Page 1

QTS-CLX-PVX

PROVOX®

Module

User Manual

Page 2

Page ii QTS-CLX-PVX September 2009

WARNING!

Identifies information about practices or circumstances that can lead to

personal injury or death, property damage, or economic loss.

These warnings help to:

• identify a hazard

• avoid the hazard

• recognize the consequences

IMPORTANT!

Identifies information that is especially important for successful

application and understanding of the product.

TIP

Identifies information that explains the best way to use the

QTS-CLX-PVX

Because of the variety of uses for the products described in this publication, those

responsible for the application and use of these products must satisfy themselves that all

necessary steps have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws, regulations, codes

and standards. In no event will Quest Technical Solutions be responsible or liable for

indirect or consequential damage resulting from the use or application of these products.

Any illustrations, charts, sample programs, and layout examples shown in this publication

are intended solely for purposes of example. Since there are many variables and

requirements associated with any particular installation, Quest Technical Solutions does

not assume responsibility or liability (to include intellectual property liability) for actual

use based upon the examples shown in this publication.

Throughout this manual we use notes to make you aware of safety considerations.

Microsoft is a registered trademark of Microsoft Corporation.

Windows, Windows 95, Windows NT, Windows 2000, Windows XP and Vista are trademarks of Microsoft Corporation.

ControlLogix, RSLinx and RSLogix 5000 are trademarks of the Allen-Bradley Company, Inc.

PROVOX is a registered trademark of FisherControls International LLC, a subsidiary of Emerson Electric.

Page 3

Page 4

QTS-CLX-PVX MODULE OVERVIEW 1

Part Number 2

Module Features 2

Power Requirements 3

Other Requirements 3

Package Contents 3

INSTALLATION 4

Prevent Electrostatic Discharge 4

Prepare the Chassis for Module Installation 4

Determine Module Slot Location 4

Insert the Module in the Chassis 5

Replacing a Module 6

Cabling and Termination 7

Software Installation 7

SUMMARY OF OPERATIONS 8

IMPORTANT CONSIDERATIONS 9

CONFIGURING THE MODULE IN RSLOGIX 5000 10

Module Configuration 10

Adding the Module 10

I/O Data Mapping 12

RSLINX 13

CONFIGURING THE I/O 14

ClxPvxCfg Software 14

Setting the Module Name 14

Setting the Module Mode 15

Page 5

QTS-CLX-PVX Page iii

Configuring from a PROVOX Control I/O Bus 16

Mapping the I/O Data 18

What gets mapped 19

Uploading and Downloading Configurations 19

Saving a Configuration File 20

Opening a Configuration File 20

Clearing the Configuration 20

The Configuration Signature 21

Aliases 21

ACCESSING I/O DATA 23

Required Connections 23

Data Updates 23

Discrete Data 23

Analog Data Format 23

Diagnostic Data 25

USING MONITOR MODE FOR MIGRATION 28

TROUBLESHOOTING 29

ControlLogix Module LEDs 29

NET LED – Control I/O Bus Status 29

CLX LED – ControlBus Status 29

OK LED – Module Health 30

All LEDs Red 30

QTS-CLX-PVX Module 4-Character Display 30

RSLogix 5000 30

The Debug Log 31

Fatal Errors 31

UPDATING THE FIRMWARE 32

Page 6

Page iv QTS-CLX-PVX September 2009

APPENDIX:CLXPVXCFG 33

APPENDIX: CONFIGURATION FILE FORMAT 35

SPECIFICATIONS 38

QTS-CLX-PVX ControlLogix Module 38

SUPPORT 39

WARRANTY 40

Page 7

QTS-CLX-PVX Module Overview

The QTS-CLX-PVX connects a ControlLogix controller to a PROVOX® Control I/O

bus.

The QTS-CLX-PVX is intended to be used to migrate PROVOX systems to

ControlLogix controllers. You can retain the PROVOX I/O as the first step in the

migration.

The module can act as a monitor or as a master on the Control I/O bus. You select the

mode by downloading different firmware to the module.

In monitor mode, the QTS-CLX-PVX sends PROVOX I/O input and output data to input

and status input data in the ControlLogix. It cannot transmit on the bus.

In master mode, the ControlLogix sends output data to the QTS-CLX-PVX, which then

transmits it as output data on the PROVOX Control I/O bus. The QTS-CLX-PVX sends

PROVOX input data to input data in the ControlLogix.

The QTS-CLX-PVX:

supports I/O bus redundancy

supports 20-series Control I/O files 1-16

supports up to 64 I/O cards. For larger systems, split the bus and use two

QTS-CLX-PVX modules.

supports 10 series I/O with serial buffer card

does not support EIC or IDI

Page 8

Page 2 QTS-CLX-PVX September 2009

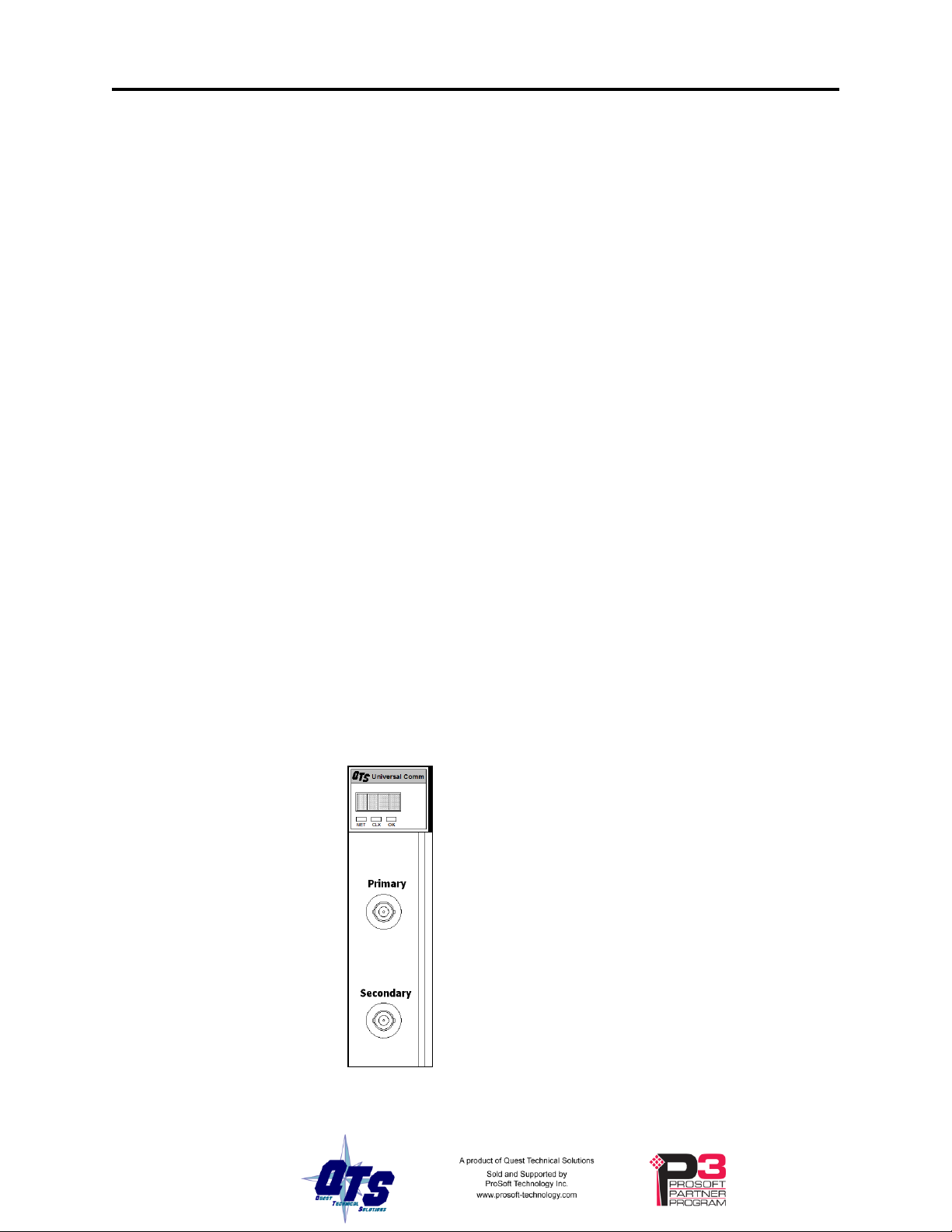

The module has:

A label that identifies the module, text QTS

Universal Comm

A 4-character scrolling display

3 LEDs, labelled NET, CLX, and OK, to indicate

the status of the I/O bus, the state of the connection

to the ControlLogix processor, and the internal state

of the module

2 BNC connectors to connect to the primary and

secondary I/O bus cables

does not support Control I/O card redundancy

The QTS-CLX-PVX communicates with the ControlLogix processor using scheduled

connections. You configure the module as a Generic Module in RSLogix 5000 with:

250 16-bit words of scheduled input data

248 16-bit words of scheduled output data

250 16-bit words of status input data

The Windows configuration program supplied with the module maps Control I/O bus

data to the scheduled data. It also:

uploads and downloads configuration data

downloads firmware to the module

saves and opens configuration files

exports aliases for use in your RSLogix 5000 application

Firmware Update

The module firmware can be updated using the Windows utility supplied (see page 32).

