Page 1

IntelliVue MP90

Service Guide

IntelliVue Patient Monitor

MP90

Patient Monitoring

Page 2

Part Number M8000-9351B

Page 3

1Table of Contents

1 Introduction 13

Who Should Use This Guide 13

How to Use This Guide 13

Abbreviations 13

Responsibility of the Manufacturer 14

Passwords 14

Warnings and Cautions 14

2 Theory of Operation 15

Monitor Theory of Operation 15

System Boundaries 15

Hardware Building Blocks 16

IntelliVue MP90 17

Optional Hardware 18

Compatible Devices 18

Power Supply 19

CPU Boards 19

I/O Boards 20

Data Flow 20

Data Acquisition 20

Data Provider System Service 21

Persistent Data Storage System Service 21

Display and User Interface Service 21

Data Output 21

Monitor Applications 22

Internal LAN (Measurement Server Link) 22

Philips Clinical Network 23

How does the Support Tool Work with the Monitor 23

Monitor Software Block Diagram 24

Block Diagram Legend 26

3 Testing and Maintenance 31

Concepts 31

Test Reporting 31

Recommended Frequency 32

Tests Recommended When Performing... 33

Installation 33

Repair 33

Preventive Maintenance 33

3

Page 4

Performance Verifications 33

Upgrades 34

Te s t s 34

Visual Test 34

Power On Test 34

NBP Tests 34

NBP Accuracy Test 35

NBP Leakage Test 36

NBP Linearity Test 36

Valve Test 36

Sidestream CO2 Per formance Test 37

Barometric Pressure Check and Calibration 37

Leakage Check 38

Pump Check 39

Flow Rate Check and Calibration 39

Noise Check 39

CO

Gas Measurement Calibration Check 39

2

Calibration Verification 40

Reset Time Counters 40

Temperature Accuracy 41

ECG/Resp Performance Test 42

ECG Performance 42

Respiration Performance 42

Invasive Pressure Performance Test 42

SpO2 Performance Test 42

Cardiac Output Performance Test 43

Service Tool Procedure, Version 1 43

Service Tool Procedure, Version 2 43

BIS Performance Test 43

PIC/DSC Test 43

Nurse Call Relay Performance Test 44

Phone Jack Type Connector Test 44

Multi-Port Nurse Call Connector Test 44

ECG Sync Performance Test 45

VueLink Tests using VueLink Test Module 46

Tes t Pr o c e d u r e 4 6

Safety Testing 47

Warnings, Cautions, and Safety Precautions 47

Safety Test Procedures 47

Touchscreen Calibration 50

4 Troubleshooting 51

Introduction 51

How To Use This Section 51

Who Should Perform Repairs 51

Replacement Level Supported 51

4

Page 5

Software Revision Check 52

Obtaining Replacement Parts 52

Troubleshooting Guide 52

Checks for Obvious Problems 52

Checks Before Opening the Instrument 52

Checks with the Instrument switched Off 52

Checks with the Instrument Switched On, AC connected 53

Initial Instrument Boot Phase 53

Troubleshooting Tables 54

How to use the Troubleshooting tables 54

Boot Phase Failures 55

External Display is blank 58

External Touch Display not functioning 58

General Monitor INOP Messages 59

Remote Alarm Device 60

Remote Extension Device 60

Keyboard/Mouse not functioning 61

Network related problems 62

Wireless Network 63

Multi-Measurement Server 64

MSL-related problems 64

Alarm Issues 66

Alarm Lamps 66

Alarm Tones 67

Alarm Behavior 67

Individual Parameter INOPS 67

Flexible Module Server 68

Printer 69

Recorder 70

MIB / RS232 70

Flexible Nurse Call Relay 71

Troubleshooting the ECG OUT 72

Data Flow Marker In and ECG Wave 72

Status Log 73

Troubleshooting with the Support Tool 74

Troubleshooting the Individual Measurements or Applications 75

5 Repair and Disassembly 77

Tools Required 77

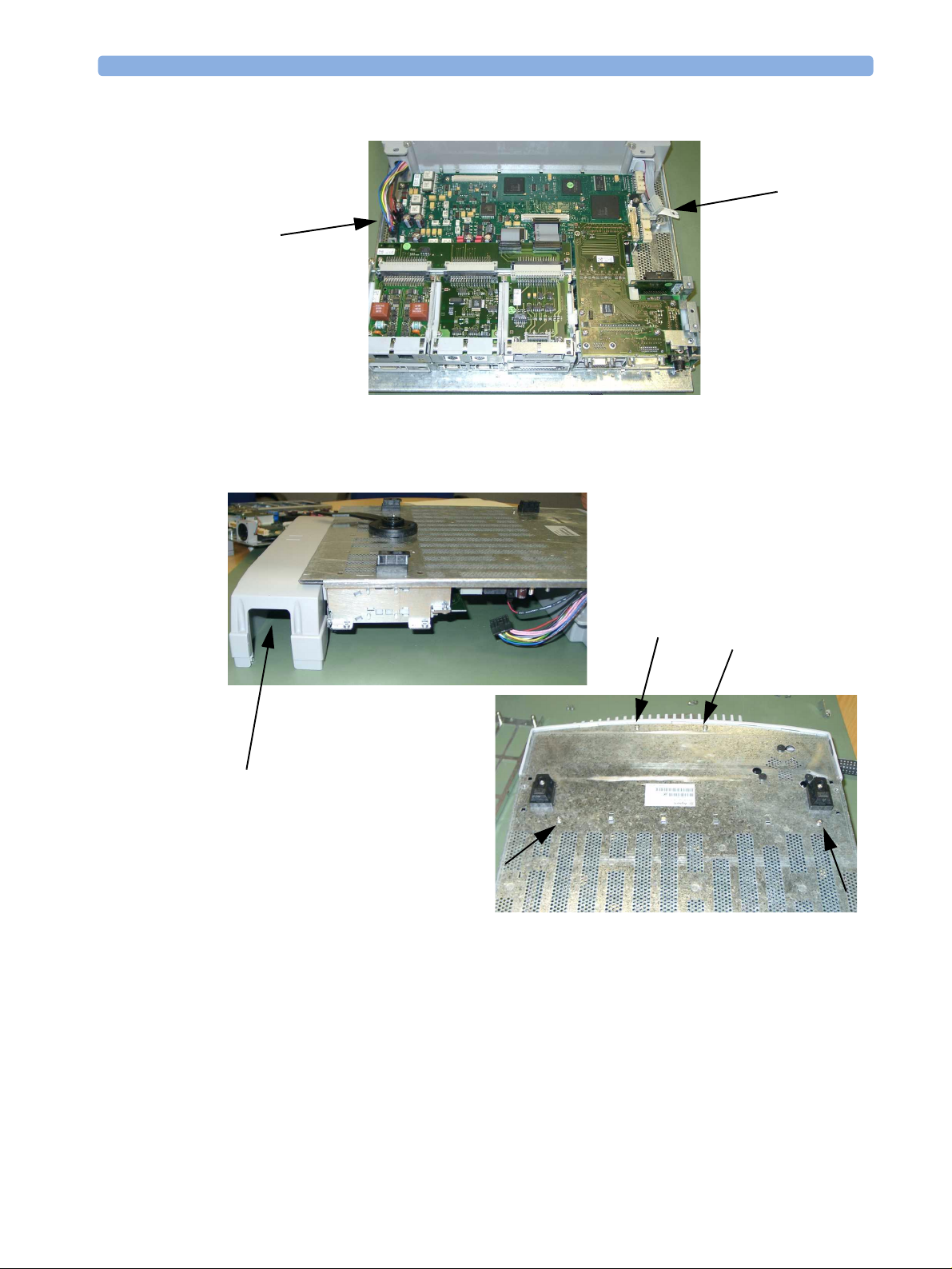

MP90 CMU Disassembly 77

Removing I/O Boards 77

Removing the Top Cover 79

Removing the Plastic Feet and/or the Locking Cam 81

Removing the optional Fans (Dual CPU Versions only)* 82

Replacing the Second (Independent) Video Board

(Dual CPU Versions only)

