Page 1

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2006

DV-490V

DV-490V-S

DVD PLAYER

DV-490V-S

DV-490V-K

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Region No. Remarks

DV-490V-S WYXZT5 AC220 to 240 V 2

DV-490V-S WVXZT5 AC220 to 240 V 2

DV-490V-K WYXZT5 AC220 to 240 V 2

DV-490V-K WYXZTUR5 AC220 to 240 V 5

DV-490V-S WYXZTUR5 AC220 to 240 V 5

ORDER NO.

RRV3432

For details, refer to "Important Check Points for Good Servicing" .

T-ZZR JUNE 2006 printed in Japan

Page 2

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians ; it is not meant for the casual doit-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trainedto properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and

may void the warranty. If you are not qualified to perform the repair of this product properly and

safely, you should not risk trying to do so and refer the repair to a qualified service technician.

WARNING !

THE AEL (ACCESSIBLE EMISSION LEVEL) OF THE LASER POWER OUTPUT IS LESS THAN CLASS 1

B

BUT THE LASER COMPONENT IS CAPABLE OF EMITTING RADIATION EXCEEDING THE LIMIT FOR

CLASS 1.

A SPECIALLY INSTRUCTED PERSON SHOULD DO SERVICING OPERATION OF THE APPARATUS.

LASER DIODE CHARACTERISTICS

FOR DVD : MAXIMUM OUTPUT POWER : 5 mW

FOR CD : MAXIMUM OUTPUT POWER : 5 mW

WAVELENGTH : 650 nm

WAVELENGTH : 780 nm

C

LABEL CHECK

Location: inside of the unit

D

E

(Printed on the Rear Panel)

Additional Laser Caution

1.

• Laser diode is driving with Q2303,Q2305(650nm LD) and Q2302,

Q2304(780nm LD)on the DVD MT PCB Assy.

Therefore, when short-circuit between the emitter and collector of these

transistors or the base voltage is supplied for transistors turn on, the

laser oscillates. (failure mode)

• In the test mode ∗ , there is the mode that the laser oscillates except

for the disc judgment and playback. LD ON mode in the test mode

oscillates with the laser forcibly.

2. When the cover is open, close viewing through the objective lens with

the naked eye will cause exposure to the laser beam.

∗ : See page 53.

F

2

1234

DV-490V-S

Page 3

5678

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

A

B

C

D

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

56

DV-490V-S

E

F

3

7

8

Page 4

1234

CONTENTS

SAFETY INFORMATION ..................................................................................................................................... 2

1. SPECIFCATIONS ............................................................................................................................................. 5

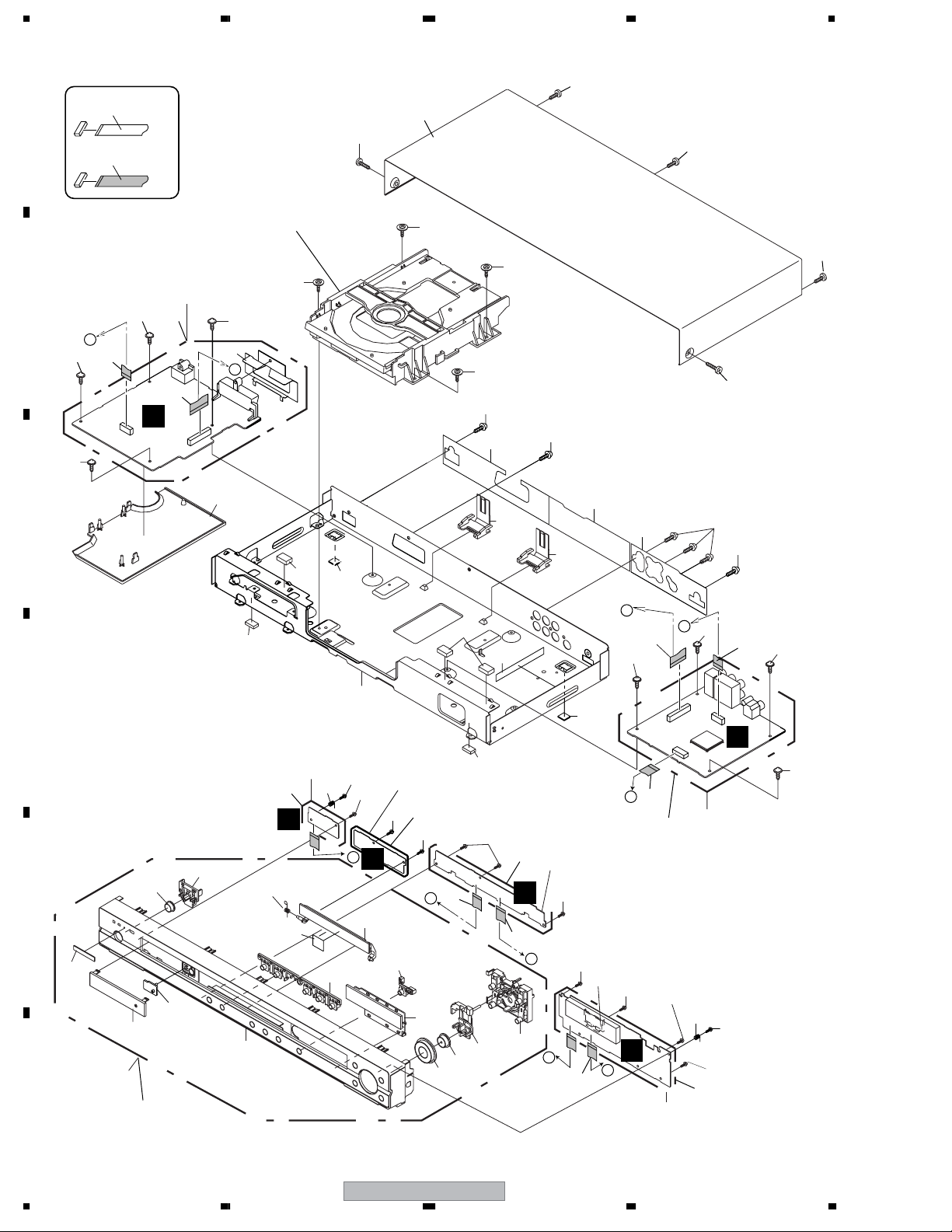

2. EXPLODED VIEWS AND PARTS LIST ............................................................................................................ 6

A

B

C

D

2.1 PACKING SECTION .................................................................................................................................. 6

2.2 EXTERIOR SECTION................................................................................................................................ 8

2.3 06 DVD MECHA SECTION...................................................................................................................... 10

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM..........................................................................................12

3.1 BLOCK DIAGRAM ................................................................................................................................... 12

3.2 OVERALL and POWER BLOCK DIAGRAM ............................................................................................ 14

3.3 OVERALL WIRING CONNECTION DIAGRAM........................................................................................ 16

3.4 DVD MT PCB ASSY (1/7)........................................................................................................................ 18

3.5 DVD MT PCB ASSY(2/7)......................................................................................................................... 20

3.6 DVD MT PCB ASSY(3/7)......................................................................................................................... 22

3.7 DVD MT PCB ASSY(4/7)......................................................................................................................... 24

3.8 DVD MT PCB ASSY(5/7)......................................................................................................................... 26

3.9 DVD MT PCB ASSY(6/7)......................................................................................................................... 28

3.10 DVD MT PCB ASSY(7/7)....................................................................................................................... 30

3.11 OPERATION, OPERATION 2 and OPERATION 3, 4 PCB ASSYS ....................................................... 32

3.12 POWER PCB ASSY (1/2) ...................................................................................................................... 34

3.13 POWER PCB ASSY (2/2) ...................................................................................................................... 36

3.14 WAVE FORMS....................................................................................................................................... 38

4. PCB CONNECTION DIAGRAM ..................................................................................................................... 41

4.1 LOADING and SW PCB ASSYS.............................................................................................................. 41

4.2 DVD MT PCB ASSY................................................................................................................................. 42

4.3 OPERATION, OPERATION 2 and OPERATION 3, 4 PCB ASSYS ......................................................... 46

4.4 POWER PCB ASSY................................................................................................................................. 50

5. PCB PARTS LIST ........................................................................................................................................... 52

6. ADJUSTMENT ............................................................................................................................................... 53

6.1 WHEN REPLACING DVD DECK ............................................................................................................. 53

6.2 TEST MODE ............................................................................................................................................ 54

6.3 TEST MODE IN........................................................................................................................................ 55

6.4 DISC REMOVAL METHOD...................................................................................................................... 56

7. GENERAL INFORMATION............................................................................................................................. 57

7.1 DIAGNOSIS ............................................................................................................................................. 57

7.1.1 DISPLAY SPECIFICATION OF THE TEST MODE............................................................................ 57

7.1.2 FUNCTIONAL SPECIFICATION OF THE SHORTCUT KEY ............................................................ 58

7.1.3 SPECIFICATION OF MODEL INFORMATION DISPLAY .................................................................. 59

7.1.4 FUNCTIONAL SPECIFICATION OF THE SERVICE MODE............................................................. 60

7.1.5 METHOD FOR DIAGNOSING DEGRADATION OF THE LDS ON THE PICKUP ASSY .................. 61

7.1.6 TROUBLE SHOOTING...................................................................................................................... 62

7.2 DISASSEMBLY ........................................................................................................................................ 65

7.3 DVD DECK SECTION.............................................................................................................................. 66

7.4 IC INFORMATION.................................................................................................................................... 70

7.5 DISC / CONTENT FORMAT PLAYBACK COMPATIBILITY ..................................................................... 82

8. PANEL FACILITIES ........................................................................................................................................ 84

8.1 FRONT PANEL SECTION ....................................................................................................................... 84

8.2 REMOTE CONTROL ............................................................................................................................... 85

E

F

4

1234

DV-490V-S

Page 5

5678

1. SPECIFCATIONS

Specifications

General

System . . . . . . . . . . . . . . . . . . . . . . . DVD player

Power requirements

. . . . . . . . . . . . . AC 220 to 240 V, 50/60 Hz

Power consumption . . . . . . . . . . . . . . . . . . . 7 W

Power consumption (standby) . . . . . . . . 0.7 W

(DV-490V-S, DV-490V-K)

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.7 kg

Dimensions

. . . .420 (W) mm x 49.5 (H) mm x 215.5 (D) mm

(DV-490V-S, DV-490V-K)

Operating temperature

Operating humidity . . . . . . . . . . . . . 5 % to 85 %

AV connector output

AV Connector (21-pin connector assignment)

AV connector output . . . . . . . 21-pin connector

This connector provides the video and audio

signals for connection to a compatible colour TV

or monitor.

. . . . . . +5 °C to +35 °C

(no condensation)

Video output

Output level . . . . . . . . . . . . . . . . . . . 1 Vp-p (75 Ω)

Jack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RCA

Audio output (1 stereo pair)

Output level . . . . . . . . . . . . During audio output

200 mVrms (1 kHz, ± 20 dB)

Number of channels . . . . . . . . . . . . . . . . . . . . . 2

Jacks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RCA

HDMI output

HDMI output . . . . . . . . . . . . . . . . . . . . . . . .19 pin

Digital audio characteristics

Frequency response . . . . . . . . . . 4 Hz to 44 kHz

(DVD fs: 96 kHz)

S/N ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . 115 dB

Dynamic range . . . . . . . . . . . . . . . . . . . . . . . 88 dB

Total harmonic distortion . . . . . . . . . . . . 0.0065 %

Wow and flutter . . . . . . . . Limit of measurement

(±0.001 % W. PEAK) or lower

A

B

C

PIN no.

1 . . . . . . . . . . . . . . . . . . . . . . . Audio 2/R out

3 . . . . . . . . . . . . . . . . . . . . . . . . . Audio 1/L out

4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GND

7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B out

8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Status

11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G out

15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . R out

17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GND

19 . . . . . . . . . . . . . . . . . . . . . . . . . . . Video out

21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GND

Component video output

Y (luminance) - Output level . . . . . . 1 Vp-p (75 Ω)

P

(color) - Output level . . . . . . . 0.7 Vp-p (75 Ω)

B

(color) - Output level . . . . . . . 0.7 Vp-p (75 Ω)

P

R

Jack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RCA

Digital output

Coaxial digital output . . . . . . . . . . . . . . .RCA jack

Optical digital output . . . . . . .Optical digital jack

Accessories

Audio/video cable

Power cable

Remote control

AA/R6P dry cell batteries

Warranty card . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Operating Instructions

The specifications and design of this product are subject to

change without notice, due to improvement.

. . . . . . . . . . . . . . . . . . . . . . . .1

. . . . . . . . . . . . . . . . . . . . . . . . . . .1

. . . . . . . . . . . . . . . . . . . . . . . . . .1

. . . . . . . . . . . . . . . . 2

D

E

56

DV-490V-S

F

5

7

8

Page 6

1234

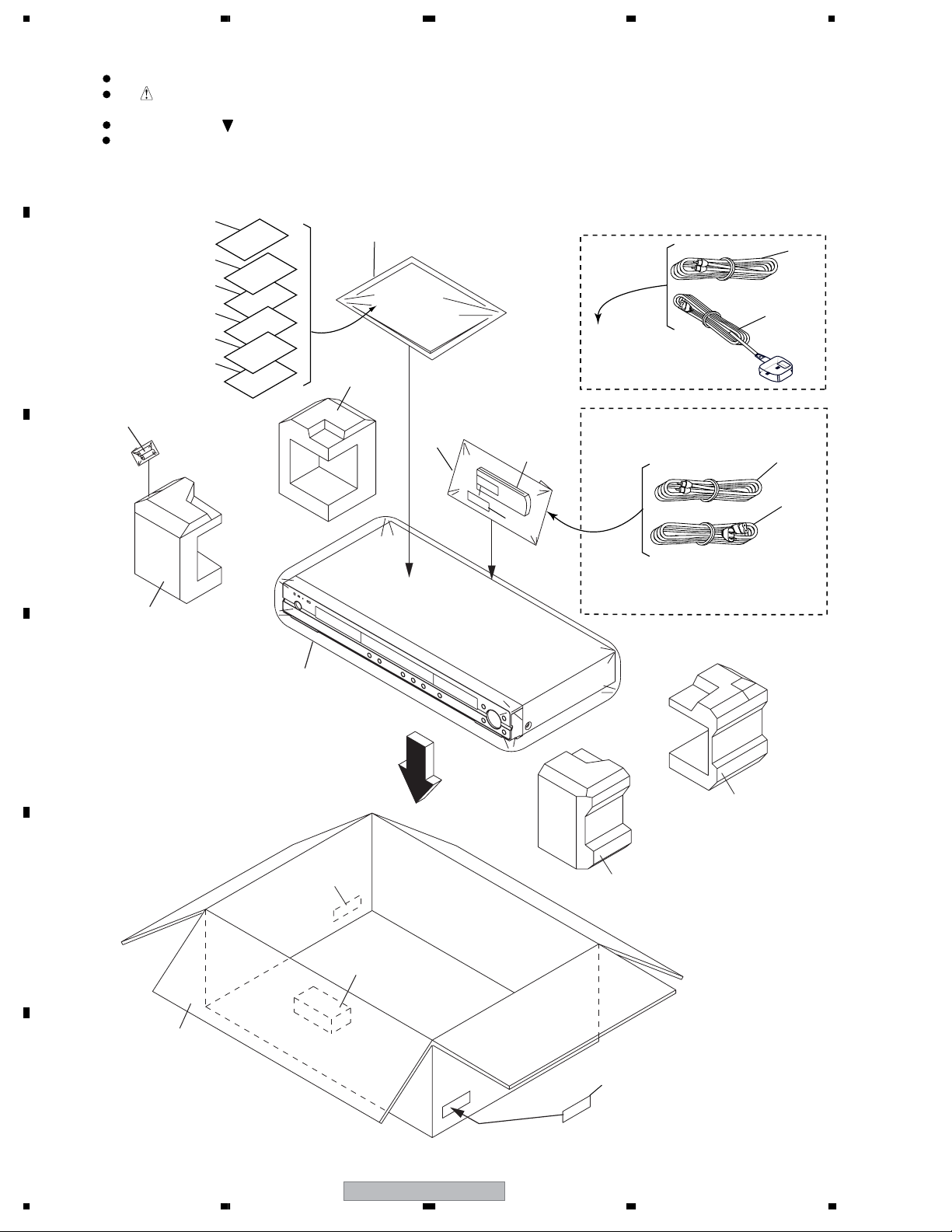

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

A

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

2.1 PACKING SECTION

GUARANTEE CARD

INSTRUCTION BOOK (E)

