Page 1

ProLinx-HART

ProLinx Gateway

HART Master with Analog I/O

October 13, 2011

DRIVER MANUAL

Page 2

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comments,

compliments or complaints about our products, documentation, or support, please write or call us.

How to Contact Us

ProSoft Technology

5201 Truxtun Ave., 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

www.prosoft-technology.com

support@prosoft-technology.com

Copyright © 2011 ProSoft Technology, Inc., all rights reserved.

ProLinx-HART Driver Manual

October 13, 2011

ProSoft Technology ®, ProLinx ®, inRAx ®, ProTalk ®, and RadioLinx ® are Registered Trademarks of ProSoft

Technology, Inc. All other brand or product names are or may be trademarks of, and are used to identify products

and services of, their respective owners.

ProSoft Technology® Product Documentation

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided on the enclosed CD-ROM in

Adobe® Acrobat Reader file format (.PDFs). These product documentation files may also be freely downloaded from

our web site: www.prosoft-technology.com

Page 3

Important Installation Instructions

Power, Input, and Output (I/O) wiring must be in accordance with Class I, Division 2 wiring methods, Article 501-4 (b)

of the National Electrical Code, NFPA 70 for installation in the U.S., or as specified in Section 18-1J2 of the Canadian

Electrical Code for installations in Canada, and in accordance with the authority having jurisdiction. The following

warnings must be heeded:

WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR

SUITABILITY FOR CLASS I, DIV. 2;

WARNING - EXPLOSION HAZARD - WHEN IN HAZARDOUS LOCATIONS, TURN OFF

POWER BEFORE REPLACING OR WIRING MODULES

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER

HAS BEEN SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

THIS DEVICE SHALL BE POWERED BY CLASS 2 OUTPUTS ONLY.

ProLinx® Products Warnings

WARNING – EXPLOSION HAZARD – DO NOT DISCONNECT EQUIPMENT UNLESS

POWER HAS BEEN SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

AVERTISSEMENT – RISQUE D'EXPLOSION – AVANT DE DÉCONNECTER L'EQUIPMENT,

COUPER LE COURANT OU S'ASSURER QUE L'EMPLACEMENT EST DÉSIGNÉ NON

DANGEREUX.

ProLinx Gateways with Ethernet Ports

Series C ProLinx™ Gateways with Ethernet ports do NOT include the HTML Web Server. The HTML Web Server

must be ordered as an option. This option requires a factory-installed hardware addition. The HTML Web Server now

supports:

8 MB file storage for HTML files and associated graphics files (previously limited to 384K)

32K maximum HTML page size (previously limited to 16K)

To upgrade a previously purchased Series C model

Contact your ProSoft Technology distributor to order the upgrade and obtain a Returned Merchandise Authorization

(RMA) to return the unit to ProSoft Technology.

To order a ProLinx Plus gateway with the -WEB option

Add -WEB to the standard ProLinx part number. For example, 5201-MNET-MCM-WEB.

Page 4

PLX Markings

Label Markings

ATEX

<Ex>

II 3 G

Ex nA IIC T4

-20°C <= Ta <= 50°C

II – Equipment intended for above ground use (not for use in mines).

3 – Category 3 equipment, investigated for normal operation only.

G – Equipment protected against explosive gasses.

Agency Approvals and Certifications

ATEX EN 60079-0:2009, EN 60079-15:2010

CE IEC 1131-2:1, EN60950:2000, EN55011:1998, Class A, EN61000-6-2:1998,

EN50021:1999

CB Safety IEC 60950-1:2005-Ed2, EN60950-1:2006, CB243333-2393116

Page 5

ProLinx-HART ♦ ProLinx Gateway Contents

HART Master with Analog I/O Driver Manual

Contents

Your Feedback Please ........................................................................................................................ 2

How to Contact Us .............................................................................................................................. 2

ProSoft Technology® Product Documentation .................................................................................... 2

Important Installation Instructions ....................................................................................................... 3

ProLinx® Products Warnings ............................................................................................................... 3

ProLinx Gateways with Ethernet Ports ............................................................................................... 3

To upgrade a previously purchased Series C model ..................................................................... 3

To order a ProLinx Plus gateway with the -WEB option ................................................................ 3

PLX Markings ...................................................................................................................................... 4

Agency Approvals and Certifications .................................................................................................. 4

1 Start Here 9

1.1

1.2

1.3

1.4

1.5

1.5.1

System Requirements ............................................................................................. 10

Package Contents ................................................................................................... 11

Mounting the Gateway on a DIN-rail ....................................................................... 12

Connecting Power to the Unit ................................................................................. 13

Installing ProSoft Configuration Builder Software ................................................... 14

Using the Online Help ............................................................................................. 14

2 Functional Overview 15

2.1

2.2

2.3

2.3.1

2.3.2

2.3.3

HART Channels ...................................................................................................... 16

Functional Specifications - HART Analog ............................................................... 17

Module Internal Database ....................................................................................... 20

HART Channel Driver Access to Database ............................................................ 20

HART Command List .............................................................................................. 21

Auto-Polling ............................................................................................................. 21

3 HART Protocol Configuration 27

3.1

3.1.1

3.1.2

3.1.3

3.2

3.2.1

3.2.2

3.2.3

3.2.4

3.2.5

3.2.6

3.2.7

3.2.8

3.2.9

3.2.10

3.3

3.3.1

3.3.2

ProSoft Technology, Inc. Page 5 of 104

October 13, 2011

[Analog HART Card x] ............................................................................................. 28

Database Register ................................................................................................... 28

CHx Low .................................................................................................................. 28

CHx High ................................................................................................................. 28

[HART PORT x] ....................................................................................................... 29

Enabled ................................................................................................................... 29

Preambles ............................................................................................................... 29

Primary Master ........................................................................................................ 29

Retry Count ............................................................................................................. 29

DB Address Status .................................................................................................. 29

Command Count ..................................................................................................... 30

Auto-Poll Code ........................................................................................................ 30

Auto-Poll DB Address .............................................................................................. 30

Auto-Poll Swap Float ............................................................................................... 30

Max Device Count ................................................................................................... 30

[HART PORT x COMMANDS] ................................................................................ 31

Command List Overview ......................................................................................... 31

HART Command Entry Formats ............................................................................. 32

Page 6

Contents ProLinx-HART ♦ ProLinx Gateway

Driver Manual HART Master with Analog I/O

3.3.3

3.4

3.5

3.3.4

3.3.5

3.3.6

3.3.7

3.3.8

3.3.9

3.3.10

3.3.11

3.3.12

3.3.13

3.3.14

3.3.15

3.3.16

3.3.17

3.3.18

3.3.19

3.4.1

3.4.2

3.4.3

3.4.4

3.4.5

3.4.6

Enable ..................................................................................................................... 32

Float DB Address .................................................................................................... 33

Poll Interval ............................................................................................................. 33

FP Word Count ....................................................................................................... 33

Swap Code ............................................................................................................. 33

Short Address ......................................................................................................... 33

Function Code......................................................................................................... 33

Int. DB Address ....................................................................................................... 34

Int Word Count ........................................................................................................ 34

Swap Code ............................................................................................................. 34

Use Long ................................................................................................................. 34

Enable DB Address ................................................................................................ 35

Done DB Address ................................................................................................... 35

Write DB Address ................................................................................................... 35

Swap Code ............................................................................................................. 35

Byte Count .............................................................................................................. 35

Fixed Data ............................................................................................................... 36

Using the CommonNet Data Map ........................................................................... 37

Internal Database Re-mapping ............................................................................... 38

From Address ......................................................................................................... 38

To Address .............................................................................................................. 38

Register Count ........................................................................................................ 38

Swap Code ............................................................................................................. 38

Delay Preset ........................................................................................................... 39

Downloading a File from PC to the Module ............................................................ 40

4 Reference 41

4.1

COMMAND 00 - Read Unique Identifier ..................................................................................... 42

COMMAND 01 - Read Primary Variable ..................................................................................... 43

COMMAND 02 - Read Current And Percent Of Range .............................................................. 44

COMMAND 03 - Read Dynamic Variables ................................................................................. 45

COMMAND 06 - Write Polling Address ....................................................................................... 46

COMMAND 12 - Read Message ................................................................................................. 47

COMMAND 13 - Read Tag, Descriptor and Date ....................................................................... 48

COMMAND 14 - Read PV Sensor Info ....................................................................................... 49

COMMAND 15 - Read Output Information .................................................................................. 50

COMMAND 16 - Read Final Assembly Number ......................................................................... 51

COMMAND 17 - Write Message ................................................................................................. 52

COMMAND 18 - Write Tag, Descriptor and Date ....................................................................... 53

COMMAND 19 - Write Final Assembly Number ......................................................................... 54

4.2

COMMAND 33 - Read Transmitter Variables ............................................................................. 55

COMMAND 34 - Write Damping Value ....................................................................................... 56

COMMAND 35 - Write Range Values ......................................................................................... 57

COMMAND 36 - Set Upper Range Value ................................................................................... 58

COMMAND 37 - Set Lower Range Value ................................................................................... 59

COMMAND 38 - Reset Configuration Changed Flag ................................................................. 60

COMMAND 39 - EEPROM Control ............................................................................................. 61

COMMAND 40 - Enter Exit Fixed Current Mode ......................................................................... 62

COMMAND 41 - Perform Transmitter Self Test .......................................................................... 63

COMMAND 42 - Perform Master Reset ...................................................................................... 64

COMMAND 43 - Set PV Zero...................................................................................................... 65

Page 6 of 104 ProSoft Technology, Inc.

