Page 1

T13.01.000.0000.0003

2019/04 Revision Index E

English

Operating Instructions

Assembly Instructions

Worm gear screw jacks type 1 and type 2

SHE BG0,5 – BG 200.1

HSE 32 –HSE 140

Columbus McKinnon Engineered Products GmbH

Am Silberpark 2-8

D-86438 Kissing

Telefon: +49(0)8233 2121 800

Telefax: +49(0)8233 2121 805

Page 2

GB

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

T13.01.000.0000.0003

2019/04 Rev. Index E

1 Intended use ............................................................................................................................ 4

1.1 Screw jacks with safety devices for lifting platforms ...................................................... 4

1.2 Worm gear screw jacks in accordance with ATEX guideline 2014/34/EC..................... 4

2 Accident prevention guide ..................................................................................................... 5

3 Safety information ................................................................................................................... 6

3.1 General safety information ............................................................................................. 6

3.2 ATEX safety information ................................................................................................ 6

3.3 Type plate ...................................................................................................................... 6

4 Technical specifications ......................................................................................................... 7

4.1 High-performance worm gear screw jacks HSE, standard and with safety features ..... 7

4.2 Worm gear screw jack SHE standards and with safety features ................................... 8

4.3 Technical specifications ATEX ...................................................................................... 9

5 Receipt of goods, storage, transport .................................................................................... 10

5.1 Receipt of goods ............................................................................................................ 10

5.2 Transport ........................................................................................................................ 10

5.3 Storage .......................................................................................................................... 10

6 Worm gear screw jacks, standard version ........................................................................... 11

6.1 Safety worm gear screw jacks ....................................................................................... 11

Safety nut (wear monitoring) ..................................................................................................... 11

6.2 Safety nut (wear monitoring) .......................................................................................... 12

6.3 Safety-trap nut (option for ball screw spindles) .............................................................. 12

6.4 Options for screw jacks Ba1 and Ba2 ............................................................................ 12

7 Assembly .................................................................................................................................. 12

7.1 Fitting positions SHE ...................................................................................................... 13

7.2 Fitting positions HSE ...................................................................................................... 14

7.3 Pivot version................................................................................................................... 15

7.4 Assembly of the inductive limit switches ........................................................................ 15

7.5 Assembly of electromechanical limit switches ............................................................... 16

7.6 Assembly of safety nut ................................................................................................... 16

7.7 Installing the nut breakage limit switch (Ba1) ................................................................. 16

7.8 Installing the nut breakage limit switch (Ba2) ................................................................. 17

7.9 Installing the pulse generator (rotational speed monitor) ............................................... 17

7.10 Mechanical fastening ..................................................................................................... 18

7.11 Screw tightening torques ............................................................................................... 19

8 Initial operation ........................................................................................................................ 19

9 Maintenance and inspection .................................................................................................. 20

9.1 Maintenance plans ......................................................................................................... 20

9.2 Maintenance instructions ............................................................................................... 20

9.3 SHE with low-viscosity grease level in the lift gear box ................................................. 22

10 Decommissioning ................................................................................................................... 22

11 Lubricants ................................................................................................................................ 23

12 Einbauerklärung / Declaration of incorporation / Déclaration d'incorporation ................. 24

13 EG-Konformitätserklärung EC-Declaration of Conformity

Déclaration "CE" de Conformité................................................................................................... 26

Subject to technical modifications Design changes under reserve Sous réserve de modifications techniques !

2

Page 3

GB

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

These operating instructions describe the Pfaff-silberblau worm gear screw jacks of the

SHE and HSE series. Please refer to our order confirmation or worm gear screw jack

compendium for details on the layout, design and permissible operating conditions for the

drives. Always observe and follow these operating instructions when using the equipment.

Read the operating instructions carefully before commissioning!

Observe the safety instructions!

Store document!

Practical information

Warning against a general hazard. Risk of injury due to neglect.

Warning against electrical voltage. Severe risk of injury due to neglect.

Information on the safety screw jacks

Danger of explosion

Important information for use in spaces with explosion hazards

T13.01.000.0000.0003

2019/04 Rev. Index E

Important information

Assembly and setting information

Disposal

SHE Worm gear screw jack

HSE High-performance worm gear screw jack

Type 1 (Ba1) Method of operation for type with lifting screw

Type 2 (Ba2) Method of operation for type with rotating screw

Specifications A = screw on housing cover side; B= screw on mounting surface side

Tr Trapezoidal thread spindle

Ku Ball screw spindle

S Buttress thread screw

P Screw pitch

DIN German industry standards

EN European norm

ISO International standards

ID Duty cycle in % / h

Subject to technical modifications Design changes under reserve Sous réserve de modifications techniques !

3

Page 4

GB

Worm gear screw jacks are incomplete machines and are intended for installation in complete machines or

that are employed for converting rotational movement into longitudinal movement

the operating instructions, in the

Modifications to the screw jacks as well as the attachment of additional devices are only permitted with our

If stated in the order confirmation, the worm gear screw jacks with corresponding additional supplementary

e responsibility of the

The manufacturer of the complete system checks that the product in combination with the complete machine

or use in the existing Ex zone must be checked or assessed in

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

T13.01.000.0000.0003

2019/04 Rev. Index E

1 Intended use

for assembly with several machines into a system.

They are drive elements

and for reducing speed or converting torque.

The drive systems may only be used for the designated purpose.

They may be used only under the application conditions specified in

technical documentation or in the order confirmation.

Operation outside the respective performance limitations / ambient conditions is not permitted.

Not suitable for use in explosive-atmosphere zones.

Not suitable for use in aggressive environments, if not constructed especially for these applications.

express and written authorisation.

Pay attention to the technical data and functional description!

equipment comply with the requirements of various standards and guidelines:

1.1 Screw jacks with safety devices for lifting platforms

in accordance with DIN EN 1570-1:2015-01; DIN EN 280:2014-02, DIN EN 1756, DIN EN 1493:2011-02

Screw jacks with safety devices such as limited pitch angle – safety nut, speed monitoring and/or wear monitoring

are designed or constructed according to the requirements of the applicable standard –

DIN EN 1570-1:2015-01 - Lifting tables

DIN EN 280:2014-02 - Elevating work platforms

DIN EN 1493:2011-02 – Vehicle lifts

DIN 56950-1:2012-05 – Event technology technical installations –

designed for installation in machines in accordance with the applicable standards.

The manufacturer of the complete system checks that the product in combination with the complete machine is in

conformity. The manufacturer of the complete system is responsible for conducting the risk assessment for the

complete system. The information in our operating instructions must be integrated in the instructions for the

complete machine.

Required prototype tests (experts' examinations) need to be carried out under th

manufacturer of the complete machine.

1.2 Worm gear screw jacks in accordance with ATEX guideline 2014/34/EC

are suited as components (2014/34/EC item 1 (3) for installation in machines for use in explosiveatmosphere zones as indicated by the ATEX marking.

For the ignition source analysis, the ATEX checklist must be filled out completely and submitted (www.pfaffsilberblau.com).

is ATEX conform, and is responsible for conducting the ignition source analysis for the complete system.

The information in our operating instructions must be integrated in the instructions for the complete machine.

The suitability of the ATEX components f

accordance with the ATEX marking, the order confirmation, conformity declaration and type plate.

Subject to technical modifications Design changes under reserve Sous réserve de modifications techniques !

4

Page 5

GB

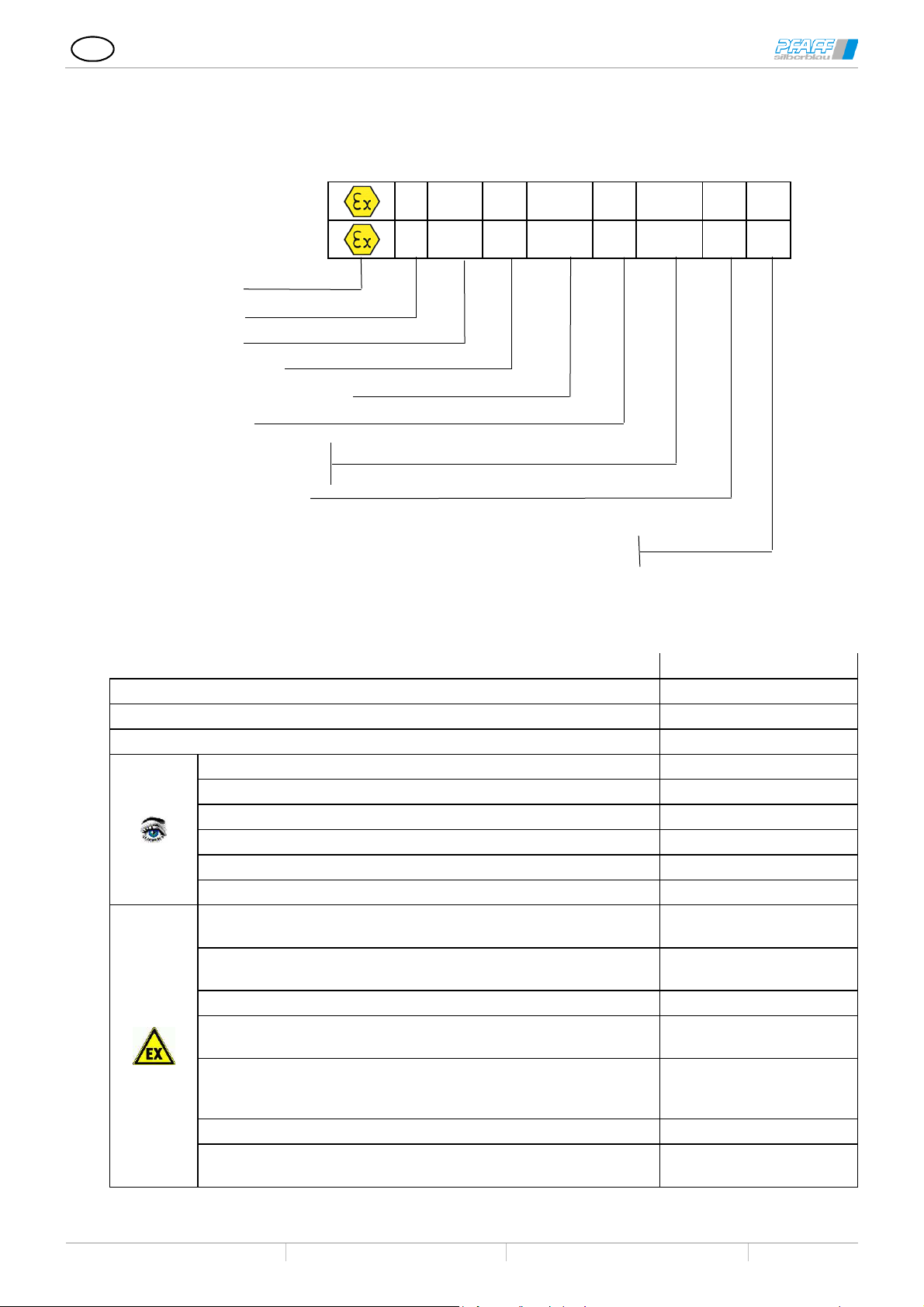

1.2.1 Marking in accordance with RL 2014/34/EC

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

T13.01.000.0000.0003

2019/04 Rev. Index E

Gas

Dust

Ex-Symbol

Device group

Category

Ignition protection type

Equipment protection level (EPL)

