Page 1

RS485 I/O

Expansion System

June 10, 2015

USER GUIDE

Page 2

Page 3

User Guide

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions,

comments, compliments or complaints about our products, documentation, or support, please write or call us.

How to Contact Us

ProSoft Technology

5201 Truxtun Ave, 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

http://www.prosoft-technology.com

support@prosoft-technology.com

Copyright © 2015 ProSoft Technology, Inc. All rights reserved.

RS485 I/O Expansion System User Guide

June 10, 2015

ProSoft Technology® Product Documentation

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product

shipments. User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided on the

enclosed DVD in Adobe® Acrobat Reader file format (.PDFs). These product documentation files may also be

freely downloaded from our web site: www.prosoft-technology.com

ProSoft Technology, Inc. Page 3 of 36

February 18, 2015

Page 4

ILX34-MBS User Manual

Page 4 of 36 ProSoft Technology, Inc.

June 10, 2015

Page 5

ILX34-MBS User Manual

Contents

Your Feedback Please ........................................................................................................................ 3

How to Contact Us .............................................................................................................................. 3

ProSoft Technology® Product Documentation .................................................................................... 3

1 Preface 7

1.1 Compliances .............................................................................................................. 8

2 System Overview 9

2.1 Highlights ................................................................................................................... 9

2.2 Hardware ................................................................................................................. 10

3 Specifications 11

3.1 Hardware and System ............................................................................................. 11

3.2 Safety and Compliance ........................................................................................... 11

3.3 RS485 Expansion I/O Module ................................................................................. 12

3.4 Digital I/O Module .................................................................................................... 12

3.5 4-20 mA I/O Module ................................................................................................ 13

3.6 0-10 V I/O Module ................................................................................................... 13

3.7 Ordering Information ............................................................................................... 13

