Page 1

D

REPEAT SEARCH

D

REPEAT SEARCH

D

TRAY TYPE MECHANISM CD PLAYER

41¢

¡

DIGITAL REMIX CD PLAYER

TRAY TYPE MECHANISM CD PLAYER

41¢

¡

DIGITAL REMIX CD PLAYER

MONITOR LEVELPHONES

ON

DELAY ECHO PAN FLANGER KEYCON OLD SAMPLE

3

EFFECT

3

ON/OFF

OPEN

PLAY

STOP

/CLOSE

/PAUSE

76

0

'

OPEN

PLAY

STOP

/CLOSE

/PAUSE

76

0

'

EFFECT LEVEL

DOWN

∞ ∞

UP

REMIX MINI COMPONENT SYSTEM

XS-R9

• This product is a system component. It combined the following components.

REMIX EFFECTOR................................EF-R9(S) /ZY

REMIX CONTROL MIXER..................... MX-R9(S) /ZY

COMPACT DISC PLAYER ....................PD-R9(S) /ZY

ORDER NO.

RRV1936

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Type

ZY DC power supplied from other system component

Model

XS-R9

Power Requirement Remarks

• This product is a system component.

For the system composition, refer to the service manual RRV1937 for SX-R9/MY.

• This product does not operate normally by itself. Please connect it to the STEREO TUNER AMPLIFIER

SX-R9/MY, for adjustment and operation inspection. Otherwise damage may result.

CONTENTS

1. SAFETY INFORMATION ...................................... 2

2. EXPLODED VIEWS AND PARTS LIST................ 3

3. SCHEMATIC DIAGRAM ..................................... 10

4. PCB CONNECTION DIAGRAM.......................... 30

5. PCB PARTS LIST ............................................... 42

6. ADJUSTMENT .................................................... 46

7. GENERAL INFORMATION ................................ 52

7.1 PARTS ......................................................... 52

7.1.1 IC .......................................................... 52

7.2.2 DISPLAY............................................... 61

7.2 DIAGNOSIS................................................. 62

7.2.1 DISASSEMBLY .................................... 62

7.2.2 TEST MODE......................................... 65

7.3 BLOCK DIAGRAM....................................... 74

8. PANEL FACILITIES AND SPECIFICATIONS.... 77

PIONEER ELECTRONIC CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE, INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER ELECTRONIC (EUROPE) N.V. Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 501 Orchard Road, #10-00 Lane Crawford Place, Singapore 0923

c

PIONEER ELECTRONIC CORPORATION 1998

T - IZY MAR. 1998 Printed in Japan

Page 2

XS-R9

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians ; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

IMPORTANT

THIS PIONEER APPARATUS CONTAINS

LASER OF CLASS 1.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DONE BY A SPECIALLY

INSTRUCTED PERSON.

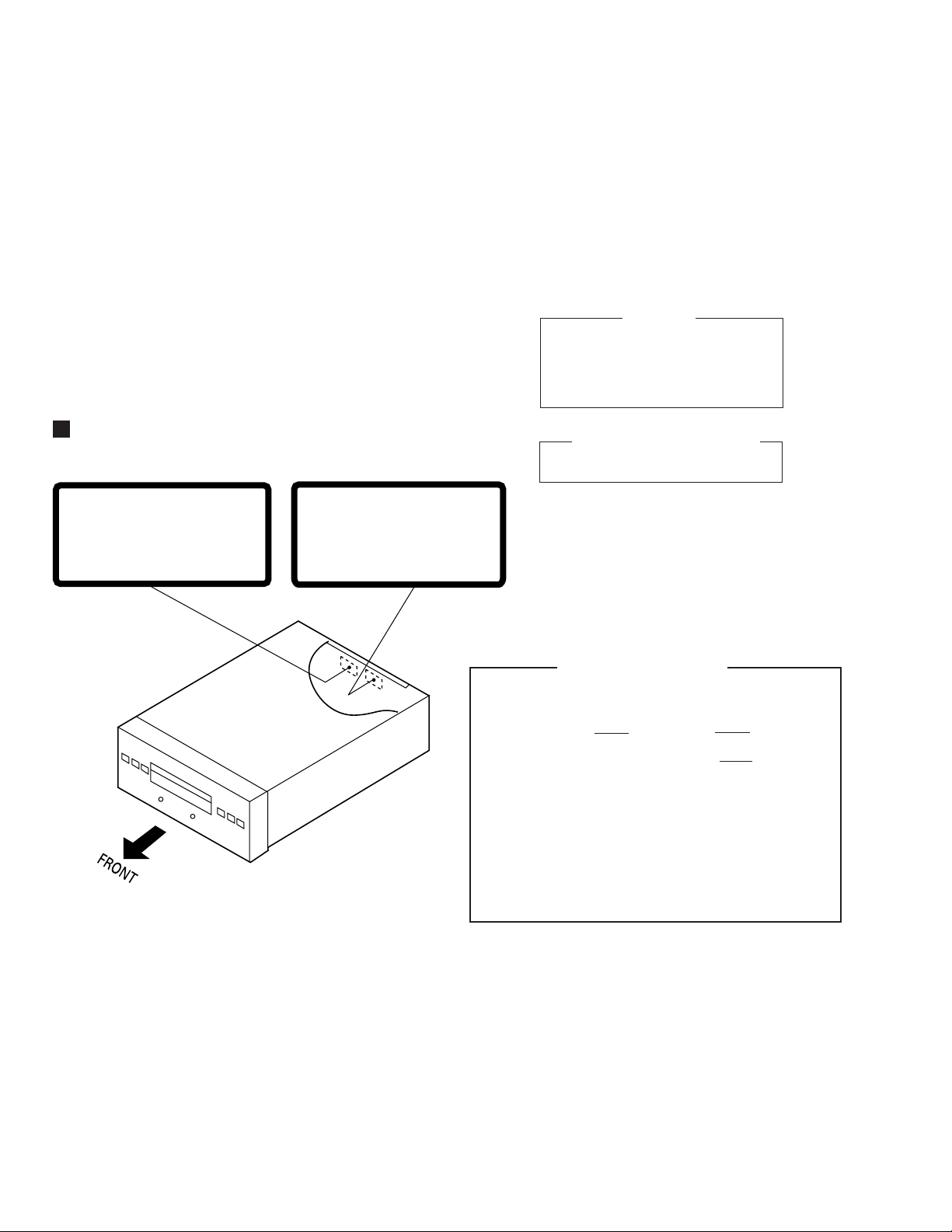

LABEL CHECK (For PD-R9(S) /ZY)

USYNLIG LASERSTRÅLING VED ÅBNING NÅR SIKKERHED SAFBRYDERE ER UDE AF FUNKTION.

UNDGÅ UDSÆTTELSE FOR STRÅLING

UNSICHTBARE LASER-STRAHLUNG TRITT AUS, WENN DECKEL

(ODER KLAPPE) GEÖFFNET IST! NICHT DEM STRAHL AUSSETZEN!

ADVARSEL

VARNING!

VRW1094

Avattaessa ja suojalukitus ohitettaessa olet alttiina näkymättömälle

lasersäteilylle. Älä katso säteeseen.

Osynlig laserstrålning när denna del

är öppnad och spärren är urkopplad.

Betrakta ej strålen.

VARO!

VARNING!

LASER DIODE CHARACTERISTICS

MAXIMUM OUTPUT POWER : 5 mw

WAVELENGTH : 780-785 nm

PRW1233

Additional Laser Caution

1. Laser Interlock Mechanism

The position of the switch (S610) for detecting loading

state is detected by the system microprocessor, and the

design prevents laser diode oscillation when the switch

(S610) is not on CLMP terminal side (CLMP signal is OFF

or high level.). Thus, the interlock will no longer function if

the switch (S610) is deliberately set to CLMP terminal side

(low level).

The interlock also does not function in the test mode ∗.

Laser diode oscillation will continue, if pin 1 of M51593FP

(IC101) on the PRE-AMP BOARD ASSY mounted on the

Pickup Assy is connected to GND, or pin 19 is connected

to low level (ON).

2. When the cover is opened, close viewing of the objective

lens with the naked eye will cause exposure to a Class 1

laser beam.

∗ : Refer to page 47.

2

Page 3

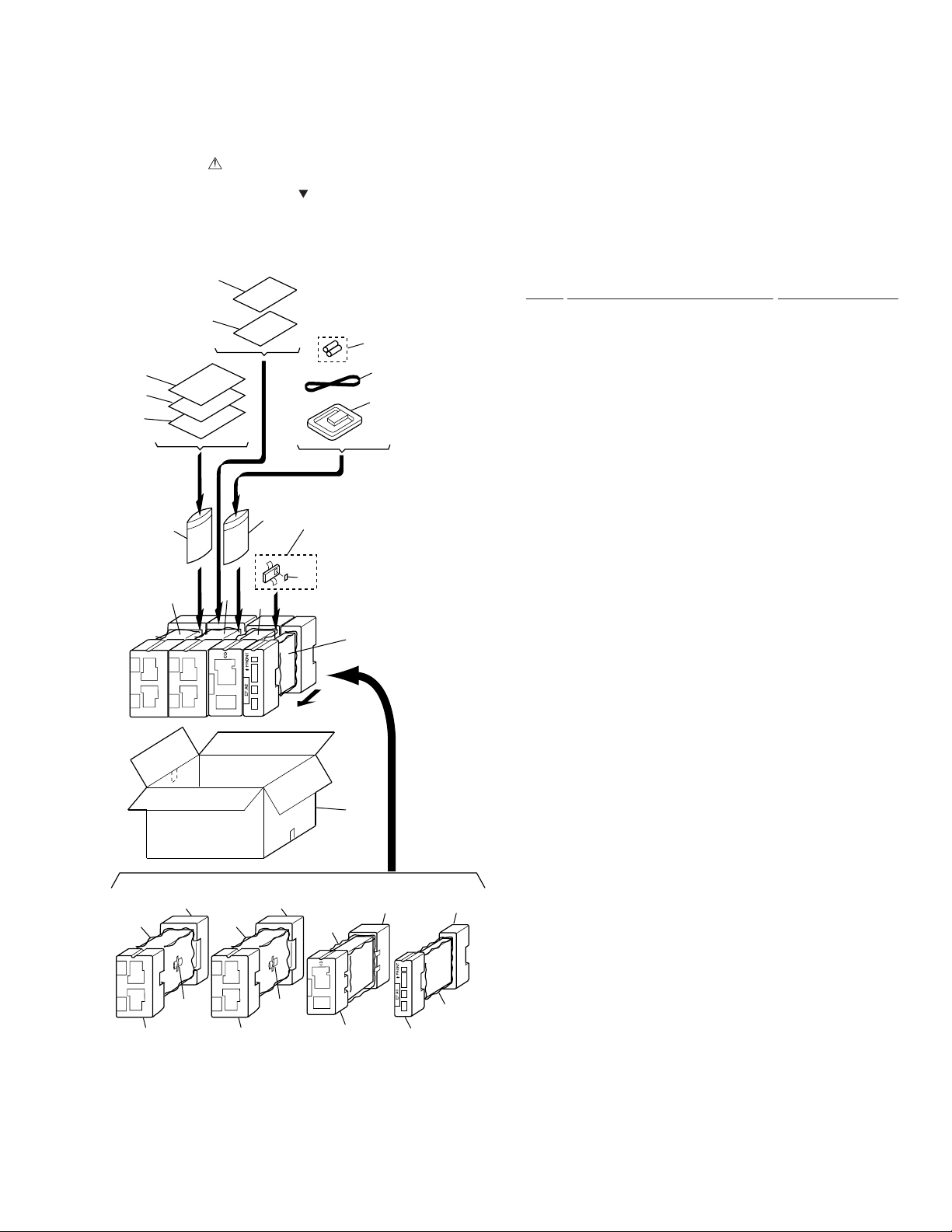

2. EXPLODED VIEWS AND PARTS LIST

NOTES:• Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

2.1 PACKING

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on the product are used for disassembly.

•

PACKING PARTS LIST

9

•

Mark No. Description Part No.

XS-R9

11

10

5

14

8

16

16

4

4

13

19

3

FRONT

7

12

1

17

NSP 1 Remix Effector EF-R9(S)

2 • • • • •

NSP 3 Remix Control Mixer MX-R9(S)

NSP 4 Compact Disc Player PD-R9(S)

5 Caution Sheet ARM7034

6 • • • • •

7 FM Antenna ADH7010

8 Operating Instructions ARC7201

(German/Italian)

NSP 9 Warranty Card ARY7008

10 Operating Instructions ARC7202

(Spanish/Dutch)

11 Operating Instructions ARE7168

(English/French)

12 AM Loop Antenna ATB7009

13 Remote Control Unit AXD7148

(CU-SX123)

NSP 14 Dry Cell Battery (R6P,AA) VEM-013

15 • • • • •

16 Poly. Bag (0.03×230×340) Z21-038

17 Master Carton AHD7613

18 • • • • •

19 Battery Cover AZA7219

20 • • • • •

21 • • • • •

22 Mirror Mat (500×650×0.5) AHG7050

23 Pad F EF AHA7189

24 Pad R EF AHA7190

25 Mirror Mat DHL1050

26 Pad L AHA7191

27 Pad R AHA7192

28 Pad F CD AHA7187

29 Pad R CD AHA7188

NSP 30 Silicagel AEN7001

25

29

30 30

28

25

28

29

22

26

27

24

25

23

3

Page 4

XS-R9

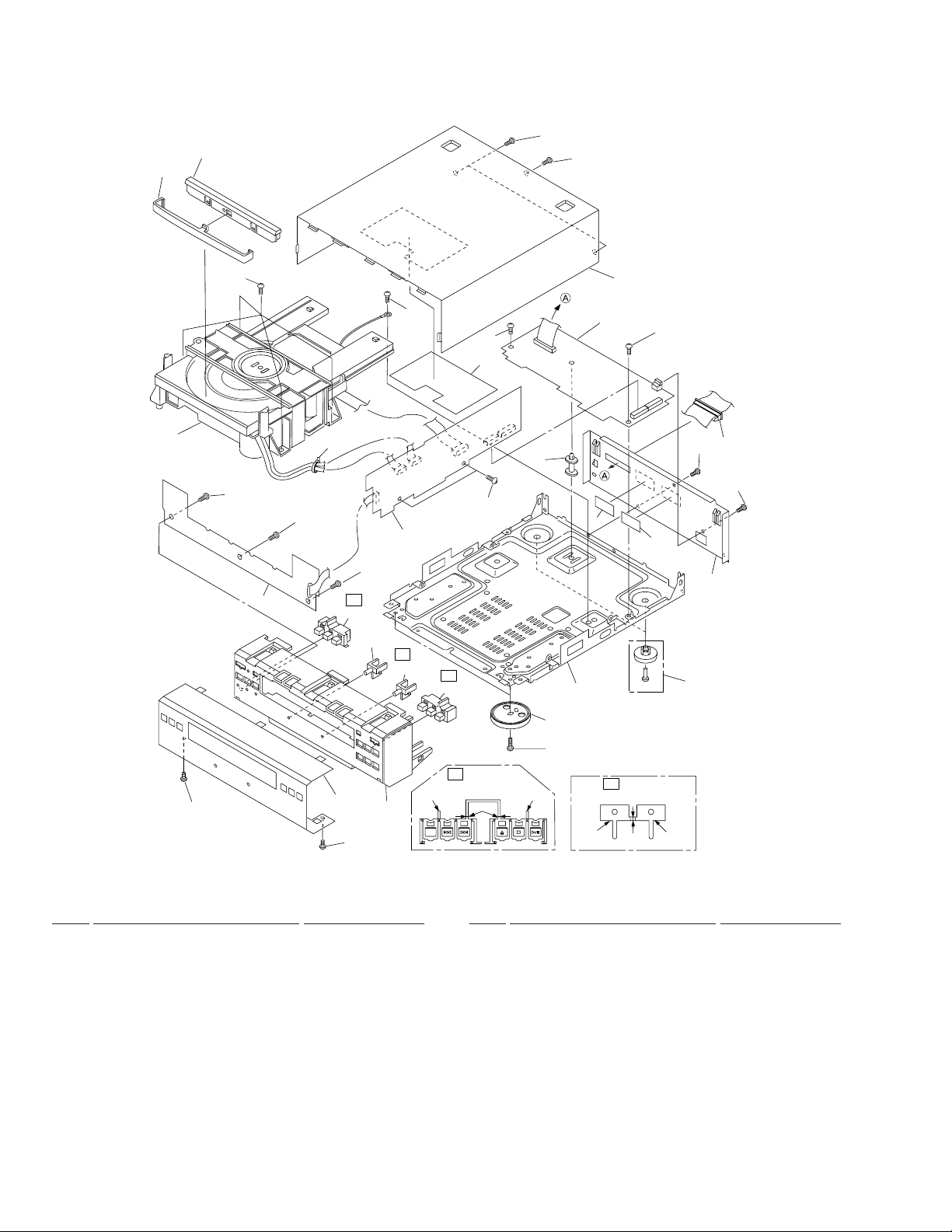

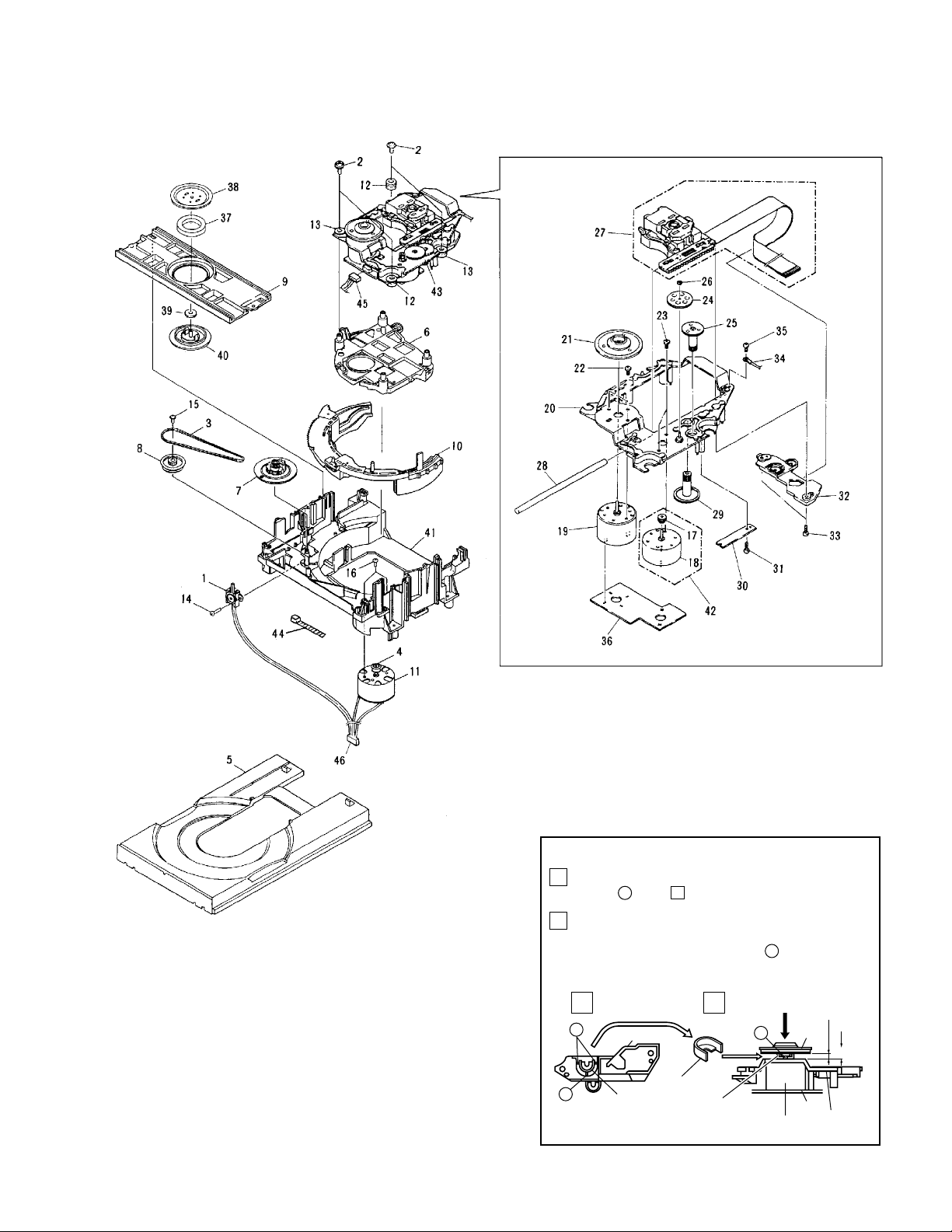

2.2 COMPACT DISC PLAYER [PD-R9(S)]

2.2.1 Exterior

11

12

22

22

20

9

Refer to

"2.3 SINGLE

MECHANISM ASSY".

