Page 1

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

Instra

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

REMOTE INSPECTION

View

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Page 2

Motion Control PMC

PMCprimo Drive2

Installation Manual – Item No. 21 486-02

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 3

1 General conditions

1.1 Copyright

Copyright 2005 Pilz GmbH & Co. KG

All rights reserved. No part of this document may be reproduced in any form (print, photocopy,

microfilm or any other format), or modified, duplicated by electronic means, without written

authorization by Pilz GmbH & Co. KG.

1.2 Notes

Pilz GmbH & Co. KG reserves the right to make amendments to this document at any time.

The examples given serve only as illustrations. No guarantee is given for their suitability in

particular applications. Although the utmost care has been taken in the production of this document,

no liability can be accepted for any mistakes that it may contain. We welcome any suggestions for

the improvement of our products, or documentation.

We reserve the right to make technical changes, which lead to the improvement of the product!

1 General conditions

1.3 Previous editions

Edition Comments

V1 Initial release

V2 Revision

Page 2 Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 4

2 Table of contents

2 Table of contents

1 General conditions ........................................................................................... 2

1.1 Copyright ................................................................................................................. 2

1.2 Notes ....................................................................................................................... 2

1.3 Previous editions ..................................................................................................... 2

2 Table of contents.............................................................................................. 3

3 Type key ............................................................................................................ 6

4 Safety instructions ........................................................................................... 7

5 European directives and standards................................................................ 8

6 Abbreviations and symbols............................................................................. 10

7 General .............................................................................................................. 11

7.1 About this manual.................................................................................................... 11

7.2 Requirements .......................................................................................................... 11

7.3 Prescribed use (Use as directed) of the control....................................................... 11

7.4 Instrument description .............................................................................................13

7.4.1 Scope of delivery.............................................................................................. 13

7.4.2 Accessories ...................................................................................................... 13

7.4.3 The PMCprimo Drive2 family............................................................................ 14

7.4.3.1 Performance data ....................................................................................14

7.4.3.2 Fieldbus Interface ....................................................................................14

7.4.3.3 Soft-PLC CoDeSys®................................................................................ 14

7.4.3.4 Interfaces ................................................................................................. 14

7.4.3.5 Power supplies ........................................................................................ 14

7.4.3.6 Power section ..........................................................................................15

7.4.3.7 Electrical supply.......................................................................................15

7.4.3.8 Power input filter ...................................................................................... 15

7.4.3.9 Operation and programming .................................................................... 15

7.4.3.10 Integrated safety.....................................................................................15

7.5 Connection to different mains supply networks .......................................................16

7.6 Block diagram – part 1............................................................................................. 17

7.7 Block diagram – part 2............................................................................................. 18

7.8 Components of a servo system ............................................................................... 19

7.9 Technical data .........................................................................................................20

7.9.1 External fusing.................................................................................................. 21

7.9.2 Permissible ambient conditions ventilation, mounting position ......................... 21

7.9.3 Conductor cross-sections ................................................................................. 22

7.9.4 LED-Display .....................................................................................................22

7.10 Grounding system ................................................................................................... 23

7.11 Control for motor-holding brake .............................................................................. 23

7.12 Regen circuit ........................................................................................................... 25

7.13 Switch-on and switch-off behaviour......................................................................... 26

7.13.1 Stop function to EN 60204 (VDE 0113) .......................................................... 26

7.13.2 Emergency Stop strategies ............................................................................ 27

7.13.2.1 Category 0.............................................................................................. 27

7.13.2.2 Category 1.............................................................................................. 27

7.14 Option -AS .............................................................................................................. 28

7.14.1 General........................................................................................................... 28

7.14.2 Prescribed use................................................................................................ 28

7.14.3 Functional description..................................................................................... 29

7.14.4 Block diagram.................................................................................................30

7.14.5 Signal diagram ............................................................................................... 30

7.14.6 Installation and Commissioning......................................................................31

7.14.6.1 Safety instructions ..................................................................................31

7.14.6.2 Application example................................................................................ 31

7.14.6.3 Connection diagram................................................................................ 31

8 Installation......................................................................................................... 32

8.1 Important instructions .............................................................................................. 32

Installation manual PMCprimo Drive2 Page 3

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 5

2 Table of contents

8.2 Assembly.................................................................................................................33

8.3 Dimensions.............................................................................................................. 34

8.4 Wiring ......................................................................................................................35

8.4.1 Connection diagram PMCprimo Drive2 - part 1................................................37

8.4.2 Connection diagram PMCprimo Drive2- part 2.................................................38

8.4.3 Pin assignments overview ................................................................................ 39

8.4.4 Pin assignments - details.................................................................................. 40

8.4.5 Pin assignments Modbus/Profibus ...................................................................41

8.4.6 Notes on connection techniques....................................................................... 42

8.5 Key operation for parameter setting ........................................................................43

8.5.1 Comparison to the key operation with PMCtendo DD4 .................................... 43

8.5.2 Basic key operation .......................................................................................... 43

8.5.3 Menu operation................................................................................................. 43

8.5.4 LED Display...................................................................................................... 44

8.5.5 Automatic detection in PMCprimo ....................................................................44

9 Interfaces........................................................................................................... 45

9.1 Power supply...........................................................................................................45

9.1.1 Mains supply (X0)............................................................................................. 45

9.1.2 24V-auxiliary supply (X4).................................................................................. 46

9.1.3 24V-Supply (X10) ............................................................................................. 47

9.1.4 Master encoder supply (X10) .......................................................................... 48

9.1.5 DC-link (X7)......................................................................................................49

9.2 Motor connection with brake (X9)............................................................................49

9.2.1 Lead length < 25m............................................................................................ 49

9.2.2 Lead length > 25m............................................................................................ 50

9.3 External regen resistor (X8)..................................................................................... 51

9.4 Feedback................................................................................................................. 52

9.4.1 Resolver connection (X2) ................................................................................. 52

9.4.2 HIPERFACE Encoder (X1)...............................................................................53

9.5 Encoder emulations.................................................................................................54

9.5.1 Incremental encoder emulation ROD (X5)........................................................ 54

9.5.2 Application example .........................................................................................54

9.5.3 SSI emulation (X5) ...........................................................................................55

9.5.4 Application example .........................................................................................55

9.6 RS232 interface, PC interface (X6) .........................................................................56

9.6.1 General............................................................................................................. 56

9.6.2 Pin assignment of the null-modem cable..........................................................57

9.7 Digital signals ..........................................................................................................59

9.7.1 Digital inputs I1:1 - I1:8 (X10) ........................................................................... 59

9.7.2 Digital inputs I2:1 - I2:4 (X3) ............................................................................. 60

9.7.3 Digital ENABLE input (X3)................................................................................61

9.7.4 Digital outputs O1:1 - O1:8 (X10) ....................................................................62

9.7.5 Digital outputs Digital-Out 1+2 (X3) .................................................................. 63

9.7.6 Relay output (X3)..............................................................................................64

9.8 Analog signals ......................................................................................................... 65

9.8.1 Analog outputs AO2 and AO3 (X3)................................................................... 65

9.8.2 Analog inputs AI1 and AI2 (X3) ........................................................................66

9.9 CAN bus interface (X11/2 and X11/1) .....................................................................67

9.9.1 General............................................................................................................. 67

9.9.2 Connecting PMCprimo Drive2 systems............................................................67

9.9.3 CAN bus cable.................................................................................................. 68

9.9.4 Speciality 1st node ...........................................................................................68

9.9.5 Speciality last node........................................................................................... 68

9.9.6 Fault detection..................................................................................................68

9.9.7 Connecting external CANopen bus devices ..................................................... 68

9.10 Master encoder interface / CAN2 (X11/4) ...............................................................69

9.10.1 CAN 2 interface .............................................................................................. 70

9.10.2 Jumper settings .............................................................................................. 71

9.10.3 Incremental encoder.......................................................................................72

9.10.4 Absolute encoder (SSI) ..................................................................................73

9.11 Bus interface (X11/3) ..............................................................................................74

9.11.1 General........................................................................................................... 74

9.11.2 MODBUS Interface......................................................................................... 74

9.11.3 Profibus interface (Option).............................................................................. 75

9.11.4 Using the MODBUS / Profibus interface with PMCprimo................................ 75

9.11.5 Example: Profibus DP slave module ..............................................................75

9.12 Virtual inputs and outputs........................................................................................ 77

9.12.1 Terms ............................................................................................................. 77

9.12.2 Application example .......................................................................................77

Page 4 Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 6

2 Table of contents

10 Commissioning................................................................................................. 78

10.1 Important notes ....................................................................................................... 78

10.2 Setup software PDRIVE..........................................................................................80

10.2.1 Use as directed............................................................................................... 80

10.2.2 Software description....................................................................................... 80

10.2.3 Hardware requirements .................................................................................. 80

10.2.4 Minimum requirements for the PC:.................................................................80

10.2.5 Installation under WINDOWS 95 / 98 / NT / 2000 / XP................................... 80

10.2.6 Working with PDRIVE..................................................................................... 80

10.3 Parametrization of the PMCprimo Drive2................................................................81

10.4 Programming of the PMCprimo Drive2 ................................................................... 81

10.5 Error messages....................................................................................................... 82

10.5.1 Error messages PMCprimo ............................................................................82

10.5.2 Error messages amplifier................................................................................ 83

10.6 Warnings.................................................................................................................84

10.7 Status messages..................................................................................................... 85

10.7.1 Status messages PMCprimo .......................................................................... 85

10.7.2 Status messages drive ................................................................................... 85

11 Appendix ........................................................................................................... 86

11.1 Notes on EMC problems ......................................................................................... 86

11.1.1 Cable screening.............................................................................................. 86

11.1.2 Metallic, large area connections ..................................................................... 87

11.1.3 PE connection, earthing, grounding................................................................ 87

11.1.4 Motor choke.................................................................................................... 87

11.1.5 Expansion board............................................................................................. 88

11.1.6 Ethernet interface of the expansion board X11/5 ........................................... 88

11.1.6.1 General...................................................................................................88

11.1.6.2 Interface.................................................................................................. 89

11.1.6.3 Configuration IP address ........................................................................90

11.2 Change of the buffer battery ...................................................................................92

11.3 Transport, storage, maintenance, disposal ............................................................. 93

11.4 Removing faults ......................................................................................................94

11.5 Index ....................................................................................................................... 96

Installation manual PMCprimo Drive2 Page 5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 7