83

5

Page 6

Removing the Second CPU/Main Board (Dual CPU Versions only) 84

Accessing the Main CPU or Primary Video Board (Dual CPU Versions) 86

Replacing the Primary Video Board 88

Removing the Main Board 90

Removing the Power Supply 93

Removing the Speaker 95

Removing the Power On/Off Switch 95

Flexible Module Server (FMS) Disassembly 97

Removing the Handle and the Measurement Server Mount 97

Plug-in Modules 102

Plug-In Module Disassembly 102

tcpO2/tcpCO2 Calibration Chamber Kit 103

Recorder Module Paper 104

Disassembly Procedures for the Measurement Server Extension 105

Removing the Front Cover 105

Removing the Extension Bottom Cover 106

Removing the CO2 Scrubber 107

Removing the Pump 108

Refit Procedures for the Measurement Server Extension 108

Refitting the CO2 Scrubber 109

Refitting the Pump 109

Refitting the Extension Bottom Cover 109

Refitting the Front Cover 110

General Reassembly/Refitting Comments 110

Following Reassembly 110

6 Parts 111

MP90 Parts 112

Exchange Parts 112

Replacement Parts 113

Flexible Module Server Parts 114

Exchange and Replacement Parts 114

Multi-Measurement Server Parts 115

Measurement Server Extension Parts (M3015A and M3016A) 117

Exchange Parts List 119

Plug-in Modules Part Numbers 119

Part Number Table 119

Exchange Modules, Table 1 120

Exchange Modules, Table 2 120

Plug-In Modules Replaceable Parts 121

Single-Width Plug-In Module 122

Double-Width Plug-In Module 122

Plug-in Module Replaceable Parts 123

Plug-In Module Language Specific Front Housings, Table 1 123

Plug-In Module Language Specific Front Housings, Table 2 123

Plug-In Module Specific Bezels 124

6

Page 7

BIS Module Replaceable Parts 124

BIS Module Components 125

tcpO2/tcpCO2 Module Accessories 125

External Display Part Numbers 126

Remote Input Devices Part Numbers 127

Remote Alarm Device Part Numbers 128

Remote Extension Device Part Numbers 129

7 Installation Instructions 131

Unpacking the Equipment 131

Initial Inspection 132

Mechanical Inspection 132

Electrical Inspection 132

Claims For Damage and Repackaging 132

Claims for Damage 132

Repackaging for Shipment or Storage 132

Installing the Monitor (M8010A) 132

Mounting Instructions 132

Assembling Mounts 132

Connections 133

Installing Interface Boards 134

Connection of MIB Devices 135

Installing Remote Devices 136

Mounting the Remote Display (M8031A) 136

Connections 136

Mounting the 17” Remote Display (M8033A) 137

Flexible Module Server and/or Multi-Measurement Server 137

Positioning the Measurement Server on a Clamp Mount 137

Mounting the MMS Mount to the FMS (M8048A) 137

Attaching the MMS to a Mount 138

Detaching the Measurement Server from a Mount 138

Mounting the Remote Extension Device to the FMS 139

Mounting the BIS Engine to the FMS 139

Mounting the FMS 140

Connections 141

MSL Cable Termination 141

Remote Alarm Device 143

Mounting 143

Connections 143

Remote Extension Device 144

Mounting 144

Connections 145

Cabling 145

Keyboard/Mouse 146

Philips Clinical Network (wired) 146

7

Page 8

Philips Clinical Network (wireless) 146

Flexible Nurse Call Relay 146

Connections 146

ECG Out Functionality 147

Connections 147

Configuration Tasks 147

Setting Altitude and Line Frequency 148

Configuring the Equipment Label 148

Configuring the printer 148

Setting the Display Resolution (M8033A only) 148

8 Site Preparation 149

Introduction 149

Site Planning 149

Roles & Responsibilities 149

Site Preparation Responsibilities 149

Procedures for Local Staff 150

Procedures for Philips Personnel 151

Monitor M8010A Site Requirements 151

Space Requirements 151

Environmental Requirements 152

Te m p e r at u r e 15 2

Humidity 152

Altitude 152

Electrical and Safety Requirements (Customer or Philips) 152

Safety Requirements 152

Electrical Requirements 153

Remote Device Site Requirements 153

Multi-Measurement Server M3001A or Flexible Module Server M8048A 154

Space Requirements Multi-Measurement Server M3001A 154

Space Requirements Flexible Module Server M8048A 154

Environmental Requirements Multi-Measurement Server M3001A 155

Environmental Requirements Flexible Module Server M8048A 155

Cabling Options and Conduit Size Requirements 155

Remote Displays - M8031A 156

Space Requirements 156

Environmental Requirements 156

Electrical and Safety Requirements 157

Remote Displays - M8033A 157

Space Requirements 157

Environmental Requirements 157

Electrical and Safety Requirements 157

Cabling Options and Conduit Size Requirements 158

Remote Alarm Devices 158

Space Requirements 158

8

Page 9

Cabling Options and Conduit Size Requirements 158

Remote Extension Device 159

Space Requirements 159

Cabling Options and Conduit Size Requirements 159

Input Devices 159

Local Printer 160

Philips Medical LAN 160

MIB Interface 160

Flexible Nurse Call Relay Interface 161

ECG Out Interface 161

9 Anesthetic Gas Module 163

Introduction 163

Description 163

Product Structure 163

Physical Specifications 163

Environmental Specifications 164

Performance Specifications 164

CO2 Measurement 165

AWRR derived from CO2 Waveform 165

N2O Measurement 165

O2 Measurement 165

Anesthetic Agent Measurement 165

Alarm Ranges 166

Alarm Delay 166

Apnea Alarm 166

INOP Alarms 166

General Measurement Principles 167

Theory of Operation 167

Main PC Board 168

Power Supply 169

Pneumatic System 169

Pump 170

Wate rt rap 170

Sample Flow Through the Pneumatic Path 171

Agent Identification Assembly 171

Measurement Principle 172

O2 Sensor 172

Specifications 172

Measurement Principle 172

Infrared Measurement Assembly 173

Installation and Patient Safety 174

Physical Installation 174

Environment 175

Label Sheet 175

Making Connections to the AGM 175

9

Page 10

Sample Gas Connections to the Gas Exhaust 176

Returning the Gas Sample 176

Setting Up the Gas Return 177

Removing the Gas Sample 178

Setup and Configuration Procedures 178

Altitude Configuration 178

Connect Sample Input Tubing 178

Preventive Maintenance (PM) Tasks 178

Post-Installation Checks 179

Safety Requirements Compliance and Considerations 179

Explanation of Symbols Used 179

Power Supply Requirements 180

Grounding the System 180

Equipotential Grounding 181

Combining Equipment 181

Checking and Calibrating the Anesthetic Gas Module 181

Access Service Functions of the M1026A Anesthetic Gas Module 181

When and how to check the Philips M1026A Anesthetic Gas Module 183

Equipment required for checking 183

Checks and adjustments 184

Performance Leakage Check 184

Performance Diagnostic Check 185

Performance Flowrate Check 185

Total Flowrate Check and Adjustment in Purge Mode 185

Measurement Path Flowrate Check and Adjustment 186

Total Flowrate Check in Normal Mode 188

Zero Calibration 188

Barometric Pressure Check and Calibration 189

Span Calibration Check 190

Disposal of Empty Calibration Gas Cylinder 192

Maintaining the Anesthetic Gas Module 193

Preventive Maintenance (PM) Tasks 193

Cleaning 194

Replace PM Parts 194

Internal Nafion Tubing with Bacterial Filters and manifold Seals 194

Room-Air Filter 196

Pump Filter 197

Performance Checks 198

Other factors to maximize uptime or reduce cost of ownership: 198

Troubleshooting the Anesthetic Gas Module 198

Compatibility Criteria for the AGM and the IntelliVue Monitors 198

Flow Charts for Communication and Measurement Type Problems 198

Hardware Related Troubleshooting Strategy 203

INOPs 204

Calibration Checks 206

Calibration Checks Troubleshooting Table 207

10

Page 11

Diagnostic Checks 208

Problem Solving Hierarchy 209

Pneumatic System Diagnostic Checks 210

O2 Assembly Diagnostic Checks 210

Optical Path Disgnostic Checks 213

IR Measurement Assembly Diagnostic Checks 214

Agent ID Assmebly Diagnostic Checks 215

Power Supply Diagnostic Checks 216

Operating Temperature Diagnostic Checks 217

Test Points, Connectors and Jumpers 217

Tes t Poi n t s 21 7

Connectors 218

Jumpers 218

Repairing the Anesthetic Gas Module 220

Introduction 220

The Top Cover 222

Removal 222

Replacement 222

Lifting the IR Measurement Mounting Bracket 224

Removal 225

Replacement 225

Infrared Measurement Assembly Head 227

Transferring NVRAM Data to a Replacement Head 227

Sample Cell 231

Removal 231

Replacement 231

Solenoid Valve #1 235

Removal 235

Replacement 235

Power Supply Unit 237

Removal 237

Replacement 237

Main PC Board 238

Removal 238

Replacement 239

O2 Sensor 240

Removal 240

Replacement 241

Agent Identification Head 243

Removal 243

Replacement 244

Pump 245

Removal 245

Replacement 245

Fan 246

11

Page 12

Removal 246

Replacement 246

Solenoid Valve #2 248

Removal 248

Replacement 248

Top C ov e r PC B o a rd 249

Removal 249

Replacement 249

Watertrap Manifold and Protector 251

Removal 251

Replacement 251

Power Fuses 252

Removal 252

Replacement 252

Test and Inspection Matrix 252

When to Perform Test Blocks 256

Safety Test Appendix 257

Parts List 259

Calibration Equipment 264

12

Page 13

This Service Guide contains technical details for the IntelliVue MP90 Patient Monitor, the MultiMeasurement Server (MMS), the Flexible Module Server (FMS) and the Measurement Server

Extensions.

This guide provides a technical foundation to support effective troubleshooting and repair. It is not a

comprehensive, in-depth explanation of the product architecture or technical implementation. It offers

enough information on the functions and operations of the monitoring systems so that engineers who

repair them are better able to understand how they work.

It covers the physiological measurements that the products provide, the Measurement Server that

acquires those measurements, and the monitoring system that displays them.

Who Should Use This Guide

1

1Introduction

This guide is for biomedical engineers or technicians responsible for troubleshooting, repairing, and

maintaining Philips’ patient monitoring systems.

How to Use This Guide

This guide is divided into eight sections. Navigate through the table of contents at the left of the screen

to select the desired topic. Links to other relevant sections are also provided within the individual

topics. In addition, scrolling through the topics with the page up and page down keys is also possible.

Abbreviations

Abbreviations used throughout this guide are:

Name Abbreviation

IntelliVue MP90 Patient Monitor the monitor

Flexible Module Server FMS

Multi-Measurement Server MMS

Measurement Server Link MSL

Medical Information Bus MIB

Anesthetic Gas Module AGM

13

Page 14

1 Introduction Responsibility of the Manufacturer

Responsibility of the Manufacturer

Philips only considers itself responsible for any effects on safety, reliability and performance of the

equipment if:

• assembly operations, extensions, re-adjustments, modifications or repairs are carried out by persons

authorized by Philips, and

• the electrical installation of the relevant room complies with national standards, and

• the instrument is used in accordance with the instructions for use.

To ensure safety, use only those Philips parts and accessories specified for use with the monitor. If nonPhilips parts are used, Philips is not liable for any damage that these parts may cause to the equipment.

This document contains proprietary information which is protected by copyright. All Rights Reserved.

Reproduction, adaptation, or translation without prior written permission is prohibited, except as

allowed under the copyright laws.

Philips Medizin Systeme Böblingen GmbH

Hewlett-Packard Str. 2

71034 Böblingen, Germany

The information contained in this document is subject to change without notice.

Philips makes no warranty of any kind with regard to this material, including, but not limited to, the

implied warranties or merchantability and fitness for a particular purpose.

Philips shall not be liable for errors contained herein or for incidental or consequential damages in

connection with the furnishing, performance, or use of this material.

Passwords

In order to access different modes within the monitor a password may be required. The passwords are

listed below.

Monitoring Mode: No password required

Configuration Mode: 71034

Demo Mode: 14432

Service Mode: 1345

Consult the configuration guide before making any changes to the monitor configuration.

Warnings and Cautions

In this guide:

•A warning alerts you to a potential serious outcome, adverse event or safety hazard. Failure to

observe a warning may result in death or serious injury to the user or patient.

14

•A caution alerts you where special care is necessary for the safe and effective use of the product.

Failure to observe a caution may result in minor or moderate personal injury or damage to the

product or other property, and possibly in a remote risk of more serious injury.

Page 15

2Theory of Operation

Monitor Theory of Operation

The IntelliVue Patient Monitor:

• displays real-time data

• controls the attached measurement servers

• alarms in the case of patient or equipment problems

• offers limited data storage and retrieval (trending)

• interfaces to the Philips Clinical Network and other equipment

2

A monitor with just a single integrated measurement server can be connected to additional building

blocks to form a monitoring system with a large number of measurements, additional interface

capabilities and multiple slave displays. These elements cooperate as one single integrated real-time

measurement system.

