Page 1

Wireless I/O System

April 20, 2015

USER GUIDE

Page 2

Page 3

User Guide

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions,

comments, compliments or complaints about our products, documentation, or support, please write or call us.

How to Contact Us

ProSoft Technology

5201 Truxtun Ave, 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

http://www.prosoft-technology.com

support@prosoft-technology.com

Copyright © 2015 ProSoft Technology, Inc. All rights reserved.

Wireless I/O System User Guide

April 20, 2015

ProSoft Technology® Product Documentation

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product

shipments. User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided on the

enclosed DVD in Adobe® Acrobat Reader file format (.PDFs). These product documentation files may also be

freely downloaded from our web site: www.prosoft-technology.com

ProSoft Technology, Inc. Page 3 of 48

April 20, 2015

Page 4

Wireless I/O System User Manual

Page 4 of 48 ProSoft Technology, Inc.

April 20, 2015

Page 5

Wireless I/O System User Manual

Contents

Your Feedback Please ........................................................................................................................ 3

How to Contact Us .............................................................................................................................. 3

ProSoft Technology® Product Documentation .................................................................................... 3

1 Preface 7

1.1 Compliances .............................................................................................................. 8

2 System Overview 11

2.1 Highlights ................................................................................................................. 11

2.2 Ease of Use ............................................................................................................. 12

2.3 Faster Deployment and Less Maintenance............................................................. 12

2.4 Faster, Smarter, Secure, Failsafe ........................................................................... 12

2.5 Customer, Scalable I/O Expansion ......................................................................... 12

2.6 Advanced Features ................................................................................................. 13

2.7 Hardware ................................................................................................................. 14

3 Specifications 15

3.1 Hardware and System ............................................................................................. 15

3.2 Safety and Compliance ........................................................................................... 15

3.3 Radio Module .......................................................................................................... 16

3.4 Digital I/O Module .................................................................................................... 17

3.5 4-20 mA I/O Module ................................................................................................ 17

3.6 0-10 V I/O Module ................................................................................................... 18

3.7 Ordering Information ............................................................................................... 18

4 Installation 19

4.1 Outdoor Enclosure Installation ................................................................................ 19

4.2 Wireless I/O System Assembly (attach from left to right) ........................................ 20

4.3 Detaching Components from the DataRail .............................................................. 24

5 Radio Setup 25

6 Signal Chain Diagram 27

7 Wiring Diagrams 29

7.1 Radio Module (BM-0900-RM1 Shown) ................................................................... 29

7.2 Digital Module (BM-D100-144 Shown) .................................................................... 30

7.3 Analog 4-20 mA Module (BM-A420-122 Shown) .................................................... 31

7.4 Analog 0-10 V Module (BM-A010-122 Shown) ....................................................... 32

8 Diagnostics 33

8.1 Radio Module .......................................................................................................... 33

ProSoft Technology, Inc. Page 5 of 48

April 20, 2015

Page 6

Wireless I/O System User Manual

9 Advanced User Interface for PC 35

9.1 Download and Install Software ............................................................................... 35

9.2 Connect USB to Mini USB Cable (Included with Radio Kit) ................................... 36

9.3 View of Graphic User Interface (GUI) ..................................................................... 37

9.4 Main Window Guide ................................................................................................ 38

9.5 Additional Diagnostics ............................................................................................ 39

9.6 Digital Module Window Guide ................................................................................. 40

9.7 4-20 mA Module Window Guide ............................................................................. 41

9.8 0-10 V Module Window Guide ................................................................................ 42

10 Frequently Asked Questions 43

11 Support, Service & Warranty 47

11.1 Warranty Information .............................................................................................. 48

Page 6 of 48 ProSoft Technology, Inc.

April 20, 2015

Page 7

Preface

1 Preface

Thank you for choosing the Wireless I/O System - an intelligent, bi-directional

wireless I/O mirroring solution that is ideal for replacing hardwire and conduit or

for implementing it into new infrastructures. The Wireless I/O System requires no

software or programming and is extremely easy to install and use. It’s the easiest

way from point A to point B, and back.

This document is designed to guide you through setting up the system by

familiarizing you with the hardware, installation, wiring, and overall system

management. This guide also provides how to use the Wireless I/O System’s

Advanced User Interface.

If you have any questions about this product, please call or email:

ProSoft Technology

5201 Truxtun Ave, 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

http://www.prosoft-technology.com

support@prosoft-technology.com

Warning: Ensure the installation of the system meets applicable state and national electrical code

requirements. The installation of the system should only be performed by a qualified installer or a

factory representative.

Warning: To prevent ignition of flammable or combustible atmospheres, disconnect power before

servicing.

Warning: Power must be disconnected or turned off prior to attaching or removing any I/O

Modules from the system – failure to comply may cause damage to the I/O Module(s).

ProSoft Technology, Inc. Page 7 of 48

April 21, 2015

Page 8

Preface

1.1 Compliances

This device MUST be professionally installed by a factory representative or a

trained authorized technician.

Changes or modifications not expressly approved by the manufacturer may

void the user’s authority to operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the

following two conditions: 1) this device may not cause harmful interference,

and 2) this device must accept any interference received, including interference

that may cause undesired operation.

To reduce potential radio interference to other users, install and use only the

antenna supplied by the manufacturer to ensure successful communications.

FCC RF Exposure

To comply with FCC RF exposure compliance requirements, a separation

distance of at least 20 cm must be maintained between the antenna of this

device and all persons.

FCC Interfere

This equipment has been tested and found to comply with the limits for a class B

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio frequency

energy and if not installed and used in accordance with the instructions, may

cause harmful communications to radio communications. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television reception, which

can be determined by turning the equipment off and on, the user is encouraged

to try to correct the interference by one of the following measures:

Page 8 of 48 ProSoft Technology, Inc.

April 21, 2015

Page 9

Preface

Reorient or relocate the antenna.

Increase the separation between the equipment and receiver.

Consult the manufacturer for technical help.

This equipment has been certified to comply with the limits for a class B

computing device, pursuant to FCC Rules. In order to maintain compliance with

FCC regulations, shielded cables must be used with this equipment. Operation

with non-approved equipment or use of unshielded cables is likely to result in

interference to radio and television reception. The user is cautioned that changes

or modifications made to the equipment without the approval of the manufacturer

could void the user’s authority to operate this equipment.

ProSoft Technology, Inc. Page 9 of 48

April 21, 2015

Page 10

Page 11

System Overview

2 System Overview

2.1 Highlights

Wireless hardwire replicator / rapid reliable wireless connectivity.

Save money and time: Wireless I/O System eliminates trenching and running

conduit / deploys in minutes.

Easy to use: no software configuration needed.

Easy to install: mounts onto a 35 mm DIN rail without any tools.

Flexible: place inputs and output on both ends of radio.

Customize I/O using Digital, 0-10 V, and/or 4-20 mA options.

Isolated: each Module provides field isolated inputs and outputs.

24-bit high-resolution Analog inputs.

Fast response time: 1 second default / turbo-mode up to 100 ms depending on

number of connection I/O Modules.

RF and I/O fail detection: NPN outputs on Radio Modules.

Secure: factory paired, secure Radio System (128-bit AES) keeps network protected

Less wire clutter: single power termination per station.

