Page 1

CPFAFFD

INSTRUCTION

B00K

Page 2

¶1

CPFAFFD

FOREWORD

true!

come

if

hove

now

you

these

find

has

the

book

are

Sewing.

simple

sewing

any

proud

experienced

on

sewing

owner

help

will

instructions

exciting

problems,

of

a

you

seamstress,

and

your

on

PFAFF

understand

please

dream

Your

are

You

instruction

This

you.

for

Even

Automatic

Follow

will

You

you

If

Automatic

iNSTRUCTIONS

—

and

this

with

dealer.

—

give

book

the

Automatic.

332-260

the

you

famitiarize

easy-to-operate

contact

Automatic

machine

find

will

yourself

your

PFAFF

Pfaff

sewing

the

you

a

exclusive

He

valuable

valuable

be

will

332-260

unlimited

tips

guide

to

G-M.PFAFFAG

Sewing

with

to

to

features

help

Machine

Ka

easy

ise

make

sewing

you

rsta

machine

automatic

glad

sewing

of

at

utern

possibilities.

—

your

time.

any

Factory

more

PFAFF

—

machine.

fun

Page 3

1

2

3

4

5

6

Buttonhole

Bobbin

Thread

Top

control

Dial

(B)

Embroidery

take-up

winder

slide

cover

pattern

lever

lever

(A)

length

I

5-

14-

lever

4

7

Slop

motion

length

length

switch

feed

plate

knob

stop

control

(forward-reverse)

control

lever

8

Stitch

9

(E)

Stitch

10

Light

11

Drop

12

Needle

5

13

14

15

16

17

18

free

sewing

Needle

Upper

SewlighI

Needle

Stitch

/

arm

tension

width

6

cover

hook)

swing-out

position

control

(enclosing

fever

lever

(D)

(C)

transverse

R

7379

rotary

19

20

21

22

23

2

Page 4

R

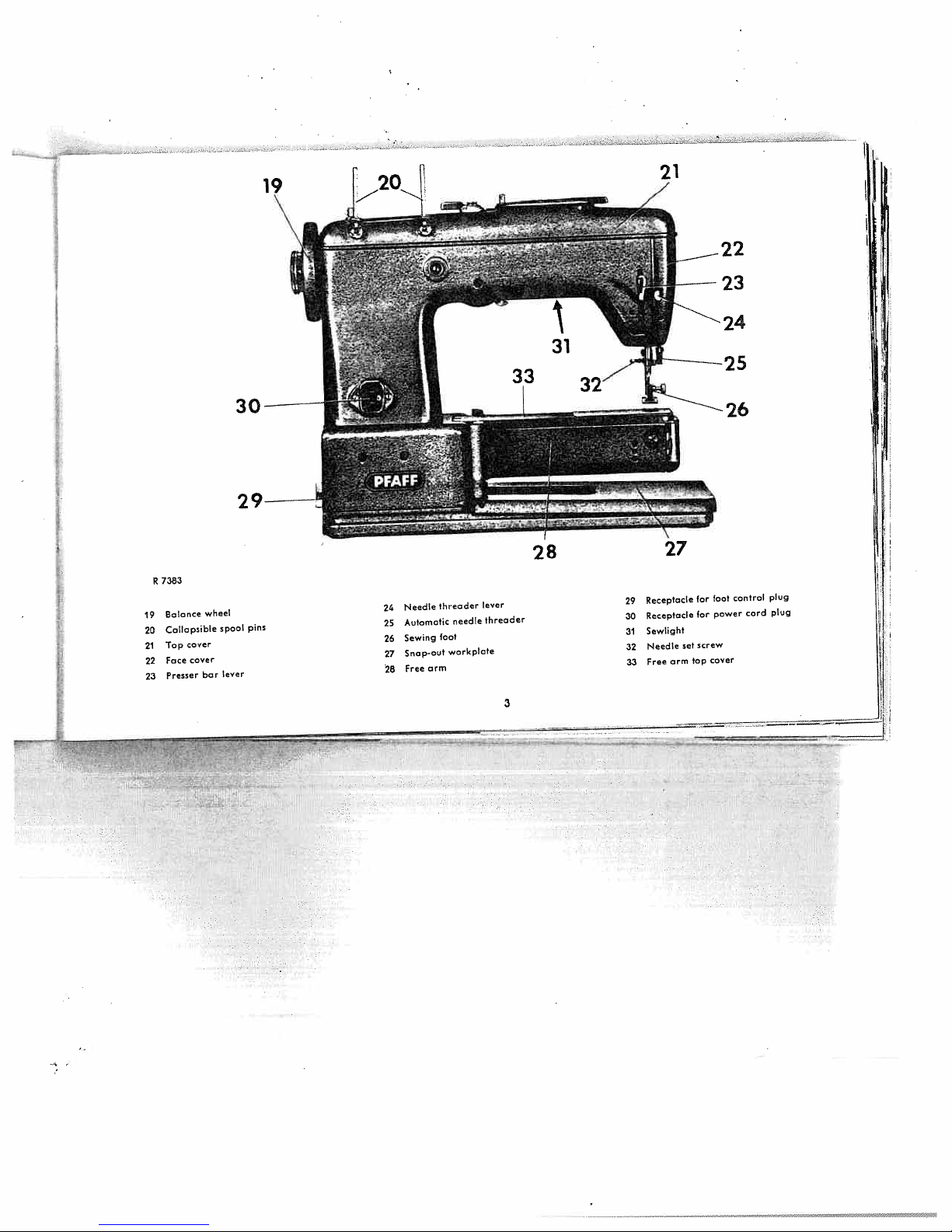

19

20

21

22

23

7383

Balance

Collapsible

cover

Top

cover

Face

Presser

wheel

bar

5pOol

lever

30

29

—j

pins

24

25

26

27

28

Needle

Automatic

Sewing

Snap-out

arm

Free

threader

needle

foot

workplate

lever

threader

plug

control

foot

arm

for

power

for

screw

set

cover

fop

cord

plug

29

30

31

32

33

Receptacle

Receptacle

Sewlight

Needle

Free

3

Page 5

naI%.nea1s

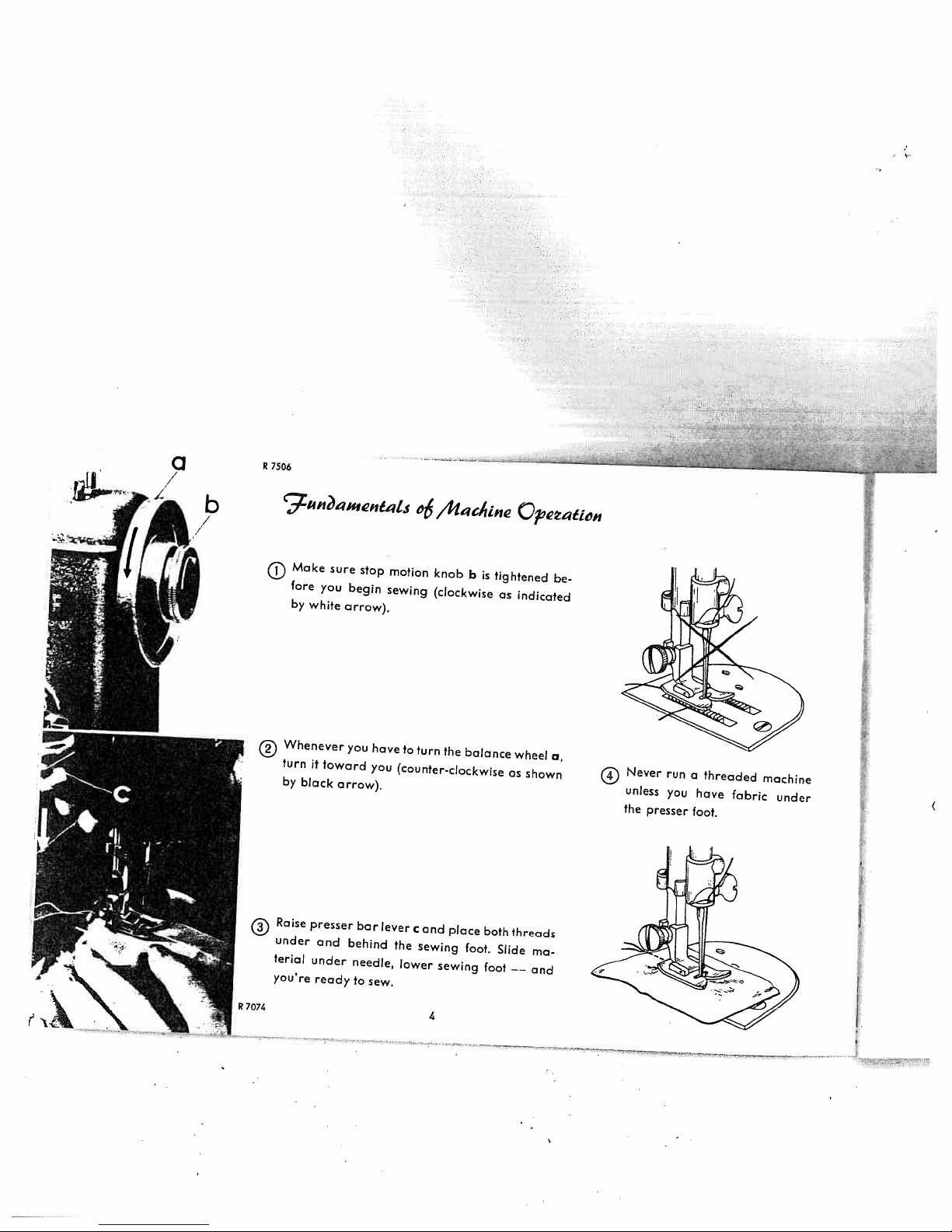

Make

sure

fore

you

by

white

stop

begin

arrow).

motion

sewing

/iac.4i,w

knob

6

is

(clockwise

Ceaticn

tightened

as

indicated

be

0

Whenever

turn

by

Raise

under

terial

you’re

it

black

presser

under

ready

toward

and

you

arrow).

bar

behind

needle,

to

have

to

turn

you

(counter-clockwise

lever

c

and

the

sewing

lower

sew.

sewing

4

the

place

balance

both

foot.

foot

as

Slide

wheel

shown

threads

ma

——

and

a,

Never

run

a

unless

the

you

presser

threaded

have

foot.

fabric

machine

under

Page 6

R

6808

chine

under

I

t

Luqctant

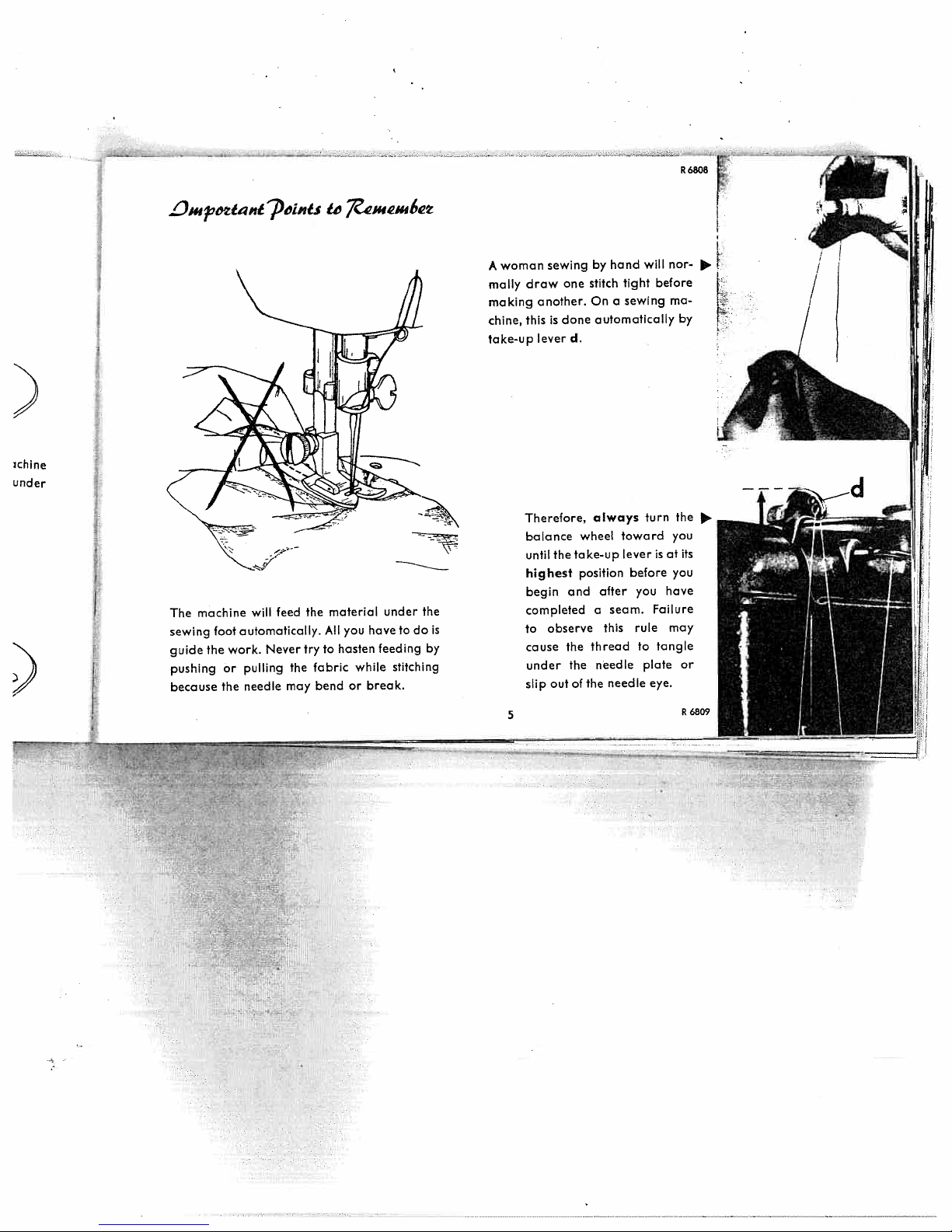

The

machine

foot

sewing

work.

the

guide

pushing

because

or

the

7cins

feed the

will

automatically.

