Page 1

Philips M1013A/M1019A/M1026B

Instructions for Use

IntelliVue G1/G5 and

Anesthetic Gas Module

M1013A/M1019A/M1026B

Patient Monitoring

Page 2

Part Number M1013-9001C

Printed in Germany 12/05

4512 610 12491

*M1013-9001C*

Page 3

M1013-9001C

1Table Of Contents

1 Using the Gas Analyzer 1

Understanding the Gas Analyzer Display 2

M1013A IntelliVue G1 & M1019A IntelliVue G5 Major Parts and Keys 2

M1013A IntelliVue G1 / M1019A IntelliVue G5 Rear Panel 3

M1026B Major Parts and Keys 3

M1026B Rear Panel 4

Watertrap M1657B 4

Understanding the Gas Measurement 5

M1013A IntelliVue G1 & M1019A IntelliVue G5 5

M1026B AGM 5

Connecting Gas Analyzer Accessories 5

Using the Gas Analyzer Setup Menus 7

Choosing Numerics for Display 7

Humidity Correction for CO

Adjusting Wave Scales 8

Changing the Apnea Alarm Delay 9

Deriving Limit Alarms from awRR 9

Alarms and Zero Calibration 9

Automatic Alarm Suppression 9

Agent Identification 10

If Agent ID is Set to Manual 10

If Agent ID is Set to Auto (M1019A IntelliVue G5 & M1026B AGM) 10

Exchanging Agents (M1019A IntelliVue G5 & M1026B AGM) 11

Agent ID During Emergence from Anesthesia

(M1019A IntelliVue G5 & M1026B AGM)

MAC Calculation 11

Uncorrected MAC 12

Ambient Pressure Corrected MAC (not available in the USA) 12

Enhanced MAC Correction (not available in the USA) 13

Removing Gas from the Circuit 15

Returning the Gas Sample 15

Removing the Gas Sample 15

Entering Gas Analyzer Standby Mode 16

Zero Calibration 17

Automatic Zero Calibration 17

M1013A IntelliVue G1 and M1019A IntelliVue G5 17

M1026B AGM 17

Carrying Out Manual Zero Calibration 17

Suppressing Zero Calibration 17

Using the Gas Analyzer During a Cardiopulmonary Bypass 18

Safety Information 18

2

11

8

i

Page 4

2 Maintenance and Troubleshooting 21

Inspecting the Equipment and Accessories 21

Inspecting the Cables and Cords 21

Maintenance Task and Test Schedule 21

Troubleshooting 23

Disposing of the Gas Analyzer 23

Disposing of Empty Calibration Gas Cylinders 23

3 Installation and Specifications 25

Intended Use 25

Manufacturer’s Information 26

Responsibility of the Manufacturer 26

Symbols 27

Installation Safety Information 28

Installation Instructions 28

Altitude and Barometric Pressure 28

M1013A IntelliVue G1 & M1019A IntelliVue G5 Specifications 29

Safety Specifications 29

Physical and Electrical Specifications 29

Environmental Specifications 29

Measurement Specifications 30

Interfering Gases and Vapours 32

M1026B Specifications 33

Safety Specifications 33

Physical and Electrical Specifications 33

Environmental Specifications 34

Measurement Specifications 35

Interfering Gases and Vapours 37

Safety and Performance Tests 38

Electromagnetic Compatibility (EMC) Specifications 38

Accessories Compliant with EMC Standards 38

Electromagnetic Emissions 38

Electromagnetic Immunity 39

Recommended Separation Distance 40

4 Patient Alarms and INOPs 41

Patient Alarm Messages 41

Technical Alarm Messages (INOPs) 43

5 Gas Analyzer Accessories 47

6 Care and Cleaning 49

General Points 49

Cleaning 50

Disinfecting 50

ii

Page 5

Gas Analyzer Accessories 50

iii

Page 6

iv

Page 7

1

1Using the Gas Analyzer

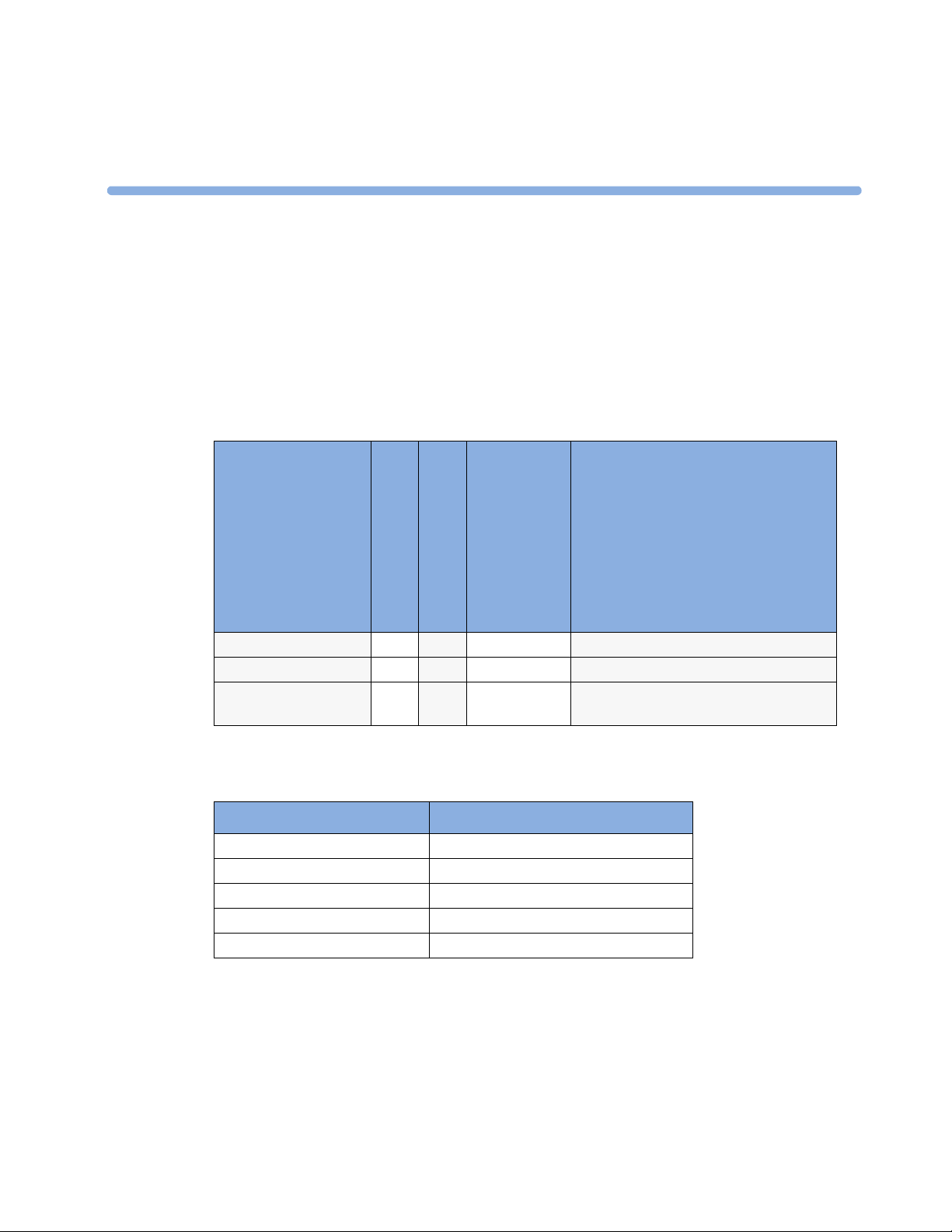

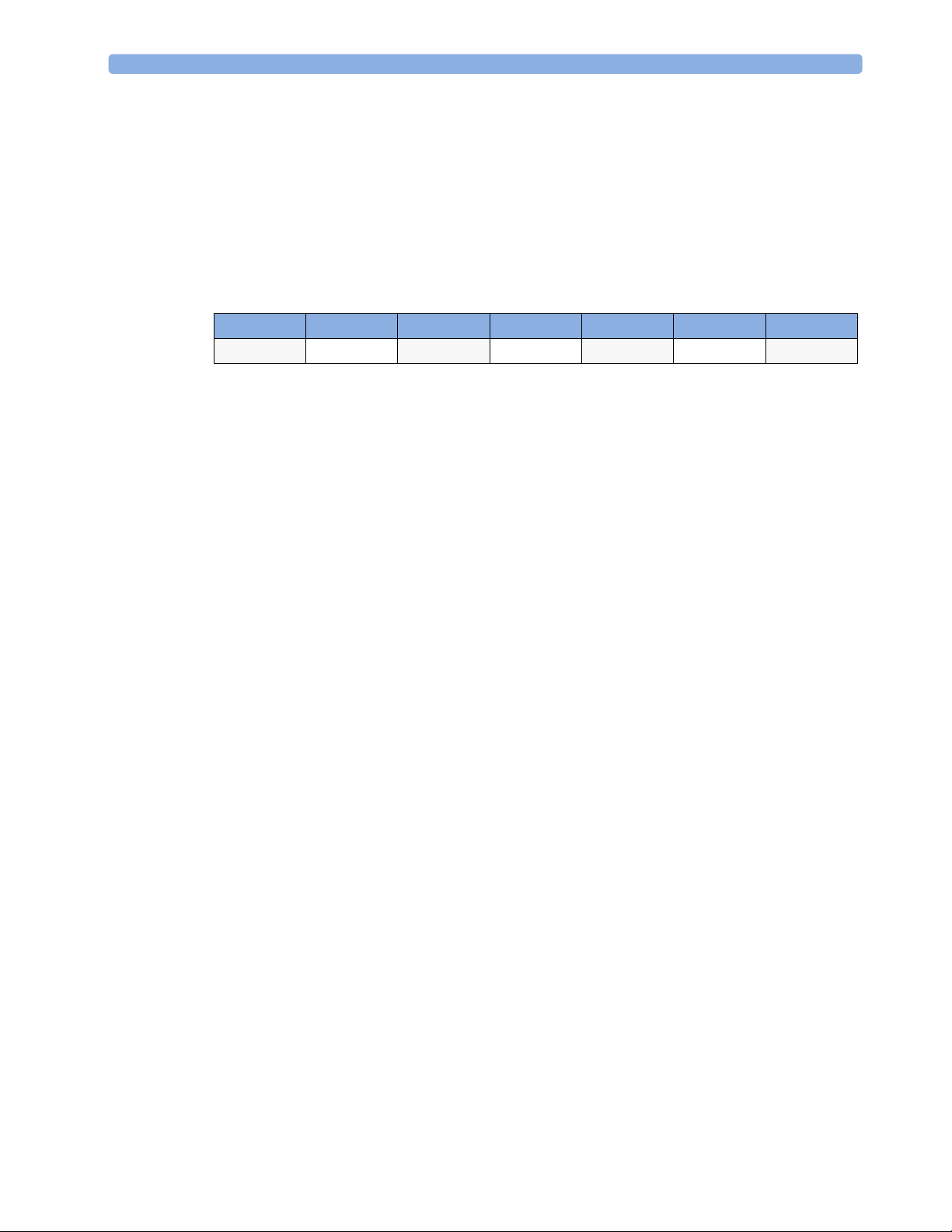

The M1013A IntelliVue G1, the M1019A IntelliVue G5 and the M1026B Anesthetic Gas Module

(AGM), hereafter referred to as the “gas analyzers”, measure patients’ anesthetic and respiratory

gases.The following table shows the main features and the patient monitor compatibility for the three

gas analyzers:

Automatic

Gas Analyzer

Agent ID

Compatibility

Number of Gases measured

M1013A IntelliVue G1 3 1n/aIntelliVue MP20/30/40/50

M1019A IntelliVue G5 3 22 out of 5IntelliVue MP20/30/40/50/60/70/80/90

M1026B AGM 3 11 out of 5IntelliVue MP40/50/60/70/80/90 and

The gas analyzers measure the Airway Respiration Rate (awRR) and provide end tidal (et) and inspired

(in) values for the following gases:

Respiratory Gases Anesthetic Agents

Carbon dioxide (CO2)Halothane

Nitrous oxide (N

Oxygen (O

The gas analyzers must only be used by qualified personnel.

