Page 1

DVD AV RECEIVER

ORDER NO.

CRT4121

AVH-P5000DVD/XN/UC

AVH-P5000DVD

/XN/UC

DVD RDS AV RECEIVER

AVH-P5000DVD

AVH-P5000DVD

This service manual should be used together with the following manual(s):

Model No. Order No. Mech.Module Remarks

CX-3212 CRT3896 MS5 DVD Mech. Module : Circuit Descriptions, Mech. Descriptions, Disassembly

Manufactured under license from Dolby Laboratories. “Dolby”, “Pro Logic”, and the double-D symbol

are trademarks of Dolby Laboratories.

Manufactured under license under U.S. Patent #: 5,451,942 & other U.S. and worldwide patents issued &

pending. DTS and DTS Digital Out are registered trademarks and the DTS logos and Symbol are trademarks of DTS, Inc. © 1996-2007 DTS, Inc. All Rights Reserved.

/XNEW5

/XN/RE

For details, refer to "Important Check Points for Good Servicing".

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2008

K-ZZZ. FEB. 2008 Printed in Japan

Page 2

1234

SAFETY INFORMATION

CAUTION

A

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer.

Qualified technicians have the necessary test equipment and tools, and have been trained to properly and safely repair

complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the warranty.

If you are not qualified to perform the repair of this product properly and safely, you should not risk trying to do so

and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of

California to cause cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 - Proposition 65

B

This product contains mercury. Disposal of this material may be regulated due to environmental considerations.

For disposal or recycling information, please contact your local authorities or the Electronics Industries

Alliance: www.eiae.org.

The backlighting lamp of LCD in this equipment contains mercury. Disposal of this material may be

regulated due to environmental considerations according to Local, State or Federal Laws. For disposal

or recycling information, please contact your local authorities or the Electronics Industries

Alliance: www.eiae.org

C

Where in a manufacturer’s service documentation, for example in circuit diagrams or lists

of components, a symbol is used to indicate that a specific component shall be replaced only

by the component specified in that documentation for safety reasons, the following symbol shall

be used:

1. Safety Precautions for those who Service this Unit.

Follow the adjustment steps in the service manual when servicing this unit. When check ing or adjusting the emitting power of the laser diode exercise caution in order to get safe, reliable results.

D

Caution:

1. During repair or tests, minimum distance of 13 cm from the focus lens must be kept.

2. During repair or tests, do not view laser beam for 10 seconds or longer .

E

F

2

1234

AVH-P5000DVD/XN/UC

Page 3

5 678

WARNING!

The AEL (accessible emission level )of the laser power output is less than CLASS 1

but the laser component is capable of emitting radiation exceeding the limit for

CLASS 1.

A specially instructed person should do servicing operation of the apparatus.

Laser diode characteristics

Wave length:

DVD:640 nm to 660 nm

CD:770 nm to 810 nm

DVD : 2.48 mW(Emitting period :9 sec.)

CD : 705 W(Emitting period : unlimited)

Additional Laser Caution

Transistors Q1101 and Q1102 in PCB drive the laser diodes for DVD and CD

respectively. When Q1101 or Q1102 is shorted between their terminals,

the laser diodes for DVD or CD will radiate beam. If the top cover is removed

with no disc loaded while such short-circuit is continued, the naked eyes may

be exposed to the laser beam.

A

B

C

D

E

F

56

AVH-P5000DVD/XN/UC

7

8

3

Page 4

1234

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

A

B

C

D

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

a Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

E

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

F

4

1234

AVH-P5000DVD/XN/UC

Page 5

5 678

CONTENTS

SAFETY INFORMATION .....................................................................................................................................2

1. SERVICE PRECAUTIONS................................................................................................................................6

1.1 SERVICE PRECAUTIONS.........................................................................................................................6

1.2 NOTES ON SOLDERING...........................................................................................................................7

2. SPECIFICATIONS.............................................................................................................................................8

2.1 SPECIFICATIONS ......................................................................................................................................8

2.2 DISC/CONTENT FORMAT .......................................................................................................................12

2.3 PANEL FACILITIES ..................................................................................................................................13

2.4 CONNECTION DIAGRAM........................................................................................................................15

3. BASIC ITEMS FOR SERVICE........................................................................................................................17

3.1 CHECK POINTS AFTER SERVICING .....................................................................................................17

3.2 PCB LOCATIONS .....................................................................................................................................18

3.3 JIGS LIST .................................................................................................................................................19

3.4 CLEANING ...............................................................................................................................................20

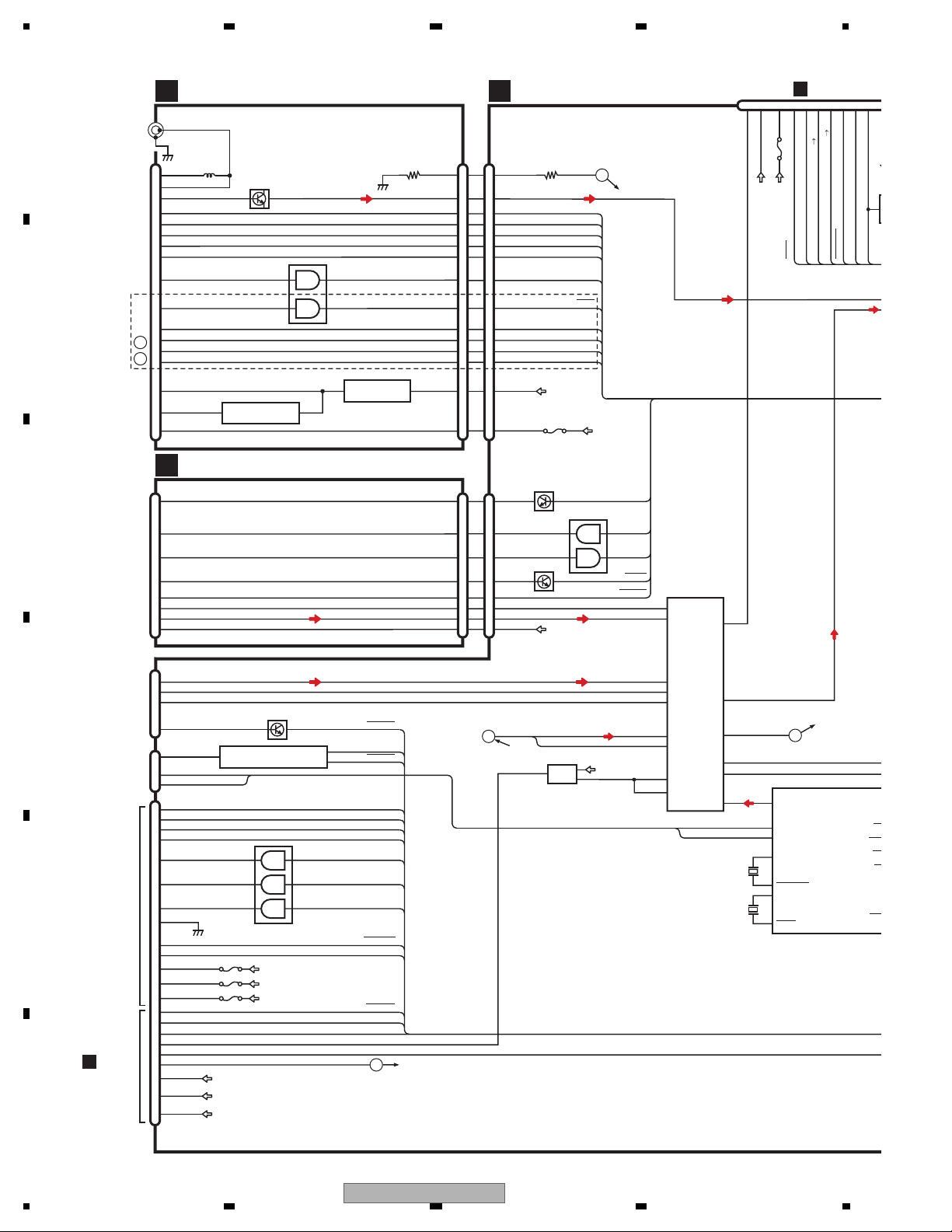

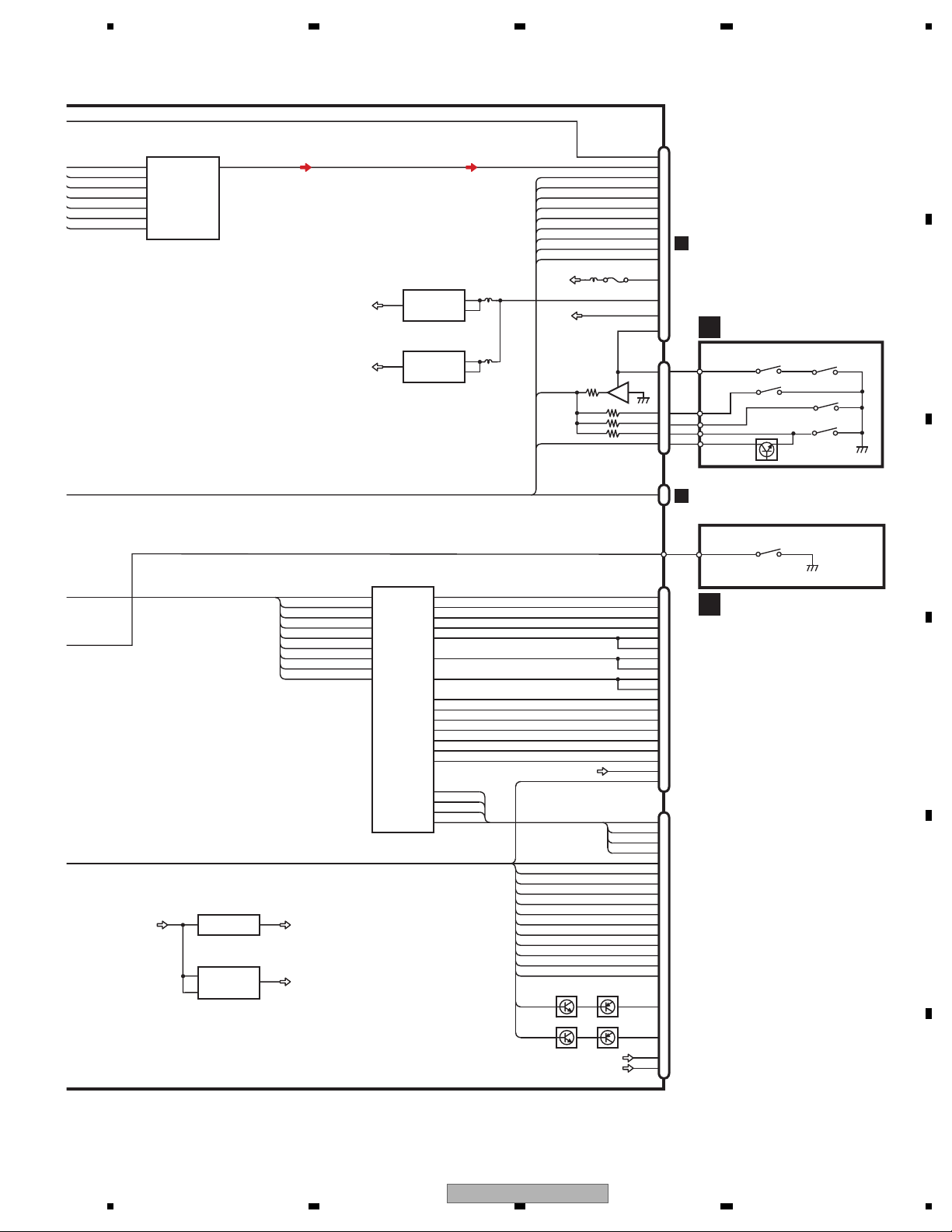

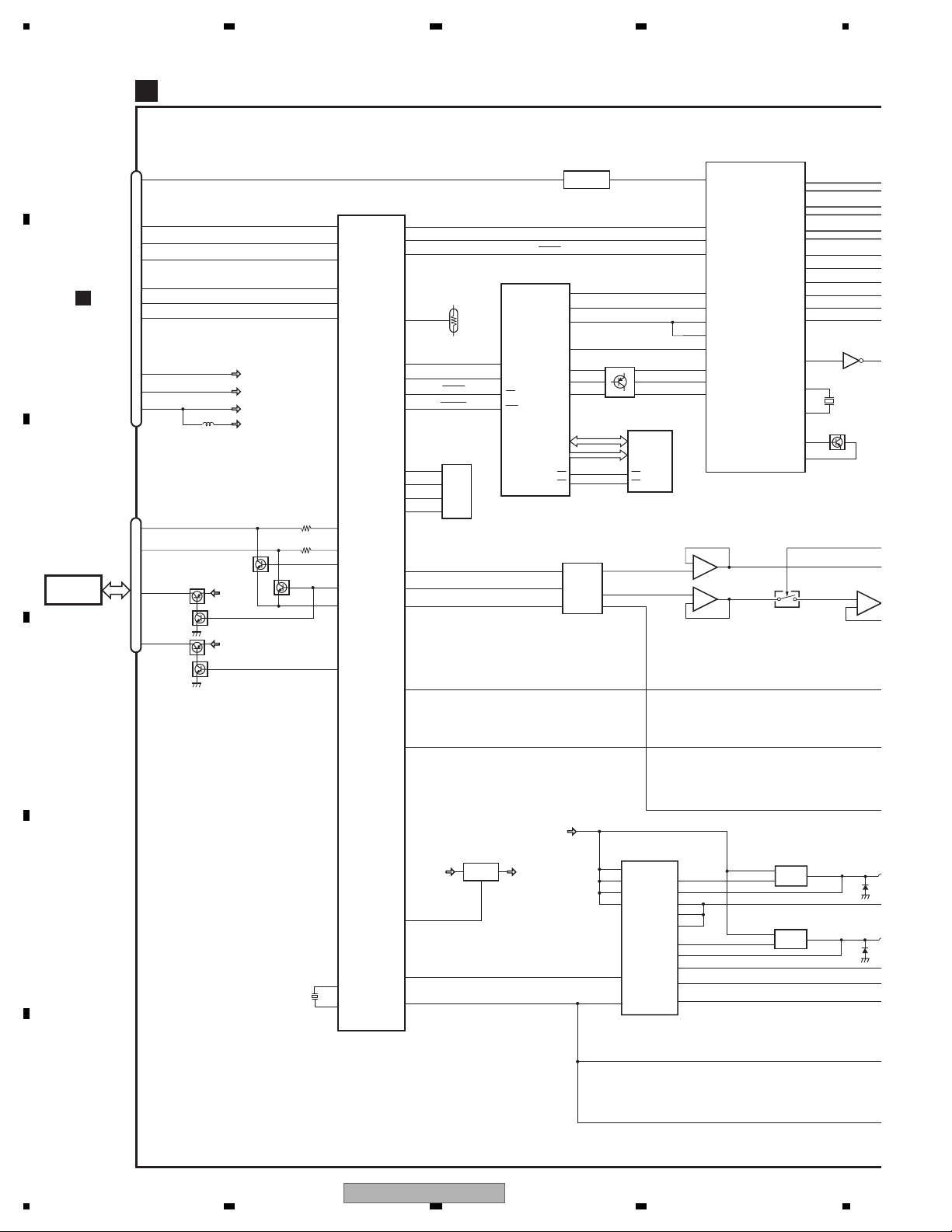

4. BLOCK DIAGRAM ..........................................................................................................................................22

5. DIAGNOSIS ....................................................................................................................................................32

5.1 OPERATIONAL FLOWCHART.................................................................................................................32

5.2 INSPECTION METHOD OF PICKUP UNIT .............................................................................................33

5.3 DIAGNOSIS FLOWCHART......................................................................................................................36

5.4 ERROR CODE LIST.................................................................................................................................58

5.5 CONNECTOR FUNCTION DESCRIPTION .............................................................................................60

5.6 SIMPLE OPERATION CHECK METHOD ................................................................................................61

6. SERVICE MODE.............................................................................................................................................62

6.1 DVD TEST MODE ....................................................................................................................................62

6.2 CALIBRATION TEST MODE ....................................................................................................................65

6.3 MONITOR TEST MODE...........................................................................................................................65

7. DISASSEMBLY...............................................................................................................................................66

8. EACH SETTING AND ADJUSTMENT............................................................................................................73

8.1 DVD ADJUSTMENT.................................................................................................................................73

8.2 DVD AMP UNIT ADJUSTMENT...............................................................................................................80

8.3 INVERTOR PCB ADJUSTMENT..............................................................................................................82

8.4 MONITOR PCB ADJUSTMENT ...............................................................................................................84

8.5 TOUCH PANEL ADJUSTMENT ...............................................................................................................87

8.6 MONITOR ADJUSTMENT........................................................................................................................95

9. EXPLODED VIEWS AND PARTS LIST ........................................................................................................104