Explosion group

Temperature class

Max. surface temperature

Equipment protection level

Equipment with partial certifikate,

CE Compliance is certified with Installation in a complete Equipment

2 Accident prevention guide

Observe the relevant instructions, regulations, and standards in the country of use. In Germany, these are

currently:

EC machinery directive 2006/42/EC

Machine safety DIN EN ISO 12100:2010

Lift devices DIN EN 1494:2009-05

Lifting tables DIN EN 1570-1:2015-01

Elevating work platforms DIN EN 280:2014-02

Loading platforms DINEN 1756

Vehicle lifts DIN EN 1493:2011-02

Stages and studios BGV C1

Stage mechanics, safety equipment DIN 56950-1:2012-05

EC guideline; Equipment and protective systems in potetially

explosive atmospheres (ATEX)

EC guideline; Improving the safety and health protection in

potentially explosive atmospheres

Explosion protection basics and methodology DIN EN 1127-1

Non-electric devices for use in explosive-atmosphere zones -

basics and requirements

Non-electric devices for use in explosive-atmosphere zones -

protection through constructional safety “c”, ignition source

monitoring "b"; liquid encapsulation “k”

Explosive atmosphere DIN EN 60079-0

Explosive atmosphere, projection, selection and set-up of

electrical systems

II 2G ck Ex h IIB T4 Gb U

II

2D c Ex h IIIB 135°C Db U

Rules and regulations

2014/34/EU

1999/92/EG (ATEX 137)

DIN EN ISO 80079-36

DIN EN ISO 80079-37

DIN EN 60079-14

Subject to technical modifications Design changes under reserve Sous réserve de modifications techniques !

5

Page 6

GB

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

T13.01.000.0000.0003

2019/04 Rev. Index E

3 Safety information

3.1 General safety information

Operation, installation and maintenance may only be carried out by qualified personnel. The responsible

operator must be authorised in writing.

It is forbidden to transport people or to stay in the danger area of devices not designed for this purpose.

Exception: Screw jacks with safety features with corresponding intended use as described in Chapter 1.1

in the framework of the corresponding product standard.

Not suitable for use in explosive atmospheres!

Exception: Screw jacks are designed and marked as components for use in explosive-atmosphere

zones, as described in Chapter 1.2

Never reach into moving parts. Cover them or cut off access to them.

Do not remove or disable the safety devices.

The operational and safety limit switches must ensure that the lifting process is safely stopped at the end

positions.

To prevent contact with rotating/moving parts, attach protective covers (such as bellows, shaft caps) or

make those areas of the machine inaccessible.

Screw/Travelling nut must be fastened on-site or be turn-secured or equipped with the optional torsional

lock (max. screw torque according to technical documents). The construction must be able to bear the

screw torque securely.

Ball thread spindles and multi-geared trapezoidal thread spindles are not self-locking. An appropriate brake

device needs to be integrated into the system.

In the standard version, the screw does not have any protection against unintended skimming out of the

gear box (Ba1) or against the travelling nut driving out the screw. A protection against skimming needs to be

realised either on site or by worm gear screw jacks with mechanical end stops.

No lateral forces on the screw.

3.2 ATEX safety information

The owner of a system must ensure that the explosion-risk conditions are adhered to.

On-site layer thickness from surface coatings (e.g. lacquering) max. 2 mm (explosion group IIA and IIB) and

0.2 mm at explosion group IIC

Requirements for the reliable operation is a properly lubricated screw and a lift gear box provided with

lubrication.

The affects from knocks and bumps on the screw jack is not permitted.

Dust deposits are to be removed regularly.

Connect the screw jacks with potential equalisation (earth) and check the bleeder resistance (<106 Ohm).

Observe the speeds and permitted drive power output specified in the technical data when operating with

rotation speed control in the potentially explosive atmospheres.

On motorized drives, monitor the motor output with output gauges or otherwise temperature monitors (e.g.

thermistors (PTC) with evaluation device). Minimum requirements according to EN 13463-6 category 2IPL2; cat. 3 –IPL1.

Materials used must be resistant against the media.

The operator must count or measure the load cycles or operating hours and document them.

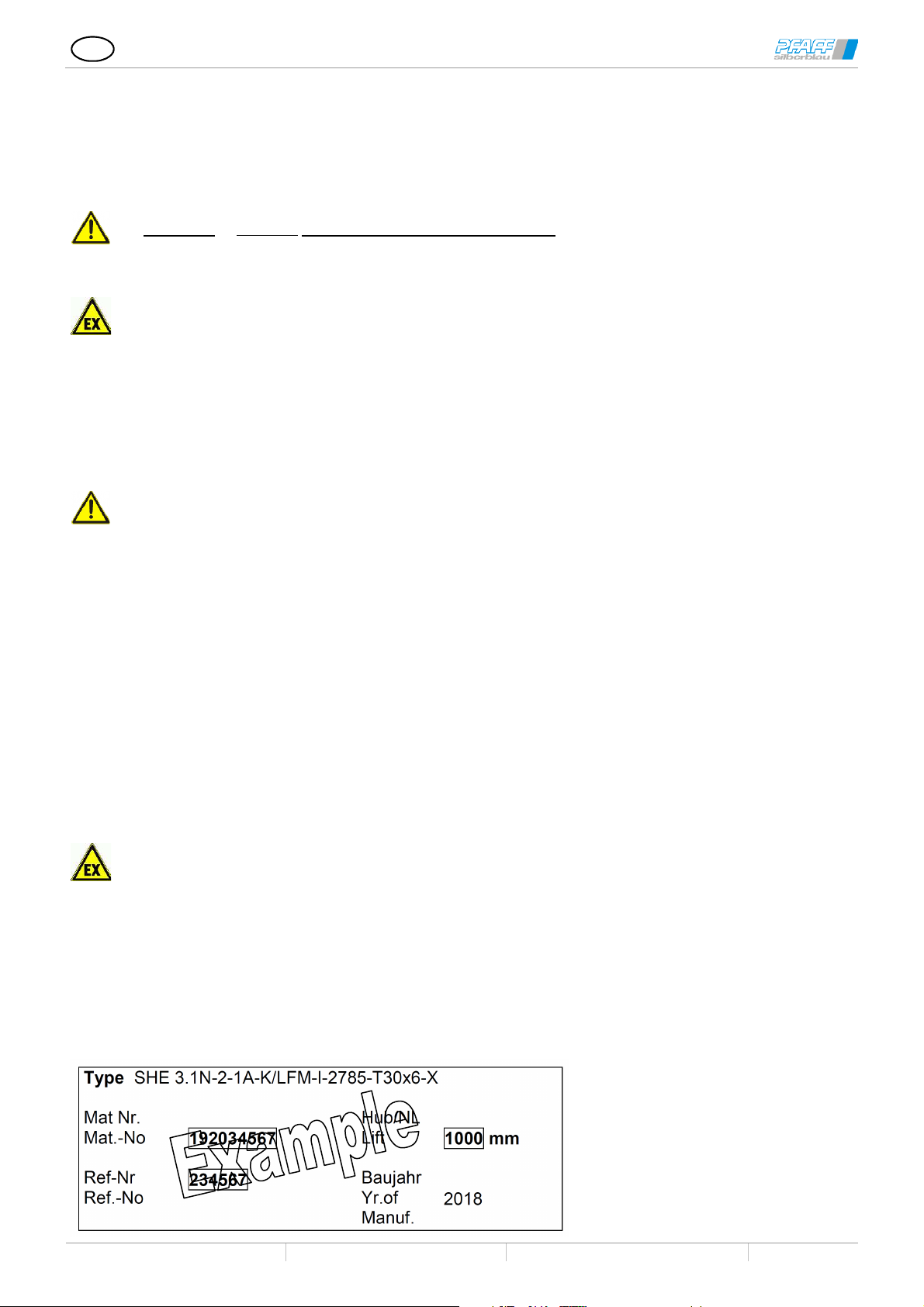

3.3 Type plate

Subject to technical modifications Design changes under reserve Sous réserve de modifications techniques !

6

Page 7

GB

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

T13.01.000.0000.0003

2019/04 Rev. Index E

3.3.1 Design variants

In the stated variants, the first letter refers to the top side refers to the head side of the screw jack and the

second letter refers to the opposite side.

