Page 1

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2002

STEREO DVD TUNER DECK

EV51DVD

SOUND MODE

KARAOKE

ST. MEMORY

DVD/CD

TUNER

DOLBY NR(DEMO)

ASES

4/1

–+

VOLUME

PLAY/PAUSE STOPTUNING – TUNING +

OPEN/CLOSE

MIC VOL

MIN

MAX

(MAIN)

(SUB)

TIMER/CLOCK ADJ

DISPLAY

ENTER

TAPE

¡/¢

LINE

REVERSE MODE

REC/STOP

MIC

MIC

XV-EV51

STEREO DVD TUNER DECK

XV-EV51

XV-EV21

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

ORDER NO.

RRV2636

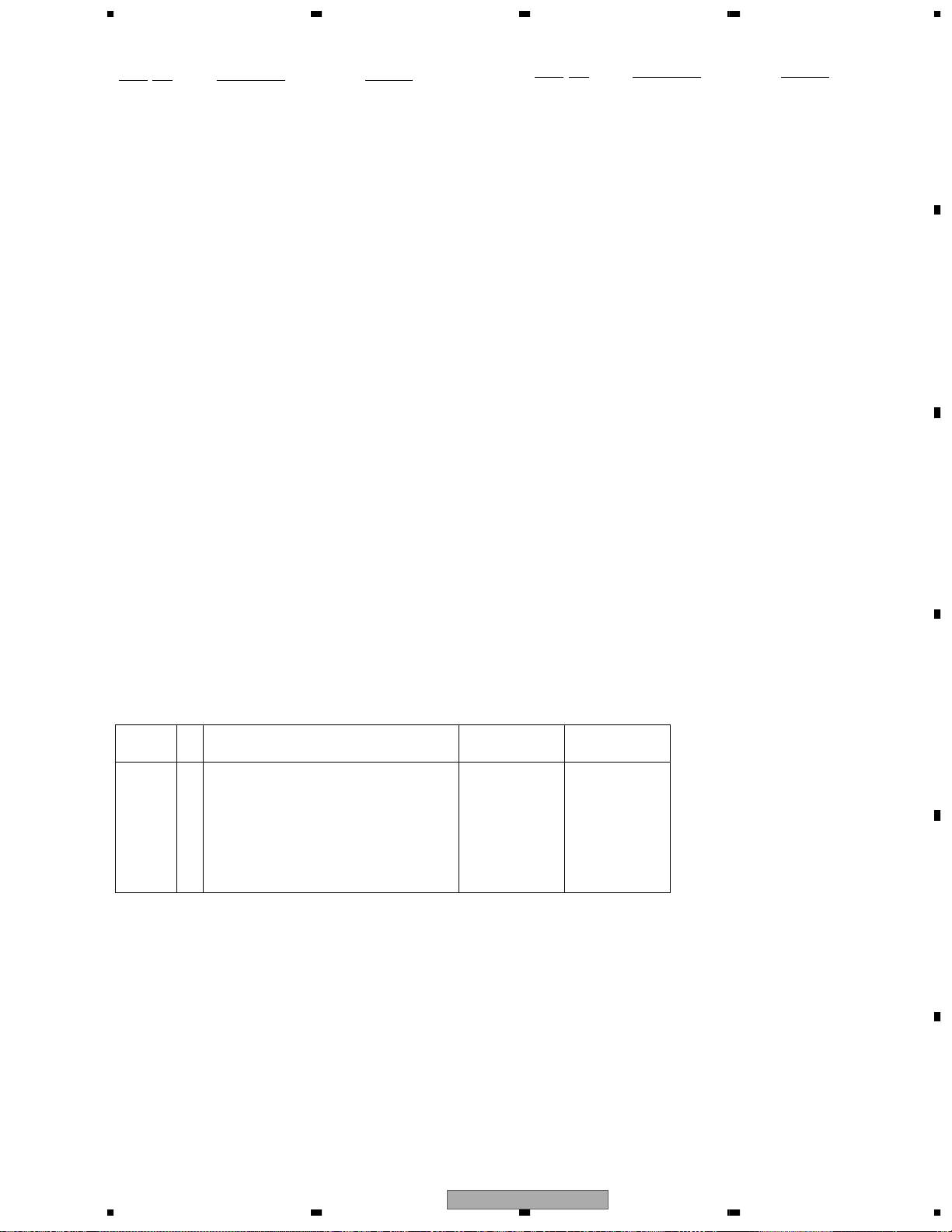

Model Type Power Requirement

Regienal restriction

codes (Region No.)

Remarks

XV-EV51 ZLXJ/NC DC Power supplied from other system component 4

XV-EV21 ZLXJ/NC DC Power supplied from other system component

4

This product does not function properly independently; to avoid malfunctions, be sure

to connect it to the prescribed system component(s), otherwise damage may result.

Component System System Service manual

MINI SYSTEM EVA-5CH EVA-2CH

Stereo DVD Tuner Deck XV-EV51 XV-EV21 RRV2636(This manual)

Stereo Power Amplifier M-EV51 M-EV21 RRV2663(EV51), RRV2664(EV21)

Speaker System S-EV51V S-EV21V RRV2640(EV51), RRV2641(EV21)

For details, refer to "Important symbols for good services" .

T-ZZR AUG. 2002 printed in Japan

Page 2

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians ; it is not meant for the casual doit-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this

manual.Improperly performed repairs can adversely affect the safety and reliability of the product

and may void the warranty. If you are not qualified to perform the repair of this product properly and

safely, you should not risk trying to do so and refer the repair to a qualified service technician.

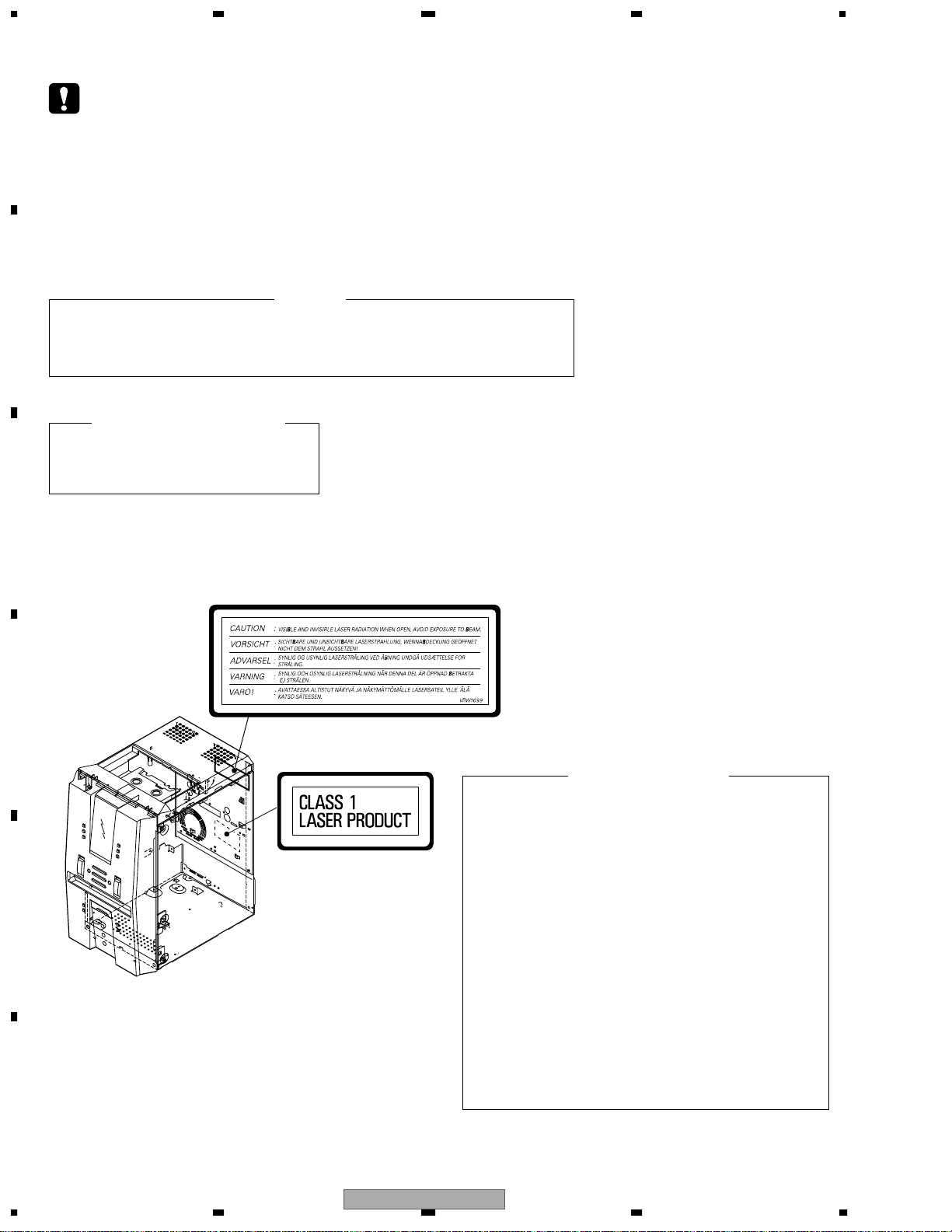

B

THE AEL (ACCESSIBLE EMISSION LEVEL) OF THE LASER POWER OUTPUT IS LESS THAN CLASS 1

BUT THE LASER COMPONENT IS CAPABLE OF EMITTING RADIATION EXCEEDING THE LIMIT FOR

CLASS 1.

A SPECIALLY INSTRUCTED PERSON SHOULD DO SERVICING OPERATION OF THE APPARATUS.

LASER DIODE CHARACTERISTICS

FOR DVD : MAXIMUM OUTPUT POWER : 5 mW

WAVELENGTH : 650 nm

FOR CD : MAXIMUM OUTPUT POWER : 5 mW

WAVELENGTH : 780 nm

C

LABEL CHECK

D

WARNING !

Additional Laser Caution

1. Laser Interlock Mechanism

• Loading switch (S101 on the LOAB Assy) is used for interlock

mechanism of the laser.

When this switch turned ON in SW2 (XCLOSE) side (OPEN signal is

(Printed on the Rear Panel A)

E

XV-EV51/ZLXJ/NC

F

2

XV-EV51

0V and XCLOSE signal is 3.5V), a laser becomes the status which

can completely oscillation.

Furthermore, the laser completely oscillates in the disc judgment and

disc playback.

When player is power ON state and laser diode is not completely

oscillating, 780nm laser diode is always oscillating by half power.

• Laser diode is driving with Q101 (650nm LD) and Q102 (780nm LD)

on the DVDM Assy.

Therefore, when short-circuit between the emitter and collector of

these transistors or the base voltage is supplied for transistors turn

on, the laser oscillates. (failure mode)

• In the test mode ∗ , there is the mode that the laser oscillates except

for the disc judgment and playback. LD ON mode in the test mode

oscillates with the laser forcibly.

The interlock mechanism mentioned above becomes invalid in this

mode.

2. When the cover is open, close viewing through the objective lens with

the naked eye will cause exposure to the laser beam.

∗ : See page 80.

1234

Page 3

[ Important symbols for good services ]

In this manual, the symbols shown-below indicate that adjustments, settings or cleaning should be made securely.

When you find the procedures bearing any of the symbols, be sure to fulfill them:

2. Adjustments

To keep the original performances of the product, optimum adjustments or specification confirmation is indispensable.

In accordance with the procedures or instructions described in this manual, adjustments should be performed.

3. Cleaning

For optical pickups, tape-deck heads, lenses and mirrors used in projection monitors, and other parts requiring cleaning,

proper cleaning should be performed to restore their performances.

5. Lubricants, glues, and replacement parts

Appropriately applying grease or glue can maintain the product performances. But improper lubrication or applying

glue may lead to failures or troubles in the product. By following the instructions in this manual, be sure to apply the

prescribed grease or glue to proper portions by the appropriate amount.For replacement parts or tools, the prescribed

ones should be used.

4. Shipping mode and shipping screws

To protect the product from damages or failures that may be caused during transit, the shipping mode should be set or

the shipping screws should be installed before shipping out in accordance with this manual, if necessary.

1. Product safety

You should conform to the regulations governing the product (safety, radio and noise, and other regulations), and

should keep the safety during servicing by following the safety instructions described in this manual.

Discs compatible with this

player

Any disc that displays one of the following

logos should play in this player. Other

formats, including DVD-Audio, DVD-RAM,

DVD-ROM, CD-ROM (except those that

contain MP3 files), SACD and Photo CD will

not play.

Audio-CD

DVD-Video

Video-CD

* : Video Mode Only

CD-R * CD-RW *

5 678

A

B

C

D

56

XV-EV51

E

F

7

8

3

Page 4

1234

CONTENTS

SAFETY INFORMATION..................................................................................................................................... 2

A

B

C

D

E

1. SPECIFICATIONS ............................................................................................................................................ 5

2. EXPLODED VIEWS AND PARTS LIST ............................................................................................................ 6

2.1 PACKING ................................................................................................................................................... 6

2.2 EXTERIOR SECTION................................................................................................................................ 8

2.3 FRONT PANEL SECTION ....................................................................................................................... 10

2.4 LOADING MECHANISM ASSY ............................................................................................................... 12

2.5 TRAVERSE MECHANISM ASSY............................................................................................................. 14

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM ..........................................................................................16

3.1 BLOCK DIAGRAM ................................................................................................................................... 16

3.2 OVERALL WIRING DIAGAM ................................................................................................................... 20

3.3 FM/AM TUNER MODULE........................................................................................................................ 24

3.4 IF ASSY ................................................................................................................................................... 26

3.5 AF ASSY(1/2) .......................................................................................................................................... 28

3.6 AF ASSY(2/2) .......................................................................................................................................... 30

3.7 DECK ASSY ............................................................................................................................................ 32

3.8 DVDM ASSY(1/2)..................................................................................................................................... 34

3.9 DVDM ASSY(2/2)..................................................................................................................................... 36

3.10 DVD IF ASSY......................................................................................................................................... 38

3.11 DISP1, DISP2, DISP3 and LED ASSYS................................................................................................ 40

3.12 DSP ASSY ............................................................................................................................................. 42

3.13 MIC ASSY.............................................................................................................................................. 44

4. PCB CONNECTION DIAGRAM ..................................................................................................................... 46

4.1 LOAB ASSY............................................................................................................................................. 46

4.2 FM/AM TUNER MODULE........................................................................................................................ 47

4.3 DVDM ASSY............................................................................................................................................ 48

4.4 DVD IF ASSY........................................................................................................................................... 52

4.5 IF ASSY ................................................................................................................................................... 54

4.6 AF ASSY.................................................................................................................................................. 56

4.7 DECK ASSY ............................................................................................................................................ 58

4.8 DISP1, DISP2, DISP3 and LED ASSYS.................................................................................................. 60

4.9 MIC ASSY................................................................................................................................................ 62

4.10 DSP ASSY(XV-EV51 Only) .................................................................................................................... 63

5. PCB PARTS LIST ........................................................................................................................................... 64

6. ADJUSTMENT ............................................................................................................................................... 72

6.1 DECK SECTION ...................................................................................................................................... 72

6.1.1 Adjustment condition ......................................................................................................................... 72

6.1.2 Playback and Recording section ....................................................................................................... 73

6.2 TUNER SECTION .................................................................................................................................... 75

6.3 DVD SECTION ADJUSTMENT ITEMS ana LOCATION.......................................................................... 76

6.4 JIGS and MEASURING INSTRUMENTS ................................................................................................ 76

6.5 NECESSARY ADJUSTMENT POINTS ................................................................................................... 77

6.6 TEST MODE ............................................................................................................................................ 78

6.7 MECHANISM ADJUSTMENT.................................................................................................................. 79

7. GENERAL INFORMATION ............................................................................................................................. 82

7.1 DIAGNOSIS ............................................................................................................................................. 82

7.2 PARTS.................................................................................................................................................... 101

7.3 CLEANING............................................................................................................................................. 120

8. PANEL FACILITIES ...................................................................................................................................... 121

F

4

1234

XV-EV51

Page 5

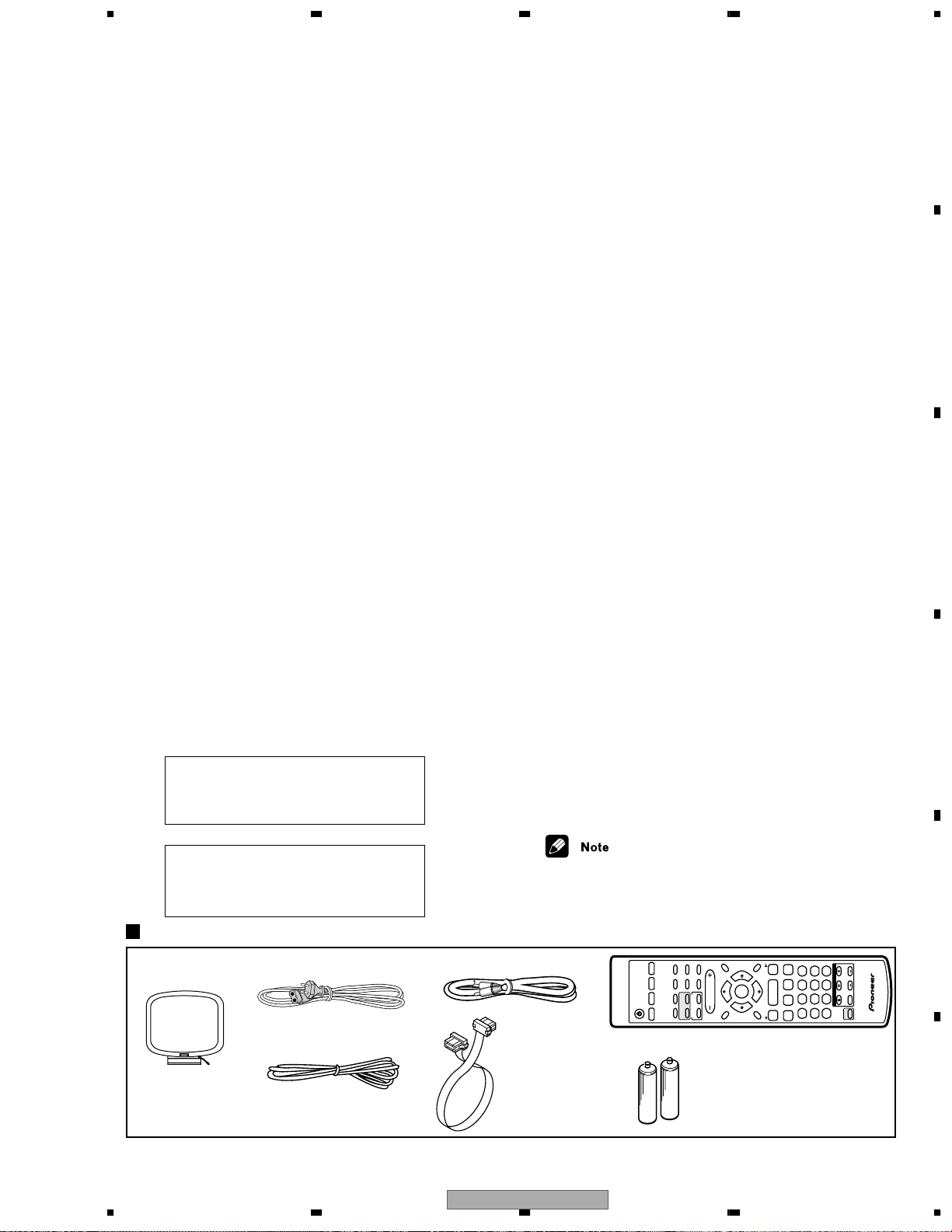

Accessories

(XXD3049)

AM loop antenna

(ATB7009)

FM wire antenna

AC Power Cord

(ADH7004)

(XDG3001)

AA size IEC R6P

Dry cell batteries (x2)

Specifications

Amplifier Section

X-EV51DVD model

Continuous Power Output:

Front

...................................

