Page 1

PMotion

Motion Control PMC

User Manual – No. 21472-EN-11

Page 2

V

1 General Information

1.1 Copyright

Copyright 2012 Pilz GmbH & Co.KG. All rights reserved.

All rights reserved. The implementation of technical changes which improve the performance of

the product is subject to change without prior notification! The product or parts of the content

may be reproduced or transmitted in any form (by printing, photocopying, microfilm or any other

method) or stored, processed, copied or distributed by electronic means without the written

permission of Pilz GmbH & Co. KG.

1.2 Notice

Pilz GmbH & Co. KG reserves the right to make amendments to this document at any time.

The examples given serve only as illustrations. No guarantee is given for their suitability in

particular applications. Although the utmost care has been taken in the production of this

document, no liability can be accepted for any mistakes that it may contain. We welcome any

suggestions for the improvement of our products, or documentation.

We reserve the right to make technical changes, which lead to the improvement of the product!

1 General Information

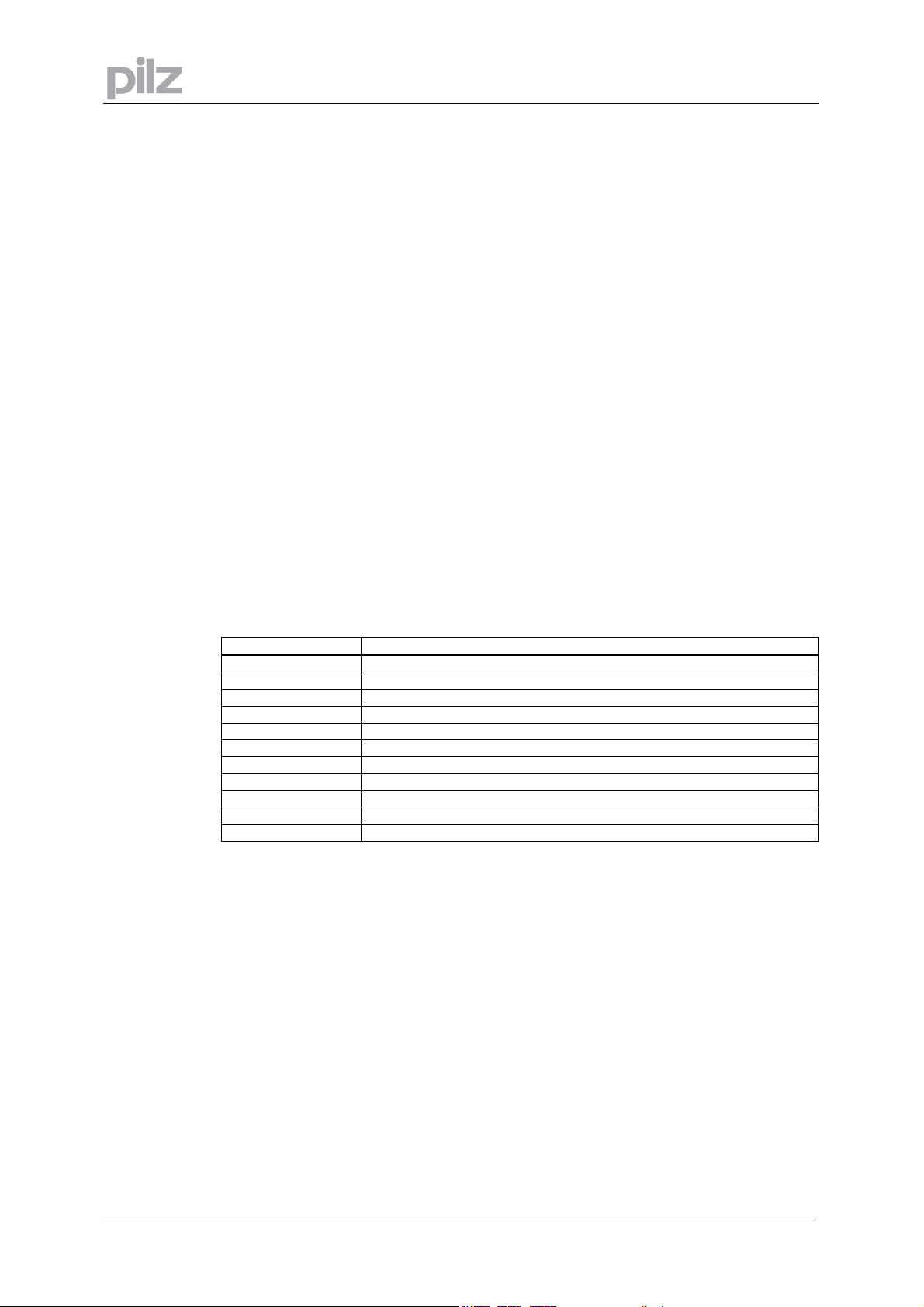

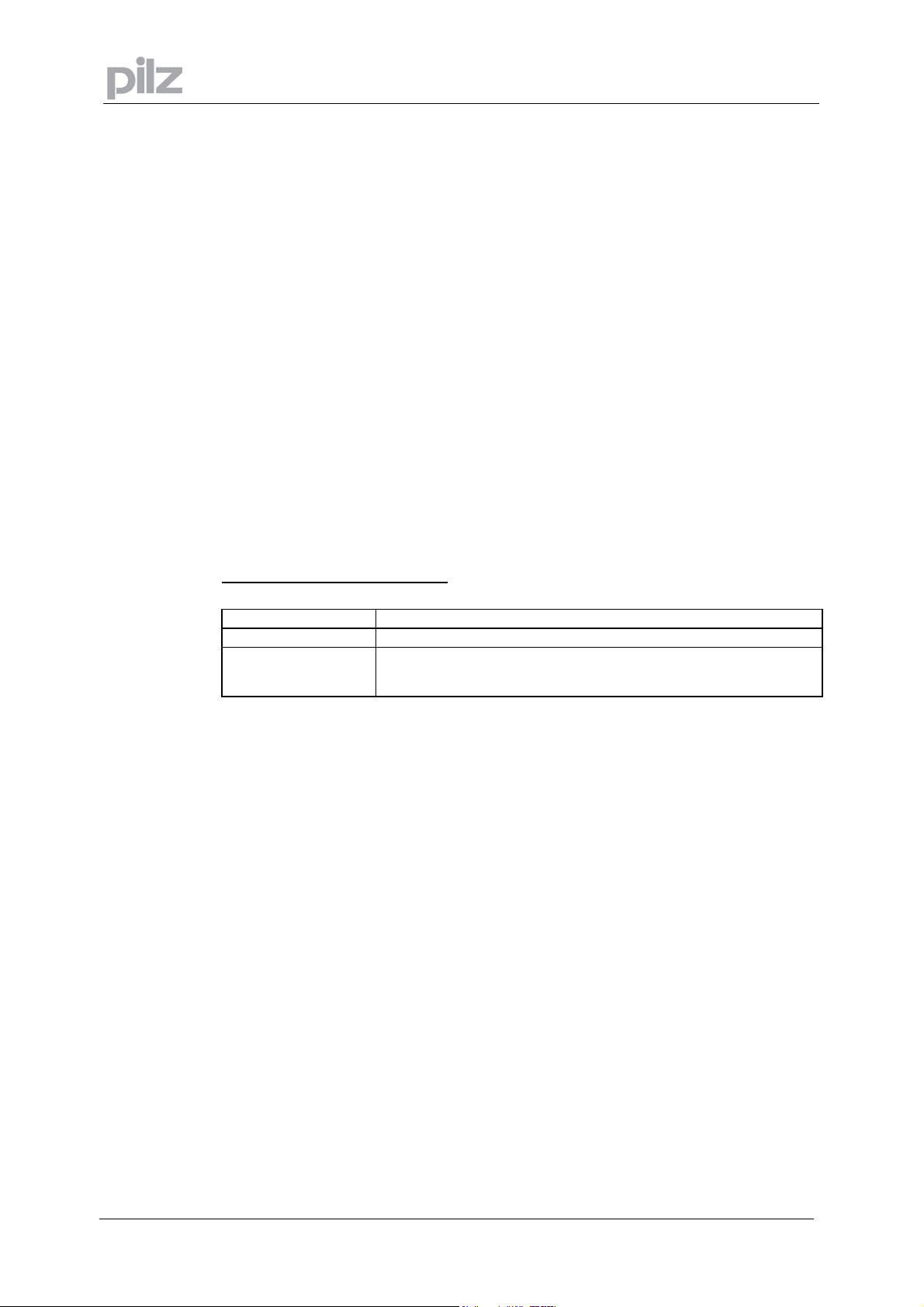

1.3 Previously published editions

ersion Notes

V1-28-06-2002 Initial version: valid from software version 2.03

V2-06-12-2002 Revised version: valid from software version 2.04

V3-10-06-2003 Revised version: valid from software version 2.05

V4-12-05-2004 Revised version: valid from software version 2.06

V5-23-02-2005 Revised version: valid from software version 2.07

V6-23-08-2005 Revised version: valid from software version 2.08

V7-15-11-2005 Revision

V8-11-10-2007 Revised version: valid from software version 3.1

V9-05-02-2008 Revised version: valid from software version 3.2

V10-02-03-2010 Revised version: valid from software version 3.3

V11-02-04-2012 Revised version: valid from software version 3.4

Page 2 User Manual for PMotion

Page 3

2 Contents

2 Contents

1 General Information 2

1.1 Copyright ................................................................................................ 2

1.2 Notice ..................................................................................................... 2

1.3 Previously published editions ................................................................. 2

2 Contents 3

3 Abbreviations and Symbols 5

3.1 Abbreviations .......................................................................................... 5

3.2 Symbols .................................................................................................. 5

4 Safety Guidelines 6

5 About this manual 7

6 Introduction 8

6.1 Installation under Microsoft Windows ..................................................... 8

6.2 Hardware requirements .......................................................................... 8

6.3 General Description ................................................................................ 9

6.3.1 Designations ........................................................................................... 9

6.3.2 Motion Generator Overview .................................................................... 10

User Manual

7 PC based Motion Generator PMotion 12

7.1 Introduction ............................................................................................. 12

7.2 Menus ..................................................................................................... 13

7.2.1 Menu "File" ............................................................................................. 13

7.2.2 Menu "Edit" ............................................................................................. 13

7.2.3 Menu "View" ........................................................................................... 14

7.2.4 Menu "Create" ........................................................................................ 15

7.2.5 Menu "Programs" ................................................................................... 16

7.2.6 Menu "Window" ...................................................................................... 16

7.3 Toolbar ................................................................................................... 17

7.4 Map Settings ........................................................................................... 18

7.4.1 Property Page „Map“ .............................................................................. 18

7.4.2 Property Page “Master” .......................................................................... 19

7.4.3 Property Page “Slave” ............................................................................ 20

7.4.4 Property Page "Machine Parameters" .................................................... 21

7.5 Edit Segment parameters ....................................................................... 22

7.6 Create a map .......................................................................................... 24

7.6.1 Map Table .............................................................................................. 24

7.6.2 Map Sequence ....................................................................................... 24

7.7 Example of using the PC based Motion Generator PMotion .................. 25

8 Internal Motion Generator 28

8.1 Commands for Internal Motion Generator .............................................. 28

8.2 Messages displayed in terminal and in status variable $MSTATUS ....... 29

8.3 Example of using the internal Motion Generator ..................................... 30

9 Segment Types 32

9.1 Segment Type "Constant Position" ......................................................... 33

9.2 Segment Type "Constant Velocity" ......................................................... 34

9.3 Segment Type "Constant Acceleration" .................................................. 35

9.4 Segment Type "Sine-Squared Velocity" and "Cycloidal" ........................ 36

9.5 Segment Type "Modified Trapezoidal" ................................................... 37

9.6 Segment Type "Modified Sine" ............................................................... 38

9.7 Segment Type "Triple Harmonic" ........................................................... 39

9.8 Segment Type "Sinusoidal" .................................................................... 40

9.9 Segment Type "Polynomial" ................................................................... 41

9.10 Segment Type "Ramp" ........................................................................... 43

for PMotion

Page 3

Page 4

2 Contents

9.11 Segment Type "Throw" ........................................................................... 44

9.12 Segment Type "Quadratic Spline" .......................................................... 45

9.13 Segment Type "Cubic Spline" ................................................................. 46

9.14 Segment Type "Sine-Constant-Cosine" .................................................. 47

9.15 Segment Type "Simple Harmonic" ......................................................... 48

10 Motion Generator: Features and Functions 49

10.1 Start and End Percentages of a Segment .............................................. 49

10.2 Summary of Segment Constraints .......................................................... 50

10.3 Summary of Segment Types and their Parameters ................................ 52

10.4 Technical Information about the Motion Generator ................................. 53

10.4.1Maximum number of segments .............................................................. 53

10.4.2Variable names used by the internal Motion Generator ......................... 53

11 Index 55

Page 4 User Manual for PMotion

Page 5

3 Abbreviations and Symbols

3 Abbreviations and Symbols

3.1 Abbreviations

Meaning

CE Communité Europeenne

COM Serial interface for a PC

DIN Deutsches Institut für Normung

ISO International Standardization Organization

MB Megabyte

PC Personal Computer

RAM Volatile memory

UL Underwriter Laboratory

VDE Verband der Elektrotechnik Elektronik Informationstechnik e.V.