4 Installation 15

4.1 Outdoor Enclosure Installation ................................................................................ 15

4.2 RS485 I/O Expansion System Assembly ................................................................ 16

4.3 RS485 Daisy-Chain Diagram .................................................................................. 20

4.4 Detaching Components from the DataRail .............................................................. 21

5 Wiring Diagrams 23

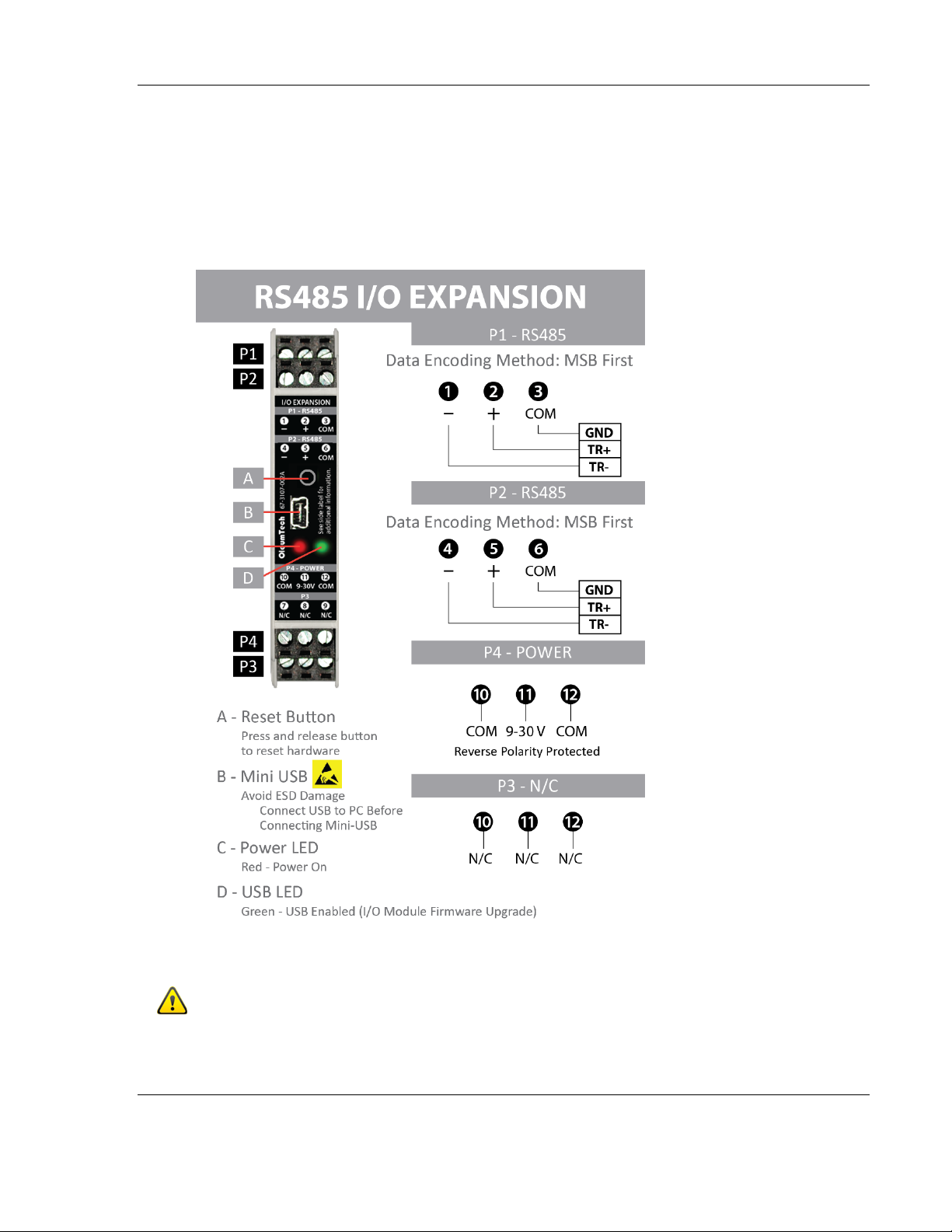

5.1 RS485 I/O Expansion Module ................................................................................. 23

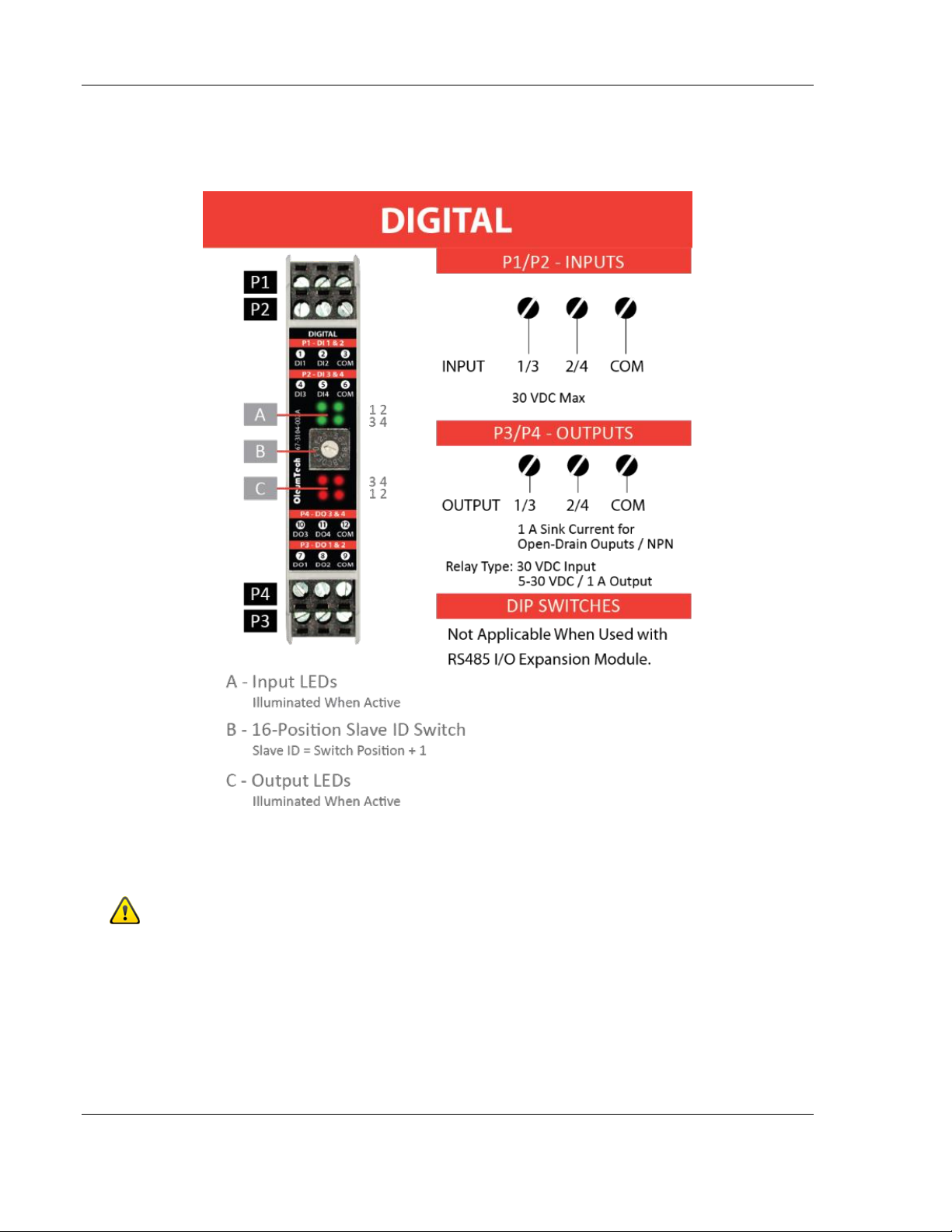

5.2 Digital Module .......................................................................................................... 24

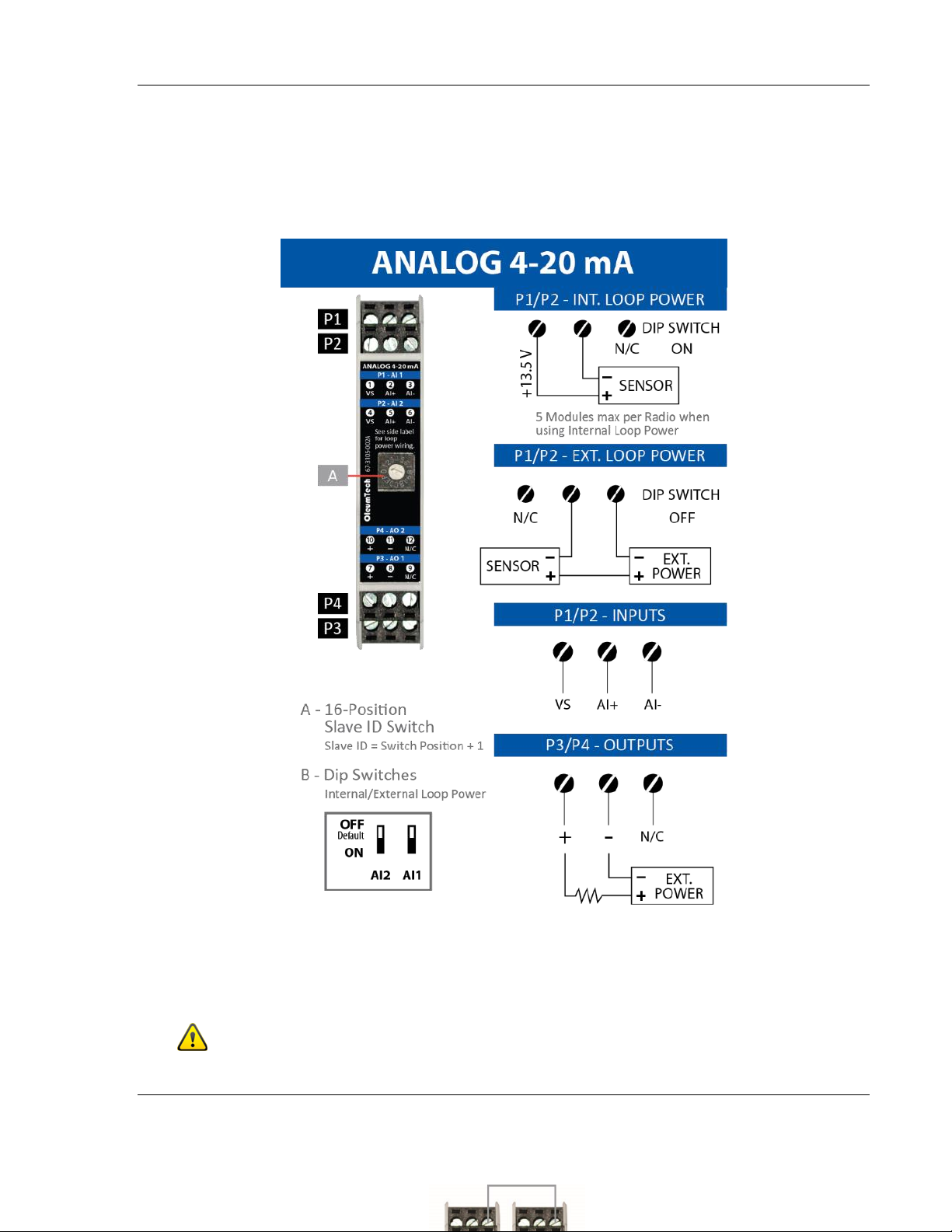

5.3 Analog 4-20 mA Module .......................................................................................... 25

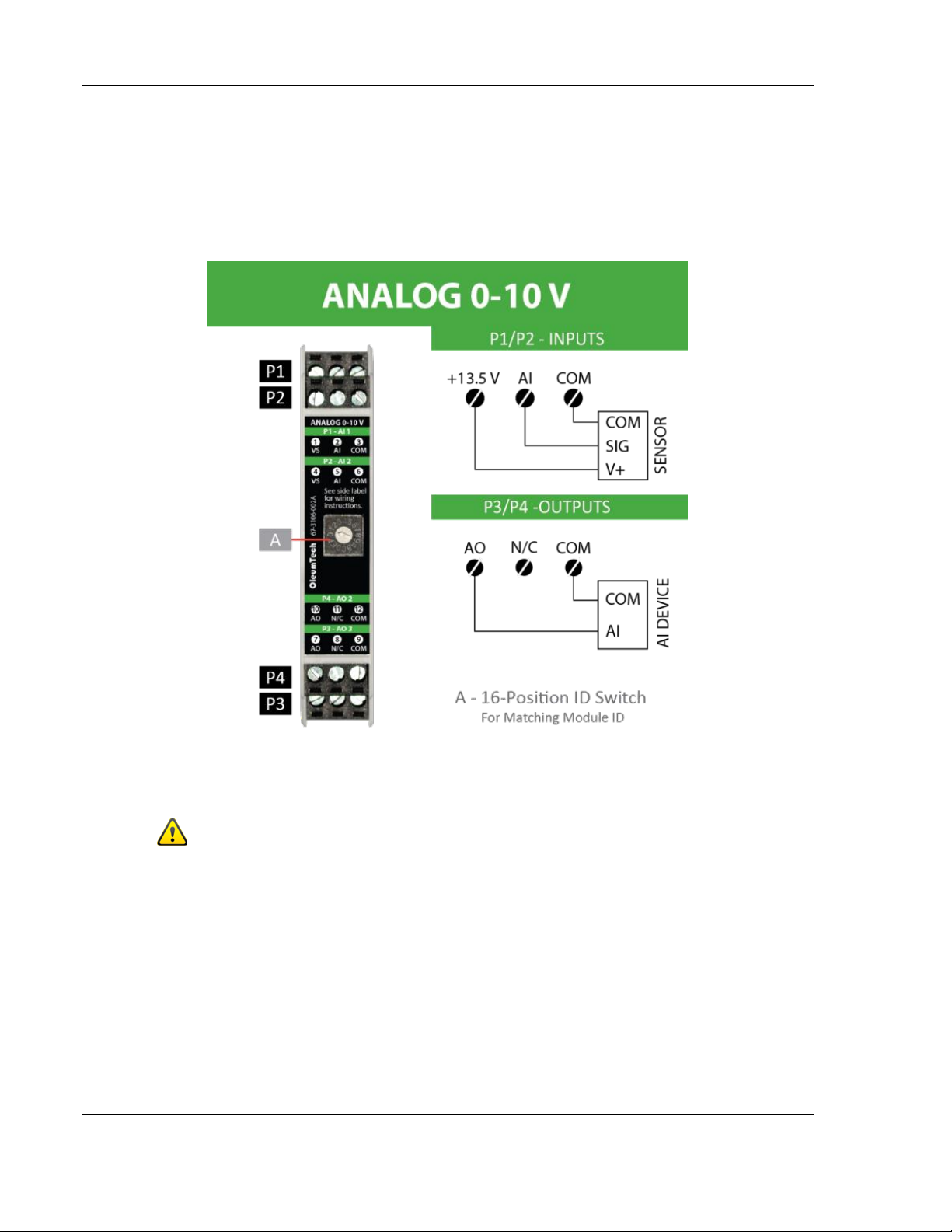

5.4 Analog 0-10 V Module ............................................................................................. 26

