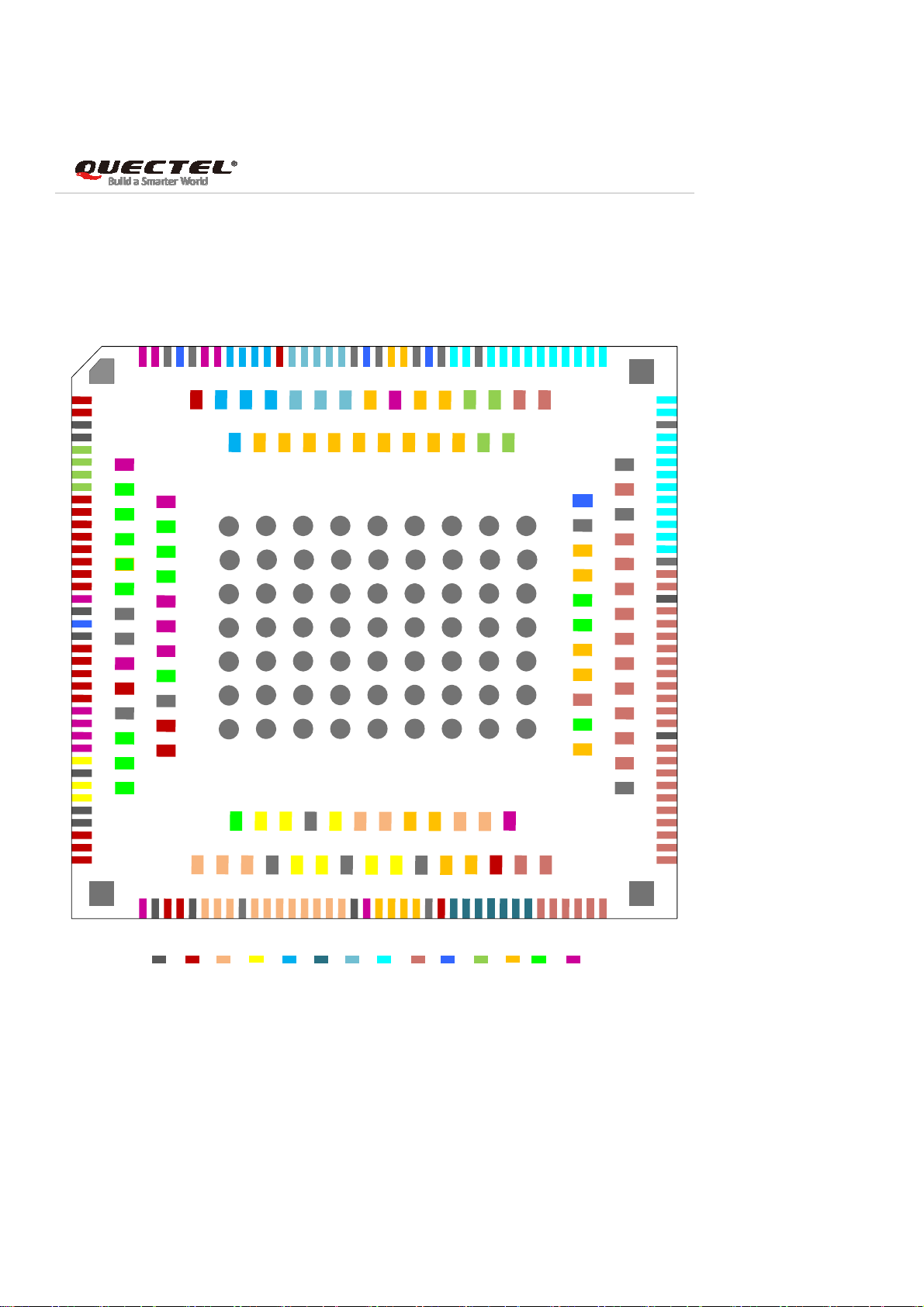

3.2. Pin Assignment

The following figure shows the pin assignment of SC600Y/SC600T module.