Part Number

The part number of the module is QTS-CLX-PVX

Module Features

The following figure shows the features of the module.

The module supports insertion and removal under power.

Page 9

The module is shipped in monitor mode, with a blank configuration.

Watchdog and Jabber Inhibit

A watchdog timer is implemented in the module’s hardware. If the firmware does not

kick the watchdog within the timeout period the watchdog times out and generates a fatal

error (see page 31) with error code D1. In master mode, the module stops scanning and

stops communicating with the ControlLogix.

A jabber inhibit timer is implemented in the module’s hardware. If the bus transmitter is

on longer than 150% of the longest frame time, the jabber inhibit forces the transmitter

off and generates a fatal error (see page 31) with error code D0. In master mode, the

module stops scanning and stops communicating with the ControlLogix.

Power Requirements

The QTS-CLX-PVX module requires 675 mA @ 24VDC and 5 mA @ 5.1VDC from I/O

chassis backplane.

Other Requirements

To use the Windows utility programs, you must have RSLinx software, version 2.54 or

later, with an activation. Use RSLinx Gateway or RSLinx Professional software. Do not

use RSLinx Lite.

QTS-CLX-PVX Page 3

Package Contents

• QTS-CLX-PVX module

• CD containing software and documentation

Page 10

Page 4 QTS-CLX-PVX September 2009

WARNING!

ATTENTION: Electrostatic discharge can damage integrated circuits

or semiconductors if you touch backplane connector pins. Follow these

guidelines when you handle the module:

Touch a grounded object to discharge static potential

Wear an approved wrist-strap grounding device

Do not touch the backplane connector or connector pins

Do not touch circuit components inside the module

If available, use a static-safe work station

When the module is not in use, keep it in its static-shield packaging

Installation

Prevent Electrostatic Discharge

The module is sensitive to electrostatic discharge.

Prepare the Chassis for Module Installation

Before you install the ControlLogix module, you must install and connect a ControlLogix

chassis and power supply. To install these products, refer to the installation instructions

you received with them.

Determine Module Slot Location

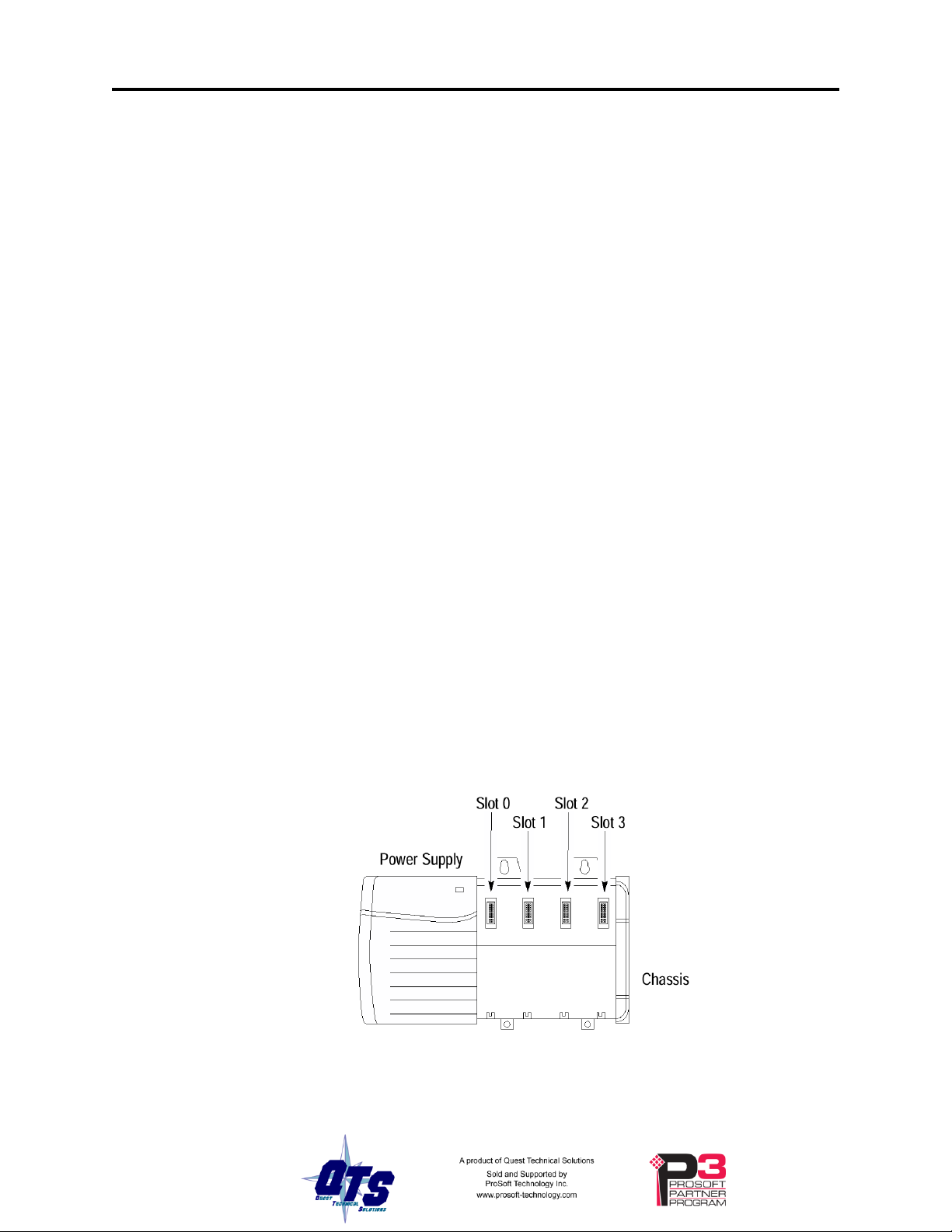

This example shows chassis slot numbering in a 4-slot chassis. Slot 0 is the first slot and

is always located to the right of the power supply. You can use any size ControlLogix

chassis and install the module in any slot.

Figure 1 Chassis Slots

Page 11

You can use multiple modules in the same chassis.

WARNING!

ATTENTION: When you insert or remove the module while

backplane power is on, an electrical arc can occur. This could cause an

explosion in hazardous location installations. Be sure that power is

removed or the area is nonhazardous before proceeding.

Repeated electrical arcing causes excessive wear to contacts on both the

module and its mating connector. Worn contacts may create electrical

resistance that can affect module operation.

