PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2006

ORDER NO.

RRV3411

XV-DV360

DVD/CD RECEIVER

XV-DV360

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement

XV-DV360 KUCXJ AC 120 V 1

Regional restriction

codes (Region No.)

Remarks

For details, refer to "Important Check Points for Good Servicing".

T-ZZK MAY 2006 printed in Japan

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

B

cause cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement

parts must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que

C

les pièces de remplacement doivent avoir la même désignation.

(FOR USA MODEL ONLY)

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

LEAKAGE CURRENT CHECK

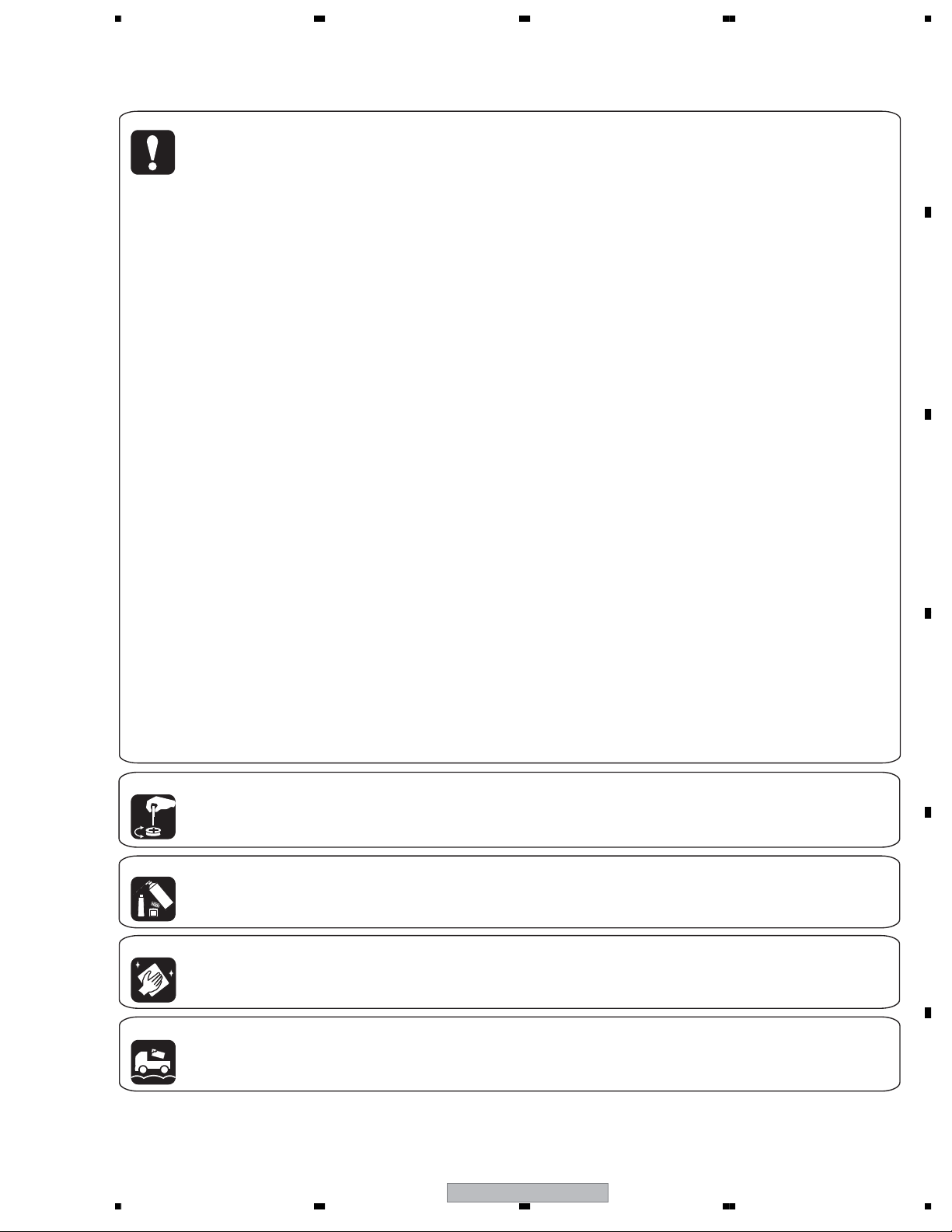

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

D

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

Leakage

current

E

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Test all

exposed metal

surfaces

AC Leakage Test

tester

Reading should

not be above

0.5 mA

Earth

ground

ANY MEASUREMENTS NOT WITHIN THE

LIMITS OUTLINED ABOVE ARE INDICATIVE

OF A POTENTIAL SHOCK HAZARD AND

MUST BE CORRECTED BEFORE RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the

protection afforded by them necessarily can be obtained

by using replacement components rated for voltage,

wattage, etc. Replacement parts which have these

special safety characteristics are identified in this

Service Manual.

Electrical components having such features are

identified by marking with a

on the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in the

parts list in this Service Manual, may create shock, fire,

or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER

Service Manual. A subscription to, or additional copies

of, PIONEER Service Manual may be obtained at a

nominal charge from PIONEER.

on the schematics and

F

2

1234

XV-DV360

5678

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

A

B

C

D

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

56

XV-DV360

E

F

3

7

8

1234

CONTENTS

SAFETY INFORMATION..................................................................................................................................... 2

1. SPECIFICATIONS ............................................................................................................................................ 5

2. EXPLODED VIEWS AND PARTS LIST ............................................................................................................ 6

A

B

C

D

E

2.1 PACKING ................................................................................................................................................... 6

2.2 EXTERIOR SECTION................................................................................................................................ 8

2.3 06 LOADER ASSY................................................................................................................................... 10

2.4 TRAVERSE MECHANISM ASSY-S ......................................................................................................... 12

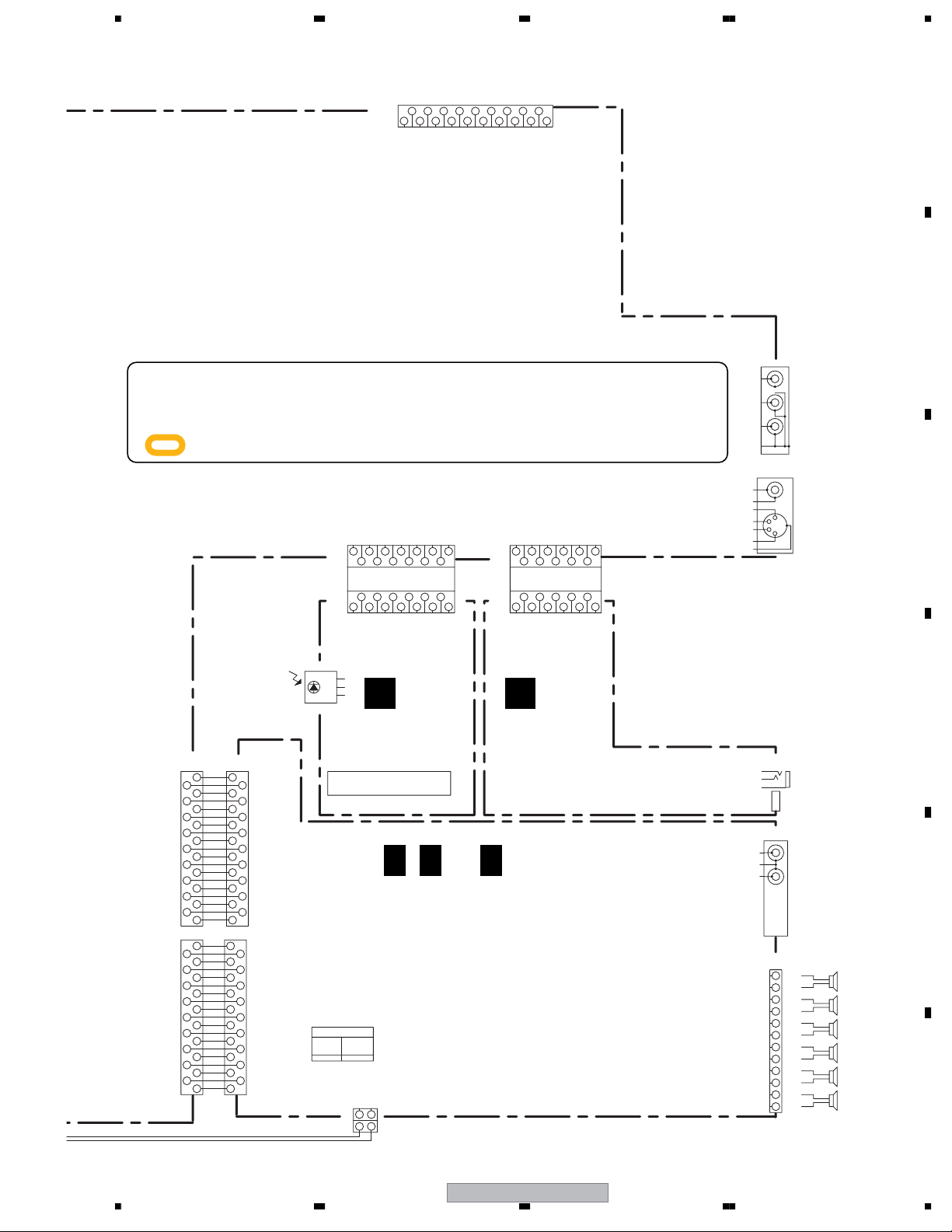

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM..........................................................................................14

3.1 BLOCK DIAGRAM ................................................................................................................................... 14

3.2 LOAB ASSY and OVERALL WIRING CONNECTION DIAGRAM ........................................................... 16

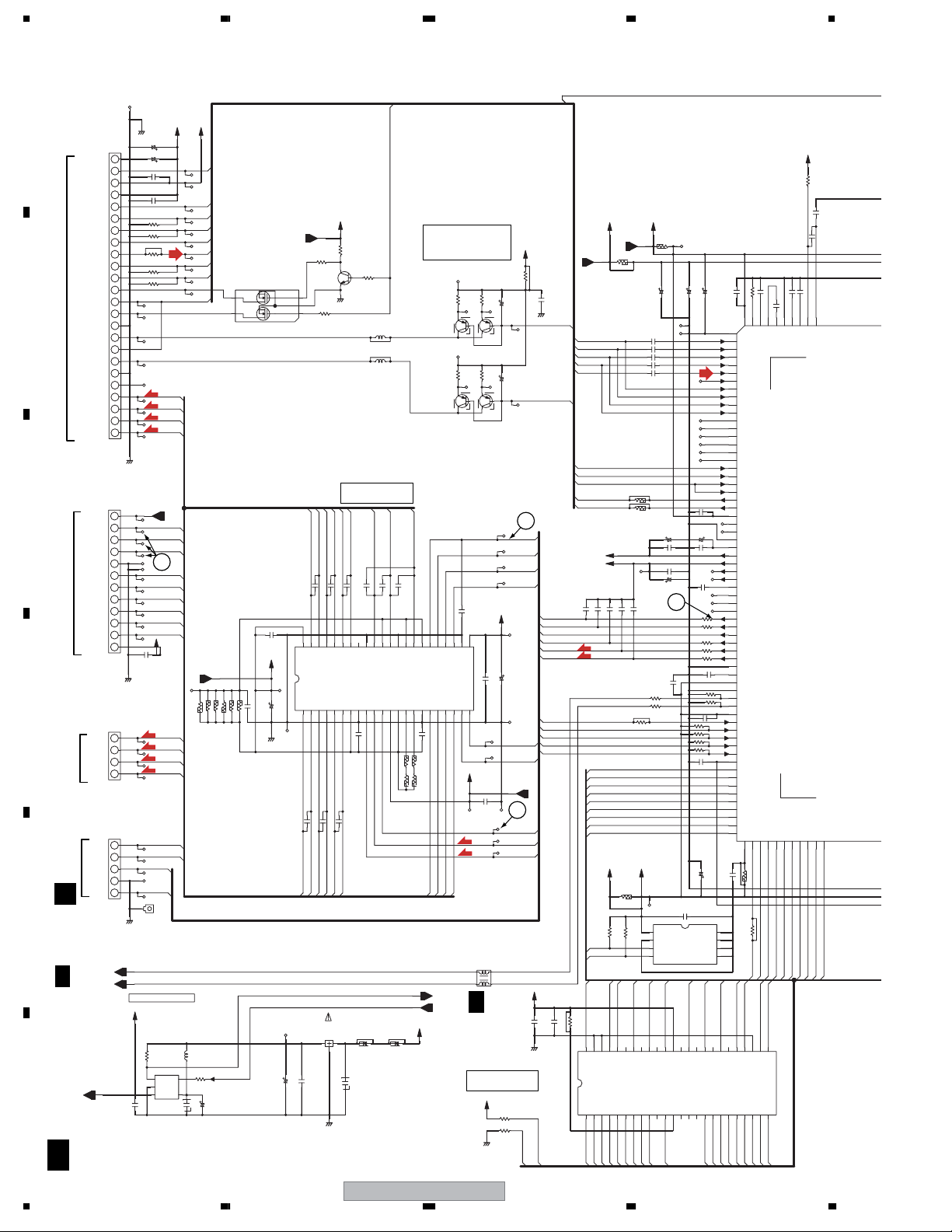

3.3 DVD MAIN ASSY (1/5)............................................................................................................................. 18

3.4 DVD MAIN ASSY (2/5)............................................................................................................................. 20

3.5 DVD MAIN ASSY (3/5)............................................................................................................................. 22

3.6 DVD MAIN ASSY (4/5)............................................................................................................................. 24

3.7 DVD MAIN ASSY (5/5)............................................................................................................................. 26

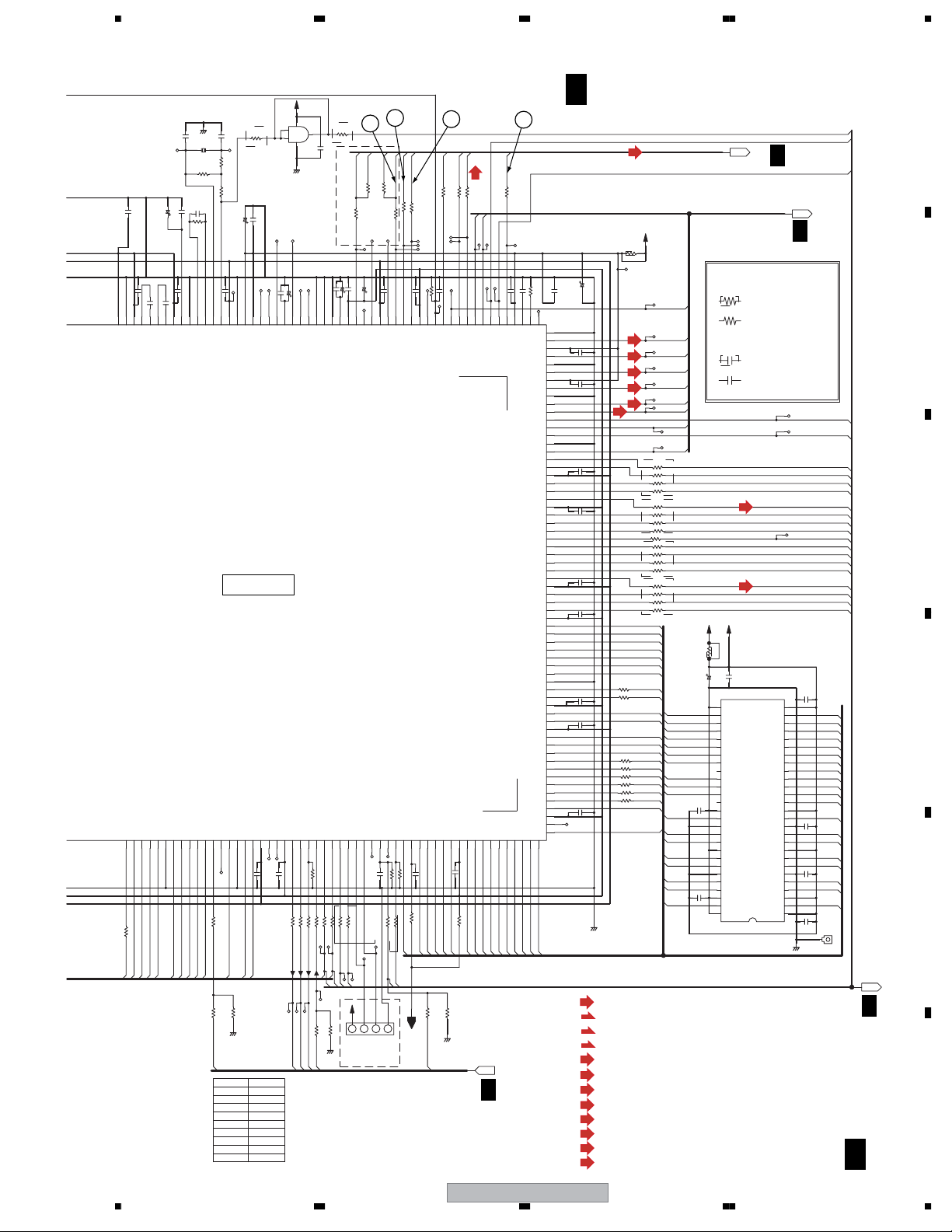

3.8 DAMP ASSY (1/2).................................................................................................................................... 28