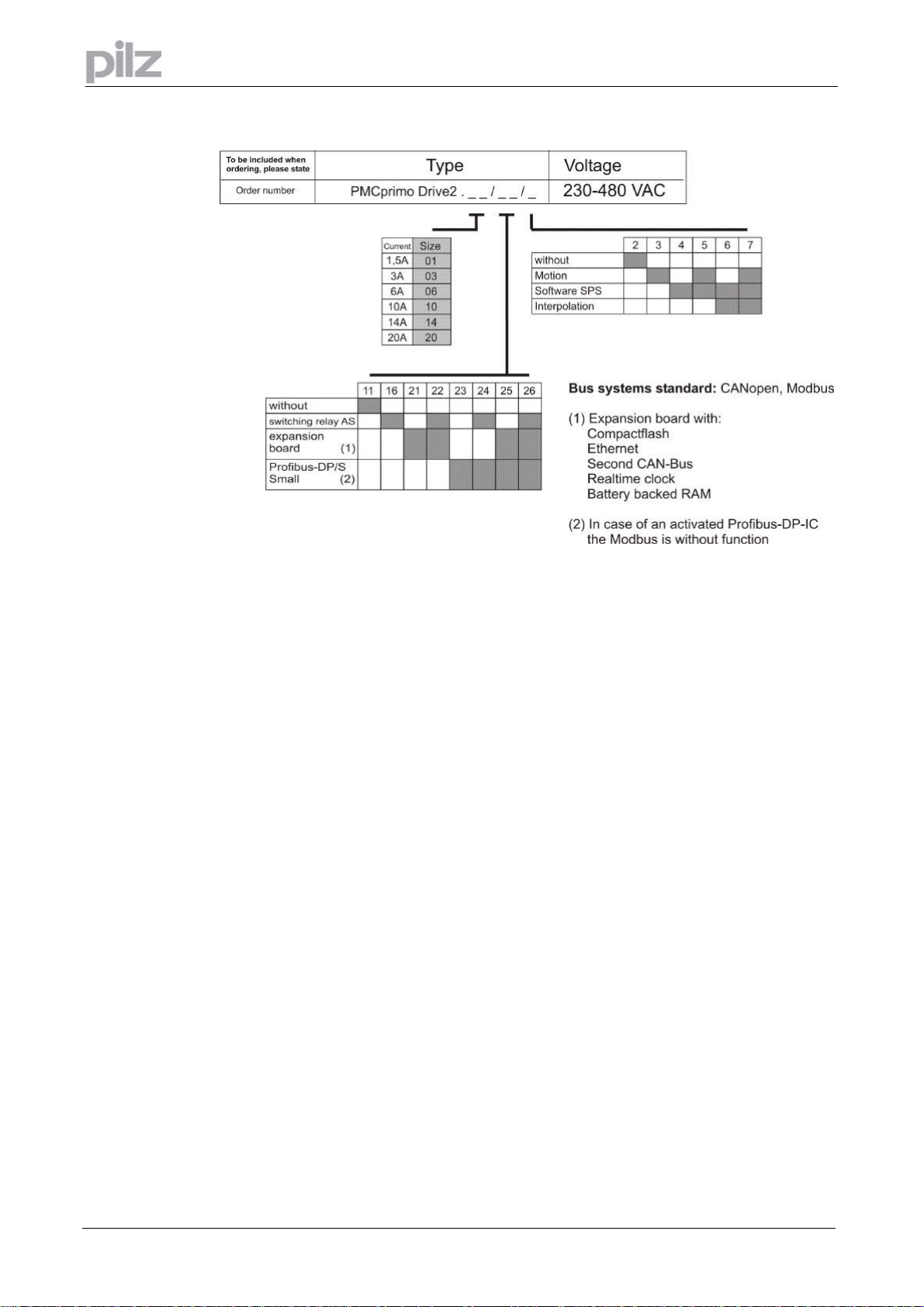

3 Type key

3 Type key

Page 6 Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 8

4 Safety instructions

4 Safety instructions

Only properly qualified personnel are permitted to perform activities such as

transport, installation, commissioning and maintenance. Properly qualified

persons are those who are familiar with the transport, assembly, installation,

commissioning and operation of the product, and who have the appropriate

qualifications for their job. The qualified personnel must know and observe:

IEC 364 and CENELEC HD 384 or DIN VDE 0100

IEC-Report 664 or DIN VDE 0110

National Accident Prevention Regulations or BGV A2

Read this documentation before carrying out installation and commissioning.

Incorrect handling of the PMCprimo Drive

damage. It is vital that you keep to the technical data and information on

connection requirements (on the nameplate and in the documentation).

The PMCprimo Drive2

be damaged by incorrect handling. Discharge your body before touching the

PMCprimo Drive2. Avoid contact with highly insulating materials (synthetic fibre,

plastic film etc.). Place the PMCprimo Drive2

Do not open the units. Keep all covers and switchgear cabinet doors closed during

operation. Otherwise there are deadly hazards, with the possibility of severe

danger to health or material damage.

During operation, PMCprimo Drives, according to their degree of enclosure

protection, may have uncovered live components. Control and power connections

may be live, even if the motor is not rotating.

PMCprimo Drives

used for cooling, it can reach temperatures above 80°C.

Never undo the electrical connections to the PMCprimo Drive2

is a danger of electric arcing with damage to contacts and danger to persons.

Wait at least five minutes after disconnecting the PMCprimo Drive2

supply voltage before touching live sections of the equipment (e.g. contacts) or

undoing connections. Capacitors can still have dangerous voltages present up to

five minutes after switching off the supply voltages. To be sure, measure the

voltage in the DC-link circuit and wait until it has fallen below 40V.

Based on the guideline 94/9/EC (ATEX guideline) this product is not suitable for the

application in potential explosive areas without evaluation of the conformity.

contains electrostatically sensitive components which may

may have hot surfaces during operation. Since the front panel is

can lead to personal injury or material

on a conductive surface.

while it is live. There

from the mains

Installation manual PMCprimo Drive2 Page 7

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 9

5 European directives and standards

Servo amplifiers are components that are intended to be incorporated into electrical plant and

machines forindustrial use. When the servoamplifiers are built into machines or plant, the intended

operation of the amplifier is forbidden until it has been established that the machine or plant fulfills

the requirements of the EC Machinery Directive 98/37/EG and the EC Directive on EMC

(89/336/EEC).

To fulfill the EC Machinery directive (98/37/EG), the following standards have to be applied: EN

60204-1 (Safety and electrical equipment of machines) EN 292 (Safety of machines)

The manufacturer of the machine must produce a hazard analysis for the machine and take

appropriate measures to ensure that unforeseen movements do not result in personal injury

or material damage.

To fulfill the Low Voltage Directive 73/23/EEC, the following standards have to be applied:

EN 60204-1 (Safety and electrical equipment of machines)

EN 50178 (Equipment of high voltage plant with electronic devices)

EN 60439-1 (Low-voltage switchgear and controlgear assemblies)

To fulfill the EC EMC regulations (89/336/EEC), the following standards have to be applied:

EN 61000-6-1 or EN 61000-6-2 (noise immunity within the domestic range/industrial range)

EN 61000-6-3 or EN 61000-6-4 (noise emission within the domestic range/industrial range)

The manufacturer of the machine or plant is responsible for ensuring that they meet the limits

required by the EMC regulations. Advice on the correct installation for EMC – such as shielding,

grounding, arrangement ofconnectors and cable routing – can be found in this documentation.

The machine / plant manufacturer must examine whether with its machine / plant still further

or other standards or EEC guidelines are to be used.

5 European directives and standards

ce- conformance

Conformity with the EC Directive on EMC 89/336/EEC and the Low Voltage Directive 73/23/EEC is

mandatory for servoamplifiers supplied within the European Union. To fulfill the EMC directive, the

standard EN 61800-3 is applied.

In the reference to noise immunity and noise emission the servoamplifier fulfills the requirement to

the category second environment (industrial environment).

The servo amplifiers have been tested by an authorized testing laboratory in a defined configuration

with the system components which are described in this documentation. Any divergence from the

configuration and installation described in this documentation means that you will be responsible for

carrying out new measurements to ensure that the regulatory requirements are fulfilled.

To fulfill the Low Voltage Directive, the standard EN 50178 has to be applied.

Page 8 Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 10

5 European directives and standards

UL and cUL- Conformance

UL (cUL)-certified servo amplifiers (Underwriters Laboratories Inc.) fulfil the relevant U.S. and

Canadian standard (in this case UL 840 and UL 508C).

This standard describes the fulfillment by design of minimum requirements for electrically operated

power conversion equipment, such as frequency converters and servo amplifiers, which is intended

to eliminate the risk of fire, electric shock, or injury to persons, being caused by such equipment.

The technical conformance with the U.S. and Canadian standard is determined by an independent

UL (cUL) fire inspector through the type testing and regular check-ups.

Apart from the notes on installation and safety in the documentation, the customer does not have to

observe any other points in direct connection with the UL (cUL)-certification of the equipment.

UL 508C

UL 508C describes the fulfillment by design of minimum requirements for electrically operated

power conversion equipment, such as frequency converters and servo amplifiers, which is intended

to eliminate the risk of fire being caused by such equipment.

UL 840

UL 840 describes the fulfillment by design of air and insulation creepage spacings for electrical

equipment and printed circuit boards.

Installation manual PMCprimo Drive2 Page 9

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 11

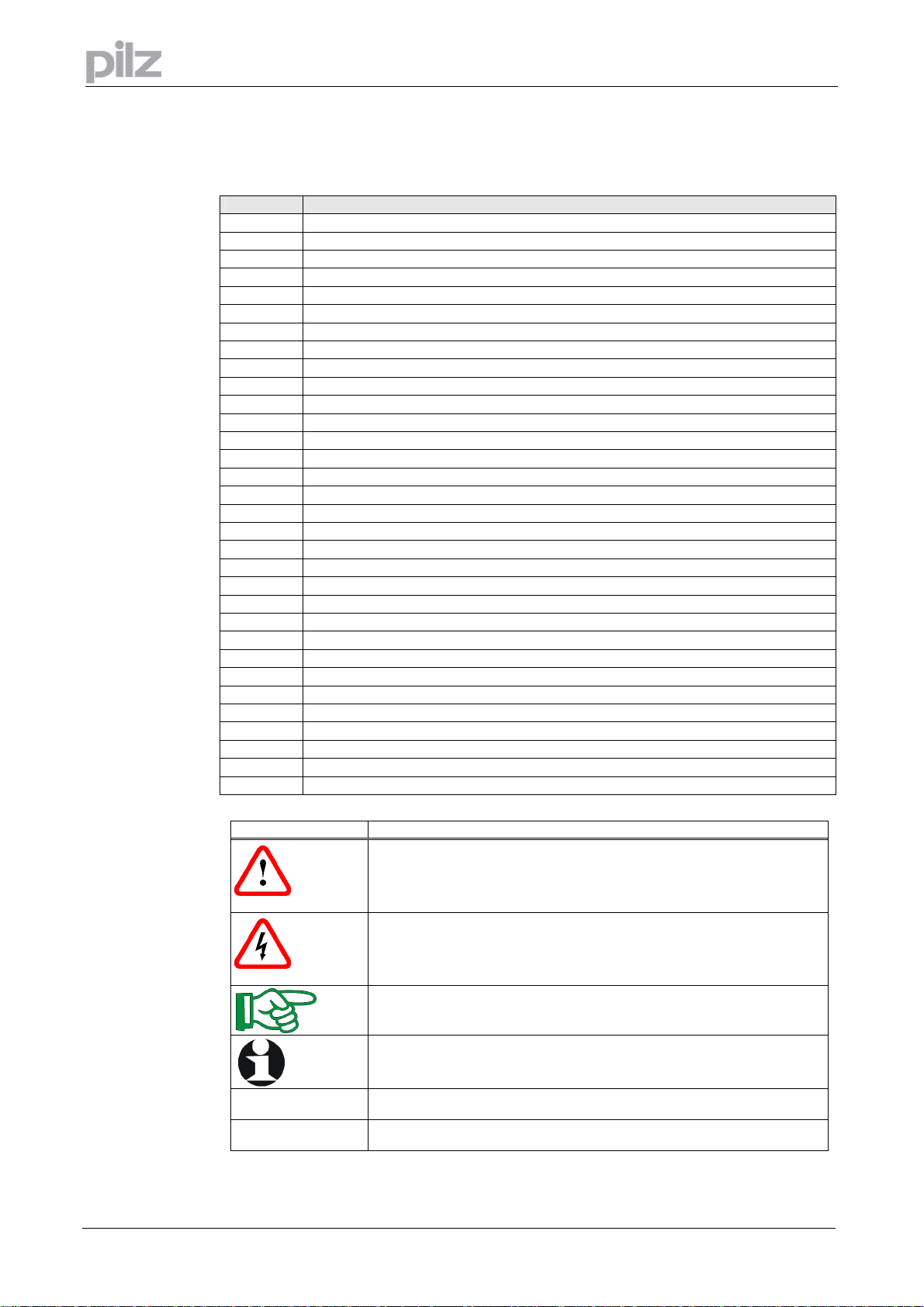

6 Abbreviations and symbols

The abbreviations used in this manual are explained in the table below.