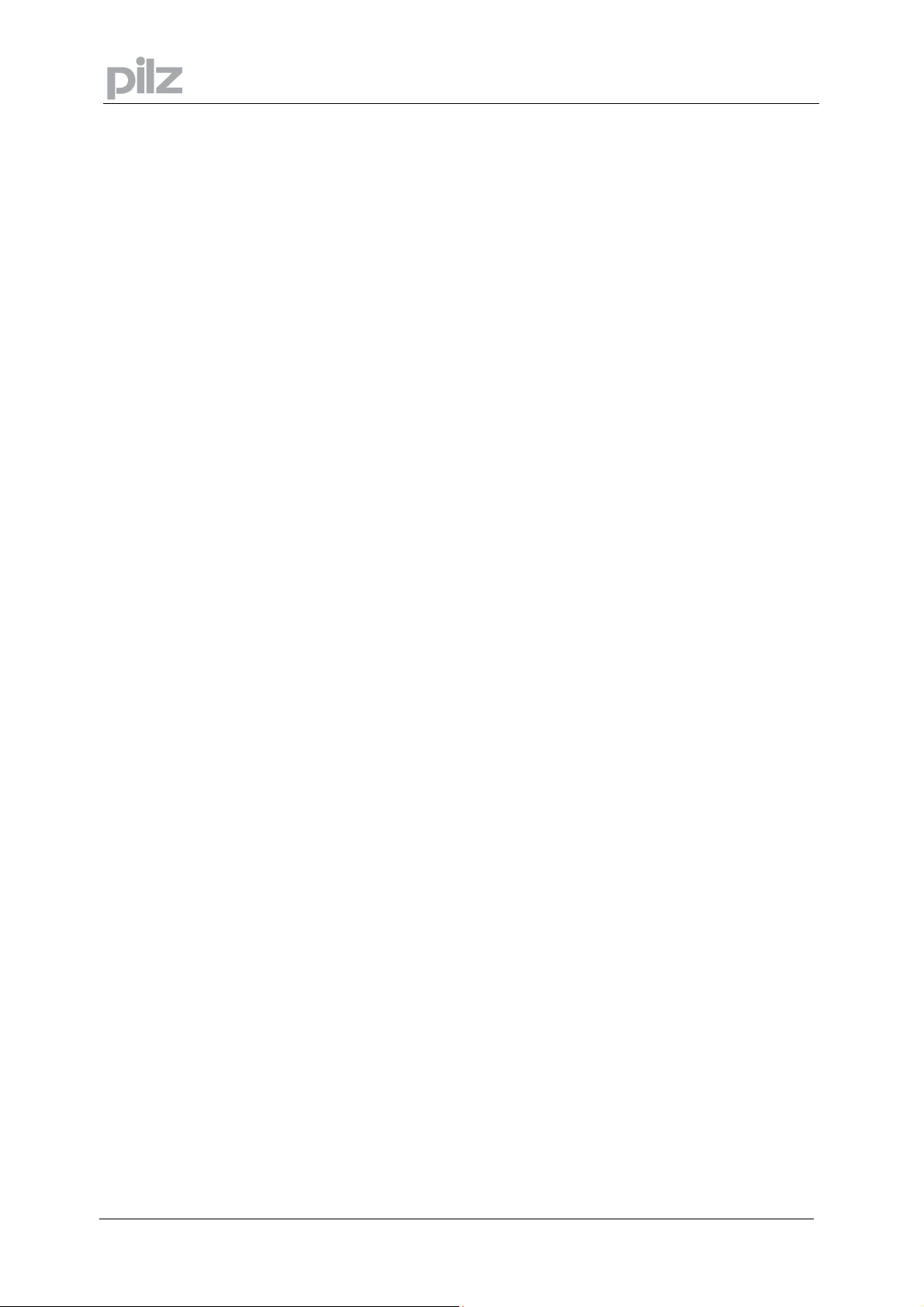

3.2 Symbols

Meaning

This symbol indicates a possible danger, hazard, risk to life and/ or

health. Ignorance may seriously affect health and cause dangerous

injuries.

•

This symbol indicates an important hint regarding the correct use

of the product. Ignorance may affect the performance of the

machinery and/or the surrounding.

This symbol indicates special user tips and/or important useful

information. These will support optimum use of the product and

functions.

Emphasis indicator

See page (cross reference)

⇒

User Manual

for PMotion

Page 5

Page 6

A

4 Safety Guidelines

Caution!

When commissioning, you must ensure that neither the controllers nor the amplifiers present

any risk to persons, plant or machinery.

ppropriate protection and precautionary measures must be put in place.

To avoid personal injury and material damage, only qualified, trained personnel should work on

the devices.

Only specialist staff with extensive knowledge of drive technology and control engineering

should be permitted to program a running drive online.

Data stored on data media is not protected from unintended changes by third parties. Data

must be checked for accuracy before it is loaded on to the hardware.

Attention!

The installation and operating instructions must be read carefully and all safety

regulations observed before installation and initial operation as danger to personnel and

damage to machinery may be caused.

• Only qualified and well-trained specialists who are familiar with the transportation,

installation, initial operation, maintenance and operation of the units as well as with the

relevant standards may carry out the corresponding works.

• Technical data and indications (Type tag and documentation) are to be kept absolutely.

4 Safety Guidelines

Page 6 User Manual for PMotion

Page 7

5 About this manual

5 About this manual

This manual explains how to use the PMotion program, a software tool used to generate

motion curves for the control systems

• PMCprimo 16+,

• PMCprimo C,

• PMCprimo Drive2 and

• PMCprimo Drive3

from Pilz. The Motion Generator, which operates internally within the control systems, is also

described.

Knowledge of the Microsoft Windows operating system and the use of a PC is assumed.

You must follow the safety, installation and commissioning instructions in the installation

manual for the servo amplifier that is used.

User Manual

for PMotion

Page 7

Page 8

6 Introduction

6.1 Installation under Microsoft Windows

The software is installed using the installation program on the "Motion Control Tools".

The CD-ROM contains an installation program which makes it easier for you to install the

software on your PC. The CD-ROM also has an "AutoPlay" function: once the CD-ROM has

been inserted, a dialogue box will open automatically, showing various selection options

(program installation, manuals, etc.). This function can also be started manually by calling up

the program minstall.exe.

Install:

Place the CD-ROM in the CD-ROM drive of your computer. After a few seconds the setup

function starts automatically, if "Autoplay" is enabled. Otherwise please start minstall.exe.

Choose "Install Motion Control Tools" and follow the on-screen instructions.

6 Introduction

6.2 Hardware requirements

Minimum specification for the PC:

Operating system

Hardware

Interface

Windows 2000, XP, Vista or 7

Minimum requirements of operating system

one free serial interface

Ethernet interface (optional)

Page 8 User Manual for PMotion

Page 9

6 Introduction

6.3 General Description

The Motion Generator is a software tool which allows the machine designer to create, modify

and implement custom positional mapping between two machine axes. It can be used as a tool

to design and implement machine cams, but without the limitations of a mechanical cam.

When using the Motion Generator each custom machine motion is called "Map" (one axis is

mapped to another). There are a number of terms and phrases associated with the Motion

Generator which have specific meanings. Look at the following description (Chapter 6.3.1).

This manual describes the Motion Generator, which operates internally within the controllers,

and the PC-based motion generator PMotion, a tool available with the "Motion Control Tools".

• The motion generator interface PMotion runs on the PC and is part of the "Motion Control

Tools" software package that operates under Windows. This component was developed to

enable the graphical generation of movements between two axes for a machine on which

the controllers’ axes are regulated. This graphical construction of a motion curve can be

loaded and stored on control systems in the form of position mapping (a table of

Master/Slave positions). The position mapping can also be loaded into control systems as

an executable program (sequence) and can be calculated there using the internal motion

generator.

• The motion generator that operates internally within the control systems can be purchased as

an accessory. This internal motion generator is a program which reads information about

defined variables from special map sequences and can use the values from these

variables to calculate tabular values for position mapping in the controller.

6.3.1 Designations

Map Shape The name for the curves displayed on the monitor, for the data stored on the PC and the list of

variables for the internal controller calculation. A map shape is the description of a Master/Slave

relationship consisting of a series of segments with the relevant additional parameters for each

segment. The data from a map shape can be used to calculate the corresponding slave position

for each stated master position.

Map Table The name for a series of position co-ordinates (for Master and Slave), which correspond to the

curves on the PC and originate from the motion generator. The controller uses the position coordinates to set up the relative positional relationship between Master and Slave (the points

between the co-ordinates are calculated through linear interpolation).

Map Sequence The name for a sequence with which a map can be calculated by the internal Motion Generator

of the controller.

Segment A single section of the map shape. A segment will have a type to define its shape and may

have certain additional parameters which affect its shape.

User Manual

for PMotion

Page 9

Page 10

6.3.2 Motion Generator Overview

The Motion Generator provides the ability for the user to create complex position mappings

between one axis and another. Before using the Motion Generator a number of issues need to

be understood:

• You are designing a map shape which relates the position of the slave axis to the position

of the master axis at any point along the master axis. This is essentially a cam, although

you can do things that a cam could not. During the design of the map shape you will

determine the map shape using segments, and setting parameters for these segments.

