Prochem Everest 408-650, LP-HP User Manual

Operating instructions (ENG)

MODELS:

EVEREST 650

HIGH PRESSURE

1.001-145.0

EVEREST 650

LOW PRESSURE

1.001-146.0

EVEREST 408

HIGH PRESSURE

1.001-151.0

EVEREST 408

LOW PRESSURE

1.001-152.0

86352170-AC

08/29/13

Read these instructions before using the machine.

Machine Data Label

Overview

Welcome…and congratulations on the purchase o f your Mobile Cleaning Unit. This instruction manual is a guide for

operating and servicing your unit. Read this manual completely before installing or operating this unit.

This unit offers you personal convenience. All of your instrumentation and controls have been positioned to give

you easy access for operation and daily maintenance.

Proper operation and service are essential to the efficient functioning of this unit. When maintained correctly, this

unit will have a long, trouble-free life.

The service methods described in this manual are explained in such a manner that servicing may be performed

accurately and safely. Proper service varies with the choice of procedure, the skill of t he mechanic, and the tools or

parts available. Before attempting any repair, make certain that you are thoroughly familiar with this equipment and

are equipped with the proper tools. Any questions pertaining to operating or servicing this unit should be directed to

your nearest dealer.

THIS UNIT MUST BE INSTALLED BY THE DEALER FROM WHOM YOU PURCHASED IT IN ACCORDANCE

WITH THE PRESCRIBED INSTALLATION PROCEDURES.

Information in this document is subject to change without notice and does not represent a commitment on the part

of PROCHEM.

Warranty Registration

Thank you for purchasing a Prochem product. Warranty registration is quick and easy.

Your registration will allow us to serve you better over the lifetime of the product.

To register your product go to :

www.prochem.com/WarrantyRegistration.aspx

For customer assistance:

1-800-776-2436

186352170 EVEREST

Table of Contents

Machine Data Label . . . . . . . . . . . . . . . . . . . . . . . . . 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table of Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Receiving Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . 4

Acceptance Of Shipment. . . . . . . . . . . . . . . . . . . . . 4

Equipment List: . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

How To Use This Manual. . . . . . . . . . . . . . . . . . . . . 5

Safety

IMPORTANT SAFETY INSTRUCTIONS. . . . . . . . . 6

Hazard Intensity Level . . . . . . . . . . . . . . . . . . . . . . . 8

Safety Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation

Dealer Responsibility. . . . . . . . . . . . . . . . . . . . . . . 10

Vehicle Requirements . . . . . . . . . . . . . . . . . . . . . . 10

Lifting Unit Onto Vehicle . . . . . . . . . . . . . . . . . . . . 11

Positioning Unit In Vehicle. . . . . . . . . . . . . . . . . . . 11

Bolting Down Unit And Waste Tank. . . . . . . . . . . . 11

Layout with 100 Gallon Waste Tank . . . . . . . . . . . 12

Waste Tank To Console Connection. . . . . . . . . . . 13

Fuel Pump Assembly Installation. . . . . . . . . . . . . . 13

Van Bulkhead Installation . . . . . . . . . . . . . . . . . . . 14

Fuel Supply & Return Line Installation. . . . . . . . . . 15

Battery Connection . . . . . . . . . . . . . . . . . . . . . . . . 16

Electrical Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Fire Extinguisher . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Operations

Technical Specifications . . . . . . . . . . . . . . . . . . . . 17

Water Requirements . . . . . . . . . . . . . . . . . . . . . . . 18

Fuel Requirements. . . . . . . . . . . . . . . . . . . . . . . . . 19

Engine Oil Requirements. . . . . . . . . . . . . . . . . . . . 19

Chemical Requirements. . . . . . . . . . . . . . . . . . . . . 19

Electronic Fuel Injection System . . . . . . . . . . . . . . 19

Emission Control Information. . . . . . . . . . . . . . . . . 20

Date Stamp Location . . . . . . . . . . . . . . . . . . . . . . . 20

Fuel Pump And Filter. . . . . . . . . . . . . . . . . . . . . . . 20

Trouble Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Lower Control Panel . . . . . . . . . . . . . . . . . . . . . . . 25

Upper Control Panel . . . . . . . . . . . . . . . . . . . . . . . 26

Filter Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Water Pumping And Heat Transfer System. . . . . . 29

Chemical Injection System. . . . . . . . . . . . . . . . . . . 32

Vacuum System. . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Pre-run Inspection / Setup . . . . . . . . . . . . . . . . . . . 34

Water Supply Connection . . . . . . . . . . . . . . . . . . . 34

High Pressure Solution Hose. . . . . . . . . . . . . . . . . 34

Vacuum Hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Priming The Chemical Pump . . . . . . . . . . . . . . . . . 35

Waste Pumpout (Optional). . . . . . . . . . . . . . . . . . . 35

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Upholstery Cleaning. . . . . . . . . . . . . . . . . . . . . . . . 36

Shutdown And Daily Maintenance. . . . . . . . . . . . . 36

High Pressure (3000 Psi) System Operation

(Optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

High Pressure Shutdown & Return To Low Pressure

System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

De-flooding Operations . . . . . . . . . . . . . . . . . . . . . 37

Freezing Protection . . . . . . . . . . . . . . . . . . . . . . . . 37

Winterizing Your Unit. . . . . . . . . . . . . . . . . . . . . . . 38

Removing Anti-freeze From The Unit . . . . . . . . . . 39

2

86352170 EVEREST

Table of Contents

Maintenance

Service Schedule . . . . . . . . . . . . . . . . . . . . . . . . . .40

Key Checkpoints. . . . . . . . . . . . . . . . . . . . . . . . . . .42

Engine Coolant System (Radiator) . . . . . . . . . . . . .42

External Fuel Pump . . . . . . . . . . . . . . . . . . . . . . . .42

Chemical Supply System . . . . . . . . . . . . . . . . . . . .42

Heat Exchanger System . . . . . . . . . . . . . . . . . . . . .42

Vacuum Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Vacuum Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Vacuum Relief Valve. . . . . . . . . . . . . . . . . . . . . . . .44

Vacuum Pump Drive Belts . . . . . . . . . . . . . . . . . . .45

Solution Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Solution Pump Drive Belt . . . . . . . . . . . . . . . . . . . .46

Solution Pump Clutch . . . . . . . . . . . . . . . . . . . . . . .46

Float Valve (Water Box) . . . . . . . . . . . . . . . . . . . . .46

Pre-filter Strainer. . . . . . . . . . . . . . . . . . . . . . . . . . .46

Waste Tank Vacuum Inlet Filter . . . . . . . . . . . . . . .46

Solution Screen (Outlet) . . . . . . . . . . . . . . . . . . . . .46

Temperature Balance Orifice . . . . . . . . . . . . . . . . .46

Check Valve (Outlet). . . . . . . . . . . . . . . . . . . . . . . .47

Chemical Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Pressure Regulator. . . . . . . . . . . . . . . . . . . . . . . . .47

Vacuum Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

High Pressure Solution Hoses . . . . . . . . . . . . . . . .47

Optional Waste Pump-Out . . . . . . . . . . . . . . . . . . .47

Engine Coolant Replacement. . . . . . . . . . . . . . . . .47

General Service Adjustments. . . . . . . . . . . . . . . . .48

Check Valve (Solution Outlet). . . . . . . . . . . . . . . . .48

Chemical Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Packing Nut Adjustment For Chemical Valves . . . .49

Pressure Regulators . . . . . . . . . . . . . . . . . . . . . . . .49

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Parts

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Panels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Control Panel Mounting . . . . . . . . . . . . . . . . . . . . 64

Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Electronic Fuel Ignition . . . . . . . . . . . . . . . . . . . . . 70

Coolant System. . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Vacuum Blower 650/650HP . . . . . . . . . . . . . . . . . 74

Vacuum Blower 408/408HP . . . . . . . . . . . . . . . . . 76

Solution Pump - Low Pressure . . . . . . . . . . . . . . . 78

Solution Pump - High Pressure. . . . . . . . . . . . . . . 80

Solution Pump - Parts. . . . . . . . . . . . . . . . . . . . . . 82

Heat Exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Helicoil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Solution Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Side Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Water Box - Low Pressure . . . . . . . . . . . . . . . . . 100

Water Box - High Pressure . . . . . . . . . . . . . . . . . 102

Pressure Regulator - Low Pressure . . . . . . . . . . 104

Pressure Regulators - High Pressure . . . . . . . . . 106

Filter Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Waste Tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Fuel Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Chemical Jug Floor Mount . . . . . . . . . . . . . . . . . 116

