Pioneer DV-588-AS Service manual

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2005

DVD PLAYER DV-588A-S

STANDBY/ON

DV-588A-S

OPEN/CLOSE

TOP MENU MENU

HOME

MENU

RETURN

ORDER NO.

RRV3139

DVD PLAYER

DV-588A-S

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Region No. Remarks

DV-588A-S KUXTL/CA AC120V 1

For details, refer to "Important Check Points for Good Servicing" .

T-ZZR APR. 2005 printed in Japan

-

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians ; it is not meant for the casual do-it

yourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

causecancer, birth defects or other reproductive harm.

B

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement

parts must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que

les pièces de remplacement doivent avoir la même désignation.

Health & Safety Code Section 25249.6 – Proposition 65

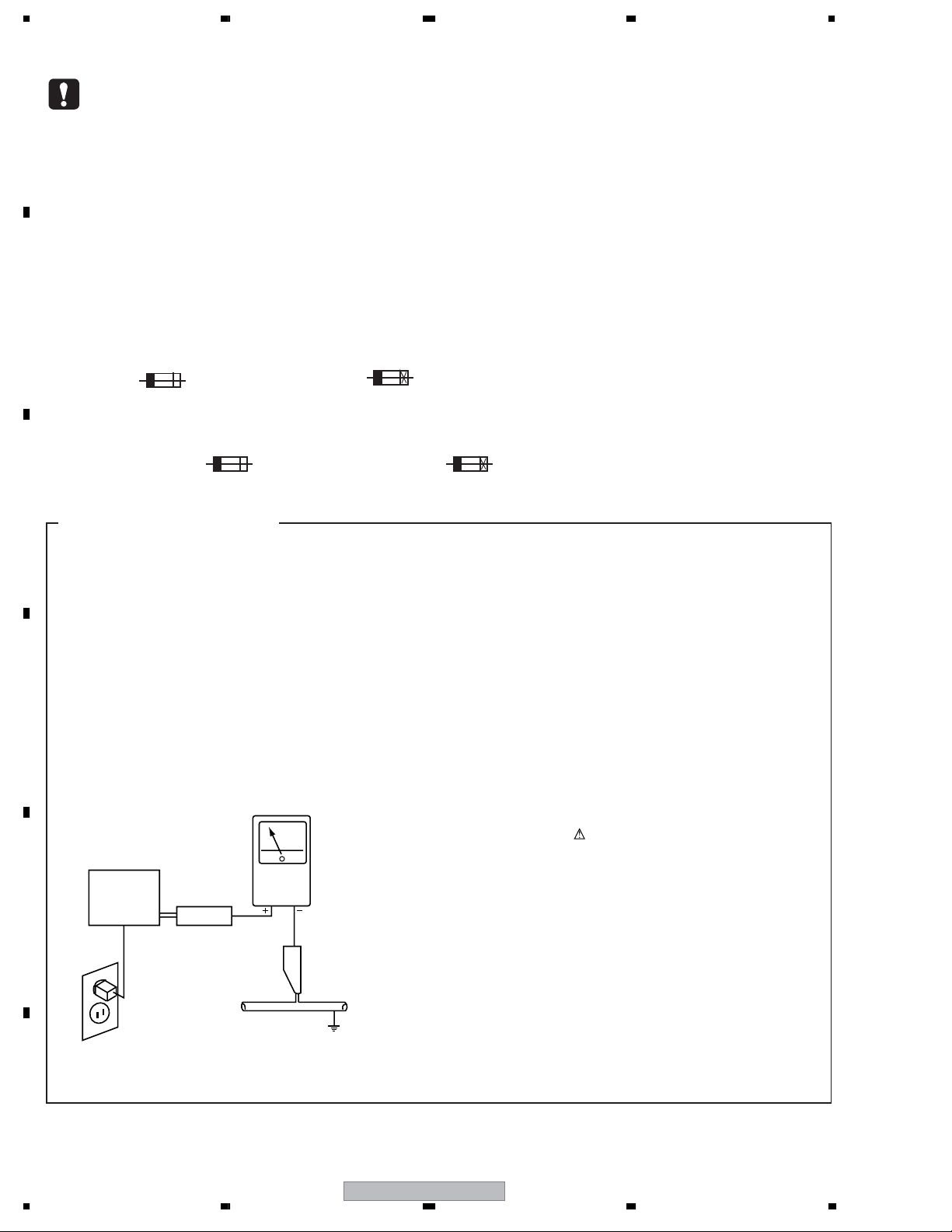

C

(FOR USA MODEL ONLY)

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and

service technician.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground (waterpipe

, conduit, etc.) by connecting a leakage current tester

such as Simpson Model 229-2 or equivalent between the

D

earth ground and all exposed metal parts of the appliance

(input/output terminals, screwheads, metal overlays, control

shaft, etc.). Plug the AC line cord of the appliance directly

into a 120V AC 60Hz outlet and turn the AC power switch

on. Any current measured must not exceed 0.5mA.

Reading should

Leakage

Device

under

E

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Test all

exposed metal

surfaces

current

tester

not be above

0.5mA

Earth

ground

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are identified

by marking with a on the schematics and on the parts list

in this Service Manual.

The use of a substitute replacement component which does

not have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in

this Service Manual, may create shock, fire, or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of, PIONEER

Service Manual may be obtained at a nominal charge

from PIONEER.

AC Leakage Test

F

2

1234

DV-588A-S

5678

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

A

B

C

D

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

56

DV-588A-S

E

F

3

7

8

1234

CONTENTS

SAFETY INFORMATION ..................................................................................................................................... 2

1. SPECIFICATIONS ............................................................................................................................................ 5

2. EXPLODED VIEWS AND PARTS LIST ............................................................................................................ 6

A

B

C

D

2.1 PACKING SECTION .................................................................................................................................. 6

2.2 EXTERIOR SECTION............................................................................................................................... 8

2.3 05 DVD MECHA SECTION...................................................................................................................... 10

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM..........................................................................................12

3.1 BLOCK DIAGRAM ................................................................................................................................... 12

3.2 OVERALL WIRING CONNECTION DIAGRAM........................................................................................ 14

3.3 DVD MT PCB (1/6) ASSY........................................................................................................................ 16

3.4 DVD MT PCB (2/6) ASSY........................................................................................................................ 18

3.5 DVD MT PCB (3/6) ASSY........................................................................................................................ 20

3.6 DVD MT PCB (4/6) ASSY........................................................................................................................ 22

3.7 DVD MT PCB (5/6) ASSY........................................................................................................................ 24

3.9 OPERATION, OPERATION 2 and OPERATION 3 PCB ASSYS ............................................................. 28

3.10 POWER PCB (1/2) ASSY ...................................................................................................................... 30

3.11 POWER PCB (2/2) ASSY ...................................................................................................................... 32

3.12 WAVEFORMS ........................................................................................................................................ 34

4. PCB CONNECTION DIAGRAM ..................................................................................................................... 37

4.1 LOADING and SW PCB ASSYS.............................................................................................................. 37

4.2 DVD MT PCB ASSY................................................................................................................................. 38

4.3 OPERATION, OPERATION 2 and OPERATION 3 PCB ASSYS ............................................................. 42

4.4 POWER PCB ASSY................................................................................................................................. 46

5. PCB PARTS LIST ........................................................................................................................................... 48

6. ADJUSTMENT ............................................................................................................................................... 52

6.1 WHEN REPLACING DVD DECK ............................................................................................................. 52

6.2 TEST MODE ............................................................................................................................................ 53

6.3 TEST MODE IN........................................................................................................................................ 54

6.4 DISC REMOVAL METHOD...................................................................................................................... 55

7. GENERAL INFORMATION............................................................................................................................. 56

7.1 DIAGNOSIS ............................................................................................................................................. 56

7.1.1 DISPLAY SPECIFICATION OF THE TEST MODE............................................................................ 56

7.1.2 FUNCTIONAL SPECIFICATION OF THE SHORTCUT KEY ............................................................ 57

7.1.3 SPECIFICATION OF MODEL INFORMATION DISPLAY .................................................................. 58

7.1.4 FUNCTIONAL SPECIFICATION OF THE SERVICE MODE............................................................. 59

7.1.5 METHOD FOR DIAGNOSING DEGRADATION OF THE LDS ON THE PICKUP ASSY .................. 60

7.1.6 TROUBLE SHOOTING...................................................................................................................... 61

7.2 DISASSEMBLY ........................................................................................................................................ 63

7.3 DVD DECK SECTION.............................................................................................................................. 64

7.4 IC INFORMATION.................................................................................................................................... 68

8. PANEL FACILITIES ........................................................................................................................................ 80

8.1 FRONT PANEL SECTION ....................................................................................................................... 80

8.2 DISPLAY .................................................................................................................................................. 81

8.3 REMOTE CONTROL ............................................................................................................................... 82

E

F

4

1234

DV-588A-S

5678

1. SPECIFICATIONS

Specifications

A

General

System . . . . . . . . . . . . . . . . . . . . . . DVD player

Power requirements . . . . . .

AC 120 V, 60 Hz

Power consumption . . . . . . . . . . . . . . . . . 8 W

Power consumption (standby) . . . . . . 0.7 W

Weight . . . . . . . . . . . . . . . . . . . . . . . .

1.8kg / 4Ib

Dimensions:

. . . 420 (W) x 49.5 (H) x 225.5 (D) mm

(16-9/16 (W) x 1-15/16 (H) x 8-7/8 (D)in.)

Operating temperature . . . . . . . +5°C to +35°C

(+41°F to +95°F)

Operating humidity . . . . . . . . . . . . . 5% to 85%

(no condensation)

Component video output

Y (luminance) - Output level . . . 1 Vp-p (75 Ω )

(color) - Output level

P

B

P

(color) - Output level . . . . . 0.7 Vp-p (75 Ω)

R

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RCA

Jack

. . . . 0.7 Vp-p (75Ω )

S-video output

Y (luminance) - Output level . . . . . 1 Vp-p (75 Ω)

C (color) - Output level . . . . . . 286 mVp-p (75 Ω)

Jack . . . . . . . . . . . . . . . . . . . . . . . . . . . . S-video

Video output

Output level. . . . . . . . . . . . . . . . . . 1 Vp-p (75 Ω)

Jack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RCA

Audio output (multi-channel / L, R, C, SW,

SL, SR)

Output level . . . . . . . . . . . . . During audio output

Number of channels . . . . . . . . . . . . . . . . . . . . . 6

Jacks . . . . . . . . . . . . . . . . . . . . . . . . . . . . RCA jack

200 mVrms (1 kHz, –20 dB)

Digital audio characteristics

Frequency response . . . . . . . . 4 Hz to 44 kHz

(DVD fs: 96 kHz)

4 Hz to 88 kHz (DVD-Audio fs: 192 kHz)

S/N ratio . . . . . . . . . . . . . . . . . . . . . . . . . 115 dB

Dynamic range . . . . . . . . . . . . . . . . . . . . 101 dB

Total harmonic distortion . . . . . . . . . . 0.0023 %

Wow and flutter . . . . . . Limit of measurement

(±0.001% W. PEAK) or lower

Digital output

Coaxial digital output . . . . . . . . . . . . .

Optical digital output . . . . . . . Optical digital jack

RCA jack

Accessories

Audio/video cable. . . . . . . . . . . . . . . . . . . . . . . . 1

Remote control. . . . . . . . . . . . . . . . . . . . . . . . . . 1

AA/R6P dry cell batteries . . . . . . . . . . . . . . . . . 2

Warranty card. . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Operating Instructions

B

C

D

Audio output (1 stereo pair)

Output level . . . . . . . . . . . . During audio output

Number of channels . . . . . . . . . . . . . . . . . . . . . 2

Jacks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

56

200 mVrms (1 kHz, –20 dB)

RCA

The specifications and design of this product are subject to

change without notice, due to improvement.

Published by Pioneer Corporation.

Copyright © 2005 Pioneer Corporation.