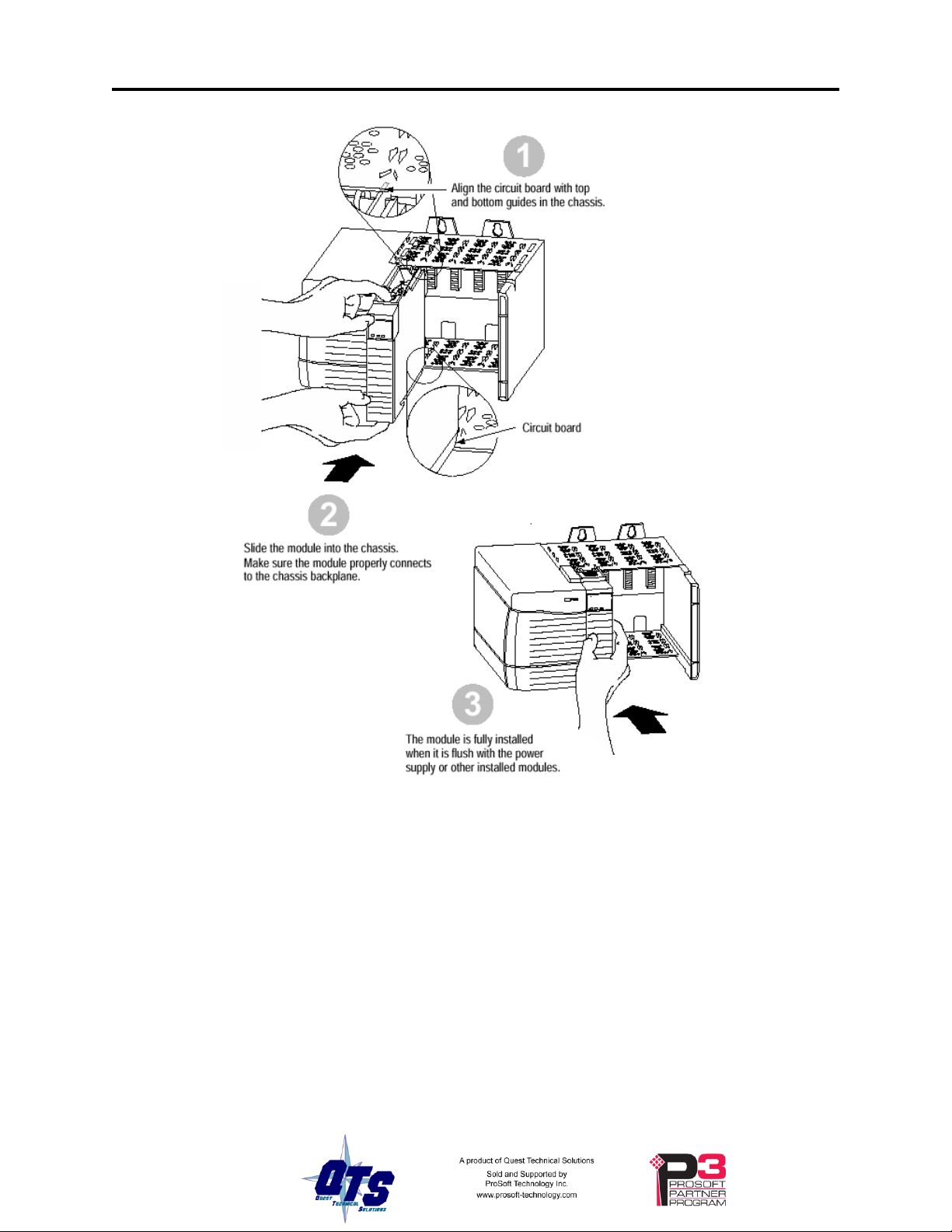

Insert the Module in the Chassis

The ControlLogix module is designed to be installed or removed while chassis power is

applied.

QTS-CLX-PVX Page 5

Page 12

Page 6 QTS-CLX-PVX September 2009

Replacing a Module

If you are replacing an existing module with an identical one, and you want to resume

identical system operation, you must:

install the new module in the same slot.

run the configuration program and download the appropriate configuration to the

module.

check that it has the correct firmware, scanner or monitor version.

ensure that the data has been synchronized

Figure 2 Inserting the Module

Page 13

Cabling and Termination

WARNING!

Connecting the module disrupts bus traffic!

Connect the module at a time when it is safe to do so.

Connect the QTS-CLX-PVX like any other device on the Control I/O bus.

The bus cable is 75-ohm RG-6, for example Belden 9290

Terminate both ends of the primary and secondary I/O bus using 75 ohm resistors

attached to the physical ends of the bus. There should be two and only two terminators on

each bus.

Refer to the following Emerson documents for details on cabling:

section 3.8 of "Installing and Maintaining the SRx Controller Family",

PN8.0:CL6640

Installing Control I/O Subsystem (PN2.1:CP6701)

Signal Wiring and Highway System Guidelines PN1:004

QTS-CLX-PVX Page 7

Software Installation

You must uninstall any previous version of the software before you can install a new

version. Use the Windows Control Panel Add and Remove Programs to remove the old

version.

Insert the CD supplied and run the program QtsPvx.msi on the CD to install the Windows

software.

Page 14

Page 8 QTS-CLX-PVX September 2009

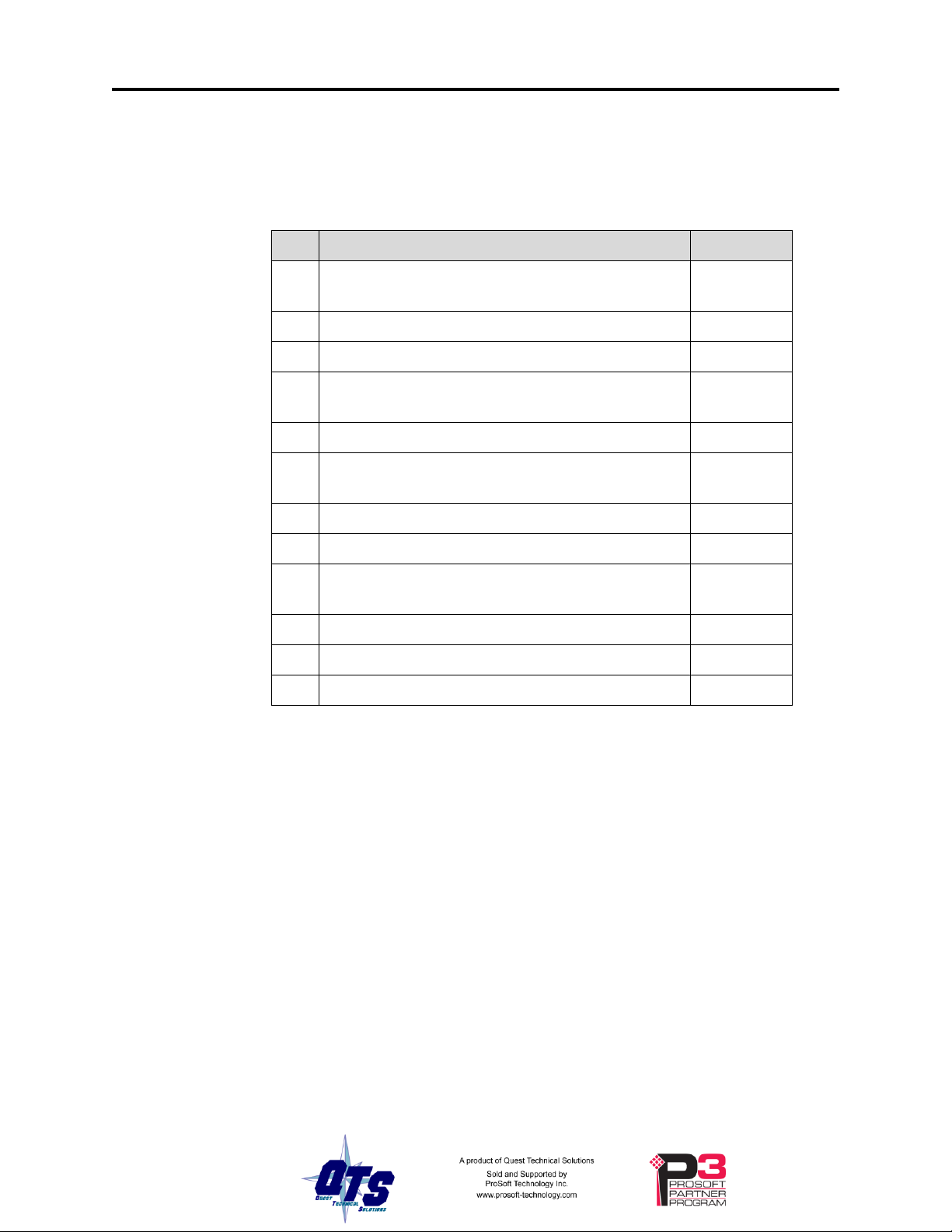

Step

Operation

See page

1

Install the QTS-CLX-PVX module in the

ControlLogix chassis

4

2

Set the module mode to monitor (the default)

15

3

Connect the module to the Control I/O bus

7

4

Autoconfigure the module from the PROVOX

Control I/O bus

16

5

Configure the module in RSLogix 5000

10

6

Decide if you are going to use monitor mode to

develop and test your application

28

7

Disconnect the PROVOX master

8

Change the module mode to master

15

9

Save the configuration and download it to the

module

19

10

Create aliases for RSLogix 5000

21

11

Import the aliases into RSLogix 5000

21

12

Use the aliases to access data

Summary of Operations

The following is a short summary of the steps typically followed. Refer to the

appropriate manual section for details.

