Page 1

QTS-CLX-APACS

®

APACS

User Manual

IOBUS Module

Page 2

Page ii QTS-CLX-APACS March 2015

Because of the variety of uses for the products described in this publication, those

responsible for the application and use of these products must satisfy themselves that all

necessary steps have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws, regulations, codes

and standards. In no event will Quest Technical Solutions be responsible or liable for

indirect or consequential damage resulting from the use or application of these products.

Any illustrations, charts, sample programs, and layout examples shown in this publication

are intended solely for purposes of example. Since there are many variables and

requirements associated with any particular installation, Quest Technical Solutions does

not assume responsibility or liability (to include intellectual property liability) for actual

use based upon the examples shown in this publication.

Throughout this manual we use notes to make you aware of safety considerations.

Identifies information about practices or circumstances that can lead to

personal injury or death, property damage, or economic loss.

These warnings help to:

WARNING!

IMPORTANT!

TIP

Microsoft is a registered trademark of Microsoft Corporation.

Windows, Windows 95, Windows NT, Windows 2000, Windows XP and Vista are trademarks of Microsoft Corporation.

ControlLogix, RSLinx and RSLogix 5000 are tradema rk s of the Allen-Bradley Company, Inc.

APACS and 4-mation are trademarks of Siemens Moore Process Automation, Inc.

• identify a hazard

• avoid the hazard

• recognize the consequences

Identifies information that is especially important for successful

application and understanding of the product.

Identifies information that explains the best way to use the

QTS-CLX-APACS

Page 3

Page 4

QTS-CLX-APACS MODULE OVERVIEW 1

Part Number 2

Module Features 2

Power Requirements 3

Other Requirements 3

Package Contents 3

INSTALLATION 4

Prevent Electrostatic Discharge 4

Prepare the Chassis for Module Installation 4

Determine Module Slot Location 4

Insert the Module in the Chassis 5

Replacing a Module 6

Cabling and Termination 7

Software Installation 7

CONFIGURING THE MODULE IN RSLOGIX 5000 8

Module Configuration 8

Adding the Module 8

RSLINX 14

MONITOR MODE OPERATION 15

ClxApacsMonCfg Software 15

Exporting a 4-mation database file 16

Configuring the IOBUS 16

Assigning ControlLogix addresses 17

What gets mapped 18

Setting the Module Name 19

Page 5

QTS-CLX-APACS Page iii

Saving a Configuration File 21

Uploading and Downloading Configurations 21

Configuring the QTS-CLX-APACS Module in RSLogix 5000. 22

Aliases 22

Opening a Configuration File 24

Clearing the Configuration 24

Setting the RSLinx Path 24

Changing the Module Mode 24

USING MONITOR MODE FOR MIGRATION 25

MASTER MODE OPERATION 27

ClxApacsMasCfg Software 28

Configuring from an APACS IOBUS 28

Assigning ControlLogix addresses 30

What gets mapped 30

Setting the Module Name 32

Saving a Configuration File 33

Uploading and Downloading Configurations 33

Configuring the QTS-CLX-APACS Module in RSLogix 5000. 34

Aliases 35

Opening a Configuration File 37

Clearing the Configuration 37

Setting the RSLinx Path 37

Changing the Module Mode 37

ACCESSING DATA 38

Required Connections 38

I/O Data 38

Page 6

Page iv QTS-CLX-APACS March 2015

Program/Run 38

Diagnostic Data 38

TROUBLESHOOTING 40

ControlLogix Module LEDs 40

NET LED – IOBUS Status 40

CLX LED – ControlBus Status 40

OK LED – Module Health 41

All LEDs Red 41

QTS-CLX-APACS Module 4-Character Display 41

RSLogix 5000 41

The Debug Log 42

Diagnostic Counters 42

Slot Status Bits 42

Fatal Errors 43

UPDATING THE FIRMWARE 44

SPECIFICATIONS 45

QTS-CLX-APACS ControlLogix Module 45

SUPPORT 46

WARRANTY 47

Page 7

QTS-CLX-APACS Module Overview

The QTS-CLX-APACS connects a ControlLogix controller to an APACS

network.

Use the QTS-CLX-APACS to migrate APACS systems to ControlLogix controllers. You

can retain the APACS I/O as the first step in the migration.

The module acts as either a monitor or as a master on the APACS IOBUS. You select the

mode by downloading different firmware to the module, using the Windows configuration

programs provided.

In monitor mode, the QTS-CLX-APACS sends APACS I/O input and output data to input

data in the ControlLogix. It cannot transm it on the bus.

In master mode, the ControlLogix sends output data to the QTS-CLX-APACS, which then

transmits it as output data on the APACS IOBUS. The QTS-CLX-APACS sends APACS

input data to input data in the ControlLogix.

The QTS-CLX-APACS:

• supports IOBUS cable redundancy

• supports up to the maximum of 39 I/O cards allowed by the APACS IOBUS in a

maximum of 4 MODULRACS

®

IOBUS

The QTS-CLX-APACS communicates with the ControlLogix processor using scheduled

connections. You configure the module in RSLogix 5000 (v19 or greater) with up to:

• 10 I/O connections, 9 for data and 1 for status

Page 8

Page 2 QTS-CLX-APACS March 2015

Each I/O connection supports:

• scheduled input data, 496 SINTs or 124 REALs

• scheduled output data, 496 SINTs or 124 REALs

The Windows configuration programs supplied with the module map IOBUS data to the

scheduled data. They also:

• upload and download configuration data

• map the IOBUS data to ControlLogix scheduled data

• save and open configuration files

• export aliases for use in your RSLogix 5000 application

• change the module mode, between monitor and master modes

Firmware Update

The module firmware can be updated using the Change Module Mode functions in the

Windows utilities supplied (see page 44).

Part Number

The part number of the module is QTS-CLX-APACS.

Module Features

The following figure shows the features of the module.

The module has:

• A label that ident if ies th e m o du le, te x t QTS

Universal Comm

• A 4-character scrolling display

• 3 LEDs, labelled NET, CLX, and OK, to indicate

the status of the I/O bus, the state of the connection

to the ControlLogix processor, and the internal state

of the module

• 2 5-pin Phoenix connectors to connect to the IOBUS

A and IOBUS B bus cables

The module supports insertion and removal under power.

The module is shipped in monitor mode, with a blank configuration.

Page 9

Watchdog and Jabber Inhibit

A watchdog timer is implemented in the module’s hardware. If the firmware does not

kick the watchdog within the timeout period the watchdog times out and generates a fatal

error (see page 43) with error code D1. In master mode, the module stops scanning and

stops communicating with the ControlLogix.

A jabber inhibit timer is implemented in the module’s hardware. If the bus transmitter is

on longer than 150% of the longest frame time, the jabber inhibit forces the transmitter

off and generates a fatal error (see page 43) with error code D0. In master mode, the

module stops scanning and stops communicating with the ControlLogix.

Power Requirements

The QTS-CLX-APACS module requires 5 mA @ 24VDC and 475 mA @ 5.1VDC from

I/O chassis backplane.

Other Requirements

To use the Windows utility programs, you must have RSLinx software, version 2.54 or

later, with an activation. Use RSLinx Gateway or RSLinx Professional software. Do not

use RSLinx Lite.

QTS-CLX-APACS Page 3

Package Contents

• QTS-CLX-APACS module

• CD containing software and documentation

Page 10

Page 4 QTS-CLX-APACS March 2015

Installation

Prevent Electrostatic Discharge

The module is sensitive to electrostatic discharge.

WARNING!

ATTENTION: Electrostatic discharge can damage integrated circuits

or semiconductors if you touch backplane connector pins. Follow these

guidelines when you handle the module:

• Touch a grounded object to discharge static potential

• Wear an approved wrist-strap grounding device

• Do not touch the backplane connector or connector pins

• Do not touch circuit components inside the module

• If available, use a static-safe work station

• When the module is not in use, keep it in its static-shield packaging

Prepare the Chassis for Module Installation

Before you install the ControlLogix module, you must install and connect a ControlLogix

chassis and power supply. To install these products, refer to the installation instructions

you received with them.

