Pioneer DVDR-7783 Service manual

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2005

NECESSARY INFORMATION FOR DHHS RULES

MARKED ON THE TOP COVER BELOW:

CAUTION – LASER RADIATION WHEN OPEN.

DO NOT STARE INTO BEAM

ORDER NO.

RRV3067

DVD-R7783

DVD-R/RW DRIVE UNIT

DVD-R7783

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Remarks

DVD-R7783 ZUCYV/WL DC Power supply from other system

This service manual should be used together with the following manual(s).

Model No. Order No. Remarks

DRM-7000 RRV2173 700 DISC CHANGER

DRM-3000 RRV2734 300 DISC CHANGER

For details on SCSI connections, refer to Service Know-How (SKB05001).

•

For details, refer to "Important Check Points for Good Servicing".

T-ZZY JAN. 2005 printed in Japan

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to cause

B

cancer, birth defects or other reproductive harm.

IMPORTANT

The pickup of this device conforms to Class 3A of the FDA Laser Restrictions

(CFR21 PART 1040), and the device, which conforms to Class A as a total

product, is not to be disassembled for repair in the U.S.A. or its territories.

In other districts, the device must be disassembled for repair only by a

specially instructed person with sufficient care against laser light.

Health & Safety Code Section 25249.6 – Proposition 65

C

VARO!

AVATTAESSA JA SUOJALUKITUS

OHITETTAESSA OLET ALTTIINA

NÄKYMÄTTÖMÄLLE LASERSÄTEIYLLE.

ÄLÄ KATSO SÄTEESEEN.

D

ADVARSEL :

USYNLIG LASERSTRÅLING VED ÅBNING

NÅR SIKKERHED SAFBRYDERE ER UDE AF

FUNKTION. UNDGÅ UDSÆTTELSE FOR

STRÅLING.

VARNING!

OSYNLIG LASERSTRÅLNING NÄR DENNA

DEL ÄR ÖPPNAD OCH SPÄRREN

E

ÄR URKOPPLAD. BETRAKTA EJ STRÅLEN.

LASER

kuva 1

Lasersateilyn

varoitusmerkki

WAVELENGTH : 658 nm

WARNING!

DEVICE INCLUDES LASER DIODE WHICH

EMITS INVISIBLE INFRARED RADIATION

WHICH IS DANGEROUS TO EYES. THERE IS

A WARNING SIGN ACCORDING TO PICTURE

1 INSIDE THE DEVICE CLOSE TO THE LASER

DIODE.

IMPORTANT

THIS PIONNER APPARATUS CONTAINS

LASER OF CLASS 1.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DONE BY A SPECIALLY

INSTRUCTED PERSON.

LASER DIODE CHARACTERISTICS

MAXIMUM OUTPUT POWER : 35 mw

LASER

Picture 1

Warning sign for

laser radiation

F

2

DVD-R7783

1234

5678

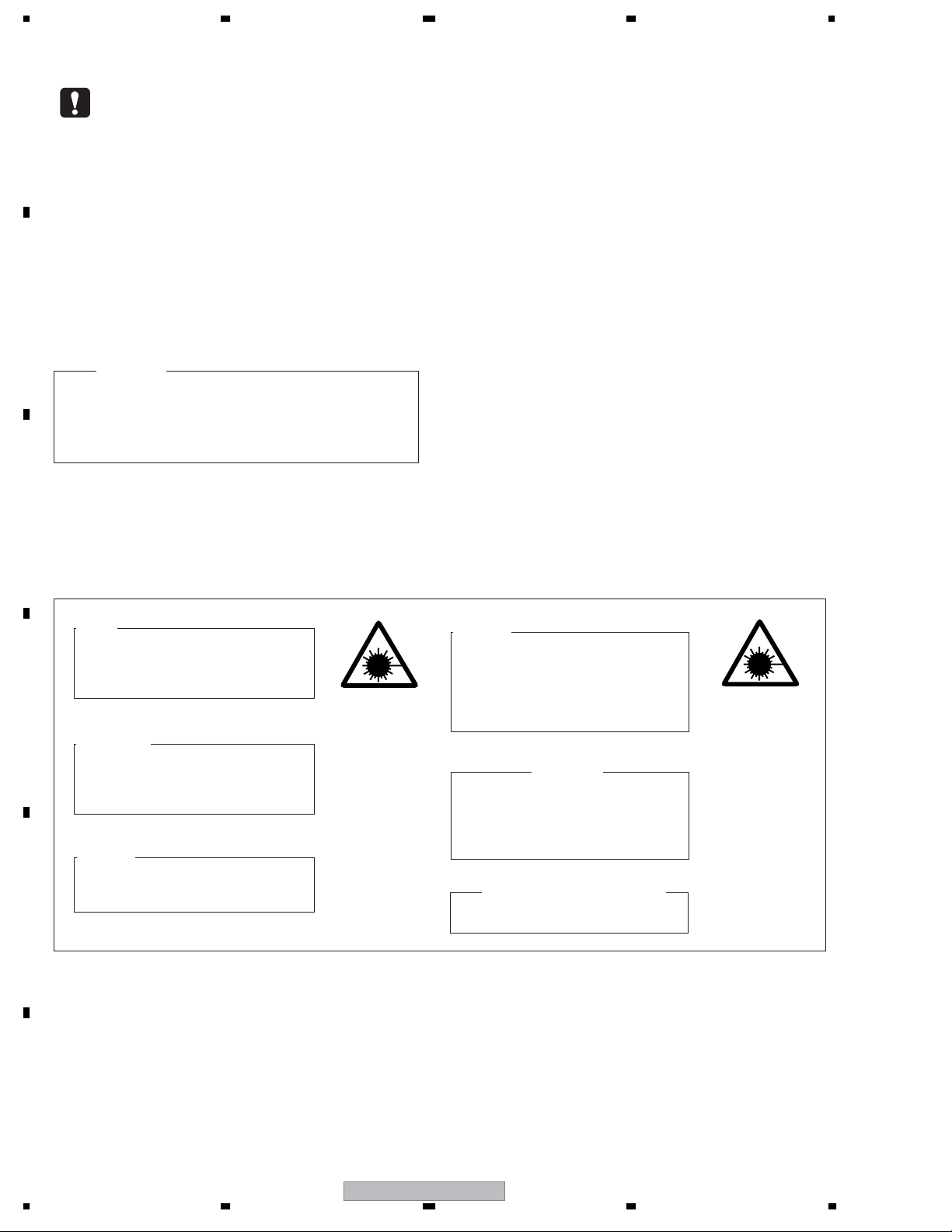

LABEL CHECK

A

B

C

Additional Laser Caution

1. The ON/OFF(ON:low level,OFF:high level) status of the

CLAMP signals for detcting the loading state are detected

by the drive CPUs, and the design prevents laser diode

oscillation when the CLAMP signal turns OFF.

In normal operation, if no disc is clamped, the laser diode

oscillation is disabled.

However, the interlock does not always operate in the test

mode.

*

2. When the cover is opened, close viewing of the objective

lens with the naked eye will cause exposure to a Class 3A

laser beam.

D

E

F

56

DVD-R7783

3

7

8

1234

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

A

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

B

C

D

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

E

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

F

4

1234

DVD-R7783

5678

CONTENTS

1. SPECIFICATIONS .............................................................................................................................................6

2. EXPLODED VIEWS AND PARTS LIST.............................................................................................................8

2.1 PACKING....................................................................................................................................................8

2.2 EXTERIOR SECTION ..............................................................................................................................10

2.3 CLAMP MECHANISM SECTION .............................................................................................................12

2.4 TRAVERSE & MAIN UNI-S (DXX2554)....................................................................................................14

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM ..........................................................................................16

3.1 BLOCK DIAGRAM....................................................................................................................................16

3.2 OVERALL WIRING DIAGRAM .................................................................................................................18

3.3 MAIN ASSY (1/4)......................................................................................................................................20

3.4 MAIN ASSY (2/4)......................................................................................................................................22

3.5 MAIN ASSY (3/4)......................................................................................................................................24

3.6 MAIN ASSY (4/4)......................................................................................................................................26

3.7 WIFB and FCRB ASSYS ..........................................................................................................................28

3.8 ATAPI/SCSI BOARD .................................................................................................................................30

3.9 WAVEFORMS...........................................................................................................................................32

4. PCB CONNECTION DIAGRAM ......................................................................................................................33

4.1 MAIN ASSY ..............................................................................................................................................34

4.2 WIFB and FCRB ASSYS ..........................................................................................................................38

4.3 ATAPI/SCSI BOARD .................................................................................................................................40

5. PCB PARTS LIST ............................................................................................................................................41

6. ADJUSTMENT ................................................................................................................................................42

7. GENERAL INFORMATION .............................................................................................................................43

7.1 DIAGNOSIS..............................................................................................................................................43

7.1.1 OPERATIONAL DIAGNOSIS PROGRAM..........................................................................................43

7.1.2 REWRITING SERIAL NO...................................................................................................................45

7.1.3 FIRMWARE VERSION UP OF MAIN ASSY ......................................................................................45

7.1.4 HOW TO CONFIRM AND UPDATE THE FIRMWARE VERSION OF THE ATAPI/SCSI BOARD ......46

7.1.5 ACQUISITION OF THE ERROR HISTORY .......................................................................................47

7.1.6 TROUBLE SHOOTING.......................................................................................................................59

7.1.7 SCSI ERROR CODE TABLE..............................................................................................................60

7.1.8 AGING MODE ....................................................................................................................................62

7.1.9 DISASSEMBLY ..................................................................................................................................64

7.1.10 INSTALLATION OF THE DRIVE.......................................................................................................67

7.2 IC INFORMATION ....................................................................................................................................68

8. PANEL FACILITIES .........................................................................................................................................95

A

B

C

D

56

DVD-R7783

E

F

5

7

8

1234

1. SPECIFICATIONS

[Supported Formats]

A

Writing format

DVD-R for General Ver. 2.0 ................ Disc at Once, Incremental

DVD-RW Ver. 1.2 ................................ Disc at Once, Incremental, Restricted Overwrite

* Recommended number of overwrites on DVD-RW media: 100 times or less

Reading format

B

DVD+R/RWs, DVD-RAMs and CD-RWs cannot be read nor written.

Does not support recording on CD-R media.

[Writing/Reading speed]

Writing Speed

DVD-R for General Ver. 2.0 Rev. 3....... 8X (ZCLV), 6X (CLV), 4X (CLV)

DVD-RW Ver. 1.2 ................................. 4X (CLV), 2X (CLV)

(at normal room temperature).

DVD-ROM, DVD-Video

DVD-R (for General / Authoring 3.95 GB, 4.7 GB)

DVD-RW Ver. 1.1, Ver. 1.2

CD-ROM Mode 1

CD-ROM XA Mode 2 (form 1, form 2)

CD-R, CD-DA, CD-Extra, Video CD

Reading Speed (max.)

C

DVD-ROM (single) ............................... 12X (CAV)

DVD-ROM (dual) ................................. 8X (CAV)

DVD-R ................................................. 8X (CAV)

DVD-RW .............................................. 8X (CAV)

CD-ROM .............................................. 40X (CAV)

CD-R .................................................... 40X (CAV)

CD-DA ................................................. 40X (CAV)

Video CD .............................................. 9.3X (CAV)

[Reading Performance]

Data transmission speed (Sustained max.)

D

E

DVD-ROM (single) .............................. 16620 KB/sec

DVD-ROM (dual) ................................. 11080 KB/sec

DVD-R ................................................. 11080 KB/sec

DVD-RW .............................................. 11080 KB/sec

CD-ROM .............................................. 6000 KB/sec

CD-R .................................................... 6000 KB/sec

Note that the transmission speed may vary depending on the state (e.g., the existence of scratches) of the disc being

used.

Access time (Random average)

DVD-ROM (single) ............................... 140 ms

DVD-ROM (dual) .................................. 160 ms

DVD-R .................................................. 150 ms

DVD-RW .............................................. 150 ms

CD-ROM .............................................. 130 ms

CD-R/RW ............................................. 130 ms

F

6

1234

DVD-R7783

5678

[Data buffer capacity]

2.0 MBytes (writing, reading)

[Interface]

Wide Ultra-2 SCSI (80 MB/s)

* Maximum effective speed approx. 40 MB/s

[Buffer under-run free mode]

Although the default setting is ON, this setting can be changed to OFF depending on the application in use. This mode is

locked in the ON mode and cannot be turned off during the 8X (ZCLV) recording of a DVD-R.

[Others]

Power supply ....................................... DC +12 V, 1.0 A

DC +5 V, 1.5 A

External dimensions ............................ 187.9 (W) x 73.3 (H) x 260.7 (D) mm

7-3/8 (W) x 2-7/8 (H) x 10-1/4 (D) in.

