Page 1

Operating Manual PIT m3.1p

Operating Manual PIT m3.1p

PIT m3.1p

Operator terminals

Operating Manual — No. 1002259-EN-02

Page 2

This document is a translation of the original document.

All rights to this documentation are reserved by Pilz GmbH & Co. KG. Copies may be made

for internal purposes.

Suggestions and comments for improving this documentation will be gratefully received.

Pilz®, PIT®, PMI®, PNOZ®, Primo®, PSEN®, PSS®, PVIS®, SafetyBUS p®, SafetyEYE®,

SafetyNET p®, the spirit of safety® are registered and protected trademarks of

Pilz GmbH & Co. KG in some countries.

SD means Secure Digital.

Preface

Page 3

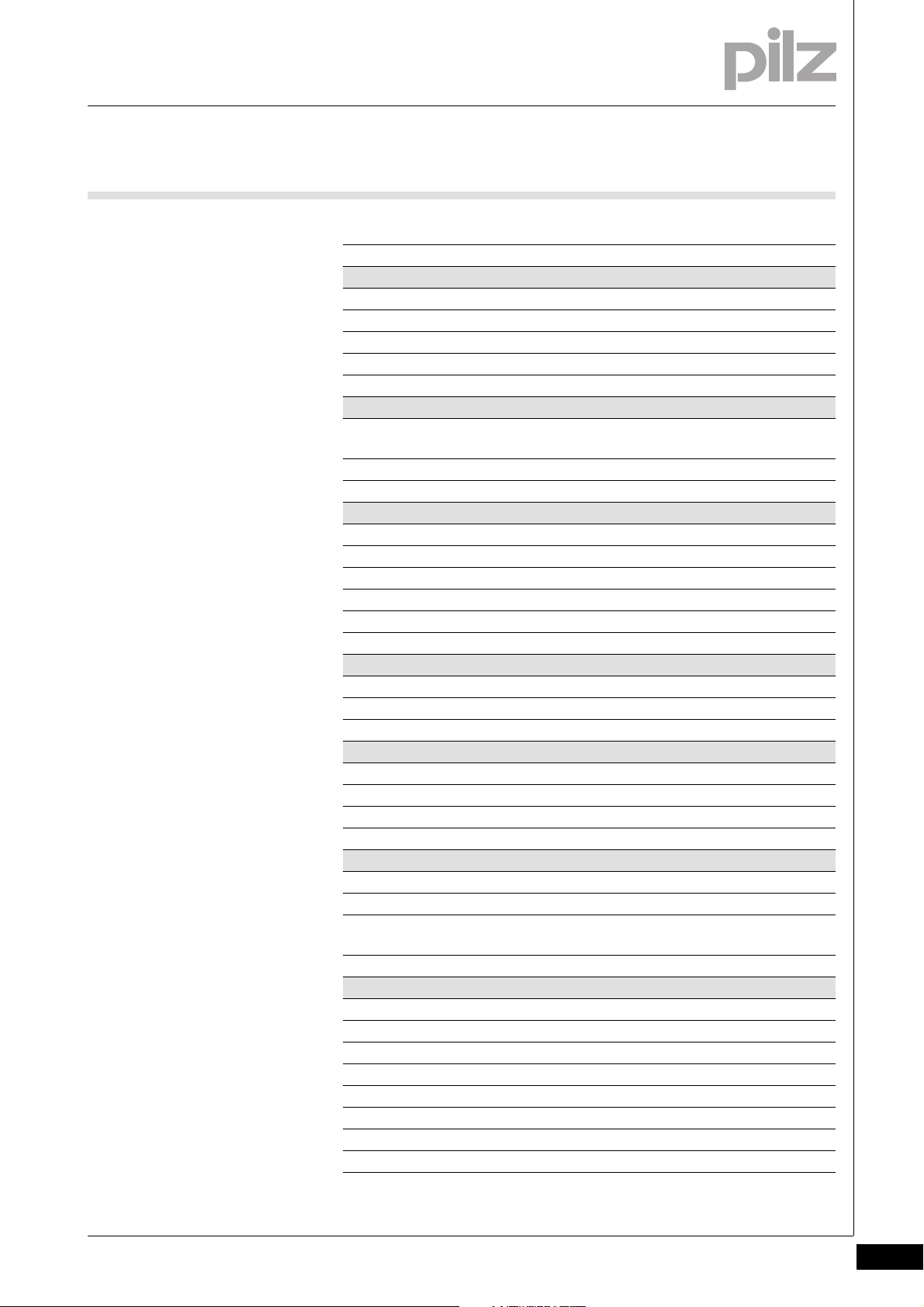

Contents

Contents

Contents Page

Chapter 1 Introduction

1.1 Validity of documentation 1-1

1.1.1 Retaining the documentation 1-1

1.2 Overview of documentation 1-2

1.3 Definition of symbols 1-3

Chapter 2 Overview

2.1 Features of the operating mode selector

2-2

switch

2.2 Actuator features 2-3

Chapter 3 Safety

3.1 Intended use 3-1

3.2 Safety regulations 3-2

3.2.1 Use of qualified personnel 3-2

3.2.2 Warranty and liability 3-2

3.2.3 Disposal 3-2

Chapter 4 Function description

4.1 Key ID number of the actuator 4-3

4.2 Communication with the control system 4-4

Chapter 5 Installation

5.1 General installation guidelines 5-1

5.1.1 Dimensions 5-1

5.1.2 Mounting cutout 5-3

Chapter 6 Wiring

6.1 Terminal Configuration 6-1

6.2 Connection to safety system (example) 6-2

6.3 Connection to PNOZmulti (example: PNOZ

m1p)

