Pilz PIT gb LLLE, PIT gb CLLE y, PIT gb KLLE, PIT gb Series, PIT gb BLLE y Operating Manual

Page 1

PIT gb

Operating Manual-1004627-EN-02

} Control and signal devices

Page 2

Preface

This document is the original document.

All rights to this documentation are reserved by Pilz GmbH & Co. KG. Copies may be made

for the user's internal purposes. Suggestions and comments for improving this documentation will be gratefully received.

Source code from third-party manufacturers or open source software has been used for

some components. The relevant licence information is available on the Internet on the Pilz

homepage.

Pilz®, PIT®, PMI®, PNOZ®, Primo®, PSEN®, PSS®, PVIS®, SafetyBUS p®,

SafetyEYE®, SafetyNET p®, the spirit of safety® are registered and protected trademarks

of Pilz GmbH & Co. KG in some countries.

SD means Secure Digital

Page 3

Contents

Operating Manual PIT gb

1004627-EN-02

3

Introduction 5

Validity of documentation 5

Using the documentation 5

Definition of symbols 5

Overview 6

Unit features 6

Scope of supply 6

Safety 6

Intended use 6

Safety regulations 7

Use of qualified personnel 7

Warranty and liability 7

Disposal 7

For your safety 8

Function description 9

Device types 9

Block diagrams 11

Assembly positions 12

Coloured caps 13

Wiring 13

Terminal assignment connectors 13

Installation 14

Installation of device 14

Attach coloured caps 15

Commissioning 15

Connection to evaluation device 15

Checking the unit 15

Troubleshooting 16

Regular checks 16

Repair and maintenance 16

Cleaning 16

Exchange of control elements 16

Page 4

Contents

Operating Manual PIT gb

1004627-EN-02

4

Dimensions 20

Technical details order no. G1000001-G1000002 21

Technical details order no. G1000003-G1000004 22

Safety characteristic data 25

Order reference 25

Product 25

Spare part 25

Accessories 26

EC declaration of conformity 26

Page 5

PIT gb

Operating Manual PIT gb

1004627-EN-02

5

Introduction

Validity of documentation

This documentation is valid for the product PIT gb. It is valid until new documentation is

published.

This operating manual explains the function and operation, describes the installation and

provides guidelines on how to connect the product.

Using the documentation

This document is intended for instruction. Only install and commission the product if you

have read and understood this document. The document should be retained for future reference.

