Page 1

Measurements and Monitoring

SERVICE GUIDE

M3/M4 Monitors

(M3046A)

Measurement Server

(M3001A and M3000A)

Measurement Server Extensions

(M3015A and M3016A)

PATIENT MONITORING

Page 2

Printed in Germany 03/05

Sixth Edition

*M3046-9300F*

Part Number M3046-9300F

4512 610 07711

S

Page 3

M3046A M2/M3/M4 Monitors

M3000A/M3001A Measurement

Servers

M3015A/M3016A Extensions to the

Measurement Servers

Service Guide

Reordering Number: 4512 610 07711

Printed in Germany. March 2005

M3046-9300F

Seventh Edition

Page 4

Notice

This document contains proprietary information which is protected by copyright. All Rights

Reserved. Reproduction, adaptation, or translation without prior written permission is

prohibited, except as allowed under the copyright laws.

Philips Medizin Systeme Böblingen GmbH

Cardiac and Monitoring Systems

Hewlett-Packard Str. 2

71034 Böblingen

Germany

Printed in Germany

Warranty

The information contained in this document is subject to change without notice.

Philips Medical Systems makes no warranty of any kind with regard to this material,

including, but not limited to, the implied warranties or merchantability and fitness for a

particular purpos e.

Philips Medical Systems shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance, or use of this

material.

© 1995-2005 Koninklijke Philips Electronics N.V.

All Rights Reserved. Reproduction in whole or in part is prohibited without the prior written

consent of the copyright holder.

Philips Electronics North America Corporation reserves the right to make changes in

specifications or to discontinu e any pro du ct at any t ime witho ut noti ce or ob lig atio n and wi ll

not be liable for any consequences resulting from the use of this publication.

Microsoft, Windows NT and Windows 2000 are trademarks of Microsoft Corporation in the

USA and other countries.

ii

Page 5

Printing History

New editions of this document will incorporate all material updated since the previous

edition. Update packages may be issued between editions and contain replacement and

additional pages to be merged by a revision date at the bottom of the page. Note that pages

which are rearranged due to changes on a previous page are not considered revised.

The documentation printing date and part number indicate its current edition. The printing

date changes when a new edition is printed. (Minor corrections and updates which are

incorporated at reprint do not cause the date to change.) The document part number changes

when extensive technical changes are incorporated.

First Edition ................................ ...... ..July 1997

Second Edition....................................February 1999

Third Edition.......................................June 2000

Fourth Edition.....................................April 2001

Fifth Edition........................................February 2002

Sixth Edition .......................................June 2003

Seventh Edition...................................March 2005

iii

Page 6

v

Responsibility of the Manufacturer

Philips Medical Systems only considers itself responsible for any effects on safety, reliability

and performance of the equipment if:

• assembly operations, extens ions, re-adjus tments, modificat ions or repairs are carr ied out by

persons authorized by Philips, and

• the electrical installation of the relevant room complies with national standards, and

• the instrument is used in accordance with the instructions for use.

To ensure safety, use only those Philips parts and accessories specified for use with the

Monitor. If non-Philips parts are used, Philips Medical Systems is not liable for any damage

that these parts may cause to the equipment.

i

Page 7

v

In this Book

This Service Guide contains technical details on the Monitor, Measurement Server and

Measurement Server Extensions.

The purpose of this book is to provide a technical foundation for the monitoring system in

order to support effective troubleshooting and repair. The book is not intended to be a

comprehensive, in-depth explanation of the product architecture or technical implementation.

Rather, it is developed to offer enough information on the functions and operations of the

monitoring systems so that engineers who rep air them are b etter able to understand how they

work.

It covers the physiological measurements that the products are designed to provide, the

Measurement Server that acquires those measurements, and the monitoring system that

displays them.

Who Should Use this Book

If you are a biomedical engineer or a technician responsible for troubleshooting, repairing,

and maintaining Philips’s patient monitoring systems, this book is designed for you. If you

are new to Philips’s pr odu ct li ne or monitoring systems, you may find t his b oo k h e lpfu l as an

orientation to the equipment. If you have already worked on the systems and now want

further details on how they work, you are likely to find much of the information you need

here.

Conventions Used in this Book

WARNING A warning alerts you to a potential serious outcome, adverse event or safety hazard.

Failure to observe a warning may result in death or serious i njury to the user or patient.

CAUTION A caution alerts you to circumstances where special care is necessary for the safe and

effective use of the product. Failure to observe a caution may result in minor or moderate

personal injury, damage to the product or other property, and possibly in a remote risk of

more serious injury.

Page 8

vi

Page 9

Contents

1 Introduction to the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Concepts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Introducing the Instrument Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Instrument Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

A Quick Description of the Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Front Panel Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Front of Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Back of Monitor: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

A Quick Description of the Measurement Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Overview of the Measurement Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Measurement Connectors for the M3000A #C06, M3001A #C06

and #C18 Measurement Servers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Measurement Connectors for the Standard M3000A and M3001A Measurement Server 7

A Quick Description of the Measurement Server Extension. . . . . . . . . . . . . . . . . . . . . . . . . . 9

Overview of the Measurement Server Extensions M3015A & M3016A . . . . . . . . . . . . . 9

Measurement Connectors for the M3015A Measurement Server Extension . . . . . . . . . . 9

Measurement Connectors for the M3016A Measurement Server Extension . . . . . . . . . 10

A Quick Description of the Main Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Theories of Operation and Functional Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Section 1 - Monitor Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Monitor Theory of Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Display and User Interface Software Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Alarm Manager Software Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Admit / Discharge / Transfer (ADT) Software Module . . . . . . . . . . . . . . . . . . . . . . . . . 13

Trend Software Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Events Software Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Printer Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Recorder Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

IrDA/Serial Communication Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Communication Software Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Support Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Functional Description of the Monitor Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Display Video Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Human Interface Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Battery Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

ECG Out/Marker In Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Infrared (IrDA) Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Wireless LAN Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Section 2 - Measurement Server Description and Features . . . . . . . . . . . . . . . . . . . . . . . . . . 19

M3001A Measurement Server Standard Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

M3001A Measurement Server Extended Measurements Packages . . . . . . . . . . . . . . . . 20

Contents vii

Page 10

M3000A Measurement Server Standard Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

M3000A #C06 Measurement Server Extended Measurements Package . . . . . . . . . . . . 20

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Measurement Server Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Functional Description of the Measurement Server Hardware . . . . . . . . . . . . . . . . . . . . . . 22

Electrocardiogram/Respiration (ECG/Resp) Measurement . . . . . . . . . . . . . . . . . . . . . . . . . 23

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

ECG/Resp Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Block Diagram of the ECG/Resp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Non-invasive Blood Pressure (NBP) Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

NBP Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Block Diagram for NBP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

NBP Measurement Characteristic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Arterial Oxygen Saturation and Pleth (SpO2/PLETH) Measurement. . . . . . . . . . . . . . . . . . 33

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

SpO2/PLETH Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Block Diagram of the SpO2/PLETH Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Temperature and Invasive Blood Pressure (Temp/Press) measurement . . . . . . . . . . . . . . . . 37

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Temp/Press Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Temperature and Invasive Pressure Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Block Diagram of the Temp/Press Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Invasive Pressure Software Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Temperature Software Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Section 3 - Measurement Server Extensions Description and Features . . . . . . . . . . . . . . . . 44

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

M3015A Measurement Server Extension Theory of Operation . . . . . . . . . . . . . . . . . . . . . . 45

Functional Description of the M3015A Measurement Server Extension Hardware. . . . . . . 46

Hardware Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Sidestream CO2 Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

viii Contents

Page 11

x

Sidestream CO2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Block Diagram of the Sidestream CO2 measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Theory of Operation for M3015A Sidestream CO

2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

M3016A Measurement Server Extension Theory of Operation . . . . . . . . . . . . . . . . . . . . . . 53

Functional Description of the M3016A Measurement Server Extension Hardware . . . . . . . 54

Hardware Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Mainstream CO2 Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Mainstream CO2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Block Diagram of the Mainstream CO2 measurement . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Theory of Operation for the M3016A Mainstream CO

2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Tutorial for the Introduction to the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Answers to the Tutorial for the Introduction to the Instrument. . . . . . . . . . . . . . . . . . . . . . . 62

2 Installing the Instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Concepts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Patient Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Patient Leakage Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Preparing to Install the Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Power Source Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Protecting against Electric Shock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Equipotential Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Combining Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Explanation of symbols used: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Unpacking the Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Installing the Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Connecting the Measurement Server... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

...with the Measurement Server directly on the Monitor . . . . . . . . . . . . . . . . . . . . . . . . 71

...with the Measurement Server Separate from the Monitor . . . . . . . . . . . . . . . . . . . . . . 73

...with the Measurement Server Attached to an M3015A/M3016A Measurement Server Ex-

tension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Attaching the Monitor to a Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Detaching the Monitor from a Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Attaching the Measurement Server to a Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Detaching the Measurement Server from a Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Positioning the Measurement Server on a Clamp Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Connecting to the Nurse Call Relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Modification for Nurse Call Alarm Relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Verification Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Contents i

Page 12

Installation of Wireless Infrastructure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Configuring the Radio Frequency of the M3/M4 Monitor . . . . . . . . . . . . . . . . . . . . . . . 78

Connecting to the ECG Output or Marker Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Configuring the Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Selecting NBP Measurement Characteristic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Installing an Additional Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Safety Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Installing the 12V Adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Using the Battery Charger and Conditioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Connecting a Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Selecting a Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Installing the Wireless Infrared Printer Connector (M3080A #H05) . . . . . . . . . . . . . . . . . . 94

Connecting a Local Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Connecting a Remote Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Connecting a Local Recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Site Preparation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Mounting Solutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Installing the Table Mount (M3080A #A10). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Installing the Universal Bed Hanger (M3080A #A11) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Warnings, Cautions, and Safety Precautions Relating to Wall Mount Installation. . . . . . . 100

