Page 1

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2002

DV-45A

DVD PLAYER

DV-45A

DV-656A

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

ORDER NO.

RRV2615

Model Type Power Requirement

DV-45A KUXJ/CA AC120V 1

DV-656A KUXJ/CA AC120V 1

Reginal restriction

codes (Region No.)

Remarks

For details, refer to "Important symbols for good services".

T-ZZE JUNE 2002 printed in Japan

Page 2

1234

SAFTY INFORMATION

A

This service manual is intended for qualified service technicians; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

B

cause cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement

parts must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que

C

les pièces de remplacement doivent avoir la même désignation.

(FOR USA MODEL ONLY)

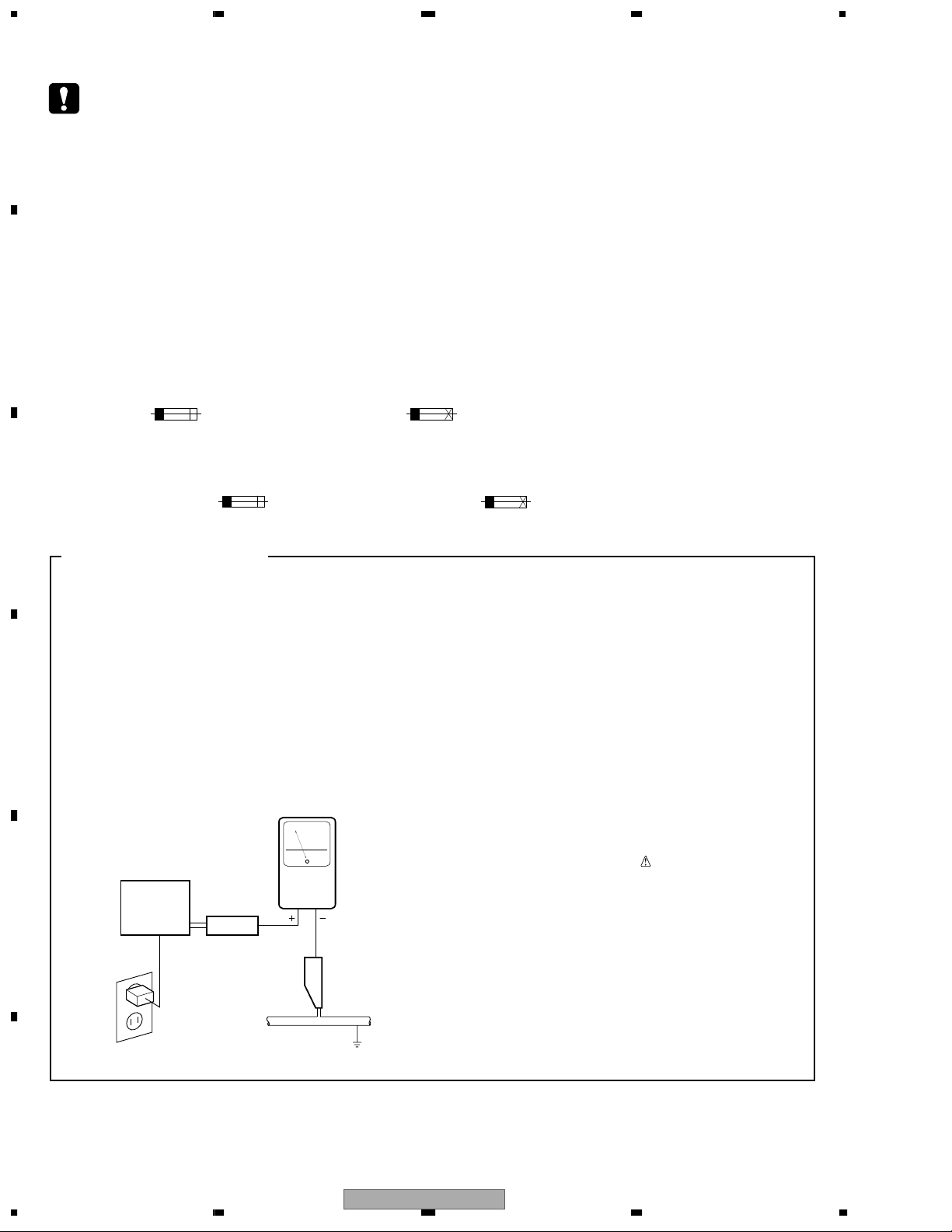

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

D

E

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

Reading should

not be above

0.5 mA

Earth

ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Test all

exposed metal

surfaces

Leakage

current

tester

AC Leakage Test

ANY MEASUREMENTS NOT WITHIN THE

LIMITS OUTLINED ABOVE ARE INDICATIVE

OF A POTENTIAL SHOCK HAZARD AND

MUST BE CORRECTED BEFORE RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the

protection afforded by them necessarily can be obtained

by using replacement components rated for voltage,

wattage, etc. Replacement parts which have these

special safety characteristics are identified in this

Service Manual.

Electrical components having such features are

identified by marking with a

on the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in the

parts list in this Service Manual, may create shock, fire,

or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER

Service Manual. A subscription to, or additional copies

of, PIONEER Service Manual may be obtained at a

nominal charge from PIONEER.

on the schematics and

F

2

1234

DV-45A

Page 3

5678

[ Important symbols for good services ]

In this manual, the symbols shown-below indicate that adjustments, settings or cleaning should be made securely.

When you find the procedures bearing any of the symbols, be sure to fulfill them:

1. Product safety

You should conform to the regulations governing the product (safety, radio and noise, and other regulations), and

should keep the safety during servicing by following the safety instructions described in this manual.

2. Adjustments

To keep the original performances of the product, optimum adjustments or specification confirmation is indispensable.

In accordance with the procedures or instructions described in this manual, adjustments should be performed.

3. Cleaning

For optical pickups, tape-deck heads, lenses and mirrors used in projection monitors, and other parts requiring cleaning,

proper cleaning should be performed to restore their performances.

4. Shipping mode and shipping screws

To protect the product from damages or failures that may be caused during transit, the shipping mode should be set or

the shipping screws should be installed before shipping out in accordance with this manual, if necessary.

A

B

5. Lubricants, glues, and replacement parts

Appropriately applying grease or glue can maintain the product performances. But improper lubrication or applying

glue may lead to failures or troubles in the product. By following the instructions in this manual, be sure to apply the

prescribed grease or glue to proper portions by the appropriate amount.For replacement parts or tools, the prescribed

ones should be used.

C

D

56

DV-45A

E

F

7

8

3

Page 4

1234

CONTENTS

SAFTY INFORMATION .......................................................................................................................................2

A

B

C

D

E

1. SPECIFICATIONS ............................................................................................................................................ 5

2. EXPLODED VIEWS AND PARTS LIST ............................................................................................................ 6

2.1 PACKING ................................................................................................................................................... 6

2.2 EXTERIOR SECTION................................................................................................................................ 8

2.3 FRONT PANEL SECTION ....................................................................................................................... 10

2.4 LOADING MECHA ASSY ........................................................................................................................12

2.5 TRAVERSE MECHANISM ASSY-S ......................................................................................................... 14

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM..........................................................................................16

3.1 BLOCK DIAGRAM ................................................................................................................................... 16

3.2 LOAB ASSY and OVERALL WIRING DIAGRAM..................................................................................... 20

3.3 DVDM ASSY 1/4 [FTS BLOCK]............................................................................................................... 22

3.4 DVDM ASSY 2/4 [FR BLOCK]................................................................................................................. 24

3.5 DVDM ASSY 3/4 [EBY/AV1 BLOCK] ....................................................................................................... 26

3.6 DVDM ASSY 4/4 [VENC BLOCK]............................................................................................................ 28

3.7 JACB ASSY 1/2 [AUDIO BLOCK] ............................................................................................................ 30

3.8 JACB ASSY 2/2 [VIDEO BLOCK]............................................................................................................ 32

3.9 SACDB ASSY .......................................................................................................................................... 34

3.10 FLKY and KEYB ASSYS ....................................................................................................................... 36

3.11 POWER SUPPLY UNIT.......................................................................................................................... 38

3.12 WAVEFORMS [DVDM ASSY] ................................................................................................................ 39

3.13 WAVEFORMS [JACB ASSY] ................................................................................................................. 40

4. PCB CONNECTION DIAGRAM ..................................................................................................................... 41

4.1 LOAB ASSY............................................................................................................................................. 41

4.2 DVDM ASSY............................................................................................................................................ 42

4.3 JACB ASSY .............................................................................................................................................44

4.4 SACDB ASSY .......................................................................................................................................... 48

4.5 FLKY and KEYB ASSYS ......................................................................................................................... 50

4.6 POWER SUPPLY UNIT............................................................................................................................ 52

5. PCB PARTS LIST ........................................................................................................................................... 53

6. ADJUSTMENT ............................................................................................................................................... 59

6.1 ADJUSTMENT ITEMS AND LOCATION ................................................................................................. 59

6.2 JIGS AND MEASURING INSTRUMENTS............................................................................................... 59

6.3 NECESSARY ADJUSTMENT POINTS ...................................................................................................60

6.4 TEST MODE ............................................................................................................................................ 61

6.5 MECHANISM ADJUSTMENT.................................................................................................................. 62

7. GENERAL INFORMATION............................................................................................................................. 65

7.1 DIAGNOSIS ............................................................................................................................................. 65

7.1.1 ID NUMBER AND ID DATA SETTTING ................................................................................................ 65

7.1.2 SELF-DIAGNOSIS FUNCTION OF PICKUP DEFECTIVE................................................................... 67

7.1.3 TEST MODE SCREEN DISPLAY ......................................................................................................... 68

7.1.4 SELF-DIAGNOSIS FUNCTION ............................................................................................................70

7.1.5 FUNCTION SPECIFICATION OF THE SERVICE MODE..................................................................... 71

7.1.6 ERROR DISPLAY ................................................................................................................................. 72

7.1.7 TEST POINTS LOCATION & WAVEFORMS ........................................................................................ 75

7.1.8 TROUBLE SHOOTING ......................................................................................................................... 77

7.1.9 DISASSEMBLY ..................................................................................................................................... 79

7.2 IC ............................................................................................................................................................. 86

7.3 DISC / CONTENT FORMAT PLAYBACK COMPATIBILITY ................................................................... 121

7.4 CLEANING............................................................................................................................................. 122

8. PANEL FACILITIES ...................................................................................................................................... 123

F

4

1234

DV-45A

Page 5

General

System ............................................DVD Player

Power requirements ................. AC 120 V, 60 Hz

Power consumption

Power consumption (standby)

........................0.3 W

Weight ..................................... 2.6 kg (5lb 12oz)

Dimensions .......420 (W) x 69 (H) x 278 (D) mm

(16

9

/16 (W) x 2 3/4 (H) x 11 (D) in.)

Operating temperature............... +5°C to +35°C

(+36°F to +96°F)

Operating humidity ........................... 5% to 85%

(no condensation)

Component Video output (Y, PB, PR)

Output level ............................ Y: 1.0 Vp-p (75 Ω)

P

B

, PR: 0.7 Vp-p (75 Ω)

Jacks ................................................ RCA jacks

S-Video output

Y (luminance) - Output level.......... 1 Vp-p (75 Ω)

C (color) - Output level........... 286 mVp-p (75 Ω)

Jack ................................................S-Video jack

Video output

Output level ...................................1 Vp-p (75 Ω)

Jack .................................................... RCA jack

Audio output (1 stereo pair)

Output level ....................... During audio output

200 mVrms (1 kHz, –20 dB)

Number of channels ........................................ 1

Jacks .................................................. RCA jack

Audio output (multi-channel / L, R, C,

SW, LS, RS)

Output level ....................... During audio output

200 mVrms (1 kHz, –20 dB)

Number of channels ........................................ 6

Jacks .................................................. RCA jack

Digital audio characteristics

Frequency response

........................ 4 Hz to 44 kHz(DVD fs: 96 kHz)

............ 4 Hz to 88 kHz (DVD-Audio fs: 192 kHz)

S/N ratio ..................................................118 dB

Dynamic range ........................................108 dB

Total harmonic distortion ....................... 0.001 %

Wow and flutter .............. Limit of measurement

(0.001% W. PEAK) or lower

Digital output

Optical digital output ........... Optical digital jack

Coaxial digital output...........................RCA jack

Other terminals

Control in ...................................Minijack (3.5 ø)

Control out ................................. Minijack (3.5 ø)

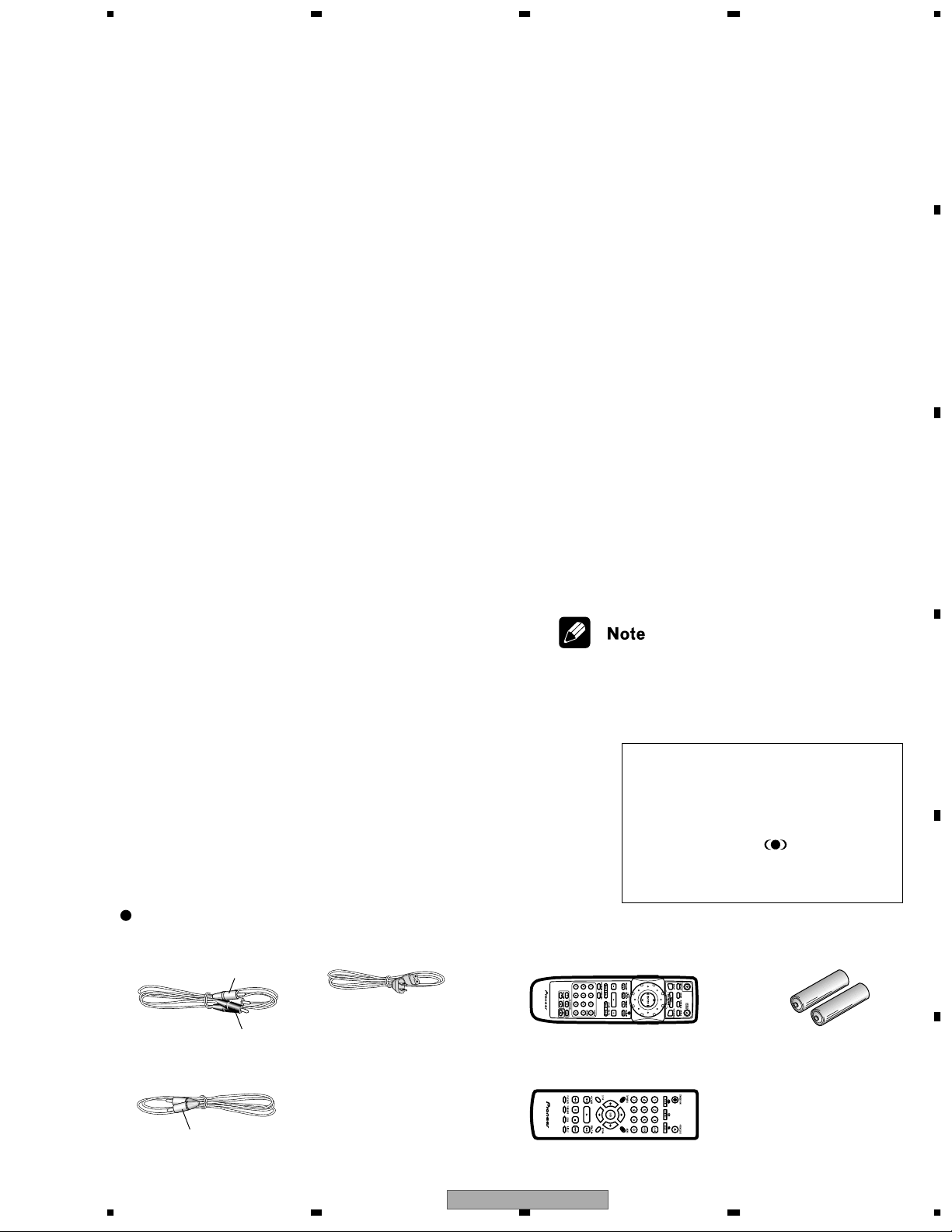

Accessories

Stereo audio cable............................................1

Video cable.......................................................1

Power cable ...................................................... 1

Remote control ................................................. 1

AA/R6P dry cell batteries ................................. 2

Operating Instructions ..................................... 1

Warranty card...................................................

1

• The specifications and design of this

product are subject to change without

notice, due to improvement.

DV-45A .................................................... 13 W

DV-656A ...................................................12

W

Accessories

• Stereo Audio Cable (VDE1052)

(L = 1.5m)

• Video Cable (VDE1053)

(L = 1.5m)

• Power Cable (ADG7022)

• AA/R6P Dry Cell Batteries

White

Red

Yellow

• Remote Control

(DV-45A : VXX2839)

• Remote Control

(DV-656A : VXX2800)

• Manufactured under license from Dolby

Laboratories. “Dolby” and the double-D

symbol are trademarks of Dolby Laboratories.

• “DTS” is a registered trademark of Digital

Theater Systems, Inc.

• TruSurround and the

® symbol are

trademarks of SRS Labs, Inc. TruSurround

technology is incorporated under license from

SRS Labs, Inc.

