Page 1

Electronic Monitoring Relays

Fault voltage monitoring

PFU6

Technical Details PFU6

Electrical data

Supply voltage AC/DC: 24 ... 42 V, 42 ... 240 V

Tolerance 85 ... 110 %

Power consumption Max. 2 W/4 VA

Switching capability in accordance

with EN 60947-4-1, 02/01 AC1: 240 V/0.1 ... 5 A/1200 VA

EN 60947-5-1, 11/97 AC15: 230 V/2 A; DC13: 24 V/1.5 A

Output contacts 1 auxiliary contact (1 C/O)

Contact material AgCdO, 3 µm gold plating for

Contact fuse protection Max. 6 A quick or max. 4 A slow

in accordance with EN 60947-5-1, 08/01

Measuring circuit

The PFU6 monitors fault voltages on

welding transformers in accordance

with VDE 0545.

Features

● Monitors voltage of 6 secondary

windings on welding transformers

● Displays fault voltage and open

circuit

● Supply voltage can be selected:

24 V … 42 VAC/DC or

42 ... 240 VAC/DC

Approvals

PFU6

●

Measuring input 0 ... 690 VAC/DC

Frequency range 50 Hz ... 1 kHz

Response value 24 VAC/DC

Impedance of the measuring inputs 1 kΩ (ca. 1 kΩ up to 20 V, 20 kΩ at

Reaction time Max. 150 ms at response value x 1.1

Response resistance ca. 350 kΩ

Mechanical data

Max. cross section of external conductors 2 x 2.5 mm

Dimensions (H x W x D) 87 x 45 x 122 mm

Weight 240 g

Description

The PFU6 is enclosed in a P-97

housing.

Features:

● 6 measuring inputs

● Relay outputs:

1 auxiliary contact (1 C/O)

●

LED indicator for supply voltage,

overvoltage, open circuit, PE

connection

● Manual reset

● Test button

● Connection for an external test

and reset button

The PFU6 monitors the secondary

windings on welding transformers for

fault voltage. If the measured voltage

exceeds the response value of 24

VAC/DC, output relay K1 deenergises and the LED for the

affected measuring circuit will light.

DC1: 24 V/0.1 ... 5 A/120 W

low load range 1-50 V/1-100 mA

100 V, 250 kΩ at 500 V)

2

Single-core or multi-core with

crimp connectors

The PFU6 monitors the measuring

lines

for open circuits and also

monitors the PE connection. If the

resistance value exceeds the

response value of 350 kΩ, output

relay K1 de-energises and the LED

for the affected measuring circuit will

flash.

The unit logs the detected faults.

Once the fault has been rectified, the

unit can be restarted by pressing the

reset button.

An integral test function checks the

measuring circuits.

