PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2008

CD RDS RECEIVER

ORDER NO.

CRT4230

DEH-1100MPB/XN/EW5

DEH-1100MPB

DEH-1100MP

DEH-1120MP

This service manual should be used together with the following manual(s):

Model No. Order No. Mech.Module Remarks

CX-3195 CRT3815 S10.5COMP2 CD Mech. Module : Circuit Descriptions, Mech. Descriptions, Disassembly

/XN/EW5

/XN/EW5

/XN/EW5

For details, refer to "Important Check Points for Good Servicing".

K-ZZZ. OCT. 2008 Printed in Japan

1234

1234

C

D

F

A

B

E

SAFETY INFORMATION

CAUTION:

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE

SPECIFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

WARNING!

The AEL (accessible emission level )of the laser power output is less than CLASS 1

but the laser component is capable of emitting radiation exceeding the limit for

CLASS 1.

A specially instructed person should do servicing operation of the apparatus.

Laser diode characteristics

Wave length : 785 nm to 814 nm

Maximum output : 1 190 µW(Emitting period : unlimited)

Additional Laser Caution

Transistors Q101 in PCB drive the laser diodes.

When Q101 is shorted between their terminals, the laser diodes will radiate beam.

If the top cover is removed with no disc loaded while such short-circuit is continued,

the naked eyes may be exposed to the laser beam.

- Safety Precautions for those who Service this Unit.

When checking or adjusting the emitting power of the laser diode exercise caution in order to get safe, reliable

results.

Caution:

1. During repair or tests, minimum distance of 13 cm from the focus lens must be kept.

CAUTION

CLASS 1M INVISIBLE LASER RADIATION WHEN OPEN. DO NOT VIEW DIRECTLY WITH OPTICAL INSTRUMENTS

2. During repair or tests, do not view laser beam for 10 seconds or longer.

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer.

Qualified technicians have the necessary test equipment and tools, and have been trained to properly and safety

repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the warranty.

If you are not qualified to perform the repair of this product properly and safety, you should not risk trying to do so

and refer the repair to a qualified service technician.

Where in a manufacturer’s service documentation, for example in circuit diagrams or lists

of components, a symbol is used to indicate that a specific component shall be replaced only

by the component specified in that documentation for safety reasons, the following symbol shall

be used:

2

DEH-1100MPB/XN/EW5

5678

56

7

8

C

D

F

A

B

E

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

a Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

DEH-1100MPB/XN/EW5

3

1234

1234

C

D

F

A

B

E

CONTENTS

SAFETY INFORMATION..................................................................................................................................... 2

1. SERVICE PRECAUTIONS............................................................................................................................... 5

1.1 SERVICE PRECAUTIONS ........................................................................................................................ 5

1.2 NOTES ON SOLDERING.......................................................................................................................... 5

2. SPECIFICATIONS............................................................................................................................................ 6

2.1 SPECIFICATIONS ..................................................................................................................................... 6

2.2 DISC/CONTENT FORMAT ........................................................................................................................ 7

2.3 PANEL FACILITIES.................................................................................................................................... 7

2.4 CONNECTION DIAGRAM ......................................................................................................................... 9

3. BASIC ITEMS FOR SERVICE........................................................................................................................ 10

3.1 CHECK POINTS AFTER SERVICING..................................................................................................... 10

3.2 PCB LOCATIONS .................................................................................................................................... 10

3.3 JIGS LIST .................................................................................................................................................11

3.4 CLEANING................................................................................................................................................11

4. BLOCK DIAGRAM.......................................................................................................................................... 12

5. DIAGNOSIS.................................................................................................................................................... 16

5.1 OPERATIONAL FLOWCHART................................................................................................................ 16

5.2 ERROR CODE LIST................................................................................................................................ 17

5.3 CONNECTOR FUNCTION DESCRIPTION............................................................................................. 18

6. SERVICE MODE............................................................................................................................................ 18

6.1 DISPLAY TEST MODE ............................................................................................................................ 18

6.2 CD TEST MODE...................................................................................................................................... 19

7. DISASSEMBLY .............................................................................................................................................. 20

8. EACH SETTING AND ADJUSTMENT ........................................................................................................... 23

8.1 CD ADJUSTMENT................................................................................................................................... 23

8.2 CHECKING THE GRATING AFTER CHANGING THE PICKUP UNIT.................................................... 24

9. EXPLODED VIEWS AND PARTS LIST.......................................................................................................... 26

9.1 PACKING ................................................................................................................................................. 26

9.2 EXTERIOR(1) .......................................................................................................................................... 28

9.3 EXTERIOR(2) .......................................................................................................................................... 30

9.4 CD MECHANISM MODULE..................................................................................................................... 32

10. SCHEMATIC DIAGRAM............................................................................................................................... 34

10.1 TUNER AMP UNIT(GUIDE PAGE)........................................................................................................ 34

10.2 KEYBOARD UNIT.................................................................................................................................. 40

10.3 CD MECHANISM MODULE(GUIDE PAGE).......................................................................................... 42

10.4 WAVEFORMS........................................................................................................................................ 48

11. PCB CONNECTION DIAGRAM.................................................................................................................... 50

11.1 TUNER AMP UNIT................................................................................................................................. 50

11.2 KEYBOARD UNIT.................................................................................................................................. 54

11.3 CD CORE UNIT(S10.5COMP2)............................................................................................................. 56

12. ELECTRICAL PARTS LIST.......................................................................................................................... 58

4

DEH-1100MPB/XN/EW5

5678

56

7

8

C

D

F

A

B

E

1. You should conform to the regulations governing

the product (safety, radio and noise, and other

regulations), and should keep the safety during

servicing by following the safety instructions

described in this manual.

2. Before disassembling the unit, be sure to turn off

the power. Unplugging and plugging the connectors

during power-on mode may damage the ICs inside

the unit.

3. To protect the pickup unit from electrostatic discharge

during servicing, take an appropriate treatment

(shorting-solder) by referring to "the DISASSEMBLY".

4. After replacing the pickup unit, be sure to check the

grating.

5. Be careful in handling ICs. Some ICs such as MOS

type are so fragile that they can be damaged by

electrostatic induction.

For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 C.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 C in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

1. SERVICE PRECAUTIONS

1.1 SERVICE PRECAUTIONS

1.2 NOTES ON SOLDERING

DEH-1100MPB/XN/EW5

5

1234

1234

C

D

F

A

B

E

2. SPECIFICATIONS

General

Power source......................... 14.4 V DC (10.8 V to 15.1 V

allowable)

Grounding system................ Negative type

Max. current consumption

...............................................10.0 A

Dimensions (W × H × D):

DIN

Chassis.................. 178 mm × 50 mm × 162

mm

Nose........................ 188 mm × 58 mm × 15 mm

D

Chassis.................. 178 mm × 50 mm × 162

mm

Nose........................ 170 mm × 48 mm × 15 mm

Weight ..................................... 1.3 kg

Audio

Maximum power output ....... 50 W × 4

Continuous power output ... 22 W × 4 (50 Hz to 15 000

Hz, 5% THD, 4

load, both

channels driven)

Load impedance .................... 4

(4 to 8 allowable)

Preout max output level ....... 2.0 V

Tone controls:

Bass

Frequency.............. 100 Hz

Gain .........................±13 dB

Mid

Frequency.............. 1 kHz

Gain ......................... ±12 dB

Treble

Frequency.............. 10 kHz

Gain ......................... ±12 dB

CD player

System .................................... Compact disc audio system

Usable discs .......................... Compact disc

Signal-to-noise ratio............. 94 dB (1 kHz) (IEC-A net-

work)

Number of channels ............ 2 (stereo)

WMA decoding format ....... Ver. 7, 7.1, 8, 9, 10, 11 (2ch

audio)

(Windows Media Player)

MP3 decoding format ..........MPEG-1 & 2 Audio Layer 3

WAV signal format ................ Linear PCM & MS ADPCM

FM tuner

Frequency range................... 87.5 MHz to 108.0 MHz

Usable sensitivity.................. 11 dBf (0 .7 μV/75

, mono,

S/N: 30 dB)

Signal-to-noise ratio............. 72 dB (IEC -A network)

MW tuner

Frequency range................... 531 kHz to 1 602 kHz

Usable sensitivity.................. 25 μV (S/N: 20 dB)

Signal-to-noise ratio............. 62 dB (IEC -A network)

LW tuner

Frequency range................... 153 kHz to 281 kHz

Usable sensitivity.................. 28 μV (S/N: 20 dB)

Signal-to-noise ratio............. 62 dB (IEC -A network)

Note

Specifications and the design are subject to modifications without notice due to improvements.