6 Modbus Mapping 27

6.1 Supported Modbus Function Codes ........................................................................ 27

6.2 Digital I/O Module – Modbus Mapping Table .......................................................... 27

6.3 4-20 mA I/O Module - Modbus Mapping Table ....................................................... 28

6.4 0-10 V I/O Module - Modbus Mapping Table .......................................................... 29

7 Diagnostics 31

7.1 Radio Module .......................................................................................................... 31

ProSoft Technology, Inc. Page 5 of 36

June 10, 2015

Page 6

ILX34-MBS User Manual

8 Frequently Asked Questions 33

9 Support, Service & Warranty 35

9.1 Warranty Information .............................................................................................. 36

Page 6 of 36 ProSoft Technology, Inc.

June 10, 2015

Page 7

Preface

1 Preface

Thank you for choosing the RS485 I/O Expansion System. This I/O expansion

solution is designed for use with any Modbus RS485 Master device as a

standalone system. This System follows the Modbus Application Protocol

Specification, v1.1b3, for Data Encoding with values represented in Big-Endian

format or MSB first (word order).

Digital/Discrete, Analog 4-20 mA, or Analog 0-10 V are available for use with the

RS485 I/O Expansion System. This System provides fast, accurate, reliable I/O's

and requires no software programming, making it extremely easy and quick to

use.

To interface with a RS485 Master device, the System utilizes a RS485 I/O

Expansion Module that transfers I/O signals between Modbus Master and

connected I/O Modules. The RS485 Module also distributes power to the I/O

Modules allowing for single point power termination.

This document is designed to guide you through setting up the system by

familiarizing you with the hardware, installation, wiring, and overall system

management.

ProSoft Technology

5201 Truxtun Ave, 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

http://www.prosoft-technology.com

support@prosoft-technology.com

ProSoft Technology, Inc. Page 7 of 36

June 10, 2015

Page 8

Preface

1.1 Compliances

Changes or modifications not expressly approved by the manufacturer may

void the user’s authority to operate the equipment.

Warning: Ensure system installation meets applicable state and national electrical code

requirements. The installation of the system should only be performed by a qualified installer or a

factory representative.

Warning: To prevent ignition of flammable or combustible atmospheres, disconnect power before

servicing.

Caution: The RS485 I/O Expansion System must be installed within an enclosure that requires a

tool to access. This is to prevent inadvertent disconnection of any of the power wiring, signal wiring

or communication cables.

Caution: EXPLOSION HAZARD. Do not disconnect equipment unless power has been switched

off or the area is known to be non-hazardous.

Caution: EXPLOSION HAZARD. Do not remove or replace fuse when energized.

Note: This equipment is designed for use in Class I, Division 2 (Zone 2) or non-hazardous

locations only.

Page 8 of 36 ProSoft Technology, Inc.

June 10, 2015

Page 9

System Overview

2 System Overview

2.1 Highlights

Local I/O expansion solution for use with any RS485 Modbus Master device.

System utilizes a pass-through RS485 Interface/Module for transferring I/O signals

between Modbus Master and connected I/O Modules

One RS485 Expansion I/O Module supports multiple Wireless I/O Modules.

System can support up to sixteen (16) Digital Modules

System can support up to eight (8) 0-10 V Modules

System can support up to five (5) 4-20 mA Modules

When adding more than five (5) I/O Modules and mixing different I/O

Modules, please determine maximum allowable I/O Module combination per

system by utilizing the power budget calculator: http://psft.com/A7U

Supports Digital, 0-10 V, and 4-20 mA Modules in any combination.

Each I/O Module provides field isolated inputs and outputs.

Easy to use: no software configuration required.

System attaches onto 35 mm x 7.5 mm DIN rail with easy, clip-on mounting system.

Reduced wire clutter: single power termination.

Wiring label provided on each Module for quick reference.

All Modules are color-coded for quick reference and identification.

The same I/O Modules can also be used for wireless application with Wireless I/O

Radio Kit.

Reduced wire clutter: single power termination.

Quick wiring reference label provided on each Module.

Wireless I/O System can support multiple I/O Modules.

System can support up to sixteen (16) Digital Modules max.

System can support up to eight (8) 0-10 V Modules max.

System can support up to five (5) 4-20 mA Modules max.

Warning: When adding more than five (5) I/O Modules and mixing different I/O Module

combinations, please determine the maximum allowable I/O Module combination per system by

utilizing the power budget calculator. See http://psft.com/A7U

ProSoft Technology, Inc. Page 9 of 36

June 10, 2015

Page 10

System Overview

2.2 Hardware

1. RS485 I/O Expansion Module: BM-1000-PM1 (US), BM-0915-RM1 (Int),

BM-2400-RM1 (US), BM-2410-RM1 (Int)

2. Digital Module: BM-D100-144 (US); BM-D100-244 (International)

3. 4-20 mA Analog Module: BM-A420-122 (US); BM-A420-122 (International)

4. 0-10 V Analog Module: BM-A010-122 (US); BM-A010-122 (International)

5. DataRail attaches onto 35 mm x 7.5 mm DIN rail (Standard length included in Radio Kit can

support 1 RS485 I/O Expansion Module + 5 I/O Modules)

6. End Terminal Bracket for securing DataRail and Modules to DIN Rail

7. DataRail Cover for protecting empty DataRail slots

Page 10 of 36 ProSoft Technology, Inc.