System Boundaries

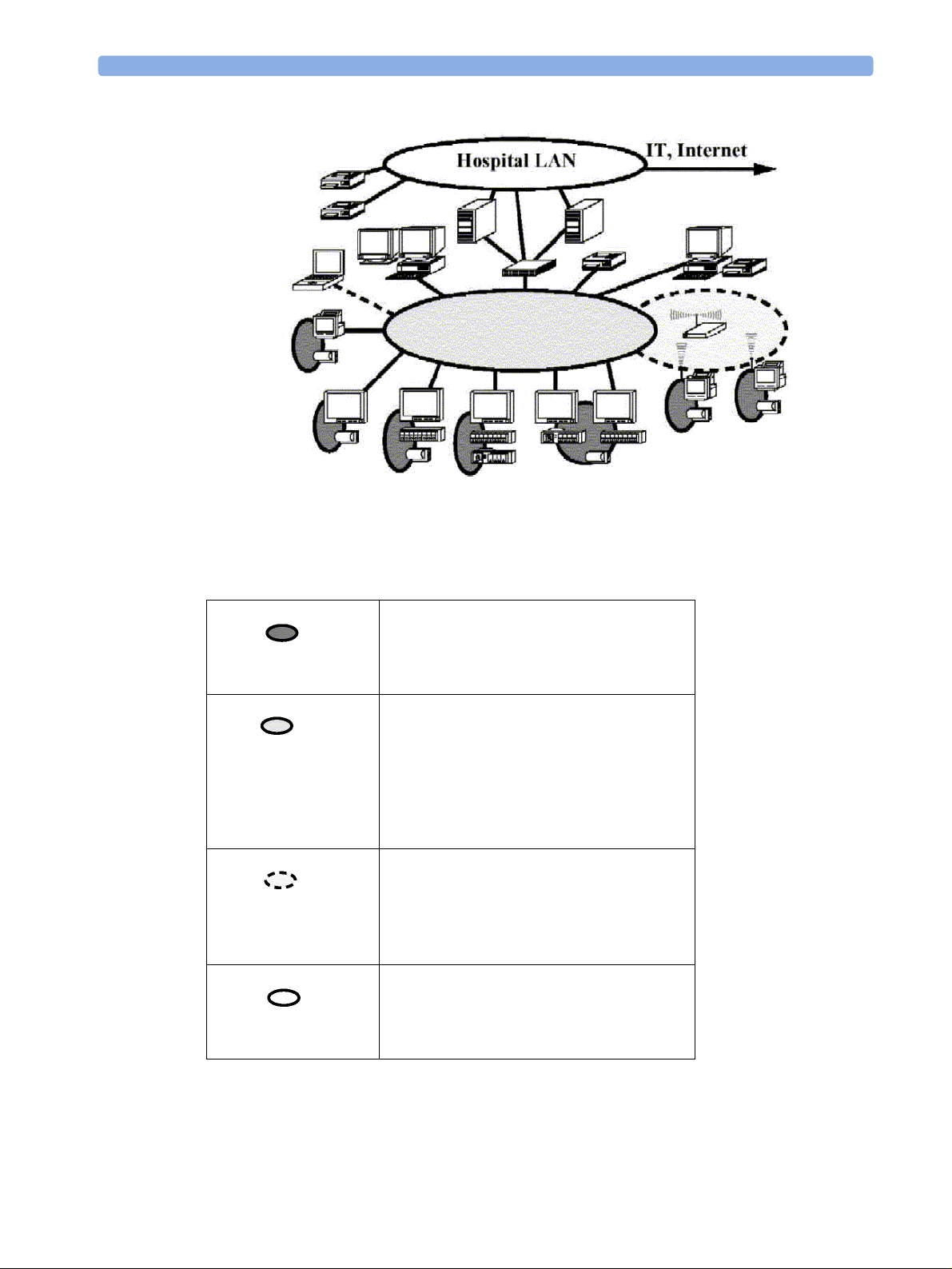

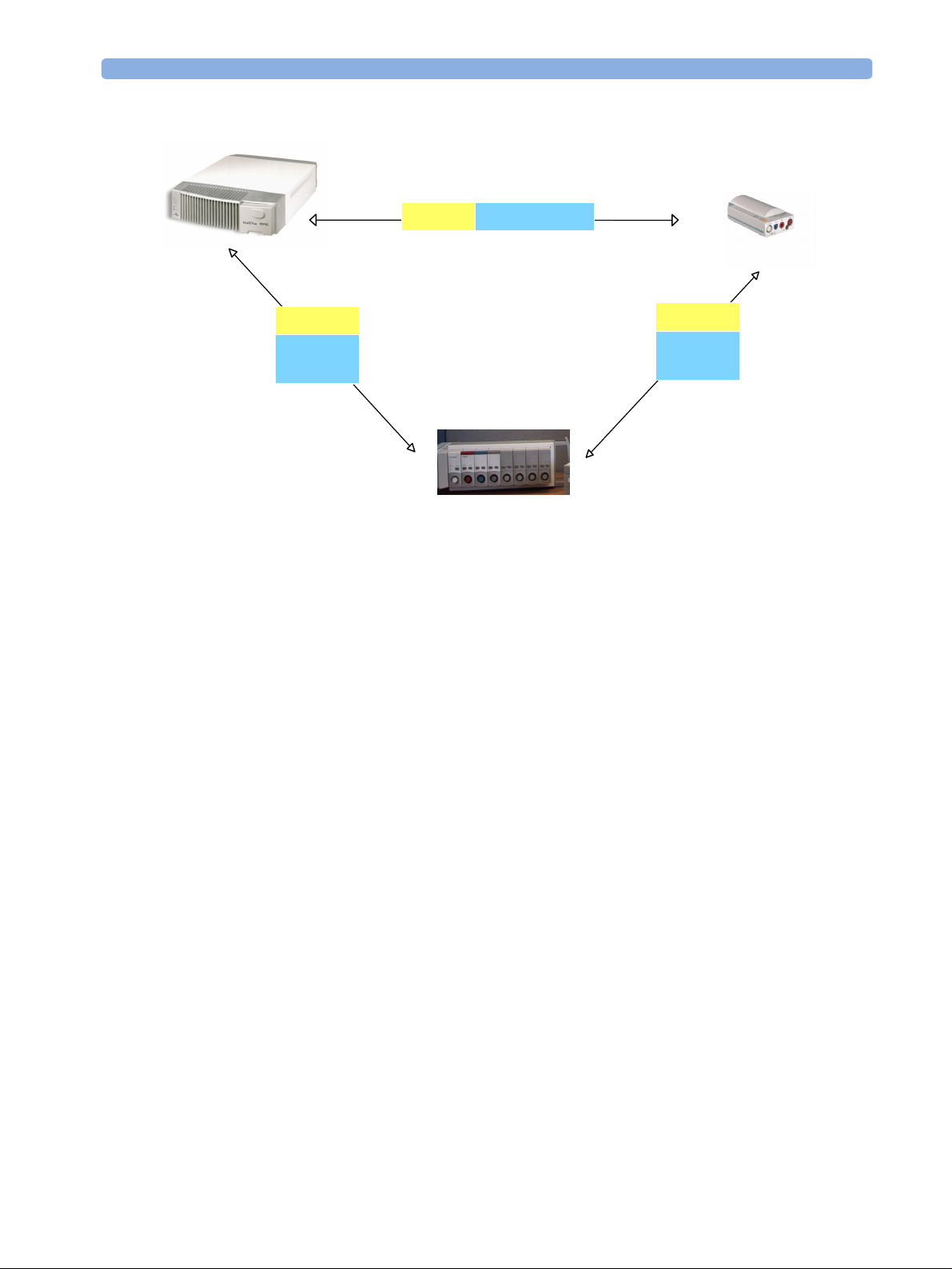

The following diagram discusses specific boundaries within the overall system with respect to their

openness and real-time requirements:

15

Page 16

2 Theory of Operation Monitor Theory of Operation

Philips Clinical Network

Measurement LAN

combines components of one patient monitor;

real time requirements across all interconnected

elements

Philips Clinical Network (wired LAN)

connects multiple patient monitors,

information centers, application servers; closed

system, only Philips qualified products (tested

and with regulatory approval) are connected,

Philips is responsible for guaranteed real-time

functionality and performance

Philips Clinical Network (wireless)

like Philips Clinical Network (wired) LAN,

however due to current wireless technologies

available it has reduced bandwidth, longer

latencies, reduced functionality

Hospital LAN, Internet

Standard Network, not under Philips control,

no guaranteed service, no real-time

requirements

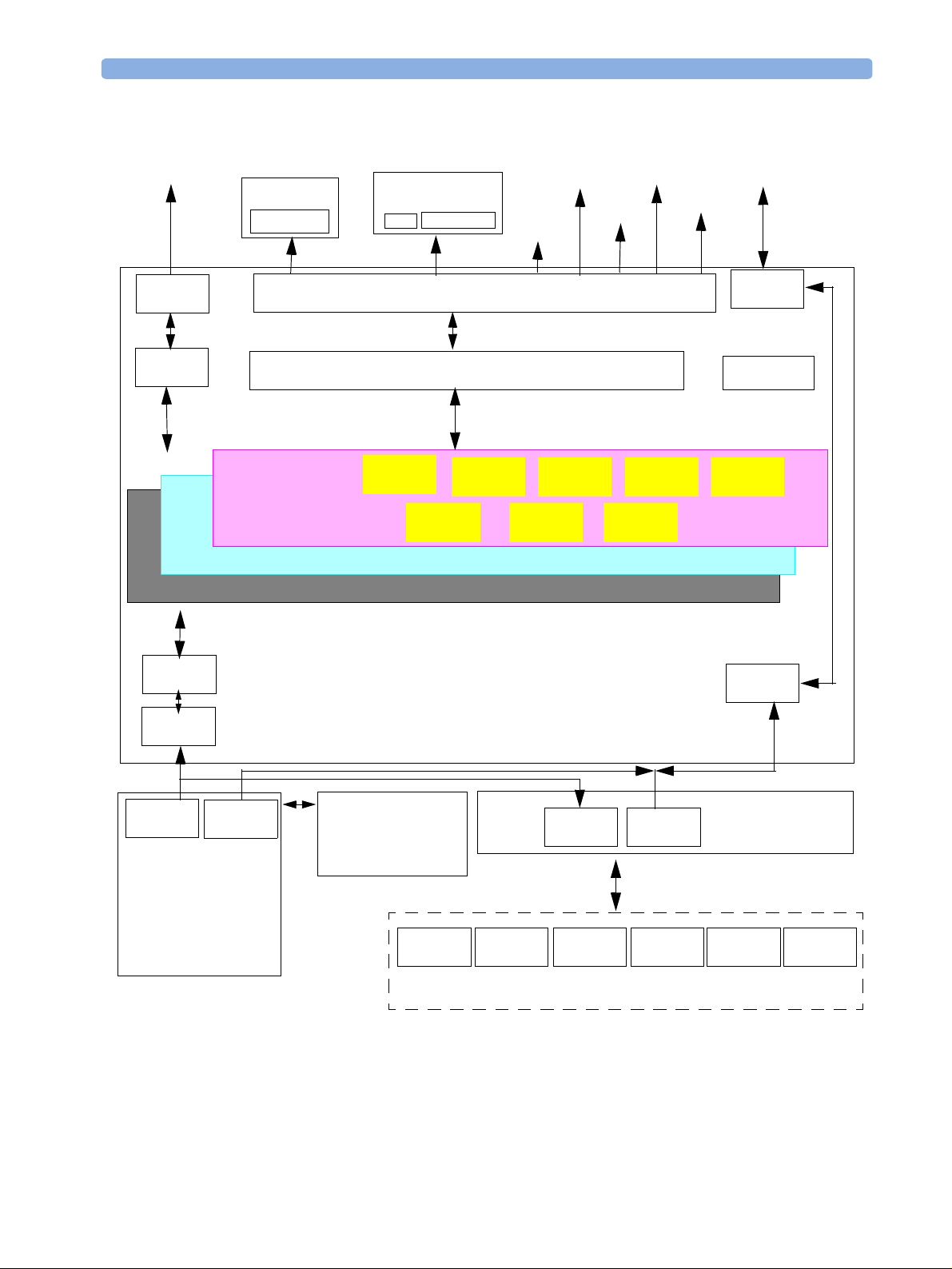

Hardware Building Blocks

The following hardware building blocks make up the monitoring system:

16

Page 17

Monitor Theory of Operation 2 Theory of Operation

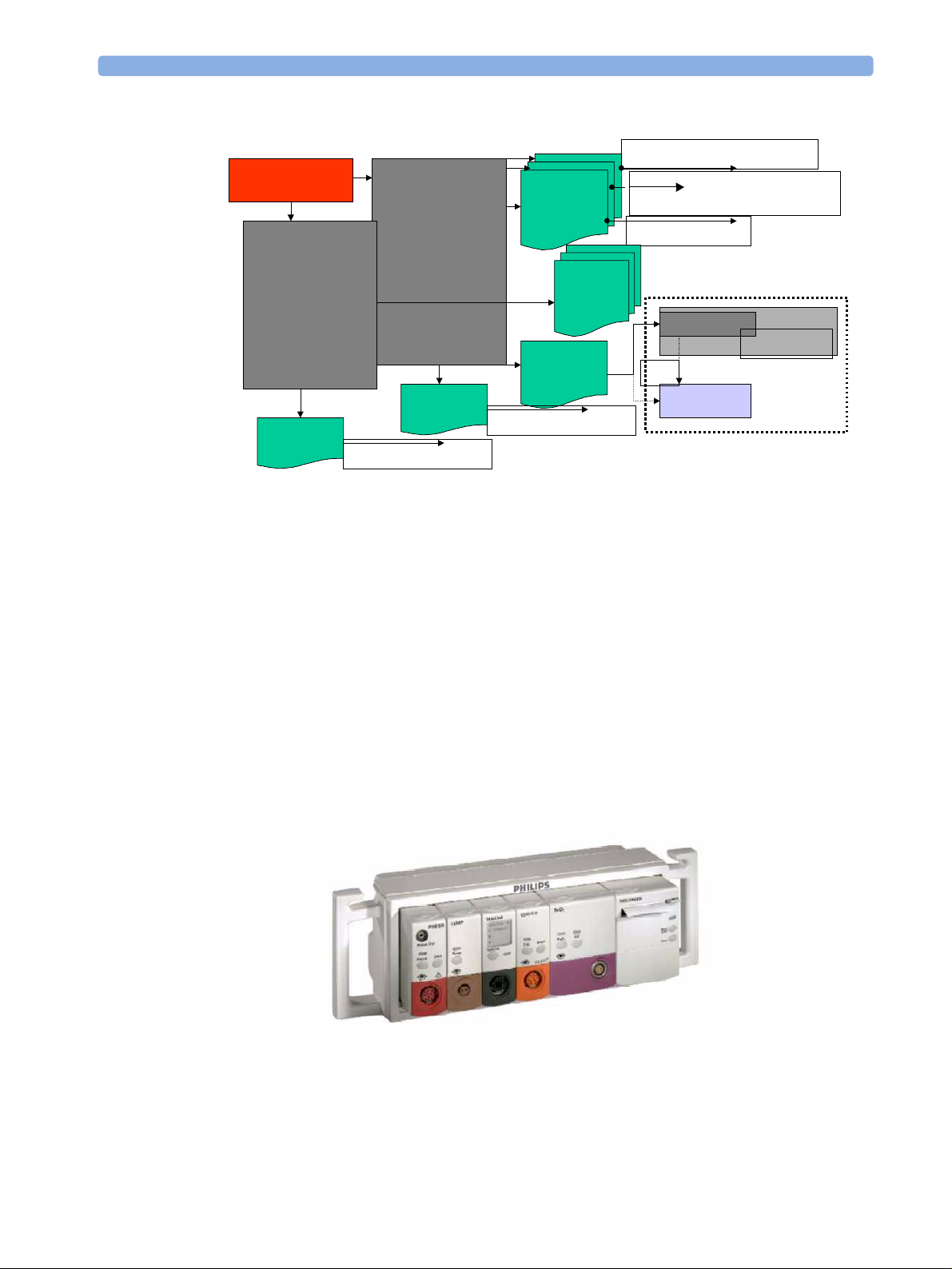

IntelliVue MP90

The MP90 monitor:

• can be used with the standalone M8031A 15-inch or the M8033A 17-inch color LCD TFT display

with touchscreen operation.