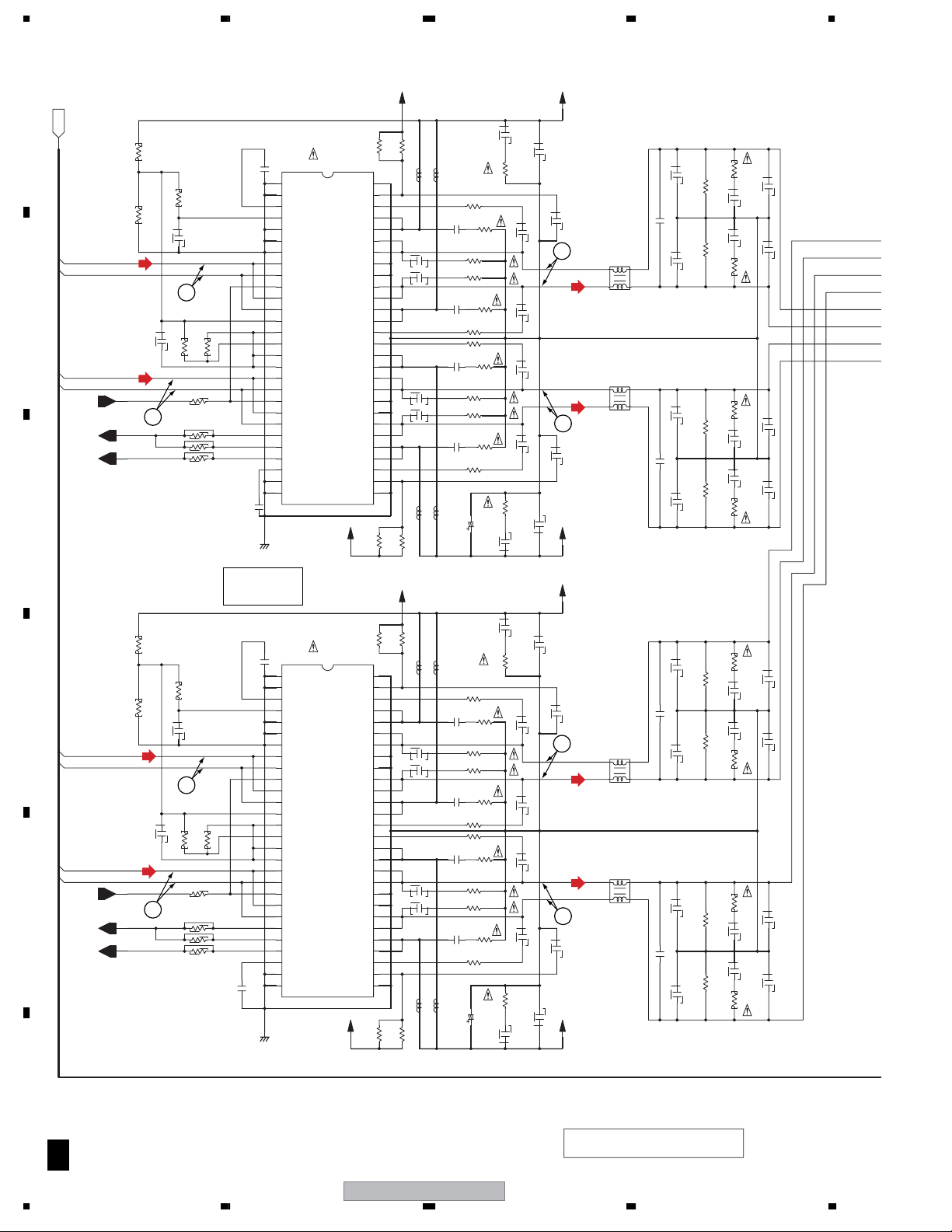

3.9 DAMP ASSY (2/2).................................................................................................................................... 30

3.10 DISPLAY and USB ASSYS.................................................................................................................... 32

3.11 POWER SUPPLY UNIT.......................................................................................................................... 34

3.12 WAVEFORMS ........................................................................................................................................ 36

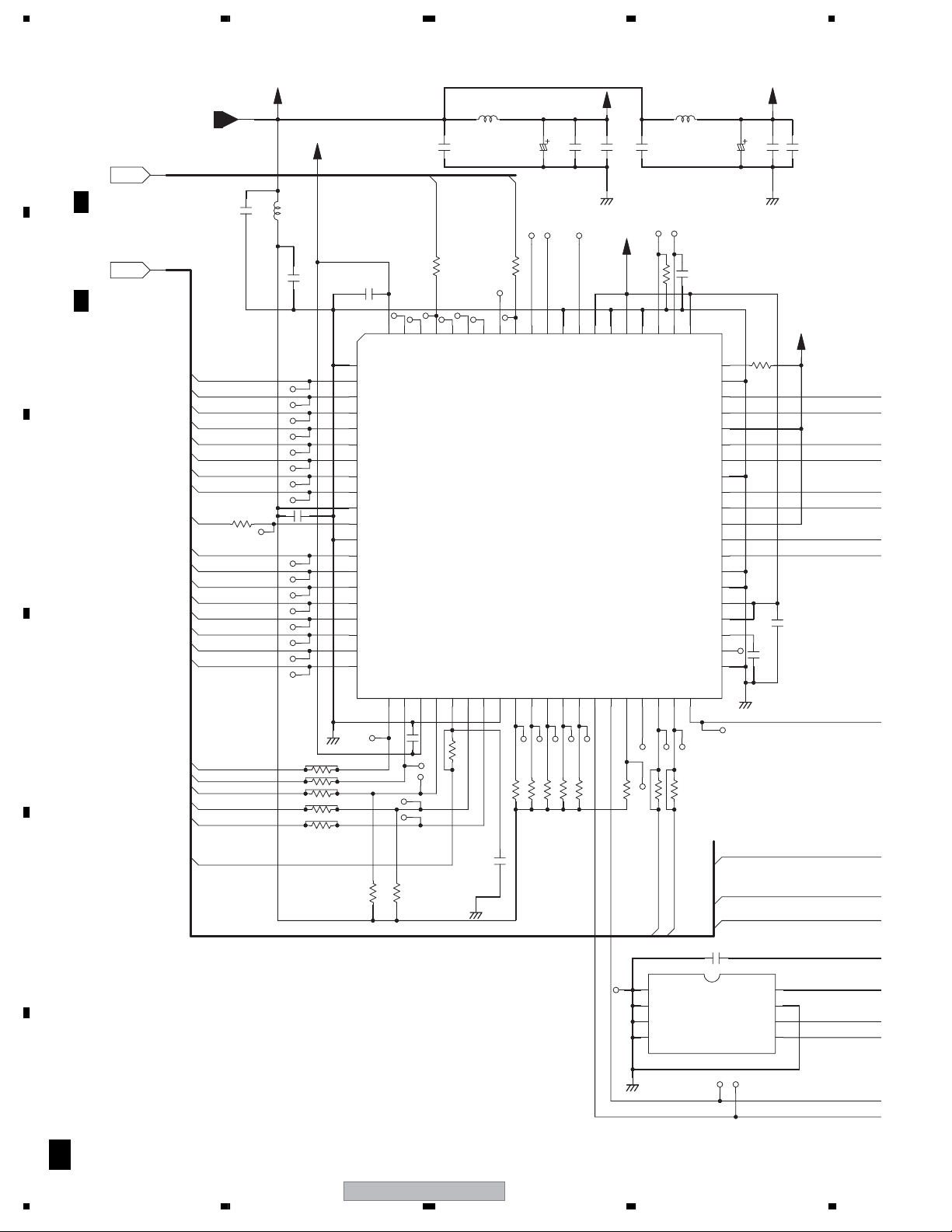

4. PCB CONNECTION DIAGRAM ..................................................................................................................... 39

4.1 LOAB ASSY............................................................................................................................................. 39

4.2 DVD MAIN ASSY..................................................................................................................................... 40

4.3 DAMP ASSY ............................................................................................................................................ 44

4.4 DISPLAY and USB ASSYS...................................................................................................................... 46

4.5 POWER SUPPLY UNIT............................................................................................................................ 48

5. PCB PARTS LIST ........................................................................................................................................... 50

6. ADJUSTMENT ............................................................................................................................................... 58

6.1 ADJUSTMENT ITEMS AND LOCATION ................................................................................................. 58

6.2 JIGS AND MEASURING INSTRUMENTS............................................................................................... 58

6.3 NECESSARY ADJUSTMENT POINTS ...................................................................................................59

6.4 TEST MODE ............................................................................................................................................ 60

6.5 MECHANISM ADJUSTMENT.................................................................................................................. 61

7. GENERAL INFORMATION............................................................................................................................. 63

7.1 DIAGNOSIS ............................................................................................................................................. 63

7.1.1 TEST MODE ...................................................................................................................................... 63

7.1.2 DISPLAY SPECIFICATION OF THE TEST MODE............................................................................ 64

7.1.3 FUNCTIONAL SPECIFICATION OF THE SHORTCUT KEY ............................................................ 65

7.1.4 SPECIFICATION OF MODEL INFORMATION DISPLAY .................................................................. 66

7.1.5 FUNCTIONAL SPECIFICATION OF THE SERVICE MODE ............................................................. 67

7.1.6 SERVICE TEST MODE ..................................................................................................................... 68

7.1.7 METHOD FOR DIAGNOSING DEGRADATION OF THE LDS ON THE PICKUP ASSY .................. 70

7.1.8 DVD TROUBLE SHOOTING.............................................................................................................. 71

7.1.9 ID NUMBER AND ID DATA SETTING ...............................................................................................74

7.1.10 CIRCUIT DESCRIPTION OF DIGITAL AMP. SECTION.................................................................. 77

7.1.11 SPECIFICATIONS FOR THE PROTECTION CIRCUITS FOR THE DIGITAL AMPLIFIER ............. 78

7.1.12 PASS/FAIL TEST PROCEDURE OF HDMI TRANSMITTER IC ...................................................... 79

7.1.13 DISASSEMBLY................................................................................................................................ 80

7.2 PARTS...................................................................................................................................................... 87

7.2.1 IC ....................................................................................................................................................... 87

8. PANEL FACILITIES ...................................................................................................................................... 102

F

4

1234

XV-DV360

5678

1. SPECIFICATIONS

• Amplifier section

RMS Power Output:

Front, Center, Surround. . . 60 W per channel

(1 kHz, 10 % T.H.D., 4 Ω)

Subwoofer. . .60 W(100 Hz, 10 % T.H.D., 4 Ω)

• Disc section

Digital audio

characteristics . . . . . . . . . DVD fs: 96 kHz, 24-bit

Type . . . . . . DVD system, Video CD/Super VCD

system and Compact Disc digital audio system

Frequency

response . . . .4 Hz to 44 kHz (96kHz sampling) /

4 Hz to 22 kHz (48kHz sampling)

Wow and Flutter . . . . . . . . Limit of measurement

(±0.001 % W.PEAK) or less (JEITA)

• FM tuner section

Frequency range. . . . . . . . 87.5 MHz to 108 MHz

Antenna. . . . . . . . . . . . . . . . . . 75 Ω, unbalanced

• AM tuner section

Frequency range:

With 9kHz step. . . . . . . . 531 kHz to 1602 kHz

With 10kHz step. . . . . . . 530 kHz to 1700 kHz

Antenna. . . . . . . . . . . . . . . . . . . . . Loop antenna

• Miscellaneous

Power requirements. . . . . . . . . .AC 120 V, 60 Hz

Power consumption. . . . . . . . . . . . . . . . . . . 44 W

Power consumption in standby . . . . . . . . 0.25 W

Dimensions. . . 420(W)mmx60(H)mmx330(D)mm

9

/16 in.(W) x 2 3/8 in.(H) x 13 in.(D))

(16

Weight. . . . . . . . . . . . . . . . . 3.1 kg / 6 lbs. 13 oz.

• Accessories (DVD/CD receiver)

Remote control . . . . . . . . . . . . . . . . . . . . . . . . . 1

AA/R6 dry cell batteries

(to confirm system operation) . . . . . . . . . . . . . . 2

Video cable (yellow plugs). . . . . . . . . . . . . . . . . 1

AM loop antenna . . . . . . . . . . . . . . . . . . . . . . . . 1

FM antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Power cord. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Warranty card . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Setup Guide

Operating instructions

Disc / content format playback

compatibility

This player is compatible with a wide range of

disc types (media) and formats. Playable discs

will generally feature one of the following logos

on the disc and/or disc packaging. Note

however that some disc types, such as

recordable CD and DVD, may be in an

unplayable format.

See the Disc compatibility table below for more

information.

DVD-Video DVD-R DVD-RW

Audio CD CD-R CD-RW

• This unit will play DVD+R/+RW discs.

• is a trademark of Fuji Photo Film Co. Ltd.

• is a trademark of DVD Format/Logo

Licensing Corporation.

• Also compatible with KODAK Picture CD.

This player supports the IECís Super VCD standard for superior picture quality, dual

soundtracks, and widescreen support.

Manufactured under license from Dolby

Laboratories.“Dolby”, “Pro Logic” and the

double-D symbol are trademarks of Dolby

Laboratories.

“DTS” and “DTS Digital Surround” are registered

trademarks of Digital Theater Systems, Inc.

Video CD

Fujicolor CD

VIDEO

CD

Super Video CD (Super VCD)

A

B

C

D

Accessories

• Power cord

(ADG7021)

• FM Antenna (ADH7030)

• Video Cable

(L = 1.5 m) (XDE3046)

• AM Loop Antenna

(ATB7013)

• AA size IEC R6

dry cell batteries

(to confirm

system operation)

XV-DV360

56

• Remote Control

(AXD7440)

E

TUNER

STANDBY

DVD/CD

(FM/AM)