21

17

25

19

24

23

7

21

1

21

2

∗1

10(1/2)

13(1/2)

∗2

13(2/2)

19

∗1

10(2/2)

15

3

27

5

19

4

22

22

26

6

8

18

COMPACT DISC PLAYER PARTS LIST

•

16

18

Mark No. Description Part No.

1 MAIN Assy AWU7142

2 FRONT Assy AWZ8889

3 REAR Assy AWU7144

4 Cord With Plug ADE7025

NSP 5 Chassis MD,CD,TC ANA7063

6 Rear Panel CD ANC7685

NSP 7 PCB Spacer AEC1371

8 Elastic Foot AEC7114

NSP 9 SINGLE MECHANISM Assy AXA7058

10 Play Button CD AAD7412

11 Tray Panel AAK7469

12 Tray Cap CD AAK7470

13 LED Lens CD,TCA AAK7472

14 Panel Base CDTC AMB7461

15 Insulator Assy AMR7189

4

22

Cut Position

∗1

10(1/2)

14

Cut

10(2/2)

13(1/2)

∗2

Cut Position

Cut

13(2/2)

Mark No. Description Part No.

16 AL Panel CD ANB7105

17 Bonnet MD,CD,TC AZN7701

18 Screw BBT30P080FZK

19 Screw BBZ30P060FCC

20 Screw BBZ30P100FMC

21 Screw PPZ30P080FMC

22 Screw VBZ30P080FZK

23 Binder (SKB-90BK) Z09-056

24 Rubber Sheet AEB7107

25 Screw PDZ30P050FMC

26 Caution Label HE PRW1233

27 Caution Label VRW1094

Page 5

2.2.2 Single Mechanism Assy

1

• How to install the disc table

Use nipper or other tool to cut the three sections

marked figure . Then remove the spacer.

While supporting the spindle motor shaft with

the stopper, put spacer on top of the motor base

(angled so it doesn't touch section ), and stick

the disc table on top (takes about 9 kg pressure).

Take off the spacer.

1

2

1 2

A

A

A

B

6.9mm

3.1mm

± 0.05mm

FFC Holder

Spacer

Spacer

Spacer Setting

Position

Spindle Motor

Carriage

Base

Disc

Table

(Pressure of

about 9kg)

PCB

B

XS-R9

5

Page 6

XS-R9

SINGLE MECHANISM ASSY PARTS LIST

•

Mark No. Description Part No.

1 Lever Switch DSK1003

2 Screw PBA1048

3 Rubber Belt PEB1193

4 Motor Pulley PNW1634

5 Tray Black V PNW2455

6 Float Base PNW2032

7 Drive Gear 2 PNW2369

8 Gear Pulley PNW2034

9 Clamper Base PNW2375

10 Clamp Cam PNW2364

11 DC Motor/0.75W PXM1010

12 Float Rubber B REB1287

13 Float Rubber G REB1288

14 Screw BPZ26P060FMC

15 Screw Z39-019

16 Screw PMZ26P040FMC

17 Pinion Gear PNW2055

18 DC Motor (CARRIAGE) PXM1027

19 D.C. Motor Assy (SPINDLE) PEA1235

20 Carriage Base PNW2699

21 Disc Holder PNW1608

22 Screw JFZ20P030FNI

23 Screw JFZ17P025FZK

24 Gear 3 PNW2054

25 Gear 2 PNW2053

26 Washer WT12D032D025

27 Pickup Assy PEA1291

28 Guide Bar PLA1094

29 Gear 1 PNW2052

30 Gear Stopper PNB1303

31 Screw BPZ20P060FMC

32 FFC Holder PNW2057

33 Screw BPZ26P100FMC

34 Earth Lead Unit PDF1104

35 Screw BBZ26P060FMC

36 MECHANISM BOARD Assy PWX1192

37 Clamp Magnet PMF1014

NSP 39 H Rubber PEB1249

NSP 43 SERVO MECHANISM Assy AXA7017

38 Yoke PNB1216

40 Clamper S PNW1609

41 Loading Base AMR7190

42 D.C. Motor Assy (CARRIAGE)PEA1246

44 Binder Z09-056

45 Connector Assy (4P) RDE1043

46 Connector Assy (5P) PDE1239

6

Page 7

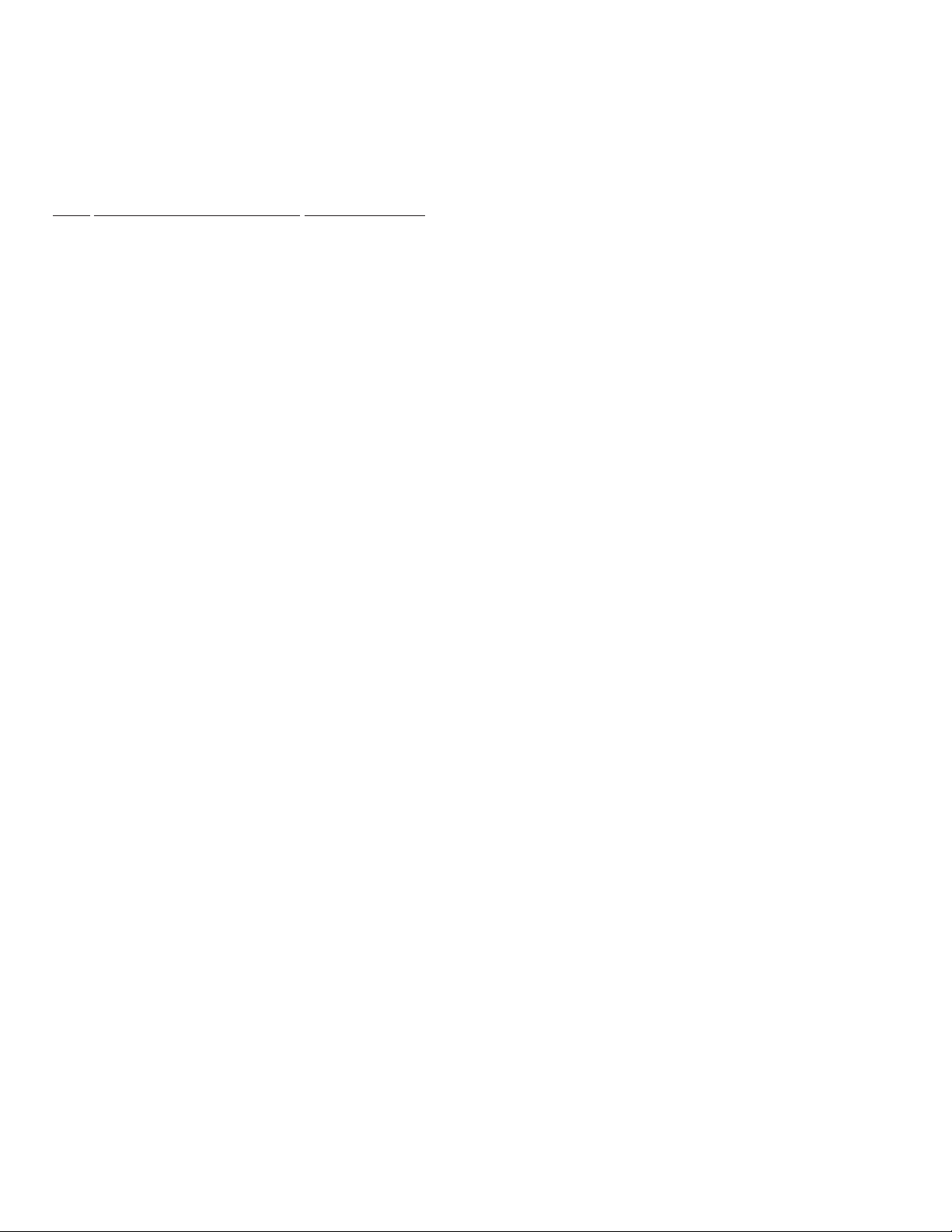

2.3 REMIX EFFECTOR [EF-R9(S)]

XS-R9

23

23

19

3

22

8

15

13

20

12

2

14

24

22

4

22

21

16

17

20

11

9

9

18

23

6

24

1

5

10

23

23

25

7

11

REMIX EFFECTOR PARTS LIST

•

Mark No. Description Part No. Mark No. Description Part No.

1 MAIN Assy AWU7067

2 FRONT Assy AWU7068

3 HEADPHONE Assy AWU7069

4 Lead Card 15P ADD7072

5 Cord With Plug ADE7016

NSP 6 Chassis SX,EF,RC ANA7062

7 Rear Panel EF ANC7687

8 Jack Plate ANG7158

9 MSPLS Support DEC1955

10 HEX. Screw KFS-4S-C1WM

11 Cushion REB1004

12 Jog Knob EF,RC AAB7182

13 Phone Knob EF AAB7139

14 Operation Button EF AAD7415

15 LED Lens EF AAK7477

NSP 18 Label VRW1629

16 Panel Base EF AMB7462

17 AL Panel EF ANB7107

19 Bonnet EF,RC AZN7702

20 Screw BBT30P080FZK

21 Screw PDZ30P050FMC

22 Screw PPZ30P080FMC

23 Screw VBZ30P080FZK

24 Screw ABA1021

25 Washer VEC1098

7

Page 8

XS-R9

2.4 REMIX CONTROL MIXER [MX-R9(S)]

23

∗1

Cut Position

13

12

30

15

11

8

5

18(1/2)

Cut

28

B

17

2

19

18(2/2)

20

18(2/2)

∗1

7

24

8

16(2/4)

∗2

14

16(1/4)

∗2

13

18(1/2)

∗1

21

7

24

A

A

3

16(4/4)

17

19

20

22

16(3/4)

∗2

∗2

∗2

Cut Position

16(1/4) 16(2/4) 16(3/4) 16(4/4)

B

Cut

Cut

29

10

9

27

26

29

29

29

32

4

9

10

6

8

Page 9

REMIX CONTROL MIXER PARTS LIST

•

Mark No. Description Part No.