INSTRUCTION BOOK (E/I)

B

INSTRUCTION BOOK (G/F)

INSTRUCTION BOOK (S/D)

INSTRUCTION BOOK (R)

7-10,17

"Operating Instructions"

5

C

PA CKAGE

BATTERY,MANGAN

6

7

8

9

10

17

POLYBAG,INSTRUCTION (RED CAUTION)

12

14

POLY BAG INSTA5

TRANSMITTER

CORD,RCA PIN

16

PA CKAGE

For WVXT5 type

2

1

For WYXZT5, WYXZTUR5 types

3

4

2

1

14

GIFT SHEET

13

Front

D

PA CKAGE

18

E

11

PA CKAGE,PAD

15

14

PA CKAGE

14

18

F

6

1234

DV-490V-S

Page 7

>

>

5678

PACKING SECTION parts List

No. Description Part No.

Mark

1 Cord Set AC See Contrast table (2)

2 Cord, RCA Pin 06CPBA2006

3 Remote Control 07650KY040

4 Battery Cover VNK4998

NSP 5 Battery,Mangan (AR, R6P) • • • •

NSP 6 Guarantee Card J2I80202A

7 Instruction Book See Contrast table (2)

8 Instruction Book See Contrast table (2)

9 Instruction Book See Contrast table (2)

10 Instruction Book See Contrast table (2)

No. Description Part No.

Mark

11 Package.Pad 792WHA0604

12 Polyethylene Bag,Instruction JB5UD400

13 Gift Sheet 791WHA0100

14 Package See Contrast table (2)

15 Gift Box See Contrast table (2)

16 Poly. Bag 791WHAA040

17 Instruction Book See Contrast table (2)

18 Carton Label See Contrast table (2)

A

(2) CONTRAST TABLE

DV-490V-S/WVXT5, /WYXZTUR5, DV-490V-K/WYXZT5, /WYXZTUR5 and DV-490V-S/WYXZT5 are constructed

the same except for the following :

Mark No. Symbol and Description

1 Cord Set AC 1206158802 1206138802 1206158802 1206158802 1206158802

7 Instruction Book (English) Not used J2I80601B Not used Not used Not used

8 Instruction Book (English, Italian) J2I80221B Not used Not used J2I80221B Not used

9 Instruction Book (German, French) J2I80222B Not used Not used J2I80222B Not used

10 Instruction Book (Spanish, Duch) J2I80223B Not used Not used J2I80223B Not used

14 Package 792WHAA190 792WHAA191 792WHAA190 792WHAA190 792WHAA190

15 Gift Box 793WCD1741 793WCDD169 793WCD1741 793WCDD170 793WCDD170

17 Instruction Book (Russian) Not used Not used J2I82501A Not used J2I82501A

18 Carton Label Not used Not used 723000D328 Not used 723000D329

DV-490V-S/

WYXZT5

DV-490V-S/

WVXZT5

DV-490V-S/

WYXZTUR5

DV-490V-K/

WYXZT5

DV-490V-K/

WYXZTUR5

B

C

D

56

DV-490V-S

E

F

7

7

8

Page 8

1234

2.2 EXTERIOR SECTION

NON-CONTACT

A

SIDE

CONTACT SIDE

Refer to

"2.3 06 DVD MECHA SECTION".

20

14

20

5

18

20

PCB240

(POWER PCB ASS'Y)

B

19

19

C

D

E

101E

F

" FRONT PANEL SECTION".

19

D

15

101C

101

4

19

7

E

31

F

11

13

PCBDF0

(OPERATION 3 PCB ASS'Y)

101G

101M

101P

101A

101N

101O

27

G

18

16

29

101I

13

8

PCBDG0

30

(OPERATION 4 PCB ASS'Y)

22

17

22

22

B

H

B

101D

101J

101B

101K

101L

20

19

16

18

21

25

28

12

18

21

12

13

24

20

23

E

31

19

21

21

D

19

15

A

13

A

9

PCB130

1

22

6

PCB280

3

(OPERATION 2 PCB ASS'Y)

22

C

(DVD PCB ASS'Y)

10

101F

C

101H

22

26

22

22

29

30

C

B

A

9

PCB270

(OPERATION 1 PCB ASS'Y)

22

2

19

8

1234

DV-490V-S

Page 9

>

5678

EXTERIOR SECTION parts List

No. Description Part No.

Mark

1DVD MT PCB Assy A2I903A130

2 OPERATION PCB Assy See Contrast table (2)

3 OPERATION 2 PCB Assy A2I802A280

4POWER PCB Assy A2I903A240

5DVD MECHA ASSY A2I802A650

6 Cord Jumper(CD604) 122H051706

7 Shield, 21Pin 761WSA0237

NSP 8 Plate,Bottom 702WSA0286

9 Cord Jumper(CD601) 122H0B1003

10 Cord Jumper(CD602) 122H091303

11 Plate,Cover power 755WPAA031

12 Holder,FFC 761WPA0396

13 Cushion,Leg VEB1349

14 Cabinet,Top See Contrast table (2)

15 Cord Jumper(CD7301) 122H0C3002

16 Cushion (15x20x16) 8965TS101B

17 OPERATION 4 PCB Assy A2I903ADG0

18 Screw,Tap Tite(S)-Bind Wash. 816423063U

19 Screw,Tap Tite(S) (3x5.5) 8107D3055U

20 Screw,Tap Tite(B) (3x6.0) See Contrast table (2)

21 Screw,Tap Tite(B)Pan (3x6) 810913060U

22 Screw,Tap Tite(P) (2.6x8) 811022680U

NSP 25 Sheet,Jack 3 See Contrast table (2)

See Contrast table (2)

No. Description Part No.

Mark

NSP 26 Double,Face-Tape 7290000156

27 OPERATION 3 PCB Assy A2I903ADF0

NSP 28 Sheet Caution 726000A140

29 Spring Earth 743WKAA015

30 Screw PAN 810213060U

31 Cord Connector (CD502) 06CPBA2006

101 Front Cabi Assy See Contrast table (2)

NSP 101A Cabinet, Front See Contrast table (2)

NSP 101B Plate, Display 711WPA0253

NSP 101C Plate, Cover

101D Flap, DVD

NSP 101E Badge,Brand See Contrast table (2)

NSP 101F Button,Frame 1 735WPA0874

NSP 101G Button,Frame 4 735WPA0879

NSP 101H Button,Frame 2 See Contrast table (2)

NSP 101I Button,Frame 5 See Contrast table (2)

NSP 101J Button,Frame 3 See Contrast table (2)

NSP 101K Button, Cap See Contrast table (2)

NSP 101L Button, Cap 2 See Contrast table (2)

NSP 101M Button, Cap 1 See Contrast table (2)

101N Spring,Flap-DVD 743WKA0052

101O SHEET DVD 7235630011

NSP 101P Glass LED 713WPA0385

A

B

C

(2) CONTRAST TABLE

DV-490V-S/WVXT5, /WYXZTUR5, DV-490V-K/WYXZT5, /WYXZTUR5 and DV-490V-S/WYXZT5 are constructed

the same except for the following :

Mark No. Symbol and Description

2 OPERATION PCB Assy A2I802A270 A2I802A270 A2I808A270 A2I802A270 A2I808A270

14 Cabinet, Top 702WSB0114 702WSB0114 702WSB0114 702WSB0115 702WSB0115

20 Screw,Tap Tite(B) (3x6.0) 8109K3060U 8109K3060U 8109K3060U 8109K3060S 8109K3060S

NSP 24 Sheet, Jack 2 7226310109 7226310109 7226310109 722631A082 722631A082

NSP 25 Sheet, Jack 3 7226310110 7226310110 722631A084 722631A083 722631A093

101 Front Cabi Assy 7A7010201A 7A7010201A 7A7010201A 7A701A724A 7A701A724A

NSP 101A Cabinet, Front 701WPJ1422 701WPJ1422 701WPJ1422 701WPJD263 701WPJD263

NSP 101E Badge, Brand 7236310014 7236310014 7236310014 7236310009 7236310009

NSP 101H Button, Frame 2 735WPB0328 735WPB0328 735WPB0328 735WPA0876 735WPA0876

NSP 101I Button, Frame 5 735WPB0329 735WPB0329 735WPB0329 735WPA0881 735WPA0881

NSP 101J Button, Frame 3 735WPB0330 735WPB0330 735WPB0330 735WPA0878 735WPA0878

NSP 101K Button, Cap 737WPB0005 737WPB0005 737WPB0005 737WPA0037 737WPA0037

NSP 101L Button, Cap 2 737WPB0006 737WPB0006 737WPB0006 737WPA0040 737WPA0040

NSP 101M Button, Cap 1 737WPJ0002 737WPJ0002 737WPJ0002 737WPDA001 737WPDA001

DV-490V-S/

WYXZT5

DV-490V-S/

WVXZT5

DV-490V-S/

WYXZTUR5

DV-490V-K/

WYXZT5

DV-490V-K/

WYXZTUR5

D

E

56

DV-490V-S

F

9

7

8

Page 10

1234

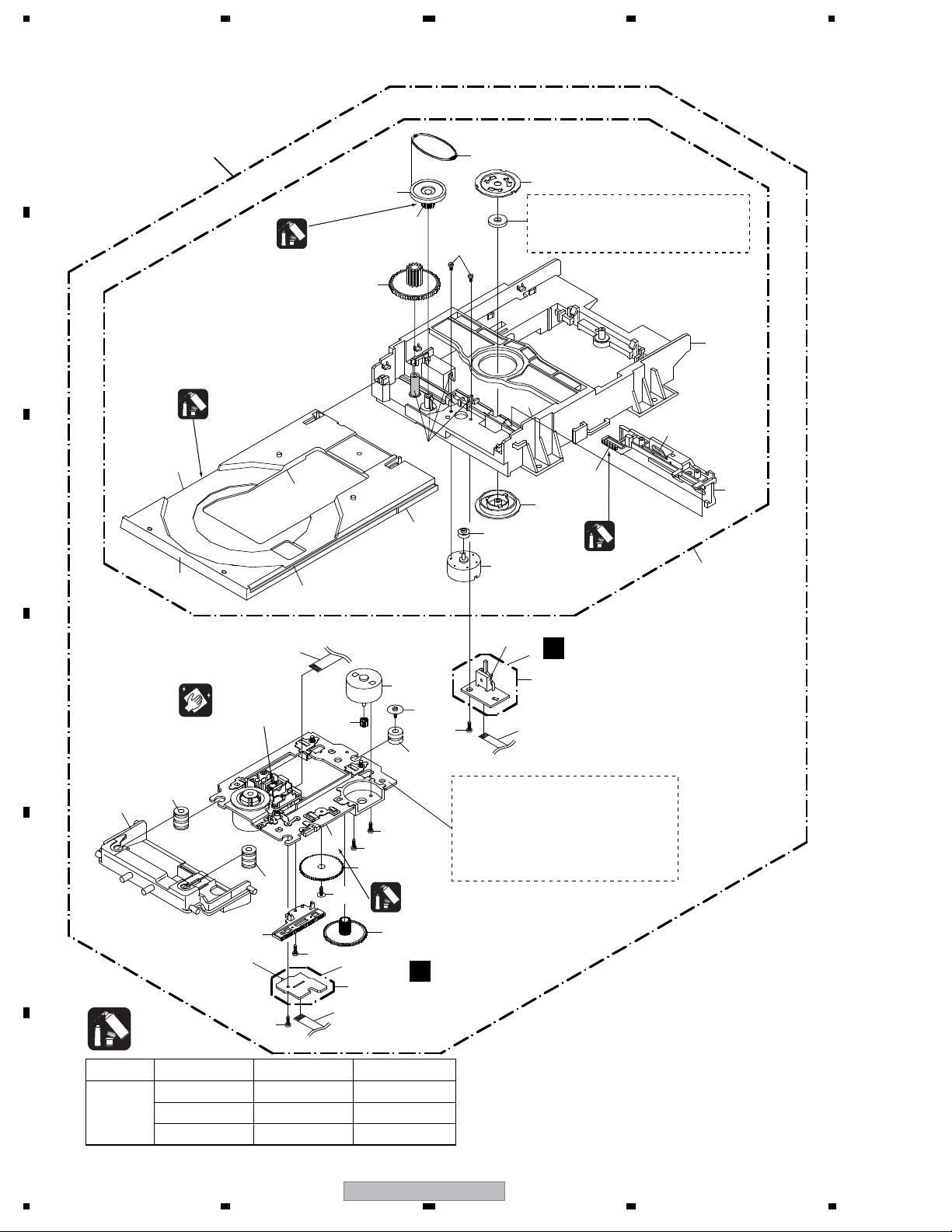

2.3 06 DVD MECHA SECTION

A

34

14

9

18

Cannot supply separately.

Lubricating Oil

GYA1001

AB

21

If the repair is needed, replace the

LOADER SUB ASS'Y.

