Page 1

F731 Universal Feeder

F734/F735 High Capacity Loader

Operator Guide

English Version

Page 2

Page 3

Table of Contents

Chapter 1—Introduction

Important Safety Notes ............................................................... 1-2

A Note to the Operator ................................................................ 1-4

About Your System .....................................................................1-4

The F731 Universal Feeder .................................................. 1-4

The F734/F735 High Capacity Loader .................................. 1-5

System Components - F734/F735 .............................................. 1-6

System Components - F731 ....................................................... 1-8

Operator Controls - F734/F735 ................................................. 1-10

Operator Controls - F731 .......................................................... 1-12

Chapter 2—Operation

F731 Universal Feeder Setup ..................................................... 2-2

Accumulator Input Frame Position ........................................ 2-2

Accumulator Ramp Height .................................................... 2-2

Power Up .............................................................................. 2-3

Select the Program ............................................................... 2-4

Loading Orientation .............................................................. 2-5

Feeder Side Guides Adjustment ........................................... 2-5

Set the Scanning Head ......................................................... 2-6

Side to Side Adjustment of OMR Scanners .......................... 2-6

Side to Side Adjustment of BCR Scanners ........................... 2-8

Setting the Material Guide Fingers ..................................... 2-10

Feeder Head Adjustment for cut sheets and booklets

up to 2.5mm (3/32") thick .................................................... 2-11

Feeder Head Adjustment for booklets 2.5mm (3/32") thick

or greater ............................................................................ 2-11

iSDC790A

Page 4

Table of Contents

Chapter 2—Operation (continued)

F734/F735 High Capacity Loader Setup ..................................2-14

Set the DI900/DI950 System .................................................... 2-16

Running the System .................................................................2-17

Chapter 3—Programming

About Programming Jobs ........................................................... 3-2

Adding a Non-Scanning Program ............................................... 3-2

Adding a Scanning Program ....................................................... 3-5

Deleting a Program ................................................................... 3-13

Modifying a Program ................................................................. 3-14

Transport Material to Accumulator ...................................... 2-12

Setting the Accumulator Side Guides ................................. 2-12

Accumulator Ramp Adjustment .......................................... 2-12

Deactivate Inline Test? ........................................................ 2-13

Load Paper ......................................................................... 2-13

Programming an 'OMR DI900/DI950' Job ............................ 3-5

Programming a 'BCR Standard' Job ................................... 3-11

Chapter 4—Troubleshooting and Maintenance

The User's Menu ........................................................................ 4-2

Options Available .................................................................. 4-2

Handling Material Stoppages ...................................................... 4-3

Stoppages in the F731 Universal Feeder ............................. 4-3

Stoppages in the F734/F735 High Capacity Loader ............. 4-4

Troubleshooting Charts ..............................................................4-5

Troubleshooting Using the F731 Scan Error Screens ................ 4-7

Operator Maintenance ................................................................ 4-8

Chapter 5—Reference

Service ........................................................................................ 5-2

Compliance ................................................................................ 5-2

Equipment Specications ...........................................................5-3

Material Specications ................................................................ 5-4

Index

Index .................................................................................... Index-1

ii SDC790A

Page 5

Contact Information

USA Contacts

Product Name - F731 (Universal Feeder) or F734 (High Capacity Loader)

▪ For frequently asked questions, go to:

Support.

▪ To place requests for service or training, go to:

Account.

▪ To order supplies and accessories, call the Supply Line™ at: 1.800.243.7824 or

go to: www.pb.com and click on Online Store.

▪ To view and pay invoices online, go to:

▪ To view inventory, go to:

▪ For direct questions, call: 1.800.522.0020. Customer Service Representatives

are available Monday through Friday, 8:00 AM - 8:00 PM ET.

www.pb.com and click on My Account.

www.pb.com and click on Customer

www.pb.com and click on My

www.pb.com and click on My Account.

Canada Contacts

Product Name - F731 (Universal Feeder) or F734 (High Capacity Loader)

▪ For frequently asked questions or to order supplies, go to: www.pitneybowes.ca

▪ For direct questions, call: 1.800.672.6937. Customer Service Representatives

are available Monday through Friday, 8:30 AM - 4:00 PM ET.

Other Country Contacts

• If you require help or wish to purchase supplies for your system, contact your

machine supplier.

• Contact information for all European Pitney Bowes companies is given in a

separate publication supplied with your system.

• If your system has been provided by a dealer or company outside the European

area, contact details will be on the rear cover of this guide, or on a label fixed to

the machine.

iiiSDC790A

Page 6

Table of Contents

iv SDC790A

Page 7

1 • Introduction

This chapter lists the key features of your system, and presents

important safety information.

Important Safety Notes ................................................................1-2

A Note to the Operator.................................................................1-4

About Your System ......................................................................1-4

The F731 Universal Feeder ................................................... 1-4

The F734/F735 High Capacity Loader .................................. 1-5

System Components - F734/F735...............................................1-6

System Components - F731 ........................................................1-8

Operator Controls - F734/F735 .................................................1-10

Operator Controls - F731...........................................................1-12

1-1SDC790A

Page 8

1 • Introduction

Important

Safety Notes

Follow the normal safety precautions for all office equipment:

• It is strongly recommended that you use only Pitney Bowes approved

supplies, in particular aerosol dusters. Improper storage and use of

aerosol dusters or flammable aerosol dusters, can cause an explosive-

like condition that could result in a personal injury and/or property

damage. Never use aerosol dusters labelled flammable and always read

instructions and safety precautions on the duster container label.

• To obtain supplies, please contact our Supply Line™ to place orders.

Material Safety Data Sheets can be obtained on the web or from

our Supply Line™. Refer to the Contact Information List for more

information.

• Use the power cord supplied with the machine and plug it into a properly

grounded wall outlet located near the machine and easily accessible.

Failure to properly ground the machine can result in severe personal

injury and/or fire.

• Avoid touching moving parts or materials while the machine is in use.

Keep hands, loose clothing, jewellery and long hair away from all moving

parts.

• Do not remove covers or defeat safety interlock switches. Covers

enclose hazardous parts that should only be accessed by properly

trained service personnel. Immediately report to service any damaged or

non-functioning components that renders the unit unsafe.

• Place the unit in an accessible location to allow for proper venting of the

equipment and to facilitate servicing.

• The power cord wall plug is the primary means of disconnecting the

machine from the AC supply.

• Do not use an adapter plug on the line cord or wall outlet.

• Do not remove the ground pin from the line cord.

• Avoid using wall outlets that are controlled by wall switches, or shared

with other equipment.

• Do not route the power cord over sharp edges or trap between furniture.

1-2 SDC790A

Page 9

Introduction • 1

Important

Safety Notes

(continued)

• Ensure there is no strain on the power cord and that it does not become

jammed between the equipment, walls or furniture.

• Be certain the area in front of the wall receptacle into which the machine

is plugged is free from obstruction.

• Before clearing a stoppage, be sure machine mechanisms come to a

stop.

• When removing stalled material, avoid using too much force to protect

against minor personal injury and damaging equipment.

• To prevent overheating, do not cover any vent openings.

• Operation of this equipment without periodic maintenance will inhibit

optimum operating performance and could cause the equipment

to malfunction. Contact your machine supplier for required service

schedule.

• Read all instructions before attempting to operate the equipment.

• Use this equipment only for its intended purpose.

• Always follow the specific occupational safety and health standards for

your workplace.

SDC790A

1-3

Page 10

1 • Introduction

A note to the Operator

About Your System

The F731

Universal Feeder

These instructions explain how to setup and use the Model F731 Universal

Feeder and the optional Model F734/F735 High Capacity Loader. Please

spend a few moments reading through them; understanding what the

system does and how it does it will keep problems to a minimum and help

you get the best performance from it and the DI900/DI950 inserting system

of which it is a part.

Before setting up and using the system, you should be thoroughly familiar

with its controls, programming options and setup procedure. You should also

be thoroughly familiar with each component of the DI900/DI950 system (see

the DI900/DI950 Operator Guide supplied with the system).

The F731 is used as part of the Pitney Bowes DI900/DI950 Inserting

System. It takes laser printed, or pre-printed cut sheet forms and efficiently

collates them into customer sets. It can also feed single booklets up to 4mm

(0.16") thick. OMR/BCR/OCR/2D Matrix scanning ensures complete integrity

and confidentiality of the sets.

Standard Features

The F731 offers an impressive array of standard features. Among them:

• Bottom feeding of material

• Variable speed control

• Overcount control

• Automatic double document detection

• Job storage - up to 99 jobs available

• Multi-function operator controls

• Easy to use self prompting display

• Out of material and jam detection

• Resettable sheet counter

• Batch count control

• Operator selectable

'User Definable' (if OMR scanning is fitted)

scan line increments: 1/6", 1/8", 1/10" and

1-4 SDC790A

Page 11

Introduction • 1

The F734/F735

High Capacity

Loader

The optional F734/F735 High Capacity Loader takes laser printed or

pre-printed cut sheets and conveys them to the feeder deck of the F731

Universal Feeder. The F734 and F735 are identical with the exception that

the F734 is designed to handle US 'Letter' sized sheets, whereas the F735

handles DIN A4 sized sheets.

After loading material into the F734/F735, operation is controlled by the

F731 Universal Feeder, as a result of which the F734/F735 will only convey

material when instructed to do so by the Universal Feeder.

In the event of a material stoppage in the Universal Feeder, the F734/F735

High Capacity Loader will stop.

