Page 1

DI900/DI950/DI950e

FastPac™ Document Inserting System

Operator Guide Addendum

US/Canada English Version

Page 2

Statement of FCC Compliance

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC rules. These limits are designed to provide reasonable protection against

interference when the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause interference to radio communications. Operation of this equipment in a residential area is likely to cause interference, in which case the user will be required to

correct the interference at his own expense.

CAUTION: Changes or modications to this equipment not expressly approved by the party responsible for

compliance (Pitney Bowes) could void the user’s authority to operate the equipment.

Canada

This class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme á la norme NMB-003 du Canada.

SV62081 Rev. A 12/07 ©2007 Pitney Bowes Inc.

All rights reserved. This book may not be reproduced in whole or in part in any fashion or stored in

a retrieval system of any type or transmitted by any means, electronically or mechanically, without

the express, written permission of Pitney Bowes. We have made every reasonable effort to ensure

the accuracy and usefulness of this manual; however, we cannot assume responsibility for errors or

omissions or liability for the misuse or misapplication of our products.

Due to our continuing program of product improvement, equipment and material specifications as

well as performance features are subject to change without notice. FastPac, DM Series, DM800i,

DM1000, SwiftStart, SureTrac, Optiflow, IntelliLink and E-Z Seal are trademarks or registered trademarks of Pitney Bowes.

Page 3

DI900/DI950 Operator

Guide Addendum

Introduction .....................................................................................4

Meet the Inserting System ..............................................................4

Fixed Function Keys ..................................................................4

Basic Operation .............................................................................. 7

Powering Up ..............................................................................7

Making Pre-Run Adjustments ....................................................8

Creating a Job ...........................................................................9

Creating a Job that Uses the Universal Feeder .......................11

Job Options .............................................................................14

Selecting a Job ........................................................................24

Troubleshooting ............................................................................26

Reference ..................................................................................... 31

System Specifications .............................................................31

Universal Feeder .....................................................................31

Feeder Tower Sheet Specifications .........................................31

DI900/DI950 Input Transport (F733) ........................................32

Add Ons and Options ...................................................................33

Universal Feeder .....................................................................33

High Capacity Loader (Optional) .............................................34

DI900/DI950 Input Transport ...................................................35

Scanning.......................................................................................40

Scanning Features ..................................................................40

3SV62081 Rev. A

Page 4

DI900/DI950/DI950e Operator Guide Addendum

Introduction

Meet the

Inserting

System

This document contains information about the new features and options

available for the DI900/DI950 Inserting System. This document should be

used in conjunction with the FastPac™ Document Inserting System Operator

Guide.

NOTE: The availability of add-ons and options for your inserting system varies by

region. Refer to your system supplier for availability details.

New Features

• The inserter can single fold up to 10 20 lb. sheets.

• The inserter supports multiple inserts into flat envelopes.

• The inserter supports mail pieces that include inflexible inserts in envelopes having a depth of 6 in. (152.4 mm) to 7 in. (177.8 mm).

• The inserter supports marking of every nth envelope if the Flats Sealer

is present on the system.

The information in this section is intended for use as a replacement or supplement to information contained in Chapter 2, Meet the Inserting System in

the DI900/DI950 FastPac™ Document Inserting System Operator Guide.

Fixed Function Keys

The Fixed Function Keys are the top row of keys under the screen. Each

of these keys has an assigned function that is enabled or disabled based

on the screen that displays. Use of each of these keys is explained next in

more detail.

4 SV62081 Rev. A

Page 5

DI900/DI950/DI950e Operator Guide Addendum

Fixed Function

Keys (continued)

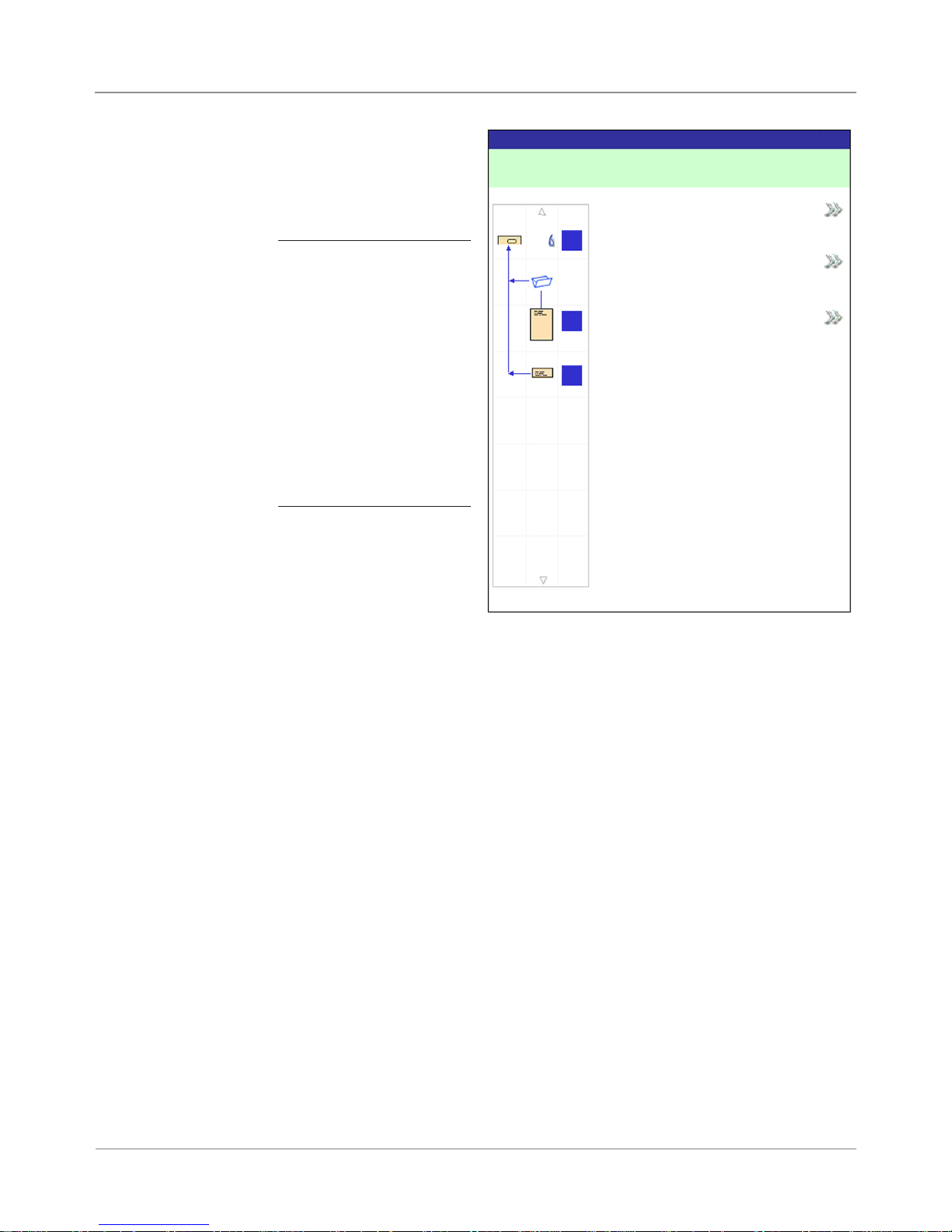

Reset Counters

The system has two

counters:

• Piece Counter

• Batch Counter

NOTE: If the Flats Sealer

is present on the system,

the “Mark Piece Count”

option will be available

on this screen. When the

“Mark Piece Count” option

is available, the “Both”

reset option changes to

“All”. Refer to Chapter 7

in the DI900/DI950 Fast-

Pac™ Document Inserting

System Operator Guide

for more information

about the Flats Sealer.

Reset Counters

Job Items

A

B

D

Job: ABC

Piece Count

Batch Count

Both

Reset Counters Screen

Resetting the Piece Counter

The Piece Counter appears in the bottom portion of the Display screen. It is

a cumulative counter, i.e., it increments for each completed mail piece.

If you run the same job but for a different customer and/or use different

materials, you'll need to zero the counter and ready it for counting the completed mail pieces in the new run.

To reset the Piece Counter:

1. Press RESET COUNTERS to display the Reset Counters screen.

2. Select "Piece Count".

3. You will be returned to the Home screen. The Piece Counter at the bottom of the screen will read "0".

SV62081 Rev. A

5

Page 6

DI900/DI950/DI950e Operator Guide Addendum

Fixed Function

Keys (continued)

Resetting the Batch Counter

The Batch Counter counts up to a set number. It increments one count for

each completed mail piece that the system detects. The system stops when

it reaches the batch count.

To reset the desired number for the job you are running:

1. Press RESET COUNTERS to display the Reset Counters screen.

2. Select "Batch Count".

3. You will be returned to the Home screen. The Batch Counter at the bottom of the screen will return to its original setting.

NOTE: The original setting for the Batch Counter cannot be less than “5” or

greater than “9999”.

Resetting the Mark Piece Count

The Mark Piece Count selection allows you to reset the counter for the envelope edge mark to zero.

