Prochem Blazer XL User Manual

BLAZER XL

MOBILE CLEANING UNIT

Operating Instructions (ENG)

MODELS: BLAZER XL

Read instructions before operating the machine.

86037390

AY PRV NO. 980156 02/14/09

MACHINE DATA LOG/OVERVIEW

MODEL _______________________________________

DATE OF PURCHASE __________________________

SERIAL NUMBER ______________________________

SALES REPRESENTATIVE # _____________________

YOUR DEALER

Name: ________________________________________________________________________________________

Address: ______________________________________________________________________________________

Phone Number: _________________________________________________________________

Welcome…and congratulations on the purchase of your Mobile Cleaning Unit. This instruction manual is a guide for operating and servicing your unit. Read this manual completely before installing or operating this unit.

This unit offers you personal convenience. All of your instrumentation and controls have been positioned to give you easy access for operation and daily maintenance. Proper operation and service are essential to the efficient functioning of this unit. When maintained correctly, this unit will have a long, trouble-free life.

The service methods described in this manual are explained in such a manner that servicing may be performed accurately and safely. Proper service varies with the choice of procedure, the skill of the mechanic, and the tools or parts available. Before attempting any repair, make certain that you are thoroughly familiar with this equipment and are equipped with the proper tools. Any questions pertaining to operating or servicing this unit should be directed to your nearest dealer.

THIS UNIT MUST BE INSTALLED BY THE DEALER FROM WHOM YOU PURCHASED IT IN ACCORDANCE WITH THE PRESCRIBED INSTALLATION PROCEDURES.

MAKE CERTAIN THAT THE WARRANTY CARD IS FILLED OUT BY THE DISTRIBUTOR FROM WHOM YOU PURCHASED THIS UNIT AND RETURNED TO!

This operation and service manual is written specifically for your Mobile Cleaning Unit which is manufactured by:

PROFESSIONAL CHEMICALS CORPORATION 325 SOUTH PRICE ROAD

CHANDLER, ARIZONA 85224

Information in this document is subject to change without notice and does not represent a commitment on the part of Professional Chemicals Corporation.

86037390 |

02/14/07 |

1 |

TABLE OF CONTENTS

Machine Data Log/Overview......................... |

1 |

Table of Contents ......................................... |

2 |

Receiving Your Unit ...................................... |

4 |

HOW TO USE THIS MANUAL |

|

How to use this Manual. ............................... |

1-1 |

SAFETY |

|

Safety Instructions ........................................ |

2-1 |

Hazard Intensity Level .................................. |

2-3 |

INSTALLATION & OPERATION |

|

Technical Specifications. .............................. |

3-1 |

Installation..................................................... |

3-2 |

Fuel............................................................... |

3-2 |

Engine Oil ..................................................... |

3-2 |

Chemicals & Water ....................................... |

3-3 |

Components ............................................... |

3-4 |

Water Pumping And Heat Transfer…………3-8 |

|

Chemical System........................................ |

.3-9 |

Vacuum System.......................................... |

3-10 |

Pre-run Inspection ...................................... |

3-11 |

Water Supply Connection ........................... |

3-11 |

High Pressure Hose.................................... |

3-11 |

Vacuum Hose ............................................. |

3-11 |

Filters.......................................................... |

3-11 |

Chemical Pump Priming ............................. |

3-12 |

Waste Pump ............................................... |

3-12 |

Cleaning...................................................... |

3-12 |

Upholstery Cleaning ................................... |

3-13 |

Shutdown and Daily Maintenance .............. |

3-13 |

Freezing Protection..................................... |

3-13 |

Overheating Protection ............................... |

3-13 |

Winterizing Your Unit .................................. |

3-14 |

Removing Anti-freeze ................................. |

3-15 |

MAINTENANCE & SERVICE

Maintenance |

|

Maintenance Schedule ........................... |

4-1 |

Engine ..................................................... |

4-4 |

Vacuum Pump ........................................ |

4-5 |

Water Pump ............................................ |

4-6 |

Vacuum Inlet Filter .................................. |

4-6 |

Vacuum Relief Valve............................... |

4-6 |

Vacuum Pump Drive Belts ...................... |

4-6 |

Water Pump Drive Belt ........................... |

4-7 |

Float Valve (Water Box).......................... |

4-7 |

Strainer Basket (Waste Tank)................. |

4-7 |

Waste Tank Float Valve.......................... |

4-7 |

Outlet Y-Strainer, Check Valve ............... |

4-7 |

Chemical Pump, Chemical And Heat |

|

Bypass Valves ........................................ |

4-7 |

Nitrogen Accumulator ............................. |

4-8 |

Pressure Regulator ................................. |

4-8 |

Vacuum Hoses........................................ |

4-8 |

High Pressure Hoses .............................. |

4-8 |

Optional Waste Pump-out....................... |

4-8 |

General Service Adjustments |

|

Engine Speed ......................................... |

4-9 |

Check Valve (Solution Outlet)................. |

4-9 |

Water Box ............................................... |

4-9 |

Chemical Pump....................................... |

4-9 |

Drive Belts (Water & Vacuum Pump....... |

4-9 |

Packing Nut Adjustment |

|

(Chemical Metering & Selector Valves) .. |

4-10 |

Pressure Regulator ................................. |

4-10 |

Troubleshooting....................................... |

4-11 |

2 |

86037390 |

02/14/07 |

TABLE OF CONTENTS

PARTS LIST

Frame................................................ |

5-1 |

Side Panel......................................... |

5-3 |

Control Panel .................................... |

5-5 |

Engine............................................... |

5-7 |

Vacuum Pump .................................. |

5-9 |

Water Pump & Chemical Pump ........ |

5-11 |

Heat Exchanger ................................ |

5-15 |

Pressure Regulator & |

|

Temperature Bypass......................... |

5-17 |

Water Box ......................................... |

5-19 |

Waste Tank....................................... |

5-21 |

Hose Accessories ............................. |

5-23 |

Battery-Floor Mount .......................... |

5-25 |

Automatic Pumpout-Optional ............ |

5-27 |

Wand-Titanium Six Jet-Optional ....... |

5-31 |

Wand-Quad Jet-Optional .................. |

5-33 |

Wand-Tri Jet-Optional....................... |

5-35 |

Stair Tool-Optional ............................ |

5-37 |

Upholstery Tool-Optional .................. |

5-39 |

Shelf Assembly-Optional................... |

5-41 |

Water Tank, Dual With |

|

Demand Pump-Optional ................... |

5-43 |

Water Tank- |

|

Demand Pump-Optional ................... |

5-45 |

Auxiliary Water Tank With Pump ...... |

5-47 |

Auxiliary Water Tank-Optional .......... |

5-49 |

Hose Reel-Optional........................... |

5-51 |

Wiring Diagram ................................. |

5-53 |

Hose Diagram ................................... |

5-54 |

Warranty ........................................... |

5-56 |

86037390 |

09/06/07 |

3 |

RECEIVING YOUR UNIT

DEALER RESPONSIBILITY

The dealer from whom you purchased this mobile cleaning unit is responsible for the correct installation of this machine. The dealer is also responsible for initial training of your operators and maintenance personnel in the proper operation and maintenance of this unit.