Never

needle

the

may

pulling

try

ic

material

All

to

fabric

bend

you

hasten

while

or

under

have

feeding

break.

the

todois

stitching

by

woman

A

mally

making

chine,

take-up

5

sewingbyhand

one

draw

another.

done

is

this

d.

lever

Therefore,

balance

take-up

the

until

highest

and

begin

completed

observe

to

cause

the

the

under

of

out

slip

stitch

tight

Onasewing

automatically

always

wheel

toward

lever

position

after

seam.

a

this

thread

needle

needle

the

will

turn

before

you

rule

to

plate

eye.

nor

before

ma

the

you

at

is

you

have

Failure

may

tangle

by

its

or

--4

Page 7

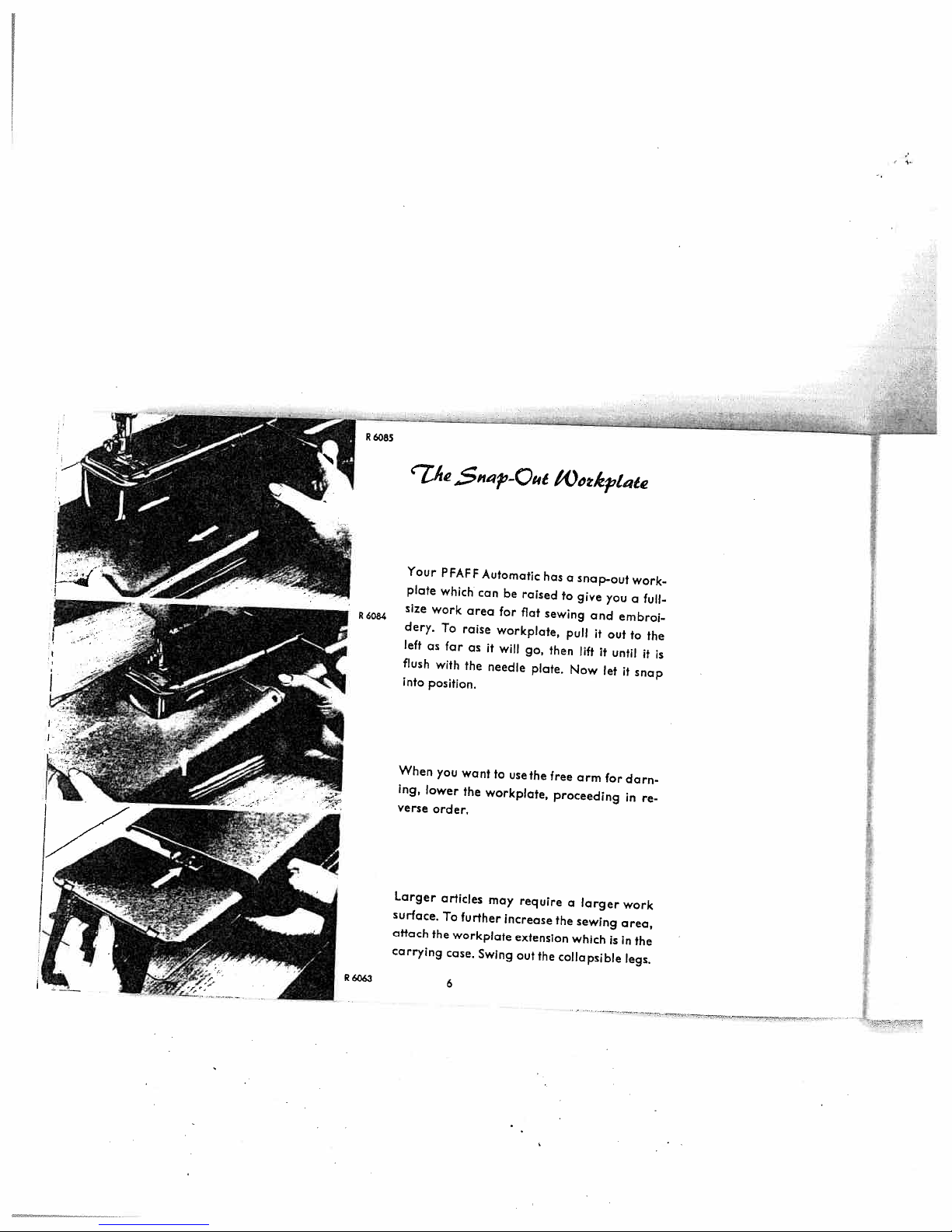

‘7he

Your

plate

size

dery.

left

flush

into

When

ing,

verse

$nq-Cs.t

PFAFF

which

work

To

raise

as

for

with

position.

you

want

lower

the

order.

Automatic

can

area

as

it

the

workplote,

be

for

flat

workplate,

will

needle

to

use

tOorkvtae

has

a

raised

to

sewing

pull

go,

then

plate.

Now

the

free

proceeding

snap-out

give

you

and

it

out

lift

it

let

arm

for

embroi

until

it

darn

in

worka

full

to

it

snap

re

the

is

Larger

surface.

attach

carrying

articles

To

the

case.

6

may

further

workptate

Swing

require

increase

extension

out

the

the

collapsible

a

sewing

which

larger

work

area,

is

in

the

legs.

Page 8

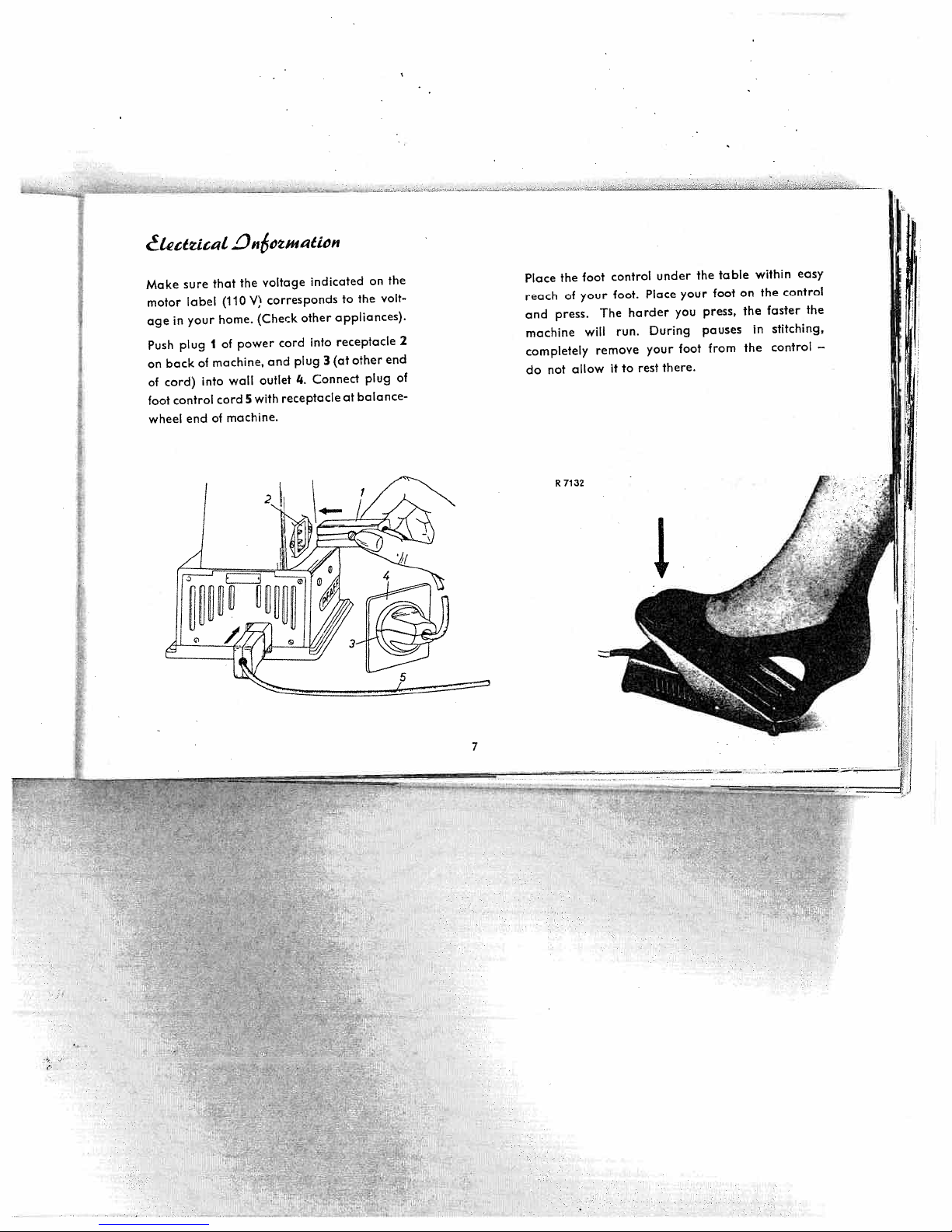

cL2c&iat

Make

motor

in

age

Push

bock

on

of

cord)

control

foot

wheel

sure

label

your

plug

end

Dn&Hssthn

that

(110

home.

of

I

machine,

of

wall

into

cord

machine.

of

the

V)

power

with

5

(Check

voltage

corresponds

other

cord

plug

and

4.

outlet

receptacle

indicated

to

appliances).

receptacle

into

(at

3

Conned

at

on

the

other

plug

balance-

the

volt

end

Place

Place

foot.

your

of

reach

harder

The

press.

and

During

run.

not

will

remove

allow

7132

R

your

there.

to

rest

it

2

of

machine

completely

do

your

you

foot

foot

press,

pauses

from

on

the

the

the

faster

in

control

stitching,

control

the

—

easy

within

table

the

under

control

foot

the

jr

7

Page 9

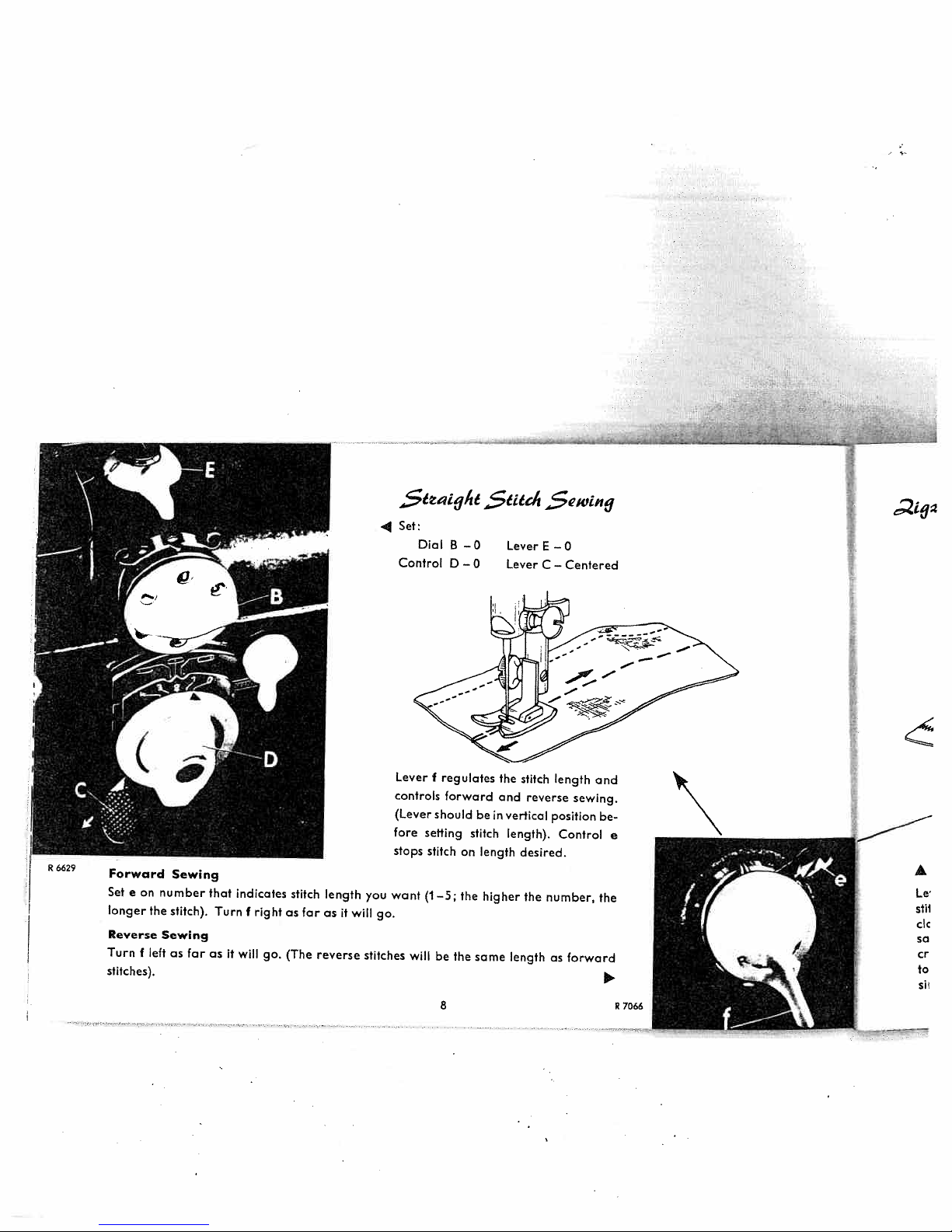

R6629

Forward

Set

eon

longer

Reverse

Turn

f

stitches).

