Pioneer DVDVP-8000 Service manual

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2006

ORDER NO.

RRV3389

DVD-V8000

DVD PLAYER

DVD-V8000

RACK MOUNT KIT

CB-A802

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Region No. Remarks

DVD-V8000 KUCXJ AC120 V 1

DVD-V8000 WYXJ5 AC 220 V to 240 V 2

CB-A802 XJ/WL5

–

XJ/WL5

For details, refer to "Important symbols for good services".

T-ZZR JULY 2006 printed in Japan

-

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians ; it is not meant for the casual do-it

yourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

causecancer, birth defects or other reproductive harm.

B

(FOR USA MODEL ONLY)

Health & Safety Code Section 25249.6 – Proposition 65

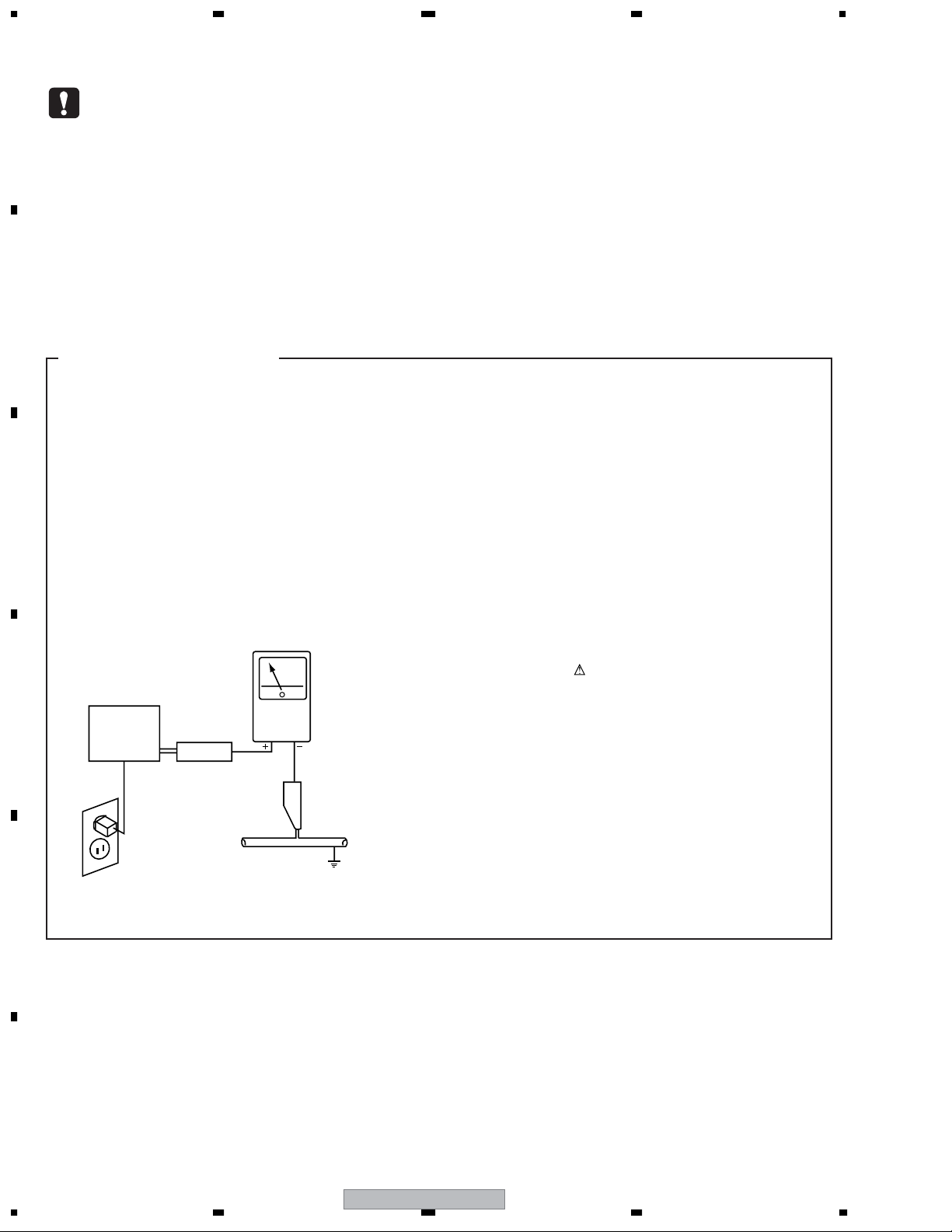

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and

service technician.

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground (waterpipe

C

D

, conduit, etc.) by connecting a leakage current tester

such as Simpson Model 229-2 or equivalent between the

earth ground and all exposed metal parts of the appliance

(input/output terminals, screwheads, metal overlays, control

shaft, etc.). Plug the AC line cord of the appliance directly

into a 120V AC 60Hz outlet and turn the AC power switch

on. Any current measured must not exceed 0.5mA.

Reading should

not be above

0.5mA

Earth

ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Test all

exposed metal

surfaces

Leakage

current

tester

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are identified

by marking with a on the schematics and on the parts list

in this Service Manual.

The use of a substitute replacement component which does

not have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in

this Service Manual, may create shock, fire, or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of, PIONEER

Service Manual may be obtained at a nominal charge

from PIONEER.

E

F

2

1234

AC Leakage Test

DVD-V8000

-

5 678

This service manual is intended for qualified service technicians ; it is not meant for the casual do-it

yourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

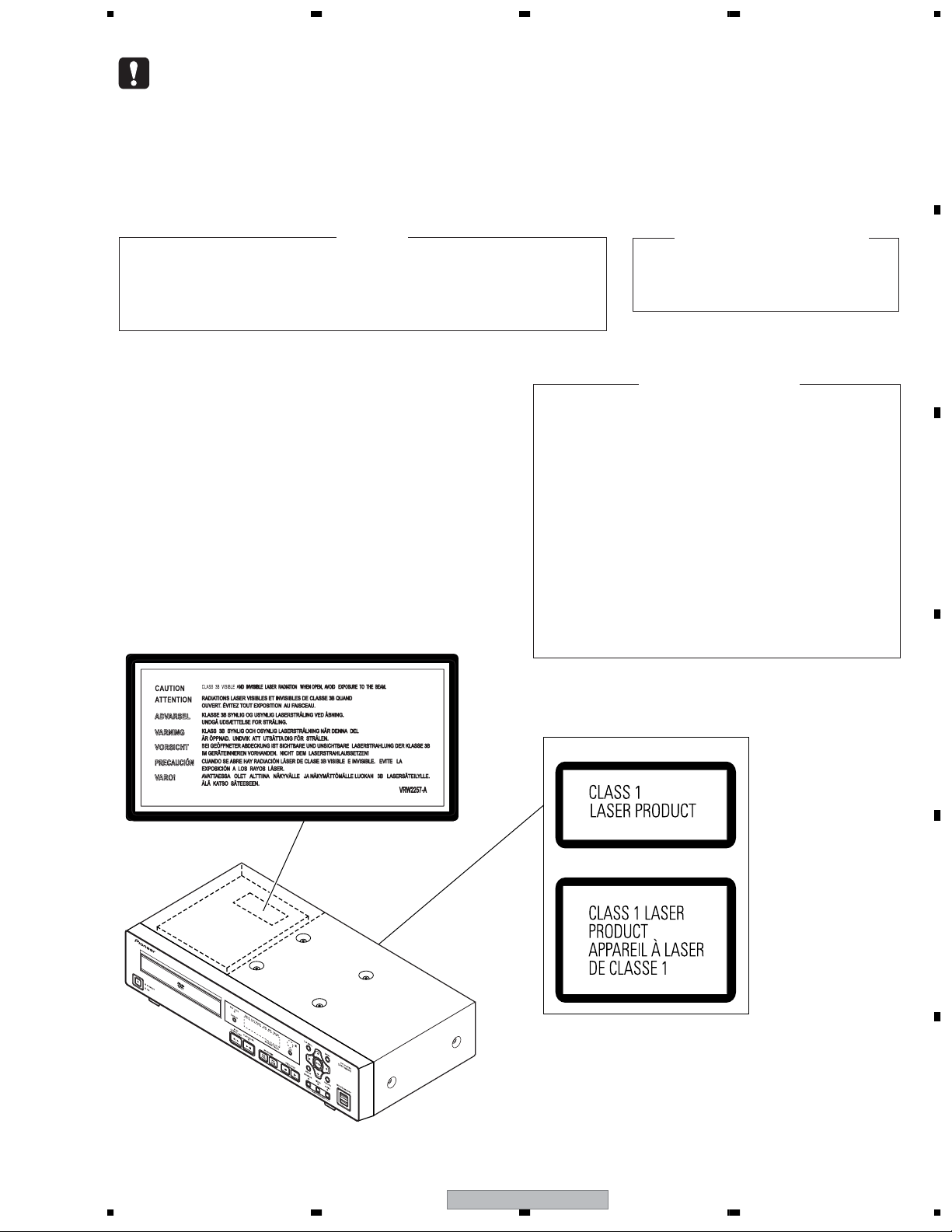

WARNING !

THE AEL (ACCESSIBLE EMISSION LEVEL) OF THE LASER POWER OUTPUT IS LESS THAN

CLASS 1 BUT THE LASER COMPONENT IS CAPABLE OF EMITTING RADIATION EXCEEDING

THE LIMIT FOR CLASS 1.

A SPECIALLY INSTRUCTED PERSON SHOULD DO SERVICING OPERATION OF THE

APPARATUS.

LASER DIODE CHARACTERISTICS

FOR DVD : MAXIMUM OUTPUT POWER : 5 mW

WAVELENGTH : 650 nm

FOR CD : MAXIMUM OUTPUT POWER : 7 mW

WAVELENGTH : 780 nm

LABEL CHECK

Additional Laser Caution

1. Loading-status detection switch (S101 on the LOAB assy) are detected

by the microprocessor (IC601 in the DVDM assy).

• To permit the laser diode to oscillate, it is required to set the loadingstatus detection switch for the clamp position (the center terminal of

S101 is shorted to +3V).

When the voltage of IC101-pin 21 is +3V, IC601 (microprocessor)

-pin 83 is +3V and IC601-pin 84 is +3V, 650nm laser diode for DVD

oscillates in the DVDM Assy.

When the voltage of IC101-pin 21 is +3V, IC601 (microprocessor)

-pin 83 is 0V (GND) and IC601-pin 84 is +3V, 780nm laser diode for

CD oscillates in the DVDM Assy.

In the test mode * , the laser diode oscillates when microprocessor

detects a PLAY signal, or when the PLAY key is pressed (S9043 ON in

the KEYB assy), with the above requirements satisfied.

A

B

C

2. When the cover is open, close viewing through the objective lens with

the naked eye will cause exposure to the laser beam.

∗ : See page 87.

(Printed on the Rear Panel)

WYXJ5

KUCXJ

D

E

56

DVD-V8000

F

7

8

3

1234

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

A

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

B

C

D

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

E

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

F

4

1234

DVD-V8000

5 678

¶ Steps to be taken during repair

The steps and care to be taken when Assys are replaced for repair or inspection are described here.

First, copy the user setting data to a USB memory device.

Before repair, inspection, or downloading of the firmware, the files indicated below must be copied to a USB memory device

just in case the user setting data are accidentally reset to default:

• SETUP menu and ADV. SETUP menu (***.set): SAVE SETUP

• Command stack (***.cmd): SAVE COMMAND STACK

The Error History must be also copied to a USB memory device. (Data on the serial number and accumulated playback

time will also be obtained.)

• Error History (***.err): SAVE ERROR LOG

For detailed operation, see the operating instructions.

When the pickup or the part that contains the pickup, such as the Traverse mechanism, is to be replaced

• For replacement, follow the procedures described in "7.6 DISASSEMBLY."

• For adjustment, follow the procedures described in "6. ADJUSTMENT."

• Perform only "How to reset playback time B" in "7.1.7."

When the POWER SUPPLY Unit is to be replaced

• Perform only "How to reset Power-on time B" in "7.1.7."

When the DVDM Assy is to be replaced

Replace the Assy, following the procedures described in "7.6 DISASSEMBLY."

• Before disconnecting the FFC cable between the Pickup Assy and the DVDM Assy (CN111), be sure to short-circuit the

short-circuiting land of the pickup with Sn-Ag-Cu alloy.

• If the AJKB Assy is to be replaced at the same time, resetting of the ID number and copying of ID data are required.

• See "7. GENERAL INFORMATION."

A

B

C

When the AJKB Assy is to be replaced

• Copying of ID data is required. Also, destination setting and input of the serial number are required.

• See "7. GENERAL INFORMATION."

• If the DVDM Assy is to be replaced at the same time, besides the settings mentioned above, resetting of the ID number is

also required.

• See "7. GENERAL INFORMATION."

When downloading the firmware

If you download the firmware via the RS-232C serial port after failing to upgrade it using the CD-R disc, settings, such as

SETUP, ADV.SETUP, and the command stack, are all reset to default.

• See "7. GENERAL INFORMATION."