Weight 2.0 kg (4.4 lb)

Operation temperature ........................ +5 °C to +35 °C (+41 °F to +95 °F)

(The temperature outside the changer)

Operation humidity .............................. 5 % to 85 % (no condensation)

(The humidity outside the changer)

Storage temperature ........................... –40 °C to +60 °C (–40 °F to +140 °F)

Storage humidity ................................ 5 % to 90 % (no condensation)

A

B

• Discs recorded on this unit may not playback properly on players or drives which do not support the same media format.

• Specifications and design subject to possible modifications without notice, due to improvements.

C

D

E

56

DVD-R7783

F

7

7

8

1234

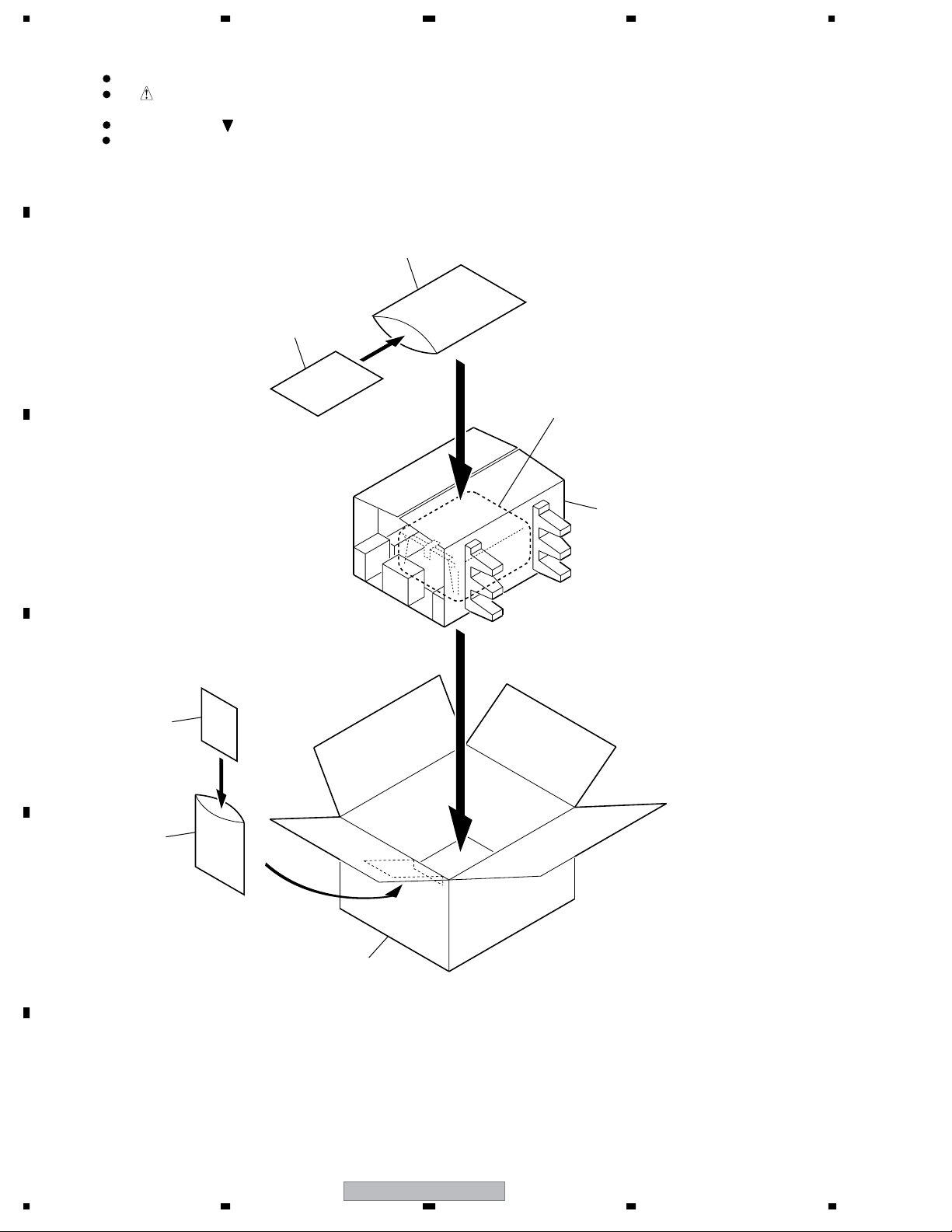

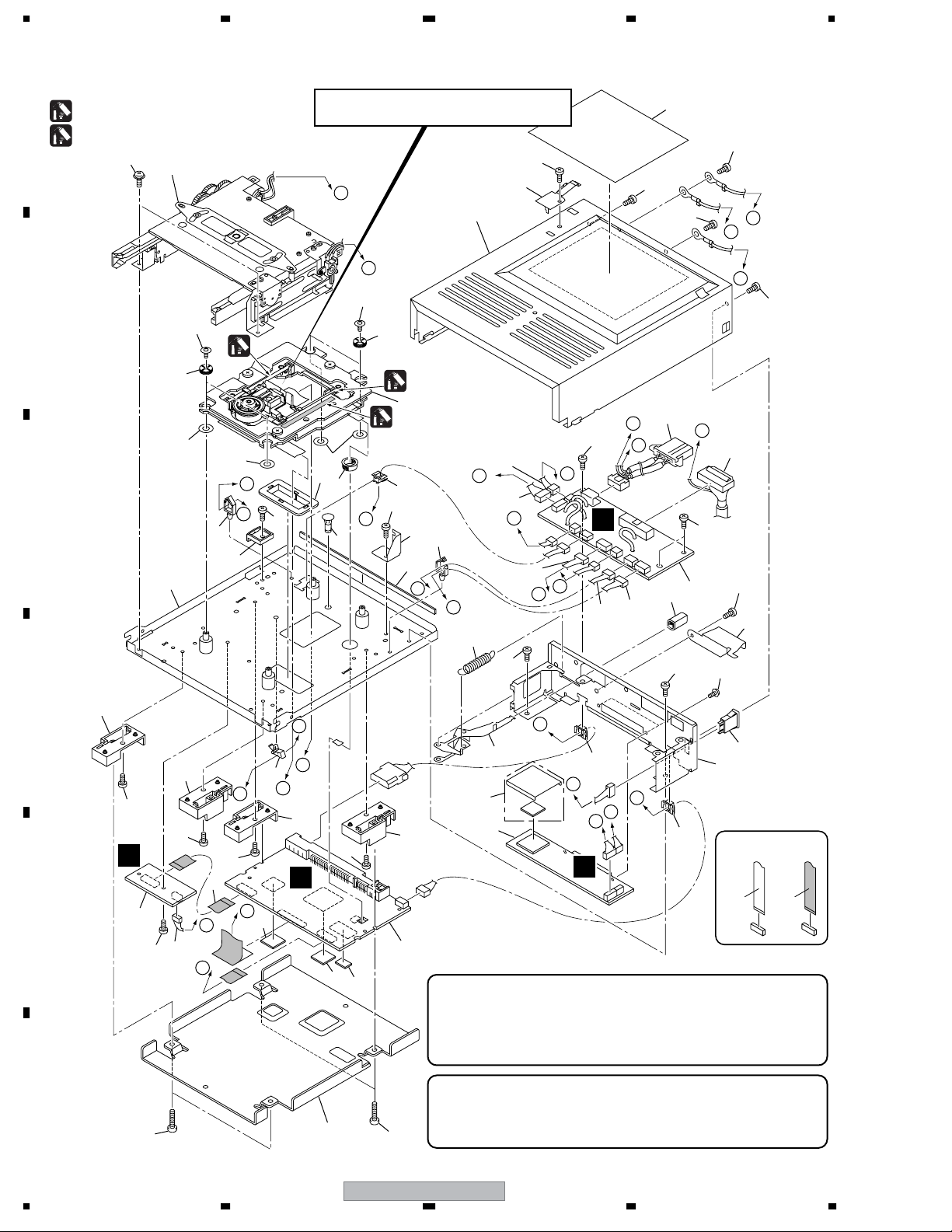

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

A

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

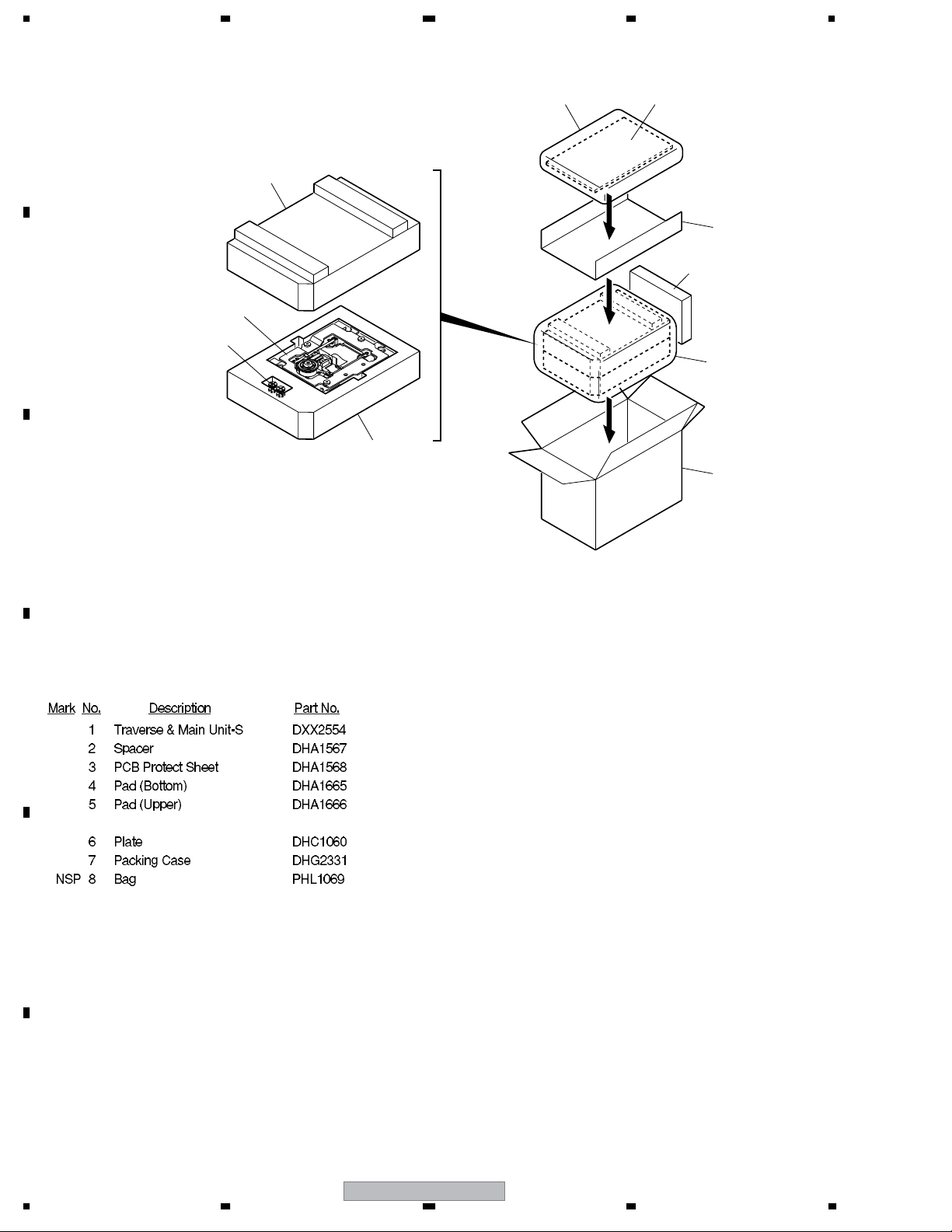

2.1 PACKING

B

C

4

2

7

5

D

E

F

1

3

6

8

1234

DVD-R7783

5678

PACKING Parts List

NSP 1 Warranty Card ARY1093

2 Operating Instructions DRC1229

(English / French / German / Chinese / Japanese)

NSP 3 Polyethylene Bag Z21-010

(0.018 x 100 x 230)

NSP 4 Polyethylene Bag Z21-038

(0.03 x 230 x 340)

5Pad DHA1494

6Packing Case DHG2455

7 Bag DHL1052

A

B

C

D

E

56

DVD-R7783

F

9

7

8

1234

2.2 EXTERIOR SECTION

Note ;

A

∗3 : Froil: ZLB-PN397B (GYA1001)

∗4 : Froil: ZLB-947P

Refer to

42

"2.3 CLAMP MECHANISM SECTION".

Note :

As the laser driver is mounted on the pickup, no short-circuit

switch for the laser diode is provided.