K Short lid

H High lid

F Guide ring

S/SR Sheath tube

SA Round sheath tube with stop collar

Sf Sheath tube with guide ring

Si Sheath tube with inductive limit switches

Sm Sheath tube with mech. limit switches

Se Sheath tube with mechanical

end stop (protection against skimming)

SV Reinforced rough sheath tube

V/VK Torsional lock through Square sheath

tube

Vi Torsional lock with ind. limit switches

Vm Torsional lock with mech. limit switches

Ve Torsional lock with end stop

VP Torsional lock by feather key

VV Reinforced sheath tube

SFM-O Short safety nut

SFM-K Short safety nut in tube cap

SFM-L Long safety nut

SFM-E Long safety nut, el. monitored

SFM-D Long safety nut, el. monitored

with speed monitoring

Pivot lug version

P = swivelling version

P = swivelling version with end stop

Pm = swivelling version with mechanical operational

limit switches

Pi = swivelling version with inductive operational limit

switches

Q = swivelling version (bore head IV, rotated 90° to

worm shaft)

Qe = swivelling version (bore head IV, rotated 90° to

work shaft) with end stop

Qm = swivelling version (bore head IV, rotated 90° to

work shaft) with mech. end stops

Qi = swivelling version (bore head IV, rotated 90° to

work shaft) with mech. end stops

Travelling nut

LFM Standard travelling nut

LSF Travelling nut with spanner flat

LSA Travelling nut with spherical contact

surface

EFM Single-flange nut (Tr or Ku)

LWZ Travelling nut with swivel pin

Combined with safety nut

-K Short safety nut

-L Long safety nut

-E Long safety nut, el. monitored

4 Technical specifications

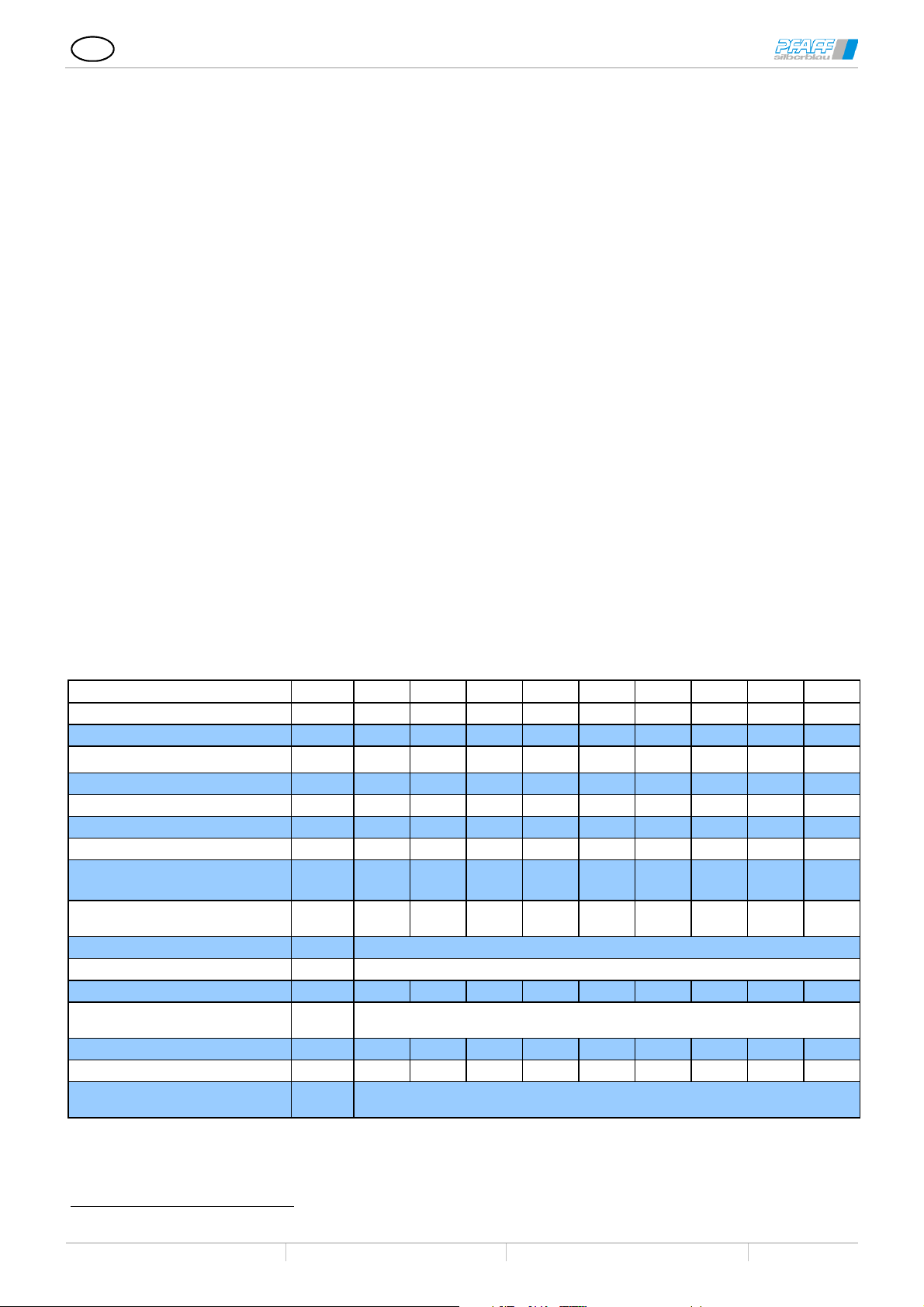

4.1 High-performance worm gear screw jacks HSE, standard and with safety features

Sizes in the HSE series 32 36.1 50.1 63.1 80.1 100.1 125.1 140 200.1

Max. lifting force [kN] 5 10 25 50 100 200 350 500 1000

Max. tension [kN] 5 10 25 50 100 178 350 500 1000

Spindle Tr1

Ratio N 4:1 5:1 6:1 7:1 8:1 8:1 10 2/3:1 10 2/3:1 13 1/3:1

Lift per rotation at ratio N [mm/U] 1,0 1,0 1,33 1,28 1,5 1,5 1,5 1,5 1,5

Ratio L 16:1 20:1 24:1 28:1 32:1 32:1 32:1 32:1 40:1

Lift per rotation at ratio L [mm/U] 0,25 0,25 0,33 0,32 0,375 0,375 0,5 0,5 0,5

Max. drive capacity2 at 20°C ambient

temp. and 20% DC/h

Max. drive capacity2 at 20°C ambient

temperature and 10% DC/h

Overall efficiency ratio N [%] See efficiency table compendium worm gear screw jack

Overall efficiency ratio L [%] See efficiency table compendium worm gear screw jack

Spindle efficiency [%] 42,5 43 40 36,5 39,5 35,5 34 30 28,5

Torque-capacity-rotation speed at 20%

ID/hr. and 20°C

Screw torque at max. lifting force [Nm] 7,4 18,4 80 190 478 1060 2600 4235 11115

Max. permit. torque on the drive shaft [Nm] 12,6 29,4 48,7 168 398 705 975 1640 4260

Max. permit. screw length at pressure

load

18x6 24x5 40x8 50x9 60x12 70x12 100x16 120x16 160x20

[kW] 0,60 0,90 1,5 2,3 3,6 4,8 7,7 10,2 17,9

[kW] 1,0 1,5 2,6 4,0 6,3 8,4 13,5 17,9 31

See power table compendium on worm gear screw jacks

[mm] See offset diagram compendium worm gear screw jacks

1 Also with Ku screw

2 Max. permissible values with BA 1 and Tr screw. Higher values are possible using BA 2 or Ku screws

Subject to technical modifications Design changes under reserve Sous réserve de modifications techniques !

7

Page 8

GB

rotation speed at 20%

Lift per rotation at

Lift per rotation at

Max. drive capacity2 at 20°C ambient

Max. drive capacity2 at 20°C ambient

Overall efficiency

Overall efficiency

rotation speed at 20%

Max. permit. screw length at pressure

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

T13.01.000.0000.0003

2019/04 Rev. Index E

4.2 Worm gear screw jack SHE standards and with safety features

Model series SHE unit size

Max. lifting capacity dyn/stat [kN] 5 10 30/45 50/75 100/150 200

Max. tensile load dyn/stat [kN] 5 10 30/45 50/75 99 178/200

Screw Tr3 18x6 24x5 30x6 40x7 60x12 70x12

Ratio N 10:1 5:1 6:1 6:1 7 2/3:1 8:1

Lift per rotation at

ratio N

Ratio L 20:1 20:1 24:1 24:1 24:1 24:1

Lift per rotation at

ratio L

Max. drive capacity4 at 20°C ambient

temp. and 20% DC/h

Max. drive capacity2 at 20°C ambient

temperature and 10% DC/h

Overall efficiency

ratio N

Overall efficiency

ratio L

Spindle efficiency [%] 54 43 40 36,5 39,5 37,5

Torque-capacity-

ID/hr. and 20°C

Screw torque at max. lifting force [Nm] 8,8 18,4 60 153 702 1009

Max. permit. torque on the drive shaft [Nm] 12 29,4 46,5 92 195 280

Max. permit. screw length at pressure

load

Model series SHE unit size

Max. lifting force

Max. tension

Screw Tr1

Ratio N

ratio N

Ratio L

ratio L

temperature and 20% DC/h

temperature and 10% DC/h

ratio N

ratio L

Spindle efficiency

Torque-capacityID/hr. and 20°C

Screw torque at max. lifting force

Max. permit. torque on the drive shaft

load

BG 0,5 1.1 3.1 5.1 15.1 20.1

[mm/U] 0,60 1,0 1,0 1,167 1,565 1,50

[mm/U] 0,30 0,25 0,25 0,292 0,50 0,5

[kW] 0,17 0,35 0,65 1,15 2,7 3,8

[kW] 0,25 0,55 0,9 1,65 3,85 5,4

[%] 31 29 27 24 27 24

[%] 24 20 19 16 17 17

See power table compendium on worm gear screw jacks

[mm] See offset diagram compendium worm gear screw jacks

BG 25 35 50.1 75 100.1 150 200.1

[kN] 250 350 500 750 800/1000 1500 2000

[kN] 250 350 500 750 800/1000 1500 -

90x16 100x16 120x16 140x20 160x20 190x24 220x28

10 2/3:1 10 2/3:1 10 2/3:1 12:1 12:1 19:1 17,5:1

[mm/U] 1,50 1,50 1,50 1,667 1,667 1,263 1,60

32:1 32:1 32:1 36:1 36:1 -

[mm/U] 0,5 0,5 0,5 0,556 0,556 -

[kW] 5,0 6,0 7,4 9,0 12,5 18,5

[kW] 7,2 8,6 10,4 12,6 17,5 26

[%] 22 21 15 18 15 15

[%] 15 14 10 12 9 -

[%] 36,5 34 30 31,6 28,5 28,8 29

See power table compendium on worm gear screw jacks

[Nm] 1725 2600 4235 7550 11115 19850

[Nm] 480 705 840 2660 2660 4260

[mm] See offset diagram compendium worm gear screw jacks

3Also with Ku screw

4 Max. permissible values with BA 1 and Tr screw. Higher values are possible using BA 2 or Ku screws

Subject to technical modifications Design changes under reserve Sous réserve de modifications techniques !