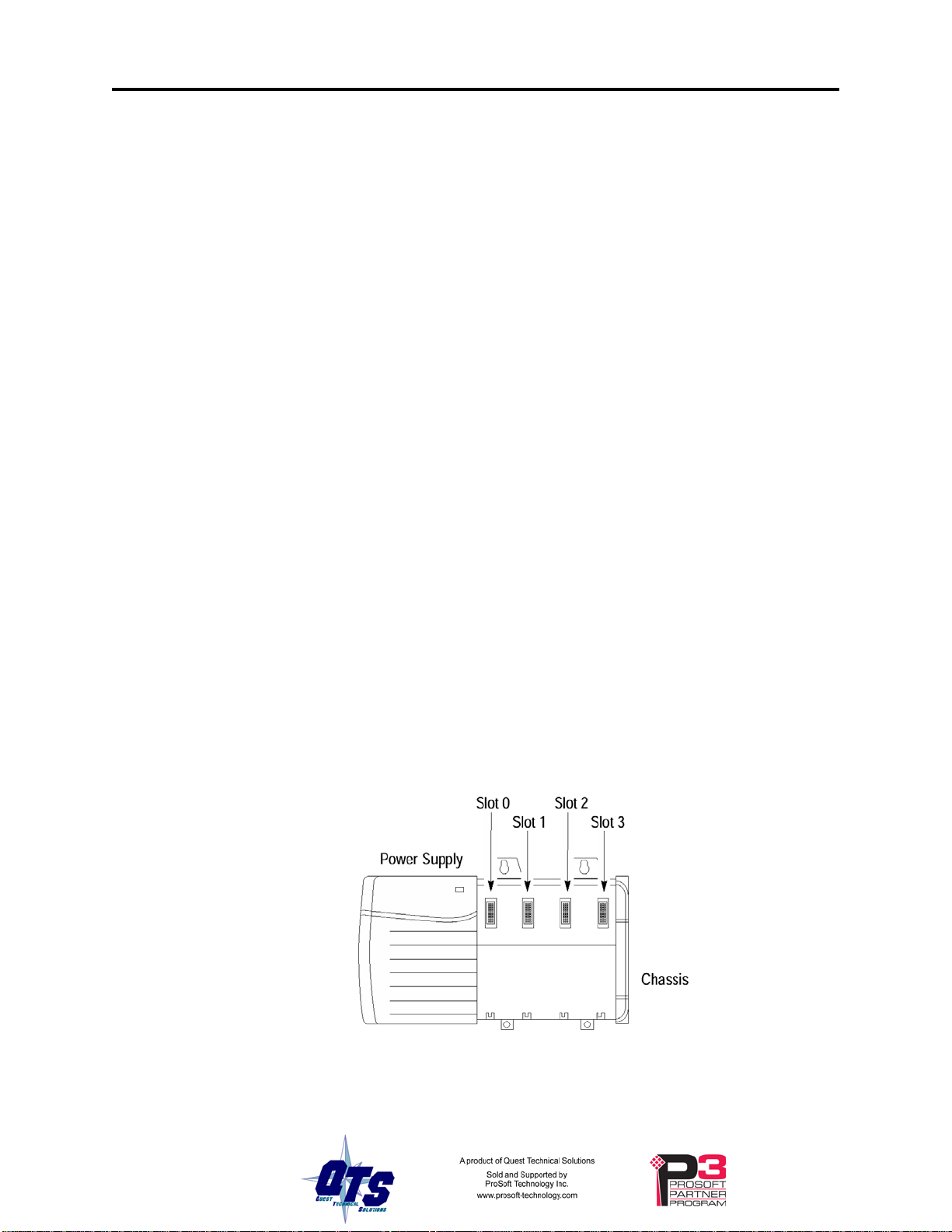

Determine Module Slot Location

This example shows chassis slot numbering in a 4-slot chassis. Slot 0 is the first slot and

is always located to the right of the power supply. You can use any size ControlLogix

chassis and install the module in any slot.

Figure 1 Chassis Slots

Page 11

You can install multiple QTS-CLX-APACS modules in the same chassis.

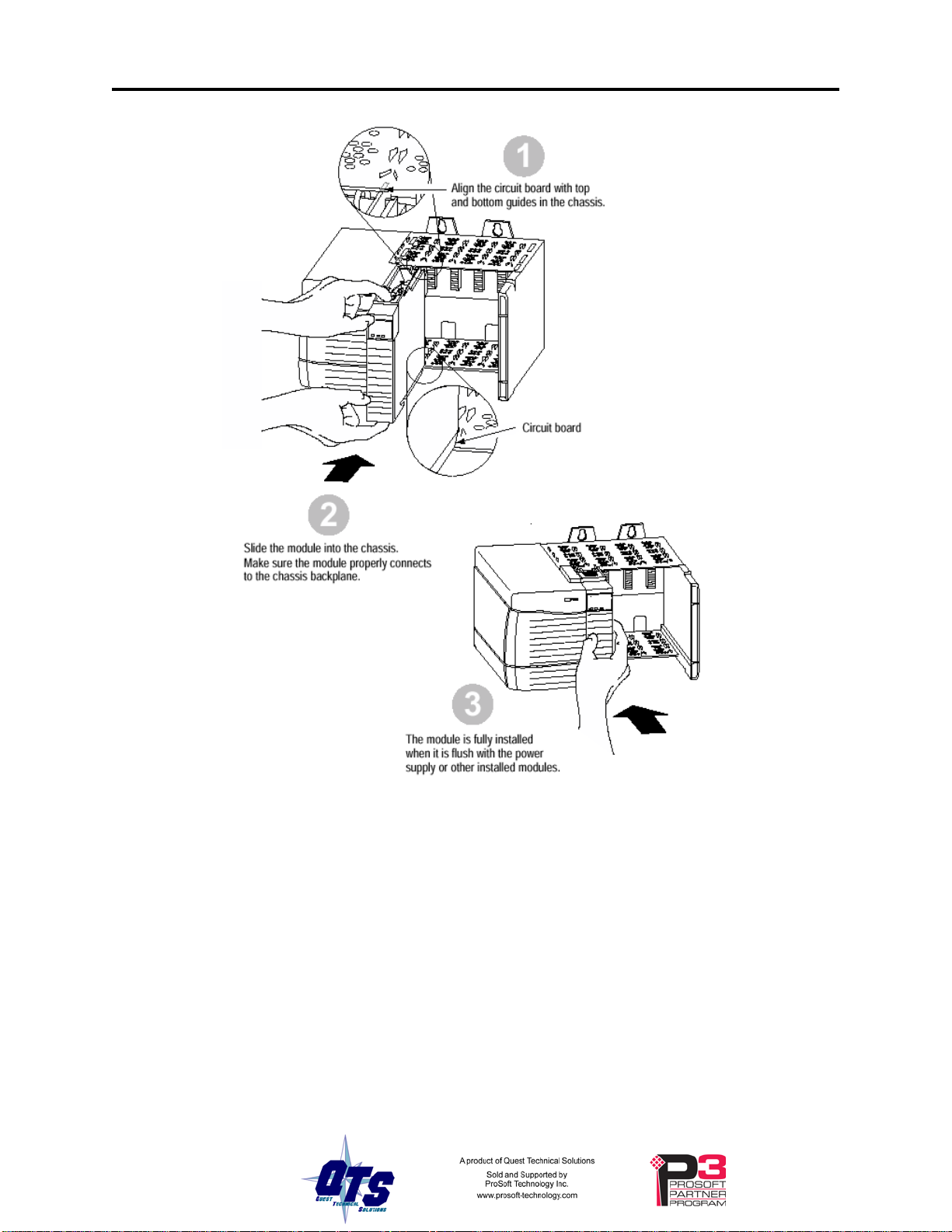

Insert the Module in the Chassis

The ControlLogix module is designed to be installed or removed while chassis power is

applied.

QTS-CLX-APACS Page 5

WARNING!

ATTENTION: When you insert or remove the module while

backplane power is on, an electrical arc can occur. This could cause an

explosion in hazardous location installations. Be sure that power is

removed or the area is nonhazardous before proceeding.

Repeated electrical arcing causes excessive wear to contacts on both the

module and its mating connector. Worn contacts may create electrical

resistance that can affect module operation.

Page 12

Page 6 QTS-CLX-APACS March 2015

Replacing a Module

If you are replacing an existing module with an identical one, and you want to resume

identical system operation, you must:

• install the new module in the same slot.

• run the configuration program and download the appropriate con figura tion to the

module.

• check that it has the correct master or monitor firmware and the correct version.

• ensure that the data has been synchronized

Figure 2 Inserting the Module

Page 13

Cabling and Termination

QTS-CLX-APACS Page 7

WARNING!

Connect the QTS-CLX-APACS like any other IOBUS device.

Refer to the following Siemens document for details on cabling:

Refer to section 2.10.2 of the manual shown above.

Place the QTS-CLX-APA CS module at the beginning or end of the currently installed

MODULRAC racks:

Connecting the module disrupts bus traffic!

Connect the module at a time when it is safe to do so.

• "APACS+ / QUADLOG MODULRAC and Local Termination Panel

Installation and Service Instructions", SD39MODULRAC-1

1. Purchase a Siemens cable that fits the end of the MODULRAC rack that will

be used (left side of first rack or right side of last rack).

2. Cut off the end of the cable that will connect to the QTS-CLX-APACS

module and strip the cabling.

3. Wire the Bus A signals IOBUS (+) to I/O A+, IOBUS (-) to I/O A-, MRET

to MRET and MEN to MEN on the top Phoenix connector.

4. Set the shunt plug on the MODULRAC from terminate to the I/O bus

continue position and place a 120 ohm resistor between I/O A+ and I/O Asignals on the top Phoenix connector.

Repeat steps 1 through 4 for IOBUS B cabling on the bottom Phoenix connector of the

QTS-CLX-APACS module.