1. Press RESET COUNTERS to display the Reset Counters screen.

2. Select "Mark Piece Count".

3. You will be returned to the Home screen. The counter will be reset to

zero.

Resetting Both (or All) Counters

The Both selection allows you to reset both the Piece Counter and the

Batch Counter to zero.

1. Press RESET COUNTERS to display the Reset Counters screen.

2. Select "Both".

NOTE: If the Mark Piece Count option is available, select “All.” The counter

for the envelope edge mark will be reset to zero as well.

3. You will be returned to the Home screen. The Piece Counter at the bottom of the screen will read "0" and the Batch Counter will return to its

original setting.

6 SV62081 Rev. A

Page 7

DI900/DI950/DI950e Operator Guide Addendum

Basic Operation

Powering Up

The information in this section is intended for use as a replacement or

supplement to information contained in Chapter 3, Basic Operation in the

DI900/DI950 FastPac™ Document Inserting System Operator Guide. These

instructions explain how to:

• properly power up the inserting system;

• create a job using the Universal Feeder on the DI900/DI950 Inserting

System; and

NOTE: You should be thoroughly familiar with each component of the Universal Feeder and the optional High Capacity Loader before creating a job

on the DI900/DI950 Inserting System (see the Model F731/F732 Universal

Feeder and the optional Model F734/F735 High Capacity Loader Operator

Guide supplied with the system).

• select a job.

Press the ON/OFF switch (located below the Control Panel) to start the

power up process.

IMPORTANT:

• If additional modules are present (e.g. High Capacity Sheet Feeder, Universal

Feeder, DI900/DI950 Input Transport, Exit Transport), power on each module

from left to right.

• When powering the system off and on, be sure to power off all modules, from

left to right, then power them all back on from left to right.

The system will automatically conduct a number of checks to verify the operational integrity of the system. If any problems are detected, the system

will display information directing you to a solution to the problem.

SV62081 Rev. A

7

Page 8

DI900/DI950/DI950e Operator Guide Addendum

Making Pre-Run

Adjustments

Adjusting the Manual Lever for Stiff Media Mode (DI950e Only)

Mail pieces with stiff inserts leave the machine through the flats exit. The

Stiff media feature requires manual lever (with sensor) to hold the flats gate

open. This hardware is included with DI950e inserters.

If the stiff media hardware is present, one or more of any insert type may be

designated “stiff”.

• Most common case is a single stiff insert from the Input Transport.

• Also possible is a job with multiple inserts from the tower that, taken together, are stiff.

Once one or more inserts have been designated “stiff”, the job requires an

envelope of length 6 in. (152.4 mm) to 7 in. (177.8 mm) and the manual lever placed in the flats position.

• Envelopes must be fed from the Feeder Tower; the HCEF cannot be

used.

• Since mail piece components may be too short to leave the machine

through the flats exit when they are not in an envelope, CLEAR DECK

does not function in Stiff Media mode. Instead, you must clear the machine manually.

To adjust the manual lever for Stiff Media mode:

1. Open the Sealer cover.

2. Adjust the lever to the stiff media position.

3. Close the Sealer cover.

Manual Lever

Position for Stiff Media

8 SV62081 Rev. A

Page 9

DI900/DI950/DI950e Operator Guide Addendum

Creating a Job

The Stiff Media option is an addition to the “Menu Options” table on page

3-27 of the DI900/DI950 FastPac™ Document Inserting System Operator

Guide:

Reply Card

Reply Envelope

Pre-Folded Insert

Small Booklet

Slip

Generic Insert

Large Booklet

Stiff Media*

*The DI950e is required to feed this item.

a. If this is a scanning job, follow the steps below. Otherwise, go

to step b.

• The Scan Type screen displays. Select the appropriate

Scan Type (OMR, Code 3 of 9, or Interleaved 2 of 5.)

• The Scan Configuration screen displays. Select the

appropriate Scan Configuration.

• The Content - In Line with Marks screen displays. If there

is content in line with the scan marks, select "Yes". If there

is no content in line with the scan marks, select "No".

b. Select the appropriate options for the insert. Press “Accept”

when done.

Refer to the Insert Options table in Chapter 3 of the FastPac™

DI900, DI950 Operator Guide for specific information about each of

the related menu options.

The following definition is an addition to the “Menu Options” table on page

3-29 of the DI900/DI950 FastPac™ Document Inserting System Operator

Guide:

Mark Piece Count Select this option if you have a Flats Sealer and want to use

the envelope edge marker to mark every nth envelope. Use the

numeric matrix to enter the appropriate value.

NOTE: The Flats Sealer is a purchasable exit option. Only lettersized envelopes can be marked using the envelope edge marker.

Refer to Chapter 7 of the FastPac™ DI900, DI950 Operator Guide

for more information about the Flats Sealer.

The following replaces the “Length of Clear Zone” definition on page 3-35 of

the DI900/DI950 FastPac™ Document Inserting System Operator Guide:

Additional Settings

(continued)

- Length of Clear Zone is the is the total length of the scan

marks plus the Clear Zones before and after the scan

marks.

The following replaces the “Insert Type” definition on page 3-36 of the

SV62081 Rev. A

9

Page 10

DI900/DI950/DI950e Operator Guide Addendum

Creating a Job

(continued)

DI900/DI950 FastPac™ Document Inserting System Operator Guide:

Insert Type includes

all items that do not

need folding or have

been pre-folded.

• Reply Envelope - is also called a Business Reply Envelope.

• Reply Card - is a thick slip.

• Pre-folded Insert - is a sheet or set of sheets already folded

together.

• Small Booklet - is a type of insert that typically has a bound or

stapled edge.

• Slip - is single thickness document that fits into the outer

envelope without folding.

• Generic - is an undeclared type of insert used by SwiftStart™

jobs.

• Large Booklet - is a type of insert that typically has a bound or

stapled edge.

NOTE: A Custom Feeder is required to feed this item.

• Stiff Media - is a type of insert that is inflexible.

NOTE: The DI950e is required to feed this item. Once one (or

more) Stiff Media insert has been selected, the job requires an

outer envelope length of 6 in. (152.4 mm) to 7 in. (177.8 mm).

In addition, the manual lever for Stiff Media must be placed in

the flats position in order to run the job. Refer to Making Pre-

Run Adjustments in this document for more information.

The following replaces the “Quantity” definition on page 3-36 of the DI900/

DI950 FastPac™ Document Inserting System Operator Guide:

Quantity is the

number of this

particular insert to

include in each mail

piece.

NOTE: This menu

option is not available

when “Large Booklet”

is the selected insert.

• 1, 2, 3, 4, 5, 6

• Custom Quantity

- Use UP/DOWN arrow keys to select number.

- Select "Accept" when done.

• Variable - used with scanning-controlled jobs.

The following replaces the “Item Over Count Quantity” definition on page

3-38 of the DI900/DI950 FastPac™ Document Inserting System Operator

Guide:

Additional Settings

(continued)

• Item Over Count Quantity is the number of inserts that cannot

be run normally.

The following replaces the “Batch Mode” definition on page 3-39 of the

DI900/DI950 FastPac™ Document Inserting System Operator Guide:

Batch Mode Toggle:

• Off means this feature will not function for this job, or

• On means this feature is active.

10 SV62081 Rev. A

Page 11

DI900/DI950/DI950e Operator Guide Addendum

Creating a Job

that Uses the

Universal Feeder

Creating a new job involves defining the contents of a new mail piece, and

optionally, saving the job for future use. This process consists of identifying

each item in the mail piece and selecting settings for the job. A Mail Piece

Icon Tree automatically builds on the screen as you add items.

To access the Create New Job screen:

1. From the Home screen, select “Menu”, then “Jobs”, and finally “Create

New Job.” The Create Job screen displays.

2. Enter the Job Name using the alphanumeric matrix.

a. Use the UP/DOWN and LEFT/RIGHT arrow keys to select a letter.

b. Press OK to add the letter to the job name. Highlight the arrow char-

acter and press OK to move the cursor within the job name.

c. Select “Accept Name” when done.

3. If scanning is present on the system, the Create - Job Type screen displays.

• If the new job does not require scanning, select "Normal Type" to

continue.

• If the new job requires scanning, select "Scanning Job".

4. The Create Outer Envelope screen displays.

• If the job does not require an Outer Envelope, select "No".

• If the job requires an Outer Envelope, select “Yes.”

- Select the appropriate Outer Envelope options for the job. Refer

to the Envelope Options table in this document for more information about each of the related menu options.

- Press “Accept” when done.

- If the job is a scanning job, the Create - Only One Envelope

screen displays. If the job requires only one envelope, select

"Yes" and proceed to step 5.

- If the job requires an additional envelope, select "No, Two Outer

Envelopes". Validate the available options, and press "Accept"

when done.

SV62081 Rev. A

NOTE: If this is a scanning job, and you will be using dynamic envelope selection, you must select “No, Two Outer Envelopes”.

11

Page 12

DI900/DI950/DI950e Operator Guide Addendum

Creating a Job

that Uses the

Universal Feeder

(continued)

5. The Create - Select Next Item screen displays. Select the appropriate

option.