October 13, 2011

HART Universal Commands ................................................................................... 42

HART Common Practice Commands ..................................................................... 55

Page 7

ProLinx-HART ♦ ProLinx Gateway Contents

HART Master with Analog I/O Driver Manual

COMMAND 44 - Write PV Units .................................................................................................. 66

COMMAND 45 - Trim DAC Zero ................................................................................................. 67

COMMAND 46 - Trim DAC Gain ................................................................................................. 68

COMMAND 47 - Write Transfer Function .................................................................................... 69

COMMAND 48 - Read Additional Transmitter Status .................................................................. 70

COMMAND 49 - Write PV Sensor Serial Number ....................................................................... 71

COMMAND 50 - Read Dynamic Variable Assignments .............................................................. 72

COMMAND 51 - Write Dynamic Variable Assignments .............................................................. 73

COMMAND 52 - Set Transmitter Variable Zero .......................................................................... 74

COMMAND 53 - Write Transmitter Variable Units ...................................................................... 75

COMMAND 54 - Read Transmitter Variable Information ............................................................ 76

COMMAND 55 - Write Transmitter Variable Damping Value ...................................................... 77

COMMAND 56 - Write Transmitter Variable Sensor Serial Number ........................................... 78

COMMAND 57 - Read Unit Tag Descriptor Date ........................................................................ 79

COMMAND 58 - Write Unit Tag Descriptor Date ........................................................................ 80

COMMAND 59 - Write Number Of Response Preambles ........................................................... 81

COMMAND 108 - Write Burst Mode Command Number ............................................................ 82

COMMAND 109 - Burst Mode Control......................................................................................... 83

COMMAND 110 - Read All Dynamic Variables ........................................................................... 84

4.3

4.4

4.3.1

4.3.2

4.4.1

4.4.2

4.4.3

Error/Status Data ..................................................................................................... 85

Viewing Error and Status Data ................................................................................ 85

Status Data Mapping Addresses (HART Channels 0 through 7) ............................ 85

ProLinx 5108 / 5208 HART Field Connections ....................................................... 90

Connections for HART Analog Point-to-Point Devices ........................................... 90

Network Power Supply Requirements .................................................................... 90

Wiring Diagrams ...................................................................................................... 91

5 Support, Service & Warranty 95

Contacting Technical Support ........................................................................................................... 95

5.1

5.2

5.1.1

5.1.2

5.1.3

5.2.1

5.2.2

5.2.3

5.2.4

5.2.5

5.2.6

5.2.7

5.2.8

5.2.9

5.2.10

Return Material Authorization (RMA) Policies and Conditions................................ 97

Returning Any Product ............................................................................................ 97

Returning Units Under Warranty ............................................................................. 97

Returning Units Out of Warranty ............................................................................. 98

LIMITED WARRANTY ............................................................................................. 99

What Is Covered By This Warranty ......................................................................... 99

What Is Not Covered By This Warranty ................................................................ 100

Disclaimer Regarding High Risk Activities ............................................................ 100

Intellectual Property Indemnity .............................................................................. 101

Disclaimer of all Other Warranties ........................................................................ 101

Limitation of Remedies ** ...................................................................................... 102

Time Limit for Bringing Suit ................................................................................... 102

No Other Warranties ............................................................................................. 102

Allocation of Risks ................................................................................................. 102

Controlling Law and Severability ........................................................................... 102

Index 103

ProSoft Technology, Inc. Page 7 of 104

October 13, 2011

Page 8

Contents ProLinx-HART ♦ ProLinx Gateway

Driver Manual HART Master with Analog I/O

Page 8 of 104 ProSoft Technology, Inc.

October 13, 2011

Page 9

ProLinx-HART ♦ ProLinx Gateway Start Here

HART Master with Analog I/O Driver Manual

1 Start Here

In This Chapter

System Requirements ........................................................................... 10

Package Contents ................................................................................. 11

Mounting the Gateway on a DIN-rail ..................................................... 12

Connecting Power to the Unit ................................................................ 13

Installing ProSoft Configuration Builder Software .................................. 14

ProSoft Technology, Inc. Page 9 of 104

October 13, 2011

Page 10

Start Here ProLinx-HART ♦ ProLinx Gateway

Driver Manual HART Master with Analog I/O

1.1 System Requirements

The ProSoft Configuration Builder configuration software for the ProLinx-HART module

requires the following minimum hardware and software components:

Pentium® II 450 MHz minimum. Pentium III 733 MHz (or better) recommended

128 Mbytes of RAM minimum, 256 Mbytes of RAM recommended

100 Mbytes of free hard disk space (or more based on application requirements)

256-color VGA graphics adapter, 800 x 600 minimum resolution (True Color 1024

768 recommended)

CD-ROM drive

Supported operating systems:

Microsoft Windows 7(32 bit) (64bit not tested)

Microsoft Windows Vista (not tested)

Microsoft Windows XP Professional with Service Pack 1 or 2

Microsoft Windows 2000 Professional with Service Pack 1, 2, or 3 (not tested)

Microsoft Windows Server 2003 (not tested)

Page 10 of 104 ProSoft Technology, Inc.

October 13, 2011

Page 11

ProLinx-HART ♦ ProLinx Gateway Start Here

HART Master with Analog I/O Driver Manual

1.2 Package Contents

The following components are included with your ProLinx-HART module, and are all

required for installation and configuration.

Important: Before beginning the installation, please verify that all of the following

items are present.

Qty. Part Name Part Number Part Description

1 ProLinx-HART

module

1 Cable Cable #15, RS232

Varies

Varies Adapter 1454-9F Adapters, DB9 Female to Screw Terminal.

1 ProSoft Solutions CD Contains sample programs, utilities and

If any of these components are missing, please contact ProSoft Technology Support for

replacements.

Cable Cable #9, Mini-

PLX-#### ProLinx communication gateway

For RS232 Connection from a PC to the

Null Modem

DIN8 to DB9 Male

Adapter

CFG Port of the module

For DB9 Connection to module’s Port. One

DIN to DB-9M cable included per

configurable serial port, plus one for module

configuration

For RS422 or RS485 Connections to each

serial application port of the module

documentation for the ProLinx-HART

module.

ProSoft Technology, Inc. Page 11 of 104

October 13, 2011

Page 12

Start Here ProLinx-HART ♦ ProLinx Gateway

Driver Manual HART Master with Analog I/O

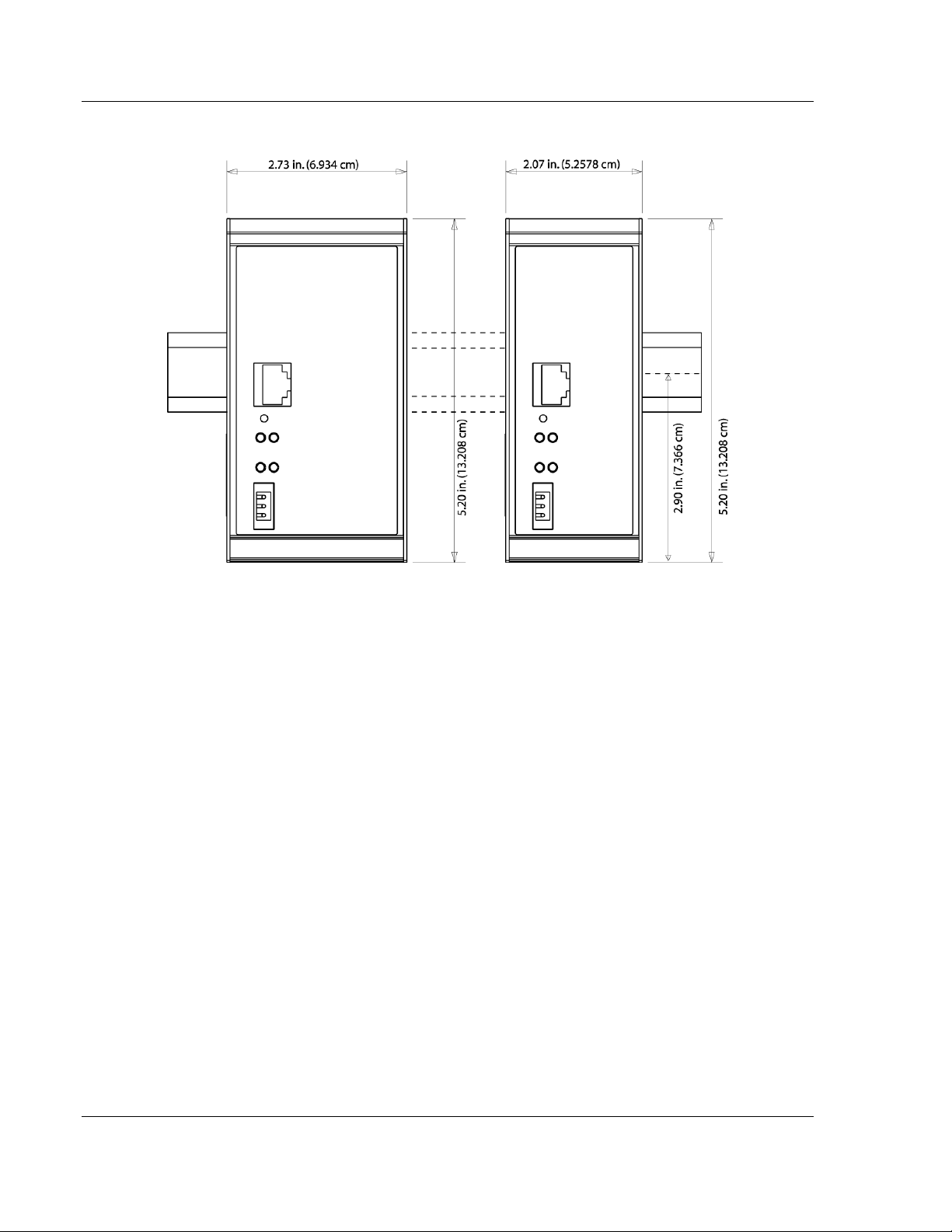

1.3 Mounting the Gateway on a DIN-rail

ProLinx 5000/6000 Series module

Page 12 of 104 ProSoft Technology, Inc.

October 13, 2011

Page 13

ProLinx-HART ♦ ProLinx Gateway Start Here

HART Master with Analog I/O Driver Manual

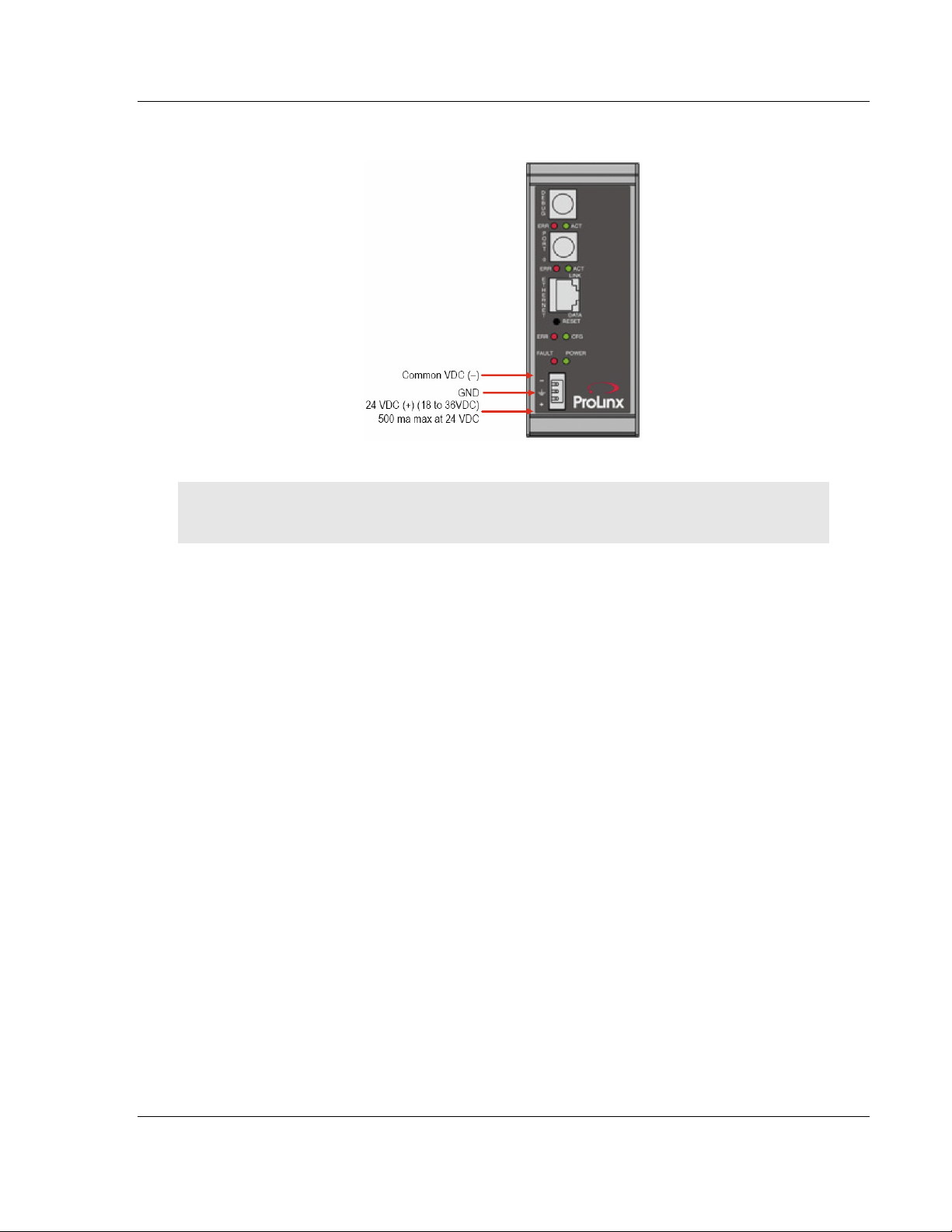

1.4 Connecting Power to the Unit

WARNING: Ensure that you do not reverse polarity when applying power to the

module. This will cause damage to the module’s power supply.