number

the

Sewing

left

Sewing

stitch).

as

far

that

indicates

Turn

asitwill

fright

go.

stitch

as

(The

far

length

as

reverse

it

you

will

stitches

Set:

.4

Control

Lever

controls

(Lever

fore

stops

want(1—5;

go.

Dial

will

f

regulates

forward

should

setting

stitch

be

8

B

—O

D—0

on

the

the

be

stitch

length

higher

same

Lever

Lever

the

and

in

vertical

length).

stitch

reverse

desired.

the

length

E

—0

C—Centered

length

and

sewing.

position

Control

number,

as

forward

be

the

.1

e

A

Le’

5th

dc

sa

cr

to

si

R

7066

Page 10

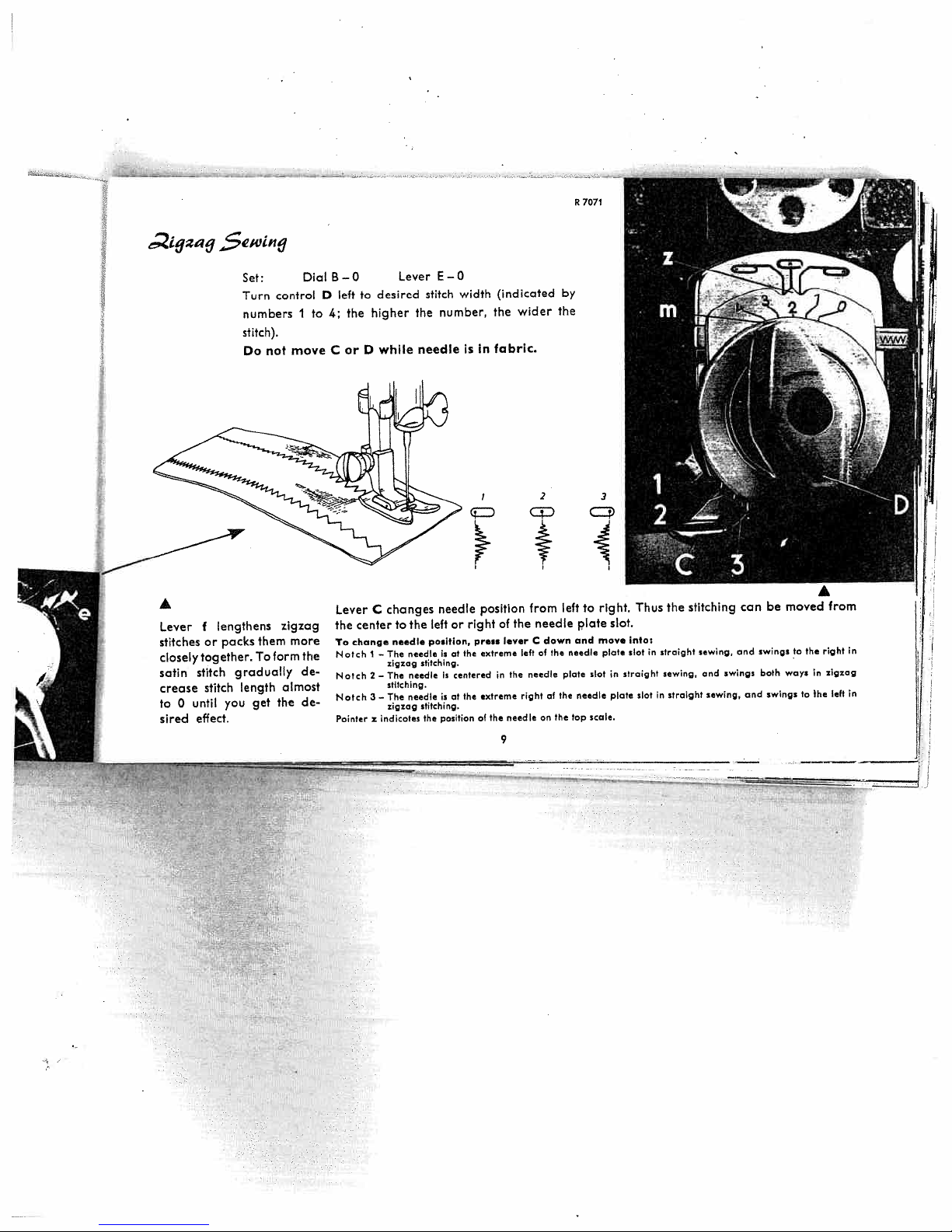

ifyza9

4

ewtn9

Set:

Turn

numbers

stitch).

Do

control

not

DiolB—O

I

to

move

7071

R

E—O

Lever

wider

by

the

2

desired

left

to

D

higher

4;

the

while

D

C

or

stitch

the

needle

number,

is

in

the

fabric.

(indicoted

width

A

Lever

stitches

closely

satin

crease

to

0

sired

lengthens

f

or

together.

stitch

stitch

until

effect.

pocks

graduolly

length

you

them

To

get

zigzag

form

almost

the

more

the

de

de

Lever

the

To

Notch

Notch

Notch

Pointer

center

change

changes

C

I

—

The

2—

stitching.

3—The

z

indicates

to

needle

zigzag

The

zigzag

the

needle

needle

needle

needle

left

position,

is

stitching.

is

is

stitching.

position

the

right

or

at

the

centered

at

the

position

press

extreme

extreme

of

the

of

is

9

the

ever

the

needle

from

C

left of

needle

right

needle

down

the

of

the

on

the

left

needle

plate

plate

and

needle

top

to

mov,

slot

scale.

right.

slot.

plate

in

plate

Thus

into:

slot

straight

slot

in

the

straight

sewing,

straight

in

stitching

sewing

and

sewing,

and

swings

can

and

be

swings

both

swings

moved

to

the

ways

to

Al

from

in

right

zigzag

in

in

left

the

Page 11

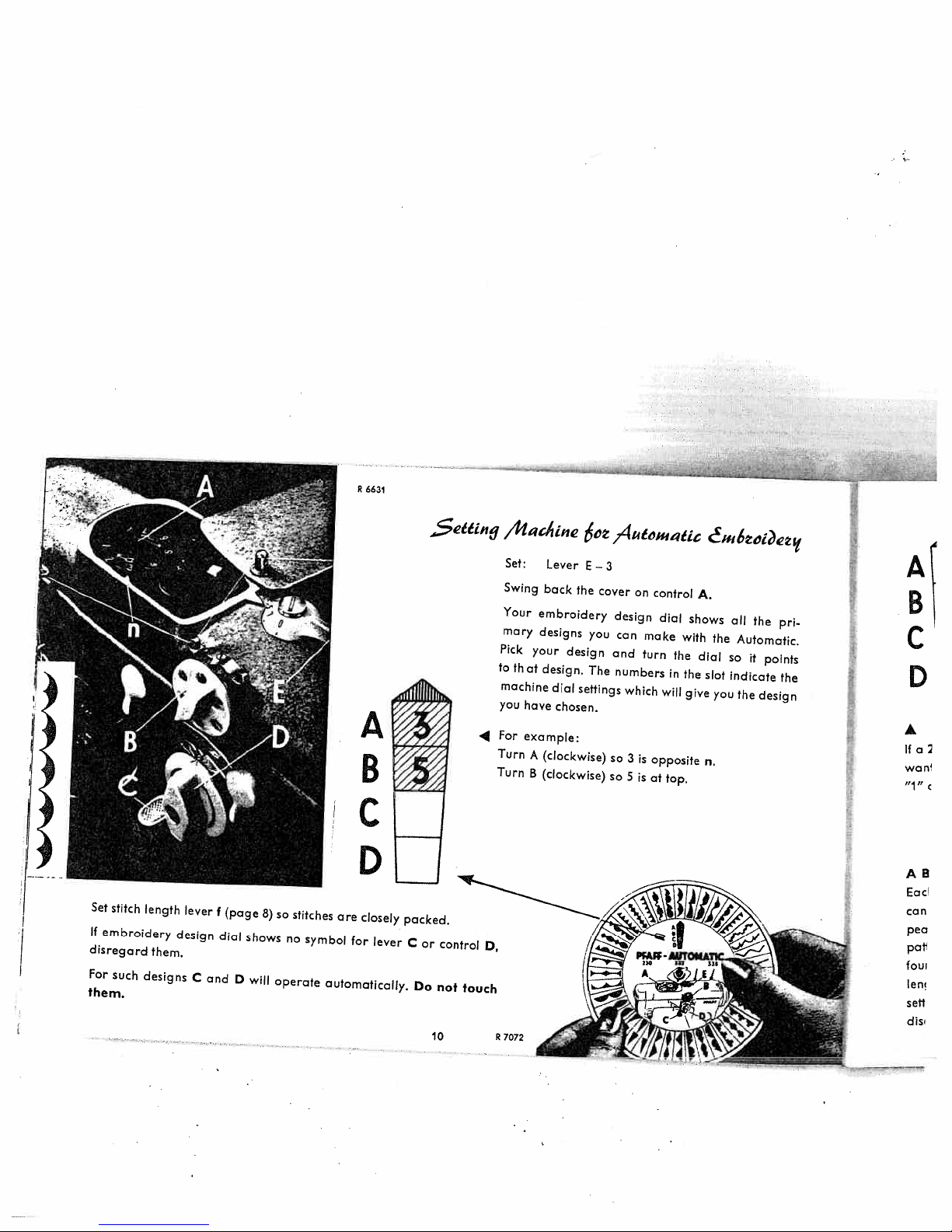

R

6631

Set

stitch

If

embroidery

disregard

For

such

them.

length

them.

designs

lever

design

C

and

f

(page

dial

D

8)

shows

will

so

stitches

no

operate

are

symbol

automatically.

B

D

closely

for

lever

$etémn9

packed.

C

or

control

Do

not

10

touch

to

you

For

Turn

Turn

D,

R7072

/i’Za€.

4

in

Set:

Swing

Your

mary

Pick

that

machine

have

example:

A

B

Lever

back

embroidery

designs

your

design

design.

dial

chosen.

(clockwise)

(clockwise)

6,t

E.-3

the

cover

you

The

settings

Au,iatic

on

design

con

make

and

turn

numbers

which

so

3

is

so

5

is

control

dial

with

the

in

will

opposite

at

top.