NOTE: These instructions apply to items being fed by the Universal Feeder.

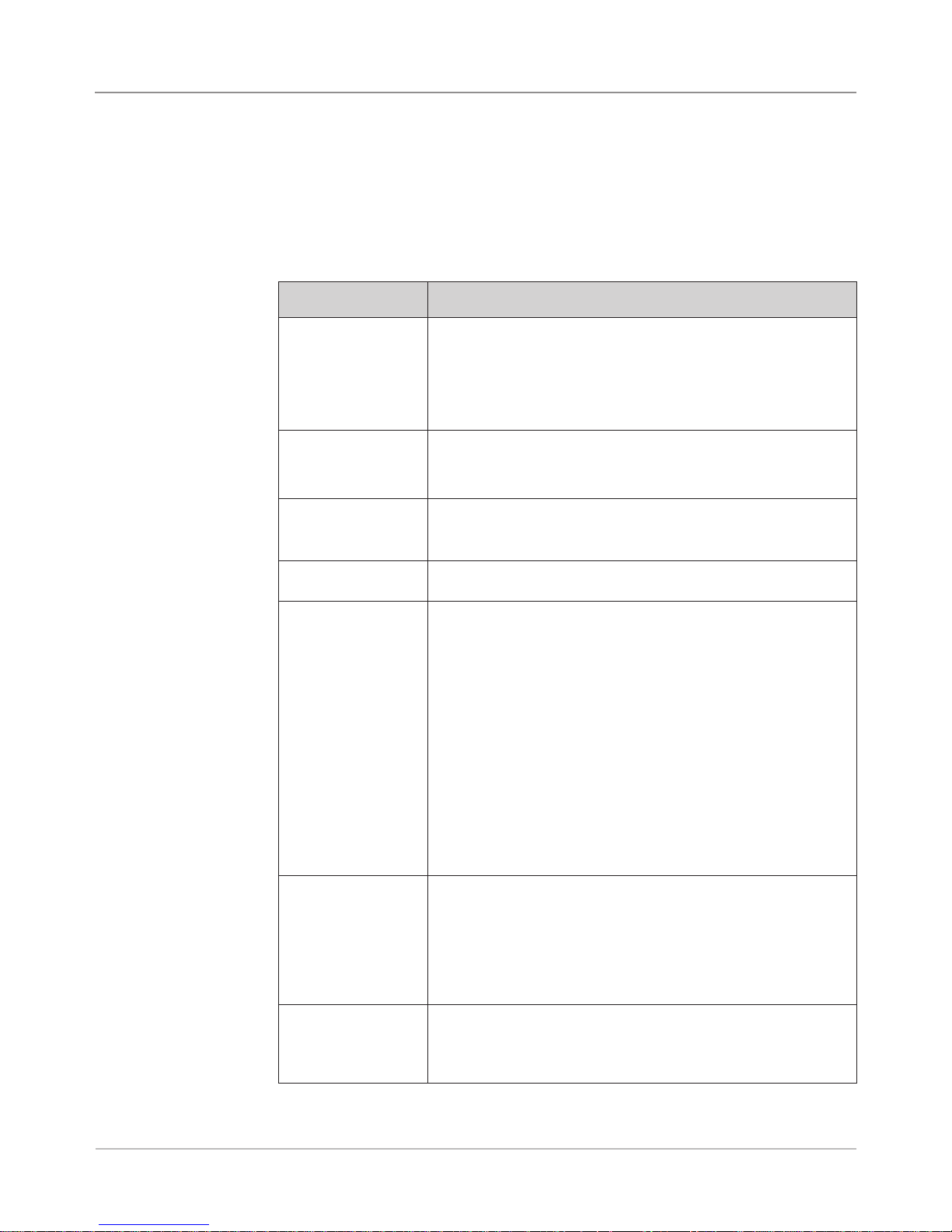

Menu Options Associated Options/Actions

Reply Card

Reply Envelope

Pre-Folded Insert

Small Booklet

Slip

Generic Insert

Large Booklet

Stiff Media

Sheet a. Select the “Custom Feeder” option. The Sheet - Personalized

a. If this is a scanning job, follow the steps in this section.

Otherwise, go to step b.

The Scan Type screen displays. Select “External Scan

Definition”.

NOTE: The External Scan Definition option is only available

if the Universal Feeder is present on the system. If the job

requires a Universal Feeder, External Scan Definition is the

only available option.

b. Select the appropriate options for the insert. Press “Accept”

when done.

Refer to the Insert Options section in this document for specific

information about each of the related menu options.

Create screen appears. Select the appropriate personalization

option. The Create - Verify Sheet screen appears.

b. If this is a scanning job, follow the steps below. Otherwise, go

to step c.

• The Scan Type screen displays. Select “External Scan

Definition”.

NOTE: The External Scan Definition option is only

available if the Custom Feeder is present on the system.

If the job requires a Custom Feeder, External Scan

Definition is the only available option.

• The Scan Configuration screen displays. Select the

appropriate Scan Configuration.

• The Content in Line with Marks screen displays. If there is

content in line with the scan marks, select "Yes". If there is

no content in line with the scan marks, select "No".

• If you selected "Yes", the Mark Locations Settings screen

appears. Follow the steps below to enter the various

mark-related measurements:

- Select an option, then use the UP/DOWN arrow keys

to enter the appropriate measurement (in millimeters).

- Press "Accept" when done entering the

measurement.

- Once all measurements have been entered, select

"Accept".

c. Select the appropriate Sheet options for the job. Press

"Accept" when done.

NOTE: If this is a scan job, set the Select Feed setting.

Refer to the Sheet Options table in this document for more

information about each of the related menu options.

d. Select the appropriate Fold options for the sheet. Press

"Accept" when done.

Refer to the Fold Options table in this document for specific

information about each of the related menu items.

12 SV62081 Rev. A

Page 13

DI900/DI950/DI950e Operator Guide Addendum

Creating a Job

that Uses the

Universal Feeder

(continued)

6. Once you have finished adding a Sheet or Insert, the Add New Item

screen appears.

• Select "Yes" to add additional items to the job. Repeat step 4 as nec-

essary.

• Select "No" if you have finished adding items to the job.

7. The Create - Edit Job Settings screen displays. Select the appropriate

options.

Menu Options Associated Options/Actions

Job Comments Use the alphanumeric matrix to enter any additional information

related to the job. If the job will be saved by a supervisor or

manager, you can make it easy for operators to identify/select the

correct job in the future by entering a job description in the job

comments area.

NOTE: Job comments can contain up to 120 characters.

Batch Mode Toggle:

• Off means this feature will not function for this job, or

• On means this feature is active.

Batch Count Use the numeric matrix to enter the batch count value.

NOTE: The batch count can contain up to four digits. The

minimum is "5" and the maximum is "9999".

Set Over Max Count Indicates what will happen to sets that exceed the set over count

quantity. Choices include Divert and Stop.

Use Postage Meter Select this option if you will be using the Mail Machine Interface

(MMI). This interface enables communication between the Inserting

System and either a DM Series™ DM800i™ or DM1000™ mailing

system via a USB connection.

The system sends start and stop signals to the mailing system, and

the mailing system can send error messages back to the inserter to

stop feeding.

Toggle:

• Off means this feature will not function for this job, or

• On means this feature is active.

NOTE: The MMI is a purchasable exit option. Only letter-sized

envelopes can be used with this interface.

Refer to Chapter 7 of the FastPac™ DI900, DI950 Operator Guide

for more information about the MMI.

Mark Piece Count Select this option if you have a Flats Sealer and want to use

the envelope edge marker to mark every nth envelope. Use the

numeric matrix to enter the appropriate value.

NOTE: The Flats Sealer is a purchasable exit option. Only lettersized envelopes can be marked using the envelope edge marker.

Refer to Chapter 7 of the FastPac™ DI900, DI950 Operator Guide

for more information about the Flats Sealer.

Advanced Allows access to advanced job settings.

IMPORTANT: Do not change the advanced job settings unless

instructed to do so. Changing settings may affect machine

performance.

SV62081 Rev. A

13

Page 14

DI900/DI950/DI950e Operator Guide Addendum

Creating a Job

that Uses the

Universal Feeder

(continued)

Job Options

8. Select "Accept" when done.

9. The Create - Saved Created Job screen displays.

• Select "Yes, Save" to save the job (optional). You must have supervisor or manager access rights to save jobs.

• Select "No, Save Later" if you do not have supervisor or manager

access rights.

This section contains descriptions of the various options you can add or

modify when creating or editing a job.

Envelope Options

Menu Item Associated Options and Actions

Name Use the alphanumeric matrix to enter the envelope name.

Size refers

specifically to the

outer envelope that

contains the final

mail piece.

Window allows use

of windowed or nonwindowed envelope.

Type allows choice of

windowed envelope.

Seal refers to using

the Moistener unit to

close the envelope.

Depth is the

dimension of an

envelope from its flap

fold to its opposite

edge.