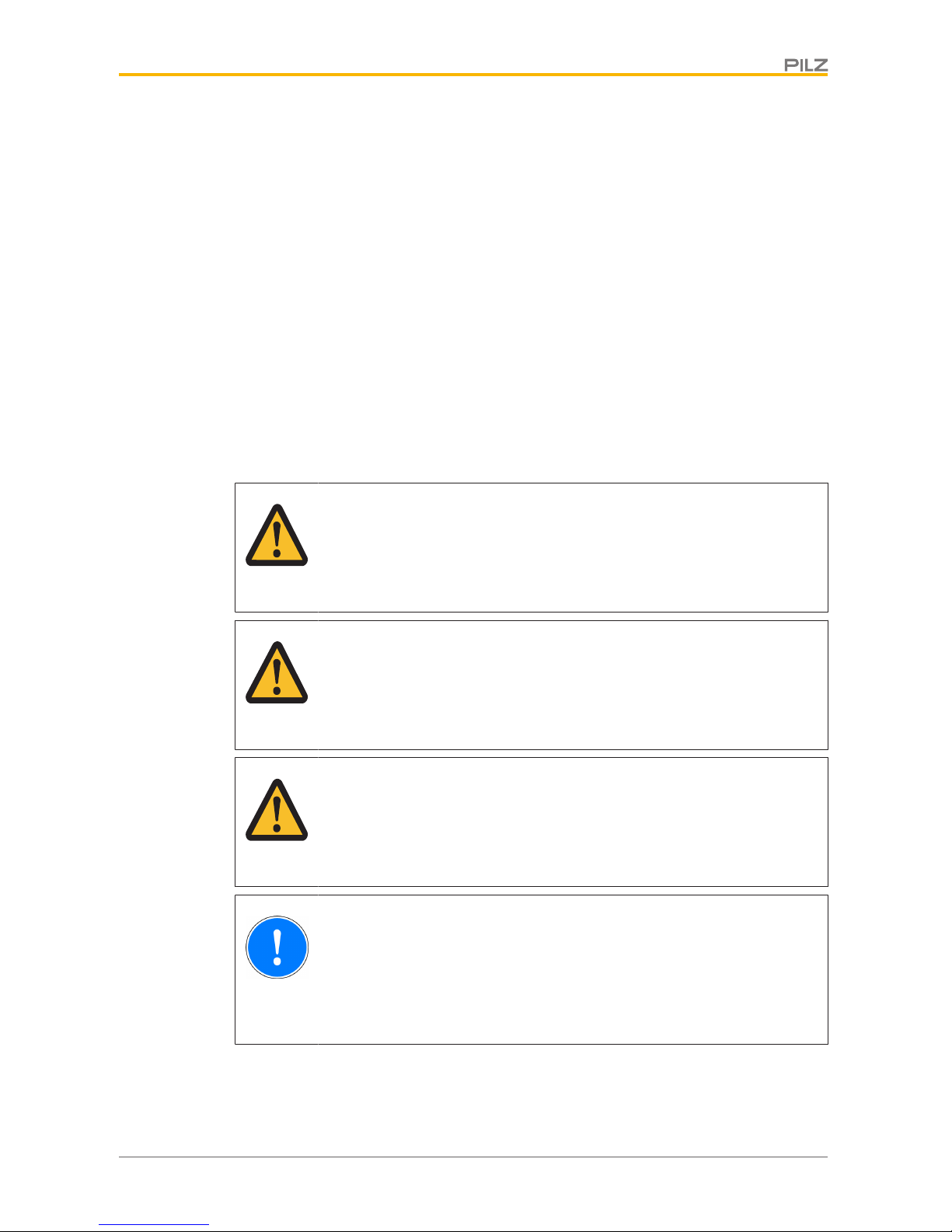

Definition of symbols

Information that is particularly important is identified as follows:

DANGER!

This warning must be heeded! It warns of a hazardous situation that poses

an immediate threat of serious injury and death and indicates preventive

measures that can be taken.

WARNING!

This warning must be heeded! It warns of a hazardous situation that could

lead to serious injury and death and indicates preventive measures that can

be taken.

CAUTION!

This refers to a hazard that can lead to a less serious or minor injury plus

material damage, and also provides information on preventive measures

that can be taken.

NOTICE

This describes a situation in which the product or devices could be damaged and also provides information on preventive measures that can be

taken. It also highlights areas within the text that are of particular importance.

Page 6

PIT gb

Operating Manual PIT gb

1004627-EN-02

6

INFORMATION

This gives advice on applications and provides information on special features.

Overview

Unit features

} Slimline design

} Housing with 12-pin M12 male connector

} Control elements can be replaced with a new control element with the same design in

the event of repair

} Labelling option for individual marking of the control elements

} Control elements finally wired and installed

} Can be installed in 16 different directions (see Assembly positions [ 12])

} Coloured caps for marking the function of the control elements (see Order reference:

Accessories [ 25])

Scope of supply

} PIT gb

} 2 washers M5

} Coloured caps (set), sorted by colour

Safety

Intended use

The unit PIT gb is intended for use in safety circuits in accordance with IEC/EN60947-5-5,

ENISO13850. Before using the device, a safety assessment of the overall system must be

performed in accordance with the Machinery Directive.

The PIT gb must be used in combination with a suitable evaluation device (see Connection

to evaluation device).

The following is deemed improper use in particular:

} Any component, technical or electrical modification to the product

} Use of the product outside the areas described in this manual

} Use of the product outside the technical details (see chapter entitled "Technical

details [ 21]").

Foreseeable misuse

} Use of the PIT gb under corrosive environmental conditions (cooling emulsions, surface

treatment, gases, …)

Please contact Pilz.

Page 7

PIT gb

Operating Manual PIT gb

1004627-EN-02

7

} Use of a different object than the intended key when using the key-operated pushbutton

or the key switch.

} Blocking of the key-operated pushbutton or the key switch with a foreign body.