15

B

Grease

GEM1036

11

AB

AB

AB

AC

AB

C

AB

4

20

3

12

AC

AB

Lubricating Oil

GYA1001

23

19

29

6

CD2001

SW1

E

1

PCB610

Pickup leneses

D

8

13

E

GEM1004

GED-008

25

30

24

AA

8

26

27

17

SW2

Note :

5

32

31

10

22

22

16

Grease

GEM1018

2

PCB640

D

(SW PCB ASS'Y)

Do not replace the parts. Because,

minute adjustments are needed if

this condition is disassembled

further more.

If the repair is needed, replace the

DVD MECHA ASS'Y.

(LOADING MOTOR PCB ASS'Y)

7

CD2302

28

33

CLASS

GREASE G-555G

F

PART NO.

GEM1018

GYA1001

PART NAME

GEM1036

G-313Y

FL-78A

CD2301

MARK

AA

AB

AC

NOTE:

Applying positions AA, AB and AC for the

grease are displayed for this section.

Check if the correct grease is applied for each

position.

10

DV-490V-S

1234

Page 11

5678

06 DVD MECHA SECTION parts List

No. Description Part No.

Mark

NSP 1 Loading Motor PCB Assy A2F101A610

2 Gear,Middle 92P100117A

3 Loading Motor 1515S98004

4 Pulley,Motor 92P100097A

5 FEED Motor 1515S98004

6 Cord Jumper (24P)(CD2001) 122J402202

7 Cord Jumper (CD2302) 122H051602

8 Insulator (F) 92P200013A

9 Belt,Loading 92P200015A

10 Insulator (R) 92P200016A

A

11 Frame,main 92P100119A

12 Tray (B) 92P100127B

13 Holder ,Traverse 92P100125A

14 Gear,Pulley 92P100123A

15 Gear,Main 92P100124A

16 Gear,Feed 92P100116A

NSP 17 SW PCB Assy (PCB640) A2F101A640

18 Plate, Clamper 92P000023A

19 LOADER SUB ASSY (B) 92AAA0019B

20 Clamper 92P100122A

21 Screw,Pan (M1.7x3 P3) 814011730U

22 Screw,Pan (M1.7x2.3 P3) 814011723U

23 Rack,Loading 92P100121A

24 Gear,Motor 92P100088A

25 Feed Rack Assy 92AAA0017A

26 Screw,T-Tite(B) (M1.7x5.0 P3) 813381750U

27 Screw,Gear Feed 92P700007A

28 Cord Jumper (CD2301) 122H061605

29 Switch (SW1) 0515S32003

30 Push Switch (SW2) 0500101036

31 Screw,Tap Tite(P) (2.6x8) 811022680U

32 Sems.Tap Tite(P) (2x8) 816112080U

33 Screw,Tap Tite(P) BI 811022080U

34 DVD MECHA ASSY A2I802A650

B

C

D

56

DV-490V-S

E

F

11

7

8

Page 12

1234

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

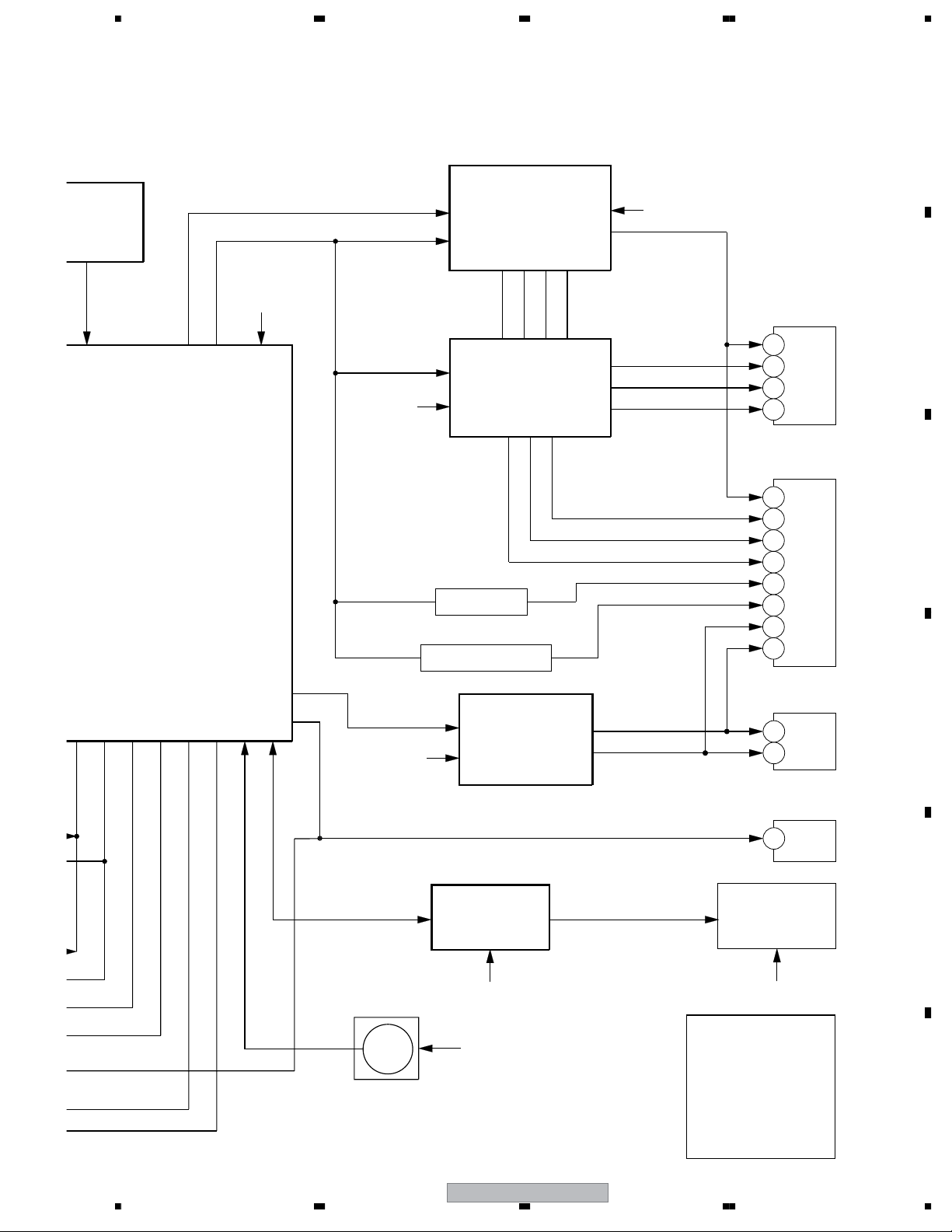

3.1 BLOCK DIAGRAM

A

B

C

DVD LOADER/MPEG BLOCK DIAGRAM

DVD LOADER/MPEG BLOCK DIAGRAM

DVD

DVD

Loader

Loader

(DM-4)

(DM-4)

OPU

OPU

SPINDLE/

SPINDLE/

STEPING/

STEPING/

SLED

SLED

MOTOR

MOTOR

C

C

IOA, V20

IOA, V20

RF, A, B, C, D, E, F, MDI1

RF, A, B, C, D, E, F, MDI1

LD_DVD, LD_CD

LD_DVD, LD_CD

T+/-, F+/-,

T+/-, F+/-,

LOAD+/-,

LOAD+/-,

MOT_SLED+/-,

MOT_SLED+/-,

MOT_SPDL+/-

MOT_SPDL+/-

A

A

Q2302~2305

Q2302~2305

LD DRIVE

LD DRIVE

D

D

MOTOR DRIVER IC

MOTOR DRIVER IC

IC2301

IC2301

LA6565VR-TLM-E

LA6565VR-TLM-E

LIMIT, TRIN, TROUT,

LIMIT, TRIN, TROUT,

TROPEN, TRCLOSE,

TROPEN, TRCLOSE,

LDO1, LDO2

LDO1, LDO2

DMSO, FMSO,

DMSO, FMSO,

TRSO, FOSO,

TRSO, FOSO,

STBY, V1P4

STBY, V1P4

RESET IC

RESET IC

A

A

X4001

X4001

27MHz

27MHz

MPEG/MICON IC

MPEG/MICON IC

MT1389FE/E-L

MT1389FE/E-L

IC4001

IC4001

BD5229G-TR

BD5229G-TR

IC4003

IC4003

RESET

RESET

D

A

A

HDMI CONNECTOR

HDMI CONNECTOR

CP5901

CP5901

1

1

D2+

D2+

E

3

3

D2-

D2-

4

4

D1+

D1+

6

6

D1-

D1-

7

7

D0+

D0+

9

9

D0-

D0-

10

10

CLK+

CLK+

CLK-

CLK-

12

12

HOTPLUG

HOTPLUG

19

19

18

18

POWER

POWER

15

15

SCL

16

16

SCL

SDA

SDA

F

A0~A20, AD0~AD7,

A0~A20, AD0~AD7,

PRD#, PCE#, PWR#

PRD#, PCE#, PWR#

16Mbit FLASH

16Mbit FLASH

IC4004

IC4004

S29AL016D70TFI020

S29AL016D70TFI020

H

H

MA0~MA11, DQ0~DQ15,

MA0~MA11, DQ0~DQ15,

DQM0, DQM1, DBA0, DBA1,

DQM0, DQM1, DBA0, DBA1,

SDCLK, SDCKE, DWE#,

SDCLK, SDCKE, DWE#,

DRAS#, DCAS#, DCS#

DRAS#, DCAS#, DCS#

64Mbit SDRAM

64Mbit SDRAM

IC4005

IC4005

EM638165TS-7G

EM638165TS-7G

HDMI TRANSMITTER IC

HDMI TRANSMITTER IC

IC5901

IC5901

MT1392E/C-L

MT1392E/C-L

A

A

A

A

EEPROM IC

EEPROM IC

IC4002

IC4002

BR24L08FJ-WE2

BR24L08FJ-WE2

A, B

A, B

SDA

SDA

SCL

SCL

92_Y0~Y7

92_Y0~Y7

92_VCK, 92_ACLK, XO

92_VCK, 92_ACLK, XO

ASPDIF

ASPDIF

HDMI_SCL

HDMI_SCL

HDMI_SDA

HDMI_SDA

SDA

SDA

SCL

SCL

12

DV-490V-S

1234

Page 13

-

ESET IC

IC4003

5229G-TR

5678

A

LETTER, I/XP,

R/CR, B/CB, G/Y, C/V

SQUEEZE, VSEL1

VIDEO DRIVER 6CH IC

IC7301

LA73054-TLM-E

C

CVBS/Y/U/V

J7302

6

CVBS

5

Y

3

U

2

V

B

RESET

A, B

VSEL1

Y OUT

CB OUT

YCMIX

CR OUT

4CH BUS SW IC

IC7302

D

SN74CBT3257PWR

21PIN CONNECTOR

J8101

19

CVBS

IC

L

SQUEEZE

21 PIN CTL

Q8101, Q8102

21 PIN CTL

BLANKING_OUT

Q8104, Q8105

VSEL1

DVD_RGB_H_OUT

15

11

7

8

16

3

1

R OUT

G OUT

B OUT

L

R

C

AUDIO JACK

AUDIO L, R

F

AUDIO AMP IC

IC8003

RC4580IDR

AUDIO R

AUDIO

L

J8003

2

R

3

L

D

ASPDIF

FP_DI, FP_DO,

FP_SCK, STB

FIP DRIVER IC

IC651

GR1~GR8, P1~P16

PT6315

A

IR

IR

A

IR RECEIVER (OS651)

ROM-N340TAO

DV-490V-S

56

COAXIAL JACK

J7301

2

FIP (V651)

