Instruction

IMPORTANT SAFETY INFORMATION. READ AND FOLLOW ALL SAFETY INSTRUCTIONS. Follow label information

and instructions concerning Wet or Damp Locations, installation near combustible materials, insulation, building materials,

n areas subject to combustible vapors or gases. Before wiring to power supply and

All servicing or relamping must be performed by

d to avoid potential electric shock or other potential hazard.

Product must be mounted in locations and at heights and in a manner consistent with its intended use, and in

quipment not recommended by

the manufacturer or installed contrary to instructions may cause an unsafe condition. Do not block light emanating from

, screens or

the like to come into contact with the product or to block light from the product, as this may cause an unsafe condition.

WARNING

– This product contains chemicals known to the State of California to cause cancer, birth defects and/or other

reproductive harm. Thoroughly wash your hands after installing, handling, cleaning, or otherwise touching this product.

NOTE: Maintain free airflow through the

Part No...........................................

and proper lamping. Do not install i

during servicing or relamping, turn off power at fuse or circuit breaker.

qualified service personnel. Product must be grounde

compliance with the National Electrical Code and local codes. The use of accessory e

product in whole or part, as this may cause an unsafe condition. Do not allow items such as drapes, curtains

INSTALLATION INSTRUCTIONS

MC10LED CYLINDER

93054545

www.prescolite.com

Sheet

CORD AND CABLE MOUNT

CAUTION: TO REDUCE THE RISK OF ELECTRICAL SHOCK, MAKE CERTAIN THAT THE

POWER SUPPLY IS TURNED OFF BEFORE INSTALLING OR SERVICING THIS PRODUCT!

fixture to avoid overheating.

CORD AND CABLE MOUNT

1. Unpack the MC10LED cylinder, the cable

mount parts bag, and the power cord from

the cylinder carton.

2. Loop the 20 foot galvanized cable around a

nearby structural member at the installation

location (Fig. 1). Assemble the crossbar and

threaded gripper as shown, using the hex

nut to lock the gripper in position. Loosen the

gripper cable lock nut and feed the cable

through the gripper as shown, and secure

the crossbar assembly to a properly installed

4" octagonal box (by others) designed to

support the weight of the fixture. NOTE: The

cable can be looped around the crossbar if

no structure is conveniently available, or if

there is no above-ceiling access (Fig. 2).

WARNING: Failure to connect the cable

end to the building structure or to a

properly installed junction box designed

to support the weight of the fixture may

allow the fixture to fall!

WARNING: Do not install cord and cable

hung fixtures in moving-air environments

such as near HVAC vents unless they are

laterally braced. Airflow may cause

continuous oscillation, which may cause

metal fatigue in the cabling system and

may cause the fixture to fall!