5678

1. SPECIFICATIONS

A

B

C

D

56

DV-45A

7

E

F

5

8

Page 6

1234

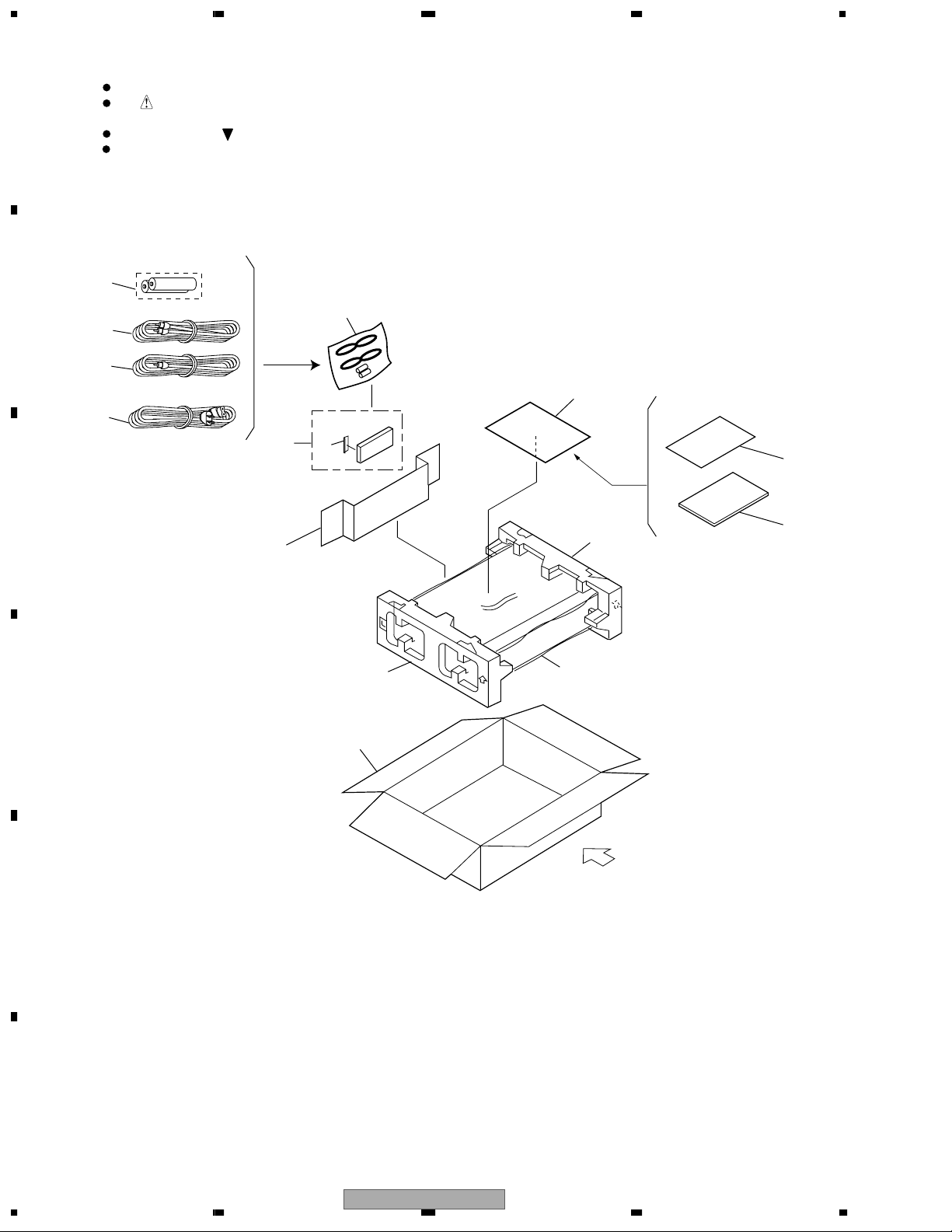

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

A

2.1 PACKING

6

B

2

3

1

C

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

9

9

4

5

12

11

8

7

10

D

13

14

FRONT

E

F

6

1234

DV-45A

Page 7

>

5678

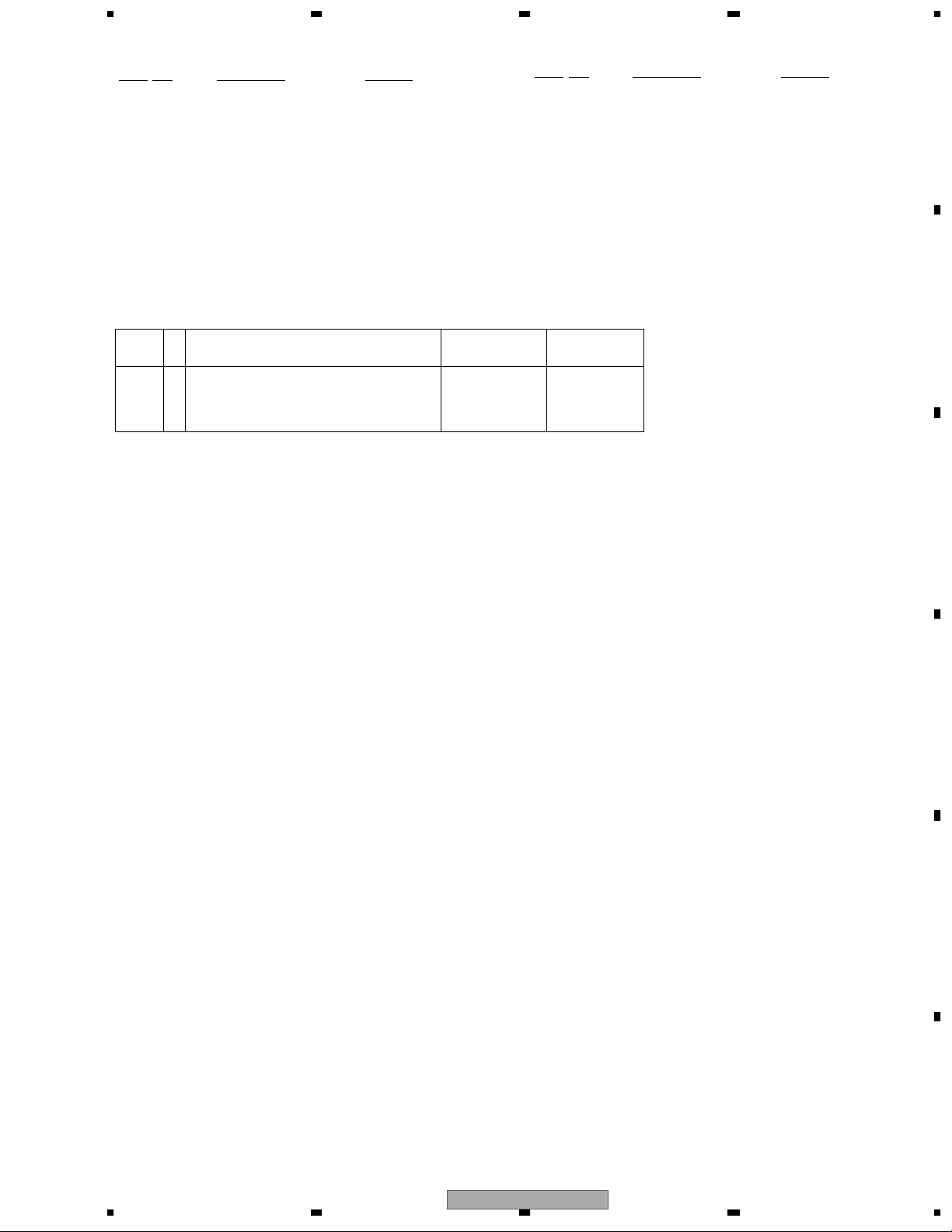

PACKING parts List

Mark No. Description Part No.

1 Power Cable ADG7022

2 Stereo Audio Cable (L = 1.5m) VDE1052

3 Video Cable (L = 1.5m) VDE1053

4 Remote Control See Contrast table (2)

5 Battery Cover See Contrast table (2)

NSP 6 AA/R6P Dry Cell Battery VEM1031

7 Operating Instructions See Contrast table (2)

(English)

Mark

No. Description Part No.

NSP 8 Warranty Card ARY7045

9 Polyethylene Bag VHL1051

10 Pad L VHA1307

11 Pad R VHA1308

12 Paper Board VHC1096

13 Packing Case See Contrast table (2)

14 Mirror Mat Sheet Z23-007

A

(2) CONTRAST TABLE

DV-45A/KUXJ/CA and DV-656A/KUXJ/CA are constructed the same except for the following:

Mark No. Symbol and Description DV-45A/KUXJ/CA

4 Remote Control VXX2839 VXX2800

5 Battery Cover VNK4423 VNK4997

7 Operating Instructions (English) VRB1297 VRB1296

13 Packing Case VHG2224 VHG2222

DV-656A/KUXJ/

CA

B

C

D

56

DV-45A

E

F

7

8

7

Page 8

1234

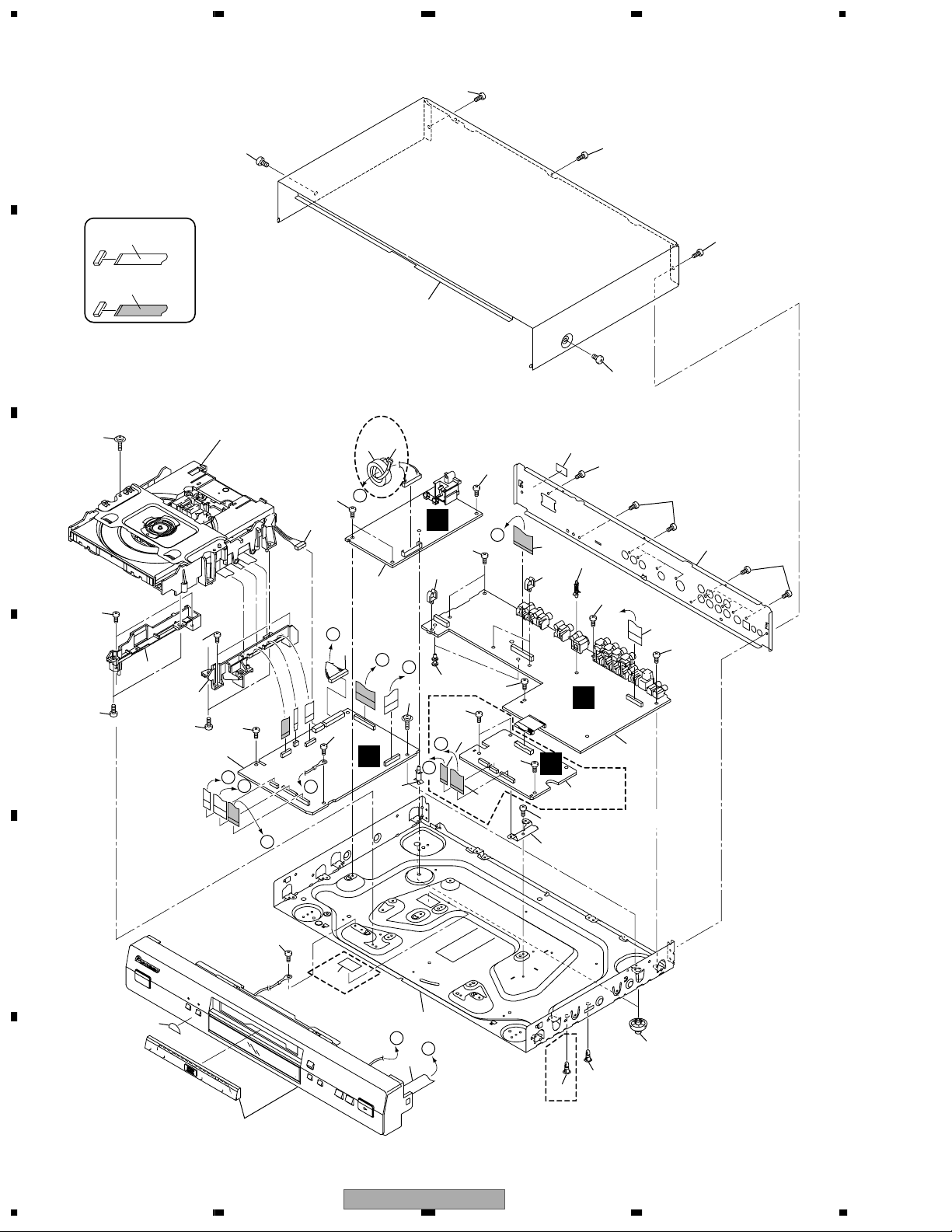

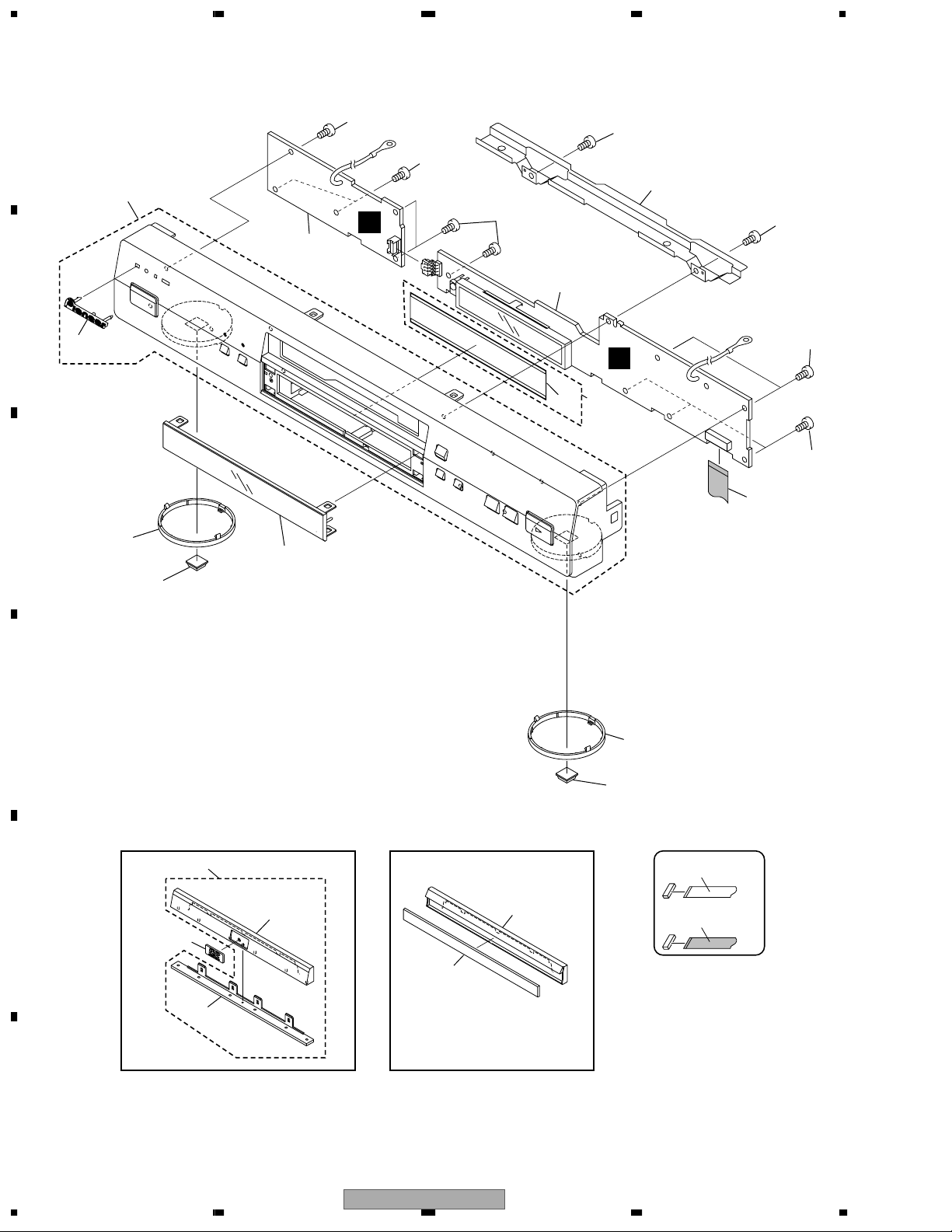

2.2 EXTERIOR SECTION

A

33

34

NON-CONTACT

SIDE

CONTACT SIDE

B

Refer to "2.4 LOADING

MECHA ASSY".

35

33

27

5

35

1

C

B

A

40

C

33

26

D

35

DV-45A/KUXJ/CA

ONLY

14

32

G

7

G

6

39

B

H

4

29

37

32

G

18

D

E

17

38

B

C

20

32

32

11

12

32

D

32

8

18

D

32

25

33

34

30

33

19

32

C

3

2

DV-45A/KUXJ/CA

ONLY

33

33

24

33

9

32

E

39

13

DV-45A/KUXJ/CA

31

F

Refer to "2.3 FRONT PANEL SECTION".

8

1234

ONLY

23

H

10

DV-45A

A

21

22

DV-45A/KUXJ/CA

ONLY

16

Page 9

>

5678

EXTERIOR SECTION parts List

Mark No. Description Part No.

1 DVDM Assy See Contrast table (2)

2 SACDB Assy See Contrast table (2)

3 JACB Assy See Contrast table (2)

4 POWER SUPPLY Unit VWR1351

NSP 5 LOADING MECHA Assy VWT1196

6 Connector Assy PF13PP-D25

7 Connector Assy PG05KK-E30

8 FFC (30P, JACB) VDA1905

9 FFC (21P, JACB) VDA1906

10 FFC (17P, FLKB) VDA1907

11 FFC (20P, DSP) See Contrast table (2)

12 FFC (40P, SACD) See Contrast table (2)

13 F Cushion See Contrast table (2)

14 Ferrite Core See Contrast table (2)

15 •••••

16 LEG Assy SX AEC7113

NSP 17 PCB Spacer (3 x 6) AEC7156

18 Mini Clamp AEC7373

NSP 19 PCB Support REC1285

20 PCB Support VEC2184

Mark

No. Description Part No.

21 PCB Holder VEC2283

22 PCB Holder See Contrast table (2)

NSP 23 Base Chassis VNA2521

24 Rear Panel See Contrast table (2)

NSP 25 PCB Base VNE2276

26 Adapter 14L VNL1941

27 Adapter 14R VNL1942

29 Bonnet Case S See Contrast table (2)

NSP 30 ID Label VRW1877

NSP 31 Energy Star Label AAX7876

32 Screw BBZ30P060FMC

33 Screw BBZ30P080FZK

34 Screw See Contrast table (2)

35 Screw PPZ30P080FMC

36 •••••

NSP 37 Binder See Contrast table (2)

38 Screw IBZ30P080FCC

39 Screw BBZ30P060FCC

40 Screw Z39-019

A

B

C

(2) CONTRAST TABLE

DV-45A/KUXJ/CA and DV-656A/KUXJ/CA are constructed the same except for the following:

Mark No. Symbol and Description DV-45A/KUXJ/CA

1 DVDM Assy VWS1533 VWS1531

2 SACDB Assy VWG2352 Not used

3 JACB Assy VWV1912 VWV1913

11 FFC (20P, DSP) VDA1909 Not used

12 FFC (40P, SACD) VDA1910 Not used

13 F Cusion VEB1348 Not used

14 Ferrite Core VTH1044 Not used

22 PCB Holder VEC2283 Not used

24 Rear Panel VNA2463 VNA2417

29 Bonnet Case S VXX2842 VXX2841

34 Screw BCZ40P060FZK BCZ40P060FNI

NSP 37 Binder ZCA-BK1 Not used

DV-656A/KUXJ/

CA

D

E

56

DV-45A

F

7

8

9

Page 10

1234

2.3 FRONT PANEL SECTION

A

7

B

8

19

19

19

F

2

1

19

5

19

19

E

DV-45A/KUXJ/CA

20

ONLY

19

C

6

4

18

3

D

6

3

• Tray Panel Section

DV-45A/KUXJ/CADV-656A/KUXJ/CA

15

E

14

13

16

17

16

NON-CONTACT

SIDE

CONTACT SIDE

F

10

1234

DV-45A

Page 11

5678

FRONT PANEL SECTION parts List

Mark

Mark No. Description Part No.

1 FLKY Assy See Contrast table (2)

2 KEYB Assy VWG2377

3 Rubber Foot VEB1325

4 FL Lens See Contrast table (2)

5 FP Angle VNE2267

6 Ring VNK4996

7 Front Panel Assy See Contrast table (2)

8 Pioneer Badge See Contrast table (2)

9•••••

10 •••••

No. Description Part No.