All rights reserved

DV-588A-S

7

E

F

5

8

1234

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

A

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

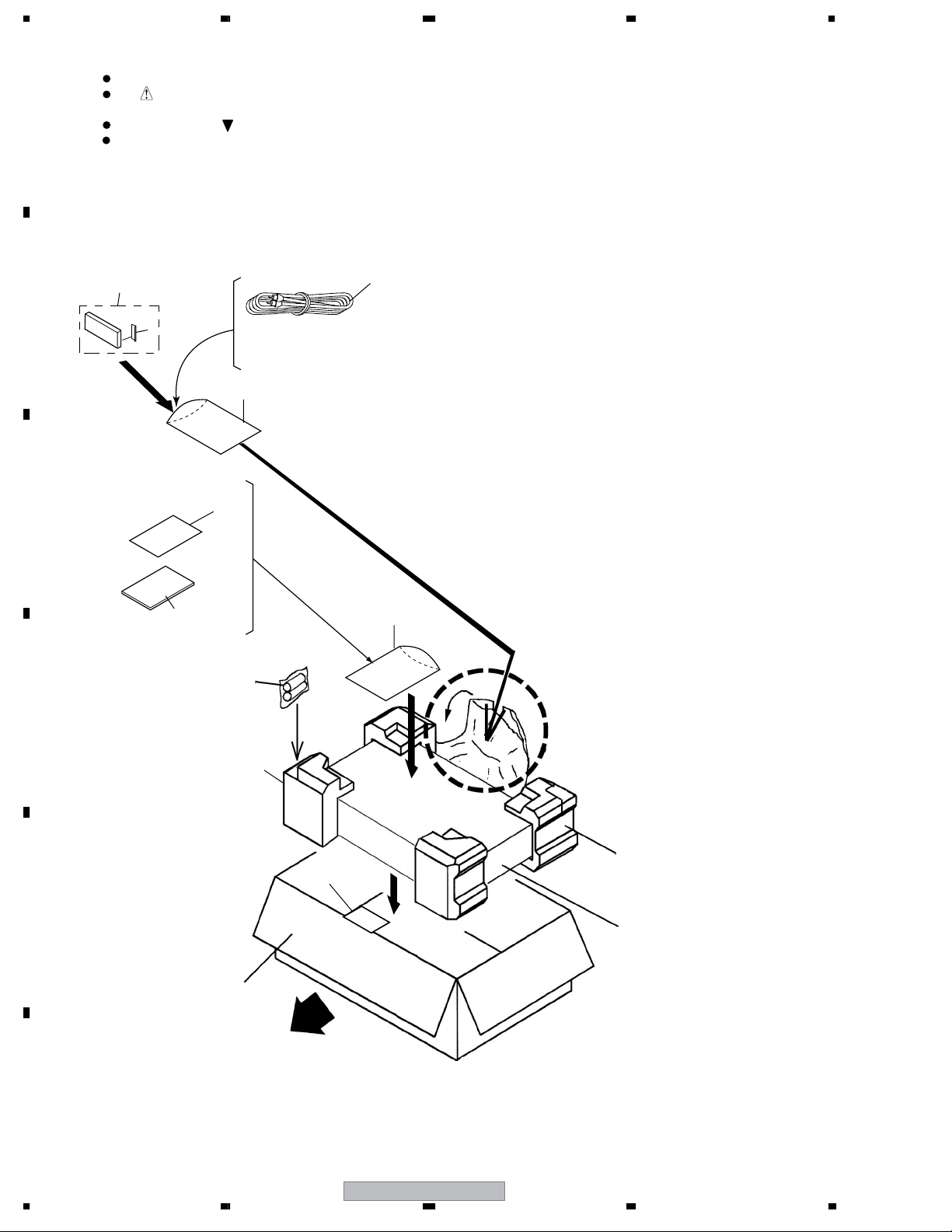

2.1 PACKING SECTION

3

B

4

C

6

2

16

"Operating Instructions"

7

5

D

14

11

E

15

12

14

13

Front

F

6

1234

DV-588A-S

5678

PACKING SECTION parts List

No. Description Part No.

Mark

1• • • • •

2 Cord, RCA Pin 06CPBA2006

3 Remote Control VXX2914

4 Battery Cover VNK4998

NSP 5 Battery,Mangan (AR, R6P) 141L003010

NSP 6 Guarntee Cade J2G00202A

7 Operating Instructions (English) J2G60101A

9• • • • •

10 • • • • •

11 Package.Pad 792WHA0604

12 Polyethylene Bag JB5KD200

13 Gift Sheet 791WHA0100

14 Package 792WHA0588

15 Gift Box 793WCD1614

NSP 16 Poly. Bag 791WHAA040

A

B

C

D

E

56

DV-588A-S

F

7

7

8

1234

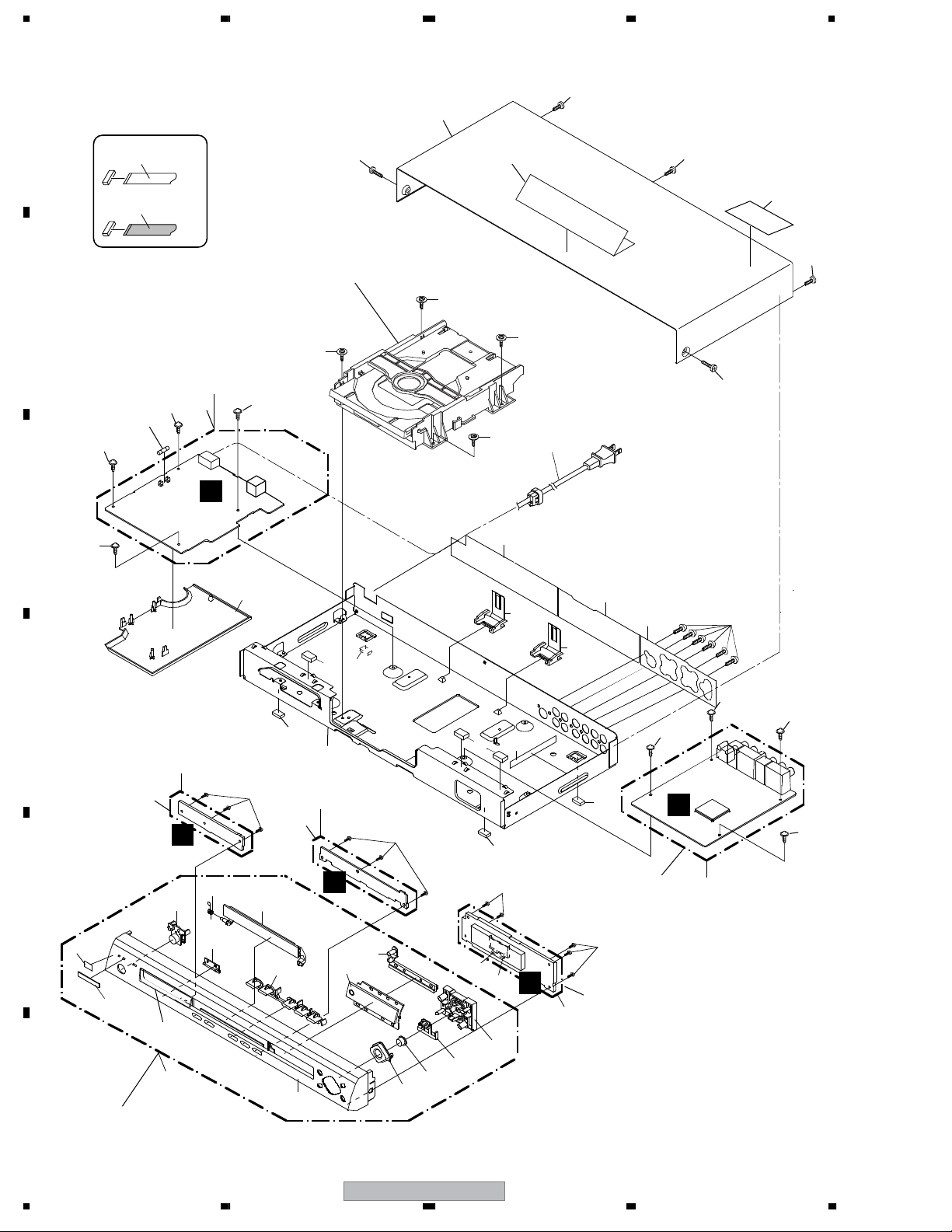

2.2 EXTERIOR SECTION

A

20

14

NON-CONTACT

SIDE

CONTACT SIDE

B

PCB240

(POWER PCB ASS'Y)

19

4

19

9

19

20

Refer to

"2.3 05 DVD MECHA ASSY".

5

18

18

18

17

18

6

20

28

20

20

F

C

19

11

25

12

24

23

21

12

13

16

19

D

13

PCBDF0

(OPERATION 3 PCB ASS'Y)

27

22

G

101K

E

15

101D

F

" FRONT PANEL SECTION".

101E

101N

101L

101

101C

101H

8

PCB280

(OPERATION 2 PCB ASS'Y)

3

22

C

101G

101B

101F

101A

101M

101I

16

7

13

26

101J

10

22

B

2

PCB270

(OPERATION PCB ASS'Y)

13

22

19

A

1

PCB130

(DVD PCB ASS'Y)

19

19

8

1234

DV-588A-S

>

>

>

>

5678

EXTERIOR SECTION parts List

No. Description Part No.