ACCEPTANCE OF SHIPMENT

Every part of your cleaning unit was carefully checked, tested, and inspected before it left our manufacturing plant. Upon receiving the unit, make the following acceptance check:

1.The unit should not show any outward signs of damage. If damaged, notify the common carrier immediately.

2.Check your equipment and packing list. The standard cleaning unit should arrive equipped with the following items (unless otherwise specified) and any optional accessories which were ordered:

EQUIPMENT LIST

1.Console.

2.Operation and service manual with engine, water pump, and vacuum pump manuals.

3.Installation bolting kit.

4.Installation mounting plates.

5.Hose clamps for fuel & vacuum hoses.

6.Carpet wand.

7.Waste tank w/float switch.

8.Waste tank filter and strainer basket.

9.100 ft. of 2” vacuum hose.

10.1 vacuum hose connector.

11.100 ft. of 1/4" high pressure hose with quick connects.

12. 50 ft. water supply hose with quick connect. 13. 5 gallon jug and holder.

Each unit will require a fuel system installation kit that is purchased separately from the unit and is specific for each manufacturer and model year of van.

4 |

86037390 |

02/14/07 |

HOW TO USE THIS MANUAL

This manual contains the following sections:

-HOW TO USE THIS MANUAL

-SAFETY

-OPERATIONS

-MAINTENANCE & SERVICE

-PARTS LIST

The HOW TO USE THIS MANUAL section will tell you how to find important information for ordering correct repair parts.

Parts may be ordered from authorized dealers. When placing an order for parts, the machine model and machine serial number are important. Refer to the MACHINE DATA box which is filled out during the installation of your machine. The MACHINE DATA box is located on the inside of the front cover of this manual.

MODEL _____________________________________

DATE OF PURCHASE ________________________

SERIAL NUMBER ____________________________

SALES REPRESENTATIVE # ___________________

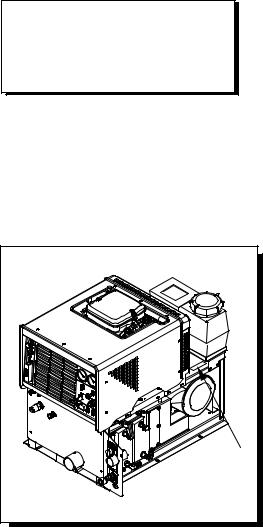

The model and serial number of your machine is on the lower front as shown.

The SAFETY section contains important information regarding hazard or unsafe practices of the machine. Levels of hazards is identified that could result in product or personal injury, or severe injury resulting in death.

The OPERATIONS section is to familiarize the operator with the operation and function of the machine.

The MAINTENANCE section contains preventive maintenance to keep the machine and its components in good working condition. They are listed in this general order:

-Engine

-Vacuum Pump

-Drive Belts, Pulleys & Hubs

-Chemical Pump

-Hoses

-Exhaust Heat Exchanger

-General Service Adjustments

-Troubleshooting

The PARTS LIST section contains assembled parts illustrations and corresponding parts list. The parts lists include a number of columns of information:

-REF – column refers to the reference number on the parts illustration.

-PART NO. – column lists the part number for the part.

-PRV NO. – reference number

-DESCRIPTION – column is a brief description of the part.

-SERIAL NO. FROM – column indicates the first machine the part number is applicable to. When the machine design has changed, this column will indicate serial number of applicable machine. The main illustration shows the most current design of the machine. The column has an asterisk (*), call manufacturer for serial number.

-NOTES – column for information not noted by the other columns.

NOTE: If a service or option kit is installed on your machine, be sure to keep the KIT INSTRUCTIONS which came with the kit. It contains replacement parts numbers needed for ordering future parts.

NOTE: The number on the lower left corner of the front cover is the part number for this manual.

86037390 01/25/08 |

1-1 |

IMPORTANT SAFETY INSTRUCTIONS

When using this machine, basic precaution must always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.

These symbols mean WARNING or CAUTION. Failure to follow warnings and cautions could result in fatality, personal injury to yourself and/or others, or property damage. Follow these instructions carefully!

Read the operator's manual before installing or starting this unit. Failure to adhere to instructions could result in severe personal injury or could be fatal.

Operate this unit and equipment only in a well-ventilated area. Exhaust fumes contain carbon monoxide which is an odorless and deadly poison that can cause severe injury or fatality. DO NOT run this unit in an enclosed area. DO NOT operate this unit where the exhaust may enter any building doorway, window, vent, or opening of any type.

Gasoline is extremely flammable and its vapors can explode if ignited. Store gasoline only in approved containers, in well-ventilated, unoccupied buildings away from sparks or flames. Never carry any gasoline or flammable material in the vehicle. Fumes may accumulate inside the vehicle and ignite, causing an explosion.

DO NOT store any type of flammable material in the vehicle.

This unit must be operated with the vehicle or trailer doors open in order to ensure adequate engine ventilation.

DO NOT operate engine if gasoline is spilled. Avoid creating any ignition until the gasoline has been cleaned up. Never use gasoline as a cleaning agent.

DO NOT place hands, feet, hair, or clothing near rotating or moving parts. Avoid any contact with moving parts! Rotating machinery can cause injury or fatality.

Never operate this unit without belt guards. The high speed moving parts, such as belts and pulleys, should be avoided while this unit is running. Severe injury, damage, or fatality may result.

DO NOT service this unit while it is running. The high-speed mechanical parts as well as high temperature components may result in severe injury or severed limbs.

Never touch electrical wires or components while the engine is running. They can be sources of electrical shock.

Engine components can get extremely hot from operation. To prevent severe burns, DO NOT touch these areas while the engine is running or immediately after the engine is turned off.

DO NOT touch any part of the exhaust system while this unit is running. Severe burns may result.

Before servicing this unit, allow it to "cool down." This will prevent burns from occurring.

Water under high pressure at high temperature can cause burns, severe personal injury, or fatality. Shut down machine, allow to cool down, and relieve system of all pressure before removing valves, caps, plugs, fittings, filters, and bolts.

Always wear hearing protection when unit is running. Always comply with your company’s Personal Protection Equipment (PPE) plan. Always comply with local noise ordinance when operating units.

2-1 |

86037390 02/14/07 |

DO NOT leave the vehicle engine running while operating this unit.