Backup current ....................... 2 mA or less

2.1 SPECIFICATIONS

6

DEH-1100MPB/XN/EW5

5678

56

7

8

C

D

F

A

B

E

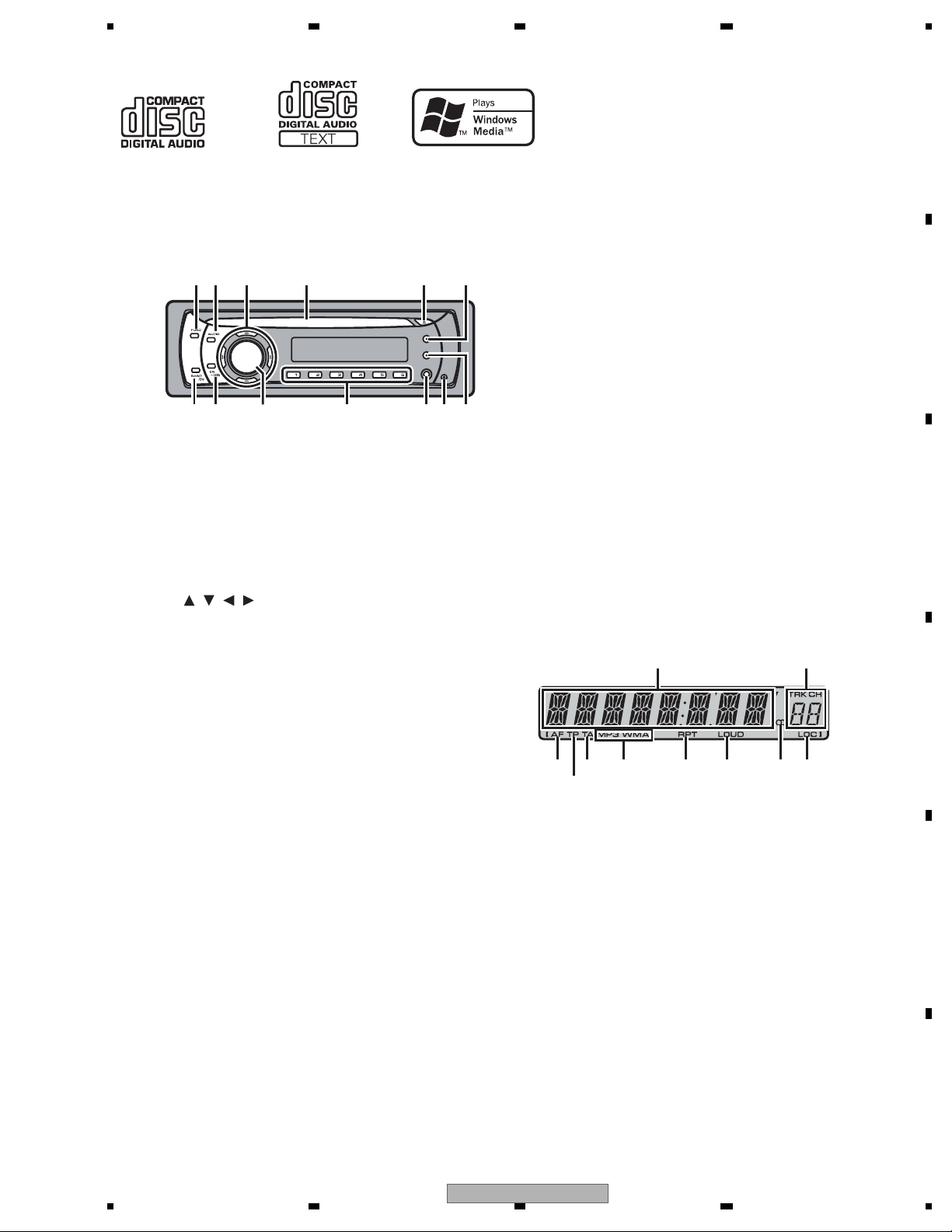

What ’s what

Head unit

12 4 5 6

d c a

89 7

3

b

1 FUNCTION button

Press to recall the function menu when operating a source.

2 AUDIO button

Press to select various sound quality controls.

3

/ / / buttons

Press to perform manual seek tuning, fast

forward, reverse and track search controls.

Also used for controlling functions.

4 Disc loading slot

Insert a disc to play.

5 EJECT button

Press to eject a CD from your built-in CD

player.

6 DISPLAY button

Press to select different displays.

Press and hold to scroll through the text information.

7 TA button

Press to turn TA function on or off. Press

and hold to turn AF function on or off.

8 DETACH button

Press to remove the front panel from the

head unit.

9 AUX input jack (3.5 mm stereo jack)

Use to connect an auxiliary device.

a 1 to 6 buttons

Press for preset tuning.

b SOURCE button, VOLUME

This unit is turned on by selecting a source.

Press to cycle through all the available

sources.

Press and hold to recall the initial setting

menu when the sources are off.

Rotate it to increase or decrease the volume.

c EQ button

Press to select various equalizer curves.

Press and hold to turn loudness on or off.

d BAND button

Press to select among MW/LW and two FM

bands and cancel the control mode of functions.

Display indication

6

3

2

1

5

4

7 8 9 a

1 Main display section

Shows the various information such as

band, play time, and other setting.

• Tuner

Band and frequency are displayed.

• RDS

Program service name, PTY information

and other literal information are displayed.

• Built-in CD Player

Elapsed playback time and literal information are displayed.

2 Preset number/track number indicator

Shows the track number or preset number.

2.2 DISC/CONTENT FORMAT

2.3 PANEL FACILITIES

DEH-1100MPB/XN/EW5

7

1234

1234

C

D

F

A

B

E

• If a track number 100 or more is selected,

on the left of the track number indica-

tor will light.

3 AF indicator

Appears when AF (alternative frequencies

search) function is on.

4 TP indicator

Appears when a TP station is tuned in.

5 TA indicator

Appears when TA (traffic announcement

standby) function is on.

6 MP3/WMA indicator

7 RPT indicator

Shows when repeat play is turned on.

8 LOUD indicator

Appears when loudness is on.

9

(stereo) indicator

Appears when the selected frequency is

being broadcast in stereo.

a LOC indicator

Appears when local seek tuning is on.

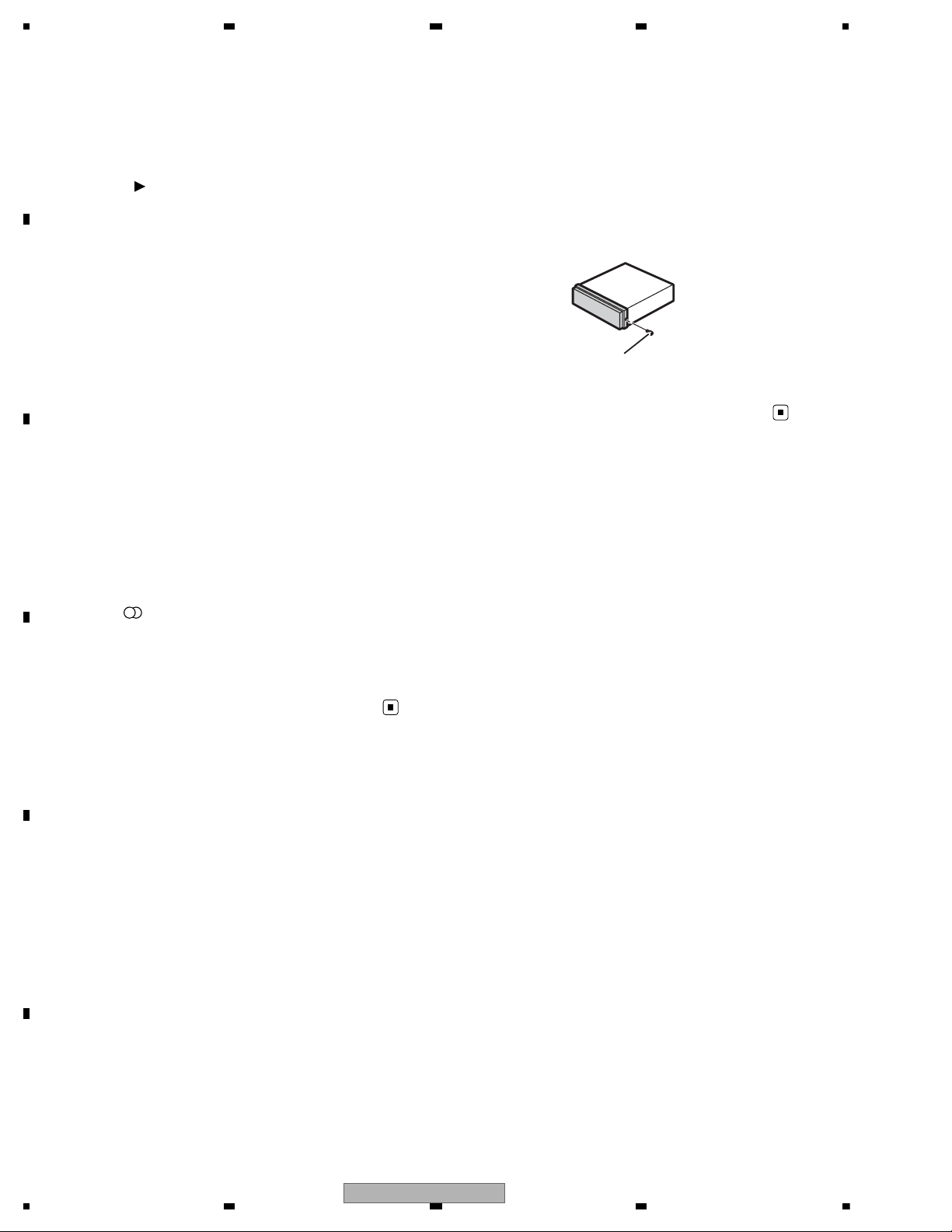

Fastening the front panel

If you do not plan to detach the front panel,

the front panel can be fastened with supplied

screw.