9.1 PACKING................................................................................................................................................104

9.2 EXTERIOR(1).........................................................................................................................................106

9.3 EXTERIOR(2).........................................................................................................................................108

9.4 EXTERIOR(3)......................................................................................................................................... 112

9.5 EXTERIOR(4)......................................................................................................................................... 114

9.6 DVD MECHANISM MODULE................................................................................................................. 116

10. SCHEMATIC DIAGRAM..............................................................................................................................118

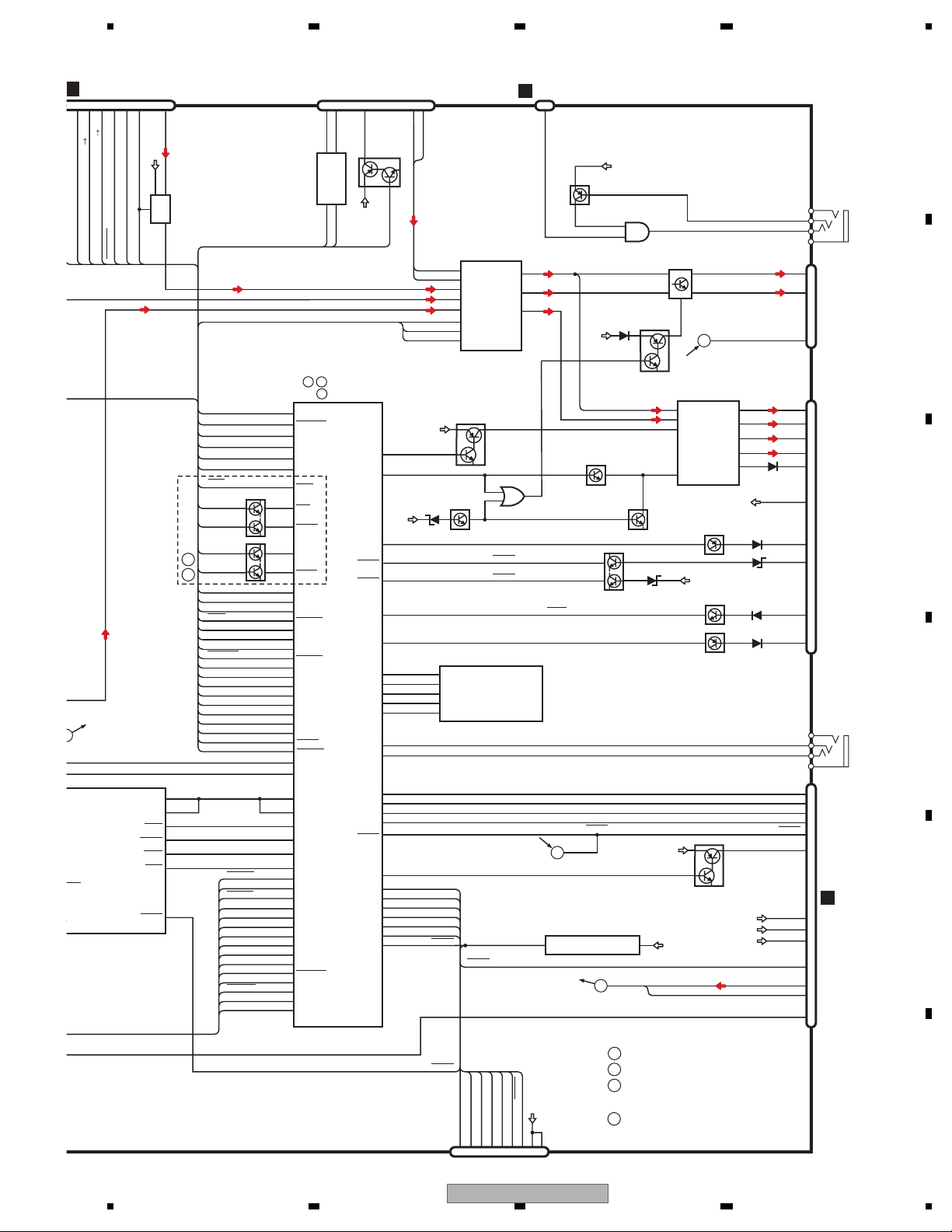

10.1 DVD AMP UNIT(ANALOG)(1/3)(GUIDE PAGE)...................................................................................118

10.2 DVD AMP UNIT(SYSTEM)(2/3)(GUIDE PAGE)...................................................................................124

10.3 DVD AMP UNIT(POWER SUPPLY)(3/3)..............................................................................................130

10.4 iPod CONNECTOR UNIT.....................................................................................................................132

10.5 KEYBOARD UNIT ................................................................................................................................134

10.6 DVD CORE UNIT(1/2)(GUIDE PAGE) .................................................................................................136

10.7 DVD CORE UNIT(2/2)..........................................................................................................................142

10.8 COMPOUND UNIT(A) AND COMPOUND UNIT(B).............................................................................144

10.9 MONITOR PCB(MONITOR)(GUIDE PAGE).........................................................................................146

10.10 MONITOR PCB(OSD,uCOM)(GUIDE PAGE) ....................................................................................152

10.11 INVERTOR PCB.................................................................................................................................158

10.12 TUNER BOX UNIT .............................................................................................................................160

10.13 WAVEFORMS.....................................................................................................................................162

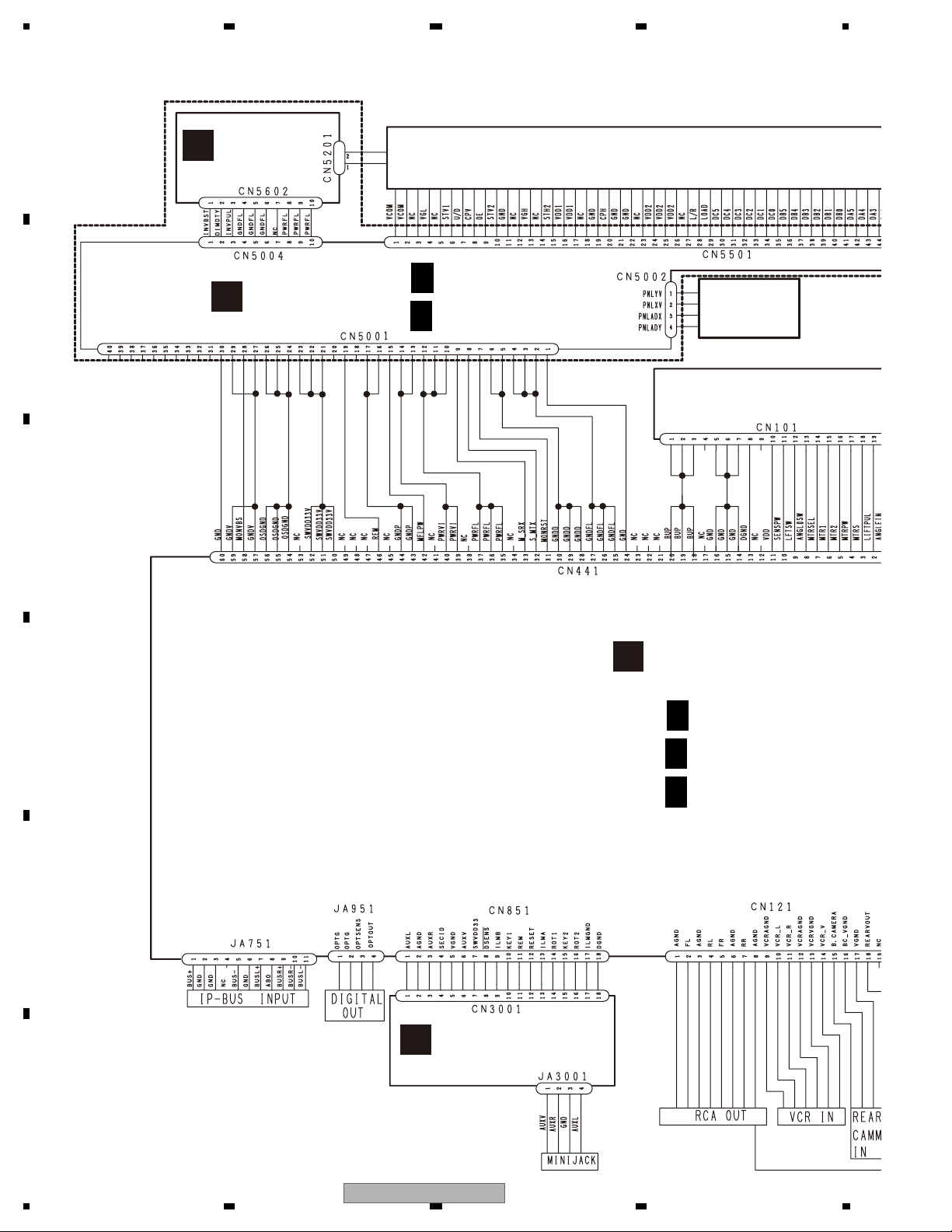

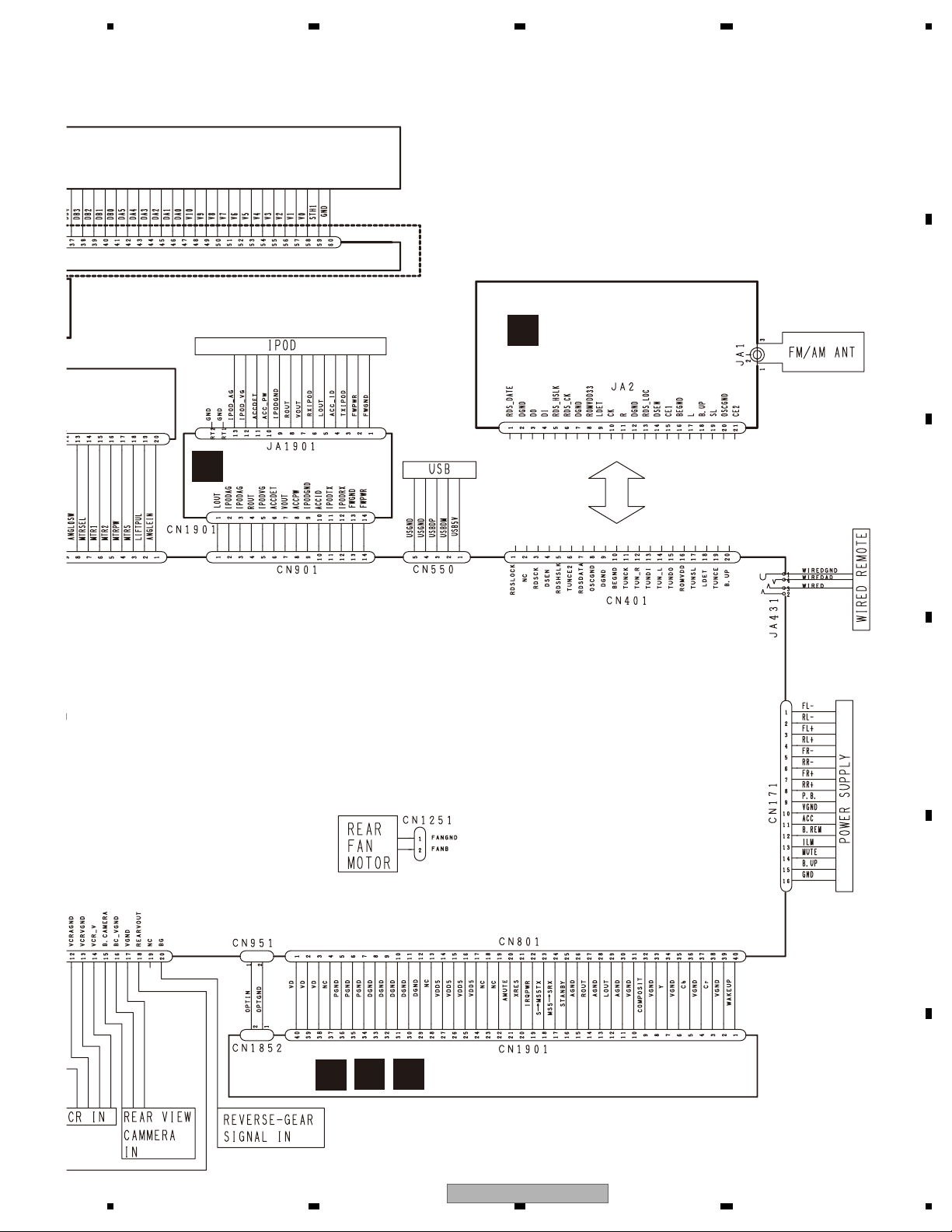

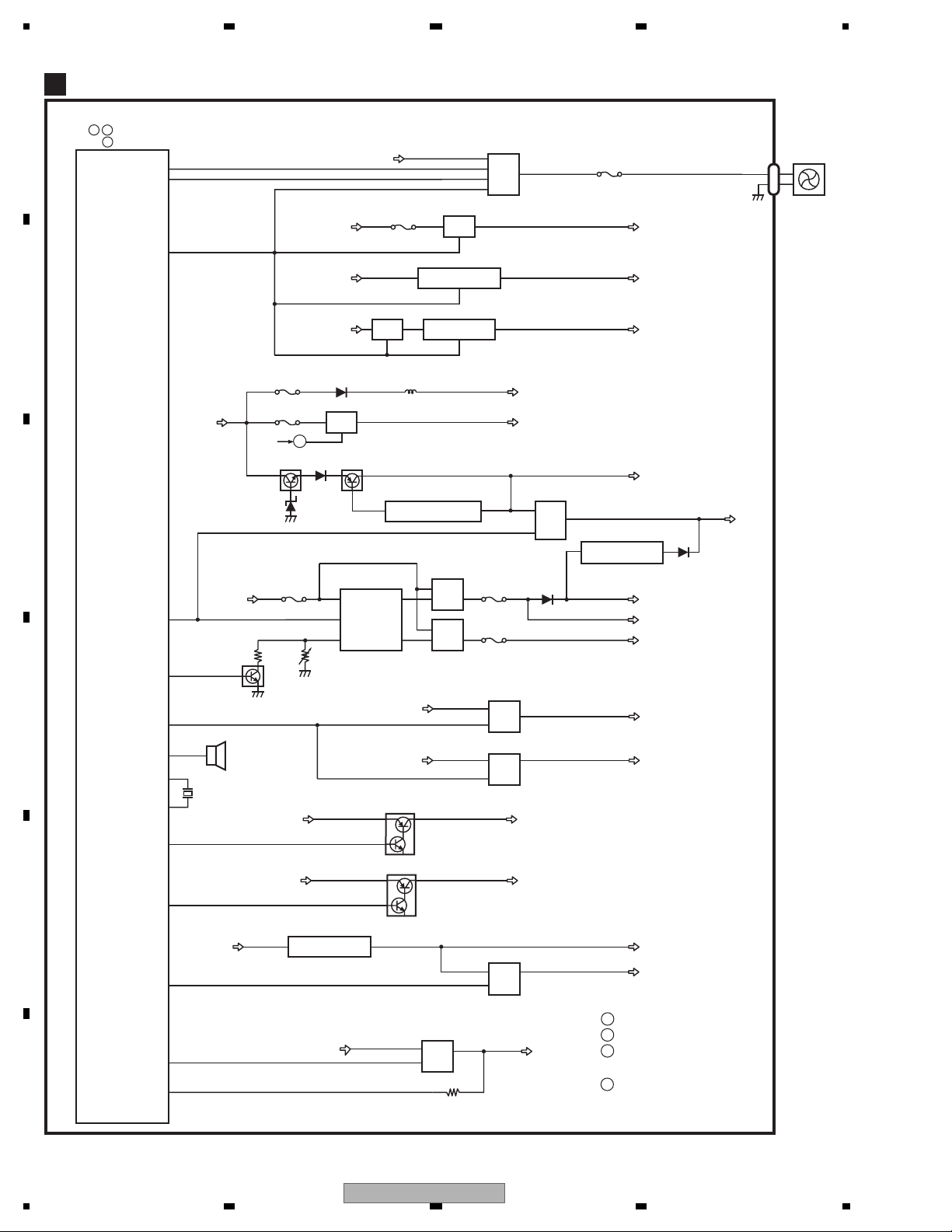

11. PCB CONNECTION DIAGRAM ..................................................................................................................164

11.1 DVD AMP UNIT ....................................................................................................................................164

11.2 iPod CONNECTOR UNIT .....................................................................................................................168

11.3 KEYBOARD UNIT.................................................................................................................................169