Standard Features:

• High Capacity, up to a maximum of 4,500 sheets

• Automatic start/stop – Controlled by downstream F731 Universal

Feeder

• Automatic paper flow control

• Automatic material detection

• Fully interlocked covers

• Operator adjustment to accommodate 'curled material'

SDC790A

F731 Universal Feeder

F734/F735 High Capacity Loader

1-5

Page 12

1 • Introduction

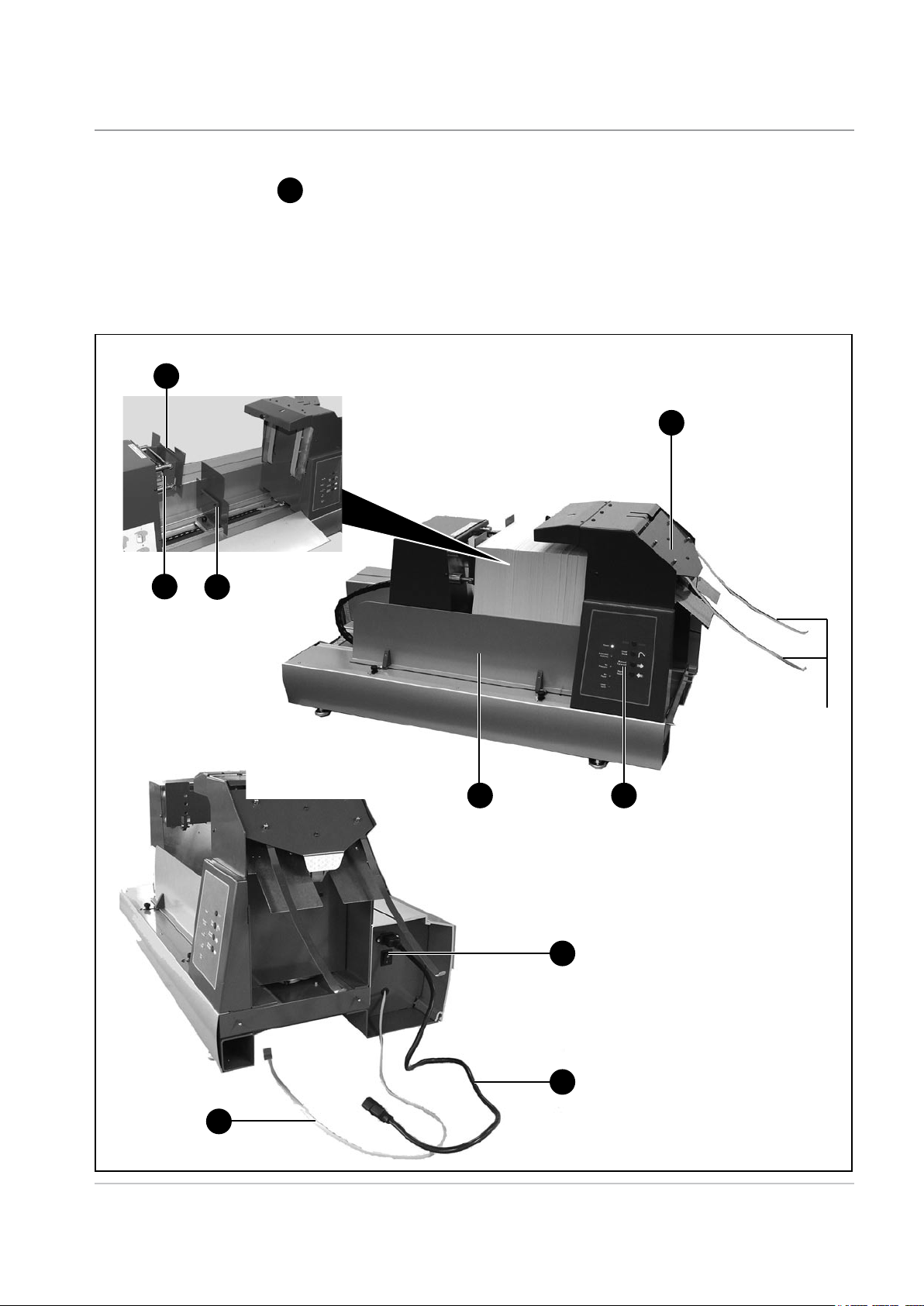

System Components

- F734/F735

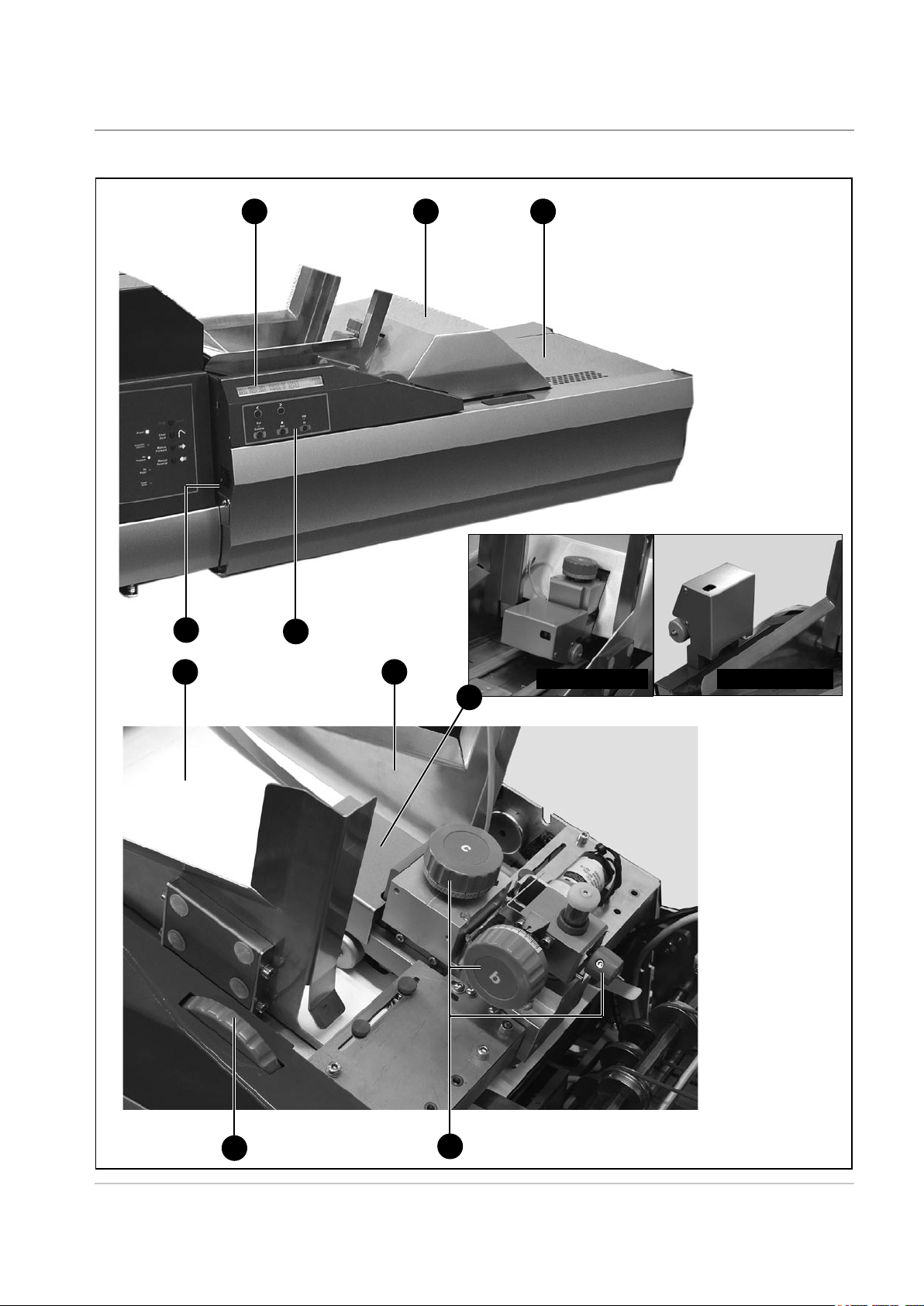

1

Front Cover

Provides access to the loading area of the machine. The cover is

interlocked to prevent machine operation when opened.

Material Support Plate

2

This is used to support the material and to keep it upright when

loading material. Move the plate to the left, load material, move the

plate against the material then prepare more material for loading.

Pressure Assembly

3

This assembly will only move when the Front Cover is CLOSED. To

load material, move the Pressure Assembly to the left. After loading,

move the Pressure Assembly against the material. When the machine

is in operation, the Pressure Assembly will automatically monitor the

amount of material and ensure that a constant pressure is applied in

order to ensure continuous, uninterrupted material feed.

4

Pressure Assembly Interrupt

Operation of this plate will interrupt the movement/operation of the

Pressure Assembly and can be used by the operator during the

material loading process.

5

Material Exit Area

Provides access to the material exit area for clearing stalled material.

The cover is interlocked to prevent machine operation when open.

The Guide Strips shown are optional and are only used for 'difficult'

material.

6

Control Panel

Operator controls are conveniently grouped on the front of the High

Capacity Loader. Four controls govern all loading and paper handling

functions. See page 1-10 for details.

7

Power Cord

Connect to the F731 power outlet. See the safety information on page

1-2 before connecting the mains cord.

8

Main Power Switch

Applies power to the F734/F735 High Capacity Loader. This switch is

not accessible when the F734/F735 is docked to the F731 Universal

Feeder. When docked, it should be left in the ON position. The F731

power switch will then control power to both modules.

1-6 SDC790A

Page 13

Introduction • 1

9

System Connector

This should be left connected to the F731 at all times. In particular,

NEVER disconnect it with power applied to the F731 or damage to the

machine may result.

3

5

4

2

Optional

Guide

Strips

1

6

8

SDC790A

7

9

1-7

Page 14

1 • Introduction

System

Components

- F731

1

Top Cover

Provides access to the accumulation area for making adjustments or

clearing stalled material. The cover is interlocked to prevent machine

operation when open.

Feed Deck

2

Equipped with side guides and separator assembly.

Control Panel

3

Operator controls are conveniently grouped on the front of the feeder.

Five multi-function controls govern all programming and paper

handling functions. See page 1-12 for details.

4

Operator Display

The display prompts you through the programming process, shows a

list of available programs and displays error messages.

5

Accumulation Area

Area of the feeder where sheets are collated into sets prior to being

fed into the DI900/DI950 system.

6

Main Power Switch

Applies power to the F731 Universal Feeder.