Abbrev. Meaning

AGND Analog ground

BTB/RTO Ready to operate

CAN Controller area network- Bus system

CE Communité Europeenne

CLK Clock

COM Serial interface of a PC-AT

DGND Digital ground

DIN Deutsches Institut für Normung

Drive Servo amplifier

EGND Ground for PMCprimo Drive2, RS232 and encoder

EMC Electromagnetic compatibility

EN Europäische Norm

ESD Electrostatic discharge

IEC International Electrotechnical Commission

IGBT Insulated Gate Bipolar Transistor

ISO International Standardization Organization

MODBUS Serial protocol for operator manuals

NI Zero pulse

RBallast Regen resistor

RBext External regen resistor

RBint Internal regen resistor

RES Revolver

PLC Programmable logic controller

SRAM Static RAM

SSI Synchronous serial interface

TN/TT-Netz Mains standard DIN 57100 T310

UL Underwriter Laboratories

V AC AC voltage

V DC DC voltage

VDE Verein deutscher Elektrotechniker

VGA Grafical display with min. 640x480 pixels

XGND Ground for the 24V supply

6 Abbreviations and symbols

Meaning/Description

This symbol indicates the possibility of a danger, risk to life and/or health.

Ignorance may seriously affect health and cause dangerous injuries.

This symbol indicates the possibility of a danger, risk to life and/or health from

electricity and its effects.

•

⇒

This symbol indicates important instructions regarding the correct use of the

product. Ignorance may affect the performance of the machinery and/or the

connected system.

This symbol indicates special user tips and/or important useful information.

These will support optimum use of the product and functions.

Emphasis

see page (or cross reference)

Page 10 Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 12

7 General

7 General

7.1 About this manual

This manual describes the digital control system PMCprimo Drive2.

Here you can find information about:

• Technical data of the PMCprimo Drive2 from page 20

• Assembly and installation from page 32

• Interfaces from page 45

• Commissioning of the PMCprimo Drive2 from page 78

The programming of the PMCprimo-motion control-systems is described explicitely in the

PMCprimo programming manual.

Useful hints about linking controls and CANopen devices via CAN bus can be found in the

manual „PMCprimo CAN network“.

Both manuals are part on the CD-ROM PMCprimo Motion Control Tools.

7.2 Requirements

Transport: only by personnel with knowledge in handling electrostatically

sensitive components.

Installation: only by electrically qualified personnel

Commissioning: only by personnel with extensive knowledge of electrical

engineering technology

7.3 Prescribed use (Use as directed) of the control

The servo amplifiers are components which are built into electrical equipment or machines, and can

only be used as integral components of such equipment.

The manufacturer of the machine must generate a hazard analysis for the machine, and take

appropriate measures to ensure that unforeseen movements cannot cause injury or damage to any

person or property.

The PMCprimo Drive2 family of servo amplifiers can be connected directly to symmetrically earthed

(grounded) three-phase industrial mains supply networks [TN-system, TT-system with earthed

(grounded) neutral point, not more than 5000 rms symmetrical amperes, 480 VAC maximum].

The servo amplifiers must not be operated directly on power supply networks >230 V without an

earth (ground) or with an asymmetrical earth (ground).

Connection to different mains supply networks (with additional isolating transformer) (page 16).

Periodic overvoltages between outer conductor (L1, L2, L3) and housing of the servo amplifier may

not exceed 1000 V (peak value).

Transient overvoltages (< 50µs) between the outer conductors may not exceed 1000 V.

Transient overvoltages (< 50µs) between outer conductors and housing may not exceed 2000 V.

If the servo amplifiers are used in residential areas, or in business or commercial premises, then

additional filter measures must be implemented by the user.

The PMCprimo Drive2 family of servo amplifiers is intended to drive specific brushless synchronous

servomotors, with closed-loop control of torque, speed and/or position. Asynchronous and linear

motors can also be used. The rated voltage of the motors must be at least as high as the DC-link

voltage of the servo amplifier.

The servo amplifiers may only be operated in a closed switchgear cabinet, taking into account the

ambient conditions defined on page 21 and the dimensions shown on page 34. Ventilation or

cooling may be necessary to prevent enclosure ambient from exceeding 45 °C (113 °F).

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 11

Page 13

Use only copper wire. Wire size may be determined from EN 60204 (or table 310-16 of the NEC

60 °C or 75 °C column for AWG size).

We only guarantee the conformance of the servo amplifiers with the standards for industrial areas,

if the components (motors, cables, amplifiers etc) are delivered by Pilz GmbH & Co. KG.

7 General

Page 12

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 14

7 General

7.4 Instrument description

7.4.1 Scope of delivery

When you order a PMCprimo Drive2 from us, you will receive:

• PMCprimo Drive2 - size 01..20

• Mating connectors X3, X4, X0A, X0B, X7, X8

The mating motor connector X9 is not part of the package!

• Assembly, installation- and commissioning instructions

• Setup software package PMCprimo Motion Control Tools on CD-ROM

• Software manual PDrive and PMCprimo programming manual on CD-ROM

7.4.2 Accessories

• Servo motor PMCtendo AC1 or PMCtendo AC2

• Motor cable (pre-assembled), or both motor connectors separately with motor cable as cut-off

length

• Feedback cable (pre-assembled) or both feedback connectors separately with feedback cable

as cut-off length

• External regen resistor

• Communication cable to the PC for parameterisation (Null modem cable)

• MODBUS panel and communication cable; Panel (2 line till Touch screen)

• CAN cables

• Software keys for Motion Generator or Soft-PLC

• Ethernet cables

• Adapter cable Modbus/Profibus

• Expansion card (page 88)

• CompactFlash Cards

• Profibus DPS-small IC

• Master encoder

• Expansion board (page 88)

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 13

Page 15

7 General

7.4.3 The PMCprimo Drive2 family

7.4.3.1 Performance data

• Position controller with 1 ms cycle time

• Digital current controller (space vector, pulse-width modulation, 62,5 µs)

• Evaluation of the resolver signals or sine-cosine signals of a HIPERFACE encoder

• 9 axes in system: 1 Motor direct, as well as 8 other axes channels for controlling further axes

• Each axis can operate in virtual motor mode

• Software gearbox

• Software differential and clutch

• Internal map generator (motion generator) as an option

• Product referencing

• Tension control

• Up to 8 cam

• Soft positioning („s-curves“)

7.4.3.2 Fieldbus Interface

• CAN-Bus with 500 kBit/s or 1 MBit/s (CANopen) – linking up to 60 PMCprimo-motion controlsystems

• Modbus interface - devices like panels

• Option: Profibus DP (small) – easy communication with SoftPLC

• Option: Ethernet 10/100 Mbit/s

• Option: second CAN interface

7.4.3.3 Soft-PLC CoDeSys®

• Soft-PLC CoDeSys® as an option

• Fully PLC functionality specified in IEC 61131-3

• PLC and PMCprimo - combined in one system

7.4.3.4 Interfaces

• 12 digital inputs, 24 V, electrically isolated

• 8 digital outputs, 24 V, short circuit protected and electrically isolated

• 2 analog outputs with ± 10 V output range

• 2 analog inputs with ± 10 V input range

• 1 input for master encoder (incremental / SSI)

7.4.3.5 Power supplies

• 24 V power supply

• Common power supply for all master encoders

Page 14

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 16

7 General

7.4.3.6 Power section

• Power supply: B6 rectifier bridge, directly off 3-phase earthed supply system,

integral power input filter and inrush circuit

• All shielding connections directly on the amplifier

• Output stage: IGBT- module with isolated current measurement

• Regen circuit: with dynamic distribution of the regen power between several

amplifiers on the same DC-link circuit. Internal regen resistor as

standard, external regen resistors if required

• DC-link voltage 260 — 900 V DC, can be paralleled

7.4.3.7 Electrical supply

• Directly off grounded 3 phase system,

230V-10% ... 480V +10% ,50 Hz,

208V-10% ... 480V +10% ,60 Hz

TN-system or TT-system with grounded neutral point, not more than 5000 rms

symmetrical amperes

• 6 current ratings (1.5 A , 3 A , 6 A , 10 A , 14 A, 20 A)

• single-phase supply (e.g. for commissioning or setting-up) is possible

7.4.3.8 Power input filter

• Interference suppression filter for the supply input (to Class A) is integrated)

• Interference suppression filter for the 24V aux. supply (to Class A) is integrated

7.4.3.9 Operation and programming

• Comfortable programming with the software package PMCprimo Motion Control Tools under

Windows 98/NT/2000/XP.

• Fully programmable with any ASCII-Terminal

7.4.3.10 Integrated safety

• Safe electrical separation to EN 50178 between the power input / motor connections and the

signal electronics, provided by appropriate insulation/creepage distances and complete

electrical isolation

• Softstart, overvoltage recognition, short-circuit protection, phase-failure monitoring

• Temperature monitoring of PMCprimo Drive2 and motor (when using motors from the

PMCtendo AC series with our pre-assembled cables)

• -AS- built-in safety relay (personnel-safety starting lock-out).

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 15

Page 17

7 General

7.5 Connection to different mains supply networks

On this page you'll find all possible connection variations to different mains supply networks.

An isolating transformer is always required for 400...480V mains networks without

earth(ground) and for networks with asymmetrical earth(ground).