D

E

56

DVD-V8000

F

7

8

5

1234

CONTENTS

SAFETY INFORMATION ..................................................................................................................................... 2

A

B

C

D

E

F

1. SPECIFICATIONS ............................................................................................................................................ 7

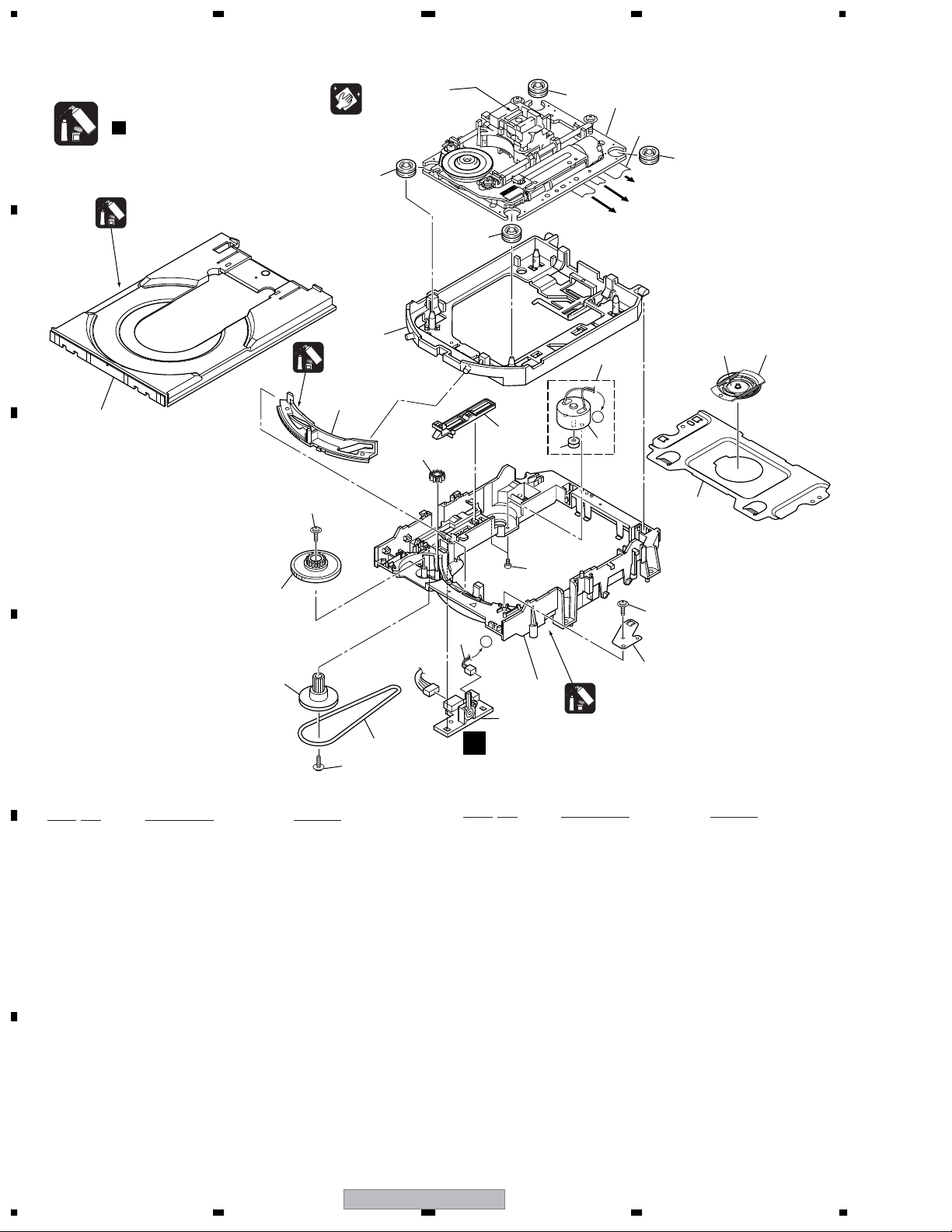

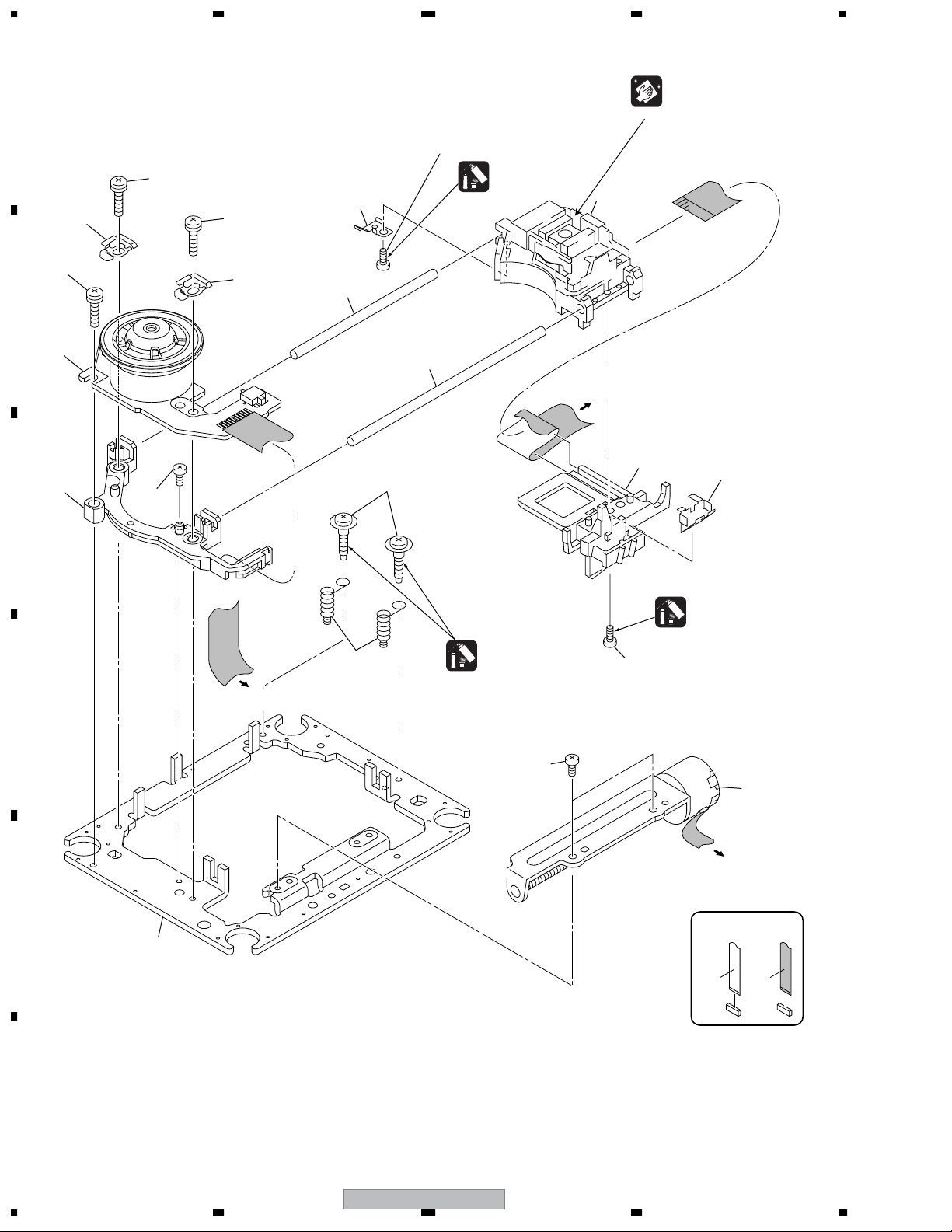

2. EXPLODED VIEWS AND PARTS LIST ............................................................................................................ 8

2.1 PACKING ................................................................................................................................................... 8

2.2 EXTERIOR SECTION.............................................................................................................................. 10

2.3 FRONT PANEL SECTION ....................................................................................................................... 12

2.4 LOADER MECHA. ASSY ......................................................................................................................... 14

2.5 TRAVERSE MECHA. ASSY-S ................................................................................................................. 16

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM..........................................................................................18

3.1 BLOCK DIAGRAM ................................................................................................................................... 18

3.2 LOAB ASSY and OVERALL WIRING DIAGRAM..................................................................................... 20

3.3 DVDM ASSY 1/6 [FTS BLOCK]............................................................................................................... 22

3.4 DVDM ASSY 2/6 [FR BLOCK]................................................................................................................. 26

3.5 DVDM ASSY 3/6 [EBY/AV1 BLOCK] ....................................................................................................... 30

3.6 DVDM ASSY 4/6 [VIDEO BLOCK]........................................................................................................... 34

3.7 DVDM ASSY 5/6 [USB/SUBCPU BLOCK]............................................................................................... 38

3.8 DVDM ASSY 6/6...................................................................................................................................... 42

3.9 VJKB and USBB ASSYS ......................................................................................................................... 44

3.10 AJKB ASSY ........................................................................................................................................... 48

3.11 KEYBY and PWSB ASSYS ................................................................................................................... 52

3.12 SYPS ASSY........................................................................................................................................... 54

3.13 WAVEFORMS ........................................................................................................................................ 56

4. PCB CONNECTION DIAGRAM ..................................................................................................................... 59

4.1 LOAB ASSY............................................................................................................................................. 59

4.2 DVDM ASSY............................................................................................................................................ 60

4.3 AJKB ASSY ............................................................................................................................................. 64

4.4 VJKB and USBB ASSYS ......................................................................................................................... 68

4.5 KEYB and PWSB ASSYS........................................................................................................................ 72

4.6 SYPS ASSY............................................................................................................................................. 76

5. PCB PARTS LIST ........................................................................................................................................... 77

6. ADJUSTMENT ............................................................................................................................................... 81

6.1 ADJUSTMENT ITEMS AND LOCATION ................................................................................................. 81

6.2 JIGS AND MEASURING INSTRUMENTS............................................................................................... 81

6.3 NECESSARY ADJUSTMENT POINTS ................................................................................................... 82

6.4 TEST MODE ............................................................................................................................................ 83

6.5 MECHANISM ADJUSTMENT.................................................................................................................. 84

6.6 ELECTRICAL ADJUSTMENT.................................................................................................................. 86

7. GENERAL INFORMATION............................................................................................................................. 87

7.1 DIAGNOSIS ............................................................................................................................................. 87

7.1.1 SELF-DIAGNOSIS FUNCTION OF PICKUP DEFECTIVE ............................................................... 87

7.1.2 TEST MODE SPECIFICATIONS ....................................................................................................... 88

7.1.3 SELF-DIAGNOSIS FUNCTION......................................................................................................... 90

7.1.4 FUNCTIONAL SPECIFICATION OF THE SERVICE MODE............................................................. 92

7.1.5 ERROR DISPLAY .............................................................................................................................. 93

7.1.6 ERROR HISTORY ............................................................................................................................. 96

7.1.7 ACCUMULATED POWER-ON TIME AND PLAYBACK TIME............................................................ 98

7.1.8 TROUBLE SHOOTING...................................................................................................................... 99

7.1.9 POWER ON SEQUENCE................................................................................................................ 101

7.1.10 FAILURE JUDGMENT OF THE HDMI TRANSMITTER IC............................................................ 103

7.2 UPGRADING ......................................................................................................................................... 104

7.2.1 UPGRADING OF THE FIRMWARE ................................................................................................ 104

7.2.2 IF UPGRADING OF THE FIRMWARE FAILS.................................................................................. 105

7.3 SETTING THE DESTINATION............................................................................................................... 106

7.4 SETTING THE ID NUMBER AND COPYING THE ID DATA.................................................................. 107

7.5 SERIAL NUMBER SETTING ................................................................................................................. 108

7.6 DISASSEMBLY ...................................................................................................................................... 109

7.7 PIN FUNCTION OF THE PCB ASSY .................................................................................................... 120

7.8 PARTS.................................................................................................................................................... 130

7.8.1 IC ..................................................................................................................................................... 130

7.8.2 LCD MODULE ................................................................................................................................. 158

7.9 DISC / CONTENT FORMAT PLAYBACK COMPATIBILITY ................................................................... 159

8. PANEL FACILITIES ...................................................................................................................................... 160

9. RACK MOUNT KIT (CB-A802) ..................................................................................................................... 164

9.1 PACKING SECTION .............................................................................................................................. 164

9.2 INSTALLATION PROCEDURES ............................................................................................................ 166

6

1234

DVD-V8000

5 678

1. SPECIFICATIONS

Specifications

A

General

System ............................................................... DVD Player

Electrical ratings

USA and Canada.......................... AC 120 V, 50 Hz/60 Hz

Europe............................... AC 220 – 240 V, 50 Hz/60 Hz

Power consumption ..................................................... 23 W

Standby power consumption ...................................... 0.8 W

Startup current

USA and Canada........................................ 22.1 A or less

Europe........................................................ 46.3 A or less

Weight ......................................................... 5.3 kg (11.7 lbs)

External dimensions

................... 420 mm (W) x 86.2 mm (H) x 309.2 mm (D)

Operating temperature ............................... +5 °C to +35 °C

16-9/16 in (W) x 3-3/8 in (H) x 12-3/16 in (D)

Operating humidity ....... 5 % to 85 % RH (no condensation)

(including protuberances)

(+41 °F to +95 °F)

Playback

Playable discs....... DVD-Video, DVD-R, DVD-RW, Video-CD,

Audio-CD, CD-R, CD-RW

Video Output

Composite ..................BNCx1, 1.0 Vp-p, 75 Ω (VIDEO OUT)

75

S-VIDEO............................. 4P mini DIN x 1 (S-VIDEO OUT)

C: 0.286 Vp-p (NTSC), 0.300 Vp-p (PAL), 75

Component ............... BNC x 3 (COMPONENT VIDEO OUT)

DVI ............................................. 24-Pin DVI-D connector x 1

(conforms to DVI 1.0, supports HDCP Ver.1.0)

Pin jack x 1, 1.0 Vp-p,

Ω (MONITOR VIDEO OUT)

Y:1.0 Vp-p, 75

Ω

Ω

Y: 1.0 Vp-p, 75

Pb: 0.7 Vp-p, 75

Pr: 0.7 Vp-p, 75

Ω

Ω

Ω

Video Input

Composite ....................BNC x 1, 1.0 Vp-p, 75 Ω (VIDEO IN)

Audio Input

Analog .........................

or more (AUDIO IN, L, R), With input level control (LEVEL)

Pin jack x 2, 2 V rms (0 dBfs), 22 k

External Sync Input

Black burst ..............................BNC x 2, 0.286 Vp-p (NTSC),

0.300 Vp-p (PAL), 75

Ω ON/OFF (EXT SYNC IN)

Other

RS-232C connector............................D-sub 9-Pin (male) x 1

EXT TERMINAL connector....Mini D-sub 15-Pin (female) x 1

MOUSE/MEMORY connectors .............................................

USB connectors 4P type A (conforms with USB 1.1) x 3

(total current supplied for all three ports: Max 0.7 A)

(conforms to RS-232C; inch threads)

(inch threads)

Accessories:

Remote control unit ............................................................1

R6 (AA) batteries ................................................................. 2

Power cord ..........................................................................1

Warranty ...........................1 (USA and Canada models only)

Operating Instructions ........................................................1

• These specifications and designs are subject to change

without notice.

Ω

B

C

D

Audio Output

Analog ..................................... Pin jack x 2, 2 Vrms (0 dBfs),

Digital .........................................Pin jack x 1, 0.5 Vp-p, 75

56

1.5 k Ω or less (AUDIO OUT L, R)

Ω

(DIGITAL AUDIO OUT COAXIAL)

Optical fiber connector x 1

(DIGITAL AUDIO OUT OPTICAL)

DVD-V8000

The specifications and design of this

product are subject to change without

notice, due to improvement.

