Pioneer VSW-1 Service manual

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2004

POWER

VIDEO

OFF ON

FADER START MODE SELECTOR

AUTO

VSW-1

PAL NTS C

OFF

ON

BA

VIDEO SWITCHER

VSW-1

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Remarks

ORDER NO.

RRV3045

VSW-1

VSW-1

KUC

RYL

AC120V

AC110-120V/220-240V With the voltage selector

For details, refer to "Important Check Points for Good Servicing" .

T-ZZR NOV. 2004 printed in Japan

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains and certain electrical parts contain chemicals which are known to the state of California to cause cancer,

B

birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement

parts must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que

C

les pièces de remplacement doivent avoir la même désignation.

(FOR USA MODEL ONLY)

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

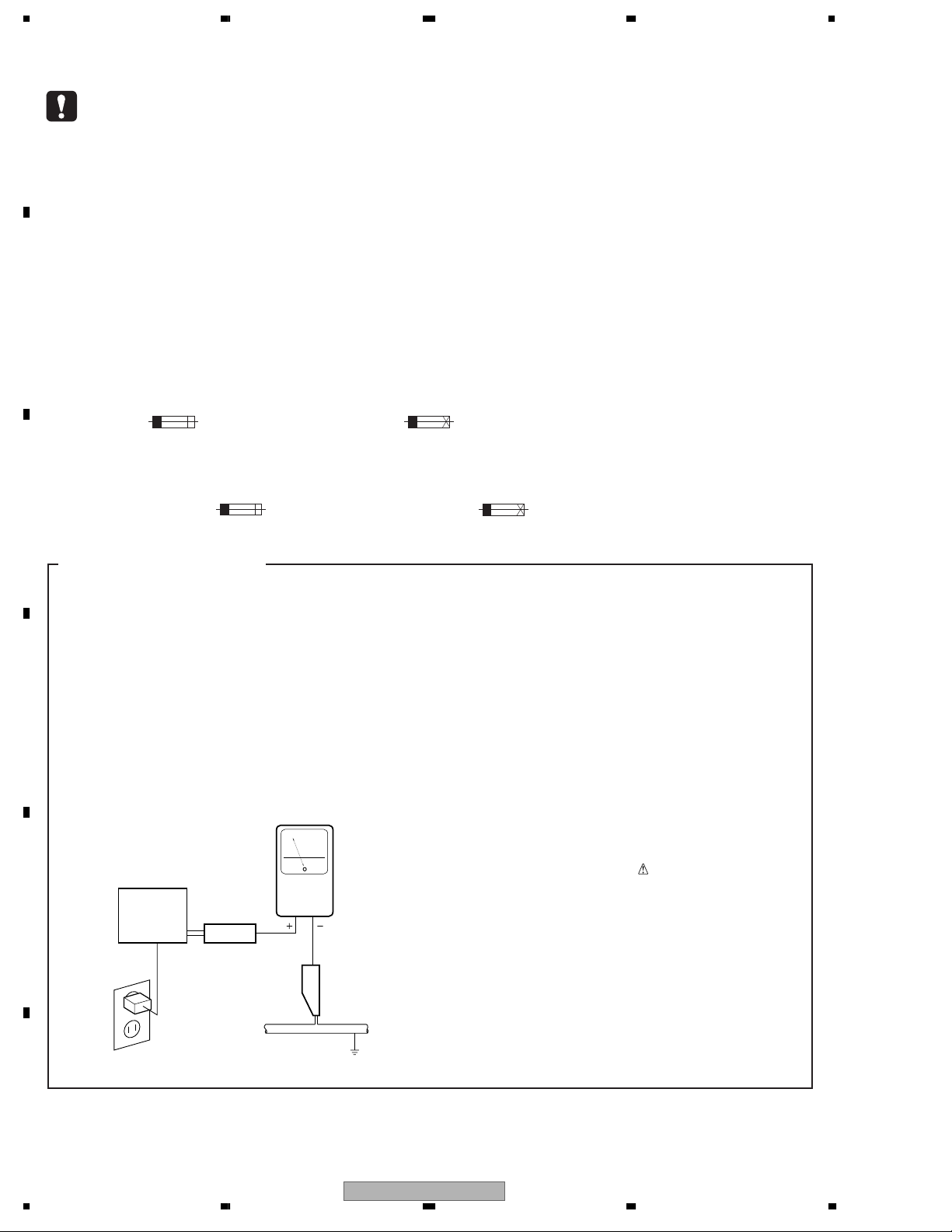

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

D

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

Leakage

current

E

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Test all

exposed metal

surfaces

AC Leakage Test

tester

Reading should

not be above

0.5 mA

Earth

ground

ANY MEASUREMENTS NOT WITHIN THE

LIMITS OUTLINED ABOVE ARE INDICATIVE

OF A POTENTIAL SHOCK HAZARD AND

MUST BE CORRECTED BEFORE RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the

protection afforded by them necessarily can be obtained

by using replacement components rated for voltage,

wattage, etc. Replacement parts which have these

special safety characteristics are identified in this

Service Manual.

Electrical components having such features are

identified by marking with a

on the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in the

parts list in this Service Manual, may create shock, fire,

or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER

Service Manual. A subscription to, or additional copies

of, PIONEER Service Manual may be obtained at a

nominal charge from PIONEER.

on the schematics and

F

2

1234

VSW-1

5678

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

A

B

C

D

56

VSW-1

E

F

3

7

8

CONTENTS

SAFETY INFORMATION..................................................................................................................................... 2

1. SPECIFICATIONS ............................................................................................................................................ 5

2. EXPLODED VIEWS AND PARTS LIST ............................................................................................................ 6

A

B

C

2.1 PACKING SECTION .................................................................................................................................. 6

2.2 EXTERIOR SECTION............................................................................................................................... 8

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM ..........................................................................................10

3.1 BLOCK DIAGRAM ................................................................................................................................... 10

3.2 OVERALL WIRING DIAGRAM................................................................................................................. 12

3.3 JACK (1/3) ASSY..................................................................................................................................... 14

3.4 JACK (2/3) ASSY..................................................................................................................................... 16

3.5 JACK (3/3) ASSY..................................................................................................................................... 18

3.6 PANL ASSY.............................................................................................................................................. 20

3.7 TRNS, PWSW and REG ASSYS............................................................................................................. 22

3.8 WAVEFORMS.......................................................................................................................................... 24

4. PCB CONNECTION DIAGRAM ..................................................................................................................... 26

4.1 JACK ASSY ............................................................................................................................................. 26

4.2 PANL ASSY.............................................................................................................................................. 30

4.3 TRNS, PWSB and REG ASSYS.............................................................................................................. 32

5. PCB PARTS LIST ........................................................................................................................................... 34

6. ADJUSTMENT ............................................................................................................................................... 36

7. GENERAL INFORMATION ............................................................................................................................. 37

7.1 DIAGNOSIS ............................................................................................................................................. 37

7.1.1 POWER ON SEQUENCE................................................................................................................... 37

7.1.2 DISASSEMBLY ................................................................................................................................... 38

7.2 IC ............................................................................................................................................................. 39

8. PANEL FACILITIES ........................................................................................................................................ 44

1234

D

E

F

4

1234

VSW-1

Specifications

1. General

Power ..........VSW-1/RYL:AC 110-120 V/AC 220-240V, 50/60 Hz

Power ........................................................ VSW-1/KUC : 120 V, 60 Hz

Power consumption ..................................

