Page 1

Electronic monitoring relays PMDsigma

True power monitoring

PMD s10

Gertebild

Bildunterschrift

True power converter for single and

three-phase electrical machinery

Approvals

PMD s10

Zulassungen

Unit features

Gertemerkmale PMD s10_Text_1

` Relay output:

2 auxiliary changeover contacts (C/

O)

` Analogue output for current and

voltage

` Galvanic isolation of the analogue

outputs

` Measuring range set automatically

for current and voltage

Gertemerkmale

` Menu-driven parameter setting

Gertemerkmale PMD s10_Text_3

` Status indicators (LEDs) for:

– Supply voltage (Power)

– Switching threshold for overload

(> max)

– Switching threshold for under-

load (< min)

– Output 1 (Out 1)

– Output 2 (Out 2)

–Fault

` Display for measured value indica-

tor, diagnostics and menu navigation

` Operating cycle counter for K1 and

K2

` Diagnostics: U

max

and I

max

` Display of operating hours and load

hours (resettable)

` Device parameters can be saved to

chip card (write)

` Device parameters can be restored

from the chip card (load)

` Suitable for use with frequency-

controlled drives

` Suitable for current transformers

Unit description

Gertebeschreibung PMD s10

The true power converter PMD s10 is

used to measure and monitor the true

power drawn and output by electrical

loads.

The PMD s10 is designed for use as a:

` True power converter for single and

three-phase electrical machines

` Trip device for underload and over-

load

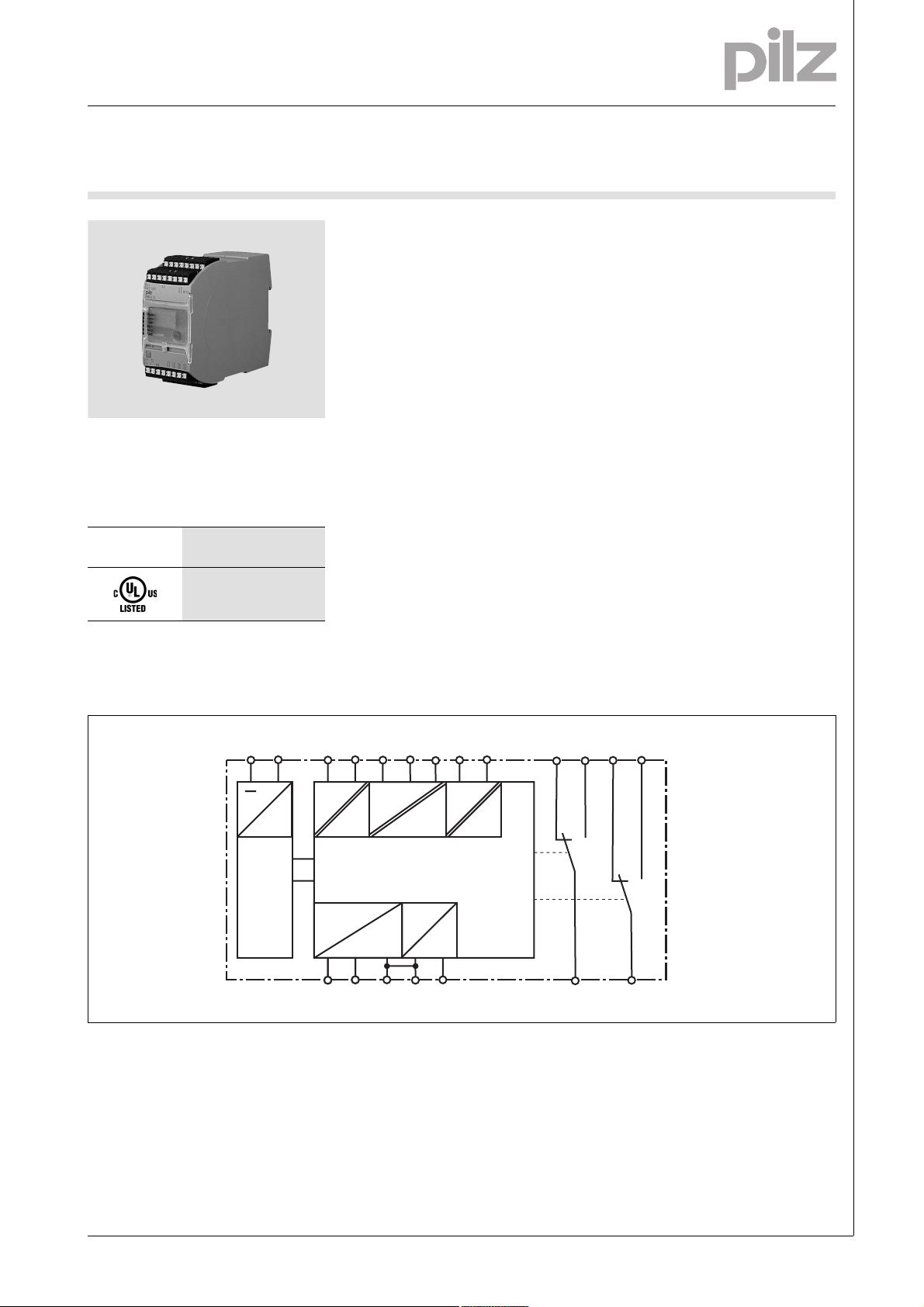

Block diagram

A1 A2

~

Power

Power

Blockschaltbild

K1 U/I1 24

I

M1

L1 L2 L3

U

M

K3 W/I3

I

M3

12

=

K1

P

U

out Iout

U I 0 V

Reset

Y2 Y1

K2

11

14

22

21

NSG-D-2-422-2010-11

Page 2

Electronic monitoring relays PMDsigma

True power monitoring

PMD s10

Function description

Funktionsbeschreibung_Text_1

The PMD s10 monitors the true power

on a single, three phase or DC supply

to ensure it doesn't exceed or drop

below a certain value. The unit operates in accordance with the Aron circuit principle.

Relay outputs (K1 and K2)

K1 and K2 operate in normally energised mode. In their default state, auxiliary contacts 11-14 and 21-24 are

closed and auxiliary contacts 11-12

and 21-22 are open. Normally energised mode is the default setting; this

setting can be changed via the menu.

Analogue outputs (U

out

and I

out

):