• can also be used with other XGA and SXGA standalone off-the-shelf displays which comply with

medical standards such as IEC 60601-1 and IEC 60601-1-2.

• has the central processing unit in a separate module

• uses the Philips SpeedPoint as primary input device whereas the Philips Touchscreen and computer

devices such as mice, trackball, and keyboard can be added optionally

• supports the Flexible Module Server (FMS)

Building Blocks:

17

Page 18

2 Theory of Operation Monitor Theory of Operation

|| I/F To Local Printer

Power Supply

I/F

Boards

1st Main Board

Remote Device I/F to

Alarm Device I/F*

Alarm Device and Remote Input

MIB To AGM

1 Main Board

I/F

2nd

Main Board

Boards

FMS CPU

FMS M/B

MSL

OR

MMS CPU

Video I/F

Board

Video I/F

Board

To Ext. Display

I/F

To Ext. Display

Optional Hardware

The M8031A 15-inch color LCD TFT display or the M8033A 17-inch color LCD TFT display (both

with touchscreen operation) can be ordered optionally. Additional input devices such as mice, trackball

or keyboard can also be added. If the monitor is ordered with the wireless LAN option an external

wireless transmitter is required. For further details regarding the wireless network please refer to the

M3185A Philips Clinical Network documentation.

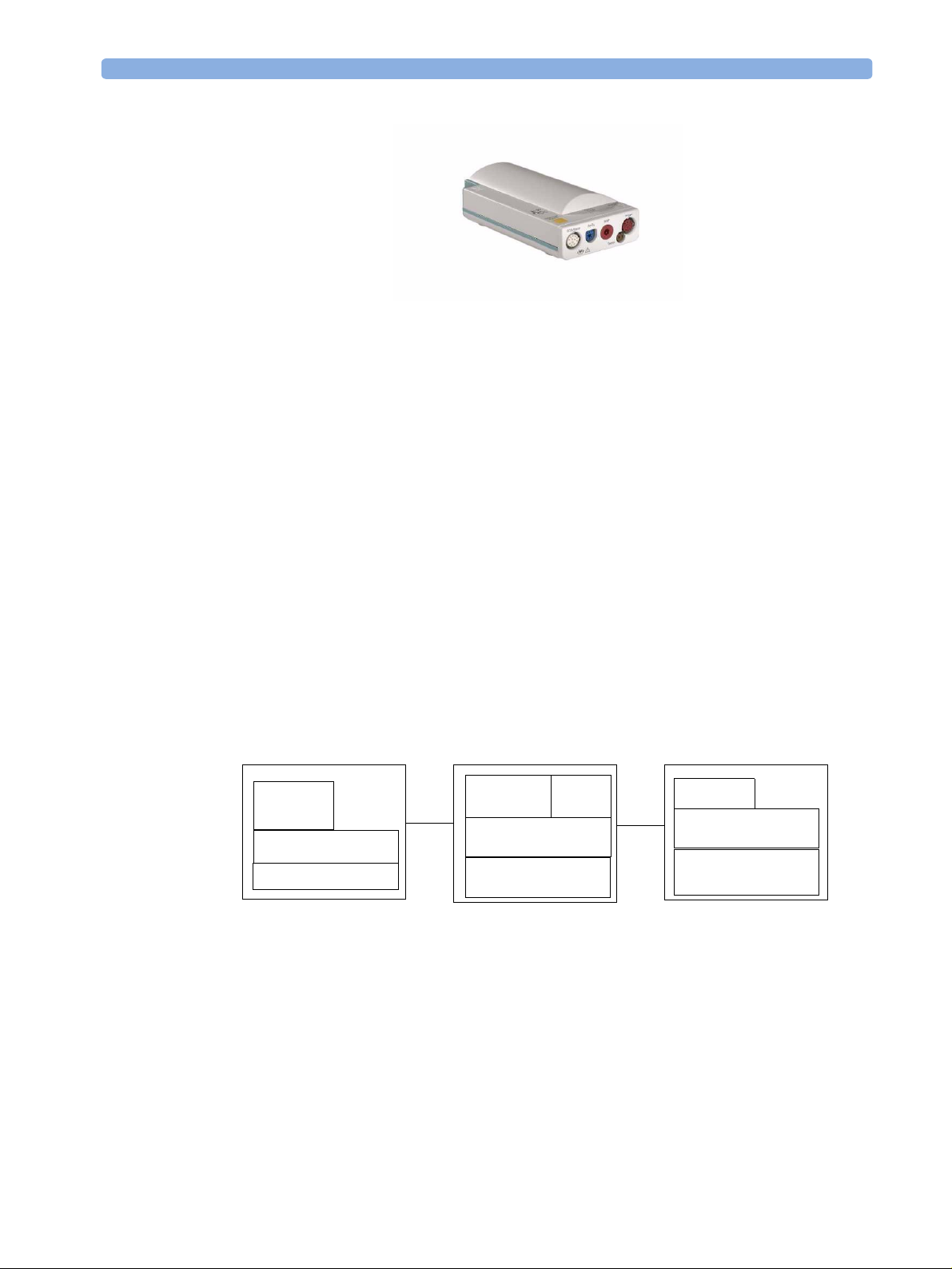

Compatible Devices

18

Figure 1 M8048A Flexible Module Server (FMS)

Page 19

Monitor Theory of Operation 2 Theory of Operation

Figure 2 M3001A Multi-Measurement Server (MMS)

Power Supply

The AC/DC converter transforms the AC power coming from the power plug into 48 V/120W DC

source and isolates the monitoring system from the AC power mains.The 48V is distributed via power

bus and supplies power to all the components of the system: The 56 V DC power needed for the FMS,

MMS and measurement server extension is created by an isolating DC/DC converter. The CPU is

supplied with 3.3 V and 5 V DC power. The transformation is performed in two steps: The first DC/

DC converter is a power regulator which reduces the variations caused by load changes on the 48V

power bus. The second DC/DC converter converts the power to the needed voltage. Interface boards

require a power of 10V AC.

CPU Boards

The CPU boards have an MPC860 50 MHz processor that provides a number of on-chip,

configurable interfaces. An array of 12 fast UARTs with configurable protocol options are

implemented in an ASIC (along with other system functions such as independent watchdogs etc.),

providing interfacing capabilities to measurement modules and I/O boards. The serial interfaces can

easily be electrically isolated. The main board contains additional video hardware.

Flexible Module Server

CPU

Bank of I/Os

Modules

The CPUs provide two LAN interfaces to interconnect CPUs (via the Internal LAN) or to connect to

the Philips Clinical Network.

IntelliVue Patient Monitor Multi-Measurement Server

CPU Video

Bank of I/Os

CPU

Bank of I/Os

Measurement

Interfaces

Acquisition

The CPU capabilities are identical. Different loading options are coded on serial EEPROMs to support

the automatic configuration of the operating system at boot time.

19

Page 20

2 Theory of Operation Monitor Theory of Operation

I/O Boards

Interfaces to the monitor are implemented via I/O boards. The location of these boards is restricted by

general rules. The I/O slot designations diagram and the I/O matrix which outline the I/O board

placement rules can be found in the Installation Instructions section.

The following is a list of Interface (I/O) boards which may be present in your monitor, depending on

your purchased configuration:

•MSL

•Video

• Philips Clinical Network (LAN wired or wireless)

•PS/2

• MIB/RS232

•Flexible Nurse Call

•Parallel printer

• Remote devices (Remote Alarm Device, Remote Extension Device)

The specifications for the above listed interfaces can be found in the technical data sheet for the

monitor and in the Specifications chapter of the Instructions for Use.

Data Flow

The following diagram shows how data is passed through the monitoring system. The individual stages

of data flow are explained below.

Display

and User

Interface

Data

Acquisition

Data

Provider

Applications

Service

Persistent

Data

Storage

Data

Output

Data Acquisition

Monitoring data (for example patient measurement data in the form of waves, numerics and alerts) is

acquired from a variety of sources:

20

Page 21

Monitor Theory of Operation 2 Theory of Operation

•Measurement Servers

The Measurement Servers connected to the internal LAN convert patient signals to digital data and

apply measurement algorithms to analyze the signals.

• External measurement devices

Data can be also acquired from devices connected to interface boards of the monitor. Software

modules dedicated to such specific devices convert the data received from an external device to the

format used internally. This applies to parameter modules and the Anesthetic Gas Module.

• Server systems on the Philips Clinical Network

To enable networked applications such as the other bed overview, data can be acquired from server

systems attached to the Philips Clinical Network, for example a Philips Information Center.

Data Provider System Service

All data that is acquired from measurement servers or external measurement devices is temporarily

stored by a dedicated data provider system service. All monitor applications use this central service to

access the data in a consistent and synchronized way rather than talking to the interfaces directly.

This service makes the applications independent of the actual type of data acquisition device.

The amount of data stored in the data provider system service varies for the different data types. for

example several seconds of wave forms and the full set of current numerical values are temorarily stored

in RAM.

Persistent Data Storage System Service

Some applications require storage of data over longer periods of time. They can use the persistent data

storage system service. Dependent on the application requirements, this service can store data either in

battery backed-up (buffered) memory or in flash memory. The buffered memory will lose its contents

if the monitor is without power (not connected to mains) for an extended period of time. The flash

memory does not lose its contents.

The trend application for example stores vital signs data in a combination of flash memory and

buffered memory, while the system configuration information (profiles) is kept purely in flash

memory.

Display and User Interface Service

Applications can use high level commands to display monitoring data or status and command windows

on the LCD panel. These commands are interpreted by the display manager application. This

application controls the dedicated video hardware which includes video memory and a special ASIC.

User input is acquired from a variety of input devices, for example the SpeedPoint, the touchscreen or

other standard input devices (keyboard, mouse) which may be attached to I/O boards. The system

software makes sure that the user input is directed to the application which has the operating focus.

Data Output

The monitoring system is very flexible and customizable regarding its data output devices. Built-in

devices (for example LAN, speaker, video) provide the basic output capabilities.

These capabilities can be enhanced by adding additional I/O boards, as required in the specific enduser setup. The additional I/O boards typically provide data to externally attached devices, for example

to printers, RS232 based data collection devices, nurse call systems etc.

21

Page 22

2 Theory of Operation Monitor Theory of Operation

The monitor can identify I/O boards by means of a serial EEPROM device that stores type and version

information. The operating system detects the I/O boards and automatically connects them with the

associated (interface driver) application. For some multi-purpose cards it is necessary to configure the

card for a particular purpose first (for example the dual MIB/RS232 card can support external touch

display, data import, data export).

Monitor Applications

The monitor applications provide additional system functionality over the basic measurement and

monitoring capabilities. This includes for example trending, report generating, event storage or derived

measurements.

In general, the monitor applications use the data provider system service to access the measurement

data. Application interfaces to the other system services allow the application to visualize data, to store

data over extended periods of time or to output data to other devices.

Internal LAN (Measurement Server Link)

All components of the monitoring system (including measurement servers and CPUs in the monitor)

communicate using an IEEE802.3/ Ethernet LAN in the Measurement Server Link (MSL). This

network is used to distribute data between the components, for example:

• Digitized patient signals including wave data, numerical data and status information (typically from

the measurement server to a display unit)

• Control data representing user interactions (typically from the display unit to a measurement server)

• Shared data structures, for example representing patient demographical data and global

configuration items

The internal LAN allows plug and play configuration of the monitoring system. The system

automatically detects plugging or unplugging of measurement servers and configures the system

accordingly.