43

A

17

21

43

39

44

44

L

K

B

36

32

30

29

44

41

F a

38

∗1

∗3

44

31

5

35

27

∗1

∗4

23

8

K

44

L

12

E a

7

A

33

J

I

16

43

18

34

4

14

C

E b

D

B

B

13

31

I

D

C

15

26

43

J

31

D

B

41

∗3

38

∗1

32

C

28

D

27

27

44

44

C

33

6

44

25

32

F b

E a

E b

37

44

F a

H

G

27

A

M

43

M

9

44

43

2

24

46

11

20

E

3

10

44

H

F b

G

47

19

48

1

∗1 ∗2

Note ∗1:

NON-CONTACT

SIDE

CONTACT SIDE

The MAIN Assy (No. 1), Traverse Mechanism Assy (No. 5),

and Float Rubber R5 (No. 38) are provided together as the

components of the Traverse & Main Unit-S (DXX2554) service

parts. For details, see "2.4 TRAVERSE & MAIN UNIT-S."

Note ∗2:

F

45

22

10

1234

If the No. 1 MAIN Assy is replaced, it is required to write the same

serial number as that of the old Assy in the new Assy. See "7.1.2

HOW TO REWRITE THE SERIAL NUMBER."

45

DVD-R7783

5678

EXTERIOR SECTION Parts List

No. Description Part No.

Mark

1 MAIN Assy DXX2554(1/2)(*1)(*2)

2 WIFB Assy DWX2388

3 FCRB Assy DWX2389

4 ATAPI/SCSI Board DWP1082

5Traverse Mechanism Assy DXX2554(2/2)(*1)

6 Flexible Cable (12P) DDD1268

7 Connector Assy DKP3486

8 Connector Assy DKP3537

9 Connector Assy (20P) DKP3675

10 Connector Assy (4P) DKP3676

11 Rotary Switch DSX1063

12 Connector Assy PD02EE-D17

13 Connector Assy PF04PP-B22

14 Connector Assy PF05PP-B15

15 Connector Assy PG05MM-G17

16 PL Lock Spring DBH1447

17 PL Earth Plate DBK1174

18 PL Lock Arm DBK1187

19 Silicone Sheet B DEB1520

20 PL Rear Panel (R7) DNC1702

21 Upper Cover DR DNE1493

22 Bottom Plate (R7) DNF1698

23 Board Stay DNF1699

24 PL Grip DNH2399

25 PL Rail DNK3665

26 PL Lock Cap DNK3667

27 Board Hook DNK4327

28 PL Base (R7) Assy DXB1823

29 Card Spacer AEC7133

30 Bush DEC1220

31 Edge Saddle (0607U) DEC1807

32 Slider Washer DEC2213

33 Locking Mini Clamp DEC2439

34 IC Cover DEC2701

35 Acetate Tape (164 x 10) DED1141

36 Protector V2 DNK3393

NSP 37 Mini Clamp VEC1597

38 Float Rubber R5 DEB1556 (*1)

(This part is also available as an optional part.)

NSP 39 Model Label DAL1159

40 • • • • •

41 Float Screw DBA1246

42 Screw DBA1258

43 Screw BBT30P060FTB

44 Screw BBZ30P060FTC

45 Screw BBZ30P180FTC

46 Screw PMA26P060FNI

47 Silicone Sheet R5 A DEB1572

48 Silicone Sheet R7 A DEB1673

A

B

C

D

E

F

56

DVD-R7783

11

7

8

1234

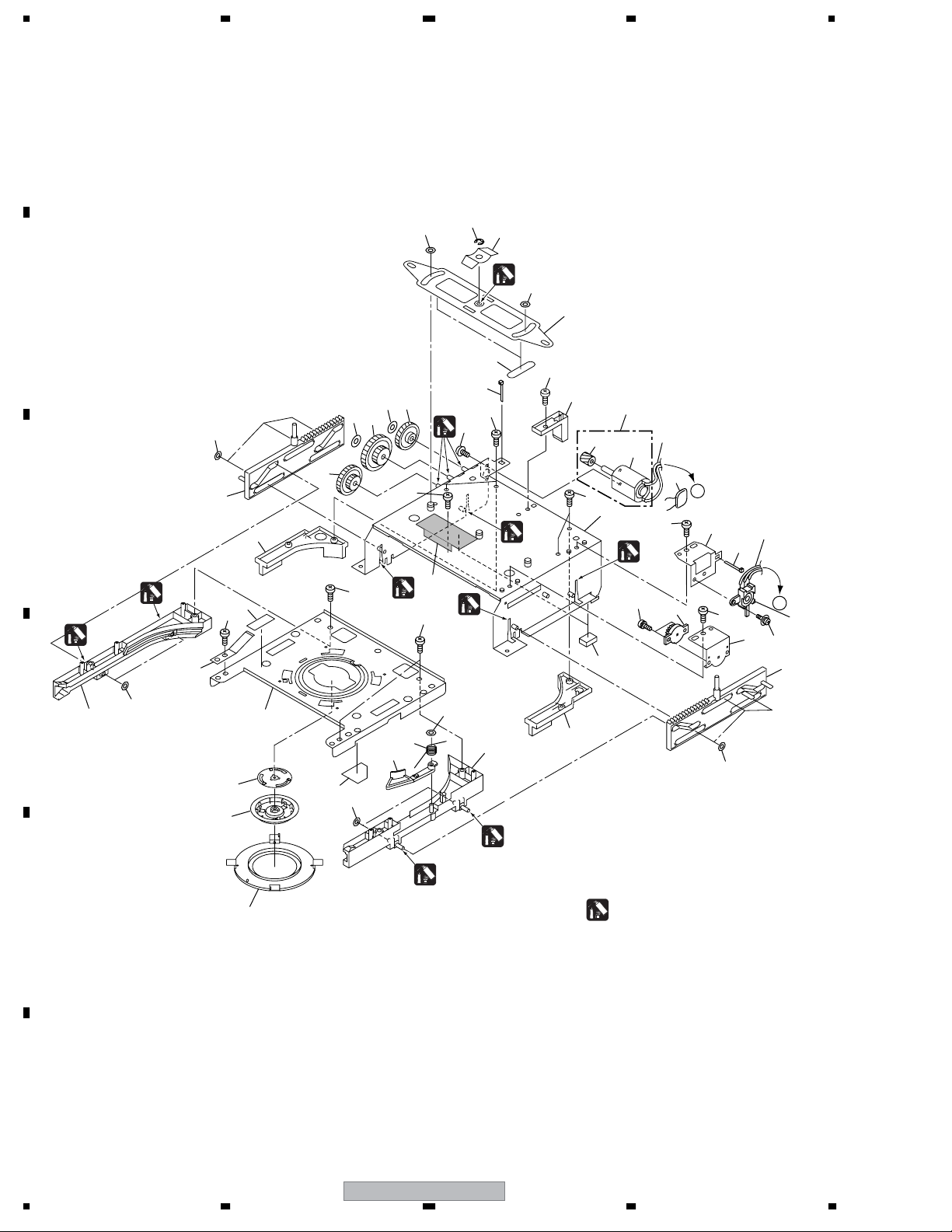

2.3 CLAMP MECHANISM SECTION

A

B

38

36

5

38

13

8

22

37

37

37

17

21

C

18

29

39

6

D

23

37

10

33

34

16

45

39

39

4

14

9

37

35

39

40

27

37

24

43

20

19

39

15

32

3

28

1

A

12

7

44

42

30

11

42

37

35

31

2

B

26

41

21

Note ;

E

F

12

1234

25

DVD-R7783

: Froil: ZLB-PN397B (GYA1001)

5678

Parts List

No. Description Part No.

Mark

1 Capacitor (C1) CFTLA224J50

2 Connector Assy (3P) DKP3281

3 Connector Assy PF02PY-B15

4 Disc Holder Spring DBH1342

5 Spring DBK1134

6 Earth Plate DBK1139

7 Cushion DEB1355

8 Slide Sheet DEC2034

9 Disc Holder Sheet DEC2700

10 Clamper Stay (R7) DND1251

11 Switch Bracket DNF1700

12 Clamper Base DNH2614

13 Joint Arm DNH2615

14 CL Disc Holder DNK3253

15 Motor Gear DNK3254

16 CL Gear (B) DNK3256

17 CL Gear (C) DNK3257

18 Disc Holder (L) DNK3289

19 Disc Holder (R) DNK3290

20 Disc Stopper DNK3291

21 Rack Plate DNK3292

22 CL Gear (A) DNK3363

23 Side Rack (L) DNK3364

24 Side Rack (R) DNK3365

25 Clamper Bracket (R7) DNK4328

26 Lever Switch DSK1003

27 Sheet DED1143

28 Motor PXM1002

29 Acetate Tape (G) REH1010

30 Damper Assy VXA1153

31 Damper Bracket DNF1701

32 Clamp Motor Assy-S DXX2336

33 Clamper Plate R5 DNE1423

34 Clamper R5 DNK4017

35 Binder ZCA-SKB90BK

36 E Ring YE30FUC

37 Washer WT26D047D050

38 Washer WT36D072D050

39 Screw BPZ30P080FCU

40 Screw PMH20P040FTC

41 Screw PMH26P060FTC

42 Screw BBZ30P060FTC

43 Screw BBZ30P080FTB

44 Screw PMA20P050FCU

45 Screw BBZ30P040FTC

A

B

C

D

E

56

DVD-R7783

F

13

7

8

1234

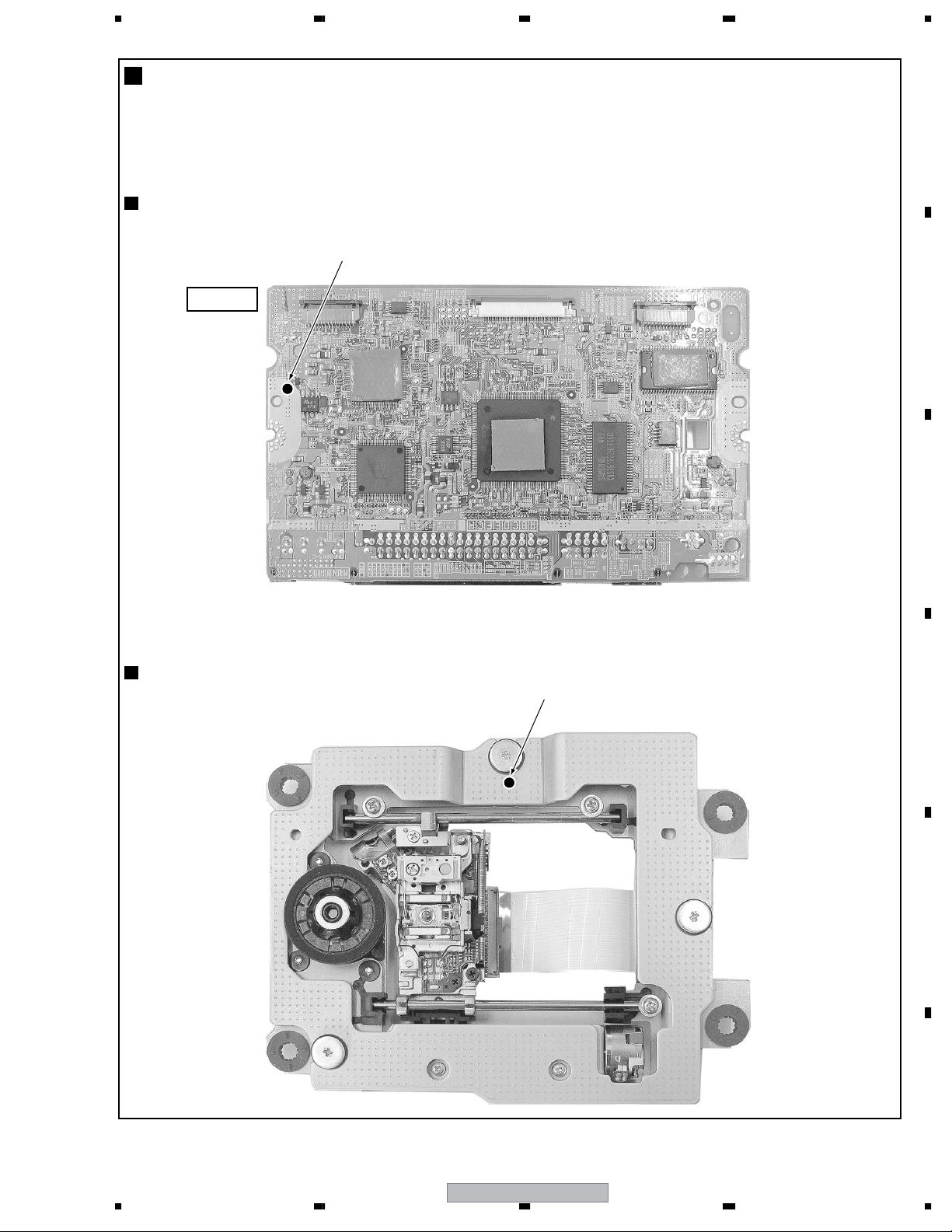

2.4 TRAVERSE & MAIN UNI-S (DXX2554)

A

5

1

(2/3)

B

(Traverse Mechanism Assy)

(3/3)

(Float Rubber R5 ×4)

1

4

1

(1/3)

3

(MAIN Assy)

6

2

8

7

C

TRAVERSE & MAIN UNIT-S (DXX2554) Parts List

D

E

F

14

1234

DVD-R7783

5678

Distinction of the parts to be provided as service parts

The Traverse & Main Unit-S, to be provided as service parts, have markings for distinction (black dot with a felt-tip marker)

at the places shown in the photos below.