The unit forms two output signals

which are proportional to the true

power. The limit value corresponds to

(see timing diagram). The status

P

max

of the threshold monitoring function is

displayed at the auxiliary contacts and

LEDs, along with the analogue output

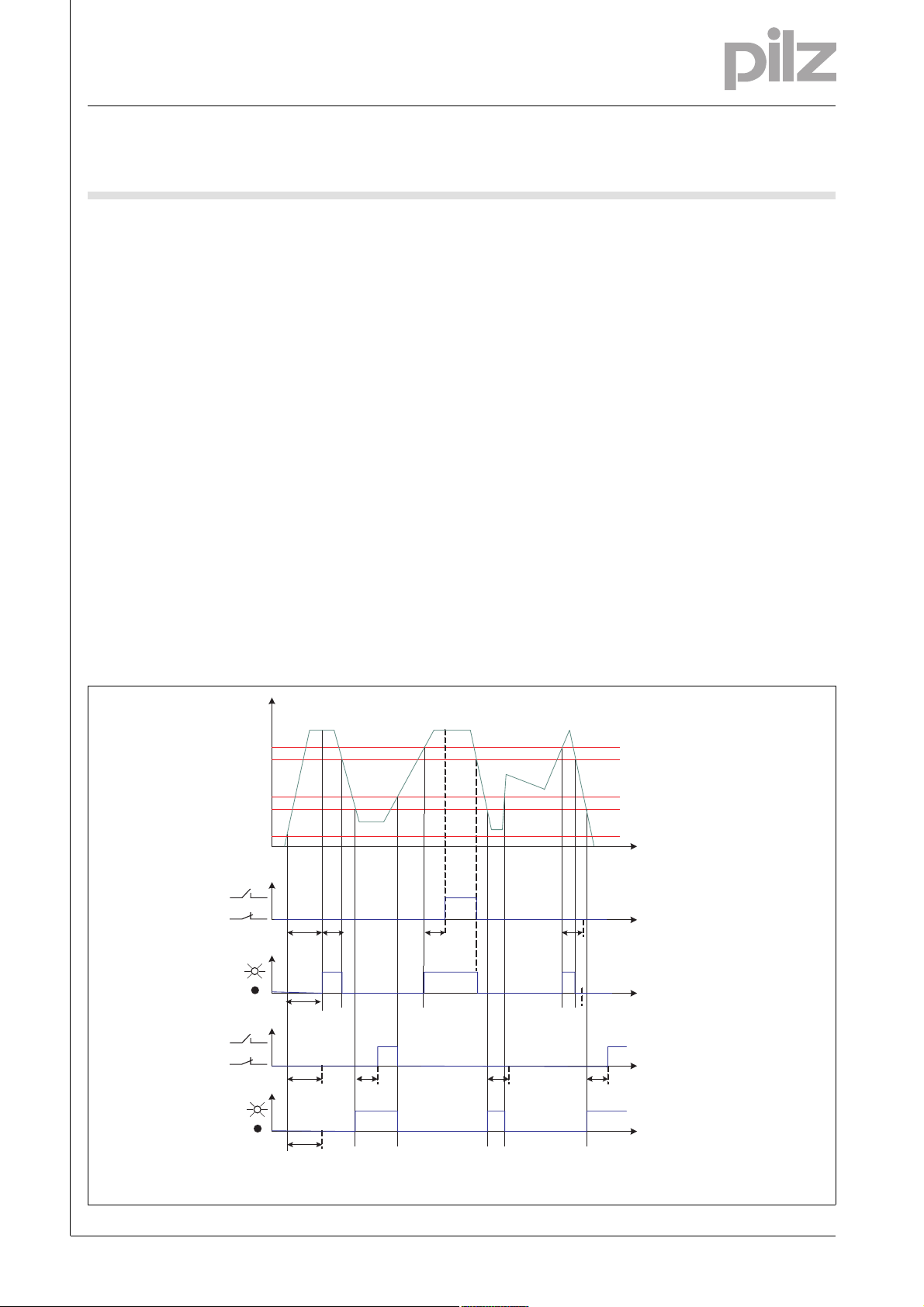

Timing diagram

signals. The hysteresis of the switching thresholds can be set between 0 %

... 50 %.

Current transformer CT:

With continuous currents > 12 A, the

measuring current must be measured

via an external current transformer.

Po function (K1 overload):

If the measured true power exceeds

the switching threshold Po, the ">

max" LED is lit. Once the response

time has elapsed (t

), the auxiliary con-

r

tact switches (default: relay K1) and

the "Out 1" LED is lit.

Pwo function (overload warning

threshold):

Serves as a warning; for function description, see Po function (K1 overload)

Funktionsbeschreibung_Text_2

Pu function (K2 underload):

If the measured true power drops below the switching threshold PU, the "<

min" LED is lit. Once the response time

has elapsed (t

), the auxiliary contact

r

switches (default: relay K2) and the

"Out 2" LED is lit.

Pwu function (underload warning

threshold):

Serves as a warning; for function description, see Pu function (K2 underload)

Start suppression time (t

Start

):

The measurement is suppressed during the machine's start-up phase, in

order to avoid spurious output signals.

The start suppression time t

Start

is infi-

nitely variable.