80 W per channel

(1kHz, 10 %, 8 Ω)

Center

......................

33 W (1kHz, 10 %, 8 Ω)

Surround

.............................

33 W per channel

(1kHz, 10 %, 8 Ω)

X-EV21DVD model

Continuous Power (RMS)

.............

80 W + 80 W

(1 kHz, THD 10%, 8 Ω)

Disc section

Digital audio

characteristics

................

DVD fs: 96 kHz, 24-bit

Type

...........

DVD system, Video CD system and

Compact Disc digital audio system

Frequency response

...................

4 Hz to 44 kHz

S/N ratio

....................................................

95 dB

Dynamic range

.........................................

95 dB

Total harmonic distortion

.....................

0.005 %

Wow and Flutter..................Limit of measurement

( 0.001 % W.PEAK) or less (EIAJ)

Cassette deck section

Systems

.........................

4 track, 2-channel stereo

Heads.......................Recording/playback head x 1

Erasing head x 1

Motor

...................................

DC servo motor x 1

Tape types

...............................

TYPE I (Normal)

FM tuner section

Frequency Range

........................

87.5 - 108MHz

Antenna

..................................

75 Ω, unbalanced

AM tuner section

FrequencyRange

With 9 kHz step

..........

531 kHz to 1,602 kHz

With 10 kHz step

........

530 kHz to 1,700 kHz

Antenna

........................................

Loop antenna

Manufactured under license from Dolby

Laboratories. “Dolby”, “Pro Logic”, and

the

double-D symbol are trademarks of Dolby

Laboratories.

"DTS" and "DTS Digital Surround" are registered

trademarks of Digital Theater Systems, Inc.

Manufactured under license from Digital Theater

Sy

±

stems, Inc.

Miscellaneous

Power Requirements

Multi voltage model .......

.......

AC 110-127/ 220-230/

Power Consumption

X-EV51DVD model

Singapore, Malaysia, Hong Kong models

....................................

....................................

175 W

All other model 465 W

X-EV21DVD model

Singapore, Malaysia models .................. 150 W

All other model 540 W

Power Consumption in standby mode .............1 W

Dimensions:

DVD Tuner Deck .................. 170 (W) x 292.5 (H)

x 260 (D) mm

Power Amplifier

....................... 170 (W) x 190 (H)

x 254 (D) mm

Weight:

DVD Tuner Deck

XV-EV51 ................................................ 3.6 kg

XV-EV21 ................................................ 3.5 kg

Power Amplifier

M-EV51 .................................................. 5.3 kg

M-EV21 .................................................. 4.8 kg

Accessories (Stereo DVD Tuner Deck)

Operating instructions..........................................2

•

Specifications and design subject to

possible modification without notice,

due to improvements.

Accessories (Stereo Power Amplifier)

Remote control .................................................... 1

Power cord

Australian, New Zealand, Central

and South American models........................... 2

All other models ............................................. 1

Power plug adapter (excluding Singapore,

Hong Kong and Malaysian models)..................... 1

Video cord............................................................ 1

System cable (EV51DVD) ................................... 2

System cable (EV21DVD) ................................... 1

FM antenna.......................................................... 1

AM loop antenna.................................................. 1

Dry cell batteries (AA/R6) ................................... 2

Video Cord

(VDE1034)

System Cable ×1

(XDE3053)

Remote control unit

240V(switchable), 50/60 Hz

TV CONTROL

123

456

7890

CLEAR

ENTER

SYSTEM SETUP

DVD SETUP

TOP MENU

DVD MENU

SHIFT

CHANNELVOLUME

INPUT

SELECT

SUBTITLE

VOLUME

ANGLE

ZOOM

ADVANCED

MONO

SYSTEM DISP

DVD DISP

ECHO

DSP

AUDIO

DVD/CD

TAPE

FM/AM LINE

SURROUND

PROGRAM

TEST TONE

REPEAT

CH LEVEL

RANDOM

SLEEP

KARAOKE

I

— KEYCON —

i

TIMER

CLOCK ADJ.

MUTE

RETURN

FOLDER +FOLDER –

SOUND

MODE

ENTER

STANDBY/ON

4

/e

E/

1

¡

¢

8

7

3

3

3

TUNE +

ST +ST –

TUNE –

1. SPECIFICATIONS

5 678

A

B

C

D

56

XV-EV51

7

E

F

5

8

Page 6

1234

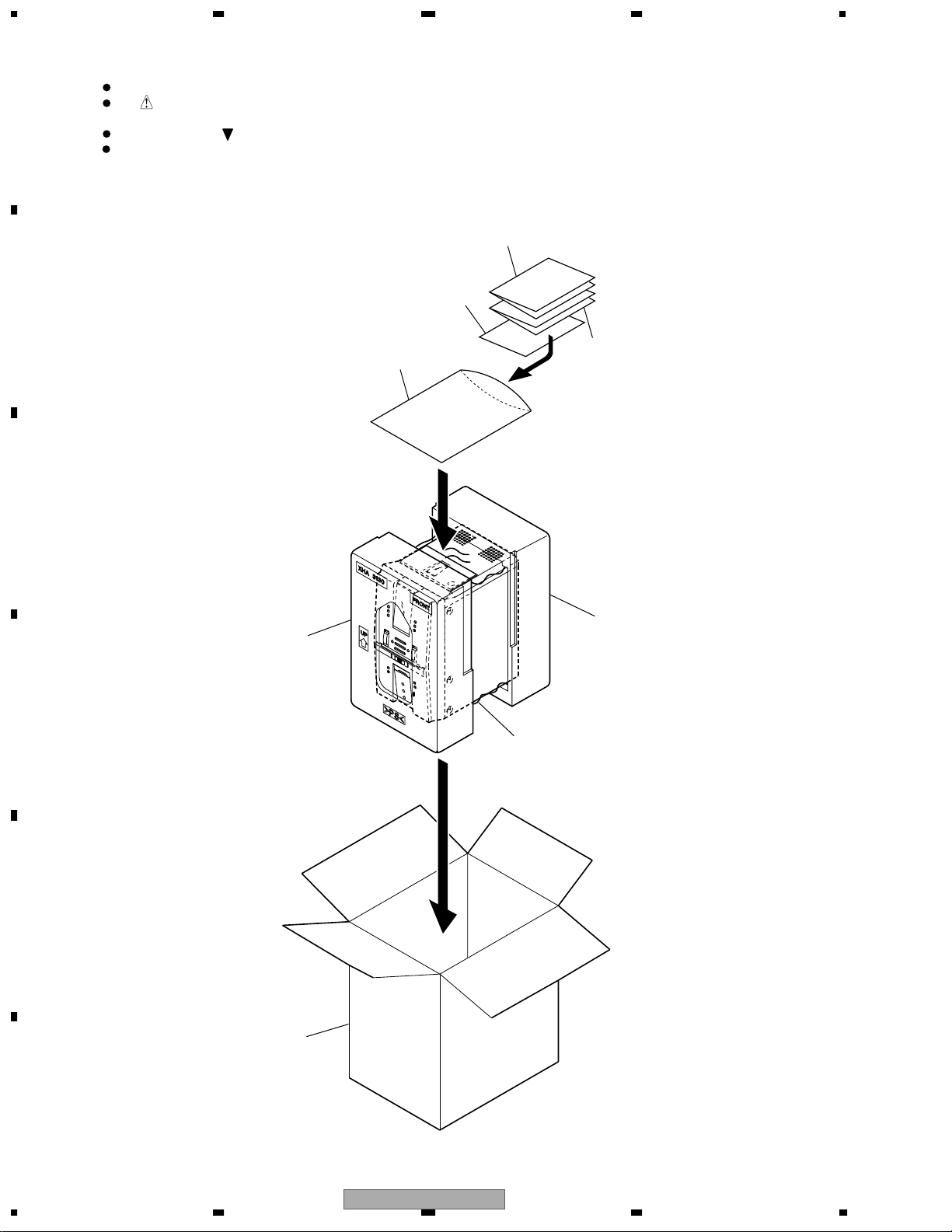

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

A

2.1 PACKING

B

C

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

1

8

2

3

6

5

D

4

E

7

F

6

1234

XV-EV51

Page 7

5 678

PACKING parts List

Mark

Mark No. Description Part No.

1 Operating Instructions XRB3017

(English)

2 Operating Instructions XRC3073

(Chinese)

NSP 3 Polyethylene Bag Z21-038

(0.03 x 230 x 340)

4 Packing Sheet AHG7053

No. Description Part No.

5 Front Pad M XHA3130

6 Rear Pad M XHA3131

7 Packing Case See Contrast table (2)

8 Correct Sheet XRH3007

(2) CONTRAST TABLE

XV-EV51/ZLXJ/NC and XV-EV21/ZLXJ/NC are constructed the same except for the following :

Mark No. Symbol and Description XV-EV51/ZLXJ/NC XV-EV21/ZLXJ/NC

7 Packing Case XHD3305 XHD3308

A

B

C

D

E

56

XV-EV51

F

7

8

7

Page 8

1234

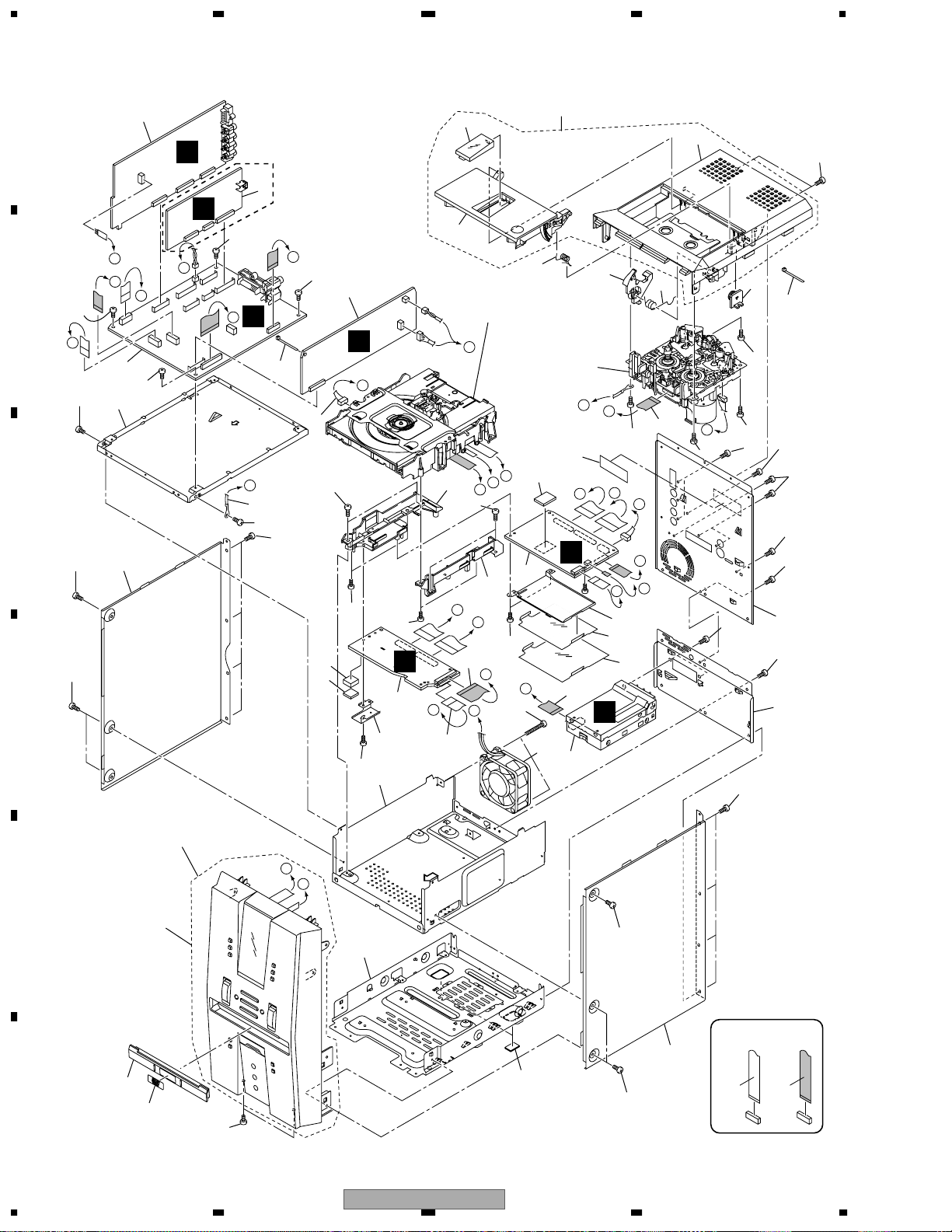

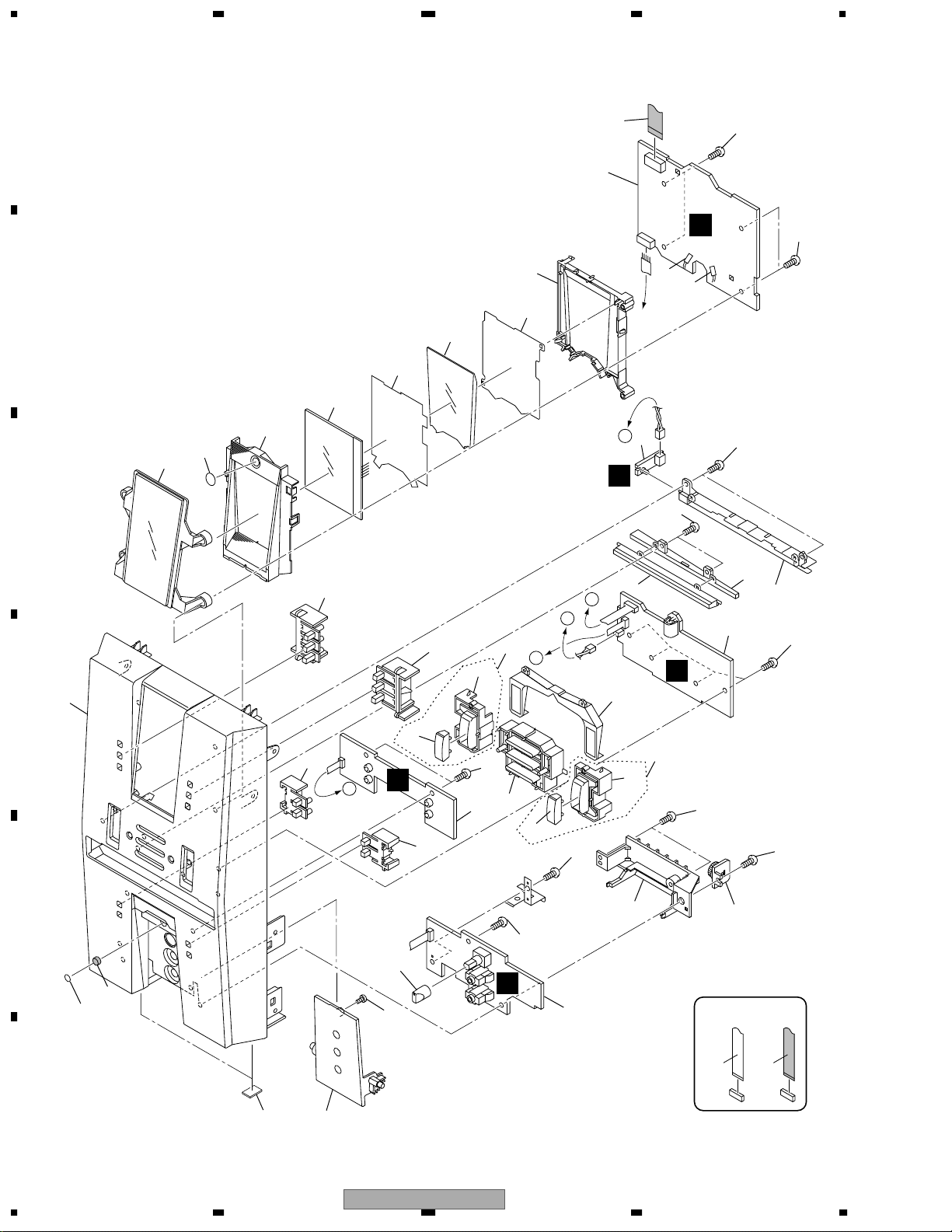

2.2 EXTERIOR SECTION

A

3

27

C

XV-EV51

Only

7

37

35

39

K

40

B

O

11

40

32

39

E

40

4

E

I

16

39

39

49

51

39

G

6

22

40

20

B

G

43

40

A

2

40

40

21

30

42

B

C

D

F

C

D

28

25

Refer to

"2.4 LOADING MECHA ASSY".