Installing the Wall Rail (M3080A #A13) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Installing the Tilt/Swivel Mount (M3080A #A14) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Screwed Directly to a Wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Mounted to the GCX Wall Channel (M3080A #A15) . . . . . . . . . . . . . . . . . . . . . . . . . 103

Attached to a Universal Pole Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Attached to the Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Installing the GCX Wall Channel (M3080A #A15) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Installing the Universal Pole Clamp (M3080A #C05) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Installing the Measurement Server Mounting Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Server Mounting Plate (M3080A #A01) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Server Mounting Plate (M3080A #A02) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Mounting Options for the Local Recorder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

MSL Cable Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Disposing of the Monitor, Measurement Server and Measurement Server Extensions . . . 115

Tutorial for Installing the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Answers to the Tutorial for Installing the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

3 Maintaining the Instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Recommendations for Maintenance Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Maintenance Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

x Contents

Page 13

x

Inspecting the Instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Inspect Cables and Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Preventive Maintenance Tasks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

M3046A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

M3000A / M3001A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Replacement of the Pump and CO2 Scrubber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Replacement of the Infrared Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

General Cleaning of the Instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Cleaning Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Cleaning Agents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Battery Handling, Maintenance and Good Practices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

About the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Checking the Battery Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Charging the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Conditioning a Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Accessing the Battery Status Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Battery INOP Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Tutorial for Maintaining the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Answers to the Tutorial for Maintaining the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

4 Testing the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Concepts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Test Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Recommendations for Test Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Test Map. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Testing Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Serial Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Passwords. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Visual Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Power On Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Functionality Assurance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Performance Assurance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Quick System Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

System Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

System Self-Test Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Preventive Maintenance Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

NBP Accuracy, Leakage, Linearity and Valve Test . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Sidestream CO2 Performance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Checking and Resetting Time Counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Documenting CO2 Test Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Accuracy and Performance Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Temperature Accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

ECG/Resp Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Contents

i

Page 14

Invasive Pressure Performance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

SpO2 Performance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Mainstream CO2 Performance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Nurse Call Relay Performance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

ECG Sync Performance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Patient Safety Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Warnings, Cautions, and Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Safety Test Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Tutorial for Testing the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Answers to the Tutorial for Testing the Instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

5 Troubleshooting the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Part 1 Troubleshooting Checklists. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Checks for Obvious Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Checks Before Opening the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

First Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Initial Instrument Boot Phase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Isolating Problems to the Correct Subassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Part 2 Isolating and Solving Instrument Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

INOP Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Isolating the Defective Component . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Part 3 Using Support Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

The Status Log and Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

List of Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Testing Wireless Network Connectivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Antenna Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Using Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Service Mode Hardware Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

How To Access the Monitor and Server Revision Screen . . . . . . . . . . . . . . . . . . . . . . 209

Troubleshooting the Installed Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Troubleshooting with Self-Test Alarm Messages

(When You Switch the Monitor On) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Troubleshooting When There is No Message on the Screen . . . . . . . . . . . . . . . . . . . . 213

Troubleshooting During/After a Software Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Troubleshooting the Printer Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Troubleshooting the Recorder Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Tutorial for Troubleshooting the Instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Answers to the Tutorial for Troubleshooting the Instrument . . . . . . . . . . . . . . . . . . . . . . . 218

6 Repairing the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

xii Contents

Page 15

x

Warnings, Cautions and Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

General Reassembly/Refitting Comments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Disassembly for the Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Removing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Removing the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Removing the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Removing the System Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Removing the Wireless Assembly (for Monitors with Wireless LAN Interface only) 226

Removing the LCD Assembly and Backlight Tubes . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Removing the Connector Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Removing the Speaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Refit Procedures for the Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Refitting the System Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Refitting the LCD Assembly and Backlight Tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Refitting the Connector Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Refitting the Speaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Refitting the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Refitting the Wireless Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Refitting the Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Refitting the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Disassembly Procedures for the M3015A Measurement Server Extension . . . . . . . . . . . . 232

Removing the Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Removing the Extension Bottom Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Removing the CO2 Scrubber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Removing the Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Refit Procedures for the M3015A Measurement Server Extension. . . . . . . . . . . . . . . . . . . 237

Refitting the CO2 Scrubber . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Refitting the Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Refitting the Extension Bottom Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Refitting the Front Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Disassembly Procedures for the M8043A Battery Charger and Conditioner . . . . . . . . . . . 239

Opening the Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Removing the Cooling Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Removing the Air Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Reassembling the Battery Charger and Conditioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Following Reassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Tutorial for Repairing the Instrument . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Answers to Tutorial for Repairing the Instrument. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

7 Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Compatibility Matrix - Release A to Release B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

List of Replacement and Exchange Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 247

Monitor Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Contents

iii

Page 16

v

Bezel Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Other Monitor Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Monitor Exchange Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Small Parts Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Multi-Measurement Server Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

M3001A Part Numbers - Front Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

M3001A MMS Part Numbers - IntelliVue Software Revision A.05.xx and Lower . . 256

M3001A MMS Part Numbers - IntelliVue Software Revision A.10.xx and Higher . . 259

M3015A Measurement Server Extension Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

M3015A Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

M3015A Exchange Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

M3016A Measurement Server Extension Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

M3016A Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

M3016A Measurement Server Extension Exchange Parts . . . . . . . . . . . . . . . . . . . . . . 271

Support-Related Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Cables and MSL Through Wall Installation Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

MMS Measurement Server Link (MSL) Cable Clamp Kit . . . . . . . . . . . . . . . . . . . . . . . . . 273

Wireless Assembly Exchange Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Battery and Battery-Related Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Battery Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Battery Exchange Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Battery Charger and Conditioner Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

XE-50p Recorder Exchange Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

xi

Contents

Page 17

1 Introduction to the Instrument

Objectives

In order to meet this chapter’s goals, you should become familiar with the Monitor,

Measurement Server and the Measurement Server Extensions, and be able to identify their

component parts in some detail. As well, you shou ld be able to explain how the Measurement

Server and Measurement Server Extensions acqui re and process phy siological measur ements

and how the Monitor displays the data.

The following topics are covered in this chapter:

• Introducing the Instrument Components

• Section 1 - Monitor Description

• Functional Description of the Monitor Hardware

• Section 2 - Measurement Server Description and Feat ur es

• Measurement Server Theory of Operation

• Functional Description of the Measurement Server Hardware

• Electrocardiogram/Respiration (ECG/Resp) Measurement

• Non-invasive Blood Pressure (NBP) Measurement

• Arterial Oxygen Saturation and Pleth (SpO2/PLETH) Measurement

• T emp erature and Inv a sive Bloo d Pressure (Temp/Pr ess) measur ement

• Section 3 - Measurement Server Extensions Description and Features

• M3015A Measurement Server Extension Theory of Operation

• Functional Description of the M3015A Measurement Server Extension Hardware

• Sidestream CO2 Measurement

• M3016A Measurement Server Extension Theory of Operation

• Functional Description of the M3016A Measurement Server Extension Hardware

• Mainstream CO2 Measurement

Concepts

The following section contains information that you need to understand in order to

competently maintain and repair an M2, M3 or M4 Monitor and Measurement Server with or

without a Measurement Server Extension.

Theory of

Operation

The theory of operation for a component describes the processing of signals

within the component.

Introduction to the Instrument 1

Page 18

Introducing the Instrument Components

Functional

Description

The functional description of a component uses a diagram of the cir cuitry

followed by short, written explanations of the component circuitry.

Introducing the Instrument Components

The M3046A Compact Portable Patient Monitor together with the Multi-Measurement

Server (M3000A or M3001A) and the M3015A and M3016A Measurement Server

Extensions forms a flexible, portable, battery or line powered patient monitor. The combined

devices are referred to as the Instrument in this manual.

The M3000A Multi-Measurement Server can be used with M3046A patient monitors up to

and including Release D, but is incompatible with Release E monitors. All equipment from

Release C and D (M3046A monitors and the Release C M3000A Measurement Server) mu st

be used in monitoring configurations where only Release B, C or D software equipment is

included. None of these parts are compatible with Release A software.

The M3001A Multi-Measurement Server is compatible only with the Release E M3046A

monitors, and is incompatible with any earlier releases.

The Hemodynamic

Server M3001A. This combination supports the transfer of patient data between IntelliVue

(M80xxA) and M3/M4 (M3046A, Revision E) monitors. The M3012A’s Pressure/

Temperature channel works in the same way as that of the M3001A, with which the M3012A

shares all specifications, as documented in the M3/M4 Instructions for Use, except for the

weight, which is 450g (0.99lb). See the table below for supported parameters. The M3012A

is not further covered in this Service Guide.

Extension M3012A is for use together with the Multi-Measurement

Measurement

Server/Server

Extension

withOption

M3000A

M3000A #C06

M3001A

T o check whi ch softwa re revis i ons are on your equipment, enter Setup and select

Revisions.