Page 16

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 18

7 General

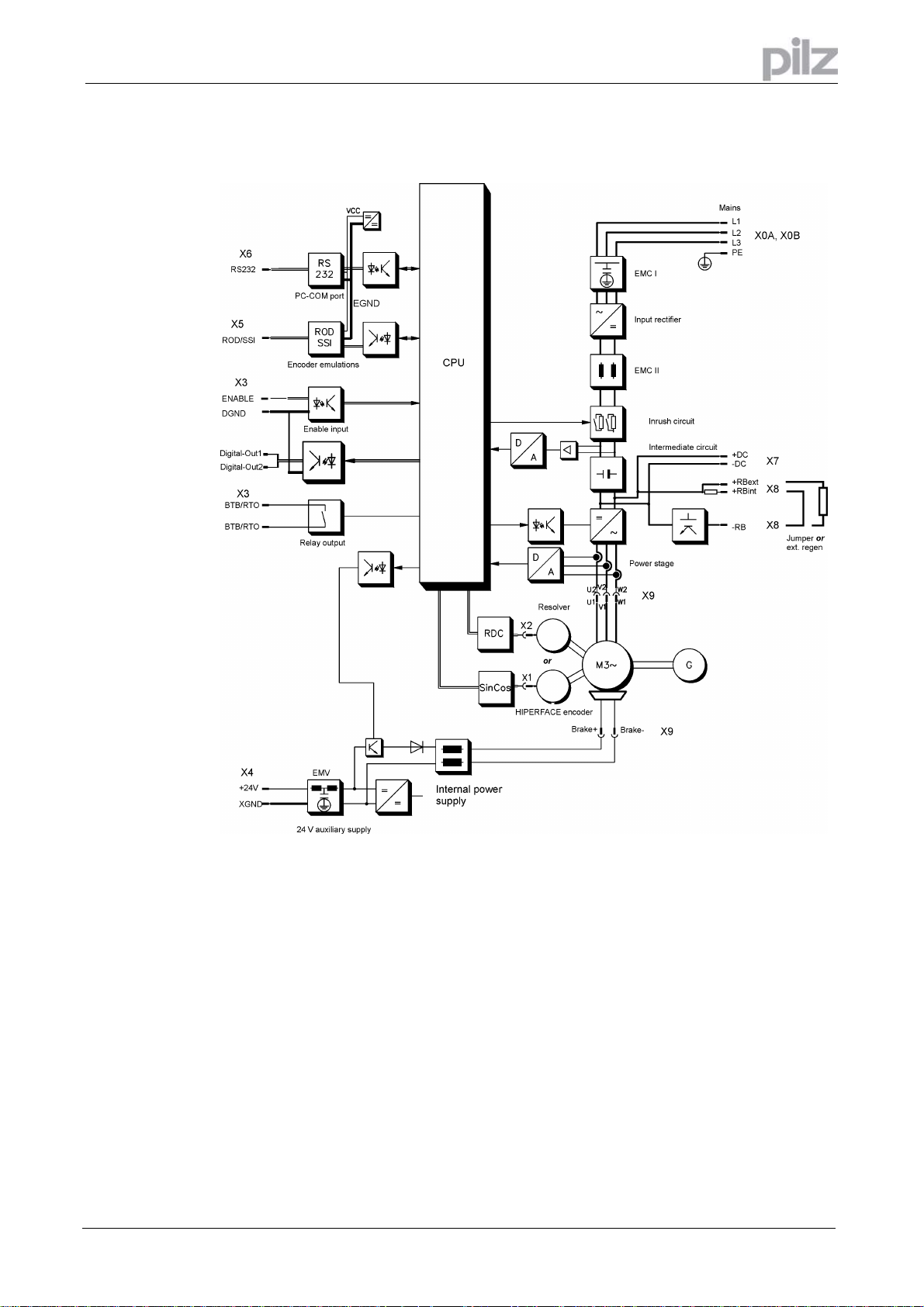

7.6 Block diagram – part 1

Installation manual PMCprimo Drive2

Page 17

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 19

7 General

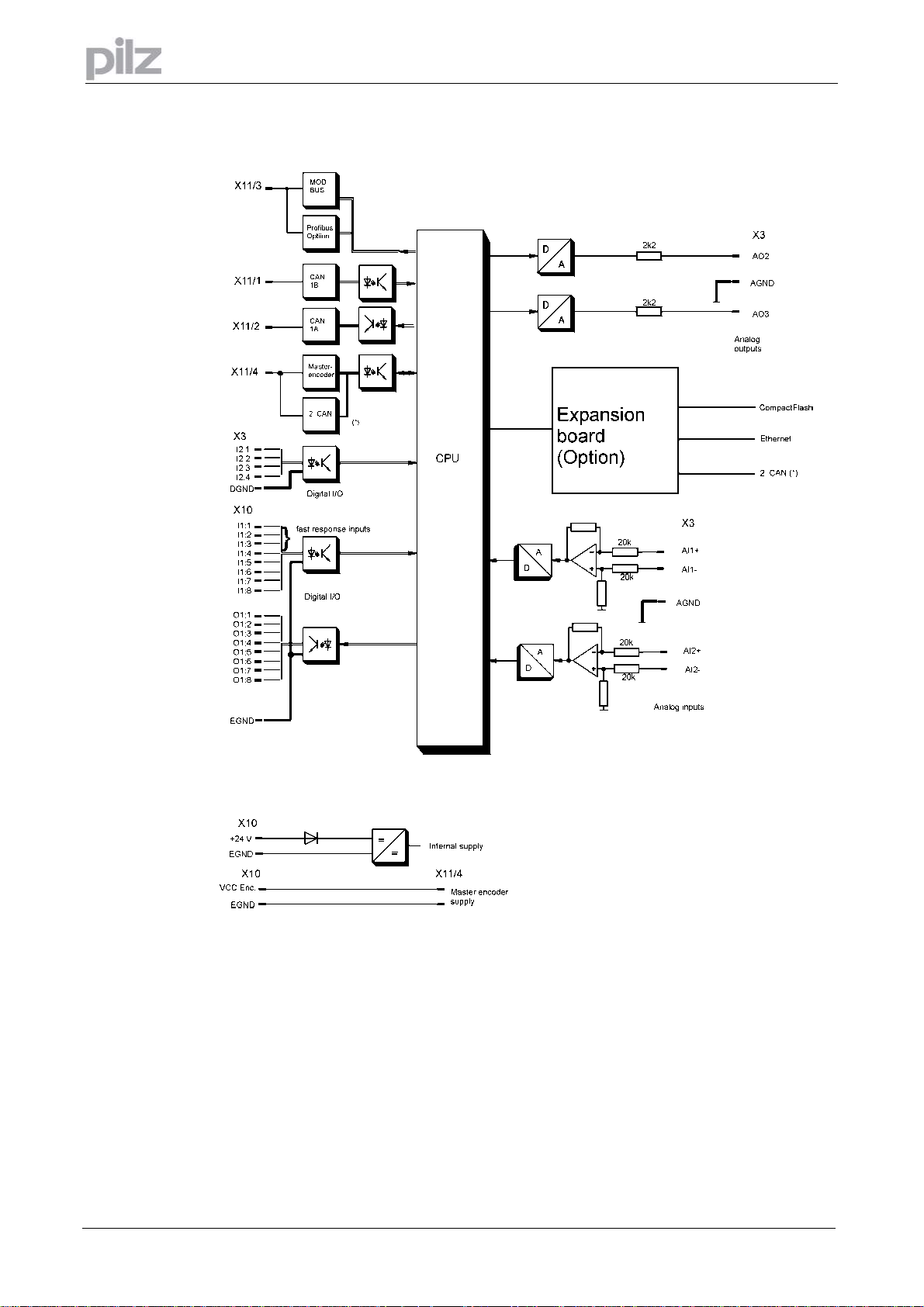

7.7 Block diagram – part 2

Page 18

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 20

7 General

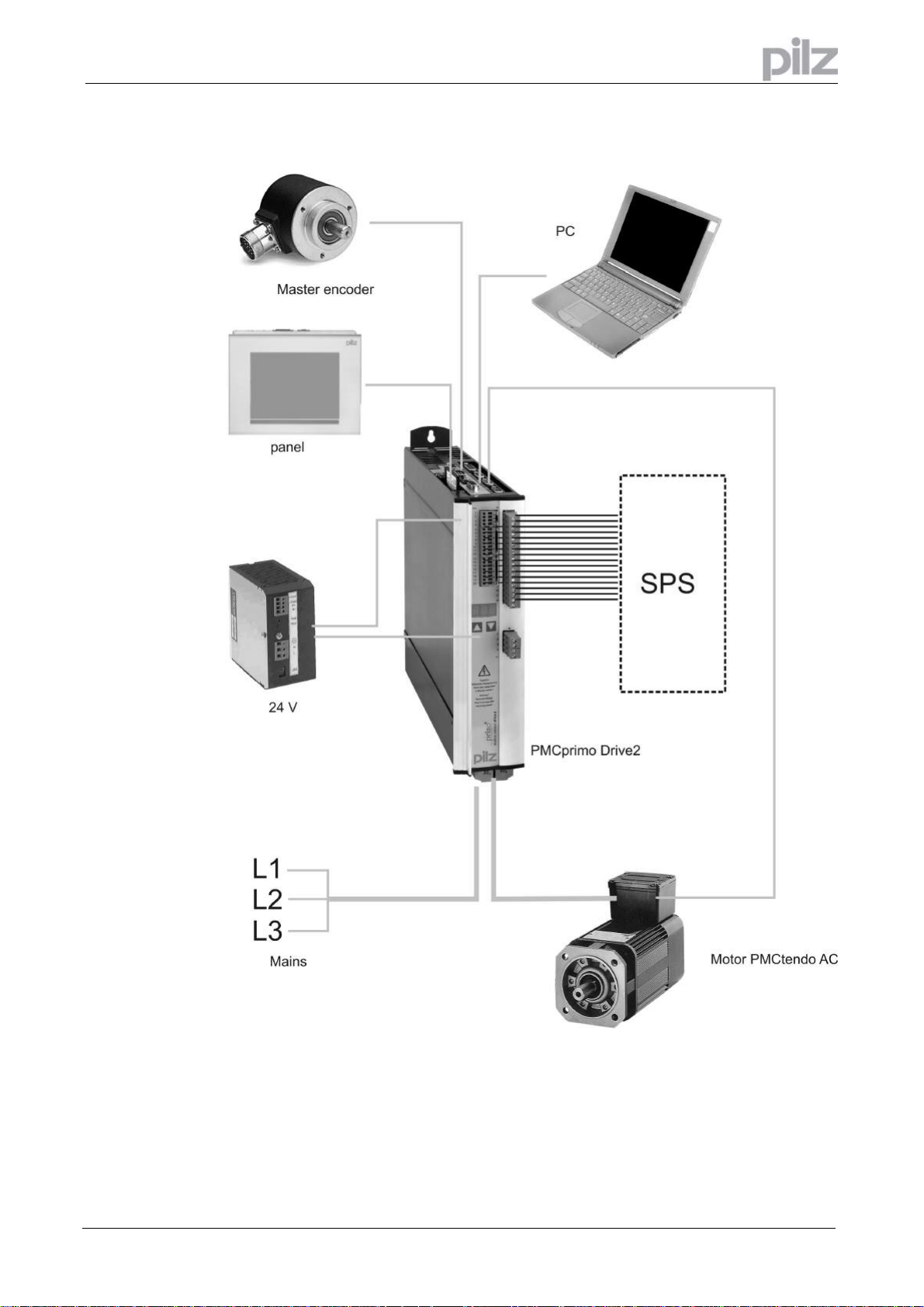

7.8 Components of a servo system

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 19

Page 21

7 General

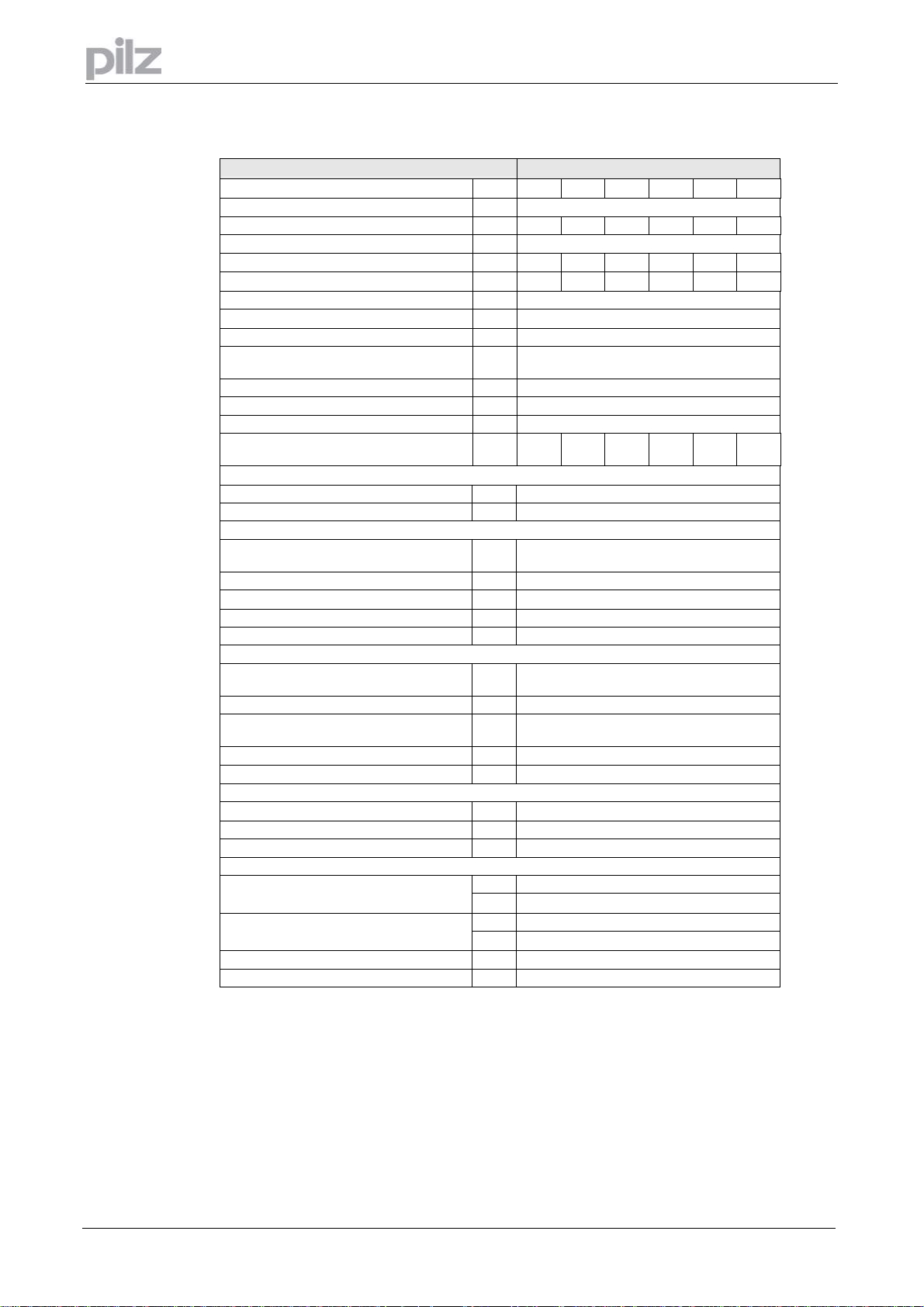

7.9 Technical data

Rated data DIM

Rated supply voltage V~ 3 x 230V-10% ... 480V+10%, 50 ... 60 Hz

Rated installed load for S1 operation kVA 1 2 4 7 10 14

Rated DC-link voltage V= 310 - 675

Rated output current (rms value, ± 3%)