The components on the internal LAN are time-synchronized to keep signal data consistent in the

system. Dedicated hardware support for synchronization eliminates any latency of the network driver

software.

The integrated LAN provides deterministic bandwidth allocation/reservation mechanisms so that the

real-time characteristic of signal data and control data exchange is guaranteed. This applies to the data

flow from the measurement server to the monitor (for example measurement signal data) and the data

flow from the monitor to a measurement server (for example to feed data to a recorder module).

Integrated communication hubs in the monitor and the FMS allow flexible cabling options (star

topology, daisy chaining of servers).

22

Page 23

Monitor Theory of Operation 2 Theory of Operation

MDSE Internal LAN

MDSE

Internal

LAN

Philips Clinical Network

The monitoring system may be connected to the Philips Clinical Network, for example to provide

central monitoring capabilities or other network services. This connection may be through a normal

wired connection or through a wireless connection.

The monitor supports the connection of an external off-the-shelf wireless adapter. This allows a simple

field upgrade as well as a technology upgrade in the future. Switching between wired and wireless

networks is automatically triggered by the plugging or unplugging of the network cable.

The Philips Clinical Network protocols function very similarly to the protocols used on the internal

LAN.

MDSE

Internal

LAN

After configuration, the monitoring system sends the digitized patient signals including wave data,

numerical data and status information onto the network. Control data representing user interactions

can be exchanged between the monitoring system and a central station bi-directionally.

Additional protocols are supported for networked applications, for example for the other bed overview

function, which allows viewing of monitoring data from other patients on the network.

For plug and play operation, the monitoring system uses the standard BootP protocol to automatically

acquire a network address.

How does the Support Tool Work with the Monitor

The support tool is a Windows application typically installed on the laptop of a customer engineer or a

biomedical engineer working in the customer’s own service department.

The purpose of the support tool is to upgrade, configure and diagnose all monitoring components

(modules, measurement servers, and monitors) in the system over the network.

23

Page 24

2 Theory of Operation Monitor Theory of Operation

The service protocol developed for this purpose uses a raw access to the devices without the need for IP

addresses etc. over a standard customer network installation, so that even defective devices can be

upgraded as long as the few kBytes of initial boot code are working. The boot code itself can also be

upgraded using the same protocol.

The tool allows access to internal service information and to serial numbers. It can be remotecontrolled, for example via a dial-up connection from a response center, provided the proper

infrastructure is in place.

For details see the Instructions for Use for the Support Tool.

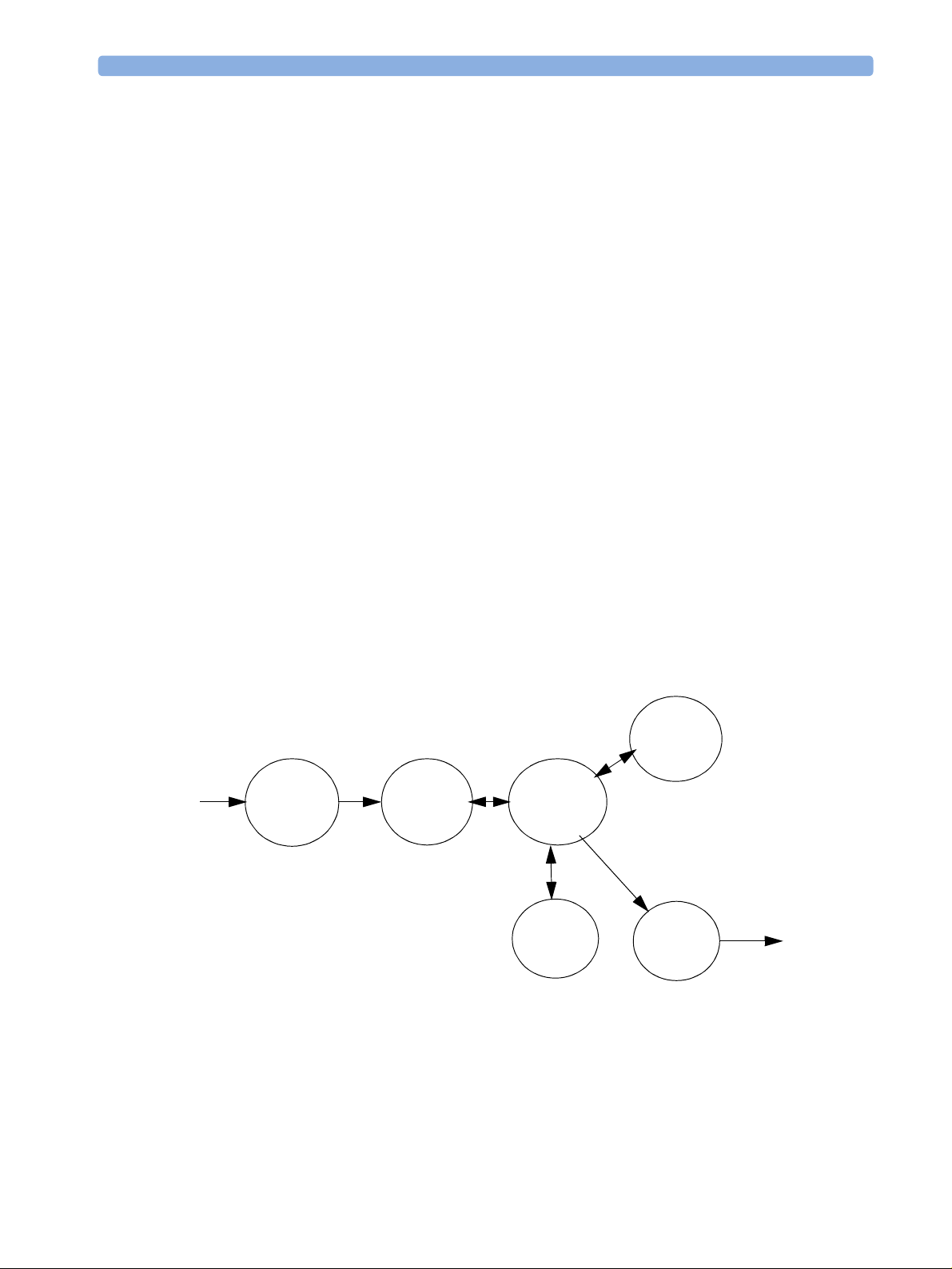

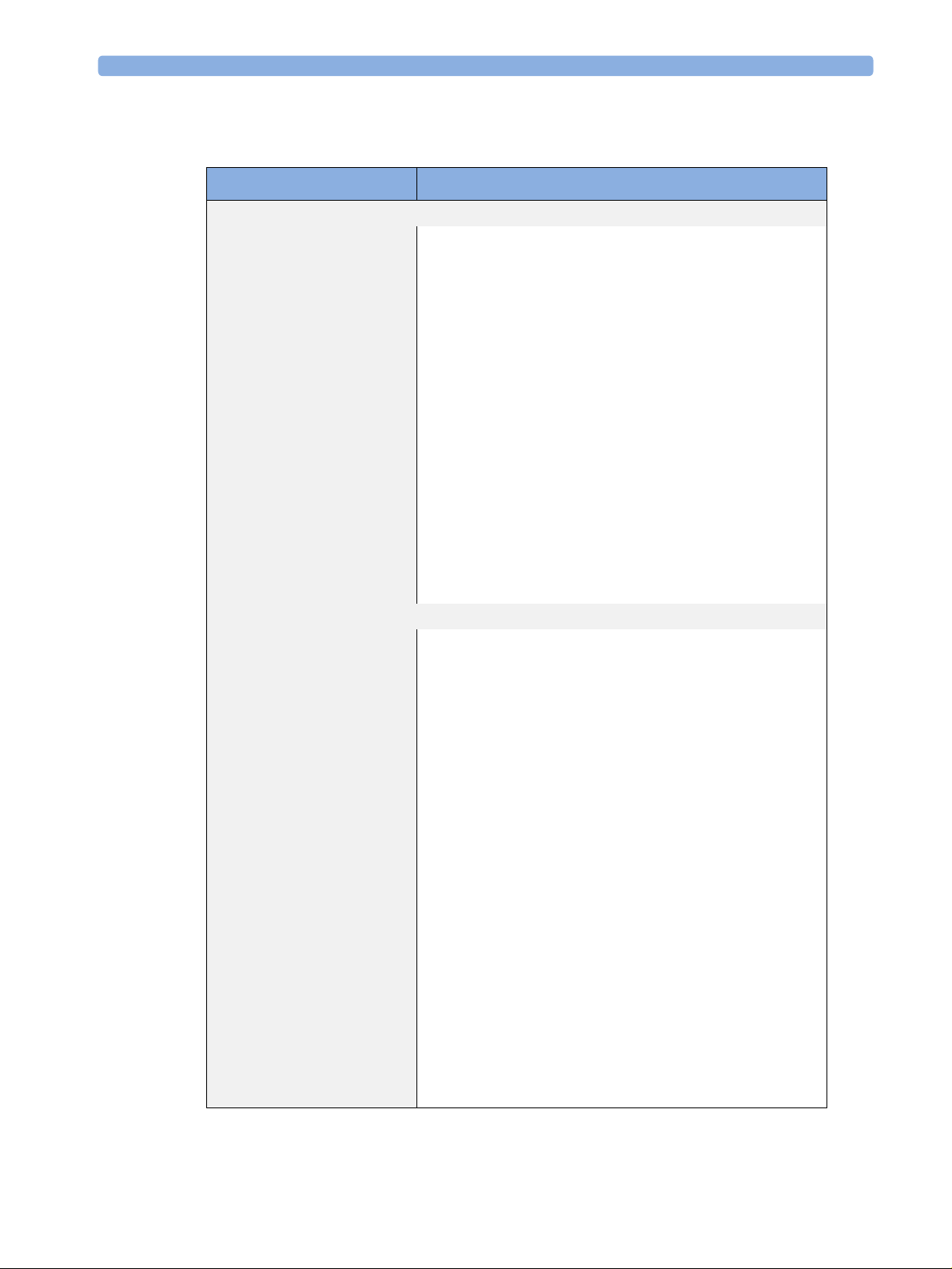

Monitor Software Block Diagram

Figure 3 shows the functional block diagram for the monitoring system. A legend explaining terms and

diagram elements follows. The information below varies depending on the purchased monitor options.

24

Page 25

Monitor Theory of Operation 2 Theory of Operation

Philips Clinical

Network

LAN

MDSE

Input Devices

(including PS/2)

Remote Extension

Device M8026A

SpeedPoint

(LAN, Centronics, Display Controller, HIF Control,RS-422, PS/2, Remote Device I/F, Nurse Call, MIB)

Applications

System Services

Real Time Operating System

Visual

Indicators

Remote Alarm Device

LEDs

Indicators

M8025A

Loudspeaker

Audio

Video Out

Centronics

Input Devices

(PS/2)

Nurse

MIB

Call

Printer Connection

Interfaces

Interface Managers

Record Alarm Trend HiRes ADT

Reports

Calc Param

Events

ECG-Out

Marker-In

ECG-Out

Marker-In

Loudspeaker

MDSE

LAN

LAN

RS-422

M3001A MultiMeasurement Server

12-lead ECG/Resp, NBP, SpO2,

Press/Temp

M3015/16A

Measurement Server

Extension

CO2, Press/Temp

M1006B

Press

Plug-In Modules

M1012A

C.O.

LAN RS-422

M1018A

tcPO2/CO2

M1029A

Temp

RS-422

Flexible

Module

Server

M1032A

VueLink

M1116B

Recorder

Figure 3 IntelliVue Patient Monitoring System Functional Block Diagram

25

Page 26

2 Theory of Operation Monitor Theory of Operation

Block Diagram Legend

Functional Block Description

Services

Operating System The Operating System (OS) provides a layer of isolation between

the specific hardware implementation and the application

software. The OS performs system checks and allocates resources

to ensure safe operation when the system is first started. This

includes internal self-tests on several hardware modules and

configuration checks for validity of configuration with the

operating software. During normal operation, the OS continues

to run checks on system integrity. If error conditions are detected

the OS will halt monitoring operations and inform the operator

about the error condition.

System Services The System Services provide generic common system services.