VSW-1/KUC : 8 W

Power consumption .....................................

VSW-1/RYL : 9 W

Operating temperature ....................................... +5°C to +35°C

Storage temperature ......................................... –40°C to +60°C

Operating humidity ..............5-85 % R.H. (without precipitation)

Weight .............................................................................. 1.4 kg

External dimensions ................. 250 (W) x 88 (D) x 87.5 (H) mm

(not including connectors, buttons and other protruding parts)

2. Video input section (input level/impedance)

Component video ................... BNC connectors x 3 (2 systems)

Y ...................................................................... 1 Vp-p / 75 Ω

C

B/PB............................................................. 0.7 Vp-p / 75 Ω

C

R/PR............................................................. 0.7 Vp-p / 75 Ω

S-Video ................................................ S connector (2 systems)

Y ...................................................................... 1 Vp-p / 75 Ω

C ............................................................... 0.286 Vp-p / 75 Ω

Composite video ............................ RCA connector (2 systems)

1 Vp-p / 75 Ω

3. Video output section (output level/impedance)

Component video ..................... BNC connectors x 3 (1 system)

Y ...................................................................... 1 Vp-p / 75 Ω

C

B/PB............................................................. 0.7 Vp-p / 75 Ω

C

R/PR............................................................. 0.7 Vp-p / 75 Ω

S-Video .................................................. S connector (1 system)

Y ...................................................................... 1 Vp-p / 75Ω

C ............................................................... 0.286 Vp-p / 75Ω

Composite video .............................. RCA connector (1 system)

1 Vp-p / 75Ω

4. Sync signal output section

Sync output .................................... BNC connector (2 systems)

Supported video modulation systems ....................... NTSC/PAL

5. Other connectors

Control input ................................... minijack (3.5 dia) 2 systems

Control output ................................ minijack (3.5 dia) 2 systems

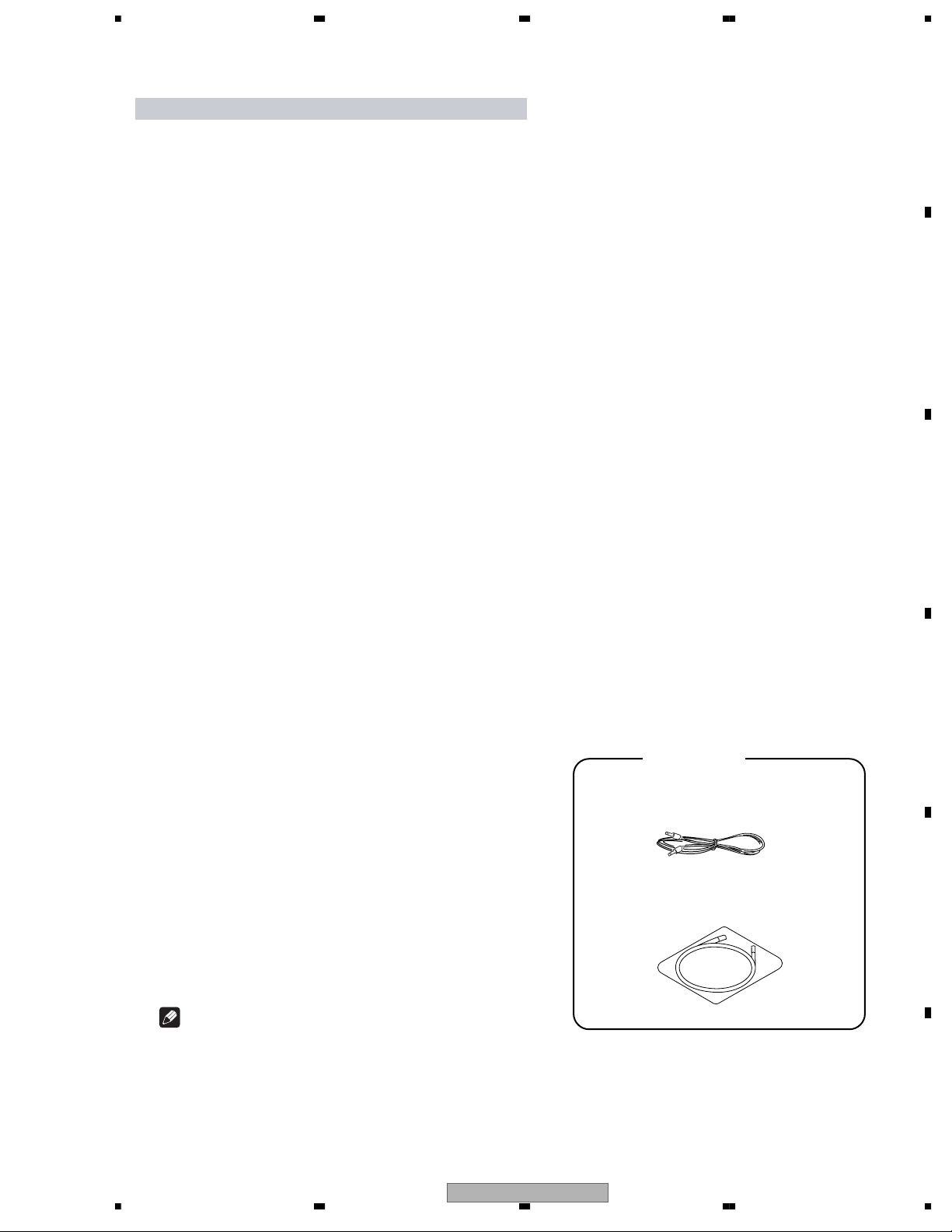

6. Accessories

¶ BNC cables.......................................................................... 2

¶ Control cables...................................................................... 2

¶ Operating Instructions ......................................................... 1

For improvement purposes, specifications and design may

besubject to modification without notice.

Note

•

The specifications and design of this

product are subject to change without

notice, due to improvement.