Be sure to replace both the Traverse Mechanism Assy and MAIN Assy when either needs to be replaced, because these

parts were adjusted as a pair, and their operations were inspected as a pair before shipment.

MAIN Assy

Marking (black dot)

A

SIDE B

Traverse Mechanism Assy

B

C

Marking (black dot)

D

DVD-R7783

56

E

F

15

7

8

1234

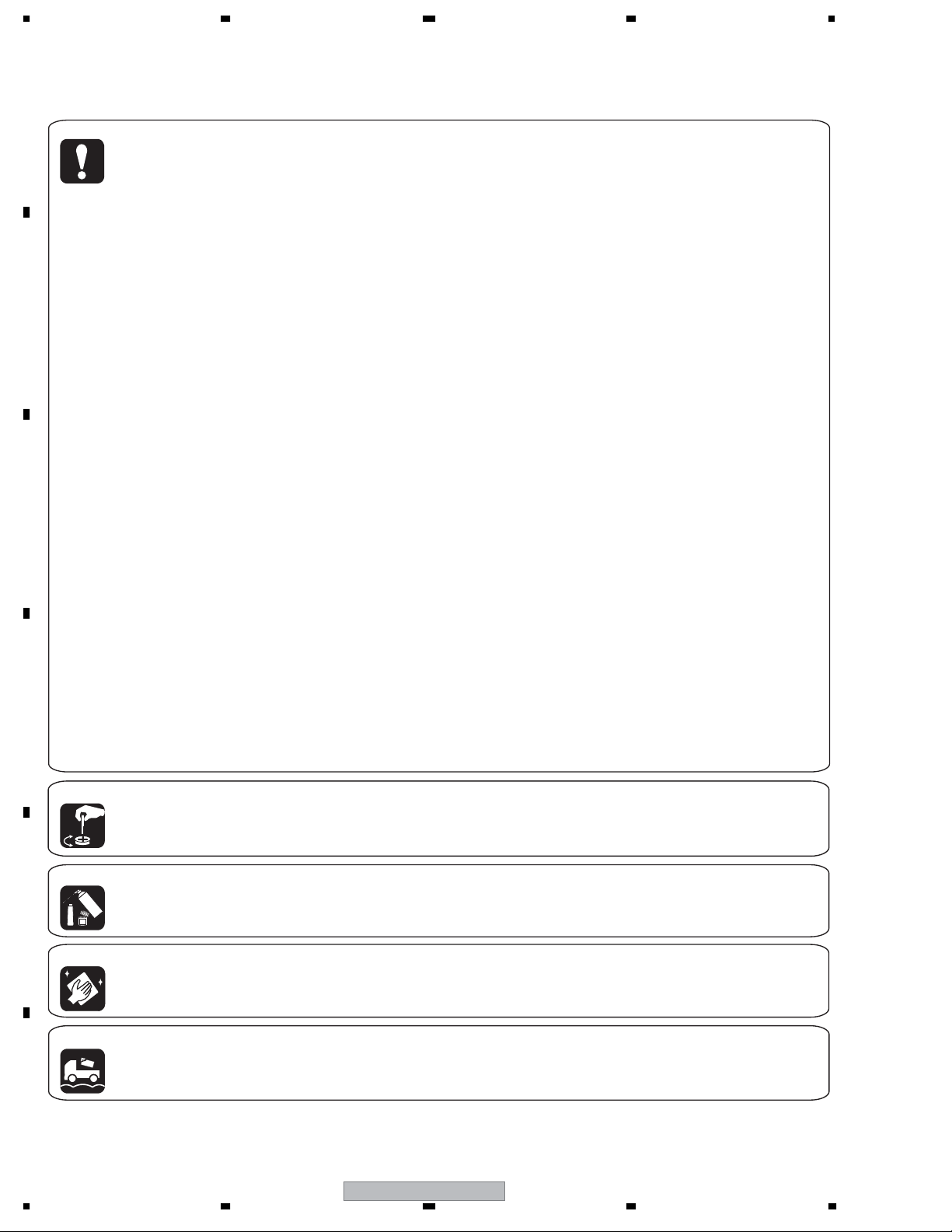

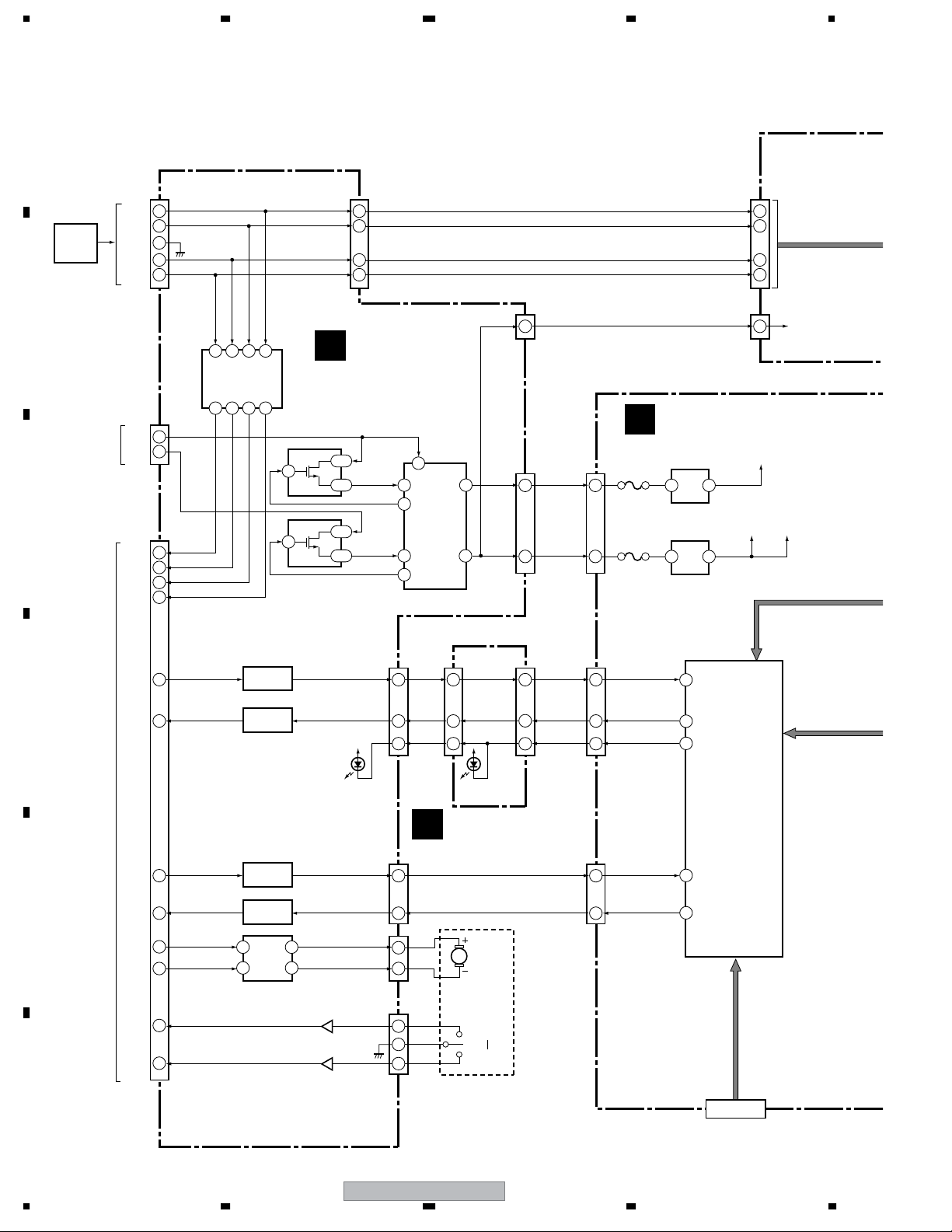

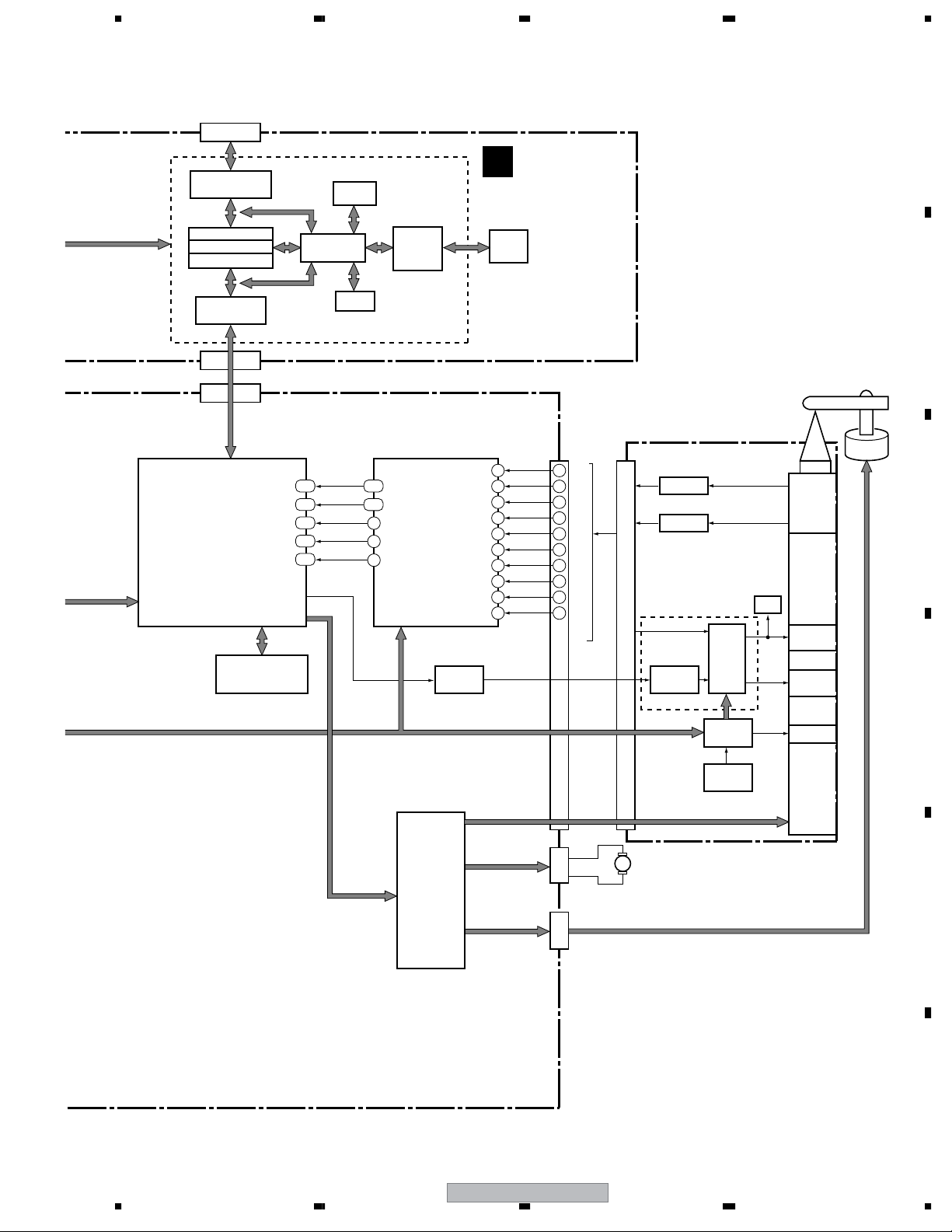

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

A

SCSI ID

SW

(1-15)

CN907 CN908

IDSW3

1

ID3

ID1

GND

ID0

ID2

IDSW1

2

3

IDSW0

4

IDSW2

5

(5P)

ID3

4

ID1

2

ID0

1

ID2

3

CN4

(5P)

ID3

4

ID1

2

ID0

1

ID2

3

B

C

D

E

F

To PIF*

(CHANGER)

To DIF*

(CHANGER)

+12V

+5V

ID2

ID0

ID1

ID3

XCLMP

XSPST

TX

RX

CMC0

CMC1

CLS0

CLS1

CN951

1

4

CN901

10

8

9

11

5

6

13

12

1

2

3

4

(4P)

(20P)

9

1 7 15

IC904

TC74HC375AF

SCSI-ID

LATCH

11 3 5 13

ID2

ID0

ID1

ID3

5V/3.3V

Converter

3.3V/5V

Converter

5V/3.3V

Converter

3.3V/5V

Converter

9

7

TA7291F

Clamp Motor Driver

Q908

Q907

Q909

Q910

IC903

B

IC954, IC955

RSS065N03

IC954

4

IC955

4

D933

BUSY

LED

13

4

Q901

Q902

WIFB ASSY

VDD

5-8

1-3

5-8

1-3

CN903

(4P)