The Multi-Measurement Server and Server Extensions acquire the following physiological

signals:

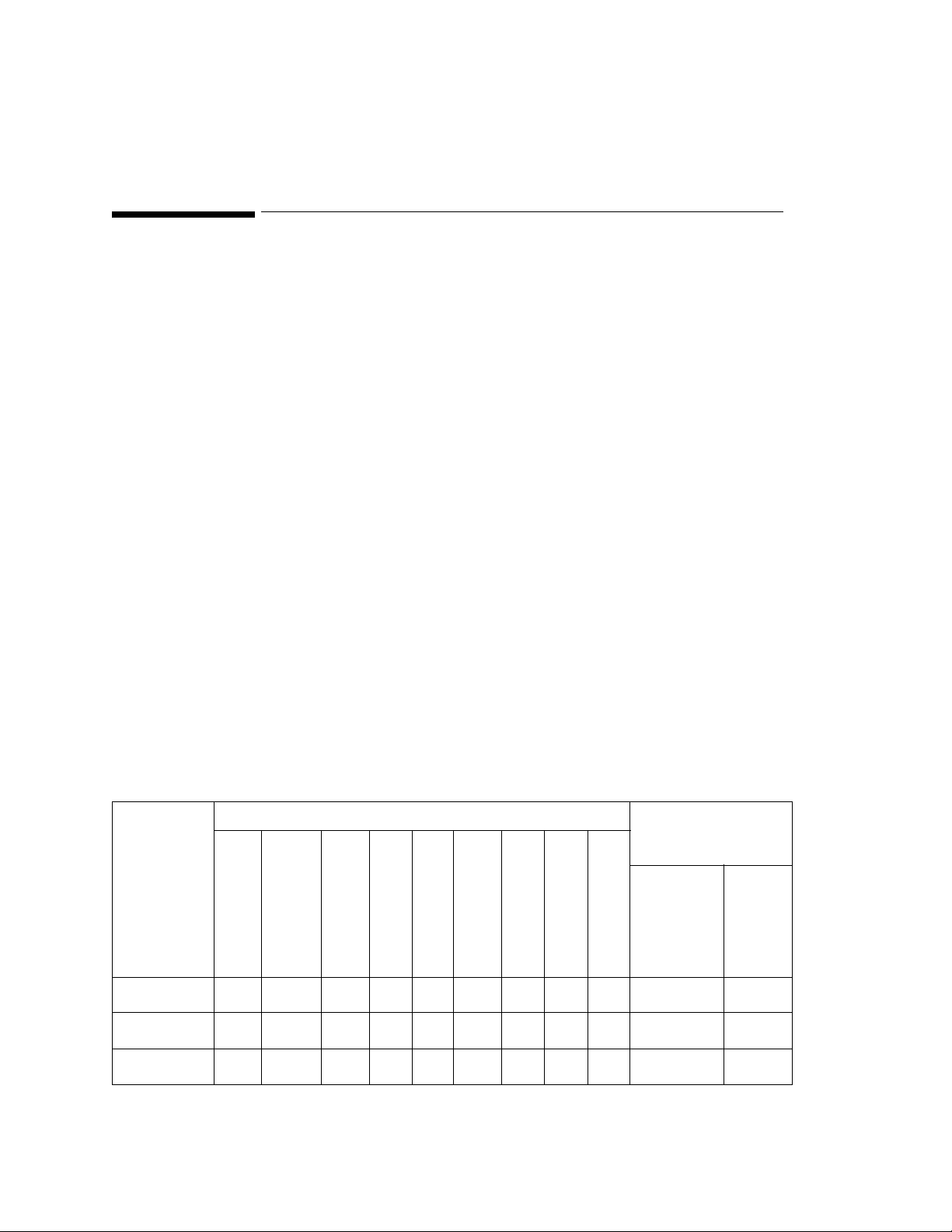

Measurements Compatible with

which M3046A

Release?

D and

lower

!

!

a

2

3-Channel ECG

EASI derived

12-Lead ECG

Respiration

Non-Invasive

Blood Pressure

Oxygen Saturation

SpO

!

!

"

"

!!!

!!!!!

!!!!!

2

Invasive

Blood Pressure

Temperature

Mainstream CO2Sidestream CO

""""

""

"""" "

E

"

"

!

2

Introduction to the Instrument

Page 19

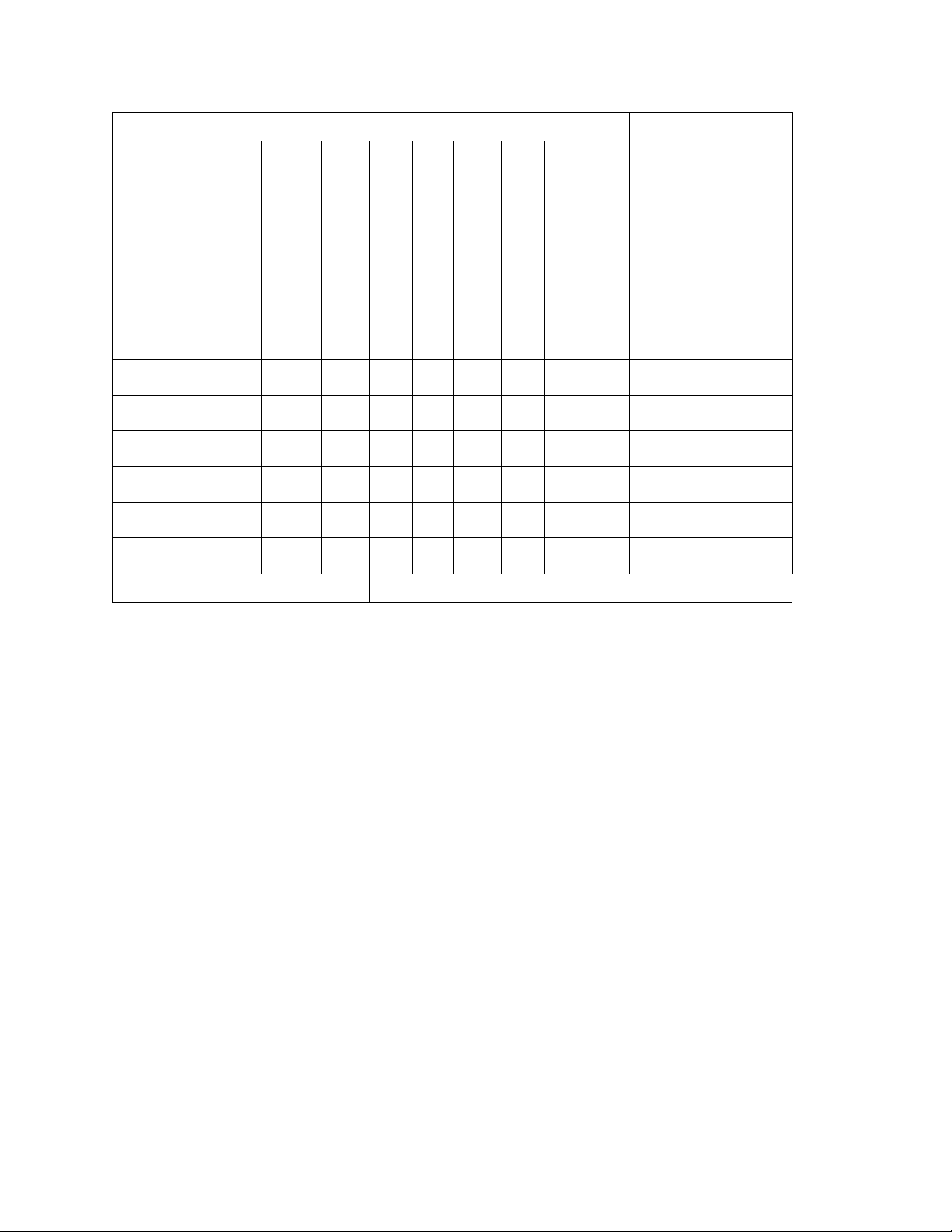

Measurement

Server/Server

Extension

withOption

Introducing the Instrument Components

Measurements Compatible with

which M3046A

a

2

3-Channel ECG

EASI derived

12-Lead ECG

Respiration

Non-Invasive

Blood Pressure

Invasive

Blood Pressure

Oxygen Saturation

SpO

Temperature

2

Mainstream CO2Sidestream CO

Release?

D and

lower

E

M3001A #C06

M3001A #C12

M3001A #C18

M3012A

M3015A

M3015A #C06

M3016A #A01

M3016A #A02

Key: ! = supported " = not supported

b

c

a. Using a standard 5-electrode lead set. You can connect a 10-electrode lead set (for example, if a patient is

transferred from an IntelliVue monitor), but only the standard five electrodes (RA, LA, RL, LL, and V) are

used for monitoring. The rest are automatically ignored.

b. Only Pressure/Temperature supported in M4 monitors.

c. Support for the CO

M4 with software revision E and D (later than D.11). Compatible with M4 only with software revision B to

D.11. No support for CO

!!!!!!!

!!!!!

"""" "

!!!!!!!

"""""!!"

""""""""

c

"""""

c

"""""

c

"""""

measurement depends on the mon itor op tion a nd softwa re revision. C ompatible with M3/

2

for earlier monitors with software revision A.

2

!!

!!!

!!

"" "

"" "

""

!! !

"

!! !

"

""

!!

!!

!

!

!

!

The signals are converted into digital data, and processed before being communicated to the

Monitor. The server device is referred to as the Measurement Server or simply the Server in

this manual. All versions of the M3000 A and M300 1A Measurement Servers are covered by

this manual.

When using the M3015A and M3016A, all the signals are converted into digital data, and

processed before being communicated to the Monitor. Server extension devices are referred

to as the Measurement Server Extensions or simply Extensions in this manual.

The M3046A Compact Portable Patient Monitor receives the processed data from the

Measurement Server and the Measurement Server Extension, examines it for alarm

conditions, and displays it. The Monitor also provides operating controls for the user, and

interfaces to other devices. This monitoring device is referred to as the Monitor in this

manual.

The M3080A #C32 12V adapter al l ows use of a vehicle power supply for t h e in strument and

the M8043A Battery Charger and Conditioner allows the recharging and conditioning of

batteries of the instrument.