• Certain restrictions have been applied, by default, to the segment to segment boundaries

to ensure that the generated map shape is physically achievable:

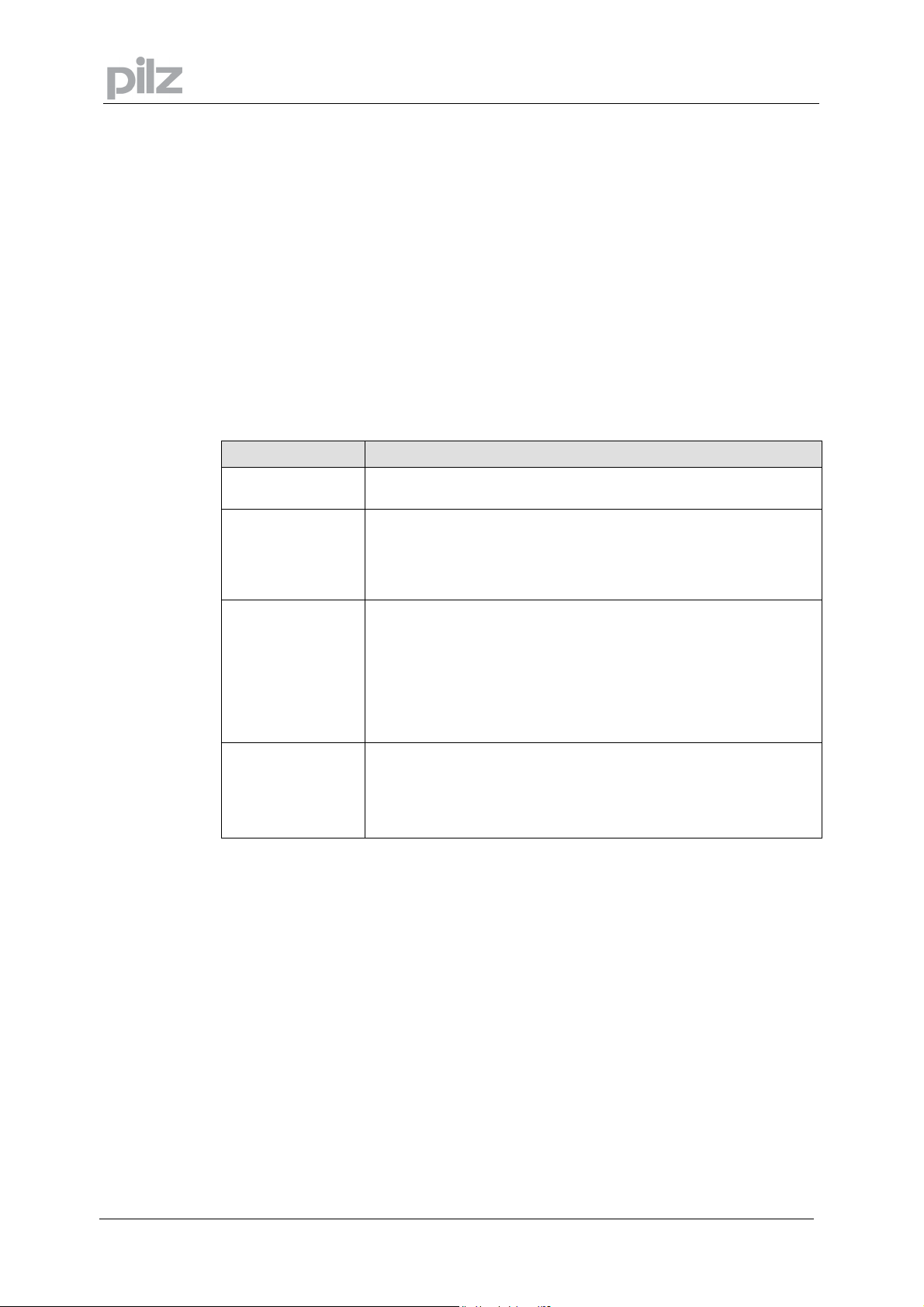

Default segment boundary conditions:

Slave Derivative Segment nn to Segment nn+1 boundary conditions (defaults)

Position

Velocity

Acceleration

Jerk

Match with previous: The start position of segment nn+1 will match

the end position of segment nn. This cannot be altered.

Match with previous: The start velocity of segment nn+1 will

automatically be adjusted to match the end velocity of segment nn.

This may have the effect of modifying the shape of segment nn+1

which can lead to unexpected segment shapes. (For certain segment

types it is possible, but not advisable, to break this matching.)

No value specified: For all segment types excluding polynomial and

cubic spline acceleration at the beginning of segment nn+1 is

determined by the segment type. Therefore there may be a step

change in acceleration across the nn to nn+1 segment boundary.

Match with previous: A polynomial segment and the cubic spline

segment automatically matches their start acceleration to the end

acceleration of segment nn. For the polynomial segment alone this

matching can be broken.

No value specified: The jerk value at the beginning of segment nn+1

is determined by the segment type. Therefore there may be a step

change in jerk across the nn to nn+1 segment boundary.

For the polynomial segment alone it is possible to change this to

match with previous or specify the required value.

6 Introduction

Page 10 User Manual for PMotion

Page 11

6 Introduction

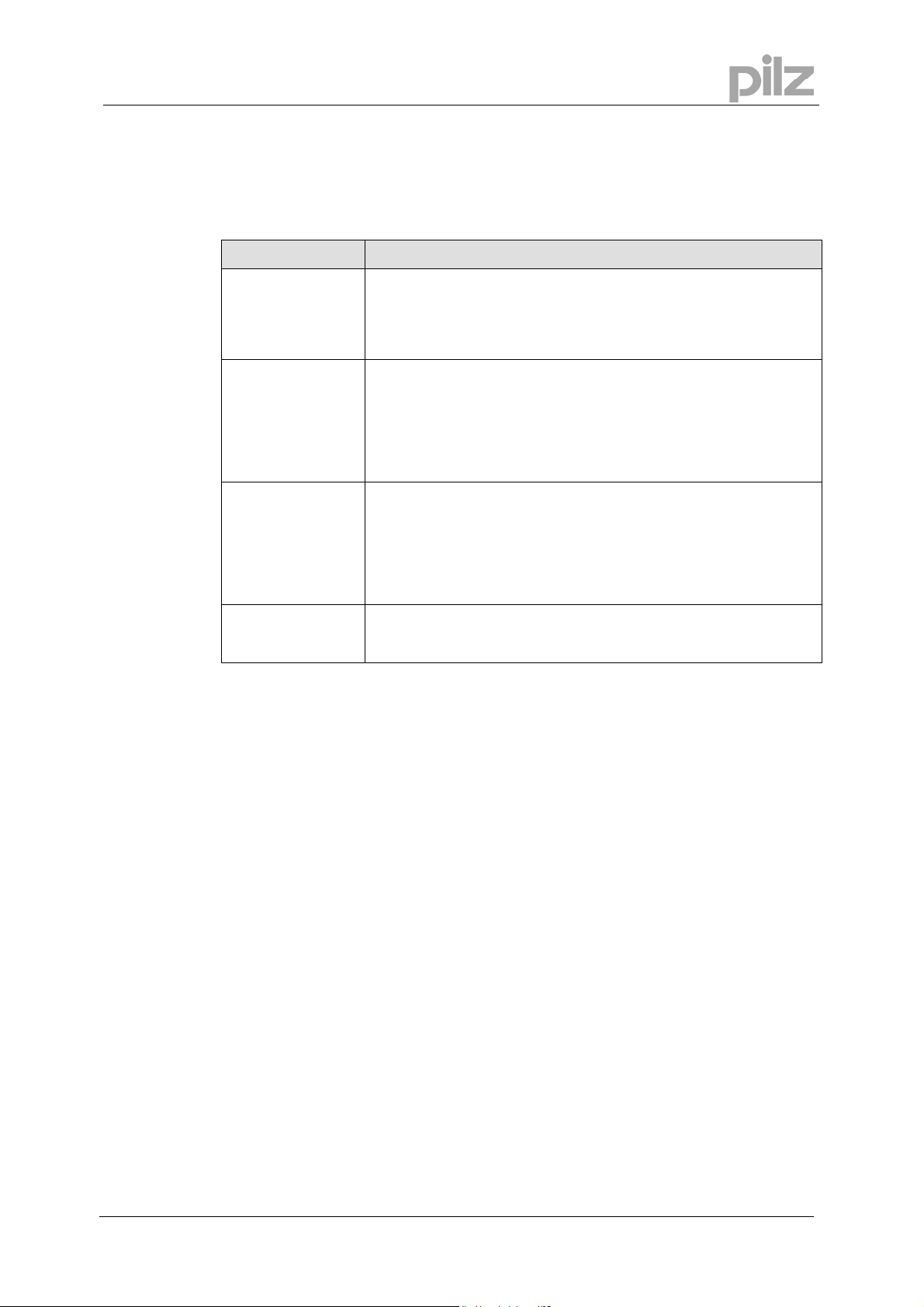

• The map shape wraps round. In other words the last segment connects to the first

segment. However the continuity laws across this segment to segment boundary are, by

default, different from those on all other segment to segment boundaries:

Last to first default segment boundary conditions:

Slave Derivative Last segment to first segment boundary conditions (defaults)

Position

Velocity

Acceleration

Jerk

• At no instance does a map shape or map table contain any time dependent information.

The velocity and acceleration of the slave axis at any point will depend upon the velocity of

the master axis.

For the PC based Motion Generator PMotion only: to enable you to develop a map shape

that is within the physical constraints of your machinery it is possible to enter the number of

cycles per minute required. This sets the master velocity at a constant value and allows the

motion generator to put figures on the slave velocity and acceleration shapes.

• The default segment type is polynomial. This segment type is the most configurable of all

the available types and should be used in preference to another type whenever possible.

With the exception of the start of segment position parameter (which must always match

the end of the previous segment) it is possible to modify the boundary constraints for all the

derivatives at both the start and end of the segment. This means that it can be configured

to provide a smooth transition between known points.

Specified value: The end position of the last segment and the start

position of the first segment can both be specified. Therefore there can

be a step change in position across this boundary. You can manually

align the end position of the last segment to match the start position of

the first segment if required (linear slave axis).

Match with previous: Normally the start velocity of the first segment

will be automatically adjusted to match the end velocity of the last

segment.

The one exception to this rule is when all segments inherit their

velocity from the previous segment: the first segment will then start

with zero velocity. In this case use a constant velocity segment to

create any required velocity offset.

No value specified: For all segment types excluding polynomial and

cubic spline the acceleration at the beginning of the first segment is

determined by the segment type.

Match with previous: If the first segment is either a polynomial or

cubic spline segment then it automatically matches it's start

acceleration with the last segment's end acceleration. For the

polynomial segment alone this matching can be broken.

No value specified: The jerk value at the beginning of the first

segment is determined by the segment type. For the polynomial

segment alone this can be changed to matching or start jerk specified.

User Manual

for PMotion

Page 11

Page 12

7 PC based Motion Generator PMotion

7 PC based Motion Generator PMotion

7.1 Introduction

PMotion is part of Motion Control Tools, which can be used for graphically design of custom

machine motions between two machine axes.