Safety regulations

Use of qualified personnel

The products may only be assembled, installed, programmed, commissioned, operated,

maintained and decommissioned by competent persons.

A competent person is a qualified and knowledgeable person who, because of their training, experience and current professional activity, has the specialist knowledge required. To

be able to inspect, assess and operate devices, systems and machines, the person has to

be informed of the state of the art and the applicable national, European and international

laws, directives and standards.

It is the company’s responsibility only to employ personnel who

} Are familiar with the basic regulations concerning health and safety / accident preven-

tion,

} Have read and understood the information provided in the section entitled Safety

} Have a good knowledge of the generic and specialist standards applicable to the spe-

cific application.

Warranty and liability

All claims to warranty and liability will be rendered invalid if

} The product was used contrary to the purpose for which it is intended,

} Damage can be attributed to not having followed the guidelines in the manual,

} Operating personnel are not suitably qualified,

} Any type of modification has been made (e.g. exchanging components on the PCB

boards, soldering work etc.).

Disposal

} When decommissioning, please comply with local regulations regarding the disposal of

electronic devices (e.g. Electrical and Electronic Equipment Act).

Page 8

PIT gb

Operating Manual PIT gb

1004627-EN-02

8

For your safety

WARNING!

Loss of safety function due to manipulation of the control elements

Manipulation of the control elements may lead to serious injury and death.

– You should prevent any possibility of the control elements being ma-

nipulated through the use of a spare control element.

– Keep the spare control element in a safe place and protect it from un-

authorised access.

– If spare control elements are used, these must be installed as de-

scribed under Exchange of control elements [ 16].

– If the original control elements are replaced with spare control ele-

ments, the original control elements must be destroyed before disposal.

– The spare control element must have the same design as the defect-

ive control element originally installed.

Page 9

PIT gb

Operating Manual PIT gb

1004627-EN-02

9

Function description

Device types

The PIT gb provides an E-STOP pushbutton and three additional control elements to control the functions of an overall plant or machine.

[1]

[2]

[3]

[4]

[5]

[6]

[6]

Legend

[1] S1 = pushbutton 1, illuminated/key-operated pushbutton/key switch or blind

plug

[2] S2 = pushbutton 2, illuminated

[3] S3 = pushbutton 3, illuminated

[4] S4 = E-STOP pushbutton

[5] Individual labelling option (width: 35 mm, height: 13mm)

[6] Rotatable mounting bracket

The following control elements are available:

Control element

Illustration PIT gb

LLLE CLLE y BLLE y KLLE

Key switch [1] 1

Key-operated pushbutton [1] 1

Pushbutton, illuminated [3], [2], [1] 3 2 2 2

Blind plug 1

Page 10

PIT gb

Operating Manual PIT gb

1004627-EN-02

10

Control element

Illustration PIT gb

LLLE CLLE y BLLE y KLLE

E-STOP

} without signal con-

tact

[4] 1 1

} with signal contact

[4] 1 1

Type code

PIT gb

Pushbutton illuminated = L

E-STOP pushbutton = E

L

L E

Blind plug = C

Pushbutton illuminated = L

Key-operated pushbutton = B

Key switch = K

Pushbutton illuminated = L

Signal contact = y

} Pushbutton

– The pushbutton is used to switch a signal and as the status display.

– The pushbutton lights up if the corresponding input is connected.

} Key switch

– The key switch is used to switch two signals and secure this switching through re-

moval of the key.

– Three locking positions (90° to the left, start position, 90° to the right)

– The key can be removed in all three positions.

} Key-operated pushbutton

– The key-operated pushbutton is used to switch a signal and secure this switching

through removal of the key.

– The key can be removed in the start position.

} E-STOP pushbutton

The E-STOP pushbutton is used to shut down plant and machine sections in order to

reduce or avert imminent or existing hazards to persons and damage to machinery or

materials.