O) Isoflurane

2

) Enflurane

2

Number of Agents

measured

Sevoflurane

Desflurane

Philips ACMS; Philips V24/26

1

Page 8

1 Using the Gas Analyzer Understanding the Gas Analyzer Display

Understanding the Gas Analyzer Display

The gas analyzers can send waves and numerics for all measured gases for display on the monitor

screen. This example shows the CO

configured to look different.

, O2, and N2O waves and numerics. Your display may be

2

CO2

O2

N2O

etCO2

imCO2

etN2O

inN2O

awRR

etO2

inO2

rpm

M1013A IntelliVue G1 & M1019A IntelliVue G5 Major Parts and Keys

Setup LED

Watertrap

Standby LED

Power on/off

Standby Key

Setup Key

The setup LED lights when the Setup Gas Analyzer menu is open, when the module is first

switched on (for 5 - 10 seconds), and if there is a problem with the communication between the gas

analyzer and the monitor. The standby LED lights up when the gas analyzer is in standby.

2

Quick Mount Release

Power LED

Page 9

M1026B Major Parts and Keys 1 Using the Gas Analyzer

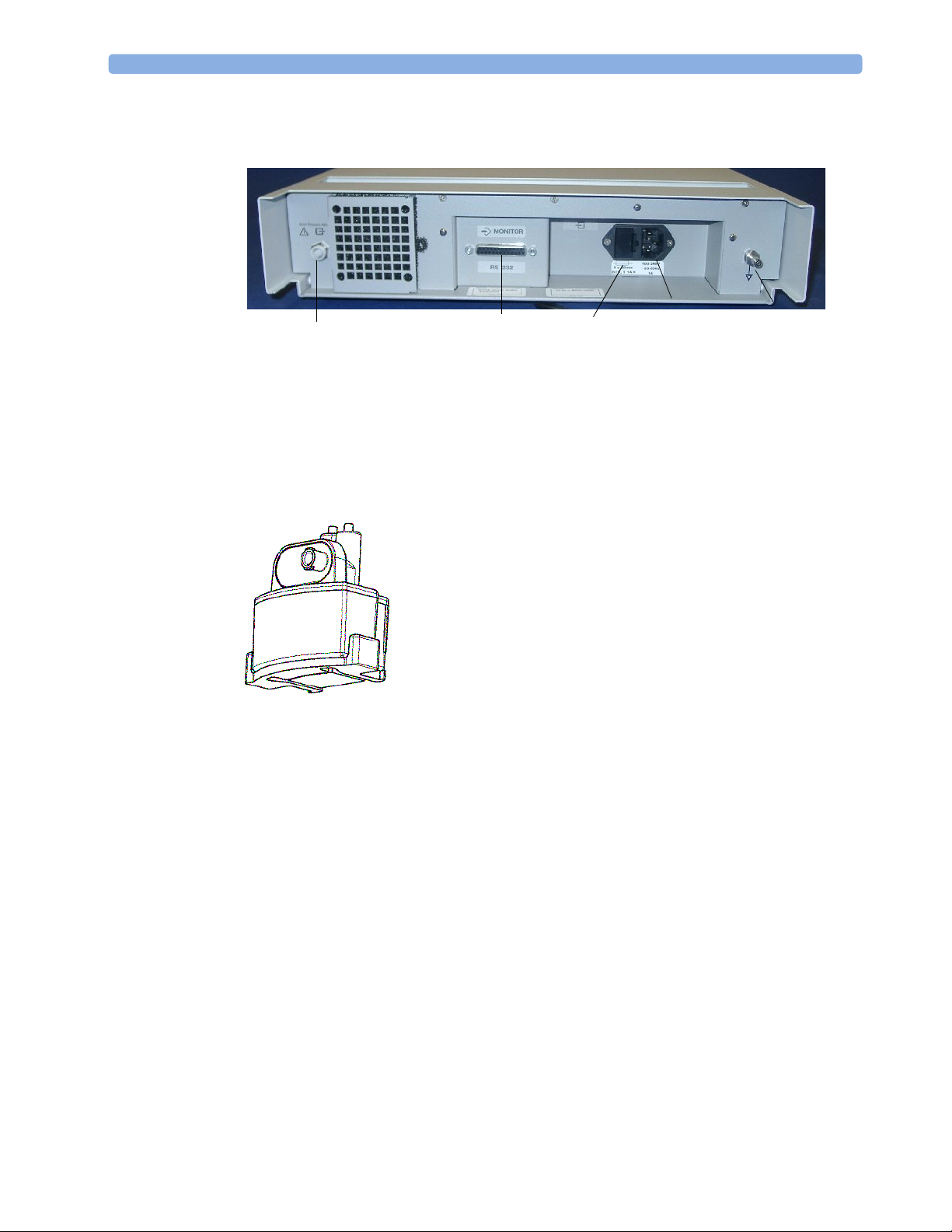

M1013A IntelliVue G1 / M1019A IntelliVue G5 Rear Panel

Power Inlet

Fuses

The RJ-45 connector is the interface connector for the Philips IntelliVue patient monitors.

WARNING • The M1013A IntelliVue G1 may only be used with the Philips IntelliVue MP20/30/40/50 patient

monitors. Connections to other devices may result in a safety hazard.

• The M1019A G5 may only be used with the Philips IntelliVue MP20/30/40/50/60/70/80/90

patient monitors. Connections to other devices may result in a safety hazard.

Equipotential Grounding Terminal

RJ-45

Gas Outlet

Make sure that the anesthetic gas outlet at the rear of the module is connected to the gas scavenging

system or the gas return line.

See your gas analyzer’s service guide for further information on connecting devices.

M1026B Major Parts and Keys

irway Gases LED

irway Gases Key

Power On/

Off switch

Power LED

Wat er tr ap

The setup airway gases LED lights when the Setup Gas Analyzer menu is open, when the module

is first switched on (for 5 - 10 seconds), and if there is a problem with the communication between the

M1026B and the monitor.

3

Page 10

1 Using the Gas Analyzer M1026B Major Parts and Keys

M1026B Rear Panel

Gas Outlet

Make sure all devices connected to the RS232 connectors are isolated. Make sure that the anesthetic

gas outlet at the rear of the module is connected to the gas scavenging system or the gas return line.

See the M1026B Anesthetic Gas Module Service Guide for further information on connecting devices.

Watertrap M1657B

RS232

Connector

The watertrap prevents water and other fluids from passing into the

gas analyzer and causing contamination and/or internal occlusions. It

has a water reservoir in which fluids are collected, two water

separation filters, and two shut-off fuses as a backup mechanism for

the water separation filters.

The watertrap is for multi-patient use. It must be exchanged at least

every two weeks or when watertrap is full.

Fuses

Power

Inlet

Equipotential

Grounding

4

Page 11

Understanding the Gas Measurement 1 Using the Gas Analyzer

Understanding the Gas Measurement

M1013A IntelliVue G1 & M1019A IntelliVue G5

The M1013A IntelliVue G1 and the M1019A IntelliVue G5 use a technique called Non-Dispersive

Infrared Gas Concentration Measurement (NDIR) to measure the concentration of certain gases.

The gases which can be measured by the M1013A IntelliVue G1 and the M1019A IntelliVue G5

absorb infrared (IR) light. Each gas has its own absorption characteristic. The gas is transported into a

sample cell, and an optical IR filter selects a specific band of IR light to pass through the gas. For

multiple gas measurement, such as in the M1013A IntelliVue G1 or the M1019A IntelliVue G5, there

are multiple IR filters. The higher the concentration of gas in a given volume the more IR light is

absorbed. This means that higher concentrations of IR absorbing gas cause a lower transmission of IR

light. The amount of IR light transmitted after it has been passed through an IR absorbing gas is

measured. From the amount of IR light measured, the concentration of gas present can be calculated.

This calculation provides the gas measurement value. Oxygen is measured by an additional sensor in

the M1013A IntelliVue G1 and the M1019A IntelliVue G5 using its paramagnetic properties. The gas

is transported into a sample cell. The higher the oxygen concentration, the higher the measured effect.

The oxygen concentration can be calculated from the amplitude of the effect.

NOTE The presence of organic cleaning solutions or gases containing freon may impact the accuracy of the

infrared gas measurement.

M1026B AGM

The M1026B Anesthetic Gas Module uses a technique called Dispersive Infrared (DIR) to measure the

concentration of certain gases. The gases measured (except oxygen) by the M1026B Anesthetic Gas

Module absorb infrared (IR) light. Each gas has its own absorption characteristic. The gas is

transported into a sample cell. A diffraction grating is used to scan the relevant wavelength range of the

IR light that passes through the sample cell. The higher the concentration of gas the more IR light is

absorbed, and from the amount of IR light measured, the concentration of gas present can be

calculated.

Individual gases have an individual spectral fingerprint. A mathematical algorithm is used to analyze

the spectrum and to identify the anesthetic agents in the gas. Oxygen is measured by an additional

sensor in the M1026B Anesthetic Gas Module using its paramagnetic properties. The gas is

transported into a sample cell. The higher the oxygen concentration, the higher the measured effect.

The oxygen concentration can be calculated from the amplitude of the effect.

NOTE The presence of organic cleaning solutions or gases containing freon may impact the accuracy of the

infrared gas measurement.

Connecting Gas Analyzer Accessories

The gas analyzer accessories and part numbers are listed in the accessories section.