133

144

151

152

150

320

1

2

3

4

5

6

153

7

8

154

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

2

4

25

26

27

28

29

30

31

32

33

34

35

36

37

38

211

155

212

156

213

157

214

158

215

159

216

160

217

161

218

162

219

163

220

164

221

165

166

146

148

147

149

2

1

0

1

6

7

142

143

145

2

0

9

1

6

8

2

2

0

0

7

8

2

2

5

5

6

5

264

257

258

265

266

259

267

260

268

261

269

262

263

270

2

2

2

2

2

3

1

6

9

138

141

140

139

2

0

6

2

2

5

5

3

4

271

272

273

274

275

276

277

2

2

2

2

5

4

1

1

7

7

0

1

134

132

135

137

136

2

2

0

0

5

4

2

5

2

278

279

280

281

282

283

284

2

2

6

1

1

7

7

2

3

131

2

2

0

0

2

3

2

2

5

5

1

0

285

286

287

288

289

290

291

2

2

2

2

7

8

1

1

7

7

5

4

127

126

128

129

130

2

2

0

0

0

1

2

2

4

9

2

2

9

2

4

4

7

8

299

292

300

293

301

294

295

302

303

296

304

297

305

298

2

2

3

3

1

0

1

1

7

7

6

7

122

125

123

124

1

9

9

2

4

6

306

307

308

309

310

311

312

2

3

2

1

7

8

120

121

1

1

9

9

7

8

2

4

5

313

314

315

316

317

318

319

2

3

3

1

1

8

7

0

9

116

117

118

119

1

9

6

1

8

1

115

323

114

113

112

111

110

109

195

108

107

194

244

243

242

241

240

239

238

237

236

235

234

106

105

193

104

103

192

102

101

191

100

99

190

98

97

189

96

95

188

94

93

187

92

91

186

90

89

185

88

87

184

86

85

183

84

83

182

82

81

80

79

78

77

321

39

42

40

41

GND POWER AUDIO USB

46

49

50

47

48

45

44

43

51

(U)SIM SD TP LCM

555657585960616263

52

53

54

CAMERA ANT UART GPIO

64

656667

68

697071

RESERVED

72

737475

OTHERS

322

76

Figure 2: Pin Assignment (Top View)

SC600Y&SC600T_Hardware_Design 20 / 134

Page 22

SC600Y&SC600T Hardware Design

Smart Module Series

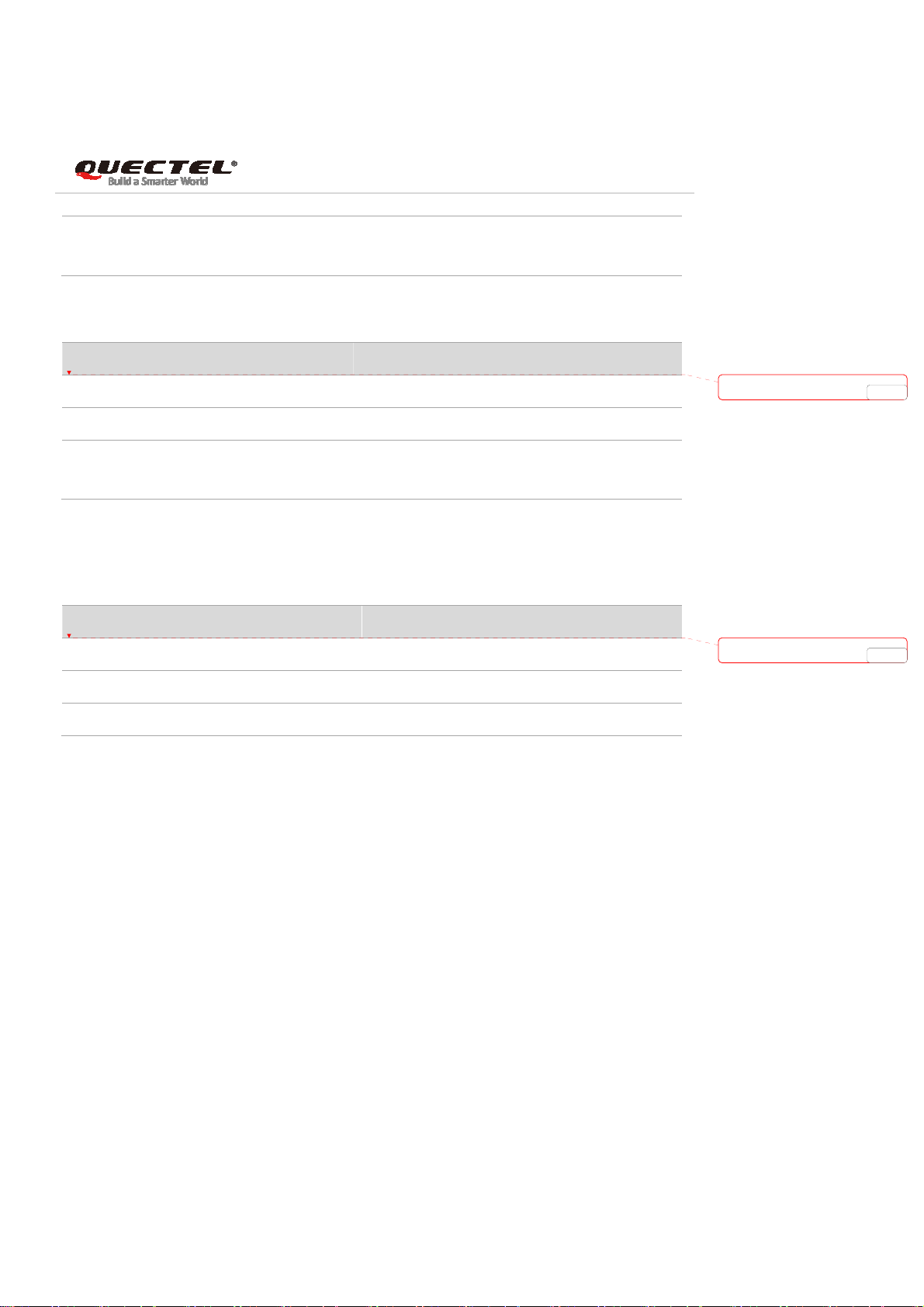

3.3. Pin Description

Table 6: I/O Parameters Definition

Type Description

AI Analog input

AO Analog output

DI Digital input

DO Digital output

IO Bidirectional

OD Open drain

PI Power input

PO Power output

The following tables show the SC600Y/SC600T’s pin definitions and electrical characteristics.