XS-R9

NSP 2 VR Assy AWZ8899

NSP 26 Label VRW1629

1 MAIN Assy AWZ8898

3 Cord With Plug ADE7019

4 Bottom Plate ANF7009

5 Fader Stay ANG7159

6 PVC Sheet AEC7119

7 POM Ring AMR7188

8 Fader Sheet AWL7029

9 Screw BPZ30P300FMC

10 Disc Guard PNM1245

11 Equalizer Knob SX AAB7135

12 Tuning Knob SX AAB7136

13 Jog Knob CP AAB7140

14 Tempo Knob AAC7004

15 Fader Knob AAC7005

16 BPM Button AAD7417

17 Loop Button AAD7419

18 Sampler Button AAD7422

19 CUE Button AAD7423

20 LED Lens CP A AAK7476

21 Display Window CP AAK7478

22 FL filter CP AAK7479

23 Fader Cover AAK7480

24 LED Lens CP B AAK7507

25 Top Panel CP AMB7464

27 Screw BBZ30P060FCC

28 Screw BMZ20P030FMC

29 Screw PPZ30P080FMC

30 Screw CPZ30P080FZK

31 Fader Assy AZW7244

32 Rear Spacer AEC7126

9

Page 10

1

23

XS-R9

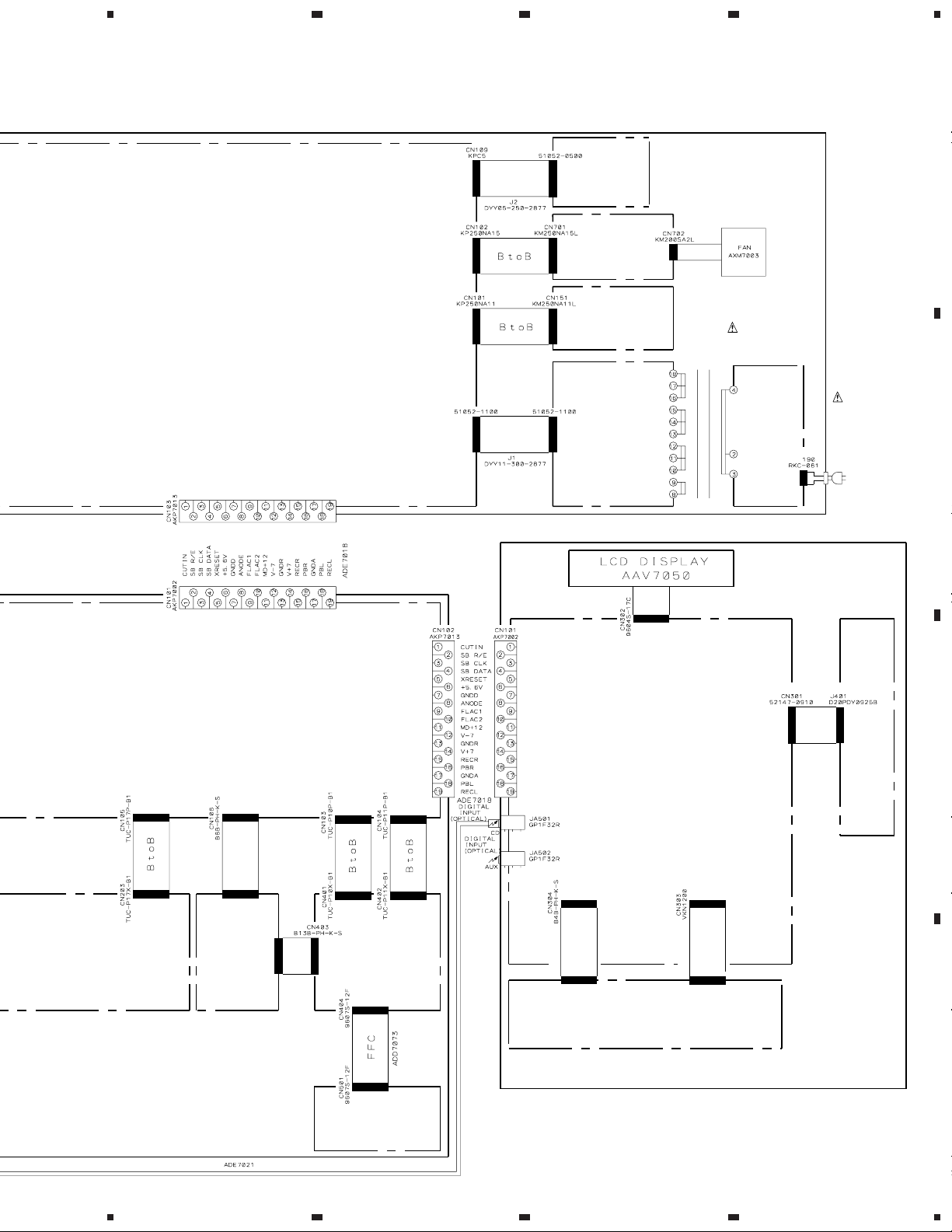

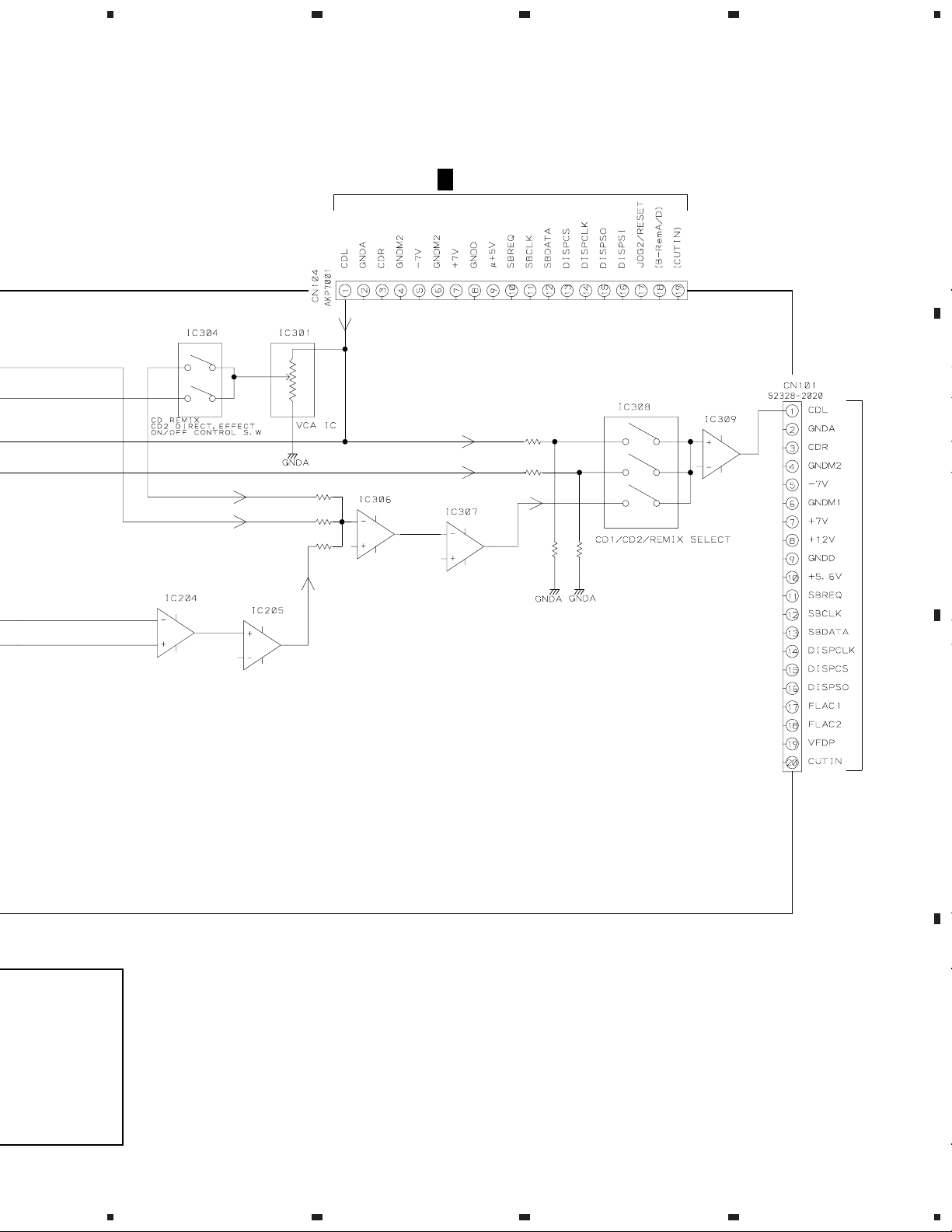

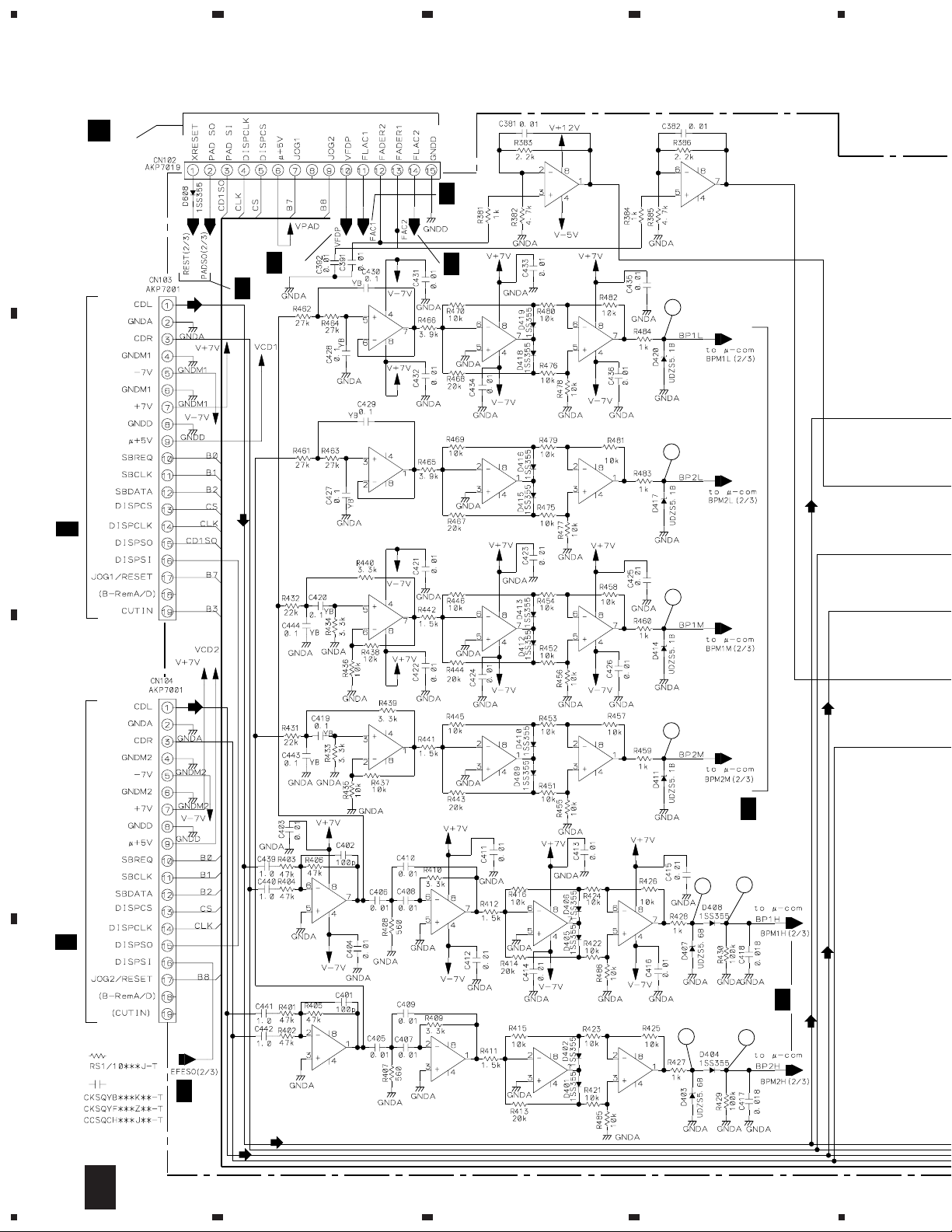

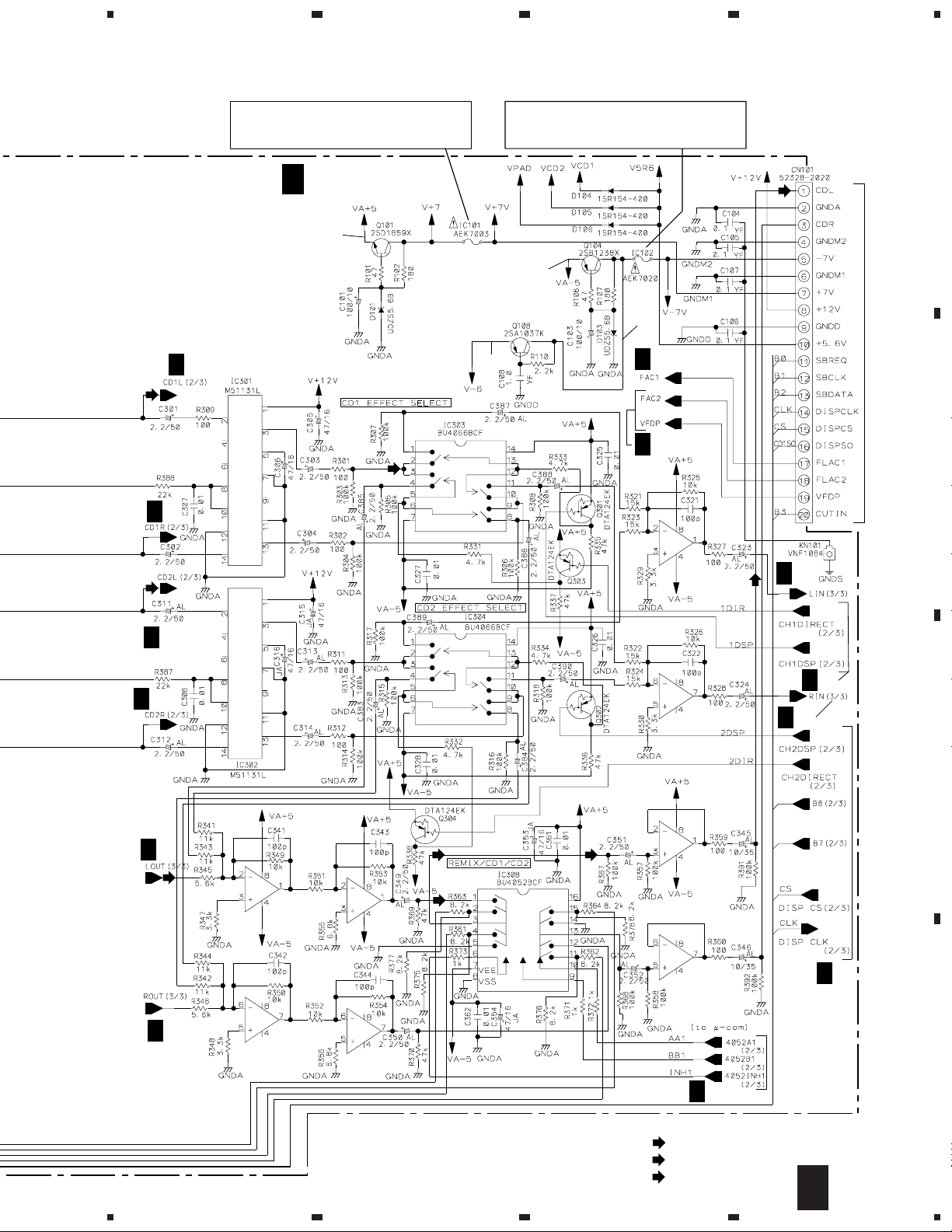

3. SCHEMATIC DIAGRAM

3.1 OVERALL CONNECTION DIAGRAM

A

4

DISPLAY ASSY

(AWU7132)

STEREO TUNER AMP

SX-R9/ZY

Refer to the service manual

RRV1937 for STEREO TUNER AMP

SX-R9/ZY.

B

FM/AM TUNER

MODULE

(AXQ7058)

SIDE ASSY

(AWU7133)

MAIN ASSY

(AWU7134)

TR ASSY

(AWU7141)

CONNECT ASSY

(AWU7137)

C

B

MAIN ASSY

(AWU7142)

MECHANISM BOARD ASSY

(PWX1192)

SINGLE MECHANISM ASSY

(AXA7058)

AA

COMPACT

C

DISC

PLAYER

PD-R9(S)

CD1

TEST PIN

for ADJ.

C C

REAR ASSY

(AWU7144)

FRONT ASSY

(AWZ8889)

1/2,

D

2/2

ADE7025

E

E E E

1/3,

MAIN ASSY

(AWU7067)

2/3,

3/3

FRONT ASSY

(AWU7068)

F

C

HEADPHONE ASSY

B

MAIN ASSY

(AWU7142)

MECHANISM BOARD ASSY

(PWX1192)

SINGLE MECHANISM ASSY

(AXA7058)

COMPACT

DISC

D

PLAYER

PD-R9(S)

CD2

TEST PIN

for ADJ.

C C

REAR ASSY

(AWU7144)

FRONT ASSY

(AWZ8889)

1/2,

D

2/2

ADE7025

MAIN ASSY

H

(AWZ8898)

REMIX

EFFECTOR

EF-R9(S)

(AWU7069)

G

VR ASSY

(AWZ8899)

I

REMIX CONTROL MIXER MX-R9(S)

10

1234

Page 11

5

678

XS-R9

Note : When ordering service parts, be sure to refer to "EXPLODED VIEWS and PAR TS LIST" or "PCB PARTS LIST".

HEADPHONE

ASSY

(AWU7138)

POWER ASSY

(AWU7135)

REG ASSY

(AWU7136)

SECONDARY

ASSY

(AWU7140)

POWER

TRANSFORMER

T1

ATS7215

PRIMARY

ASSY

(AWU7139)

AC

POWER

CORD

PDG1003

AC220V–230V

50/60Hz

A

B

CONNECT ASSY

(AWZ8894)

MAIN

ASSY

(AWZ8891)

DECK

MECHA

(RYM1264)

DECK

CT-R5/ZY

Refer to the service manual

RRV1933 for DECK CT-R5/ZY.

MCOM

ASSY

(AWZ8893)

FRONT ASSY

(AWZ8892)

MAIN ASSY

(AWU7152)

FRONT ASSY

MD MECHA ASSY

(AXA7054)

MINI DISC

RECORDER

MJ-R5/ZY

Refer to the service manual

RRV1934 for MINI DISC RECORDER MJ-R5/ZY.

C

(AWZ8887)

D

11

5

6

7

8

Page 12

1

23

XS-R9

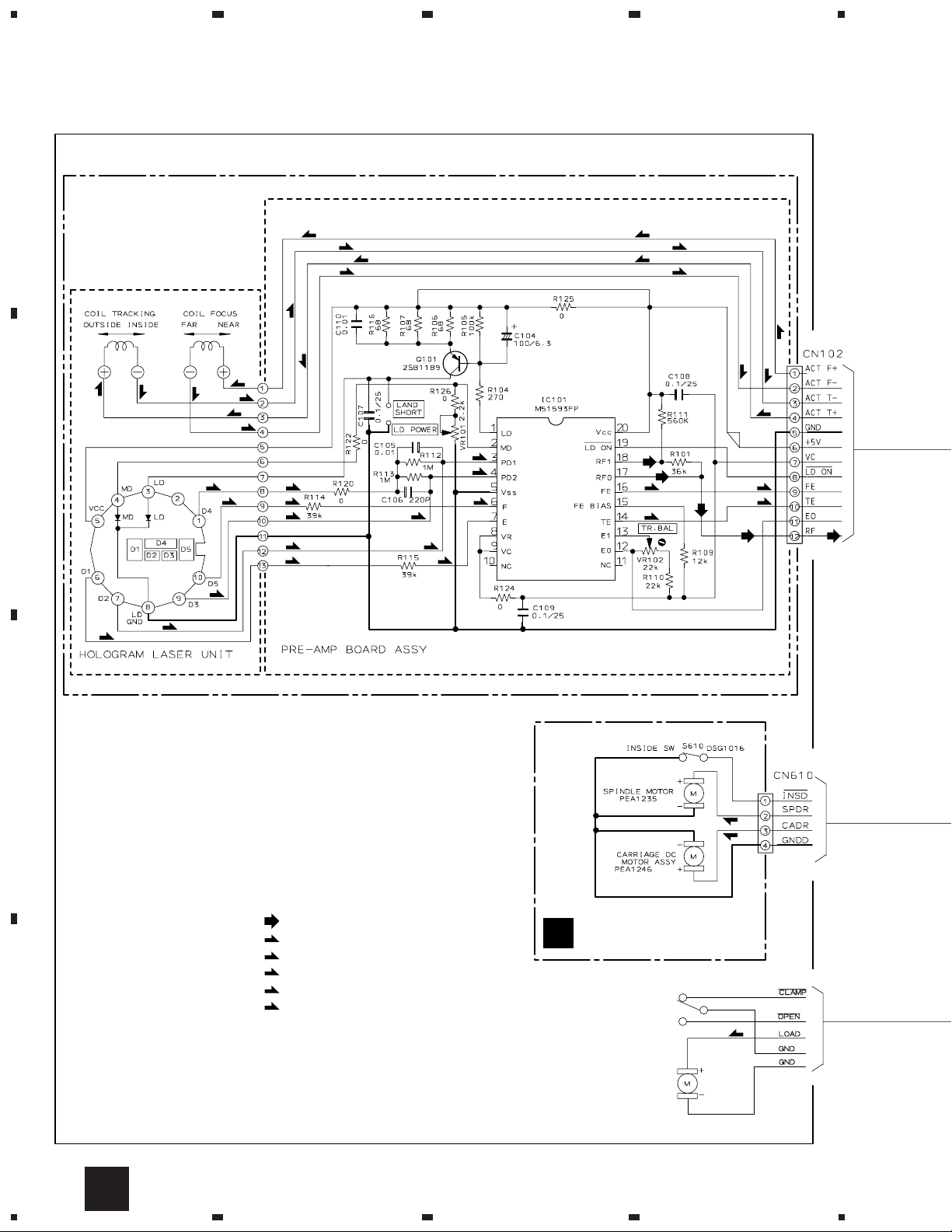

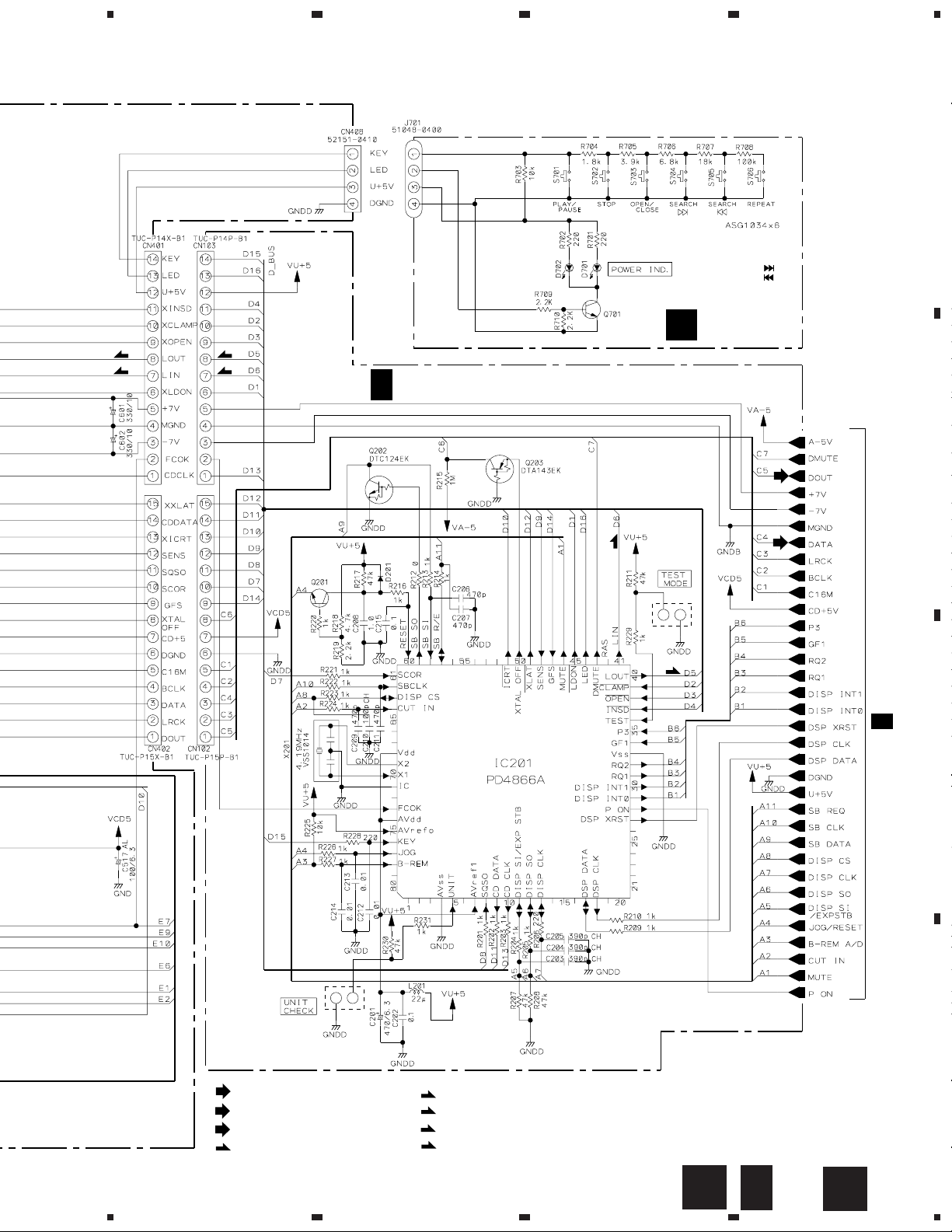

3.2 COMPACT DISC PLAYER [PD-R9(S)]

3.2.1 OVERALL CONNECTIONS AND SINGLE MECHANISM ASSY

A

PICKUP ASSY

(PEA1291)

(TS)

(TS)

(FS)

(FS)

(TS)

(TS)

(FS)

(FS)

(TS)

(TS)

(FS)

(TS)

(TS)

(FS)

(TS)

(TS)

(FS)

4

(FS)

(FS)

(TS)

(TS)

(TS)

(FS)

(FS)

(TS)

(FS) (FS)

(TS)

(TS)

B

(FS)

(TS)

(FS)

(FS)

(TS)

(FS)

(FS)

(TS)

(FS)

(TS)

(FS)

(FS)

SINGLE MECHANISM ASSY

C

(AXA7058)

SIGNAL ROUTE

: RF SIGNAL ROUTE

(FS)

: FOCUS SERVO LOOP LINE

(TS)

: TRACKING SERVO LOOP LINE

(SM)

: SPINDLE MOTOR ROUTE

(CM)

: CARRIAGE MOTOR ROUTE

(LM)

: LOADING MOTOR ROUTE

MECHANISM BOARD ASSY

A

(PWX1192)

S601

CLAMP SW

(DSK1003)

(SM)

(CM)

(LM)

D

12

A

LOADING

MOTOR

(PXM1010)

1234

Page 13

TEST PIN

for ADJ.

5

678

XS-R9

A

D

FRONT ASSY

(AWZ8889)

B

MAIN ASSY

B

(AWU7142)

C

1/2,

C C

REAR ASSY

(AWU7144)

2/2

CN103:CD1,CN104:CD2

1/3

E

C

MINI DISC

RECORDER

(MJ-R5/ZY)

MAIN ASSY

JA501

CONNECTOR

ASSY

PDE1239

D

13

5

6

7

8

Page 14

1

23

XS-R9

3.2.2 MAIN, REAR(1/2) AND FRONT ASSEMBLIES

MAIN ASSY

B

(FS)

A

(TS)

(FS)

(TS)

(LM)

B

TO SINGLE MECHANISM ASSY

(AWU7142)

C415

GNDD

33p

470

F401

(D)

ATF7013

1SS355

(D)

470

(A)

1SS355

470

4

470

+5.0V

1SS355

(SM)

(CM)

(LM)

(SM)

(LM)

(LM)

UDZS6.2B

(LM)

(SM)

(SM)

VNF1084

(A)

(D)

C

TEST PIN for ADJ.