ProSoft Technology, Inc. Page 13 of 104

October 13, 2011

Page 14

Start Here ProLinx-HART ♦ ProLinx Gateway

Driver Manual HART Master with Analog I/O

1.5 Installing ProSoft Configuration Builder Software

You must install the ProSoft Configuration Builder (PCB) software to configure the

module. You can always get the newest version of ProSoft Configuration Builder from the

ProSoft Technology website.

To install ProSoft Configuration Builder from the ProSoft Technology website

1 Open your web browser and navigate to http://www.prosoft-technology.com/pcb

2 Click the link at the Current Release Version section to download the latest version of

ProSoft Configuration Builder.

3 Choose S

4 Save the file to your Windows Desktop, so that you can find it easily when you have

finished downloading.

5 When the download is complete, locate and open the file, and then follow the

instructions on your screen to install the program.

If you do not have access to the Internet, you can install ProSoft Configuration Builder

from the ProSoft Solutions Product CD-ROM, included in the package with your module.

To install ProSoft Configuration Builder from the Product CD-ROM

1 Insert the ProSoft Solutions Product CD-ROM into the CD-ROM drive of your PC.

Wait for the startup screen to appear.

2 On the startup screen, click P

Explorer file tree window.

3 Click to open the U

you will need to set up and configure your module.

4 Double-click the S

and follow the instructions on your screen to install the software on your PC. The

information represented by the "*" character in the file name is the PCB version

number and, therefore, subject to change as new versions of PCB are released.

AVE

or S

AVE FILE

TILITIES

ETUP CONFIGURATION TOOL

when prompted.

RODUCT DOCUMENTATION

folder. This folder contains all of the applications and files

. This action opens a Windows

folder, double-click the PCB_*.

EXE

file

Note: Many of the configuration and maintenance procedures use files and other

utilities on the CD-ROM. You may wish to copy the files from the Utilities folder

on the CD-ROM to a convenient location on your hard drive.

1.5.1 Using the Online Help

Most of the information needed to help you use ProSoft Configuration Builder is provided

in a Help System that is always available whenever you are running ProSoft

Configuration Builder. The Help System does not require an Internet connection.

To view the help pages, start ProSoft Configuration Builder, open the H

then choose C

ONTENTS

.

Page 14 of 104 ProSoft Technology, Inc.

October 13, 2011

ELP

menu, and

Page 15

ProLinx-HART ♦ ProLinx Gateway Functional Overview

HART Master with Analog I/O Driver Manual

2 Functional Overview

In This Chapter

HART Channels .................................................................................... 16

Functional Specifications - HART Analog .............................................. 17

Module Internal Database ..................................................................... 20

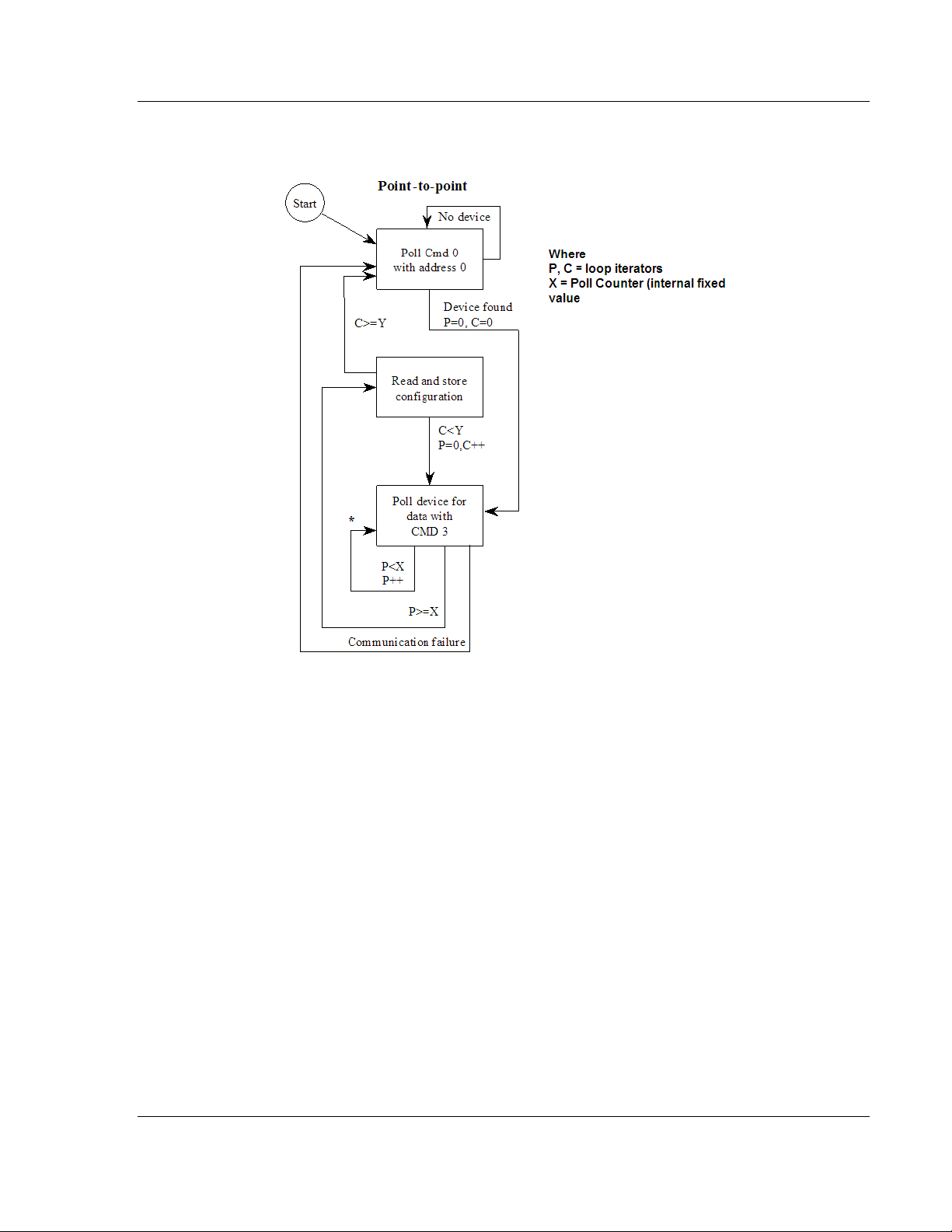

The HART Master + Analog I/O Protocol exists in 4 and 8 channel implementations. This

driver can be configured on an individual channel basis to operate as a HART Master +

Analog I/O Station and supports all the available HART commands including Universal,

Common Practice and Device Specific Commands. Each HART channel is independently

configured to interface with the internal database in the module.

HART® is a registered trademark of the HART Communication Foundation

ProSoft Technology, Inc. Page 15 of 104

October 13, 2011

Page 16

Functional Overview ProLinx-HART ♦ ProLinx Gateway

Driver Manual HART Master with Analog I/O

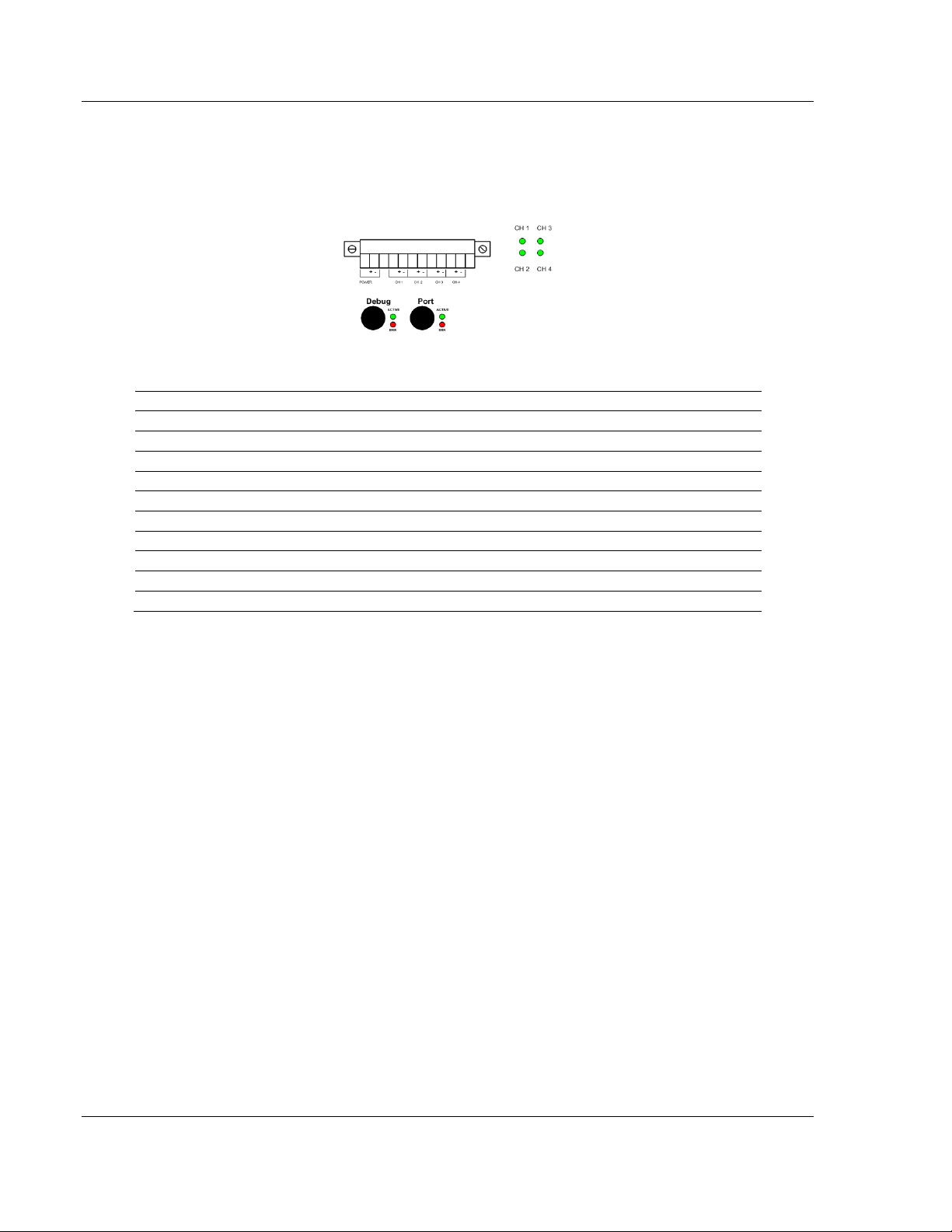

2.1 HART Channels

The ProLinx module supports the HART protocol as a Master on up to 4 channels per

interface card, with one or two cards per gateway. Each channel is individually

configurable.