Wiring label on each device for quick reference.

Color-coded labels for easy device identification.

FailSafe: user can defines how outputs are failed over when RF or I/O

communication is ever lost.

FailSafe output modes:

Digital: On, off, last known value (default)

Analog: Any value on scale (Advanced UI required), last known value (default)

Provides manual FailSafe override function via dry contact input on Radio Module.

Wireless I/O System can support multiple I/O Modules.

System can support up to sixteen (16) Digital Modules max.

System can support up to eight (8) 0-10 V Modules max.

System can support up to five (5) 4-20 mA Modules max.

Warning: When adding more than five (5) I/O Modules and creating different I/O Module

combination, please determine maximum allowable I/O Module combination per system by utilizing

the power budget calculator. See http://psft.com/A5D

ProSoft Technology, Inc. Page 11 of 48

April 21, 2015

Page 12

System Overview

2.2 Ease of Use

When faced with having to replace an existing hardwired system or installing new

infrastructure, the Wireless I/O System is the fastest, easiest, and most

economical methods for wirelessly duplicating discrete, 4-20mA, or 0-10V signal

wire. All I/O Modules feature isolated inputs and outputs. The Wireless I/O

System requires no configuration or software and is extremely quick and easy to

install. The Wireless I/O System mounts to 35 mm DIN rail. Then, you just need a

screwdriver and a wire stripper to terminate input, outputs, and power.

2.3 Faster Deployment and Less Maintenance

Significant amount of time and money can be saved by avoiding permitting and

trenching to run wires. Because deployment time is so rapid using the Wireless

I/O System, you can even use it as an emergency backup system when a

hardwired system is down for repair or maintenance. And by removing the

hardwire run, it also eliminates the potential cost for future wire failure

replacement and maintenance due to natural disasters such as lightning.

Troubleshooting also become much easier and quicker with the Wireless I/O

System since there are less points of failure than a hardwire system.

2.4 Faster, Smarter, Secure, Failsafe

In the Wireless I/O System, the Radio Modules control and power everything.

They manage all signal traffic and provide critical alarms and diagnostics when

either RF link failure or I/O mismatch is detected and trigger NPN digital outputs

for notification. At the same time, the Radio Module overrides all outputs into the

user’s predetermined FailSafe output states on each I/O Module. Each output is

independently controlled. It also provides the ability to locally force outputs when

setting up the system without needing a real signal source. The paired Radio

Modules communicate at a default response time of 1 second.

The Radio Modules can be put to Turbo Tx mode and the response time varies

with the number of connected I/O Modules, up to 100 ms. The Radio Modules

utilize AES encryption for securely delivering data and are offered in 900 MHz or

2.4 GHz (license-free ISM), in both domestic (US) and international versions.

Antennas and antenna cables are sold separately so that you can select the

appropriate antenna and cable lengths to fit your application.

2.5 Customer, Scalable I/O Expansion

The Radio Kit is the foundation of the Wireless I/O System that allows you to

build your custom I/O solution. The two (2) factory-paired Radio Modules are

packaged in the Wireless I/O Radio Kit. The Kit also includes all the mounting

hardware so you simply need to add the I/O Modules of your choice. Up to five

(5) pairs of I/O Modules of any kind can be operated using the Radio Kit. If

additional I/O Modules are needed for expansion, the Wireless I/O System can

support many more pairs of I/O Modules using a longer DataRail.

Page 12 of 48 ProSoft Technology, Inc.

April 21, 2015

Page 13

System Overview

2.6 Advanced Features

The Wireless I/O System also offers an Advanced User Interface for PC. By

connecting the PC to the Radio Module’s mini-USB port, you can check vital

system health such as RSSI (Received Signal Strength Indication), view

input/output status, adjust transmit power level, and adjust RF timeout interval.

You can also locally force local outputs, set FailSafe settings individually for

analog outputs. Digital outputs are set using DIP switches that are physically on

the device.

ProSoft Technology, Inc. Page 13 of 48

April 21, 2015

Page 14

System Overview

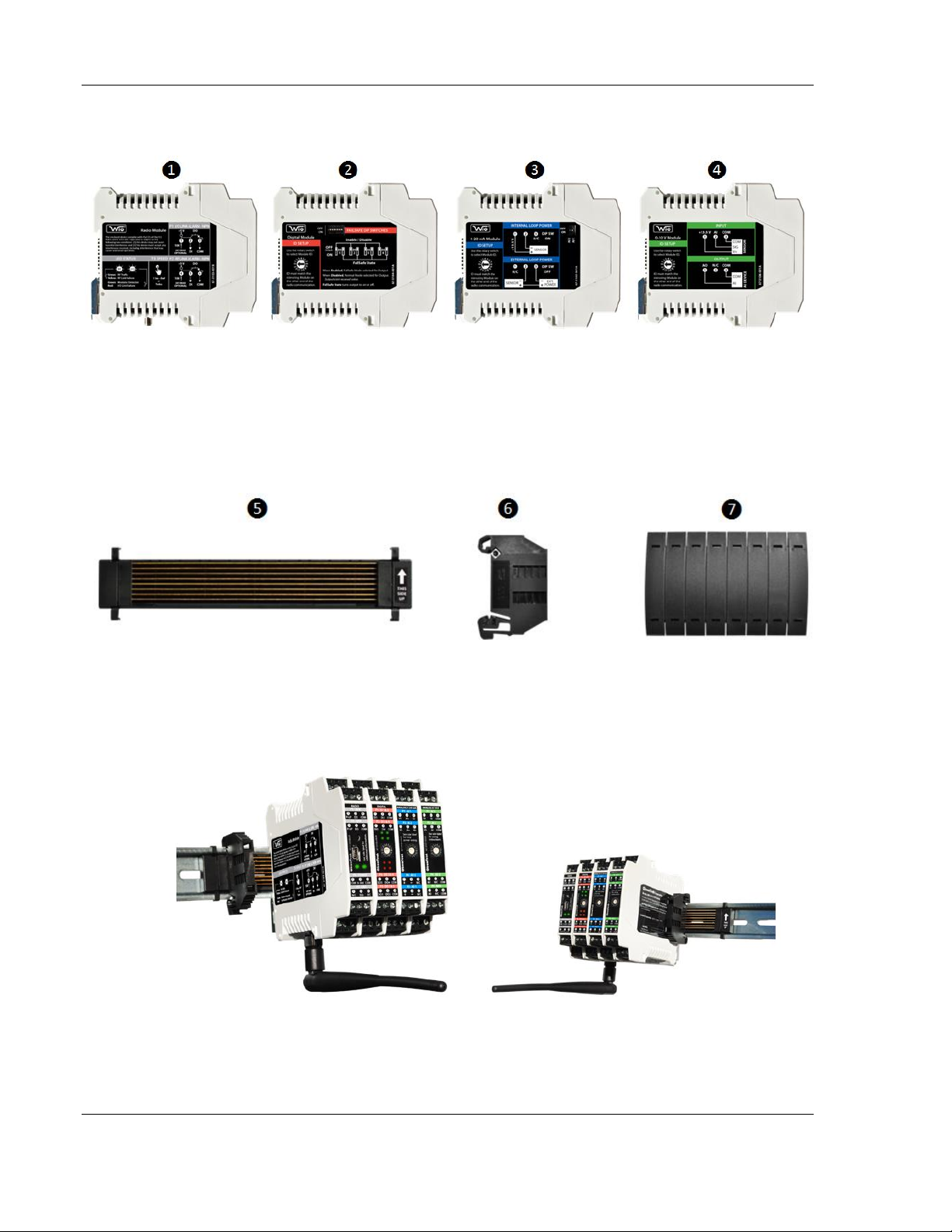

2.7 Hardware

1. Radio Module: BM-0900-RM1 (US), BM-0915-RM1 (Int),

BM-2400-RM1 (US), BM-2410-RM1 (Int)

