Page 1

Operating Manual PDP67 F 8DI ION HP

Operating Manual PDP67 F 8DI ION HP

PDP67 F 8DI ION HP

Decentralised periphery

Operating Manual — No. 1002225-EN-03

Page 2

This document is a translation of the original document.

All rights to this documentation are reserved by Pilz GmbH & Co. KG. Copies may be made

for internal purposes.

Suggestions and comments for improving this documentation will be gratefully received.

Pilz®, PIT®, PMI®, PNOZ®, Primo®, PSEN®, PSS®, PVIS®, SafetyBUS p®, SafetyEYE®,

SafetyNET p®, the spirit of safety® are registered and protected trademarks of

Pilz GmbH & Co. KG in some countries.

SD means Secure Digital.

Preface

Page 3

Contents

Contents

Contents Page

Chapter 1 Introduction

1.1 Validity of documentation 1-1

1.1.1 Retaining the documentation 1-1

1.2 Overview of documentation 1-2

1.3 Definition of symbols 1-3

Chapter 2 Overview

2.1 Unit structure 2-1

2.1.1 Scope of supply 2-1

2.1.2 Unit features 2-1

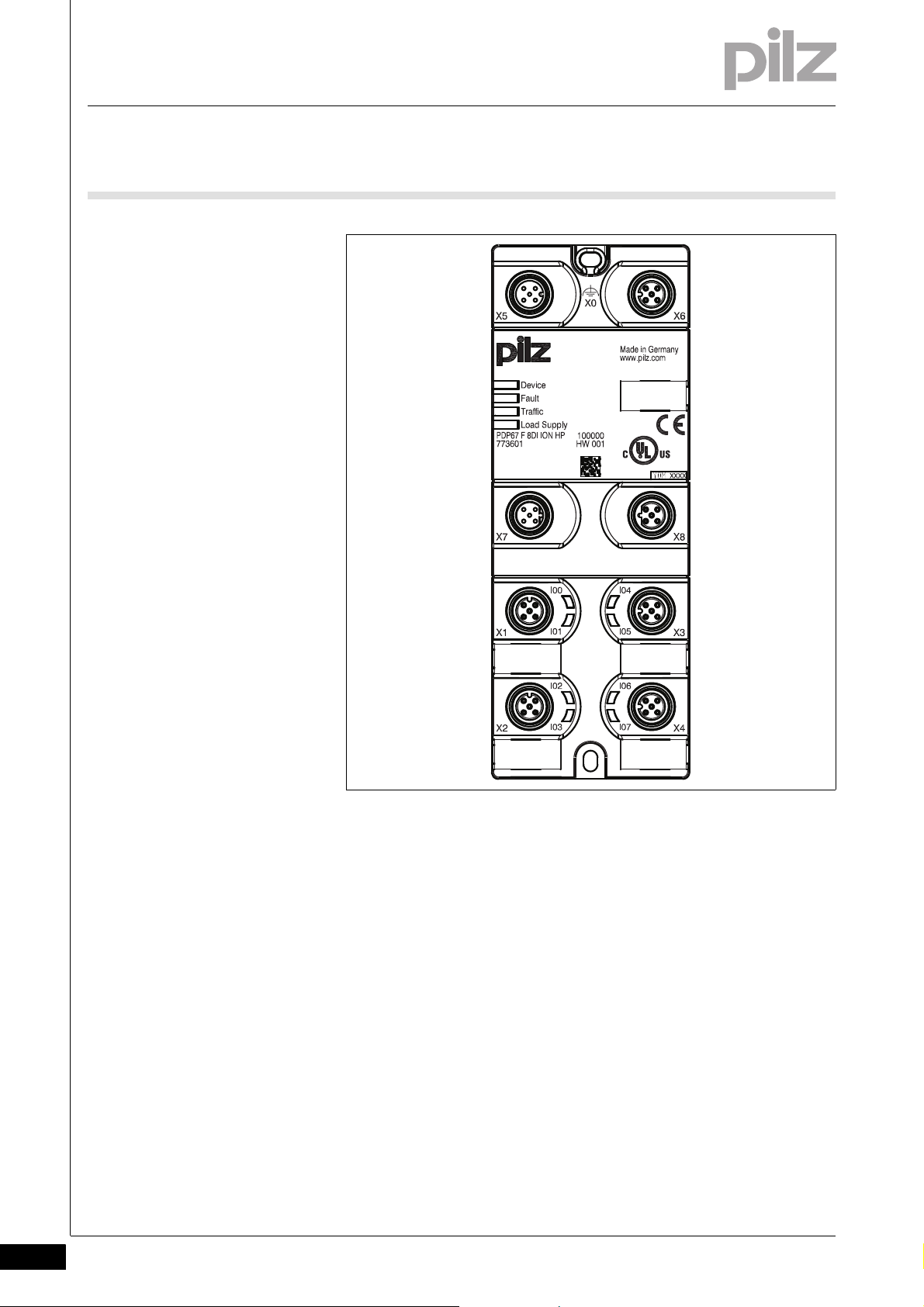

2.2 Front view 2-2

Chapter 3 Safety

3.1 Intended use 3-1

3.2 Safety regulations 3-2

3.2.1 Use of qualified personnel 3-2

3.2.2 Warranty and liability 3-2

3.2.3 Disposal 3-2

Chapter 4 Function description

4.1 Unit properties 4-1

4.1.1 Operation 4-1

4.1.1.1 Inputs 4-1

4.1.1.2 Outputs 4-1

4.1.2 Data download 4-1

4.1.3 Diagnostics 4-2

Chapter 5 Installation

5.1 General installation guidelines 5-1

5.1.1 Dimensions 5-1

Chapter 6 Supply Voltage

Chapter 7 Wiring

7.1 General wiring guidelines 7-1

7.2 Connector pin assignment 7-2

7.3 Wiring examples 7-4

7.3.1 Example: Single-channel, failsafe input device, without test pulse

7.3.2 Example: Dual-channel input devices,

without test pulses

7.3.3 Example: Single-channel, failsafe input device, with test pulse

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7-4

7-5

7-7

1

Page 4

Contents

7.3.4 Example: Dual-channel, failsafe input device, with test pulse

Chapter 8 Operation

8.1 Messages 8-1

8.1.1 Display elements for device diagnostics 8-1

Chapter 9 Technical details

9.1 Technical details 9-1

9.2 Order reference 9-4

7-8

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

2

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 5

1 Introduction

1.1 Validity of documentation

11000IntroductionIntroduction1-1.1Validity of docume ntation1100Validity of documenta tion1-Einf Gltigkeit der Dokumentati onPDP67_VA

This documentation is valid for the products PDP67 F 8DI ION HP,

PDP67 F 8DI ION HP VA. It is valid until new documentation is pub-

Einf Einleitung

1.1.1 Retaining the documentation

Retaining the documentation1-Einf Aufbewahren

lished.

This operating manual explains the function and operation, describes

the installation and provides guidelines on how to connect the product.

This documentation is intended for instruction and should be retained