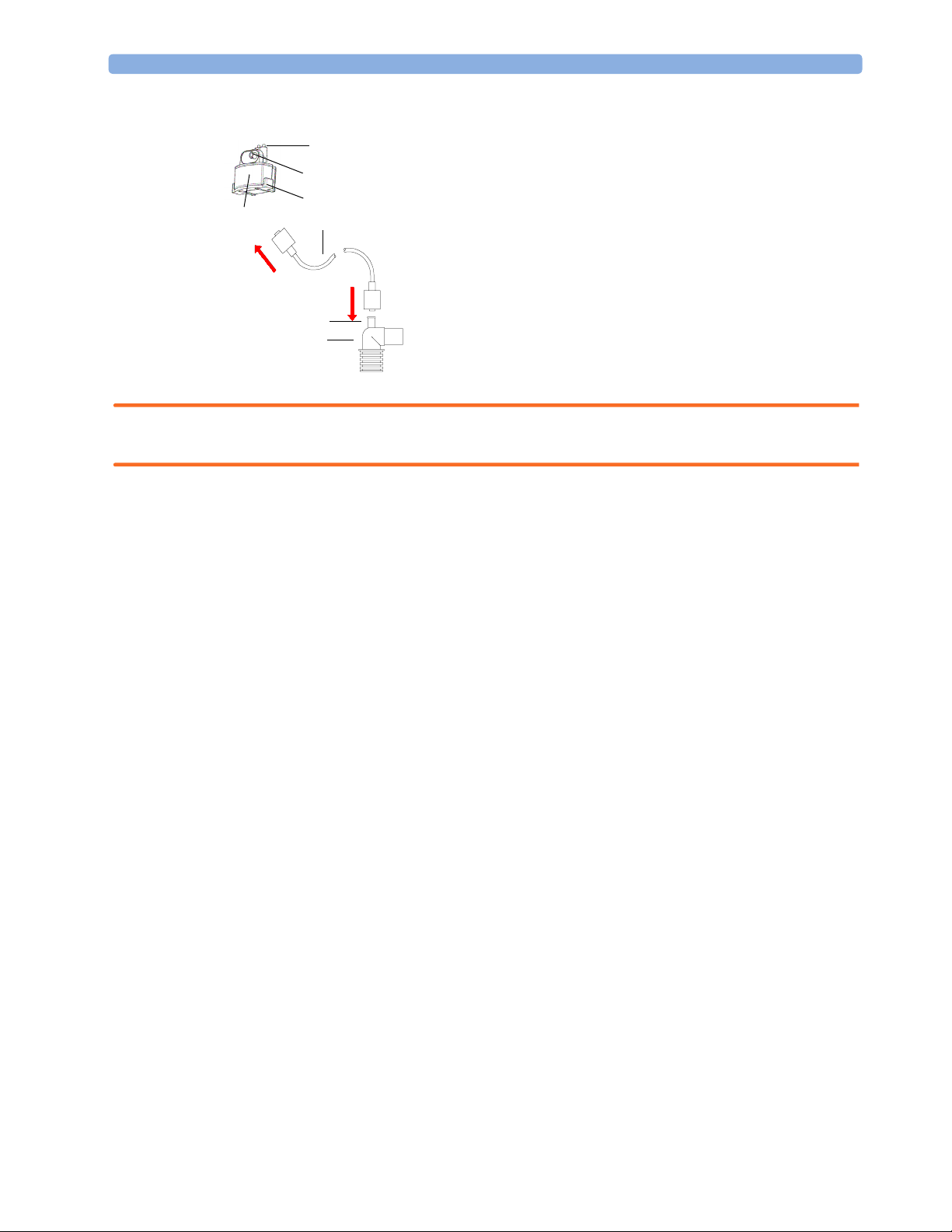

1 Insert the M1657B watertrap into the watertrap socket by gently pushing

it up and in. Make sure that the watertrap snap lock clicks into place

2 Connect the gas sample tubing to the Luer connector of the watertrap.

5

Page 12

1 Using the Gas Analyzer Connecting Gas Analyzer Accessories

3 Connect the other end of the gas sample tubing to the patient via the airway adapter.

2

3

4

1

5

6

7

1 M1657B Watertrap

2 Watertrap connector prongs

3 Luer connector (gas sample inlet)

4Snap lock

5 M1658A Gas Sample Tubing

6Gas sample port

7Airway Adapter, either

13902A Elbow Airway Adapter

or M1612A Straight Airway Adapter

8 Connects to the patient

9 Connects to the Anesthesia Machine

9

8

WARNING Make sure that you do not accidentally connect the luer connector of the gas sample line to an infusion

link or any other links in the patient vicinity.

6

Page 13

Using the Gas Analyzer Setup Menus 1 Using the Gas Analyzer

CAUTION Airway Adapter: Use a Philips Airway Adapter listed in the Accessories section of this manual and

position it so that the part connecting to the gas sample tube is pointing upwards. This prevents

condensed water from passing into the gas sample tube and causing an occlusion. Philips airway

adapters have a built-in port extending from the adapter wall, which reduces the risk of a blockage

occurring.

Watertrap: To minimize the risk of internal contamination, never leave the gas analyzer running

without a watertrap attached (except during a watertrap exchange).

Gas Sample Tube: Do not use the gas sample tube if it is kinked, as it may cause an occlusion or

leakage.

Room Ventilation Make sure that the room in which the gas analyzer is used is well-ventilated with

fresh air. Gases or fumes that mix with and contaminate the room air may degrade measurement

accuracy. Use either a Gas Exhaust Return Filter/Gas Exhaust return Tubing to return gas samples to

the breathing circuit or connect a scavenging system to the gas exhaust port and remove the gas sample.

Note that Gas Exhaust return tubing may not be available for use in all geographies.

Do not use the gas analyzer in a hyperbaric chamber with oxygen enrichment. Also, the ambient air

must be free of CO

enrichment.

2

WARNING Ensure that the connections are tight. Any leak in the system can result in erroneous readings due to

ambient air mixing with patient gases.

Using the Gas Analyzer Setup Menus

Many gas analyzer settings can be changed just like other measurement settings. These are described in

the chapter on Basic Operation in the Instructions for Use of your patient monitor, only gas analyzerspecific settings are described here.

To change settings for individual gases, enter the setup menu for the individual gas:

♦ select the measurement numeric on the monitor screen, or

♦ select the required gas label in the Setup <Gas Analyzer> menu.

To change Gas Analyzer settings, enter the

♦ select one of the gas analyzer numerics on the monitor screen and then select the menu item

Setup <Gas Analyzer>, or press the Setup hardkey or Airway Gases hardkey on the gas

analyzer.

Choosing Numerics for Display

For each gas the gas analyzer measures, you can choose which numerics are displayed with the

waveform on the screen:

Setup <Gas Analyzer> menu:

et displays the endtidal numerics,

–

in displays the inspiratory numerics,

–

et+in displays both endtidal and inspiratory numerics.

–

Off switches off measurement of that particular gas.

–

7

Page 14

1 Using the Gas Analyzer Using the Gas Analyzer Setup Menus

– MAC displays the minimum alveolar concentration of an anesthetic agent at which patients do not

respond with movement to a painful stimulus.

– MACawk (MAC awake) displays the minimum alveolar concentration of an anesthetic agent at

which patients respond to verbal command.

No waveforms or numerics will be shown for gases set to

To change the displayed numeric, in the

measured to call up a pop-up list of numerics available and then select the numeric you want to display.

As the inspired minimum is measured for CO

Humidity Correction for CO2

The gas analyzer is configured to correct the CO2 measurement for either Body Temperature Pressure

Saturated (BTPS), to account for humidity in the patient’s breath, or Ambient Temperature Pressure

Dry (ATPD).

♦ In the Setup CO2 menu, see the menu item Humidity Corr. to see which correction

applies. It is either

Please refer to the Measurement Specifications in the Installation and Specifications chapter of this

manual for details on the humidity correction.

Wet for BTPS or Dry for ATPD.

Adjusting Wave Scales

1 In the Wave menu or the Setup menu for the gas, select Scale.

2 Choose a suitable scale range from the pop-up list.

Off, and no alarms will be generated.

Setup <Gas Label> menu, select the label of the gas

(imCO2), the numeric label is im instead of in.

2

8

Page 15

Changing the Apnea Alarm Delay 1 Using the Gas Analyzer

Changing the Apnea Alarm Delay

The apnea alarm delay time determines the time limit after which the monitor alarms if the patient

stops breathing.

1 In the Setup CO2 menu, select awRR.

2 In the Setup awRR menu, select Apnea Time.

3 Choose the apnea alarm delay time.

WARNING The safety and effectiveness of the respiration measurement method in the detection of apnea,

particularly the apnea of prematurity and apnea of infancy, has not been established.

Deriving Limit Alarms from awRR

1 In the Setup CO2 menu or in the Setup <Gas Analyzer> menu, select awRR.

2 In the Setup awRR menu, select Alarms.

3 Select On to derive alarms from the airway respiration signal or Off to disable them.

Alarms and Zero Calibration

When a zero calibration is in progress, the physiological alarm detection is suspended. When the

calibration is finished, the gas analyzer resumes alarm detection. If an alarm condition is present after

the zero calibration, the alarm will be activated within the specified alarm delay time.

WARNING If an apnea occurs during a zero calibration, the time delay between the start of apnea and the

activation of the apnea alarm could be up to 24 seconds plus the configured apnea delay time. After

startup or after continuous operation of the M1013A IntelliVue G1 or the M1019A IntelliVue G5 of

4 months or more the time delay could be up to 93 seconds plus the configured apnea time for a single

time.

Automatic Alarm Suppression

Your monitor can be set to suppress alarms until it detects that a patient has been connected to the gas

analyzer (when breathing is detected). This feature is called

or

Off in the monitor’s Configuration Mode.