Hose Diagram - Low Pressure . . . . . . . . . . . . . . 118

Hose Diagram - High Pressure. . . . . . . . . . . . . . 119

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Options

Hose Accessories . . . . . . . . . . . . . . . . . . . . . . . . 124

Flexible Exhaust Diverter Kit- Optional . . . . . . . . 126

Automatic Pumpout - Dual Diaphragm - Optional 128

Wand - Titanium Six Jet - Optional . . . . . . . . . . . 130

Wand - Ergo Titanium Six Jet - Optional. . . . . . . 132

Wand - Quad Jet - Optional . . . . . . . . . . . . . . . . 134

Wand - Tri Jet -Optional . . . . . . . . . . . . . . . . . . . 136

Stair Tool - Optional . . . . . . . . . . . . . . . . . . . . . . 138

Upholstery Tool - Optional . . . . . . . . . . . . . . . . . 140

Shelf Assembly - Optional. . . . . . . . . . . . . . . . . . 142

Water Tank Dual with Demand Pump - Optional 144

Water Tank - Demand Pump - Optional . . . . . . . 146

Auxiliary Water Tank with Pump-Optional . . . . . 148

Hose Reel - Optional. . . . . . . . . . . . . . . . . . . . . . 150

Motorized Hose Reel - Tank - Optional. . . . . . . . 152

Motorized Hose Reel - Optional . . . . . . . . . . . . . 154

E Z - Charge Water Softener - Tank & Tray -

Optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

E Z - Charge Water Softener - Filter - Optional . 158

E Z - Charge Water Softener - Brine System -

Optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

86352170 EVEREST

3

Receiving Your Unit

Acceptance Of Shipment

Every part of your cleaning unit was carefully checked,

tested, and inspected before it left our manufacturing

plant. Upon receiving the unit, make the following

acceptance check:

1. The unit should not show any outward signs of

damage. If damaged, notify the common carrier

immediately.

2. Check your equipment and packing list. The

cleaning unit should arrive equipped with the

following items (unless otherwise specif ied ) an d

any optional accessories which were ordered.

NOTE: Do not modify unit without written permission

from manufacturer.

Equipment List:

1. Console.

2. Waste tank.

3. Fuel Pump Assembly, Power and Regulator

Cord.

4. Filter box.

5. 150 ft. of 2" vacuum hose.

6. 2 vacuum hose connectors.

7. 150 ft. of 1/4” solution pressure hose with quick

connects.

8. 50 ft. water supply hose with quick connect.

9. Installation bolting kit.

10. Installation mounting plates.

1 1. Operation and service manuals for engine, solution

pump, and vacuum pump.

12. Hose clamps for vacuum hoses.

4

86352170 EVEREST

How To Use This Manual

Model:

Date of Purchase:

Serial Number:

Dealer:

Address:

Phone Number:

Sales Representative:

This manual contains the following sections:

• How To Use This Manual

•Safety

• Installation

• Operations

• Maintenance & Service

•Parts List

The HOW TO USE THIS MANUAL section will tell you

how to find important information for ordering correct

repair parts.

Parts may be ordered from authorized dealers. When

placing an order for parts, the machine mod el and

machine serial number are important. Refer to the

MACHINE DATA box which is filled out during the

installation of your machine. The MACHINE DATA box

is located on the inside of the front cover of this manual.

The model and serial number of your machine is on the

side approximately where shown.

The INSTALLATION section contains information on

how to properly install the unit in your vehicle.

The OPERAT IONS section is to familiarize the operator

with the operation and function of the machine.

The MAINTENANCE section contains preventive maintenance to keep the machine and its components in

good working condition. They are listed in this general

order:

•Engine

• Vacuum Pump

• Solution Pump

• Drive Belts, Pulleys & Hub

• Chemical Pump

• Hoses

• Vac/Exhaust Heat Exchanger

• General Service Adjustments

• Troubleshooting

The PARTS LIST section contains assembled parts

illustrations and corresponding parts list. The parts lists

include a number of columns of information:

• REF - column refers to the reference number on

the parts illustration.

• P ART NO. - column list s the part numbe r for the

part.

• PRV NO. - Reference No.

• DESCRIPTION - column is a brief description of

the part.

• SERIAL NO. FROM - If this column has an (*)

and a Reference number, see the SERIAL

NUMBERS page in the back of your manual. If

column has two asterisk (**), call manufacturer

for serial number. The serial number indicates

the first machine the part number is applicable

to. The main illustration shows the most current

design of the machine. When a boxed illustration is shown, it displays the older design.

• NOTES - column for information not noted by

the other columns.

NOTE: If a service or option kit is installed on your

machine, be sure to keep the KIT INSTRUCTIONS

which came with the kit. It contains replacement parts

numbers needed for ordering future parts.

The SAFETY section contains important information

regarding hazardous or unsafe practices for this

machine. Levels of hazards are identified that could

result in product damage, personal injury, or severe

injury resulting in death.

NOTE: The part number for this manual is in the

lower left corner of the cover page.

86352170 EVEREST

5

Safety

IMPORTANT SAFETY INSTRUCTIONS

When using this machine, basic precaution

must always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.

These symbols mean WARNING or CAUTION. Failure to follow warnings and

cautions could result in fatality, personal injury to yourself and/or others, or property

damage. Follow these instructions carefully!

Read the operator's manual before installing or starting this unit. Failure to adher e to instructions could r esult

in severe personal injury or could be fatal.

Operate this unit and equipment only in a well-ventilated area. Exhaust fumes cont ain carbon monoxide which is an

odorless and deadly poison that can cause severe injury or fatality. DO NOT run this unit in an enclosed area. DO

NOT operate this unit where the exhaust may enter any building doorway, window, vent, or opening of any type.

Gasoline is extremely flammable and its vapors can explode if ignite d. Store gasoline only in approved containers,

in well-ventilated, unoccupied buildings away from sparks or flames. Never carry any gasoline or flammable

material in the vehicle. Fumes may accumulate inside the vehicle and ignite, causing an explosion.

DO NOT store any type of flammable material in the vehicle.

This unit must be operated with all vehicle cargo area or trailer rear doors open in order to ensure adequate engine

ventilation.

DO NOT operate engine if gasoline is spilled. Avoid creatin g any ignition source until the gasoline has been cleaned

up. Never use gasoline as a cleaning agent.

DO NOT place hands, feet, hair, or clothing near rotating or moving parts. Avoid any contact with moving parts!

Rotating machinery can cause injury or fatality.

Never operate this unit without belt guards or heat guards. Th e high speed moving par ts, such as belt s and pulleys,

should be avoided while this unit is running. Severe injury, damage, or fatality may result.

DO NOT service this unit while it is running. The high-speed mechanical parts as well as high temperature

components may result in severe injury or severed limbs.

Never touch electrical wires or components while the engine is running. Th ey can be sources of electrical shock.

Engine components can get extremely hot from operation. To prevent severe burns, DO NOT touch these areas

while the engine is running - or immediately after the engine is turned off.

DO NOT touch the exhaust system while this unit is running. Severe burns may result.

Before servicing this unit, allow it to cool down. This will prevent burns from occurring.

Water under high pressur e at high temperature can cause burns, severe personal injury, or fatality. Shut down

machine, allow to cool down, and relieve system of all pressure before removing valves, caps, plugs, fittings, filters,

and bolts.

DO NOT leave the vehicle engine running while operating this unit.

Dangerous Acid, Explosive Gases! Batteries contain sulfuric acid. To prevent acid burns, avoid contact with skin,

eyes and clothing. Batteries produce explosive hydrogen gas while being charged. To prevent a fire or explosion,

charge batteries only in well ventilated areas. Keep sparks, open flames, and other sources of ignition away from

the battery at all times. Keep batteries out of the reach of children. Remove all jewelry when servicing batteries.

6

86352170 EVEREST

Safety

Before disconnecting the negative (-) ground cable, make sure all switches are OFF . If ON, a sp ark will occur at the

ground cable terminal which could cause an explosion if hydrogen gas or gasoline vapors are present. When

disconnecting the battery, ALWAYS disconnect the negative (-) terminal FIRST.

DO NOT smoke around the unit. Gas fumes may accumulate and be ignited. The battery is also extremely

flammable. This will prevent possible explosions.