Table 7: Pin Description

Power Supply

Pin Name Pin No. I/O Description

VBAT

VDD_RF 1, 2

VPH_PWR 220, 221 PO

36, 37,

38

PI/

Power supply for the

PO

module

Connect to external

bypass capacitors to

eliminate voltage

fluctuation of RF part.

Power supply for

peripherals

DC

Characteristics

Vmax=4.4V

Vmin=3.55V

Vnorm=3.8V

Do not load externally.

Vmax=4.4V

Vmin=3.55V

Comment

It must be provided

with sufficient current

up to 3.0A.

It is suggested to use a

TVS to increase

voltage surge

withstand capability.

It can provide a

maximum continuous

SC600Y&SC600T_Hardware_Design 21 / 134

Page 23

SC600Y&SC600T Hardware Design

Smart Module Series

Vnorm=3.8V current of 1A

approximately.

The value of capacitors

placed on this pin

should not exceed

120uF.

VRTC 16

PI/PO Power supply for

internal RTC circuit

max=3.2V

V

O

=2.0V~3.25V

V

I

Power supply for

LDO5_1P8 9 PO

1.8V output power

supply

Vnorm=1.8V

max=20mA

I

O

external GPIO’s pull up

circuits and level shift

circuit.

Power supply for VDD

of sensors and TPs.

Add a 1.0uF~4.7uF

bypass capacitor if

used.

LDO10_2P8 11 PO

2.8V output power

supply

Vnorm=2.8V

max=150mA

I

O

If unused, keep this pin

open.

Power supply for I/O

VDD of cameras,

LCDs and sensors.

LDO6_1P8 10 PO

1.8V output power

supply

Vnorm=1.8V

max=300mA

I

O

Add a 1.0uF~2.2uF

bypass capacitor if

used.

If unused, keep this pin

open.

Power supply for

cameras and LCDs.

Add a 1.0uF~4.7uF

bypass capacitor if

used.

LDO17_2P85 12 PO

2.85V output power

supply

Vnorm=2.85V

max=300mA

I

O

If unused, keep this pin

open.

Power supply for

DVDD of front camera.

Add a 1.0uF~2.2uF

bypass capacitor if

used.

LDO23_1P2 15 PO

1.2V output power

supply

Vnorm=1.2V

max=600mA

I

O

If unused, keep this pin

open.

SC600Y&SC600T_Hardware_Design 22 / 134

Page 24

SC600Y&SC600T Hardware Design

Smart Module Series

Power supply for

DVDD of rear camera.

Add a 1.0uF~2.2uF

bypass capacitor if

used.

LDO2_1P1 13 PO

1.1V output power

supply

Vnorm=1.1V

max=1200mA

I

O

If unused, keep this pin

open.

Power supply for

AVDD of camera.

Add a 1.0uF~4.7uF

bypass capacitor if

used.

LDO22_2P8 14 PO

2.8V output power

supply

Vnorm=2.8V

max=150mA

I

O

If unused, keep this pin

open.

3, 4, 18,

20, 31,

34, 35,

40, 43,

47, 56,

62, 87,

98, 101,

112, 125,

GND

128, 130,

133, 135,

Ground

148, 150,

159, 163,

170, 173,

176, 182,

193, 195,

219, 225,

243,

257~323

Audio Interfaces

Pin Name Pin No. I/O Description

MIC_BIAS 167 AO

MIC1_P 44 AI

MIC1_N 45 AI

MIC_GND 168

Microphone bias

voltage

Microphone input for

channel 1 (+)

Microphone input for

channel 1 (-)

Microphone

reference ground

DC

Characteristics

=1.6V~2.85V

V

O

Comment

If unused, connect this

pin to the ground.

SC600Y&SC600T_Hardware_Design 23 / 134

Page 25

SC600Y&SC600T Hardware Design

Smart Module Series

MIC2_P 46 AI

MIC3_P 169 AI

Microphone input for

headset (+)

Microphone input for

channel 2 (+)

EAR_P 53 AO Earpiece output (+)

EAR_N 52 AO Earpiece output (-)

SPK_P 55 AO Speaker output (+)

SPK_N 54 AO Speaker output (-)

HPH_R 51 AO

HPH_REF 50 AI

HPH_L 49 AO

HS_DET 48 AI

LINE_OUT_P 227 AO

LINE_OUT_N 228 AO

Headphone right

channel output

Headphone

reference ground

Headphone left

channel output

Headset insertion

detection

Audio line differential

(+)

Audio line differential

(-)

It should be connected

to main

GND.