/ON

OPEN/

CLOSE

USB

LINE

AUDIO

13

2

SUBTITLE

46

5

ANGLE

7

89

ZOOM

CLEAR

DISPLAY

0

TUNE

TOP MENU

MENU

ST

ST

ENTER

HOME

MENU

RETURN

TUNE

TEST TONE

SURROUND

SETUP

SOUND

TV CONTROL

SLEEP

INPUT VOLUME CHANNEL

MUTE

VOLUME

F

5

7

8

1234

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

A

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

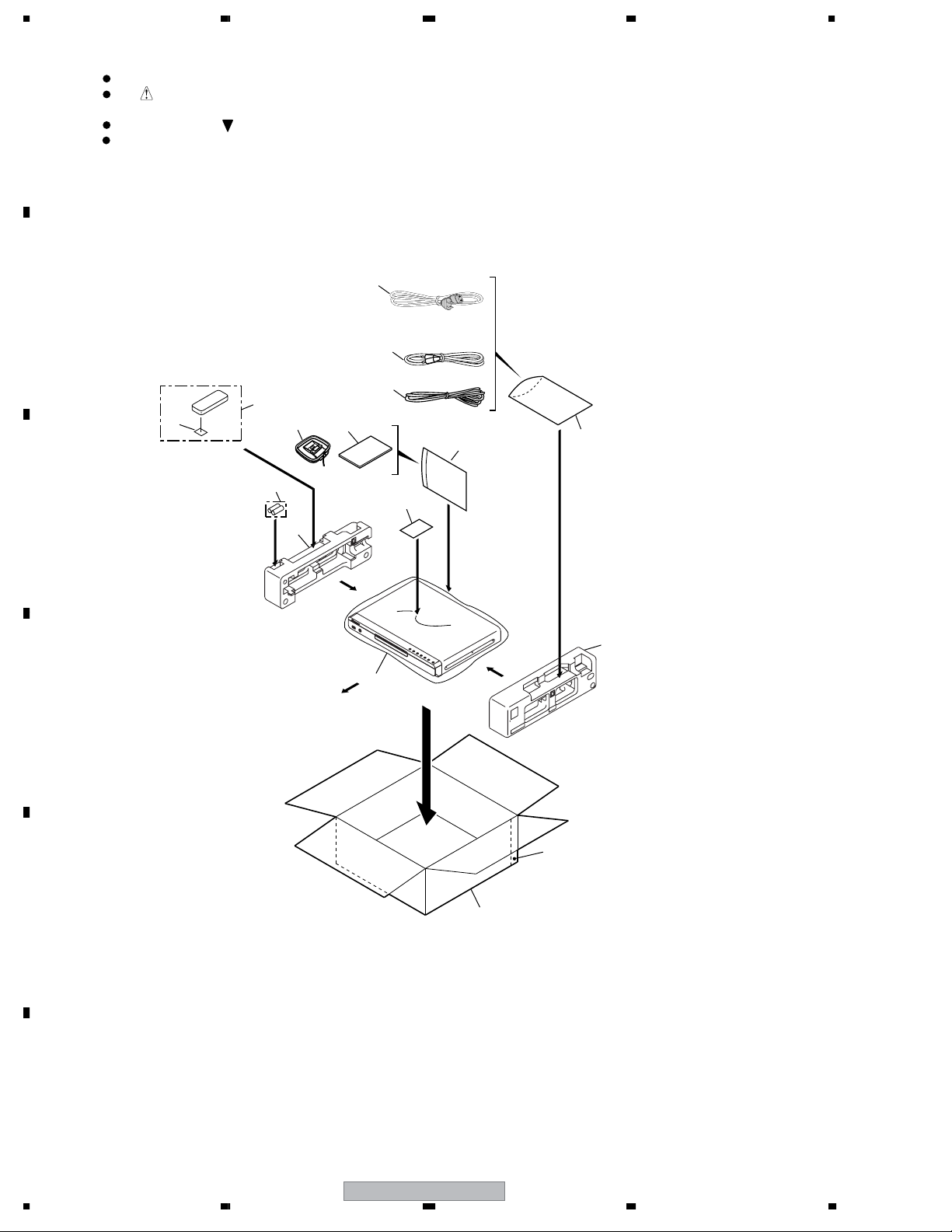

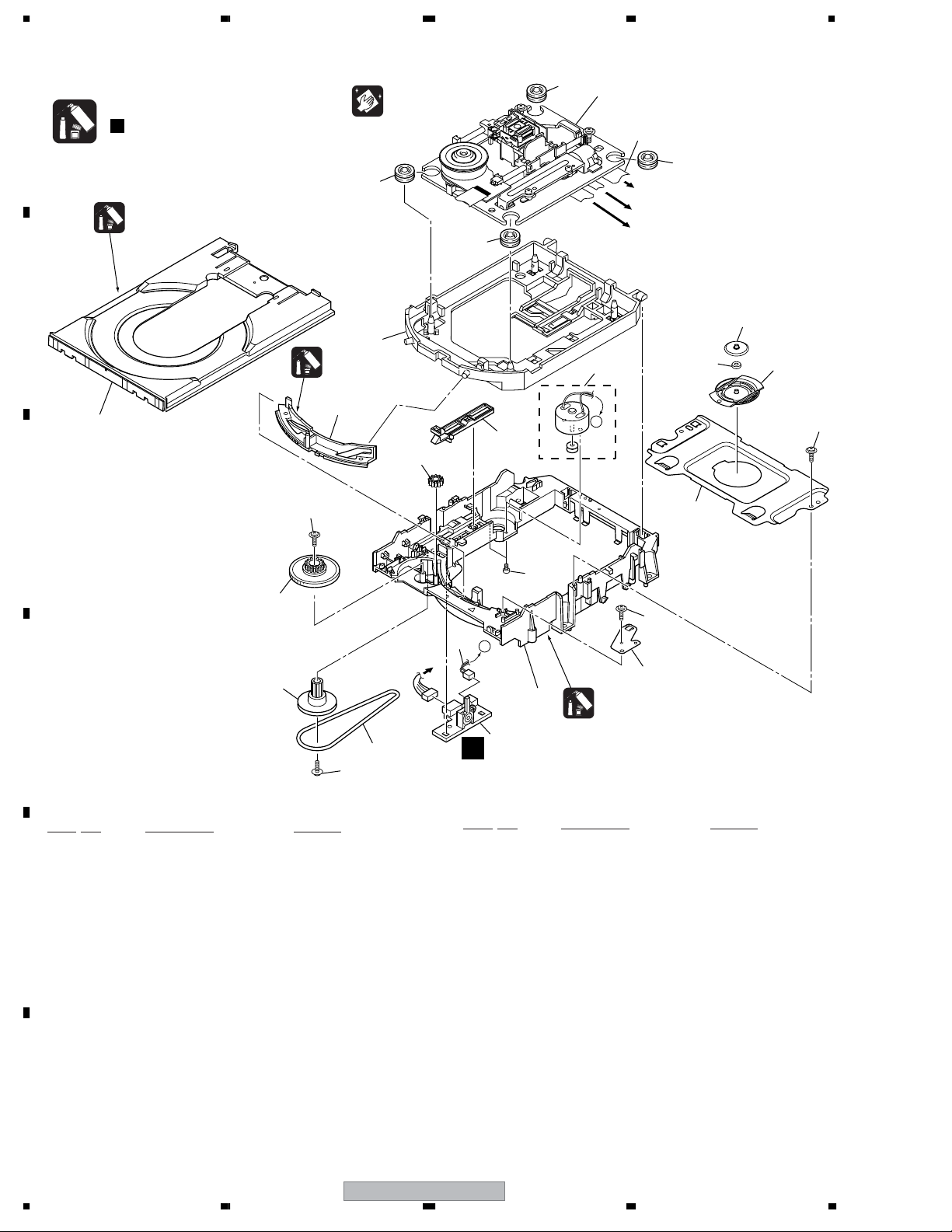

2.1 PACKING

B

C

17

16

1

5

2

3

4

21

7, 8

19

6

19

22

20

D

E

Front side

Joint of Packing

23

F

6

1234

XV-DV360

>

5678

PACKING SECTION PARTS LIST

No. Description Part No.

Mark

1AC Power Cord ADG7021

2 FM Antenna ADH7030

3 AM Loop Antenna ATB7013

NSP 4 Dry Cell Battery (AA/R6) XEX3002

5 Video Cable XDE3046

NSP 6 Warranty Card ARY7045

7 Operating Instructions ARE7614

(English/French)

8 Setup Guide (English/French) ARE7604

9• • • • • •

10 • • • • • •

11 • • • • • •

12 • • • • • •

13 • • • • • •

14 • • • • • •

15 • • • • • •

16 Remote Control AXD7440

17 Battery Cover AZN8018

18 • • • • • •

NSP 19 Polyethylene Bag AHG7117

20 Packing Sheet AHG7053

A

B

C

21 Pad L AHA7454

22 Pad R AHA7455

23 Packing Case AHG8457

D

E

56

XV-DV360

F

7

7

8

1234

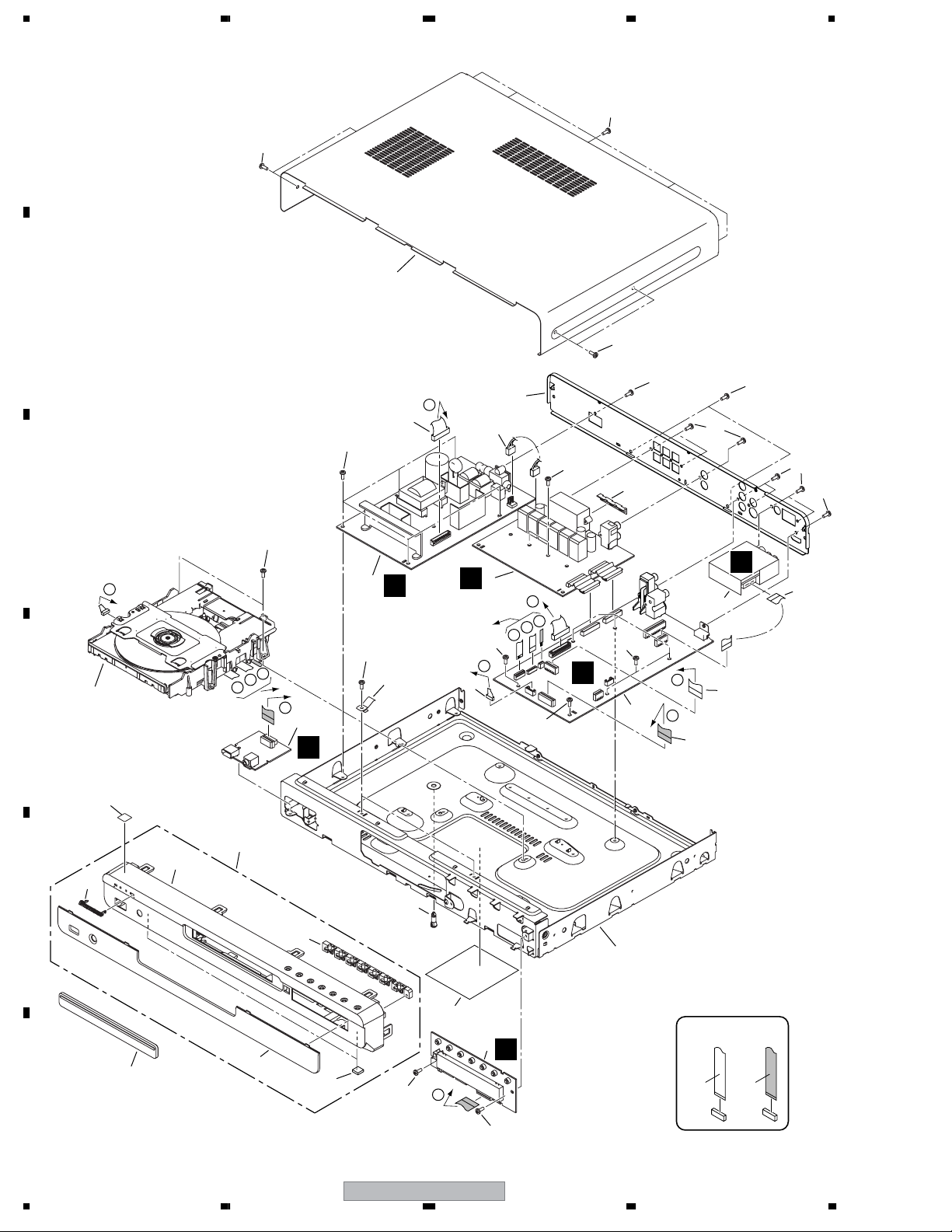

2.2 EXTERIOR SECTION

A

B

C

15

Refer to

D

"2.3 06 LOADER ASSY".

32

32

28

32

32

32

14

32

F

19

12

32

17

32

32

32

33

H

1

C

13

F

C

B

A

32

E

32

B

32

2

D

7

G

8

10

9

32

6

G

16

E

C

B

A

G

3

E

31

21

24

25

E

22

23

27

F

26

8

1234

20

D

32

XV-DV360

29

18

4

D

32

NON-CONTACT

SIDE

CONTACT SIDE

>

5678

EXTERIOR SECTION PARTS LIST

No. Description Part No.

Mark

1DAMP ASSY AWK7932

2DVD MAIN ASSY AWM8027

3 USB ASSY AWU8290

4 DISPLAY ASSY AWU8289

5• • • • • •

6POWER SUPPLY UNIT AWR7046

7 FM/AM TUNER UNIT AXX7172

8 11P FFC/60V ADD7542

9 11P FFC/60V ADD7543

10 13P FFC/60V ADD7541

A

11 • • • • • •

12 2P Housing Wire Assy ADX7480

13 CONNECTOR ASSY PF05PP-B40

14 CONNECTOR ASSY PG13KK-F22

NSP 15 06 Loader Assy VWT1226

16 Earth Spring W5.1 ABH7240

17 Gnd Plate W5.1 ABH7241

NSP 18 Chassis ANA7187

19 Rear Panel ANC8402

20 Locking Card Spacer AEC7372

21 Front Panel Assy AXG7295

NSP 22 Button AAD7753

NSP 23 Display Window AAK8327

NSP 24 Front Panel AMB7911

25 Pioneer Name Plate VAM1129

26 Rubber Foot VEB1325

27 Tray Panel AAK8329

28 Bonnet AZN8017

NSP 29 Name Label AAL7424

30 • • • • • •

NSP 31 Energy Star Label AAX8022

32 Screw BBZ30P080FNI

33 Screw BSZ30P060FTC

B

C

D

56

XV-DV360

E

F

9

7

8

1234

2.3 06 LOADER ASSY

A

B

C

Note :

Refer to

" Application of Lubricant".

Daifree

GEM1036

23

Lubricating Oil

GYA1001

13

22

Pickup leneses

Cleaning liquid

GEM1004

Cleaning paper

GED-008

8

12

16

8

8

17

Refer to

2

"2.4 Traverse Mechanism Assy-S".

6

8

To DVD MAIN CN101 (Pickup)

To DVD MAIN CN104 (Stepping Motor)

To DVD MAIN CN102 (Spindle Motor)

18

3

A

24

19

20

22

15

14

D

06 LOADER ASSY PARTS LIST

Mark

No. Description Part No.

NSP 1 LOAB Assy VWG2346

2Traverse Mechanism Assy-S DXX2575

3 Loading Motor Assy VXX2912

E

4• • • • •

5• • • • •

6 Flexible Cable (24P) ADD7545

7 Connector Assy 2P VKP2253

8 Floating Rubber VEB1351

9 Belt VEB1358

10 Stabilizer VNE2253

22

To

DVDM CN103

9

21

22

7

A

10

11

1

A

Mark No. Description Part No.

16 Drive Gear VNL1923

17 SW Lever VNL1925

18 Clamper Plate 04 VNE2342

19 Bridge 04 VNE2343

20 Clamper 04 VNL1969

21 Screw JGZ17P028FTC

22 Screw VBA1094

23 Tray VNL1920

24 Clamp Magnet VMG1029

Lubricating Oil

GYA1001

11 Loading Base VNL1917

12 Float Base 04 VNL1968

F

13 Drive Cam VNL1919

14 Gear Pulley VNL1921

15 Loading Gear VNL1922

10

1234

XV-DV360

5678

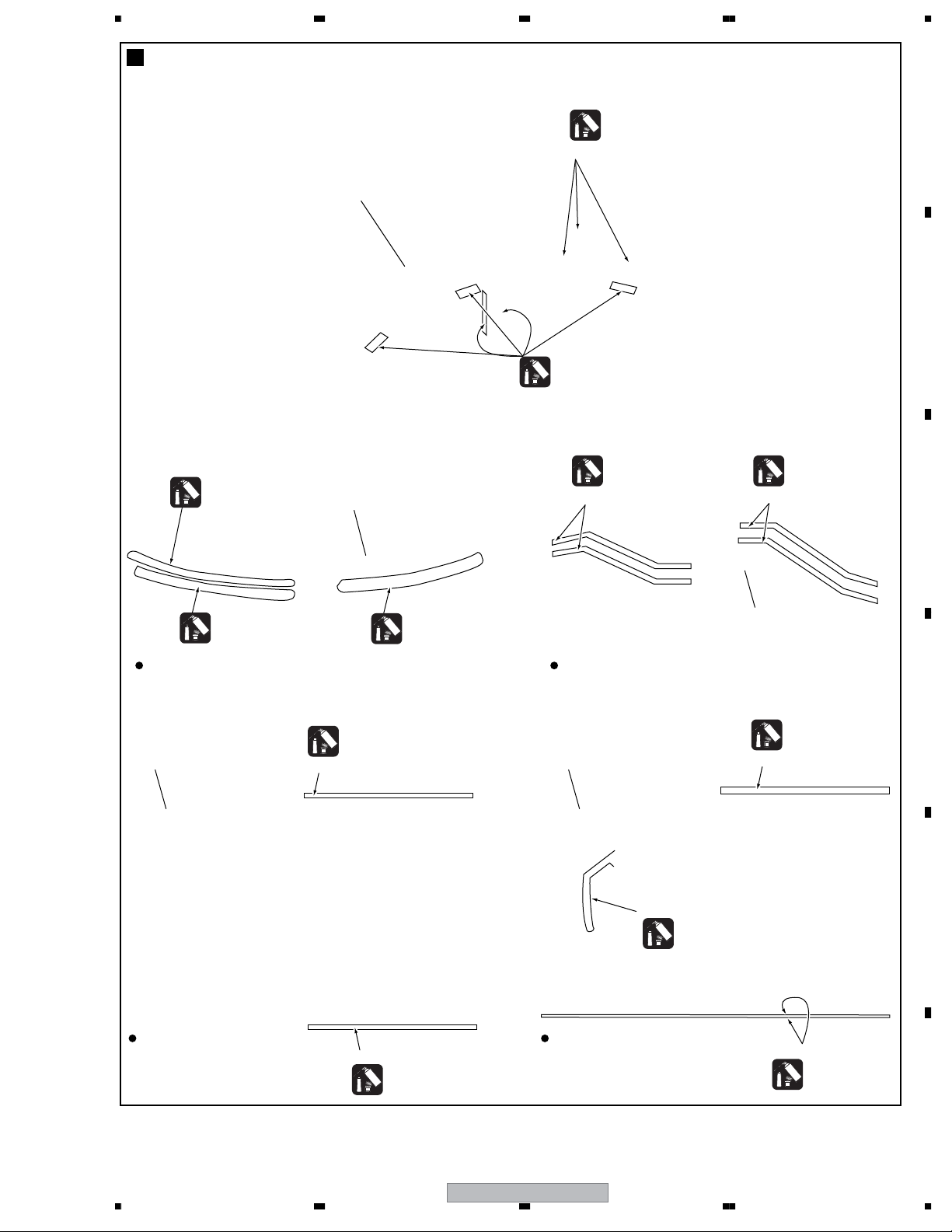

Application of Lubricant

Lubricating Oil

GYA1001

No. 11

Loading Base

No. 13

Drive Cam

Lubricating Oil

GYA1001

Around the shaft

Lubricating Oil

GYA1001

Lubricating Oil

GYA1001

Inner side of a ditch

A

B

Lubricating Oil

GYA1001

Inner side of a ditch

C

Lubricating Oil

GYA1001

Lubricating Oil

GYA1001

Front View Rear View

No. 23

Tray

Daifree

GEM1036

Concave of unevenness

No. 23

Tray

Top View Bottom View

Concave of unevenness

Daifree

GEM1036

Inner side of a ditch

Daifree

GEM1036

No. 13

Drive Cam

D

Daifree

GEM1036

Concave of unevenness

E

Side of the rib

Daifree

GEM1036

F

56

XV-DV360

11

7

8

1234

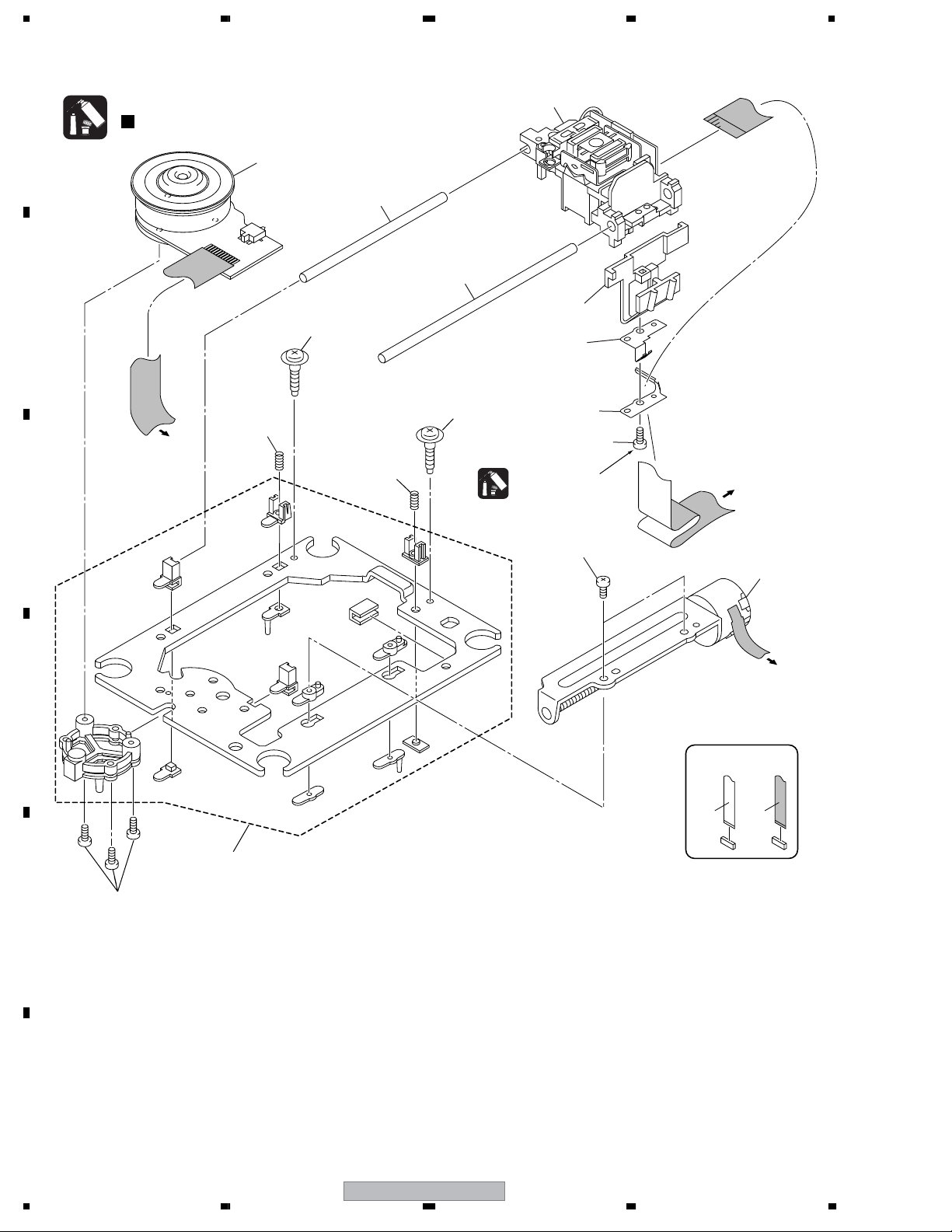

2.4 TRAVERSE MECHANISM ASSY-S

Note :

A

B

C

Refer to

" Application of Lubricant".