2. Digital Module: BM-D100-144 (US); BM-D100-244 (International)

3. 4-20 mA Analog Module: BM-A420-122 (US); BM-A420-122 (International)

4. 0-10 V Analog Module: BM-A010-122 (US); BM-A010-122 (International)

5. DataRail attaches onto 35 mm x 7.5 mm DIN rail (Standard length included in Radio Kit

can support 1 Radio + 5 I/O Modules)

6. End Terminal Bracket for securing DataRail and Modules to DIN Rail

7. DataRail Cover for protecting empty DataRail slots

Page 14 of 48 ProSoft Technology, Inc.

April 21, 2015

Page 15

Specifications

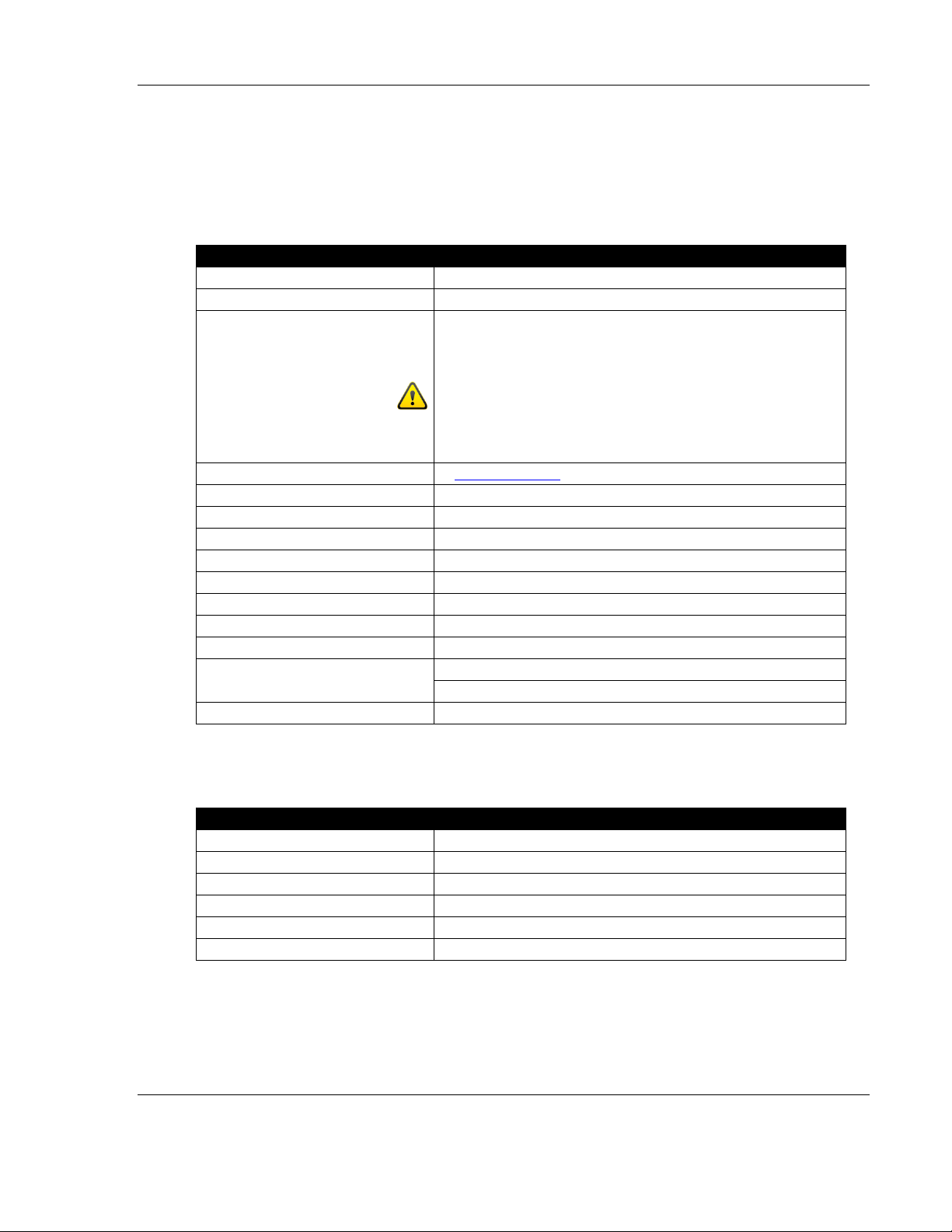

HARDWARE & SYSTEM

Unique System Features

Bi-Directional Wireless Communication System

No Software or Programming Required

Maximum Network Capacity*

System can support up to sixteen (16) Digital Modules max

System can support up to eight (8) 0-10 V Modules max

System can support up to five (5) 4-20 mA Modules max

When adding more than five (5) I/O Modules and creating different

I/O Module combination, please determine maximum allowable I/O

Module combination per system by utilizing the power budget

calculator.

Use Power Budget Calculator

http://psft.com/A5D

DIN Rail Mounting Compatibility

35 mm x 7.5 mm DIN Rail

DataRail™ (Included with Radio Kit)