Pulled up internally.

USB Interface

Pin Name Pin No. I/O Description DC Characteristics Comment

Charging power input.

USB_VBUS 41, 42

Power supply output

PI/

for OTG device

PO

USB/charger insertion

Vmax=10V

Vmin=4.0V

Vnorm=5.0V

detection

AI/

USB_DM 33

USB_DP 32

USB 2.0 differential

AO

data bus (-)

AI/

USB 2.0 differential

AO

data bus (+)

USB_ID 30 AI USB ID detection

USB_SS_RX

_P

USB_SS_RX

_M

171 AI

172 AI

USB 3.0 differential

receive data (+)

USB 3.0 differential

receive data (-)

90Ω differential

impedance.

USB 2.0 standard

compliant.

High level by default.

90Ω differential

impedance.

USB 3.0 standard

compliant.

SC600Y&SC600T_Hardware_Design 24 / 134

Page 26

SC600Y&SC600T Hardware Design

Smart Module Series

USB_SS_TX

_P

USB_SS_TX

_M

174 AO

175 AO

USB 3.0 differential

transmit data (+)

USB 3.0 differential

transmit data (-)

USB Type-C control

USBC_CC2 223 AI

configuration channel

2

USB Type-C control

USBC_CC1 224 AI

configuration channel

1

USB_SS_SEL 226 DO

USB Type-C switch

control

If Micro USB is

intended to be used,

this pin should be

USB_OPT 217

Type-C/Micro USB

select control

connected to ground

via a 1KΩ resistor;

If Type-C is intended to

be used, this pin

should be left open.

(U)SIM Interfaces

Pin Name Pin No. I/O Description DC Characteristics Comment

Active low.

Require external

pull-up to 1.8V.

If unused, keep this

pin open.

Disabled by default

USIM1_DET 145 DI

(U)SIM1 card

hot-plug detection

max=0.63V

V

IL

min=1.17V

V

IH

and can be enabled

through software

configuration.

V

max=0.4V

OL

USIM1_RST 144 DO (U)SIM1 card reset

min=

V

OH

0.8 × USIM1_VDD

V

max=0.4V

OL

USIM1_CLK 143 DO (U)SIM1 card clock

min=

V

OH

0.8 × USIM1_VDD

max=

V

IL

0.2 × USIM1_VDD

USIM1_DATA 142 IO (U)SIM1 card data

V

min=

IH

0.7 × USIM1_VDD

max=0.4V

V

OL

SC600Y&SC600T_Hardware_Design 25 / 134

Page 27

SC600Y&SC600T Hardware Design

Smart Module Series

VOHmin=

0.8 × USIM1_VDD

1.8V (U)SIM:

Vmax=1.90V

USIM1_VDD 141 PO

(U)SIM1 card power

supply

Vmin=1.70V

2.95V (U)SIM:

Either 1.8V or 2.95V

(U)SIM card is

supported.

Vmax=3.04V

Vmin=2.7V

Active low.

Require external

pull-up to 1.8V.

If unused, keep this pin

open.

Disabled by default

USIM2_DET 256 DI

(U)SIM2 card

hot-plug detection

max=0.63V

V

IL

min=1.17V

V

IH

and can be enabled

through software

configuration.

V

max=0.4V

OL

USIM2_RST 207 DO (U)SIM2 card reset

min=

V

OH

0.8 × USIM2_VDD

V

max=0.4V

OL

USIM2_CLK 208 DO (U)SIM2 card clock

min=

V

OH

0.8 × USIM2_VDD

V

max=

IL

0.2 × USIM2_VDD

min=

V

IH

USIM2_DATA 209 IO (U)SIM2 card data

0.7 × USIM2_VDD

max=0.4V

V

OL

min=

V

OH

0.8 × USIM2_VDD

1.8V (U)SIM:

Vmax=1.90V

USIM2_VDD 210 PO

(U)SIM2 card power

supply

Vmin=1.70V

2.95V (U)SIM:

Either 1.8V or 2.95V

(U)SIM card is

supported.

Vmax=3.04V

Vmin=2.7V

UART Interfaces

Pin Name Pin No. I/O Description DC Characteristics Comment

UART2_TXD 5 DO

UART2 transmit data.

Used for debugging

max=0.45V

V

OL

min=1.35V

V

OH

1.8V power domain.

If unused, keep these

SC600Y&SC600T_Hardware_Design 26 / 134

Page 28

SC600Y&SC600T Hardware Design

Smart Module Series

by default pins open.

UART2 receive data.