Chapter 7 Operation

7.1 Select operating mode 7-2

7.2 Time monitoring 7-3

7.3 Select special mode (service) 7-4

7.4 Evaluation through safety system 7-5

7.5 Troubleshooting 7-6

7.6 Diagnostics 7-7

7.6.1 Signal outputs for status information 7-7

6-3

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1

Page 4

Contents

Chapter 8 Technical details

8.1 Technical details 8-1

8.2 Order reference 8-3

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

2

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 5

1 Introduction

1.1 Validity of documentation

11000IntroductionIntroduction1-1.1Validity of docume ntation1100Validity of documenta tion1-Einf Gltigkeit der Dokumentation

This documentation is valid for the product PIT m3.1p. It is valid until

Einf Einleitung

1.1.1 Retaining the documentation

Retaining the documentation1-Einf Aufbewahren

new documentation is published.

This operating manual explains the function and operation, describes

the installation and provides guidelines on how to connect the product.

This documentation is intended for instruction and should be retained

for future reference.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1-1

Page 6

1 Introduction

1.2 Overview of documentation

1.2Overview of documentation1200Overview of documentation1-Einf_Uebersicht_BAWS

1 Introduction

The introduction is designed to familiarise you with the contents, structure and specific order of this manual.

2 Overview

This chapter provides information on the product's most important features.

3 Safety

This chapter must be read as it contains important information on safety

and intended use.

4 Function description

This chapter describes the product's mode of operation.

5 Installation

This chapter explains how to install the product.

6 Wiring

This chapter describes the product's commissioning and wiring.

7 Operation

This chapter describes how to operate the product and gives tips in the

case of a fault.

8 Technical Details

1-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 7

1 Introduction

1.3 Definition of symbols

1.3Definition of symbols1300Definition of symbols1-Einfhrung Zeichen

Information that is particularly important is identified as follows:

DANGER!

This warning must be heeded! It warns of a hazardous situation

that poses an immediate threat of serious injury and death and

indicates preventive measures that can be taken.

WARNING!

This warning must be heeded! It warns of a hazardous situation

that could lead to serious injury and death and indicates preventive measures that can be taken.

CAUTION!

This refers to a hazard that can lead to a less serious or minor

injury plus material damage, and also provides information on

preventive measures that can be taken.

NOTICE

This describes a situation in which the unit(s) could be damaged

and also provides information on preventive measures that can

be taken. It also highlights areas within the text that are of particular importance.

INFORMATION

This gives advice on applications and provides information on

special features.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1-3

Page 8

1 Introduction

1-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 9

2 Overview

24 V DC

Actuator

Evaluation device

PIT m3.1p

Higher-level

process controller

PNOZmulti

Safety system with

"1ooN" evaluation

OM1

OM2

OM3

OM4

OM5

Service

In n

In n+1

In n+2

In n+3

In n+4

SI3:0

4

ID Interface

6

PIT m3.1p

22000OverviewOverview2-Übersicht_BAWS_Einführung

The operating mode selector switch PIT m3.1p can only be operated in

conjunction with an actuator. 5 actuators are available, each with different authorisations.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2-1

Page 10

2 Overview

2.1 Features of the operating mode selector switch

2.1Features of the operating mode selector switch2100Features of the operating mode selector switch2-Merkmale BAWS

Supply voltage 24 VDC

4 buttons for switching and displaying the operating mode

Button is back-lit when operated

4 operating modes

1 special service mode

5 monitored semiconductor outputs (24 V) for each operating mode

(OM1 ... OM5)

4 signal outputs (24 V) for status information, divided into information

classes (SI0 ... SI3):

– Selected operating mode

– Set authorisation

– Messages (e.g. user error and fault)