for future reference.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1-1

Page 6

1 Introduction

1.2 Overview of documentation

1.2Overview of documentation1200Overview of documentation1-][BA Einf Übersicht PDP

1 Introduction

The introduction is designed to familiarise you with the contents, structure and specific order of this manual.

2 Overview

This chapter provides information on the product's most important features.

3 Safety

This chapter must be read as it contains important information on intended use.

4 Function Description

This chapter describes the product's individual components.

5 Installation

This chapter explains how to install the product.

6 Supply Voltage

This chapter explains what you need to consider when connecting the

supply voltage.

7 Wiring

This chapter describes the product's wiring.

8 Operation

This chapter explains the display elements and advises on what to do if

a fault occurs.

1-2

9 Technical Details

This chapter contains the product's technical details and order reference.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 7

1 Introduction

1.3 Definition of symbols

1.3Definition of symbols1300Definition of symbols1-Einfhrung Zeichen

Information that is particularly important is identified as follows:

DANGER!

This warning must be heeded! It warns of a hazardous situation

that poses an immediate threat of serious injury and death and

indicates preventive measures that can be taken.

WARNING!

This warning must be heeded! It warns of a hazardous situation

that could lead to serious injury and death and indicates preventive measures that can be taken.

CAUTION!

This refers to a hazard that can lead to a less serious or minor

injury plus material damage, and also provides information on

preventive measures that can be taken.

NOTICE

This describes a situation in which the unit(s) could be damaged

and also provides information on preventive measures that can

be taken. It also highlights areas within the text that are of particular importance.

INFORMATION

This gives advice on applications and provides information on

special features.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1-3

Page 8

1 Introduction

1-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 9

2 Overview

2.1 Unit structure

22000OverviewOverview2-2.1Unit structure2100Unit structure2-

2.1.1 Scope of supply

Scope of supply2-Eigenschaften

2.1.2 Unit features

Unit features2-Gerätemerkmale_Verwendung_PDP_VA

Verwendung/Bildunterschrift_PDP_DI

Geraetemerkmale_Zusatz BA Einleitung

Decentralised input module PDP67 F 8DI ION HP/PDP67 F 8DI ION

HP VA

4 blind plugs 380 324

Application of the products PDP67 F 8DI ION HP, PDP67 F 8DI ION

HP VA:

Decentralised input module for connection to a Pilz control system, for

use in a rugged industrial environment up to protection type IP67.

