Quadra-Fire 21M-ACC-NZ, 21M-ACC-AU, 43M-ACC-NZ Installations

QUADRA-FIRE 2100 & 4300 MILLENIUM ACC WOOD BURNER INSTALLATION INSTRUCTIONS

QUADRA-FIRE 2100 & 4300 MILLENIUM ACC WOOD BURNER INSTALLATION INSTRUCTIONS

Model:

21M-ACC-NZ

21M-ACC-AU

43M-ACC-NZ

INSTALLATIONS T O COMPLY WITH AS/NZS2918:2001

AND WILL REQUIRE A BUILDING CONSENT

IMPORTANT: Read all instructions carefully before starting installation. Failure to follow these

instructions may result in a fi re hazard and will void the warranty.

• Fig. 3,4,5 and Table 1 & 2 relate to installations with tested fl ue systems; as per AS/NZS 2918:2001 -

Appendix F, with a ceiling angle between 0° - 30° inclusive.

• For installations with a ceiling angle greater than 30°, refer to Fig. 6 & 7 and AS/NZS 2918:2001 4.6.3(b)

• Ceiling Plate may vary in size depending on ceiling angle. Please specify ceiling pitch prior to ordering the

ceiling plate.

• Quadra-Fire 2100 & 4300 Millenium ACC wood burner’s are tested and approved to the N.Z. National

Environmental Standards;

21M-ACC-NZ - 2100 Millenium ACC Softwood Certifi ed

Particulate Emissions = 0.6 g/kg Space Heating Effi ciency = 72%

21M-ACC-AU - 2100 Millenium ACC Hardwood Certifi ed

Particulate Emissions = 2.0 g/kg Space Heating Effi ciency = 81%

43M-ACC-NZ - 4300 Millenium ACC

Softwood Particulate Emissions = 0.4 g/kg Space Heating Effi ciency = 71%

Hardwood Particulate Emissions = 2.5g/kg Space Heating Effi ciency = 78%

www.quadrafi re.com

7037-141D

October 12. 2015

2100 & 4300 Millennium ACC Wood Burner

and Welcome to the Quadra-Fire Family!

Hearth & Home Technologies welcomes you to our tradition

of excellence! In choosing a Quadra-Fire appliance, you

have our assurance of commitment to quality , durability , and

performance.

This commitment begins with our research of the market,

including ‘Voice of the Customer’ contacts, ensuring we

make products that will satisfy your needs. Our Research

and Development facility then employs the world’s most

advanced technology to achieve the optimum operation of

4300 MILLENNIUM ACC

R

MILLENNIUM ACC WOODFIRE COMPLIANCE LABEL

This appliance has been TESTED TO AS/NZS4013 for Softwood by Applied Research Services Ltd. Report # 07/1717 Date tested: November 2007

This appliance has been TESTED TO AS/NZS4013 for Hardwood by HRL Technology Report # HCMG/12/016 Date tested: March 2012

OVERALL AVERAGE EFFICIENCY

AVERAGE PARTICULATE EMISSION FACTOR

MAXIMUM AVERAGE HEAT OUTPUT

SERIAL NO.

room for .14 x .875” S/N

007037

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC

2015

2016 2017

1.5” x .375 Barcode Label

WETBACK - ALL MODELS

MODEL QUADRA-FIRE 4300 MILLENNIUM ACC

TESTED TO AS/NZS 4012

TESTED TO AS/NZS 4013

APPROVED FUEL

MANUFACTURED BY

our stoves, inserts and fi replaces. And yet we are old-fash-

ioned when it comes to craftsmanship. Each unit is meticulously fabricated and surfaces are hand-fi nished for lasting

beauty and enjoyment. Our pledge to quality is completed

as each model undergoes a quality control inspection.

We wish you and your family many years of enjoyment in

the warmth and comfort of your hearth appliance. Thank

you for choosing Quadra-Fire.

SOFTWOOD

71%

0.4 g/kg

10 kW

HARDWOOD

78%

2.5 g/kg

11.8 kW

BURN ONLY WOOD WITH A MOISTURE CONTENT LESS THEN 25% (dry

basis).

Wetbacks are NOT an approved option and must not be tted.

Hearth & Home Technologies, 1445 North Highway, Colville, WA

99114, United States of America.

PERFORMANCE MAY VARY FROM TEST VALUES DEPENDING ON ACTUAL

OPERATING CONDITIONS.

U.S. ENVIRONMENTAL PROTECTION AGENCY

Export stove. May not be operated within the United States.