CN904

(4P)

CN905

CN906

1 14

2

Overcurrent

7 8

6

1

3

4

2

1

1

2

1

2

3

3

IC953

HIP1013CB

Protection

CN102

XCLMP

XSPST

BUSY

C

TX

RX

CLM+

CLM-

CLS0

COM

CLS1

(4P)

1

3

4

BUSY LED

FCRB ASSY

M

CLAMP SW

CLAMP MECHA

ASSY

CN953

(2P)

CN952

(4P)

CN101

(12P)

D101

CLAMP

MOTOR

UNCLAMP

CLAMP

+5V

1 1

MAIN ASSY

A

+12V

1

+5V

4

LPS2

3

(CLOSE)

LPS1

2

(OPEN)

LED1 LED1

4

REMI

REMO

CN401

55

58

10

11

9

2

1

(3/3)

CN601

(12P)

CLOSE

OPEN

CN302

(4P)

IC404

S-8520X52MC-LZL

5

IC402

S-8520X15MC-LYA

5

73

72

25

M30700FKLGP

30

29

CONFIGURATION

3

3

IC301

CPU

V+5L

(5.2V)

V+15A

(1.5V)

CN3

(2P)

V+15D

Bus Line

CN401

(2/3)

V+5V

16

DVD-R7783

1234

5678

LVD SCSI INTERFACE

SCSI Controller

Buffer

DMA Controller

Control Register

IDE Controller

IDE

Bus

Line

IC201

UPD63630GM-UEV

S-Combo II DSP

• DVD/CD Decoder

• DVD/CD Encoder

• ATAPI

• Read Channel

• Wobble DPLL

• Servo

K4S161622D-TC80

CN1 (68P)

CN2 (40P)

CN401

IC202

DRAM 16M

RISC

Processor

(1/3)

SWRF1B

126 115

SWRF2B

127

139

141

AWOBBLE

143

Internal

ROM

SRAM

FE

TE

External

UPC3330GC-YEB

116

S-Combo II RF

87

RF, TE, FE, APC,

OPC, Wobble

85

81

Flash

ROM

I/F

IC101

LVDS

DRIVER

ATAPI/SCSI

D

BOARD

Flash

ROM

CN101

(45P)

2 44

3 42

B

8 36

C

9 35

A

7 32

D

10 31

17 40

16 39

14 38

15 37

RF+

RF-

M4

M1

M3

M2

S2

S1

S4

S3

CN101

(45P)

OEIC

FM OEIC

PICKUP ASSY

LD

LVDS

Receiver

Driver

SHF

Pickup

650n

Laser

780n

Laser

SPINDLE

MOTOR

A

B

C

FD, TD,

MD, SL

IC501

BD7905BFS

6 ch Driver

SPDL

Serial Line

CN502

(4P)

CN501

(12P)

STEPPING

M

MOTOR

PU

Controller

Temp.

Sensor

LC TILT

Actuator

Focus/

Tracking

D

E

F

56

DVD-R7783

17

7

8

1234

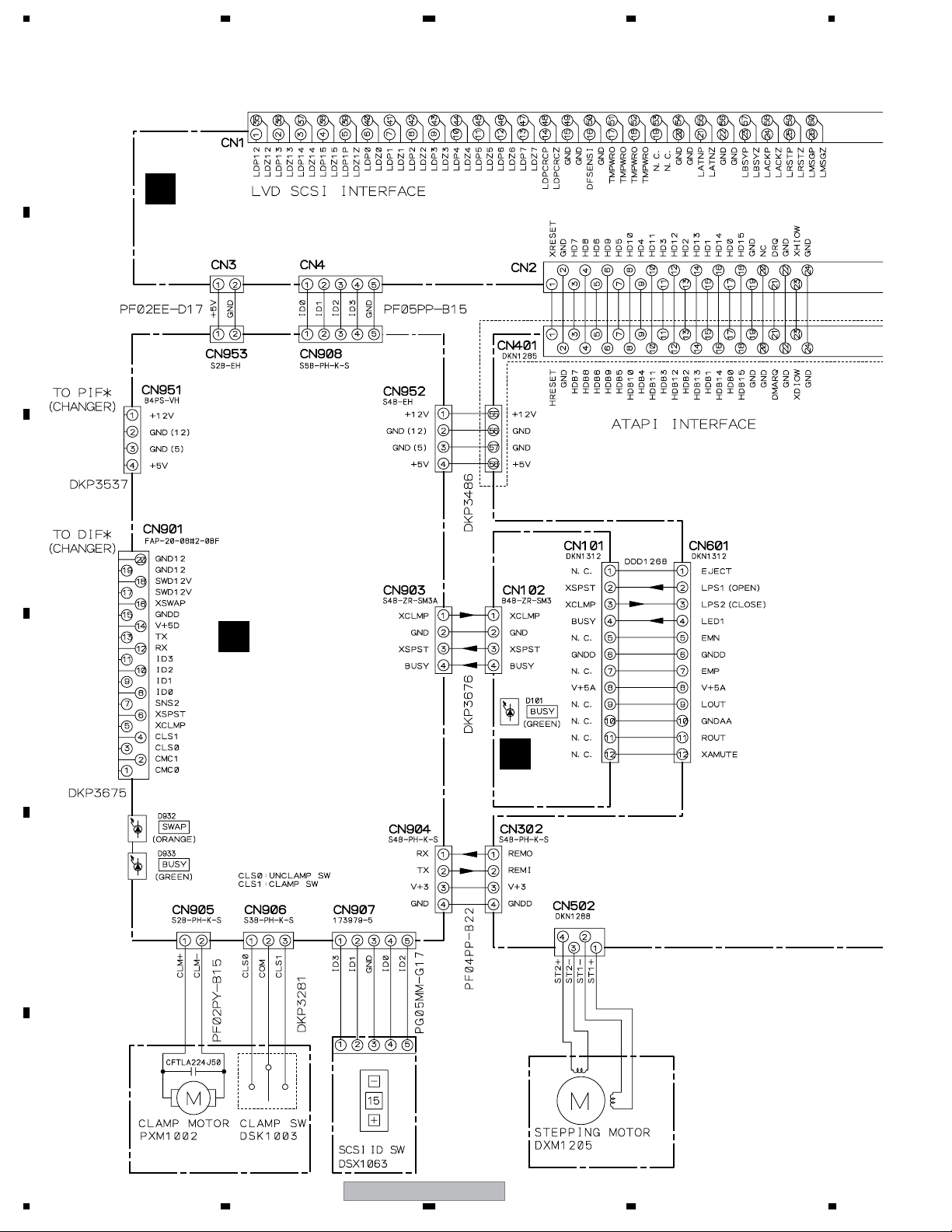

3.2 OVERALL WIRING DIAGRAM

A

D

ATAPI/SCSI BOARD

(DWP1082)

B

C

WIFB ASSY

B

(DWX2388)

D

C

FCRB ASSY

(DWX2389)

E

F

CLAMP MECHA ASSY

18

1234

DVD-R7783

5678

÷

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS

LIST" or "PCB PARTS LIST".

÷

The > mark found on some component parts indicates the importance of the safety

factor of the part. Therefore, when replacing, be sure to use parts of identical

designation.

÷

: The power supply is shown with the marked box.

A

B

C

A

A 1/4 - A 4/4

MAIN ASSY (DWX2312)

PICKUP ASSY

(OWY8044)