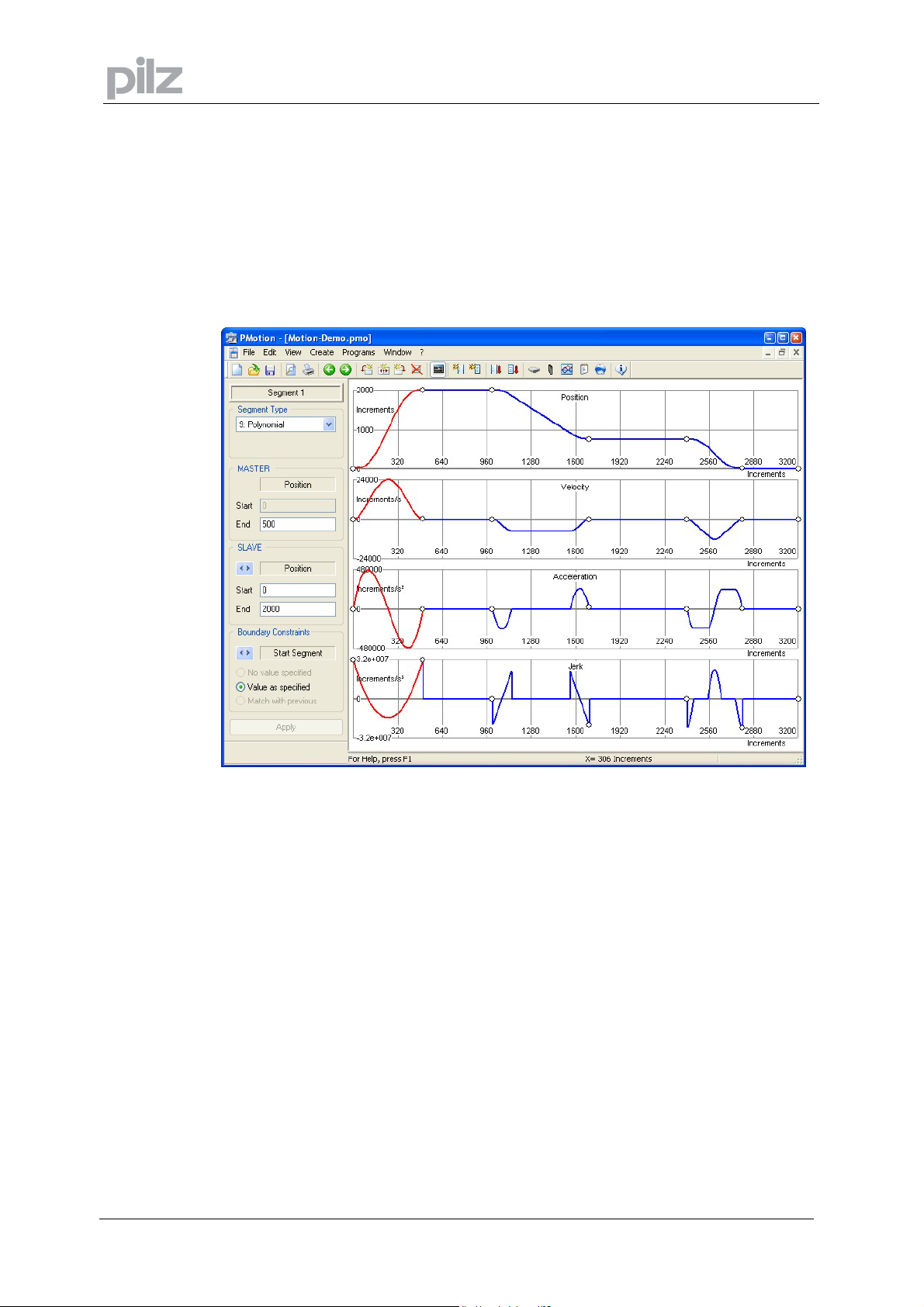

Screen layout:

The Motion Generator window presents the current map shape as a series of segments. In the

above picture position, velocity, acceleration and jerk are being viewed. The currently selected

segment is highlighted in red and the position of the mouse pointer is given in map coordinates

in the status bar.

When PMotion is first started a map consisting of a single segment is displayed. This map can

then be edited as required, or a previous session can be loaded from the PC disk.

The following sections detail all the menus, dialogue boxes and actions associated with the

Motion Generator.

Page 12 User Manual for PMotion

Page 13

7 PC based Motion Generator PMotion

7.2 Menus

7.2.1 Menu "File"

New Creates a new map with the default segment type "Polynomial".

Open Loads a map from the PC disk.

Close Closes the current map file. If the file has been changed, the user will

be indicated to save the changes.

Save Saves the current map to the PC disk.

Save as Saves the current map on using a different file name.

Print Prints the current map. In a dialogue box you can choose the printer.

Print Preview Preview a print – see what your program will look like when printed.

Printer Setup Printer configuration.

Send Send the current map via email.

Exit Quits PMotion.

7.2.2 Menu "Edit"

Undo You can undo the last change of your map you are working on.

Segment left Selects the segment on the left side of the currently selected segment.

Segment right Selects the segment on the right side of the currently selected

segment.

Insert Segment Inserts a segment to the left of the currently selected segment. The

new segment will be 1000 counts long and of a polynomial type. The

master cycle length will be stretched automatically.

Split Segment Splits a Segment into two parts.

Append Segment Adds a segment to the end of your map shape. The new segment will

be 1000 counts long and of a polynomial type. The master cycle length

will be stretched automatically.

Delete Segment Deletes the currently selected segment. You cannot delete the

segment if it is the only one in a map shape.

Segment parameters Opens a dialogue bar on the left side of the view, where you can

configure the currently selected segment settings.

User Manual

for PMotion

Page 13

Page 14

7 PC based Motion Generator PMotion

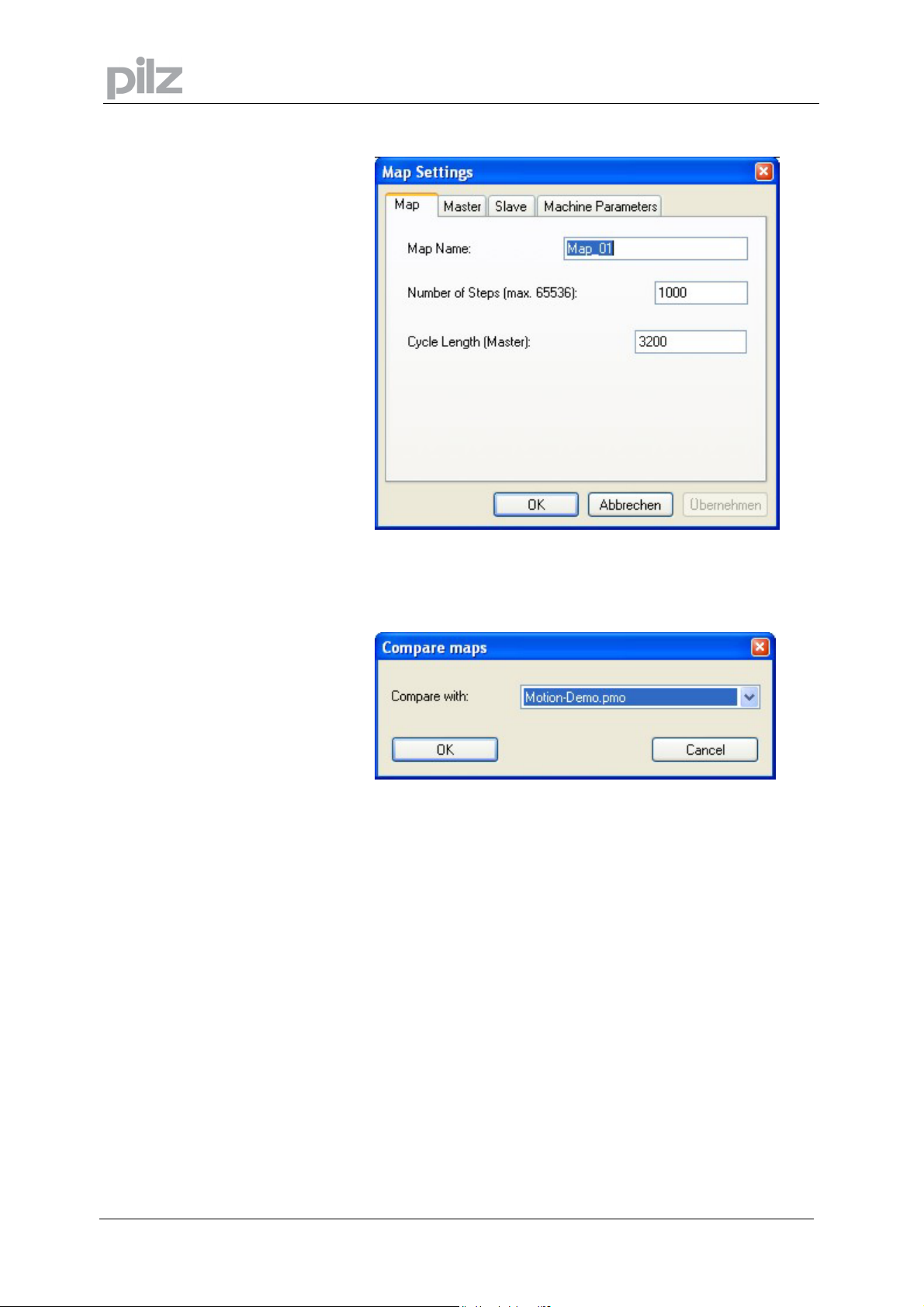

Map Settings Opens a dialogue box, where you can configure the map shape

settings.

Map variables Shows a dialogue box in which you can edit the map variables.

Colours and Lines Adjustment of colours and lines for the motion view.

Show comparison map Show/Hide a further map in the motion view. Select a map in the

following dialog to compare it to the current map.

7.2.3 Menu "View"

Position Shows or hides the view „Position“.

Velocity Shows or hides the view „Velocity“.

Acceleration Shows or hides the view „Acceleration“.

Jerk Shows or hides the view „Jerk“.

Toolbar Shows or hides the toolbar.

Status bar Shows or hides the status bar.

Page 14 User Manual for PMotion

Page 15

7 PC based Motion Generator PMotion

7.2.4 Menu "Create"

Create Map Table Creates the current map shape as a map table in a ptf-file (ptf = PMC

text file). With the text editor PEdit you can download this map to the

controller.

Create Map Sequence Creates the current map shape as a map sequence in a ptf-file (ptf =

PMC text file). With the text editor PEdit you can download this

sequence to the controller. The internal Motion Generator on the

controller is able to generate maps from this sequence during runtime.

Download map table Downloads the current map shape as a map table directly to the

controller.

Download map sequence

Downloads the current map shape as a controller sequence directly to

the controller. The internal Motion Generator on the system is able to

generate maps from this sequence during runtime.

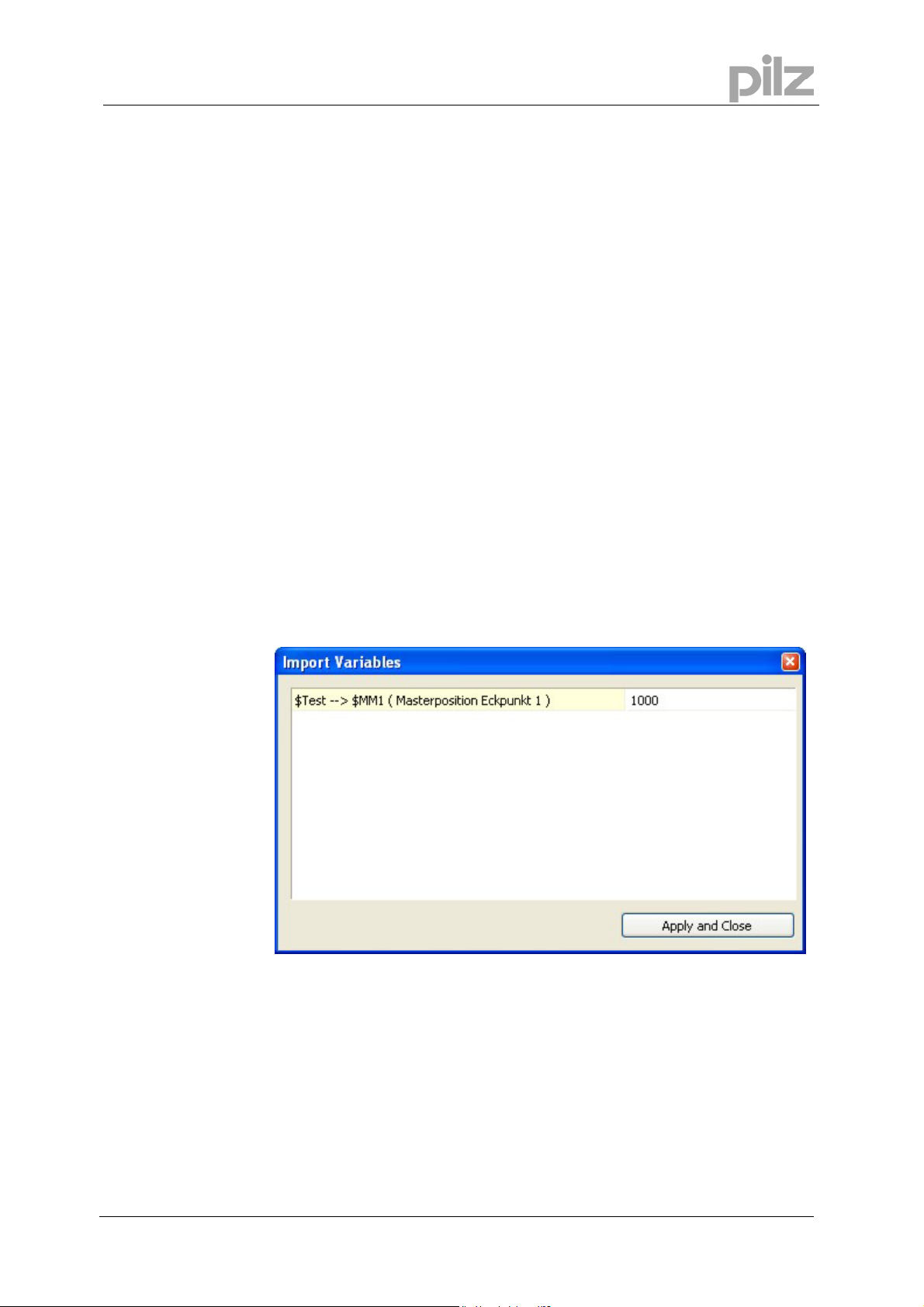

Import map

Active map from system

Imports the last map sequence to be executed (XS command) from

the connected controller.