9

H

52

L

48

39

K

J

M

44

F

5

45

M

N

40

14

D

C

13

E

15

41

F

10

1

29

8

O

G

N

47

J

46

50

38

23

12

38

I

L

K

A

24

32

38

XV-EV51

38

H

39

39

39

Only

39

39

39

39

19

39

18

Refer to

"2.3 FRONT PANEL SECTION".

A

B

E

F

8

33

36

17

26

34

39

42

43

31

NON-CONTACT

SIDE

CONTACT SIDE

XV-EV51

1234

Page 9

5 678

EXTERIOR SECTION parts List

Mark No. Description Part No.

1 FM/AM TUNER Module AXQ7228

2 IF Assy See Contrast table (2)

3 AF Assy See Contrast table (2)

4 DECK Assy See Contrast table (2)

5 DVDM Assy AWM7684

6 DVD IF Assy AWM7677

7 DSP Assy See Contrast table (2)

8 DECK Mechanism Unit XYM3015

NSP 9 LOADING MECHA Assy VWT1203

10 DC Fan Motor AXM7025

NSP 11 Earth Lead Wire DE012VF0

12 11P Flat Flexible Cable XDD3114

13 13P Flat Flexible Cable XDD3115

14 30P Flat Flexible Cable XDD3116

15 16P Flat Flexible Cable XDD3117

16 Connector Assy 5P XDE3055

NSP 17 Chassis XNA3011

18 Rear Panel A See Contrast table (2)

19 Rear Panel B See Contrast table (2)

20 Mecha Frame XNG3082

21 DVD Shield XNG3083

22 GND Plate XNG3084

23 Ratch Spring ABH7130

24 Damper Assy AXA7052

25 Door Spring L XBH3010

26 Leg Cushion XEB3028

Mark

No. Description Part No.

27 Deck Lens XAK3327

28 Deck Door XAN3047

29 Ratch Mold XMR3001

30 Side Bonnet L XNE3026

31 Side Bonnet R XNE3027

32 Binder ZCA-SKB90BK

33 Tray Cap XAK3325

34 DVD Badge XAK3331

35 Top Panel XAK3326

NSP 36 Front Panel Assy See Contrast table (2)

NSP 37 Top Panel Assy XXG3131

38 Screw VPZ30P080FZK

39 Screw BBZ30P080FZK

40 Screw BBZ30P080FMC

41 Screw BPZ30P350FZK

42 Screw VPZ30P080FNI

43 Screw BBZ30P080FNI

44 Adapter 02 L ANW7247

45 Adapter 02 R ANW7248

46 Shield Case ANK7108

47 Heat plate ANG7426

48 Radiation Sheet AEB7255

49 Cushion AEB7267

50 FFC Barrier AEC7443

51 FFC Spacer AEC7442

52 Caution Label VRW1699

A

B

C

(2) CONTRAST TABLE

XV-EV51/ZLXJ/NC and XV-EV21/ZLXJ/NC are constructed the same except for the following :

Mark NO Symbol and Description

2 IF Assy XWZ3617 XWZ3627

3 AF Assy XWZ3618 XWZ3628

4 DECK Assy XWX3067 XWX3066

7 DSP Assy AWX8059 Not used

18 Rear Panel A XNC3160 XNC3180

19 Rear Panel B XNC3161 XNC3176

NSP 37 Front Panel Assy XXG3129 XXG3130

XV-EV51/ZLXJ/

NC

XV-EV21/ZLXJ/NC

D

E

F

56

XV-EV51

7

8

9

Page 10

1234

2.3 FRONT PANEL SECTION

A

9

B

13

11

7

14

15

12

11

8

1

D5108

6

B

4

33

J

D5107

6

33

33

L

C

33

33

18

19

2

31

33

33

21

B

22

30

D

27

24

H

A

25

E

10

38

36

39

26

3

33

35

23

M

A

29

33

33

5

16

C

I

17

34

28

37

NON-CONTACT

F

10

1234

32

20

XV-EV51

SIDE

CONTACT SIDE

Page 11

5 678

FRONT PANEL SECTION parts List

Mark No. Description Part No.

1 DISP 1 Assy XWZ3619

2 DISP 2 Assy XWZ3620

3 DISP 3 Assy XWZ3621

4 LED Assy XWZ3622

5 MIC Assy See Contrast table (2)

Mark

No. Description Part No.

21 Display Button L XAD3149

22 Display Button R XAD3150

23 Play Button XAD3151

24 Dolby Button L XAD3154

25 Dolby Button R XAD3155

A

6 LED (D5107, D5108) NSPWF50BS-9706

7 LCD XAV3016

8 11P Flat Flexible Cable XDD3113

9 LCD Holder XMR3052

10 MIC Knob XAA3024

11 Diffusion Sheet XAK3321

12 Display Window See Contrast table (2)

13 LCD LT Cond XAK3323

14 LCD Cover XAK3324

15 Sensor Cover XAK3330

16 Tray Lens XAK3332

17 FUNC. LT Cond XAK3333

18 LT Cond XAK3334

19 LT Cover XAK3335

20 Jack Door XAN3048

26 FUNC. Button L XAD3152

27 FUNC. Cover L XAK3328

28 FUNC. Button R XAD3153

29 FUNC. Cover R XAK3329

30 Front Panel M See Contrast table (2)

31 Damper Assy XXA3029

32 Leg Cushion XEB3028

33 Screw VPZ30P080FZK

34 FUNC. Assy R XAD3158

35 FUNC. Assy L XAD3157

36 Cushion XEB3004

37 Gap Cover XMR3055

38 Magnet XMF3003

39 Screw 2x4 B XBA3011

(2) CONTRAST TABLE

XV-EV51/ZLXJ/NC and XV-EV21/ZLXJ/NC are constructed the same except for the following :

Mark No. Symbol and Description XV-EV51/ZLXJ/NC XV-EV21/ZLXJ/NC

5 MIC Assy XWZ3626 XWZ3623

12 Display Window XAK3322 XAK3343

30 Front Panel M XMB3084 XMB3089

B

C

D

E

F

56

XV-EV51

7

8

11

Page 12

2

1234

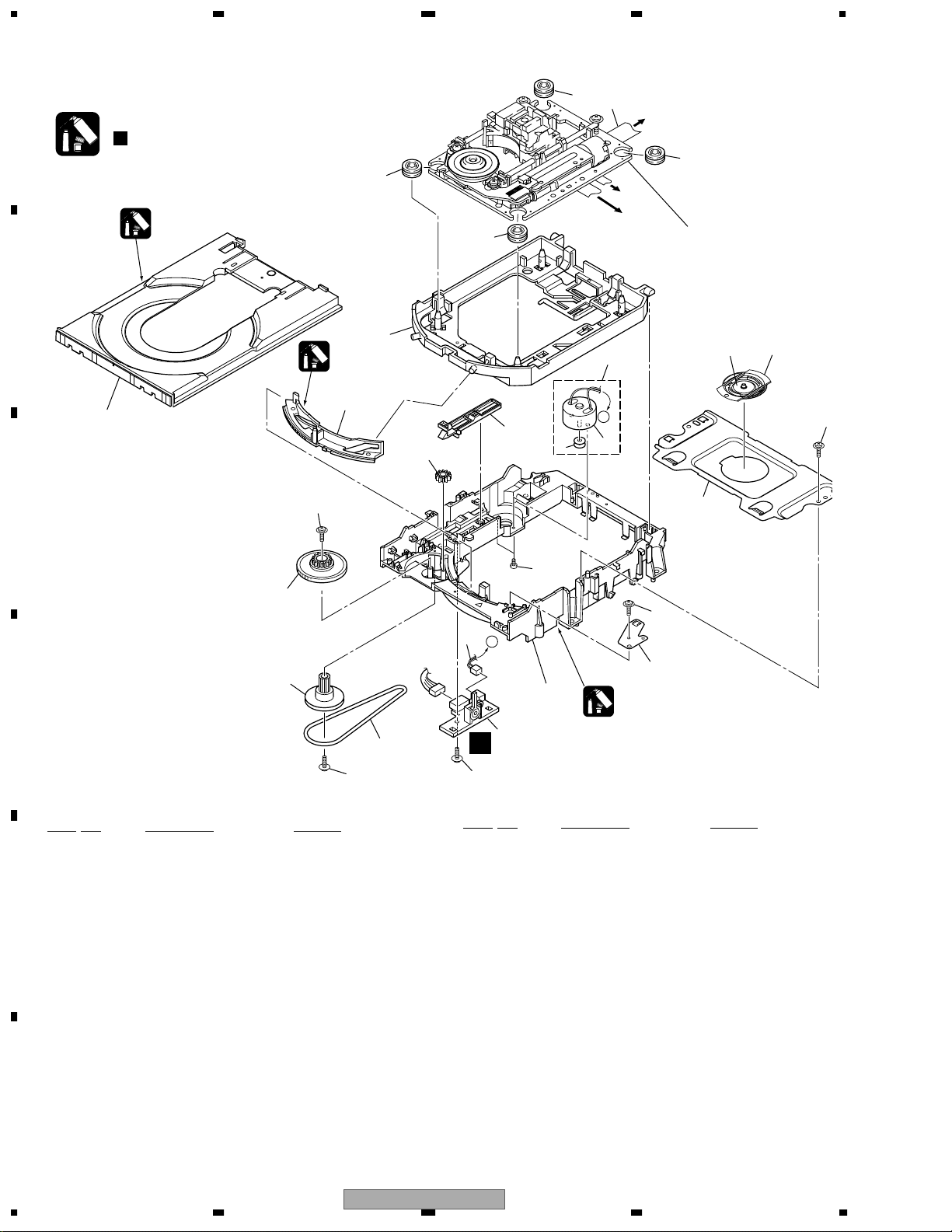

2.4 LOADING MECHANISM ASSY

Note :

A

Refer to

8

To

6

DVDM

CN8

" Application of Lubricant".

8

8

To DVDM

CN4

3

A

5

To DVDM

CN2

2

Refer to

"2.5 TRAVERSE MECHANISM

ASSY-S".

18

19

20

2

Daifree

GEM1036

B

12

Lubricating Oil

GYA1001

23

C

13

16

22

8

17

4

D

LOADING MECHANISM ASSY parts List

Mark No. Description Part No.

NSP 1 LOAB Assy VWG2346

2 Traverse Mechanism Assy-S VXX2858

3 Loading Motor Assy VXX2505

4 Motor Pulley PNW1634

E

5 Carriage DC Motor / 0.3W PXM1027

6 Flexible Cable (26P) VDA1864

7 Connector Assy 2P VKP2253

8 Float Rubber VEB1327

9 Belt VEB1330

10 Stabilizer VNE2253

15

14

7

9

22 22

D

Mark No. Description Part No.

16 Drive Gear VNL1923

17 SW Lever VNL1925

18 Clamper Plate VNE2251

19 Bridge VNE2252

20 Clamper VNL1924

21 Screw JGZ17P028FMC

22 Screw Z39-019

23 Tray VNL1920

21

22

A

10

11

1

Lubricating Oil

GYA1001

11 Loading Base VNL1917

12 Float Base DVD VNL1918

13 Drive Cam VNL1919

F

14 Gear Pulley VNL1921

15 Loading Gear VNL1922

12

1234

XV-EV51

Page 13

5 678

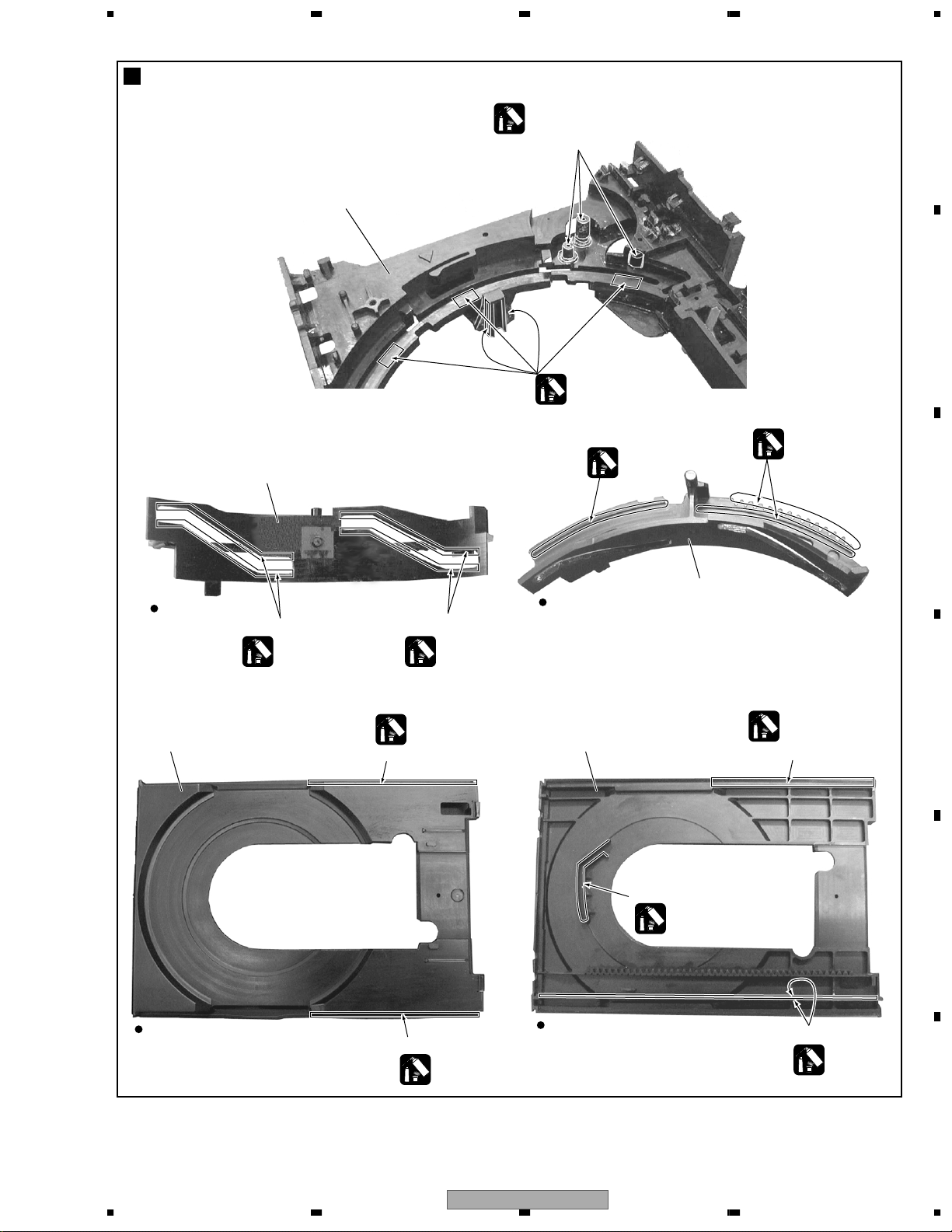

Application of Lubricant

No. 11

Loading Base

Lubricating Oil

GYA1001

Around the shaft

Concave of unevenness

Concave of unevenness

Concave of unevenness

No. 13

Drive Cam

No. 13

Drive Cam

No. 23

Tray

No. 23

Tray

Top View

Rear View

Top View

Bottom View

Daifree

GEM1036

Daifree

GEM1036

Daifree

GEM1036

Daifree

GEM1036

Daifree

GEM1036

Side of the rib

Inner side of a ditch

Inner side of a ditch

Lubricating Oil

GYA1001

Lubricating Oil

GYA1001

Inner side of a ditch

Lubricating Oil

GYA1001

Lubricating Oil

GYA1001

Lubricating Oil

GYA1001

A

B

C

D

E

XV-EV51

56

7

8

F

13

Page 14

1234

2.5 TRAVERSE MECHANISM ASSY

A

18

17 (Torque : 0.12 ± 0.01 N•m)

Silicone Adhesive

12

8

GEM1037

3

10

B

18

1

C

13

D

16

18

10

To SSIB

CN1

7

14

6

19

4 (Adjustment Screw)

5

Screw Tight

5

GYL1001

17 (Torque : 0.12 ± 0.01 N•m)

17 (Torque : 0.12 ± 0.01 N•m)

15

Silicone Adhesive

GEM1037

9

Silicone Adhesive

GEM1037

DVDM

To

CN8

16

2

E

11

F

14

1234

XV-EV51

To DVDM

CN4

NON-CONTACT

SIDE

CONTACT SIDE

Page 15

>

5 678

TRAVERSE MECHANISM ASSY parts List

Mark No. Description Part No.