Toggle:

• Letter generally has smaller depth and contains folded sheets,

or

• Flat generally is larger than Letter size and typically contains

unfolded sheets. If the job will contain a Large Booklet, you

must select this envelope size.

Refer to Envelopes in Chapter 6 of the FastPac® DI900, DI950

Operator Guide for specification information.

Toggle:

• Yes means you are using a windowed envelope, or

• No means you are using a non-windowed envelope.

• Standard Flap is a regular envelope.

• Forward Flap means the window and flap are on the same

side of the envelope.

• Bottom Flap means the flap is at the bottom (instead of the

top) of the envelope.

• Off means the envelope will not be sealed closed, or

• On means the envelope will be sealed closed.

• Safe Seal means the envelope will be sealed closed. However,

the envelope moves through the system at a slower rate to

provide more time for better sealing. This option is available

only for flat envelopes, when the Flats Sealer is present on the

system.

NOTE: If you are using a mailing machine in-line with the inserting

system, you must instruct the system to seal the envelope.

• Auto Measure - system measures depth when envelope is fed.

• Custom Depth - allows you to enter the depth of the envelope.

• Letter Options: #10 - 105 mm, #6 ¾ - 165 mm, C5 - 162 mm,

C6 - 114 mm. Flat Options: #12 ½ - 317 mm, C4 - 229 mm.

14 SV62081 Rev. A

Page 15

DI900/DI950/DI950e Operator Guide Addendum

Job Options

(continued)

Envelope Options (continued)

Menu Item Associated Options and Actions

Additional Settings Double Detect allows the system sense when multiple envelopes

are fed unintentionally.

• Double Detect Feature allows you to toggle:

- Off means this feature will not function for this item, or

- On means this feature is active.

• Location allows you to toggle:

- Default, or

- Custom.

• Custom Location for Top Edge allows you to enter a specific

measurement (distance from the edge feeding first into the

feeder) where the system should attempt to detect a double.

Set this option when Location is set to "Custom".

- Use the UP/DOWN arrow keys to adjust the measurement

(in millimeters).

- Select "Accept" when you are done.

NOTE: The double detect region cannot be within 25 mm of

the lead or trail edges of the envelope.

If the envelope is feeding from the HCEF, measure from the

bottom of the envelope.

If the envelope is feeding from the Feeder Tower, measure

from the top of the envelope. The custom location must be at

least 5 mm away from the edge of the window (if present), at

least 5 mm away from the edge of flap, and cannot lie on top

of a seam.

For best results, be sure to avoid areas that overlap with the

window, flap, or seams.

• Action On Double allows you to select where the items should

be fed to if a double is detected.

Feeder Type allows you to change the Feeder setting when

material is problematic.

• Normal is used for most items.

• Special Feeder helps problematic material run better.

NOTE: The Special Feeder is a purchasable option. If available,

it will be located at the top left or right of the Feeder Tower. It is

an option for one or more tower feeders to improve feeding of

thin prefolded items or booklets with thin covers. It reduces the

tendency of these items to separate while they are being fed. You

must push the “Special Feeder” lever up to run a job when the

Feeder Type is set to Special Feeder.

Feeder Linking allows multiple Feeders to feed the same

envelope.

• None means there is no linking of Feeder Trays.

• Two Feeders indicates that two Feeder Trays are linked and

feeding the same material.

NOTE: Feeders must be on the same module and on the same

side of the tower to be linked. For scanned items, always load

linked feeders at a collation break.

SV62081 Rev. A

15

Page 16

DI900/DI950/DI950e Operator Guide Addendum

Job Options

(continued)

Envelope Options (continued)

Menu Item Associated Options and Actions

Additional Settings

(continued)

Envelope Select Feed allows you to indicate when the envelope

should be used.

Toggle:

• Main

• Alternate

NOTE: This option is enabled only when the Scan feature is

activated, two Outer Envelopes have been defined in a job and

either one of the following:

• The Item Over Count Action is set to “Use Alternate Envelope”

on the control document in the job, OR

• An Envelope Select mark is contained in the scan

configuration file associated with the control document in the

job.

Fold Options

Menu Item Associated Options and Actions

Fold Type refers

to the way sheets

are folded to be

able to show certain

portions through a

window, and/or when

a sheet is opened.

Auto Fold Lengths

lets the system

choose the type of

fold.

Fold 1 Length

Fold 2 Length

• C Fold

• Z Fold

• Single Fold

• Double Fold

• No Fold

Toggle:

• Yes means the system calculates the fold length, or

• No means you will enter the fold lengths you want.

Fold Length is shown on the display screen for each fold type/

address combination.

• Use the UP/DOWN Arrow Keys to select desired length.

• Press "Accept" when done.

16 SV62081 Rev. A

Page 17

DI900/DI950/DI950e Operator Guide Addendum

Job Options

(continued)

Sheet Options

Menu Item Associated Options and Actions

Name Use the alphanumeric matrix to enter the job name.

Control Document

is the top sheet in

the Mail Piece Icon

Tree. This field is

read-only.

Type identifies the

printing source of the

job.

Personalized refers

to the top sheet that

contains the address

that will show in the

windowed envelope

and/or a sheet that

contains information

customized to a

specific recipient.

Quantity is the

number of this type

of sheet to include in

each mail piece.

Page Order

identifies the feeding

pattern of multiple

sheets that are not

identical.

Read-Only field

• Yes, or

• No

• Printed Separately - indicates the sheet is not printed by the

Attached Printer.

• Printed by Attached Printer - indicates the sheet is printed by

the Attached Printer.

NOTE: This menu option is available only with configurations that

contain an Attached Printer. If an Attached Printer is not present,

this option appears as a read-only field with “Printed Separately” as

the default setting.

• Top Address

• Middle Address

• Bottom Address

• Not Personalized

• Personalized - No Address

• 1, 2, 3, 4, 5, 6

• Custom Quantity

- Use UP/DOWN arrows to select number.

- Select "Accept" when done.

NOTE: Quantity is always set to Variable (n) for scanning jobs.

Forward - indicates page 1 is on top and pages 2, 3, 4, etc. follow in

that order.

Reverse - indicates that the last page, for example, page 4, is first

followed by pages 3, then 2, then 1.

NOTE: This menu option appears as a read-only field when the

job requires a Custom Feeder. The feeding pattern is set by the

Custom Feeder.

SV62081 Rev. A

17

Page 18

DI900/DI950/DI950e Operator Guide Addendum

Job Options

(continued)

Sheet Options (continued)

Menu Item Associated Options and Actions

Length is the

dimension of the

sheet in the direction

of the feed.

Additional Settings. Double Detect allows the system to sense when multiple sheets

• Auto measure - measures the recommended length

automatically.

NOTE: This menu option appears as a read-only field when

the job requires a Custom Feeder.

• Custom Length - allows increase or decrease of sheet length.

- Use UP/DOWN arrows to select number.

- Select "Accept" when done.

NOTE: If the job requires a Custom Feeder, you must enter

the sheet length using the Custom Length option. The job will

not be valid if the sheet length is not entered.

• Letter - 279 mm, Legal - 356 mm, and A4 - 279 mm are

additional options.

NOTE: The “Legal” option is not available when the sheet

is printed by the Attached Printer. Additionally, legal-sized

documents cannot be fed from the High Capacity Sheet

Feeder. The system will assign these documents to a Tower

Feeder, even when the High Capacity Sheet Feeder is

available.

are fed unintentionally.

NOTE: This menu option is not available when the job requires a

Custom Feeder.

• Double Detect Feature allows you to toggle:

- Off means this feature will not function for this item, or

- On means this feature is active.

• Location allows you to toggle:

- Default, or

- Custom.

• Custom Location for Top Edge allows you to enter a specific

measurement (the distance from the edge feeding first into the

feeder) where the system should attempt to detect a double.

NOTE: Set this option when Location is set to "Custom". The

double detect region cannot be within 25 mm of the lead or trail

edges of the sheet.

- Use the UP/DOWN arrow keys to adjust the measurement

(in millimeters).

- Select "Accept" when you are done.

• Action On Double allows you to select where the items should

be fed to if a double is detected.

18 SV62081 Rev. A

Page 19

DI900/DI950/DI950e Operator Guide Addendum

Job Options

(continued)

Sheet Options (continued)

Menu Item Associated Options and Actions

Additional Settings.

(continued)

Feeder Type allows you to change the Feeder setting when

material is problematic, or to indicate that the job requires a Custom

Feeder.

NOTE: This menu option is not available when the job requires an

Attached Printer.

• Normal is used for most items.

• Manual Feed is used when items will be fed into the system

by hand. Refer to Manual Feeder in Chapter 2 for more

information.

• Custom Feeder is used when items will be fed into the system

by the Custom Feeder.

Feeder Linking allows multiple Feeders to feed the same material.

NOTE: This menu option is not available when the job requires a

Custom Feeder or an Attached Printer.

• None means there is no linking of Feeder Trays.

• Two Feeders indicates that two Feeder Trays are linked and

feeding the same material.