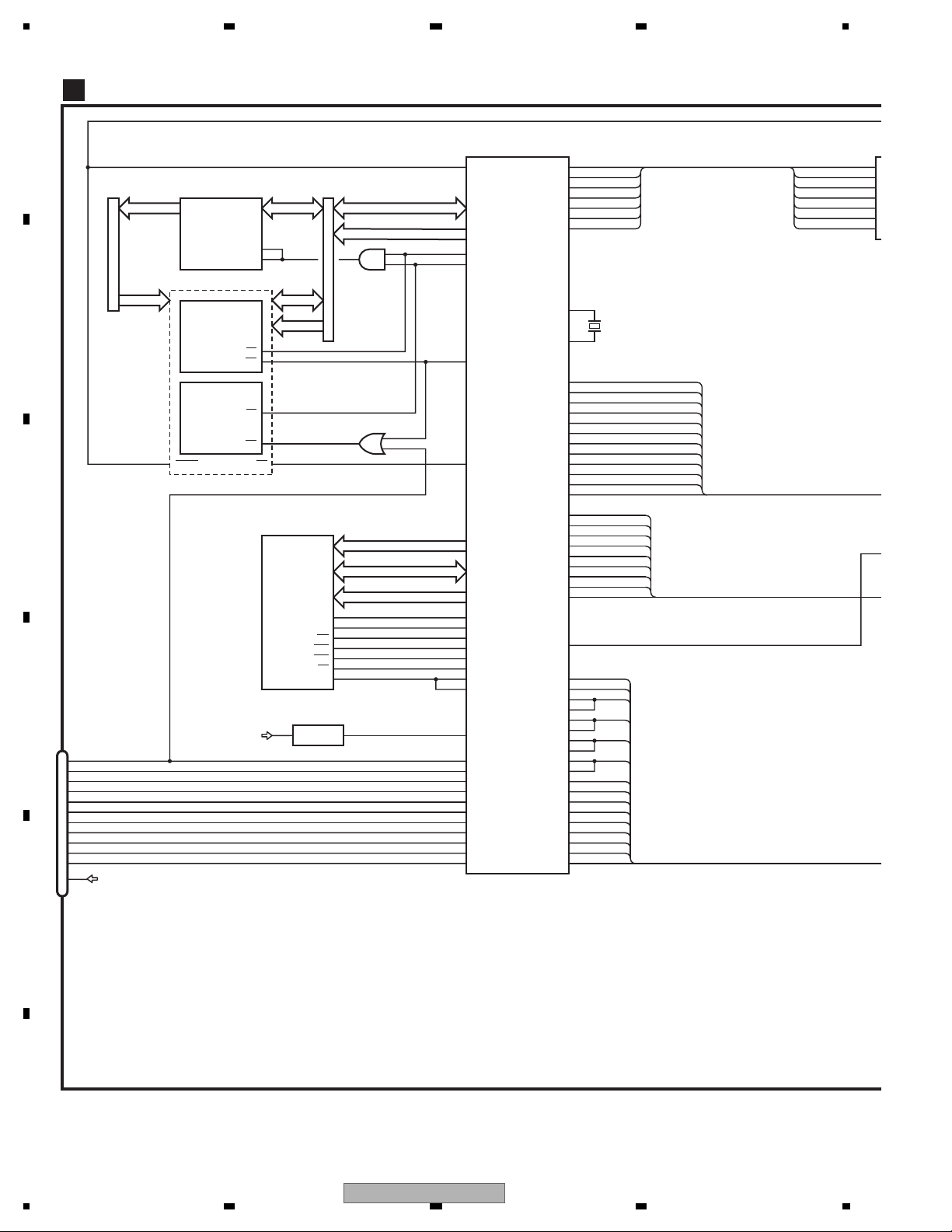

11.4 DVD CORE UNIT..................................................................................................................................170

11.5 COMPOUND UNIT(A) AND COMPOUND UNIT(B) .............................................................................174

11.6 MONITOR PCB.....................................................................................................................................176

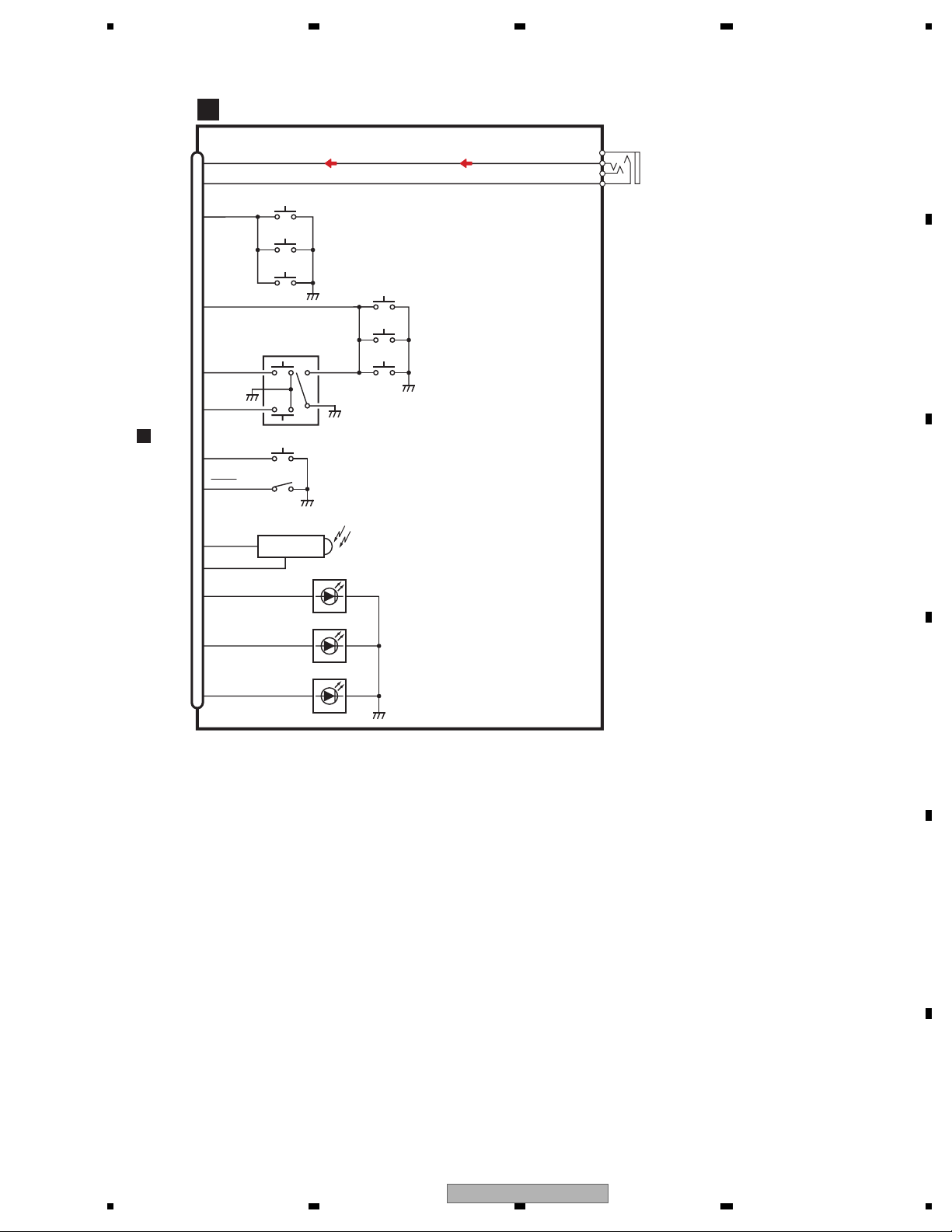

11.7 INVERTOR PCB...................................................................................................................................180

11.8 TUNER BOX UNIT................................................................................................................................182

12. ELECTRICAL PARTS LIST.........................................................................................................................184

A

B

C

D

E

F

56

AVH-P5000DVD/XN/UC

7

8

5

Page 6

1234

1. SERVICE PRECAUTIONS

1.1 SERVICE PRECAUTIONS

A

1) You should conform to the regulations governing the product (safety, radio and noise, and other regulations),

and should keep the safety during servicing by following the safety instructions described in this manual.

2) Be careful in handling ICs. Some ICs such as MOS type are so fragile that they can be damaged by electrostatic

induction.

3) Before disassembling the unit, be sure to turn off the power. Unplugging and plugging the connectors

during power-on mode may damage the ICs inside the unit.

4)To protect the pickup unit from electrostatic discharge during servicing, take an appropriate treatment

(shorting-solder) by referring to "the DISASSEMBLY" .

5) After replacing the pickup unit, be sure to skew adjustment.

6)During disassembly, be sure to turn the power off since an internal IC might be destroyed when a connector

is plugged or unplugged.

B

7) In case the internal fuse blows out, check the latter part of voltage.

8) Touch panel consists of the glass. Take good care for its handling.

Dropping the panel or adding severe impact on it may cause the risk of cracking.

Also, the end face of glass is not chamfered.

Use gloves and the like to protect your fingers from being cut.

9) AVH-P5000DVD will be operated only when Tuner Box is connected.

When operating it without connecting Tuner Box such as in the case of confirming operation,

short R678 (B face) of the DVD Amp Unit by soldering.

*When returning it to the customer, do not forget to remove the shorted part as described above.

It is the resistance land that enables operation in case the AVH-P5000DVD is returned to the service deposit with TUNER BOX excluded.

If you return this land in the state of leaving it shorted after completion of repair, the failure may arise after returning it to the customer,

who will claim that the product does not go OFF even by the detach.

(See details to “5.6 SIMPLE OPERATION CHECK METHOD” on the page 61.)

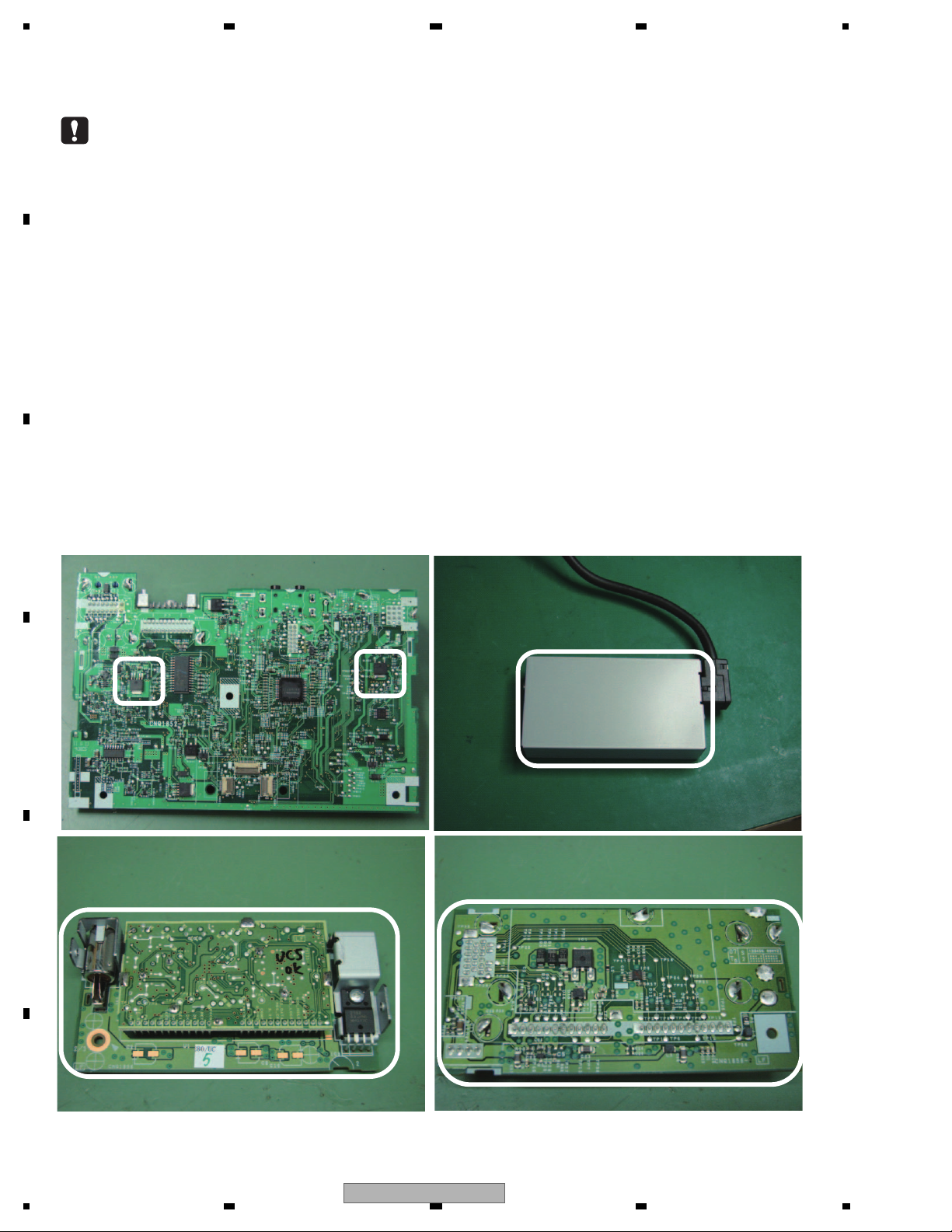

10) Hot areas

C

White area: Hot area. Be careful not to burn yourself

DVD Amp Unit

Tuner Box

D

E

F

6

1234

AVH-P5000DVD/XN/UC

Page 7

5 678

1.2 NOTES ON SOLDERING

For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 C.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 C in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