Response time (t

):

r

With transient load fluctuations, the

switching threshold can be suppressed. The response time t

is infi-

r

nitely variable.

Reset mode:

The fault status (value below Pu or

above Po) can be reset automatically

or via an external reset button.

P

100%

Po

Pu

5%

0%

OUT1

LED >max

OUT2

LED <min

Zeitdiagramm

ts tr tr

tr

ts

ts

tr tr

tr

Hysterese/

Hysteresis/

Hystérésis

Hysterese/

Hysteresis/

Hystérésis

t

t

t

t

P tatsächliche Wirkleistung/Actual true power/puissance active réelle

t

s Startunterdrückungszeit/Start suppression time/Temps de suppression au démarrage

t

r Reaktionszeit/Response time/Temps de résponse

ts

t

NSG-D-2-422-2010-11

-2

Page 3

Electronic monitoring relays PMDsigma

True power monitoring

PMD s10

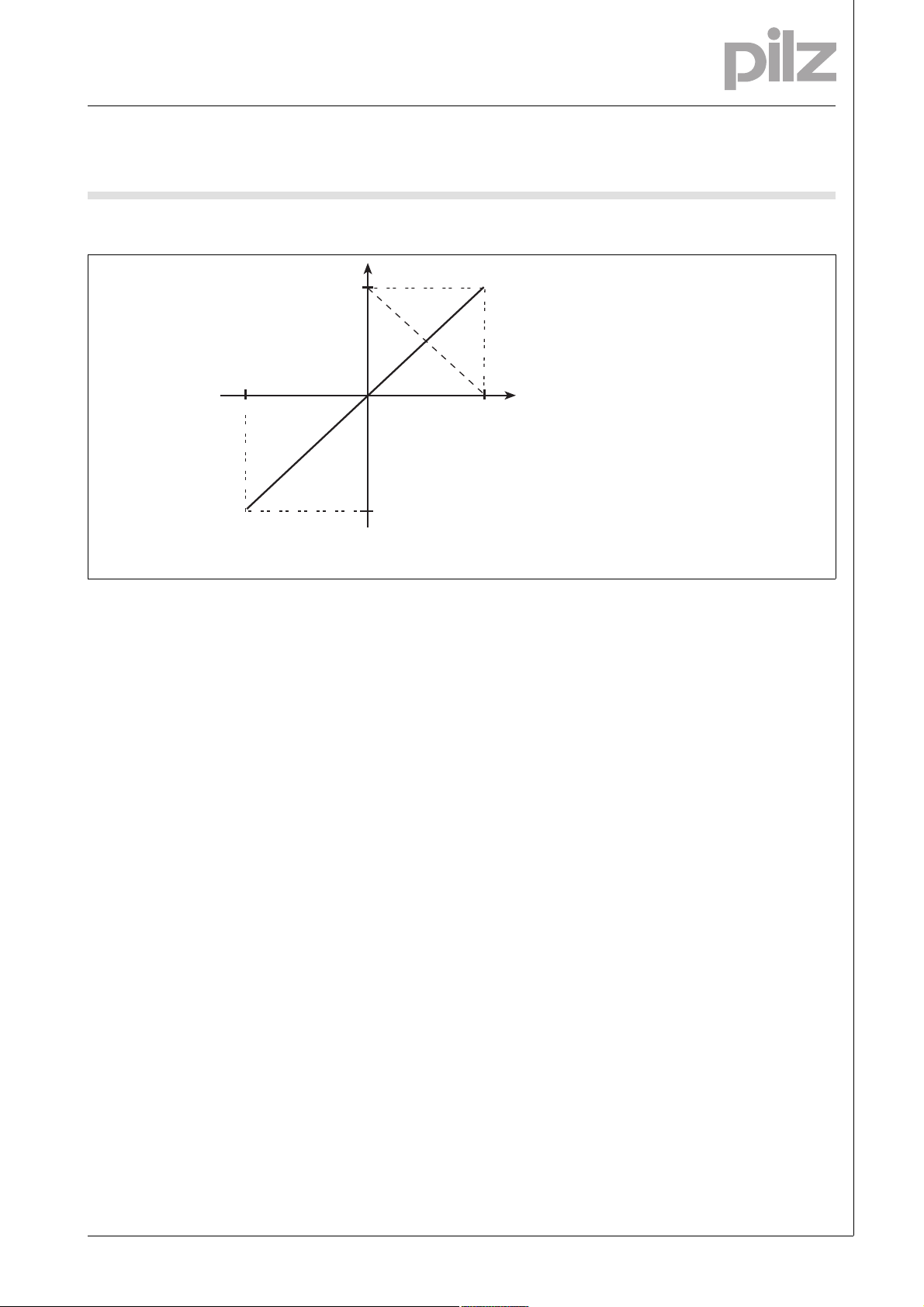

Timing diagram

Zeitdiagramm

Generatorbetrieb/

Generator/

Fonctionnement

avec générateur

-P

max

U

P tatsächliche Wirkleistung/Actual true power/puissance active réelle

U/I analoges Ausgangssignal, Spannung oder Strom/Analogue output signal, voltage or current/

signal de sortie analogique, intensité ou tension

Wiring

Inbetriebnahme_fuer_PDB

Note:

` Only wire the unit when the supply

voltage is switched off!

` Use copper wiring.

` To prevent contact welding, a fuse

should be connected before the

output contacts (see technical details).

10 V

20 mA

4 mA

0

1* U bei/at/à 10 ... 0 V

1*

V

-10 V

U/I

Motorbetrieb/

Motor/

Fonctionnement

avec moteur

P

max

` Ensure that the cables are laid care-

fully, because an open circuit in the

measuring circuit will cause the unit

function to fail.

` Information given in the “Technical

details” must be followed.

P

W

NOTICE

Ensure that there is adequate fuse

protection on the connection cables to

terminals L1, L2, L3, K1, K3, A1 and

A2!

Preparing for operation