Note : When part #2 replaced,

2

11

To DVDM CN102

(Spindle Motor)

part #13 also need to be

replaced at the same time.

4

3

10

10

11

1

5

6

14

Silicone Adhesive

GEM1037

9

To

DVDM CN101

(Pickup Assy)

12

7

To

DVDM CN104

(Stepping Motor)

D

NON-CONTACT

8

Note : Spindle screw (DBA1252) of No.13 is the screw which applied special bond.

E

13

Therefore the adhesion becomes inteffective when takes it off once. Spindle screw is the part which cannot recycle.

When part #2 is replaced, part #13 also need to be replaced at the same time.

SIDE

CONTACT SIDE

F

12

1234

XV-DV360

>

5678

TRAVERSE MECHANISM ASSY-S PARTS LIST

No. Description Part No.

Mark

1 06SD Pickup Assy OXX8020

2 Spindle Motor N200 DXM1197

NSP 3 Guide Shaft VK1 DLA1940

NSP 4 Sub Guide Shaft VK1 DLA1941

NSP 5 Joint VK1B DNK4272

NSP 6 Joint Spring VK1 DBK1235

7 Stepping Motor VK1 DXM1201

NSP 8 Mechanism Frame VK1 DNK4160

9 Precision Screw VK1 DBA1209

10 Skew Screw VK1 DBA1211

A

11 Skew Spring VK1 DBH1516

NSP 12 Stepping Screw DBA1205

13 Spindle Screw VK1(for Service) DBA1252

NSP 14 Hold Spring DBK1297

B

C

D

56

XV-DV360

E

F

13

7

8

1234

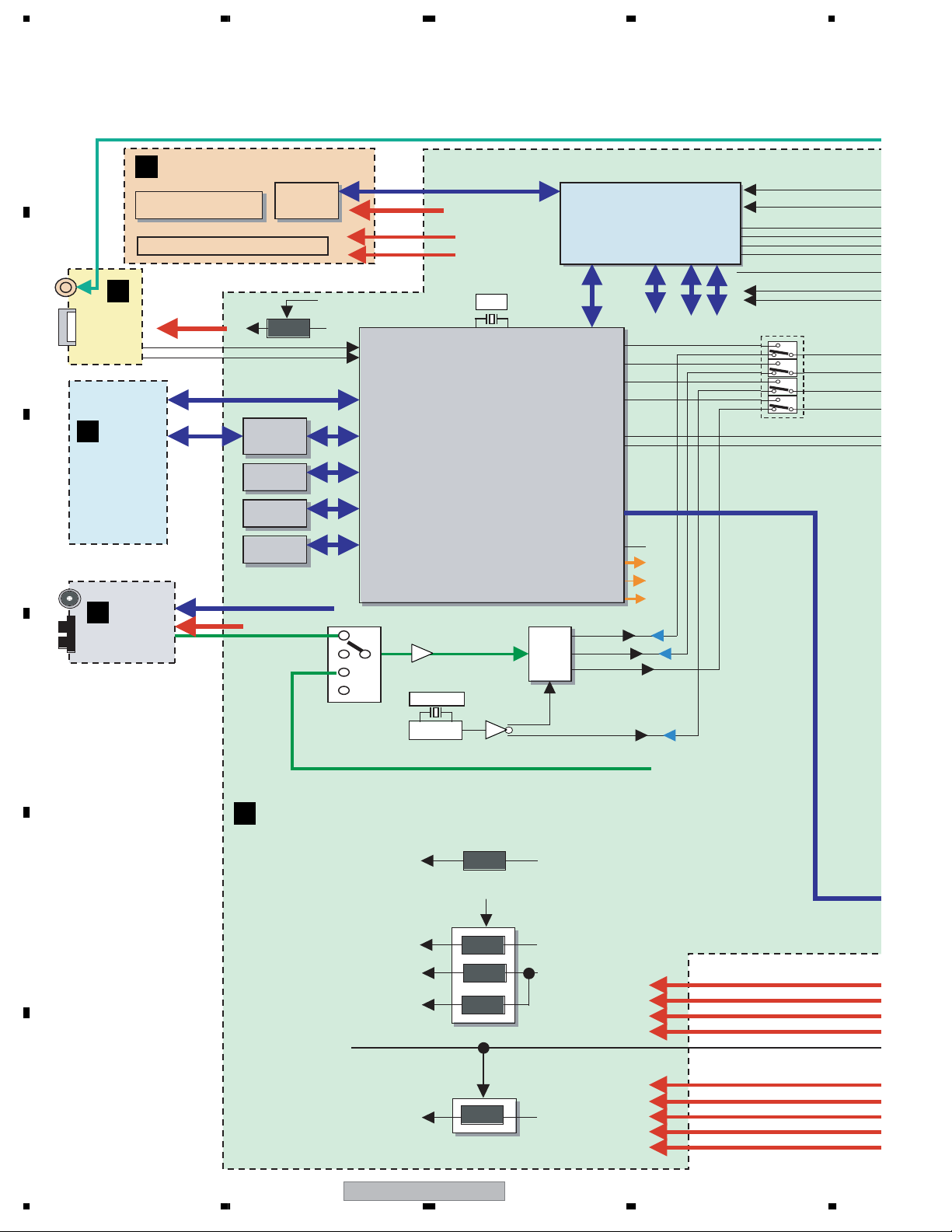

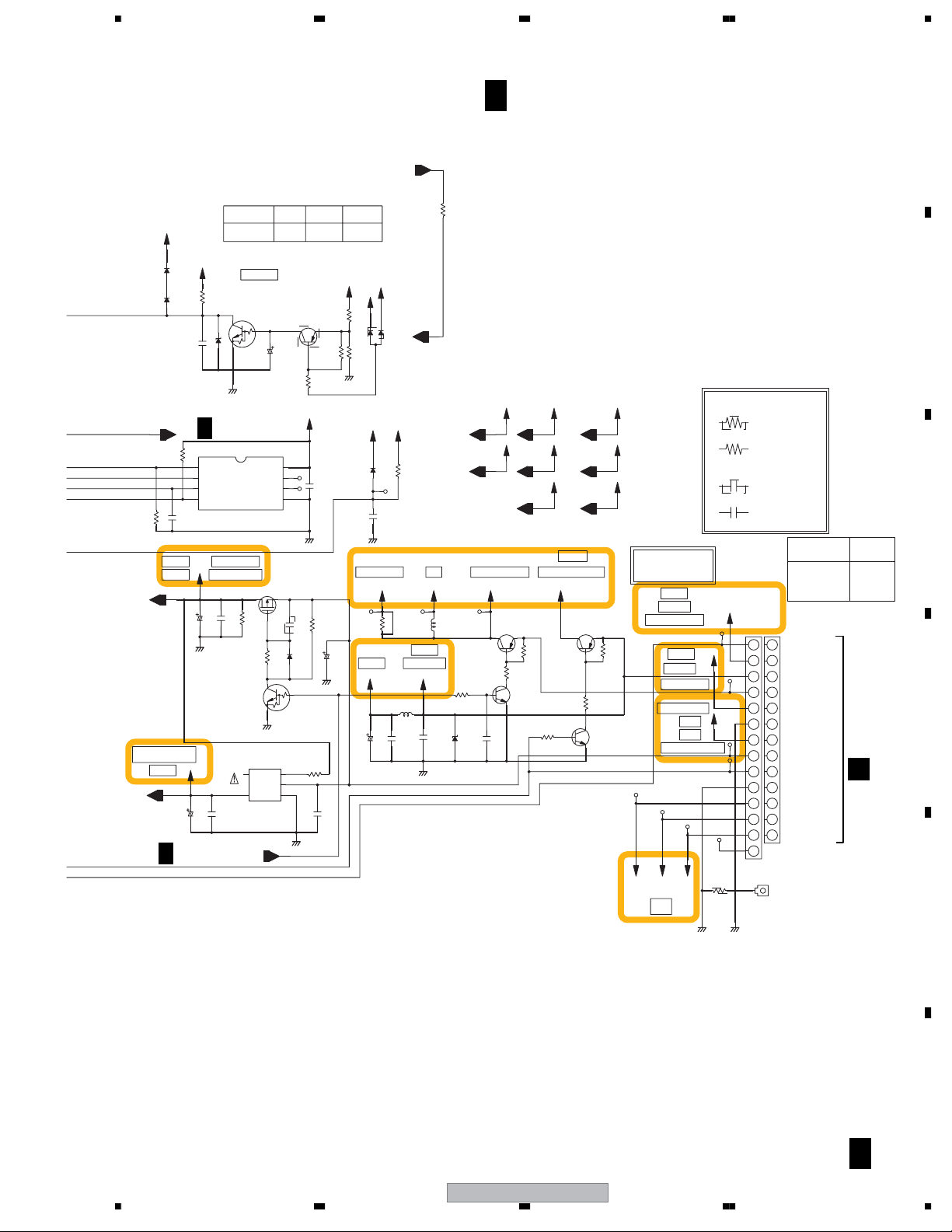

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

A

D

DISPLAY ASSY

MOTOR

DRIVER

64M

SDRAM

FLASH

EEPROM

+9V

16M

16k

Display

Driver

5V

TUNER

LINE/TV

USB POWER

6.8V5V

FL DC+/-

-25.5V

• AUDIO PROCESSING

-Audio Decode

-Bass Management

-Virtual Surround

-Preset EQ

etc.

EV5V

27M

BE

MT1389FE

IC201

IC3003

A/D

AK5358ET

Y , Cb , Cr

ADBCK

ADLRCK

ADDATA

FL

KEY

E

B

USB

ASSY

USB DP

USB DM

A

LOAB ASSY

C

LOADER

MECHA

FM/AM

H

TUNER

UNIT

Y,C

V

IC5501

SYSTEM

µ-com

ACLK

ALRCK

MCLK

ASDAT0

ASDAT1

ASDAT2

PCON(fromSMPSorD-AMP)

DC DET

SCL

SDA

MUTE

RESET

PDN

SD

OTW

BCKO

LRCKO

MCKO

DATAO

D

12.288M

TC7WU04FU

IC3004

B

DVD MAIN ASSY

+9V

9V

DVD POWER

ADMCK0

ADMCK1

LINE

SW+10.5V

E

SW

SW

V+1R8

PWRCONT

F

1.8V

SW

SW5.0VV+5V

SW3.3V(A)V+3

EV+5VV+5

14

XV-DV360

1234

5678

A

C

DAMP ASSY

MODULATER

TAS5508BPAG

IC3101

LINE

HP SEL

PWMA P

PWMA M

RESET

SD

PWMB P

PWMB M

ch7 ch8 PWM

+B+3.3V

TAS5122DCA

LPF

HP AMP

DRIVER

IC3201

IC3301

IC3401

FRONT L

FRONT R

CENTER

SUB WOOFER

REAR L

REAR R

LINE

B

C

GND

FLDC +-

-25.5V

EV5.0V

SW3.3V (A)

SW 3.3V (B)