Page 15

QTS-CLX-PVX Page 9

Important Considerations

The operation of the QTS-CLX-PVX is different in several important ways from that of a

standard ControlLogix module and in some ways from a PROVOX controller.

It is essential that you be aware of the following:

the QTS-CLX-PVX in master mode write changes in the ControlLogix output data

table to PROVOX outputs even in program mode. If you make a change in the output

table, it will appear on the bus

in master mode, if the I/O configuration in the QTS-CLX-PVX changes, it is

essential that you clear the ControlLogix output table for the module before you

connect it to the Control I/O bus

the QTS-CLX-PVX continues to scan the Control I/O bus even if the the connection

to the ControlLogix processor is lost. This is so that I/O on the bus does not time out.

on the Control I/O bus, data is passed only when it changes. In monitor mode, the

QTS-CLX-PVX sees only data that changes while it is connected to the bus. In

master mode, the QTS-CLX-PVX writes outputs only when they change and receives

inputs only when they change.

configuring the QTS-CLX-PVX module requires that you reset the PROVOX

controller. This can cause major disruptions to the running system. Reset the

controller only when you know it is safe to do so. A reset can last up to 3 minutes.

if you switch from a real PROVOX scanner to a QTS-CLX-PVX scanner, you

should download the configuration to the QTS-CLX-PVX. This forces a reset on the

Control I/O bus. A reset is necessary because the two scanners implement the bus

token passing slightly differently. A reset ensures that all files and cards update.

Page 16

Page 10 QTS-CLX-PVX September 2009

Configuring the Module in RSLogix 5000

You configure the module in RSLogix 5000 to set how much scheduled data to transfer

and how often to transfer it.

The terms input and output are relative to the ControlLogix.

In master mode, the ControlLogix sends output data to the QTS-CLX-PVX, which then

transmits it as output data on the PROVOX Control I/O bus. The QTS-CLX-PVX sends

PROVOX input data to input data in the ControlLogix.

In monitor mode, the QTS-CLX-PVX sends PROVOX I/O input and output data to input

and status input data in the ControlLogix. It cannot transmit on the bus.

You should always access data using the aliases generated by the configuration program.

Module Configuration

Configure the module as a Generic module in RSLogix 5000.

The same ControlLogix configuration is used for master and monitor modes of the QTS-

CLX-PVX.

Adding the Module

To add the module to the I/O configuration in RSLogix 5000, you must be offline.

1. If you are creating a new project, select File/New to create a new project,

give the processor a name, and enter the slot it occupies in the ControlLogix

rack.

2. Right click on the I/O configuration Folder, or on the bridge module in

the desired remote chassis in the I/O Configuration Folder, and select

New Module…

3. Expand the Other tab, select a module of Type 1756-MODULE Generic

1756 Module and click OK.

Page 17

QTS-CLX-PVX Page 11

4. RSLogix 5000 displays the New Module dialog box.

5. Assign the module a Name and optionally a Description.

6. Set the Comm Format to Data – INT – With Status.

7. Set the Slot to match the slot number of the QTS-CLX-PVX module in the

chassis.

Page 18

Page 12 QTS-CLX-PVX September 2009

8. Set the Connection Parameters as shown above. Click OK.

9. Next set the RPI.

Selecting an RPI.

The module supports RPIs from 0.2 to 750.0 ms. The default RPI is 5 ms.

Select an RPI appropriate to the I/O bus scan time and to your process. It makes no sense

to use an RPI that is much faster than the bus or process update time. Typical RPIs are

from 100 to 150 ms.

Remote Connections

If you are using the QTS-CLX-PVX in a remote chassis, for example a chassis connected

to the controlling ControlLogix processor over Ethernet or ControlNet, it may be

necessary to increase the RPI, as the intermediate network may not have sufficient

bandwidth to support faster updates (small RPIs).

I/O Data Mapping

The configuration program (see page 14) maps the I/O data to ControlLogix tags.

The configuration program creates aliases to I/O data that you can import into RSLogix

5000 to access I/O data. The alias names address data by file, card and channel.

10. Click OK to accept the module

Use these aliases to access data in any applications you develop. If the mapping changes,

you simply re-import aliases and the application accesses the correct I/O location. The

configuration program also creates aliases to diagnostic data which is not easily

accessible other than by using the aliases.

Page 19

QTS-CLX-PVX Page 13

Parameter

Value

Device Name

CLX-PVX-MON (Monitor)

CLX-PVX-MAS (Master)

Vendor

832 (Quest Technical Solutions)

Product Type

12

Product Code

1052 (Monitor)

1051 (Master)

Revision

depends on firmware

Serial Number

depends on module

RSLinx

When you right click on the module in RSLinx and select Properties, RSLinx displays the

following:

RSLinx Properties

To use the Windows utility programs, you must have RSLinx software, version 2.54 or

later, with an activation. Use RSLinx Gateway or RSLinx Professional software. Do not

use RSLinx Lite.

The installation CD contains EDS files for the QTS-CLX-PVX in monitor and master

modes.

Page 20

Page 14 QTS-CLX-PVX September 2009

Configuring the I/O

ClxPvxCfg Software

The QTS-CLX-PVX module is supplied with a Windows configuration tool,

ClxPvxCfg.exe.

Use this configuration tool to:

Switch between monitor and master mode

Autoconfigure the monitor from an attached Control I/O bus

Convert the configuration for master mode

Map I/O data to ControlLogix scheduled connections

Save and load configuration files

Download and upload configurations

Set the RSLinx path to the QTX-CLX-PVX module

Export aliases for I/O data for import into RSLogix 5000, for both master and

monitor modes

Update the module firmware

ClxPvxCfg is an offline configuration tool; any changes must be downloaded to the QTS-

CLX-PVX module.

Setting the Module Name

To set the module name, right click on the QTS-CLX-PVX at the root of the tree and

select Edit Module Properties.

Page 21

QTS-CLX-PVX Page 15

TIP

Use the same name that you assign the module in RSLogix 5000 to make

it easy to associate aliases with the module.

You can use the name of the controller you are monitoring, for example,

SRx101.

IMPORTANT!

If you change the mode (monitor to master or master to monitor), any

configuration on the module is cleared. If the firmware you download is

the same as the firmware already on the module (for example, if you are

The QTS-CLX-PVX Module Properties dialog appears.

Enter the Module Name. It can be up to 15 characters long. It should follow the rules for

naming ControlLogix aliases; it should contain only alphanumeric characters and the

underscore. Click OK to accept the name.

The name is displayed on the 4-character display and is used by ClxPvxCfg to build

aliases for ControlLogix data.

The default name assigned when you perform an autoconfiguration is Auto_Scan.

The name should be unique so that if you have more than one QTS-CLX-PVX module,

the alias names associated with each module are unique.

Setting the Module Mode

To switch between modes or to update module firmware, select Actions/Change Module

Mode… Changing the module mode downloads firmware to the card.

If the RSLinx path has not been set, select the module in the tree.

The Set QTS-CLX-PVX Mode dialog appears.

It shows the current mode and lets you select the firmware to download.

Page 22

Page 16 QTS-CLX-PVX September 2009

updating firmware), the configuration is unaffected.

WARNING!

Connecting the module to the Control I/O disrupts bus traffic!

Connect the module only at a time when it is safe to do so.

Click Apply to download the firmware.

When the firmware download is successful, the module displays the following message

and shows the version of firmware downloaded.

Click OK to clear the message, then click Done.

If you change the module mode from master to monitor or from monitor to master:

the configuration in the configuration program is converted to the new mode

data mappings change

The ControlLogix controller with the connection to the module must be in program mode

when you change mode. If the processor is in run mode, the following message appears.

The QTS-CLX-PVX displays the module and firmware and version on the 4-character

display.