7

E

F

7

8

1234

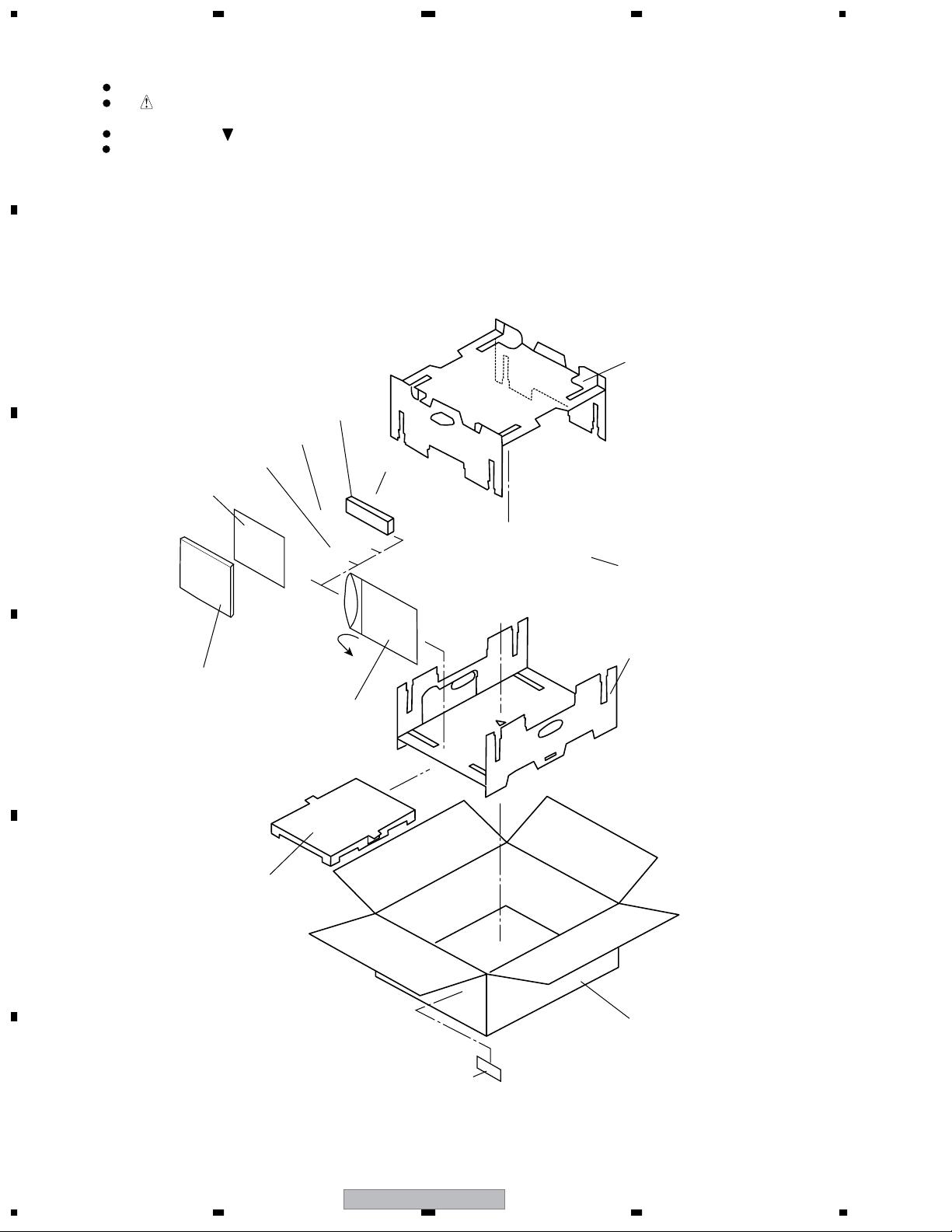

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

A

2.1 PACKING

B

C

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

2

8

7

(/KUCXJ)

9

11

10

(/WYXJ5)

1

3

6

D

13

E

5

4

12

F

8

1234

DVD-V8000

5 678

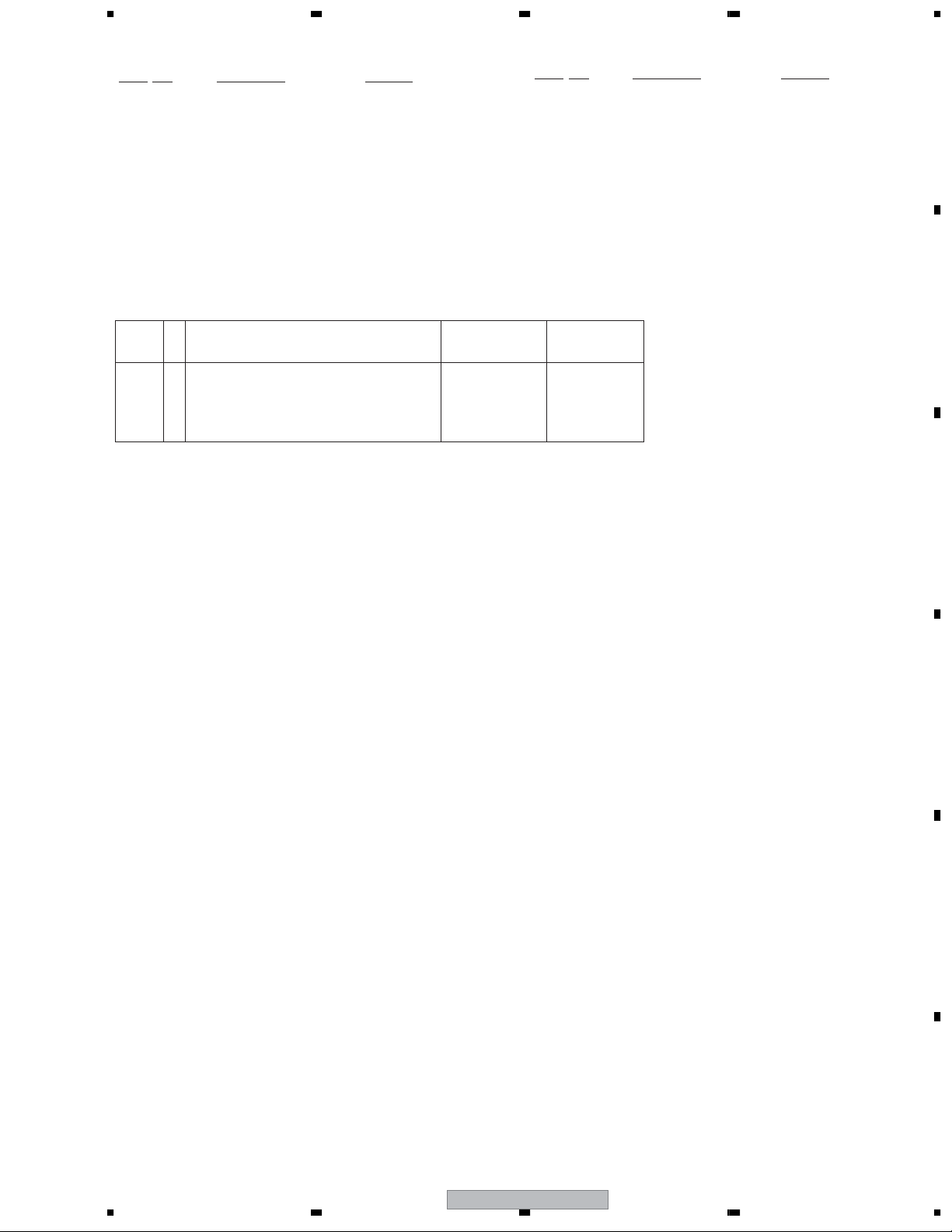

PACKING parts List

Mark

Mark

No. Description Part No.

1 Mirror Mat (850 x 750) DHL1156

2Pad (Top) DHA1704

3Pad (Bottom) DHA1703

4Packing Case See contrast table (2)

NSP 5 Polyethylene Bag AHG7117

6 Instruction Manual DRE1031

(English, French)

7Power Cord See contrast table (2)

>

No. Description Part No.

8 Remote Control Unit DXX2574

NSP 9 Bettery (R6P, AA) VEM1031

10 Label (WEEE) See contrast table (2)

NSP 11 Warranty Card PUSA See contrast table (2)

NSP 12 Label VRW1629

13 Spacer DHA1719

(2) CONTRAST TABLE

DVD V8000/KUCXJ and DVD-V8000/WYXJ5 are construccted the same except for following:

Mark No. Symbol and Description

4Packing Case DHG2601 DHG2600

>

NSP 11 Warranty Card PUSA DRY1240 Not used

7Power Cord ADG1215 ADG1214

10 Label (WEEE) Not used ARW7322

DVD-V8000

/KUCXJ

DVD-V8000

/WYXJ5

A

B

C

D

E

56

DVD-V8000

F

7

8

9

1234

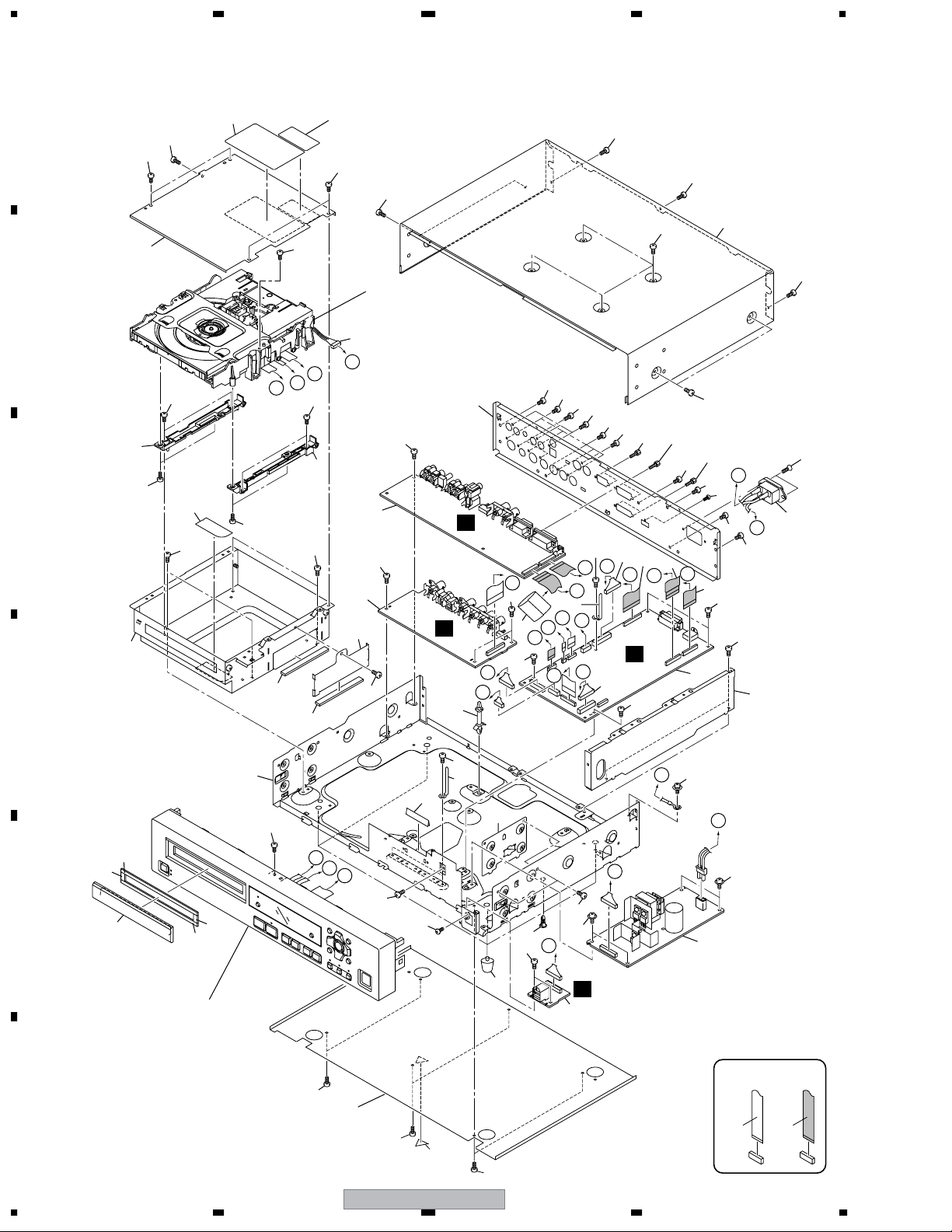

2.2 EXTERIOR SECTION

A

38

38

20

B

38

24

39

C

17

D

38

27

34

39

H

26

46

I

26

38

38

25

35

38

37

47

Refer to

"2.4 LOADER MECHA ASSY".

11

K

J

18

38

2

38

38

C

38

L

38

J

30

I

H

38

B

A

C

22

1

B

38

14

45

39

M

38

38

38

19

38

37

36

F

38

48

G

38

38

N

5

38

38

41

7

37

39

38

38

36

36

38

10

6

E

N

K

5

L

M

A

D

9

38

4

23

28

29

E

Refer to

"2.3 FRONT PANEL SECTION".

F

32

10

1234

28

29

15

38

38

38

45

31

21

A

B

C

16

38

38

40

12

38

13

33

38

38

42

D

D

3

G

43

F

E

42

8

NON-CONTACT

SIDE

CONTACT SIDE

DVD-V8000

>

>

5 678

EXTERIOR SECTION parts List

Mark

No. Description Part No.

1 VJKB Assy DWZ1175

2 AJKB Assy DWZ1176

3 USBB Assy DWZ1179

4DVDM Assy DWS1364

5 FFC (24P) DDD1294

6 FFC (29P) DDD1296

7AC Inlet Assy DKP3770

8 SYPS Assy DWR1401

9 Connector Assy PF12PP-D12

10 Connector Assy PF13PP-D35

11 Connector Assy PG05KK-E30

12 Spacer AEC1065

13 Leg Assy SX (PLS) AEC7113

14 PCB Support AEC7513

NSP 15 Base Shassis DNA1330

16 Bottom Plate DNA1331

17 Mecha Case (Bottom) DNA1332

18 Rear Panel See contrast table (2)

19 Bonnet Case S DXX2576

20 Mecha Case (Top) DNH2702

21 Hole Cover DNH2705

22 Mecha Case (Side) DNH2727

23 Barrier DNH2758

24 Adapter 3 L (ABS) VNL1958

25 Adapter 3 R (ABS) VNL1959

Mark No. Description Part No.