Control Cables

(ADE7108) L=1 m

BNC Cable

(DDE1126) L=1.5 m

Accessories

5678

1. SPECIFICATIONS

A

B

C

D

E

56

VSW-1

F

5

7

8

1234

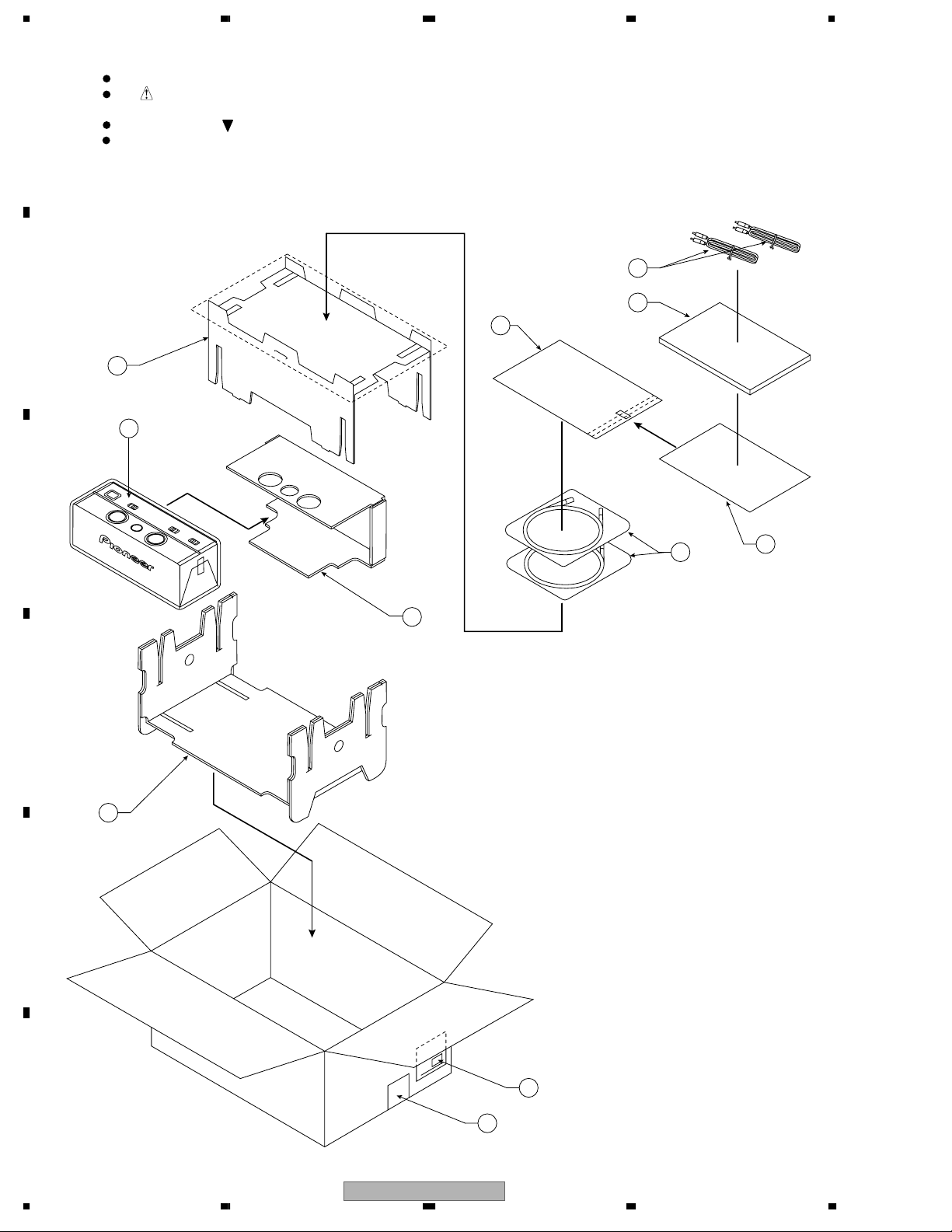

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

A

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

2.1 PACKING SECTION

B

12

9

C

3

1

8

2

10

D

11

E

7

14

F

6

1234

VSW-1

13

5678

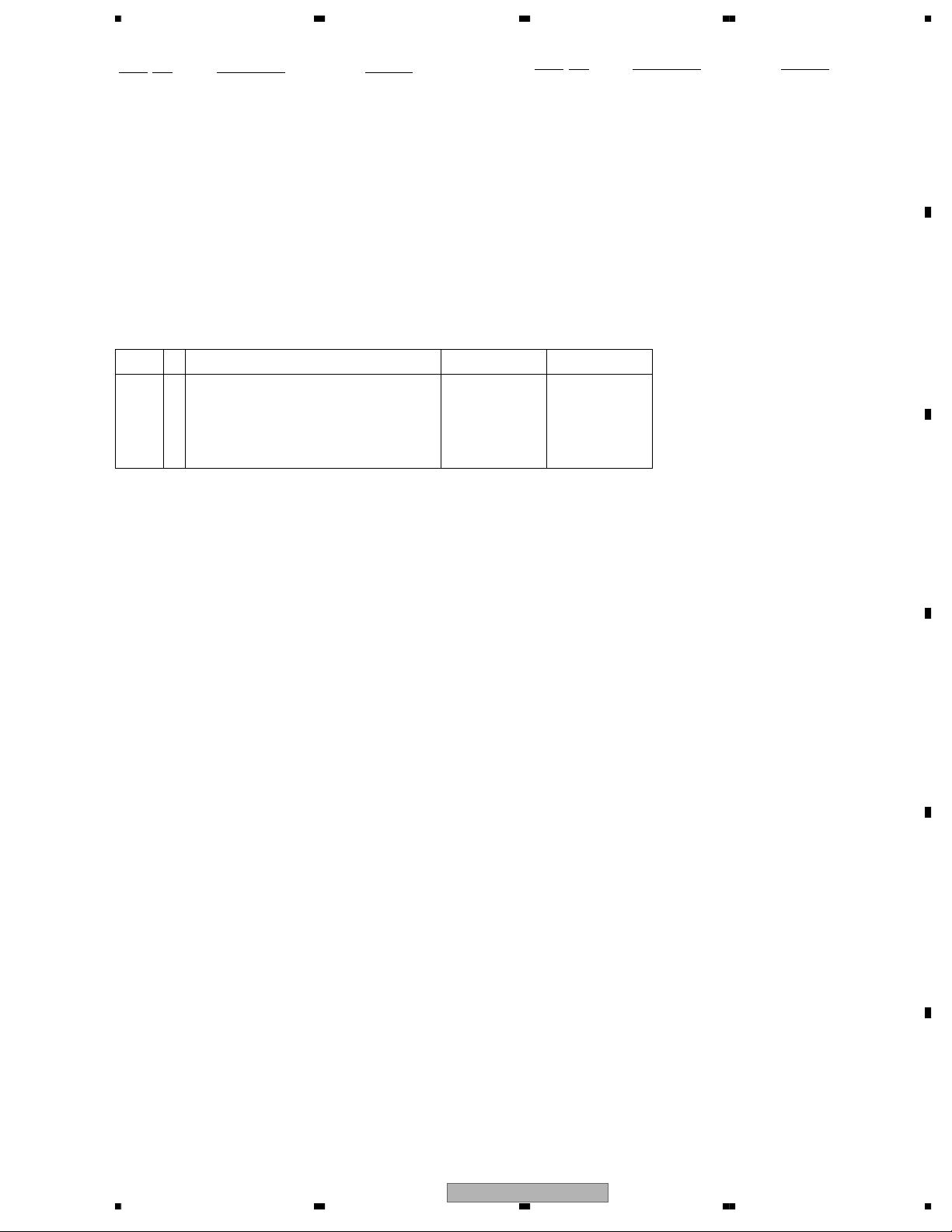

PACKING SECTION parts List

No. Description Part No.

Mark

1 Instruction Manual See Contrast table (2)

2 BNC Cable DDE1126

3 Cord With Mini Plug ADE7108

4• • • •

5• • • •

6• • • •

7Warranty Card See Contrast table (2)

NSP 8 Polyethylene Bag AHG7117

(0.06x230x340)

9Packing Sheet DHX1008

No. Description Part No.