Mark

1DVD MT PCB Assy A2G601A130

2 OPERATION PCB Assy A2G601A270

3 OPERATION 2 PCB Assy A2G501A280

4POWER PCB Assy A2G601A240

5DVD MECHA ASSY A2G512A650

6 Cord AC Bush 1209618901

7 PLATE, FIP 752WSA0466

NSP 8 Plate,Bottom 702WSA0239

9 Fuse (F501 : 1.6A) 080NT1R604

10 Sheet,Caution 7260000356

A

11 Plate,Cover Power 755WPA0046

12 Holder,FFC 761WPA0396

13 Cushion,Leg VEB1349

14 Cabinet,Top 702WSB0114

NSP 15 Enargy Star Label 7230007965

16 Cushion (15x20x16) 8965TS1015

NSP 17 POP Label 7236310013

18 Screw,Tap Tite(S)Bind Wash. 816423063U

19 Screw,Tap Tite(S) (3x5.5) 8107D3055U

20 Screw,Tap Tite(B) (3x6.0) 8109K3060U

21 Screw,Tap Tite(B)Pan (3x6) 810913060U

22 Screw,Tap Tite(P)Flat (2.6x10) 8110326A0U

23 Sheet,Jack 1 7226310050

24 Sheet,Jack 2 7226310051

25 Sheet,Jack 3 7226310052

26 Double,Face-Tape 7290000156

27 OPERATION 3 PCB Assy A2G501ADF0

28 Sheet, Caution 7250000597

101 Front Cabi Assy 7A7010082A

NSP 101A Cabinet,Front 701WPJ1320

NSP 101B Plate,Display 711WPA0226

101C Flap,DVD 712WPD0182

101D Badge,Brand 7236310014

NSP 101E Button, Power 738WPB0052

NSP 101F Button,Cap 1 737WPB0003

B

C

D

NSP 101G Button,Frame 3 738WPA0142

NSP 101H Button,Frame 4 738WPB0053

NSP 101I Button,Frame 1 738WPA0132

NSP 101J Button,Frame 2 738WPA0133

101K Spring,Flap-DVD 743WKA0052

101L Plate, Cover 711WPD0681

NSP 101MButton, Cap 2 737WPB0004

NSP 101N Holder, Tag 761WPA0374

56

DV-588A-S

E

F

9

7

8

1234

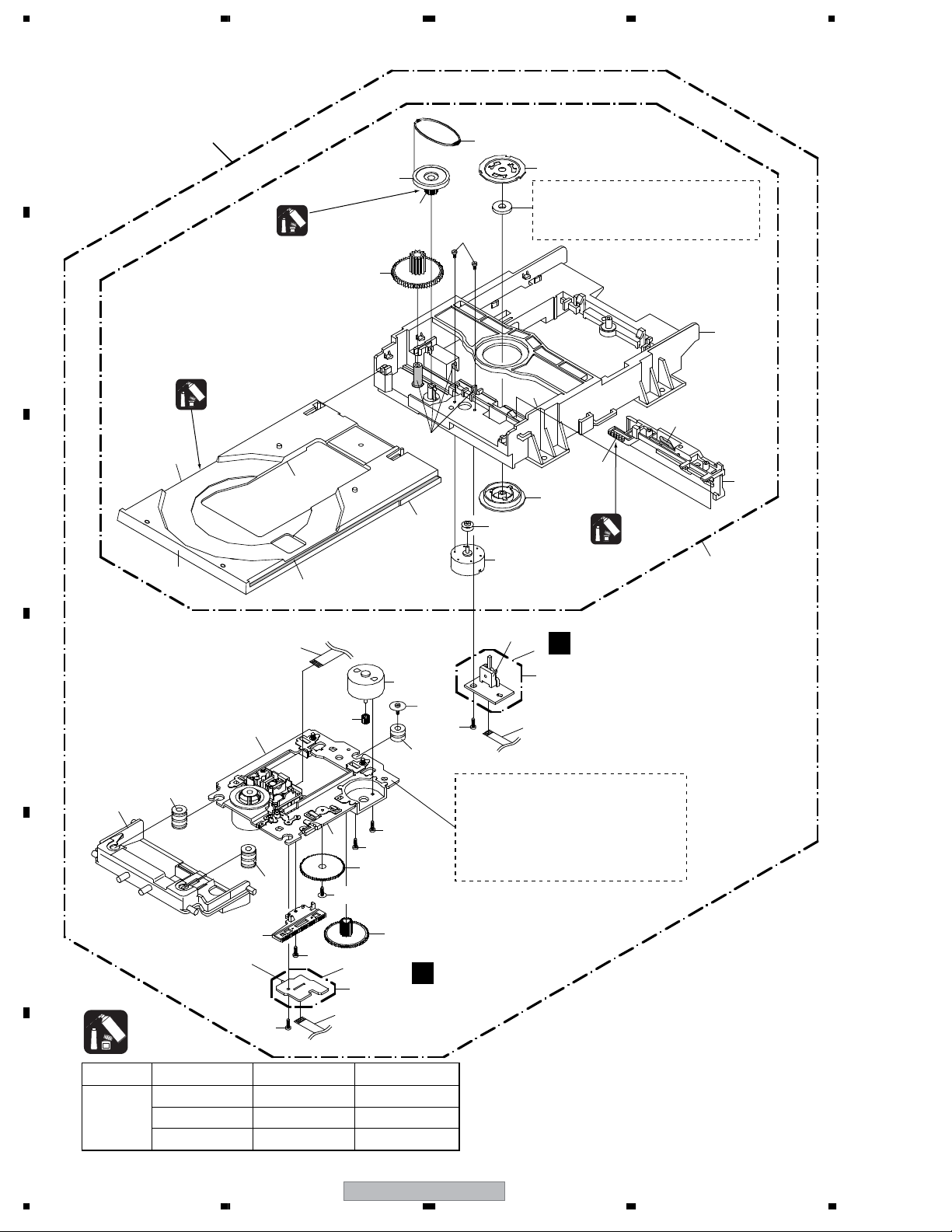

2.3 05 DVD MECHA SECTION

A

34

9

14

18

Cannot supply separately.

Lubricating Oil

GYA1001

AB

21

If the repair is needed, replace the

DVD MECHA ASS'Y.

15

B

11

Daifree

GEM1036

AB

AB

AB

AC

AB

C

AB

4

20

3

12

AC

AB

Lubricating Oil

GYA1001

23

19

29

6

CD2001

SW1

E

1

PCB610

5

22

2

32

31

10

Do not replace the parts. Because,

minute adjustments are needed if

this condition is disassembled

further more.

If the repair is needed, replace the

DVD MECHA ASS'Y.

D

D

35

8

13

AA

24

22

16

8

E

25

30

SW2

Note :

27

26

17

PCB640

(SW PCB ASS'Y)

(LOADING MOTOR PCB ASS'Y)

7

CD2302

28

33

CLASS

GREASE G-478B

F

PART NO.

GEM1018

GYA1001

PART NAME

GEM1036

CD2301

PN-397

ME-913A

MARK

AA

AB

AC

NOTE:

Applying positions AA, AB and AC for the

grease are displayed for this section.

Check if the correct grease is applied for each

position.

10

DV-588A-S

1234

>

>

5678

05 DVD MECHA SECTION parts List

No. Description Part No.

Mark

1 Loading Motor PCB Assy A2F101A610

2 Gear,Middle 92P100117A

3 Loading Motor 1515S98004

4 Pulley,Motor 92P100097A

5 FEED Motor 1515S98004

6 Cord Jumper (24P)(CD2001) 122H0O2305

7 Cord Jumper (CD2302) 122H051602

8 Insulator (F) 92P200013A

9 Belt,Loading 92P200015A

10 Insulator (R) 92P200014A

A

11 Frame,main 92P100119A

12 Tray (B) 92P100127A

13 Holder ,Traverse 92P100125A

14 Gear,Pulley 92P100123A

15 Gear,Main 92P100124A

16 Gear,Feed 92P100116A

17 SW PCB Assy (PCB640) A2F101A640

18 Plate,Clamper 92P000023A

NSP 19 Loader SUB Assy 92AAA0019A

20 Clamper 92P100122A

21 Screw,Pan (M1.7x3 P3) 814011730U

22 Screw,Pan (M1.7x2.3 P3) 814011723U

23 Rack,Loading 92P100121A

24 Gear,Motor 92P100088A

25 Feed Rack Assy 92AAA0017A

26 Screw,T-Tite(B) (M1.7x5.0 P3) 813381750U

27 Screw,Gear Feed 92P700007A

28 Cord Jumper (CD2301) 122H061605

29 Switch (SW1) 0515S32003

30 Push Switch (SW2) 0500101036

31 Screw,Tap Tite(P) (2.6x8) 811022680U

32 Sems.Tap Tite(P) (2x8) 816112080U

33 Screw (Bind 2x8) 811022080U

>

34 DVD MECHA ASSY A2G512A650

NSP 35 Traverse SUB ASSY 92AAA0016A

B

C

D

56

DV-588A-S

E

F

11

7

8

1234

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

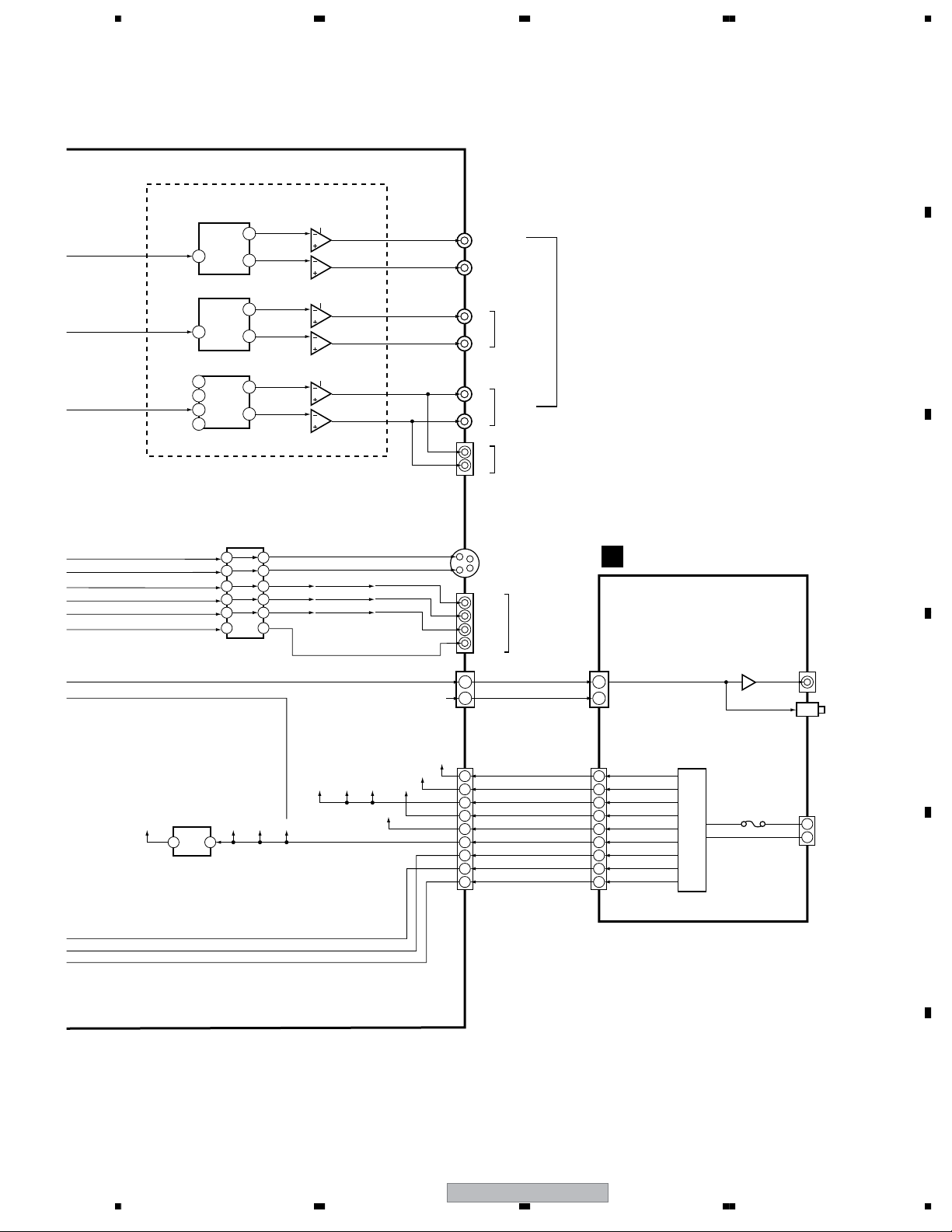

3.1 BLOCK DIAGRAM

A

DVD MT PCB ASSY

A

DVD MECHA

ASSY

PICKUP

B

D

SW PCB ASSY

SPINDLE

M

MOTOR

SLED

M

MOTOR

C

E

LOADING MOTOR

PCB ASSY

LOADING

M

MOTOR

SW1

A

11 11

B

10 10

C

7 7

D

6 6

E

5 5

F

2 2

T+

21 21

T–

22 22

F+

23 23

F–

24 24

SP1+

6 1

SP1–

5 2

SLD+

4 3

SLD–

3 4

LD+

2 4

LD–

1 5

OPEN

3 3

CLOSE

5 1

CP2301

CP2303CD2301

CP2302CD2302

7

6

9

IC2301

8

Motor Drive

11

10

IC

51213 4

IC4004

16Mbit Flash

3

4

5

2

18

19

48

49

IC4005

64Mbit SDRAM

IC4002

MPEG / MICON

/ RF-AMP

Å 1/6

228 229

X4001

(27MHz)

IC4001

EEPROM

219

218

217

225

194

196

203

200

202

198

ASDAT2

ASDAT1

ASDAT0

ASPDIF

S_Y

S_C

CR

Y

CB

CVBS

D

C

OPERATION 2

PCB ASSY

CP4002

10101111996

CP605

-28V

V+3E

FLDC–

FLDC+

E

CP604

6

V+3E

CP601

CP602CP603

Power

IC651

FIP Driver IC

V651 FL TUBE

30

F

OPERATION 3

G

PCB ASSY

OPERATION

B

PCB ASSY

12

DV-588A-S

1234

Å 4/6

IC8004 PCM1742KE

AUDIO DAC (C, Lfe)

ASDAT2

2

IC8005 PCM1742KE

AUDIO DAC (Ls, Rs)

ASDAT1

2

IC8003 PCM1742KE

AUDIO DAC (L, R)

16

1

ASDAT0

2

3

5678

A

AUDIO LPF & AMP

IC8006-1/2

BA4560F

2

VOUTL

7

VOUTR

8

VOUTL

7

Å

VOUTR

8

VOUTL

7

VOUTR

8

3

6

5

2

3

6

5

2

3

6

5

8

1

7

IC8006-2/2

IC8007-1/2

BA4560F

8

1

7

IC8007-2/2

IC8008-1/2

BA4560F

8

1

7

IC8008-2/2

J8002

CENTER

SUB

WOOFER

J8002

L

R

J8001

L

R

L

R

SURROUND

FRONT

AUDIO

OUT (2 ch)

AUDIO

OUT

(5.1 ch)

B

V+1P8

(CORE)

Å 6/6

IC4006

REG+1.8V IC

2 3

Å 5/6

IC7301

Video Driver

6 ch

S_Y OUT

6

21

S_C OUT

2

26

14

10

12

CR out

16

Y out

20

CB out

18

V out

4

23

V+3

V+3A V+3E

(AUDIO VIDEO DAC)

(MPEG SDRAM FLASH)

(VIDEO OPT/COAX)

(AUDIO DAC)

V+5V V+5S

V+5A

(FLIP/LED/IR/RESET)

(OPU)

V+3F

(F/E)

V+6A

V+12AT

(MOTOR)

J7301

S VIDEO OUT

J7302

CR

Y

VIDEO

OUT

CB

CVBS

CP8001

(2P)

1 1

2 2

(AUDIO AMP)

V+12

(AUDIO MUTE)

2

3

5

6

8

9

12

13

14

P.CON+12V

AT+12V for MUTE

P.CON+5V

P.CON+6V

P.CON+3.3V

SPDIF

GND

AT+3.3V

FL DC–

FL DC+

-28V

CP8001

(2P)