No Al til Breath and can be set to On

9

Page 16

1 Using the Gas Analyzer Agent Identification

Agent Identification

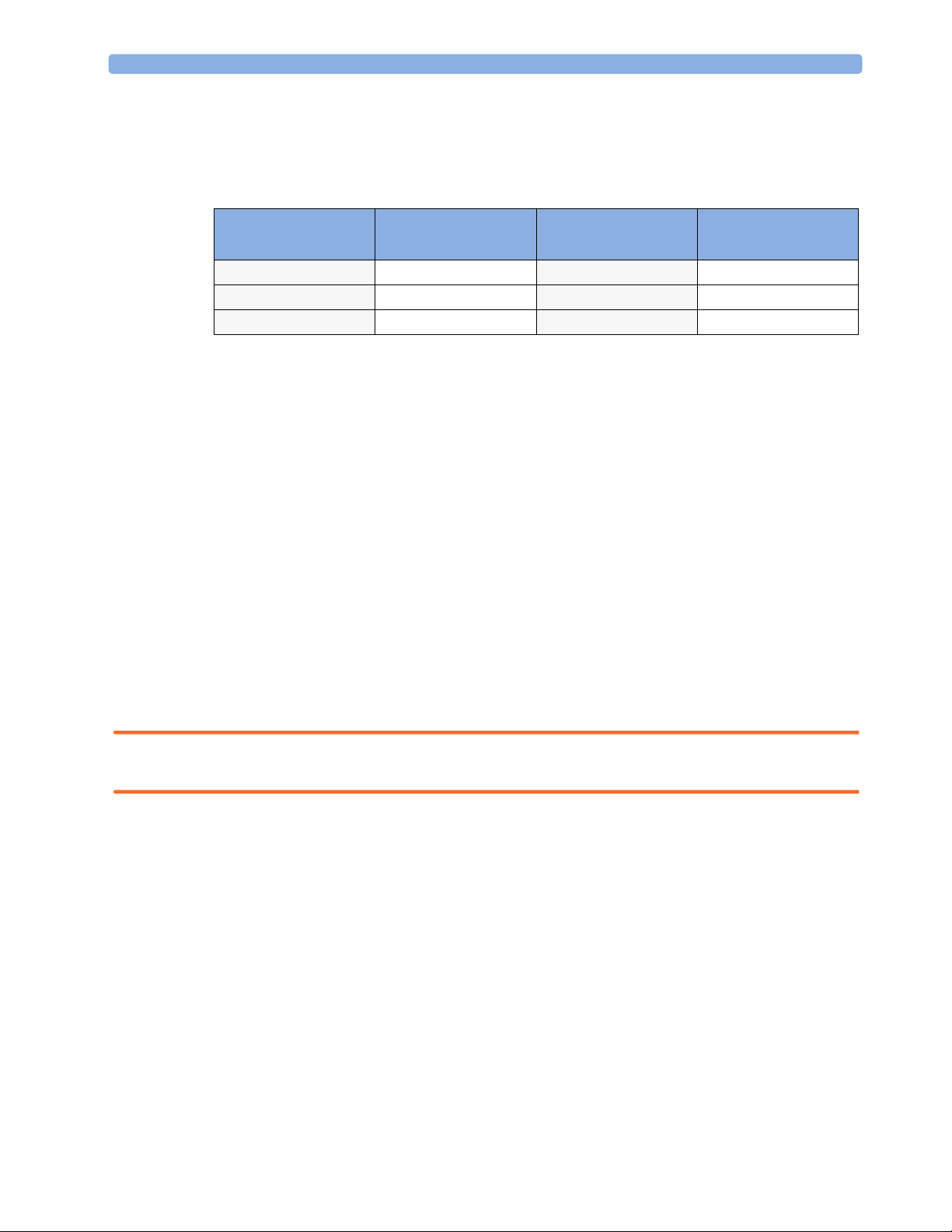

The following table shows the Agent Identification possibilities of the different gas analyzers:

Gas Analyzer Manual Agent

Identification

M1013A IntelliVue G1 yes no n/a

M1019A IntelliVue G5 no yes 2

M1026B AGM yes yes 1

NOTE Only the M1026B AGM allows switching the agent identification mode between Agent Id:

Manual and Agent Id: Auto. Nevertheless, agent identification behavior for the M1013A

IntelliVue G1 and the M1019A IntelliVue G5 is described below in the Manual Agent ID (M1013A)

and the Automatic Agent ID (M1019A) sections.

Setting the agent identification mode to Agent Id: Manual lets you choose the anesthetic agent

manually. If you choose the setting Agent Id: Auto, the gas analyzer automatically identifies the

predominant anesthetic agent(s) in the breathing circuit.

♦ To change the agent identification mode, in the Setup AGT menu, select Agent Id: to toggle

between the settings

Auto and Manual.

Automatic Agent

Identification

Number of agents

identified

If Agent ID is Set to Manual

To change the agent monitored, when Agent Id is set to Manual:

♦ In the Setup <Agent label> menu, select Agent to call up a pop-up list of available agents

and select the agent you want to monitor. For example, Setup HAL.

M1026B only: If the manually selected agent does not match the agent detected, the INOP CHECK

AGENT appears.

WARNING Make sure to select the correct agent for monitoring. Selecting the wrong agent will cause erroneous

readings.

If Agent ID is Set to Auto (M1019A IntelliVue G5 & M1026B AGM)

As soon as the M1019A IntelliVue G5 or the M1026B AGM has detected the agent(s), a waveform

and numerics for this agent appears on the monitor screen, if they are configured to be displayed.

During the process of identification, the generic label

G5) is shown as a placeholder.

For an anesthetic agent to be detected by automatic agent identification, its concentration must exceed

the identification threshold. The presence of other substances in the patient’s breathing circuit such as

methanol or acetone can influence the agent identification and lead to incorrect values and incorrect

identification.

AGT (AGT1 and AGT2 when using an IntelliVue

10

Page 17

MAC Calculation 1 Using the Gas Analyzer

Exchanging Agents (M1019A IntelliVue G5 & M1026B AGM)

If the anesthetic agent administered to the patient changes, a mixture of both gases is detected by the

M1019A IntelliVue G5 or the M1026B AGM during the transition. The time needed to complete the

exchange depends on the type of anesthesia (low flow or high flow), and the characteristics of the

agents administered (pharmacokinetics). During the exchange, you will see the INOP message

MIXTURE

AGM only: If you are using automatic agent identification, when one of the agents decreases below its

threshold and the other agent predominates, the monitor will recognize the exchange.

M1013A IntelliVue G1 and M1026B AGM only: If you are using manual agent identification, you

must change the agent in the

and (with AGM only) -?- next to the affected numerics.

Agent Setup menu to match the administered agent.

AGT

Agent ID During Emergence from Anesthesia (M1019A IntelliVue G5 & M1026B AGM)

If automatic agent identification is selected during emergence from anesthesia and the agent

concentration falls below the identification threshold, the agent will no longer be identified. The agent

label will remain on the display and the numeric will show

IntelliVue G5) until the monitor detects that a patient is no longer connected. After this, the generic

label

AGT (AGT1 / AGT2 for M1019A IntelliVue G5) will be shown.

0.00 % (numeric unavailable with

♦ To display the correct agent and value, change to manual identification and select the agent

manually.(AGM only)

MAC Calculation

The MAC (Minimum Alveolar Concentration) value of an anesthetic gas or agent denotes the

concentration at which 50% of a population of anesthetized patients do not respond with movement

to a painful stimulus (e.g. a standardized incision through the skin). The MAC awake represents the

concentration at which 50% of a population of anesthetized patients responds to verbal command.

The Philips IntelliVue patient monitors offer three configurable methods of MAC calculation:

•Uncorrected MAC

•Ambient Pressure Corrected MAC

• Enhanced MAC Correction

The preferred method must be set in configuration mode of your patient monitor. The total MAC and

MACawk values can then be selected for display on your monitor. The sections below describe how

these values are calculated with the different methods.

To switch the MAC and/or the MACawk parameter on, set MAC and /or MACawk to ON in the gas

analyzer setup menu.

NOTE • The MACawk value can only be displayed if MAC Correction is configured to “Enhanced”.

• MAC Calculation is only available in IntelliVue patient monitors with software revision C.0 or

higher.

• Ambient Pressure Corrected MAC and Enhanced MAC Correction are not available in the USA.

11

Page 18

1 Using the Gas Analyzer MAC Calculation

Uncorrected MAC

If the MAC Correction is configured to “Off” the uncorrected MAC is calculated. The MAC value is

not corrected for ambient pressure, age, temperature or any other individual factors influencing the

effect of volatile anesthetic agents.

In order to calculate the MAC value the standard 1MAC concentrations of anesthetic agents and

nitrous oxide are required. The following table lists these concentrations (according to the EN ISO

21647:2004 standard). The values are based on the assumptions that the patient is 40 years old (except

for Desflurane where 25 years are assumed), the body temperature is 37° and the atmospheric pressure

is 760 mmHg (1 atm):

Agent Halothane Enflurane Isoflurane Desflurane Sevoflurane N2O

1MAC 0.77 vol% 1.7 vol% 1.15 vol% 7.3 vol% 2.1 vol% 105 vol%

For each volatile anesthetic agent detectable by the gas analyzer the MAC value for the specific agent

(MAC(AA)) is calculated as follows:

etConc(AA)

MAC(AA)

-----------------------------

=

1MAC(AA)

where AA = Anesthetic Agent and etConc = end-tidal concentration

In the same way, the MAC value for nitrous oxide (MAC(N2O) is derived from the measured value of

the nitrous oxide end-tidal concentration (etConc(N2O)):

etCONC(N2O)

MAC(N2O)

Finally, the total MAC value of nitrous oxide and the selected anesthetic agent is calculated as follows:

------------------------------------

=

1MAC(N2O)

MAC MAC(N2O) MAC(AA)+=

NOTE Gas components (N2O and/or anesthetic agent) which are switched off, are not included in the total

MAC computation.

Ambient Pressure Corrected MAC (not available in the USA)

If the MAC Correction is configured to “Amb. Pressure”, the MAC is corrected to reflect the effect of

a different partial pressure at another altitude.

12

Page 19

MAC Calculation 1 Using the Gas Analyzer

)

The total MAC value is calculated in the same way as for the uncorrected MAC and then corrected for

ambient pressure according to the following equation:

Pamb

MAC uncorrected total MAC

-------------------------- -

×=

760 mmHg

Enhanced MAC Correction (not available in the USA)

If the MAC Correction is configured to “Enhanced”, the MAC value is corrected for age, temperature

and ambient pressure.

The basic 1MAC values used for enhanced MAC Correction are listed in the table below.These values

are taken from the scientific article Age, minimum alveolar anaesthetic concentration and minimum

alveolar anaesthetic concentration-awake by Edmond I Eger II (Anesth Analg 2001, 93: 947-53)and

differ slightly from the standard 1MAC values used for the uncorrected MAC.

NOTE There is no correction data available for Enflurane, so the standard 1MAC value is used in this case.

For standard conditions as assumed for the uncorrected MAC the values are:

Agent Halothane Enflurane Isoflurane Desflurane Sevoflurane N2O

1MAC 0.757 vol% no correction 1.19 vol% 6.45 vol% 1.8 vol% 114 vol%

The patient age can either be entered into the IntelliVue patient monitor, or provided by the

information system if the monitor is networked. The patient temperature is obtained from a

temperature measurement by the monitor. Only the following temperature labels are accepted for

correction (listed in order of priority):

–Tcore

–Tblood

Patient Age Range: 1 to 100 years

Temperature Range: 25 to 45°C

Any age or temperature value outside the supported ranges is rounded to the according lower or upper

boundary.

If the patient age is not available, the MAC correction will assume a default age of 40 years. If none of

the listed temperatures is measured, a default temperature of 37°C is taken for MAC Calculation. In all

of these cases the INOP “MAC CORRECTION?” is issued and the MAC numerics are marked

questionable.

The 1MAC value for a specific potent inhaled anesthetic agent at age 40 (see table above) is corrected

for patient age and temperature effects as follows (T given in degree Celsius and the age given in years):

1MACcorr(AA) (1 ((0.05)–(37T)))–× 1MAC(AA) 1.32 10

×××=

-(0.00303 Age

×

13

Page 20

1 Using the Gas Analyzer MAC Calculation

With the 1MAC value corrected for age and temperature at a standard pressure of 760mmHg, the

MAC value of an anesthetic agent can be calculated as follows:

etConc(AA)

MAC(AA)

MAC(ENF)

The MAC value of nitrous oxide is obtained from the 1MAC concentration of nitrous oxide at age 40

corrected for the patient’s age only (no correction is made for temperature):

MAC(N2O)

----------------------------------------------------------------------------------------------- -

=

1MAC(N2O) 1.378 10×

The total MAC value for the combination of nitrous oxide plus the selected agent is obtained by

adding the MAC value for the agent and the MAC value for nitrous oxide and correcting this sum for

ambient pressure:

-------------------------------------- -

=

1MACcorr(AA)

etConc(ENF)

------------------------------- -

=

1MAC(ENF)

etConc(N2O)

×

(for all agents except Enflurane)

(for Enflurane)

-(0.00347 Age)×

Pamb

MAC MAC(N2O) MAC(AA) or MAC(ENF)+[]

NOTE Gas measurements which are switched off, are not included in the total MAC computation. The

calculated MAC values for a 40 year old patient at a temperature of 37°C are similar but not identical

to the 1MAC values given in the table for uncorrected MAC configuration.