Inbetriebnahme_Anschluss

` Connect the supply voltage UB to

A1/A2.

` Single-phase:

– Measuring voltage U

: Connect

M

to terminals L1 and L2

– Link terminals L1-K1

– Measuring circuit: Connect

phase L1 of the motors to termi-

nal U/I1

` Three-phase:

– Measuring voltage U

: Connect

M

to terminals L1, L2 and L3

– Link terminals L1-K1, L3-K3

– Measuring circuit: Connect

phase L1 of the motor to terminal

U/I1, phase L2 to terminal L2 and

L3 to W/I3

` Please refer to the connection dia-

grams for details of how to connect

external current transformers

and an external reset (see "Application").

` Connect the output contacts in ac-

cordance with the relevant application circuit.

Leerzeilen

Inbetriebnahme_Anwendung

NOTICE

Only connect the unit as shown in the

examples below! Do not connect unlabelled terminals.

The following circuit examples show

typical applications for the true power

converter PMD s10.

With continuous currents > 12 A, the

measuring current must be measured

via an external current transformer.

NSG-D-2-422-2010-11

Page 4

Electronic monitoring relays PMDsigma

True power monitoring

PMD s10

Circuit for three-phase motor

Inbetriebnahme_Anwendung_Bild_1

L1

L2

L3

N

24V

0V

I

N

PE

K1

M1

< 12A

UVW

M3~

U/I1

Y2

I

A

V

L2

PMD s10

0V

L3

W/I3

K3

Reset

extern

A1

12 14

11

A2

22

24

21

K1

H2

L1

K1

Y1

U

NSG-D-2-422-2010-11

-4

Page 5

Electronic monitoring relays PMDsigma

True power monitoring

PMD s10

Circuit for three-phase motor with CT

Inbetriebnahme_Anwendung_Bild_2

L1

L2

L3

N

24V

0V

k

K

L

k

K

L

l

l

L1

K1

U/I1

L2

PMD s10

L3

W/I3

K3

Reset

extern

I

N

PE

K1

M1

> 12A

UVW

M3~

Y1

Y2

U

I

A

V

11

0V

21

12 14

22

A1

A2

24

K1

H2

NSG-D-2-422-2010-11

Page 6

Electronic monitoring relays PMDsigma

True power monitoring

PMD s10

Circuit for motor (1 AC)