Map sequence from system

Imports a map from a map sequence saved on a controller.

Map sequence from file

Imports a map from a map sequence saved in a ptf file.

If values in the map sequence are defined as variables, you can

enter a value for these during import for showing the map.

User Manual

Export map as FB for SoftPLC

for PMotion

Exports the current map (map table or map sequence) as a function

block for the system integrated Software PLC.

Page 15

Page 16

7.2.5 Menu "Programs"

PTerm Starts the terminal program PTerm.

PDrive Starts the setup software PDrive.

PScope Starts the scope function PScope.

PEdit Starts the text editor PEdit.

7.2.6 Menu "Window"

New window Opens a further window for the current document.

Cascade Arranges all the windows you are editing in a neat, cascaded, pile.

Tile Tiles all the windows you are editing horizontally across the screen.

Arrange icons Arranges all icons in the bottom area of the window.

7 PC based Motion Generator PMotion

Page 16 User Manual for PMotion

Page 17

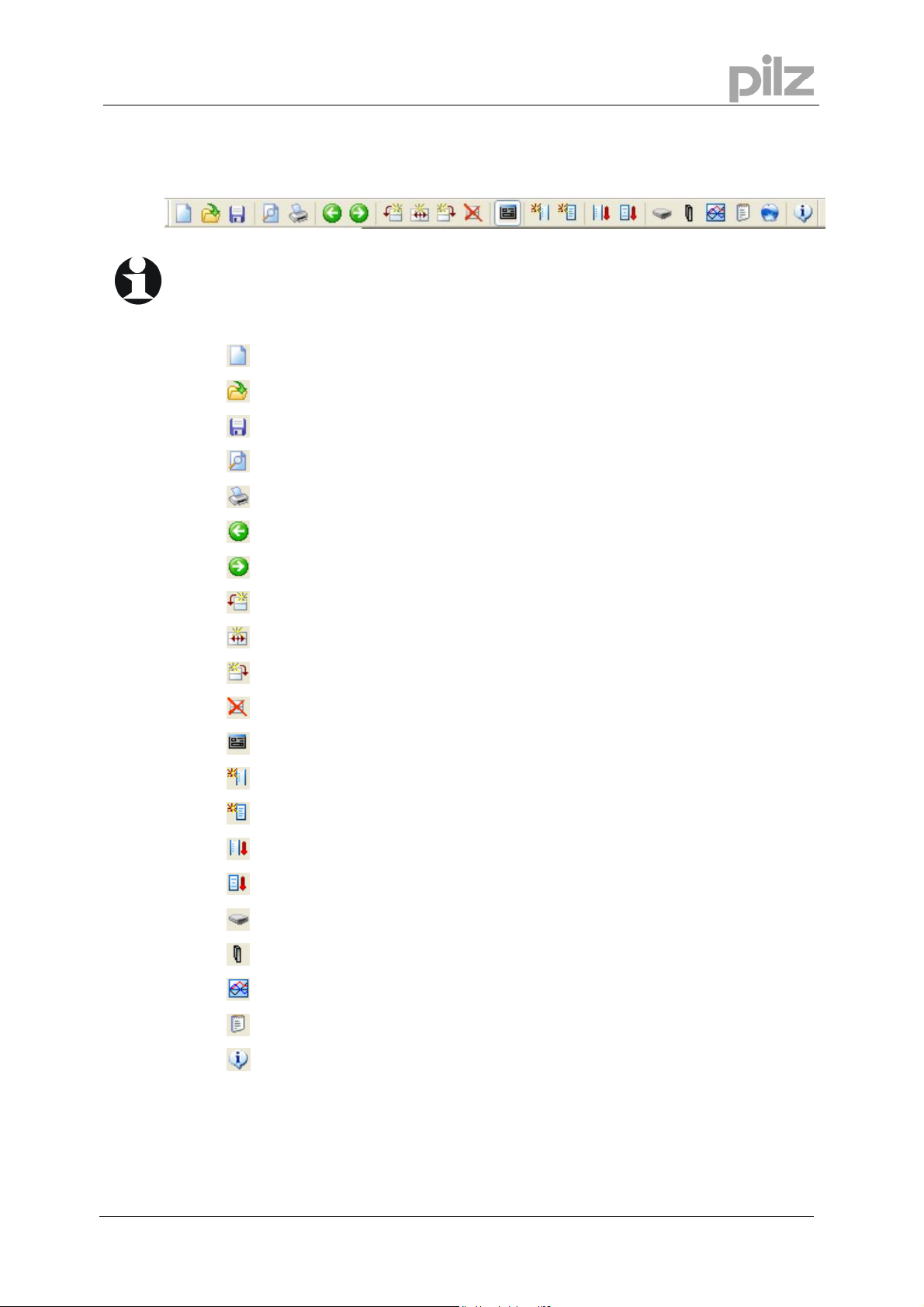

7 PC based Motion Generator PMotion

7.3 Toolbar

With the toolbar you have direct access to important functions of the program.

Creates a new map.

Opens an existing map.

Saves the current map file.

Displays full pages of the current map before printing.

Prints the current map.

Selects the segment on the left side of the currently selected segment.

Selects the segment on the right side of the currently selected segment.

Inserts a new segment to the left side of the currently selected segment.

Splits a segment into two parts.

Adds a segment to the end of your map shape.

Deletes the currently selected segment.

Opens a dialogue bar on the left side of the view to configure the segment settings.

Creates a map table in a ptf-file (ptf = PMC text file).

Creates a map sequence in a ptf-file (ptf = PMC text file).

Downloads a map table to the controller.

Downloads a map sequence to the controller.

Starts the terminal program PTerm.

Starts the setup software PDrive.

User Manual

for PMotion

Starts the scope function PScope.

Starts the text editor PEdit.

Opens the “About” dialog.

Page 17

Page 18

7.4 Map Settings

The map settings dialogue is presented when the menu option "Edit" -> "Map Settings"

is chosen.

The dialogue consists of four property pages:

7.4.1 Property Page „Map“

7 PC based Motion Generator PMotion

Map Name:

Number of

Steps:

Cycle Length

(Master):

Each map has its unique name on the controller. The name consists of an alphanumeric

expression with a maximum of 20 characters. This identifier will be used for the map table

when it is downloaded into the controller.

When a map shape is turned into a map table the Motion Generator needs to know what

resolution you require. The more map steps the greater the resolution of the map table, but

also the larger the memory space for saving the table in the Flash EPROM. The maximum

number of steps is 65536.

The master length is the length of the map shape along the master axis (horizontal) in position

units. If this value is changed the whole map is scaled and all the master and slave positions

are affected. The length of the master axis and the machine’s cycle speed are used to calculate

the curves.

Page 18 User Manual for PMotion

Page 19

7 PC based Motion Generator PMotion

7.4.2 Property Page “Master”

Scaling / Unit

Offset

PMotion can work with user defined units. Therefore it needs the name of the chosen unit and

the scaling factor (numerator and denominator) for the conversion between the new unit and

the standard encoder counts. This factor is necessary, because the internal position values of

the controller must be defined in increments (encoder counts).

A offset of master position can be entered to shift the map horizontally.

Attention: The offset will not be transmitted to the motion control system. Use the command

“MB” to shift a map on the system.

User Manual

for PMotion

Page 19

Page 20

7.4.3 Property Page “Slave”

7 PC based Motion Generator PMotion

Scaling / Unit

Show

maximum

values

Like the master axis user defined units are also possible on the slave axis. Therefore PMotion

needs the name of the chosen unit and the scaling factor (numerator and denominator) for the

conversion between the new unit and the standard encoder counts. This factor is necessary,

because the internal position values of the controller must be defined in increments (encoder

counts).

The maximum values for position, velocity, acceleration and jerk can be defined. These

maximum values will be displayed as horizontal lines in the diagrams. The colour can be

changed in the dialog box “Colours and lines”.

Page 20 User Manual for PMotion

Page 21

7 PC based Motion Generator PMotion

7.4.4 Property Page "Machine Parameters"

Cycles/Minute

A map shape does not contain any time information. For a correct calculation of the derivations

and considering the mechanical limits of the machine you can set the machine cycles per

minute in this property page. This determines the constant velocity of the master axis and

allows PMotion to put a scale to the slave velocity, acceleration and jerk.

User Manual

for PMotion

Page 21

Page 22

7.5 Edit Segment parameters

The parameters of a segment are shown in the toolbar

on the left side of the PMotion window. This toolbar can

be toggled by using the button „Segment parameters“ in

the menu „Edit“.

The parameter bar is used to set all the parameters for

the selected segment. If you change segment selection

the parameter bar is updated automatically.

The toolbar remains on the screen while editing the map

or using other menu commands. This feature allows you

to perform quickly changes of the map shape and

analyse certain points.

Parameter changes can be applied by pressing the

“Return” button or the “Apply” button on the bottom of

the parameter bar. With this update method it is possible

to analyse the current segment and make quickly

changes.

7 PC based Motion Generator PMotion

Segment ...

Segment Type

Start / End

Master position

The available setting options are divided into various

subsections by borders and title descriptions.

Number of the current selected segment in the motion view.

In the „Segment type“ box you can select the mathematical function for the segment. It is

possible to choose from up to 16 different mathematical functions, which are described in

chapter 9 („Segment types).

There are extra settings for some segment types when pressing the button „Type parameters“.

These parameters depend on the selected segment type and can define the mathematical

function in more detail.

The default segment type is polynomial, which has no extra parameter settings.

The length of a segment is specified by the absolute start and end master position values.

The master start position corresponds to the end position of the previous segment. If you

change the start position of a segment, the end position of the previous segment will be

updated automatically.

Equally changing the master end position of a segment will influence the start position of the

next segment.

Attention: If the next segment is not able to accommodate the position change, a message box

appears indicating that the values have to be entered again.

Page 22 User Manual for PMotion

Page 23

7 PC based Motion Generator PMotion

Start / End

Slave

Passage

conditions

Apply

Depending on the current selected derivative of mathematical function the slave display refer to

position, velocity, acceleration or jerk. You can change from one derivative to another by

pressing the horizontal arrow buttons. If the text entry boxes are activated it is possible to

specify new slave values. This is especially the case if the passage condition „value as

specified“ is selected.

Altering slave positions modifies the current segment and the next segment.

Attention: If the next segment is not able to accommodate the changes, a message box

appears indicating that the values have to be entered again.

The available passage conditions at the start and the end of a segment depend on the selected

segment type. You can toggle between “Start Segment” and “End Segment” by pressing the

horizontal arrow buttons. The following passage conditions can be selected:

No value specified:

The value is fixed by the selected segment type.

Value as specified:

The value can be altered in a text entry box.

Match with previous:

The start value of the current selected segment corresponds to the end value of the previous

segment.

The changes are applied. The map shape is updated.