UART2_RXD 6 DI

Used for debugging

by default

UART4_TXD 7 DO UART4 transmit data

UART4_RXD 8 DI UART4 receive data

UART5_RXD 198 DI UART5 receive data

UART5_TXD 199 DO UART5 transmit data

UART5_RTS 245 DO

UART5 request to

send

UART5_CTS 246 DI UART5 clear to send

max=0.63V

V

IL

min=1.17V

V

IH

max=0.45V

V

OL

min=1.35V

V

OH

max=0.63V

V

IL

min=1.17V

V

IH

max=0.63V

V

IL

min=1.17V

V

IH

max=0.45V

V

OL

min=1.35V

V

OH

max=0.45V

V

OL

min=1.35V

V

OH

max=0.63V

V

IL

min=1.17V

V

IH

SD Card Interface

Pin Name Pin No. I/O Description DC Characteristics Comment

1.8V SD card:

max=0.45V

V

OL

min=1.4V

V

OH

SD_CLK 70 DO SD card clock

2.95V SD card:

max=0.37V

V

OL

min=2.2V

V

OH

1.8V SD card:

V

max=0.58V

IL

min=1.27V

V

IH

max=0.45V

V

OL

min=1.4V

V

OH

SD_CMD 69 IO SD card command

2.95V SD card:

max=0.73V

V

IL

min=1.84V

V

IH

max=0.37V

V

OL

min=2.2V

V

OH

1.8V SD card:

SD_DATA0 68 IO SD card data

VILmax=0.58V

min=1.27V

V

IH

SC600Y&SC600T_Hardware_Design 27 / 134

Page 29

SC600Y&SC600T Hardware Design

Smart Module Series

V

max=0.45V

OL

min=1.4V

V

SD_DATA1 67 IO

OH

2.95V SD card:

max=0.73V

V

SD_DATA2 66 IO

SD_DATA3 65 IO

IL

min=1.84V

V

IH

max=0.37V

V

OL

min=2.2V

V

OH

SD_DET 64 DI

SD_LDO11 63 PO

SD card insertion

detection

Power supply for SD

card

SD_LDO12 179 PO 1.8V/2.95V output

max=0.63V

V

IL

min=1.17V

V

IH

Vnorm=2.95V

max=800mA

I

O

Vnorm=1.8V/2.95V

max=50mA

I

O

Active low.

Power supply for SD

card’s pull-up circuit.

TP (Touch Panel) Interfaces

Pin Name Pin No. I/O Description DC Characteristics Comment

TP0_RST 138 DO TP0 reset

TP0_INT 139 DI TP0 interrupt

max=0.45V

V

OL

min=1.35V

V

OH

max=0.63V

V

IL

min=1.17V

V

IH

1.8V power domain.

Active low.

1.8V power domain.

TP0_I2C_SCL 140 OD TP0 I2C clock 1.8V power domain.

TP0_I2C_SDA 206 OD TP0 I2C data 1.8V power domain.

TP1_RST 136 DO TP1 reset

TP1_INT 137 DI TP1 interrupt

max=0.45V

V

OL

min=1.35V

V

OH

max=0.63V

V

IL

min=1.17V

V

IH

1.8V power domain.

Active low.

1.8V power domain.

TP1_I2C_SDA 204 OD TP1 I2C data 1.8V power domain.

TP1_I2C_SCL 205 OD TP1 I2C clock 1.8V power domain.

LCM Interfaces

Pin Name Pin No. I/O Description DC Characteristics Comment

SC600Y&SC600T_Hardware_Design 28 / 134

Page 30

SC600Y&SC600T Hardware Design

Smart Module Series

LCD_BL_A 21 PO

LCD_BL_K1 22 AI

LCD_BL_K2 23 AI

LCD_BL_K3 24 AI

LCD_BL_K4 25 AI

PMU_MPP4 152 DO PWM output

LCD0_RST 127 DO LCD0 reset

LCD0_TE 126 DI LCD0 tearing effect

LCD1_RST 113 DO LCD1 reset

LCD1_TE 114 DI LCD1 tearing effect

DSI0_CLK_N 116 AO

DSI0_CLK_P 115 AO

DSI0_LN0_N 118 AO

DSI0_LN0_P 117 AO

DSI0_LN1_N 120 AO

DSI0_LN1_P 119 AO

DSI0_LN2_N 122 AO

DSI0_LN2_P 121 AO

DSI0_LN3_N 124 AO

Current output for

LCD backlight

Current sink for LCD

backlight

Current sink for LCD

backlight

Current sink for LCD

backlight

Current sink for LCD

backlight

LCD0 MIPI clock

signal (-)

LCD0 MIPI clock signal

(+)

LCD0 MIPI lane 0 data

signal (-)

LCD0 MIPI lane 0 data

signal (+)

LCD0 MIPI lane 1 data

signal (-)

LCD0 MIPI lane 1 data

signal (+)

LCD0 MIPI lane 2 data

signal (-)

LCD0 MIPI lane 2 data

signal (+)

LCD0 MIPI lane 3 data

signal (-)

V

OL

V

OH

V

OL

V

OH

V

IL

V

IH

V

OL

V

OH

V

IL

V

IH

max=0.45V

min=1.35V

max=0.45V

min=1.35V

max=0.63V

min=1.17V

max=0.45V

min=1.35V

max=0.63V

min=1.17V

1.8V power domain.