D

E

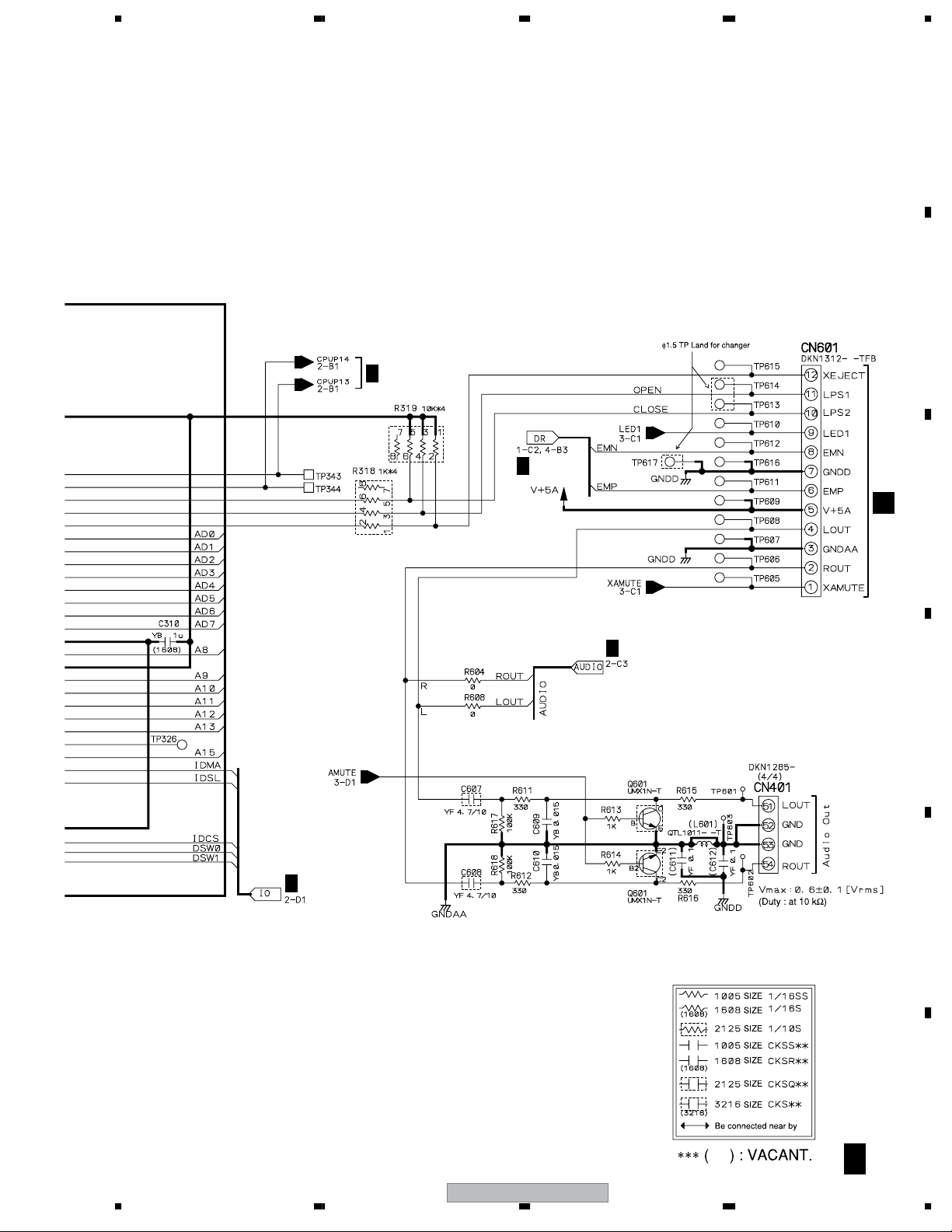

56

DVD-R7783

F

19

7

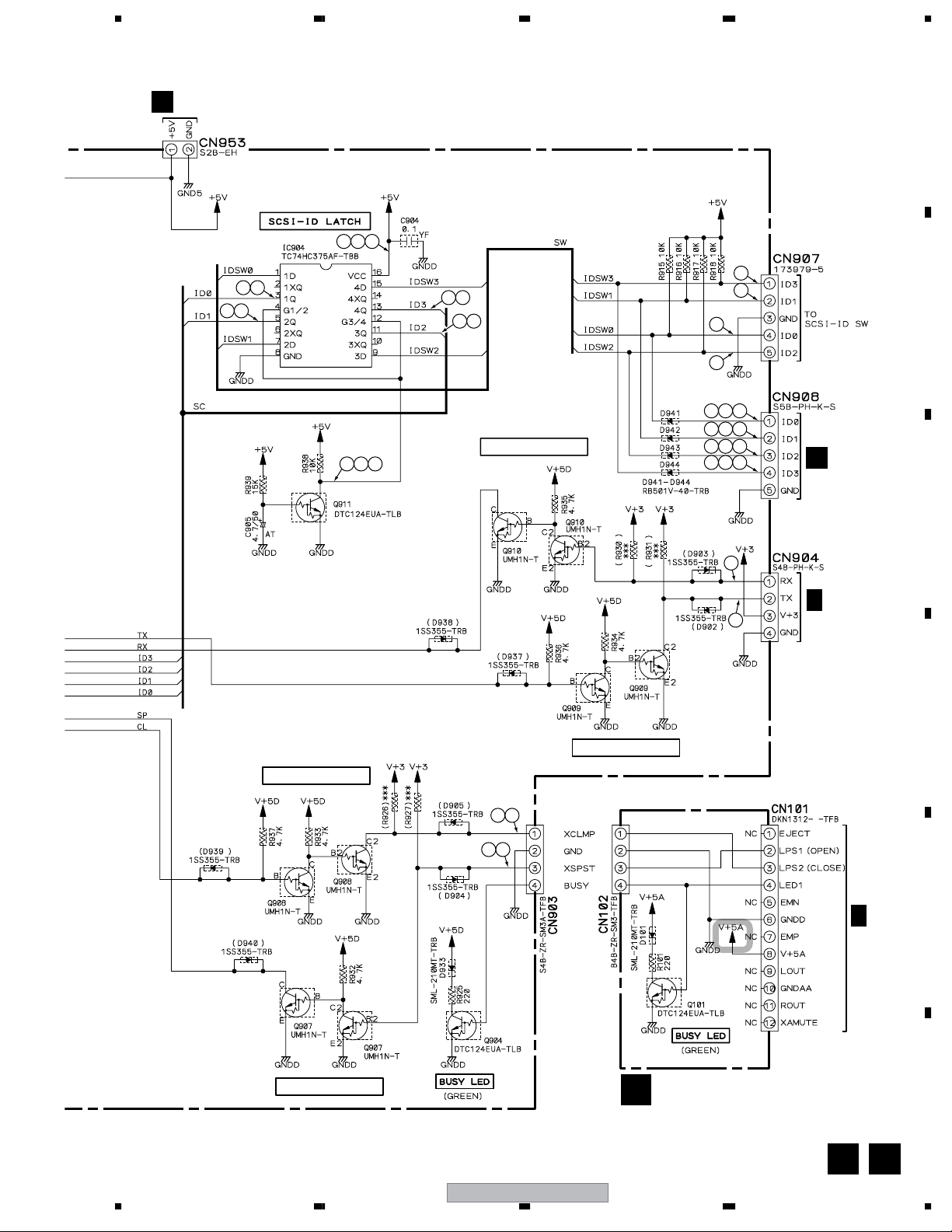

8

1234

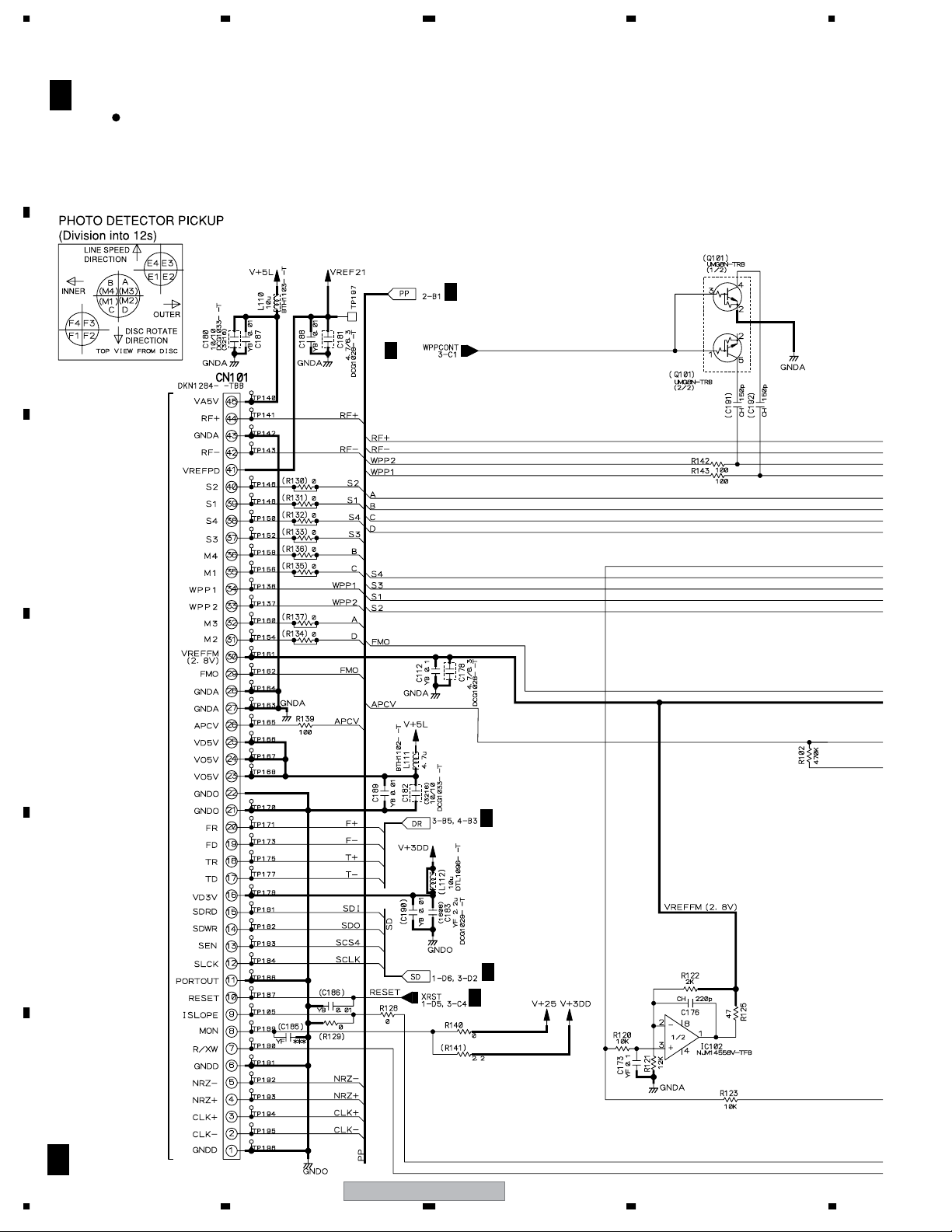

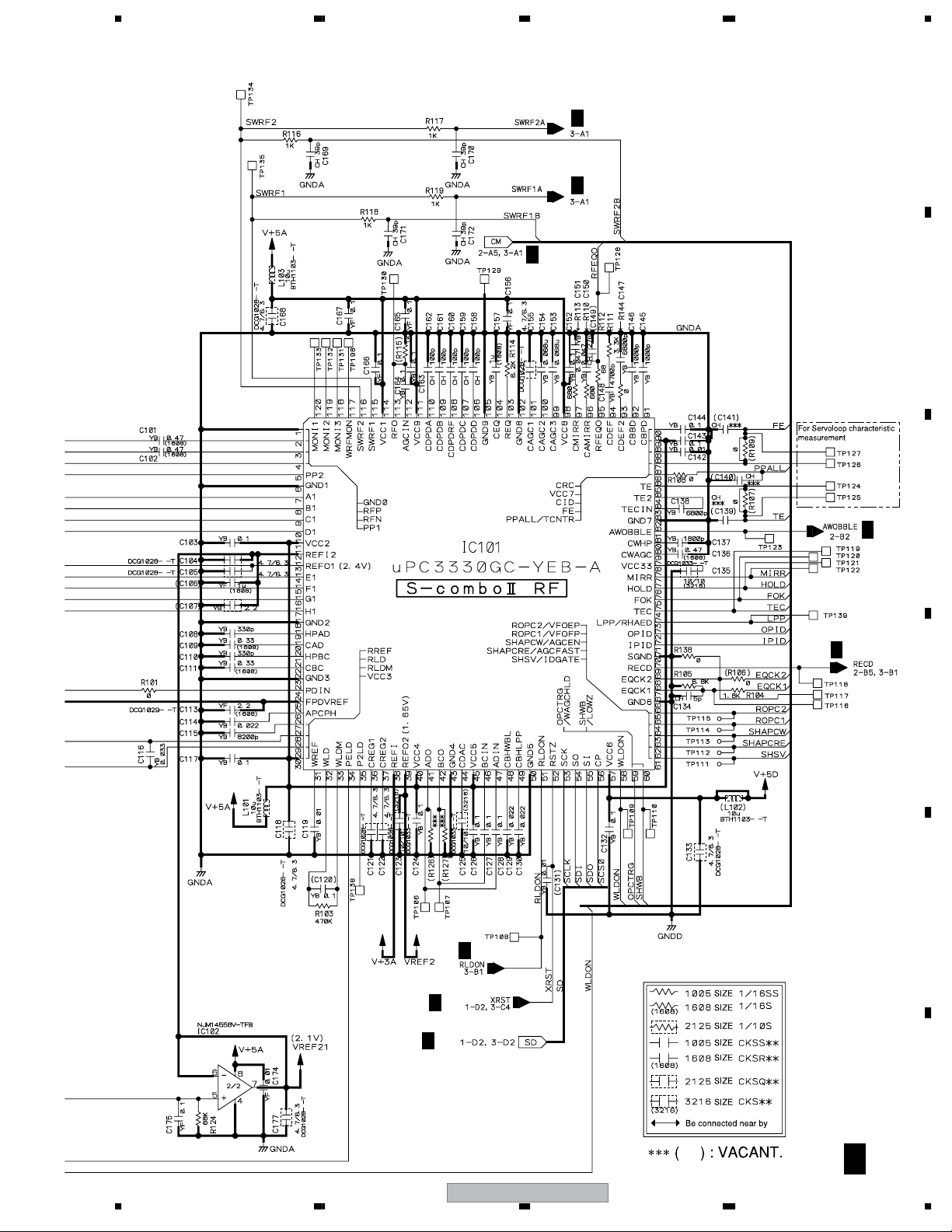

3.3 MAIN ASSY (1/4)

A

B

C

A 1/4

MAIN ASSY (DWX2312)