6.1" / 156 mm - Supports Up Five (5) I/O Modules,

Other Lengths Also Available

Module Slave ID Selection

16-Position Rotary Switch

DataRail Mounting Hardware

4-Claw Attachment to 35 mm DIN Rail

with End Terminal Bracket

Built-In Mounting Hardware

Spring-Loaded Clip-On System

Wire Gauge

Solid / Stranded (AWG) 28-12 Gauge

Wire Rating

UL: 300 V RMS, 80 °C and 300 V, 105 °C

CSA: 300 V RMS, 105 °C

Warranty

2-Year Limited

SAFETY & COMPLIANCE

RADIO

Operational Temperature

-40 °C to 85 °C / -40 °F to 185 °F

Ambient Temperature

-20 °C to 85 °C / -4 °F to 185 °F

Humidity

0 to 99 %, Non-condensing

Degree of Protection / Housing Type

IP20 / Plastic

Hazardous Locations Classifications

Class I; Division 2 (Zone 2), Pending

RF Emissions

FCC Part 15/IC

3 Specifications

3.1 Hardware and System

3.2 Safety and Compliance

ProSoft Technology, Inc. Page 15 of 48

April 21, 2015

Page 16

Specifications

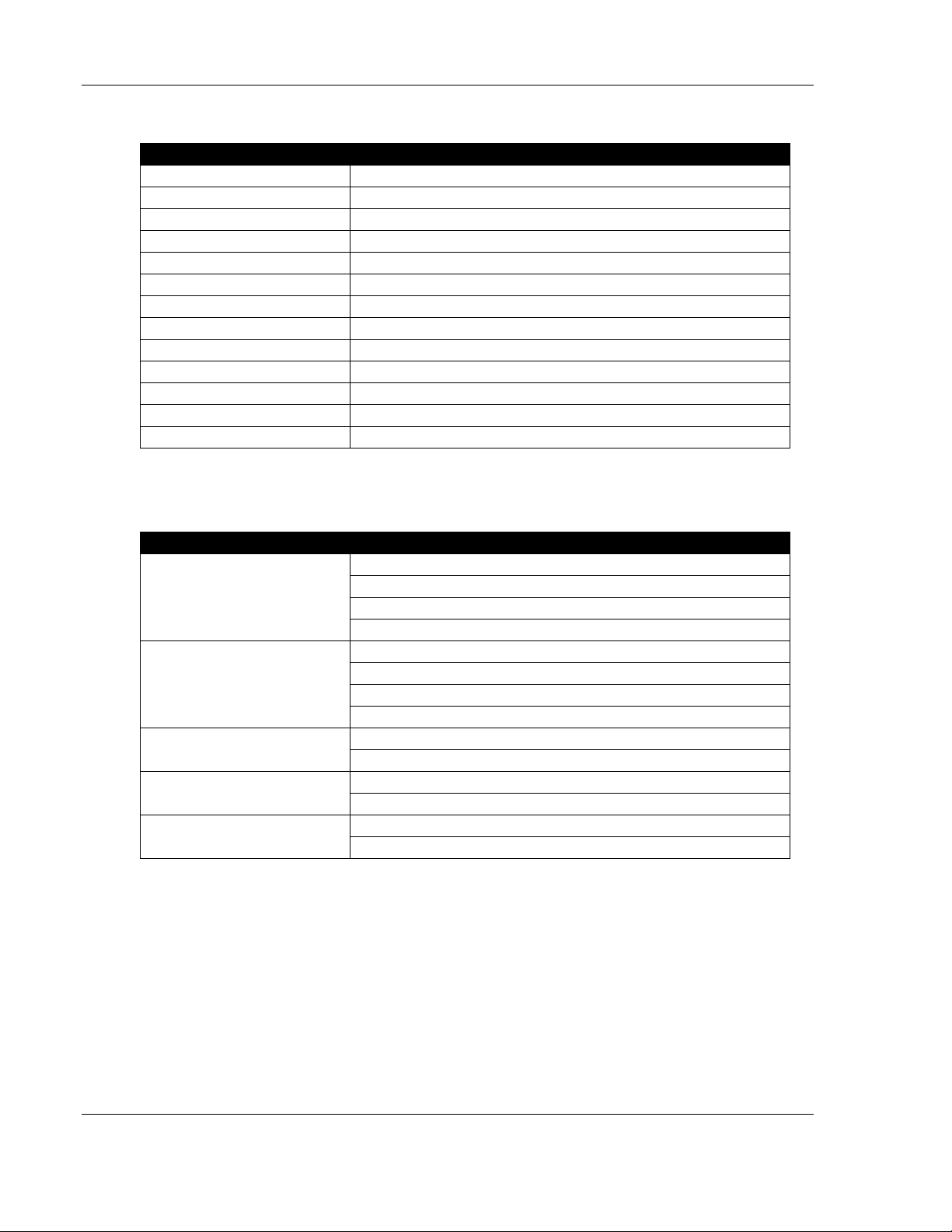

RADIO MODULE 900 MHz or 2.4 GHz

Frequency

902-928 MHz or 2.4 GHz License-Free ISM Band

Antenna Connector Type

SMA (Female Connector)

Default Transmit Speed / Update

1 Second

Turbo Tx Speed Based on

1=100 ms, 2-3=200 ms, 4=250 ms, 5-6=333 ms,

# of I/O Modules

7-11=500 ms, 12-16=1 second

Outdoor / Line of Sight Max Range

900 MHz: 4 Miles (6.4 Km) / 2.4 GHz: 1 Mile (1.6 Km) /

(900MHz@250mW/2.4GHz@63mW)

2.4 GHz International: 2500 ft (750 m)

Indoor / Urban Max Range

900 MHz: 1000 ft (305 m) / 2.4 GHz: 300 ft (90 m) /

(900MHz@250mW/2.4GHz@63mW)

2.4 GHz International: 200 ft (60 m)

Maximum Transmit Power

900 MHz: 24 dBm (250 mW) / 2.4 GHz: 18 dBm (63 mW) /

(Adjustable by Software)

2.4 GHz International: 10 dBm (10 mW)

Receiver Sensitivity

900 MHz: -101 dBm / 2.4 GHz: -100 dBm

Spread Spectrum

900 MHz: FHSS / 2.4 GHz DSSS

RF Security

128-bit AES

Manual FailSafe Override

Yes, via Provided Dry Contact Input

RF Link Alarm Digital Output

10-Second RF Timeout Trigger (NPN) - User Selectable

I/O Link Alarm Digital Output

I/O Mismatch, Bus or Module Failure (NPN)

RF Link Diagnostics (Left LED)

Green = RF Traffic / Yellow = RF Link Fail

I/O Link Diagnostics (Right LED)

Green = I/O OK, Modules Detected / Red = I/O Link Fail

Supply Voltage Range

9 to 30 VDC (± 5 %)

Protection Against Polarity

Yes

Advanced User Interface Features

Test RSSI, Tx Power Adjustment, Force Local Output(s),

Set FailSafe Parameters, and Additional Diagnostics

Power Consumption

35 mA @ 12V AVG (10% Duty Cycle)

Kit Packaging Dimensions (WxHxD)

5.5x10.1x2.8-in / 140x257x72mm

Net Dimensions

0.7x3.9x4.5-in / 17.5x99x114mm

Kit Packaging Weight

1.3 lbs / 590 g

Net Weight (Single Radio)

0.3 lbs / 136 g

3.3 Radio Module

Page 16 of 48 ProSoft Technology, Inc.

April 21, 2015

Page 17

Specifications

DIGITAL I/O MODULE

Number of Inputs

4

Number of Outputs

4

Isolation Voltage

2500 V r.m.s.

Input Voltage Range

3-30 VDC

Input Voltage Threshold

1 Signal ("H"): > 2.3 VDC

0 Signal ("L"): < 1.1 VDC

Output Rating

1 A Sink Current for

Open-Drain Outputs / NPN

FailSafe Modes

On, Off, or Last Known Value (default)

Green LEDs

Line Driven Input Indicators

Red LEDs

Output Indicators

Power Consumption

Typical: 18 mA / Max: 26 mA @12 VDC

Packaging Dimensions

(WxHxD) 4.8 x 5.1 x 2.8-in / 123 x 129 x 72mm

Net Dimensions

0.7 x 3.9 x 4.5-in / 17.5 x 99 x 114mm

Packaging Weight

Single: 0.5 lbs / 227 g; Double: 0.8 lbs / 363 g

Net Weight (Single)

0.3 lbs / 136 g

ANALOG 4-20 mA I/O MODULE

Number of Inputs

2 (24-bit Resolution)

Number of Outputs

2 (16-bit Resolution)