Mark

10 Pad A DHA1629

11 Pad B DHA1630

12 Pad C DHA1631

13 Packing Case See Contrast table (2)

14 Label VRW1629

A

(2) CONTRAST TABLE

VSW-1/KUC and VSW-1/RYL are constructed the same except for the following :

Mark No. Symbol and Description VSW-1/KUC VSW-1/RYL

Instruction Manual (German, French,

1

Duch, Italian, Spanish, Swedish, Chinese)

1 Instruction Manual (English)

Warranty Card ARY7043

7

Packing Case

13

Not used DRB1375

DRB1374 Not used

Not used

DHG2486 DHG2487

B

C

D

56

VSW-1

E

F

7

7

8

1234

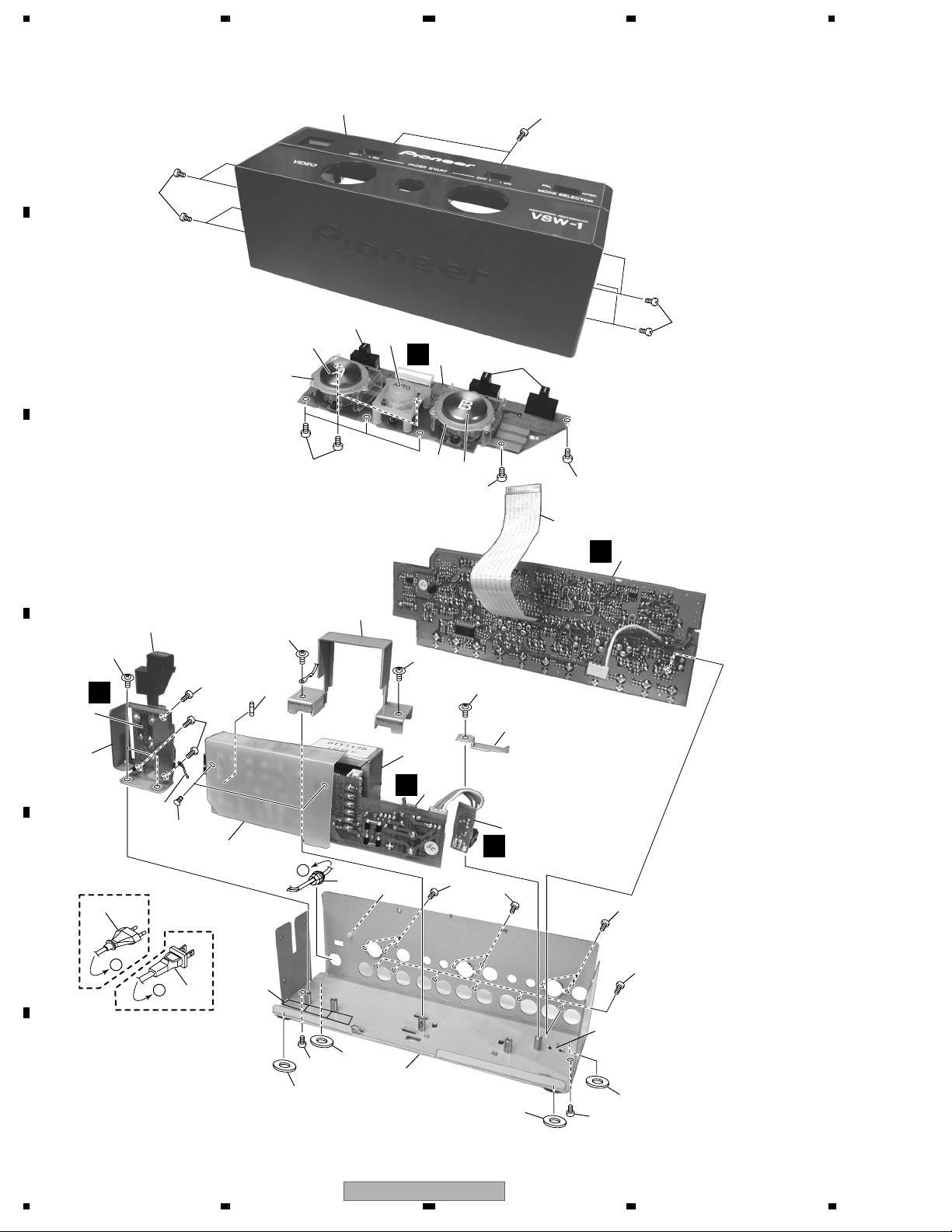

2.2 EXTERIOR SECTION

7

28

6

10

9

B

1

11

8

28

A

27

B

11

C

10

27

12

28

A

27

2

28

22

25

14

26

24

C

13

29

29

15

4

5

E

30

30

30

27

32

25

25

28

17

29

27

D

D

E

F

3

18

RYL type only

23

A

19

21

KUC type only

A

23

27

20

29

16

A

33

25

8

1234

VSW-1

>

5678

EXTERIOR SECTION parts List

No. Description Part No.

Mark

1PANL Assy DWS1357

2JACK Assy DWG1589

3 PWSB Assy DWS1358

4 TRANS Assy See Contrast table(2)

5 REG Assy DWR1396

6 Control Panel DNK4367

7 Select Knob (A) Assy DXB1835

8 Select Knob (B) Assy DXB1836

9AUTO Knob DNK4365

10 Slide Knob DNK4368

11 Ring Lens DNK4252

12 Flexible Cable 20P DDD1271

> 13 Power Transformer See Contrast table(2)

14 Trans Support DNH2632

15 Regulator Support DNH2633

> 16 FU1 Fuse See Contrast table(2)

17 POWER Knob DNK4366

18 SW Bracket DNH2631

No. Description Part No.

Mark

NSP 19 Binder ZCB-4772B

20 Shield Sheet DEC2732

21 Nylon Rivet RBM-003

22 Cord Stopper See Contrast table(2)

> 23 AC Power Cord See Contrast table(2)

NSP 24 Chassis See Contrast table(2)

25 Insulator DEC2734

26 Hole Plug AEC7040

27 Screw BBZ30P100FTB

28 Screw BPZ30P080FTC

29 Screw AMZ30P060FTC

30 Screw BPZ26P080FTC

31 • • • •

32 Contact Sheet DEC2733

33 Caution Label See Contrast table(2)

A

B

(2) CONTRAST TABLE

VSW-1/KUC and VSW-1/RYL are constructed the same except for the following :