INSTALLATION

DATE

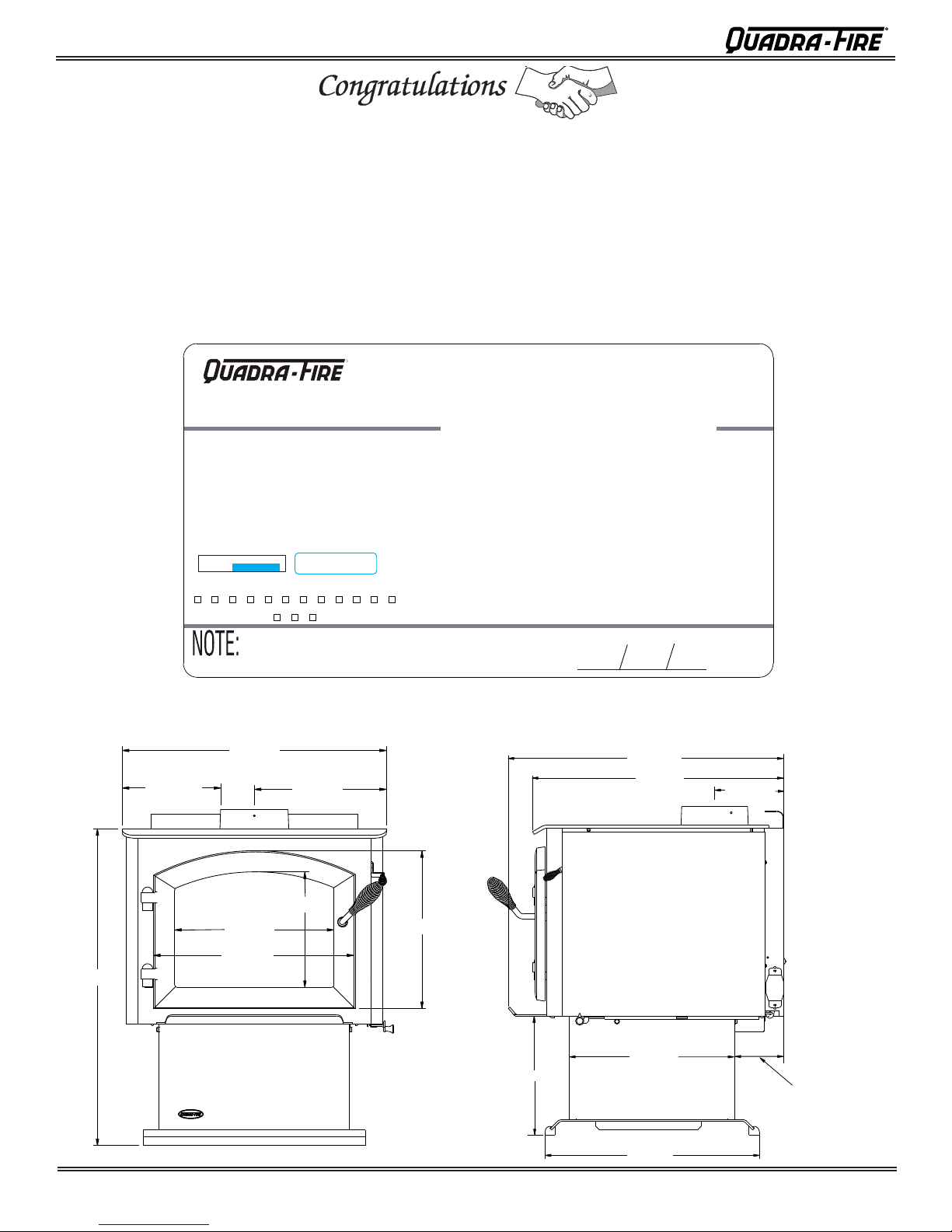

Fig. 2 - Quadra-Fire 4300 Millenium ACC Wood Burner Dimensions

660mm

C

247mm

762mm

L

383mm

475mm

330mm

271mm

373mm

292mm

729mm

668mm

406mm

7037-147B

170mm

C

L

C

L

108mm

Outside Air

Connection

Page 2

7037-141D

527mm

October 12, 2015

2100 & 4300 Millennium ACC Wood Burner

2100 (NZ-SOFTWOOD) MILLENNIUM ACC

R

MILLENNIUM ACC WOODFIRE COMPLIANCE LABEL

This appliance has been TESTED TO AS/NZS4013 by Applied Research Services Ltd. Report # 07/1716

ECan Authorisation Number

083786

ECan Expiry Date

Date tested: November 2007

24/10/2013

MODEL QUADRA-FIRE 2100 MILLENNIUM ACC

OVERALL AVERAGE EFFICIENCY BURNING SOFTWOOD

AVERAGE PARTICULATE EMISSION FACTOR BURNING SOFTWOOD

MAXIMUM AVERAGE HEAT OUTPUT BURNING SOFTWOOD

SERIAL NO. / NUMÉRO DE SÉRIE / SERIENUMMER

room for .14 x .875” S/N

007036

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC

2012

PERFORMANCE MAY VARY FROM TEST VALUES DEPENDING ON ACTUAL

OPERATING CONDITIONS.

U.S. ENVIRONMENTAL PROTECTION AGENCY

Export stove. May not be operated within the United States.

WHEN TESTED IN ACCORDANCE WITH AS/NZS 4012

WHEN TESTED IN ACCORDANCE WITH AS/NZS 4013

1.5” x .375 Barcode Label

2013 2014

APPROVED FUEL

WETBACK - ALL MODELS

MANUFACTURED BY

72%

0.6 g/kg

9 kW

BURN ONLY SOFTWOOD WITH A MOISTURE CONTENT LESS THEN

25% (dry basis).