11 •••••

12 •••••

13 Sub Panel See Contrast table (2)

14 DVD A/V Badge See Contrast table (2)

15 Tray Panel Assy See Contrast table (2)

16 Tray Panel See Contrast table (2)

17 Door See Contrast table (2)

18 FFC (17P, FLKB) VDA1907

19 Screw BBZ30P100FZK

20 FL Filter See Contrast table (2)

(2) CONTRAST TABLE

DV-45A/KUXJ/CA and DV-656A/KUXJ/CA are constructed the same except for the following:

Mark No. Symbol and Description DV-45A/KUXJ/CA

1 FLKY Assy VWG2354 VWG2376

4 FL Lens VEC2277 VNK5028

7 Front Panel Assy VXA2517 VXA2515

8 Pioneer Badge VAM1109 VAM1129

13 Sub Panel Not used VNK5023

DV-656A/KUXJ/

CA

A

B

14 DVD A/V Badge Not used VAM1131

15 Tray Panel Assy Not used VXA2518

16 Tray Panel VNK5021 VNK5022

17 Door VEC2279 Not used

20 FL Filter VEC2280 Not used

C

D

E

56

DV-45A

F

7

8

11

Page 12

2

1234

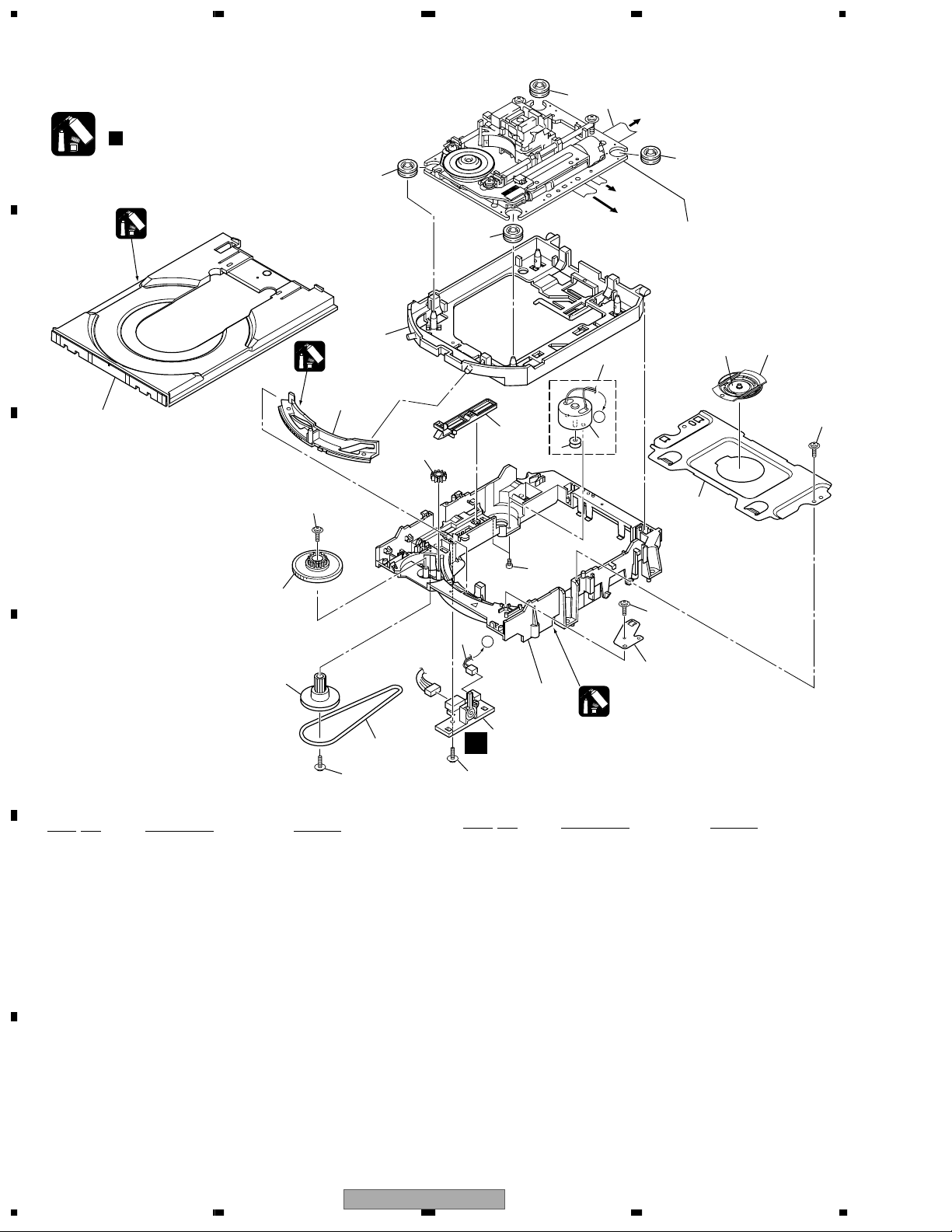

2.4 LOADING MECHA ASSY

Note :

A

Refer to

8

6

To

DVDM

CN101

" Application of Lubricant".

8

8

To DVDM

CN114

3

A

5

To DVDM

CN115

2

Refer to

"2.5 TRAVERSE MECHANISM

ASSY-S".

18

19

20

2

Daifree

GEM1036

B

12

Lubricating Oil

GYA1001

23

C

13

16

22

8

17

4

D

LOADING MECHA ASSY parts List

Mark No. Description Part No.

NSP 1 LOAB Assy VWG2346

2 Traverse Mechanism Assy-S VXX2782

3 Loading Motor Assy VXX2505

4 Motor Pulley PNW1634

E

5 Carriage DC Motor / 0.3W PXM1027

6 Flexible Cable (26P) VDA1864

7 Connector Assy 2P VKP2253

8 Float Rubber VEB1327

9 Belt VEB1330

10 Stabilizer VNE2253

11 Loading Base VNL1917

12 Float Base DVD VNL1918

13 Drive Cam VNL1919

F

14 Gear Pulley VNL1921

15 Loading Gear VNL1922

15

14

7

9

22 22

A

Mark No. Description Part No.

16 Drive Gear VNL1923

17 SW Lever VNL1925

18 Clamper Plate VNE2251

19 Bridge VNE2252

20 Clamper VNL1924

21 Screw JGZ17P028FMC

22 Screw Z39-019

23 Tray VNL1920

21

22

A

10

11

1

Lubricating Oil

GYA1001

12

1234

DV-45A

Page 13

5678

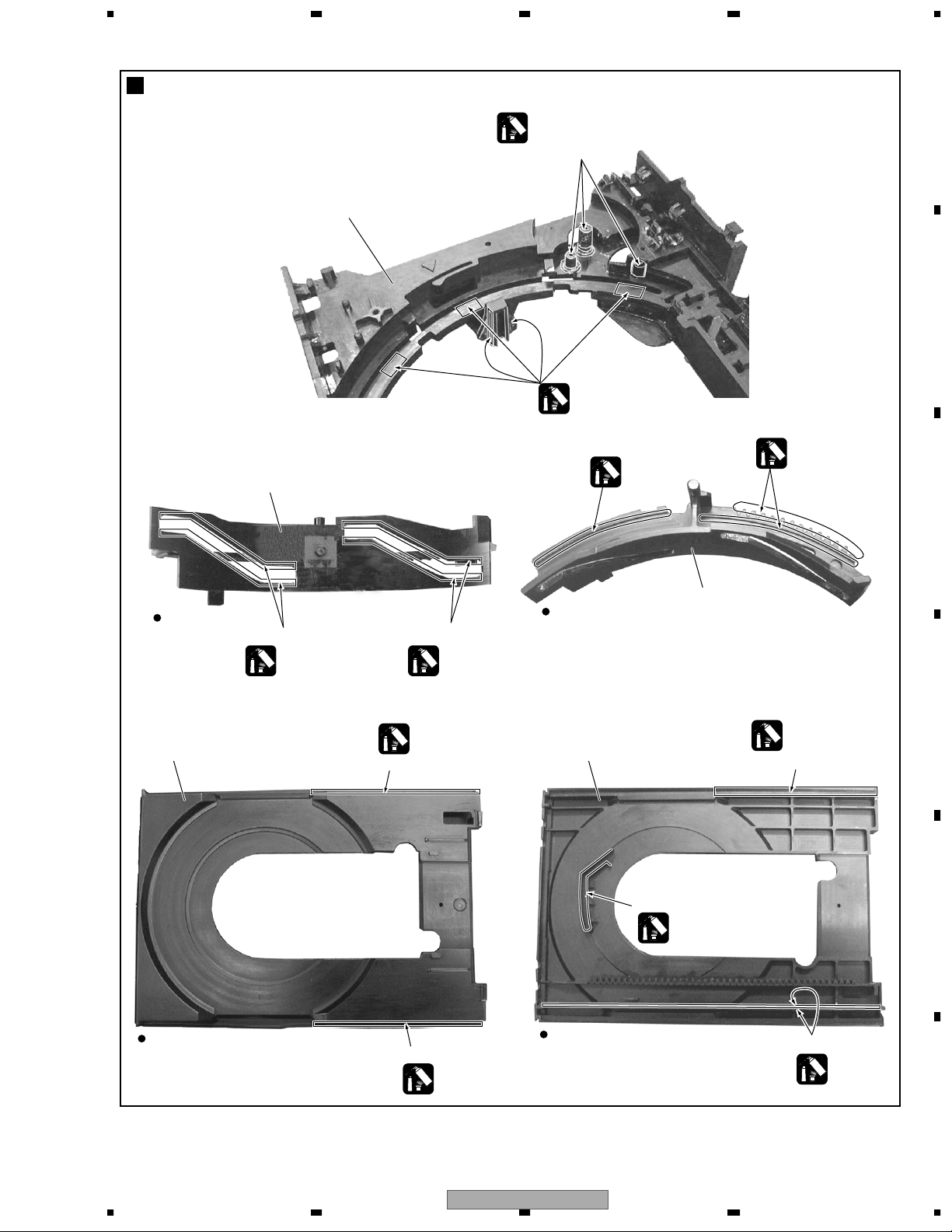

Application of Lubricant

No. 11

Loading Base

Lubricating Oil

GYA1001

Around the shaft

Concave of unevenness

Concave of unevenness

Concave of unevenness

No. 13

Drive Cam

No. 13

Drive Cam

No. 23

Tray

No. 23

Tray

Top View

Rear View

Top View

Bottom View

Daifree

GEM1036

Daifree

GEM1036

Daifree

GEM1036

Daifree

GEM1036

Daifree

GEM1036

Side of the rib

Inner side of a ditch

Inner side of a ditch

Lubricating Oil

GYA1001

Lubricating Oil

GYA1001

Inner side of a ditch

Lubricating Oil

GYA1001

Lubricating Oil

GYA1001

Lubricating Oil

GYA1001

A

B

C

D

E

DV-45A

56

F

7

8

13

Page 14

1234

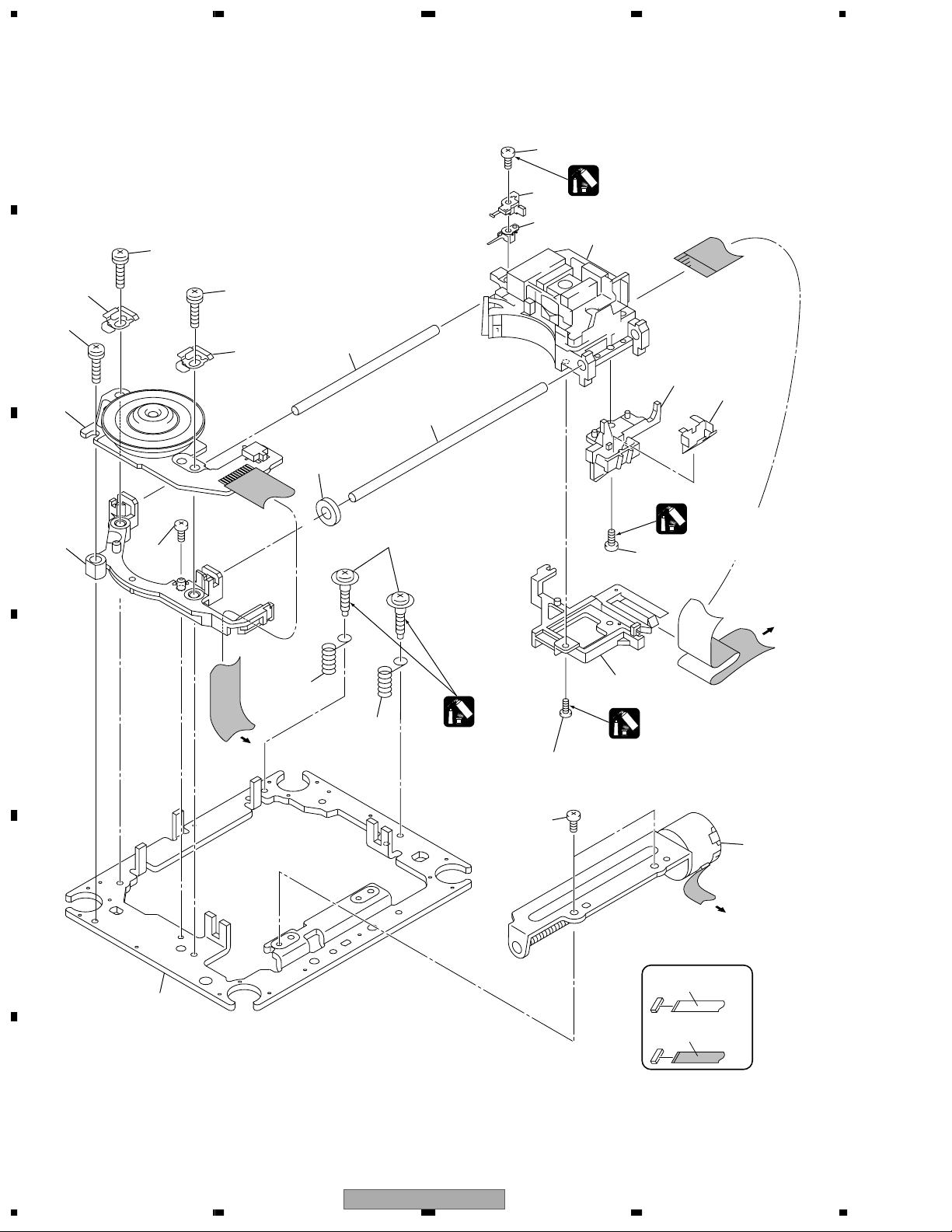

2.5 TRAVERSE MECHANISM ASSY-S

A

18

17 (Torque : 0.12 ± 0.01 N•m)

Silicone Adhesive

12

8

GEM1037

3

10

B

18

1

C

13

D

16

18

10

To DVDM

CN115

7

14

6

19

4 (Adjustment Screw)

5

Screw Tight

5

GYL1001

17 (Torque : 0.12 ± 0.01 N•m)

17 (Torque : 0.12 ± 0.01 N•m)

15

Silicone Adhesive

GEM1037

9

Silicone Adhesive

GEM1037

To

DVDM

CN111

16

2

E

NON-CONTACT

11

F

14

1234

DV-45A

SIDE

CONTACT SIDE

To DVDM

CN114

Page 15

>

5678

TRAVERSE MECHANISM ASSY-S parts List

Mark No. Description Part No.