A.

shows

dial

the

give

cm6z1.i?eg

all

the

Automatic.

so

slot

indicate

you

the

n.

the

it

design

pri

points

the

A

B

C

D

A

If

won

,,1,,

AB

Ea

con

pea

poi

fou

len

sett

dis

a

C

c

Page 12

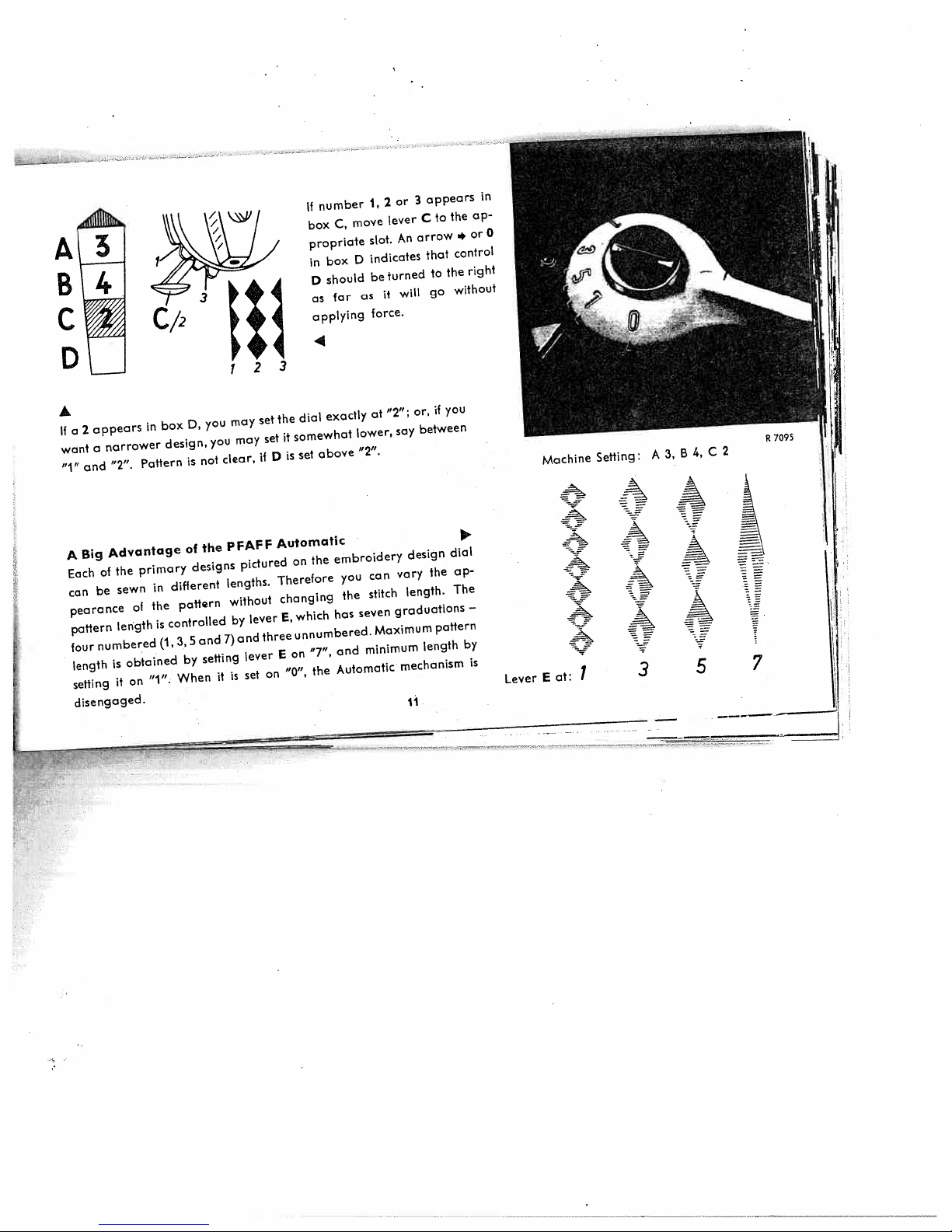

Au

B4’

A

2

a

If

want

and

“1”

appears

narrower

a

“2”.

box

in

design,

Pattern

number

If

C,

box

propriate

box

in

should

D

far

as

applying

move

D

as

or

2

1,

lever

An

slot.

indicates

turned

be

will

it

force.

appears

3

C

arrow

that

to

go

to

the

*

control

the

without

ap

or

right

in

0

123

you

if

or,

“2”;

at

exactly

dial

the

set

may

you

D,

may

you

clear,

not

is

set

if

it

is

D

somewhat

set

above

lower,

“2”.

soy

between

Machine

Setting:

7095

R

2

C

4,

B

3,

A

Big

A

of

Each

be

con

pearance

pattern

numbered

four

length

setting

disengaged.

Advantage

primary

the

sewn

of

length

obtained

is

“1”.

on

it

different

in

the

controlled

is

(1,3,5

of

designs

pattern

by

When

the

and

setting

PFAFF

lengths.

without

by

7)

is

it

pictured

lever

three

and

lever

set

Automatic

on

Therefore

changing

which

E,

unnumbered.

on

E

“0”,

on

the

“7”,

the

embroidery

can

you

stitch

the

seven

has

Maximum

minimum

and

Automatic

design

the

vary

length.

graduations

pattern

length

mechanism

dial

ap

The

by

A

—

is

Lever

at:

E

A

I

3

5

7

Page 13

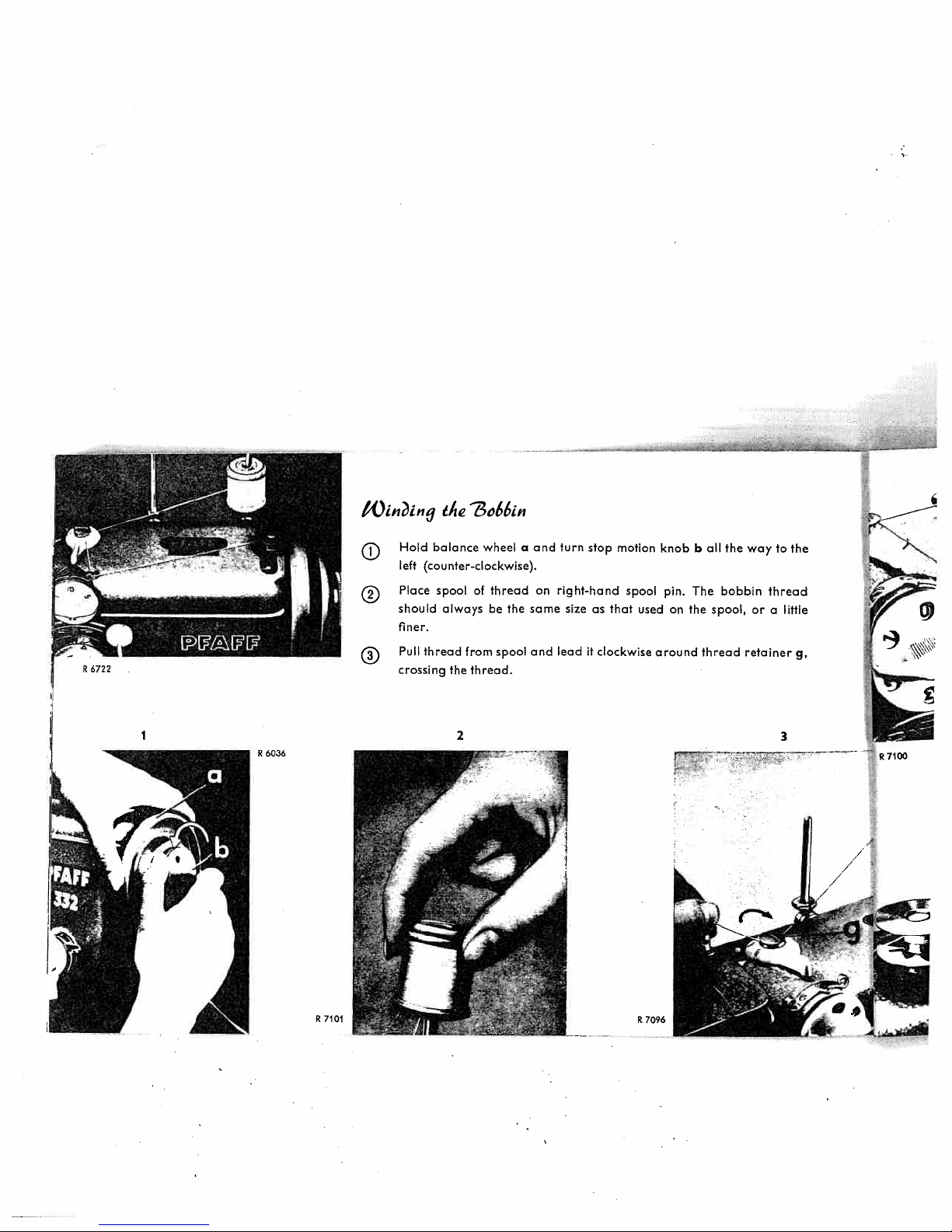

/Oin?in

9

th

2o6in

balance

Hold

left

(counter-clockwise).

spoolofthread

Place

should

always

finer.

Pull

thread

from

crossing

the

2

wheelaand

the

be

spool

thread.

on

same

and

turn

stop

right-hand

size

as

lead

it

clockwise

motion

spool

that

used

knob b

pin.

on

around

h.

The

the

all the

spool,

thread

bobbin

waytothe

thread

a

little

or

retainer

3

g,

7100

Page 14

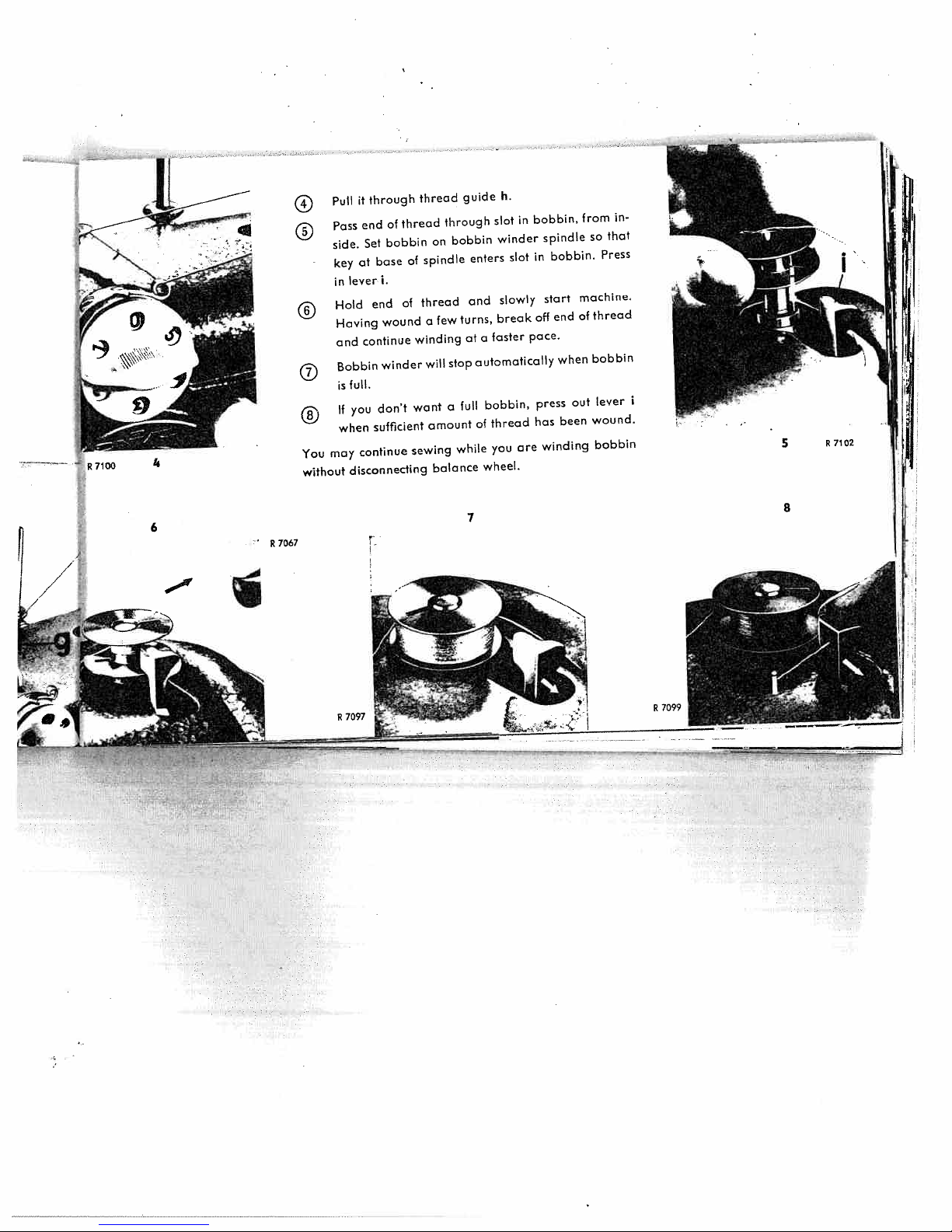

R71O0

0

You

without

it

Pull

end

Pass

Set

side.

ot

key

lever

in

Hold

Having

continue

and

Bobbin

full.

is

you

If

when

continue

may

disconnecting

through

of

bobbin

base

i.

end

wound

winder

don’t

sufficient

thread

of

of

winding

wont

sewing

thread

on

spindle

threod

few

a

will

amount

balance

guide

through

bobbin

enters

and

turns,

at

stop

full

a

while

h.

in

slot

winder

slot

slowly

break

pace.

faster

a

automatically

bobbin,

thread

of

are

you

wheel.

bobbin,

spindle

bobbin.