In addition, the MAC

values can be determined as follows:

awake

MACawk(AA)

=

MACawk(HAL)

MAC(AA)

------------------------- -

0.343

MAC(HAL)

----------------------------- -

=

0.551

(for all agents except Halothane)

-------------------------- -

×=

760 mmHg

(for Halothane)

14

Page 21

Removing Gas from the Circuit 1 Using the Gas Analyzer

MAC(N2O)

MACawk(N2O)

The total MACawk value is obtained by adding the indivdual MACawk values up:

---------------------------- -

=

0.551

(for nitrous oxide)

MACawk MACawk(N2O) MACawk(AA) or MACawk(HAL)+=

Removing Gas from the Circuit

If inhalation anesthetics are used during anesthesia, pollution of the operating room should be

prevented by either returning the filtered gas sample to the breathing circuit (may not be available in all

geographies) or by disposing of the gas sample.

Your hospital policy may not permit the use of gas return systems.

WARNING Make sure that you do not accidentally connect the luer connector of the gas sample line to an infusion

link or any other links in the patient vicinity.

Returning the Gas Sample

NOTE Gas Sample Return may not be available in all geographies.

Use an M1656B Gas Exhaust Return Filter and M1655B Exhaust Return Tubing as instructed in the

documentation supplied with the filter or the gas exhaust return line to return the gas sample to the

patient’s breathing circuit. Make sure the sample gas is routed through the CO

back to the patient.

absorber before going

2

Removing the Gas Sample

To remove the gas sample from the breathing circuit, a scavenging system must be connected to the gas

exhaust port. Use either:

• a gas exhaust scavenging tube

• a ventilator reservoir, where the suction pressure does not exceed 0.3-0.4mm Hg

• a scavenging interface.

CAUTION Make sure to compensate for any possible reduction of tidal volume caused by gas sampling.

15

Page 22

1 Using the Gas Analyzer Entering Gas Analyzer Standby Mode

Entering Gas Analyzer Standby Mode

During standby, the gas analyzer’s gas sample intake pump and other internal components are

automatically switched off to increase the lifetime of the device. The message

STANDBY

M1026B AGM to warm up to resume monitoring. The M1013A IntelliVue G1 and the M1019A

IntelliVue G5 require up to 30 seconds warm up time before you can resume monitoring.

The gas analyzer standby mode is linked to the monitor standby mode:

• If the monitor enters standby mode, the gas analyzer also enters standby mode.

• If the monitor leaves standby mode, the gas analyzer automatically also leaves standby mode.

• If the gas analyzer enters or leaves standby mode, this does not affect the monitor.

• If the gas analyzer is disconnected from the monitor, it enters standby mode automatically after 3 to

5 minutes (M1013A IntelliVue G1 and M1019A IntelliVue G5 only).

The gas analyzer enters standby mode automatically when no breath is detected for a configured period

of time (for M1026B AGM: if CO

goes below adaptive threshold).

is shown on the monitor. When you exit standby, you do not need to wait for the

is less than 4 mmHg, for M1013A G1 and M1019A G5: if CO2

2

<GAS ANALYZER>

16

Page 23

Zero Calibration 1 Using the Gas Analyzer

To enter or leave standby mode manually:

•in the

Setup <Gas Analyzer> menu, select Set to Standby or Exit Standby or press the

IntelliVue G1 or IntelliVue G5 Standby hardkey

Zero Calibration

The gas analyzer zero calibration maintains the accuracy of the gas measurements by sampling and

analyzing room air. It takes about 15 to 21 seconds (M1013A G1 and M1019A G5) / 10 to 20 seconds

(M1026B) to complete and may not be interrupted. If a zero calibration fails, a second zero calibration

is performed automatically. The M1013A G1 and the M1019A G5 also attempt a third zero

calibration if the second one fails. During the zero calibration, the waveform is flat and numerics are

not updated. In case of apnea the numerics (except awRR) are marked invalid on the M1013A G1 and

the M1019A G5, and in case of a zero retry they are marked not available on all gas analyzers.

NOTE After startup or continuous operation for 4 months of the M1013A IntelliVue G1 and the M1019A

IntelliVue G5 the zero calibration can take up to 93 seconds. If necessary, the zero calibration can be

suspended for 5 minutes.

Automatic Zero Calibration

M1013A IntelliVue G1 and M1019A IntelliVue G5

A zero calibration is carried out automatically during warmup. After monitoring has been started zero

calibrations are not performed more than every 2 hours. If the M1013A G1 or the M1019A G5 was in

standby when one of the above triggers for zero calibration occurred, the zero calibration is carried out

when the gas analyzer leaves standby. Typical zero time is 21 seconds. A longer zero calibration may

occur if the M1013A G1 or the M1019A G5 is not switched off (i.e. running or in standby) for a

longer period of time.

M1026B AGM

A zero calibration is carried out automatically after the module has been switched on, and then once

every hour after monitoring has been started. If the M1026B was in standby when one of the above

triggers for zero calibration occurred, the zero calibration is carried out when the M1026B leaves

standby. Maximum zero time is 20 seconds.

Carrying Out Manual Zero Calibration

♦ To manually start a zero calibration, in the Setup <Gas Analyzer> menu, select Zero Cal,

then select the

Confirm pop-up key.

Suppressing Zero Calibration

To temporarily prevent an automatic zero calibration from being started,

♦ in the Setup <Gas Analyzer> menu, select No Zero for 5min.

Selecting

This is not possible if a zero calibration is pending (automatic zero requested).

No Zero for 5min again before the timer has timed out resets the timer to five minutes.

17

Page 24

1 Using the Gas Analyzer Using the Gas Analyzer During a Cardiopulmonary Bypass

Using the Gas Analyzer During a Cardiopulmonary Bypass

CAUTION During a cardiopulmonary bypass, the anesthesiologist may cease periodic mechanical ventilation. In

these cases, it is important to note that an active gas analyzer will continue to suck gases from the

patient-ventilator circuit during that time. This will cause the airway pressure to drop if no active

measures are taken to keep the patient-ventilator circuit stable.

To stop the gas analyzer from sucking gases out of the circuit, either:

• activate the gas analyzer standby mode or

disconnect the sample line from the gas analyzer or from the patient-ventilator circuit.

Safety Information

To avoid condensed water collecting in the gas sample tube, position the gas analyzer at or above the

patient level. Do not set up the gas analyzer in a position where liquid could spill onto it.

WARNING Detecting leaks: Any leak in the tubing and connections from the patient to the gas analyzer may

result in dilution of the gas mixture with ambient air. If this leak exceeds a certain magnitude, the value

of gases and anesthetic agents displayed on the monitor may differ significantly from the actual

concentration in the patient’s breathing circuit. Erroneous values may lead to inappropriate

intervention and patient safety may be at risk.

Unexpected values: If an unexpected gas concentration value appears on the monitor, or if the waves

appear to be flatter than normal, visually inspect the entire tubing and replace if necessary. If no

occlusion or leakage can be found, replace the watertrap with a new one and check the values.

CAUTION Gas Analyzer ports: Do not apply excessive pressure to the gas analyzer’s inlet or outlet ports, for

example from a syringe, as this may cause damage to the pneumatic and optical systems.

Cleaning: Switch off the gas analyzer during cleaning, as an intake of cleaning fluids or fumes may

damage the device.

M1013A IntelliVue G1 and M1019A IntelliVue G5: Since the M1013A IntelliVue G1 and the

M1019A IntelliVue G5 contain no internal bacterial filters never switch them on without a watertrap

installed. Operating these gas analyzers without a watertrap may result in damage to the instrument.

18

Page 25

Safety Information 1 Using the Gas Analyzer

WARNING • Possible Explosion Hazard if used in the presence of flammable anesthetics.

• Do not use antistatic or conductive breathing tubes as they may cause burns in case of

electrosurgery.

• Do not open the gas analyzer. Contact with exposed electrical components may cause electrical

shock.

• Make sure that you do not accidentally connect the luer connector of the gas sample line to an

infusion link or any other links in the patient vicinity.

19

Page 26

1 Using the Gas Analyzer Safety Information

20

Page 27

10Maintenance and

Troubleshooting

WARNING Schedule: Failure on the part of the responsible individual hospital or institution employing the use of

this equipment to implement a satisfactory maintenance schedule may cause undue equipment failure

and possible health hazards.

Contact: If you discover a problem with any of the equipment, contact your service personnel, Philips,

or your authorized supplier.

Inspecting the Equipment and Accessories

2

You should perform a visual inspection before every use, and in accordance with your hospital’s policy.

With the gas anaylzer switched off:

1 Examine unit exteriors for cleanliness and general physical condition. Make sure that the housings

are not cracked or broken, that everything is present, that there are no spilled liquids and that there

are no signs of abuse.

2 Inspect all accessories (cables, transducers, sensors and so forth). If any show signs of damage, do

not use.

Inspecting the Cables and Cords

Examine all system cables, the power plug and cord for damage. Make sure that the prongs of the plug

do not move in the casing. If damaged, replace it with an appropriate Philips power cord.

Maintenance Task and Test Schedule

The following tasks are for Philips-qualified service professionals only. All maintenance tasks and

performance tests are documented in detail in the Service Guide for your gas analyzer.

Ensure that these tasks are carried out as indicated by the gas analyzer’s maintenance schedule, or as

specified by local laws. Contact a Philips-qualified service provider if your gas analyzer needs a safety or

performance test. Clean and disinfect equipment to decontaminate it before testing or maintaining it.

21

Page 28

2 Maintenance and Troubleshooting Maintenance Task and Test Schedule

Maintenance and Test Schedule Frequency

Safety checks according to IEC 60601-1 At least once every two years, or as needed, after any repairs

where the power supply is replaced, or if the gas analyzer has

been dropped.

M1013A IntelliVue G1 and M1019A

IntelliVue G5 preventive maintenance

and safety and performance assurance

(SPA)

M1026B AGM preventive maintenance At least once every two years or if you suspect the measurement

M1026B Safety and Performance

Assurance (SPA)

M1013A IntelliVue G1, M1019A

IntelliVue G5 and M1026B AGM

ventilator fan

At least once a year or if you suspect the measurement values are

incorrect.

values are incorrect.

At least once a year or if you suspect the measurement values are

incorrect.

Check at least every six months.

22

Page 29

Troubleshooting 2 Maintenance and Troubleshooting

Troubleshooting

If you suspect a problem with the gas measurement, read the Using the Gas Analyzer chapter and

doublecheck that you have set up the measurement correctly.

If you suspect an intermittent, system-wide problem call your service personnel.