(FS)

(CM)

(FS)

(TS)

(TS)

(TS)

(CM)

(FS)

(TS)

(TS)

D

14

B

(FS)

(TS)

1234

Page 15

5

678

XS-R9

A

S701 : PLAY/PAUSE

S702 : STOP

S703 : OPEN/CLOSE

S704 : SEARCH

S705 : SEARCH

S706 : REPEAT

(LM)

(LM)

(LM)

(LM)

2SC2412K

C

D701,D702 : SLR-342VCT31

REAR ASSY

(AWU7144)

1/2

1SS355

MICROCOMPUTER

2SC2412K

(LM)

(LM)

FRONT ASSY

D

(AWZ8889)

(D)

(A)

B

2/2

C

C

SIGNAL ROUTE

: RF SIGNAL ROUTE

(D)

: DIGITAL AUDIO OUTPUT

(A)

: ANALOG AUDIO OUTPUT

(FS)

: FOCUS SERVO LOOP LINE

5

(TS)

: TRACKING SERVO LOOP LINE

(SM)

: SPINDLE MOTOR ROUTE

(CM)

: CARRIAGE MOTOR ROUTE

(LM)

: LOADING MOTOR ROUTE

6

D

B

7

C

1/2

D

8

15

Page 16

1

XS-R9

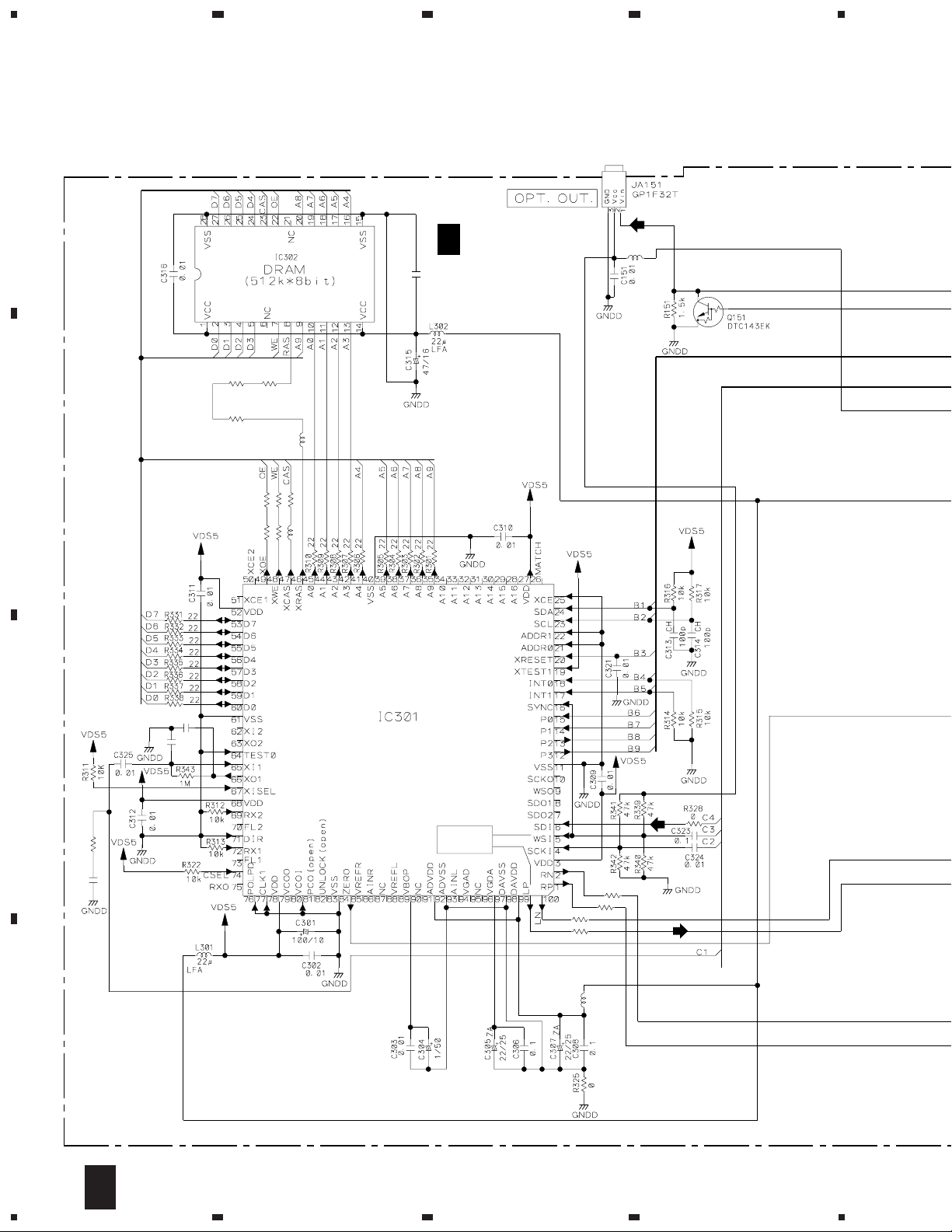

3.2.3 REAR ASSY(2/2)

A

B

R327

R345

L313-L315:

PTL1014

0

330

HM514800CJ-7

R349

0

L314

47

R346

470

R348 330L313

0

R319

R320 R347

23

MJ-R5/ZY

MAIN ASSY

JA501

(D)

C317

0.01

C

REAR ASSY

(AWU7144)

2/2

L151

10

4

C318

33p

C319

33p

C

68

R318

56p

C327

MN19413A

DSP IC

BUILT-IN

DAC

R382 2.7k

R384

R381

2.7k

R383 2.7k

L304

(A)

2.7k

(A)

68

D

16

2/2

C

1234

Page 17

(D)

5

678

XS-R9

SIGNAL ROUTE

(D)

: DIGITAL AUDIO OUTPUT

(A)

(A)

+5.0V

+5.0V

C

1/2

Q103

2SD2395

: ANALOG AUDIO OUTPUT

+5.0V

A

B

1.2k

1.2k

1.2k

1.2k

CAUTION : FOR CONTINUED PROTECTION AGAINST

RISK OF FIRE. REPLACE ONLY WITH

SAME TYPE NO. AEK7006 MFD, BY

LITTELFUSE INK. FOR IC101.

IC351(2/2)

NJM2068M

IC351(1/2)

NJM2068M

(A)

1SS355

1SS355

IC352(2/2)

NJM2068M

IC352(1/2)

NJM2068M

-5.0V

+7.3V

-7.3V

CN103:(CD1),CN104:(CD2)

1/3

(A)

VNF1084

(A)

E

C

D

2/2

C

5

6

7

8

17

Page 18

1

XS-R9

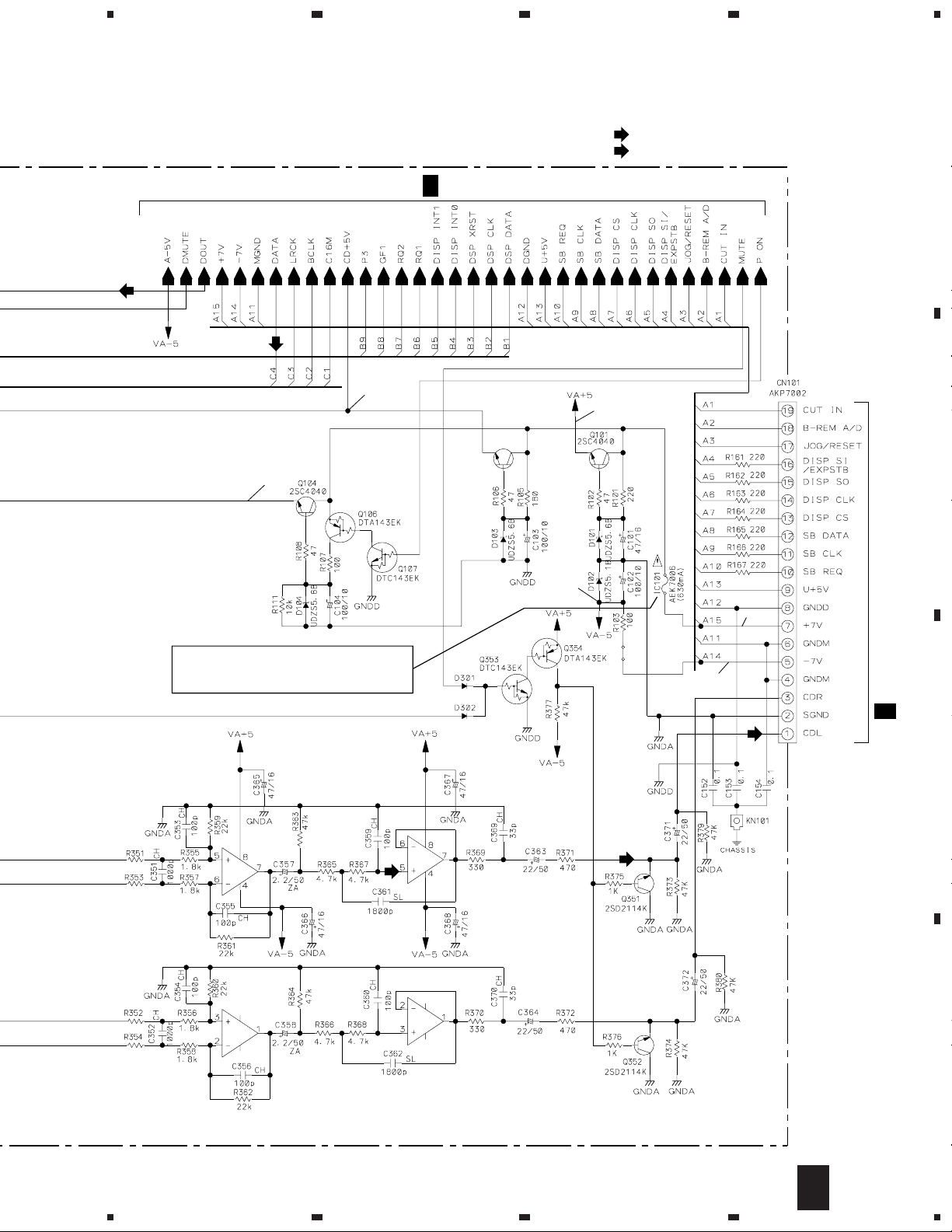

3.3 REMIX EFFECTOR [EF-R9(S)]

3.3.1 OVERALL CONNECTION DIAGRAM

A

CN102

H

23

2/2

C

CN101(CD1)

4

E

B

C

E E E

1/3,

MAIN ASSY

(AWU7067)

2/3,

3/3

FRONT ASSY

(AWU7068)

D

HEADPHONE ASSY

(AWU7069)

G

18

1234

F

Page 19

5

678

XS-R9

A

2/2

C

CN101(CD2)

B

MAIN ASSY CN104

STEREO TUNER AMP(SX-R9/ZY)

C

D

19

5

6

7

8

Page 20

1

XS-R9

3.3.2 MAIN ASSY(1/3)

H

A

CN102

23

NC

2/3

E

IC310(1/2)

BA4558F

IC310(2/2)

BA4558F

4

CD2 VCA CONTROL

1/3

E

(CD1)

B

E

2/3

IC408(2/2)

BA4558F

IC408(1/2)

BA4558F

1/3

E

IC409(2/2)

BA4558F

IC409(1/2)

BA4558F

IC410(2/2)

BA4558F

CD1 VCA CONTROL

11

A

11

B

CN101(CD1)

2/2

C

(CD2)

(CD1)

BA4558F

IC406(2/2)

BA4558FIC405(2/2)

IC407(2/2)

BA4558F

IC410(1/2)

BA4558F

12

(CD1)

A

12

B

C

IC405(1/2)

BA4558F

IC406(1/2)

BA4558F

IC403(2/2)

BA4558F

IC407(1/2)

BA4558F

IC404(2/2)

BA4558F

13

E

2/3

14

A

A

(CD2)

CN101(CD2)

2/2

C

D

2/3

E

(CD1)

(CD2)

20

1/3

E

1234

IC401(2/2)

BA4558F

IC401(1/2)

BA4558F

IC402(2/2)

BA4558F

IC402(1/2)

BA4558F

IC403(1/2)

BA4558F

IC404(1/2)

BA4558F

13

(CD2)

2/3

E

B

14

B

(CD1)

Page 21

5

678

XS-R9

(CD1)

E

E

2/3

2/3

CAUTION : FOR CONTINUED PROTECTION AGAINST

RISK OF FIRE. REPLACE ONLY WITH

SAME TYPE NO. AEK7003 MFD, BY

LITTELFUSE INK. FOR IC101.

E

MAIN ASSY

1/3

(AWU7067)

5.009V

(CD1)

VCA IC

315mA

CAUTION : FOR CONTINUED PROTECTION AGAINST

RISK OF FIRE. REPLACE ONLY WITH

SAME TYPE NO. AEK7020 MFD, BY

LITTELFUSE INK. FOR IC102.

-4.98V

125mA

-7.06V

-6.20V

E

E

2/3

1/3

A

B

SX-R9/ZY MAIN ASSY CN104

(CD2)

E

E

E

2/3

2/3

3/3

VCA IC

IC306(1/2)

BA4558F

IC307

(1/2)

BA4558F

IC309(1/2)

NJM2068M

IC305(1/2)

BA4558F

IC305(2/2)

BA4558F

IC309(2/2)

NJM2068M

E

E

3/3

E

3/3

2/3

E

C

2/3

E

3/3

IC306(2/2)

BA4558F

5

IC307(2/2)

BA4558F

D

2/3

E

SIGNAL ROUTE

(CD1)

: CD1 AUDIO SIGNAL

(CD2)

: CD2 AUDIO SIGNAL

: AUDIO SIGNAL

1/3

E

6

7

8

21

Page 22

1

23

XS-R9

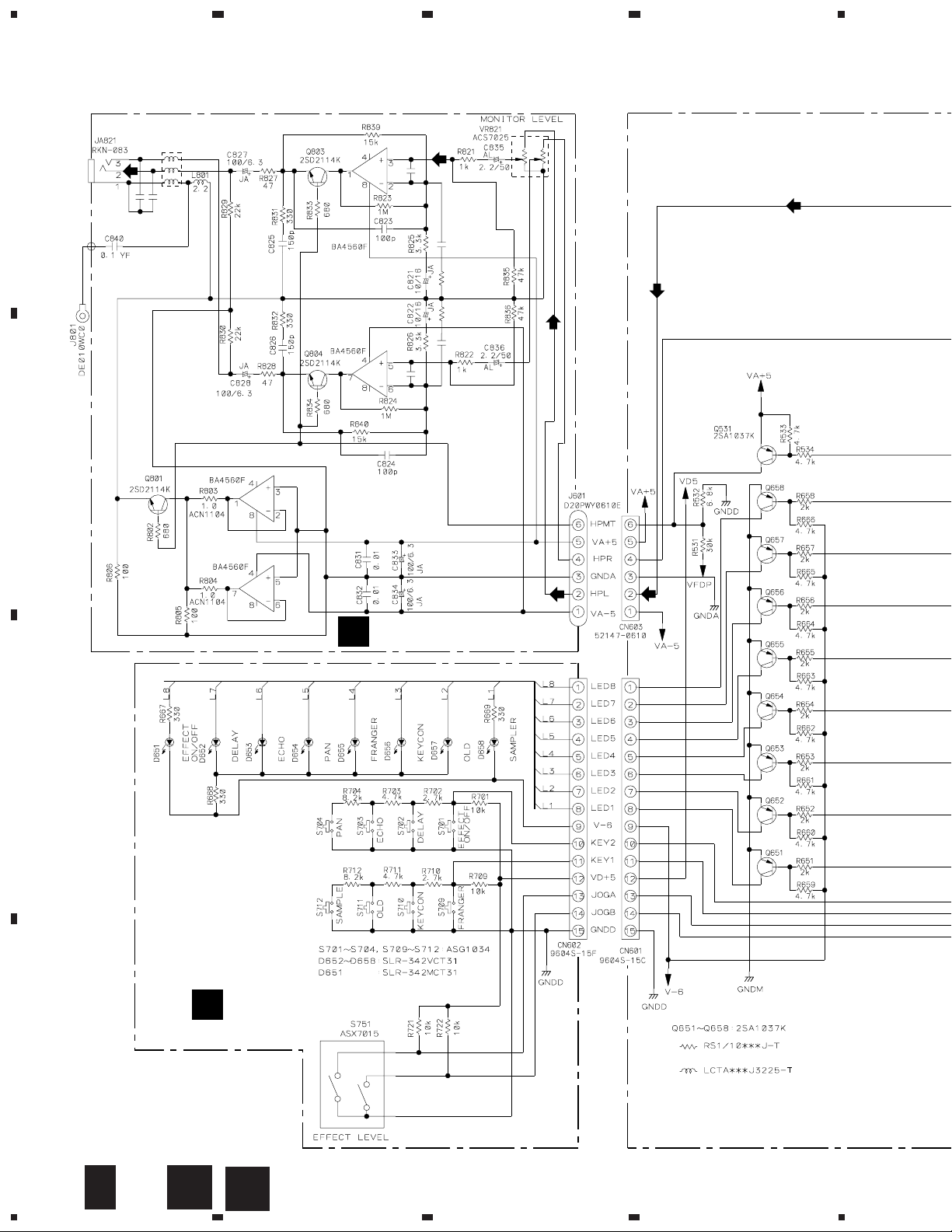

3.3.3 MAIN(2/3), FRONT AND HEADPHONE ASSEMBLIES

F801

ATF7016

A

C847

0.01

C848

0.01

IC801(1/2)

IC801(2/2)

C841

C842

47p

C843

R841

R842

C844

47p

4

220p

10

10

220p

B

IC802(1/2)

IC802(2/2)

HEADPHONE ASSY

(AWU7069)

G

C

S701 : EFFECT ON/OFF

S702 : DELAY

S703 : ECHO

S704 : PAN

S709 : FRANGER

S710 : KEYCON

S711 : OLD

S712 : SAMPLE

S751 : EFFECT LEVEL

FRONT ASSY

F

(AWU7068)

D

22

2/3

E

1234

F

G

Page 23

5

678

XS-R9

SIGNAL ROUTE

: AUDIO SIGNAL

(CD1)

: CD1 AUDIO SIGNAL

E

A

1/3

B

E

2/3

1/3

E

1/3

E

MAIN ASSY

(AWU7067)

H.P. CD1&CD2/CD1/CD2 SELECT

(CD1)

3/3

E

4

E

1/3

MICROCOMPUTER

1

2

3

6

5

X1

X2

1/3

E

C

3/3

E

1/3

E

3/3

E

1/3

E

D

2/3

E

5

6

7

8

23

Page 24

1

XS-R9

3.3.4 MAIN ASSY(3/3)

E

A

3/3

MAIN ASSY(AWU7067)

23

4

47

R275

0

R281

0

R261

B

R276

47×4

DCN1090

7

HM514400CJ-7

R280 0 R274 47

R279 0 R273 47

R278 0 R272 47

R277 0 R271 47

C233

0.01

10

9

MN19413A

2/3

8

DSP IC

E

C

E

1/3

D

24

3/3

E

1234

Page 25

5

V5D2 V+7 V+7VAD5

Q103

2SD1859X

V+5V

C113

GNDP GNDP GNDP GNDA GNDA

J102

DB017ND0

0.01

DTA124EK

47

R104

D102

UDZS5.6B

Q105

56

R105

C102

100/10

GNDP

L101

22

C112

0.01

678

L203

22

Q102

2SD1859X

R103

DTA124EK

47

D107

UDZS5.6B

Q109

R109

C109

220

100/10

J101

ADB-005

0.01

C114

GNDP

Q106

DTC124EK

GNDD

E

PWR

(2/3)

2/3

XS-R9

A

B

GNDP

GNDD

IC204(2/2)

BA4558F

DSP L.P.F OUTPUT

IC204(1/2)

BA4558F

IC205(1/2)

BA4558F

IC205(2/2)

BA4558F

E

1/3

E

1/3

E

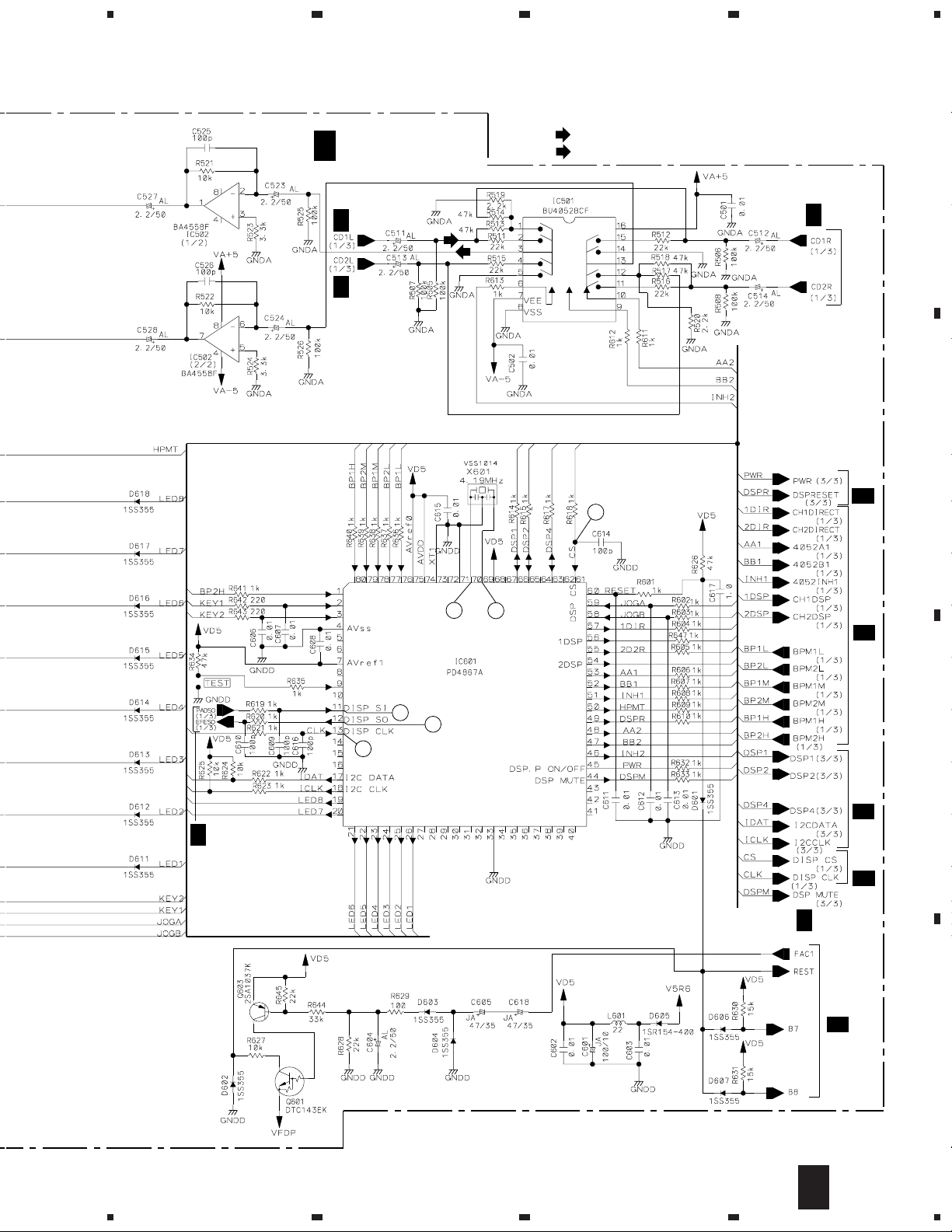

C

2/3

D

3/3

E

5

6

7

8

25

Page 26

XS-R9

WAVEFORMS OF REMIX EFFECTOR [EF-R9(S)]

•

Note :

No.

in the table correspond to the measurement points of schematic diagrams.