Interface (signal outputs IDsync, IDclock, IDo0, IDo1 and inputs IDi0

and IDi1) for downloading the Key ID number of the connected actuator

2-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 11

2 Overview

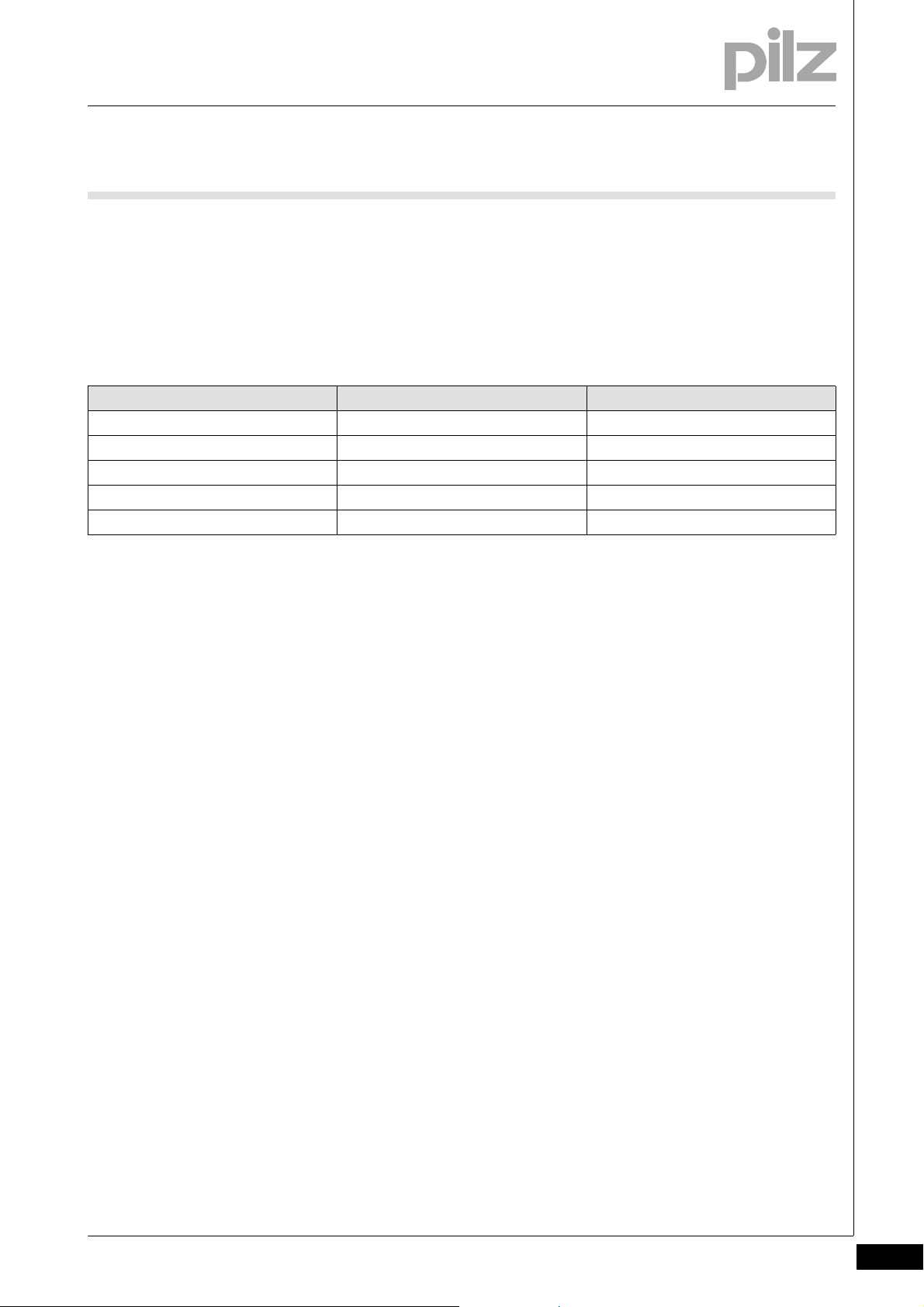

2.2 Actuator features

2.2Actuator features2200Actuator features2-Merkmale Betätiger BAWS

The actuator has a write-protected area in which the permitted operating modes and a Key ID number are stored.

Replaces the mechanical key

Memory for authorisations

The following coding is printed on the actuator:

Designation Marking Authorisation for operating mode

Key Mode 01 Key Mode 1 OM1

Key Mode 02 Key Mode 2 OM1+ 2

Key Mode 03 Key Mode 3 OM1+ 2 + 3

Key Mode 04 Key Mode 4 OM1+ 2 + 3 + 4

Key Mode Service Key Mode 5 OM1+ 2 + 3 + 4 + 5 (Service)

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2-3

Page 12

2 Overview

2-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 13

3 Safety

3.1 Intended use

33000SafetySafety3-3.1Intended use3100Intended use3-Bestimm_Verwendung_BAWS

The operating mode selector switch enables you to switch between defined operating modes such as set-up, shutdown, automatic operation

and service. An actuator is used to assign access rights and authorisation to switch operating modes.

A safety system must be used to evaluate the operating modes. Switching must not initiate a hazardous movement, nor can it cancel an existing

control command.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-1

Page 14

3 Safety

3.2 Safety regulations

3.2Safety regulations3200Safety regulations3-

3.2.1 Use of qualified personnel

Use of qualified personnel3-Sich Qualif. Personal

The products may only be assembled, installed, programmed, commissioned, operated, maintained and decommissioned by competent persons.

A competent person is someone who, because of their training, experience and current professional activity, has the specialist knowledge required to test, assess and operate the work equipment, devices,

systems, plant and machinery in accordance with the general standards

and guidelines for safety technology.