NOTE: Scanned sheets can be linked vertically in both the High

Capacity Sheet Feeder and the Feeder Tower.

Scan Items allows you to indicate whether or not an item should be

scanned.

Toggle:

• Yes means this feature is active, or

• No means this feature will not function for the item.

SV62081 Rev. A

19

Page 20

DI900/DI950/DI950e Operator Guide Addendum

Job Options

(continued)

Insert Options

Menu Item Associated Options and Actions

Name Use the alphanumeric matrix to enter the job name.

Insert Type includes

all items that do not

need folding or have

been pre-folded.

Personalized

means the insert

contains information

customized to a

specific recipient.

NOTE: This menu

option is not available

when “Large Booklet”

is the selected insert.

Quantity is the

number of this

particular insert to

include in each mail

piece.

NOTE: This menu

option is not available

when “Large Booklet”

is the selected insert.

Page Order identifies

the feeding pattern of

multiple inserts that

are not identical.

NOTE: This menu

option is not available

when “Large Booklet”

is the selected insert.

• Reply Envelope - is also called a Business Reply Envelope.

• Reply Card - is a thick slip.

• Pre-folded Insert - is a sheet or set of sheets already folded

together.

• Small Booklet - is a type of insert that typically has a bound or

stapled edge.

• Slip - is single thickness document that fits into the outer

envelope without folding.

• Generic - is an undeclared type of insert used by SwiftStart™

jobs.

• Large Booklet - is a type of insert that typically has a bound or

stapled edge.

NOTE: A Custom Feeder is required to feed this item.

• Stiff Media - is a type of insert that is inflexible.

NOTE: Once one or more “Stiff Media” insert has been

selected, the job requires an outer envelope length 6 in.

(152.4 mm) to 7 in. (177.8 mm). In addition, the Stiff Media

lever must be placed in the flats position in order to run the

job. Refer to Making Pre-Run Adjustments in this document for

more information.

Yes means there is unique information on this insert, or

No means the insert does not contain unique information.

• 1, 2, 3, 4, 5, 6

• Custom Quantity

- Use UP/DOWN arrow keys to select number.

- Select "Accept" when done.

• Variable - used with scanning-controlled jobs.

Forward - indicates page 1 is on top and pages 2, 3, 4, etc. follow

in that order.

Reverse - indicates that the last page, for example, page 4, is first

followed by pages 3, then 2, then 1.

20 SV62081 Rev. A

Page 21

DI900/DI950/DI950e Operator Guide Addendum

Job Options

(continued)

Insert Options (continued)

Menu Item Associated Options and Actions

Length is the

dimension of the

insert in the direction

of the feed.

Additional Settings Double Detect allows the system sense when multiple inserts are

• Auto measure - measures the recommended length

automatically.

NOTE: Auto measure is not available when “Large Booklet” is

the selected insert or when the job requires a Custom Feeder.

• Custom Length - allows increase or decrease of insert length.

- Use the UP/DOWN Arrow Keys to select number.

- Select "Accept" when done.

NOTE: If the job requires a Large Booklet, you must enter the

sheet length using this Custom Length option. The job will not

be valid if the booklet length is not entered.

• Custom Length (Large Booklet Only) - allows selection of large

booklet size: 8.5” x 11” (215.9 mm x 279.4 mm) or 5.5” x 8.5”

(139.7 mm x 215.9 mm).

NOTE: If the job requires a Large Booklet, you must enter the

sheet length using this Custom Length option. The job will not

be valid if the booklet length is not entered.

fed unintentionally.

NOTE: This menu option is not available when the job requires a

Custom Feeder.

• Double Detect Feature allows you to toggle:

- Off means this feature will not function for this item, or

- On means this feature is active.

• Location allows you to toggle:

- Default, or

- Custom.

• Custom Location for Top Edge allows you to enter a specific

measurement (the distance from the edge feeding first into the

feeder) where the system should attempt to detect a double.

NOTE: Set this option when Location is set to "Custom". The

double detect region cannot be within 25 mm of the lead or trail

edges of the insert.

- Use the UP/DOWN arrow keys to adjust the measurement

(in millimeters).

- Select "Accept" when you are done.

• Action On Double allows you to select where the items should

be fed to if a double is detected.

SV62081 Rev. A

21

Page 22

DI900/DI950/DI950e Operator Guide Addendum

Job Options

(continued)

Insert Options (continued)

Menu Item Associated Options and Actions

Additional Settings Feeder Type allows you to change the Feeder setting when

material is problematic, or to indicate that the job requires a Custom

Feeder.

NOTE: This menu option is not available when the job requires

an Attached Printer. The Custom Feeder is selected automatically

when “Large Booklet” is the selected insert.

• Normal is used for most items.

• Manual Feed is used when items will be fed into the system

by hand. Refer to Manual Feeder in Chapter 2 for more

information.

• Custom Feeder is used when items will be fed into the system

by the Custom Feeder.

Feeder Linking allows multiple Feeders to feed the same material.

NOTE: This menu option is not available when the job requires a

Custom Feeder.

• None means there is no linking of Feeder Trays.

• Two Feeders indicates that two Feeder Trays are linked and

feeding the same material.

Scan Items allows you to indicate whether or not an item should be

scanned.

Toggle:

• Yes means this feature is active, or

• No means this feature will not function for the item.

22 SV62081 Rev. A

Page 23

DI900/DI950/DI950e Operator Guide Addendum

Job Options

(continued)

Insert Options (continued)

Menu Item Associated Options and Actions

Additional Settings

(continued)

Scan Settings

NOTE: The “Content in Line with Marks”, “Marks On”, “Marks on

First Page Only”, and “Mark Location Settings” options are not

available when the job requires a Custom Feeder.

• Scan Configuration allows choice of saved scan configurations

to interpret scan marks.

• Content in Line with Marks indicates that content is in line with

the scan marks in the feed direction.

• Marks On indicates if marks are on the front or back of the

page.

• Marks on First Page Only indicates marks are on only the first

of multiple inserts.

• Mark Location Settings allows setup of various mark-related

measurements.

- Top of Page to First Mark is the distance from the top of

the page to the first mark.

- Total Length of Marks is the length from the top of the first

possible mark to the bottom of the last mark.

- Top of Page to Clear Zone is distance from the top of the

page to the beginning of the Clear Zone.

- Length of Clear Zone is the is the total length of the scan

marks plus the Clear Zones before and after the scan

marks.

Refer to OMR Specifications in Chapter 8 for more information

on the Clear Zone and mark location settings.

• Item Over Count Quantity is the number of inserts that cannot

be run normally.

NOTE: At this time, only a single insert can be added to each

mail piece. When using a flat envelope, the insert must be a

Reply Envelope (BRE).

• Item Over Count Action indicates what will happen to items that

exceed the item over count quantity. Choices include:

- Divert - Select this option if the Scan Configuration does

not have the Divert Sheet (DVS) scan mark, and you

want the system to divert items once the item over count

quantity has been exceeded.

- Stop - Select this option if you want the system to stop

processing items once the item over count quantity has

been exceeded.

Refer to Scanning Features in Chapter 8 for more information

on divert sheet functionality.

Select Feed (SF) Settings allows assignment of a Feeder to one of

the 9 Select Feed scan marks.

NOTE: This option is not available if the item requires a

Custom Feeder and a High Capacity Sheet Feeder is part of the

configuration.

SV62081 Rev. A

23

Page 24

DI900/DI950/DI950e Operator Guide Addendum

Selecting a Job

If the job that you want to run is the one that currently displays in the Home

screen, proceed to the Running a Trial Piece section of this chapter.

IMPORTANT: If the job requires the Universal Feeder, you must select the job on

the Universal Feeder and on the inserter before running a Trial Piece.

• Select the job on the inserter rst to avoid job validation errors on the Universal Feeder.

• The “Custom Feeder not Ready” message will appear on the display screen if

the selected job requires the Universal Feeder and the job is not selected on

the Universal Feeder.

Refer to Chapter 2, Operation, Select the Program in the F731/F732 Universal

Feeder and F734/F735 High Capacity Loader Operator Guide for information

about selecting the job at the Universal Feeder.

If the job that you want to run is not displayed on the Home screen, follow

the steps below to select the job.

1. From the Home screen:

• Select "Select Another Job" to view a list of saved jobs. Skip to step

3, below.

OR

• Select "Menu", then "Jobs", and finally "Select Job". The Select Job

Type screen displays.