Introduction to the Instrument

3

Page 20

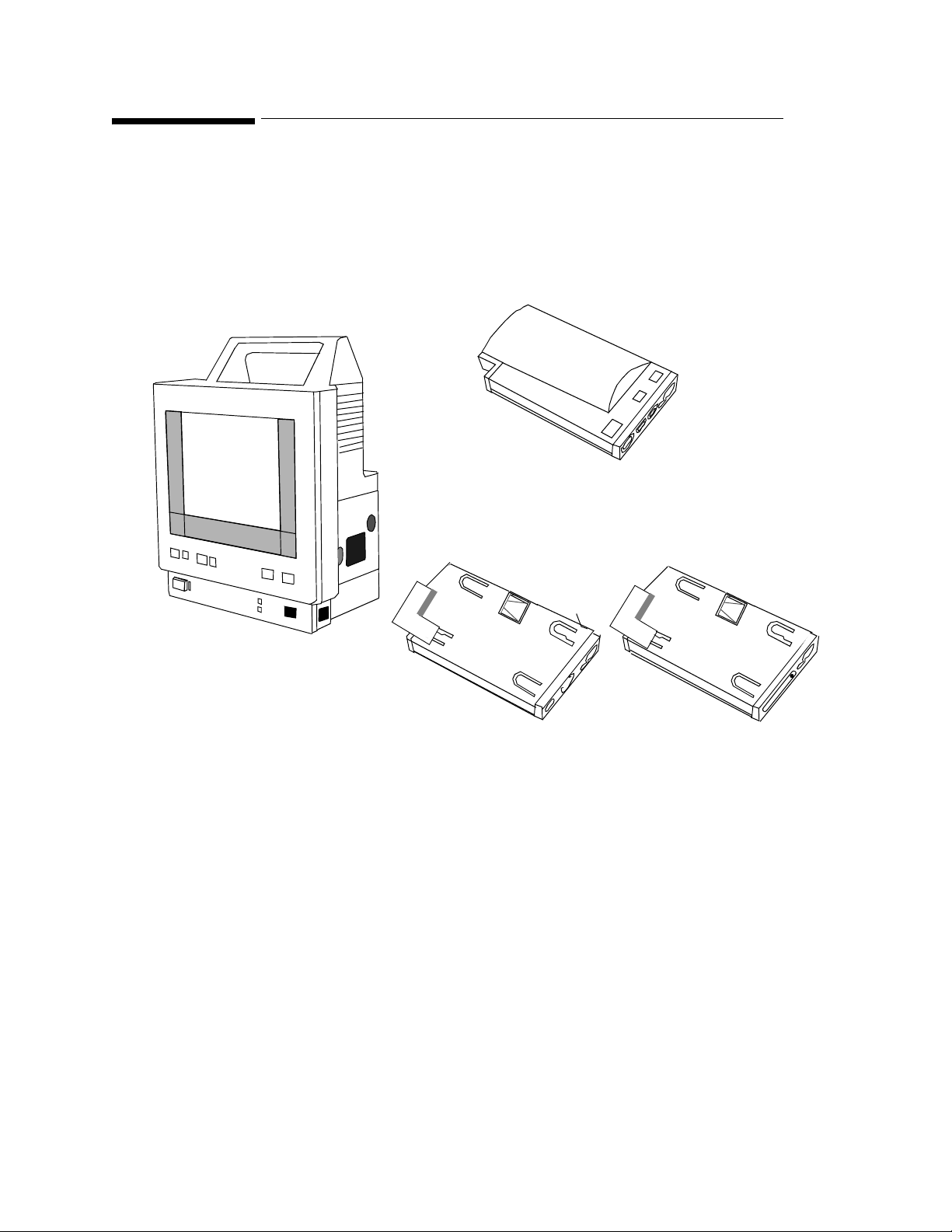

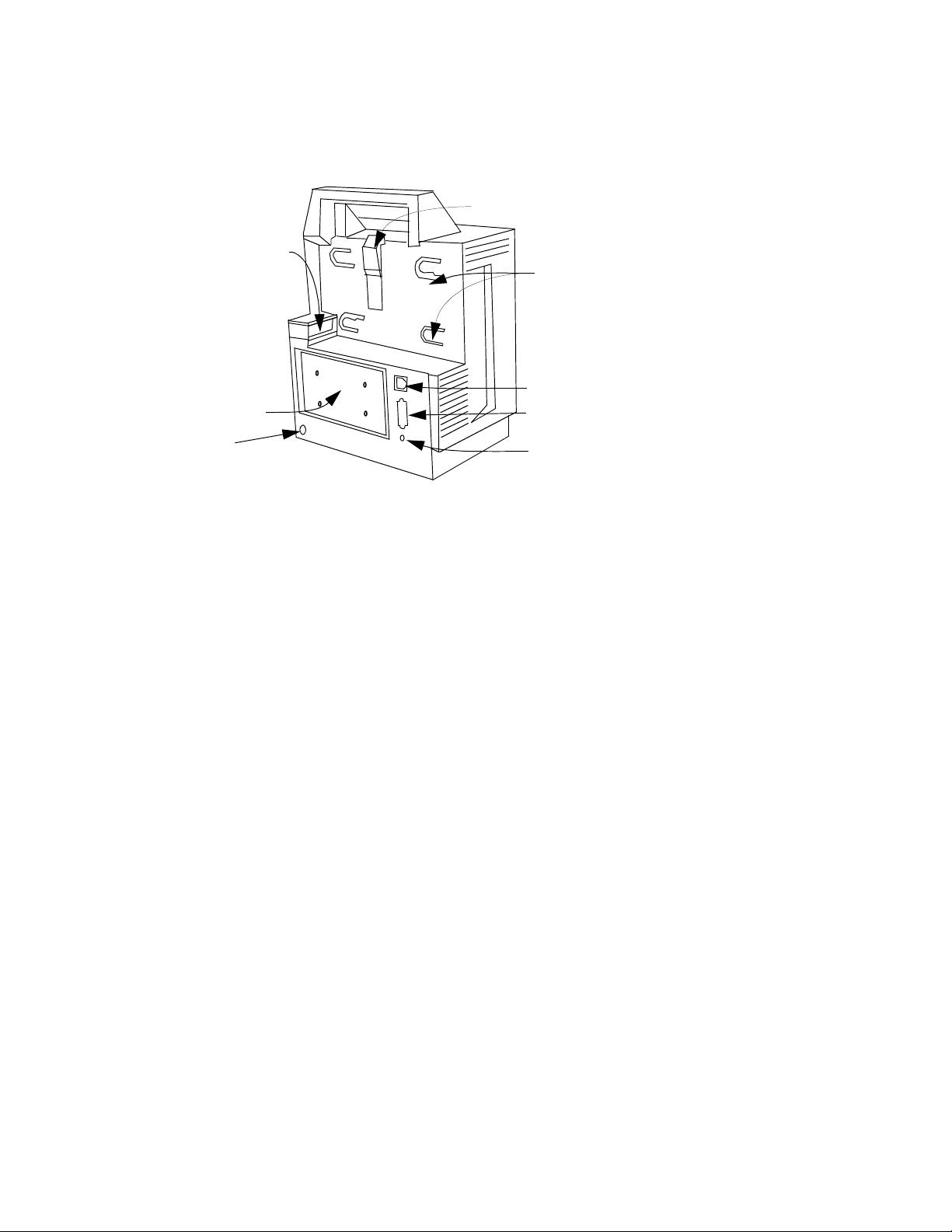

Instrument Components

Instrument Components

The Monitor, the Measurement Server, and Measurement Server Extensions are shown in the

following diagram:

Measurement Server (M3000A and M3001A)

M3000A has a

gray bezel.

M3001A has a

white bezel.

Measurement Server

Extensions

Monitor (M3046A)

Functional descriptions of these components are to be found later in this chapter.