8

Page 9

GB

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

T13.01.000.0000.0003

2019/04 Rev. Index E

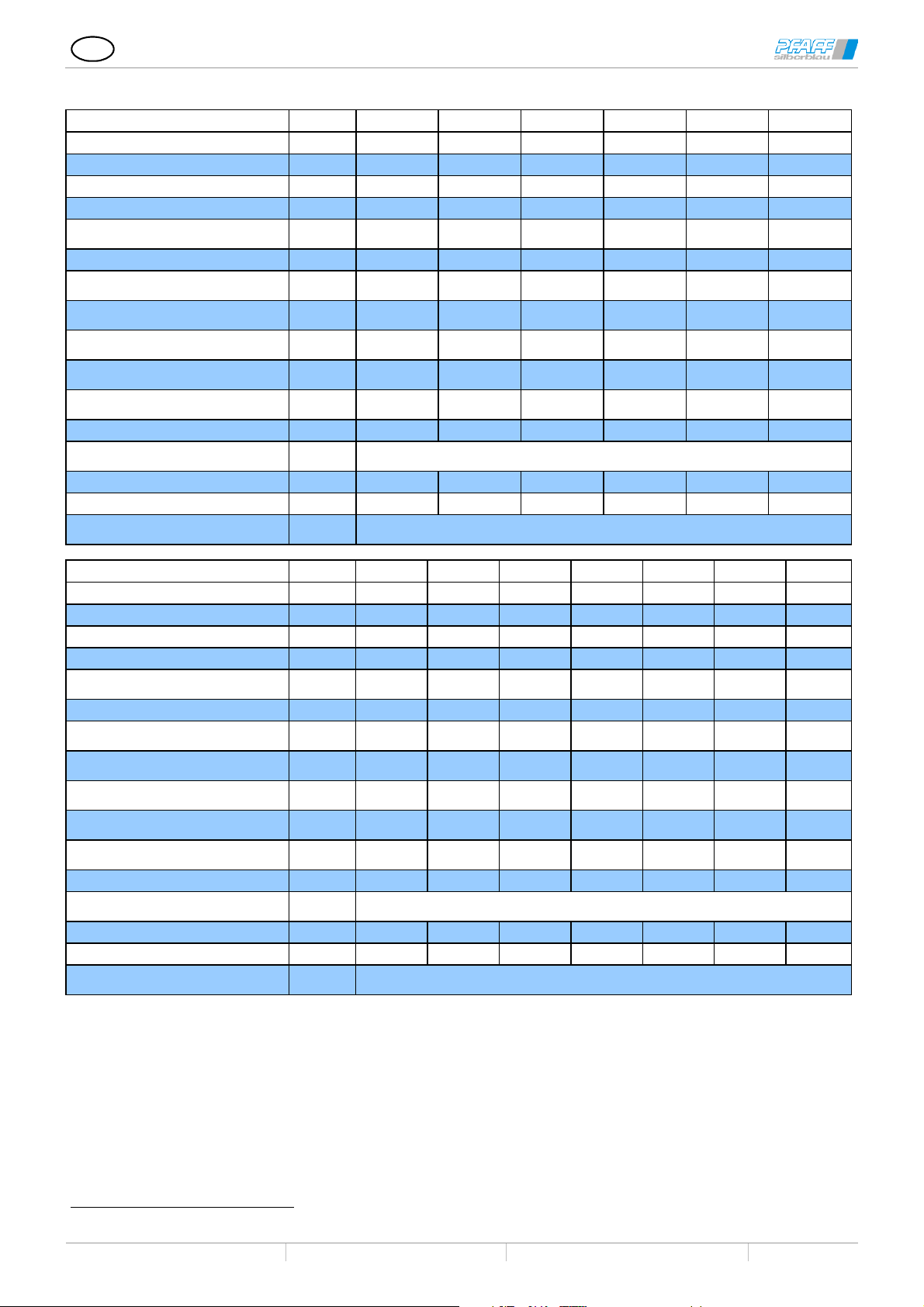

4.3 Technical specifications ATEX

Worm gear screw jack for use in spaces with explosion hazards are designed based on the

environmental influences (ATEX checklist) that have been given to us. The technical specifications and

ATEX terms and conditions specified in the order confirmation must be adhered to. The manufacturer of the

total system needs to evaluate the suitability according to the identification.

The declaration of conformity, in accordance with guideline 2014/34/EC, is rendered void if the

technical data and ATEX conditions are not adhered to

4.3.1 Worm gear screw jacks SHE for explosive-atmosphere zones in acc. with 2014/34/EC (ATEX)

Model series SHE unit size

Max. lifting capacity dyn/stat [kN] 10 30/45 50/75 100/150 200 250

Max. tensile load dyn/stat [kN] 10 30/45 50/75 99 178/200 250

Screw Tr5 24x5 30x6 40x7 60x12 70x12 90x16

Ratio N 5:1 6:1 6:1 7 2/3:1 8:1 10 2/3:1

Lift per rotation at ratio N [mm/U] 1,0 1,0 1,167 1,565 1,50 1,50

Ratio L 20:1 24:1 24:1 24:1 24:1 32:1

Lift per rotation at ratio L [mm/U] 0,25 0,25 0,292 0,50 0,5 0,5

Max. drive capacity at 20°C ambient temperature and 20%

DC/h

Max. drive capacity at 20°C ambient temperature and 10%

DC/h

Overall efficiency ratio N [%] 29 27 24 27 24 22

Overall efficiency ratio L [%] 20 19 16 17 17 15

Spindle efficiency [%] 43 40 36,5 39,5 37,5 36,5

Torque-capacity-speed at 20% DC/h and 20°C See power table compendium on worm gear screw jacks

Screw torque at max. lifting force [Nm] 18,4 60 153 702 1009 1725

Max. permit. torque on the drive shaft [Nm] 29,4 46,5 92 195 280 480

Max. permit. screw length at pressure load [mm] See offset diagram compendium worm gear screw jacks

Model series SHE unit size

Max. lifting force [kN] 350 500 750 800/1000 1500 2000

Max. tension [kN] 350 500 750 800/1000 1500 Screw Tr 100x16 120x16 140x20 160x20 190x24 220x28

Ratio N 10 2/3:1 10 2/3:1 12:1 12:1 19:1 17,5:1

Lift per rotation at ratio N [mm/U] 1,50 1,50 1,667 1,667 1,263 1,60

Ratio L 32:1 32:1 36:1 36:1 -

Lift per rotation at ratio L [mm/U] 0,5 0,5 0,556 0,556 -

Max. drive capacity at 20°C ambient temperature and 20%

DC/h

Max. drive capacity at 20°C ambient temperature and 10%

DC/h

Overall efficiency ratio N [%] 21 15 18 15 15

Overall efficiency ratio L [%] 14 10 12 9 -

Spindle efficiency [%] 34 30 31,6 28,5 28,8 29

Torque-capacity-speed at 20% DC/h and 20°C See power table compendium on worm gear screw jacks

Screw torque at max. lifting force [Nm] 2600 4235 7550 11115 19850

Max. permit. torque on the drive shaft [Nm] 705 840 2660 2660 4260

Max. permit. screw length at pressure load [mm] See offset diagram compendium worm gear screw jacks

BG 1.1 3.1 5.1 15.1 20.1 25

[kW] 0,18 0,33 0,7 1,4 2,0 2,5

[kW] 0,35 0,65 1,15 2,7 3,8 5,0

BG 35 50.1 75 100.1 150.1 200.1

[kW] 3,0 3,8 4,5 6,5 9,5

[kW] 6,0 7,4 9,0 12,5 18,5

5Also with Ku screw

Subject to technical modifications Design changes under reserve Sous réserve de modifications techniques !

9

Page 10

GB

y and quality. Regrease for

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

T13.01.000.0000.0003

2019/04 Rev. Index E

4.3.2 HSE for explosive-atmosphere zones in acc. with 2014/34/EC (ATEX)

Model series HSE unit size

Max. lifting force [kN] 10 25 50 100 200 350 500 1000

Max. tension [kN] 10 25 50 100 178 350 500 1000

Screw Tr6 24x5 40x8 50x9 60x12 70x12 100x16 120x16 160x20

Ratio N 5:1 6:1 7:1 8:1 8:1 10 2/3:1 10 2/3:1 13 1/3:1

Lift per rotation at ratio N [mm/U] 1,0 1,33 1,28 1,5 1,5 1,5 1,5 1,5

Ratio L 20:1 24:1 28:1 32:1 32:1 32:1 32:1 40:1

Lift per rotation at ratio L [mm/U] 0,25 0,33 0,32 0,375 0,375 0,5 0,5 0,5

Max. drive capacity at 20°C ambient

temperature and 20% DC/h

Max. drive capacity at 20°C ambient

temperature and 10% DC/h

Overall efficiency ratio N [%] See efficiency table compendium worm gear screw jack

Overall efficiency ratio L [%] See efficiency table compendium worm gear screw jack

Spindle efficiency [%] 43 40 36,5 39,5 35,5 34 30 28,5

Torque-capacity-rotation speed at 20% ID/hr.

and 20°C

Screw torque at max. lifting force [Nm] 18,4 80 190 478 1060 2600 4235 11115

Max. permit. torque on the drive shaft [Nm] 29,4 48,7 168 398 705 975 1640 4260

Max. permit. screw length at pressure load [mm] See offset diagram compendium worm gear screw jacks

36.1 50.1 63.1 80.1 100.1 125.1 140 200.1

[kW] 0,45 0,75 1,2 1,8 2,4 3,8 5,5 9

[kW] 0,9 1,5 2,3 3,6 4,8 7,7 10,2 17,9

See power table compendium on worm gear screw jacks

5 Receipt of goods, storage, transport

5.1 Receipt of goods

Startup with defective screw jacks is forbidden.

Immediately check if the contents of delivery correspond with the shipping documents upon receipt. No

other warranties can be approved for subsequent defect claims.

Claims on defects and incompleteness are to be made immediately at Pfaff-silberblau.

Claims on perceivable damages due to transport are to be reported to the transport company immediately.

Small parts such as limit switches are usually delivered unattached and packed individually.

5.2 Transport

Lift / transport the screw jack by the appropriate hoisting points.

Pay attention to the attachment parts. No person is to stand under suspended loads.

Use hoisting gear in good condition.

Keep long screws from getting warped. Support screw by appropriate means.

5.3 Storage

Storage period

< 3 years

Check corrosion protection; renew or repair, if necessary.

Check lubrication of moveable machinery, relubricate if necessary.

Check oil level of gears; refill, if necessary.

Check corrosion protection; renew or repair, if necessary.

Storage period

> 3 years

Check lubrication of moveable machinery, relubricate if necessary.

Clean spindle and grease with fresh lubricant along the whole length.

Drain gear oil, and fill gear unit with the prescribed oil quantit

grease lubrication.

6 Also with Ku screw

Subject to technical modifications Design changes under reserve Sous réserve de modifications techniques !

10

Page 11

GB

2

3

4

5

2

3

4

5

6

2

3

4

6

2

3

4

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

T13.01.000.0000.0003

2019/04 Rev. Index E

General information

6 Worm gear screw jacks, standard version

Feature Description

Rotating worm wheel Ba1

Lifting screw Ba1

Rotating screw Ba2

Lifting travelling nut Ba2

SHE: Worm gear with grease lubrication

HSE: Worm gear with oil lubrication

Thread spindle with grease lubrication

Suitable for an ambient temperature

-10 to +40 °C

Translation thread or ball screw nut integrated into the worm wheel

Trapezoidal thread, buttress thread, multiple trapezoidal thread, ball

screw

From worm gear propelled trapezoidal, buttress, or ball thread spindle.