DO NOT damage the vehicle in any manner dur ing installation. When routing fuel lines DO NOT place the hose in

any location where damage may occur to the hose or vehicle. Avoid any contact with moving parts, areas of high

temperature, brake lines, fuel lines, muffler, catalytic converter, or sharp objects.

DO NOT cut or splice any of the vehicle fuel lines during fuel line installation. This may result in fuel leaks and

potentially dangerous conditions. There is no fuel solenoid shut of f on this unit. Use only the pr ovided fuel ho se for

fuel lines. When traversing the vehicle floor with fuel lines, always use a bulkhead adapter. This will prevent leakage

and ensure that the hose is not punctured by vehicle vibration abrasion.

DO NOT exceed your vehicle's weight limit: The console with empty 100 gallon waste tank and accessories weighs

approximately 1300 lbs. Make certain to account for any additional accessories in your weight and balance

calculations. Make certain that the vehicle has the correct axle rating, to prevent unsafe vehicle driving conditions.

We require high-back seats on all vehicles in which units are to be installed for head and neck protection. We

recommend using a metal partition between the seats and equipment.

DO NOT operate this unit without the water supply attached and turned on. The solution pump and other vital

components may be seriously damaged if this unit is permitted to operate dry without water. Running with out

adequate water supply could damage solution pump. Ensure always to have an adequate water supply.

DO NOT operate this unit without the filter installed in the waste tank.

Keep your vehicle work area clean. Wands, stair tools, and other accessories must be securely fastened before

driving the vehicle.

All high pressure hoses must be rated for 3000 PSI at 250°F . T hermoplastic hoses do not meet these specifications

and should not be used. Severe burns and injury may result if the hoses do not meet these requiremen ts. Pressure

wash hoses must be rated at 4000 PSI.

The winterizing loop hose assembly, is for winterizing use only . If used improperly, live steam may escape from this

hose, causing it to whip around. Burns or injury may result.

Make certain that you receive complete training by the distributor from whom you purchased this unit.

This unit uses high pressure and temperature. Improper or irresponsible use may result in serious injury.

Do not modify this unit in any manner. Improper modification can cause severe personal injury or fatality.

CALIFORNIA PROPOSITION 65 WARNING: Engine exhaust from this product contains chemicals known to the

State of California to cause cancer, birth defects, or other reproductive harm.

86352170 EVEREST

7

Safety

The following symbols are used throughout this guide as indicated in their descriptions:

Hazard Intensity Level

There are three levels of hazard intensity identified by signal words - WARNING and CAUTION and FOR SAFETY .

The level of hazard intensity is determined by the following definitions:

WARNING - Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION - Hazards or unsafe practices which could result in min or personal in jury or pr oduct or pr operty damage.

FOR SAFETY: To Identify actions which must be followed for safe operation of equipment.

Report machine damage or faulty operation immediately. Do not use the machine if it is not in proper operating

condition. Following is information that signals some potentially dangerous conditions to the operator or the equipment. Read this information carefully. Know when these conditions can exist. Locate all safety devices on the

machine. Please take the necessary steps to train the machine operating personnel.

FOR SAFETY:

DO NOT OPERATE MACHINE:

Unless Trained and Authorized.

Unless Operation Guide is Read and understood.

In Flammable or Explosive areas.

In areas with possible falling objects.

WHEN SERVICING MACHINE:

Avoid moving parts. Do not wear loose clothing; jackets, shirts, or sleeves when working on the machine. Use

Prochem approved replacement parts.

8

86352170 EVEREST

SOLUTION PRESSURE

Safety

WARM

TEMPERATURE

BALANCE ORIFICE

WARM

WATER OUTLET

WATER INLET

OIL DRAIN

ENGINE

LOW PRESSURE

SOLUTION REGULATOR

VACUUM

LUBRICATION

LUBRICATE

WITH VACUUM

INLETS SEALED

LOW

PRESSURE

SOLUTION

SCREEN

CHEMICAL

CHECK

VALVE

CARPET AND

UPHOLSTERY

SOLUTION

LOW

PRESSURE

SOLUTION

OUTLETS

HOT

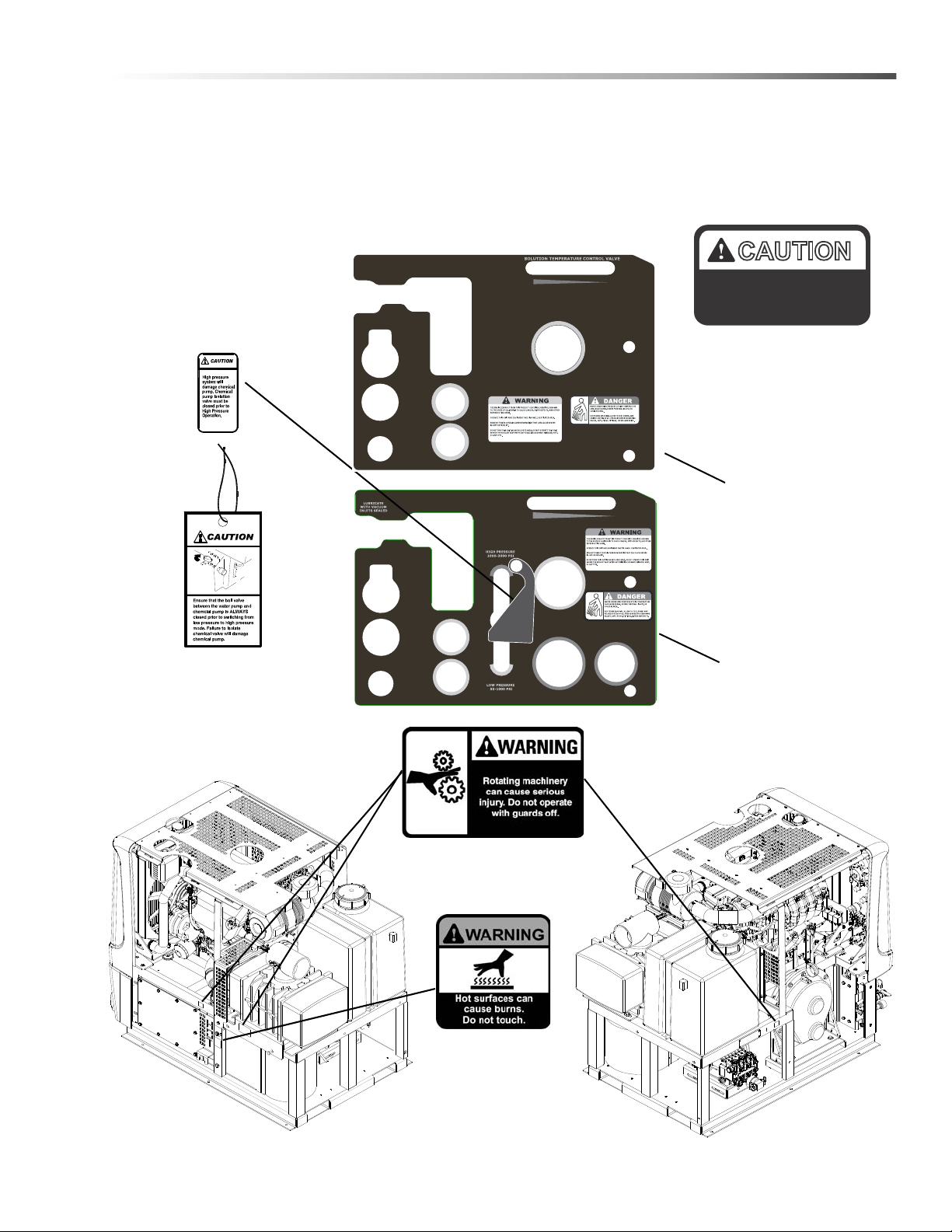

Safety Labels

The following WARNING LABELS are found on your cleaning unit. These labels point out important Warnings and

Cautions which should be followed at all times. Failure to follow warnings and cautions could result in fatality,

personal injury to yourself and/or others, or property damage. Follow these instructions carefully! DO NOT remove

these labels.

NOTE: If at any time the labels become illegible, promptly replace them.

CAUTION

Caution label

P/N 86186510

UNLEADED FUEL ONLY.

E85 FUEL WILL DAMAGE

INSTALLED EQUIPMENT.

Caution Label

P/N 86352580

Installation on

vehicle fuel door.