A

B

C

D

E

56

AVH-P5000DVD/XN/UC

F

7

8

7

Page 8

1234

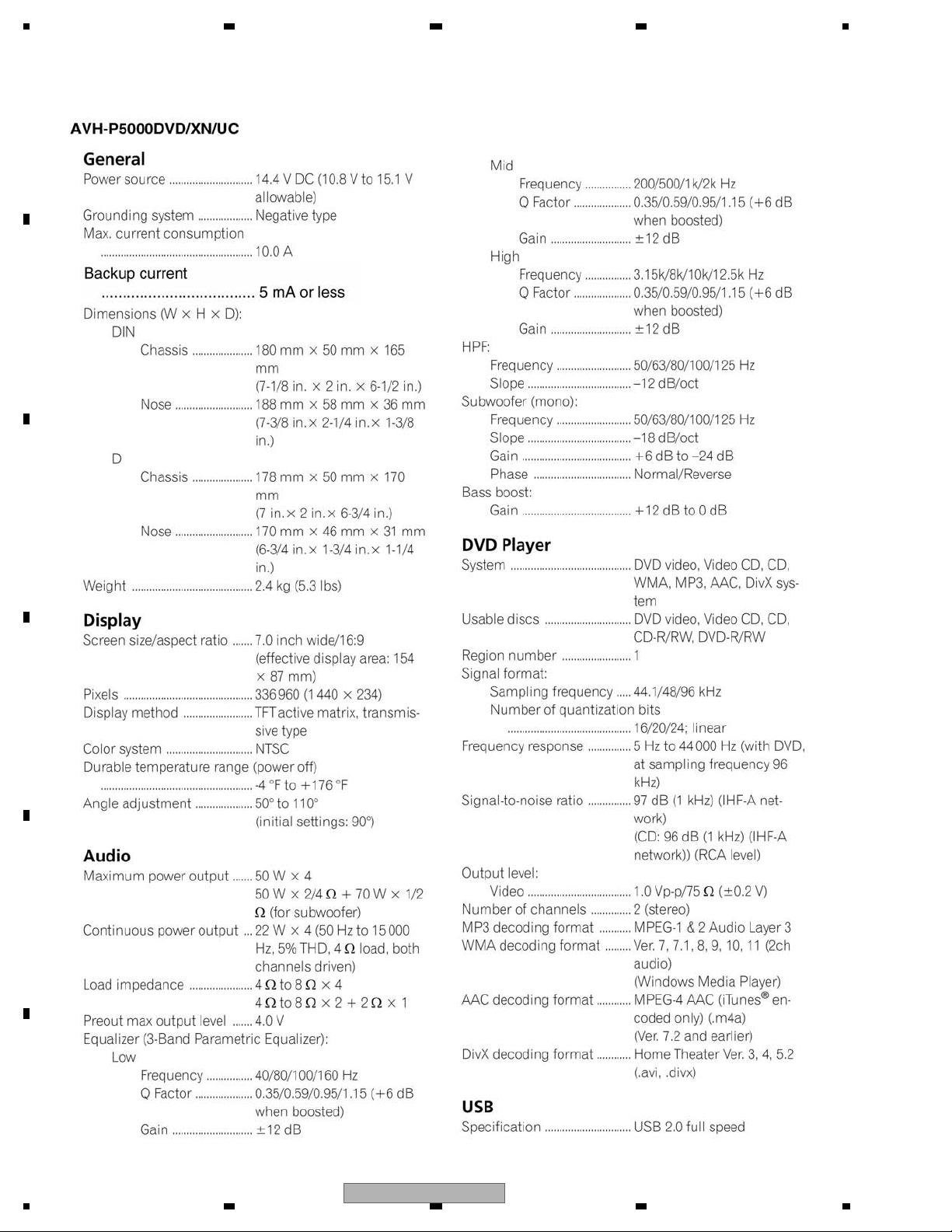

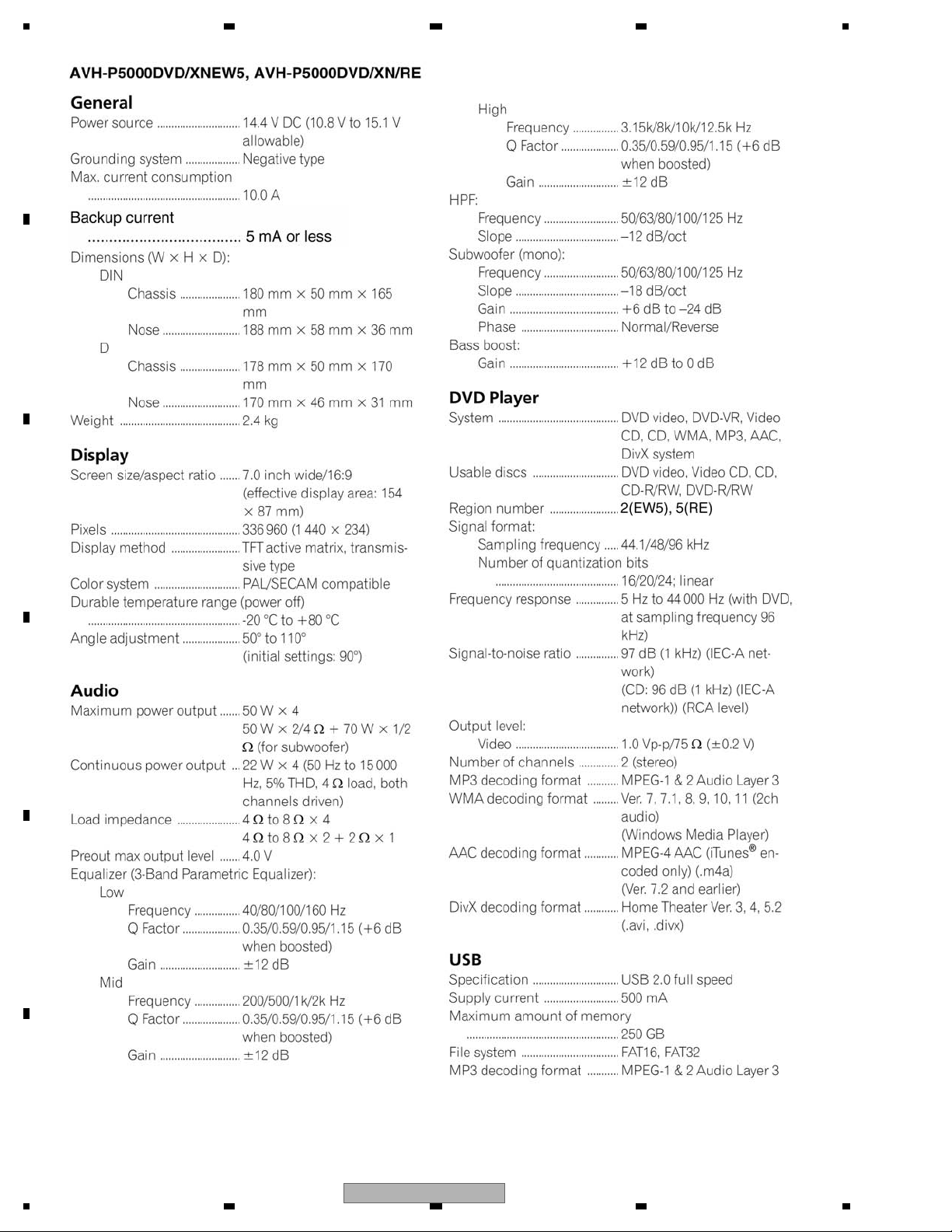

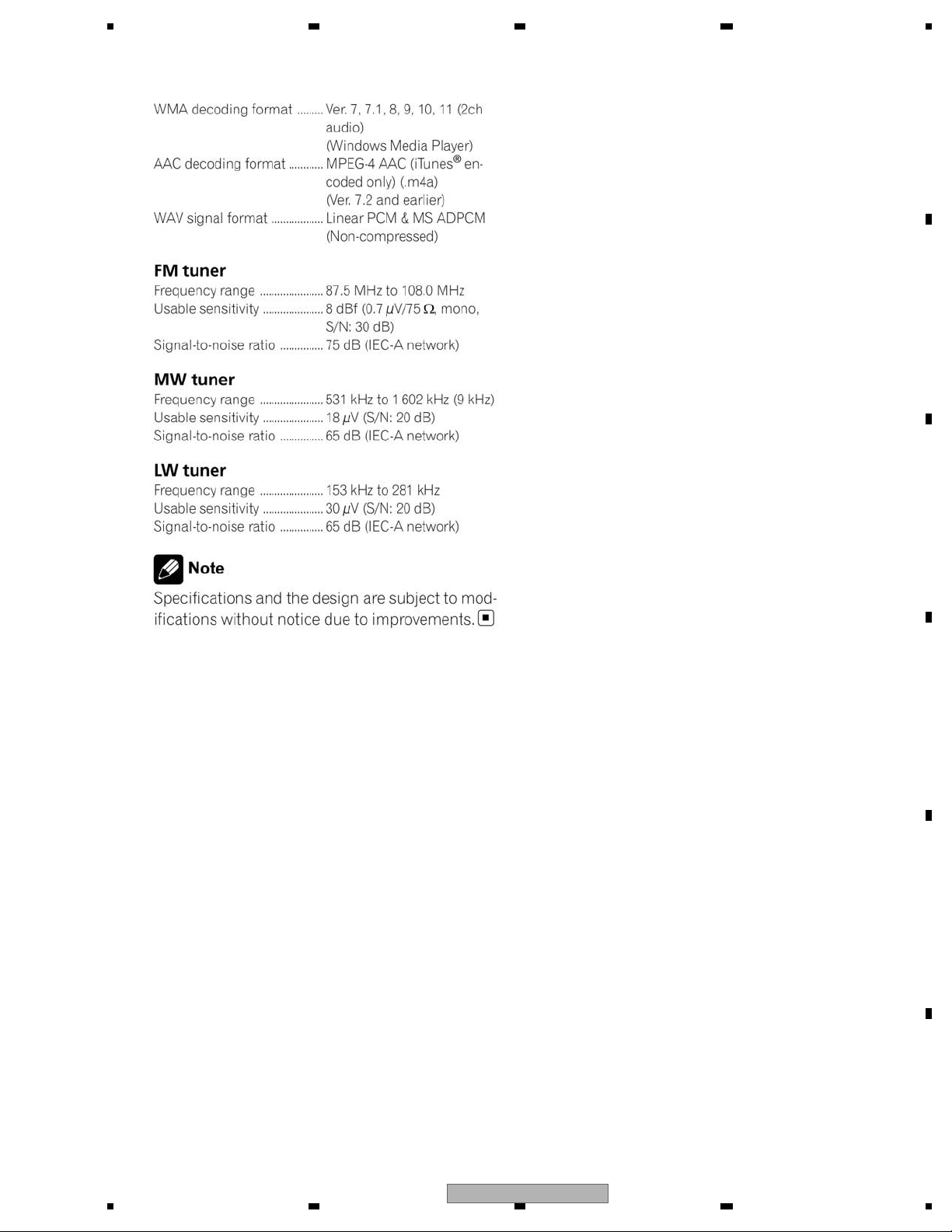

2. SPECIFICATIONS

2.1 SPECIFICATIONS

A

B

C

D

E

F

8

1234

AVH-P5000DVD/XN/UC

Page 9

5 678

A

B

C

D

E

56

AVH-P5000DVD/XN/UC

F

7

8

9

Page 10

1234

A

B

C

D

E

F

10

1234

AVH-P5000DVD/XN/UC

Page 11

5 678

A

B

C

D

E

56

AVH-P5000DVD/XN/UC

F

7

8

11

Page 12

1234

2.2 DISC/CONTENT FORMAT

A

is a trademark of DVD Format/Logo Licensing Corporation.