7

Feeder Head Adjustment Controls (a, b and c)

Adjusts the separator and feed mechanisms so that single items of

material are fed into the accumulation area. Control c adjusts the initial

separation of the material being run. Controls a and b adjust the feed

(take-away) of the single piece of material to the accumulation area.

8

Feeder Side Guides and Control

Used to control the material being fed into the system. Rotate the

control to adjust the guides.

Loader Control Sensor (t)

9

This sensor is only supplied if an F734/F735 High Capacity Loader is

used in the system. It must be fitted onto the F731 Feeder Head (as

shown in the illustration) whenever the F734/F735 is being used. If

the F731 Universal Feeder is being used without the F734/F735, the

sensor must be removed from the Feeder Head and stored in the two

slots in the F731 Rear Cover

1-8 SDC790A

Page 15

14 5

Introduction • 1

6

2

3

8

Sensor Fitted Sensor Stored

9

SDC790A

8

7

1-9

Page 16

1 • Introduction

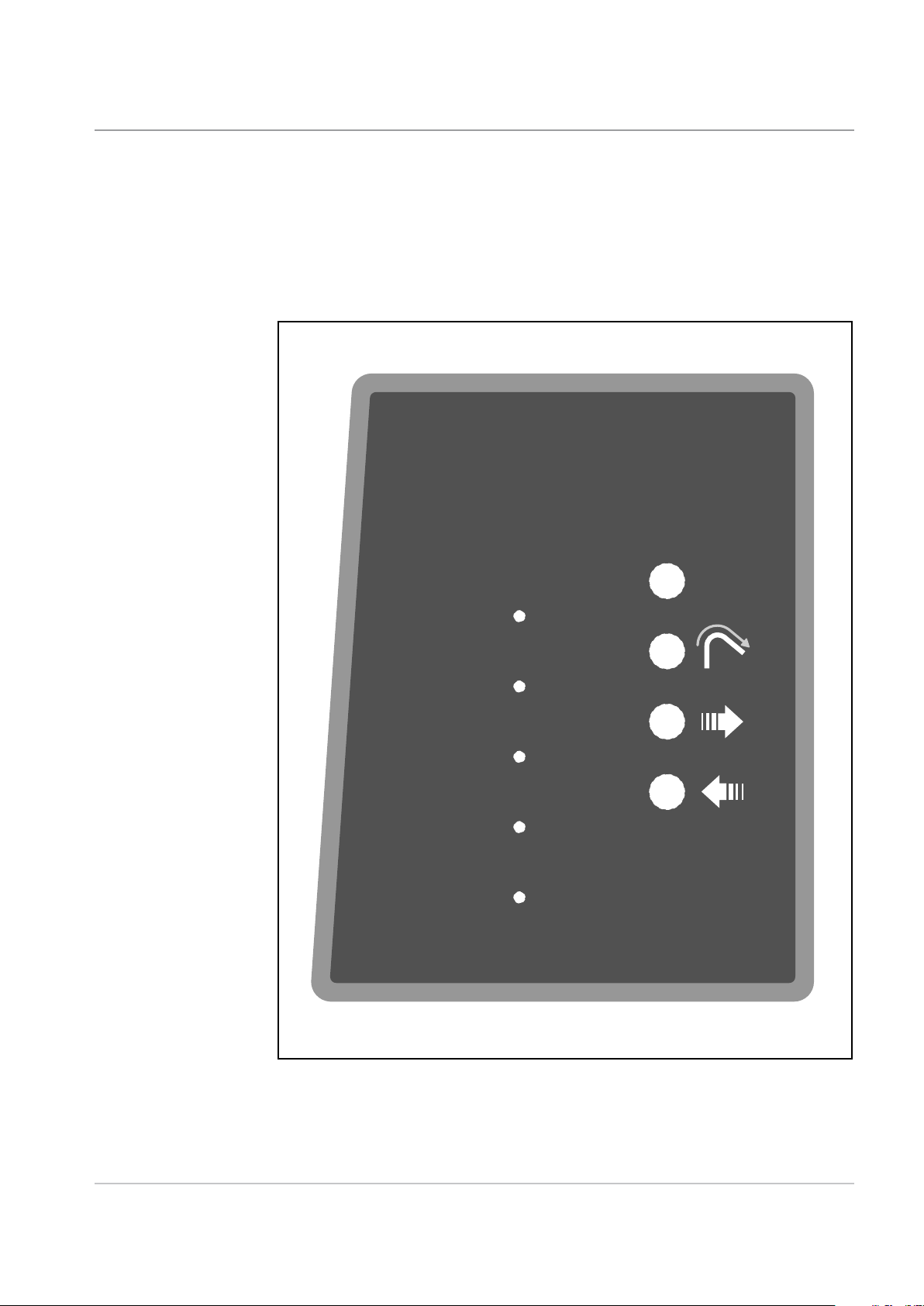

Operator Controls

- F734/F735

Manual Reverse Button

With ALL covers closed, press and hold the Manual Reverse Button, the

Pressure Assembly will move to the left. Releasing the button will stop

movement of the Pressure Assembly.

When loading material, you will need to move the Pressure Assembly as

far to the left as is required in order to load your material. When the Manual

Reverse Button is pressed, the No Pressure Indicator light will stay ON.

Manual Forward Button

With ALL covers closed, press and hold the Manual Forward Button, the

Pressure Assembly will move to the right. Releasing the button will stop

movement of the Pressure Assembly.

After loading material, you will need to move the Pressure Assembly to the

right until it contacts the material, and the No Pressure Indicator light goes

OUT.

Clear Deck Button

With ALL covers closed, press and hold the Clear Deck Button. The drive

motors will transport any remaining material out of the machine. Under

normal circumstances it is not necessary to use this button, as the material

would automatically feed out into the F731 Universal Feeder. However, at

the end of a material run, if some material remains in the machine, use the

Clear Deck button to remove it.

Stop/Auto Button

Use this button to set the machine for Automatic operation, after loading

the material. Whenever the Auto mode is active, the Automatic Controls

Indicator light will be ON. If a material stoppage is detected on the F734/

F735, automatic operation is stopped and all the yellow indicator lights on

the Control Panel will FLASH. To reactivate the Automatic mode, simply

press the Stop/Auto Button once.

When the F734/F735 High Capacity Loader is in Auto mode, pressing this

button will stop it immediately.

Power Indicator

The Power Indicator light will stay ON whenever power is applied to the

machine, and the Main Power Switch is ON.

Automatic Controls Indicator

This light will be ON whenever the machine is in Automatic mode.

No Pressure Indicator

This light will be ON whenever there is insufficient pressure on the material.

1-10 SDC790A

Page 17

Introduction • 1

Power

Automatic

Controls

No

Pressure

No

Paper

Cover

Open

AutoStop

Clear

Deck

Manual

Forward

Manual

Reverse

No Paper Indicator

This light will be ON whenever the material supply is exhausted.

Cover Open Indicator

This light will be ON whenever any of the interlocked covers are open.

SDC790A

F734/F735 High Capacity Feeder Control Panel

1-11

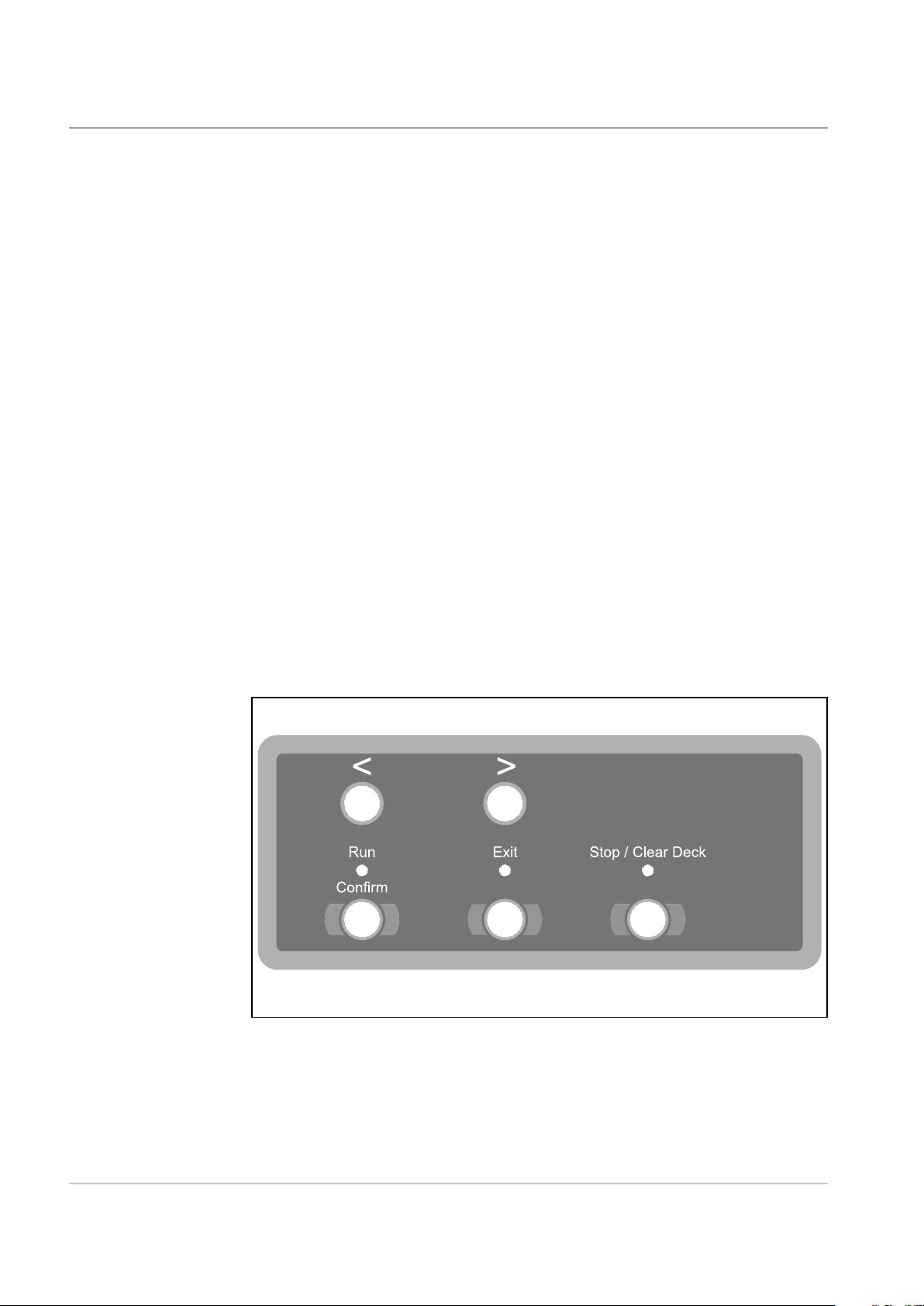

Page 18

1 • Introduction

Operator

Controls

- F731

Arrow Buttons <>

1. In the operating mode, scroll through available (up to 99) programs in

the program list.