Caution Tag

P/N 86186500

VACUUM

LUBRICATION

WARM

WATER OUTLET

WATER INLET

ENGINE

OIL DRAIN

TEMPERATURE

BALANCE ORIFICE

CHEMICAL

CHECK

VALVE

LOW

PRESSURE

SOLUTION

SCREEN

LOW

PRESSURE

SOLUTION

OUTLETS

CARPET AND

UPHOLSTERY

SOLUTION

Warning label

P/N 86186520

HOT

LOW PRESSURE

SOLUTION REGULATOR

SOLUTION REGULATOR

HIGH PRESSURE

WARM

HIGH PRESSURE

SOLUTION OUTLET

Front lower panel decal

(Low Pressure)

P/N 86179470

Front lower panel decal

(High Pressure)

P/N 86179480

Caution label

P/N 86012220

86352170 EVEREST

9

Installation

Dealer Responsibility

Your distributor from whom you purchased this mobile

cleaning unit is responsible for correct installation of

this machine. The dealer is also responsible for initial

training of your operators and maintenance personnel

in proper operation and maintenance of this unit.

V e hicle Requirements

1. The unit should NOT be mounted in any motor

vehicle of less than 3/4 ton capacity.

DO NOT exceed the vehicle’s axle weight limit.

Include the console, full tanks, accessories, and

operators in calculations.

2. If mounting in a trailer, make certain that trailer is

rated for the total weight of UNIT AND TRAILER.

Electric or hydraulic brakes should be provided,

and a strict compliance with any State and Federal

vehicle laws must be maintained.

3. The vehicle tires should have a load rating above

the combined vehicle and unit weight.

4. We do not recommend using flooring materials that

absorb water. This could result in rust and

corrosion of the vehicle floor.

5. Padding under rubber floor mats should be

removed before installing this unit.

6. We highly recommend using a drip tray under

console (Part #86055040).

7. If using a trailer, console should be positioned so

that it balances properly with respect to axle. Ten

percent (10%) of the overall unit weight should be

on tongue.

Example: If loaded trailer weight is 2,000 lbs.,

tongue weight needs to be a minimum of 200 lbs.

to tow properly .

10

86352170 EVEREST

Installation

Lifting Unit Onto Vehicle

Since the console weighs approximately 1150 lbs., we

recommend using a forklift to lift unit onto vehicle.

Position forks under unit from front and make CERT AIN

that forks are spread to insert into frame slots.

Positioning Unit In Vehicle

Because vehicles vary in size and openings, individuals

have their own preference as to where they want their

units installed. We strongly recommend a side door

installation for this and DO NOT recommend a rear

door installation.

1. Enough space should be provided to assure

adequate engine ventilation and room for service

and maintenance.

2. The unit with waste tank and accessories must

NOT exceed vehicle's axle weight limit. An empty

100 gallon waste tank and console weighs 1300

lbs.

3. DO NOT position the console closer than 12" from

bottom of driver and passenger seats.

NOTE: For individuals who wish to make an

engineering layout prior to positioning unit, refer to

“Dimensional Data” illustrations for waste tank and

console dimensions.

Bolting Down Unit And Waste Tank

When positioning waste tank with respect to console,

hook up the vacuum hose from blower to waste tank.

This will ensure that waste tank is positioned correctly.

Proceed once unit and waste tank are positioned in

vehicle in desired location.

Before drilling any mounting holes in vehicle floor,

make certain that when drilling, you will not do any

damage to fuel tank, fuel lines, or any vital component

which might affect operation or safety of vehicle.

1. Using console and waste ta nk mounting holes a s a

template, drill six 13/32" diameter holes for

mounting console and six more 13/32" diameter

holes for mounting waste tank.

2. Using installation hardware kit:

a. Insert six 3/8-16 x 2" hex head cap screws with

flat washers through mounting holes in console,

and six 3/8-16 x 2" hex head cap screws with flat

washers through mounting holes in waste tank.

b. Install mounting plates underneath vehicle floor.

c. Screw 3/8-16 hex head locknuts on mounting

screws and tighten them until console and waste

tank are firmly secured to vehicle floor.

86352170 EVEREST

11

Installation

2'-8

1

2

"

3'-4

3

4

"

3'-11

1

8

"

4'-3

1

8

"

4'-4

1

8

"

1'-1

5

8

"

10

5

8

"

5

5

16

"

5'-6

1

2

"

3'-2

1

16

"

4'-5

13

16

"

1

1

2

"

1'-9

1

2

"

6

5

8

"

Layout with 100 Gallon Waste Tank

12

86352170 EVEREST

Installation

Waste Tank To Console Connection

NOTE: Before connecting any hoses to the waste

tank, make certain the hose clamps are on each

hose.

1. Connect the section of 4.5" I.D. internal vac hose to

the 4.5” diameter vac outlet tube on the waste ta nk

and to the vacuum pump relief valve on the

console. It may be necessary to cut this hose to fit.

Tighten the hose clamps.

2. Connect the 2” I.D. waste removal hose to the 2”

diameter tube at the bottom of the waste tank.

Connect other end to 2” tube on the Pre-Filter Box.

Tighten the hose clamps.

3. Connect the 3/16 blue hose from the water box

temperature relief valve to the 1/4 fitting (pointed

downward) on the waste tank that does not have a

spray jet installed inside the tank.

4. Connect the console engine shut-off cord to th e

waste tank level sensor cord.

5. Connect the 3/16 blue hose from the Flow Setup

V alve to the other 1/4 fitting (poin ted downward) on

the waste tank that has a spray jet installed inside

the tank.

Fuel Pump Assembly Installation

Before drilling the fuel line holes in the vehicle

floor, make certain that when drilling you will not do

any damage to the fuel tank(s), fuel lines, brake

lines, heat shields, or any other vital component

which might affect the operation or safety of the

vehicle.

Do not mount this assembly, any hoses or components near the catalytic converter, exhaust, or any

areas of high temperature. Avoid any contact with

moving parts, areas of high temperature, brak e

lines, fuel lines, muffler, catalytic converter, or

sharp objects.

1. Determine the mounting location of the fuel system

assembly. Mount bottom of box parallel to the

ground and side perpendicular. Ensure that the

power cord length will support the mounting

location. Mount the pump as low as possible while

still being protected by the frame from road

hazards. The pump end with the electrical connections is the discharge end. Additional mounting

holes are provided to allow for different mounting

options.

2. Cut a 6" piece of 5/16 fuel hose and connect from

the outlet side of the fuel filter to the inlet side of

the fuel pump. Use supplied hose clamps and

fasten securely.

NOTE: On the high-pressure pump supplied with the

EFI unit, add 2-3 drops of lubricating oil to the inlet

side of the fuel pump to protect the pump during initial

startup.

3. Prior to drilling, check to ensure that the cord

length will support the location of the hole. Drill a

5/8" hole in the vehicle floor for routing the fuel

pump power cord to the truckmount console and

install the hole grommet. Drill a 1-3/8" hole in the

vehicle floor for routing the electronic fuel pressu re

regulator cord to the truckmount console.

4. Do not connect the power cords to the truckmount

console wiring harness until installation is

complete.