Travelling nut conducts the lift movement.

If the temperatures deviate from these specifications, the design must

be adapted by our technical office.

1 Screw

2 Worm wheel

3 Worm

4 Housing

5 Sheath tube

6 Travelling nut

6.1 Safety worm gear screw jacks

The worm gear screw jacks are equipped with a long safety nut, and an electric nut breakage monitoring

system for lifting tables acc. to EN 1570-1, elevating work platforms acc. to DIN EN 280, vehicle lifts acc. to

DIN EN 1493 and stages and studios acc. to BGV C1/DIN56950-1.

The manufacturer is responsible for the risk assessment of the entire system.

Feature Description

Safety nuts

Visual wear indicator

Electrical nut breakage monitoring

Self-locking/self-braking spindle

option

To protect against falling of the load in case of wear of the carrying nut.

For monitoring the wear of the carrying nut

For monitoring the carrying nut for breakage

On lift devices that must safely brake in the event of the failure of a

connection element, worm gear screw jacks with self-locking or selfbraking screws are required

Speed monitoring option

Standstill monitor option

Load monitor option

To monitor the synchronisation of all screw jacks or the standstill of a

screw jack in one lifting system with several worm gear screw jacks.

Electronic load monitor for monitoring the power of the drives

The selection of self-locking or braking options must be made on a case by case basis, taking into

account the complete system. Depending on lift speed and positioning accuracy, additional brake(s) will

be required.

Safety nut (wear monitoring)

Subject to technical modifications Design changes under reserve Sous réserve de modifications techniques !

11

Page 12

GB

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

T13.01.000.0000.0003

2019/04 Rev. Index E

6.2 Safety nut (wear monitoring)

1 Visual wear monitoring

2 Inductive sensor

3 Pulse recession

4 Guide ring

5 Tube cab

6 Nut breakage limit switch

7 Travelling nut

8 Safety nut

Principle: With further wear, the gap X diminishes (documentation see 9.2.6)

Once the wear limit has been reached, the safety limit switch is activated.

The switch signals should be processed by the controller according to the requirements of the respective product

standards.

Only possible with trapezoidal thread spindles or buttress thread screws.

6.3 Safety-trap nut (option for ball screw spindles)

If the ball screw nut malfunctions, the ball screw spindle catches on the thread of the trap nut.

As a result, the power requirement of the drive motors increases. The unit needs to be

switched off by the controller or otherwise by a load monitor.

6.4 Options for screw jacks Ba1 and Ba2

6.4.1 Protection against skimming "Se", "Ve";

The end stop is a safety device and should not be used as a "working stop". If the end stop is run against

the block, this can cause damages to the screw or gears.

6.4.2 Ball thread spindle “Ku”

Please note during assembly and transport. Ball thread spindles are not self-locking.

Driving only permitted with a brake motor.

6.4.3 Multi-geared trapezoidal thread screws

Please note during assembly and transport. Multi-geared trapezoidal screw are not self-locking.

Driving only permitted with a brake motor.

6.4.4 Buttress thread screws "S"

Only in combination with 2 guide rings.

7 Assembly

Inspecting the used screw jacks for compliance with the technical requirements.

Add-on construction, supporting structure and groundwork is designed for the maximum forces.

For screw torques, see 7.11

Protect screws from soiling during transport, assembly, construction and storage.

Screws need to be protected during operation against soiling, e.g. by bellows, coils or on-site covers.

On worm gear screw jacks with oil lubrication, check the oil level, refill if necessary, insert bleed plug, pull

pin at bleed plug.

If necessary, mount and set limit switch.

Avoid misalignment and angular offset.

Provide movable load support points if necessary.

Distortions increase power consumption and reduce the service life!

Carry out assembly and run-in phase without explosive atmosphere.

The ATEX marking on the incorporated components must correspond to the existing

ATEX atmosphere.

Subject to technical modifications Design changes under reserve Sous réserve de modifications techniques !

12

Page 13

GB

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

T13.01.000.0000.0003

2019/04 Rev. Index E

SHE Tr screw

HSE Tr screw

SHE Ku screw

HSE Ku screw

1. Align screw and screw jacks (e.g. with a spirit level, 0.3 mm/m), then screw tight, and anchor if necessary.

2. Make sure the screw is parallel to the on-site guides.

3. Avoid distortions. The worm shaft should turn easily and evenly throughout the entire lift height.

4. Clean screw and grease along the entire lift height.

5. For HSE and SHE with oil lubrication:

Pull tapered pin at the venting or insert pressure venting screw at the highest point.

Check lubrication level and top up if necessary.

6. For SHE with grease lubrication: Lubricate the gear using the grease gun at the lubrication nipple. Housing

needs to be filled completely with grease.

For HSE for the ATEX area, insert the pressure bleed plug at the highest

point for venting.

For multi-screw units

7. Check turning directions of all screw jacks.

8. Even out uneven support surfaces (use metal shims).

9. Move the screws/travelling nuts to the same height before depositing, aligning and fastening the

load.

To even out alignment errors between the individual elements, use rotationally elastic couplings,

rotationally elastic propeller shafts or cardan shafts.

Monitor the lubrication film and the screw temperature during the run-in phase. If there is rapid lubrication

consumption and excessive temperature despite compliance with the duty cycles and the maximum

capacity specifications, this indicates impermissible lateral forces.

7.1 Fitting positions SHE

Version A

Version B

Subject to technical modifications Design changes under reserve Sous réserve de modifications techniques !

13

Page 14

GB

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

7.1.1 SHE oil fixtures with oil lubrication

Fitting

position

Pos 2

Pos 3

Pos 4

Pos 5

Pos 6

M1A

M1B

7.2 Fitting positions HSE

T13.01.000.0000.0003

2019/04 Rev. Index E

M2A

M2B

M3A

M3B

M4A

M4B

/

M5A

M5B

M6A

M6B

7.2.1 HSE oil fixtures

Oil sight glass or lock

screw

Version A

Mount

ing

position

Pos 1

Pos 2

Pos 3

Pos 4

Pos 5

Version B

M1A

M1B

M2A

M2B

Fill screw/

venting

M3A

M3B

/

/

M4A

M4B

Drain screw

M6A

M6B

1 Bleed plug

2 Venting pin

( pull at initial operation)

Pressure bleed plug

3 Oil level

(e.g. ATEX)

Tighten the venting screws always to the highest position.

Subject to technical modifications Design changes under reserve Sous réserve de modifications techniques !

14

Page 15

GB

4

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

7.3 Pivot version

Version P Version Q

Version P or Q defines the position of the worm

shaft towards the swivel axis.

T13.01.000.0000.0003

2019/04 Rev. Index E

Display SHE (also deliverable as HSE)

No side forces due to alignment errors. Distortions increase power consumption and reduce the service life!

If necessary, install movable load support points or pivoting bearings.

Fasten screw jacks using only quality bolts and screws.

Secure bolts and screws.

7.4 Assembly of the inductive limit switches

1

3 2

Run switch cam on sight

Screw in the displacement sensor until it is aligned with the inner diameter of

the tube wall thickness.

Secure the sensor emitter by tightening the hexagon nut and ensure that the

emitter does not turn or the position is otherwise changed.

If the sensor protrudes toward the interior, it will be destroyed.

Observe the maximum tightening torque!

Material Type Maximum tightening torque [Nm]

M 8 2,5

1 Switching cam

2 Counter nut

Metal

M 12 7

3 Inductive sensor

4 Sensor fittings

M 18 35

Adjusting the switch point:

Loosen screws (4).

Slide the holding plate up or down

Tighten screws. Observe the tightening torques!

Subject to technical modifications Design changes under reserve Sous réserve de modifications techniques !

15

Page 16

GB

1 3 2

7.5 Assembly of electromechanical limit switches

1 Switching cam

2 Holding plate

3 Mechanical limit switch

4 Limit switch fittings

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

1. Run switch cam on sight.

2. Screw the limit switch (3) onto the bracket; tighten screws only slightly.

Push the switch all the way in until the roll rests against the switch cam

phase.

3. Measure limit switch distance (for example, the back edge of the switch

housing).

4. Pull the limit switch back 1 mm and tighten it.

5. Carry out the lift test and set the actual lift.

Individual adjustments ± x according to the order confirmation / drawing

Secure screws against unintentional loosening.

Adjusting the switch point:

Loosen screws (4).

Slide the holding plate (3) up or down to the desired position.

Retighten the screws. Observe the tightening torques!

T13.01.000.0000.0003

2019/04 Rev. Index E

7.6 Assembly of safety nut

Pay attention to the installation position and force directions (pull/push)

The safety nut has to be placed subsequently in the load direction of the travelling nut.

Ba1

1 Wear indication ring

= Load direction

7.7 Installing the nut breakage limit switch (Ba1)

1. Screw the limit switch (6) onto the bracket; tighten screws only slightly. Push

the switch all the way in until the roll rests against the safety nut.

2. Measure limit switch distance (for example, the back edge of the switch

housing).

Ba2

3. Pull the limit switch back by the distance b (=1 mm) and tighten it.

Subject to technical modifications Design changes under reserve Sous réserve de modifications techniques !

Secure screws against unintentional loosening.

Observe the tightening torques!

16

Page 17

GB

7.8 Installing the nut breakage limit switch (Ba2)

7.8.1 Distance b, SHE series

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

1. Screw limit switch (6) onto safety nut (8), slightly tighten screw (9).

2. Adjust distance of the limit switch (measurement b).

3. Tighten screws

Secure screws against unintentional loosening.

Observe the tightening torques!

T13.01.000.0000.0003

2019/04 Rev. Index E

Size Dimension b Distance X Limit switches Drawing no.

SHE 1.1 62,5 5 XCK T2110P16 13.02.103/0023

SHE 3.1 66 10 XCK T2110P16 13.02.105/0000-2600

SHE 5.1 68 10 XCK T2110P16 13.02.108/0000-2600

SHE 15.1 66 10 XCK T2110P16 13.02.109/0000-2600

SHE 20.1 66 10 XCK T2110P16 13.02.115/0028

86 10 XCK T2110P16 13.02.115/0027

SHE 25 87 10 XCK P102 13.02.012/0046-0000

SHE 35.1 94 15 XCK T2110P16 13.02.035/0016-0000

80 10 XCK T2110P16 13.02.035/

SHE 50.1 99 15 XCK T2110P16 13.02.113/0006

SHE 75 97 15 XCK T2110P16 13.02.075/0000-2300

SHE 100.1 15

7.8.2 Dimension b, HSE series

Size Dimension b Distance X Limit switches Drawing no.