Configuring from a PROVOX Control I/O Bus

The QTS-CLX-PVX must be configured by capturing configuration information sent by

a PROVOX master to a running PROVOX system.

Use the following steps to configure the QTS-CLX-PVX.

1. Connect the module, in monitor mode, to a running PROVOX bus.

Page 23

QTS-CLX-PVX Page 17

WARNING!

Resetting the PROVOX controller disrupts the running system!

Reset the controller only at a time when it is safe to do so.

2. Use the Actions/Start Auto Configuration menu command or use Auto

Configuration toolbar command to start an auto-configuration cycle.

3. Reset the PROVOX master. The QTS-CLX-PVX captures the configuration

data the master sends out and passes it to the configuration program, which

analyzes it and builds the tree.

4. Download the captured configuration to the QTS-CLX-PVX.

5. Export aliases from the configuration tool to a file.

6. Import those aliases into RSLogix 5000.

7. Use the aliases to monitor data on the PROVOX bus.

If the module does not capture the configuration within a timeout period (approximately

60 seconds), it displays this message.

Page 24

Page 18 QTS-CLX-PVX September 2009

WARNING!

If the configuration in the PROVOX controller changes, you must repeat

this procedure to capture the new configuration. Failure to do so results

in the monitored values being incorrect.

WARNING!

Whenever the data mapping changes, make sure you export a new alias

file and re-import it into RSLogix 5000 so that you are using the correct

Note: If the ControlLogix processor previously had a connection open to the QTS-CLXPVX module when the autoconfiguration timed out, that connection remains open, even

though there is now no configuration on the module. However, if the module has no

configuration, itwill not accept new connections.

Card and Data Limits

The QTS-CLX-PVX supports a maximum of 64 cards in monitor or master mode. If

there are more than 64 cards in the captured configuration, ClxPvxCfg displays a

message. You will have to delete some cards from the configuration. Right click on the

card and select Delete.

Note: You cannot delete a 10 Series Communication Card. It disappears automatically

when you delete all the other cards in the file.

In addition there are limits on the amount of available ControlLogix data space.

Depending on the type of cards, you may exceed one of these limits without exceeding

the maximum of 64 cards. In monitor mode, you will have to remove some cards from

the configuration or use two QTS-CLX-PVX modules as monitors. In master mode, you

can split the bus and use a QTS-CLX-PVX master on each bus.

Monitor-Only Files

A monitor-only file is created under two circumstances:

the captured configuration contains an unsupported card type

a card in the PROVOX controller’s configuration is not responding on the bus

A monitor-only file can be used with the QTS-CLX-PVX in monitor mode but cannot be

converted for use in master mode.

Mapping the I/O Data

When you autoconfigure the monitor from the PROVOX bus, the configuration tool

automatically maps the I/O data to locations in the ControlLogix scheduled input and

status input data.

When you change the module to master mode, the configuration tool remaps the data to

ControlLogix scheduled input and output data.

If you delete any cards from the configuration, all mappings are cleared. Unassigned I/O

addresses are shown as Undefined in the tree. To remap the data, select Actions/Autoallocate Logix Addressing.

Page 25

addresses for data.

Failure to do so will result in writing incorrect data and may result in

injury or death.

If the QTS-CLX-PVX is in master mode and data mappings change,

make sure you clear the output data table for the module in the

ControlLogix processor before you connect the QTS-CLX-PVX to the

Control I/O bus.

What gets mapped

Master Mode

PROVOX inputs (AI, DI) are mapped to ControlLogix inputs (path:I).

PROVOX outputs (AO, DO) are mapped to ControlLogix outputs (path:O)

Diagnostics are mapped to ControlLogix inputs and status inputs (path:S).

Monitor Mode

PROVOX inputs (AI, DI) are mapped to ControlLogix inputs (path:I).

QTS-CLX-PVX Page 19

PROVOX outputs (AO, DO) are mapped to ControlLogix status inputs (path:S).

Diagnostics are mapped to ControlLogix inputs and status inputs.

Uploading and Downloading Configurations

To download a configuration to the QTS-CLX-PVX, select Actions/Download

Configuration or use the Download Configuration to Module button on the toolbar.

To upload a configuration from the QTS-CLX-PVX, select Actions/Upload

Configuration or use the Upload Configuration from Module button on the toolbar. The

uploaded configuration will be given the default file name Untitled.

If the RSLinx path to the module has not been set when you upload or download, an

RSLinx Path Selection window opens.

Page 26

Page 20 QTS-CLX-PVX September 2009

TIP

In master mode, to do the equivalent of a PROVOX reset, download the

configuration to the module.

If the ControlLogix processor with the connection to the QTS-CLX-PVX is in run mode

when you download, the following message is displayed.

Saving a Configuration File

To save a configuration to disk, select File/Save or File/Save As.

Opening a Configuration File

To open a configuration file, select File/Open..

This does not change the configuration in the module; the configuration in the module

changes only when you download.

Clearing the Configuration

To clear the configuration in the program, select File/New.

Page 27

This does not change the configuration in the module; the configuration in the module

changes only when you download.

The Configuration Signature

The configuration signature is displayed at the root of the tree. It can be used to

determine if there are differences between a configuration file and the configuration in

the module.

Open the configuration file and note the configuration signature. Now upload the

configuration from the module and compare the configuration signatures. If they are the

same, the configurations are identical.

Aliases

The configuration tool creates aliases for I/O data that can be exported and imported into

RSLogix 5000.

You should write programs in terms of these aliases rather than using absolute addresses.

If the mapping of the I/O data changes, simply reimport the new aliases and the program

will point to the new data locations.

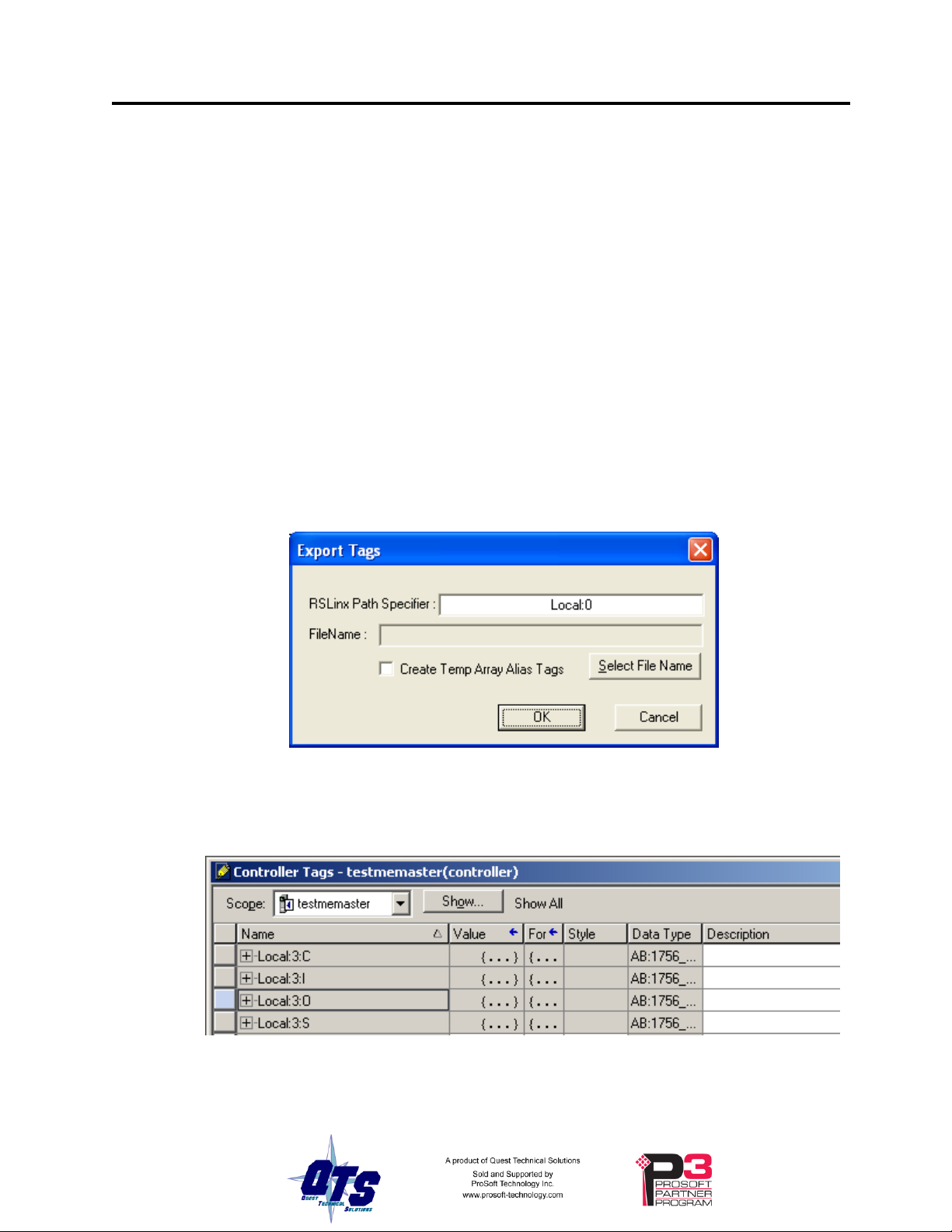

To export aliases, select Files/Export Tags…

QTS-CLX-PVX Page 21

Enter the RSLinx Path Specifier to set the location of the module. In the example shown,

the module is in slot 0 of the Local chassis.