Active low.

1.8V power domain.

1.8V power domain.

Active low.

1.8V power domain.

SC600Y&SC600T_Hardware_Design 29 / 134

Page 31

SC600Y&SC600T Hardware Design

Smart Module Series

DSI0_LN3_P 123 AO

DSI1_CLK_N 103 AO

DSI1_CLK_P 102 AO

DSI1_LN0_N 105 AO

DSI1_LN0_P 104 AO

DSI1_LN1_N 107 AO

DSI1_LN1_P 106 AO

DSI1_LN2_N 109 AO

DSI1_LN2_P 108 AO

DSI1_LN3_N 111 AO

DSI1_LN3_P 110 AO

LCD0 MIPI lane 3 data

signal (+)

LCD1 MIPI clock signal

(-)

LCD1 MIPI clock signal

(+)

LCD1 MIPI lane 0 data

signal (-)

LCD1 MIPI lane 0 data

signal (+)

LCD1 MIPI lane 1 data

signal (-)

LCD1 MIPI lane 1 data

signal (+)

LCD1 MIPI lane 2 data

signal (-)

LCD1 MIPI lane 2 data

signal (+)

LCD1 MIPI lane 3 data

signal (-)

LCD1 MIPI lane 3 data

signal (+)

Camera Interfaces

Pin Name Pin No. I/O Description

CSI0_CLK_N 89 AO

CSI0_CLK_P 88 AO

CSI0_LN0_N 91 AI

CSI0_LN0_P 90 AI

CSI0_LN1_N 93 AI

CSI0_LN1_P 92 AI

CSI0_LN2_N 95 AI

CSI0_LN2_P 94 AI

MIPI clock signal of

rear camera (-)

MIPI clock signal of

rear camera (+)

MIPI lane 0 data signal

of rear camera (-)

MIPI lane 0 data signal

of rear camera (+)

MIPI lane 1 data signal

of rear camera (-)

MIPI lane 1 data signal

of rear camera (+)

MIPI lane 2 data signal

of rear camera (-)

MIPI lane 2 data signal

of rear camera (+)

DC

Characteristics

Comment

SC600Y&SC600T_Hardware_Design 30 / 134

Page 32

SC600Y&SC600T Hardware Design

Smart Module Series

CSI0_LN3_N 97 AI

CSI0_LN3_P 96 AI

CSI1_CLK_N 184 AO

CSI1_CLK_P 183 AO

CSI1_LN0_N 186 AI

CSI1_LN0_P 185 AI

CSI1_LN1_N 188 AI

CSI1_LN1_P 187 AI

CSI1_LN2_N 190 AI

CSI1_LN2_P 189 AI

CSI1_LN3_N 192 AI

CSI1_LN3_P 191 AI

CSI2_CLK_N 78 AO

CSI2_CLK_P 77 AO

CSI2_LN0_N 80 AI

CSI2_LN0_P 79 AI

CSI2_LN1_N 82 AI

CSI2_LN1_P 81 AI

CSI2_LN2_N 84 AI

MIPI lane 3 data signal

of rear camera (-)

MIPI lane 3 data signal

of rear camera (+)

MIPI clock signal of

depth camera (-)

MIPI clock signal of

depth camera (+)

MIPI lane 0 data signal

of depth camera (-)

MIPI lane 0 data signal

of depth camera (+)

MIPI lane 1 data signal

of depth camera (-)

MIPI lane 1 data signal

of depth camera (+)

MIPI lane 2 data signal

of depth camera (-)

MIPI lane 2 data signal

of depth camera (+)

MIPI lane 3 data signal

of depth camera (-)

MIPI lane 3 data signal

of depth camera (+)

MIPI clock signal of

front camera (-)

MIPI clock signal of

front camera (+)

MIPI lane 0 data signal

of front camera (-)

MIPI lane 0 data signal

of front camera (+)

MIPI lane 1 data signal

of front camera (-)

MIPI lane 1 data signal

of front camera (+)

MIPI lane 2 data signal

of front camera (-)

Can be multiplexed

into differential data of

the fourth camera (-).

Can be multiplexed

into differential data of

the fourth camera (+).

Can be multiplexed

into differential clock of

the fourth camera (-).

Can be multiplexed

into differential clock of

the fourth camera (+).