RF BLOCK

2/4A

3/4

A

D

PICKUP ASSY

E

F

CN101

A

A

3/4

3/4, 4/4

3/4A

A 1/4

20

DVD-R7783

1234

5678

3/4A

A

3/4

A

2/4, 3/4A

B

C

A

2/4

2/4, 3/4

A

D

E

3/4

A

3/4

A

3/4

A

56

DVD-R7783

F

A 1/4

21

7

8

1234

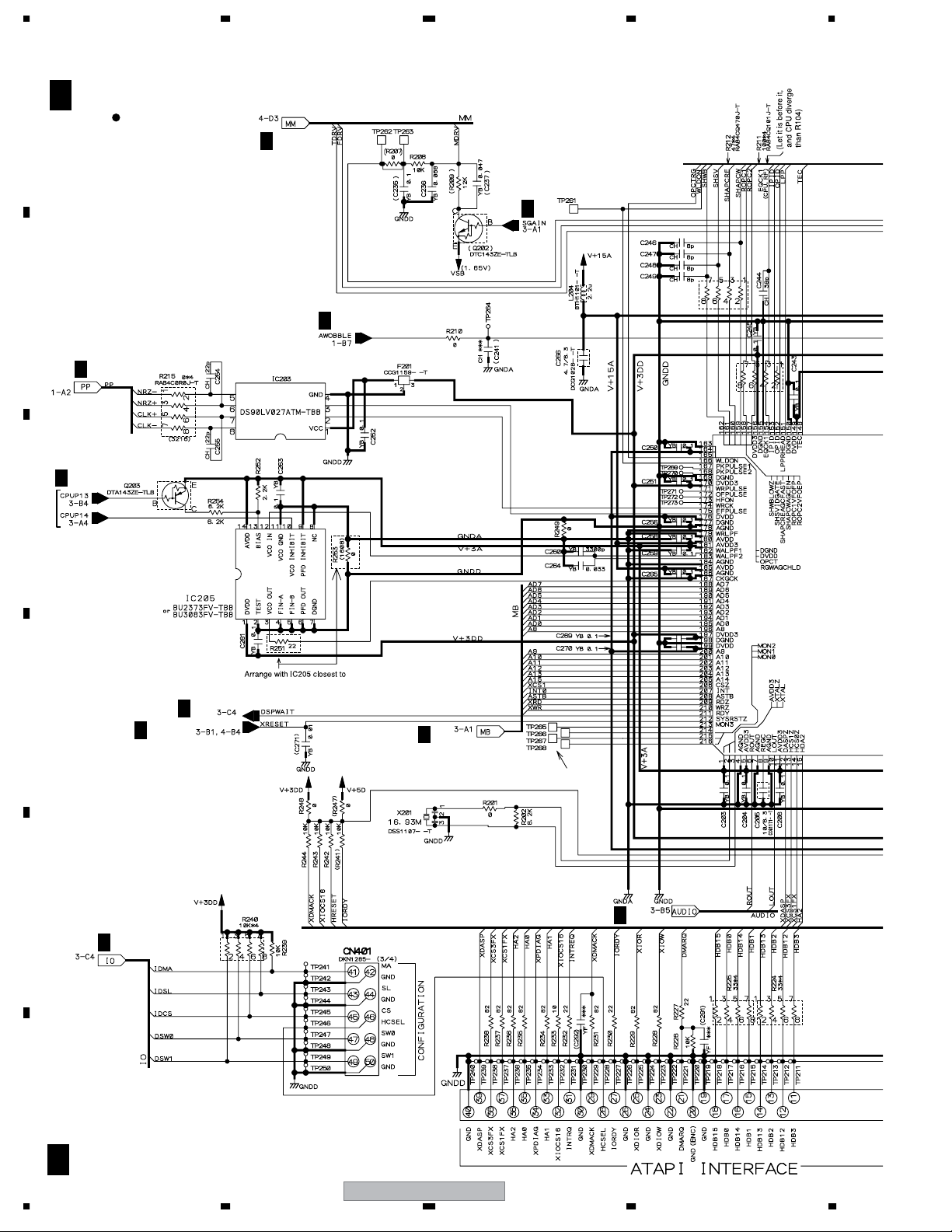

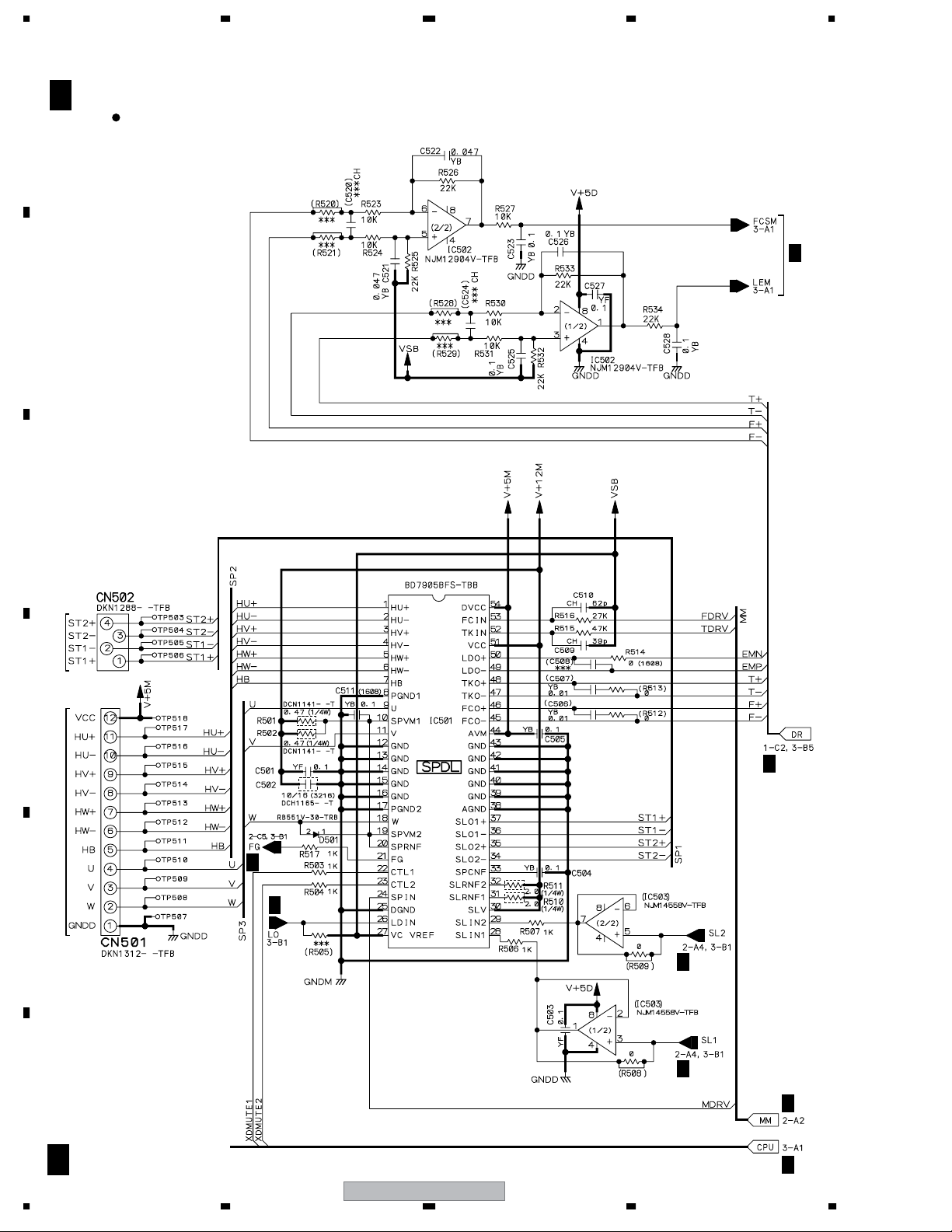

3.4 MAIN ASSY (2/4)

A

B

C

A 2/4

A

1/4

3/4

A

MAIN ASSY (DWX2312)

DSP BLOCK

4/4A

A

3/4

A

1/4

A

D

A

E

3/4

A

F

3/4

3/4, 4/4

A

3/4

Arrange four TP terminals on B side

3/4

A

A 2/4

22

DVD-R7783

1234

5678

3/4, 4/4A

3/4

A

1/4, 3/4

A

1/4, 3/4

A

A

B

C

D

3/4, 4/4A

E

CN2

D

56

DVD-R7783

F

A 2/4

23

7

8

1234

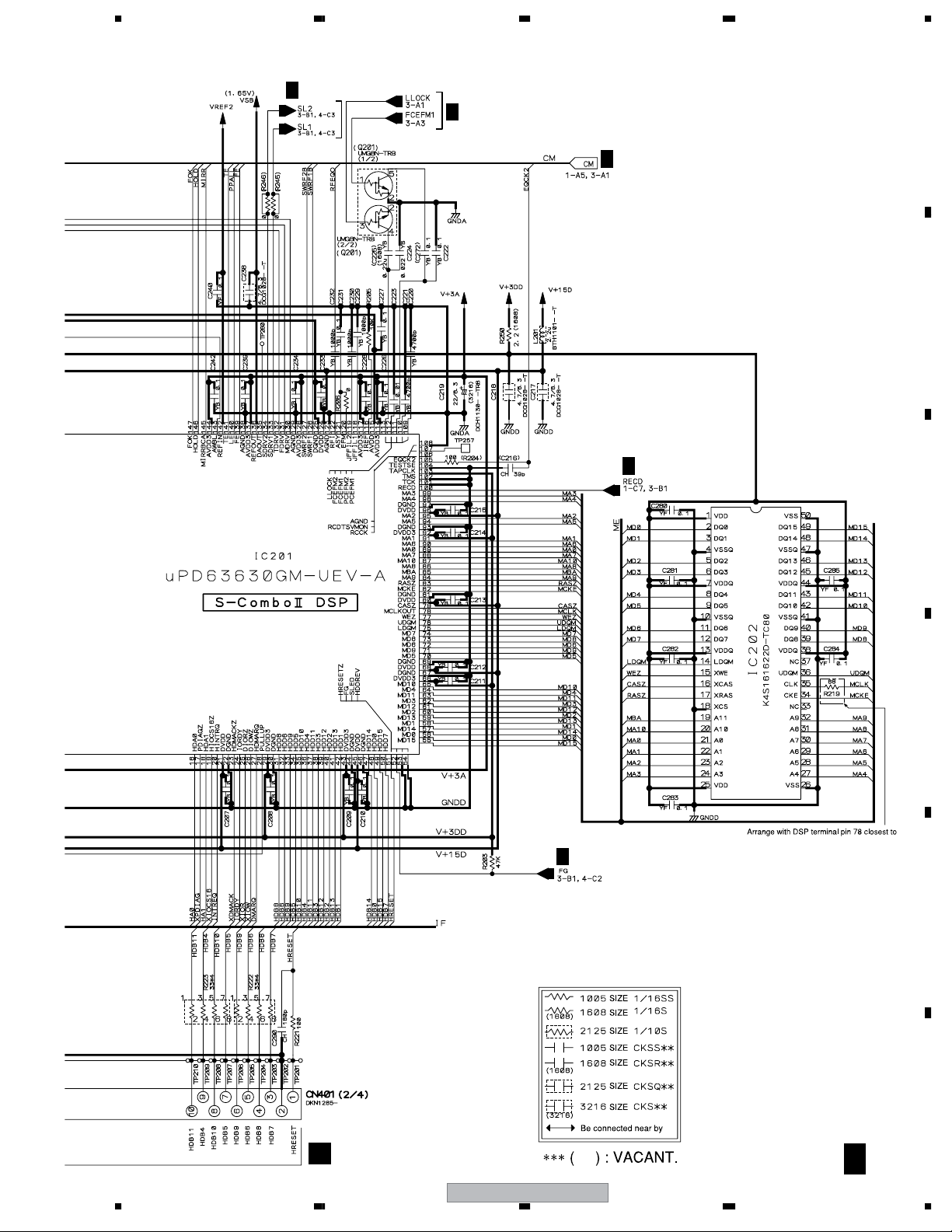

3.5 MAIN ASSY (3/4)

A

B

C

A 3/4

2/4

A

A

4/4

A

1/4A

2/4, 4/4

A

MAIN ASSY (DWX2312)