It is the company's responsibility only to employ personnel who:

Are familiar with the basic regulations concerning health and safety /

accident prevention

Have read and understood the safety guidelines given in this descrip-

tion

Have a good knowledge of the generic and specialist standards ap-

plicable to the specific application.

3.2.2 Warranty and liability

Warranty and liability3-Sich Gewhrleistung

3.2.3 Disposal

Disposal3-Si ch Entsorgung

All claims to warranty and liability will be rendered invalid if:

The product was used contrary to the purpose for which it is intended

Damage can be attributed to not having followed the guidelines in the

manual

Operating personnel are not suitably qualified

Any type of modification has been made (e.g. exchanging compo-

nents on the PCB boards, soldering work etc.).

In safety-related applications, please comply with the mission time t

M

in the safety-related characteristic data.

When decommissioning, please comply with local regulations regard-

ing the disposal of electronic devices (e.g. Electrical and Electronic

Equipment Act).

3-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 15

4 Function description

User Interface

RFID

Receiver

=

=

A1

A

2

O

M

1

Actuator

OM2

O

M

3

O

M

4

O

M

5

SI0

S

I

1

S

I

2

S

I

3

IDsync

I

Dc

l

o

c

k

I

D

o

0

I

Do

1

I

D

i

0

I

Di

1

Input

Power

44000Function descriptionFunction description4-Funktionsbeschreibung_allgemein_BAWS

The operating mode selector switch enables you to switch between 5

different operating modes. Operating modes OM1 ... OM4 plus a special

service mode (OM5.)

For OM1 ... OM4, one button each is available. For the special service

mode (OM5), button 1 must be operated for a certain time period (see

Time monitoring -> Operating time). Each button is assigned a monitored semiconductor output. Operating the button changes the semiconductor output from low to high. The semiconductor outputs must be

evaluated via a safety control system. The operating mode selector

switch guarantees that only one of the semiconductor outputs is high at

any one time.

Block diagram:

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-1

Page 16

4 Function description

The operating mode selector switch is protected against unauthorised

operation. A switch between operating modes must be enabled via an

actuator.

There are 5 actuators in total; each actuator provides authorisation to

switch up to 5 operating modes, including special authorisations:

Actuator Key Mode 01: OM 1

Actuator Key Mode 02: OM 1 and 2

Actuator Key Mode 03: OM 1 and 2 and 3

Actuator Key Mode 04: OM 1 and 2 and 3 and 4

Actuator Key Mode Service: OM 1 and 2 and 3 and 4 and 5 (Service)

When the actuator is removed, the set operating modes OM1 – OM4 are

retained.

Service mode (OM5) is an exception. When the "Service" actuator is removed, the mode switches to OM1.

4-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 17

4 Function description

Bit 7 ... Bit 0

Bit 15 ... Bit 8

Bit 23 ... Bit 16

Bit 27 ... Bit 24

Key Mode

Bit 27

Bit 26

Bit 25

Bit 24

01

02

03

04

Service

0

1

0

0

0

0

0

0

1

1

0

0

0

1

1

1

1

1

0

0

consecutive number

Key-ID-Nummer: 130000044

1101

Key-ID-Nummer: 020000510

11111110

00000001

00000000

0010

00101100

00000000

00000000

(Key Mode Service)

(Key Mode 02)

4.1 Key ID number of the actuator

4.1Key ID number of the actuator4100Key ID number of the actuator4-Key_ID_Nummer

Once an actuator has been connected, the actuator's unique Key ID

number is downloaded to the higher-level process controller using a defined protocol.

The Key ID number is used to clearly identify the actuator and is unique.

It is printed on the actuator's type label as a 9-digit decimal figure.

INFORMATION

Please note that the Key ID number is not printed on the actuator packaging.

If the actuator is lost, it is impossible to supply a replacement

actuator with an identical Key ID number.

The Key ID number consists of two parts:

Bit 27 … 24 is the Key Mode

Bit 23 … 0 is the consecutive number.

Example:

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-3

Page 18

4 Function description

100 ms

IDsync

IDclock

Bi t

26

Bit

27

Bit 22 … Bi t 16

Bit 8 … Bit 2

IDo0

IDo1

IDi0

IDi1

(b) (c) (d)

T

(e)

100 ms

(a)

Bit

25

Bit

24

Bit

23

Bit

15

Bit

14

Bi t

12

Bit

13

Bit

11

Bit

10

Bit 9 Bit 1 Bit 0

Bit

26

Bit

27

Bit 22 … Bi t 16

Bit

25

Bit

24

Bi t

23

Bit

15

Bit

14

Bit 8 … Bit 2

Bit

12

Bit

13

Bit

11

Bit

10

Bit 9 Bit 1 Bit 0

4.2 Communication with the control system

4.2Communication with the control system4200Communication with the control system4-Kommunikat ion Steuerung BAWS

Key:

IDsync - The "IDsync" signal indicates that the download has started

- The "IDsync" signal is present for 100 ms

IDclock - T = 100 ms

- Duty cycle = 50 %

- The "IDclock" signal is driven by the operating mode selector switch

IDo0, IDo1 - Data output;

these signal lines are used to download the Key ID number from the operating mode selector switch to the control system.