In particular:

It uses a real-time clock component to track time. It synchronizes

to network time sources and verifies the accuracy of the system

time information. It is also responsible for managing persistent

user configuration data for all Measurement Servers, Flexible

Module Servers and IntelliVue Patient Monitoring System

software modules. User configuration data is stored in a nonvolatile read/write storage device

Applications

Reports The Reports Service retrieves current and stored physiological

data and status data to format reports for printing paper

documentation. The following reports are supported:

•Vital Signs Report

• Graphical Trend Report

• Event Review Report

•Event Episode Report

• ECG Report (12 Lead/Multi-Lead)

• Cardiac Output Report

• Calculations Report (Hemodynamic/Oxygenation/

Ventilation)

• Calculations Review Report

•Wedge Report

•Test Report

• Other reports (e.g. Loops, Review Applications, Drug

report)

The Reports service generates report data which can be printed

on a local or a central printer.

26

Page 27

Monitor Theory of Operation 2 Theory of Operation

Functional Block Description

Record The Record Service retrieves current and stored physiological

data and status data to format a continuous strip recording. A

recording can be triggered manually by the operator or

automatically by an alarm condition. The Record Service uses the

services of the Recorder Interface to control an M1116B

Recorder in the FMS. The Record Service can also send data to a

central recorder.

Alarm The Alarm Service contains logic that prioritizes alarm conditions

that are generated either by the Measurement Servers, Flexible

Module Server, or by IntelliVue Patient Monitoring System

software modules. Visual alarm messages are displayed at the top

of the IntelliVue Patient Monitoring System display and alarm

sounds are generated by a loudspeaker. Alarm conditions may be

generated when a physiological parameter exceeds preselected

alarm limits or when a physiological parameter or any other

software module reports an inoperative status (technical alarm,

for example, the ECG leads may have fallen off the patient). The

Alarm service manages the alarm inactivation states, for example

suspension of alarms, silencing of alarms, and alarm reminder.

Alarm signals may also be configured as latching (alarm signals

are issued until they are acknowledged by the operator, even

when the alarm condition is no longer true). The Alarm service

controls the visual alarm signals (alarm lamps).

Trend The Trend service stores the sample values of physiological data

and status data with a resolution of 12 seconds, 1 minute or 5

minutes for a period of up to 48 hours. The data is kept in

battery buffered read/write storage and flash memory devices to

be preserved across power failures. The stored data is protected

via consistency checks and checksums. When a new patient is

admitted, the trend database erases all data of the previous

patient.

HiRes The OxyCRG (Oxygen CardioRespiroGram) service derives a

high-resolution trend graph from the Beat-to-Beat Heart Rate,

SpO

or tcpO2, and Respiration physiological data. The

2

OxyCRG is specialized for neonatal applications, allowing the

opeartor to identify sudden drops in Heart Rate (Bradycardia)

and SpO

or tcpO2 (Desaturations), and supporting the operator

2

in visualizing Apnea situations.

ADT The ADT (Admit/Discharge/Transmit) service maintains the

patient demographics information. The operator may admit a

new patient, discharge the old patient and enter or modify the

patient demographics. The ADT service also supports the

transport of a patient (trend database) with the M3001A MultiMeasurement Server. The ADT service controls the deletion of

old patient data, the upload of trend data from the M3001A and

the switching back of all settings to user defaults. It also

synchronizes patient information with a central station on the

network.

27

Page 28

2 Theory of Operation Monitor Theory of Operation

Functional Block Description

Calc Param The Calc Param (Calculated Parameters) service accesses current,

stored and manually entered physiological data as input to

calculation formulas. With these formulas, derived

hemodynamic, oxygenation and ventilation variables are

computed. The calculation results, including the input

parameters, are stored for later review using the Trend service.

Interface Managers

MDSE The MDSE (Medical Data Service Element) Interface Manager is

responsible for the exchange of real-time data between the

IntelliVue Patient Monitoring System display unit and the

Measurement Servers and Flexible Module Server as well as

between the IntelliVue Patient Monitoring System display unit

and other devices attached to the network. MDSE establishes and

maintains a data communication link between the devices. It

provides configuration information about the remote device to

applications in the local device and it allows the exchange of

measurement data and status information between the devices.

Printer The Printer Interface Manager provides a high level interface to a

printer. It provides means to:

• establish a connection to the printer

• transfer data to the printer

• get status of the printer

• close connection to the printer

The Printer Interface Manager also supervises the connection to

the printer and whether the printer accepts data (for example

paper out). The Printer Interface Manager notifies the operator

in such cases.

28

Page 29

Monitor Theory of Operation 2 Theory of Operation

Functional Block Description

Display & Operator Interface The Display and Operator Interface Manager performs the

following tasks:

• Screen presentation of real-time and stored physiological

measurement data, alarm condition data and status

information received from the MDSE interface manager,

the Alarm service or other IntelliVue Patient Monitoring

System modules

• Screen presentation of operating controls (control

windows)

• Processing of operating control commands received from

HIF Control interface. The module verifies and interprets

the received commands and forwards them to other

software modules of the IntelliVue Patient Monitoring

System display unit, Measurement Servers or Flexible

Module Server

• Sound generation (issues audible alarm signals and

generates audible information signals, for example QRS

and SpO

Interfaces

LAN The LAN interface implements the physical layer of IEEE 802.3.

The LAN interface performs Manchester encoding/decoding,

receive clock recovery, transmit pulse shaping, jabber, link

integrity testing, reverse polarity detection/correction, electrical

isolation, and ESD protection. Electronically separated interfaces

are used for communication to the Measurement Servers or

Flexible Module Server and to the network.

Centronics The Centronics interface implements the standard signaling

method for bi-directional parallel peripheral devices according to

IEEE 1284-I. The interface is used as a parallel interface to a

standard printer with electrical isolation and ESD protection.

Display Controller The Display Controller Interface consists of a video controller

chip, video RAM and the controlling software. The Display

Controller interface processes the high level display commands

(character and graphic generation, wave drawing) and translates

them into pixels, which are written into the video RAM where

the video controller chip generates the video synchronization

signals and the pixel stream for the external display.

HIF Control The HIF (Human Interface Control) interface scans the Human

Interface devices for operator controls (Touch Screen, Trim

Knob, and PS/2 devices), formats the collected data and sends it

to the display and Operating Interface.

tones, operator audible feedback)

2

29

Page 30

2 Theory of Operation Monitor Theory of Operation

Functional Block Description

ECG-Out Marker-In The ECG Out/Marker In interface receives the ECG waveform

directly from the ECG/Resp Arrhythmia ST-Segment

physiological algorithm via an RS-422 serial interface and

converts the digital ECG signal to an analog ECG signal. In

addition, the ECG Out controller receives from a connected

device the marker information and forwards this data to the

ECG/Resp Arrhythmia ST-Segment physiological algorithm.

The converted analog signal is used to synchronize a connected

device to the patient’s ECG

RS-422 The serial link RS-422 interface communicates the ECG signal

to the ECG Output/Marker In of the IntelliVue Patient

Monitoring System display unit. The interface is a serial,

differential, full-duplex link. The interface is ESD protected.

PS/2 The PS/2 interface supports the serial protocol of standard PS/2

devices (mouse). The PS/2 serial protocol is interpreted by the

HIF Control interface.

Remote Device Interface The remote device interface is an interface to the remote alarm

device and the remote extension device. The interface

communicates with the remote devices via a differential serial

link.

Nurse Call The Nurse Call board contains 2 connectors. A phone jack type

connector and a multi-port connector. The phone jack type

connector has a single close-on-alarm relay. The multi-port

connector has three alarm relays which are configurable to be

open or closed on alarm. In addition, this interface has an audible

alert capability for loss of AC power.

MIB The MIB interface allows full-duplex, short-haul asynchronous

binary communication between the monitor and an arbitrary

(medical/non-medical) device using an eight-pin RJ45 modular

connector. Switching between MIB and RS232 protocol is

possible.

30

Page 31

3Testing and Maintenance

Concepts

This chapter provides a checklist of the testing and maintenance procedures for the monitor, the MMS

the Measurement Server Extensions and the FMS associated modules.

Preventive Maintenance refers specifically to the series of tests required to make sure the Instrument

measurement results are accurate. The measurements requiring these reported tests are NBP and

sidestream CO

readings are in question or as specified.

. The accuracy and performance procedures are designed to be completed when

2

Test Reporting

Authorized Philips personnel report test results back to Philips to add to the product development

database. Hospital personnel, however, do not need to report results. This table shows you what to

record on the service record after completing the tests in this chapter.

3

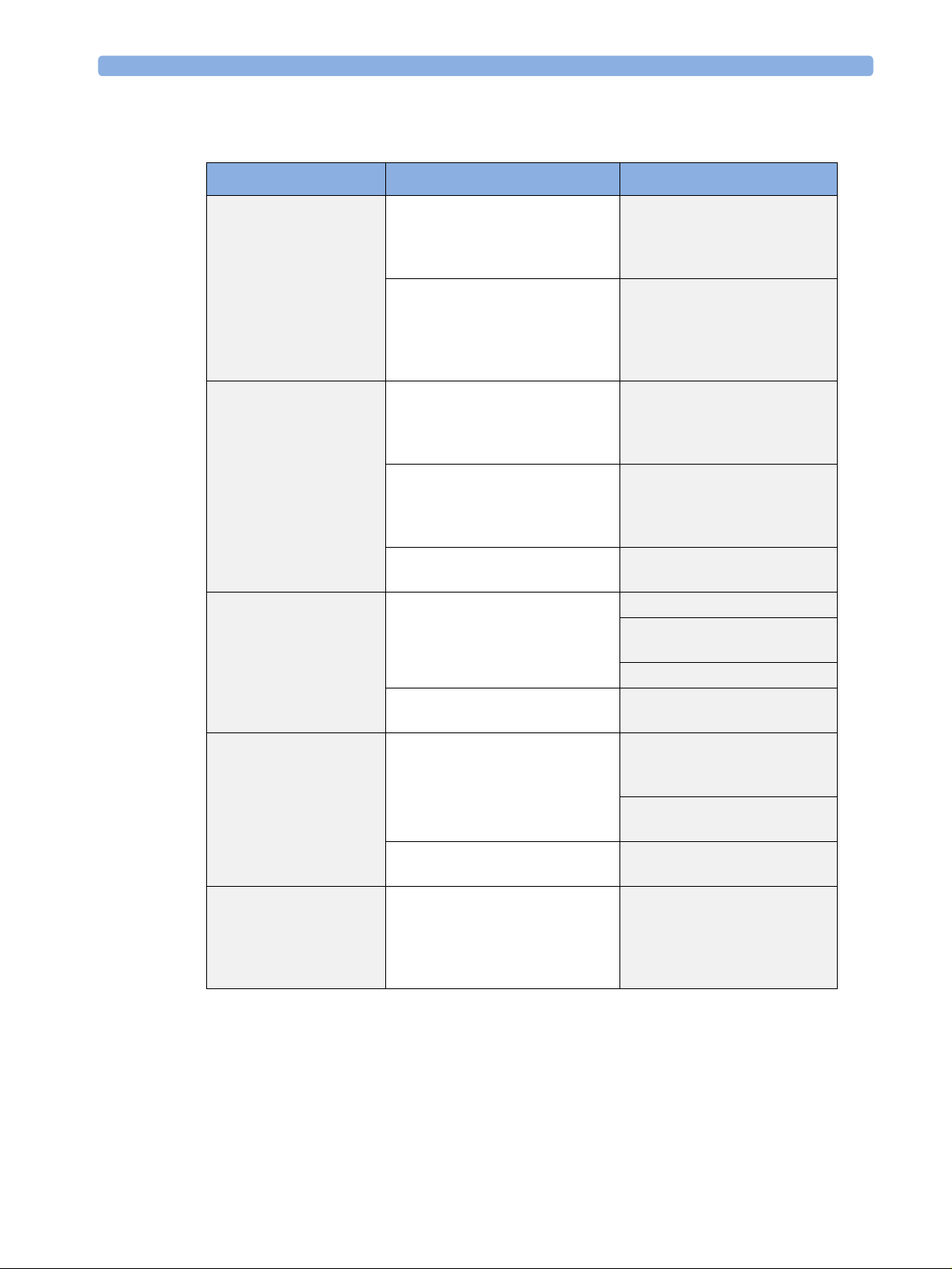

Test What to record

Visual V:P or V:F

Power On PO:P or PO:F

P NIBP PN:P/X1/X2/X3/X4 or

PN:F/X1/X2/X3/X4

P CO

2

Safety S(1):P/x1/x2 or

Where P = Pass, F = Fail and X/x are the measured values as defined in the tests described in this

chapter.