To determine the RSLinx Path Specifier, look at the raw tags for the module in RSLogix

5000.

The RSLinx Path Specifier includes everything up to but not including the colon before I,

O, C or S. In the example shown, it is Local:3

Page 28

Page 22 QTS-CLX-PVX September 2009

WARNING!

If you change the I/O or ControlLogix configuration, re-import aliases so

that the ControlLogix processor uses the correct addresses and clear the

ControlLogix output table so that values don’t get written to incorrect

addresses.

TIP

If you have changed mode on the QTS-CLX-PVX, delete any aliases

you previously imported into RSLogix 5000 before you import the new

aliases.

Use the Select File Name button to enter the file location.

If you are using monitor mode to develop your application, check the Create Temp Array

Alias Tags checkbox. You should also create an array of 250 INTs with name

TempPvxOutputArray in the ControlLogix.

Click OK to create the alias file.

Importing Aliases in RSLogix 5000

To import the alias file into RSLogix 5000, you must be offline. Select Tools/Import…

and import the alias file.

Alias Format

ClxPvxCfg builds each alias name from the Module name and address information

supplied by the configuration program

The ControlLogix data address is built from the RSLinx Path Specifier you enter and the

data mappings created by the configuration program.

For example,

ALIAS,"","D3R_Mas_AI_F01C01C01","D3R_Mas_AI_F01C01C01","","Local:0:I.Data[2]""

In this example, the module is in slot 0. The alias is for an analog input at PROVOX

address File 1, card 1, channel 1, which is mapped to ControlLogix address input data at

offset 2. The module name is D3R_Mas.

To build the alias name, ClxPvxCfg appends an underscore and F01C01C01 to the

module name. The module is in slot 0 of the local chassis so the alias data address is

Local:0:I.Data[2]

Page 29

Number, percent

High byte, hex

Low byte, hex

Number, hex

-13.97%

F2

08

F208

-1.75%

FE

40

FE40

0.00%

00

00

0000

1.75%

01

C0

01C0

25%

19

00

1900

25.25%

19

40

1940

50%

32

00

3200

75%

4B

00

4B00

100%

64

00

6400

Required Connections

In master mode, the QTS-CLX-PVX does not begin scanning the I/O bus until all

ControlLogix connections to the module are present.

If the connection is later closed, the QTS-CLX-PVX continues scanning the bus. Inputs

do not update in the ControlLogix while the connection is closed and outputs do not

update.

In monitor mode, the module does not wait for ControlLogix connections.

Data Updates

It is important to remember always that the PROVOX Control I/O bus updates data only

when the data changes.

Any changes that occur when the module is not connected to the bus will not be captured.

Discrete Data

QTS-CLX-PVX Page 23

Accessing I/O Data

Use the aliases created by ClxPvxCfg to access discrete data to ensure that you are using

the correct address and bit.

Analog Data Format

Analog values on the Control I/O bus are expressed in PROVOX Percent Format. The

number is shown in the PROVOX controller as a percent with 3 decimal places. The

range is -13.969% to +113.970%.

Each 16-bit word consists of:

upper byte = signed byte, represents the whole number part of the percentage

lower byte = unsigned byte, represents the fractional part, as a fraction of 256

Some examples:

Page 30

Page 24 QTS-CLX-PVX September 2009

Number, percent

High byte, hex

Low byte, hex

Number, hex

113.97%

71

F8

71F8

Modules like thermocouples linearize the inputs to percent of range, 1 to 5V.

Add-on instructions for RSLogix 5000 to convert between PROVOX percent and

ControlLogix real numbers are available from the downloads area of the Rockwell

Automation support website

http://samplecode.rockwellautomation.com/

In the Sample Code Library, search for “AOI for QTS-CLX-PVX PROVOX Module REV”

Converting PROVOX Percent Format to ControlLogix Real

For positive values (high bit of upper byte clear), add the whole number part (upper byte)

to the fraction (lower byte divided by 256).

For negative values (high bit of upper byte set), subtract 256 from the whole number part

and add the fractional part.

Example 1:

To convert 1940 hex, first note that the number is positive (high bit clear).

Convert the whole number part, 19 hex, to 25 decimal. The fractional part is 40 hex = 64

decimal. Convert it to a fraction = 64/256 =.25 and add the whole number part to get

25.25%.

Example 2:

To convert E780 hex, first note that the number is negative (high bit set). Subtract 256

from the whole number part (E7 hex = decimal 231), to get -25. The fractional part is 80

hex =128 decimal. Convert it to a fraction = 128/256 = .5. Add the parts to get -25 + .5

= -24.5%

Converting ControlLogix Real to PROVOX Percent Format

For positive values:

1. Convert the whole number part and store it in the upper byte.

2. Multiply the fractional part by 256 and store it in the lower byte.

For negative values:

1. First add 256 to the whole part. If the fractional part is non-zero (in practice,

greater than .039), subtract 1 from the result. Store the result in the upper

byte.

2. Subtract the fractional part from 1 and multiply the result by 256. Store the

result in the lower byte.

Page 31

Example 1:

Bit

15

14

13

12

11

10 9 8 7 6 5 4 3 2 1 0

File

16

15

14

13

12

11

10 9 8 7 6 5 4 3 2

1

TIP

You can use the file error tables to determine if a particular piece of data

is valid.

To convert 74.5%, first convert 74 to hexadecimal 4A and store it in the upper byte.

Multiply .5 by 256 to get 128 = 80 hex and store it in the lower byte.

The result is 4A80 hex.

Example 2:

To convert -1.75%:

Since the number is negative and the fractional part is non-zero, first add 256 to -1 to get

255 and subtract 1. Put 254 = FE hex in the upper byte.

The fractional part is .75. Subtract it from 1 to get .25, multiply by 256 to get 64 = 40

hex, and put 40 hex in the lower byte.

The result is FE40 hex.

Diagnostic Data

The QTS-CLX-PVX maintains diagnostic counters and other diagnostic status

information.

QTS-CLX-PVX Page 25

Primary and Secondary File Error Table

In both master and monitor modes, the first two words of ControlLogix input data contain

a table that shows which card files have communication problems on either the primary

or secondary bus.

The first word, at offset 0, corresponds to the primary.

The second word, at offset 1, corresponds to the secondary.

In each word, bit 0 corresponds to file 1, bit 1 corresponds to file 2, and so on.

The bit is set if there’s at least one card in the file with a problem on that bus.

The bits are 0 for unconfigured card files.

If there’s a problem with the connection to the QTS-CLX-PVX module, the

ControlLogix processor sees all bits in this table as set to 1.

Integrity Bits

In master mode, PROVOX integrity bits for each configured card are mapped to

ControlLogix status inputs. Use the aliases created by ClxPvxCfg to access the integrity

bits.