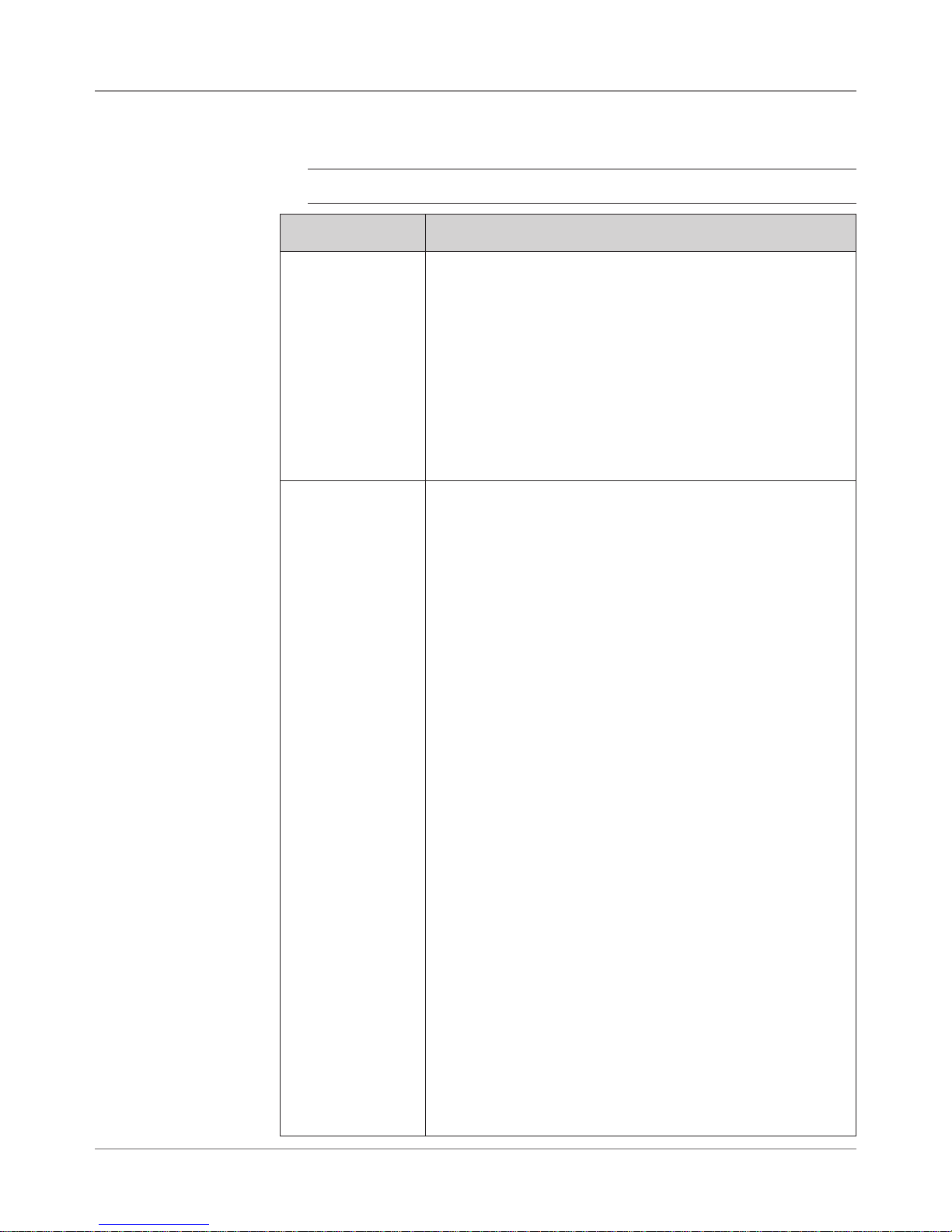

Select Job Type

Select Job Type Screen

Saved Jobs

Recently Run Jobs

Library Jobs

24 SV62081 Rev. A

Page 25

DI900/DI950/DI950e Operator Guide Addendum

2. The Job Type screen provides access to all the jobs that are in your system. This screen displays three categories to search for the job that you

want to run:

• "Saved Jobs" displays the list of jobs that you created and saved.

• "Recently Run Jobs" displays a list of the last 8 jobs that your sys-

tem ran. This list shows each job's name and the date/time that the

job ran.

• "Library Jobs" displays the names of the pre-defined jobs that came

loaded on your system.

Select the desired category to display the list of jobs that are available in

that category.

3 Select the desired job from the list.

• If the job does not appear on the first page, use the UP/DOWN ar-

row keys to scroll through the list.

• As any job is highlighted in the list, the Mail Piece Icon Tree for the

job appears on the display so that it can be identified

4. If you are using a Universal Feeder for this job, you must select the appropriate job on the Universal Feeder. Refer to Chapter 2, Operation,

Select the Program in the F731/F732 Universal Feeder and F734/F735

High Capacity Loader Operator Guide.

SV62081 Rev. A

25

Page 26

DI900/DI950/DI950e Operator Guide Addendum

Troubleshooting

The information in this section is intended for use as a replacement or

supplement to information contained in Chapter 5, Troubleshooting in the

DI900/DI950 FastPac™ Document Inserting System Operator Guide.

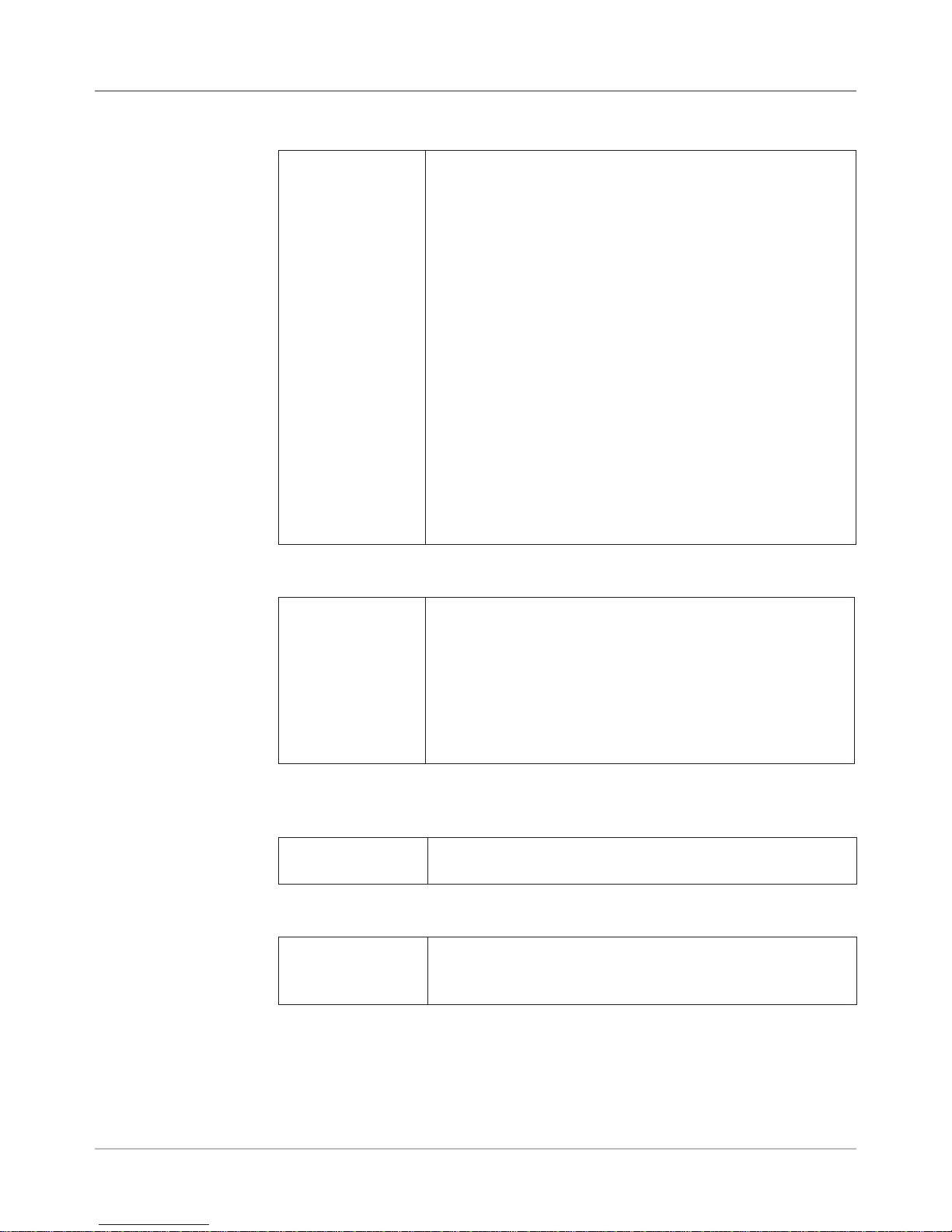

Table 5-6 Insertion Area/Envelope Flapper Area Problems

Problem Cause Action

Stoppage in insertion area or

flapper area; failure to insert.

Outer envelope is skewed. Check Side Guides; incorrect adjustment can cause

skewing.

Refer to Adjusting Tray Side Guides in Chapter 3 of

this guide for instructions.

Envelope openers improperly

adjusted.

Envelope

Size

Flat No Yes Yes 3

Letter, DL,

6x9 and C5

*3 fingers if collation is thicker than 4 mm.

Inner Envelope Openers

Fulls Size

Booklet Sheets

Yes Yes No 3

Yes Yes Yes 3

Yes No No 3

Yes No Yes 3

No Yes No 5

n/a Yes No 5

n/a Yes Yes 5*

The standard insertion finger configuration is five

fingers (three inner envelope openers and two outer

envelope openers). The alternative configuration is

three fingers (three inner envelope openers).