Gertemerkmale_PDP_IP67

The product has the following features:

Protection type IP67

8 inputs for connecting 8 single-channel or 4 dual-channel sensors

8 outputs, which can be configured as

– Standard outputs

– test pulse outputs

– 24 V outputs

Separate output supply for applications with higher current consump-

tion

Module is galvanically isolated from CAN bus

LED for:

– Operating state

– Errors

– Connection status

– Supply voltage

– Input status at each input

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2-1

Page 10

2 Overview

2.2 Front view

2.2Front view2200Front view2-Klemmenbelegung PDP67 8DI ION HP

2-2

Legende PDP IP67

Legend:

X1 ... X4:

Inputs

X5:

Interface to the control system or to X6 on the upstream module

X6:

Interface to X5 on the downstream module

X7:

Interface to the 24 V supply or to X8 on the upstream module

X8:

Interface to the 24 V supply or to X7 on the downsteam module

LEDs:

–Device

–Fault

–Traffic

– Load Supply

– IO0 ... IO7

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 11

3 Safety

3.1 Intended use

33000SafetySafety3-3.1Intended use3100Intended use3-Bestimmung/Gertebeschreibung_PDP_DI

Bestimmung/Gertebeschreibung_PDP_DI_HP_Anschluss_Multi

Bestimmung/Gerätebeschreibung_EMV+Ausschluss

The products PDP67 F 8DI ION HP, PDP67 F 8DI ION HP VA are decentralised input modules designed for use in a rugged industrial environment up to protection type IP67.

The module can be connected to a link module PNOZ ml2p or PNOZ

mml2p from the configurable control system PNOZmulti.

Intended use includes making the electrical installation EMC-compliant.

The product is designed for use in an industrial environment. It is not

suitable for use in a domestic environment, as this can lead to interference.

The following is deemed improper use in particular:

Any component, technical or electrical modification to the product

Use of the product outside the areas described in this manual

Use of the product outside the technical details (see chapter entitled

“Technical Details”)

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-1

Page 12

3 Safety

3.2 Safety regulations

3.2Safety regulations3200Safety regulations3-

3.2.1 Use of qualified personnel

Use of qualified personnel3-Sich Qualif. Personal

The products may only be assembled, installed, programmed, commissioned, operated, maintained and decommissioned by competent persons.

A competent person is someone who, because of their training, experience and current professional activity, has the specialist knowledge required to test, assess and operate the work equipment, devices,

systems, plant and machinery in accordance with the general standards

and guidelines for safety technology.

It is the company's responsibility only to employ personnel who:

Are familiar with the basic regulations concerning health and safety /

accident prevention

Have read and understood the safety guidelines given in this descrip-

tion

Have a good knowledge of the generic and specialist standards ap-

plicable to the specific application.

3.2.2 Warranty and liability

Warranty and liability3-Sich Gewhrleistung_ohne_Veränderungen...

3.2.3 Disposal

Disposal3-Si ch Entsorgung

All claims to warranty and liability will be rendered invalid if:

The product was used contrary to the purpose for which it is intended

Damage can be attributed to not having followed the guidelines in the

manual or

Operating personnel are not suitably trained.

In safety-related applications, please comply with the mission time t

M

in the safety-related characteristic data.

When decommissioning, please comply with local regulations regard-

ing the disposal of electronic devices (e.g. Electrical and Electronic

Equipment Act).

3-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 13

4 Function description

4.1 Unit properties

44000Function descriptionFunction description4-4.1Unit properties4100Unit properties4-

4.1.1 Operation

Operation4-Funktionen_PDP_DI_Konfiguration

The functions of the inputs and outputs are configured in the system

software.

4.1.1.1 Inputs

Inputs4-Funktionen_PDP_DI_Eingänge

Single and dual-channel sensors can be connected to the inputs, with

or without test pulses.

Input signals must show a “High” (“1” signal) of 15 VDC (+15 ... +30 VDC)

and a “Low” (“0” signal) of 0 VDC (-3 ... +5 VDC).

4.1.1.2 Outputs

Outputs4-Funktionen_PDP_DI_Ausgänge

The input status is signalled to the control system via the bus.

Green LEDs indicate the status of the inputs.

Test pulses can be used to check the inputs for shorts across contacts

and correct functionality.

The outputs can be used as standard outputs, as test pulse outputs or

as 24 VDC outputs.

The test pulse outputs are suitable for testing the sensor wiring. All safety-related inputs must operate in accordance with the failsafe principle

(on switching off).

Two test pulses are available on each plug-in connector; these test pulses are permanently assigned to the inputs. The assignment of the test

pulses to the inputs cannot be changed in the system software's configurator.

If the test pulse outputs are not being used, they can be configured as

standard outputs or 24 VDC outputs in the system software's configurator.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-1

Page 14

4 Function description

4.1 Unit properties

4.1.2 Data download

Data download4-Funktionen_PDP_Datenübertragung

Communication with the control system is via a safe data link. Data is

exchanged cyclically.