Dangerous Acid, Explosive Gases! Batteries contain sulfuric acid. To prevent acid burns, avoid contact with skin, eyes and clothing. Batteries produce explosive hydrogen gas while being charged. To prevent a fire or explosion, charge batteries only in well ventilated areas. Keep sparks, open flames, and other sources of ignition away from the battery at all times. Keep batteries out of the reach of children. Remove all jewelry when servicing batteries.

Before disconnecting the negative (-) ground cable, make sure all switches are OFF. If ON, a spark will occur at the ground cable terminal which could cause an explosion if hydrogen gas or gasoline vapors are present. When disconnecting the battery, ALWAYS disconnect the negative (-) terminal FIRST.

DO NOT smoke around the unit. Gas fumes may accumulate and be ignited. The battery is also extremely flammable. This will prevent possible explosions.

DO NOT damage the vehicle in any manner during installation. When routing fuel lines DO NOT place the hose in any location where damage may occur to the hose or vehicle. Avoid any contact with moving parts, areas of high temperature, brake lines, fuel lines, muffler, catalytic converter, or sharp objects.

There is no fuel solenoid shut off on this unit. Use only the provided abrasion resistant fuel hose for fuel lines. When traversing the vehicle floor with fuel lines, always use a bulkhead adapter. This will prevent leakage and ensure that the hose is not punctured by vehicle vibration abrasion.

DO NOT exceed your vehicle's weight limit. The console with empty and accessories weighs approximately 710 lbs (800 lbs. if mounted on water tank). Make certain that the vehicle has the correct axle rating. This will prevent unsafe vehicle driving conditions.

We require high-back seats on all vehicles in which units are to be installed for head and neck protection.

We recommend using a metal partition between the seats and equipment.

DO NOT operate this unit without the water supply attached and turned on. The water pump and other vital components may be seriously damaged if this unit is permitted to operate dry without water.

Keep your vehicle work area clean. Wands, stair tools, and other accessories must be securely fastened before driving the vehicle.

All high pressure hoses must be rated for 3000 PSI at 250°F. Thermoplastic hoses do not meet these specifications and should not be used. Severe burns and injury may result if the hoses do not meet these requirements.

The winterizing loop hose assembly, Part #86260700, PRV NO. 10-805380, is for winterizing use only. If used improperly, live steam may escape from this hose, causing it to whip around. Burns or injury may result.

Make certain that you receive complete training by the distributor from whom you purchased this unit. This unit uses high pressure and temperature. Improper or irresponsible use may result in serious injury. Do not modify this unit in any manner. Improper modification can cause severe personal injury or fatality.

CALIFORNIA PROPOSITION 65 WARNING: Engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm.

86037390 02/14/07 |

2-2 |

HAZARD LEVEL INTENSITY

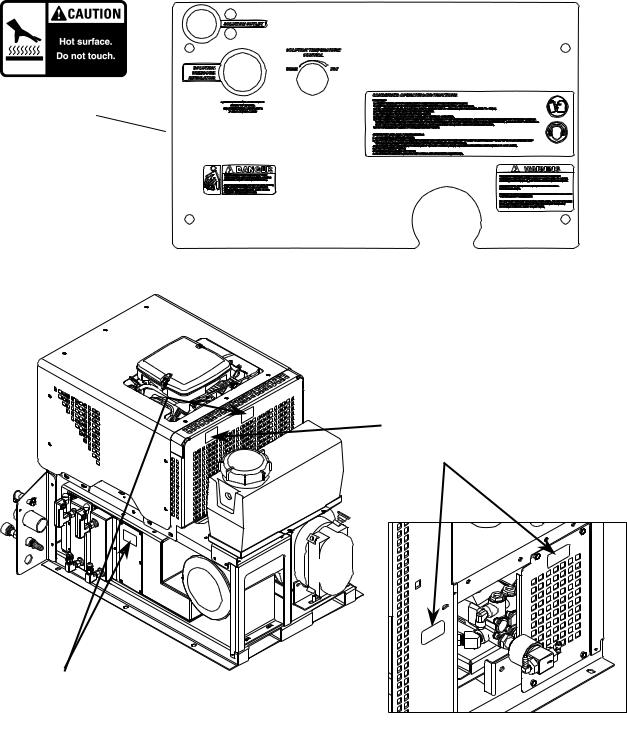

The following WARNING LABELS are found on your cleaning unit. These labels point out important Warnings and Cautions which should be followed at all times. Failure to follow warnings and cautions could result in fatality, personal injury to yourself and/or others, or property damage. Follow these instructions carefully! DO NOT remove these labels.

NOTE: If at any time the labels become illegible, promptly replace them.

Lower front panel decal With warning labels 86186630

PRV NO. 500836

Warning label

86186520

PRV NO.# 500769 (3)

Caution label

86186530

Part # 500770 (2)

2-3 |

86037390 02/14/07 |

|

|

TECHNICAL SPECIFICATIONS |

|

|

|

ITEM |

DIMENSION/CAPACITY |

|

Engine speed |

3200 rpm |

|

|

1400 (idle speed) |

|

Water pump rpm |

1625 rpm |

|

Vacuum pump rpm |

3200 rpm |

|

Water flow rate |

3.5 GPM (maximum) |

|

Water pump pressure |

1000 PSI (maximum) |

|

Vacuum relief valve |

13” Hg |

|

Waste tank capacity |

60 gallons |

|

Console weight |

500 lbs. (590 lbs. If mounted on water tank) |

|

Console weight (with waste tank & accessories) |

710 lbs (If waste tank is empty) |

|

|

(1225 lbs. If waste tank is full) |

|

|

(1740 lbs. If auxiliary water tank & waste tank are full) |

|

TORQUE VALUES |

|

|

Engine rear Vac pump pulley |

264 inch lbs |

22 foot/lbs |

Engine front stub shaft |

264 inch lbs |

22 foot/lbs |

Engine front water pump pulley on stub |

168 inch lbs |

14 foot/lbs |

JET SIZING:

Prochem recommends floor tool tip sizing not exceed a total of “.030”. Using larger jet sizes on your tool may reduce cleaning temperatures.

Example: |

Tri-jet wand uses three 95010 jets (95° spray angle w/ 010 orifice). |

|

|

01 x 3 = 030 |

|

Upholstery tool jet size: |

80015 |

|

Stair tool jet size: |

9502 |

|

86037390 01/25/08 |

3-1 |

OPERATION

INSTALLATION REQUIREMENTS

Prior to starting the installation, first read the ENTIRE "Installation” section of this manual. Since the cleaning unit (with empty waste tank and accessories) weighs approximately 710 pounds (800 lbs. if mounted on water tank), consider the following recommendations before installing this unit.