26 Cable Packing DEC2885

27 Eject Hole Sheet DEC2891

28 Tray Packing A DEC2894

29 Tray Packing B DEC2895

30 EMI Sheet B DEC2960

NSP 31 Sheet VEX1024

32 Tray Panel DNK4535

NSP 33 Caution Label DRW1975

34 Service Caution Label DRW2306

35 Laser Caution (PAP) VRW2257

36 Hexagon Head Screw BBA1051

37 Screw BBT40P080FTB

38 Screw BBZ30P060FTB

39 Screw BPZ30P080FCC

40 Screw CBA1805

41 Screw CBZ30P080FTB

42 Screw IBZ30P060FCC

43 Screw PMB40P080FTC

45 Cord Clamper RNH-184-0

46 Screw VBA1094

NSP 47 LOADER MECHA ASSY VWT1229

48 Screw PMZ25P050FTC

A

B

C

(2) CONTRAST TABLE

DVD-V8000/KUCXJ and DVD-V8000/WYXJ5 are construccted the same except for following:

Mark No. Symbol and Description

NSP 18 Rear Panel DNC1781 DNC1780

DVD-V8000

/KUCXJ

DVD-V8000

/WYXJ5

D

E

F

56

DVD-V8000

7

8

11

1234

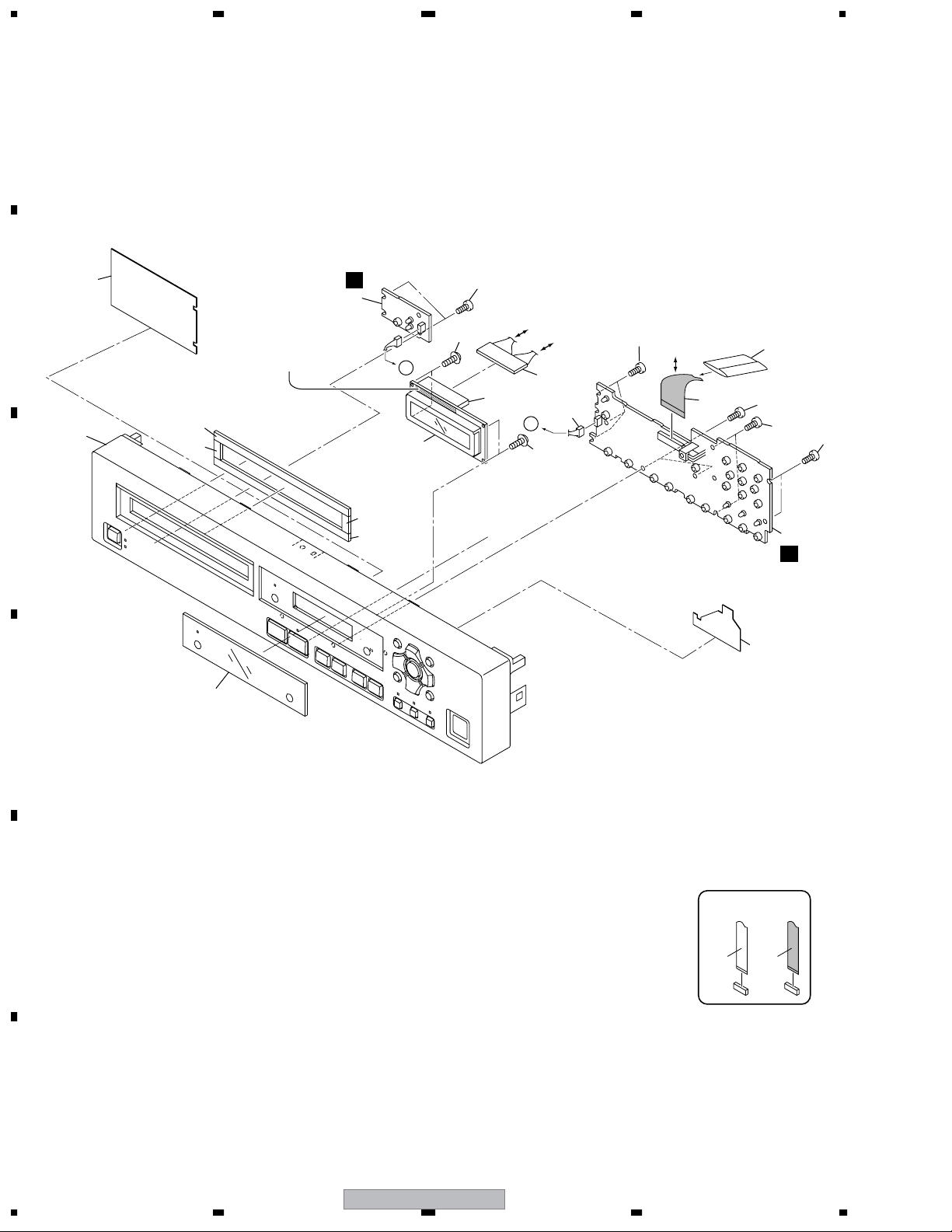

2.3 FRONT PANEL SECTION

A

12

B

Solder

the No."4" together

with the No."7".

14

C

8

9

F

2

A

7

9

8

16

15

DVDM

CN1502

DVDM

CN1501

5

4

6

A

16

15

DVDM

CN1504

10

3

15

15

15

1

E

11

13

D

E

NON-CONTACT

F

12

1234

DVD-V8000

SIDE

CONTACT SIDE

5 678

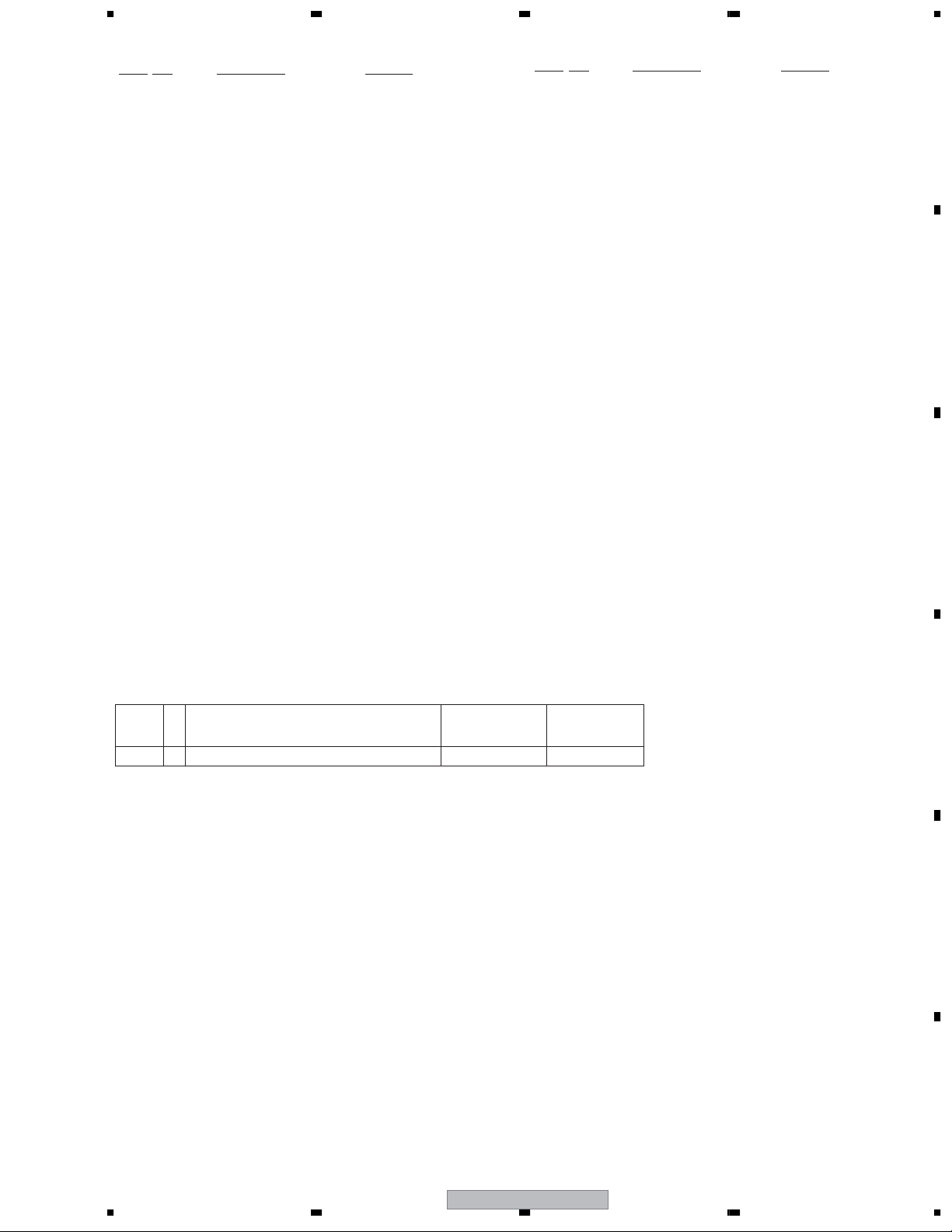

FRONT PANEL SECTION parts List

Mark

No. Description Part No.

1 KEYB ASSY DWZ1177

2 PWSB ASSY DWZ1178

3 FFC (24P) DDD1297

4 Connector DKN1418

5 Connector Assy DKP3746

6 Connector Assy DKP3747

7 LCD Module DWG1590

8Tray Packing C DEC2896

9Tray Packing D DEC2897

10 EMI Sheet A DEC2959

11 Display Sheet A DEC2971

12 Display Sheet B DEC2972

13 Display Window DAH2429

14 Front Panel Assy DXA2066

15 Screw BPZ30P080FCC

16 Screw IPZ30P080FTC

A

B

C

D

E

56

DVD-V8000

F

7

8

13

1234

2.4 LOADER MECHA. ASSY

Note :

A

Refer to

" Application of Lubricant".

Daifree

GEM1036

B

21

C

20

Cleaning paper

GED-008

6

10

Lubricating Oil

GYA1001

11

14

6

6

15

3

Refer to

1

"2.5 TRAVERSE MECHA. ASSY-S".

5

6

To DVDM CN101 (Pickup Assy-S)

To DVDM CN104 (Stepping Motor)

To DVDM CN105 (Spindle Motor)

2

A

4

16

17

18

D

LOADER MECHA. ASSY parts List

Mark

No. Description Part No.

1Traverse Mecha. Assy-S VXX3125

2 Loading Motor Assy VXX2912

3 Motor Pulley PNW1634

NSP 4 Motor VXM1107

5 Flexible Cable (24P) VDA2135

E

6 Floating Rubber VEB1351

7 Belt VEB1358

8 Stabilizer VNE2253

9 Loading Base VNL1917

10 Float Base DVD VNL1918

13

12

20

19

20

23

A

8

9

22

7

G

Mark No. Description Part No.

17 Bridge VNE2343

18 Clamper VNL1924

19 Screw JGZ17P028FTC

20 Screw VBA1094

21 Tray VNL1920

NSP 22 LOAB Assy VWG2426

23 Connector Assy (2P) VKP2253

Lubricating Oil

GYA1001

11 Drive Cam VNL1919

12 Gear Pulley VNL1921

13 Loading Gear VNL1922

14 Drive Gear VNL1923

F

15 SW Lever VNL1925

16 Clamper Plate VNE2342

14

1234

DVD-V8000

5 678

Application of Lubricant

No. 9

Loading Base

Lubricating Oil

GYA1001

Around the shaft

Lubricating Oil

GYA1001

A

B

Front View

No. 21

Tray

Lubricating Oil

GYA1001

Lubricating Oil

GYA1001

No. 11

Drive Cam

Lubricating Oil

GYA1001

Daifree

GEM1036

Concave of unevenness

Lubricating Oil

GYA1001

Inner side of a ditch

Rear View

No. 21

Tray

Inner side of a ditch

Daifree

GEM1036

Lubricating Oil

GYA1001

Inner side of a ditch

No. 11

Drive Cam

Daifree

GEM1036

Concave of unevenness

C

D

E

Top View Bottom View

Concave of unevenness

Daifree

GEM1036

DVD-V8000

56

Side of the rib

Daifree

GEM1036

7

8

F

15

1234

2.5 TRAVERSE MECHA. ASSY-S

A

15 (Torque : 0.15 ± 0.01 N•m)

Cleaning paper

GED-008

Cleaning liquid

GEM1004

17

8

10

17

B

1

13

C

16

17

10

7

6

4 (Adjustment screw)

Silicone Adhesive

GEM1037

3

To

DVDM CN101

(Pickup Assy)

14

9

Silicone Adhesive

GEM1037

5

(Adjustment

To DVDM CN105

D

(Spindle Motor)

spring)

Screw Tight

GYL1001

15 (Torque : 0.15 ± 0.01 N•m)

16

2

To

DVDM CN104

(Stepping Motor)

E

11

NON-CONTACT

SIDE

CONTACT SIDE

F

16

1234

DVD-V8000

5 678

TRAVERSE MECHA. ASSY-S parts List

Mark

No. Description Part No.

1 Spindle Motor VXM1112

2 Stepping Motor VXM1113

3 Pickup Assy-S OXX8018

4Skew Screw VBA1091

5Skew Spring VBH1335

6 Guide Bar VLL1514

7 Sub Guide Bar VLL1515

8 Leaf Spring VNC1023

9 Joint Spring VNC1019

10 Support Spring VNC1020

NSP 11 Mecha.Chassis VNE2344

12 Damper Sheet VEB1335

13 Spacer VNL1913

14 Joint 03 VNL1949

15 Tapping Screw VBA1092

16 Screw BBZ20P050FTC

17 Screw PMA26P100FTC

A

B

C

D

E

56

DVD-V8000

F

7

8

17

y

1234

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

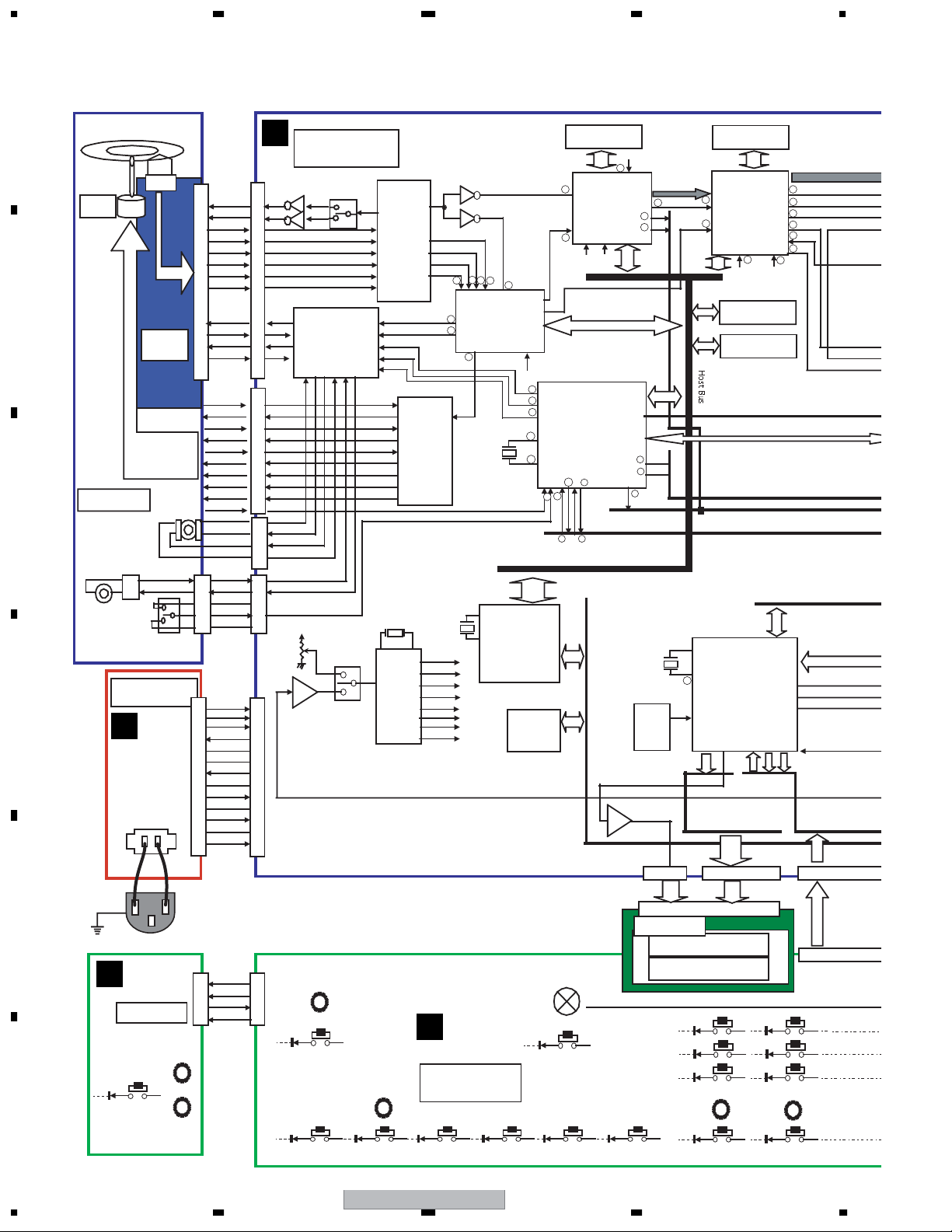

3.1 BLOCK DIAGRAM

A

A

DVDM ASSY

OEIC

SPDL

MOTOR

B

PU ASSY

LOADING

C

Mecha ASSY

STEPPING ST2- LODPOS

MOTOR ST2+

(Slider) ST1+

2

1

LOADING V+5V 6MHz

MOTOR LOAB A ~ Z

CN602 CN111

LD(650) AD00

7

9

$

^

#

@

(

*

4

3

2

1

1

2

3

4

5

ASSY 27MAV1 X1501

%

LD(780)