Peak output current (max. ca. 5s, ± 3%)

Clock frequency of the output stage kHz 8

Technical data for regen circuit —

Overvoltage protection threshold V 450...900

Form factor of the output current

(at rated data and min. load inductance)

Bandwidth of subordinate current controller kHz > 1,2

Residual voltage drop at rated current V 5

Quiescent dissipation, output stage disabled W 15

Dissipation at rated current (incl. power

supply losses, without regen dissipation)

Internal fusing (external fusing ⇒ page 21)

Auxiliary supply 24V — internal 3.15 AT

Regen resistor — internal electronic

Inputs

Analog inputs (X3), resolution 14bit (AI1) and

12bit (AI2)

Common-mode voltage max. V ±10

Input resistance

Digital inputs (X3) according to IEC 1131

Digital inputs (X10) according to IEC 1131

Outputs

Output current digital outputs (X10), each

channel

Output current digital outputs (X3) mA max 10 (open collector)

Voltage range analog outputs (X3) ,

resolution 10 Bit

Output resistance

Max. output current, brake A 2

Master encoder PMCprimo Drive2

Input resistance

Transfer rate MHz 1

Pulse width (Z-track incremental encoder) ns mind. 200

Power dissipation

without brake, no load

with brake, no load

Encoder supply - 5-24 V, see datasheet encoder

12V supply CAN mA 10 each client

Arms 1,5 3 6 10 14 20

Arms 3 6 12 20 28 40

01 03 06 10 14 20

— 1.01

W 30 40 60 90 160 200

V ±10

kΩ

mA max. 100 (overload protection)

V ± 10

kΩ

Ω

V 24 (-0% +15%) 24 V supply supply, electrically isolated

mA 1000

V 24 (-0% +15%) 24 V supply supply, electrically isolated

mA 3000

PMCprimo Drive2

⇒ S. 24

20

2.2

200

Page 20

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 22

7 General

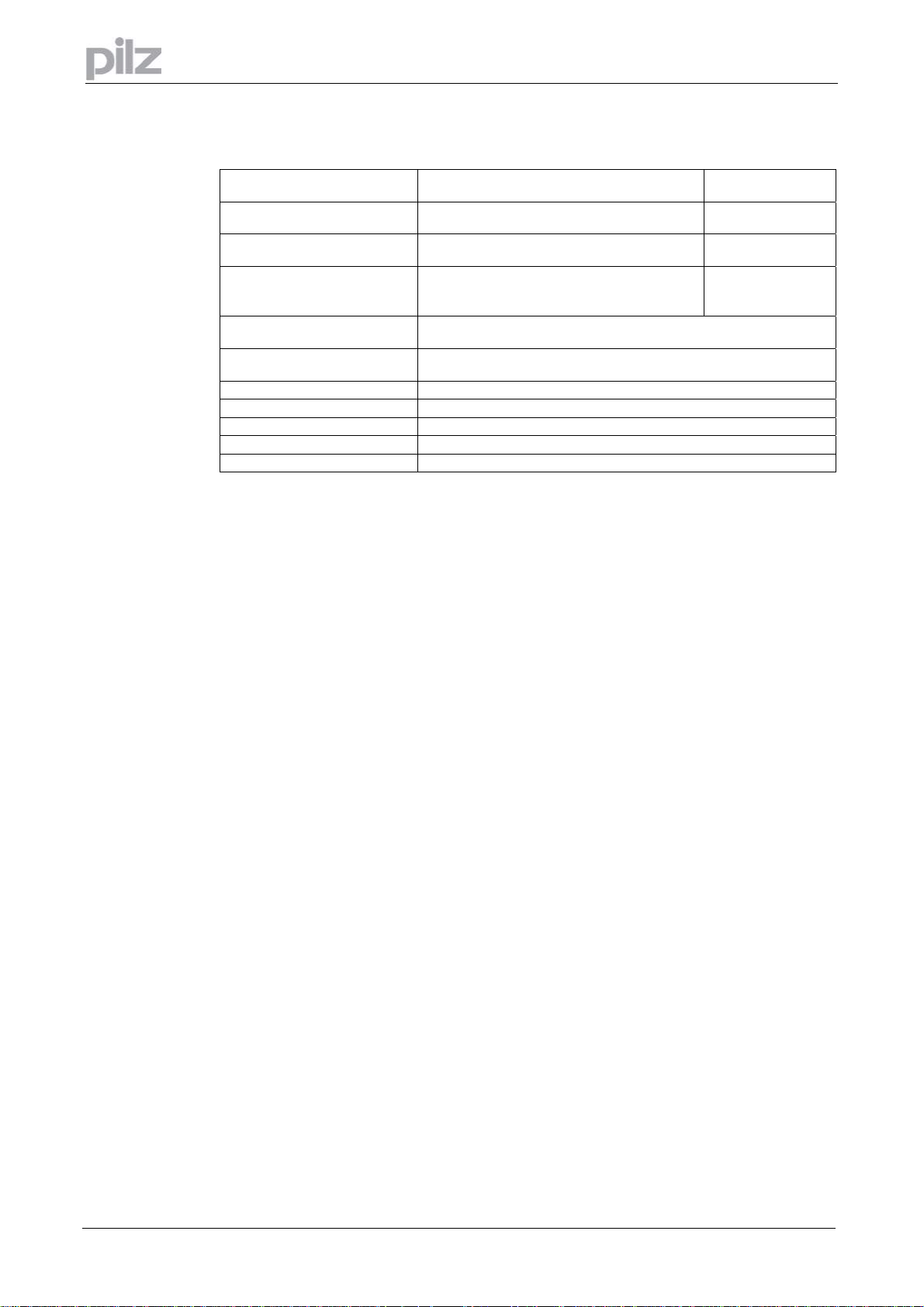

Connections DIM

Control signals (X3) — Combicon 5.08 / 18pole , 2,5mm²

24 V supply (X4) — Combicon 5.08 / 4 pole , 2,5mm²

24 V supply (X10) — Combicon 3.5 / 11 pole , 1mm²

Encoder supply (X10) — Combicon 3.5 / 11 pole , 1mm²

Digital inputs (X10) — Combicon 3.5 / 11 pole , 1mm²

Digital outputs (X10) — Combicon 3.5 / 8 pole , 1mm²

Power signals (X0,X7,X8,X9) — Power Combicon 7.62 / 4x4 + 1x6-pole, 4mm²

Resolver input (X2) — SUB-D 9pol. (plug)

HIPERFACE input (X1) — SUB-D 15pol. (plug)

PC interface (X6) — SUB-D 9pol. (socket)

Encoder emulation, ROD/SSI (X5) — SUB-D 9pole (plug)

Master encoder (X11/4) / CAN2 (Option) — SUB-D 9pole (socket)

MODBUS (X11/3) / Profibus (Option) — RJ45

CAN-1A (X11/2) — SUB-D 9pole (plug)

CAN-1B (X11/1) — SUB-D 9pole (socket)

Mechanical

Weight kg 4 5 7,5

Height without connectors mm 275

Width mm 70 100 120

Depth without connectors mm 265

01 03 06 10 14 20

PMCprimo Drive2

7.9.1 External fusing

Fusible cutouts or similay

AC supply FN1/2/3 6 AT 10 AT 20 AT

24V supply FH1/2 max. 16 AF

Regen resistor FB1/2 4 AF 6 AF 6 AF

PMCprimo Drive2

01 / 03

PMCprimo Drive2

06 / 10

7.9.2 Permissible ambient conditions ventilation, mounting position

Storage temperature/humidity,duration

Transport temperature / humidity

Supply voltage tolerances

Input power

Aux. power supply

Ambient temperature in operation

Humidity in operation rel. humidity 85%, no condensation

Site altitude up to 1000m a.m.s.l. without restriction

Pollution level Pollution level 2 to EN60204/EN50178

Enclosure protection IP 20

Mounting position

Ventilation built-in fan

Vibration Vibration: 1g sinuid according to 60068-2-Fc

⇒ S. 93

⇒ S. 93

min 3x230V

24 V DC (-0% +15%)

0...+45°C at rated data

1000...2500m a.m.s.l. with power derating 1.5%/100m

generally vertical. ⇒S. 33

Shock: 15g, 11ms, 60068-27-Ea

-10%

AC / max 3x 480V

+10%,

50 ... 60 Hz

Make sure that there is sufficient forced ventilation within the switchgear cabinet!

PMCprimo Drive2

14 / 20

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 21

Page 23

7 General

7.9.3 Conductor cross-sections

Following EN 60204 (for AWG: table 310-16 of the NEC 60°C or 75°C column), we recommend:

AC connection PMCprimo Drive2 sz. 01-10 : 1,5 mm²

DC-link PMCprimo Drive2 sz. 01-10 : 1,5 mm²

Motor cables up to 25 m length PMCprimo Drive2 sz. 01-10 : 1 - 1,5mm²

Motor cables 25 to 100 m length

Resolver, thermostat-motor 8x0.25 mm² twisted pairs, shielded, max.100m,

HIPERFACE Encoder, thermostatmotor

Analog In- and outputs, AGND 0.25 mm² , twisted pairs, shielded

Control signals, BTB, DGND 0.5 mm²

Holding brake (Motor) min. 0.75 mm², shielded, check voltage drop

+24 V / XGND max. 2.5 mm², check voltage drop

24 V (X10) EGND / VCC Enc. Max. 1 mm2, check voltage drop

PMCprimo Drive2 sz. 14/20 : 4 mm²

PMCprimo Drive2 sz 14/20 : 4 mm²

PMCprimo Drive2 sz. 14/20 : 2,5 mm²

PMCprimo Drive2 sz. 01-10 : 1 mm²

PMCprimo Drive2 sz. 14/20 : 2,5 mm²

capacitance <120pF/m

10x0.14 mm² twisted pairs, shielded, max.100m,

capacitance <120pF/m

600V, 105°C, twisted

shielded for length >

20 cm

shielded,

capacitance<150pF/m

shielded with motor

choke MD400

7.9.4 LED-Display

A 3-character LED displays the servo amplifiers firmware version after switching on the 24V supply

for two seconds (e.g. “2.46”).

Afterwards the status of up to 10 axes is shown (or just “run”).

When an error occurs the error number is displayed (⇒ S. 83 ).

Page 22

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 24

7 General

7.10 Grounding system

AGND

DGND

XGND

EGND

ground for analog inputs and outputs, internal analog ground

ground for digital inputs and outputs ( X3), optically isolated

ground for 24V aux. supply (X4)

ground for encoder-emulation, RS232, digital In-and outputs (X10); power supply PMCprimo

Drive2 and master encoder, optically and inductively isolated

The potential isolation is shown in the block diagram (⇒ S. 17/18).