4.1.3 Diagnostics

Diagnostics4-Funktionen_PDP_DI_Diagnose

The status and error messages shown by the LEDs are saved in an error

stack. The system software can read this error stack.

4-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 15

5 Installation

29,6

5,6

22,1

60

162

37

125

58

29

5.1 General installation guidelines

55000InstallationInstallation5-5.1General installation guidelines5100General installation guidelines5-Montagefläche_PDP

The product must be fastened to a flat mounting surface, so that there

is no strain on the housing when the module is screwed down. The

mounting distances will depend on which plug-in connectors are used

and on the bending radius of the cables.

Montage_PDP - Vorgehensweise

Montage_PDP - Vorgehensweise_Funktionserde an Schraube

Unused connectors should be sealed using blind plugs.

To install the system, proceed as follows:

Fit 2 x M4 internal threads on the mounting surface.

Use two fixing screws to attach the product to the mounting plate.

With shielded cables, connect the functional earth to the upper fixing

screw X0.

5.1.1 Dimensions

Dimensions5-Abmessungen_PDP 67_8DI ION_HP

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

5-1

Page 16

5 Installation

5-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 17

6 Supply Voltage

66000Supply VoltageSupply Voltage6-Versorgungsspannung PDP

Please note the following:

When selecting the power supply, please refer to the requirements

Overvoltage or interference voltage can damage or even destroy the

stated under “Technical Details”.

electronics on the products PDP67 F 8DI ION HP, PDP67 F 8DI ION

HP VA. The affected outputs on the control system are shut down.

You should therefore take note of the relevant EMC measures.

WARNING!

Safe electrical isolation must be ensured for the 24 V supply.

Failure to do so could result in electric shock. Power supplies

must conform to EN 60950, section 2.3, EN 60742 or EN 50178.

To achieve the lowest possible residual ripple, we recommend

that you install a three-phase bridge rectifier or regulated supply.

The “Ground” connection to the earth bar or earth fault moni-

tor must be in accordance with the relevant national regulations (e.g. EN 60204-1, NFPA 79:17-7, NEC: Article 250).

Anschluss_Weiterl PDP

INFORMATION

The module's output circuits have been designed to guarantee

maximum safety. To achieve this, extensive tests are carried out

internally. Momentary interruptions to the “Supply” voltage during a test procedure can falsify the test result, causing the following malfunction: If the “Supply” voltage is interrupted

momentarily, the unbuffered test pulse outputs will transmit a

“0” signal. The buffered module electronics reads this signal at

the pulsed inputs, thereby triggering the user's configured reaction.

Example: The system reacts as though an E-STOP button has

been operated, although this is not the case: there has been a

supply interruption.

Remedy: The “Supply” must be buffered.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-1

Page 18

6 Supply Voltage

Supply

Supply

Use a 5-pin M12 plug-in connector to connect the module to the external supply voltage.

The module also has an M12 socket which is physically adjacent to the

M12 connector; this is used to distribute the supply voltage to other

modules.

Anschluss_Weiterl_Zeichnung PDP

Anschluss_Weiterl_Warnung PDP

Anschluss_Weiterl_Funktionserde PDP

Pinbelegung PDP

Fig. 6-1: Example for connecting and distributing the supply voltage

WARNING!

The current load capacity of the M12 plug-in connector is 4 A

per connector. You must ensure that this value is not exceeded.

Exceeding the permitted current load capacity can damage the

plug-in connector. Please note that the connection of the additional supply voltage is not monitored for overload.

INFORMATION

We recommend that you connect the functional earth to the

upper fixing screw.

6-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 19

6 Supply Voltage

2

3

4

1

5

X7 (male connector)

X8 (female connector)

4

1

2

3

5

Fig. 6-2: Pin assignment for the supply voltage

Key:

1: + 24 VDC

2: + 24 VDC

3: 0 V

4: 0 V

5: n.a.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-3

Page 20

6 Supply Voltage

6-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 21

7 Wiring

7.1 General wiring guidelines

77000WiringWiring7-7.1General wiring g uidelines7100Ge neral wiring guidelin es7-Verdrahtung_PDP_DI

Please note:

Information given in the “Technical details” must be followed.

In safety-related applications, it is essential that short circuits and

open circuits are unable to cause a hazardous condition within a

plant. The way in which this is done will depend on the degree of hazard from the plant section, the switching frequency of the sensors and

the level of safety of the sensors and actuators.

Please refer to the link module's operating instructions for details of

the maximum cable length.

Pilz pre-assembled cable can be used to connect the inputs and out-

puts (see order reference).

We recommend you use pre-assembled Pilz connectors to connect

the inputs and test pulse outputs (see order reference).

CAUTION!