86352170 EVEREST

13

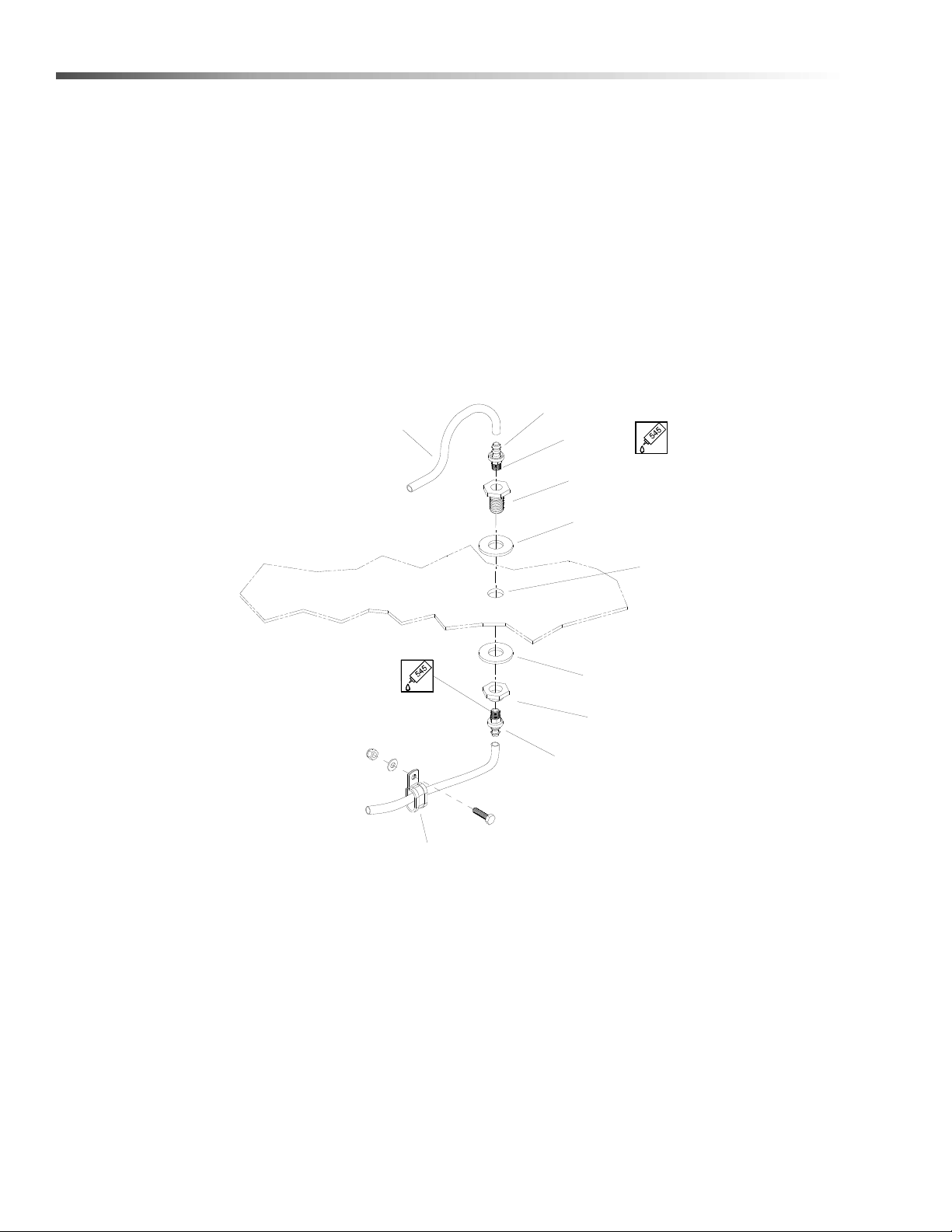

Installation

BULKHEAD ADAPTER

BULKHEAD NUT

HOSEBARB

HOSEBARB

HOSE MOUNTING CLAMPS

FUEL HOSE

VEHICLE FLOOR

5/8" DIA HOLE

LOCTITE

FUEL PRESSURE REGULATOR

FUEL HOSE FROM

BULKHEAD GASKET

BULKHEAD GASKET

TO CONSOLE

USE AS NEEDED

Van Bulkhead Installation

1. Select a location on the vehicle floor to drill the hole for the bulkhead adapter. This location should be situated

in a position that eliminates the possibility of fuel line contact by either the operator(s) or accessories during the

working hours or maintenance periods. Make certain that the supplied hoses will reach the location and work

with the configuration you choose.

2. Drill a 5/8" (.625) diameter hole through the ve hicle fl oo r at the ins tallation poin t cho se n for the bulkhe ad .

3. Install the 1/8 NPT bulkhead adapter by inserting the adapter an d tightening the nut o n the opposite side of th e

van floor.

4. Install (1) 1/8P x 5/16 push-on hosebarb fitting on to the bulkhead (inside van).

5. Attach the 5/16" fuel hose from the console to the hosebarb fitting on the bulkhead. DO NOT USE HOSE

CLAMPS AT THIS CONNECTION.

14

86352170 EVEREST

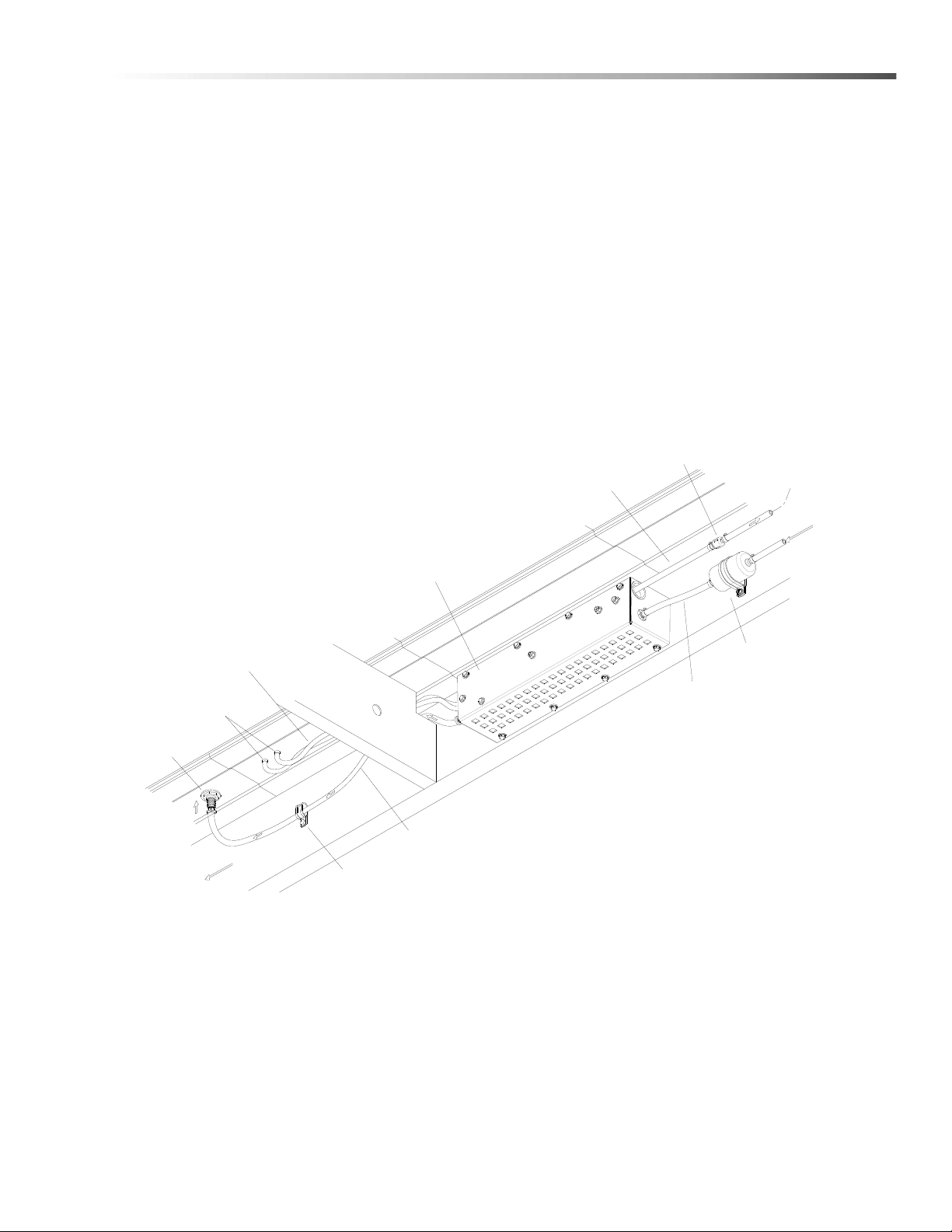

Installation

CONNECTOR

CHECK VALVE

5/16" SUPPLY HOSE

HOSE MOUNTING CLAMP

FRONT OF VAN

BULKHEAD

BUSHINGS

ELECTRICAL CORDS

PUMP ASSEMBLY

ELECTRICAL FUEL

USE AS NEEDED

5/16" SUPPLY HOSE

FUEL SUPPLY

RETURN TO VEHICLE

FROM VEHICLE

FUEL SUPPLY

FUEL FLOW

FUEL FILTER

1/4" RETURN HOSE

Fuel Supply & Return Line Installation

(Underneath Van)

1. Spray th e inside of the supplied 90 degree plastic barbed fitting with water displacing lubricant. Push plastic

fitting onto the return tube on filler neck adapter tube until fitting securely snaps into place.

2. Measure and cut a length of 5/16" fuel hose and connect to the plastic barbed fitting on the return tube of the

filler neck adapter tube. Connect other end of hose to 1/4 x 5/16 brass hose adapter and attach adapter to 1/4"

fuel hose from electronic fuel pressure regula to r. Fasten securely using supplied hose clam ps.