1.The unit should NOT be mounted in any motor vehicle of less than 1/2 ton capacity, or 3/4 ton if equipped with one or more auxiliary fresh water tanks.

The console with waste tank and accessories must NOT exceed the vehicle's axle weight limit.

2.If mounting in a trailer, make certain that the trailer is rated for the total weight of the UNIT AND TRAILER. Electric or hydraulic brakes should be provided, and a strict compliance with any State and Federal vehicle laws must be maintained.

3.The vehicle tires should have a load rating above the combined vehicle and unit weight.

4.We do not recommend using flooring materials that absorb water. This could result in rust and corrosion of the vehicle floor.

5.Padding under rubber floor mats should be removed before installing this unit.

6.We highly recommend using a galvanized drip tray under the console (Part #86050370, PRV NO. 56-501845, or Part #86050380, PRV NO. 56-501930 for units mounted on a water tank.)

7.If using a trailer, the console should be positioned so that it balances properly with respect to the axle. Ten percent (10%) of the overall unit weight (without accessories or water) should be on the tongue.

FUEL REQUIREMENTS

Use unleaded gasoline ONLY. DO NOT use any gasoline additives. We recommend the use of clean, fresh, unleaded gasoline intended for automotive use. High octane gasoline should NOT be used with the engine on this unit.

ENGINE OIL REQUIREMENTS

Use high quality detergent oil of at least API (American Petroleum Institute) service class SF or SG. Select the viscosity based on the air temperature at the time of operation as shown in the following table. NOTE: Using less than service class SF or SG oil or extending oil change intervals longer than recommended can cause engine damage.

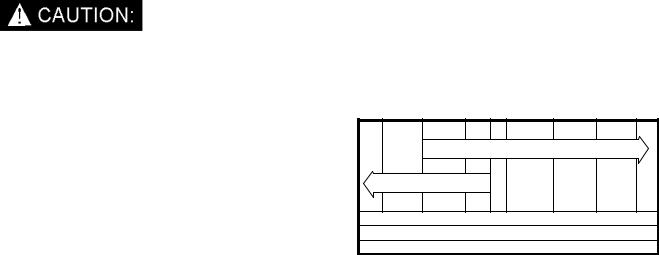

RECOMMENDED SAE VISCOSITY GRADE

|

|

|

|

|

10W-30 |

|

|

|

5W-20, 5W-30 |

|

|

|

|

|

|

||

°F -20 |

0 |

20 |

32 |

40 |

|

60 |

80 |

100 |

°C -30 |

-20 |

-10 |

0 |

|

10 |

20 |

30 |

40 |

TEMPERATURE RANGE EXPECTED BEFORE NEXT OILCHANGE |

||||||||

ALTITUDE REQUIREMENTS

Engines perform differently with increases/decreases in altitude. Be sure to check engine speeds during initial installation. See engine speeds in Technical Specifications section.

3-2 |

86037390 02/14/07 |

CHEMICAL REQUIREMENTS

The unit, due to its chemical injection pump design, can be used with a variety of water-diluted chemical compounds (either acidic or alkaline), depending on the job to be done. However, to obtain optimum results with this unit, we recommend using the Prochem line of chemicals. For information on using the cleaning compounds, refer to the chemical manual.

WATER REQUIREMENTS

Hard water deposits will adversely affect the plumbing and heat exchange systems on this unit. The map below will give you an idea of where areas of high water hardness may occur. However, any water supply obtained from a well is almost always hard water and a water softener will be needed to protect your equipment.

OPERATION

NOTE: Equipment malfunction or component failure caused by hard water scaling is NOT covered under the warranty.

If you are operating this unit in an area where the unit will be using water in which the hardness exceeds 3-1/2 grains, we highly recommend a suitable water softener be installed. If using a water softener, it must have a five (5) GPM (or greater) flow capacity without any hose constrictions.

Using a water softener will reduce maintenance and decrease down time caused by hard water scaling. It will also allow cleaning chemicals to be more effective in lower concentrations.

If you require a water softener, your dealer has a model to meet your needs. Please contact your nearest distributor for information, price, and availability.

86037390 02/14/07 |

3-3 |

OPERATION

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

2 |

3 |

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

18 |

|

|

4 |

17 |

5 |

|

|

|

6 |

16 |

7 |

|

|

|

8 |

15 |

9 |

14 |

10 |

|

11

12

13

3-4 |

86037390 01/10/08 |

1.VACUUM GAUGE

This gauge indicates in inches of mercury how much vacuum the system is producing at any given time.

2.WASTE PUMPOUT SWITCH/OVERRIDE

This two-position switch is for activating the waste pumpout device.

3.SOLUTION PRESSURE GAUGE

This gauge registers the amount of pressure in the system.

4.CHOKE

The choke cable is for restricting air to the carburetor, this enriches the fuel mixture. The primary purpose is for starting in cold temperatures. When the cable is pulled out air is restricted, when pushed in the engine is in run position.

5.KEY SWITCH

The key switch controls the power for the machine. To turn the machine on, rotate the key clockwise while holding solution pump switch to override position until the starter engages the engine. When machine is running let off the switch and engine will continue to run. To turn power off, rotate key counter clockwise to stop position, engine will then stop.

6.THROTTLE

This serves to set the speed of the engine. “T” handle pushed in sets engine to idle. “T” handle pulled out sets engine speed to maximum. “T” handle clockwise to lock in position and counter clockwise to move or change throttle settings.

OPERATION

7.CIRCUIT BREAKERS

These serve to protect the circuits from electrical spike and over loads and protects wires from damage and fire.

8.HOUR METER

The hour meter records the number of hours the unit has run. This serves as a time recorder for servicing the machine.

9.OIL CUP

The oil cup allows lubricant spray to reach the vacuum blower.

10.VACUUM INLET

The vacuum inlet serve as connecting point for vacuum hoses.

11.WATER INLET

This quick connect allows the water supply hose to be connected to the unit.

12.WASTE PUMPOUT (OPTIONAL)

This auxiliary pump serves to empty the waste collection tank automatically. A float located inside the tank automatically turns off and on when the solution level reaches certain points.

13.TEMPERATURE BYPASS VALVE

This valve allow the operator to control the solution temperature by bypassing hot water to the waste tank, for low temperature cleaning such as upholstery. Turning the valve counter clockwise opens the valve. Turning clockwise closes the valve and has the effect of stopping water from bypassing.

86037390 01/25/08 |

3-5 |

OPERATION

14. PRESSURE CONTROL REGULATOR

The pressure regulator sets the pressure of the solution system. This spring loaded valve can be adjusted up or down setting the pressure of the unit by turning the valve clockwise. The pressure is increased or reduced by turning the valve counter clockwise. (This valve must be maintained in accordance with this manuals maintenance table.)