Mark No. Symbol and Description VSW-1/KUC VSW-1/RYL

TRANS Assy

>

>

>

4

13 Power Transformer

Fuse (FU1 : 125mA) DEK1090

16

Fuse (FU1 : 80mA) Not used

16

Cord Stopper

22

AC Power Cord

23

Chassis

24

Caution Label

33

DWR1395 DWR1397

DTT1174 DTT1175

Not used

DEK1089

CM-22C CM-22B

ADG7024 VDG1061

DNH2630 DNH2634

DRW2251 DRW2252

C

D

E

56

VSW-1

F

9

7

8

1234

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

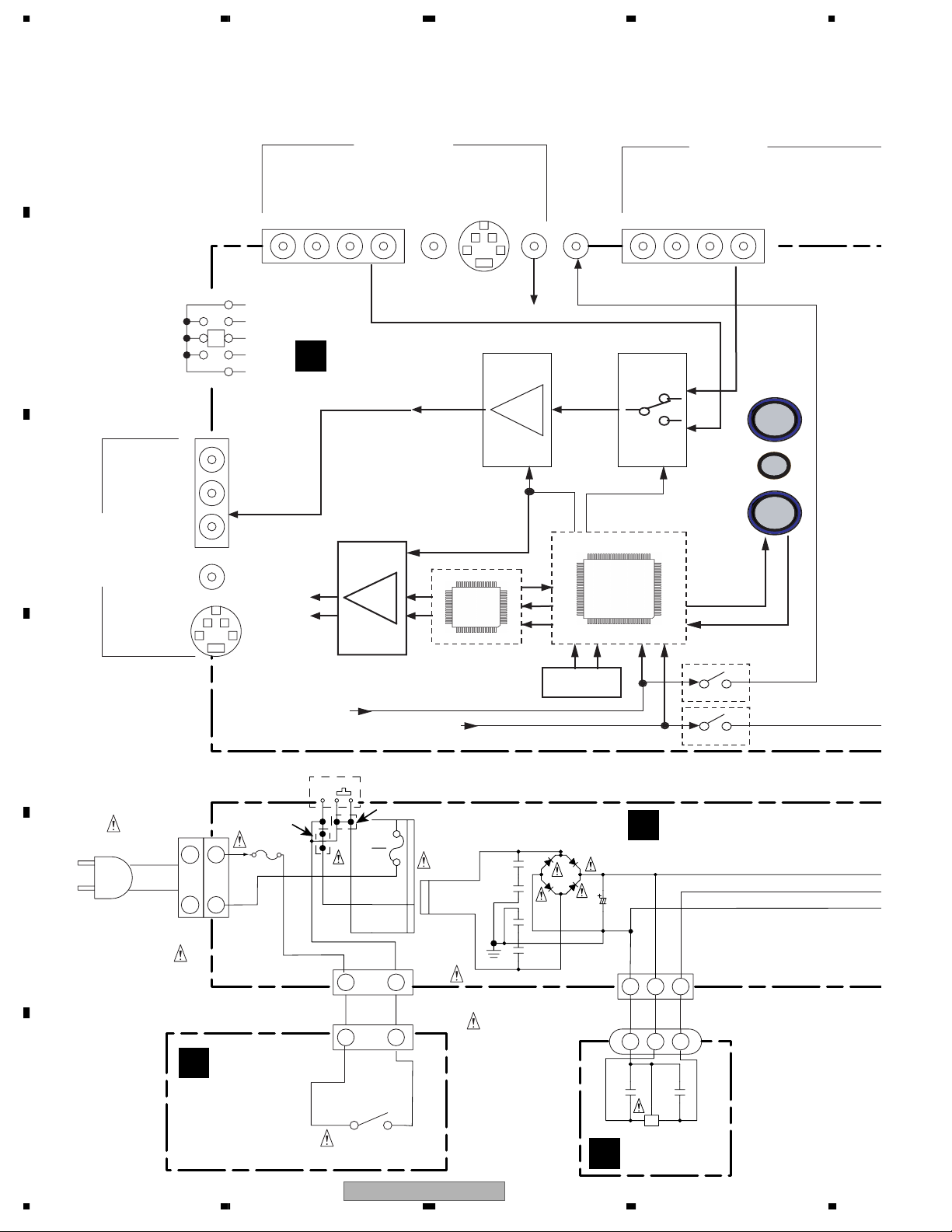

3.1 BLOCK DIAGRAM

A

PLAYER A

R R

B B

Y

C /P

INPUT

SELECTOR

B

COMPONENT

COMPOSITE

S VIDEO

S101

DSH1054

CC

JA207

DKB1062

JACK ASSY

A

C /P

SYNC

COMPOSITE

JA201

S VIDEO

JA205

DKB1064

Video amplifier

DKB1063

# A

NJM2573

+6dB

CONT PL A

DKN1371

JA102

CONT MX A

JA101

DKN1371

Video system select

Y

NJM2284

/NJM2285

B B

C /P

JA208

DKB1062

PLAYER B

R R

C /P

SYNC

B

Y

C /P

C

OUTPUT

COMPOSITE

D

B B

C /P

R R

S VIDEO

JA209

DKB1061

JA203

DKB1064

JA204

DKB1063

Video amplifier

NJM2573

+6dB

# A

Power save

SYNC-GENERATOR

BU1427KV

Chroma phase correction

START CUE-BACK

# B

PAL/NTSC

START CUE-BACK

A/B Switching

Set SW

The control MCU

PEG098A

AUTO

A

LED Control

SwitchingSW

Fader ON/OFF

Fader

ON/OFF

DSA1026

/RYL Only

AC CORD

AC IN

E

LL

NN

D

F

FU1

2

1

CN2

RKP1751

PWSB ASSY

10

1234

S2

2

DSA1029

S1

/RYL Only

/KUC Only

12

1

POW SW

VSW-1

T1:P.T.