MAIN ASSY (1/3)

1/3

E

11

A

BP1L (CD1 PLAY MODE)

11

B

BP2L (CD2 PLAY MODE)

12

A

BP1M (CD1 PLAY MODE)

12

B

BP2M (CD2 PLAY MODE)

14

A

BP1H (CD1 PLAY MODE)

14

B

BP2H (CD2 PLAY MODE)

• CD1 PAD TRIM VOL – 6dB

(Output level of receiver Rec

Out 0.42VRMS)

2V/div, 10ms/div, f=24Hz

11

A (11B)

12

A (12B)

14

A (14B)

MAIN ASSY (2/3)

2/3

E

4

IC601-Pin 61 (CS)

IC601-Pin 11 (DISP SI)

1

IC601-Pin 12 (DISP SO)

2

IC601-Pin 13 (DISP CLK)

3

PLAY MODE

5V/div, 5ms/div

11

A

BP1L (CD1 PLAY MODE)

11

B

BP2L (CD2 PLAY MODE)

12

A

BP1M (CD1 PLAY MODE)

12

B

BP2M (CD2 PLAY MODE)

13

A

BP1H (CD1 PLAY MODE)

13

B

BP2H (CD2 PLAY MODE)

14

A

BP1H (CD1 PLAY MODE)

14

B

BP2H (CD2 PLAY MODE)

• CD1 PAD TRIM VOL – 6dB

(Output level of receiver Rec

Out 0.43VRMS)

2V/div, 20µs/div, f=8Hz

11

A (11B)

12

A (12B)

13

A (13B)

14

A (14B)

6

X1 IC601-Pin 70 (X1)

X2 IC601-Pin 69 (X2)

5

PLAY MODE

2V/div, 200ns/div

11

A

BP1L (CD1 PLAY MODE)

11

B

BP2L (CD2 PLAY MODE)

12

A

BP1M (CD1 PLAY MODE)

12

B

BP2M (CD2 PLAY MODE)

14

A

BP1H (CD1 PLAY MODE)

14

B

BP2H (CD2 PLAY MODE)

• CD1 PAD TRIM VOL – 6dB

(Output level of receiver Rec

Out 0.43VRMS)

2V/div, 500µs/div, f=500Hz

11

A (11B)

12

A (12B)

14

A (14B)

26

E

3/3

7

8

4

1

2

3

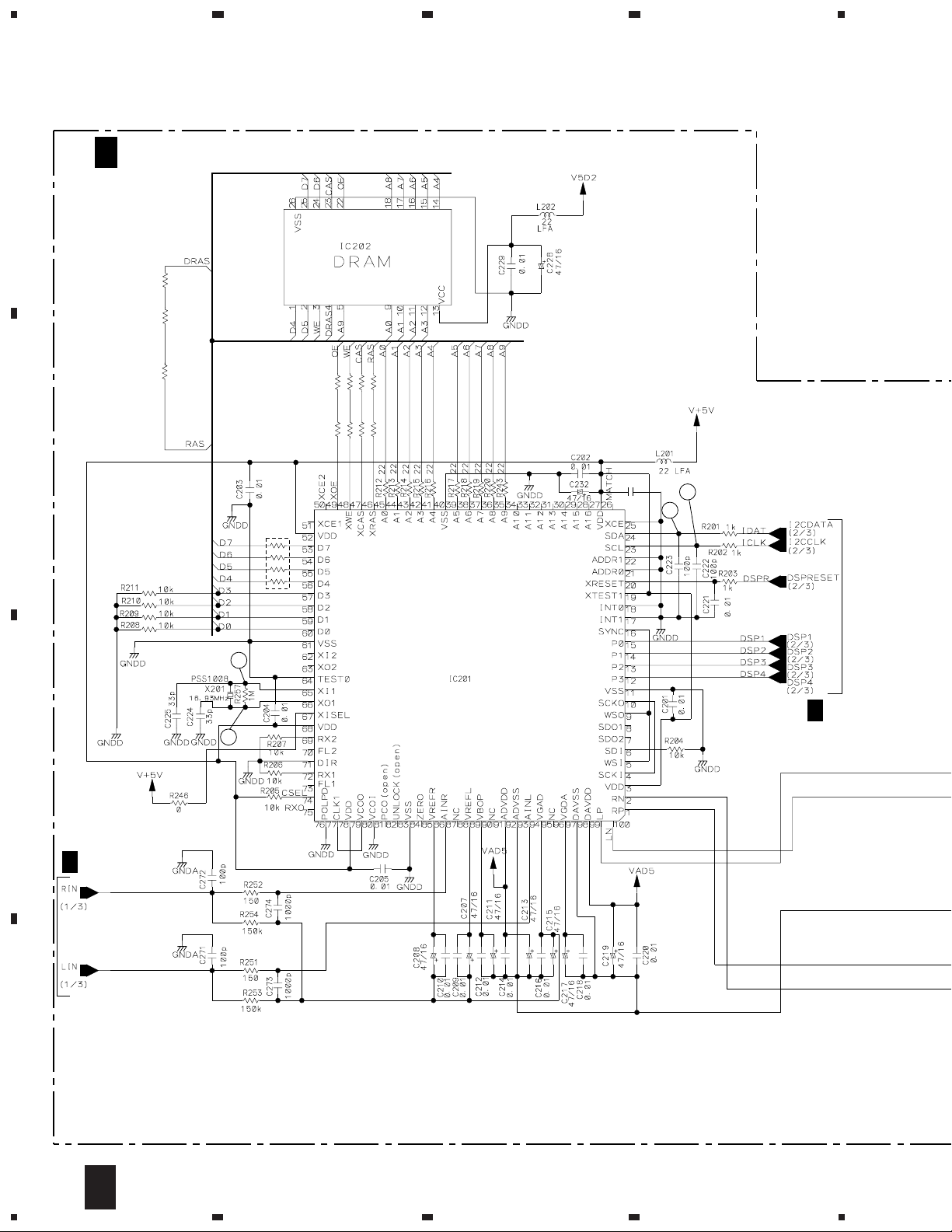

MAIN ASSY (3/3)

IC201-Pin 65 (XI1)

IC201-Pin 66 (XO1)

7

8

PLAY MODE

5V/div, 50ns/div

6

5

9

IC201-Pin 24 (SDA)

IC201-Pin 23 (SCL)

10

9

10

PLAY MODE

2V/div, 20µs/div

Page 27

1

234

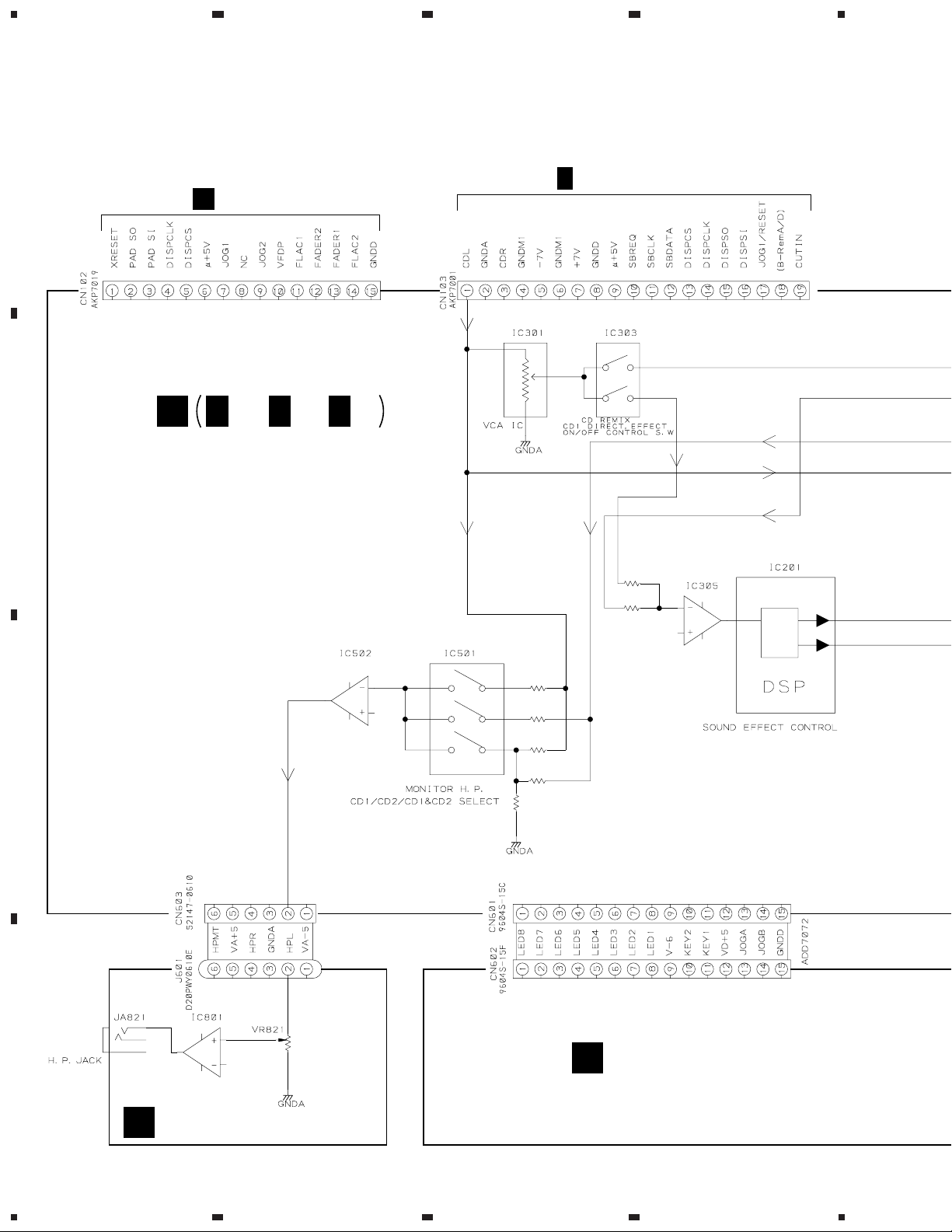

3.4 REMIX CONTROL MIXER [MX-R9(S)]

3.4.1 OVERALL CONNECTION DIAGRAM

CN102

E

1/3

XS-R9

A

B

MAIN ASSY

H

(AWZ8898)

C

VR ASSY

I

(AWZ8899)

27

1

2

3

4

D

Page 28

1

23

XS-R9

3.4.2 MAIN AND VR ASSEMBLIES

4

A

B

MAIN ASSY

H

(AWZ8898)

5.0V

TEST

MICROCOMPUTER

ASG1034

1SS355

C

S104–S129:

ASG1034

1SS355

1SS355

D

VR ASSY

I

(AWZ8899)

–17V

+5.0V

IC102(1/2)

BA4558F

IC102(2/2)

BA4558F

1SS355

1SS355

1SS355

1SS355

28

H

I

1234

Page 29

5

678

XS-R9

A

FL Spacer

AEB7095 × 2

AAV7046

V101

–34V

3.1V

FADER

Center

10.5Vp-p

8.4Vp-p

–23V

–23V

+5.0V

+5.0V

3.1V

FADER

Center

+5.0V

CN102

1/3

E

B

C

S101 : EFFECT JOG

S102 : JOG1

S103 : JOG2

S104 : SAMPLER PLAY

S105 : CD1 MASTER TEMPO

S106 : REMIX

S107 : CD2 TIME/AUTO CUE

S108 : CD1

S109 : CD1 TIME/AUTO CUE

S110 : CD2 LOOP

S111 : CD2

S112 : CD1 CUE

S113 : CD1

S114 : CD2 MASTER TEMPO

S115 : CD2 CUE

S116 : CD1

S117 : CD1

S118 : MONITER SELECT

S119 : CD2

S120 : SAMPLER MEMORY

S121 : CD1 LOOP

S122 : FADER START

S123 : CD2

S124 : A.B.E.

S125 : EFFECT ON/OFF

S126 : BPM/TIME

S127 : CD2

S128 : EFFECT SELECT

S129 : EFFECT MODE

S130 : TAP

H

5

6

7

8

29

D

Page 30

1

23

XS-R9

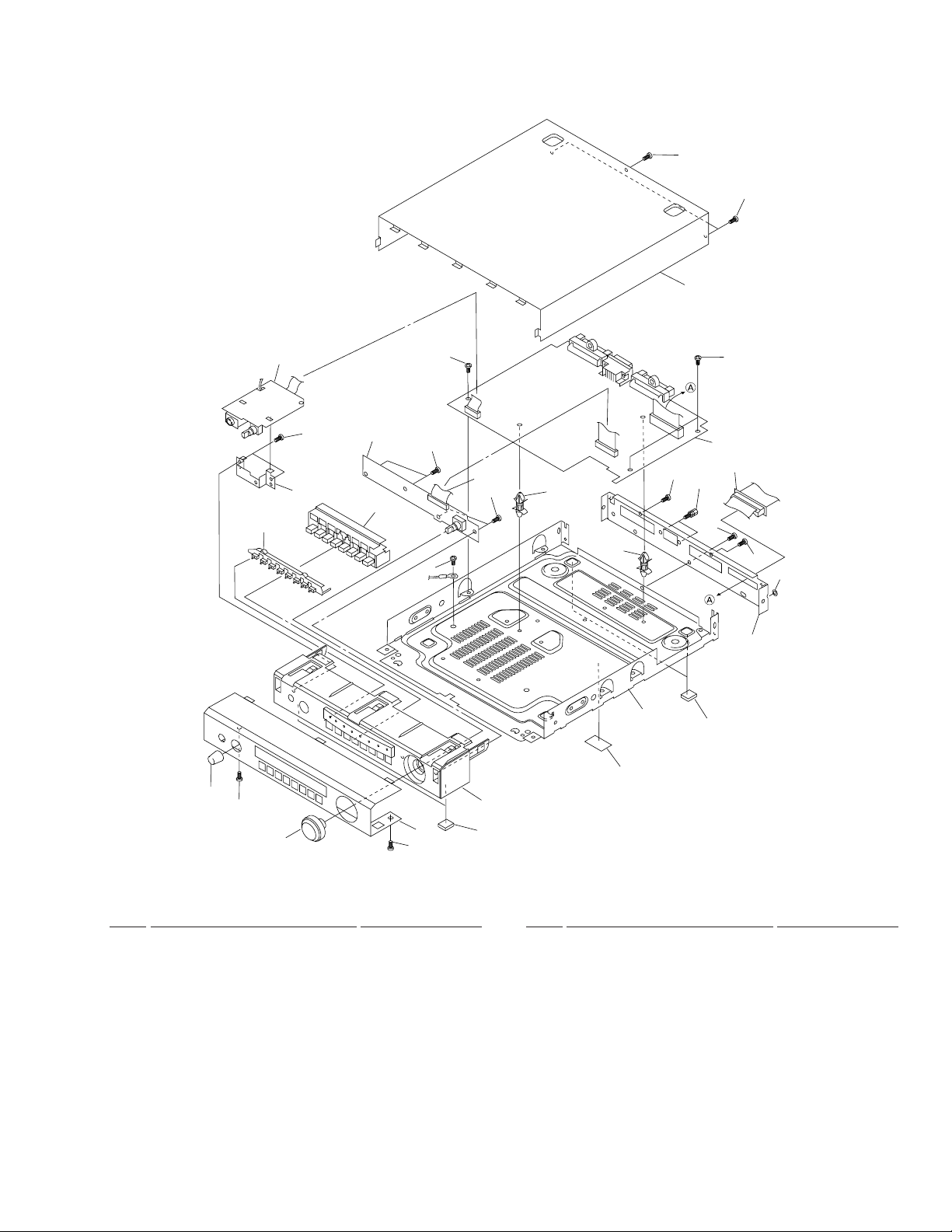

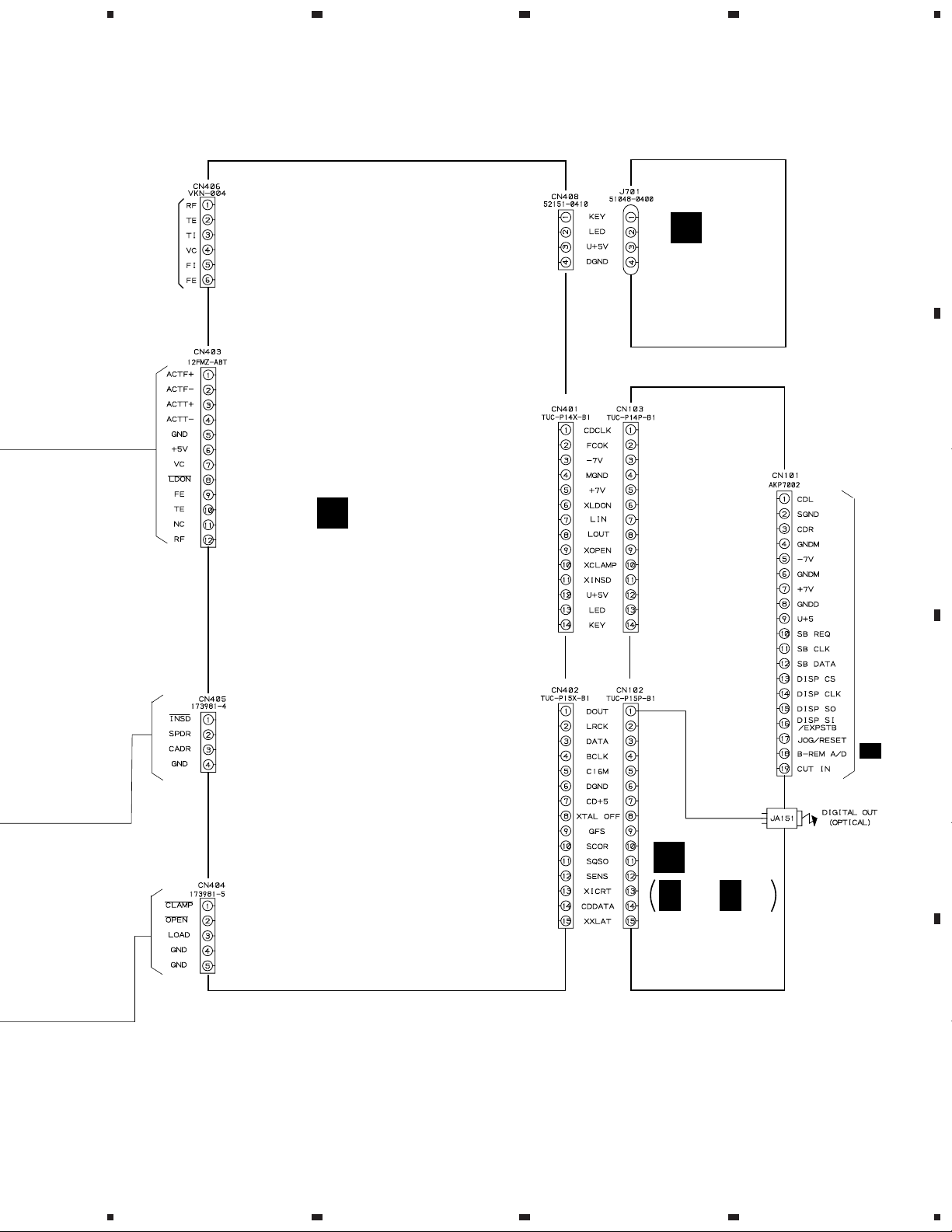

4. PCB CONNECTION DIAGRAM

A

NOTE FOR PCB DIAGRAMS :

1. Part numbers in PCB diagrams match those in the schematic

diagrams.