15.SOLUTION OUTLET

The solution outlet is the connecting point for the high pressure cleaning hoses. This outlet has a quick disconnects that allow hoses to be plugged into the unit.

16.FLOW METER

The flow meter is a gauge to indicate how much liquid chemical is being introduced in the water system. The quantity can be increased by turning the chemical flow knob counter clockwise.

17.CHEMICAL PRIME CONTROL VALVE

This valve allows the chemical to circulate through the chemical system with little or no restriction. It also purges out air that may be trapped in the lines and cavities of the chemical pump. By turning the valve clockwise the injection system is enabled.

18.CHEMICAL METERING VALVE

The chemical metering valve regulates the amount of chemical that is injected into the system. Clockwise rotation of the knob closes the valve. Counter clockwise rotation opens the valve, allowing more chemical to enter the system.

3-6 |

86037390 02/14/07 |

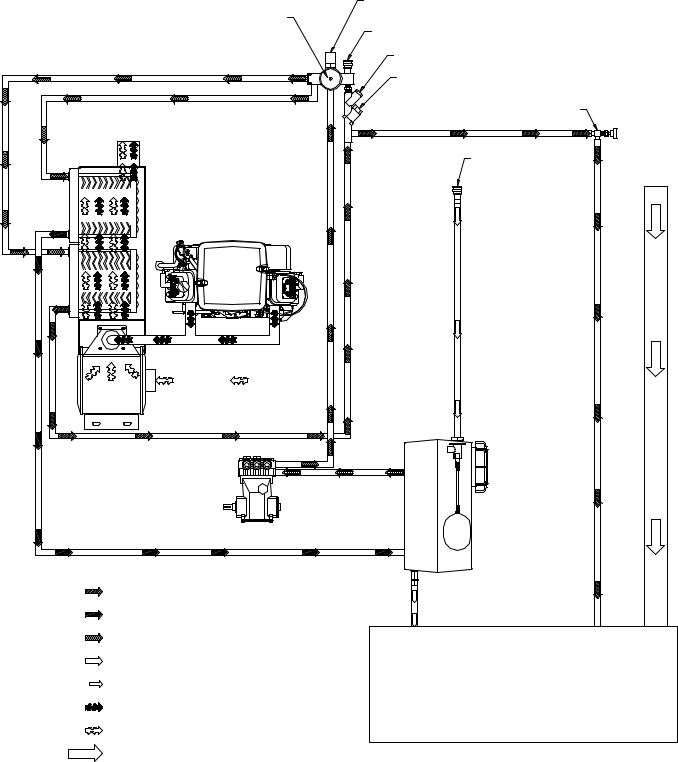

NITROGEN ACCUMULATOR

VACUUM EXHAUST

RADIATOR-TYPE

HEAT EXCHANGER

BRIGGS & STRATTON

VANGUARD

ENGINE

VACUUM

EXHAUST

WATER PUMP

VERY HOT WATER FLOW

HOT WATER FLOW

WARM WATER FLOW

COLD WATER FLOW

BYPASS FLOW

ENGINE EXHAUST FLOW

VACUUM EXHAUST FLOW

VACUUM FLOW

OPERATION

PRESSURE REGULATOR

SOLUTION OUTLET

OUTLET Y-STRAINER

OUTLET CHECK VALVE

TEMPERATURE CONTROL VALVE

WATER INLET

VACUUM INLET

WATER BOX

145° TEMPERATURE RELIEF VALVE

WASTE TANK

3-7

86037390 02/14/07

OPERATION

Always wear hearing protection and proper personal protection equipment when operating unit.

WATER PUMPING AND HEAT

TRANSFER SYSTEM

Cold water enters the console through the water inlet. When the water box is full the valve will automatically shut off.

Water then flows from the water box, through a strainer, into the water pump where it is pumped to the pressure regulator manifold where the pressure regulator provides and maintains the desired pressure setting.

The pressure regulator manifold includes a nitrogen charged accumulator which helps reduce pressure spikes from the pump.

A certain amount of water is by-passed from the pressure regulator due to over pumping capacity of the water pump. Water that is not called for in the

= COLD WATER = WARM WATER = HOT WATER = NO WATER

cleaning process is channeled through a heat exchanger box into the first heater core from the front of the unit. This bypass water may circulate several times through the bypass heat exchanger allowing the water to be pre-warmed.

The next stage of plumbing and heat exchange takes place in the 2nd heater core located in the heater box. This is the hottest point of the gases coming from the vacuum pump and the engine. These hot gases are forced through heater core #2 creating the second stage of heat transfer to the cleaning solution.

Finally, the hot solution passes to the outlet manifold where cleaning chemicals are injected from the chemical pulse pump. This manifold serves as a connecting point for the high-pressure hoses. Also a check valve is located in this outlet manifold prohibiting chemicals from backing up into the system.

The cleaning solution then passes through highpressure hoses and is distributed by the cleaning tool to a surface that is being cleaned, completing the water pumping and heating cycle of the cleaning unit.

VACUUM EXHAUST

HEAT EXCHANGERS

WATER BOX |

|

|

|

|

|

WASTE TANK |

|

|

THERMO |

|

|

|

RELIEF |

|

|

WATER PUMP |

B & S VANGARD ENGINE |

||

TO PRESSURE |

|

|

|

GUAGE |

|

|

|

|

|

TEMPERATURE |

|

|

|

CONTROL BYPASS |

|

|

CHEMICAL |

|

|

|

INJECTION |

|

|

WATER |

|

|

|

INLET |

|

|

|

SOLUTION |

|

OUTLET CHECK VALVE |

|

|

OUTLET Y STRAINER |

||

OUTLET |

ACCUMULATOR |

||

|

|||

|

|

||

PRESSURE REGULATOR |

|

|

|

3-8 |

86037390 |

01/25/08 |

|

CHEMICAL INJECTION SYSTEM

The chemical injection system is unique in that it utilizes the pressure spikes generated by the highpressure water pump to move chemical into the main pressure stream. The high pressure spikes move the diaphragm in the chemical pulse pump forcing small amounts of liquid chemical to be moved in a single direction of flow with the aid of two check valves.

The chemical is picked up from the container and fed through the flow meter to the chemical pulse pump where it is pressurized.

OPERATION

After reaching the chemical pulse pump the chemicals can either go into a bypass loop to purge air from the system. The chemical can then be directed by the chemical selector valve to the metering valve. The metering valve creates an orifice allowing the correct amount of chemical to enter the outlet manifold. The outlet manifold assembly is complete with a check valve that will not allow the chemicals to travel upstream into the plumbing system of the unit.

The chemicals are then mixed with hot pressurized water that make up a solution for cleaning application.