Disposing of the Gas Analyzer

WARNING To avoid contaminating or infecting personnel, the environment or other equipment, make sure you

disinfect and decontaminate the gas analyzer appropriately before disposing of it in accordance with

your country’s laws for equipment containing electrical and electronic parts. For disposal of parts and

accessories, where not otherwise specified, follow local regulations regarding disposal of hospital waste.

You can disassemble the gas analyzer as described in the Service Guide for your gas analyzer.

– The top cover uses only one kind of steel.

– You can recycle the paper Instructions for Use.

– Dispose of accumulated fluids in the watertrap according to your local regulations and hospital

policy.

Disposing of Empty Calibration Gas Cylinders

1 Empty the cylinder completely by pushing in the pin of the regulator valve or by pulling out the

pin of the fill wave using a tire valve stem wrench or a pair of needle nose pliers.

2 When the cylinder is empty, either remove the valve stem from the fill (or regulator) hole, or drill a

hole in the cylinder.

3 Write “Empty” on the cylinder and dispose of it appropriately for scrap metal.

WARNING Ensure that the cylinder is completely empty before trying to remove the valve stem or drill the tank.

23

Page 30

2 Maintenance and Troubleshooting Disposing of Empty Calibration Gas Cylinders

24

Page 31

11Installation and Specifications

The specifications in this section apply to the M1013A IntelliVue G1, the M1019A IntelliVue G5 and

the M1026B Anesthetic Gas Module (AGM).

The M1013A IntelliVue G1 and the M1019A IntelliVue G5 must be installed by qualified personnel.

The M1026B AGM is not user installable and must be installed by qualified service personnel only.

Intended Use

The M1013A IntelliVue G1 and the M1019A IntelliVue G5 provide a non-dispersive infrared

measurement of respiratory and anesthetic gases and a paramagnetic measurement of oxygen (Fast O

The M1026B Anesthetic Gas Module provides a dispersive infrared measurement of respiratory and

anesthetic gases and a paramagnetic measurement of oxygen (Fast O

The M1013A IntelliVue G1 is designed to work with the Philips IntelliVue MP20/30/40/50 monitors,

the M1019A IntelliVue G5 and the M1026B is designed to work with the Philips IntelliVue MP20/

30/40/50/60/70/80/90 monitors. In addition the M1026B Anesthetic Gas Module is designed to work

with the Philips ACMS and V24/V26 patient monitors. All gas analyzers are intended for measuring

the airway gases of ventilated patients in health care facilities.

3

).

2

).

2

The M1013A IntelliVue G1, the M1019A IntelliVue G5 and the M1026B AGM are not therapeutic

devices.

CAUTION U.S. Federal Law restricts this device to sale by or on the order of a physician.

Use only hospital grade power lines.

Do not store or operate the gas analyzer outside the storage and operating conditions specified in this

chapter.

Do not expose the gas analyzer to excessive heat or sunlight as this could lead to overheating of the

instrument and result in injuries.

Avoid any restriction or blockage of air flow as this could cause overheating of the gas analyzer and

result in injuries.

Follow the mounting and installation instructions in your service guide closely to avoid injuries caused

by the gas analyzer or of the device mounted on top of it falling down.

Mechanical vibrations or shock may have adverse effects on gas measurement values.

25

Page 32

3 Installation and Specifications Manufacturer’s Information

Manufacturer’s Information

You can write to Philips at this address

Philips Medizin Systeme Boeblingen GmbH

Hewlett-Packard Str. 2

71034 Boeblingen

Germany

Visit our website at: www.philips.com.

© Copyright 2002 - 2005. Koninklijke Philips Electronics N.V. All Rights Reserved.

Responsibility of the Manufacturer

Philips considers itself responsible for any effects on safety, reliability and performance of the

equipment only if:

• assembly operations, extensions, re-adjustments, modifications or repairs are carried out by persons

authorized by Philips.

• the electrical installation of the relevant room complies with national standards.

• the instrument is used in accordance with the instructions for use.

To ensure safety, use only those parts and accessories specified for use with the M1013A IntelliVue G1,

the M1019A IntelliVue G5 and the M1026B AGM. If other parts are used, Philips is not liable for any

damage that these parts may cause to the equipment.

See your sales contract for product warranty information.

26

Page 33

Symbols 3 Installation and Specifications

Symbols

These symbols appear on the gas analyzers:

Symbols

Setup*

Refer to accompanying

documents

Standby*

Power On/Off*

Alternating current Electrical input

Applied part has

special protection

against electric

shocks (Type BF

according to IEC

60601-1)and is

defibrillator proof

Protective earth RS232 connector Applied part has

The device

0366

complies with the

requirements of the Council

Directive 93/42/EEC of 14 June

1993 (Medical Device

Directive).

RS-232

Equipotential

grounding

indicator

Gas output indicator Gas input indicator

200206

Electrical output

indicator

Identifies year

and month of

manufacture

special protection

against electric

shocks (Type CF

according to IEC

60601-1) and is

defibrillator proof

* These symbols are replaced by English text in the U.S.A.

27

Page 34

3 Installation and Specifications Installation Safety Information

Installation Safety Information

WARNING • The M1013A IntelliVue G1 may only be used with the Philips IntelliVue MP20/30/40/50 patient

monitors. Connections to other devices may result in a safety hazard.

• The M1019A IntelliVue G5 may only be used with the Philips IntelliVue MP20/30/40/50/60/70/

80/90 patient monitors. Connections to other devices may result in a safety hazard.

• If multiple instruments are connected to multiple socket outlets, the sum of the enclosure leakage

currents must not exceed the limits given in IEC/EN60601-1 and IEC 60601-1-1 respectively.

Consult your service personnel.

NOTE The party assembling or modifying medical electrical units to install a medical electrical system or

assembling or modifying electrical systems according to standard EN/IEC 60601-1-1 (safety

requirements for medical electrical systems) is responsible for the compliance of all requirements of the

standard.

Grounding The M1013A IntelliVue G1, the M1019A IntelliVue G5 and the M1026B AGM must be

grounded during operation. If a three-wire receptacle is not available, consult the hospital

electrician. Never use a three-wire to two-wire adapter.

Equipotential

Grounding

Combining equipment Combinations of medical equipment with non-medical equipment must comply with

Fusing The monitor uses double pole/neutral fusing.

If the M1013A IntelliVue G1, the M1019A IntelliVue G5 or the M1026B AGM is used

in internal examinations on the heart or brain, ensure that the room incorporates an

equipotential grounding system to which the monitor and M1013A IntelliVue G1,

M1019A IntelliVue G5 or M1026B AGM have separate connections.

IEC 60601-1-1. Never use a multiple portable socket-outlet or extension cord when

combining equipment unless the socket outlet is supplied specifically for use with that

equipment.

Installation Instructions

Please refer to the your gas analyzer’s service guide for detailed installation instructions.

Altitude and Barometric Pressure

Altitude and barometric pressure affect gas measurements. The host monitor must be configured at

installation to the correct altitude and the correct barometric pressure values for your hospital site. The

gas analyzers measure barometric pressure with each zero calibration. If the barometric pressure

measured by the gas analyzer differs by more than 60 mmHg from the monitor settings the INOP

Zero Failed is issued to indicate that either the altitude setting is incorrect or the pressure sensor is

defective. In the latter case, the conversions from concentration (vol%) to partial pressure (mmHg,

kPa) may be erroneous.

28

Page 35

M1013A IntelliVue G1 & M1019A IntelliVue G5 Specifications 3 Installation and Specifications

M1013A IntelliVue G1 & M1019A IntelliVue G5 Specifications

Safety Specifications

The M1013A IntelliVue G1 and the M1019A IntelliVue G5 comply with:

IEC 60601-1:1988 + A1:1991 + A2:1995; EN60601-1:1990 + A1:1993 + A2:1995; UL 606011:2003; CAN/CSA C22.2#601.1-M90; IEC 60601-1-2:2001; EN 60601-1-2:2001.

Classification (according to IEC 60601-1): Class 1, Type BF, Continuous Operation.

This ISM device complies with Canadian ICES-001. Cet appareil est conforme a la norme NMB-001

du Canada.

The possibility of hazards arising from software errors was minimized in compliance with

ISO14971:2000, EN60601-1-4:1996 + A1:1999 and IEC 60601-1-4:1996 + A1:1999

Physical and Electrical Specifications

Gas

Analyzer

M1013A

IntelliVue G1

M1019A

IntelliVue G5

Power Consumption: peak: 45W, typical: 25W

Power Range 100 - 240 VAC

Sound Pressure: < 60 dB

If the M1013A IntelliVue G1 or the M1019A Intellivue G5 and its host monitor are without power

for less than one minute, monitoring will resume with all active settings unchanged. If they are without

power for more than one minute, the behavior depends on your configuration. If Automat.

Default is set to Yes, the default profile will be loaded when power is restored. If Automat.

Default is set to No, all active settings are retained, if power is restored within 48 hours. The

Automat. Default setting is made in Configuration Mode of the patient monitor.

Weig ht Size (H x W x D )

< 4,5 kg

< 9,92 lb

< 4,5 kg

< 9,92 lb

90 x 300 x 232 mm

3.54 x 11.81 x 9.13 in

90 x 300 x 232 mm

3.54 x 11.81 x 9.13 in

Environmental Specifications

The M1013A IntelliVue G1 and the M1019A IntelliVue G5 may not meet the performance

specifications given here if stored or used outside the specified temperature and humidity ranges.

When the M1013A IntelliVue G1, the M1019A IntelliVue G5 and related products have differing

environmental specifications, the effective range for the combined products is that range which is

common to the specifications for all products.

29

Page 36

3 Installation and Specifications M1013A IntelliVue G1 & M1019A IntelliVue G5 Specifications

Item Condition Range

Temperature Range Operating 10 to 40 oC (50 to 104 °F)

Non-operating

Humidity Range Operating 5 to 90% Relative Humidity (RH) max. @ 40 °C (104 °F)

Non-operating

Altitude Range Operating -305 m to 2900 m (-1000 to 9515 ft)

Non-operating

Atmospheric Pressure

Range

Warmup Ti m e After switching on: 1 - 2 minutes to measure, 6 minutes for full

Operating 70 kPa to 106 kPa

Non-operating

-20 to 65 oC (-4 to 149 °F)

(non-condensing)

5 to 95% Relative Humidity (RH) max. @ 65 °C (150 °F)

-305 m to 5000 m (-1000 to 16404 ft)

50kPa to 106 kPa

accuracy

Measurement Specifications

Parameter Item Specification

CO

2

O

2

N2O Range 0 to 100 vol%

Halothane

Enflurane

Isoflurane

Sevoflurane

Desflurane

awRR Range 0 to 60 rpm

Range 0 to 76 mmHg

Accuracy

Resolution

Rise Time

Range 5 to 100 vol%

Accuracy

Resolution

Rise Time

Accuracy

Resolution

Rise Time

Range

Accuracy

Resolution

Rise Time

Accuracy

Resolution

Detection Criteria

+0.5 vol% or 12% relative, whichever is greater

1 mmHg

350 msec typical

+ 3 vol%

1 vol%

500 msec typical

2.0 vol% + 8% relative

1 vol%

500 msec typical

Halothane: 0 - 8.5 vol%

Enflurane: 0 - 10.0 vol%

Isoflurane: 0 - 8.5 vol%

Sevoflurane: 0 - 10.0 vol%

Desflurane: 0 - 20.0 vol%

0.15 vol% + 15.0% relative

0.05

500 ms typical

+ 1 rpm

1 rpm

adaptive threshold.