1 Spindle Motor VXM1088

2 Stepping Motor VXM1090

3 Pickup Assy-S OXX8003

4 Skew Screw VBA1080

5 Skew Spring VBH1335

6 Guide Bar VLL1514

7 Sub Guide Bar VLL1515

8 Hold Spring VNC1017

9 Joint Spring VNC1019

10 Support Spring VNC1020

NSP 11 Mechanism Chassis VNE2248

12 Slider VNL1811

13 Spacer VNL1913

14 Joint VNL1914

15 FFC Holder VNL1915

16 Screw BBZ20P050FZK

17 Tapping Screw OBA8009

18 Screw PMA26P100FMC

19 Damper Sheet VEB1335

A

B

C

D

E

F

56

DV-45A

7

8

15

Page 16

1234

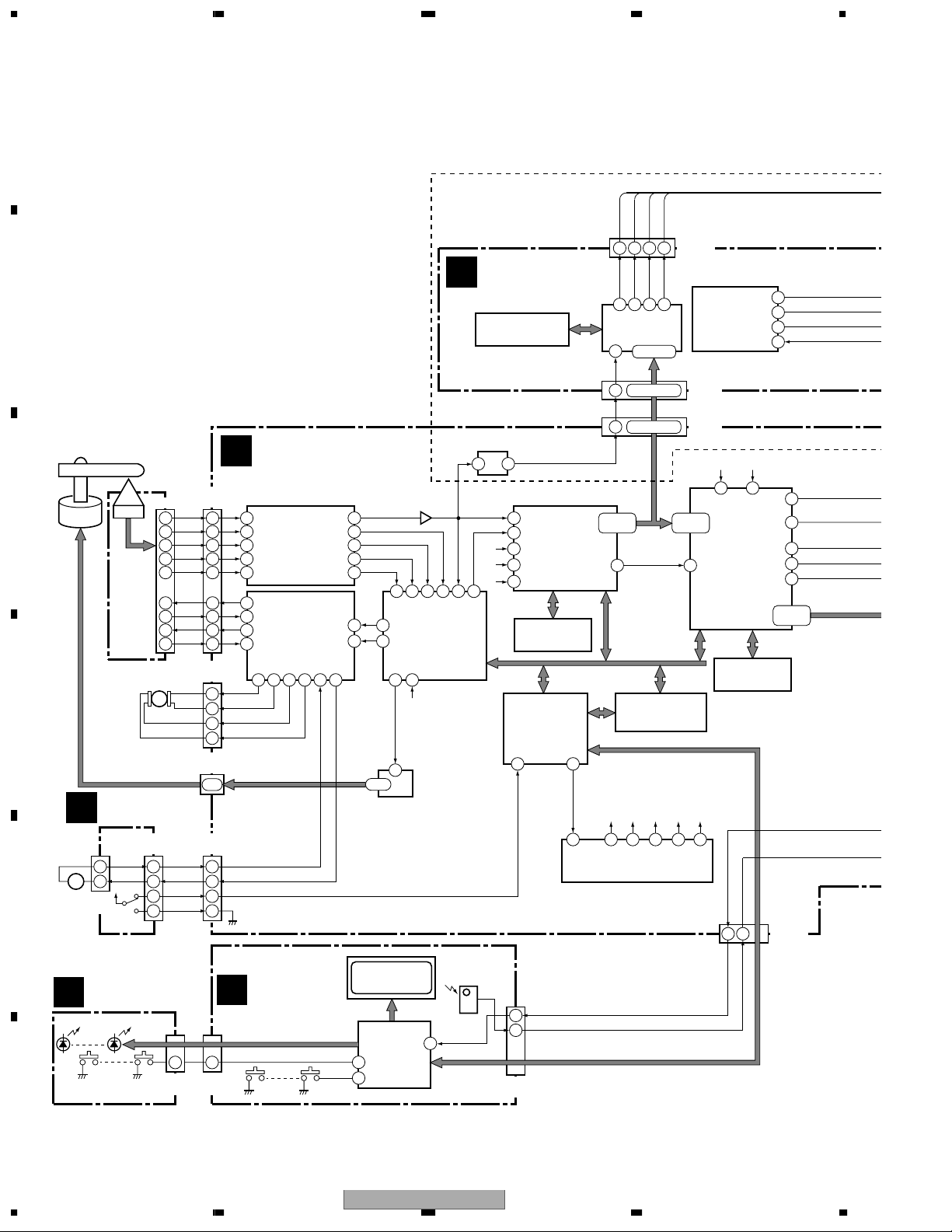

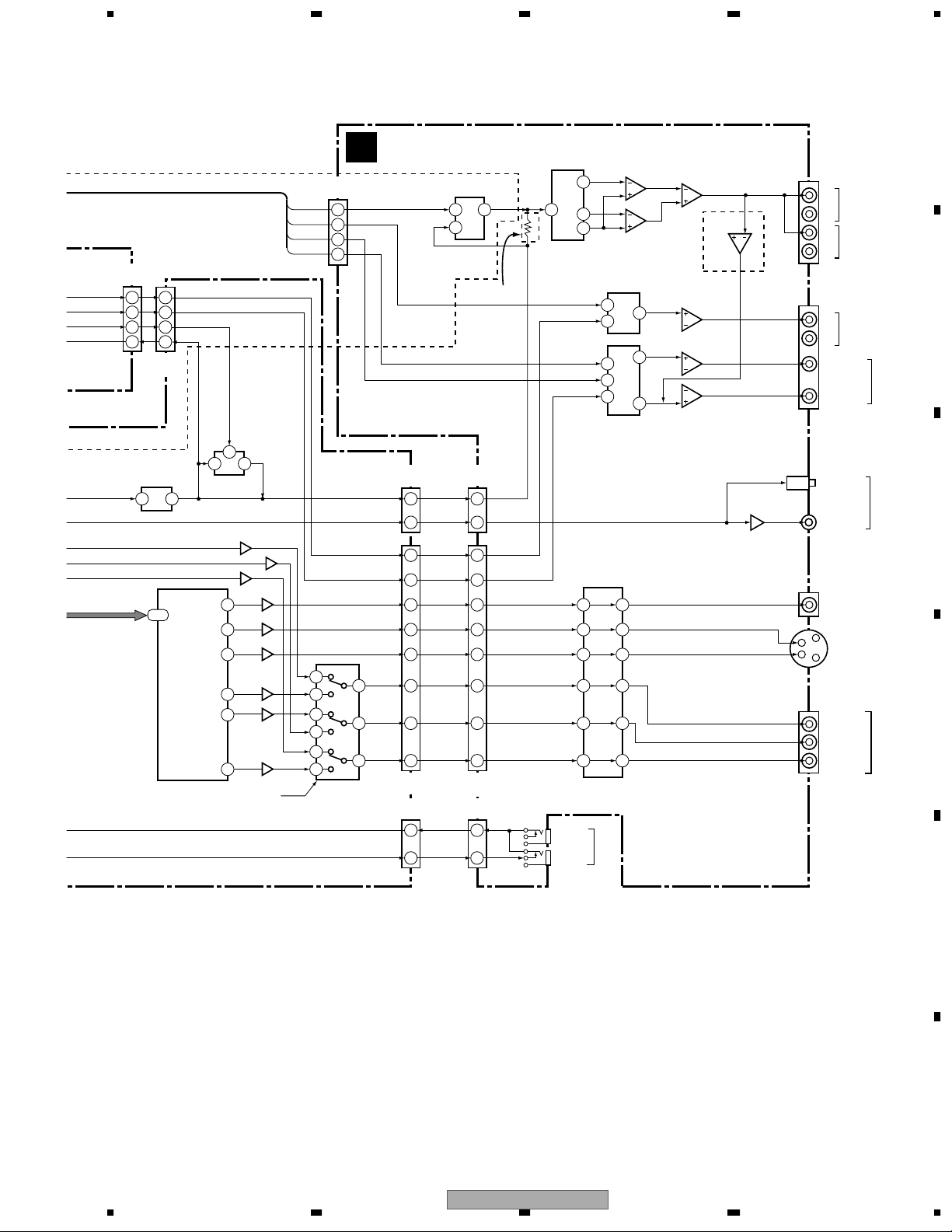

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

A

7 SIGNAL ROUTE

DV-45A Only

SACDB ASSY

D

B

DVDM ASSY

B

CN111

RF+

11

20

21

15

16

T DRV

25

T RTN

24

F DRV

23

F RTN

26

ST1+

ST1-

ST2+

ST2-

LOAD-

LOAD+

SW2

SW1(GNDS)

4

CN201

(4P)

(26P)

16

B1

7

B2

6

B3

12

B4

11

2

12

3

13

4

1

10

CN114

(4P)

2

1

3

4

CN115

(12P)

4-9

CN103

(5P)

1

2

4

5

E

FLKY ASSY

4

CN102

(4P)

3

5

4

7

6

9

35

RFP

PD2

PD1

PD4

PD3

VM4+

VM4VM3VM3+

VM1-34VM1+

IC101

LA9704W

RF IC

IC351

M56788AFP

FTS Driver

VM2-

VM2+

31 15 14

32

RFO

BHMIX

IN3-

IN4-

VM5-

KEY0

KEY1

RFO AIN

60

BH

49

PH

BH

52

FE

FE

41

TE

TE

42

32 33 30 39 331

FDO

32047

TDO

48

VM5+

46 14

21

9-14

IC251

BA6664FM

Spindle Driver

V101

VAW1073

FL TUBE

IC101

PE5314B

22

FL Control

21

TE

SPDO

SPDO

Q106

FE

XIN

16M

DSPRF

RF PH

RF BH

IC201

LC78652W

Servo DSP

Remote

Sensor

Unit

IR101

17

(26P)

C

SPINDLE

MOTOR

OEIC

PICKUP

ASSY

STEPPING

MOTOR

M

D

LOAB ASSY

A

LOADING

MOTOR

ASSY

+–

M

CN602

E

(2P)

KEYB ASSY

F

CN601

2 1

1 2

3.3V

S101

(5P)

4

5

IC902

HY57V161610DTC-8

16M SDRAM

IC211

TK15404M

EFMIN

3 2

36M

33M

16M

ROMXA

LOD POS

CN101

(17P)

RFSACD

172

185

4

5

169

HY57V16160DTC-8

Control CPU

AN7

57

2

9

RFSACD

RFSACD

AIN

IC701

PE5286A

CDDT

DVD Decoder

DMCK

EBY-CHIP

DMACKI

16M SDRAM

IC601

PD6345A

System

SEL IR

IR

ADATA0

IC741

PK4

105

44×48

14 3 13 9 10 15

FSEL1

SACD Decoder

126

24

17

13,14,

19-24

194

(For IC751)

CLK27M

Clock Generator

DSD_LS

DSD_LFE

DSD_C

DSD_L

121416

8

DSD_L

DSD_LS

74

64

IC901

CXD2753R

8-12, 35-37

16M Flash Memory

27M

(For IC201,IC701)

IC481

SM8707HV

DSD_C

DSD_LFE

71

69

169-176

BD0-BD7

BD0-BD7

4-6, 29-33

BD0-BD7

CDDATA

IC603

VYW2016

16M

(For IC701)

36M

36M

CLK16M

CN902

201-208

(For IC751)

(19P)

IC801

XCA56367PV150

DVD-Audio

DSP

CN901

(40P)

CN531

(40P)

27M

106

CLKIN

CDDIN

163

IC751

M65776AFP

MPEG2 Decoder

AV-1

M2V64S40DTP-7

64M SDRAM

22/24AV1

(For IC701)

33M

22/24M

CLK33M

SEL IR

2

22/24AV1

172

ACLKI

DOUT0

IC781

IR

9

6

5

4

10

AO0

164

170

PAY

119

PAB

116

PAR

122

184-186,

188-192

CN402

(17P)

SDO2

SDO1

SDO0

DATA0A

AO00

DOUT0

PRGA_Y

PRGA_B

PRGA_R

PD0-PD7

F

16

DV-45A

1234

Page 17

5678

A

CN801

(20P)

18

17

19

6

TC74VHC541FT

AO00 AO0

DOUT0

PRGA_Y

PRGA_B

PRGA_R

PD0-PD7

4

3

2

15

CN502

(20P)

IC786

7

2-9

ADV7172KST

DATA2

DATA1

DATA0B

AO0

13

IC801

Video

Encoder

2

Q935

Q937

1

35

33

29

28

25

24

IC553

TC7WH157FU

5

Q940

Q932

V

Q933

Y

Q934

C

Q936

Y/G

CB/B

Q939

Q938

CR/R

DSD_L

DSD_LS

DSD_LFE

DSD_C

1

2

5

3

13

12

IC931

P/XI

TC74HC4053AFT

Selector

CN102

(19P)

12

8

6

4

JACB ASSY

C

TC74VHC157F

DSD_L DSD_L

DATA0

CN551 (1/2)

(21P)

DATA0 DATA0

DOUT DOUT

DATA2

DATA1

V

Y

C

YOUT

15

CBOUT

4

CROUT

14

CN901

(30P)

CN551 (2/2)

(21P)

SEL IR

IR

CN101 (1/2)

11

14

4

2

15

19

17

21

23

25

CN101 (2/2)

16

18

DV-45A Only

IC201

13

12

14

DV-656A Only

(21P)

11

14

4

2

15

19

17

21

23

25

CN701

(30P)

(21P)

16

18

DATA2

DATA1

V

Y

C

Y/G/P_Y

CB/B/P_CB

CR/R/P_CR

SEL IR

IR

IC301

PCM1738EG-3

26

5

25

20

R207

IC401 DSD1702EG

IC403 PCM1742KE

DSD_LS

DATA2

DSD_C

DSD_LFE

DATA1

IC501 DSD1702EG

IC503 PCM1742KE

LA73054

Video Driver Amp.

2

8

6

11

14

16

JA801

IN

OUT

JA802

NJM4565M

(DV-45A)

(DV-656A)

1

4

1

2

4

(DV-45A)

(DV-656A)

IC701

CONTROL

IC302

2

3

6

5

33

28

31

25

23

21

10

9

9

1

7

IC304

NJM2068M

2

3

IC402

NJM2068M

5

6

5

6

2

3

IC502

NJM2068M

1

IC305

7

7

1

2

3

1

NJM2068M

DV-656A

Only

Q601

C

CR

JA301

L

AUDIO OUT

(2 ch)

R

L

FRONT

R

JA302

L

R

SURROUND

B

CENTER

SUB

WOOFER

(5.1 ch)

AUDIO OUT

JA602

OPTICAL

JA601

COAXIAL

DIGITAL

AUDIO OUT

C

JA701

V

Y

C

VIDEO OUT

S VIDEO OUT

CN704

Y

B

Y (GREEN)

PB (BLUE)

P

R (RED)

JA702

COMPONENT

D

VIDEO OUT

56

DV-45A

E

F

7

8

17

Page 18

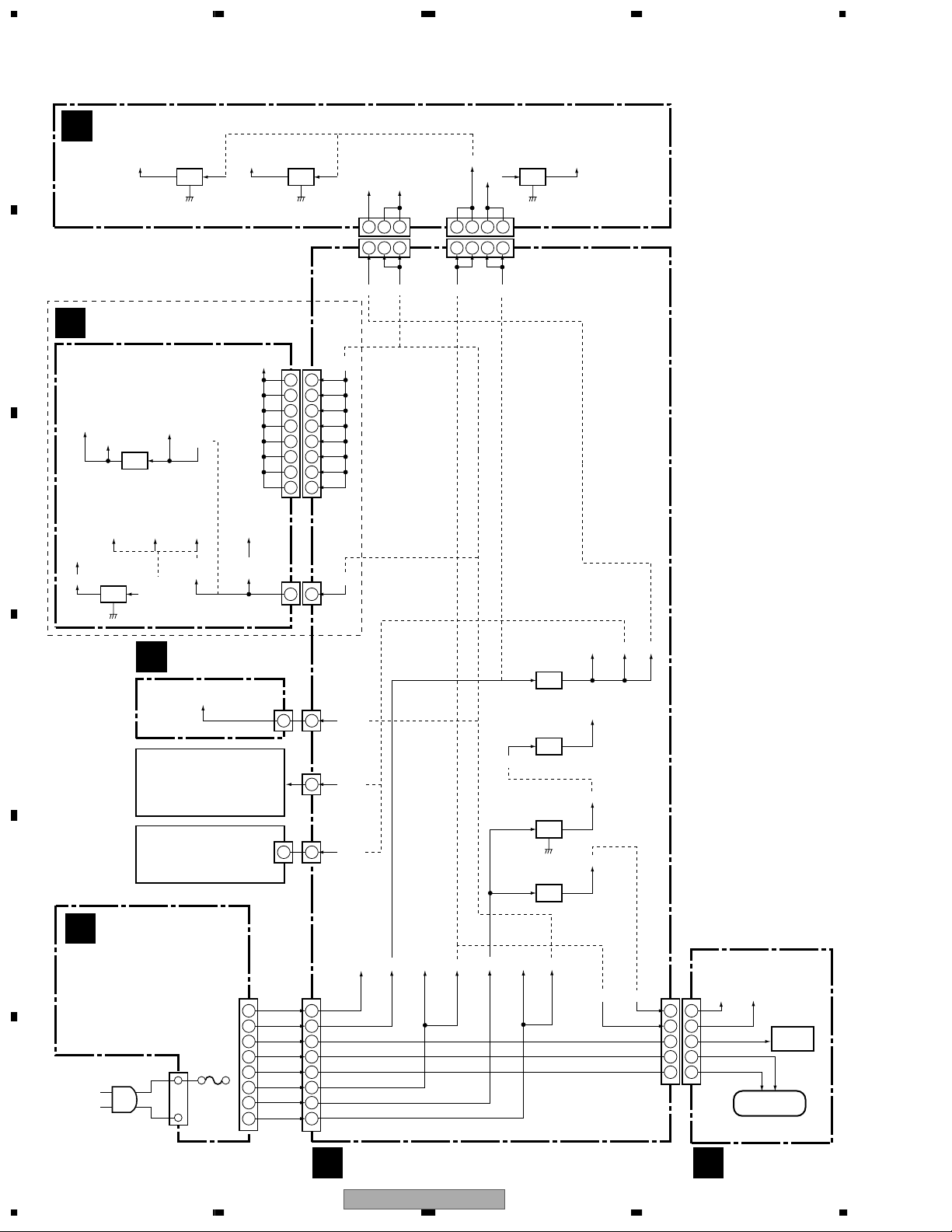

1234

7 POWER SUPPLY BLOCK

A

JACB ASSY

C

IC102

NJM78M05FA

V+3_18REG

V+3D

V+3_SDV+3IOV+3DSD

V+3D

(SACD)

V+3D

(SACD)

LOAB ASSY

A

B

C

DV-45A Only

SACDB ASSY

D

V18_ADSP1

V18D

MM1561JF

1.8V REG.

V+2C

V+25V

IC906

V+5A

IC808

V+8A

V+3D

(SACD)

CN901

V+3V_ADSP1

V+3D

(DVDAUDIO)

CN801

IC101

NJM78M08FA

1526

1427

1328

12

29

11

30

10

31

9

32

8

33

(40P)

2 19

(20P)

CN101

(21P)

CN551

(21P)

V+3D

CN531

(40P)

V+3D

CN502

(20P)

V+5D

V+3D

1917171212

19

V+5D V+3D

V+12V

8

8

EV+6

11

9 13

9 13

11

V+6EVV+12

IC702

PQ05RD11

CN701

(30P)

CN901

(30P)

IC402

MM1565AF

5V REG

V+5V

SW+5 V+5S V+5D

8 19

CN103

(5P)

33

CN115

(12P)

11

CN111

(26P)

V+3D

V+5S

V+5S

V+25V

IC791

MM1561JF

1.8V REG

IC403

PQ025EZ01

2.5V REG

IC404

MM1385EN

V18D

V+25V

V33EV

V+3D

CN601

(5P)

D

SPINDLE

MOTOR

PICKUP

ASSY-S

E

G

POWER SUPPLY

UNIT

LIVE

AC IN

F

NEUTRAL

CN1

CN101

F1

(13P)

11

13

1

2

3

4

5

9

EV6V (B)

EV6V (A)

-28V

FLDC+

FLDC-

SW+12V

EV+4V

SW+3.3

CN401

(13P)

1

2

3

4

5

9

11

13

V+6M

V+6EV V12M

V+12

EV+4V

V3VD

V+3D

V+12

-28V

FLDC+

FLDC-

CN402

(17P)

V+12

V+3EV33EV

14

14

16

16

3

3

7

7

5

5

CN101

(17P)

V101

FL TUBE

IC101

18

DVDM ASSY

B

FLKY ASSY

E

DV-45A

1234

Page 19

5678

A

B

C

D

E

56

DV-45A

F

7

8

19

Page 20

1234

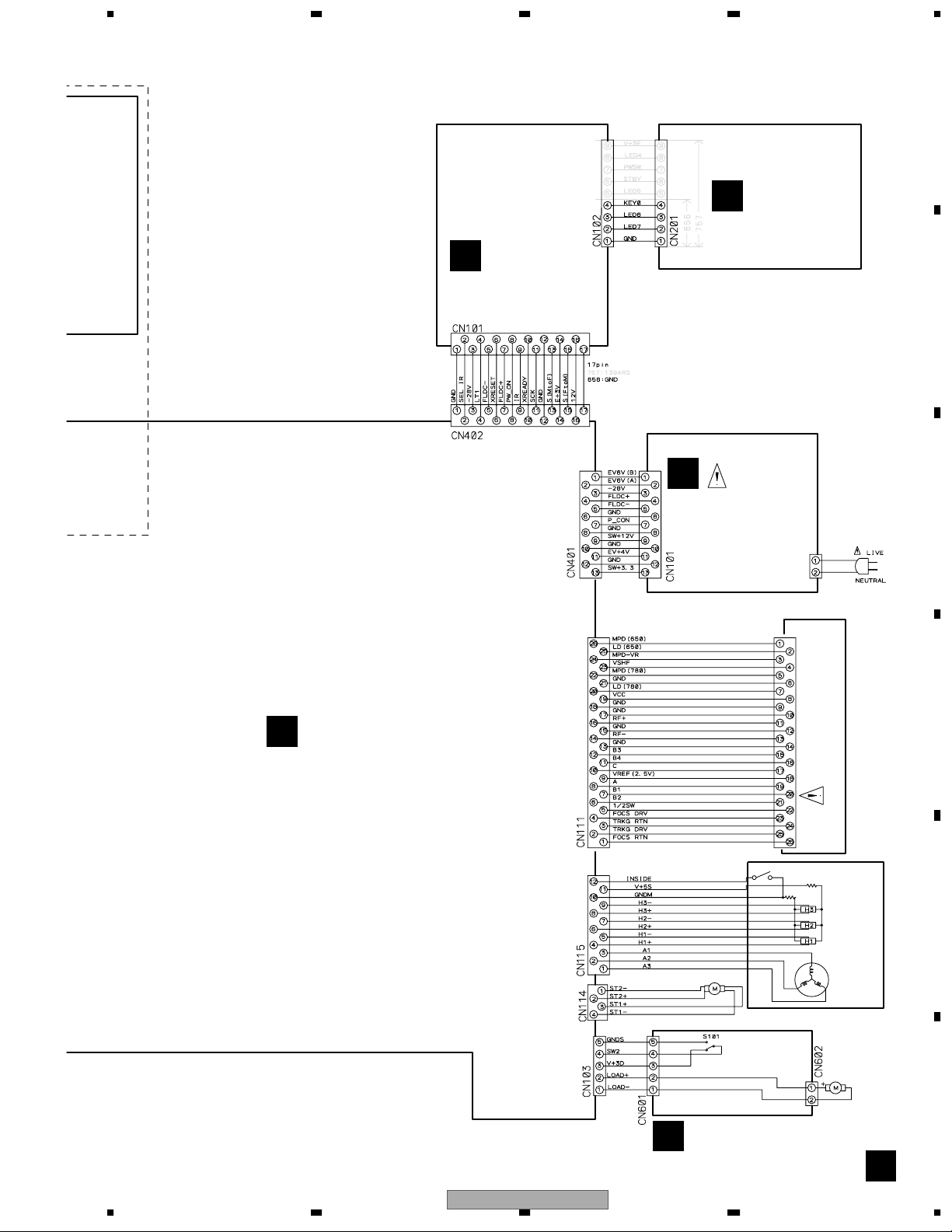

3.2 LOAB ASSY and OVERALL WIRING DIAGRAM

A

SACDB ASSY

D

(VWG2352)

B

C

D

JACB ASSY

C

DV-45A ONLY

(DV-45A : VWV1912)

(DV-656A : VWV1913)

E

Note : When ordering service parts, be sure

F

20

1234

DV-45A

to refer to "EXPLODED VIEWS and

PARTS LIST" or "PCB PARTS LIST".