To obtain the alternative configuration, slide the

fingers outside of the envelope. If the envelope is

too wide to have the fingers completely out of the

envelope, take the lower part of the outside fingers

off.

Insert/Small

Booklet

Inner Envelope Openers

Recommended

Finger Setting

26 SV62081 Rev. A

Recommended 3 Finger Setting

Outer Envelope Openers

Recommended 5 Finger Setting

Page 27

DI900/DI950/DI950e Operator Guide Addendum

Table 5-6 Insertion Area/Envelope Flapper Area Problems

Problem Cause Action

Stoppage in insertion area or

flapper area; failure to insert.

(continued)

Envelope openers improperly

adjusted. (continued)

Large booklet: Binding must be parallel to the feed direction; most likely booklets

that are inserted in flat envelopes that are close to the size of a full sheet.

15 mm

to

25 mm

Recommended

distance: 15 to 25

mm between the tip

of the outside finger

and the edge of the

envelope.

Feed direction

Binding parallel to feed direction

Small booklet: Binding must be perpendicular to the feed direction; most likely

booklets that are inserted in C5 or 6x9 envelopes.

Feed direction

Binding perpendicular to feed direction

Refer to Adjusting the Envelope Openers in Chapter 3 of this guide for instructions to

perform the setup adjustment.

Insufficient edge clearance. Check clearance: envelope width must be at least 13

mm greater than the sum of the width of the widest

insert plus the insert pack thickness.

Insertion pack or envelopes

not centered.

Ensure that Side Guides are set correctly. Too much

clearance between Side Guides and material can

cause material to become skewed in machine.

Refer to Adjusting Tray Side Guides in Chapter 3 of

this guide for instructions.

SV62081 Rev. A

27

Page 28

DI900/DI950/DI950e Operator Guide Addendum

Table 5-6 Insertion Area/Envelope Flapper Area Problems

Problem Cause Action

Stoppage in insertion area or

flapper area; failure to insert.

(continued)

• Contents of insertion

pack are catching on

side seam inside of

envelope.

• Contents of insertion

pack are thick and

difficult to insert into

smaller envelopes.

Adjust the Aligner custom settings:

NOTE: If the contents of the insertion pack are

thick, and you are having trouble inserting the pack

into a small envelope, be sure to set the "Envelope

Width" and "Widest Enclosure Width" to the exact

dimensions of the insertion pack.

1. From the Home screen, select "Menu", then

"Jobs".

2. Select "Edit Current Job", "Edit Job Settings",

then "Advanced".

3. Select "Aligner", then "On with Custom Settings".

The Customer Aligner Settings screen displays.

4. Select "Envelope Width". Use the UP/DOWN

arrow keys to increase or decrease the

measurement, as necessary. Select "Accept"

when done.

5. Select "Widest Enclosure Width". Use the

UP/DOWN arrow keys to increase or decrease

the measurement, as necessary. Select "Accept"

when done.

6. Select "Accept" on the Custom Aligner Settings

screen once the necessary adjustments have

been made.

28 SV62081 Rev. A

Page 29

DI900/DI950/DI950e Operator Guide Addendum

Table 5-7 Moistener/Mail Piece Exit Problems

Problem Cause Action

No seal, failure to seal,

incomplete seals.

High seal: flap is folded and

sealed above crease line.

Sealing is off in job set up. • Check job definition.

• Make sure sealer is ON.

Low sealant level. Add water or sealing solution.

Poor quality envelopes. Inspect envelopes. Examine glue lines.

Worn moistener brushes. Inspect. Replace if necessary. Refer to Replacing the

Moistener Brushes for instructions.

Worn moistener wick. Inspect. Replace if necessary. Refer to Replacing the

Moistener Wick for instructions.

Outer envelope or content

skew.

• Check Side Guide adjustment.

• Check for proper loading of material in Trays.

• Contents of insertion

pack are catching on

side seam inside of

envelope.

• Contents of insertion

pack are thick and

difficult to insert into

smaller envelopes.

Poor quality envelopes. Check side seam(s) inside of envelope for excessive

Adjust the Aligner custom settings:

NOTE: If the contents of the insertion pack are thick,

and you are having trouble inserting the pack into a

small envelope, be sure to set the "Envelope Width"

and "Widest Enclosure Width" to the exact dimensions

of the insertion pack.

1. From the Home screen, select "Menu", then

"Jobs".

2. Select "Edit Current Job", "Edit Job Settings", then

"Advanced".

3. Select "Aligner", then "On with Custom Settings".

The Customer Aligner Settings screen displays.

4. Select "Envelope Width". Use the UP/DOWN

arrow keys to increase or decrease the

measurement, as necessary. Select "Accept"

when done.

5. Select "Widest Enclosure Width". Use the UP/

DOWN arrow keys to increase or decrease the

measurement, as necessary. Select "Accept"

when done.

6. Select "Accept" on the Custom Aligner Settings

screen once the necessary adjustments have

been made.

stickiness. Glue residue inside of the envelope may

prevent it from opening fully and easily.

SV62081 Rev. A

29

Page 30

DI900/DI950/DI950e Operator Guide Addendum

Table 5-7 Moistener/Mail Piece Exit Problems

Problem Cause Action

Stoppage in envelope exit area. Glue contamination or debris

in transport.

Box seal: material obstructs

envelope fold, causing flat area

at crease.

Envelope exit through letter

path is unreliable; envelope is

damaged.

Materials are not inserted

deep enough into envelope.

Collations may be too stiff

to exit through the letter exit

path.

Inspect and clean transport.

Adjust the Envelope Crease Line upstream so

materials are inserted deeper into the envelope:

1. At the Home screen select: "Menu", then

"Tools", then "Configure System", and finally "Set

Envelope Crease".

2. Select the appropriate envelope position.

3. Press "Finished" three times to return to the Home

screen.

IMPORTANT: This setting is a system setting; it will be

effective for all the applications on the machine.

If the envelope is longer than 152 mm, process it

through the flat exit path:

1. At the Home screen select: “Menu”, then “Job”.

2. Select “Edit Current Job”, then “Choose the Item

to modify” and “Edit Highlighted Item”.

3. Select “Additional Setting”, then “Advanced”, and

“Stiff Media”.

4. Select “Yes”.

NOTES:

• If the Stiff media option is not available (grayed

out), make sure that the Stiff Media option is

enabled in the system setting.

• If the envelope is not a flat envelope, the system

will assign the envelope to a Tower feeder even if

a HCEF is installed on the machine.

Table 5-11 Universal Feeder Problems

Problem Cause Action

“Custom Feeder not Found”

message displays.

30 SV62081 Rev. A

The Universal Feeder and/or

Input Transport may not be

powered on.

Turn the Universal Feeder and/or Input Transport on.

NOTE: You may need to power the system off and

then on again. When powering the system off and on,

be sure to power off all modules, from left to right, then

power them all back on from left to right.

Page 31

DI900/DI950/DI950e Operator Guide Addendum

Reference

System

Specifications

20”

(51 mm)

The information in this section is intended for use as a replacement or

supplement to information contained in Chapter 6, Reference in the DI900/

DI950 FastPac™ Document Inserting System Operator Guide.

Dimensions

All dimensions are approximate.

Length overall, height Weight, unboxed

Universal Feeder

Universal Loader

Input Transport

39.4" (1000 mm), 18.5" (47 mm) 141 lb. (64 kg)

35.4" (900 mm), 20" (51 mm) 132 lb. (60 kg)

20" (51 mm), 10.5" (27 mm) 42 lb. (19 kg)

20” (51 mm)

10.5”

(27 mm)

35.4” (900 mm)

High Capacity Loader Universal Feeder Input Transport

Universal Feeder

Feeder

Tower Sheet

Specifications

39.4” (1000 mm)

20” (51 mm)

Refer to the Model F731/F732 Universal Feeder and the optional Model

F734/F735 High Capacity Loader Operator Guide for system specifications

and requirements.

The following table replaces the Feeder Tower - Sheet Specifications table

on page 6-11 of the DI900/DI950 FastPac™ Document Inserting System Operator Guide:

Feeder Tower - Sheet Specifications

Parameter Minimum Value Maximum Value

Width

Length

Thickness 0.003 inches (0.076 mm) 0.012 inches (0.305 mm)

Paper Weight 16 lb. (60 gsm) 44 lb. (175 gsm)

5 inches (127 mm) 9.84 inches (250 mm)

6.7 in (170 mm) 14 inches (356 mm)

SV62081 Rev. A

31

Page 32

DI900/DI950/DI950e Operator Guide Addendum

DI900/DI950 Input

Transport (F733)

Material

Sheet Dimensions Width: 6.89” (175 mm) to 9.84” (250 mm)

Booklet Dimensions Width: 5.31” (135 mm) to 9.84” (250 mm)

Throughput • A4 sheets: up to 5400 collations per hour.

Notes The processing capability of the Input Transport is limited by the

If you are using the Input Transport divert trays, refer to the tables below to ensure the

material meets the size specifications for each of the divert trays.