Bit 27 … Bit 14 are sent via the data line IDo0.

Bit 13 … Bit 0 are sent via the data line IDo1.

IDi0, IDi1 - Data input;

The control system uses these signal lines to confirm receipt of the previous Key ID number

(Bit 27 … Bit 0) to the operating mode selector switch.

Bit 27 … Bit 14 are received via the data line IDi0.

Bit 13 … Bit 0 are received via the data line IDi1.

(a) The operating mode selector switch sets the "IDsync" signal, thereby signalling to the control system

that transmission is starting

(b) A rising edge at the "IDclock" signal indicates that the data ("IDo0" and "IDo1") is present and valid and

is being read in by the control system.

(c) The control system must output the data that was read in to lines "IDi0" and "IDi1" by the time there is

a falling edge at the "IDclock" signal.

(d) With a rising edge at the "IDclock" signal, the operating mode selector switch reads the feedback from

(e) Even at the end of the download, the control system must leave the data for at least 100 ms after the

the control system at IDi0 and IDi1 and checks it for equivalence.

last rising edge at the "IDclock" signal.

Download procedure:

4-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 19

4 Function description

4.2 Communication with the control system

INFORMATION

If the control system does not feed back the previously read Bits

correctly, the download is aborted and restarted. The "IDsync"

signal is set once again. The download is repeated until the Key

ID number is downloaded completely.

The download of the Key ID number takes 1.4 s.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-5

Page 20

4 Function description

4-6

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 21

5 Installation

5.1 General installation guidelines

55000InstallationInstallation5-5.1General installation guidelines5100General installation guidelines5-Montage_Hinweise_BAWS

5.1.1 Dimensions

Dimensions5-Abmessungen BAW S

The installation site must conform to the protection type IP54.

Ensure that the operating mode selector switch has sufficient ventila-

tion.

Attach the operating mode selector switch using the brackets provid-

ed.

Make sure that the gasket is seated correctly.

Front view

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

5-1

Page 22

5 Installation

5.1 General installation guidelines

Side view

5-2

Plan view

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 23

5 Installation

62,5

2.46"

87

3.43"

5.1 General installation guidelines

5.1.2 Mounting cutout

Mounting cutout5-Montageausschnitt_BAWS

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

5-3

Page 24

5 Installation

5-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 25

6 Wiring

+

2

4

V

D

C

X

2

1

2

3

4

5

6

7

8

9

1

0

O

M

5

O

M

4

O

M

3

O

M

2

O

M

1

n

.

c

A

2

A

1

X

1

1

2

3

4

5

6

7

8

0

V

SI0

IDclock

SI1

SI2

SI3

IDsync

IDo0

IDo1

IDi0

IDi1

1

8

1

10

6.1 Terminal Configuration

66000WiringWiring6-6.1Terminal Configuration6100Terminal Configuration6-Klemmenbelegung BAWS

INFORMATION

The connection terminals are not supplied with the unit.

Connect the supply voltage X1 (A1/A2). The power supply must meet

the regulations for extra low voltages with safe separation (SELV,

PELV).

Connect the semiconductor outputs X1 (OM1 ... OM5) to a safety sys-

tem that supports a safe 1 from n evaluation.

Connect the signal outputs X2 (SI0 ... SI3) to a control system that

supports evaluation of the status information.

Connect the interface X2 (signal outputs IDsync, IDclock, IDo0, IDo1

and inputs IDi0 and IDi1) to a control system that supports the download of the Key ID number.

Functional earth connection.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-1

Page 26

6 Wiring

PIT m3.1p

n.c.

A1

A2

X1

PLC

24V

GND

OM1

OM2

OM3

OM4

OM5

8

7

6

5

4

3

2

1

M4

X1

Input

Input

Input

Input

Input

L+

PE

L-

6.2 Connection to safety system (example)

6.2Connection to safety sys tem (example)6200Connectio n to safety system ( example)6-Verbindung Steuerung BAWS

Wiring without detection of shorts across contacts

6-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 27

P N O Z m u lti C o n fig u ra to r

O perating m ode selector

sw itch block

PIT m 3.1p Process

controller

n.c.