1 Spindle Motor VXM1088

2 Stepping Motor VXM1090

3 Pickup Assy-S OXX8004

4 Skew Screw VBA1080

5 Skew Spring VBH1335

6 Guide Bar VLL1514

7 Sub Guide Bar VLL1515

8 Hold Spring VNC1017

9 Joint Spring VNC1019

10 Support Spring VNC1020

A

NSP 11 Mechanism Chassis VNE2248

12 Slider VNL1811

13 Spacer VNL1913

14 Joint VNL1914

15 FFC Holder VNL1915

16 Screw BBZ20P050FZK

17 Tapping Screw OBA8009

18 Screw PMA26P100FMC

19 Damper Sheet VEB1335

B

C

D

56

XV-EV51

E

F

7

8

15

Page 16

1234

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

A

3.1.1 SIGNAL ROUTE(1/2)

B

IF ASSY

Refer to 3.1.2 SIGNAL ROUTE(2/2)

B

DVDM ASSY

F

CN5903

CN5901

CN

(D)

G

DVD IF ASSY

C

DECK ASSY

E

16,17

CN5801

EV-51 : PDC093

EV-21 : PDC097

(V)

(Y)

(C)

(D)

7

348

D

17 16 2

CN2506

DISP1 ASSY

E

J

RECL

PBL

(REC)

8

4

5,6

CN5509

73

CN5101

5,6

DSP ASSY

H

XV-EV51 Only

F

16

1234

XV-EV51

Page 17

5 678

A

(PB)

(V)

(Y)

(C)

CN5504

(REC)

CN5503

CN8101

CN8901

C

(PB)

(TX)

(PB)

(REC)

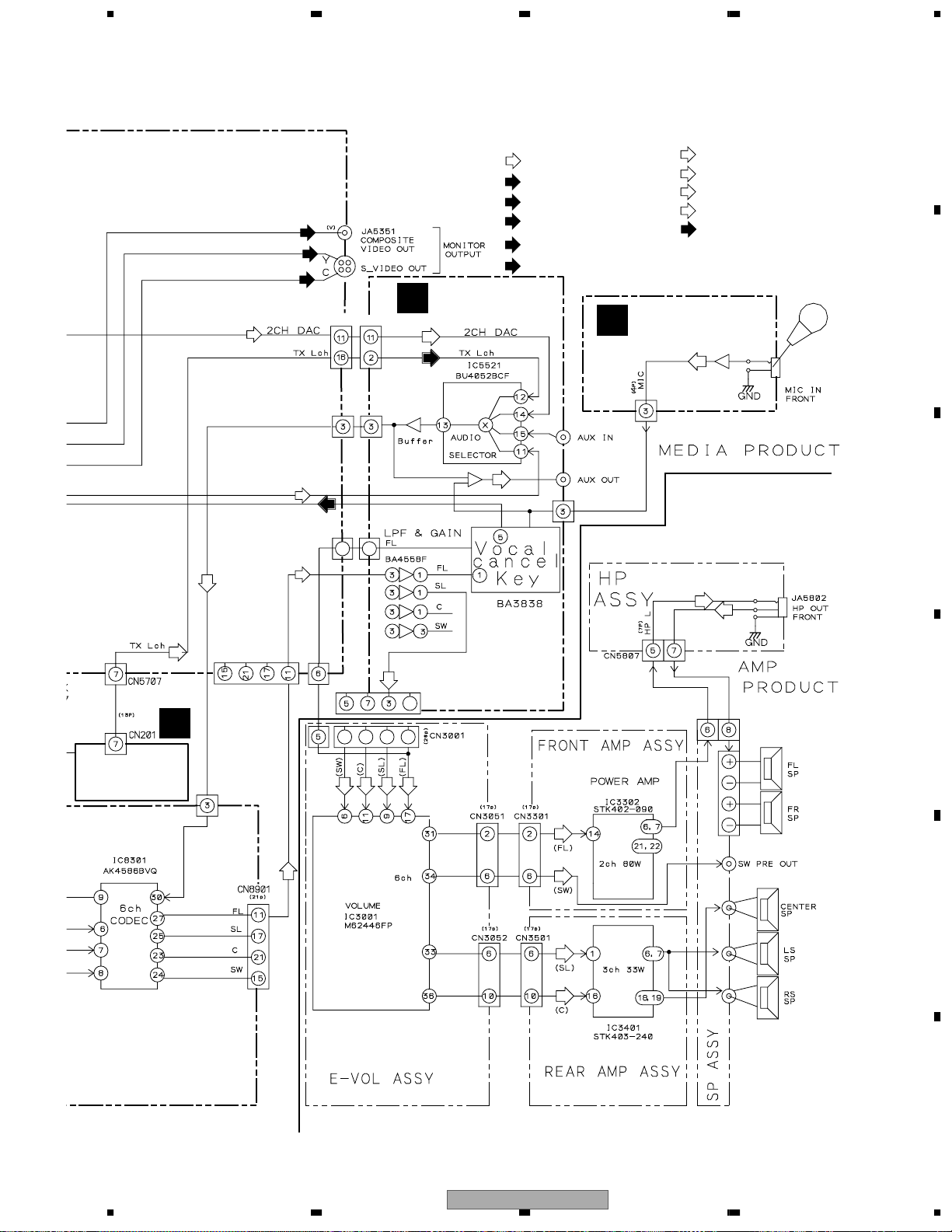

(TX)

AF ASSY

(PB)

SIGNAL ROUTE

: PB SIGNAL

: RECORDING SIGNAL

: AUDIO SIGNAL (TUNER)

(V)

: V SIGNAL VIDEO

(Y)

: Y SIGNAL VIDEO

(C)

: C SIGNAL VIDEO

M

CN8301

(SL)

: SL AUDIO SIGNAL

(FL)

: FL AUDIO SIGNAL

(C)

: C AUDIO SIGNAL

(SW)

: SW AUDIO SIGNAL

(D)

: DIGITAL AUDIO ROUTE

MIC ASSY

(PB)

J5401

M-EV51

(POWER AMPLIER)

Service Manual

Order No.RRV2663

B

JA5401

C

(TX)

A

FM/AM TUNER

MODULE

CN5501

CN8701

D

CN3002

E

56

XV-EV51

F

7

8

17

Page 18

1234

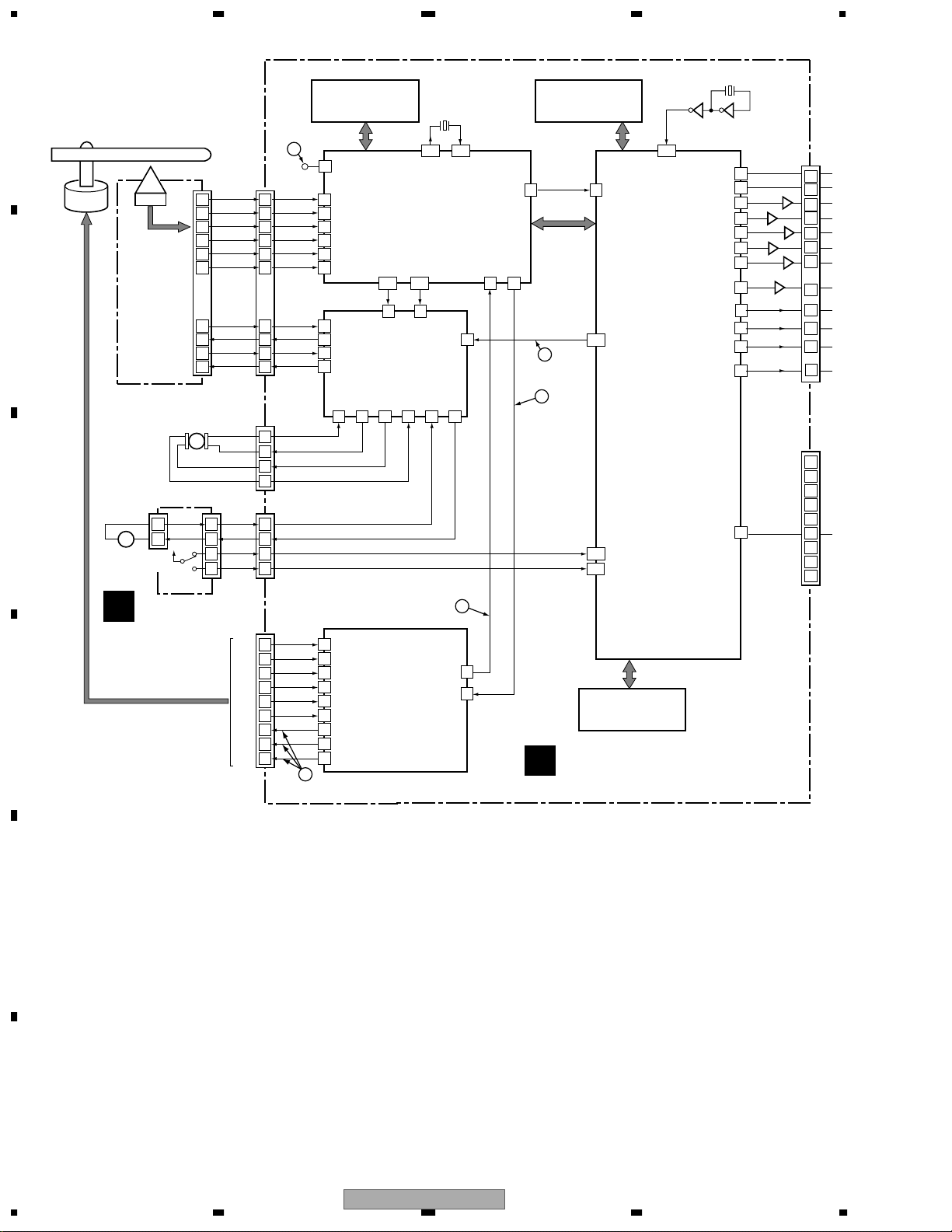

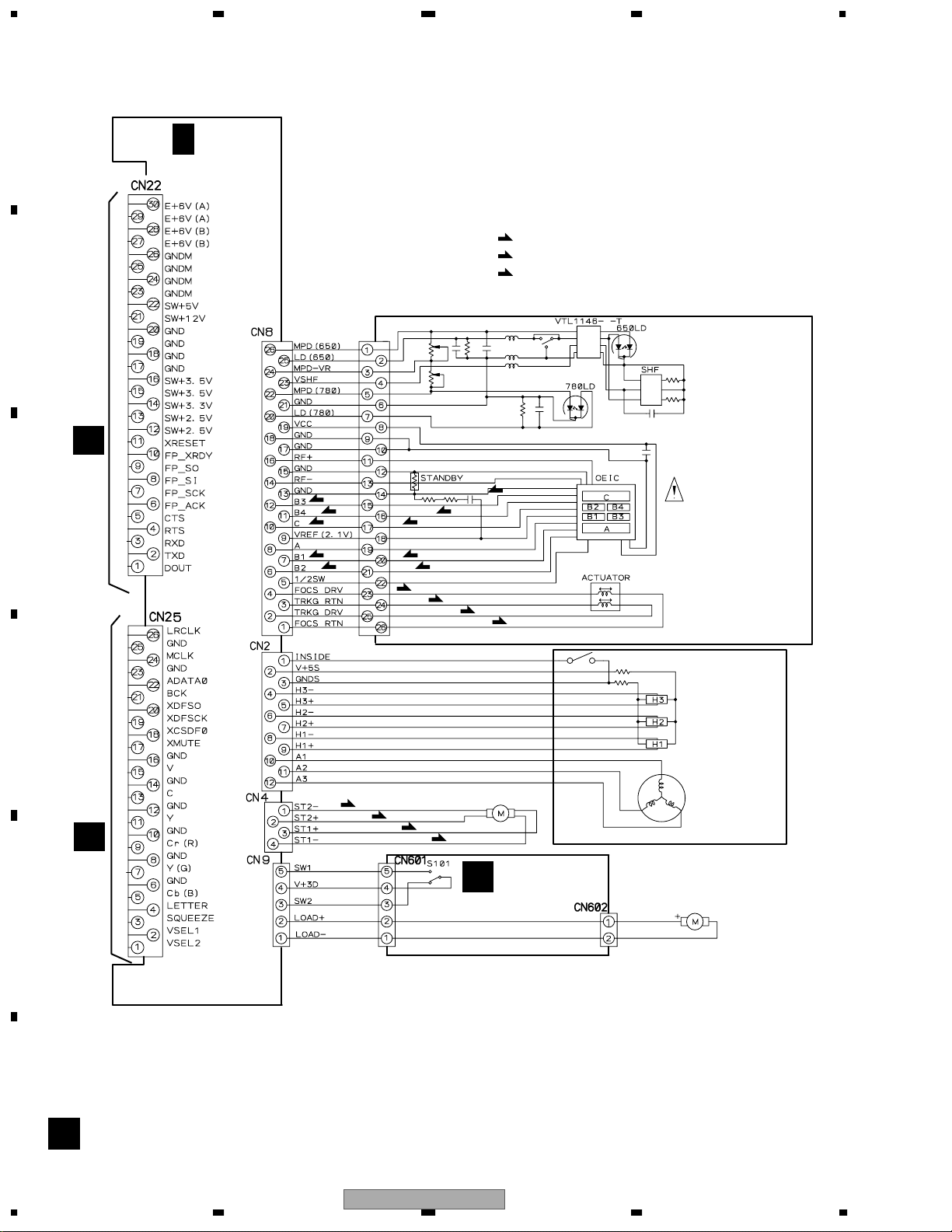

3.1.2 SIGNAL ROUT(2/2)

A

Spindle

Motor

PICKUP

B

Loading

C

Motor

Assy

M

CN602

ASSY

1

+–

2

(2P)

20

21

15

16

19

17

24

25

26

23

Stepping

Motor

(Carriage)

M

3.3V

S101

(26P)

CN601

(5P)

1

2

B1

B2

B3

B4

A

C

T_RTN

T_DRV

F_RTN

F_DRV

ST1-

ST1+

ST2+

ST2-

LOD-

LOD+

SW2

SW1

Work RAM for Error Correction

IC302

K6T1008V2E-TB70

1M SRAM

1

RF(TP)

CN151

7

6

12

11

8

10

3

2

1

4

(26P)

10

12

18

16

25

24

13

12

10

3

9

A

B

C

D

E

F

VM4VM4+

VM3+

VM3-

RFSACD

FRONT END IC

IC301

L6315ATXXTY

• RF Demodulation

• Servo Control

• Servo Decode

• Error Correction

FACT

123

FDO

3 20

IN3-

IC351

M56788AFP

FTS Driver

Focus, Tracking,

Stepper and

Loading Drive

VM1+

CN4

(4P)

4

3

2

1

CN9

(5P)

1

2

33

55

VM1-35VM2-31VM2+32VM5-15VM5+

34

XCLOSE

OPEN

X301

20MHz

131

132

FREOUT FREIN

OUT_DATA(0) S_DATA

TACT

124

TDO

IN4-

IN5-

17

14

Work RAM for MPEG Decode

IC604

K4S641632F-TC75

64M SDRAM

FE_DATA

PC(2) PC(6)

4238

FG

84

SPDL

PDM

LOAD_DRV

16

116

5

4

STI5519AVB-B0C

205

204

X601

27MHz

IC605 TC7WU04FU

120

HSYNC

_PWM0

PIXCLK

PIO381

PIO382

B_OUT

G_OUT

R_OUT

Y_OUT

C_OUT

CV_OUT

PCMDATA0

DAC_SCLK

PCKCLK

LRCLK

IC601

BACK END IC

• System Control

• MPEG Video Decode

• Video Encode

• Video DAC

• Audio Decode

(MP3, Dolby)

• Sub-picture Decode

XCLOSE

OPEN

SPDIF

3562

SQUEEZ

7

LETTER

8

25

26

27

32

33

Q602

34

A_DATA0

52

A_BCK

51

A_MCLK

55

A_LRCK

56

DOUT

57

Q607

Q605

Q603

CN25

(26P)

Q606

Q604

CN22

(30P)

3

4

5

7

9

11

13

15

22

21

24

26

1

FG

EC

2

FG

24

22

SPDL PDM

8M FLASH ROM

DVDM ASSY

F

IC603

VYW1948

LOAB ASSY

D

D

H1+

CN2

(12P)

4

5

6

7

8

9

3

2

1

H1+

9

H1-H1-

10

H2+H2+

11

H2-H2-

12

H3+H3+

13

H3-H3-

14

A1A1

7

A2A2

4

A3A3

2

IC251

BA6664FM

Spindle

Driver

• Spindle Drive

• FG Detection

3

CN401

(13P)

E

F

18

XV-EV51

1234

Page 19

G

DVD IF ASSY

Cb IN

YOUT b

YOUT a

COUT

VOUT b

VOUT a

CYOUT b

CYOUT a

CrOUT b

CrOUT a

CbOUT b

CbOUT a

Y

14

28

27

V

31

30

G

25

24

R

19

18

B

22

21

C

33

CN1961

(30P)

CN1901

(30P)

CN1962

(26P)

CN1902

(16P)