B

C

D

E

F

12

1234

AVH-P5000DVD/XN/UC

Page 13

5 678

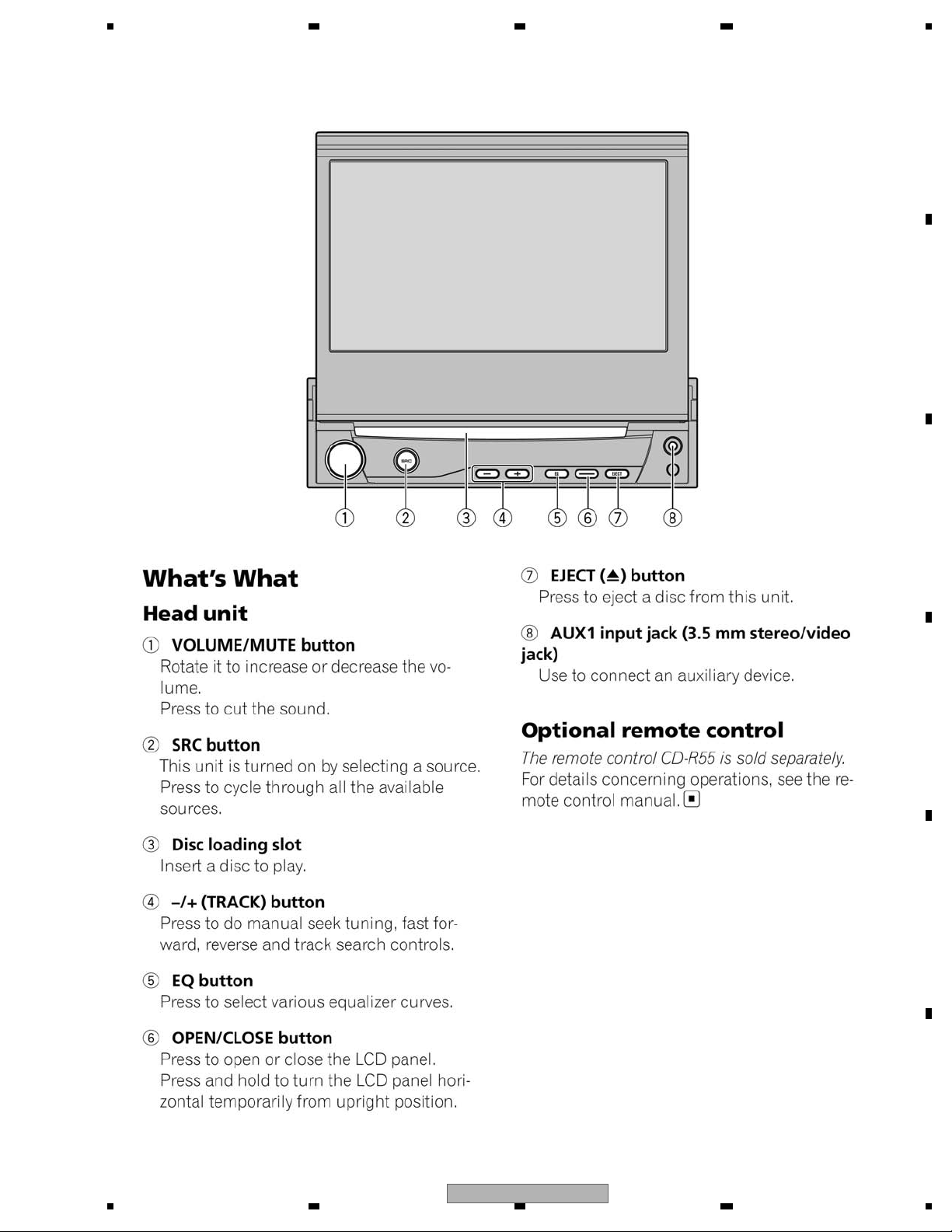

2.3 PANEL FACILITIES

A

B

C

D

E

56

AVH-P5000DVD/XN/UC

F

7

8

13

Page 14

1234

A

B

C

D

E

F

14

1234

AVH-P5000DVD/XN/UC

Page 15

5 678

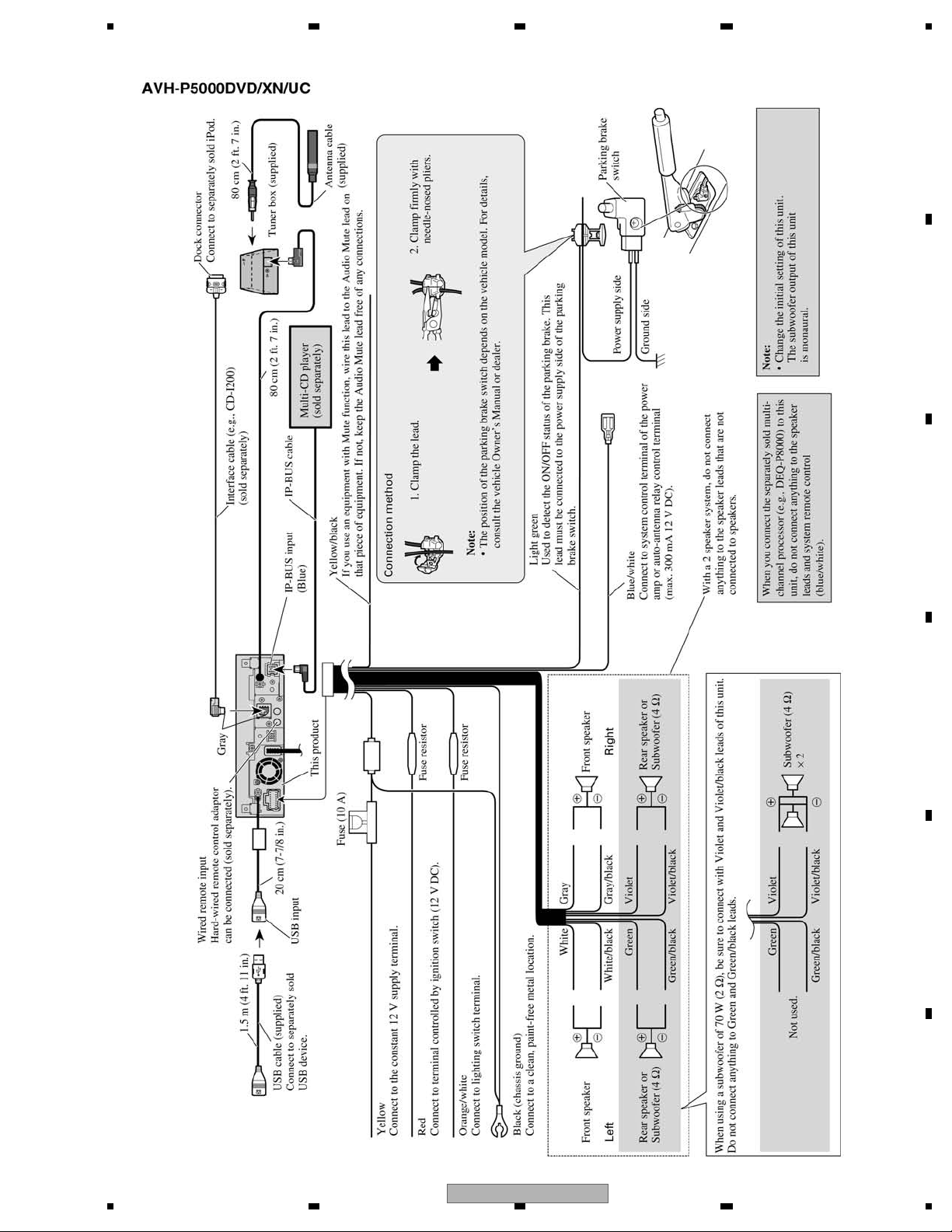

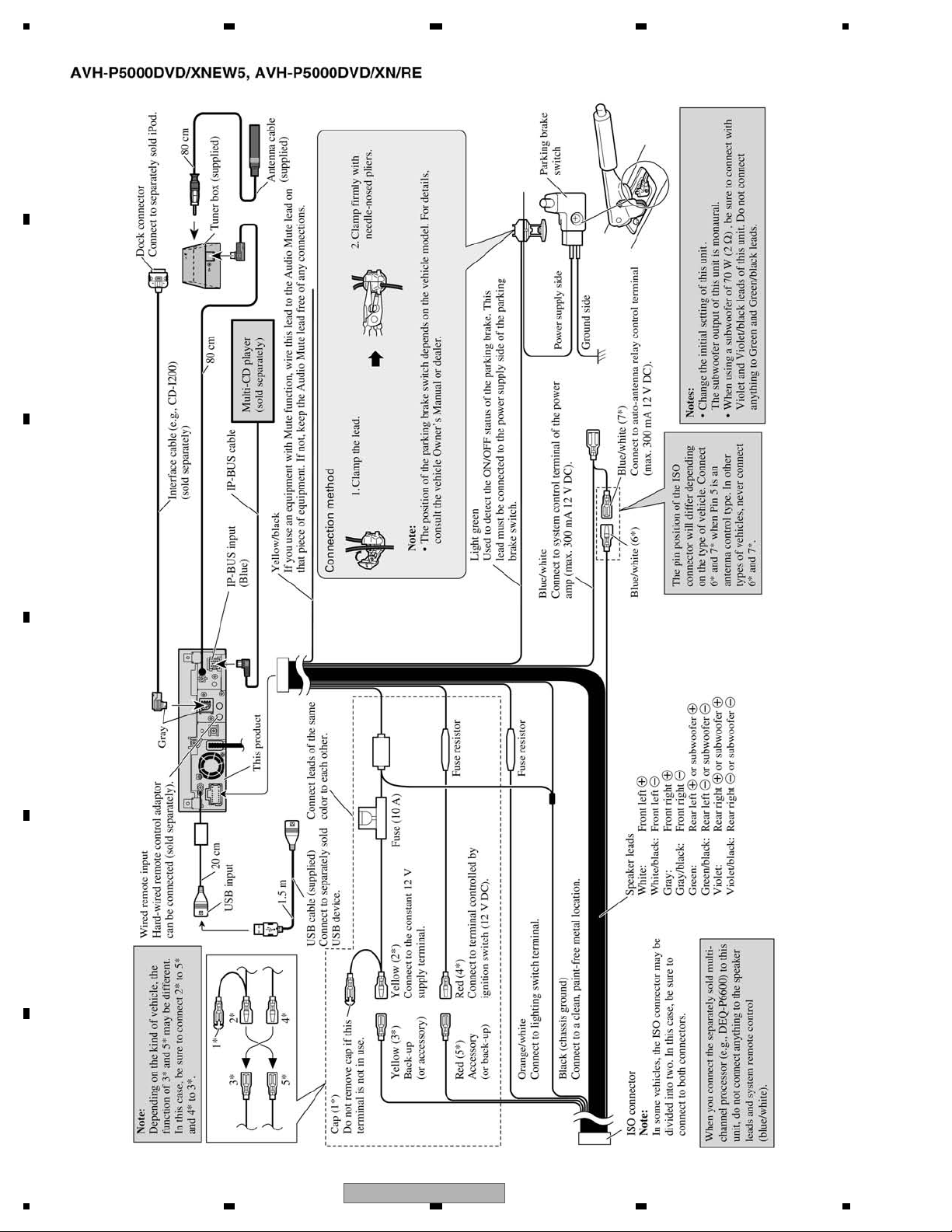

2.4 CONNECTION DIAGRAM

A

B

C

D

E

56

AVH-P5000DVD/XN/UC

F

7

8

15

Page 16

1234

A

B

C

D

E

F

16

1234

AVH-P5000DVD/XN/UC

Page 17

5 678

p

(

)

(

)

S

j

g

g

g

g

g

3. BASIC ITEMS FOR SERVICE

3.1 CHECK POINTS AFTER SERVICING

To keep the product quality after servicing, please confirm followingcheck points.

1 Confirm whether the customer complain has

2 Flap-mecha Check the operation of the flap mechanism. The flap mechanism operation must be

3 DVD Measure playback error rates at the

4 DVD Play back a DVD.

5 CD Play back a CD.

6 FM/AM tuner Check FM/AM tuner action.

7 Check whether no disc is inside the product. The media used for the operating check

See the table below for the items to be checked re

been solved.

If the customer complain occurs with the

specific media, use it for the operation

check.

innermost and outermost tracks by using the

test mode with the following disc.

DVD test disc (GGV1025)

Menu operation;Title/chapter search

Track search

(Seek, Preset)

witch band to check both FM and AM.

ardingvideo and audio:

Item to be checked regarding video Item to be checked regarding audio

Disturbed ima

Too bri

Mottled color

e (video jumpiness) Volume too high

kcehCserudecorP.oN

The customer complain must not be

reappeared.

Display, video, audio and operations must

be normal.

smooth without making

scratches.

Deterioration of mecha-drive can be

checked.

The error rates must be less than 2.5e-4

Display, video, audio and operations must

be normal.

Display, audio and operations must be

normal.

Display, audio and operations must be

normal.

must be e

receivin

ected.

it for service.

noitrotsiDesion-kcolB

esioNesionlatnoziroH

wolootemuloVesiontoD

the noise and

nitautculfemuloVkradooT

detpurretnidnuoSth

A

krameRstnio

When flap-mecha

exists

.

B

retfaecnaraeppastinotridrosehctarcsoNkcehcecnaraeppA8

C

D

E

F

56

AVH-P5000DVD/XN/UC

7

8

17

Page 18

1234

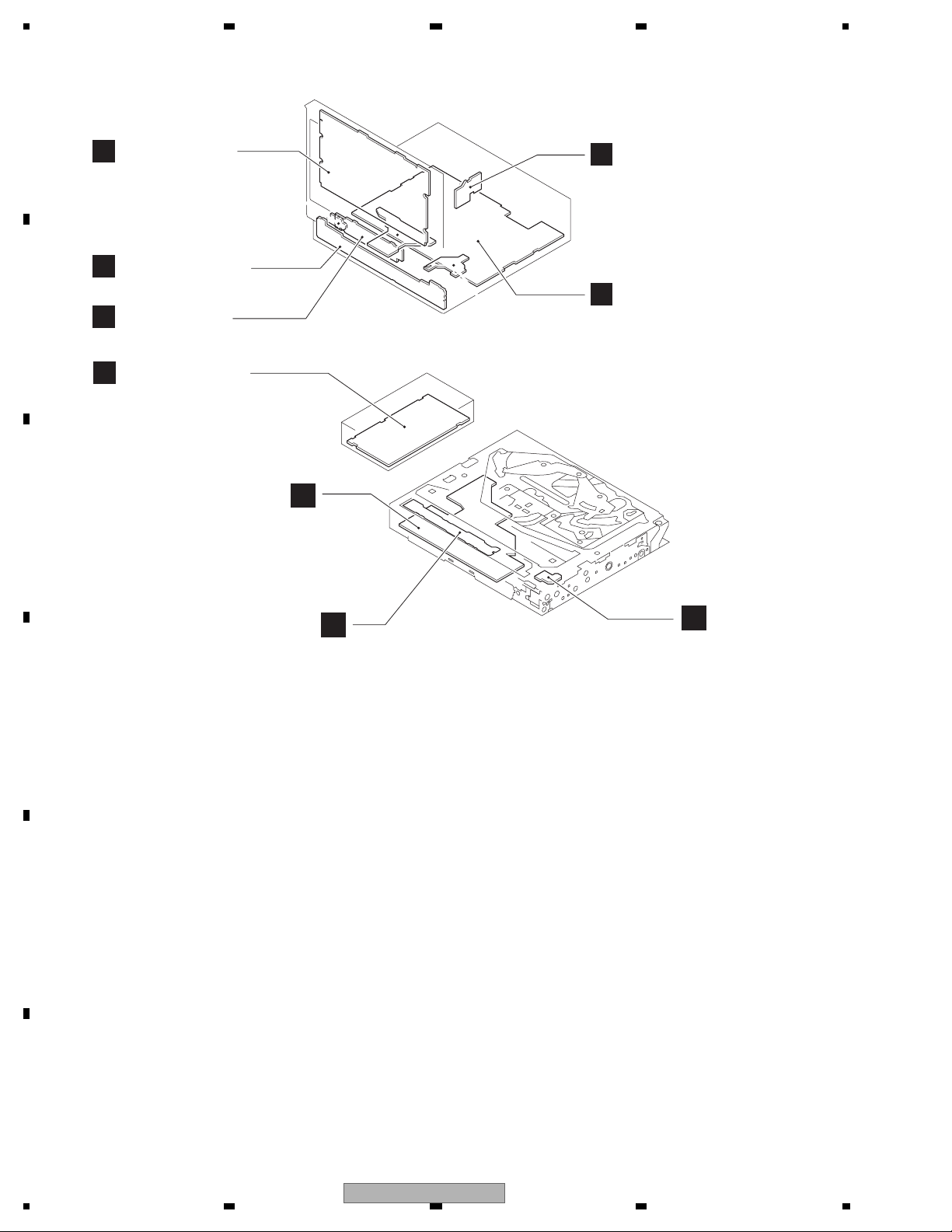

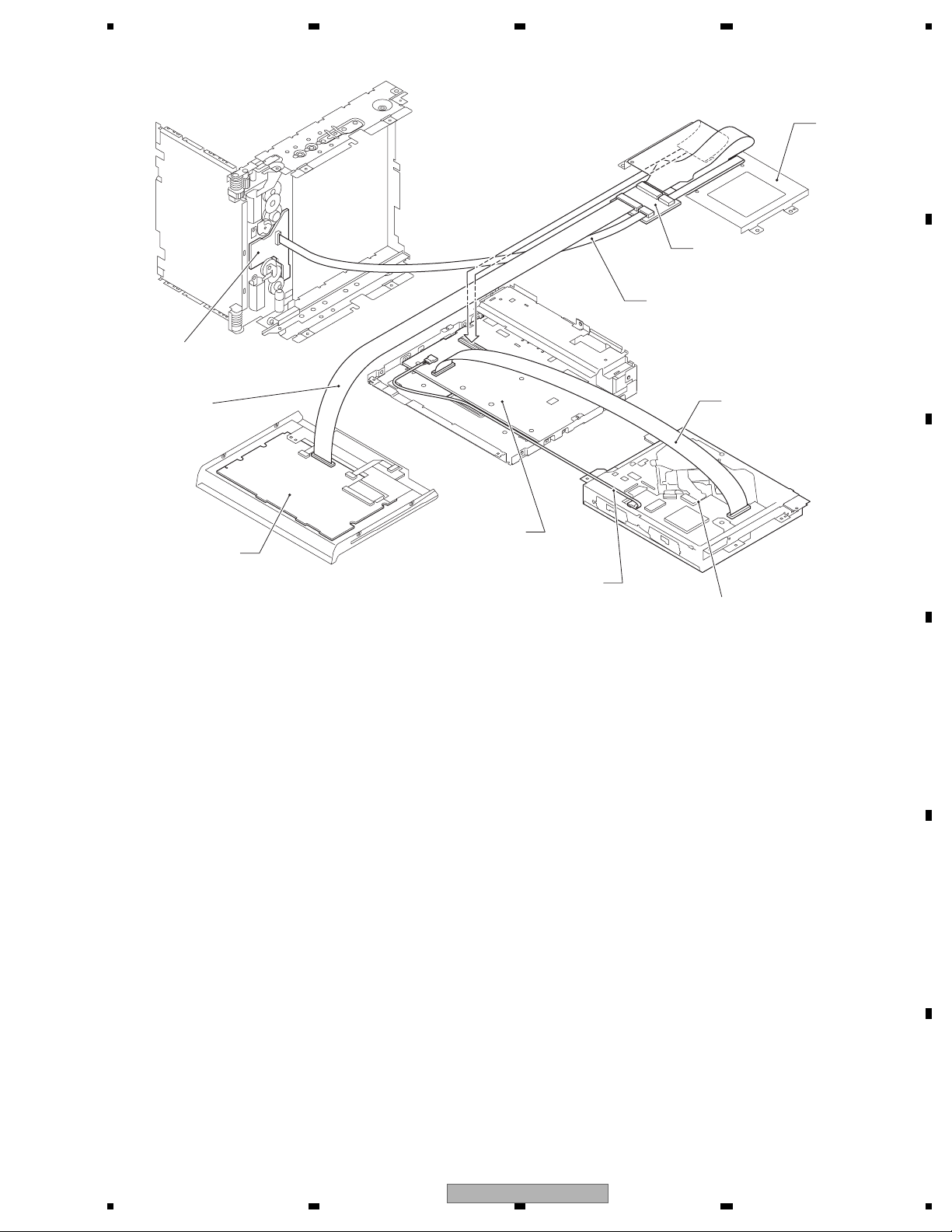

3.2 PCB LOCATIONS

A

Monitor PCB

G

C

Keyboard Unit

B

H

Invertor PCB

Tuner Box Unit

I

iPod Connector Unit

B

DVD Amp Unit

A

D

C

Unit Number :

D

E

Unit Name : DVD Amp Unit

Unit Number :

Unit Name : Keyboard Unit

Unit Number :

Unit Name : iPod Connector Unit

Monitor Unit

Consists of

Monitor PCB

Invertor PCB

Unit Number : CWN3138

Unit Name : Monitor Unit

DVD Core Unit

E

Compound Unit(A)

F

Compound Unit(B)

Unit Number : CWN3130(UC)

Unit Number : CWN3129(EW5,RE)

Unit Name : Tuner Box Unit

Unit Number : YWX5005

Unit Name : DVD Core Unit

Unit Number : CWX3595

Unit Name : Compound Unit(A)

Unit Number : CWX3559

Unit Name : Compound Unit(B)