June 10, 2015

Page 11

Specifications

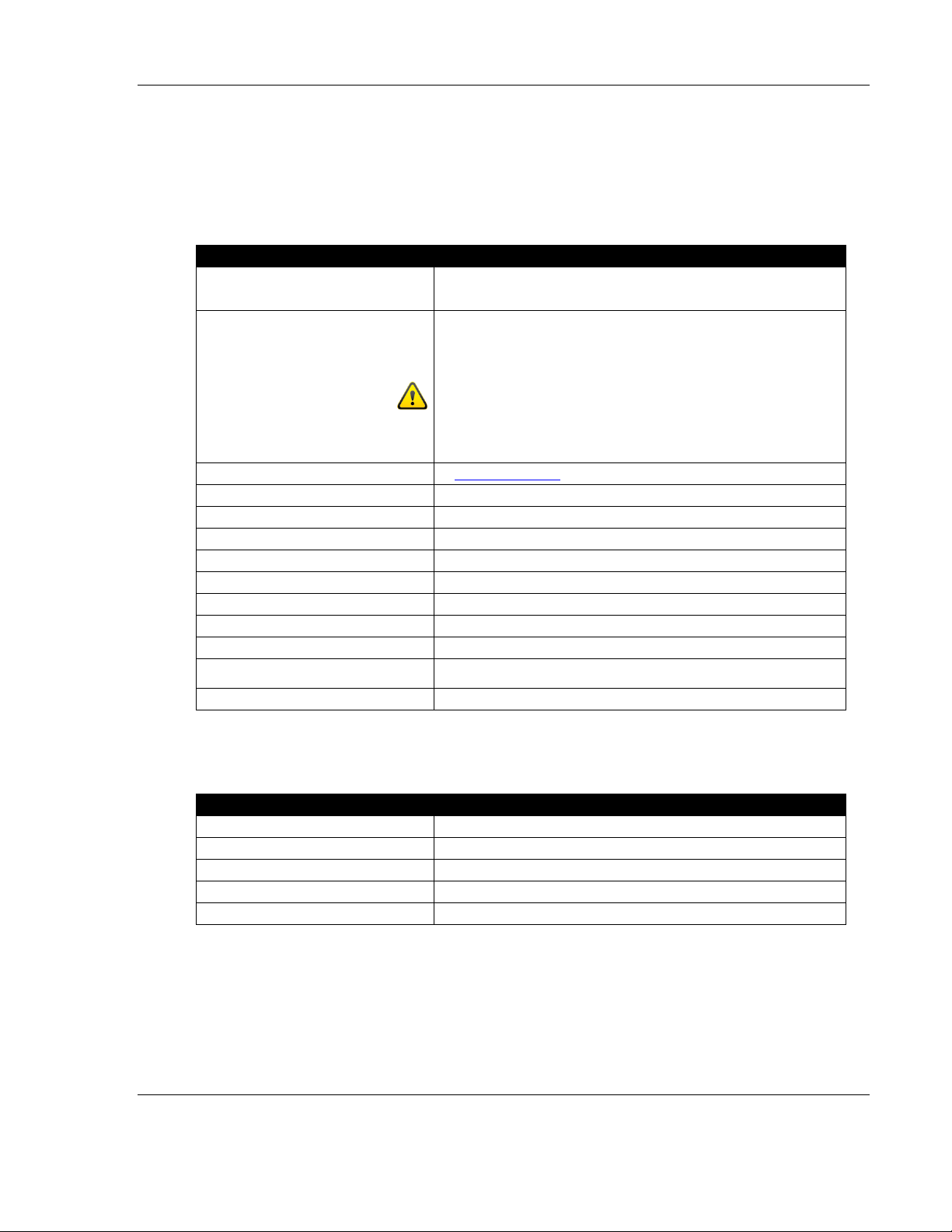

HARDWARE & SYSTEM

Unique Features

Works with Any Modbus RS485 Master Device

No Software Configuration Required

Single Point Power Termination

Maximum Network Capacity*

System can support up to sixteen (16) Digital Modules max

System can support up to eight (8) 0-10 V Modules max

System can support up to five (5) 4-20 mA Modules max

When adding more than five (5) I/O Modules and creating different

I/O Module combinations, please determine maximum allowable I/O

Module combination per system by utilizing the power budget

calculator.

Power Budget Calculator

http://psft.com/A7U

Data Encoding Method

MSB First

I/O Module Slave ID Selection

16-Position Rotary Switch (+1 for Modbus Slave ID)

DIN Rail Mounting Compatibility

35 mm x 7.5 mm DIN Rail

DataRail™ (Included w/ Kit)

6.1" / 156 mm - Supports Up to Exp. + 5x I/O Modules

Auto-Detection of Modules

Yes, via DataRail at Power-Up

DataRail Mounting Hardware

4-Claw Attachment to 35 mm DIN Rail with End Terminal Bracket

Built-In Mounting Hardware

Spring-Loaded Clip-On System

Wire Gauge

Solid / Stranded (AWG) 28-12 Gauge

Wire Rating

UL: 300 V RMS, 80 °C and 300 V, 105 °C

CSA: 300 V RMS, 105 °C

Warranty

2-Year Limited

SAFETY & COMPLIANCE

RADIO

Operational Temperature

-40 °C to 85 °C / -40 °F to 185 °F

Ambient Temperature

-20 °C to 85 °C / -4 °F to 185 °F

Humidity

0 to 99 %, Non-condensing

Degree of Protection / Housing Type

IP20 / Plastic

Hazardous Locations Classifications

Class I; Division 2 (Zone 2), Pending

3 Specifications

3.1 Hardware and System

3.2 Safety and Compliance

ProSoft Technology, Inc. Page 11 of 36

June 10, 2015

Page 12

Specifications

RS485 Expansion I/O Module

Baud Rate

9600 bits per second

Data Bits

8

Parity / Stop Bits

None / 1

RS485 Modbus Slave Addressing

Interface Supports up to 16 Addresses / I/O Modules*

Red LED (Left)

Power

Green LED (Right)

USB-Ready (For Firmware Update)

Supply Voltage Range

9 - 30 VDC (± 5 %)

Protection Against Polarity

Yes

Power Consumption

Typical: 20 mA / Max: 24 mA @12 VDC

Packaging Dimensions (WxHxD)

5.5 x 10.1 x 2.8-in / 140 x 257 x 72mm

Net Dimensions (WxHxD)

0.7 x 3.9 x 4.5-in / 17.5 x 99 x 114mm

Packaging Weight

0.8 lbs / 363 g

Net Weight

0.3 lbs / 136 g

Digital I/O Module

Number of Inputs

4

Number of Outputs

4

Isolation Voltage

2500 V r.m.s.

Input Voltage Range

3-30 VDC

Input Voltage Threshold

1 Signal ("H"): > 2.3 VDC

0 Signal ("L"): < 1.1 VDC

Output Rating

1 A Sink Current for Open-Drain Outputs / NPN

Green LEDs

Input Indicators

Red LEDs

Output Indicators

Power Consumption

Typical: 18 mA / Max: 26 mA @12 VDC

Packaging Dimensions

(WxHxD) 4.8 x 5.1 x 2.8-in / 123 x 129 x 72mm

Net Dimensions

0.7 x 3.9 x 4.5-in / 17.5 x 99 x 114mm

Packaging Weight

Single: 0.5 lbs / 227 g; Double: 0.8 lbs / 363 g

Net Weight (Single)

0.3 lbs / 136 g

3.3 RS485 Expansion I/O Module

3.4 Digital I/O Module

Page 12 of 36 ProSoft Technology, Inc.

June 10, 2015

Page 13

Specifications

Analog 4-20 mA I/O Module

Number of Inputs

2 (24-bit Resolution)

Number of Outputs

2 (16-bit Resolution)

Isolation Voltage

2500 V r.m.s.

Signal Range

4 mA to 20 mA

Accuracy

< 0.28 % of Full Scale

Internal Loop Power

+13.5 VDC

AI Input Impedance (loop)

128 Ohm

AO Terminal Voltage Range

10 VDC Min. / 31.5 VDC Max.

Power Consumption

Typical: 50 mA / Max: 75 mA @12 VDC

Packaging Dimensions

(WxHxD) 4.8 x 5.1 x 2.8-in / 123 x 129 x 72mm

Net Dimensions

0.7 x 3.9 x 4.5-in / 17.5 x 99 x 114mm

Packaging Weight

Single: 0.5 lbs / 227 g; Double: 0.8 lbs / 363 g

Net Weight (Single)

0.3 lbs / 136 g

Analog 0-10 V I/O Module

Number of Inputs

2 (24-bit Resolution)

Number of Outputs

2 (16-bit Resolution)

Isolation Voltage

2500 V r.m.s.

Signal Range

0 VDC to 10 VDC (10.5 V Max)

Accuracy

< 0.1 % of Full Scale

AI Input Impedance

40K Ohm

AO Output Impedance

10 Ohm

Power Consumption

Typical: 40 mA / Max: 45 mA @12 VDC

Packaging Dimensions

(WxHxD) 4.8 x 5.1 x 2.8-in / 123 x 129 x 72mm

Net Dimensions

0.7 x 3.9 x 4.5-in / 17.5 x 99 x 114mm

Packaging Weight

Single: 0.5 lbs / 227 g; Double: 0.8 lbs / 363 g

Net Weight (Single)

0.3 lbs / 136 g

ORDERING INFORMATION

RS485

RS485 Expansion Kit

BM-1000-PM1K

Kit Content

RS485 Expansion I/O Module, DataRail,

2x End Terminal Brackets, DataRail Cover,

Quick Start Guide, Technician's Screwdriver

Digital I/O

1-Pack: BM-D100-144S

2-Pack: BM-D100-144D

4-20 mA I/O

1-Pack: BM-A420-122S

2-Pack: BM-A420-122D

0-10 V I/O

1-Pack: BM-A010-122S

2-Pack: BM-A010-122D

3.5 4-20 mA I/O Module

3.6 0-10 V I/O Module

3.7 Ordering Information

ProSoft Technology, Inc. Page 13 of 36

June 10, 2015

Page 14

Specifications

Page 14 of 36 ProSoft Technology, Inc.