The relationship between the port labeling on the front of the ProLinx module and the

application is as follows:

Port Label Function

Debug Debug/configuration

Port 0 Communications Port 0

Channel 1 Hart Port 0

Channel 2 Hart Port 1

Channel 3 Hart Port 2

Channel 4 Hart Port 3

Channel 5 Hart Port 4

Channel 6 Hart Port 5

Channel 7 Hart Port 6

Channel 8 HART Port 7

The HART protocol uses the Bell 202 standard frequency shift keying (FSK) signal to

communicate at 1200 baud, superimposed at a low level on the 4 to 20 mA analog

measurement signal. Having an average value of zero, an FSK signal causes no

interference with the analog value. The HART devices are powered from this 4 to 20 mA

analog loop.

User configured commands determine the HART commands to be issued on each

channel to the HART devices. Up to 100 commands can be defined for each port. Data

read from the devices are placed in the virtual database. Any write requests or device

specific command for the HART slave devices are sourced with data from the virtual

database or from a configured constant data block. In the commands it can be specified

whether to use the HART device’s short or long address. If the long address is selected,

the device is polled first with short address to ask for the long one. Then the device is

polled with the long address. The module does all this processing of the address

automatically.

The module can be configured to place slave devices that are not responding to

commands from the master ports at a lower priority. If the module recognizes that a slave

device has failed to respond to a message after the user defined retry count, it will mark

the slave as "in communication failure" and set the error delay time to the specified value.

Each time that the error delay time expires, the slave will be polled and if the answer is

successful, the slave is placed again in an active status. This facility can improve

communication throughput on the HART network.

In a HART network, it is possible to have two masters. The ProLinx module fully supports

the existence of a second master, but it can reduce the throughput on the HART network.

This facility is enabled or disabled in the module’s configuration. If the ability to have a

second master on the network is disabled, then maximum throughput is achieved.

Page 16 of 104 ProSoft Technology, Inc.

October 13, 2011

Page 17

ProLinx-HART ♦ ProLinx Gateway Functional Overview

HART Master with Analog I/O Driver Manual

2.2 Functional Specifications - HART Analog

The HART Analog Protocol exists in 4 and 8 channel implementations. This driver can be

configured on an individual channel basis to operate as a HART Master Station and

supports all the available HART commands including Universal, Common Practice and

Device Specific Commands. Each HART channel is independently configured to interface

with the internal database in the module.

The auto-poll mode allows the module to automatically collect data from each HART

instrument on the channel and store the data in the module’s database without the use of

user commands. The module automatically generates HART commands 0, 3, 13, 14 and

15.

General Parameters

Internal Database 4000 registers (words) available

Communication parameters Number of HART Preambles: 2 to 50

Enable Handheld: Y or N

Primary Master: Y or N

Configurable Parameters per Channel Auto-Poll Enable

Short / Long Address Retries

Retries After Error

Poll Time After Error

Number of Commands

Slave List Error Pointer

HART Driver

Command List Up to 100 command per channel, each fully configurable

for function, slave address, register to/from addressing and

word count for Floating Point or Integer Data

Status Data Error codes returned by the HART protocol available on an

individual command basis. In addition, a slave status list is

maintained per active channel.

Polling of command list User configurable polling of commands, including disabled,

continuous, on change of data (write only) and dynamically

user or automatic enabled.

Isolated HART Analog Input Specifications

Input Range Current: 4 to 20mA with HART

Resolution 16bits

Input Filter First Order Sync: 10 Hz

Current Input Resistance 247.6 ohms +/- 1%

Open circuit detection time 1/2 second maximum

Over current +/-40mA continuous, maximum

Common Mode Noise Rejection 105dB

Calibrated Accuracy @ 25°C 4 to 20 mA: 0.05% of reading

Input Isolation Voltage 2500 V RMS per UL 1577, transformer isolated

24V DC Isolation Voltage 1500 VDC

HART® is a registered trademark of the HART Communication Foundation

ProSoft Technology, Inc. Page 17 of 104

October 13, 2011

Page 18

Functional Overview ProLinx-HART ♦ ProLinx Gateway

Driver Manual HART Master with Analog I/O

HART Commands supported

Universal Command Set

00 Read Unique Identifier

01 Read Primary Variable

02 Read Current And Percent Of Range

03 Read Dynamic Variables

06 Write Polling Address

11 Read Unique Identifier Associated With Tag

12 Read Message

13 Read Tag Descriptor Date

14 Read PV Sensor Info

15 Read Output Information

16 Read Final Assembly Number

17 Write Message

18 Write Tag Descriptor Date

19 Write Final Assembly Number

Page 18 of 104 ProSoft Technology, Inc.

October 13, 2011

Page 19

ProLinx-HART ♦ ProLinx Gateway Functional Overview

HART Master with Analog I/O Driver Manual

Common Practice Command Set

33 Read Transmitter Variables

34 Write Damping Value

35 Write Range Values

36 Set Upper Range Value

37 Set Lower Range Value

38 Reset Configuration Changed Flag

39 EEprom Control

40 Enter Exit Fixed Current Mode

41 Perform Transmitter Self Test

42 Perform Master Reset

43 Set Pv Zero

44 Write Pv Units

45 Trim Dac Zero

46 Trim Dac Gain

47 Write Transfer Function

48 Read Additional Transmitter Status

49 Write Pv Sensor Serial Number

50 Read Dynamic Variable Assignments

51 Write Dynamic Variable Assignments

52 Set Transmitter Variable Zero

53 Write Transmitter Variable Units

54 Read Transmitter Variable Information

55 Write Transmitter Variable Damping Value

56 Write Transmitter Variable Sensor Serial Number

57 Read Unit Tag Descriptor Date

58 Write Unit Tag Descriptor Date

59 Write Number Of Response Preambles

108 Write Burst Mode Command Number

109 Burst Mode Control

110 Read All Dynamic Variables

The ProLinx HART module supports version 5 of the HART protocol.

ProSoft Technology, Inc. Page 19 of 104

October 13, 2011

Page 20

Functional Overview ProLinx-HART ♦ ProLinx Gateway

Driver Manual HART Master with Analog I/O

2.3 Module Internal Database

The internal database is central to the functionality of the module. This database is

shared between all the ports on the module and is used as a conduit to pass information

from one device on one network to one or more devices on another network. This permits

data from devices on one communication port to be viewed and controlled by devices on

another port. In addition to data from the slave and master ports, status and error

information generated by the module can also be mapped into the internal database.

2.3.1 HART Channel Driver Access to Database

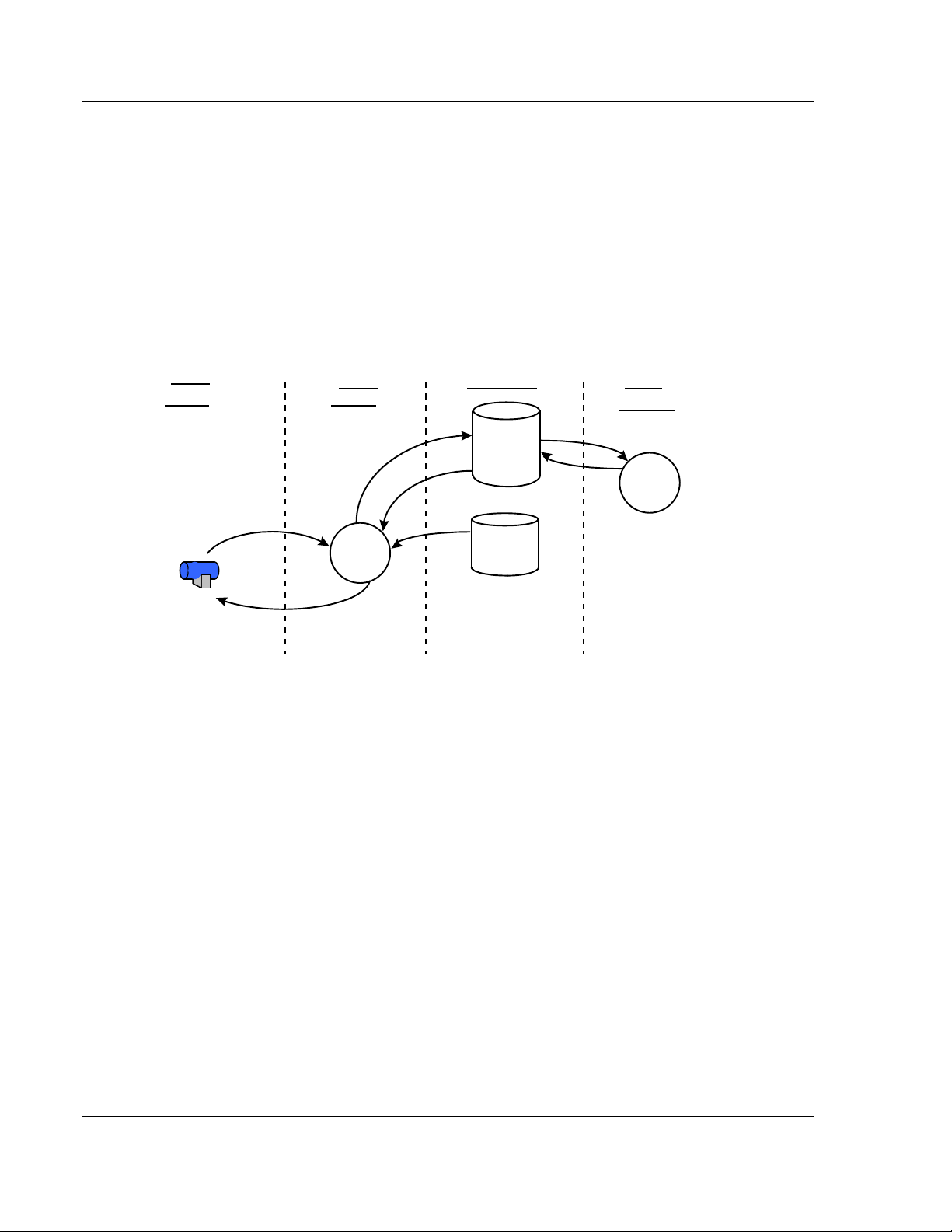

The following illustration describes the flow of data between the HART channel drivers

and the internal database.