HNV-08SS44T

E

G

A.......AT+3.3V

B.......+1.8V

C.......P.CON+5V

D.......P.CON+6V

E.......AT+12V

F.......P.CON+12V

F

G.......-28V

H.......V+5H

13

7

8

Page 14

1234

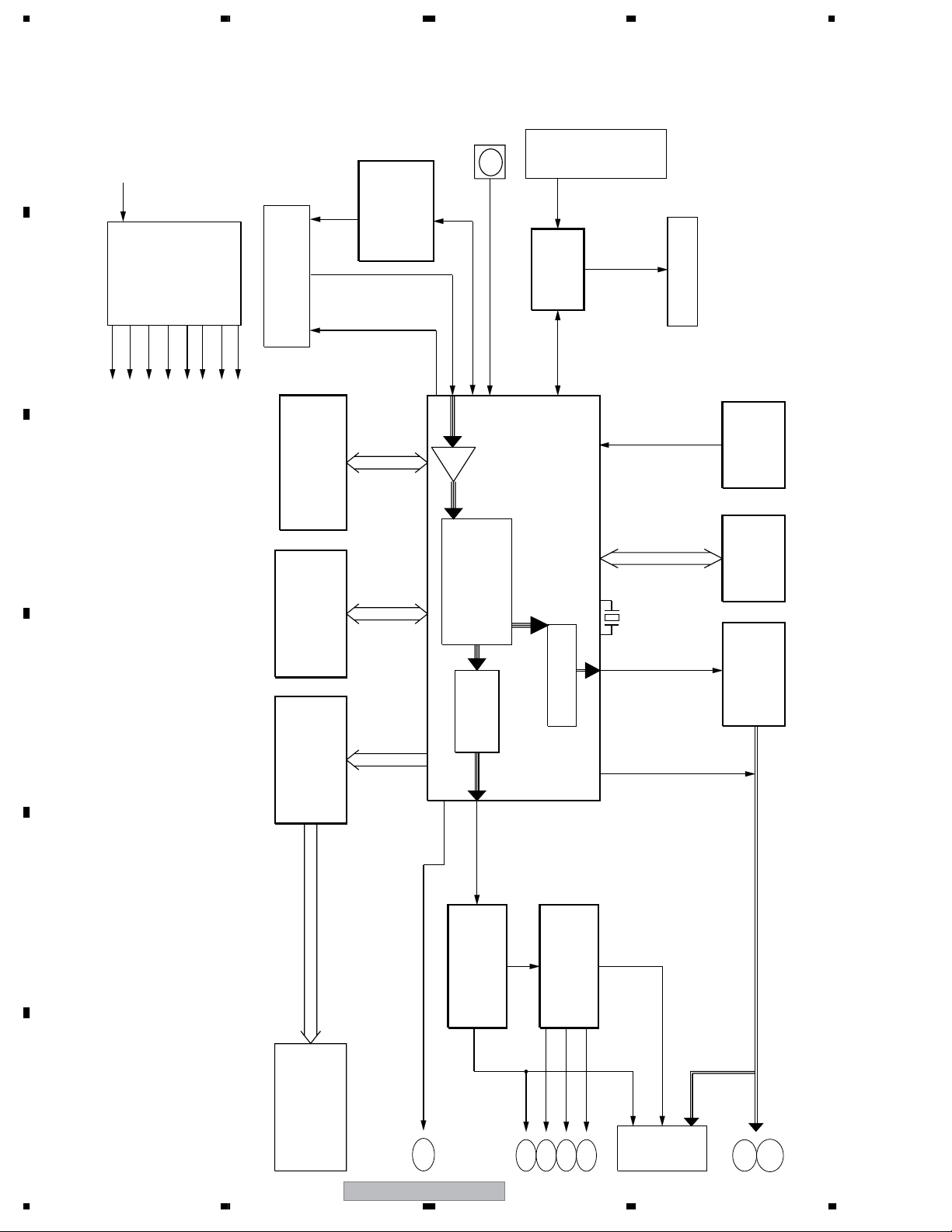

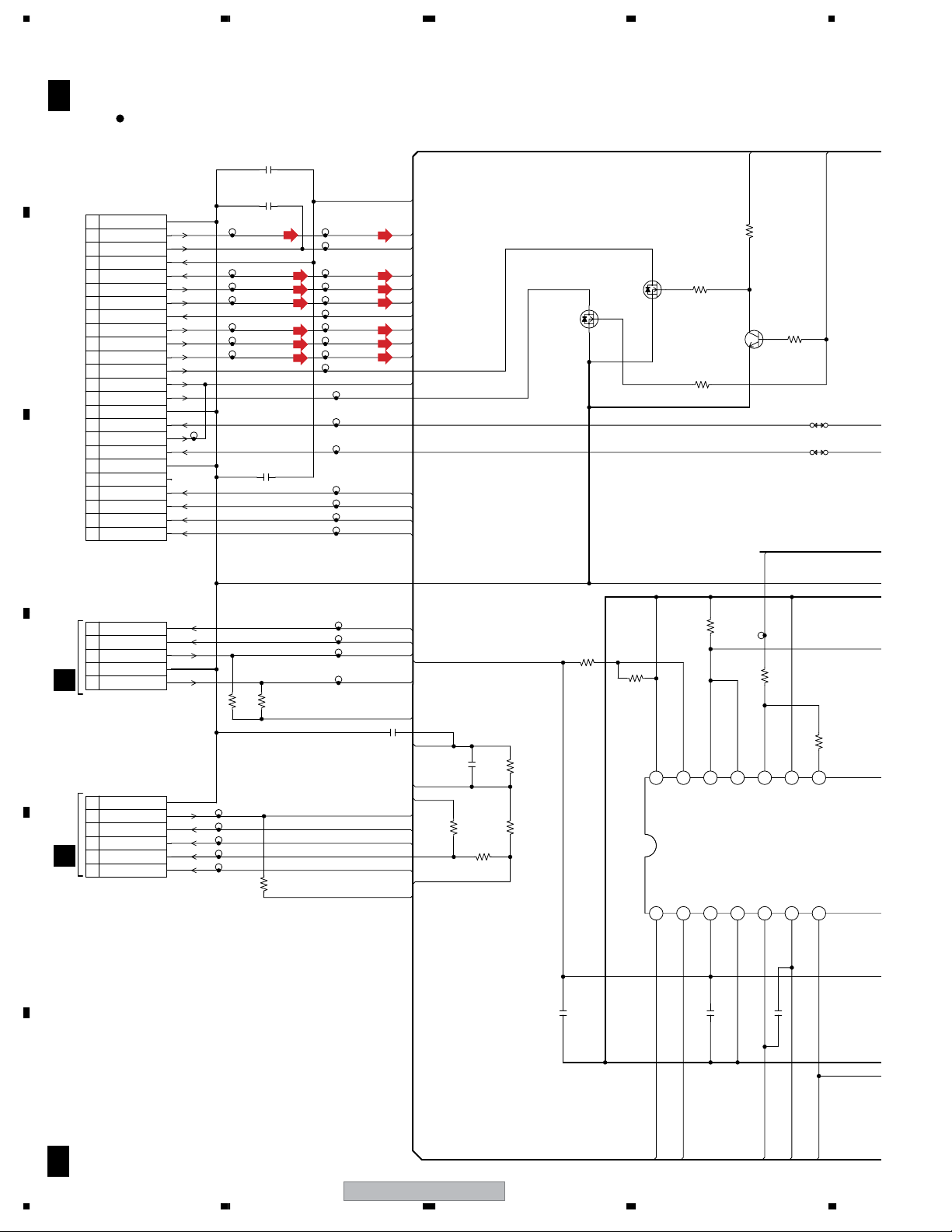

3.2 OVERALL and POWER BLOCK DIAGRAM

A

• OVERALL BLOCK DIAGRAM

AC220 V

SUPPLY

POWER

DVD LOADER

(DM4)

LA6565VR-TLM-E

SERVO

MOTOR DRIVER

IC2301

RF

IR RECEIVER (OS651)

ROM-N340TAO

IR

IR

SERVO

FIP DRIVER IC

PT6315

IC651

KEY

HNV-08SS44T

FIP

B

LD_DVD,

LD_CD

FLDC+/-

-28V

AT+12V for mute

+1.8V

AT+3.3V

P.CON+6V

P.CON+5V

P.CON+12V

S29AL016D70TFI020

16Mbit FLASH

IC4004

AD0~AD7

RF

A0~A20,

C

DECORDER

MPEG-1/2/

VIDEO

EM638165TS-7G

64Mbit SDRAM

IC4005

MA0~MA11,

DQ0~DQ15

HDMI TRANSMITTER IC

D

MT1392E/C-L

IC5901

JPEG

TV Encoder

108MHz

FP,STB

MPEG/MICON BLOCK

MT1389FE/E-L

IC4001

AUDIO CODEC/

INTERNAL DAC

27MHz

AUDIO_R

RESET

SDA, SCL

AUDIO_L,

BD5229G-TR

RESET IC

IC4003

BR24L08FJ-WE2

8K EEPROM

IC4002

AUDIO AMP IC

RC4580IDR

IC8003

92_Y0~Y7,

92_VCK,

92_ACLK

ASPDIF

4CH VIDEO DAC

E

TX0+/-,

TX1+/-,

TX2+/-,

TXC+/-

CONNECTOR

CP5901

HDMI

COAXIAL

VIDEO DRIVER 6CH IC

LA73054-TLM-E

IC7301

SN74CBT3257PWR

4CH BUS SW IC

IC7302

AMUTE

AMP_AUDIO_L/R

RGB OUT

F

21PIN

R

L

14

CO

DV-490V-S

CVBS

U

V

Y

1234

Page 15

5678

• POWER BLOCK DIAGRAM

+1.8V

P.CON+12V

AT+12V for mute

P.CON +12V SW

Q510

P.CON+5V

P.CON +5V SW

Q515

P.CON+6V

V+5H

IC5902

HDMI+5V REG IC

AT+3.3V

P.ON-H

PQ1K503M2ZPH

FL DC -

FL DC +

A

-28V

B

C

IC501

KIA431A-AT

VOLTAGE CTL

IC504

PHOTO COUPLER

PS2561AL1-1-V (W)

IC4006

REG+1.8V

LM1117S-ADJ

IC502

POWER CTL

STR-A6131M

IC503

6V REG

PQ070XF01SZH

T501

TRANS

SWITCHING

P.CON SW

Q505

FL+ P.CON SW

Q504

Q502

-28V P.CON SW

D

E

AC IN

DV-490V-S

56

F

15

7

8

Page 16

1234

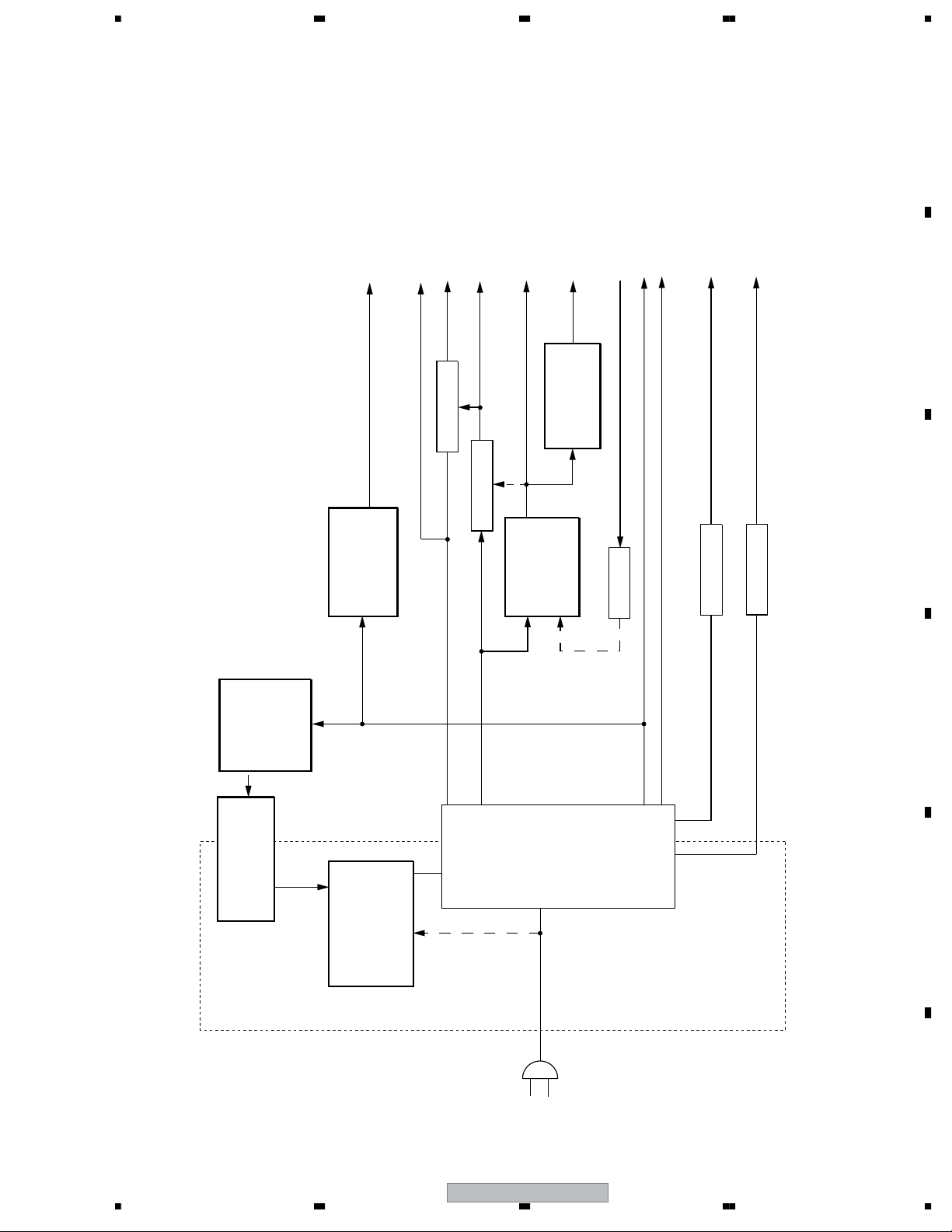

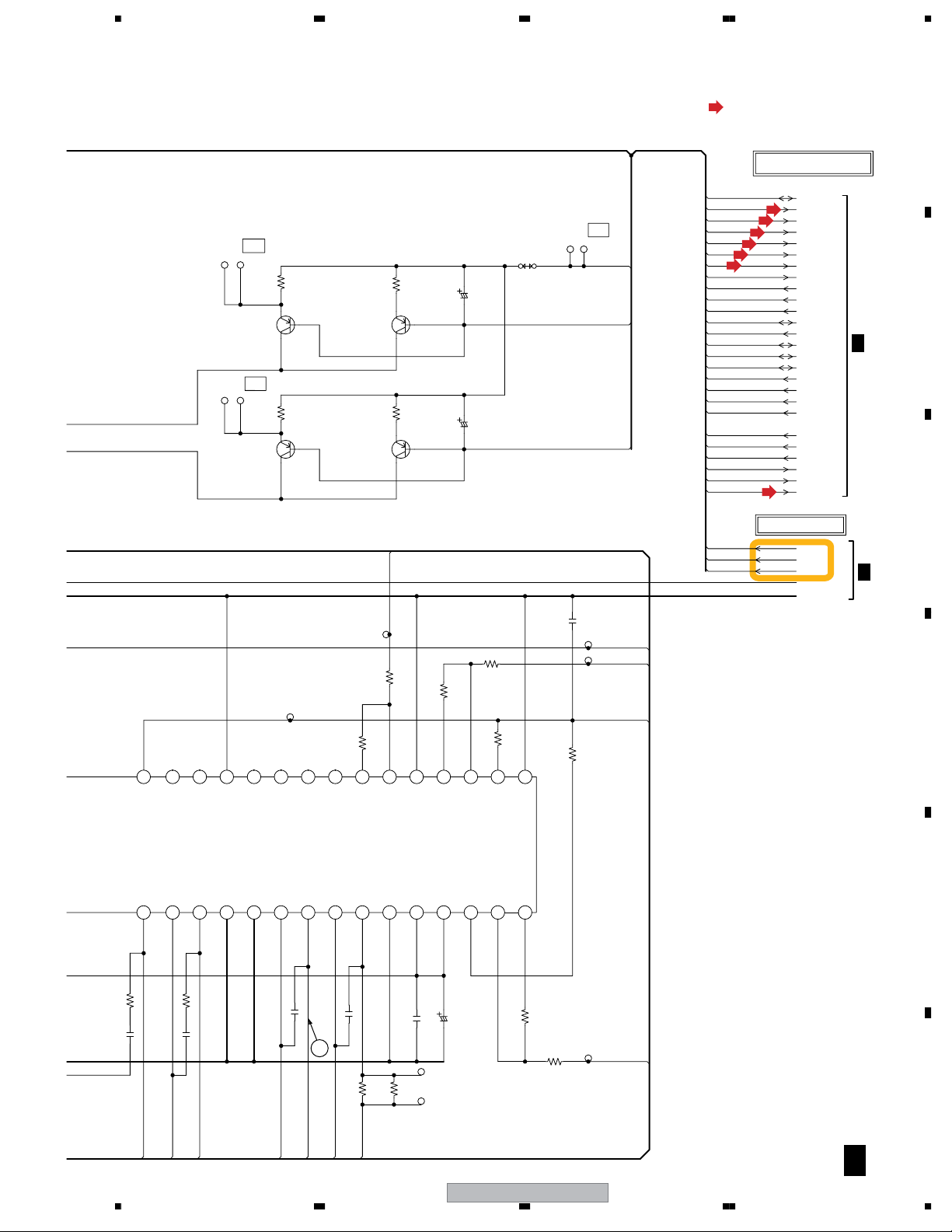

3.3 OVERALL WIRING CONNECTION DIAGRAM

A

OPERATION 4 PCB ASSY

H

(A2I903ADG0)

HDMI LED(RED)

R664

330 1/4W

W808W807

D660

LTL-1CHEE-002A

G

OPERATION 3 PCB ASSY

B

C

V+3E

GND(NC)

2

1

2

1

(CD604)

8

9

54321

V+3E

GND(NC)

LED

3

3

7

LED

SW2

POWER

5

4

5

4

5

6

SW2

POWER

CP605

OPERATION 2

C

PCB ASSY

(A2I802A280)