#

A ROMXA

8

C

6

B1

9

B2

0

B3 FE DSPRF 27MAV1 22/24AV1

3

B4

4

TRKG DRV FDO

*

(

)

_

9

8

7

6

5

4

3

2

1

=

4

3

2

1

1

2

3

4

5

CN115

CN114

CN103

~

9

0

TRKG RTN TDO

FOCS DRV LDDRV

FOCS RTN ST1

H3-

H3+

H2- SPDO

H2+

H1- X601

H1+ 16.5 MHz SDA1

A1 SCL1

A2

A3 XCSDF0

SLDPOS SLDPOS

ST1- LT1

LOAD- SSCK

LOAD+

V+3D SI

SW2

GNDS 13.824MHz X1201 DP1,2,3

SYPS ASSY

EV6V(B) 16MDSP REL_CS

D

H

1

2

3

4

5

6

7

8

9

0

=

~

CN101

NEUTRAL

E

CHASSIS GND

LIVE

AC Inlet

CN9501

F

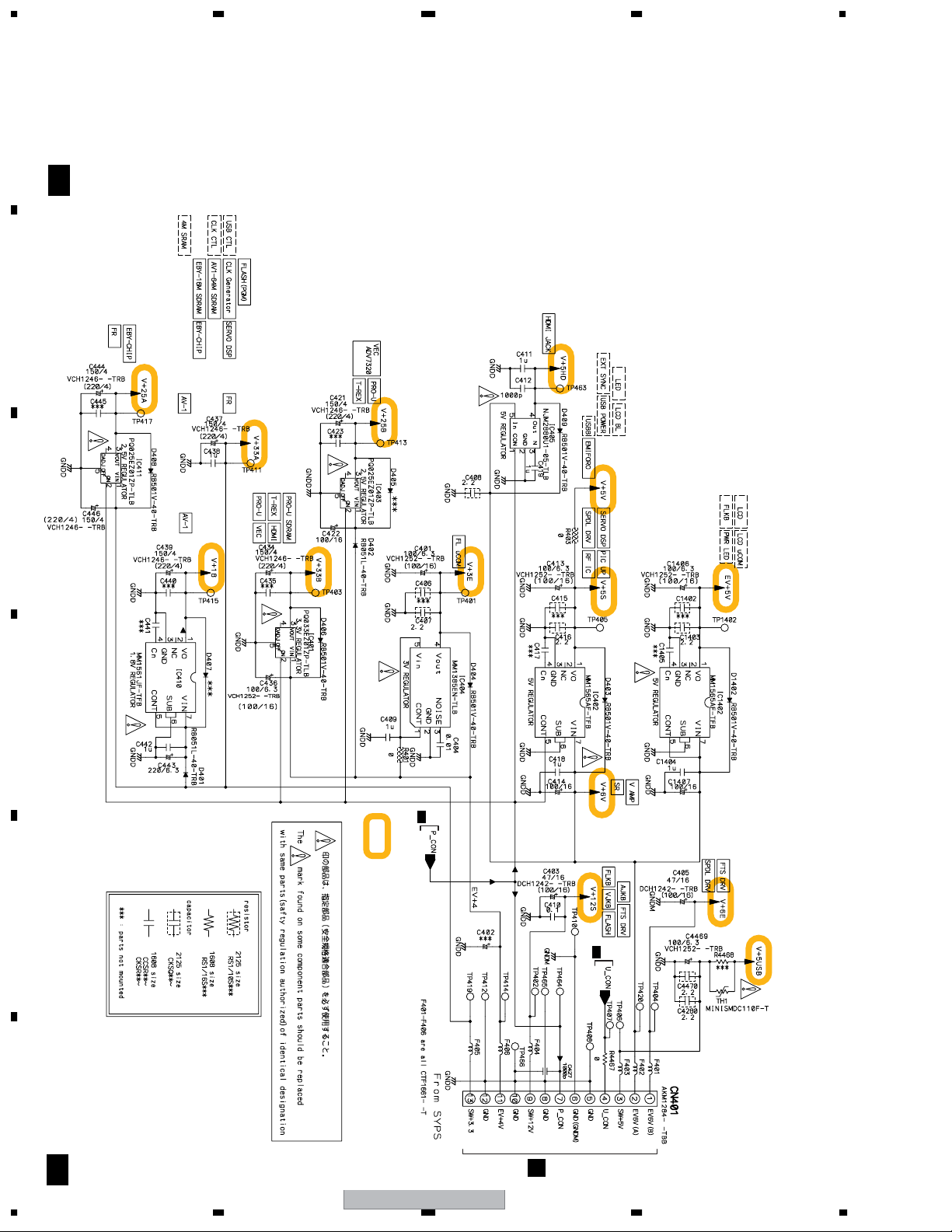

PWSB ASSY

1

2

3

4

1

EV6V(A)

2

SW+5V

3

U_CON

4

GND

5

GND

6

p_CON

7

GND

8

SW+12V

9

GND

0

Ev+4V

-

GND

=

SW+3.3

~

CN401

CN9002

GND IC9001 IR

1

POWER_SW

2

POWER_LED

3

V+5E

4

IC102

TC7W53FU

Q101

7

6

Q102

IC351 M56788AFP

=

FTS

DRIVER

@!

32

31

35

34

IC473

7

6

-

+

ANALOG

SW

Key Lock LED

1

%

=

5

6

7

4

1

IC101

LA9704WS1

RFIC

3

&

$

≠

£

ST2

!

~

IC202

=

BA6664FM

0

SPDL

9

DRIVER

7

4

2

X471

IC481

CY22389

CLK

IC

Q602

”

Q602

PH

]

—

BH

TE

›

‹

32

33

31

30

39

IC201 LC78652W

SERVO

47

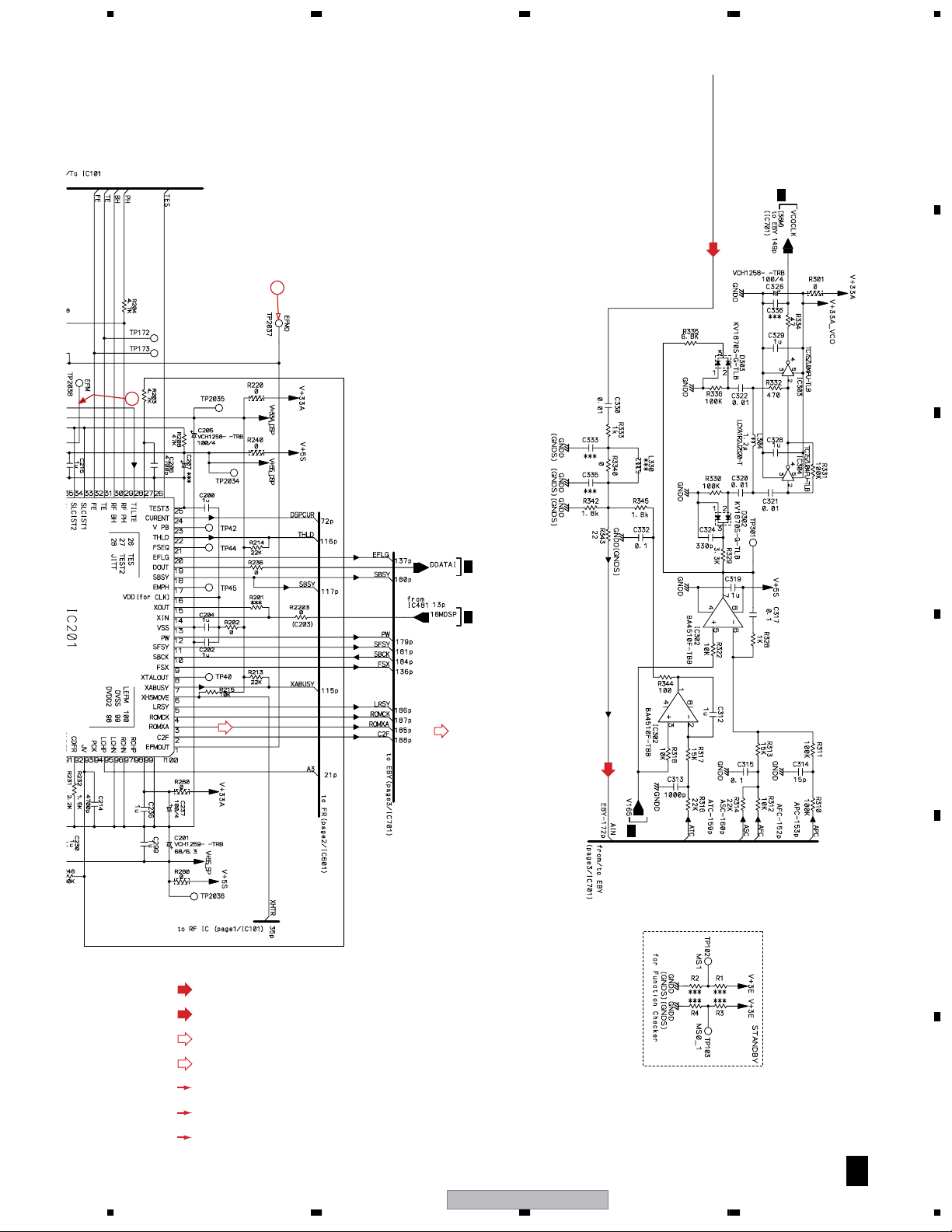

48

DSP

46

*

D8 ~ D15,A0 ~ A11 SO

!

16MDSP

IC1201

49

47

48

134

135

UHC124BF

8

=

33MEBY1 REL_DA

~

7

4

22/24AV1 RST

0

22/24HDM

9

USB

CONT

36MEBY 5MHz

16MEBY REL_CK

22/24M

IC1202,3,4

UPD16876

P.CONT IC

x3

E

STANDBY LED

F

POWER KEY

ON LED

Disp KEY

KEYB ASSY

PLAY LED

IC741 16M

SDRAM

IC701

172

PE5286B

AIN

EBY

CHIP

185

45

36MEBY 33MEBY

3

^

D8 ~ D15,A3

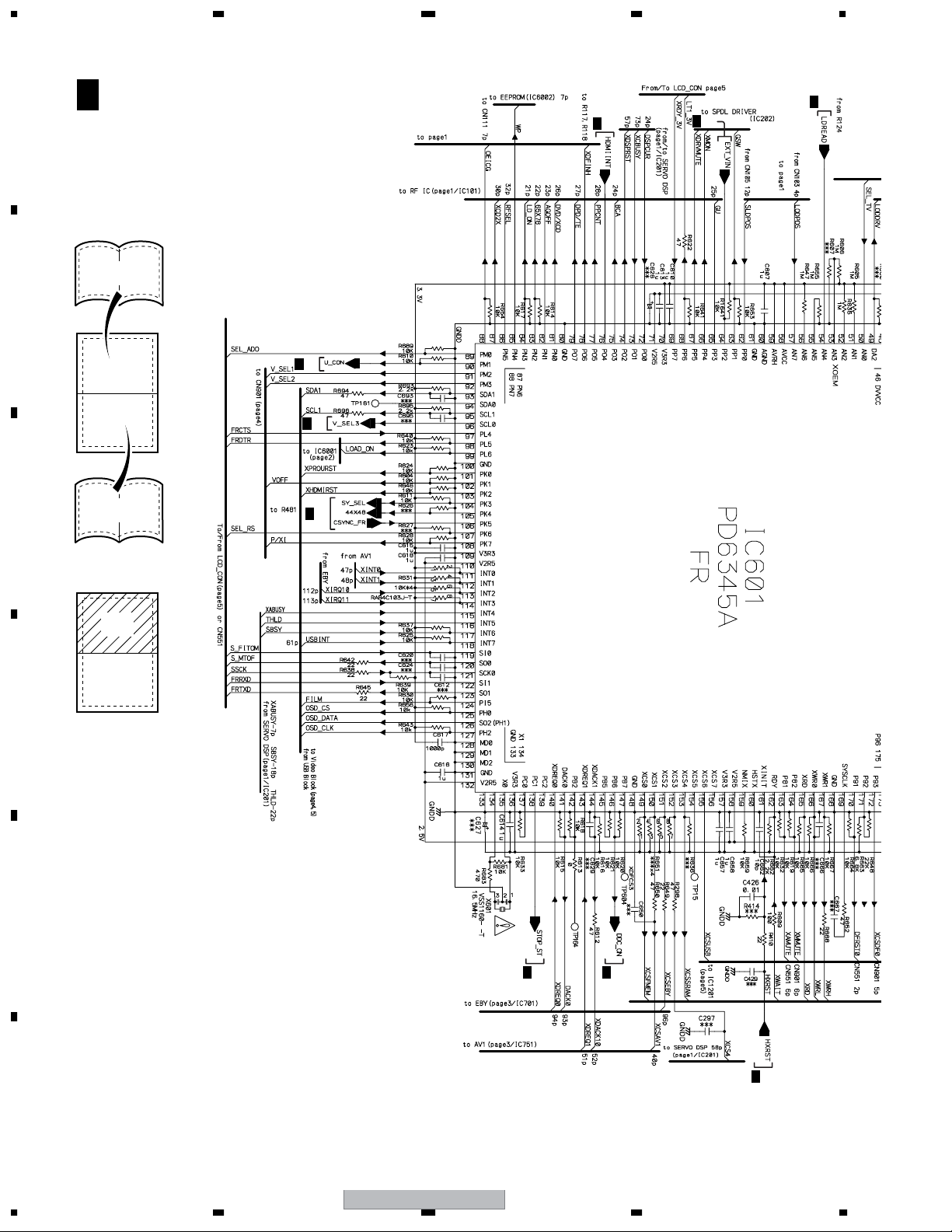

IC601

PD6345A

FR

FRDTR

FRTXD

123

98

57

62

97

122

FRCTS

FRRXD

MP1,2,3

+5V

x3

LCD KEY

-

+

RS,R/XW/E VLED,VLEDG

IC781 64M

SDRAM

36MEBY PD0-PD7

189

D0 ~ D15,A0 ~ A22

BD0-BD7

194

XDFSO0 CDDATA LRCKA0

32

XDFSCK0 DATAI

31

D8 ~ D15,

A0 ~ A16

93

95

172

IC1505

PST3228

RESET

IC

LCD_VR

LCD_VR DB0 ~ 7

LCD MODULE

D0 ~ D15,

A1 ~ A11

Ú

71

”