Screw

BPZ20P080FTC

8

DEH-1100MPB/XN/EW5

5678

56

7

8

C

D

F

A

B

E

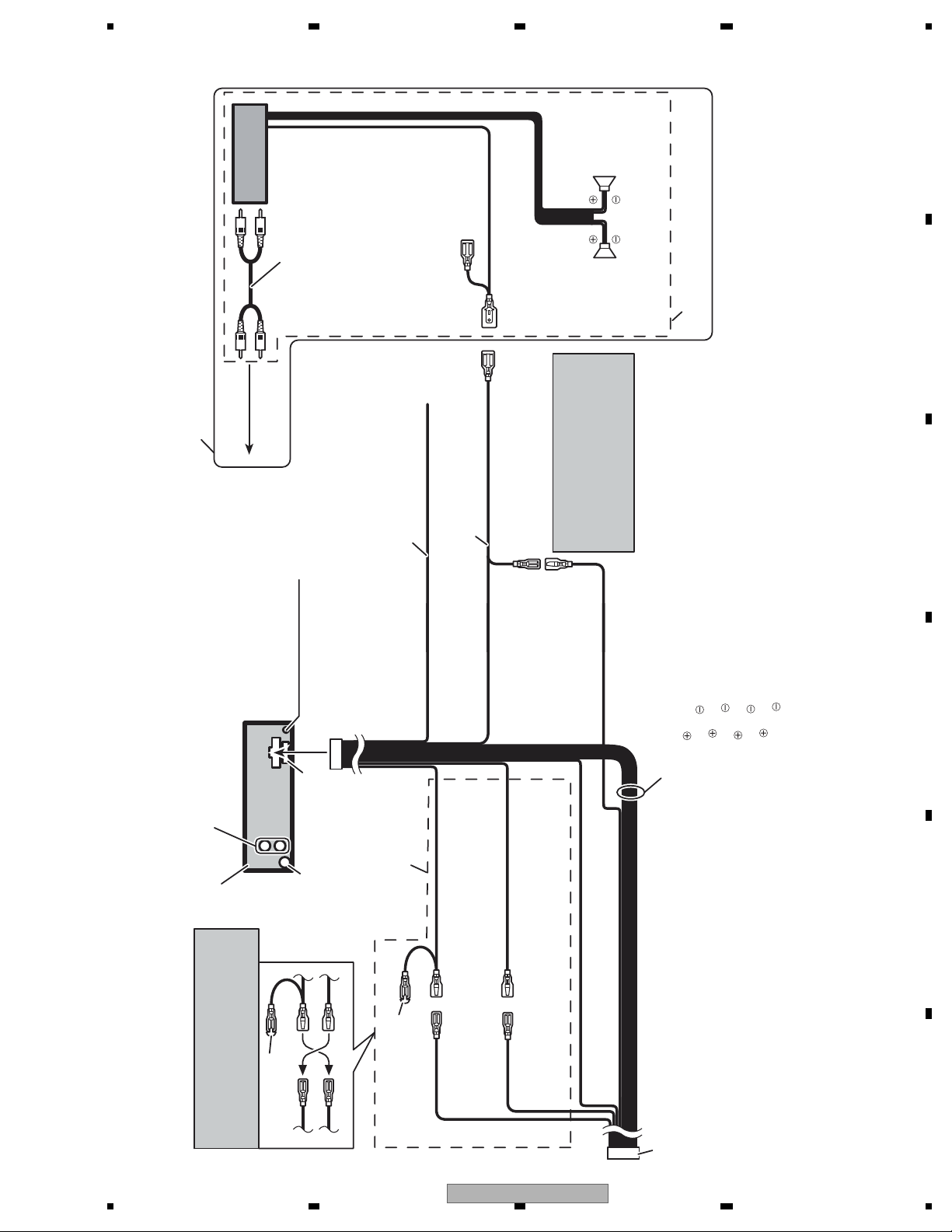

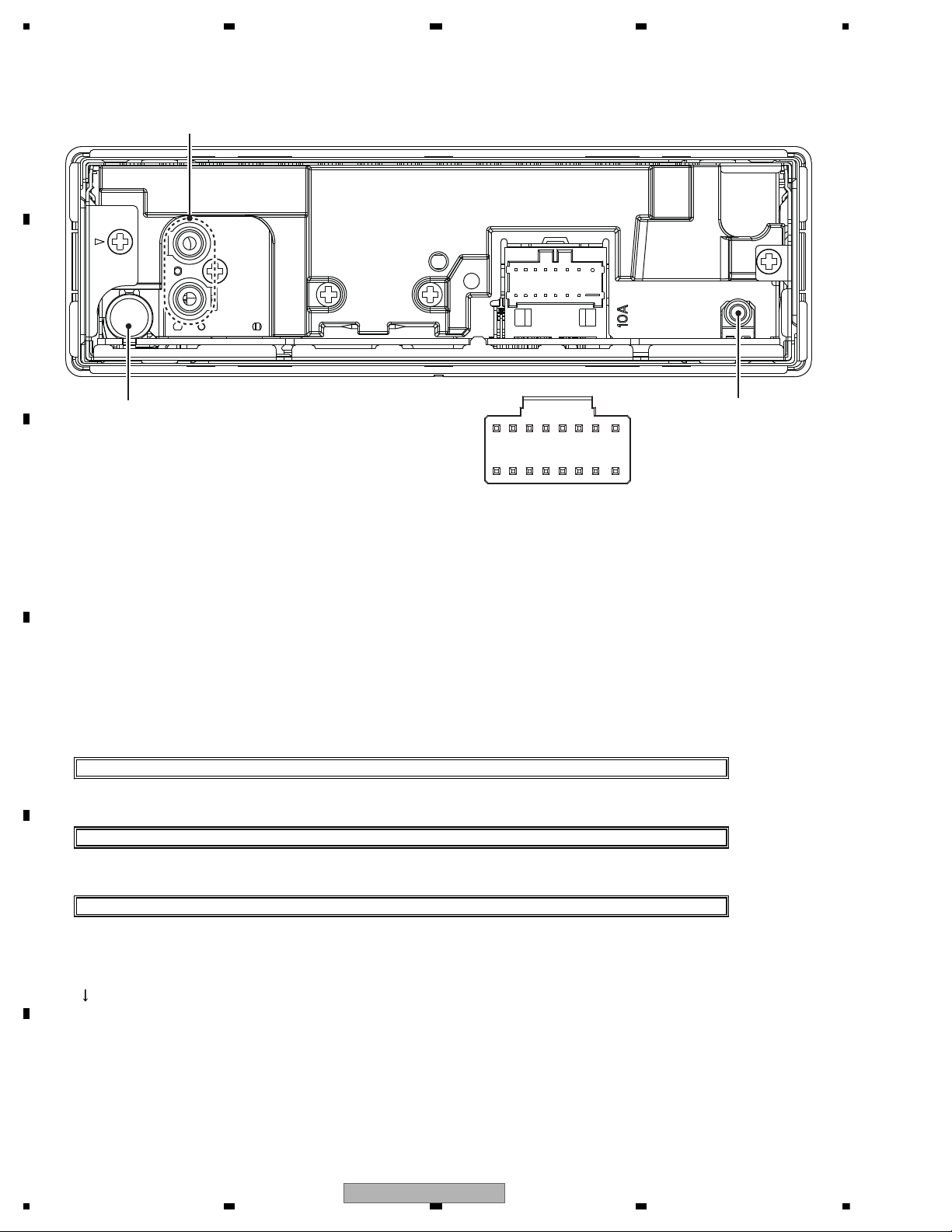

1*

2*3*

4*5*

1 This product

2 Antenna jack

3 Fuse (10 A)

4 Note:

Depending on the kind of vehicle, the function

of 3* and 5* may be different. In this case, be

sure to connect 2* to 5* and 4* to 3*.

5 Connect leads of the same

color to each other.

6 Cap (1*)

Do not remove cap if this

terminal is not in use.

7 Yellow (3*)

Back-up

(or accessory)

8 Yellow (2*)

Connect to the constant 12 V supply

terminal.

9 Red (5*)

Accessory

(or back-up)

10 Red (4*)

Connect to terminal controlled by

ignition switch (12 V DC).

11 Black (chassis ground)

Connect to a clean, paint-free metal location.

12 ISO connector

In some vehicles, the ISO connector may be

divided into two. In this case, be sure to

connect to both connectors.

13 Speaker leads

White: Front left

White/black: Front left

Gray: Front right

Gray/black: Front right

Green: Rear left

Green/black: Rear left

Violet: Rear right

Violet/black: Rear right

19 Rear output

(DEH-1120MP/DEH-1100MPB/

DEH-1100MP)

16 Blue/white

Connect to system control terminal of the

power amp (max. 300 mA 12 V DC).