A1

A2

X1

PNOZ m1p

A1.A1

A1.A1

A1.A2

A1.A2

X7

OM1

GND

+24V

OM2

OM3

OM4

OM5

X

5

A1.I5

A1.I4

A1.I3

A1.I1

Input

ID i1

ID i0

ID o 1

ID o 0

ID c lo c k

ID sync

SI3

SI2

SI1

SI0

X2

1

L+

A1.I0

2

3

4

5

6

7

8

9

1

0

8

7

6

5

4

3

2

1

PE

M4

Input

Input

Input

Input

Input

Input

Input

O utput

O utput

L-

X1

6 Wiring

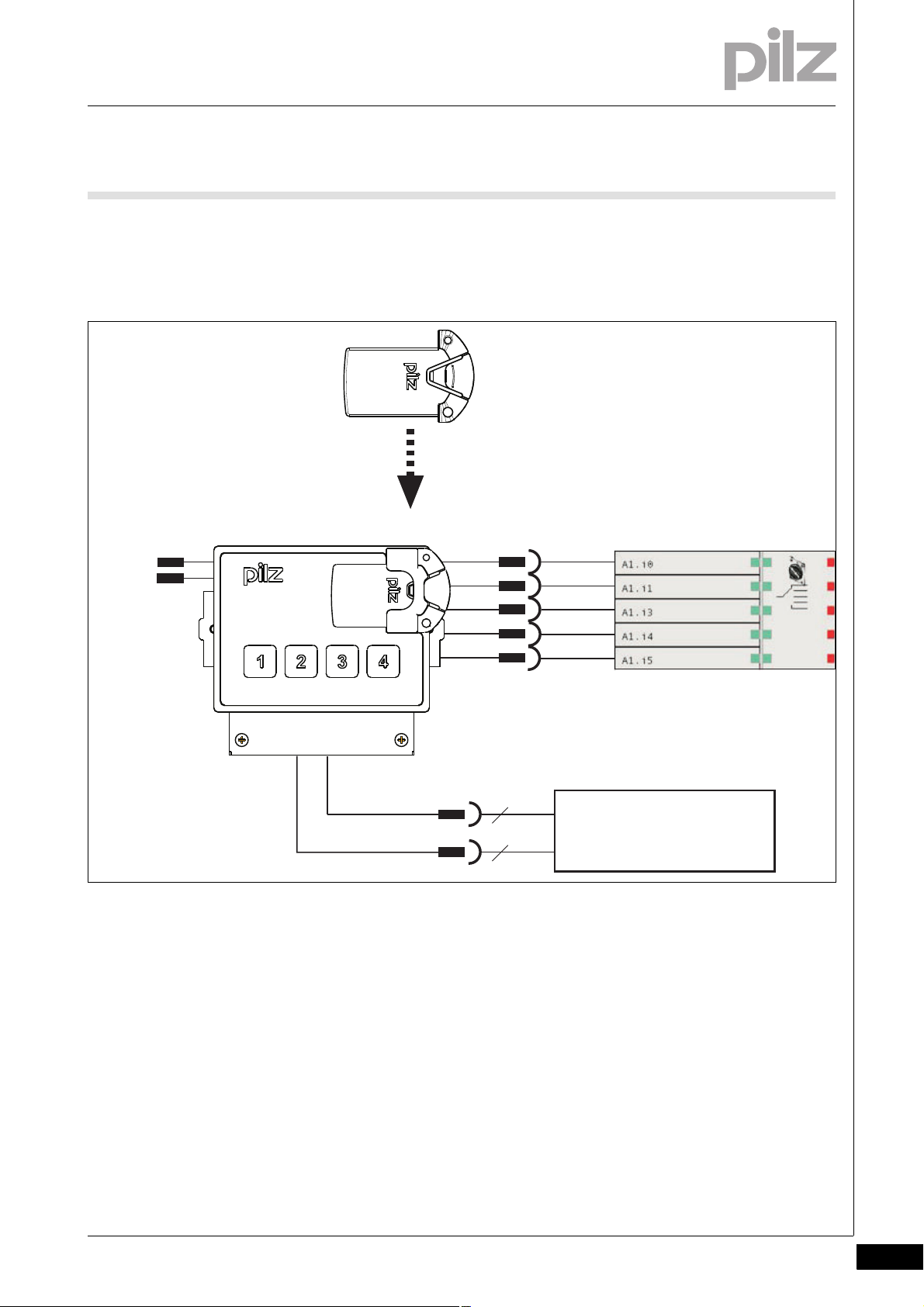

6.3 Connection to PNOZmulti (example: PNOZ m1p)

6.3Connection to PNOZmulti ( example: PNOZ m1p)6300Connection to PNOZmult i (example: PNOZ m1p )6-Verbindung PNOZ m1p BAWS

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-3

Page 28

6 Wiring

6-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 29

7 Operation

77000OperationOperation7-Betrieb allgemein BAWS

CAUTION!

The operating mode selector switch PIT m3.1p may only be

used in conjunction with the actuator and a safety control system. The safety control system must enable safe "1 from n"

evaluation of the semiconductor outputs (OM1 ... OM5) on the

operating mode selector switch.

CAUTION!

If an error occurs, the unit will not change operating modes at

the semiconductor outputs (OM1 ... OM5).

INFORMATION

When voltage is reapplied, operating mode OM1 is automatically

selected, even when no actuator is connected or the actuator is

not recognised correctly.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7-1

Page 30

7 Operation

7.1 Select operating mode

7.1Select operating mode7100Select operating mode7-BA u mschalten BAW S

An operating mode can only be selected if the corresponding actuator

is recognised.