3. Install (1) 1/8P x 5/16 push-on hosebarb fitting on to the bulkhea d adapter.

4. Measure and cut a length of 5/16" fuel hose and connect between the outlet side of the electronic fuel pressure

regulator and the 1/8P x 5/16 push-on hosebarb fitting at the bulkhead. DO NOT USE HOSE CLAMPS AT

THIS CONNECTION.

NOTE: Fuel tap kit installation instructions are found with appropriate fuel tap kit. Refer to Fuel Tap Kit

Information Sheet (86349940)

86352170 EVEREST

15

Installation

Battery Connection

Dangerous Acid, Explosive Gases! Batteries

contain sulfuric acid. To prevent acid burns, avoid

contact with skin, eyes, and clothing.

Batteries produce explosive hydrogen gas while

being charged. To prevent a fire or explosion,

charge batteries only in well-ventilated areas. Keep

sparks, open flames, and other sources of ignition

away from the battery at all times. Keep batteries

out of the reach of children. Remove all jewelry

when servicing batteries.

Before disconnecting the negative (- ) ground cable,

make sure all switches are OFF. If ON, a spark will

occur at the ground cable terminal which could

cause an explosion if hydrogen gas or gasoline

vapors are present. When disconnecting the

battery, ALWAYS disconnect the negative (-)

terminal FIRST.

1. Attach the red positive (+) battery cable from the

console starter solenoid to the positive (+) terminal

on the battery and tighten the holding nut.

2. Next, attach the black negative (-) battery cable

from the console ground to the negative (-) terminal

on the battery and tighten the holding nut.

Electrical Wiring

Ensure all electrical wiring and battery cables are free

from contact with any metal edge. Engine vibration

could cause metal edge to cut wiring and possibly

result in a fire. Be aware of where battery cables are

run.

Fire Extinguisher

We recommend that a fire extinguisher, preferably

rated for A, B, & C type fires, be installed inside the

vehicle.

16

86352170 EVEREST

Technical Specifications

Item Dimension / Capacity

Operations

Engine speed

Solution pump rpm 1357 rpm

Vacuum pump rpm 3125 rpm

Water flow rate 5 GPM (maximum)

Solution pump pressure (low pressure) 1200 PSI (maximum)

Solution pump pressure (high pressure) (Optional) 3000 PSI (maximum)

Vacuum relief valve 13" Hg

Waste tank capacity 100 gallons

Console weight (Model 408 & HP 408) 1065 lbs

Console weight (Model 650 & HP 650) 1150 lbs

Console weight (with waste tank & waste tank accessories)

(Model 408 & HP 408)

Console weight (with waste tank & waste tank accessories)

(Model 650 & HP 650)

Torque Values

2200 rpm (high speed)

900 rpm (idle speed)

1215 lbs

1300 lbs

Engine pulley 360 inch lbs 30 foot/lbs

Vacuum pump hub 300 inch/lbs 25 foot/lbs

86352170 EVEREST

17

Operations

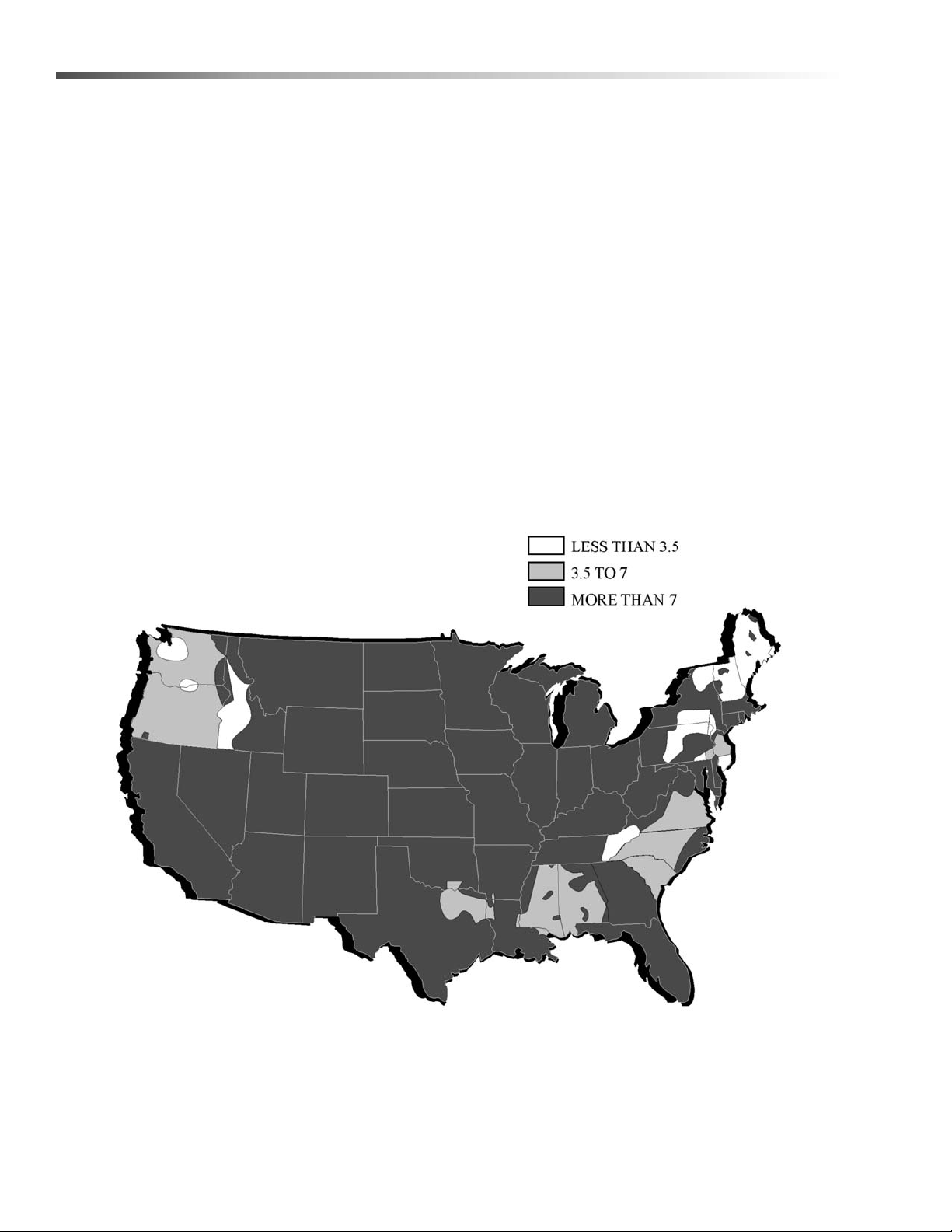

Water Requirements

Hard water deposits will adversely affect the plumbing

and heat exchange systems on this unit. The map

below will give you an idea of where areas of high water

hardness may occur. However, any water supply

obtained from a well is almost always hard water and a

water softener will be needed to protect your equipment.

NOTE: Equipment malfunction or component failure

caused by hard water scaling is NOT covered under

the warranty.

If you are operating this unit in an area where the unit

will be using water in which the hardness exceeds

3-1/2 grains, we highly recommend a suitable water

softener be installed. If using a water softener, it must

have a five (5) GPM (or greater) flow capacity without

any hose constrictions.

Using a water softener will reduce maintenance and

decrease down time caused by hard water scaling. It

will also allow cleaning chemicals to be more effective

in lower concentrations.

If you require a water softener , your dealer has a model

to meet your needs. Please contact your nearest

distributor for information, price, and availability.

18

86352170 EVEREST

Operations

Fuel Requirements

Use unleaded gasoline ONLY. DO NOT use any

gasoline additives. We recommend the use of clean,

fresh, unleaded gasoline intended for automotive use.

High-octane gasoline should NOT be used with the

engine on this unit. This unit is not compatible with E-85

fuel.

Engine Oil Requirements

Use high quality detergent oil of at least API (American

Petroleum Institute) service class SH. NOTE: Using

less than service class SH oil or extending oil change

intervals longer than recommended can cause engine

damage. The recommended SAE viscosity grade is

10W-40 or 15W-40 for regular oil. It is recommended

that a good quality synthetic oil be used after the first 25

hour break-in period to extend the service interval to

150 hours. Oils rated for high mileage engines have

been shown to help keep internal engine components

clean and keep seals and other rubber components

pliable, increasing service life. Synthetic oils of the

following viscosities are recommended: 10W-30, 10W40, 15W-50 and 20W-50. Higher viscosity oils should

be used in high temperature operating conditions and

lower viscosity oils should be used in cooler temperature operating conditions.