The supply voltages for an external device must be extra low

voltages with safe electrical separation (PELV or SELV) in

accordance with VDE 0100, Part 410.

CAUTION!

In order to guarantee protection type IP67, unused connectors

should be sealed using the blind plugs supplied.

CAUTION!

Make sure that the plug-in connectors are connected to the sensors correctly. Once you have run a function test to check that

the connectors are connected to the sensors correctly, the

inputs should be labelled. If the inputs are connected to the sensors incorrectly, life-threatening situations may arise on the

plant.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7-1

Page 22

7 Wiring

2

3

4

1

5

2

3

4

1

5

2

3

4

1

5

4

1

2

3

5

7.2 Connector pin assignment

7.2Connector pin assignment7200Connector pin assignment7-Anschluss_PDP_DI_Schnittstellenbelegung mit Versorungsspannung

Inputs/outputs

X1 to X4

5-pin M12 female connector

A-coded

Assignment

1: Test pulse x / 24 VDC / ST output.

2: Input X

3: 0 V

4: Input X + 1

5: Test pulse X + 1 / 24 VDC / ST output

Interface to the link module: X5

5 pin M12 male connector

A-coded

Interface to the next decentralised module: X6

5-pin M12 female connector

A-coded

Interface to the 24 V supply or to previous decentralised module: X7

5 pin M12 male connector

B-coded

Assignment

1: VCC

2: CAN3: GND

4: CAN+

5: Shield

Assignment

1: VCC

2: CAN3: GND

4: CAN+

5: Shield

Assignment

1: + 24 VDC

2: + 24 VDC

3: 0 V

4: 0 V

5: n.a.

7-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 23

7 Wiring

2

3

4

1

5

7.2 Connector pin assignment

Interface to the 24 V supply or to next decentralised module: X8

5-pin M12 female connector

B-coded

Assignment

1: + 24 VDC

2: + 24 VDC

3: 0 V

4: 0 V

5: n.a.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7-3

Page 24

7 Wiring

7.3 Wiring examples

7.3Wiring examples7300Wiring examples7-

7.3.1 Example: Single-channel, failsafe input device, without test pulse

Example: Single-channel, failsafe input device, without test pulse7-Bsp 1: einkan fehlersich Sensor ungetaktet

Features:

Depending on the application area and its respective regulations, this

connection diagram is suitable for input devices with frequent and

infrequent operation in accordance with EN ISO 13849-1 up to PL

d and EN IEC 62061 up to SIL CL 2.

The input device must be approved for failsafe applications.

Bsp: WARNUNG Kurzschluss Bsp. 1

Please read the instructions provided with the input device.

WARNING!

Short circuits between the cable to the input device and the 24 V

line or between cables to various input devices will not be

detected. Depending on the application, serious injury or death

may result.

Avoid short circuits by

Appropriate wiring

Wiring in accordance with the requirements of IEC 61076-2-

101 and IEC 60204-1, clause 14.1.1 and 14.1.2

Bsp 1: einkan fehlersich Sensor ungetaktet_Zeichnung HP

7-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 25

7 Wiring

24 V

L+

L-

24 V

Single-channel, failsafe input device

Please ensure safety regulations and EMC guidelines are met!

7.3 Wiring examples

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7-5

Page 26

7 Wiring

7.3 Wiring examples

7.3.2 Example: Dual-channel input devices, without test pulses

Example: Dual-channel input devices, without test pulses7-Bsp 2: zweikan Sensor ungetaktet

Features:

This type of connection is mainly used for signal inputs with frequent

operation.

Depending on the application area and its respective regulations, this

connection diagram is suitable for input devices with frequent operation and diverse channels in accordance with EN ISO 13849-1 up

to PL e and EN IEC 62061 up to SIL CL 3, provided the functionality

of both input device channels is monitored in the user program via a

feasibility check.

The input device must be approved for failsafe applications.

If you are using input devices with different (diverse) channels, adja-

cent inputs may be used. The user program will detect short circuits

Bsp: WARNUNG Kurzschluss Bsp. 2

via the feasibility check.

Bsp 2: zweikan Sensor ungetaktet_Zeichnung HP

WARNING!

On input devices with identical channels, short circuits between

the cable to the input device and the 24 V line or between cables

to both input devices will not be detected. Depending on the

application, serious injury or death may result.

Avoid short circuits by

Appropriate wiring

Wiring in accordance with the requirements of IEC 61076-2-

101 and IEC 60204-1, clause 14.1.1 and 14.1.2

7-6

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 27

7 Wiring

24 V

L+

L-

Dual-channel input device

with different

(diverse) channels

Please ensure safety regulations and EMC guidelines are met!