2. A comparison between the main parts of PCB and schematic

diagrams is shown below.

Symbol In PCB

Diagrams

BCE

BCE

D

Symbol In Schematic

Diagrams

BCEBCE

BCE

DGGSS

BCE

DGS

Part Name

Transistor

Transistor

with resistor

Field effect

transistor

4

3. The parts mounted on this PCB include all necessary parts for

several destinations.

For further information for respective destinations, be sure to

check with the schematic diagram.

4. View point of PCB diagrams.

Connector

Capacitor

SIDE A

P.C.Board

Chip Part

SIDE B

B

Resistor array

3-terminal

regulator

4.1 COMPACT DISC PLAYER [PD-R9(S)]

4.1.1 MECHANISM BOARD ASSY

MECHANISM BOARD ASSY

A

C

SPINDLE

MOTOR

INSIDE

M

CARRIAGE

MOTOR

M

(PNP1239-C)

CN405

B

SIDE A

D

30

A

1234

Page 31

1

CN102

C

MAIN

ASSY

B

MAIN

ASSY

B

CN103

C

(ANP7204-D)

(ANP7204-D)

J701

D

TO PICKUP

ASSY

CN102

SINGLE

MECHANISM

ASSY

CN610

A

IC451

IC452

IC401

IC501

IC601

IC602

VR601

VR602

Q401

VC451

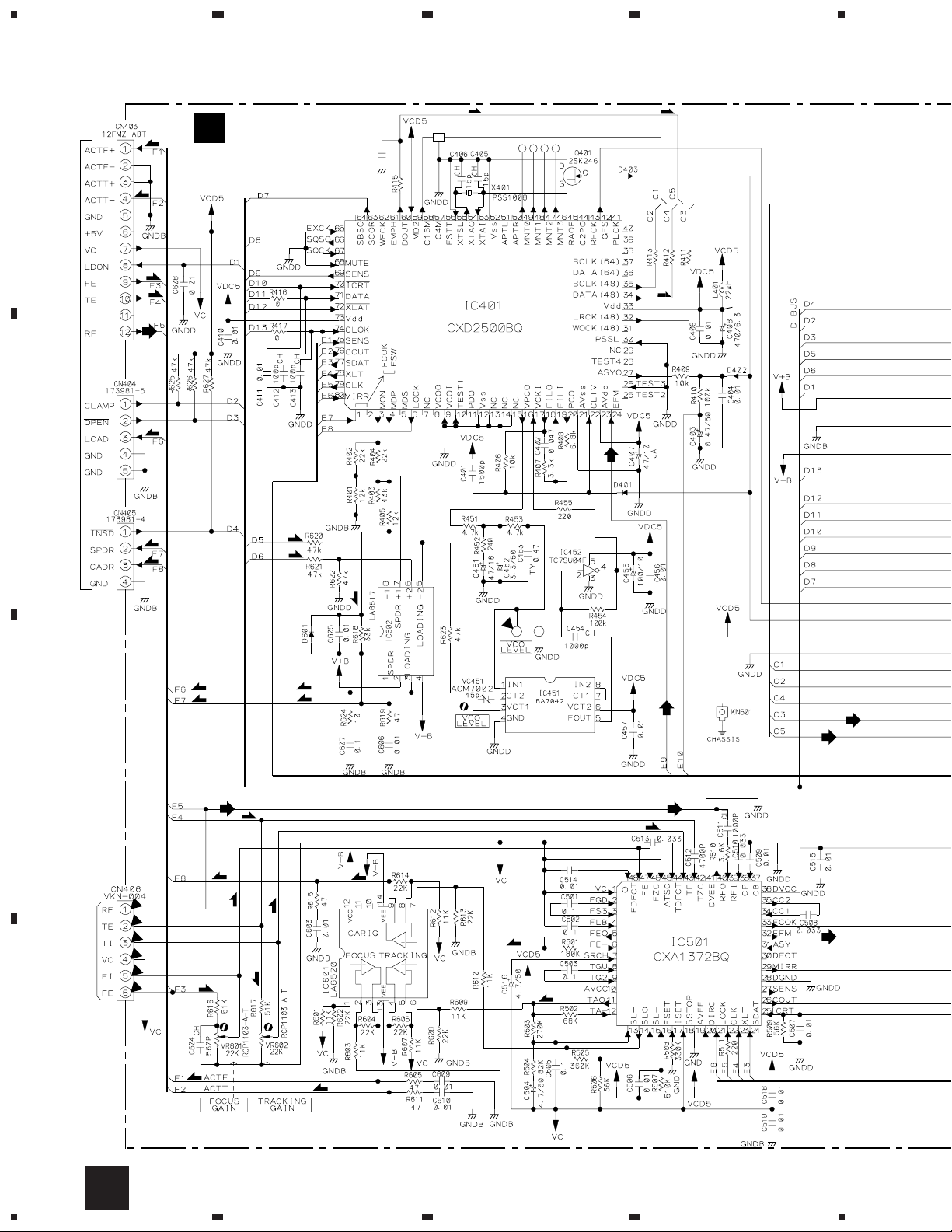

4.1.2 MAIN ASSY

234

XS-R9

A

B

C

D

SIDE A SIDE B

1

2

3

B

4

31

Page 32

1

XS-R9

4.1.3 REAR ASSY

23

4

A

REAR ASSY

C

B

CN402

B

CN401

Q151

MJ-R5/ZY

MAIN ASSY

IC301

IC303

B

IC302

IC351

Q353 Q354

IC352

Q351

Q352

C

Q202

Q201 Q203

IC102 IC101

Q101

IC201

E

CN103 : CD1

CN104 : CD2

Q104

Q106

Q107

Q102

Q103

D

(ANP7204-D)

32

SIDE A

C

1234

Page 33

1

234

XS-R9

A

REAR ASSY

C

B

C

(ANP7204-D)

D

SIDE B

C

1

2

3

4

33

Page 34

1

XS-R9

4.1.4 FRONT ASSY

A

B

FRONT ASSY

D

23

FRONT ASSY

D

4

C

D

CN408

B

(ANP7204-D)

(ANP7204-D)

SIDE A SIDE B

34

D

1234

Page 35

1

234

4.2 REMIX EFFECTOR [EF-R9(S)]

XS-R9

4.2.1 FRONT AND HEADPHONE ASSEMBLIES

FRONT ASSY

F

HEADPHONE ASSY

G

E

CN603

CN601

E

A

(ANP7251-A)

B

SIDE A

FRONT ASSY

F

G

1

HEADPHONE ASSY

2

C

(ANP7251-A)

D

SIDE B

GF

3

4

35

Page 36

XS-R9

4.2.2 MAIN ASSY

J601

G

A

B

1

MAIN ASSY

E

23

4

C

CN101

(CD1)

H

CN102

C

CN101

(CD2)

C

SX-R9/ZY

MAIN

ASSY

F

CN602

CN104

(ANP7251-A)

D

Q651-Q658 IC601

Q102Q531 Q109 IC201

IC401-IC404

Q106

Q108

IC204

Q603

IC502 IC501

Q101 Q104IC101 IC102

IC202

IC205

Q301-Q304 IC310IC301-IC304

IC306-IC309

Q103Q201 Q202

Q105IC405-IC410

SIDE A

36

E

1234

Page 37

1

(

)

234

XS-R9

MAIN ASSY

E

A

B

C

ANP7251-A

D

SIDE B

E

1

2

3

4

37

Page 38

1

23

XS-R9

4.3 REMIX CONTROL MIXER [MX-R9(S)]

4.3.1 MAIN AND VR ASSEMBLIES

A

MAIN ASSY

H

E

CN102

B

4

C

D

VR ASSY

I

SIDE A

38

H I

1234

Page 39

5

678

XS-R9

A

IC101

Q101

B

VR102 VR103

VR104 VR105

IC102

Q106

C

Q102-Q105

D

(ANP7207-C)

SIDE A

H I

5

6

7

8

39

Page 40

A

Y

B

XS-R9

1

MAIN ASSY

H

23

4

C

D

VR ASS

I

SIDE B

40

H I

1234

Page 41

5

678

XS-R9

A

B

R ASSY

C

D

(ANP7207-C)

SIDE B

H I

5

6

7

8

41

Page 42

XS-R9

Mark No. Description Part No.

Mark No. Description Part No.

5. PCB PARTS LIST

NOTES:•Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

When ordering resistors, first convert resistance values into code form as shown in the following examples.

•

Ex.1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by J=5%,

and K=10%).

560 Ω→56 × 10

47k Ω→47 × 103→ 473 ........................................................ RD1/4PU 4 7 3 J

0.5 Ω→R50 ..................................................................................... RN2H

1 Ω→1R0 ..................................................................................... RS1P

Ex.2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62k Ω→ 562 × 10

Mark No. Description Part No.

LIST OF ASSEMBLIES

NSP COMPACT DISC PLAYER PD-R9(S)

NSP SINGLE MECHANISM ASSY AXA7058

NSP SERVO MECHANISM ASSY AXA7017

NSP CD MAIN ASSY AWM7372

NSP REMIX EFFECTOR EF-R9(S)

NSP EF MAIN ASSY AWM7366

NSP REMIX CONTROL MIXER MX-R9(S)

NSP PAD MAIN ASSY AWM7304

NSP VR ASSY AWZ8899

MECHANISM BOARD ASSY PWX1192

MAIN ASSY AWU7142

REAR ASSY AWU7144

FRONT ASSY AWZ8889

MAIN ASSY AWU7067

FRONT ASSY AWU7068

HEADPHONE ASSY AWU7069

MAIN ASSY AWZ8898

COMPACT DISC PLAYER [PD-R9(S)]

MECHANISM BOARD ASSY

A

SWITCH

S610 DSG1016

1

→ 561 ........................................................ RD1/4PU 5 6 1 J

R 5 0

1 R 0

1

→ 5621 ...................................................... RN1/4PC 5 6 2 1 F

Mark No. Description Part No.

IC452 TC7SU04F

Q401 2SK246

D401-D403 1SS355

D601 UDZS6.2B

COIL AND FILTER

F401 CHIP EMI FILTER ATF7013

L401 LCTA220J3225

CAPACITORS

VC451 (45pF) ACM7002

C412,C413 CCSQCH101J50

C454,C511 CCSQCH102J50

C405,C406 CCSQCH150J50

C415 CCSQCH330J50

C604 CCSQCH561J50

C517 CEAL101M6R3

C455 CEAT101M10

C601,C602 CEAT331M10

C452 CEAT3R3M50

C451 CEAT470M16

C408 CEAT471M6R3

C504,C516 CEAT4R7M50

C403 CEATR47M50

C407 CEJA470M10

C453 CFTYA474J50

C404,C409-C411,C456,C457 CKSQYB103K50

C506,C507,C509,C514,C515 CKSQYB103K50

C518,C519,C603,C605,C606 CKSQYB103K50

C608-C610 CKSQYB103K50

K

K

OTHERS

CN610 MT CONNECTOR 4P 173979-4

MAIN ASSY

B

SEMICONDUCTORS

IC451 BA7042

IC501 CXA1372BQ

IC401 CXD2500BQ

IC602 LA6517

IC601 LA6520

42

C607 CKSQYB104K25

C401 CKSQYB152K50

C508,C510,C513 CKSQYB333K50

C512 CKSQYB472K50

C402 CKSQYB473K50

C501-C503,C505 CKSQYF104Z50

RESISTORS

VR601,VR602 (22kΩ) RCP1103

Other Resistors RS1/10S J

Page 43

XS-R9

Mark No. Description Part No.

OTHERS

CN403 CONNECTOR 12P 12FMZ-ABT

CN405 MT CONNECTOR 4P 173981-4

CN404 MT CONNECTOR 5P 173981-5

CN408 4P JUMPER CONNECTOR 52151-0410

X401 CRYSTAL RESONATOR PSS1008

CN401 CONNECTOR 14P TUC-P14X-B1

CN402 CONNECTOR 15P TUC-P15X-B1

CN406 6P SIDE POST VKN-004

KN601 EARTH METAL FITTING VNF1084

REAR ASSY

C

(16.9344MHz)

PCB BINDER VEF1040

SEMICONDUCTORS

IC101 (630mA) AEK7006

IC302 HM514800CJ-7

IC301 MN19413A

IC351,IC352 NJM2068M

IC201 PD4866A

Q201 2SC2412K

Q101,Q104 2SC4040

Q351,Q352 2SD2114K

Q103 2SD2395

Q106,Q203,Q354 DTA143EK

Q202 DTC124EK

Q107,Q151,Q353 DTC143EK

D201,D301,D302 1SS355

D102 UDZS5.1B

D101,D103,D104 UDZS5.6B

Mark No. Description Part No.

RESISTORS

All Resistors RS1/10S J

OTHERS

CN101 CONNECTOR 19P AKP7002

JA151 OPTICAL LINK OUT GP1F32T

CN103 CONNECTOR 14P TUC-P14P-B1

CN102 CONNECTOR 15P TUC-P15P-B1

KN101 EARTH METAL FITTING VNF1084

X201 CERAMIC RESONATOR VSS1014

FRONT ASSY

D

PCB BINDER VEF1040

(4.19MHz)

SEMICONDUCTORS

Q701 2SC2412K

D701,D702 SLR-342VCT31

SWITCHES

S701-S706 ASG1034

RESISTORS

All Resistors RS1/10S J

OTHERS

701 4P CABLE HOLDER 51048-0400

J701 JUMPER WIRE 4P D20PDY0415E

COILS

L151 LCTA100J3225

L304 LCTA680J3225

L201,L301,L302 LFA220J

L313,L314 CHIP BEADS PTL1014

CAPACITORS

C210,C313,C314,C353-C356 CCSQCH101J50

C359,C360 CCSQCH101J50

C351,C352 CCSQCH102J50

C318,C319,C369,C370 CCSQCH330J50

C203-C205 CCSQCH391J50

C327 CCSQCH560J50

C361,C362 CCSQSL182J50

C102-C104,C301 CEAT101M10

C304 CEAT1R0M50

C363,C364,C371,C372 CEAT220M50

C101,C315,C365-C368 CEAT470M16

C201 CEAT471M6R3

C305,C307 CEZA220M25

C357,C358 CEZA2R2M50

C151,C212-C214,C302,C303 CKSQYB103K50

C309-C312,C316,C317,C321 CKSQYB103K50

C324,C325 CKSQYB103K50

C153,C202,C215,C306,C308 CKSQYB104K25

C323 CKSQYB104K25

C206,C207,C209,C211 CKSQYB471K50

C152,C154 CKSQYF104Z50

C208 CKSQYF105Z16

REMIX EFFECTOR [EF-R9(S)]

MAIN ASSY

E

SEMICONDUCTORS

IC101 (315mA) AEK7003

IC102 (125mA) AEK7020

IC204,IC205,IC305-IC307,IC310 BA4558F-HT

IC401-IC410,IC502 BA4558F-HT

IC308,IC501 BU4052BCF

IC303,IC304 BU4066BCF

IC202 HM514400CJ-7

IC301,IC302 M51131L

IC201 MN19413A

IC309 NJM2068M

IC601 PD4867A

Q108,Q531,Q603,Q651-Q658 2SA1037K

Q104 2SB1238X

Q101-Q103 2SD1859X

Q201,Q202 2SD2114K

Q105,Q109,Q301-Q304 DTA124EK

Q203 DTA143EK

Q106 DTC124EK

Q601 DTC143EK

D104-D106,D605 1SR154-400

D401,D402,D404-D406 1SS355

D408-D410,D412,D413 1SS355

D415,D416,D418,D419 1SS355

D601-D604,D606-D608 1SS355

D611-D618 1SS355

D411,D414,D417,D420 UDZS5.1B

D101-D103,D107,D403,D407 UDZS5.6B

43

Page 44

XS-R9

Mark No. Description Part No.

COILS

L601 LCTA220J3225

L101,L201-L203 LFA220J

CAPACITORS

C222,C223,C271,C272 CCSQCH101J50

C321,C322,C341-C344 CCSQCH101J50

C401,C402,C525,C526 CCSQCH101J50

C609,C610,C614,C616 CCSQCH101J50

C224,C225,C263,C264 CCSQCH330J50

C253-C256,C259,C260 CCSQCH471J50

C251,C252 CCSQSL152J50

C345,C346 CEAL100M35

C257,C258,C267-C270 CEAL2R2M50

C311-C314,C323,C324 CEAL2R2M50

C349-C352,C383-C390 CEAL2R2M50

C511-C514,C523,C524 CEAL2R2M50

C527,C528,C604 CEAL2R2M50

C101-C103,C109 CEAT101M10

C301-C304 CEAT2R2M50

C207,C208,C211,C213,C215 CEAT470M16

C217,C219,C228,C232 CEAT470M16

C305,C306 CEAT470M16

C601 CEJA101M10

C265,C266,C315,C316 CEJA470M16

C353,C354 CEJA470M16

C605,C618 CEJA470M35

C273,C274 CKSQYB102K50

C112-C114,C201-C205 CKSQYB103K50

C209,C210,C212,C214,C216 CKSQYB103K50

C218,C220,C221,C229,C233 CKSQYB103K50

C307,C308,C325-C328 CKSQYB103K50

C361,C362,C381,C382 CKSQYB103K50

C391,C392,C403-C416 CKSQYB103K50

C421-C426,C431-C436 CKSQYB103K50

C501,C502,C602,C603 CKSQYB103K50

C606-C608,C611-C613,C615 CKSQYB103K50

C419,C420,C427-C430 CKSQYB104K25

C443,C444 CKSQYB104K25

C417,C418 CKSQYB183K50

C261,C262 CKSQYB332K50

C104-C107,C275 CKSQYF104Z50

C108,C439-C442,C617 CKSQYF105Z16

Mark No. Description Part No.