HART

Slaves

Response

HART

Master

Write for Read

Command

HART

Driver

Databases Other

Virtual

Database

Write

Read for

Write Command

Read

Command

List

Protocol

Read

Other

Driver

Slave

Device

Request

The HART Master + Analog I/O driver uses the database in two ways:

A read command issued to a slave device by the master driver will return the slave

data into the internal database

A write command issued to a slave device by the master driver use the data in the

internal database to write to the slave device

In addition to data from the Master HART channels, detailed status and error information

generated by the module can also be mapped into the internal database.

Page 20 of 104 ProSoft Technology, Inc.

October 13, 2011

Page 21

ProLinx-HART ♦ ProLinx Gateway Functional Overview

HART Master with Analog I/O Driver Manual

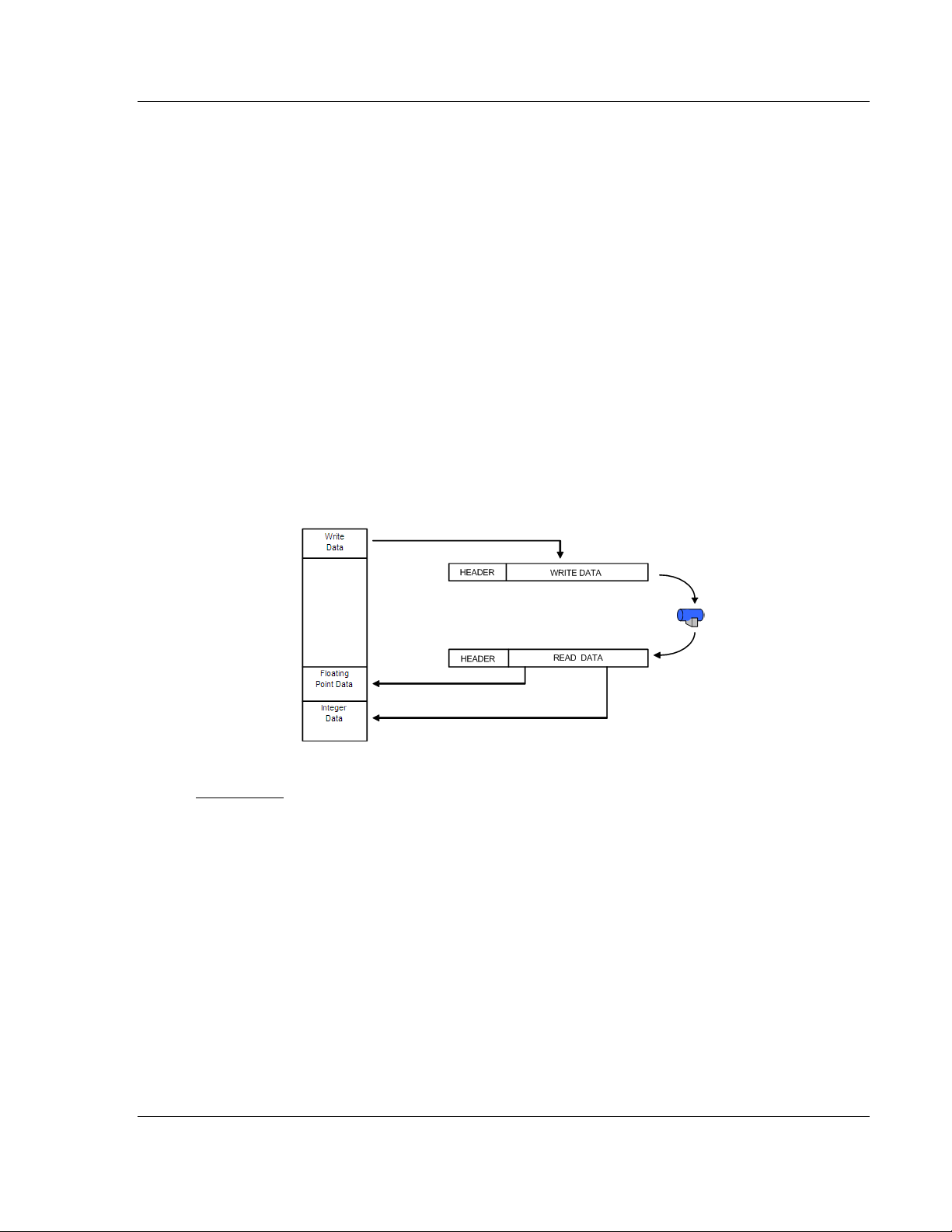

2.3.2 HART Command List

The HART Command List specifies the commands to be executed to the HART devices

connected to a channel. A HART command can be seen as an outgoing message to the

HART devices that provides Write Data for a specific command or a response message

that carries process data (Read Data) back to the module. The ProLinx module supports

three kinds of data blocks in the Universal and Common Practice commands. These data

blocks are:

Integers

IEEE 754 Floating Point Numbers (32 bits)

Packed ASCII character strings

The Packed ASCII character strings are unpacked and placed with the integers data

block.

For all commands, it is possible to select where the Write Data comes from; it can be in

the module’s internal database or it can be configured as a fixed data block in the

command.

For response messages from HART devices, it is possible to configure where the

Floating Point Data and Integer Data will be placed in the module’s internal database, but

this is only possible for the Universal and Common Practice commands. In the case of

Device Specific commands, all the Read Data is placed in the Integer data section. See

HART Command Support for a listing of supported HART commands.

Burst Mode

If a slave on a network will be placed in burst mode, its data can be placed in the

module's database. For the command to be burst by slave device, enter a command in

the user command list with the appropriate HART command number. Set the type field to

0 to disable the command. The parameters in the command will be used to store the data

received from the bursting slave. There can only be one slave bursting on the network at

any one time. This mode can be used for faster update of data from a slave.

2.3.3 Auto-Polling

This feature is enabled by setting the AUTO-POLL CODE (in the configuration file) to a

value of P (point-to-point). If the value N is entered for the parameter, the auto-poll

feature is disabled. When the feature is disabled, the channel will only execute the

commands enabled in the user command list. When the auto-polling mode is enabled,

the module will automatically acquire data from the HART instruments attached to a

channel without the use of user commands. If user commands are present and enabled

when the feature is enabled, they will also be executed independent of auto-polling.

ProSoft Technology, Inc. Page 21 of 104

October 13, 2011

Page 22

Functional Overview ProLinx-HART ♦ ProLinx Gateway

Driver Manual HART Master with Analog I/O

With the auto-poll feature enabled, the module automatically generates the following

HART commands and stores the data in the module's database at the user-specified

location:

CMD Description

0 Read Unique Identifier

3 Read Current and Four Dynamic Variables

13 Read Tag, Descriptor and Date

14 Read PV Sensor Information

15 Read Output Information

If the unit is set for point-to-point mode, the module will automatically gather the

information for the device with the polling address (short address) of zero and place the

data into the database. Each device requires a 50-word database area with the format

shown in the following table.

DB Byte

Offset

0 byte Auto-polling command status bits 1 App Status

1 byte Last first status byte received from

2 byte Last second status byte received

3 byte Manufacture ID Code 1 CMD 0 LongAddress

4 byte Device Type Code 1 CMD 0 LongAddress

5 byte Minimum number of preambles 1 CMD 0 Msgconstruction

6 byte Universal Command Major Rev # 1 CMD 0 Msgchoice

7 byte Device Revision Level 1 CMD 0 Info

8 byte Software Revision Level 1 CMD 0 Info

9 byte Hardware Revision Level/Physical

10 byte Device Flags 1 CMD 0 Info

11 to 13 byte Device ID 3 CMD 0 Long Address

14 byte Minimum number of preambles to

15 byte Maximum number of device

16 to 17 word Configuration Change Counter 2 CMD 0 Info

18 byte Extended Field Device Status 1 CMD 0 Info

19 byte Primary variable units code 1 CMD 3 Cfg

20 byte Secondary variable units code 1 CMD 3 Cfg

21 byte Tertiary variable units code 1 CMD 3 Cfg

22 byte Quaternary variable units code 1 CMD 3 Cfg

23 to 30 byte Tag name 8 CMD 13 Info

31 to 46 byte Descriptor 16 CMD 13 Info

47 to 49 byte Tag/Descriptor data 3 CMD 13 Info

50 to 52 byte Transducer serial number 3 CMD 14 Info

Type Description Byte

Cnt

1 Resp Status

device

1 Resp Status

from device

1 CMD 0 Info

Signaling Code

1 CMD 0

be sent with the response message

from the slave to the master.

1 CMD 0 Info

variables

Data

Source

Use of Data

Page 22 of 104 ProSoft Technology, Inc.

October 13, 2011

Page 23

ProLinx-HART ♦ ProLinx Gateway Functional Overview

HART Master with Analog I/O Driver Manual

DB Byte

Offset

53 byte Transducer limits and min span

54 byte PV alarm selection code 1 CMD 15 Info

55 byte PV transfer function code 1 CMD 15 Info

56 byte PV upper and lower range value

57 byte Write protection code 1 CMD 15 Status

58 byte Private label distributor code 1 CMD 15 Info

59 byte PV analogchannel flag 1 CMD 15 Info

TOTAL BYTE COUNT 60

DB Byte

Offset

60 to 63 float Primary variable value 4 CMD 3 Status

64 to 67 float Secondary variable value 4 CMD 3 Status

68 to 71 float Tertiary variable value 4 CMD 3 Status

72 to 75 float Quaternary variable value 4 CMD 3 Status

76 to 79 float Upper transducer limit 4 CMD 14 Cfg

80 to 83 float Lower transducer limit 4 CMD 14 Cfg

84 to 87 float Minimum span 4 CMD 14 Cfg

88 to 91 float PV upper range value 4 CMD 15 Cfg

92 to 95 float PV lower range value 4 CMD 15 Cfg

96 to 99 float PV damping value (in seconds) 4 CMD 15 Cfg

TOTAL FLOAT BYTE COUNT 40

Type Description Byte

Cnt

1 CMD 14 Info

units code

1 CMD 15 Info

units code

TOTAL WORD COUNT 30

Type Description Byte

TOTAL FLOAT WORD COUNT 20

Data

Source

Cnt

Data

Source

Use of Data

Use of Data

DB Regs/Device 50

Max DB Regs/channel for 15 Devices 750

Max DB Regs for HART Card 3000

The following table defines the auto-polling command status bits:

Bit # Description

0 Long Address Set (command 0 successful)

1 Command 13 successful (configuration)

2 Command 14 successful (configuration)

3 Command 15 successful (configuration)

4 Command 3 successful (data polling)

5 Reserved

6 Reserved

7 Reserved

ProSoft Technology, Inc. Page 23 of 104

October 13, 2011

Page 24

Functional Overview ProLinx-HART ♦ ProLinx Gateway

Driver Manual HART Master with Analog I/O

The following topics describe the modes of module operation.