CP603

SW1

CP604

STOP

PLAY/+SKIP

PAUSE/-SKIP

V+3E

POWER

SW2

GND

LED

(A2I903ADF0)

B

(CD602)

9

9

8

7

6

5

4

3

2

1

1

8

2

7

3

6

4

5

5

4

6

7

3

8

2

9

1

OPERATION PCB ASSY

(A2I802A270 : Other)

(A2I808A270 : WYXZT5_Only)

CP602

SW1

1

2

3

PAUSE/-SKIP

4

5

6

7

8

9

OS651

STOP

PLAY/+SKIP

V+3E

POWER

SW2

GND

LED

B+

GND

2

3

DI (M to F)

DO (F to M)

Vout

1

CP601 CP4002

CLK

STB

IR

V+3E

DGND

DGND

FLDC+

-28V

FLDC-

(CD601)

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

1

2

3

4

5

6

7

8

9

10

11

1

2

3

4

5

6

7

8

9

10

11

CLK

DI (M to F)

STB

DO (F to M)

IR

V+3E

DGND

DGND

FLDC+

-28V

FLDC-

D

AC220 V-240 V_50 Hz/60 Hz

CD501_2

AC IN

WHITE

BLACK

E

F

AC INLET

N

NN

21

1 2

L

L

J501

21PIN CONNECTOR

J8101

1

220

NC

4

5

6

NC

7

8

9

NC

10

11

NC

12

POWER PCB ASSY (A2I903A240)

E 1/2, E 2/2

13

14

15

16

17

18

19

NC

21 3

CP503_1

G

GND

B

GND

R

RGB-H

FS

CVBS

GND

AUDIO L

GND

AUDIO R

CP502

GND

P.CON+12V

AT+12V for MUTE

GND

P.CON+5V

P.CON+6V

GND(M)

AT+3.3V

P.ON-H

GND(D)

FL DC-

FL DC+

-28V

CD7301

12

12

11

11

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

112

(CD502)

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

1

2

3

4

5

6

7

8

9

10

11

1

2

3

4

5

6

7

8

9

10

11

12

13

14

CP7301_1

1

G

2

GND

3

B

4

GND

5

R

6

RGB-H

7

FS

8

CVBS

9

GND

10

AUDIO L

11

GND

12

AUDIO R

CP4003

1

P.CON+12V

2

AT+12V for MUTE

3

4

P.CON+5V

5

P.CON+6V

6

GND(M)

7

AT+3.3VAT+3.3V

8

AT+3.3V

9

P.ON-H

10

GND(D)

11

FL DC-

12

FL DC+

13

14

GND

GND

-28V

16

DV-490V-S

1234

Page 17

5678

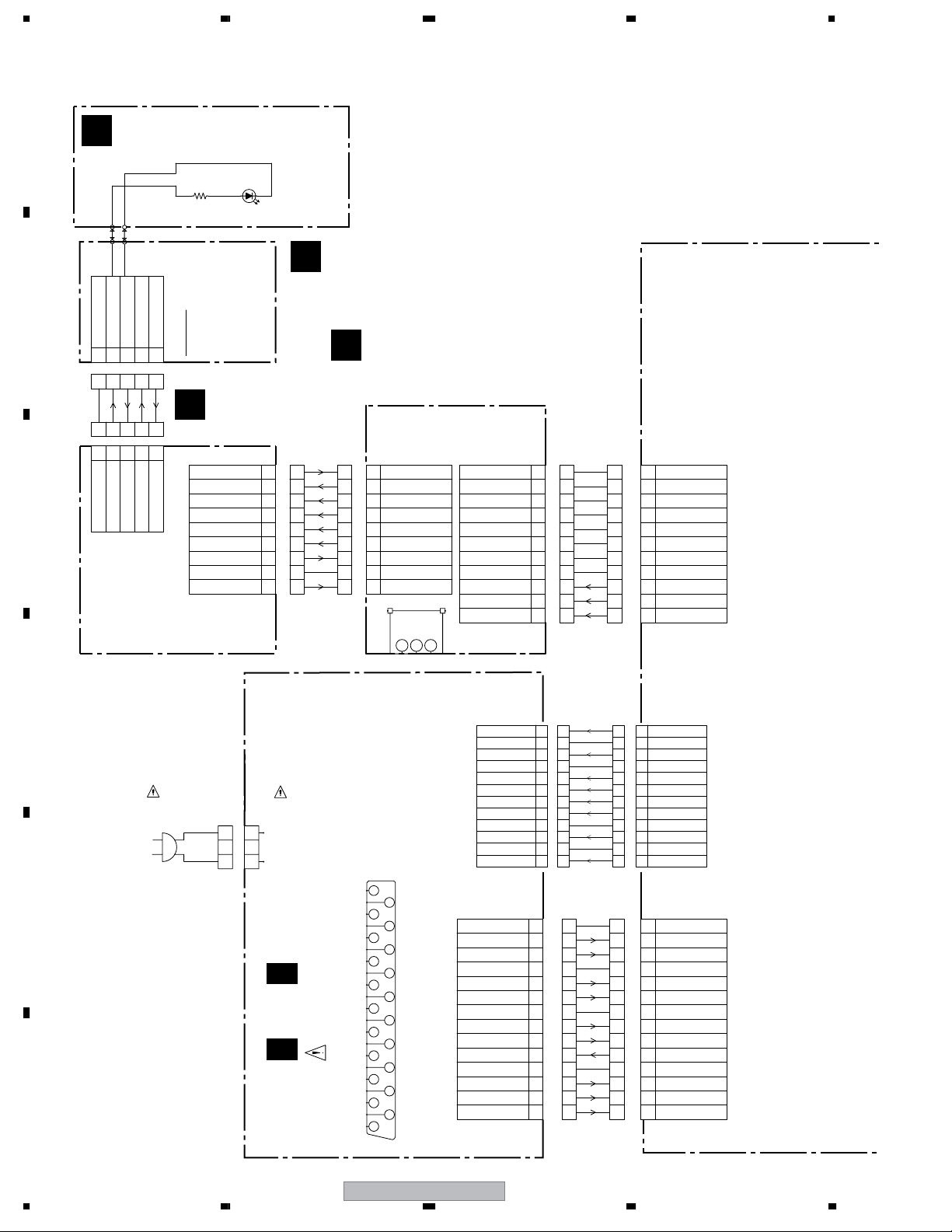

÷

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or

"PCB PARTS LIST".

÷

The > mark found on some component parts indicates the importance of the safety factor

A

of the part. Therefore, when replacing, be sure to use parts of identical designation.

÷

H

2

1

E

COAXIAL

J7301

A

A 1/7- A 7/7

DVD MT PCB ASSY (A2I903A130)

: MPEG/MICON/RF-AMP BLOCK

A 1/7

: MEMORY BLOCK

A 2/7

: LOADER/MOTOR DRV BLOCK

A 3/7

: AUDIO JACK BLOCK

A 4/7

: VIDEO JACK BLOCK

A 5/7

: HDMI BLOCK

A 6/7

: POWER PORT BLOCK

A 7/7

: The power supply is shown with the marked box.

VIDEO OUT

(COMPOSITE)AUDIO OUTDIGITAL OUT

H1H2

23

1

E

DVD AUDIO OUT

J8003

CVBS/Y/U/V

J7302

H1H2EH1H2

23

56

1

E

4

CP2301

24

F RTN

23

F DRV

22

T RTN

21

T DRV

20

NC

19

GND

18

LD(DVD)

17

PD/GND

16

LD(CD)

15

GND

14

VR(CD)

13

VR COM

12

VR(DVD)

11

A

10

B

C

D

E

VCC

VS

F

GND

CP2303

SP1+

SP1-

SLD+

SLD-

SW(GND)

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

VRF(RF_OUT)

SW1(DVD/CD)

LIMIT SW

CP2302

CLOSE

1

GND(D)

2

OPEN

3

4

LD- LD-

5

DVD MECHA ASSY

(A2I802A650)

B

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1

2

3

4

5

6

CD2302

F RTN

F DRV

T RTN

T DRV

NC

GND

LD(DVD)

PD/GND

LD(CD)

GND

VR(CD)

VR COM

VR(DVD)

A

B

VRF(RF_OUT)

SW1(DVD/CD)

C

D

E

VCC

VS

F

GND

SW PCB ASSY

D

(A2F101A640)

CD2301

SP1+

SP1-

SLD+

SLD-

LIMIT SW

SW(GND)

LOADING MOTOR

E

PCB ASSY

M2601

SPINDLE MOTOR

M

M2602

M

SW2

ESE22MH22

(A2F101A610)

SW-2(CLOSE)

GND(SW)

SW-1(OPEN)

LD+LD+

LOADING MOTOR

M

DVD

DRIVE

DM-4PB

OPTICAL PICK-UP

JCV9B12

BCZ3B05

SLED MOTOR

SW1

SSS-28-5

M2603

BCZ3B05

C

D

E

D2-

D2+

D2-S

3

2

1

CP5901

HDMI CONNECTOR

56

D1+

D1-S

D1-

645

D0+

7

D0-S

8

D0-

9

CLK+

10

CLK-S

11

CLK-

12

CEC

13

NC

14

SCL

15

SDA

16

GND

17

POWER

HOTPLUG

18

19

DV-490V-S

F

D E

17

7

8

Page 18

1234

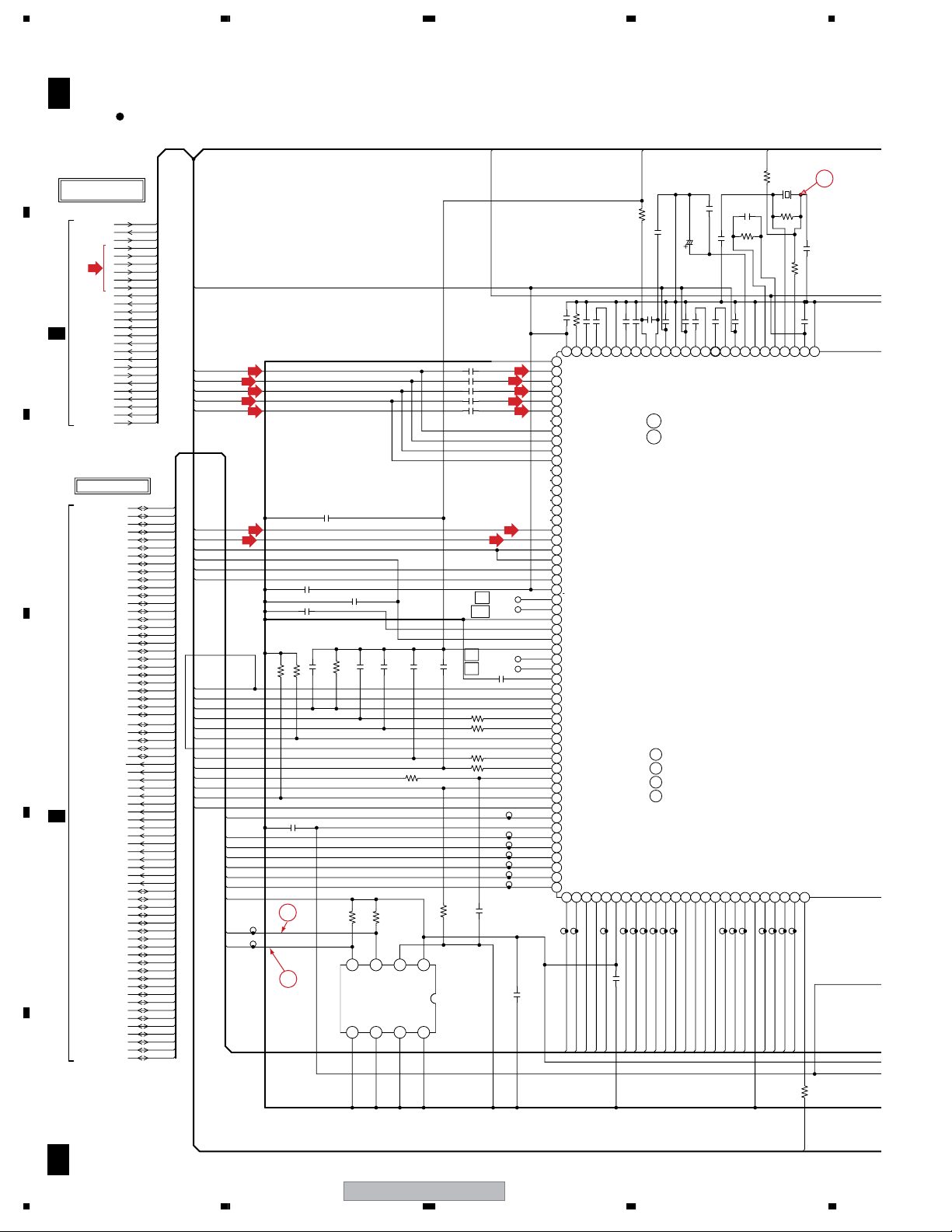

3.4 DVD MT PCB ASSY (1/7)

A

B

C

D

E

F

18

A 1/7

A 1/7

DVD MT PCB ASSY (A2I903A130)

MPEG/MICON/DSP BLOCK

FROM/TO

LOADER/MOTOR DRIVE

MDI1

V20

STBY

A

B

(RF)

C

D

E

F

LDO1

LDO2

DMSO

FMSO

TRCLOSE

TROPEN

TRSO

FOSO

OPO

OP+

OP-

IOA

TRIN

TROUT

LIMIT

V1P4

RF

FROM/TO MEMORY

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

AD0

AD1

AD2

AD3

AD4

AD5

AD6

AD7

PWR#

PRD#

PCE#

DQM0

DQM1

DWE#

DCAS#

DRAS#

2/7A 3/7A

DCS#

DQ0

DQ1

DQ2

DQ3

DQ4

DQ5

DQ6

DQ7

DQ8

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

DBA0

DBA1

MA0

MA1

MA2

MA3

MA4

MA5

MA6

MA7

MA8

MA9

MA10

MA11

SDCKE

SDCLK

1234

V+3

D

A

B

C

RF

E

F

MDI1

V20

LDO2

LDO1

OPO

OPOP+

DMSO

FMSO

TROPEN

ADIN

TRSO

FOSO

LIMIT

IOA

TRCLOSE

STBY

(D)

(C)

(RF)

(V+3D)

(A)

(B)

(F)

SCL

SDA

(E)