PCO2:P/X1/X2/X3/X4/X5/X6/X7/X8 or

PCO2:F/X1/X2/X3/X4/X5/X6/X7/X8

S(1):F/x1/x2

S(2): P/x1 or

S(2): F/x1

S(3): P/x1 or

S(3): F/x1

31

Page 32

3 Testing and Maintenance Recommended Frequency

Recommended Frequency

The testing checklist appears in the next section of this chapter. Perform the procedures as indicated in

the suggested testing timetable. These timetable recommendations do not supersede local

requirements.

Suggested Testing Timetable Frequency

Preventive Maintenance Tests

•NBP Calibration

• Sidestream CO

•CO

pump / CO2 scrubber replacement

2

Calibration

2

Performance and Safety Tests

• Temperature Accuracy

• ECG/Resp Performance

• Invasive Pressure Performance

•SpO

•Mainstream CO

Per formance

2

Per formance

2

•EEG Performance

• C.O. Performance

•BIS Performance

•SvO2 Performance

Required

• Once a year, or as specified by local laws.

• Once a year or after 4,000 hours continuous

use and following any instrument repairs or

the replacement of any instrument parts.

• Once every three years or after 15 000

operating hours

Once every two years, or if you suspect the

measurement is incorrect

32

•tcGas Performance

• VueLink Performance

• Nurse Call Relay Performance*

• ECG Sync Performance*

*Only when in use as part of hospital protocols

Safety Checks (in accordance with IEC 60601-

1)

• System Enclosure Leakage Current

•Protective Earth

• Patient Leakage Current

Once every two years and after repairs where

the power supply is replaced or the monitor

has been damaged by impact.

Page 33

Tests Recommended When Performing... 3 Testing and Maintenance

Tests Recommended When Performing...

Installation

Service Event

(When performing...

Installation of monitor with a non-medical device

connected.

Repair

Service Event

(When performing...

Repairs of M3015A Perform Power On and M3015A tests

Repairs where the monitor has been damaged by

impact

Repairs where the power supply is replaced Perform Safety (2) Test Block

All other IntelliVue Monitoring System repairs Perform Power On Test Block

Preventive Maintenance

Perform preventive maintenance tests:

Tes t Bl o c k s R e q u i r e d

...Complete these tests)

Perform Visual, Power On and Safety (1) Test

Blocks

Tes t Bl o c k s R e q u i r e d

...Complete these tests)

Perform Power On and Safety (2) and (3) Test

Blocks

•NBP calibration

• Sidestream CO

• Pump and scrubber replacement.

calibration

2

Performance Verifications

Perform all safety, accuracy and performance test procedures listed in the following sections. If a

particular measurement is in question, perform the measurement performance test only.

33

Page 34

3 Testing and Maintenance Tests

Upgrades

Service Event

(When performing...

Hardware and software upgrades Perform Power On Test Block unless otherwise

Tests

Some of the following testprocedures must be performed in service mode. To enter service mode select

Operating Modes in the main menu. Then select Service Mode and enter the password.

If required, open the screen menu in the monitor info line at the top of the screen and select

Service to access the service screen. This is required particularly for Anesthetic Gas Module testing

procedures.

Visual Test

Inspect the system for obvious signs of damage. Also check all external leads and accessories.

The expected test result is pass: the system has no obvious signs of damage.

Power On Test

Tes t Bl o c k s R e q u i r e d

...Complete these tests)

specified in the Upgrade Installation Notes shipped

with the upgrade.

NOTE An external display must be connected to the MP90 computer module unit.

1 Switch on the monitor and connect the MMS.

2 Observe whether the system boots up successfully and if an ECG wave appears on the screen.

The expected test result is pass: the monitor boots up and displays an ECG wave. The wave might be a

flat line if no simulator is attached.

NBP Tests

This section describes NBP test procedures.The monitor must be in service mode to perform these

tests.

34

Page 35

Tests 3 Testing and Maintenance

NBP Accuracy Test

This test checks the performance of the non-invasive blood pressure measurement. Connect the

equipment as shown:

Expansion Chamber

Tubing

Manometer

To NBP Input

Tools required:

• Reference manometer (includes hand pump and valve), accuracy 0.2% of reading.

• Expansion chamber (volume 250 ml +/- 10%)

• Appropriate tubing.

In service mode, the systolic and diastolic readings indicate the noise of NBP channels 1 and 2

respectively. When static pressure is applied, the reading in NBP channel 1 should be below 50. The

value in parentheses indicates the actual pressure applied to the system.

1 Connect the manometer and the pump with tubing to the NBP connector on the MMS and to the

expansion chamber.

2 In service mode, select the Setup NBP menu.

3 Select Close Valves: On

4 Raise the pressure to 280 mmHg with the manometer pump.

5 Wait 10 seconds for the measurement to stabilize.

6 Compare the manometer values with the displayed values.

7 Document the value displayed by the monitor (x1).

8 If the difference between the manometer and displayed values is greater than 3 mmHg, calibrate

the MMS. If not, proceed to the leakage test.

9 To calibrate the MMS, select Close Valves off then Cali brate NBP and wait for the

instrument to pump up the expansion chamber.Wait a few seconds after pumping stops until

EnterPrVal is highlighted and then move the cursor to the value shown on the manometer. If

one of the following prompt messages appears during this step, check whether there is leakage in

the setup:

– NBP unable to calibrate – cannot adjust pressure

– NBP unable to calibrate – unstable signal

10 Press Confirm.

If the INOP NBP Equipment Malfunction message occurs in monitoring mode, go back to service

mode and repeat the calibration procedure.

35

Page 36

3 Testing and Maintenance Tests

NBP Leakage Test

The NBP leakage test checks the integrity of the system and of the valve. It is required once per year

and when you repair the monitor or replace parts.

1 If you have calibrated, repeat steps 2 to 6 from the accuracy test procedure so that you have 280

mmHg pressure on the expansion chamber.

2 Watch the pressure value for 60 seconds.

3 Calculate and document the leakage test value (x2).

x2 = P1 - P2

where P1 is the pressure at the beginning of the leakage test and P2 is the pressure displayed after

60 seconds.

The leakage test value should be less than 6 mmHg.

NBP Linearity Test

1 Reduce the manometer pressure to 150 mmHg.

2 Wait 10 seconds for the measurement to stabilize.

3 After these 10 seconds, compare the manometer value with the displayed value.

4 Document the value displayed by the monitor (x3)

Valve Test

5 If the difference is greater than 3 mmHg, calibrate the MMS (see steps 9 to 10 in the accuracy test

procedure).

1 Raise the pressure again to 280 mmHg.

2 Select Close valves: Off.

3 Wait five seconds and then document the value displayed. The value should be less than 10

mmHg.

4 Document the value displayed by the monitor (x4).

Test Expected test results

Accuracy test x1 = value displayed by monitor

Difference ≤ 3mmHg

Leakage test x2 = leakage test value

x2 < 6 mmHg

Linearity test x3 = value displayed by monitor

Difference ≤ 3mmHg

36

Valve Test x4 = value < 10 mmHg

Page 37

Tests 3 Testing and Maintenance

Sidestream CO2 Performance Test

Allow five seconds between individual service procedures to ensure stable equipment conditions. When

certain monitor procedures are running, service procedures are not possible and trying to start them

will result in a message Service Operation Failed in the monitor’s status line. Wait until

the monitor completes the current operation, then restart the service procedure.

This test checks the performance of the CO

measurement for the sidestream extension. The CO2

2

performance test is required once per year and when the instrument is repaired or when parts are

replaced.

This test uses calibration equipment that you can order (see the Parts section for the part number). The

procedure is summarized in the following steps. Refer to the documentation accompanying the

equipment for detailed instructions.

Tools Required:

• Standard tools, such as screwdriver, tweezers

• Electronic flowmeter, M1026-60144.

• Gas calibration equipment:

• Cal 1 gas 15210-64010 (5% CO

• Cal 2 gas 15210-64020 (10% CO

)

2

)

2

• Cal gas flow regulator M2267A

• Cal tube 13907A

You also need a local barometric pressure rating received from a reliable local source (airport, regional

weather station or hospital weather station) which is located at the same altitude as the hospital.

The CO

calibration for the sidestream extension consists of the following steps:

2

• Barometric pressure check and calibration, if required.

• Leakage check

•Pump check

• Flow check and calibration, if required.

•Noise check

•CO

•CO

Cal check and calibration, if required.

2

Cal verification using 2nd cal gas

2

Perform all checks in the same session.

Barometric Pressure Check and Calibration

Check the barometric pressure value in the sidestream CO2 extension as follows:

1 Go into service mode and select Setup CO

2 Connect a FilterLine to the sidestream CO

Extension.

3 The status line at the bottom of the screen displays “CO2 pressure reading (ambient/cell) xxx/yyy”

where xxx is the ambient pressure and yyy is the measured cell pressure. Check whether the

ambient pressure value (x1) matches (within the acceptable tolerance of ±12mm Hg) the reference

menu.

2

input. This activates the pump in the sidestream CO2

2

37

Page 38

3 Testing and Maintenance Tests

value you have received. If so, proceed to the leakage check. If the value is not correct, calibrate as

follows.

Leakage Check

The leakage check consists of checking the tubing between:

• the pump outlet and the measurement server extension outlet and

• the pump inlet and FilterLine inlet.

Check the user’s guide of the flowmeter for details on how to make a correct flow reading.

Part 1

1 Go into service mode and select Setup CO

2 Connect a FilterLine to the sidestream CO

3 Check the ambient pressure and the cell pressure shown in the monitor’s status line. The cell

a. Select CO

then select Barom.Press to activate a table of values.

2

b. Select the value in the table which matches the reference value received from a reliable local

source (airport, regional weather station or hospital weather station). (The values are displayed

with a resolution of 2 mmHg up to 500 mmHg and a resolution of 1 mmHg from 500 mmHg

to 825 mmHg.) Note: the selected value must be within ±10% of the current measured ambient

pressure, otherwise an error message will occur at restarting the monitor.

c. Confirm the barometric pressure setting.

d. Check that the ambient pressure displayed in the status line at the bottom of the screen is the

same as the value which you selected from the list in step b.

menu.

2

input to start the pump running.

2

pressure should be approximately 20 mmHg lower than ambient pressure.

4 Connect the flowmeter outlet to the FilterLine inlet using a flexible connecting tube.

5 Block the measurement server extension outlet using your fingertip and observe the flowmeter

display. The value on the flowmeter (x2) should decrease to between 0 and 4 ml/min, accompanied

by an audible increase in pump noise. If the value is within the tolerance limits, continue with part

2 of the leakage check.

6 If the value is outside the tolerance limits, there is a leakage between the pump outlet and the

measurement server extension gas outlet.

7 Open the measurement server extension and check the tubing connections at the pump outlet and

the extension gas outlet. If the connections are good, then there is a leakage in the tubing and you

must exchange the measurement server extension.

Part 2

1 Disconnect the flowmeter from the Part 1 setup and connect the flowmeter inlet to the M3015A

gas outlet.

2 Leave the Filterline connected to the M3015A inlet.

3 Block the inlet of the FilterLine using your fingertip and observe the flowmeter display. The value

on the flowmeter (x3) should decrease to between 0 and 4 ml/min, accompanied by an audible

increase in pump noise. Do not block the inlet for longer than 25 seconds as this will lead to an

“Occlusion” INOP. If the value is within the tolerance limits, there are no leakages and the leakage

check is completed; proceed to the pump check.

38

Page 39

Tests 3 Testing and Maintenance

If the value is not within the tolerance limits, there is a leakage between the FilterLine inlet and the

4

pump inlet.

5 Check the FilterLine connections and open the M3015A to check the tubing connections at the

pump inlet and the M3015A gas inlet. If the connections are good, try replacing the FilterLine and

repeating the leakage check. If the situation remains, there is a leakage in the tubing and the

M3015A must be exchanged.

Pump Check

1 Connect the flowmeter inlet to the M3015A gas outlet.

2 Connect the FilterLine to the M3015A inlet.

3 Block the inlet of the FilterLine using your fingertip and observe the cell pressure on the M3046A

display. The cell pressure (x4) should be more than 120 mmHg below the ambient pressure shown.