Wetbacks are NOT an approved option and must not be tted.

Hearth & Home Technologies, 1445 North Highway, Colville, WA

99114, United States of America.

INSTALLATION

DATE

7039-145C

2100 (AU-HARDWOOD) MILLENNIUM ACC

R

MILLENNIUM ACC WOODFIRE COMPLIANCE LABEL

This appliance has been TESTED TO AS/NZS4013 for Hardwood by HRL Technology Report # HCMG/12/014A Date tested: March 2012

MODEL QUADRA-FIRE 2100 MILLENNIUM ACC FREESTANDING WOOD STOVE

OVERALL AVERAGE EFFICIENCY BURNING HARDWOOD

AVERAGE PARTICULATE EMISSION FACTOR BURNING HARDWOOD

MAXIMUM AVERAGE HEAT OUTPUT BURNING HARDWOOD

SERIAL NO.

007044

JAN FEB MAR APR MAY JUN JUL AUG SEP OCT NOV DEC

2015

2016 2017

PERFORMANCE MAY VARY FROM TEST VALUES DEPENDING ON ACTUAL

OPERATING CONDITIONS.

U.S. ENVIRONMENTAL PROTECTION AGENCY

Export stove. May not be operated within the United States.

WHEN TESTED IN ACCORDANCE TO AS/NZS 4012

WHEN TESTED IN ACCORDANCE TO AS/NZS 4013

APPROVED FUEL

WETBACK - ALL MODELS

MANUFACTURED BY

81%

2.0 g/kg

7.2 kW

BURN ONLY HARDWOOD WITH A MOISTURE CONTENT LESS THEN

25% (dry basis).

Wetbacks are NOT an approved option and must not be tted.

Hearth & Home Technologies, 1445 North Highway, Colville, WA

99114, United States of America.