NITROGEN ACCUMULATOR

CHEMICAL PUMP

CHEMICAL JUG

WATER PUMP

COLD WATER FLOW

BYPASS FLOW

VACUUM FLOW

CHEMICAL INJECTION

PRESSURE REGULATOR

SOLUTION OUTLET

OUTLET Y-STRAINER

OUTLET CHECK VALVE

TEMPERATURE CONTROL VALVE

WATER INLET

VACUUM INLET

WATER BOX

FLOAT VALVE

145° TEMPERATURE RELIEF VALVE

WASTE TANK

86037390 02/14/07 |

3-9 |

OPERATION

VACUUM SYSTEM

The engine turning a vacuum/blower generates airflow. The air is channeled in one side of the vacuum/blower, compressed and discharged on the opposite side, creating a vacuum.

The vacuum is used to do the work necessary for the extraction process. A vacuum nozzle applied to the carpet surface removes moisture, dirt and spent chemicals. These elements are conveyed back to a separating tank utilizing hoses and the force of air. Particles of moisture and dirt are separated in the vacuum tank using a series of changes in direction and velocity. The air is then filtered and rushes into the vacuum/blower.

The vacuum/blower compresses and heats the incoming air. The hot discharged air is forced down stream into a silencer for noise abatement. After exiting the silencer, this hot air is mixed with the hot air and gases from the engine. This mixture of hot air and gases are then forced through 3 radiators serving as heat collectors. Heat from the engine and vacuum pump is then transferred into the plumbing system raising the water temperature for better cleaning.

The engine and blower speeds are factory set to maximize vacuum pressure and provide sustained system life. Do not alter the engine or vacuum speeds outside the recommended ranges shown in the Technical Specifications section.

VACUUM EXHAUST

OUTLET

FROM PRESSURE

REGULATOR

|

VACUUM EXHAUST |

|

|

TO WATER BOX |

"RADIATOR TYPE" |

|

|

|

COPPER |

|

|

|

HEAT EXCHANGER |

|

|

FROM PRESSURE |

|

|

|

REGULATOR |

|

|

|

TO |

VACUUM EXHAUST |

|

|

SOLUTION OUTLET |

"RADIATOR TYPE" |

|

|

|

STAINLESS STEEL |

|

|

|

HEAT EXCHANGER |

|

|

VACUUM |

LUBRICATION |

VACUUM |

|

CUP |

GAUGE |

||

INLET |

|||

|

|

||

|

VACUUM |

|

|

|

RELIEF |

|

|

|

VALVE |

|

VACUUM VACUUM SILENCER BLOWER

LEVEL SENSOR

(ENGINE SHUT-OFF SWITCH)

STRAINER |

FILTERS |

|

|

|

WASTE TANK |

3-10 |

86037390 01/25/08 |

PRE-RUN INSPECTION

NOTE: Operation of this unit is simple. However, only trained personnel should proceed.

Operate this unit and equipment only in a wellventilated area. Exhaust fumes contain carbon monoxide which is an odorless and deadly poison that can cause severe injury or fatality. DO NOT operate this unit where the exhaust may enter any building doorway, window, vent, or opening of any type.

CHECK FOR ADEQUATE FUEL

Check the fuel tank to be certain there is adequate fuel to complete the job. This unit uses approximately .95 to 1.25 gallons of fuel per hour, depending on the speed setting.

REMOVE TOOLS FROM VEHICLE

Remove any tools or hoses from the van which you will require.

WATER SUPPLY CONNECTION

NOTE: Before connecting your water hose to the supply faucet, flush out the faucet until the water is free of any debris. Flush out any debris which may be in your water inlet hose.

1.Connect the water supply hose to the water inlet quick-connect at the left front of the console. Connect the hose to the water supply faucet.

NOTE: Never use your waste pump outlet hose as a water inlet hose. Use only clean hoses for water inlet.

2.Turn the water supply faucet on. The water will fill the water box.

OPERATION

HIGH PRESSURE HOSE

Before starting the unit, connect the pressure hose to the outlet connection at the front of the unit. Connect the cleaning tool to the pressure hose.

DANGER

DANGER

WATER UNDER HIGH PRESSURE AT HIGH TEMPERATURE CAN CAUSE BURNS, SEVERE PERSONAL INJURY, OR COULD BE FATAL. SHUT DOWN MACHINE, ALLOW TO COOL DOWN, AND RELIEVE SYSTEM OF ALL PRESSURE BEFORE REMOVING VALVES, CAPS, PLUGS, FITTINGS, FILTERS AND BOLTS.

ROTATING |

|

DANGER |

|

||

MACHINERY. |

|

|

WATER UNDER |

|

|

PRESSURE AT HIGH |

|

DO NOT MODIFY |

TEMPERATURE. |

|

|

IMPROPER |

|

UNIT WITHOUT |

MODIFICATION OF |

|

WRITTEN |

EQUIPTMENT CAN |

|

PERMISSION |

CAUSE SEVERE |

|

FROM |

PERSONAL INJURY |

|

|

OR COULD BE |

|

MANUFACTURER |

FATAL. |

|

|

VACUUM HOSE

Connect the vacuum hose to the vacuum inlet connection at the front of the unit. Connect the other end of the vacuum hose to the cleaning tool.

FILTERS

Ensure all filters on machine and in waste tank are free of debris.

3-11

86037390 02/14/07

OPERATION

PRIMING THE CHEMICAL PUMP

1.Connect water hose to water inlet connection and turn on water supply.

2.Connect cleaning and vacuum hoses to the desired cleaning tool and console.

3.Insert chemical inlet and prime tubing into chemical container.

4.Pull out engine choke. While holding waste pump out switch in the override position, turn ignition key to start.

5.Push in engine choke after engine has started.

6.Set throttle to idle speed.

7.Fill chemical container and inspect chemical filter.

8.Turn chemical prime valve to prime and allow chemical to circulate. After all air bubbles have been removed from chemical tubing, turn the valve to the horizontal (off) position and open the chemical metering valve, triggering the solution flow on the cleaning tool. Set the desired chemical flow rate while observing the flow meter indicator.

9.Set throttle to maximum position with vacuum port blocked off for quick unit heat up.

WASTE PUMP (OPTIONAL)

1.If your unit is equipped with an automatic waste pump, connect one end of a garden hose to the pump-out connection on the console and the other end to an appropriate waste disposal.

2.Turn the pump-out switch on the control panel to the ON position. The waste pump will operate automatically throughout the cleaning operation.

We recommend that you use a 3/4" I.D. water hose as a waste pump outlet hose. DO NOT use a hose smaller than 5/8" I.D.

NEVER use your automatic waste pump outlet hose as a water inlet hose.

NEVER dispose of waste in storm drains, waterways, or on ground areas. Always dispose of waste in accordance with Local, State, and Federal laws.