Isolation Voltage

2500 V r.m.s.

Signal Range

4 mA to 20 mA

Accuracy

< 0.28 % of Full Scale

Internal Loop Power

+13.5 VDC

AI Input Impedance (loop)

128 Ohm

AO Terminal Voltage Range

10 VDC Min. / 31.5 VDC Max.

Power Consumption

Typical: 50 mA / Max: 75 mA @12 VDC

FailSafe Modes

Any value on scale (Advanced UI required), or Last Known Value

(default)

Packaging Dimensions

(WxHxD) 4.8 x 5.1 x 2.8-in / 123 x 129 x 72mm

Net Dimensions

0.7 x 3.9 x 4.5-in / 17.5 x 99 x 114mm

Packaging Weight

Single: 0.5 lbs / 227 g; Double: 0.8 lbs / 363 g

Net Weight (Single)

0.3 lbs / 136 g

3.4 Digital I/O Module

3.5 4-20 mA I/O Module

ProSoft Technology, Inc. Page 17 of 48

April 21, 2015

Page 18

Specifications

ANALOG 0-10 V I/O MODULE

Number of Inputs

2 (24-bit Resolution)

Number of Outputs

2 (16-bit Resolution)

Isolation Voltage

2500 V r.m.s.

Signal Range

0 VDC to 10 VDC (10.5 V Max)

Accuracy

< 0.1 % of Full Scale

AI Input Impedance

40K Ohm

AO Output Impedance

10 Ohm

Power Consumption

Typical: 40 mA / Max: 45 mA @12 VDC

FailSafe Modes

Any value on scale (Advanced UI required), or Last Known Value (default)

Packaging Dimensions

(WxHxD) 4.8 x 5.1 x 2.8-in / 123 x 129 x 72mm

Net Dimensions

0.7 x 3.9 x 4.5-in / 17.5 x 99 x 114mm

Packaging Weight

Single: 0.5 lbs / 227 g; Double: 0.8 lbs / 363 g

Net Weight (Single)

0.3 lbs / 136 g

ORDERING INFORMATION

Radio Kit

US/N.Am: 900 MHz BM-0900-RM1K

US/N.Am: 2.4 GHz BM-2400-RM1K

Intl: 900 MHz BM-0915-RM1K

Intl: 2.4GHz BM-2410-RM1K

Radio Kit Content

2x Radio Modules (Factory Paired)

2x DataRails, 4x End Terminal Brackets

2x DataRail Covers, USB to Mini USB Cable

Quick Start Guide

Digital I/O

1-Pack: BM-D100-144S

2-Pack: BM-D100-144D

4-20 mA I/O

1-Pack: BM-A420-122S

2-Pack: BM-A420-122D

0-10 V I/O

1-Pack: BM-A010-122S

2-Pack: BM-A010-122D

3.6 0-10 V I/O Module

3.7 Ordering Information

Page 18 of 48 ProSoft Technology, Inc.

April 21, 2015

Page 19

Installation

4 Installation

4.1 Outdoor Enclosure Installation

1. Install or use an existing outdoor NEMA-type enclosure.

2. Be sure the Wireless I/O System meets applicable grounding requirements.

3. Install a 35 mm x 7.5 mm DIN rail (at least 166 mm (6.5-inch) wide) inside the enclosure.

4. Provide external power supply: 9-30 VDC.

5. Provide antenna and antenna cable to connect to Wireless I/O Radio Module.

a. There are various types of antennas including bulkhead, omni, and yagi. Please use the

appropriate type for your application.

6. Connecting a lightning arrestor is highly recommended.

7. Install antenna (performing a RF site survey prior to installation is highly recommended).

8. Make a hole on the bottom of the enclosure to run wires.

9. Run conduit for power and antenna cable.

10. Connect antenna cable to antenna and then feed cable into enclosure.

11. Feed power wiring into enclosure.

12. Repeat above steps for other site locations.

ProSoft Technology, Inc. Page 19 of 48

April 21, 2015

Page 20

Installation

4.2 Wireless I/O System Assembly (attach from left to right)

Warning: Power must be disconnected or turned off prior to attaching or removing any I/O

Modules from the system – failure to comply may cause damage to the hardware.

1. Securely attach DataRail onto a 35 mm x 7.5 mm DIN rail by gently pressing

on all four (4) corner clips.

2. Secure DataRail to DIN rail by attaching an End Terminal Bracket.

a. First, hook the metal end of the Bracket to DIN rail and then snap the

other end onto DIN rail into place. (Make sure to position the Bracket on

the far left of the DataRail where the metal blades meet the plastic).

Page 20 of 48 ProSoft Technology, Inc.

April 21, 2015

Page 21

Installation

3. Attach Radio Module to DataRail (next to the Bracket without any gap).

a. First, latch the top hook onto the rail, then snap in the spring-loaded clip

into place.

b. Connect Antenna. The Radio Module is equipped with a SMA (female)

connector. For outdoor installation, place a lightning arrestor between

Antenna and Radio Module connection.

4. Attach I/O Module(s) to the system.

a. Place Modules in any combination (do not leave gaps between Modules).

b. When using more than five (5) I/O Modules, determine maximum I/O

Module combination by using power budget calculator. http://psft.com/A5D

ProSoft Technology, Inc. Page 21 of 48

April 21, 2015

Page 22

Installation

c. Use the 16-position switch located on the front of each I/O Module to set

device ID(s). Each pair of Modules must have a unique ID.

5. Attach the other End Terminal Bracket to secure the Modules (place it next to

the last module without leaving a gap).

Page 22 of 48 ProSoft Technology, Inc.

April 21, 2015

Page 23

Installation

6. Protect any unused DataRail slots with a cover. Snap-off extra pieces and

7. Terminate the I/O and supply power as required. Use solid or stranded wire

store for future use.

(AWG) 28-12.

ProSoft Technology, Inc. Page 23 of 48

April 21, 2015

Page 24

Installation

4.3 Detaching Components from the DataRail

Warning: All live wiring connections and power must be safely disconnected before taking any

components off the DataRail or Wireless I/O System!

1. The End Terminal Bracket can be removed from DIN rail by inserting the tip

of a flathead screwdriver into the removal slot. Control the direction with the

screwdriver handle to pull the latch away from the DIN rail for safe removal.

2. Wireless I/O Modules can be removed from the DIN rail by inserting the tip of

a flathead screwdriver into removal slot located on the metal clip. Lift-up on

the screwdriver handle to pull the spring-loaded clip away from the DIN rail

for safe removal.

Page 24 of 48 ProSoft Technology, Inc.

April 21, 2015

Page 25

Radio Setup

5 Radio Setup

1. When installing antennas, avoid walls, tall buildings, trees, and other solid

obstructions for improving RF signal quality.

2. Having a clear line of sight between antennas is ideal for best RF signal quality.

3. Use the appropriate antenna and use high quality antenna cables with the Wireless

I/O System for best performance.

4. After the entire system is installed, verify if the RF LED on Radio Module is green,

which serves as indication for good RF traffic.

5. Advanced: Run an RSSI test. Connect a PC to the Radio Module’s mini USB port

and utilize the Wireless I/O System Advanced Software to evaluate Received Signal

Strength. In general, achieving above -85 dBm is recommended for signal quality. In

an environment with low interference, 90-100% packet throughput can be achieved

at lower levels, as low as -100 dBm.