A2

A3

A4

A5

A6

A7

A8

TP4036

TP4037

C4002 0.1 B

C4003

0.1 B

R4015 10K

R4014 10K

C4001

0.1 B

7

8

0.1 B

C4103

C4005

0.0022 B

C4007 0.1 B

R4003

680K

C4089

0.015 B

10K

R4002

R4004

3.3

5 6 7 8

SDA

EEPROM

GND

0.0

1.8V

C4101

C4090

0.1 B

R4001 33

10K

3.3

0.0

WP

SCL

NC

NC

0.0

0.0

DV-490V-S

470P CH

3.3

VCC

NC

1234

0.0

C4011 1 B

C4012 1 B

C4013 1 B

C4014 1 B

C4088 1 B

C4102

470P CH

R4006 10K

R4007 15K

R4009 12K

R4010 12K

10K

R4061

IC4002

EEPROM

V+1R8

(D)

(A)

(B)

(C)

(RF)

(E)

(F)

CS

TP4008

TP4009

RFLV

FE

TP4010

TP4011

TE

C4006 0.1 B

TP4001

TP4002

TP4003

TP4004

TP4005

TP4006

TP4007

C4010

220P CH

BR24L08FJ-WE2

C4016

V+3RF

C4018

0.1 B

3.3

0.0

110111213141516171819 22021222324

AGND

1.5

DVDA

1.5

3

DVDB

1.5

4

DVDC

1.5

5

DVDD

1.7

6

DVDRF IP

NC

DVDRF IN

2.1

89

MA

2.1

MB

2.1

MC

2.1

MD

NC

SA

NC

SB

NC

SC

NC

SD

CDFON

NC

CDFOP

NC

2.1

TNI

2.1

TPI

0.2

MDI1

0.2

MDI2

2.5

LDO2

3.3

LDO1

3.5

SVDD3

3.4

CSO/RFOP

2526272829

2.1

RFLV/RFON

0.0

SGND

2.8

V2REFD

2.0

V2D

1.4

VREFD

30313233343536373839

1.3

FEO

1.3

TEO

1.3

TEZISLV

2.5

OP_OUT

1.6

OP_INN

1.4

OP_INP

2.1

DMO

1.3

FMO

0.0

TROPENPWM

1.4

PWMOUT1/ADIN0

40414243444546474849

1.4

TRO

1.4

FOO

2.5

FG/ADIN1/GPIO (PU)

3.4

GPIO0/VSYN/YUV1

0.0

GPIO1/HSYN/INT4#/YUV2

3.3

GPIO2/SPMCLK

2.2

IOA2 (PU)

1.8

DVDD18

1.8

IOA3 (PU)

2.2

IOA4 (PU)

50

1.6

IOA5 (PU)

51525354

2.7

IOA6 (PU)

1.9

IOA7 (PU)

2.2

HIGHA0(PU)

55

0.2

TP4012

0.1 B

A18

V1P4

R4020

100K

C4027

C4024 0.1 B

C4022 0.033 B

C4019 0.1 B

R4018 15K

1.7

1.4

0.9

RFGC

56 57 58 59

0

3.300.5

TP4013

PWR#

A19

A16

C4020 0.1 B

OSN

C4025

0.001 B

1.7

1.4

1.5

2.0

0.0

1.7

OSP

HRFZC

RFGND

CRTPLP

RFRPAC

215

55

56

57

58

HIGHA7 (PU)

DVDD3

HIGHA6 (PU)

HIGHA5 (PU)

HIGHA4 (PU)

60 61 62 63 64 65 66 67 68 69770 71 72 73 74 75 76 77 78 79

3.3

0.9

2.8

2.7

2.7

TP4014

TP4015

TP4016

TP4017

TP4018

0.1 B

C4023

A15

A14

A13

A12

A11

C4032

1025V KA

22P CH

C4030

C4028

C4029

0.1 B

0.047 B

C4026 0.1 B

1.6

1.6

1.6

3.3

0.0

3.3

LPFIN

LPFOP

RFVDD3

ADCVSS

RFRPDC

ADCVDD3

AVDD3216

IREF

IOA18 (PD)

IOA19 (PD)

IOWR# (PU)

A16 (PU)

HIGHA3 (PU)

HIGHA2 (PU)

HIGHA1 (PU)

IOCS# (PU)

IOA1 (PU)

IOA20/YUV0 (PD)

0.1

0.0

1.8

0.5

1.8

0.0

TP4019

TP4020

PCE#

A10A9A20A1AD0

XO

100GT02720

68

R4027

C4035

390P CH

0.47 B

R4022

9P CH

750K

C4033

C4031

0.047 B

0.1 B

C4034

1.0

1.3

0.0

0.1

3.3

1.8

LPFIP

IOOE#

PRD#

JITFN

LPFON

PLLVSS

PLLVDD3

IDACEXLP

MPEG/MICON IC

IC4001

MT1389FE/E-L

AD0

AD1

AD2

AD3

DVSS(1.8)

0.0

1.5

1.0

1.1

TP4023

TP4022

AD1

AD2

1.5

TP4024

TP4025

AD3

AD4

1.2

TP4021

X4001

27MHz

R4024

100K

C4037

R4025 68

C4036

0.1 B

0.0

1.8

0.7

0.9

191192193194195196197198199200201202203204205206207208209210211212213214215216

JITFO

XTALI

XTALO

RFVDD18

AD4

AD5

AD6

IOA21/YUV7/GPIO (PD)

0

1.6

1.6

TP4026

TP4027

AD5

AD6

R4056

(A21)

92_Y7

1

11P CHC4047

RFGND18

22

Page 19

5678

C4046 CLOSED TO 189/ 190PIN

V+3

LETTER

TP4043

TP4042

SQ

LE

1B

C4039

1.6

1.0

1.6

AVCM(A)

AL/SDATA2(A)

AR/SDATA1(A)

DVDD3

UWR# (PU)

URD# (PU)

3.3

2.6

3.1

NCNCNC

R4034 10K

R4036 10K

R4037 10K

R4039 10K

C4057 0.1 B

C4060

0.1 B

92_VCK

I/XP

SQUEEZE

1025V KA

0.0

0.0

3.3

3.3

ARS/GPIO(A)

ADACVSS1(A)

ADACVSS2(A)

ARF(SW)/GPIO(A)

UP1_2 (PU)

UP1_3 (PU)

UP1_4 (PU)

GPIO6/YUVCLK (PD)

3.2

2.9

0.0

3.1

33

R4029

R4030 33

B4011

MMZ1608

R102CT

FP_DI

FP_SCK

W805

C4063

0.1 B

C4059

0.0015 B

3.3

1.0

0.0

APLLVSS(A)

APLLCAP(A)

APLLVDD(A)

162

161

160

159 SPDIF

UP1_5 (PU)

UP1_6/SCL (PU)

UP1_7/SDA (PU)

3.0

3.3

3.3

NR4001

4D03WGJ0330T5E

STB

FP_DO

MMZ1608R102CT

NCNC NC

1.4

0.1

3.3

AKIN1(A)

ADVCM(A)

AADVDD(A)

FS(V)

VREF(V)

DACVDDC(V)

107

RD5

108

DVDD3

UP3_0/RXD (PU)

UP3_1/TXD (PU)

UP3_4/RXD/SCL (PU)

0.0

2.6

2.6

HDMI_SCL

V+3A

AMUTE

10006.3V YK

C40460.0068 B

W832

C4038

0.0

3.3

3.3

3.3

ADACVDD1(A)

ADACVDD2(A)

ALF(CTR)/GPIO(A)

ALS/SDATA0/GPIO(A)

(RF)

: RF SIGNAL ROUTE

: VIDEO SIGNAL ROUTE

(SY)

: S VIDEO SIGNAL ROUTE (Y ch)

(SC)

: S VIDEO SIGNAL ROUTE (C ch)

(R/CR)

: VIDEO SIGNAL ROUTE (R/CR ch)

(G/Y)

: VIDEO SIGNAL ROUTE (G/Y ch)

(B/CB)

: VIDEO SIGNAL ROUTE (B/CB ch)

(D)

: AUDIO DATA SIGNAL ROUTE

(DA)

: AUDIO SIGNAL ROUTE (Digital)

DVDD18

ALE (PU)

AD7

IOA0 (PU)

A17 (PU)

80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99

2.0

1.0

1.701.8

TP4030

TP4029

A0

AD7

A17

SDA

SCL

56

B4010

C4064

0.1 B

0.0

0.1

AKIN2(A)

UP3_5/TXD/SDA (PU)

3.3

0.0

RXD

TXD

HDMI_SDA

3.3

0.7

0.0

0.7

0.7

G/Y(V)

B/CB(V)

R/CR(V)

AADVSS(A)

DACVSSA(V)

DACVDDA(V)

MC_DATA/INT2#/YUV0/GPIO

(PD) ASDATA3/YUV6/GPIO

(PD) ASDATA2/YUV5/GPO

(PD) ASDATA1/YUV4/GPO

(PD) ASDATA0/YUV2/GPO

(PD) ALRCLK/YUV1/GPO

ACLK/YUV0/GPIO

ABCK/YUV0/GPIO

GPIO5/INT3#/SPBCK

GPIO4/SPLRCK

GPIO3/INT1#/SPDATA

ICE (PD)

PRST# (PU)IRDQM0#

INT0# (PU)

GPIO7/YUV3 (PD)

100

101 102103 104105 106 107108

0.1

3.3

1.9

3.3

2.6

NC

TP4033

TP4078

DQM0

R405522

92_Y3

THE DC VOLTAGE EACH PART WAS

NOTE :

MEASURED WITH THE DIGITAL TESTER

DURING PLAYBACK.

ANALOG AUDIO OUTPUT!!

DON'T CROSS VIDEO SIGNAL

ANALOG VIDEO OUTPUT!!NECESSARY SHIELD

V+3V

R4050

R4049

C4072

100P CH

C4066

1B

C4067

0.1 B

R4074

33

150 +-1%

MMZ1608R102CT

R405710K

4D03WGJ0330T5E

C4077

0.0082 B

RESET IC

IC4003

BD5229G-TR

TP4035

RESET

C4065

0.1 B

R4045 15K

3.3

0.0

0.7

163164165166167168169170171172173174175176177178179180181182183184185186187188189190

CVBS/C(V)

DACVSSB(V)

DACVDDB(V)

DVSS(3.3)

DVDD18

RA4

RA5

RA6

RA7

RA8

RA9

(PD) RA11

CKE

DVDD3

RCLK

RA3

RA2

RA1

DVDD18

RA0

RA10

BA1

BA0

RCS#

RAS#

CAS#

RWE#

DQM1

RD8

RD9

DVSS(1.8)

RD10

RD11

RD12

RD13

RD14

RD15

RD0

RD1

RD2

RD3

RD4

RD7

RD6

1.9

1.9

1.9

TP4077

DQ7

DQ6

DQ5

R4076

100

C4058

0.1 B

R4046

2.7K+-1%

0.0

1.3

1.3

3.3

1.6

DACVSSC(V)

3.3

0.0

0.0

3.3

1.6

1.6

1.6

1.6

1.9

0.0

0.0

0.0

1.8

1.2

1.2

1.2

1.2

1.2

1.2

1.2

1.9

3.3

1.7

1.5

2.0

1.2

1.8

1.1

0.1

1.6

1.6

2.0

1.5

3.0

3.3

1.9

1.9

1.9

0.0

1.9

1.9

1.9

1.9

0.0

1.9

1.9

1.9

1.9

1.9

1.9

109 110111 112113 114 115116 117 118119 120 121122 123 124125 126 127128 129130 131 132133 134 135136 137 138139 140 141142 143 144145 146147 148 149150 151 152153 154 155156 157 158159 160161 162

3.3

0.1 B

C4071

C4075 100PCH

C4073 0 .1 B

C4074 0.1 B

IR

DV-490V-S

NECESSARY SHIELD

(B/CB)

R4051

R4052

150 +-1%

150 +-1%

3

B4007

NR4003

4D03WGJ0220T5E

R4053 22

R4054 22

R4062 10

R4065 33

R4066 33

TP4055

TP4056

TP4057

TP4058

TP4059

R4072 33

TP4060

R4073 33

TP4061

NR4002

TP4062

TP4063

TP4064

TP4065

TP4066

TP4067

1.9

CT

V_OUT

VDD

123

3.3

3.3

R4075

1K

C4079

0.1 B

(R/CR)

(G/Y)

150 +-1%

TP4095

NC

45

VSS NC

0.0

NOTE :THIS SCHEMATIC DIAGRAM IS THE LATEST AT THE TIME

OF PRINTING AND SUBJECT TO CHANGE WITHOUT NOTICE

AL

AR

R/CR

B/CB

G/Y

C/V

PWDN#

1.8V

ASPDIF

92_Y6

92_Y5

92_Y4

92_Y2

92_Y1

92_Y0

92_ACLK

TROUT

TRIN

VSEL1

MA4

MA5

MA6

MA7

MA8

MA9

2

MA11

SDCKE

SDCLK

MA3

MA2

MA1

MA0

MA10

DBA1

DBA0

DCS#

DRAS#

DCAS#

DWE#

DQM1

DQ8

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

DQ0

DQ1 STB

DQ2

DQ3

DQ4

3.3V

FLDC-

-28V

FLDC+

FP_DO

FP_DI

FP_SCK

C4081 33P CH

C4082 100P CH

C4083 33P CH

C4084 100P CH

D_GND

V+3E

IR

W833

W834

C4114

FROM/TO POWER PORT

TO VIDEO JACK

(R/CR)

(B/CB)

(G/Y)

FROM/TO HDMI

TO AUDIO JACK

FROM/TO DISPLAY

TP4087

TP4088

TP4089

1B

TP4081

TP4082

TP4083

TP4084

TP4085

TP4086

V+3E

V+3

V+1R8

PWDN#

-28V

FLDCFLDC+

ADAC_GND

D_GND

R/CR

B/CB

G/Y

C/V

SQUEEZE

LETTER

I/XP

VSEL1

XO

92_Y7

92_Y6

92_Y5

92_Y4

92_Y3

92_Y2

92_Y1

92_Y0

92_VCK

92_ACLK

SCL

SDA

HDMI_SCL

HDMI_SDA

AL

AR

AMUTE

ASPDIF

GND

(CP601)

CP4002

00_6232_011_006_800+

FLDC-

11

-28V

10

FLDC+

9

DGND

8

DGND

7

V+3E

6

IR

STB

CLK

5

4

3

2

1

DO (F to M)

DI (M to F)