Terminate both ends of the IOBUS A and B using termination provided by the

MODULRAC racks or a 120 ohm resistor attached to the physical ends of the bus, if the

QTS-CLX-APACS module is placed at the beginning or end of the bus. There should be

two and only two terminators on each bus.

The cabling is the same for monitor and master modes of the QTS-CLX-APACS.

Software Installation

You must uninstall any previous version of the software before you can install a new

version. Use the Windows Control Panel Add and Remove Programs to remove the old

version.

Insert the CD supplied and run the program QtsApacs_vx.x.exe on the CD to install the

Windows software.

Page 14

Page 8 QTS-CLX-APACS March 2015

Configuring the Module in RSLogix 5000

You configure the module in RSLogix 5000 to set how much scheduled data to transfer

and how often to transfer it.

The terms input and output are relative to the ControlLogix.

In monitor mode, the QTS-CLX-APACS sends APACS IOBUS input and output data to

input data in the ControlLogix. The QTS-CLX-APACS cannot transmit on the bus.

In master mode, the ControlLogix sends output data to the QTS-CLX-APACS, which

then transmits it as output data on the APACS IOBUS. The QTS-CLX-APACS sends

APACS input data to input data in the ControlLogix.

You should always access data using the aliases generated by the configuration programs.

Module Configuration

The ControlLogix configuration may be different for master and monitor modes of the

QTS-CLX-APACS.

The Windows configuration tools show the required connections and minimum

connection sizes.

The QTS-CLX-APACS module supports up to 10 scheduled connections. Connection 9

is reserved for diagnostics.

Discrete data is mapped from connection 0 upwards, analog data is mapped to connection

8 downwards.

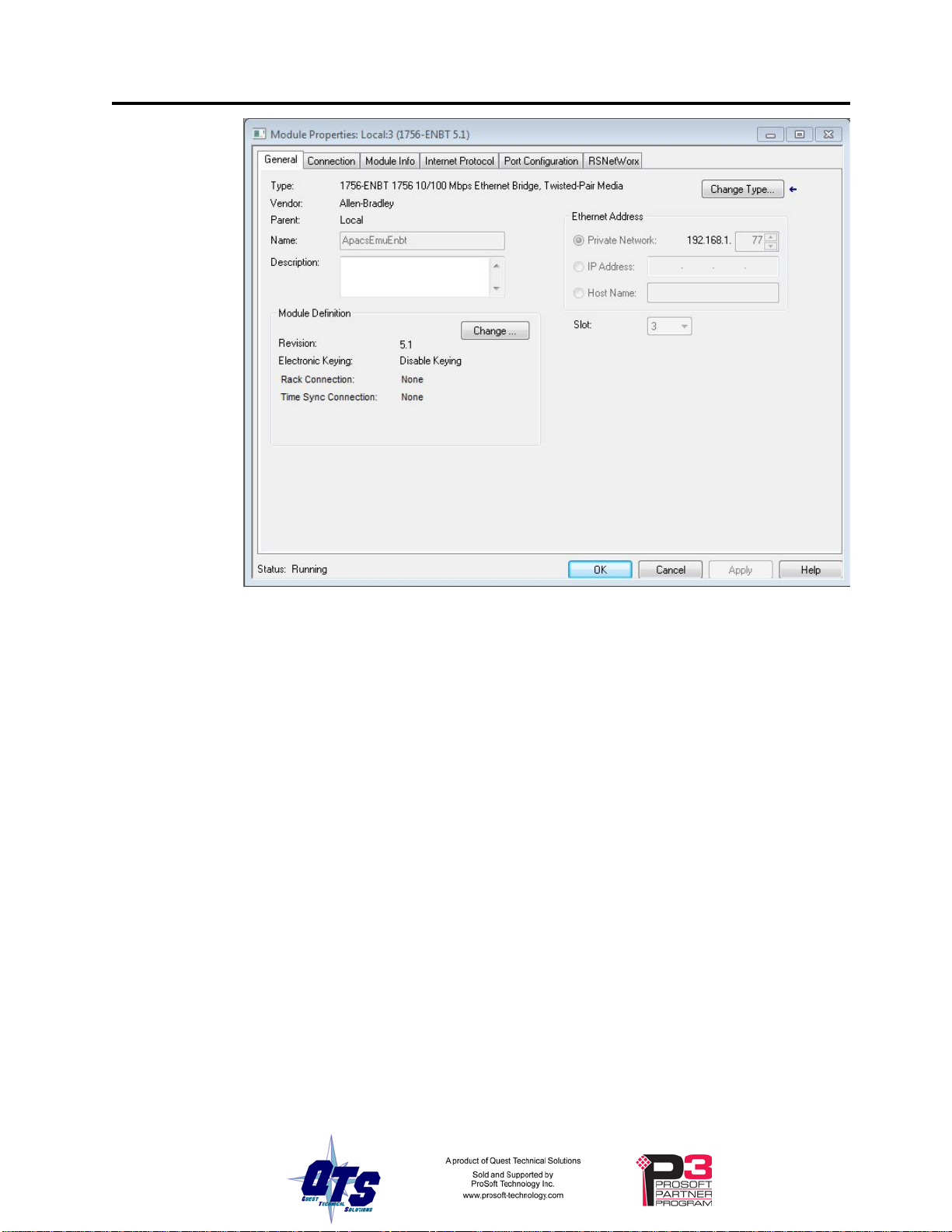

Adding the Module

1. Place an ENBT in the I/O tree.

Disable keying, set the Rack Connection to None, and set the slot to whatever slot the

QTS-CLX-APACS is in.

The IP address doesn't matter, e.g., use Private Network 192.168.1.77

The Name doesn't matter, e.g., use ApacsEmuEnbt

Page 15

QTS-CLX-APACS Page 9

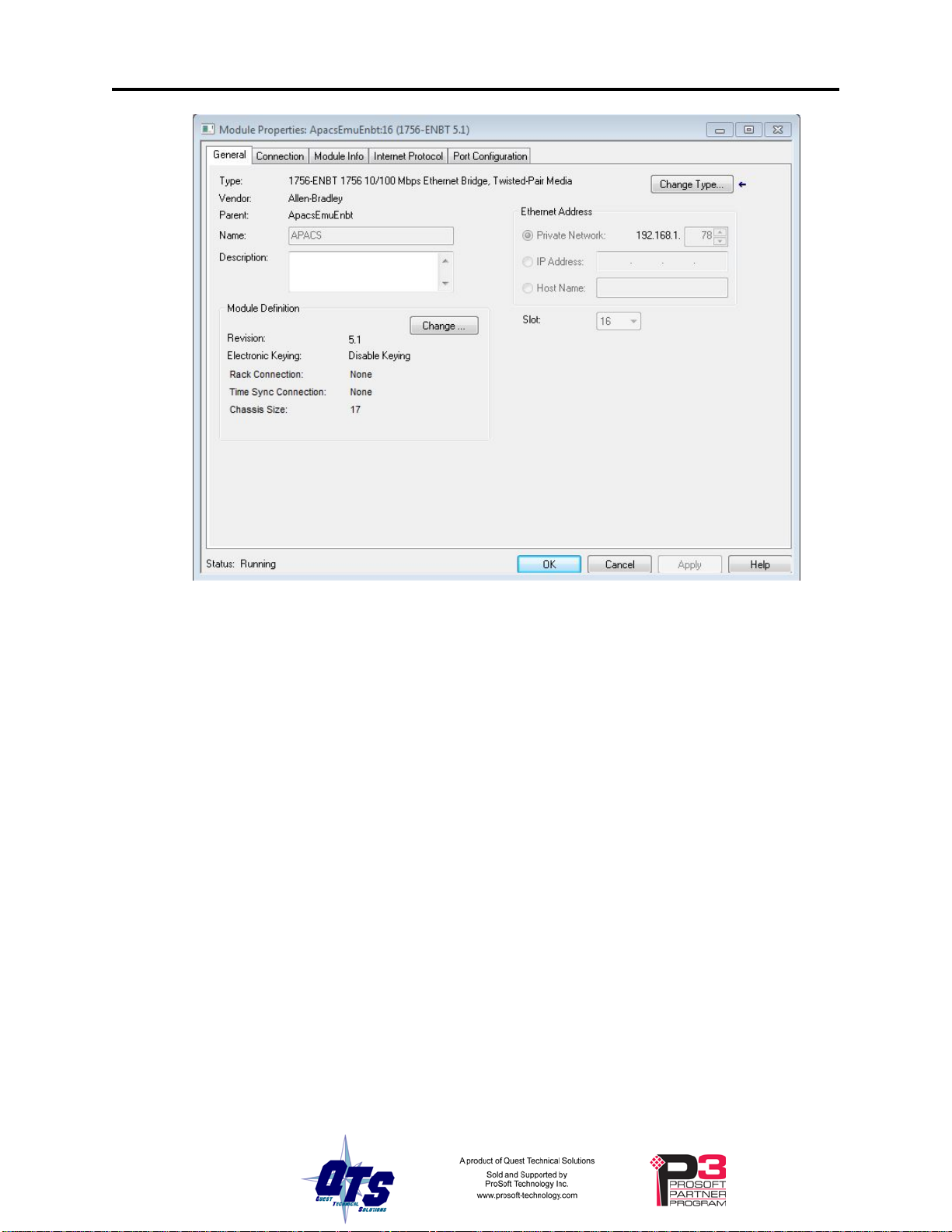

2. Place another ENBT on the Ethernet under the first ENBT.

Disable keying, set the Rack Connection to None, set the slot to 16.