2. In programming mode, select alpha or numeric characters or other

variable settings.

Run Confirm (Green)

In the programming mode, answers YES to prompts.

After set-up with the pre-run adjustments, operation of the SYSTEM

will be through the DI900/DI950 Inserter control panel. This includes

both single cycle (Trial Piece) and continuous operation.

Exit (Blue)

Used when advancing through options in the programming mode.

Stop/Clear Deck (Red)

In the programming mode, answers NO to prompts; also acts as a STOP

button during continuous operation.

If material is in the accumulation area of the F731 i.e. the last set in a job

run, pressing this button will eject the material through the DI900/DI950

Inserting System.

F731 Universal Feeder Control Panel

1-12 SDC790A

Page 19

2 • Operation

This chapter tells you how to setup, load and run the F734/F735 High

Capacity Loader and the F731 Universal Feeder.

F731 Universal Feeder Setup......................................................2-2

Accumulator Input Frame Position ........................................ 2-2

Accumulator Ramp Height ..................................................... 2-2

Power Up ............................................................................... 2-3

Select the Program ................................................................ 2-4

Loading Orientation ............................................................... 2-5

Feeder Side Guides Adjustment ............................................ 2-5

Set the Scanning Head .......................................................... 2-6

Side to Side Adjustment of OMR Scanners ........................... 2-6

Side to Side Adjustment of BCR Scanners ............................ 2-8

Setting the Material Guide Fingers ...................................... 2-10

Feeder Head Adjustment for cut sheets and booklets

up to 2.5mm (3/32") thick ......................................................2-11

Feeder Head Adjustment for booklets 2.5mm (3/32") thick

or greater ..............................................................................2-11

Transport Material to Accumulator ....................................... 2-12

Setting the Accumulator Side Guides .................................. 2-12

Accumulator Ramp Adjustment ........................................... 2-12

Deactivate Inline Test? ........................................................ 2-13

Load Paper .......................................................................... 2-13

F734/F735 High Capacity Loader Setup ...................................2-14

Set the DI900/DI950 System .....................................................2-16

Running the System ..................................................................2-17

2-1SDC790A

Page 20

2 • Operation

F731 Universal Feeder Setup

Accumulator

Input Frame

Position

This section explains how to select a program and set the F731 for the

material being run:

NOTE:

A support latch will engage each

time the Top Cover is opened.

It is necessary to manually release

this latch in order to close the Top

Cover.

Lower the F731 Front Cover.

Set lever d to the required position:

3 for sheets

2 for thin booklets up to

2.5mm (3/32") thick

1 for thick booklets up to

4mm (5/32") thick

Close the Front Cover.

Accumulator

Ramp Height

2-2 SDC790A

Open the Top Cover.

The ramp must be set to the raised position for sheets or the lowered

position for booklets. Simply grasp the ramp and set it to the required

position.

Raised for sheets Lowered for booklets

Page 21

NOTE:

If the reverse accumulator kit is fitted

to your machine, the ramp height

has three settings controlled by the

position of the lever f located inside

the Front Cover:

1 for reverse accumulate of sheets

i.e. sheet order …3, 2, 1,

2 for booklets

3 for forward accumulate of sheets

i.e. sheet order 1, 2, 3….

Operation • 2

Power Up

Before turning the system ON, refer to the Important Safety Notes on

page 1-2.

Turn the F731 Main Power Switch ON. The F731 will momentarily display

the version number of the software, and then show the listing of available

programs. The Exit (Blue) indicator will light.

Program Listing

012: JOB1 PAPER/DF C=1 <PROG

013: JOB2 PAPER/DF C=1 USB

USB indicates that

the USB link to the

DI900/DI950 Inserter

is operational.

HINT:

If nothing happens, turn the Main Power Switch OFF. Make sure all covers

are closed, then turn the Main Power Switch ON again.

SDC790A

2-3

Page 22

2 • Operation

Select the

Program

The instructions which follow assume that the program you want is available

from the list in the machine’s memory. If necessary, see ‘Adding a NonScanning Program’ on page 3-2, or ‘Adding a Scanning Program’ on page

3-5 for programming instructions.

The display will show the last program run on the top line. Use the Arrow

Buttons to scroll through the list of available programs.

To select a program, scroll so it appears on the first line of the display as

indicated by the arrow and <PROG prompt. Press the Green button to

select the program.

New program. Pre run adjustments?

Green=YES Blue=EXIT Red=NO

The display asks if you wish to run pre-run adjustments. If this is a new job,

press Green and carry out the adjustments as described on pages 2-5 to

2-13. If it is the current job, or the pre-run adjustments have already been

completed, then press Red.

Number of sheets

in each collated set

Material and

Program Name

Handling Options

Loading Orientation

JOB1 PAPER/DF C=1 ORIENTATION 3

Count: 00 Total: 000000 R... Speed: 100%

'Live' count of

sheets fed in

current collation

The display shows the program selected and the main program options.

To set speed, use the Arrow Buttons until the speed you want is displayed.

You may need to adjust the speed when running booklets or certain paper

finishes.

Total Count for

this job run

R shows the

F731 is ready

OMR status

- see page 2-17

Speed selected

DI900/DI950

Inserter signal

confirmation

- see page 2-17

2-4 SDC790A

Page 23

Operation • 2

Loading

Orientation

The Loading Orientation is shown when you select a program. There are

four possible loading orientations:

1 Face up, bottom first

2 Face up, top first

3 Face down, bottom first

4 Face down, top first

When feeding individual pieces of material during setup, or when loading

material prior to a job run, it is important to observe the correct loading

orientation for the program selected.

Feeder Side

Guides

Adjustment

Rotate the Feeder Side Guide

adjusting wheel anticlockwise until

the side guides are wider apart

than the material to be run.

Place a sheet or booklet onto the

Feed Deck.

Turn the Feeder Side Guide

adjusting wheel clockwise to close

the side guides up to the sheet or

booklet, then turn it anticlockwise

6 notches allowing an overall

clearance of approximately 3mm

(0.1") between the material and

guides.

SDC790A

2-5

Page 24

2 • Operation

Set the Scanning

Head

Side to Side

Adjustment of

OMR Scanners

The Scanning Head is used to read OMR/BCR/OCR/2D Matrix scan marks

printed on your material. If you are using this option, carry out the following

settings. If you don’t use this option, continue with ‘Setting the Material

Guide Fingers’ on page 2-10.

Bottom Scanning

Connect power and turn ON. Open the Top and Front Covers.

Open the separator. Unlock lever

a, turn knob b clockwise as far as

it will go and hold in position while

locking lever a.

The OMR scan marks are read from the underside of the sheet and so to be

able to set the scanner position, you must mark their position on the upper

face of the sheet.

Slide a sheet under the separator

and observe the scanner beam on

the sheet.

Adjust the scanner side to side until

the beam is centred on the scan

marks. Use the top adjusting knob

for rear scanning and the lower

knob for front scanning.

Close the covers.

2-6 SDC790A

Page 25

Top Scanning

Connect power and turn ON. Open the Top Cover.

Open the separator. Unlock lever

a, turn knob b clockwise as far as

it will go and hold in position while

locking lever a.

Slide a sheet under the separator

and observe the scanner beam on

the sheet.

Operation • 2

Adjust the scanner side to side

until the beam is centred on the

scan marks. Loosen the knurled

knob shown, align the scanner and

retighten the knob.

Close the cover.

SDC790A

2-7

Page 26

2 • Operation

Side to side

Adjustment of

BCR Scanners

Bottom Scanning

Connect power and turn ON. Open the Top and Front Covers.

Open the separator. Unlock lever

a, turn knob b clockwise as far as

it will go and hold in position while

locking lever a.

The BCR marks are read from the underside of the sheet and so to be able

to set the scanner position, you must mark their position on the upper face

of the sheet.

Press the Green, Blue and Red buttons at the same time to enter the Menu.

Use the Arrow Buttons to select 'User Menu', then press Green to confirm.

Use the Arrow Buttons to select 'BCR Test', then press Green to confirm.

If your system has more than one BCR scanner, use the Arrow Buttons to

select 'BCR Location', then press Green to confirm. Select the location of

the scanner you wish to test, then press Green to confirm.

Slide a sheet under the separator

and observe the scanner beam on

the sheet.

2

Adjust the scanner side to side until

the marks are centred on the beam

area.

Unscrew the locking knob 1. Grasp

handle 2, slide the scanning head

out and reposition the scanning

head. Slide the unit back into the machine and check the alignment.

When in 'BCR Test', the scanner red lights will flash slowly. If the code is

read successfully i.e. the scanner is correctly aligned, the lights will flash

faster and the characters read will display on the operator display.

When the scanner is positioned correctly, tighten locking knob 1.

Exit from the User Menu and close the covers.

1

2-8 SDC790A

Page 27

Operation • 2

Top Scanning

Connect power and turn ON. Open the Top Cover.

Open the separator. Unlock lever

a, turn knob b clockwise as far as

it will go and hold in position while

locking lever a.

Press the Green, Blue and Red buttons at the same time to enter the

Menu. Use the Arrow Buttons to select 'User Menu', then press Green to

confirm. Use the Arrow Buttons to select 'BCR Test', then press Green to

confirm.