Inbetriebnahme_Anwendung_Bild_3

L1

N

24V

0V

I

N

PE

K1

M1

< 12A

U/I1

Y2

I

A

V

L2

PMD s10

0V

L3

W/I3

K3

Reset

extern

A1

12 14

11

A2

22

24

21

K1

H2

L1

K1

Y1

U

U2

U1

M1~

NSG-D-2-422-2010-11

-6

Page 7

Electronic monitoring relays PMDsigma

True power monitoring

PMD s10

Circuit for motor (1 AC) with CT

Inbetriebnahme_Anwendung_Bild_4

L1

Inbetriebnahme

U/I1

L2

PMD s10

L3

W/I3

K3

Reset

extern

L1

K1

24V

N

0V

k

K

L

l

K1

U2

U1

M1

M1~

I

> 12A

N

PE

Parameter setting

Funktionsbeschreibung

Parameters such as switching thresholds, start-up suppression time, reaction time and rest mode, for example,

are set via a rotary knob.

Installation

Montage_Sigma_allgemein

` The unit should be installed in a

control cabinet with a protection

type of at least IP54.

` Use the notch on the rear of the unit

to attach it to a mounting rail.

` In environments exposed to heavy

vibration or when installing on a vertical mounting rail (35 mm), the unit

should be secured using a fixing element (e.g. retaining bracket or end

angle).

` Push the unit upwards or down-

wards before lifting it from the

mounting rail.

Y1

Y2

U

I

A

V

11

0V

21

12 14

22

A1

A2

24

K1

A display indicates the current values

plus the set values.

The parameters can be saved on a

chip card. This chip card can be used

H2

as a backup copy of the parameters or

can be used to transfer the parameters

to another unit.

NSG-D-2-422-2010-11

Page 8

Electronic monitoring relays PMDsigma

True power monitoring

PMD s10

Notice

][WICHTIG_PDB_alt

This data sheet is only intended for use

Montage

during configuration. For installation

and operation, please refer to the operating instructions supplied with the

unit.

Technical details

Electrical data

Supply voltage UB AC/DC 24 - 240 V

Voltage tolerance -20 %/+10 %

Power consumption at U

Power consumption at U

Frequency range AC 50 - 60 Hz

Utilisation category in accordance with EN 60947-4-1

Auxiliary contacts: AC1 at 240 V I

Auxiliary contacts: DC1 at 24 V I

Utilisation category in accordance with EN 60947-5-1

Auxiliary contacts: AC15 at 230 V I

Auxiliary contacts: DC13 at 24 V (6 cycles/min) I

Contact material AgNi10

External contact fuse protection (I

Blow-out fuse, quick

Auxiliary contacts: 6 A

Blow-out fuse, slow

Auxiliary contacts: 4 A

Circuit breaker 24 VAC/DC, characteristic B/C

Auxiliary contacts: 4 A

Safety-related characteristic data

PL in accordance with EN ISO 13849-1 PL c (Cat. 1)