M3016A

M3015A

4

Introduction to the Instrument

Page 21

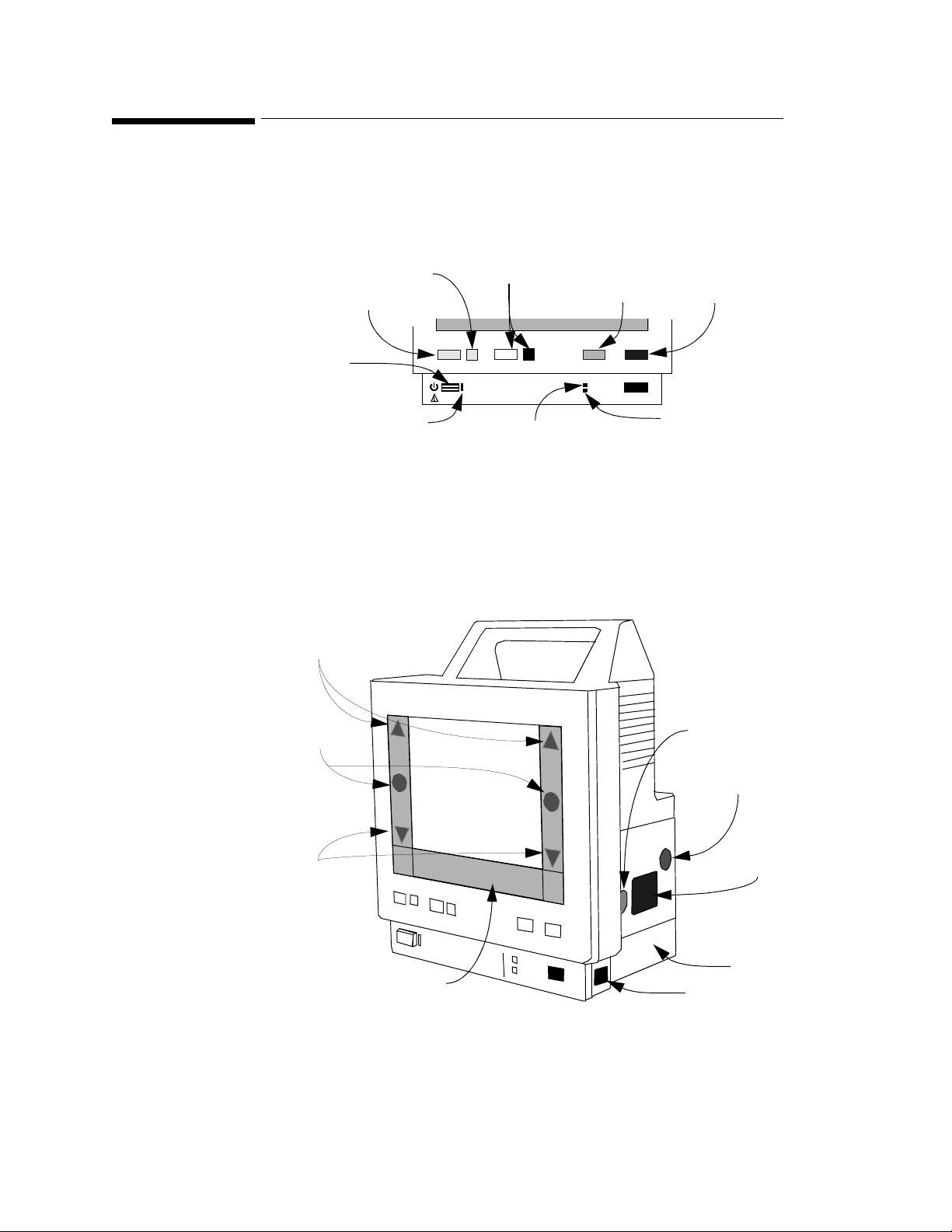

A Quick Description of the Monitor

c

A Quick Description of the Monitor

Front Panel Keys

Alarm

Indicator

Alarm

Silence/Reset Key

On Off/Standby

On Off/Standby LED

Green when Monitor is on

Front of Monitor

Menu Highlight

Up Key

Alarm Suspend

Key & Indicator

Silence

Reset

Suspend Setup

On

Off/Standby

AC Power LED

Green when AC Power

is Connected

AC Power

Battery

Setup

Key

Main

Screen

Main Screen

Key

Battery LED

Green

- Battery full (>95%)

- Battery charging

Yellow

Blinking Red

- Battery empty

Menu Enter

Key

Menu

Highlight

Down Key

Introduction to the Instrument

TouchStrips

ECG Out/

Marker In (≤12V)

Equipotential

Grounding Post

AC Power

Connector

(100 to 240Va

50/60Hz)

Battery

Compartment

Infrared Printer Port

or

Serial connector for

local recorder

(depending on option)

5

Page 22

A Quick Description of the Monitor

P

c

f

Back of Monitor:

Connector to

the Measurement

Server (≤48V)

Mounting Plate

rotective earth

onnector point

or additional display

Locking Mechanism for

the Measurement Server

Catches for

attaching the

Measurement

Server

LAN/Software Update

Connector (≤5V)

Connector for an additional

display (VGA Interface) (≤3.3V)

Nurse Call Relay

Connector (≤36V)

6

Introduction to the Instrument

Page 23

A Quick Description of the Measurement Server

e.

A Quick Description of the Measurement Server

Overview of the Measurement Server

6

7

9

8

Measurement Connectors for the M3000A #C06, M3001A #C06

and #C18 Measurement Servers

5

4

3

2

Note:

Press and Temp cannot

be used at the same tim

1

Measurement Connectors for the Standard M3000A and M3001A Measurement Server

3

2

1

Introduction to the Instrument

7

Page 24

A Quick Description of the Measurement Server

M3001A Connectors and Keys

1 White ECG/Resp connector. 6

NBP Start/Stop key - starts or stops NBP

measurements.

2 Blue SpO2 connector 7

Either:

NBP STAT key - starts NBP STAT series of

measurements.

or

Zero key -

connected pressure transducer when pressed and held

for a second.

3 Red NBP connector 8 Alarm Silence/Reset

4 & 5Combined pressure (red) and temperature (brown)

connector - connect either invasive pressure

transducer or temperature probe (M3000A #C06;

M3001A #C06 and #C18 only).

Press and temp cannot be used at the same time.

You might have a version of the Measurement Server

that does not have this connector.

9

MSL cable connector to the monitor.