B2P3-VH

CN3

DKP3727

J2

0.1

C11 C5

0.1

D1

C6

0.1

C12

0.1

D4

D3

D2

C

10000/16

CCH1412-

C7

GND

123

123

C8

E

REG ASSY

TRNS ASSY

CN5

5V

UNREG

S3B-EH

PF03EN-D05

J6

0.1

BA05T

IC1

0.1

C9

5678

A

S VIDEO

COMPOSITE

CONT MX B

CONT PL B

PANL ASSY

B

JA202

JA206

DKB1064

DKB1063

GND

V+5

GND

VLED

2314

J100

PF04EN-D20

1324

CN4

S4B-EH

JA104

# B

JA103

DKN1371

CN102

52492-2020

DKN1371

10

12

14

16

18

20

CN301

DDD1271

1

2

3

4

5

6

7

8

9

11

13

15

17

19

52492-2020

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

A-FS1IN

A-FS2IN

A-FS1OUT

A-FS2OUT

A-SW

B-SW

AUTOSW

XPALSW

XLEDA

XLEDB

LEDAT

VLED

VLED

V+5D

GNDD

GNDD

B-FS1IN

B-FS2IN

B-FS1OUT

B-FS2OUT

Q302

AUTO

Q314-Q317

Q301

Ch.A

Q304-Q308

Q303

Ch.B

Q309-Q313

S301

DSG1079

S303

DSG1079

S302

DSG1079

S306

DSH1055

S304

DSH1055

S305

DSH1055

A

AUTO

B

NTSC/PAL

FADER

START A

ON/OFF

FADER

START B

ON/OFF

B

C

D

56

VSW-1

E

F

11

7

8

1234

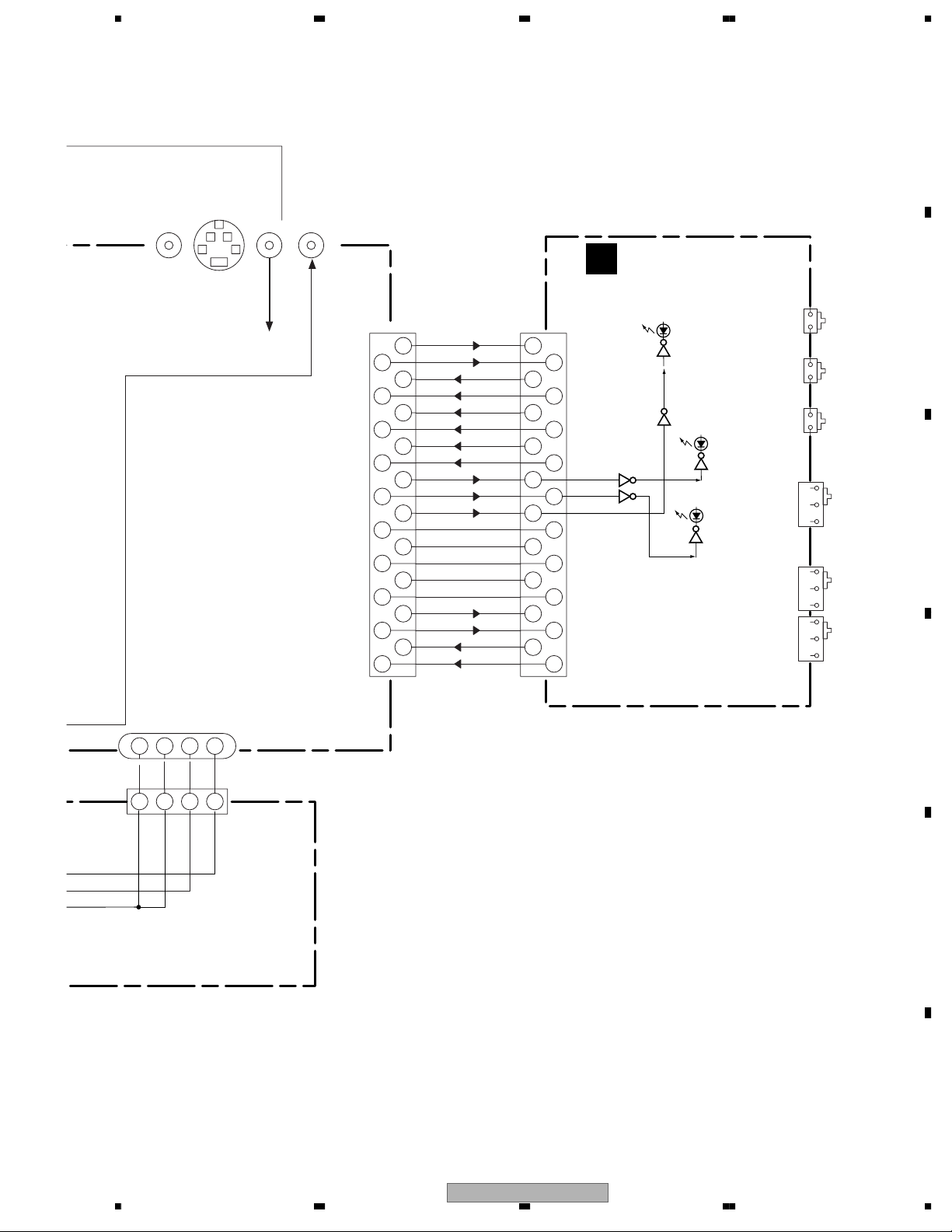

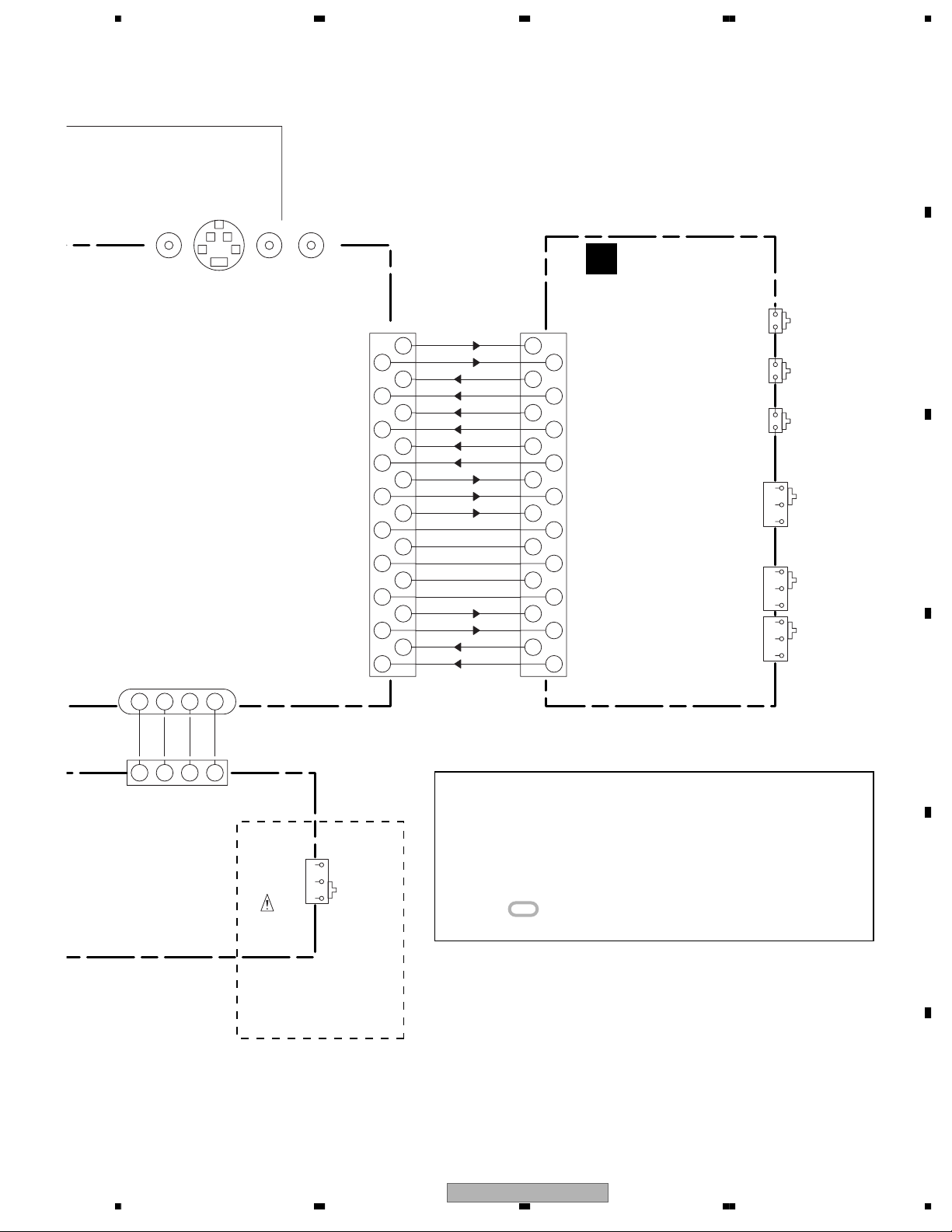

3.2 OVERALL WIRING DIAGRAM

A

Y

C /P

JA207

DKB1062

B

C

COMPONENT

COMPOSITE

INPUT

SELECTOR

S VIDEO

C /P

B B

C /P

R R

S101

DSH1054

CC

Y

JA209

DKB1061

B B

PLAYER A

R R

C /P

SYNC

JA205

DKB1064

A

S VIDEO

JA102

DKB1063

CONT PL A

JA101

DKN1371

A 1/3 - A 3/3

COMPOSITE

JA201

JACK ASSY (DWG1589)

CONT MX A

DKN1371

C /P

Y

JA208

DKB1062

PLAYER B

R R

B B

C /P

SYNC

D

E

F

OUTPUT

COMPOSITE

S VIDEO

AC CORD

/KUC:ADG7024

/RYL:VDG1061

JA203

DKB1064

JA204

DKB1063

TRNS ASSY

C

LL

NN

2

RKP1751

1

CN2

PWSB ASSY

D

(DWS1358)

T1:P.T.