If your system has more than one BCR scanner, use the Arrow Buttons to

select 'BCR Location', then press Green to confirm. Select the location of

the scanner you wish to test, then press Green to confirm.

Slide a sheet under the separator and observe the scanner beam on the

sheet.

Adjust the scanner side to side until

the marks are centred on the beam

area.

When in 'BCR Test', the scanner

red lights will flash slowly. If the

code is read successfully i.e. the

scanner is correctly aligned, the

lights will flash faster and the

characters read will display on the

operator display.

When the scanner is positioned correctly, exit from the User Menu.

Close the cover.

SDC790A

2-9

Page 28

2 • Operation

Setting the

Material Guide

Fingers

Open the Top Cover.

The guide fingers can be raised or lowered into one of three detented

positions, depending on the material being run:

Lowered for sheets.

Mid position for thin booklets of

approx. 2.5mm (3/32") thickness.

Raised for thick booklets up to

4mm (5/32") thickness.

Loosen the knurled locking knobs and adjust the guide fingers side to side

to control material. If bottom scanning is being used, one of the guide fingers

must be positioned directly above the scanning head to control the material

as it is scanned.

Close the cover.

2-10 SDC790A

Page 29

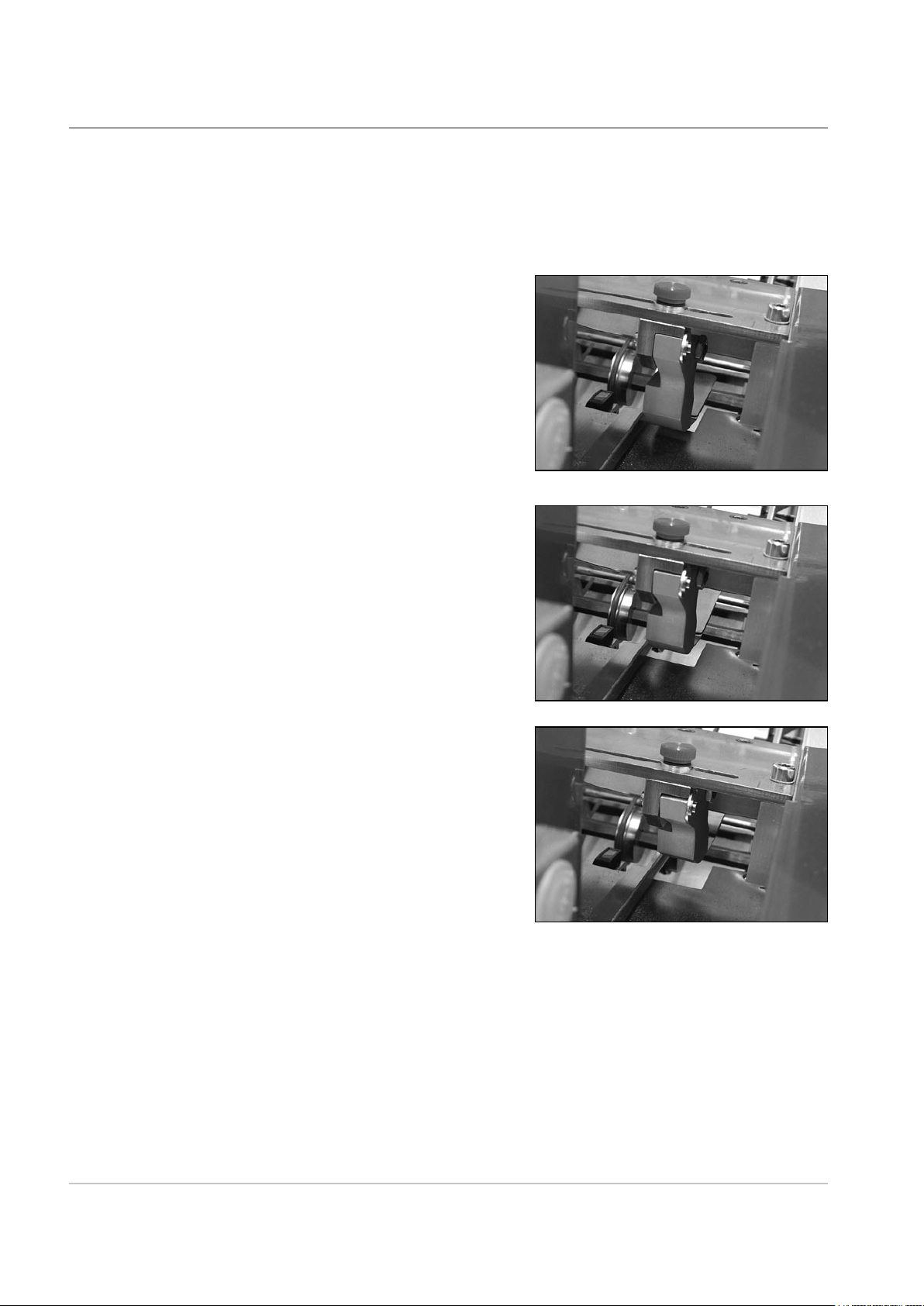

Operation • 2

Feeder Head

Adjustment for

cut sheets and

booklets up to

2.5mm (3/32”)

thick

Open the Top Cover.

Turn knob c anticlockwise until it

stops.

Unlock lever a and, with no

material in the feeder, let the

Feeder Head come to rest.

Turn knob b anticlockwise as far as it will go, hold knob b in place and lock

lever a.

Close all covers and press the Run Confirm (Green) button to make the

feeder motor run.

Take two pieces of the material to be run and feed them, by hand, into the

separator. If both pieces feed completely under the separator, pull them out

and tighten knob c clockwise slightly.

Feeder Head

Adjustment for

booklets 2.5mm

(3/32”) thick or

greater

Repeat the previous step until only one piece feeds completely and the

second piece is held back.

Open the F731 Top Cover.

Turn knob c anticlockwise until it stops.

Unlock lever a, then turn knob b clockwise all the way and hold.

Place a booklet all the way under the first and second rollers.

Release knob b so that the Feeder Head rests on the booklet.

Rotate knob b anticlockwise 8 divisions on the scale and hold in this

position whilst locking lever a.

Try to slide a second booklet under the separator. If it goes under, pull it

back and turn knob c clockwise enough that a second booklet cannot slide

under the separator.

SDC790A

Close the cover.

2-11

Page 30

2 • Operation

Transport

Material to

Accumulator

Setting the

Accumulator

Side Guides

Lower the Front Cover and turn

knob g anticlockwise to open the

Accumulator Side Guides. Close

the Front Cover.

Load a sheet or booklet.

Press Run Confirm (Green) until

a piece is fed into the accumulator

area.

Raise the F731 Top Cover and

lower the Front Cover.

Rotate knob g clockwise to set the

Accumulator Side Guides. The

correct setting allows approximately

3mm (0.1") overall clearance so

that the material is controlled but

not restricted.

Accumulator

Ramp

Adjustment

2-12 SDC790A

Ensure a piece of material is in

the accumulator area as in the

Accumulator Side Guide setting

above.

Squeeze the tabs e together and

slide the ramp until the yellow

indicators on the ramp align with

the material rear edge.

Close all covers.

Page 31

Operation • 2

Deactivate Inline

Test?

Load Paper

The normal response to this is to select Green to deactivate, and the

material will transport from F731 to the Inserter.

TIP:

Should you want to test any aspect

of the job setup before the material

is transported to the inserter, select

Red (No) to the prompt and the

sheets will be stacked in the F733

Outsort Tray.

You only need to carry out this step if you are NOT using the F734/F735

High Capacity Loader. If the loader IS being used, it will automatically load

sheets onto the F731's Feed Deck. See F734/F735 setup on the next page.

Flex and aerate the material stack to

ensure good separation.

SDC790A

Position the stack on the Feed Deck

in the correct orientation for the job

being run:

1 Face up, bottom first

2 Face up, top first

3 Face down, bottom first

4 Face down, top first

IMPORTANT: Fan the paper stack as

shown in the photograph.

TIP:

When initially loading the paper stack, load about 200 sheets then fully load

the feeder once you commence operation. The F731 can be reloaded while

the system is in operation.

If you are not using a F734/F735 High Capacity Loader, go straight to 'Set

the DI900/DI950 System' on page 2-16.

2-13

Page 32

2 • Operation

F734/F735 High Capacity Loader Setup

The F734/F735 High Capacity Loader is an optional unit. If you are not using

the loader, continue with 'Set the DI900/DI950 System' on page 2-16.

Make sure the Loader Control

Sensor t is located onto the F731

Feeder Head.

Press and hold the Manual

Reverse Button until the Pressure

Assembly is far enough to the left.

Open the Front Cover and move

the Material Support Plate to the

left.

Before loading material, you need to ascertain its loading orientation. This

depends on the job settings. The F731 job display will indicate which loading

orientation is required for the job (numbered 1 to 4).

The four possible loading

orientations are illustrated on a

label located behind the F734/F735

Front Cover:

1 Face up, bottom first (as fed

into the F731 feeder)

2 Face up, top first (as fed into

the F731 feeder)

3 Face down, bottom first (as fed

into the F731 feeder)

4 Face down, top first (as fed into

the F731 feeder)

Load material up against the right

hand side of the loader flat against

the Feed Belts.

2-14 SDC790A

Page 33

Operation • 2

Push the Material Support Plate

up against each individual batch of

material during the loading process

to support it while you fetch the

next batch.

Important Loading Tips

• When loading the first batch of sheets, do not slide the material in from

the front across the Feed Belts, as this will cause the first couple of

sheets to twist and jam. Instead move the paper from left to right, up to

the Feed Belts. For subsequent batches of material you can slide the

sheets in from the front, between the material already loaded and the

Material Support Plate.

• Once you have completed

the loading process, it is

recommended that you push

the entire paper stack towards

the right using the Material

Support Plate. This will ensure

that the material stack is kept

upright and that all the air is

removed from between the

individual sheets.

SDC790A

If the material is curled along the

top edge, the separation can be

adjusted by rotating the Separator

Adjustment Knob as required.