DB0 ~ 7

CN1501 CN1502

IC751

163

M65776B

AV1

162

106

D0 ~ D15,A1 ~ A20

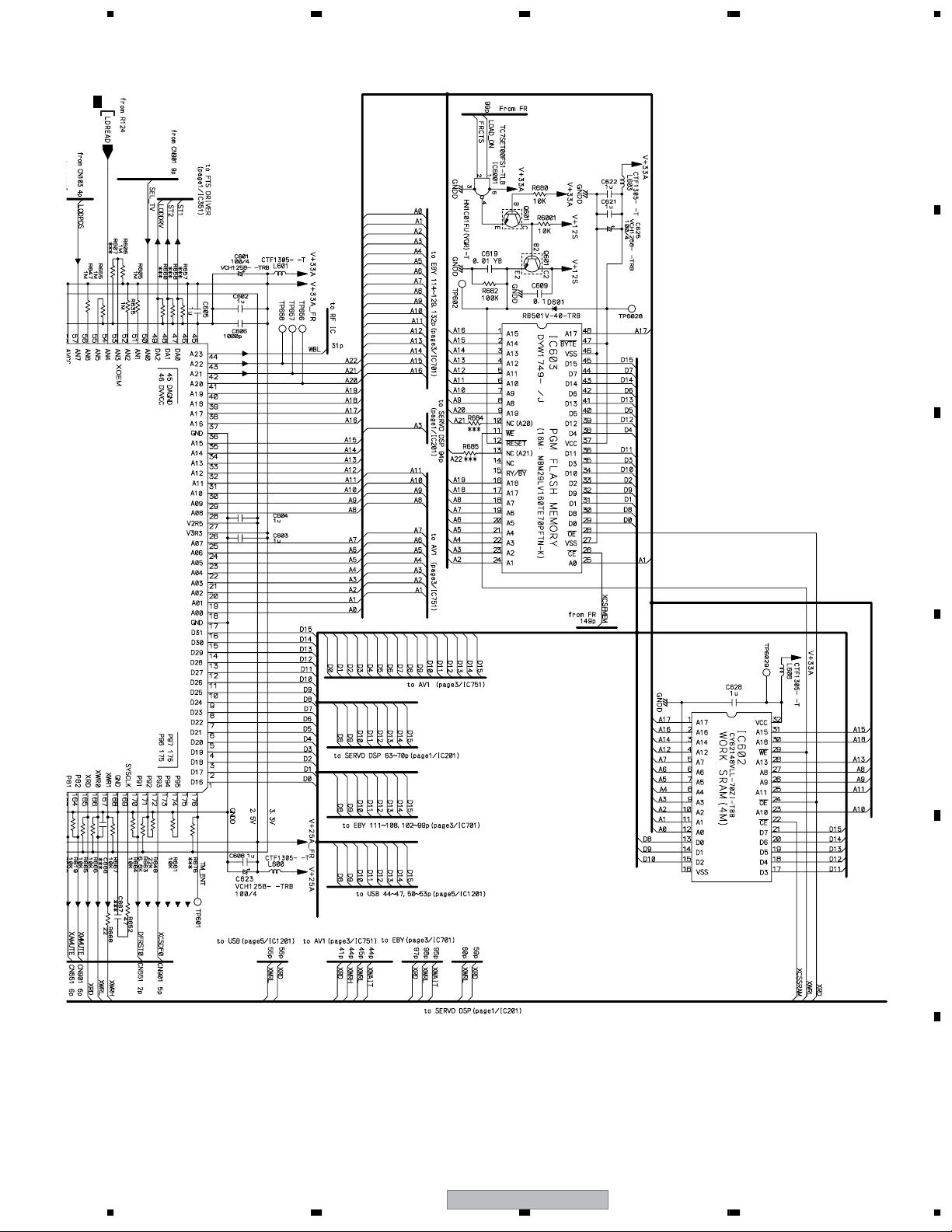

IC603 16M FLASH

IC602 4M S-RAM

Host Bus

D8 ~ D15,A0 ~ A18

OSD_CS,OSD_CLK,OSD_DATA,OSD_RST

IC1501

PE5557-B

SUB CPU

DB0 ~ 7

ABCDEFGHIJKL

123456789012

176

BCKA0

164

159

DOUT0

170

178

CSYNC

177

PD

172

XRD

JAMMER

$

%

#

’

IR

Keyi

Ke

18

Stop/Open KEY

Play/Pouse Key KEY

SCAN/SKIP KEY

STILL/STEP KEY SELECT_M KEY SELECT_V KEY

DVD-V8000

1234

A

B

+

+

+

+

5 678

A

IC902 16M

SDRAM

PD0-PD7

176

BCKA0

AD00 PPD0-PPD7 OSD_RST

164

LRCKA0 OSD_CS

159

DOUT0

170

178

CSYNC SCL1 OSD_DATA

177

PD

2

V1

H

IC786

BUF

IC1101

3V→5V

BUF

IC901 CD0040AF

PRO-U

SDA1

135

136

OSD_CS,OSD_CLK,OSD_DATA,OSD_RST

SDA1 OSD_DATA

SCL1 V V CV V_out

IC903

21

ADV7320KSTZ

22

VIDEO

ENCODER

TA,OSD_RST

SDA1 PPD0-PPD7 TCLK+,-

49

IC1001

SCL1 24PIN

50

PD0280B

T-REX

22/24HDM QG2-QG9 DP3

@

IC1051

SDA1

#

SCL1

CN1504

CN9001

SII9190CTG64

HDMI

Trs

IC1301

LM1881

M

SYNC

SEP.

CN1201

+5V MP1,2

USBB ASSY

LT1

XRD

SSCK 22/24M PCMCLK 22/24M

SO XDFSO0 MD MD

SI XDFSCK0 MC MC LCX157 D-SUB9

JAMMER SCL1 SCL1 SCL1 DTR DTR

A

~ Z BCKA1 BCK BCKA1

$

REL_DA DOUT0 DOUT0

%

REL_CK RXD

REL_CS FRRXD RXD CTS

#

’

IR

Keyin1 ~ 4 Keyout1 ~ 5 LED CSYNC CSYNC_IN MD

02

EDG DP1,2 LRCKA1

Keyout1 ~ 5

Keyin1 ~ 4

LED

PB0-PB9

PC0-PC9

6dB UP OSD_CK

4

2

6

OSD_RST

OSD_CS

OSD_CK

DVI-D

USB

(MOUSE

MEMORY)

TXD

)

(

*

&

=

0

8

6

4

2

9

~

@

%

^

7

5

3

$

0

=

9

4

3

2

7

CN7001

AO0

LRCKA1

CN8001

CN8701

3

7

IC7101

V CV OUT

2

6

LA73054

6

8

Video

-

AMP

!

#

B

VJKB ASSY

IC8802

5

6

MC

BCKA1

AO0

0.22Fx 2 superC

4

32k

EEPROM

=

CTS

JAMMER A ~ D,X,Y,Z,E SPDIF OUT

~

IC8101

!

PCM1742K

@

AUDIO

1

DAC

2

3

#

7

8

9

44

42

S_C S_C S_C S_C

S_Y S_Y S_Y S_Y

43

YYYY

39

Cb Cb Cb Cb

38

Cr Cr Cr Cr Y_out

37

PB0-PB9 Td1+,-

PC0-PC9 Td2+,-

QB2-QB9

QR2-QR9 MP3

0

%

&

(

_

¡

£

CN901

Td0+,- Cb_out

DDCDA Cb OUT

DDCCL

+5V

CN551

9

~

XCSDF0 ML ML RXD RXD

@

SDA1 SDA1 SDA1 RXD TXD TXD

%

^

7

AO0 DATA

5

LRCKA1 LRCK

3

$

CN1503

JAMMER FRCTS CTS

A

~ Z

0

-

FRTXD

=

FRDTR DTR TXD TXD

9

REL_DA RTC_DATA REL_DA

4

REL_CK RTC_CLK REL_CK

3

REL_CS RTC_CS REL_CS

2

7

DP1,2 ML

MP1,2

+5VUSB V+3E 22/24 M

CN9701

)

9

IC7301

0

PDC084

9

@

OSD

IC

~

Cvout

33

31

C_out S OUT

28

25

Y/G_out

23

21

Cr_out Y OUT

IC8703

SP232EEN

RS232C

9

DRIVER

0

RECEIVER

-

IC8702

SP232EEN

9

RS232C

=

DRIVER

-

DTR

RECEIVER

0

!

~

=

5

3

1

-

-

+

6dB UP RIN R IN

+

IC8701

7

8

6dB UP

V+3V

2

3

!

~

6dB UP

-

75 Ω DRIVER

!

-

-

8

7

8

~

DTR

!

7

LOUT

ROUT

LIN

CV IN

(P/A/N)

OSD OUT

Cr OUT

D-SUB15

L OUT

R OUT

L IN

B

C

D

E

-

D

USB(MOUSE,MEMORY)