17 Blue/white (7*)

Connect to auto-antenna relay control

terminal (max. 300 mA 12 V DC).

18 Blue/white (6*)

The pin position of the ISO connector will

differ depends on the type of vehicle.

Connect 6* and 7* when Pin 5 is an

antenna control type. In another type of

vehicle, never connect 6* and 7*.

14 Wired remote input

Hard-wired remote control adaptor

can be connected (sold separately).

15 Yellow/black

If you use an equipment with Mute function,

wire this lead to the Audio Mute lead on that

equipment. If not, keep the Audio Mute lead

free of any connections.

20 This diaglam is for DEH-1120MP/DEH-1100MPB/DEH-1100MP.

22 Connect with RCA cables

(sold separately)

23 Power amp

(sold separately)

24 System remote control

26 Right25 Left

27 Rear speaker 27 Rear speaker

28 Perform these connections when using

the optional amplifier.

21 To Rear output

2.4 CONNECTION DIAGRAM

DEH-1100MPB/XN/EW5

9

1234

1234

C

D

F

A

B

E

3. BASIC ITEMS FOR SERVICE

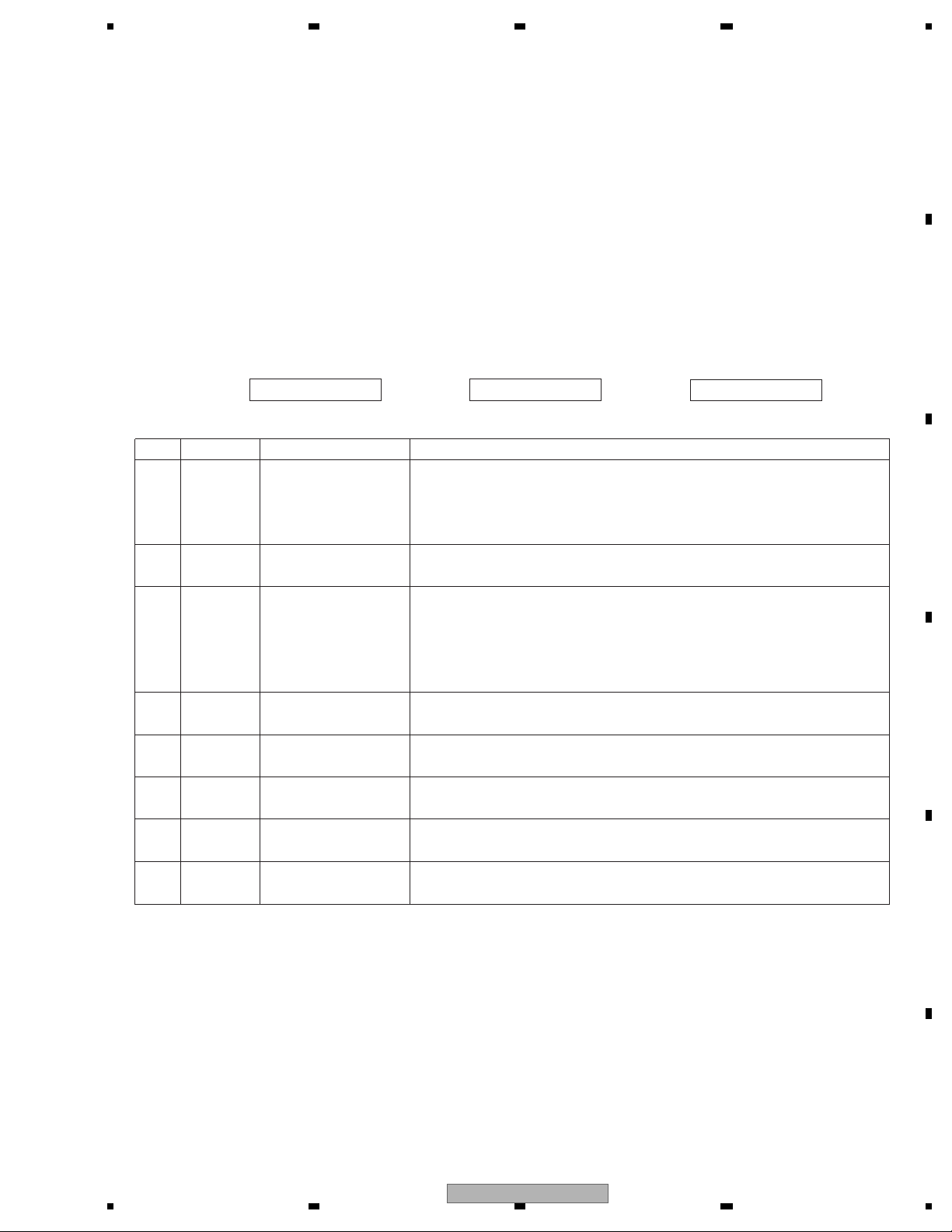

demrifnocebotmetIserudecorP.oN

1 Confirm whether the customer complain has

been solved.

If the customer complain occurs with the

specific media, use it for the operation check.

The customer complain must not be

reappeared.

Display, audio and operations must be

normal.

2 CD Play back a CD.

(Track search)

No malfunction on display, audio and

operation.

3 FM/AM tuner Check FM/AM tuner action.

(Seek, Preset)

Switch band to check both FM and AM.

Display, audio and operations must be

normal.

4 Check whether no disc is inside the product. The media used for the operating check must

be ejected.

retfaecnaraeppastinotridrosehctarcsoNkcehcecnaraeppA5

receiving it for service.

Item to be checked regarding audio

A

B

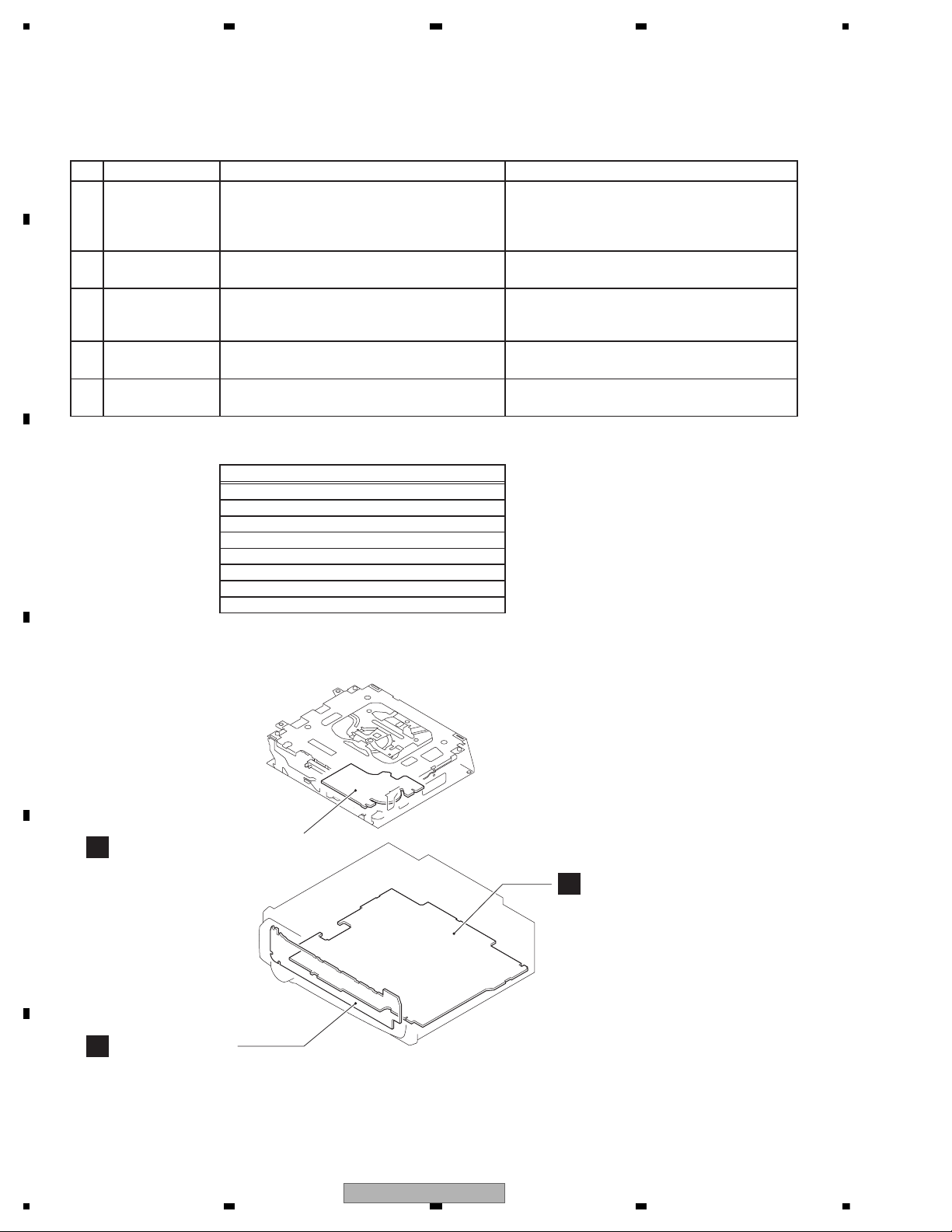

Keyboard Unit

CD Core Unit (S10.5COMP2)

C

Tuner Amp Unit

Unit Number : QWM3032

Unit Name : Tuner Amp Unit

Unit Number : (1120MP)

Unit Name : Keyboard Unit

Unit Number : (1100MP)

Unit Number : (1100MPB)

Unit Name : Keyboard Unit

Unit Number : CWX3514

Unit Name : CD Core Unit(S10.5COMP2)

3.1 CHECK POINTS AFTER SERVICING

To keep the product quality after servicing, please confirm following check points.