Page 21

5678

A

KEYB ASSY

F

(VWG2377)

FLKY ASSY

E

(DV-45A : VWG2354)

(DV-656A : VWG2376)

B

DVDM ASSY

B

(DV-45A : VWS1533)

(DV-656A : VWS1531)

G

POWER SUPPLY UNIT

(VWR1351)

STEPPING MOTOR

: VXM1090

PICKUP ASSY-S

(OXX8003)

SPINDLE

MOTOR

: VXX1088

C

D

E

56

DV-45A

LOAB ASSY

A

(VWG2346)

LOADING

MOTOR ASSY

: VXX2505

F

A

7

8

21

Page 22

1234

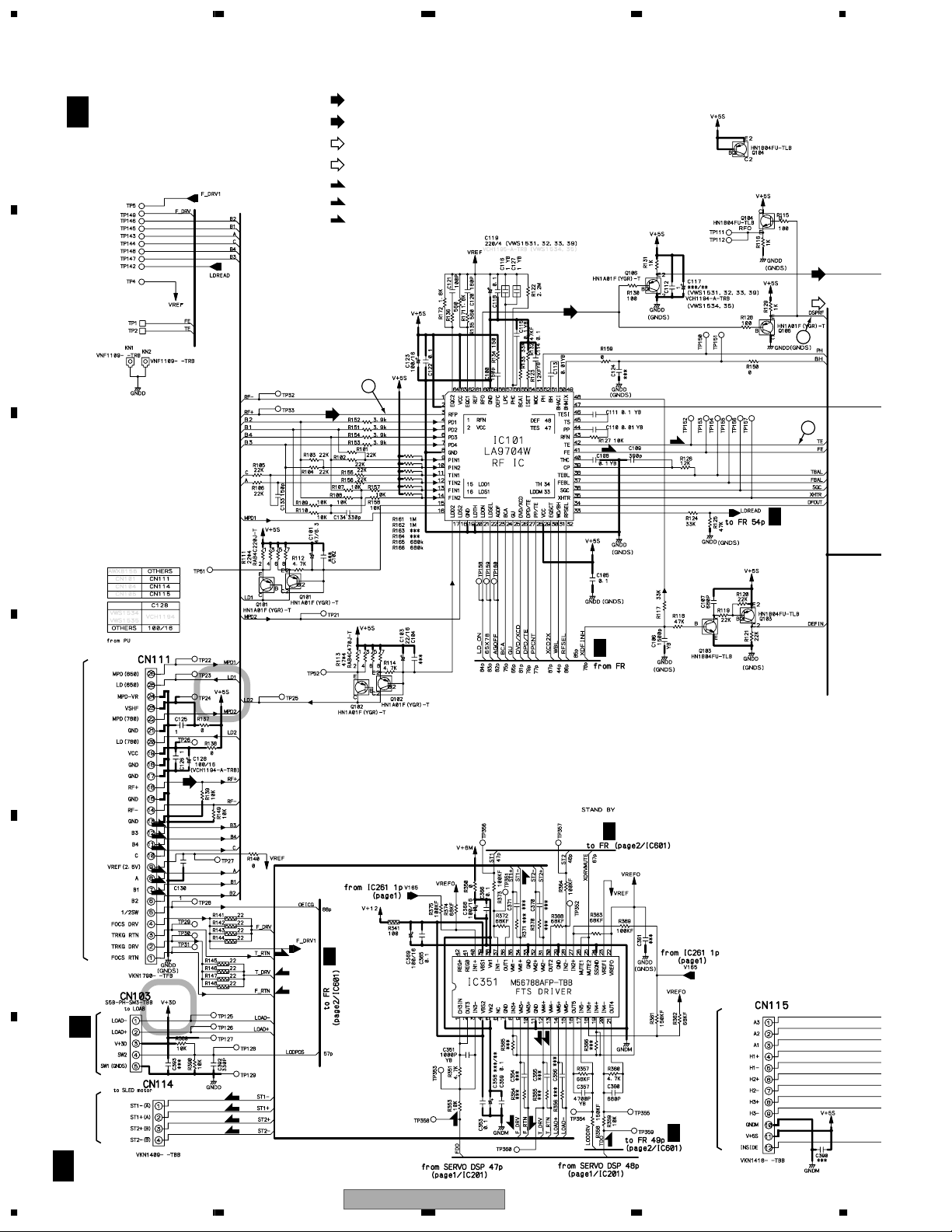

3.3 DVDM ASSY 1/4 [FTS BLOCK]

A

B 1/4

DVDM ASSY

(DV-45A : VWS1533)

(DV-656A : VWS1531)

(RF_V)

(RF_A)

(AD)

(RF)

: RF SIGNAL ROUTE

: RF (VIDEO) SIGNAL ROUTE

: RF (AUDIO) SIGNAL ROUTE

: AUDIO DATA SIGNAL ROUTE

(F)

: FOCUS SERVO LOOP LINE

(T)

: TRACKING SERVO LOOP LINE

(S)

: STEPPING SERVO LOOP LINE

(RF_V)

B

(RF_A)

2

4

2/4

B

1

(RF)

C

D

(RF)

(F)

B

2/4

(T)

E

F

PICKUP ASSY

A

CN601

STEPPING

B 1/4

22

(RF)

(F)

MOTOR

(F)

(T)

(T)

(F)

(F)

(T)

B

(T)

(F)

(S)

(S)

(S)

(S)

2/4

Focus, Tracking

and Loading Driver

(F)

(S)

(T)(T)

(F)

(F)

B

2/4

MOTOR

SPINDLE

B

(T)

2/4

DV-45A

1234

Page 23

5678

B

(RF_V)

3/4

VCO Circuit

B

3/4

DV-45A ONLY

B

2/4

(RF_V)

DV-45A ONLY

B

3/4

B

2/4

: The power supply is shown with

B

3/4

B

2/4

RF Amp.

(RF for SACD Water

Mark detection)

A

B

the marked box.

C

B

2/4

(T)

(F)

(RF_A)

6

(AD)

5

(F)

(T)

B

2/4

8 9

B

3/4

7

1110

D

E

B

3/4

Spindle Driver

DV-45A

56

B

3/4

F

B 1/4

7

8

23

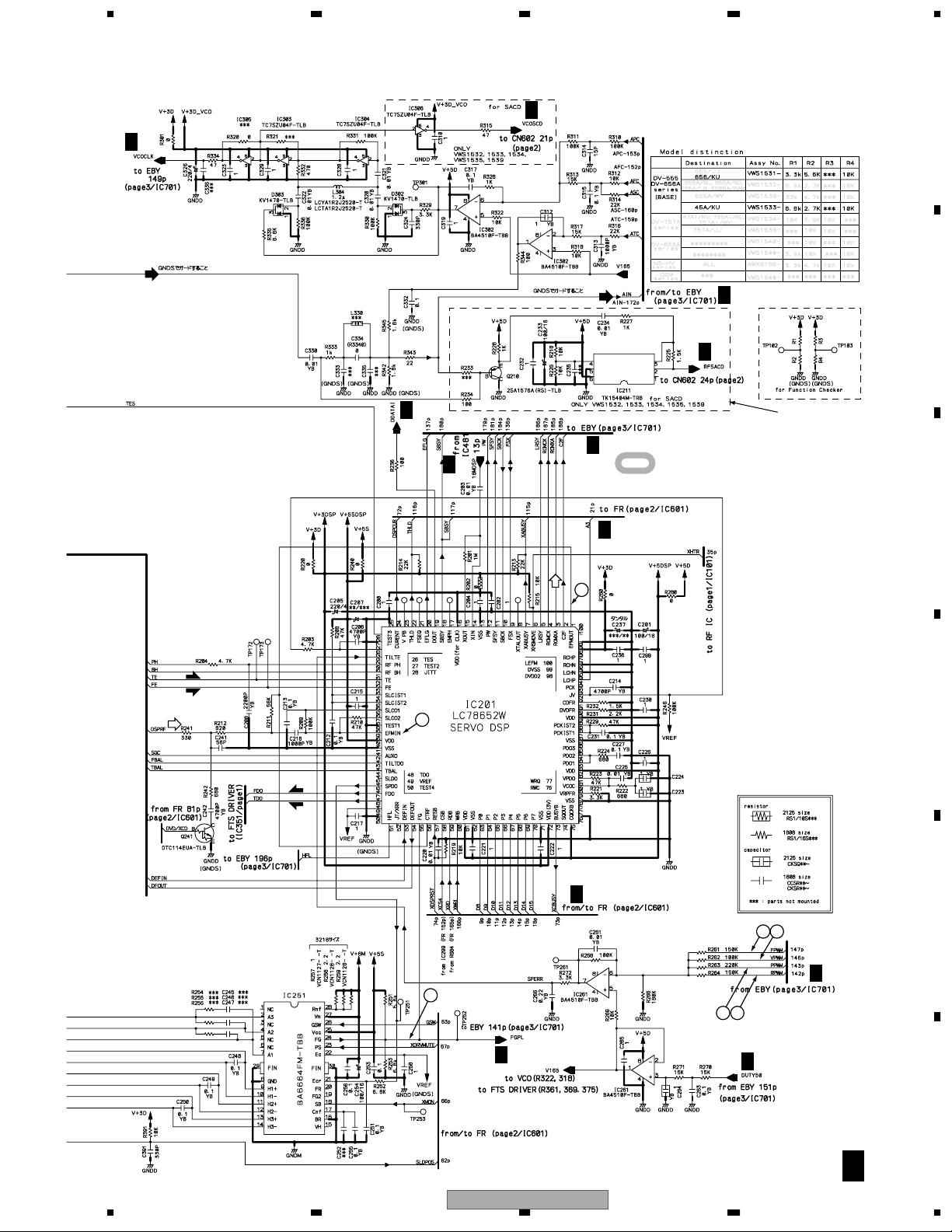

Page 24

1234

3.4 DVDM ASSY 2/4 [FR BLOCK]

A

B 2/4

DVDM ASSY

(DV-45A : VWS1533)

(DV-656A : VWS1531)

B

B

C

B

1/4

B

1/4

PGM 16M FLASH MEMORY

B

3/4

1/4

B

3/4

B

B

3/4

B

1/4

3/4

B

3/4

B

3/4

B

4/4

B

4/4

D

E

F

B 2/4

24

B

1/4

B

1/4

B

4/4

FR CPU

B

1/4

B

1/4

B

3/4

B

1/4

1/4

B

4/4

B

4/4

B

1/4

B

4/4

B

4/4

3/4

B

DV-45A

B

1234

Page 25

5678

B

3/4

Clock Signals: Refer to "7.1.7 TEST POINT LOCATION

B

4/4

B

3/4

B

3/4

& WAVEFORMS"