INSTALLATION

DATE

7039-148B

Fig. 1 - Quadra-Fire 2100 Millenium ACC Wood Burner Dimensions

709mm

219mm

594mm

C

L

342mm

432mm

297mm

235mm

324mm

292mm

671mm

618mm

406mm

527mm

C

L

170mm

C

L

108mm

Outside Air

Connection

October 12, 2015

7037-141D

Page 3

2100 & 4300 Millennium ACC Wood Burner

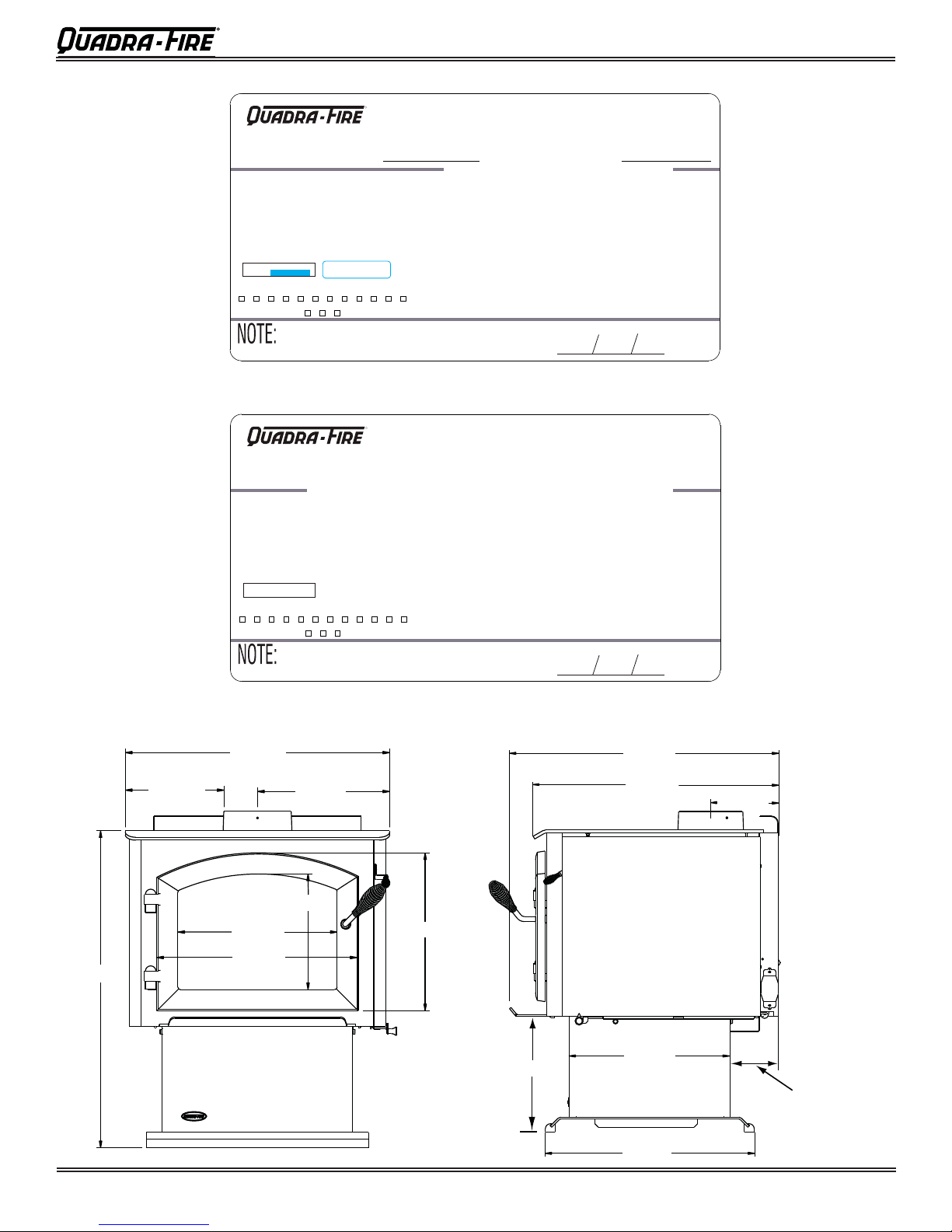

FLOOR PROTECTOR

1.QF.1B

Quadra-fire 2100 & 4300 Millennium ACC do not require a insulating Floor Protector, as they are tested

and comply with the minimum Floor Protector requirements of AS/NZS 2918:2001.

Note:

Fitted

200

ŀ The minimum Floor Protector sizes are specified in the clearance chart, see Table 1 & 2.

ŀ A Floor Protector can include ceramic tiles with grouted joints fixed directly onto a wooden floor or a

sheet of toughened glass, panel steel or any other non combustible material laid directly onto a

wooden floor.

ŀ If installed directly onto a concrete slab, the concrete slab can be considered as the floor protector,

but must maintain the minimum measurement listed.

PARALLEL POSITIONING

Fig. 3

A

E

B

D

Drawing not to scale

G

C

Table 1

A Min. Clearance from fi rebox to rear wall 150 160 200

B Min. clearance from fi rebox to side wall 550 280 400

C Min. distance from fi rebox opening to fl oor protector front 300 300 300

D Min. distance from fi rebox to fl oor protector side 76 76 69

E Min. distance from fl ue centre to side wall 847 577 730

F Min. distance from rear wall to front of fl oor protector 1034 1043 1 133

G Width of fl oor protector 746 746 798

Pioneer Double Flue Mounted Shield Universal

Pioneer Double Flue Mounted Shield Universal

A Min. clearance from firebox to rear wall 150

B

Min. clearance from firebox to side wall 550 400

C

Min. distance from firebox opening to floor protector front 300 300

D Min. distance from firebox to floor protector side 76 69

E Min. distance from flue centre to side wall 847 730

F Min dist ance from rear wall to front of floor protector 1034 1133

G Width of floor protector 746 798

DESCRIPTION

DESCRIPTION

Shall be Fitted

Shall be

Fitted

NOTE: HEAT SHIELD REQUIREMENTS FOR HEAT SENSITIVE WALLS

Clearances may be reduced by provision of an appropriately located heat shield refer to