See the table below for the items to be checked regarding audio:

Distortion

Noise

Volume too low

Volume too high

Volume fluctuating

Sound interrupted

3.2 PCB LOCATIONS

10

DEH-1100MPB/XN/EW5

5678

56

7

8

C

D

F

A

B

E

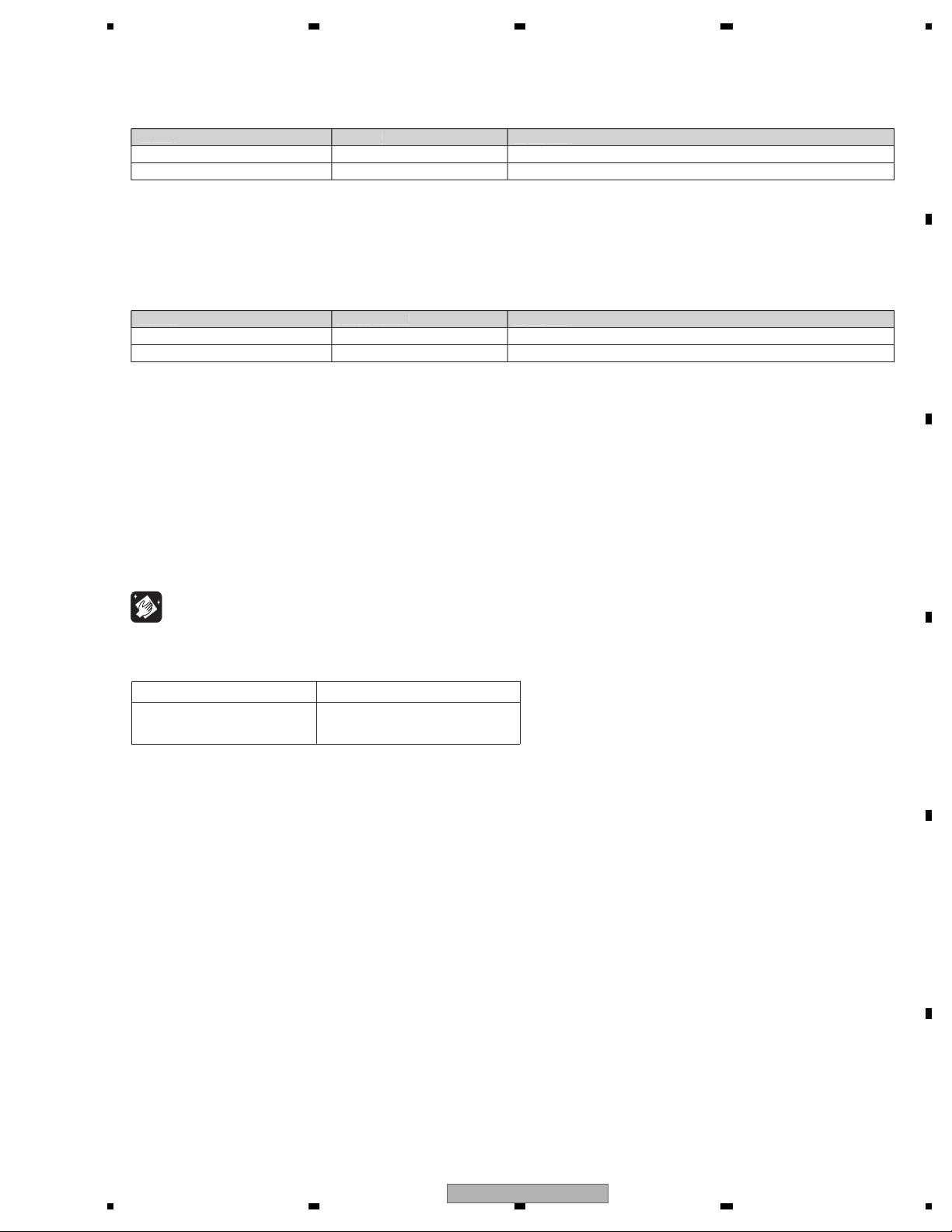

- Jigs List

Name

Test Disc

L.P.F.

Jig No.

TCD-782

Remarks

Checking the grating

Checking the grating (Two pieces)

Name

Jig

- Grease List

Name

Grease

Grease

Grease No.

GEM1024

GEM1045

Remarks

CD Mechanism Module

CD Mechanism Module

e

Before shipping out the product, be sure to clean the

following portions by using the prescribed cleaning

tools:

Portions to be cleaned Cleaning tools

CD pickup lenses Cleaning liquid : GEM1004

Cleaning paper : GED-008

3.3 JIGS LIST

m

3.4 CLEANING

No.

rease No.