June 10, 2015

Page 15

Installation

4 Installation

4.1 Outdoor Enclosure Installation

1. Install or use existing outdoor NEMA-type enclosure.

2. Be sure the RS485 I/O Expansion System meets applicable grounding requirements

in the enclosure.

3. Install a 35 mm x 7.5 mm DIN rail (at least 166 mm (6.5-inch) wide) inside the

enclosure.

4. Provide external power supply: 9-30 VDC.

5. Make a hole on the bottom of the enclosure to run wires.

6. Run conduit for power and I/O cabling.

7. Feed power wiring into enclosure.

8. Terminate RS485 wiring.

ProSoft Technology, Inc. Page 15 of 36

June 10, 2015

Page 16

Installation

4.2 RS485 I/O Expansion System Assembly

Warning: Power must be disconnected or turned off prior to attaching or removing any I/O

Modules from the system – failure to comply may cause damage hardware.

1. Securely attach the DataRail onto a 35 mm x 7.5 mm DIN rail by gently

pressing on all four (4) corner clips.

2. Secure DataRail to DIN rail by attaching an End Terminal Bracket.

a. First, hook the metal end of the Bracket to DIN rail and then snap the

other end onto the DIN rail. (Make sure to position the Bracket on the far

left of the DataRail where metal blades meet the plastic).

Page 16 of 36 ProSoft Technology, Inc.

June 10, 2015

Page 17

Installation

3. Attach RS485 I/O Expansion Module to DataRail (place it next to the Bracket

4. Attach I/O Module(s) to the system.

without any gap).

a. First, latch the top hook onto the rail, then snap-in the spring-loaded clip

into place.

a. Place Modules in any combination (do not leave gaps between Modules).

b. When using more than five (5) I/O Modules, determine maximum I/O

Module combination by using power budget calculator: http://psft.com/A7U

c. Use the 16-position switch located on the front of each I/O Module to set

the Modbus Slave ID(s). Slave ID = Switch position number + 1.

Ex: Switch ID 0 + 1 = Slave ID 1

ProSoft Technology, Inc. Page 17 of 36

June 10, 2015

Page 18

Installation

5. Attach the other End Terminal Bracket to secure the Modules. (Place it next

to the last module without leaving a gap)

6. Protect any unused DataRail slots with the cover. Snap-off extra pieces and

store for future use.

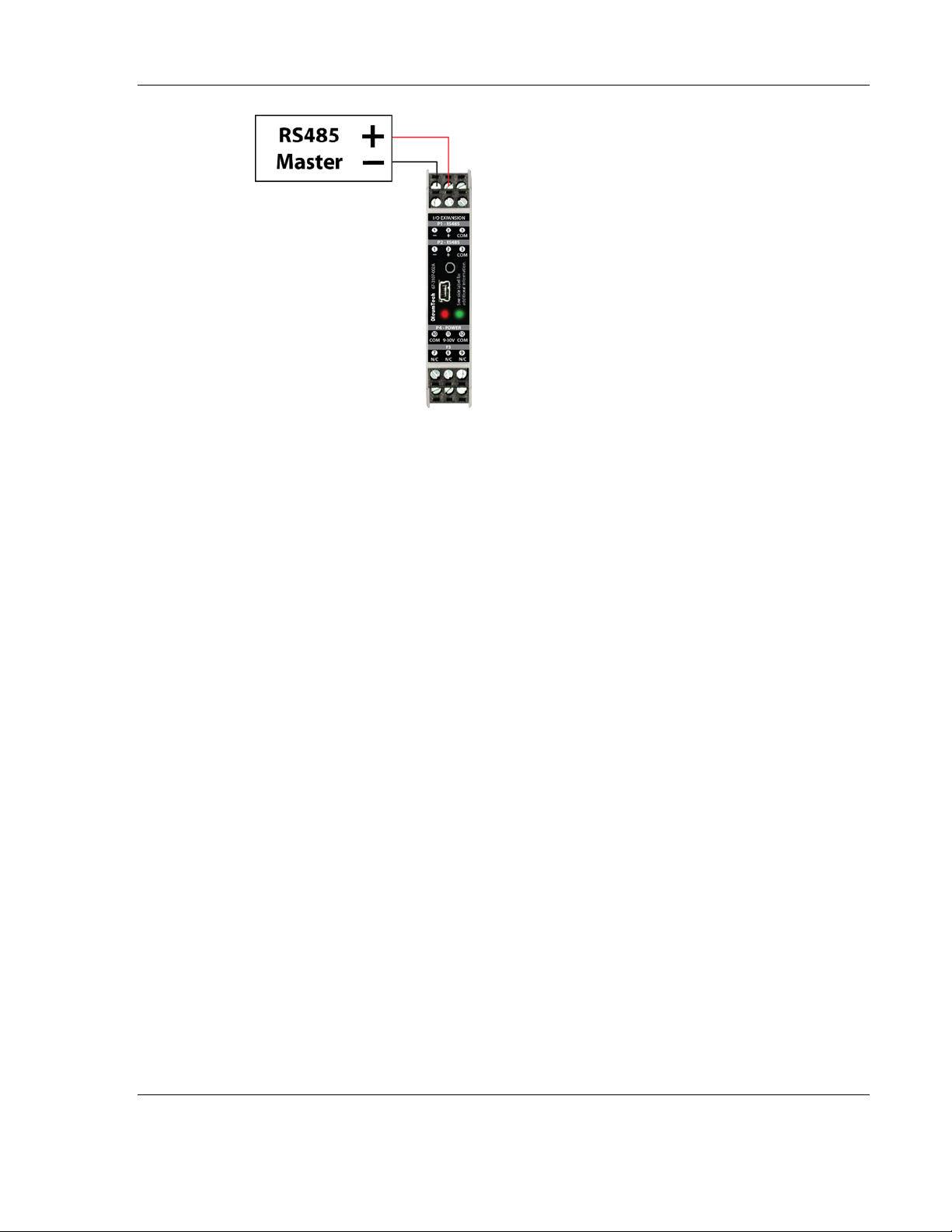

7. Terminate the RS485 terminals.

Page 18 of 36 ProSoft Technology, Inc.

June 10, 2015

Page 19

Installation

8. Terminate I/O and supply power as required. Use solid or stranded wire

(AWG) 28-12.