in

start

end

off

when

press

has

winding

out

been

from

that

so

Press

machine.

thread

of

bobbin

lever

wound.

bobbin

in

i

6

R7067

7097

R

7

7099

R

Page 15

_________

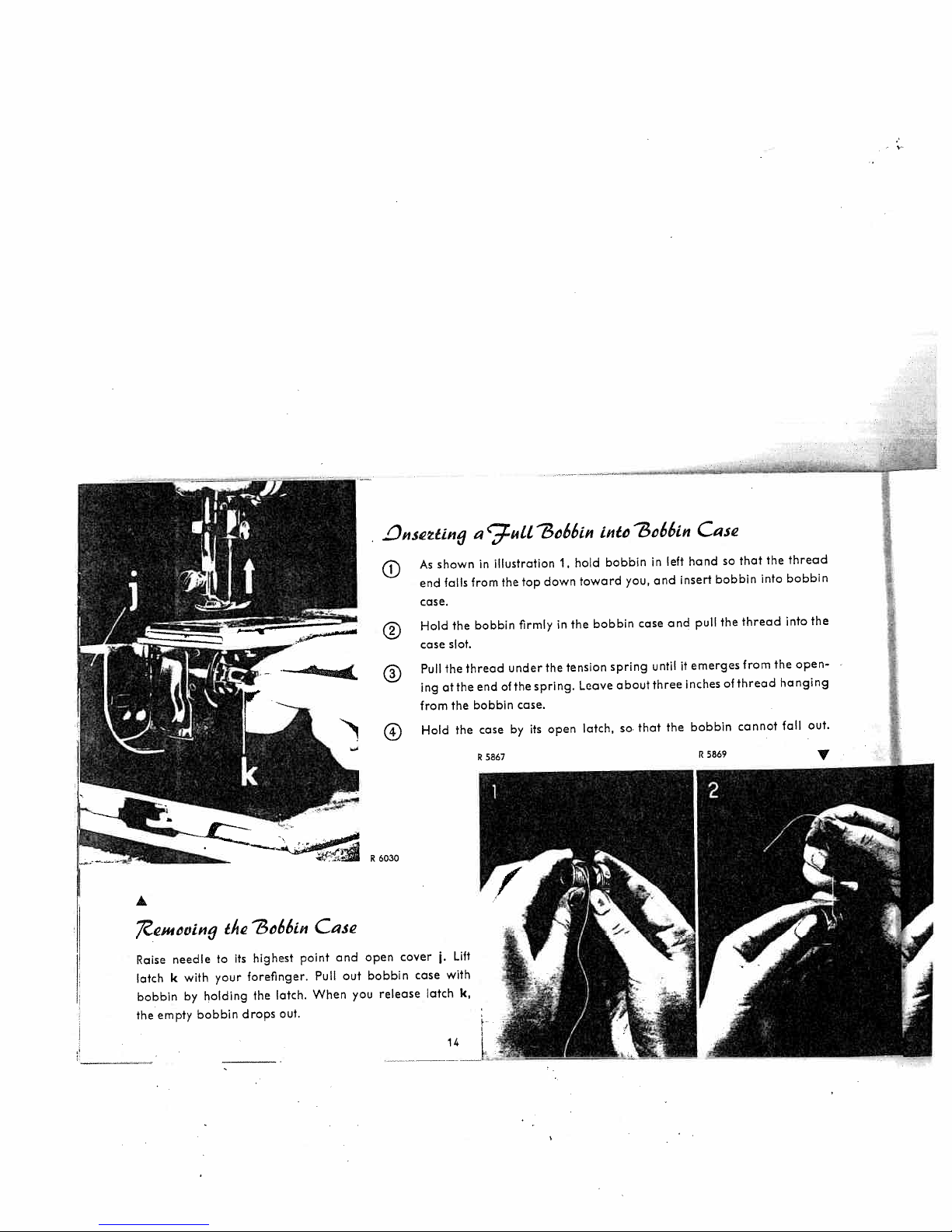

eu.ovin

needle

Raise

k

latch

bobbin

empty

the

with

by

to

your

holding

bobbin

the

its

7o6

6in

highest

forefinger.

the

drops

latch.

out.

Ca5e

point

When

Pull

and

out

you

.Dnwrtin

9

0

6030

cover

open

bobbin

release

As

end

case.

Hold

case

Pull

ing

from

Hold

case

shown

latch

j.

falls

slot.

the

at

with

the

the

the

Lift

thread

the

k,

i9idt

in

from

bobbin

end

bobbin

case

73c66in

illustration

the

top

firmly

under

spring.

the

of

case.

by

its

down

in

the

open

hold

1,

the

tension

into

toward

bobbin

Leave

latch,

bobbin

you,

spring

about

so

3o66mn

case

that

in

and

until

three

left

and

the

Case

hand

insert

pull

emerges

it

inches

bobbin

so

bobbin

the

of

thread

that

thread

from

cannot

the

into

thread

bobbin

into

open

the

hanging

fall

the

out.

14

Page 16

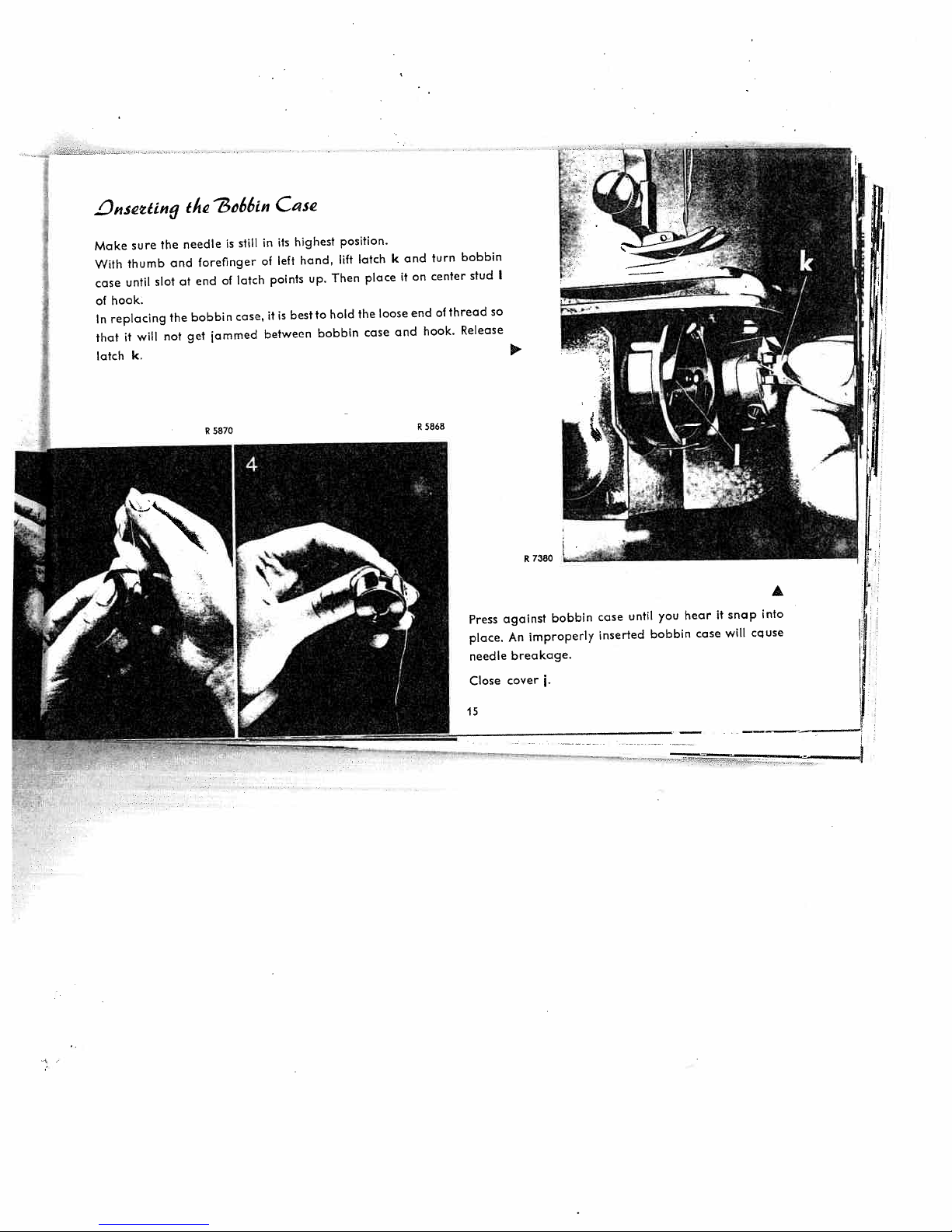

Dn.stin

9

sure

Make

thumb

With

until

case

hook.

of

replacing

In

will

it

that

k.

latch

slot

the

not

arid

the

th

needle

at

bobbin

get

end

73c66

in

is

forefinger

of

jammed

still

latch

case,

Casz

its

in

left

of

points

is

it

between

highest

hand,

best

up.

to

bobbin

position.

lift

Then

hold

latch

place

the

case

k

loose

and

it

and

on

end

turn

center

of

hook.

bobbin

thread

Release

stud

Press

place.

needle

Close

I

so

against

7380

R

improperly

An

breakage.

cover

I

I.

I

bobbin

case

inserted

until

you

bobbin

hear

case

A

into

snap

it

cquse

will

15

Page 17

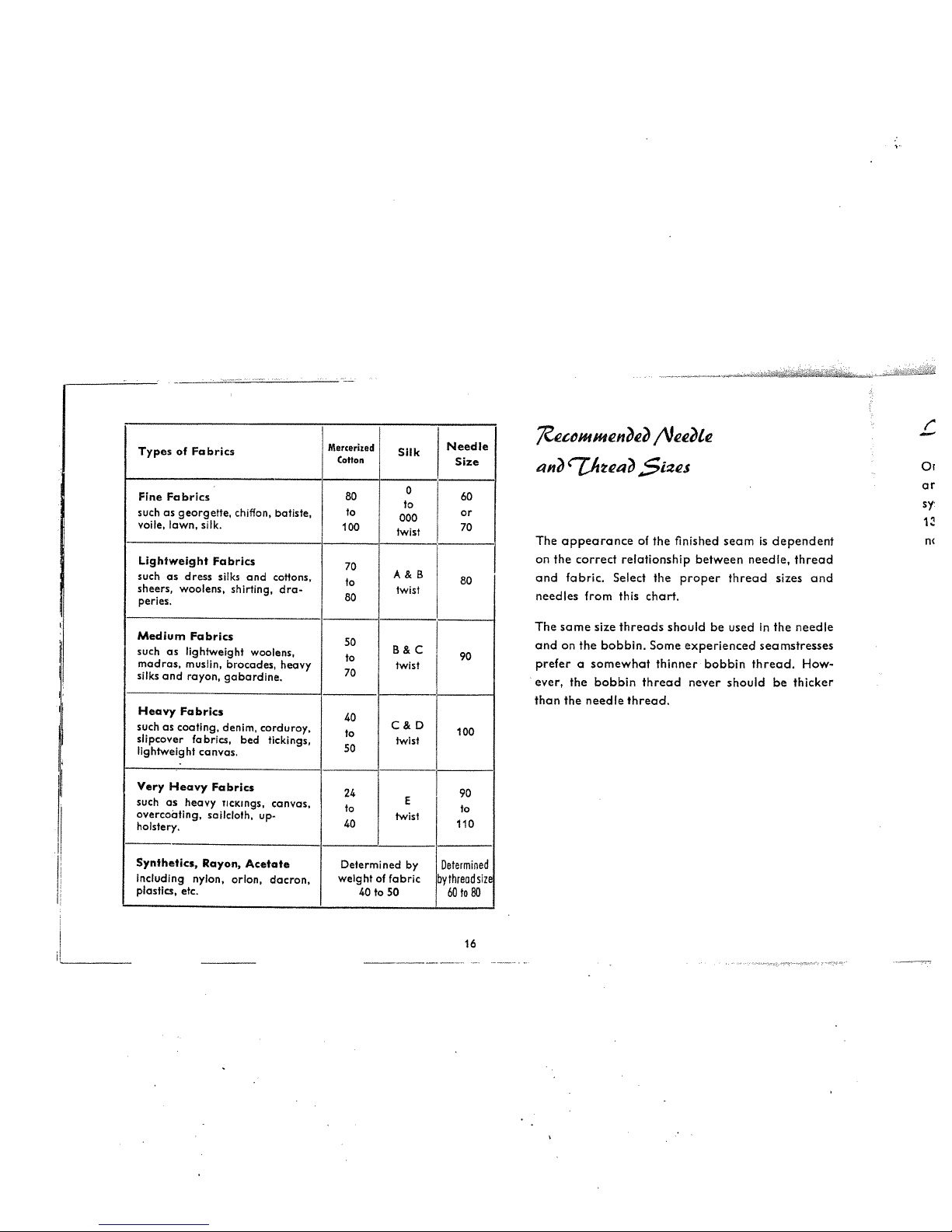

TyposofFabrics

Fine

Fabrics

suchasgeorgette,

voile,

lawn,

silk.