CP502CP4003

POWER PCB ASSY

F

2

3

5

6

8

9

12

13

14

T501

Power Transformer

Q8103

F501

Fuse

J8004

DIGITAL OUT

COAXIAL

OS8101

OPTICAL

J501

L

AC IN

N

C

D

E

56

DV-588A-S

F

13

7

8

1234

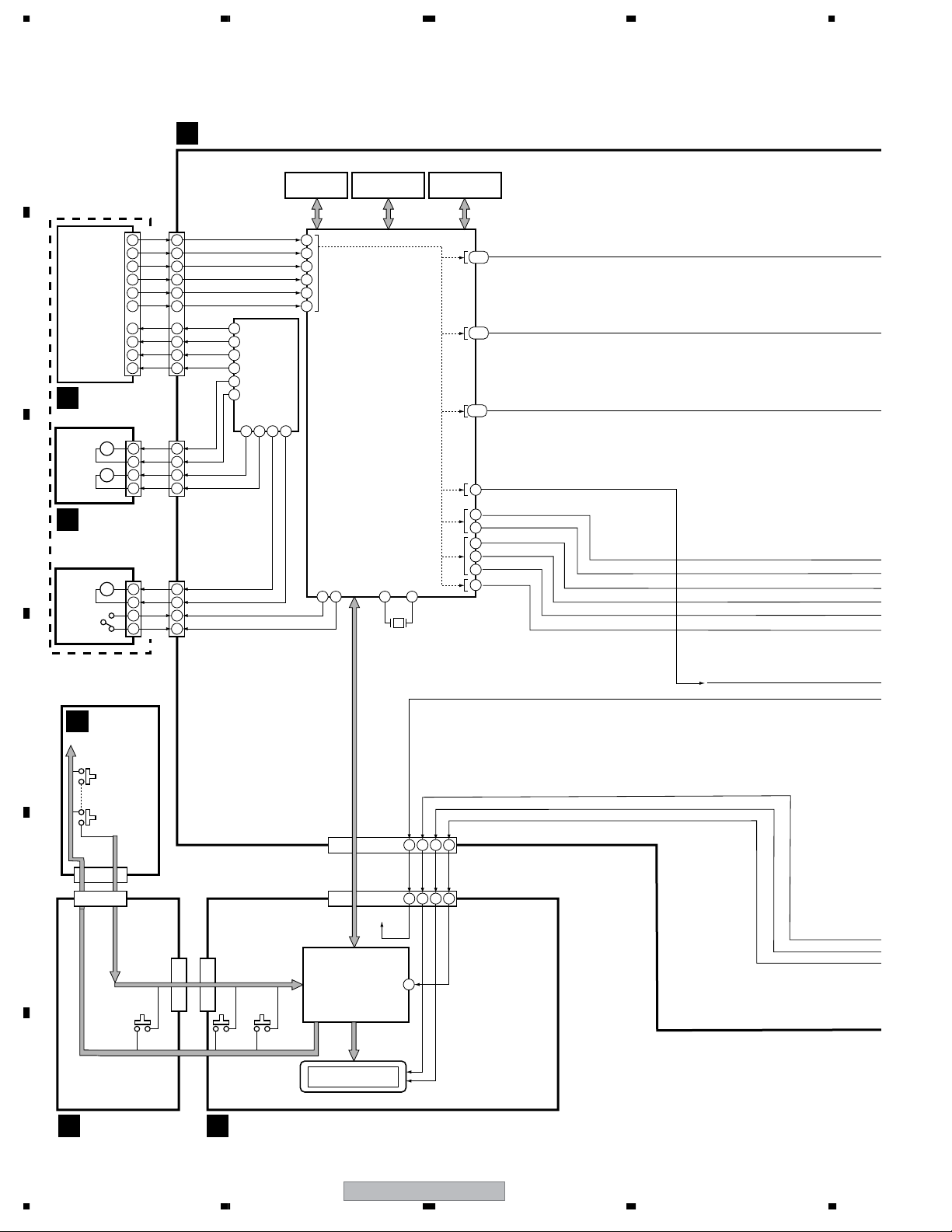

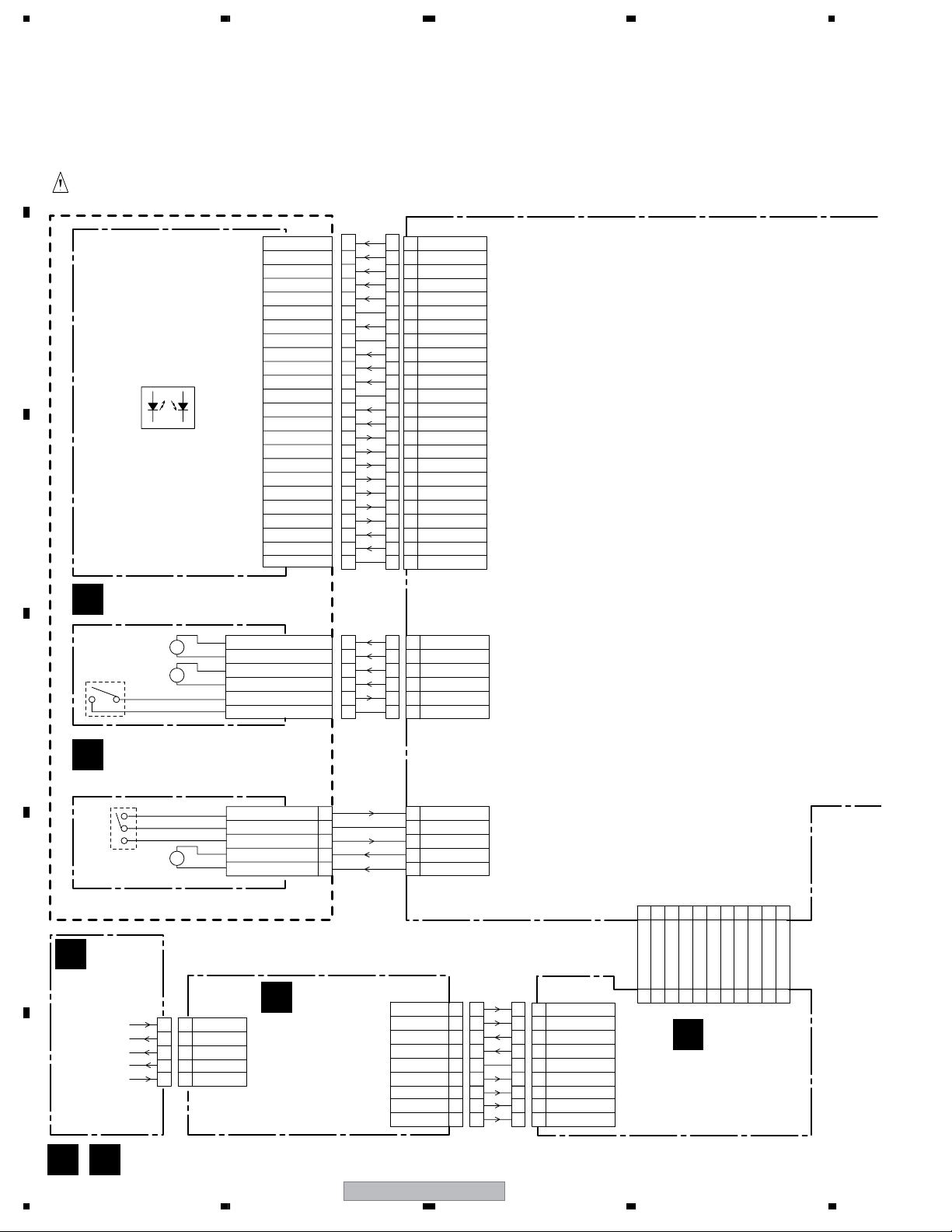

3.2 OVERALL WIRING CONNECTION DIAGRAM

A

DVD MECHA ASSY (A2G512A650)

CP2301

FF+

TT+

B

OPTICAL PICKUP

C

NC

GND(CD)

VOL(DVD)

GND(DVD)

LD(DVD)

GND(DVD)

VOL(CD)

MON(COM)

MON(DVD)

A

B

RF

DVD/CD(SW)

C

D

E

VCC

VREF

F

GND

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

24

23

22

21

20

19

LD_DVD(650)

18

17

16

15

14

13

12

11

10

VRF(RF_OUT)

9

SW1(DVD/CD)

8

7

6

5

4

3

2

1

FOCS RTN

FOCS DRV

TRKG RIN

TRKG DRV

NC

GND

PD/GND

LD_CD(780)

GND

VR780(CD)

VRCOM

VR650(DVD)

A

B

C

D

E

VCC

VS

F

GND

D

E

F

14

SW PCB ASSY

D

(A2F101A640)

M2601

SPINDLE

JCV9B06

MOTOR

SW2

ESE22MH24

E

M2602

BCZ3B03

SLED MOTOR

LOADING MOTOR

PCB ASSY

(A2F101A610)

SW1

SSS-13-2

M2603

BCZ3B52

LOADING MOTOR

C

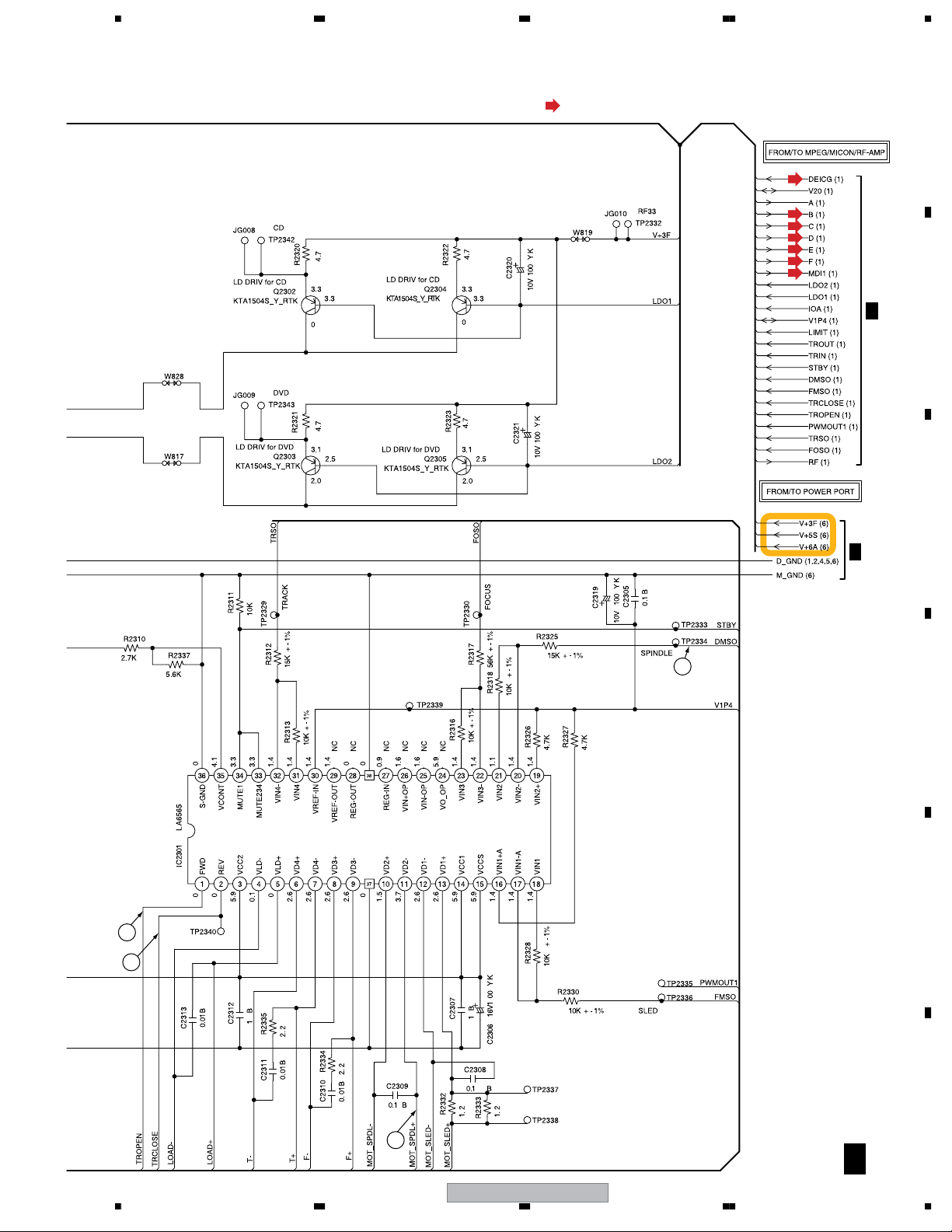

CP605

OPERATION 2

PCB ASSY

(A2G501A280)

D E

1234

M

M

M

CP604

069EV53050

069EV53050

5

5

SW2

4

4

PAUSE/–SKIP

3

3

PLAY/+SKIP

2

2

STOP

1

1

SW1

CD604(5P FFC)

122H051001

CD2301

2H062102

SPINDLE MOTOR (+)

SPINDLE MOTOR (-)

FEED MOTOR (+)

FEED MOTOR (-)

PICK UP INNER LIMIT SWITCH

LOADING MOTOR(+)

LOADING MOTOR(-)

GND(SW)

CD2302

2H052601

SW-2(CLOSE)

GND(SW)

SW-1(OPEN)

5

4

3

2

1

G

OPERATION 3

PCB ASSY

(A2G501ADF0)

6

5

4

3

2

1

FFC

1

2

3

4

5

6

069EV93050

PAUSE/–SKIP

DV-588A-S

CP2303

1

2

3

4

5

6

CP2302

1

2

3

4

5

CP603

IR

GND

V+3E

POWER

SW2

PLAY/+SKIP

STOP

SW1

SP1+

SP1SLD+

SLD-

LIMIT SW

SW(GND)

CLOSE

GND(D)

OPEN

LD+

LD-

1

1

2

2

3

3

4

4

5

5

6

6

77

898

9

CD603(6P FFC)

122H062801

CD601(11P FFC)

122H0B1002

CP602

069EV93050

9

8

8

9

7

7

6

6

5

5

4

4

PAUSE/–SKIP

PLAY/+SKIP

3

3

2

2

1

1

CP4002

069EVB3030

I R

GND

V+3E

POWER

SW2

STOP

SW1

CLK

STB

DI (M to F)

I R

V+ 3E

DO (F to M)

DGND

B

OPERATION

PCB ASSY

(A2G601A270)

987654321

1110

DGND

FL DC+

– 28V

987654321

1110

CP601

069EVB3050

FL DC –

5678

÷

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or

"PCB PARTS LIST".