ProSoft Technology, Inc. Page 19 of 36

June 10, 2015

Page 20

Installation

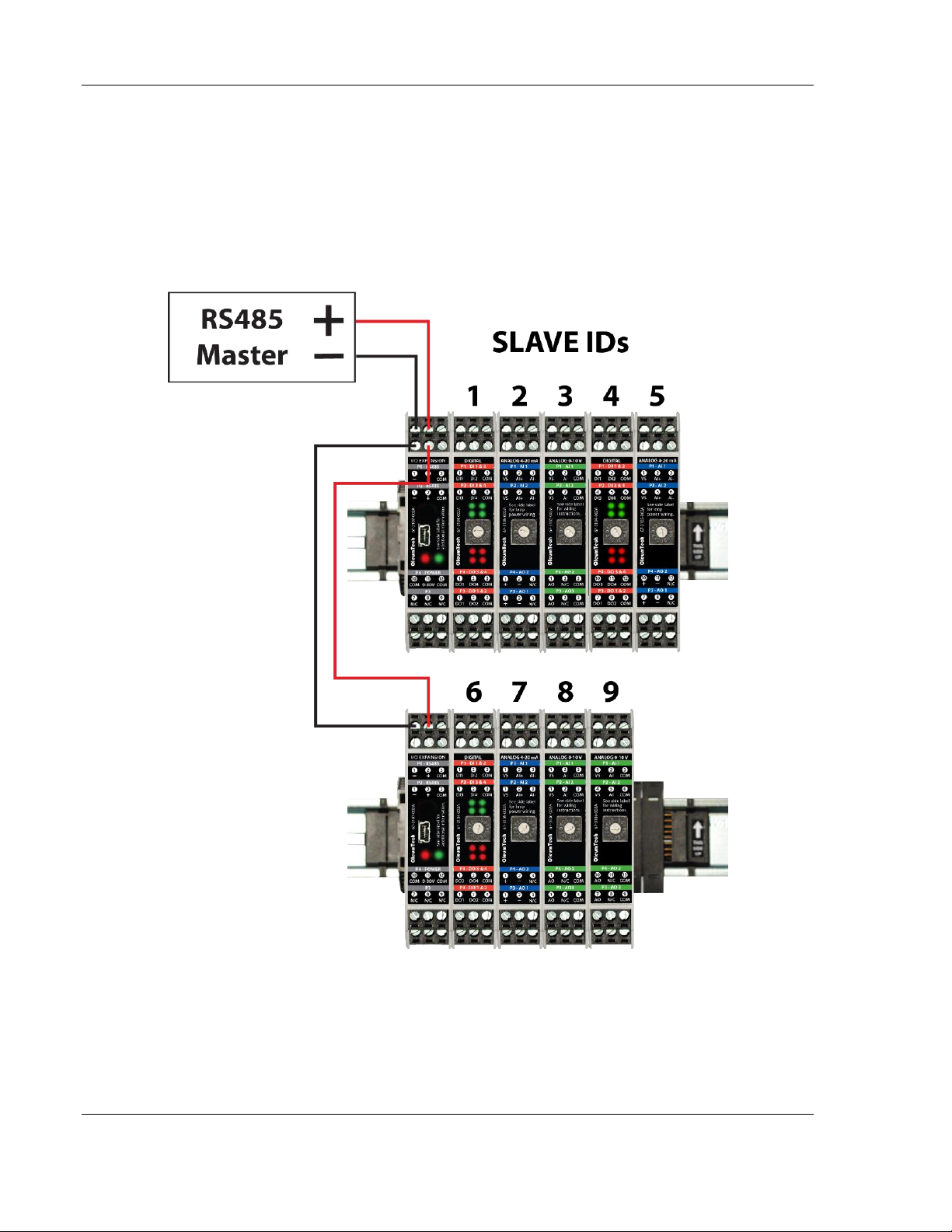

4.3 RS485 Daisy-Chain Diagram

1. If more I/O Modules are required, another RS485 I/O Expansion Module (Kit) set

can be deployed simply using the daisy-chain method.

2. The System holds up to 16 I/O Module Slave addresses regardless of the number

of RS485 I/O Expansion Modules deployed.

3. Each Module must be set to a unique Modbus Slave address.

Page 20 of 36 ProSoft Technology, Inc.

June 10, 2015

Page 21

Installation

4.4 Detaching Components from the DataRail

Warning: All live wiring connections and power must be safely disconnected before taking any

components off the DataRail or Wireless I/O System!

1. The End Terminal Bracket can be removed from the DIN rail by inserting the

tip of a flathead screwdriver into the removal slot. Control the direction with

the screwdriver handle to pull the latch away from the DIN rail.

2. Wireless I/O Modules can be removed from the DIN rail by inserting the tip of

a flathead screwdriver into removal slot located on the metal clip. Lift-up on

the screwdriver handle to pull the spring-loaded clip away from the DIN rail.

ProSoft Technology, Inc. Page 21 of 36

June 10, 2015

Page 22

Page 23

Wiring Diagrams

Data Encoding Method

(Word Order):

MSB First

Data Encoding Method

(Word Order):

MSB First

5 Wiring Diagrams

5.1 RS485 I/O Expansion Module

(BM-1000-PM1 Shown)

ProSoft Technology, Inc. Page 23 of 36

June 10, 2015

Use Solid / Stranded (AWG) 28-12 Wire Gauge

RS485 I/O Expansion Module does not share a common ground with I/O

Modules. All inputs and outputs on I/O Modules provide field isolation.

Page 24

Wiring Diagrams

5.2 Digital Module

(BM-D100-144 Shown)

Use Solid / Stranded (AWG) 28-12 Wire Gauge

Digital I/O Module does not share a common ground with RS485 Module. All inputs and

outputs on I/O Modules provide field isolation.

If input sensor is powered from the same source as RS485 Module, be sure to

establish a common ground, otherwise sensor will not work properly.

Page 24 of 36 ProSoft Technology, Inc.

June 10, 2015

Page 25

Wiring Diagrams

5.3 Analog 4-20 mA Module

(BM-A420-122 Shown)

VS/External Power (min) = 10 + Max Current (Amp) * R

R

4-20 mA I/O Module does not share a common ground with RS485 Module.

All inputs and outputs on I/O Modules provide field isolation.

= Total Loop Impedance

loop

Use Solid / Stranded (AWG) 28-12 Wire Gauge

loop

ProSoft Technology, Inc. Page 25 of 36

June 10, 2015

Page 26

Wiring Diagrams

5.4 Analog 0-10 V Module

(BM-A010-122 Shown)

Use Solid / Stranded (AWG) 28-12 Wire Gauge

0-10 V I/O Module does not share a common ground with RS485 Module.

All inputs and outputs on I/O Modules provide field isolation.

Page 26 of 36 ProSoft Technology, Inc.

June 10, 2015

Page 27

Modbus Mapping

Digital

Digital, 4-20mA, 0-10 V

Digital, 4-20mA, 0-10 V

Digital

0x10

0x0F

Write Single Coil

Write Single Register

Write Multiple Registers

Write Multiple Coils

0x06

Definitions

Applicable Module(s)