initiates a zero procedure for the

8

Introduction to the Instrument

Page 25

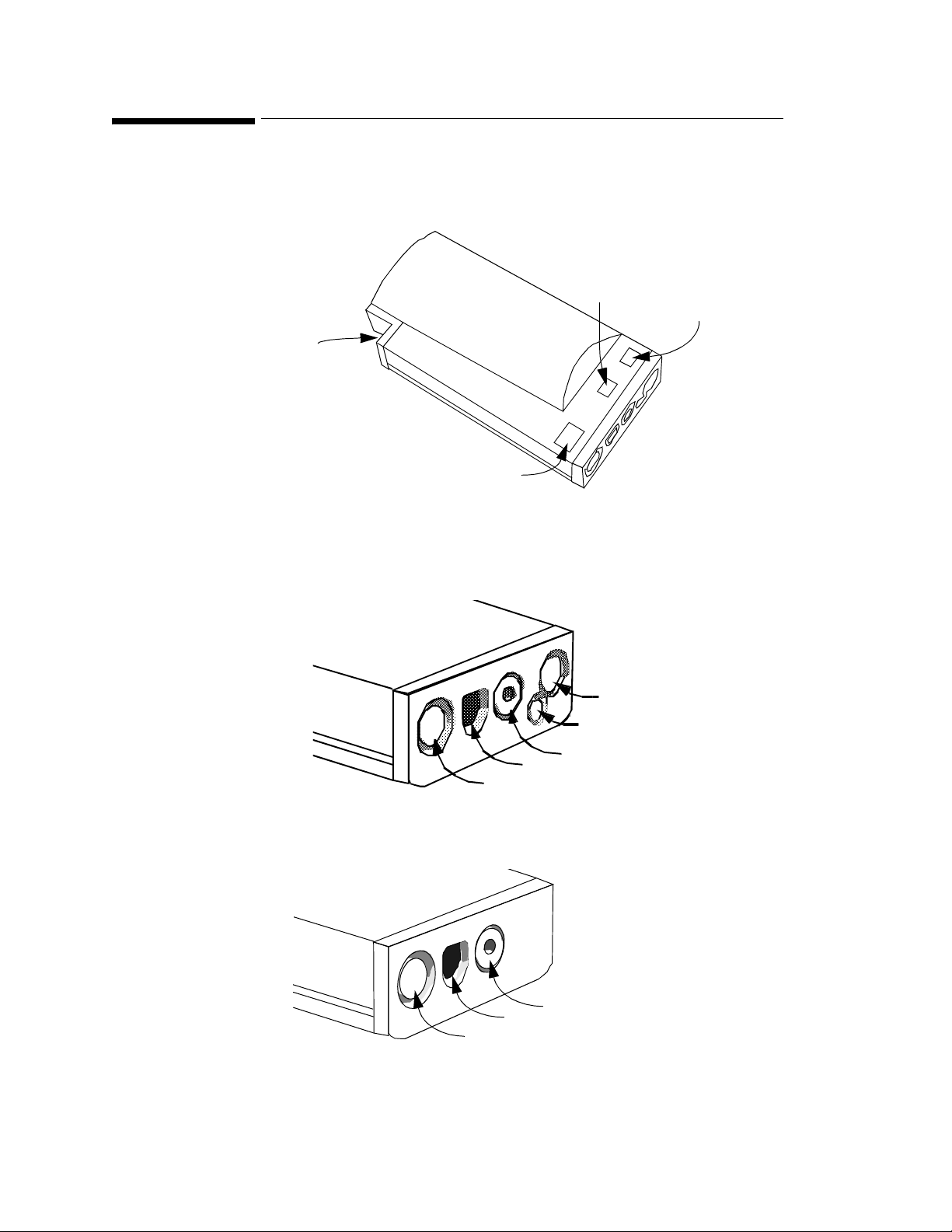

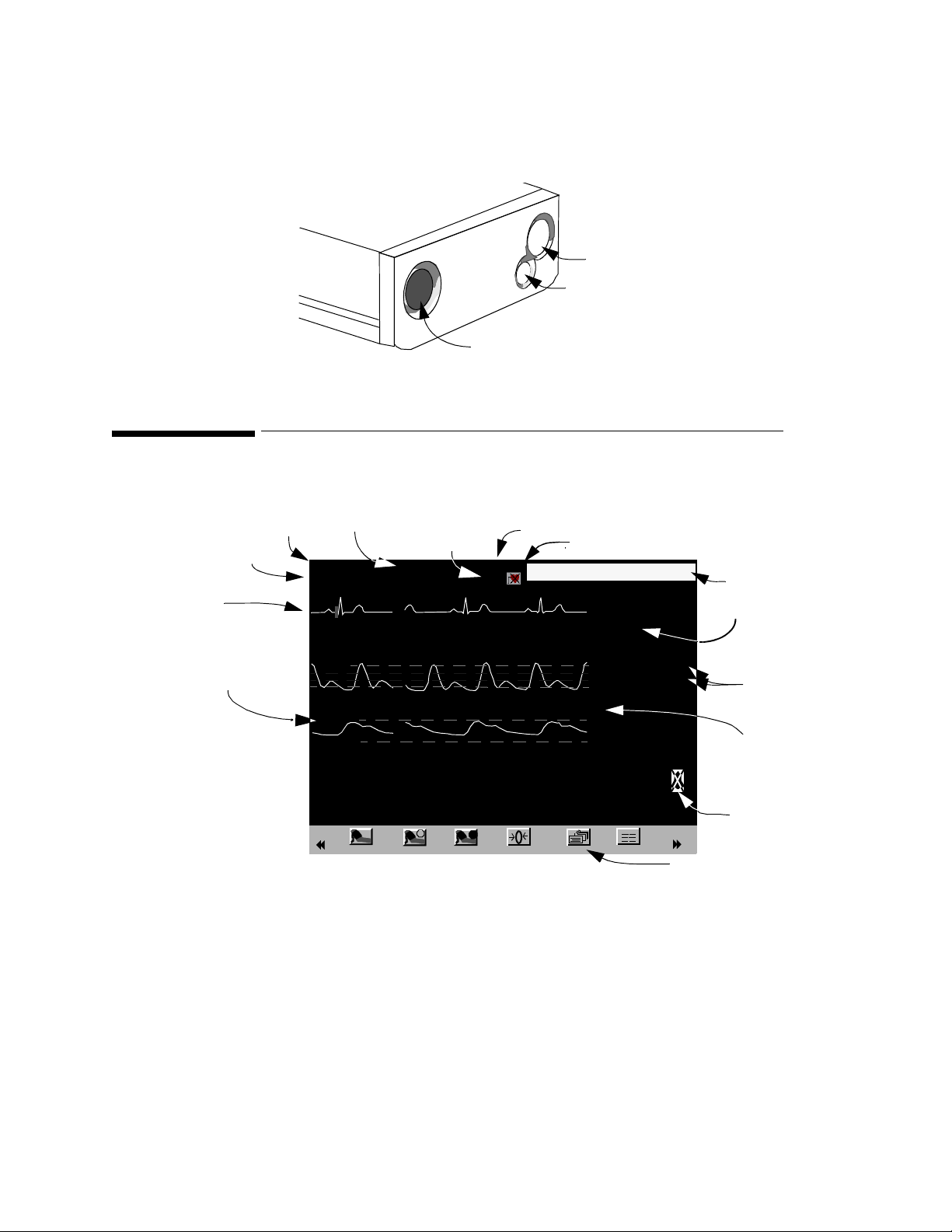

A Quick Description of the Measurement Server Extension

)

A Quick Description of the Measurement Server

Extension

Overview of the Measurement Server Extensions M3015A & M3016A

Catches for

attaching the

Measurement

Server

Connectors

to Monitor &

Measurement

Server

Measurement

Connectors

Measurement Connectors for the M3015A Measurement Server Extension

Press

Temp

gas inlet

SIDESTREAM CO

gas outlet (exhaust)

Note:

Press and Temp (M3015A #C06 only

cannot be used at the s am e time on

the same Extension.

2

Introduction to the Instrument

9

Page 26

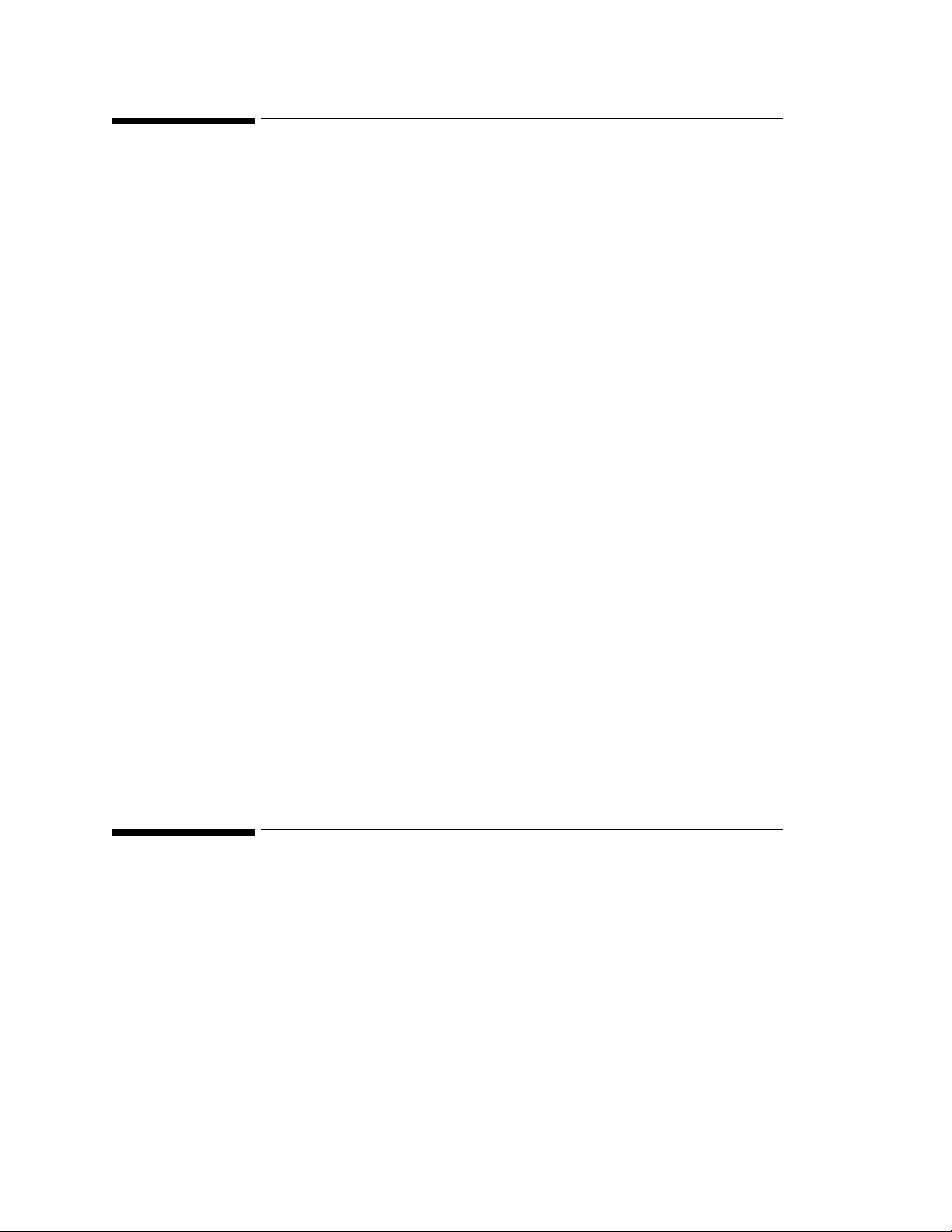

A Quick Description of the Main Screen

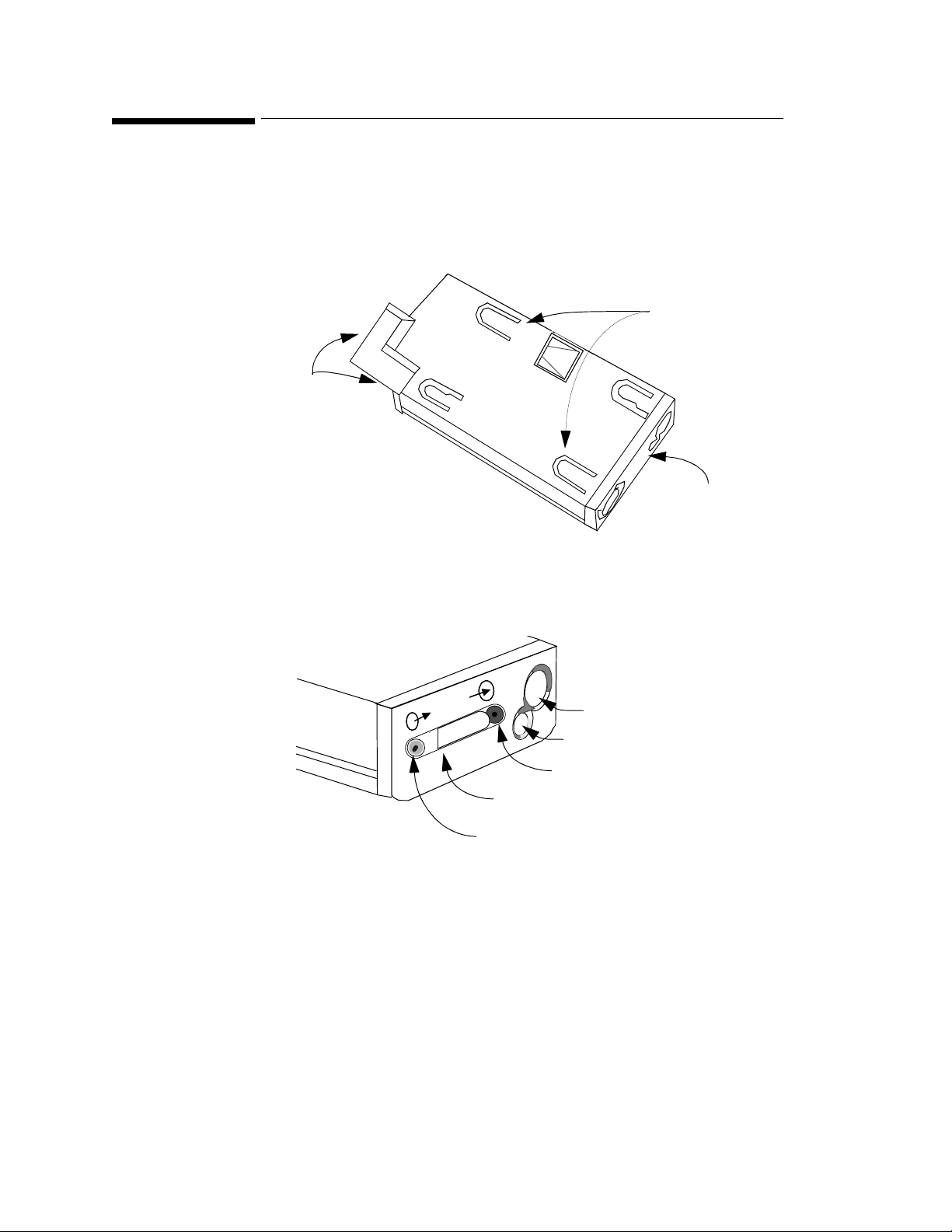

Measurement Connectors for the M3016A Measurement Server Extension

A Quick Description of the Main Screen

Monitor Label

Patient Name

Wave

Wave Label

QuickSet

SCHLACK, ANDREAS

II

1 mV

Pleth

ABP

120

0

NBP

135

Start/Stop

Patient Siz e

QuickSet 1

/

101

NBP STAT

Auto

MAINSTREAM CO

Time

23:11

Adult

Sinus Rhythm

60min

(120)

STOP

Stop All

Alarms Suspended

17:15

mean

120

90

Zero

Press

Temp

Note:

Press and Temp cannot

be used at the same time

on the same Extension.