Category in accordance with EN 954-1 Cat. 1

SIL CL in accordance with EN IEC 62061 SIL CL 1

PFH in accordance with EN IEC 62061 6.05E-07

SIL in accordance with IEC 61511 SIL 1

PFD in accordance with IEC 61511 5.30E-02

t

in years 20

M

Times

Typ. response time of analogue output at DC 20 ms

Response time of analogue output at 15 ... 60 Hz 70 - 16 ms

Response time of analogue output at 60 ... 400 Hz 16 ms

Response time t

of auxiliary contact (selectable) 0.01 - 30.00 s

r

Start suppression time t

Measuring circuit

Measuring voltage UM (AC/DC) 100 - 550 V

Measuring current I

Frequency range 0, 15 - 400 Hz

Measuring range limit value (selectable) 1.0 W - 11.5 kW

Measuring range limit value P

Performance range of 1 A current transformer 1.5 - 7.5 VA

Performance range of 5 A current transformer 2.5 - 15.0 VA

Current transformer class 3

Max. measuring current AC/DC 12 A

Temperature coefficient 0.10 %/K

AC 5.0 VA

B

DC 3.0 W

B

min

P

max

min

P

max

max

max

= 1 kA) to EN 60947-5-1

K

(selectable) 0.0 - 30.0 s

start

(AC/DC) 1 - 12 A

M

with external current transformer 100.0 W - 11.5 MW

max

: 0.10 A , I

: 1200 VA

: 0.10 A , I

: 120 W

: 5.0 A

: 2.0 A

max

max

Technische Daten PMD s1 0

: 5.0 A

: 5.0 A

NSG-D-2-422-2010-11

-8

Page 9

Electronic monitoring relays PMDsigma

True power monitoring

PMD s10

Output signals during motor operation

Output voltage U

Output voltage U

Terminating impedance (apparent ohmic resistance) R

Output current I

Output current I

Terminating impedance (apparent ohmic resistance) R

Output signals during generator operation

Output voltage U

Terminating impedance (apparent ohmic resistance) R

Output current I

Terminating impedance (apparent ohmic resistance) R

Environmental data

EMC EN 61000-6-2, EN 61000-6-4

Vibration to EN 60068-2-6

Frequency 10 - 55 Hz

Amplitude 0.35 mm

Climatic suitability EN 60068-2-78

Airgap creepage in accordance with IEC 60664-1

Pollution degree 2

Overvoltage category III

Rated insulation voltage 300 V

Rated impulse withstand voltage

Measuring circuit 6.0 kV

Supply voltage, auxiliary contacts, analogue output 4.0 kV

Ambient temperature -10 - 55 °C

Storage temperature -25 - 85 °C

Protection type

Mounting (e.g. cabinet) IP54

Housing IP40

Terminals IP20

Mechanical data

Housing material

Housing PC

Front PC

Cross section of external conductors with screw terminals

1 core flexible 0.25 - 2.50 mm² , 24 - 12 AWG No. 760100

with crimp connectors, without insulating sleeve 0.25 - 1.00 mm² , 24 - 16 AWG No. 760100

without crimp connectors or with TWIN crimp connectors 0.20 - 1.50 mm² , 24 - 16 AWG No. 760100

Torque setting with screw terminals 0.50 Nm No. 760100

Cross section of external conductors with spring-loaded terminals: Flexible with/without crimp connectors

Stripping length 9 mm No. 761100

Dimensions

Height 100.0 mm No. 761100

Width 45.0 mm

Depth 120.0 mm

Weight 370 g

0... 10 V 0 - 10 V

out

10 ... 0 V 10 - 0 V

out

4 ... 20 mA 4 - 20 mA

out

0 ... 20 mA 0 - 20 mA

out

out

0 - -20 mA

out

Bestelldaten

min. 1 kOhm

out

max. 0.5 kOhm

out

0 - -10 V

min. 1 kOhm

out

max. 0.5 kOhm

out

0.20 - 2.50 mm² , 24 - 12 AWG No. 761100

98.0 mm No. 760100

Order reference

Type Features Terminals Order no.

PMD s10 24 - 240 V AC/DC With screw terminals 760 100

PMD s10 C 24 - 240 V AC/DC With cage clamp terminals 761 100

NSG-D-2-422-2010-11

Loading...

Loading...