Once an operating mode is selected, the corresponding semiconductor

output OM1 ... OM4 and special service mode (OM5) are activated.

The selected operating mode is displayed via the back-lit button and is

dual-channel monitored via a safety control system.

You can switch between the individual operating modes OM1, OM2,

OM3 and OM4 as required.

7-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 31

7 Operation

t1 t1

OM5

OM1

OM2

OM3

OM4

7.2 Time monitoring

7.2Time monitoring7200Time monitoring7-Zeitüberwachung BAWS

A change of operating modes is only detected once a button has been

operated for a certain time period.

Operating time:

OM1, OM2, OM3, OM4: > 50 ms and < 5 s

Special mode (service) OM5: > 5 s and < 10 s

When a button is released, the semiconductor outputs will switch once

the switchover delay t1 has elapsed (see Technical details).

When changing operating modes, the PIT m3.1p initiates a defined

pause of 50 ms to guarantee that the operating modes do not overlap.

To select an operating mode, follow the instructions below:

Select an operating mode by pressing one of the four buttons. The actuator must be connected to the operating mode selector switch for the

whole time the button is operated; it can be removed afterwards.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7-3

Page 32

7 Operation

7.3 Select special mode (service)

7.3Select special mode (service)7300Select special mode (service)7-Sonderbetriebsart BAWS

Special mode (service) OM5 can be selected from any of the operating

modes OM1 ... OM4, provided the relevant authorisation has been recognised via the "Key Mode Service" actuator.

Proceed as follows:

Slide the “Key Mode Service” actuator on to the bracket of the oper-

ating mode selector switch.

INFORMATION

The actuator must be connected to the operating mode selector

switch for the whole duration of special mode (service).

INFORMATION

Press button 1 and keep it held down for a minimum 5 s/maximum 10 s.

INFORMATION

All four buttons will flash during special mode (service).

If you remove the actuator while the machine is in special service mode

(OM5), the machine's operating mode will automatically switch to OM1.

7-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 33

7 Operation

7.4 Evaluation through safety system

7.4Evaluation through safety system7400Evaluation through safety system7-Auswertung durch Steuerung BAWS

Evaluation must take place via a safe function block, which meets the

following requirements:

The function block must enable safe "1 from n" evaluation of the sem-

iconductor outputs (OM1 ... OM5) on the operating mode selector

switch.

If two or more operating modes are present at the same time, this

must be detected as an error.

The function block must bridge the t1 switchover delay.

Bridging of the switchover pause should not last longer than one sec-

ond.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7-5

Page 34

7 Operation

7.5 Troubleshooting

7.5Troubleshooting7500Troubleshooting7-Fehlerbehebu ng BAWS

If an error occurs on the operating mode selector switch, the last operating mode to be set will be retained.

Error Possible cause Remedy

Unable to switch the operating mode Multiple operation of buttons Make sure that only one button is op-

erated.

... Operating time too long or too short Make sure that the period of operation

is observed.

... Actuator is not detected Make sure that the actuator is con-

nected to the operating mode selector

switch correctly.

... No valid authorisation Make sure that the relevant actuator is

used.

7-6

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 35

7 Operation

7.6 Diagnostics

7.6Diagnostics7600Diag nostics7-Diagnose BAWS

For monitoring and diagnostics of the operating mode selector switch

4 back-lit buttons and 4 signal outputs are available. The outputs report

status information, which is divided into the following information classes:

Selected operating mode

Set authorisation

Messages (e.g. user error and fault)

The status information can be evaluated through a control system.

The back-lit buttons indicate the operating mode selected on the operating mode selector switch.

7.6.1 Signal outputs for status information

Signal outputs for status information7-Meldeausgänge Statusinform ation BAWS

The status information indicates the actions performed by the operator.

These actions are: actuator connected, actuator removed and operating

mode selected.

NOTICE

If OM is selected (SI3:0=8h ... Bh) information remains active

indefinitely. All other information stays active for just 200 ms.

After that time the selected operating mode is again displayed.

Status information SI 3 (MSB) SI 2 SI 1 SI 0 (LSB) SI3:0= [hex]

Reserve 0 0 0 0 0h

Reserve 0 0 0 1 1h

Reserve 0 0 1 0 2h

Reserve 0 0 1 1 3h

Key Mode 1 - connected 0 1 0 0 4h

Key Mode 2 - connected 0 1 0 1 5h

Key Mode 3 - connected 0 1 1 0 6h

Key Mode 4 - connected 0 1 1 1 7h

OM1 selected 1 0 0 0 8h

OM2 selected 1 0 0 1 9h

OM3 selected 1 0 1 0 Ah

OM4 selected 1 0 1 1 Bh

No authorisation 1 1 0 0 Ch

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7-7

Page 36

7 Operation

7.6 Diagnostics

Status information SI 3 (MSB) SI 2 SI 1 SI 0 (LSB) SI3:0= [hex]