24 V

24 V

7.3 Wiring examples

7.3.3 Example: Single-channel, failsafe input device, with test pulse

Example: Single-channel, failsafe input device, with test pulse7-Bsp 3: einkan fehlersich Sensor getaktet

Bsp: ACHTUNG Kurzschluss Bsp. 3

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Features:

Depending on the application area and its respective regulations, this

connection diagram is suitable in accordance with EN ISO 13849-1

up to PL d and EN IEC 62061 up to SIL CL 2.

The input device must be approved for failsafe applications.

Test pulses can be used to check the inputs for short circuit to 24 V

and correct functionality. Short circuits that short out the input device

(cable from the test pulse to the input device and cable from the input

device to the input) will not be detected.

Please read the instructions provided with the input device.

Only input devices with N/C contacts can be tested.

7-7

Page 28

7 Wiring

24 V

L+

L-

Test pulse T0

Single-channel, failsafe input device

Please ensure safety regulations and EMC guidelines are met!

7.3 Wiring examples

Bsp 3: einkan fehlersich Sensor getaktet_Zeichnung HP

CAUTION!

Short circuits between the cable to the input device and the 24 V

line or between cables to various input devices will not be

detected.

Avoid short circuits by

Appropriate wiring

Wiring in accordance with the requirements of IEC 61076-2-

101 and IEC 60204-1, clause 14.1.1 and 14.1.2

7-8

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 29

7 Wiring

24 V

L+

L-

Dual-channel input device

with diverse channels

Please ensure safety regulations and EMC guidelines are met!

Test pulse T1

Test pulse T0

Test pulse T1

Test pulse T0

Dual-channel input device

with identical channels

7.3 Wiring examples

7.3.4 Example: Dual-channel, failsafe input device, with test pulse

Example: Dual-channel, failsafe input device, with test pulse7-Bsp 4: zweikan fehlersich Sensor getaktet

Features:

Depending on the application area and its respective regulations, this

connection diagram is suitable in accordance with EN ISO 13849-1

up to PL e and EN IEC 62061 up to SIL CL 3.

The input device must be approved for failsafe applications.

This type of connection is mainly used for signal inputs with infrequent

operation.

As the test pulses are permanently assigned to the inputs, all short

circuits will be detected, with the exception of short circuits that short

out the input device (cable from the test pulse to the input device and

Bsp 4: zweikan fehlersich Sensor getaktet_Zeichnung HP

cable from the input device to the input).

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7-9

Page 30

7 Wiring

7-10

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 31

8 Operation

8.1 Messages

88000OperationOperation8-8.1Messages81 00Messages8-Betr ieb_Meldungen_PDP _DI

The module is ready for operation when the "Ready" LED on the link

module is lit continuously.

8.1.1 Display elements for device diagnostics

Display elements for device diagnostics 8-Anzeige Legende 3x

Legend:

Betrieb_Anzeige_PDP_DI_ HP

LED on

LED flashes

LED off

LED LED status Meaning

Device Green The unit is ready for operation

The unit is not ready for operation

FAULT Red Internal error

No error

Traffic Yellow Connection to control system established

Yellow Error in the connection to the control system. Flashing stops a max. of 1 min.

after the fault has been rectified.

No connection to control system established

Input LEDs Green 1 signal is present

Green Link module has detected a pulse error.

Once the fault has been rectified, the decentralised input module will continue

to work normally after a wait of just a few seconds.

0 signal is present

Load Supply Yellow Voltage is present

Yellow The supply voltage is/was too low.

Once the fault has been rectified, the LED will not stop flashing until the system

has been switched off and then on again.

Voltage is missing

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

8-1

Page 32

8 Operation

8-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 33

9 Technical details

9.1 Technical details

99000Technical detailsTechnical details9-9.1Technical details9100Technical details9-][Technische Daten_PDP_DI

Technical details

Application range Standard/Failsafe

Electrical data

Internal supply voltage Supply

Supply voltage U

Voltage tolerance -30 %/+25 %

Power consumption at U

Inputs

Number 8

Input voltage 24 V DC

Input current 3.0 mA

Potential isolation between input and internal bus voltage yes

Outputs (configurable as semiconductor outputs or

test pulse outputs)

Infeed for Load Supply

Voltage 24 V DC

Voltage tolerance -30 %/+25 %

Max. continuous current that the external power supply

must provide

Max. unit fuse protection F1 4 A

Max. unit fuse protection F1 in according with UL508 4 A

Number of positive-switching single-pole semiconductor

outputs

Short circuit-proof yes

Potential isolation between semiconductor output and in-

ternal bus voltage

Potential isolation between semiconductor output and input

Typ. output current at “1” signal and rated voltage of sem-

iconductor output

Permitted current range 0.00 - 0.60 A

Residual current at “0” signal 0.02 mA

Permitted loads inductive, capacitive, resistive

Max. internal voltage drop 200 mV

Terminal voltage when switching off inductive loads -45 V

Number of test pulse outputs 8

Number of outputs that can be configured as test pulses 8

Max. output current at “1” signal 0.50 A

Short circuit-proof yes

Max. cable runs between test pulse output and input 20 m

Hardware processing times

Max. processing time for input when signal changes from

“1” to “0”