emarks

emarks

DEH-1100MPB/XN/EW5

11

1234

1234

C

D

F

A

B

E

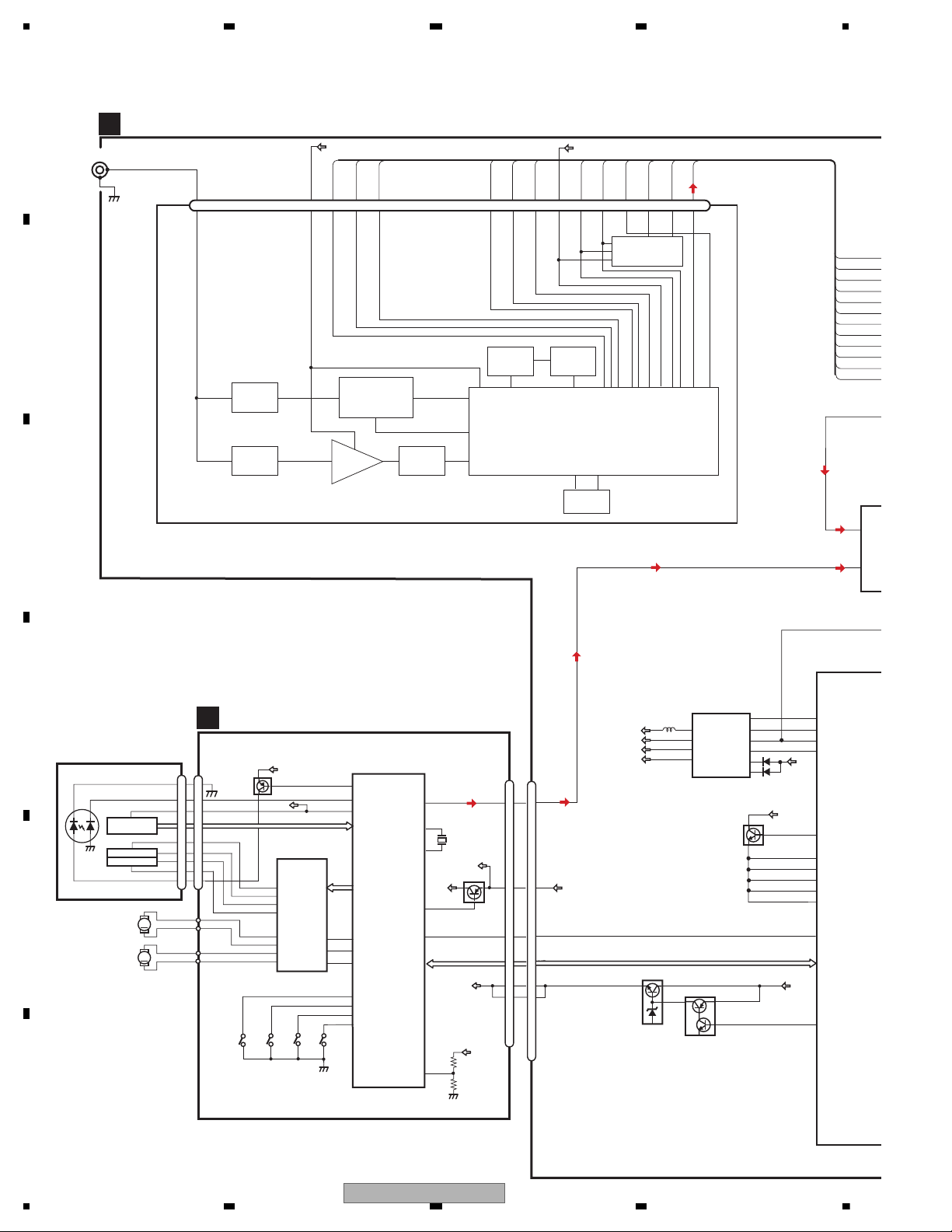

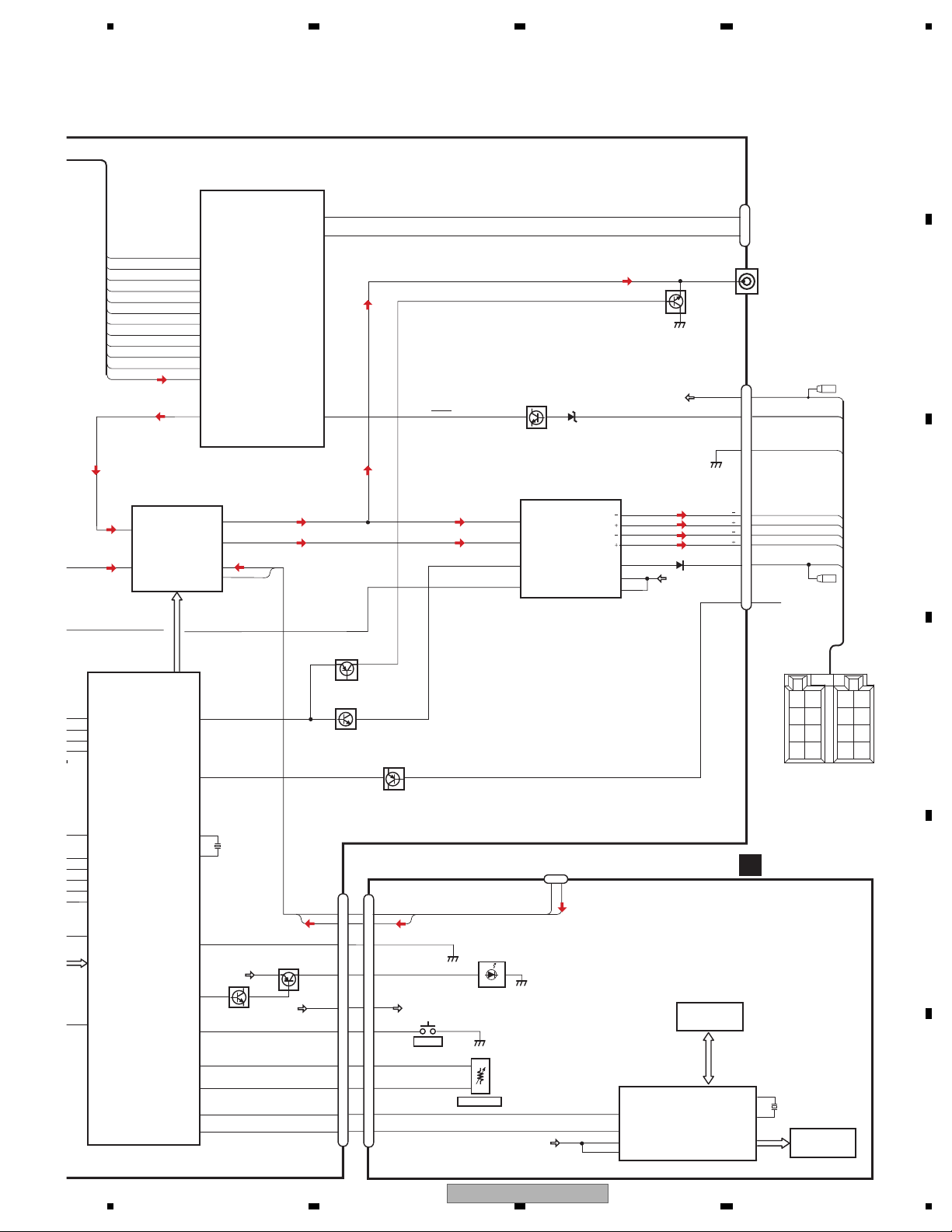

4. BLOCK DIAGRAM

PICKUP UNIT

(P10.5)(SERVICE)

D

CD CORE UNIT(S10.5COMP2)

C

BRST,BRXEN,BSRQ

CN701

Q101

M

LASER

DIODE

MONITOR

DIODE

S903

DSCSNS

SPINDLE

MOTOR

M

CARRIAGE

MOTOR

LOAD/

LD-

MD

15

5

HOLOGRAM

UNIT

IC301

BA5839FP

IC201

PE5668A

RF-AMP, CD DECODER,

MP3/WMA DECODER,

DIGITAL SERVO /

DATA PROCESSOR

CD

DRIVER

2

VD

VD

13

LOUT

9

CN101

16

SOP

15

SOM

18

LCOP

17

LCOM

21

CLCONT

55

LOUT

9

CONT

TD,FD

AC,BD,F,E

SD,MD

S901

HOME

S904

12EJ

S905

8EJ

LD+

14

141

LD

142

PD

12EJ

CONT

CLCONT

HOME

8

9

43

41

VDD

1

VDD

BDATA,BSCK

Q102

39

/PUEN

VDD

15

5

FOCUS ACT.

TRACKING ACT.

FOP

TOP

2

1

TOP

FOP

11

FOP

14

TOP

2

1

14

8EJ

7

DSCSNS

6

VCC

16

/RESET

8

/RESET

88

VREF

REFO

133

REFOUT

33

FOM

FOM

12

FOM

44

TOM

TOM

13

TOM

22

LOEJ

LOEJ

5

52

50

X201

XTAL

/XTAL

16.93MHz

VDSENS

11

VD

IN1_L

IN2_L

1

ELEC

SOU

TUNL

2

CN401

1

2

CN651

TUNER AMP UNIT

LOUT

A

SYS+B

ANTENNA

IFA

IFB

CDRESET

3

B.UP

VDD

5

VD

Q991

14

7

SWVDD

SWD5V

6

5

IC 911

BA49181-V12

BSENS

TOP41

POWEROFF

2

1

36

47

15

SWVDD

4

1

15

Q992

BRST,BRXEN,BSRQ,BDATA,BSCK

8

RESET

16

FM/AM TUNER UNIT

AM_ANT

SL-IN

REFA

REFB

LDET

SWVDD

DI

CK

CE1

DO

CE2

SLOUT

SL-IN

IFA

IFB

REFA

REFB

LDET

DI

CK

CE1

DO

CE2

SLOUT

PDL3

126

CD VD

CDL

3

REGULATOR IC

B.UP

10

9

VDD

SYS+B

8

7

IC 601(2

PN5016

SYSTEM M

COMPUT

SYSPW

DREG

85

SWVDD

Q601

PLL_VDD

DVDD3

REGC(M)

55

9

57

DVDD2

94

DVDD4

121

VD

ATT

ATT

TANK

ATT RF

LFP

LFPVCO

CF

IC1

MIX / IF / PLL

IC2

EEPROM

1 2 3 4 5 6 7 8 9 10 12 13 14 15 16 17 18 19 2011

ANT

VCC

SLIN

IFOUTA

IFOUTB

DGND

REFINA

REFINB

LDET

VDD

DI

CK

CE1

DO

CE2

SLOUT

RFGND1

RFGND2

RFGND3

RFGND4

12

DEH-1100MPB/XN/EW5

5678

56

7

8

C

D

F

A

B

E

IN1_L

IN2_L

1

IC 151

PML014A

ELECTRONIC VOLUME/

SOURCE SELECTOR

TUNL

2

7

Rear_L

B.UP

35

44

MUTE

21

23

3

5

VCC

VCC

FL

FL

RL

RL

FL

FL

RL

RL

B.REMOTE

ACC

22

AMP

IC 301

PAL007C

Q931

MUTE

CN831

VCK, VDT, VST

Q201(1/2)

Q851

Q201(2/2)

26

TELIN

B.UP

Q821

SYSTEM MICRO

COMPUTER

ACC SENSE

14

8

6

5

7

16

15

CN901

9

10

11

4

13

14

12

SOURCE

DSENS

ILM+B

ROT1

ROT0

ROT1

ROT0

DPDT

KYDT

SRC

33

34

ILMPW

2

111

110

DPDT/SELF

23

KEYDT/SELF

24

CN351

RLIn

12

DSENS

Q822

ASENS

6

Front_L

FLIn

14

XOUT

XIN

82

X601

74.1MHz

81

Q351

MUTE

20

6

25

BREM

ASENS

2

RL

11

TEL

9

CDRESET

BSENS

TOP41

POWEROFF

36

47

15

SWVDD

1

16

SL

62

SL-IN

IF_INA

77

IFA

IF_INB

78

IFB

FREF_A

96

REFA

FREF_B

97

REFB

LOCK

99

LDET

DI

100

DI

CK

101

CK

CE

102

CE1

DO

103

DO

VST

109

CE2

ADIN7

136

SLOUT

L_OUT

59

PDL3

126

CDL

B.UP

IC 601(2/2)

PN5016A

SYSTEM MICRO

COMPUTER

4

STBY

B.UP

AUX-G

6

AUX-L

7

AUX-L

4

AUX-G

5

IN4+_L

IN4-_L

ILMPW

DREG

85

PLL_VDD

DVDD3

REGC(M)

55

9

57

DVDD2

94

DVDD4

121

MUTE

SRC

DSENS

ILL+B

ROT1

ROT0

DPDT

KYDT

IC 1801

PD6340A

LCD DRIVER/

KEY CONTROLLER

KEY DATA

LCD1801

CN1801

KEYBOARD UNIT

10

11

18

20

DPDT

KYDT

B

13

12

D1803-D1821

3

SWVDD

SWD5V

3

SWVDD

SWVDD

4

X0

X1

22

X1801

5MHz

23

KEY MATRIX

10

56

VLCD

VDD

9

14

VOLUME

S1801(2/2)

1

2

SOURCE

S1801(1/2)

6

7

CN1802

AUX G

AUX L

AUX G

AUX L

AUX IN

2

1

IC 601(1/2)

PN5016A

W.REM

KEYD

KEYAD

3

2

CN871

FL

FL

RL

RL

BACK UP

GND

RR

RR

FR

FR

FL

FL

RL

RL

ACC

GND

BACK

UP

B.