A

B

3/4

B

1/4

B

4/4

B

3/4

3.3V Regulator

B

C

CN101

G

D

B

1/4

B

3/4

D

B

1/4

B

3/4

DV-45A ONLY

56

CN901

DV-45A

E

CN101

E

F

B 2/4

7

8

25

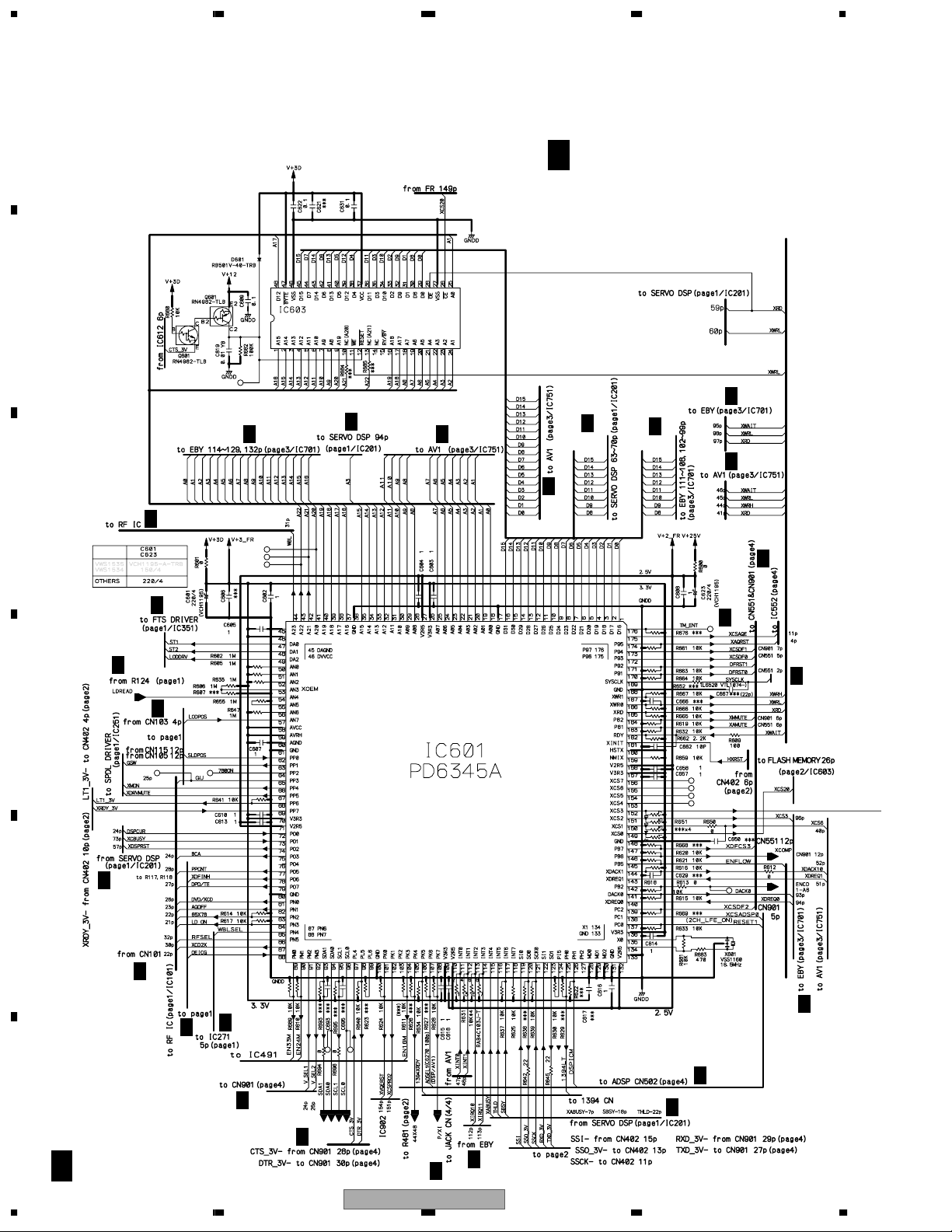

Page 26

1234

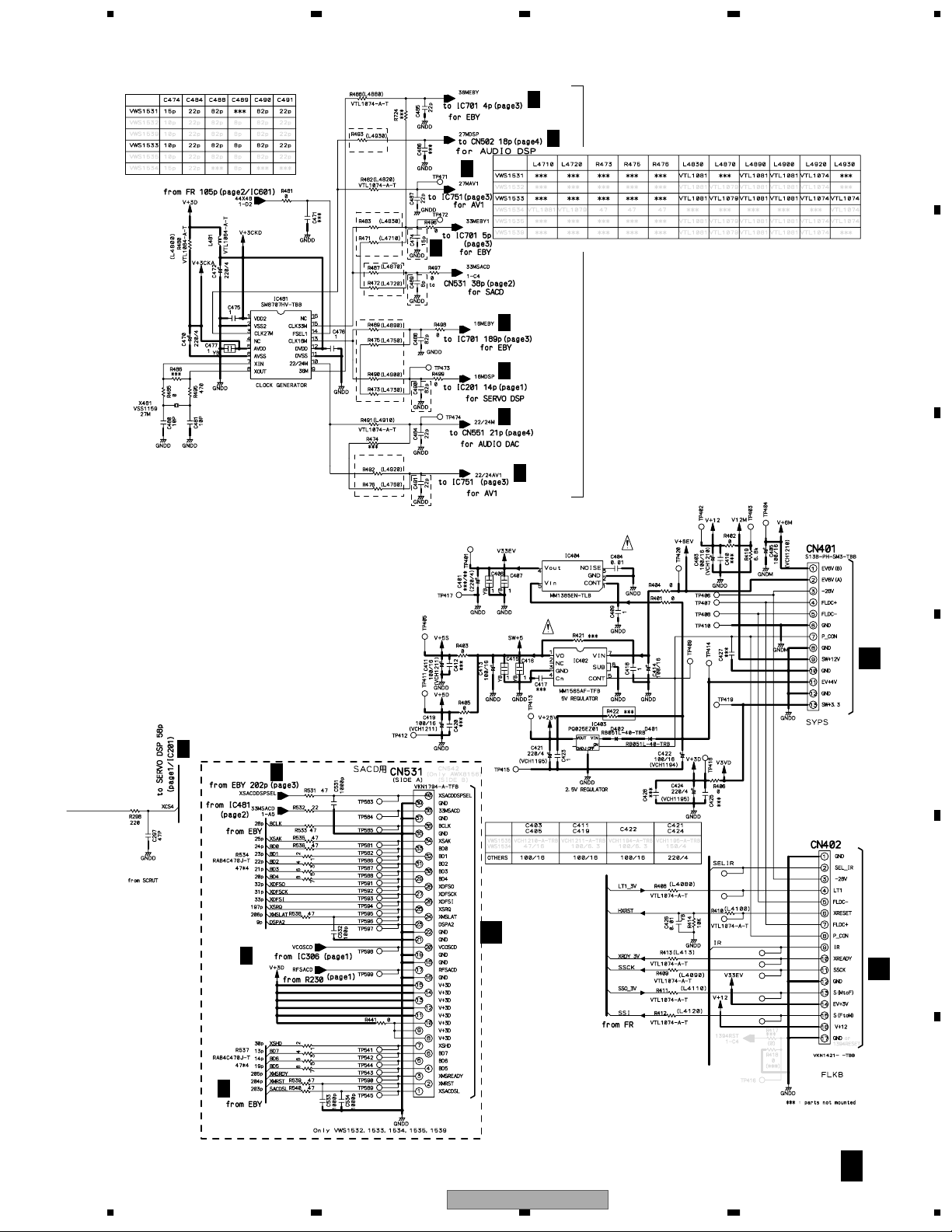

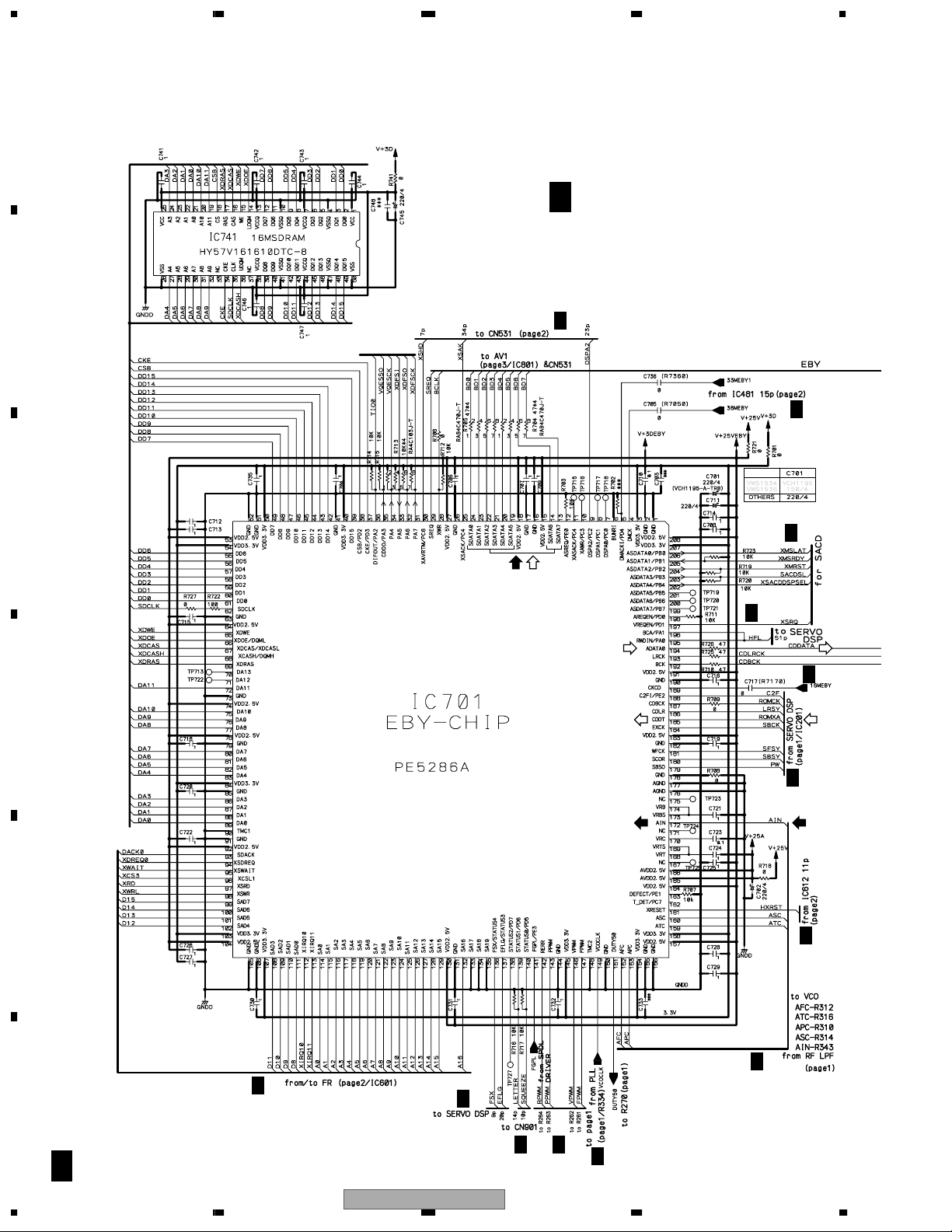

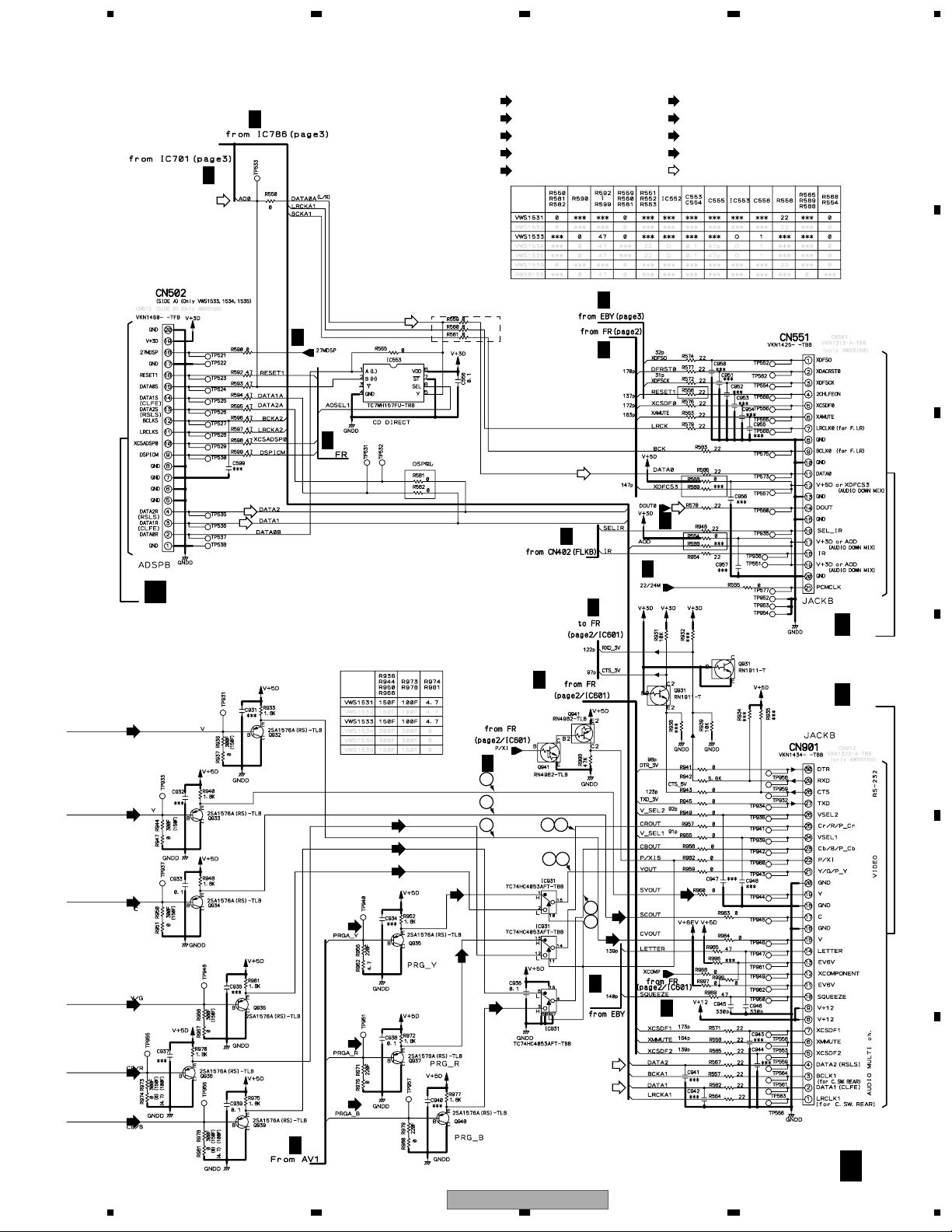

3.5 DVDM ASSY 3/4 [EBY/AV1 BLOCK]

A

B 3/4

DVDM ASSY

(DV-45A : VWS1533)

(DV-656A : VWS1531)

B

C

(VD)

(AD)

B

2/4

B

2/4

B

2/4

B

1/4

(D)

(D)

B

2/4

D

E

F

B 3/4

26

(AD)(AD)

B

1/4

DVD data Decoder

(RF_V)

B

B

2/4

DV-45A

1234

B

1/4

B

4/4B1/4

B

1/4

1/4

(RF_V)

B

2/4

Page 27

5678

: The power supply is shown with the marked box.

B

1/4

B

B

4/4

B

2/4

(VD)

(AD)

(VD)

2/4

(D)(D)

(D)(D)

B

4/4

A

B

C

(D)

MPEG, DVD-Audio, DTS Decoder

and

Progressive scan Processer

(RF_V)

(VD)

(AD)

(D)

(P_Y)

(P_Pb)

(P_Pr)

(D)

B

2/4

: RF (VIDEO) SIGNAL ROUTE

: VIDEO DATA SIGNAL ROUTE

: AUDIO DATA SIGNAL ROUTE

: AUDIO (DIGITAL) SIGNAL ROUTE

: PROGRESSIVE SCAN VIDEO SIGNAL ROUTE [Y]

: PROGRESSIVE SCAN VIDEO SIGNAL ROUTE [Pb]

: PROGRESSIVE SCAN VIDEO SIGNAL ROUTE [Pr]

B

D

(P_Pr)

(P_Y)

(P_Pb)

4/4

E

F

56

DV-45A

B 3/4

7

8

27

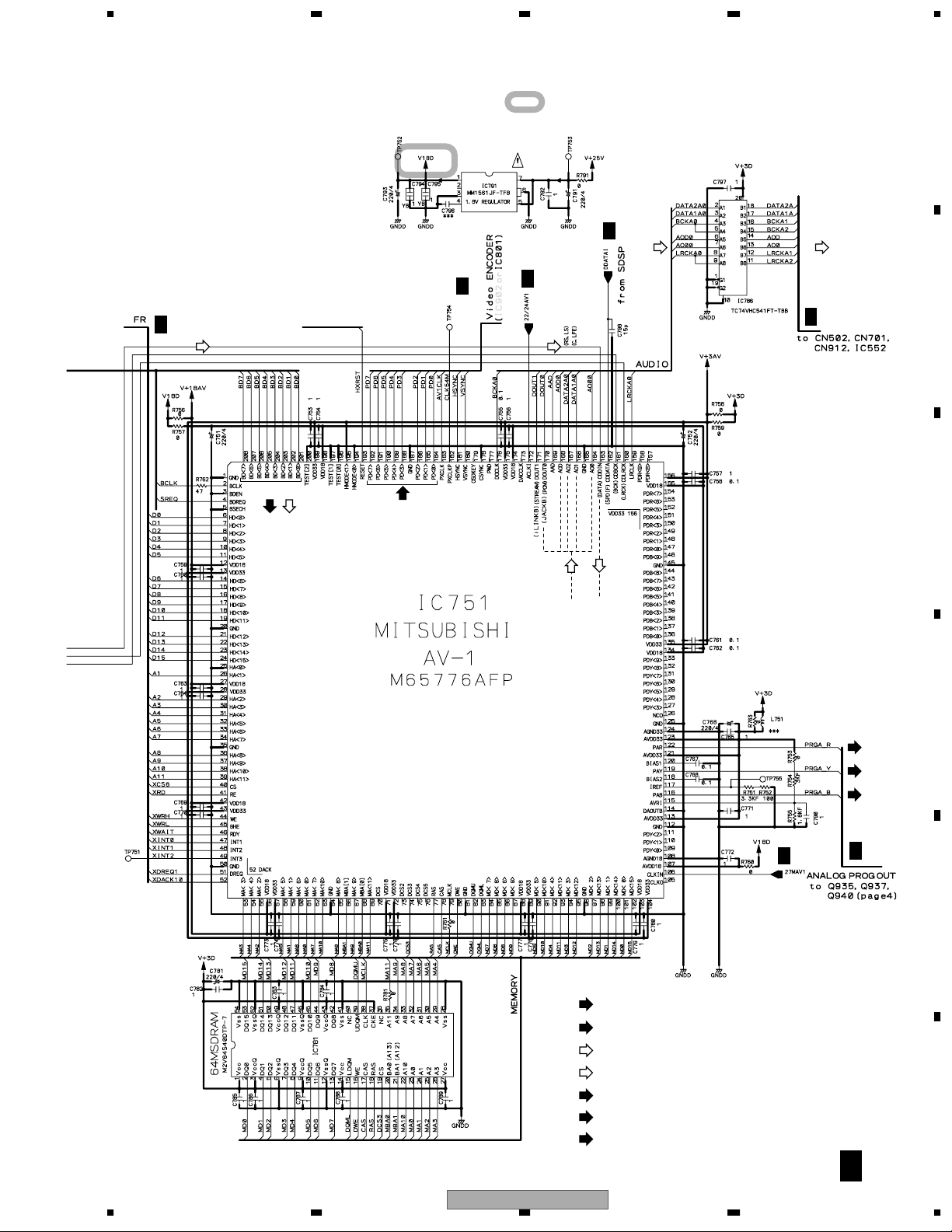

Page 28

1234

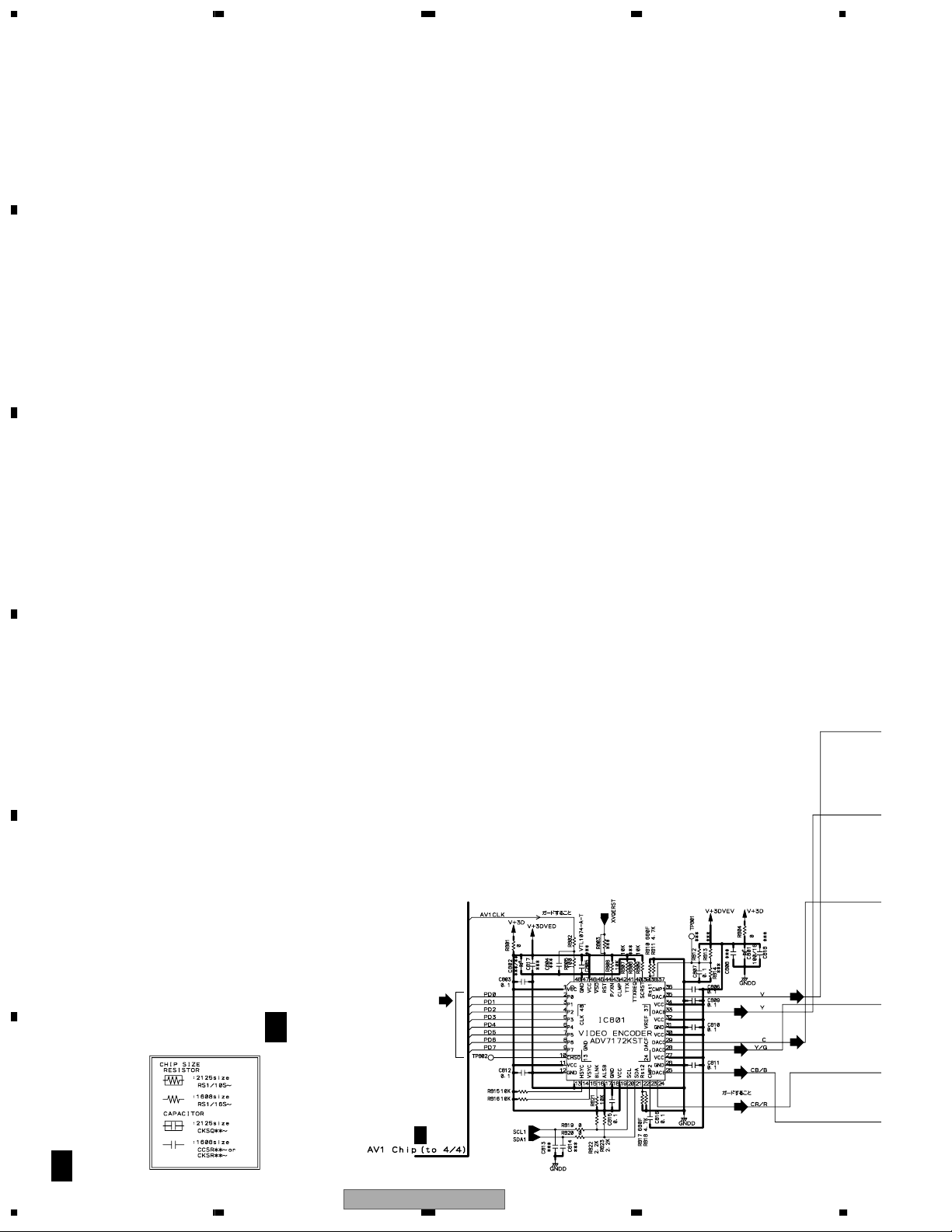

3.6 DVDM ASSY 4/4 [VENC BLOCK]

A

B

C

D

E

F

B 4/4

28

(VD)

B 4/4

DVDM ASSY

(DV-45A : VWS1533)

(Y)

(Y)

(Pb)

(V)

(C)

(DV-656A : VWS1531)

(Pr)

B

3/4

1234

DV-45A

Page 29

5678

(D)

(VD)

: VIDEO DATA SIGNAL ROUTE

(V)

B

3/4

B

3/4

(D)

B

2/4

B

2/4

(D)

(D)

: V SIGNAL ROUTE

(Y)

: Y SIGNAL ROUTE

(C)

: C SIGNAL ROUTE

(Pb)

: Pb SIGNAL ROUTE

B

3/4

B

2/4

(D)

B

2/4

(Pr)

: Pr SIGNAL ROUTE

(P_Y)

: PROGRESSIVE SCAN VIDEO SIGNAL ROUTE [Y]

(P_Pb)

: PROGRESSIVE SCAN VIDEO SIGNAL ROUTE [Pb]

(P_Pr)

: PROGRESSIVE SCAN VIDEO SIGNAL ROUTE [Pr]

(D)

: AUDIO (DIGITAL) SIGNAL ROUTE

(D)

B

3/4

A

B

C

(V)

(Y)

(C)

(Y)

(Pr)

(Pb)

D

CN801

Buffer

B

2/4

B

2/4

Buffer

B

2/4

14

13

Buffer

Buffer

Buffer

Buffer

(P_Y)

(P_Pr)

(Pr)

(Pb)

(Y)

(P_Y)

Buffer

Buffer

12

(P_Pr)

(P_Pb)

Interlace/Progressive

(P_Pb)

B

3/4

Buffer

2017

18

15

SW for

Video select

16

19

(C)

(V)

B

3/4

(D)

(D)

DV-45A

56

B

2/4

C 1/2

CN101

C 2/2

CN701

(Y)

B

2/4

D

E

F

B 4/4

7

8

29

Page 30

1234

3.7 JACB ASSY 1/2 [AUDIO BLOCK]

A

D

CN902

C 1/2

JACB ASSY

(DV-45A : VWV1912)

DV-45A ONLY

B

(D)

(D)

(D)

(D)

DV-45A ONLY

DV-656A

R207, R208, R210 : 0

W356

: DV-656A ONLY

SW for Audio Digital data select

of SACD or others (3 lines)

DV-45A ONLY

+8V Regulator

C

(D)

(D)

(DV-656A : VWV1913)

Audio DAC

for Front channel

(2 ch)

(D)

21 22

24 23

DV-656A ONLY

+5V Regulator

(D)

DIGITAL AUDIO OUT

D

E

B 4/4

CN551

(D)

C

2/2

(D)

(D)

COAXIAL

DIGITAL AUDIO OUT

OPTICAL

(D)

(D)

Audio DAC

for Ls, Rs

(2 ch)

(D)

F

C 1/2

30

Audio DAC

for C, LFE (Sub Woofer)

(2 ch)

DV-45A

1234

Page 31

5678

(D)

SW

for Mute Control Signal

25

: AUDIO (DIGITAL) SIGNAL ROUTE

: AUDIO SIGNAL ROUTE

Q350, Q351, Q360, Q361:

Mute SW

A

IC302, IC303:

I to V change

circuit

SW

for Mute Control

Signal

SW

for Mute Control

Signal

Reference voltage

generation

for Audio Amp.

Differential Amp.