Digital

Digital

Digital, 4-20mA, 0-10 V

Read Coils

Read Discrete Inputs

Read Holding Registers

0x01

0x02

0x03

0x05

Supported Function Codes

6 Modbus Mapping

6.1 Supported Modbus Function Codes

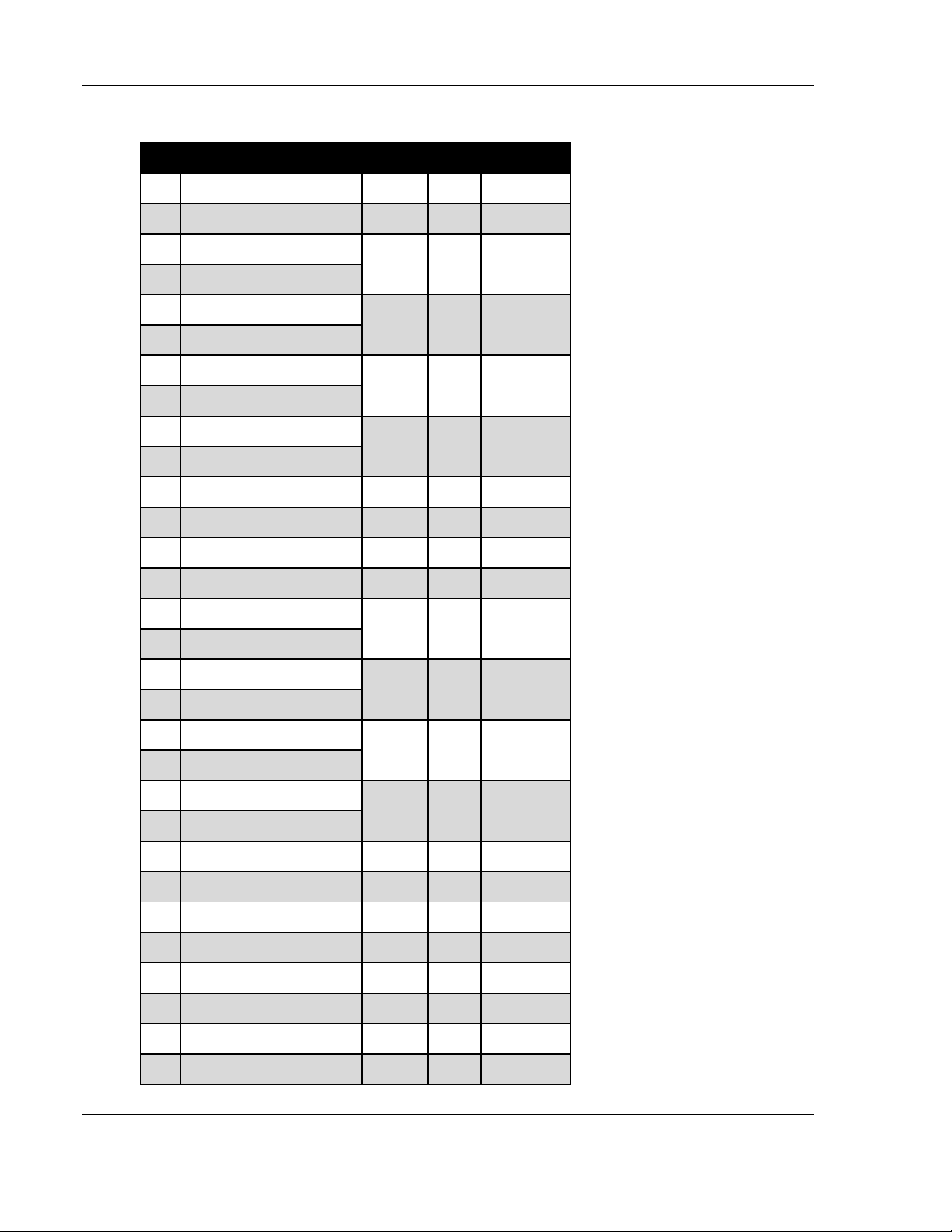

6.2 Digital I/O Module – Modbus Mapping Table

ProSoft Technology, Inc. Page 27 of 36

June 10, 2015

Page 28

Modbus Mapping

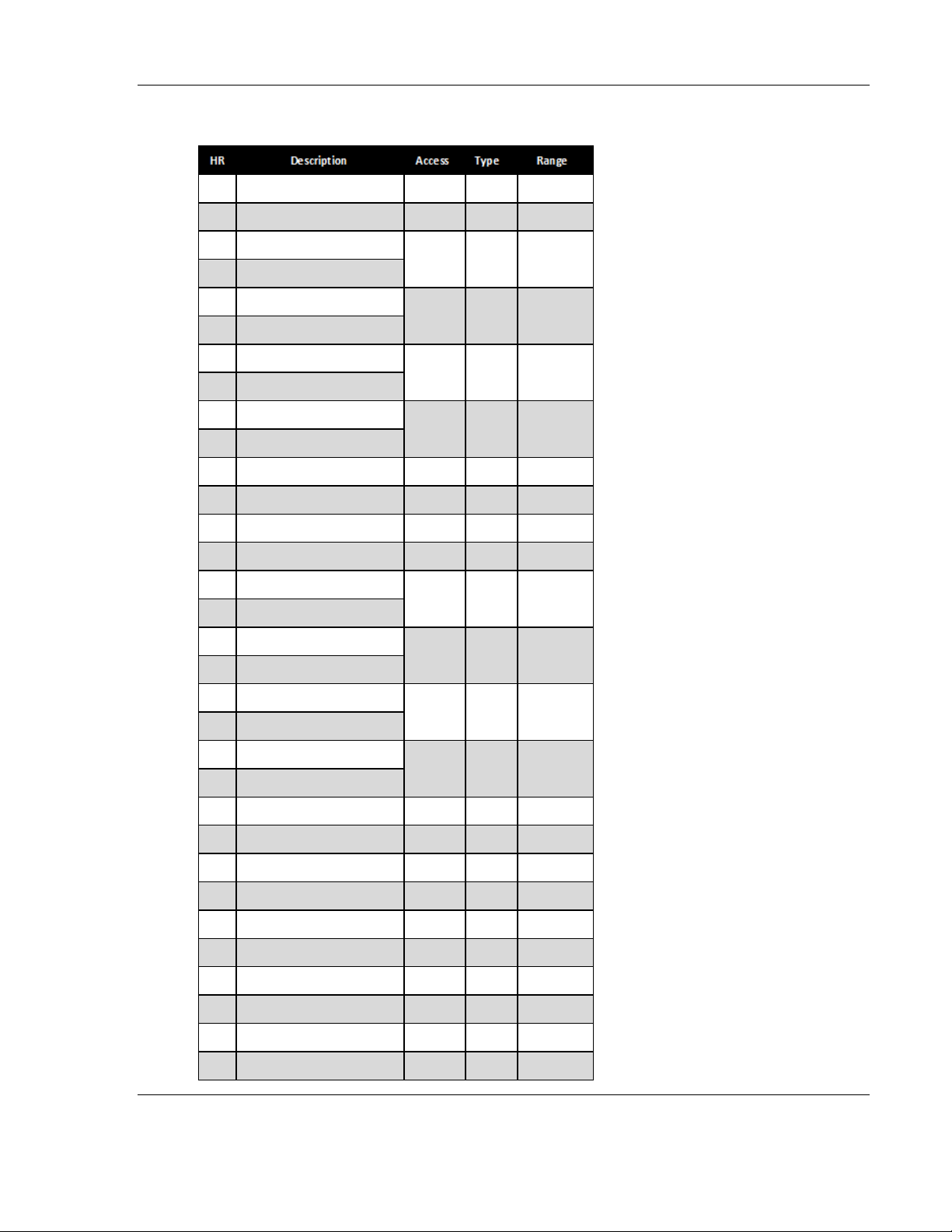

HR Description Access Type Range

3001 Analog Input 1 Current /1 000 Read UINT 16 4000..20,000

3002 Analog Input 2 Current /1 000 Read UINT 16 4000..20,000

3003 Analog Input 1 Raw Split-Hi

3004 Analog Input 1 Raw Split-Lo

3005 Analog Input 2 Raw Split-Hi

3006 Analog Input 2 Raw Split-Lo

3007 Analog Input 1 Current Split-Hi

3008 Analog Input 1 Current Split-Lo

3009 Analog Input 2 Current Split-Hi

3010 Analog Input 2 Current Split-Lo

3011 Analog Output 1 Current /1 000 Read/Write UINT 16 0..20,000

3012 Analog Output 2 Current /1 000 Read/Write UINT 16 0..20,000

3013 Analog Output 1 % /100 Read/Write UINT 16 0..10,000

3014 Analog Output 2 % /100 Read/Write UINT 16 0..10,000

3015 Analog Output 1 Current Split-Hi

3016 Analog Output 1 Current Split-Lo

3017 Analog Output 2 Current Split-Hi

3018 Analog Output 2 Current Split-Lo

3019 Analog Output 1 % Split-Hi

3020 Analog Output 1 % Split-Lo

3021 Analog Output 2 % Split-Hi

3022 Analog Output 2 % Split-Lo

5001 Analog Input 1 Raw Read UINT 32 0..8,388,607

5002 Analog Input 2 Raw Read UINT 32 0..8,388,607

7001 Analog Input 1 Current Read IEE FLOAT 4 .0..20.0

7002 Analog Input 2 Current Read IEE FLOAT 4 .0..20.0

7003 Analog Output 1 Current Read/Write IEE FLOAT 4.0..20.0

7004 Analog Output 2 Current Read/Write IEE FLOAT 4.0..20.0

7005 Analog Output 1 % Read/Write IEE FLOAT 0.0..100.0

7006 Analog Output 2 % Read/Write IEE FLOAT 0.0..100.0

Read/Write

UINT 32

0..8,388,607

UINT 32

0..8,388,607

Read

Read

IEE FLOAT

0.0..100.0

IEE FLOAT

0.0..100.0

IEE FLOAT

4.0..20.0

IEE FLOAT

4.0..20.0

IEE FLOAT

4.0..20.0

IEE FLOAT

4.0..20.0

Read

Read

Read/Write

Read/Write

Read/Write

6.3 4-20 mA I/O Module - Modbus Mapping Table

Page 28 of 36 ProSoft Technology, Inc.