30

Accuracy specifications refer to BTPS for mmHg kPa and STPD for vol% at 40 - 60% relative

humidity. All Performance and accuracy specifications are valid based on gas sample tubing M1658A,

including watertrap M1657B, and airway adapter 13902A.

Page 37

M1013A IntelliVue G1 & M1019A IntelliVue G5 Specifications 3 Installation and Specifications

Humidity Correction: For CO2 the humidity correction can be set to “wet” or “dry”.

Wet: p [mmHg] = c [Vol%] * (p_abs - p_H

O)/100

2

Dry: p [mmHg] = c [Vol%] * p_abs /100

Where p = partial pressure, c = gas concentration, p_abs = pressure in breathing circuit, p_H

mmHg, partial pressure of water vapor of exhaled gas (37

°

C, 100% rh).

O = 47

2

For all other gases the readings are always given as dry values.

Sample Flow Rate: 200ml/min

±20 ml/min

Sample Delay Time: All measurements and alarms are subject to a delay of 5 seconds.

Total System Response Time = 5 + 0.5 seconds (sum of the delay time and rise time).

Leakage < 5ml/min

Air Ingression < 50ml per zero

The drift of measurement accuracy is automatically compensated by the auto zero calibrations.

IntelliVue G1/G5

Alarm

Specifications

etCO2 High 20 to 76 mmHg (2.7 to 10.1 kPa) 19 seconds if no automatic zero calibration

etCO2 Low 10 to 75 mmHg (1.3 to 10.0 kPa)

imCO2 High 0 to 20 mmHg (0 to 2.7 kPa)

inO2 High 19 to 100 vol%

inO2 Low 18 to 99%

inN2O 0 to 82 vol%

in/et

HAL/ISO/ENF

High

in/et

HAL/ISO/ENF

Low

in/et SEV High 0.1 to 9.0 vol%

in/et SEV Low 0.0 to 8.9 vol%

in/et DES High 0.2 to 20.0vol%

in/et DES Low 0.0 to 19.8 vol%

awRR High Neonatal: 30 to 60 rpm

awRR Low 0 to 55 rpm settings < 20 rpm: less than 9seconds

Apnea delay 10 to 40 seconds within 2 sec after alarm criterion (no detected

High Limit Range Delay

occurs within that time.

0.1 to 7.5 vol%

0.0 to 7.4 vol%

Adult & Pediatric: 10 to 60 rpm

> 20 rpm: less than 19 seconds

breath within the adjusted delay time) is met, if

no automatic zero calibration occurs.

31

Page 38

3 Installation and Specifications M1013A IntelliVue G1 & M1019A IntelliVue G5 Specifications

IntelliVue G1/G5

Alarm

Specifications

IntelliVue G5 only:

Agent ID Response Time 14 s for first agent, 19 s for second agent

First Agent

Detection /

Identification

Threshold

Second Agent

Detection /

Identification

Threshold

High Limit Range Delay

All agents max. 0.3 vol%

All agents max. 0.4 vol% of a second agent, except if a

second agent is added to Desflurane, this causes

a mixture identification at the latest if the

concentration of the second agent exceeds 10

vol% of the current Desflurane concentration.

Interfering Gases and Vapours

At the gas levels listed below there is no influence on the specified accuracy of the M1013A IntelliVue

G1 and the M1019A IntelliVue G5.

Gas or Vapour Gas Level in % volume fraction

Nitrous Oxide 60

Halothane 4

Enflurane 5

Isoflurane 5

Sevoflurane 5

Xenon Not for use with Xenon

Helium 50

Metered dose inhaler propellants Not for use with metered dose

inhaler propellants

Desflurane 15

Ethanol 0.3

Isopropanol 0.3

Acetone 0.1

Methane 3

32

Page 39

M1026B Specifications 3 Installation and Specifications

M1026B Specifications

Safety Specifications

The M1026B complies with:

IEC 60601-1:1988 + A1:1991 + A2:1995; EN60601-1:1990 + A1:1993 + A2:1995; UL 606011:2003; CAN/CSA C22.2#601.1-M90; IEC 60601-1-2:2001; EN 60601-1-2:2001.

Classification (according to IEC 60601-1): Class 1, Type CF, Continuous Operation.

This ISM device complies with Canadian ICES-001. Cet appareil est conforme a la norme NMB-001

du Canada.

Physical and Electrical Specifications

Gas

Analyzer

M1026B

AGM

Power Consumption: peak: 35W, typical: 25W

Power Range: 100 - 240 VAC

If the M1026B AGM and its host monitor are without power for less than one minute, monitoring

will resume with all active settings unchanged. If they are without power for more than one minute, the

behavior depends on your configuration. If Automat. Default is set to Yes, the default profile

will be loaded when power is restored. If Automat. Default is set to No, all active settings are

retained, if power is restored within 48 hours. The Automat. Default setting is made in

Configuration Mode of the patient monitor.

Weig ht Size (H x W x D )

6.3 kg

13.9 lb

90 x 370 x 467 mm

3.54 x 14.5 x 18.4 in

33

Page 40

3 Installation and Specifications M1026B Specifications

Environmental Specifications

The M1026B AGM may not meet the performance specifications given here if stored or used outside

the specified temperature and humidity ranges.

When the gas analyzers and related products have differing environmental specifications, the effective

range for the combined products is that range which is common to the specifications for all products.

Gas Analyzer Item Condition Range

M1026B AGM Temperature Range Operating 15 to 40 °C (59 to 104 °F)

Non-operating -20 to 65 °C (-4 to 149 °F)

Humidity Range

Altitude Range

Atmospheric Pressure

Range

Warmup Ti m e

Operating Up to 95% Relative Humidity (RH) max. @ 40 °C (104 °F)

(non-condensing)

Non-operating Up to 95% Relative Humidity (RH) max. @ 65 °C (150 °F)

Operating -305 m to 3048 m (-1000 to 10 000 ft)

Non-operating -305 m to 5486 m (-1000 to 18 000ft)

Operating 70 to 106 kPa

Non-operating 50 to 106 kPa

Full accuracy after selftest is finished (max. 2 min.)

34

Page 41

Measurement Specifications 3 Installation and Specifications

Measurement Specifications

Parameter Item Specification

CO

2

O

2

N2O Range 0 to 85 vol%

Halothane

Enflurane

Isoflurane

Sevoflurane Range 0 - 9.0

Desflurane Range 0 - 20.0

awRR Range 0 to 60 rpm

Agent ID Response Time 15 s typical

Agent Thresholds

for the primary halogenated

anesthetic agent

1. During warmup, the thresholds are three times the values listed.

1

Range 0 to 76 mmHg

Accuracy

Resolution

Rise Time

Range 0 to 100 vol%

Accuracy

Resolution

Rise Time

Accuracy

Resolution

Rise Time

Range

Accuracy

Resolution

Rise Time

Accuracy

Resolution

Rise Time

Accuracy

Resolution

Rise Time

Accuracy

Resolution

Detection Criteria

HAL, ISO, ENF

SEV

DES

+ 1.5 mmHg (0 - 30 mmHg)

5 vol % (30 - 76 mmHg)

+

1 mmHg

410 msec typical

+ 3 vol%

1 vol%

640 ms typical

+1.5 vol% + 5% relative

1 vol%

510 msec typical

0 - 7.5 vol%

+ (0.1 vol% + 4.0% relative)

0.05

Halothane: <900 ms typical

Enflurane < 620 ms typical

Isoflurane < 610 ms typical

+ (0.1 vol% + 4.0% relative)

0.05

< 570 ms typical

+ (0.1 vol% + 4.0% relative)

0.05

< 540 ms typical

+ 2 rpm

1 rpm

6 mmHg variation in CO2.

0.20 vol%

0.24 vol%

0.30 vol%

All Performance and accuracy specifications are valid based on gas sample tubing M1658A, including

watertrap M1657B, and airway adapter 13902A.

Humidity Correction: For CO

the humidity correction can be set to “wet” or “dry”.

2

35

Page 42

3 Installation and Specifications Measurement Specifications

Wet: p [mmHg] = c [Vol%] * (p_abs - p_H2O)/100

Dry: p [mmHg] = c [Vol%] * p_abs /100

Where p = partial pressure, c = gas concentration, p_abs = pressure in breathing circuit, p_H

°

mmHg, partial pressure of water vapor of exhaled gas (37

C, 100% rh).

2

For all other gases the readings are always given as dry values.

Sample Flow Rate: 150 ml/min

±15 ml/min

Sample Delay Time: All measurements and alarms are subject to a delay of 3 seconds.

Total System Response Time = 3 + 0,64 seconds (sum of the delay time and the rise time).

The drift of measurement accuracy is automatically compensated by the auto zero calibrations.

O = 47

36

Page 43

Measurement Specifications 3 Installation and Specifications

AGM Alarm

Specifications

etCO2 High 20 to 76 mmHg (2.7 to 10.1 kPa) 1 mmHg (0.1 kPa) less than 18 seconds

etCO2 Low 10 to 75 mmHg (1.3 to 10.0 kPa)

imCO2 High 2 to 20 mmHg (0.3 to 2.7 kPa) 1 mmHg (0.1 kPa)

inO2 90 to 800 mmHg

inN2O 0 to 660 mmHg

in/et

HAL/ISO/ENF

in/et SEV 0 to 72 mmHg

in/et DES 0 to 160 mmHg

awRR High Adult/pedi: 10 to 60 rpm

awRR Low Adult/pedi: 0 to 55 rpm

Apnea delay 15 to 40 seconds 5 second steps set apnea delay time + 8 seconds

Range Adjustment Delay

10 mmHg

12 to 107 kPa

18 to 100 vol%

0 to 88 kPa

0 to 82 vol%

0 to 60 mmHg

0.0 to 8 kPa

0.0 to 7.5 vol%

0.0 to 9.6 kPa

0.0 to 9.0 vol%

0.0 to 21.2 kPa

0.0 to 20.0vol%

Neo: 30 to 60 rpm

Neo: 0 to 55 rpm

1 kPa

1 vol%

10 mmHg

2 kPa

2 vol%

1 mmHg

0.1 kPa

0.1 vol%

1 mmHg

0.1 kPa

0.1 vol%

2 mmHg

0.2 kPa

0.2 vol%

under 20 rpm: 1 rpm

over 20 rpm:5 rpm

settings < 20 rpm: less than 8 seconds

> 20 rpm: less than 18 seconds

Interfering Gases and Vapours

At the gas levels listed below there is no influence on the specified accuracy of the M1026B AGM.