FRONT ASSY

F

SEMICONDUCTORS

D651 SLR-342MCT31

D652-D658 SLR-342VCT31

SWITCHES

S701-S704,S709-S712 ASG1034

S751 ASX7015

RESISTORS

All Resistors RS1/10S J

OTHERS

CN602 15P FFC CONNECTOR 9604S-15F

HEADPHONE ASSY

G

SEMICONDUCTORS

IC801,IC802 BA4560F

Q801,Q803,Q804 2SD2114K

COIL AND FILTER

F801 EMI FILTER ATF7016

L801 LCTA2R2J3225

CAPACITORS

C823,C824 CCSQCH101J50

C825,C826 CCSQCH151J50

C843-C846 CCSQCH221J50

C841,C842 CCSQCH470J50

C835,C836 CEAL2R2M50

C821,C822 CEJA100M16

C827,C828,C833,C834 CEJA101M6R3

C831,C832 CKSQYB103K50

C847,C848 CKSQYB223K50

C840 CKSQYF104Z50

RESISTORS

R803,R804 (1Ω) ACN1104

VR821 (10kΩ-B) ACS7025

Other Resistors RS1/10S J

RESISTORS

R276 (47Ω) DCN1090

Other Resistors RS1/10S J

OTHERS

CN603 6P JUMPER CONNECTOR 52147-0610

CN101 20P JUMPER CONNECTOR 52328-2020

CN601 15P FFC CONNECTOR 9604S-15C

CN102 D-SUB MINI 15P AKP7019

X201 CRYSTAL RESONATOR PSS1008

KN101 EARTH METAL FITTING VNF1084

X601 CERAMIC RESONATOR VSS1014

(4.19MHz)

44

OTHERS

J601 JUMPER WIRE 6P D20PWY0610E

JA821 STEREO JACK KN-083

19P SOCKET AKP7001

(16.9344MHz)

Page 45

XS-R9

Mark No. Description Part No.

REMIX CONTROL MIXER [MX-R9(S)]

MAIN ASSY

H

SEMICONDUCTORS

IC102 BA4558F-HT

IC101 PDG208A

Q101-Q106 DTC143ES

D101-D103,D105-D108 1SS355

D110-D114 SLR-342MCT31

D116 SLR-342VCT31

D104 UDZ16B

COILS

L101,L102 LCTA220J3225

SWITCHES

S104-S130 ASG1034

S102,S103 ASX7016

S101 ASX7019

CAPACITORS

C105,C109-C111 CCSQCH101J50

C129 CEAT100M50

C123,C127 CEAT470M16

C201 CEAT470M50

C101,C104 CEAT471M6R3

Mark No. Description Part No.

C102,C103,C106-C108 CKSQYB103K50

C112-C119,C124-C126,C128 CKSQYB103K50

C132,C144,C145 CKSQYB103K50

C122,C135,C146 CKSQYF104Z50

C120 CKSQYF105Z16

C121,C140-C143 CKSQYF473Z50

RESISTORS

R159 RA12T104J

R156,R158 RA15T104J

R157 RA5T104J

VR104,VR105 (10kΩ-B) ACS7026

VR102,VR103 (10kΩ-B) ACU7001

Other Resistors RS1/10S J

OTHERS

X101 CERAMIC RESONATOR EFOEC8004A4

V101 FL TUBE AAV7046

J101 CONNECTOR ASSY PG03MR-E10

VR ASSY

I

RESISTORS

VR101 (10kΩ-B) ACU7002

Other Resistors RS1/10S J

PORON SHEET AEB7095

OTHERS

CN101 MT CONNECTOR 3P 173979-3

45

Page 46

XS-R9

6. ADJUSTMENT

6.1 ADJUSTMENT OF COMPACT DISC PLAYER [PD-R9(S)]

6.1.1 PREPARATIONS

1. Jigs and Measuring Instruments

8-cm DISC

(With at least about

20 minutes recording)

Ball point hexagon wrench

(size: 1.5mm)

GGK1002

2. Necessary Adjustment Points

When Adjustment points

Exchange

CD TEST DISC

(YEDS-7)

screwdriver

(large)

PICKUP

Precise

screwdriver

Low-frequency

oscillator

screwdriver

(small)

Dual-trace

oscilloscope

(10 : 1 probe)

2. 3. 4. 5. 6. 7. → Page 48 to 51

screwdriver

(medium)

39 kΩ

0.001µF

Low pass filter

(39 kΩ + 0.001µF)

Exchange

MAIN ASSY

Exchange

SERVO MECH ASSY

Exchange

SPINDLE MOTOR

46

1. 2. 3. 5. 6. 7. → Page 48 to 51

2. 3. 4. 5. 6. 7. → Page 48 to 51

ADJ → Page 5

Page 47

6.1.2 ADJUSTMENT

1. How to Start/Cancel Test Mode

TEST MODE : ON

XS-R9

POWER

ON

CD

FUNCTION

CD-SET

TEST MODE : PLAY

TEST DISC: YEDS-7

inwards

Pickup Move

outwards

TEST MODE : STOP → CANCEL

POWER

TEST MODE

Short point

MAIN ASSY

REPEAT

Laser diode: LIGHTS UP

Focus servo: CLOSE

TEST MODE

Short point

MAIN ASSY

Spindle motor: START

Spindle servo: CLOSE

CLOSE

Tracking servo

OPEN

Stop all operation

2. Adjustment Location

PICKUP ASSY

ADJUSTMENT SCREW

(Radial direction)

ADJUSTMENT SCREW

(Tangential tilt direction)

TEST MODE

Short

point

OFF

REAR AssY

TEST MODE

(REAR)

VCO TP

GND

(FRONT)

VC451

(VCO.LEVEL)

VR601

(FO.GAIN)

VR602

(TR.GAIN)

MAIN ASSY

CN406

TP1

1. RF

2. TRER

3. TRIN

4. VC

5. FOIN

6. FOER

47

Page 48

XS-R9

3. Check and Adjustment

1. VCO Adjustment

Test mode

None disc

START

VCO TP

VCO LEVEL

GND

MAIN ASSY

2. Focus Offset Check

DC voltage

2.5 ± 0.5V

VC451

MAIN ASSY

Oscilloscope

DC Mode

V: 1V/div

H: 10mSec/div

Player

Probe (10:1)

GND

48

START

FOER

Test mode

None disc

TP1

(CN406)

6

VC

4

MAIN ASSY

Check

Player

DC voltage

0 ± 50mV

If not → repair

Oscilloscope

DC Mode

V: 5mV/div

H: 10mSec/div

Probe (10:1)

GND

Page 49

3. Tracking Error Balance Check

XS-R9

Test mode

FOCUS servo → CLOSE

SPDL servo → CLOSE

TRKG servo → OPEN

TEST DISC

START

YEDS–7

R=35mm

PLAY

TP1

(CN406)

TRER

2

VC

4

MAIN ASSY

Check

Player

Low pass filter

39 kΩ

0.001µF

A = B

A

VREF

LEVEL

B

If not → repair

Oscilloscope

DC Mode

V: 50mV/div

H: 5mSec/div

Probe (10:1)

GND

4. Pickup 1 Radial/ 2 Tangential Direction Tilt Adjustment

Test mode

FOCUS servo → CLOSE

SPDL servo → CLOSE

TRKG servo → CLOSE

TEST DISC

PLAY

Position where the screw is

visible through the adjustment

hole of the float base after

moving toward the outer

peripheral.

START

TP1

(CN406)

RF

1

VC

4

MAIN ASSY

1

2

TEST DISC

2

Remove lock tight

Player

1

Eye patternNGOK (Smooth)

Oscilloscope

AC Mode

V: 20mV/div

H: 200nSec/div

Probe (10:1)

GND

49

Page 50

XS-R9

5. RF Level Check

Test mode

FOCUS servo → CLOSE

SPDL servo → CLOSE

TRKG servo → CLOSE

YEDS–7

TEST DISC

R=35mm

PLAY

START

TP1

(CN406)

RF

1

1

VC

4

MAIN ASSY

Check

Player

1.2VP-P

± 0.2V

If not → repair

Oscilloscope

AC Mode

V: 50mV/div

H: 10mSec/div

Probe (10:1)

GND

6. Focus Servo Loop Gain Adjustment

Test mode

FOCUS servo → CLOSE

SPDL servo → CLOSE

TRKG servo → CLOSE

PLAY

(CN406)

FOIN

VC

MAIN ASSY

YEDS–7

R=35mm

TP1

6

5

4

VR601

MAIN ASSY

Player

Probe (10:1)

Probe (10:1)

100kΩ

TEST DISC

START

FOER

Lissajous Waveform

Oscilloscope

X-Y Mode

X: 20mV/div

Y: 5mV/div

Low-frequency

oscillator

1.2kHz

1Vp-p

GND

GND

50

Page 51

7. Tracking Servo Loop Gain Adjustment

Test mode

FOCUS servo → CLOSE

SPDL servo → CLOSE

TRKG servo → CLOSE

YEDS–7

TEST DISC

PLAY

START T

TP1

(CN406)

TRIN

TRER

VC

MAIN ASSY

R=35mm

3

2

4

100kΩ

VR602

MAIN ASSY

Player

Probe (10:1)

Probe (10:1)

39 kΩ

0.001µF

Lissajous Waveform

Oscilloscope

X-Y Mode

X: 50mV/div

Y: 20mV/div

Low-frequency

oscillator

1.2kHz

2Vp-p

GND

GND

XS-R9

Low pass filter

6.2 REMIX EFECTOR [EF-R9(S)]

• No adjustment is required.

6.3 REMIX CONTROL MIXER [MX-R9(S)]

• No adjustment is required.

51

Page 52

XS-R9

7. GENERAL INFORMATION

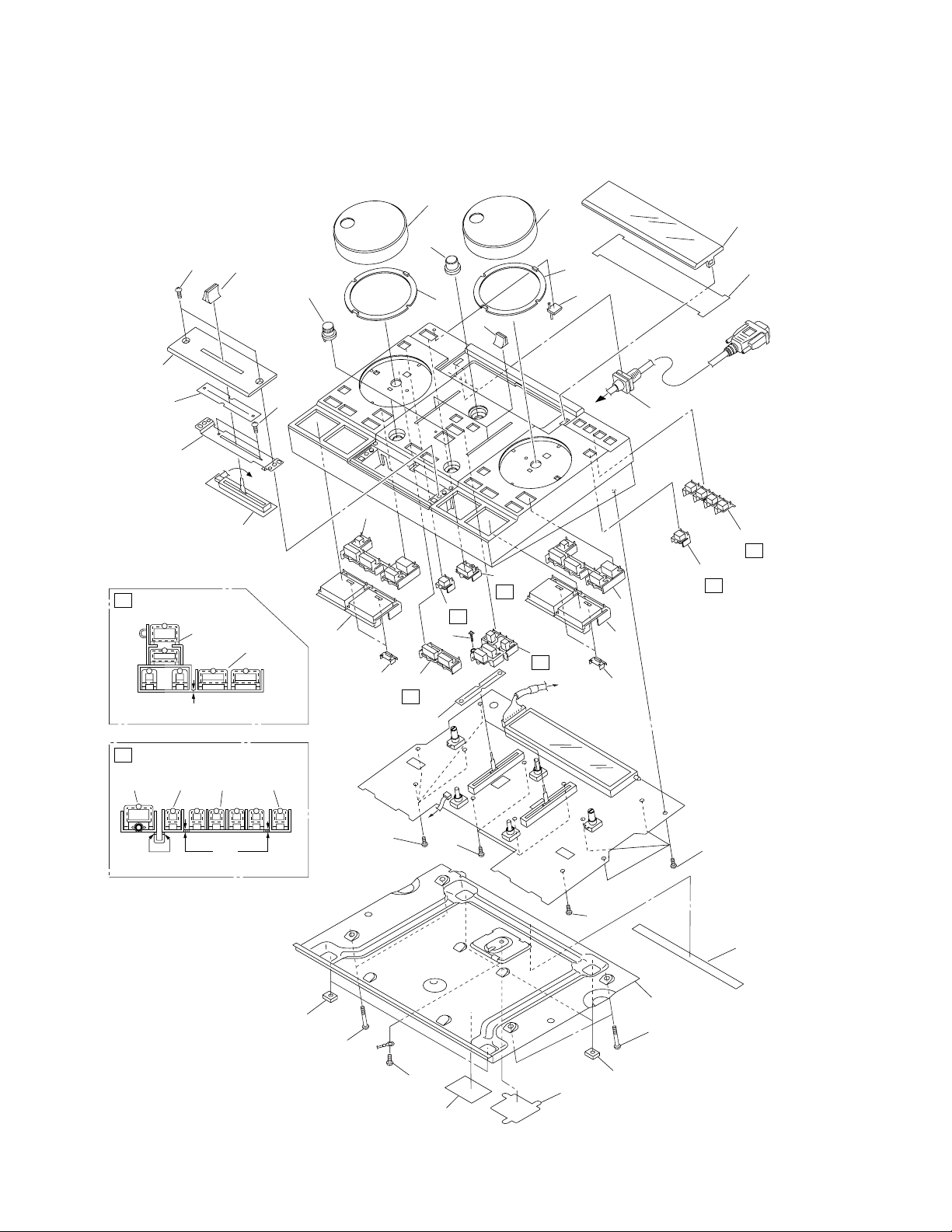

7.1 PARTS

7.1.1 IC

• The information shown in the list is basic information and may not correspond exactly to that shown in the schematic diagrams.

List of IC

•

PD4866A, MN19413, HM514400CJ-7, TC7S08F : COMPACT DISC PLAYER [PD-R9(S)]

PD4867A : REMIX EFECTOR [EF-R9(S)]

PDG208A : REMIX CONTROL MIXER [MX-R9(S)]

COMPACT DISC PLAYER [PD-R9(S)]

PD4866A (REAR ASSY : IC201)

• CD CONTROL MICROCOMPUTER

Pin Arrangement (Top view)

•

XT2

KEY

AVref0

75

747372

76

AVdd

AVref0

P10/ANI0

FCOK

AVdd

IC

71

IC

XT2

P07/XT1

PD4866A

X2X1NC

70

696867

X1

X2

NC

Vdd

66

Vdd

P05/INTP5

P06/INTP6

DISP CS

CUT INNCSCOR

65

646362

P02/INTP2

P03/INTP3

P04/INTP4

P127/RTP7

P126/RTP6

P125/RTP5

P124/RTP4

P123/RTP3

P122/RTP2

P121/RTP1

P120/RTP0

P66/ WAIT

SBCLK

61

P01/INTP1/TI01

P00/INTP0/TI00

RESET

P37

P36/BUZ

P35/PCL

P34/TI2

P33/TI1

P32/T02

P31/T01

P30/T00

P67/ASTB

P65/ WR

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

RESET

SB SO

SB SI

SB R/E

NC

NC

NC

NC

NC

ICRT

XTAL OFF

XLAT

SENS

GFS

MUTE

LDON

LED

DMUTE

RAS

LIN

1

NC

2

NC

3

NC

4

AVss

5

UNIT

6

NC

AVref1

SQSO P70/SI2/RxD

CD DATA

DISP SI/EXP STB

CD CLK

DISP SO P21/SO1

DISP CLK

DSP DATA P26/SO0/SDA1

DSP CLK

7

8

9

10

11

12

13

14

NC

15

NC P24/BUSY

16

NC

17

18

19

NC

20

NC P41/AD1

B-REM

NC

NC

797877

80

P12/ANI2

P13/ANI3

P14/ANI4

P15/ANI5

P16/ANI6

P17/ANI7

AVss

P130/AN00

P131/AN01

AVref1

P71/SO2/TxD

P72/ SCK2/ASCK

P20/SI1

P22/ SCK1

P23/STB

P25/SI0/SDA0

P27/ SCK0/SCL

P40/AD0

JOG

P11/ANI1

P50/A8

Pin Function

•

P43/AD3

P44/AD4

P42/AD2

21NC222324

NC

NC

P47/AD7

P46/AD6

P45/AD5

25

26NC272829

NC

NC

P51/A9

P53/A11

P52/A10

30

P ON

DISP INT0

DISP INT1

DSP XRST

P55/A13

P54/A12

31

323334

RQ1

RQ2

Vss

Vss

P60

P57/A15

P56/A14

35

36

P3

GF1

TEST

P61

P62

373839

INSD

OPEN

P64/ RD

P63

40

LOUT

CLAMP

No. Pin Function Pin Name I/O Function

1 P15/ANI5 NC O ––

2 P16/ANI6 NC O ––

3 P17/ANI7 NC O ––

4 AVss AVss – GND

5 P130/AN00 UNIT I Check input of the unit board (L : unit board check)

6 P131/AN01 NC O ––

7 AVref1 AVref1 – +5V

8 P70/SI2/RxD SQSO I CD subcode input

9 P71/SO2/TxD CD DATA O Data output of CD decoder

10 P72/ÅPSCK2/ASCK CD CLK O Clock for CD decoder communication

11 P20/S11 DISP SI/EXP STB I/O Data input for display communication

12 P21/SO1 DISP SO O Data output for display communication

13 P22/ÅPSCK1 DISP CLK O Clock output for display communication

14 P23/STB NC O ––

15 P24/BUSY NC O ––

52

Page 53

No. Pin Function Pin Name I/O Function

16 P25/SIO/SDA0 NC O ––

17 P26/S00/SDA1 DSP DATA O CD DSP data output

18 P27/SCK0/SCL DSP CLK O CD DSP clock output

19 P40/AD0 NC O ––

20 P41/AD1 NC O ––

21 P42/AD2 NC O ––

22 P43/AD3 NC O ––

23 P44/AD4 NC O ––

24 P45/AD5 NC O ––

25 P46/AD6 NC O ––

26 P47/AD7 NC O ––

27 P50/A8 DSP XRST O DSP reset output (L : reset)

28 P51/A9 P ON O DSP power supply ON/OFF (H :ON)

29 P52/A10 DISP INT0 O Not used

30 P53/A11 DISP INT1 O Not used

31 P54/A12 RQ1 O DSP WRITE (Writing request)

32 P55/A13 RQ2 O DSP READ (Reading request)

33 Vss Vss – GND

34 P56/A14 GF1 I DSP data compare/delay time

35 P57/A15 P3 I DSP sampling memory

36 P60 TEST I CD TEST input (L : TEST mode)

37 P61 INSD I Carriage inside SW input (L : inside)

38 P62 OPEN I Tray OPEN SW (L : OPEN completion)

39 P63 CLAMP I Tray CLAMP SW (L : CLAMP completion)

40 P64/RD LOUT O Loading motor output (LOUT, LIN: Stop ; L, H = CLOSE ; H, L = OPEN)

41 P65/WR LIN O Refer to LOUT (pin 40)

42 P66/WAIT RAS O D-RAM reset output (Pulse output when switching the function CD)

43 P67/ASTB DMUTE O Optical digital output mute (H : mute)

44 P30/T00 LED O Front LED output (H : lights up)

45 P31/T01 LDON O Laser diode output (L : lights up)

46 P32/T02 MUTE O CD mute (H : mute)

47 P33/TI1 GFS I CD GFS signal input

48 P34/TI2 SENS I CD sense signal input

49 P35/PCL XLAT O CD decoder latch output

50 P36/BUZ XTAL OFF O CD decoder crystal ON/OFF (H : ON)

51 P37 ICRT O CD decoder reset output (L : reset)

52 P120/RTP0 NC O ––

53 P121/RTP1 NC O ––

54 P122/RTP2 NC O ––

55 P123/RTP3 NC O ––

56 P124/RTP4 NC O ––

57 P125/RTP5 SB R/E I/O System bus request/enable

58 P126/RTP6 SB SI I System bus data input

59 P127/RTP7 SB SO O System bus data output

60 RESET RESET – Microprocessor reset input (L :reset)

61 P00/INTP0/TI00 SCOR I CD sync. signal input

62 P01/INTP1/TIO1 SBCLK I System bus clock input

63 P02/INTP2 DISP CS I/O Display communication data start / end input and output (↑ : start, ↓ : end)

64 P03/INTP3 CUT IN I/O Cut-in REC start input (L output at not used)

65 P04/INTP4 NC O ––

66 P05/INTP5 NC O ––

67 P06/INTP6 NC O ––

68 Vdd vdd – +5V

69 X2 X2 – Main system clock

70 X1 X1 – ––

71 IC IC – ––

72 XT2 XT2 – ––

73 P07/XT1 FCOK I CD focus OK input (H : OK)

74 AVdd AVdd – +5V

75 AVref0 AVref0 – ––

76 P10/ANI0 KEY I Main key A/D input

77 P11/ANI1 JOG I PAD/remix controller JOG A/D input

78 P12/ANI2 B - REM I/O Not used (L output)

79 P13/ANI3 NC – ––

80 P14/ANI4 NC – ––

XS-R9

53

Page 54

XS-R9

K

COMPACT DISC PLAYER [PD-R9(S)]

MN19413A (REAR ASSY : IC301)

• DSP IC

Pin Arrangement (Top view)

•

RP

RN

VDD

SCKI

WSI

SDI

SDO2

SDO1

WSO

SCKO

VSS

P3

P2

P1

P0

SYNC

INT1

INT0

XTEST1

XRESET

ADDR0

ADDR1

SCL

SDA

XCE

VGDA

LP

DAVSS

LN

DAVDD

[N.C.]