IC8801

7

REL_DA

S-35190A

3

REL_CK EXT SYNC IN

RTC

REL_CS

5

6dB UP

X8801

32.768 kHz

-

+

+

F

ECT_V KEY

SELECT_A KEY

C

AJKB ASSY

75

56

DVD-V8000

7

EXT SYNC IN

19

8

1234

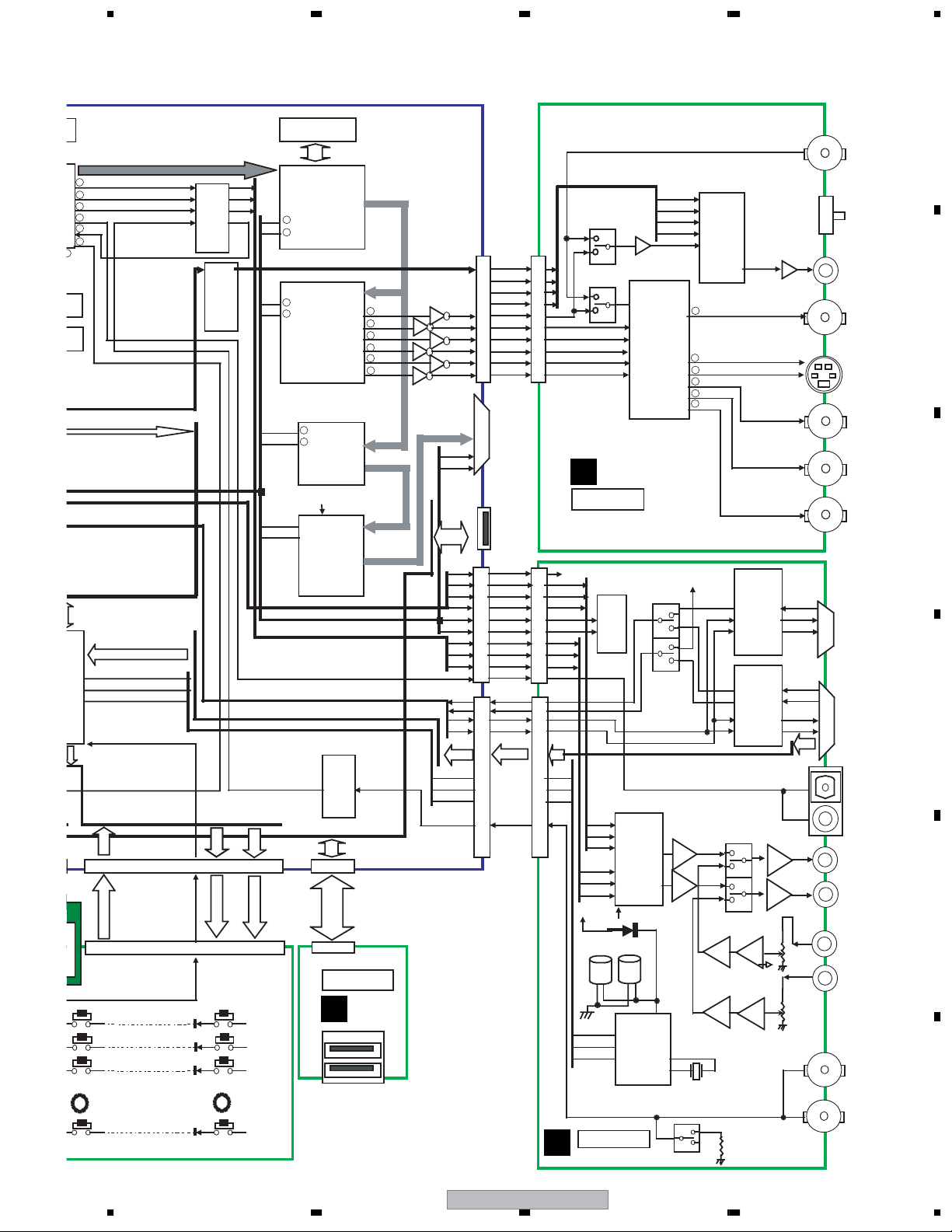

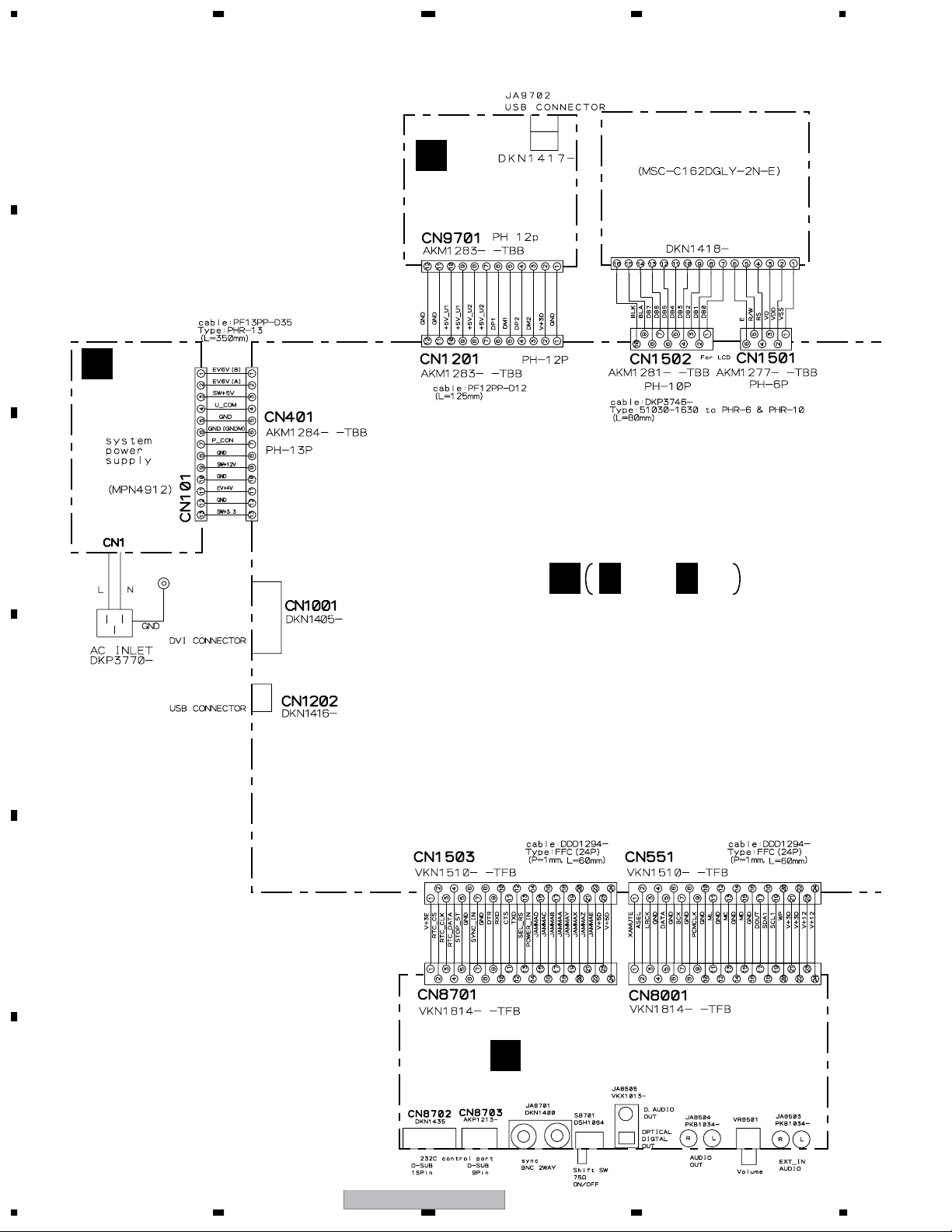

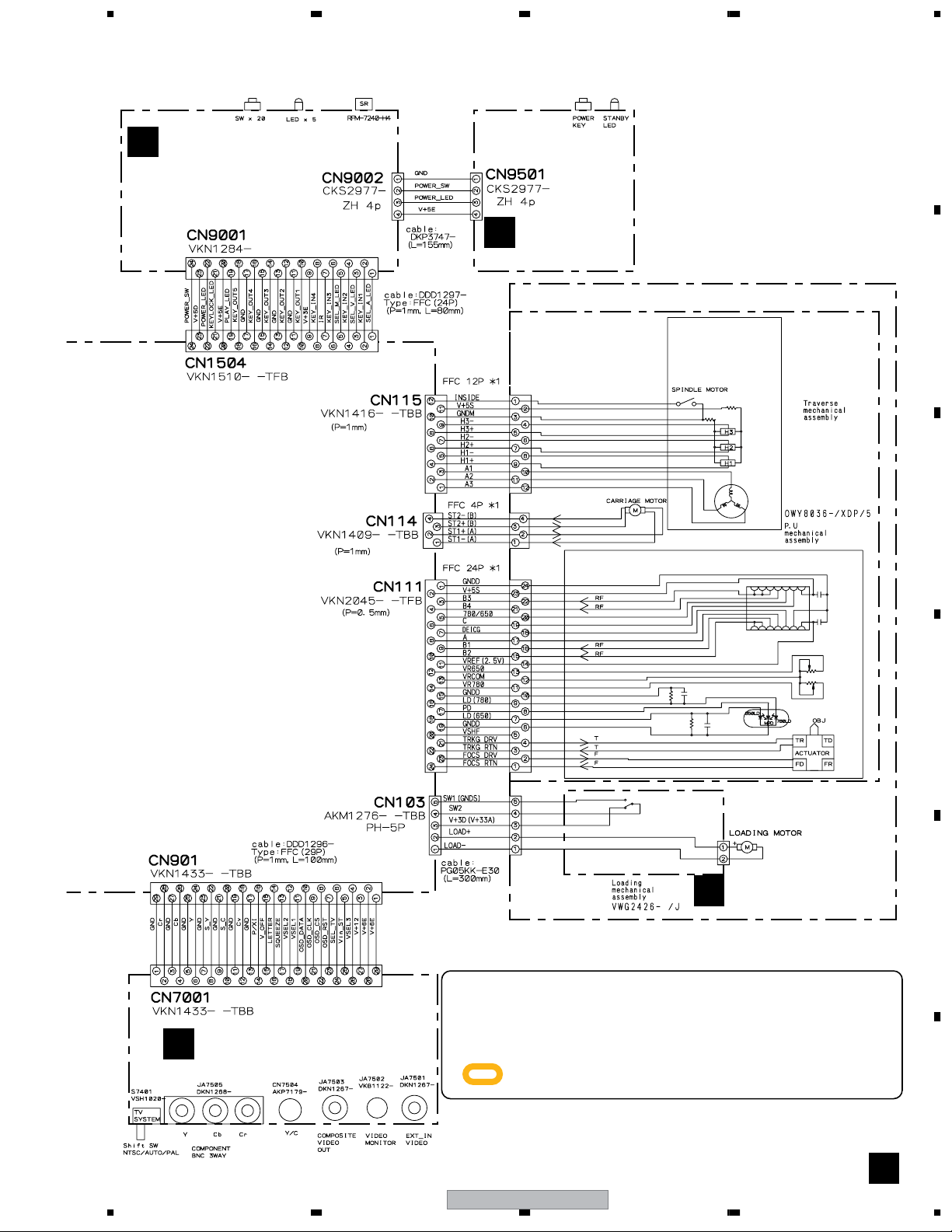

3.2 LOAB ASSY and OVERALL WIRING DIAGRAM

A

D

USBB ASSY

(DWZ1179)

B

H

SYPS ASSY

(DWR1401)

LCD MODULE

(DWG1590)

C

A

DVDM ASSY (DWS1364)

D

E

A 1/6 - A 6/6

AJKB ASSY (DWZ1176)

C

F

20

1234

DVD-V8000

5 678

KEYB ASSY (DWZ1177)

E

PWSB ASSY

F

(DWZ1178)

A

Loading Mecha ASSY (VWT1229)

Traverse Mecha

ASSY-S

(VXX3125)

SPINDLE

MOTOR

(VXM1112)

Pickup ASSY-S (OXX8088)

B

C

D

CN601

÷

When ordering service parts, be sure to refer to "EXPLODED VIEWS

and PARTS LIST" or "PCB PARTS LIST".

÷

The > mark found on some component parts indicates the

VJKB ASSY (DWZ1175)

B

56

importance of the safety factor of the part. Therefore, when

replacing, be sure to use parts of identical designation.

÷

: The power supply is shown with the marked box.

DVD-V8000

S101

7

LOAB

G

LOAB ASSY

(VWG2426)

CN602

E

F

G

21

8

1234

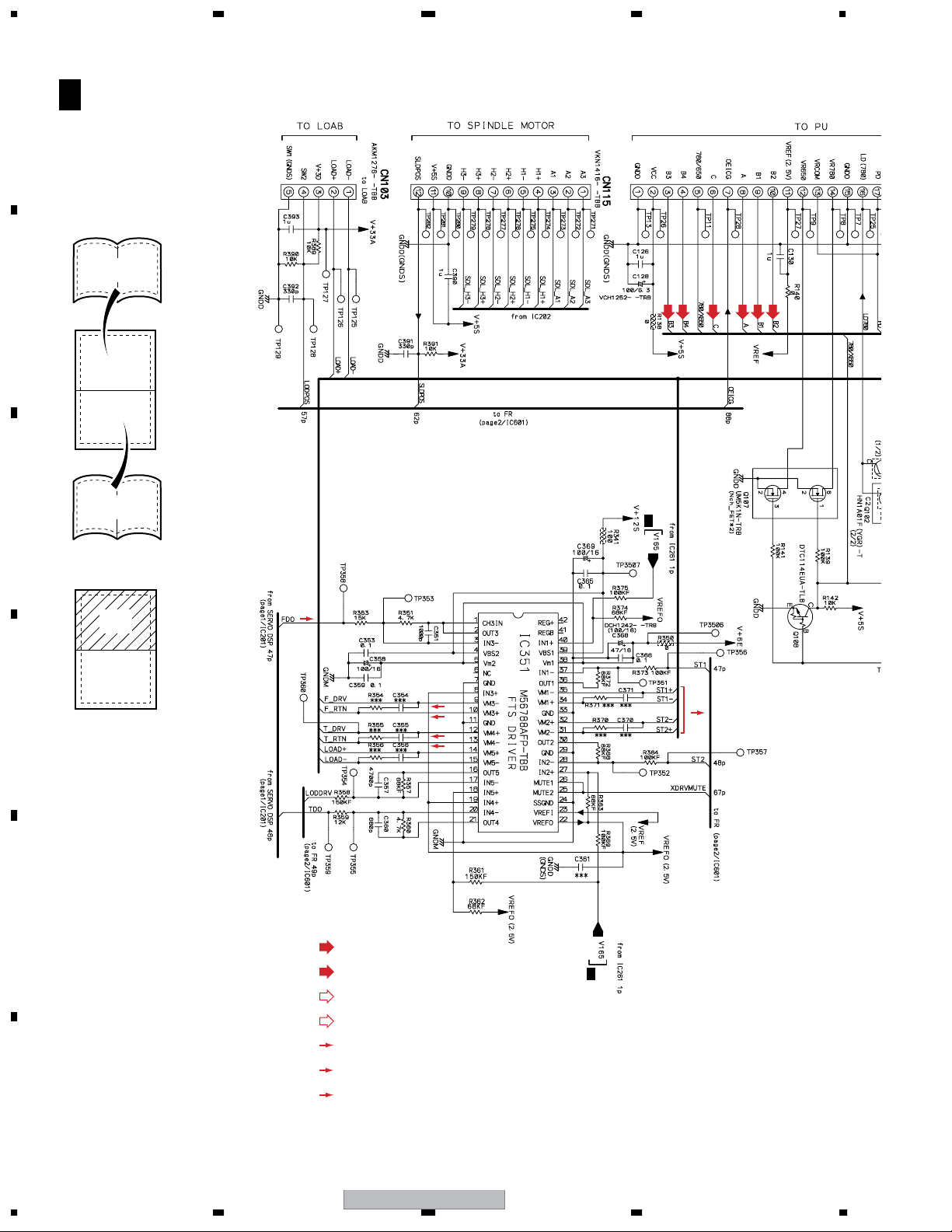

3.3 DVDM ASSY 1/6 [FTS BLOCK]

A

A 1/6

DVDM ASSY (DWS1364) (1/2)

Large size

SCH diagram

1/2

B

C

2/2

1/6A

(RF)

(RF)

(RF)

(RF)

(RF)

(RF)

(F)

1/2

D

E

(RF)

: RF SIGNAL ROUTE

(RF_V)

: RF (VIDEO) SIGNAL ROUTE

(RF_A)

: RF (AUDIO) SIGNAL ROUTE

(AD)

: AUDIO DATA SIGNAL ROUTE

(F)

: FOCUS SERVO LOOP LINE

(T)

: TRACKING SERVO LOOP LINE

(S)

: STEPPING SERVO LOOP LINE

F

(F)

(F)

(T)

(T)

1/6A

(S)

22

1234

DVD-V8000

5 678

The following waveforms were measured at the point of the corresponding

NOTE:

balloon number in the schematic diagram and PCB diagram.

4

(S)

(S)

(S)

(F)

(F)

(T)

(T)

(S)

(RF)

(RF)

1/6A

(RF)

A

B

1

C

D

(RF)

E

1/6,A 2/6A

DVD-V8000

56

(RF_A)

(RF_V)

2

7

8

F

23

F

F

1234

A

A 1/6

B

C

DVDM ASSY (DWS1364) (2/2)

(RF_A)

(F)

(T)

5

7

Large size

SCH diagram

1/2

3/6A

1/6A

D

E

2/2

2/2

11

10

3/6A

8

9

(

(R

(R

(

F

A 1/6

24

The following waveforms were measured at the point of the corresponding

NOTE:

balloon number in the schematic diagram and PCB diagram.