Lightweight

such

as

sheers,

Medium

such

madras,

silks

such

slipcover

lightweight

Very

such

overcodting,

hoistery,

dress

woolens,

peries.

as

and

Heavy

Fabrics

ascoatlng,denim,

Heavy

as

heavy

Fabrics

lightweight

muslin,

rayon,

fabrics,

canvas.

Fabrics

sailcloth,

chiffon,

Fabrics

silks

shirting,

brocades,

gabardine.

bed

TIcKrngz,

and

cottons,

woolens,

corduroy,

tickings,

canvas,

up

batiste,

dra.

heavy

Mercerized

Cotton

80 60

to

ioo

70

to

80

50

to

70

40

to

50

24

to

40

Silk

0

to

000

twist

A&B

twist

B

&

twist

C&D

twist

E

twist

C

Needle

Size

or

70

80

90

90

to

110

iftuwn?

an

‘7h&’a?

The

appearance

on

the

correct relationship

and

fabric.

needles

The

and

prefer

ever,

than

from

same

on

the

a somewhat

the

the

needle

Select

size

bobbin.

bobbin

$i.c

of

this

threads

thread.

/l4?e?1

the

the

chart.

should

Some

thinner

thread

finished

between

proper

be

experienced

bobbin

never

seamisdependent

needle,

thread

used

thread

sizes

in

the

needle

seamstresses

thread. How

be

thicker

should

Or

ar

sy

13

n<

and

Synthetics,

including

plastics,

etc.

Rayon,

nylon,

Acetate

orion,

dacron,

Determined

weight

40

to

of

fabric

50

by

Determined

bythresdsiz

60to80

16

Page 18

Dit,1tant

9acts

4&14t

/Ve&2ks

R

6798

PFAFF

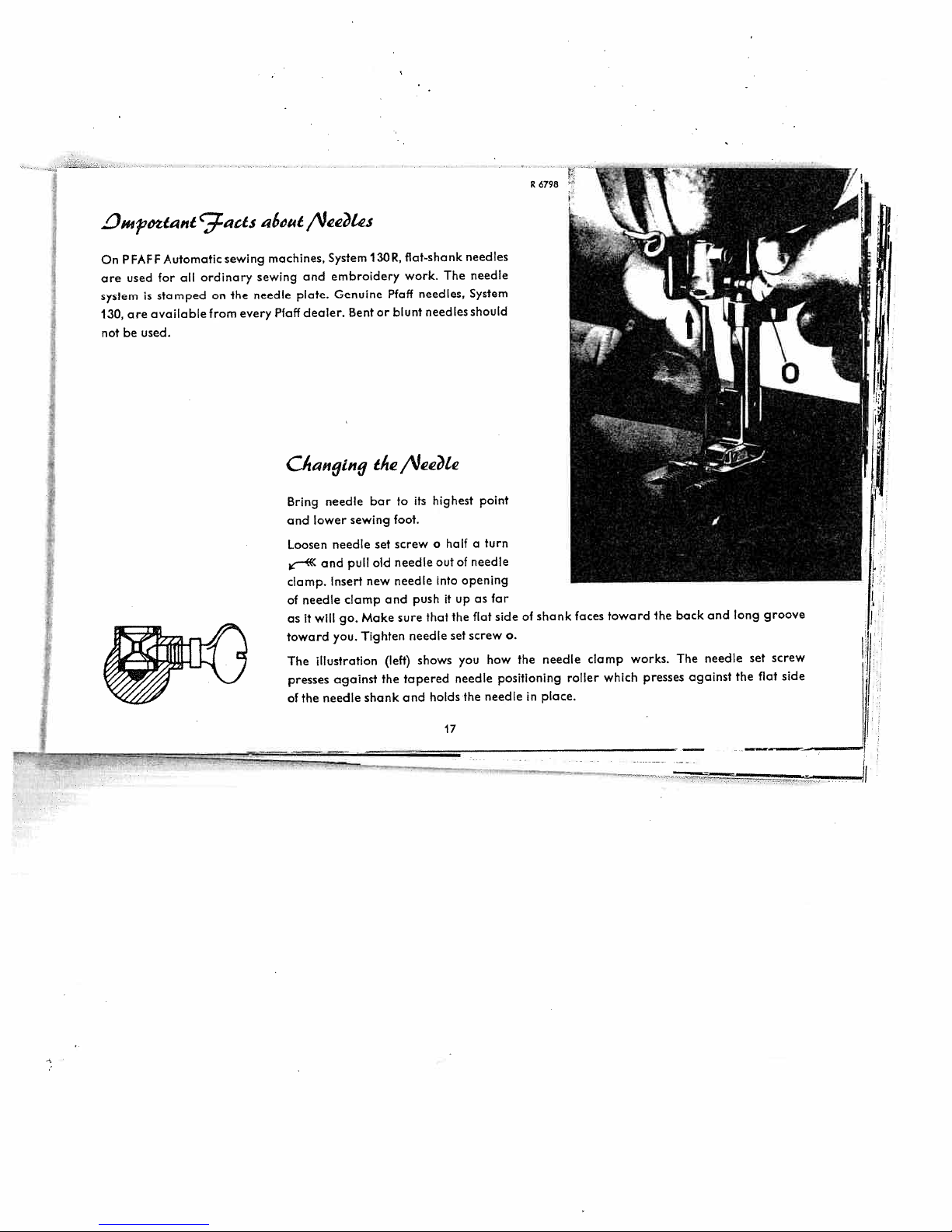

On

are

system

130,

not

be

used

are

Automatic

for

stamped

is

available

used.

all

sewing

ordinary

The

on

from

needle

every

machines,

sewing

Pfoff

C6aqinq

and

toward

and

plate.

dealer.

Bring

Loosen

,c—’tEC

clomp.

of

needle

as

it

The

presses

the

of

System

embroidery

Genuine

Bentorblunt

needle

sewing

lower

needle

pull

and

Insert

clamp

go.

will

you.

illustration

against

needle

130R,

Pfaff

the

bar

set

old

new

and

Make

Tighten

(left)

the

shank

flat-shank

work.

needles,

/Vete

its

to

foot.

screw

needle

needle

push

sure that

needle

shows

tapered

and

The

needles

highest

o

half

out

into

it

set

holds

needles

System

should

of

opening

up

the

screw

you

needle

the

needle

point

turn

a

needle

far

as

flat

how

needle

of

shank

side

0.

the

positioning

in

needle

place.

faces

roller

clamp

which

toward

works.

the

presses

back

The

and

needle

against

long

the

set

flat

groove

screw

side

17

Page 19

Place

thread

guides

thread

in

openings4(see

on

spool

illustration

I

and

pin

and

2

and

3

opposite).

lead

through

thread

both

end

through

thread

holes

retainer

Pull

thread

clockwise

lead

it

tension

the

thread

the

Bring

take-up

to

at

thread

left

left

will

right

slots

leftofneedle

Then

threader

between

cup

check

lever

through

thread

of

clamp

needle,

do

(Fig.

(Arrow,

spring

7

one

10.

this

any

for

two

of

the tension

until

Fig.

which

high

the

of

you

Ill).

easily

snaps

it

The

holdsitdown

it

as

holes

8

and9,and

II)

as

guides

fronttoback.

into

thread

willgoand

its

at

PFAFF’s

quickly.

and

discs

square

the

passes

permanently.

pass

Pull

end.

then

into

Automatic

(Fig.I)and

5,

notch

underneath

thread

thread

the

from

into

slot

needle

18

in

11

at

HI

Page 20

R

7378

19

Page 21

S

R

7c169

7068

4

Before

the

of

the

sewing

you

begin,

ascending

foot

With

your

penetrates

Hold

thread

needle

the

make

take-up

and

left

needle

threader.

Auiô,sate

sure

lever

—

hand

push

eye.

loosely

and

that

d

Keep

the

is

in

threader

lead

,‘\ee1e

needle

line

with

lever

p

from

‘7hea?er

is

at

the

engaging

in

this

left

around

its

highest

bottom

position.

edge

lever

pin

position

of

p

behind

q

up

the

—

top

until

hook

when

cover.

the

threader

of

prong

lower

Now

hole

lower

prong

w

Pus

its

1ev

$1

Sir

on

V

Slowly

the

eye.

Jerk

lever

thread

Pull

I

S

7089

2

lower

lever

up

p

through

p

slightly

needle

part

R7088

way

until

prongwreverses

so

the

thread

ioop

will

fall

off

the

and

pulls

prong.

thread

Release

through

lever

p.

eye.

3

R7087

4

Page 22

$390

R

When

may

Push

its

lever

through

—

Since

the

eye

V

shorten

lever

end

p.

take-up

needle,

before

you

is

about

Prong

needle

hove

p

pull

you

the

up.

w

lever

had

procedure

Place

1/2

inch

now

eye.

d

about

begin

sufficient

thread

the!right

to

end

pulls

not

is

four

sewing.

follows:

as

,behind

of

its

at

inches

needle

the

highest

of

threading

hook

the

of

thread

thread

of

prong.

instead

—

point

through

7

awinj

Hold

until

highest

needle

fabric

prong

when

needle

the

position.

plate

into

practice,

w

Slowly

of

you

the

14

thread

needle

slot.

machine.

so

the

thread

needle

you

that

lower

loop

the

lightly

moves

Lightly

Place

‘3c6t

4

1n

in

down

needle

pull

both

your

and

threads

‘7hea’

hand.

left

again

up

thread

back

Turn

to

under

and

draw

balance

take-up

bobbin

sewing

wheel

thread

foot

lever

toward

before

reaches

through

up

you

you

put

9kJ

A

its

iJ

21

Page 23

A

check

To

balanced,

fabric

seams.

drawn

sketch

seam

surest

The

examining

is

equally

fabric,

the

exactly

tension

whether

take

sew

and

If

the

on

in

Ill),

way

a

zigzag

wide

that

the

at

adjustment

a

a

straight

both

to

on

is,

zigs

tensions

the

closely

straight

few

stitches

sides

tensions

the

double-check

seam.

surface

threads

the

if

zagsofthe

and

correct.

is

woven

of

If

and

the

the

R

7374

correctly

are

piece

and

are

fobric

correct.

ore

this

zigzag

underside

ore

seom,

zigzag

tightly

(see

is

seam

locked

of

by

of

the

Ctrett

Balanced

will

you

Sketch

Cause:

Sketch

Cause:

7encion

tensions

have

I

—

II

—

perfect

The

Upper

The

Upper

are

threads

tension

threads

tension

7Z9u1ation

essential

seams

interlock

too

interlock

too

as

loose

tight

for

sketched

sewing.Ifyour

(Ill)

underside

the

on

lower

or

surface

the

on

lower

or

below.

tension

tension

of

tension

of

the

too

the

too

fabric.

tight.

fabric.

loose.

is

correct,

V

22

Page 24

kt

79

utaan

9

Bobbin

should

the

by

Determine

thumb

tension

pulled

slightly,

V

tension

be

small

Turn

Turn

and

should

down

the

little

a

screw

ii

it

correct

forefinger

bobbin

rarely

left

right

be

by

ch

tighter

(x)

c—<

bobbin

strong

its

‘/ea

)tm

own

case

needs

than

on

ond

adjusting,

for

the

looser

for

for

tension

letting

enough

weight.

should

7n.on

ordinary

bobbin

lighter

gradually

except

case:

tension.

tension.

holding

by

the

keep

to

However,

sewing.

bobbin

the

6946

R

slide

embroidery

for

Adtustment

thread

the

case

bobbin

you

as

down.

hang

case

jerk

end

23

is

between

freely.

from

your

when

mode

being

it

The

hand

The

upper

The

tension

complete

the

The

For

set

final

tension

Turn

Turn

upper

—

tension

higher

ordinary

between

stitch

left

right

tension

loose

turn

dial

the

appearance

knob

gE(

to

the

of

indicate

number,

sewing,

and

3

)*—

is

tight

5.

as

(y)

for

so

tension

the

can

follows:

looser

tighter

for

designed

can

—

knob.

different

greater

the

upper

tension.

that

be

degrees

regulated

be

tension.

all

covered

The

the

tension

grades

with

numbers

tension.

of

tension.

should

A

by

one

on

of

be

t

‘Ii

I:

__

Page 25

7

zc2inf7

The

machine

embroidery

To

drop

and

lower

feed

tli?

feed

,41ac4ine

is

button

feed

control

dropped

sewing.

below

v

for

the

needle

clockwise.