F

18

1234

AVH-P5000DVD/XN/UC

Page 19

5 678

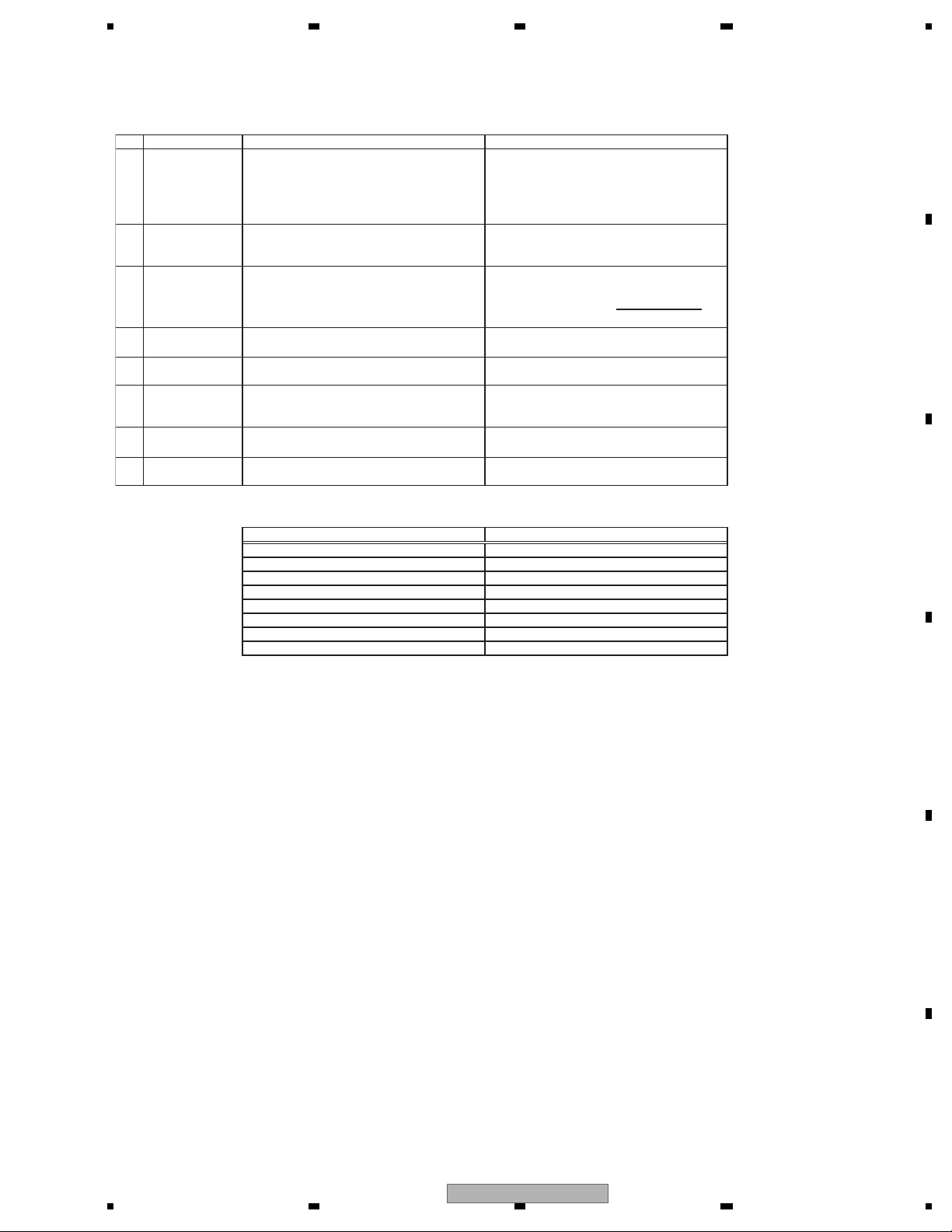

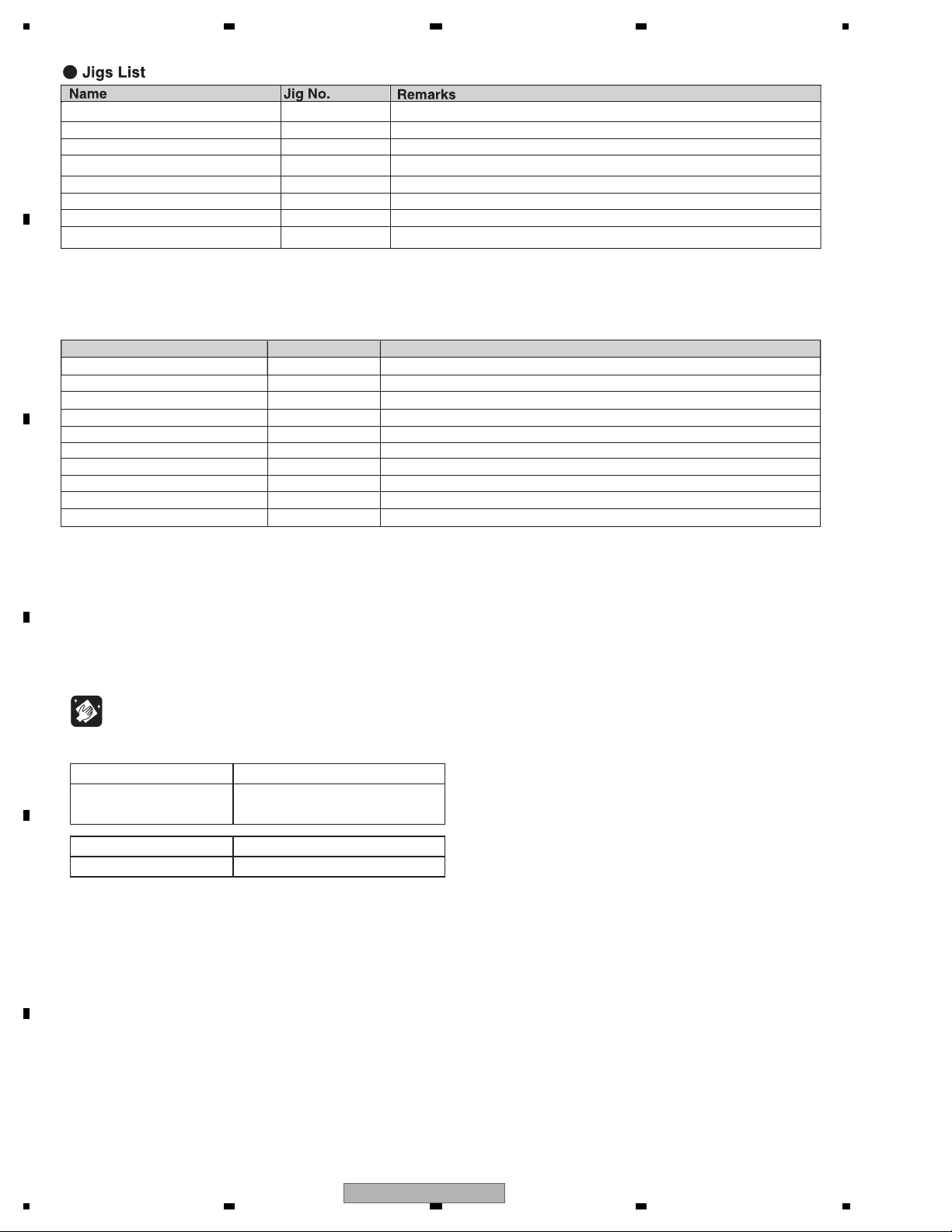

3.3 JIGS LIST

Main PCB Unit

GGD1170

40-Pin FFC

Monitor PCB

DVD Amp Unit

GGF1461

40-Pin + 20-Pin Relay PCB

GGD1209

20-Pin FFC

Bracket

GGD1284

40-Pin FFC BBR

A

B

C

Cord

CDE8589

DVD Mechanism Module

D

E

56

AVH-P5000DVD/XN/UC

F

7

8

19

Page 20

1234

DVD-Video GGV1025 Skew adjustment

A

CD-DA TCD-782 Skew adjustment

TORX driver(T2) GGK1095 Skew adjustment

Bond GEM1033 Skew adjustment

40-Pin FFC GGD1170 Monitor PCB <--> Relay PCB

20-Pin FFC GGD1209 Main PCB Unit <--> Relay PCB

40-Pin FFC BBR GGD1284 DVD Mechanism Module <--> DVD Amp Unit

40-Pin + 20 Pin Relay PCB GGF1461 DVD Amp Unit <--> Monitor PCB, Main PCB Unit

B

- Grease List

Name

Grease

Grease

Grease

Grease

Locking agents

Grease

Grease

Grease

Grease

C

Grease

Jig No.

GEM1024

GEM1043

GEM1045

GEM1050

1401M

GEM1011

GEM1047

GEM1071

GEM1072

GEM1070

Remarks

DVD Mechanism Module and Chassis

DVD Mechanism Module and Chassis

DVD Mechanism Module

DVD Mechanism Module

DVD Mechanism Module (1401M:produced by THREE BOND)

Chassis

Chassis

Chassis

Chassis

Chassis

3.4 CLEANING

D

Before shipping out the product, be sure to clean the following portions by using the prescribed cleaning tools:

Portions to be cleaned Cleaning tools

DVD pickup lenses Cleaning liquid : GEM1004

Cleaning paper : GED-008

Portions to be cleaned Cleaning tools

Fans Cleaning paper : GED-008

E

F

20

1234

AVH-P5000DVD/XN/UC

Page 21

5 678

A

B

C

D

E

56

AVH-P5000DVD/XN/UC

F

7

8

21

Page 22

1234

4. BLOCK DIAGRAM

A

INVERTOR

H

PCB

MONITOR PCB

B

G

G

G

MONITOR

1/2

OSD,uCOM

2/2

LCD MODULE

CWX3264

TOUCH

PANEL

CSX1115

DRIVE UNIT

CXC9160

C

DVD AMP UNIT

A

D

A

A

A

E

ANALOG

1/3

SYSTEM

2/3

POWER SUPPLY

3/3

KEYBOARD UNIT

C

F

22

1234

AVH-P5000DVD/XN/UC

Page 23

5 678

A

UNIT

160

iPod CONNECTOR

B

UNIT

TUNER BOX UNIT

I

B

C

D

UPPLY

E

D

56

DVD MECHANISM MODULE

F

AVH-P5000DVD/XN/UC

E

F

7

8

23

Page 24

1234

B

S

X

S

T

S

CN1901

TUNER BOX UNIT

I

iPod

JA1

1

2,3

AM_ANT

1

FM_ANT

3

Lch

23

SL

5

CE2

6

CE1

8

CK

9

DI

10

DO

14

LDET

11

RDS_CK

18

RDS_DATA

19

A

RDS_LOCK

20

RDS_HSLK

B

21

VCC

4

VDD_3.3

17

13

B

4

3

6

10

11

7

5

2

JA1901

3

ROM_VDD

iPod CONNECTOR UNIT

ACC_ID

TXIPOD

RXIPOD

ACC_PW

ACCDET

VOUT

LOUT

FMPWR

Q2

TUN3.3V

IC1

NJM2391DL1-33

IC5

1

TC7WH08FU

TUN+B

2

NJM2388F84

17

53

IC3

DSEN

CE2

CE1

LDET

RDS_CK

RDS_DATA

RDS_LOCK

RDS_HSLK

B.UP

1

ROMVDD33

CN1901

ACC_ID

TXIPOD

RXIPOD

ACC_PW

ACCDET

VOUT

LOUT

FMPWR

JA2

SL

CK

DO

14

L

17

19

21

15

10

DI

4

3

9

6

1

13

5

18

8

10

11

12

8

6

7

1

14

A

FM/AM

ANTENNA

FM/AM

TUNER UNIT

B

C

CONNECTOR

DVD AMP UNIT (1/2)

A

CN401

DSEN

4

TUN_L

14

TUNSL

17

TUNCE2

6

TUNCE

19

TUNCK

11

TUNDI S_TTUN

13

15

18

3

7

1

5

20

16

10

11

12

8

6

7

1

14

TUNDO

LDET

RDSCK

RDSDATA

RDSLOCK

RDSHSLK

B.UP

ROMVDD

ACCID

IPODTX

IPODRX

ACCPW

ACCDET

VOUT

LOUT

FMPWR

Q903

(1/2)

Q903

(2/2)

SWBUP

P402

FMPW

T_STUN

LDET

IC701

TC7WH08FU

E

VDD33

53

71

TXIPOD

RXIPOD

PSENS

PSENSG

PID

43

19

AV SELECTOR

IC301

AN15887A

V4-1

L4-1

V1-1

37

32

CN801

COMPOSIT

D

I

I

3

1

17

14

21

22

VD

VDD5

XRES

IRQPWRIRQPW

P801

VD8

VD5

XRES

23

S MS5TXS_MSTX

MS5 SRXMS_SRX

242025

STANBYSTANDBY

40

AMUTE

WAKEUP

REAR VIEW CAMERA/

REVERSE-GEAR

D

E

G

F

VCR/

SIGNAL IN

USB

Drive

Unit

CN5001

CN121(1/2)

VCR_L

10

VCR_V

14

B.CAMERA

15

BG

20

CN550

USB5V

1

USBDM

2

USBDP

3

CN441

ANGLEIN

1

LIFTPUL

2

MTRS

3

MTRPW

4

MTR2 MTR2

5

MTR1 MTR1

6

MTRSEL

7

GNDD

13

ANGLOSW

8

LFTSW

9

SENSPW

10

VDD

11

18

BUP

I

20

MONRST

31

S_MTX

32

M_SRX

33

MONVBS

58

REM

46

MFLPW

42

35

PWRFL

I

37

PWRVI

39

.

40

50

I

52

BGSENS

Q141

5

IC551

VOUT

R5523N001B

IC441

TC74VHCT08AFTS1

P442

ACC5

P441

ACC33

P443

BUP

PWFL

PWVI

SWVDD33

1

EN

3

FLG

23

1211

98

BGSENS

USBCNT

USBFLG

ANGLE

LFTPUL

MTRSEL

DEGOSW

MONRST

D

TO 2/2

F

AUX_L

AUX_V

MONITOR VBS BUFFER

Q351

Q352

SYS+B

8

L2-1

39

V2-1

47

V6-1

23

L5-1

45

V5-1

34

VOUT1

33

FB1

LOUT1

VOUT2

USBDM

USBDP

SDA

SCL

L3-1

28

32

35

36

15

X502

48.000

MHz

X501

16.934

MHz

R_VOUT

55

50

52

4

5

1

2

LOUT

DM

DP

USBXTAL1

USBXTAL2

XTAL1

XTAL2

G

USB CONTROL

IC501

PE5611B

AVSDA

AVSCL

B

BR

B

S

RE

24

1234

AVH-P5000DVD/XN/UC

Page 25

5 678

21

CN1901

D

224023

24

20

25

STANBY

IRQPWRIRQPW

S MS5TXS_MSTX

MS5 SRXMS_SRX

STANDBY

29

LOUT

AMUTE

WAKEUP

SYS+B

Q801

Q802

MS_L MS_L

SYSTEM MICOM

Q401

Q402

144

114

113

101

100

107

106

105

132

116

115

129

124

122

126

125

123

127

70

69

68

18

19

98

63

64

61

62

21

76

66

31

32

30

60

59

22

23

49

50

51

54

53

48

47

94

95

17

24

29

25

26

TUNSL

TUNPCE2

TUNPCE

TUNCK

TUNPDO

TUNPDI

LDET

RCK

RDSLK

RDT

RD57K

EVSEL

EVSCK

EVSDA

XRESET

IRQPW

TXMS5

RXMS5

STNDBY

WAKEUP2

AMUTE

TXIE

RXIE

ASENBO

PID

TXIPOD

RXIPOD

PSENS

PSENSG

AVSDATA

AVSCK

BSI

BSO

BSCK

BRXEN

BSRQ

BRST

BGSENS

USBCNT

USBFLG

ANGLE

LFTPULS

MTRS

MTRPW

MTR2

MTR1

MTRSEL

DEGOSW

LFTSW

MONIRST

TXMON

RXMON

USB CONTROL

IC501

PE5611B

AL1

AL2

AVSDA

AVSCL

BSO

BSCK

BRXEN

BSRQ

STBY

RESET

TUNSL

TUNCE2

TUNCE

TUNCK

S_TTUN

T_STUN

LDET

RDSCK

RDSLOCK

RDSDATA

A

RDSHSLK

B

EVSTB

EVSCK

EVSDT

XRES

IRQPW

S_MSTX

MS_SRX

STANDBY

WAKEUP

AMUTE

PID

21

BSI

22

23

26

27

47

16

BSIO

BSCK

BRXEN

BSRQ

BRST

BGSENS

USBCNT

USBFLG

ANGLE

LFTPUL

MONRST

S-MTX

M-SRX

1

BUS-

BUS+

JA751

6

5

+

BUS

IC751

DIN1

HA12241FP

1

2

TXIE

RXIE

IC601(1/2)

A

B

:PE5632A

C

:PE5633A

IP-BUS INPUT

5

8

ABO

-

BUS

ROUT

BUP

AMPPW

SYSMUTE

PBSENS

ASENS

BSENS

ISENS

TELMUTEIN

CPCLK

PCK

PRDY

PDT

PRST

WIRED

WIREDAD

ROTIN1

ROTIN2

KEYIN1

KEYIN2

DSENS

SECID

DCK

FLMDO

DMS

DRST

DDI

DDO

RESET

CN1852

IC201

Pre/SW_L

REAR_L

ASENS

BSENS

IPOD CP

341S2094

D

1

OPTIN

CN951

10

Front_L

12

11

PBSENS

ISENS

IC550

POWER ON RESET

12

S-80827CNNB-B8M

7

11

BUSL-

BUSL+

Q751

ASENBO

TUN_L

LOUT

117

80

BUP

46

74

75

143

82 TELMUTE

38

36

3

35

4

140

141

137

136

139

138

135

28

41

8

42

20

39

40

14

BUSL+

BUSL-

SYS+B

11

15

38

EVOL CAPTAIN

3

IN4+_L

4

IN4-_L

7

IN1_L

2

IN5+_L

6

IN2_L

21EVSTB

STB

20EVSCK

CLK

19EVSDT

DATA

Q153

OFFMUTE

Q155

2

XIN

7

I2C_SCL

CP_READY

I2C_SDA

nRESET

RESET

PML018A

RESET

E

BUP

Q154

(1/2)

ASENS

Q172

BSENS

DSENS

IC602

ROT1

ROT2

KEY1

KEY2

ACC5

Q951

IC951

TC7SET08FUS1

1

2

PA_FL

PA_RL

AMPMUTE

Q154

(2/2)

F

4

RCA MUTE

Q152

12

14

4

22

ISENS

TELMUTE

VDD33

VDD33

AUX_L

AUX_V

Q101

FLIN

RLIN

STBY

MUTE

R_VOUT

G

AMP

IC151

PAL007C

B.REMOTE

PBSENS

Q171(1/2)

B.UP

Q173

Q171(2/2)

Q851

FL+

FL-

RL+

RL-

BUP

ILMA

ILMB

SWVDD33

5

3

21

23

25

JA951

OPTG

OPTSENS

OPTOUT

OPTG

CN121

REARVOUT

CN171

B.REM

MUTE

JA431

WIRED

WIREDAD

WIREDGND

CN851

DSENS

SECID

RESET

(2/2)

B.UP

ACC

ROT1

ROT2

KEY1

KEY2

AUXL

AUXV

REM

FL+

RL+

RL-

P.B.