ProSoft Technology, Inc. Page 25 of 48

April 21, 2015

Page 26

Page 26 of 48 ProSoft Technology, Inc.

April 21, 2015

Page 27

Signal Chain Diagram

6 Signal Chain Diagram

ProSoft Technology, Inc. Page 27 of 48

April 21, 2015

Page 28

Page 28 of 48 ProSoft Technology, Inc.

April 21, 2015

Page 29

Wiring Diagrams

Connect I/O Link Alarm output

to report when there is an I/O

link failure. Once the failure is

corrected, you must reset

power.

Connect RF Link Alarm

output to report when there

is an RF link failure.

This Input allows connection

of a dry contact switch for

manually overriding system

into FailSafe state for all

outputs.

7 Wiring Diagrams

7.1 Radio Module (BM-0900-RM1 Shown)

ProSoft Technology, Inc. Page 29 of 48

April 21, 2015

Use Solid / Stranded (AWG) 28-12 Wire Gauge

Radio Module does not share a common ground with I/O Modules.

All inputs and outputs on I/O Modules provide field isolation.

Page 30

Wiring Diagrams

7.2 Digital Module (BM-D100-144 Shown)

Use Solid / Stranded (AWG) 28-12 Wire Gauge

Digital I/O Module does not share a common ground with Radio Module.

All inputs and outputs on I/O Modules provide field isolation.

If input sensor is powered from the same source as Radio Module, be sure to establish

a common ground, otherwise sensor will not work properly.

Page 30 of 48 ProSoft Technology, Inc.

April 21, 2015

Page 31

Wiring Diagrams

7.3 Analog 4-20 mA Module (BM-A420-122 Shown)

VS/External Power (min) = 10 + Max Current (Amp) * R

R

4-20 mA I/O Module does not share a common ground with Radio Module.

All inputs and outputs on I/O Modules provide field isolation.

= Total Loop Impedance

loop

Use Solid / Stranded (AWG) 28-12 Wire Gauge

loop

ProSoft Technology, Inc. Page 31 of 48

April 21, 2015

Page 32

Wiring Diagrams

7.4 Analog 0-10 V Module (BM-A010-122 Shown)

Use Solid / Stranded (AWG) 28-12 Wire Gauge

0-10 V I/O Module does not share a common ground with Radio Module.

All inputs and outputs on I/O Modules provide field isolation.

Page 32 of 48 ProSoft Technology, Inc.

April 21, 2015

Page 33

Diagnostics

8 Diagnostics

8.1 Radio Module

1. RF LED (Left):

2. Green: RF traffic / data rate

a. Yellow: RF link failure

i. Indication of RF link failure after 10 second RF timeout and showing

the Wireless I/O System is operating in FailSafe mode.

ii. RF Link Alarm Output (P2 - NPN) is triggered to report failure status.

iii. Check antenna connections and power at both Radio stations.

iv. Check for clear line of sight, any obstruction in the path may

negatively impact RF signal quality.

3. I/O LED (Right):

a. Green: Modules detected, I/O ok

b. Red: I/O link failure

i. Visual indication of I/O link failure.

ii. I/O Link Alarm Output (P1 – NPN) is triggered to report failure status.

iii. Functioning I/O will perform normally under alarm condition.

iv. Any mismatched I/O Modules will be put to FailSafe mode.

v. Check for I/O mismatch – check each pair of Modules is set to its

vi. Check both Radio Stations have matching Modules.

vii. Check DataRail condition – check for any sign of wear, debris,

viii. For signal integrity verification, perform Remote Loop Back

own ID.

oxidation.

diagnostics by wiring the based on diagram below.

ProSoft Technology, Inc. Page 33 of 48

April 21, 2015

Page 34

Diagnostics

Page 34 of 48 ProSoft Technology, Inc.

April 21, 2015

Page 35

Advanced User Interface for PC

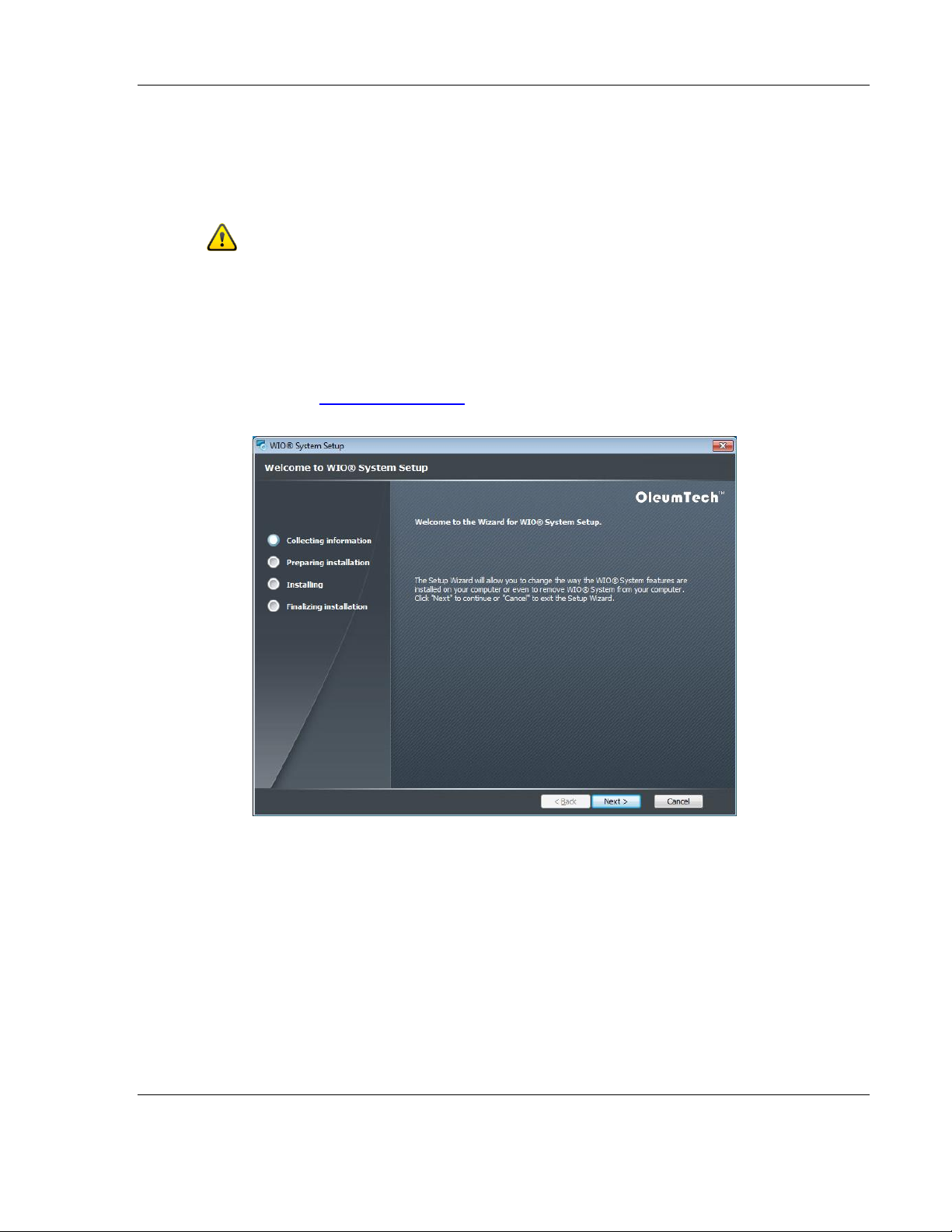

9 Advanced User Interface for PC

Wireless I/O System Advanced User Interface is not required to operate

or configure the system. This software is intended for users that want to

take advantage of all the features available on the Wireless I/O System.