R7O66

darning,

plate,

Fabric

4

and

turn

hoop

turn

$uut6

4

Set

fin

Set

e

desired

To

sew

Control

Stitch

fin

the

until

desired

e

will

neutral

so

its

stitch

backwards,

e

length

forward

regulate

right

h?nth

pointer

length.

stops

may

stitch

)—

(vertical

stitch

also

sewing

the

is

turn

stitch

length

until

7

9utafltn

position).

the

on

Turn

lever

lever

length,

be

regulated

position

length

is

obtained.

stops.

it

indicator

f

to

f

toward

to

1

5,

as

by

turning

by

scale

the

on

turning

far

To

number

right

the

left

indicator

as

it

f

slowly

hold

the

as

e

will

far

as

scale.

all

stitch

corresponding

as

it

will

far

asitwill

the

way

go.

Sew

toward

length

left

a

the

go.

go.

few

left

in

to

arid

stitches

position,

the

When control

as

it

Wii

automatically

go,

v

is

ieedng

when

turned

you

of

to

the

start

the

right

fabric

sewing.

as

resumes

far

R

24

6029

Page 26

7085

R

Chan

9in7

both

Lift

turn

and

loosened

Tilt

the

tighten

and

needle

screw

by

foot

the

and

c

hand,

sideways

screw

$e,uin

presser

the

to

if

but

and

c.

it

left.

is

bars

pull

too

The

9ctt

to

tight,

down.

it

their

screw

use

highest

usuaily

screw

a

Slip

on

positions

can

driver.

foot

new

be

R7086

t

rear.

the

from

bar

activated.

is

the

hook

lever

to

foot

needle

lower

d

e,

illustrated

as

the

presser

set

darning

screw,

bar

Remove

Hold

and

that

so

foot

lever

the

spring

tighten

when

will

so

e

stay

sewing

clip

screw

that

you

in

the

foot.

so

b

Attach

c.

lower

position.

upper

Attach

that

darning

behind

is

it

darning

presser

Remember

tension

25

Page 27

,4aintenani

Longevity

proper

Pfaff

Use

vegetable

or

moving

All

to

able

needle

the

points

oiling

an

and

cleaning

sewing

and

establish

plate

smooth

oils.

ore

7377

R

machine

Remove

rotating

pattern

a

oiling

and

marked

machine

and

oiling.

only.

oil

all

parts

when

the

by

performance

Never

before

lint

require

oiling

mechanism

arrows.

oiling.

regular

your

are

lubricate

machine.

the

in

dependent

machine

lubrication.

Begin

arm.

free

with

by

The

regular

on

animal

is

It

removing

principal

advis

Ca

and

6A32

R

I

I.

A

The

portant

raceway

cause

each

into

This

oiled.

raceway

oiling

each

rapid

of

essential

is

wear.

the

in

point.

day

two

the

to

sewing

Put

you

Don’t

oil

keep

forget

holes

one

sew.

the

hook

drop

A

to

behind

hook

dry

is

put

the

the

oil

of

raceway

drop

a

sewing

shaft

most

into

bearing

of

foot.

im

the

will

oil

;

Page 28

The

easily

applied

the

soil

two

or

Before

tween

7381

R

oiling

5

points

removing

by

sparingly.

work

drops

you

and

and

of

remove

To

7.

in

oil

the

cause

pull

machine

top

the

Excessive

machine

usually

top

the

cover

arm

cover.

quantities

will

cover,

up.

can

Oil

sluggishness.

suffice.

lever

set

back

tilt

it

be

should

of

reached

may

oil

One

E

and

be

be—

lift.

head

the

in

Oiling

machine

points

27

:,

I

Page 29

4

5esøliqht

25-waft

The

to

light

the

change

To

lever

Swing

pull

and

inserting

When

slots.

bulb

Press

sewlight

illuminate

the

u

out.

in

9aai

light

up

the

and

bulb:

(see

turn

is

a

new

recessed

larger

arrow)

bulb,

right.

under

working

and

sure

be

hold.

the

to

machine

area.

Push

slide

bulb

bulb

arm.

up

pins

into

into

Lever

socket,

swings

u

bayonet

turn

Press

front

to

and

out

left.

socket

of

switch

off.

the

the

button

machine

the

on

sewlight

the

base

on

Page 30

The

electric

attention,

should

service.

be

motor

except

replaced

requires

that

after

the

400

no

R

special

brushes

hours

6546

I

Ait.sttiii

Your

PFAFF

332

(Type

PE

332),

main

shaft

by

means

,4ctc

Automatic

which

is

ofadriving

is

housed

3

e1i

equipped

in

the

belt.

‘7n.%ion

with

a

machine

30-watt

base

electric

and

drives

d

motor

the

Ii

If

driving

the

cover

tension

Idler

r

belt

clips

of

When

position.

t

and

is

should

you

belt

remove.

obtained.

and

revolves

tighten

be

tension

set

just

screw

needs

Loosen

far

evenly.

s,

adjustment,

screws

enough

make

sure

take

out

four

the

s

and

adjust

idler

left

that

it

synchronizes

the

washer

until

r

isinthe

screws

correct

with

correct

the

in

U

29

:

;

-

-

I

-

—

1-

---

-*1!

-

4•—

-

Page 31

‘7ou61e

Machine

1.

Ca

use:

Needle

Wrong

Needle

Machine

Needle

Needle

2.

Cause:

The

above

breakage.

Thread

Poor

or

Hook

race

oiling.

Burrs

or

4

ShOOtUlf?

Skips

incorrectly

needle.

bent.

threaded

too

fine

Thread

mentioned

tension

knotty

is

jammed

sharp

or

too

thread

edges

Stitches

inserted.

improperly.

too

thick

Breaks

may

tight.

used.

with

thread

needle

on

for

cause

the

plate

thread.

thread

or

needs

slot.

Remedy:

Push

groove

The

correct

Insert

Check

correct

Use

Remedy:

See

remedies

Adjust

Use

good

Clean

Polish

needle

faces

new

and

tensions

quality

and

needle

up

you,

needle

needle.

correct

needle

listed

oil

plate

as

hook

as

far

and

system

threading

and

under

instructed.

threads

raceway.

slot

asitwilt

flat

part

is

thread.

1.

only.

with

of

stamped

as

above.

fine

go

and

needle

on

instructed.

emery

away

needle

cloth.

be

sure

that

the

long

from

you.

plate.

30

I

Page 32

Needle

3.

Cause:

Bent

Needle

Fabric

needle

Bobbin

Faulty

4.

Cause:

Improper

Thread

Bobbin

Pieces

3.

Cause:

Feed

enough

needle

too

pulls

plate.

case

too

unevenly

of

Machine

dog

Breaks

strikes

thin

needle

inserted

Stitch

tension.

heavy,

thread

set

above

or

Formation

wound.

between

Feeds

too

needle

point

thread

it

so

incorrectly.

knotty

Improperly

and

low

of

too

bends

or

tension

plate

sewing

heavy.

and

hard.

does

level.

hook.

strikes

discs.

not

rise

up

Remedy:

Replace

correct

Use

Don’t

bobbin

Push

Remedy:

Adjust

only

Use

fabric.

Don’t

around

it

Release

Remedy:

Have

needle

force

tensions

run

your

31

needle

the

case

first-rote

thread

tension

upper

Pfaff

once

at

and

feeding

until

instructed.

as

over

stud

tension

dealer

thread

prevent

to

thread

motion.

you

—

finger

top

on

by

make

hear

—

when

setting

sizes.

Guide

it

the

cover

the

further

the

snap

correct

winding

and

on

ii

necessary

damage.

material

into

size

through

“0”

lightly.

ploce.

the

for

bobbin,

the

thread

remove

and

adjustment.

needle

but

guide

and

lead

h.

thread.

1

I

Page 33

Accumulations

betweenfeedteeth.

packed

of

lint

Take

off

needle

plate

and

remove

lint

with

brush.

a

stiff

Machine

6.

Cause:

Motor

belt

and

causes

raceway

Hook

pieces

of

Mechanism

Bobbin

(When

Snarled

bushing.

Thread

If

thread

Works

loose

is

excessive

lacks

thread.

cloggedbyinferior

working

winder

bobbin

a

thread

Jamming

jams

The

hook

Tighten

Move

Take

thread

If

Thread

is

between

in

thread

raceway.

the

the

iamming

Heavily

and

oil

not

the

the

balance

end

is

slips,

pressure

or

while

being

balance

sewing

will

stop

of

still

or

an

obstructed

is

sewing.

filled).

come

motion

wheel

the

jammed,

can

has

bearings.

oil.

wheel

hook

out

thread

be

shrunk

by

and

mechanism

more

knob.

away

and

call

avoided

from

your

easily

pull

by

Remedy:

Loosen

Clean

Use

only

Stop

bobbin

Unwind

and

if

you.

it

out

Pfaff

following

or

and

and

blocks

you

while

dealer

tighten

oil

Piaff

put

hook

sewing

winder.

remove

it,

a

rocking

for

the

motor

belt

raceway.

machine

thread.

proceed

few

drops

the

help.

instructions

adjusting

by

oil—never

as

follows:

of

balance

on

oil

pages

or

wheel.

idler.

salad

cleaning

4

and

or

oil

glycerine.

fluid

into

the

5.

32

Page 34

Edge

Stitching

E—0

B—C

Stitch

edge

the

E—0

8—0

Stitch

Setting:

Stitcher

parallel

stitches

fabric

the

seam

The

machine

screw.

Stitcher

with

rows

surface

the

and

C—2

D

Length:

No.

stitcher

seam

C—2

Length:

No.

quilting

the

gauge

row

tea

covers

Machine

Edge

Sew

zigzag

from

justable

the

gauge).

to

thumb

Quilting

Machine Setting:

Edge

Used

parallel

entire

guide

preceding

Attractive

pads,

—0to4

rows

various

at

edge

guide

bed

—0

D

of

stitching

of

the

of

cosies,

41

(without

guide

41350.

finger

stitches.

can

(optional)

—4

2

350.

straight

of

distances

using

53077

is

2

along

be

and

quilting

fastened

long

the

it

sews

over

Always

seat

quilted.

ad

by

No.

with

or2(optional)

—

I

gauge

fabric.

slippers,

or

the

the

or

of

on

of

straight

other

Use

other

Insertion

Setting:

E—0

B—C

Length:

Stitch

Foot

No.

baste

fabric.

whether

the

Turn

seam

stitch

sideinone

right

types

directions

closed

Position

fabric

fabric

across

edge

C—3

D—0

300.

51

zipper

or

to

close

lower

continuous

of

of

in

your

—2

1

not

to

right

to

foot

zipper

of

zipper

you

overlap

left

end

as

zipper

wrong

on

want

side.

edge

and

opera

a

guide.

insertion,

pack

de

the

the

Run

up

of

Zipper

Machine

Zipper

Pin

side

pends

edge

zipper.

a

‘

zipper,

the

tion.

For

follow

age.

R7104

33

Page 35

41242

iI

iI

flp

Machine

Flatfelled

in

two

Flat

used

First

4

Lay

1/e

inch.

stitch

the

but

than

fabric

piece

sure

allowance

needle

down

not

needle

a

beyond

R

7171

Second

Open

ridge

second

The

felling.

1

the

into

seam

felling

Seam

two

felling

foot

pieces,

is

placed

has

foot

a

place

needle

them

opening,

close

to

slot,

and

the

under

edge

rather

Setting:

operations.

felled

for

felling

Seam

pieces

Feed

is

folded

and

that

right

the

to

hole,

Flat

seams

seams

together

both

stitched

protruding

is

not

side

left.

it.

to

34

Felled

E

8—0

Stitch

are

usually

elasticized

on

over

down.

folded

up,

Make

permit

—o

used

wrong

pieces

edge

insert

sure

Seams

Length:

to

ore

sides

into

of

Make

seam

twice.

seam

that

zigzag

durably

straight

fabrics

facing

felling

top

R7154

C-2

D

1—2

ioin

only.

—0

two

stitched.

up

foot,

or

2

pieces

with

as

illustrated,

(oplional)

of

fabric.

Narrow

the

bottom

zigzag

piece

that

so

They

are

made

stitches

protruding

the

bottom

are

i

I

I

Page 36

4626?

Rolled

Hems

11246

Hemming

R

6083

Machine

E—O

B—O

Stitch

Rolled

fabrics.

cate

ease

I

to

tension,

hem

the

hems

thread

To

3.

and

has

Setting:

Length:

are

For

tension

hem

use

a

C—2

D—2to4

used

smooth,

a

tricot

the

rolled

2

—4

to

slightly

widest

shell

(optional)

finish

unpuckered

fabrics

zigzag

effect.

sheer

and

increase

set

stitch

want

hem

using.

you

folded

show.

needle

hem.