(with LPF)

(Front 2ch/Down mixed stereo)

Circuitry to do LPF of a low

level ingredient from Front L, R

in order to add it to LFE

DV-656A ONLY

DV-45A

C371→ R3371 (0)

R/FR ch.

L/FL ch.

FR ch.

FL ch.

Audio out

B

C

D

SW

for Mute Control

Signal

Audio Amp.

(with LPF)

SW

for Mute Control

Signal

Audio Amp.

(with LPF)

: The power supply is shown with the marked box.

DV-45A

56

Q410, Q420, Q510, Q520:

Mute SW

LPF: Low Pass Filter

7

Ls ch.

Rs ch.

Center

ch.

LFE ch.

(Sub

Woofer)

Audio out

C 1/2

8

E

F

31

Page 32

1234

3.8 JACB ASSY 2/2 [VIDEO BLOCK]

A

C 2/2

JACB ASSY

(DV-45A : VWV1912)

(DV-656A : VWV1913)

(D)

(D)

B

B 4/4

CN901

(C)

C

(V)

(Y)

(Pr/P_Pr)

C

1/2

(Y/P_Y)

(Pb/P_Pb)

(Pr/P_Pr)

(V)

(Y)

(Y/P_Y)

(Pb/P_Pb)

(C)

(V)

(C)

(Y)

(Y)

(Pb)

(Pr)

D

(V)

: V SIGNAL ROUTE

(Y)

: Y SIGNAL ROUTE

(C)

: C SIGNAL ROUTE

(Pb)

: Pb SIGNAL ROUTE

(Pr)

: Pr SIGNAL ROUTE

(P_Y)

: PROGRESSIVE SCAN VIDEO SIGNAL ROUTE [Y]

(P_Pb)

: PROGRESSIVE SCAN VIDEO SIGNAL ROUTE [Pb]

E

(P_Pr)

: PROGRESSIVE SCAN VIDEO SIGNAL ROUTE [Pr]

(D)

: AUDIO (DIGITAL) SIGNAL ROUTE

F

C 2/2

32

1234

DV-45A

Page 33

5678

(Pr)

: The power supply is shown with the marked box.

(V)

(C)

(Y)

(Y)

(Pb)

(V)

(Y)

(C)

Composite Video out

A

B

Video out

C

(Pb)

(Pr)

(Y)

Component Video out

D

E

56

DV-45A

F

C 2/2

7

8

33

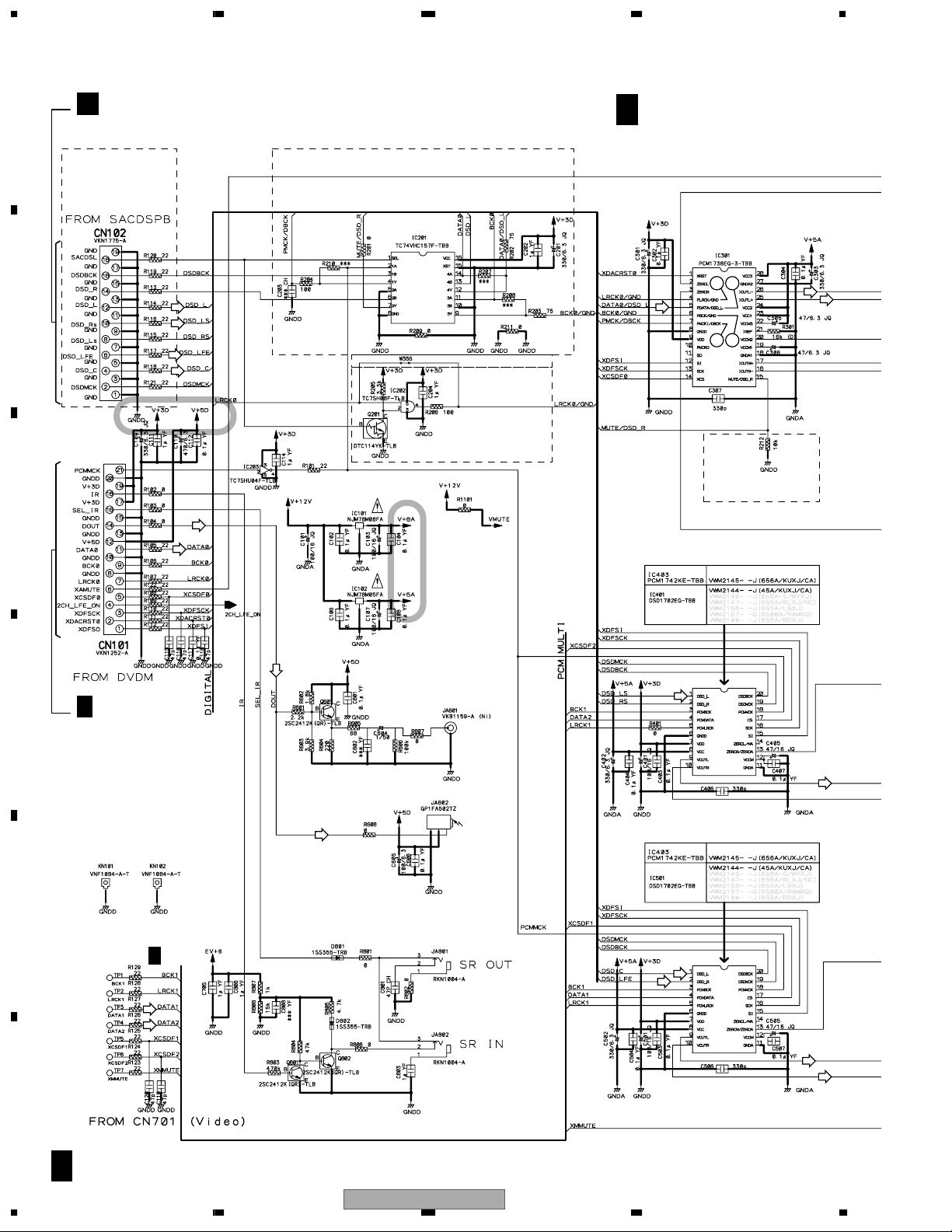

Page 34

1234

3.9 SACDB ASSY

A

B

C

SACDB ASSY

D

(VWG2352)

D

(AD)

E

(AD)

B 2/4

CN502

CN531

B 4/4

(AD)

F

(AD)

34

D

DV-45A

1234

Page 35

5678

: The power supply is shown with the marked box.

(AD)

: AUDIO DATA SIGNAL ROUTE

(D)

: AUDIO (DIGITAL) SIGNAL ROUTE

A

B

C

(AD)

(D)

(D)

(D)

(D)

(D)

(D)

(D)

(D)

C 1/2

CN102

D

E

F

56

DV-45A

D

7

8

35

Page 36

1234

3.10 FLKY and KEYB ASSYS

A

FLKY ASSY

E

(DV-45A : VWG2354)

(DV-656A : VWG2376)

B

C

D

E

F

36

E

DV-45A

1234

Page 37

5678

A

: The power supply is shown with the marked box.

KEYB ASSY

F

(VWG2377)

B

FLKY ASSY

S101 : 0 (OPEN/CLOSE)

S102 : 7 (STOP)

S103 : 8 (PAUSE)

S104 : 3 (PLAY)

S105 : ¡¢

S106 : 41

C

D

B 2/4

CN402

E

KEYB ASSY

S201 : VIDEO OFF

S202 : PROGRESSIVE

S203 : POWER STANDBY/ON

56

DV-45A

F

E F

7

8

37

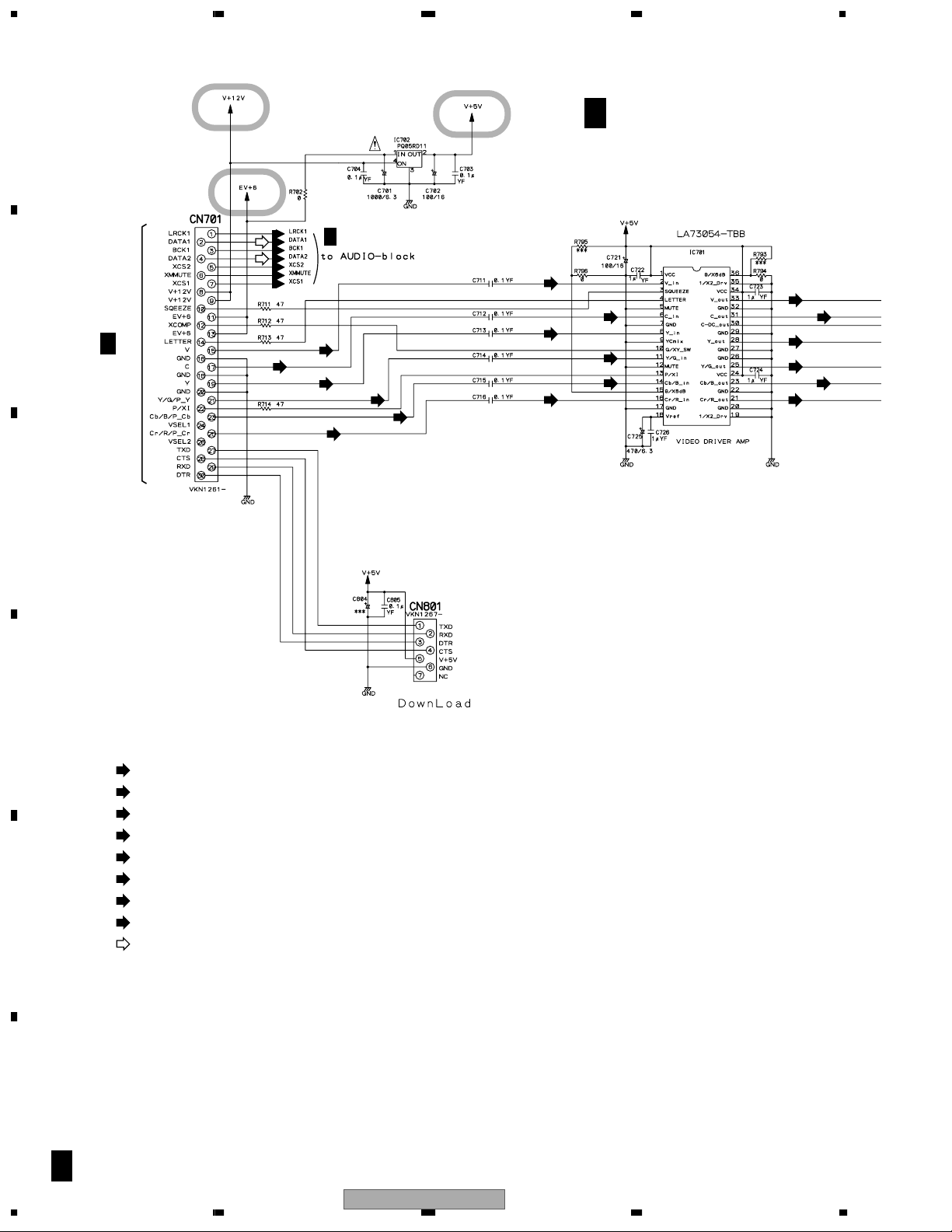

Page 38

1234

3.11 POWER SUPPLY UNIT

A

CN101

B

CAUTION : FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE ONLY WITH SAME TYPE NO. 491.800 MFD, BY

LITTELFUSE INC. FOR P101 (AEK7063).

CAUTION : FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE ONLY WITH SAME TYPE NO. 49101.6 MFD, BY

LITTELFUSE INC. FOR P102 (AEK7066).

CAUTION : FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE ONLY WITH SAME TYPE NO. 491002 MFD, BY

LITTELFUSE INC. FOR P104 (AEK7067).

1.6A

AEK7066

AEK7067

2.0A

B 2/4

1.6A

AEK7012

CN401

CAUTION : FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE ONLY WITH SAME TYPE NO. 49101.6 MFD, BY

LITTELFUSE INC. FOR P103 (AEK7012).

C

800mA

AEK7063

D

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE WITH SAME TYPE AND RATINGS ONLY.

E

CAUTION -

• NOTE FOR FUSE REPLACEMENT

REK1077

1.6A

POWER SUPPLY UNIT (VWR1351)

F

G

G

38

• In case of repairing, use the described parts only to prevent an accident.

• Please write the red mark on the board when the primary section of POWER SUPPLY (SYPS) Unit is repaired.

• Please take care to keep the space, not touching other parts when replacing the parts.

NOTE OF SPARE PARTS IN POWER SUPPLY (SYPS) UNIT

CN1

AC IN

C2, C6, C106, C303, Z1: STANDBY

G

1234

DV-45A

Page 39

5678

3.12 WAVEFORMS [DVDM ASSY]

Note : The encircled numbers denote measuring point in the schematic diagram.

DVDM ASSY

B

Measurement condition

: No. 1 to 4 and 6 to 11 : MJK1, Title 1-chp 1 No. 12 to 14 : DVD-REF-A1, T2-Chap.1

No. 5 : CD, ABEX-784 Track 1 No. 15 to 20 : DVD-REF-A1, T2-Chap.19

IC101-pin 3 (RF)

1

V: 200mV/div. H: 0.1µsec/div.

Q106-emitter (RFO)

2

V: 500mV/div. H: 0.1µsec/div.

3

AC mode

GND

AC mode

GND

IC251 - pin 24 (FG)

7

V: 1V/div. H: 5msec/div.

Foot of R261 (FPWM)

8

V: 1V/div. H: 10µsec/div.

Foot of R262 (VPWM)

9

V: 1V/div. H: 10µsec/div.

GND

GND

Foot of R963 (C)

13

V: 0.2V/div. H: 10µsec/div.

Foot of R960 (Y)

14

V: 0.2V/div. H: 10µsec/div.

Foot of R959 (Y)

15

V: 0.2V/div. H: 10µsec/div.

Foot of R958 (Pb)

19

V: 0.2V/div. H: 10µsec/div.

Foot of R957 (Pr)

20

V: 0.2V/div. H: 10µsec/div.

A

B

C

IC101-pin 42 (Tracking Error)

4

(AI-Inner Tracking Off)

V: 500mV/div. H: 2msec/div.

IC201 - pin 39 (EFM before slice)

5

V: 0.5V/div. H: 0.2µsec/div.

IC201 - pin 1 (EFM)

6

V: 1V/div. H: 0.2µsec/div.

AC mode

GND

GND

Foot of R263 (PPWM)

10

V: 1V/div. H: 0.2msec/div.

Foot of R264 (RPWM)

11

V: 1V/div. H: 5msec/div.

Foot of R964 (V)

12

V: 0.2V/div. H: 10µsec/div.

GND

GND

GND

Foot of R958 (Pb)

16

V: 0.2V/div. H: 10µsec/div.

Foot of R957 (Pr)

17

V: 0.2V/div. H: 10µsec/div.

Foot of R959 (Y)

18

V: 0.2V/div. H: 10µsec/div.

D

E

GND

DV-45A

56

F

7

8

39

Page 40

1234

3.13 WAVEFORMS [JACB ASSY]

A

Note : The encircled numbers denote measuring point in the schematic diagram.

JACB ASSY

C

Measurement condition

IC301-pin 4 (LRCK)

21

V: 1V/div. H: 5µsec/div.

B

IC301-pin 5 (DATA0)

22

V: 1V/div. H: 500nsec/div.

: No. 21 to 25 : DVD-REF-A1, T2-Chap.1

C

D

E

IC301-pin 6 (BCK)

23

V: 1V/div. H: 100nsec/div.

IC301-pin 7 (PMCK)

24

V: 1V/div. H: 20nsec/div.

IC302 - pin 1 (Analog OUT)

25

V: 1V/div. H: 500µsec/div.

F

40

1234

DV-45A

Page 41

5678

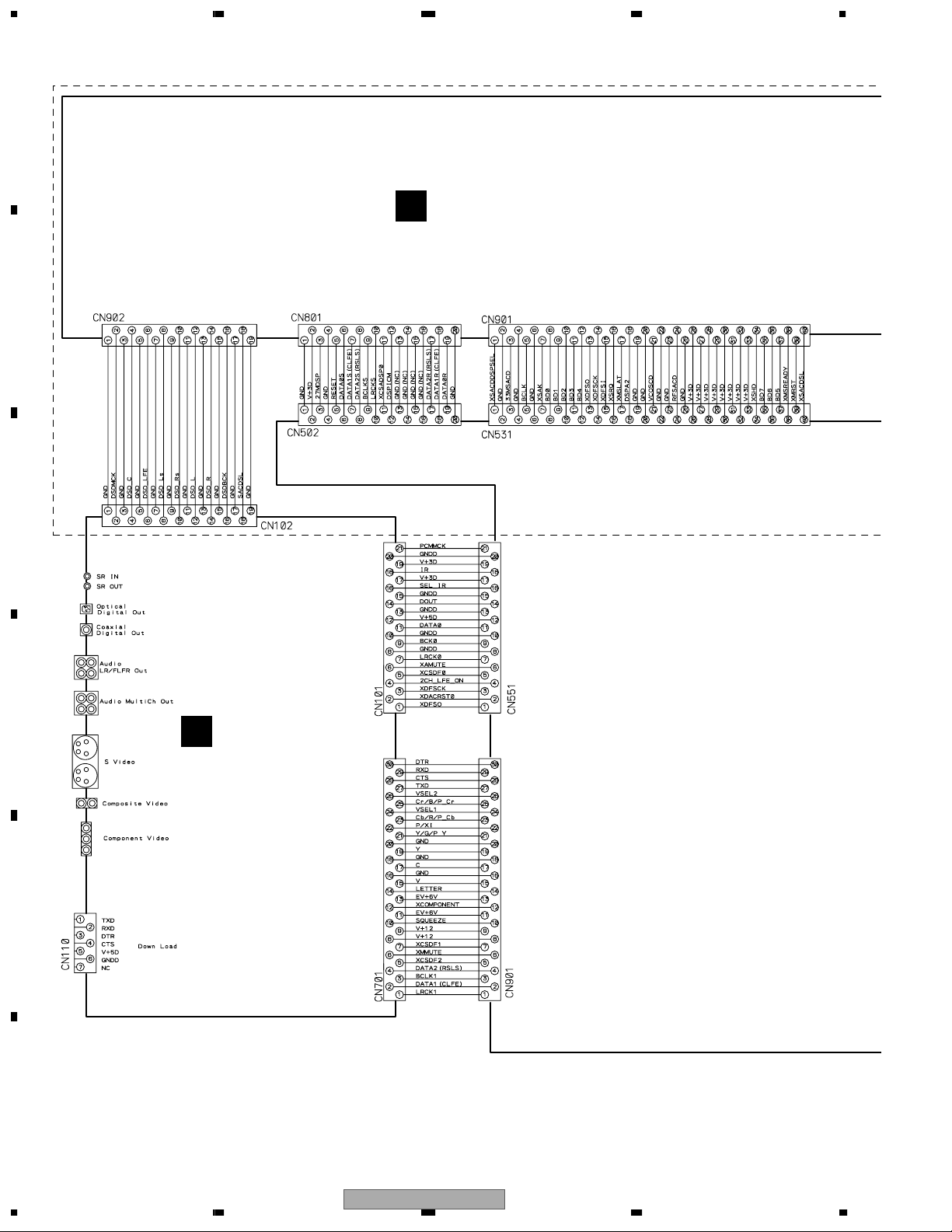

4. PCB CONNECTION DIAGRAM

4.1 LOAB ASSY

NOTE FOR PCB DIAGRAMS :

1. Part numbers in PCB diagrams match those in the schematic

diagrams.