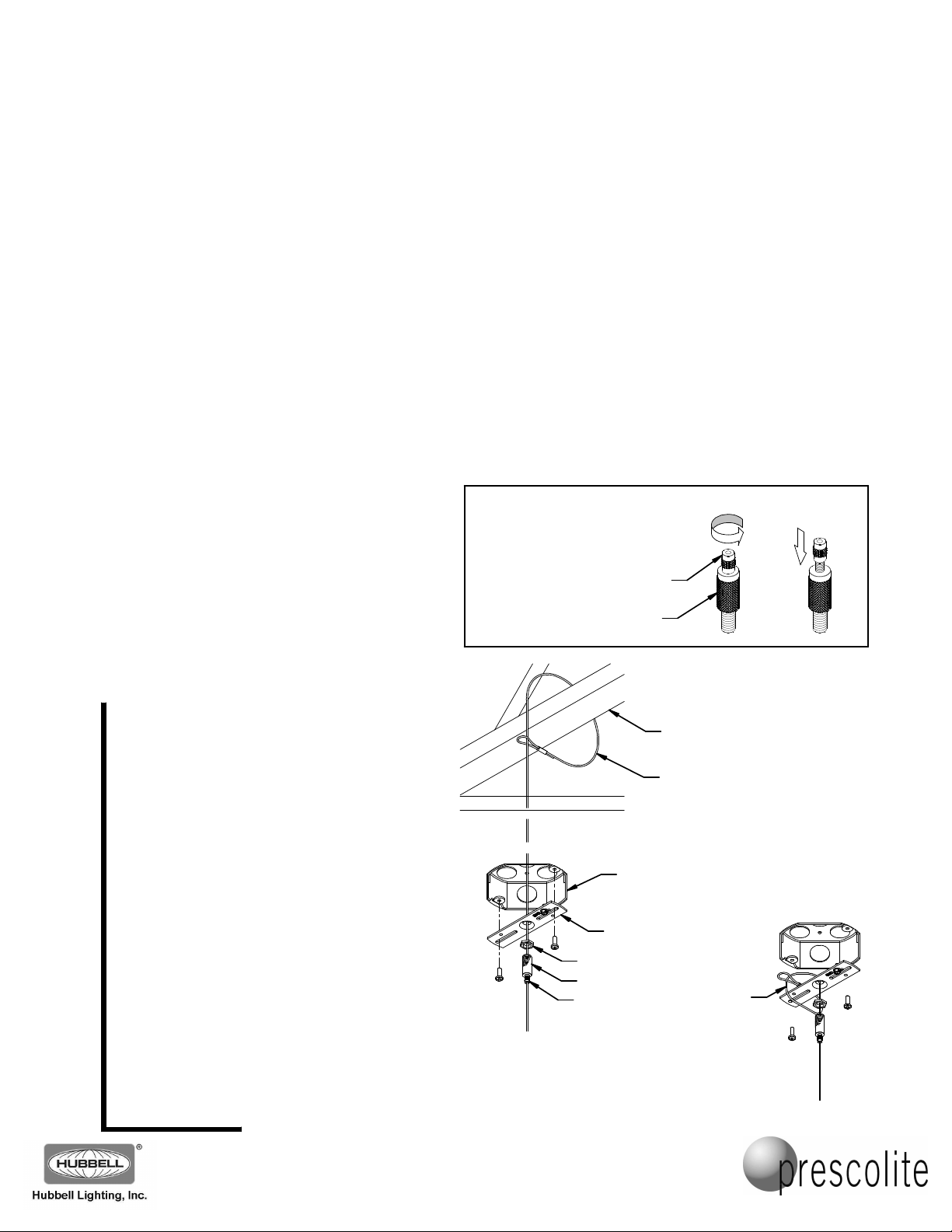

NOTE:

HOW THE GRIPPERS

AND LOCK NUTS WORK

LOCK NUT

GRIPPER

CEILING

Fig. 1

OCTAGONAL

BOX IN CEILING

CROSSBAR

HEX NUT

GRIPPER

LOCK NUT

UNLOCK

BUILDING

STRUCTURE

CABLE LOOP

AROUND

STRUCTURE

CABLE

LOOPED

AROUND

CROSSBAR

Fig. 2

PRESS

TO

RELEASE

Prescolite Toll Free Technical Support

1.888.PRS.4TEC

Hours: 8am - 5pm ET

701 Millennium Blvd• Greenville, SC 29607

With representatives offices in principal cities throughout North America.

Copyright , revision, All Rights Reserved - Printed in U.S.A.

2014 03/26/14

I

ns

t

r

uc

t

io

n

S

h

e

e

t

Part No...........................................

3. Lock the strain relief to the power cord with allowance for wiring connections, and thread the power cord

through the canopy wire hole (Fig. 3). Snap the cord assembly into the canopy. Make the ground connection

to the ground screw on the crossbar assembly and the Green-Striped ground conductor on the power cord.