June 10, 2015

Page 29

Modbus Mapping

3001 Analog Input 1 Volts /1000 Read UINT 16 0..10,000

3002 Analog Input 2 Volts /1000 Read UINT 16 0..10,000

3003 Analog Input 1 Raw Split-Hi

3004 Analog Input 1 Raw Split-Lo

3005 Analog Input 2 Raw Split-Hi

3006 Analog Input 2 Raw Split-Lo

3007 Analog Input 1 Volts Split-Hi

3008 Analog Input 1 Volts Split-Lo

3009 Analog Input 2 Volts Split-Hi

3010 Analog Input 2 Volts Split-Lo

3011 Analog Output 1 Raw Read/Write UINT 16 0..65,535

3012 Analog Output 2 Raw Read/Write UINT 16 0..65,535

3013 Analog Output 1 Volts / 1000, % /100 Read/Write UINT 16 0..10,000

3014 Analog Output 2 Volts /1000, % / 100 Read/Write UINT 16 0..10,000

3015 Analog Output 1 V olts Split-Hi

3016 Analog Output 1 Volts S plit-Lo

3017 Analog Output 2 V olts Split-Hi

3018 Analog Output 2 Volts S plit-Lo

3019 Analog Output 1 % Split-Hi

3020 Analog Output 1 % Split-Lo

3021 Analog Output 2 % Split-Hi

3022 Analog Output 2 % Split-Lo

5001 Analog Input 1 Raw Read UINT 32 0..8,388,607

5002 Analog Input 2 Raw Read UINT 32 0..8,388,607

7001 Analog Input 1 Volts Read IEE FLOAT 0.0..10.0

7002 Analog Input 2 Volts Read IEE FLOAT 0.0..10.0

7003 Analog Output 1 Raw Read/Write IEE FLOAT 0.0..65,535.0

7004 Analog Output 2 Raw Read/Write IEE FLOAT 0.0..65,535.0

7005 Analog Output 1 Volts Read/Write IEE FLOAT 0.0..10.0

7006 Analog Output 2 Volts Read/Write IEE FLOAT 0.0..10.0

7007 Analog Output 1 % Read/Write IEE FLOAT 0.0..100.0

7008 Analog Output 2 % Read/Write IEE FLOAT 0.0..100.0

0..8,388,607

UINT 32

0..8,388,607

UINT 32

Read

Read

IEE FLOAT

0.0..10.0

IEE FLOAT

0.0..100.0

IEE FLOAT

0.0..100.0

IEE FLOAT

0.0..10.0

IEE FLOAT

0.0..10.0

IEE FLOAT

0.0..10.0

Read/Write

Read

Read

Read/Write

Read/Write

Read/Write

6.4 0-10 V I/O Module - Modbus Mapping Table

ProSoft Technology, Inc. Page 29 of 36

June 10, 2015

Page 30

Page 30 of 36 ProSoft Technology, Inc.

June 10, 2015

Page 31

Diagnostics

7 Diagnostics

7.1 Radio Module

1. Power LED (Left)

a. Red: Power on

b. LED not on: No power

i. Verify power supply wiring and polarity. (+ to 9-30V, - to COM)

ii. Verify correct pin outs are used. (pin 11 for +, pin 10 or 12 for - )

iii. Verify 9-30 VDC is supplied to the unit.

ProSoft Technology, Inc. Page 31 of 36

June 10, 2015

Page 32

Diagnostics

2. I/O LED (Right):

a. Green: USB enabled

b. LED not on: No power

i. Connect USB to PC first, then to I/O Expansion Module.

ii. Verify unit is powered on, Power LED (left) should be red.

iii. Verify the PC is on.

3. Unable to Read/Write Modbus Values

a. Verify that the Modbus slave ID is the Module ID + 1

Example: If the Module ID is 0, the Modbus slave ID will be 1

b. Select MSB first when applicable when setting up Modbus Master device.

c. Verify Modbus RS485 wiring (3-wire).

d. Verify baud rate, data bits, parity, and stop bits (9600 / 8 / None / 1).

e. Refer to Modbus Mapping (page 27).

i. Verify the Modbus function code.

ii. Verify the Modbus register address.

iii. Verify the data type (integer/float, 16/32 bit).

iv. Verify if address has read/write or only read function capabilities.

Page 32 of 36 ProSoft Technology, Inc.

June 10, 2015

Page 33

Frequently Asked Questions

8 Frequently Asked Questions

1. What is the RS485 I/O Expansion System designed for?

a. It is designed to easily and economically add local I/O points to any industrial

monitoring or control system via RS485 Modbus connectivity.

2. What type of I/O’s are available?

a. Digital/discrete

b. Analog 4-20 mA

c. Analog 0-10 V

3. Does this System require software configuration?

a. No, it requires absolutely no software.

b. Slave ID switch on each I/O Module is used to set the Slave ID.

c. The RS485 I/O Expansion Modules provides power and controls the I/O images.

4. How many I/O Modules can I connect to one RS485 expansion I/O system?

a. Digital: up to 16

b. 4-20 mA: up to 5

c. 0-10 V: up to 8

d. When mixing Modules, use Power Budget Calculator to determine max number

of Modules per system: http://psft.com/A7U

5. Can I use the same I/O Modules with the WIO® Wireless System for replicating

hardwire?

a. Yes, the WIO I/O Modules can be used for both wireless and RS485 I/O

applications

6. Do the I/O Modules require a firmware change when changing from RS485 to

wireless application?

a. No, the I/O Modules are designed to work with either the WIO® Radios or RS485

I/O Expansion Module.

7. How many I/O modules can be connected with the standard DataRail (6.1”) shipped

with RS485 Kit?

a. Standard DataRail supports up to five (5) I/O modules in addition to one RS485

Module.

8. What is the mini USB port on the RS485 Module used for?

a. For updating device firmware via PC.

9. Can the RS485 I/O Expansion System be used in hazardous locations?

a. Yes, the system can be used in Class 1, Division 2 or Zone 2 locations.

Certification pending.

10. How can I obtain tech support or RMA?

a. Please email us at support@prosoft-technology.com or give us a call to begin the

service process. You will be guided by our helpful customer service staff member

to help you get through any issue you are having with the Wireless I/O System.

ProSoft Technology, Inc. Page 33 of 36

June 10, 2015

Page 34

Page 34 of 36 ProSoft Technology, Inc.

June 10, 2015

Page 35

Support, Service & Warranty

9 Support, Service & Warranty

ProSoft Technology, Inc. (ProSoft) is committed to providing the most efficient

and effective support possible. Before calling, please gather the following

information to assist in expediting this process:

1 Product Version Number

2 System architecture

3 Network details

If the issue is hardware related, we will also need information regarding:

1 Module configuration and associated ladder files, if any

2 Module operation and any unusual behavior

3 Configuration/Debug status information

4 LED patterns

5 Details about the serial, Ethernet or fieldbus devices interfaced to the module,

if any.

Note: For technical support calls within the United States, an after-hours answering system allows

24-hour/7-days-a-week pager access to one of our qualified Technical and/or Application Support

Engineers. Detailed contact information for all our worldwide locations is available on the following

page.

ProSoft Technology, Inc. Page 35 of 36

June 10, 2015

Page 36

Support, Service & Warranty

Internet

Web Site: www.prosoft-technology.com/support

E-mail address: support@prosoft-technology.com

Asia Pacific

(location in Malaysia)

Tel: +603.7724.2080, E-mail: asiapc@prosoft-technology.com

Languages spoken include: Chinese, English

Asia Pacific

(location in China)

Tel: +86.21.5187.7337 x888, E-mail: asiapc@prosoft-technology.com

Languages spoken include: Chinese, English

Europe

(location in Toulouse, France)

Tel: +33 (0) 5.34.36.87.20,

E-mail: support.EMEA@prosoft-technology.com

Languages spoken include: French, English

Europe

(location in Dubai, UAE)

Tel: +971 (0)4.214.6911,

E-mail: mea@prosoft-technology.com

Languages spoken include: English, Hindi

North America

(location in California)

Tel: +1 661-716-5100,

E-mail: support@prosoft-technology.com

Languages spoken include: English, Spanish

Latin America

(Oficina Regional)

Tel: +1-281-298-9109,

E-Mail: latinam@prosoft-technology.com

Languages spoken include: Spanish, English

Latin America

(location in Puebla, Mexico)

Tel: +52-222-399-6565,

E-mail: soporte@prosoft-technology.com

Languages spoken include: Spanish

Brasil

(location in Sao Paulo)

Tel: +55-11-5083-3776,

E-mail: brasil@prosoft-technology.com

Languages spoken include: Portuguese, English

9.1 Warranty Information

For complete details regarding ProSoft Technology’s TERMS & CONDITIONS

OF SALE, WARRANTY, SUPPORT, SERVICE AND RETURN MATERIAL

AUTHORIZATION INSTRUCTIONS please see the documents on the Product

DVD or at www.prosoft-technology.com/warranty.

All documentation is subject to change without notice.

Page 36 of 36 ProSoft Technology, Inc.

June 10, 2015

Loading...

Loading...