4

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

NSG-D-2-307-2005-04

Page 2

Electronic Monitoring Relays

Fault voltage monitoring

PFU6

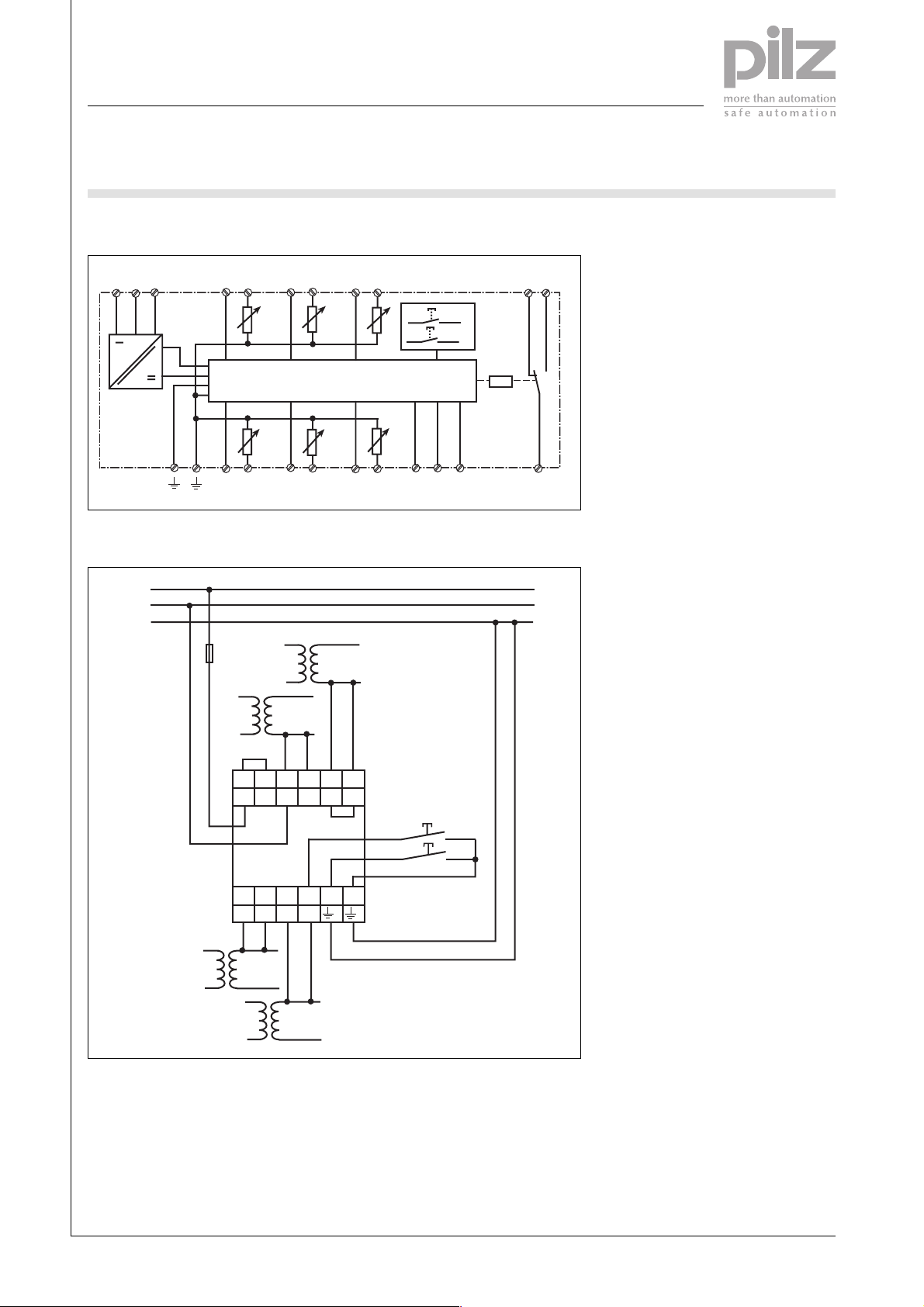

Schematic internal wiring diagram

U

B

B3

A1 E1

A2

~

1

2

PE

Connection example

L1

N

PE

Measuring circuits

E2 F1 F2 G1 G2

Monitoring

H1 H2 J1 J2 YR YT Y0K1 K2

Measuring circuits Reset and test button

Aux. contact

12 14

RESET

TEST

K1

11

4

E1

E2 F1 F2 G1 G2

A1

A2B3

H1 H2

PFU6

12 14

11 YR YT Y0

J1 J2 K1 K2

1

Reset

Test

2

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

NSG-D-2-307-2005-04

Page 3

Electronic Monitoring Relays

Fault voltage monitoring

PFU6

General details

Unless stated otherwise in the technical details for the specific unit.

Electrical data

Frequency range AC 50 ... 60 Hz

Residual ripple DC 160 %

Contact material AgSnO

Continuous duty 100 %

Environmental data

EMC EN 50081-1, 01/92, EN 61000-6-2, 03/00

Vibration in accordance with Frequency: 10 ... 55 Hz,

EN 60068-2-6, 04/95 Amplitude: 0.35 mm

Climatic suitability DIN IEC 60068-2-3, 12/86

Airgap creepage DIN VDE 0110 Part 1, 04/97

Ambient temperature -10 ... +55 °C

Storage temperature -40 ... +85 °C

Mechanical data

Torque setting for connection terminals 0.6 Nm (screws)

Mounting position Any

Housing material PPO UL 94 V0

Protection types Mounting: IP 54

2

Housing: IP 40

Terminals: IP 20

Units have been tested in accordance with the standards valid at the time of

development.

Order reference

Type U

PFU6 24 ... 42 VAC/DC; 42 V ... 240 VAC/DC 841 000

B

Order No.

4

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

NSG-D-2-307-2005-04

Loading...

Loading...