SW 10.5V

SW 6.8V

SW 5.0V

Y, Cb, Cr

V

Y, C

G

POWER SUPPLY UNIT

Video

AMP

GND +B

Y, Cb, Cr

V

Y, C

IC931

HDMI

Transmitter

MT1392E/C-L

Component

Video

D

Composite

S-Video

TX

HDMI OUT

E

AC IN

F

56

XV-DV360

15

7

8

1234

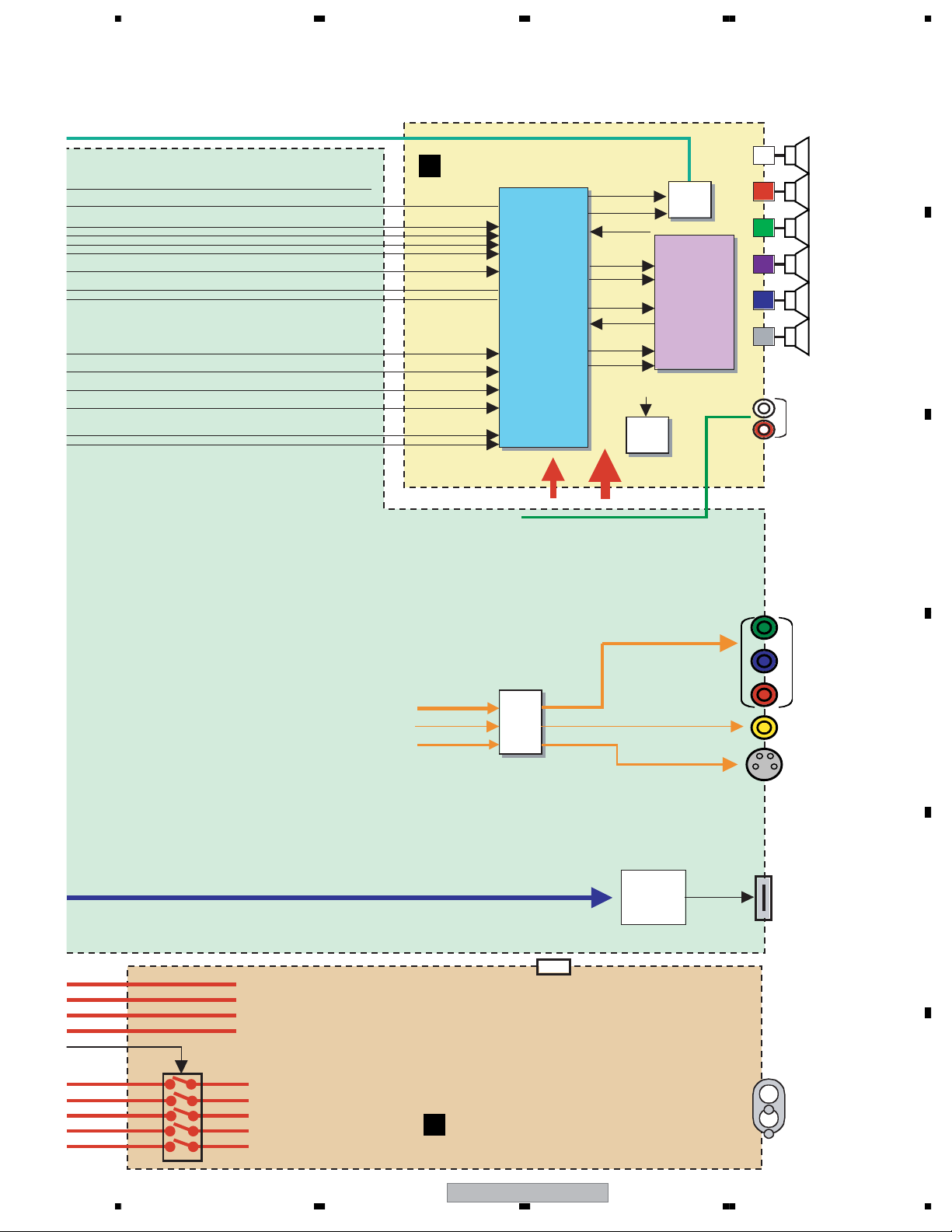

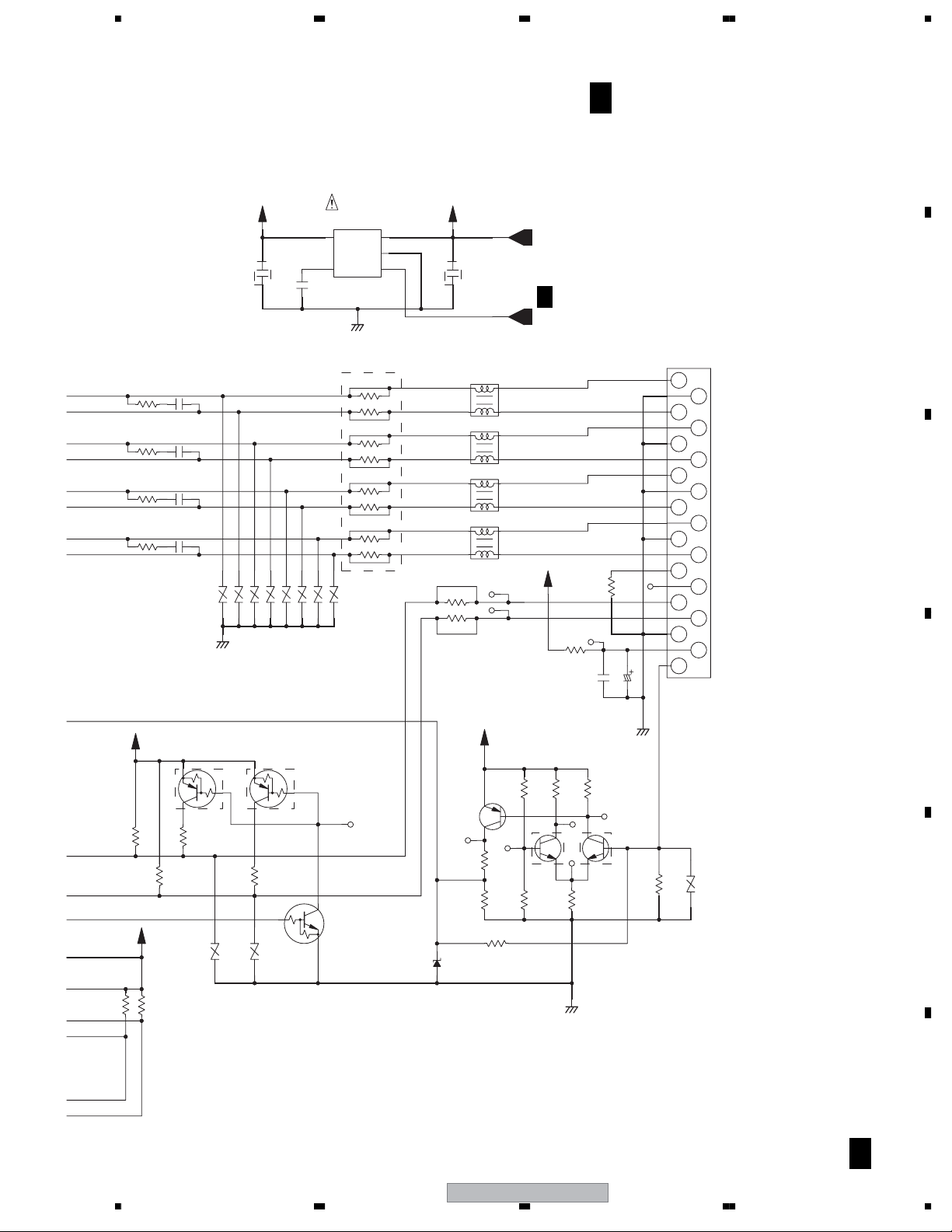

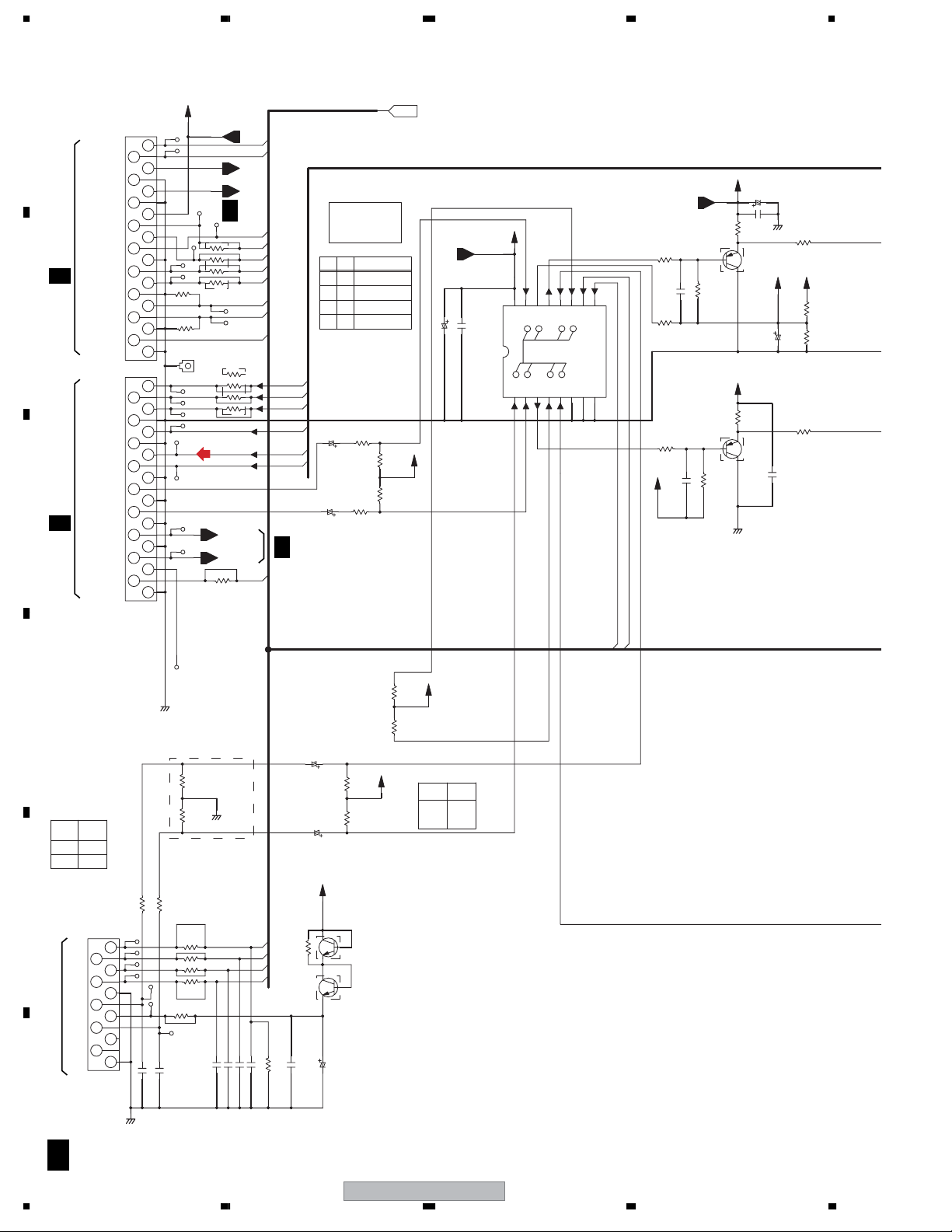

3.2 LOAB ASSY and OVERALL WIRING CONNECTION DIAGRAM

A

H

FM/AM TUNER

UNIT

FM

AM

B

No schematic Diagram

(AXX7172)

CN1

CE

DI

CLK

DO

GND

TXL

+9V

TXR

VSM

RDS

GND

(ADD7543)

11P FFC

CN5701

CKS3376-

1

2

3

4

5

6

7

8

9

10

11

CE

DI

CLK

DO

GND

TXL

+9V

TXR

VSM

RDS

GND

B B B( 1/5- 5/5)

DVD MAIN ASSY

(AWM8027)

C

D

E

AC POWER CORD

F

POWER

SUPPLY UNIT

G

(AWR7046)

CN1

LIVE

2

NEUTRAL

1

B2P-VH

CN2

+B

2

B13B-PH-K-S

SW3.3V(B)

SW3.3V(A)

GND

1

CN3

AC_DET

SW10.5V

EV5.0V

SW5.0V

SW6.8V

GND

Pwr-ctr

GND

FL DC-

FL DC+

-25.5V

11

121012

13

( )

11 11

2

2

3

3

4

44

5

5

676

7

8

8

9

99

10

11 111011

13

KU,GA BASE

PG13KK-F22

B13B-PH-K-S

2332

545

676

898

13 13

7

10

1212

CN1001

EU,J,

EU,J,

( )

KU,GA BASE

AC_DET

SW10.5V

EV5.0V

SW5.0V

SW6.8V

GND

SW3.3V(B)

SW3.3V(A)

Pwr-ctr

GND

FL DC-

FL DC+

-25.5V

CN101

VKN2045 OKN8001

GNDD

F

VS(VREF)

VCC

E

D

C

SW(DVD/CD)

RF

B

A

VR650

VRCOM

VR780

GNDD

LD(780)

PD

LD(650)

GNDD

VSHF

TRKG DRV

TRKG RTN

FOCS DRV

FOCS RTN

DVD LOADER

CN1

(ADD7545-)24P FFC

GNDD

F

VS(VREF)

VCC

E

D

C

SW(DVD/CD)

RF

B

A

VR650

VRCOM

VR780

GNDD

LD(780)

PD

LD(650)

GNDD

VSHF

TRKG DRV

TRKG RTN

FOCS DRV

FOCS RTN

PICK UP ASSY

OWY8087-

LOADING

MOTOR ASSY

: VXX2912

A

LOAB ASSY

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

(VWG2346)

VWT1226-

CN602

2

1

INSIDE

WW

V

U

HB

W-

W+

SPINDLE MOTOR

V-

V+

U-

U+ U+

V+5S

ST2-(~B~)

ST2+(B)

ST1+(A) ST1+(A)

ST1-(~A~)

STEPPING MOTOR

LOAB ASSY

VWG2346-

CN601 CN104

S5B-PH-K-S B5B-PH-K-S

LOAD-

1

LOAD+

22

3

SW2

4

GNDD

55

SW1 SW1

12P FFC

4P FFC

PF05PP-B40

CN102

VKN1243

12

11

10

9

8

7

6

5

4

3

2

1

CN103

VKN1235

1

2

3

4

1

3

4

INSIDE

V

U

HB

W-

W+

V-

V+

U-

V+5S

ST2-(~B~)

ST2+(B)

ST1-(~A~)

LOAD-

LOAD+

SW2

GNDD

16

ADX7480-

XV-DV360

1234

5678

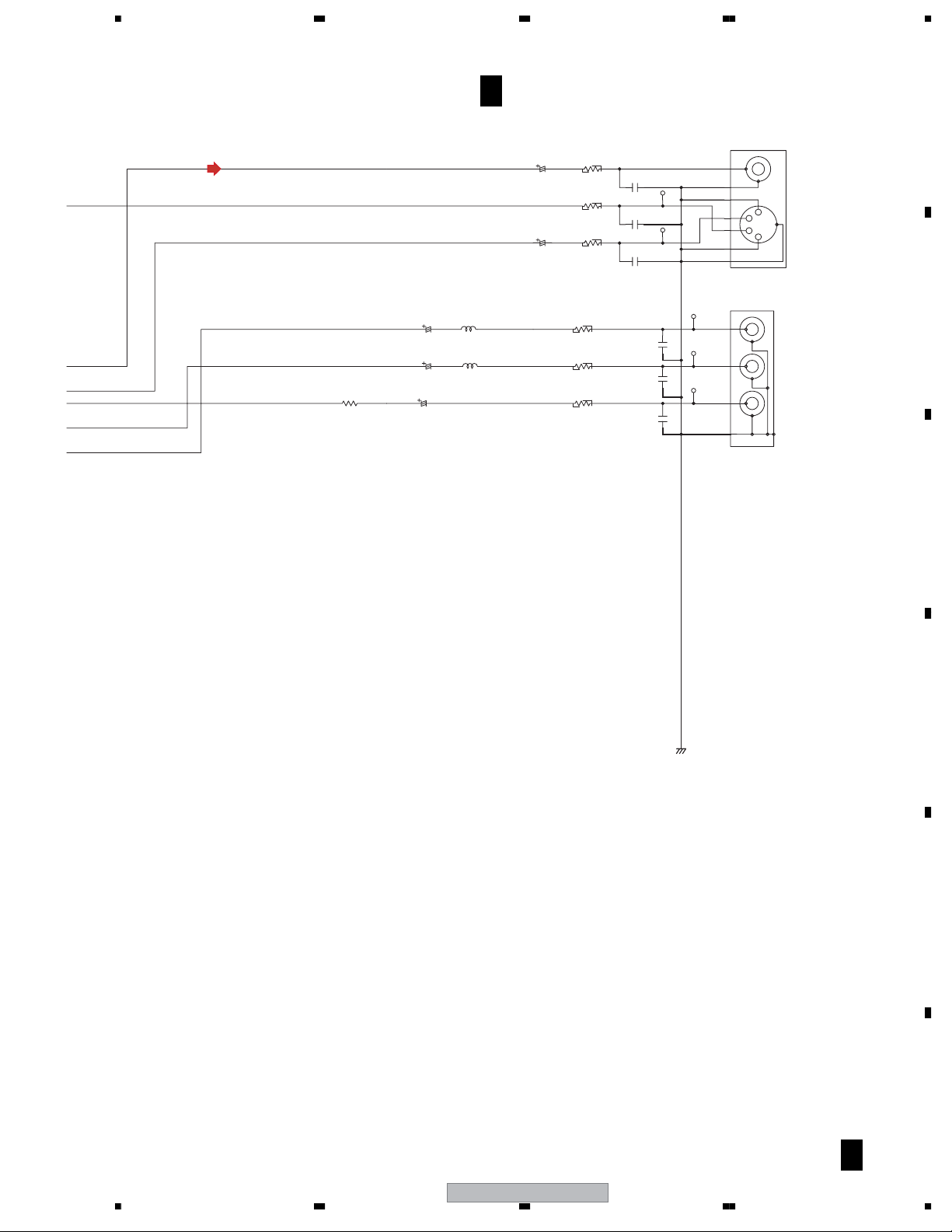

HDMI OUTPUT

654

DATA1-

7

DATA0+

DATA0 SHIELD

1098

DATA0-

CLOCK+

12

14

151613

NC

CEC

CLOCK-

CLOCK SHIELD

HDMISCL

HDMISDA

18

1917

+5V

DDC/CEC GND

HOT PLUG DETECT

2

111

3

AKP7210-

(AKP7211)

CN931

DATA2-

DATA1+

DATA2+

DATA1 SHIELD

DATA2 SHIELD

÷

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or

"PCB PARTS LIST".

÷

The > mark found on some component parts indicates the importance of the safety factor

of the part. Therefore, when replacing, be sure to use parts of identical designation.

÷

: The power supply is shown with the marked box.

VFDP

FLDATA

FLCK

FLCS

VE+5

13 11

9785

10

12

CKS3378-

IC5902

RPM7540-H9

Vcc

GND

Vout

CN5602

CN5901

CKS3378-

FLCK

FLDATA

13P FFC(ADD7541)

3214569107

VE+5

FLCS

REMOCON

D

VFDP

DISPLAY ASSY

(AWU8289)

CN3001 CN3101

AKP7199- AKM7077-

PCON

191819

XHPSEL

HPL

17

GND

16

HPR

15

GND

14

3.3V

13

XRST

XPDN

111211

XMUTE

10

GND

9

SDA

8

SCL

7

GND

6

XOTW

5

XSD

4

GND

3

POWER

2

GND GND

11

CN3002 CN3102

AKP7199- AKM7077-

SDATA1

191819

SDATA2

SDATA3

17

GND

16

MCLK

15

GND

14

SCLK

13

LRCLK

12

GND

11

LIN1_L

10

GND

9

LIN1_R

8

GND

7

S_TVOUT_L

6

GND

S_TVOUT_R

5

4

RECMUTE

3

FANCONT

2

GND GND

17

15

13

9

7

5

3

17

15

13

11

9

7

5

3

11

PCON

XHPSEL

18

HPL

GND

16

HPR

GND

14

3.3V

XRST

12

XPDN

XMUTE

10

GND

SDA

8

SCL

GND

6

XOTW

XSD

4

GND

POWER

2

SDATA1

SDATA2

18

SDATA3

GND

16

MCLK

GND

14

SCLK

LRCLK

12

GND

LIN1_L

10

GND

LIN1_R

8

GND

S_TVOUT_L

6

GND

S_TVOUT_R

4

RECMUTE

FAN CONT/GND *

2

*

CN3102 2P

AWK7931

AWK7932

AWK7933

AWK7934

FL

AAV7104(AAV7107)

C C C( 1/2- 2/2)

GND

FAN CONT

B2P-VH

CN3201

GND

+B

2

1

FLDC-

FLDC-

8

FLDC+

FLDC+

GNDD

GNDD

46

GNDD

GNDD

KEY1

321

KEY1

HPMUTE

HP_L

KEY2

GNDD

12

1311

KEY2

GNDD

GNDD

11 9105

82

CKS3376-

CN5601

11P FFC

(ADD7542)

4

123

CKS3376-

CN5902

HP_L

HP_R

GNDD

HPMUTE

HP_DET

HP_DET

GNDUSB

476

78569

V5USB

3

V5USB

USB_DM2

USB_DP2

1

10

USB_DP2

USB_DM2

11

GNDUSB GNDUSB

V5USB

V5USB

GNDUSB

HP_R

E

USB ASSY

(AWU8290)

DAMP ASSY

(AWK7932)

HEAD PHONE

JA402

XKB3061

JA401

XKB3059

JA5902

AKN7003-

JA3111

XKB3062

CN3211

AKE7121

1

2

3

4

5

6

7

8

9

10

11

12

(VKB1153)

Cr

Cb

Y

(VKB1178)

V

COMPOSITE

Y/C

USB

(RKB1041)