ILM

FL

RL

FL-

2

3

4

1

2

4

18

3

1

4

2

12

15

9

11

13

14

2

3

4

1

14

16

10

15

8

4

13

9

7

12

1

6

11

RCA OUT

POWER

SUPPLY

CN3001

C

DIGITAL

OUT

WIRED

REMOTE

A

B

C

D

E

RESET

RESET

VDD33

DCK

FLMDO

CN601

2

FLASH WRITE

CONNECTOR

DMS

5

3.3V

DRST

RESET

DDI

DDO

6

748

9

11

10

AVH-P5000DVD/XN/UC

56

A

:AVH-P5000DVD/XNEW5

B

:AVH-P5000DVD/XN/RE

C

:AVH-P5000DVD/XN/UC

D

:TO 2/2

7

F

8

25

Page 26

1234

DVD AMP UNIT (2/2)

A

SYSTEM MICOM

A

B

IC601(2/2)

A

B

C

:PE5632A

:PE5633A

CLCNT1

CLCNT2

SYSPW

BUP

BUP

BUP

BUP

SWBUP

SYS8.4V

24

IC1101

BA00CC0WFP

HIOUT 12V

65

IC1202

LT3461AES6

Q1201

Q1202

P1151

111

112

6

SYSPW

SYSPW

SYSPW

SYSPW

Q1151

Q1152

FAN

Q1251

|

Q1254

1

4

P1251

SWBUP

SYS+B

EV12

CN1251

FAN

2

1

P1051

BUP

P1071

TO 1/2

Q1002

C

ACCPW

DDCCTL

D

E

VDCONT

BEEP

X1

X2

RED_ON

BLUE_ON

SWVDD

7

55

65

56

12

13

79

78

37

ACCPW

ACCPW

X601

4.718592MHz

ACC5

BUP

Q1405

BZ601

1,2 4

PWVI

PWFL

Q1071

Q1072

MFLPW

D

Q1001

VDD33V

2

IC1001

S-812C33AUA-C2N

3

DC/DC CONVERTER

IC1401

P1403

VR1401

9

3

2

VDCONT

AN8011S

VCC

ON/OFF

RT

OUT2

OUT1

7

10

5.4V

Q1402

Q1404

Q1401

Q1403

P1401

P1402

VD5

Q1701

Q1702

VD8

ILMA

Q1542

ILMB

Q1522

8V

VDCONT

8V

8V ILMB

ACC33V

IC1601

BA00BC0WFP

Q1501

Q1502

SWVDD33V

Q1621

Q1622

PWVI

PWFL

ILMA

Q1031

Q1032

2

S-1206B41-U3

USB33

IC1031

VDD33

USB33

3

ACC5

5.4V

8V

VD5

VD8

ACC33

SWVDD33

A

:AVH-P5000DVD/XNEW5

B

:AVH-P5000DVD/XN/RE

C

:AVH-P5000DVD/XN/UC

D

:TO 1/2

PPOWER

VDSENS

133

131

BUP

Q1303

Q1305

|

FWPW

FIREWIRE PW

F

26

1234

AVH-P5000DVD/XN/UC

Page 27

5 678

KEYBOARD UNIT

C

CN3001

AUXL

1

AUXV

6

KEY1

10

KEY2

15

ROT1

14

ROT2

16

CN851

A

RESET

12

DSENS

8

S3007

EJECT

S3008

OPEN/CLOSE

S3009

ATT&VOLUME

1

3

2

S3002

RESET

S3001

DSENS

EQ

S3003

S3004

SOURCE

S3005

REVERSE

S3006

FORWARD

4

5

JA3001

GND

L

R

VIDEO

2

4

3

1

A

B

11

7

13

9

4

REMOTE CONTROL

REM

SWVDD33

ILMA

ILMB

SECID

SENSOR

1

IC3001

GP1UX31RK

3

C

D3017-D3027

D3006-D3016

D3028

D

E

56

AVH-P5000DVD/XN/UC

F

7

8

27

Page 28

1234

O

P

DVD CORE UNIT

D

A

B

C

D

NRES

LATCH

IC1352

TC74LCX16373FT

A0-15

A0-15

12

FLASH 16M

CWW1439

CWW1440

RESET

IC1401

IC1402

AD0-15

48

1LE

25

2LE

AD0-15

A16-19

XCSSR26

CE

WE

WE

XWR111

XCSFM26

CE

11 XWR2

XRDNRES 28 50

OE

SDRAM

IC1481

EDS1232AATA-75

IC1403

TC7SZ32FU

AD0-15

A16-19

1

4

2

IC1351

TC7SZ08FU

1

4

2

MA0-11

MDQ0-31

DQM0-3

22

BA0

23 10

BA1

WE

CAS

RAS

20

CS

68

CLK

VOLTAGE DETECT

IC1003

S-80859CNNB-B9K

2 1 VSENS

CN1951

PR_A20 92

11

EXTRG1_SPD_SW

10

SCLOCK

9

SDATA

8

EXTRG0

7

TRCCLK

6

TRCD0

5

TRCD1

4

TRCD2

DEBUG

3

TRCD3

2

TRCST

1

12

VCC33

|

13

VD8

OUTVDD

XWE17 3

XCAS18 4

XRAS19 5

XCSM 6

MCK 234

XCSSR

XCSFM

VIDEO+AUDIO

MN2DS0016AAUB

101

NRST

77

XCSSR

51

NEXCE

62

NEXWE

NEXOE

8

BA0

BA1

NWE

NCAS

NRAS

NCSM

MCK

232

MCKI

88

VSENCE

P0

189

EXTRG1

192

SCLOCK

191

SDATA

190

EXTRG0

188

TRCCLK

187

TRCDATA0

186

TRCDATA1

185

TRCDATA2

184

TRCDATA3

183

TRCST

IC1501

SRCK

ADOUT3

LRCK

SDODAC

SCKDAC

LTD AC

DACCK

OSCO

OSCI

Comp

STANDBY

SLVSTS

HOSTCMD

IRQPWR

AMUTE

DSCSNS

PHOTOSNS

IECOUT

CONT2

CONT1

DRV3

DRV2

LOADIN

CLAMP

HOME

TEMP

VIN2RF

VIN2

VIN1RF

VIN1

VIN3RF

VIN3

VIN4RF

VIN4

VIN5

VIN6

CDMPD

DVDMPD

RFINN

F+H_G+H

E+G_E+F

LPCO2

LPCO1

174

175

173

91

90

74

172 DACCLK

169

170

152

Cr

153

Cb

154

Y

161

78

79

80

89

87

147

144

179

85

84

95

96

97

MD

93

99

FG

150

FD

149

TD

94

98

145

122

142

123

143

121

140

120

141

136

137

130

128

116

134

135

131

129

X1501

(CR)

(CB)

(COMPOSIT)

LDIN

B

A

C

D

FE1

FE2

RF

(Y)

COMPOSIT

STANBY

STSCOMN

CMDCOMN

AUDI

SRCK

ADOUT3

LRCK

SDODAC

SCKDAC

LTD AC

DACCLK

1

2

3

13

14

15

16

CR

CB

Y

E

VDD5

F

28

1234

AVH-P5000DVD/XN/UC

Page 29

5 678

AUDIO 2CH ANALOG OUT

SRCK

ADOUT3

LRCK

SDODAC

SCKDAC

LTD AC

DACCLK

1

2

3

13

14

15

16

VDD5 VCC33

IC1801

PCM1753DBQ

VOUTL

BCK

DATA

LRCK

MD

MC

ML

SCK

NJM2885DL1-33

R1232D121B

2

VIN

3

7

3.3V REG.

IC1007

OUTIN

1.2V REG.

IC1008

VDD

A

CN1901

XRESETNRES

COMPOSIT

STANBY

SLVSTS

HSTCMD

IRQPWR

AMUTE

WAKE UP

CN1301

DiscDetect

1

2

12cm

PhotoPHOTOSNS

VD5

VD8

8cm

8cm

21

29

CR

38

CB

36

Y

34

32

25

24

23

CN801

A

22

20

14

|

17

3

2

|

1

40

3

2

4

5

1

COMPOUND UNIT(A)

E

S1203

DISC SENS

4

3

2

5

6

8cm

12cm

8cm

S1202

Q1299

S1204

S1201

S1205

B

VCC5

AVCC 5

VCC5 REG.

IC1004

NJM2880U1-05

4

VOUT

AVCC5 REG.

IC1005

S-L2980A50MC-C7J

5

VOUT

CONT

ON/OFF

5

VIN

1

1

VIN

3

LOUT

STSCOMN

CMDCOMN

VDD5

VD8

DISC DET

IC1301

TC7SZ125FU

ANALOG LOUT

FU1901

4DSCSNS

CN1852

IECOUT

1

CN951

A

C

CLAMP1

MOTOR DRIVER

IC1201

BD7996EFV

CONT2

CONT1

DRV3

DRV2

MD

FD

TD

31

8

LX

VCC12

20 18

CTL2 SLO2-

21

CTL1

SLO1-

25

SLIN2

SLO2+

26

SLIN1

SLO1+

29

SPIN

LDIN

FG

ACTIN1

ACTIN2

HW-

HW+

HV+

HU-

HU+

ACO1ACO1+

ACO2+

ACO2-

V

W

U

HB

HV-

10

13

51

50

16

17

15

42

39

44

36

30

31

32

33

34

35

2

FOM

1

FOP

TOM

3

4

TOP

COILV

COILW

COILU

HBM

HWM

HWP

HVM

HVP

HUM

HUP

LPCO2

LPCO1

VDD5

HALL_BIAS+

Q1104Q1102

Q1103Q1101

VREF

VCC5

CN1201

COIL_V

COIL_W

COIL_U

HALL_BIAS-

HALL_W-

HALL_W+

HALL_V-

HALL_V+

HALL_U-

HALL_U+

SWITCHHOME

CN1101

FOM

FOP

TOM

TOP

FE1

FE2

78MDCDMPD

65MDDVDMPD

F+H/G+HF+H_G+H

E+G/E+FE+G_E+F

LD(CD)

LD(DVD)

VCC

B-

AB+

A+

FF+

TT+

THTEMP

B

A

C

D

RF

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

20

1

2

3

4

5

7

8

9

10

11

12

14

15

PU (DP8)

17

21

22

24

25

19

20

TP1

F

S1206

CLAMP

COMPOUND UNIT(B)

D

E

56

AVH-P5000DVD/XN/UC

F

7

8

29

Page 30

1234

A

E

MONITOR PCB

G

A

PICTURE SPLIT IC

IC5401

CN5001

MONVBS

28

MONRST

7

S-MTX

8

M-SRX

9

MFLPW

15

18

19

10

I

12

13

.

14

21

I

23

CN5002

4

3

1

2

SWVDD

REM

PNLADY

PNLADX

PNLYV

PNLXV

Q5702

(1/2)

Q5701

(1/2)

Q5702

(2/2)

Q5701

(2/2)

Q5703

(1/2)

SWVDD33

SWVDD33

PWRFL

PWRVI

SWVDD33

SWD33

Q5703

(2/2)

CN441

A

B

C

TOUCH

PANEL

MONITOR uCON

IC5603

PE5634A

14

RESET

36

DPDT1

35

KYDT1

85

MFLPW

65

STEST1

48

REM

89

PNLADY

90

PNLADX

83

PNLVD

81

PNLYV

92

TOUCHAD

82

PNLXV

PIPCK

PIPDA

PIPRST

TEMPSEN

OSDSCL

OSDDATA

OSDCS

OSDRES

EPRDI

EPRDO

EPRCK

EPRCS

DACDI

DACCLK

DACLD

DIMMER

23

22

21

TH5601

TEMP. SENSOR

100

52 OSDCK

51 OSDDA

62

OSDCS

OSDRST

63

EEPROM

IC5604

S-93C56BD0I-J8

43

4

DO

3

44

DI

2

47

SK

45

1

CS

18

19

17

28

DACDI

DACCLK

DACLD

PIPCK

PIPDA

PIPRES

OSD IC

IC5802

PDC169B

OSCin

VSYNC

HSYNC

5

SCLK

6

SIN

7

CS

15

RST

BLK

ROUT

GOUT

BOUT

OE OE

M62343FP

6

7

CLK

8

IC5301

NJM2505AF

2

9

11

30

34

35

36

D0-11

A0-17

58

57

IC5501

DILDA02

A01

A03

14

OSDCLK

Q5801-Q5802

26

28

2

1

3

OSDV

OSDH

BLK

OSD ROM

IC5801

PEH172A

CECE

OSDR

OSDG

OSDB

66

Sub_C.

Video_IN1

104

Bus_Clock_IN

105

Bus_Data_IN

107

Reset_IN

91

OSD_Clock_Out

92

OSD_V.Sync_Out

93

OSD_C/H.Sync_Out

88

Main_RGB_Sync_IN1-2

101

OSD_Blank_High_IN

78

R_IN.2

79

G_IN.2

80

B_IN.2

2

1

+

3

IC5503

NJM2100V

5

7

+

6

-

TC90A96BFGSING

R2-7_D-Out

G2-7_D-Out

B2-7_D-Out

X'tal_OUT

DAC_Out

IC5505

TC7S66FU

STH

Load

CPH

OE

CPV

STV

Vcom

X'tal_IN

PLL_IN

VCOM AMP

4

DIMMER

143-148

153-158

166-171

139

138

137

136

135

134

TC7SET04FUS1

133

52

X5401

42MHz

53

Q5401

60

56

IC5502

521

6

42

I

NJ

+

-

D

38

INVPUL

PWRVI

SWVDD33 OSD33V

E

DDCON_SEL

12

X5601

5MHz

XIN

13

XOUT

OSDPW

MVIPW

61

30

80

Q5607

Q5608

D/D CONVERTER

IC5103

BD6171KV

11

PVCC1

6

OUT2

PVCC2

41

PVCC

42

PVCC3

VCC

PVCC4

PVCC5

OUT1

OUT3

43

FIN

OUT4

32

OUT5

EN1

7

4

VS2

23

48

37

10

13

VS1

22

47

38

INVPUL

8V REGULATOR

Q5103

4

S

1,2,5,6

D

3

G

3.3V REGULATOR

Q5102

4

S

1,2,5,6

D

3

G

CH

R

F

30

1234

AVH-P5000DVD/XN/UC

Page 31

5 678

I

I

5

0

LCD MODULE

A

CN5501

143-148

ut

153-158

ut

166-171

ut

H

d

H

E

V

134

V

IC5502

TC7SET04FUS1

133

m

52

N

53

T

60

ut

56

N

X5401

42MHz

Q5401

42

IC5504

TC7SET04FUS1

2

4

DC0-5

DB0-5

DA0-5

DRIVER

IC5506

TC74VHC04FTS1

1,3,5

9,11,13

LADDER NETWORK

2,4,6

8,10,12

VCCM12V

VCC18V

VCC5V

VCC3.3V

OM AMP

IC5507

52

+

6

-

NJM082BV

3

+

7

2

-

FU

MER

PUL

VCOM DRIVE

1

Q5501

Q5502

PWRFL

V0-10

STH1139

LOAD138

CPH137

CPV135

STV1

VCOM

VCOM

VGL

VGH

VDD2

L/R

VDD1

CN5004

DIMDTY

INVPUL

30

|

35

36

|

41

42

|

47

59

29

20

OE136

9

8

6

48

|

58

1

2

4

13

24

I

26

28

16

.

17

LCD

B

LCD BACK LIGHT

C

INVERTOR PCB

H

CN5201

LCD DRIVE

IC5204

CN5602

8

8

PWRFL

I

I

10

10

DIMDTY

2

2

INVPUL

3

3

5V REGULATOR

IC5201

TA78L05F

Q5202 Q5203

IC5203

TC7SET08FUS1

1,2

4

Q5204

531

14

15

3

7

9

18

OZ961ISN

VDDA

DIM

LCT

ENA

V2500

FB

CT

PDRV_A

PDRV_B

PDRV_C

PDRV_D

OVP

Q5207

19

20

Q5208

12

11

VR5201

17

RT

2

T5201

4,5

6

2,3

7

2

1

FL2

FL1

D

INVBST

LATOR

3

1,2,5,6

D

LATOR

2

1,2,5,6

D

CHARGE PUMP

REGULATOR

2.5V REGULATOR

5

IC5102

S-1132B25-U5

4

1.5V REGULATOR

5

IC5101

S-1132B15-U5

4

1

1

VCC8V

V33IO

V33

VCC3.3V

V33D

VCC5V

VCC18V

VCCM12V

V25

V25P

V25AM

V25AS

V15

V15M

V15D

AVH-P5000DVD/XN/UC

56

INVBST

1

1

Q5205

Q5201

Q5206

E

F

7

8

31

Page 32

1234

5. DIAGNOSIS

5.1 OPERATIONAL FLOWCHART

A

Power ON

Vdd = 3.3 V

Pin 9

BSENS

Pin 75

B

ASENS

Pin 74

ACCPW H

Pin 7

Starts

C

communication

with Display

microcomputer.

500 ms

SWVDD H

Pin 37

300 ms

Source keys

operative

D

In case of the above signal, the communication

with Grille microcomputer may fail.

If the time interval is not 500/300 msec, the oscillator

may be defective.

Source ON or

Back Camera ON

SYSPW H

Pin 6

Completes power-on operation.

E

(After that, proceed to each source operation)

F

32

1234

AVH-P5000DVD/XN/UC

Page 33

5 678

5.2 INSPECTION METHOD OF PICKUP UNIT

Disc to be used

CD-DA: TCD-782

DVD-Video: GGV1025

Execution method

START

A

Replace the PICK UP

LD turned on? Check parts

No

Yes

LD current check

Is it OK?

Check point:

LD current check

Replace the PICK UP

No

Yes

RF level check

Is it OK?

No

Yes

Error rate check

Check point:

AS MAX check

PICK UP

cleaned?

Yes

Check point:

Error rate check

No

Check point:

AS MAX check

Check point:

Error rate check

Perform lens

cleaning

Replace the PICK UP

SKEW ADJ.

RF level check

Is it OK?