AS/ NZS 2198:2001 3.2.3 Table 3.1

F

With Double Flue Shield Fitted

With Double Flue

Shield

2100-NZ 2100-AU 4300

2100 4300

Page 4

7037-141D

October 12, 2015

F

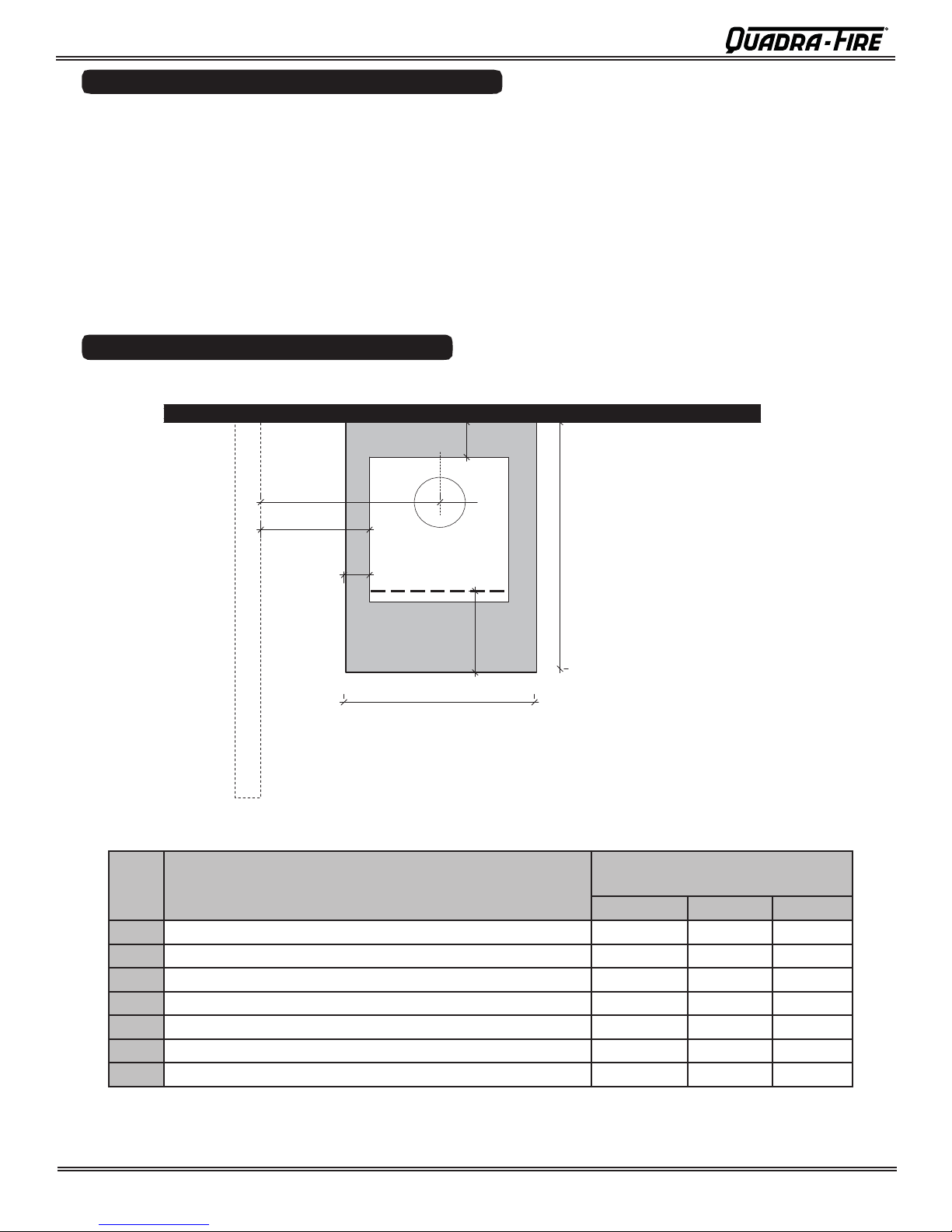

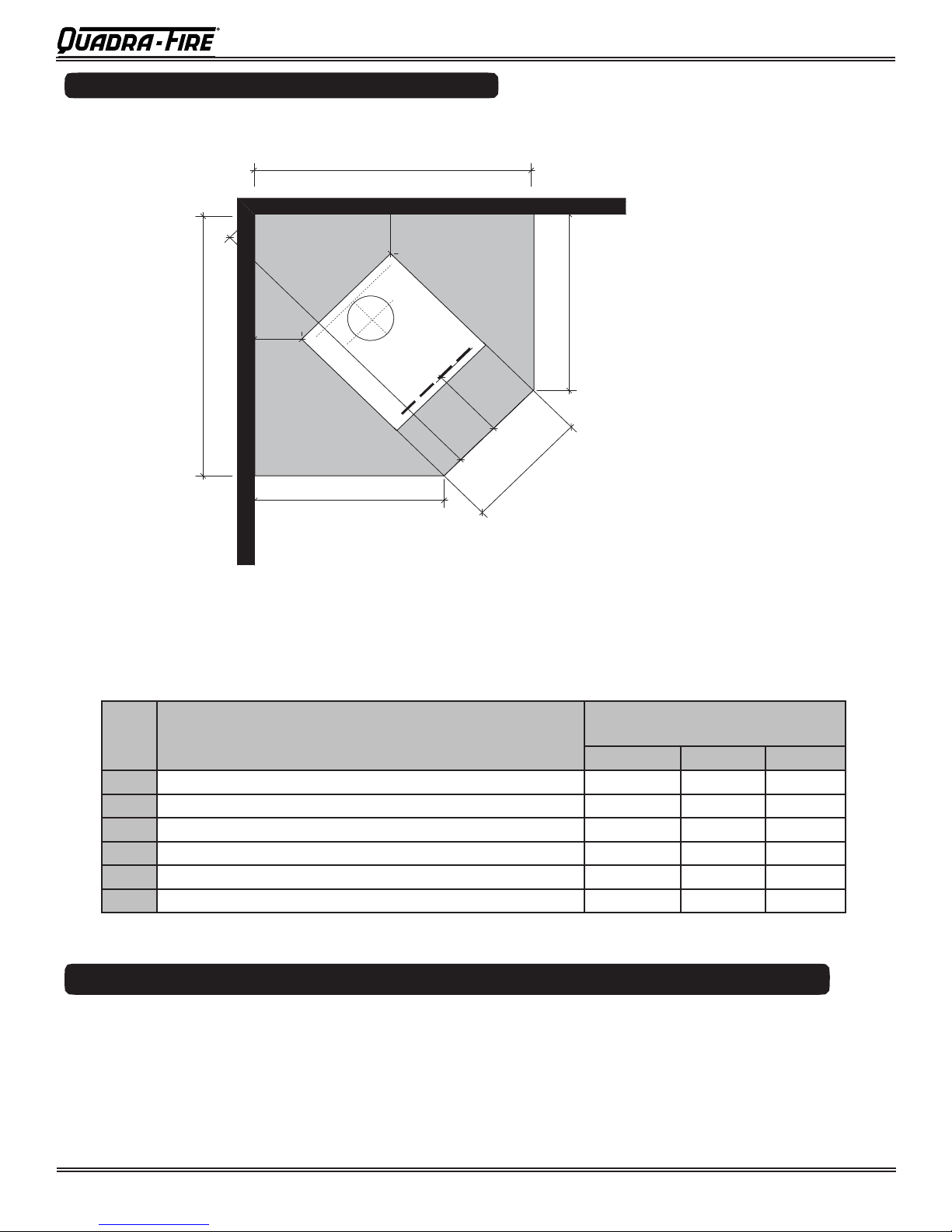

CORNER POSITIONING (45°)

CORNER POSITIONING

(45˚)

2100 & 4300 Millennium ACC Wood Burner

1.Q

.1C

Fig. 4

Drawing not to scale

C

A

C

A

D

B

E

F

Table 2

D

Pioneer Double Flue Mounted Shield Universal

A Min. clearance from fi rebox to corner walls 230 210 250

B Min. distance from fi rebox to fl oor protector front 300 300 300

C Min. distance from rear wall to fl oor protector front 1280 1228 1380

D Min. fl oor protector projection from wall 860 808 910

E Min. overall fl oor protector depth 1510 1440 1620

F Min. fl oor protector front width 594 594 660

Pioneer Double Flue Mounted Shield Universal

A Min. clearance from firebox to corner walls 230 250

B

Min. distance from firebox to floor protector front 300 300

C

Min. distance from rear wall to front of protector 1280 1380

D Min. floor protector projection from wall 860

E Min. overall floor protector depth 1510 1620

F Min floor protector front width 594 660

DESCRIPTION

DESCRIPTION

Shall be

Fitted

Shall be Fitted

FIREBOX INSTALLATION

1. If a separate floor protector is being used position now. Place the firebox on the floor protector to

suit the minimum installation clearances. (See Fig 3 or 4).