IC801

MM1567AJ

6 IN • 6 OUT

VIDEO AMP

BCKIN

1

DATA

2

MCLK

16

LRCKIN

3

IC711

PCM1742KE

Audio 2ch DAC

• LPF

• AMP

• Driver

1

B

CY IN

12

G

Cr IN

16

R

Y IN

6

S_Y

C IN

2

S_C

R721

R722

R723

V IN

4

V

DIGITAL

OUT

Vout L

LOUT

7

Vout R 8

ROUT

C812

C822

C832

AUDIO

OUT

3

4

24

5

26

21

7

9

11

13

22

15

10

24

14

16

6

8

30

28

12

7

12

11

8

9

10

2 5

6

1

3 4

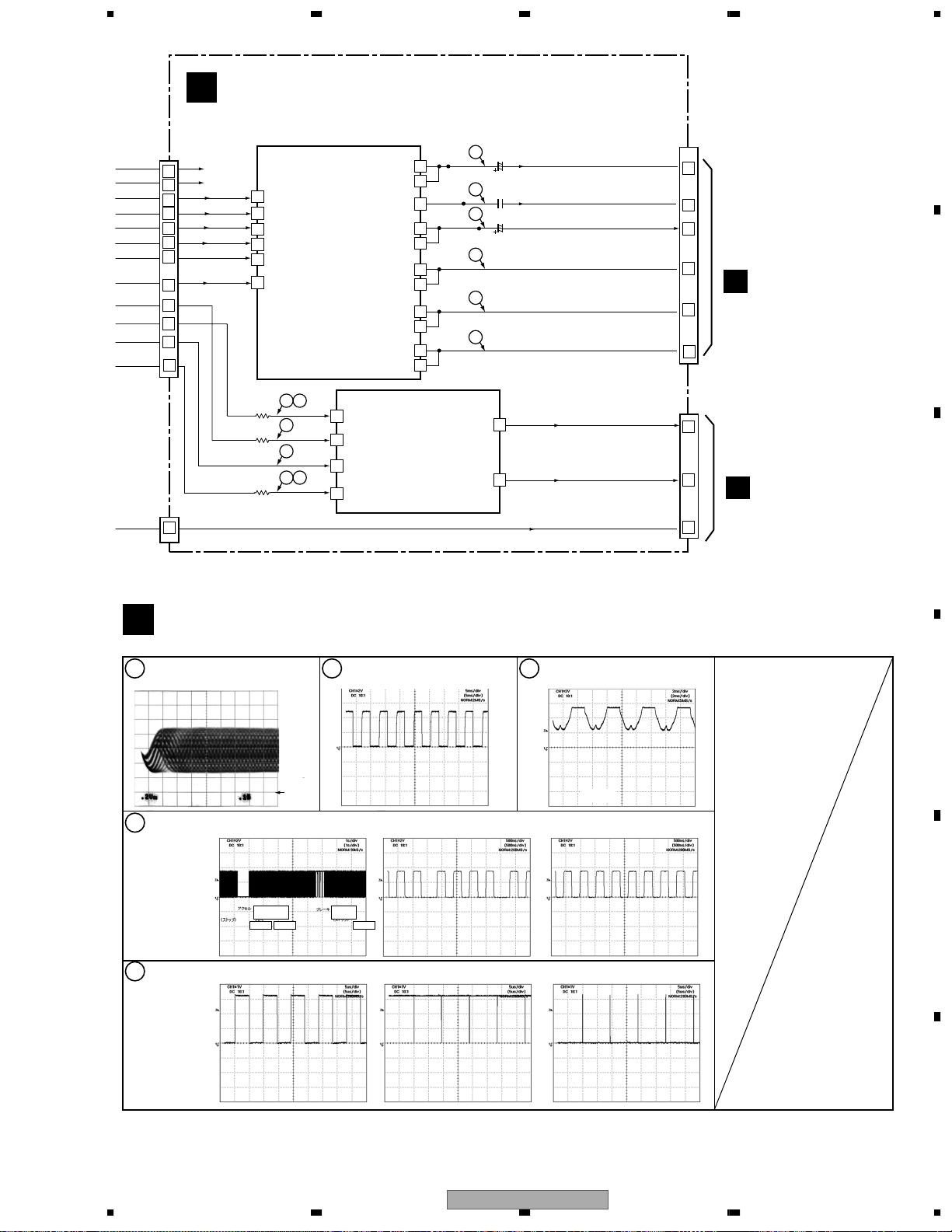

1– =: Refer to "3.1.3 WAVEFORMS".

3.1.3 WAVEFORMS

CN5903

B

B

CN5901

1

IC301 - pin 3 [RF]

V: 200mV/div. H: 0.1µsec/div.

2

IC251 - pin 24 [FG]

V: 1V/div. H: 5msec/div.

GND

5

IC601 - pin 116 [LOAD_DRV]

V: 1V/div. H: 5µsec/div.

4

IC301 - pin 42 [SPDL_PDM]

DVDM ASSY

F

[Tray stops][Tray is opening][Tray is closing]

[PLAY][STOP→PLAY→STOP] [STOP]

STOP STOPPLAY

Accelertar

ON

Brakes

ON

V: 2V/div. H: 500nsec/div.

V: 2V/div. H: 500nsec/div.

3

IC251 - pin 2, 4, 7

[Spidle driver -A3, A2, A1]

V: 2V/div. H: 2msec/div.

[PLAY]

V: 2V/div. H: 1sec/div.

Note : The encircled numbers denote measuring point in the schematic diagram.

Measurement condition

: No. 1 and 2 : reference A1 (DVD), T2-chp 19, Color-bar

5 678

A

B

C

D

E

XV-EV51

56

F

7

8

19

Page 20

1234

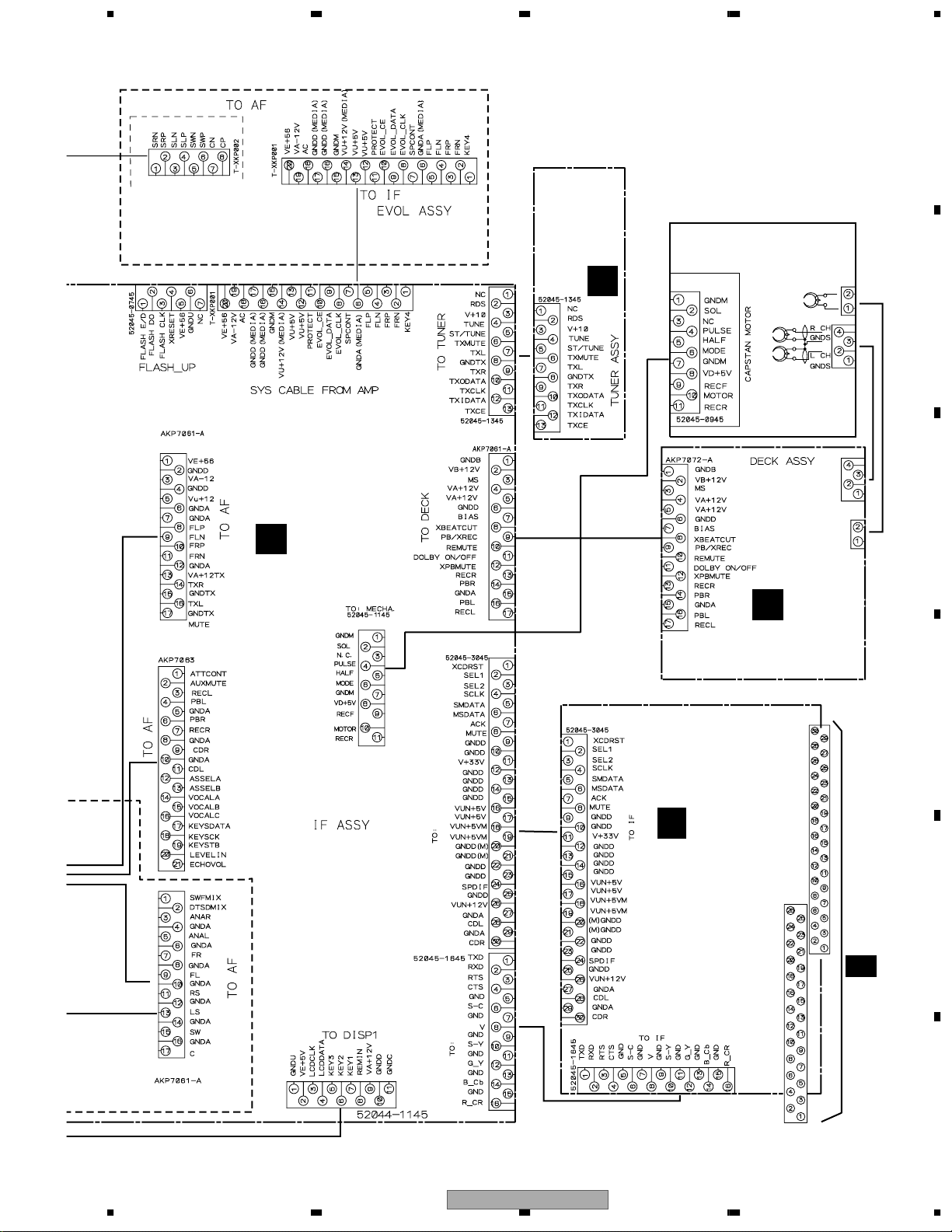

3.2 OVERALL WIRING DIAGAM

A

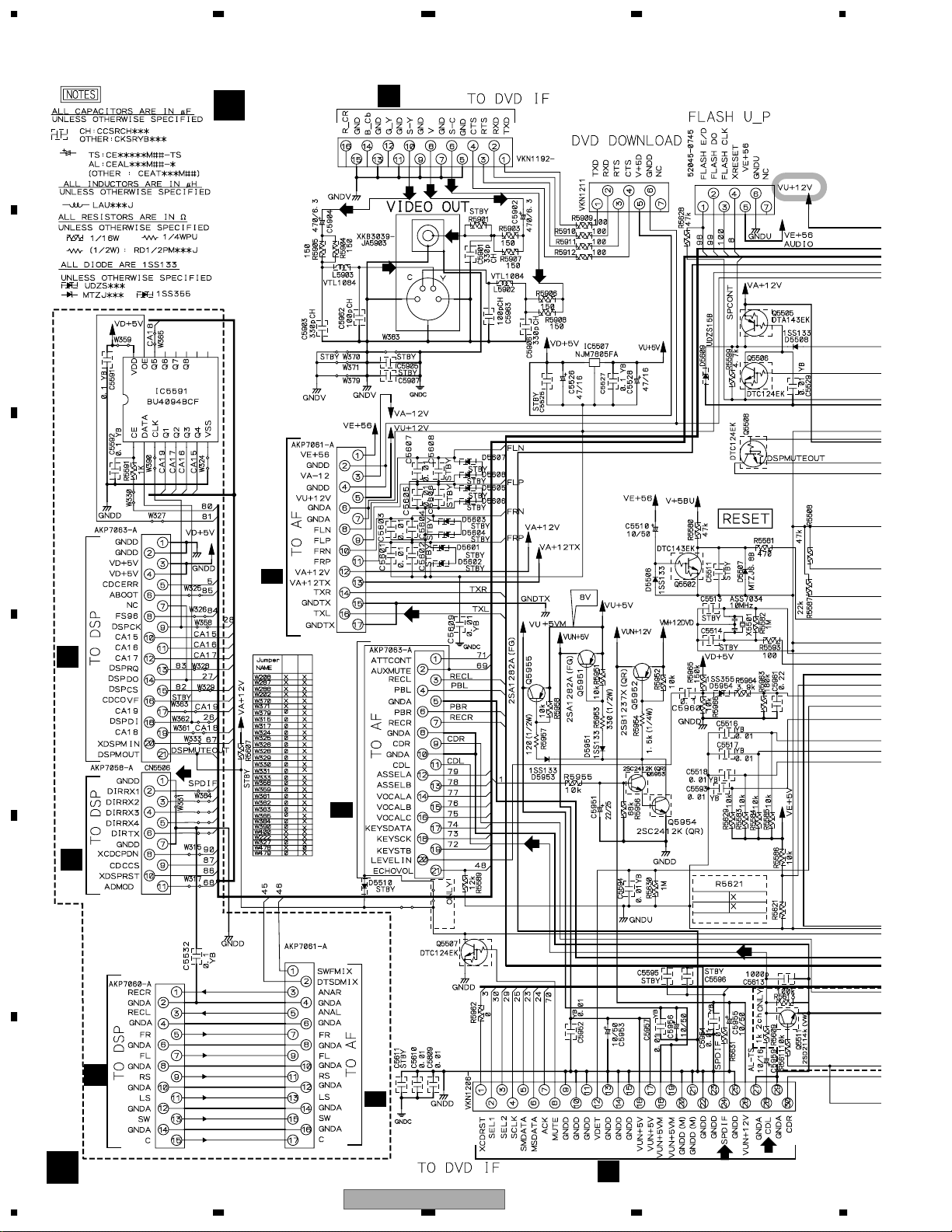

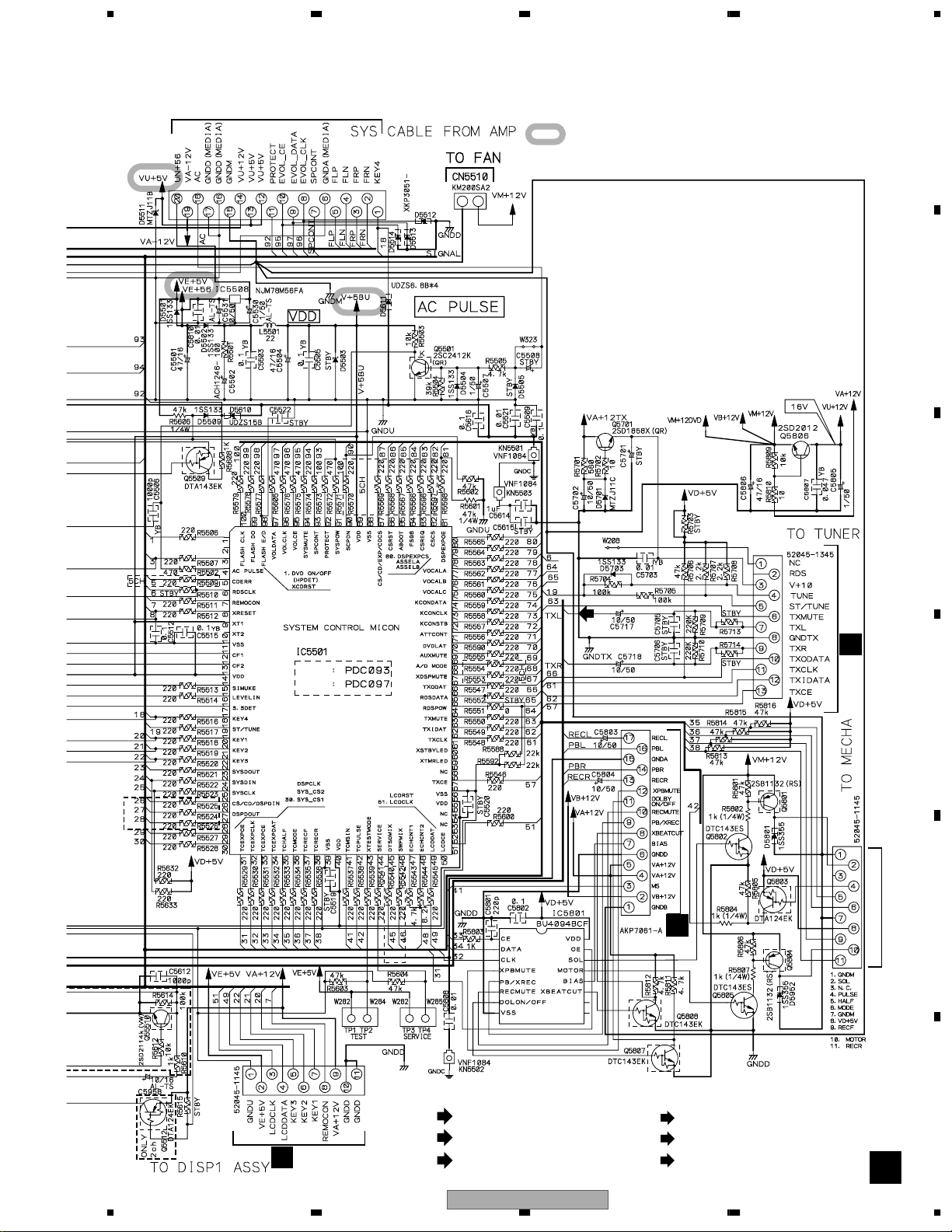

3.2.1 OVERALL WIRING DIAGRAM(MEDIA PART 1/2)

Note : When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST"

CN8701

CN8901

XV-EV51 Only

XV-EV51

Only

B

- 2/2

1/2

C

AF ASSY

(XWZ3618 / XV-EV51)

(XWZ3628 / XV-EV21)

CN8101

K

C

DSP ASSY

MIC ASSY

(XWZ3626/

XV-EV51)

(XWZ3623/

XV-EV21)

D

M

CN8301J5401

CN8751

CN8001

DSPCK

DSPRQ

DSPRO

DSPCS

CDCOVF

CN8002

DIRRX1

DIRRX2

DIRRX3

DIRRX4

DIRTX

(AWZ8059 / XV-EV51)

XDSPRST

CN8003

ADCR

ADCL

CN5902

CN5507

CN5506

E

L

DISP3 ASSY

(XWZ3621)

I

DISP2 ASSY

(XWZ3620)

J5102

CN5101

CN5102

CN5508

H

(XWZ3622)

LED ASSY

F

CN5203

20

1234

5301

J5202

J5203

XV-EV51

DISP1 ASSY

J

(XWZ3619)

Page 21

XV-EV51 Only

5 678

A

CN3002

(STEREO POWER AMPLIFIER)

M-EV51

Service Manual

order no. RRV2663

CN5502

CN5503

B

IF ASSY

(XWZ3617 / XV-EV51)

(XWZ3627 / XV-EV21)

CN5504

CN5802

CN3001

CN5501

CN5701

CN5801

CN5903

FM/AM TUNER

CN201

XDD3115

MODULE

(AXQ7228)

A

DECK

MECHA. (XYM3015)

ERASE

HEAD

REC/PB

HEAD

E

CN2506

DECK ASSY

(XWX3067 / XV-EV51)

(XWX3066 / XV-EV21)

CN2301

CN2302

B

C

CN5505

XDD3113

CN5509

DVD IF ASSY

DVD IF ASSY

CN5901

CN1901

XDD3116

XDD3117

DVD IF ASSY

G

(AWM7677)

CN1962

CN1902

CN1961

D

(AWM7684)

DVDM ASSY

- 2/2

E

1/2

F

F

56

XV-EV51

7

8

21

Page 22

1234

3.2.2 OVERALL WIRING DIAGRAM (MEDIA PART 2/2)

A

1/2

- 2/2

F

DVDM ASSY

(AWM7684)

(F)

: FOCUS SERVO LOOP LINE

(T)

: TRACKING SERVO LOOP LINE

(S)

: SLIDER SERVO LOOP LINE

B

DVD IF ASSY

(AWM7677)/CN1961

G

(F)

C

(F)

(T)

(F)

(F)

(F)

(F)

(T)

(F)

(F)

(T)

(T)

(F)

PICKUP ASSY-S

(OXX8003)

(F)

D

DVD IF ASSY

(AWM7677)/CN1962

G

E

F

ABCDE

D

STEPPING MOTOR

(S)

(S)

(S)

: VXM1090

(S)

LOAB ASSY

D

(VWG2346)

SPINDLE

MOTOR

: VXX1088

LOADING

MOTOR ASSY

: VXX2505

22

1234

XV-EV51

Page 23

CDAB

1

IC301 - pin 3 [RF]

V: 200mV/div. H: 0.1µsec/div.