Page 32

Page 26 QTS-CLX-PVX September 2009

Name

Description

StatPrimRxGood

Number of good packets received on primary

channel

StatPrimAbortErr

Number of abort packets on primary channel

StatPrimNoiseErr

Number of error packets caused by noise on

primary channel

StatPrimFrameErr

Number of packet frame errors on primary

channel

StatPrimCrcErr

Number of packets with CRC errors on primary

channel

StatPrimPacketLenErr

Number of short packets received on primary

channel

StatSecRxGood

Number of good packets received on secondary

channel

StatSecAbortErr

Number of abort packets on secondary channel

StatSecNoiseErr

Number of error packets caused by noise on

secondary channel

StatSecFrameErr

Number of packet frame errors on secondary

channel

StatSecCrcErr

Number of packets with CRC errors on

secondary channel

StatSecPacketLenErr

Number of short packets received on secondary

channel

Channel Status Bits

In master mode, PROVOX channel status bits for each channel are mapped to

ControlLogix status inputs. Use the aliases created by ClxPvxCfg to access the channel

status bits.

Diagnostic Counters

In both monitor and master mode, the module maintains diagnostic counters that can be

used to diagnose bus problems.

Use the aliases generated by the configuration program to access the diagnostic counters.

The counters are slightly different for monitor and master modes.

Monitor Diagnostic Counters

Page 33

Master Diagnostic Counters

Name

Description

StatPrimTxGood

Number of good packets sent on primary

channel

StatPrimRxGood

Number of good packets received on

primary channel

StatPrimAbortErr

Number of abort packets on primary

channel

StatPrimNoiseErr

Number of error packets caused by noise on

primary channel

StatPrimFrameErr

Number of packet frame errors on primary

channel

StatPrimCrcErr

Number of packets with CRC errors on

primary channel

StatPrimPacketLenErr

Number of short packets received on

primary channel

StatPrimRxTimeOut

Number of packet timeout errors on primary

channel

StatSecTxGood

Number of good packets sent on secondary

channel

StatSecRxGood

Number of good packets received on

secondary channel

StatSecAbortErr

Number of abort packets on secondary

channel

StatSecNoiseErr

Number of error packets caused by noise on

secondary channel

StatSecFrameErr

Number of packet frame errors on

secondary channel

StatSecCrcErr

Number of packets with CRC errors on

secondary channel

StatSecPacketLenErr

Number of short packets received on

secondary channel

StatSecRxTimeOut

Number of packet timeout errors on

secondary channel

QTS-CLX-PVX Page 27

Page 34

Page 28 QTS-CLX-PVX September 2009

Using Monitor Mode for Migration

You can use monitor mode on the QTS-CLX-PVX to migrate existing PROVOX

applications to ControlLogix.

In monitor mode, the QTS-CLX-PVX captures live inputs and outputs from the

PROVOX bus.

You first create an array of 250 INTs with name TempPvxOutputArray in the

ControlLogix.

The configuration program creates aliases for PROVOX inputs and outputs and for

dummy outputs in the temporary array.

You import those aliases into RSLogix 5000, then create a new ControlLogix application

that reads live inputs from the PROVOX bus and writes outputs to the temporary array,

always using the aliases from ClxPvxCfg.

You compare the outputs from the new ControlLogix application (in the temporary array)

with the live outputs from PROVOX.

When you are satisfied that the new application duplicates the behaviour of the existing

PROVOX control application (state of outputs and timing), disconnect the PROVOX

controller and switch the QTS-CLX-PVX module to master mode.

Export aliases from ClxPvxCfg in master mode and import them into RSLogix 5000.

The names for the output aliases will be the same as those that pointed to the temporary

array but now they will point to the corresponding PROVOX outputs. Your new

ControlLogix application will write to the real outputs instead of the temporary array.

Since you developed your application using these aliases, no further changes will be

necessary.

You will start up with a ControlLogix application that has been tested and proved to

duplicate the behaviour of the previous PROVOX control application.

Example:

This is the alias ClxPvxCfg generated in monitor mode for a PROVOX monitored output

ALIAS,"","SRx101_AO_F01C01C01","SRx101_AO_F01C01C01","","TempPvxOutputArray[0]"

and this is the alias it generated for the same output in master mode

ALIAS,"","SRx101_AO_F01C01C01","SRx101_AO_F01C01C01","","Local:3:O.Data[0]"

The alias names are the same but in the first case the program would write to the

temporary array; in the second it would write to a ControlLogix output.

Page 35

ControlLogix Module LEDs

Color

Meaning

Solid Red

Card offline - happens when there is no configuration

on the module

Flashing red

Net LED blinks RED for 1 second with every bus error.

A burst of bus errors causes the LED to stay red for

longer than 1 second.

Yellow

One or more configured cards is offline (can't be

reached via primary or secondary links)

Green

All configured cards are online

Color

Meaning

Green

All required connections are open

Yellow

Idle, no scheduled connections, ControlLogix PLC

does not have a configuration for the QTS-CLX-PVX

module or the configuration is inhibited.

Flashing

Red/Off

The module has returned a CIP error within the last

second - no scheduled connections, QTS-CLX-PVX

module configuration not present

Solid Red

The module has returned a CIP error - no scheduled

connections.

The module has three status LEDs to indicate the state of internal operations. The LEDs

are labeled NET, CLX and OK.

NET LED – Control I/O Bus Status

The NET LED shows the status of I/O communication. The NET LED states are the

same for master and monitor modes.

In order of priority, highest first, these are:

QTS-CLX-PVX Page 29

Troubleshooting

CLX LED – ControlBus Status

The CLX LED indicates the status of communication with the ControlLogix processor.

Page 36

Page 30 QTS-CLX-PVX September 2009

OK LED – Module Health

The OK LED indicates module health. A red LED indicates that module startup

diagnostics have failed or a major module fault has occurred. Green indicates that the

module has passed all power-up diagnostics and is functioning normally.

All LEDs Red

If all three LEDs are solid red and the 4-character display shows something like M#66,

this indicates that a fatal error has occurred. Refer to page 31 for information on clearing

fatal errors. If a fatal error occurs, clear the fatal error, save the file and contact

Technical Support.

QTS-CLX-PVX Module 4-Character Display

The 4-character display shows the firmware in the module, either CLX-PVX-MON or

CLX-PVX-MAS, followed by the firmware version number, and the Module Name you

entered in the module configuration (see page 14).

If there is no configuration in the module, the display shows <NoConfig> instead of the

module name.

RSLogix 5000

If there is a problem with the connection to the module, it is shown with a yellow triangle

in the I/O Configuration tree

The Connection Tab for the QTS-CLX-PVX module displays an error message if there is

a problem with the connection to the module.

Page 37

QTS-CLX-PVX Page 31

If the module has no PROVOX configuration, it refuses connection requests from the

ControlLogix processor and returns an error.

The Debug Log

The firmware on the module maintains a log of informational and diagnostic messages

that can be useful in determining the cause of configuration and I/O bus problems.

To view the log, run the program LogMon from the Start Menu.

Fatal Errors

Fatal errors occur when the firmware on the module encounters an unexpected condition.

The module stops running, turns all three LEDs red, and displays the fatal error number

on the 4-character display. The module also records its state at the time the fatal error

occurred in a log.

To clear the fatal error and capture the fatal error log:

Contact technical support. Provide them with the fatal error log, which will help

diagnose the cause of the problem.

1. Cycle power on the module. The 4-character display should show

“FatalErrorCapture required”.

2. Run the utility FatalCapt.exe from the subdirectory Tools where you installed

the configuration tool (ususally Program Files\QtsPvx)

3. Store the fatal error log to a file. This also clears the fatal error on the

module.

Page 38

Page 32 QTS-CLX-PVX September 2009

Updating the Firmware

The module firmware is updated using the configuration program.

Select Actions/Set Module Mode.

To update the firmware, set the mode to match the firmware already loaded in the

module.

Set Module Mode uses the firmware files (*.qtf) in the same directory as ClxPvxCfg.exe.

The configuration program displays the version after the firmware has been downloaded.

The module displays the firmware and version currently loaded on the 4-character

display.

Page 39

QTS-CLX-PVX Page 33

Menu Item

Description

File Menu

New File

Close the configuration in ClxPvxCfg and open a

new file

Open File

Open a configuration file from disk

Save File

Save a configuration file to disk

Save File As

Save a configuration file to disk under a new name

Export Alias File

Export a file that contains aliases for import into

RSLogix 5000

Recent File list

Open a file that has been previously opened

Exit

Exit ClxPvxCfg

Actions Menu

Upload Config

Upload a configuration from the QTS-CLX-PVX to

ClxPvxCfg

Download Config

Download a configuration from ClxPvxCfg to the

QTS-CLX-PVX module

Start Auto Configuration

Monitor mode only. Capture a configuration from a

Control I/O Bus

Auto Allocate CLX Addressing

Assign ControlLogix data addresses

Change Module Mode

Download firmware to the QTS-CLX-PVX module,

to switch between monitor/master modes or to

update firmware

If there is a configuration in ClxPvxCfg and you

change modes, the configuration is also converted.