User Manual

for PMotion

Page 23

Page 24

7.6 Create a map

The number of steps is an important factor for creating a map. This parameter sets the

resolution of a map table (maximum 65536 steps). The higher the resolution of the table, the

smoother the motion will be, the more memory space is allocated in the flash EPROM of the

system. The number of map steps can be altered in the dialog box “Map Settings”. Furthermore

there are some relevant parameters for the creation of a map like master cycle length and

complexity of the calculated map.

There are two possibilities to create a map, to generate a map table or a map sequence

(sequence for internal calculation of a map).

7.6.1 Map Table

A map table can be created by pressing the button „Create map table“ in the menu „Create”.

This function generates an ASCII table of position values and saves it into a text file (extension

ptf = PMC text file). This file can be opened in the text editor PEdit and transmitted to the

controller.

7 PC based Motion Generator PMotion

7.6.2 Map Sequence

A map sequence can be created by pressing the button „Create map sequence“ in the menu

„Create”. This function generates a sequence with special variables, which represent all

relevant map parameters and saves it into a file. The controller can generate map tables at

runtime by executing this sequences. The generated ASCII file can be opened in the text editor

PEdit and transmitted to the controller.

Page 24 User Manual for PMotion

Page 25

7 PC based Motion Generator PMotion

7.7 Example of using the PC based Motion Generator PMotion

In the following example representing a printing machine a web is drawn through the machine

by using tension control. It is required to print on the web in dependence of existing print marks.

The circumference of the printing drum is not the same as the distance between the marks. The

speed of the drum has to match with the speed of the web while printing and to accelerate or

decelerate for the rest of the cycle for compensating the deviation between the drum

circumference and the print mark distance. The position data of the web is measured by an

encoder and of the drum by the encoder emulation of the motor amplifier.

A typical map for the print drum (Y-axis is slave) dependent on the web (X-axis is master) is:

User Manual

for PMotion

Page 25

Page 26

7 PC based Motion Generator PMotion

Segment 1 and 3 are constant velocity segments to reach an exact printing result, segment 2 is

a sine-squared velocity segment for catching up or pausing. The master cycle length is 23874

increments (300 mm with a resolution of 79.58 inc. per mm). The print area is 80 mm either side

of zero from position 17508 to 6336. The circumference of the print drum is 374 mm and the

encoder resolution is 27.76 inc. per mm. This indicates that the cycle length of the slave axis is

10382 inc. and the printing area of slave axis is from position 8155 through zero to 2210 inc.

How to create the map:

• Start the motion design tool PMotion. A default map with a polynomial segment appears in

the motion screen.

• Insert two segments by using the function „Append Segment“ in the menu „Edit“. The new

segments are polynomials, the default length is 1000 inc. The master cycle length is

matched automatically when inserting new segments.

• Open the dialog box “Map Settings“ in the menu „Edit“ or press „CTRL+M“. Type in a name

for the map in the text box „Map Name” or retain the default name. The default value of

number of steps (1000) can be kept on. Enter the master cycle length of 23874 increments.

When applying the new value a message box appears with the question, if the map should

be extended or the last segment has to be adapted. Please choose “Yes” for extending the

map.

• In the toolbar „Segment parameters“ on the left side of the window the segments can be

configured. Choose the segment types and edit the required master and slave values. To

change selection of segments click with the left mouse button into the area of a segment or

use the arrow buttons in the toolbar for segment navigation.

The velocity of slave axis in the area “Constant velocity” is calculated from the master

velocity (0.349 * V

). The result is 8328 increments per second.

master

Segment 1:

- Select segment type „Constant velocity“

- Enter master end position: 6336 inc.

- Select „Slave velocity“ by switching the right arrow button in the dialog „Slave“, select

„Value as specified“ for „Start segment“ in the dialog „Passage Conditions“ and enter

the slave velocity of 8328 inc./sec. in the text entry box „Slave start“. To apply the

changes press enter or the button “Apply” on the bottom of the segment parameters

toolbar.

Segment2:

- Select segment type „Sine-squared velocity“

- Enter master end position: 17508 inc. (start printing)

- Enter slave end position: 8155 inc. (start printing)

Segment3:

- Select segment type „ Constant velocity “

- Enter master end position: 23874 inc. (= master cycle length)

- Select „Slave velocity“ by switching the right arrow button in the dialog „Slave“, select

„Value as specified“ for „Start segment“ in the dialog „Passage Conditions“ and enter

the slave velocity of 8328 inc./sec. in the text entry box „Slave start“. To apply the

changes press enter or the button “Apply“ on the bottom of the segment parameters

toolbar.

Page 26 User Manual for PMotion

Page 27

7 PC based Motion Generator PMotion

• Save the map into a pmo-file.

• Create the map by using the functions „Create map table“ or „Create map sequence“ in the

menu „Create“. Open the generated file with the text editor PEdit and download it to the

controller.

For testing, execute the map on the system using two axes in virtual mode. For analysing

the movement, the scope function PScope can be used.

Example to start the map:

CH0.2;VM1;SB23874;SV20000;SA300000;DC300000;PC;VC+ (master axis)

CH0.1;VM1;SB10376;ML0.2;MW01000001;TMMap_01;XMMap_01 (slave axis)

The scope function can be used to show channel 1 demand position, channel 2 demand

position and channel 1 demand speed.

• If the map was created as a sequence, it can be calculated on the controller at runtime by

executing the map sequence as followed: CH0.1;XS map_01.

User Manual

for PMotion

Page 27

Page 28

8 Internal Motion Generator

The controller internal motion generator is a calculation engine for map tables. The map is

defined using specific variables (see chapter 10.4.2). The internal motion generator reads these

variables and calculates the corresponding map.

For initially creation of a map the PC based motion generator PMotion should be used. For

generating a map by the internal motion generator, a map sequence has to be created and

downloaded to the controller. If the sequence is present in the system, the calculation routine of

the internal motion generator has to be started. This is done using the command $MSTART=1

(often the last line in the map sequence). A message will be displayed in the terminal program

indicating that calculation process has been started. Success or failure of map creation is

indicated by further messages. If calculation has been finished successful, the new map table

will exist on the system.

An important feature of the internal motion generator is the possibility to modify the map

immediately by editing the specific variables from external systems, e. g. operators panel or

PLC. Thereby a change between master and slave positions can be realized very quickly, e. g.

to modify product lengths.

8.1 Commands for Internal Motion Generator

8 Internal Motion Generator

The following commands are significant for calculating a map in the internal motion generator:

• $MSTART is a trigger variable to start the generation of a map.

• $MRESET is a trigger variable to set all variables to their default values.

• $MNAME contains the name of the appropriate map table.

• $MREADY is a trigger variable used to indicate the end of map generation. During the map

calculation the variable is set to 0, when the map calculation is finished it is set to 1.

• $MNPT is used to define the number of map steps.

• $MSAVE is used to save the map on the controller ($MSAVE=1) after generating or not

($MSAVE=0).

Page 28 User Manual for PMotion

Page 29

8 Internal Motion Generator

8.2 Messages displayed in terminal and in status variable $MSTATUS

The internal motion generator reports progress and errors (or warnings) of map generation by

displaying messages in the terminal program. Furthermore coded message numbers are saved

in the status variable $MSTATUS.

The following error messages can occur during generation of a map:

Error

No.

0 Map generation successful.

1 Error, too less values defined.

2 Slave position information missing.

3 Segment type information missing.

4 Map name missing.

5 Map is currently active.

6 Master start value must be zero..

7 Master values are not strictly monotonic increasing.

8 Segment type index not found.

9 Variable $MWn not defined.

10

Start velocity (segment type 1) not defined.

11 Slave position at segment start must be matched.

12 Percentage for start value of a segment missing (Seg. type 2 or 3).

13 Percentage for end value of a segment missing (Seg. type 2 or 3).

14 Percentage for start value must be less than for end value (Seg. type 2 or 3).

15 Percentage for start value must be less than 50% (Seg. type 3).

16 Percentage for end value must be greater than 50% (Seg. type 3).

17 Start velocity (Seg. type 3) not defined.

18 Start acceleration (Seg. type 4) not defined.

19 Start jerk (Seg. type 4) not defined.

20 End velocity (Seg. type 4) not defined.

21 End acceleration (Seg. type 4) not defined.

22 End jerk (Seg. type 4) not defined.

23 Sine % (Seg. type 5) must be defined by $MA.

24 Constant % (Seg. type 5) must be defined by $MB.

25 Cosine % (Seg. type 5) must be defined by $MC.

26 Sum of Sine %, Constant % and Cosine % (Seg. type 5) must be 100 %.

27 $MNPT not defined.

Error messages

User Manual

for PMotion

Page 29

Page 30

8.3 Example of using the internal Motion Generator

This example refers to the example already described in section 7.7 on page 25. The internal

controller calculation of the tabular values is designed so that entries made via an operator

panel will influence the map. In this example, the print length and the distance between the print

marks are modified. It is assumed that the print length will be entered via the operator panel in

the variable $LEN in mm, and that the distance between the print markers will be entered in

variable $REG, also in mm. The dimensions stated in mm must be converted into increments.

In variables $ECM and $PCM, the conversion factors are increments/mm x 100. The

corresponding messages are output to the operator panel with the variables $MSG. The

command line for starting the motion generator is normally part of a program which is stored in

the controller’s Flash-EPROM. This program is called up when the map is to be recalculated.

The variables $REG and $LEN are written via the operator panel!

$REG=300 # Registration distance, mm

$LEN=150 # Print length, mm

$ECM=7958 # Web Encoder Counts x 100

$PCM=2776 # Print Drum Encoder Counts x 100

# Sequence for map calculation:

ES Map_01

$MSG=3 # Operators Panel Message „Calculating Map“

$MRESET=1 # Reset map variables

$MNAME=Map_01 # Map name

# Master

$MM0=0 # Master start position

$MM1=((($LEN/2+5)*$ECM)/100) # Half print distance (+5mm window)

$MM3=($REG*($ECM/100)) # Registration distance

$MM2=($MM3-$MM1) # Start of print

# Slave

$MS0=0 # Slave start position

$MS1=((($LEN/2+5)*$PCM)/100) # Half print distance (+5mm window)

$MS3=(374*($PCM/100)) # Cycle length slave

$MS2=($MS3-$MS1) # Start of print

# Segment 1: Constant Velocity

$MF1=1 # Constant velocity for printing

$MA1=348831 # Start velocity

$MW1=21000000 # Velocity matched with previous segment

# Segment 2: Sine-squared velocity

$MF2=3 # Sine-squared velocity for catching up / pausing

$MX2=0 # Start at 0%

$MY2=100000000 # End at 100%

$MW2=22001000 # End position segment 2 defined

# Segment 3: Constant velocity

$MF3=1 # Constant velocity for printing

$MW3=22000000 # Velocity matched with previous segment

$MNPT=1000 # Number of steps (points)

$MSTART=1 # Trigger internal motion generator

NS

8 Internal Motion Generator

Page 30 User Manual for PMotion

Page 31

8 Internal Motion Generator

Downloading and testing map sequence:

• Download the map sequence to a controller by using the text editor PEdit and generate

the map by entering the command line “XS Map_01” into terminal program.

The variable $MSTART=1 at the end of the sequence starts the map calculation. The

messages „Mapgenerator started!“ while generating and “Mapgenerator ready!” when

finished map generation are displayed in the terminal program.

• The generated map can be tested by using two axes in virtual mode analysed by using

scope function PScope to record movements.

Example to start the map:

CH0.2;VM1;SB$MM3;SV20000;SA300000;DC300000;PC;VC+ (master axis)

CH0.1;VM1;SB$MS3;ML0.2;MW01000001;TMMap_01;PC;XMMap_01 (slave axis)

The scope function can be used to show channel 1 demand position, channel 2 demand

position and channel 1 demand speed.