DVD-V8000

1234

5 678

A

3/6A

(RF_V)

6

B

5

(AD)

(AD)

C

3/6A

4/6A

D

(RF_V)

1/6A

E

(RF)

: RF SIGNAL ROUTE

(RF_V)

: RF (VIDEO) SIGNAL ROUTE

(RF_A)

: RF (AUDIO) SIGNAL ROUTE

(AD)

: AUDIO DATA SIGNAL ROUTE

(F)

: FOCUS SERVO LOOP LINE

(T)

: TRACKING SERVO LOOP LINE

(S)

: STEPPING SERVO LOOP LINE

56

DVD-V8000

F

A 1/6

7

8

25

1234

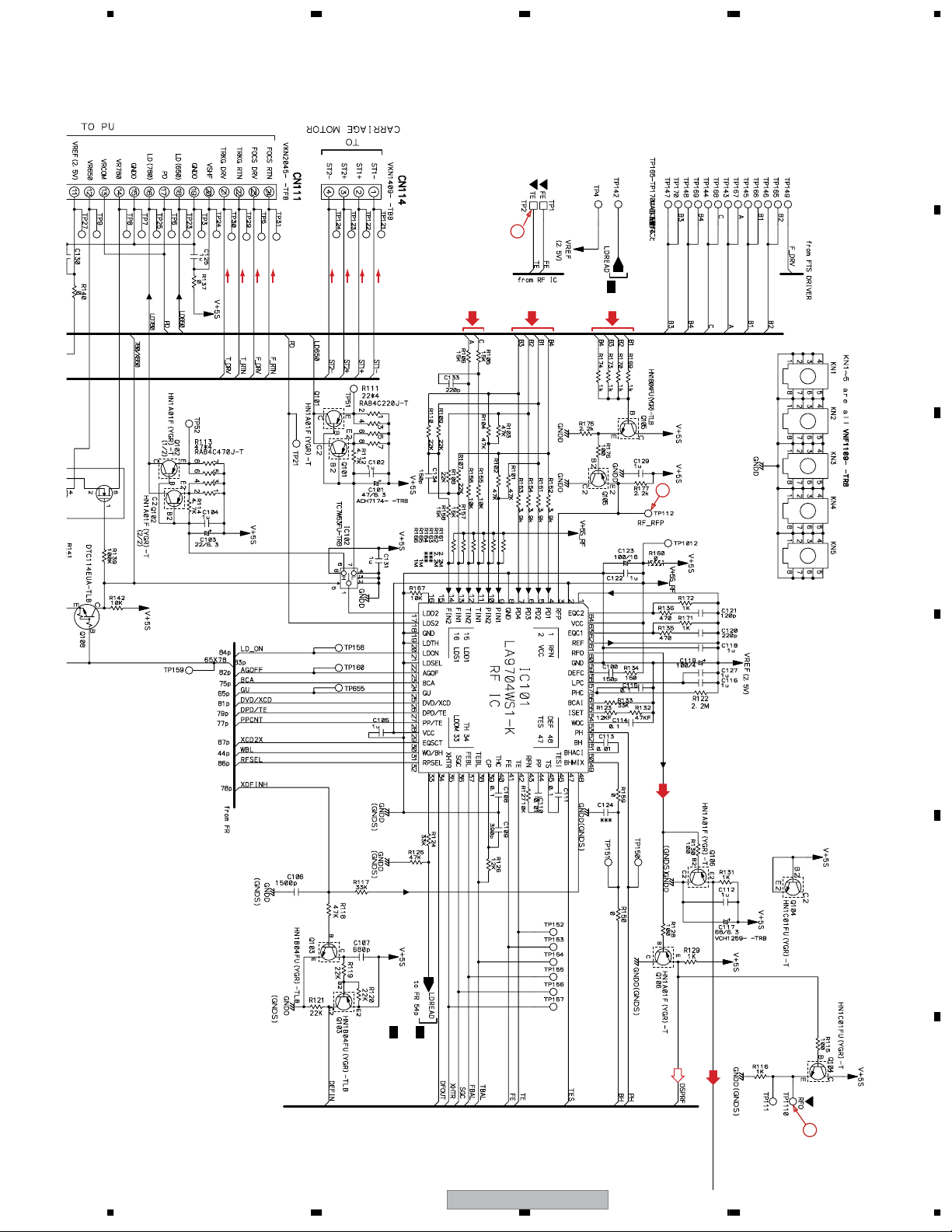

3.4 DVDM ASSY 2/6 [FR BLOCK]

A

A 2/6

DVDM ASSY (DWS1364) (1/2)

1/6

A

4/6

4/6

A

A

Large size

SCH diagram

1/2

B

2/6

A

4/6

A

C

2/2

2/6

A

1/2

D

E

5/6 4/6

AA

5/6

A

F

26

1234

DVD-V8000

5 678

1/6A

A

B

C

D

E

F

56

DVD-V8000

7

8

27

1234

A

B

C

A 2/6

DVDM ASSY (DWS1364) (2/2)

D

A

5/6

: The Power supply is shown with the marked box.

E

2/6

A

F

A 2/6

28

CN101

H

1234

DVD-V8000

5 678

A

2/6

A

3/6

A

3/6

5/6

A

A

TC7W53FU-TRB

2/6

A

A

2/6

B

C

Large size

SCH diagram

1/2

D

5/6

5/6

A

A

A

3/6

AA

3/6

A

A

3/6 1/6

DVD-V8000

56

3/6

2/2

3/6

A

E

2/2

F

A 2/6

7

8

29

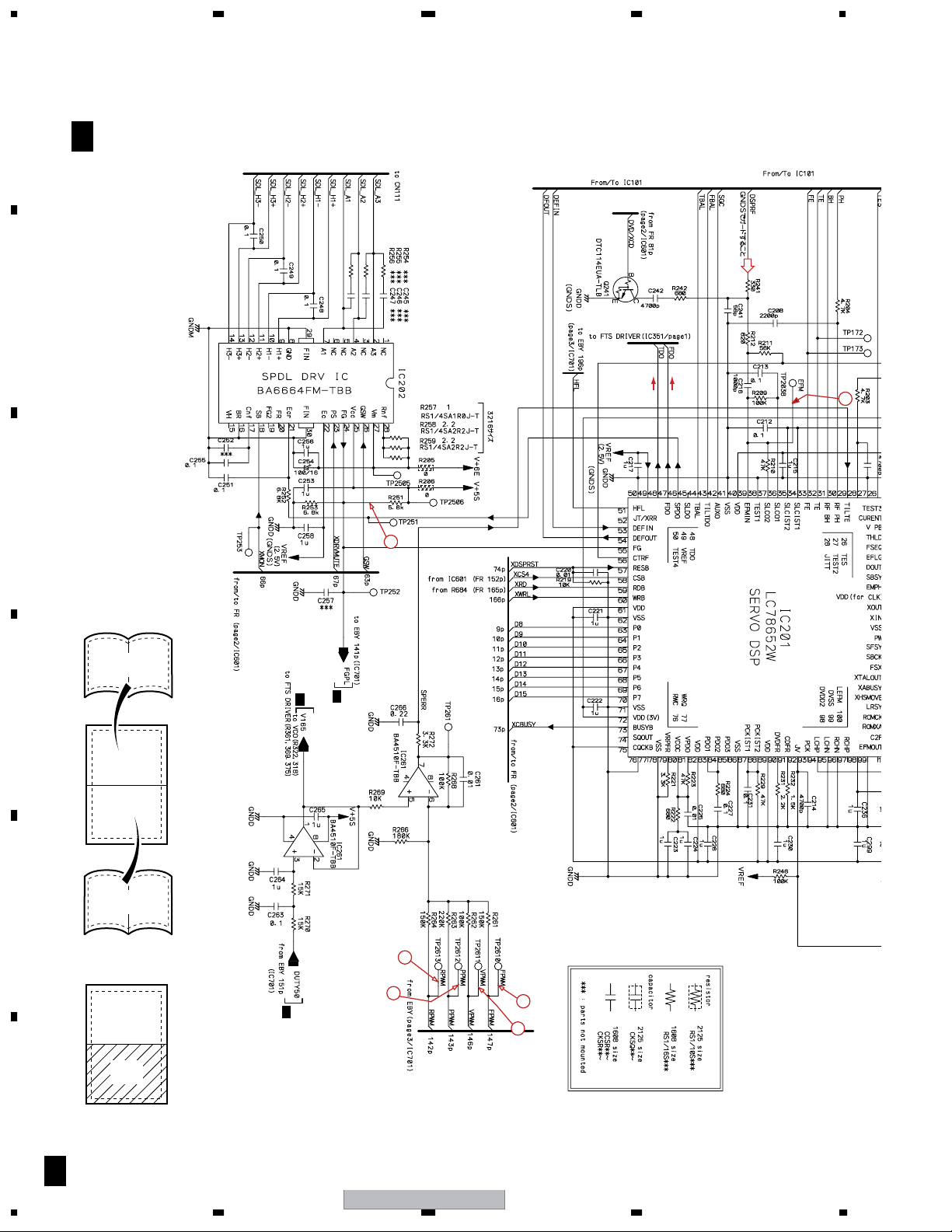

1234

A

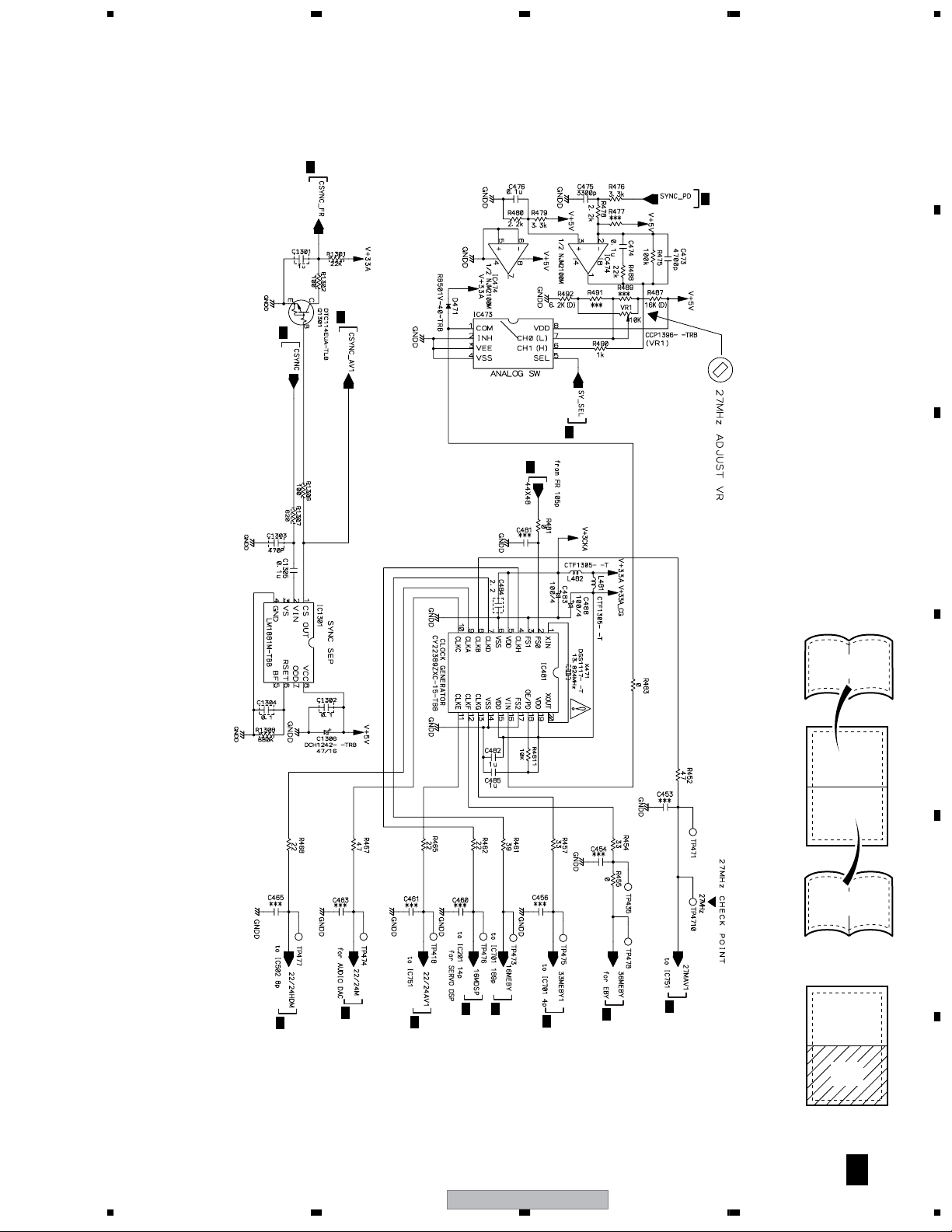

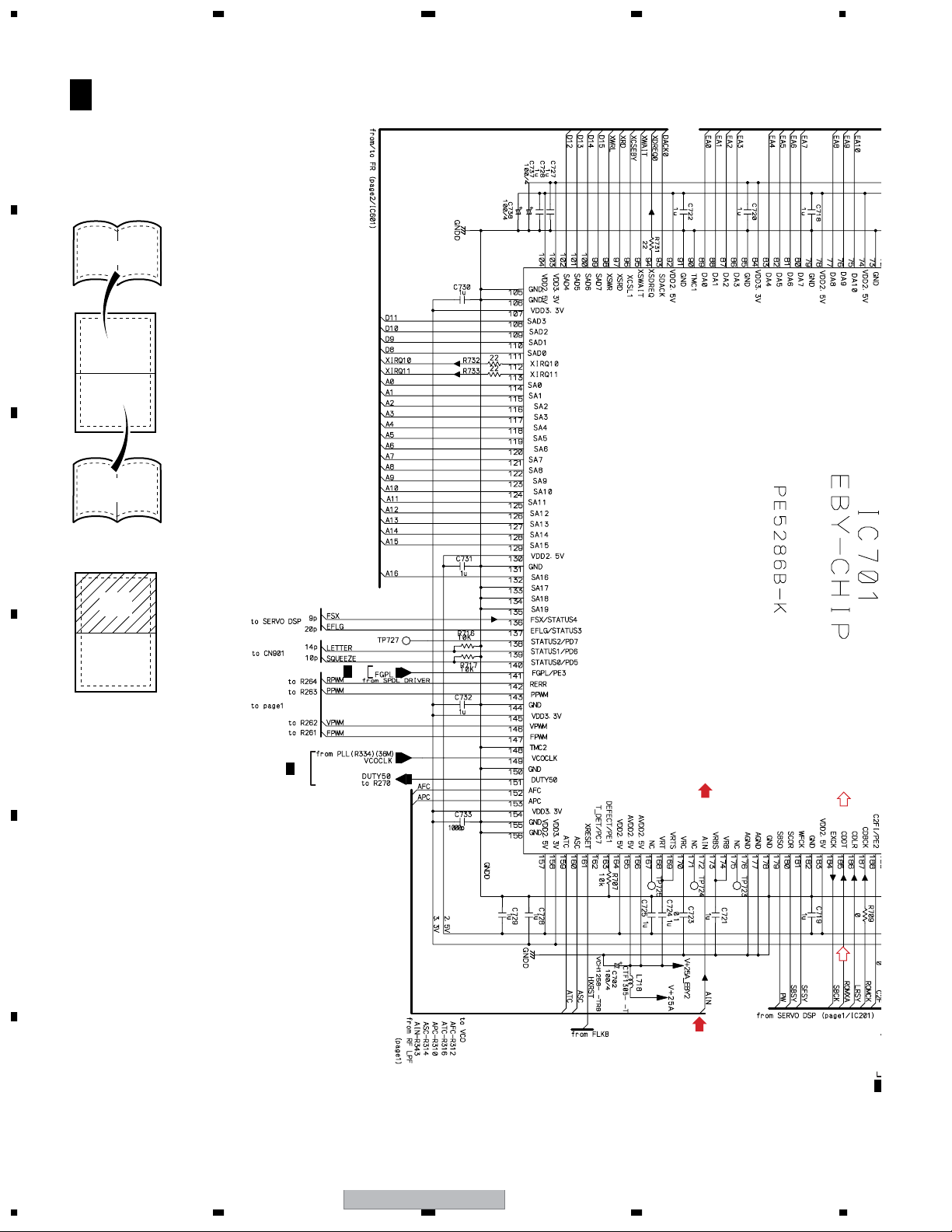

3.5 DVDM ASSY 3/6 [EBY/AV1 BLOCK]

A

A 3/6

DVDM ASSY (DWS1364) (1/2)

Large size

SCH diagram

1/2

B

2/2

C

1/2

1/6A

D

1/6A

(RF_V)

E

(RF_V)

(AD)

(AD)

F

30

1234

DVD-V8000

Loading...

Loading...