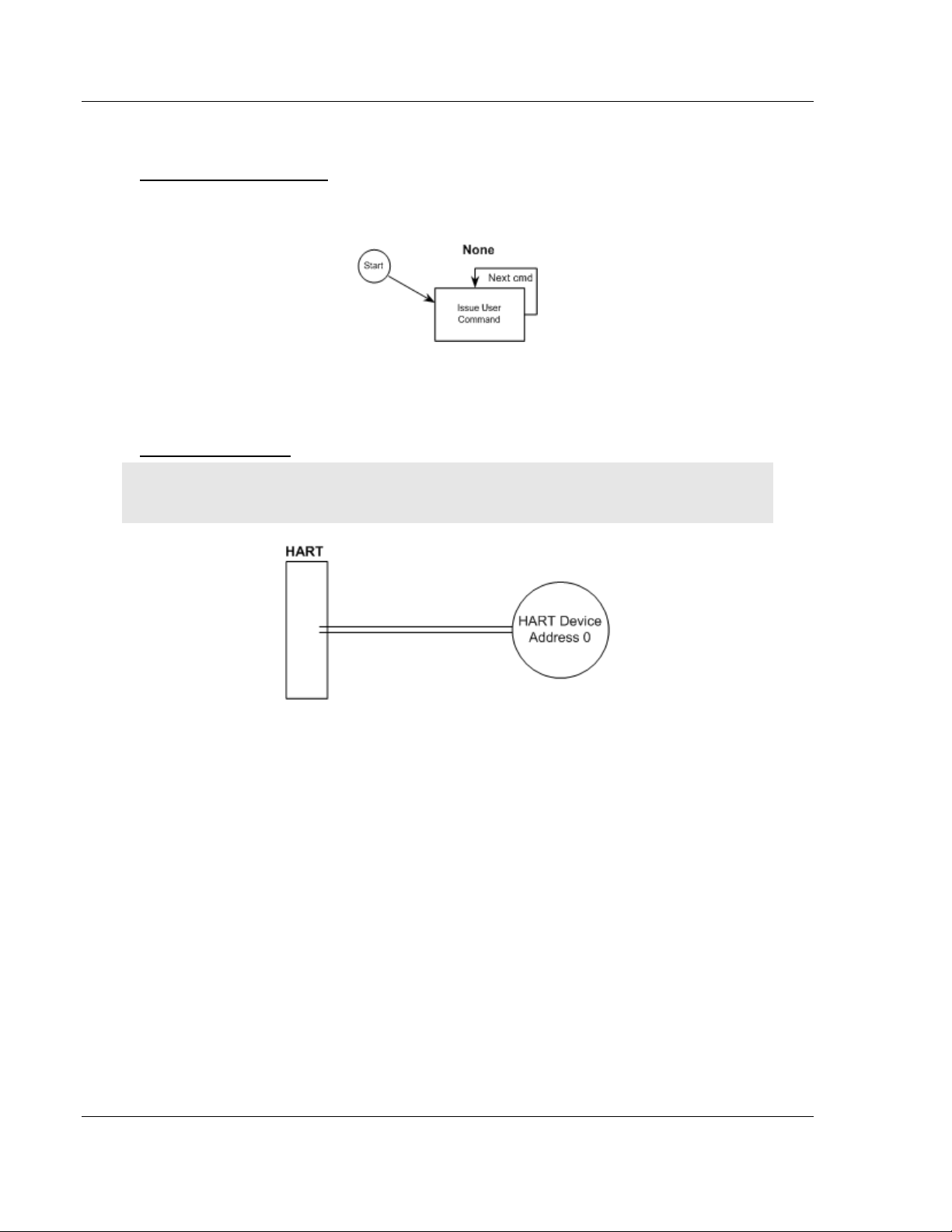

Auto-Poll Disabled Mode

If the auto-polling feature is disabled (Auto-Poll Code = N), the module functions as

shown in the following diagram:

Only the user commands are executed and all data is placed in and sourced from the

module's internal database. The user is responsible for constructing all commands to

control and monitor the instruments attached to the channel.

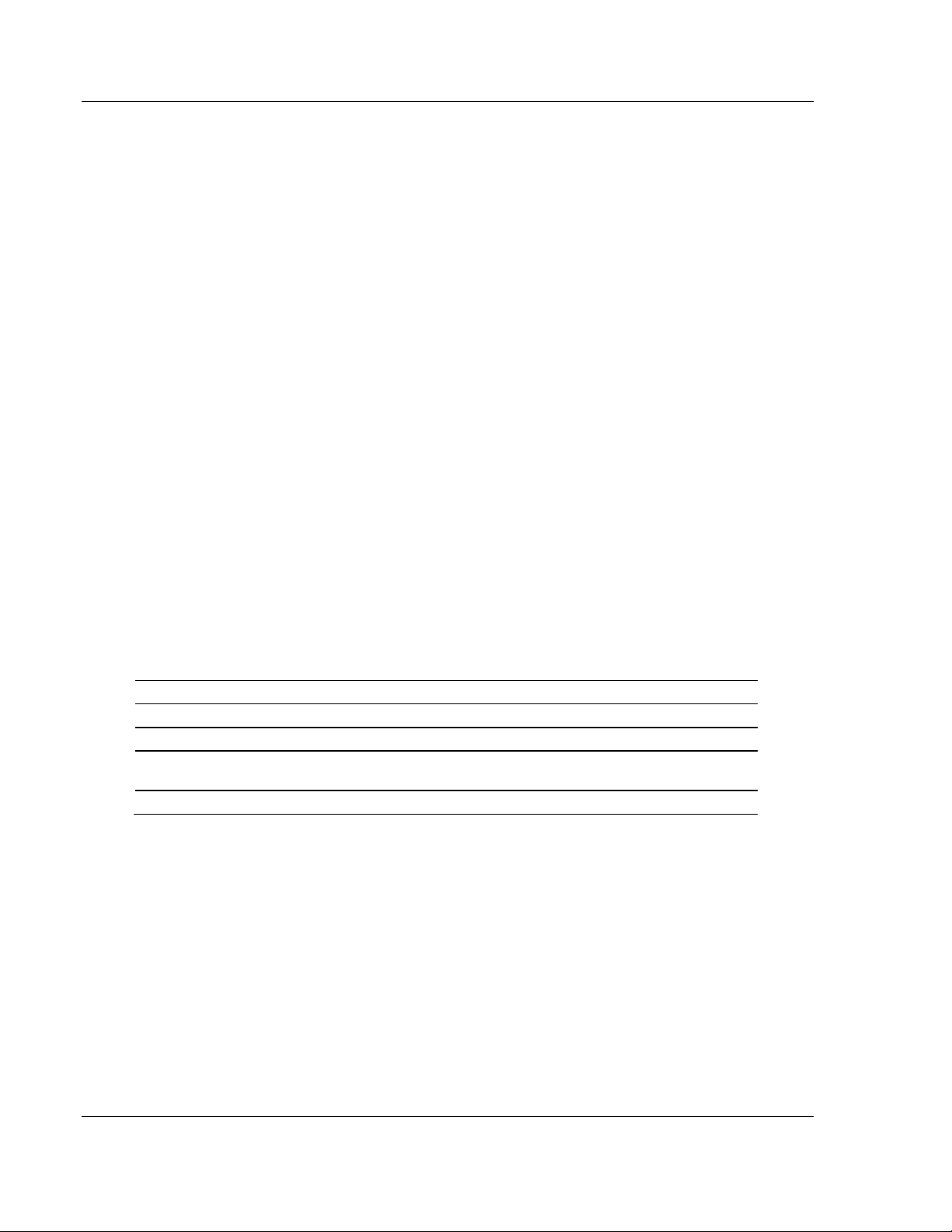

Point-to-Point Mode

Important: If the HART device address is 0 you must configure the channel for

Point-to-Point mode.

In point-to-point mode, the module only polls for a single instrument with a polling

address of zero. When the instrument is found by the channel, it continuously polls for the

data using command 3. Occasionally, it will poll for the configuration information for the

device. This is accomplished with HART commands 13, 14 and 15. Less frequently, the

channel will perform a HART command 0 request to see if any of the data for the

instrument has changed. If communications is lost with the device, the module will try to

establish communications with the device using command 0. If user commands are

present and enabled, they will be executed after each data poll.

Page 24 of 104 ProSoft Technology, Inc.

October 13, 2011

Page 25

ProLinx-HART ♦ ProLinx Gateway Functional Overview

HART Master with Analog I/O Driver Manual

When the point-to-point mode of auto-polling is enabled (Auto-Poll Code = P), the

following diagram applies to the channel operation:

ProSoft Technology, Inc. Page 25 of 104

October 13, 2011

Page 26

Functional Overview ProLinx-HART ♦ ProLinx Gateway

Driver Manual HART Master with Analog I/O

Page 26 of 104 ProSoft Technology, Inc.

October 13, 2011

Page 27

ProLinx-HART ♦ ProLinx Gateway HART Protocol Configuration

HART Master with Analog I/O Driver Manual

3 HART Protocol Configuration

In This Chapter

[Analog HART Card x] ........................................................................... 28

[HART PORT x] ..................................................................................... 29

[HART PORT x COMMANDS] ............................................................... 31

Using the CommonNet Data Map .......................................................... 37

Downloading a File from PC to the Module ........................................... 40

ProSoft Technology, Inc. Page 27 of 104

October 13, 2011

Page 28

HART Protocol Configuration ProLinx-HART ♦ ProLinx Gateway

Driver Manual HART Master with Analog I/O

3.1 [Analog HART Card x]

3.1.1 Database Register

-1, 0 to 3984

This parameter sets the database address in the module where the following values will

be placed:

Digitized values (4 Registers)

Counters (4 Registers)

Scaled values (8 Registers, 4 floating values)

Counters are incremented, usually about 15 times per second, to show the number of

times digital values have been scaled.

If the parameter is set to -1, these registers will not be placed in the database.

3.1.2 CHx Low

IEEE 32-bit (4-byte) floating-point numbers range in value from -3.402823E38 to -

1.401298E-45 for negative values and from 1.401298E-45 to 3.402823E38 for positive

values.

3.1.3 CHx High

IEEE 32-bit (4-byte) floating-point numbers range in value from -3.402823E38 to -

1.401298E-45 for negative values and from 1.401298E-45 to 3.402823E38 for positive

values.

These are user-defined scaling values to convert 4mA-20mA value to engineering units.

All values are provided as digitized values and scaled values in the module database and

are placed by the user if the Database Register (page 28) value is used.

For example, to disable these scaled values on all channels, enter a value of 0 (zero) for

the CH Low and CH High. You may also disable one at a time.

If you enter 0 to 1000, these will be scaled:

4.0mA will be scaled to a value of zero (0)

20.0 mA will be scaled to a value of 1000

and so on.

Page 28 of 104 ProSoft Technology, Inc.