Page 11

PIT gb

Operating Manual PIT gb

1004627-EN-02

11

Block diagrams

3

5

10

1

6

12

9

11

8

4

2

7

S4.1

S3

S2

S1

S4.2

H3

H2

H1

3

5

1

6

12

9

8

4

2

7

S4.1

S3

H2

S4.2

S4.3

S2

H3

PIT gb LLLE PIT gb CLLE y

3

5

1

6

12

9

8

4

2

7

11

S3

S2

S1

S4.1

H2

S4.2

S4.3

H3

3

5

1

6

12

9

8

4

2

7

11

S3

S2

S1.1

S4.1

H2

S4.2

H3

S1.2

PIT gb BLLE y PIT gb KLLE

PIN PIT gb LLLE PIT gb CLLE y PIT gb BLLE y PIT gb KLLE

1 +24 V UB +24 V UB +24 V UB +24 V UB

2 0 V UB 0 V UB 0 V UB 0 V UB

3 E-STOP channel 1 E-STOP channel 1 E-STOP channel 1 E-STOP channel 1

7 E-STOP channel 1 E-STOP channel 1 E-STOP channel 1 E-STOP channel 1

5 E-STOP channel 2 E-STOP channel 2 E-STOP channel 2 E-STOP channel 2

9 E-STOP channel 2 E-STOP channel 2 E-STOP channel 2 E-STOP channel 2

8 Pushbutton 3 Pushbutton 3 Pushbutton 3 Pushbutton 3

10 LED pushbutton 3

(H3)

LED pushbutton 3

(H3)

LED pushbutton 3

(H3)

LED pushbutton 3 (H3)

4 Pushbutton 2 Pushbutton 2 Pushbutton 2 Pushbutton 2

6 LED pushbutton 2

(H2)

LED pushbutton 2

(H2)

LED pushbutton 2

(H2)

LED pushbutton 2 (H2)

11 Pushbutton 1 Not connected Key-operated pushbut-

ton

Key switch channel 1 (key

turned 90° to the right)

12 LED pushbutton 1

(H1)

Signal contact Signal contact Key switch channel 2 (key

turned 90° to the left)

Page 12

PIT gb

Operating Manual PIT gb

1004627-EN-02

12

Assembly positions

Possible assembly positions for the PIT gb:

The mounting brackets with which the PIT gb is fastened to the mounting surface can be

turned before assembly PIT gb (see figures).

Without turning the mounting brackets Turning the mounting brackets 1x to the left

Turning the mounting brackets 1x to the

right

Turning the mounting bracket 2x to the right

Page 13

PIT gb

Operating Manual PIT gb

1004627-EN-02

13

Coloured caps

} The control elements can be marked with coloured caps according to the function of the

control elements (see Order reference: Accessories [ 25])

Wiring

Please note:

} Information given in the Technical details [ 21] must be followed.

} The power supply must meet the regulations for extra low voltages with protective sep-

aration (SELV, PELV) in accordance with EN60204-1.

} Ensure the wiring and EMC requirements of EN 60204-1 are met.

} To connect the PIT gb to the evaluation devices, use a 12-pin cable with an A-coded

M12 female connector (see Order reference: Accessories [ 26]).

Terminal assignment connectors

1

2

3

4

5

6

7

8

9

10

11

12

12-pin M12 male connector

PIN Wire colour

1 Brown

2 Blue

3 White

4 Green

5 Pink

6 Yellow

7 Black

8 Grey

9 Red

10 Purple

11 Grey-pink

12 Red-blue

NOTICE

The colour marking for the connection lead only applies for the cable that

Pilz supplies as an accessory

Page 14

PIT gb

Operating Manual PIT gb

1004627-EN-02

14

Installation

Installation of device

Please note:

} The mounting surface must have a max. unevenness of 0.5mm.

} The housing of the PIT gb must make contact with the mounting surface over at least

5mm on both ends (see figure).

5 mm

[2]

[2]

[3]

5 mm

[1]

Legend

[1] Mounting surface

[2] Mounting bracket

[3] Housing

} To fasten the PIT gb, use M5 screws and the provided washers M5.

} Torque setting: Please note the information provided under Technical details [ 21].

Procedure:

1. Provide the mounting surface with drill holes for fastening the PIT gb (see

Dimensions [ 20]).

2. Turn the housing of the PIT gb in the bracket to the correct position for installation.

3. Fasten the PIT gb to the mounting surface and tighten the screws (incl. washers) with 4

Nm.