User Manual

for PMotion

Page 31

Page 32

9 Segment Types

The following segment types are available in the motion generator (The index number refers to

the value that would be saved in the map variable $MFnn):

Index

0 Constant Position

1 Constant Velocity

2 Constant Acceleration

3 Sine-Squared Velocity

4 Cycloidal

5 Modified Trapezoidal

6 Modified Sine

7 Triple Harmonic

8 Sinusoidal

9 Polynomial

10 Ramp

11 Throw

12 <reserved>

13 Quadratic Spline

14 Cubic Spline

15 Sine-Constant-Cosine

16 Simple Harmonic

9 Segment Types

Segment Type

In the following sections all segment types are described in more detail. The description

contains guidelines for using the segments and what parameters can be modified. Furthermore

a list of specific variables depending on the different segment types is given out.

The units of parameters refer to the controller internal motion generator. The following

abbreviations are used in the description:

P: Position $: Variable

V: Velocity nn: Segment number: 01 to 100 is possible

A: Acceleration [...]: Parameters not alterable

J: Jerk

$MMnn und $MSnn must be entered in increments!

Page 32 User Manual for PMotion

Page 33

9 Segment Types

9.1 Segment Type "Constant Position"

This segment type is a polynomial segment with both the

velocity and the acceleration fixed to zero. The slave position

remains constant throughout at the end value of the previous

segment. This means that only the position is matched from the

previous segment, which can lead to an instantaneous change

in velocity.

Parameters:

• Segment type $MFnn=0

• Segment start constraints: [P matched, V, A & J not defined]

• Segment end constraints: [P, V, A & J not defined]

• $MWnn=20000000

• Master end position $MMnn=<value> sets end segment master position

Slave end position $MSnn=<value> will be identical in value to $MSnn-1

User Manual

for PMotion

Page 33

Page 34

9.2 Segment Type "Constant Velocity"

This segment type is a polynomial segment with the

acceleration fixed at zero. The velocity is constant throughout

and is determined either by the end velocity of the previous

segment or by a specific value. The slave position change

depends on both the velocity value for the segment and the

value of the master increment.

Parameters:

• Segment type $MFnn=1

• Segment start constraints: [P matched], V matched ($MWnn=22000000) or specified

($MWnn=21000000), [A & J not defined]

• Segment end constraints: [P, V, A & J not defined]

• Master end position $MMnn=<value> sets end segment master position

• Slave end position $MSnn=<value> will be correct for map as saved

• Start velocity $MAnn=<value> sets start velocity if $MWnn=21000000. Scaling of $MAnn is

as a polynomial segment.

9 Segment Types

Page 34 User Manual for PMotion

Page 35

9 Segment Types

9.3 Segment Type "Constant Acceleration"

In this segment type the acceleration is fixed at a constant value.

For the first half of the segment the acceleration is positive, for

the second half it is negative. The difference between start and

end positions determines the value of the acceleration and

deceleration.

Parameters:

• Segment type $MFnn=2

• Segment start constraints: [P matched], V matched ($MWnn=22000000) or not matched

($MWnn=20000000), [A & J not defined]

• Segment end constraints: [P specified, V, A & J not defined]

• Master end position $MMnn=<value> sets end segment master position

• Slave end position $MSnn=<value> sets end segment slave position

• Percentage of segment used: Start at $MXnn=<value> & end at $MYnn=<value> (see

chapter 10.1 page 49)

User Manual

for PMotion

Page 35

Page 36

9 Segment Types

9.4 Segment Type "Sine-Squared Velocity" and "Cycloidal"

Mathematically both the “Sine-Squared Velocity” segment type and

the “Cycloidal” segment type are identical. The acceleration profile

is one cycle of a sine wave, the length is set by the master position

increment and the magnitude is set by the slave position change

across the segment.

Parameters:

• Segment type $MFnn=3 for sine-squared velocity and $MFnn=4 for cycloidal

• Segment start constraints: [P matched], V matched ($MWnn=22000000) or not specified

($MWnn=20222222), [A & J not defined]

• Segment end constraints: [P specified, V, A & J not defined]

• Master end position $MMnn=<value> sets end segment master position

• Slave end position $MSnn=<value> sets end segment slave position

• Percentage of segment used: Start at $MXnn=<value> & end at $MYnn=<value> (see

chapter 10.1 page 49)

Page 36 User Manual for PMotion

Page 37

9 Segment Types

9.5 Segment Type "Modified Trapezoidal"

For this segment type the magnitude of the acceleration profile

is set by the master position increment and the slave position

change across the segment. This type of segment is useful for

heavy, stiff systems running at low or medium speeds.

Parameters:

• Segment type $MFnn=5

• Segment start constraints: [P matched], V matched ($MWnn=22000000) or not specified

($MWnn=20000000), [A & J not defined]

• Segment end constraints: [P specified, V, A & J not defined]

• Master end position $MMnn=<value> sets end segment master position

• Slave end position $MSnn=<value> sets end segment slave position

• Percentage of segment used: Start at $MXnn=<value> & End at $MYnn=<value> (see

chapter 10.1 page 49)

User Manual

for PMotion

Page 37

Page 38

9.6 Segment Type "Modified Sine"

For this segment type the magnitude is set by the master

position increment and the slave position change across the

segment. This type of segment is useful for systems with some

backlash and for medium or high speeds.

9 Segment Types

Parameters:

• Segment type $MFnn=6

• Segment start constraints: [P matched], V matched ($MWnn=22000000) or not specified

($MWnn=20000000), [A & J not defined]

• Segment end constraints: [P specified, V, A & J not defined]

• Master end position $MMnn=<value> sets end segment master position

• Slave end position $MSnn=<value> sets end segment slave position

• Percentage of segment used: Start at $MXnn=<value> & End at $MYnn=<value> (see

chapter 10.1 page 49)

Page 38 User Manual for PMotion

Page 39

9 Segment Types

9.7 Segment Type "Triple Harmonic"

This segment will always start and finish with zero velocity and

acceleration (the possibility to match velocity has been switched

off for this segment). The acceleration profile is defined by

following parameters: Three normalised amplitudes for the

harmonics used to construct the curve. These values form the

three coefficients of a three term fourier series. Example: set the

first harmonic to 2*Pi and both the second and third harmonics

to zero, then the acceleration profile will be identical to a

cycloidal segment. Usually only the first two harmonics have to

be specified and the third is calculated to satisfy the constraints

from the neighbouring segments.

Parameters:

• Segment type $MFnn=7

• Segment start constraints: [P matched], V matched ($MWnn=22000000) or not specified

($MWnn=20000000), [A & J not defined]

• Segment end constraints: [P specified, V, A & J not defined]

• Master end position $MMnn=<value> sets end segment master position

• Slave end position $MSnn=<value> sets end segment slave position

• Amplitudes for the three harmonics are $MAnn<value>, $MBnn<value> and

$MCnn<value> in normalised units of a three term fourier series x 10

6

.

User Manual

for PMotion

Page 39

Page 40

9.8 Segment Type "Sinusoidal"

This segment type is a sine wave in master – slave position. Start position (in terms of

degrees), Amplitude (in slave axis units) and the number of sine wave cycles used for the

segment can be set.

These three parameters determine the slave end position and the velocity and acceleration

within the segment. Due to the default setting “velocity matched with previous segment“ the

curve often looks like a „S“ instead of a sine wave. This is because a sine wave doesn’t start

with zero velocity and the end velocity of other segments is zero.

Parameters:

• Segment type $MFnn=8

• Segment start constraints: [P matched], V matched ($MWnn=22000000) or not specified

($MWnn=20000000), [A & J not defined]

• Segment end constraints: [P specified, V, A & J not defined]

• Master end position $MMnn=<value> sets end segment master position

• Slave end position $MSnn=<value> sets end segment slave position, value will be ignored

by the motion generator, because end position is determined by other parameters.

• Amplitude of sine wave $MAnn<value> in encoder counts (inc.).

• Cycle start angle $MBnn<value> in degrees x 10

• Number of sine wave cycles $MCnn<value> (no units x 10

9 Segment Types

6

.

6

).

Page 40 User Manual for PMotion

Page 41

9 Segment Types

9.9 Segment Type "Polynomial"

This segment type can be used multilaterally and is the most adjustable segment. Therefore it

is the default segment type. A polynomial segment is a shape which fits various boundary

constraints.

Parameters:

• Segment type $MFnn=9

• Segment start and end constraints: The segment type „Polynomial“ determines its shape

by applying boundary constraints. The variable $MWnn is used for setting these constraints

and has the following format:

A eight digit decimal number contains the constraints for each of the four derivatives at

both ends of the segment. Each digit represents a boundary constraint and can have one

of the following three values:

0 No value specified: The boundary constraint will not be applied.

1 Value as specified: This boundary constraint will be specified by the relevant variable

(see below).

2 Matched with previous: This boundary constraint can only be used at segment start.

The start value of the segment matches equivalent with the end boundary value of the

previous segment.

$MWnn

Entry

Digit 8

Digit 7

Digit 6

Digit 5

Digit 4

Digit 3

Digit 2

Digit 1

Therefore the default setting for the variable $MWnn of a polynomial segment is 22201110.

Example: $MWnn=21101110 indicates that the start velocity and the start acceleration

along with the end velocity and acceleration have been specified. The variables $MAnn,

$MBnn, $MXnn and $MYnn contain the relevant values and need to be present for this

segment.

Segment

boundary

Start

End

Boundary Constraint Default value

Position

Velocity

Acceleration

Jerk

Position

Velocity

Acceleration

Jerk

2 (matched with previous) cannot

be changed

2 (matched with previous)

2 (matched with previous)

0 (no value specified)

1 (value as specified) cannot be

changed

1 (value as specified)

1 (value as specified)

0 (no value specified)

User Manual

The format of this constraint word applies to all segment types, though different

segments have different limitations for the boundary constraints.

for PMotion

Page 41

Page 42

9 Segment Types

• Master end position $MMnn=<value> sets end segment master position

• Slave end position $MSnn=<value> sets end segment slave position

• Derivative specification parameters are used when the segment constraint specifies that

the particular derivative is specified:

Segment

Boundary

Start

End

Derivative Variable Units:

Slave encoder counts (inc.) per

Velocity

Acceleration

Jerk

Velocity

Acceleration

Jerk

$MAnn

$MBnn

$MCnn

$MXnn

$MYnn

$MZnn

6

Master counts

1x10

8

Master counts

1x10

1x109 Master counts3

1x106 Master counts

8

Master counts

1x10

1x109 Master counts3

2

2

Examples: For every master position count:

$MAnn=1000000 means that slave position increases by 1 count.

$MAnn=-24000000 means that slave position decreases by 24 counts.

$MAnn=50000 means that slave position increases by 0.05 counts.

$MBnn=50000000 means that slave velocity increases by 0.5 counts per master count

(equivalent to a increase in $MAnn of 500000).

$MZnn=-2000000000 means that slave acceleration decreases by 2 counts per master count

(equivalent to a decrease in $MYnn of 200000000).

Page 42 User Manual for PMotion

Page 43

9 Segment Types

9.10 Segment Type "Ramp"

The profile of a ramp segment is shown in the diagram. The

width of the acceleration and deceleration pulses can be set

(here acceleration set to 20% and deceleration set to 40%).

Parameters:

• Segment type $MFnn=10

• Segment start constraints: [P matched], V matched ($MWnn=22000000) or not specified

($MWnn=20000000), [A & J not defined]

• Segment end constraints: [P specified, V, A & J not defined]

• Master end position $MMnn=<value> sets end segment master position

• Slave end position $MSnn=<value> sets end segment slave position

• Length of acceleration pulse at segment start $MAnn<value> and of deceleration pulse at

segment end $MBnn<value> in percent x 10

100%).

6

(range 0 to 100%; $MAnn+$MBnn <=

User Manual

for PMotion

Page 43

Page 44

9.11 Segment Type "Throw"

The segment type “Throw” starts with a smooth motion profile

and ends with both velocity and acceleration at zero, with a

slave position change of zero. The magnitude of the position

change at the midpoint of the segment is changeable. The

segment is symmetrical about the midpoint and should only be

used in preference to two sequential ramp segments.