SC600Y&SC600T_Hardware_Design 31 / 134

Page 33

SC600Y&SC600T Hardware Design

Smart Module Series

CSI2_LN2_P 83 AI

CSI2_LN3_N 86 AI

CSI2_LN3_P 85 AI

MCAM_MCLK 99 DO

SCAM_MCLK 100 DO

MIPI lane 2 data signal

of front camera (+)

MIPI lane 3 data signal

of front camera (-)

MIPI lane 3 data signal

of front camera (+)

Master clock of rear

camera

Master clock of front

camera

MCAM_RST 74 DO Reset of rear camera

MCAM_PWDN 73 DO

Power down of rear

camera

SCAM_RST 72 DO Reset of front camera

SCAM_PWDN 71 DO

Power down of front

camera

max=0.45V

V

OL

min=1.35V

V

OH

max=0.45V

V

OL

min=1.35V

V

OH

max=0.45V

V

OL

min=1.35V

V

OH

max=0.45V

V

OL

min=1.35V

V

OH

max=0.45V

V

OL

min=1.35V

V

OH

max=0.45V

V

OL

min=1.35V

V

OH

1.8V power domain.

1.8V power domain.

1.8V power domain.

1.8V power domain.

1.8V power domain.

1.8V power domain.

CAM_I2C_SCL 75 OD I2C clock for camera 1.8V power domain.

CAM_I2C_SDA 76 OD I2C data for camera 1.8V power domain.

DCAM_MCLK 194 DO

CAM4_MCLK 236 DO

Master clock of depth

camera

Master clock of fourth

camera

DCAM_RST 180 DO Reset of depth camera

DCAM_PWDN 181 DO

DCAM_I2C_

SDA

DCAM_I2C_

SCL

197 OD

196 OD

Power down of depth

camera

I2C data for depth

camera

I2C clock for depth

camera

max=0.45V

V

OL

min=1.35V

V

OH

max=0.45V

V

OL

min=1.35V

V

OH

max=0.45V

V

OL

min=1.35V

V

OH

max=0.45V

V

OL

min=1.35V

V

OH

1.8V power domain.

1.8V power domain.

1.8V power domain.

1.8V power domain.

1.8V power domain.

1.8V power domain.

Keypad Interfaces

Pin Name Pin No. I/O Description

DC

Characteristics

Comment

SC600Y&SC600T_Hardware_Design 32 / 134

Page 34

SC600Y&SC600T Hardware Design

Smart Module Series

PWRKEY 39 DI Turn on/off the module

VOL_UP 146 DI Volume up

VOL_

DOWN

147 DI Volume down

SENSOR_I2C Interface

Pin Name Pin No. I/O Description

SENSOR_I2C_

SCL

SENSOR_I2C_

SDA

131 OD

132 OD

I2C clock for external

sensors

I2C data for external

sensors

ADC Interfaces

Pin Name Pin No. I/O Description

PMI_ADC 153 AI

General purpose ADC

interface

max=0.63V

V

IL

min=1.17V

V

IH

max=0.63V

V

IL

min=1.17V

V

IH

max=0.63V

V

IL

min=1.17V

V

IH

DC

Characteristics

Pull-up to 1.8V

internally.

Active low.

If unused, keep this pin

open.

If unused, keep this pin

open.

Comment

1.8V power domain.

1.8V power domain.

DC

Characteristics

Comment

Maximum input

voltage: 1.5V.

PMU_MPP2 151 AI

General purpose ADC

interface

Maximum input

voltage: 1.7V.

Charging Interface

Pin Name Pin No. I/O Description

DC

Characteristics

Comment

Differential input of

BAT_PLUS 27 AI

battery voltage

Must be connected.

detection (+)

Differential input of

BAT_MINUS 28 AI

battery voltage

Must be connected.

detection (-)

Antenna Interfaces

Pin Name Pin No. I/O Description

ANT_MAIN 19

ANT_DRX 149 AI

AI/

Main antenna interface

AO

Diversity antenna

interface

DC

Characteristics

Comment

50Ω impedance.