÷

The > mark found on some component parts indicates the importance of the safety factor

A

of the part. Therefore, when replacing, be sure to use parts of identical designation.

÷

: The power supply is shown with the marked box.

A

A 1/6- A 6/6

DVD MT PCB ASSY (A2G601A130)

: MPEG/MICON/RF-AMP BLOCK

A 1/6

: MEMORY BLOCK

A 2/6

: LOADER/MOTOR DRV BLOCK

A 3/6

: AUDIO JACK BLOCK

A 4/6

: VIDEO SEC BLOCK

A 5/6

: POWER PORT BLOCK

A 6/6

J8002

CENTER

SUB

WOOFER

J8002

L

R

J8001

L

R

J7302

CVBS

Y

Cb

Cr

J7301

Y

C

J8001

L

R

SURROUND

FRONT

VIDEO OUT

(COMPOSITE)

S VIDEO OUT

AUDIO OUT

AUDIO

OUT

(5.1 ch)

B

C

D

GND

GND

CP4003

069S2E0629

1

1

P. CON+5V

P. CON+ 12V

AT+12V for MUTE

3

2

5

4

3

2

GND(M)

P. CON+6V

P. CON+3.3V(AT)

8

7

645

6

8

7

AT+3.3V

9

9

GND(D)

STBY L

11

10

11

10

FL DC +

FL DC –

13

12

13

12

– 28V

14

14

GND2

SPDIF

CP8001

A2001WV2-2P

1

2

1

CP502(14P)

Cord Connector

06C32E3504

1

1

CP502

GND

5

4

3

2

5

4

3

2

GND

P. CON+5V

P. CON+ 12V

AT+12V for MUTE

6

8

7

6

8

7

GND(M)

P. CON+6V

P. CON+3.3V

F

9

10

9

10

AT+3.3V

P. ON-H

12

11

12

11

FL DC –

GND(D)

14

13

14

13

– 28V

FL DC +

CP8102

F 1/2- F 2/2

2

1

2

1

GND

SPDIF

C3223003

POWER PCB ASSY (A2G601A240)

: POWER BLOCK

F 1/2

: DIGITAL AUDIO BLOCK

F 2/2

56

DV-588A-S

E

J8102

CP501

BLACK(L)

WHITE(N)

COAXIAL

OS8101

1

2

OPTICAL

BLACK

1

2

WHITE

DIGITAL

AUDIO

OUT

AC IN

F

15

7

8

1234

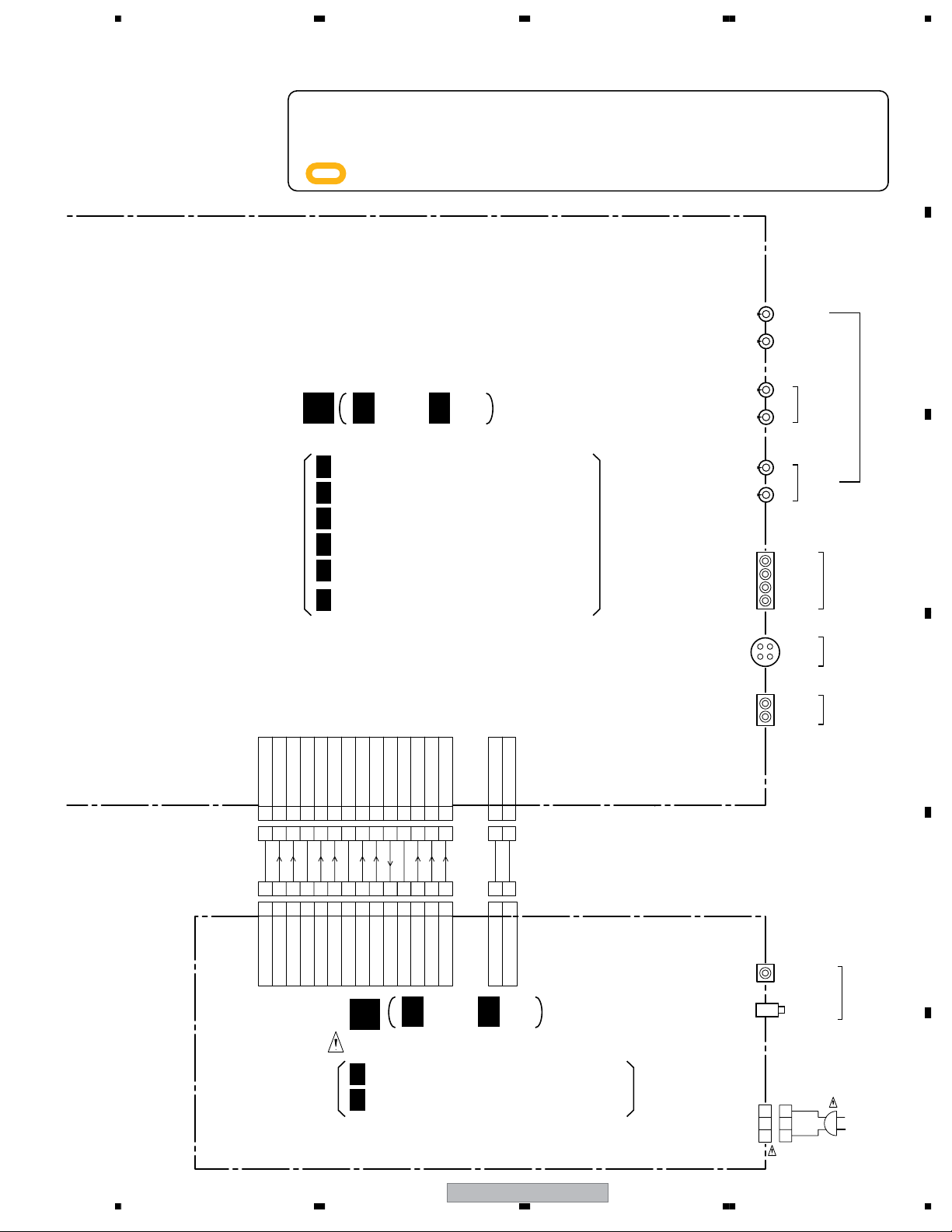

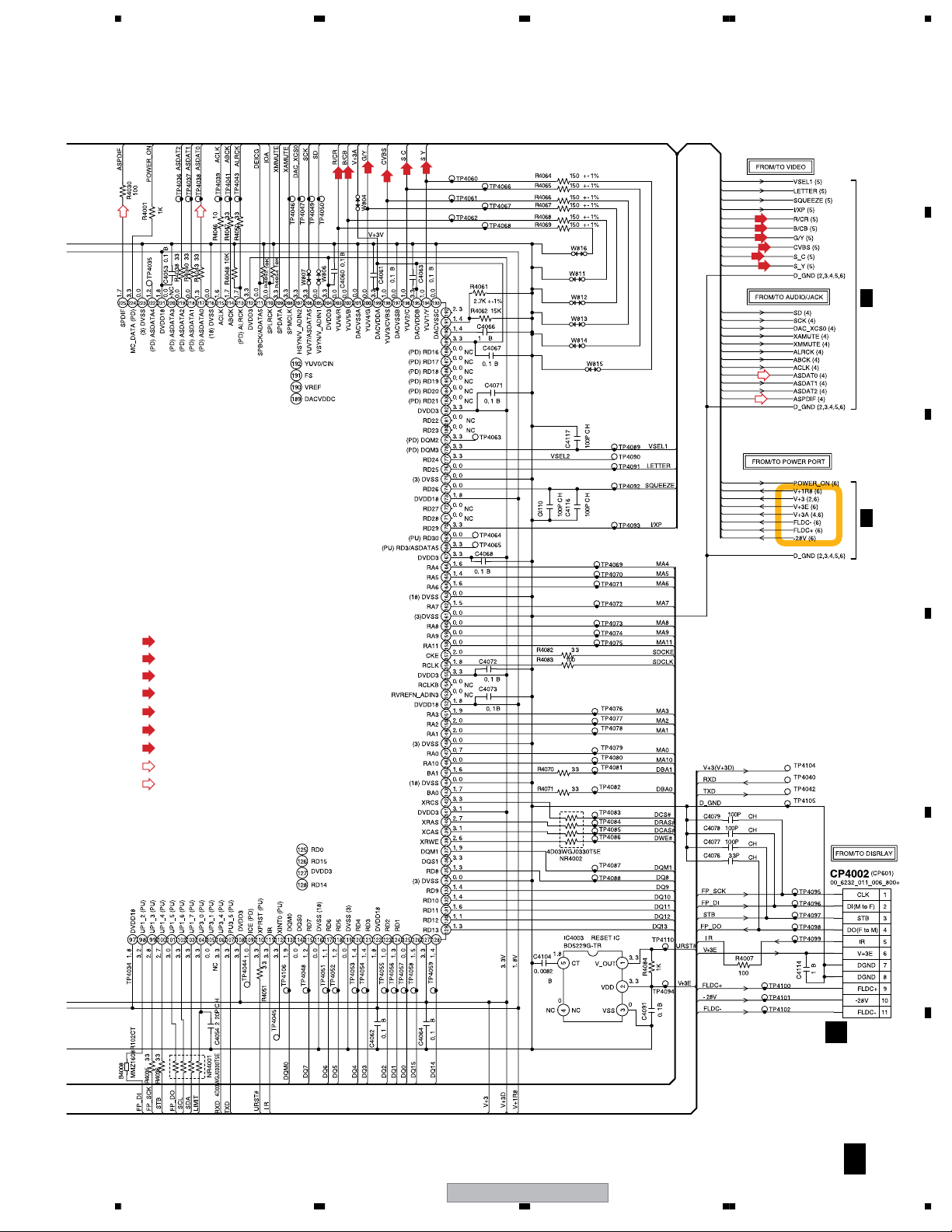

3.3 DVD MT PCB (1/6) ASSY

A

B

C

A 1/6

(RF)

3/6A2/6A

DVD MT PCB ASSY (A2G601A130)

MPEG/MICON/RF-AMP BLOCK

(D)

(A)

(B)

(C)

(RF) (RF)

1

(E)

(F)

(E)

(D)

(A)

(B)

(C)

(F)

17

D

E

EEPROM

MPEG/MICON

F

16

A 1/6

DV-588A-S

1234

5678

A

(SY)

(SC)

(G/Y)

(B/CB)

(R/CR)

(D)

(DA)

(R/CR)

(B/CB)

(G/Y)

(SC)

(SY)

(RF)

: RF SIGNAL ROUTE

: VIDEO SIGNAL ROUTE

(SY)

: S VIDEO SIGNAL ROUTE (Y ch)

(SC)

: S VIDEO SIGNAL ROUTE (C ch)

(R/CR)

: VIDEO SIGNAL ROUTE (R/CR ch)

(G/Y)

: VIDEO SIGNAL ROUTE (G/Y ch)

(B/CB)

: VIDEO SIGNAL ROUTE (B/CB ch)

(D)

: AUDIO DATA SIGNAL ROUTE

(DA)

: AUDIO SIGNAL ROUTE (Digital)