3

IC711 - pin 3 [AUDIO DAC -LRCK]

V: 2V/div. H: 5µsec/div.

2

IC251 - pin 24 [FG]

V: 1V/div. H: 5msec/div.

1 2

IC711 - pin 16 [AUDIO DAC -MCK]

V: 1V/div. H: 20nsec/div.

IC711 - pin 1 [AUDIO DAC -BCK]

V: 2V/div. H: 200nsec/div.

GND

5

IC601 - pin 116 [LOAD_DRV]

V: 1V/div. H: 5µsec/div.

4

IC301 - pin 42 [SPDL_PDM]

5

4

IC711 - pin 3

[AUDIO DAC -LRCK]

V: 2V/div. H: 500nsec/div.

IC711 - pin 1

[AUDIO DAC -BCK]

V: 2V/div. H: 500nsec/div.

6

IC711 - pin 2

[AUDIO DAC -DATA]

V: 2V/div. H: 500nsec/div.

8

Foot of C842 (IC801 - pin 24, 25)

[Component Video output -Y]

V: 1V/div. H: 10µsec/div.

9

Foot of C852 (IC801 - pin 18, 19)

[Component Video output -Cb]

V: 2V/div. H: 10µsec/div.

11

Foot of C832 (IC801 - pin 27, 28)

[S Video output -Y]

V: 1V/div. H: 10µsec/div.

12

Foot of C822 (IC801 - pin 33)

[S Video output -C]

V: 1V/div. H: 10µsec/div.

10

Foot of C862 (IC801 - pin 21, 22)

[Component Video output -Cr]

V: 2V/div. H: 10µsec/div.

7

Foot of C812 (IC801 - pin 30, 31)

[Composite Video output]

V: 1V/div. H: 10µsec/div.

DVDM ASSY

F

DVD IF ASSY

G

GND

4

5

6

8

9

11

12

10

[Tray stops][Tray is opening][Tray is closing]

[PLAY][STOP→PLAY→STOP] [STOP]

STOP STOPPLAY

Accelertar

ON

Brakes

ON

V: 2V/div. H: 500nsec/div. V: 2V/div. H: 500nsec/div.

3

IC251 - pin 2, 4, 7

[Spidle driver -A3, A2, A1]

V: 2V/div. H: 2msec/div.

[PLAY]

V: 2V/div. H: 1sec/div.

Note : The encircled numbers denote measuring point in the schematic diagram.

Measurement condition

: No. 1 and 2 : reference A1 (DVD), T2-chp 19, Color-bar

Measurement condition

: No. 1 to 6 : reference A1 (DVD), T2-chp 1

No. 7 to 12 : reference A1 (DVD), T2-chp 19, Color-bar

3.1.3 WAVEFORMS

5 678

A

B

C

D

XV-EV51

56

E

7

8

F

23

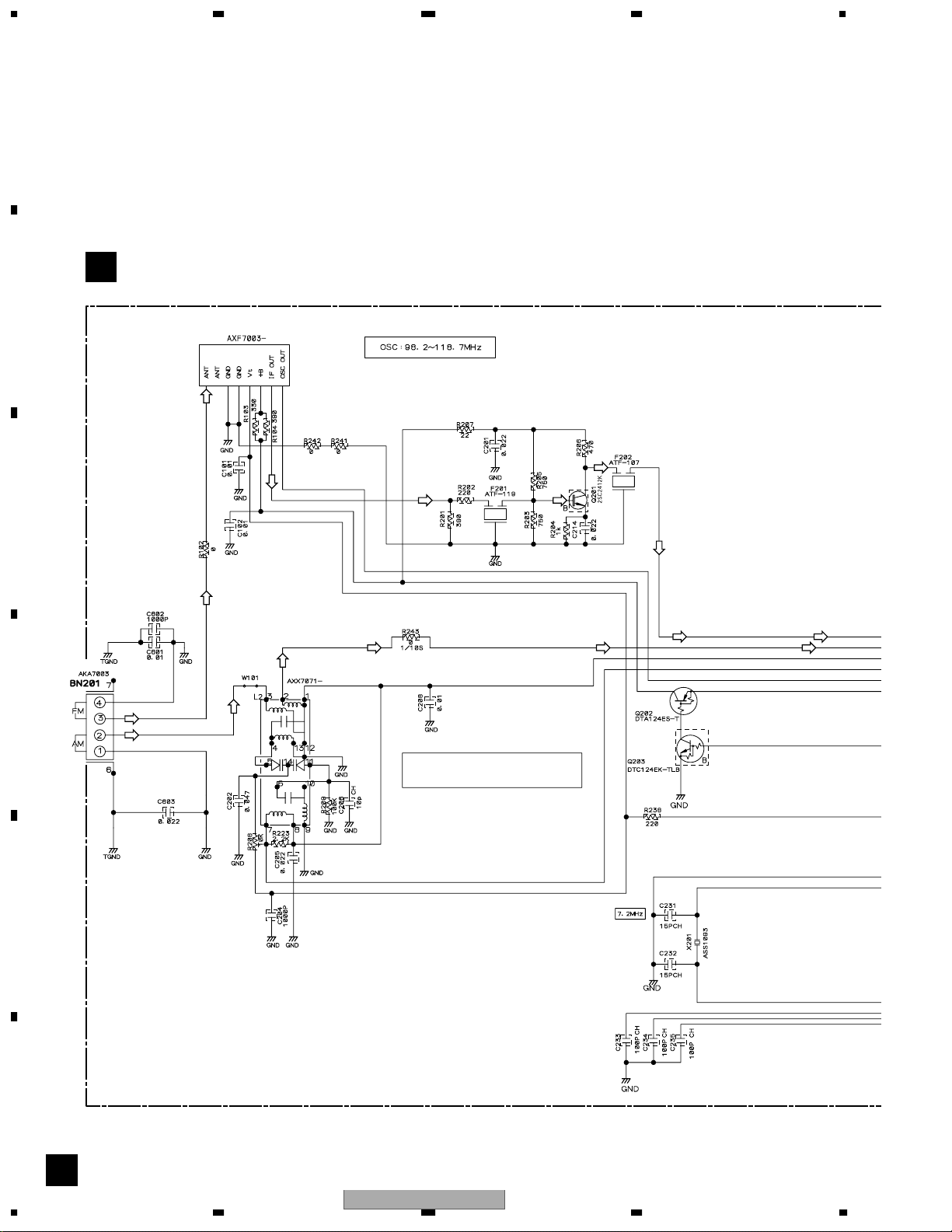

Page 24

1234

3.3 FM/AM TUNER MODULE

A

FM/AM TUNER MODULE (AXQ7228)

A

B

FM FRONT END

(FM)

(FM)

C

(FM) (FM)

(AM) (AM)

MW RF TUNING BLOCK

(AM)

D

(FM)

(AM)

(AM)

OSC : 981 - 2052kHz 9k step

(FM)

(FM)

(FM)

(FM) (FM)

(AM)

E

F

A

24

1234

XV-EV51

Page 25

5 678

A

: The power supply is shown with the marked box.

(TX)

: AUDIO SIGNAL ROUTE (TUNER)

(AM)

: AM SIGNAL ROUTE

(FM)

: FM SIGNAL ROUTE

B

(AM)

(FM)

(AM)

(AM)

(AM)

(AM)

(FM)

(AM)

(AM)

(FM)

(AM)

L201

ATE7003

(TX)

(AM)

(FM)

(TX)

(TX)

(TX)

(TX)

CN201

CN5701

C

B

D

56

XV-EV51

E

F

A

7

8

25

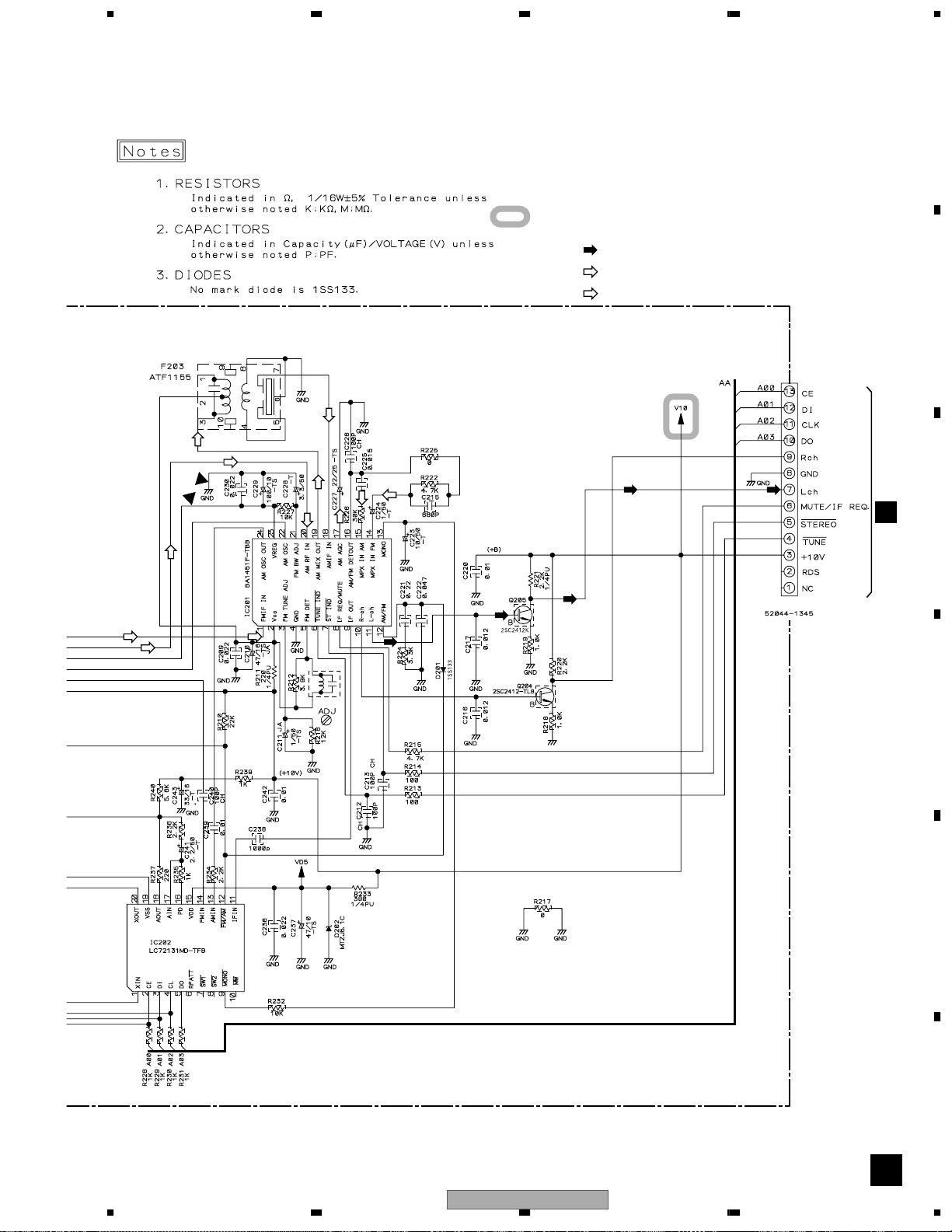

Page 26

3.4 IF ASSY

A

1234

CN1902

B

IF ASSY

G

(XWZ3617

/ XV-EV51)

CN5901

(XWZ3627

/ XV-EV21)

(S_Y)

(S_Y)

(V)

(S_C)

(V)

CN5902

CN5502

(S_Y)

B

CN5503

C

CN5507

CN8901

(S_C)

2/2

C

(TX)

CN8001

EV-

K

D

EV-

51

21

CN5504

(D)

CN8101

2/2

C

CN8002

K

E

CN5506

XV-EV51

ONLY

CN5508

CN8003

K

CN5505

CN8751

2/2

EV-51

Only

(CD)

EV-51

EV-21

(CD)

Only

XV-EV21

C

F

(D)

(CD)

26

B

CN5903

CN1902

G

1234

XV-EV51

Page 27

5 678

TO M-EV51 or M-EV21 Power Amplfier

CN5501

A

: The power supply is shown with the marked box.

B

C

CN5701

EV-51

EV-51

EV-21

EV-51

(TX)

CN5801

CN2506

E

CN201

A

To. Mecha Deck

CN5802

D

E

SIGNAL ROUTE

(CD)

: CD AUDIO SIGNAL ROUTE

(TX)

: AUDIO SIGNAL ROUTE (TUNER)

(D)

: DIGITAL SIGNAL ROUTE

XV-EV21

Only

CN5509

CN5101

J

XV-EV51

56

(V)

: V SIGNAL ROUTE

(S_C)

: S-VIDEO OUT C SIGNAL ROUTE

(S_Y)