Parameters:

• Segment type $MFnn=11

• Segment start constraints: [P matched], V matched ($MWnn=22000000) or not specified

($MWnn=20000000), [A & J not defined]

• Segment end constraints: [P, V, A & J not defined]

• Master end position $MMnn=<value> sets end segment master position

• Slave end position $MSnn=<value> sets end segment slave position, value will be ignored

by the motion generator (value is identical with $MSnn-1).

• Extent of throw $MAnn<value> in slave position units.

9 Segment Types

Page 44 User Manual for PMotion

Page 45

9 Segment Types

9.12 Segment Type "Quadratic Spline"

A quadratic spline is a special case of a polynomial segment.

The position and velocity are both continuously to the previous

segment. The length and width of the segment can be defined.

A number of these segments perform a quadratic spline

between the data points (end segment coordinates).

Parameters:

• Segment type $MFnn=12

• Segment start constraints: [P und V matched, A & J not defined]

• Segment end constraints: [P specified, V, A & J not defined]

• Master end position $MMnn=<value> sets end segment master position

• Slave end position $MSnn=<value> sets end segment slave position

User Manual

for PMotion

Page 45

Page 46

9.13 Segment Type "Cubic Spline"

A cubic spline is a special case of a polynomial segment. The

position, velocity and acceleration are continuously to the

previous segment. The length and width of the segment can be

defined. A number of these segments perform a cubic spline

between the data points (end segment coordinates).

Parameters:

• Segment type $MFnn=13

• Segment start constraints: [P, V und A matched, J not defined]

• Segment end constraints: [P specified, V, A & J not defined]

• Master end position $MMnn=<value> sets end segment master position

• Slave end position $MSnn=<value> sets end segment slave position

9 Segment Types

Page 46 User Manual for PMotion

Page 47

9 Segment Types

9.14 Segment Type "Sine-Constant-Cosine"

The „Sine-Constant-Cosine“ type is a very adjustable segment

type and is often be used in place of other segment types with

sine and cosine acceleration profiles. The acceleration profile is

a sine wave followed by a constant area and a cosine wave. It

is possible to modify the segment portions by changing the

relevant percentage values and so to create very complex

shapes. The magnitude of the acceleration is set by the master

increment and the slave position change.

Parameters:

• Segment type $MFnn=14

• Segment start constraints: [P matched], V matched ($MWnn=22000000) or not defined

($MWnn=20000000), [A & J not defined]

• Segment end constraints: [P specified, V, A & J not defined]

• Master end position $MMnn=<value> sets end segment master position

• Slave end position $MSnn=<value> sets end segment slave position

6

• Length of sine acceleration at segment start $MAnn<value> in percent x 10

(range 0 to

100%).

• Length of constant acceleration in the middle of the segment $MBnn<value> in percent x

6

10

(range 0 to 100%).

6

• Length of cosine acceleration at segment end $MCnn<value> in percent x 10

(range 0 to

100%).

• Percentage of segment used: Start at $MXnn=<value> & End at $MYnn=<value> (see

chapter 10.1 page 49)

Note: $MAnn + $MBnn + $MCnn = 100%

User Manual

for PMotion

Page 47

Page 48

9 Segment Types

9.15

Segment Type "Simple Harmonic"

This segment type has an acceleration profile of the first half of

a cosine wave. The magnitude of the acceleration profile is set

by the master position increment and the slave position change.

It is possible to use only parts of the segment by entering start

and end percentage values. This segment type is useful for

systems with some backlash at low to medium speeds.

Parameters:

• Segment type $MFnn=15

• Segment start constraints: [P matched], V matched ($MWnn=22000000) or not defined

($MWnn=20000000), [A & J not defined]

• Segment end constraints: [P specified, V, A & J not defined]

• Master end position $MMnn=<value> sets end segment master position

• Slave end position $MSnn=<value> sets end segment slave position

• Percentage of segment used: Start at $MXnn=<value> & End at $MYnn=<value> (see

chapter 10.1 page 49).

Page 48 User Manual for PMotion

Page 49

10 Motion Generator: Features and Functions

10

10.1

Motion Generator: Features and Functions

This section contains detailed explanations of certain features of the motion generator and

some summaries of the information contained in the previous section (Segment types).

Start and End Percentages of a Segment

For the following segment types it is possible to define, which part of the segment is used:

2: Constant Acceleration

3: Sine-Squared Velocity

4: Cycloidal

5: Modified Trapezoidal

6: Modified Sine

10: Ramp

14: Sine-Constant-Cosine

15: Simple Harmonic

The entry of the percentage values is done by using the variables $MXnn und $MYnn for the

controller internal motion generator and in PMotion by pressing the button „Type parameters“ in

the segment parameters toolbar.

Scaling:

• PC based motion generator (PMotion):

Required percentage values, entered directly in the text entry boxes in the dialog „Type

parameters“.

• Controller internal motion generator:

Required percentage values x10

100%).

The following diagram illustrates the effect of setting both the start and end percentages to

values ≠ 0 for the segment type „Constant acceleration“.

$MXnn

Anfang [%]

$MYnn

Ende [%]

6

, into variables $MXnn and $MYnn ($MXnn+$MYnn ≤

User Manual

By changing the start and end percentage special segment profiles can be created, e. g. a

modified sine profile with no deceleration and with an acceleration ≠ 0 at the end of the

segment.

for PMotion

Page 49

Page 50

10.2 Summary of Segment Constraints

Segment Type Segment start constraints

10 Motion Generator: Features and Functions

0: Constant Position

1: Constant Velocity

2: Constant Acceleration

3: Sine-Squared Velocity

4: Cycloidal

5: Modified Trapezoidal

6: Modified Sine

7: Triple Harmonic

8: Sinusoidal

10: Ramp

11: Throw

14: Sine-Constant-Cosine

15: Simple Harmonic

9: Polynomial

12: Quadratic Spline

13: Cubic Spline

P

matched

V A J not specified

P

matched

V matched or specified,

A J

not specified

P matched

V matched or not specified

A J

not specified

P matched

V A J

matched or specified or not specified

P V matched

A J not specified

P V A matched

J not specified

Legend:

P: Position V: Velocity

A: Acceleration J: Jerk

• Matched means that the derivative value doesn’t change from the

end of one segment to the beginning of the next (matched with previous).

• Specified means that the derivative value can be set at that point

on the segment (value as specified).

• Not specified means that the derivative value cannot be altered at that point of the

segment (no value specified).

Page 50 User Manual for PMotion

Page 51

10 Motion Generator: Features and Functions

Segment Type Segment end constraints

0: Constant Position

1: Constant Velocity

8: Sinusoidal

11: Throw

2: Constant Acceleration

3: Sine-Squared Velocity

4: Cycloidal

5: Modified Trapezoidal

6: Modified Sine

7: Triple Harmonic

10: Ramp

13: Quadratic Spline

14: Cubic Spline

15: Sine-Constant-Cosine

16: Simple Harmonic

9: Polynomial

Legend:

P: Position V: Velocity

A: Acceleration J: Jerk

• Matched means that the derivative value doesn’t change from the end of one segment to

the beginning of the next (matched with previous).

P V A J not specified

P matched

V A J not specified

P matched

V A J specified or not specified

• Specified means that the derivative value can be set at that point on the segment (value

as specified).

• Not specified means that the derivative value cannot be altered at that point of the

segment (no value specified).

User Manual

for PMotion

Page 51

Page 52

10 Motion Generator: Features and Functions

10.3 Summary of Segment Types and their Parameters

The following table summaries the variables used for each segment type in the controller

internal motion generator:

Segment Type

$MMnn $MSnn $MFnn $MAnn $MBnn $MCnn $MXnn $MYnn $MZnn $MWnn

Constant Position

Constant Velocity

Constant

Acceleration

Sine-Squared

Velocity

Cycloidal

Modified

Trapezoidal

Modified Sine

Triple Harmonic

Sinusoidal

Polynomial

Ramp

Throw

>

>

> >

> >

> >

> >

> >

> >

>

r

> >

> >

> >

0

1 Start

2 Start % End %

3 Start % End %

4 Start % End %

5 Start % End %

6 Start % End %

7 1.

8 Amplitude Cycle

9 Start

10 Start % End %

11 Extent of

Velocity

Harmonic

Velocity

Throw

*

2.

Harmonic

Start

Start

Accel.

3.

Harmonic

No. of

Cycles

Start

Jerk

End

Velocity

End

Accel.

End

Jerk

>

>

>

>

>

>

>

>

>

>

>

Quadratic Spline

Cubic Spline

Sine-ConstantCosine

Simple Harmonic

> >

> >

> >

> >

13

14

15 Sin % Constant % Cosine % Start % End %

16 Start % End %

> Standard definition applies

r Variable may be present (and standard definition applies), but will not be used

<blank> The variable does not apply to the segment type

<text> Short description of the meaning of the variable specific to the segment type

* Start velocity will only be required for segment type „Constant Velocity“ if the

velocity is not matched with previous segment.

>

>

Page 52 User Manual for PMotion

Page 53

10 Motion Generator: Features and Functions

10.4

Technical Information about the Motion Generator

This section details some technical information about the motion generator.

10.4.1 Maximum number of segments

The maximum number of segments of a map is limited by memory to 100 in both the PC based

motion generator PMotion and the controller internal motion generator.

10.4.2 Variable names used by the internal Motion Generator

Map start coordinates:

• $MM0: Master position (range ±4000000 inc.)

• $MS0: Slave position (range ±4000000 inc.)

For each segment (nn is 1 to 100 inclusive, leading zero when appropriate):

• $MFnn: Segment type (range 0 to15 inclusive, no units)

• $MMnn: Master position (range ±4000000 inc.).

• $MSnn: Slave position (range ±4000000 inc.).

• $MWnn: constraint word:

$MWnn – Entry Segment boundary

Boundary constraint

Digit 8

Digit 7

Digit 6

Digit 5

Digit 4

Digit 3

Digit 2

Digit 1

Each digit can be 0 (no value specified), 1 (value as specified) or 2 (matched with previous).

Valid entries will depend on the segment type.

• $MMSB: contains the master cycle length after calculation.

• $MSSB: contains the slave cycle length after calculation.

Start

End

Position

Velocity

Acceleration

Jerk

Position

Velocity

Acceleration

Jerk

User Manual

for PMotion

Page 53

Page 54

10 Motion Generator: Features and Functions

• $MAnn, $MBnn, $MCnn, $MXnn, $MYnn & $MZnn: The meaning of the variables is

dependent on the segment type, as shown in the following table:

Segment

Variables

Description

Type

1 $MAnn Start velocity, required only when „Value as

specified“ is selected using $MWnn.

2 $MXnn & $MYnn Start & End percentages x 106

3 $MXnn & $MYnn Start & End percentages x 106

4 $MXnn & $MYnn Start & End percentages x 106

5 $MXnn & $MYnn Start & End percentages x 106

6 $MXnn & $MYnn Start & End percentages x 106

7 $MAnn, $MBnn & $MCnn Normalised amplitudes of the three harmonics of

a three term fourier series x 10

8 $MAnn, $MBnn & $MCnn Amplitude (inc.), Cycle start angle (degrees x 106)

and No. of cycles (no units x 10

9 $MAnn, $MBnn

$MCnn, $MXnn

Start & End derative values

(when applicable with $MWnn).

6

6

)

$MYnn & $MZnn

10 $MAnn & $MBnn Start & End percentages x 106

11 $MAnn Extent of throw (inc.)

13 $MAnn Slave end position (inc.)

15 $MAnn, $MBnn,

$MCnn,

$MXnn & $MYnn

Percentage x 106 of sine-, constant- or cosine

portion of the segment.

Start & End percentages x 10

6

16 $MXnn & $MYnn Start & End percentages x 106

• $MNAME specifies the name of the map.

• $MNPT specifies the number of points saved in the map table (max. 65536).