Max. processing time for input when signal changes from

“0” to “1”

Min. processing time for input when signal changes from

“1” to “0”

Min. processing time for input when signal changes from

“0” to “1”

DC 24 V

B

B

1.2 W

4.0 A

8

yes

no

0.50 A

1.000 ms

1.200 ms

0.50 ms

0.70 ms

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

9-1

Page 34

9 Technical details

9.1 Technical details

Environmental data

Climatic suitability EN 60068-2-78

Ambient temperature in accordance with EN 60068-2-14 -30 - 60 °C

Storage temperaturein accordance withEN 60068-2-1/-2 -40 - 70 °C

Climatic suitability in accordance with EN 60068-2-78 93 % r. h. at 40 °C

Condensation temporary No. 773601

EMC EN 55011: class A, EN 61000-4-11, EN 61000-4-2, EN

61000-4-3, EN 61000-4-4, EN 61000-4-5, EN 61000-4-6,

EN 61000-4-8, EN 61000-4-9

Vibration to EN 60068-2-6

Frequency 10 - 55 Hz

Max. acceleration 1g

Shock stress

EN 60068-2-27 15g

11 ms

EN 60068-2-29 10g

16 ms

Protection typein accordance withEN 60529

Housing IP67

Terminals IP67

Airgap creepage in accordance with IEC 60664-1

Overvoltage category III

Pollution degree 2

Mechanical data

Connection type M12 No. 773601

Stainless steel 1.4305 No. 773615

Housing material

Top Valox 855

Labelling bracket (accessories) PC

Dimensions

Height 162.0 mm

Width 60.0 mm

Depth 30.0 mm

Weight 375 g

Si-Kennzahlen_alle

Safety characteristic data

9-2

Unit Operating mode EN ISO 13849-

1: 2006

EN 954-1

Category

EN IEC 62061

SIL CL

PFH [1/h] EN ISO

PL

Input

SC inputs single-channel PL d (Cat. 2) Cat. 2 SIL CL 2 9.06E-09 20

SC inputs dual-channel PL e (Cat. 4) Cat. 4 SIL CL 3 1.24E-09 20

Bus interface

Bus interface PL e (Cat. 4) Cat. 4 SIL CL 3 1.94E-09 20

Si_Kennzahlen_Erläuterung_1

All the units used within a safety function must be considered when cal-

Technische Daten_Satz No rmen

culating the safety characteristic data.

The standards current on 2010-03 apply.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

13849-1:

2006

[year]

T

M

Page 35

9 Technical details

9.2 Order reference

9.2Order reference9200Order reference9-Bestelldaten PDP67 F 8DI ION HP

Order reference

Product type Features Order no.

PDP67 F 8DI ION HP Decentralised input module 773 601

PDP67 F 8DI ION HP VA Decentralised input module, V2A ring nut 773 615

Bestelldaten Zubehör PD P67 F 8DI ION HP

Order reference: Accessories for PDP67 F 8DI ION HP

Product type Features Order no.

Caps for IP67 modules Blind plugs 380 324

Order reference: Cable

Product type Features Order no.

PSS SB BUSCABLE LC Cable, shielded 1 - 100 m 311 074

PSS67 I/O Cable Cable 1 - 30 m 380 320

PSS67 Cable M8sf M12sm Cable, straight M12 connector, straight M8 socket, 4-pin 3 m 380 200

PSS67 Cable M8sf M12sm Cable, straight M12 connector, straight M8 socket, 4-pin 5 m 380 201

PSS67 Cable M8sf M12sm Cable, straight M12 connector, straight M8 socket, 4-pin 10 m 380 202

PSS67 Cable M8sf M12sm Cable, straight M12 connector, straight M8 socket, 4-pin 30 m 380 203

PSS67 Cable M8sf M12sm Cable, straight M12 connector, angled M8 socket, 4-pin 3 m 380 204

PSS67 Cable M8sf M12sm Cable, straight M12 connector, angled M8 socket, 4-pin 5 m 380 205

PSS67 Cable M8sf M12sm Cable, straight M12 connector, angled M8 socket, 4-pin 10 m 380 206

PSS67 Cable M8sf M12sm Cable, straight M12 connector, angled M8 socket, 4-pin 30 m 380 207