: S-VIDEO OUT Y SIGNAL ROUTE

F

B

7

8

27

Page 28

1234

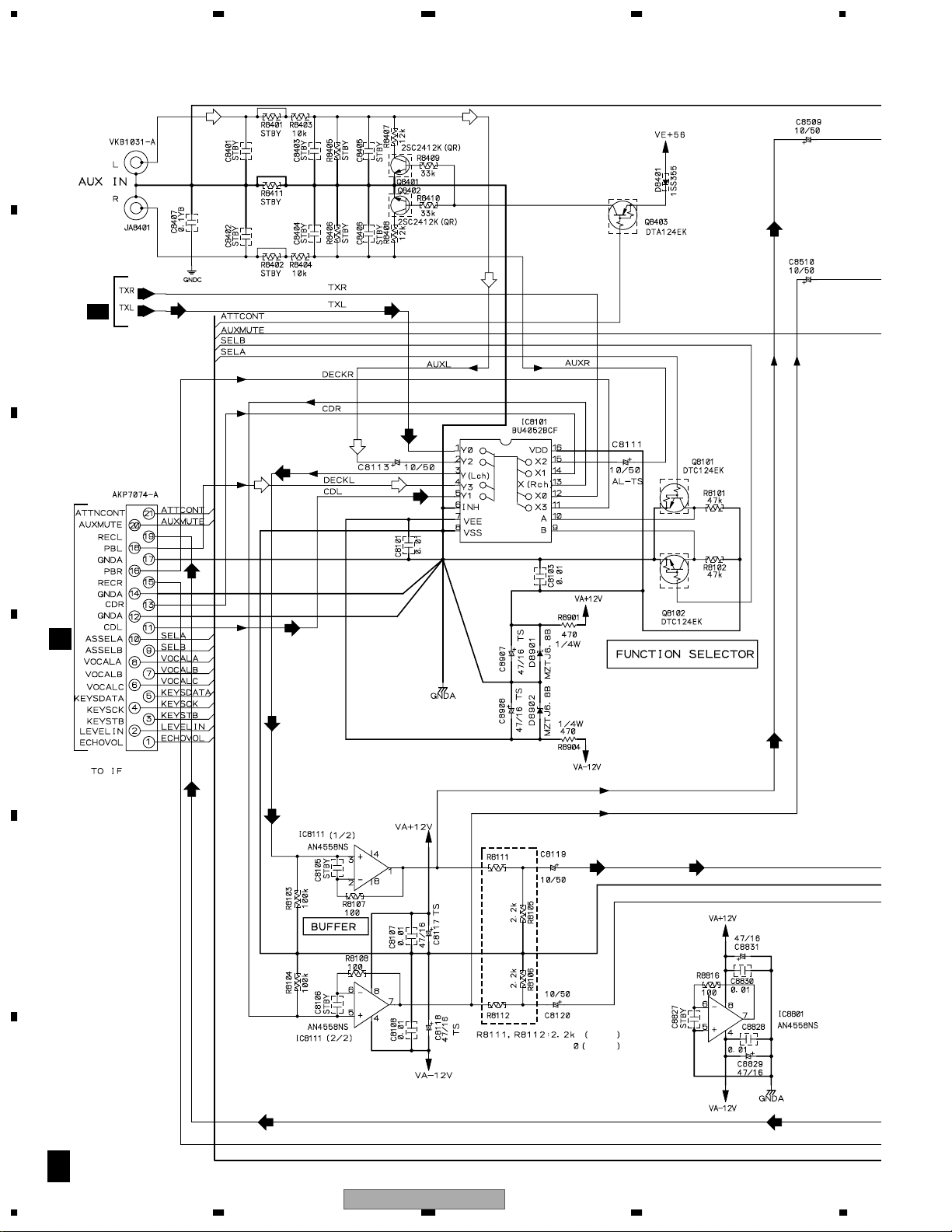

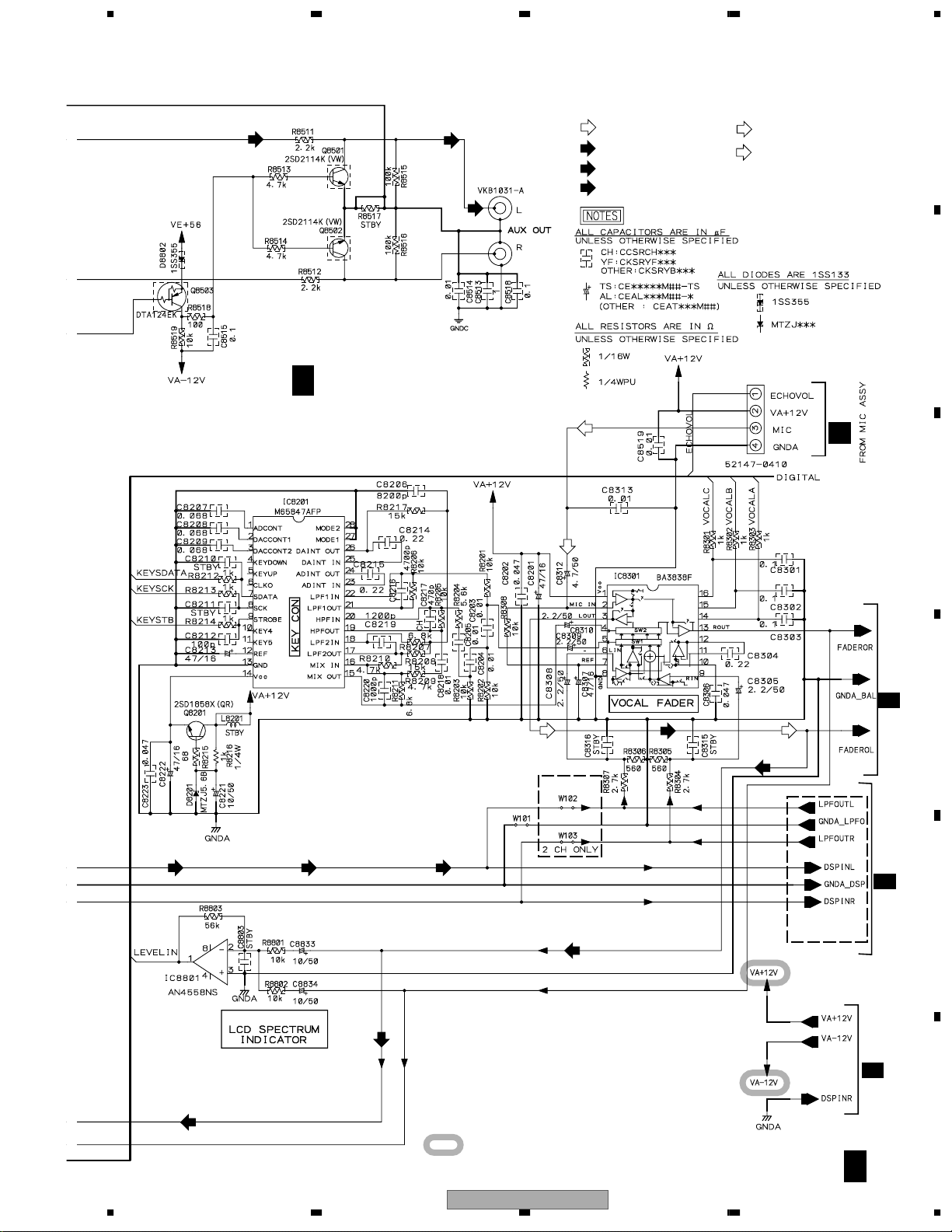

3.5 AF ASSY(1/2)

A

B

2/2

C

(AUX)

(TX) (TX)

(AUX)

(AUX)

(CD)(CD)

(AUX)

(REC)

CN8101

C

(REC)

(PB)

(TX)

(PB)

(CD)

CN5504

B

D

(REC)

(CD)

(TX) (REC)

XV-EV51 Only

(REC) (TX)

E

EV-51

EV-21

F

1/2

C

28

1234

(REC) (REC)

XV-EV51

Page 29

5 678

(CD)

(CD)

1/2

C

AF ASSY

(XWZ3618 / XV-EV51)

(XWZ3628 / XV-EV21)

(CD)

JA8401

SIGNAL ROUTE

(PB)

: PB SIGNAL

(REC)

: RECORDING SIGNAL

(TX)

: AUDIO SIGNAL (TUNER)

(CD)

: CD SIGNAL

(MIC)

(MIC)

(AUX)

: AUX SIGNAL

(MIC)

: MIC OUT SIGNAL

CN8301

A

B

J5401

M

C

(REC) (REC)(TX)

(REC)

(REC)

(MIC) (MIC)

EV21 Only

(REC)

(TX)

(REC)

XV-EV51 Only

2/2

C

D

2/2

C

E

2/2

C

F

: The power supply is shown with the marked box.

XV-EV51

56

1/2

C

7

8

29

Page 30

1234

3.6 AF ASSY(2/2)

A

1/2

(MIC) (MIC)

C

SIGNAL ROUTE

(MIC)

: MIC SIGNAL

(TX)

: AUDIO SIGNAL (TUNER)

B

1/2

C

C

XV-EV51

Only

D

CN8751

CN5505

B

E

F

30

C

2/2

XV-EV51

1234

Page 31

5 678

(MIC)

(MIC)

2/2

C

AF ASSY

(XWZ3618 / XV-EV51)

(XWZ3628 / XV-EV21)

(MIC)

XV-EV51

Only

(TX)

(MIC)

CN8901

(TX)

A

B

CN5503

B

C

CN8701

(TX)

1/2

C

D

To M-EV51 Power Amplfier

E

: The power supply is shown with the marked box.

XV-EV51

56

F

2/2

C

7

8

31

Page 32

1234

3.7 DECK ASSY

A

E

CN2301

B

C

CN2302

(REC)

DECK ASSY

(XWX3067/XV-EV51)

(XWX3066/XV-EV21)

(PB)

(PB)

(REC)

(REC)

(REC)

(REC)

D

E

F

E

32

1234

XV-EV51

Page 33

5 678

A

: The power supply is shown with the marked box.

(PB)

(PB)

(PB)

B

(PB)

(REC)

(PB)

(REC)

SIGNAL ROUTE

(PB)

: PB SIGNAL

(REC)

: RECORDING SIGNAL

EV-51

EV-21

EV51:-16.3dBV

EV21:- 6.5dBV

(REC)

C

D

(REC)

(PB)

CN2506

CN5801

B

XV-EV51

56

E

F

E

7

8

33

Page 34

1234

3.8 DVDM ASSY(1/2)

A

F 2/2

F 1/2

DVDM ASSY (AWM7684)

(S)

(S)

(S)

(S)

B

D

CN601

(F)

(T)

(F)

(T)

C

(RF)

(RF)

(RF)

D

PICKUP ASSY-S

(RF)

(RF)

(RF)

(F)

(T)

(T)

(F)

(F)

(T)

E

F

F 1/2

34

(T)

(T)

(S)

(S)

(S)

MOTOR

(S)

3

STEPPING

MOTOR

SPINDLE

XV-EV51

1234

2

Page 35

5 678

A

1,2,3,4 : Refer to "3.1.3 WAVEFORMS".

(RF)

: RF SIGNAL ROUTE

: DATA SIGNAL ROUTE

(F)

: FOCUS SERVO LOOP LINE

(T)

: TRACKING SERVO LOOP LINE

(S)

: SLIDER SERVO LOOP LINE

B

F 2/2

C

IC302

K6T1008V2E-TB70

WORK SRAM (1M)

D

1

(RF)

4

E

(RF)

: The power supply is shown with the marked box.

XV-EV51

56

F

F 1/2

7

8

35

Page 36

1234

3.9 DVDM ASSY(2/2)

A

F 2/2

DVDM ASSY

(AWM7684)

B

C

IC603 VYW1848

(MBM29LV800TA-90PFTN)

PGM 8M FLASH MEMORY

5

D

(R/Cr)

(S_Y)

(V)

(S_C)

(D)

(D)

(D)

(G/Y)

E

(B/Cb)

F

F 2/2

36

F 1/2

XV-EV51

1234

Page 37

5 678

IC604

K4S641632F-TC75

64M SDRAM

: The power supply is shown with the marked box.

5: Refer to "3.1.3 WAVEFORMS".

G

CN1961

(D)

(D)

A

B

C

(S_C)

(S_Y)

(V)

(S_C)

(S_Y)

(R/Cr)

(G/Y)

(V)

(V)

(S_C)

(S_Y)

(R/Cr)

(G/Y)

(B/Cb)

(R/Cr)

(G/Y)

(B/Cb)

(B/Cb)

(V)

(S_C)

(S_Y)

(R/Cr)

(G/Y)

(B/Cb)

: DATA SIGNAL ROUTE

(V)

: V SIGNAL ROUTE

(S_C)

: S-VIDEO OUT C SIGNAL ROUTE

(S_Y)

: S-VIDEO OUT Y SIGNAL ROUTE

(R/Cr)

: R/Cr SIGNAL ROUTE

(G/Y)

: G/Y SIGNAL ROUTE

(B/Cb)

: B/Cb SIGNAL ROUTE

: AUDIO SIGNAL ROUTE

(D)

: AUDIO (DIGITAL) SIGNAL ROUTE

G

D

CN1962

E

F

56

XV-EV51

F 2/2

7

8

37

Page 38

1234

3.10 DVD IF ASSY

A

DVD IF ASSY (AWM7677)

G

(D) (D)

B

(D)

CN21

F 2/2

C

(D)

(S_C)

(V)

(S_Y)(S_Y)

D

(G/Y)(G/Y)

(B/Cb)(B/Cb)

(R/Cr) (R/Cr)

(S_C)(S_C)

(V)(V)

(S_Y)

(G/Y)

(B/Cb)

(R/Cr)

CN25

(S_C)

F 2/2

E

(R/Cr)

(B/Cb) (B/Cb)

(V)

(S_Y)

(G/Y)(G/Y)

F

G

38

1234

XV-EV51

Page 39

5 678

(D)

265

3 4

(V)

: V SIGNAL ROUTE

(S_C)

: S-VIDEO OUT C SIGNAL ROUTE

(S_Y)

: S-VIDEO OUT Y SIGNAL ROUTE

1

(D) (D)

(R/Cr)

: R/Cr SIGNAL ROUTE

(G/Y)

: G/Y SIGNAL ROUTE

(B/Cb)

: B/Cb SIGNAL ROUTE

: AUDIO SIGNAL ROUTE

(D)

: AUDIO (DIGITAL) SIGNAL ROUTE

A

B

C

(B/Cb)

(R/Cr)

(S_C)

(V)

(S_Y)

(G/Y)

(S_C) (S_C)

(V) (V)

(S_Y) (S_Y) (S_Y)

(G/Y) (G/Y)

(B/Cb) (B/Cb) (B/Cb)

CN5903

B

(D)

D

(S_C)

E

CN5901

B

(R/Cr)(R/Cr)(R/Cr)

1, 2, 3, 4, 5, 6: Refer to "3.1.3 WAVEFORMS"

: The power supply is shown with the marked box.

XV-EV51

56

F

G

7

8

39

Page 40

1234

3.11 DISP1, DISP2, DISP3 and LED ASSYS

A

B

C

LED ASSY

L

(XWZ3622)

CN5203

DISP 1 ASSY

J

(XWZ3619)

J5203

DISP 2 ASSY

I

(XWZ3620)

CN5101

CN5509

B

D

CN5102

E

J5102

I

DISP 1 ASSY

S5101: Sound Mode

S5102: EV-51_Karaoke

EV-21_Vlrtual Surround

S5103: ST Memory

S5104: Enter

S5105: Display

S5106: TIME/CLOCK ADJ

F

I J L

40

1234

XV-EV51

Page 41

5 678

A

J5102

CN5102

J

B

J5202

DISP 2 ASSY

I

(XWZ3620)

DISP 2 ASSY

S5201: PLAY

S5202: VOL S5203: ( - )

S5204: DVD / CD

S5205: STOP

S5206: VOL +

S5207: ( + )

S5208: TAPE

S5209: LINE 1

S5210: OPEN/CLOSE

S5211: TUNNER

J5202

DISP 3 ASSY

H

C

(XWZ3621)

D

DISP 3 ASSY

S5301: ASES

S5202: DOBLY NR

S5203: REV MODE

S5204: REC/STOP

E

: The power supply is shown with the marked box.

XV-EV51

56

F

H I

7

8

41

Page 42

1234

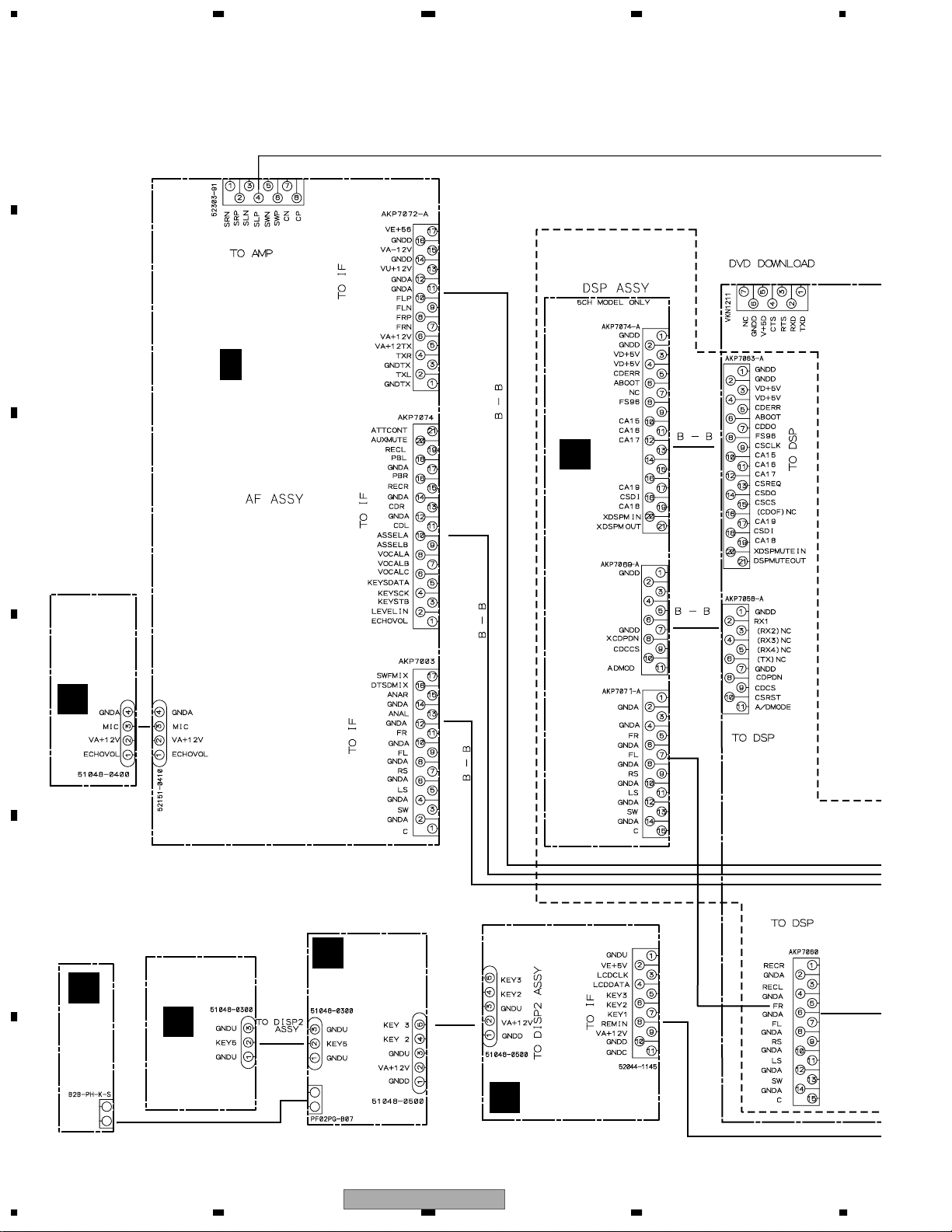

3.12 DSP ASSY

A

K

XV-EV51 : Only

B

DSP ASSY

(AWZ8059)

C

D

E

F

K

42

1234

XV-EV51

Page 43

5 678

A

B

CN5503

B

CN5506

B

CN5504

B

C

D

E

: The power supply is shown with the marked box.