TVIN_L

TVIN_R

FR+

FR-

RR+

RR-

FL+

FL-

RL+

RL-

C+

C-

SW+

SW-

COMPONENT

VIDEO

OUTPUT

VIDEO

OUTPUT

S VIDEO

OUTPUT

HP OUT

JA602

XKP3086

A

B

C

D

E

6ch SP OUT

F

56

XV-DV360

17

7

8

1234

3.3 DVD MAIN ASSY (1/5)

A

to PICK UP

CN101

VKN2045-

1

GNDD

2

F

3

VREF

4

VCC

5

E

6

D

7

C

8

SW

9

RF

10

B

11

A

VR650

12

VRCOM

13

B

C

D

E

F

VR780

14

GNDD

15

LD(780)

16

PD

17

LD(650)

18

GNDD

19

VSHF

20

TRKG DRV

21

TRKG RTN

TRAVERSE MECHA ASSY CN1

STEPPING

B

V+5USB

22

FOCS DRV

23

FOCS RTN

24

GNDD

to SPINDLE MOTOR

CN102

VKN1243

12

INSIDE

11

W

10

V

9

U

8

HB

7

W-

6

W+

5

V-

4

V+

3

U-

2

U+

SPINDLE MOTOR

1

V+5S

GNDD

to STEPPING MOTOR

CN103

VKN1235

1

ST2-(~B~)

2

ST2+(B)

3

ST1+(A)

4

ST1-(~A~)

MOTOR

to LOAB ASSY

CN104

B5B-PH-K-S

LOAD-

1

LOAD+

2

SW2

3

CN601

GNDD

4

SW1

5

A

GNDD

3-C1

USBP

3-C1

3/5

USBN

C773

0.1/16

GNDD

C374

100/6.3

C373

STBY

C372

0.1

C371

0.1

R375

***

R374

***

(RF)

R373

***

R372

***

R371

***

(T)

(T)

(F)

(F)

LIMIT

4

HW-

HW+

HV-

HV+

HU-

HU+

V+5S

C140

1

(S)

ST2-

(S)

ST2+

(S)

ST1+

(S)

ST1-

LOAD-

LOAD+

TRIN

TROUT

KN103

STBY

USB POWER CONTROL

V+5USB

R772

100k

3

2

1

C771

V+5S V20

MDI1

T+

T-

F+

F-

W

V

U

L772

ATL7002-A-T

R771

4

IC771

AAT4618IGV-0.5-1-TLB

5

1/16

B 1/5

18

1234

F

E

D

C

IOA

RF

B

V+6R8

220

4.7

R131

A

STBY

C772

4.7

R132

XFLAG

Q305

UM5K1N

43

51

C102

1

V+6R8

C101

100/10

4.7

4.7

4.7

4.7

***

C133

GNDM

R134

R135

R133

R136

CTL

C781

10/50

2

VCC

IC101

LDOP

1326475

LOAD-

NJM2845DL-05

V+5S

R313

100K

R318

100K

HU-

HU+

HV+

***

C141

43444237383940

41

HU-

HV+

HU+

FCO+

LDON

FCO-

C153

C152

YBYBYB

0.01

LOAD+F+F-T+T-

IC781

OUT IN

STBY

C783

GNDD

V+5S

10K

R314

Q304

2SC4154(EFG)

(2SC4081(QR))

GNDD

FTS Driver

HV-

HW+

HW-

***

***

C142

C143

HB

HV-

HW-

HW+

SERVO DRIVER

BD7995EFS

AGND

AVM

TKO+

TKO-

8

1

C103

C151

0.01

0.01

13

2

2.2

C782

IOA

R315

10K

L309

***

L308

***

2200p

C145

C144

2200p

33353436313032

U

SPVM1

SPGND1

TKIN

FCIN

LDIN

1011129141516

D781D782

LD CURRENT

CONTROL

Q308

HN1A01F(YGR)

(1/2)

Q307

HN1A01F(YGR)

(1/2)

WUV

C146

2200p

29262724252823

V

W

FG

CTL1

SPRNF

SPVM1

SPGND2

SLO1P

SLO1N

SLO2N

SLO2P

DVCC

SLGND

SLVDD

13

1

C104

1

1

R151

R153

1.8

1.8

R154

R152

ST1-

ST1+

XFLAG

3-C2

USBPOWER

3-B4

V+6R8

STBYSTBY

XV-DV360

6

6

CTL2

SLIN2

ST2+

R326

R325

SPIN

DGND

SLIN1

SLRNF2

21

2017181922

V+5M

ST2-

4.7

4.7

V+3

Q308

HN1A01F(YGR)

2415

2415

HN1A01F(YGR)

(2/2)

R321

R322

(2/2)

Q307

***

R310

4.7

C310

47/35

GNDD

3

4.7

C309

47/35

3

1

FG

ENDM

STBY

DMSO

V1P4

C161

1000p

VC

0.1

***

C131

C132

SLRNF1

PWMOUT1

FMSO

V+5M

C121

2

1

TROPEN A19

(F)

B

(T)

VTH1047

L761

4

1

32

3/5

FOSO

TRSO

V+3D

C289

GNDD

FLASH

V+3D

R284

10k

R285

***

GNDD

PCE#

C320

1

PWR#

STBY

LDO1

LDO2

DMSO

FMSO

TROPEN

PWMOUT1

TRSO

FOSO

FG

TROUT

TRIN

STBY

ENDM

C296

FLASH

IC203

1000p

IOA

V+1R8

V+1R8

D

A

B

C

RF

E

F

MDI1

LDO2

LDO1

V20

V1P4

2200p

C208

0.1

C209

(T)

(F)

SCL

SDA

A17

***

R282

48474642434544

A16

VSS

~BYTE~

A13

A15

A14

S29AL016D70TFI010

1238674

A14

A16

A15

V+3

R207

V+3

STBY

R200

STBY

C214

C201

STBY

C343

1

C346

1

C345

1

C344

1

(RF)

C347

1

3.3v

STBY

R238

R239

STBY

C203

47/35

47/35

C204

0.1

C213

C205

0.1

C206

47/35

100p

2200p

C210

C211

R208

STBY

10K

R218

AD7A0AD6

D7

D15

3

C212

100p

R201

R202

R204

R205

R206

C218

0.1

R769

33

R767

R770

R214

***

A2

A3

A4

A5

A6

A7

A8

A18

V+3DV+3

10K

R219

41

D6

D14

R768

33

C216

R213

R212

R211

R210

C217

3.3v

C290

0.1

81

VCC NC

7

IC204

WP

6

SCL

EEPROM

5

SDA

S-24CS04AFJ

AD5

AD3

AD4

383739

40

D4

D12D5D13

VCC

AYW7096

A9

A8

A12

A10

A11

A19

5

A13A9A11

A12

~WE~NC~RESET~NCNC

11

1091215161413

PWR#

A10

A20

C202

220/6.3

220/6.3

SUBA

SUBB

SUBC

SUBD

C207

0.1

C215

0.1

C200

0.1

1.5K

22K

22k

51k

51k

C219

5600p

15k

15k

0.1

10K

10K

STBY

STBY

0.1

1.8v

***

C221

C220

2

NC

3

NC

4

GND

AD1

AD2

343536

332831293032262527

D2D9D0D8D1

D10D3D11

A18

RY/~BY~A6A4A5A7

A17

A19

A8A7A6A3A2

A18

15k

R256

0.1

C273

256

254

255

1

AGND

2

DVDA

3

DVDB

4

DVDC

5

DVDD

6

DVDRFIP

7

DVDRFIN

8

MA

9

MB

10

MC

11

MD

12

SA

13

SB

14

SC

15

SD

16

CDFON

17

CDFOP

18

TNI

19

TPI

20

MIDI1

21

MIDI2

22

LDO2

23

LDO1

24

SVDD3

25

CSO/RFOP

26

RFLV/RFON

27

SGND

28

V2REFO

29

V2O

30

VREFO

31

FEO

32

TEO

33

TEZISILV

34

OP_OUT

35

OP_INN

36

OP_INP

37

DMO

38

FMO

39

TROPENPWM

40

PWMOUT1/V_ADIN9

41

TRO

42

FOO

43

VPLLVSS

44

CAPPAD

45

VPLLVDD3

46

USB_VSS

47

USBP

48

USBM

49

USB_VDD3

50

FG/V_ADIN8 (PU)

51

TDI/V_ADIN4 (JTAG)

52

TMS/V_ADIN5 (JTAG)

53

TCK/V_ADIN6 (JTAG)

54

TDO/V_ADIN7 (JTAG)

55

DVDD18

56

IOA2 (PU)

57

IOA3 (PU)

58

IOA4 (PU)

59

IOA5 (PU)

60

IOA6 (PU)

61

IOA7 (PU)

62

HIGHA0(PU)

63

IOA18 (PU)

64

IOA19 (PU)

656867

66

STBY

0.1

R217

STBY

R232

A16

PWR#

AD0

PCE#

PRD#

VSS

~OE~

A3A1A2

19181720212324

22

A5

A4

C272

~CE~

0.1

253

A15

A1

A0

3.3v

1.8v

C271

0.1

C269

252

250

251

OSP

RFGND

IREF:255

AVDD3:256

65:DVDD3

HIGHA6(PU)

HIGHA5(PU)

A14

A13

A12

V1P4

100K

R255

C268

0.033

248

249

HRFZC

CRTPLP

RFRPAC

OSN:253

RFGC:254

66:IOWR#

67:A16

68:HIGHA7(PU)

HIGHA4(PU)

HIGHA3(PU)

HIGHA2(PU)

7273707169

A11

A10

22p

C265

C267

1000p

0.1

247

RFRPDC

HIGHA1(PU)

IOA20

75

74

A9

A20

5678

246

RFVDD3

0.1

C264

C266

0.1

244

245

ADCVSS

XIOCS

7776788180

0

R233

C259

243

LPFOP

ADCVDD3

IOA1

XIOCE

PRD#A1PCE#

AD0

242

79

LPFIN

AD0

0.047

AD1

241

LPFIP

AD1

10/50

C256

C258

240

0.047

LPFON

DVSS

9p

C251

0.47

C255

C260

239

238

PLLVDD3

IDACEXLP

AD2

AD3

AD2

AD3

VSS1168

C254

1000p

R254

750K

0.1

237

PLLVSS

AD4

AD4

GNDD

X201

R251

100K

236

JITFN

AD5

AD5

1

C245

194

195

VREF

YUV4/G

YUV5/B

YUV6/R

YUV7

DVSS

IO_17

C0/IO_0

C1/IO_1

DVDD18

C2/IO_2

C3/IO_3

C4/IO_4

DVDD3

C5/IO_5

C6/IO_6

C7/IO_7

Y1/IO9

Y2/IO10

Y2/IO11

Y3/IO12

DVDD18

DVDD3

RA11

DVSS

RCLK

DVDD3

DVDD18

RA10

XRCS

XRAS

XCAS

XRWE

DQM1

DVDD3

IO_18

126

127

DQ10

FS

RA4

RA5

RA6

RA7

RA8

RA9

CKE

RA3

RA2

RA1

RA0

BA1

BA0

RD8

2.2k

R279

193

192

191

190

YUV0/CIN

189

188

187

186

185

184

183

182

181

180

179

178

177

176

175

174

173

172

171

170

169

168

167

166

165

164

163

162

161

160

159

158

157

156

155

154

153

152

151

150

149

148

147

146

145

144

143

142

141

140

139

138

137

136

135

134

133

132

131

130

129

128

DQ9

3.3v

1.8v

3.3v

0.1

C250

C236

3.3v

1.8v

(RF)

(F)

(T)

(S)

(C/V)

(S_Y)

(S_C)

(R/Cr)

(G/Y)

(B/Cb)

(AD)

(HDMI)

B

C243

C244

C235

C234

C233

0.1

C232

0.1

C231

0.1

C230

0.1

HDMI

C237

0.1

0.1

0.1

0.1

0.1

V+3

*1

5

2

R257

12p

235

JITFO

234

XTALI

233

XTALO

C252

R253

R252

C238

232

RFVDD18

680

0

C262

0.1

231

RFGND18

10/50

230

ADACVDD2

0.1

C261

228

229

ALF/(CTR)

ADACVDD1

1

STBY

C240

227

226

225

AVCM

AL/SDATA2

ALS/SDATA0

3

GNDD

224

IC201

MT1389FE/H-L

DVD BE

DVDD18

IOA0

A17

URD#

UWR#

9298959697

0.1

C224

A17

A0

6.8k

KUC

DVDD3

949391

0.1

C225

3.3v

1.8v

3333333333

R221

MDATA

506751

0

0

0

0

10

33

33

33

33

AD6

8685848382

AD6

IOA21

879089

33

R224

R291

XREADY

78

DVSS

AD7

ALE

88

AD7

R292

3.3k

GNDD

*1

R257

R269

R240

R247

R243

R248

R262

R263

R222

IC205

STBY

4

1.8v

10/50

C241

223

222

ARF(SW)

AR/SDATA1

ARS/SDATA3

UP1_4 (PU)

UP1_3 (PU)

UP1_2 (PU)

99

R235

4.7k

R234

R237

SCLK

ACK

C270

220

221

ADACVSS1

UP1_5 (PU)

101

100

33

R259

R258

SCL

3.3k

R215

SDATA

GNDD

49

ADACVSS2

UP1_6 (PU)

*1

R269

*1

STBY

R248

STBY

10/50

C242

C222

219

218

217

APLLCAP

APLLCSS

APLLVDD3

UP3_0 (PU)

UP1_7 (PU)

UP3_1 (PU)IRXINT0

103

102

104

R263

R260

R262

SDA

HDMISCL

HDMISDA

V+3DR

132

6.8k

R216

B4B-PH-K-S

11

HSPDIF

ASPDIF

R247

0.1

C223

10/50

C228

215

216

SPDIF

MC_DATA

UP3_4 (PU)

UP3_5 (PU)

106

105

C226

*1

TXD

RXD

CN204

DOWNLOAD

R240

214

213

DVDD18

ASDATA4

ICE (PD)

107

108

0.01

13

HCLK

212

ASDATA3

XPRST

109

R236

33

R223

XDVDRST

4

ACLK

10

R243

0.1

C239

211

110

STBY

R222

*1

INT0#

ACLK

210

111

DQM0

ABCK

ABCK

DQM0

33

R242

STBY

R220

209

ALRCK

IO_19

112

33

R261

ALRCK

33

R241

LIMIT

208

DVDD3

RD7

113

DQ7

10k

0.1

C247

R230

207

SPBCLK

RD6

114

220p

C227

DQ6

R293

XDVDRST

80

206

SPLRCK

RD5

115

DQ5

3.3k

12

ADDATA

STBY

R250

0.1

C248

205

SPDATA

RD4

116

0.1

C229

DQ4

R294

GNDD

204

117

DQ3

ASDAT2

ASDAT1

33

33

R245

R246

SQUEEZE

202

203

SPMCLK

ASDATA1/GPO_1

ASDATA2/GPO_0

DACVSSC:192

YUV1/Y:191

DACVDDB:190

YUV2/C:189

DVDD3

RD3

RD2

119

118

33k

R272

DQ1

DQ2

6.8k

(AD)

LETTER

201

200

GPIO_3

RD1

120

121

DQ0

B

GPIO_4

199

RCLKB/GPIO_5

RD0

RD15

122

DQ15

14

ASDAT0

33

R244

0.1

C246

197

196

198

DACVDDC

RVREF/GPIO_6

DACVSSB

ASDATA0/GPO_2

YUV3/CVBS

DACVDDA

DACVSSA

VSYNC/V_ADIN1

HSYNC/VADIN2

YUVCLK/IO_8

Y4/IO_13

Y5/IO_14

Y6/IO_16

Y7/IO_16

126:RD11

127:RD10

128:RD9

RD14

RD13

RD12

123

124

125

DQ12

DQ14

DQ13

DQ11

UCOM

3-A1,5-A2

3/5,5/5

XV-DV360

56

DVD MAIN ASSY

1/5

(AWM8027)

GNDD

220/6.3

(AD)

(B/Cb)

3.3v

1.8v

RAB4C330J

(S_Y)

(S_C)

(C/V)

(G/Y)

R229

R228

R227

R226

R225

33*4

R209

STBY

(R/Cr)

R266

0

33

33

33

0

V+3

MA11

SDCKE

SDCLK

MA10

DBA1

DBA0

DCS#

DRAS#

DCAS#

DWE#

DQM1

MA4

MA5

MA6

MA7

MA8

MA9

MA3

MA2

MA1

MA0

DQ8

to AUDIO PART

(Page 2/2)

I/XP

S_Y

S_C

CVBS

G_CY

B_CB

R_CR

VSEL2

VSEL1

R264

RAB4C330J-T

R265

RAB4C330J-T

R267

RAB4C330J-T

R271

RAB4C330J-T

C281

220/6.3

MA4

MA5

MA6

MA7

MA8

MA9

MA11

SDCKE

SDCLK

DQM1

C284

DQ8

0.1

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

C285

DQ15

0.1

V+3D V+3DR

R281

to VIDEO PART

Chip Size

RESISTOR

CAPACITOR

(MDMI)

(MDMI)

STBY

C282

VSS

28

A4

29

A5

30

A6

31

A7

32

A8

33

A9

34

A11

35

NC

36

CKE

37

CLK

38

UDQM

39

NC

40

VSS

41

DQ8

42

VCCQ

43

DQ9

44

DQ10

45

VSSQ

46

DQ11

47

DQ12

48

VCCQ

49

DQ13

50

DQ14

51

VSSQ

52

DQ15

53

VSS

54

AUDIO

(Page 2/2)

: 2125 Size

RS1/10S***J

:1608 Size

(F):RS1/16S****F

OTHERS:RS1/16S***J

: 2125 Size

CKSQ**~

:1608 Size

CH:CCSRCH~

OTHERS:CKSRYB~

1

64M SD-RAM

IC202

B

2/5,3/5,5/5

VCC

27

A3

26

A2

25

A1

24

A0

23

A10/AP

22

BA1

21

BA0

20

CS

19

RAS

18

CAS

17

WE

16

LDQM

15

VCC

14

DQ7

13

VSSQ

12

DQ6

11

HY57V641620ETP-H

DQ5

10

VCCQ

9

DQ4

8

DQ3

7

VSSQ

6

DQ2

5

DQ1

4

VCCQ

3

DQ0

2

VCC

1

GNDD

: RF SIGNAL ROUTE

: FOCUS SERVO LOOP LINE

: TRACKING SERVO LOOP LINE

: STEPPING SERVO LOOP LINE

: VIDEO SIGNAL ROUTE(C/V)