ADVSS

VGAD

ADVDD

AINL

9998979695949392919089888786858483828180797877

100

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26272829303132333435363738394041424344454647484950

MN19413A

VBOP

[N.C.]

[N.C.]

VREFL

AINR

VREFR

ZFLG

VSS

UNLOC

PCO

VCOI

VCOO

VDD

CLKI

POLPD

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

RX0

CSEL

FL1

RX1

DIR

FL2

RX2

VDD

XISEL

XO1

XI1

TEST0

XO2

XI2

VSS

D0

D1

D2

D3

D4

D5

D6

D7

VDD

XCE1

Pin Function

•

VDD

MATCH

A16

A15

A14

A13

A12

A11

A10

A9

A8

A7A6A5

VSS

A4

A3

A2

A1

A0

XCAS

XRAS

XWE

.oNemaNniPT/O/InoitcnuF.oNemaNniPO/InoitcnuF

1PRO )evitisop(tuptuogolanahc-RA/D510TP/0PT/O/I

hcnarb

2NRO )evitagen(tuptuogolanahc-RA/D61CNYSI )tupninoitidnoc(.cnysmargorproftupnI

3DDV

−

)V5(ylppusrewoplatigiD711TNII 1tupnitpurretnI

4IKCSI tupnilairesrofkcolclaireS810TNII 0tupnitpurretnI

5ISWI tupnilairesroftcelesdroW911TSETXI )V5yllamron(tupnitseT

6IDSI tupnilairesrofataD02TESERXI tupnitesermetsyS

72ODSO 2tuptuolairesrofataD120RDDAI subCIIrof0tcelessserddA

81ODSO 1tuptuolairesrofataD221RDDAI subCIIrof1tcelessserddA

9OSWO tuptuolairesroftcelesdroW32LCSO/IsubCIIrofkcolclaireS

01OKCSO tuptuolairesrofkcolclaireS42ADSO/IsubCIIrofatadlaireS

11SSV

−

)V0(dnuorglatigiD52ECXI subCIIrofelbanepihC

213PT/O/I3tropesopruplareneG62HCTAMO subCIIroftupnitneiciffeoctahctamsserddA

312PT/O/I2tropesopruplareneG72DDV

411TP/1PT/O/I

hcnarb

noitidnocrof1galF/1tropesopruplareneG

8261AO

−

XOE

XCE2

noitidnocrof0galF/0tropesopruplareneG

)V5(ylppusrewoplatigiD

MARlanretxerof61sserddA

).desutonsisserddanehwnepO(

54

Page 55

.oNemaNniPT/O/InoitcnuF.oNemaNniPO/InoitcnuF

9251AO MARlanretxerof51sserddA561IXI tupni1kcolcmetsyS

0341AO MARlanretxerof41sserddA661OXO tuptuo1kcolcmetsyS

1331AO MARlanretxerof31sserddA76LESIXI )1IX:1,2IX:0(noitceleskcolcmetsyS

2321AO MARlanretxerof21sserddA86DDV

3311AO MARlanretxerof11sserddA962XRO/ItupnilangisoidualatigiD

4301AO MARlanretxerof01sserddA072LFO tuptuolangiskcabdeef2XR

539AO MARlanretxerof9sserddA17RIDI )esuRIDlanretni:1(noitcelesRID

638AO MARlanretxerof8sserddA271XRO/I1tupnilangisoidualatigiD

737AO MARlanretxerof7sserddA371LFO tuptuolangiskcabdeef1XR

836AO MARlanretxerof6sserddA47LESCI

935AO MARlanretxerof5sserddA57OXRO tuptuolangisoidualatigiD

04SSV

144AO MARlanretxerof4sserddA77IKLCI

243AO MARlanretxerof3sserddA87CN

342AO MARlanretxerof2sserddA97OOCVO tuptuoOCVni-tliuB

441AO MARlanretxerof1sserddA08IOCVI tupniOCVni-tliuB

540AO MARlanretxerof0sserddA18OCPO tuptuorotarapmocesahpLLP

64SARXO

74SACXO

84EWXO MARlanretxerofelbaneetirW48GLFZO tuptuognitcetedtupni0A/D

94EOXO MARlanretxerofelbanetupetirW58RFERV

052ECXO MARSlanretxerof2elbanepihC68RNIAI tupnigolanahcRD/A

151ECXO MARSlanretxerof1elbanepihC78CN

25DDV

357DO/I

456DO/IMARlanretxerof6ataD09CN

555DO/IMARlanretxerof5ataD19DDVDA

654DO/IMARlanretxerof4ataD29SSVDA

753DO/IMARlanretxerof3ataD39LNIAI tupnigolanahcLD/A

852DO/IMARlanretxerof2ataD49DAGV

951DO/IMARlanretxerof1ataD59CN

060DO/IMARlanretxerof0ataD69ADGV

16SSV

262IXI tupni2kcolcmetsyS89DDVAD

362OXO tuptuo2kcolcmetsyS99PLO )evitisop(tuptuogolanahcLA/D

460TSETI )V0yllamroN(tupnitseT001NLO )evitagen(tuptuogolanahcLA/D

−

−

−

)V0(dnuorglatigiD67DPLOPI noitcelesytiraloptuptuoOCP

)desutontanepo(

MARDlanretxerofebortssserddawoR

MARDlanretxerofebortssserddanmuloC

)desutontanepo(

)V5(ylppusrewoplatigiD88LFERV

).7ot4Dottcennoc,desu

)V0(dnuorglatigiD79SSVAD

28KCOLNUO tuptuogalfkcolnuLLP

38SSV

siMARDanehW(MARlanretxerof7ataD

98POBV

−

tupnikcolcOCV

−

−

−

−

−

−

−

−

−

−

−

−

−

−

noitcennocnoN

noitcennocnoN

noitcennocnoN

noitcennocnoN

XS-R9

)V5(ylppusrewoplatigiD

noitceleskcolcretsamA/D,D/A

)sf483:1,sf652:0(

).)OOCV(tuptuoOCVehttcennoC(

)V0(dnuorglatigiD

)V0.1(nipegatlovecnereferhcRD/A

)V0.1(nipegatlovecnereferhcLD/A

)V5.2(.pmaPOni-tliubfoegatlovsaiB

)V5(ylppusrewopgolanaD/A

)V0(dnuorggolanaD/A

)V5.2(dnuorggolanaD/A

)V5.1(dnuorggolanaA/D

)V0(dnuorggolanaA/D

)V5(ylppusrewopgolanaA/D

55

Page 56

XS-R9

COMPACT DISC PLAYER [PD-R9(S)]

HM514400CJ-7 (REAR ASSY : IC302)

• DRAM (4M BIT) IC

Pin Arrangement (Top view)

•

Pin Function

•

I/O1

I/O2

WE

RAS

A9

A0

A1

A2

A3

Vcc

1

2

3

4

5

6

7

8

9

10

Vss

20

I/O4

19

I/O3

18

CAS

17

16

OE

A8

15

A7

14

A6

13

A5

12

A4

11

.oNemaNniPnoitcnuF.oNemaNniPnoitcnuF

11O/I

22O/I215A

tuptuo/tupniataD

114A

3EWelbaneetirW/daeR316A

4SARebortssserddawoR417A

59A

518A

60A61EOelbanetuptuO

71A71SACebortssserddanmuloC

tupnisserddahserfeR/tupnisserddA

82A813O/I

93A914O/I

01CCVylppusrewoP02SSVdnuorG

tupnisserddahserfeR/tupnisserddA

tuptuo/tupniataD

56

Page 57

REMIX EFFECTOR [EF-R9(S)]

PD4867A (MAIN ASSY : IC601)

• DSP CONTROL µ-COM

Pin Arrangement (Top view)

•

XS-R9

BP2H

KEY1

KEY2

GND

NC

NC

Avref1

NC

TEST

NC

DISP SI

DISP SO

DISP CLK

NC

NC

NC

I2C DAT

I2C CLK

LED8

LED7

1

P15/AN15

2

P16/AN16

3

P17/AN17

4

Avss

5

P130/ANO0

6

P131/ANO1

7

Avref1

8

P70/SI2/RxD

9

P71/SO2/TxD

10

P72/SCK2/ASCK

11

P20/SI1

12

P21/SO1

13

P22/SCK1

14

P23/STB

15

P24/BUSY

16

P25/SI0/SB0/SDA0

17

P26/SO0/SB1/SDA1

18

P27/SCK0/SCL

19

P40/AD0

20

P41/AD1

BP2M

BP1H

80

79

P13/ANI3

P14/ANI4

P42/AD2

P43/AD3

22

21

LED5

LED6

BP2M

BP2L

777675

78

P11/ANI1

P12/ANI2

P45/AD5

P44/AD4

25

24

23

LED4

LED3

Avref0

Avdd

BP1L

74

AVdd

AVref0

P10/ANI0

PD4867A

P50/A8

P46/AD6

P47/AD7

27

26

NC

LED1

LED2

NC

NC

73

72

TX2

XT1/P07

P51/A9

P52/A10

28

29

NC

NC

X1

Vpp

71

70

X1

Vpp

P53/A11

31

30

NC

NC

VD5

X2

69

68

X2

Vdd

P54/A12

Vss

P55/A13

33

32

NC

GNDD

DSP1

DSP2

NC

67

66

656463

P05/INTP5

P06/INTP6

P04/INTP4

P56/A14

P57/A15

P60

36

35

34

NC

NC

NC

DSP3

DSP4

62

P03/INTP3

P02/INTP2

P61

P62

39

38

37

NC

NC

DSP CS

NC

61

RESET

P127/RTP7

P126/RTP6

P01/INTP1/TI01

P00/INTP0/TI00

P125/RTP5

P124/RTP4

P123/RTP3

P122/RTP2

P121/RTP1

P120/RTP0

P37

P36/BUZ

P35/PCL

P34/TI2

P33/TI1

P32/TO2

P31/TO1

P30/TO0

P67/ASTB

P66/WAIT

P65/WR

P63

P64/RD

40

NC

NC

60

RESET

59

JOGA

58

JOGB

57

1D1R

56

1DSP

55

2D2R

54

2DSP

53

AA1

52

BB1

51

INH1

50

HPMT

49

DSPR

48

AA2

47

BB2

46

INH2

45

PWR

44

DSPM

43

NC

42

NC

41

NC

Pin Function

•

No. Pin Function Pin Name I/O Function

1 P15/AN15 BP2H I CD2 music signal High-pass

2 P16/AN16 KEY1 I Key data input (A/D)

3 P17/AN17 KEY2 I Key data input

4 Avss GND – GND

5 P130/ANO0 –– – ––

6 P131/ANO1 –– – ––

7 Avref1 AVref1 – Connect to VD5V

8 P70/SI2/RxD –– – ––

9 P71/SO2/TxD TEST I L : test mode IN

10 P72/SCK2/ASCK –– – ––

11 P20/SI1 DISP SI I Display communication DATA IN

12 P21/SO1 DISP SO O Display communication DATA OUT

13 P22/SCK1 DISP CLK I Display communication CLK

14 P23/STB –– – ––

15 P24/BUSY –– – ––

16 P25/SI0/SB0/SDA0 –– – ––

17 P26/SO0/SB1/SDA1 I2C DATA O IIC DATA for DSP

18 P27/SCK0/SCL I2C CLK O IIC CLK for DSP

19 P40/AD0 LED8 O L : SAMPLER

20 P41/AD1 LED7 O L : OLD

21 P42/AD2 LED6 O L : KEYCON

22 P43/AD3 LED5 O L : FLANGER

23 P44/AD4 LED4 O L : PAN

24 P45/AD5 LED3 O L : ECHO

25 P46/AD6 LED2 O L : DELAY

57

Page 58

XS-R9

No. Pin Function Pin Name I/O Function

26 P47/AD7 LED1 O L : EFFECT ON

27 P50/A8 –– – ––

28 P51/A9 –– – ––

29 P52/A10 –– – ––

30 P53/A11 –– – ––

31 P54/A12 –– – ––

32 P55/A13 –– – ––

33 Vss GNDD – GND

34 P56/A14 –– – ––

35 P57/A15 –– – ––

36 P60 –– – ––

37 P61 –– – ––

38 P62 –– – ––

39 P63 –– – ––

40 P64/RD –– – ––

41 P65/WR –– – ––

42 P66/WAIT –– – ––

43 P67/ASTB –– – ––

44 P30/TO0 DSPM O H : DSP MUTE

45 P31/TO1 PWR O H : DSP power ON

46 P32/TO2 INH2 O H : HP MUTE

47 P33/TI1 BB2 O L : CD1 L : CD1 H : MUTE H : CD2 L : /2

48 P34/TI2 AA2 O L : CD1 L : CD1 H : MUTE H : CD2 L : /2

49 P35/PCL DSPR O L : DSP RESET

50 P36/BUZ HPMT O H : HP MUTE

51 P37 INH1 O H : MUTE

52 P120/RTP0 BB1 O L : REMIX H : CD1 L : MUTE H : CD2

53 P121/RTP1 AA1 O L : REMIX H : CD1 L : MUTE H : CD2

54 P122/RTP2 2DSP O L : CH2 DSP signal ON

55 P123/RTP3 2D2R O L : CH2 DIRECT signal ON

56 P124/RTP4 1DSP O L : CH1 DSP signal ON

57 P125/RTP5 1D1R O L : CH1 DIRECT signal ON

58 P126/RTP6 JOGB I Jog input

59 P127RTP7 JOGA I Jog input

60 RESET RESET – RESET

61 P00/INTP0/TI00 DSP CS I Display communication chip select

62 P01/INTP1/TI01 –– – ––

63 P02/INTP2 DSP4 O OLD sound output control

64 P03/INTP3 DSP3 O NC

65 P04/INTP4 DSP2 O DSP general purpose port connection

66 P05/INTP5 DSP1 I H : during sampler memory

67 P06/INTP6 –– – ––

68 Vdd VD5 – VD5V

69 X2 X2 – OSC (4.19MHz)

70 X1 X1 – OSC (4.19MHz)

71 Vpp Vpp – OSC (4.19MHz)

72 XT2 –– – ––

73 XT1/P07 –– – ––

74 AVdd AVdd – Connect to VD5V

75 AVref0 AVref0 – Connect to VD5V

76 P10/ANI0 BP1L I CD1 music signal Low-pass

77 P11/ANI1 BP2L I CD2 music signal Low-pass

78 P12/ANI2 BP2M I CD1 music signal intermediate-pass

79 P13/ANI3 BP2M I CD2 music signal intermediate-pass

80 P14/ANI4 BP1H I CD1 music signal high-pass

58

Page 59

REMIX CONTROL MIXER [MX-R9(S)]

PDG208A (MAIN ASSY : IC101)

• SYSTEM µ-COM

Pin Arrangement (Top view)

•

S12

S11

S10

S07

S09

S08

S13

S14

S15

S16

S17

S18

S19

S20

S21

S22

S23

S24

S25

S26

S27

S28

S29

S30

S31

S32

NC

NC

NC

XS-R9

LED6

Pin Function

•

S06

S05

S04

S03

S02

S01

G15

G14

Vdd

G13

G12

G11

G10

G09

G08

G07

G06

G05

G04

G03

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

80

1

GO2

79

2

GO1

77

78

3

4

Vdd

DISP CS

76

5

TAP

75

6

TEST

71

72

73

74

8

91011

7

GND

TEST

EFFECT JOG1

EFFECT JOG2

67

68

70

69

PDG208A

13

12

14

KI0

KI2

KI1

TEST

66

15

KI3

65

16

KI4

64

17

KI5

63

18

KI6

62

19

NC

61

20

NC

59

60

22

21

NC

DISP CLK

58

57

23

24

PAD SI

PAD SO

25

56

NC

55

26

NC

54

27

NC

53

28

AVref

52

29

CD1 LEVEL

.oNemaNniPO/InoitcnuF.oNemaNniPO/InoitcnuF

12OG

21OG12

3DDV

4SCPSIDI

OtuptuodirgLF

−

DDVottcennoC22KLCPSIDI noitacinummocyalpsidfokcolclaireS

tcelespihcnoitacinummocyalpsiD

)doirepnoitacinummocgnirud:L(

02

−−−

−−−

O)tuptuoL(CN

32ISDAPI

5PATI )NOyeK:L(tupniyekEPAT42OSDAPO

6TSETI )FFO/NOedomtseT:L(tupniedomtseT52

81GOJTCEFFEI 1tupniGOJTCEFFE72

−−−

−−−

O)tuptuoL(CN7DNGI DDNGottcennoC62

−−−

92GOJTCEFFEI 2tupniGOJTCEFFE82FERVAI retrevnocD/AfotupniegatlovecnerefeR

01TSETO)tuptuoL(CN92LEVEL1DCI LEVEL1DCfotupnigolanA

11TSETO)tuptuoL(CN03LEVEL2DCI LEVEL2DCfotupnigolanA

210IK

13TC1.FOPMETI 1redafopmetfotupnigolanapatretneC

311IK232.FSSORCI edis2edafssorctatupnigolanA

412IK331.FSSORCI edis1edafssorctatupnigolanA

513IK43TC2.FOPMETI 2redafopmetfotupnigolanapatretneC

ItupninruteryekdnanacsyeK

614IK531.FOPMETI 1redafopmetfotupnigolanA

715IK632.FOPMETI 2redafopmetfotupnigolanA

816IK73SSVA

91

−−−

O)tuptuoL(CN83TSRXI )teseR:L(tupniteseR

−

)DDNG

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

CD2 LEVEL

noitacinummoc

noitacinummoc

LED5

LED4

LED3

LED2

LED1

VFDP

Vdd

TEX

TX

Vss

XTAL

EXTAL

XRST

AVss

TEMPO F.2

TEMPO F.1

TEMPO F.2CT

CROSS F.1

CROSS F.2

TEMPO F.1CT

yalpsidfotupniatadlaireS

yalpsidfotuptuoatadlaireS

ottcennoc(retrevnocD/AfodnuorG

59

Page 60

XS-R9

.oNemaNniPO/InoitcnuF.oNemaNniPO/InoitcnuF

93LATXEI

04LATXO 1761S

14SSV

24XTOCN3741S

34XET

44DDV

54PDFV

641DELO )puthgil:H(lortnocDELYALP2DC7701S

742DELO )puthgil:H(lortnocDELEUC2DC8790S

843DELO

944DELO )puthgil:H(lortnocDELYALP1DC0870S

055DELO )puthgil:H(lortnocDELEUC1DC1860S

156DELO )puthgil:H(lortnocDELXIMER2850S

25

−−

35

−−

45

−−

5523S

6513S7851G

7503S8841G

8592S98DDV

9582S0931G

0672S1921G

1662S2911G

2652S3901G

3642S4990G

4632S5980G

5622S6970G

6612S7960G

7602S8950G

8691S9940G

9681S00130G

−

−

−

−

O)tuptuoH(CN

OtuptuotnemgesLF