12

DSA1029

S1

POW SW

21

(/KUC : DWR1395)

(/RYL : DWR1397)

/KUC : DDT1174

/RYL : DTT1175

B2P3-VH

CN3

DKP3727

J2

GND

123

123

REG ASSY

E

(DWR1396)

FU1

/KUC : DEK1090

T125mAL250V

/RYL : DEK1089

T80mAL250V

5V

UNREG

CN5

S3B-EH

PF03EN-D05

J6

12

VSW-1

1234

5678

S VIDEO

COMPOSITE

JA202

GND

2314

DKB1064

V+5

GND

JA206

DKB1063

VLED

J100

PF04EN-D20

CONT PL B

JA103

JA104

DKN1371

CONT MX B

DKN1371

CN102

52492-2020

10

12

14

16

18

20

A

PANL ASSY

B

(DWS1357)

CN301

DDD1271

1

2

3

4

5

6

7

8

9

11

13

15

17

19

52492-2020

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

A-FS1IN

A-FS2IN

A-FS1OUT

A-FS2OUT

A-SW

B-SW

AUTOSW

XPALSW

XLEDA

XLEDB

LEDAT

VLED

VLED

V+5D

GNDD

GNDD

B-FS1IN

B-FS2IN

B-FS1OUT

B-FS2OUT

S301

DSG1079

S303

DSG1079

S302

DSG1079

S306

DSH1055

S304

DSH1055

S305

DSH1055

A

AUTO

B

NTSC/PAL

FADER START A

ON/OFF

FADER START B

ON/OFF

B

C

D

1324

CN4

S4B-EH

/RYL Only

VOLTAGE

SELECTOR

NOTES: • When ordering service parts, be sure to refer to “EXPLODED

VIEWS and PARTS LIST” or “PCB PARTS LIST”.

• The > mark found on some component parts indicates the

importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical

designation.

S2

DSA1026

110-120V / 220-240V

• : The power supply is shown with the marked box.