The IP Address doesn't matter, e.g., Private Network 192.168.1.78

Name this ENBT what you want the Controller Tag Name to be, e.g., APACS.

Make this name the same as the name you give the module in the

configuration program (monitor or master).

This name will prefix all aliases.

TIP

This name will appear on the module’s 4-character scrolling display so

you can easily identify it if you have more that one QTS-CLX- APACS

module.

Page 16

Page 10 QTS-CLX-APACS March 2015

3. Place generic 1756-MODULEs in slots 0 to 9, as required.

The configuration programs assign IOBUS data to connections 0 to 8. Discrete inputs and

outputs and module status bytes are mapped to SINT data in connection 0 and up. That

is, if connection 0 is full, the configuration programs start mapping data to connection 1,

and so on.

Analog inputs and outputs are mapped to REAL data in connection 8 and down. That is,

if connection 8 is full, the configuration programs start mapping data to connection 7, and

so on

Diagnostic counters are mapped to INT data in connection 9.

Right click on the backplane associated with the second ENBT and select New Module.

Expand the Other tab, select a module of Type 1756-MODULE Generic 1756 Module

and click OK.

RSLogix 5000 displays the New Module dialog box.

Assign the module a Name and optionally a Description.

Set the Slot to match the connection number

Connection for SINT data

Set the Comm Format to Data – SINT

.

Set the Connection Parameters as shown. The sizes sh own are the maxim um values.

Page 17

QTS-CLX-APACS Page 11

Click OK

Connection for REAL data

Set the Comm Format to Data – REAL

Set the Connection Parameters as shown. The sizes show n are the maxim um values.

Click OK.

Page 18

Page 12 QTS-CLX-APACS March 2015

Connection for Diagnostic Data

Diagnostics are always mapped to connection 9. Connection 9 is not required but we

strongly recommend that you create it.

Set the Comm Format to Data – INT

Set the Connection Parameters as shown.

Do not reduce the connection size for connection 9 from the values shown. In addition to

the diagnostic counters, other undocumented diagnostic information which may be useful

for technical support is also mapped to connection 9.

The sizes of connections 0 to 8 (as needed) can be smaller than the maximum to reduce

traffic in the ControlLogix backplane. Double click on the root of the network tree in the

APACS configuration programs to determine the minimum connection sizes.

RPI

Next, set the RPI for the connection.

Selecting an RPI.

The module supports RPIs from 2.0 to 750.0 ms. The default RPI is 5 ms.

Select an RPI appropriate to the I/O bus scan time and to your process. It makes no sense

to use an RPI that is much faster than the bus or process update time.

You can use different RPIs for each connection, depending on the requirements of your

application.

Page 19

QTS-CLX-APACS Page 13

For example, you can use a longer RPI for the diagnostic data in connection 9, for

example 500 milliseconds, since diagnostics do not need to be updated as frequently as

I/O data.

Remote Connections

If you are using the QTS-CLX-APACS in a remote chassis, for example a chassis

connected to the controlling ControlLogix processor over Ethernet or ControlNet, it may

be necessary to increase the RPI, as the intermediate network may not have sufficient

bandwidth to support faster updates (small RPIs).

Page 20

Page 14 QTS-CLX-APACS March 2015

Parameter

Value

CLX-APACS-MAS (Master)

Vendor

832 (Quest Technical Solutions)

Product Type

12

1061 (Master)

Revision

depends on firmware

Serial Number

depends on module

RSLinx

When you right click on the module in RSLinx and select Properties, RSLinx displays the

following:

Device Name CLX-APACS-MON (Monitor)

Product Code 1062 (Monitor)

RSLinx Properties

To use the Windows utility programs, you must have RSLinx software, version 2.54 or

later, with an activation. Use RSLinx Gateway or RSLinx Professional software. Do not

use RSLinx Lite.

When you create a driver for the configuration programs to access the QTS-CLX-APACS

module, use the Remote Devices via Linx Gateway driver.

Page 21

QTS-CLX-APACS Page 15

Monitor Mode Operation

The following is a short summary of the steps typically followed. Refer to the

appropriate manual section for details.

Step Operation See page

Install the QTS-CLX-APACS module in the

ControlLogix chassis

Connect the module to the APACS IOBUS 7

Export the database from 4-mation software 16

Run the monitor configuration software 15

Import a 4-mation exported object file (obt) 16

Assign ControlLogix addresses to the IOBUS data 17

Set the module name 19

Save the configuration 21

Download the configuration to the module 21

Configure the module in RSLogix 5000 8

Create aliases for RSLogix 5000 22

Import the aliases into RSLogix 5000 23

Use the aliases to access the data 38

ClxApacsMonCfg Software

4

The QTS-CLX-APACS module is supplied with a Windows configuration tool,

ClxApacsMonCfg.exe for using the module as a monitor.

Use this configuration tool to:

• Configure the monitor from a 4-mation software object (obt) file

• Map I/O data to ControlLogix scheduled connections

• Save and load configuration files

• Set the RSLinx path to the QTS-CLX-APACS module

• Download and upload configurations

• Export aliases for I/O data for import into RSLogix 5000

• Switch between monitor and master modes

• Update the module firmware

Page 22

Page 16 QTS-CLX-APACS March 2015

Exporting a 4-mation database fi le

The monitor configuration program uses a database file exported from the Siemens

4-mation Configuration Program.

To export a database file:

1. Go to the Module tree and put your cursor on the ACM

2. Select File/Export/Database…

3. In the Export Options box, check ASCII Format

4. Use the Directories: list to choose the destination

5. Click the Export button

Configuring the IOBUS

Run the monitor configuration tool, ClxApacsMonCfg.exe

Select Tools/Import APACS Configuration and select the 4-mation *.obt file to import.

When the file has been imported, check the module tree and confirm that the APACS

modules are all present and correct.

Page 23

QTS-CLX-APACS Page 17

Double click on each module and confirm that the channel types for that module are all

present and correct.

Assigning ControlLogix a ddresses

Select Tools/Auto-allocate CLX Addressing to map the APACS IOBUS data to

ControlLogix addresses.

The module tree now shows the CLX addresses associated with each APACS module.

Page 24

Page 18 QTS-CLX-APACS March 2015

What gets mapped

I/O Data

APACS IOBUS discrete inputs and outputs are mapped to the input data on ControlLogix

connections from 0 upwards, as required. Discrete input and output data points consist of

a byte of data and are mapped to SINT data in the ControlLogix. The low bit in each

SINT corresponds to the value of the point (0 or 1, False or True).

APACS IOBUS analog inputs and outputs are mapped to the input data on ControlLogix

connections from 8 downward, as required. Analog inputs and outputs are mapped to

REAL data in the ControlLogix.

In addition, each discrete output, analog input and analog output has an associated status

byte. These are also mapped to SINT input da ta in the ControlLogix, in connections 0

and up.

Diagnostic Counters

QTS-CLX-APACS diagnostic counters are integers are mapped to ControlLogix input

data of type INT on connection 9.

Alias Name Offset Description

StatRxGood 0 Good packets received from the network

StatAbortErr 1 Bad packets, abort errors

Page 25

QTS-CLX-APACS Page 19

Alias Name Offset Description

StatBusANoiseErr 2 Bad packets, network noise

StatFrameErr 3 Bad packets, framing errors

StatCrcErr 4 Bad packets, CRC errors

StatProtocolErr 5 Protocol errors

StatRxTimeOut 6 Bad packets, timeout errors

Each alias name is prefixed by the module name and an underscore.

In addition, bit 0 of the first word of output data on connection 9 is used for the command

to clear the diagnostic counters. The alias name is StatResetBit. The counters are cleared

when this bit changes from 0 to 1.

Slot Status Bits

The QTS-CLX-APACS maintains an array of bits that indicate the status of the APACS

modules.

In master mode, the bit is 0 if the module has good communication status and is 1 if the

associated module is in error or is not responding.

Use the slot status bits to determine when you can access data from a module in master

mode. Some APACS modules take several seconds to go online.

In monitor mode, the bits do not update and are always 0. Aliases to the bits are provided

by the configuration tool for compatibility with master mode.

Aliases for these bits have names like

APACS_SlotStatus_R01S04

for the bit associated with the module in rack 1 slot 4.

Use the aliases to access the status bits.

If the ControlLogix loses communication with the QTS-CLX-APACS, it

sets the first four bytes of connection 0 to FF hexadecimal (11111111

TIP

binary).

Monitor these four bytes to determine if there is a problem.