Page 15

PIT gb

Operating Manual PIT gb

1004627-EN-02

15

Attach coloured caps

Apply the coloured cap (provided) to the control element and press on the coloured cap until it noticeably engages.

Ensure that the alignment marking on the coloured cap (see figure) is aligned flush with the

PIT gb or at a 90° angle to this.

[1]

Legend

[1] Alignment marking

Commissioning

Connection to evaluation device

Suitable Pilz evaluation devices for the actuation of the LED and reading out all control elements include:

} PNOZmulti

} PSSuniversal PLC

Suitable Pilz evaluation devices for the evaluation of the E-STOP:

} PNOZelog

} PNOZsigma

} PNOZ X

The correct connection to the respective evaluation device is described in the operating

manual for the evaluation device. Make sure that the connection is made in accordance

with the specifications in the operating manual for the selected evaluation device.

Checking the unit

Once the unit has been installed and aligned, final inspections must be carried out before it

can be put into service.

INFORMATION

This inspection may only be carried out by qualified personnel.

Page 16

PIT gb

Operating Manual PIT gb

1004627-EN-02

16

} Always test the function with a connected evaluation device.

} Check the function of the E-STOP.

} Check the function of the other control elements.

Troubleshooting

Error Cause Description/measure

LED off 0V voltage supply not

present and/or no signal

at corresponding input

Check the wiring of the inputs

and outputs and rectify wiring

errors

No output signal with control

element operation

24V voltage supply not

present

Check the wiring of the inputs

and outputs and rectify wiring

errors

Control element damaged External force Exchange defective control ele-

ment

Function of the unit impaired Connection cable dam-

aged

Check connection cable and exchange if necessary

Regular checks

Monthly check

} Perform a manual function test [ 15] of the PIT gb every month.

INFORMATION

This inspection may only be carried out by qualified personnel.

Check after modifications

Check the PIT gb each time the plant/machine is modified. Changing the PIT gb or swapping PIT gb components should also be regarded as a modification.

You must comply with the requirements of the applicable national regulations.

Repair and maintenance

Cleaning

Clean the unit every month with a soft cloth and a mild cleaning agent.

Exchange of control elements

Prerequisites

} The plant that is controlled by the PIT gb is not in operation and cannot be restarted

without an equivalent safety device.

} The new control element has the same design as the defective control element.

Page 17

PIT gb

Operating Manual PIT gb

1004627-EN-02

17

Required tool

} PIT gb fixing spanner (see Accessories [ 26]) for threaded ring of the control ele-

ment

} Screwdriver for Torx Tx20

Procedure:

} Torque setting: Please note the information provided under Technical details [ 21].

1. Disconnect the connection of the PIT gb to the evaluation device.

2. Loosen the fixing screws of the PIT gb at the mounting surface.

3. Loosen the 6 fixing screws for the terminating plate of the PIT gb and remove the terminating plate.

[1]

Legend

[1] Terminating plate

Page 18

PIT gb

Operating Manual PIT gb

1004627-EN-02

18

4. Loosen the fixing screws of the printed circuit board and carefully lift off the printed circuit board (see figures).

5. Loosen the threaded ring of the control element that is to be exchanged and remove

the threaded ring (see figure).

6. Remove the control element on the front of the PIT gb and insert the part of the new

control element.

The control element has a stud on its side to secure it against twisting. The stud must

be positioned correctly when inserting the control element.

Page 19

PIT gb

Operating Manual PIT gb

1004627-EN-02

19

7. Screw the control element to the threaded ring again using 1,2 Nm (see figure) and apply the printed circuit board again.

a Make sure that the strands are not damaged, crushed or twisted here.

8. Screw the printed circuit board to the fixing screws with 1,8 Nm (see figure).

9. Screw the fixing screws for the PIT gbterminating plate in again and tighten the screws

with 1,8 Nm.

a Make sure that the strands are not damaged, crushed or twisted here.

[1]

Legend

[1] Terminating plate

10. Screw the PIT gb onto the mounting surface with the fixing screws with 4 Nm.

11. Connect the PIT gb to the evaluation device.

12. Perform a manual function test [ 15] on the unit.

Only commission the plant that is controlled by the unit if the function test was successful.