2. A comparison between the main parts of PCB and schematic

diagrams is shown below.

Symbol In PCB

Diagrams

BCE

B

D

C

E

S

Symbol In Schematic

Diagrams

EB C E

BC

S

BC

DG

BCE

DGG

Transistor

E

S

Part Name

Transistor

with resistor

Field effect

transistor

3. The parts mounted on this PCB include all necessary parts for

several destinations.

For further information for respective destinations, be sure to

check with the schematic diagram.

4. View point of PCB diagrams.

Connector

Capacitor

SIDE A

P.C.Board

Chip Part

SIDE B

A

B

Resistor array

3-terminal

regulator

SIDE A SIDE B

LOAB ASSY

A

(VNP1836-B)

CN601CN602 CN602CN601

CN103

B

M

LOADING

MOTOR

ASSY

C

D

E

F

AA

56

DV-45A

7

8

41

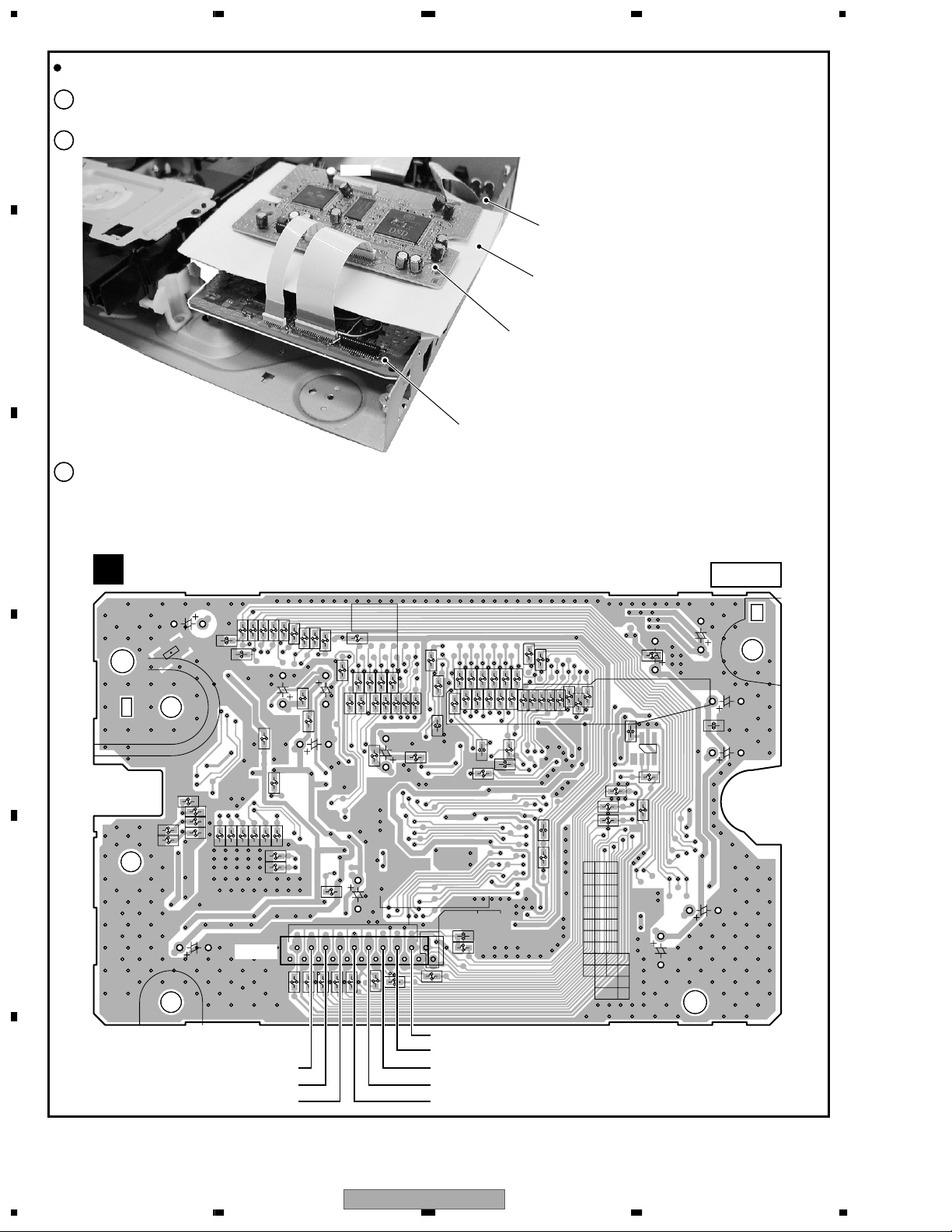

Page 42

1234

4.2 DVDM ASSY

SIDE A

A

DVDM ASSY

R821

R816

R859

R871

R815

33 48

C852

33 48

R872

C843

IC831

R842

R841

R839

49 64

C758

C204

R328

5

R318

4

R317

C313

R311

C314

R313

FPWM

VPWM

PPWM

RPWM

C693

R694

C695

R696

R695

R640

R693

C610

R641

R535

R531

R536

R533

C531

CONTACT SIDE

49

R322

R647

R602

R534

C317

IC302

R270

R261

R262

R263

R264

R606

R605

CN531

32

C263

R271

R310

R312

C315

C760

R314

R316

R607

R635

C266

B

2

2

R864

R868

C851

C847

C761

C759

R266

C532

CONTACT SIDE

R986

R929

R832

R831

17 32

C842

C917

R928

C838

C837

116

R835

116

R875

C766

R753

R752

D

52

C770

C769

C326

R718

PRI-FLUX

26

R908

R760

C772

C771

1

R985

DVI

R923

R863

R862

17

64

R836

C833

R758

R759

C752

C762

C764

C763

C702

R725

R726

R483

C265

C264

R537

SACD

2

2

R269

4

IC261

1

C534

1

1

C474

C711

R471

C

R762

R538

AWX8156VWS15 -

VWS1535-

R741

R540

R539

R408

1

1

C533

R272

8

R268

C261

R721

5

R441

C903

50

C913

C796

14

1

4

R757

105

105

R756

104

C794

104

C780

C779

C777

R761

R476

R474

C484

C774

C773

C782

53

53

52

C781

R301

C489

R493

R487

R482

C486

R497

R472

C701

R704

R705

R706

R713

BAR CODE

R414

C426

R413

R410

R898

R907

C902

HEAT RESISTANCE

25

C751

C487

C795

C778

D

R492

R491

C776

C775

R781

R473

R489

R490

R488

C485

R714

C745

R417

R411

R409

CN901

R942

R943

R935

R934

PW

CN401

1

113

EV6

D401

EV4

JACK(VIDEO)

CONTACT SIDE

R939

30

R931

NP

R938

R997

R404

30

Q931

R959

R945

R958

R957

R854

EV3

C849

C848

R856

R873

R855

C850

C401

C815

R822

R823

C414

IC403

5V

R403

C412

C801

C808

5S

C411

CN101

G

CN401

B

CN601

A

13

D402

R406

1

15

C422

CN103

LOAD

R389

R390

C392

5

1

1

C126

CN103

C

PICKUP

ASSY

CN111CN115

26

26

CN101

CONTACT SIDE

1

1

CN114

CN114

D

STEPPING

M

4

4

CN104

6M

MOTOR

SLDR

4

CONTACT SIDE

1

1

112

CN105

12

R391

C391

12V

R224

C226

R223

C230

R229

C231

C227

A

E

SPINDLE

MOTOR

M

HCT163

R422

C393

R138

FDRV

PU

R341

94V-0

C283

C284

R287

2

2

26

26

29

1

LDREAD

R662

C662

C657

C658

R619

R664

C128

12

12

1

R651

C369

GNDM

SPDL

CN115

FG

R622

C616

C614

R633

R669

R620

R666

R288

C285

1

1

25

25

C299

R663

1

C272

C282

CN111

C205

X601

R652

R285

R149

R661

R290

C286

R289

8

5

IC281

4

R161

C273

C271

C274

R282

R283

R286

C281

R284

R281

B1

B2

A

C

B4

B3

RF+

RF-

R139

C119

C207

CONTACT SIDE

C358

C217

R350

C221

C368

R221

C222

R222

C225

30

R280

C201

R681

R629

R683

132

133

R615

R668

R676

C666

176

1

R667

C667

C270

8

8

1

1

R240

51

IC201

75

C224

R630

(SECOND)

SIDE A

C

R996

R963R964

R948

R933

C933

C931

Q934

Q932

R960

R940

C932

Q933

R947

R944

C846

R804

C811

C806

R812

R813

C807

2.5V

5

5

4

4

R166

R165

R164

R163

R162

R211

R210

C215

50

76

A

C223

R645

R637

R638

R631

R598

R592

R590

R599

CN701

C816

R818

R817

25

C810

C809

3625

36

R810

R814

R811

R806

R803

IC271

C101

R119

C103

C123

C100

C107

R120

VREF

C127

R628

C618

C603

20

20

CN502

DSP

CONTACT SIDE

R951

R950

24

2413

37

37

R809

R808

R807

C805

R168

R167

R150

Q103

R134

R242

R212

C216

R209

C213

R232

R231

R626

C604

19

19

R121

C212

R129

IC801

C236

R937

R936

R115

26

1

1

130

R801

13

12

121

1

48

48

R838

R837

C841

R844

R846

C798

C755

C117

RFO

R241

TE

C241

R208

R204

C208

C206

25

R201

1

100

IC601

CN912

30

30

291

29

CN901

CN951

R865

R866

C802

C812

C844

C839

C803

R845

R843

R805

C840

C804

R802

C834

C845

C832

R833

C757

C767

R751

C768

156

156

157 208

157

C756

C108

C106

R118

R117

C754

C753

FE

208

IC751

1

1

R236

R215

C202

C319

R202

C200

8

C203

C312

1

C233

89

R624

88

R623

R611

R627

C615

C613

C607

R655

C605

45

44

40

40

R593

2

2

39

39

1

1

R475

1

C793

7

57

R481

R412

C909

5

R724

IC901

C480

R485

17

C916

C912

R579

R754

R755

C790

C476

R701

R791

C908

C471

C472

R673

C924

9

9

16

C791

(VNP1886-B)

CONTACT SIDE

CN551

21

21

1

R577

1

R563

R632

R568

R570

21

R954

21

1

R946

1

R583

IC791

C792

C470

R486

16

IC481

C

CN701

1

1

C799

R798

R671

R672

R674

R675

24

24

VWS1534VWS1533VWS1532- VWS1539VWS1531-

KN1

R418

FL

CN402

17

CONTACT SIDE

T.O.

KN2

CN561

JACK(AUDIO)

R555

VNP1886-

DVDM

R480

X481

C481

R495

8

C477

C475

1

18

27M

L481

iLINK

CONTACT SIDE

Q931

Q932

Q934

Q933

CN101

C

CN551

Q103

IC901

IC403

IC831

IC801

IC271

IC281

IC791

IC481

IC751

IC201

IC302

IC261

IC601

F

D

CN801

CN502

D

CN901

CN531

CN402

CN101

E

42

B

DV-45A

1234

Page 43

SIDE B

B

54

28

27

1

14

57

24

13

12

1

111

12

22

23

33

34 44

1

40

41

80

81 120

121

160

1

16

18

9

116

17

32

33 48

49

64

5

4

3

1

5

4

3

1

1

28 15

14

5

4

3

1

5

4

3

1

208

157

156105

104

53

52

1

1

10

11

20

7

R911

C915

C914

C911

C910

C907

C906

C901

C905

R922

C930

C923

R920

R919

R565

C920

C922

C921

R914

R918

R917

C919

R916

R913

R915

R912

R910

C918

C787

C783

R621

R113R111

C786

C785

IC781

C789

C788

C784

R610

C423

R793

R998

Q941

R589

C936

R581

IC402

C746

C741

C742C743

C927

C124

C929

R532

R330

R332

R329

R331

IC552

R659

IC404

R909

R618

C944

C494

C493

R763

R582

R665

C404

R171

R795

R797

R405

R114

R796

R978

C736

R642

R609

R680

C619

C609

R682

D601

R689

C310

C418

C417

C406

R925

R921

R799

R924

C420

R320

C900

IC741

C407

C409

R401

R601

R600

R616

C419

R976

R897

C716

C254

R252

C725

R128

R971

R639

C115

R203

C405

C940

C328

C425

IC491

Q601

C424

C114

C121

R135

C109

R988

R987

R597

R596

R595

R594

R992

R990

R984

R983

R588

R421

CN513

R982

R586

R550

R585

C252

C255

IC902

C904

C893

C765

IC211

C403

R402

C410

C421

IC553

IC931

Q935

Q940

Q937

Q939

Q936

Q938

C555

C814

C813

R820

R819

R561

R560

R553

R552

R551

C553

C552

R559

C554

C744

C415

C413

C416

C896

R246

R106

R105

C895

R893

C894

R903

R902

R901

R894

R974R967

C836

R900

R899

C891

R891

R941

R906

R905

R904

R965

R932

R557

R834

R558

C125

R226

R225

C134

R218

C390

C234

R227

C232

R564

R567

R554

R556

R140

R315

C835

R840

L751

R977

R980

R979

R956

R952

C934

R973

C937

R962

R970

C935

R961

C747

C608

C623

R625

R614

R612

C629

R650

C650

C297

R298

R617

C601

C602

IC603

R219

R966

C939

R975

L304

C321

C322

C320

R794

C938

R126

C120

C122

C928

C110

C941

R677

R927

C945

R172

R896

R419

C898

C897

R685

C556

R895

R684

R571

R572

R576

R574

R562

R969

R968

R342

C332

R345

C330

R344

C333

C335

C334

R333

R214R213

C105

C214

C329

R334

C336

R4

R2

R1

R131

R130

L330

D302

C237

C256

R257

IC101

R3

C324

IC303

IC304

D303

R335

R336

R353

C359

R358

R359

C360

R351

C357

R357 R360

C351

C353

IC351

C365

R372

R363

R373

R368

C361

R364

R361

R362

R354

C354

R355

C355

R356

C356

R371

C371

R370

C370

R321

R258

R259

R124

R125

C366

R137

TP1

TP2

R112

R374

R375

R369

R366

R365

C242

IC251

C250

C249

C248

R256

C247

C246

R255

C245

R254

C251

C253

C258

R251

R253

R141

R142

R143

R144

R146

R147

R148

R145

R152

R153

R154

R151

Q210

Q241

R116

R101

R156

R155

R122

R234

C104

R133

R127

C118

R136

Q104

C113

R109

R110

R107

R108

R104

R103

R102

R132

R220

Q101

C116

C111

C130

R157

Q102

R123

R260

Q106

IC305

R972

C133

C899

C102

R158

IC306

C323

R233

R228

C112

C631

C622

R981

R949

R955

C220

R926

R999

C946

R792

IC701

R343

R995

R994

R993

C708

C705

R710

C714

C710

R709

C717

R703

R711

C709

C707

C706

C704C735

C713

C712

C715C718

C720

C722

C726

C727

C730

C731

C732

C733

C729

C728

C724

C723

C721

C719

R707

R708

R702

R712

R715

R716

R717

R720

R719

R722

CN542

R159

C488

R634

R613

C495

C490

C491

C797

IC786

CN412

C943

C599

C948

R498

R727

R499

R496

C947

C235

R723

C942

CONTACT SIDE

CONTACT SIDE

CONTACT SIDE

IREF

RFO

AWX8

VWS1

(FIRST)

SIDE B

Q104

Q102

Q106

Q937

Q101

IC552

IC211

IC351

IC304

Q210

Q241

IC404

IC741

IC491

IC902

IC553

IC931

IC603

IC101

IC251

IC402

Q941

Q601

Q935

IC786

IC701

Q940

IC781

Q938

Q936

Q939

13

45

26

50

1

25

2

20

19

1

1

6

4

8

5

4

24

1

48

25

012345678

9

001122334455667788

99

A-

42

22

21

1

NP

2

40

1

39

1

DVDM ASSY

B

(VNP1886-B)

5678

A

B

C

D

E

F

56

DV-45A

7

8

43

Page 44

1234

3

W285

8

4.3 JACB ASSY

SIDE A

A

JACB ASSY

C

(VNP1887-C)

GREEN & BLUE & REDYELLOW

17

1

V+12V

C804

GNDD

W306

W305

D

AUDIO_R

SQEEZE

VSEL1

GNDA

W218

V+12V

W436

W266

C781

AUDIO_L

V+5V

7

GNDD

W215

W262

W263

W264

W265

W307

19

W216

GNDD

W337

CN801

W432

GNDD

+5V

W297

W335

W214

GNDD

W431

W298

C782

W336

E

KN102

B

CODE SECTION 25249.6 - PROPOSITION 65

GNDD

W217

ELECTRICAL PARTS CONTAIN CHEMICALS WHICH ARE KNOWN

THIS PRODUCT CONTAINS LEAD IN SOLDER AND CERTAIN

TO THE STATE OF CALIFORNIA TO CAUSE CANCER, BIRTH

DEFECTS OR OTHER REPRODUCTIVE HARM. HEALTH & SAFETY

WARNING

C

GNDD

GNDD

CONTACT SIDE

VCY

G

B

1

GND

119

W299

CN702

VSEL2

R

9

8

2

1

C771C772C775

W433

15

RY702

V+12V

W430

15

W434

+5V

C702

W429

W447

W448

GNDD

CN703

610

W295

610

RY701

Print side

GNDD

14

IC702

W446

GNDD

VWV1921(858AViJ)

VWV1920(49KU)

VWV1919(755AiRL)

W296

W435

GNDD

GNDD

W445

W261

W449

W211

C725

GNDD

W250

W425

12

456

JA702

C763C762

W210

W249

W294

C701

W209

W248

W245

W246

W247

W293

W332

VWV1918(757AJJ)

VWV1917(757AiWY)

VWV1916(47AiKU)

VWV19**(655ARD)

VWV1915(655ARL)

W208

C761

W244

W496

W292

W291

D

W207

C721

3

W206

W205

GNDD

GNDD

W242

W243

W290

30

30

VWV1926(6500ARAM)

VWV1925(655ALB)

VWV1914(656AWY)

VWV1913(656AKU)

VWV1912(45AKU)

CN701

EV+6V

W444

C741

W289

GNDD

W443

W330

GNDD

JA703

W329

RXD

DTR

TXD

CTS

B

C742

78M08

78M05

V+12V

Cr/R

Cb/B

Y/G

YCV

VSEL2

VSEL1

P/XI

GND

GND

CN901

W333

W328

GND

IC101

GNDA

W241

IC102

CN701

EVER6,SW5

EVER6,SW5

LETTER

SQEEZE

XCOMP

6

JA701

C103

W240

C107

EV+6V

W288

1

1

CONTACT SIDE

V+12V

LRCK1

XCS1

XCS2

BCK1

XMMUTE

V+12V

DATA2

DATA1

C751

W239

GNDA

W204

C101

CN705

215

2

1

C105

W287

W286

JACB

5

C753

8

87-

E

IC702

IC101

IC102

F

C

44

1234

DV-45A

Page 45

5678

BLACK

RED & WHITE

BLACK

CN551

B

SIDE A

A

CN101

TZ

5

24

5

2

W204

W239