Rotate the knob anticlockwise for

curled material, but move the knob

in small increments – 2 to 3mm

(approx.. 1/10") maximum.

2-15

Page 34

2 • Operation

Close the Front Cover.

Press and hold the Manual

Forward Button until the Pressure

Assembly is fully to the right, and

the No Pressure Indicator light is

OFF.

Set the DI900/ DI950 System

Press the Stop/Auto Button. The

Automatic Controls Indicator light

will now be ON. The machine is

ready.

You must now set the rest of the DI900/DI950 system to accept the material

from the F731. Details are given in the separate DI900/DI950 Operator

Guide.

2-16 SDC790A

Page 35

Operation • 2

Running the System

Once a program is selected and material loaded, the F731 is controlled

by the DI900/DI950 Inserting System's control panel. Use the DI900/

DI950 controls to run a Trial Piece and to start and stop continuous

operation.

If the F731 is running an OMR program, three blocks will show on the

display as illustrated below. When running non-OMR jobs, blocks 2 and 3

only will show on the display.

JOB1 PAPER/DF C=1 ORIENTATION 3

Count: 00 Total: 000000 R Speed: 100%

Block 1

Block 2

Block 3

Block 1 shows that the F731 has read the first scan dash mark on the

page, indicating that the scanning system is functioning.

Block 2 shows that the F731 has confirmed to the Inserter that the

collation on the conveyor is ready for transfer into the

Inserter.

Block 3 indicates that the Inserter has sent back a collation signal to

the F731.

SDC790A

The F731 will continue operation until:

• You stop it by pressing

or

• You open one of the covers. The safety interlock switch will stop the

machine.

or

•

The material runs out or stalls. In this case the machine will stop

automatically.

TIP:

At the completion of each job run, it is recommended that you check the

two trays in the F733 Outsort Tray for diverted sets.

Stop/Clear Deck (Red).

2-17

Page 36

2 • Operation

2-18 SDC790A

Page 37

3 • Programming

This chapter explains how to program and manage jobs that can be

held in the F731 Universal Feeder's memory.

About Programming Jobs ............................................................3-2

Adding a Non-Scanning Program ................................................3-2

Adding a Scanning Program........................................................3-5

Programming an 'OMR DI900/DI950' Job ............................. 3-5

Programming a 'BCR Standard' Job .....................................3-11

Deleting a Program....................................................................3-13

Modifying a Program .................................................................3-14

3-1SDC790A

Page 38

3 • Programming

About Programming Jobs

Adding a Non-Scanning Program

The F731's memory holds up to 99 pre-programmed jobs that you can recall

with a few button presses.

This chapter explains how to program jobs into the system. It commences

with a non-scanning job and follows with some examples of typical scanning

jobs.

The range of scanning options and job requirements available mean that not

all possibilities can be covered in a document such as this. The examples

chosen will allow you to understand the programming procedure so that you

can adapt it to meet your individual requirements.

This section covers programming a job where scanning is not required. To

program the feeder for a scanning job, see page 3-5. When you program the

F731 for a particular non-scanning job, you:

• Assign the job a name and/or number

• Enter a batch count (if required)

HINT: We advise you keep a ‘hard copy’ of all your programmed jobs for

your own future reference.

Step-by-Step Instructions

With the feeder ON, press the Green, Blue and Red buttons at the same

time. The display will show:

Select: NEW NON-SCANNING JOB

<-->=SELECT Green=Confirm Blue=EXIT

Press the Green button to select ‘NEW NON-SCANNING JOB’.

NOTE: If you press the Blue button, you will return to the job listing screen.

The display shows the program naming screen:

017> Name of new program :

--------

<-->=ALPHA Green=CONFIRM Red=GO ON

You can enter a program name up to eight characters long, using any

combination of alpha and numeric characters.

Use the Arrow Buttons until the first character of your program name

appears.

3-2 SDC790A

Page 39

Programming • 3

Press the Green button to confirm each character.

When the name is complete, press Red to continue. The display shows the

material selection screen:

017> Material: PAPER/DF

<-->=SELECT Green=CONFIRM Blue=EXIT

Use the Arrow Buttons to select the material for this job:

Paper/DF Sheets with double detect turned ON (default setting).

This will be the most common setting for sheets.

Paper Sheets with the double detect turned OFF. This is not

recommended as the feeder will not sense double

feeds. Select this mode for material (sheets) above

160g/m2 (42 lb).

Booklet Booklets with separator motor turned OFF. This is the

normal mode for booklets. Double Detect is disabled

with this mode.

Booklet/RM Booklets with separator motor turned ON. This is

used for special applications. Double Detect is

disabled with this mode.

Paper/DF+ Sheets with double detect turned on at a custom

setting. This is normally used for sheets with

heavily printed block areas and will be used only on

advice from your service representative.

Press Green to confirm your selection. The display shows the material

loading orientation selection:

017> Loading orientation : 3.DOWN-BOTTOM

<-->=SELECT Green=CONFIRM Blue=EXIT

Use the Arrow Buttons to select the material loading orientation:

1 Face up, bottom first

2 Face up, top first

3 Face down, bottom first

4 Face down, top first

SDC790A

Press Green to confirm your selection. The display shows the counter

selection:

3-3

Page 40

3 • Programming

Setting a count tells the feeder how many sheets are in each collated set.

The F731 will collate the requested number of forms before transporting

them into the DI900/DI950 system. The default setting is 01 – a single sheet

insert (one piece per cycle). The count can be set from 01 to 25.

017> Counter : 01 Sheets

<-->=VALUE Green=CONFIRM Red=GO ON

a. Use the

then press Green to enter the number.

b. Repeat this process for the second digit.

The display will return to the program listing display.

Programming a non-scanning job is now complete.

Arrow Buttons until the first number of your entry appears,

3-4 SDC790A

Page 41

Programming • 3

Adding a Scanning Program

Programming

an 'OMR DI900/

DI950 Job

Background information on scanning is given in the DI900/DI950 Operating

Guide. This section assumes you understand scanning and how it applies

to the job you are programming. It also assumes you are familiar with

programming non-scanning jobs as described on page 3-2.

NOTE: If you select booklets, no scanning is available.

The following sections give two examples of setting up scanning jobs. One

for OMR scanning and one for BCR scanning.

HINT: We advise you keep a ‘hard copy’ of all your programmed jobs for

your own future reference.

When you program the feeder for an OMR scanning job, you enter the

program in a similar way as a non-scanning job, then…

• Specify the

• Select the scan functions you wish to use

• Specify the distance from the lead edge to the

• Specify where each scan line is in relation to the first line

scan line increments

bench mark

Step by Step Instructions

With the feeder ON, press the Green, Blue and Red buttons at the same

time. The display shows the program type selection:

Select: NEW NON-SCANNING JOB

<-->=SELECT Green=Confirm Blue=EXIT

Press the Arrow Buttons to select ‘NEW SCANNING JOB’.

Select: NEW SCANNING JOB

<-->=SELECT Green=Confirm Blue=EXIT

Press Green to enter the scanning programming mode.

The display shows the program naming screen:

SDC790A

3-5

Page 42

3 • Programming

018> Name of new program :

--------

<-->=ALPHA Green=CONFIRM Red=GO ON

You can enter a program name up to eight characters long, using any

combination of alpha and numeric characters.

Use the Arrow Buttons until the first character of your program name

appears.

Press the Green button to confirm each character.

When the name is complete, press Red to continue. The display shows the

material selection screen:

018> Material: PAPER/DF

<-->=SELECT Green=CONFIRM Blue=EXIT

Use the Arrow Buttons to select the material for this job:

Paper/DF Sheets with double detect turned ON (default setting).

This will be the most common setting for sheets.

Paper Sheets with the double detect turned OFF. This is not

recommended as the feeder will not sense double

feeds. Select this mode for material (sheets) above

160g/m2 (42 lb).

Booklet This function is not used in scanning mode.

Booklet/RM This function is not used in scanning mode.

Paper/DF+ Sheets with double detect turned on at a custom

setting. This is normally used for sheets with

heavily printed block areas and will be used only on

advice from your service representative.

Press Green to confirm your selection. The display shows the material

loading orientation selection:

018> Loading orientation : 3.DOWN-BOTTOM

<-->=SELECT Green=CONFIRM Blue=EXIT

3-6 SDC790A

Page 43

Programming • 3

Use the Arrow Buttons to select the material loading orientation:

1 Face up, bottom first

2 Face up, top first

3 Face down, bottom first

4 Face down, top first

Press Green to confirm your selection. The display requests the scanning

version:

018> Vers.: OMR DI900/DI950

<-->=SELECT Green=CONFIRM Blue=EXIT

Use the Arrow Buttons to select which scanning mode you want. In this

example, select ‘OMR DI900/DI950'.

Press Green to confirm. The display requests the OMR scanner location:

018> OMR location : BOTTOM-FRONT

Green=CONFIRM Blue=EXIT

If you have more than one scanning head fitted to your system, you must

now tell the system which scanning head to use for this job.

If you only have one scanning head, this step is not required.

Use the Arrow Buttons to select where the OMR scanner is located:

Bottom Rear, Bottom Front, Top Rear or Top Front.

Press Green to confirm. The display shows the scan line increment

selection:

018> Scan line increments : 1/6 Inch

<-->=SELECT Green=CONFIRM Blue=EXIT

Use the Arrow Buttons to select the scan line increments. You can select

one of the three (1/6", 1/8" or 1/10") scan line increments shown, or you can

select a custom ‘User Defined’ increment. Press Green to confirm.

If you select ‘User Defined’, you must now enter the increment:

SDC790A

018> Scan line increments :

[0.01MM]

---

<-->=SELECT Green=CONFIRM Blue=EXIT

Take a sample of your OMR with the largest number of scan lines you can

obtain. Measure the length of the code in millimetres, and then divide this by

the number of gaps between lines to obtain an average increment.