13. Recommission the plant that is controlled by the PIT gb.

Page 20

PIT gb

Operating Manual PIT gb

1004627-EN-02

20

Dimensions

239

Ø 5,4

40

277

293

293

73,7

Ø 30

20

40

49,4

Front view Side view

Page 21

PIT gb

Operating Manual PIT gb

1004627-EN-02

21

Technical details order no. G1000001-G1000002

General G1000001 G1000002

Approvals CE, UL/cUL CE, UL/cUL

Self-monitored No No

Lamp

Kind LED LED

Colour white white

Electrical data G1000001 G1000002

Supply voltage

Voltage 24 V 24 V

Kind DC DC

Voltage tolerance -20 %/+20 % -20 %/+20 %

Output of external power supply

(DC) 12 W 12 W

Duty cycle 100 % 100 %

Min. contact current 1 mA 1 mA

E-STOP G1000001 G1000002

Quantity 1 1

Number of N/C contacts 2 2

Number of signal contacts – 1

E-STOP release type Turn release Turn release

Utilisation category

In accordance with the standard EN 60947-5-1 EN 60947-5-1

DC13 at 24 V 24 V

Current 0,1 A 0,1 A

Contact material Ag Ag

Contact material signal contact – Au

Mechanical life 6050 cycles 6050 cycles

Signal output

Output voltage – 24 V

Max. current – 0,1 A

Pushbutton G1000001 G1000002

Quantity 3 2

Number of N/O contacts 3 2

Utilisation category

In accordance with the standard EN 60947-5-1 EN 60947-5-1

DC13 at 24 V 24 V

Max. current 0,1 A 0,1 A

Mechanical life

1.000.000 cycles 1.000.000 cycles

Contact material Ag Ag

Environmental data G1000001 G1000002

Ambient temperature

Temperature range -20 - 60 °C -20 - 60 °C

Page 22

PIT gb

Operating Manual PIT gb

1004627-EN-02

22

Environmental data G1000001 G1000002

Storage temperature

Temperature range -25 - 70 °C -25 - 70 °C

Climatic suitability

In accordance with the standard EN 60068-2-78 EN 60068-2-78

Humidity 93 % r. h. at 40 °C 93 % r. h. at 40 °C

Vibration

In accordance with the standard EN 60947-5-2 EN 60947-5-2

Frequency 10 - 55 Hz 10 - 55 Hz

Amplitude 1 mm 1 mm

Shock stress

In accordance with the standard EN 60947-5-2 EN 60947-5-2

Acceleration 30g 30g

Duration 11 ms 11 ms

Airgap creepage

In accordance with the standard EN 60947-1 EN 60947-1

Overvoltage category III III

Pollution degree 3 3

Protection type

Housing IP65 IP65

Mechanical data G1000001 G1000002

Mounting position Any Any

Connection type M12, 12-pin male connector M12, 12-pin male connector

Material

Housing Zn Zn

Fixing screws torque settings 4 Nm 4 Nm

Torque setting terminating plate 1,8 Nm 1,8 Nm

Torque setting circuit board 1,8 Nm 1,8 Nm

Torque setting control element 1,2 Nm 1,2 Nm

Dimensions

Height 293 mm 293 mm

Width 40 mm 40 mm

Depth 40 mm 40 mm

Weight 800 g 800 g

Technical details order no. G1000003-G1000004

General G1000003 G1000004

Approvals CE, UL/cUL CE, UL/cUL

Self-monitored No No

Lamp

Kind LED LED

Colour white white

Page 23

PIT gb

Operating Manual PIT gb

1004627-EN-02

23

Electrical data G1000003 G1000004

Supply voltage

Voltage 24 V 24 V

Kind DC DC

Voltage tolerance -20 %/+20 % -20 %/+20 %

Output of external power supply

(DC) 12 W 12 W

Duty cycle 100 % 100 %

Min. contact current 1 mA 1 mA

E-STOP G1000003 G1000004

Quantity 1 1

Number of N/C contacts 2 2

Number of signal contacts 1 –

E-STOP release type Turn release Turn release

Utilisation category

In accordance with the standard EN 60947-5-1 EN 60947-5-1

DC13 at 24 V 24 V