Device error 1 1 0 1 Dh

Button operated incorrectly 1 1 1 0 Eh

Actuator removed 1 1 1 1 Fh

7-8

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 37

8 Technical details

8.1 Technical details

81000Technical detailsTechnical details8-8.1Technical details1100Technical details8-][Technische Daten BAWS

Technical details

Sensor's mode of operation Transponder

Typ. operating distance 5.0 mm

Electrical data

Supply voltage UB DC 24 V

Voltage tolerance -15 %/+10 %

Residual ripple DC 20 %

Power consumption at U

Times

Switch-on delay after applying U

Supply interruption before de-energisation 20 ms

Switchover delay t1 50 ms

Operating time of button 1 ... 4 50 ms ... 5 s

Operating time of Service button 5 s ... 10 s

Outputs operating modes

Number of positive-switching single-pole semiconductor

outputs

Switching current per output 20 mA/24 V

Short circuit-proof yes

Residual current at "0" 0.3 mA

Signal level at "1" UB - 3.5 V DC at 20 mA

Status display LED

Signal outputs

Number 8

Switching current per output 20 mA/24 V

Short circuit-proof yes

Residual current at "0" 0.3 mA

Signal level at "1" UB - 3.5 V DC at 20 mA

Inputs

Number 2

Voltage and current at Input circuit DC: 24 V DC 1.5 mA

Galvanic isolation no

Signal level at "0" -3 - +5 V DC

Signal level at "1" 15 - 30 V DC

Safety-related characteristic data

PL in accordance with EN ISO 13849-1: 2006 PL d (Cat. 3)

Category in accordance with EN 954-1 Cat. 3

SIL CL in accordance with EN IEC 62061 SIL CL 2

PFH in accordance with EN IEC 62061 5.75E-09

SIL in accordance with IEC 61511 SIL 2

PFD in accordance with IEC 61511 3.19E-04

T

[year] in accordance with EN ISO 13849-1: 2006 20

M

Environmental data

Vibration to EN 60068-2-6

Frequency 10 - 55 Hz

Amplitude 0.35 mm

EMC EN 60947-5-1

Climatic suitability DIN IEC 60068-2-3

Airgap creepage in accordance with EN 60664-1

Overvoltage category II

Pollution degree 2

Rated insulation voltage 60 V

B

B

2.5 W

1.0 s

5

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

8-1

Page 38

8 Technical details

8.1 Technical details

Environmental data

Rated impulse withstand voltage 0.80 kV

Ambient temperature -10 - 55 °C

Storage temperature -40 - 85 °C

Climatic suitability in accordance with EN 60068-2-78 95 % r. F. at 40 °C

Mechanical data

Protection type

Mounting (e.g. cabinet) IP54

Housing IP20

Terminals IP20

Torque setting for the fixing screws 0.30 Nm

Housing material

Front ABS

Housing ST + 10µ Zn

Maximum cable runs 30 m

Cross section of external conductors with spring-loaded

terminals: Flexible with/without crimp connectors

Spring-loaded terminals: Terminal points per connection 1

Stripping length 9 mm

Weight 210 g

0.20 - 2.50 mm² , 24 - 12 AWG

Technische Daten_Satz No rmen

The standards current on 2010-02 apply.

8-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 39

8 Technical details

8.2 Order reference

8.2Order reference8200Order reference8-Bestelldaten

Order reference

Type Features Order No.

PIT m3.1p Operating mode selector switches 402 220

Order reference: Accessories

Type Features Order No.

Spring-loaded terminals 1 set 402 301

PIT m3p key mode 1 Actuator Key Mode 01 402 211

PIT m3p key mode 2 Actuator Key Mode 02 402 212

PIT m3p key mode 3 Actuator Key Mode 03 402 213

PIT m3p key mode 4 Actuator Key Mode 04 402 214

PIT m3p key service Actuator Key Mode Service 402 215

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

8-3

Page 40

8 Technical details

8.2 Order reference

8-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 41

...

1002259-EN-02, 2012-03 Printed in Germany

© Pilz GmbH & Co. KG, 2011

+49 711 3409-444

support@pilz.com

Pilz GmbH & Co. KG

Felix-Wankel-Straße 2

73760 Ostfildern, Germany

Telephone: +49 711 3409-0

Telefax: +49 711 3409-133

E-Mail: pilz.gmbh@pilz.de

Internet: www.pilz.com

Technical support

In many countries we are

represented by our subsidiaries

and sales partners.

Please refer to our homepage

for further details or contact our

headquarters.

InduraNET p

®

, Pilz

®

, PIT

®

, PMCprotego

®

, PMI

®

, PNOZ

®

, Primo

®

, PSEN

®

, PSS

®

, PVIS

®

, SafetyBUS p

®

, SafetyEYE

®

, SafetyNET p

®

, the spirit of safety

®

are registered and protected trademarks

of Pilz GmbH & Co. KG in some countries. We would point out that product features may vary from the details stated in this document, depending on the status at the time of publication and the scope

of the equipment. We accept no responsibility for the validity, accuracy and entirety of the text and graphics presented in this information. Please contact our Technical Support if you have any questions.

Contact address

Loading...

Loading...