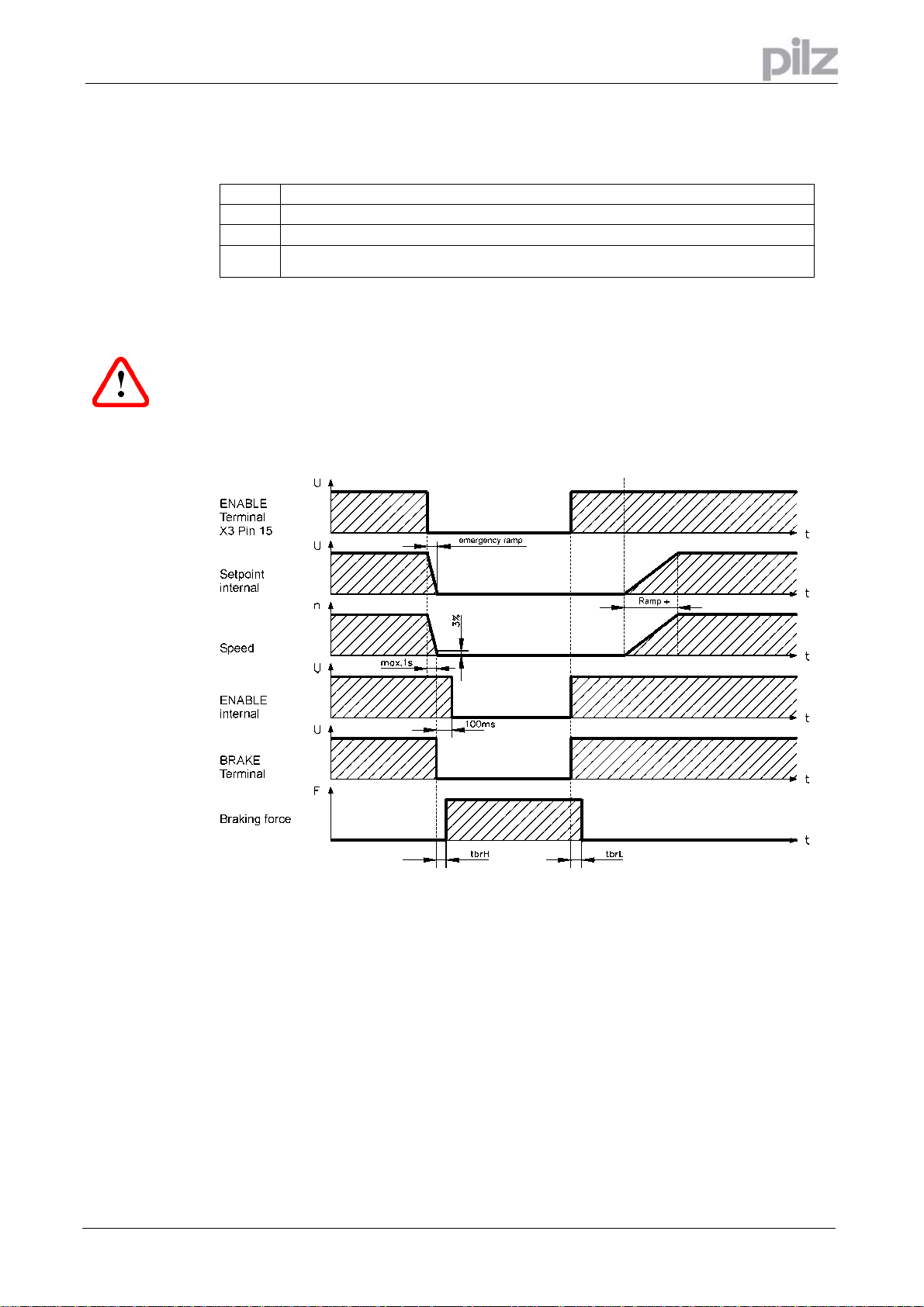

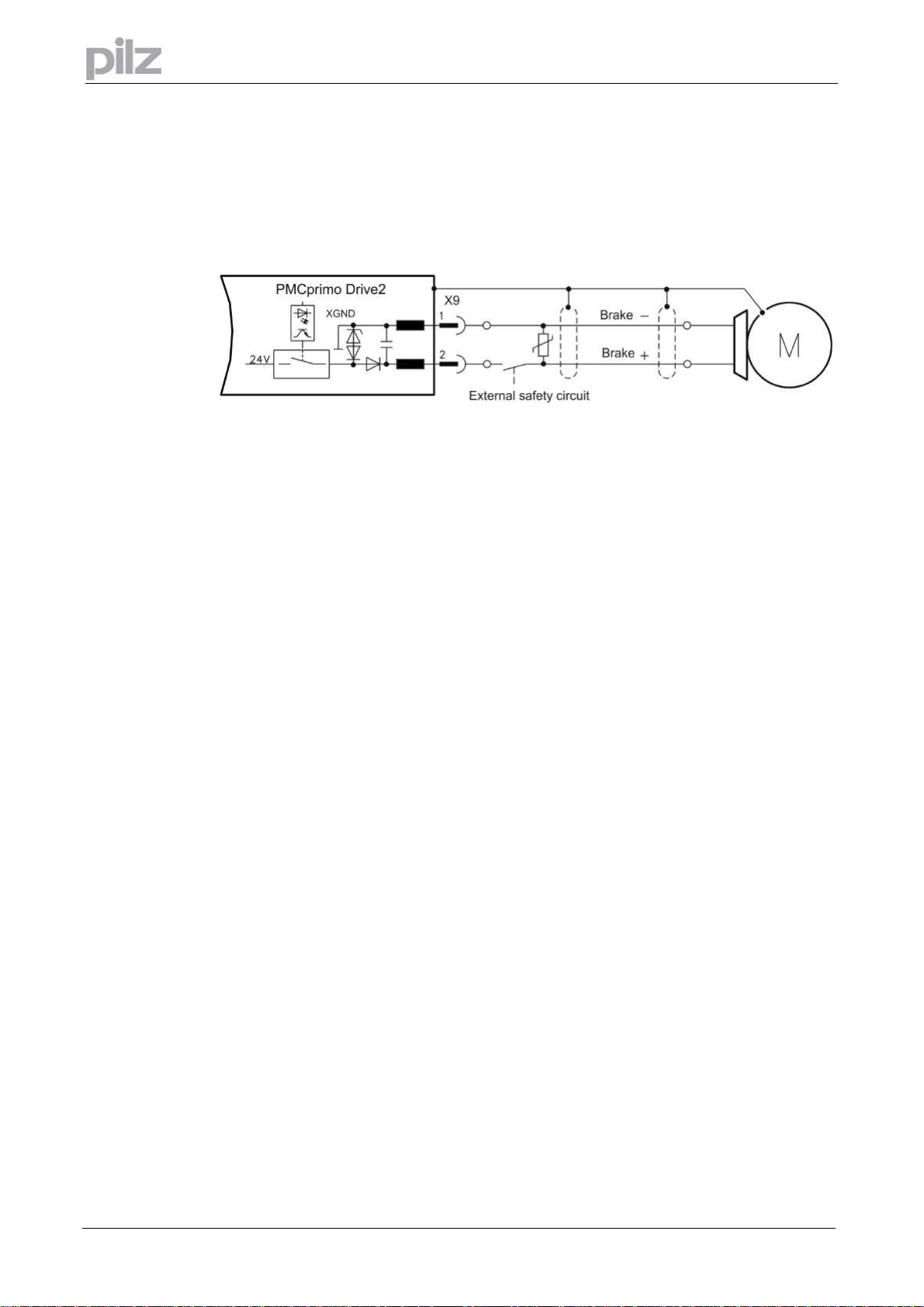

7.11 Control for motor-holding brake

A 24V / max. 2A holding brake in the motor can be controlled directly by the PMCprimo Drive2.

This function does not ensure personnel safety! (s. Option –AS- page 28)

The brake function must be enabled through the setup software PDRIVE with the parameter

„brake“.

In the diagram below you can see the time and functional relationships between the ENABLE

signal, speed setpoint, speed and braking force.

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 23

Page 25

During the internal ENABLE delay time of 100ms the speed setpoint of the PMCprimo Drive2 is

internally driven down a 10ms ramp to 0V. The brake output is switched on when 3% of the final

speed is reached. The rise (fbrH) and fall (fbrL) times of the holding brake which is built into the

motors are different for the various types of motor (see motor manual). A description of the interface

can be found on page 49.

A safe (for personnel) operation of the holding brake requires an additional “make” (n.o.) contact in

the brake circuit and a suppressor device (varistor) for the recommended brake circuit diagram

7 General

Page 24

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 26

7 General

7.12 Regen circuit

During braking with the aid of the motor, energy is fed back to the PMCprimo Drive2. This energy is

converted into heat in the regen resistor. The regen circuit (thresholds) are adjusted to the supply

voltage with the help of the setup software PDRIVE.

Our applications department can help you with the calculation of the regen power which is required.

A description of the interface can be found on page 50 .

Internal regen resistor: PMCprimo Drive2 sz. 01/03 66 Ohm

PMCprimo Drive2 sz. 06-20 33 Ohm

External regen resistor: PMCprimo Drive2 sz. 01-20 33 Ohm

Functional description:

1. Individual amplifiers, not coupled through the DC-link (DC+, DC-)

The circuit starts to respond at a DC-link voltage of 400V, 720V or 840V (depending on the supply

voltage). If the energy which is fed back from the motor, as an average over time or as a peak

value, is higher than the preset regen power, then the PMCprimo Drive2 will output the status

“regen power exceeded” and the regen circuit will be switched off. At the next internal check of the

DC-link voltage (after a few ms) an overvoltage will be detected and the PMCprimo Drive2 will be

switched off with the error message “Overvoltage” (⇒ page 82).

BTB/RTO contact (terminal X3, Pin2+3) will be opened at the same time (⇒page 64)

2. Several servo amplifiers coupled through the DC-link circuit (DC+, DC-)

Thanks to the built-in regen circuit with its patented w-characteristic, several amplifiers (even with

different current ratings) can be operated off a common DC-link, if they have a common supply

voltage. This is achieved by an automatic adjustment of the regen thresholds (which vary, because

of tolerances). The regen energy is distributed equally among all the amplifiers. The combined

power of all the amplifiers is always available, as continuous or peak power. The switch-off takes

place as described under 1. (above) for the PMCprimo Drive2 with the lowest switch-off threshold

(resulting from tolerances). The RTO (BTB) contact of this amplifier (terminals X3, Pin2+3) will be

opened at the same time (⇒ S. 64).