REM

ACC

B.REM

DEH-1100MPB/XN/EW5

13

1234

1234

C

D

F

A

B

E

SEGMENT

COMMON

LCD (CAW1927)

14

DEH-1100MPB/XN/EW5

5678

56

7

8

C

D

F

A

B

E

SEGMENT

COMMON

LCD (CAW1932)

DEH-1100MPB/XN/EW5

15

1234

1234

C

D

F

A

B

E

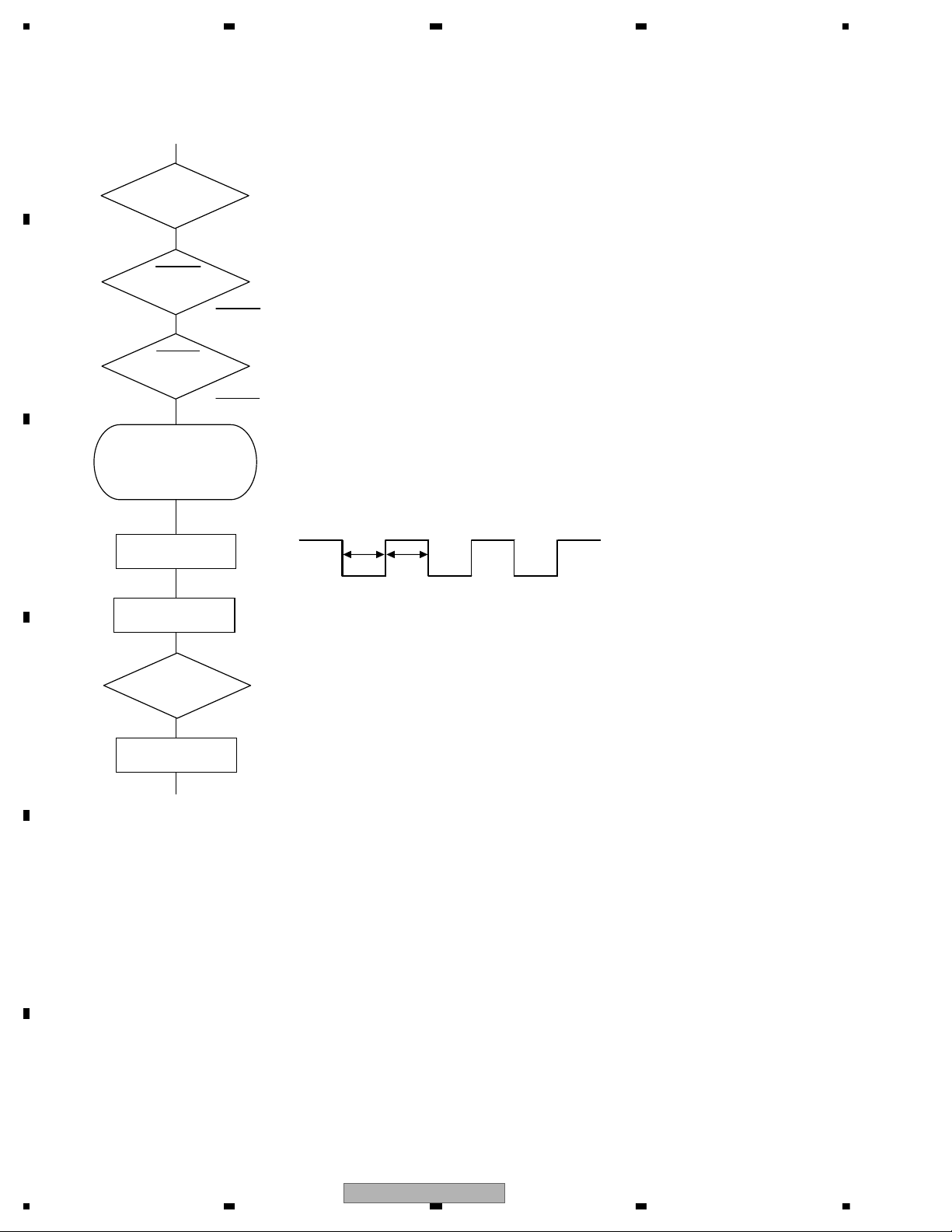

5. DIAGNOSIS

VDD = 5 V

Pin 8

BSENS

Pin 36

ASENS

Pin 35

BSENS = L

Starts

communication

with Grille

microcomputer.

SWVDD <- H

Pin 1

Source keys

operative

Source ON

SYSPW <- H

Pin 15

300 ms

300 ms

Completes power-on operation.

(After that, proceed to each source operation)

In case of the above signal, the communication

with Grille microcomputer may fail.

If the time interval is not 300 msec, the oscillator

may be defective.

Power ON

ASENS = L

5.1 OPERATIONAL FLOWCHART

16

DEH-1100MPB/XN/EW5

5678

56

7

8

C

D

F

A

B

E

- Error Messages

If a CD is not operative or stopped during operation due to an error, the error mode is turned on and cause(s) of

the error is indicated with a corresponding number. This arrangement is intended at reducing nonsense calls from

the users and also for facilitating trouble analysis and repair work in servicing.

(1) Basic Indication Method

1) When SERRORM is selected for the CSMOD (CD mode area for the system), error codes are written to DMIN

(minutes display area) and DSEC (seconds display area). The same data is written to DMIN and DSEC. DTNO

remains in blank as before.

2) Head unit display examples

Depending on display capability of LCD used, display will vary as shown below. xx contains the error number.

8-digit display 6-digit display 4-digit display

ERROR-xx ERR-xx E-xx

(2) Error Code List

Code Class Displayed error code Description of the code and potential cause(s)

10 Electricity Carriage Home NG CRG can't be moved to inner diameter.

SERVO LSI Com- CRG can't be moved from inner diameter.

munication Error -> Failure on home switch or CRG move mechanism.

Communication error between microcomputer and SERVO LSI.

11 Electricity Focus Servo NG Focusing not available.

-> Stains on rear side of disc or excessive vibrations on REWRITABLE.

12 Electricity Spindle Lock NG Spindle not locked. Sub-code is strange (not readable).

Subcode NG -> Failure on spindle, stains or damages on disc, or excessive vibrations.

A disc not containing CD-R data is found.

Turned over disc are found, though rarely.

CD signal error.

17 Electricity Setup NG AGC protection doesn't work. Focus can be easily lost.

-> Damages or stains on disc, or excessive vibrations on REWRITABLE.

30 Electricity Search Time Out Failed to reach target address.

-> CRG tracking error or damages on disc.

44 Electricity ALL Skip Skip setting for all track.

(CD-R/RW)

50

Mechanism

CD On Mech Error Mechanical error during CD ON.

-> Defective loading motor, mechanical lock and mechanical sensor.

A0 System Power Supply NG Power (VD) is ground faulted.

-> Failure on SW transistor or power supply (failure on connector).

Remarks: Mechanical errors are not displayed (because a CD is turned off in these errors).

Unreadable TOC does not constitute an error. An intended operation continues in this case.

Upper digits of an error code are subdivided as shown below:

1x: Setup relevant errors, 3x: Search relevant errors, Ax: Other errors.