2. Seismically restrain the firebox and the floor protector to the floor.

3. Fit 2 x 6mm fixings suitable for the floor material. DO NOT over tighten.

4. Fit timber trim pedestal edging to front and back of base (optional).

With Double Flue

With Double Flue Shield Fitted

Shield

2100 4300

Fitted

2100-NZ 2100-AU 4300

910

October 12, 2015

7037-141D

Page 5

2100 & 4300 Millennium ACC Wood Burner

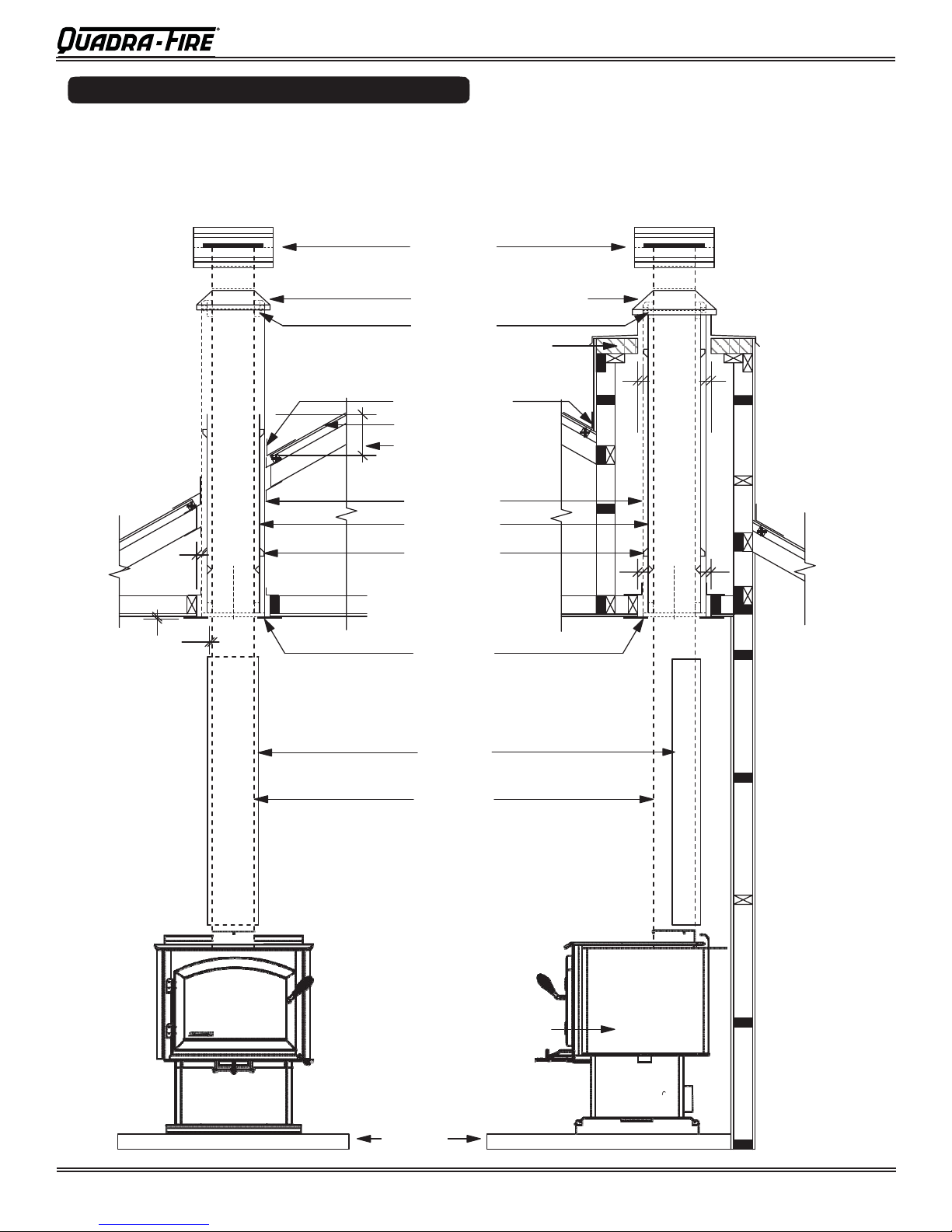

GENERAL INSTRUCTIONS FOR FLUE SYSTEM

ƒ Flue pipe installed crimp/narrow end down

ƒ Outer casings installed crimped/narrow end up. (Critical when exposed above the roof)

ƒ Inner casings - direction not critical

ƒ Flue pipes - seal all joints including firebox spigot.

- fix with a minimum of 3 stainless steel rivets

ƒ Flue pipe spacers - affix to flue pipe

ƒ Flue system termination point - Refer to AS/NZS 2918:2001 4.9.1, see Fig. 9.

ƒ Flue pipe shall extend not less than 4.6m above top of the floor protector as per

AS/NZS 2918:2001 4.9.1(a)

ƒ Façade or chase systems - same rule applies as above.

ƒ Roof penetration and flashing method refer to NZ Building Code E2.(From 01/07/05)

Note: These instructions apply to 150mm diameter flue pipe systems as tested to

AS/NZS 2918:2001

1. Either locate the appliance in position or by measuring at the ceiling mark the flue pipe centre

position. Check that the outer casing is unobstructed through the attic space or roof area.

2. Spike the centre with a nail. Transfer this position to the next surface above. Plumb bob/laser.

3. Cut out the ceiling penetration hole – square or rectangle – short axis equals outer casing

diameter plus 50mm, long axis as required. See Table 5 . Perform the same at the roof

penetration.

4. Frame out the hole with minimum 75 x 50 timber or as requ ired for roofing material. Minimum

requirement at roof penetration see NZ Building Code E2 Acceptable Soluti on (from 01/07/05).

5. Install the outer casing so that :-

(i) lower end is flush with the underside of the ceiling material and

(ii) with the addition of metal “L” brackets, affix to the outer casing at 90 degrees secure the outer

casing centrally to the ceiling and roof nogs. Alternatively substitute the “L” brackets for 25mm

thick non heat sensitive packers. Secure the outer casing th rough the packers with horizontal

fixings to the nogs. Refer to the General Instruction for termination height. The option of outer

casing slips to be taken into account.

6. Flash the outer casing to the roof material with the appropriate approved flashing.

7. If using an outer/inner casing combination, now install the inner casing ensuring it extends a

minimum 200mm above the high side of the roof penetration. If not using a combination see ‘11’

below.

8. Refer to Firebox Installation, points 1 & 2.

9. Prepare the ceiling plate and place upside down over the flue spigot.

10. Install the flue pipes by preferred method – either up or down the outer casing. Affix each length

per the notes in General Instructions (above). Extend the flue pipe above the outer

casing to suit the casing cover/cowl assembly.