Yes

Error rate check

Is it OK?

Yes

B

No

C

No

D

Is it OK?

No

Yes

Ckeck parts

other than PICK UP

PICK UP

cleaned?

No

Yes

AVH-P5000DVD/XN/UC

56

Perform lens

cleaning

Replace the PICK UP

7

Finished

E

F

8

33

Page 34

1234

LD current check

A

Mode: DVD

No. Disc Check Point Threshold Remarks: LD current

Status: [Foucs closed] of TEST MODE

1

B

DVDLD1

GGV1025

DVDLD1 – VCC5_3

(mV)

10 – 65 (mA)

VCC5_3

C

Status: [Foucs closed] of TEST MODE

Mode: CD

No. Disc Check Point Threshold Remarks: LD current

2 TCD-782 CDLD1 – VCC5_3 (mV) 10 – 60(mA)

D

CDLD1

VCC5_3

E

Notes: Please pay attention to the laser diode damage by static electricity.

F

34

1234

AVH-P5000DVD/XN/UC

Page 35

5 678

ASMAX check

ASMAX value shows the value of RF level.

Status: [Foucs closed] of TEST MODE

No. Disc Check Point Threshold Remarks:

8 digits value of

1

GGV1025

2 TCD-782

ASMAX

on display 0000 0600

8 digits value of

ASMAX

on display 0000 0C00

more than

more than

Only four last digits are

displayed according to

the product.

Only four last digits is

displayed according to

the product.

In this case, the value is displayed for a split second.

When you tried to perform [FOCS CLOSE],

the display will charge automatically in the following order.

[1FFF0000]->[FEMAX]->[FE MIN]->[AS MAX

]->

[ENV MAX]->[FE normal]->[Spindle gain]->

[TEMAX]->[TEMIN] ->[20000000]

Watch carefully the value of ASMAX.

A

B

C

Error rate check

Status: [Tracking Closed] of TEST MODE

No. Disc Check Point Threshold Remarks:

1

2

GGV1025

GGV1025

3 TCD-782 ID: HOME Position

ID: 40000

ID: 200000

less than

1.000E-03

less than

1.000E-03

less than

2.500E-03

D

E

56

AVH-P5000DVD/XN/UC

F

7

8

35

Page 36

1234

5.3 DIAGNOSIS FLOWCHART

BACK END section flow

A

START

Can the

playback

start?

YES

NO

Standby OK?

Execute check 1.

YES

NO

Is VDD5

(VCC33, VCC12)

power supply

voltage OK?

Execute

check 2.

YES

NO

Does the

B

NO

operation

take time?

YES

Is the life of flash

memory OK?

Conduct check item 12.

NO

YES

C

NO

Is the image

in error?

Is AVCC5

NO

voltage OK?

Execute check 8.

Is the video

NO

circuit OK?

Execute check 11.

YES

YES

YES

NO

NO

NO

NO

Is the sound

in error?

YES

Is AVCC5

voltage OK?

Execute check 8.

YES

Is DACCLK

normal?

Execute check 9.

YES

Is the audio

circuit OK?

Execute check 10.

NO

NO

section check.

Is SDRAM

IF OK?

Execute check 6.

YES

Is VD8, VCC5

power supply

voltage OK?

Execute check 7.

YES

Go to FE

NO

Reset OK?

Execute check 3.

NO

NO

Is VSENS

Execute check 4.

Is 27 MHz

Execute check 5.

Replace the unit.

YES

OK?

YES

OK?

YES

YES

Go to FE

section check.

D

Repair the

defective part.

Go to FE

section check.

NO

Normal?

YES

FE section check.

END

Is FE section

E

normal?

NO

Go to FE related

repair process.

YES

Replace the unit.

NO

Normal?

YES

END

F

36

1234

AVH-P5000DVD/XN/UC

Page 37

5 678

DGND1

STANBY

Check 1: Standby OK?

<Check> Check the voltage at the “STANBY” test point while the power is on.

Use the “DGND1” test point at the reference.

NO. Check point Module No.

STANBY-DGND1 ALL

1

Specification value

VCC33 V-

Unit

V

0.6 V or more

Side A

A

B

C

Fig 1.1: STANBY check point

D

E

F

56

AVH-P5000DVD/XN/UC

7

8

37

Page 38

1234

DGND1

VCC 12_1

VCC 33

VDD 5_3

Check 2: Is VDD5 (VCC33, VCC12) power supply voltage OK?

A

VDD5

VDD5

F.E. driver control system

IC1007

3.3 V output regulator

IC1008

DC/DC converter

1.2 V output

VCC33 (= 3.3 V )

VCC12 (= 1.2 V )

IC1401 FLASH power supply (Data)

IC1402 FLASH power supply (Program)

IC1481 SDRAM power supply

IC1501 DVD-LSI power supply

IC1501 DVD-LSI power supply

B

Fig 2.1: Power supply configuration

<Check> Check the voltage at the “VDD5_3, VCC33_3 and VCC12_1” test point while the power is on.

Use the “DGND1” test point at the reference.

NO. Check point Module No.

VDD5_3 - DGND1

1

VCC33_3 - DGND1

2

VCC12_1 - DGND1

3

ALL

ALL

ALL

Specification value

5.0 ± 0.4

3.3 ± 0.15

1.2 ± 0.12

Unit

V

V

V

Side A

C

D

E

F

38

Fig 2.2: VDD5, VCC33, VCC12 voltage check points

AVH-P5000DVD/XN/UC

1234

Page 39

5 678

DGND1

XRES

Check 3: Reset OK?

<Check> Check the voltage at the “XRES” test point while the power is on.

Use the “DGND1” test point at the reference.

NO. Check point Module No. Specification value Unit

1 XRES-DGND1 ALL

Side A

VCC33 ×

0.7 or more

V

A

B

Fig 3.1: RESET check point

C

D

E

56

AVH-P5000DVD/XN/UC

F

7

8

39

Page 40

1234

DGND1

VSENS

Check 4: Is VSENS OK?

CN1901

A

HOST I/F

VD8 VSENS

IC1003

detection IC

IC1501

DVD-LSI

VDD5

B

IC1007

Regulator

IC1008

DC/DC converter

VCC33

VCC12

STANBY

XRES

Fig 4.1: Power supply configuration and VSENS

<Check> Check the voltage at the “VSENS” test point while the power is on.

Use the “DGND1” test point at the reference.

NO. Check point

VSENS - DGND1 ALL

Module No.

Specification value

VCC33 × 0.7

or more

C

Side A

Unit

V1

D

E

Fig 4.2: VSENS check point

F

40

1234

AVH-P5000DVD/XN/UC

Page 41

5 678

DGND1

IC1501 169pin

Check 5: 27 MHz Normal?

<Outline> Each clock is created inside the IC1501 using the 27 MHz master crystal oscillator (X1501).

IC1501

DVD-LSI

X1501

OSCO

27 MHz

crystal

OSCI

VCC33 VCC12

Fig 5.1: Clock configuration

<Check method> Turn the power on, and check with DGND being the reference.

In case of NG, check the applicable line, periphery of IC1501,

soldering of the peripheral components and defective components.

NO. Check point Module No.

2 IC1501 169pin ALL

Specification value

27 MHz

± 50 ppm

Unit

ppm

A

B

C

GND

Side A

Specification

value

Fig 5.2: Clock specification value

D

E

Fig 5.3: 27 MHz check point

AVH-P5000DVD/XN/UC

56

F

7

8

41

Page 42

1234

Check 6: Is SDRAM I/F OK?

A

<Outline> In order to secure the MPEG stream data as the buffer,

the capacity of communication I/F SDRAM between the LSI and the memory is 128Mbit.

Be careful as XCSM, XWE, XCAS, XRAS and XSCM of IC1481 are called differently in IC1501,

namely NCSM, NWE, NCAS, NRAS, NCSM.

IC

1481

SDRAM

B

MA0~11

MDQ0~31

MCK

XWE (NWE)

XCAS (NCAS)

XRAS (NRAS)

XCSM (NCSM)

DQM0

DQM1

DQM2

DQM3

BA0

BA1

IC1501

DVD-LSI

Fig 6.1: SDRAM I/F

C

D

E

F

42

1234

AVH-P5000DVD/XN/UC

Page 43

5 678

<Check> Check the conductivity at “check point 1” and “check point 2” without power.

In case of NG, check the soldering and defective components throughout the

“output t input” of the applicable section.

A

NO.

Signal name Check point 1 Check point 2 Specification value

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

MA0

MA1

MA2

MA3

MA4

MA5

MA6

MA7

MA8

MA9

MA10

MA11

MDQ0

MDQ1

MDQ2

MDQ3

MDQ4

MDQ5

MDQ6

MDQ7

MDQ8

MDQ9

MDQ10

MDQ11

MDQ12

MDQ13

MDQ14

MDQ15

MDQ16

MDQ17

MDQ18

MDQ19

MDQ20

MDQ21

MDQ22

MDQ23

MDQ24

MDQ25

MDQ26

MDQ27

MDQ28

MDQ29

MDQ30

MDQ31

MCK

XWE

XCAS

XRAS

XCSM

DQM0

DQM1

DQM2

DQM3

BA0

BA1

IC1481 25pin

IC1481 26pin

IC1481 27pin

IC1481 60pin

IC1481 61pin

IC1481 62pin

IC1481 63pin

IC1481 64pin

IC1481 65pin

IC1481 66pin

IC1481 24pin

IC1481 21pin

IC1481 2pin

IC1481 4pin

IC1481 5pin

IC1481 7pin

IC1481 8pin

IC1481 10pin

IC1481 11pin

IC1481 13pin

IC1481 74pin

IC1481 76pin

IC1481 77pin

IC1481 79pin

IC1481 80pin

IC1481 82pin

IC1481 83pin

IC1481 85pin

IC1481 31pin

IC1481 33pin

IC1481 34pin

IC1481 36pin

IC1481 37pin

IC1481 39pin

IC1481 40pin

IC1481 42pin

IC1481 45pin

IC1481 47pin

IC1481 48pin

IC1481 50pin

IC1481 51pin

IC1481 53pin

IC1481 54pin

IC1481 56pin

IC1481 68pin

IC1481 17pin

IC1481 18pin

IC1481 19pin

IC1481 20pin

IC1481 16pin

IC1481 71pin

IC1481 28pin

IC1481 59pin

IC1481 22pin

IC1481 23pin

IC1501 16pin

IC1501 18pin

IC1501 20pin

IC1501 22pin

IC1501 21pin

IC1501 19pin

IC1501 17pin

IC1501 15pin

IC1501 11pin

IC1501 9pin

IC1501 14pin

IC1501 7pin

IC1501 237pin

IC1501 239pin

IC1501 241pin

IC1501 243pin

IC1501 248pin

IC1501 250pin

IC1501 252pin

IC1501 254pin

IC1501 253pin

IC1501 251pin

IC1501 249pin

IC1501 244pin

IC1501 242pin

IC1501 240pin

IC1501 238pin

IC1501 236pin

IC1501 29pin

IC1501 31pin

IC1501 33pin

IC1501 37pin

IC1501 39pin

IC1501 41pin

IC1501 43pin

IC1501 45pin

IC1501 44pin

IC1501 42pin

IC1501 40pin

IC1501 38pin

IC1501 34pin

IC1501 32pin

IC1501 30pin

IC1501 28pin

IC1501 234pin

IC1501 3pin

IC1501 4pin

IC1501 5pin

IC1501 6pin

IC1501 255pin

IC1501 256pin

IC1501 26pin

IC1501 27pin

IC1501 8pin

IC1501 10pin

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

0.17

ohm or lower

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

56 ohm ± 5 %

B

C

D

E

F

56

AVH-P5000DVD/XN/UC

7

8

43

Page 44

1234

Side B

A

B

C

Side A

D

E

Check point 1 (IC1481)

Check point 2 (IC1501)

F

44

1234

AVH-P5000DVD/XN/UC

Fig 6.2: SDRAM I/F check point

Page 45

5 678

VCC5_1

AGND1

VD

VD8_1

PGND3

Check 7: Is VD8, VCC5 power supply voltage OK?

A

VD8_1

F.E. driver system

DISC detection LED

VD VCC5 (= 5.0V )

IC1004

REG IC

Power supply

for PU

for VCC 5V.

Fig 7.1: Power supply configuration

<Check> Check the voltage at the “VD8_1, VD and VCC5_1” test point while the power is on.

Use the “PGND3 and AGND1” test point at the reference.

NO. Check point Module No. Specification value Unit

VD8_1 - PGND3

1

VD - PGND3

2

VCC5_1- AGND1

3

ALL

ALL

ALL

8.0 ± 0.4

8.0 ± 0.4

5.0 ± 0.1

V

V

V

Side A

B

C

Fig 7.2: VD8, VCC5 voltage check points

D

E

F

56

AVH-P5000DVD/XN/UC

7

8

45

Page 46

1234

PGND3

AVC C5

GNDAU

VD

Check 8: Is AVCC5 voltage OK?

A

VD AVCC5 (= 5.0 V )

<Check> Playback DVD-REF-A1 TITLE 1 and check the voltage at the stylus.

Check with PGND and GNDAU being the reference.

IC1005

REG IC

for AVCC 5 V.

Fig 8.1: Power supply configuration

IC1801

Audio-DAC

B

NO. Check point

VD - PGND_3

1

AVCC5 - GNDAU1

2

Module No. Specification value Unit

ALL

ALL

8.0 ± 0.4

5.0 ± 0.1

V

V

Side A

C

D

E

F

46

Fig 8.2: VD8, AVCC5 voltage check points

AVH-P5000DVD/XN/UC

1234

Page 47

5 678

Check 9: Is DACCLK normal?

<Outline> DACCLK for Audio-DAC is created by IC1501 using the 27 MHz master crystal oscillator (X1501).

IC1501

A

IC1801

Audio-DAC

27 MHz

DVD-LSIX1501

DACCLK

crystal

VCC33 VCC12

Fig 9.1: Clock configuration

<Check method>

DVD: DVD-REF-A1 TITLE 1

CD: Playback a normal CDDA.

Common to all DVD-V compatible modules.

Check with DGND being the reference.

In case of NG, check the applicable line, the periphery of IC1501, soldering of the peripheral components and

defective components.

NO.

Check point 1 (stylus)

12DACCK

DACCK

Media Specification value 1 Specification value 2 Specification value 3

DVD

CD

2.0 V~VCC33 V

2.0 V~VCC33 V

DGND~0.8 V

DGND~0.8 V

36.864 0 MHz ± 300 ppm

33.868 8 MHz ± 300 ppm

Specification

value 1

Specification

value 2

Specification

value 3

B

C

GND

Side A

Fig 9.2: Clock specification value

D

E

Check point 2 (IC1501 172 pin)

Check point 1 (stylus)

Fig 9.3: 27 MHz, DACCLK check point

AVH-P5000DVD/XN/UC

56

F

7

8

47

Page 48

1234

SRCK

LRCK

ADOUT3

Check 10: Is the audio circuit OK?

<Outline> The serial 3 lines digital output + DACCLK, output from DVD-LSI (IC1501), are converted to analog audio

A

signal at Audio-DAC (IC1801) and are output from the HOST I/F (CN1901).

Simultaneously, the analog MUTE signal is also output from DVD-LSI (IC1501) via the HOST I/F.

The digital audio signal (IECOUT), output from DVD-LSI (IC1501), is output via CN1852.

CN1901

HOST I/F

IC1501

DVD-LSI

LRCK LO

ADOUT3

IC1801

Audio-DAC

SRCK RO

B

GNDAU

CN1852

IEC

Fig 10.1: Audio circuit

<Check method> Playback DVD-REF-A1 TITLE 2 CHAPTER 1 (48 k/16 bit 1 kHz 0 dB),

and check with DGND being the reference.

In case of NG, check the applicable line, periphery of major components as described in the above drawing,

soldering of the peripheral components and defective components.

C

NO. Check point 1 (stylus)

1

ADOUT3

2

SRCK

3

LRCK

Specification value 1

VCC33 V-0.6 V or higher

VCC33 V-0.6 V or higher

VCC33 V-0.6 V or higher

Specification value 2

0.4 V or lower

0.4 V or lower

0.4 V or lower

Reference waveform

Waveform 1

Waveform 2

Waveform 3

Specification

Specification

value 2

value 1

GND

D

E

F

48

Fig 10.2: Serial 3 lines specification value

Side A

Fig 10.3: Serial 3 lines check points

AVH-P5000DVD/XN/UC

1234

Page 49

5 678

LO

RO

GNDAU1

The following checks shall be conducted using the following measurement circuits with GNDAU1 being the reference.

47 kohm 47 kohm

LO GNDAU1 RO

NO.

Check point 1 (stylus)

4

LO

5

RO

Specification value (rms)

1 400 ± 150 mV

1 400 ± 150 mV

Reference waveform

Waveform 4

Waveform 4

A

Side A