AUDIO BLOCK

4/4A

1/4A

2/4A

1/4, 2/4

A

2/4, 4/4

3/4

A

A

2/4, 4/4

1/4, 2/4

A

D

A

4/4

A

3/4

E

A

1/4

A

1/4

A

2/4

F

24

A 3/4

B

CN904

1/4

A

DVD-R7783

1234

5678

A

B

2/4A

A

1/4, 4/4

CN101

C

C

2/4A

D

A

2/4

E

56

DVD-R7783

F

A 3/4

25

7

8

1234

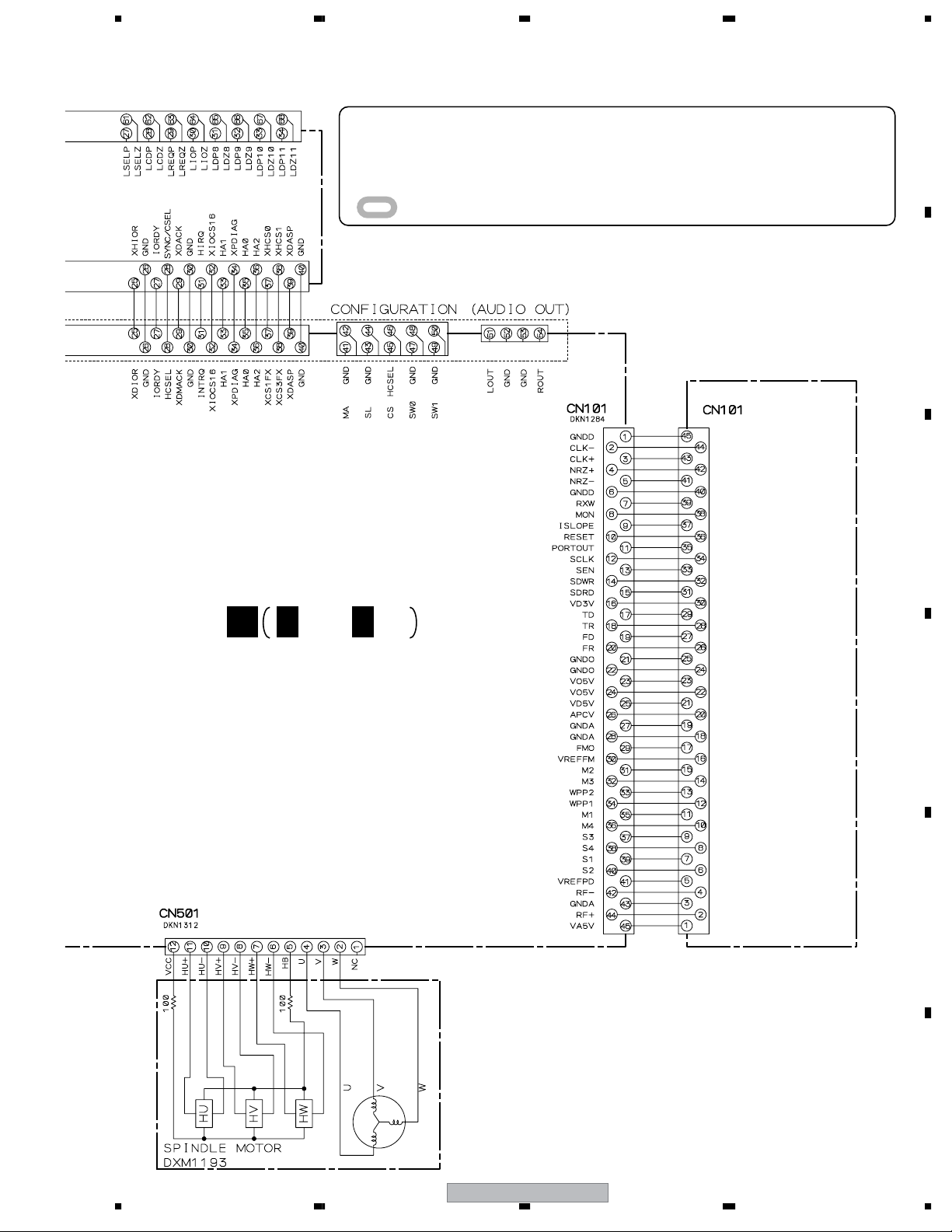

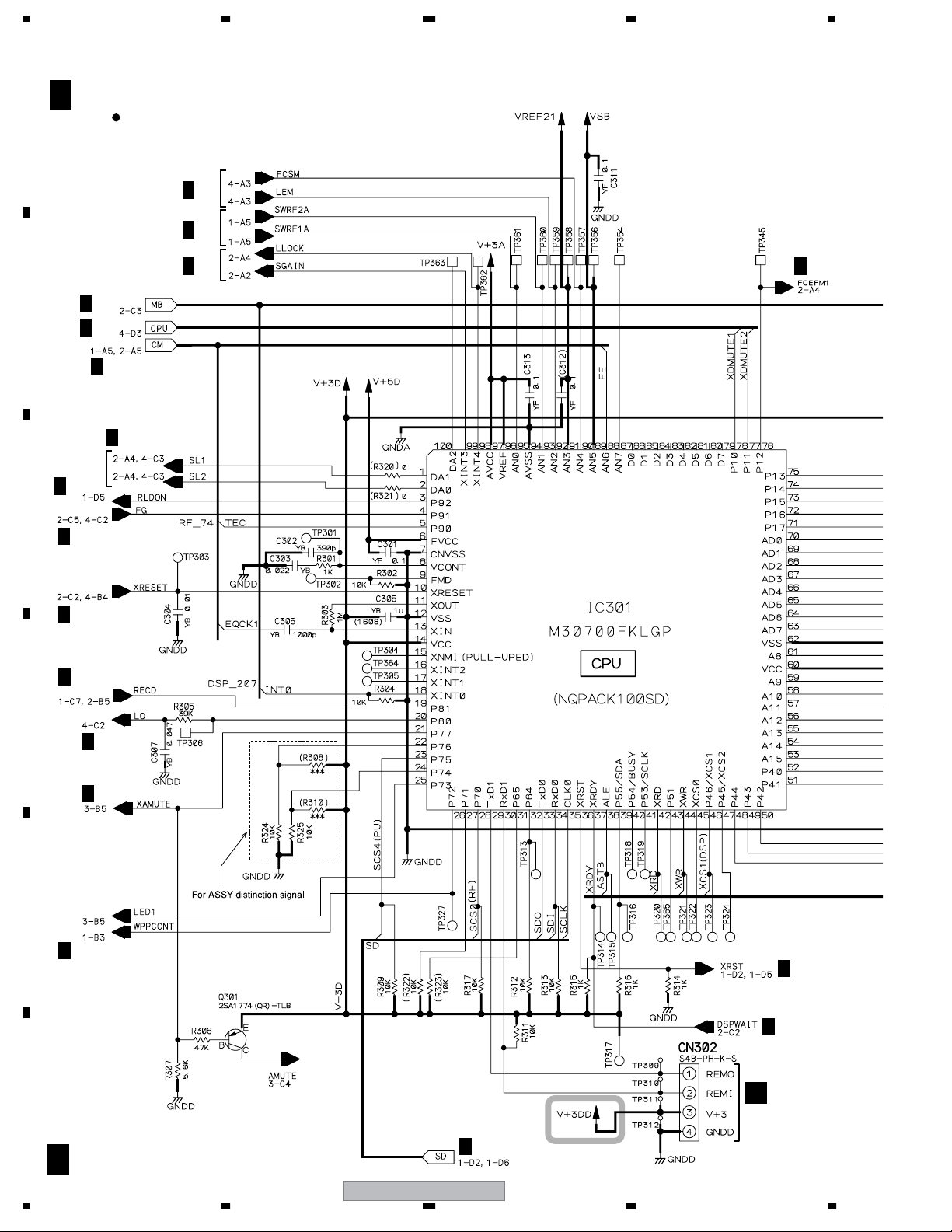

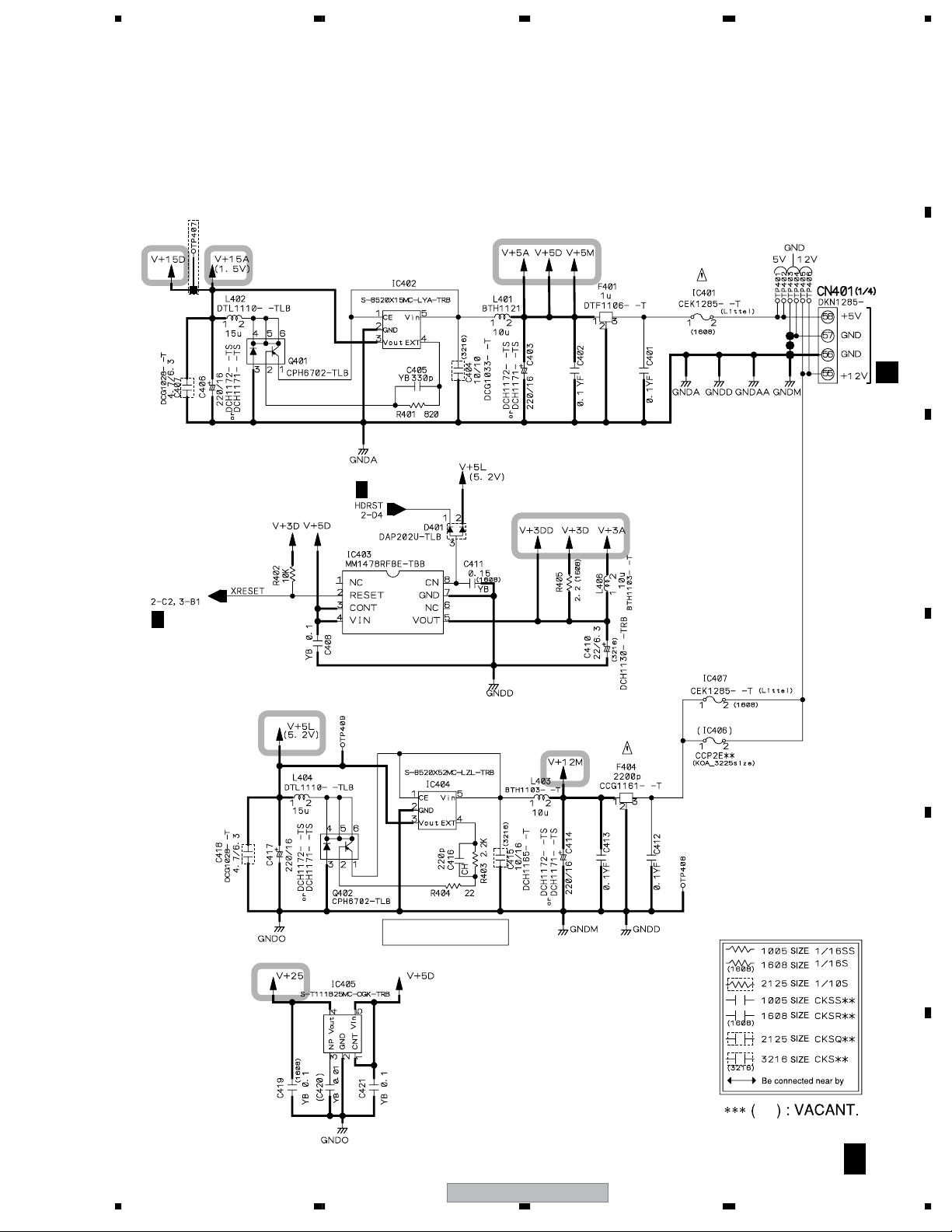

3.6 MAIN ASSY (4/4)

A

B

C

A 4/4

MAIN ASSY (DWX2312)

POWER SUPPLY / DRIVER BLOCK

3/4A

STEPPING MOTORSPINDLE MOTOR

D

E

F

A

1/4, 3/4

2/4, 3/4A

3/4A

A

2/4, 3/4

2/4, 3/4A

2/4

A

A 4/4

26

3/4

A

DVD-R7783

1234

5678

A

B

CN952

B

2/4, 3/4

A

2/4A

5.2V Generateor for LDD

Imax = 0.5A

C

D

E

56

DVD-R7783

F

A 4/4

27

7

8

1234

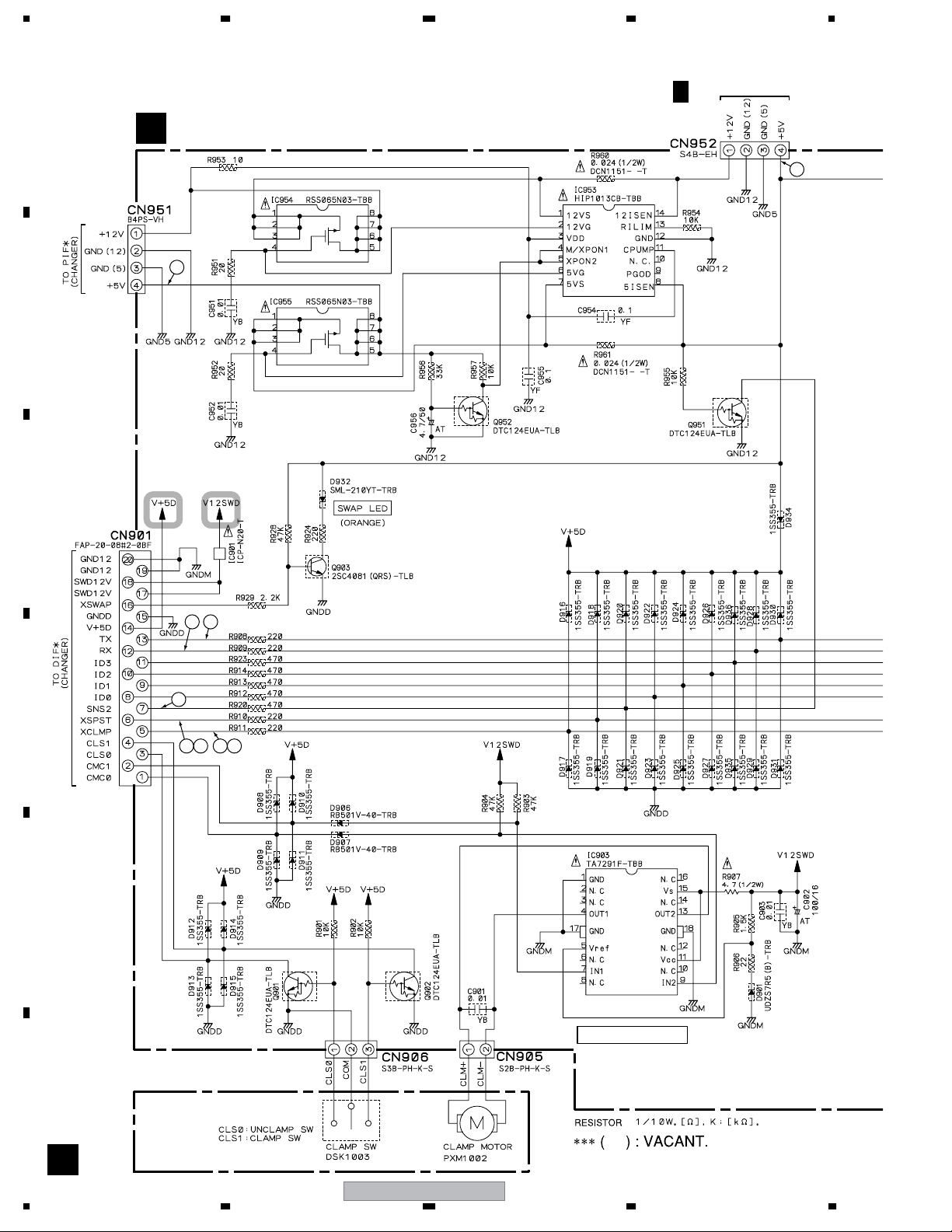

3.7 WIFB and FCRB ASSYS

A

WIFB ASSY (DWX2388)

B

33

B

A 4/4

CN401

34

C

12

D

E

35

6 5 9

10

Clamp Motor Driver

F

BB

28

CLAMP MECHA ASSY

DVD-R7783

1234

D

5678

CN3

21 25 29

A

23 27

23 27

24 28 32

27 31

23 27

3.3V / 5V Converter

17

19

20

18

B

262213

262214

262215

261630

4

D

CN4

C

A 3/4

3

CN302

D

5V / 3.3V Converter

5V / 3.3V Converter

11

7

12

8

3.3V / 5V Converter

56

DVD-R7783

FCRB ASSY (DWX2389)

C

7

A 3/4

CN601

B CB C

8

E

F

29

Loading...

Loading...