(DA)

4/6A

(D)

6/6A

B

C

D

RESET IC

DV-588A-S

56

E

CP601

B

F

A 1/6

17

7

8

1234

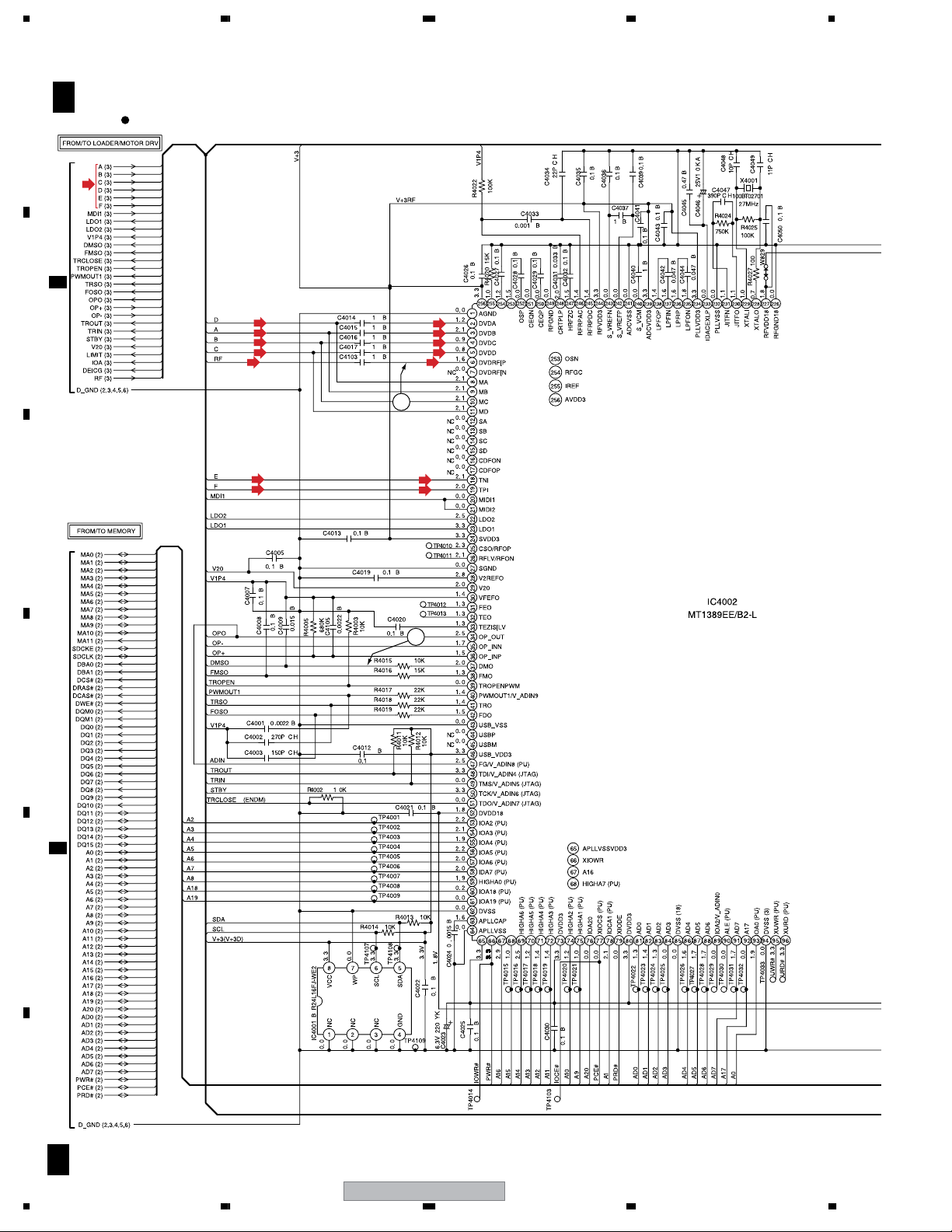

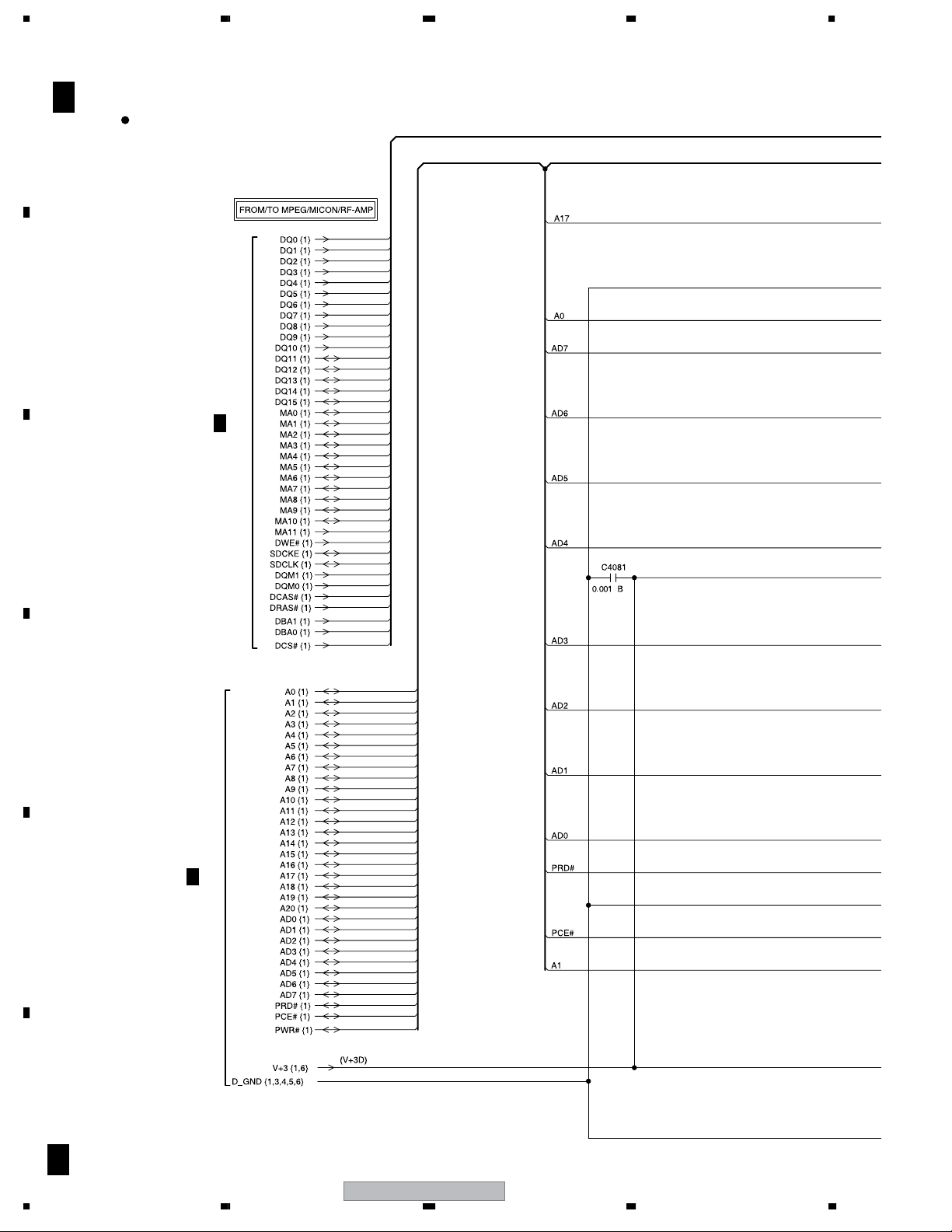

3.4 DVD MT PCB (2/6) ASSY

A

B

C

A 2/6

DVD MT PCB ASSY (A2G601A130)

MEMORY BLOCK

1/6A

D

E

F

18

A 2/6

1/6A

NOTE : THE DC VOLTAGE EACH PART WAS

MEASURED WITH THE DIGITAL TESTER

DURING PLAYBACK.

DV-588A-S

1234

NOTE : THIS SCHEMATIC DIAGRAM IS THE LATEST

AT THE TIME OF PRINTING AND SUBJECT TO

CHANGE WITHOUT NOTICE

5678

A

64Mbit SDRAM

16Mbit FLASH

B

C

D

E

56

DV-588A-S

F

A 2/6

19

7

8

1234

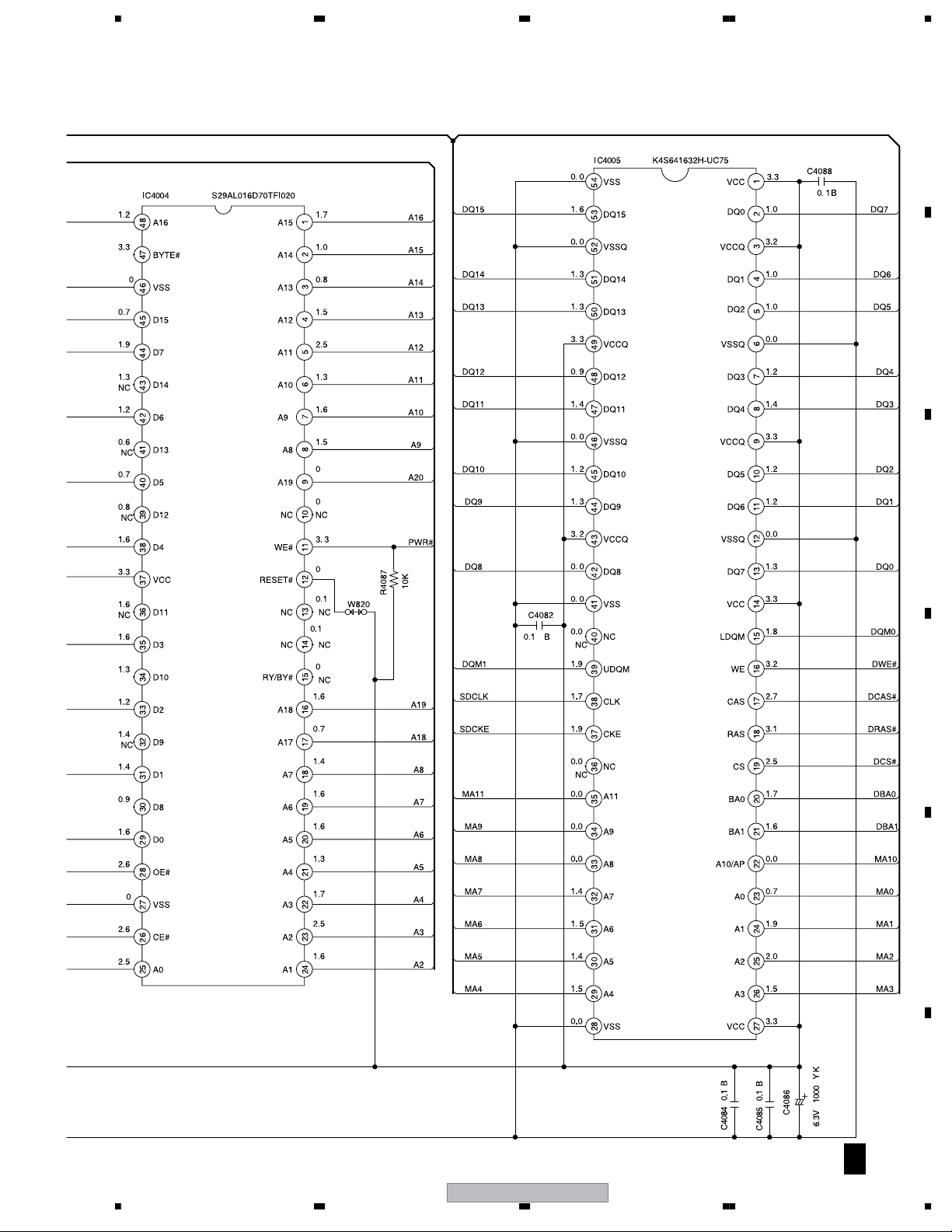

3.5 DVD MT PCB (3/6) ASSY

A

B

C

A 3/6

DVD MT PCB ASSY (A2G601A130)

To PICKUP

LOADER/MOTOR DRV BLOCK

(F)

(E)

(D)

(C)

(RF)

(B)

(A)

(F)

(E)

(D)

(C)

(RF)

(B)

(A)

CD2302

E

D

CD2301

D

E

NOTE : THE DC VOLTAGE EACH PART WAS

MEASURED WITH THE DIGITAL TESTER

DURING PLAYBACK.