Current 0,1 A 0,1 A

Contact material Ag Ag

Contact material signal contact Au –

Mechanical life 6050 cycles 6050 cycles

Signal output

Output voltage 24 V –

Max. current 0,1 A –

Pushbutton G1000003 G1000004

Quantity 2 2

Number of N/O contacts 2 2

Utilisation category

In accordance with the standard EN 60947-5-1 EN 60947-5-1

DC13 at 24 V 24 V

Max. current 0,1 A 0,1 A

Mechanical life

1.000.000 cycles 1.000.000 cycles

Contact material Ag Ag

Key switch G1000003 G1000004

Quantity 1 –

Number of N/O contacts 1 –

Utilisation category

In accordance with the standard EN 60947-5-1 –

DC13 at 24 V –

Max. current 0,1 A –

Mechanical life

30.000 cycles

–

Service life mechanical, key not removed

300.000 cycles

–

Contact material Ag

–

Page 24

PIT gb

Operating Manual PIT gb

1004627-EN-02

24

Key switch G1000003 G1000004

Quantity – 1

Number of N/O contacts – 2

Utilisation category

In accordance with the standard – EN 60947-5-1

DC13 at – 24 V

Max. current – 0,1 A

Mechanical life –

30.000 cycles

Service life mechanical, key not removed

–

300.000 cycles

Contact material

–

Ag

Environmental data G1000003 G1000004

Ambient temperature

Temperature range -20 - 60 °C -20 - 60 °C

Storage temperature

Temperature range -25 - 70 °C -25 - 70 °C

Climatic suitability

In accordance with the standard EN 60068-2-78 EN 60068-2-78

Humidity 93 % r. h. at 40 °C 93 % r. h. at 40 °C

Vibration

In accordance with the standard EN 60947-5-2 EN 60947-5-2

Frequency 10 - 55 Hz 10 - 55 Hz

Amplitude 1 mm 1 mm

Shock stress

In accordance with the standard EN 60947-5-2 EN 60947-5-2

Acceleration 30g 30g

Duration 11 ms 11 ms

Airgap creepage

In accordance with the standard EN 60947-1 EN 60947-1

Overvoltage category III III

Pollution degree 3 3

Protection type

Housing IP65 IP65

Mechanical data G1000003 G1000004

Mounting position Any Any

Connection type M12, 12-pin male connector M12, 12-pin male connector

Material

Housing Zn Zn

Fixing screws torque settings 4 Nm 4 Nm

Torque setting terminating plate 1,8 Nm 1,8 Nm

Torque setting circuit board 1,8 Nm 1,8 Nm

Torque setting control element 1,2 Nm 1,2 Nm

Dimensions

Height 293 mm 293 mm

Width 40 mm 40 mm

Depth 40 mm 40 mm

Page 25

PIT gb

Operating Manual PIT gb

1004627-EN-02

25

Mechanical data G1000003 G1000004

Weight 800 g 800 g

Safety characteristic data

NOTICE

You must comply with the safety characteristic data in order to achieve the

required safety level for your plant/machine.

Safety characteristic data

B10d in accordance with EN ISO 13849-1:2015

and EN 62061

130.000

Order reference

Product

Product type Features Order no.

PIT gb LLLE Housing with three illuminated push-

buttons, one E-STOP and coloured

caps

M12, 12-pin male connector G1 000 001

PIT gb CLLE y Housing with blind plug, two illumin-

ated pushbuttons, one E-STOP with

signal contact and coloured caps

M12, 12-pin male connector G1 000 002

PIT gb BLLE y Housing with key-operated pushbut-

ton, two illuminated pushbuttons, one

E-STOP with signal contact and coloured caps

M12, 12-pin male connector G1 000 003

PIT gb KLLE Housing with key switch, two illumin-

ated pushbuttons, one E-STOP and

coloured caps

M12, 12-pin male connector G1 000 004

Spare part

Product type Features Order no.