HSE 32

HSE 36.1 66 10 XCK T2110P16 16.02.101/0000-0000Bl05

HSE 50.1 66 10 XCK T2110P16 16.02.113/0000-0000Bl05

HSE 63.1 66 10 XCK T2110P16 16.02.114/0000-0000Bl05

HSE 80.1 66 10 XCK T2110P16 16.02.104/0000-0000Bl05

HSE 100.1 130 15 XCK J 567 16.02.105/0000-0000Bl05

89,5 10 XCK P 2102P16 16.02.105/0013

HSE 125.1 88 15 XCK P 2102P16 16.02.106/0001-0000

7.9 Installing the pulse generator (rotational speed monitor)

7.9.1 Pulse by cam

1. Turn the worm wheel (worm) until the pulse cam is visible in the fixing

thread of the pulse generator.

2. Screw in the sensor until it contacts the outer diameter of the pulse

cam.

3. Turn the transmitter back again by 0.5 to 1 rotation until the distance

between the transmitter and the pin is between 0.5 and 1 mm

(measurement a).

4. Tighten the hexagon nut to fasten the pulse generator. When doing

this, ensure that the pulse generator does not turn!

Subject to technical modifications Design changes under reserve Sous réserve de modifications techniques !

17

Page 18

GB

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

7.9.2 Pulse by recession or flattening

Should the sensor extend inwards, it will break and its sheared off parts have to be removed from

the gears.

Observe the maximum tightening torque!

7.10 Mechanical fastening

7.10.1 Screw jack housing

T13.01.000.0000.0003

2019/04 Rev. Index E

1. Turn the worm wheel (worm) until the pulse levelling is not visible in the

fixing thread of the pulse generator.

2. Screw in the pulse transmitter until it lies at the outer diameter of the

safety nut.

3. Turn the transmitter back again by 0.5 to 1 rotation until the distance

between the transmitter and the safety nut is between 0.5 and 1 mm

(dimension a).

4. Tighten the hexagon nut to fasten the pulse generator. When doing

this, ensure that the pulse generator does not turn!

SHE

Screws

(quality class min. 8.8)

Screws head II

Number of screws

HSE

Size

Screws

(quality class min. 8.8)

Number of screws

Size

0,5 1.1 3.1 5.1 15.1 20.1 25 35 50.1 75 100.1 150.1

M 8 M 8 M 12 M 16 M 18 M 24 M 33 M 33 M 42 M 42 M 48 M 48

M 6 M 8 M 12 M 16 M 18 M 24 M 24 M 30 M 30 M 42 M 48 M 48

2 4 4 4 4 4 4 4 4 6 6 8

32 36.1 50.1 63.1 80.1 100.1 125.1 140.1 200.1

M 8 M 8 M 12 M 16 M 20 M 24 M 36 M 42 M 64

4 4 4 4 4 4 8 4 4

7.10.2 Screw heads

SHE Size 0,5 1.1 3.1 5.1 15.1 20.1 25 35 50.1 75 100.1 150.1

a k6

∅

b

e

∅

n x ∅ f

Thread M

o H8

∅

l-

0.2

HSE

a k6

∅

b

e

∅

n x ∅ f

Thread M

o

∅

l

-0.2

Size

18h9 15 20 25 40 50 70 80 100 110 140 160

20 24 30 40 50 54 63 80 125 125 175 200

45 50 75 85 105 140 155 200 225 270 280 310

4 x 7 4 x 9 4 x 14 4 x 17 4 x 21 4 x 26 4 x 27 4 x 33 4 x 35 6x45 6 x 52 8x52

18x1.5 16x1.5 22x1.5 30x2 40x3 56x3 70x3 80x3 100x5 120x6 140x6 160x6

15 20 25 35 50 60 70 80 100 120 140 160

20 25 30 42 60 75 90 105 120 140 160 180

32 36.1 50.1 63.1 80.1 100.1 125.1 140.1 200.1

18h9 15 20 30 40 50 80 95 130

17 24 29 39 49 54 79 99 119

45 50 65 85 105 135 170 205 270

4 x 7 4 x 9 4 x 14 4 x 17 4 x 21 6 x 26 8 x 30 8 x 33 8 x 45

18x1.5 16x1.5 20x1.5 30x2 42x3 56x3 80x3 100x4 140x4

15 20 25 35 50 60 80 100 140

20 25 30 40 60 75 100 120 160

For the exact mounting dimensions, please request our dimensional drawings.

Subject to technical modifications Design changes under reserve Sous réserve de modifications techniques !

18

Page 19

GB

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

7.10.3 Joint heads

Screw jacks with joint heads are available as special models.

When using joint bearings or joint heads, a torsional lock needs to be installed on

the gear side.

7.11 Screw tightening torques

Tightening torque M A [Nm]

Coarse-pitch thread

Quality 8.8 Quality 10.9 Quality 12.9

M 4

M 6

M 8

M 10

M 12

M 16

M 20

M 24

M 27

M 30

M 36

M 42

M 45

M 48

M 56

2,8 4,1

9,5 14

23 34

46 68

79 117

195 280

390 560

670 960

1000 1400

1350 1900

2330

3676

5502

5636

8856

T13.01.000.0000.0003

2019/04 Rev. Index E

4,8

16,5

40

79

135

330

650

1120

1650

2250

8 Initial operation

Always observe and follow these operating instructions when using the equipment.

Any use other than the intended use is prohibited.

Commissioning may only be performed by authorised personnel.

Check lubrication level.

Check limit switches.

Pay attention to the proper polarization of the electrical installation the the motor's sense of direction.

Put lift unit into operation without a load. (1x lifting 1x lower)

Operate intermittently, gradually increasing the load.

During initial operation, constantly control the operating temperature, the motor's current consumption and

the spindle contact pattern.

After 5 hours of operation, check that the screws are tight. Retighten where necessary.

Monitor the lubrication film and the screw temperature during the run-in phase. Rapid lubrication

consumption and excessive temperature indicate undue lateral forces even if the power-on time and the

maximum power specifications are complied with.

Carry out commission and run-in phase in secure explosive-free atmosphere.

Check the earthing of the mounted parts. (Discharge resistance less than 10

6

Ω)

Units for spaces with explosion hazards should be checked by a specially authorised person before

commissioning. (TRBS 1203-1). Observe the ATEX safety instructions in Chapter 3.2.

Check that the ATEX marking corresponds to the existing atmosphere.

Subject to technical modifications Design changes under reserve Sous réserve de modifications techniques !

19

Page 20

GB

lubrication level and refill

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

T13.01.000.0000.0003

2019/04 Rev. Index E

9 Maintenance and inspection

Regular (at least 1x per year) inspection/maintenance must be performed by a qualified person (in acc. with

*)

TRBS 1203-1)

All tests and modifications must be documented (e.g. machine file, inspection log).

7

contracted by the operator.

The operator has to count or measure the alternations of load or operating hours and document them.

Risk analysis by the manufacturer of the overall system.

Carry out maintenance/inspection in secure explosive-free atmosphere.

Conduct a technical ATEX safety inspection by an especially qualified person (acc. to TRBS 1203-1) every 3

years.

Power must be turned off before maintenance and inspection of the unit.

Observe to the pertinent safety regulations during maintenance and inspection.

Support the load.

9.1 Maintenance plans

Screw jack

Every 50

hours of

operation**

Prior to

every

Quarterly

Every 300 hours of

operation or

annually

operation

SHE Ba1

Safety test

SHE Ba2

Grease the screw

Check the gear

lubrication level and

refill if necessary.

Damaged surface

treatment should be

HSE Ba1

properly repaired

immediately

Grease the

torsional lock

HSE Ba2

Check the screw's grease level and

refill if necessary.

Check screw jack externally for leaks.

Check the gear

if necessary.

** For special operating conditions, the lubrication intervals can be coordinated with us.

9.2 Maintenance instructions

9.2.1 Wear limits

Every 5 years

or after 1,000

hours of

operation

Change the

grease in the

gear box

Gear box oil

change

Tr screw

Max. wear [mm]

Tr screw

Max. wear [mm]

Tr screw

Max. wear [mm]

14x4 18x4 18x6 20x4 24x5 26x6.28 30x6 35x8 40x7

1,0 1,0 1,5 1,0 1,3 1,5 1,5 2 1,6

40x8 50x9 58x12 60x9 60x12 65x12 70x10 70x12 80x10

2 2,3 3,0 2,3 3,0 3,0 2,5 3,0 2,5

90x16 100x10 100x16 120x14 120x16 140x20 160x20 190x24 220x28

4,0 2,5 4,0 3,5 4,0 5,0 5,0 6,0 7,0

Wear limits of special pitches upon request or otherwise in operating instructions specific for the order.

7 We recommend having this check performed by the service department of CMCO.

Subject to technical modifications Design changes under reserve Sous réserve de modifications techniques !

20

Page 21

GB

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

9.2.2 Standard screw jack with trapezoidal thread screw

Safety test:

The wear of the nut thread in the worm wheel / in the travelling nut needs

to be checked regularly, at least once per year.

Replacement is urgently required once the wear limit has been reached.

X = maximum wear (see Table 9.2.1)

9.2.3 Standard screw jack with ball thread screw

Safety test:

Pay attention to the running noises of the Ku screws during operation. An increase in noise indicates

wear of the Ku nuts. The nuts and screws need to be replaced promptly.

The Ku screws/nuts should generally be exchanged at the end of its service life.

9.2.4 Safety screw jacks

For utilisation in systems in acc. with EN 280, EN1570-1, EN1593; DIN 56950-1

In accordance with BetrSichV, lifting equipment must undergo an examination by an authorised person in

intervals (at least 1x per year) specified by the operator (TRBS 1203-1).8

9.2.5 Screw jacks with safety nut

T13.01.000.0000.0003

2019/04 Rev. Index E

Safety test:

Check the wear in the screw jacks (dimension x) of the

1 = Wear indication ring

translation thread in the worm wheel / travelling nut.

Prompt replacement of the carry nut and safety nuts is

required should the safety nut (wear indication ring) align

with the upper and lower edge of the housing or the wear

limit has been reached (dimension X).

Wear limit = X - max. wear

(see Table 9.2.1)

9.2.6 Wear measurement log

We recommend recording the new condition and the results from measuring the wear (dimension

X).