XV-EV51

56

F

K

7

8

43

Page 44

1234

3.13 MIC ASSY

A

M

MIC ASSY

(XWZ3626 / XV-EV51)

(XWZ3623 / XV-EV21)

B

C

D

JA5401

EV-51

EV-21

JA5402

E

F

M

44

1234

XV-EV51

Page 45

5 678

A

CN8301

C

B

J5401

C

D

E

56

XV-EV51

F

M

7

8

45

Page 46

1234

4. PCB CONNECTION DIAGRAM

4.1 LOAB ASSY

A

NOTE FOR PCB DIAGRAMS :

1. Part numbers in PCB diagrams match those in the schematic

diagrams.

2. A comparison between the main parts of PCB and schematic

diagrams is shown below.

Symbol In PCB

Diagrams

B

BCE

BCE

D

Symbol In Schematic

Diagrams

BCEBCE

BCE

DGGSS

BCE

DGS

Part Name

Transistor

Transistor

with resistor

Field effect

transistor

3. The parts mounted on this PCB include all necessary parts for

several destinations.

For further information for respective destinations, be sure to

check with the schematic diagram.

4. View point of PCB diagrams.

Connector

Capacitor

SIDE A

P.C.Board

Chip Part

SIDE B

Resistor array

C

3-terminal

regulator

SIDE A SIDE B

D

E

LOAB ASSY

D

CN601CN602 CN601 CN602

M

LOADING

MOTOR

ASSY

(VNP1837-B)

CN9

F

LOAB ASSY

D

(VNP1837-B)

F

D

46

1234

XV-EV51

Page 47

5 678

(ANP7338-B)

(ANP7338-B)

CN5701

B

FM/AM TUNER MODULE

A

FM/AM TUNER MODULE

A

IC201 Q205

Q204

Q203

IC202

Q201

Q202

A

A

SIDE A

SIDE A

SIDE B

SIDE B

CN201

4.2 FM/AM TUNER MODULE

A

B

C

D

E

56

XV-EV51

7

F

47

8

Page 48

1234

0

C

D301

R401

4.3 DVDM ASSY

SIDE A

A

DVDM ASSY

F

IC601 IC301

Q607 Q606 Q605 Q604 Q603 Q602

IC303

R546

R564

C650

R662

C622

R563

C611 C612

C605

A

C335

R317

R316

R399

R340

R574

R576

R578

R580

R581

C606

R583

R586

R587

R589

IC301

C321

R309

R310

B

73

C328

108

D

231

B

C603

231

1

CN601

23

C624

157

C625

224

C

R575

R582

R584

R600

156

156

CN602

C623

C616

224

231

E

CN603

224

R630

C626

R565

R642

105

R566

104

E

R641

C327

C322

109

C340

72

R567

R643

C641

R569

C333

R306

C615

C613

R304

R322

R632

C651

C302

R330

C323

R631

C301

R305

R301

C332

C326

R300

R332

329

R339

R623

R625

1

1

1

C317

L310

B

L308

CN21

C315

C342

1

4

IC303

C313

CONTACT SIDE

R400

CN22

1

4

CN11

A

R541

R551

R398

208157

R552

10

1

1

R553

C607

R572

R571

R670

1

C608

1

1

Q607

Q606

R545

R617

C609

R612

Q605

Q604Q603

IC601

52

C621

R613

R556

R555

Q602

CN23

CONTACT SIDE

C610

R562

R558

R559

53

R619

R620

V+5V

26

26

C628

C316

R624

R621

R622

26

D

E

R585

R501

R502

CN12

R588

R503

1

C

CN25

VNP1866

E88558

ND SIDE

F

CN25

CN22

48

F

CN1962

G

1234

XV-EV51

CN1961

G

Page 49

5 678

T

E

C302

C

R632

2

IC301

R631

C301

R305

R301

C332

C326

R300

R332

C329

R258

R259

C334

144

R257

C259

37

36

1

R333

R256

FC

37

C331

C343

R302

C311

IC110 IC111

C256

R254

R255

DC

C359

R379

R329

C339

C330

C338

R303

C

C105

R396

R395

1

C324

C325

R366

R393

R394

C257

R351

R353

C373

IC251 IC351 Q101

C258

R261

30

29

C351

1

R365

R357

21

R338

R392

V+5S

C251

IC251

R121

R123

Q102

R266

1528

14

C353

650

C255

F

22

Q101

25

1

CN5

C248

C249

17

IC351

R368

C361

26

26

1

CN2

12

CONTACT SIDE

A

C365

C366

R370

R355

C362

R377

F

4

1

CN4

C250

R391

C391

R371

R372

R378

R354

CN2

SPINDLE

MOTOR

CN4

STEPPING

MOTOR

SIDE A

A

B

C

D

2

961

C315

C342

IC303

CON

CN2

C313

D301

R401

R400

RF

X301

C104

R155

IC110

8

IC111

C109

1

SECOND SID

30

8

5

4

4

1

C401

30

30

C

R328

R380

5

4

4

R3

R358

R361

R359

C360

R4

C357

R362

R360

GND

1

R157

1

C103

R146

C108

R145

R144

780

CN9

C106

R147

R156

R158

Q102

R136

R137

R140

R133

1

5 1

5

C107

D

56

XV-EV51

1

2

CN7

CN90

CN9

CN601

CN8

(VNP1866-D)

7

CN8

PICKUP

ASSY

E

B

F

F

49

8

Page 50

A

4

R

R

C

SIDE B

1234

DVDM ASSY

F

IC302

Q300

Q103 Q105

I

C307

R318

R384

R407

C308

R319

IC304

C309

R331

R385

C318

R673

17

L300

9

L311

32

R320

8

9

336

337

C643

C404

SIDE

LEAD FREE SOLDER

1

B

CN2

CN2 CN4 CN8

C

R327

R326

C157

D

E

26

1

12

R341

CN4

1

4

R373

R364

R100

26

2

R126

1

17

V+6B

C368

C158

R172

R171

C148

R128

R127

V+12M

R356

R110

C110

25

R118

1

R129

GNDM

C149

R115

R125

Q103

C112

C101

C102

5

R138

C369

R344

R346

6

1

R111

R265

R345

4

3

R139

R142

1

R367

R375

R374

R376

R141

R262

R113

R2

NORMAL SOLDER

C254

C253

C304

V+5S

C305

R154

3

C113

R150

R149

C111

R1

Q105

4

R152

R151

VREF21

C405

C403

30

R153

1

6

PRE-FLAX

R177

R176

R179

R178

IC302

Q300

C

98765432

B

A

R315

R321

C310

C341

C413

C412

R405

V+3R5D

R406

HEAT-RESISTANCE

F

CN22CN9

F

50

1234

XV-EV51

Page 51

5 678

7

9

SIDE B

IC605 IC603

Q651

IC304 IC604

R603

R604

R607

9

8

7

6

5

4

3

2

1

0

R699

C637

C697

R609

R610

C620

7

C699

1

C696

C627

IC604

C698

C636

C618

R557

26

AWM

VWS1

R505

C635

27

L602

R702

1

R560

R675

R678

R679

R676

L603

R561

R681

R682

R568

C617

R684

R685

C633

R645

R616

R674

C645

R687

54

28

R677

R688

R570

R695

R618

R680

0

1

321

32

9

R336

R337

C643

0

R311

1

16

R312

R314

C414

R334

R335

654321

17

C307

R318

R384

C318

R40

C308

R319

IC304

C30

R331

R385

R673

R320

L300

8

9

L311

1

R313

L324

R606

C319

V+2R5

0

0

R608

R605

R626

99

88

77

66

55

44

R660

33

22

11

00

C404

R659

N

Q

J

1

CN

A-

FIRST SIDE

C614

R646

R638

C638

48

C619

C648

R683

R691

R690

25

R686

Q601 Q652

X601

5

8

4

6

1

C632

3

1

R544

L601

4

IC605

1

R543

1

R689

R719

R717

R647

R648

R651

Q651

R720

D601

R650

R652

Q652

R654

R668

R554

R542

R718

C634

R590

R666

R504

R547

R579

Q601

IC603

R671

C629

R640

C630

24

1

R577

R639

C631

R601

R602

R653

A

B

C

D

E

CN25

XV-EV51

56

(VNP1866-D)

F

F

7

8

51

Page 52

1234

4.4 DVD IF ASSY

SIDE A SIDE A

A

DVDIF ASSY

G

CN5901

B

B

B

C1902

C1907

V+5V

C1911

V+3.3

VPRE+5M

C1994

C1919

Q1901

IC1902

IC1903

1

1

4

4

C1991

C1992

IC1901

C1997

85

8

5

C1905

VPRE+5

C

V+5D

C1995

D

C1912

D1902

CN1902

CONTACT

UPSIDE

16 1

16 1

C1906

R1982

C1993

C1908

C1903

C1996

IC1906

R1927

C1929

IC1921

916

R1902

IC1905

16 9

C1918

R1901

D1901

C1915

C1914

C1928

R1983 C1978

C1980

C1976

C1930

C1979

C1977

C1975

C1910

GNDD

C1926

CN1902

ICT

FC

V+12

A

GNDA

Lch

DOUT

30 1

30

1

CONTACT

26

26

1

R1981

C1932

Rch

R1993

CN1961

R1992

UPSIDE

CN1962

IC1902

IC1903

IC1901

CN1961

IC1906

IC1905

CN1962

C1931

E M B1N

R1932

R1931

V+6M

GNDM

C1981

V+3.5

V+2.5

C1925

L1981

C1922

C1971

C1923

81

81

R1924

R1926

C1972

R1925

R1930

C1973

C1974

R1929

R1928

1

CN22

F

DVD IF UNIT

C1917

L1903

AWM7677

L1901

R1903

C1909

C1990

C1916

R1904

E

IC1904

1/4

C

C1950

D

C1943

C1941

C1945

C1948

C1955

4

41

1

C1947

CN1963

CN25

F

IC1904

(ANP7425-A)

F

G

52

1234

XV-EV51

Page 53

5 678

ABC

1

0

0

321

0

987654321

0

1

14 8

71

1

30

34 18

171

14 8

71

5

1

UPSIDE

CONTACT

1

1

14 8

71

30

1

34 18

171

14 8

71

D1932

R1908

D1931

R1986

C1999

R1963

R1972

R1906

R1938

R1907

R1933

R1946

R1945

R1939

C1998

R1935

R1936

C1982

C1933

R1934

C1953

R1970

R1961

R1905

C1956

R1962

Q1931

R1994

C1962

R1995

R1942

R1923

IC1962

Q1921

R1940

C1957

Q1922

C1904

Q1942

R1969

R1966

Q1961

R1944

C1951

CN1901

R1968

C1954

R1952

Q1941

C1927

R1965

R1967

R1921

C1921

C1920

L1902

IC1941

C1949

R1964

R1974

C1901

R1985

R1922

R1941

R1971

C1924

C1984

C1913

C1983

C1963

R1937

C1986

C1985

R1975

C1988

C1961

D1934

IC1961

IC1986

Q1932

C1987

R1912

D1933

D1935

R1987

R1920

C1952

C1989

R1943

R1911

R1988

SIDE B SIDE B

G

DVD IF ASSY

G

(ANP7425-A)

CN1961

CN1962

CN1901

Q1941

Q1942

IC1889

IC1941

Q1922

Q1961

IC1962

Q1932

Q1931

Q1921

IC1961

A

B

C

D

E

XV-EV51

56

F

7

8

53

Page 54

4.5 IF ASSY

SIDE A

A

1234

W283

W260

1

21

1

11

1

15

W261

VA+12V

W229

K

OPEN

1

21

1

11

OPEN

1

15

CN5507

CN5506

CN5508

GNDU

CN8003

20

20

R5914

GNDD

DSPCLK

W390

W363

W362

W361

W360

J4

OPEN

W331

VE+5V

W317

W318

W493

W302

VE+5V

GNDU

W300

SERVICE

W285

W282

W284

TEST

VE+5V

W258

W281

W257

VM+12V

R5913

W259

W230

L5701

C5713

X5701

For Binder

To M-EV51 or M-EV21

Power amplfier

CN5501 CN5901

UPPER SIDE

VU+12V

W397

GNDD

W301

VD+5V

W228

A

W387

W389

W388

DVDCS

W316

GNDU

W256

Q5805

SIDE

J3

GNDM

17.GNDD

18.AC

19.VA-12V

20.UN+56

DSPOUT

IC5591

DSPMUTEOUT

EXPCS

W328

W329

W330

CMKS-P3X

W255

W252

W254

VD+5V

W253

R5804

R5807

CONTACT

1

1

12.VU+5V

13.VU+5V

14.VU+12V

15.GNDM

16.GNDD

VA+12V

GNDU

W327

W325

W326

R5601

IF ASSY

IC5501

W280

W249

W251

W250

1

11

Q5802

R5802

10

CN5509

11

1

W386

KEY4

6.GNDA

7.SPCON

8.EVOL-CLK

9.EVOL-DATA

10.EVOL-CE

11.PROTECT

W359

W358

W355

W357

W356

VE+56

W324

W485

W494

L5501

D5503

C5504

W299

KEY2

KEY3

W279

W278

W248

W480

10

CN5802

W226

W227

W225

W207

11

DISP FFC

1

CN5501

W385

4.FLN

5.FLP

W498

W354

GNDU

W491

D5501

R5606

W315

V+5BU

KEY1

ST/TUNE

W247

W277

W481

1

DECK FFC

11

W396

W484

W246

GNDV

3.FRP

X5501

W244

W383

2.FRN

1.KEY4

SPDIF

W384

W245

VA+12V

GNDC

C5501

J2

W276

W353

C5502

W241

W223

IC5801

AC

W352

D5502

-+

W313

W275

SYSDOUT

SIDE

CONTACT

PRINTED

W242

W220

EVOLCS

EVOLDATA

W351

W350

W323

D5508

D5509

W312

W314

W298

1.FLASH E/D

2.FLASH DO

W272

W273

SYSCLK

W243

SIDE

W224

W222

W221

W206

W205

JA5903

EVOLCLK

W382

NJM7805FA

IC5507

C5508

W311

W297

4.XRESET

3.FLASH CLK

W271

SYSDIN

B

E

2SD2012

W203

W204

71

71

C5902

SPCONT

PROTECT

W322

W380

W381

SIDE

CONTACT

1

1

W296

7.NC

5.VE+56

6.GNDU

W295

W274

VDET

W238

W239

Q5806

W237

W217

W218

W219

W379

C5904

D5511

W349

PRINTED SIDE

IN OUT

D5505

C5507

D5504

D5506

W294

W293

C5951

C5805

C5806

C5803

CN5902

7

CN5502

7

W216

C5804

CONTACT

6.GNDD

5.V+5D

4.CTS

7.NC

3.RTS

W377

W500

W378

W348

C5528 C5526

C5510

D5507

VUN+12V

VM+12V

VUN+5V

VUN+5VM

C5956

C5953

1.GNDB

2.VB+12V

3.MS

4.VA+12V

5.VA+12V

6.GNDD

7.BIAS

8.XBEATCUT

W215

9.PB/XREC

10.RECMUTE

11.DOLBY ON/OFF

12.XPBMUTE

13.RECR

14.PBR

W202

W376

W320

W321

C5955

W482

GNDM

W214

2.RXD

W347

W267

W266

W265

W201

1.TXD

W375

GNDD

W270

W268

W269

W236

1

15.GNDA

16.PBL

17.RECL

KN5501

W374

V+8V

GNDA

W235

1

17

C

W373

W372

VD+5V

R5954

D5951

D5953

W292

W291

W264

SIDE

CONTACT

1

J1

GNDD

W213

OPEN

1

CN5801

17

CN1902

G

B

W371

W370

30.CDR

W346

29.GNDA

28.CDL

27.GNDA

26.VUN+12V

25.GNDD

16

24.SPDIF

1

23.GNDD

22.GNDD

21.GNDD(M)

20.GNDD(M)

19.VUN+5VM

18.VUN+5VM

17.VUN+5V

16.VUN+5V

15.NC

14.NC

13.NC

12.GNDD

1

11.VDET

10.NC

9.GNDD

8.MUTE

7.ACK

6.MSDATA

5.SMDATA

4.SCLK

3.SEL2

2.SEL1

1.XCDRST

W306

W309

W308

R5953

Q5952

Q5951

Q5955

30

W234

30

1

SIDE

CONTACT

16

CN5901

R5957

CN5903

KN5502

B

IF ASSY

CN8002

K

CN8001

C

GNDM

1

1

ATTCONT

1.

AUXMUTE

2.

3.RECL

4.PBL

5.GNDA

6.PBR

7.RECR

8.GNDA

9.CDR

10.GNDA

11.CDL

W395

W368

W369

CN5510

W345

W344

W343

W342

W341

W340

12.ASSELA

13.ASSELB

14.VOCALA

15.VOCALB

16.VOCALC

17.KEYSDATA

18.KEYSCK

19.KEYSTB

20.LEVELIN

W489

21.ECHOVOL

CN8901

CN5503

KN5503

A

W499

W478

W339

W488

W490

1

GNDA

W400

GNDM

VE+56

1

1

IC5508

GNDD

CN5503

17

17

W479

5 CH

1

1

CN5504

W338

21

21

OPEN

VM+12V

VA+12V

OPEN

1

1

CN5506

W483

W393

IN

W367

W337

To FAN

CN5510

B

IC5508

IC5591

C

IC5507

IC5501

(1 RED,2 BLACK)

D

Q5952

Q5951

17

17

Q5955

CN5505

Q5701

Q5806

E

Q5802

C5959 C5958

10

W263