Chemical Requirements

This cleaning unit, due to its chemical injection pump

design, can be used with a variety of water-diluted

chemical compounds (either acidic or alkaline),

depending on the job to be done. However, to obtain

optimum results with this unit, we recommend using the

PROCHEM line of chemicals. For information on using

the cleaning compounds, refer to the PROCHEM

chemical manual.

Electronic Fuel Injection System

This unit is equipped with the latest port fuel Electronic

Fuel Injection (EFI) technology. The EFI technology

provides more effective fuel distribution and improved

power management through the use of an electronic

"brain" called the electronic control unit (ECU). The

ECU also provides improved engine emissions through

more effective combustion of the fuel/air mixture. The

fuel system, engine set up, and exhaust system are

systems approved by the Environmental Protection

Agency (EP A). Any alteration or modification to the

system must receive approval from the EPA.

86352170 EVEREST

19

Operations

EMISSION CONTROL

LABEL

SERIAL

NUMBER

FUEL PUMP

FUEL FILTER

CATALYTIC

CONVERTER

SERIAL NUMBER

Emission Control Information

The Zenith Power Products (ZPP) Emission control

labels are located on the valve cover of the engine near

the oil fill cap, and on the side of the catalytic converter.

The catallytic converter is located behind the heat

shield cover.

Date Stamp Location

When referring to an engine for assistance from your

dealer, Proche m, or ZPP please identify your engine b y

the serial # and date code stamped on the surface on

the back of the engine block, approximately where indicated.

Fuel Pump And Filter

Your Everest console was shipped to the dealer with a

specific fuel pump and fuel filter. Ensure that ONLY

these items are used in the installation of your unit.

The system is much more sensitive to unwanted

material in the fuel stream. Contamination of the fuel

stream may clog the injectors and adversely affect

performance. Please be sure to adhere to the filter

maintenance schedule located in the Operations

Section of this manual.

20

86352170 EVEREST

Operations

T rouble Codes

A feature of the ZPP 416 ECM is that DTC's (Diagnostic Trouble Codes) can be displayed to a technician to indicate

what historic faults are present without requiring the use of a personal computer. The DTC's can be flashed over th e

MIL output while the RS232 serial receive input (PC RX) is grounded . This input may be grounded a t the diagnostic

connector (pin A-brown/white wire). This connector is located behind the intake manifold near the front cylinder.

Once the ECM recognizes that the user is requesting flash codes, ignition key on-engine off, it will flash or blink a

leader code (111) x 3 times in a row. If the machine has been shut down due to a full waste tank you will also

observe flash code 552 (DTC1552) and 554 (DTC1554). Af ter the leader code has been flashed for 3 times, the first

flash code in the active faults category will be flashed at the same rate. This will repeat depending on the number

of faults retained in memory. Once all faults have been flashed the leader flash code (111) will be repeated. The

codes are retained in memory. Once any issue is resolved and the machine started-ru n-stopped for 3 times without

a fault detected the light will go out on the 4th start. If an issue has not been resolved the light will remain on and

another code stored in history.

History faults will clear automatically after 20 start-run-stop cycles if the fault has not been detected.

DTC/

#

Pcode

Leader/Trailer Code 111

1 P0016

2 P0091 Fuel Pressure low voltage 94 4 Yes 291

3 P0092 Fuel Pressure high voltage 94 3 Yes 292

4 P0107 MAP Signal open or shorted to ground 106 4 Yes 127

5 P0108 MAP signal shorted high 106 16 Yes 128

6 P0112 IAT signal Low/Shorted to GND 105 4 Yes 112

7 P0113 IAT signal High/Open 105 3 Yes 113

8 P0116 ECT higher than warning threshold 110 15 Yes 116

9 P0117 ECT Sensor Low/Shorted Input 110 4 Yes 117

10 P01 18 ECT Sensor High/Open Input 110 3 Yes 118

11 P0121 TPS1 voltage lower than TPS2 voltage 51 1 Yes 121

12 P0122 Throttle Position Signal 1 low voltage 51 4 Yes 122

13 P0123 Throttle Position Signal 1 high voltage 51 3 Yes 123

14 P0134 Pre-Cat O2 Signal No Activity 724 10 Yes 134

15 P0154 Post-Cat O2 Signal No Activity 520208 10 Yes 154

16 P0171 Gasoline bank 1 A/F is lean (adaptive learn) 520200 0 Yes 171

17 P0172 Gasoline bank 1 A/F is rich (adaptive learn) 520200 1 Yes 172

18 P0182 Gasoline Fuel Temp Low Voltage 174 4 Yes 182

19 P0183 Gasoline Fuel Temp High Voltage 174 3 Yes 183

22 P0217 ECT higher than engine shutdown threshold 1 10 0 Yes 217

23 P0219 Engine Over speed Condition 515 15 Yes 219

24 P0221 TPS1 voltage higher than TPS2 voltage 51 0 Yes 221

25 P0222 Throttle Position Signal 2 low voltage 520251 4 Yes 222

CRANK or CAM could not synchronize during

start

Fault Description

CAN

SPN

636 8 Yes 216

CAN

FMI

Turns on

MIL?

MIL Flash

Code

86352170 EVEREST

21

Operations

DTC/

#

Pcode

Fault Description

CAN

SPN

CAN

FMI

T urns on

MIL?

MIL Flash

Code

26 P0223 Throttle Position Signal 2 high voltage 520251 3 Yes 223

27 P0261 Injector 1 Low/Open 651 5 Yes 261

28 P0262 Injector 1 High/Short 651 6 Yes 262

29 P0264 Injector 2 Low/Open 652 5 Yes 264

30 P0265 Injector 2 High/Short 652 6 Yes 265

31 P0267 Injector 3 Low/Open 653 5 Yes 267

32 P0268 Injector 3 High/Short 653 6 Yes 268

33 P0270 Injector 4 Low/Open 654 5 Yes 269

34 P0271 Injector 4 High/Short 654 6 Yes 271

35 P0326 Knock signal excessive or erratic 731 2 Yes 326

36 P0327 Knock signal open or not present 731 4 Yes 327

37 P0336 CRANK signal noise 636 2 Yes 336

38 P0337 No CRANK signal 636 4 Yes 337

39 P0341 CAM signal noise 723 2 Yes 341

40 P0342 No CAM signal 723 4 Yes 342

41 P0420 Catalyst inactive on gasoline 520211 10 Yes 421

42 P0524 Engine Oil Pressure Too Low 100 1 Yes 524

43 P0562 Battery Voltage Low 168 17 Yes 562

44 P0563 Battery Voltage High 168 15 Yes 563

45 P0601 Microprocessor failure - FLASH 628 13 Yes 621

46 P0604 Microprocessor failure - RAM 630 12 Yes 624

47 P0606 Microprocessor failure - COP 629 31 Yes 626

48 P0615 Starter relay coil open 1321 5 Yes 615

49 P0616 Starter relay control short to GND 1321 4 Yes 616

50 P0617 Starter relay coil short to 12V 1321 3 Yes 617

51 P0642 5V Reference #1 voltage low 1 079 4 Yes 642

52 P0643 5V reference #1 voltage high 1079 3 Yes 643

53 P0650 Malfunction Indicator Lamp open 1213 5 Yes 651

54 P0652 5V Reference #2 voltage low 1080 4 Yes 652

55 P0653 5V Reference #2 voltage high 1080 3 Yes 653

56 P0685 Power relay coil open 1485 5 Yes 685

57 P0686 Power relay short to GND 1485 4 Yes 686

58 P0687 Power relay short to 12V 1485 3 Yes 687

22

86352170 EVEREST

Operations

DTC/

#

Pcode

63 P1155 Closed-loop gasoline bank 1 A/F is too lean 520204 0 Yes 155

64 P1156 Closed-loop gasoline bank 1 A/F is too rich 520204 1 Yes 156

86 P1551 Aux Digital Input 1 High (Float Switch Voltage Hig h) - - Yes 1551

87 P1552

88 P1553

89 P1554

94 P1612 Watchdog processor blocked outputs (RTI 1) 629 31 Yes 712

95 P1613 Microprocessor failure - RTI 2 P0629 P0031 Yes 713

96 P1614 Microprocessor failure - RTI 3 P0629 P0031 Yes 714

97 P1615 Microprocessor failure - A/D P0629 P0031 Yes 715

98 P1616 Microprocessor failure - Interrupt P0629 P0031 Yes 716

99 P1644 MIL control short to GND P1213 P0004 No 644

100 P1645 MIL control short to 12V P1213 P0003 No 645

101 P2111 Unable to reach Lower TPS P0051 P0007 Yes 211

102 P2112 Unable to reach higher TPS P0051 P0007 Yes 212

110 P2300 Ignition coil A low current P1268 P0005 Yes 411

111 P2301 Ignition coil A high current P1268 P0006 Yes 412

112 P2303 Ignition coil B low current P1269 P0005 Yes 421

113 P2304 Ignition coil B high current P1269 P0006 Yes 422

AUX DIGITAL INPUT 1 low voltage-force idle-waste

tank full.