NOTE : THIS SCHEMATIC DIAGRAM IS THE LATEST

AT THE TIME OF PRINTING AND SUBJECT TO

CHANGE WITHOUT NOTICE

F

A 3/6

20

DV-588A-S

1234

5678

(RF)

: RF SIGNAL ROUTE

(RF)

(A)

(B)

(C)

(D)

(E)

(F)

A

B

1/6A

15

C

6/6A

17

D

MOTOR DRIVE IC

E

16

18

DV-588A-S

56

F

A 3/6

21

7

8

1234

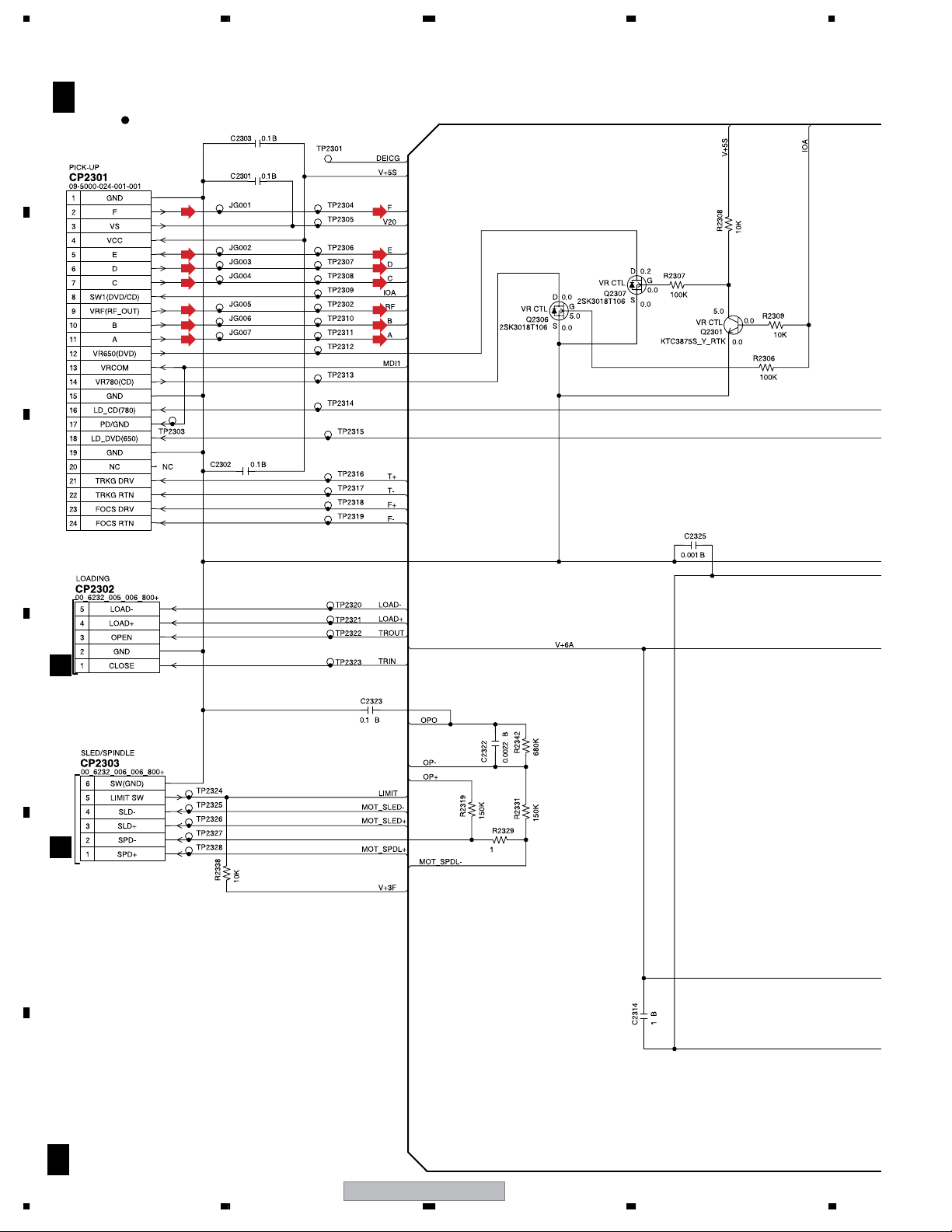

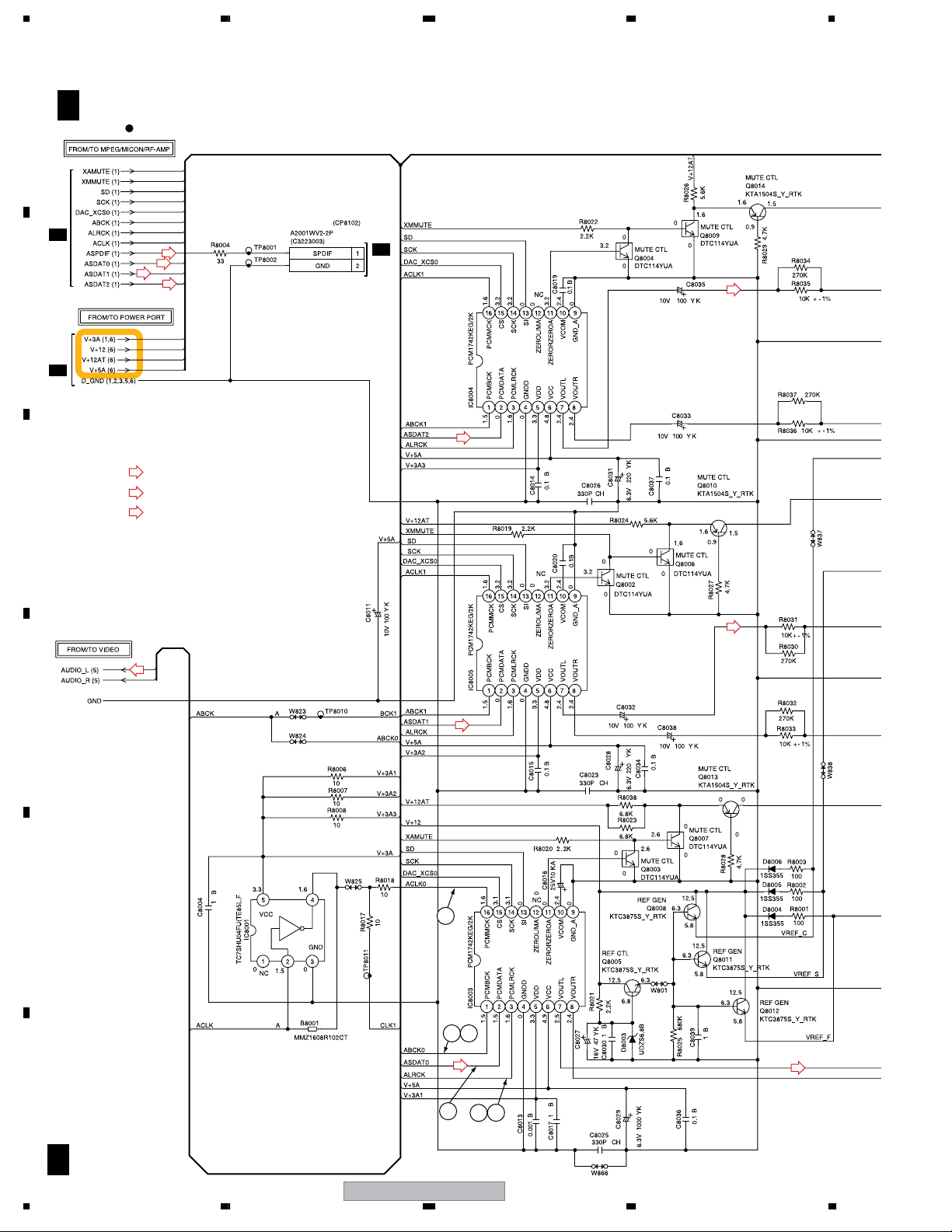

3.6 DVD MT PCB (4/6) ASSY

A

B

C

A 4/6

1/6A

6/6A

DVD MT PCB ASSY (A2G601A130)

AUDIO JACK BLOCK

CP8001

(DA)

(D)

(D)

(D)

(D)

: AUDIO DATA SIGNAL ROUTE

(DA)

: AUDIO SIGNAL ROUTE (Digital)

: AUDIO SIGNAL ROUTE (L ch)

2/2F

AUDIO DAC (C,Lfe)AUDIO DAC (Ls,Rs)

(D)

(DA)

D

E

INVERTER

(D)

3

AUDIO DAC (L,R)

4 7

(D)

F

22

A 4/6

8

6

5

DV-588A-S

1234

5678

A

NOTE : THE DC VOLTAGE EACH PART WAS

MEASURED WITH THE DIGITAL TESTER

DURING PLAYBACK.