Connect the line voltage to the Black-Striped conductor, the neutral to the White-Striped conductor. Make

any dimming control connections to the 2 extra conductors (Blue-Striped and Red-Striped, to be connected

in the fixture in the next steps – cap off these conductors if not used). Make all connections with properly

sized, UL listed connectors. Thread the 20 foot cable through the canopy center hole. Thread the 20 foot

cable through the barrel coupler, and slide it up to the canopy. Place the wiring and connections into the

junction box and push canopy up flush to the ceiling surface. Thread the barrel coupler onto the threaded

gripper body to retain the canopy. Tighten the cable gripper lock nut on the cable.

GROUND

SCREW

GRIPPER

LOCK NUT

CORD

STRAIN

RELIEF

POWER Cord

THREADED

GRIPPER

BODY

CANOPY

BARREL

COUPLER

93054545

www.prescolite.com

Prescolite Toll Free Technical Support

Fig. 3

4. Assemble the cable puck by dropping the ball-stop ends of the three 24 inch cables into the slots on the

puck bottom half (Fig. 4). Assemble the puck top half, making sure the cord opening in the top half lines up

with the one in the bottom half. Thread the ¼-20 gripper into the top center opening and tighten to hold the

puck assembly together.

1/4-20

GRIPPER

PUCK TOP

HALF

BALL-STOP

CORD

OPENING

ENDS

PUCK BOTTOM

HALF

24 INCH

CABLES

1.888.PRS.4TEC

Hours: 8am - 5pm ET

Fig. 4

701 Millennium Blvd• Greenville, SC 29607

With representatives offices in principal cities throughout North America.

Copyright , revision, All Rights Reserved - Printed in U.S.A.

2014 03/26/14

I

ns

t

r

uc

t

io

n

S

h

e

e

t

Part No...........................................

93054545

5. Loosen the lock nuts on the 3 swivel grippers on the top casting of the cylinder (Fig. 5). Insert the end of each of

the 24 inch cables from the puck assembly into a corresponding swivel gripper on the top casting. The cables

need to protrude through the grippers at least 1 inch (VIEW A). Tighten the lock nuts. (These cables can be

adjusted later in the installation.)

6. Loosen the lock nut on the ¼-20 gripper on the puck assembly and slide the puck assembly and fixture onto the

20 foot cable to the height the fixture is intended to hang. Loosen the locknuts on the three 24 inch cables and

adjust the fixture and the puck to level the fixture and set the cable lengths needed for the installation.

NOTE: The fixture weight will need to be lifted and supported so the grippers will release to allow adjustment of

the cables. After adjustment to the final position, tighten the lock nuts on all the grippers.

7. After the adjustment of the cable lengths is complete, slide the end of the 20 foot cable through one side of the

cable locking tube, loop the remaining length through the support tab hole, and then back through the other side

of the cable locking tube (VIEW B). Leave a couple of inches of slack in the 20 foot cable below the puck (this

cable should not be holding the fixture weight below the puck) and tighten the two screws on either side of the

cable locking tube. Trim the ends of the cables if needed using the proper cable cutting tool (such as a FELCO

C7). To prevent fraying of the cut cable ends, use a drop of superglue or solder the cable end.

CAUTION: Always leave at least 1 inch of cable beyond the body of the grippers.

20 FOOT

CABLE

www.prescolite.com

Prescolite Toll Free Technical Support

VIEW B

20 FOOT

CABLE

CABLE

LOCKING

TUBE

SUPPORT TAB

LOCK NUT

SWIVEL

GRIPPER

(1 OF 3)

VIEW A

1 INCH OF

CABLE

MINIMUM

LOCK NUT

1/4-20

GRIPPER

PUCK

ASSEMBLY

Fig. 5

SLACK IN

CABLE

BELOW

THE PUCK

1.888.PRS.4TEC

Hours: 8am - 5pm ET

701 Millennium Blvd• Greenville, SC 29607

With representatives offices in principal cities throughout North America.