Screw jack 1 Screw jack 2 Screw jack. 3 Screw jack 4 Date/Signature

New condition

Dimension X

Wear measurement

on _____________

Wear measurement

on _____________

Wear measurement

on _____________

Wear measurement

on _____________

9.2.7 Spindle lubrication

Clean the screw with grease evenly with a brush.

We recommend an automatic lubricant dispenser in places of difficult accessibility, a longer power time or in

dirty environments.

Automatic lubricant dispensers are also available with ATEX conformity.

8 We recommend having this check performed by the service department of CMCO.

Subject to technical modifications Design changes under reserve Sous réserve de modifications techniques !

21

Page 22

GB

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

T13.01.000.0000.0003

2019/04 Rev. Index E

9.2.8 Gear unit lubrication

For information on the oil level, location of the oil sight glasses, venting and drain screw, refer to Chapter

7.1.1 and 7.2.1 Mounting positions

9.2.9 SHE with grease lubrication

Lubricate the lubrication nipple (1) at the gear box with the grease gun.

Press the grease until it discharges from the seal lip or from the venting

bore.

Max. grease amount 20 ml or at least SHE 20.1 5% of the complete filling

amount (see 9.2.12)

Observe screw jack and attachment parts.

Remove excess grease (e.g. in sheath tube or bellows).

9.2.10 Grease the torsional lock (V)

Lubricate the lubrication nipple (2) at the guiding tube with the grease gun.

Grease amount about 20 ml at 500 mm lift height.

9.2.11 HSE and SHE with oil lubrication

Check oil fill level at the oil sight glass and refill if necessary.

Visual check for leaks

9.2.12 Lubrication amounts

SHE gear box with grease lubrication

SHE unit size 0,5 1.1 3.1 5.1 15.1 20.1

Grease amount about (kg)

0,05 0,1 0,2 0,35 0,9 2,0

SHE unit size 25 35 50.1 75 100.1 150.1 200.1

Grease amount about (kg)

1,3 2,5 4 5 10 10

Gear box with oil lubrication

SHE unit size 0,5 1.1 3.1 5.1 15.1 20.1

Oil amount about (l)

0,05 0,1 0,2 0,35 0,9 2,0

SHE unit size 25 35 50.1 75 100.1 150.1 200.1

Oil amount about (l)

1,3 2,5 4 5 10 10

HSE size 32 36.1 50.1 63.1 80.1 100 125 140 200

Oil amount about (l)

0,07 0,15 0,4 0,7 1,5 2,1 5,0 10 15,5

9.3 SHE with low-viscosity grease level in the lift gear box

Low-viscosity lubrication according to order confirmation, The maintenance of the lift gear box with lowviscosity grease level does not differ from screw jacks with standard grease filling.

Observe the types of grease according to the order confirmation

10 Decommissioning

When decommissioning the system, recycle or dispose of the various system components and/or screw

jacks according to the legal requirements.

Subject to technical modifications Design changes under reserve Sous réserve de modifications techniques !

22

Page 23

GB

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

11 Lubricants

T13.01.000.0000.0003

2019/04 Rev. Index E

SHE/Merkur

gear box and

Tr. screws

SHE0.5-100

Ambient

temperature

range [°C]

-30 up to 0

-15 to +40

M1 –M8

+20 to +80

+40 to +180

SHE screws

BG150 / BG200

SHE gears

BG150 / BG200

SHE screws

(trapezoidal

thread)

HSE gear -30 up to 0

SHE gear

oil lubrication

Ku screws

0 to +50 °C

0 to +50 °C CLP VG 680

-30 up to 0

-15 to +80

+40 to +120

-15 to +40

+40 to +120 VG680

-30 up to 0 Synth. oil PGLP VG100 Klübersynth GH 6-100

-15 to +40

+20 to +80 Mineral oil CLP VG680

+40 to +120 Synth. oil PGLP VG680

-30 up to 0

-15 to +80

+40 to +120

Lubricant 1)

Grease KP2E-

40

Grease KP2K-

20

Grease KP2K-

20

Grease KP2S-

20

Grease KP0K-

20

Grease KP2E-

30

Grease KP2K-

20

Grease KP2S-

20

CLP-PG

Synth. oil

Mineral oil CLP VG220

Grease KP2E-

30

Grease KP1K-

20

Grease KP1K-

20

ISO-

NLGI1)

NLGI 2

NLGI 2

NLGI 2

NLGI 2

NLGI 0

VG 68 Klübersynth GH 6-80

VG220

NLGI 2

NLGI 1

NLGI 1

SKF LGLT 2 4)

EP 2 special

grease for lifting

gears

EP 2 special

grease for lifting

gears

SKF LGLT 2 4)

PS-Grease 011

Divinol ICL ISO

220 5)

SKF LGLT 2 4)

1)

1)

ISOFLEX LDS 18

Special A

Klüberplex

BE 11-462

Klüberplex

BE 11-462

Klübersynth

BH 72-422

Grafloscon C-SG

2000 Ultra

Klüberoil

GEM 1-680 N

ISOFLEX LDS 18

Special A

Klüberplex

GE 11-680

Klübersynth

BH 72-422

Klübersynth GH 6-220

Klübersynth GH 6-680

Klüber oil

GEM 1-220 N

Klüberoil

GEM 1-680 N

Klübersynth

GH 6-680

ISOFLEX LDS 18

SPEZIAL A

Stabutherm GH 461

Stabutherm GH 461

Molub-Alloy 243

Arktik

Molub-Alloy 936

SF Heavy

Optigear

BM 680

Molub-Alloy 243

Arktik

Molub-Alloy 936

SF Heavy

Tribol 800/220 Glycolube 220

Optigear

BM 220

Optigear

BM 680

gleitmo 585 K

URETHYN E/M 2

UNIREX

S 2

Beacon

EP 2

Beacon

EP 2

UNIREX

S 2

Spartan EP

220

Spartan EP

680

gleitmo 585K

gleitmo 585K

gleitmo 585K

URETHYN E/M 2

CEPLATTYN KG

10 HMF 2500

GEARMASTER

gleitmo 585K

gleitmo WSP

URETHYN E/M 2

Gearmaster

PGP 220

Gearmaster

PGP 680

Gearmaster

Gearmaster

Gearmaster

PGP 680

URETHYN E/M 2

CLP 680

5040

CLP 220

CLP 680

Printed bold = Standard lubricants: Factory-filed gear lubrication or otherwise lubrication recommendation for screws

Attention: The alternatives to our standard lubricants are specifications of the lubricant manufacturers.

Pfaff-silberblau does not have any references whether the lubricants meet the manufacturer specifications.

Lubricant selection: The temperature ranges refer to the ambient temperature. Higher lubricant temperatures that may result

during the operation of the drive elements have already been taken into account.

Standard temperature range: -15 °C to +40 °C

Only if the limits of the standard temperature range is exceeded should lubricants of other temperature ranges be

used.

To operate the drive elements in temperature ranges that deviate from the standard, design modifications are necessary

along with possible construction measures. Observe the technical data according to the order confirmation and the operating

instructions.

Observe the lubricant specifications in the type plate.

Mineral and synthetic lubricants should not be mixed together. It is recommended to generally not mix lubricants or to check

the composition.

1) Specifications refer to the factory lubricant

2) Critical start-up characteristics at low temperatures should be

observed.

4) SKF GmbH

5) Zeller+Gmelin GmbH & Co. KG

Used lubricants are to be disposed of in accordance with legal requirements!

Subject to technical modifications Design changes under reserve Sous réserve de modifications techniques !

23

Page 24

GB

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

T13.01.000.0000.0003

2019/04 Rev. Index E

12 Einbauerklärung / Declaration of incorporation / Déclaration d'incorporation

für unvollständige Maschinen

im Sinne der EG-

Maschinenrichtlinie

2006/42/EG,

for incomplete machines

according to EC machine

directive 2006/42/EC,

Annex II, No. 1B

pour machines incomplètes

conformément à la directive

européenne relative aux

machines 2006/42/CE,

Anhang II, Nr. 1B

Spindelhubelemente SHE;

HSE Ba 1 und Ba 2

Worm Gear Screw Jack SHE

and HSE type 1 and type 2

Vérins à vis sans fin SHE et

HSE type 1 et type 2

annexe II, n 1B

Antriebselement zum Einbau in

eine Maschine

ist eine unvollständige Maschine nach Artikel

2g und ausschließlich zum Einbau in eine

Maschine oder zum Zusammenbau mit

anderen Maschinen oder Ausrüstung

vorgesehen.

Folgende grundlegenden Sicherheits- und

Gesundheitsschutzanforderungen gemäß

Anhang I dieser Richtlinie kommen zur

Anwendung und wurden eingehalten 1.1.2;

1.1.3; 1.1.5; 1.3.2; 1.3.3; 1.3.4; 1.3.7; 1.3.9;

1.5.2; 1.7.3; 1.7.4; 4.1.2.3; 4.1.2.6

Die speziellen technischen Unterlagen gemäß

Anhang VII B wurden erstellt und sie werden

der zuständigen nationalen Behörde auf

Verlangen in elektronischer Form übermittelt

Diese unvollständige Maschine ist in

Übereinstimmung mit den Bestimmungen der

folgenden EG Richtlinien

Angewendete harmonisierte Normen,

insbesondere:

Actuator element for assembly in

a machine

is an incomplete machine according to Article

2 g and has been designed exclusively for

installation in a machine or for assembly with

other machines or equipment.

The following basic health and safety

requirements in Annex I to this Directive are

applicable and have been observed 1.1.2;

1.1.3; 1.1.5; 1.3.2; 1.3.3; 1.3.4; 1.3.7; 1.3.9;

1.5.2; 1.7.3; 1.7.4; 4.1.2.3; 4.1.2.6

The special technical documentation referred

to in Annex VII B has been prepared and will

be forwarded to the competent national

authority, upon request in electronic form

This incomplete machine is in compliance

with the provisions of the following EC

directives

Applied harmonised standards, in particular: Normes harmonisées utilisées, en

DIN EN 1494:2000; DIN EN ISO 12100:2010

Angewendete nationale Normen und

technische Spezifikationen, insbesondere:

Applied national technical standards and

specifications, in particular:

Diese unvollständige Maschine darf erst

dann in Betrieb genommen werden, wenn

festgestellt wurde, dass die Maschine, in die

diese unvollständige Maschine eingebaut

werden soll, den Bestimmungen der EGMaschinenrichtlinie entspricht

This incomplete machine may only be put

into operation if it has been determined that

the machine into which this incomplete

machine will be installed complies with the

provisions of the EC machine directive

Ort/Datum Kissing, 03.04.2019

Propulsife élément pour

assemblée dans une machine

est une machine incomplète selon l'article 2g

et a été conçue uniquement pour être montée

dans une machine ou à être assemblée avec

d'autres machines ou équipement.