NEVER dispose of waste in storm drains, waterways, or on ground areas. Always dispose of waste in accordance with Local, State, and Federal laws.

Once you have completed steps 1 through 8, proceed with the cleaning operation. Your unit should be in the correct throttle position for your cleaning operation or extracting. A float switch located inside the waste tank will automatically shut down the unit when it reaches its full capacity. When this occurs, empty the waste tank before continuing.

CLEANING

Observe the following guidelines, while cleaning:

1.Before proceeding make sure the nozzles are functioning properly.

a.To check , hold the wand about one foot above the surface to be cleaned and open the wand valve. A full spray should be observed from the cleaning nozzles.

b.If the nozzles are not showing a full spray pattern, adjust nozzles for proper pattern, clean, or replace nozzles, if required.

2.Normally chemical is applied on the push stoke of the wand when cleaning and vacuuming is done on the pull stroke. For heavily soiled carpets the wand may be used in a scrubbing manner, apply chemical in both push and pull strokes. Always finish up an area with a vacuum stroke.

3.When cleaning, keep the working opening (mouth) flat on the surface being cleaned. Keep the wand moving when the valve is open.

4.The unit will automatically shut-down when the waste tank is full. This will prevent water being drawn into the vacuum pump. If shut-down occurs, empty the waste tank before proceeding.

3-12 |

86037390 01/25/08 |

UPHOLSTERY CLEANING

Upholstery tool, part #86285260, PRV NO. 78513

1.Set temperature as desired and slow down the engine speed to minimize excess heat.

2.Use one (1) “86229980, PRV NO. 80015” spray tip in tool.

SHUTDOWN AND DAILY MAINTENANCE

1.Close chemical metering valve.

2.Allow the unit to run for 2 minutes with the vacuum hose disconnected to remove moisture. Spray WD40 (or equivalent) into the vacuum lubrication cup. This will prevent corrosion due to moisture.

3.Set engine throttle at idle position and allow the water temperature to cool down, unitizing the bypass valve in the open position to bleed off residual hot water left in the system.

4.Turn off ignition switch.

5.Disconnect all hoses and tools.

6.Drain waste tank and rinse with clean water.

OPERATION

FREEZING PROTECTION

If the unit is exposed to freezing weather the water

in the unit may freeze, causing SERIOUS DAMAGE to the unit. To avoid this, the following is recommended during the cold weather season.

When the unit is not in use, always park it in a heated building.

While in operation, avoid long shutdowns as the unit provides heat while running. Shut it down just prior to leaving for the next job.

If a heated building is not available, we recommend that you winterize the unit with anti-freeze. At present, it is only possible to winterize units, which do not have an auxiliary water tank. Units with auxiliary water tanks must be stored in a heated building when not in use.

OVERHEATING PROTECTION

Air cooled engines rely on the flow of air over the engine for cooling operations. Ensure that there is sufficient air flow in the van. Never operate the unit with all the vehicle doors closed and no alternate ventilation system.

3-13

86037390 02/14/07

OPERATION

WINTERIZING YOUR UNIT

1.Shut off the water supply. Disconnect the water inlet hose from the front of your console.

2.Connect all high pressure hoses and tools that may have water in them.

3.Start the unit. Open the tool valve until water pressure drops and water stops flowing.

4.Turn off the engine.

5.Fill the water box with approximately two gallons of 100% glycol base anti-freeze.

6.Start the unit.

7.Open the tool valve until anti-freeze begins to come out of the tool. Recover ALL anti-freeze that comes out of the tools into an approved container. We strongly recommend that you recycle and re-use the anti-freeze.

Repeat this procedure with all the remaining tools. After all tools and pressure hoses have been filled with anti-freeze, disconnect and store them.

8.Turn unit off and attach the winterizing loop hose with attachment, Part # 86260700, PRV NO. 10-805380, to the solution outlet connection and the water inlet connection. Turn the solution pump switch ON.

Allow the unit to run for approximately 3 minutes with the winterizing loop hose attached.

Open bypass valve and allow anti-freeze to flow to waste tank.

9.Prime the chemical system with 50/50 antifreeze/water mix. Insert the chemical inlet and prime discharge tubes into the anti-freeze container. Turn the chemical valve to PRIME until anti-freeze begins to flow out of the prime hose.

10.Now turn the chemical valve to the open position, making certain that the flow meter indicates flow and that all anti-freeze drains out of the chemical hose into an approved container, after 30 seconds, turn off both valves.

When disposing of used anti-freeze, observe local laws and regulations. Do not drain onto the ground or into storm drainage systems.

3-14 |

86037390 |

01/25/08 |

|

REMOVING ANTI-FREEZE FROM THE UNIT

1.Connect one end of the winterizing loop hose to the solution outlet connection. Place the other end of the loop hose, without the attachment, into an approved container.

2.Start the unit. Allow the anti-freeze to flow into the container until flow stops.

3.Fill the water box with fresh water and repeat step #2.

4.Connect the water inlet hose to the water inlet connection on the console. Turn the water supply on.

5.Connect all solution hoses and any tools which require purging of anti-freeze to the solution outlet connection(s).

6.Open the tool valves and drain the anti-freeze into an approved container until the flow is clear and all anti-freeze is purged from the tools and hoses.

OPERATION

7.Place the chemical prime hose into the approved container. Submerge the chemical inlet hose in water. Turn the chemical valve to the PRIME position until clear water comes through the prime hose, and then remove the prime hose from the container.

Turn the chemical valve to the ON (CHEMICAL) position. This will allow water to flow into the other side of the system.

Once all of the anti-freeze is removed, the unit is ready to use.

Eventually, the anti-freeze in your storage container will become diluted with water. If the anti-freeze level drops below 50% of the total, dispose of it and start with fresh 100% antifreeze.

When disposing of used anti-freeze, observe local laws and regulations. Do not drain onto the ground or into storm drainage systems.