Copyright , revision, All Rights Reserved - Printed in U.S.A.

2014 03/26/14

I

ns

t

r

uc

t

io

n

S

h

e

e

t

I

ns

t

r

uc

t

io

n

S

h

e

e

t

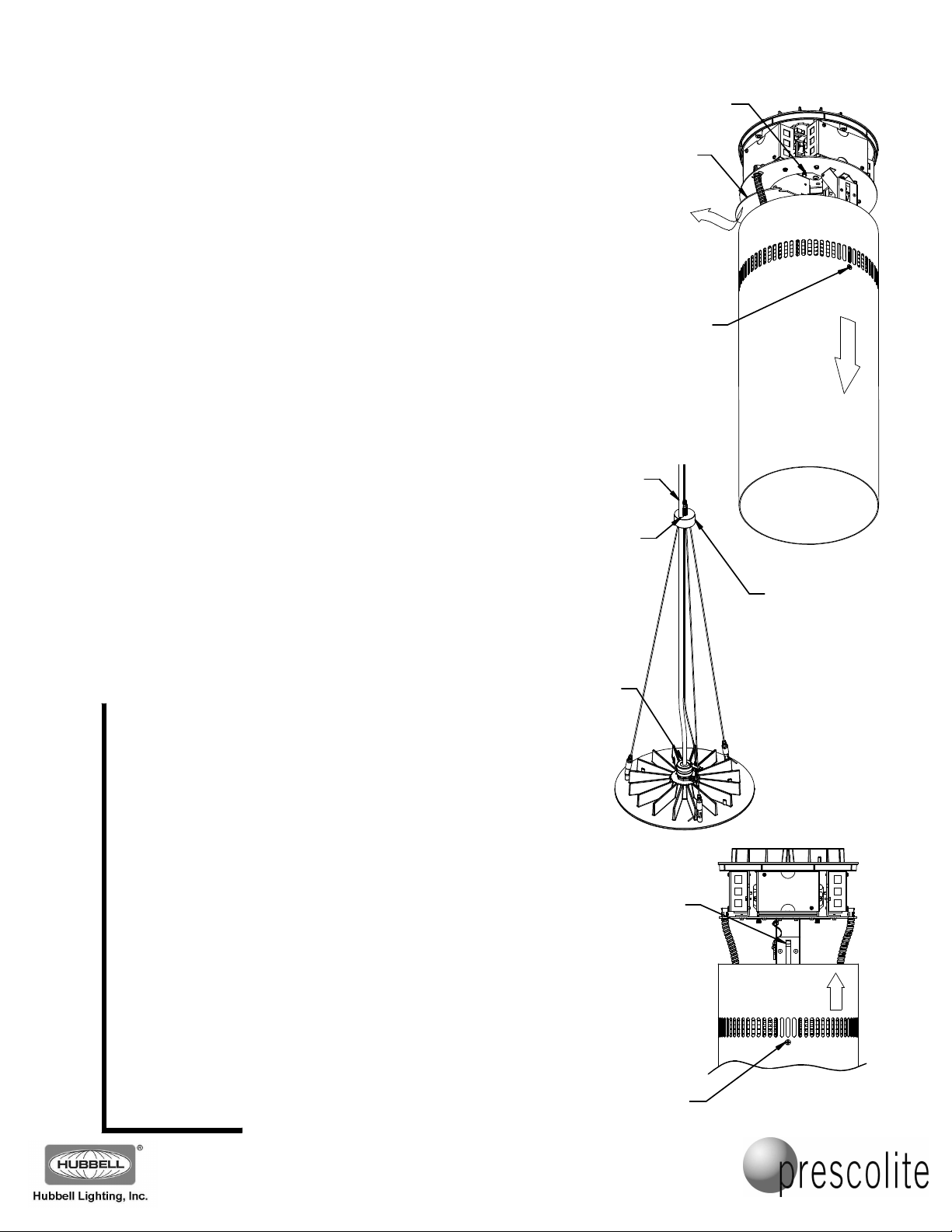

8. Carefully open the cylinder housing by loosening (do not

remove) the two Phillips screws on opposite sides of the

cylinder (near the vent slots) until the screws disengage from

the internal locking slots, and the cylinder housing is free to

slide down. Slide the outer cylinder housing open towards the

reflector (it should move about 7 inches from the top finned

casting) and tighten the two Phillips screws (Fig. 6).