Setting the Module Name

To set the module name, right click on the QTS-CLX-APACS at the root of the tree and

select Edit Module Properties.

Page 26

Page 20 QTS-CLX-APACS March 2015

The QTS-CLX-APACS Module Properties dialog appears.

Enter the Module Name. It can be up to 15 characters long. It should follow the rules for

naming ControlLogix aliases; it should contain only alphanumeric characters and the

underscore. Click OK to accept the name.

The name is displayed on the 4-character disp lay and i s used by ClxApacsMonCfg to

build aliases for ControlLogix data.

The default name assigned when you create a monitor configuration is MonImport.

The name should be unique so that if you have more than one QTS-CLX-APACS

module, the aliases associated with each module are unique.

Page 27

Use the same name that you assign the second ENBT module associated

TIP

with the QTS-CLX-APACS in RSLogix 5000 to make it easy to

associate aliases with the module. See page 9.

Saving a Configuration Fil e

To save a configuration to disk, select File/Save or File/Save As.

Uploading and Downloading Conf igurations

To download a configuration to the QTS-CLX-APACS, select Tools/Download

Configuration or use the Download Configuration to Module button on the toolbar.

To upload a configuration from the QTS-CLX-APACS, select Tools/Upload

Configuration or use the Upload Configuration from Module bu tton on the toolbar. The

uploaded configuration will be given the default file name Untitled.

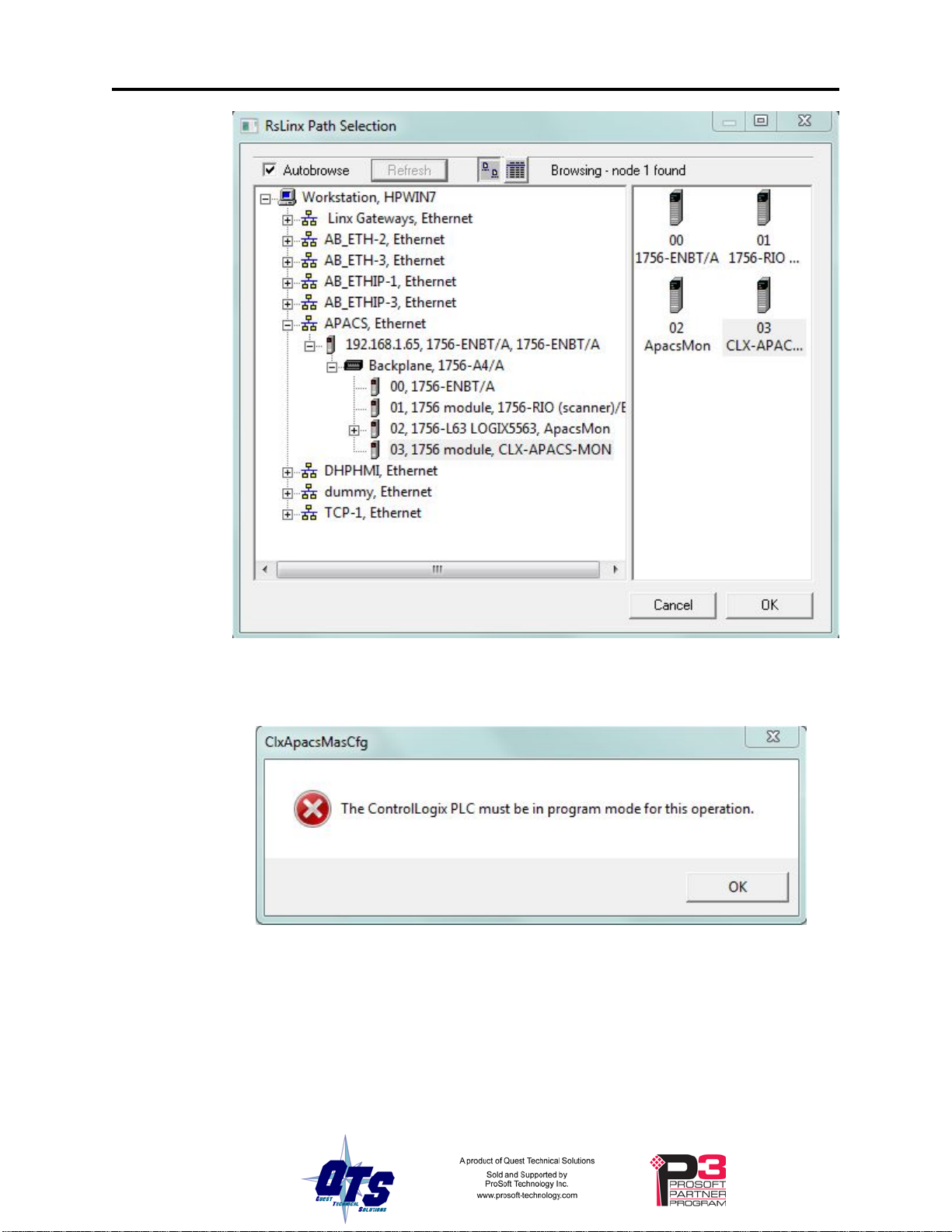

If the RSLinx path to the module has not been set when you upload or download, an

RSLinx Path Selection window opens.

QTS-CLX-APACS Page 21

Page 28

Page 22 QTS-CLX-APACS March 2015

Configuring the QTS-CLX-APACS Module in RSLogix 5000.

Follow the procedure on page 8 to configure the QTS-CLX-APACS in RSLogix 5000.

To determine which connections you need to create, right click on the root of the tree and

select Edit Module Properties.

The QTS-CLX-APACS Module Properties dialog box appears. It shows the required

connections and the minimum connection sizes.

Aliases

In the example shown, the required connections are:

• connection 0 with type SINT, minimum input size 70 and minimum output size 1

• connection 8 with type REAL, minimum input size 39 and minimum output size 1

In addition, connection 9 is always shown, although it is not required. Connection 9 is

used for module diagnostics. It is recommended that you always create connection 9,

with the sizes shown.

In monitor mode, the QTS-CLX-APACS does not wait for all connections to be open.

The configuration tool creates aliases for I/O data that can be exported and imported into

RSLogix 5000.

Write programs using these aliases rather than using absolute addresses. If the mapping

of the I/O data changes, simply reimport the new aliases and the program will point to the

new data locations.

To export aliases, select Files/Export Alias File…

Page 29

QTS-CLX-APACS Page 23

Enter the RSLinx Path Specifier to set the location of the module. This will be the name

of the second ENBT module associated with the QTS-CLX-APACS modules (see page

8). In the example shown, the name is APACS.

Type the FileName or use the Select File Name button to enter the file location where the

exported aliases will be saved.

If you are using monitor mode to develop an application that will be used in master

mode, check the Create Temp Array Alias Tags checkbox. This creates aliases fo r the

internal arrays you will need. Refer to page 25 for details.

Click OK to create the alias file.

WARNING!

Importing Aliases in RSLogix 5000

To import the alias file into RSLogix 5000, you must be offline. Select Tools/Import…

and import the alia s file.

TIP

Alias Format

ClxApacsMonCfg builds each alias name from the Module Name and address

information (Rack, Slot and Channel) supplied by the configuration program

The ControlLogix data address is built from the RSLinx Path Specifier you enter and the

data mappings created by the configuration program.

If you change the I/O or ControlLogix configuration, re-import aliases so

that the ControlLogix processor uses th e corre ct addr es ses and clear the

ControlLogix output table so that values don’t get written to incorrect

addresses.

If you have changed mode on the QTS-CLX-APACS, delete any aliases

you previously imported into RSLogix 5000 before you import the new

aliases.

Example:

ALIAS,"","APACS_AI_R01S06C02","APACS_AI_R01S06C02","","APACS:8:I.Data[1]"

Page 30

Page 24 QTS-CLX-APACS March 2015

In this example, the module is in rack 1slot 6. The alias is for an analog input from

channel 2 on the module, which is mapped to ControlLogix address input data at offset 1

of connection 8.

To build the alias name, ClxApacsMonCfg prefixes the name with the module name and

an underscore. It prefixes the address with the RSLinx path specifier.

Opening a Configuration File

To open a configuration file, select File/Open..

This does not change the configuration in the module; the configuration in the module

changes only when you download.

Clearing the Configuration

To clear the configuration in the program, select File/New.

This does not change the configuration in the module; the configuration in the module

changes only when you download.

Setting the RSLinx Path

Select Tools/Set RSLinx Path… to assign or change the current RSLinx path.

This may be useful if, for example, you have more than one QTS-CLX- APACS module.

Changing the Module Mode

Select Tools/Change Module Mode… to switch a QTS-CLX-APACS module between

monitor and master modes, or to update the module firmware (see page 44)

Select the firmware to download and click Apply. When the download is complete,

ClxApacsMonCfg displays the version of the firmware downloaded.

Page 31

QTS-CLX-APACS Page 25

Using Monitor Mode for Migration

You can use monitor mode on the QTS-CLX-APACS to migrate existing APACS

applications to ControlLogix.