(Option #A01 only)

2

Non-Paced Symbol

HR

70

SpO

2

97

ABP

120

70

/

(91)

Resp

12

Store Screen

Trends

Alarm Message

90

65

PVC

5

100

sys.

150

100

Numeric

90

Alarm

Limits

Numeric

Label

Alarm Off

Symbol

(measurement)

SmartKey Label/Icon

You can return to the display with the waves and the numerics at any time by pressing the

blue Main Screen key.

10

Introduction to the Instrument

Page 27

Theories of Operation and Functional Descriptions

Theories of Operation and Functional Descriptions

The theories of operation and functional descriptions are presented in three sections:

Section 1 Monitor Description

• M3046A Monitor The ory of Operation

• Functional Description of the Monitor Hardware

Section 2 M3001A/M3000A Measurement Server Description and Features

• Measurement Server Theory of Operation

• Functional Description of the Measurement Server Hardware

• Electrocardiogram/Respiration (ECG/Resp) Measurement

• Non-invasive Blood Pressure (NBP) Measurement

• Arterial Oxygen Saturation and Pleth (SpO2/PLETH) Measurement

• Temperature and Invasive Blood Pressure (Temp/Press) measurement

Section 3 Measurement Server Extensions Description and Features

• M3015A Measurement Server Extension Theory of Operation

• Functional Description of the M3015A Measurement Server Extension

Hardware

• Sidestream CO2 Measurement

• M3016A Measurement Server Extension Theory of Operation

• Functional Description of the M3016A Measurement Server Extension

Hardware

• Mainstream CO2 Measurement

Section 1 - Monitor Description

The M3046A Patient Monitor is a small size, lightweight monitor with a TouchBar human

interface. The monitor has a color display with a wide viewing angle, and excellent visibility

from a distance, so that data can easily be recognized. For appl ications where a lar ger display

is required, an additional display can be connected to the monitor via the standard VGA

output.

Trend data, and manual and automatic ev ent storage, together with a ran ge of report styles are

available for tracking and documenting the patient’s progress.

The Monitor receives the processed data from the Measu rement Server and the Meas urement

Server Extension, examines it for alarm conditions, and displays it. The Monitor also

provides operating controls for the user, and interfaces to other devices.

Introduction to the Instrument

11

Page 28

Monitor Theory of Operation

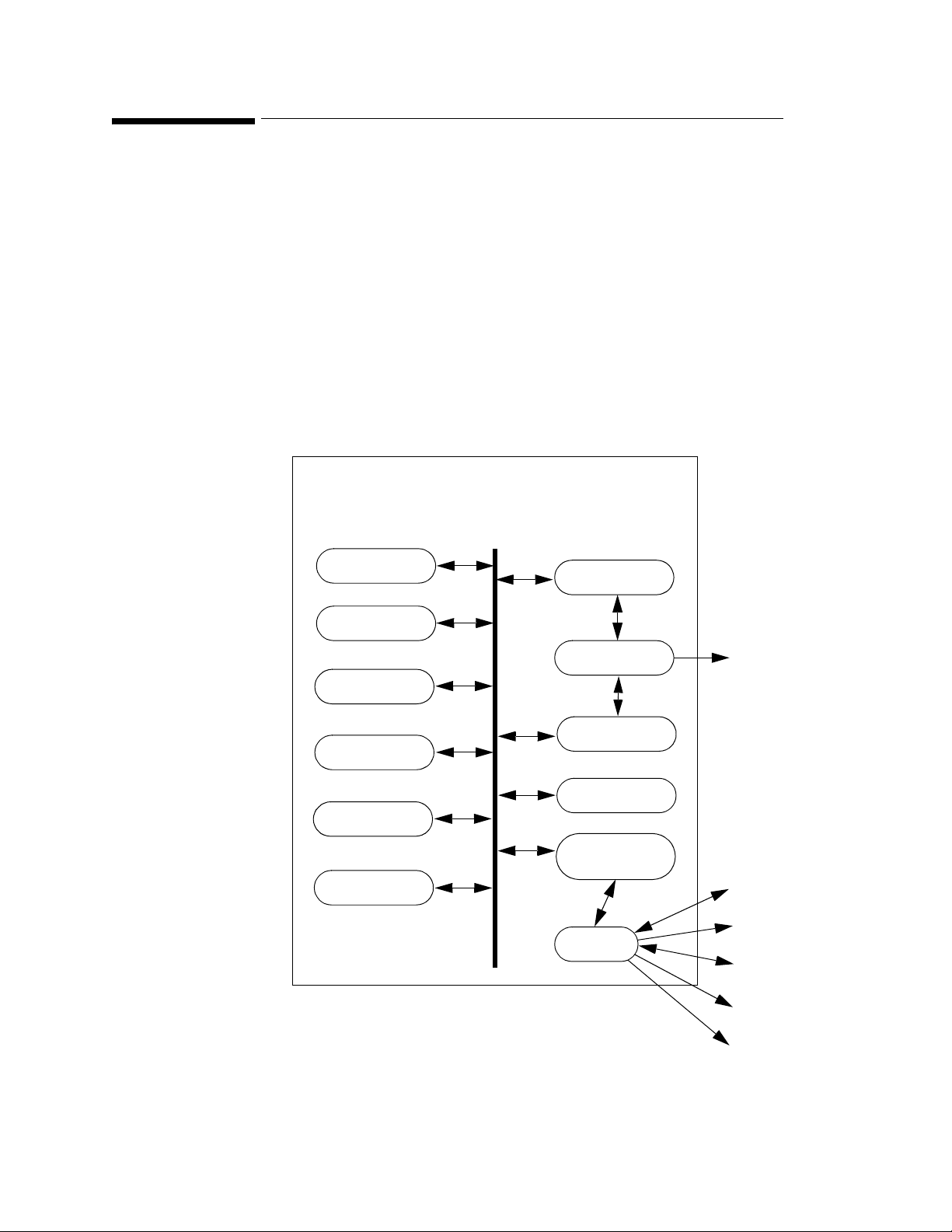

Monitor Theory of Operation

The Monitor receives data passed from the patient through the Measurement Server and,

where present, the Measurement Server Extension. The Monitor displays the data in

numerics and waves on the screen.

The Monitor is prepared with a number of software modules, which communicate with each

other as sho wn in the diag ram below. The Monitor software communicates with the

Measurement Server and, where present, the Measurement Server Extension via a normal

local area network (LAN) link. Data from the Monitor can be output to a printer via an

infrared serial link or via the LAN connector to a central print server. The Monitor can

communicate with an Philips Information Center via the LAN Connector (wired network) or

via the Wireless LAN Assembly (wireless networ k) when the appropriate options are p resent.

M3046 CPU System

Inter-process

Communications

Communication

Module

Trend

Module

Events

Module

ADT Module

Support

Services

Alarm

Manager

Printer

Manager

IrDA/Serial

Communication

Recorder

Manager

Display

Controller

Display and

Operator

Interface

HIF

Controller

IrDA/Serial

Interface

Operating

controls

LEDs

Battery

controller

Alarm

Relay

Loudspeaker

Each of these modules is described in the following sections.

12

Introduction to the Instrument

Page 29

Monitor Theory of Operation

Display and User Interface Software Module

The Display and User Interface Software displays measurement data and status information

on the color LCD display, and processes the operator inputs from the HIF Controller. The

interface consists of the following sub-modules:

• Screen Configuration.

• Numerics and Wave Presentation.

• Key and To uchStrip Processing.

• Alarm and Status Presentation.

Alarm Manager Software Module

The visual and audible alarms generated by the Measurement Server, the Measurement

Server Extension or by the Monitor software modules are assigned priorities by the Alarm

Manager. The Alarm Manager also:

• Monitors the “alarm suspended”, “alarm silence” and “alarm reminder” functionality.

• Manages alarm latching (alarms remain in effect until reset or turned off by the user).

• Triggers the Nurse Call Relay.

• Generates alarm event triggers for any user-defined trigger conditions.

Admit / Discharge / Transfer (ADT) Software Module

This module maintains the patient’s demographics and controls the upload of trend data from

the Measurement Server and the Measurement Server Extension. It allows the user to:

• Admit a new patient.

• Transfer a patient to another Monitor.

• Discharge a patient.

Trend Software Module

This module manages a trend database. It stores physiological values from the Measurement

Server and from the Measurement Server Extension in two separate databases, a short-term

and a long-term database. The content s of thes e data base s is bat te ry-b uffered, so that no data

is lost in the event of a power failure.

Events Software Module

The events software module allows the user to take snapshots of the Monitor state and store

them for later viewing or printing.This can be done automatically, triggered by alarms, if the

monitor is configured appropriately. The types of data that can be captured are as follows:

• All physiological values.

• All current alarms.

• The last 20 seconds of wave data.

Introduction to the Instrument

13

Page 30

Monitor Theory of Operation

Printer Manager

The printer manager formats and prints the following reports on either a locally attached

printer or a remote printer connected to the Instrument via the M3 Print Server:

• Tabular Trend Report—The printer manager takes raw data from the trend module and

generates a formatted report. The user can sp ecify w hether to pri n t shor t -te rm or lon g-term

trend data, and the period for which the data should be printed.