If the pressure difference is less than 120 mmHg, the pump is not strong enough and you should

replace it, irrespective of the Pump OpTime.

Flow Rate Check and Calibration

Check the flow rate in the sidestream CO2 extension as follows:

Noise Check

1 Connect the flowmeter to the CO

2 Check on the flowmeter the flow that the sidestream CO

50 ml/min ± 7.5 ml/min. If the value is within tolerance, proceed to the CO

FilterLine.

2

extension pump draws (x5). It should be

2

Gas calibration

2

check. If the value is not within tolerance, calibrate as follows.

3 Adjust the flow in the instrument by selecting Increase Flow or Decrease Flow until it

is as close as possible to 50 ml per minute as indicated on the flowmeter gauge.

4 When you are satisfied that the flow is set as close as possible to 50 ml per minute, select Store

Flow and confirm the setting. If you do not store the adjusted flow within 60 seconds of the

adjustment, the old flow setting is restored.

5 If you cannot adjust the flow to within tolerance, replace the pump. If you still cannot make the

flow adjustment, this indicates a fault in the measurement extension, which must be replaced.

1 With the monitor in service mode, select Setup CO

2 Disconnect the flowmeter and connect the 5% calibration gas and flow regulator in its place.

3 Open the valve to apply the 5% calibration gas and wait until the value is stable.

4 Check the noise index (x6) displayed next to the CO

of noise on the CO

wave). If the value exceeds 3 mmHg, replace the measurement extension.

2

menu.

2

value on the display (this indicates the level

2

CO2 Gas Measurement Calibration Check

After switching the measurement extension on, wait at least 20 minutes before checking the

calibration. Check the calibration of the CO

1 Check that the 5% calibration gas and flow regulator are connected.

gas measurement as follows:

2

39

Page 40

3 Testing and Maintenance Tests

Calculate the expected measurement value in mmHg as follows:

2

0.05 x (ambient pressure) = value mmHg

for example 0.05 x 736 = 36.8 mmHg (with an ambient pressure of 736 mmHg)

3 Open the valve on the flow regulator to allow 5% CO

gas to flow into the extension. Allow the

2

value to stabilize.

4 Check that the value on the instrument (measurement value on the main screen, x7)) matches the

calculated mmHg value ± 2.6 mmHg. If the value is outside the tolerance, calibrate as described in

step 9 in this procedure onwards.

5 Disconnect the 5% calibration gas and connect the 10% calibration gas.

6 Calculate the expected measurement value and tolerance in mmHg as follows:

0.1 x (ambient pressure) = value mmHg

±0.07 x (value mmHg) = tolerance

for example 0.1 x 737 mmHg = 73.7 mmHg (with an ambient pressure of 737 mmHg)

±0.07 x 73.7 mmHg = ±5.16 mmHg tolerance

7 Open the valve on the flow regulator to allow 10% CO

gas to flow into the extension. Allow the

2

value to stabilize.

8 Check that the value on the instrument (x8) matches the calculated mmHg value within the

calculated tolerance. If so, the measurement extension is correctly calibrated. If the value is outside

the tolerance, calibrate as follows.

9 If not already connected, connect the 5% calibration gas.

10 Select Cal. CO

11 Select the value for the calibration gas. (The default value is 5.0%.)

.

2

12 Open the valve on the calibration gas to allow CO

to stabilize before the start of the calibration. Leave the valve open until the instrument gives a

prompt that gas can be removed.

13 The extension calibrates and prompts when calibration is successful.

Calibration Verification

1 Reopen the 5% gas valve and allow the value to stabilize.

2 Check that the value displayed on the monitor is correct within the tolerance (see step 2 above).

3 Disconnect the 5% calibration gas and connect the 10% calibration gas.

4 Open the valve on the flow regulator to allow 10% CO

value to stabilize.

5 Check that the value displayed on the monitor is correct within the tolerance (see step 6 above).

If one or both values are not within tolerances, you must exchange the measurement server extension.

Reset Time Counters

You must check the time counters on the sidestream CO2 extension before calibrating the instrument.

As well, when parts are replaced, the appropriate counters must be reset to zero.

gas to flow into the extension. Allow the value

2

gas to flow into the extension. Allow the

2

40

Page 41

Tests 3 Testing and Maintenance

The counters for CO2 pump, IR Src and Last Cal are displayed in the status line. The values are

updated when entering the Setup CO

menu.

2

Observe the following guidelines:

• When calibrating the CO

extension, if no parts have been replaced, check the displayed values of

2

Reset PumpOpTi me and Reset IRSourceTime selections to make sure that they are

within suggested guidelines for use (15, 000 hours of continuous use). If the counter time is greater

than 15, 000 hours, replace the appropriate part. See Repair and Disassembly for details.

• When calibrating the CO

extension, if parts have been replaced, reset the appropriate values using

2

the Reset PumpOpTime and Reset IRSourceTime selections. See Repair and Disassembly

for details.

Resetting the PumpOpTime generates the INOP: “CO

OCCLUSION”. To clear this INOP you

2

must perform a flow check and store the flow in service mode (select Store Flow).

Table 1 Documenting CO

Test Results

2

Test Expected Test Results

Barometric Pressure

Check

x1 = difference between the reference pressure and the

measured ambient pressure displayed on the monitor

(x1<12 mmHg)

Leakage Check parts

1 and 2

x2 = value of part 1 leakage check on flowmeter

(x2< 4.0 ml/min)

x3 = value of part 2 leakage check on flowmeter

(x3< 4.0 ml/min)

Pump Check x4 = difference in pressure between cell pressure and ambient

Flow Check x5 = difference between measured value and 50.0 ml/min

Noise Check x6 = noise index displayed on monitor (x6<3.0)

CO

Gas

2

Calibration Check

CO

2 Cal Verification

Temperature Accuracy

This test checks the performance of the temperature measurement.

Tools required: Patient simulator (with 0.1

1 Connect the patient simulator to the temperature connector on the MMS or measurement server

extension.

2 Configure the patient simulator to 40

pressure displayed on the monitor during occlusion (x4 >120

mmHg)

(x5<7.5 ml/min)

x7 = difference between measured CO2 value and calculated

value, based on 5% CO

cal. gas. (x7 < 2.6 mmHg)

2

x8 = difference between measured CO2 value and calculated

value, based on 10% CO

cal. gas.

2

(x8 < ± {0.07 x value calculated})

o

C or 0.2oF).

o

C or 100 oF.

41

Page 42

3 Testing and Maintenance Tests

The value should be 40 oC ± 0.2 oC or 100 oF ± 0.4 oF.

3

ECG/Resp Performance Test

This test checks the performance of the ECG and respiration measurements.

Tools required: Patient simulator.

ECG Performance

1 Connect the patient simulator to the ECG/Resp connector on the measurement server.

2 Configure the patient simulator as follows:

– ECG sinus rhythm.

– HR = 100 bpm.

3 Check the displayed ECG wave and HR value against the simulator configuration.

4 The value should be 100bpm +/- 2bpm.

Respiration Performance

1 Change the Patient Simulator configuration to:

– Base impedance line 1500 Ohm.

– Delta impedance 0.5 Ohm.

– Respiration rate 40 rpm.

2 The value should be 40 rpm +/- 2 rpm.

Invasive Pressure Performance Test

This test checks the performance of the invasive pressure measurement.

Tools required: Patient simulator.

1 Connect the patient simulator to the pressure connector on the MMS or the measurement server

extension.

2 Set the patient simulator to 0 pressure.

3 Make a zero calibration.

4 Configure the patient simulator as P(static) = 200 mmHg.

5 Wait for t he d isp lay.

6 The value should be 200 mmHg ± 5 mmHg. If the value is outside these tolerances, calibrate the

MMS or measurement server extension. If the MMS was calibrated with a dedicated reusable

catheter, check the calibration together with this catheter.

SpO2 Performance Test

This test checks the performance of the SpO2 measurement.

Tools required: none

42

1 Connect an adult SpO

2 Measure the SpO

value on your finger (this assumes that you are healthy).

2

transducer to the SpO2 connector on the MMS.

2

Page 43

Tests 3 Testing and Maintenance

The value should be between 95% and 100%.

3

Cardiac Output Performance Test

These tests check the performance of the cardiac output measurement.

1 Connect the patient simulator to the C.O. module using the patient cable.

2 Configure the patient simulator as follows:

Injection temperature: 2 °C

Computation Const: 0.542

(Edward's Catheter)

Flow: 5 l/min

3 Check displayed value against the simulator configuration.

4 Expected test result: C.O. = 5 +/– 1 l/min.

Service Tool Procedure, Version 1

This procedure applies for Service Tool M1012-61601 and/or C.O. modules without option C10.

1 In monitoring mode, connect the C.O. interface cable to the module.

2 Connect one side of the service tool to the injectate receptacle of C.O. interface cable and the other

side to catheter cable receptacle.

3 Enter the C.O. Procedure window and check the results. The expected test result is:

o

– Tblood = 37.0

C +/- 0.1oC

Service Tool Procedure, Version 2

This procedure applies only for Service Tool M1012-61601 in combination with C.O. modules with

option C10.

1 In monitoring mode, connect the C.O. interface cable to the module.

2 Connect one side of the service tool to the injectate receptacle of the C.O. interface cable and the

other side to the catheter cable receptacle.

3 Enter Setup C.O. menu and check results for:

– Method of measurement

– Catheter constant

–Tblood

4 Enter C.O. Procedure window and check results. The expected results are

–Transpulmonary 341

o

– Tblood = 37.0

C +/- 0.1oC

BIS Performance Test

These tests check the performance of the BIS measurement.

PIC/DSC Test

1 In monitoring mode connect the sensor simulator (for maximum usage please refer to the

documentation delivered with the sensor simulator) to the patient interface cable.

43

Page 44

3 Testing and Maintenance Tests

Enter the BIS menu and select Open Window.

2

3 Start impedance check by pressing StartCyclicCheck. Check the displayed results. Expected

results are:

– Electrode 1 (+): 4-6 kΩ

– Electrode 2 (Ref): 8-12 kΩ

– Electrode 3 (1-): 1-3 kΩ

– Electrode 4 (2-): 1-3 kΩ

Nurse Call Relay Performance Test

The nurse call relay performance test can be performed either at the phone jack type connector (this

only tests one relay) or at the multi-port nurse call connector (to test all three relays).

Phone Jack Type Connector Test

This test checks the operation of the Nurse Call Relay. The Nurse Call Relay test is recommended for

customer sites where the nurse call is in use. The Nurse Call relay functions as follows:

• Standard Operation—Relay open.

• Alarm Condition—Relay closed.

Tools required: Ohmmeter.

1 Plug a phono connector into the Nurse Call Relay connector.

2 Connect the ohmmeter.

3 If no alarm occurs, the relay contacts are open. When an alarm occurs, the relay contacts close.

Multi-Port Nurse Call Connector Test

This test checks the operation of the Flexible Nurse Call Relay. The Nurse Call Relay test is

recommended for customer sites where the nurse call is in use. The following diagram and table show

the pins and relay identifiers of the connector:

44

Page 45

Tests 3 Testing and Maintenance

Pin Cable Color Coding Relay

1black R2-closure

2brown R2-middle

3red R2-opener

4orange R3-closure

5yellow R3-middle

6 green R3-opener

7blue n/a

8purple n/a

9gray n/a

10 white n/a

11 pink R1-closure

12 light green R1-middle

13 black/white R1-opener

14 brown/white n/a

15 red/white n/a

16 orange/white n/a

17 blue/white R_failure_closure

18 purple/white R_failure_middle

19 green/white R_failure_opener

20 red/black n/a

The Nurse Call relay functions as follows:

• During standard operation R1,R2,R3 _opener are closed; R1,R2,R3_closure are open.

• During alarm condition R1,R2,R3_opener are open; R1,R2,R3_closure are closed.

Tools required: Ohmmeter.

1 Plug an M8087-61001 cable into the Nurse Call Relay connector.

2 Connect the ohmmeter and measure the pins as indicated in the diagram and table.

3 The relay contacts should behave as described above. The behavior may vary depending on

configuration choices. See the Configuration Guide for details on Alarm Relay settings.

ECG Sync Performance Test

This test checks the performance of ECG synchronization between the monitor and a defibrillator. It