In monitor mode, the QTS-CLX-APAC S captures live inputs and outputs from the

APACS IOBUS.

You first create two arrays in the ControlLogix:

• [Module name]_TempApacsSintOutputArray[8,500] of type SINT

• [Module name]_TempApacsRealOutputArray[8,125] of type REAL

The configuration program creates aliases for IOBUS inputs and outputs and for dummy

outputs in the temporary arrays.

You import those aliases into RSLogix 5000, then create a new ControlLogix application

that reads live inputs from the APACS IOBUS and writes outputs to the temporary

arrays, always using the aliases from ClxApacsMonCfg.

You compare the outputs from the new ControlLogix application (in the temporary array)

with the live outputs fro m IOBUS.

When you are satisfied that the new application duplicates the behaviour of the existing

control application (state of outputs and timing), disconnect the APACS controller and

switch the QTS-CLX-APACS module to master mode.

Export aliases from ClxApacsMasCfg in master mode and import them into RSLogix

5000. The names for the output aliases will be the same as those that previously pointed

to the temporary array but now they will point to the corresponding IOBUS outputs.

Your new ControlLogix application will write to the real outputs instead of the temporary

array. Since you developed your application using these aliases, no further changes

should be necessary.

You will start up with a ControlLogix application that has been tested and proven to

duplicate the behaviour of the previous APACS control application.

Example:

This is the alias ClxApacsMonCfg generated in monitor mode for a monitored discrete

output

ALIAS,"","APACS_DO_R01S04C01","APACS_DO_R01S04C01","","APACS_TempApacsSintOutp

utArray[0,0]"

and this is the alias it generated for the same output in master mod e

ALIAS,"","APACS_DO_R01S04C01","APACS_DO_R01S04C01","","APACS:0:O.Data[0] "

The alias names are the same but in the first case the program wrote to the temporary

SINT array; in the second it wrote to a ControlLogix output.

Similarly for analog outputs, this is the alias ClxApacsMonCfg generated in monitor

mode for a monitored analog output

ALIAS,"","APACS_AO_R01S06C01","APACS_AO_R01S06C01","","APACS_TempApacsRealOutp

utArray[0,0]"

Page 32

Page 26 QTS-CLX-APACS March 2015

and the corresponding alias in master mode

ALIAS,"","APACS_AO_R01S06C01","APACS_AO_R01S06C01","","APACS:8:O.Data[0] "

The alias names are the same but in the first case the program wrote to the temporary

REAL array; in the second it wrote to a ControlLogix output.

Slot Status Bits

In monitor mode, the bits do not update and are always 0. Aliases to the bits are provided

by the configuration tool for compatibility with master mode.

When you develop your control application using monitor mode, include logic that

monitors the slot status bits to determine when you can access I/O data, so that the logic

will be in place when you switch to master mode.

Page 33

WARNING!

The following is a short summary of the steps typically followed. Refer to the

appropriate manual section for details.

QTS-CLX-APACS Page 27

Master Mode Operation

Never connect the APACS in master mode to the network while the

ACM is controlling I/O. It transmits even if there is no configuration

and will disrupt communication.

Step Operation See page

1 Install the QTS-CLX-APACS module in the

ControlLogix chassis

2 Power down all APACS racks.

3 Connect the module to the APACS IOBUS 7

4 Run the QTS-CLX-MAS master configuration

program, ClxApacsMasCfg.exe

5 Temporarily load the monitor firmware on the

QTS-CLX-APACS

6 Clear the stored ACM configuration on the

QTS-CLX-APACS

7 Power up the APACS racks and wait for the OK

LEDs on all modules to be green

8 Read the captured configuration data that the ACM

sent to the modules

9 Check that all modules and channels are correct 28

10 Assign ControlLogix addresses to the IOBUS data 30

11 Set the module name 32

4

28

28

28

28

12 Save the configuration 33

13 Remove the ACM

14 Change the QTS-CLX-APACS to master mode 37

15 Download the configuration to the module 33

16 Configure the module in RSLogix 5000 8

17 Create aliases for RSLogix 5000 35

18 Import the aliases into RSLogix 5000 36

19 Use the aliases to access the data 38

Page 34

Page 28 QTS-CLX-APACS March 2015

ClxApacsMasCfg Software

The QTS-CLX-APACS module is supplied with a Windows configuration tool,

ClxApacsMasCfg.exe for configuring the module as a master.

Use this configuration tool to:

• Switch between monitor and master mode

• Capture IOBUS configuration data from a running network

• Map I/O data to ControlLogix scheduled connections

• Save and load configuration files

• Set the RSLinx path to the QTS-CLX-APACS module

• Download and upload configurations

• Export aliases for I/O data for import into RSLogix 5000

• Update the module firmware

Configuring from an APACS IOBUS

The QTS-CLX-APACS master must be configured by capturing configuration

information sent by an APACS ACM master to a running APACS IOBUS system at

powerup. Power must be cycled to all APACS modules in all APACS racks in the

system. All APACS modules must be present and configured. Check that the OK LEDs

on all modules are green.

WARNING!

Wire the QTS-CLX-APACS as described on page 7. If you have been using monitor

mode, the wiring does not need to be changed.

Power down all APACS racks.

Run the master config tool, ClxApacs Ma sCfg .ex e.

Select Tools/Change Module Mode to temporarily load the monitor firmware.

Select Tools/Clear ACM Config to cl ear any previously stored configuration.

Power up the rack and wait for the OK LEDs on all APACS modules to go green.

Select Tools/ Read ACM Config to build the module tree from the configuration data the

QTS-CLX-APACS has captured..

Connecting the module to the IOBUS disrupts bus traffic!

Connect the module only at a time when it is safe to do so.

Check the module tree and confirm that the APACS modules are all present and correct.

Page 35

QTS-CLX-APACS Page 29

Double click on each module and confirm that the channel types for that module are all

present and correct.

Page 36

Page 30 QTS-CLX-APACS March 2015

Assigning ControlLogix a ddresses

Select Tools/Auto-allocate CLX Addressing to map the APACS IOBUS data to

ControlLogix addresses.

The module tree shows the CLX addresses associated with each APACS module.

What gets mapped

APACS IOBUS discrete inputs are mapped to the input data on ControlLogix

connections from 0 upwards, as required. Discrete outputs are mapped to the output data

on ControlLogix connections from 0 upwards, as required

Discrete input and output data points consist of a byte of data and are mapped to SINT

data in the ControlLogix. The low bit in each SINT corresponds to the value of the point

(0 or 1, False or True).

APACS IOBUS analog inputs are mapped to the input data on ControlLogix connections

from 8 downward, as required. APACS IOBUS analog outputs are mapped to the output

data on ControlLogix connections from 8 downward, as required. Analog inputs and

outputs are mapped to REAL data in the ControlLogix.

In addition, each discrete output, analog input and analog output has an associated status

byte. These are also mapped to SINT input data in the ControlLogix, in connections 0

and up.

Page 37

QTS-CLX-APACS Page 31

Diagnostic Counters

QTS-CLX-APACS diagnostic counters are integers and are mapped to ControlLogix

input data of type INT on connection 9.

Alias Name Offset Description

StatTxGood 0 Good packets transmitted on both channels

StatBusARxGood 1 Good packets received on bus A

StatBusARxTimeOut 2 Receive timeouts on bus A

StatBusAAbortErr 3 Abort errors on bus A

StatBusANoiseErr 4 Noise errors on bus A

StatBusACrcErr 5 CRC errors on bus A

StatBusBRxGood 6 Good packets received on bus B

StatBusBRxTimeOut 7 Receive timeouts on bus B

StatBusBAbortErr 8 Abort errors on bus B

StatBusBNoiseErr 9 Noise errors on bus B

StatBusBCrcErr 10 CRC errors on bus B

StatProtocolErr 11 Protocol errors

The alias names are prefixed with the module name and an underscore.

In addition, bit 0 of the first word of output data on connection 9 is used for the command

to clear the diagnostic counters. The alias name is StatResetBit. The counters are cleared

when this bit changes from 0 to 1.

Slot Status Bits

The QTS-CLX-APACS maintains an array of bits that indicate the status of the APACS

modules.

Use the slot status bits to determine when you can access data from a module. Some

APACS modules take several seconds to go online.

In master mode, the bit is 0 if the module has good communication status and is 1 if the

associated module is in error or is not responding.

In monitor mode, the bits do not update and are always 0. Aliases to the bits are provided

by the configuration tool for compatibility with master mode.

Aliases for these bits have names like

APACS_SlotStatus_R01S04

for the bit associated with the module in rack 1 slot 4.

Use the aliases to access the status bits.

Page 38

Page 32 QTS-CLX-APACS March 2015

If the ControlLogix loses communication with the QTS-CLX-APACS, it

sets the first four bytes of connection 0 to FF hexadecimal (11111111

TIP

binary).

Monitor these four bytes to determine if there is a problem.

Setting the Module Name

To set the module name, right click on the QTS-CLX-APACS at the root of the tree and

select Edit Module Properties.