October 13, 2011

Page 29

ProLinx-HART ♦ ProLinx Gateway HART Protocol Configuration

HART Master with Analog I/O Driver Manual

3.2 [HART PORT x]

The configuration file sections [HART PORT 0] through [HART PORT 3] (for 4 channel

modules) or [HART PORT 0] through [HART PORT 7] (for 8 channel modules) set HART

channel communication parameters, define the protocol specific parameters, and set the

command list parameters. The parameters are the same for all channels. The command

list parameters for each HART channel are entered in a different section in the

configuration file.

3.2.1 Enabled

Y or N

This parameter enables or disables the specific HART channel. If the parameter is set to

"Y", the channel will be utilized. If set to "N", the channel will not be used.

3.2.2 Preambles

2 to 50

This parameter defines the number of 0xFF characters (preambles) that will be placed at

the start of each HART frames.

3.2.3 Primary Master

Yes or No

This parameter specifies the Link Quiet / Slave Timeout. If set to Yes, the selected Link

Quiet / Slave Timeout is 305 milliseconds which corresponds to the Primary Master. If set

to No, then this time is 380 milliseconds which corresponds to the Secondary Master.

3.2.4 Retry Count

0 to 10

This parameter sets the number of retries for a command if the command response is not

received from the slave device. This parameter is normally set to a value of 3. The

module will accept values of 0 to 10.

3.2.5 DB Address Status

-1, 0 to 3999

This parameter is utilized to set the database address in the module where the status

word for the channel will be placed. If the parameter is set to -1, the word value will not

be placed in the database. If a value from 0 to 3999 is set for the parameter, the status

word for the channel will be placed at the specified database offset. This word is bit

mapped with each bit representing a slave device. The bit will be set if slave device has a

communication error.

ProSoft Technology, Inc. Page 29 of 104

October 13, 2011

Page 30

HART Protocol Configuration ProLinx-HART ♦ ProLinx Gateway

Driver Manual HART Master with Analog I/O

3.2.6 Command Count

0 to 99

This parameter sets the number of user commands to be utilized. The first command in

the list is always reserved for the auto-poll command so the user should configure this

value considering one command for the auto-poll. For example, if the user configures two

commands, the command count parameter should be set as 3. This parameter can be

set from 0 to 99. If the parameter is set to a value other than 0, commands should be

present in the [HART PORT x COMMANDS] section.

3.2.7 Auto-Poll Code

p2p or Not used

This parameter sets the auto-poll mode of the channel. If the parameter is set to "p2p",

the module will automatically poll device 0 in point-to-point mode. If the parameter is set

to "Not used", the auto-polling option will be disabled and only commands in the

command list will be utilized for the channel. In the auto-poll mode, the module will

automatically execute HART commands 0, 3, 13, 14, and 15.

3.2.8 Auto-Poll DB Address

0 to 3700

This parameter sets the starting address for the data obtained by the auto-poll feature.

Each device on a channel requires 50 words in the database. The data area selected

must not overlap any portion of the database used by other channels or the module.

3.2.9 Auto-Poll Swap Float

0 to 3

This parameter swaps the floating-point data values received by the auto-poll feature.

Swap Code Description

0 None - No Change is made in the byte ordering (1234 = 1234)

1 Words - The words are swapped (1234=3412)

2 Words & Bytes - The words are swapped then the bytes in each word are

swapped (1234=4321)

3 Bytes - The bytes in each word are swapped (1234=2143)

Depending on the host processor using the data, the proper swap code must be utilized

to present the data in the correct format.

3.2.10 Max Device Count

1 to 15

This parameter sets the maximum number of slave devices to be utilized for the auto-poll

feature. In point-to-point mode, the parameter should be set to a value of 1.

Page 30 of 104 ProSoft Technology, Inc.

October 13, 2011

Page 31

ProLinx-HART ♦ ProLinx Gateway HART Protocol Configuration

HART Master with Analog I/O Driver Manual

3.3 [HART PORT x COMMANDS]

The [HART PORT x COMMANDS] sections of the configuration file contain the userdefined HART command lists for each channel. The commands in these lists are sent to

slave devices attached to the HART channels. The module supports up to 100

commands per channel.

3.3.1 Command List Overview

The ProLinx-HART module uses a command list to interface with HART slave devices.

The commands in the list specify

the slave device to be addressed

the function to be performed (read or write)

the registers in the internal database to be associated with the device data.

There is a separate command list for each HART channel, with up to 100 commands

allowed per channel. The command list is processed from top (Command #0) to bottom

(Command #99), then the process is repeated.

A poll interval parameter is associated with each command to specify a minimum delay

time in seconds between the issuance of a command. For example, a poll interval of 10

executes the command no more frequently than every 10 seconds.

Write commands have a special feature, as they can be set to execute only if the data in

the write command changes. If the register data values in the command have not

changed since the command was last issued, the command will not be executed. If the

data in the command has changed since the command was last issued, the command

will be executed. Use of this feature can lighten the load on the HART network. In order

to implement this feature, set the enable code for the command to a value of 2.

The module supports all the Universal (page 42) and Common Practice (page 55)

commands, as well as device specific commands. A Device Specific command is

supported without any translation of the data.

ProSoft Technology, Inc. Page 31 of 104

October 13, 2011

Page 32

HART Protocol Configuration ProLinx-HART ♦ ProLinx Gateway

Driver Manual HART Master with Analog I/O

3.3.2 HART Command Entry Formats

Refer to the Reference (page 41, page 42, page 30) chapter for a complete discussion of

the HART commands supported by the module, and the structure and content of the data

returned for each command.

The following illustration shows a command list section of the configuration file:

3.3.3 Enable

0, 1, 2, 3, 4, 5

This field defines whether the command is to be executed and under what conditions.

Code Description

0 The command is disabled and will not be executed in the normal polling

sequence. This can be used to process a command from a bursting slave

device.

1 Causes the command to be executed each scan of the command list if the Poll

Interval Time is set to zero. If the Poll Interval time is set, the command will be

executed, when the interval timer expires.

2 The command will execute only if the internal data associated with the command

changes. This value is valid only when there is a specified "Write DB Address"

(see below) with a non zero byte count for write commands.

3 The HART module will send the command if either the ProLinx-HART module

OR the HART device is powered up. This is mainly used for configuration of

HART devices on startup.

4 Places the command in enabled mode. This option is valid only if there is a

specified "Enabled DB Address" (see below). If the Virtual Database word

specified in "Enabled DB Address" has "-1" the command will be executed

otherwise it will not.

5 Places the command in one shot enabled mode. This option is valid only if there

is a specified "Enabled DB Address" (see below). If the Virtual Database word

specified in "Enabled DB Address" has a value of "-1" the command will be

executed otherwise it will not. When the command has been successful the

Virtual Database word specified in "Enabled DB Address" will be written with "0",

so the command will be executed only once.

Refer to Command Enable Control Block (9902) and Command Disable Control Block

(9903) for more information on how to use the enable code.

Page 32 of 104 ProSoft Technology, Inc.

October 13, 2011

Page 33

ProLinx-HART ♦ ProLinx Gateway HART Protocol Configuration

HART Master with Analog I/O Driver Manual

3.3.4 Float DB Address

0 to 3998

This field specifies the internal database register where the floating point values returned

by the command will be placed.

3.3.5 Poll Interval

0

TO

65535

This parameter specifies the minimum interval between executions of a continuous

commands (Enable code of 1). The value is in seconds. Therefore, if a value of 10 is

entered, the command will execute no more frequently than once every 10 seconds.

3.3.6 FP Word Count

-1 to 125

This parameter specifies the number of words from the floating point data returned by a

HART command that will be placed on the Virtual Database. If this parameter is 0 no data

will be written to the Database. If this parameter is -1 then all the floating point data will

be written in the integer block of data.

Special care should be taken with this number, because is a word count and a floating

point value is 2 words long. For example if you execute a HART command 3 which takes

5 floating point values from the device, you should place a word count of 10 words.

3.3.7 Swap Code

0, 1, 2, 3

This parameter defines the byte order of each four-byte group of data received. This

parameter is helpful when dealing with floating-point or other multi-register values, as

there is no standard byte order for storing these data types. The following table describes

the values and their associated operations:

Swap Code Description

0 None - No Change is made in the byte ordering (1234 = 1234)

1 Words - The words are swapped (1234=3412)

2 Words & Bytes - The words are swapped then the bytes in each word are

swapped (1234=4321)

3 Bytes - The bytes in each word are swapped (1234=2143)

3.3.8 Short Address

0 = Point-to-Point Mode (only)

This parameter specifies the HART slave node address on the network to which the

command will be sent. Since the Analog module supports only point-to-point mode (no

multi-point support), only the value of 0 is permitted for this parameter. If the device to be

addressed only accepts long address, then the parameter "Use Long" should be selected

so the module can ask for the long address with the short one and then execute the

command.

3.3.9 Function Code

0 to 255

ProSoft Technology, Inc. Page 33 of 104

October 13, 2011

Page 34

HART Protocol Configuration ProLinx-HART ♦ ProLinx Gateway

Driver Manual HART Master with Analog I/O

This parameter specifies the HART function to be executed. Any HART function can be

executed, even device specific ones, but only supported commands will return formatted

data and classified in floating point data and integer data.

3.3.10 Int. DB Address

0 to 3999

This field specifies the internal database register where the integer or packed ASCII

string values returned by the command will be placed.

If the Floating Point Word Count parameter is "-1", then all the data returned by the

HART command will be placed in this address without any formatting.

3.3.11 Int Word Count

0 to 125

This parameter specifies the number of words from the integer or packed ASCII string

data returned by a HART command that will be placed on the Virtual Database. If this

parameter is "0", no data will be written to the Database.

3.3.12 Swap Code

0, 1, 2, 3

This parameter defines the byte order of each four-byte group of data received. This

parameter is helpful when dealing with floating-point or other multi-register values, as

there is no standard byte order for storing these data types. The following table describes

the values and their associated operations:

Swap Code Description

0 None - No Change is made in the byte ordering (1234 = 1234)

1 Words - The words are swapped (1234=3412)

2 Words & Bytes - The words are swapped then the bytes in each word are

swapped (1234=4321)

3 Bytes - The bytes in each word are swapped (1234=2143)

3.3.13 Use Long

0 or 1

This parameter defines if the command will be executed with short or long address. If the

value is "0", then the configured command will be executed using the Short Address

specified. If the value is "1" then the specified Short Address will be used only to ask for

the long address and that will be used to execute the configured command.

Page 34 of 104 ProSoft Technology, Inc.

October 13, 2011

Page 35

ProLinx-HART ♦ ProLinx Gateway HART Protocol Configuration

HART Master with Analog I/O Driver Manual

3.3.14 Enable DB Address

0 to 3999

This field specifies the internal database register to be used to enable the execution of a

command. This parameter is only used if "Enable" is "4" or "5". If the value of this

database register is "-1", then the command will be executed, otherwise it will not. If the

"Enable" value is "5", then after the successful execution of the command this value will

become "0"

3.3.15 Done DB Address

-1 to 3999

This field specifies the internal database register to be used to signal the successful

execution of a command. When a command is successfully executed a "-1" is written to

this register. This "Done DB Address" can be shared with the "Enable DB Address" of

another command to do a chained command execution.