Aux Digital Input 2 High (Float Switch Voltage High

Engine Shut Down) 1553

AUX DIGITAL INPUT 2 low voltage-after 15 secondsengine shut-down-waste tank full

Fault Description

CAN

SPN

520222 3 Yes 552

--Yes1553

520223 4 Yes 554

CAN

FMI

T urns on

MIL?

MIL Flash

Code

OBD = On Board diagnostics (Nomenclature)

DTC = Diagnostic Trouble Code

MIL = Malfunction Indicator Light

TPS1 = Throttle Position Sensor

EGO = Exhaust Gas Oxygen

ECT = Engine Coolant Temperature

86352170 EVEREST

CAM = Cam Sensor Input

CAN = Controller Ares Network

CPS = Crank Position Sensor

MAP = Manifold Absolute Pressure

Pcode= Powertrain Code

23

Operations

UPPER CONTROL

PANEL

PANEL

LOWER CONTROL

FILTER BOX

13

12

11

10

9

8

7

6

5

4

3

2

1

O

p

e

r

a

t

i

o

n

.

H

i

g

h

P

r

e

s

s

u

r

e

c

l

o

s

e

d

p

r

i

o

r

t

o

v

a

l

v

e

m

u

s

t

b

e

p

u

m

p

i

s

o

l

a

t

i

o

n

p

u

m

p

.

C

h

e

m

i

c

a

l

d

a

m

a

g

e

c

h

e

m

i

c

a

l

s

y

s

t

e

m

w

i

l

l

H

i

g

h

p

r

e

s

s

u

r

e

Components

24

LOWER CONTROL PANEL

86352170 EVEREST

Operations

Lower Control Panel

1. Lubrication Cup

The lubrication cup allows lubricant spray to reach

the vacuum blower.

2. Warm Wa te r Outlet

The warm water outlet allows the cleaning technician to drain warm water from the water box for

mixing chemical.

3. Water Inlet

This quick connect allows the water supply hose to

be connected to the unit.

4. Engine Oil Drain

The engine oil drain plug is removed to allow the

engine oil to be drained.

5. Solution Outlets

The solution outlets are the connecting point for the

high pressure solution hoses. These outlets are

quick disconnects that allow hoses to be plugged

into the unit.

6. Pressure System Valve (Option)

This lever when in the up position actuates the

high-pressure system and regulator. When in the

down position the low pressure cleaning system

and regulator are actuated.

7. High Pressure Solution Regulator (HP Only)

The high pressure regulator sets the pressure of

the pressure washing circuit. This spring loaded

valve can be adjusted up or down. The pressure is

increased by turning the valve clockwise, or

reduced by turning the valve counterclockwise.

(This valve must be maintained in accordance with

this manuals maintenance table.)

8. High Pressure Solution Outlet (Option)

The high-pressure solution outlet is the connecting

point for the high-pressure washing hose. This

outlet is a quick disconnect that allows the

pressure washing hose to be plugged into the unit.

9. Low Pressure Solution Regulator

The pressure regulator sets the pressure of the

solution system. This spring loaded valve can be

adjusted up or down. The pressure is increased by

turning the valve clockwise, or reduced by turning

the valve counterclockwise. (This valve must be

maintained in accordance with this manuals maintenance table.)

10. Solution Screen

The solution screen is located on the front of the

machine. The function of this screen is to trap

foreign particles from exiting the machine and

plugging the orifices of the cleaning tools. This

screen is part of the machine maintenance

cleaning.

11. Chemical Check Valve

The chemical check valve allows chemicals to

enter the system and travel in a singular direction

to the wand. The chemical check valve prevents

chemicals from traveling upstream into the solution

system of the unit.

12. Temperature Balance Orifice

The temperature balance orifice helps to balance

and stabilize the solution temperature within the

system.

13. Solution Temperature Control Lever

This lever directs hot engine and blower exhaust

gases through or around the heat exchangers.

86352170 EVEREST

25

Operations

3

1

2

4

18

5

17

6

16

15

14

7

13

8

12

11

10

9

15

20

10

8

Upper Control Panel

26

86352170 EVEREST

Operations

Upper Control Panel

1. Service Engine Soon (Amber)

This light, when flashing, signals a problem with

the unit. When this occurs, troubleshooting is

required.

2. Solution Temperature Gauge

This gauge measures the temperature of the

cleaning solution as it exits the machine.

3. Panel Light

This light is useful if the machine is used in a poorly

lit area or night use. It is helpful in reading the

instruments and gauges.

4. Waste Tank Full Indicator Light (Red)

This indicator light is activated when the waste tank

is full. This unit is equipped with a slow down

feature. This feature will help to protect the engine

from damage by causing a slow down for 15

seconds prior to shutting down the engine. When

this indicator light is on, it indicates that the waste

tank must be emptied before the unit can be

brought back into service.

NOTE: Never dispose of wastewater in storm drains,

waterways or on ground areas. Always dispose of

waste in accordance with local state and federal law.

5. Vacuum Gauge

This gauge indicates in inches of mercury how

much vacuum the system is producing at any given

time.

6. Waste Pumpout

This switch actuates the optional waste pumpout.

7. Ignition Switch

The ignition switch controls the power for the

machine. To turn the machine on, rotate the key

clockwise until the starter engages the engine.

When machine is running let off the switch and

engine will continue to run. To turn power off,

rotate key counter cl ockwise to stop position,

engine will then stop.

8. Circuit Breakers

These serve to protect the circuits from electrical

spike and over loads and protects wires from

damage and fire.

9. Flow Setup Valve

This valve allows solution to move through the

machine and chemical to be injected simulating the

cleaning process. This allows the operator to set

the chemical flow level without connecting tools to

the machine. It is also useful in troubleshooting.

10. 12 Volt Outlet

The 12 volt outlet is used for accessories such as

auxiliary lighting.

11. Chemical Metering Valve

The chemical metering valve regulates the amount

of chemical that is injected into the system.

Clockwise rotation of the knob closes the valve.

Counter clockwise rotation opens the valve,

allowing more chemical to enter the system.

12. Flow Meter

The flow meter is a gauge to indicate how much

liquid chemical is being introduced in the water

system. The quantity can be increased by turning

the chemical metering valve knob counter clockwise.

13. Chemical Selector Valve

This valve allows the chemical to circulate through

the chemical system with little or no restriction. It

also purges out air that may be trapped in the lines

and cavities of the chemical pump. By turning the

valve counter clockwise the injection system is

enabled.

86352170 EVEREST

27

Operations

2

1

14. Hour Meter

The hour meter records the number of hours the unit

has run. This serves as a time recorder for servicing

the machine.

15. Engine Speed Control

This serves to set the engine speed and operating

parameters. The 'Low', 'Medium' and 'High' settings

are set for upholstery cleaning, single wand cleaning,

and dual wand cleaning respectively.

16. Solution Pump Switch

This switch serves to energize the magnetic clutch to

turn the

activating the pump and counter clockwise for deactivating the pump.

solution pump on or off. Turn clockwise for

Filter Box

17. Auxiliary Water Tank Pump Switch

The Auxiliary Water Tank Pump Switch is used to

actuate an optional fresh water demand pump

18. Solution Pressure Gauge

This gauge registers the amount of pressure in the

system.

1. Vacuum Inlets

The vacuum inlets serve as the connecting point for

vacuum hoses.

2. Waste Tank Drain

This allows the waste tank to be emptied. Must be

closed for operation.

28

86352170 EVEREST

Loading...

Loading...