AUDIO LPF&

AUDIO LPF&

B

C

D

AUDIO LPF&

DV-588A-S

56

E

F

A 4/6

23

7

8

1234

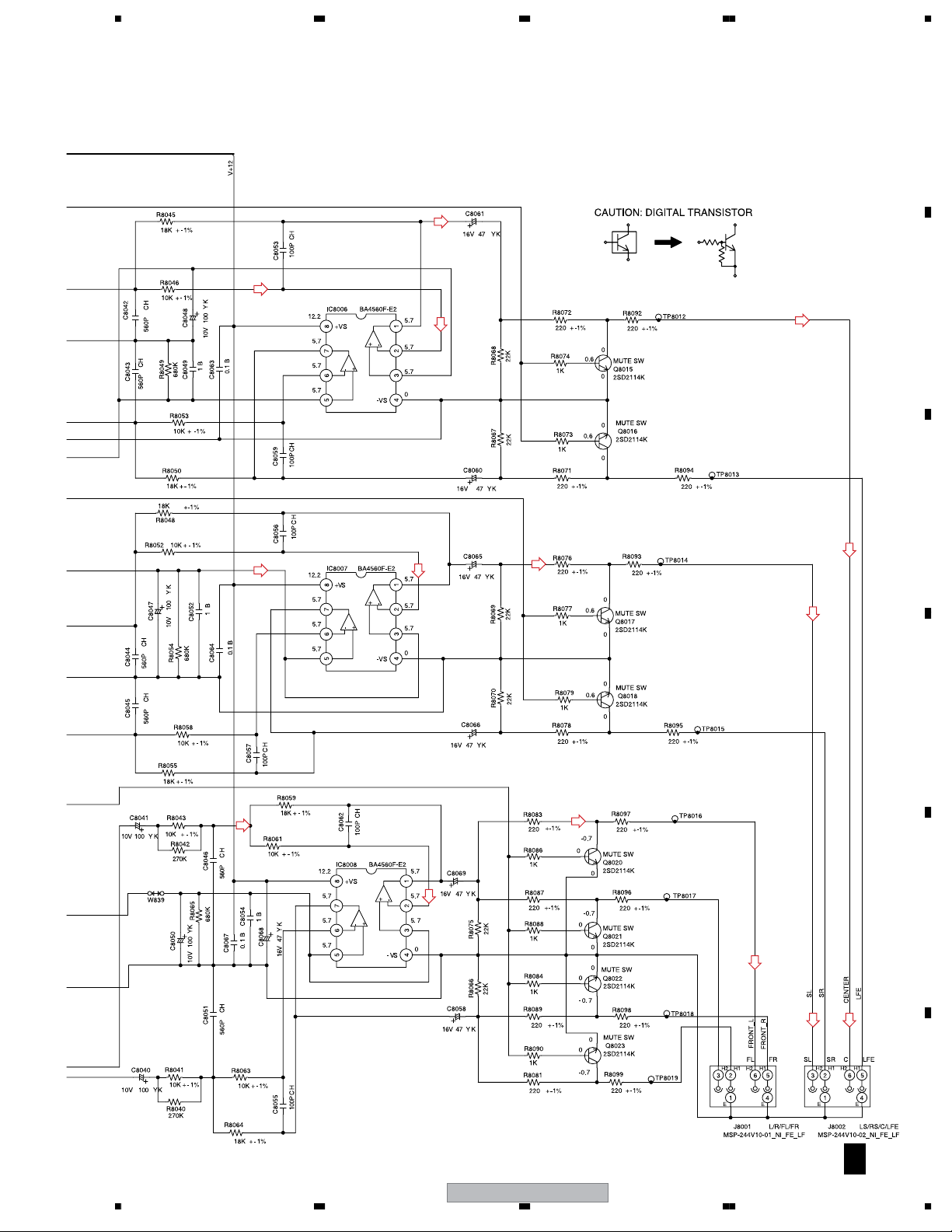

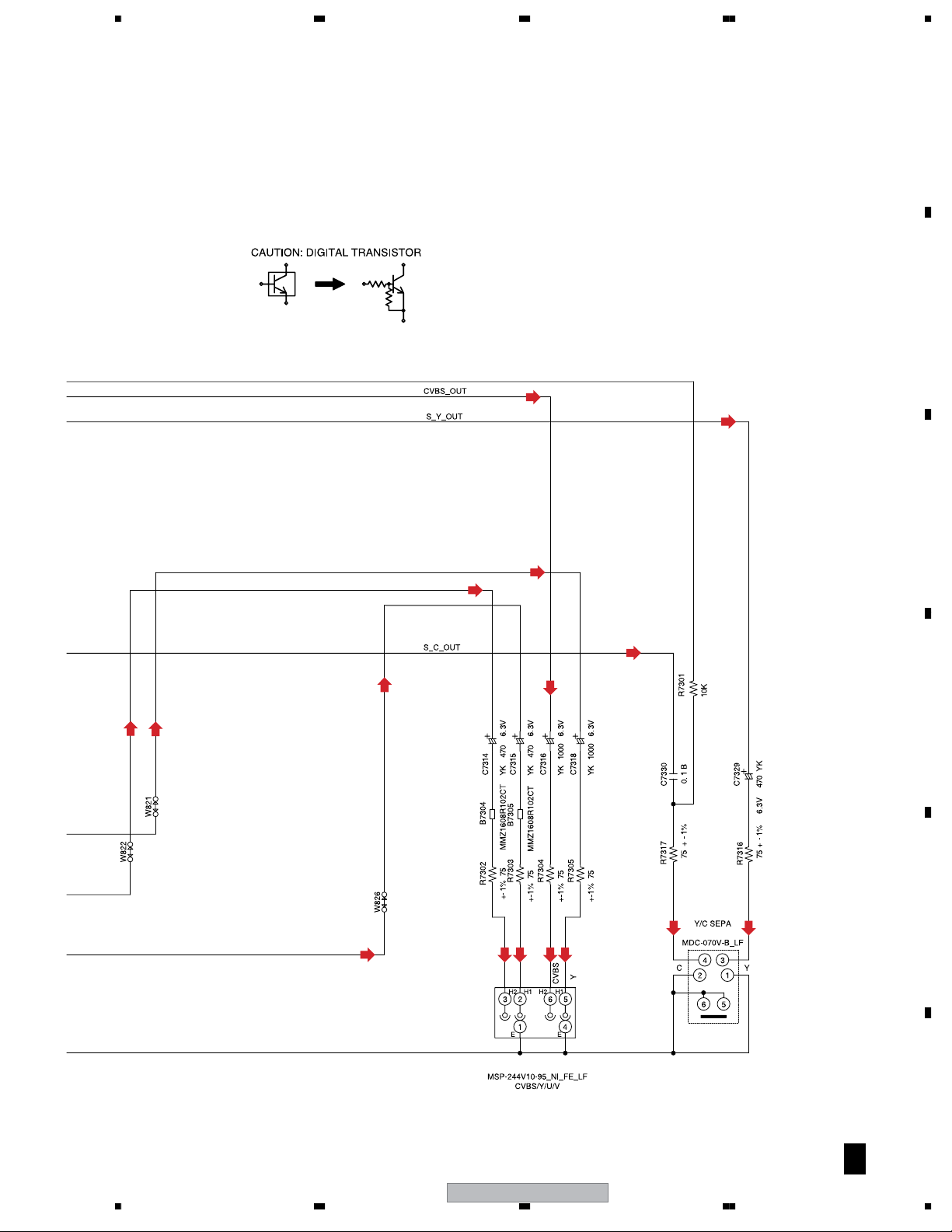

3.7 DVD MT PCB (5/6) ASSY

A

A 5/6

DVD MT PCB ASSY (A2G601A130)

VIDEO SEC BLOCK

: VIDEO SIGNAL ROUTE

(SY)

(DA)

B

1/6A

C

6/6A

(SC)

(SY)

(CB)

(CR)

(Y)

: S VIDEO SIGNAL ROUTE (Y ch)

(SC)

: S VIDEO SIGNAL ROUTE (C ch)

(CR)

: VIDEO SIGNAL ROUTE (CR ch)

(Y)

: VIDEO SIGNAL ROUTE (Y ch)

(CB)

: VIDEO SIGNAL ROUTE (CB ch)

(D)

: AUDIO DATA SIGNAL ROUTE

(DA)

: AUDIO SIGNAL ROUTE (Digital)

: AUDIO SIGNAL ROUTE (L ch)

VIDEO DRIVER 6CH

(SC)

(SC)

14

D

(SY)

9

(SY)

(Y)

E

(CB)

(CR)

(Y)

(CB)

(CR)

13

10

11

12

F

24

A 5/6

DV-588A-S

1234

5678

A

NOTE : THE DC VOLTAGE EACH PART WAS

MEASURED WITH THE DIGITAL TESTER

DURING PLAYBACK.

B

(SY)

(CB)

C

(Y)

(CB)

(SC)

(CR)

(Y)

J7301

(SY)

(CR)

(CB)

CB

CR

(CR)

(SC)

(Y)

D

E

J7302

DV-588A-S

56

F

A 5/6

25

7

8

1234

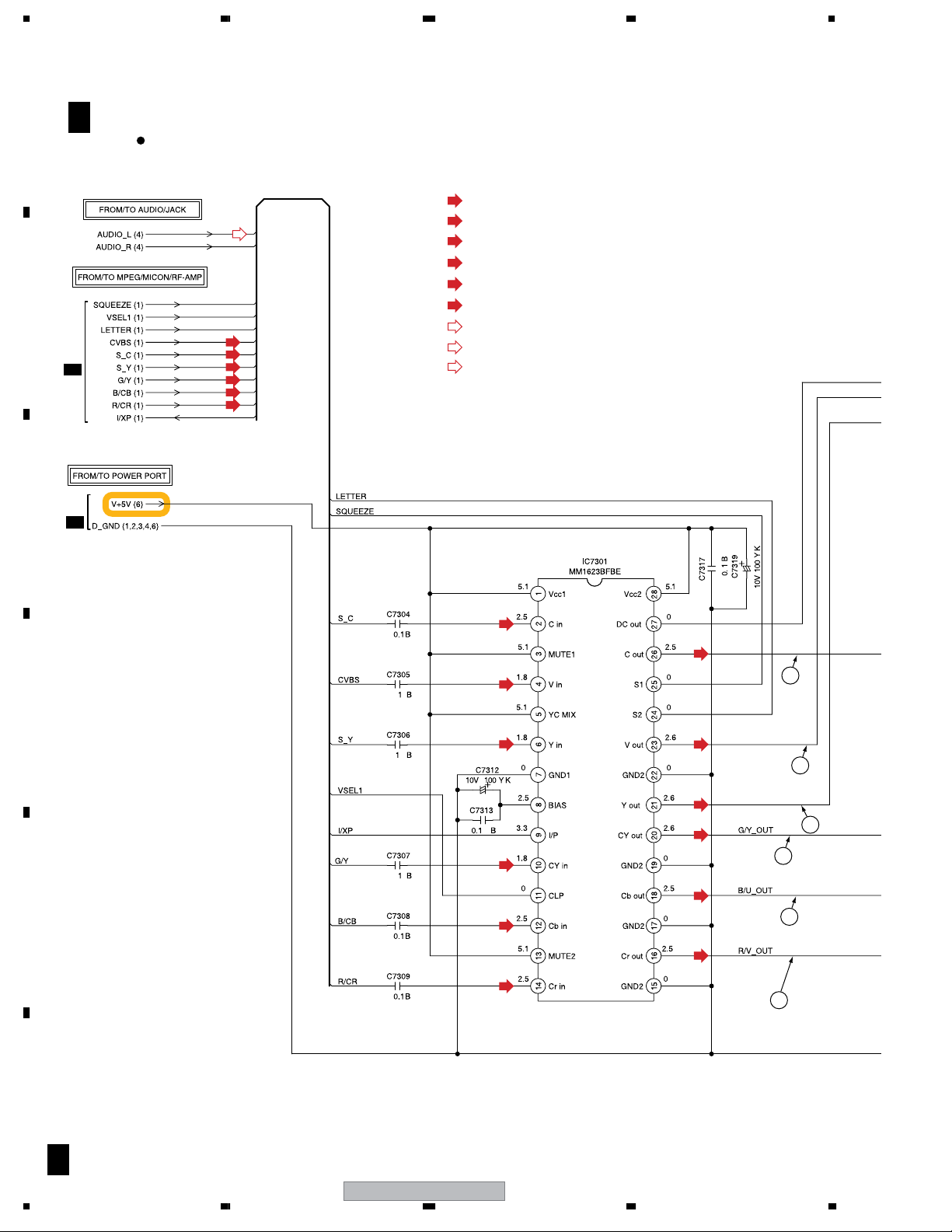

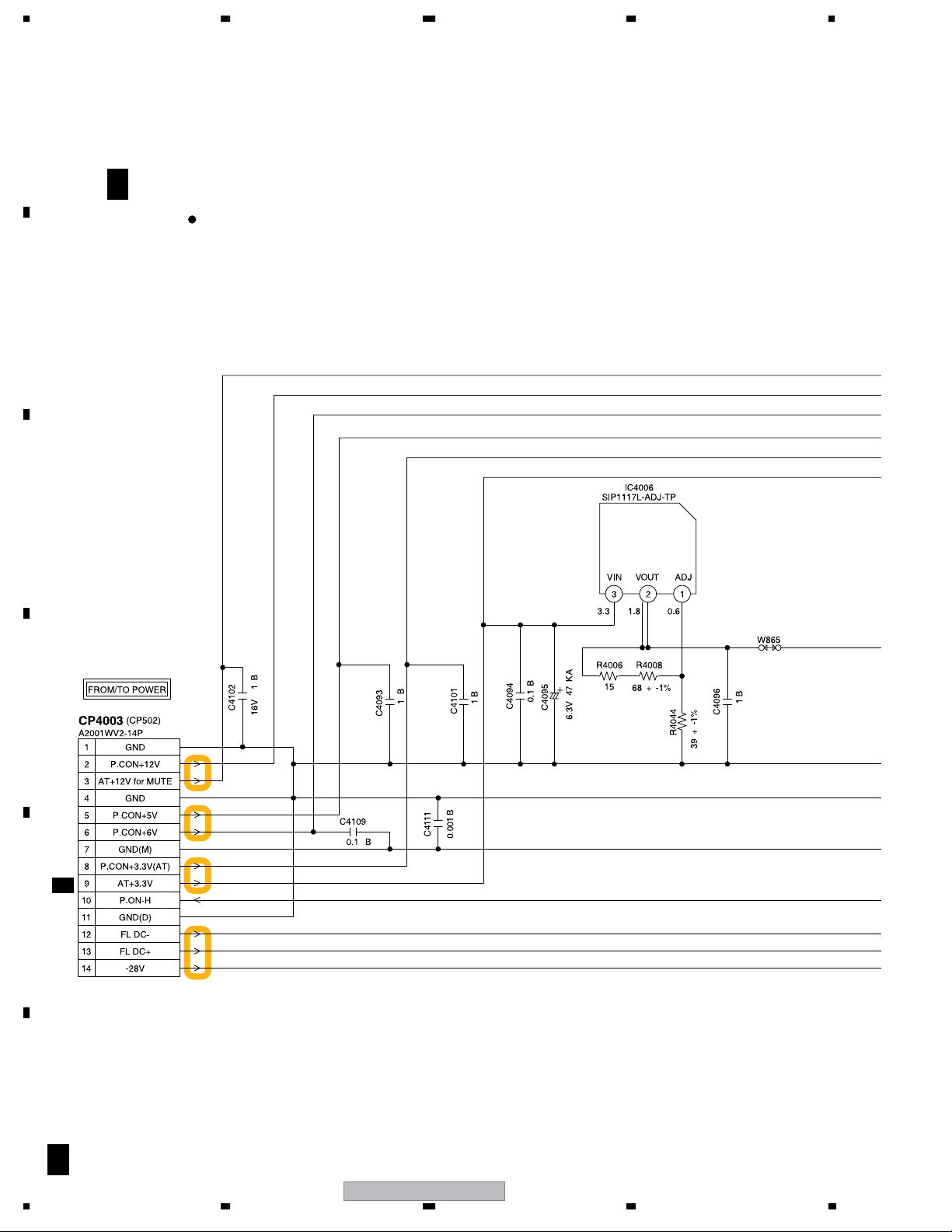

3.8 DVD MT PCB (6/6) ASSY

A

A 6/6

B

C

DVD MT PCB ASSY (A2G601A130)

POWER PORT BLOCK

REG+1.8V IC

D

CP502

F 1/2

E

F

A 6/6

26

DV-588A-S

1234

Loading...

Loading...