The QTS-CLX-APACS Module Properties dialog appears.

Page 39

QTS-CLX-APACS Page 33

Enter the Module Name. It can be up to 15 characters long. It should follow the rules for

naming ControlLogix aliases; it should contain only alphanumeric characters and the

underscore. Click OK to accept the name.

The name is displayed on the 4-character display and is used by ClxApacsMasCfg to

build aliases for ControlLogix data.

The default name assigned when you create a monitor configuration is HeardCfg.

The name should be unique so that if you have more than one QTS-CLX-APACS

module, the aliases associated with each module are unique.

Use the same name that you assign the second ENBT module associated

TIP

with the QTS-CLX-APACS in RSLogix 5000 to make it easy to

associate aliases with the module. See page 9.

Saving a Configuration Fil e

To save a configuration to disk, select File/Save or File/Save As.

Uploading and Downloading Conf igurations

To download a configuration to the QTS-CLX-APACS, select Tools/Download Config or

use the Download Config to Module button on the toolbar.

To upload a configuration from the QTS-CLX-APACS, select Tools/Upload Config or

use the Upload Config from Module button on the toolbar.

If the RSLinx path to the module has not been set when you upload or download, an

RSLinx Path Selection window opens.

Page 40

Page 34 QTS-CLX-APACS March 2015

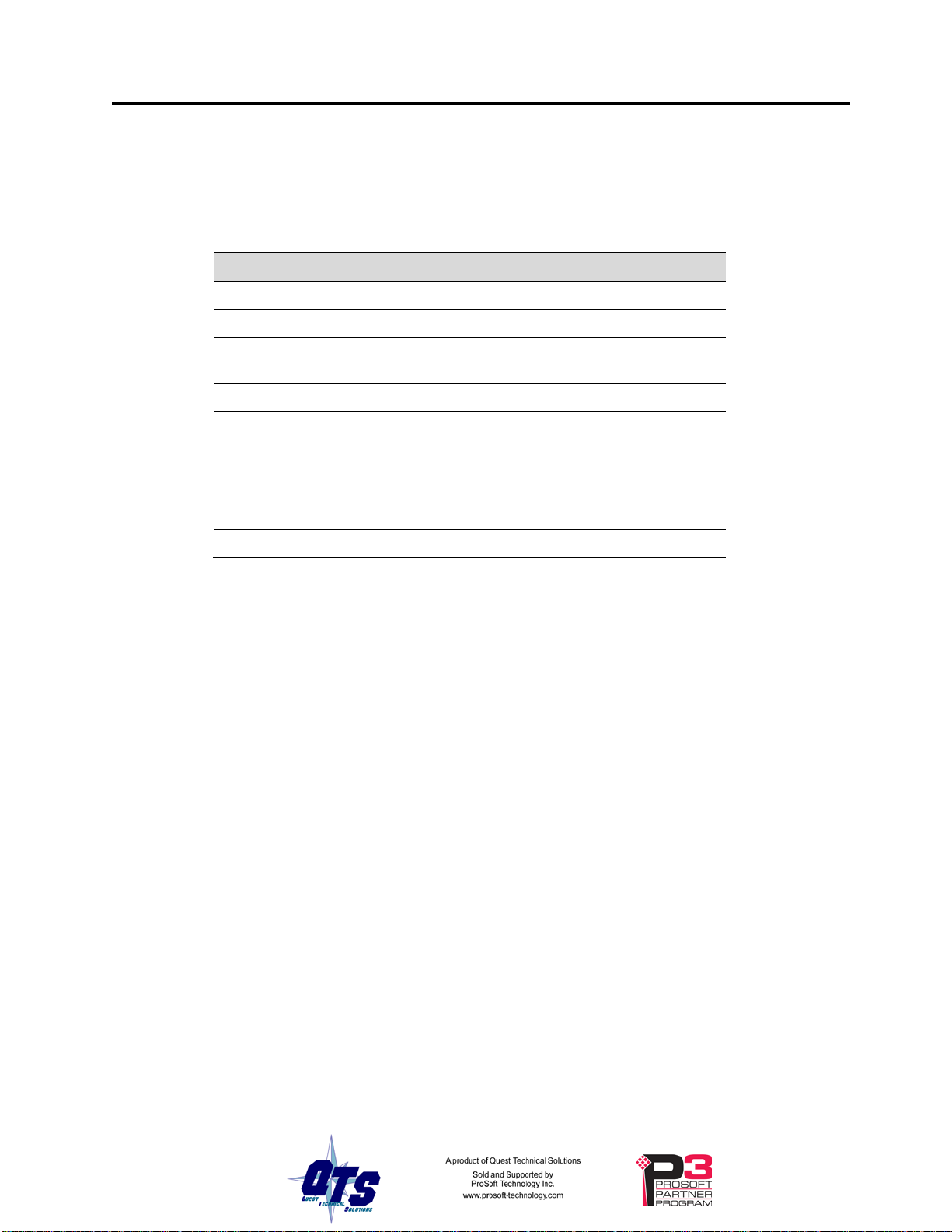

If the ControlLogix processor with the connection to the QTS-CLX-APACS is in run

mode when you download, the following message is displayed.

Configuring the QTS-CLX-APACS Module in RSLogix 5000.

Follow the procedure on page 9 to configure the QTS-CLX-APACS in RSLogix 5000.

To determine which connections you need to create, right click on the root of the tree and

select Edit Module Properties.

Page 41

QTS-CLX-APACS Page 35

The QTS-CLX-APACS Module Properties dialog box appears. It shows the required

connections and the minimum connection sizes.

Aliases

In the example shown, the required connections are:

• connection 0 with type SINT, minimum input size 60 and minimum output size 9

• connection 8 with type REAL, minimum input size 37 and minimum output size 1

In addition, connection 9 is always shown, although it is not required. Connection 9 is

used for module diagnostics. It is recommended that you always create connection 9,

with the sizes shown.

The configuration tool creates aliases for I/O data that can be exported and imported into

RSLogix 5000.

Write programs using these aliases rather than using absolute addresses. If the mapping

of the I/O data changes, simply reimport the new aliases and the program will point to the

new data locations.

To export aliases, select Files/Export Alias File…

Page 42

Page 36 QTS-CLX-APACS March 2015

Enter the RSLinx Path Specifier to set the location of the module. This will be the name

of the second ENBT module associated with the QTS-CLX-APACS modules (see page

9). In the example shown, the name is APACS.

Type the FileName or use the Select File Name button to enter the file location where the

exported aliases will be saved.

Click OK to create the alias file.

If you change the I/O or ControlLogix configuration, re-import aliases so

WARNING!

that the ControlLogix processor uses th e corre ct addr es ses and clear the

ControlLogix output table so that values don’t get written to incorrect

addresses.

Importing Aliases in RSLogix 5000

To import the alias file into RSLogix 5000, you must be offline. Select Tools/Import…

and import the alia s file.

If you have changed mode on the QTS-CLX-APACS, delete any aliases

TIP

you previously imported into RSLogix 5000 before you import the new

aliases.

Alias Format

ClxApacsMasCfg builds each alias name from the Module name and address information

(Rack, Slot and Channel) supplied by the configuration program

The ControlLogix data address is built from the RSLinx Path Specifier you enter and the

data mappings created by the configuration program.

To build the alias name, ClxApacsMasCfg prefixes the name with the module name and

an underscore. It prefixes the ControlLogix address with the RSLinx specifier you

supply.

Examples:

ALIAS,"","APACS_DO_R01S04C05","APACS_DO_R01S04C05","","APACS:0:O.Data[1] "

In this example, the alias is for a discrete output on channel 5 of the module in rack 1 slot

4, which is mapped to ControlLogix address output data at offset 1 of connection 0. The

module name is APACS, as is the RSLinx path.

ALIAS,"","APACS_DI_R01S05C01","APACS_DI_R01S05C01","","APACS:0:I.Data[18]"

In this example, the alias is for a discrete input on channel 1 of the module in rack 1 slot

5, which is mapped to ControlLogix address input data at offset 18 of connection 0.

ALIAS,"","APACS_AI_R01S06C03","APACS_AI_R01S06C03","","APACS:8:I.Data[2]"

In this example, the alias is for an analog input on channel 3 of the module in rack 1 slot

6, which is mapped to ControlLogix address input data at offset 2 of connection 8.

ALIAS,"","APACS_AO_R01S06C01","APACS_AO_R01S06C01","","APACS :8:O.Data[0] "

Page 43

In this example, the alias is for an analog output on channel 1 of the module in rack 1 slot

6, which is mapped to ControlLogix address output data at offset 0 of connection 8.

Opening a Configuration File

To open a configuration file, select File/Open..

This does not change the configuration in the module; the configuration in the module

changes only when you download.

Clearing the Configurat ion

To clear the configuration in the program, select File/New.

This does not change the configuration in the module; the configuration in the module

changes only when you download.

Setting the RSLinx Path

QTS-CLX-APACS Page 37

Select Tools/Set RSLinx Path… to assign or change the current RSLinx path.