3-15

86037390 02/14/07

MAINTENANCE

SERVICE SCHEDULE

Engine |

Daily |

Check engine oil level. *** Fill to proper level |

|

(Do not overfill) |

|||

|

|

||

Vacuum Pump |

Daily |

Spray WD-40 in lubrication cup at front of console for 5 |

|

sec. |

|||

|

|

||

Water Pump |

Daily |

Check oil level.** Fill to proper level (Do not overfill) |

|

Solution Outlet Strainer |

Daily |

Check strainer for blockage, remove any debris |

|

Vacuum Inlet Filter (In Waste Tank) |

Daily |

Clean filter, inspect, replace if damaged |

|

Vacuum Hoses |

Daily |

Wash out with clean water |

|

Automatic Waste Pump |

Daily |

Inspect and remove any debris or sediment |

|

Chemical Filter |

Daily |

Inspect daily |

|

Vacuum Pump |

Weekly* |

Check oil level. Fill to proper level |

|

Water Box Float Valve |

Weekly |

Check for proper seating and shut-off |

|

Water Pump Inlet Filter |

Weekly* |

Check for debris and clean |

|

Battery |

Weekly* |

Check for proper fluid level. Fill with distilled water only |

|

Solution Outlet Y-Strainer |

Weekly* |

Inspect and remove any debris or blockage |

|

High Pressure Hoses |

25 hrs |

Inspect for damage or impending damage |

|

Pressure Regulator |

50 hrs |

Lubricate o-rings |

|

Pressure Regulator |

50 hrs |

Lubricate plug behind spring |

|

Engine |

50 hrs |

Change engine oil*** |

|

Engine |

50 hrs |

Change oil filter*** |

|

Engine |

100 hrs |

Check fan belt tightness |

|

Battery |

100 hrs* |

Clean battery terminals |

|

Automatic Waste Pumpout |

100 hrs |

Clean inlet and outlet ports |

|

Belts/pulleys |

100 hrs |

Check belt wear and tension. Check pulley alignment. |

|

Water Box Float Valve Seal |

200 hrs. |

Inspect and replace seal as needed |

|

Engine |

200 hrs |

Service air cleaner elements* |

|

Fuel Pump |

200 hrs |

Check hose connections |

|

Fuel Hose, Fuel Fittings |

200 hrs |

Check connections and hose wear |

|

Engine |

200 hrs |

Check spark plugs for carbon deposits and proper gap |

|

Chemical Valves |

200 hrs |

Inspect and/or adjust packing nuts |

|

Heat Bypass Valve |

200 hrs |

Inspect and/or adjust packing nuts |

4-1 |

86037390 |

01/25/08 |

|

|

|

MAINTENANCE |

|

|

SERVICE SCHEDULE |

|

|

|

Vacuum pump |

250 hrs |

Lubricate bearing on pulley end with grease |

Vacuum Exhaust Heat Exchanger |

500 hrs |

Inspect cores and remove debris. |

Water Pump |

500 hrs |

Change oil** |

Pulley Set Screws & Hub Cap |

500 hrs |

Check for proper torque value. Re-torque, if |

Screws |

|

required**** |

Drive Pulley |

500 hrs |

Inspect, clean and check for pulley groove wear**** |

Drive Pulley |

500 hrs |

Check pulley alignment**** |

Drive Belts |

500 hrs |

Inspect and clean**** |

Drive Belts |

500 hrs |

Check belt tension**** |

Chemical Pump & Check Valves |

500 hrs |

Replace diaphragm and check valves. |

Vacuum Lubrication Lines |

500 hrs |

Check for line obstructions. Replace tubing if cracked |

|

|

or damaged |

Engine |

500 hrs |

Replace in-line fuel filter on engine. |

Heater Core |

500 hrs |

Clean and inspect. |

Engine |

1000 hrs |

Replace spark plugs. |

Check Valve (Solution Outlet) |

1000 hrs |

Inspect, clean, and repair, if needed. |

Waste Tank Shut-off Float Switch |

Monthly |

Check for debris hindering movement |

Vacuum pump |

Yearly |

Drain, flush and replace oil***** |

Nitrogen Accumulator |

Yearly* |

Replace Accumulator. |

Waste Tank Filters/Strainers |

Yearly |

Check for damage and blockage. Replace if needed. |

Engine |

Yearly |

Replace air cleaner element |

Engine |

3 years |

Replace ignition wires. |

*Or as often as required

**Change water pump crankcase oil after the first 50 hours

***Change engine crankcase oil and filter after the first 5 hours

****Perform drive belt, pulley and hub maintenance after the first 25 hours of operation, and then again at 100 hours

*****If using AEON PD synthetic lubricant, 4500 hours or every 2 years, whichever comes first

4-2

86037390 01/25/08

MAINTENANCE

KEY CHECKPOINTS

Note: Initiation of a planned preventative maintenance program will assure that your unit has optimum performance, a long operating life, and a minimal amount of "down" time.

EXTERNAL FUEL PUMP MAINTENANCE

The power plant for the unit receives fuel from the main gas tank of your van/truck. An external fuel pump that provides this fuel is located on the underside of the van/truck. Loose fittings and hose connections will cause your unit to perform poorly. Follow the recommended fuel pump maintenance in the Maintenance Schedule in this manual. Refer any additional questions to your dealer.

CHEMICAL SUPPLY SYSTEM

MAINTENANCE

The chemical supply system pulls chemicals from your chemical bottle utilizing a pump that works off the water pump pulsing. Any clogged filters or loose connections will result in a chemical supply system malfunction or a malfunction at the cleaning tool. Maintenance of the solution outlet check valve and strainer are vital to effective cleaning operation and minimal unit downtime. Additionally, the hoses related to supplying water and chemical to the outlet manifold are under high pressures and experience thermal expansion and contraction. Periodic inspections of these hoses for tears, cracks, and failing connectors are necessary to avoid unwanted leaks. To keep your chemical system functioning properly, follow the chemical pump and solution outlet maintenance in the Maintenance Schedule in this manual. Refer any additional questions to your dealer.

HEAT EXCHANGER SYSTEM

MAINTENANCE

The heat exchange system in your unit transfers energy between the unwanted heat of the power plant/blower and the solution supply system. The heat transfer of this system is highly dependent on the surface area contact in the heat exchanger cores located in the heat exchanger box. This surface area amount is adversely minimized when the supplied water is not softened to recommended levels. Hard water will result in scaling on the inside walls of the heat exchanger tubes. It is recommended that you use a dealer approved water softener to avoid premature heat exchanger core failure. Contact your local dealer for advice on the water hardness levels in your area.

Additionally, the heat exchanger tubes are very sensitive to freezing conditions. As the water freezes during cold conditions, it expands in the heat exchanger tubes and causes damage. Often the tubes are cracked and require the replacement of the heat exchanger core. Refer to the Freeze Protection instructions section in this manual. Refer any additional questions to your dealer.

VACUUM PUMP MAINTENANCE

(Refer to manufacturer’s manual for specific maintenance instructions)

The total function of the unit is based around the performance of the vacuum pump. Heat transfer used to raise the temperature of the solution is gained from the air drawn by the vacuum pump and solution is removed from the carpet with the vacuum suction of the vacuum pump. General maintenance actions for the vacuum pump as listed in this manual are vital to prolonged vacuum pump operations. Daily lubrication of the pump is required to avoid seizure of the system. Also, waste tank filters and strainers must be maintained to prevent unwanted debris from entering the vacuum pump.

4-3 |

86037390 |

02/14/07 |

|

Loading...

Loading...