3.3.16 Write DB Address

-1 to 3999

This field specifies the internal database register to be as a source of data for HART

command which includes data. It is possible to include data with every HART command,

but it depends of the command and of the device if it will accept this data.

If this value is "-1", it indicates that there will not be data with the command or that it will

not come from database.

3.3.17 Swap Code

0, 1, 2, 3

This parameter defines the byte order of each four-byte group of data received. This

parameter is helpful when dealing with floating-point or other multi-register values, as

there is no standard byte order for storing these data types. The following table describes

the values and their associated operations:

Swap Code Description

0 None - No Change is made in the byte ordering (1234 = 1234)

1 Words - The words are swapped (1234=3412)

2 Words & Bytes - The words are swapped then the bytes in each word are

swapped (1234=4321)

3 Bytes - The bytes in each word are swapped (1234=2143)

3.3.18 Byte Count

0 to 250

This parameter specifies the number of bytes to be sent to a HART device in the

command. If the command has no data then this value should be "0".

If the value of this field is different of "0" and "Write DB Address" is different of "-1" then

the data for the command will be taken from the Virtual Database. If the value of this field

is different of "0" and "Write DB Address" is "-1" then the data for the command will be

from the "Fixed Data" field for the command.

ProSoft Technology, Inc. Page 35 of 104

October 13, 2011

Page 36

HART Protocol Configuration ProLinx-HART ♦ ProLinx Gateway

Driver Manual HART Master with Analog I/O

3.3.19 Fixed Data

Up to 250 HEX values separated by space

This parameter is a string of HEX values to be sent with the HART command. There

should be at least the number of bytes specified in the "Byte Count" parameter. The

bytes should be written in hexadecimal format and separated by a space. This data will

be sent if the Parameter "Write DB Address" is "-1" and "Byte Count" is greater than "0",

and it will be sent in the same order that they are written.

Page 36 of 104 ProSoft Technology, Inc.

October 13, 2011

Page 37

ProLinx-HART ♦ ProLinx Gateway HART Protocol Configuration

HART Master with Analog I/O Driver Manual

3.4 Using the CommonNet Data Map

The Data Map section allows you to copy data between areas in the module's internal

database.

You can copy a maximum of 100 registers per Data Map command, and you can

configure a maximum of 200 separate copy commands.

You can copy data from the error or status tables in upper memory to internal database

registers in the User Data memory area.

You can rearrange the byte and/or word order during the copy process. For example, by

rearranging byte or word order, you can convert floating-point values to the correct format

for a different protocol.

You can also use the Data Map to condense widely dispersed data into one contiguous

data block, making it easier to access.

ProSoft Technology, Inc. Page 37 of 104

October 13, 2011

Page 38

HART Protocol Configuration ProLinx-HART ♦ ProLinx Gateway

Driver Manual HART Master with Analog I/O

3.4.1 Internal Database Re-mapping

Depending on the application, you may need to copy data from one section of the

module’s internal database to another section. The [Data Map] section of the CFG file

allows a user to selectively copy data registers, one register up to 100 registers at a time,

from one internal database to another. Up to 200 entries can be made in the [Data Map]

section, providing a wide and powerful range of functionality.

3.4.2 From Address

0 to 3999

This field specifies the internal database register to copy from. This address can range

from the Data area as well as the Status Data Area of the product

3.4.3 To Address

0 to 3999

The destination for the copy is always going to be the Register Data area.

3.4.4 Register Count

1 to 100

This parameter specifies the number of registers to copy.

3.4.5 Swap Code

0, 1, 2, 3

There may be a need to swap the order of the bytes in the registers during the copy

process in order to change from alignment of bytes between dissimilar protocols. This

parameter is helpful when dealing with floating-point or other multi-register values, as

there is no standard method of storage of these data types in slave devices.

The following table defines the values and their associated operations:

Swap Code Description

0 None - No Change is made in the byte ordering (1234 = 1234)

1 Words - The words are swapped (1234=3412)

2 Words & Bytes - The words are swapped then the bytes in each word are

swapped (1234=4321)

3 Bytes - The bytes in each word are swapped (1234=2143)

Page 38 of 104 ProSoft Technology, Inc.

October 13, 2011

Page 39

ProLinx-HART ♦ ProLinx Gateway HART Protocol Configuration

HART Master with Analog I/O Driver Manual

3.4.6 Delay Preset

This parameter sets an interval for each Data Map copy operation. The value you put for

the Delay Preset is not a fixed amount of time. It is the number of firmware scans that

must transpire between copy operations.

The firmware scan cycle can take a variable amount of time, depending on the level of

activity of the protocol drivers running on the ProLinx gateway and the level of activity on

the gateway's communication ports. Each firmware scan can take from 1 to several

milliseconds to complete. Therefore, Data Map copy operations cannot be expected to

happen at regular intervals.

If multiple copy operations (several rows in the Data map section) happen too frequently

or all happen in the same update interval, they could delay the process scan of the

gateway protocols, which could result in slow data updates or missed data on

communication ports. To avoid these potential problems, you should set the Delay Preset

to different values for each row in the Data Map section and set them to higher, rather

than lower, numbers.

For example, Delay Preset values below 1000 could begin to cause a noticeable delay in

data updates through the communication ports. And you should not set all Delay Presets

to the same value. Instead, use different values for each row in the Data Map such as

1000, 1001, and 1002 or any other different Delay Preset values you like. This will

prevent the copies from happening concurrently and prevent possible process scan

delays.

ProSoft Technology, Inc. Page 39 of 104

October 13, 2011

Page 40

HART Protocol Configuration ProLinx-HART ♦ ProLinx Gateway

Driver Manual HART Master with Analog I/O

3.5 Downloading a File from PC to the Module

1 Use a null-modem serial cable to connected the serial COM port on your PC and the

Debug/Configuration serial port on the module.

2 Open the P

3 On the M

for communication ports on your PC. When the scan is complete, the Download

dialog box opens.

ROJECT

ODULE

menu, and then choose M

menu, choose D

OWNLOAD.

ODULE

Wait while ProSoft Configuration scans

.

4 Select the

5 Click the D

PORT

to use for the download.

OWNLOAD

button.

Page 40 of 104 ProSoft Technology, Inc.

October 13, 2011

Page 41

ProLinx-HART ♦ ProLinx Gateway Reference

HART Master with Analog I/O Driver Manual

4 Reference

In This Chapter

HART Universal Commands ................................................................. 42

HART Common Practice Commands .................................................... 55

Error/Status Data ................................................................................... 85

ProLinx 5108 / 5208 HART Field Connections ...................................... 90

ProSoft Technology, Inc. Page 41 of 104

October 13, 2011

Page 42

Reference ProLinx-HART ♦ ProLinx Gateway

Driver Manual HART Master with Analog I/O

4.1 HART Universal Commands

COMMAND 00 - Read Unique Identifier

Description

This command gets the long address of the HART device plus other manufacturer

information like Manufacturer ID, Device Type Code, Software Revision, Hardware

Revision, and so on.

Write Parameters

NONE

Floating Point Data Returned

NONE

Integer Data Returned

Word High Byte Low Byte

0 STATUS WORD

1 Constant "254" Manufacturer Identification Code

2 Manufacturer Device Type Code Number of Preambles

3 Universal Command Revision Transmitter Specific Command Revision

4 Software Revision Hardware Revision

5 Device Function Flags Device ID Number 1

6 Device ID Number 2 Device ID Number 3

Page 42 of 104 ProSoft Technology, Inc.

October 13, 2011

Page 43

ProLinx-HART ♦ ProLinx Gateway Reference

HART Master with Analog I/O Driver Manual

COMMAND 01 - Read Primary Variable

Description

This command gets the device Primary Variable and the Primary Variable Units

Write Parameters

NONE

Floating Point Data Returned

Word High Byte Low Byte

0 Primary Variable Value

1

Integer Data Returned

Word High Byte Low Byte

0 STATUS WORD

1 Primary Variable Units Code 0

ProSoft Technology, Inc. Page 43 of 104

October 13, 2011

Page 44

Reference ProLinx-HART ♦ ProLinx Gateway

Driver Manual HART Master with Analog I/O

COMMAND 02 - Read Current And Percent Of Range

Description

This command gets the current of the loop that is forced by the HART device and the

Percent of Range of the Current.

Write Parameters

NONE

Floating Point Data Returned

Word High Byte Low Byte

0 Current (mA)

1

2 Percent of Range

3

Integer Data Returned

Word High Byte Low Byte

0 STATUS WORD

Page 44 of 104 ProSoft Technology, Inc.

October 13, 2011

Page 45

ProLinx-HART ♦ ProLinx Gateway Reference

HART Master with Analog I/O Driver Manual

COMMAND 03 - Read Dynamic Variables

Description

This command gets the current and four (predefined) dynamic Variables.

Write Parameters

NONE

Floating Point Data Returned

Word High Byte Low Byte

0 Current (mA)

1

2 Primary Variable

3

4 Second Variable

5

6 Third Variable

7

8 Fourth Variable

9

Integer Data Returned

Word High Byte Low Byte

0 STATUS WORD

1 Primary Variable Units Code Second Variable Units Code

2 Third Variable Units Code Fourth Variable Units Code

ProSoft Technology, Inc. Page 45 of 104

October 13, 2011

Page 46

Reference ProLinx-HART ♦ ProLinx Gateway

Driver Manual HART Master with Analog I/O

COMMAND 06 - Write Polling Address

Description

This command sets the polling address of a HART device. Extreme care should be taken

when you use this command because you can loose the communication with the device.

Write Parameters

Word High Byte Low Byte

0 Polling Address Polling Address

Floating Point Data Returned

NONE

Integer Data Returned

Word High Byte Low Byte

0 STATUS WORD

1 Polling Address 0

Page 46 of 104 ProSoft Technology, Inc.

October 13, 2011

Page 47

ProLinx-HART ♦ ProLinx Gateway Reference

HART Master with Analog I/O Driver Manual

COMMAND 12 - Read Message

Description

This command reads an ASCII message contained in the HART Device and written by

the Write Message command 17.

Write Parameters

NONE

Floating Point Data Returned

NONE

Integer Data Returned

Word High Byte Low Byte

0 STATUS WORD

1 Message ASCII Character 0 Message ASCII Character 1

2 Message ASCII Character 2 Message ASCII Character 3

.

.

.

14 Message ASCII Character 28 Message ASCII Character 29

15 Message ASCII Character 30 Message ASCII Character 31

.

.

.

ProSoft Technology, Inc. Page 47 of 104

October 13, 2011

Page 48

Reference ProLinx-HART ♦ ProLinx Gateway

Driver Manual HART Master with Analog I/O

COMMAND 13 - Read Tag, Descriptor and Date

Description

This command reads an ASCII Tag which identifies the device, an ASCII descriptor of the

device and the last Date it has been configured.

Write Parameters

NONE

Floating Point Data Returned

NONE

Integer Data Returned

Word High Byte Low Byte