This may be useful if, for example, you have more than one QTS-CLX- APACS module.

Changing the Module Mode

Select Tools/Change Module Mode… to switch a QTS-CLX-APACS module between

monitor and master modes, or to update the module firmware (see page 44).

Select the firmware to download and click Apply. When the download is complete,

ClxApacsMasCfg displays the version of the firmware downloaded.

Page 44

Page 38 QTS-CLX-APACS March 2015

Accessing Data

Required Connections

In master mode, the QTS-CLX-APACS does not begin scanning the I/O bus until all

ControlLogix connections to the module are present.

In monitor mode, the module does not wait for the ControlLogix connections.

I/O Data

Use the aliases created by ClxApacsMonCfg or ClxApacsMasCfg to access data to

ensure that you are using the correct address.

Each discrete point is mapped to a SINT in the ControlLogix. The data value is the low

bit in the SINT. Use the low bit of the Alias to read or change the data value.

Each analog point is mapped to a REAL in the ControlLogix.

Program/Run

In master mode, the QTS-CLX-APACS does not scan I/O in program mode.

Diagnostic Data

The QTS-CLX-APACS maintains diagnostic counters and other diagnostic status

information.

SlotStatus Bits

The QTS-CLX-APACS maintains an array of bits that indicate the status of the APACS

modules.

Use the slot status bits to determine when you can access data from a module. Some

APACS modules take several seconds to go online.

In master mode, the bit is 0 if the module has good communication status and is 1 if the

associated module is in error or is not responding.

Page 45

QTS-CLX-APACS Page 39

In monitor mode, the bits do not update and are always 0. Aliases to the bits are provided

by the configuration tool for compatibility with master mode.

Aliases for these bits have names like

APACS_SlotStatus_R01S04

for the bit associated with the module in rack 1 slot 4.

Use the aliases to access the status bits.

If the ControlLogix loses communication with the QTS-CLX-APACS, it

sets the first four bytes of connection 0 to FF hexadecimal (11111111

TIP

binary).

Monitor these four bytes to determine if there is a problem.

Diagnostic Counters

Refer to page 18 for details about monitor mode diagnostic counters.

Refer to page 31 for details about master mode diagnostic counters.

Page 46

Page 40 QTS-CLX-APACS March 2015

Troubleshooting

ControlLogix Module LEDs

The module has three status LEDs to indicate the state of inte rn a l ope rations. The LED s

are labeled NET, CLX and OK.

NET LED – IOBUS Status

The NET LED shows the status of I/O communication.

Monitor Mode

Color Meaning

Red Bad frame received

Green Receiving good frames

Off Idle

Master Mode

Color Meaning

Red Cable A error

Yellow Cable B error

Green Receiving good frames

Flashing One or more APACS modules offline

Off Idle, not trying to talk to APACS modules

CLX LED – ControlBus Status

The CLX LED indicates the status of communication with the ControlLogix processor.

Color Meaning

Green All required connections are open

Flashing

Green/Off

Not all required connections are open (master mode)

Yellow Connection 0 not open (master mode)

Page 47

OK LED – Module Health

The OK LED indicates module health. A red LED indicates that module startup

diagnostics have failed or a major module fault has occurred. Green indicates that the

module has passed all power-up diagnostics and is functioning normally.

All LEDs Red

If all three LEDs are solid red and the 4-character display shows something like M#66,

this indicates that a fatal error has occurred. Refer to page 43 for information on clearing

fatal errors. If a fatal error occurs, clear the fatal error, save the file and contact

Technical Support.

QTS-CLX-APACS Module 4-Character Display

The 4-character display shows the firmware in the module, either APACS-MON or

APACS-MAS, followed by the firmware version number, and the Module Name you

entered in the module configuration.

If there is no configuration in the module, the display shows <NoConfig> instead of the

module name.

QTS-CLX-APACS Page 41

RSLogix 5000

If there is a problem with the connection to the module, the connections are shown with

yellow triangles in the I/O Configuration tree

The Connection tab for each connection to the QTS-CLX-APACS module displays an

error message if there is a problem with the connection to the module.

Page 48

Page 42 QTS-CLX-APACS March 2015

If the module has no configuration, it refuses connection requests from the ControlLogix

processor and returns an error.

The Debug Log

The firmware on the module maintains a log of informational and diagnostic messages

that can be useful in determining the cause of configuration and I/O bus problems.

To view the log, run the program LogMon from the Start Menu.

Diagnostic Counters

Refer to page 18 for details about monitor mode diagnostic counters.

Refer to page 31 for details about master mode diagnostic counters.

Slot Status Bits

The QTS-CLX-APACS maintains an array of bits that indicate the status of the APACS

modules.

Use the slot status bits to determine when you can access data from a module. Some

APACS modules take several seconds to go online.

In master mode, the bit is 0 if the module has good communication status and is 1 if the

associated module is in error or is not responding.

In monitor mode, the bits do not update and are always 0. Aliases to the bits are provided

by the configuration tool for compatibility with master mode.

Aliases for these bits have names like

APACS_SlotStatus_R01S04

Page 49

for the bit associated with the module in rack 1 slot 4.

Use the aliases to access the status bits.

TIP

Fatal Errors

Fatal errors occur when the firmware on the module encounters an unexpected condition.

The module stops running, turns all three LEDs red, and displays the fatal error number

on the 4-character display. The module also records its state at the time the fatal error

occurred in a log.

To clear the fatal error and capture the fatal error log:

QTS-CLX-APACS Page 43

If the ControlLogix loses communication with the QTS-CLX-APACS, it

sets the first four bytes of connection 0 to FF hexadecimal (11111111

binary).

Monitor these four bytes to determine if there is a problem.

1. Cycle power on the module. The 4-character display should show

“FatalErrorCapture requi re d”.

2. Run the utility FatalCapt.exe from the subdirectory Tools where you installed

the configuration tool.

3. Store the fatal error log to a file. This also clears the fatal error on the

module.

Contact technical support. Provide them with the fatal error log, which will help

diagnose the cause of the problem.

Page 50

Page 44 QTS-CLX-APACS March 2015

Updating the Firmware

The module firmware is updated using either of the two configura tion program s.

Copy the new firmware file to the same directory as ClxApacsMonCfg.exe or

ClxApacsMasCfg.exe.

Select Tools/Set Module Mode.

To update the firmware, set the mode to match the firmware already loaded in the

module.

The configuration program displays the version after the firmware has been downloaded.

The QTS-CLX-APACS module displays the firmware and version currently loaded on

the 4-character display.

Page 51

QTS-CLX-APACS ControlLogix Module

Parameter Specification

Module Location ControlLogix chassis

Function ControlLogix module for APACS IOBUS

QTS-CLX-APACS Page 45

Specifications

Maximum Backplane

Current Load

Power dissipation 2.5W maximum

Environmental

Conditions:

Operational

Temperature

Storage Temperature –40 to 85°C (–40 to 185°F)

Relative Humidity 5-95% without condensation

5 mA @ 24VDC and 475 mA @ 5.1VDC

from I/O chassis backplane

0-60°C (32-140°F)

Page 52

Page 46 QTS-CLX-APACS March 2015

Support

How to Contact Us: Sales and Support

Sales and Technical Support for this product are provided by ProSoft Technology.

Contact our worldwide Sales or Technical Support teams directly by phone or email:

Asia Pacific

+603.7724.2080, asiapc@prosoft-technology.com

Europe – Middle East – Africa

+33 (0) 5.34.36.87.20, Europe@prosoft-technology.com

North America

+1.661.716.5100, support@prosoft-technology.com

Latin America (Sales only)

+1.281.298.9109, latinam@prosoft-technology.com

.

Page 53

QTS-CLX-APACS Page 47

Warranty

Quest Technical Solutions warrants its products to be free from defects in workmanship

or material under normal use and service for three years after date of shipment. Quest

Technical Solutions will repair or replace without charge any equipment found to be

defective during the warranty period. Final determination of the nature and responsibility

for defective or damaged equipment will be made by Quest Technical Solutions

personnel.

All warranties hereunder are contingent upon proper use in the application for which the

product was intended and do not cover products which have been modified or repaired

without Quest Technical Solutions approval or which have been subjected to accident,

improper maintenance, installation or application, or on which original identification

marks have been removed or altered. This Limited Warranty also will not apply to

interconnecting cables or wires, consumables nor to any damage resulting from battery

leakage.

In all cases Quest Technical Solutions’ responsibility and liability under this warranty

shall be limited to the cost of the equipment. The purchaser must obtain shipping

instructions for the prepaid return of any item under this Warranty provision and

compliance with such instruction shall be a condition of this warranty.

Except for the express warranty stated above Quest Technical Solutions disclaims all

warranties with regard to the products sold hereunder including all implied warranties of

merchantability and fitness and the express warranties stated herein are in lieu of all

obligations or liabilities on the part of Quest Technical Solutions for damages including,

but not limited to, consequential damages arising out of/or in connection with the use or

performance of the Product.

Loading...

Loading...