Parameter Minimum Maximum

Width 5.31” (135 mm) 8.58” (218 mm)

Length 5.47” (180 mm) 14.09” (358 mm)

Letter-size or A4 sheets or booklets

Length: 5.47” (139 mm) to 14.09” (358 mm)

Basis Weight: 16 lb. (60 gsm) to 47 lb. (175 gsm)

Length: 3.66” (93 mm) to 11.81” (300 mm)

Basis Weight: 24 lb. (90 gsm) to 47 lb. (175 gsm)

• Letter-size sheets: up to 5500 collations per hour.

requirements of the downstream upstream device (either the

HCSF or Base). Refer to the Chapter 6, Reference in the DI900/

DI950 FastPac™ Document Inserting System Operator Guide for

these requirements.

Lower Divert Tray

Upper Divert Tray

Parameter Minimum Maximum

Width 8.19” (208 mm) 8.58” (218 mm)

Length 5.47” (180 mm) 14.09” (358 mm)

32 SV62081 Rev. A

Page 33

DI900/DI950/DI950e Operator Guide Addendum

Add Ons and

Options

Universal Feeder

The information in this section is intended for use as a supplement to

Chapter 7, Add Ons and Options in the DI900/DI950 FastPac™ Document

Inserting System Operator Guide.

The Universal Feeder takes laser printed or pre-print cut sheets and efficiently collates them into customer sets. It can also feed single booklets up

to 4 mm (0.16”) thick. OMR/BCR/OCR/2D Matrix scanning ensures complete integrity and confidentiality of the sets.

Standard Features:

• Bottom feeding of material

• Variable speed control

• Overcount control

• Automatic double document detection

• Job storage - up to 99 jobs available

• Multi-function operator controls

• Easy to use self prompting display

• Out of material and jam detection

• Resettable sheet counter

• Batch count control

• Operator selectable ‘User Definable’ (if OMR scanning is fitted)

Refer to the Model F731/F732 Universal Feeder and the optional Model

F734/F735 High Capacity Loader Operator Guide for more information.

SV62081 Rev. A

Optional High

Capacity

Loader

Universal Feeder

33

Page 34

DI900/DI950/DI950e Operator Guide Addendum

High Capacity

Loader

(Optional)

The optional F734/F735 High Capacity Loader takes laser printed or preprinted cut sheets and conveys them to the feeder deck of the F731/F732

Universal Feeder.

The F734 and F735 are identical with the exception that the F734 is designed to handle US ‘Letter’-sized sheets, whereas the F735 handles DIN

A4 sized sheets.

After loading material into the F734/F735, operation is controlled by the

F731/F732 Universal Feeder. The F734/F735 will only convey material

when instructed to do so by the Universal Feeder.

In the event of a material stoppage on the F731/F732 Universal Feeder, the

High Capacity Loader will stop.

Standard Features:

• Automatic start/stop – Controlled by downstream F731/F732 Universal

Feeder

• Automatic paper flow control

• Automatic material detection

• Fully interlocked covers

• Operator adjustment to accommodate ‘curled material’

Refer to the Model F731/F732 Universal Feeder and the optional Model

F734/F735 High Capacity Loader Operator Guide for more information.

34 SV62081 Rev. A

Page 35

DI900/DI950/DI950e Operator Guide Addendum

DI900/DI950 Input

Transport

The DI900/DI950 Input Transport is located between the Universal Feeder

and either:

• the base unit or the

• a High Capacity Sheet Feeder (HCSF).

The Input Transport receives sheet(s) (in the form of complete collations),

inserts (or accumulations of inserts) and booklets from the Universal Feeder. It has the capability of buffering the material ahead of the base unit or

HCSF until the downstream unit is ready to receive the material.

Input Transport Top Cover

Power

button

Input Transport Attached to Base Unit

Input Transport Front Cover

SV62081 Rev. A

35

Page 36

DI900/DI950/DI950e Operator Guide Addendum

DI900/DI950

Input Transport

(continued)

The Input Transport has two sheet divert trays: an upper divert tray and a

lower divert tray. The lower divert tray provides capacity and function identical to the divert tray shipped with the basic DI900/DI950 system. The upper

divert tray provides a divert path accessible only to the upstream external

device.

Upper Divert Tray

Lower Divert Tray

NOTES:

• Refer to Reference, DI900/DI950 Input Transport in this guide for divert

tray material specications.

• The upper divert tray will accept input of up to 25 sheets with a basis

weight of 32 lb. (120 gsm) per sheet.

• Stiff media is not allowed in the upper divert tray since it will not be able to

negotiate the bend down from the paper path into the divert path.

36 SV62081 Rev. A

Page 37

DI900/DI950/DI950e Operator Guide Addendum

DI900/DI950

Input Transport

(continued)

The front cover of the Input Transport has two LED lights: the upper light

is for upper (upstream) divert tray; the lower light is for lower (DI900/DI950

base unit) divert tray. The LED lights indicate the following:

• No light means the divert tray is empty.

• Green light means tray has material in it.

• Red light means that tray is full.

LED for Upper Divert Tray

LED for Lower Divert Tray

SV62081 Rev. A

37

Page 38

DI900/DI950/DI950e Operator Guide Addendum

DI900/DI950

Input Transport

(continued)

There are two blue jam clearance knobs on the Input Transport.

• Knob 30 clears stoppages that occur while material enters the Input

Transport.

• Knob 31 clears stoppages that occur while material exits the Input

Transport.

NOTE: This knob also turns belts in the Feeder Tower. Be sure to open the

Feeder Tower cover when clearing a stoppage using this knob.

To access the jam clearance knobs, open the Input Transport front cover.

Jam Clearance Knobs

38 SV62081 Rev. A

Page 39

DI900/DI950/DI950e Operator Guide Addendum

DI900/DI950

Input Transport

(continued)

Adjusting the Stop on the Lower Divert Tray

Adjust the stop on the lower divert tray to the size of the material being fed

into the tray.

NOTE: The system must be stopped in order to perform this procedure. Opening

the covers while the system is running will cause an error.

1. Open the Input Transport covers.

2. Lift the blue lever and slide the stop to the position that corresponds with

the material size. Lower the stop into the appropriate slot to lock it in

place. The letter (11”) and A4 slots are marked for your convenience.

Letter (11”) Stop

3. Close the Input Transport covers.

SV62081 Rev. A

39

Page 40

DI900/DI950/DI950e Operator Guide Addendum

Scanning

Scanning

Features

The information in this section is intended to replace information contained

in Chapter 8, Scanning in the DI900/DI950 FastPac™ Document Inserting

System Operator Guide.

Dynamic Envelope Selection

Dynamic envelope selection allows you to create scanning jobs on DI950

systems (with or without a High Capacity Sheet Feeder) that will insert mail

piece contents into either letter-sized or flat envelopes.

Letter-sized envelopes are loaded at the High Capacity Envelope Feeder.

Flat envelopes are loaded at the Feeder Tower, and can be linked so that

they feed from Feeder A and Feeder C.

NOTE: You cannot use a windowed at envelope with Top Address, Z folded

jobs. Dynamic envelope selection cannot be used when the stiff media insert is

selected.

This feature is implemented in one of two ways:

• Using the Envelope Select (ES) scan mark. The Envelope Select scan

mark is available on systems that have BCR scanning or the Selective

Operations level of OMR scanning enabled. Refer to BCR and OMR

Mark Levels in this Chapter 8, Scanning of the DI900/DI950 FastPac™

Document Inserting System Operator Guide for more information about

the various levels of scanning.

• Setting the “Item Overcount Action” to “Use Alternate Envelope”. Refer

to Creating a Job in Chapter 3 or Assigning a Scan Configuration to an

Existing Job in Chapter 8 of the DI900/DI950 FastPac™ Document Inserting System Operator Guide for more information.

Jobs using dynamic envelope selection must be set up with two outer envelopes. The first set in the job must contain the information necessary to

make the envelope selection (either the Envelope Select scan mark or “Item

Overcount Action” setting). Secondary sets of scanned material, generic

(non-scanned) material, or sets containing select fed sheets can be included in a dynamic envelope selection job.

Additionally, a single Reply Envelope (BRE) can be included in the job. If

you wish to add an insert type other than a BRE to the flat envelope, the

insert must be called a BRE in the Mail Piece Icon Tree.

NOTE: Thick inserts (such as booklets) may have trouble accumulating in the

Pre-fold Accumulator and are not recommended for use.

The BRE/insert will accumulate with the flat set in the Pre-fold Accumulator

prior to insertion into the envelope.

40 SV62081 Rev. A

Page 41

Page 42

1 Elmcroft Road

Stamford, Connecticut 06926-0700

www.pb.com

For Service or Supplies

5500 Explorer Drive

Mississauga, Ontario L4W 5C7

www.pitneybowes.ca

PB Form SV62081 Rev. A 12/07

© 2007 Pitney Bowes Inc.

All Rights Reserved

Printed in the USA or Canada

Printed on recyclable paper

Loading...

Loading...