Regen circuit: technical data

Supply voltage

3 x 230 V Upper switch-on level of regen circuit V 400 – 430

Switch-off level of regen circuit V 380 – 410

Continuous power of regen circuit (RBint) W 80 200

Continuous power of regen circuit (RBext) max. kW 0,25 0,75

Pulse power, internal (RBint max. 1s) kW 2,5 5

Pulse power, external (RBext max. 1s) kW 5

3 x 400 V Upper switch-on level of regen circuit V 720 – 750

Switch-off level of regen circuit V 680 – 710

Continuous power of regen circuit (RBint) W 80 200

Continuous power of regen circuit (RBext) max. kW 0,4 1,2

Pulse power, internal (RBint max. 1s) kW 8 16

Pulse power, external (RBext max. 1s) kW 16

3 x 480 V Upper switch-on level of regen circuit V 840 – 870

Switch-off level of regen circuit V 800 – 830

Continuous power of regen circuit (RBint) W 80 200

Continuous power of regen circuit (RBext) max. kW 0,5 1,5

Pulse power, internal (RBint max. 1s) kW 10,5 21

Pulse power, external (RBext max. 1s) kW 21

Rated data

PMCprimo Drive2

DIM 01 - 03 06 - 20

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 25

Page 27

7 General

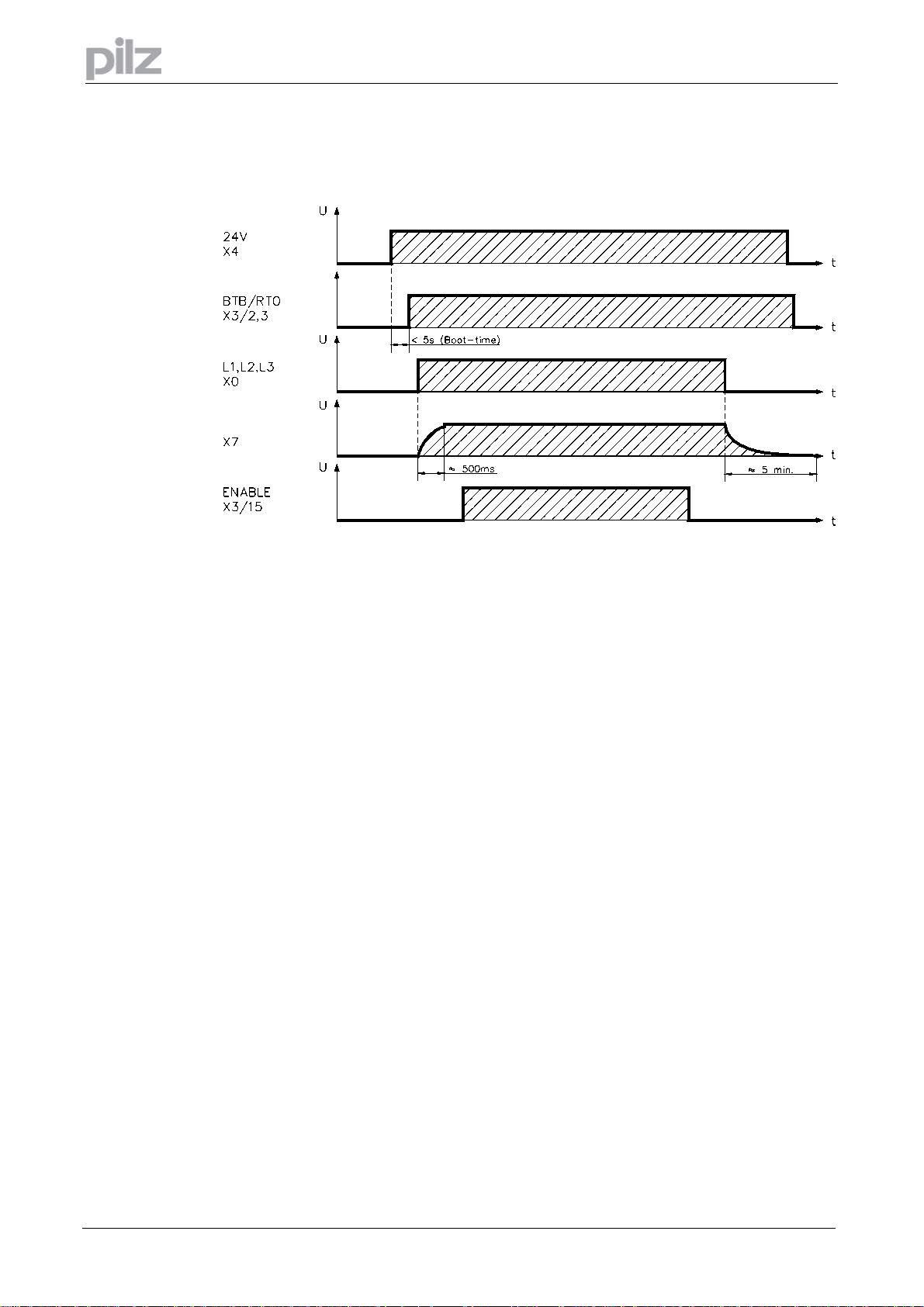

7.13 Switch-on and switch-off behaviour

The diagram below illustrates the correct functional sequence for switching the PMCprimo Drive2

on and off.

7.13.1 Stop function to EN 60204 (VDE 0113)

If a fault occurs (⇒ S. 81) ) the output stage of the PMCprimo Drive2 is switched off and the

BTB/RTO contact is opened. Instruments which are equipped with a selected “Brake” function use

a special sequence for switching off the output stage (⇒ S. 49).

The -AS- option can be used to switch off the drive via a positive-action (BG-approved) safety relay,

so that personnel safety is ensured at the drive shaft.

The stop functions are defined in EN 60204 (VDE 0113), Para. 9.2.2, 9.2.5.3.

There are three categories of stop functions:

Category 0: Shut down by immediately switching off the supply of energy to the drive

machinery (i.e. an uncontrolled shut-down);

Category 1: A controlled shut-down, during which the supply of energy to the drive

machinery is maintained to perform the shut-down, and where the energy

supply is only interrupted when the shut-down has been completed;

Category 2: A controlled shut-down, where the supply of energy to the drive machinery

is maintained.

Every machine must be equipped with a stop function to Category 0. Stop functions to Categories 1

and/or 2 must be provided if the safety or functional requirements of the machine make this

necessary.

Page 26

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 28

7 General

7.13.2 Emergency Stop strategies

The Emergency Stop function is defined in EN 60204 (VDE 0113), Para. 9.2.5.4.

You can find wiring recommendations in our application note “Stop and Emergency Stop

functions with PMCtendo DD4”.

7.13.2.1 Category 0

The controller is switched to “disable”, the electrical supply (400VAC) is disconnected. The drive

must be held by an electromagnetic holding device (brake).

In multiaxis systems with connected DC-link bus (intermediate circuit) the motor leads have to be

disconnected by a changeover switch (contactor, e.g. Siemens 3RT1516-1BB40) and shortcircuited

by resistors connected in a star configuration

7.13.2.2 Category 1

If hazardous conditions can result from an emergency stop switch-off with an unbraked rundown,

then the drive can be switched off by a controlled shut-down.

Stop Category 1 permits electromotive braking with a switch-off when zero speed has been

reached.

Safe shutdown can be achieved, when the loss of the mains supply is not rated as a fault and the

control takes over the disabling of the PMCprimo Drive2.

In the normal situation, only the supply power is switched off in a safe manner.

The 24V auxiliary supply remains switched on.

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 27

Page 29

7 General

7.14 Option -AS

7.14.1 General

A frequently required application task is the protection of personnel against the restarting of drives.

This can not be achieved by an electronic inhibit, but must be implemented with mechanical

elements (positively driven relay contacts).

To get round this problem, up to now either the main contactor in the mains supply line was

switched off, or another contactor was used to disconnect the motor from the PMCprimo Drive2.

The disadvantages of this method are:

• the DC-link has to be charged up again at restart

• wear on the contacts of the contactors, caused by switching under load

• extensive wiring required, with additional switching components

The -AS- option avoids these disadvantages. A safety relay in the servo amplifier is activated either

by the PLC or manually. Positively driven contacts provide a safe disconnection of the PMCprimo

Drive2, the setpoint input of the PMCprimo Drive2 is inhibited, and a signal is sent to the safety.

The advantages of the Option -AS-:

• the DC-link remains charged up, since the mains supply line remains active

• only low voltages are switched, so there is no contact wear

• very little wiring is required

• the functionality and the personnel safety when using the circuit recommendations in this

documentation have been approved by the trade liability association

7.14.2 Prescribed use

The -AS- restart lock is exclusively intended to provide safety for personnel, by preventing the

restart of a system.

To achieve this personnel safety, the wiring of the safety circuits must meet the safety requirements

of EN60204, EN292 and VDI 2853.

The -AS- restart lock must only be activated,

• when the motor is no longer rotating (speed = 0 rpm).

Drives with a suspended load must have an additional safe mechanical blocking (e.g. by a

motor-holding brake).

• when the monitoring contacts (KSO1/2 and BTB/RTO) for all PMCprimo Drives are wired into

the control signal loop (to recognize a cable break).

The -AS- restart lock may only be controlled by a CNC if the control of the internal safety relay is

arranged for redundant monitoring

The -AS- restart lock must not be used if the drive is to be made inactive for the following reasons:

1. - cleaning, maintenance and repair operations

- long inoperative periods

In such cases, the entire system should be disconnected from the supply by the personnel,

and secured (main switch).)

2. - emergency-stop situations

In an emergency-stop situation, the main contactor is switched off (by the emergency-stop

button or the BTB-contact in the safety circuit).)

Page 28

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 30

7 General

7.14.3 Functional description

An additional connector (X12) is mounted on the front panel of the PMCprimo Drive2. The coil

connections and a make (n.o.) contact of a safety relay are made available through 4 terminals on

this connector.

The 24V DC safety relay in the servo amplifier (TÜV approved) is controlled externally. All the relay

contacts have positive action.

Two contacts switch off the driver supply of the output stage in the PMCprimo Drive2, and short the

internal setpoint signal to AGND (0 V).

The make (n.o.) contact used for monitoring is looped into the control circuit.

If the safety relay is not energized, then the monitoring contact is open and the PMCprimo Drive2 is

ready for operation.

If the drive is electronically braked, the PMCprimo Drive2 is disabled and the motor-holding brake is

on, then the safety relay is energized (manually or by the controls).

The supply voltage for the driver circuit of the output stage is switched off in a safe manner, the

internal setpoint is shorted to 0V, and the monitoring contact bridges the safety logic in the control

circuit of the system (monitoring of protective doors etc.)

Even if the output stage or driver is destroyed, it is impossible to start the motor.

If the safety relay itself is faulty, then the monitoring contact cannot bridge the safety logic of the

system. Opening the protective devices will then switch off the system.

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 29

Page 31

7 General

7.14.4 Block diagram

7.14.5 Signal diagram

Page 30

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 32

7 General

7.14.6 Installation and Commissioning

7.14.6.1 Safety instructions

• Observe "Use as directed" on page 11.

• The monitoring contacts (KSO1/2) for each PMCprimo Drive2 with an -AS- option must be

looped into the control circuit. This is vital, so that a malfunction of the internal safety relay or a

cable break can be recognized.

• If the -AS- option is automatically activiated by a control system (KSI1/2), then make sure that

the output of the control is monitored for possible malfunction. This can be used to prevent a

faulty output from activating the -AS- option while the motor is running.

7.14.6.2 Application example

The following application example describes the function of the –AS- option. A PLC is controlling

the function:

1. The PLC sets the signal „activate AS“ with a digital output to a digital input of the PMCprimo

Drive2

2. The PMCprimo Drive2 triggers a program which stops the motor and goes in the motor-off

state (MO).

3. The ENABLE-signal (X3/pin 15) has to go low (0V).

4. The motor brake is activated from the PMCprimo Drive2

5. Now another PMCprimo Drive2 program sets an output and activates the option –AS

6. The PLC will get the message „AS activated“ via the monitoring contacts KSO1/2

If the PLC doesn’t gets the message „AS activated“ after setting „activate –AS“ to PMCprimo Drive2

there is a malfunction in the system.

The master contactor should be opened in this case.

7.14.6.3 Connection diagram

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 31

Page 33

8 Installation

8 Installation

8.1 Important instructions

• Protect the PMCprimo Drive2 from impermissible stresses. In particular, do not let any

components become bent or any insulation distances altered during transport and handling.

Avoid contact with electronic components and contacts.

• Check the combination of PMCprimo Drive2 and motor. Compare the rated voltage and current

of the units. Carry out the wiring according to the connection diagram on page 31.

• Make sure that the maximum permissible rated voltage at the terminals L1, L2, L3 or +DC,

–DC is not exceeded by more than 10% even in the most unfavourable case (see EN 60204-1

Section 4.3.1). An excessive voltage on these terminals can lead to destruction of the regen

circuit and the PMCprimo Drive2.

Use the PMCprimo Drive2 only on an earthed 3-phased supply system, to drive a synchronous

servomotor of the PMCtendo AC1 or PMCtendo AC2 series.

• The fusing of the AC supply input and the 24V supply is installed by the user (⇒ page 21).

• Take care that the PMCprimo Drive2 and motor are earthed properly. Do not use painted (non-

conductive) mounting plates.

• Route power and control cables separately. We recommend a separation of at least 20 cm.

This improves the interference immunity required by EMC regulations. If a motor power cable

is used which includes cores for brake control, the brake control cores must be separately

shielded. Earth the shielding at both ends (⇒ page 49).

• Install all heavy-current cables with an adequate cross-section, as per EN 60204.

• Wire the BTB/RTO contact in series into the safety circuit of the installation. Only in this way is

the monitoring of the PMCprimo Drive2 assured.

• Install all shielding with large areas (low impedance), with metallized connector housings or

shield connection clamps where possible.

• Ensure that there is an adequate flow of cool, filtered air into the bottom of the switchgear

cabinet. See page 21.

• It is permissible to alter the PMCprimo Drive2 settings by using the setup software.

Any other alterations will invalidate the warranty.

Caution

Never disconnect the electrical connections to the PMCprimo Drive2 while it is live. In un-

favourable circumstances this could result in destruction of the electronics.