9.1 Download and Install Software

1. Download the latest version of the software from the ProSoft Technology

web site http://psft.com/A5D

2. Install the software and follow the setup guide.

3. Run the program.

ProSoft Technology, Inc. Page 35 of 48

April 21, 2015

Page 36

Advanced User Interface for PC

Avoid ESD damage!

-Always connect Mini-USB LAST.

-Always disconnect Mini-USB FIRST.

9.2 Connect USB to Mini USB Cable (Included with Radio Kit)

1. First, connect USB end to PC.

2. Connect Mini-USB to Radio Module’s Mini USB port.

3. Wait for the completion of driver installation on PC (May take up to a few

minutes).

Page 36 of 48 ProSoft Technology, Inc.

April 21, 2015

Page 37

Advanced User Interface for PC

OFF / DISCONNECTED

ON / CONNECTED

Click on WIO® button to view Radio Firmware Version, Radio Model, and Software Version.

9.3 View of Graphic User Interface (GUI)

OFF - When PC is not connected to a Radio Module, all gauges and controls are

disabled.

ON - When PC is connected to a Radio Module (powered on), all gauges and

controls will be enabled.

ProSoft Technology, Inc. Page 37 of 48

April 21, 2015

Page 38

Advanced User Interface for PC

9.4 Main Window Guide

1. Screen Size – Zoom In/Out

2. Local RSSI (Received Signal Strength Indicator)

a. This level indicates the incoming signal strength received from remote Radio.

3. Remote RSSI

a. This level indicates the outgoing signal strength from local Radio to remote Radio.

b. Adjusting Transmit Power will impact Remote RSSI.

4. Apply button – Appears when any setting is modified. Must click Apply in order for any changes to

become effective on the local device.

5. RF Link Alarm Output and Operating in FailSafe mode is triggered by this RF timeout interval.

a. 10-second default RF timeout (1-second increments: 2 to 30 second range).

6. Transmit Power Adjustor – for optimization of power level and power consumption.

7. I/O Module Tray – this tray displays all connected I/O Modules - use the arrow button to expand or

minimize I/O Module Tray view.

8. Green color code indicates 0-10 V Analog Module.

9. Blue color code indicates 4-20 mA Analog Module.

10. Red color code indicates Digital Module.

11. Empty Module Slot

Page 38 of 48 ProSoft Technology, Inc.

April 21, 2015

Page 39

Advanced User Interface for PC

9.5 Additional Diagnostics

1. RF Link Failure Indicator

a. The RF Link Fail Output (NPN) is triggered when RF link failure occurs.

2. I/O Link Failure Indicator

a. The I/O Link Fail Output (NPN) is triggered when I/O link failure occurs.

3. Red Border I/O Link Failure Indicator

a. Indicates the specific Module that has failed or is mismatched.

ProSoft Technology, Inc. Page 39 of 48

April 21, 2015

Page 40

Advanced User Interface for PC

9.6 Digital Module Window Guide

1. Digital Input(s) Status: Green = On ; Dimmed = Off

2. Digital Output(s) Status

3. Red LED: displayed when output is normally operated; Dimmed = Off

4. Force Output Button – click the “F” button

a. Once activated, the user has the option of turning output on or off by pressing on

virtual output buttons.

b. To disable forcing an output, click “F” again to deactivate force mode.

c. Closing the User Interface or unplugging the mini USB cable will automatically

deactivate any forced output(s).

5. Orange LED: displayed when output is forced on.

6. Displays FailSafe mode that has been set using DIP Switches located on the Digital

Module.

a. In the example shown, DO 1 output will turn on when RF or I/O link fail detected

(Fs indication on).

b. DO 2 output will turn off when RF link fail detected (Fs indication off).

c. DO 3 and 4 will output last known value when RF link fail detected (No Fs

indication).

7. Blue border indicates selected I/O Module.

8. Orange border indicates forced output is active.

Page 40 of 48 ProSoft Technology, Inc.

April 21, 2015

Page 41

Advanced User Interface for PC

9.7 4-20 mA Module Window Guide

1. Input 1 Status

2. Input 2 Status

3. Output 1 Status (Red Needle)

4. Output 2 Status (Red Needle)

5. FailSafe

a. Without the User Interface (default), the output reports last known value when RF or I/O failure

occurs.

b. Click the “Fs” button and a specific value can be assigned for output when RF failure occurs: Use the

Blue Triangle needle to set a specific value. Set value is indicated in blue on dial and numeric display

including last known value.

c. Apply button – must click apply for changes to take effect.

6. Force Output Button

a. Click “F” button to manually force a specific output. Forcing an output bypasses normal signal: Use

the Yellow needle for adjustment.

b. To disable forcing an output, click “F” again to deactivate force mode.

c. Closing the User Interface or unplugging the mini USB cable will automatically deactivate any forced

output(s).

7. Apply button – must click in order for changes to take effect.

8. Blue border indicates selected I/O Module.

9. Orange border indicates forced output is active.

ProSoft Technology, Inc. Page 41 of 48

April 21, 2015

Page 42

Advanced User Interface for PC

9.8 0-10 V Module Window Guide

1. Input 1 Status

2. Input 2 Status

3. Output 1 Status (Red Needle)

4. Output 2 Status (Red Needle)

5. FailSafe

a. Without the User Interface (default), the output reports last known value when RF or I/O failure

occurs.

b. Click the “Fs” button and specific value can be assigned for output when RF or I/O failure

occurs: Use the Blue Triangle needle to set specific value. Set value is indicated in blue on dial

and numeric display.

c. Apply button – must click apply for changes to take effect.

6. Force Output Button

a. Click the “F” button to manually force a specific output. Forcing an output bypasses normal

signal: Use the Yellow needle for adjustment.

b. To disable forcing an output, click “F” again to deactivate force mode.

c. Closing the User Interface or unplugging the mini USB cable will automatically deactivate any

forced output(s).

7. Apply button – must click in order for changes to take effect.

8. Blue border indicates selected I/O Module.

9. Orange border indicates forced output is active.

Page 42 of 48 ProSoft Technology, Inc.

April 21, 2015

Page 43

Frequently Asked Questions

10 Frequently Asked Questions

1. What does the Wireless I/O System do?

a. It allows replacement of hardwires.

b. Point-to-point / bi-directional system.

c. Eliminate trenching and running conduit.

d. Ultimately helps save money and time.

e. It’s easy to use.

2. What type of I/O's are available?

a. Digital/discrete

b. Analog 4-20 mA

c. Analog 0-10 V

3. Does Wireless I/O System follow a certain communication protocol?

a. No, it’s simply an I/O mirroring solution. What comes in is what goes out.

b. It does not speak Modbus or any other protocol.

c. Inputs received are replicated on the end of the radio spectrum as outputs.