VSW-1

56

E

F

13

7

8

1234

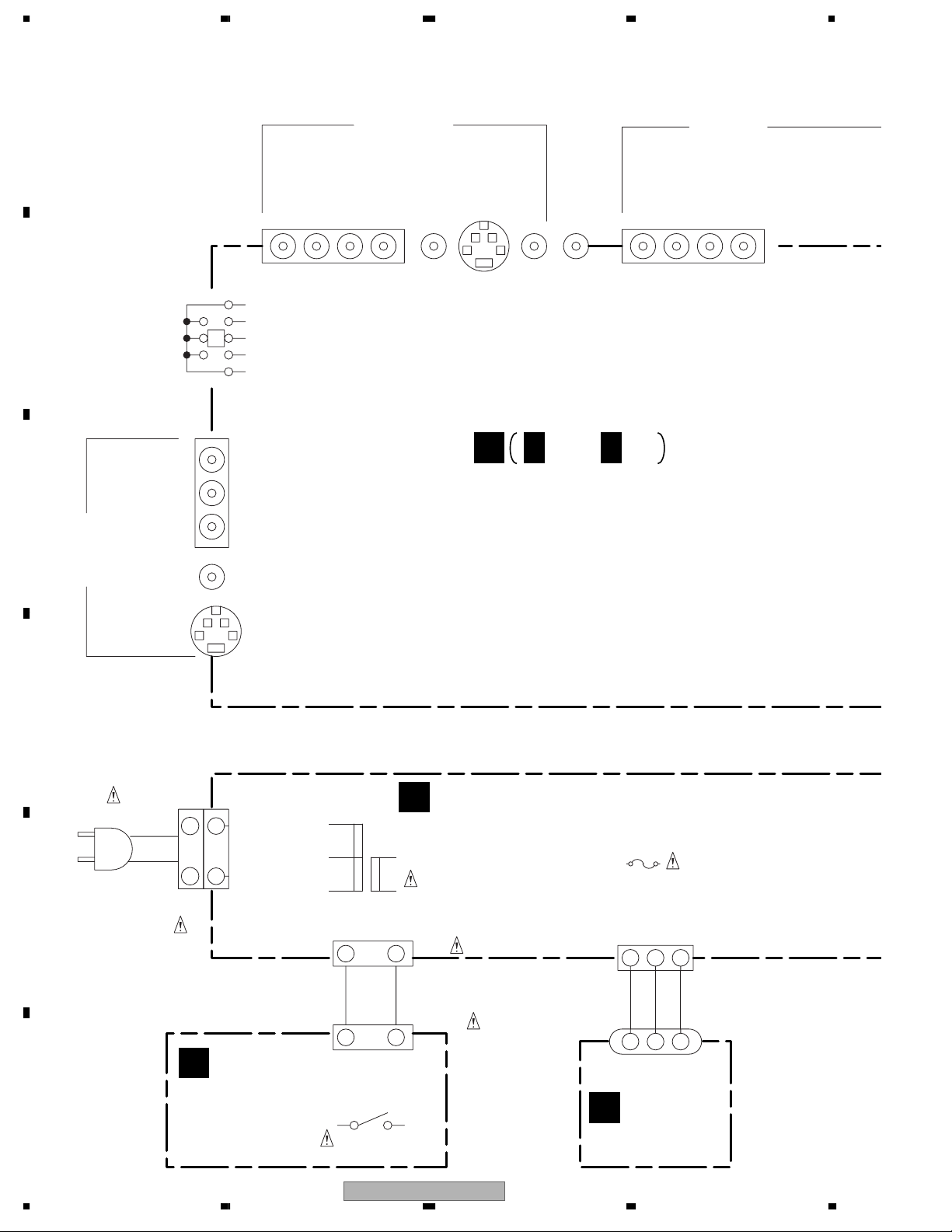

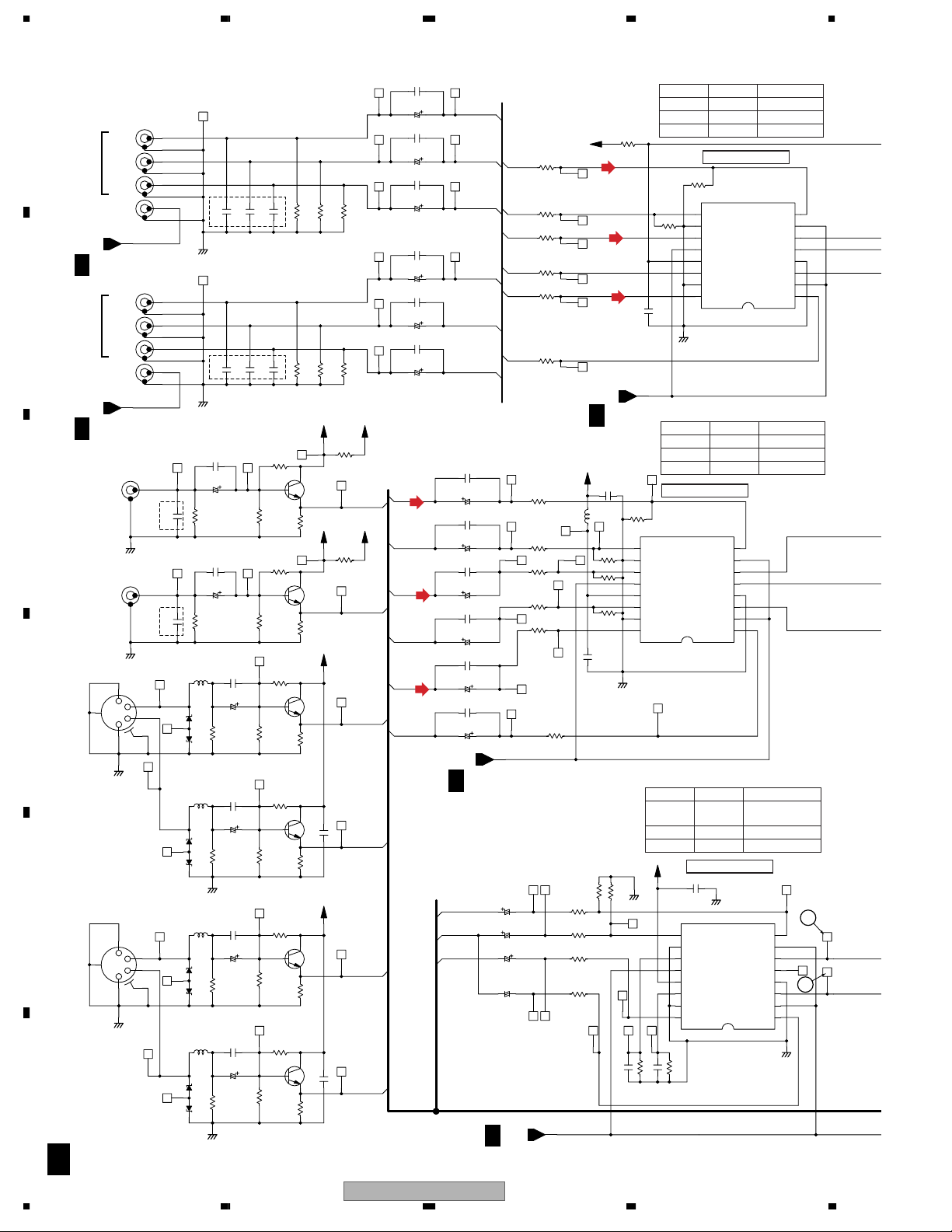

3.3 JACK (1/3) ASSY

A

B

C

D

E

F

COMPONENT

IN A

COMPONENT

IN B

COMPOSITE

S VIDEO

IN A

S VIDEO

IN B

A

14

SYNC A

SYNCA

A

2/3

SYNC B

SYNCB

A

2/3

COMPOSITE

IN A

IN B

JA205

GNDV

(A-SCIN)

JA206

DKB1063

(B-SCIN)

1/3

Y

C /P

R R

C /P

B B

Y

C /P

R R

C /P

B B

JA201

DKB1064

GNDV

JA202

DKB1064

GNDV

GNDV

JA207

DKB1062

JA208

DKB1062

(B-CMPIN)

(A-SYIN)DKB1063

(B-SYIN)

(A-CMPIN)

C130

C131

VTL1077

UDZS6R2(B)

UDZS6R2(B)

UDZS6R2(B)

VTL1077

UDZS6R2(B)

GNDV

GNDV

C140

0.01

C270

100/10

75F

R213

C141

0.01

C271

100/10

75F

R215

L59 C142

D110

D111

VTL1077

UDZS6R2(B)

L60 C143

75F

D112

R229

D113

GNDV

L61 C144

D116

D117

VTL1077

UDZS6R2(B)

D126

D127

GNDV

UDZS6R2(B)

UDZS6R2(B)

C119

C122

0.01

75F

R227

0.01

0.01

75F

R245

0.01

75F

R247

C282

100/10

C283

C253

100/10

C145L62

C254

STBY

STBY

10/16

10/16

C120

C123

R214

R216

R228

R230

R246

R248

C121

C124

33k

33k

33k

33k

R235

33k

33k

R217

R219

R231

R233

R250

20k

B

Q201

20k

B

Q202

20k

B

Q203

20k

B

Q204

20k

B

Q205

20k

B

Q206

R201

R210

R218

R220

R232

R234

R249

R251

(A-YIN)

(A-CrIN)

(A-CbIN)

75F

75F

75F

2SC4081(QRS)

C

E

2SC4081(QRS)

C

E

2SC4081(QRS)

C

E

2SC4081(QRS)

C

E

2SC4081(QRS)-TLB

C

E

2SC4081(QRS)-TLB

C

E

75F

R202

R203

(B-YIN)

(B-CrIN)

(B-CbIN)

75F

75F

R211

R212

V5VA

R557

0

A-CMP

1k

V+5V

V5VB

R558

0

B-CMP

1k

V5VA

A-SY

1k

C208

0.01

A-SC

1k

V5VB

B-SY

1k

C209

0.01

B-SC

1k

V+5V

C201

0.01

C256

C202

0.01

C257

C203

0.01

C258

C204

0.01

C259

C205

0.01

C260

C216

0.01

C269

A-CMP

B-CMP

A-SY

B-SY

A-SC

INSCMP

B-SC

2.2/50

10/16

10/16

2.2/50

10/16

10/16

C292

C293

C294

C295

C296

C268

C297

C272

10/16

10/16

10/16

10/16

XA/B

A

A-SY

A-CMP

A-SC

A-Y

A-CR

A-CB

B-Y

B-CR

B-CB

0.01

C261

0.01

C262

0.01

C263

0.01

C264

0.01

10/16

0.01

10/16

3/3

10/16

10/16

A

INYUV

C227

C230

C231

2

10/16

NP

3/3

A-Y

B-Y

A-CR

B-CR

A-CB

B-CB

10/16

C237

R526

R521

R523

1

R553

R552

R548

R549

R550

R551

R522

R524

R525

CP/XYC

PIN No Voltage

IC211

2, 7, 12 0V Ach SELECT

4, 10, 15 0V

R504

V+5V

0

(Y)

0

0

(Cr)

0

0

(Cb)

0

0

XA/B

A

3/3

IC202

V+5V

C45

0.1

0

0

R132

0

0

0

0

L14

0.1

C218

100k

100k

100k

R131

R133

GNDV

R134

10

11

12

13

14

15

16

13 4.74V

VIDEO SWICH

R143

100k

IN3B IN3A

9

R144

100k

0.1

C195

GND3

10

IN2A OUT3

11

CTL2

12

V+

13

IN2B

14

GND1

15

IN1A IN1B

16

NJM2284V

GNDV

PIN No Voltage

2, 7, 12 0V Ach SELECT

4, 10, 15 0V

13 4.74V

VIDEO SWICH

100k

IC202

IN3B

9

GND3

IN2A

CTL2

V+

IN2B

GND1

IN1A

NJM2285V

IN3A

CTL3

OUT3

OUT2

GND2

OUT1

CTL1

IN1B

IC203 PIN No Voltage

R527

R528

R529

R530

2 , 7, 12 0V

4, 10, 15 0V

R135

R136

100k

100k

GNDV

0

0

0

0

0.1

1M

C180

C181

R137

4.67V

13 4.75V

VIDEO SWICH

V+5V

C225

0.1

IN3B

9

GND3 CNT3

10

IN2A

11

CTL2 OUT2

12

V+

13

IN2B

14

GND1

15

IN1A IN1B

16

1M

0.1

R138

IC203

NJM2285V

8

7

6

5

4

3

2

1

S101 : S VIDEO

: Other

GNDV

OUT3

GND2

IC211

Condition

IN3A

OUT1

CNT1

Condition

CTL3

OUT2

GND2

OUT1

CTL1

Condition

8

7

6

5

4

3

2

1

GNDV

8

7

6

5

4

3

2

1

13

14

VSW-1

1234

Loading...

Loading...