3-7

Page 44

3 • Programming

Example: 26mm code length with 6 scan lines gives an increment of 26

divided by 5 (the number of gaps) = 5.2mm

Enter this increment using the Arrow Buttons. The figure entered is in units

of 0.01mm i.e. in the example above 5.2mm would be entered as 520. Press

Green to confirm. The display now moves to the scan functions selection:

Use the Arrow Buttons to select the scan functions. For each scan line in

order as printed on the page, select the function required and confirm by

pressing Green.

Examples:

Benchmark control in position 1

Benchmark control : [ 1]

<-->=SELECT Green=CONFIRM

Beginning of collation in position 2

Beginning of collation : [ 2]

<-->=SELECT Green=CONF. Blue=END Red=GAP

Select feed 1 in position 3

Select feed 1 : [ 3]

<-->=SELECT Green=CONF. Blue=END Red=GAP

End of collation in position 4

End of collation/present : [ 4]

<-->=SELECT Green=CONF. Blue=END Red=GAP

When the required scan functions are set, press Blue to exit.

HINT:

If you make an error at any time during this process, pressing Red will allow

you to modify your selections.

NOTE:

If your OMR marks are not contiguous (i.e. some mark positions are not

being used), you must define where the unused positions are so that the

system does not interpret the unused positions as an error. After each scan

line function is set, if you wish to insert a gap, press Red, select the number

of scan positions for the gap using the Arrow Buttons and then press

Green to confirm.

UDV (Upstream divert) : [ 3]

<-->=GAP Green=CONF. Blue=END Red=DEL.

3-8 SDC790A

Page 45

Programming • 3

You must now enter the distance from the lead edge to the bench mark:

Dist. lead edge to bench mark : 00 mm

<-->=VALUE Green=CONFIRM Red=GO ON

Use the Arrow Buttons to set the distance, then confirm by pressing

Green. Refer to the diagrams below for details of where to take this

measurement. In each case, dimension X should be entered.

FEED DIRECTION

TOP

BOTTOM

Top first

forward scanning

TOP

BM

BM

FEED DIRECTION

X

reverse scanning

TOP

BOTTOM

Top first

TOP

X

BM

BM

SDC790A

BOTTOM

FEED DIRECTION

Bottom first

reverse scanning

X

BOTTOM

FEED DIRECTION

Bottom first

forward scanning

X

3-9

Page 46

3 • Programming

You now need to tell the system in which direction to read the scan code:

The options available are:

Use the Arrow Buttons to select the option you want, then press Green to

confirm.

018> OMR scanning : NORMAL

<-->=SELECT Green=CONFIRM Blue=EXIT

NORMAL Where the system will expect the Bench Mark to be

the FIRST mark in the scan code.

REVERSE Where the system will expect the Bench Mark to be

the LAST mark in the scan code.

NOTE:

Take into account the direction of feed of your material when making this

setting. i.e. whether the material is being fed top first or bottom first. The

setting selected must match whether the Bench Mark is fed past the scanner

first or last.

The display will return to the program listing display.

Programming an OMR scanning job is now complete.

3-10 SDC790A

Page 47

Programming • 3

Programming a

'BCR Standard'

Job

Step by Step Instructions

With the feeder ON, press the Green, Blue and Red buttons at the same

time. The display will show:

Select: NEW NON-SCANNING JOB

<-->=SELECT Green=Confirm Blue=EXIT

Press the Arrow Buttons to select ‘NEW SCANNING JOB’.

Select: NEW SCANNING JOB

<-->=SELECT Green=Confirm Blue=EXIT

Press the Green button to enter the scanning programming mode. The

display will show the program naming screen:

019> Name of new program :

--------

<-->=ALPHA Green=CONFIRM Red=GO ON

You can enter a program name up to eight characters long, using any

combination of alpha and numeric characters.

Use the Arrow Buttons until the first character of your program name

appears.

Press the Green button to confirm each character.

When the name is complete, press Red to continue.

The display shows the material selection screen:

019> Material: PAPER/DF

<-->=SELECT Green=CONFIRM Blue=EXIT

Use the Arrow Buttons to select the material for this job:

SDC790A

3-11

Page 48

3 • Programming

Paper/DF Sheets with double detect turned ON (default setting).

This will be the most common setting for sheets.

Paper Sheets with the double detect turned OFF. This is not

recommended as the feeder will not sense double

feeds. Select this mode for material (sheets) above

160 g/m2 (42 lb).

Booklet This function is not used in scanning mode.

Booklet/RM This function is not used in scanning mode.

Paper/DF+ Sheets with double detect turned on at a custom

setting. This is normally used for sheets with

heavily printed block areas and will be used only on

advice from your service representative.

Press Green to confirm your selection. The display shows the material

loading orientation selection:

019> Loading orientation : 3.DOWN-BOTTOM

<-->=SELECT Green=CONFIRM Blue=EXIT

Use the Arrow Buttons to select the material loading orientation:

1 Face up, bottom first

2 Face up, top first

3 Face down, bottom first

4 Face down, top first

Press Green to confirm your selection. The display requests the scanning

version:

019> Vers.: BCR Standard

<-->=SELECT Green=CONFIRM Blue=EXIT

Use the Arrow Buttons to select which scanning mode you want. In this

example, select ‘BCR Standard’. Press Green to confirm.

The display will now ask where the BCR Scanner is located:

3-12 SDC790A

Page 49

Programming • 3

019> BCR location : Top Front

<-->=SELECT Green=CONFIRM Blue=EXIT

Use the Arrow Buttons to select where the BCR scanner is located,

Bottom Rear, Bottom Front, Top Rear or Top Front. Press Green to confirm.

Programming a BCR scanning job is now complete.

Deleting a Program

With the feeder ON, press the Green, Blue and Red buttons at the same

time. The display will show:

Select: NEW NON-SCANNING JOB

<-->=SELECT Green=Confirm Blue=EXIT

Use the Arrow Buttons to select ‘DELETE JOB’.

Select: DELETE JOB

<-->=SELECT Green=Confirm Blue=EXIT

Press the Green button to enter the job delete mode.

Use the Arrow Buttons to display the program you want to delete on the

top line of the display.

CAUTION: Make sure you’ve selected the right program and that you

really want to delete it. You can’t recover a deleted program. If you

accidentally delete a program, you’ll have to reprogram the feeder for

that particular job.

SDC790A

Press the Green button to delete the program.

The display will briefly prompt 'Program ******** Deleted' and return to the

program listing.

3-13

Page 50

3 • Programming

Modifying a Program

With the feeder ON, press the Green, Blue and Red buttons at the same

time. The display will show:

Select: NEW NON-SCANNING JOB

<-->=SELECT Green=Confirm Blue=EXIT

Use the Arrow Buttons to select ‘MODIFY JOB’.

Select: MODIFY JOB

<-->=SELECT Green=Confirm Blue=EXIT

Press the Green button to enter the job modify mode.

Use the Arrow Buttons to display the program you want to modify on the

top line of the display. Then press the Green button to select it.

You can now review the job using the Arrow Buttons. You can also edit any

of the following parameters:

• Name of program

• Material

• Loading

• Counter (non-scanning job only)

• Scan line increments (scanning job only)

• Distance – Lead edge to

To edit any of these parameters, with the parameter displayed:

• Press the

• P

ress the Arrow Buttons to make the change.

• Confirm the change by pressing the

orientation

bench mark (scanning job only)

Green button to select the parameter.

Green button.

3-14 SDC790A

Page 51

4 • Troubleshooting &

Maintenance

This chapter will help you should you have any problems whilst

running your system. It also describes the regular maintenance

operations that you can carry out to maintain optimum system

performance.

The User's Menu .........................................................................4-2

Options Available ................................................................... 4-2

Handling Material Stoppages ......................................................4-3

Stoppages in the F731 Universal Feeder .............................. 4-3

Stoppages in the F734/F735 High Capacity Loader .............. 4-4

Troubleshooting Charts ...............................................................4-5

Troubleshooting Using the F731 Scan Error Screens .................4-7

Operator Maintenance .................................................................4-8

4-1SDC790A

Page 52

4 • Troubleshooting & Maintenance

The User’s Menu

Options

Available

To access the User Menu functions:

Press the Green, Blue and Red buttons at the same time.

Use the Arrow Buttons to select ‘User Menu’, then press Green to confirm.

Select: USER MENU

<-->=SELECT Green=Confirm Blue=EXIT

The User Menu offers the options listed below. Use the Arrow Buttons to

select an option, then press Green to confirm.

When you are finished with any option, press Red to go to the next

selection.

Material Feed Belt Cleaning

The Material Feed Belts should be cleaned if the belts appear contaminated

and/or if material feed is sluggish.

This option allows you to stop and start the belts using the Green button to

facilitate cleaning.

Press the button momentarily and the feed belts will run for approximately 3

seconds. Press and hold the button to run the feed belts continuously.

It is recommended that the material feed belts are cleaned weekly with

water and a good quality cloth.

BCR Test

This function allows you to test that a BCR scanner is reading a code.

When selected, the scanner red lights will flash slowly. Manually position

the bar code above or below the scanner as applicable. If the code is read

successfully, the lights will flash faster and the characters read will display

on the operator display.

Total Feed Cycles

This option displays the total cycles that the F731 has performed.

Motor Test

LED and Key Test

Show Sensor Status

Double Feed Adjust

These are primarily for service use. Only access these options at the

request of a representative of your machine supplier.

4-2 SDC790A

Page 53

Troubleshooting & Maintenance • 4

Handling Material Stoppages

Stoppages in the

F731 Universal

Feeder

This section describes how to clear material stoppages from the F734/F735

High Capacity Loader and the F731 Universal Feeder.

The F731 may stop indicating a misfeed. The indicator on the Stop/Clear

Deck (Red) button will be flashing.

Follow the relevant procedure below:

Feeder Head section…

Remove the material from the Feed Deck.

Open the Top Cover. Unlock lever a and turn knob b fully clockwise and lock

lever a to keep the separator area open.

Carefully clear any material in this

area.

Unlock lever a, turn knob b

anticlockwise as far as it will go and

lock lever a to secure the assembly

closed.

Close the Top Cover, reload the paper

and press Run Confirm (Green) to

restart operation.