6

TP4091

TP4092

TP4093

TP4094

W842

C4080

RXD

TXD

V+3D

2206.3V YK

V+3

A 1/7

7

8

A

7/7A

B

5/7A

6/7A

C

4/7A

D

CP601

B

E

F

19

Page 20

1234

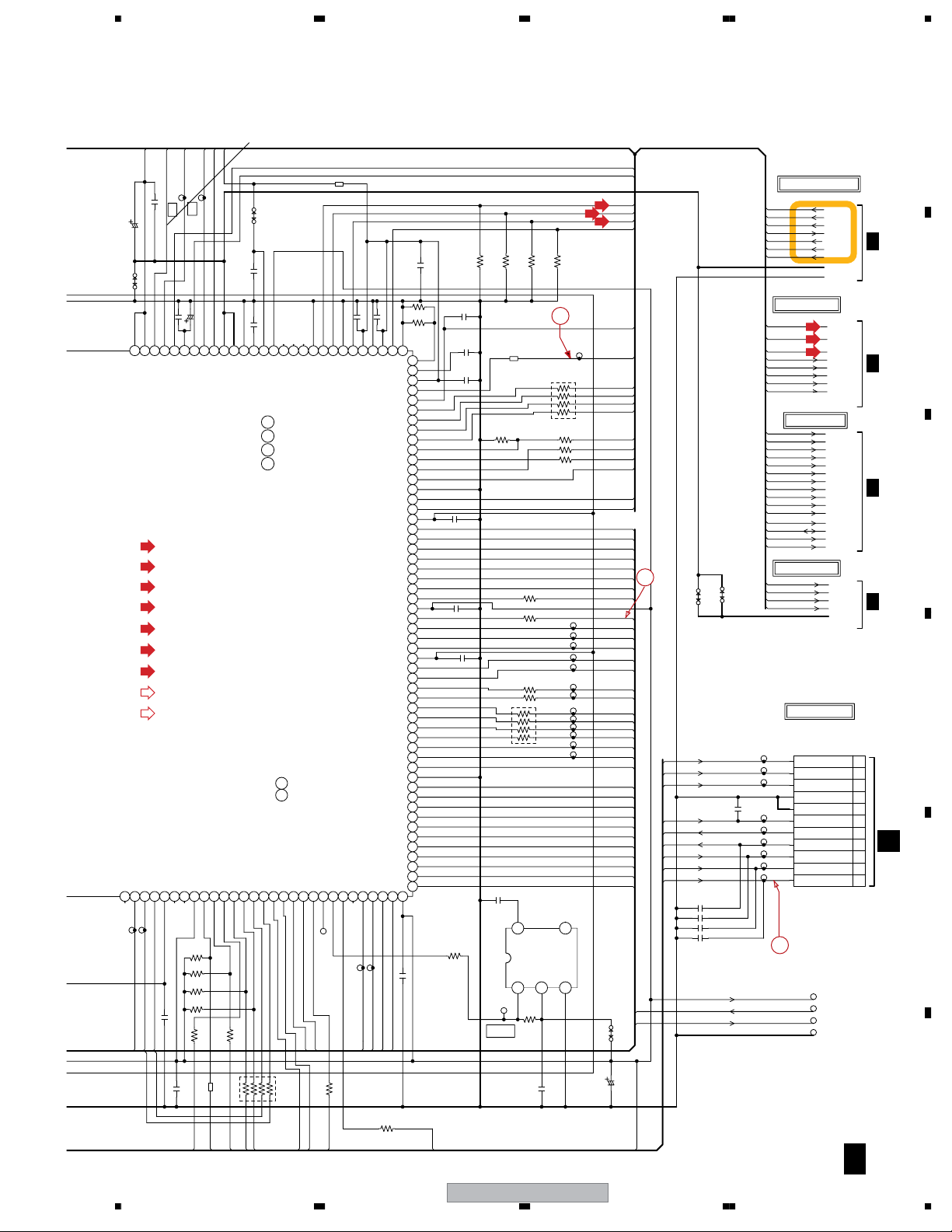

3.5 DVD MT PCB ASSY(2/7)

A

B

C

A 2/7

DVD MT PCB ASSY (A2I903A130)

MEMORY BLOCK

1/7A

D

1/7A

E

A

7/7

F

A 2/7

20

DV-490V-S

1234

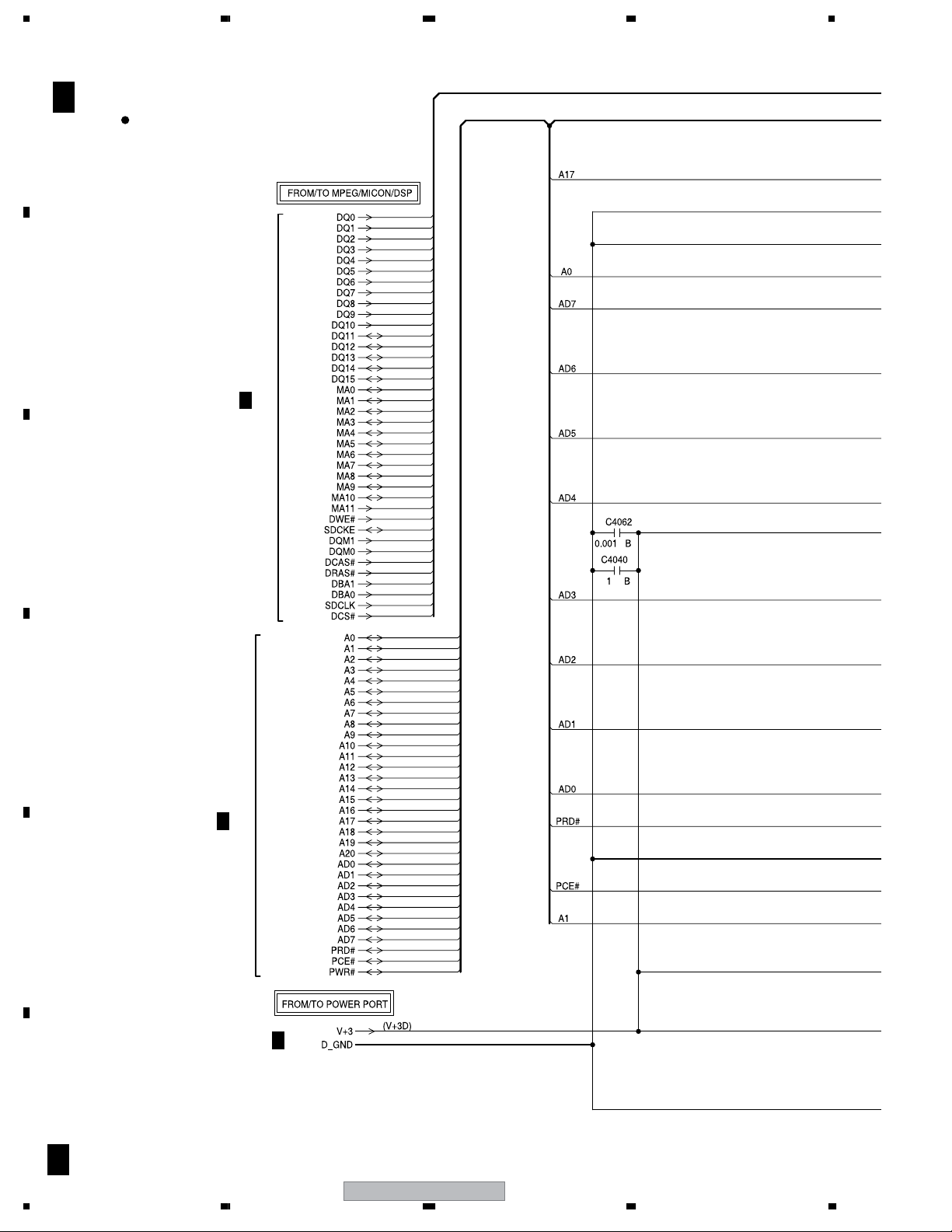

Page 21

5678

A

16Mbit FLASH IC

S29AL016D70TFI020

B

C

D

E

NOTE :THIS SCHEMATIC DIAGRAM IS THE LATEST AT THE TIME

OF PRINTING AND SUBJECT TO CHANGE WITHOUT NOTICE

56

NOTE : THE DC VOLTAGE EACH PART WAS

MEASURED WITH THE DIGITAL TESTER

DURING PLAYBACK.

DV-490V-S

7

F

A 2/7

21

8

Page 22

1234

3.6 DVD MT PCB ASSY(3/7)

A

B

C

A 3/7

PICK-UP(GOLD)

CP2301

LD07T2-24ND-03

1

2

3

4

5

6

7

8

9

10

11

12

13

To PICKUP

14

15

16

17

18

19

20

21

22

23

24

DVD PCB ASSY (A2I903A130)

LOADER/MOTOR DRIVE BLOCK

C2303

0.1 B

C2301

GND

F

VS

VCC

E

D

C

SW1(DVD/CD)

VRF(RF_OUT)

B

A

VR650(DVD)

VRCOM

VR780(CD)

GND

LD_CD(780)

PD/GND

LD_DVD(650)

GND

NC

TRKG DRV

TRKG RTN

FOCS DRV

FOCS RTN

TP2303

NC

JG001

JG002

JG003

JG004

JG005

JG006

JG007

0.1 B

0.1 B

(F)

C2302

(E)

(D)

(C)

(RF)

(B)

(A)

TP2304

TP2305

TP2306

TP2307

TP2308

TP2309

TP2302

TP2310

TP2311

TP2312

TP2313

TP2314

TP2315

TP2316

TP2317

TP2318

TP2319

(E)

(D)

(C)

(RF)

(B)

(A)

V+5S

V+5S

(F)

V20

IOA

MDI1

T+

T-

F+

F-

F

VCR_CTL

Q2307

2SK3018T106

G

4.9

0.0

0.2

D

0.0

R2307

G

100K

S

0.0

KTC3875S_Y_RTK

R2306

100K

E

D

C

RF

B

A

0.0

VCR_CTL

Q2306

2SK3018T106

D

S

5.0

VCR_CTL

Q2301

R2308

0.0

10K

0.0

IOA

R2309

10K

W864

W865

TRSO

LOADING

CP2302

00_6232_005_006_800+

5

LOAD-

4

LOAD+

3

CD2302

E

D

CD2301

D

OPEN

2

GND

1

CLOSE

SLED/SPINDLE

CP2303

00_6232_006_006_800+

SW(GND)

6

LIMIT SW

5

SLD-

4

SLD+

3

SPD-

2

SPD+

1

R2341

TP2324

TP2325

TP2326

TP2327

TP2328

10K

R2343

R2338

10K

10K

E

TP2320

TP2321

TP2322

TP2323

LOAD-

LOAD+

TROUT

TRIN

V+3F

C2323

0.1 B

LIMIT

MOT_SLED-

MOT_SLED+

MOT_SPDL+

V+3F

V+6A

OPO

OP-

OP+

R2319

MOT_SPDL-

C2322

150K

R2329

10K

R2311

R2310

2.7K

680K

R2342

0.0022 B

R2331

150K

1

C2314

1B

R2337

5.6K

0.0 4.0 3.3 3.3

S-GND

IC2301

MOTOR DRIVER

LA6565VR-TLM-E

FWD

123

0.0 5.9 0.10.0 0.8 2.6

MUTE1

VCONT

MOTOR DRIVER

REV

VCC2

C2312

1B

TRACK

TP2329

R2312

10K +-1%

1.4 1.4

4041424344

VIN4-

MUTE234

VLD-

NC

4

567

C2313

0.01 B

NC

VLD+

R2313

3839

VIN4

VD4+

10K +-1%

F

22

A 3/7

TROPEN

TRCLOSE

LOAD-

LOAD+

T-

DV-490V-S

1234

Page 23

5678

THE DC VOLTAGE EACH PART WAS

NOTE :

MEASURED WITH THE DIGITAL TESTER

DURING PLAYBACK.

CD

JG008

TP2341

R2320

LD DRIV for CD

Q2302

KTA1504S_Y_RTK

DVD

JG009

TP2342

R2321

LD DRIV for DVD

Q2303

KTA1504S_Y_RTK

VC2

NOTE : THIS SCHEMATIC DIAGRAM IS THE LATEST AT THE TIME

4.7

3.3

LD DRIV for CD

3.3

KTA1504S_Y_RTK

0

4.7

LD DRIV for DVD

3.1

2.5 2.5

KTA1504S_Y_RTK

2.0 2.0

TP2339

R2322

Q2304

R2323

Q2305

FOSO

TP2330

R2317

OF PRINTING AND SUBJECT TO CHANGE WITHOUT NOTICE

RF33

JG010

C2305

TP2332

0.1 B

TP2333

TP2334

V+3F

LDO1

LDO2

STBY

DMSO

SPINDLE

V1P4

4.7

3.3

3.3

0

4.7

3.1

FOCUS

10K +-1%

R2318

C2320

C2321

10K +-1%

W807

10010V YK

10010V YK

R2325

15K +-1%

(RF)

: RF SIGNAL ROUTE

(A)

(B)

(C)

(D)

(E)

(F)

(RF)

FROM/TO MPEG/MICON/DSP

V20

A

B

C

D

E

F

MDI1

LDO2

LDO1

IOA

V1P4

LIMIT

TROUT

TRIN

STBY

DMSO

FMSO

TRCLOSE

TROPEN

TRSO

FOSO

OPO

OP+

OPRF

FROM POWER PORT

V+3F

V+5S

V+6A

D_GND

M_GND

A

A

B

1/7A

C

7/7

D

NC

1.4

VREF-IN

VD4-

89

2.5 2.5 2.6 0.0 0.0 2.72.5 5.9 5.9 1.4 1.4 1.43.91.4

2.2

R2335

C2311

0.01 B

T+

NC

0.0

NC

REG-OUT

VREF-OUT

VD3+

VD3-

PGND2

10 11 12 13 14 15 16 17 18 19 20 21 22

2.2

R2334

C2310

0.01 B

F-

F+

56

NC

REG-IN

PGND1

NC

VIN-OP

VIN+OP NC

VD2+

VD2-

0.1 B

C2309

18

MOT_SPDL-

MOT_SPDL+

R2316

NC

3031323334353637

VO_OP

VD1-

C2308

0.1 B

R2332

MOT_SLED-

MOT_SLED+

VIN3

VD1+

10K+-1%

1.41.4

1.2

VIN3-

NC

R2333

C2307

1.2

NC

VCC1

1B

TP2337

TP2338

VIN2

VCCS

C2306 10010V YK

R2326

4.7K

1.41.41.1

VIN2-

VIN2+

VIN1+A

VIN1-A

DV-490V-S

23242526272829

NC

VIN 1

R2328

10K+-1%

R2330

10K+-1%

R2327

4.7K

TP2336

SLED

7

E

FMSO

F

A 3/7

23

8

Page 24

1234

3.7 DVD MT PCB ASSY(4/7)

A 4/7

A

FROM POWER PORT

B

C

7/7

A

DVD MT PCB ASSY (A2I903A130)

AUDIO JACK BLOCK

V+5

D_GND

V+12AT

V+12

V+5

C8036

1B

B8004

MMZ1608R102CT

R8037

1.8K

5.0

(DA)

2.8

2.1

3.9K

R8036

R8038

R8035

2.2K

COAXIAL DRIV

Q8005

KTC3875S_Y_RTK

C8038

R8039

75

150V KA

220

R8040

100K

C8042

11

100P CH

C8074

330P CH

W840

COAXIAL

J7301_1

RCA-125-01

H

2

ASPDIF

(DA)

1

AMUTE

E

R8044

8.2K

FROM MPEG/MICON/DSP

1/7A

D

E

AMUTE

ASPDIF

AL

AR

GND

(DA)

R8060

470K

AL

AR

C8053

4716V NA

C8051

4716V NA

R8059

10K +-1%

R8049

10K +-1%

R8048

470K

GND

F

24

A 4/7

DV-490V-S

1234

Page 25

5678

ZERO MUTE(H:ON)

Q8010

KRC407-RTK/P

0.1

0

2.7

PWDN#

R8014

R8065

4.7K

XAMUTE(L:ON)

Q8013

KRC407-RTK/P

2.7

THE DC VOLTAGE EACH PART WAS MEASURED

NOTE :

WITH THE DIGITAL TESTER DURING PLAYBACK.