Set RSLinx Path

Set or change the path to a QTS-CLX-PVX module

View Menu

Toolbar

Display/hide the toolbar

Status Bar

Display/hide the status bar

Help Menu

Help Topics

Display the help main window

About ClxPvxCfg

Display about box, shows version

Appendix:ClxPvxCfg

ClxPvxCfg is the configuration program for the QTS-CLX-PVX module. It is an offline

configuration program; you must upload or download configuration data.

Summary of Operations

Page 40

Page 34 QTS-CLX-PVX September 2009

Menu Item

Description

Right Click on Module

Edit Module Properties

Change module name

Auto-allocate CLX Addressing

see above

Change Module Mode

see above

Right click on card

Delete Card

Delete a card from the configuration

Also clears all ControlLogix addresses

View Card Properties

Display cofiguration data for a card

Page 41

QTS-CLX-PVX Page 35

Card Type

Value, Hex

Value, Decimal

AIO_CARD_TYPE

0D

13

DIO_CARD_TYPE

0F

15

TPO_CARD_TYPE

11

17

Appendix: Configuration File Format

Configuration files for the QTS-CLX-PVX are text files. The following information is

provided for reference only. It is recommended to use the auto-configuration capabilities

of the gateway, as this reduces the risk of introducing configuration errors through

manually creating or editing configuration files.

The first line of the configuration file consists of:

Number of Cards: 39 Name: D3R_Mas Mode: 54cd3514 Options: 01010101 Cfg

Id: 43960cce

Number of cards = the number of configured card to follow

Name: the module name

Mode = hexadecimal value that indicates whether this is a master or monitor file

(54cd3514 – master, 54cd3512 - monitor)

Options: the starting card in each of the four scan segments

Cfg Id: the hexadecimal configuration ID calculated by ClxPvxCfg.exe.

This is followed by card definitions for each card.

Card definitions

A typical card definition consists of:

Byte Address: 001 Type: 13 State: 9

Priority: 01 CfgMask: ffff IpMask: ffff OpMask: 0000

TokenLst: 2 2 2 2

ChanType: 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14 14

ChanParam: 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Input Copy Table

1 4 32

Output Copy Table

0 0 0

The Byte Address is the address of the card, stored in decimal; however, if you convert it

to hex it is more meaningful: upper nibble = cardfile -1, lower nibble = card number

i.e. decimal 17 = 11 hex = card file 2, card 1

The Type is the base card type.

Supported card types are:

Page 42

Page 36 QTS-CLX-PVX September 2009

Card Type

Value, Hex

Value, Decimal

PCI_CARD_TYPE

16

22

Channel Type

Value, Hex

Value, Decimal

DO_MOMENTARY_TYPE_CODE

04

4

DO_LATCHING_TYPE_CODE

06

6

DI_CHANNEL_TYPE_CODE

05

5

PCI_CHANNEL_TYPE_CODE

16

22

TPO_CONTINUOUS_TYPE_CODE

12

18

TPO_ONESHOT_TYPE_CODE

13

19

AI_CHANNEL_ISO_1TO5

0b

13

AI_CHANNEL_ISO_0TO10

0c

12

AI_CHANNEL_SINGLE_ENDED

0e

14

AI_CHANNEL_LOW_VOLTAGE

10

16

AI_CHANNEL_TYPEJ_LOW

22

34

AI_CHANNEL_TYPEJ_HIGH

23

35

AI_CHANNEL_TYPEK_HIGH

24

36

AI_CHANNEL_TYPEK_LOW

25

37

AI_CHANNEL_TYPE_T

26

38

AI_CHANNEL_TYPE_E

27

39

AI_CHANNEL_TYPE_R

28

40

AI_CHANNEL_LOW_SP1

29

41

AI_CHANNEL_LOW_SP2

2a

42

AI_CHANNEL_TYPE_B

2e

46

AI_CHANNEL_TYPE_S

2f

47

AI_CHANNEL_RTD_270_140

36

54

State is used with card redundancy, which is not supported. Always set the value to 9.

Priority defines the card priority, 1,2 or 4

CfgMask, IpMask and OpMask define which channels are configured, which channels are

inputs and which channels are outputs, respectively.

TokenList gives the card address this card will give the token to (for all 4 scan segments)

ChanType is an array of 16 bytes, one byte per channel starting at channel 1

Possible channel types are:

Page 43

QTS-CLX-PVX Page 37

Channel Type

Value, Hex

Value, Decimal

AI_CHANNEL_RTD_148_212

37

55

AI_CHANNEL_RTD_100_600

38

56

AI_CHANNEL_RTD_32_392

39

57

AI_CHANNEL_RTD_32_1112

3a

58

AI_CHANNEL_RTD_100_500

3b

59

AI_CHANNEL_RTD_32_300

3c

60

AI_CHANNEL_RTD_SPEC

3d

61

AO_CHANNEL_TYPE_CODE

02

2

Area

ControlLogix data area

0

no data mapped

1

input (I.Data[])

2

status (S.Data[])

3

output (O.Data[])

ChanParam is an array of 16 bytes containing any channel parameters

Input Copy Table and Output Copy Table define where the input and output data for the

card are copied to or from in the ControlLogix.

The layout is:

CLX area, CLX Offset (byte offset), Length (bytes)

If you edit the configuration file manually, set the entries for the copy tables to 0 and let

the configuration tool assign ControlLogix addresses.

Page 44

Page 38 QTS-CLX-PVX September 2009

Parameter

Specification

Module Location

ControlLogix chassis

Function

ControlLogix module for PROVOX Control I/O

bus

Maximum Backplane

Current Load

675 mA @ 24VDC and 5 mA @ 5.1VDC

from I/O chassis backplane

Power dissipation

20W maximum

Environmental

Conditions:

Operational

Temperature

0-60°C (32-140°F)

Storage Temperature

–40 to 85°C (–40 to 185°F)

Relative Humidity

5-95% without condensation

Specifications

QTS-CLX-PVX ControlLogix Module

Page 45

QTS-CLX-PVX Page 39

Support

How to Contact Us: Sales and Support

Sales and Technical Support for this product are provided by ProSoft Technology.

Contact our worldwide Sales or Technical Support teams directly by phone or email:

Asia Pacific

+603.7724.2080, asiapc@prosoft-technology.com

Europe – Middle East – Africa

+33 (0) 5.34.36.87.20, Europe@prosoft-technology.com

North America

+1.661.716.5100, support@prosoft-technology.com

Latin America (Sales only)

+1.281.298.9109, latinam@prosoft-technology.com.

Page 46

Page 40 QTS-CLX-PVX September 2009

Warranty

Quest Technical Solutions warrants its products to be free from defects in workmanship

or material under normal use and service for three years after date of shipment. Quest

Technical Solutions will repair or replace without charge any equipment found to be

defective during the warranty period. Final determination of the nature and responsibility

for defective or damaged equipment will be made by Quest Technical Solutions

personnel.

All warranties hereunder are contingent upon proper use in the application for which the

product was intended and do not cover products which have been modified or repaired

without Quest Technical Solutions approval or which have been subjected to accident,

improper maintenance, installation or application, or on which original identification

marks have been removed or altered. This Limited Warranty also will not apply to

interconnecting cables or wires, consumables nor to any damage resulting from battery

leakage.

In all cases Quest Technical Solutions’ responsibility and liability under this warranty

shall be limited to the cost of the equipment. The purchaser must obtain shipping

instructions for the prepaid return of any item under this Warranty provision and

compliance with such instruction shall be a condition of this warranty.

Except for the express warranty stated above Quest Technical Solutions disclaims all

warranties with regard to the products sold hereunder including all implied warranties of

merchantability and fitness and the express warranties stated herein are in lieu of all

obligations or liabilities on the part of Quest Technical Solutions for damages including,

but not limited to, consequential damages arising out of/or in connection with the use or

performance of the Product.

Loading...

Loading...