SDC790A

Accumulator Area…

Open the Top Cover.

Carefully clear any stalled material,

taking care not to damage the

accumulator drive O rings.

Close the Top Cover.

Press Run Confirm (Green) to restart

operation.

TIP:

If you are running stiff material, it may aid removal if the Accumulator Ramp

e is moved out of the way. Make sure you return the ramp to its original

position after clearing the stoppage.

4-3

Page 54

4 • Troubleshooting & Maintenance

Stoppages in the

F734/F735 High

Capacity Loader

This section describes how to clear material stoppages from the F734/F735

High Capacity Loader and the F731 Universal Feeder.

The F734/F735 may stop and indicate

a misfeed. In this case, ALL the

indicator lights on the Control Panel

will FLASH.

To access any stalled material in the

Feed Section, move the Pressure

Assembly 1 to the left and open the

Front Cover 2.

To access material in the Material Exit

Area, open the cover 3 and remove

any stalled material.

After clearing any stalled material

and closing all the interlocked covers,

remember to press the Stop/Auto

Button once to prepare the machine

for use.

1

2

3

TIP:

Make sure that stoppages in the Material Exit Area are not caused by the

sheets hitting the F731 Feeder Side Guides. Opening the Side Guides

slightly may help in these cases.

4-4 SDC790A

Page 55

Troubleshooting & Maintenance • 4

Troubleshooting Charts

The charts in this section describe problems you may see on your system

and the corrective action(s) you need to take.

Problem Possible Cause

System fails to

start

F731 powers up

but won't display

program list or

displays random

characters.

F731 will not

respond to

controls, display

prompts 'Cover

Open'. Program

button blinks.

No power at outlet. Check the supply circuit breaker

or ON/OFF switch.

Power cord disconnected or Main Power Switch on

F734/F735 or F731 turned OFF.

F731 program has failed to load. Turn F731 Main

Power Switch OFF then ON again to reset. Also

make sure that the covers are securely closed. If

F731 continues to fail at startup, call for service.

A cover is open. Check the F734/F735 Front and

Exit Area Covers and the F731 Front and Top

Covers. Close all covers securely.

F731 will not

respond to

controls. Controls

appear locked.

F734/F735 will

not respond to

controls, yellow

indicator lights

flash.

Material feed

appears slow/

sluggish.

Turn the F731 main power switch OFF then ON

again to reset.

Communication with DI900/DI950 has been

interrupted. Power down all modules together, then

re-power system.

If controls continue to lock, call for service.

A cover is open. Check the F734/F735 Front and

Exit Area Covers and the F731 Front and Top

Covers. Close all covers securely.

Check for an error condition on the F731 display.

Check for correct position of the F731 Feeder Side

Guides (see page 2-5).

Clean the material feed belts (see page 4-2).

Check the Feeder Head/Separator adjustments

(see page 2-11 for the F731 or page 2-15 for the

F734/F735).

SDC790A

4-5

Page 56

4 • Troubleshooting & Maintenance

Problem Possible Cause

Material stops

in the F731

accumulation area.

Display prompts

'Double feed error'.

Material stops in

the separation

area. Display

prompts 'Double

feed error'.

Multiple feed

errors or stream

feed errors.

Feeder display

indicates 'DF

Sensor Out of

Limit'.

Check the Accumulator Side Guide settings (see

page 2-12) and the Ramp settings (see page 2-13).

Wrong program selected from listing.

The F731 has detected a 'Double Feed'. Push the

Stop/Clear Deck button to advance the material

into the accumulator area for error correction. If

double feeds persist, refer to the Feeder Head

adjustment on page 2-11.

Check the Feeder Head adjustment

(see page 2-11).

The material is too thick to be sensed by the double

detection system.

Check that you have selected the correct program

(see page 2-4).

Check that the job is programmed correctly i.e.

'Paper' or 'Booklet' (if appropriate) selected in

material selection to turn double detect off (see

pages 3-2, 3-5 or 3-11).

Feeder display

indicates

'Current Job Not

Compatible'.

Feeder display

indicates 'No

Material for Double

Feed Adjustment'.

Feeder display

indicates 'Wrong

Accumulation

Direction'.

4-6 SDC790A

Check the job setups on the F731 Universal Feeder

AND the material listed for feeder Y on the DI900/

DI950 Inserter to ensure that both have the same

material type and loading orientation.

If scanning is being used, check it is selected in

both the F731 AND the DI900/DI950 programs.

Take a single sheet and load it onto the F731 Feed

Deck (see page 2-5).

Material not being transported to Take-Away Roller.

Adjust Feeder Head settings (see page 2-11).

Check the position of the Accumulator Ramp (see

page 2-2).

Page 57

Troubleshooting & Maintenance • 4

Problem Possible Cause

Feeder display

indicates 'Wrong

Input Frame

Position'.

Feeder display

indicates 'Misfeed

on Conveyor'.

Feeder display

indicates 'Scan

System Error'.

F734/F735 will not

go into automatic

mode.

Check the position of the Input Frame (see page

2-2).

Check the Accumulator Side Guides settings (see

page 2-12).

Check to ensure that the green accumulator belts

are properly installed on all pulleys.

Scanner not positioned correctly above/below the

scan marks (see pages 2-6 and 2-7 for OMR, or

pages 2-8 and 2-9 for BCR).

Scan head may be blocked or dusty. Clean scan

head surface with a soft cloth.

Check that the Input Sensor is properly installed

(see page 2-14).

Check Exit Area Cover is closed.

SDC790A

4-7

Page 58

4 • Troubleshooting & Maintenance

Troubleshooting Using the F731 Scan Error Screens

It is possible to use the Scan Error Screens to check that the Universal

Feeder has read the appropriate scan marks. An example Scan Error

Screen is shown below:

Scan System Error ................- - -

Green=CONFIRM Red=RELOAD PAPER

If some marks are missing or printed in the wrong position on the material,

you will be able to see this by checking the display on the Scan Error

Screen.

a. There should be no marks (black blocks on the display) indicated in the

area shown in the illustration below. If marks are shown, a scanning

error has been detected.

No marks should

appear in this area

Scan System Error ................- - -

Green=CONFIRM Red=RELOAD PAPER

Operator Maintenance

b. Whenever the sheet feeder stops and indicates a scanning error, you

should compare the marks on the Universal Feeder display with those

on the material.

In cases a and b above, examine the page which has been transported

under the scanning head and into the accumulator area. Check the

print quality of the scan dash marks and their positions on the page. If

the material appears to be OK, check the scanning program settings on

the Universal Feeder, especially the setting 'Lead edge to bench mark'

described on page 3-9.

To aid efficient transport through the conveyor sections of the High Capacity

Loader and Universal Feeder, it is recommended that the Material Feed and

Transport Belts are cleaned weekly with water.

The 'Material Feed Belt Cleaning' function within the User Menu can be

used to assist in belt cleaning (see page 4-2).

The external covers of the units can be cleaned using a non-spirit based

cleaner. Always turn power OFF before cleaning the exterior covers of

the system.

4-8 SDC790A

Page 59

5 • Reference

This chapter contains reference information that you might find useful

from time to time.

Service.........................................................................................5-2

Compliance .................................................................................5-2

Equipment Specifications ............................................................5-3

Material Specifications.................................................................5-4

5-1SDC790A

Page 60

5 • Reference

Service

Compliance

Service for your system is available throughout the world.

Should you have questions about your system, or require service or

assistance with your particular application, please call your machine

supplier. Contact details are given at the front of this book or in a separate

document supplied with your system.

Your machine supplier will also offer a service maintenance contract to keep

your system in top condition at nominal cost.

Conforms to the Following:

FCC Rules

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC rules. These limits

are designed to provide reasonable protection against interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause interference

to radio communications. Operation of this equipment in a residential area is

likely to cause interference, in which case the user will be required to correct

the interference at his own expense.

CAUTION: Changes or modifications to this equipment not expressly

approved by the party responsible for compliance could void the user’s

authority to operate the equipment.

It is certified that the system complies with all applicable Directives

of the European Union.

For a formal Declaration of Conformity please contact Compliance

Engineering. Contact information is given in the front of this guide or on a

separate document supplied with your system.

WARNING: This is a Class A product. In a domestic environment this

product may cause radio interference in which case the user may be

required to take adequate measures.

5-2 SDC790A

Page 61

Reference • 5

Equipment Specifications

Electrical

F731: 100-240VAC, 50/60Hz, 5A

F734/F735: 100-240VAC, 50/60Hz, 5A

Physical Dimensions

F731: 480mm High x 600mm Wide x 1000mm Long

(19" High x 23.6" Wide x 39.4" Long)

F734/F735: 500mm High x 500mm Wide x 900mm Long

(19.7" High x 19.7" Wide x 35.4" Long)

Weight

F731: 64kg (141 lb)

F734/F735: 60kg (132 lb)

Speed

Up to a maximum speed of 15,000 sheets per hour.

Noise Level

F731: Below 70 dBA

F734/F735: Below 30 dBA

Operating Temperature Range

Minimum: 10°C (50°F)

Maximum: 35°C (95°F)

SDC790A

5-3

Page 62

5 • Reference

Material Specifications

F731 Universal Feeder

Weight (Sheets)

60g/m2 (16 lb) minimum to 165g/m2 (42 lb) maximum

Thickness (Booklets)

4mm (0.16") maximum

Length (without loader fitted)

175mm (7") minimum to 358mm (14") maximum

Width (without loader fitted)

130mm (5") minimum to 250mm (9.8") maximum

Feed Tray Capacity (without loader fitted)

Up to a maximum stack height of 35mm (1.4").

Can be reloaded whilst running.

F734/F735 High Capacity Loader

Sheet Size

F734: 8.5" x 11" only

F735: DIN A4 size (210mm x 297mm) only

Sheet Weight

60g/m2 (16 lb) minimum to 125g/m2 (33 lb) maximum

Capacity

up to 4,500 sheets

5-4 SDC790A

Page 63

Index

Index-1SDC790A

Page 64

Index

A