SC600Y&SC600T_Hardware_Design 33 / 134

Page 35

SC600Y&SC600T Hardware Design

Smart Module Series

ANT_GNSS 134 AI

ANT_WIFI/BT 129

GNSS antenna

interface

AI/

Wi-Fi/BT antenna

AO

interface

ANT_FM 244 AI FM antenna interface

GPIO Interfaces

Pin Name Pin No. I/O Description

GPIO_0 248 IO

GPIO_1 247 IO

GPIO_2 201 IO

GPIO_3 200 IO

GPIO_33 238 IO

GPIO_36 237 IO

GPIO_42 252 IO

GPIO_43 253 IO

GPIO_44 254 IO

GPIO_45 255 IO

GPIO_66 234 IO

GPIO_89 232 IO

GPIO_90 231 IO

GPIO_96 230 IO

GPIO_97 229 IO

GPIO_98 177 IO

General-purpose

input/output

General-purpose

input/output

General-purpose

input/output

General-purpose

input/output

General-purpose

input/output

General-purpose

input/output

General-purpose

input/output

General-purpose

input/output

General-purpose

input/output

General-purpose

input/output

General-purpose

input/output

General-purpose

input/output

General-purpose

input/output

General-purpose

input/output

General-purpose

input/output

General-purpose

input/output

DC

Characteristics

max=0.63V

V

IL

min=1.17V

V

IH

max=0.45V

V

OL

min=1.4V

V

OH

Comment

SC600Y&SC600T_Hardware_Design 34 / 134

Page 36

SC600Y&SC600T Hardware Design

Smart Module Series

GPIO_99 178 IO

General-purpose

input/output

SPI Interfaces

Pin Name Pin No. I/O Description

DC

Characteristics

SPI_CS 58 DO SPI chip select

SPI_CLK 59 DO SPI clock

SPI_MOSI 60 DO SPI master-out slave-in

SPI_MISO 61 DI SPI master-in salve-out

FP_SPI_CS 203 DO SPI chip select

FP_SPI_CLK 250 DO SPI clock

FP_SPI_MOSI 249 DO SPI master-out slave-in

FP_SPI_MISO 251 DI SPI master-in salve-out

Comment

Can be multiplexed

into UART6_CTS.

Can be multiplexed

into UART6_RTS.

Can be multiplexed

into UART6_TXD.

Can be multiplexed

into UART6_RXD.

Can be multiplexed

into I2S_WS.

Can be multiplexed

into I2S_SCK.

Can be multiplexed

into I2S_D0.

Can be multiplexed

into I2S_D1.

Vibrator Drive Interface

Pin Name Pin No. I/O Description

VIB_GND 160

Vibrator ground

(-)

DC

Characteristics

Comment

Connected to the

negative terminal of

vibrator.

Connected to the

VIB_DRV 161 PO Vibrator drive (+)

positive terminal of

vibrator.

Flashlight Interfaces

Pin Name Pin No. I/O Description

FLASH_LED1 26 AO

FLASH_LED2 162 AO

Flash/torch current

driver output

Flash/torch current

driver output

DC

Characteristics

Comment

Support flash and torch

modes.

Emergency Download Interface

Pin Name Pin No. I/O Description

DC

Characteristics

Comment

SC600Y&SC600T_Hardware_Design 35 / 134

Page 37

SC600Y&SC600T Hardware Design

Smart Module Series

Pulled up to

LDO5_1P8 during

power-up will force the

module to enter

emergency download

USB_BOOT 57 DI

Force the module enter

emergency download

mode

mode.

Other Interfaces

Pin Name Pin No. I/O Description

BAT_ID 17 AI Battery type detection

DC

Characteristics

Comment

If unused, keep this pin

open.

Internally pulled up.

BAT_THERM 29 AI

Battery temperature

measurement

Externally connected

to GND via a 47K NTC

resistor.

For test purpose only.

GNSS_LNA_EN 202 DO LNA enable control

If unused, keep this pin

open.

GRFC_5 242 IO Generic RF control 1

GRFC_7 241 IO Generic RF control 2

S1A 215

S1A and S1B are

Only used for RF tuner

control.

connected in the

S1B 216

S2A 211

module

S2A and S2B are

connected in the

S2B 233

module

Reserved Interface

Pin Name Pin No. I/O Description

DC

Characteristics

Comment

154, 155,

156, 157,

158, 164,

RESERVED

165, 166,

212, 213,

Reserved Keep these pins open.

214, 218,

222, 235,

239, 240,

SC600Y&SC600T_Hardware_Design 36 / 134

Page 38

SC600Y&SC600T Hardware Design

Smart Module Series

3.4. Power Supply

3.4.1. Power Supply Pins

SC600Y/SC600T provides 3 VBAT pins and 2 VPH_PWR pins. VBAT pins are dedicated for connection

with an external power supply. VPH_PWR pins can supply power for peripherals, and it can provide a

maximum continuous current of 1A approximately. The value of capacitors placed on this pin should not

exceed 120uF.

3.4.2. Decrease Voltage Drop

The power supply range of the module is from 3.55V to 4.4V, and the recommended value is 3.8V. The

power supply performance, such as load capacity, voltage ripple, etc. directly influences the module’s

performance and stability. Under ultimate conditions, the module may have a transient peak current up to

3A. If the power supply capability is not sufficient, there will be voltage drops, and if the voltage drops

below 3.1V, the module will be powered off automatically. Therefore, please make sure the input voltage

will never drop below 3.1V.

Figure 3: Voltage Drop Sample

To decrease voltage drop, a bypass capacitor of about 100µF with low ESR (ESR=0.7Ω) should be used

in VBAT pins, and a multi-layer ceramic chip capacitor (MLCC) array should also be reserved due to its

ultra-low ESR. It is recommended to use three ceramic capacitors (100nF, 33pF, 10pF) for composing the

MLCC array, and place these capacitors close to VBAT/VDD_RF/VPH_PWR pins. The width of VBAT

trace should be no less than 3mm. In principle, the longer the VBAT trace is, the wider it will be.

SC600Y&SC600T_Hardware_Design 37 / 134

Page 39

SC600Y&SC600T Hardware Design

Smart Module Series

In addition, in order to get a stable power source, it is suggested to use a 0.5W TVS and place it as close