Les exigences suivantes de sécurité et

relatives à la santé, conformes à l'annexe I de

cette directive, ont été appliquées et

respectées 1.1.2; 1.1.3; 1.1.5; 1.3.2; 1.3.3;

1.3.4; 1.3.7; 1.3.9; 1.5.2; 1.7.3; 1.7.4; 4.1.2.3;

4.1.2.6

La documentation technique spéciale

conforme à l'annexe VII B a été préparée et

sera transmise aux autorités nationales

compétentes, également sous forme

électronique, si nécessaire.

Cette machine incomplète est conforme aux

dispositions des directives européennes

suivantes

particulier :

Normes et spécifications techniques

nationales qui ont été utilisées, notamment

Cette machine incomplète ne doit être mise

en service que lorsqu'il a été déterminé, que

la machine dans laquelle cette machine

incomplète doit être montée, est conforme

aux dispositions de la directive européenne

relative aux machines

Der Unterzeichnende ist bevollmächtigt die

technischen Unterlagen gemäß Anhang VII A

zusammenzustellen und der zuständigen Behörde

auf Verlangen zu übermitteln.

The undersigned is authorised to prepare the

technical documentation referred to in Annex VII A

and submit it to the responsible authorities on

request.

Le signataire est habilité à réunir la documentation

technique spéciale conforme à l'annexe VII A et à la

transmettre aux autorités compétentes si

nécessaire.

Columbus McKinnon Engineered Products GmbH

Am Silberpark 2-8

D-86438 Kissing, Germany

Phone: +49(0)8233 2121 800

Fax: +49(0)8233 2121 805

Page 25

GB

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

T13.01.000.0000.0003

2019/04 Rev. Index E

Einbauerklärung Declaration of

incorporation

für unvollständige Maschinen

im Sinne der EG-

Maschinenrichtlinie

2006/42/EG,

Anhang II, Nr. 1B

Spindelhubelemente SHE;

HSE Ba 1 und Ba 2

for incomplete machines

according to EC machine

directive 2006/42/EC,

Annex II, No. 1B

Worm Gear Screw Jack SHE

and HSE type 1 and type 2

Déclaration

d'incorporation

pour machines incomplètes

conformément à la directive

européenne relative aux

machines 2006/42/CE,

annexe II, n 1B

Vérins à vis sans fin SHE et

HSE type 1 et type 2

mit Sicherheitseinrichtungen with safety devices avec équipement de sûreté

Antriebselement zum Einbau in

Hubtische, Hebebühnen,

Hubarbeitsbühnen oder

Fahrzeughebebühnen

ist eine unvollständige Maschine nach Artikel

2g und ausschließlich zum Einbau in eine

Maschine oder zum Zusammenbau mit

anderen Maschinen oder Ausrüstung

vorgesehen.

Folgende grundlegenden Sicherheits- und

Gesundheitsschutzanforderungen gemäß

Anhang I dieser Richtlinie kommen zur

Anwendung und wurden eingehalten 1.1.2;

1.1.3; 1.1.5; 1.3.2; 1.3.3; 1.3.4; 1.3.7; 1.3.9;

1.5.2; 1.7.3; 1.7.4; 4.1.2.3; 4.1.2.6

Die speziellen technischen Unterlagen gemäß

Anhang VII B wurden erstellt und sie werden

der zuständigen nationalen Behörde auf

Verlangen in elektronischer Form übermittelt

Diese unvollständige Maschine ist in

Übereinstimmung mit den Bestimmungen der

folgenden EG Richtlinien

Angewendete harmonisierte Normen,

insbesondere:

DIN EN ISO 12100:2010; DIN EN 1494:2000; EN1570; EN280; EN1756; EN1493

Angewendete nationale Normen und

technische Spezifikationen, insbesondere:

Diese unvollständige Maschine darf erst

dann in Betrieb genommen werden, wenn

festgestellt wurde, dass die Maschine, in die

diese unvollständige Maschine eingebaut

werden soll, den Bestimmungen der EGMaschinenrichtlinie entspricht

Ort/Datum Kissing, 03.04.2019

Actuator element for assembly in

lifting tables, lifting platforms,

working platforms or vehicle lifting

platforms

is an incomplete machine according to Article

2 g and has been designed exclusively for

installation in a machine or for assembly with

other machines or equipment.

The following basic health and safety

requirements in Annex I to this Directive are

applicable and have been observed 1.1.2;

1.1.3; 1.1.5; 1.3.2; 1.3.3; 1.3.4; 1.3.7; 1.3.9;

1.5.2; 1.7.3; 1.7.4; 4.1.2.3; 4.1.2.6

The special technical documentation referred

to in Annex VII B has been prepared and will

be forwarded to the competent national

authority, upon request in electronic form

This incomplete machine is in compliance

with the provisions of the following EC

directives

Applied harmonised standards, in particular: Normes harmonisées utilisées, en

Applied national technical standards and

specifications, in particular:

Propulsif élément pour installation

dans table de levage, plateforme

élévatrice, plateforme de travaille,

plateforme de levage pour véhicule

est une machine incomplète selon l'article 2g

et a été conçue uniquement pour être montée

dans une machine ou à être assemblée avec

d'autres machines ou équipement.

Les exigences suivantes de sécurité et

relatives à la santé, conformes à l'annexe I de

cette directive, ont été appliquées et

respectées 1.1.2; 1.1.3; 1.1.5; 1.3.2; 1.3.3;

1.3.4; 1.3.7; 1.3.9; 1.5.2; 1.7.3; 1.7.4; 4.1.2.3;

4.1.2.6

La documentation technique spéciale

conforme à l'annexe VII B a été préparée et

sera transmise aux autorités nationales

compétentes, également sous forme

électronique, si nécessaire.

Cette machine incomplète est conforme aux

dispositions des directives européennes

suivantes

particulier :

Normes et spécifications techniques

nationales qui ont été utilisées, notamment

This incomplete machine may only be put

into operation if it has been determined that

the machine into which this incomplete

machine will be installed complies with the

provisions of the EC machine directive

Cette machine incomplète ne doit être mise

en service que lorsqu'il a été déterminé, que

la machine dans laquelle cette machine

incomplète doit être montée, est conforme

aux dispositions de la directive européenne

relative aux machines

Der Unterzeichnende ist bevollmächtigt die

technischen Unterlagen gemäß Anhang VII A

zusammenzustellen und der zuständigen Behörde

auf Verlangen zu übermitteln.

Subject to technical modifications Design changes under reserve Sous réserve de modifications techniques !

The undersigned is authorised to prepare the

technical documentation referred to in Annex VII A

and submit it to the responsible authorities on

request.

Le signataire est habilité à réunir la documentation

technique spéciale conforme à l'annexe VII A et à la

transmettre aux autorités compétentes si

nécessaire.

25

Page 26

GB

Worm gear screw jack SHE type1 and type2

High-performance screw jack HSE type1 and type2

T13.01.000.0000.0003

2019/04 Rev. Index E

13 EG-Konformitätserklärung EC-Declaration of Conformity Déclaration "CE" de Conformité

im Sinne der

ATEX Richtlinie 2014/34/EU

ATEX Directive 2014/34/EU

Anhang X B

Hiermit erklären wir, dass Herewith we declare that the supplied model

Spindelhubelemente SHE; HSE

of

Worm Gear Screw Jack SHE and

Ba 1 und Ba 2

ein Gerät im Sinne der RL 2014/34/EG

Artikel 1 (3) ist und die Anforderungen

gemäß Anhang II der RL 2014/34/EG

erfüllt.

Das Spindelhubelement ist geeignet

an equipment as defined by EC

Directive 2014/34/EC article 1(3) is and

fulfills the requirement according to

annex II of the Directive 2014/34/EC

The worm gear screw jack is

für den Einsatz in

explosionsgefährdeten Bereichen

hazardous environment according

entsprechend der Kennzeichnung

as defined by

annex X B

HSE type 1 and type 2

suitable for the operation in

to the marking

conformément à la directive "CE"

ATEX 2014/34/EU

Annexe X B

Nous ne déclarons que le modèle

Vérins à vis sans fin SHE et HSE

type 1 et type 2

un appareil dans le sens de la directive

2014/34/EC article 1 (3) est et les

exigences conformément à l'annexe II

de la directive 2014/34/EC ré

vérins à vis sans fin est approprié

pour l'application dans les secteurs

explosifs conformément au

marquage

II 2G ck-Ex h IIB T4 Gb U

Angewendete harmonisierte Normen,

insbesondere:

II 2G D c-Ex h IIIB T135°C Db U

Applied harmonised standards, in particular: Normes harmonisées utilisées, notamment

DIN EN 1127-1-2011 (Explosionsschutz Grundlagen und Methodik/ Explosion prevention Basic concepts

and methodolgy/ Prévention de l’explosion Notations fondamentales et

méthodologie)

DIN EN ISO 80079-36 (Grundlagen und Anforderungen/ Basic method and requirement/

Prescriptions et méthode de bases)

DIN EN ISO 80079-37 (Schutz durch konstruktive Sicherheit „c“, Zündquellenüberwachung „b“,

Flüssigkeitskapselung „k“

Non-electrical type of protection constructional safety ’’c’’, control of ignition

sources ’’b’’,liquid immersion ’’k’’

Mode de protection non électrique par sécurité de construction "c", par contrôle de

la sourced’inflammation "b", par immersion dans un liquide "k"

2014/34/EU Anhang VIII / Annex VIII / annexe VIII

Angewendete nationale Normen und

technische Spezifikationen, insbesondere:

Applied national technical standards and

specifications, in particular:

Normes et spécifications techniques

nationales qui ont été utilisées, notamment

Auftragsbestätigung bzw. technisches Datenblatt sind Bestandteil dieser Konformitätserklärung.

Order confirmation or technical data sheet is part of these declaration of conformity

Vor Inbetriebnahme ist die gesamte Anlage durch eine, für

Explosionsgefährdung, besonders befähigte Person zu prüfen.

Die technische Dokumentation für Spindelhubelemente der

Kategorie 2 ist bei der benannten Stelle 0035 unter der

Registriernummer 296/Ex-Ab 1498/10 hinterlegt.

Ort/Datum Kissing, 03.04.2019

Before commissioning, the complete system must be

inspected by a person specifically qualified in explosion

hazards.

The technical documentation for worm gear screw jacks for

category 2 is deposited at the notified body 0035 under

registration number 296/Ex-Ab 1498/10.