4. Does Wireless I/O System require any software for programming or configuration?

a. No, it requires absolutely no software. It is ready out of the box to install.

5. Is Wireless I/O offered in 900 MHz license-free ISM band?

a. Yes, both US and International versions are available.

6. Is Wireless I/O offered in 2.4 GHz license-free ISM band?

a. Yes, both US and International versions are available.

7. At max RF power of 250 mW, what is the expected RF range?

a. Up to 4 miles using 900 MHz

b. Up to 1 mile using 2.4 GHz (65 mW)

8. Does the Wireless I/O System support point-to-multipoint communication?

a. The Radios come paired and secured and is meant for point-to-point applications

only.

9. How much power does Wireless I/O Modules consume?

a. Radio 35 mA @ 12 VDC AVG (10% Duty Cycle)

b. Digital 26 mA @ 12 VDC MAX

c. 4-20 mA 82.5 mA @ 12 VDC MAX

d. 0-10 V 58 mA @ 12 VDC MAX

10. How many I/O modules can be connected to a Radio Module?

a. It depends on the type and number of Modules.

b. Please use the Power Budget Calculator to determine maximum I/O Module

capacity per Radio when using more than five (5) I/O Modules.

http://psft.com/A5D

ProSoft Technology, Inc. Page 43 of 48

April 21, 2015

Page 44

Frequently Asked Questions

11. How many I/O modules can be connected with the standard DataRail (6.1”) shipped

with Radio Kit?

a. Standard DataRail supports up to five (5) I/O modules in addition to one Radio

module.

12. How do I setup each I/O module once connected to the Radio module?

a. Use a small flat screwdriver (technician’s screwdriver) and turn ID switch to

select desired ID number.

b. Be sure the matching module at the other Radio station is also assigned to the

same device ID.

13. Does the Radio module automatically detect new I/O modules when connected to

DataRail?

a. Yes, but only during hardware reset by power cycling the Radio module.

14. What is the mini USB port on the Radio module used for?

a. The mini USB port is designated to plug in a PC running Wireless I/O Software

Tool for users wanting to take full advantage of all the features the Wireless I/O

System has to offer.

15. What types of features are available with the Wireless I/O Advance User Interface?

a. Perform RF strength test (RSSI), change RF channel, adjust RF power level to

balance power consumption and performance, change RF timeout interval, force

local outputs, or set FailSafe settings for Analog outputs.

16. Can the Wireless I/O System be used in hazardous locations?

a. Yes, the system can be used in Class 1, Division 2 or Zone 2 locations.

17. Can Radio modules be reprogrammed?

a. Radio Module firmware can be upgraded when updates become available via

mini USB port.

b. For security reasons, once two Radio modules are paired together from factory,

they cannot be unpaired.

18. Is the Wireless I/O System compatible with Wireless HART protocol?

a. No, the Wireless I/O System is a proprietary RF protocol developed to provide

superior reliability and ease of use for the sake of replacing conduit and wires.

19. In case of an emergency, how can I manually force the Wireless I/O System into

FailSafe condition for managing outputs (ESD)?

a. Radio Module provides a discrete input for connecting a dry contact switch

b. When dry contact is closed or active, Radio Module will instantly operate in the

FailSafe mode.

c. User can configure the Discrete Module by manipulating the FailSafe dip

switches located directly on the device.

d. Analog Modules defaults to last known value. The Advanced UI, the FailSafe

output point can be set to any value.

20. In the unlikely event my Radio Module gets damaged, can I just buy one module to

replace into my system?

a. No. Since the Radio Modules are a fixed pair system, a new pair of Radio

Modules is needed for replacement.

Page 44 of 48 ProSoft Technology, Inc.

April 21, 2015

Page 45

Frequently Asked Questions

21. In the unlikely event one of my I/O Module gets damage, can I just buy one module to

replace into my system?

a. Yes. You do not need to purchase it in pairs like the Radio Modules. I/O Modules

are sold as singles and pairs to fit your need.

22. How can I obtain tech support or RMA?

a. Please email us at support@prosoft-technology.com or give us a call to begin the

service process. You will be guided by our helpful customer service staff member

to help you get through any issue you are having with the Wireless I/O System.

ProSoft Technology, Inc. Page 45 of 48

April 21, 2015

Page 46

Page 46 of 48 ProSoft Technology, Inc.

April 21, 2015

Page 47

Support, Service & Warranty

11 Support, Service & Warranty

ProSoft Technology, Inc. (ProSoft) is committed to providing the most efficient

and effective support possible. Before calling, please gather the following

information to assist in expediting this process:

1 Product Version Number

2 System architecture

3 Network details

If the issue is hardware related, we will also need information regarding:

1 Module configuration and associated ladder files, if any

2 Module operation and any unusual behavior

3 Configuration/Debug status information

4 LED patterns

5 Details about the serial, Ethernet or fieldbus devices interfaced to the module,

if any.

Note: For technical support calls within the United States, an after-hours answering system allows

24-hour/7-days-a-week pager access to one of our qualified Technical and/or Application Support

Engineers. Detailed contact information for all our worldwide locations is available on the following

page.

ProSoft Technology, Inc. Page 47 of 48

April 21, 2015

Page 48

Support, Service & Warranty

Internet

Web Site: www.prosoft-technology.com/support

E-mail address: support@prosoft-technology.com

Asia Pacific

(location in Malaysia)

Tel: +603.7724.2080, E-mail: asiapc@prosoft-technology.com

Languages spoken include: Chinese, English

Asia Pacific

(location in China)

Tel: +86.21.5187.7337 x888, E-mail: asiapc@prosoft-technology.com

Languages spoken include: Chinese, English

Europe

(location in Toulouse, France)

Tel: +33 (0) 5.34.36.87.20,

E-mail: support.EMEA@prosoft-technology.com

Languages spoken include: French, English

Europe

(location in Dubai, UAE)

Tel: +971-4-214-6911,

E-mail: mea@prosoft-technology.com

Languages spoken include: English, Hindi

North America

(location in California)

Tel: +1.661.716.5100,

E-mail: support@prosoft-technology.com

Languages spoken include: English, Spanish

Latin America

(Oficina Regional)

Tel: +1-281-2989109,

E-Mail: latinam@prosoft-technology.com

Languages spoken include: Spanish, English

Latin America

(location in Puebla, Mexico)

Tel: +52-222-3-99-6565,

E-mail: soporte@prosoft-technology.com

Languages spoken include: Spanish

Brasil

(location in Sao Paulo)

Tel: +55-11-5083-3776,

E-mail: brasil@prosoft-technology.com

Languages spoken include: Portuguese, English

11.1 Warranty Information

For complete details regarding ProSoft Technology’s TERMS & CONDITIONS

OF SALE, WARRANTY, SUPPORT, SERVICE AND RETURN MATERIAL

AUTHORIZATION INSTRUCTIONS please see the documents on the Product

DVD or at www.prosoft-technology.com/warranty.

All documentation is subject to change without notice.

Page 48 of 48 ProSoft Technology, Inc.

April 21, 2015

Loading...

Loading...