Setting:

Length:

hemmer

with

to

foot.

edge

the

of

feed

feeding.

before

C—2

D—O

2

foot

to

sew

straight

the

on

Clip

facilitate

Feed

in

is

hemmer

less,

twice

Avoid

Press

plate

you

to

2

or

—4

indispensable

is

a

uniform

orzigzag

type

the

off

insertion

fabric

line

fabric

the

the

and

endsbyslowing

ugly

the

the

on

come

(optional)

4

fabric

of

corner

so

with

foot

raw

fabric

sideofthe

left

to

the

hem.

stitches,

of

into

that

the

opening.

will

against

end

if

You

you

the

the

the

left

not

edge

of

Machine

E—O

B—O

Stitch

or

deli

hem,

0

on

the

so

The

you

can

depending

are

fabric

hemmer

raw

edge

If

be

will

down

the

foot

the

7375

R

•1

35

R

5915

Page 37

LJJ

Overcasting

Edges

R

6070

Machine

similor

Two

gether

way.

pieces

under

sheets.

of

and

Cut

of

the

Setting:

pieces

joined

out

sheet

needle.

worn

under

—0

E

B—0

Stitch

of

with

center

Join

fabric

zigzag

the

them

Length:

strip.

sewing

with

1

which

stitches.

Place

foot

close,

C-2

0—3

—

do

3

Worn

the

so

or

not

that

wide

Machine

Overcasting

stitch

after

4

(optional)

4

ravel

bed

selvaged

the

zigzag

Butt

sheets

abutted

into

fabric

Seaming

easily

edges

stitches.

Setting:

prevents

the

is

may

may

edges

36

fabric

cut

be

the

of

Hem

—0

E

B—0

Stitch

and

and

butted

be

mended

remaining

are

row

Length:

frayed

the

before

44088

centered

edges

to

this

edges.

other

the

C—2

D

—4

3

over

pieces

—

Sew

are

2

to

edge

its

(optional)

4

with

edge.

joined.

You

the

needle

may

taking

overcast

one

edges

7169

R

Page 38

Attaching

Machine

can

You

ration.

narrow

with

and

lace

V

Lace

Setting:

attach

Overlap

fabric

lace

lace

zigzag

and

E

—0

Stitch

stitches,

the

B

Length:

edging

raw

on

other

—0

C

in

edge.

taking

into

—2

I

one

—

lace

2

simple

Sew

one

D

to

stitch

only.

—Ito

fabric

ope

into

3

4O88

Machine

baste

or

Pin

with

gether

fabric

into

Carefully

lace.

underneath.

Inserting

Setting:

needle

alone

lace

E

C-2

Stitch

on

and

trim

Lace

—0

fabric.

taking

excess

B—0

D

Length:

one

one

—

Sew

into

I

to

1

stitch

fabric

R

3

—2

to

the

7161

7177

R

-

W

I

V

-

------

Page 39

7-

‘406e

Inserting

Patches

R

For

to

7156

additional

seams.

strength

stitch

over

corners

MachineSetting:

holes

Large

fabrics.

tricot

for

potch

the

Place

medium

twice.

length.

Turn

con

over

be

Cut

over

and

E—O

B—O

Stitch

patched

patch

the

trim

Length:

quickly.

so

damaged

close

that

I

its

area.

C-.2

D—4

The

grain

following

will

Sew

match

it

method

down

the

with

moy

rest

also

of

zigzag

the

be

fabric.

stitch

used

j

of

I

i

38

Page 40

Single-Needle

Machine

Trace

under

Setting:

pattern

the

Followthe

groove

pattern

Cording

fabric

on

E

—o

B—O

Stitch

in

and

the

hold

Length:

and

sole

the

place

of

filler

the

C-2

D-2

—1

filler

a

cording

thread

thread

foot.

lightly.

46121

Machine

Follow

but

than

and

the

depends

thread

When

seam,

thread

shirring

ing.

Leave

or

depending

shirring

Shirring

place

on

filler

groove

you

slide

the

pull

Setting:

above

filler

top

thread

of

on

used.

distribute

to

with

filler

it

will

directions

of

the

the

have

material

a

out

on

be

—0

E

B—O

Stitch

Ease

thread

the

both

foot.

thickness

finished

fullness.

of

line

thread

you

as

the

exposed.

—2

C

D—2to2

1

/2

Length:

Tension

Upper

shirring

for

under

fabric.

guided

are

of

Width

the

of

the

the

along

Finish

straight

the

in

straight-stitch,

to

stress

7162

R

to

2

rather

Fabric

zigzag

filler

zigzag

filler

the

stitch-

shirring

which

3

in

7152

71S9

R

39

R

Page 41

7163

R

6612!

61

Machine

Stitch

or

Pin

edges.

satin

Applique

Setting:

Length

applique

baste

Appliques

stitchorany

Work

—o

E

B—O

Minimum

on

can

also

embroidery

fabric

be

C—2

D—V/to3

and

attached

design.

overcast

with

R

7155

a

R

7167

40

Page 42

4612!

are

There

embroider

using

twice

medium-wide

the

so

even

Openwork

Machine

hundreds

25-square

the

short

satin

corners

Setting:

of

straight

stitch.

of

Embroidery

patterns

box

stitches.

Make

squares

your

—o

E

B—O

Stitch

excellent

illustrated.

Then

sure

Length:

sew

that

look

for

First,

your

neat.

R7179

C-2

D—Oand

Minimum

openwork

over

rows

embroidery.

over

sew

straight-stitch

satin

of

21/a

all

traced

lines

stitching

Let’s

with

lines

a

are

.4

When

modern

instead

you

finish

design,

satin

of

sewing,

outline

stitching.

41

out

cut

flowers

every

or

free

other

farms

square.

with

make

To

embroidery

an

an

attractive

design

IL

Page 43

R

7158

Stitch

Scalloping

PFAFF

be

articles.

The

adds

to

doubled

above),

and

4O88

Length:

332

used

effectively

illustrations

sparkle

do

it.

guide

ScaIIopng

can

Automatic.

First,

piece

place

needle

scallops

cally.

the

scallops

lever

of

have

along

Machine

E—1-7(optional)

A—5

Minimum

be

done

as

trimming

left

toachild’s

trace

of

fabric.

fabric

along

ore

You

may

by

(see

F

finished,

scalloped

in

Scalloped

show

collar.

collar

Set

under

produced

vary

changing

sketch).

trim

edge.

Setting:

a

how

pattern

machine

traced

excess

liffy

edges

on

numerous

scalloping

Here’s

sewing

automati

the

the

When

on

(shown

line.

length

setting

fabric

8—3

D—2

your

can

how

on

foot

The

you

of

a

Machine

Stitch

Length:

Draw

designs

embroidery

scrollwork

move

hoop

rhythm

An

exciting

variegated

Setting:

and

ScII’WWk

on

hoop.

outline

right,

direction

the

note

may

thread.

—0

E

B—0

Minimum

fabric.

you

As

with

then

left,

be

Clamp

ore

wide

of

your

added

C—2

D—2to4

work

following

satin

alternating

movements.

by

into

the

stitches,

the

using

‘V

87168

42

R7150

I

I

•1I

•

-i-’.

-

Page 44

Beautiful

be

can

cost.

extra

to

suited

penetrations

needle

the

cannot

needle

Hemstitching

first

Sew

I

machine

Step

2

sewing

Liti

3

second

Sew

4

needle

ore

you

If

S

of

right

Imitation

Machine

hemstitching

with

made

Loosely

hemstitching

close

screw

set

be

simple

very

is

the

en

row

when

turn

toot,

row,

previous

holes

of

making

pinls,

turning

Pfaff’s

woven

up.

threaded

left

needle

fabric

shown

on

more

Hemstitching

Setting:

effects

System

fabrics,

while

Since

must

be

sketch).

(see

of

area

the

in

is

the

in

sketch,

in

zigzag

two

than

fabric

pivot

woolly

the

turned

with

to

tabric

direction

stitches

lines

on

on

—0

E

Length:

Stitch

Increase

handkerchiefs,

(wing)

130

as

such

fabrics

hemstitching

out

Automatic

the

hemstitched.

be

right.

the

on

orrow,

of

material

guiding

descends

it

on

hemstitching,

of

needle,

end

—2

C

Tensions

batiste,

are

enough

far

ond

on

alternately

proceed

—0

B

1

—1/s

blouses,

available

needle

organdy,

recommended

not

has

needle

for

threader.

needle

toot

lower

to

the

mstitc

right.

as

leave

d,rected

first

parallel

He

Hemstitching

fabrics.

twilled

ordinary

on

several

Draw

machine

Set

and

stitch

making

strip,

thread

both

in

other,

threads

the

is

this

rows

Set

bar

from

length

line

edging.

—

D

dresses,

georgette,

slightly

a

insertion.

again.

row

needle

above.

n

hi

g

is

For

needle.

threads

for

along

sew

sure

ore

stitch

width

the

you

and

—

43

21

/s

and

Pfaff

at

etc.,

because

thicker

The

needle

that

so

in

tabric

succesful

type

this

out

medium-wide

a

both

“zigs”

that

exactly

length

you

until

edge

want.

will

you

forth,

so

stores

well

are

needle

shank,

hemstitching

penetrates

lett

the

on

linen

on

of

work

fabric.

the

of

zigzag

edges

“zags”

and

opposite

according

desire.

your

Zigzag

have

at

and

and

of

each

Draw

fringe

along

picot

use

the

Q

7138

R

to

7140

R

Page 45

R

7139

46669

(L

I

Hemming

easily

No.

Pfaff

sewing

thread.

j’

Next

Turn

used

fold

evenly,

stitch

edge

finished,

on

44088

store,

follow

fabric

on

twice

guide.

and

foot

edge

holding

Blindstitching

Machine

dresses

PFAFF

your

blindstitch

with

Attach

Use

slot,

procedure:

this

wrong

hem,

of

2).

(Fig.

top

0

Set

right

the

will

stitches

Setting:

skirts

and

on

the

guide

No.70

a

up.

side

fold

It

is

hem

so

that

stitchupto

not

—0

by

medium

guide

so

On

material

advisable

edge

needle

be

visible

hand

and

No.

that

needle,

scivage

against

takes

or

its

once

to

over

on

B

—0

Stitch

a

is

heavy

46669,

vertical

a

edge

(Fig.

pin

the

left

top

Length:

laborious

fabrics.

which

flange

loose

or

I).

baste

or

vertical

stitch

hem

the

side.

C

upper

if

On

—3

exactly

task,

Use

you

can

goes

tension

seam

bias

unselvoged

hem.

flange

edge.

D

—1

Maximum

can

You

zigzag

buy

through

and

binding

Guide

of

the

the

in

When

to

at

fabric,

blind-

folded

hem

2

do

foot

your

thin

work

it

the

is

is

44088

Automatic

Used

Machine

Blindstitching

be

these

number

regular

hem

that

stitches

Bulky

left

draperies

for

Setting:

visibleonthe

fabrics

of

intervals.

as

illustrated.

narrow

pierce

work

the

of

Blindstitching

or

—1

E

A

—6

used

is

right

should

narrow

needle.

and

Use

Feed

stitches

zigzag

fold.

placedinmachine

is

Set

curtains

medium

for

of

side

be

blindstitched

one

thread

fold

are

leverCon

B—i

C

sheer

wide

that

against

“3”.

—1

and

and

matches

made

with

heavy

filmy

with

zigzag

left

on

bulk

Stitch

the

stitch

fabric

inside

hem

fabrics

fabrics.

Automatic

edge

edge

material

of

44

Length

and

are

and

_V/s

1

would

Therefore

so

sewn

fold

foot

of

wide

and

to

the

the

a

at

so

R

7371

Page 46

6064

R

Sewing

Machine

setting

The

So

holes.

clockwise,

notches

the

and

ordinary

the

for

of

bars

V

Buttonholes

Setting:

control

of

can

you

illustrated.

as

the

of

other

lingerie

width

stitch

buttonhole

the

—0

E

Stitch

easily

buttonhole

“3”

at

buttonholes.

setting

0

is

for

grow

—0

B

Length:

changed

return

lever

Put

slide,

bartacking.

change

wider.

the

When

Minimum

several

control

C

one

1

C

times

to

notch

in

position

setting

This

F

lever

accordingly,

while

previous

its

1,

at

moved

is

Use

and

gauge

sired.

inent

cord

foot.

of

length,

loosely

under

insert

you

will

so

D

“Viz”

corresponds

both

and

buttonhole

slide

set

buttonhole

to

you

If

buttonholes,

through

To

sew

woven

the

piece

a

ore

setting,

be

for

further,

up

the

prefer

the

the

get

on

fabrics,

material.

of

making

turn

caught

sewing

to

parallels

foot

on

more

pull

hole

correct

piece

a

firmly

button

lever

two

in

sides,

size

the

stops

the

and

51016

No.

buttonhole

length

prom

filler

a

left

in

stitch

scrap

of

is

it

strengthen

To

woven

F

of

de

toe

material.

advantageous

buttonholes

material

cotton

In

to

making

place

in

between

buttonholes

piece

a

tricot

the

of

and

fabric

tissu,e

knit

layers.

soft

in

fabrics,

6088

R

paper

or

45

Page 47

c

0

-a

®

CD

Change

Trim

row

needle

Trim

ripper

both

and

the

®

D