V+12AT

4.7K

4.7K

R8051

0.1

0

JACK MUTE(H:ON)

Q8014

KTA1504S_Y_RTK

0.30.1

0

R8056

4.7K

NOTE : THIS SCHEMATIC DIAGRAM IS THE LATEST AT THE TIME

OF PRINTING AND SUBJECT TO CHANGE WITHOUT NOTICE

CAUTION: DIGITAL TRANSISTOR

(DA)

: AUDIO SIGNAL ROUTE (Digital)

: AUDIO SIGNAL ROUTE (L ch)

A

B

C

V+12

W880

R8057

22K

C8056

C8057

560P CH

560P CH

C8058

C8059

R8061

R8063

27K +-1%

0.1 B

0.1 B

10K

R8067

27K +-1%

C8069

R8066

68P CH

10K

6.3 6.3 6.30

-VS

567 8

6.3 6.3 6.3

C8066

10010V YK

+

-

C8067

68P CH

R8069

22K

+

12.5

1234

+VS

C8073

4716V YK

IC8003

RC4580IDR

AUDIO AMP IC

C8070

4716V YK

C8072

0.1 B

R8073

R8074

22K

22K

R8080

220 +-1%

R8081

470

R8078

470

R8079

220 +-1%

R8082

220+-1%

R8076

470

R8077

220 +-1%

-1.2

-1.2

R8083

470

R8085

220 +-1%

0

MUTE SW

Q8018

KTC2875-B

0

0

MUTE SW

Q8019

KTC2875-B

0

-1.1

R8084

220 +-1%

-1.1

0

MUTE SW

Q8021

KTC2875-B

0

0

MUTE SW

Q8020

KTC2875-B

0

9

C8077

330P CH

C8070

C8078

330P CH

10

AUDIO OUT

J8003

RCA-207B-02

L R

23

1

E

H1H2

AUDIO_L

AUDIO_R

D

E

F

56

DV-490V-S

A 4/7

25

7

8

Page 26

1234

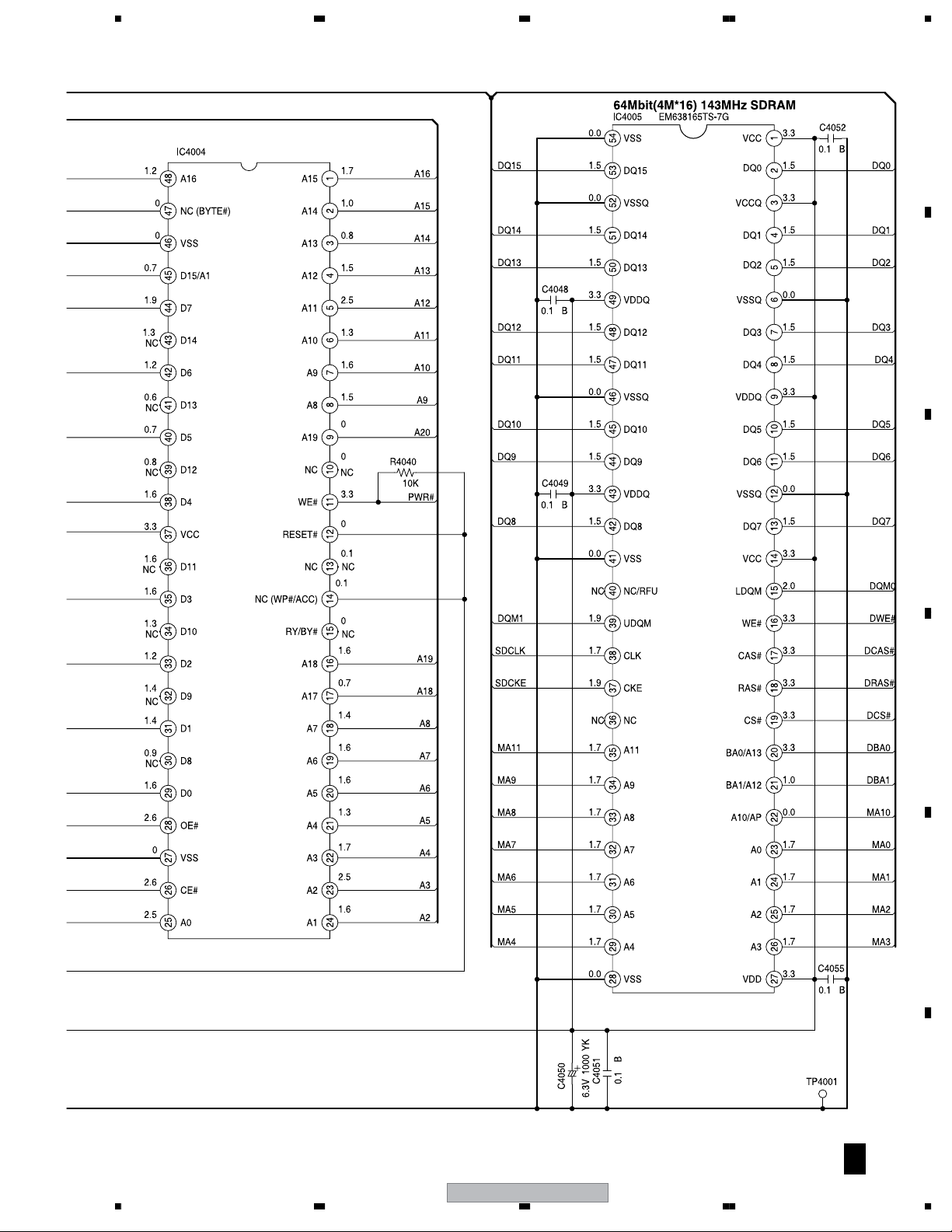

3.8 DVD MT PCB ASSY(5/7)

A

B

C

D

A 5/7

FROM MPEG/MICON/DSP

1/7A

FROM POWER PORT

A

7/7

DVD PCB ASSY (A2I903A130)

VIDEO JACK BLOCK

LETTER

SQUEEZE

VSEL1

V+6A

V+5

D_GND

I/XP

R/CR

B/CB

G/Y

C/V

C/V

SQUEEZE

LETTER

(R/CR)

(B/CB)

(G/Y)

(SC)

YCMIX

VSEL1

G/Y

B/CB

R/CR

I/XP

P-H/I-L

C7309

1B

R7302

1K

P-H/I-L

Q7302

KRC407-RTK/P

W886

C7307

1B

C7308

1B

3.3

V+5V

(SC)

W868

C7310

1B

0

0

C7303

4706.3V YK

C7305

0.1 B

(B/CB)

(R/CR)

C7306

1B

(SY)

(GY)

C7311

10010V YK

C7312

0.1 B

(SC)

VIDEO DRIVER 6CH IC

IC7301 LA73054

5.0

1101112131415161718

VCC1

0

2

CVBS in

0

3

SQ

0

456789

LE

0

MUTE1

(ON=H,OFF=L)

2.8

C in

0

GND11

2.9

Y1 in

4.1

YC-MIX

(MIX=H,OFF=L)

0

IN SW

(RGB=H,YUV=L)

2.9

Y2 in

0

MUTE2

(ON=H,OFF=L)

0

LPF

(P=H,I=L)

2.8

CB in

0

AMP2

(9dB=H,6dB=L)

2.8

CR in

0

GND12

2.0

REG

AMP1

(9dB=H,6dB=L)

DRIVE1

(1D=H,2D=L)

VCC21

CVBS out

GND21

C out

C-DC out

GND22

Y1 out

GND23

GND24

Y2 out

VCC22

CB out

GND25

CR out

GND26

DRIVE2

(1D=H,2D=L)

0

0

0

2.6

0

2.5

0

30 31 32 33 34 35 36

0

2.6

0

0

2.7

5.0

2.5

0

2.5

0

20 21 22 23 24 25 26 27 28 29

0

19

+5V

TP7302

GND

TP7303

C7304

0.1 B

C7313

0.1 B

(GY)

(B/CB)

(R/CR)

E

F

26

A 5/7

: VIDEO SIGNAL ROUTE

(SY)

: S VIDEO SIGNAL ROUTE (Y ch)

(SC)

: S VIDEO SIGNAL ROUTE (C ch)

(R/CR)

: VIDEO SIGNAL ROUTE (R/CR ch)

(G/Y)

: VIDEO SIGNAL ROUTE (G/Y ch)

(B/CB)

: VIDEO SIGNAL ROUTE (B/CB ch)

(D)

: AUDIO DATA SIGNAL ROUTE

(DA)

: AUDIO SIGNAL ROUTE (Digital)

W887

W888

: AUDIO SIGNAL ROUTE (L ch)

D_GND

DV-490V-S

1234

Page 27

5678

THE DC VOLTAGE EACH PART WAS MEASURED

NOTE :

WITH THE DIGITAL TESTER DURING PLAYBACK.

(G/Y)

(B/U)

(R/V)

NOTE : THIS SCHEMATIC DIAGRAM IS THE LATEST AT THE TIME

OF PRINTING AND SUBJECT TO CHANGE WITHOUT NOTICE

SQUEEZE

B7301

MMZ1608R102CT

VSEL1

B7302

AUDIO_R

MMZ1608R102CT

AUDIO_L

G/Y_OUT

B/U_OUT

R/V_OUT

P-H/I-L_RGB-H

ASP/FS

(G/Y)

(B/U)

(R/V)

CAUTION: DIGITAL TRANSISTOR

TO POWER

VIDEO/AUDIO for 21PIN

CP7301

(CP503)

IMSA-9604S-12C

AUDIO L

AUDIO R

GND

GND

RGB-H

FS

CVBS

GND

GND

1

G

2

3

B

4

CP503

5

R

6

7

8

E 1/2

9

10

11

12

A

B

C

(R/CR)

(GY)

(B/CB)

VSEL1

YCMIX

V+6A

4CH BUS SW IC

IC7302

SN74CBT3257PWR

3.33.3

S

1

1.8

1B1

2345678

2.4

1B2

2.6

1A

1.3

2B1

2.5

2B2

2.5

2A

0

GND

VCC

/OE

4B1

4B2

3B1

3B2

CVBS_OUT

(SY)

(SC)

W889

TP7304

5.9

0

C7315

0.001 B

1K

5.9

0

5.0

4A

1.3

2.4

10 11 12 13 14 15 16

2.4

3A

9

R7305

C7316

B7304

R7319

R7315

U_OUT

V_OUT

4706.3V YK

C7317

B7305

MMZ1608R102CT

1.2K

75 +-1%

R7316

14

U

23

CVBS/Y/U/V

J7302

RCA-405A-08

1

E

4706.3V YK

10006.3V YK

C7318

MMZ1608R102CT

1.2K

R7320

R7317

75 +-1%

75 +-1%

12

15

V

CVBS

H1H2EH1H2

56

4

Y_OUT

C7319

R7318

Y

10006.3V YK

R7321

75 +-1%

13

D

1.2K

E

56

DV-490V-S

F

A 5/7

27

7

8

Page 28

1234

3.9 DVD MT PCB ASSY(6/7)

A

B

C

D

A 6/7

DVD PCB ASSY (A2I903A130)

HDMI BLOCK

(92_DV33)

FROM POWER PORT

D_GND

7/7A

FROM/TO MPEG/MICON/DSP

1/7A

V+3H

DVDD18

V+5H

92_VCK

92_Y0

92_Y1

92_Y2

92_Y3

92_Y4

92_Y5

92_Y6

92_Y7

SCL

SDA

PWDN#

ASPDIF

92_ACLK

HDMI_SCL

HDMI_SDA

XO

B5905

MMZ1608R102CT

92_VCK

92_Y0

92_Y1

92_Y2

92_Y3

92_Y4

92_Y5

92_Y6

92_Y7

SCL

SDA

W850

W851

VCK

TP5931

C5901

0.1 B

C5902

0.1 B

NC

NC

NC

NC

NC

NC

NC

NC

TP5916

TP5917

TP5927

TP5926

92_ABCK

92_ALRCK

DVDD18

0.0

0.0

1.8

0.0

110111213141516171819 220

2.6

0.0

C1 (PD)

0.0

456

C2 (PD)

0.0

C3 (PD)

0.0

C4 (PD)

0.0

C5 (PD)

0.0

C6 (PD)

0.0

9

C7 (PD)

3.4

DVDD33

1.5

VCK

0.0

DVSS

1.0

Y0 (PD)

1.0

Y1 (PD)

1.0

Y2 (PD)

1.0

Y3 (PD)

1.5

Y4 (PD)

1.7

Y5 (PD)

1.0

1.1

21 22 23 24 25 26 27 28 29330 31 32 33

3.2

DVDD18SSCK

ALRCK

21C0 (PD)

19

20

SSD

3.2

ABCK

DVSS

Y6 (PD)

Y7 (PD)

DVD18

1.8

3.3

TP5925

92_ACLK

92_SDATA0

1.6

AD0

ACK

/RST (PD)

/PWDN (PU)

3.3

TP5915

92_SDATA1

92_SDATA2

92_SDATA3

2.6

2.6

2.6

AD1

AD2

HDMI TRANSMITTER

MT1392E/C-L

CLK

INT

1.1

0.0

0.0

ASPDIF

2.6

AD3

IC5901

DVSS

0.0

SPDIF

A7/GPO0 (PD)

92_R/CR

1.1

1.7

R

A6/GPO1 (PD)

0.0

92_G/Y

92_B/CB

0.0

1.1

6869770717273747576777879880

G

B

AVSS

TRAP2/GPO2 (PD)

TRAP1/GPO3 (PD)

TRAP0/GPO4 (PD)

NCNCNCNCNC

0.0

0.0

0.0

1.1

E

F

28

A 6/7

C5903

NO MOUNT(READY)

C5905

0.001 B

0.1 B

C5908

C5904

R5922

10010V YK

PWDN#

1K

R5923

0.1 B

R5906

820

100

XO

DV-490V-S

1234

Page 29

5678

C5925

476.3V KA

C5919

C5918 0.1 B

3.3

AVDD

MSCK/GPO5

34 35 36 37 38 39 40

NC

0.0

0.1 B

W829

92DAC_AVDD3

C5917 0.1 B

3.3

0.0