: VIDEO SIGNAL ROUTE (S_Y)

: VIDEO SIGNAL ROUTE (S_C)

: VIDEO SIGNAL ROUTE (R/Cr)

: VIDEO SIGNAL ROUTE (G/Y)

: VIDEO SIGNAL ROUTE (B/Cb)

: AUDIO DATA SIGNAL ROUTE

: VIDEO/AUDIO SIGNAL ROUTE (HDMI)

7

B

C288

C287

C283

0.1

0.1

C286

0.1

0.1

4-A1

VIDEO

4/5

DRAS#

DCAS#

KN202

STBY

PUSEL

MA3

MA2

MA1

MA0

MA10

DBA1

DBA0

DCS#

DWE#

DQM0

DQ0

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

XO

PRDN

VSYNC

HSYNC

C0

C1

C2

C3

C4

C5

C6

C7

VCK

Y0

Y1

Y2

Y3

Y4

Y5

Y6

Y7

B 1/5

8

HDMI

B

A

B

C

D

E

2-A1

2/5

F

19

1234

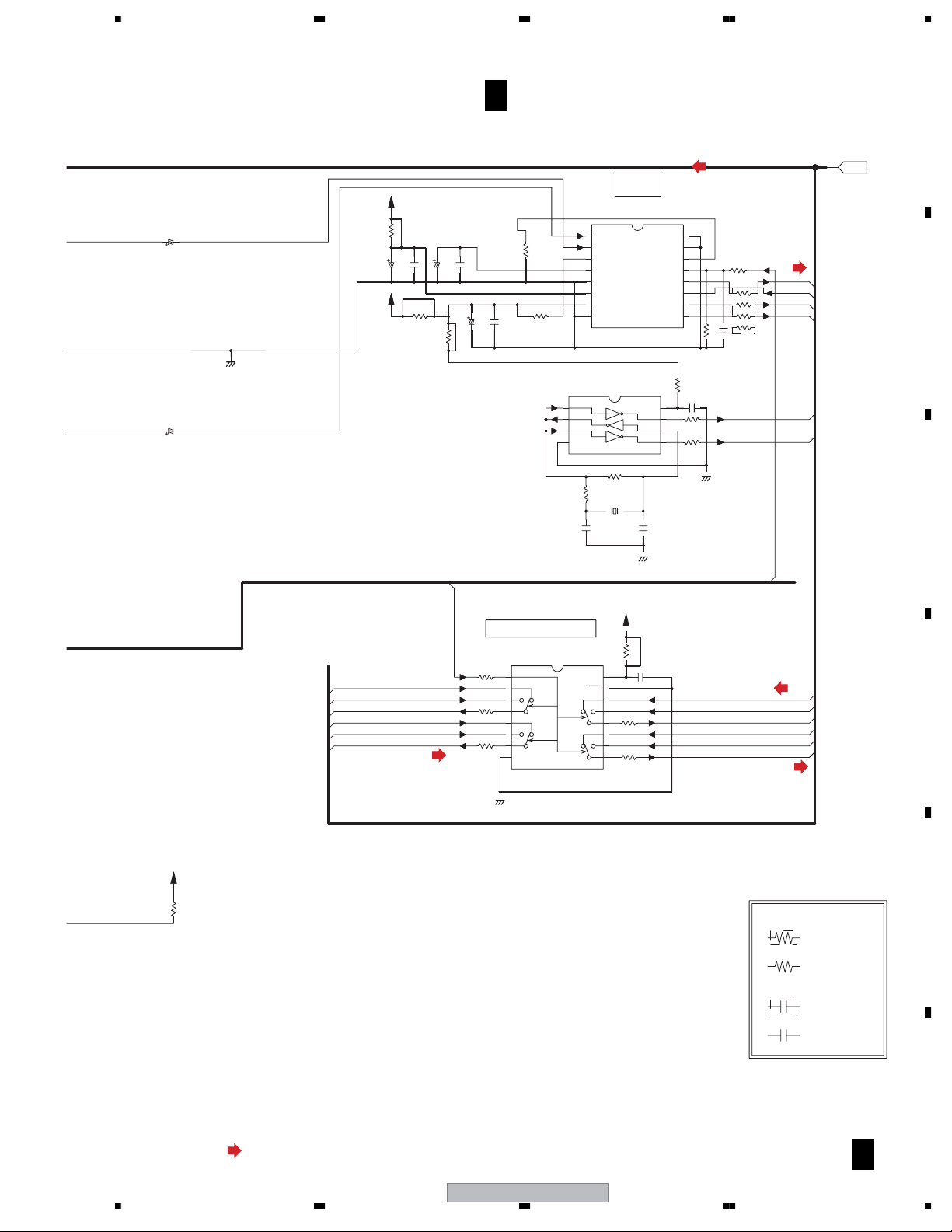

3.4 DVD MAIN ASSY (2/5)

FS

L936

VREF

SWING

HTPLG

GPO10

40

V+3R3TX

C944

AVDD

AVSS

TX2+

TX2-

AVDD

TX1+

TX1-

AVSS

TX0+

TX0-

AVDD

TCK+

TCK-

AVSS

AVSS

AVDD

AVDD

PLLC1

PLLC0

AVSS

0.1

C953

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

GNDD

47/35

R934

C954

GNDD

510

(F)

0.1

V+3R3TX

0.1

C946

C945

5600p

C956

1000p

A

V+3

V+1R8

V+3

AUDIO

B

1/5,3/5,5/5

0.1

C985

ATL7010

L937

0.1

C935

HCLK

L931

ATL7010

10

HDMI

1-D6

B

B

1/5

C987

1000p

C931

0.1

R911

80 777879 7576 7374 7172 70 69 68 67

AD1

AD0

RST

252426

CLK

AD2

INT

27

ACK

DVDD18

SSCK

21

ALRCK

SSD

22

ABCK

PWDN

DVDD18

23

1

10

11

12

13

14

15

16

17

18

19

20

2

3

4

5

6

7

8

9

DVSS

C0

C1

C2

C3

C4

C5

C6

C7

DVDD33

VCK

DVSS

Y0

Y1

Y2

Y3

Y4

Y5

Y6

Y7

C0

C1

C2

C3

C4

C5

C6

C7

C

VCK

Y0

R931

0

C942

0.1

Y1

Y2

Y3

Y4

Y5

Y6

Y7

D

V+3R3HD

0.1

C933

C932

47/35

HSPDIF

YUV6

YUV5

10

R906

B

R

AD3

SPDIF

AVSS

IC931

MT1392E/C-L

HDMI Transmitter

DVSS

28

A7/GPO0

293230

TRAP2/GPO2

A6/GPO1

31

TRAP1/GPO3

1000p

C934

GNDD

YUV4

V+3R3HD

66 65 63 6264 61

G

AVSS

AVDD

MSD/GPO6

MSCK/GPO5

TRAP0/GPO4

333435

0.1

C955

R933

AVDD

GPO8

GPO7

373839

36

ATL7010

560

AVSS

GPO9

0.1

10k

R914

C943

1k

R915

GNDD

R945

STBY

0.1

C936

STBY

R936

STBY

R937

STBY

R938

STBY

R939

STBY

R940

STBY

R935

STBY

R944

STBY

R943

HDMISCL

HDMISDA

C940

IC932

STBY

EEPROM

PUSEL

STBY

8

7

6

VSYNC

HSYNC

1

2

3

45

SCL

SDA

PRDN

XO

INT0#

R901

R902

R903

R904

R905

GNDD

STBY

STBY

STBY

STBY

STBY

XDVDRST

E

GNDD

F

B

2/5

A

20

XV-DV360

1234

5678

R947 C947

STBYSTBY

R948 C948

STBY STBY

R949 C949

STBY STBY

R950 C950

STBY STBY

V+5HD

R959

4.7k

R961

V+3

STBY

R941

R960

4.7k

STBY

R942

Q934

UMB1N

2.7k

STBY *8

GNDD

VA901

V+5HD

VA931

VA932

R962

STBY

C982

VA933

Q934

UMB1N

2.7k

STBY

VA902

2.2

VA935

VA934

NJM2872BF05

5

4

0.1

C984

VA937

VA936

(DTC114YUA)

IC981

Vout

Vin

GND

Nr

VC

GNDD

R951

R952

R953

R954

R955

R956

R957

R958

STBY

VA938

Q933

RT1N144M

UDZS5R1(B)

B

DVD MAIN ASSY

2/5

A

(AWM8027)

V+6R8

1

2

3

D933

1

C983

ATH7022 *4

L932

431

L933

342

L934

32

4

L935

41

R974

STBY

R975

STBY

V+5HD

Q936

STBY

R971

R967

STBY

STBY

R970

1k

2

1

1

23

R963

R968

V+6R8

B

3/5,4/5

DVDPOWER

V+5HD

R973

R964

STBY

STBY

Q935

STBY

R969

STBY

0

R965

STBY

GNDD

R972

STBY

0.1

C951

STBY

C952

GNDD

Q935

STBY

10/50

R966

CN931

AKP7210

(AKP7211)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

47k

VA903

DATA2+

DATA2 SHIELD

DATA2DATA1+

DATA1 SHIELD

DATA1DATA0+

DATA0 SHIELD

DATA0CLOCK+

CLOCK SHIELD

CLOCKCEC

NC

HDMISCL

HDMISDA

DDC/CEC GND

+5V

HOT PLUG DETECT

STBY

B

C

D

E

56

XV-DV360

F

B

2/5

21

7

8

1234

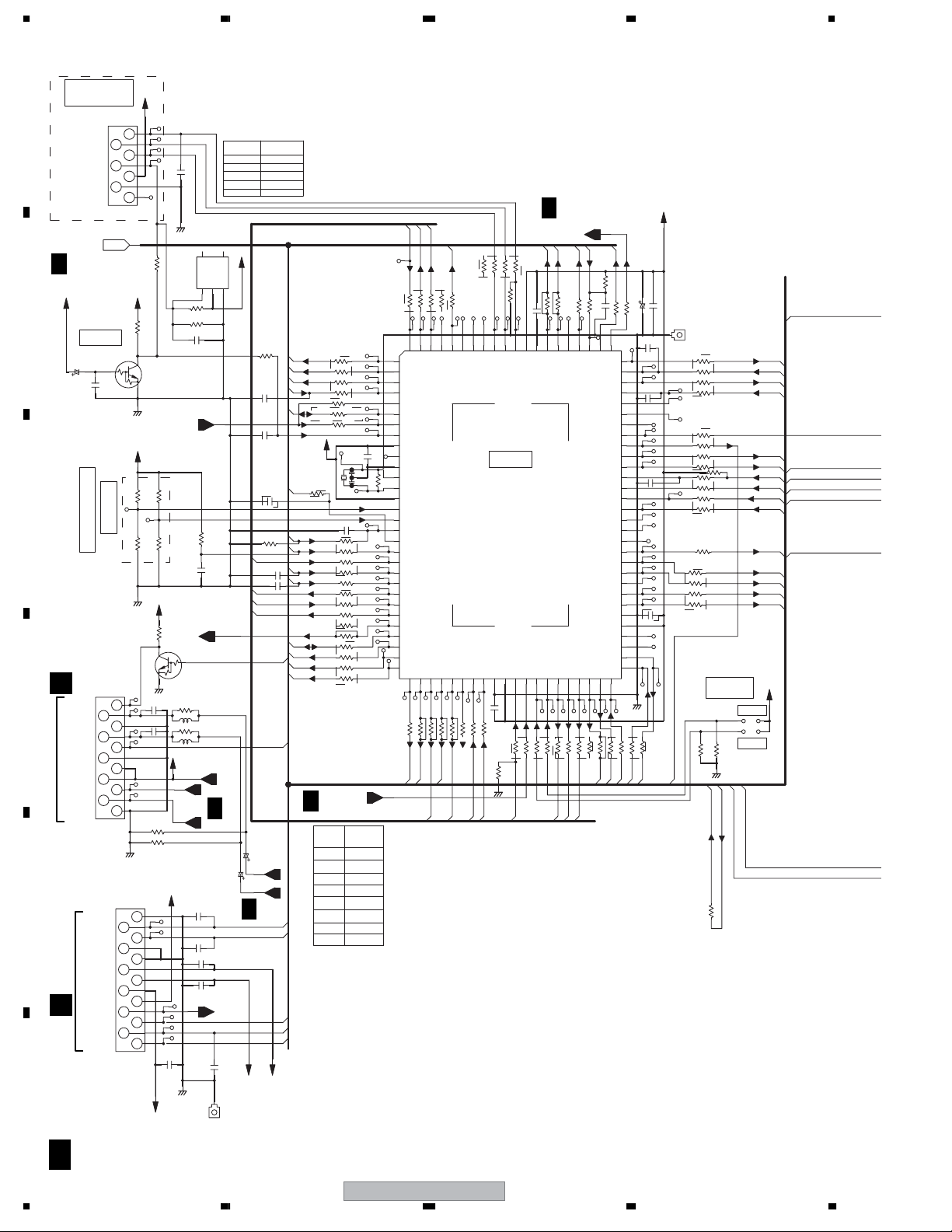

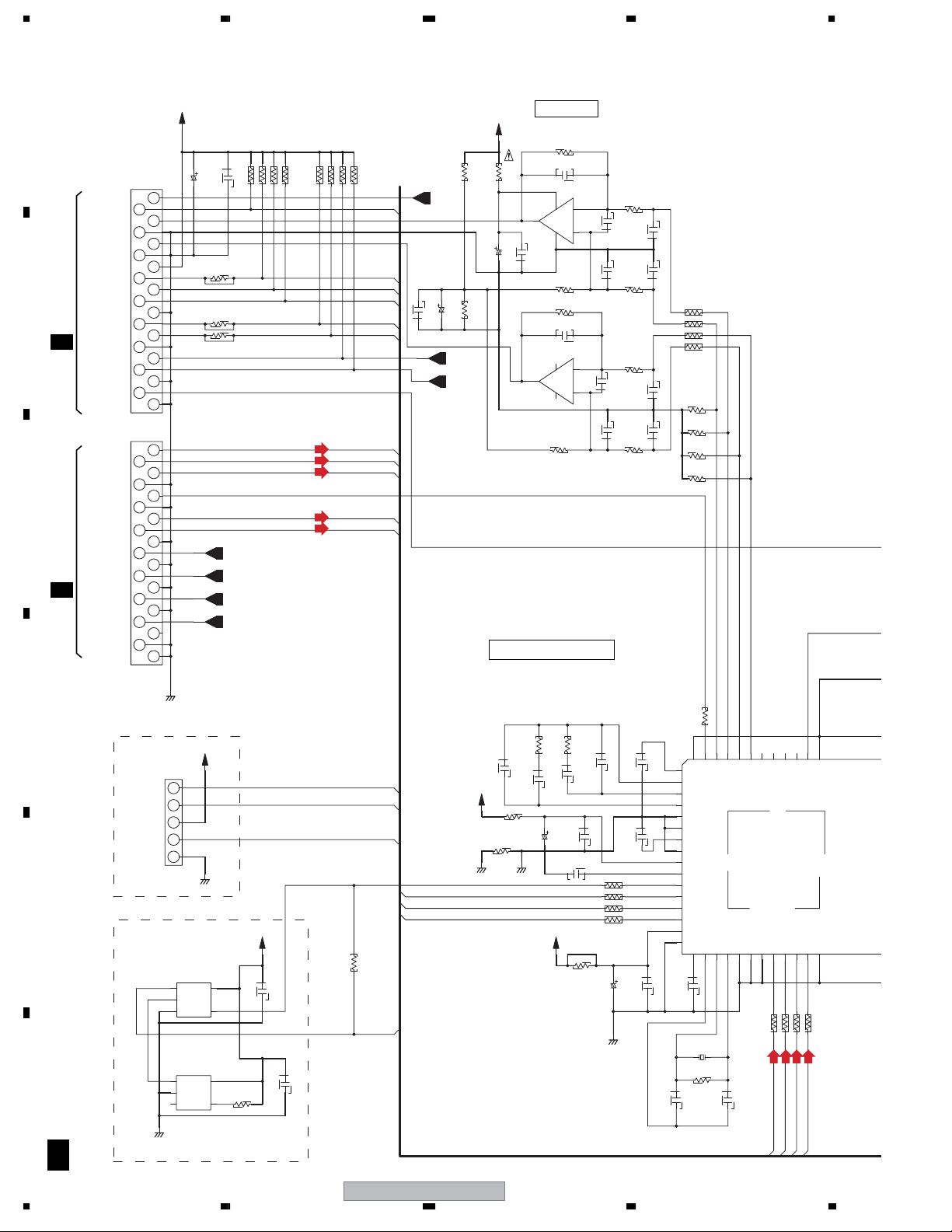

3.5 DVD MAIN ASSY (3/5)

A

B

C

D

E

F

DOWNLOAD

µ-COM

CN5501

52045-0745

WEN/DI

WDD

WCLK

RST

VCC

VSS

STBY

UCOM

1-D6,5-A2

B

1/5,5/5

VE+5

RESET

C5524

10/50

C5525

DESTINATION

CN5902

CN5601

E

HPMUTE

HP_L

GNDD

HP_R

HP_DET

GNDUSB

V5USB

V5USB

USB_DP2

USB_DM2

GNDUSB

GNDD

GNDD

GNDD

FLDC+

FLDC-

CN5901

D

REMOCON

FLDATA

NC

B

STBY

MODEL

CKS3376-

11

10

9

8

7

6

5

4

3

2

1

CN5602

KEY2

KEY1

VFDP

VE+5

FLCS

FLCK

VE+5

2

531

64

7

VU+5

R5510

C

E

(DTC143EUA)