Gas or Vapour Gas Level in % volume fraction

Nitrous Oxide 60

Halothane 4

Enflurane 5

Isoflurane 5

Sevoflurane 5

Xenon Not for use with Xenon

Helium Not for use with Helium

Metered dose inhaler propellants Not for use with metered dose

Desflurane 15

Ethanol 0.1

Isopropanol 0.1

Acetone 0.1

Methane 0.02

inhaler propellants

37

Page 44

3 Installation and Specifications Safety and Performance Tests

Safety and Performance Tests

You must observe any national regulations on the qualification of the testing personnel and suitable

measuring and testing facilities. See the maintenance section for a list of required tests. Safety and

performance tests, and what to do if the instrument does not meet these specifications are described in

your gas analyzer’s service guide.

Electromagnetic Compatibility (EMC) Specifications

CAUTION The M1013A IntelliVue G1, the M1019A IntelliVue G5 and the M1026B AGM are not intended for

use with MRI.

Take special precautions regarding electromagnetic compatibility (EMC) when using medical electrical

equipment. You must operate your monitoring equipment according to the EMC information

provided in this book. Portable and mobile radio frequency (RF) communications equipment can

affect medical electrical equipment.

Accessories Compliant with EMC Standards

All accessories listed in the accessories section comply with the requirements of IEC 60601-1-2:2001.

WARNING Using accessories other than those specified may result in increased electromagnetic emission or

decreased electromagnetic immunity of the monitoring equipment.

Electromagnetic Emissions

The gas analyzers are suitable for use in the electromagnetic environment specified in the table below.

You must ensure that they are used in such an environment

Emissions test Compliance Avoiding Electromagnetic Interference

Radio Frequency (RF) emissions Group 1 The gas analyzers use RF energy only for their internal

function. Therefore, their RF emissions are very low and are

not likely to cause any interference in nearby electronic

equipment

RF emissions CISPR 11 Class A The gas analyzers are suitable for use in all establishments

Harmonic emissions IEC 61000-3-2 n/a

Voltage fluctuations IEC 61000-3-3 n/a

WARNING • The M1013A IntelliVue G1 can only be stacked with the IntelliVue MP20/30/40/50 patient

monitors.

• The M1019A IntelliVue G5 can only be stacked with the IntelliVue MP20/30/40/50/60/70 patient

monitors.

other than domestic and those directly connected to the

public low-voltage power supply network that supplies

buildings used for domestic purposes

38

Page 45

Safety and Performance Tests 3 Installation and Specifications

Electromagnetic Immunity

The gas analyzers are suitable for use in the specified electromagnetic environment. The user must

ensure that they are used in the appropriate environment as described below.

Immunity test

Electrostatic

discharge (ESD)

IEC 61000-4-2

Electrical fast

transient/burst

IEC 61000-4-4

Surge

IEC 61000-4-5

Power frequency

(50/60 Hz)

magnetic field

IEC 61000-4-8

Voltage dips and

short

interruptions on

power supply

input lines

IEC 61000-4-11

Conducted RF

(IEC 61000-4-6)

Radiated RF

(IEC 61000-4-3)

IEC 60601-1-2

test level

± 6 kV contact

± 8kV air

± 2 kV for power supply lines

± 1 kV for input/output lines

± 1 kV differential mode

± 2 kV common mode

3 A/m 3 A/m In close vicinity to this equipment,

U

<5%

T

(> 95% dip in U

cycles

U

40%

T

(60% dip in U

U

70%

T

(30% dip in U

U

< 5%

T

(> 95% dip in U

150kHz - 80 MHz:

3 V/m

80 MHz - 2.5 GHz:

3 V/m

) for 0.5

T

) for 5 cycles

T

) for 25 cycles

T

) for 5 sec

T

Compliance level

± 6 kV contact

± 8kV air

± 2 kV for power supply

lines

± 1 kV for input/output lines

± 1 kV differential mode

± 2 kV common mode

<5% U

T

(> 95% dip in U

cycles

U

40%

T

(60% dip in U

U

70%

T

(30% dip in U

cycles

U

< 5%

T

(> 95% dip in U

3 V/m Recommended separation distance

3 V/m Recommended separation distance

) for 0.5

T

) for 5 cycles

T

) for 25

T

) for 5 sec

T

Electromagnetic environment

guidance

Floors should be wood, concrete, or

ceramic tile. If floors are covered

with synthetic material, the relative

humidity should be at least 30%.

Mains power quality should be that

of a typical commercial and/or

hospital environment

Mains power quality should be that

of a typical commercial and/or

hospital environment

no equipment with extraordinary

power frequency magnetic fields

(power transformers, etc.) should be

operated

Mains power quality should be that

of a typical commercial and/or

hospital environment. If the user of

the monitor requires continued

operation during power mains

interruptions, it is recommended

that the monitor is equipped with

an internal battery or is powered

from an uninterruptible power

supply.

from portable and mobile RF

transmitters with transmission

1

power P

including its lines:

from portable and mobile RF

transmitters with transmission

power P

including its lines:

to this equipment

12m, P×

1

to this equipment

12m, P×

In this table, U

1

For P the highest possible “Equivalent isotropic radiated power” of the adjacent rf transmitter has to

be inserted (value in Watt). Also in the vicinity of equipment marked with the symbol

is the a.c. mains voltage prior to application of the test level.

T

interference may occur. Field strengths from fixed, portable or mobile rf transmitters at the location of

this equipment should be less than 3 V/m in the frequency range from 150 kHz to 2.5 GHz and less

than 1 V/m above 2.5 GHz.

39

Page 46

3 Installation and Specifications Safety and Performance Tests

Recommended Separation Distance

The gas analyzers are intended for use in an electromagnetic environment in which radiated RF

disturbances are controlled. The customer or user of the gas analyzers can help prevent electromagnetic

interference by maintaining a minimum distance between portable and mobile RF communications

equipment and the gas analyzers as recommended below, according to the maximum output power of

the communications equipment.

Frequency of transmitter 150 kHz to 80 MHz 150 kHz to 800 MHz 800 MHz to 2,5 GHz

Equation

Rated max. output power

of transmitter (W)

0.01 0.1 0.1 0.2

0.1 0.4 0.4 0.7

1 1.3 1.3 2.3

10 3.8 3.8 7.3

100 12.0 12.0 23.0

d12P,= d12P,= d23P,=

Separation distance (m) Separation distance (m) Separation distance (m)

* 3 V/M distance to transmitters with frequencies from 150 kHz to 2.5 GHz, otherwise 1 V/m

distance.

40

Page 47

12Patient Alarms and INOPs

This chapter lists patient alarms and technical alarms (INOPs) generated by the gas analyzers in

alphabetical order, irrespective of their priority.

Patient Alarm Messages

Alarm Message Condition Indication

4

***APNEA or

***APNEA xxx sec

**awRR HIGH The airway respiration rate has exceeded the

**awRR LOW The airway respiration rate has dropped below

**et <Agent label>

HIGH

**et <Agent label>

LOW

**etCO2 HIGH The end tidal CO2 high alarm limit has been

**etCO2 LOW The end tidal CO2 value has fallen below the

**etO2 HIGH The end tidal O2 high alarm limit has been

**etO2 LOW The end tidal O2 value has fallen below the

**imCO2 HIGH The inspired minimum CO2 high alarm limit

Respiration has stopped for longer than the

preset apnea time. “xxx” denotes the Apnea

duration.

high alarm limit.

the low alarm limit.

The end tidal agent high alarm limit has been

exceeded.

The end tidal agent value has fallen below the

low alarm limit.

exceeded.

low alarm limit.

exceeded.

low alarm limit.

has been exceeded.

numeric flashes, red alarm lamp,

alarm tone.

numeric flashes and high limit is

highlighted, yellow alarm lamp,

alarm tone.

numeric flashes and low limit is

highlighted, yellow alarm lamp,

alarm tone.

numeric flashes and high limit is

highlighted, yellow alarm lamp,

alarm tone.

numeric flashes and low alarm limit

is highlighted, yellow alarm lamp,

alarm tone.

numeric flashes and high limit is

highlighted, yellow alarm lamp,

alarm tone.

numeric flashes and low limit is

highlighted, yellow alarm lamp,

alarm tone.

numeric flashes and high limit is

highlighted, yellow alarm lamp,

alarm tone.

numeric flashes, and low limit is

highlighted, yellow alarm lamp,

alarm tone.

numeric flashes and high limit is

highlighted, yellow alarm lamp,

alarm tone.

41

Page 48

4 Patient Alarms and INOPs Patient Alarm Messages

Alarm Message Condition Indication

**in <Agent label>

HIGH

**in <Agent label>

LOW

**inN2O HIGH The inspired N2O high alarm limit has been

**inO2 HIGH The inspired O2 high alarm limit has been

**inO2 LOW The inspired O2 value has fallen below the low

***inO2 LOW OXYGEN The inspired O2 value has fallen below 18

**AGT MIX MAC>3 An agent mixture has been detected and the

The inspired agent high alarm limit has been

exceeded.

The inspired agent value has fallen below the

AGT low alarm limit.

exceeded.

exceeded.

alarm limit.

vol.%.

sum of the 2 agent MAC components + MAC

O) is ≥ 3 MAC (uncorrected)

(N

2

numeric flashes, high limit is

highlighted, yellow alarm lamp,

alarm tone.

numeric flashes, low limit is

highlighted, yellow alarm lamp,

alarm tone.

numeric flashes, high limit is

highlighted, yellow alarm lamp,

alarm tone.

numeric flashes, high limit is

highlighted, yellow alarm lamp,

alarm tone.

numeric flashes, low limit is

highlighted, yellow alarm lamp,

alarm tone.

numeric flashes, low limit is

highlighted, red alarm lamp, alarm

tone.

yellow alarm lamp, alarm tone

42

Page 49

Technical Alarm Messages (INOPs) 4 Patient Alarms and INOPs

Technical Alarm Messages (INOPs)

INOP Message, Indication What to do

<GAS ANALYZER> ACCURACY?

Numerics shown with ?

<GAS ANALYZER> ALARM SUPPRESS Gas Analyzer alarms will be suppressed until breathing activity is first

<GAS ANALYZER> INCOMPATIBLE

INOP tone

<GAS ANALYZER> MALFUNCTION

Numerics replaced by -?-, INOP tone, Gas

Analyzer Setup LED may be blinking

<GAS ANALYZER> NO BREATH

et and in numerics show the same value

<GAS ANALYZER> NOT AVAILABLE

INOP tone.

<GAS ANALYZER> OCCLUSION

Numerics replaced by -?-, INOP tone

<GAS ANALYZER> SELFTEST

Numerics replaced by -?-

<GAS ANALYZER> STANDBY To resume gas monitoring, select Exit Standby in the Setup GA

<GAS ANALYZER> UNABLE TO MEAS

Numerics replaced by -?-, INOP tone

<GAS ANALYZER> ZERO FAILED

Numerics shown with ?

<GAS ANALYZER> ZERO RUNNING

First zero: numerics shown with ?

(G1/G5 only: replaced by -?- if apnea),

Second/Third zero: numerics are

unavailable, INOP tone

<GAS ANALYZER> SWITCHED OFF

INOP tone

<GAS ANALYZER> WARMUP The Gas Analyzer has not yet reached operating temperature and the

<GAS ANALYZER> CHECK

WATERTRAP

INOP tone

<GAS ANALYZER> COMPONENT MALF A gas analyzer component is in malfunction. Some parameters may be