Residual charges in the capacitors can have dangerous levels up to 300 seconds after

switching off the mains supply voltage. Measure the bus voltage at the DC-link pins (+DC/-

DC), and wait until the voltage has fallen below 40V.

Control and power connections can still be live, even when the motor is not rotating.

Page 32

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 34

8 Installation

8.2 Assembly

Material: 2 or 4 hexagon socket screws to DIN 912, M5

Tool required: 4 mm Allen key

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 33

Page 35

8 Installation

8.3 Dimensions

Page 34

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 36

8 Installation

-

8.4 Wiring

Only professional staff who are qualified in electrical engineering are allowed to install the

PMCprimo Drive2.

The installation procedure is described as an example. A different procedure may be sensible or

necessary, depending on the application of the equipment.

Caution !

Only install and wire up the equipment when it is not live, i.e. when neither the mains

power supply nor the 24 V auxiliary voltage nor the operating voltages of any other

connected equipment is switched on.

Take care that the cabinet is safely disconnected (with a lock-out, warning signs etc.).

The individual voltages will be switched on for the first time during commissioning.

Note !

The ground symbol ;, which you will find in all the wiring diagrams, indicates that

you must take care to provide an electrically conductive connection with the largest

possible area between the unit indicated and the mounting plate in the switchgear cabinet.

This connection is for the effective grounding of HF interference, and must not be confused

with the PE- symbol : (a protective measure to EN 60204).

Use the following connection diagrams:

— Power and control connections: page 37

— Resolver: page 52

— HIPERFACE encoder: page 53

— Encoder emulation ROD: page 54

— Encoder emulation SSI: page 55

— RS232 / PC: page 56

— Power supply: page 45

— Digital signals: page 59

— Analog signals: page 65

— Master encoder: page 69

— Panel/Profibus: page 74

— CAN bus: page 67

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 35

Page 37

g

The following notes should assist you to carry out the installation in a sensible sequence, without

overlooking anything important.

In a closed switchgear cabinet. Observe page 21 .

The site must be free from conductive or corrosive

ma materials.

For the mounting position in the cabinet ⇒ page 33

Assemble the PMCprimo Drive2 and power supply close

together on the conductive, earthed mounting plate in the

cabinet.

Select cables according to EN 60204 ⇒ page 22.

Site

Ventilation

Assembly

Cable selection

Check that the ventilation of the PMCprimo Drive2 is

unimpeded and keep within the permitted ambient

temperature ventilation ⇒ page 21.

Keep the required space clear above and below the

PMCprimo Drive2 ⇒ page 33.

8 Installation

EMC-compliant shielding and grounding (⇒ page 86).

Earth the mounting plate, motor housing and CNC-GND

of the controls.

Grounding

Shieldin

Wiring

— Route power leads and control cables separately.

— Wire the BTB/RTO contact in series into the

safety loop of the installation.

— Connect the digital control inputs to the PMCprimo

Drive2.

— Connect up AGND.

— Connect the analog signals, if required.

— Connect up the feedback unit (resolver or

HIPERFACE encoder).

— Connect the input and output signals.

— Connect the motor leads.

Connect shielding to EMC connectors at both ends

Use motor choke on length >25m (MD400)

— Connect motor-holding brake, connect shielding to

EMC connectors at both ends.

— If required, connect the external regen resistor (with

fusing.

— Connect aux. supply (24 V).

(for max. permissible voltage values⇒ page 20)

— Connect main power supply.

(for max. permissible voltage values⇒ page 20)

Page 36

— Connect PC (⇒ page 80).

Final check

— Final check of the implementation of the wiring,

according to the wiring diagrams which have been

used.

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 38

8 Installation

8.4.1 Connection diagram PMCprimo Drive2 - part 1

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 37

Page 39

8 Installation

8.4.2 Connection diagram PMCprimo Drive2- part 2

Page 38

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 40

8 Installation

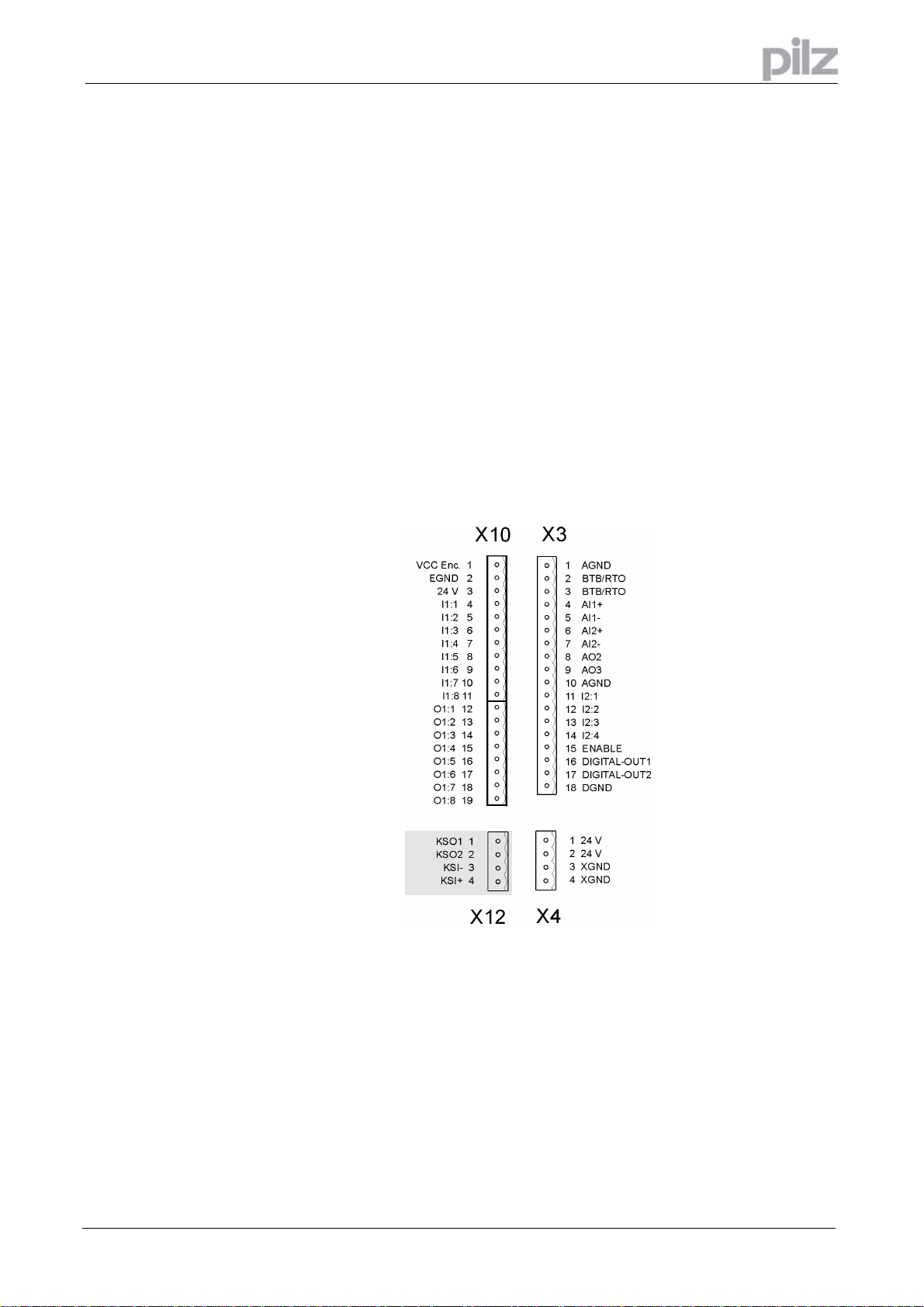

8.4.3 Pin assignments overview

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 39

Page 41

8 Installation

8.4.4 Pin assignments - details

Page 40

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 42

8 Installation

8.4.5 Pin assignments Modbus/Profibus

Note: It is not possible to use Modbus and Profibus the same time. For usage an adapter cable is

needed.

RJ 45

Note: Adapter cable RJ45 D-Sub9 is available.

RJ 45 Signal

Modbus

1 GND DP-GND 5

2 9

3 4

4 /RxD DP- 8

5 RxD DP+ 3

6 /TxD 7

7 TxD 2

8 5V/100mA 6

- 1

Signal

Profibus

D-Sub9

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 41

Page 43

8 Installation

8.4.6 Notes on connection techniques

Shielding connection to the front panel:

Remove the outer covering of the

cable and the shielding braid from

the cores for the required length.

Secure the cores with a cable tie.

Remove the outer covering of the

cable over a length of about

30mm, without damaging the

shielding braid.

Pull a cable tie through the slot in

the shielding rail (front panel) of

the PMCprimo Drive2.

Use the cable tie to clamp the

shielding braid of the cable firmly

to the shielding rail.

Page 42

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 44

8 Installation

8.5 Key operation for parameter setting

8.5.1 Comparison to the key operation with PMCtendo DD4

The key operation for PMCprimo Drive2 is like the key operation for PMCtendo DD4 (see

installation manual for PMCtendo DD4). This means that the two keys are used in the same way

and also the menus are named similarly.

8.5.2 Basic key operation

The two keys can be used to perform the following functions:

Key symbol Functions

press once: go up one menu item, increase number by one

press twice in rapid succession: increase number by ten

press once: go down one menu item, decrease number by one

press twice in rapid succession: decrease number by ten

Press and hold right key, then press left key as well:

enter a number, return function name

8.5.3 Menu operation

For accessing the menu press the right key while switching on the 24 V power supply. Then

this parameters can be set with the menu:

• The operating mode

(0: Standalone, 2 Node and 3 Host+Node)

When changing the operate mode between 2 and 3 then the application program in the

flash memory is not erased. The memory is even not erased if mode 0 is selected by a

mistake.

• The CAN node number depending from the operating mode:

Standalone: from 1 to 127

Node: from 1 to 60

Host+Node: Not available because node number is fixed

• The CAN baud rate. For similar settings as for the PMCtendo DD4 only two settings are

supported: 7 (500Kbit/s) and 10 (1Mbit/s). The other baud rates as for the PMCtendo DD4

(0 to 6 and 8 to 9) are not available

• The proportional Gain Kp (GV command) for the velocity loop of the drive.

• Save parameters.

After changing the parameter and returning from the function the changed parameter have

to be saved with the menu for saving. Then the system has to be switched off and on to

enable the changed settings.

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 43

Page 45

8 Installation

8.5.4 LED Display

The LED display will show the menu for changing the parameters:

Operating mode

CAN node number

Baud rate

KP speed control

to

to

to

to

to

to

Save parameters in Flash

8.5.5 Automatic detection in PMCprimo

For automatic detection of a new drive no special change in the firmware is necessary.

Inside the autostart sequence it is determined if a new drive is in the cabinet.

This can be done for example with reading the serial number of the drive.

Example:

AS AUTOSTART

ES AUTOSTART

CH0.1

$SER1="SERIALNO"

IF($SER1!=$SER1ACTUAL);XS DRIVE_0;$SER1ACTUAL=$SER1;SP2

NS

The sequence gets the actual serial number and compares it with the last saved number. If there is

a difference then it calls the drive sequence which adjusts all parameters. Then it stores the new

serial number. Therefore the drive parameters are stored only once.

Page 44

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 46

9 Interfaces

9 Interfaces

All important interfaces of the PMCprimo Drive2 are shown in this chapter. The precise location of

the connectors and terminals can be seen on page 39.

9.1 Power supply

9.1.1 Mains supply (X0)

• Direct to earthed 3~ supply, 230V

• Fusing (e.g. fusible cut-outs) provided by the user ⇒ page 21

• For single phase operation use L1 and L2!

-10%

... 480V

+10%,

50 ... 60 Hz, integrated filter

Installation manual PMCprimo Drive2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Page 45

Page 47

9 Interfaces

9.1.2 24V-auxiliary supply (X4)

• Electrically isolated, external 24V DC supply, e.g. with insulating transformer

• Required current rating⇒ page 20

• Integrated EMC filter for the 24V auxiliary supply

• See important notes to commissioning ⇒ page 78

Page 46

Installation manual PMCprimo Drive2