GNDD

VE+5

*

R5513

*

R5515

GNDD

GNDD

CKS3378-

1

2

3

4

5

6

7

8

9

10

11

12

13

0

R5509

47k

Q5525

RT1N431M

*

R5514

*

R5516

VE+5

R3955

C

E

GNDD

C3953

STBY

C3954

STBY

R3951

47k

R3952

47k

C5601

1000p

VFDP

C5597

GNDD

R5500

R5503

C5503

3-B5

1.8k

4-C5

B

RT1N241M

(DTC124EUA)

R3953

STBY

CTF1346-

V+5USB

V+5USB

1-D1

USBP

USBN

1-D1

VE+5

C5604

C5605

GNDD

STBY

5

STBY

IC5503

1

2

STBY

STBY

STBY

REMOCON

R5519

10k

0.01

C5519

XTVMUTE

Q3951

CTF1346-

L3951

R3954

STBY

L3952

B

STBY

STBY

STBY

C5606

CHASSIS GND

R5513

R5514

R5515

R5516

43

1/5

C3952

C5603

1000p

C5602

1000p

REMOUT

3-A5

KN5601

STBY

AMW

DSP

VE+5

C3951

100/16

5-A1

5-A1

B

FLDC- FLDC+

R5508

2.2K

C5504

0.01

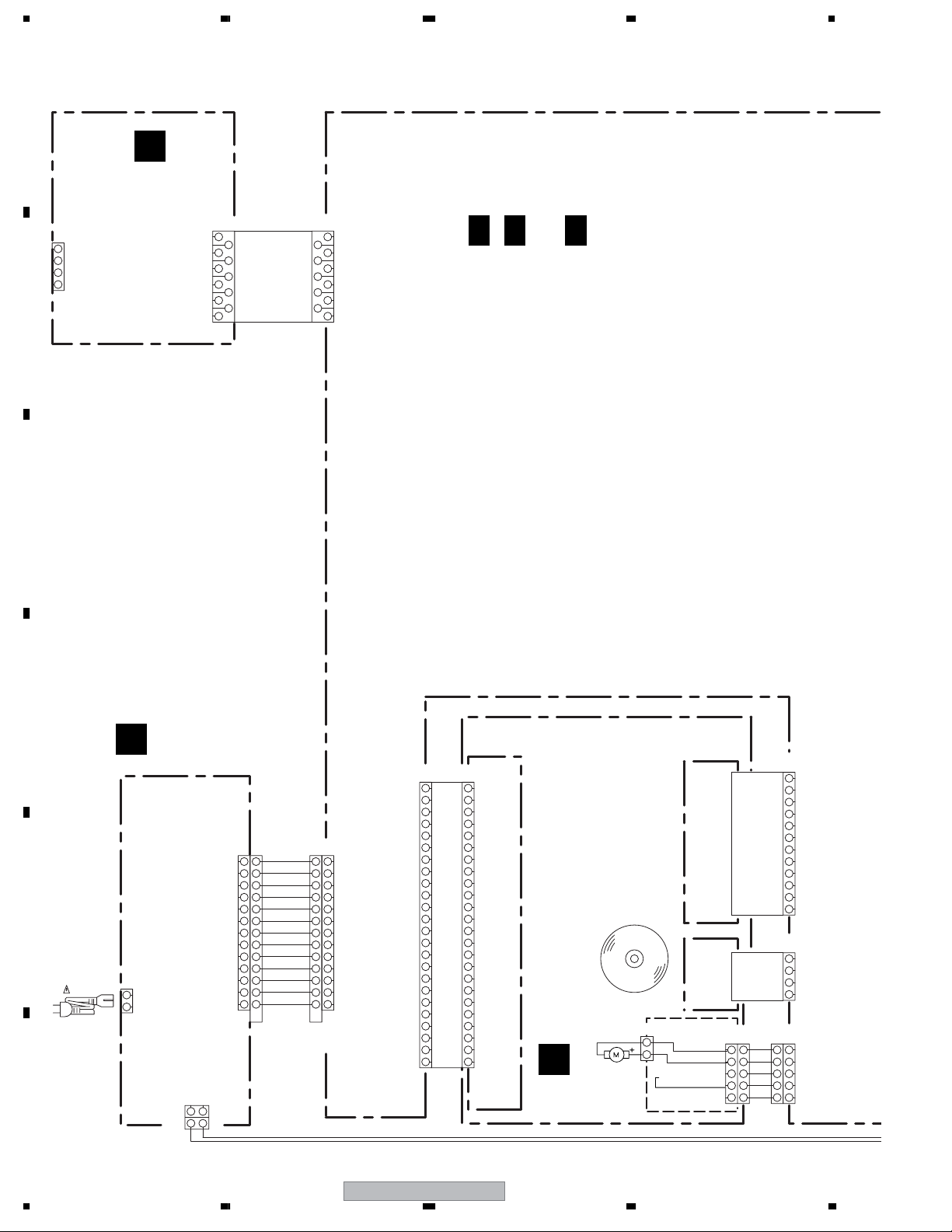

C5508

0.01

C5518

0.01

R5518

1M

20

C5521

0.1

C5522

0.01

23

24

25

100/16

5/5

HP_L

HP_R

/KUCXJ

UPPER

8027

39k

68k

33k

15k

31

83

19

69

2

3

1

1

2

3

4

R5505

EU

6

R5506

7

R5507

VU+5

X5501

ASS7034

10MHz

R5569

220

69

C5517

R5517

17

19

RAB4C221J

21

22

R5522

RAB4C221J

R5525

STBY

27

28

R5527

29

30

RAB4C221J

B

R5522

R5531

R5537

R5538

R5542

R5544

R5598

R5543

UCOM

R5501

RAB4C221J

220

0.01

220

R5521

220

220

XFLAG

1/5

*1

220

220

220

0.1/16

C5509

R5512

220

*1

1-D2

KUC BASE

STBY

0

STBY

STBY

STBY

0

STBY

0

STBY

*1

R5598

100

220

RAB4C221J

100

FLDAT

XFLCS

FLCLK

ACDET

P_ON

6743512

RDSCLK

REMOCON

XRESET

XT1

XT2

VSS1

CF1

1312111098

CF2

VDD1

SIMUKE

MODEL

VDET

KEY1

191816 171514

KEY2

DIRERR

PCONFIG

XPROTECT

DSPDI

DSPDO

DSPCK

26252422 232120

XTVMUTE

DASDA

DASCK

29 302827

INPUTSELA

INPUTSELB

313433

*1

R5531

313234

99

32

STBY

R5532

98

STBY

R5533

33

96

97989993969495

STBY

STBY

R5534

R5535

35

220

R5590

RAB4C221J

R5597

R5596

STBY

9291908788898685848182

(SWMIX)

FLASHCLK

(TXPOWER)

(DMUTECHECK)

XDIRCS

XDIRRST

(DTSMIX)

FLASHDO

FLASHE/D

FANCONT

DIRDO

µ-COM

IC5501

PDC133A

LC875C96B

XHPMUTE

ADMD

XRECMUTE

XADPDN

LED

DSPMUTE

XDEC MUTE

DSPHREQ

VSS4

VDD4

*1

C5539

R5538

*1

R5544

GNDD

383741

BUSY

0.1/16

353736383940414342

STBY

*1

R5536

R5537

B

878486

STBY

15K

0.1

C5589

R5587

VSS3

VDD3

BEATCUT2

HPDET

PWRCONT

DSPMODE

DATASEL

XFLAG

STEST

UTEST

44474645484950

220

RAB4C221J

R5541

2/5,4/5

DVDPOWER

83

STBY

220

10k

R5584

R5586

R5583

83

XDVDRST

FLCONT

BEATCUT1

SHUTDWN

HPSEL

USBPOWER

DVDPOWER

XDAMUTE

TXIDATA

RDSDATA

RDSPOW

TXODATA

MDATA

SDATA

XDSPSS

XDSPRST

*1

220

RAB4C221J

R5542

464547

R5574

C5579

XOTW

XREADY

SR+RX

SR+TX

DIGSEL

XDAPDN

XDARST

KEY1

EEP_DI

DVDACK

TXCLK

EEP_SK

EEP_DO

EEP_CS

VSS2

VDD2

TXCE

SCLK

STBY

R5545

100k

NC

NC

NC

NC

4948525150

82

1000p

220

R5582

7576777880 79

686971 707274 73

63 6264656667

56 555759 5861 60

515254 53

GNDD

220

R5581

C5578

0.01

C5577

0.01

C5569

C5502

0.01

100/10

VE+5

C5501

C5555

0.1/16

220

R5548

RAB4C221J

STBY

KN5501

STBY

CHASSIS GND

R5562

R5546

72

R5577

RAB4C221J

220

R5570

RAB4C221J

220

R5563

R5566

RAB4C221J

220

220

R5557

RAB4C221J

220

SHORT for

TEST POINT

10k

10k

R5547

GNDD

4

72

ACDET

DSPMUTE

*1

R5543

10k

UTEST

STEST

84

PWRCONT

VE+5

80

79

78

77

71

70

69

68

67

66

62

61

60

58

57

22

XPROTECT

57

60

58

68

17

22

B

A

3/5

XV-DV360

1234

5678

V+10

D1416

V+3R3

*3

D1417

*3

R1415

USBPOWER

1-D2

B

IC5502

47k

R5559

1

CS

2

SK

3

DI

4

DO

CH

47p

47k

R5558

C5558

HDMI FLASH ROM

V+3

SDRAM BACK END IC

V+3

C1202

GNDD

BACK END IC

V+1R8

HDMI

V+1R8

C1103

47/35

B

2/5,4/5

KUC GA BASE

Q1413

1.8k

(DTC124EUA)

*3

STBY

C1415

D1415

GNDD

1/5

S-93C46BD01-J8T1

EEPROM

1

C1201

STBY

Q1201

RT1N141-11

(DTC114EUA)

NJM2846DL3-18

STBY

C1102

DVDPOWER

*3

PROTECT

RT1N241M

S

STBY

R1204

R1202

C

E

GNDD

IC1101

5

4

UDZS

4.7B

*3

C1413

VE+5

8

VCC

7

NC

6

TEST

5

GND

Q1202

RSR015P03

D

G

C1204

470k

1

2

3

Q1402

2SA1602A

C

B

R1404

GNDD

0.056

D1201

MA111

B

R1101

220

GNDD

C1413D1415

STBY

E

39k

GNDD

C1101

D1416

D1417

STBY

V+10

V+6R8

V+5

R1401

3.9k

R1403

R1402

3.3k

47K

GNDD

MA111

D802

0.1/16

C5557

C801

STBY

GNDD

FTS DRIVER

V+5M V+5S V+5V

R1305

STBY

10k

R1201

µcom FL DRIVER

STBY

C1203

VU+5

C1505

C1501

100/10

1

B

3/5

REMOUT

3-D1

0

R5943

D1403

MC2846-11

REMOCON

3-B1

V+5S V+5M

V+3V+5V

R801

4.7k

PU VIDEO DRIVER INPUT SELECTOR

L1305

VTL1095

µcom

VE+5

L1501

22

LAU-TA

0.01

C1502

GNDD

D1501

0.1

560(1/10W)

R1306

10k

STBY

V+5V

R1304

B

C1301

V+5V

Q1302

2SA1577(QR)

C

E

1

DVD MAIN ASSY

V+6R8

V+5MV+5S

V+5

V+3R3

R1303

Q1304

2SC4154(EFG)

(2SC4081(QR))

V+6R8

V+5 VE+5

VE+5

V+3R3

V+10

SCART

V+5

Q1301

2SA1602A(EF)

(2SA1576A(QR))

47k

R1307

4.7k

C

B

E

V+10

R1301

R1302

3.9k

Q1303

2SC4154(BFG)

(2SC4081(QR))

SUPPLY

47k

FLDC-

POWER

TX

SCART

AUDIO BUFFER

HDMI

USB BUS

FTS DRIVER

MODULATOR

DSP

A/D

DATA SELECTOR

FLDC+ VFDP

FL

(AWM8027)

Chip Size

RESISTOR

: 2125 Size

RS1/10S~

: 1608 Size

: 2125 Size

: 1608 Size

CN1002

B14B-PH-K-S

2

33

4

5

6

7

9

10

11

12

13

14

KN1001

STBY

RS1/16S~

CKSQ**~

CCSR**~

CKSR**~

141

2

5

6

7

88

9

10

11

12

13

BEAT_CUT

CAPACITOR

V+10

V+6R8

V+3R3

R1001

STBY

GNDM GNDD

GA UPPER

GA MID

KUC

CN1001

B13B-PH-K-S

AC_DET

SW10.5V

EV5.0V

SW5.0V

SW6.8V

GND

SW3.3V(B)

SW3.3V(A)

Pwr-ctr

GND

FL DC-

FL DC+

-25.5V

CHASSIS GND

A

B

C

CN1002

CN1001

D

CN3

G

E

56

XV-DV360

F

B

3/5

23

7

8

1234

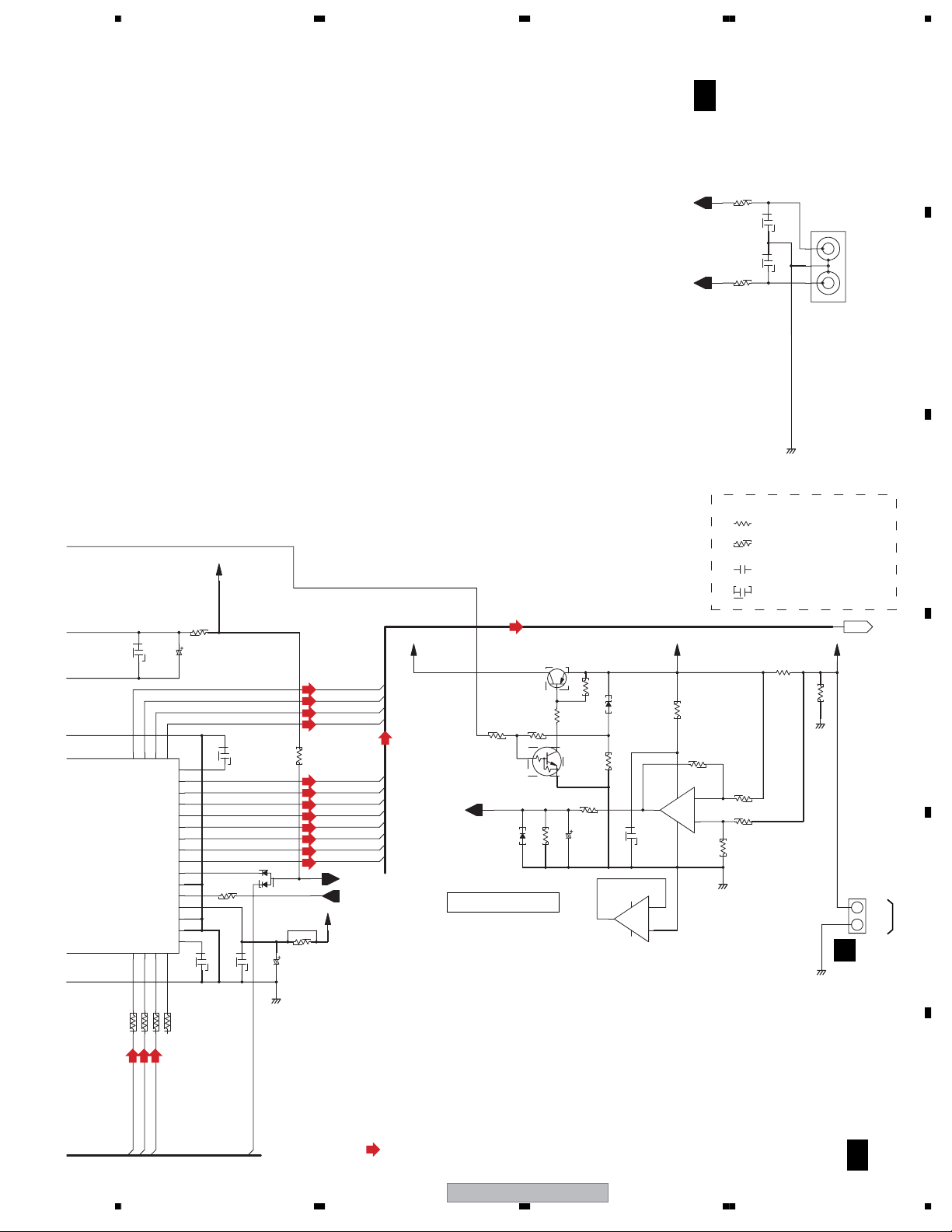

3.6 DVD MAIN ASSY (4/5)

(Page 1/4)

VIDEO

A

1-A6

B

1/5

B

C

from DVD PART

S_C

R411

CVBS

R412

S_Y

R413

G_CY

R414

B_CB

R415

R_CR

R416

SQUEEZE

LETTER

I/XP

150(F)

R431

STBY

150(F)

R432

STBY

150(F)

R433

STBY

150(F)

R434

STBY

150(F)

R435

STBY

150(F)

R436

STBY

C447

STBY

C449

STBY

C451

STBY

C453

STBY

C455

STBY

C457

STBY

GNDD

C411

0.1

C412

C413

C414

C415

0.1

C416

0.1

(S_C)

V+5V

(C/V)

IC401

GNDD

V+5V

VCC2

DC out

C out

V out

GND2

Y out

GND2

GND2

R/Cr out

GND2

R405

STBY

0.1

C402

C401

28

27

26

25

S1

24

S2