PSS67 Cable M12sf

M12sm

PSS67 Cable M12sf

M12sm

PSS67 Cable M12sf

M12sm

PSS67 Cable M12sf

M12sm

PSS67 Cable M12sf

M12sm

PSS67 Cable M12sf

M12sm

PSS67 Cable M12sf

M12sm

PSS67 Cable M12sf

M12sm

PSS67 Supply Cable IN sf

OUT sm

PSS67 Supply Cable IN sf

OUT sm

PSS67 Supply Cable IN sf

OUT sm

PSS67 Supply Cable IN af

OUT am

Cable, straight M12 connector, straight M12 socket, 5-pin 3 m 380 208

Cable, straight M12 connector, straight M12 socket, 5-pin 5 m 380 209

Cable, straight M12 connector, straight M12 socket, 5-pin 10 m 380 210

Cable, straight M12 connector, straight M12 socket, 5-pin 30 m 380 211

Cable, angled M12 connector, angled M12 socket, 5-pin 3 m 380 212

Cable, angled M12 connector, angled M12 socket, 5-pin 5 m 380 213

Cable, angled M12 connector, angled M12 socket, 5-pin 10 m 380 214

Cable, angled M12 connector, angled M12 socket, 5-pin 30 m 380 215

Cable, IN socket straight, OUT connector straight, B-coded 3 m 380 250

Cable, IN socket straight, OUT connector straight, B-coded 5 m 380 251

Cable, IN socket straight, OUT connector straight, B-coded 10 m 380 252

Cable, IN socket angled, OUT connector angled, B-coded 3 m 380 253

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

9-3

Page 36

9 Technical details

9.2 Order reference

Product type Features Order no.

PSS67 Supply Cable IN af

OUT am

PSS67 Supply Cable IN af

OUT am

PSS67 Supply Cable IN sf Cable, IN socket straight, B-coded 3 m 380 256

PSS67 Supply Cable IN sf Cable, IN socket straight, B-coded 5 m 380 257

PSS67 Supply Cable IN sf Cable, IN socket straight, B-coded 10 m 380 258

PSS67 Supply Cable IN af Cable, IN socket angled, B-coded 3 m 380 259

PSS67 Supply Cable IN af Cable, IN socket angled, B-coded 5 m 380 260

PSS67 Supply Cable IN af Cable, IN socket angled, B-coded 10 m 380 261

Order reference: Adapters

Cable, IN socket angled, OUT connector angled, B-coded 5 m 380 254

Cable, IN socket angled, OUT connector angled, B-coded 10 m 380 255

Product type Features Order no.

PSEN ma adapter Adapter for connection to safety switch PSENmag 380 300

PSEN cs adapter Adapter for connection to safety switch PSENcode 380 301

Order reference: Connectors

Product type Features Order no.

PSS67 M12 connector Connector, M12, straight, 5-pin, A-coded 380 308

PSS67 M12 connector Socket, M12, straight, 5-pin, A-coded 380 309

PSS67 M12 connector Connector, M12, angled, 5-pin, A-coded 380 310

PSS67 M12 connector Socket, M12, angled, 5-pin, A-coded 380 311

PSS67 M8 connector Connector, M8, straight, 4-pin 380 316

PSS67 M8 connector Socket, M8, straight, 4-pin 380 317

PSS67 M8 connector Connector, M8, angled, 4-pin 380 318

PSS67 M8 connector Socket, M8, angled, 4-pin 380 319

PSS67 M12 connector Connector, M12, straight, 5-pin, B-coded 380 312

PSS67 M12 connector Socket, M12, straight, 5-pin, B-coded 380 313

PSS67 M12 connector Connector, M12, angled, 5-pin, B-coded 380 314

PSS67 M12 connector Socket, M12, angled, 5-pin, B-coded 380 315

9-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 37

...

1002225-EN-03, 2012-03 Printed in Germany

© Pilz GmbH & Co. KG, 2011

+49 711 3409-444

support@pilz.com

Pilz GmbH & Co. KG

Felix-Wankel-Straße 2

73760 Ostfildern, Germany

Telephone: +49 711 3409-0

Telefax: +49 711 3409-133

E-Mail: pilz.gmbh@pilz.de

Internet: www.pilz.com

Technical support

In many countries we are

represented by our subsidiaries

and sales partners.

Please refer to our homepage

for further details or contact our

headquarters.

InduraNET p

®

, Pilz

®

, PIT

®

, PMCprotego

®

, PMI

®

, PNOZ

®

, Primo

®

, PSEN

®

, PSS

®

, PVIS

®

, SafetyBUS p

®

, SafetyEYE

®

, SafetyNET p

®

, the spirit of safety

®

are registered and protected trademarks

of Pilz GmbH & Co. KG in some countries. We would point out that product features may vary from the details stated in this document, depending on the status at the time of publication and the scope

of the equipment. We accept no responsibility for the validity, accuracy and entirety of the text and graphics presented in this information. Please contact our Technical Support if you have any questions.

Contact address

Loading...

Loading...