9. Loosen the two thumbscrews holding the wiring compartment

cover closed, rotate the cover to free it, and carefully slide it

out of the way (there is a safety cable to hold it while the wiring

is being completed).

10. Feed the power cord through the hole in the puck assembly

and insert the end of the power cord through the cord grip and

into the cylinder wiring compartment (Fig. 7). Trim the power

cord to length, if needed. NOTE: If desired, tie the power cord

to the 20 foot cable with nylon cable ties every foot

trimming the power cord to length! Strip the jacket from the

power cord and strip the end of each conductor 3/8ths of an

inch. Make the electrical connections in the fixture wiring

compartment. The line voltage (Black-Striped) conductor

connects to the two-position connector with the Red thermal

protector wire. The neutral (White-Striped) conductor attaches

to the empty position on the connector with the White wires.

Connect the ground (Green-Striped) conductor to the twoposition connector with the Green wire. Use the two extra

power cord conductors (Blue-Striped and Red-Striped) to

connect to the dimming control wires, if provided. Make sure to

follow the same connection colors as used in Step 3. Cap off

these conductors if not used.

CAUTION: When making these connections, be careful

that no stray strands of wire stick out of the connectors

that might cause electrical shorts!

CAUTION: Do not allow the weight of the fixture to be

supported by the power cord! The weight of the fixture

should be supported by the cable system alone!

11. After the electrical connections are completed, replace the

wiring compartment cover and tighten the thumbscrews to

complete the wiring at the fixture.

12. Once again loosen (do not remove) the two Phillips screws on

opposite sides of the cylinder until the cylinder housing is free

to slide. Slide the MC10LED outer cylinder housing upwards

until it seats on the finned casting.

CAUTION: Do not pinch any wires between the cylinder

housing and any other parts of the fixture!

Be sure the cylinder housing is completely seated, and tighten

the two Phillips screws to lock the cylinder housing in place.

NOTE: If the cylinder housing does not fully seat when closing,

you may need to loosen the screws a little more to slide it

closed. This will allow the ends of the screws to pass the

locking slots at the very end of the slide travel (Fig. 8).

before

93054545

Part No...........................................

Part No...........................................

THUMBSCREW

(1 OF 2)

COMPARTMENT

POWER

CORD

POWER

CORD

HOLE

CORD

GRIP

WIRING

COVER

Fig. 6

PHILLIPS

SCREW

(1 OF 2)

LOCKING

SLOT

Fig. 8

SLIDE

HOUSING

OPEN

PUCK

Fig. 7

SLIDE

HOUSING

CLOSED

93054545

www.prescolite.com

www.prescolite.com

Prescolite Toll Free Technical Support

Prescolite Toll Free Technical Support

1.888.PRS.4TEC

1.888.PRS.4TEC

Hours: 8am - 5pm ET

Hours: 8am - 5pm ET

KEEP THESE INSTALLATION INSTRUCTIONS!

701 Millennium Blvd• Greenville, SC 29607

701 Millennium Blvd• Greenville, SC 29607

With representatives offices in principal cities throughout North America.

With representatives offices in principal cities throughout North America.

Copyright , revision, All Rights Reserved - Printed in U.S.A.

Copyright , revision, All Rights Reserved - Printed in U.S.A.

2014 03/26/14

2014 03/26/14

PHILLIPS

SCREW

(1 OF 2)

Loading...

Loading...