• Event Report—The printer manager take s raw data from the event module and generat es a

formatted event report. The user can specify a manual event, an alarm event, or a print

screen report.

• Event List Report—The printer manager takes the raw event list data from the events

module and generates a formatted event list report.

A number of drawing functions support the printer manager and provide it with graphics

capabilities. The output from the printer manager is in PCL (Printer Command Language)

format, and is fed to the locally attached prin ter, which is connected via an infr ared data link ,

or to a remote printer. If the link to the printer is interrupted for a certain time, the printer

manager displays a prompt of the color LCD display, notifying the user.

Recorder Manager

The recorder manager formats and records the following on a local recorder:

• Real-time or Delayed Recording—The user can select between a real-time local

recording or a delayed recording.

A real-time recording is started by pressing the Local Record SmartKey. When a r ecording

is running, you can stop it by pressing the key again.

A delayed recording can be started by pressing the Local Delayed SmartKey. Pressing the

key again will extend the recording.

• Tabular Trend Report—The recorder manager takes raw data from the trend module and

generates a formatted report. The user can specify whether to record short-term or longterm trend data, and the period for which the data should be recorded.

• Event Report—The recorder manager takes raw data f rom t he event m odule and generat es

a formatted event report, and this is recorded on the local recorder.

• Alarm Recording—If a local recorder is connected to the monitor via the optional serial

interface, you can make local alarm recordings. In configuration mode, you can select the

local recorder or the Information Center, or both, to record alarms . If one of the configu red

alarms occurs, a recording for that alarm is started automatically at the local recorder (and/

or requested form the Information Center).

See Chapter 2, Installing the Instrument for more details on connecting to a recorder.

A number of drawing functions support the recorder manager and provide it with graphics

capabilities. The output from the recorder manager suports the GSI Lumonics XE-50pspecific serial protocol, and output is fed to the local recorder, which is connected via a

dedicated serial cable. The recorder manager displays prompt and status messages on the

monitor’s color LCD display.

14

Introduction to the Instrument

Page 31

Monitor Theory of Operation

IrDA/Serial Communication Manager

The IrDA/Serial Communication manager is responsible for sending raw data to the local

recorder (serial protocol) or printer (in a format that complies with the IrDA (Infrared Data

Association) standard). The IrDA/Serial Communication manager provides a general printer

or recorder device interface to the printer or recorder manager, and maps the general printer/

recorder services to the device protocol. The general printer services are as follows:

• Establishing and terminating the printer/recorder connection.

• Transferring data to the printer/recorder.

• Retrieving the printer/recorder status.

The IrDA/Serial Communication manager feeds the printer/recorder status (time out, paper

out, and so on) back to the printer or recorder manager, which in turn notifies the user of any

errors in the print/record process.

Communication Software Module

The communication module maintains a data link between the Monitor, the Measurement

Server and the Measurement Server Extension, and controls the exchange of data between

them. This data includes the following:

• Measurement data.

• status in f ormation.

• Control information.

• Configuration data.

Support Services

The support services software module contains miscellaneous functions that both the

Monitor, the Measurement Server and the Measurement Server Extension require. These

functions are as follows:

• Date and Time.

• Settings Handler.

• Status Revision and Display.

• Heart Rate Selector.

Introduction to the Instrument

15

Page 32

Functional Description of the Monitor Hardware

t

Functional Description of the Monitor Hardware

The Monitor receives data from the Measurement Server and Measurement Serv er Extension

via the Server-to-Monitor link bar and presents this data on the color LCD display. The

following block diagram shows the main functional areas.

AC

AC

Power Supply

System Board

DC/DC Converter

48V current limiter

Battery charger

Processor (Battery

Controller)

48Vlim +5V Vbuf

HIF(83C552)

(TouchStrip,Keys,Sound,

LEDs, Alarm Relay,

Battery)

48V,

AC present

6 Pin

Connector

Vbat 48V

AC

present

I2C

I2C

Rx,Tx

Alarm

Relay

Connector

Board

LAN

VGA

(Network)

CPU System(360)

(Flash,SRAM,DRAM)

Display

Video

Controller

Vbat,

5 Pin

Connector

48 Pin

Connector

uP bus

I2C

SRL

LAN

Serial Link

ECG Out/

Marker In

Controller

Optional

Smart Battery

Optional

Wireless LAN

140 Pin

Connector

Ventilator

Fan

SRL to

Measuremen

Server

(M3000A)

ECG

Out

34 Wire

Flat Cable

Bezel Assembly

Keys

PIC LEDs,Standby

Alarm LEDs

TouchStrip

Display Assembly

Video

40 Wire

Flat Cable

Keyboard

16

Standby On/Off (PIC)

4 hardkeys(HIF)

TouchStrips

LEDs:

On/Off(+5V)

AC Power(PIC)

Battery(PIC)

X Bell(HIF)

red alarm(HIF)

yellow alarm(HIF)

IrDA

(Infrared)

or

Serial

Interface

Display Adapter

Board

6 Pin

cable

Inverter Board

31 Pin

Flex

2x2 Pin

cable

LCD

Display

Backlight

Introduction to the Instrument

Page 33

Functional Description of the Monitor Hardware

The main functional areas are summarized in the following:

• System Board—Comprising a 68360 Controller, the Memory System, the Video System,

LAN (network) connector link to Server, ECG-Out, Human Interface and DC/DC

Converter.

• Connector Board—Connecting the System Board to the AC Power Supply and battery.

The LAN (network) filter and connector, the VGA connector and the Alarm Relay Output

(Nurse Call) are located on the Connector Board. The Connector Board has a 48-pin

connector to the System Board.

• Display Assembly—Comprising a 6.5 inch TFT color LCD display (including 2 backlight

tubes), the Display Adapter Board and the associated backlight inverter board (generates

the high voltage for the tubes). These parts are packed into a soft, rubber-based holder

(sometimes referred to as the cushion). The LCD display uses thin-film-technology and is

sometimes referred to as a TFT display.

The Display Assembly connects to the System Board via a 40-wire flat ribbon cable.

• Bezel Assembly—Comprising the U-shaped TouchStrip, the Keyboard (which includes

operating keys, alarm LEDs, On/Off switch and AC and battery indicator LEDs), and the

IrDA Board (infrared printer interface) / recorder interface board..

The Bezel Assembly connects to the System Board via a 34-wire flat ribbon cable.

• Speaker—Connected to the System Board with a 2-wire cable. The loudspeaker provides

the audible output for alarms, and audible feedback when the user presses a manual control.

• AC Power Supply—Connected to the Connector Board to power the Instrument and/or

charge the battery depending on the operating mode.

• Smart Battery—As an option, a standard, intelligent battery with an I2C interface to the

DC/DC controller.

• Wireless LAN Assembly — Comprising the Wireless LAN CPU Board and the radio

frequency (RF) Board. The Wireless LAN Assembly connects to the System Board via a

140-pin extension connector. The RF Board connects to the antenna, which is built into the

monitor handle via a coax cable.

• V entilator Fan — Connected to the System Board with a 2 -wire cable. The fan controls the

temperature inside the Monitor when the Wireless LAN option is installed.

Detailed descriptions are given in the following sections.

Display Video Controller

The Display Video Controller runs the software that controls the display. This software

processes the high level display command to gener ate and format the screen characters,

graphics, and wave plots, and also generates the video control signals for the LCD display.

The software continuously checks the functionality of the hardware in the Display Controller,

and issues an error indication in the event of a hardware malfunction.

Introduction to the Instrument

17

Page 34

Functional Description of the Monitor Hardware

Human Interface Controller

The Human Interface Controller (HIF) is the interface between the operator and the Monitor

itself. It monitors the operator controls and the Battery Controller, formats the data, and

routes it to the Display & Operator Controls Manager from which it receives commands and

status also. As well, the HIF controls the features listed below.

Visual Indicators

The Instrument is fitted with the following front panel indicators:

• Yellow LED—This flashes in addition to the visual indication on the LCD display when a

yellow-alarm situation occurs (medium severity alarm).

• Red LED—This flashes in addition to the visual indication on the LCD display and the

audible tone from the loudspeaker when a red-alarm situation occurs (high severity alarm).

• Crossed Bell LED—This is illuminated when all alarms have been suspended.

Alarm Relay

In addition to the audible and visual alarms, an alarm relay is provided, which energizes

when an alarm condition occurs. This enables a remote alarm indicator (such as a Nurse Call)

to be connected to the device.

Battery Controller

The battery controller is the interface to the Smart battery. Signals fro m the battery inform the

battery controller of the most effective charging current with which to load the battery. Two

LEDs are mounted on the Battery Controller:

• Battery LED—This is illuminated green if the battery is fully charged and yellow if the

battery is charging. If the remaining battery-operating time is only 5 minutes, the LED

flashes red at a repetition rate of 1.5 flashes per second.

• AC LED—This is illuminated green when the power cord is connected and AC power is

available. Otherwise it is extinguished. The AC LED is fed directly from the AC power

supply.

For a detailed description of the battery, see chapter 3, “Maintaining the Instrument”.

ECG Out/Marker In Controller

The ECG Out/Marker In Controller is the interf ace between the Monitor and any d efibrillator

that might be connected. It converts a digital waveform signal received from the

Measurement Server ECG/Respiration module into an analog ECG signal, which it feeds to

the defibrillator in order to synchronize it. The ECG Out controller also processes the marker

information from the defibrillator and feeds the data back to the Measurement Server ECG/

Respiration measurement module.

18

Introduction to the Instrument

Page 35

Section 2 - Measurement Server Description and Features

Infrared (IrDA) Interface

The IrDA interface provides a wireless interface to an external printer. This interface