11. If the inner casing has not been installed, install now. Refer to 7 above for minimum height.

12. Install the cowl assembly, i.e. Top spacer, casing cover and cowl.

13. Position and secure the ceiling plate with the screws and spacers.

14. Wipe the flue pipe to remove finger marks.

15. Refer to Firebox Installation, point 3.

16. If flue offset is required, refer to AS/NZS 2918:2001 4.1

1.QF.1D

Page 6

7037-141D

October 12, 2015

2100 & 4300 Millennium ACC Wood Burner

FLUE PENETRATION

FLUE PENETRATION

Tested flue systems, as per AS/NZS 2918:2001

Fig. 5

Drawing not to scale

25

12

12.5

ADD Cowl

Casing Cover

Spider Bracket

Approved Flashing

Roof Line

Inner Casing 200mm

above roof line

Outer Casing

Inner Casing

Internal Swage

Ceiling Plate

Double Flue

C

L

Quadra-fire Millennium

Floor

Protector

oversized casing cover

is necessary

Non combustible material

Hebel block or 12mm

Promina board or similar

under the flashing

V

ented

Pioneer

Shield

Flue Pipe

1.QF.1E

minimum 25mm gap

between flue pipe casing &

combustible material

25 25

25 25

C L

C

L

October 12, 2015

7037-141D

Page 7

2100 & 4300 Millennium ACC Wood Burner

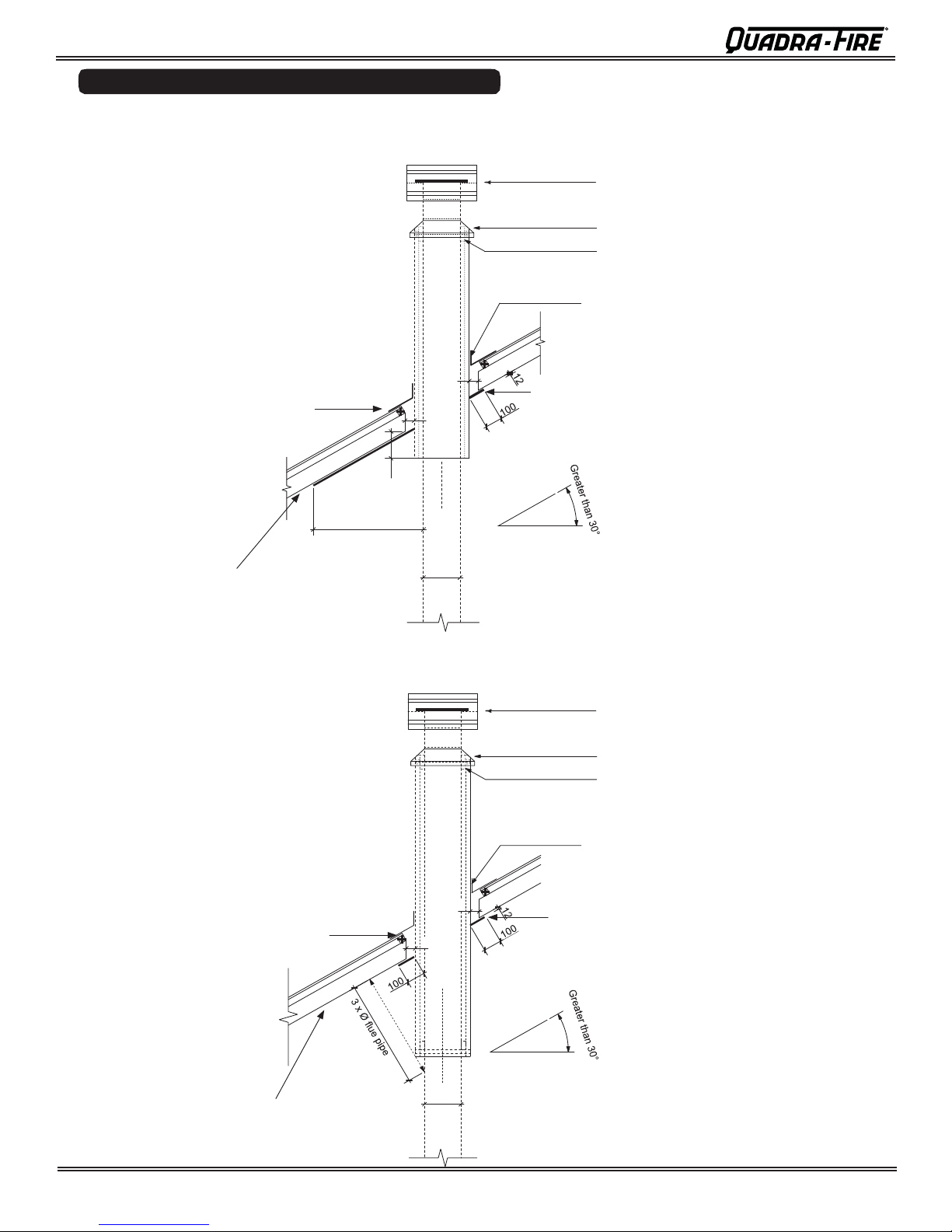

FLUE PENETRATION

Un-tested flue systems, as per AS/NZS 2918:2001, 4.6.3(b)

Fig. 6

AS/NZS2918:2001

Un-tested flue with sloped ceiling

penetration greater than 30° from

horizontal

A = 25mm

4.6.3(b)

Fig 4.6 = downward distance of

casing and 3 x ø flue distance of

the ceiling plate

Batten

150

A

A

Fig. 7

Ceiling

AS/NZS2918:2001

Un-tested flue with sloped ceiling

penetration greater than 30° from

horizontal

A = 25mm

4.6.3(b)

Fig 4.6 = 3 x ø flue from active flue

to heat sensitive surface

Batten

3 x Ø flue pipe

flue pipe

Ø

A

A

Ceiling

flue pipe

Ø

ADD Cowl

Casing Cover

Spider Bracket

Approved Flashing

Ceiling Plate

ADD Cowl

Casing Cover

Spider Bracket

Approved Flashing

Ceiling Plate

1.QF.1F

Page 8

7037-141D

October 12, 2015

Loading...

Loading...