PIT gb es1 E-STOP without signal contact G1 000 005

PIT gb es2 E-STOP with signal contact G1 000 011

PIT gb push button Pushbutton, illuminated G1 000 006

PIT gb key button Key-operated pushbutton G1 000 007

PIT gb key switch Key switch with 2 locked positions G1 000 008

PIT gb blind cover Blind plug G1 000 010

Page 26

PIT gb

Operating Manual PIT gb

1004627-EN-02

26

Accessories

Product type Features Order no.

PIT gb fixing spanner

Fixing spanner for threaded rings G1 000 012

PIT gb color covers Coloured caps (set), sorted by colour G1 000 009

Product type Features Connector X1 Connector X2 Connector X3 Order no.

PSEN op cable axial

M12 12-pole 3m

3 m M12, 12-pin fe-

male connector, straight

631 080

PSEN op cable axial

M12 12-pole 5m

5 m M12, 12-pin fe-

male connector, straight

631 081

PSEN op cable axial

M12 12-pole 10m

10 m M12, 12-pin fe-

male connector, straight

631 082

PSEN op cable axial

M12 12-pole 20m

20 m M12, 12-pin fe-

male connector, straight

631 083

PSEN op cable axial

M12 12-pole 30m

30 m M12, 12-pin fe-

male connector, straight

631 084

PSEN op cable axial

M12 12-pole 50m

50 m M12, 12-pin fe-

male connector, straight

631 085

EC declaration of conformity

This product/these products meet the requirements of the directive 2006/42/EC for machinery of the European Parliament and of the Council. The complete EC Declaration of

Conformity is available on the Internet at www.pilz.com/downloads.

Authorised representative: Norbert Fröhlich, Pilz GmbH & Co. KG, Felix-Wankel-Str. 2,

73760 Ostfildern, Germany

Page 27

The Best of

German

En

gineering

Partner of:

Support

Technical support is available from Pilz round the clock.

Americas

Brazil

+55 11 97569-2804

Canada

+1 888-315-PILZ (315-7459)

Mexico

+52 55 5572 1300

USA (toll-free)

+1 877-PILZUSA (745-9872)

Asia

China

+86 21 60880878-216

Japan

+81 45 471-2281

South Korea

+82 31 450 0680

Australia

+61 3 95600621

Europe

Austria

+43 1 7986263-0

Belgium, Luxembourg

+32 9 3217575

France

+33 3 88104000

Germany

+49 711 3409-444

Ireland

+353 21 4804983

Italy, Malta

+39 0362 1826711

Scandinavia

+45 74436332

Spain

+34 938497433

Switzerland

+41 62 88979-30

The Netherlands

+31 347 320477

Turkey

+90 216 5775552

United Kingdom

+44 1536 462203

You can reach our

international hotline on:

+49 711 3409-444

support@pilz.com

CMSE

®

, InduraNET p

®

, PAS4000

®

, PAScal

®

, PASconfig

®

, Pilz

®

, PIT

®

, PLID

®

, PMCprimo

®

, PMCprotego

®

, PMCtendo

®

, PMD

®

, PMI

®

, PNOZ

®

, Primo

®

, PSEN

®

, PSS

®

, PVIS

®

, SafetyBUS p

®

,

SafetyEYE

®

, SafetyNET p

®

, THE SPIRIT OF SAFETY

®

are registered and protected trademarks of Pilz GmbH & Co. KG in some countries. We would point out that product features may vary

from the details stated in this document, depending on the status at the time of publication and the scope of the equipment. We accept no responsibility for the validity, accuracy

and entirety of the text and graphics presented in this information. Please contact our Technical Support if you have any questions.

Pilz develops environmentally-friendly products using

ecological materials and energy-saving technologies.

Oces and production facilities are ecologically designed,

environmentally-aware and energy-saving. So Pilz oers

sustainability, plus the security of using energy-ecient

products and environmentally-friendly solutions.

Pilz GmbH & Co. KG

Felix-Wankel-Straße 2

73760 Ostfildern, Germany

Tel.: +49 711 3409-0

Fax: +49 711 3409-133

info@pilz.com

www.pilz.com

200XXXX-EN-0X

0-0-2-3-000, 2017-00 Printed in Germany

© Pilz GmbH & Co. KG, 2017

Back cover

1004627-EN-02, 2018-04 Printed in Germany

© Pilz GmbH & Co. KG, 2015

Loading...

Loading...