5.2 ERROR CODE LIST

DEH-1100MPB/XN/EW5

17

1234

1234

C

D

F

A

B

E

5.3 CONNECTOR FUNCTION DESCRIPTION

REAR

OUTPUT

ANTENNA

1 FR+

2 RR+

3 FR4 RR5 FL+

6 RL+

7 FL8 RL-

9 MUTE

10 NC

11 B.REM

12 NC

13 A.ANT

14 ACC

15 GND

16 B.UP

1

3

5

7 9

11

13 15

2

4

6

8 10

12

14 16

WIRED REMOTE

CONTROL

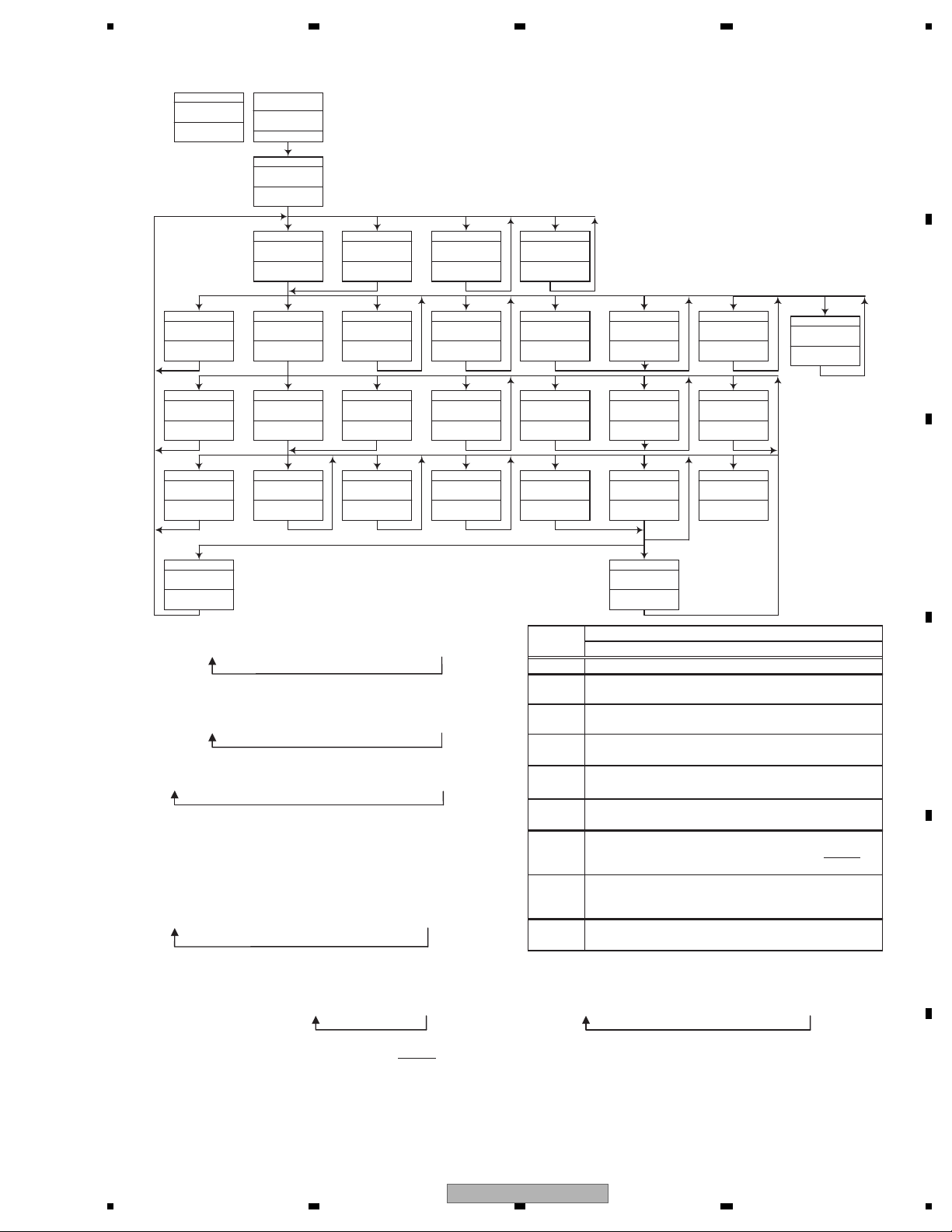

1. To enter the test mode

Turn on ACC and Backup while pressing the 1 and the 3 buttons together.

2. To exit from the test mode

Turn off the ACC and Backup.

3. Operation method

Change display as follows by pushing the 1 and the 3 buttons together.

All lighting of display

ROM Correction version display

6. SERVICE MODE

6.1 DISPLAY TEST MODE

18

DEH-1100MPB/XN/EW5

5678

56

7

8

C

D

F

A

B

E

[Key]

Contents

Display

[4] + [6] + Reset or

[4] + [6] + BU + ACC

Test Mode In

[CD] or [SOURCE]

Source On

TRK MIN SEC

[BAND]

Power On

(T.Offset is adjusted)

TRK MIN SEC

00 00 00

[3]

Power On

(T.Offset is not adjusted)

99 99 99

[2]

RF AMP

Gain switching

GG GG GG

*1

[4]

SPINDLE

Speed switching

SP SP SP

*9

[3]

Focus Close

S curve check

TRK MIN SEC

91 91 91

[6]

Focus Mode switching

0X 0X 0X

*2

[1]

Tracking Servo

Close

00 00 00

or 99 99 99

[>]

CRG +

[2]

Self-adjusting

switching

TRK MIN SEC

?? ?? ??

*3*8

[<]

CRG -

*8

[BAND]

Power Off

TRK MIN SEC

[BAND]

Power Off

TRK MIN SEC

[BAND]

Power Off

TRK MIN SEC

[BAND]

Power Off

TRK MIN SEC

[1]

T.Close & AGC

Applicable servomechanism

TRK MIN SEC

?tr ?min ?sec

[6] [3]

RF AGC /

RF AGC coefficient display

[>]

CRG +

8X 8X 8X

or 9X 9X 9X

[2]

T.Balance adjustment /

T.BAL coefficient display

TRK MIN SEC

?? ?? ??

[<]

CRG -T.Close

Applicable servomechanism

?? ?? ??

[1]

F,T,RF AGC

F.Bias display switching

TRK MIN SEC

TRK MIN SEC

TRK MIN SEC

TRK MIN SEC

?tr ?min ?sec

TRK MIN SEC

[3] [6]

CRG/TR jump

value switching

[>]

CRG/TR Jump +

[2]

Tracking Open

[<]

CRG/TR Jump -

?tr ?min ?sec

TRK MIN SEC

TRK MIN SEC

TRK MIN SEC

?tr ?min ?sec

00 00 00

or 99 99 99

TRK MIN SEC

TRK MIN SEC

?tr ?min ?sec

8X 8X 8X

or 9X 9X 9X

8X 8X 8X

or 9X 9X 9X

00 00 00

or 99 99 99

TRK MIN SEC

?tr ?min ?sec?? ?? ??

*7

F,T AGC / F.Bias

RF AGC

8X 8X 8X

or 9X 9X 9X

[2]

Tracking Open

*6

*5

*4 *4

Operation

[Key]

Test Mode

[BAND] Power On/Off

[>]

CRG + / TR Jump +

(Direction of the external surface)

[<]

CRG - / TR Jump (Direction of the internal surface)

[1] T. CLS & AGC & Applicable servomechanism /

AGC,AGC display setting

[2] RF Gain switching / Offset adjustment display /

T.Balance adjustment / T. Open

[3] F. Close,S Curve / Rough Servo and RF AGC /

F,T,RF AGC

[4]

SPDL 1X/2X switching

As for the double speed(2x), audio output cannot be

supported.

[5]

Error Rate measurement

ON : ERR 30Counts Start

BER display data[%]

[6] F. Mode switching / Tracking Close / CRG•TR

Jump Switching

*) • After the [Eject] key is pressed keys other than the [Eject] key should not be pressed, until disc ejection is complete.

• When the key [2] or [3] is pressed during the Focus Search, the power supply should be immediately turned off (otherwise the lens

sticks to Wall, causing the actuator to be damaged).

• In the case of TR jump other than to 100TR, the function shall continue to be processed even if the TR jump key is released. As for

the CRG Move and 100TR Jump, the mechanism shall be set to the Tracking Close mode when the key is released.

• When the power is turned on/off the jump mode is reset to the Single TR (91) while the gain of the RFAMP is reset to 0 dB. At the

same time all the self-adjusting values shall return to the default setting.

*10

TRK MIN SEC

[5]

Gop Mode

Gop Mode switching

OL OL OL

- Flow Chart

*1) TYP → + 6 dB → + 12 dB

TRK

MIN

SEC

TRK06MIN06SEC

06

TRK12MIN12SEC

12

*2) Focus Close

→ S Curve check setting → F EQ measurement setting

TRK00MIN00SEC

00

TRK

01

MIN01SEC

01

TRK02MIN02SEC

02

(

TRK99MIN99SEC

99)

*3) F.Offset Display → RF.Offset → T.Offset Display → Switch to the

order of the original display

*4) 1TR/4TR/10TR/32TR/100TR

*5) Single

→ 4TR → 10TR → 32TR → 100TR → CRG Move

9x(8x):91(81) 92(82) 93(83) 94(84) 95(85) 96(86)

*6) Only at the time of CRG move, 100TR jump

*7) TRK/MIN/SEC

→ F.AGC → T.AGC Gain → F.Bias → RF AGC

*8) CRG motor voltage = 2 [V]

*9) TYP (1X)

→ 2X → 1X

TRK

MIN

SEC

TRK

22

MIN22SEC

22

TRK11MIN11SEC

11

*10) OFF(TYP)

→ FORCUS → TRACKING

TRK

MIN

SEC

TRK

70

MIN70SEC

70

TRK71MIN71SEC

71

• As for the double speed (2x), audio output cannot be supported

6.2 CD TEST MODE

DEH-1100MPB/XN/EW5

19

Loading...

Loading...